Novel electronic component resistor sleeve penetrating equipment

A technology for electronic components and bushings, applied in electrical components, resistors, resistor components, etc., can solve the problems of no longer protecting thermal resistance, vibration, etc., to avoid relative position changes and increase friction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

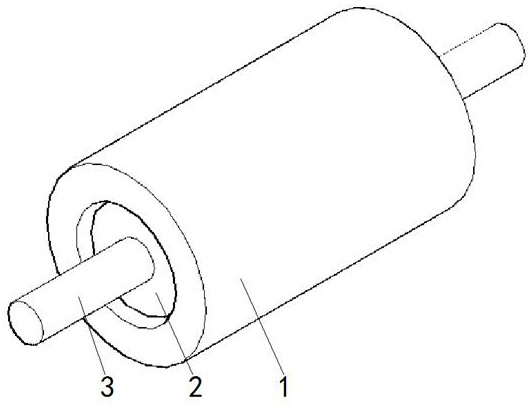

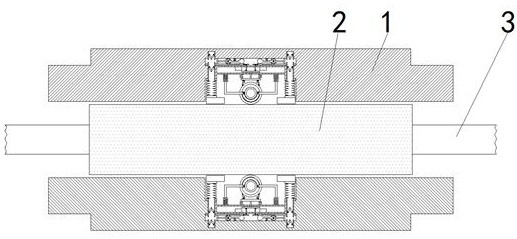

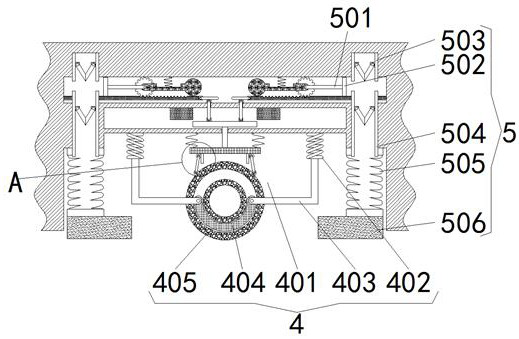

[0023] see Figure 1-Figure 5 , a new type of electronic component resistance through casing equipment, including a casing 1, the interior of the casing 1 is provided with a thermal resistance 2, the two sides of the thermal resistance 2 are fixedly connected with connecting wires 3, and the interior of the casing 1 includes a positioning mechanism 4, The positioning mechanism 4 includes a detection cavity 401 opened on the inner wall of the housing 1, and a contraction spring 402 is fixedly connected to the inner wall of the detection cavity 401 away from the thermal resistance 2 side. The contraction spring 402 is initially in a state of being squeezed and contracted, so that the squeeze wheel 405 continues to squeeze the thermal resistance 2, the side of the contraction spring 402 close to the thermal resistance 2 is fixedly connected with the support frame 403, the other side of the support frame 403 is rotatably connected with the support arc block 404, and the side of the...

Embodiment 2

[0028] see Figure 1-Figure 5 , a new type of electronic component resistance through casing equipment, including a casing 1, the interior of the casing 1 is provided with a thermal resistance 2, the two sides of the thermal resistance 2 are fixedly connected with connecting wires 3, and the interior of the casing 1 includes a positioning mechanism 4, The inside of the housing 1 includes a tightening mechanism 5, and the tightening mechanism 5 includes an inflatable rod 501 rotatably connected to the side of the driving wheel 416, and an inflatable plate 502 is fixedly connected to the side of the inflatable rod 501 away from the center of the air cavity 418, and the air cavity 418 is far away from the center. One side of the thermal resistance 2 is interspersed with a one-way air intake pipe 503, and the other side of the air cavity 418 is interspersed with an inflatable pipe 504. The inflatable pipe 504 communicates with the air spring 505 and the air cavity 418 respectively, a...

Embodiment 3

[0031] see Figure 1-Figure 5 , a new type of electronic component resistance through casing equipment, including a casing 1, the interior of the casing 1 is provided with a thermal resistance 2, the two sides of the thermal resistance 2 are fixedly connected with connecting wires 3, and the interior of the casing 1 includes a positioning mechanism 4, The positioning mechanism 4 includes a detection cavity 401 opened on the inner wall of the housing 1, and a contraction spring 402 is fixedly connected to the inner wall of the detection cavity 401 away from the thermal resistance 2 side. The contraction spring 402 is initially in a state of being squeezed and contracted, so that the squeeze wheel 405 continues to squeeze the thermal resistance 2, the side of the contraction spring 402 close to the thermal resistance 2 is fixedly connected with the support frame 403, the other side of the support frame 403 is rotatably connected with the support arc block 404, and the side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com