Patents

Literature

80results about How to "Reduce the pressure gradient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

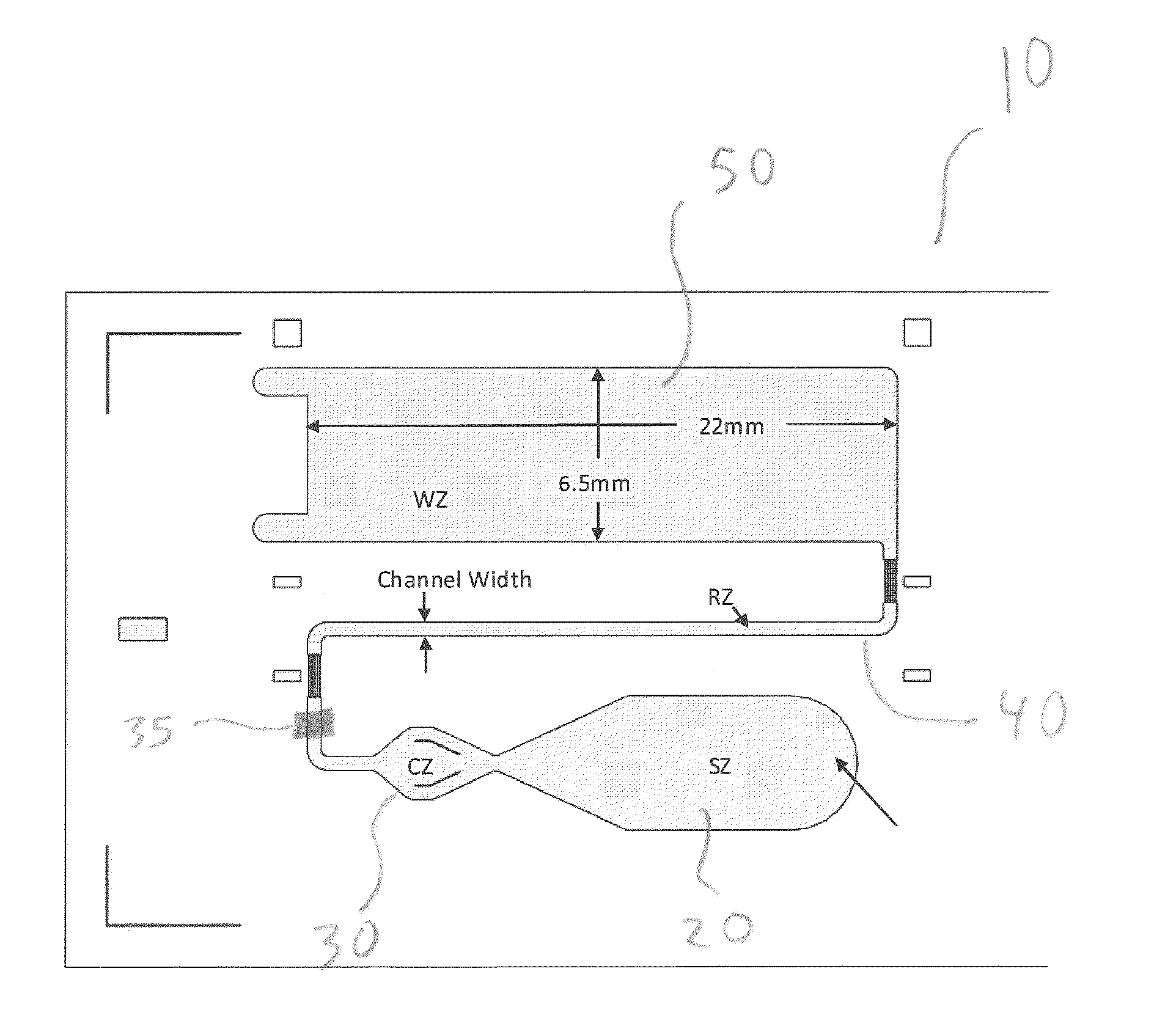

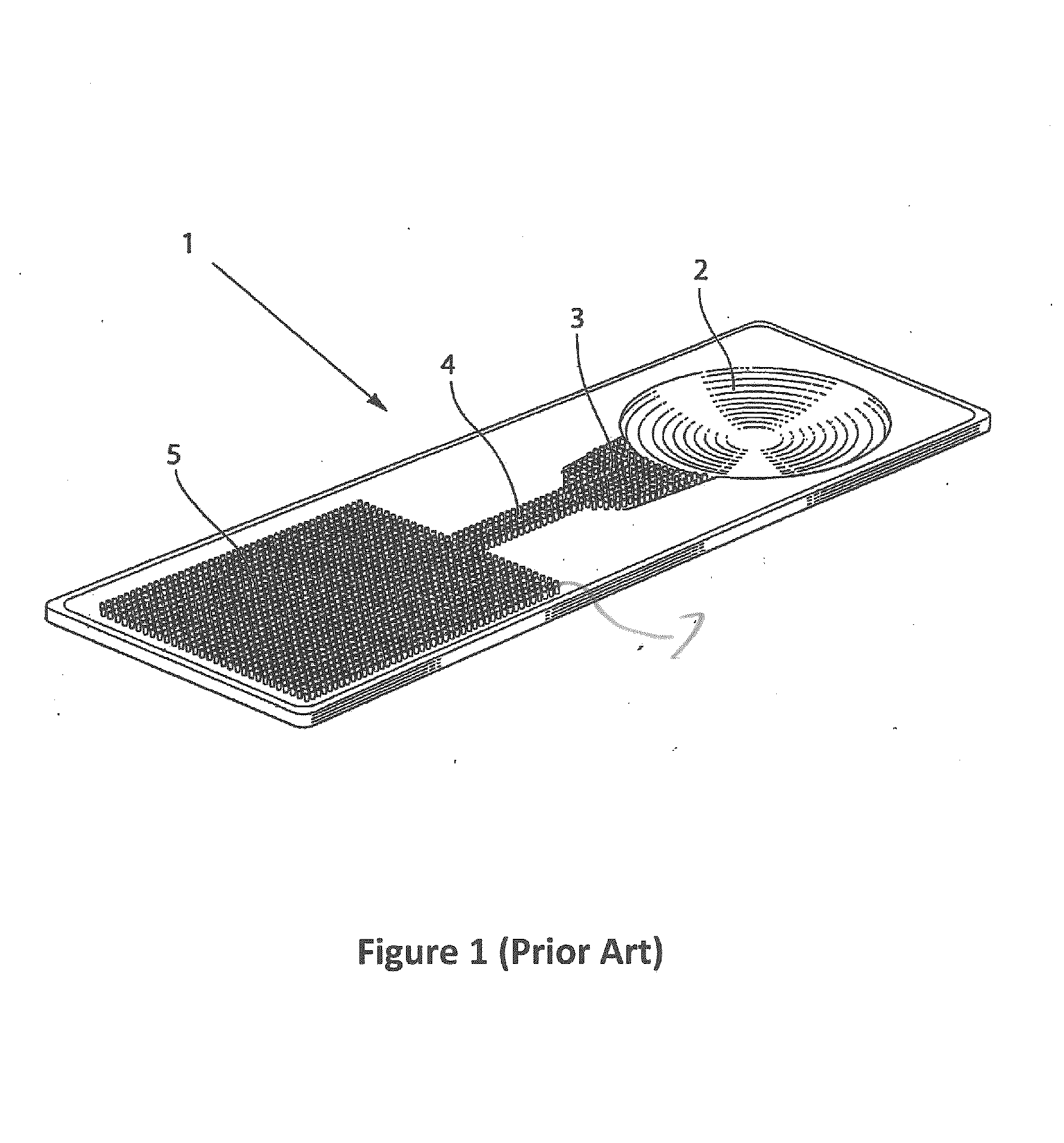

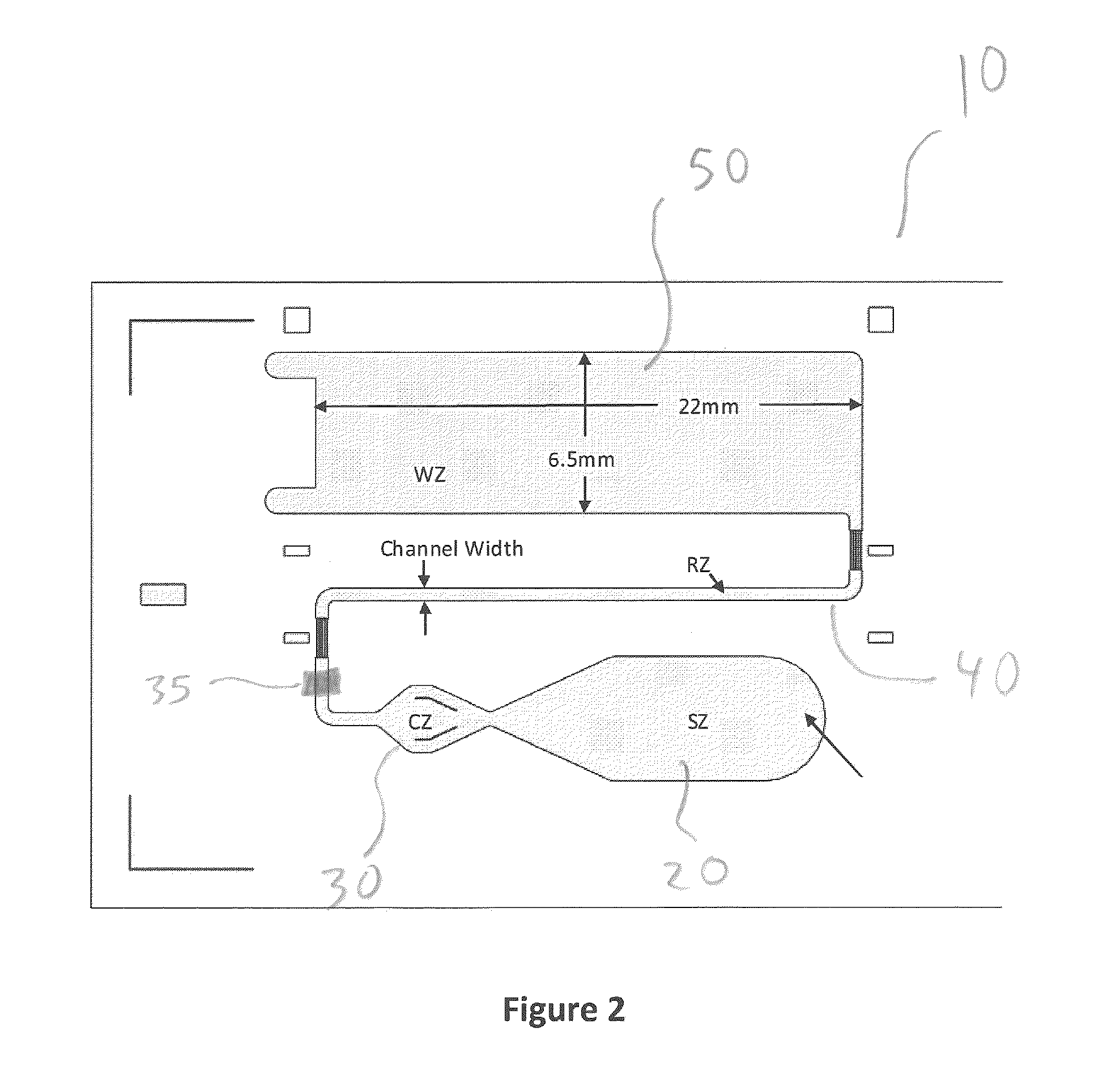

Controlling Fluid Flow Through An Assay Device

InactiveUS20130210036A1Reduce the pressure gradientExtended flow timeBioreactor/fermenter combinationsBiological substance pretreatmentsAssayMechanical engineering

An assay device includes: a detection zone which includes a first set of projections which are capable of generating capillary flow. A wicking zone (WZ) has a capacity to receive liquid sample flowing from the detection zone and includes a second set of projections which are capable of generating capillary flow. The WZ is rectangular in shape and the longer side of the rectangle extends in the direction of flow to thereby reduce the pressure gradient in the assay device which increases the total flow time of liquid sample compared to a WZ having equal length sides and same volume. At least a portion of the second set of projections have at least one dimension selected from a diameter, a center-to-center spacing, or a gap between projections that is different from the first set of projections, and is selected to increase the total flow time of the sample.

Owner:ORTHO-CLINICAL DIAGNOSTICS

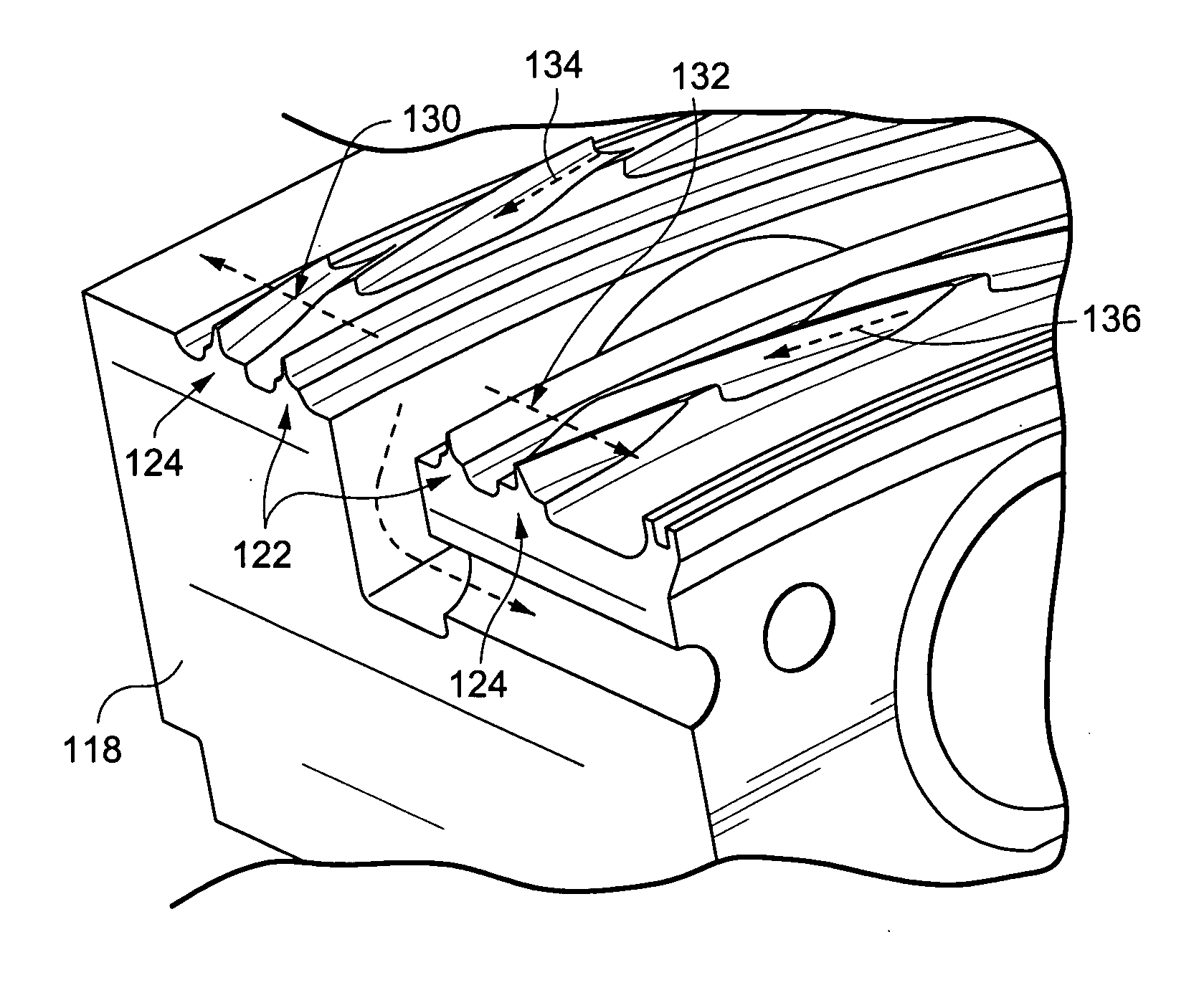

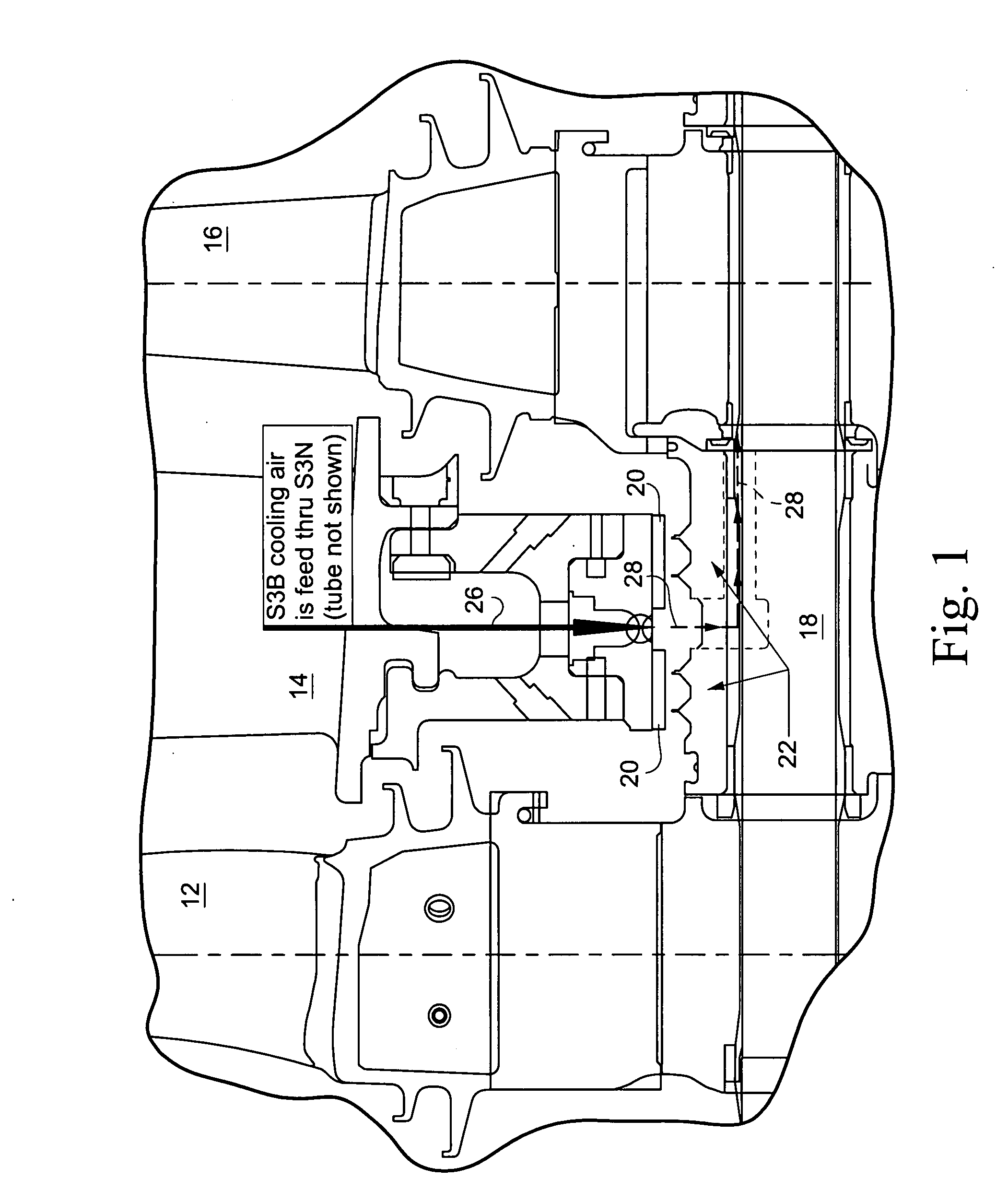

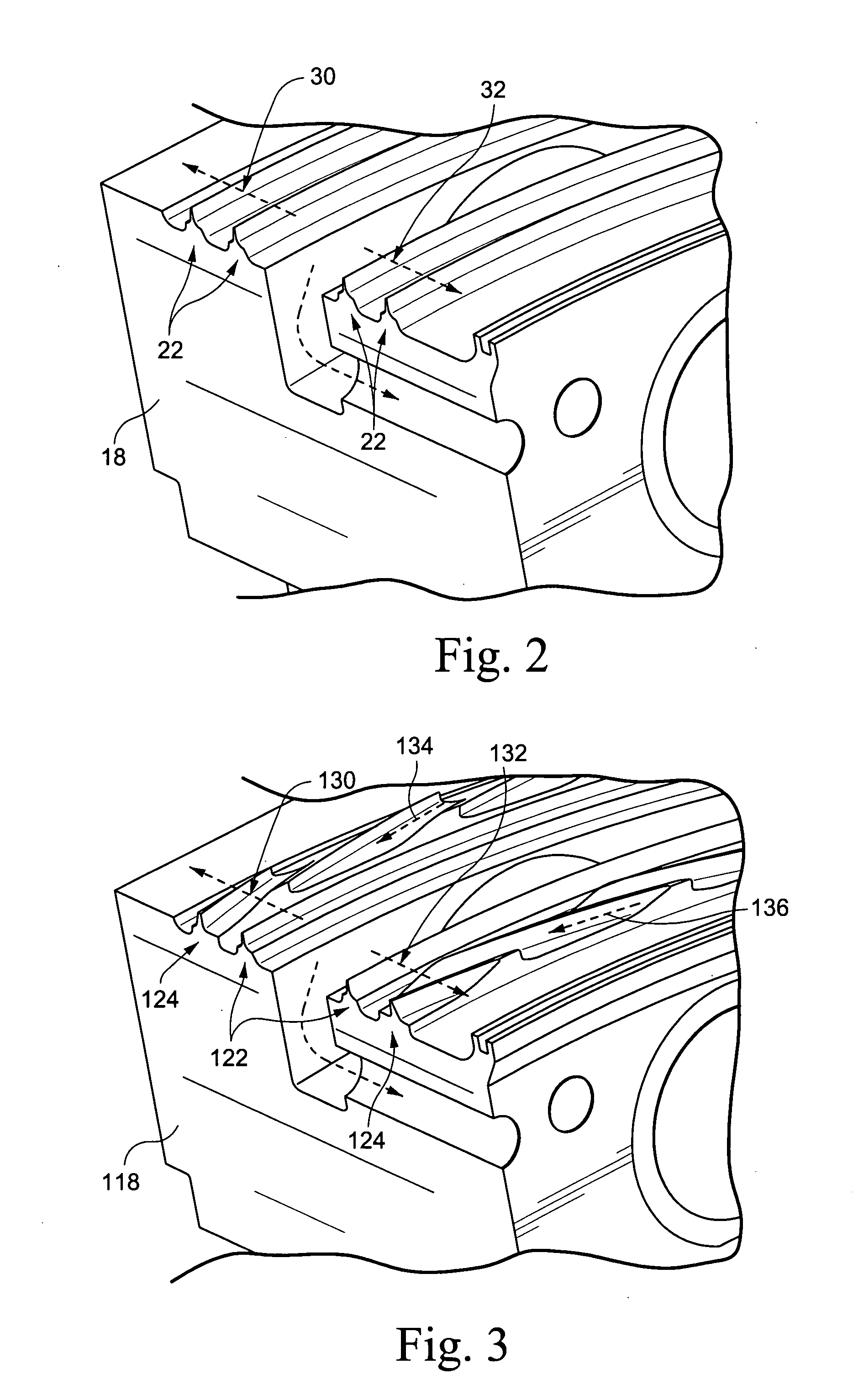

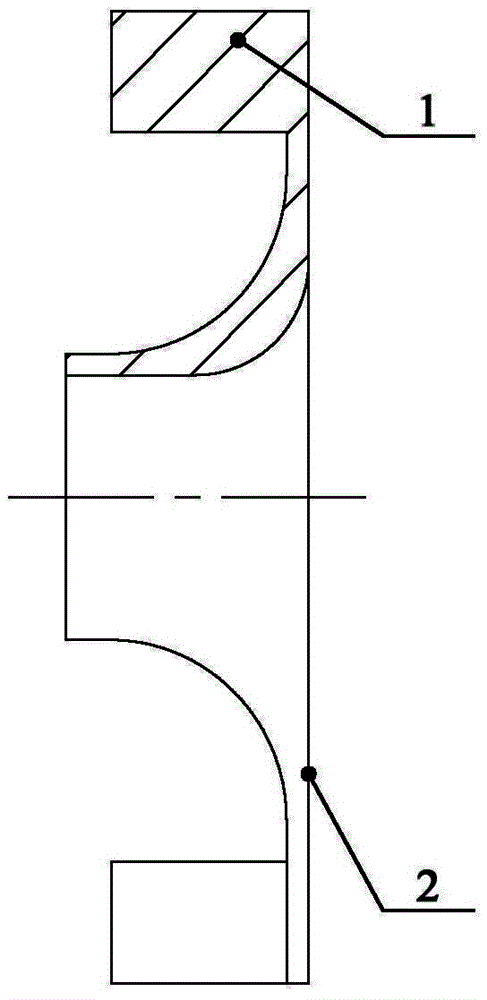

Labyrinth compression seal and turbine incorporating the same

InactiveUS20090058013A1Improve axial sealingReduce the pressure gradientEngine sealsPump componentsEngineeringMechanical engineering

A uniquely configured rotating seal tooth is used in conjunction with commonly used labyrinth-type seals that provide a seal between a rotating component and a stationary component. The uniquely configured rotating seal tooth produces a compression mechanism to counter leakage flow through the labyrinth of seal teeth, thereby lessening the pressure gradient that drives leakage and reversing the direction of some of the leakage flow.

Owner:GENERAL ELECTRIC CO

Fiber composite sand control process without sieve tube and treatment agent formula

The invention relates to a method for preventing sand in oil natural gas well, and the formula of relative processing agent, wherein the invention uses fiber to form three-dimension mesh structure, to control the process of discharging sand from storage layer and the formula of processing agent. The invention is characterized in that: first using crack machine and ground tube to extrude pretreatment liquid into storage layer; then using salt water clean liquid to crack; then using fiber composite to process main crack; extruding and completing sand prevention. The invention can eliminate the damage on former oil well storage layer, to improve the leakage condition; and the well eye is filled with fiber composite ring around; the invention can improve yield, realize non-screen sand prevention, and save cost.

Owner:PETROCHINA CO LTD

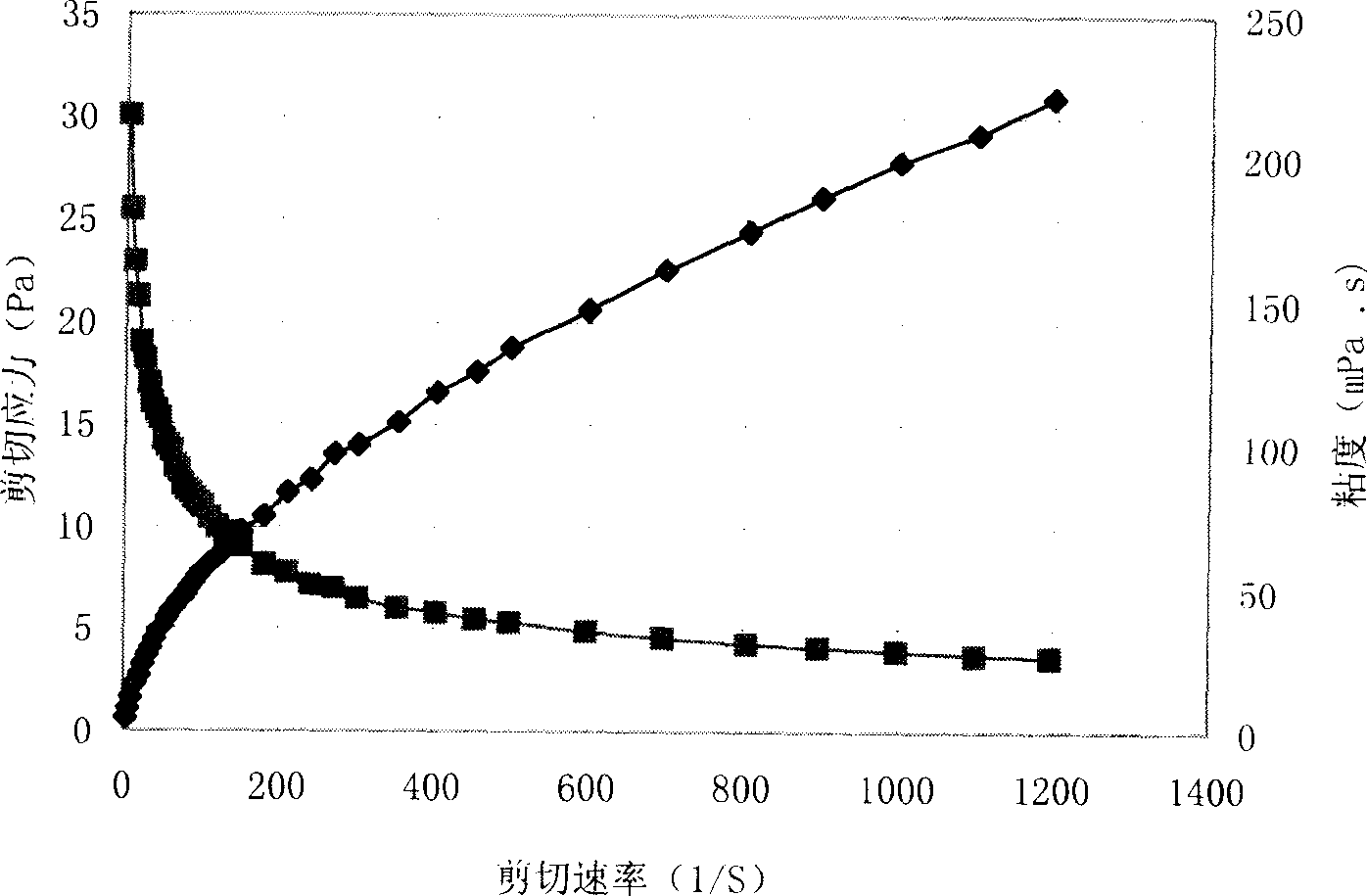

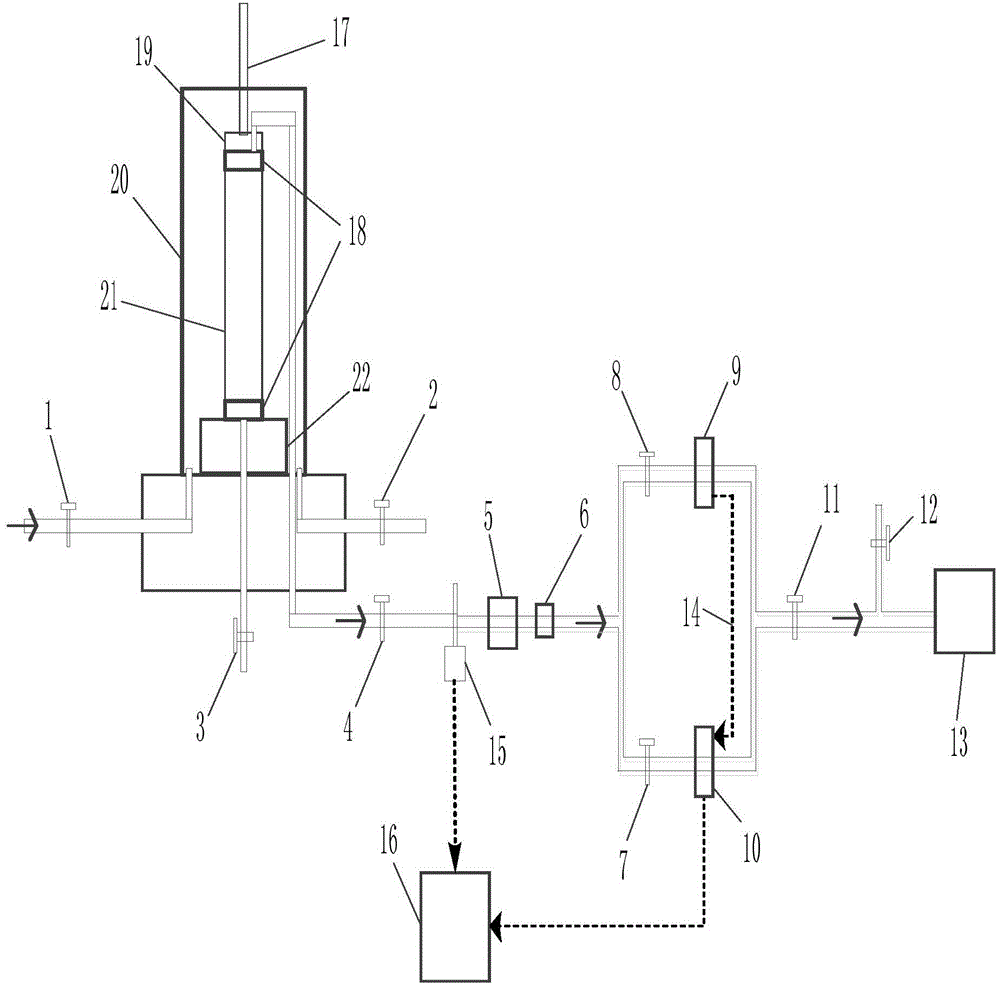

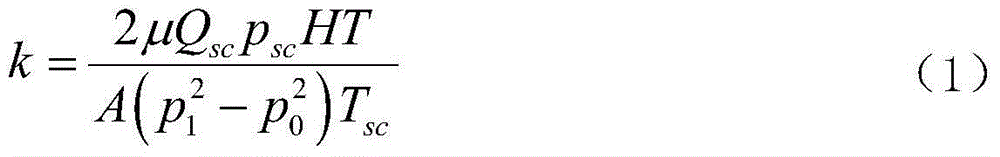

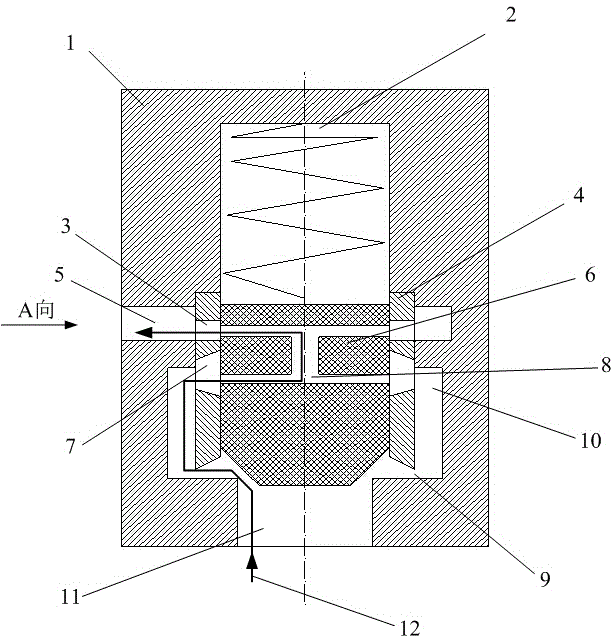

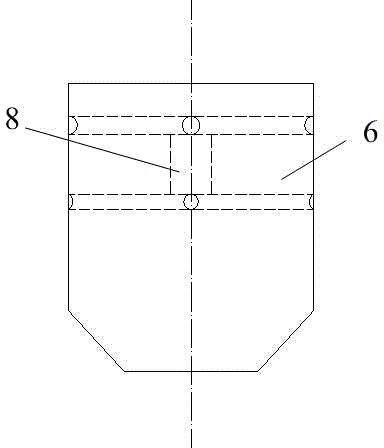

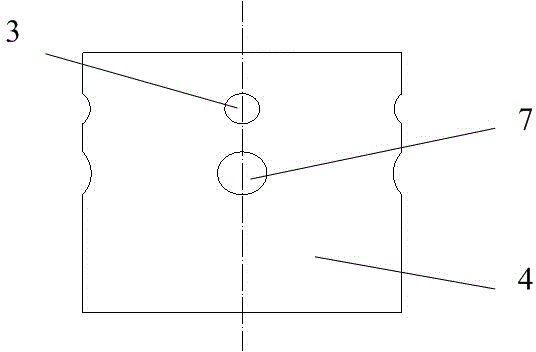

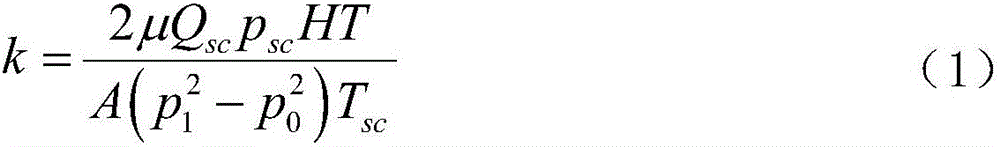

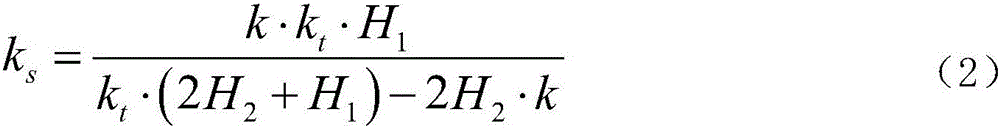

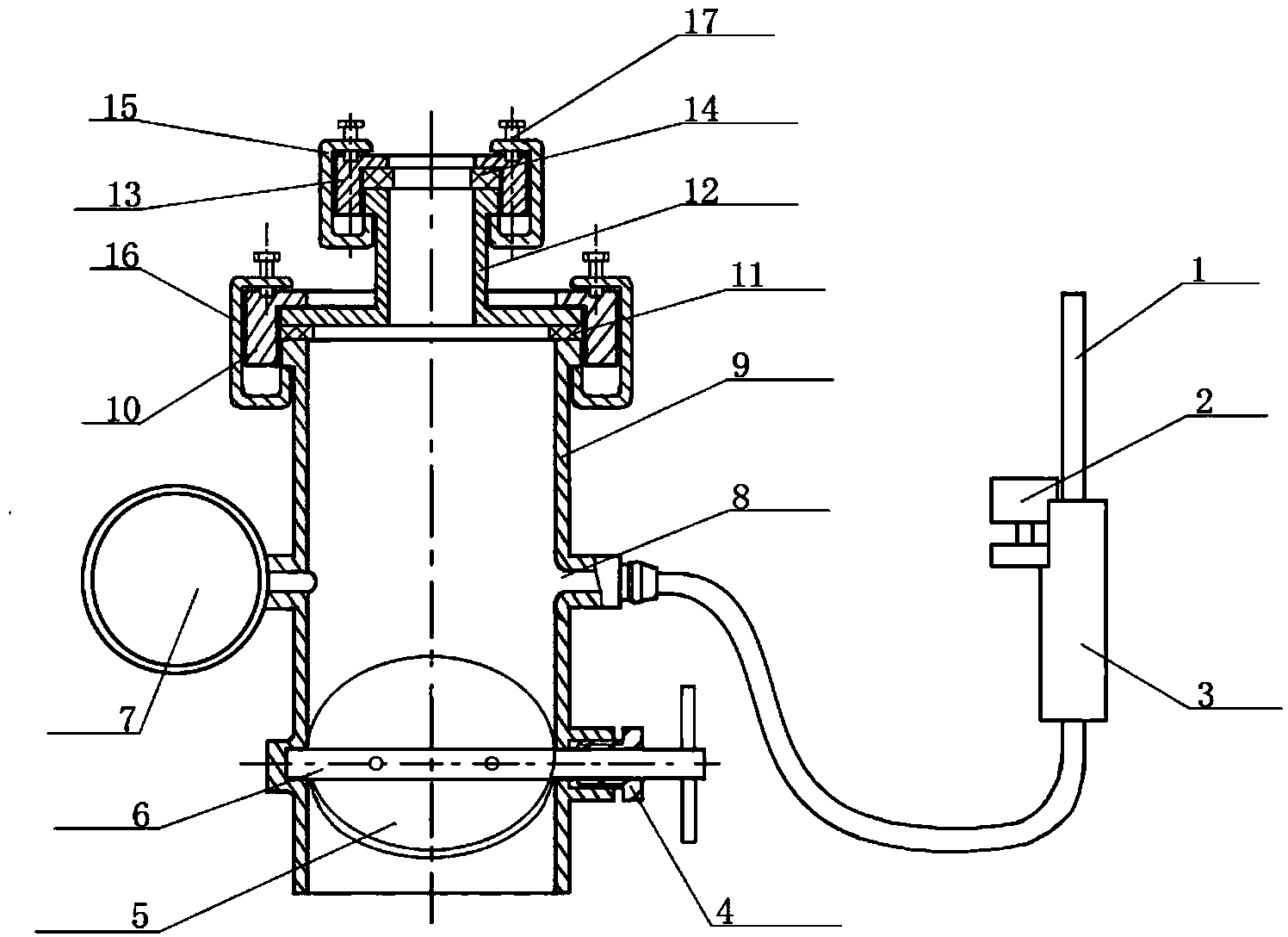

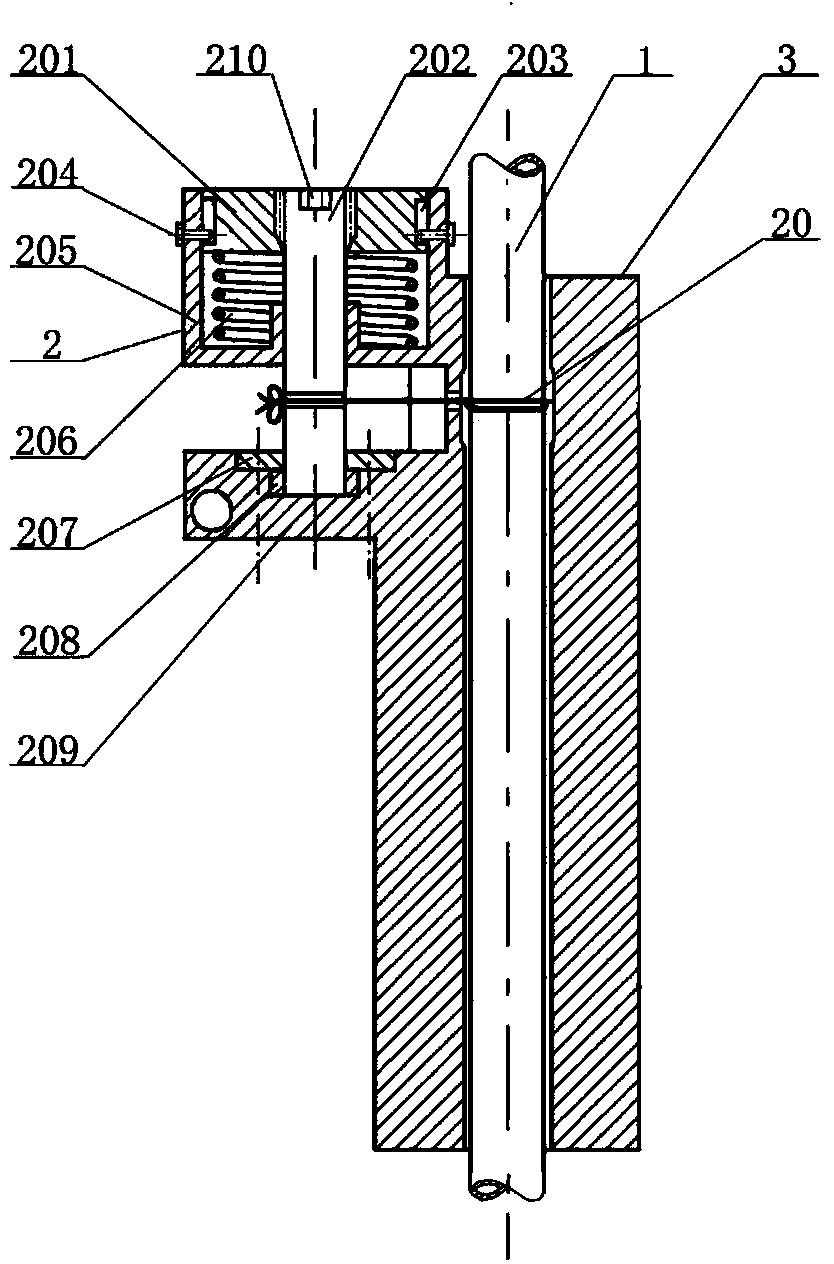

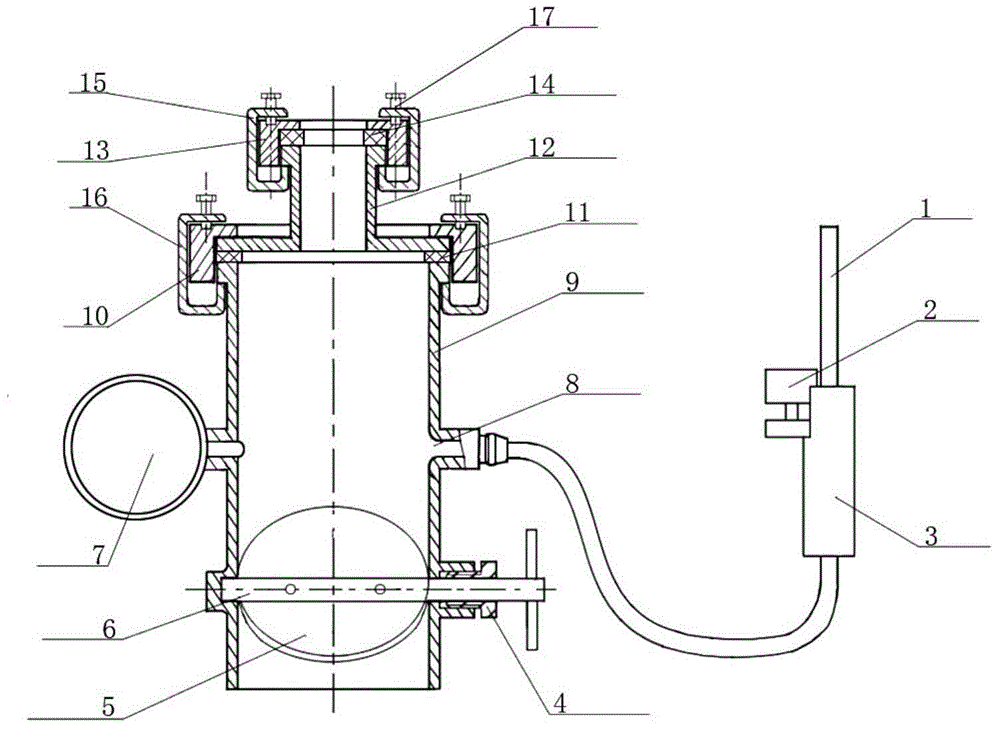

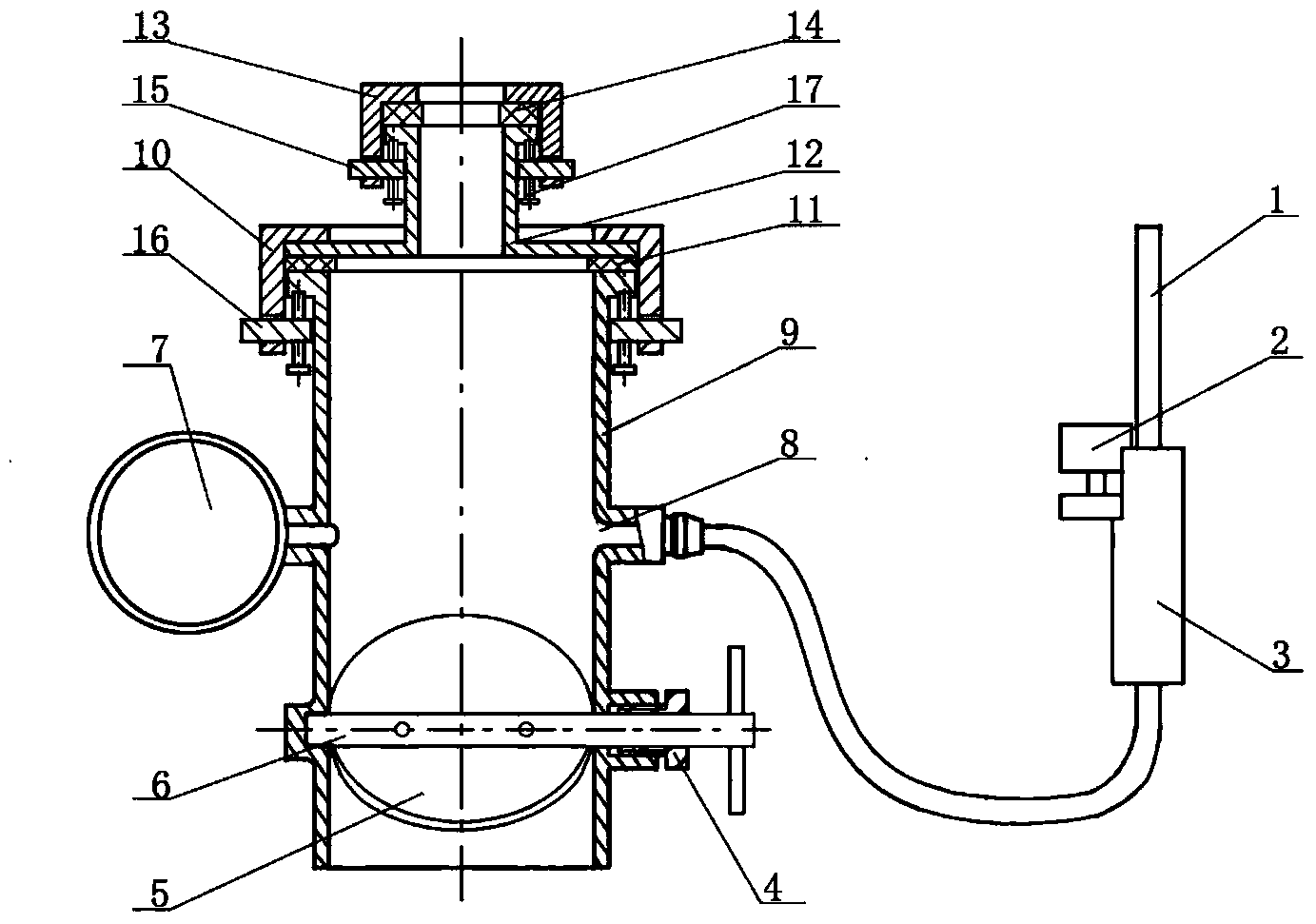

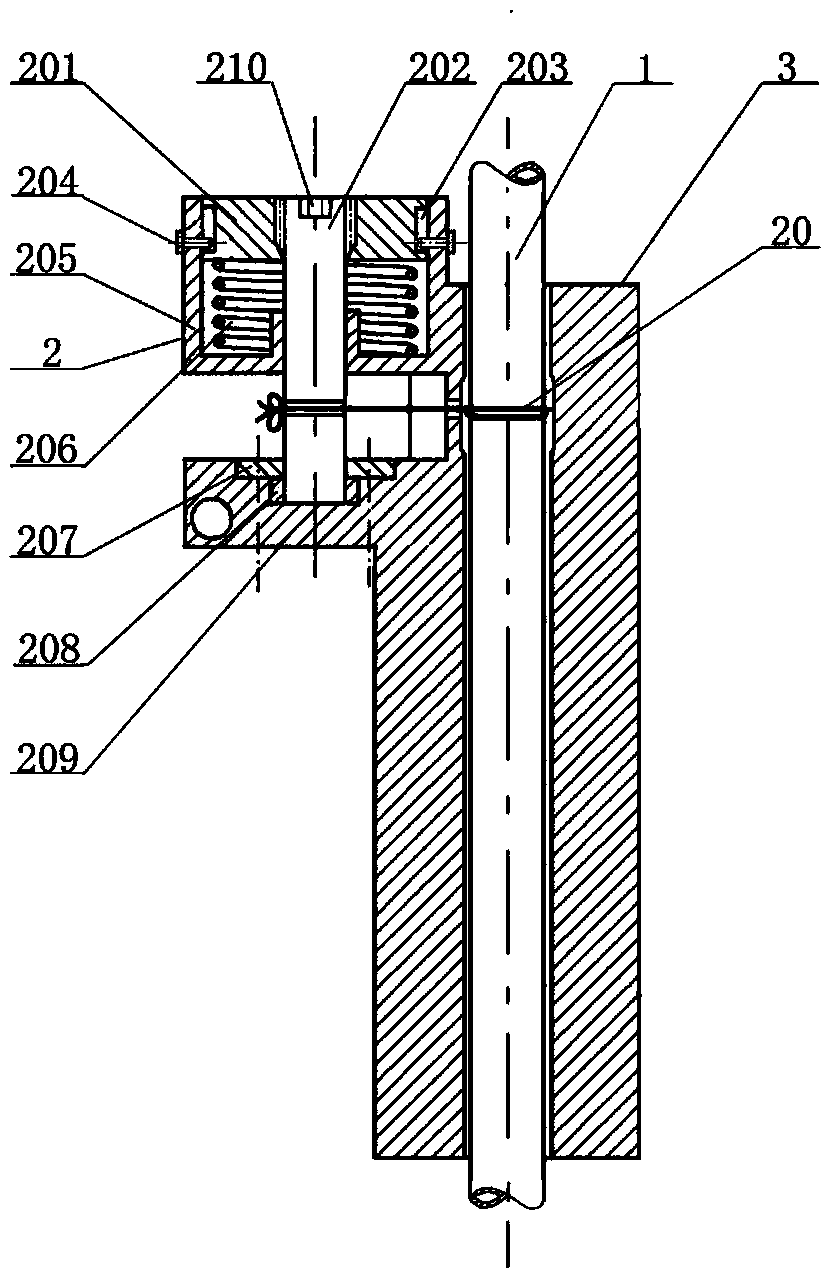

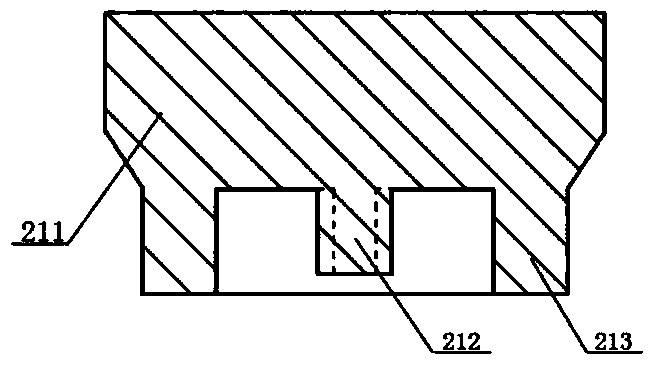

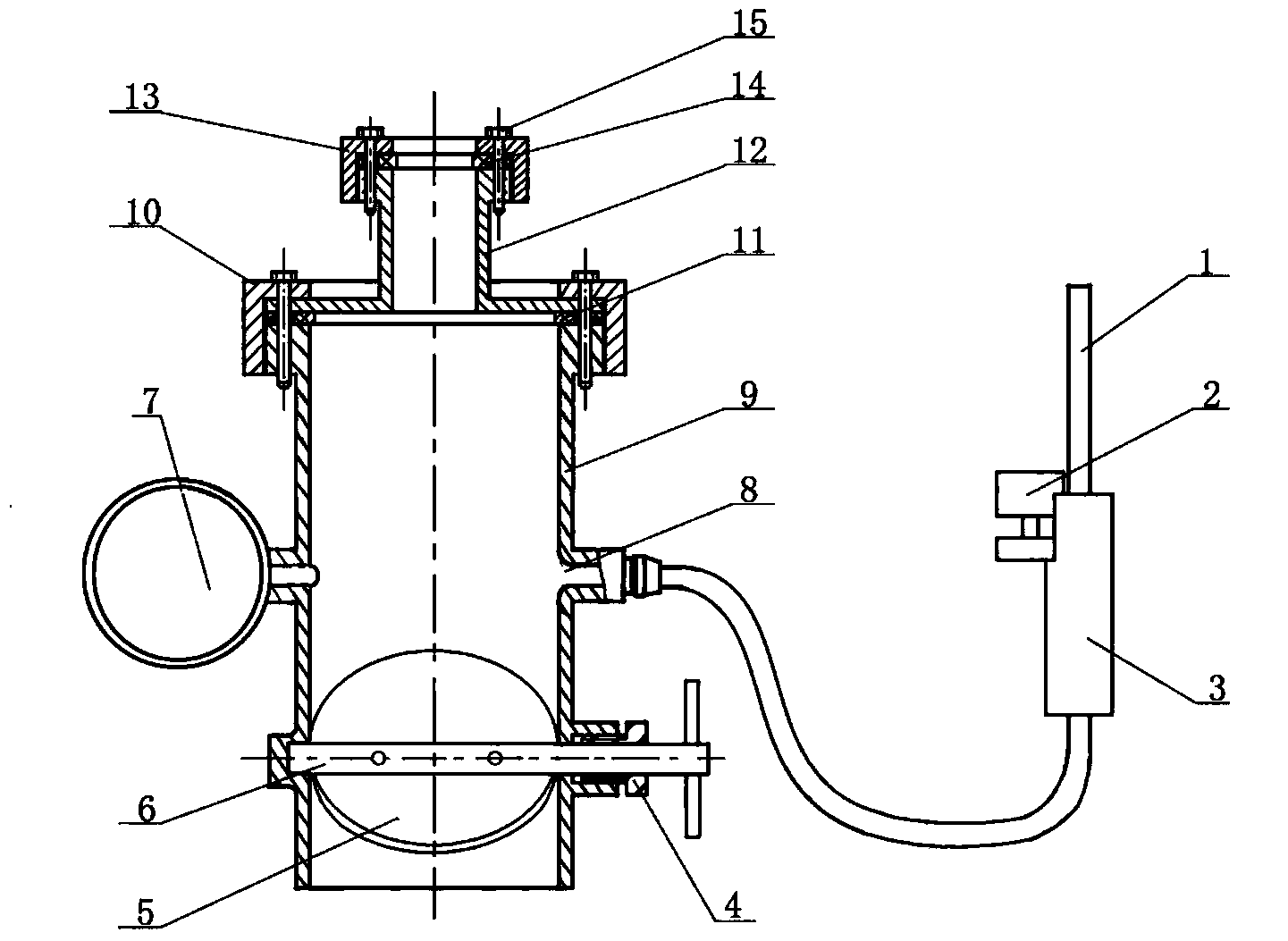

Soil triaxial apparatus-based unsaturated soil gas-permeability measuring method

InactiveCN103913407AGuaranteed tightnessReduce the pressure gradientPermeability/surface area analysisSoil sciencePermeability measurements

The invention provides a soil triaxial apparatus-based unsaturated soil gas-permeability measuring method. The soil triaxial apparatus-based unsaturated soil gas-permeability measuring method utilizes a triaxial apparatus as a basic device and gas pressure and mass flow measuring devices as additional devices to realize unsaturated soil gas-permeability measurement. According to the soil triaxial apparatus-based unsaturated soil gas-permeability measuring method, based on a gas exhaust principle, sample circular-side sealing is realized by small confining pressure application so that the confining pressure influence on a sample pore structure is reduced. The soil triaxial apparatus-based unsaturated soil gas-permeability measuring method utilizes a triaxial apparatus as the basic device so that gas permeability measurement is realized, study of an unsaturated soil pore structure change rule under triaxial test conditions is realized, and stress, strain and gas permeability can be synchronously measured under the triaxial test conditions.

Owner:63653 FORCES PLA

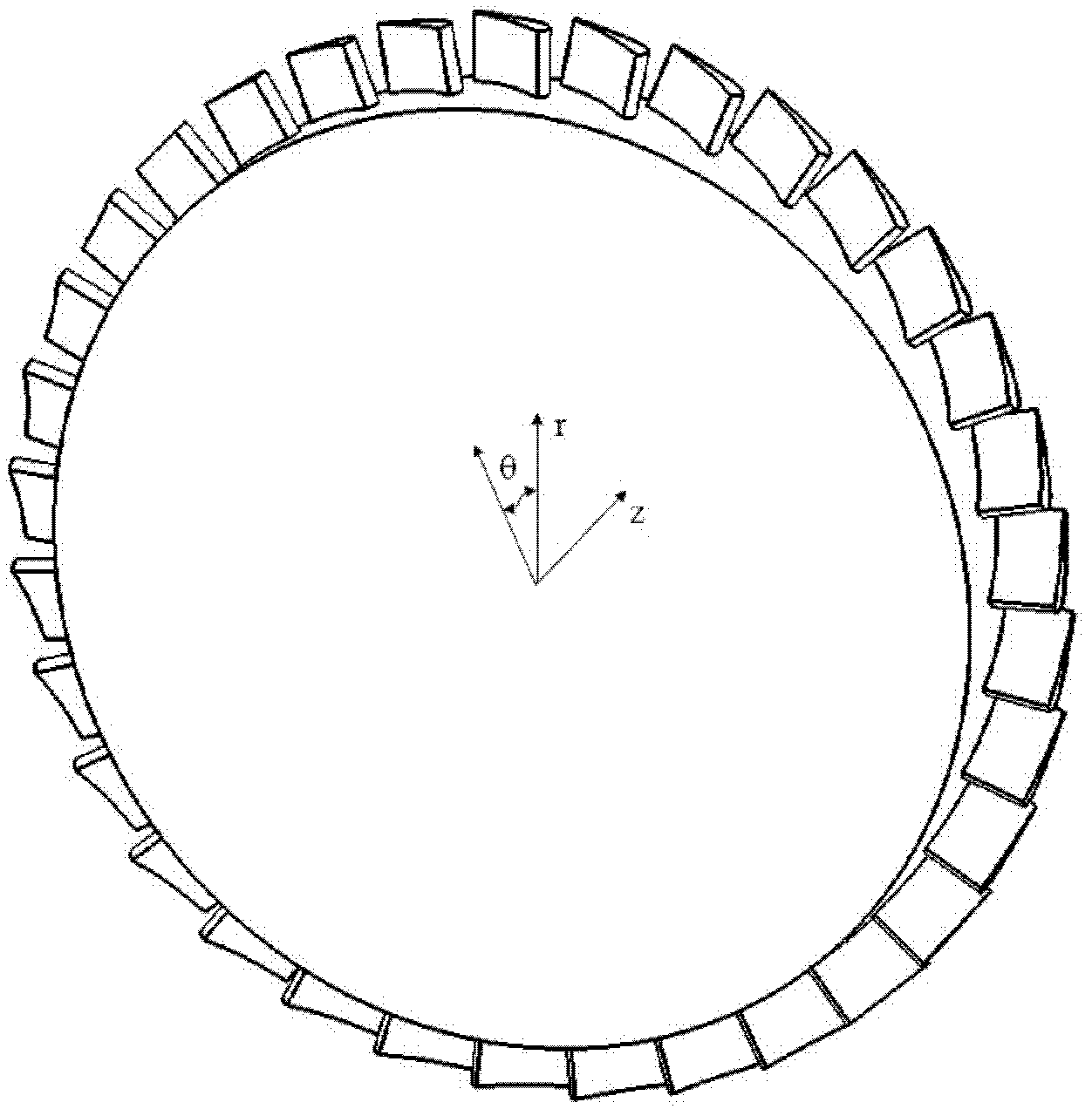

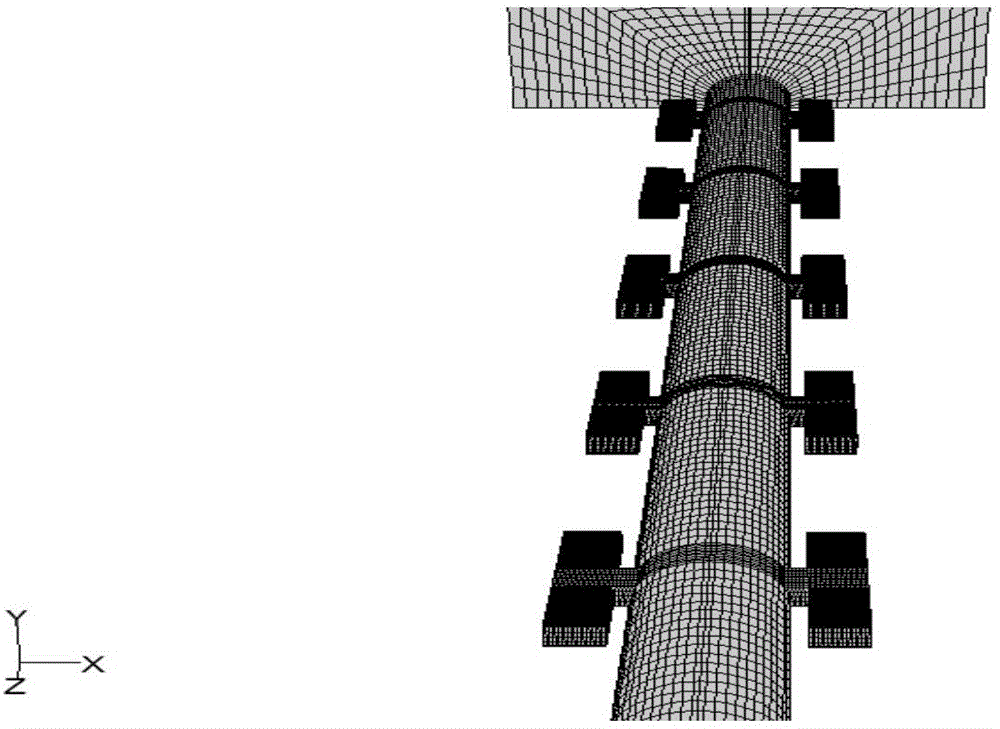

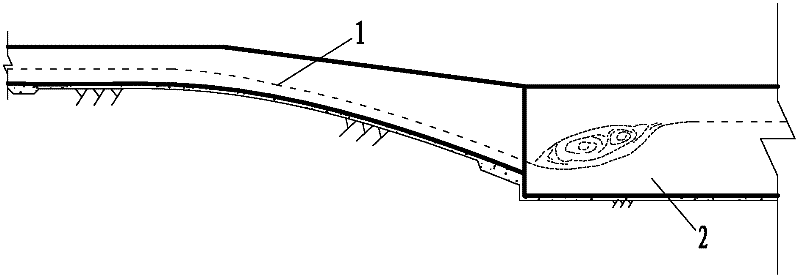

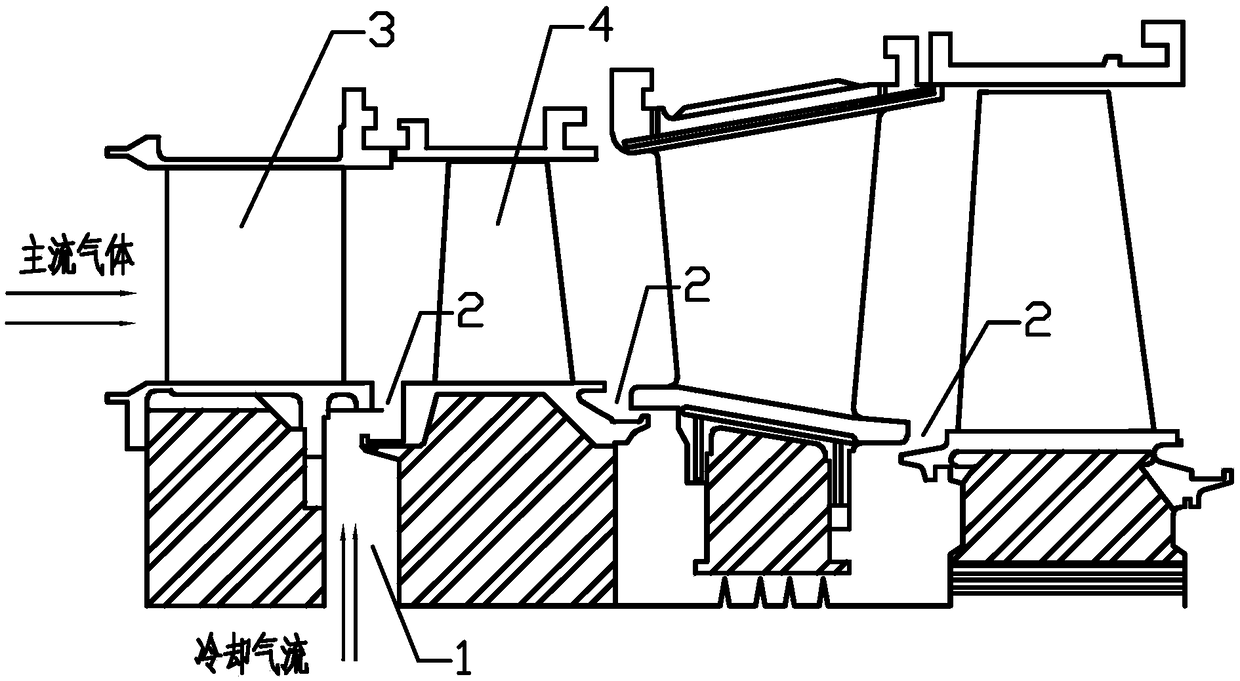

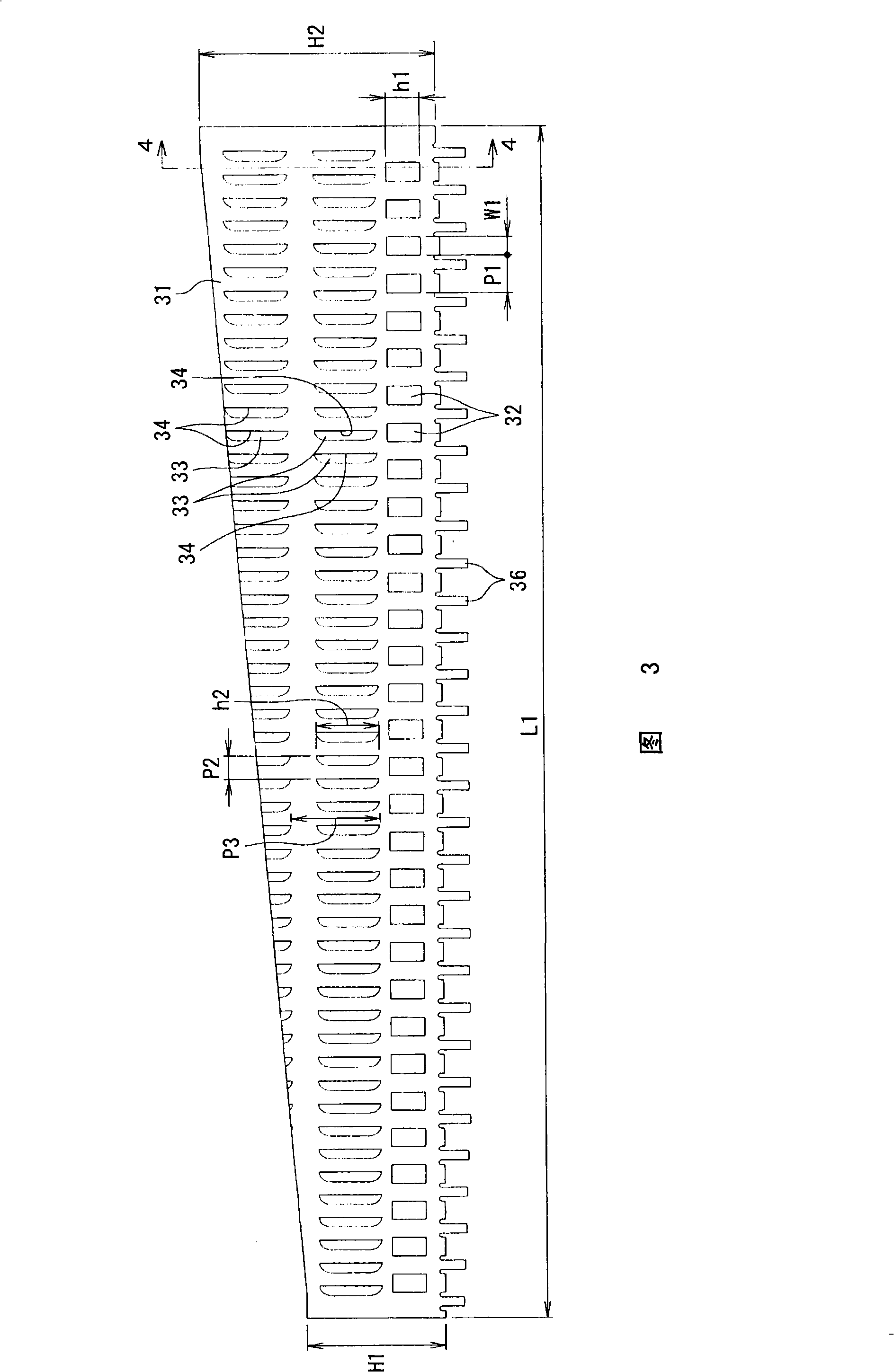

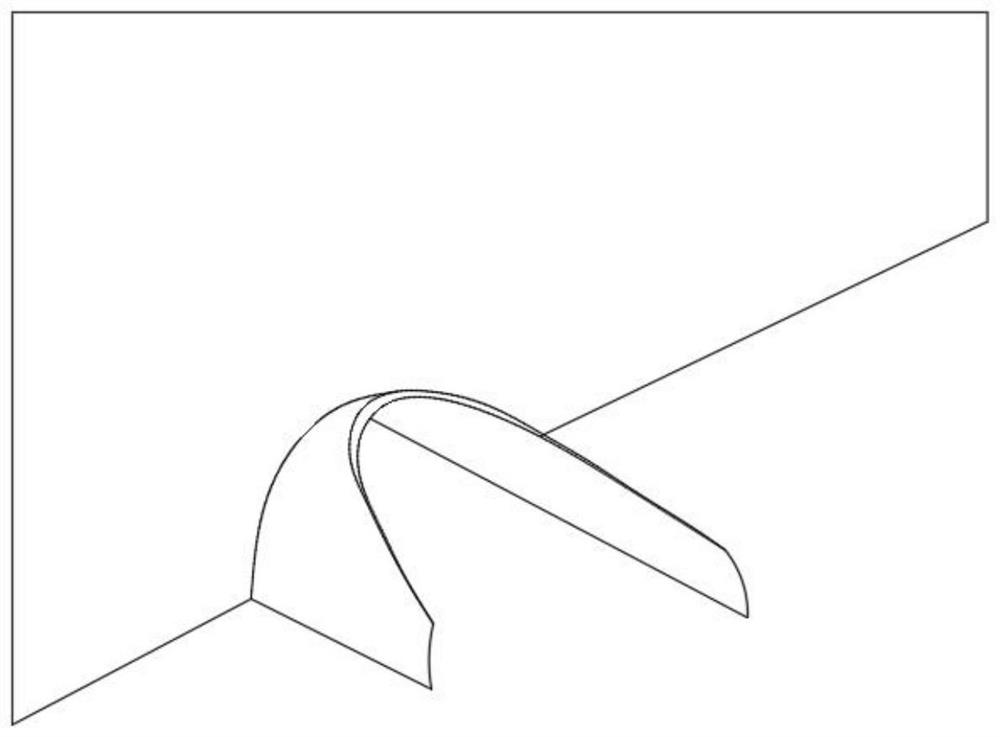

Modeling method for axis-asymmetric end wall of annular blade grid of air compressor or turbine

InactiveCN102536329AImprove performanceSimple structurePump componentsBlade accessoriesAxial compressorModel method

The invention provides a modeling method for an axis-asymmetric end wall of an annular blade grid of an air compressor or a turbine. The method comprises the following steps: firstly, zoning modeling zones of a convex part structure or a concave part structure; modeling a convex part control curve or a concave part control curve in the axial direction of the blade grid or the circumferential direction of the blade grid; and finally modeling a curved surface control function in the radial direction of the blade grid. The invention particularly provides a novel convex part or concave part control function. Through the adoption of the method, the axis-asymmetric end wall of the annular blade grid of the air compressor or the turbine can be modeled conveniently and flexibly; and through the adoption of the axis-asymmetric end wall, the pressure gradient in a passage can be reduced effectively, the airflow at the exit of the passage can be more uniform, the total pressure loss coefficient in the passage can be reduced considerably, the secondary flow loss in the passage can be reduced, and further the performance of the blade grid of the air compressor or the turbine can be improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

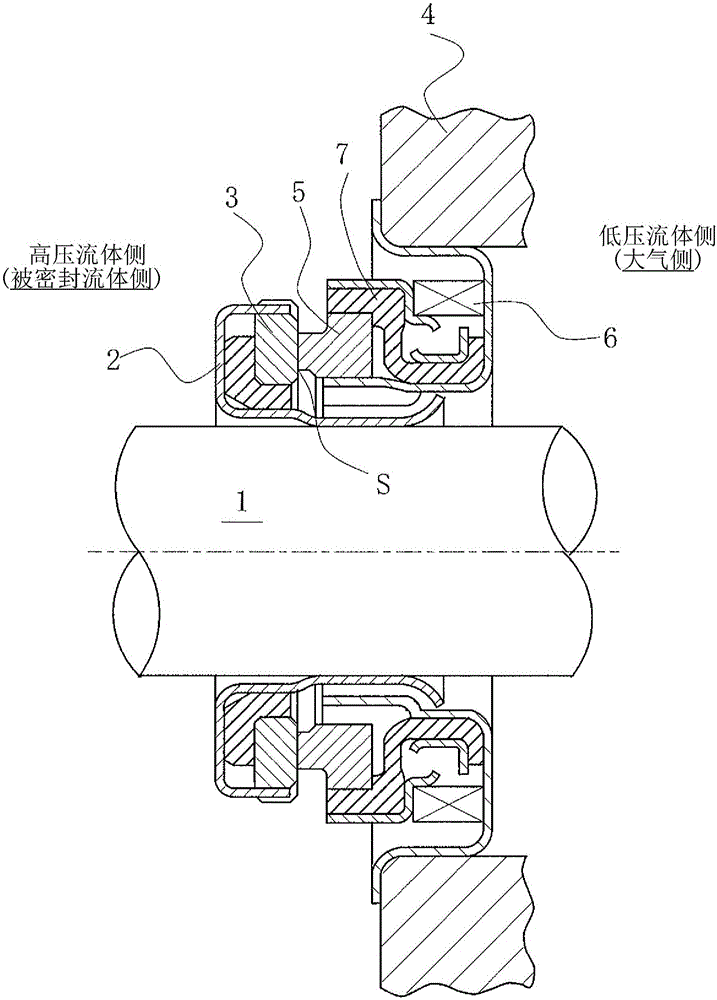

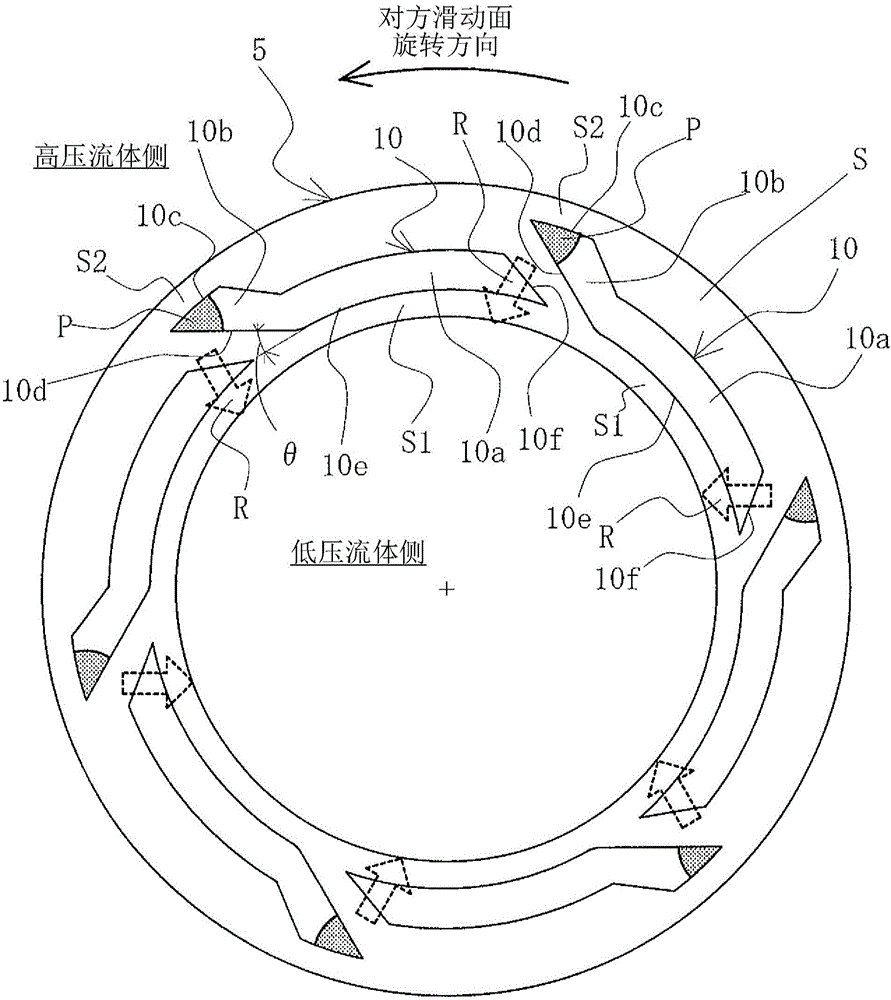

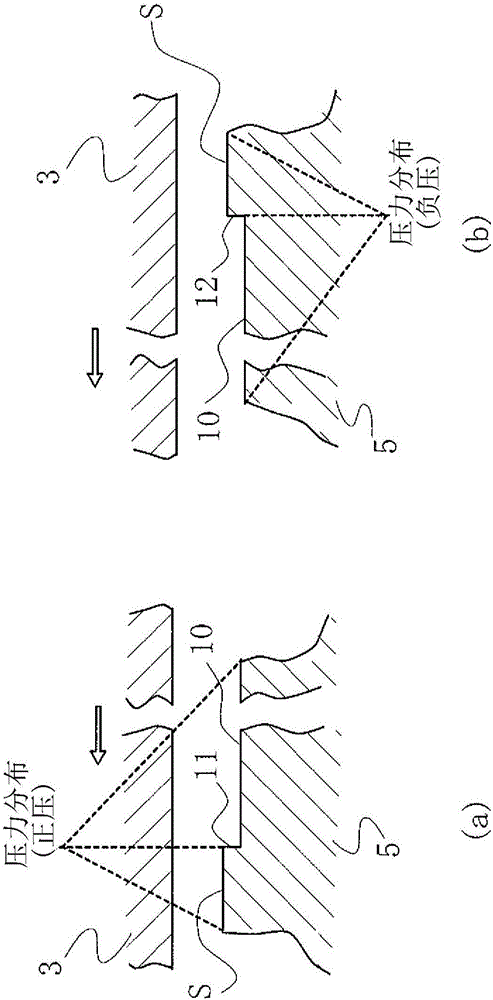

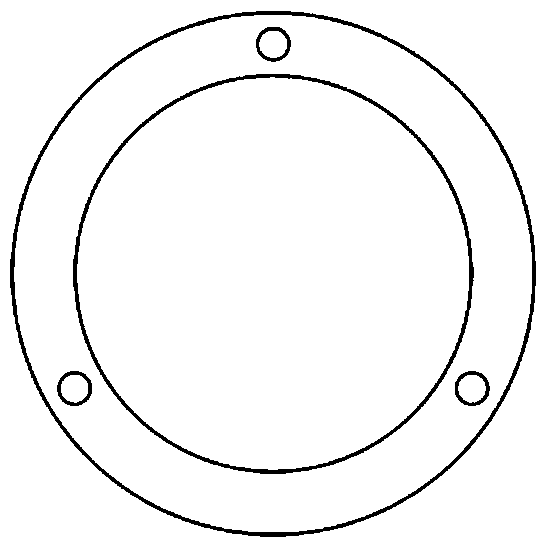

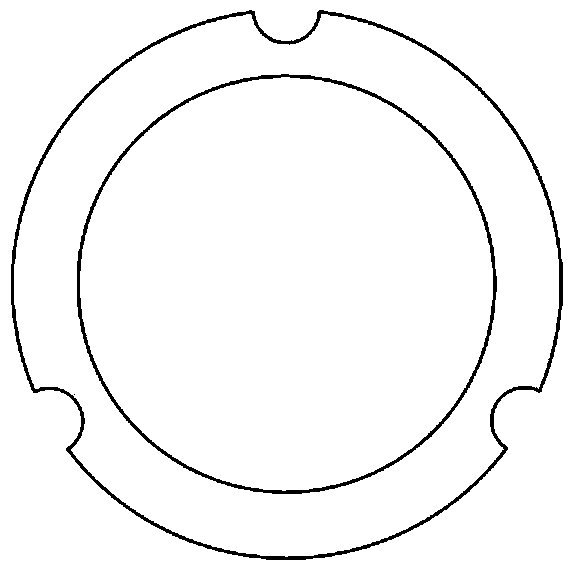

Sliding component

Owner:EAGLE INDS

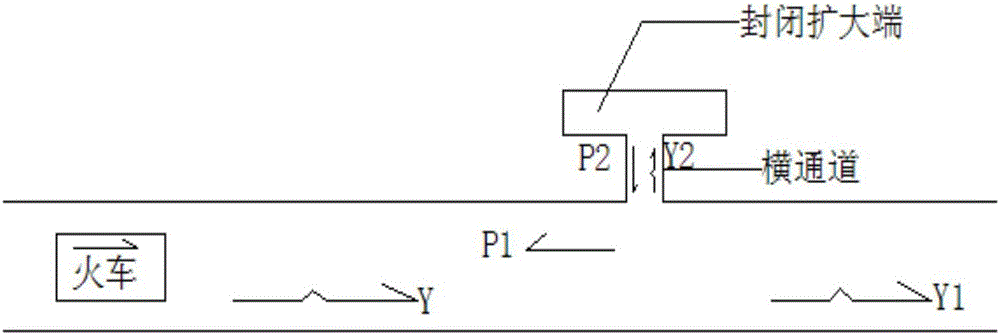

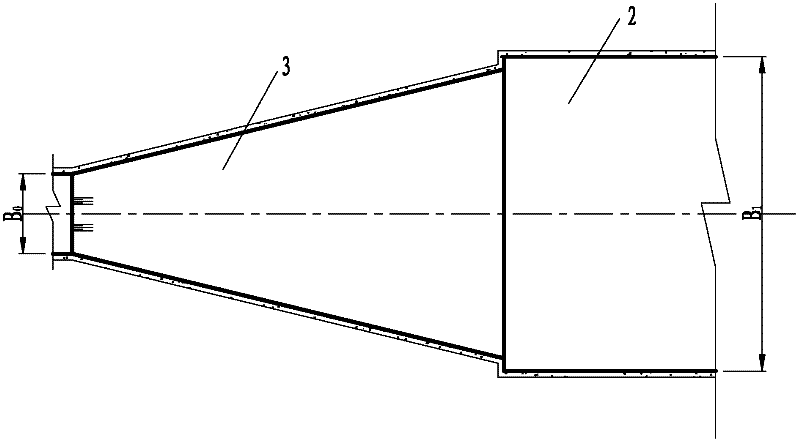

Enlarged chamber alleviation structure on end part of high-speed railway tunnel

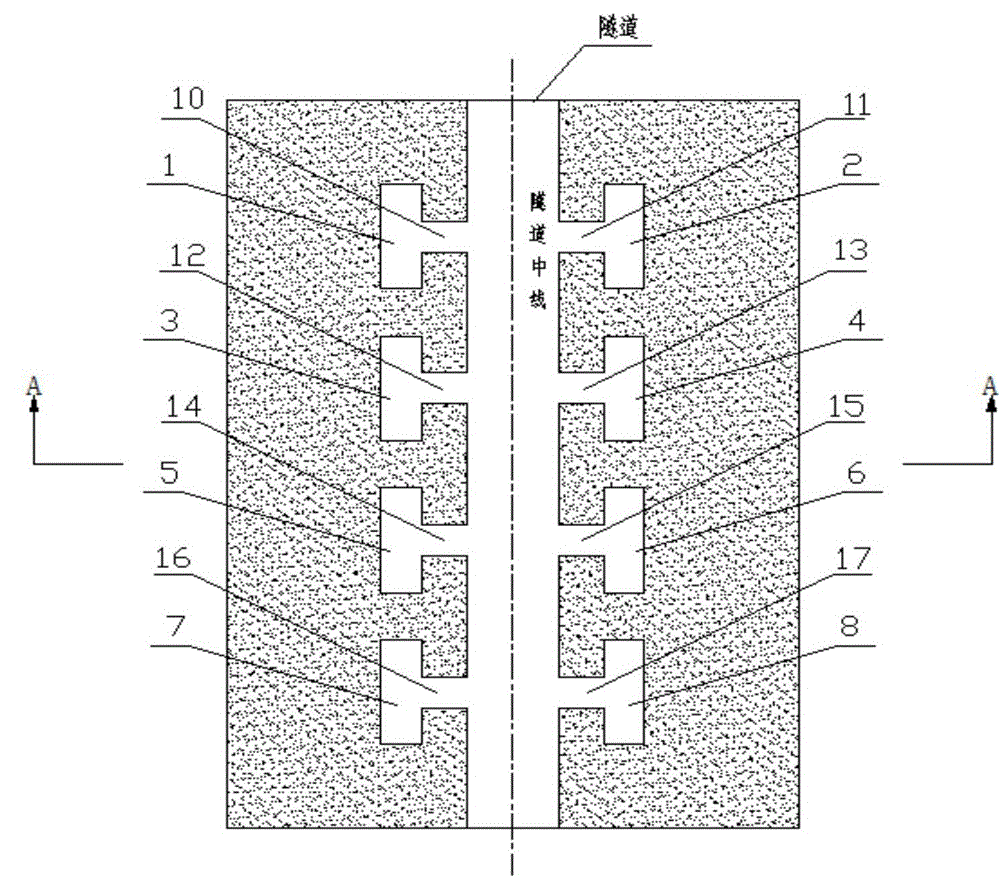

InactiveCN105003282AReduce the pressure gradientReduce the peak value of microwave wavesTunnelsRailway tunnelEngineering

The invention discloses an enlarged chamber alleviation structure on the end part of a high-speed railway tunnel. The enlarged chamber alleviation structure is arranged in the vicinity of the end part of the high-speed railway tunnel, is used for reducing a pressure gradient and a micro-pressure wave peak of compression waves at a tunnel portal, and is characterized in that enlarged chambers are formed in the two transverse sides of the tunnel respectively, wherein the chambers are connected with the tunnel through linking taxiways; the sizes of the chambers are 80 to 130m<3>; the lengths of the linking taxiways are ranged from 2m to 20m, and can be selected according to engineering requirements, and the sectional areas of the linking taxiways are 20 to 40m<2>. According to the structure, the pressure gradient of the compression waves is obviously reduced, the micro-pressure wave peak generated when the compression waves reach the exit of the tunnel is greatly reduced, and the influence of running of a high-speed train on the surrounding of the tunnel is reduced.

Owner:SOUTHWEST JIAOTONG UNIV

Micro-channel parallel flow evaporator

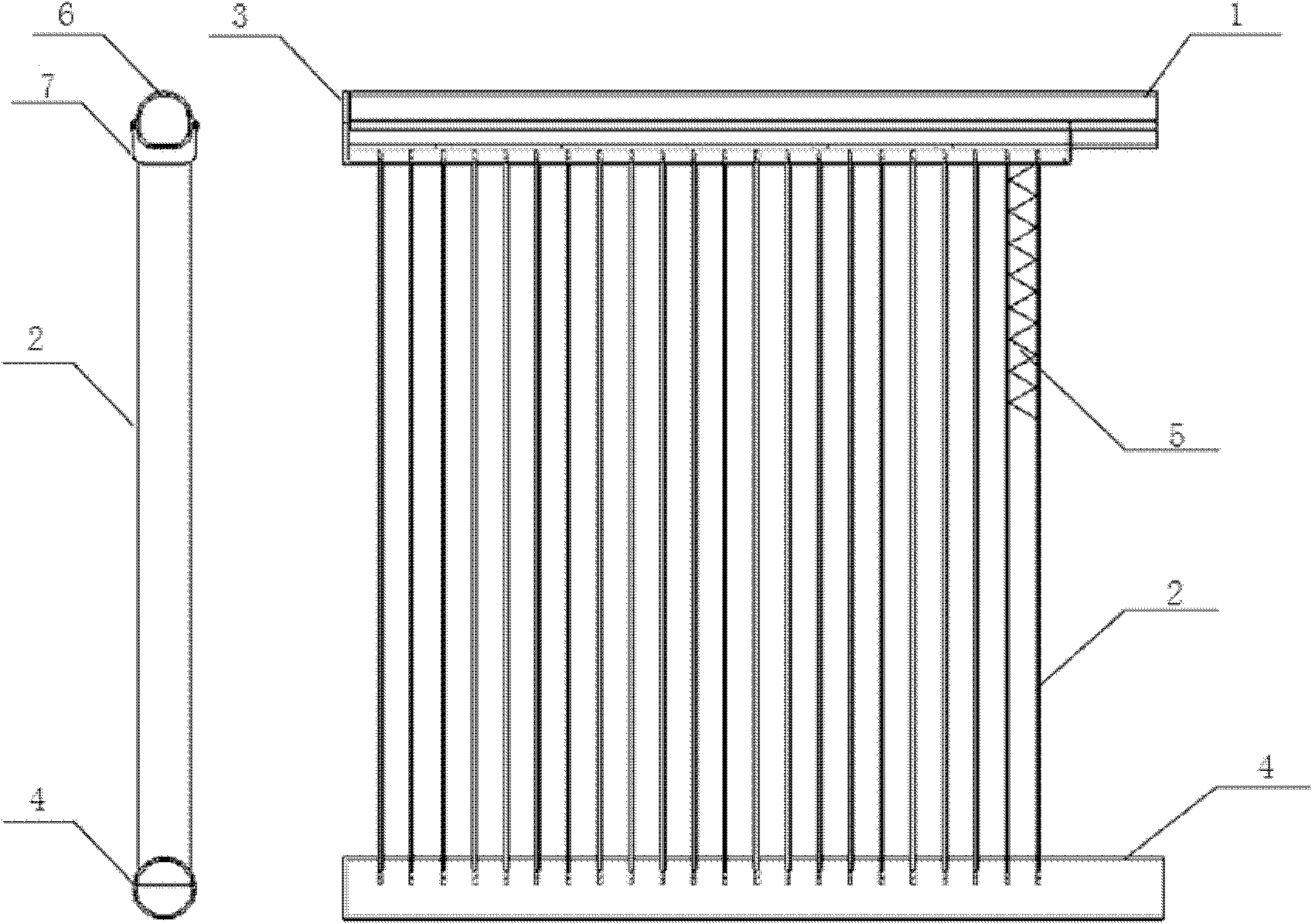

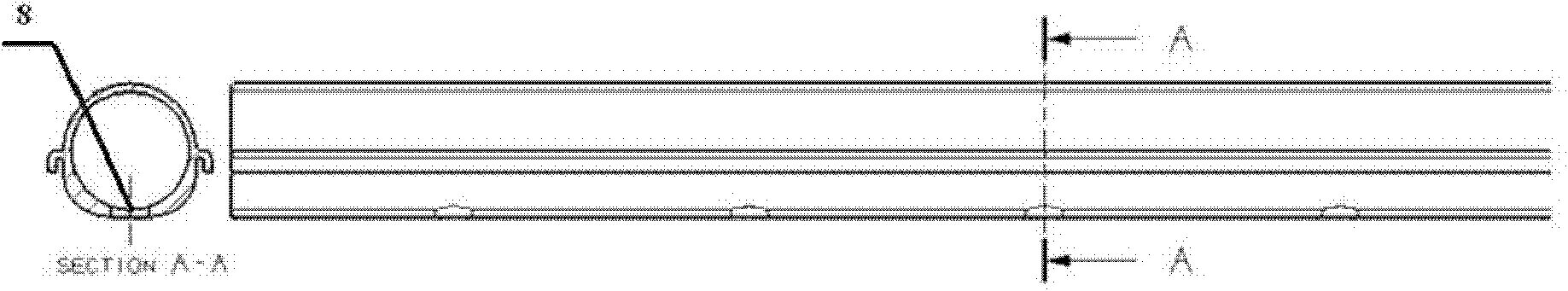

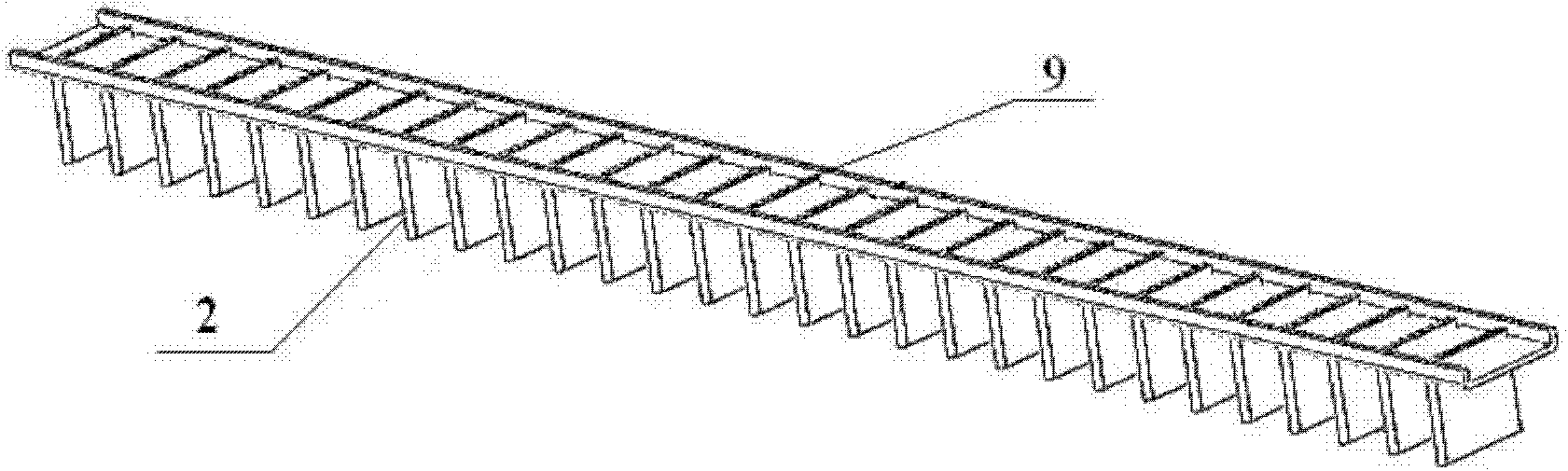

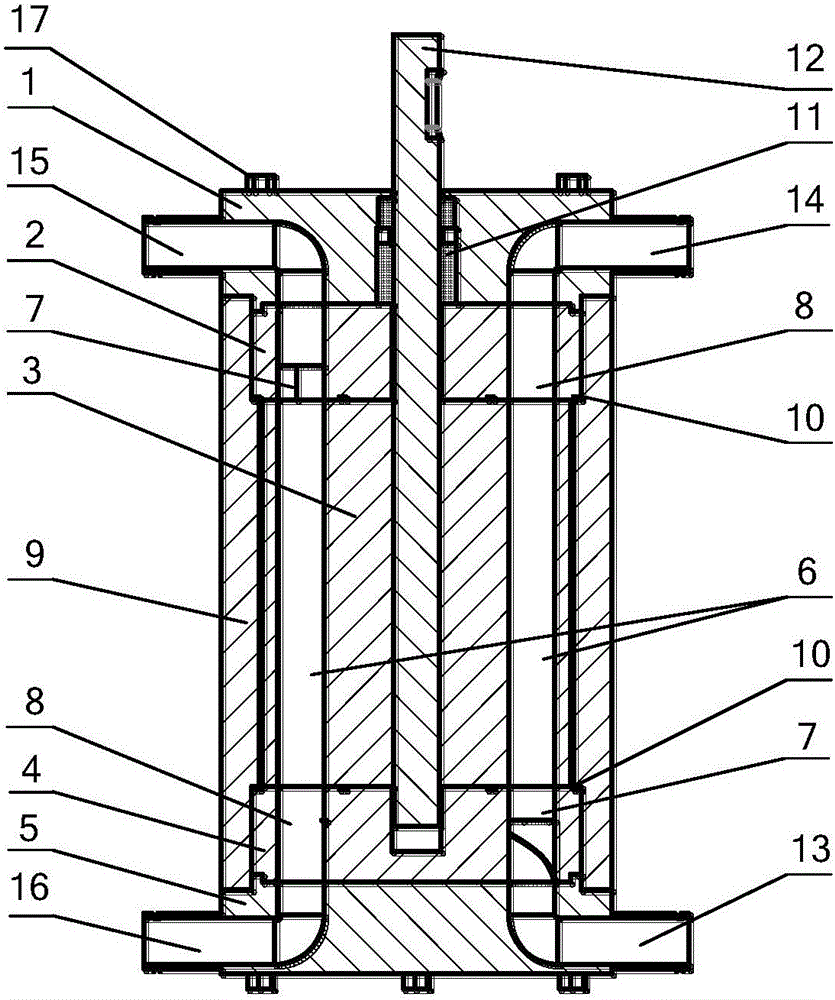

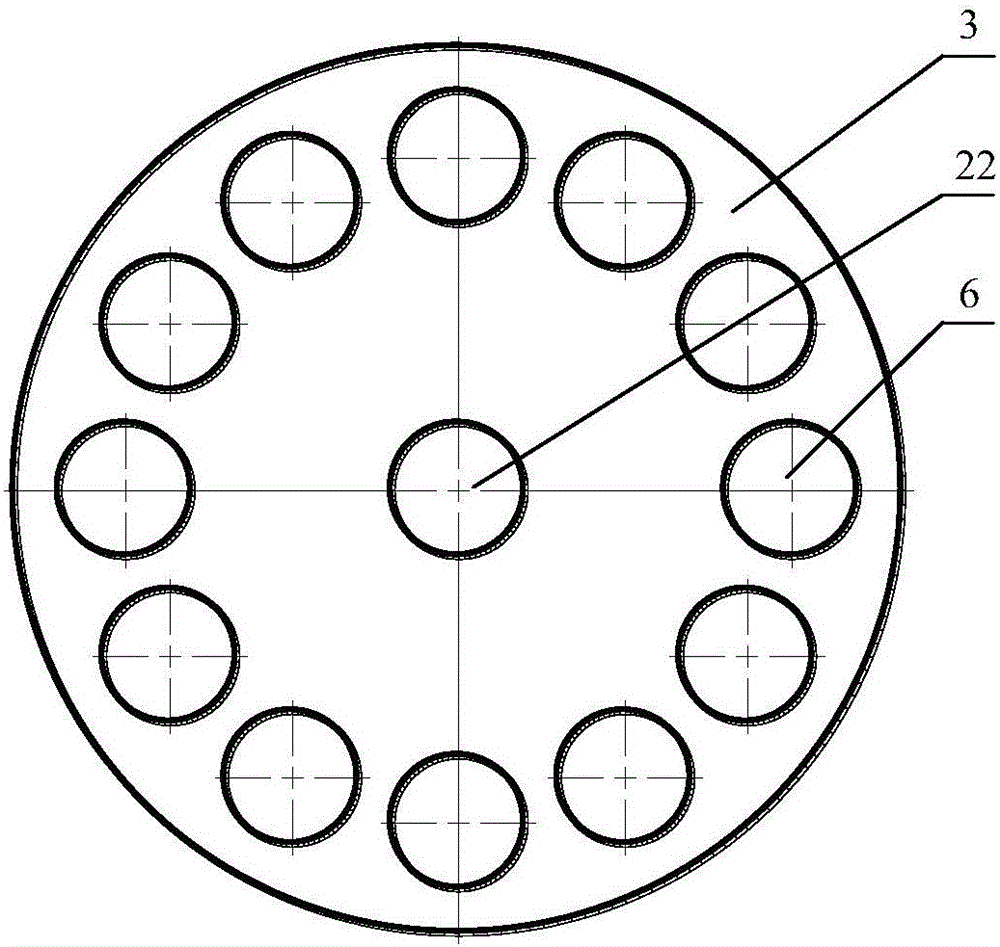

ActiveCN102141326AWell mixedReduce the pressure gradientEvaporators/condensersPulp and paper industryAir conditioning

The invention discloses a micro-channel parallel flow evaporator, which relates to the technical field of air conditioning systems. The micro-channel parallel flow evaporator comprises an upper liquid collection tube component, a plurality of flat tubes arrayed uniformly, two end covers and a lower liquid collection tube, wherein two end surfaces of the upper liquid collection tube component are connected with the two end covers respectively, and two ends of each flat tube are connected with the bottom of the upper liquid collection tube component and the lower liquid collection tube respectively. By the invention, the uniform flowing of a refrigerant into each flat tube is guaranteed, the refrigerating capability and the air outlet temperature distribution uniformity of the evaporator are improved, the efficiency is improved, and the comfortableness is also improved.

Owner:SHANGHAI JIAO TONG UNIV

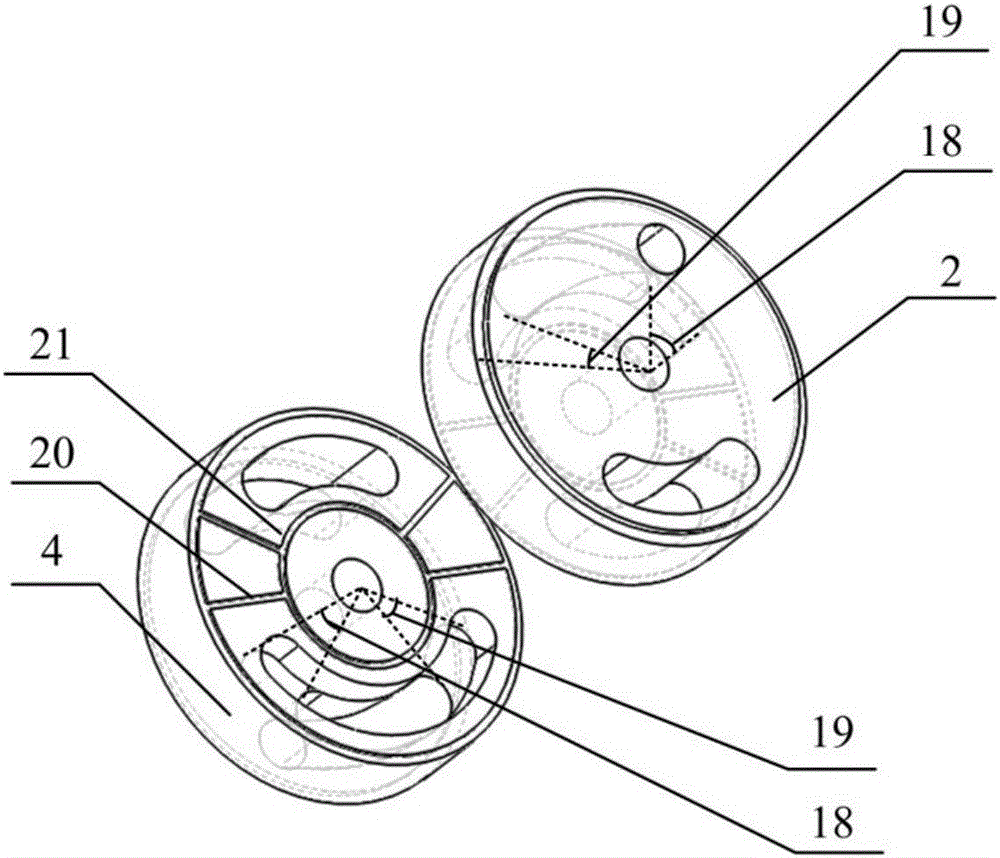

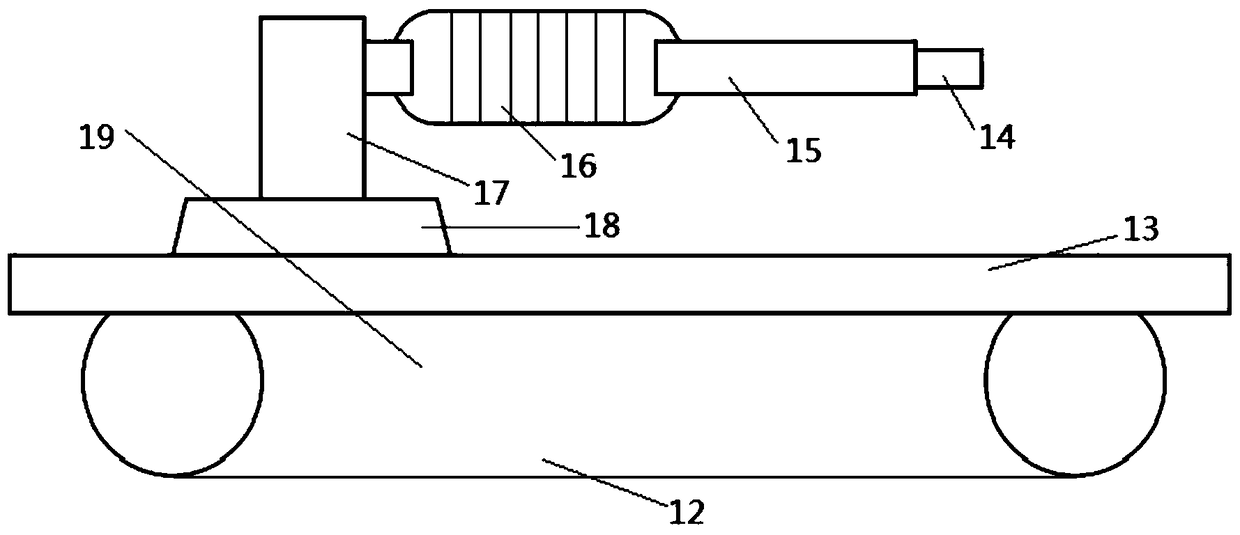

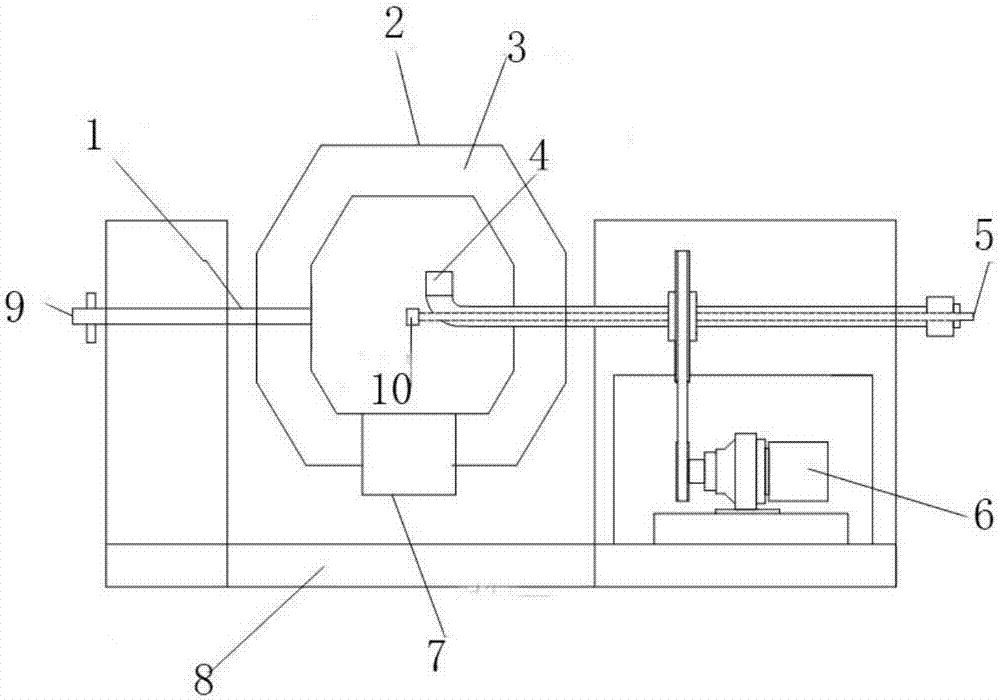

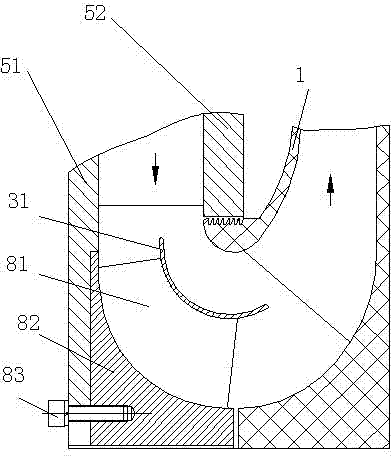

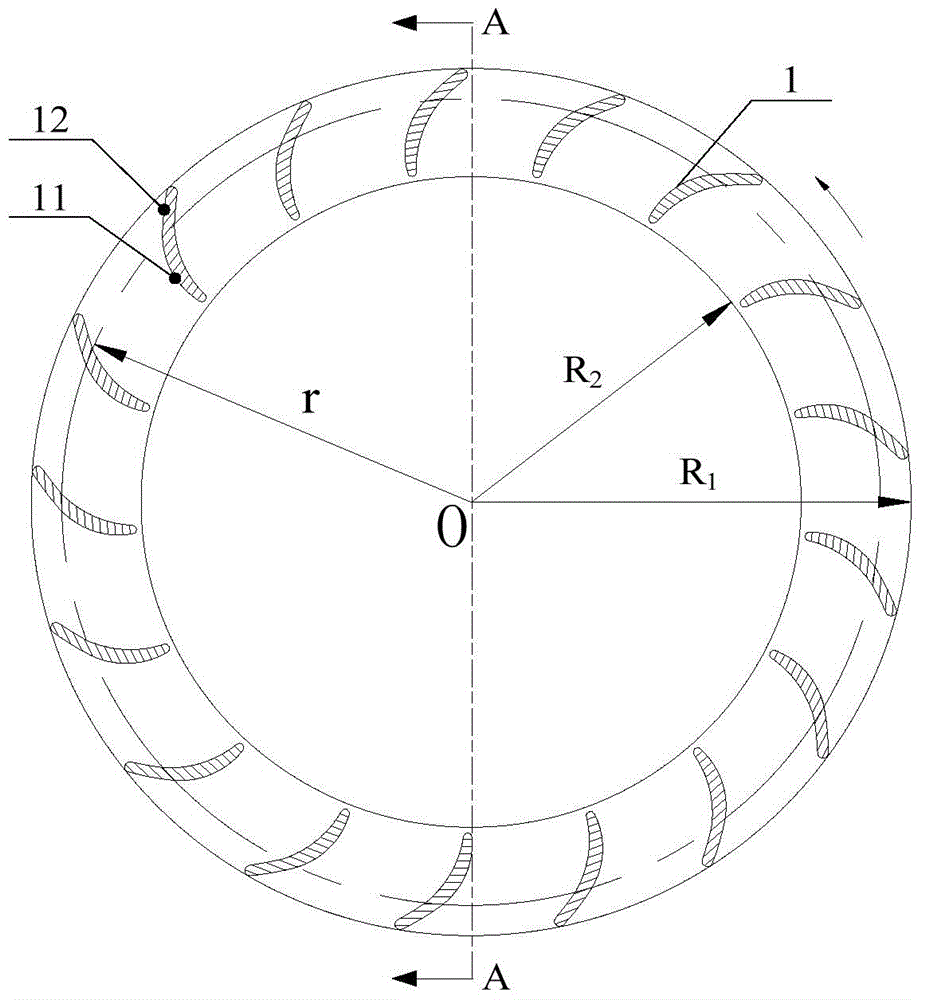

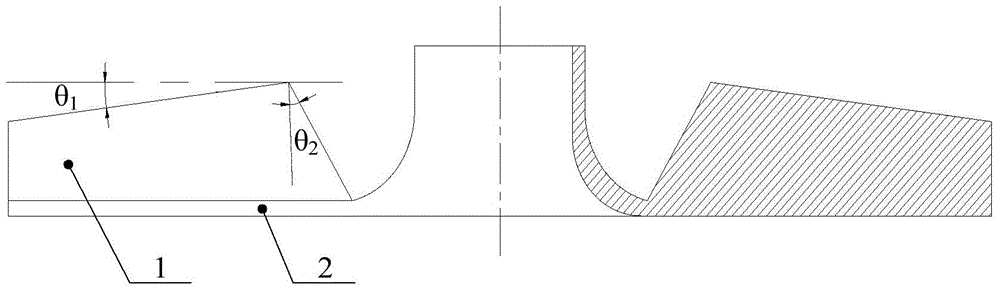

Rotary power exchanger with extended inflow angle structure

ActiveCN105114368AReduce Jet BlendingReduce the average velocityMachines/enginesEngineeringPore pressure gradient

The invention discloses a rotary power exchanger with an extended inflow angle structure, and belongs to the technical field of fluid residual pressure recycling. The exchanger comprises a rotor, an upper stator and a lower stator which are positioned at the two ends of the rotor, and a rotor sleeve, wherein the stators are provided with inflow liquid collecting slots with extended angle structures, so that pressure gradient is remarkably reduced when speed is in gradient change in a switching process among a high-pressure communication region, a sealing region and a low-pressure communication region of a duct, and therefore, jet-flow mixing of the liquid can be effectively reduced. The rotary power exchanger disclosed by the invention is reasonable in inflow structure design, simple and convenient to manufacture, and capable of effectively restraining jet-flow mixing in the duct and guaranteeing concentration quality of a first liquid pressurized in a pressure energy transmission process, so that a concentration value at a high-pressure outlet is within a stable range, and the efficient operation of the power exchanger and a membrane system is guaranteed.

Owner:XI AN JIAOTONG UNIV

Facility for eliminating negative pressure of bottom plate at torrent diffusion slope-variable section of flood discharging tunnel

InactiveCN102251504AAvoid destructionReduce pressure changes along the wayBarrages/weirsWater flowPhysical model

The invention relates to a facility for eliminating the negative pressure of a bottom plate at a torrent diffusion slope-variable section of a flood discharging tunnel, The facility comprises a step-down floor and pressing holes, wherein the step-down floor is arranged in front of a negative pressure region of the bottom plate at a diffusion section of the flood discharging tunnel; the pressing holes are arranged at two ends of the step-down floor outside a side wall of the flood discharging tunnel; a hollow cavity formed between a jet flow surface generated by discharged water in the flood discharging tunnel flowing across the step-down floor and a step-down floor bottom plate surface is communicated with air through the pressing holes so that the negative pressure of the bottom plate of the flood discharging tunnel is reduced and partial damage of the bottom plate of the flood discharging tunnel is avoided. In general, the step-down floor height is 0.30-1.00m, and the sizes of the pressing holes are determined by factors, such as the step-down floor height, step-down floor aerating capacities, a negative pressure region range and the like. A physical model test result shows that the pressing facility provided by the invention can be used for effectively eliminating a negative pressure value of the bottom plate at the torrent diffusion section of the flood discharging tunnel, increasing water flow aerating concentration and improving the energy dissipation effect of a stilling basin.

Owner:SICHUAN UNIV

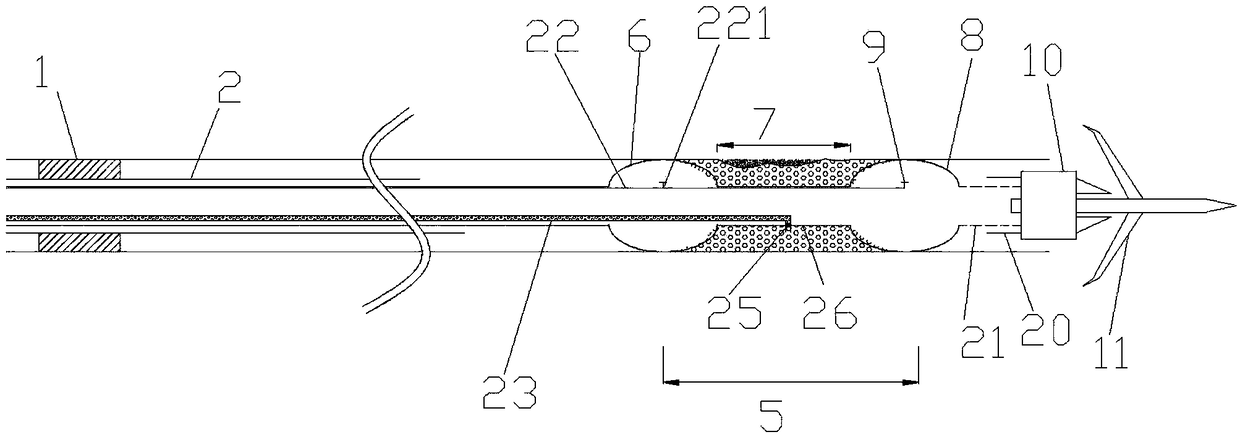

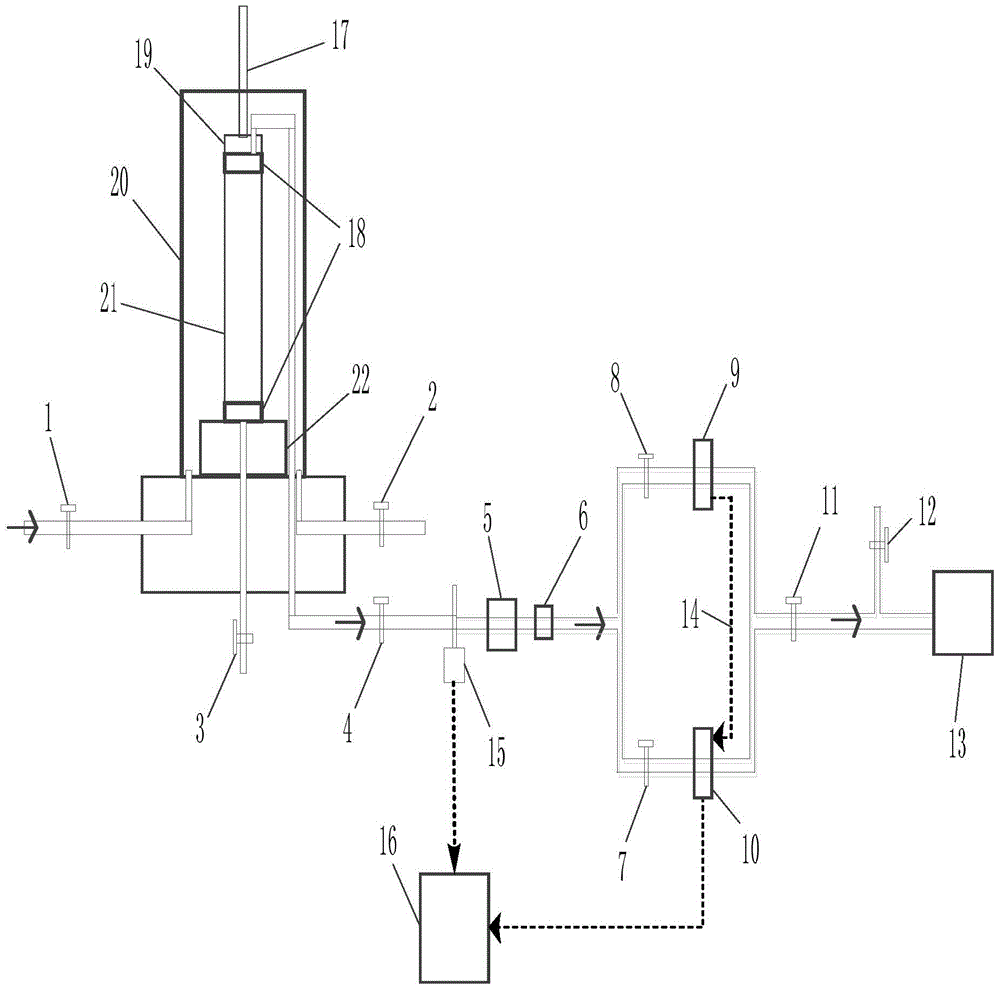

Foam concrete slip-casting system and method for mine hole collapse prevention

The invention discloses a foam concrete slip-casting system for mine hole collapse prevention. The system comprises a crawler hydraulic drilling machine capable of adjusting the inclination and power,a sleeve rod device, an inflation or water injection capsule device, an inflation or water injection and monitoring and feedback device, and a slip-casting device for slip-casting at a hole collapseposition. In addition, the invention also discloses a foam concrete slip-casting method for mine hole collapse prevention. The method includes: after rod retracting, a sleeve rod is conveyed again; anouter rod is removed; air inflation or water injection of a capsule is carried out; a foam concrete slurry is conveyed; and hole sealing is carried out after initial setting of the foam concrete slurry. The foam concrete prepared based on a chemical foaming method has advantages of high gas permeability, high strength and low cost. The capsule that can be expanded and has high flexibility can beapplied to drilling under conditions of different hole diameters, different inclination angles and different coal qualities. The foam concrete slip-casting system can be applied to mines with different geology with high practicability.

Owner:XIAN UNIV OF SCI & TECH

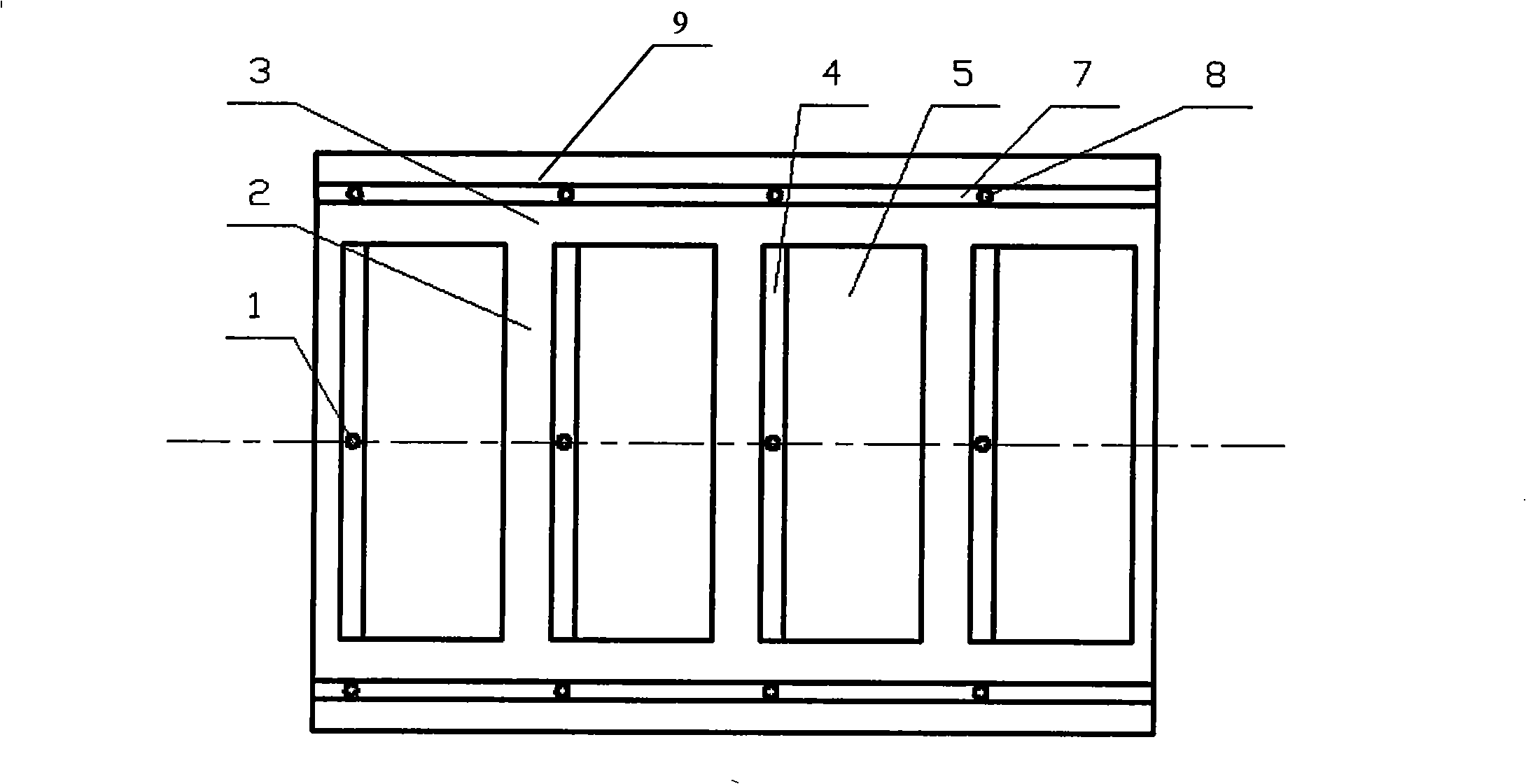

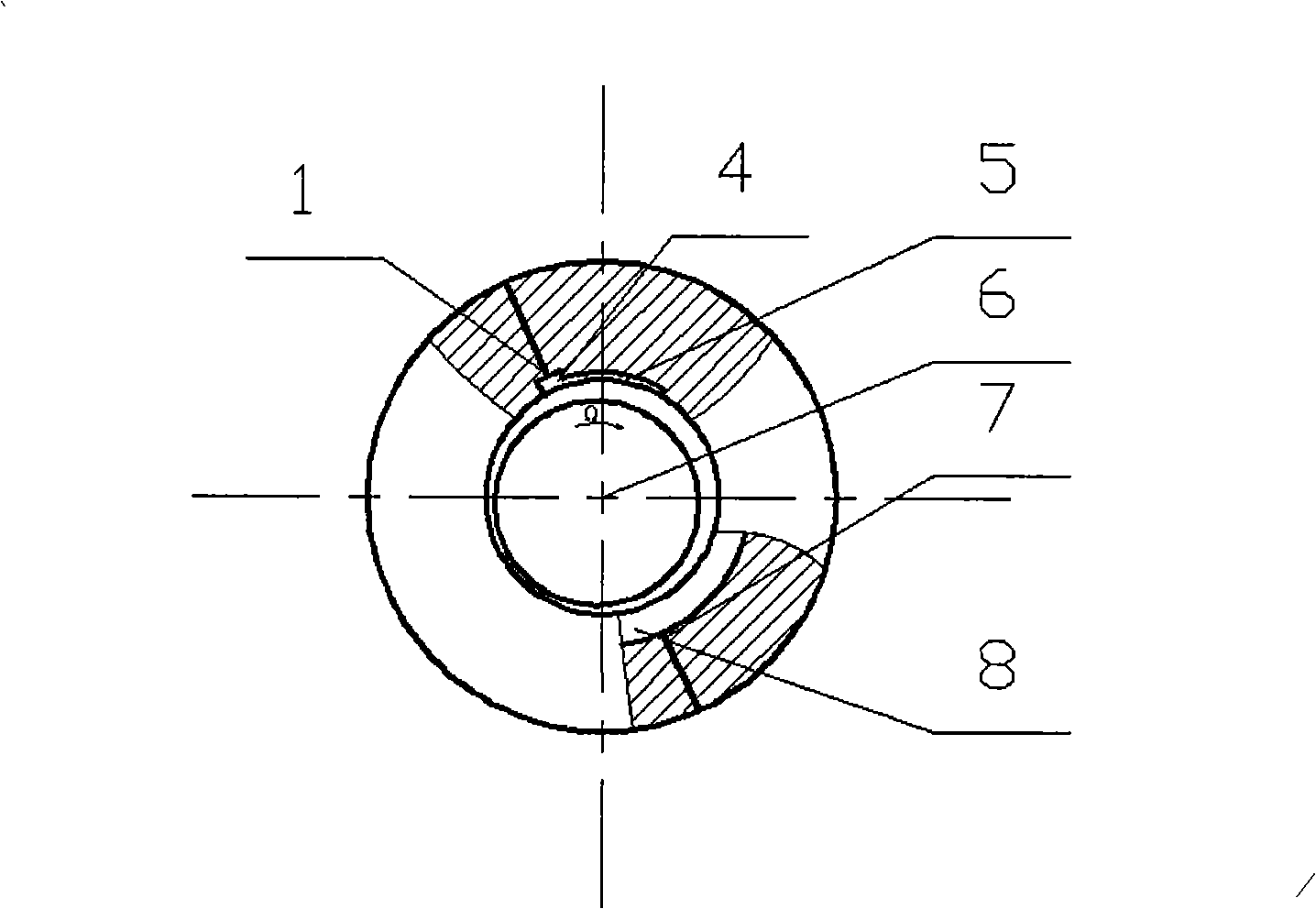

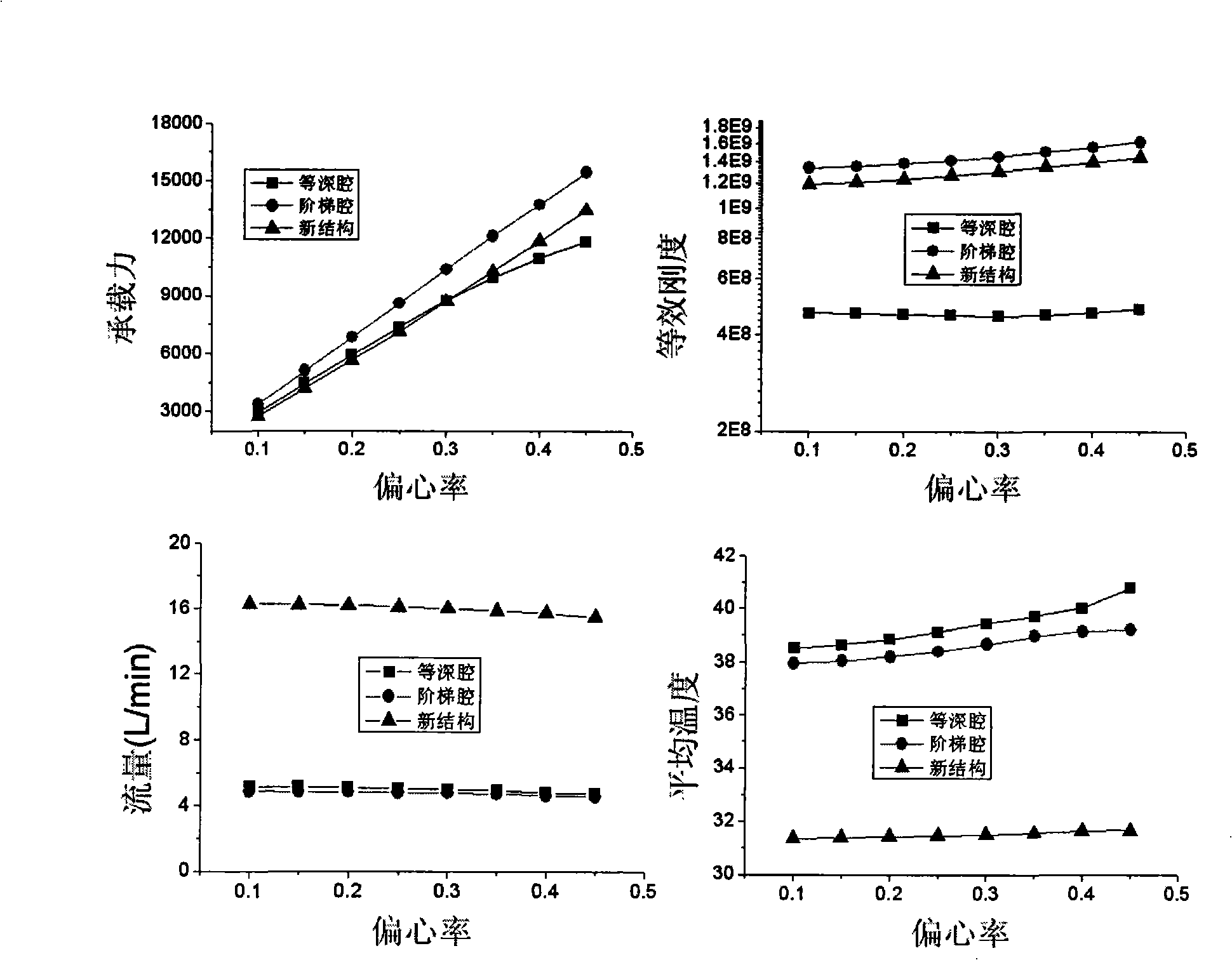

Ring groove cooling water lubrication dynamic and static pressure high speed bearing

InactiveCN101338786ASpeed up the flowIncrease the cross-sectional areaSliding contact bearingsBearing coolingEngineeringMechanical engineering

The present invention relates to a grooved cooling water-lubricated high-speed hydro-hybrid bearing, which comprises a bearing body and multiple groups of oil cavities; wherein, each of the oil cavities arranged in the middle of the inner wall of the bearing body is composed of a deep cavity and a shallow cavity; an oil inlet is arranged on each deep cavity; adjacent oil cavities are partitioned by a circumferential oil-sealing side; axial oil-sealing sides are formed on the edges of the oil cavities and the bearing body; annular grooves are symmetrically arranged on the axial oil-sealing sides on both sides of each oil cavity; moreover, the annular grooves are provided with cooling holes which penetrate the wall of the bearing body. Since the axial oil-sealing sides with the maximum heat quantity is provided with the annular grooves and the cooling holes into which lubricating medium can flow, hot medium can be mixed with the medium with normal temperature, moreover, the pressure gradient is reduced, and therefore temperature rise is reduced under the premise that rigidity is affected as little as possible.

Owner:XI AN JIAOTONG UNIV

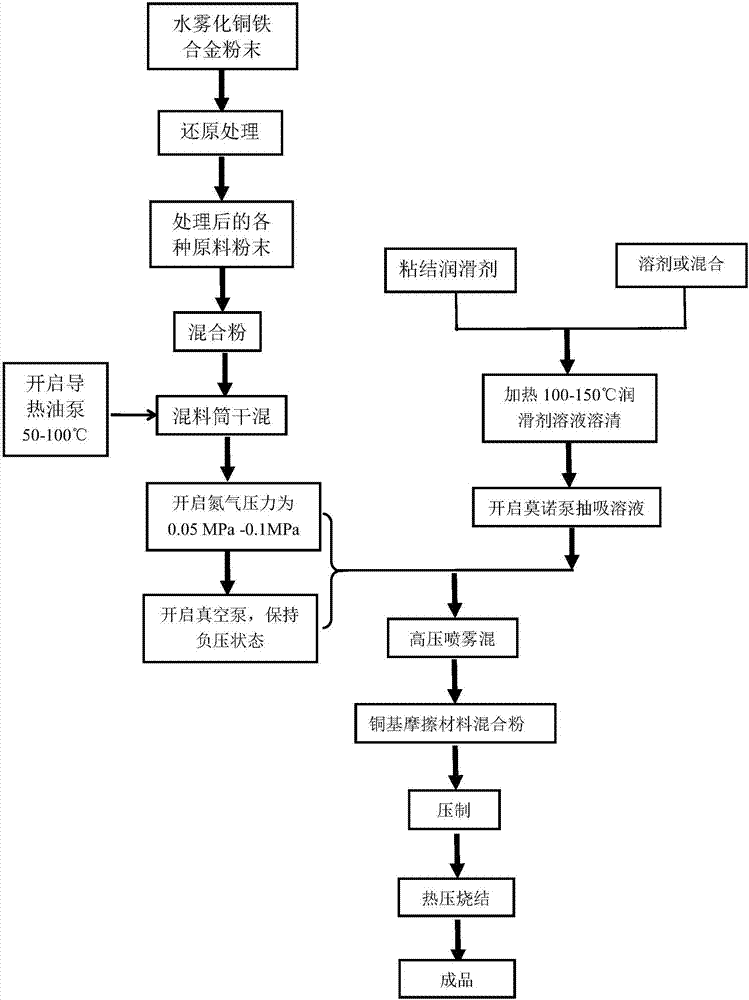

Method for preparing powder metallurgy copper-based friction material through adhesion process

ActiveCN107326205AImprove uniformityUniform compositionTransportation and packagingMetal-working apparatusMaterials scienceTin

The invention discloses a method for preparing a powder metallurgy copper-based friction material through an adhesion process, and belongs to the technical field of preparation of a copper-based high-speed train brake block through a powder metallurgy process. The mass fraction of copper powder in the raw material powder is 60-75%, the grain size of the copper powder is 100-150 [mu]m, the grain size of iron powder is 10-25 [mu]m, the grain size of nickel powder is 10-25 [mu]m, the grain size of tin powder is 10-25 [mu]m, and the grain size of SiO2 is 10-25 [mu]m. Adhesion lubricating agents are added in the mixing process, double-cone spray adhesion treatment is conducted, and accordingly the surfaces of large-granularity copper powder particles are evenly wrapped with fine iron powder, the powder is mixed evenly in proportion and then subjected to cold compression molding, and after hot pressed sintering, the copper-based powder metallurgy brake block prepared by the adhesion process is obtained. Compared with a traditional brake block preparation process, the adhesion process can enhance the powder mixing uniformity, the pressure gradient on the powder in the filling process is reduced, the shrinkage uniformity of the material in the sintering process is improved, and therefore the material component and density distribution are more uniform, and the prepared powder metallurgy copper-based friction material can have the better frictional wear performance.

Owner:山东鲁银新材料科技有限公司

Composite binder for powder injection moulding and preparation and application method

ActiveCN105860886AImprove liquidityGood liquidity lowNon-macromolecular adhesive additivesTransportation and packagingMicrocrystalline waxInjection moulding

The invention discloses composite binder for powder injection moulding and a preparation and application method. The composite binder for powder injection moulding comprises raw materials including furfuryl alcohol, trimethylolpropane, polypropylene, o-hydroxybenzoic acid, polyacrylamide, palm wax, microcrystalline wax and epoxidized soybean oil and further comprises boric acid and water. The composite binder combining thermoplasticity and a thermosetting system is adopted, advantages of thermoplasticity and the thermosetting system are utilized, on one hand, the problems that conventional binder is excessively long in thermal degreasing time and low in production efficiency are solved, and the degreasing rate can reach 90% or above within 6 hours; on the other hand, the yield rate of a powder injection moulding product is raised, and quality of a finished product is improved.

Owner:ANHUI SANLIAN UNIV

Orthogonal guide rectifier

InactiveCN102192191AAvoid disadvantagesReduce the pressure gradientPump componentsPumpsCentrifugal compressorLeft wall

An orthogonal guide rectifier is arranged at a junction place of adjacent two-stage compression unit of a multistage centrifugal compressor and is composed of a stream guidance part for guiding for the gas and a rectification part for guiding upstream gas into a lower stage compression unit. The orthogonal guide rectifier is mainly composed of a guiding ring, radial rib pieces and a mounting seat. A plurality of radial rib pieces are uniformly distributed at the periphery of the mounting seat and fixed on the mounting seat for supporting guiding ring arranged on the top. The guiding ring is a stream guiding part for guiding, the radial rib sheets are the rectification part for rectifying. The orthogonal guide rectifier is mounted on a left wall of a shell. The orthogonal guide rectifier intakes the advantages of the traditional guiding ring, meanwhile overcomes the shortcoming of the traditional guiding ring, and abandons the mounting mode of an import bolt. And the orthogonal guide rectifier disclosed in the invention, not only has the guidance function of the traditional stream guidance device, but also has the rectification function for guiding the gas still having rotation degree at the same time of guiding the gas.

Owner:宋波

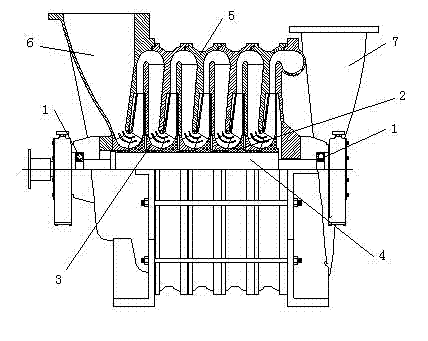

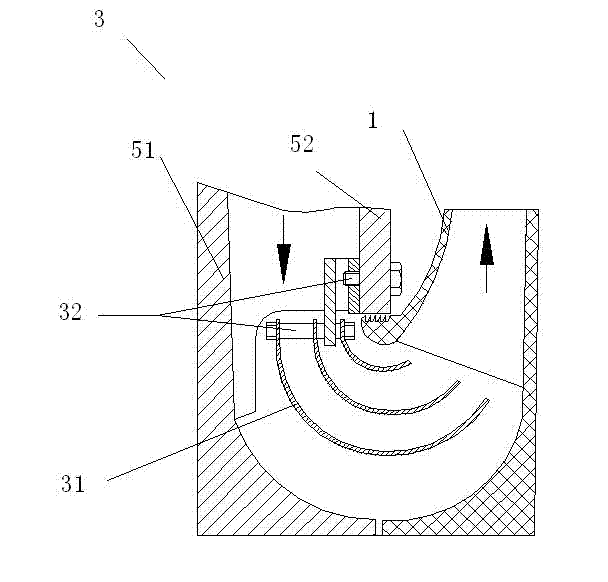

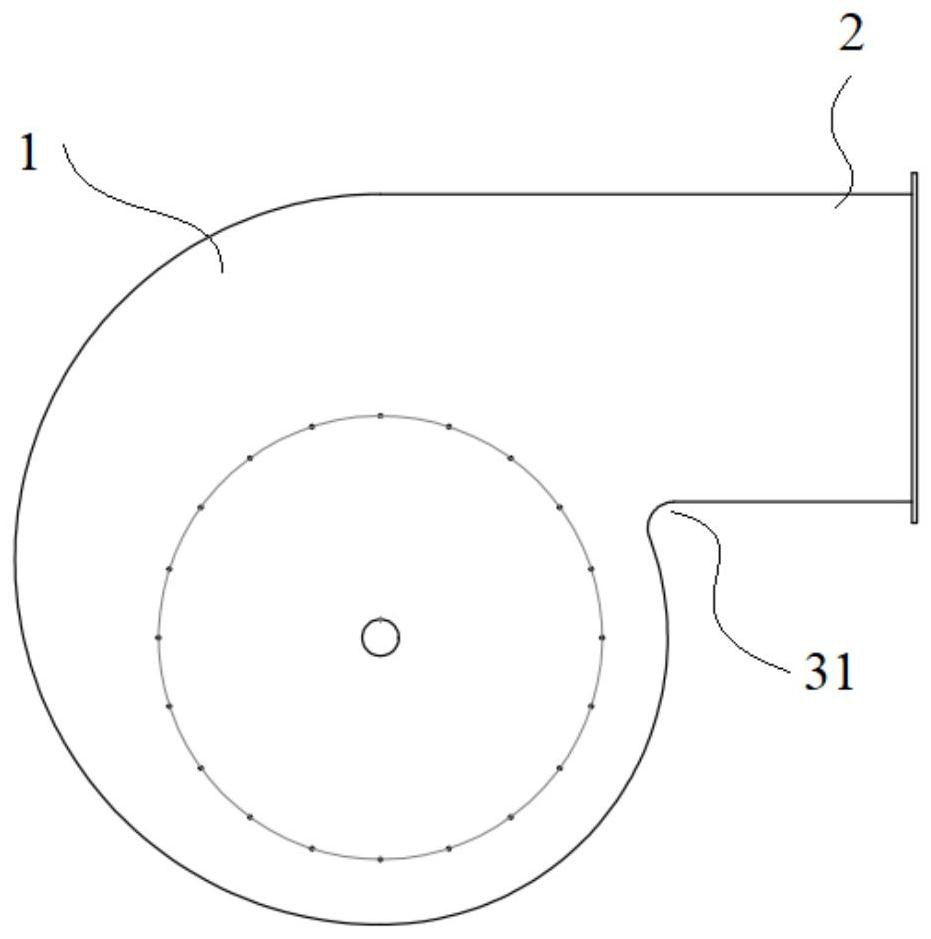

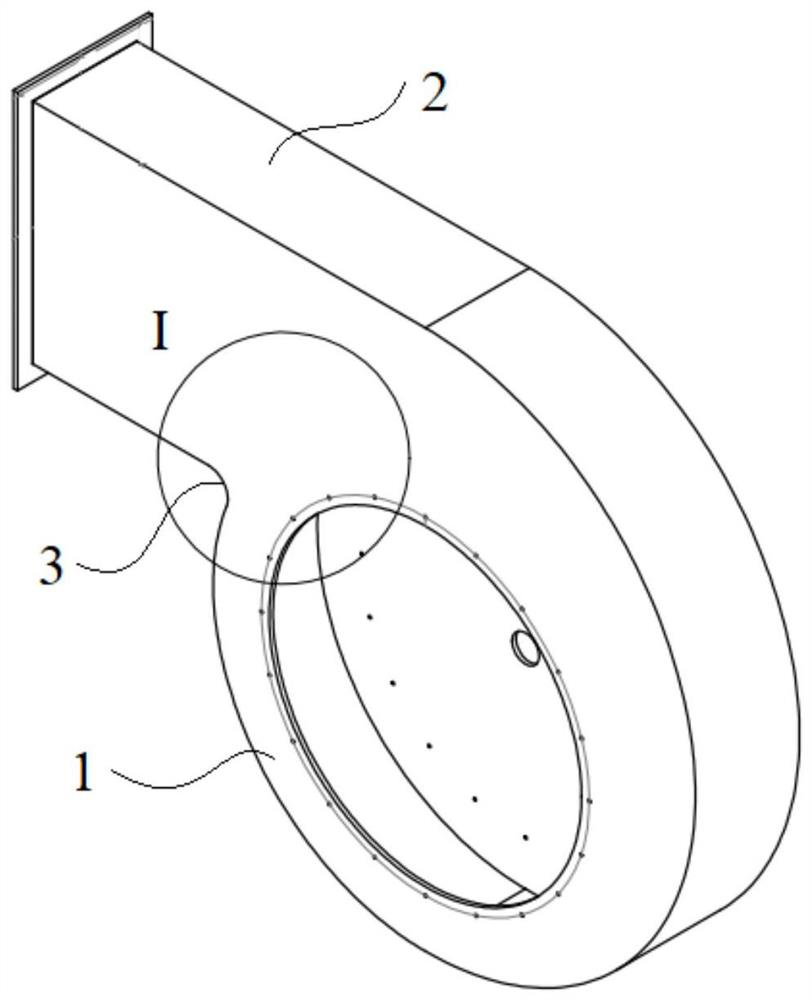

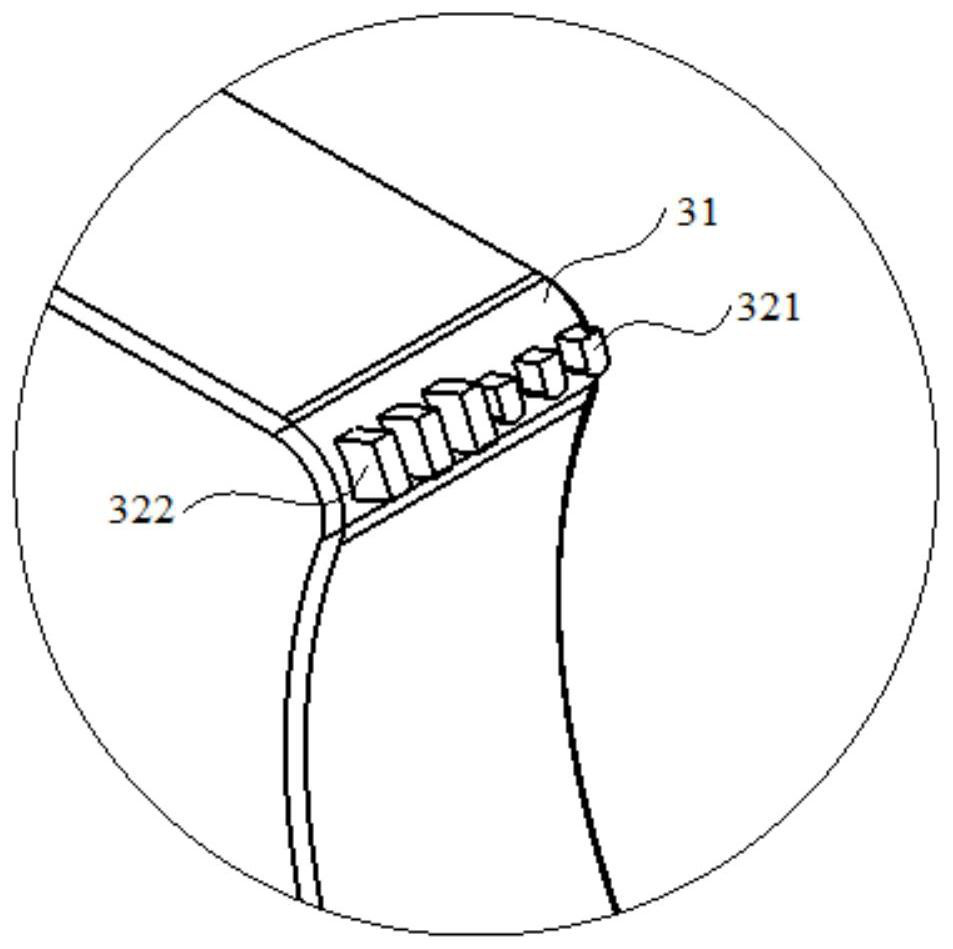

Noise reduction volute tongue structure and centrifugal fan

ActiveCN111997935AAvoid endless loopsReduce the pressure gradientPump componentsPumpsTongue structureAcoustics

The invention discloses a noise reduction volute tongue structure and a centrifugal fan. The volute tongue structure comprises a volute tongue body formed by a volute and a shell wall at the joint ofan air outlet, and a plurality of protruding blocks at the top of the volute tongue body, wherein the plurality of protruding blocks are sequentially distributed in the axis direction of the volute, and an airflow channel for airflow to pass through is arranged between every two adjacent protruding blocks. According to the noise reduction volute tongue structure and the centrifugal fan, the distance between the volute tongue and an impeller blade is reduced by the protruding blocks, so that the effect of reducing the continuous rotation of the airflow along with an impeller is achieved, the airflow is prevented from continuously circulating in a cavity part of the volute, and then the working efficiency of the centrifugal fan is improved; and gaps between the protruding blocks can be usedas the airflow channels, when the airflow leaves the tail end of the impeller blade, the impact of the outlet airflow on the volute tongue structure is reduced, the pressure gradient of the airflow near the volute tongue is reduced to a certain extent, the effective flow area of the airflow is increased, the superposition of noise in the volute tongue area is inhibited, and therefore the aerodynamic noise of the centrifugal fan can be effectively reduced.

Owner:华电章丘发电有限公司 +2

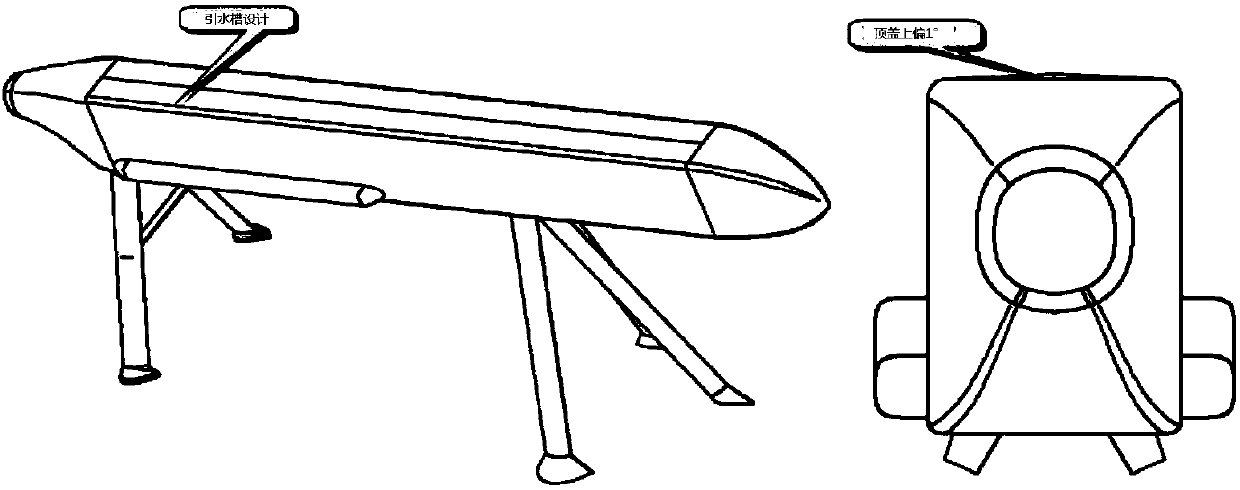

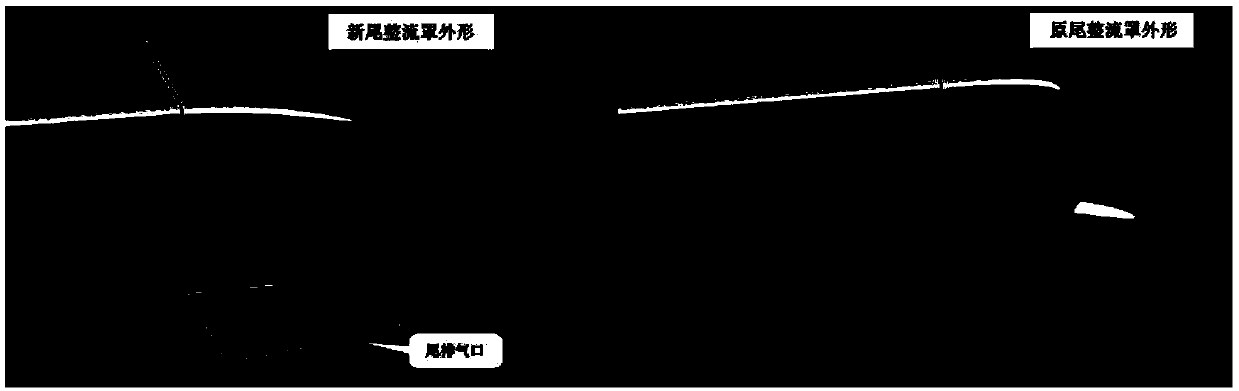

Direction-finding antenna cover with balance beam appearance

InactiveCN107799895AObvious advantagesGood effectAntenna adaptation in movable bodiesRadiating element housingsLow speedEngineering

The invention designs a direction-finding antenna cover with a balance beam appearance, and belongs to the overall aerodynamic appearance design field. Due to relatively large appearance dimension ofan added antenna, a design method of mixing front and back rectifying regions with a transitional streamline of the antenna cover appearance in the layout design of the antenna cover is adopted, so that separation occurring when air flow flows through the antenna cover can be lowered, and air-flow flow field can be improved; through comparison and analysis on low-speed aerodynamic characteristics,flow field characteristics and a vorticity graph, the optimal scheme is determined; and under the premise of satisfying the use requirement of a task system, the appearance dimension of the antenna cover is reduced as far as possible, so as to reduce influence to the aerodynamic characteristics of an aerial carrier from the added antenna cover; the antenna cover adopts multiple items of overall aerodynamic comprehensive optimization design measures of a variable parameter control contour line, CFD calculation, a wind tunnel test and the like, so that the appearance dimension of the antenna cover is optimized to the largest extent; the problems of small internal space, inconvenience in waterproof and rain leakage prevention design of the existing antenna cover with the balance beam appearance are solved; and the novel direction-finding antenna cover optional scheme with the balance beam appearance is provided.

Owner:SHAANXI AIRCRAFT CORPORATION

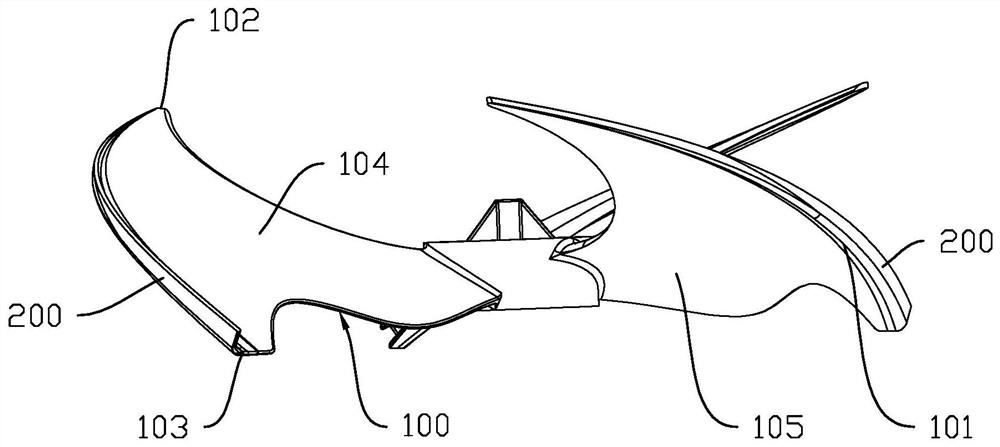

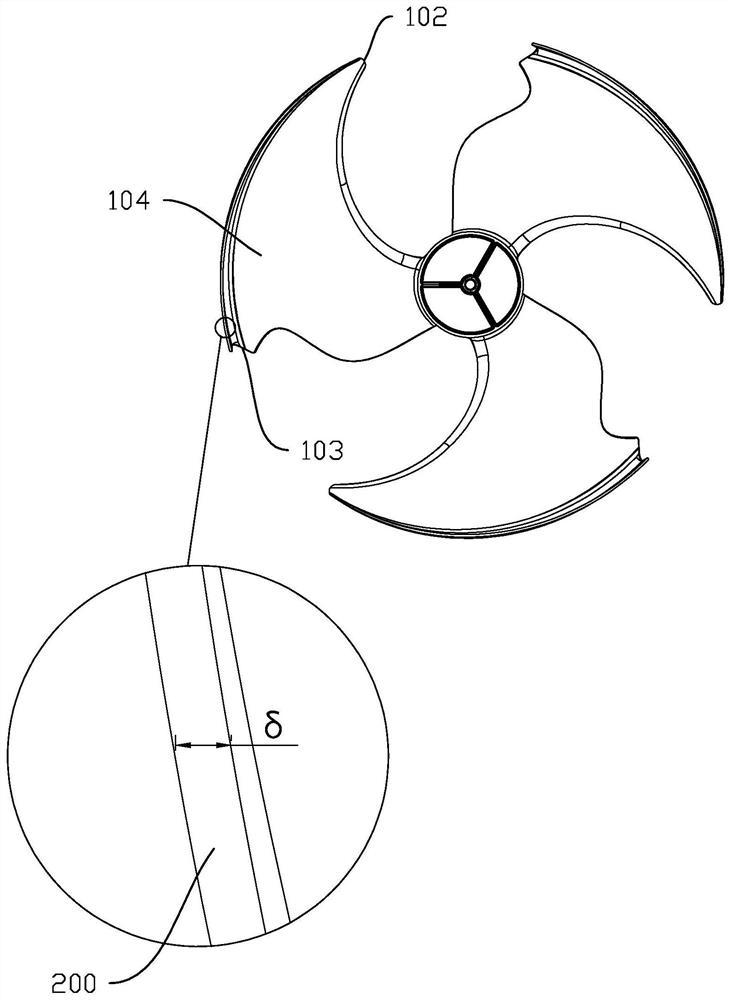

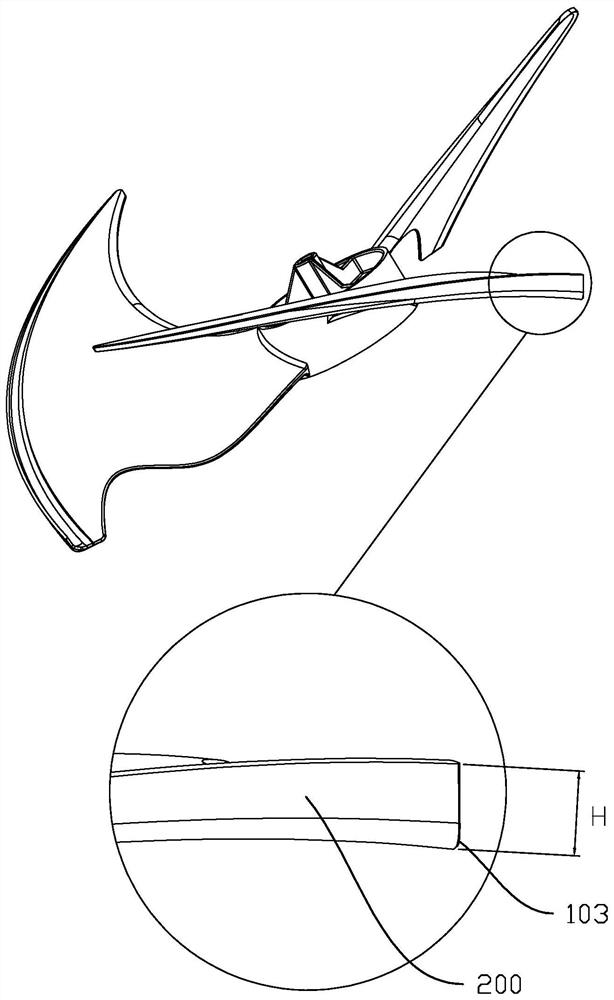

Draught fan impeller and blade skeleton line fitting method thereof as well as draught fan

The invention discloses a draught fan impeller and a blade skeleton line fitting method thereof as well as a draught fan. The draught fan impeller comprises a rear disc and a blade arranged on the rear disc, wherein the blade comprises a blade inlet section and a blade outlet section which are connected; the blade inlet section and the blade outlet section are sequentially distributed along the length direction of the blade; the blade inlet section is close to the central axis of the rear disc; the blade inlet section is in a wing-shaped structure; the blade outlet section is in an equal-circular-rector flow type structure. According to the draught fan impeller disclosed by the invention, the blade outlet section is designed into the equal-circular-rector flow type structure, and a momentum moment at the blade outlet section along the meridian plane of the draught fan impeller keeps constant, so that the pressure gradient of airflow at the blade outlet section is effectively reduced, the airflow separation at the blade outlet section is inhibited, and the influences on the aerodynamic performances and the noise levels by the draught fan are reduced.

Owner:GREE ELECTRIC APPLIANCES INC

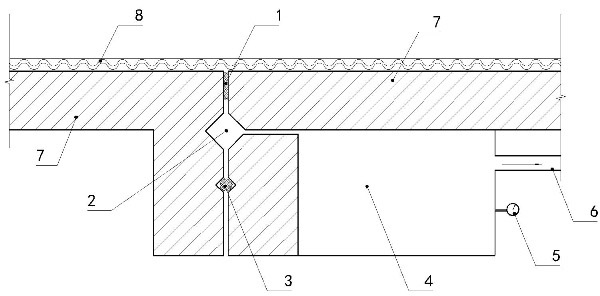

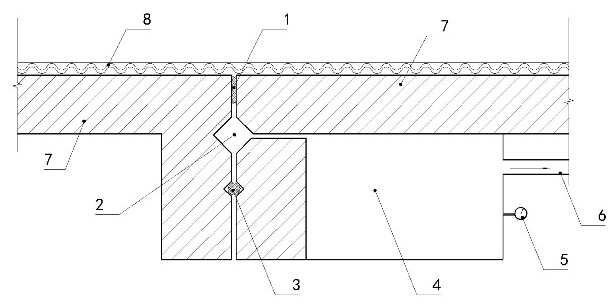

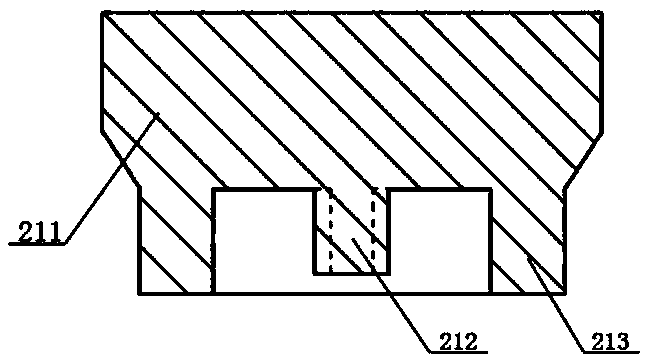

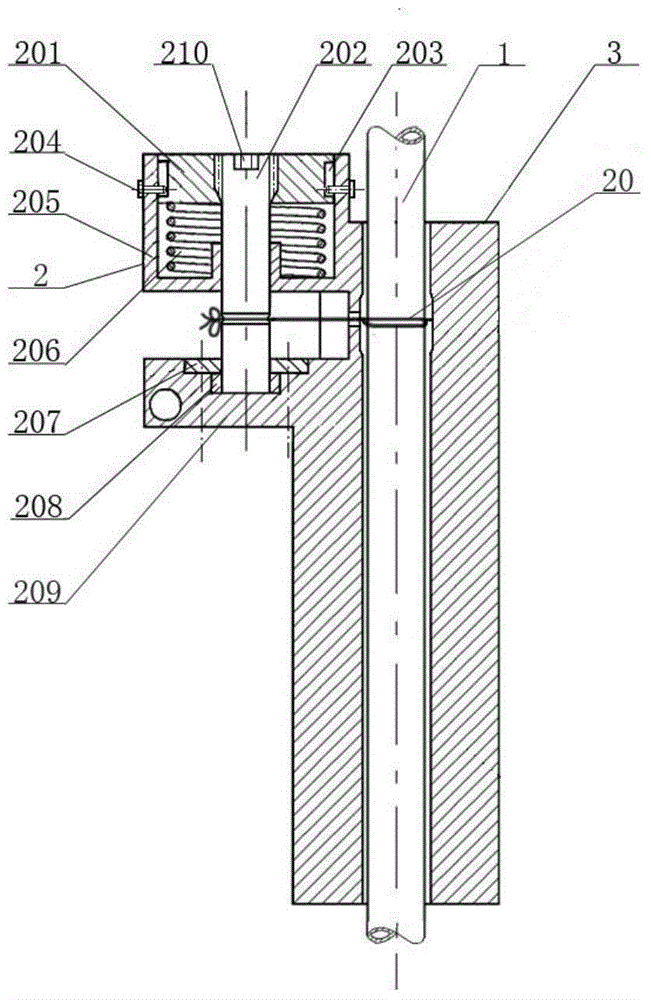

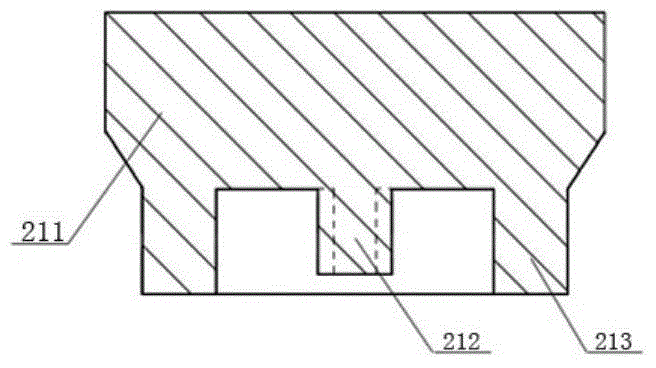

Low-pressure sealing system applied to sectional form mould core/mould and sealing method thereof

InactiveCN102135182AReduce the pressure gradientReduce air leakageEngine sealsElectricityRubber ring

The invention relates to a low-pressure sealing system applied to a mould core / mould and a sealing method thereof, in particular to a low-pressure sealing system applied to a sectional form mould core / mould and a sealing method thereof. The low-pressure sealing system consists of two parts of an inner-layer sealing system (1) and an outer-layer low-pressure sealing system, wherein the outer-layerlow-pressure sealing system comprises an air guiding system (2), a large sealed space (4), an air pressure measuring system (5), a sealing rubber ring (3) and a suction system, and the air guiding system (2) comprises at least one air guiding channel; the large sealed space (4) comprises at least one sealed container; the air pressure measuring system (5) comprises at least one vacuum gauge or barometer; the sealing rubber ring (3) insulates the air guiding groove from the outside atmospheric pressure and is deformed to be tightly close to the wall of the air guiding groove by difference of pressures inside and outside the sealed rubber ring (3) so as to realize the sealing function; and the suction system (6) comprises a vacuum pump, a suction pipeline and a regulating valve. The low-pressure sealing system and the sealing method disclosed by the invention can be applied to sealing connection parts of a large wind turbine blade mould core / mould (7) and ensure that the connection parts of a mould core / mould device are airtight in a vacuum-casting process of mould / blade manufacture so that the quality of casting is ensured; meanwhile, the low-pressure sealing system disclosed by the invention is easy to monitor in the using process and convenient to maintain.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Low noise cone valve

ActiveCN104895857AReduce axial hydraulic forceReduce the pressure gradientServomotor componentsFluid-pressure actuator componentsLow noiseEngineering

The invention discloses a low noise cone valve. A center hole working as an oil inlet is formed in the bottom surface of a valve body; a valve sleeve is disposed in the center hole of the valve body; the valve sleeve is in a threaded connection with the valve body; a valve core is covered with the valve sleeve and in sliding cooperation with the valve sleeve; the valve core is connected to the bottom of the center hole of the valve body; a valve sleeve oil outlet and a valve sleeve oil inlet are respectively formed in the upper and lower side surfaces of the valve sleeve; an oil outlet communicated with the valve sleeve oil outlet is formed in the side wall of the valve body on the valve sleeve oil outlet; an annular gap channel communicated with the valve sleeve oil inlet is formed in the side wall of the valve body on the valve sleeve oil inlet; a gap forming a valve sleeve front throttling port is formed between the front end of the valve sleeve and the inner wall of the gap channel; and the oil inlet in the bottom surface of the valve body is connected with the gap channel via the valve sleeve throttling port. The low noise cone valve is advantaged by simple structure, great manufacturability and simple operation; and valve noise can be reduced.

Owner:ZHEJIANG UNIV

A Method for Measuring Gas Permeability of Unsaturated Soil Based on Soil Triaxial Apparatus

InactiveCN103913407BGuaranteed tightnessReduce the pressure gradientPermeability/surface area analysisSoil gasSoil science

Owner:63653 FORCES PLA

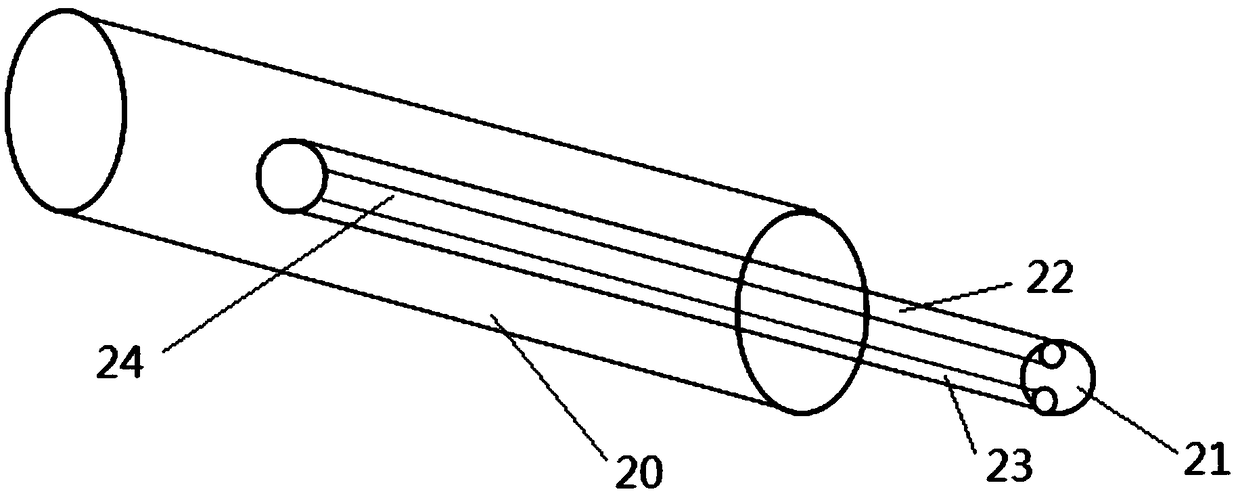

Tube orifice diameter variable spliced sampling instrument

The invention relates to a tube orifice diameter variable spliced sampling instrument which structurally comprises a steady flow buffer tube for receiving a pumped polluted water sample and performing steady flow conveying on the polluted water sample, a pump tube connection mechanism connected with a polluted water sample output pump tube, a diversion pressure regulating valve for regulating water flow pressure of the polluted water sample, a pressure gauge for detecting the water flow pressure, a sampling hose leading the polluted water sample under a laminar condition out of the steady flow buffer tube via a streamline water outlet for water sampling, and a concentric flow regulator for regulating a flow rate of the collected water sample. The instrument changes the composition, the structure and the operating principle of the original organic polluted water sampling device, has the characteristics of small size, light weight, wide application scope, convenience in carrying and mounting, simplicity in operation, safety in use, prevention of a pollution link in a collection process of the sample and the like, improves the fidelity of the collected sample, lowers the collecting cost of the sample, and ensures the safety of personnel and equipment, and the universality of the sampling instrument is improved.

Owner:INST OF HYDROGEOLOGY & ENVIRONMENTAL GEOLOGY CHINESE ACAD OF GEOLOGICAL SCI

Axial flow wind wheel structure and axial flow fan

PendingCN112253538AReduce flow lossImprove static pressure efficiencyPump componentsPumpsLeading edgeSuction force

Owner:GUANGDONG SUNWILL PRECISING PLASITC CO LTD

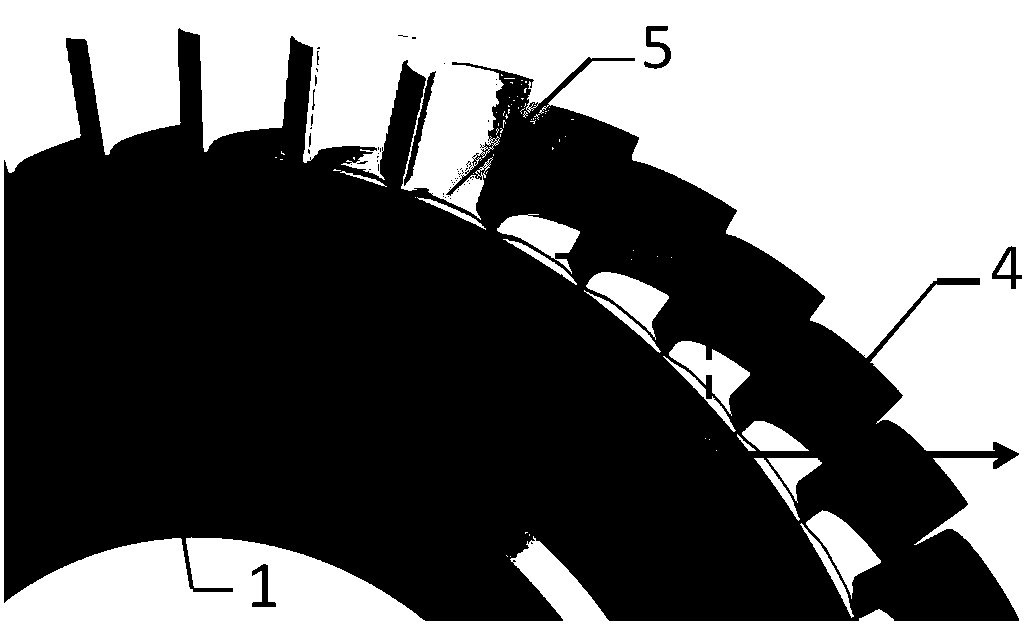

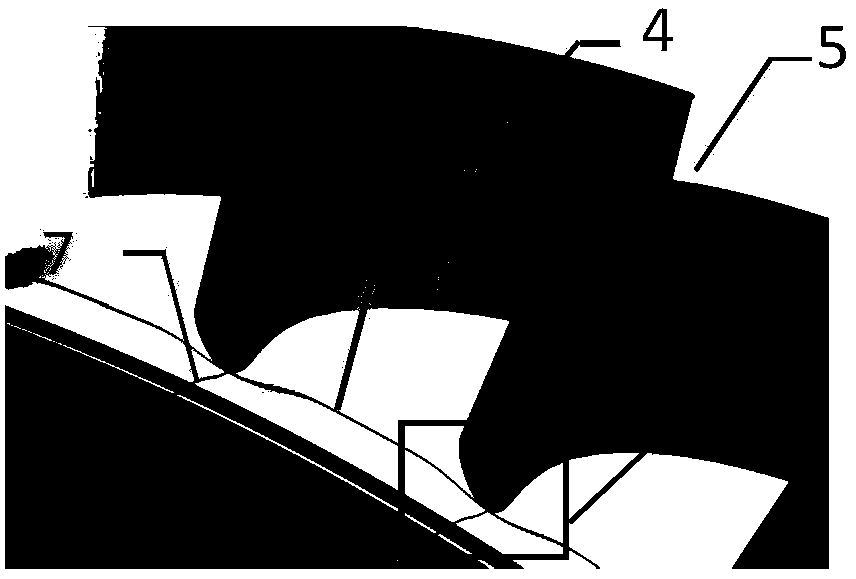

Modeling structure of non-axisymmetric end wall of local ball impression on lower end wall of front edge of movable blade of gas turbine

ActiveCN108643974AImprove economySmall pressure fluctuationsBlade accessoriesMachines/enginesGas turbinesEngineering

The invention discloses a modeling structure of a non-axisymmetric end wall of a local ball impression on the lower end wall of the front edge of a movable blade of a gas turbine. The modeling structure of the non-axisymmetric end wall of the local ball impression is arranged on the lower end wall of the front edge where a rotary-static disc cavity of the gas turbine is in contact with a high pressure stage movable blade of the gas turbine of a radial rim sealing structure. Non-axisymmetric end wall modeling is carried out on the lower end wall of the front edge of the movable blade by means of an end wall modeling axial control line and an end wall modeling circumferential control line. Main flow gas forms a near wall vortex in the upstream of the front edge of the movable blade by meansof the local ball impression end wall formed by the modeling structure of the non-axisymmetric end wall of the local ball impression, so that the pressure flotation in the circumferential direction ofa main flow near a sealing outlet of a rim is reduced effectively, and therefore, the invasion degree of gas is reduced, the temperature of a turbine disc is reduced, and the heat transfer stabilityof the turbine disc is improved. Meanwhile, the efficiency loss increased by end wall modeling is controlled to a very small degree by means of a relatively small sunken degree, and the influence on integral operation of the turbine is very small.

Owner:XI AN JIAOTONG UNIV

Nozzle variable diameter plug-in sampler

InactiveCN103743596BNo pollutionAvoid man-made pollutionWithdrawing sample devicesWater flowEngineering

The invention relates to a tube orifice diameter variable spliced sampling instrument which structurally comprises a steady flow buffer tube for receiving a pumped polluted water sample and performing steady flow conveying on the polluted water sample, a pump tube connection mechanism connected with a polluted water sample output pump tube, a diversion pressure regulating valve for regulating water flow pressure of the polluted water sample, a pressure gauge for detecting the water flow pressure, a sampling hose leading the polluted water sample under a laminar condition out of the steady flow buffer tube via a streamline water outlet for water sampling, and a concentric flow regulator for regulating a flow rate of the collected water sample. The instrument changes the composition, the structure and the operating principle of the original organic polluted water sampling device, has the characteristics of small size, light weight, wide application scope, convenience in carrying and mounting, simplicity in operation, safety in use, prevention of a pollution link in a collection process of the sample and the like, improves the fidelity of the collected sample, lowers the collecting cost of the sample, and ensures the safety of personnel and equipment, and the universality of the sampling instrument is improved.

Owner:INST OF HYDROGEOLOGY & ENVIRONMENTAL GEOLOGY CHINESE ACAD OF GEOLOGICAL SCI

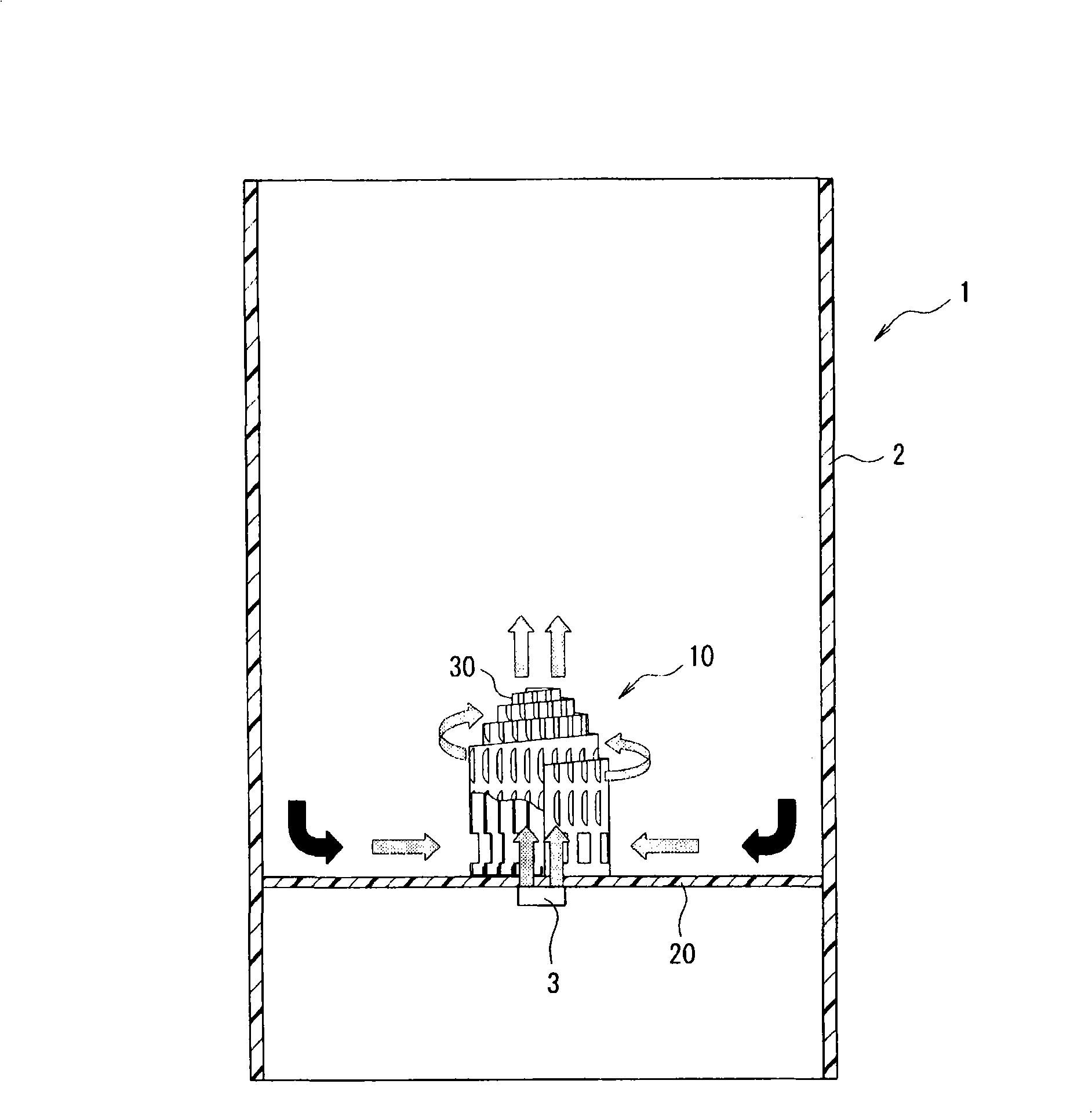

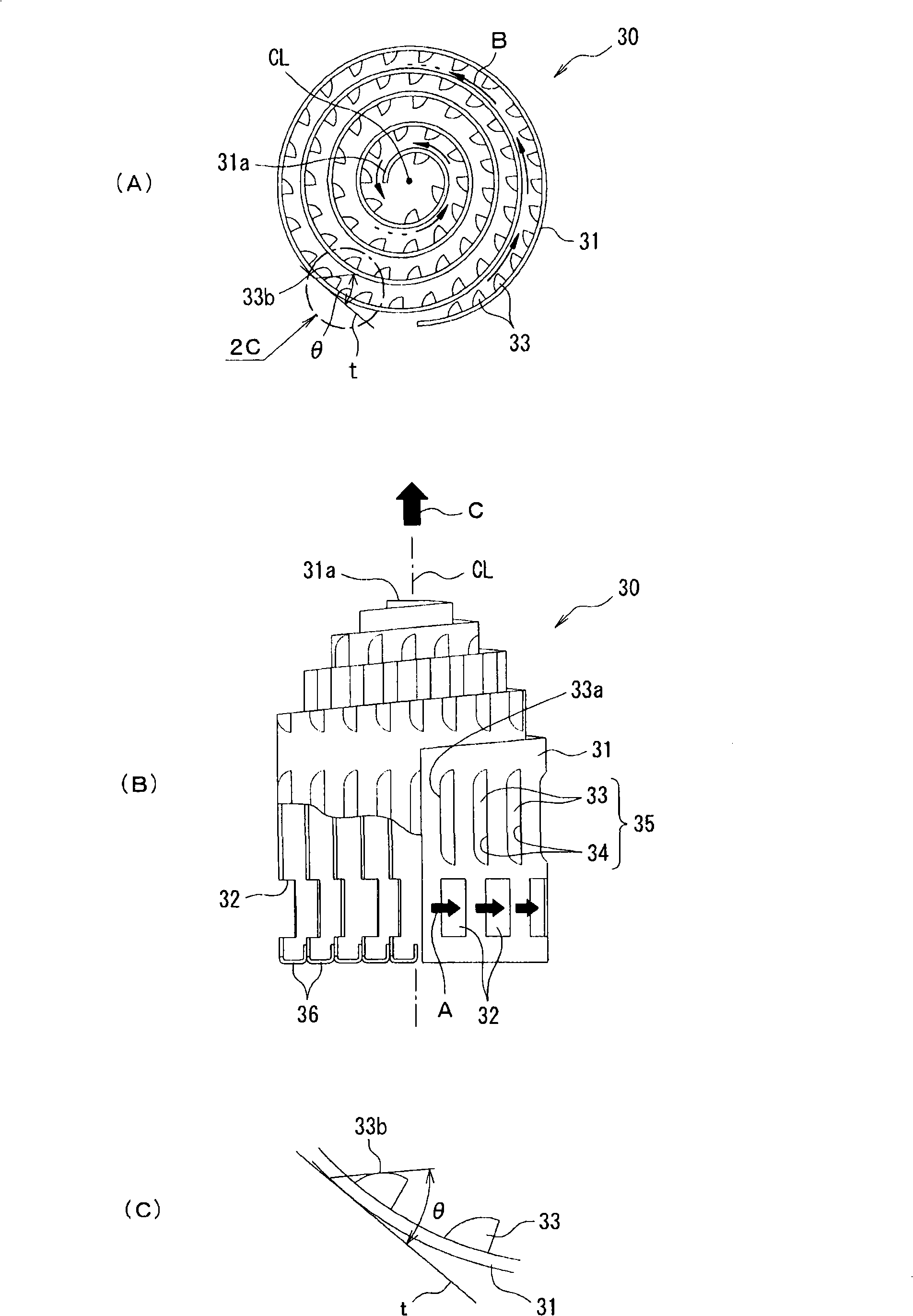

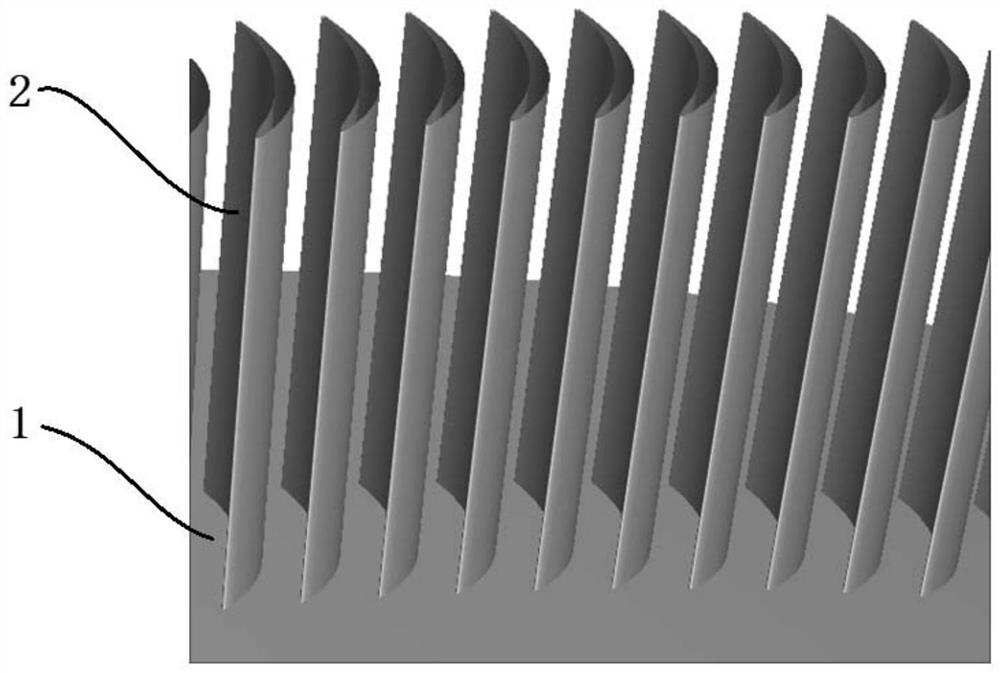

Heatsink and cooling apparatus

InactiveCN101338889AIncrease flow rateImprove cooling effectPoint-like light sourceSemiconductor/solid-state device detailsNatural convectionEngineering

The present invention provides a natural convection-type heatsink for cooling a heating element, which is suitable for an LED lighting device and has increased cooling capacity, and a cooling apparatus. The heatsink (30) for cooling a heating element (3) comprises a metal plate (31) in the form of a band rolled around a central axis (CL) to have the shape of a scroll, wherein the height of one end in the central axis direction of the scroll from the radial outside gradually increases towards the centre part (31a) in the radial direction. A plurality of through air intake openings (32) pass through the metal plate (31) and are in the end other end in the central axis direction. A cooling apparatus (10) comprises the heatsink (30), and a printed circuit board (20). The heatsink (30) is mounted on an upper surface of the printed circuit board and the heating element is mounted on an undersurface thereof, wherein the heating element (3) is located in a central position in the radial direction and opposite the heatsink (30), such that the other end in the central axis direction is located below.

Owner:TE CONNECTIVITY GERMANY GMBH

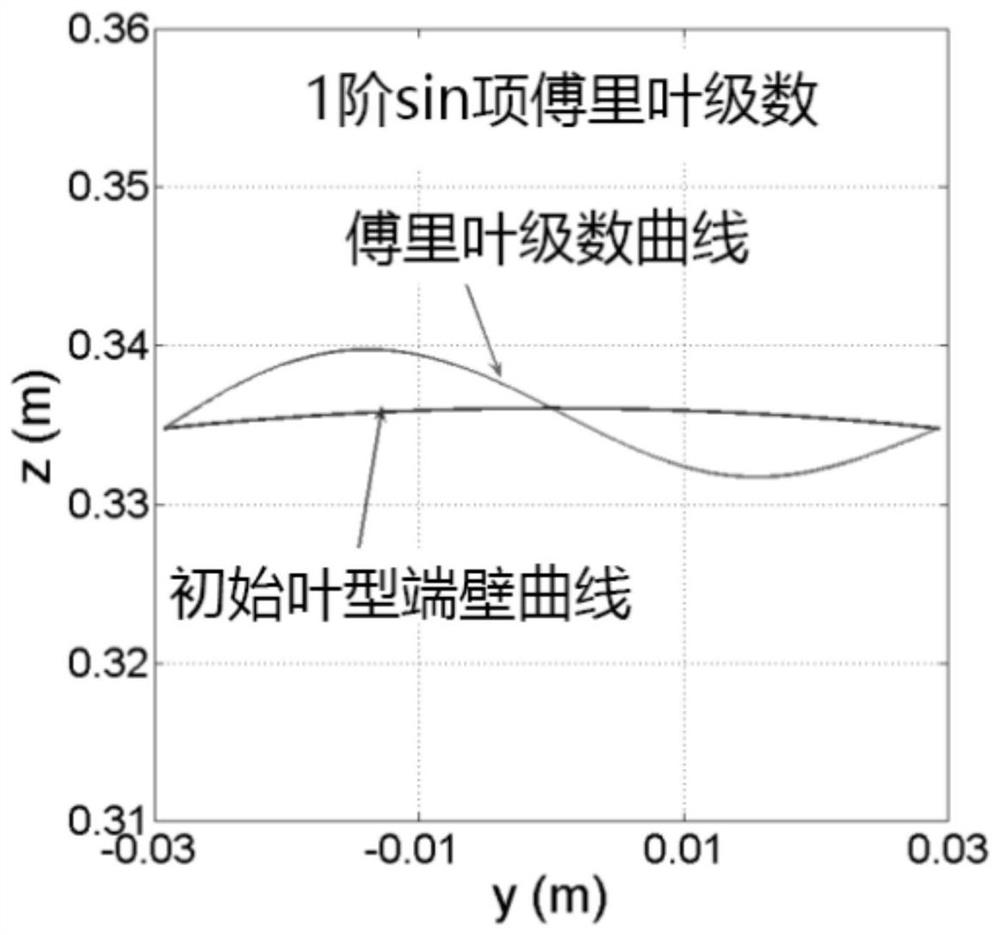

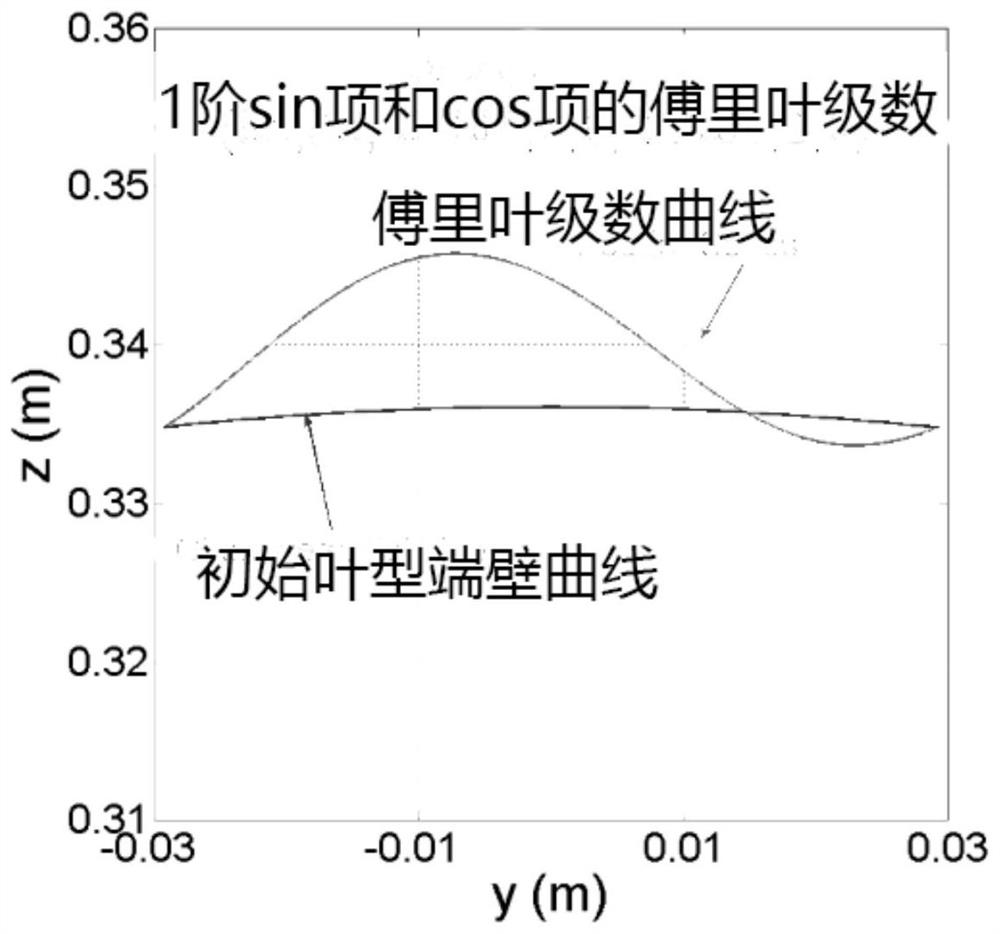

Modeling method for non-axisymmetric end wall of axial flow impeller

PendingCN112560195ASimple structureFlexible structureGeometric CADPump componentsImpellerEngineering

The invention provides a modeling method for a non-axisymmetric end wall of an axial flow impeller, which comprises the following steps: for end wall molded surfaces with different concavities and convexity, firstly, dividing a configuration area, and flexibly constructing various complex end wall structures on the basis of applying fewer variables by adopting a circumferential three-order Fourierseries curve; and then reading a three-order Fourier series curve in the circumferential direction of the blade, enabling spline curves to subjected to smooth connection in the axial direction, and forming a non-axisymmetric end wall model. A three-order Fourier series curve mode is adopted in the circumferential direction to accord with the distribution rule of a blade channel pressure field, the axial section area of a flow channel can be kept almost unchanged, the total loss near the end wall is reduced, flowing separation of airflow is reduced, the outlet flow field and the airflow angleare more uniform, and the performance of a fan and a compressor blade is improved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Tube orifice diameter variable spliced sampling instrument

The invention relates to a tube orifice diameter variable spliced sampling instrument which structurally comprises a steady flow buffer tube for receiving a pumped polluted water sample and performing steady flow conveying on the polluted water sample, a pump tube connection mechanism connected with a polluted water sample output pump tube, a diversion pressure regulating valve for regulating water flow pressure of the polluted water sample, a pressure gauge for detecting the water flow pressure, a sampling hose leading the polluted water sample under a laminar condition out of the steady flow buffer tube via a streamline water outlet for water sampling, and a concentric flow regulator for regulating a flow rate of the collected water sample. The instrument changes the composition, the structure and the operating principle of the original organic polluted water sampling device, has the characteristics of small size, light weight, wide application scope, convenience in carrying and mounting, simplicity in operation, safety in use, prevention of a pollution link in a collection process of the sample and the like, improves the fidelity of the collected sample, lowers the collecting cost of the sample, and ensures the safety of personnel and equipment, and the universality of the sampling instrument is improved.

Owner:INST OF HYDROGEOLOGY & ENVIRONMENTAL GEOLOGY CHINESE ACAD OF GEOLOGICAL SCI

Pipe orifice variable plug-in type sampling instrument

InactiveCN103759975AImprove fidelityNo pollutionWithdrawing sample devicesWater flowEnvironmental engineering

The invention relates to a pipe orifice variable plug-in type sampling instrument which structurally comprises a steady flow buffer pipe used for receiving a pumped polluted water sample and steadily conveying the polluted water sample, a pump pipe connecting mechanism connected with a polluted water sample output pump pipe, a flow dividing pressure regulating valve used for regulating the pressure of the water flow of the polluted water sample, a pressure gauge for detecting the pressure of the water flow, a sampling hose used for leading out the laminar-condition polluted water sample from the steady flow buffer pipe through a streamline water outlet and collecting the water sample, and a concentric type flow regulator used for regulating the flow of the collected water sample. The sampling instrument provided by the invention changes the composition, the structure and the working principle of an original organic matter polluted water sample collecting device, and has the characteristics of small size, light weight, wide application range, convenience for carrying and installing, simplicity in operation, safe use, avoidance of polluting the sample in the collecting process, etc., so that the fidelity of the collected sample is increased, the sample collecting cost is lowered, the safety of staffs and equipment is guaranteed, and the universality of the sampling instrument is improved.

Owner:INST OF HYDROGEOLOGY & ENVIRONMENTAL GEOLOGY CHINESE ACAD OF GEOLOGICAL SCI

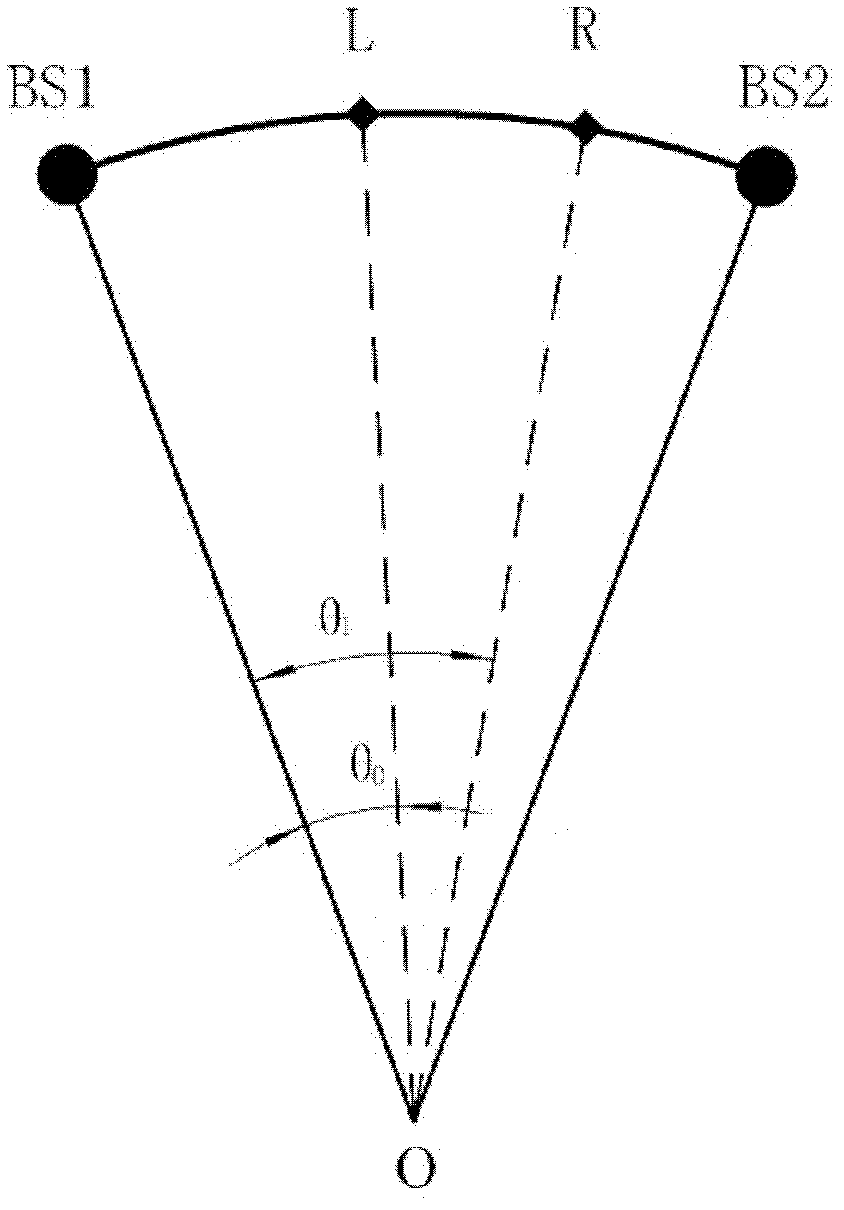

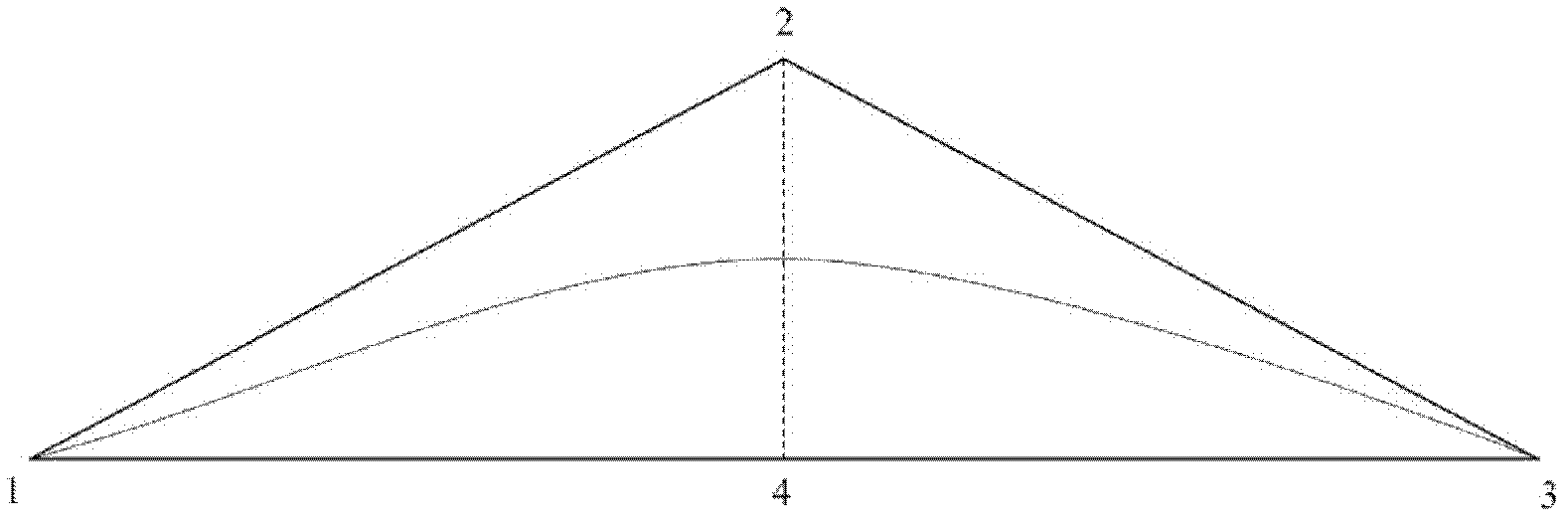

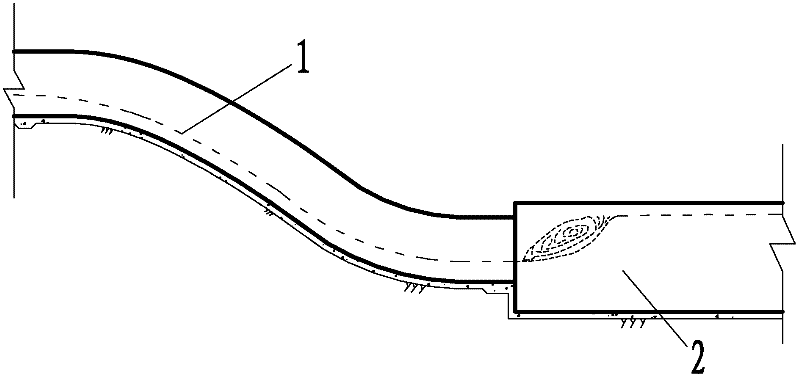

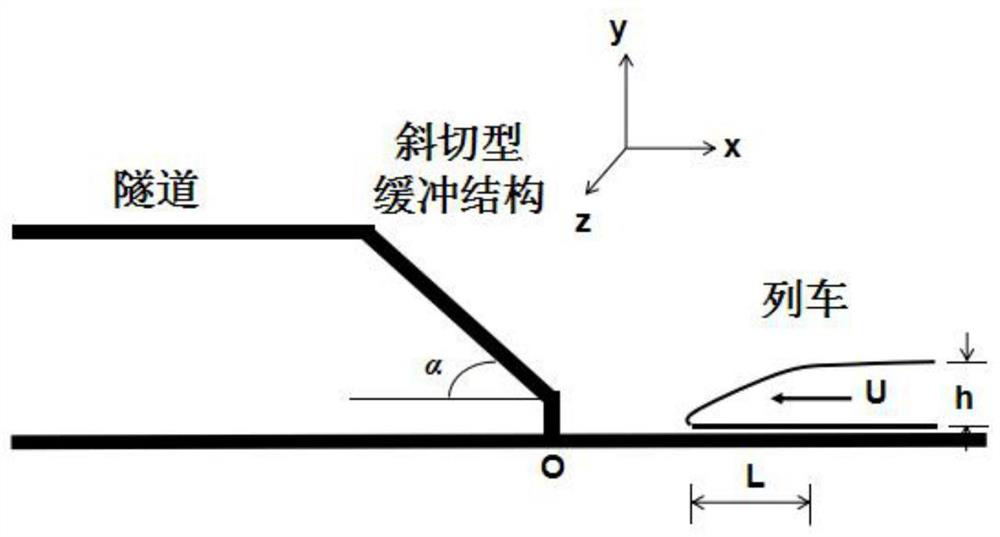

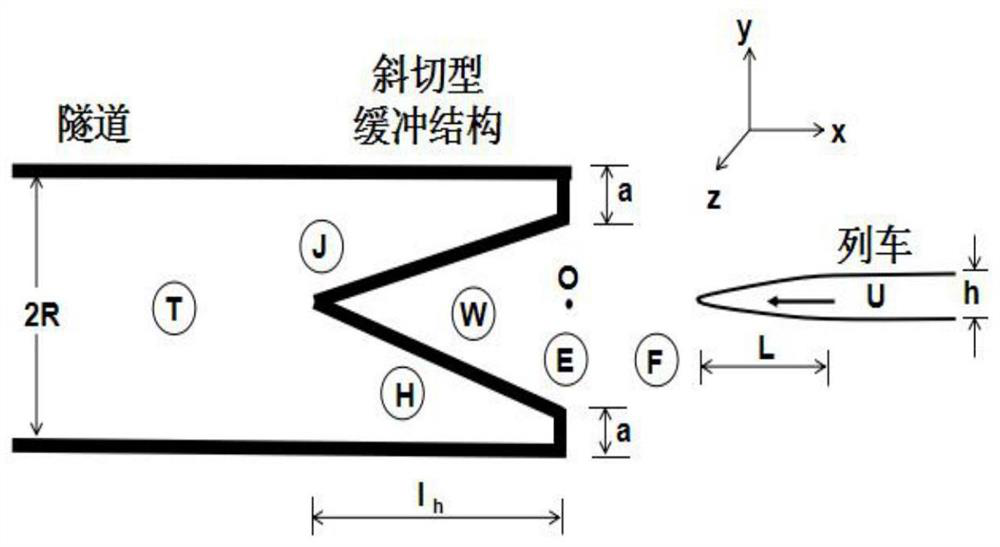

Design optimization method for buffer structure at entrance of beveled tunnel

ActiveCN112814696ASimple and scientific designLow costMining devicesSustainable transportationEngineeringStructural engineering

The invention provides a design optimization method for a buffer structure at an entrance of a beveled tunnel. After the beveled buffer structure is arranged, the wavefront thickness of initial compression waves is remarkably increased, so that the rise time of the compression waves is prolonged, the pressure gradient of the initial compression waves is reduced, micro-pneumatic waves at an exit of the tunnel are relieved, and the aerodynamic effect inside and outside the tunnel can be effectively relieved. The design optimization method for the buffer structure at the entrance of the beveled tunnel specifically comprises the following steps of 1, calculating a model; 2, solving the aerodynamic effect of the tunnel based on aeroacoustics; and 3, optimizing the buffer structure. The design optimization method can be popularized and applied to the field of high-speed railway construction; the entrance of the tunnel is transformed and optimized; the structural design is scientific and reasonable; and the design optimization is accurate and easy to operate.

Owner:HEBEI UNIV OF ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com