Patents

Literature

795results about How to "Reduce air leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

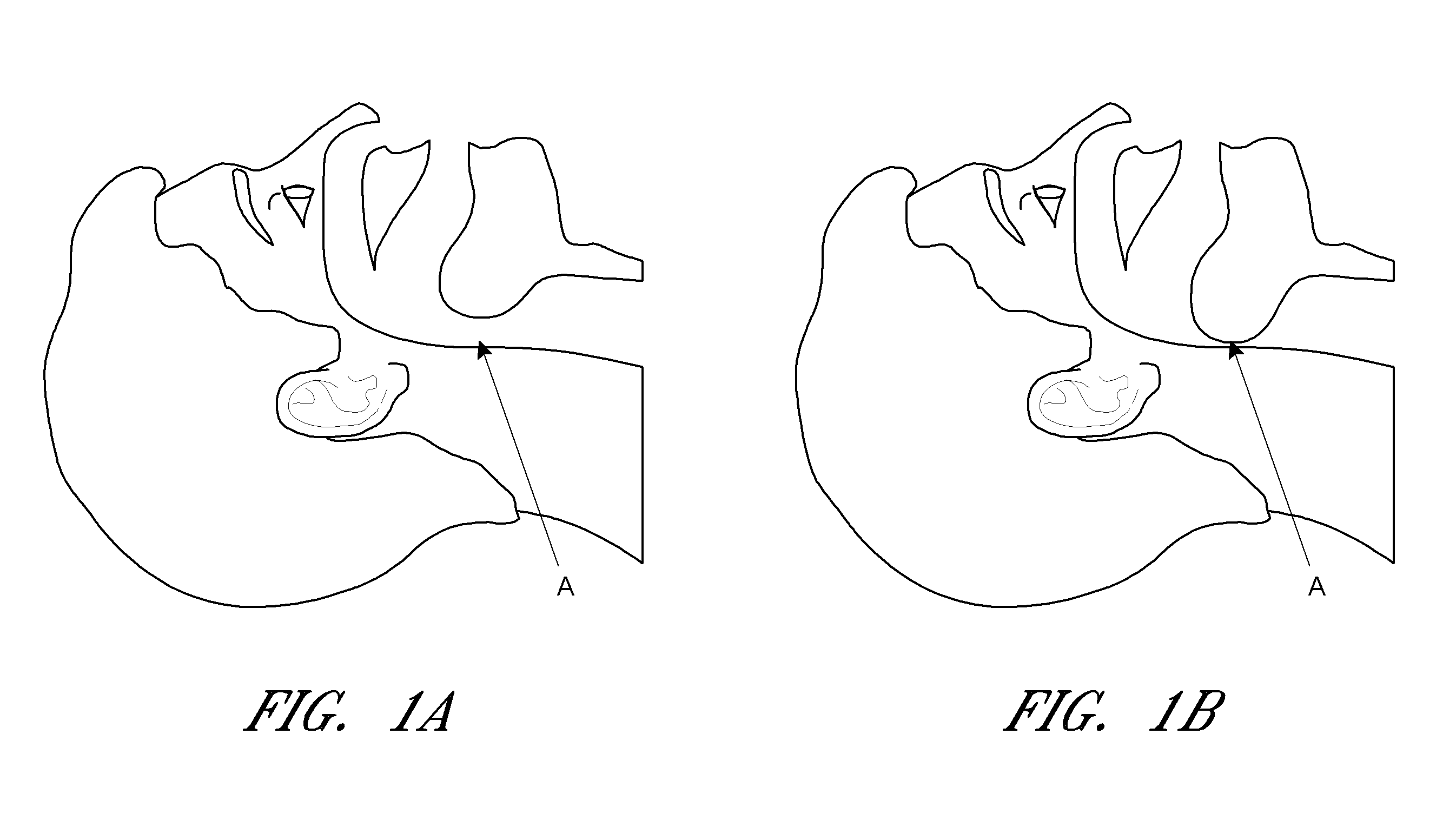

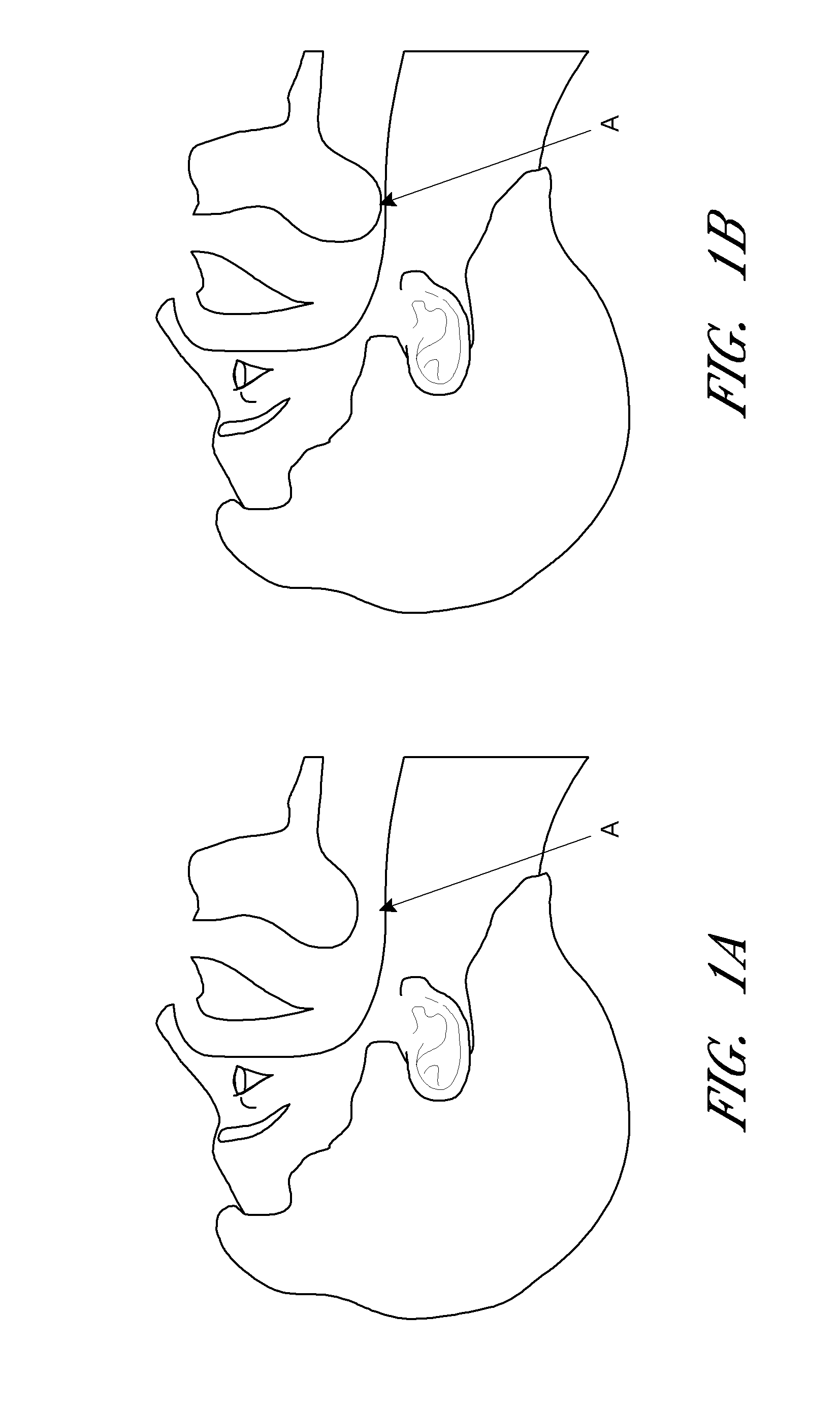

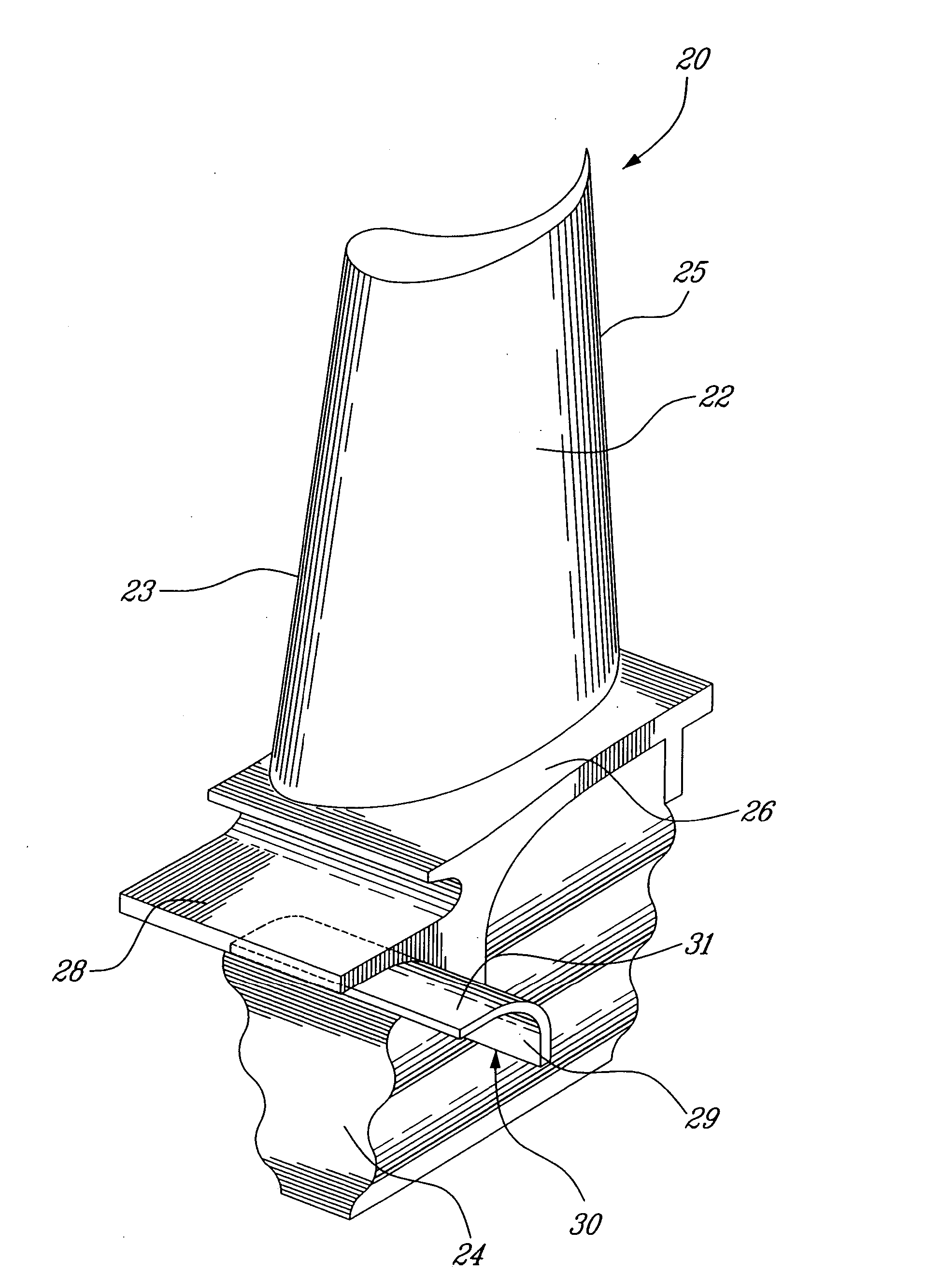

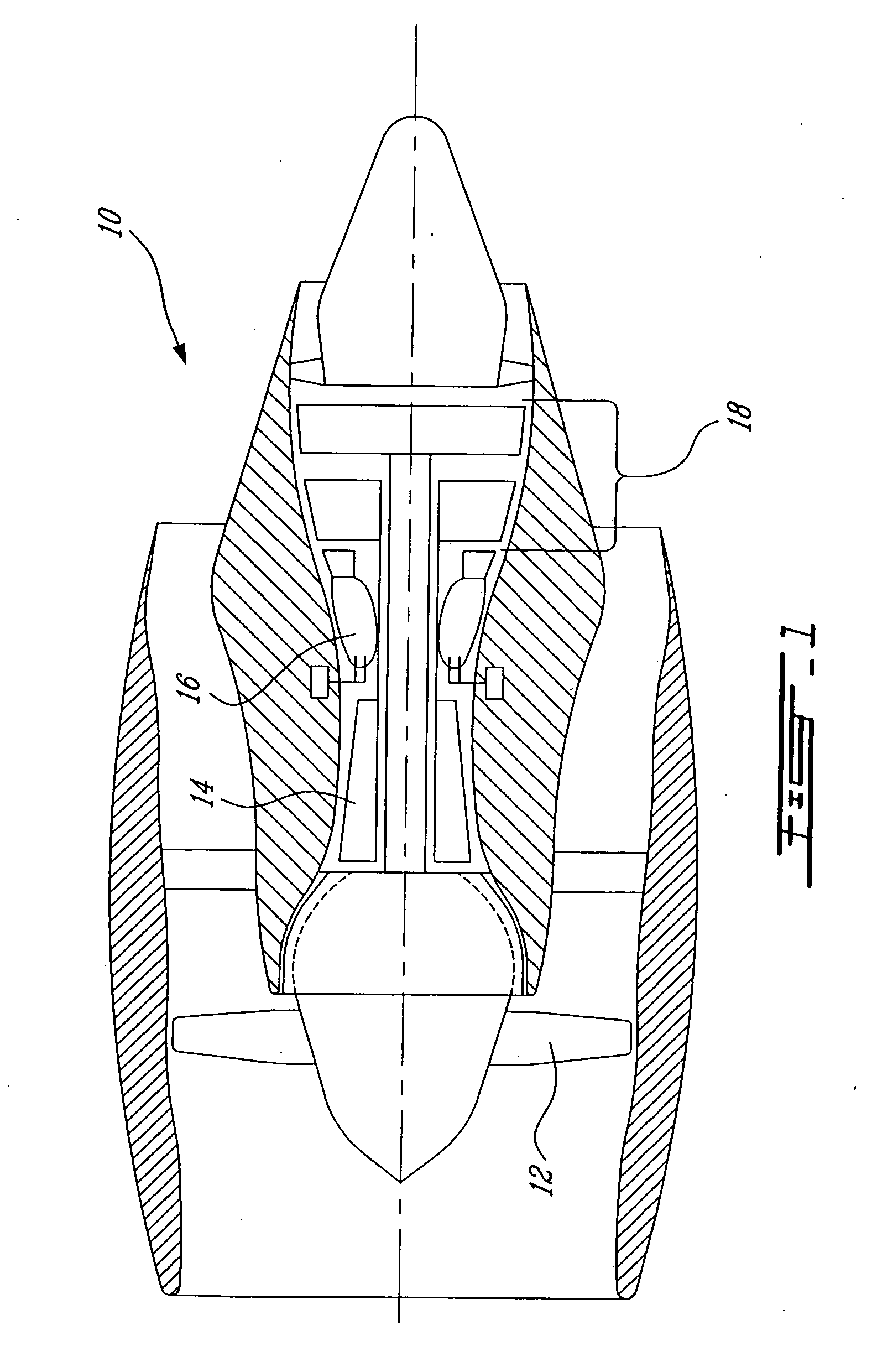

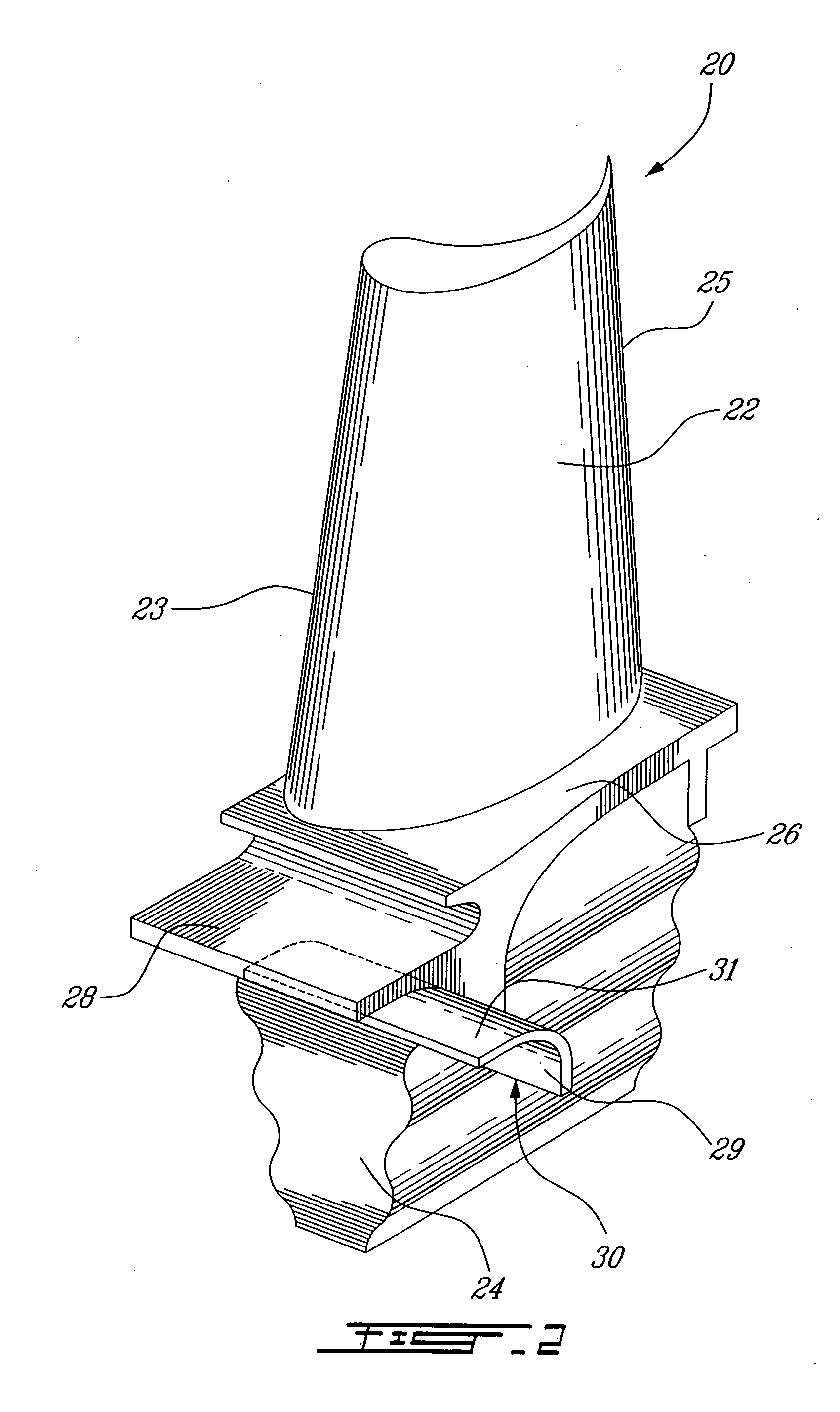

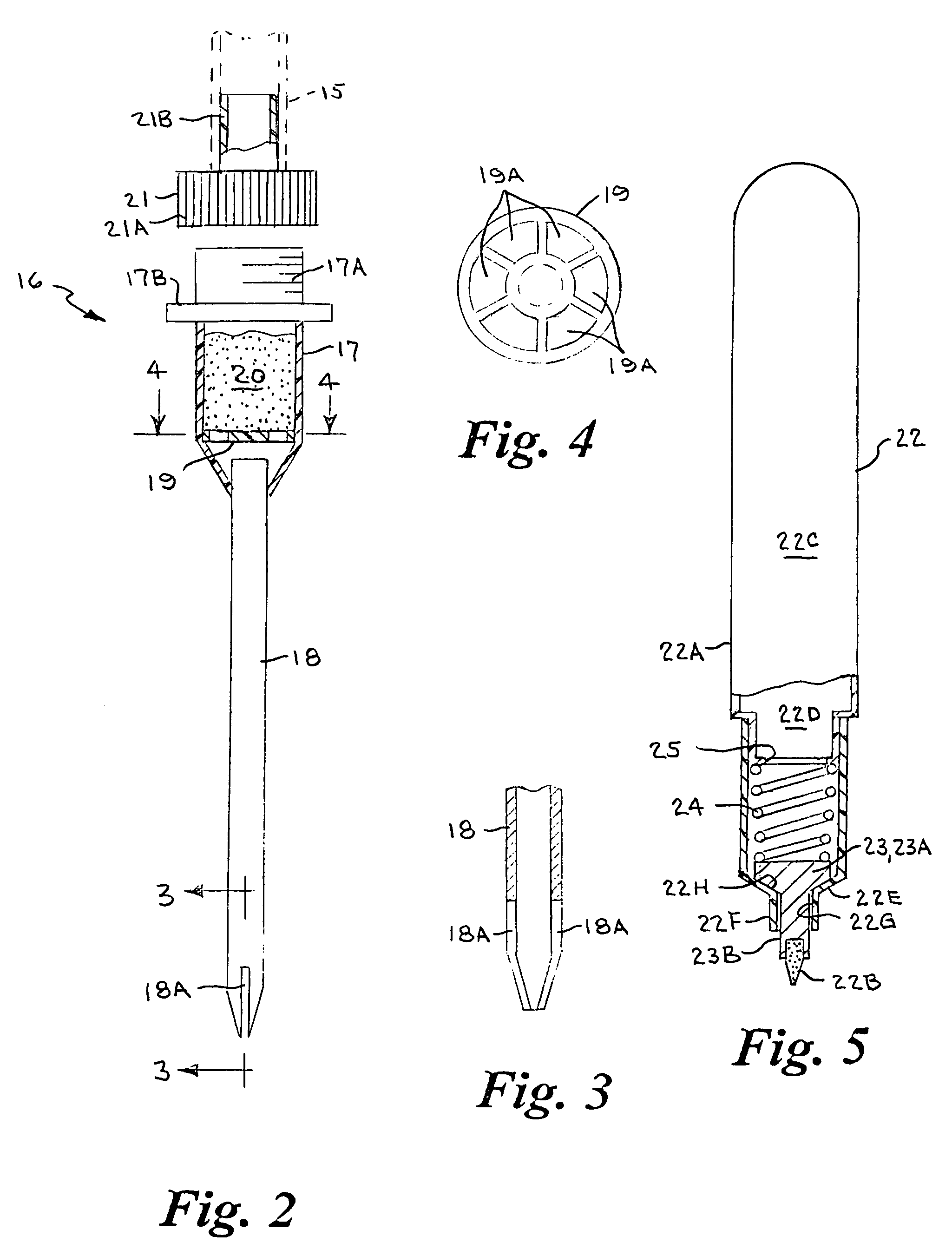

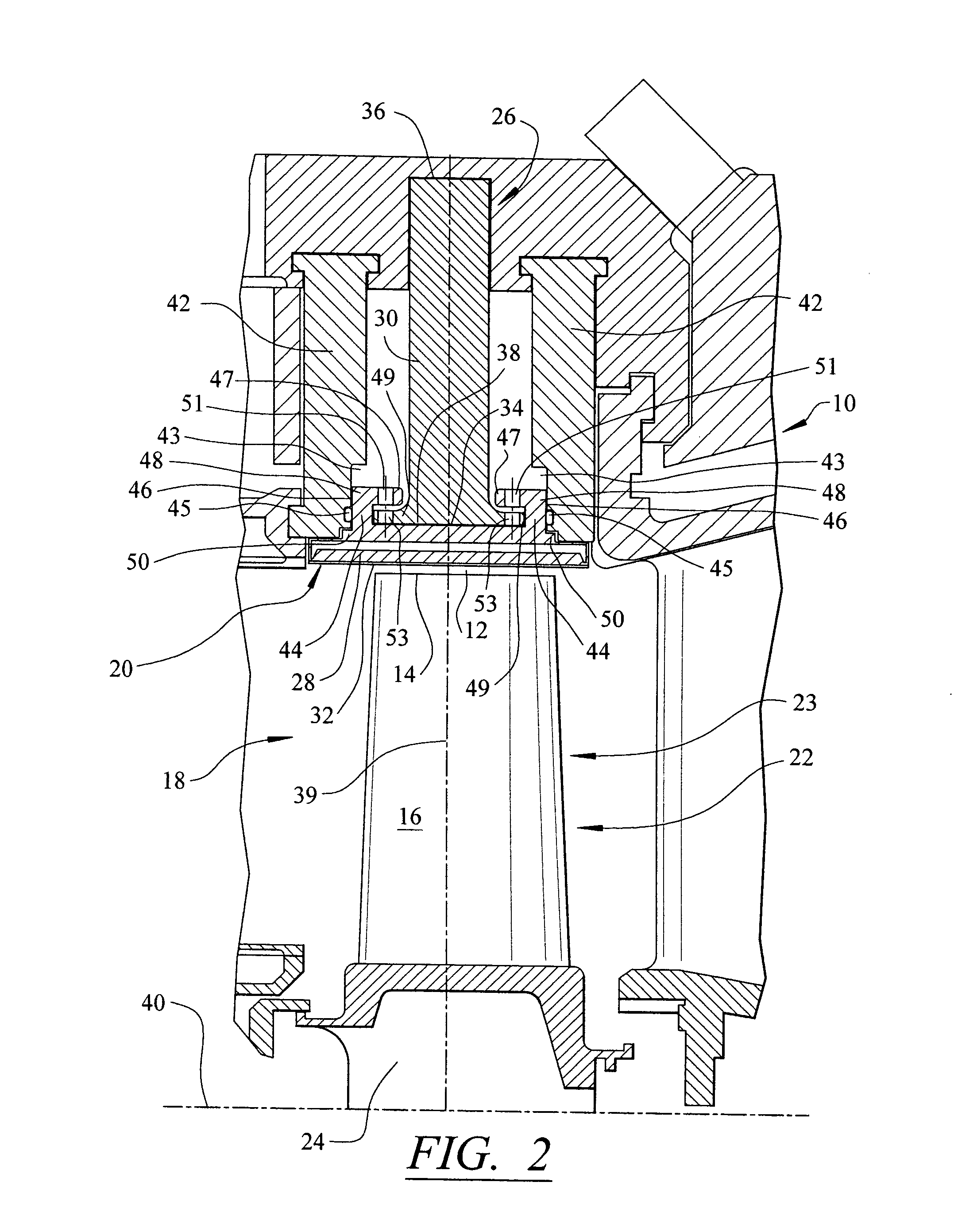

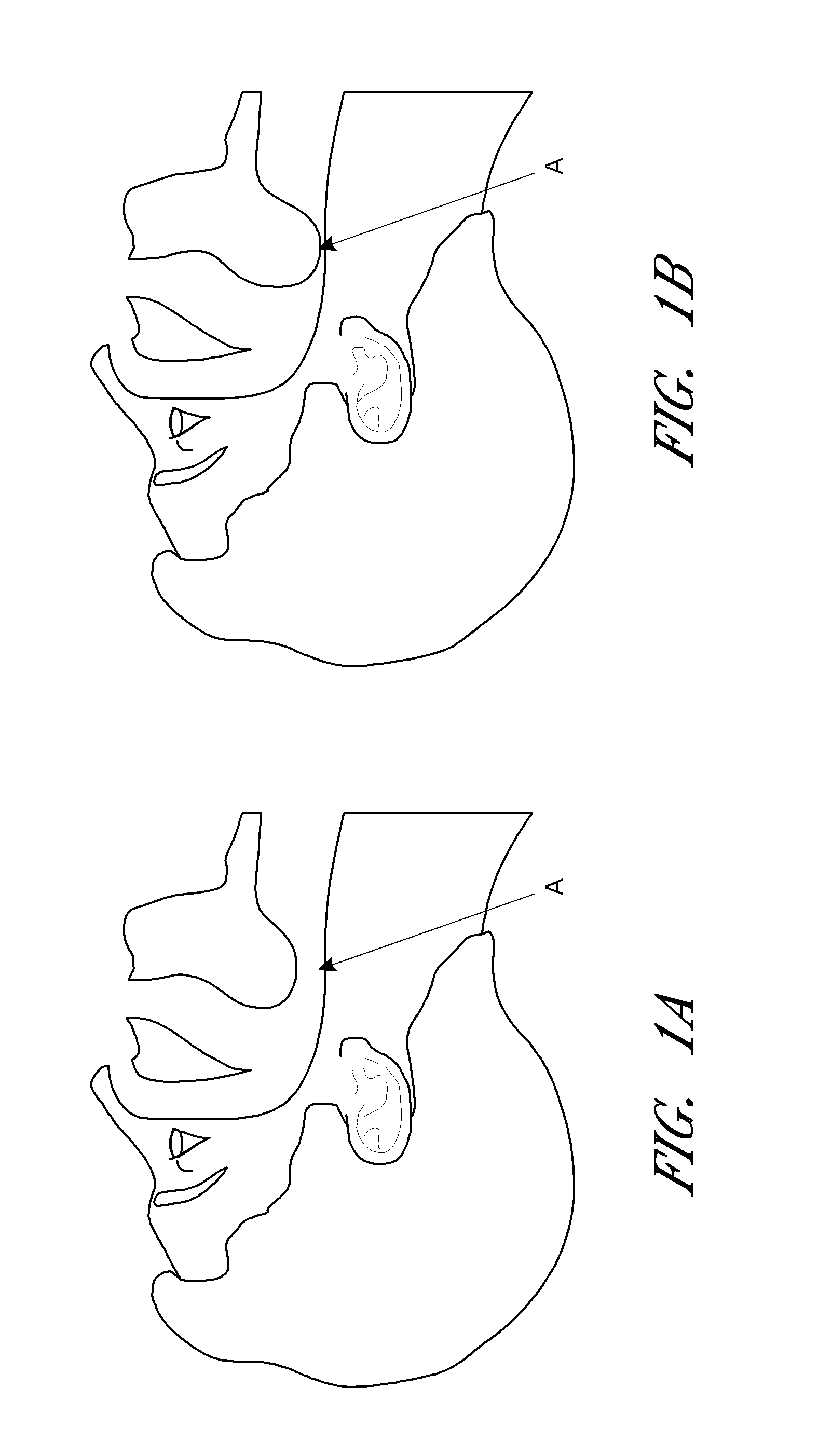

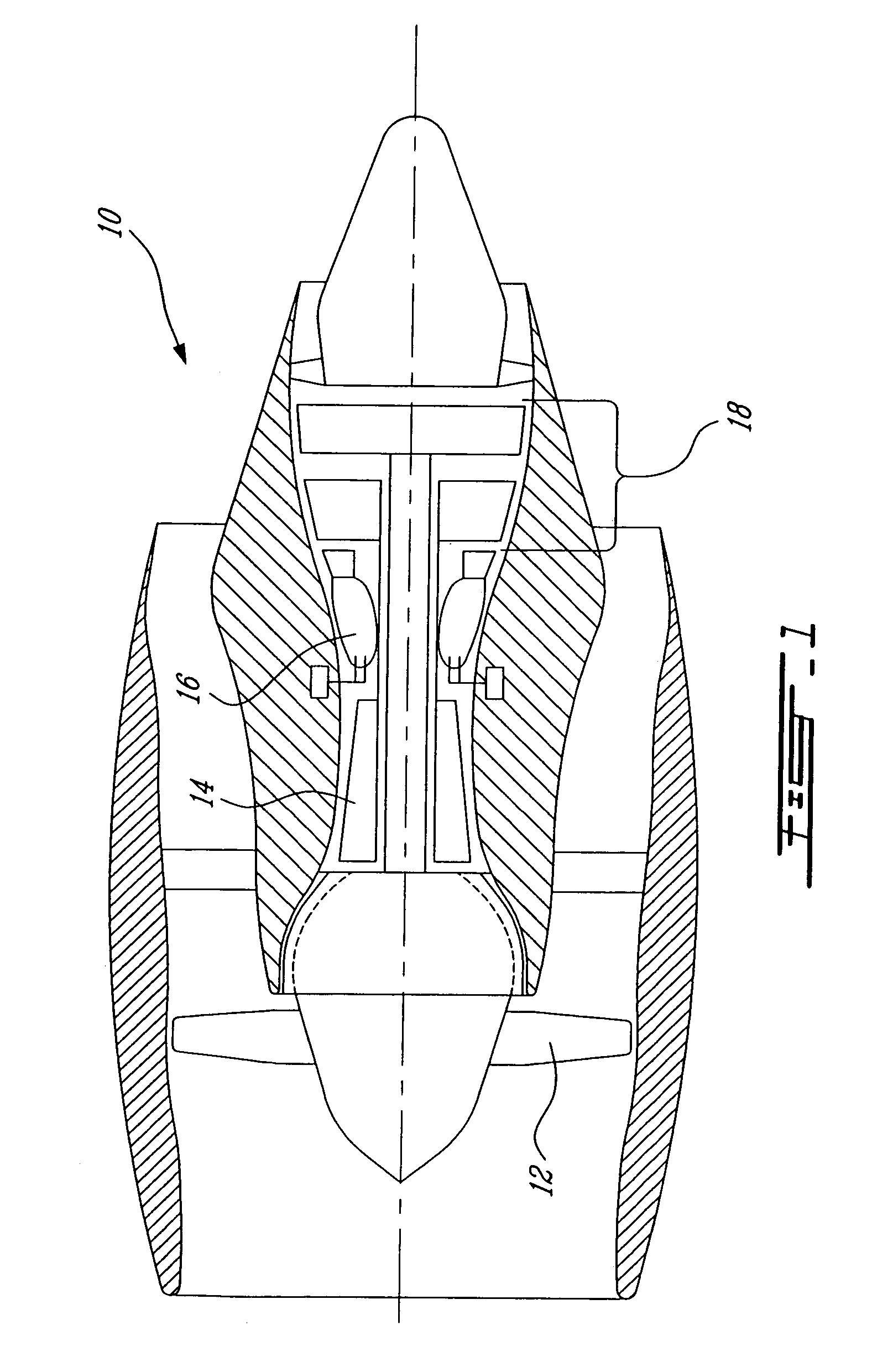

Lung device with sealing features

InactiveUS20060025815A1Reduce air leakageMitigates pneumothorax and hemothoraxSurgical needlesMedical devicesThoracic structureThoracic cavity

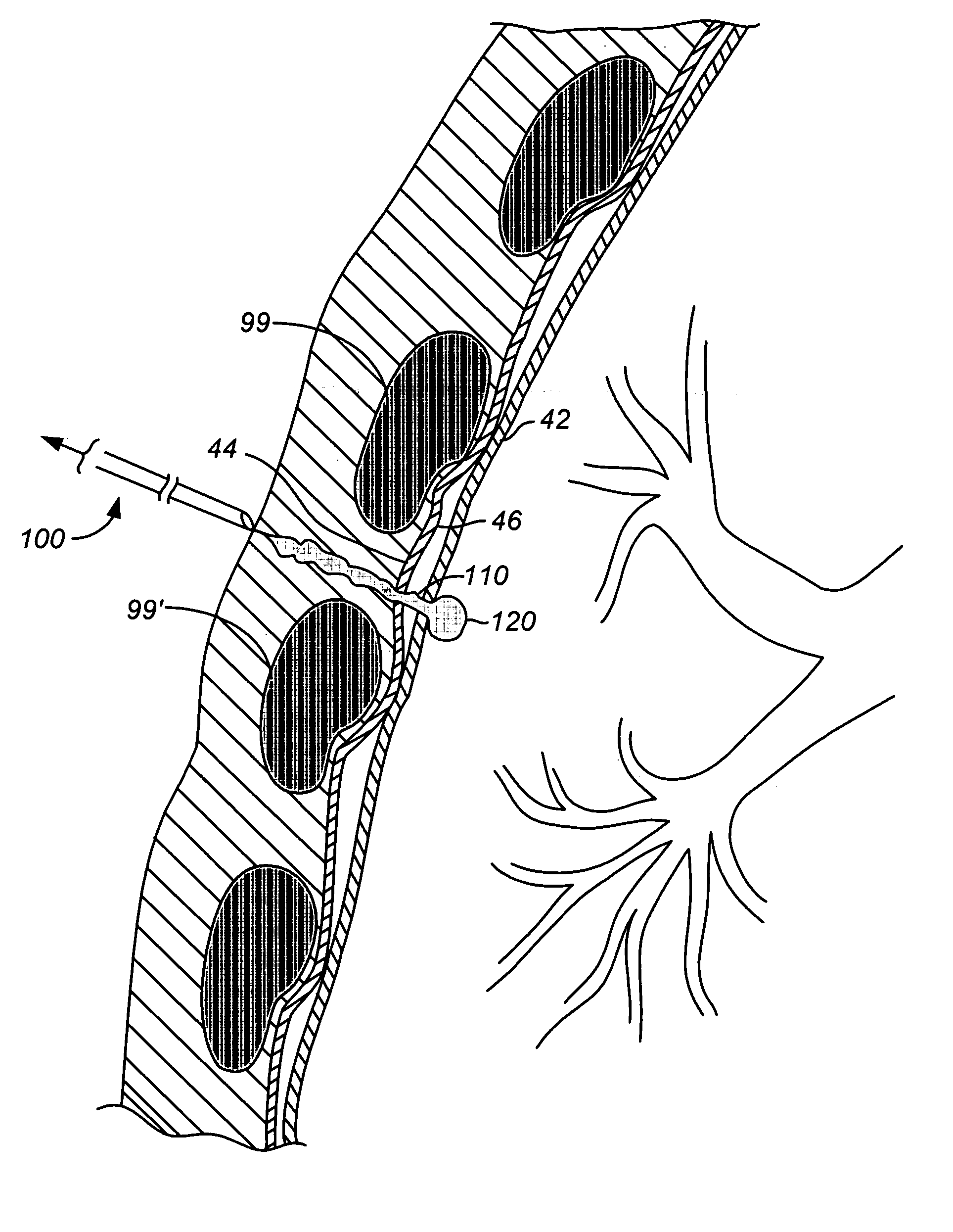

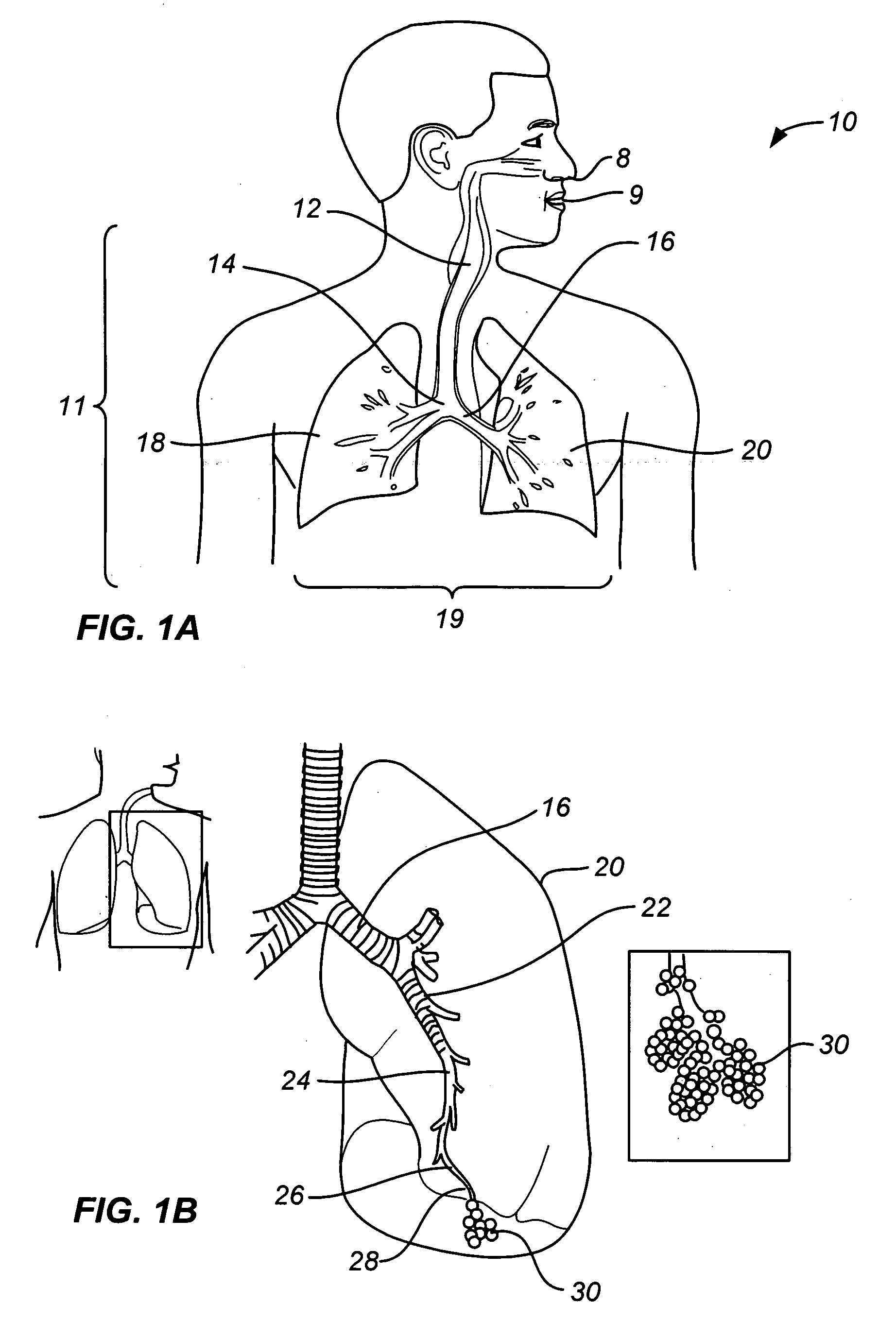

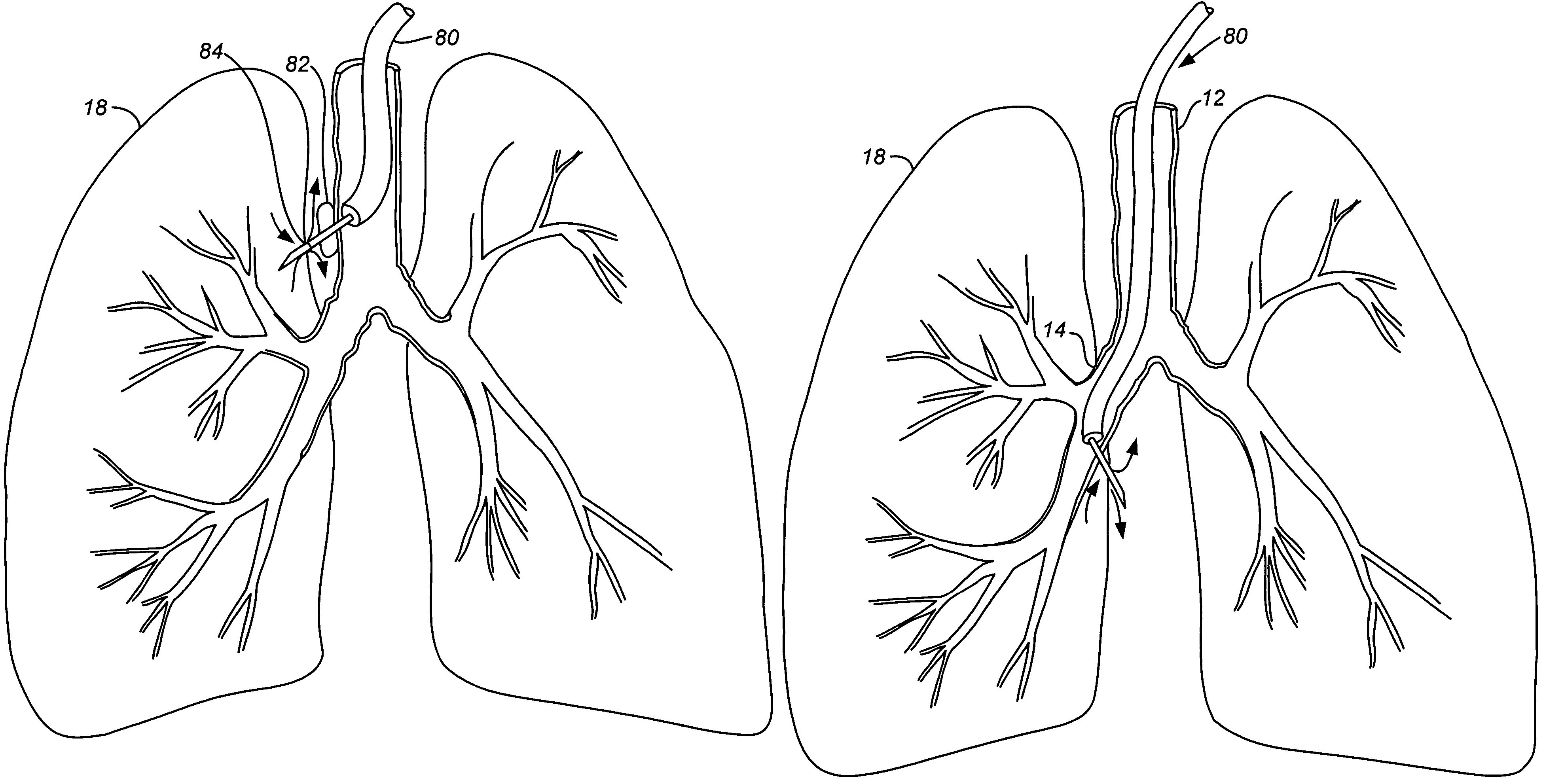

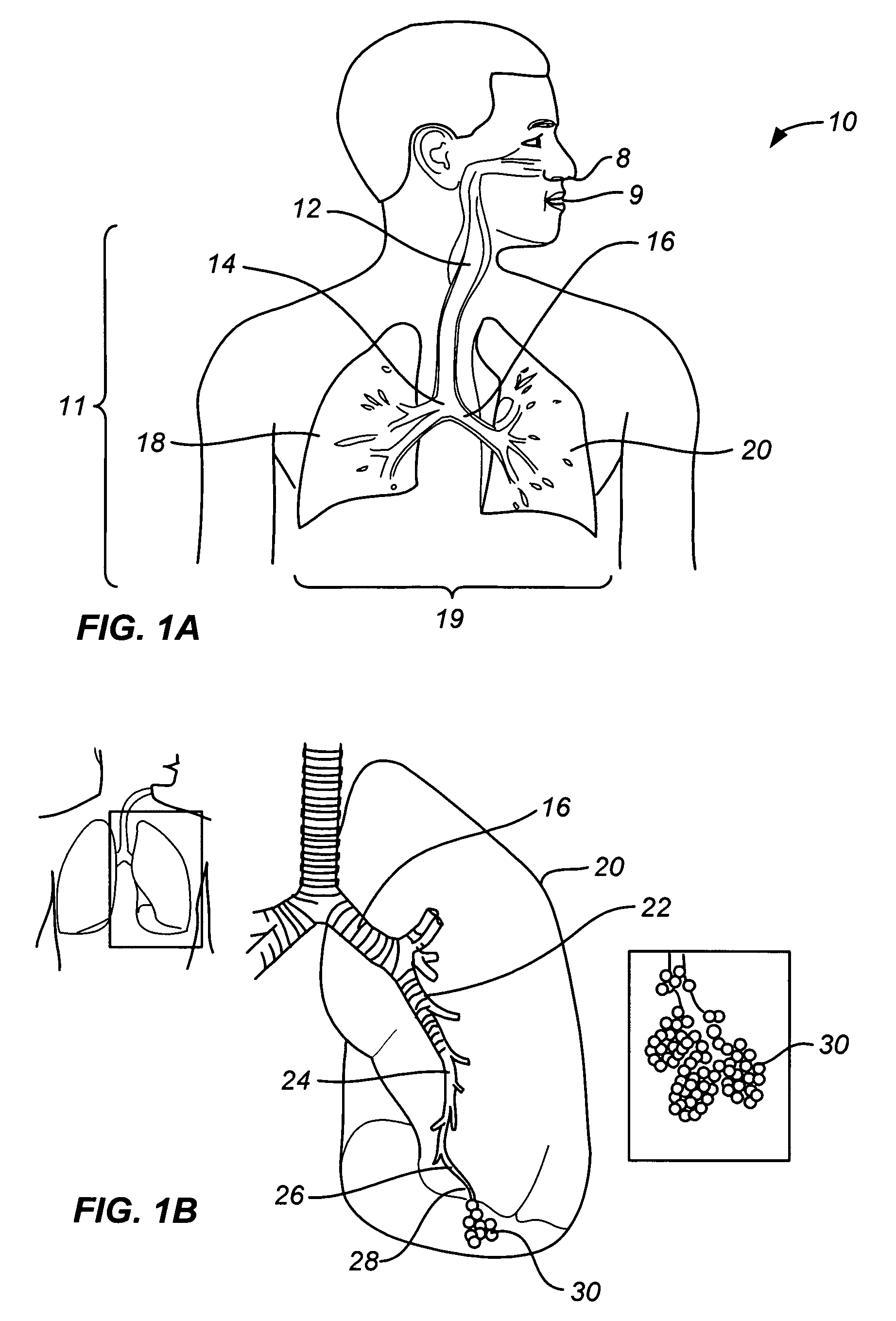

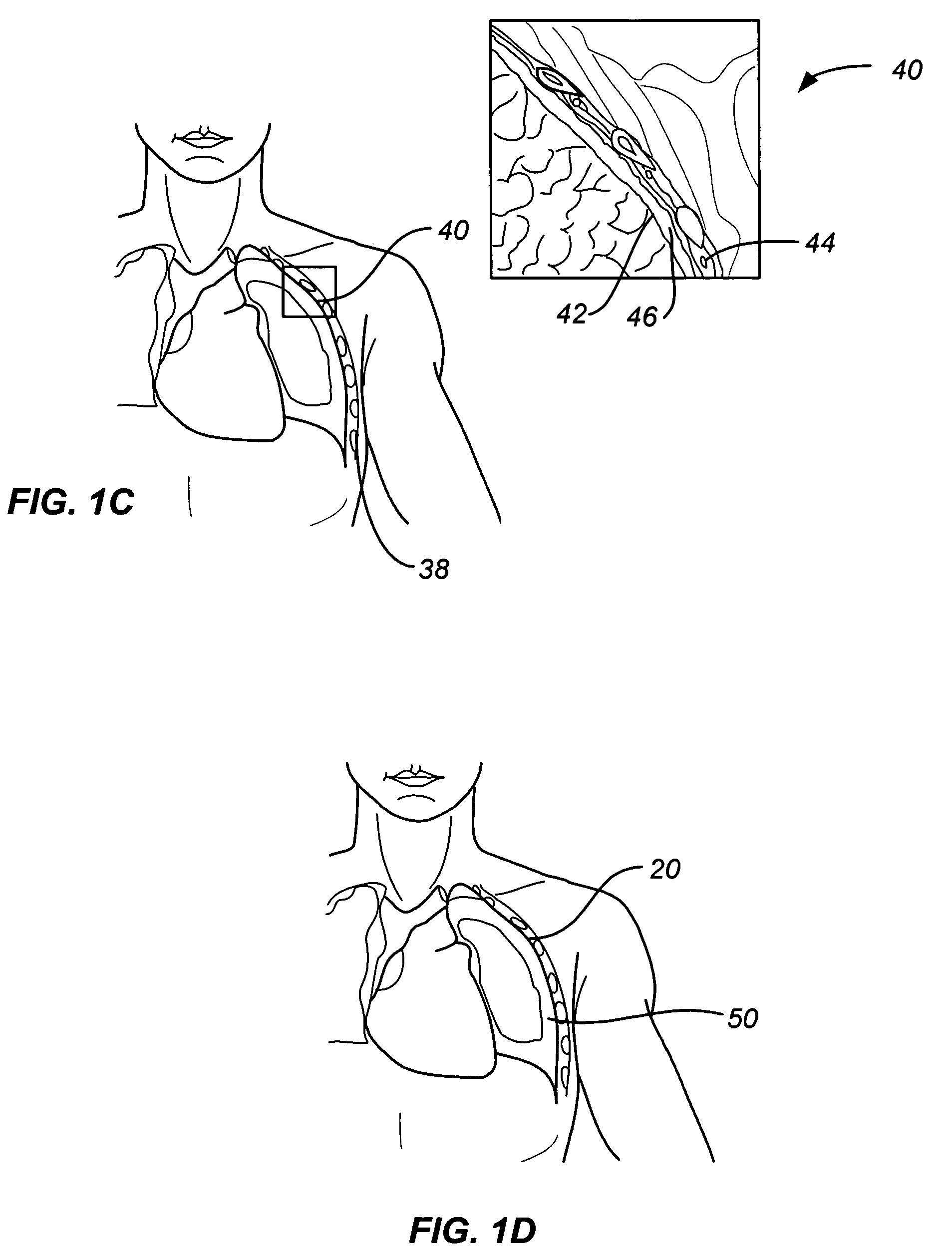

This invention relates generally to a design of lung devices for safely performing a transthoracic procedure. In particular, the invention provides devices and methods of using these devices to access the thoracic cavity with minimal risk of causing pneumothorax or hemothorax. More specifically, the invention enables diagnostic and therapeutic access to a thoracic cavity using large bore instruments. This invention also provides a method for diagnostic and therapeutic procedures using a device capable of sealing the wound upon withdrawal of the device. The invention includes a device comprising an elongated body adapted to make contact with a tissue of a subject through an access hole, and a sealant delivery element. The invention also includes a method of performing tissue treatment or diagnosis in a subject.

Owner:EKOS CORP

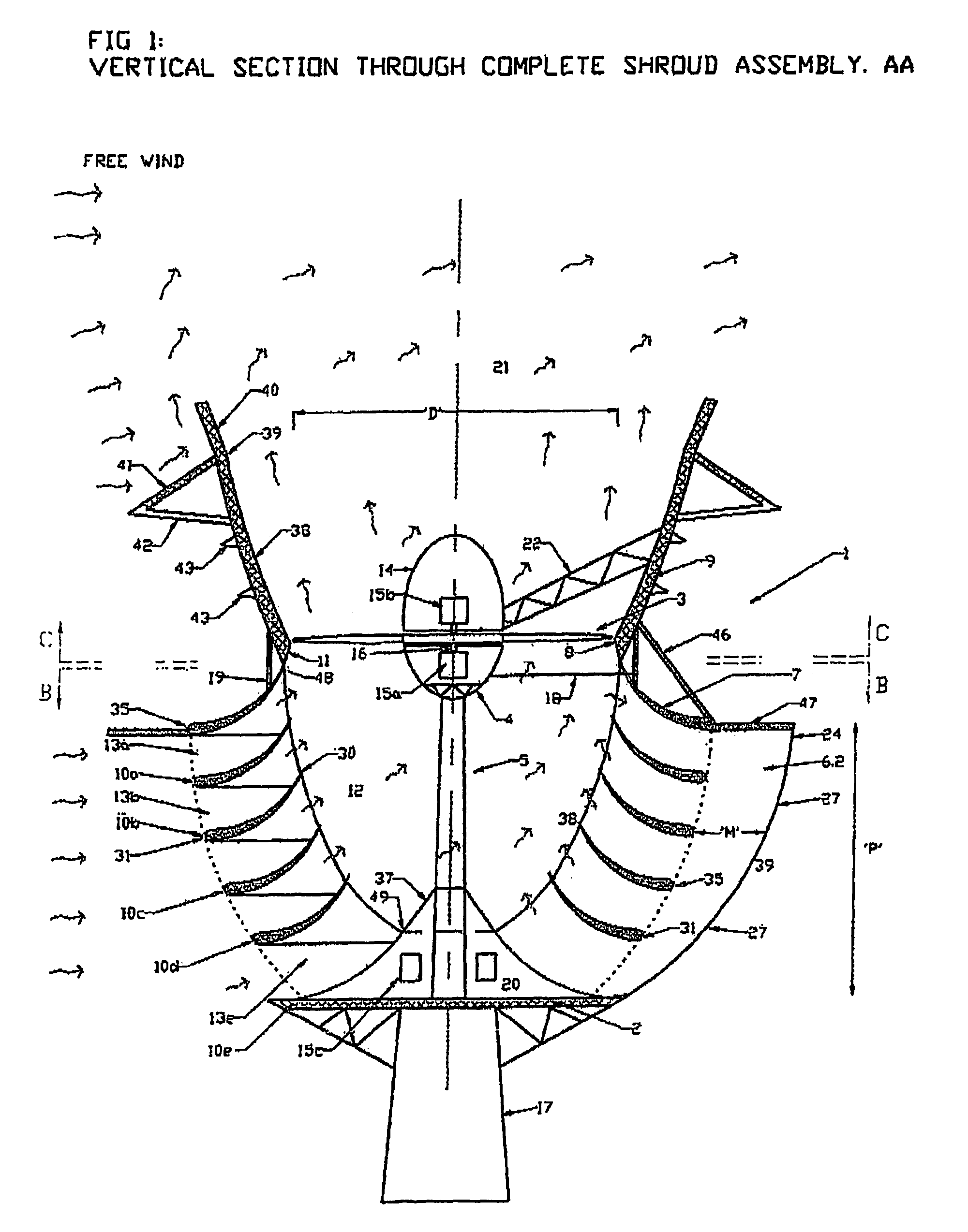

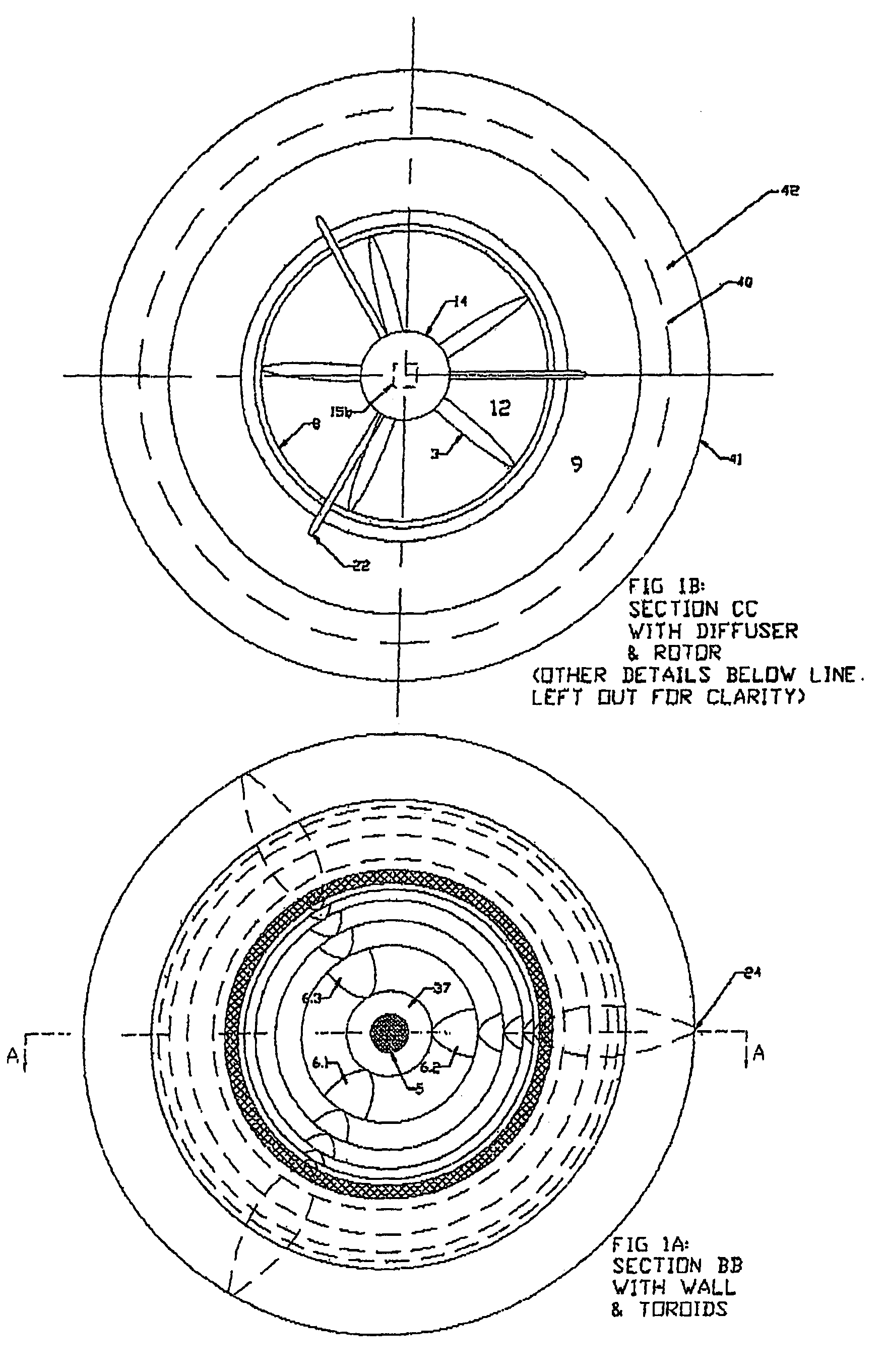

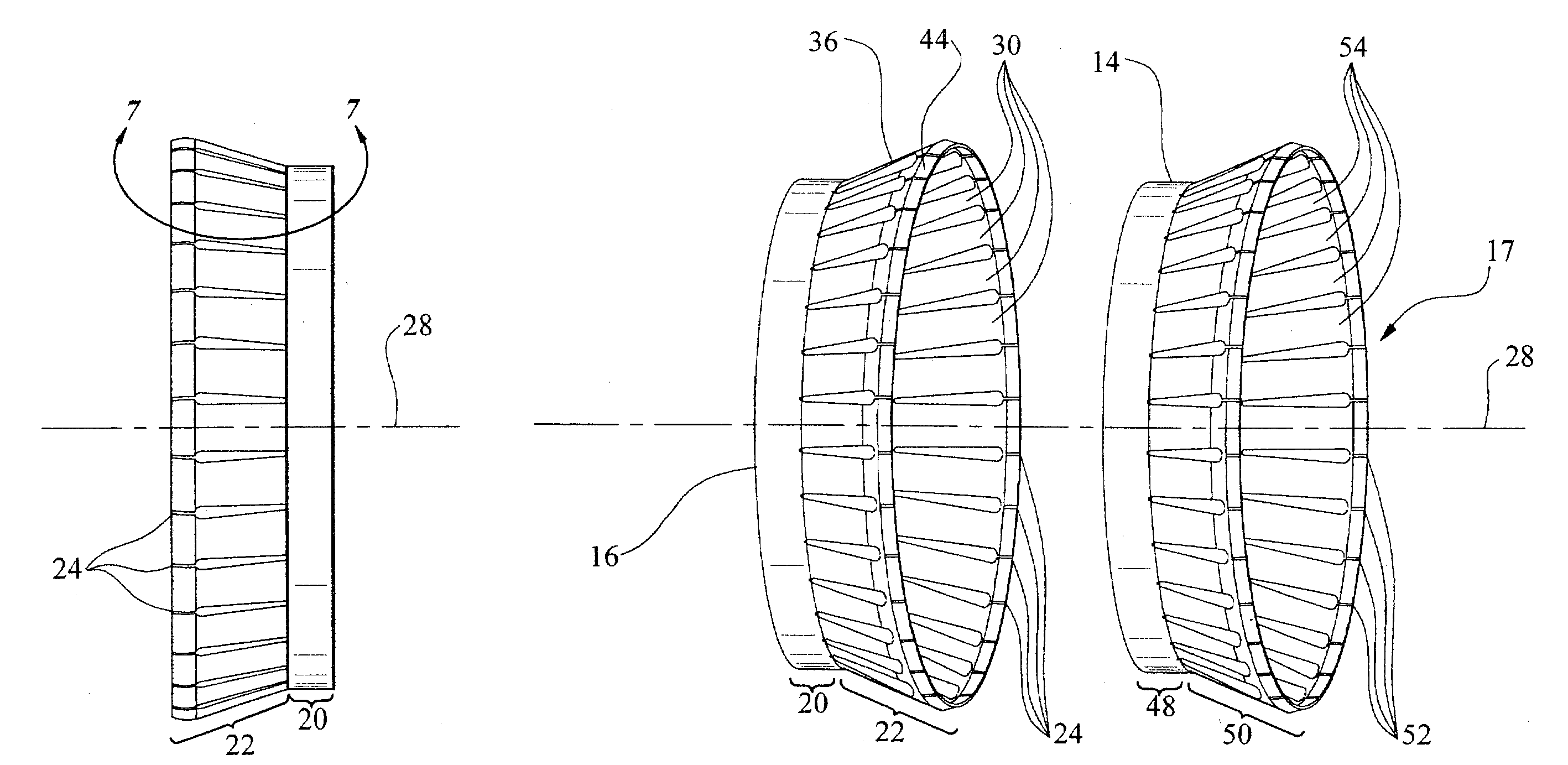

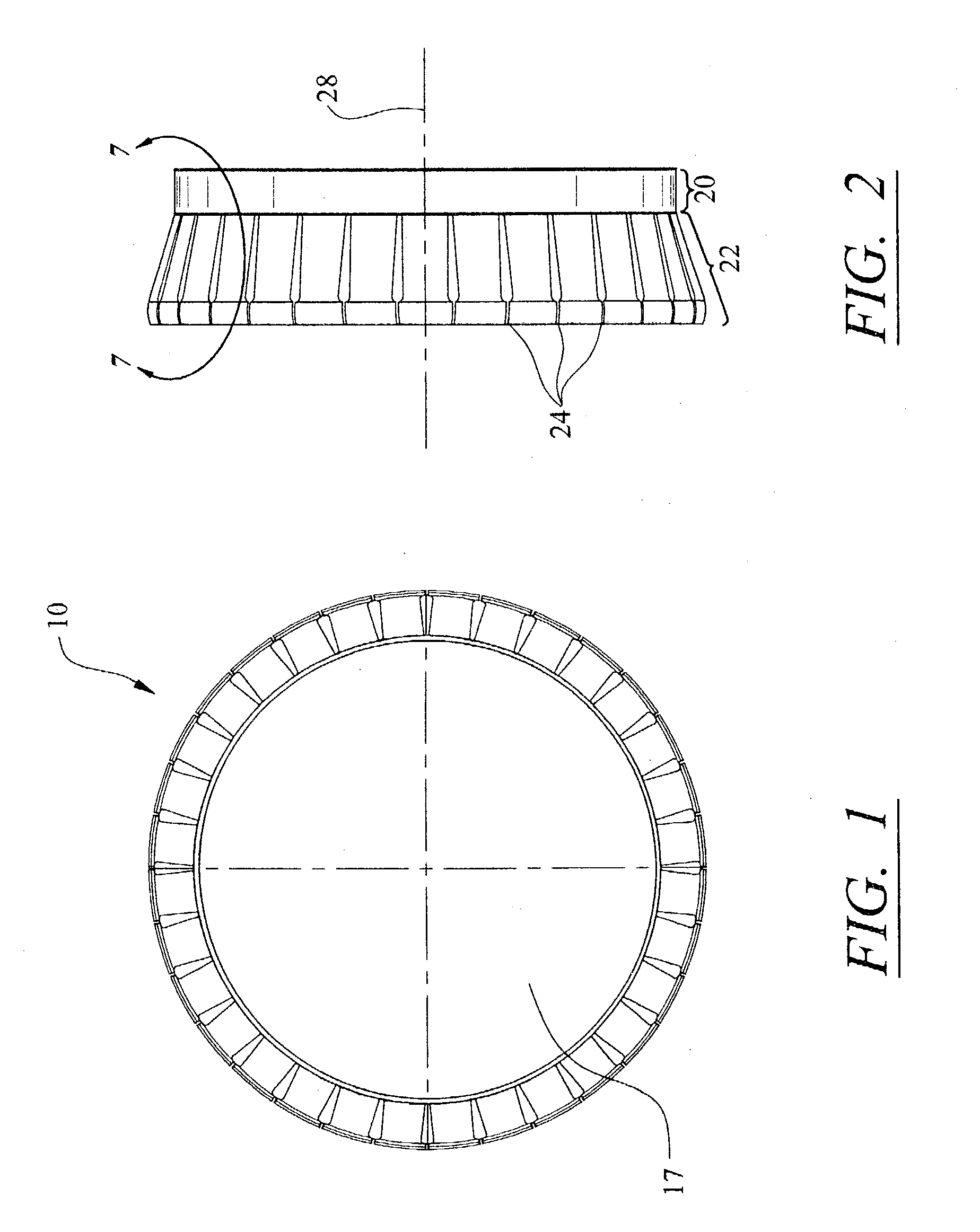

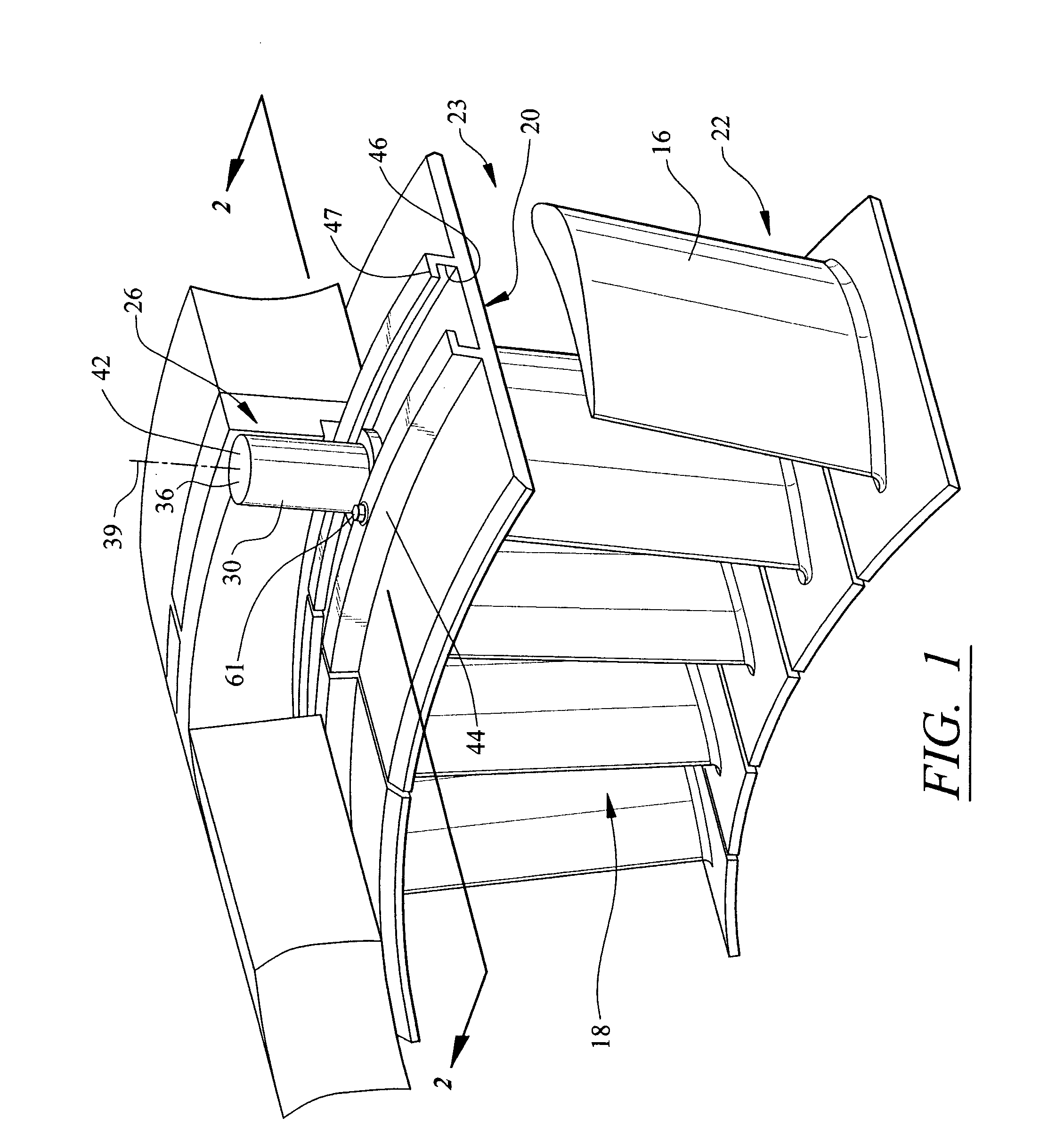

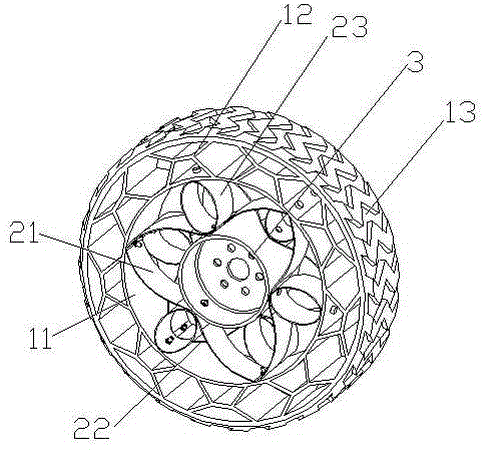

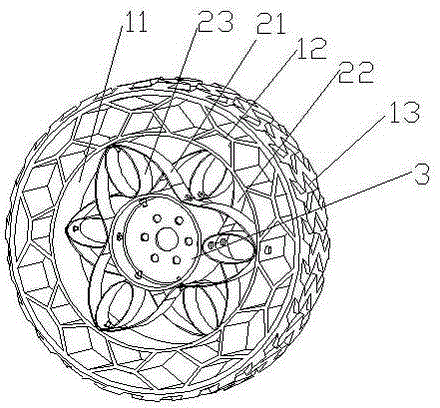

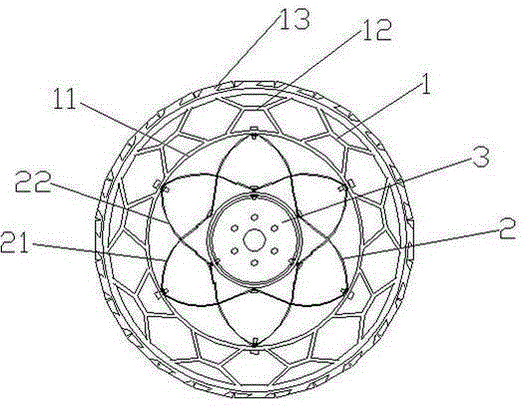

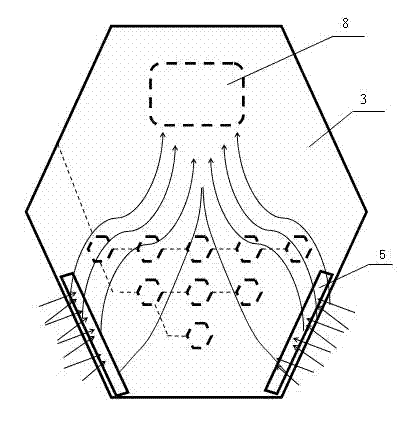

Omni-directional wind turbine

ActiveUS7400057B2Reduce air leakageGuaranteed to be free from interferenceWind motor controlMachines/enginesStream flowOmni directional

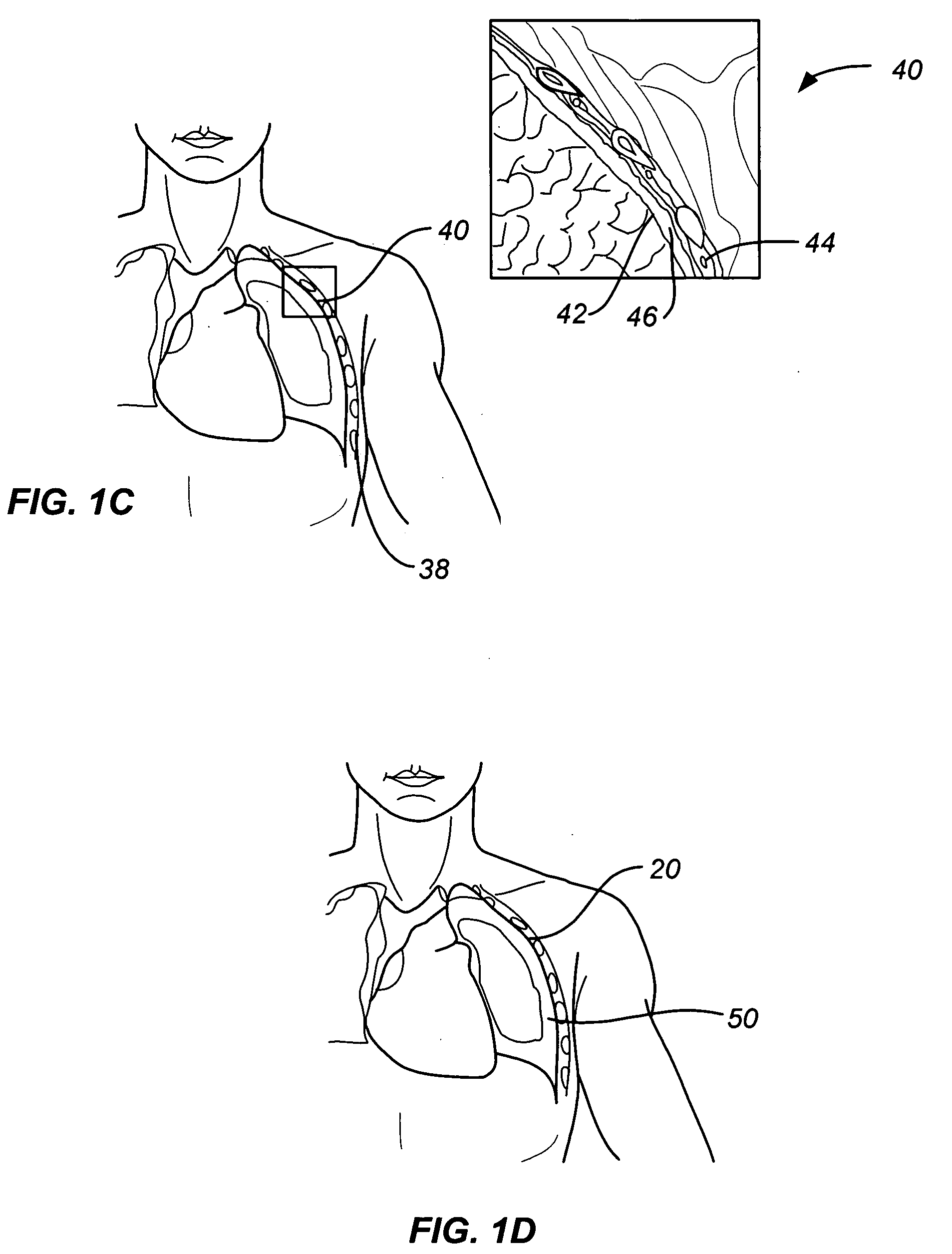

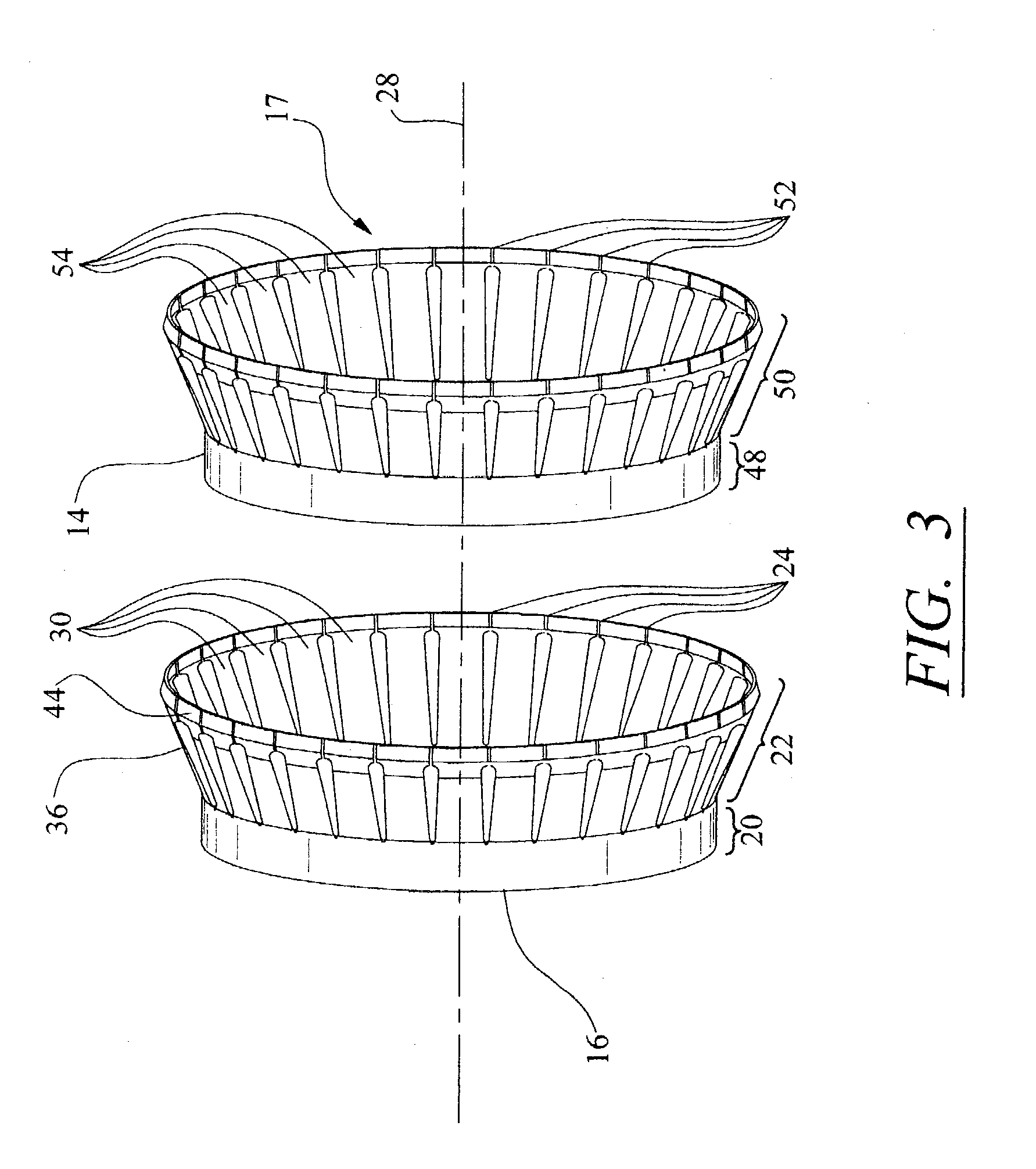

An omni directional, vertical discharge wind turbine, consisting of a shroud that captures wind from any direction and directs it to flow vertically through a throat section where an aerofoil multi-bladed rotor is mounted. The rotor shaft is connected to an electrical power generator. The intake of the shroud incorporates multiple horizontally curved blades of toroidal form varying up to nearly twice the size of the rotor diameter, stacked, staggered and secured in place by multiple aerodynamic vertical walls in the radial direction, to form a central collection chamber for wind. The blade curving angles and the stacking arrangement are such that while accelerating and focusing the wind, across the full swept area of the rotor blades, the loss of air from the central collection chamber is significantly reduced by air flow forming a fluid dynamic gate across inactive faces. Utilizing a wedge and collar near the open top discharge the free wind stream flowing across the open top assists in increasing the flow of air through the rotor. With the increased extraction and wider operational envelop, the energy produced per annum of this omni-directional shrouded vertical wind turbine is anticipated to be much higher than that of a standard free wind turbine of same rotor diameter.

Owner:KATRU ECO INVENTIONS PTY LTD

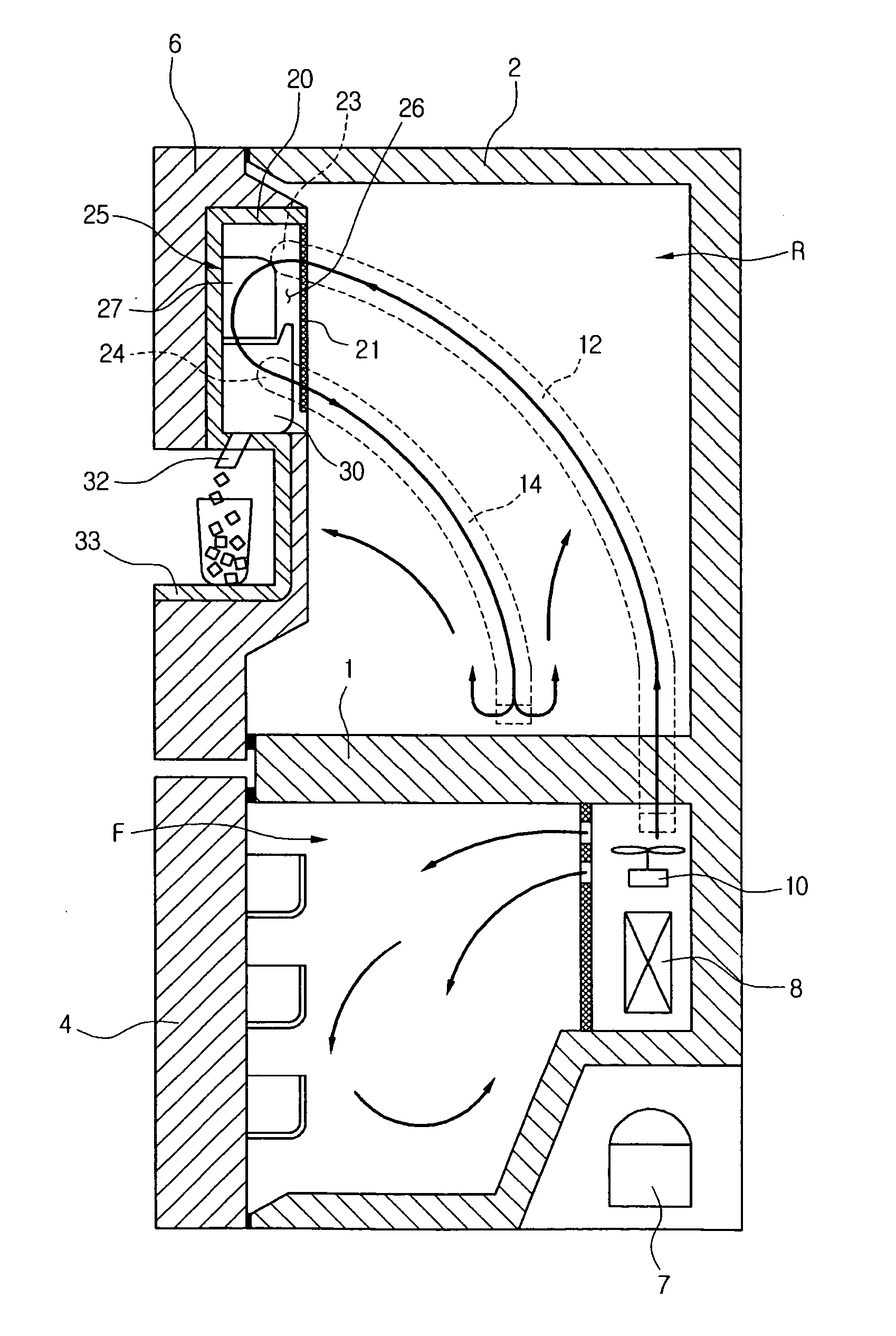

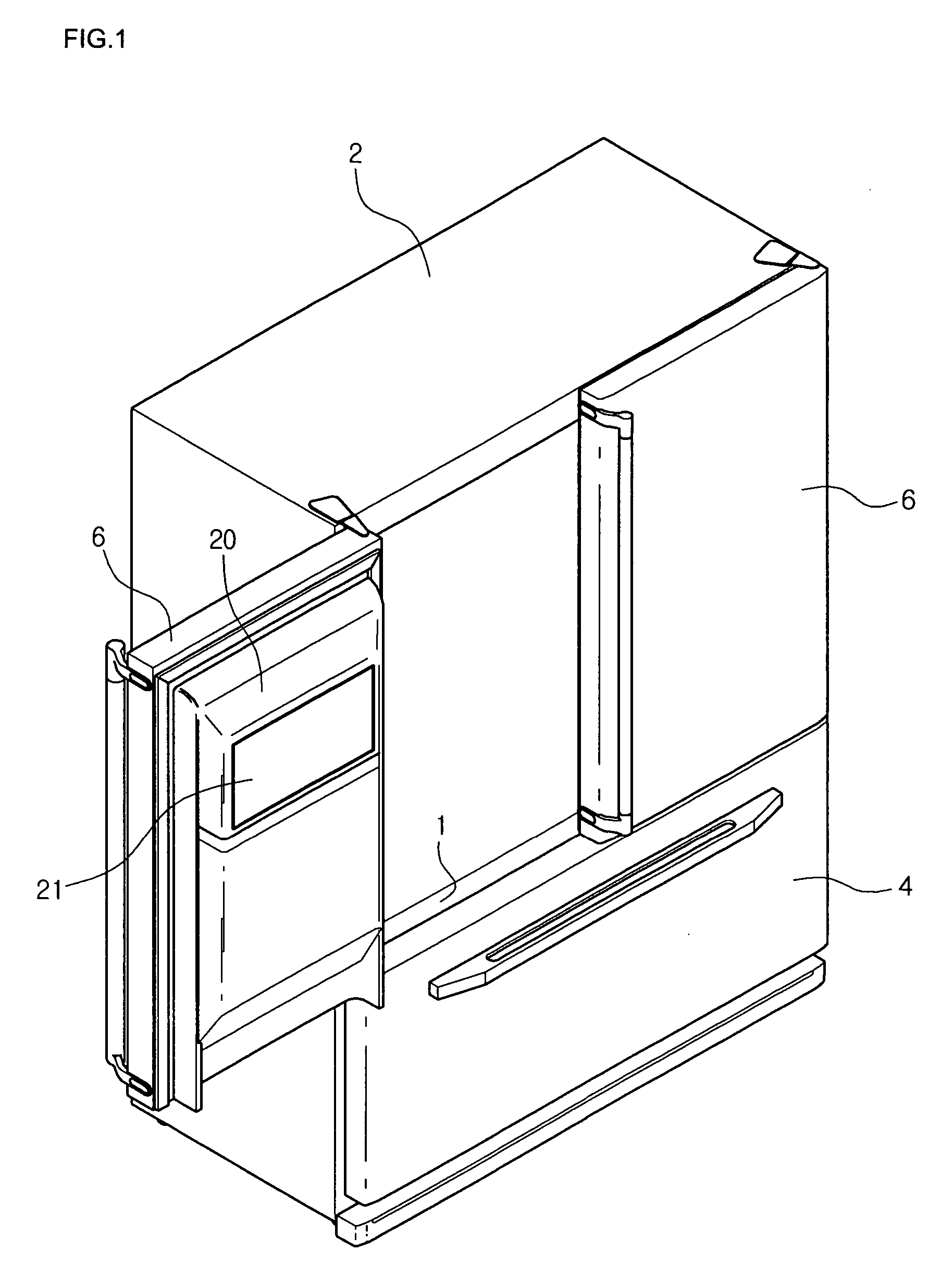

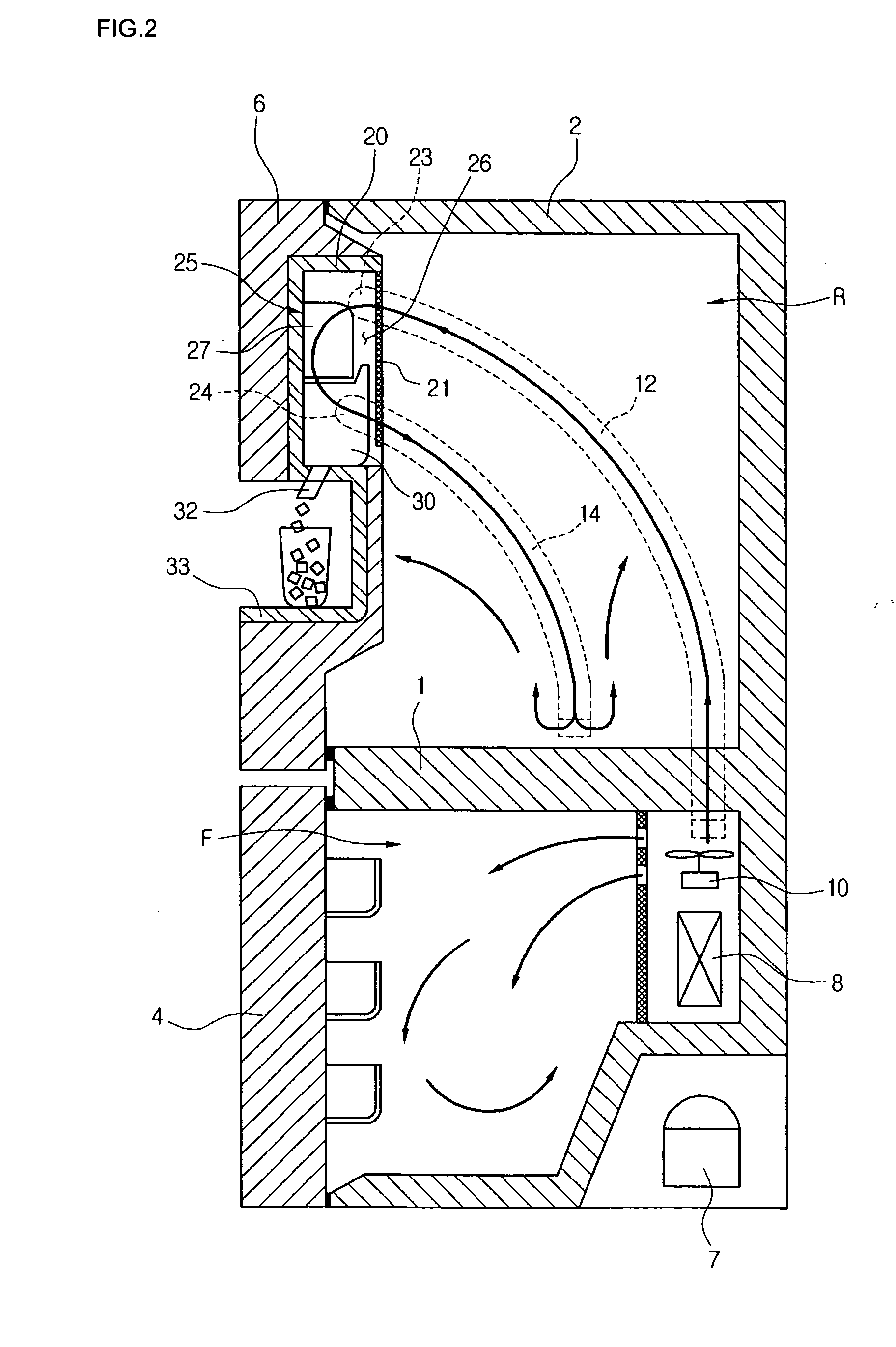

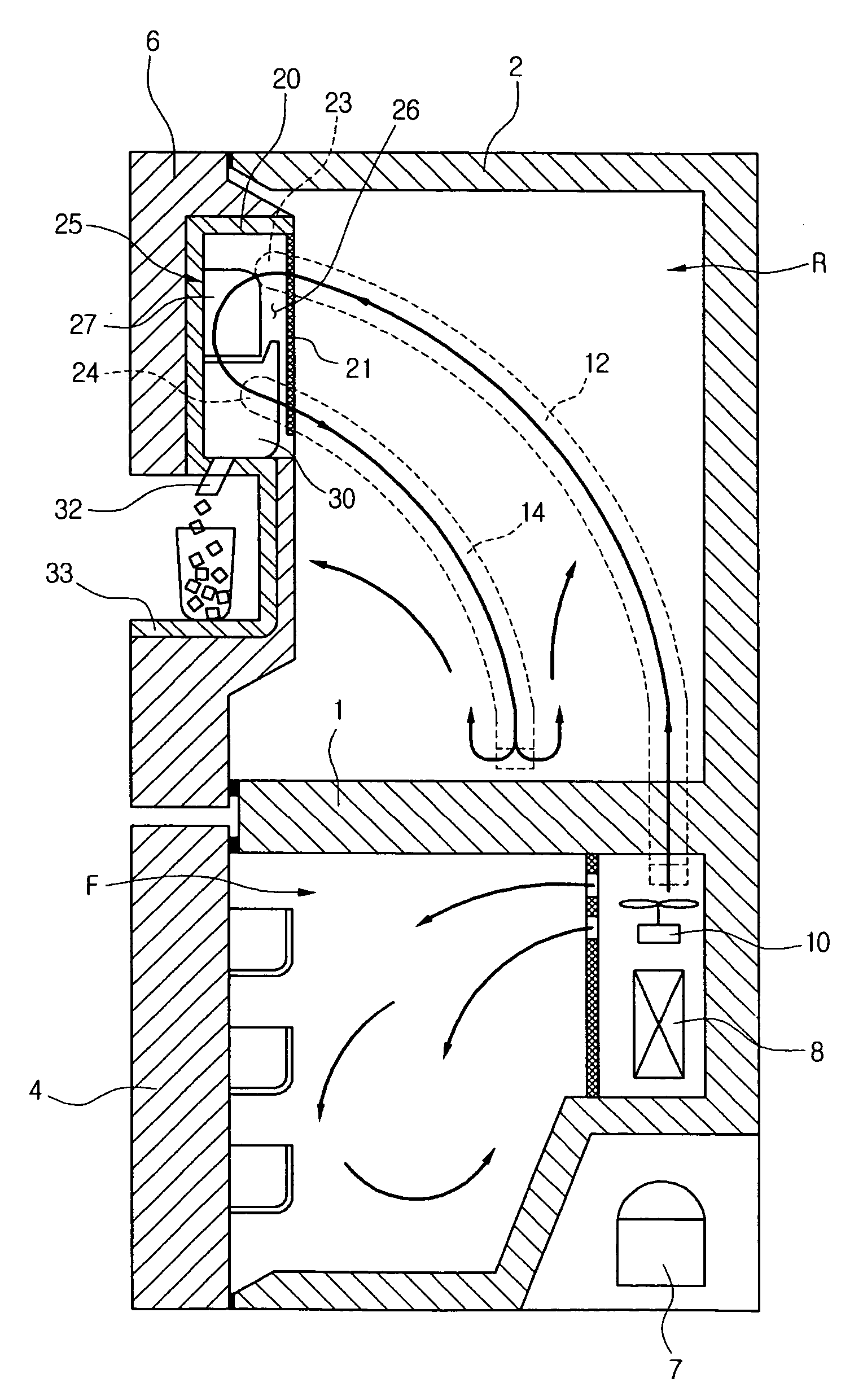

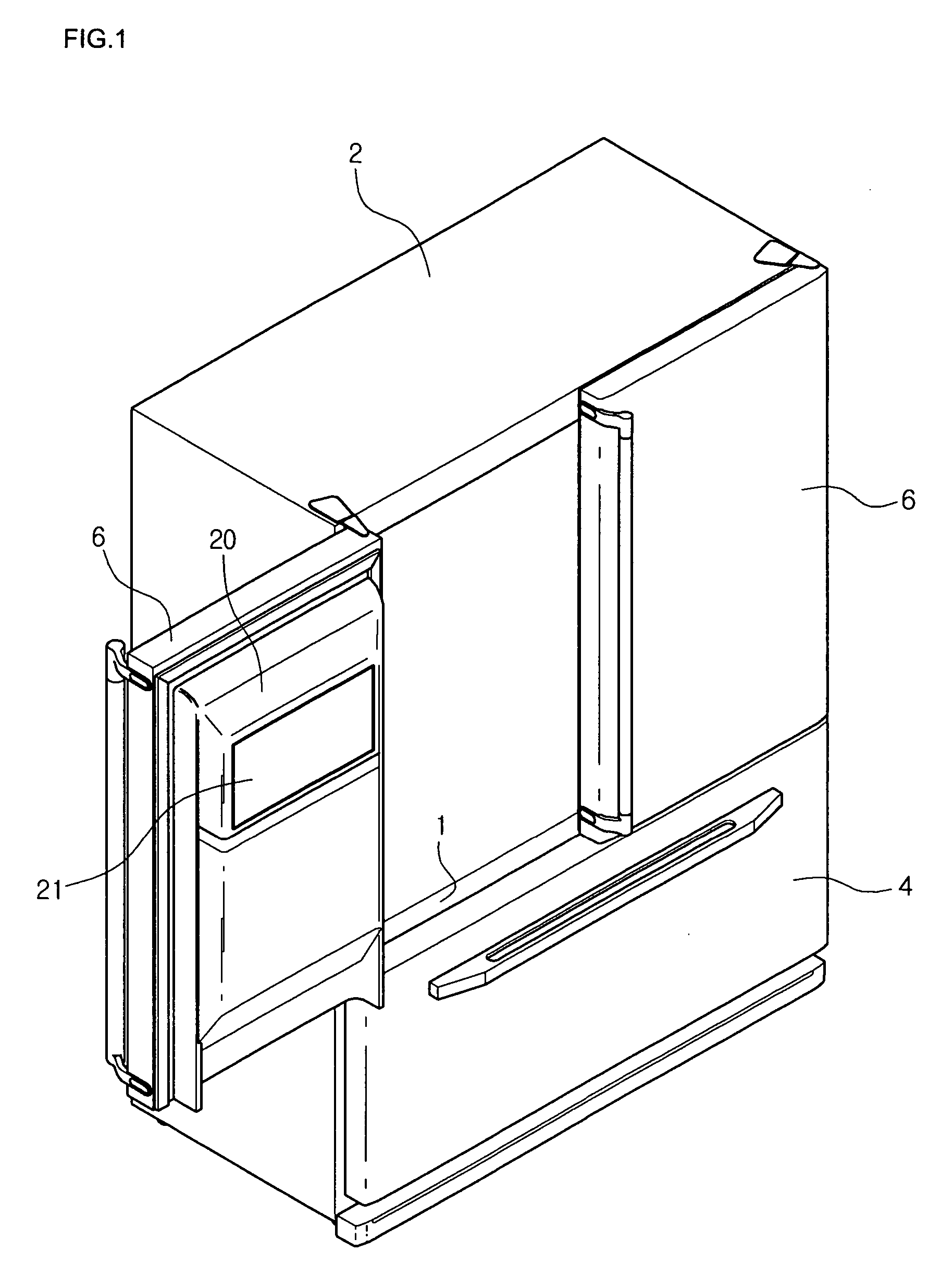

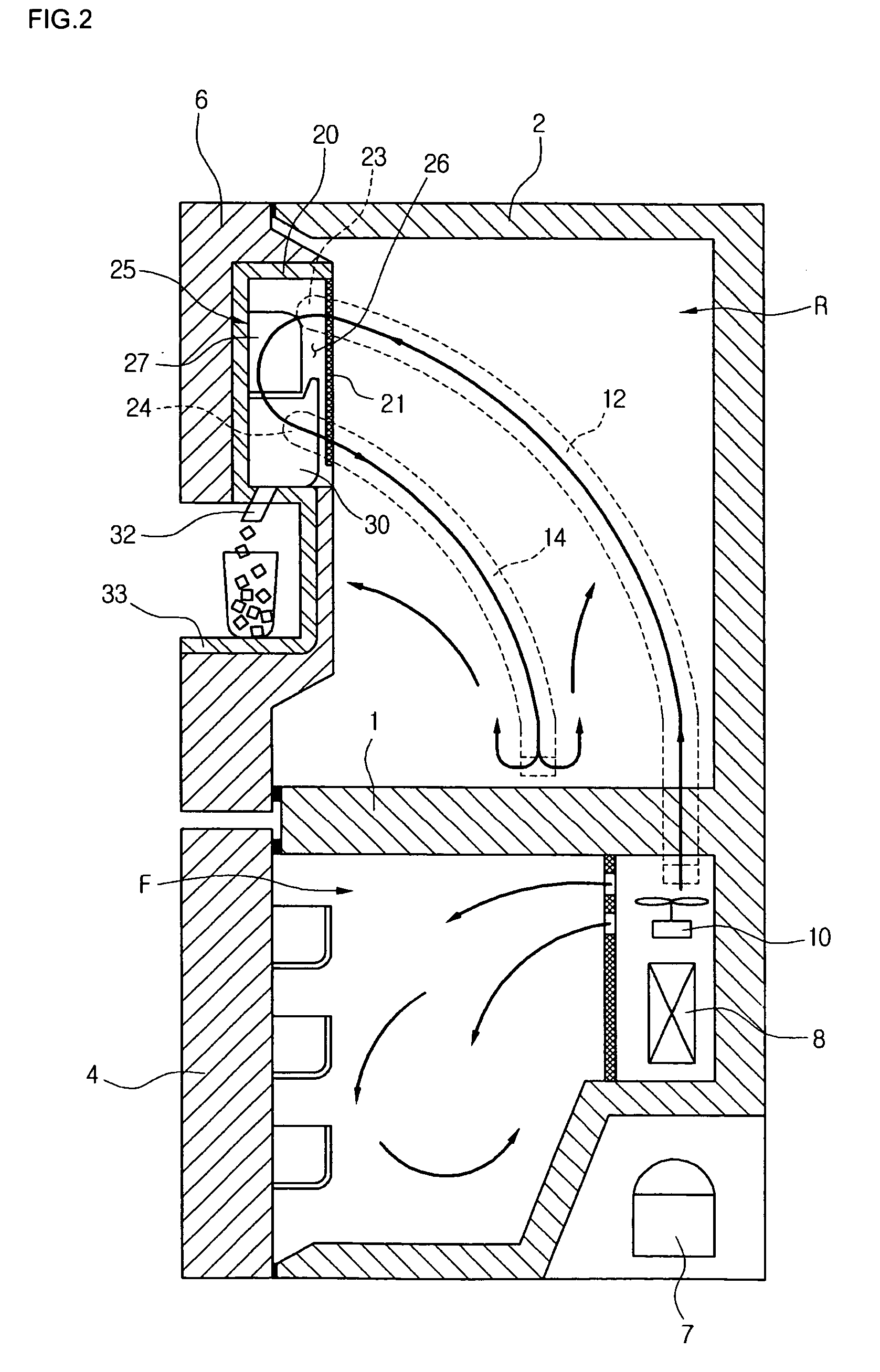

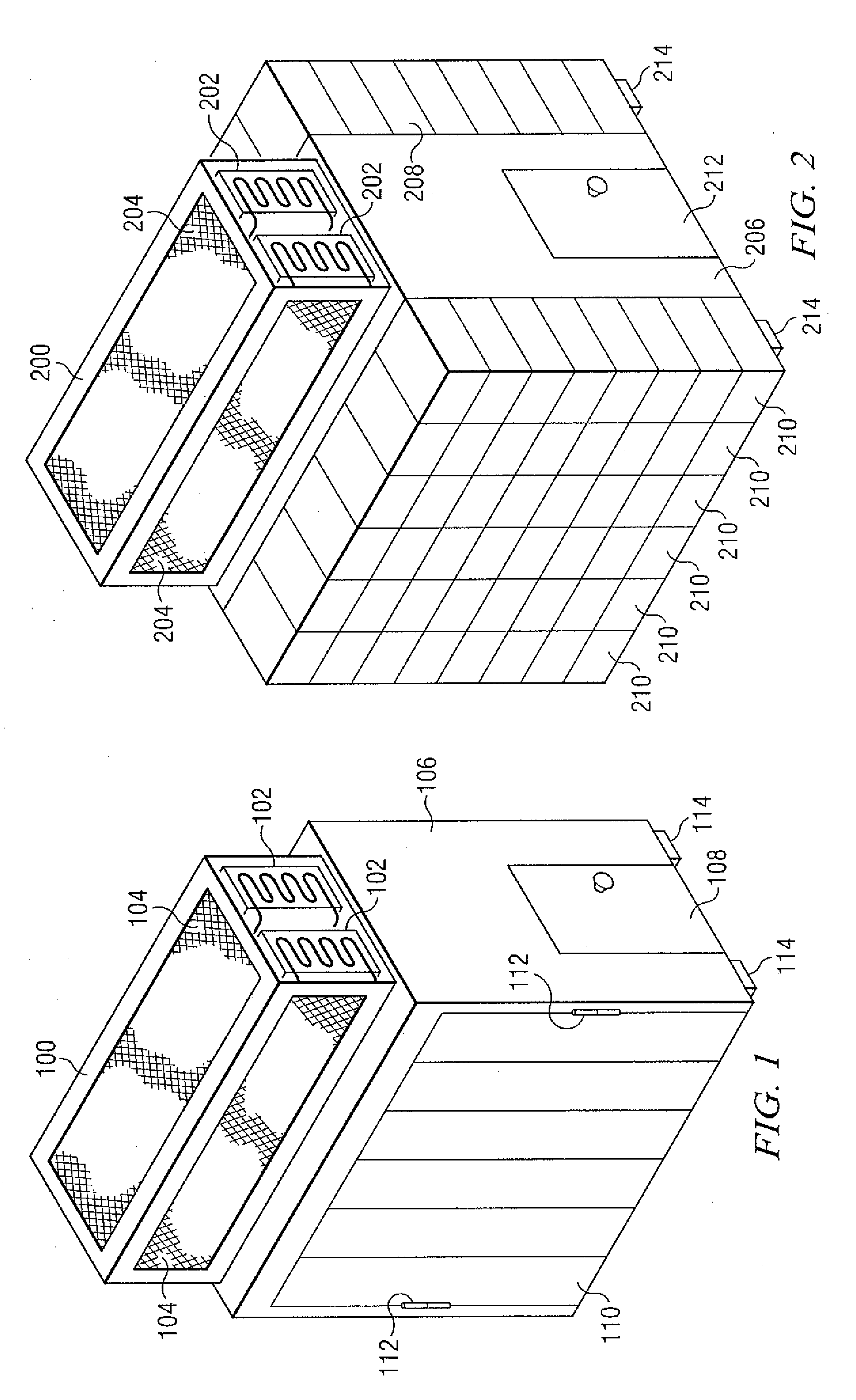

Refrigerator and airflow passage for ice making compartment of the same

ActiveUS20050252232A1Increase volumePrevent leakageDucting arrangementsLighting and heating apparatusRefrigerated temperatureForeign substance

A refrigerator is provided with an airflow passage for an ice making compartment of the refrigerator. In the refrigerator, a main body has an opened side, and a door selectively closes the opened side of the main body. An ice making compartment is formed in the door, the ice making compartment being insulated from the outside and being kept at a low temperature. A duct is formed in the main body for exchanging cooling air with the ice making compartment, and a cooling air passage is formed at an outer surface of the ice making compartment to connect the duct with the ice making compartment. A switching unit closes the cooling air passage when the door is opened, and opens the cooling air passage when the door is closed. With this arrangement, the cooling air can be sufficiently supplied to the ice making compartment without the penetration of foreign substance.

Owner:LG ELECTRONICS INC

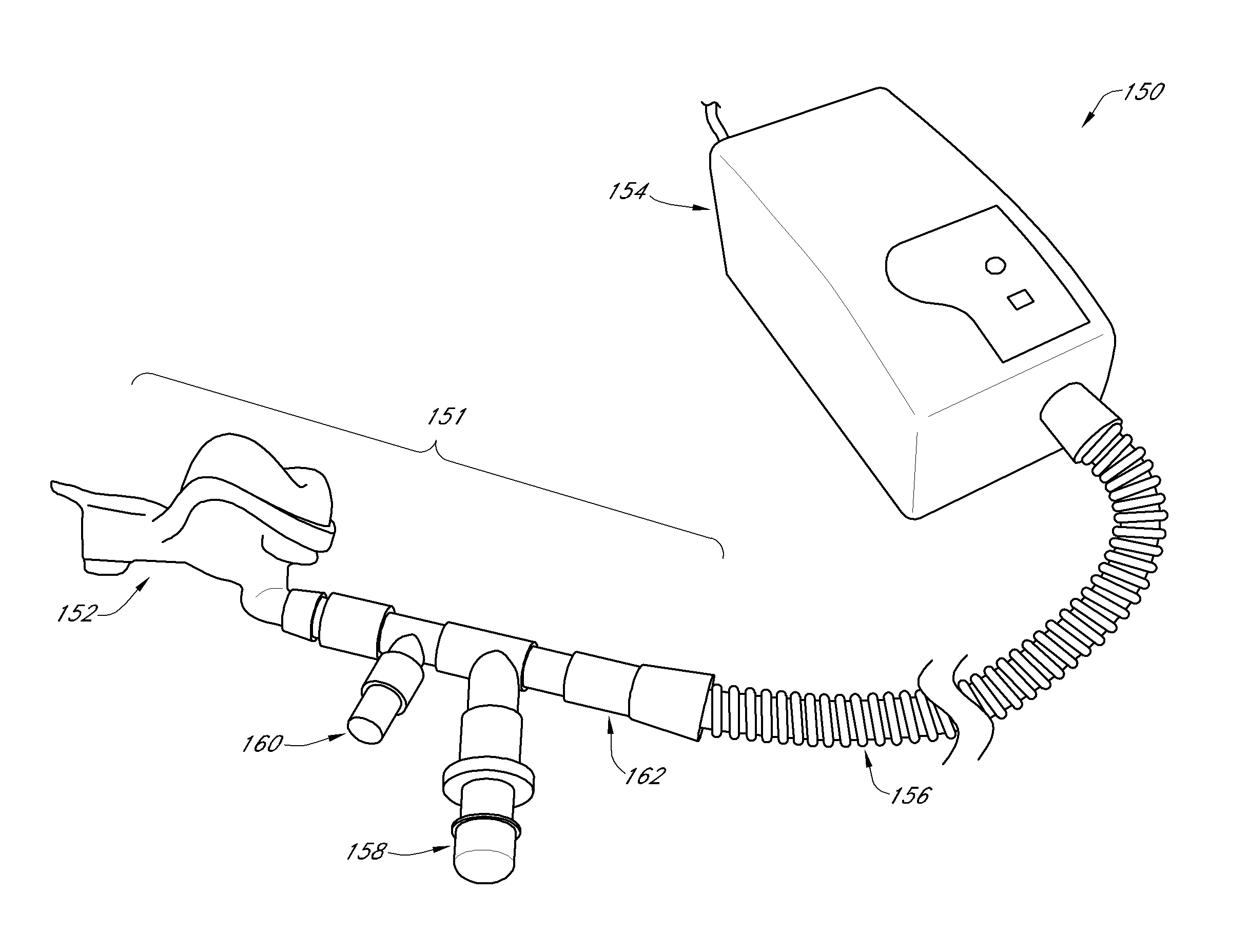

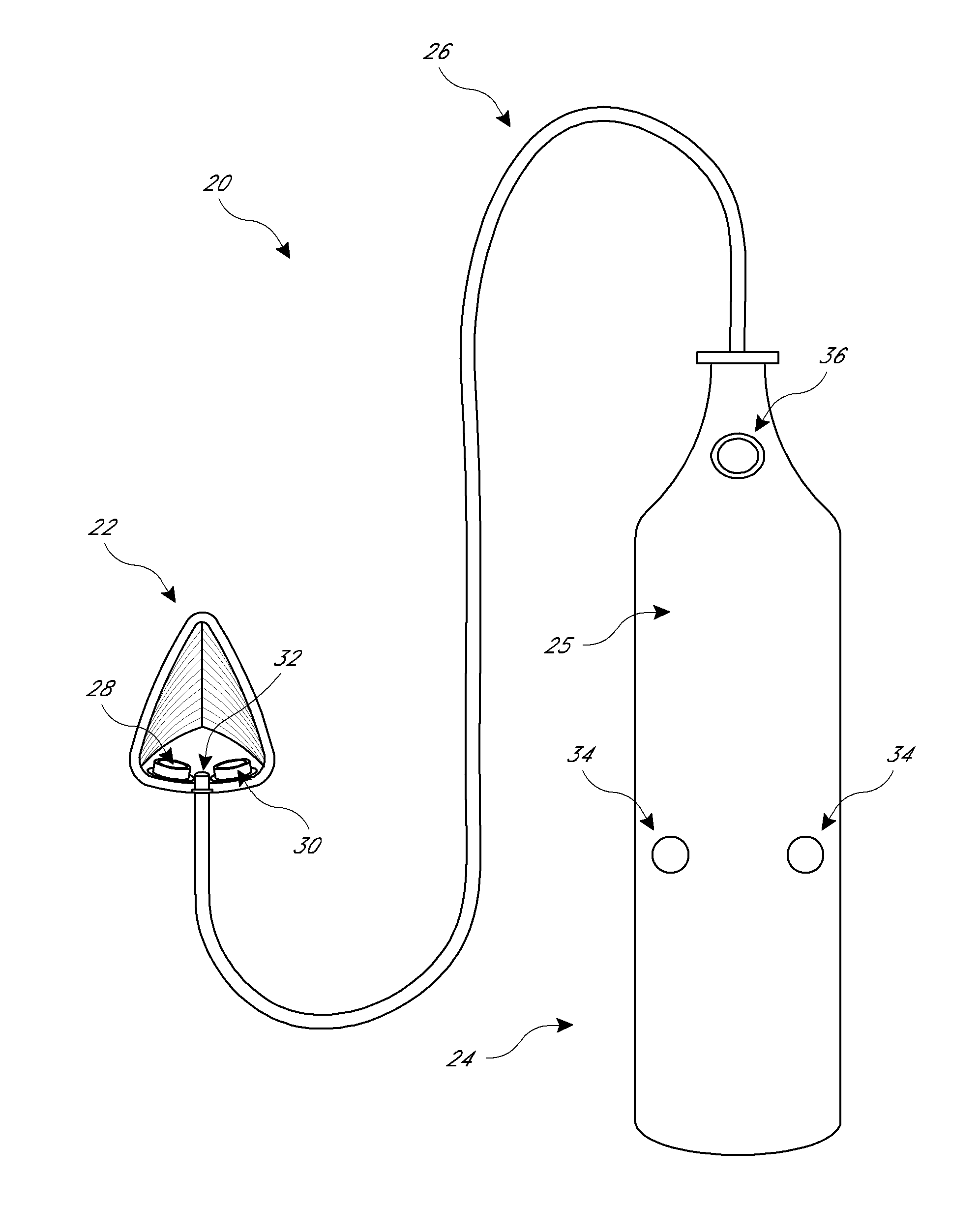

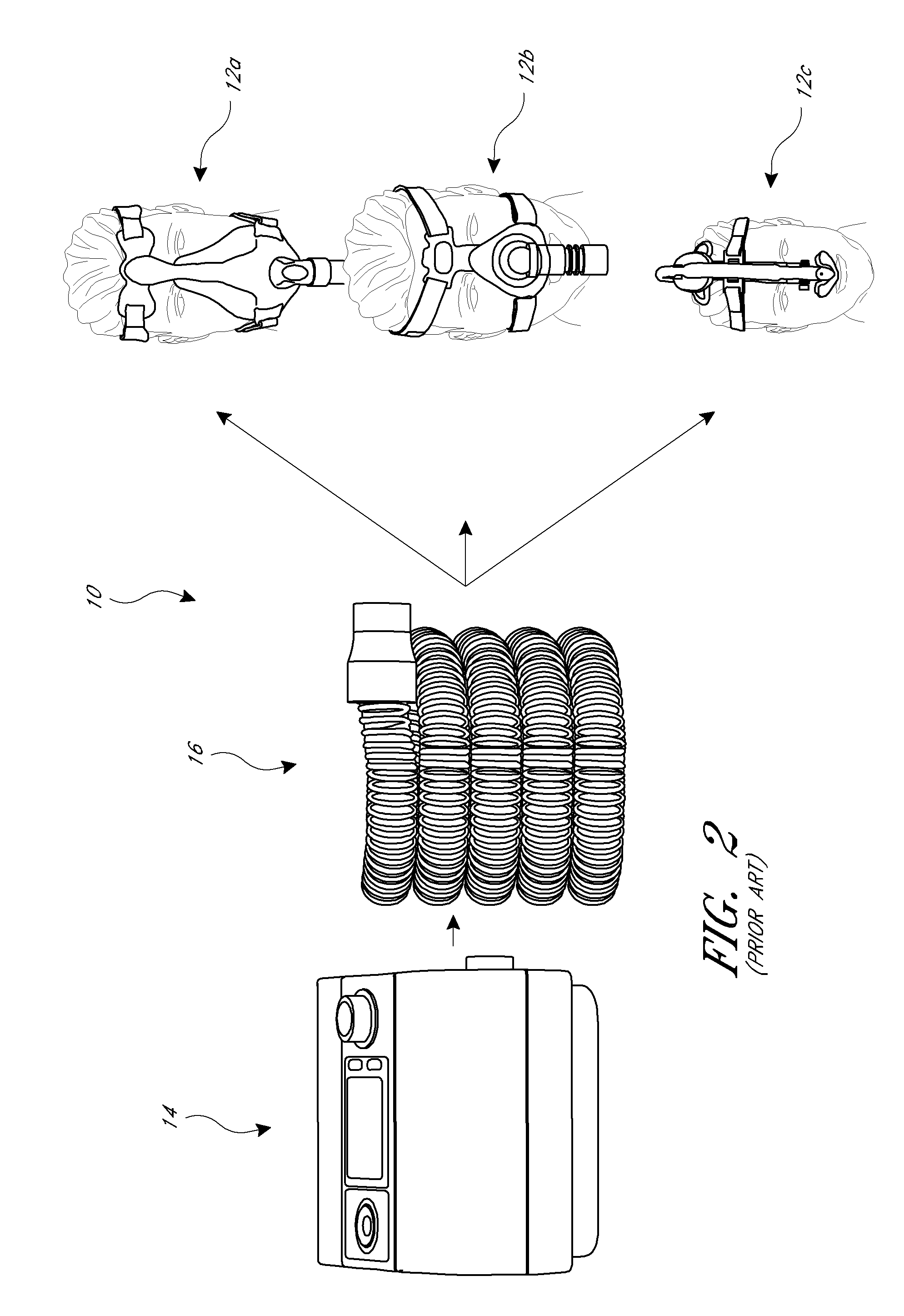

Auto-feedback valve for a sleep apnea device

ActiveUS20140246025A1Less side effectsConvenient treatmentOperating means/releasing devices for valvesElectrocardiographyExpiratory valveSurgery

A device for treating a patient suffering from obstructive sleep apnea or snoring can include an expiratory valve connected to a manifold. The expiratory valve can include a body portion including a feedback port configured to be connected to an air flow generator. The expiratory valve can include a plunger at least partially disposed in the body portion. The expiratory valve can include a pressurizing chamber positioned between an end of the plunger and an end of the expiratory valve. The pressurizing chamber can be configured to receive air from the air flow generator through the feedback port.

Owner:FRESCA MEDICAL

Lung device with sealing features

InactiveUS7766891B2Reduce air leakageMitigates pneumothorax and hemothoraxSurgical needlesMedical devicesThoracic structureThoracic cavity

This invention relates generally to a design of lung devices for safely performing a transthoracic procedure. In particular, the invention provides devices and methods of using these devices to access the thoracic cavity with minimal risk of causing pneumothorax or hemothorax. More specifically, the invention enables diagnostic and therapeutic access to a thoracic cavity using large bore instruments. This invention also provides a method for diagnostic and therapeutic procedures using a device capable of sealing the wound upon withdrawal of the device. The invention includes a device comprising an elongated body adapted to make contact with a tissue of a subject through an access hole, and a sealant delivery element. The invention also includes a method of performing tissue treatment or diagnosis in a subject.

Owner:EKOS CORP

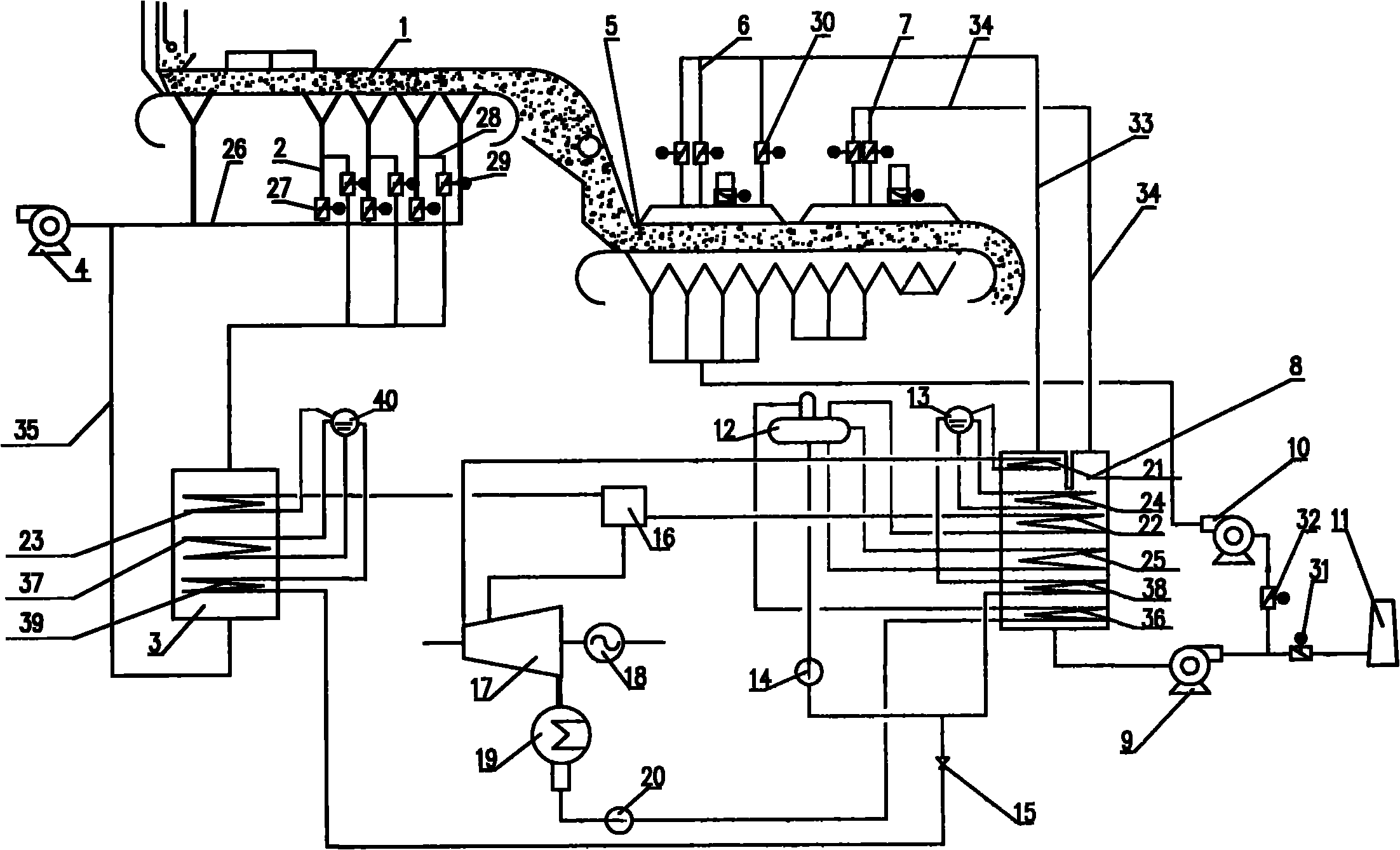

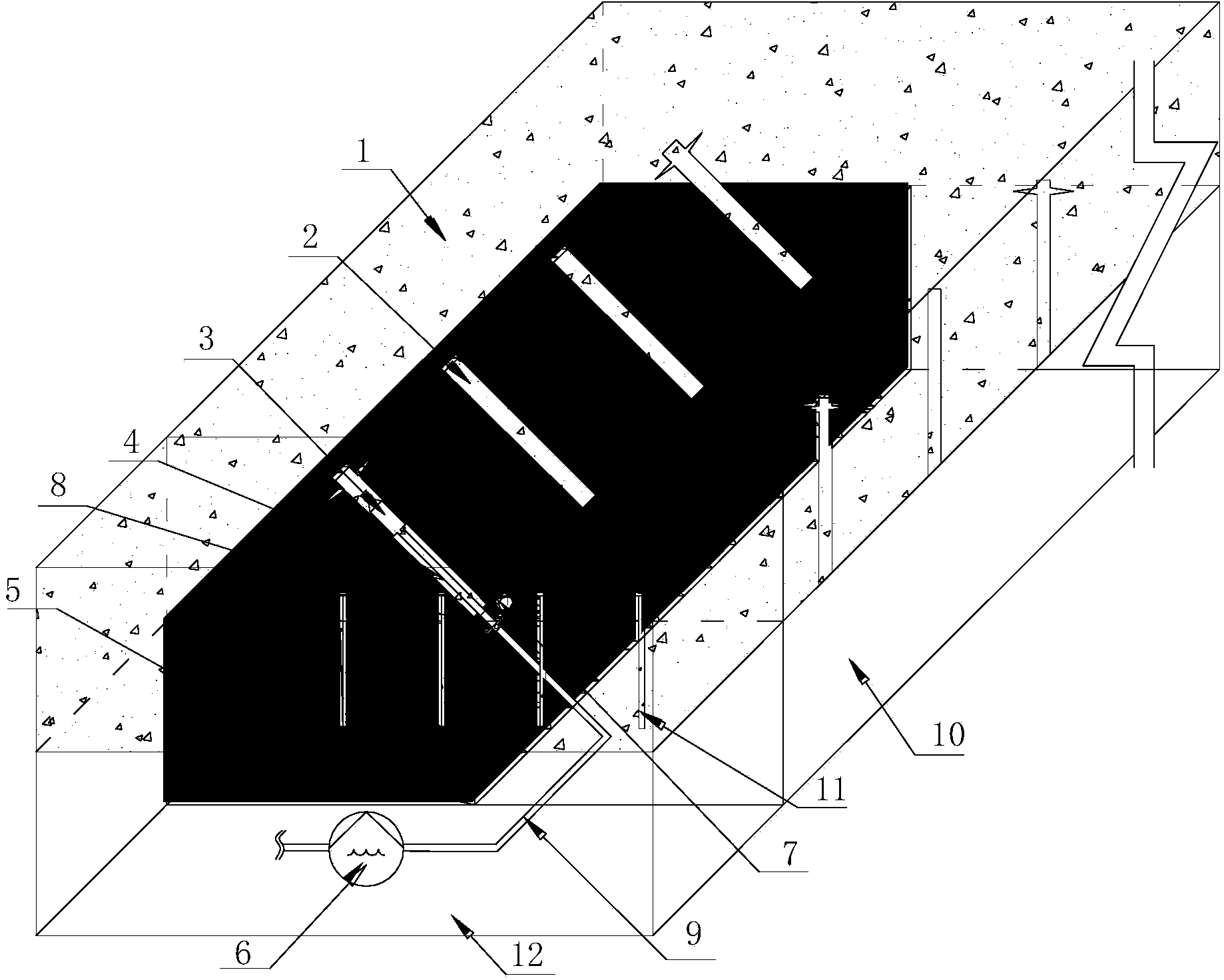

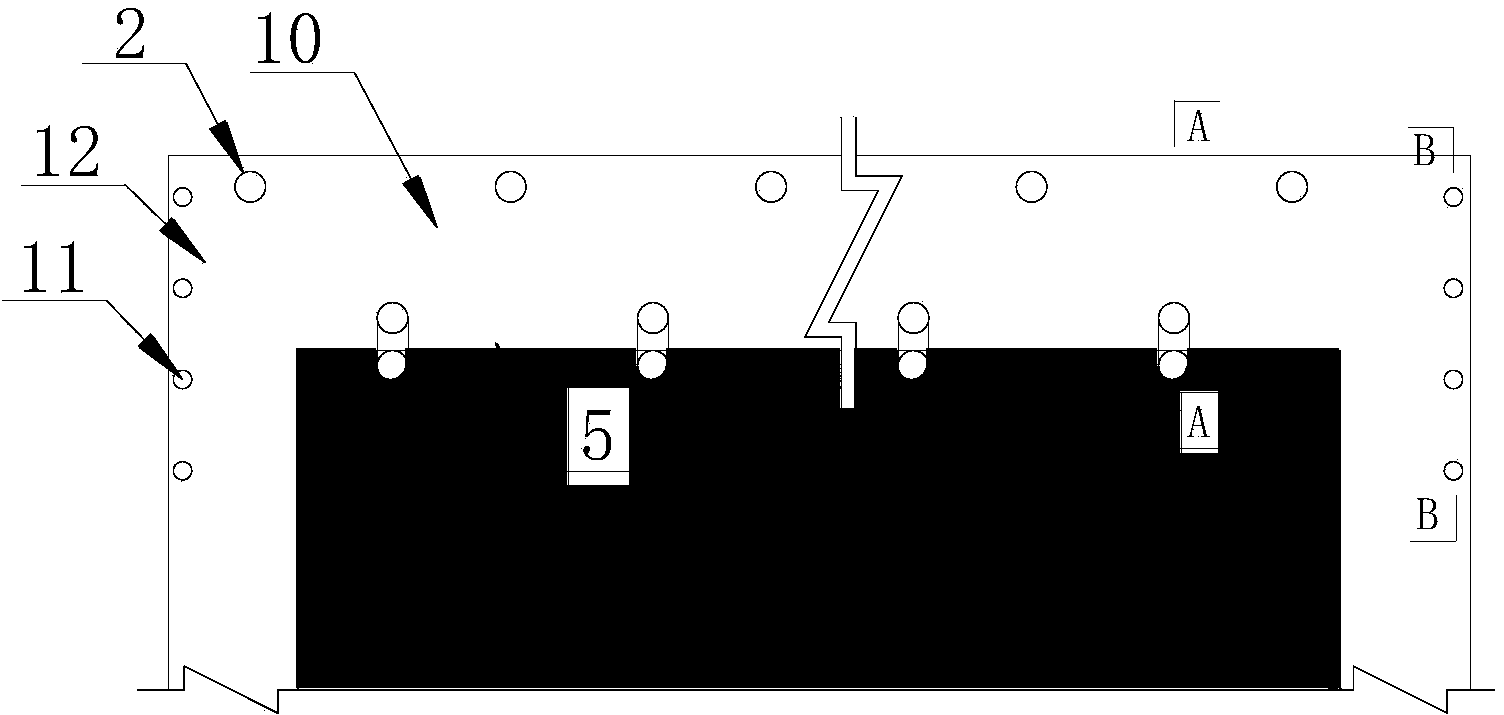

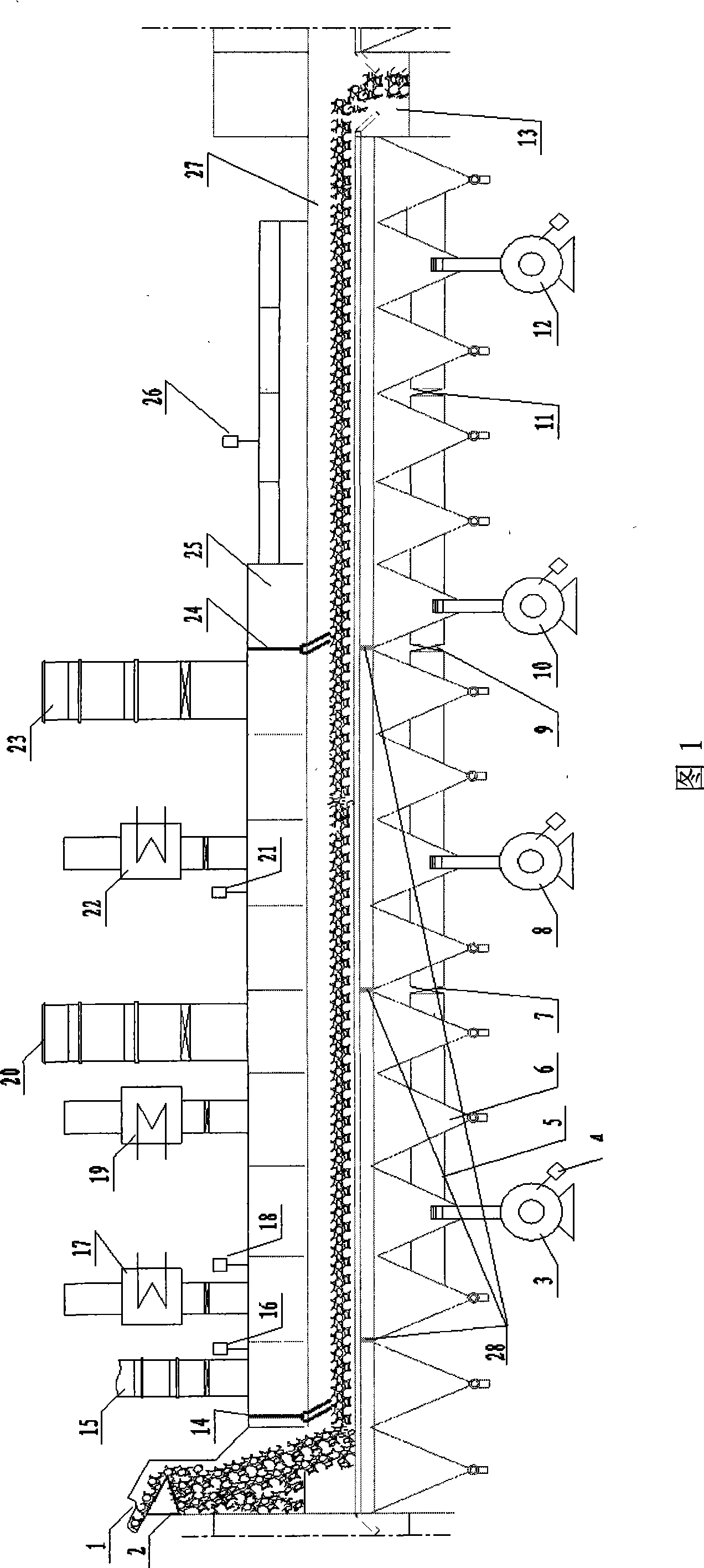

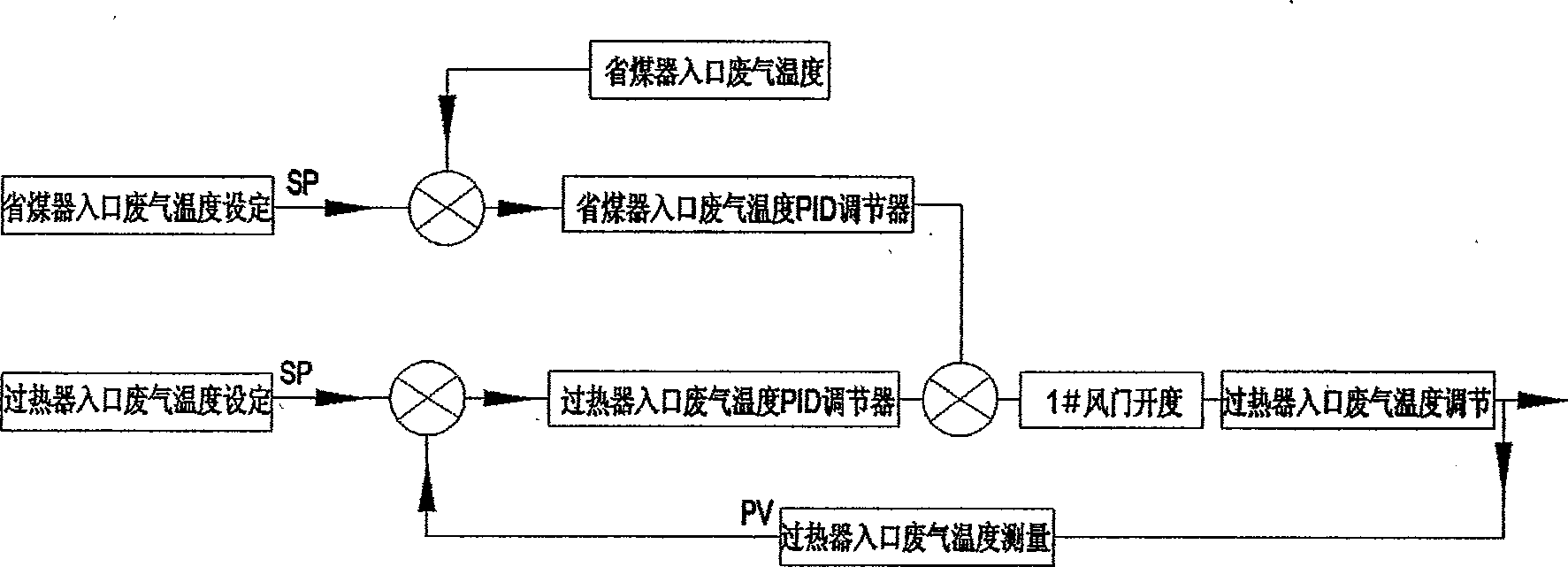

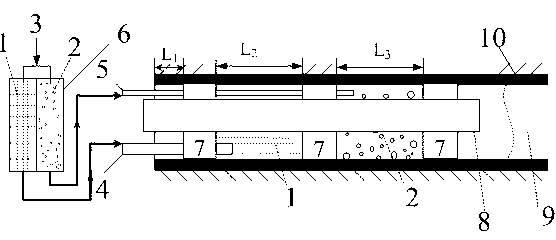

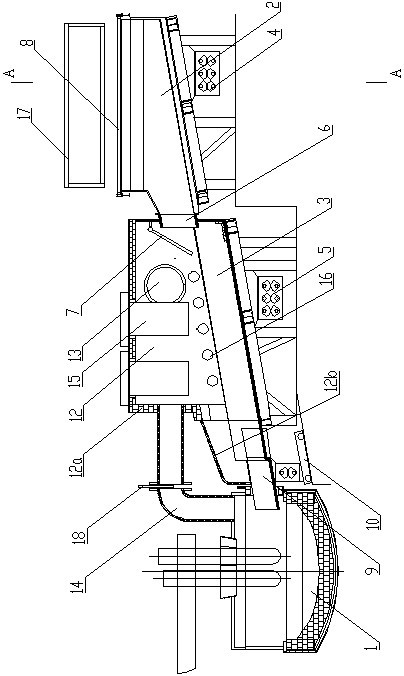

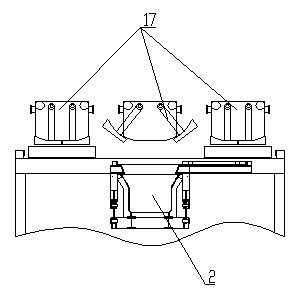

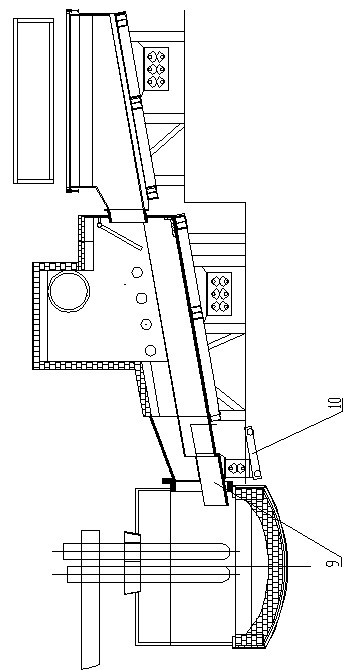

System and method for using sintering waste heat to generate electricity

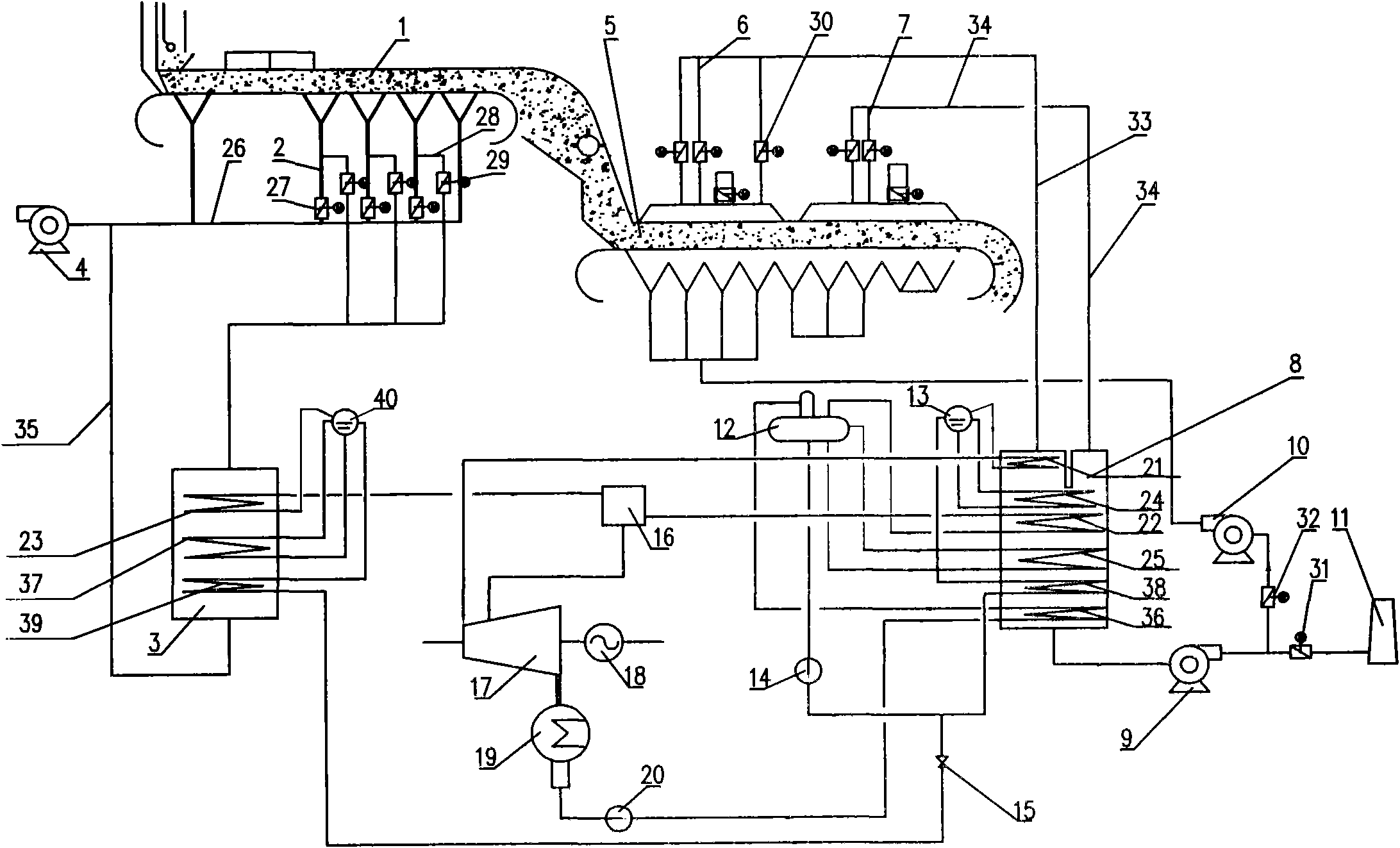

InactiveCN101806230AImprove utilization efficiencyIncrease waste heat power generationIncreasing energy efficiencySteam engine plantsElectricityExhaust fumes

The invention discloses a system and a method for using sintering waste heat to generate electricity and belongs to the technical field of sintering waste heat electricity generation of the steel works. The system comprises a sintering machine, a hot gas outlet pipe, a gas waste heat boiler, a main exhaust fan, a ring cooling machine, a first and second stage heat waste gas collecting pipe, a waste gas heat boiler, a draught fan, a circulating fan, a chimney, a low pressure steam drum, a middle pressure steam drum, a feed pump, a pressure reducing valve, a collecting header, a steam turbine, a generator, a condenser and a condensate pump. The invention realizes utilizing the waste heat of the non-desulfurization flue header of the sintering machine without arranging an inducing fan by reasonably designing the hot gas connecting mode of the air box at the tail part of the sintering machine and the gas resistance of the waste gas heat boiler. First and second stage sealing covers of the ring cooling machine are uniformly provided with a plurality of waste gas branch pipes so as to realize uniform distribution of the waste gas pressure in the sealing covers and reduce air leakage. Part of waste gas is adopted to circulate to improve the temperature of the waste gas. Compared with the existing system for using sintering waste heat to generate electricity, the system of the invention sufficiently uses the waste heat of the sintering system, improves the waste heat generated energy and reduces the operation cost.

Owner:湖南永清环境科技产业集团有限公司

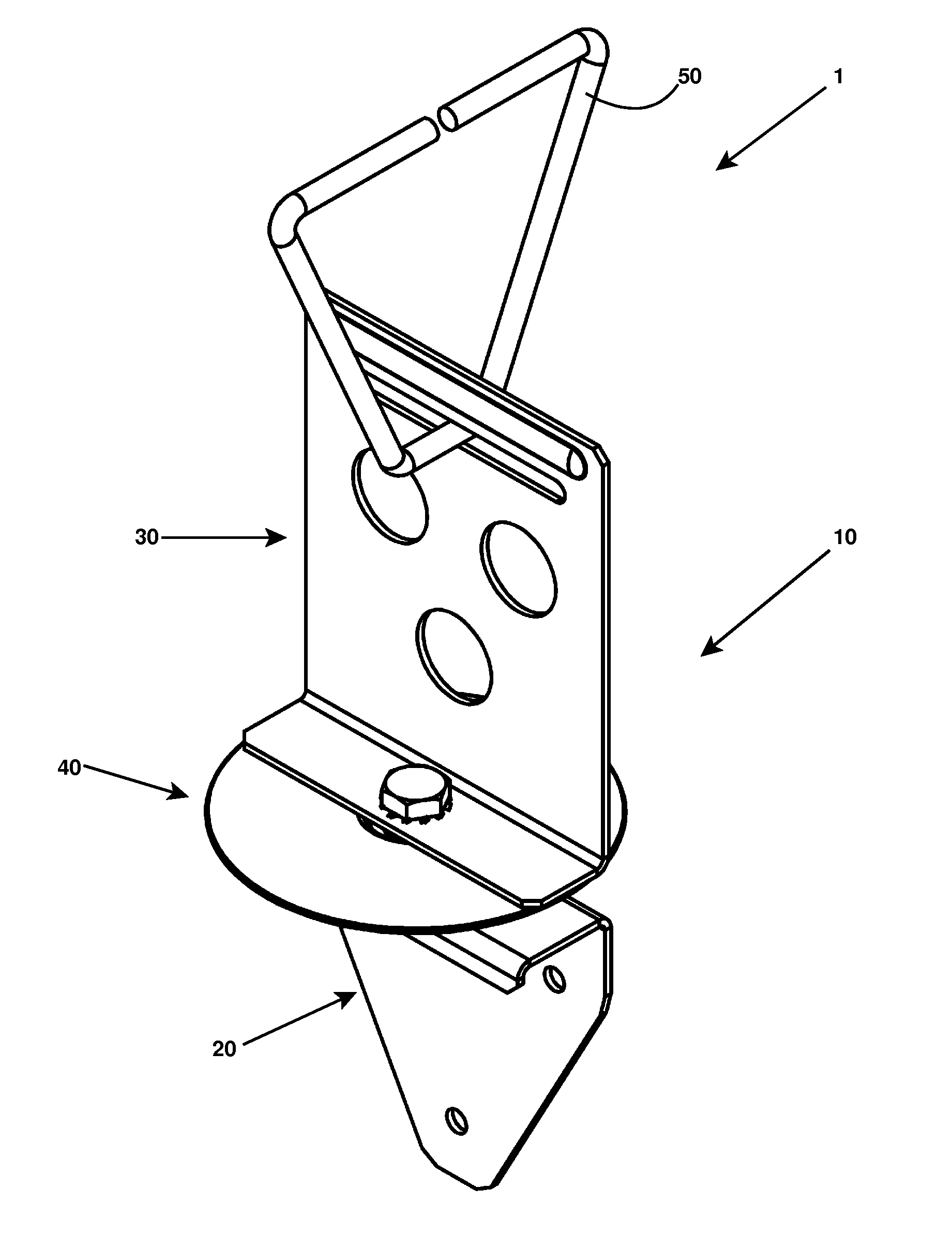

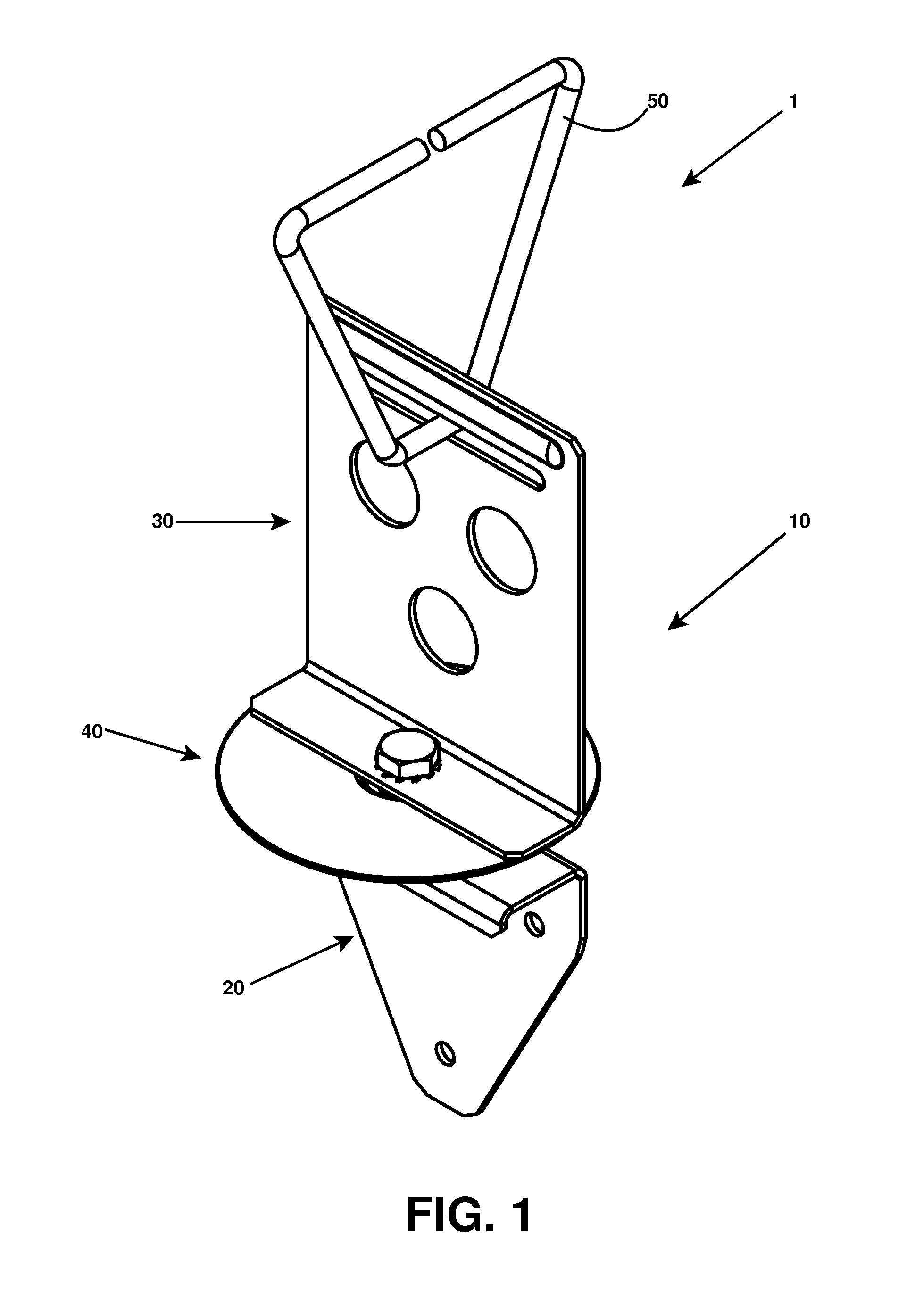

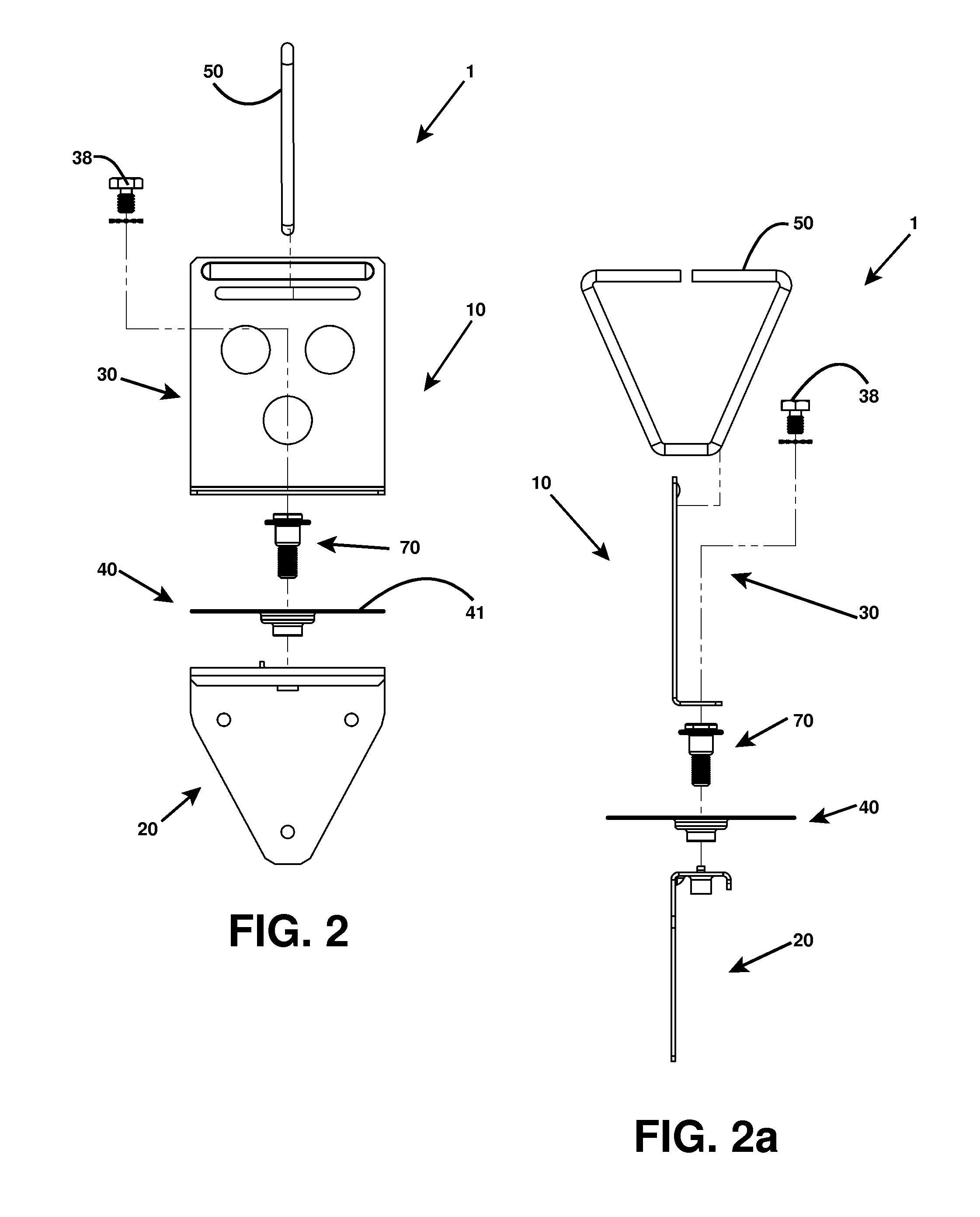

Multi-piece anchor system for use with masonry over stud back-up walls

InactiveUS20130008121A1Increase contactControl deformationCovering/liningsBuilding repairsBrickEngineering

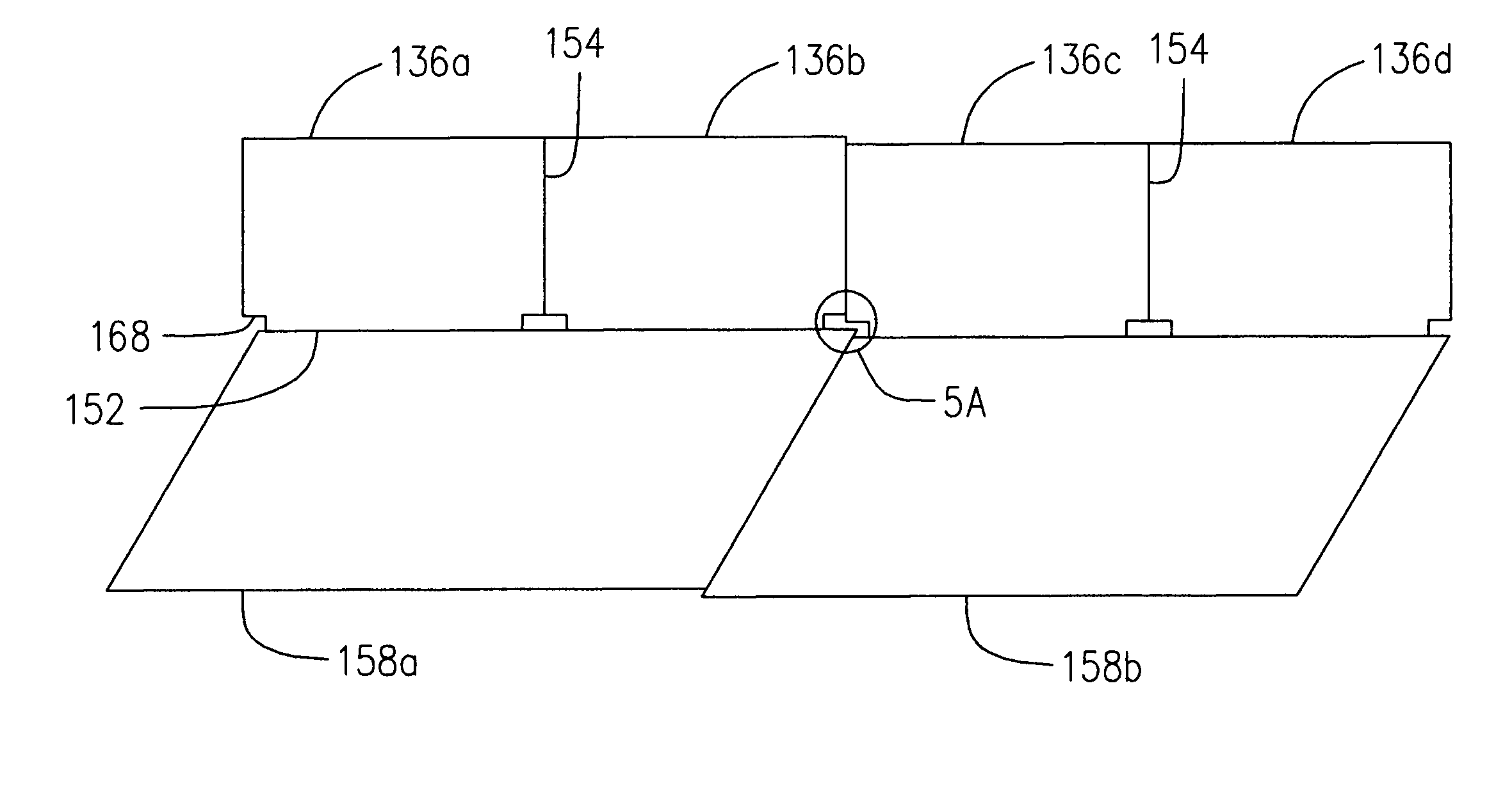

There is described an improved multi-piece anchor body for use with masonry over stud back-up walls, the anchor body made up of an inner anchor body for connection to a back-up wall, a separate outer anchor body for connection to a masonry wall, and a separate intermediate membrane flange attachable to and between the outer anchor body and the inner anchor body.

Owner:PLEXUS INNOVATIONS

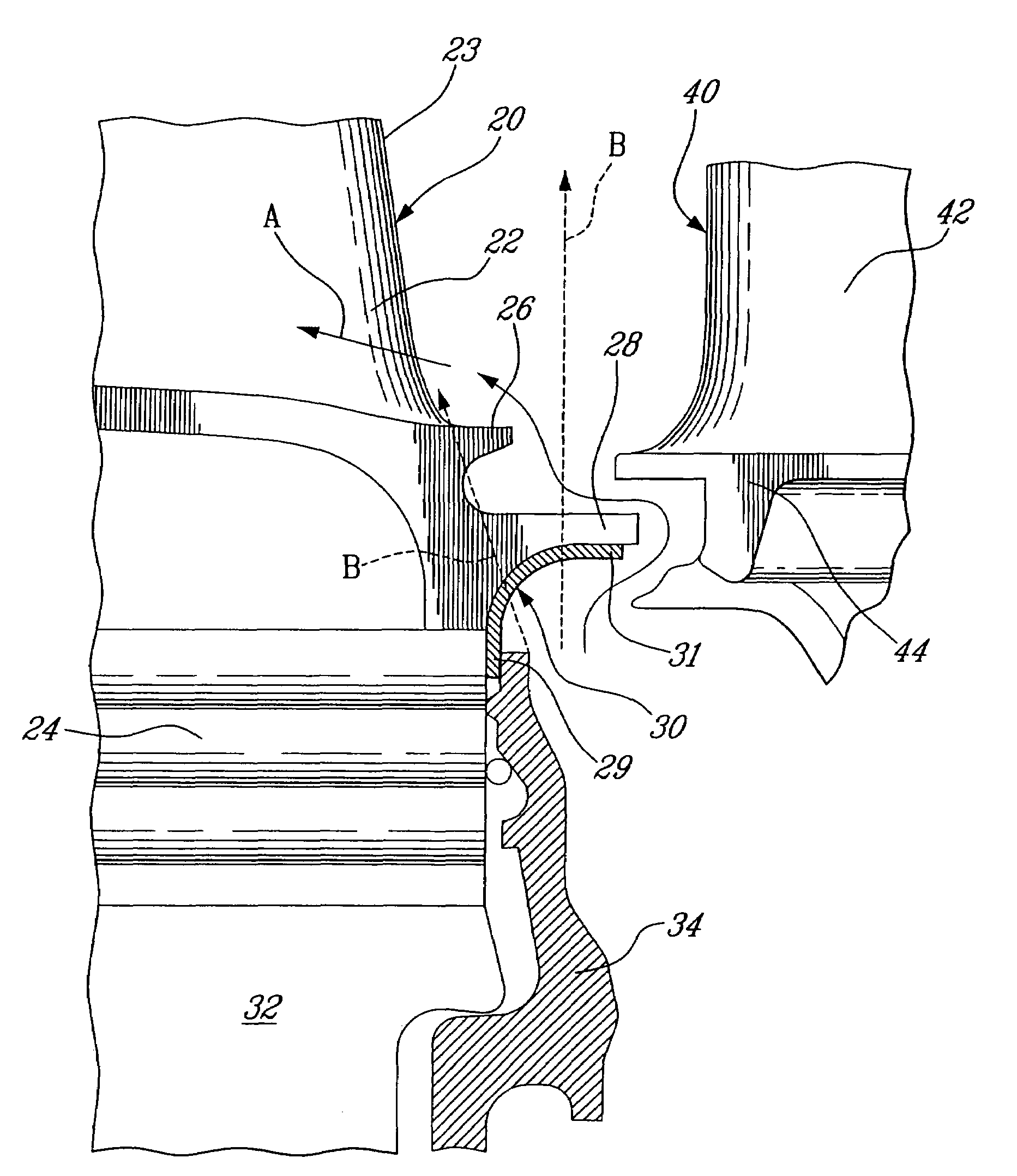

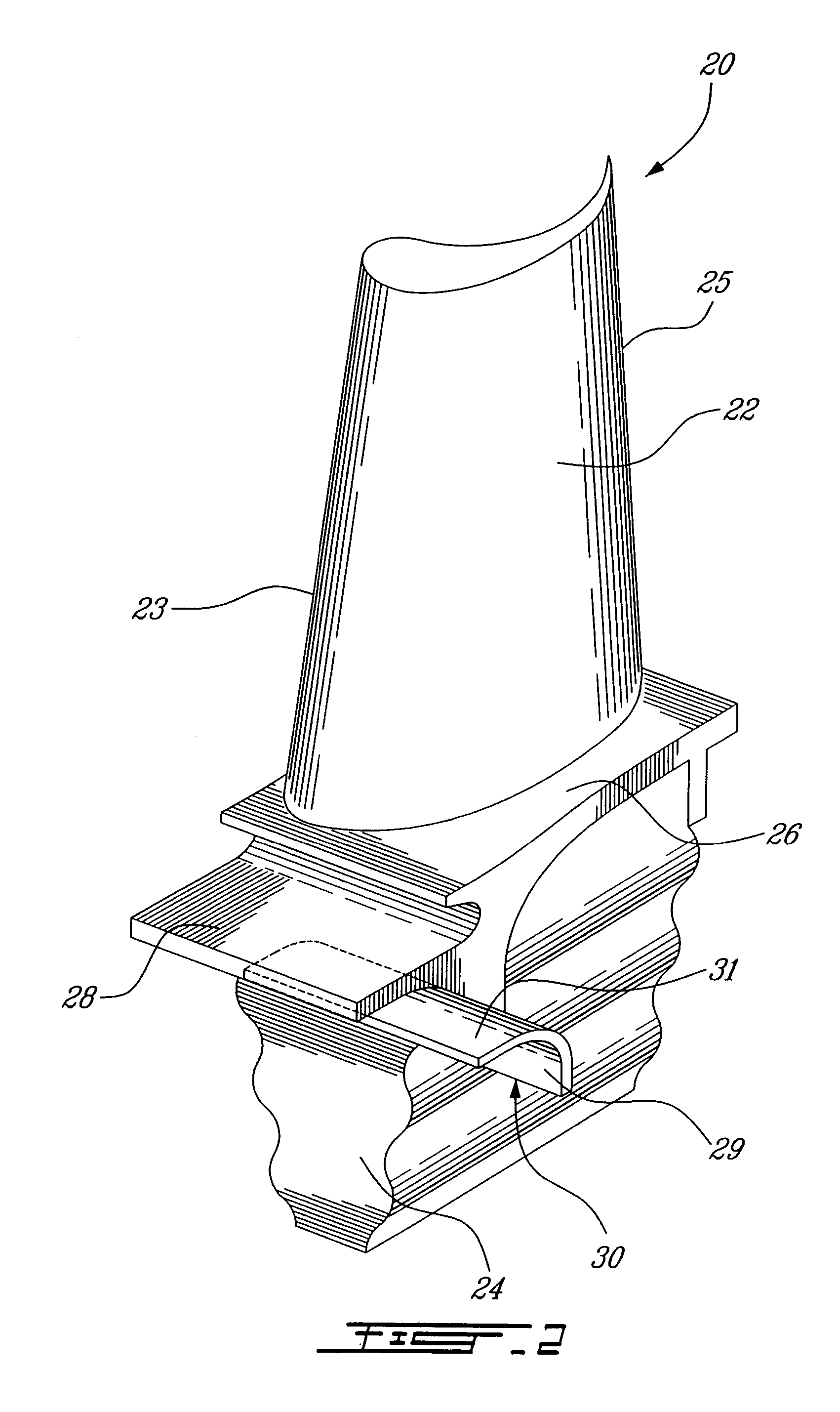

Turbine blade tip clearance control device

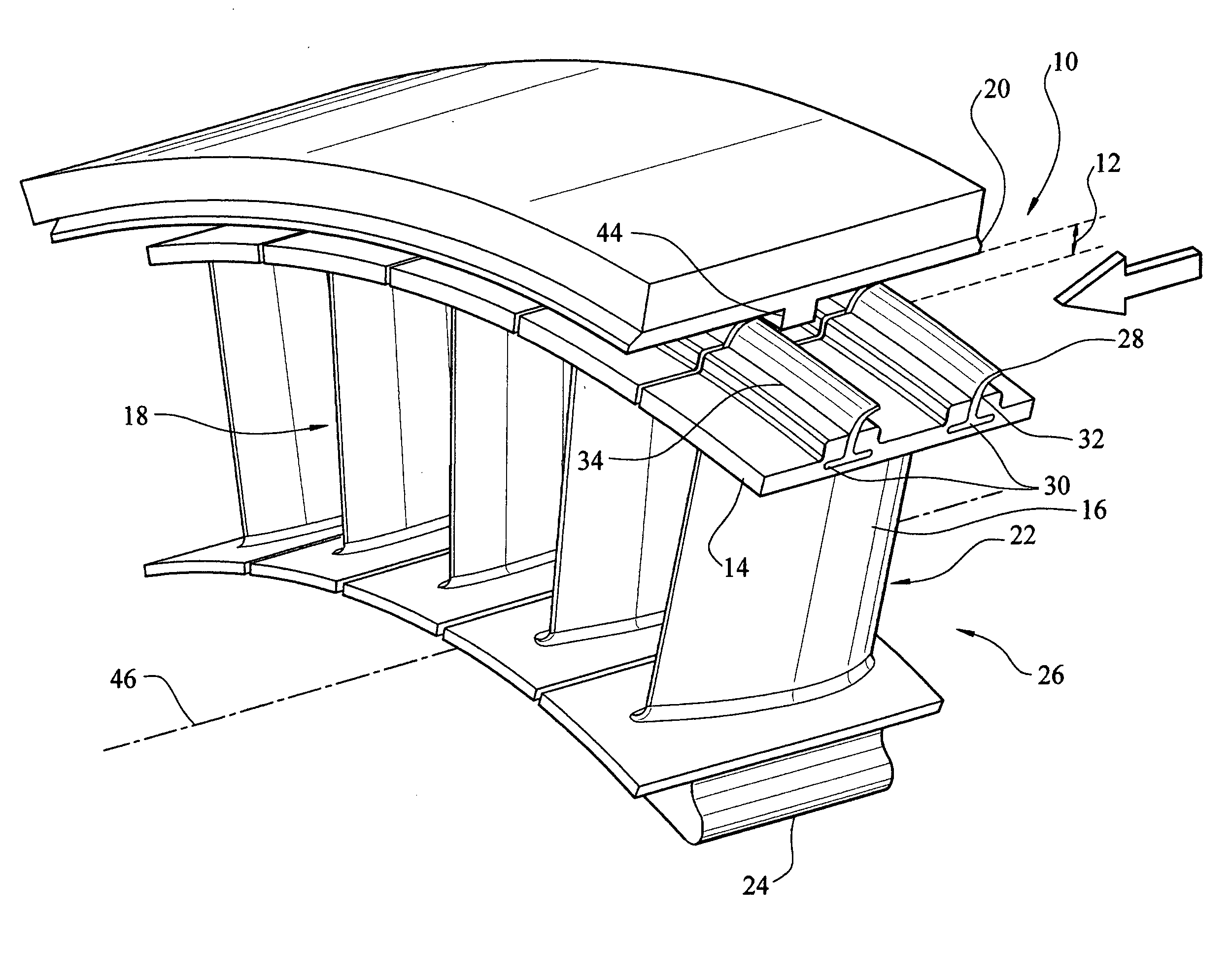

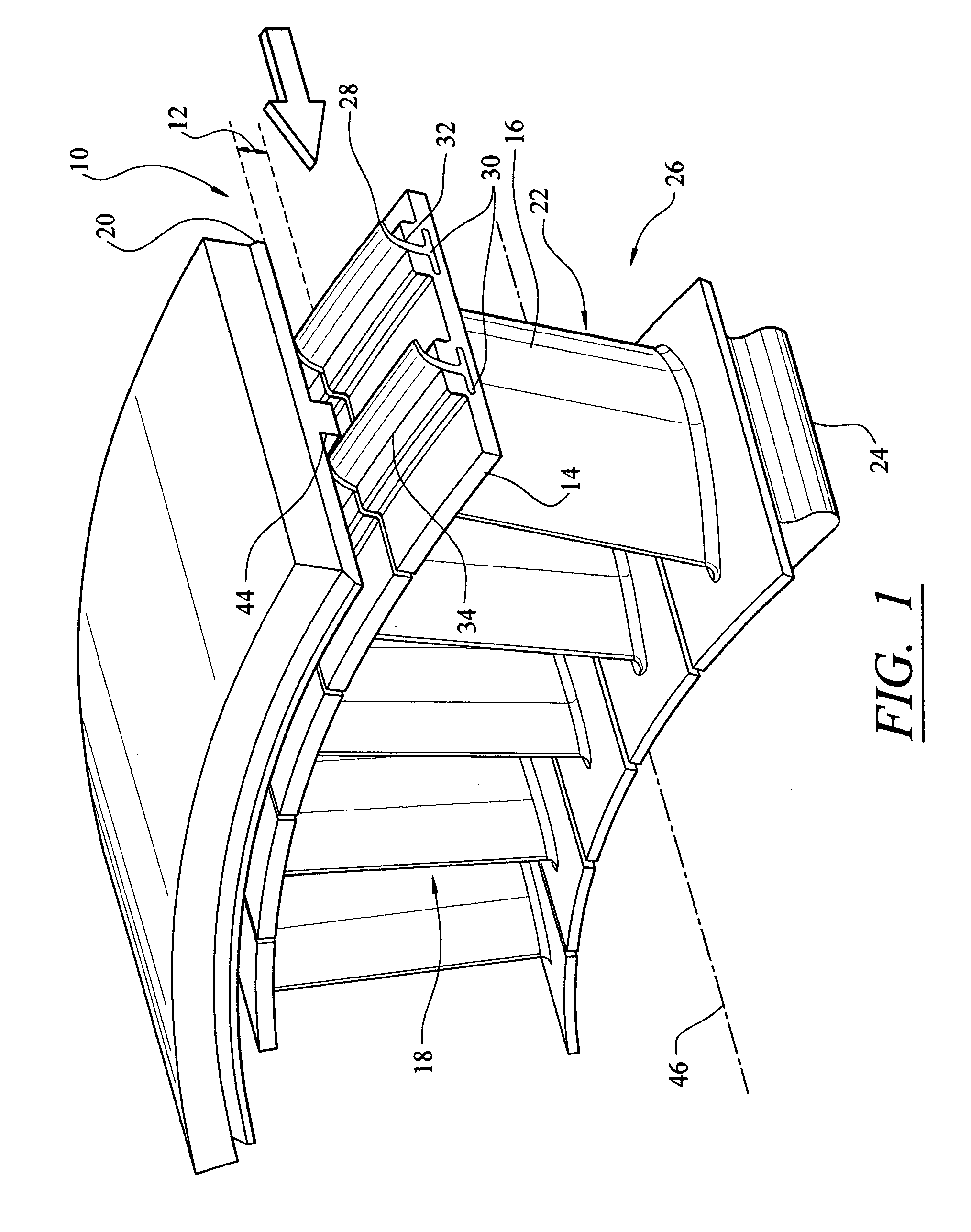

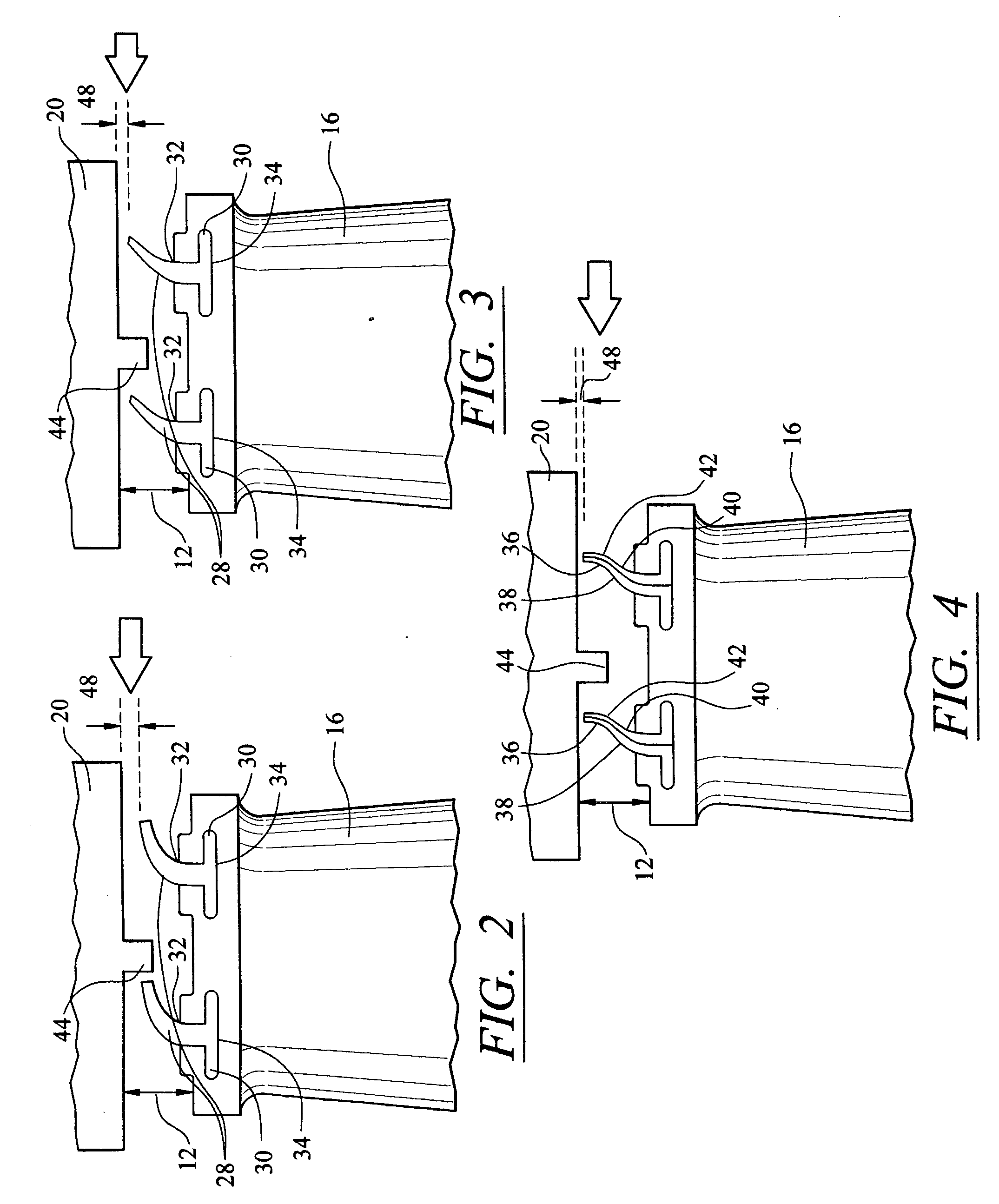

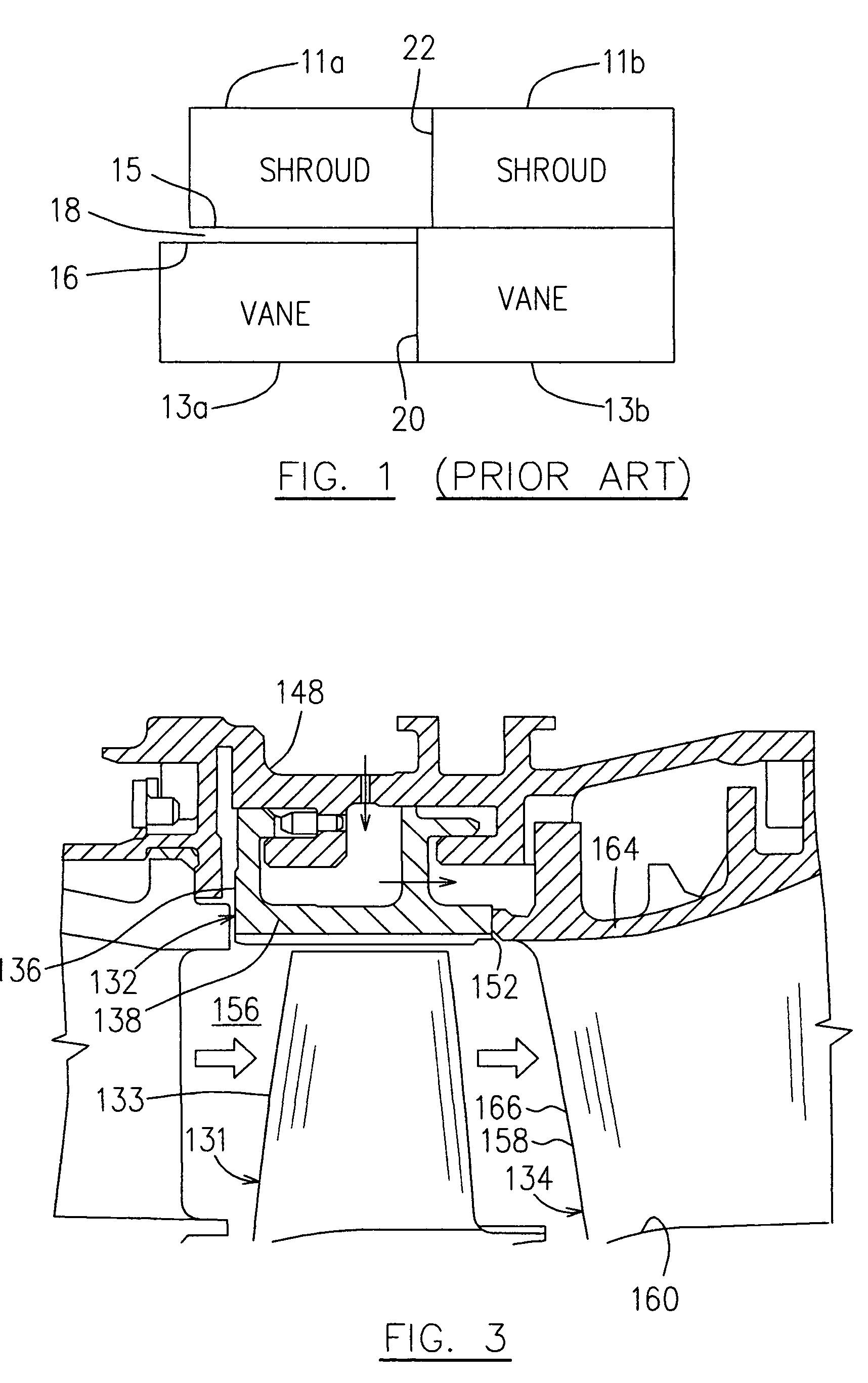

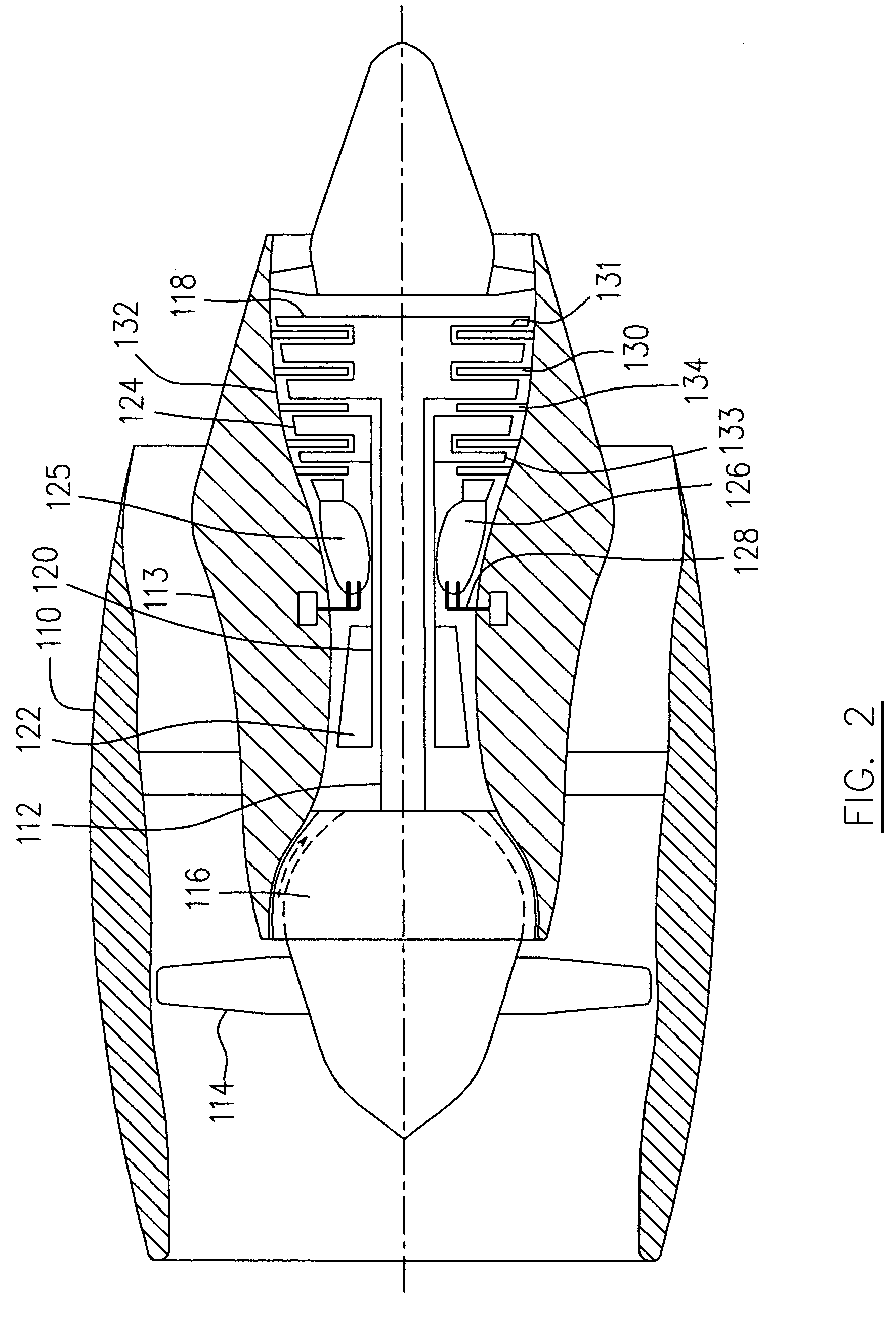

InactiveUS6926495B2Reduce air leakageImprove efficiencyWind motor controlPump componentsTurbine bladeTip clearance

A sealing system for reducing a gap between a tip of a shrouded turbine blade and a stationary shroud of a turbine engine. The sealing system includes one or more seal lands extending from a shrouded turbine blade toward a stationary shroud of a turbine engine. During operation of the turbine engine, the seal lands straighten and extend towards the stationary shroud of the turbine engine, thereby reducing the leakage of air past the shrouded turbine blades and increasing the efficiency of the turbine engine. The sealing system may also include one or more protrusions extending from the stationary shroud towards the tips of the shrouded turbine blades.

Owner:SIEMENS ENERGY INC

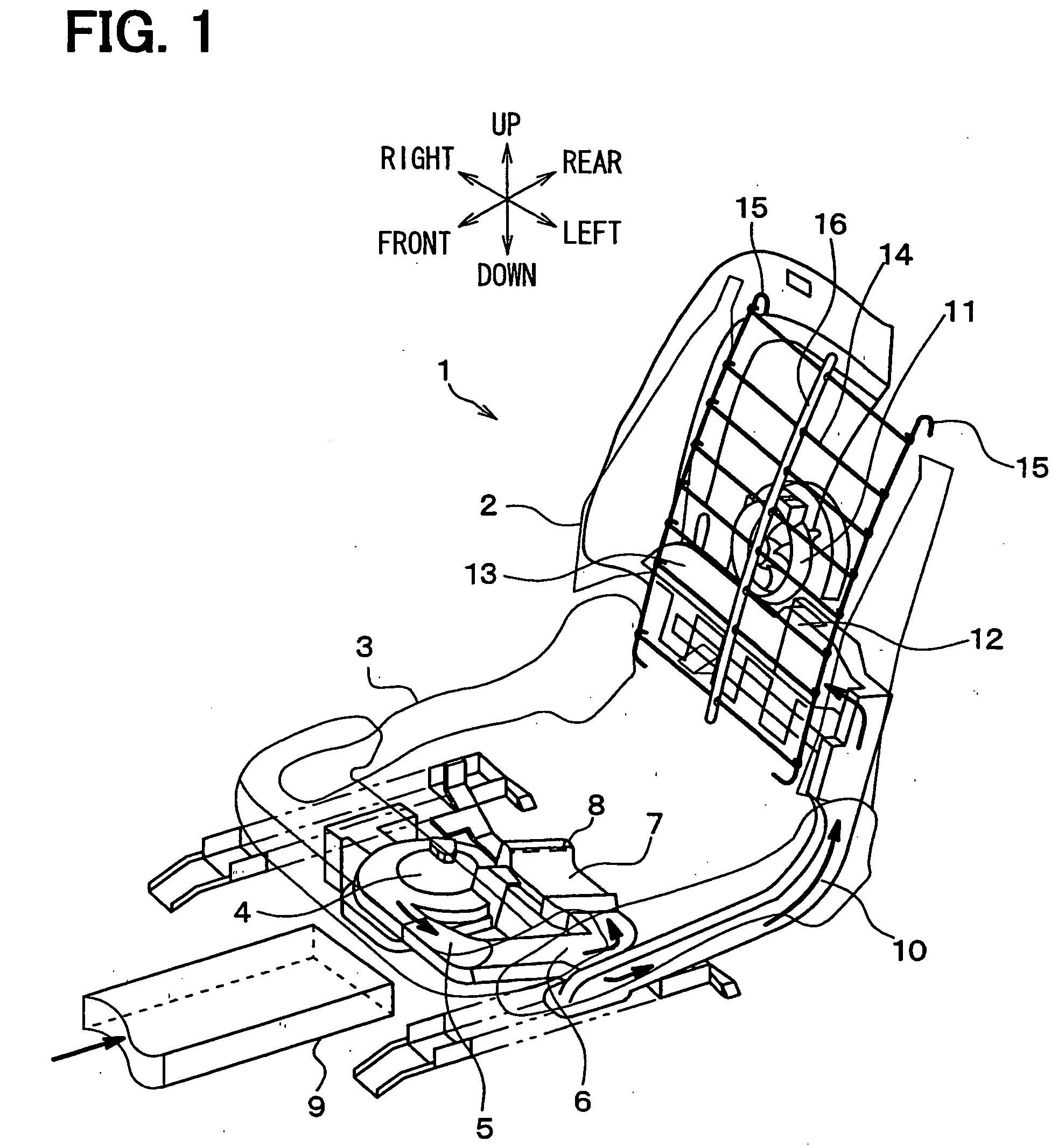

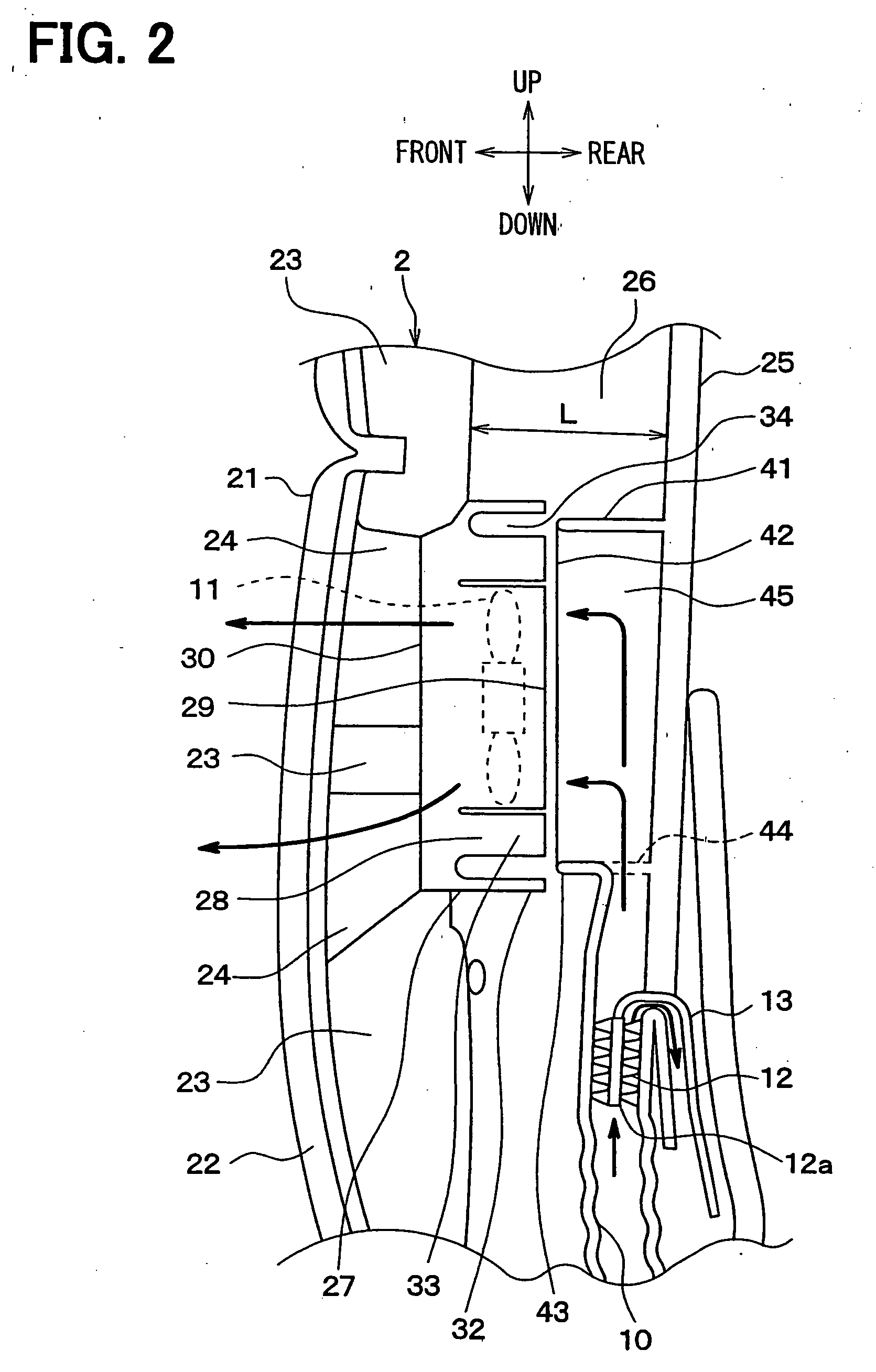

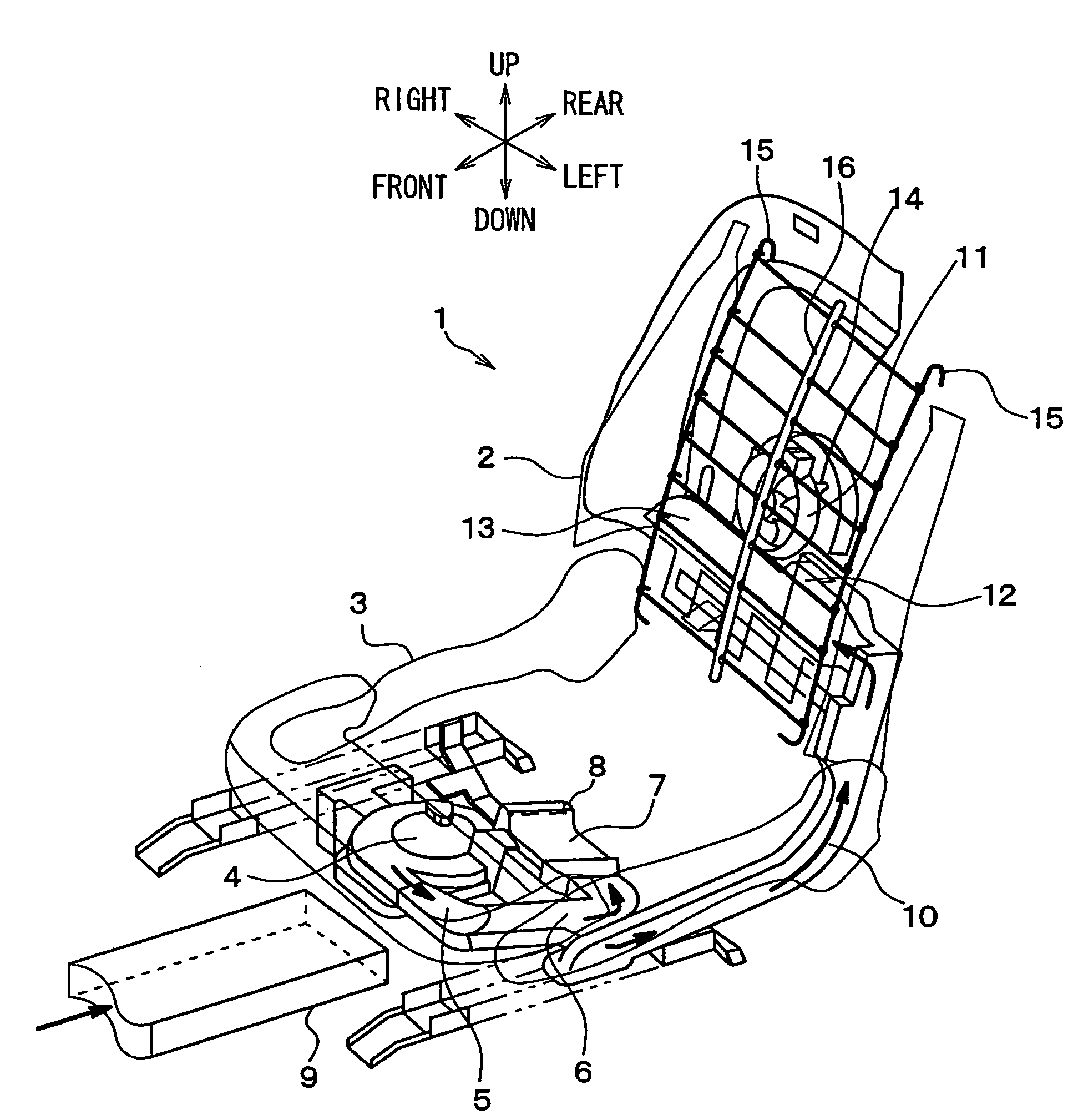

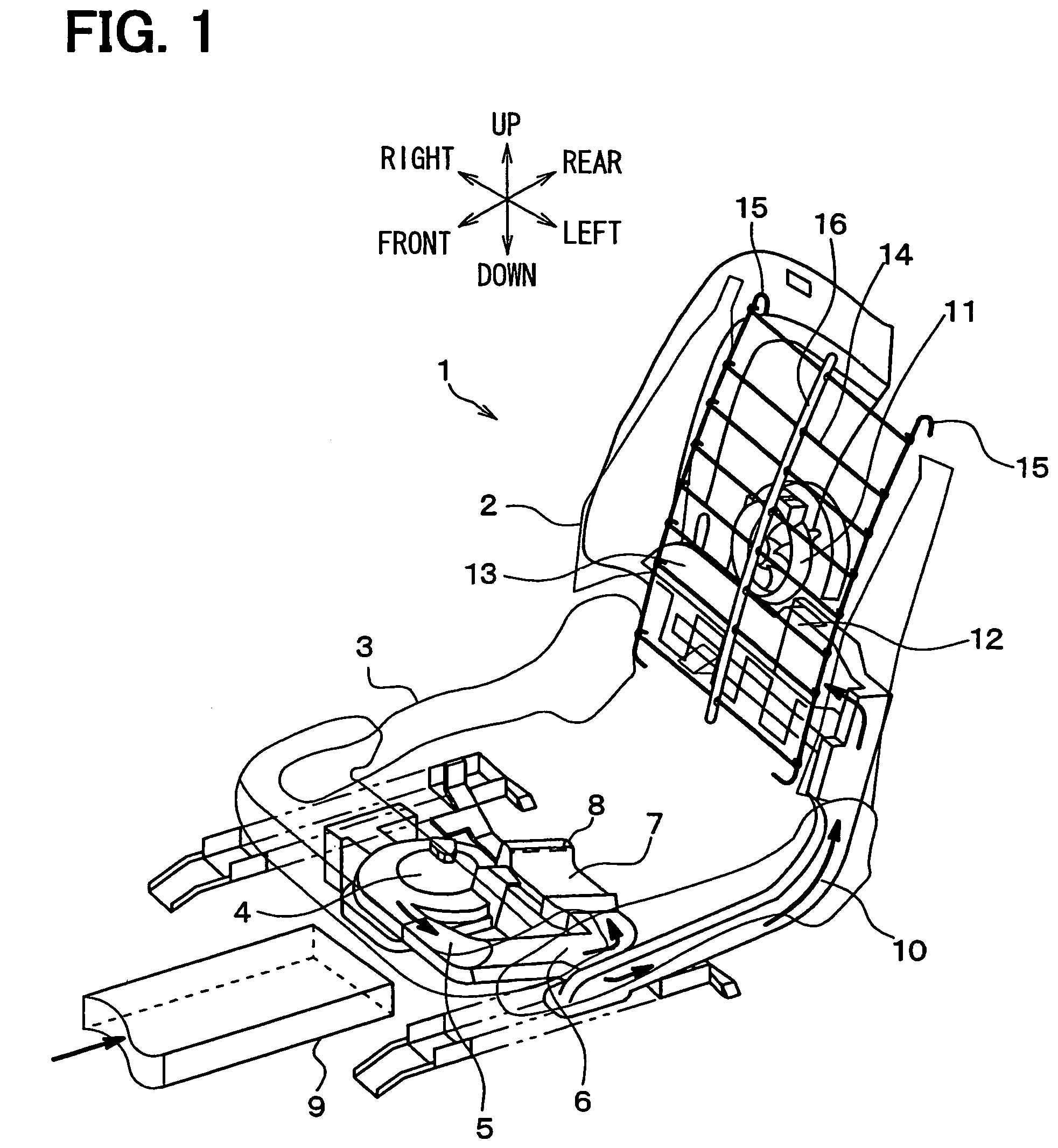

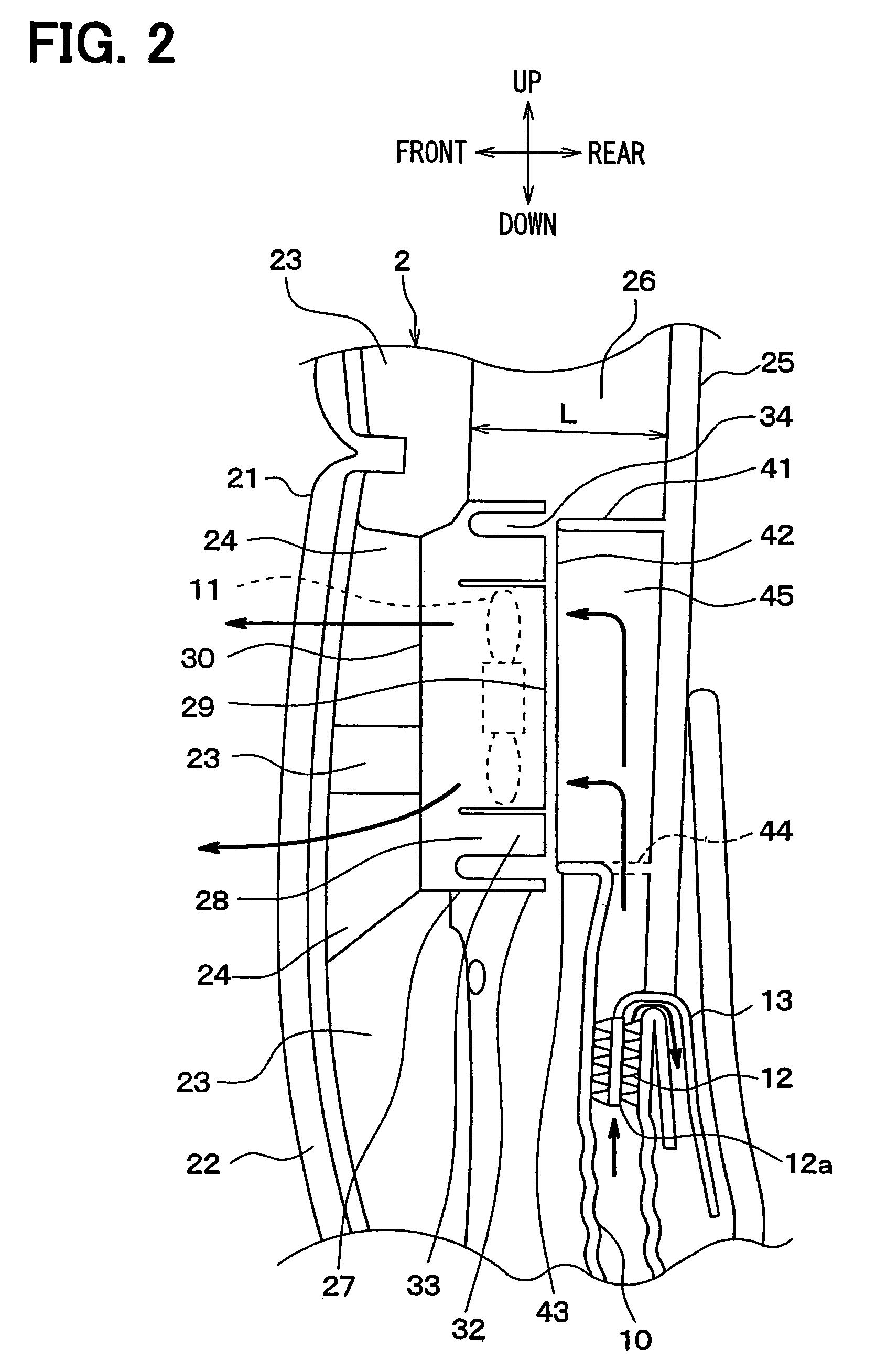

Air conditioning unit for seat

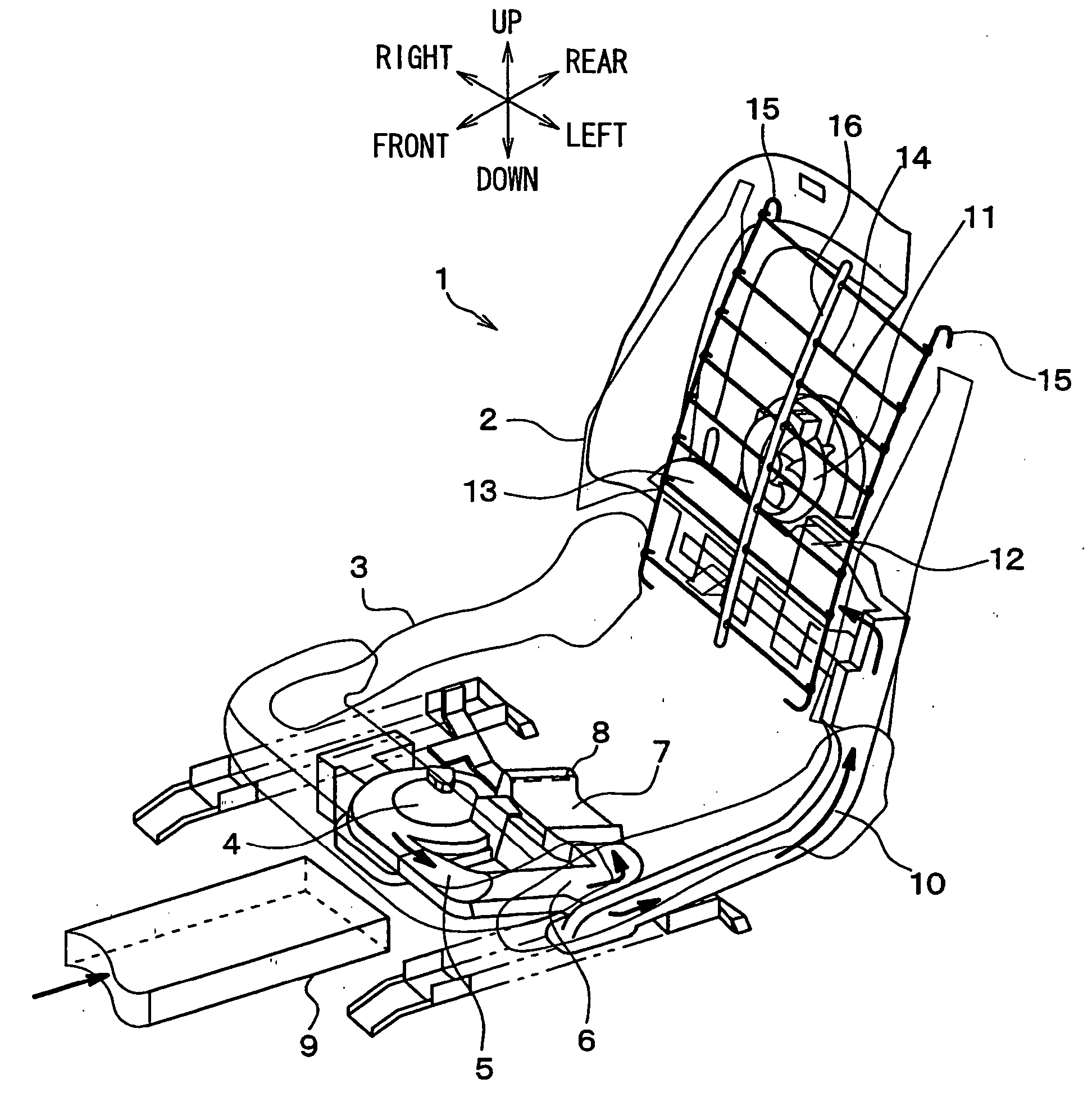

InactiveUS20060290176A1Effectively introducing airIncreased pressure lossVehicle seatsAir-treating devicesAir conditioningCushion

An air conditioning unit for introducing air to a surface of a seat back has a first air guide, a second air guide and a flexible connecting part. The first air guide is disposed on a rear side of a cushion member of the seat back to follow an elastic deformation of the cushion member. An upstream portion of the first air guide defines an inlet port. A downstream portion of the first air guide communicates with a seat back opening formed in the cushion member. The second air guide is disposed on a back board, which is located on the rear side of the cushion member with a space. The second air guide has an inlet port at an upstream portion thereof and an outlet port at a downstream end thereof. The flexible connecting part flexibly connects the outlet port of the second air guide and the inlet port of the first air guide.

Owner:DENSO CORP

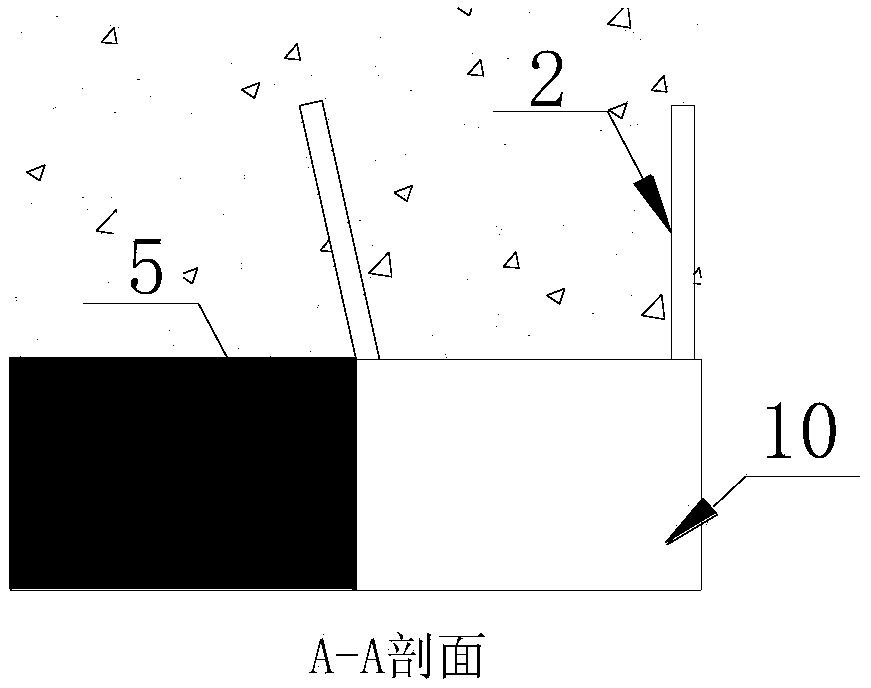

Hydraulic fracturing control method of cut tight roof/top coal

ActiveCN103527198AFacilitate orientationReduce air leakageUnderground miningSurface miningFracture controlCoal

The invention relates to a hydraulic fracturing control method of cut tight roof / top coal. The method comprises the following steps: constructing two rows of fracturing drill holes at intervals in the roof / top coal above an open-off cut by a drilling machine to a set depth, wherein one row of fracturing drill holes is close to a main upper of the open-off cut while the other row is close to an auxiliary upper of the open-off cut; constructing a row of anchor cable drill holes to the roof / top coal at the left and right ends of the open-off cut, respectively; or constructing rows of fracturing drill holes in different directions in a measure lane of the roof above the open-off cut; carrying out hydraulic fracturing on the drill holes, so that one or more cracks are generated on a rock body in a given plane to split the rock stratum to blocks or layers in certain shapes and sizes so as to damage the integrity of the rock and reduce the strength of the rock. Therefore, pressure of the roof in a large area and sudden extrusion of accumulated gases in a worked out section in an early mining stage on a coal face are prevented, air leak on the coal face is reduced, and the safety is ensured. Meanwhile, caving of top coal can be improved. The method is simple, convenient to construct, safe and reliable and good in effect.

Owner:CHINA UNIV OF MINING & TECH

Refrigerator and airflow passage for ice making compartment of the same

ActiveUS7272949B2Increase volumePrevent leakageDucting arrangementsLighting and heating apparatusEngineeringRefrigerated temperature

A refrigerator is provided with an airflow passage for an ice making compartment of the refrigerator. In the refrigerator, a main body has an opened side, and a door selectively closes the opened side of the main body. An ice making compartment is formed in the door, the ice making compartment being insulated from the outside and being kept at a low temperature. A duct is formed in the main body for exchanging cooling air with the ice making compartment, and a cooling air passage is formed at an outer surface of the ice making compartment to connect the duct with the ice making compartment. A switching unit closes the cooling air passage when the door is opened, and opens the cooling air passage when the door is closed. With this arrangement, the cooling air can be sufficiently supplied to the ice making compartment without the penetration of foreign substance.

Owner:LG ELECTRONICS INC

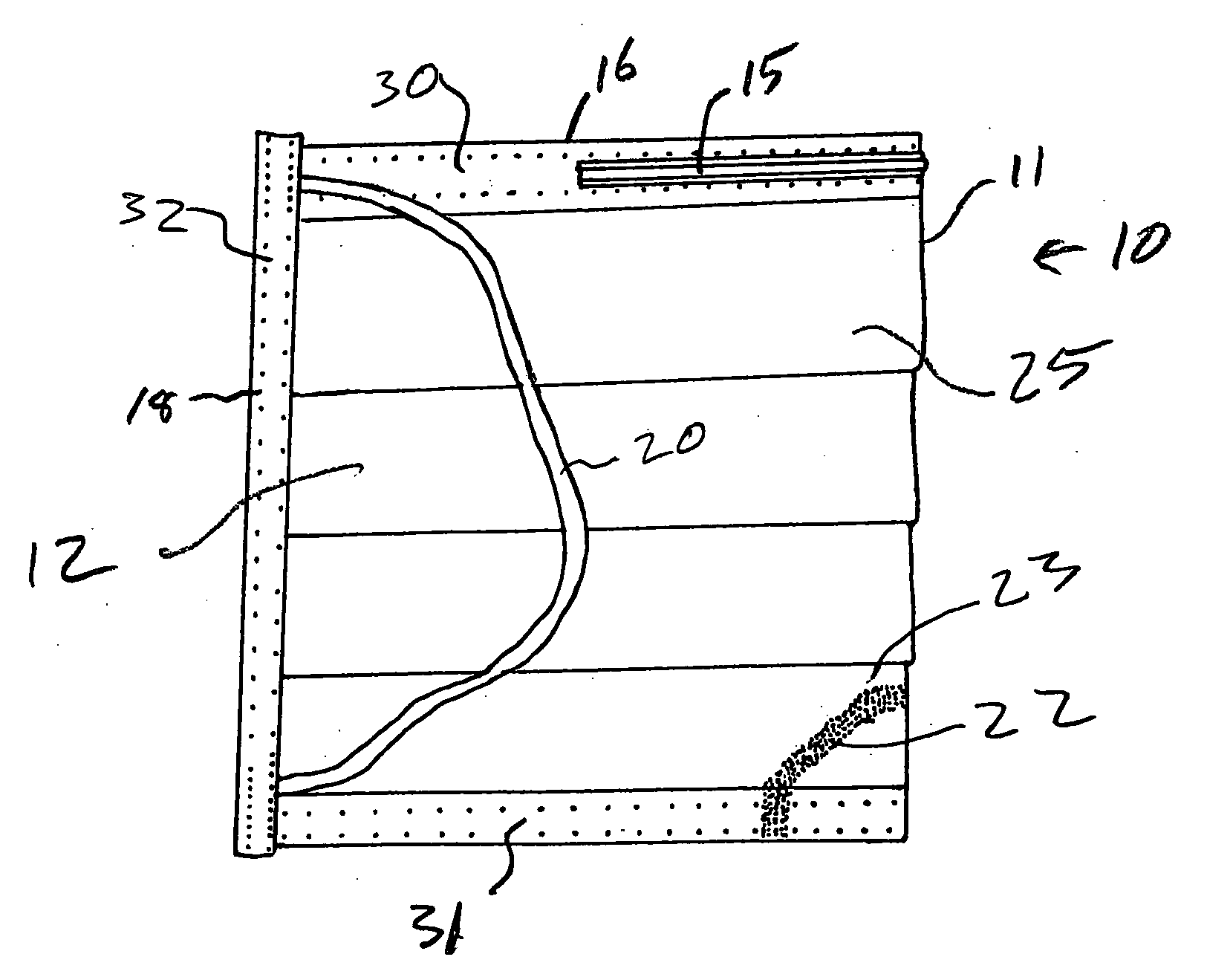

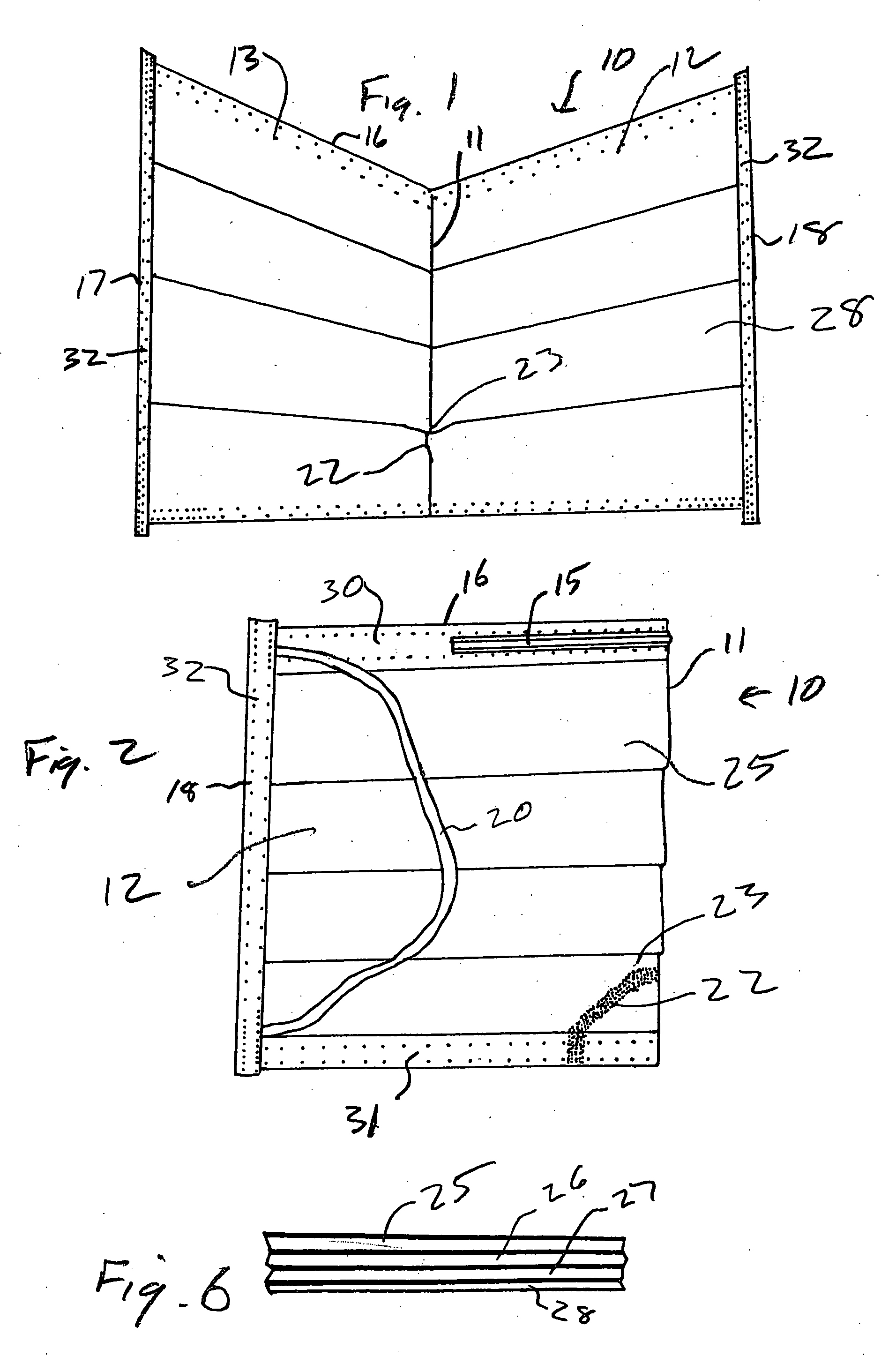

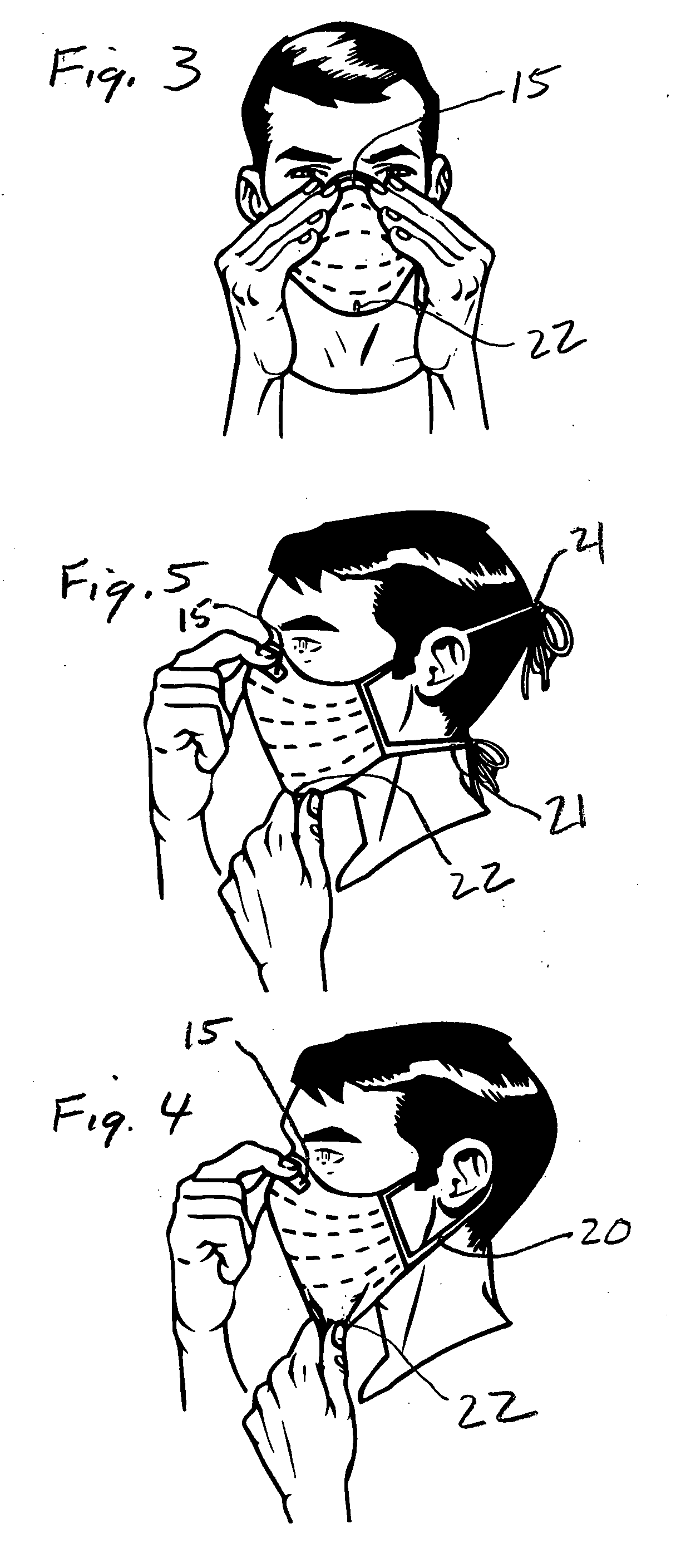

Personal protection, procedural and surgical mask

InactiveUS20070175477A1Reduce air leakageAvoid passingBreathing filtersBreathing masksChinRespirator

A preformed seam, crease, or fold in the bottom portion of a surgical, procedural, or personal protection mask forms a chin pocket in the bottom of the mask to receive the user's chin therein. This pocket has been found to provide a better mask fit to reduce the air leakage around the mask not only around the user's chin, but around the entire face. The mask may also have a unique construction of the filter material which includes a filter layer and a moisture resistant layer. The mask also may include a soft comfortable layer for placement against the face of a user. The filter layer can provide an activated charcoal filter and / or a particulate filter which allows gas to pass therethrough but resists passage of bacteria, viruses, and particulate materials.

Owner:MEDSPRING GRP

Air conditioning unit for seat

InactiveUS7275984B2Effectively introducing airIncreased pressure lossAir-treating devicesSeat heating/ventillating devicesEngineeringAir conditioning

Owner:DENSO CORP

Turbine spring clip seal

InactiveUS6869082B2Avoid passingImprove turbine efficiencyContinuous combustion chamberEngine sealsCombustorEngineering

An improved turbine spring clip seal for directing gases to be mixed with fuel in a combustor basket. The turbine clip seal may include an inner housing and an outer housing. The inner housing or the outer housing, or both, may include one or more tapered leaves forming a portion of the spring clip seal. At least one leaf may include a flared end for limiting gas from passing through the slots in the spring clip seal. In at least one embodiment, the turbine clip seal may include a center sealing member positioned between the inner and outer housings.

Owner:SIEMENS ENERGY INC

Shroud and vane segments having edge notches

ActiveUS7114920B2Easy to controlReduce air leakagePump componentsGas turbine plantsStructural engineeringMechanics

Owner:PRATT & WHITNEY CANADA CORP

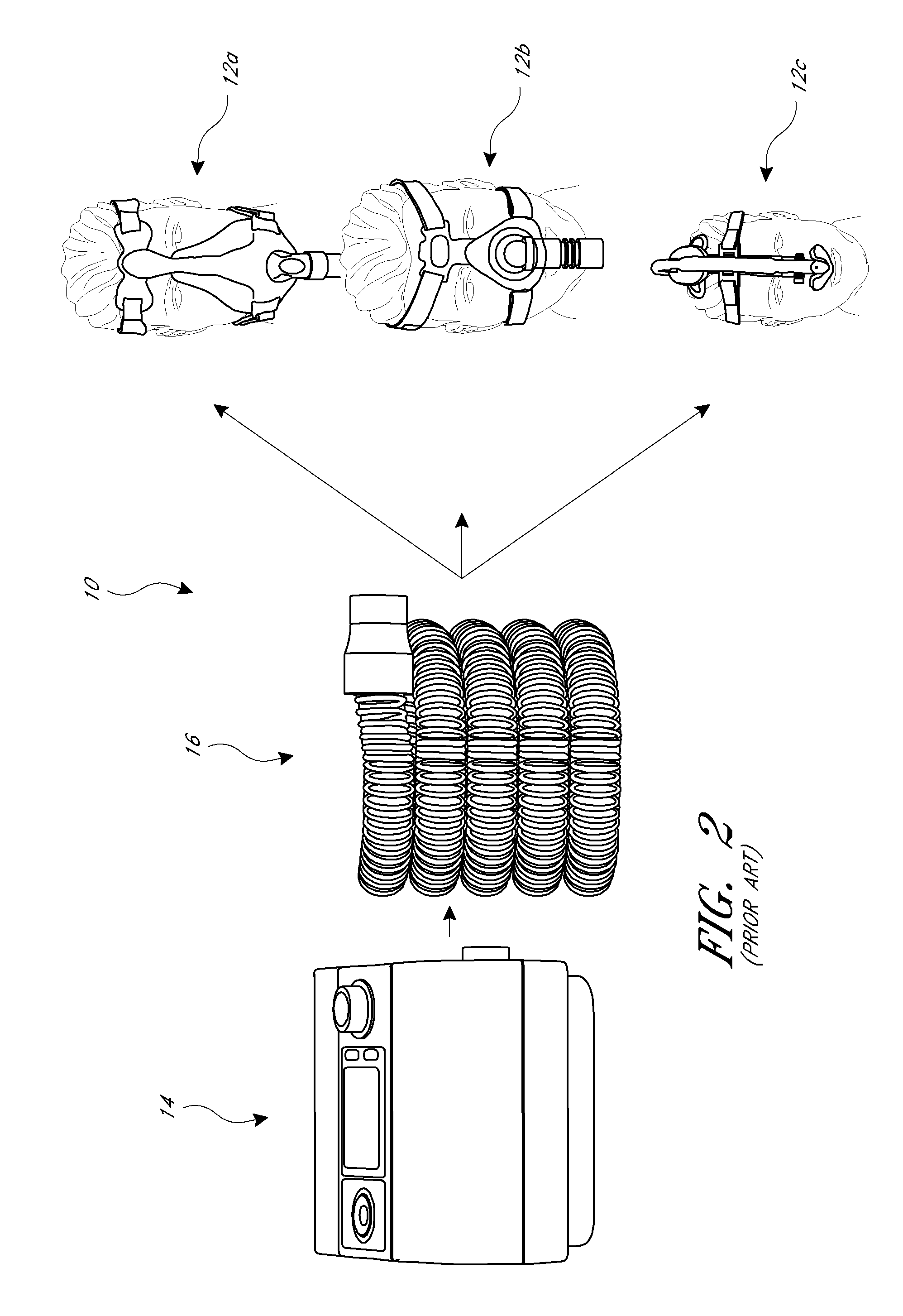

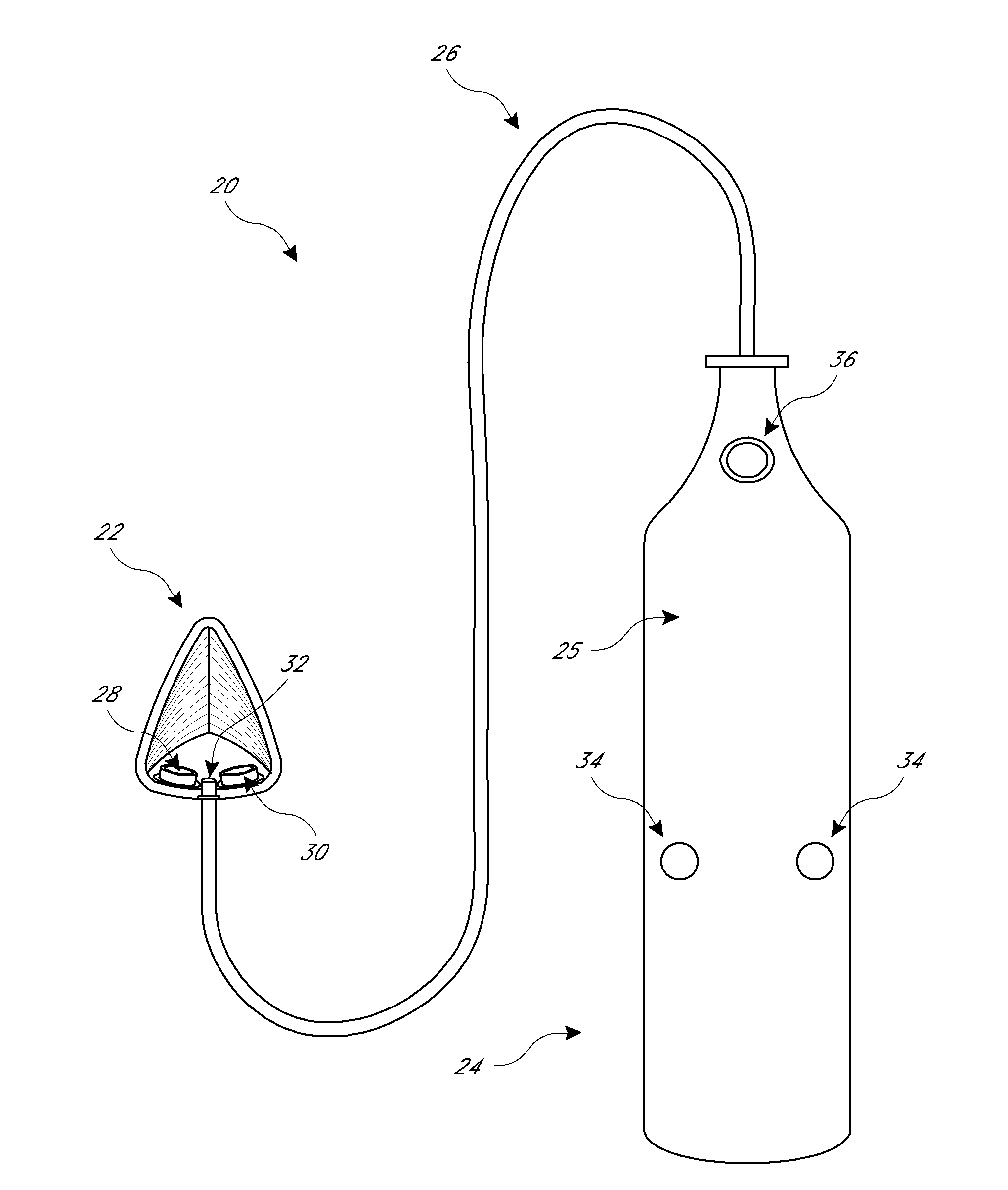

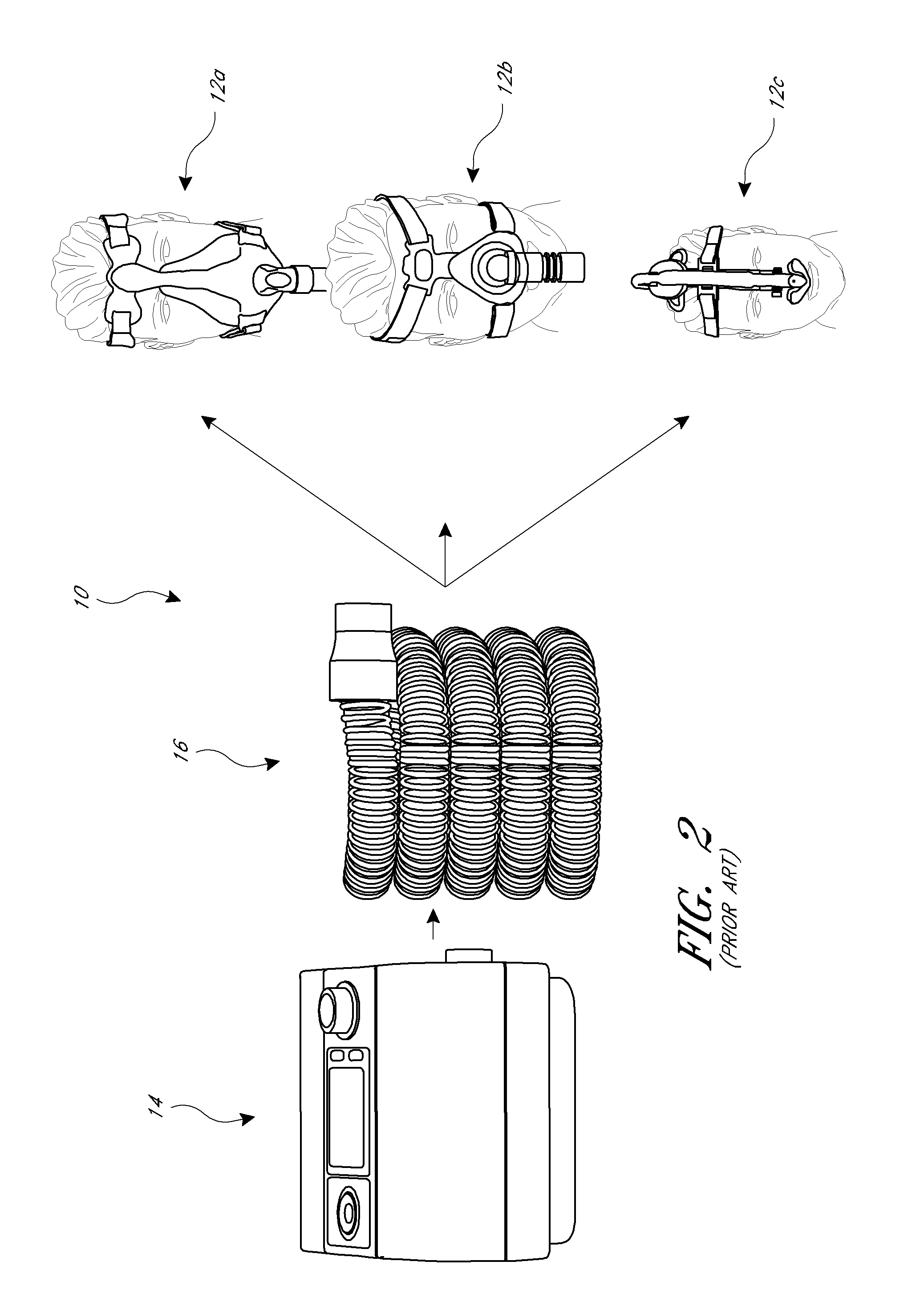

Sleep apnea device

ActiveUS20130312757A1Less side effectsConvenient treatmentRespiratory masksMedical devicesNostrilIntensive care medicine

A system for treating a patient suffering from obstructive sleep apnea may include a mask, a portable air flow generator configured to generate air flow at a relatively low flow rate, and a tube connecting the air flow generator and the mask such that air flow from the generator passes through an air flow generator valve on the mask. The mask may include a contact surface for forming a seal between the mask and the patient's face such that the mask surrounds the patient's nostrils, an expiration valve that opens during expiration, and an air flow generator valve that opens during inspiration. In some embodiments, the mask may further include an inspiration valve that opens during inspiration to allow air from outside the system to enter the mask.

Owner:FRESCA MEDICAL

Blades for a gas turbine engine with integrated sealing plate and method

ActiveUS20070258816A1Reducing cooling air leakageReduce air leakagePropellersRotary propellersEngineeringKnife blades

A blade for a rotor assembly including a root portion, a platform with an overhang, an airfoil portion and a sealing plate. The sealing plate protrudes from the blade along a circumferential direction.

Owner:PRATT & WHITNEY CANADA CORP

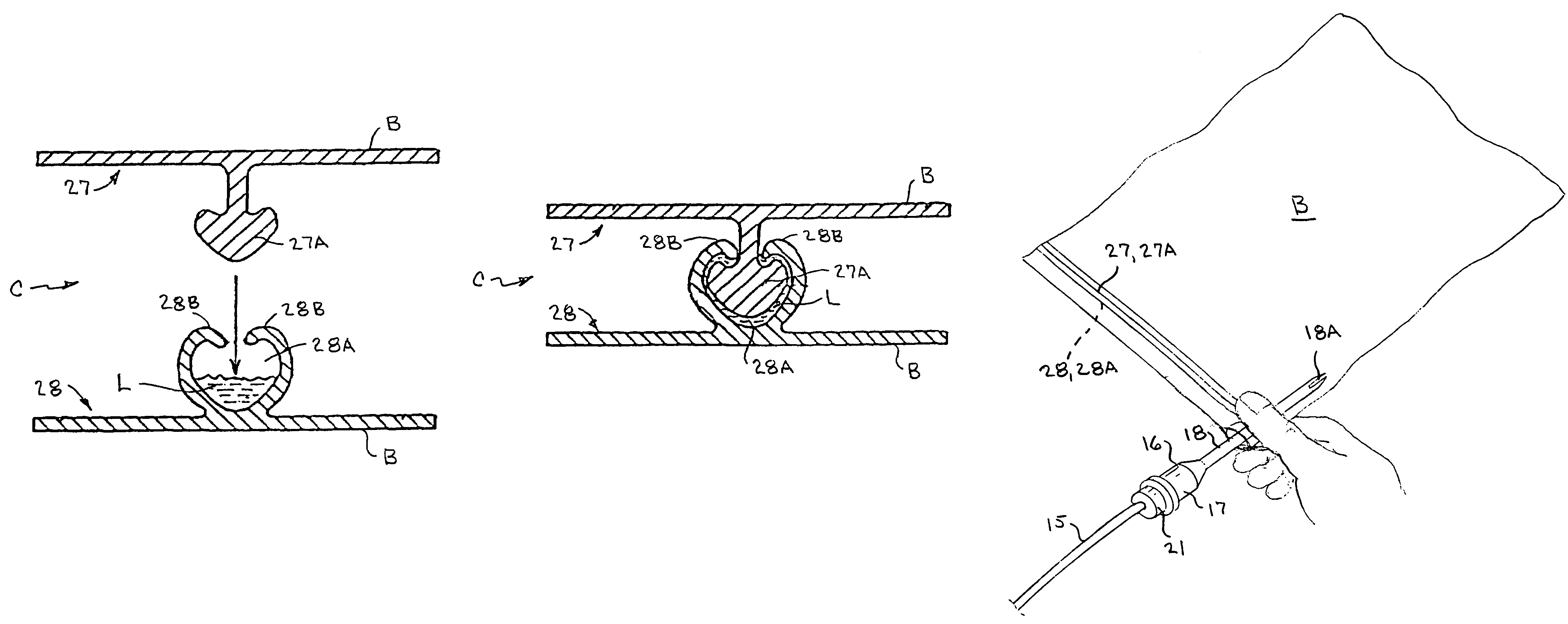

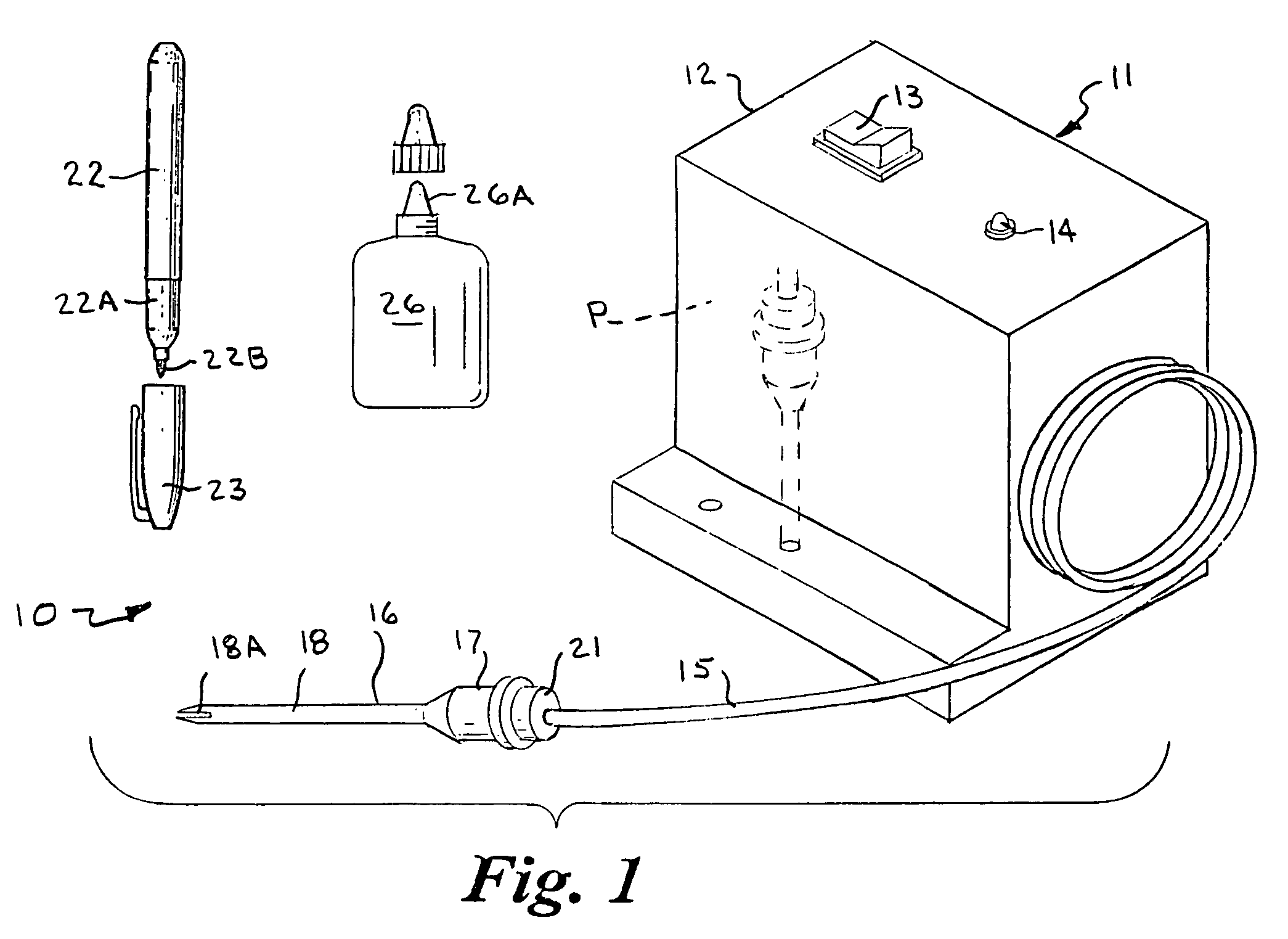

Method and apparatus for vacuum sealing zip lock plastic bags

InactiveUS7316101B1Improve the immunityReduce air leakagePackaging by pressurising/gasifyingShock-sensitive articlesEngineeringVacuum pump

A vacuum sealing method and system for evacuating air from and sealing a flexible plastic bag of the type having a mating male rib and a female sealing channel closure along the length of the bag opening. A flowable liquid is applied to the female channel. The rib and channel are engaged along their length to leave a short portion of the closure unclosed, a hollow tubular evacuation tube connected with a vacuum pump is inserted into the bag through the unclosed portion, pinching pressure is manually applied to sandwich the evacuation tube between the unclosed portion to prevent air from escaping, the vacuum pump is operated to withdraw a substantial amount of air from the bag, and thereafter the evacuation tube is quickly pulled from the bag so that the pinching pressure is transferred to the closure thereby closing the unclosed portion and sealing the evacuated bag with the liquid filling voids between the mating elements and providing a supplemental seal to increase resistance to air entering the sealed bag.

Owner:NGUYEN VINCENT +1

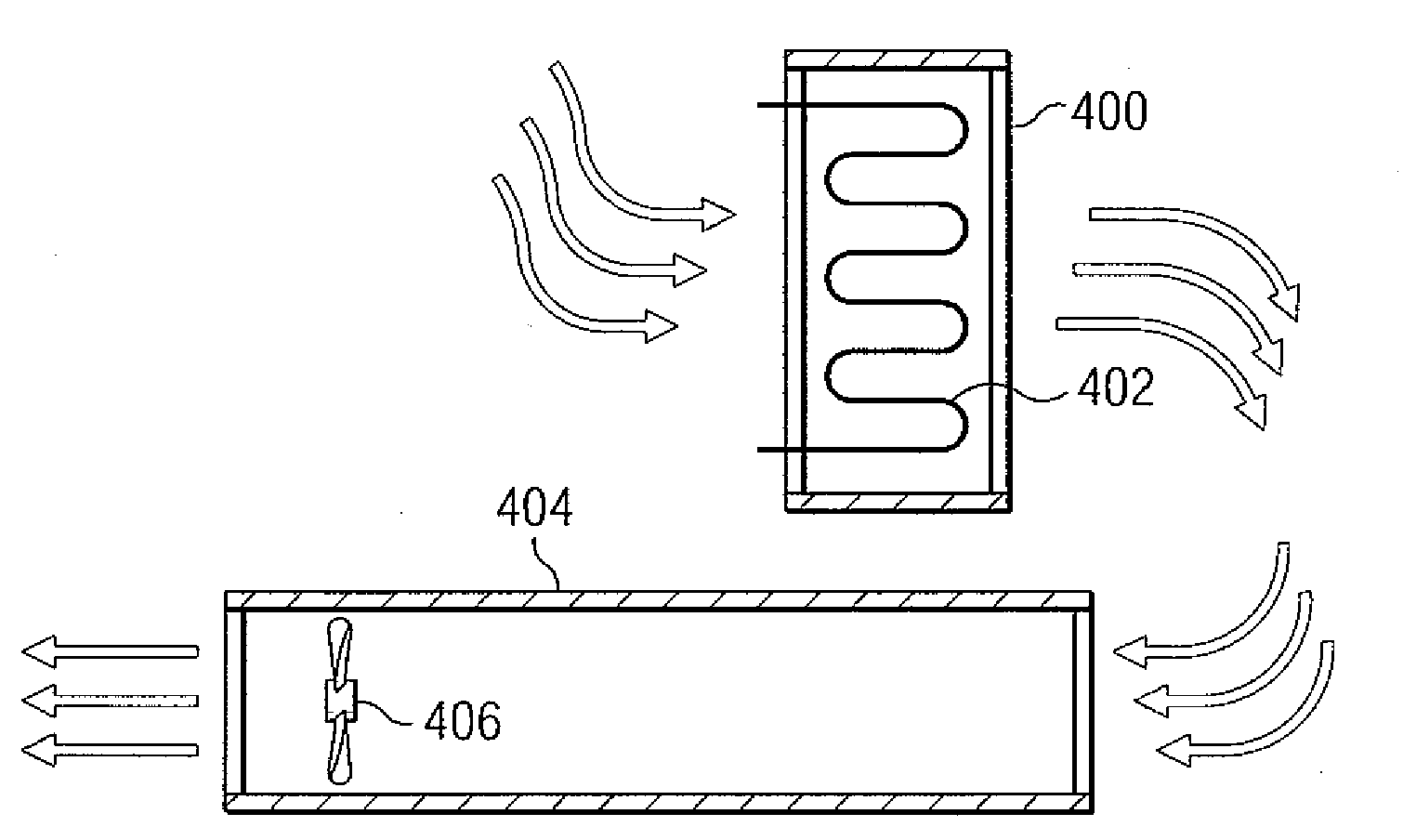

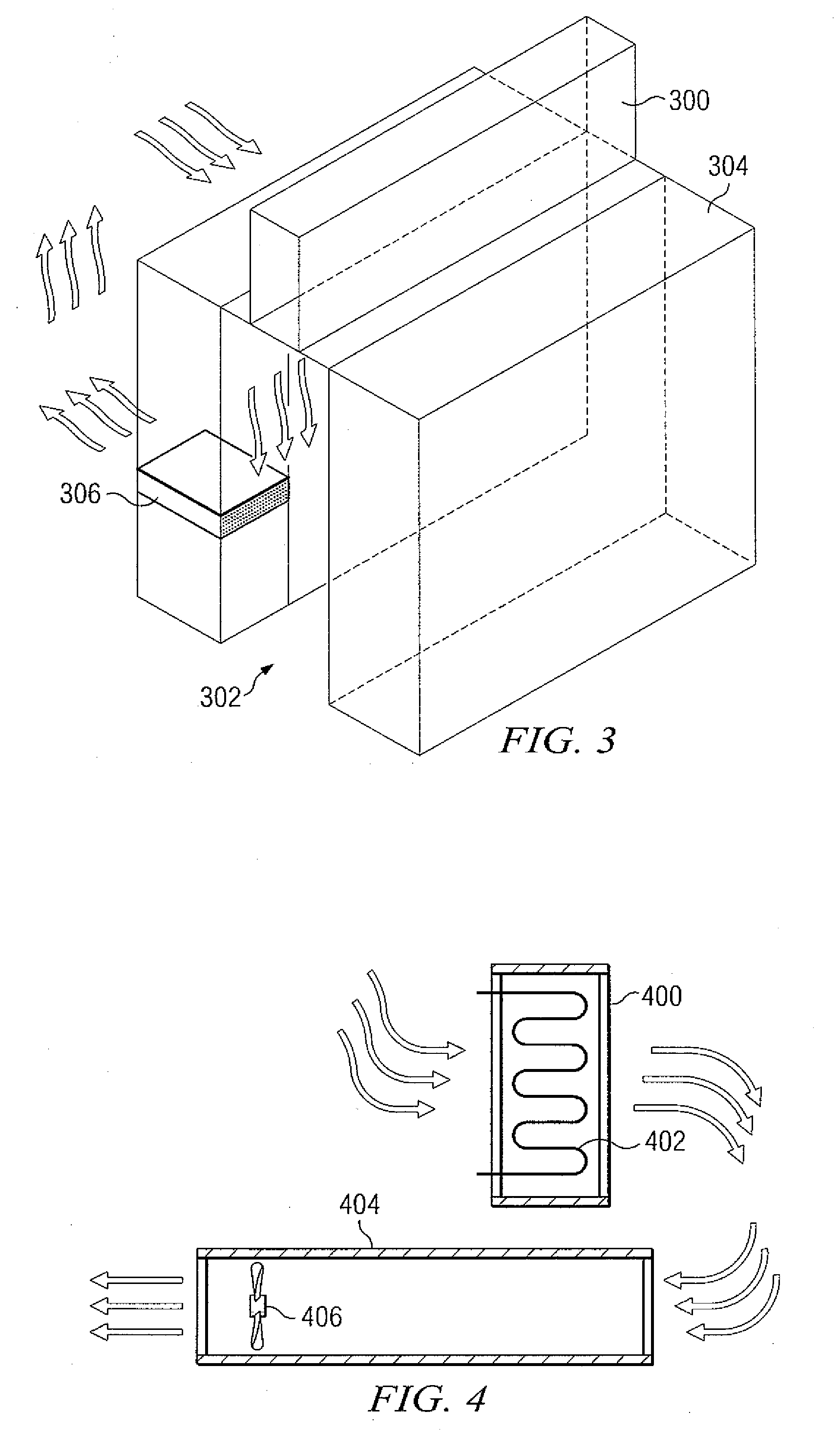

Cold Row Encapsulation for Server Farm Cooling System

InactiveUS20100091448A1Improve cooling effectReduce air leakageServersSpace heating and ventilation safety systemsCold airData center

Apparatuses, methods, and systems directed to efficient cooling of data centers. Some embodiments of the invention allow encapsulation of cold rows through an enclosure and allow server fans to draw cold air from the cold row encapsulation structure to cool servers installed on the server racks. In other particular embodiments, the systems disclosed can be used to mix outside cool air into the cold row encapsulation structure to cool the servers. In some embodiments, the present invention involves using multiple cold row encapsulation structures to cool the servers installed on the racks.

Owner:R2 SOLUTIONS

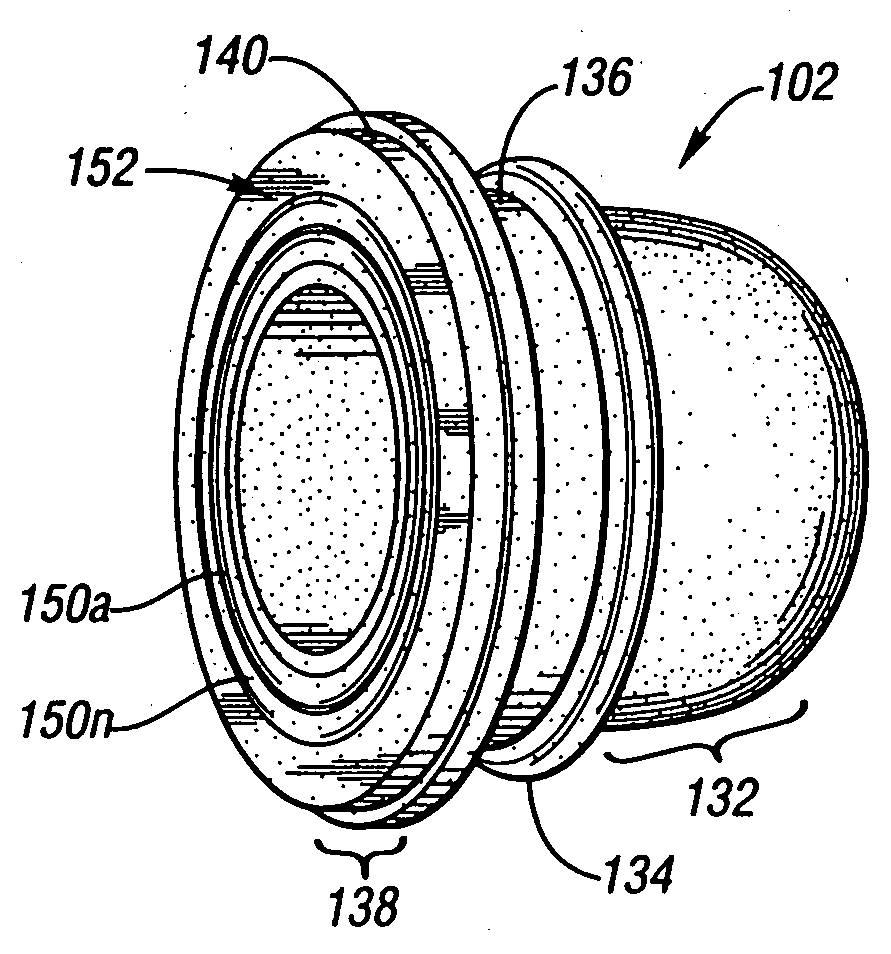

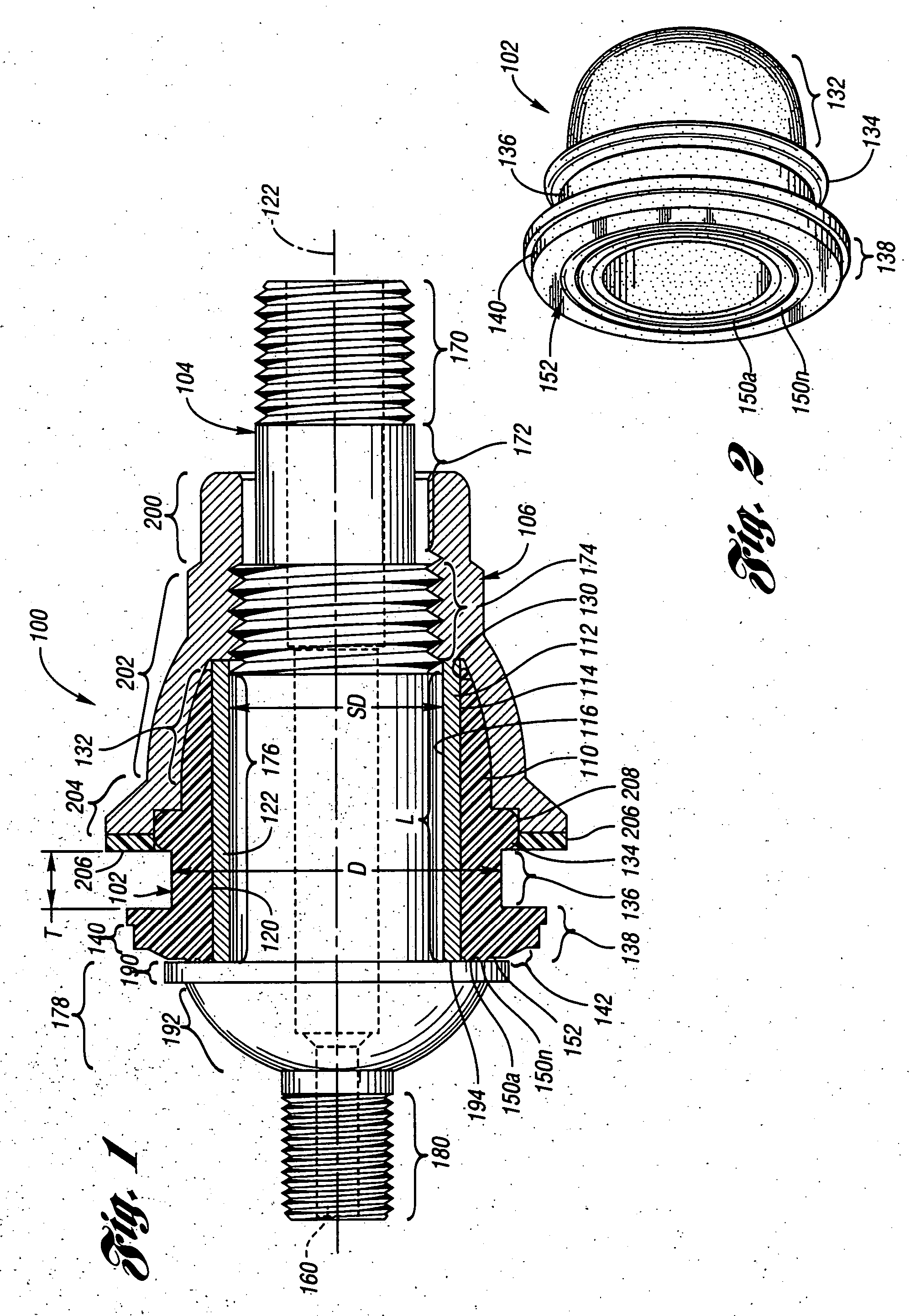

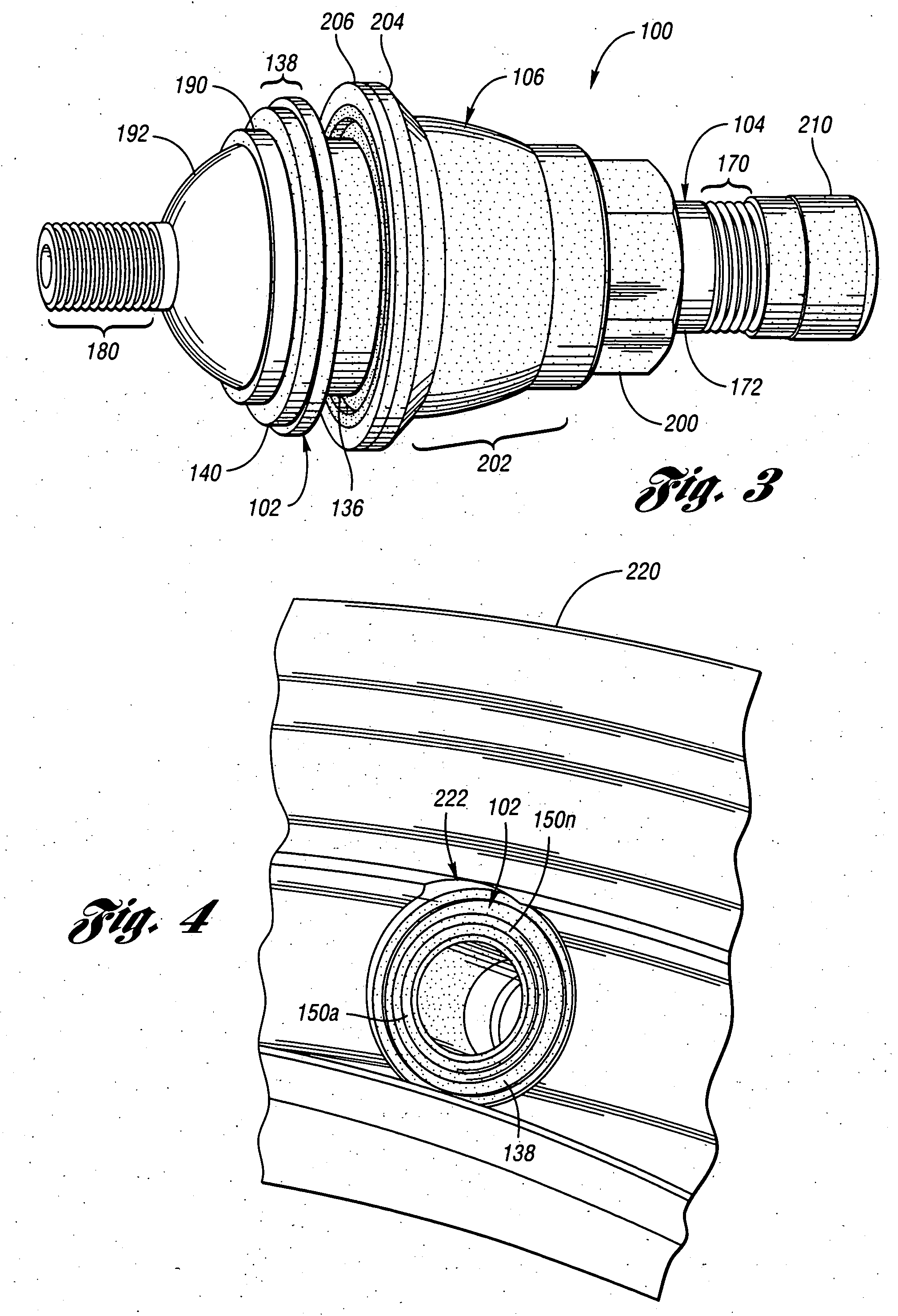

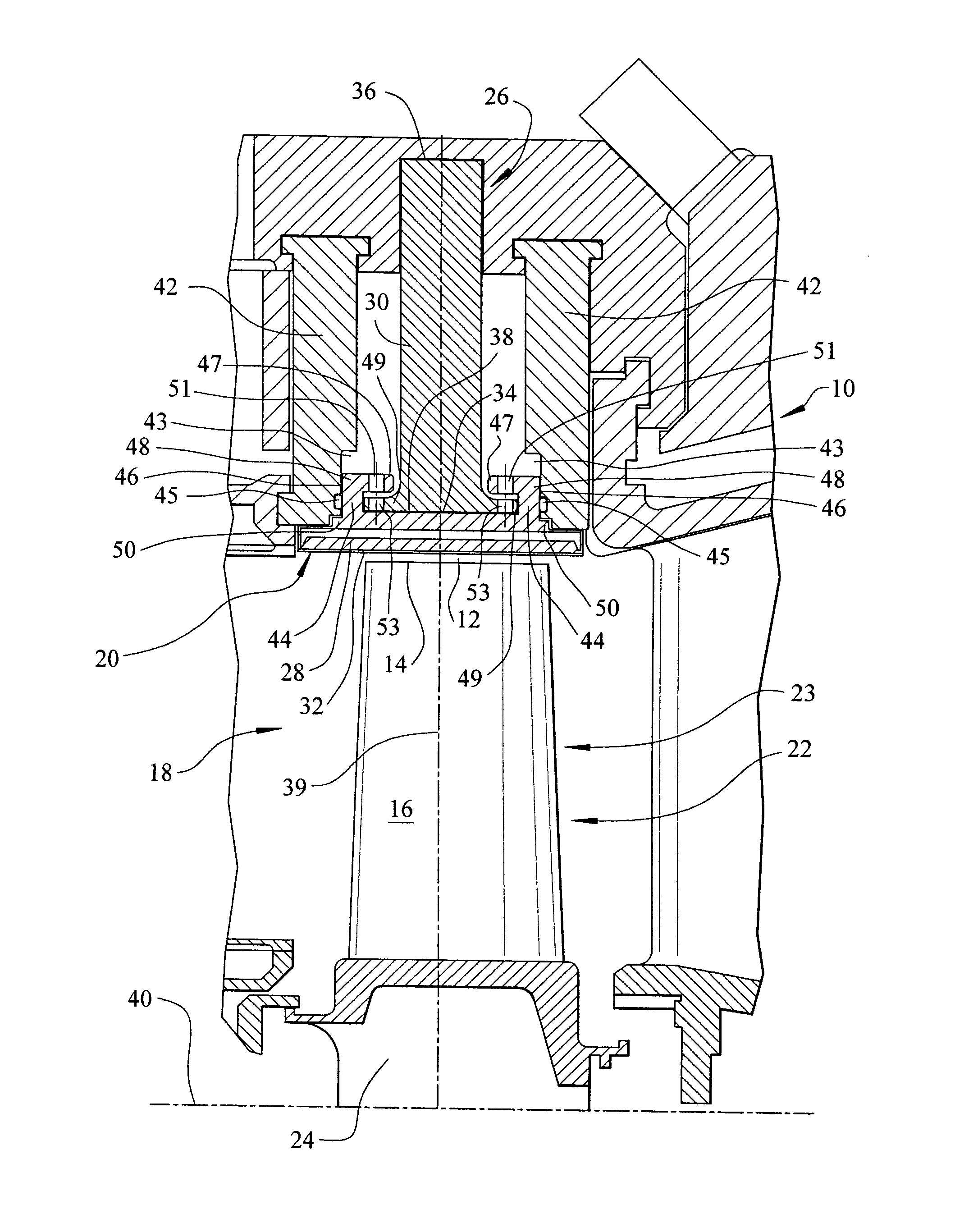

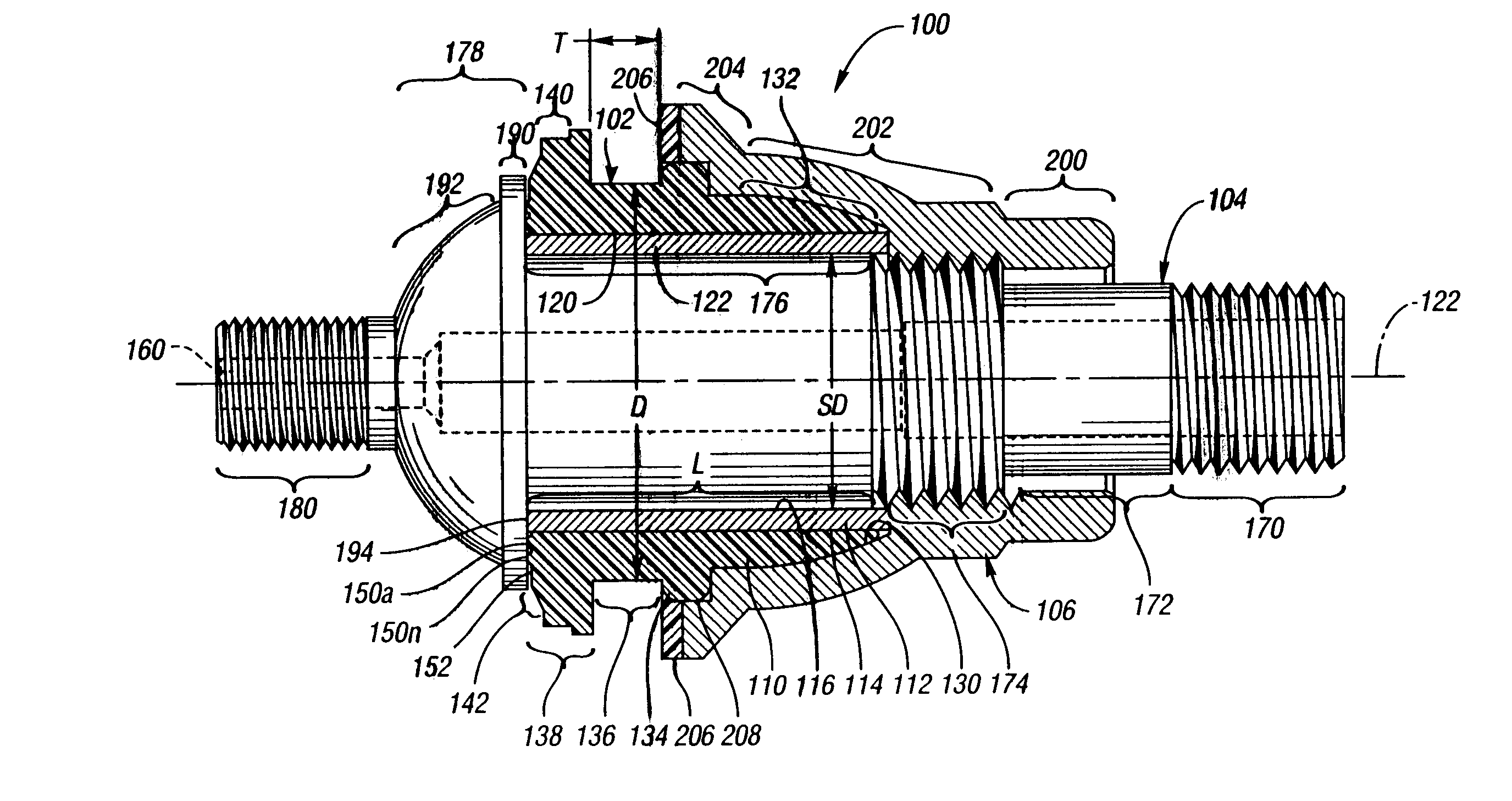

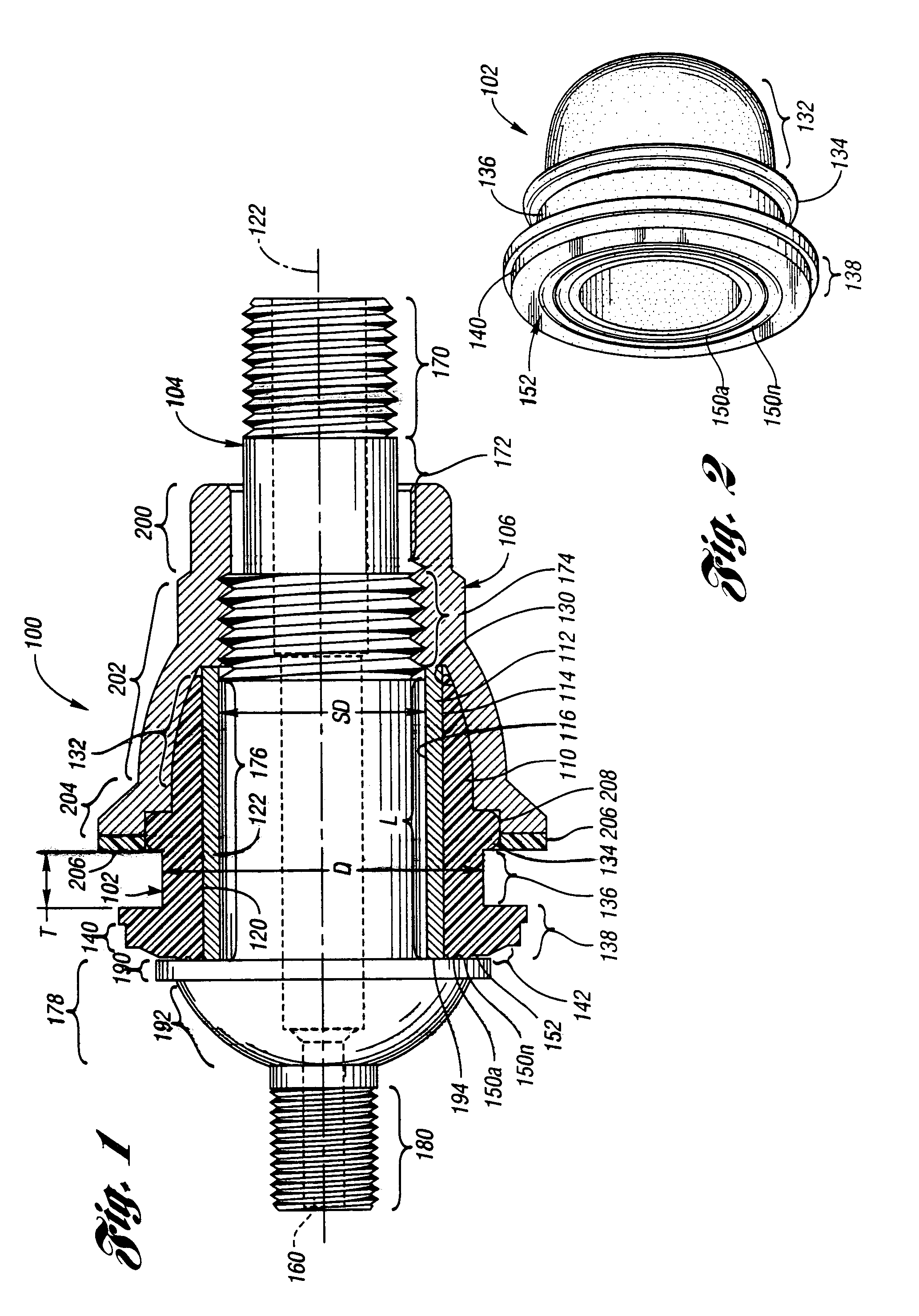

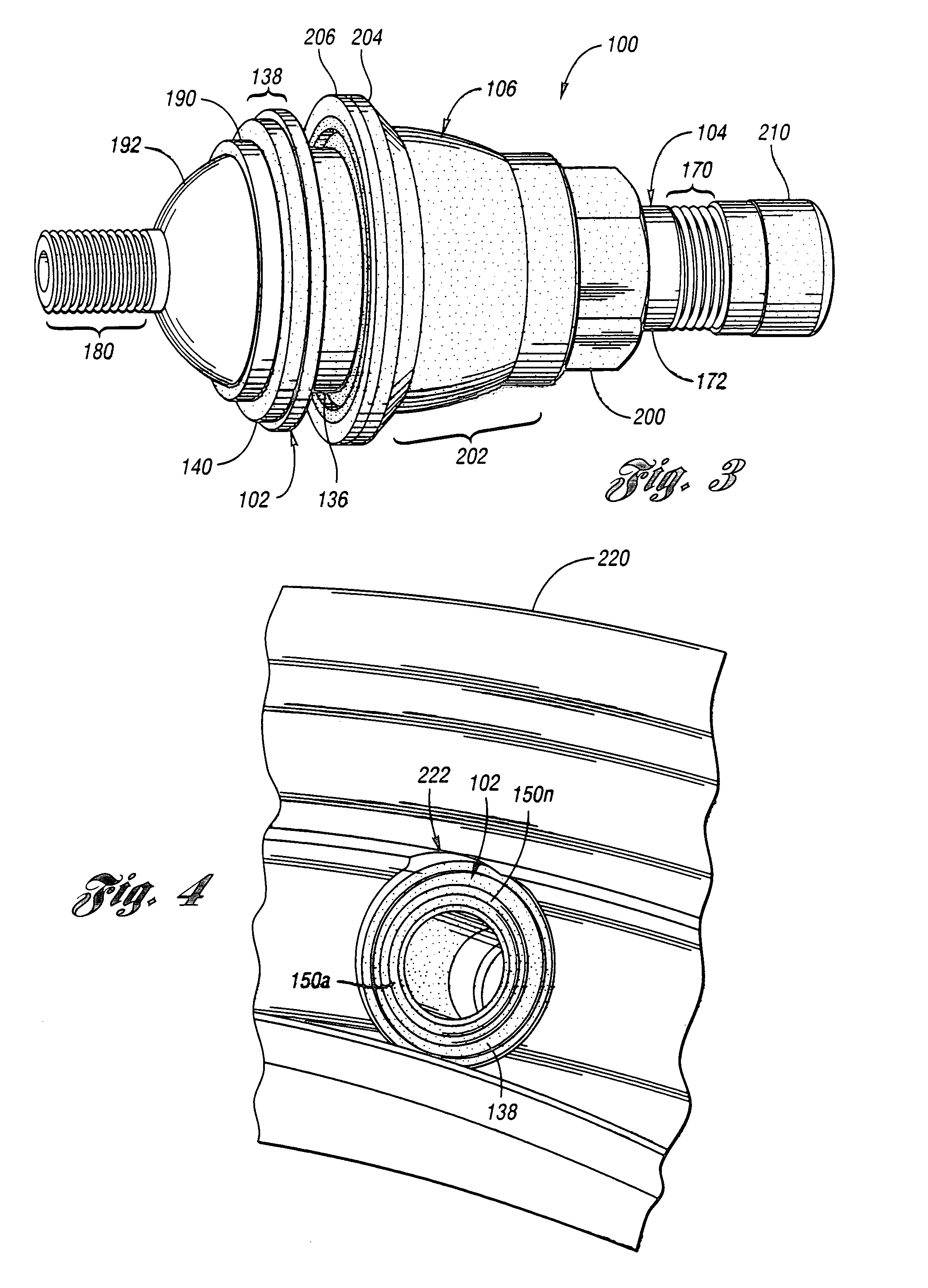

Snap-in grommet for a valve stem assembly

ActiveUS20050087228A1Reduce air leakageImprove sealingCheck valvesTyre measurementsEngineeringGrommet

The present invention includes a grommet and valve stem assembly. The assembly includes a grommet having a body, a nose section at a grommet first end, a cylindrical section having a first end adjoined to the nose section and a second end from which a flange section projects radially. The flange section has a substantially flat surface opposite to the cylindrical section. At least one interface seal is formed on the flat surface as a hemispherical projection located concentrically about a grommet center axis. An axial bore passes centrally through the body, and a valve stem is configured for insertion through the grommet bore. The valve stem includes a threaded portion configured to receive a retaining nut and a flange having a substantially flat surface configured to form at least one sealing interface with the at least one interface seal when the nut is tightened to the valve stem.

Owner:SENSATA TECHNOLOGIES INC

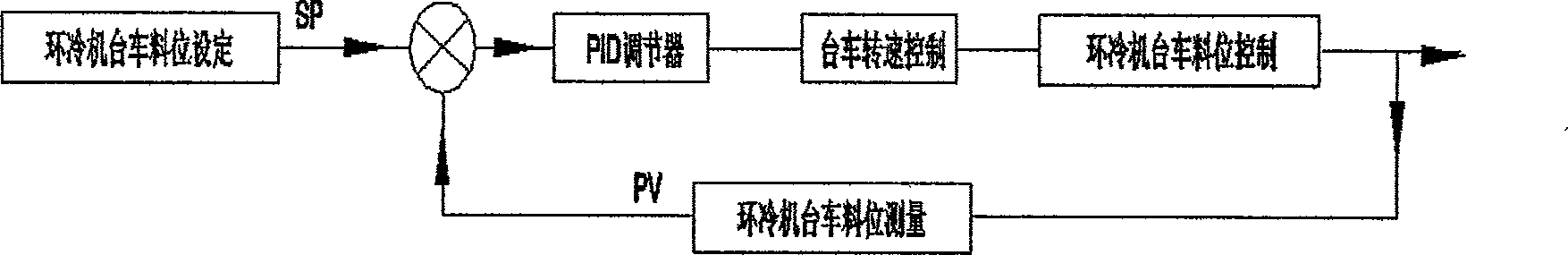

Control method for stabilizing and enhancing sintered ring cooling wind temperature while smelting steel

InactiveCN101424484AEasy to controlGuaranteed uptimeTemperature control with auxillary non-electric powerFurnace typesTaking temperaturesMaterials science

The invention relates to the field of reclaiming of waste gas and waste heat in the steel industry and power generation by the waste gas and the waste heat, in particular to a control method and a device for stabilizing and improving air taking temperature of a sintered ring in steel smelting. The device and the method are characterized in that the device and the technical method can achieve relative stabilization and moderate improvement of the temperature of the waste gas at the upper part of an inner batch layer of a cooling trolley through increasing and adjusting speed and cooled air of a circular cooler and uniformity for transversely feeding at a feed opening; and at the same time, under the premise that the temperature of the waste gas reaches the technical requirement of a waste heat generating technique, flow of the waste gas at the upper part of the batch layer is increased by properly increasing blown air amount at the lower part of the cooling trolley, so as to ensure relative stabilization and moderate improvement of air inlet temperature and flow of a waste heat boiler, and promote stabilization and improvement of vapor yield of the waste heat boiler and generated energy of a generating system.

Owner:昆明阳光基业股份有限公司

Turbine engine sealing device

InactiveUS6896484B2Reduce air leakageImprove efficiencyPropellersPump componentsTurbine bladeThermal expansion

A sealing system for reducing a gap between a tip of a turbine blade and a shroud of a turbine engine. As a turbine engine reaches steady state operating conditions, components of the sealing system reach their maximum expansion and reduce the size of the gap located between the blade tips and the engine shroud, thereby reducing the leakage of air past the turbine blades and increasing the efficiency of the turbine engine. The sealing system includes a ring segment having a sealing surface positioned proximate to a tip of a turbine blade. The ring segment may be coupled to a blade ring using a spindle having a coefficient of thermal expansion greater than the coefficient of thermal expansion for the blade ring.

Owner:SIEMENS ENERGY INC

Snap-in grommet for a valve steam assembly

The present invention includes a snap-in grommet provided for use in a valve stem assembly. The grommet includes a body consisting of a nose section at the body first end, the nose section having a substantially conical shape to provide for insertion of the body into an inflation hole of a wheel rim. The body further contains an annular section at a base of the nose section, the annular section projecting radially from the base of the nose section and a cylindrical section sized to match the inflation hole and having a first end adjoined to the annular section. A flange section projects radially from a cylindrical section second end, and an axial bore passes centrally through the body. A sleeve is located within the grommet body bore, the sleeve having an outer surface configured to match the body bore and having a bore configured to receive a valve stem.

Owner:SENSATA TECHNOLOGIES INC

Mining-coal bed nearly horizontal gas extraction borehole sealing method

InactiveCN103195390AIncrease extraction concentrationImprove the extraction effectSealing/packingStructure of the EarthCement grout

A mining-coal bed nearly horizontal gas extraction borehole sealing method is mainly suitable for gas extraction boreholes at sites like coal faces in underground coal mines and coal roadways. The sealing method mainly includes two parts: static sealing and dynamic sealing. For a gas extraction borehole, static sealing is performed firstly and includes two times of grouting: for the first grouting, expansion cement grout is adopted to seal positions outside a fissure zone, and for the second grouting, slurry is adopted to seal positions inside the fissure zone; after a period of time, dynamic sealing is performed and includes that the expansion cement grout and the slurry are constantly grouted into the borehole by utilizing underground compressed air to enable the borehole and surrounding fractures to be always filled with the expansion cement grout and the slurry so as to realize dynamic sealing. By the method, grouting fluid can be enabled to effectively seal space inside the borehole and coal fracture areas surrounding the borehole in real time, and maximization of space and fracture sealing is realized. The mining-coal bed nearly horizontal gas extraction borehole sealing method is simple in structure, convenient to operate, low in cost and evident in effect.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV +1

Auto-feedback valve for a sleep apnea device

InactiveUS20140246024A1Small and lightLess side effectsOperating means/releasing devices for valvesElectrocardiographyExpiratory valveSurgery

A device for treating a patient suffering from obstructive sleep apnea or snoring can include an expiratory valve connected to a manifold. The expiratory valve can include a body portion including a feedback port configured to be connected to an air flow generator. The expiratory valve can include a plunger at least partially disposed in the body portion. The expiratory valve can include a pressurizing chamber positioned between an end of the plunger and an end of the expiratory valve. The pressurizing chamber can be configured to receive air from the air flow generator through the feedback port.

Owner:FRESCA MEDICAL

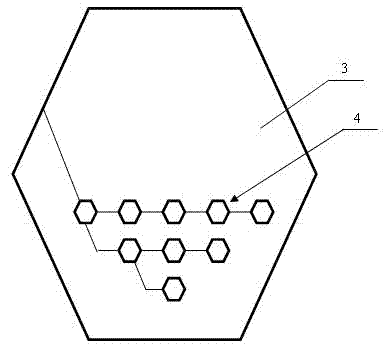

Off-road vehicle wheel free of inflation

InactiveCN104786731AImprove firmnessImprove bearing capacitySpoked wheelsHigh resiliency wheelsHoneycombBuggy vehicle

The invention discloses an off-road vehicle wheel free of inflation. The off-road vehicle wheel free of inflation is composed of a flexible rim, elastic spokes and a rigid hub. The off-road vehicle wheel free of inflation is normally installed on an off-road vehicle. When the off-road vehicle runs, the off-road vehicle wheel free of inflation bears the action of a complicated road surface, and the flexible rim and the elastic spokes generate elastic deformation under the action of external force. When the external force is eliminated, the flexible rim and the elastic spokes recover. In this way, the external force is effectively buffered, shock of the vehicle is reduced, and the bearing capacity of the vehicle is improved. Through a polyurethane interlayer of a hexagonal structure similar to a honeycomb, the firmness of the wheel is improved, a load is evenly distributed, and therefore the environmental adaptability and the safety are improved. A rubber layer is provided with rubber wheel thorns, and therefore the traction performance and the adhesion performance of the vehicle are improved. The off-road vehicle wheel free of inflation is simple in structure, convenient to replace, high in applicability and suitable for various complicated road surfaces, air leakage and burst are avoided, the shock of the vehicle can be effectively reduced, the bearing capacity and the buffering capacity of a vehicle body are improved, the environment adaptability and the safety are improved, and the traction performance and the adhesion performance of the vehicle are improved.

Owner:JILIN UNIV

Blades for a gas turbine engine with integrated sealing plate and method

Owner:PRATT & WHITNEY CANADA CORP

Mask

ActiveCN102763917AExtended service lifeEasy to wearProtective garmentRadiationSurface layerRespirator

Owner:周瓴 +1

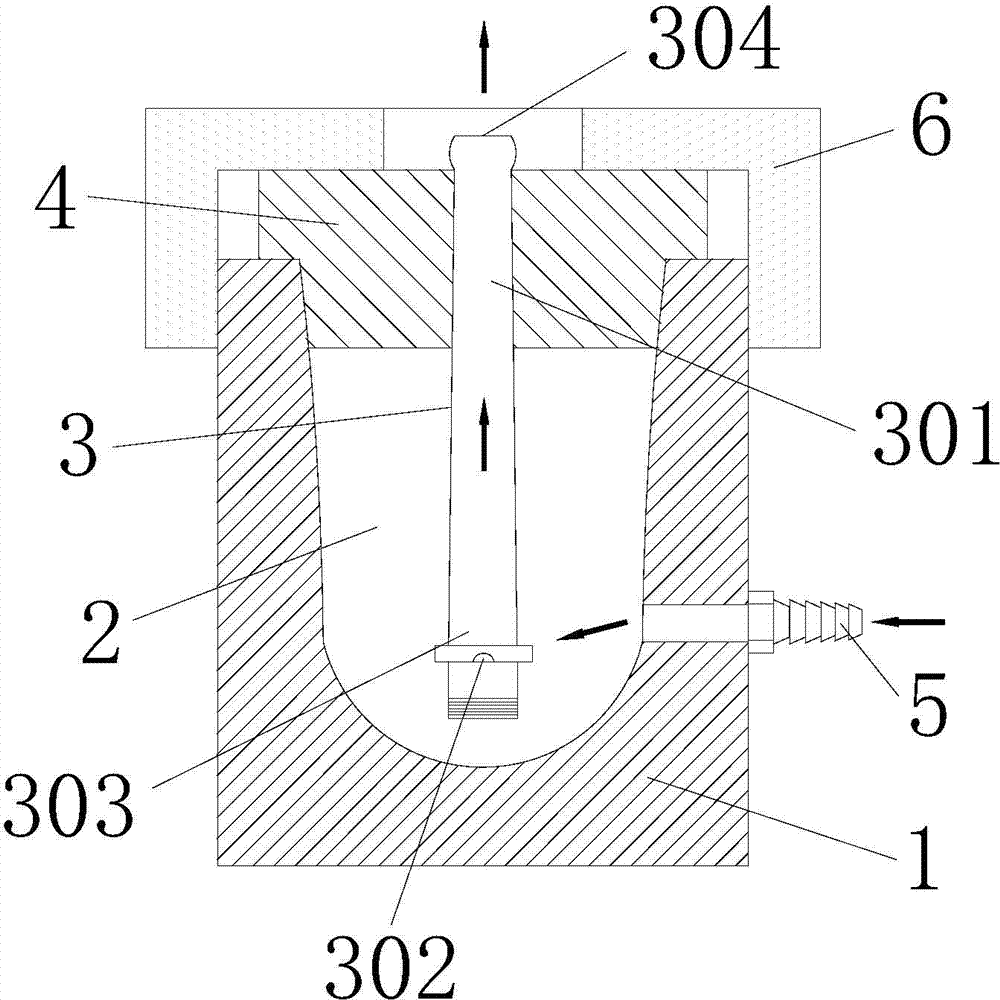

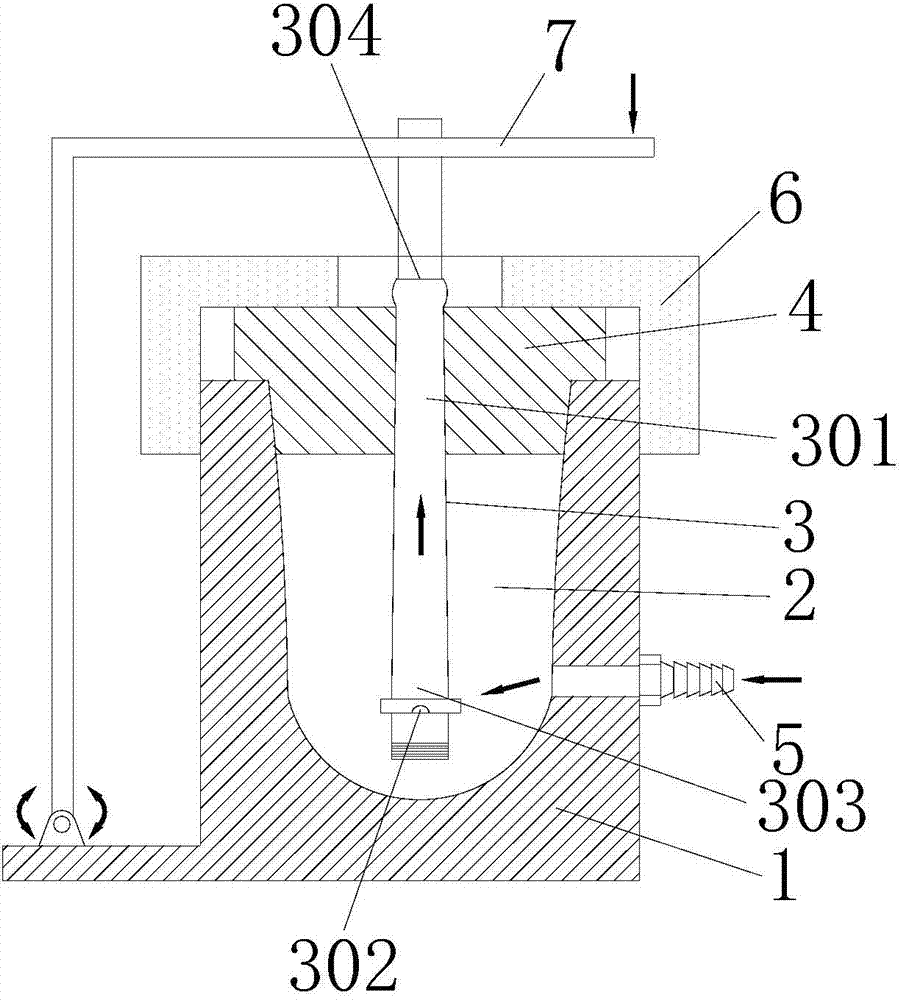

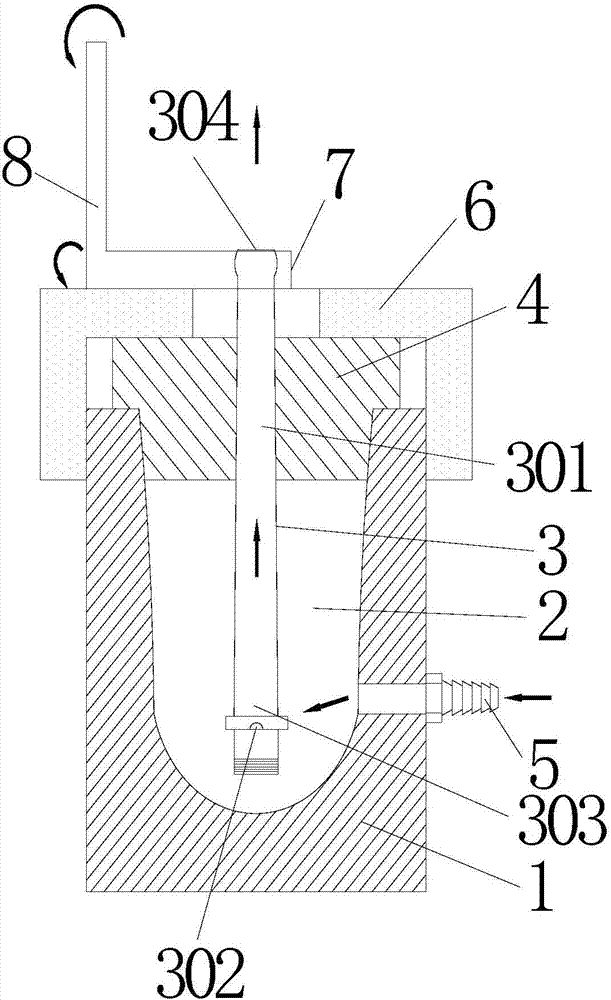

Differential motion airtight feeding electric furnace smelting device and feeding method thereof

ActiveCN102181601AShorten the lengthIncrease the feeding speedCharge manipulationElectric furnaceEngineeringHeat losses

The invention discloses a differential motion airtight feeding electric furnace smelting device and a feeding method thereof. The device comprises an electric furnace and a charging device, wherein the charging device comprises a cold receiving conveying trough and a heat conveying trough; the lower sides of the cold receiving conveying trough and the heat conveying trough are provided with an independently-controlled excitation device respectively; the outlet of the cold receiving conveying trough is provided with a conveying throat opening which is extended into the heat conveying trough; and the distance between the conveying throat opening and the bottom of the heat conveying trough is greater than or equal to the depth of the heat conveying trough. By the feeding method, shock excitation at different frequencies is applied to the two conveying troughs to realize the differential motion conveying of raw materials, so that a thicker material layer can be laid on the cold receiving conveying trough, and the material loading speed is increased; simultaneously, a shorter cold receiving conveying trough and a shorter material-conveying bottom elongated slot can be designed, so that the device and the method make project implementation convenient. In addition, due to the adoption of the throat opening and a sealed door structure, the possibility of material blocking and the air leakage rate are greatly reduced, and the device has low heat loss and a good dedusting effect, and is high-efficient, energy-saving and environment-friendly during smelting.

Owner:CISDI ENG CO LTD

Flow fixture for air cooling flow test on hollow blades

InactiveCN104849014AReduce production delivery cycleReduce air leakageAerodynamic testingLevitationEngineering

The present invention discloses a flow fixture for the air cooling flow test on hollow blades, which comprises a fixture body with an opening on one side thereof. The fixture body is provided with a fixture inner cavity used for the levitation of a hollow blade and communicated with the outside through the opening, a seal gasket covered onto the outer surface of he hollow blade and closed inside the opening of the fixture inner cavity, and a fixture air inlet for being connected with a flow tester and feeding the cooling air into the fixture inner cavity. The tenon air inlet of the hollow blade and the lower margin plate of the hollow blade are positioned in the fixture inner cavity. The shrouded air outlet of the hollow blade is positioned inside the fixture inner cavity to be communicated with the outside, so that a flow channel for the cooling air is formed, wherein the cooling air flows into the flow channel through the fixture air inlet and flows out of the flow channel through the shrouded air outlet. In this way, the stability of measured results is ensured and the floating error of measured results on a single part during multiple tests is almost zero. Therefore, whether the blade is qualified or not can be quickly tested. The production and delivery period of the blade is shortened.

Owner:CHINA HANGFA SOUTH IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com