Patents

Literature

70 results about "Fracture control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

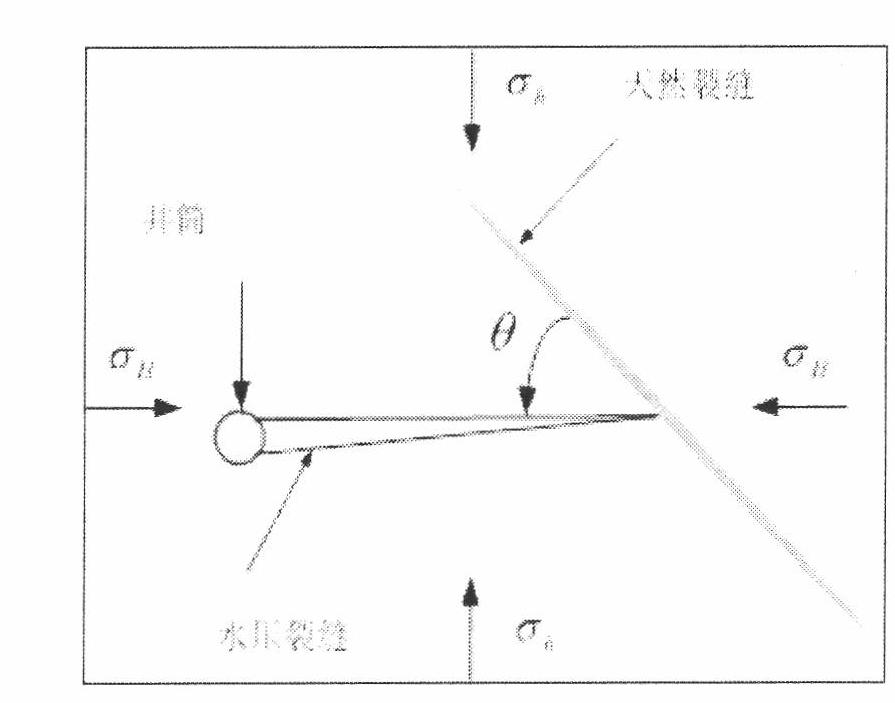

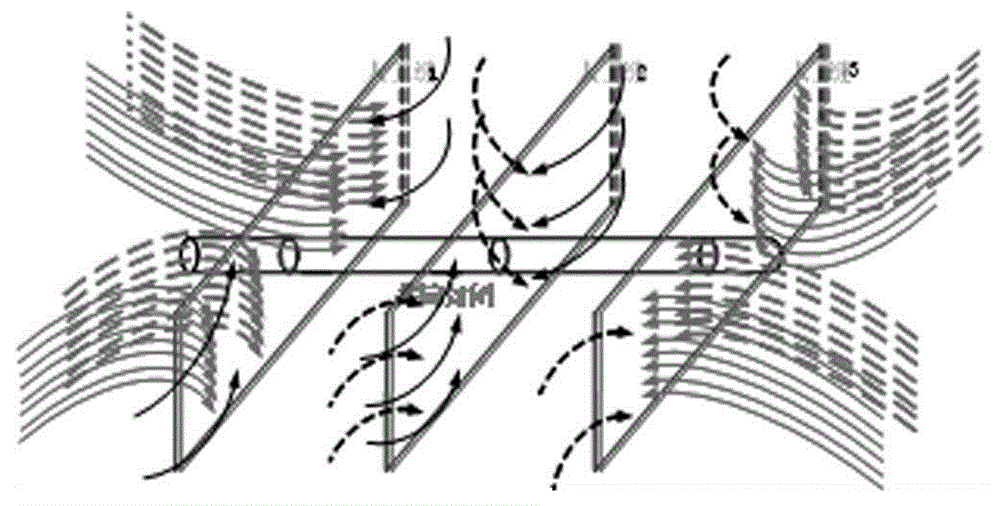

Non-planar network fracturing control method for fractured reservoir

The invention discloses a non-planar network fracturing construction control method for a fractured reservoir, which includes the step: firstly, performing pre-fracturing evaluation by (1) obtaining the intrinsic fracture development degree and directions according to FMI (formation micro-scanner image) logging and conventional logging data, (2) determining man-made fracture directions, (3) judging the angle relation between man-made fractures and intrinsic fractures, and (4) judging the non-planar network fracturing formation adequacy; secondly, establishing a stress field inversion constrained optimization model by utilizing a numerical value inversion method combining multi-well constrained optimization and finite elements so as to obtain numerical simulation of three-dimensional geostress states and rock mechanical parameters of a fractured reservoir area; thirdly, selecting corresponding construction parameters, and fracturing strata so as to force the intrinsic fractures and holes to open as large as possible; and fourthly, according to the opened equivalent number and openness of the intrinsic fractures explained by test fracturing, selecting grain sizes and use amount of propping agents matched with the intrinsic fractures or the holes, and leading fracturing fluid carrying the propping agents to enter the intrinsic fractures or the holes.

Owner:ORIENT BAOLIN TECH DEV BEIJING

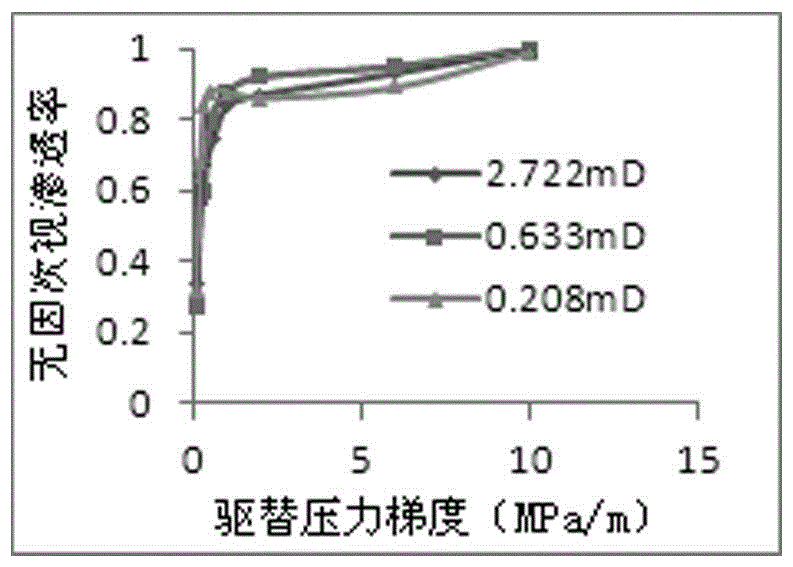

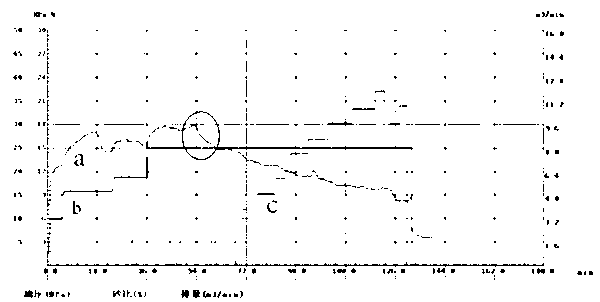

Method for calculating staged fracturing productivity of compact reservoir horizontal well

ActiveCN105840187ACalculations are reliableGood application effectInformaticsSpecial data processing applicationsBottom hole pressureMultiple fracture

The invention relates to the technical field of oil fracturing, in particular to a method for calculating the staged fracturing productivity of a compact reservoir horizontal well. The method is characterized by including the steps of firstly, dividing a reservoir infiltration area into four parts; secondly, obtaining the equivalent hole diameter of each fracture; thirdly, obtaining the yield of each fracture during multiple fracture disturbance; fourthly, coupling the yield of each fracture with the hydraulic pressure drop flow model in a horizontal wellbore to obtain a group of bottom hole pressure, iteratively solving until the bottom hole pressure difference of the previous step and the next step is smaller than tolerance, namely convergence, and taking the determined group of yield as the fracture-control yield of each fracture and the sum of the fracture-control yield of the fractures as the total yield of the horizontal well. The method is real and reliable in calculation result and good in application effect.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

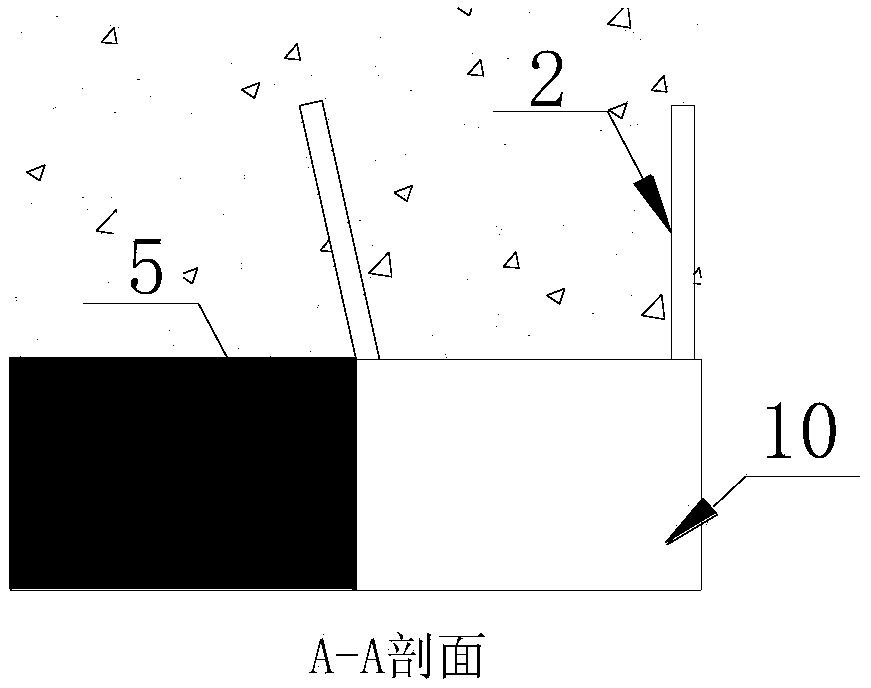

Hydraulic fracturing control method of cut tight roof/top coal

ActiveCN103527198AFacilitate orientationReduce air leakageUnderground miningSurface miningFracture controlCoal

The invention relates to a hydraulic fracturing control method of cut tight roof / top coal. The method comprises the following steps: constructing two rows of fracturing drill holes at intervals in the roof / top coal above an open-off cut by a drilling machine to a set depth, wherein one row of fracturing drill holes is close to a main upper of the open-off cut while the other row is close to an auxiliary upper of the open-off cut; constructing a row of anchor cable drill holes to the roof / top coal at the left and right ends of the open-off cut, respectively; or constructing rows of fracturing drill holes in different directions in a measure lane of the roof above the open-off cut; carrying out hydraulic fracturing on the drill holes, so that one or more cracks are generated on a rock body in a given plane to split the rock stratum to blocks or layers in certain shapes and sizes so as to damage the integrity of the rock and reduce the strength of the rock. Therefore, pressure of the roof in a large area and sudden extrusion of accumulated gases in a worked out section in an early mining stage on a coal face are prevented, air leak on the coal face is reduced, and the safety is ensured. Meanwhile, caving of top coal can be improved. The method is simple, convenient to construct, safe and reliable and good in effect.

Owner:CHINA UNIV OF MINING & TECH

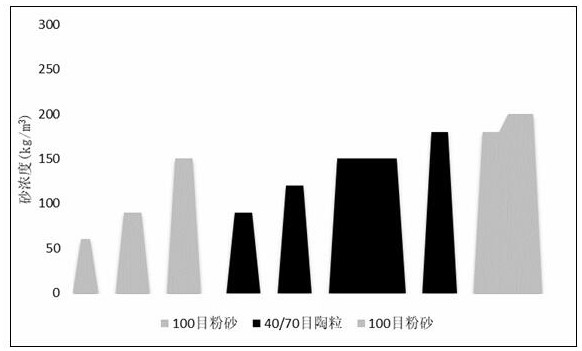

Multi-crack fracturing control method for medium-depth coal beds

ActiveCN103244097AJoin smoothlyOvercoming poor sand-carrying abilityFluid removalFracturing fluidHigh pressure

The invention relates to an oil extraction process for oil fields, in particular to a multi-crack fracturing control method for medium-depth coal beds. The method comprises six steps of 1) preparation of a filtrate reduction fracturing fluid; 2) utilization of a high-pressure pump set; 3) utilization of a high-pressure pump set; 4) utilization of a high-pressure pump set; 5) phased utilization of a prepad liquid; and 6) ending of work. According to the multi-crack fracturing control method, prior conventional active-water sand fracturing method is changed through theoretical analysis and on-site verification, and the filtrate reduction fracturing fluid, the prepad liquid variable displacement technology, a multi-stage particle size slug technology, a reasonable mortar-sand ratio raising technology and the like are used, accordingly, difficulties such as large filter losses, poor sand carrying capabilities and excess leak-off of the fracturing liquid and high construction pressure during opening of natural cracks are overcome. Multi-crack is effectively prevented and treated through the means of the filtrate reduction fracturing fluid, and the prepad liquid variable displacement technology and the multi-stage particle size slug technology, so that the construction pressure is reduced, smooth adding of a propping agent is guaranteed, and the fracturing construction success rate is improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

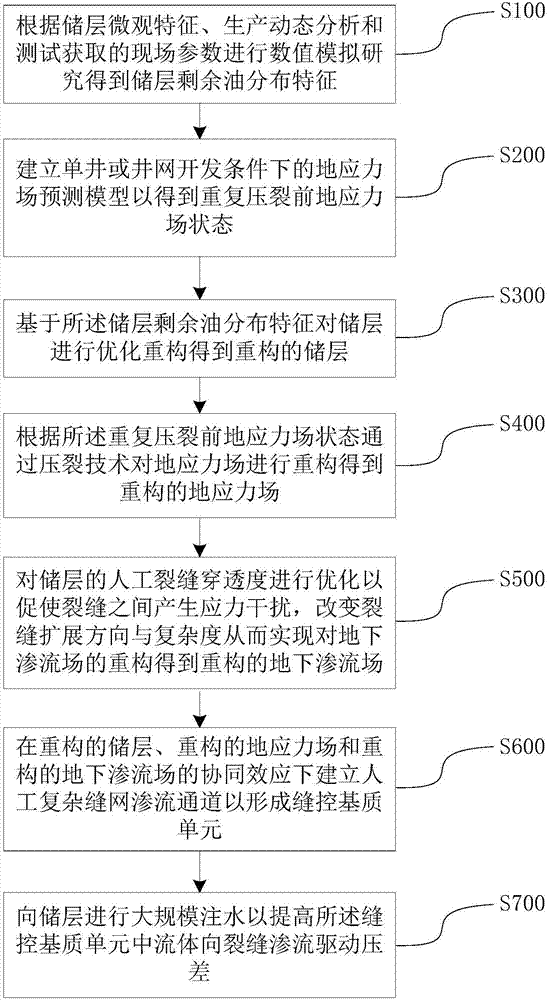

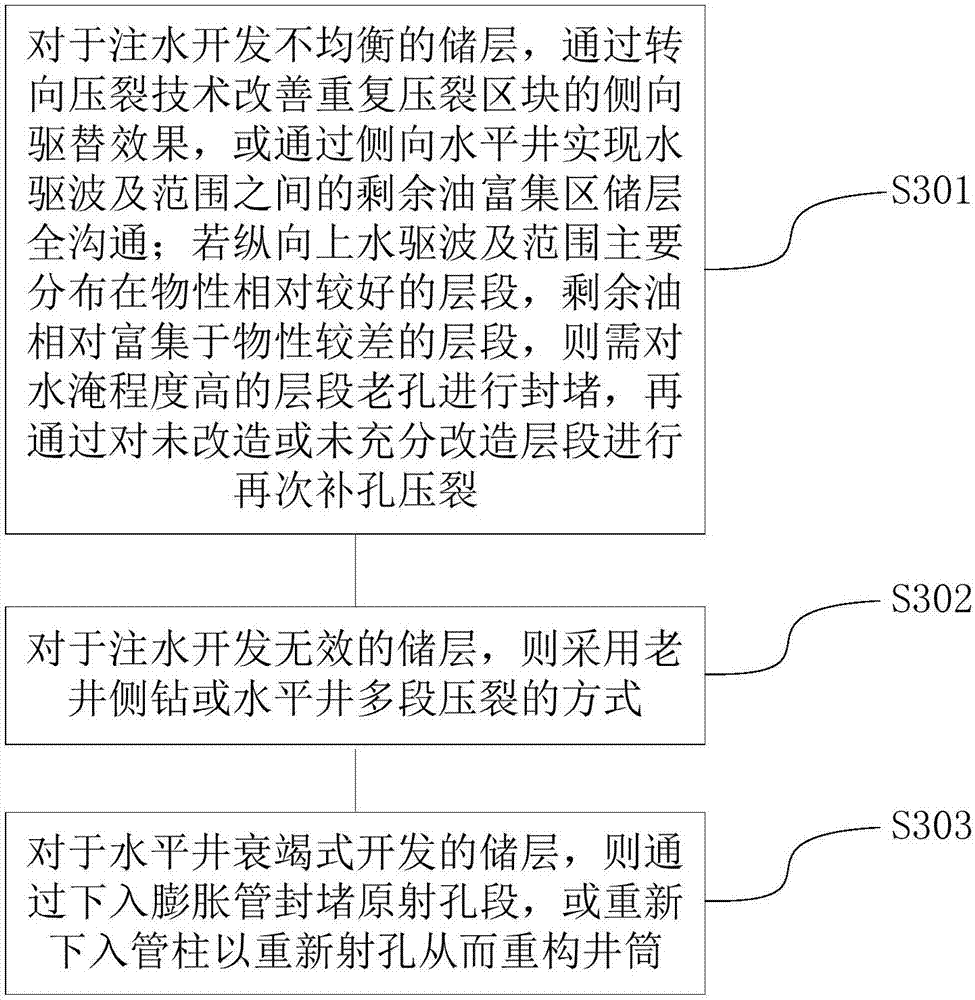

Repeated fracturing method for low-yielding and low-efficiency old oil well

ActiveCN107191169AGood effectImprove driving abilityFluid removalDesign optimisation/simulationRepeated fracturesOil distribution

The invention discloses a repeated fracturing method for a low-yielding and low-efficiency old oil well, and relates to the technical field of repeated fracturing and production-increasing. The method comprises the steps that numerical simulation is conducted to obtain the reservoir remaining oil distribution characteristic according to the reservoir microscopic characteristic, the production performance analysis and the site parameter obtained by testing; a crustal stress field prediction model is established under the development condition of a single well or a well net to obtain the crustal stress field state before repeated fracturing is conducted; a reconstructed reservoir is obtained based on the reservoir remaining oil distribution characteristic; a reconstructed crustal stress field is obtained according to the crustal stress field state before repeated fracturing is conducted; the penetration of artificial fractures of the reservoir is optimized to promote generation of the stress interference between the fractures, and the spreading directions and the complexity of the fractures are changed to obtain a reconstructed underground seepage field; artificial complex fracture net seepage channels are established under the reconstructed reservoir, the reconstructed crustal stress field and the reconstructed underground seepage field to form a fracture control matrix unit; and full-scale water injection is conducted on the reservoir to improve the driving pressure difference of seepage of fluid in the fracture control matrix unit to the fractures.

Owner:PETROCHINA CO LTD

Directional fracturing device and method for underground drilling

ActiveCN110344805AAvoid mindless fracturingImprove fracturing precisionFluid removalGas removalEngineeringFracture control

The invention discloses a directional fracturing device and method for underground drilling. The device comprises a plurality of sections of casing pipes and fracturing pipes which are connected end to end, wherein the casing pipes are provided with directional fracturing control devices, and each directional fracturing control device comprises a screw hole with an adjustable angle and a one-way destructive conical screw matched with the screw hole; and the casing pipes are connected through stroke-controllable threaded connection assemblies or flange connection assemblies, and alignment scribed lines corresponding to the positions of the directional fracturing control devices in the circumferential direction are arranged on the casing pipes, so that the alignment scribed lines and the directional fracturing devices are always aligned. The method is mainly characterized in that after a hole is drilled in a roadway, the casing pipes are sent into the drilled hole, and the annular spacebetween the casing pipes and the drilled hole is sealed by grouting; and fracturing pipes provided with front packers and rear packers are sent into the casing pipes, and after entering the casing pipes from the fracturing pipes, the pressurized fluid flushes the casing pipes to fracture the coal rock mass when the pressure reaches the maximum bearing pressure of the directional fracturing controldevices. According to the directional fracturing device and method for underground drilling, provided by the invention, the fracturing direction is controllable, and various directional expansion forms can be realized.

Owner:CHINA UNIV OF MINING & TECH

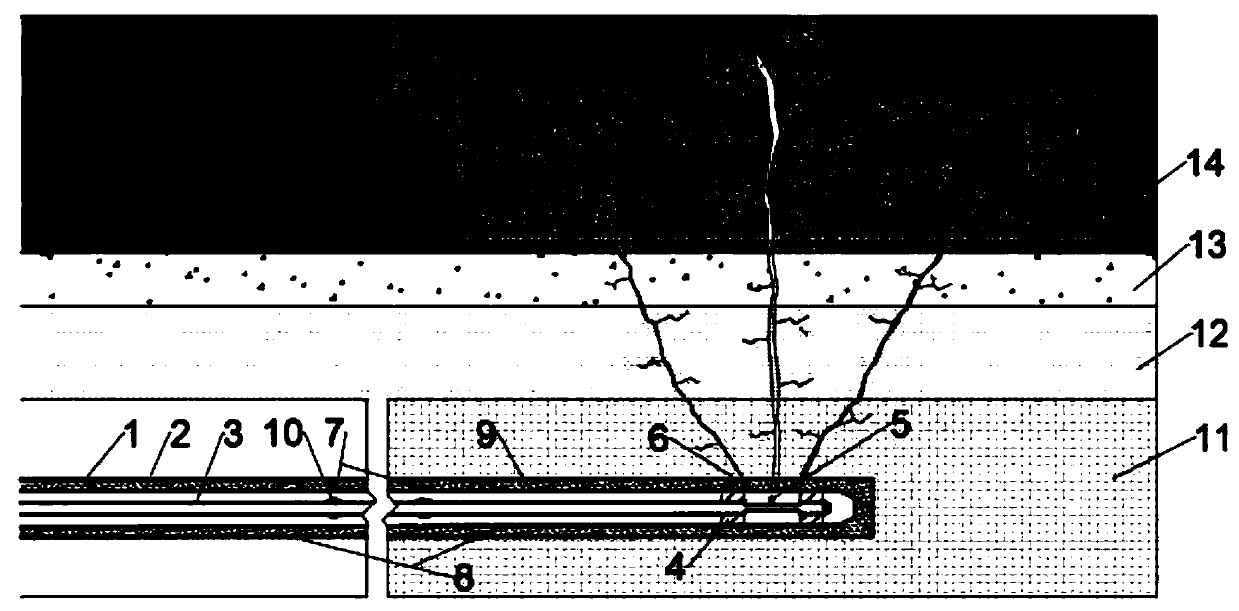

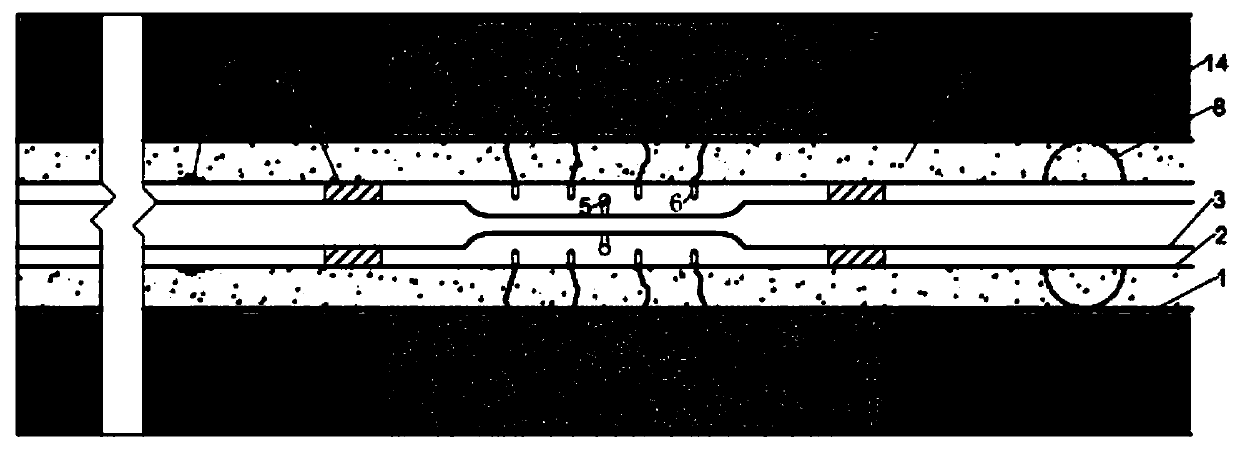

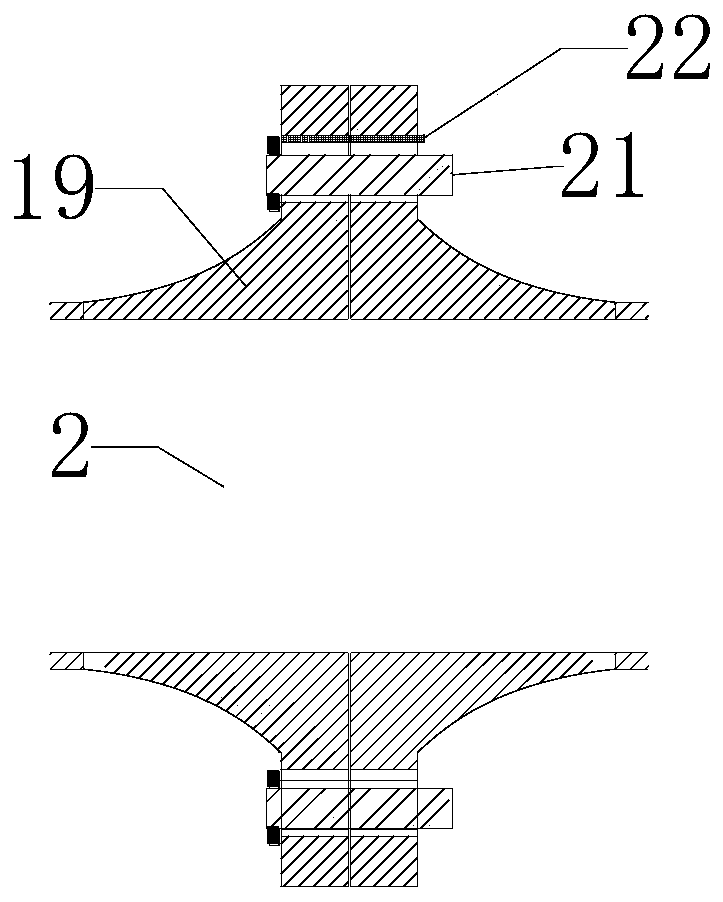

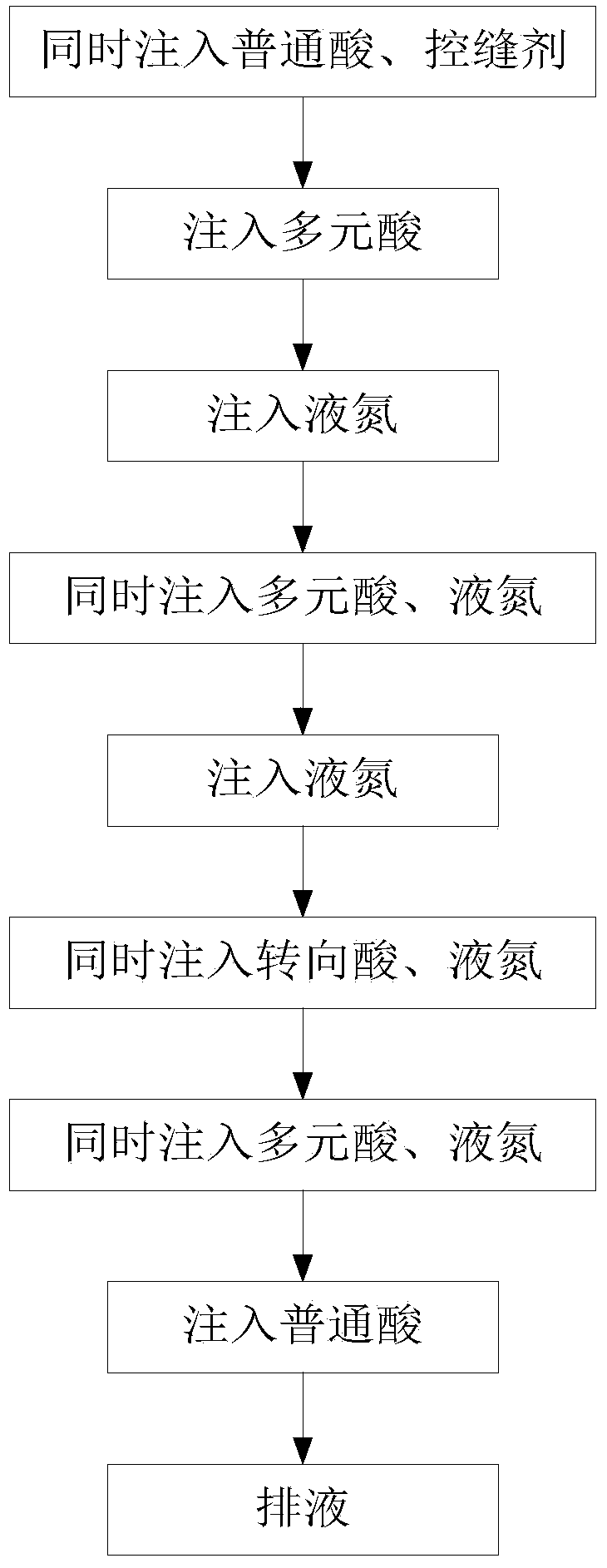

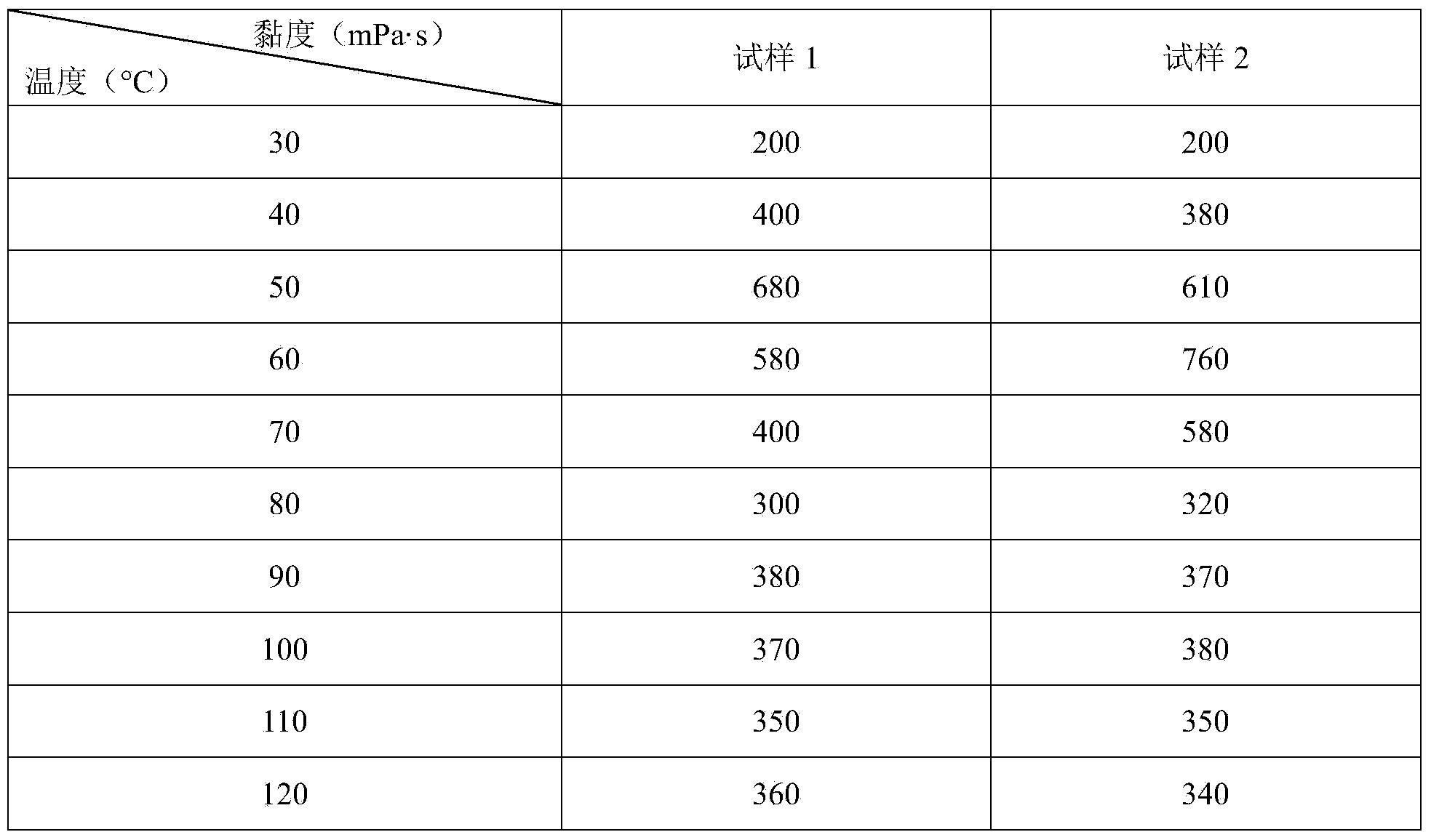

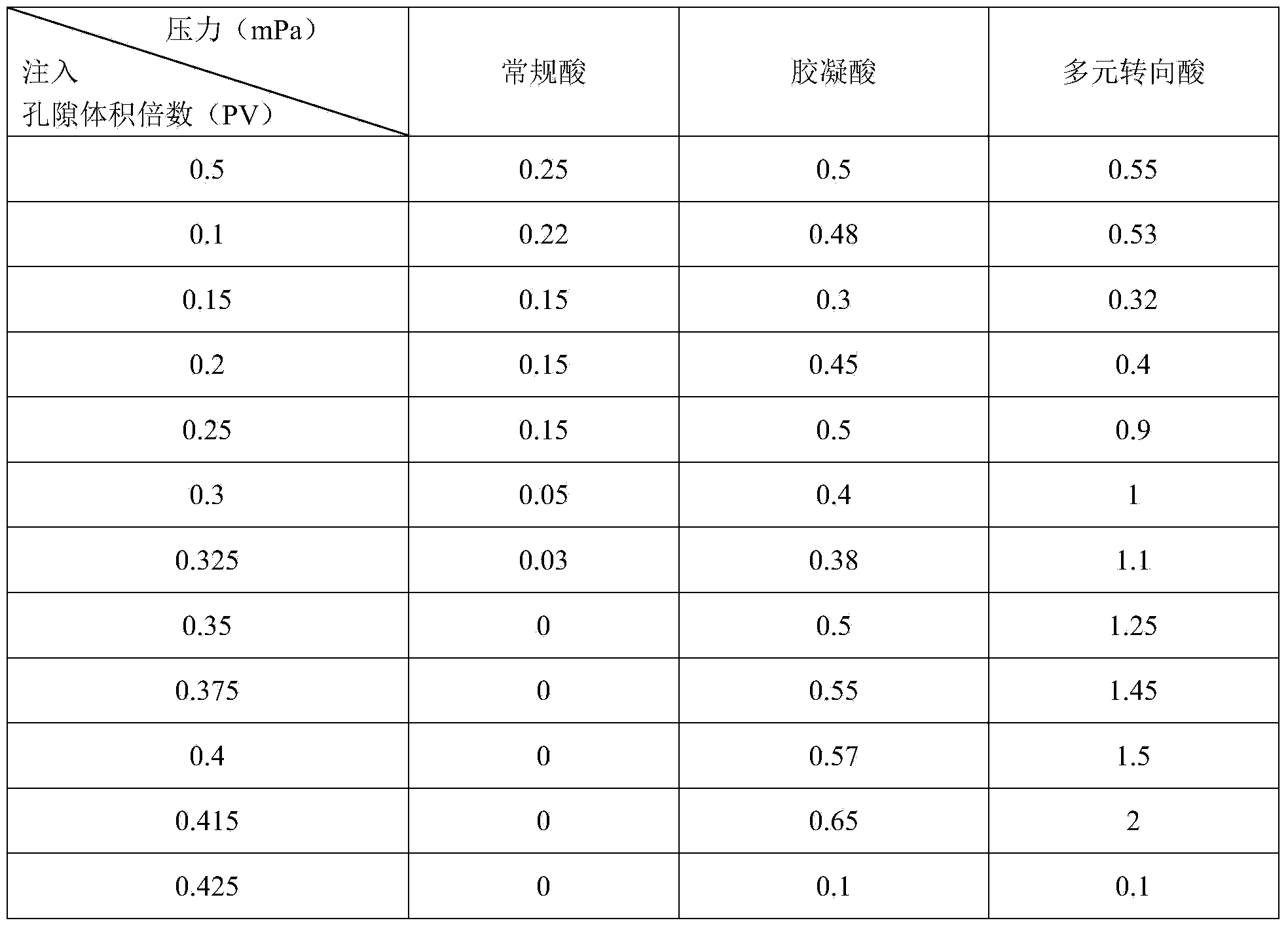

Fracture height-adjustable acid fracturing method adopting polyatomic acid and steering acid

InactiveCN103953324AIncrease effective lengthImprove diversion capacityFluid removalDrilling compositionAcid fracturingFracture control

The invention discloses a fracture height-adjustable acid fracturing method adopting polyatomic acid and steering acid. The method comprises the steps: firstly preparing the polyatomic acid, the steering acid and common acid, and then simultaneously injecting a fracture control agent and the common acid into a target stratum of an oil-gas well; then injecting the polyatomic acid; injecting liquid nitrogen; injecting the polyatomic acid and the liquid nitrogen at the same time; injecting the liquid nitrogen again; injecting the liquid nitrogen and the steering acid at the same time; injecting the polyatomic acid and the liquid nitrogen at the same time again; injecting the common acid; finally discharging all liquid injected into a wellhead into a liquid discharging basin. According to the method disclosed by the invention, the polyatomic acid is used for preparing a long slit, the steering acid is used for dredging a micro crack, and the liquid nitrogen supplements the energy of the stratum; the polyatomic acid, the steering acid and the liquid nitrogen are injected into the stratum in a section plugging manner, so that the length of the slit is increased, the dredging capacity of the micro crack is improved, and quick liquid discharging is enhanced.

Owner:惠建龙

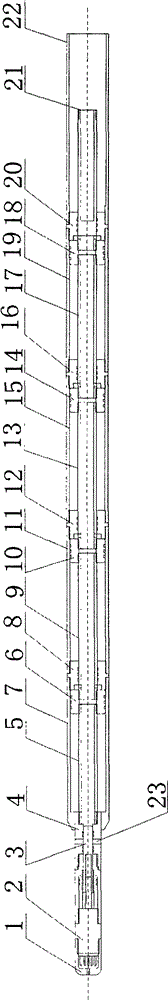

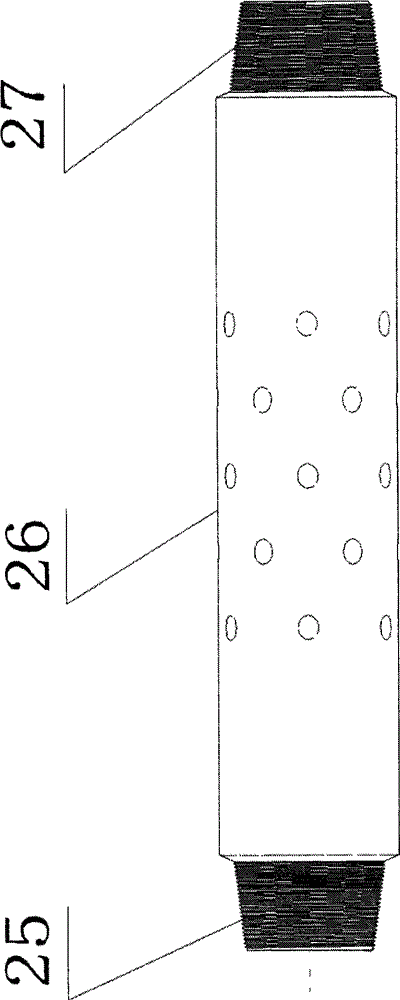

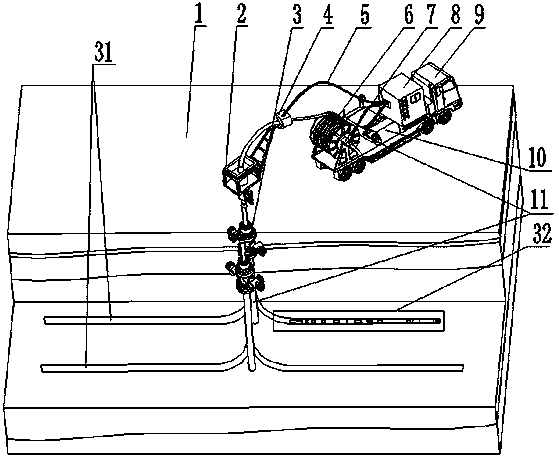

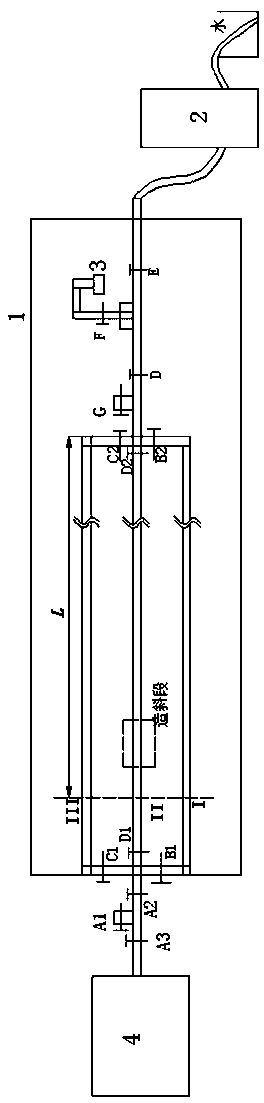

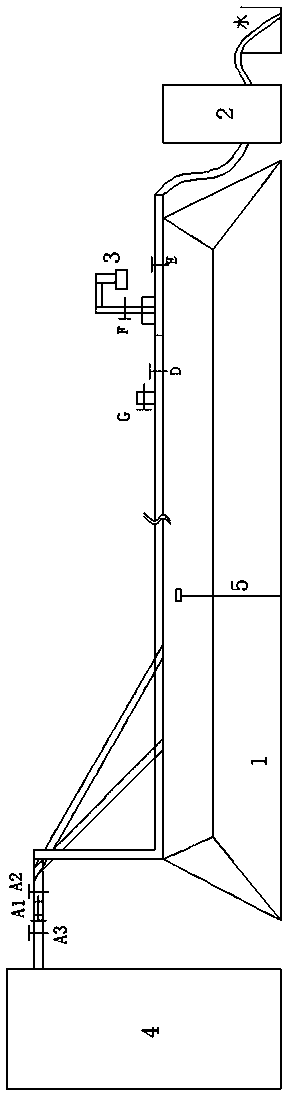

Feeding-controlling full-bore sliding sleeve sectional fracturing tube column

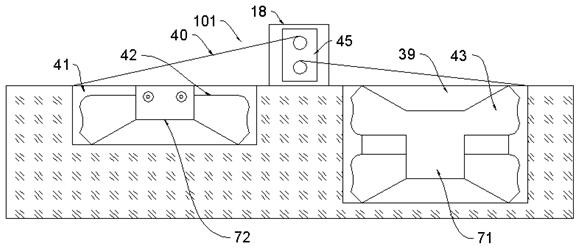

The invention discloses a feeding-controlling full-bore sliding sleeve sectional fracturing tube column, and aims to solve the problems in the prior art that great danger can be caused, the process is complex, the operation cost is high and the like if an explosive powder column is taken as power. The feeding-controlling full-bore sliding sleeve sectional fracturing tube column (see the figure 4) comprises two parts, namely, an underground part and a fracturing control part, wherein the underground part consists of a casing pipe 42, a timing sliding sleeve 48 and a plurality of feeding-controlling sliding sleeves; the number 49 refers to a fractured interval; the fracturing control part consists of a cable 41, a cable head 43, a positioning instrument 44, a cable hydraulic feeding tool 45 and high-strength hydrolysis bridge plugs 47.

Owner:陈爱民

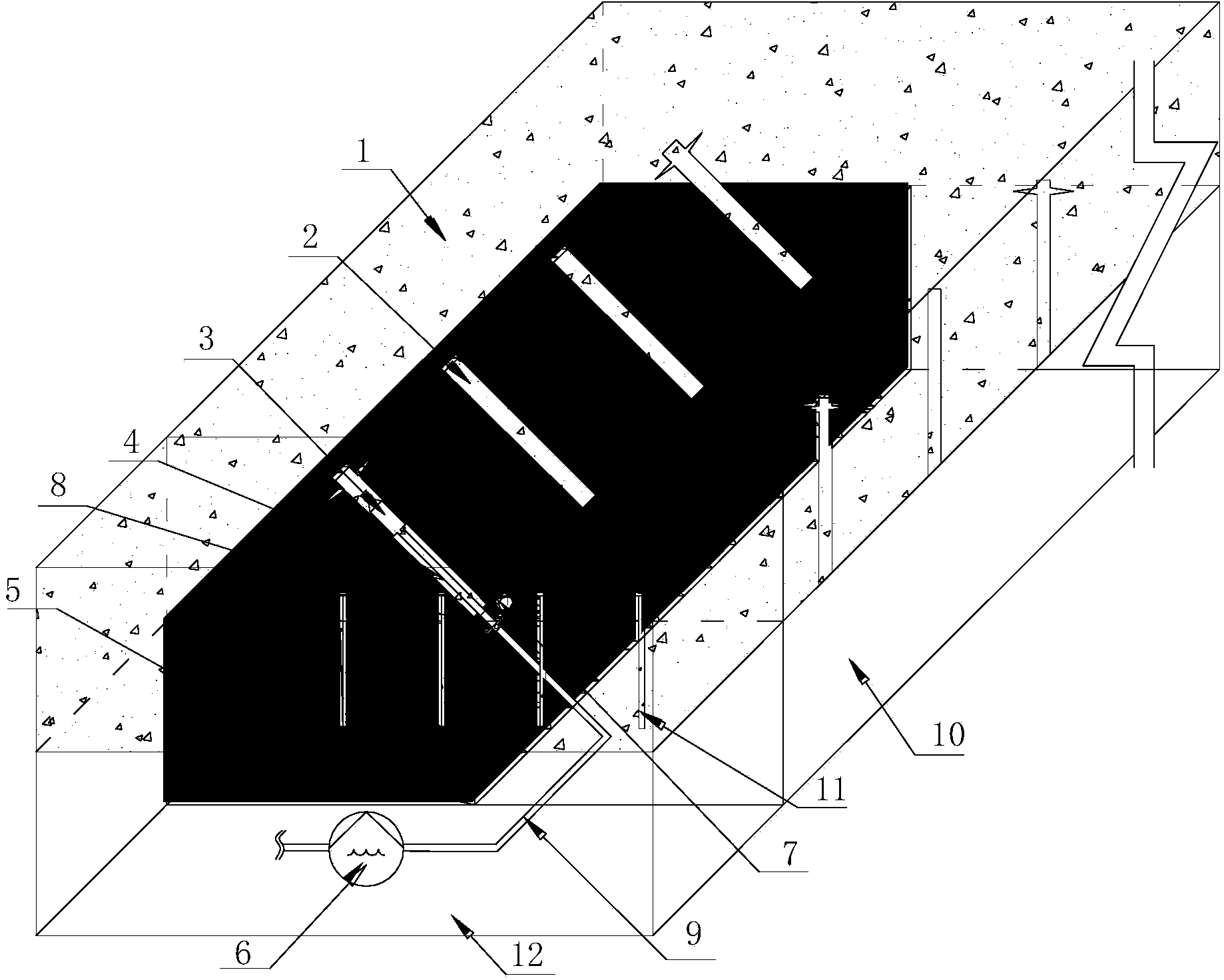

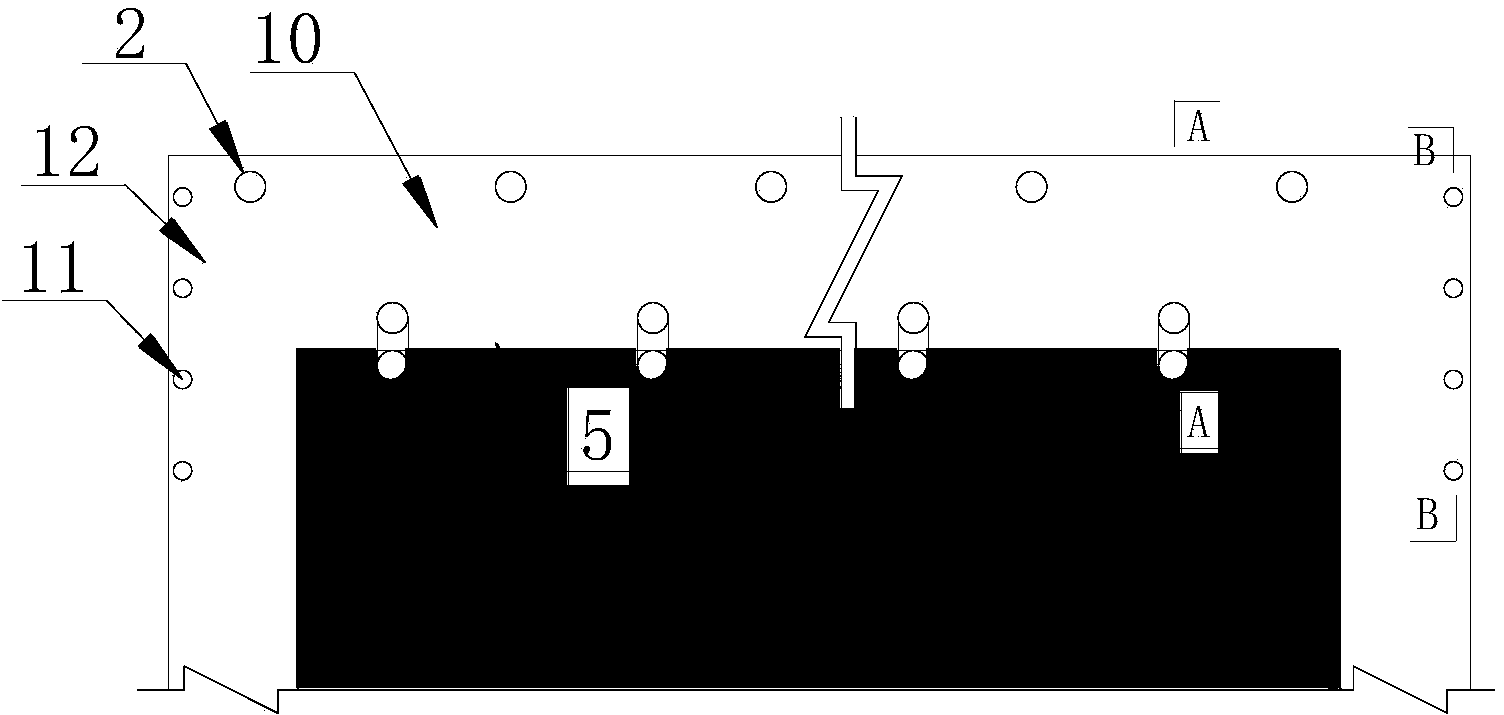

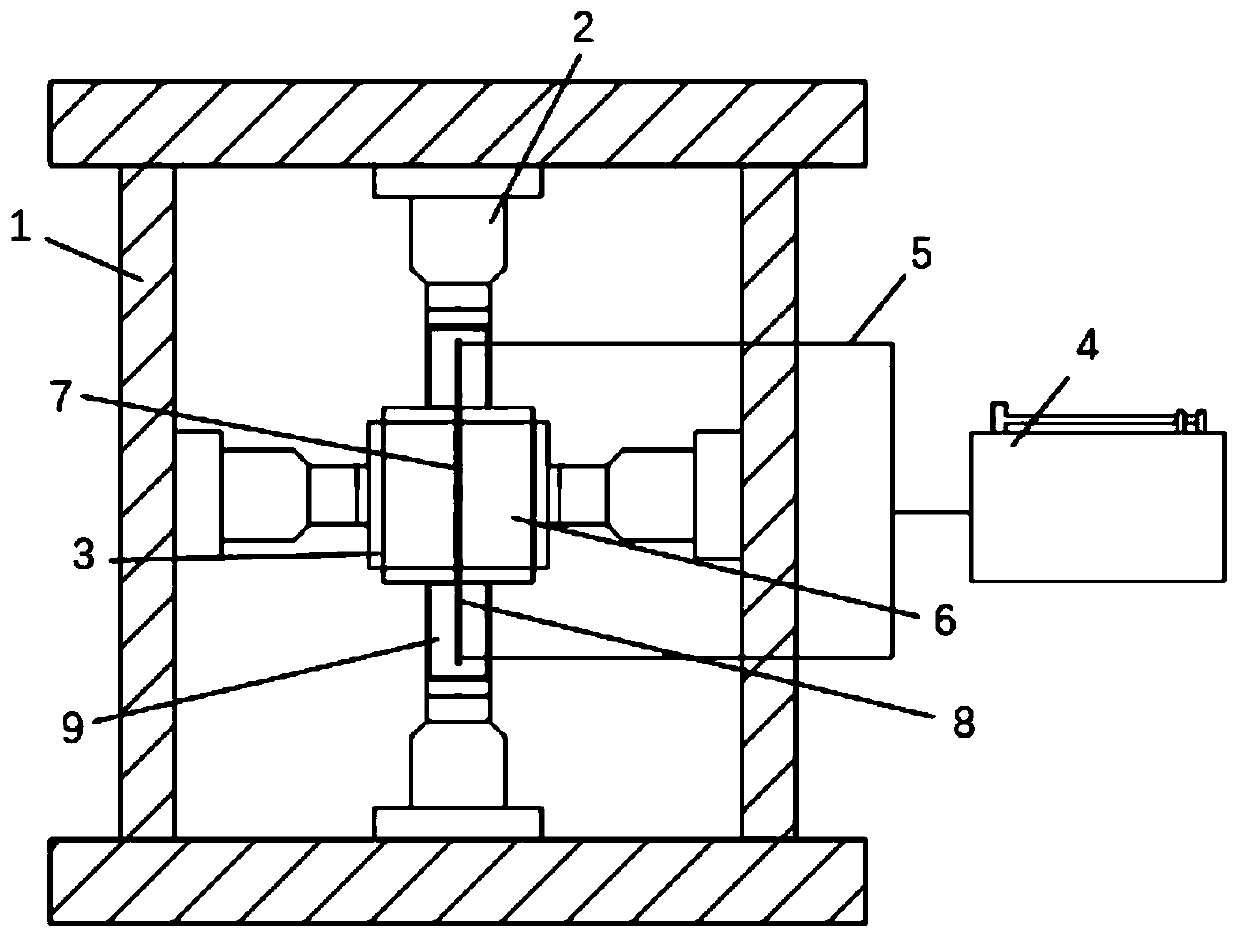

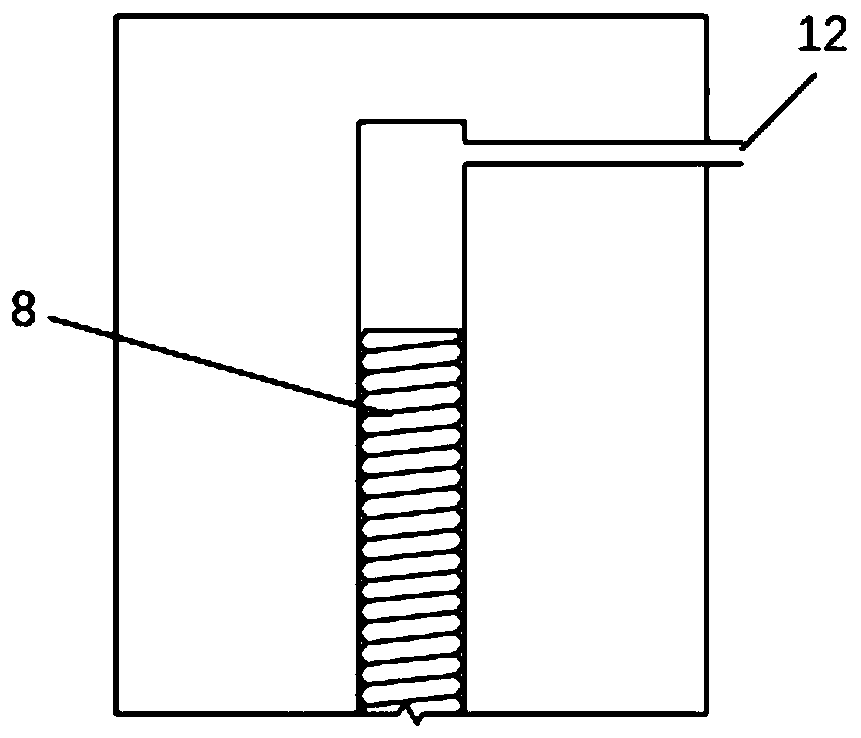

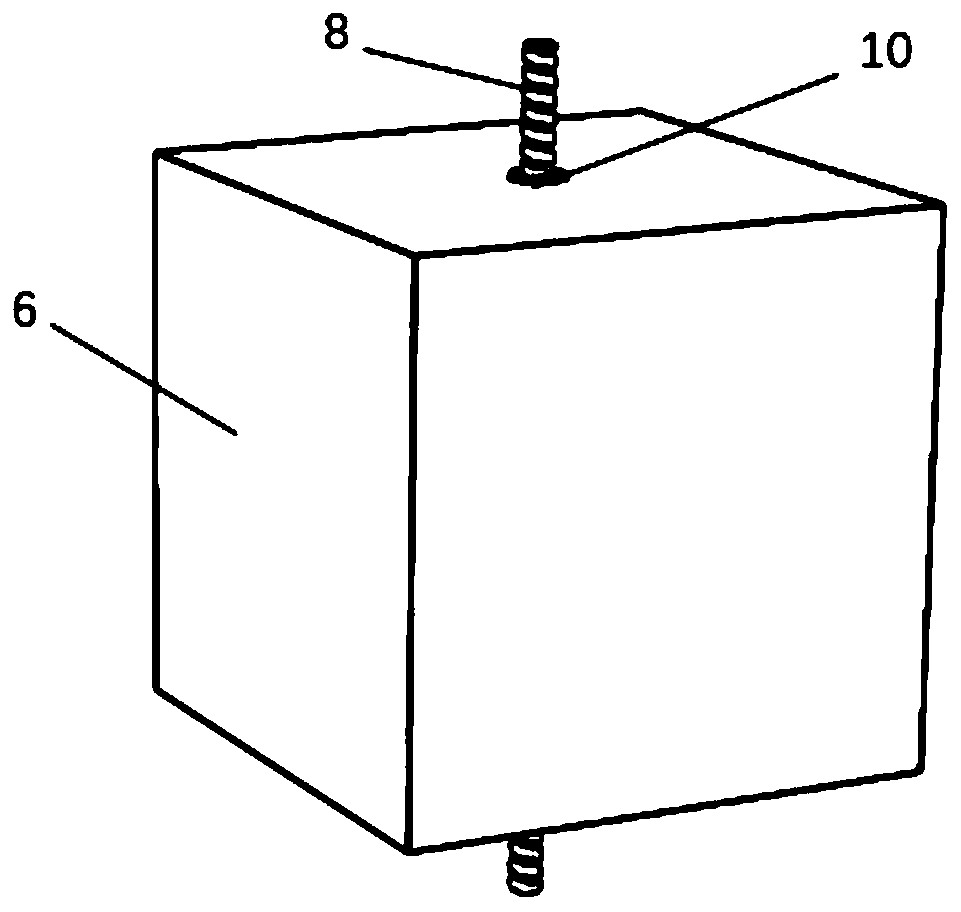

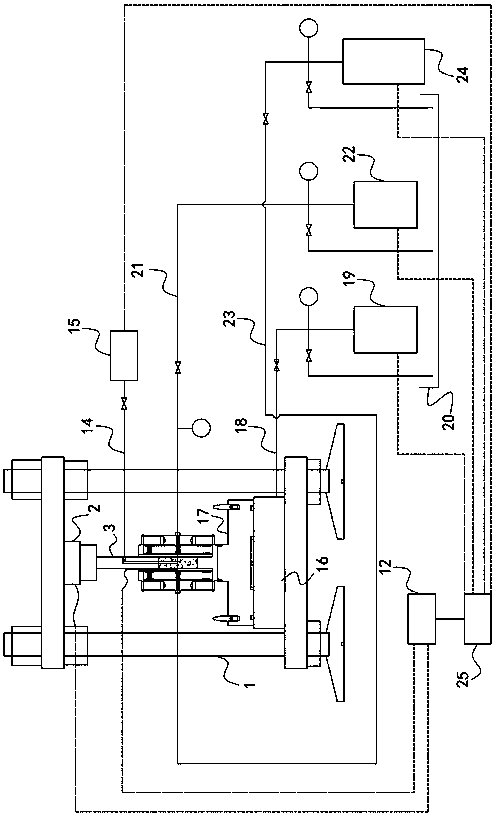

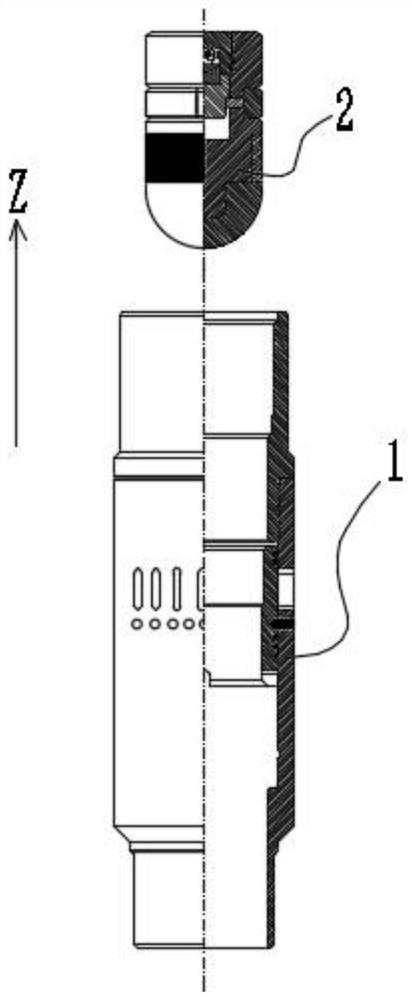

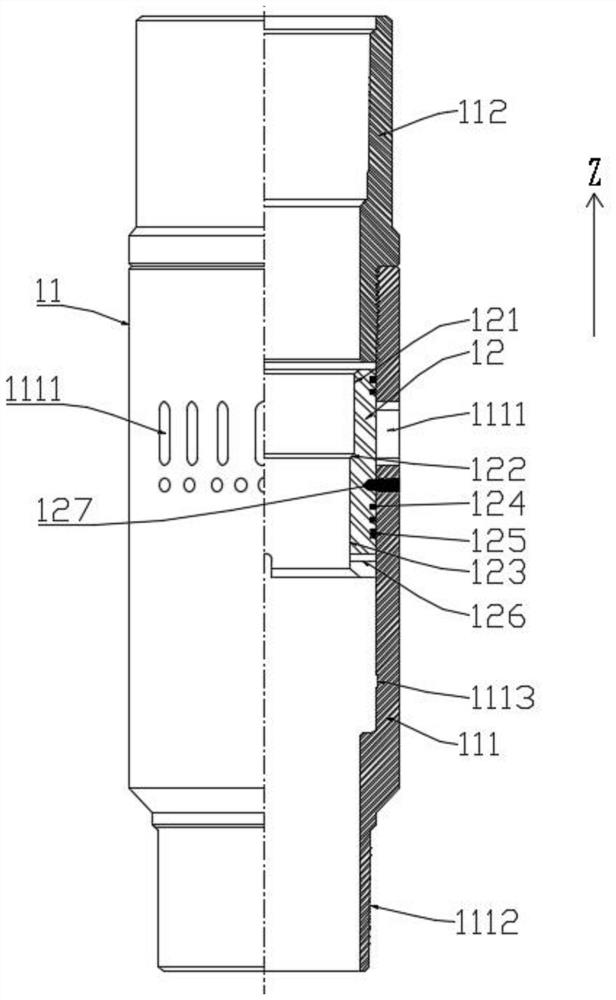

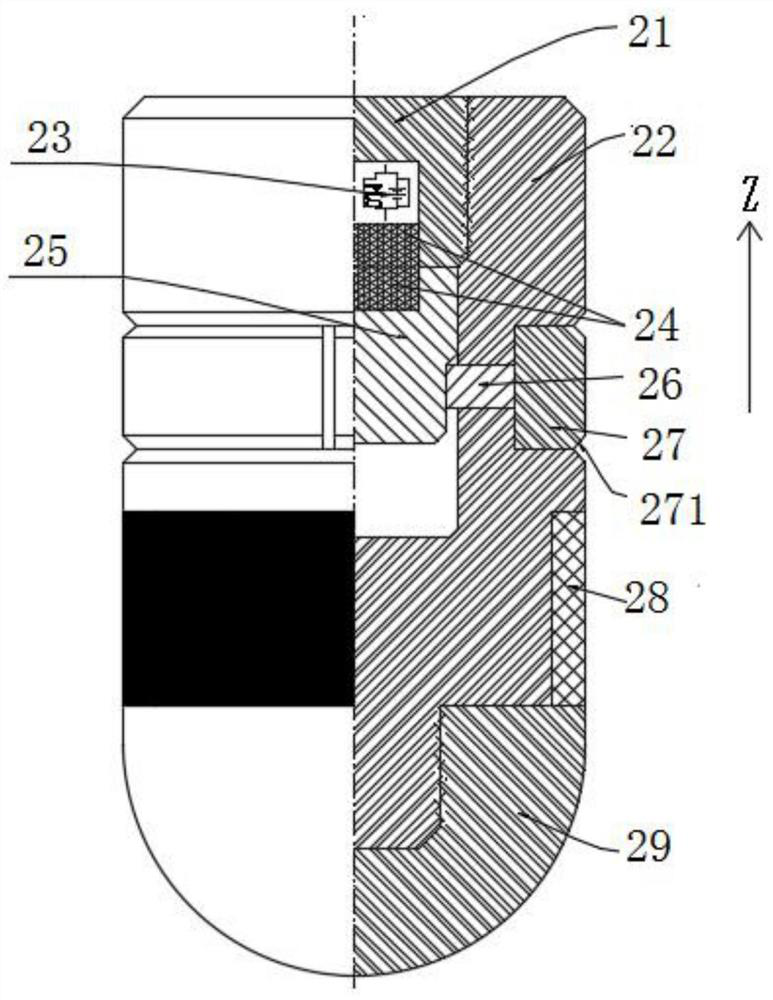

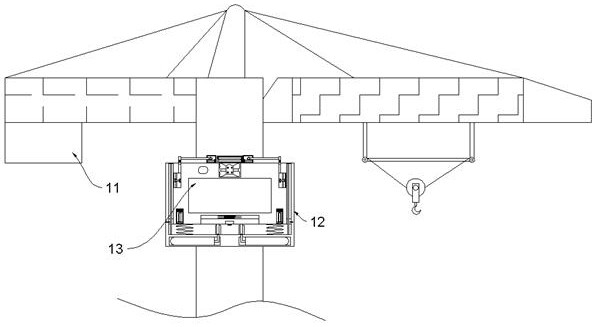

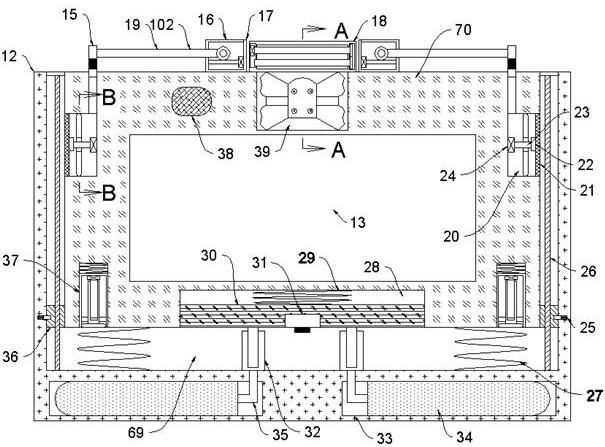

Lab simulation testing device for staged fracturing of horizontal well, and operation method for same

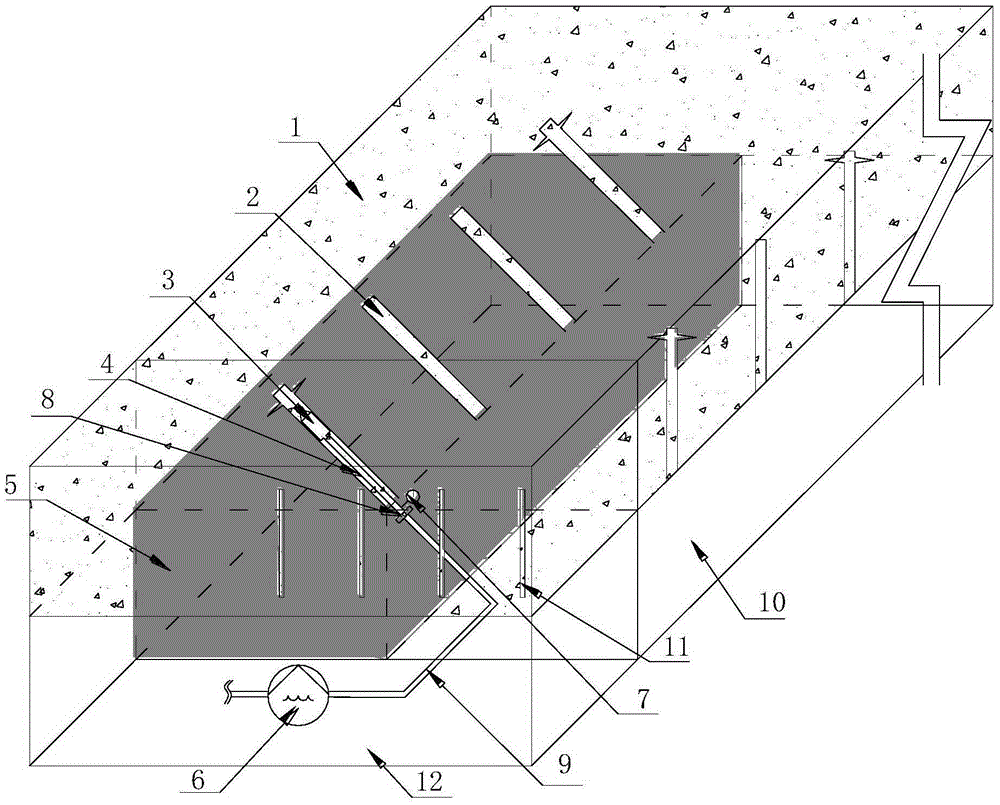

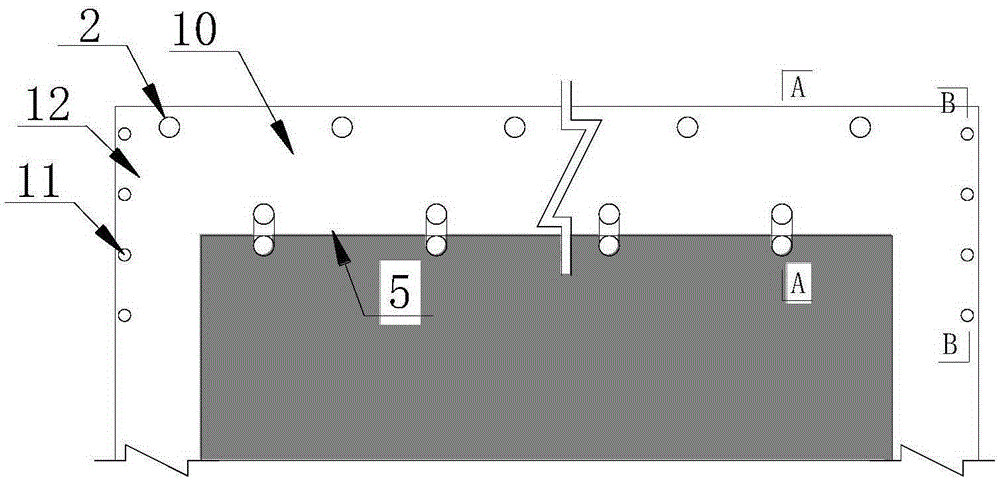

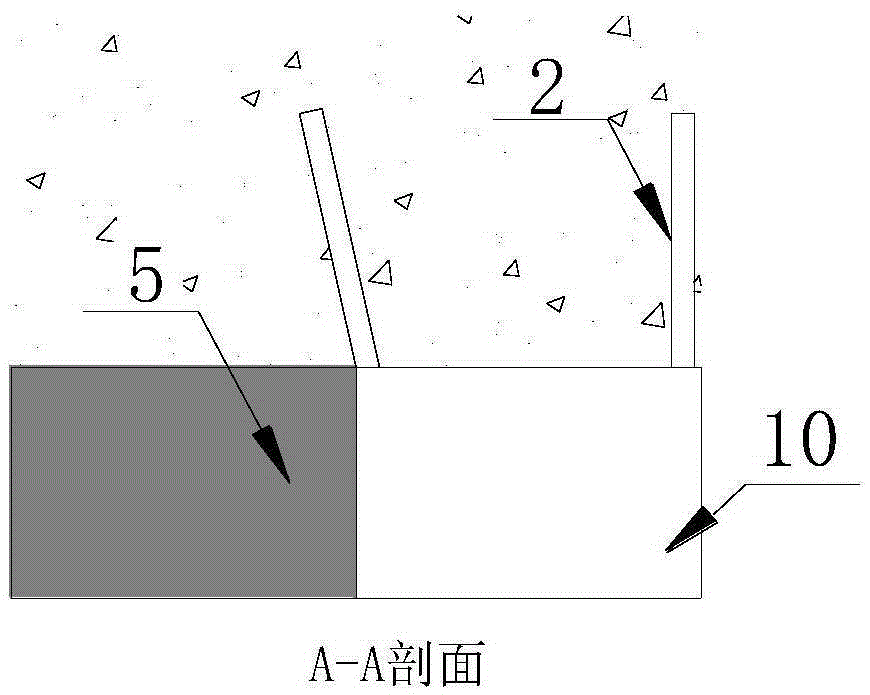

ActiveCN111119831AStrong targetingIncrease flexibilityFluid removalGeothermal energy generationAxial pressureHorizontal wells

The invention discloses a lab simulation testing device for staged fracturing of a horizontal well, and an operation method for the same and solves the problems of existing hydraulic fracturing tests,that operations are complicated, flexibility is low, and accuracy is not high; the structure is simple and operations are convenient; testing cost can be effectively reduced; testing efficiency can be increased; and testing conditions are provided for research on crack expansion mechanisms of staged fracturing of the horizontal well. The technical solution is characterized in that the device comprises a tri-axial loading unit, a fracturing control unit and a hydraulic loading unit, wherein the tri-axial loading unit comprises a testing frame and a loading cylinder which is installed on the inner side of the testing frame and can provide three-directional axial pressures; the fracturing control unit comprises a shaft sleeve, a liquid injection screw rod, a pressure bearing plate and a connecting base; two ends of the shaft sleeve are in threaded connection to a liquid injection screw rod respectively, and the liquid injection screw rods penetrate the pressure bearing plate and are connected to the connecting base to form a liquid injection channel; and the hydraulic loading unit can pump a fracturing liquid into the simulation horizontal well.

Owner:SHANDONG UNIV

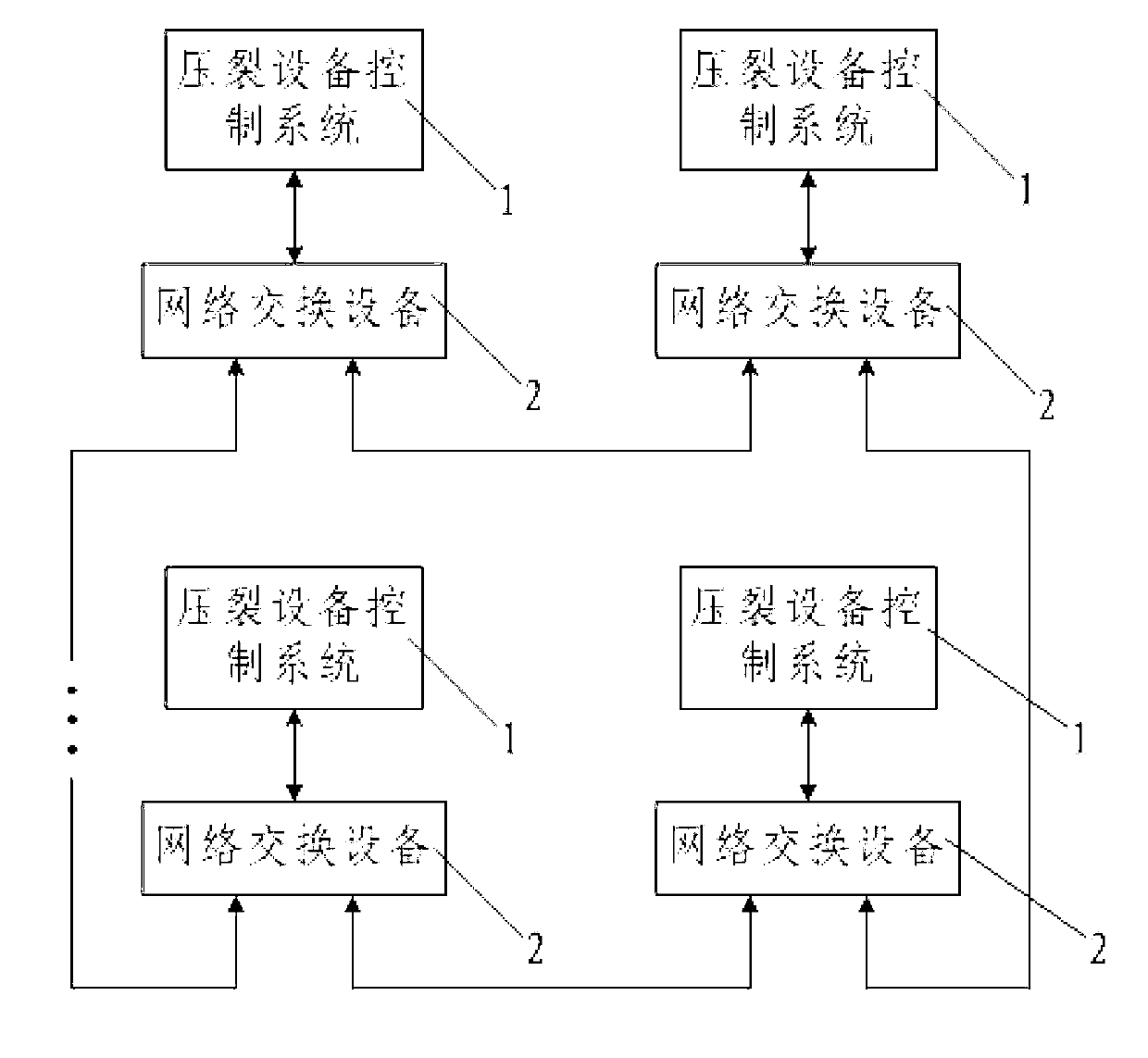

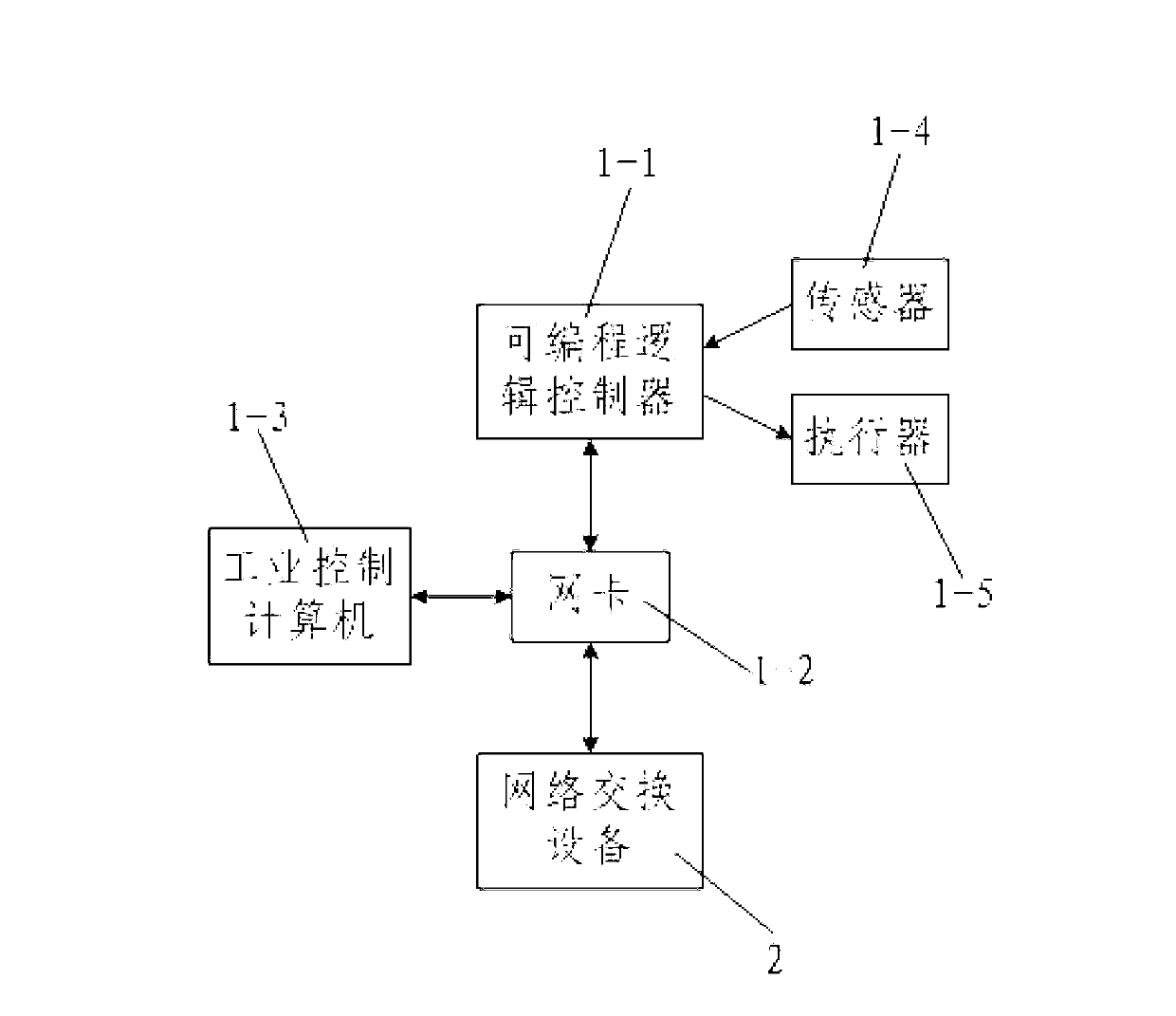

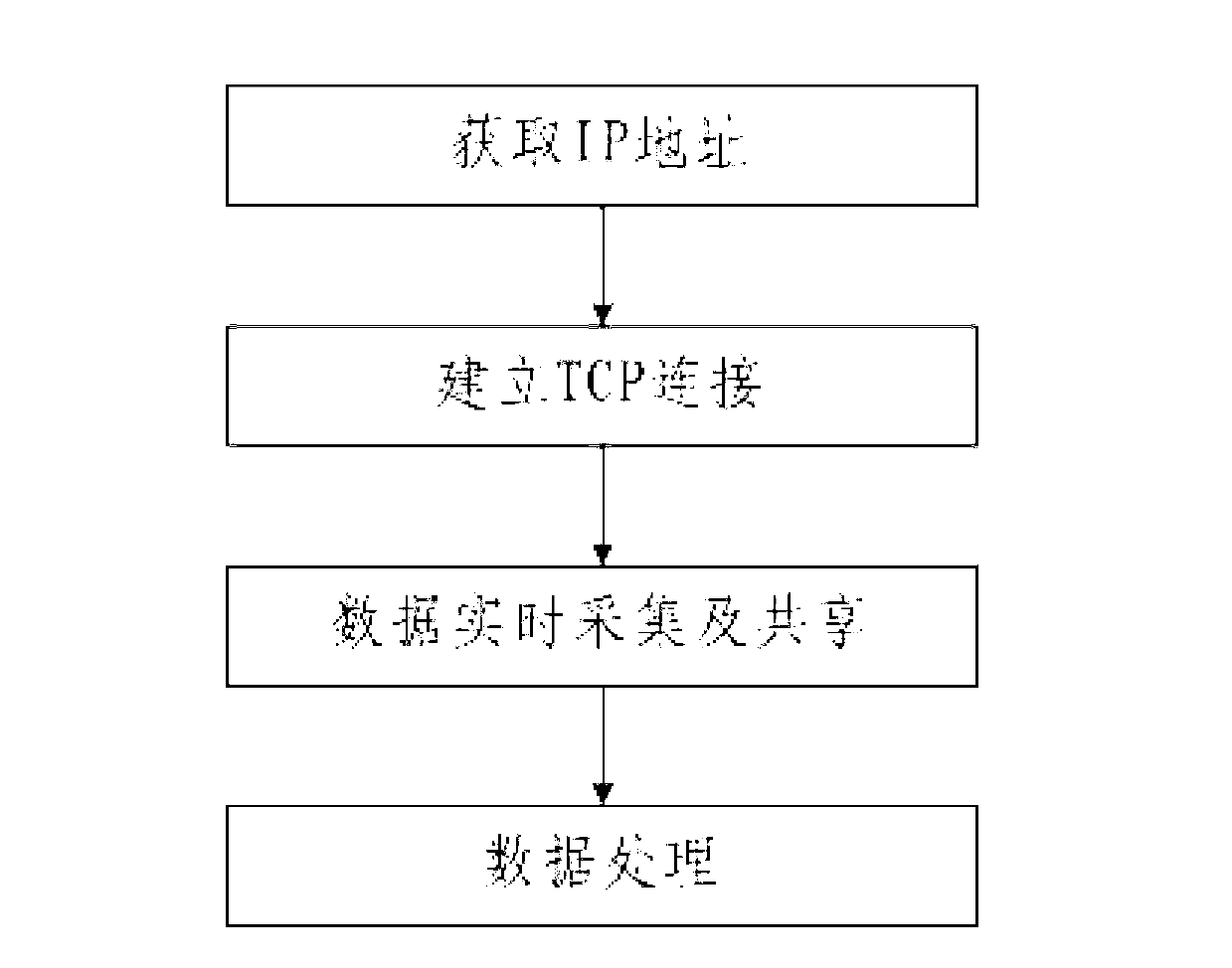

Intelligent network control system and method of fracturing device

InactiveCN103105839ASimple structureNovel and reasonable designTotal factory controlProgramme total factory controlIp addressActuator

The invention discloses an intelligent network control system and a method of a fracturing device. The intelligent network control system of the fracturing device comprises a plurality of fracturing device control systems and a plurality of network switching devices which are respectively corresponding to each other and are connected with the plurality of the fracturing device control systems. A plurality of network switching device cascades compose an ethernet ringlike network. The fracturing control systems comprises programmable logic controllers and industrial control computers which are connected with the programmable logic controllers through network cards. Input ends of the programmable logic controllers are connected with sensors and the output ends of the programmable logic controllers connected with actuators. The industrial control computers connected with the network switching devices through the network cards. The method of the fracturing device comprises the following steps: 1. acquiring internet protocol (IP) address, 2. establishing a transmission control protocol (TCP) connection, 3. acquiring data in real time and sharing, 4. and processing the data. The intelligent network control system and the method of the fracturing device are simple in structure, novel and reasonable in design, convenient to realize, free and flexible in network structure, high in stability, strong in practical applicability and high in popularization and application value and can meet the need of large-scale construction.

Owner:XIAN RISING NEW ENERGY

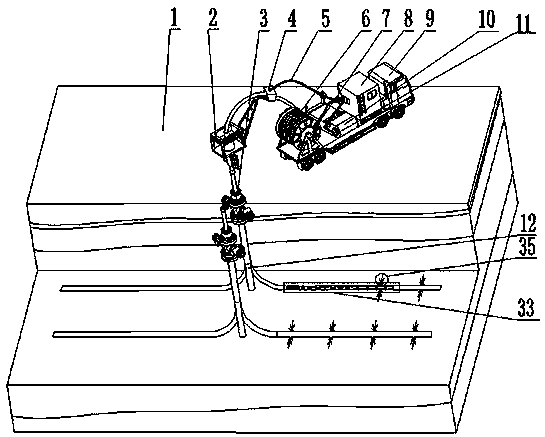

Robot-adopting explosive hydraulic compound fracturing drilling and completion system for hot-dry rocks

ActiveCN108729896ASolve the costSolve the poor effect of fracturingFluid removalDirectional drillingClosed loopData acquisition

A robot-adopting explosive hydraulic compound fracturing drilling and completion system for hot-dry rocks comprises a ground control system, a robot, a drilling execution system, an explosive fracturing execution system, a hydraulic fracturing execution system, a directional execution system and a reentry execution system. The ground control system comprises a data processing center, a ground dataacquisition sensor, a well drilling completion controller, a ground signal transmitting-receiving device, a blowout preventer, a continuous oil pipe well mouth device, a continuous oil pipe operationtruck, an input device and a storage unit. The robot comprises a well bottom data acquisition sensor, a CPU, a drilling control module, a well bottom signal transmitting-receiving device, a reentry tool control module, a directional tool control module, an explosive fracturing control module and a hydraulic fracturing control module. By adopting the robot technology, intelligent closed-loop welldrilling is achieved, the operation cost is effectively reduced, a burning explosion and a hydraulic compound fracturing technology are adopted, a hot-dry rock fracture network can be remarkably optimized, and the risk of 'heat transfer short circuit' is reduced.

Owner:SOUTHWEST PETROLEUM UNIV

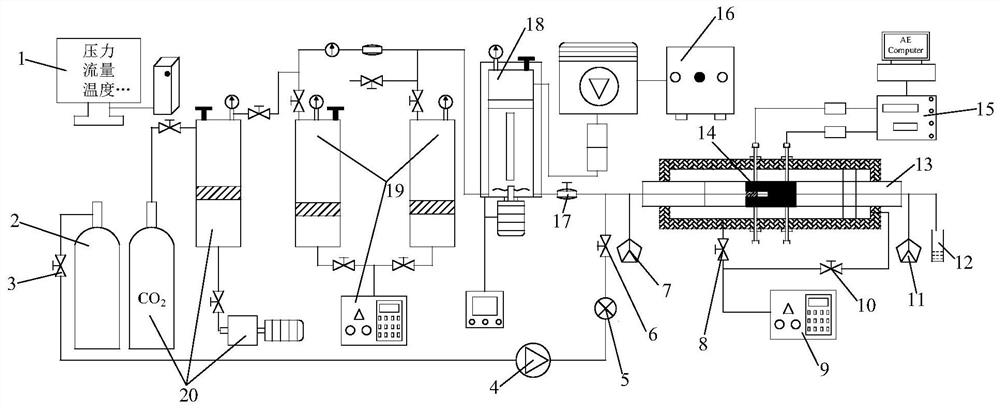

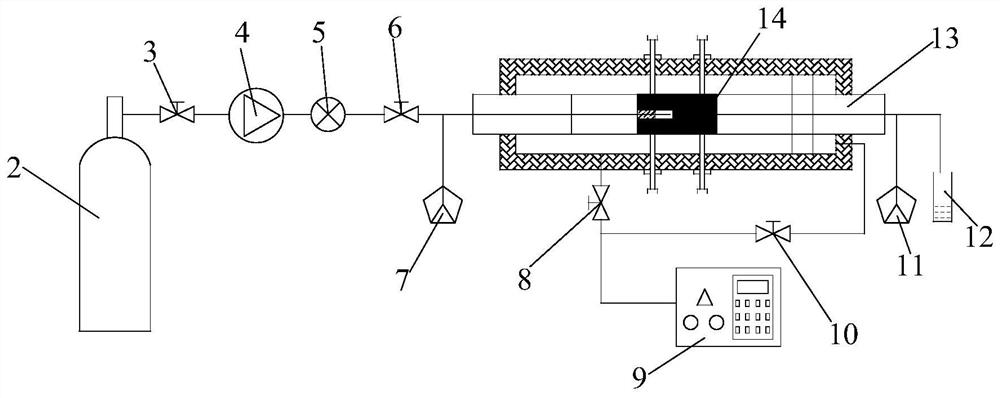

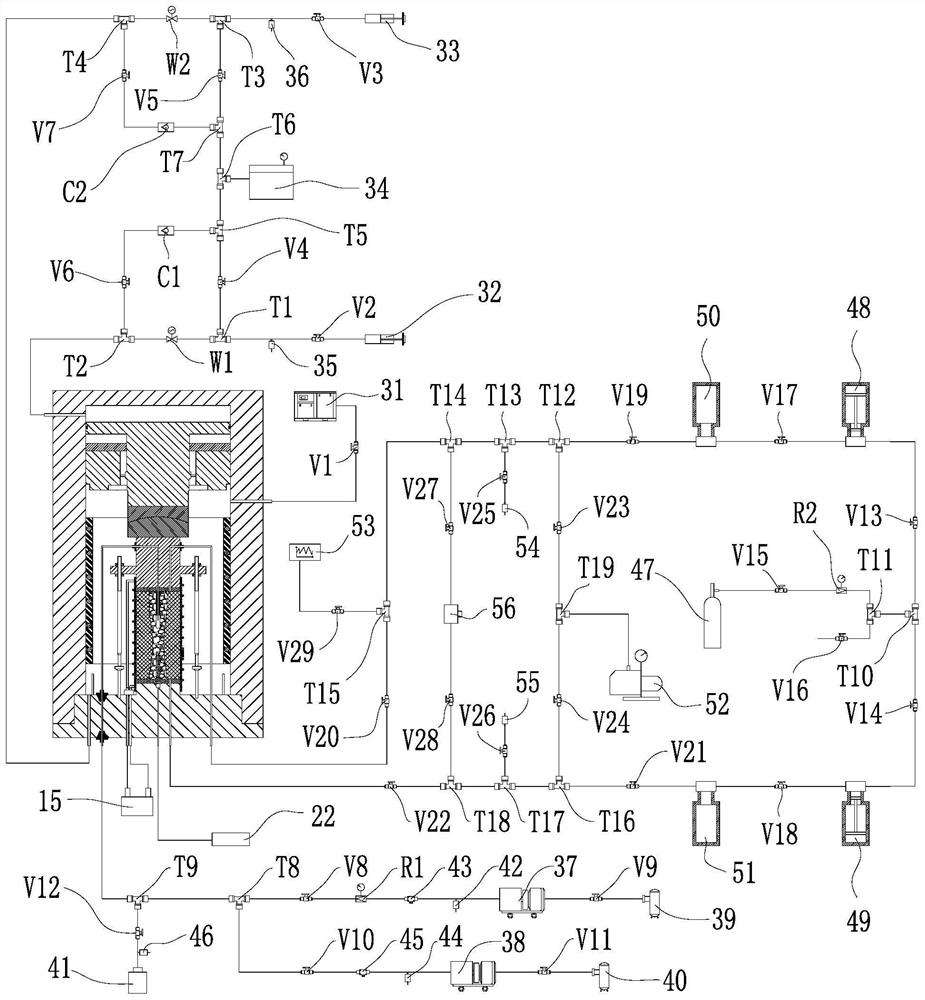

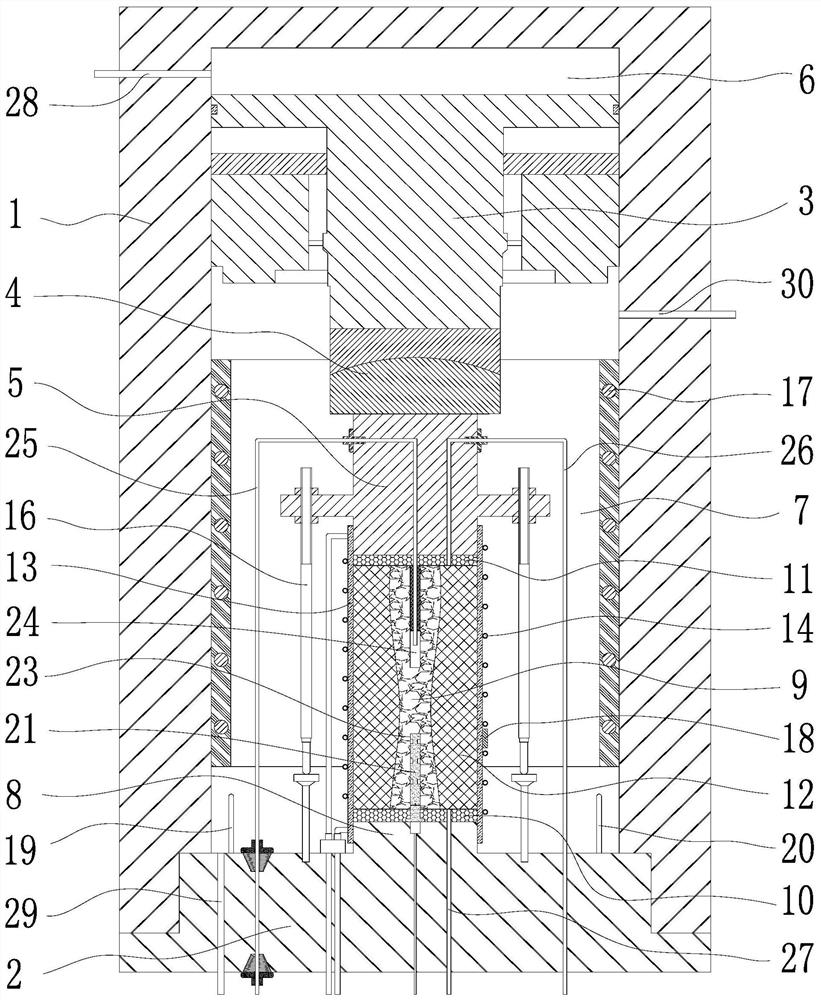

Pulsation CO2 foam fracturing and evaluation simulation integrated test device and method

ActiveCN113530516APrecisely formulatedOptimum ratioOther gas emission reduction technologiesFluid removalFracturing fluidEngineering

The invention discloses pulsating CO2 foam fracturing and an evaluation simulation integrated test device and method. According to the pulsating CO2 foam fracturing and the evaluation simulation integrated test device and method, the preparation of CO2 foam fracturing fluids with different foam qualities is realized through a CO2 pressurizing and liquefying system and a foam fracturing fluid quantitative injection system; a high-temperature and high-pressure foam performance evaluation system can simulate and research the stability performance of CO2 foams with different proportions in a deep high-temperature and high-pressure environment; a pulsating fracturing control system can realize high-frequency large-amplitude pulsating fracturing; a triaxial core holder can simulate a deep in-situ stress environment, and can be combined with a acoustic emission monitoring system to research crack propagation and fracture energy rules in the fracturing process; in addition, the triaxial core holder is combined with a permeability measuring system, so that the change condition of the permeability of a sample before and after fracturing can be evaluated; therefore, the pulse CO2 foam fracturing process of a unconventional natural gas reservoir can be simulated, test data under various different conditions can be obtained, the proportion of the CO2 foam fracturing fluid can be optimized, and the influence of different pulse parameters on the fracturing effect can be researched.

Owner:CHINA UNIV OF MINING & TECH

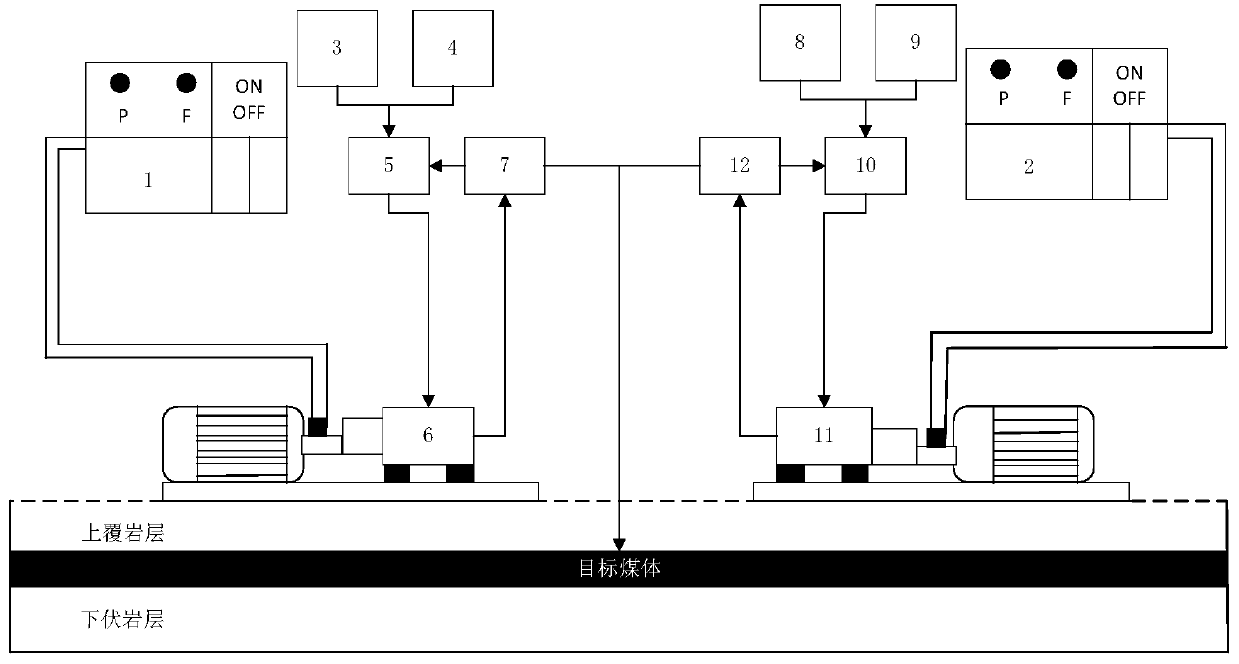

Method for uniformly fracturing coal body by compounding hydraulic power and liquid nitrogen

InactiveCN110924900AFully uniform crackingImprove production safetyFluid removalThermodynamicsHydraulic fracturing

The invention discloses a method for uniformly fracturing a coal body by compounding hydraulic power and liquid nitrogen. The method comprises the following specific steps: constructing a horizontal fracturing drilling hole in a selected side of an excavation roadway, sealing the hole, and connecting the hole to a hydraulic fracturing system and a liquid nitrogen fracturing system separately; starting the master control to coal body hydraulic fracturing through a hydraulic fracturing control operation table, wherein a hydraulic fracturing process comprises two stages, the first stage is a conventional hydraulic fracturing stage, and the second stage is a sand-containing hydraulic fracturing stage; after the hydraulic fracturing process is ended, immediately starting liquid nitrogen freezing to a coal body to cause fracture through a liquid nitrogen fracturing control operation table; and after the fracturing of each fracturing drilling hole is ended for 48 hours, performing the hydraulic fracturing and liquid nitrogen fracturing of next fracturing drilling hole until the fracturing of the last fracturing drilling hole is completed.

Owner:CHINA UNIV OF MINING & TECH

Numerical-control laser fracture-control cutting machine

InactiveCN102310275AAvoid edge saggingIncrease profitLaser beam welding apparatusNumerical controlLaser cutting

The invention relates to a numerical-control laser fracture-control cutting machine. In the invention, a CNC (Computerized Numerical Control)-contouring control machine tool is taken as a control unit; an auxiliary gas unit sucks back the whole friable and falling waste materials by utilizing strong airflow generated by a compressor with the aid of magnetic partition; and high-speed and controllable cut-off operation is carried out on a friable material which is easy to be broken due to heat by a laser beam heating mode, and during the cutting process, the surface temperature of the material is increased to the temperature at a boiling point in a high speed so as to avoid melting caused by heat conduction in the event that the material is heated by high-power density laser beams, wherein, a part of the material is vaporized to form steam and disappears, and a part of the material is taken as a spraying object to be sucked back by the auxiliary airflow from the bottom of a cutting seam. By adopting a laser cutting mode, the numerical-control laser fracture-control cutting machine based on the auxiliary gas from the compressor has the advantages that the obtained cutting seam is fine, the obtained cutting surface is smooth, the cutting speed is fast, heat deformation is small, the contact with the surface of the material can be avoided during the cutting process, more materials can be saved, and the machine is suitable for machining large products. The numerical-control laser fracture-control cutting machine can be applied to machining sheet metals in the heavy / light industry, medical treatment industry and other related industries, cutting and forming rotors, stators and blades, and manufacturing various chains and components in the automobile manufacturing industry; and meanwhile the machine is also suitable for the advertisement and decoration industry, the artwork manufacturing industry and the like.

Owner:胡忠

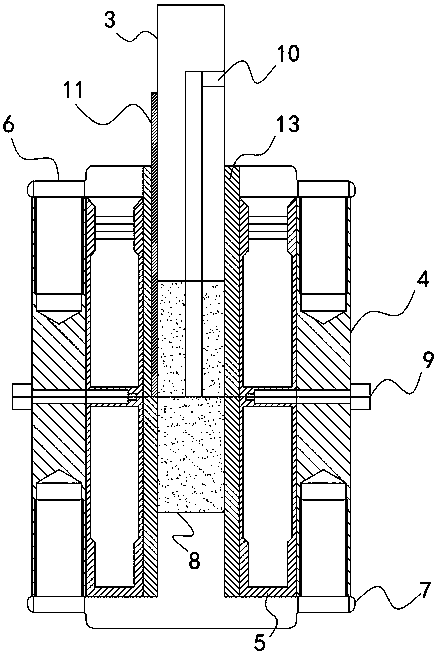

Device for testing true triaxial hydraulic fracturing strain characteristic of rock

InactiveCN107941621ACompact and beautiful structureVersatileMaterial strength using tensile/compressive forcesRock coreControl system

The invention discloses a device for testing the true triaxial hydraulic fracturing strain characteristic of a rock. The device includes a loading frame, an axial lifting mechanism, an axial load sensor, a hydraulic fracturing plug, a strain gauge, a static strain gauge, a true triaxial clamper, an X-direction stress control system, a Y-direction stress control system and a hydraulic fracturing control system, the axial lifting mechanism is arranged at the bottom of the loading frame, and the axial load sensor is arranged at the upper part of the loading frame; the X-direction stress control system and the Y-direction stress control system are respectively connected to the left side and the right side of the cylindrical shell of the clamper through stress joints; and the strain gauge is vertically arranged in a cavity and contacts with a rock core to be tested, and the static strain gauge is respectively electrically connected with the strain gauge and the axial load sensor. The devicerealizes the development of indoor hydraulic fracturing experiments and test of the stress and strain characteristics of the rock during the experiments by using true triaxial stress loading, and hasthe advantages of beautiful and compact overall structure, complete functions and easiness in operation.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD +1

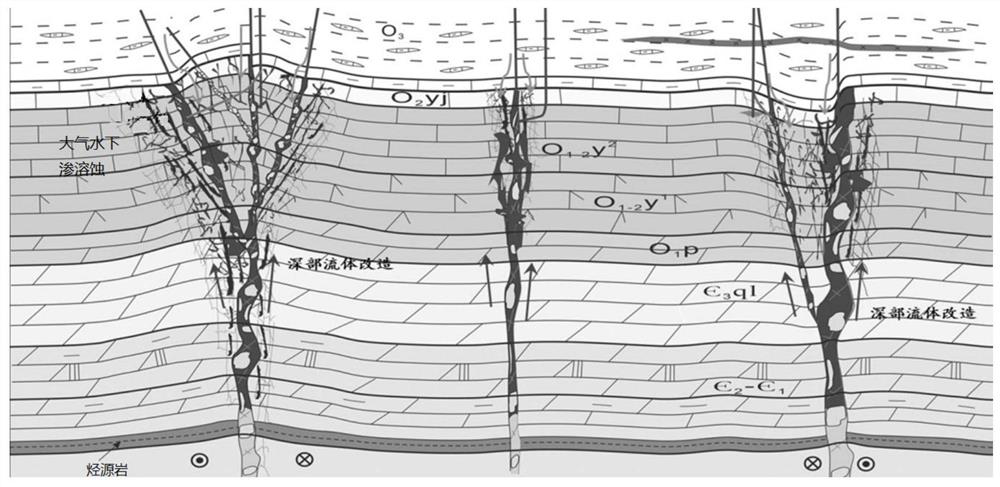

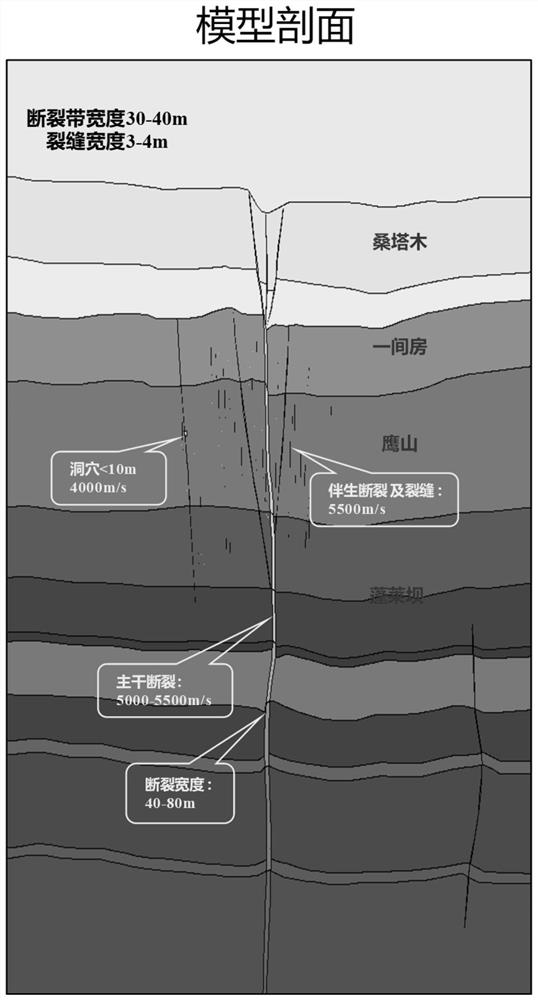

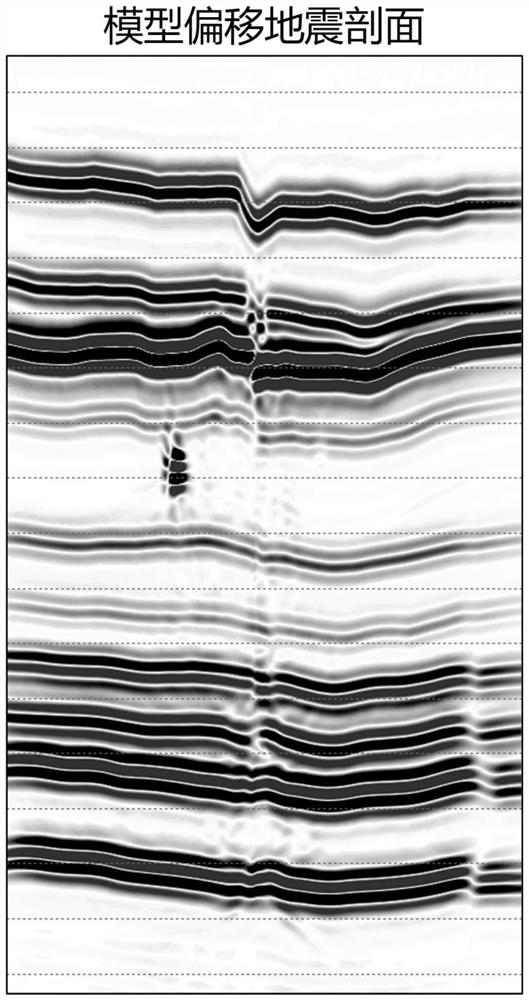

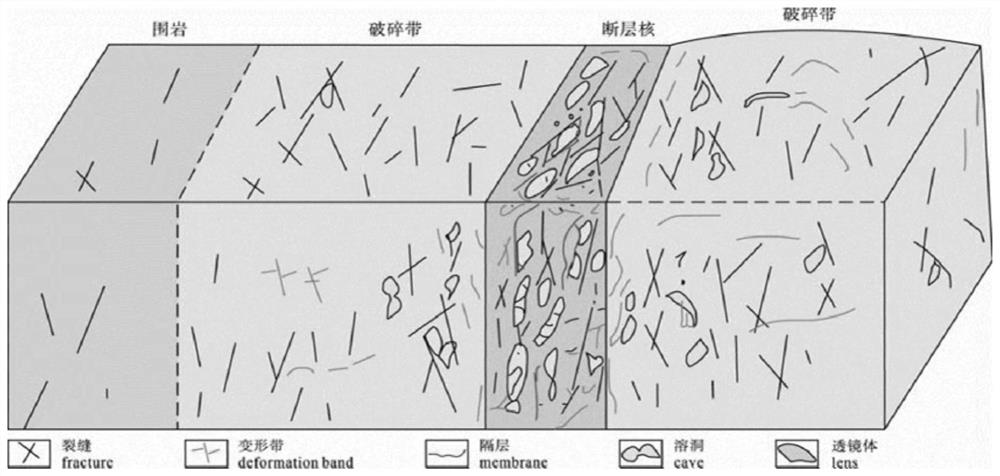

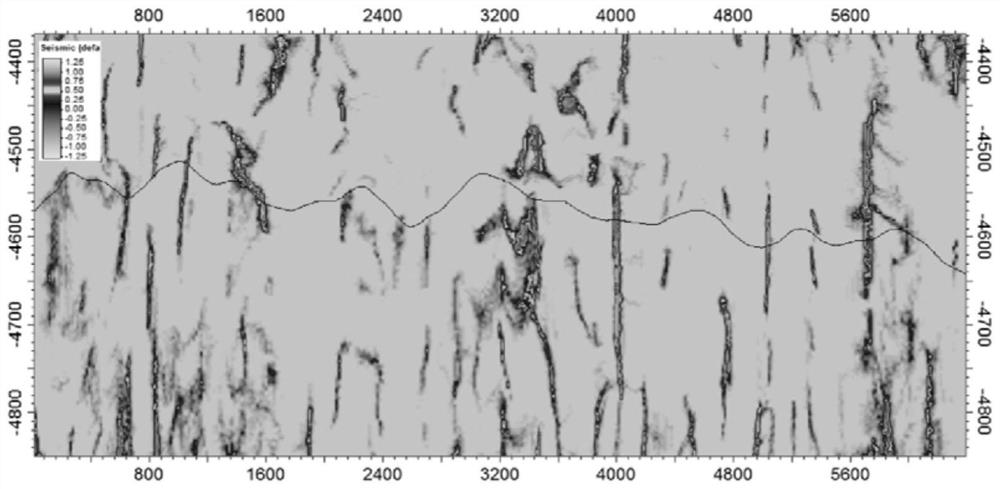

Deep and large fracture system space depicting method

PendingCN112698398ADetailed description of developmental characteristicsSeismic signal processingSeismology for water-loggingFracture controlCompressed sensing

The invention discloses a deep and large fracture system space depicting method. Through application of multiple advanced geophysical means such as seismic forward model research, seismic data fracture enhancement processing, multi-scale fracture identification, structure tensor attributes, amplitude curvature attributes and compressed sensing inversion, a fault solution identification mode is effectively determined, and spatial distribution of strike-slip fractures is clearly depicted. Development characteristics of different types of fault solution reservoirs are finely described, and a sufficient basis is provided for spatial depiction and favorable target prediction of the fault solution reservoirs under deep and large fracture control.

Owner:PETROCHINA CO LTD

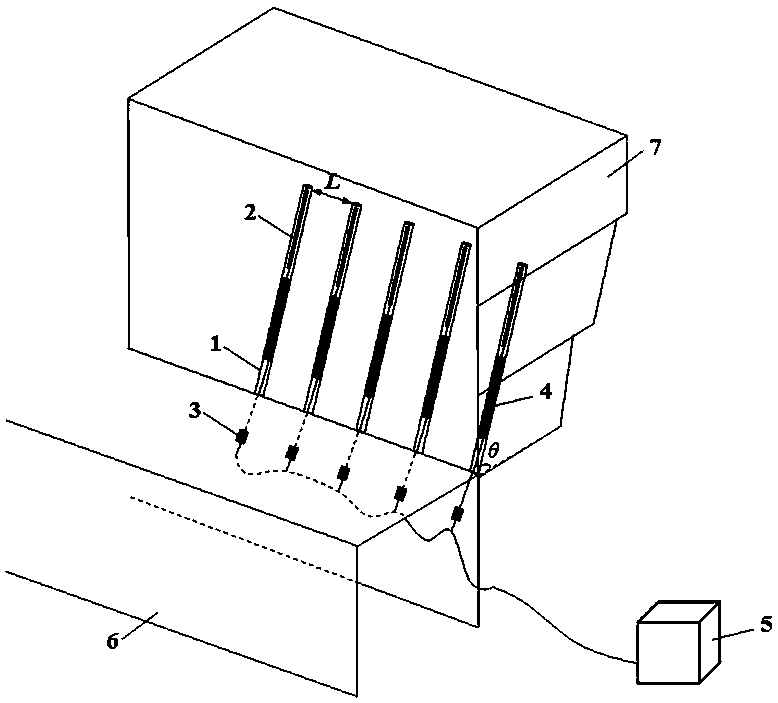

Coal mine hard roof directional fracturing control method

The invention relates to a coal mine hard roof pressure relief method, in particular to a coal mine hard roof directional fracturing control method. The coal mine hard roof directional fracturing control method solves the problem that an existing coal mine hard roof fracturing control method cannot achieve accuracy and high efficiency. The coal mine hard roof directional fracturing control methodcomprises the following steps that a, a lateral suspension top not-caved roof of a roadway is selected as a directional fracturing control area, a drilling machine is adopted to drill holes at the interval of L, the drilled holes are linearly arranged in the length direction of the roadway, each drilled hole is located in the vertical plane in the length direction of the roadway roof and forms anangle theta with the roadway roof, wherein L is 1-3 m, and the angle theta is 60-80 degrees; b, complex perforators are assembled; c, each drilled hole is internally provided with one complex perforator, all the drilled holes are sealed, leads of the complex perforators in all the drilled holes penetrate through the hole seal to be led out of the drilled holes, the leads are connected with detonators at the outlets of the drilled holes, and all the detonators are connected with an detonation instrument; d, the detonation instrument is ignited, and operation is completed. The coal mine hard roof directional fracturing control method achieves accurate fracture generation of the coal mine hard roof.

Owner:DATONG COAL MINE GRP

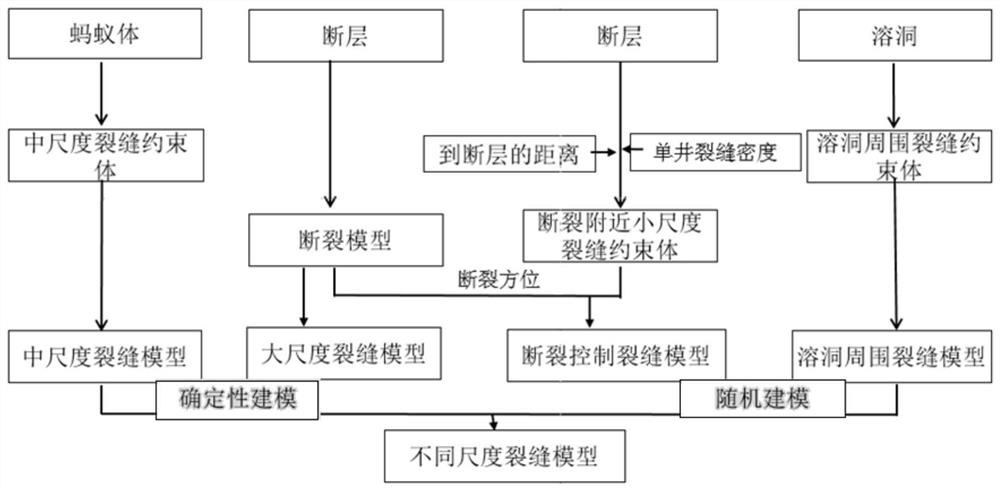

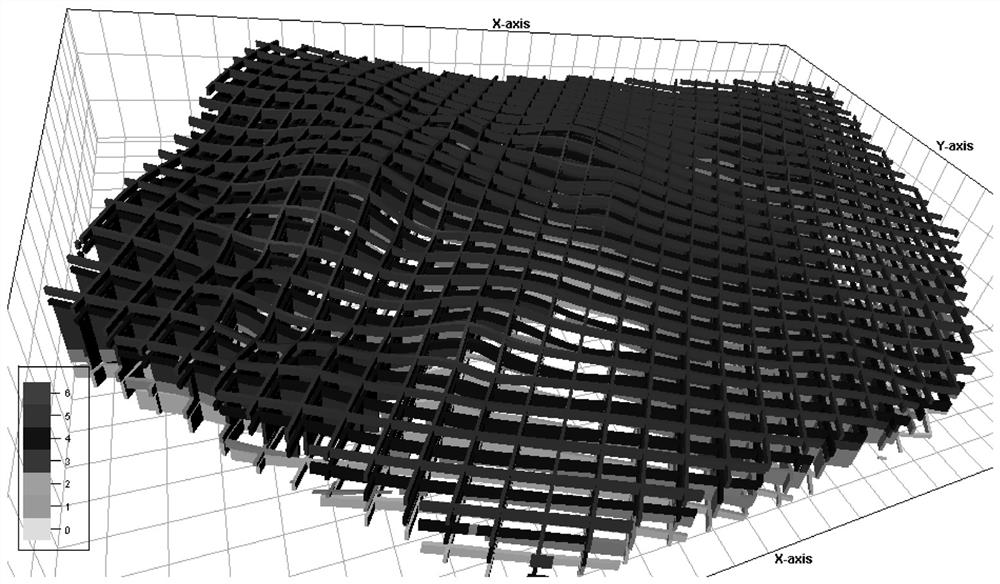

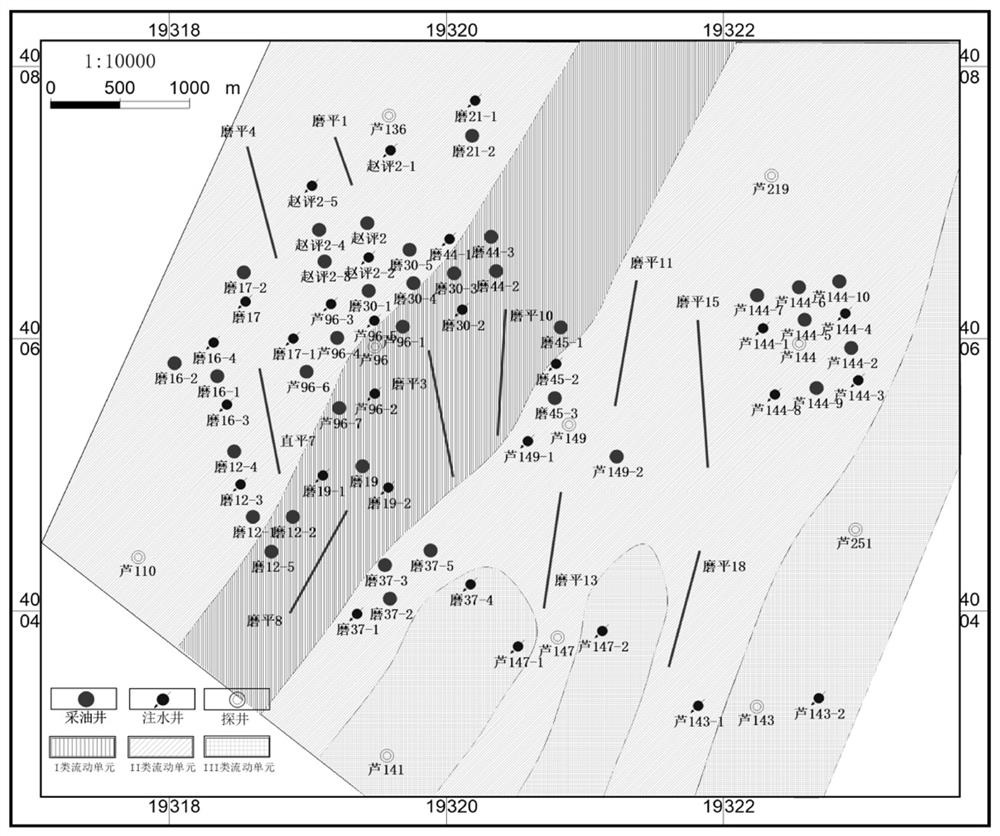

Multi-scale fracture modeling method for fracture-cavity type carbonate rock oil reservoir

PendingCN111695228AOptimize the matching relationshipConform to developmental characteristicsDesign optimisation/simulation3D modellingFracture controlGeophysics

The invention provides a multi-scale fracture modeling method for a fracture-cavity type carbonate rock oil reservoir. The method comprises the following steps: firstly, identifying a scale accordingto cracks; dividing cracks into large-scale cracks, medium-scale cracks and small-scale cracks; secondly, aiming at a fracture-vug type carbonate rock fracture forming mechanism, subdividing small-scale cracks into fracture control cracks and karst cave control cracks; establishing a fracture model by adopting a deterministic modeling method according to characteristics of large-scale and medium-scale fractures, establishing a fracture model by adopting a random indication point method according to small-scale fractures, and finally forming a multi-scale fracture model through fusion, so thatthe fracture modeling precision of the fracture-cavity type oil reservoir is effectively improved, and the geological modeling method of the fracture-cavity type oil reservoir is perfected.

Owner:CHINA PETROLEUM & CHEM CORP +1

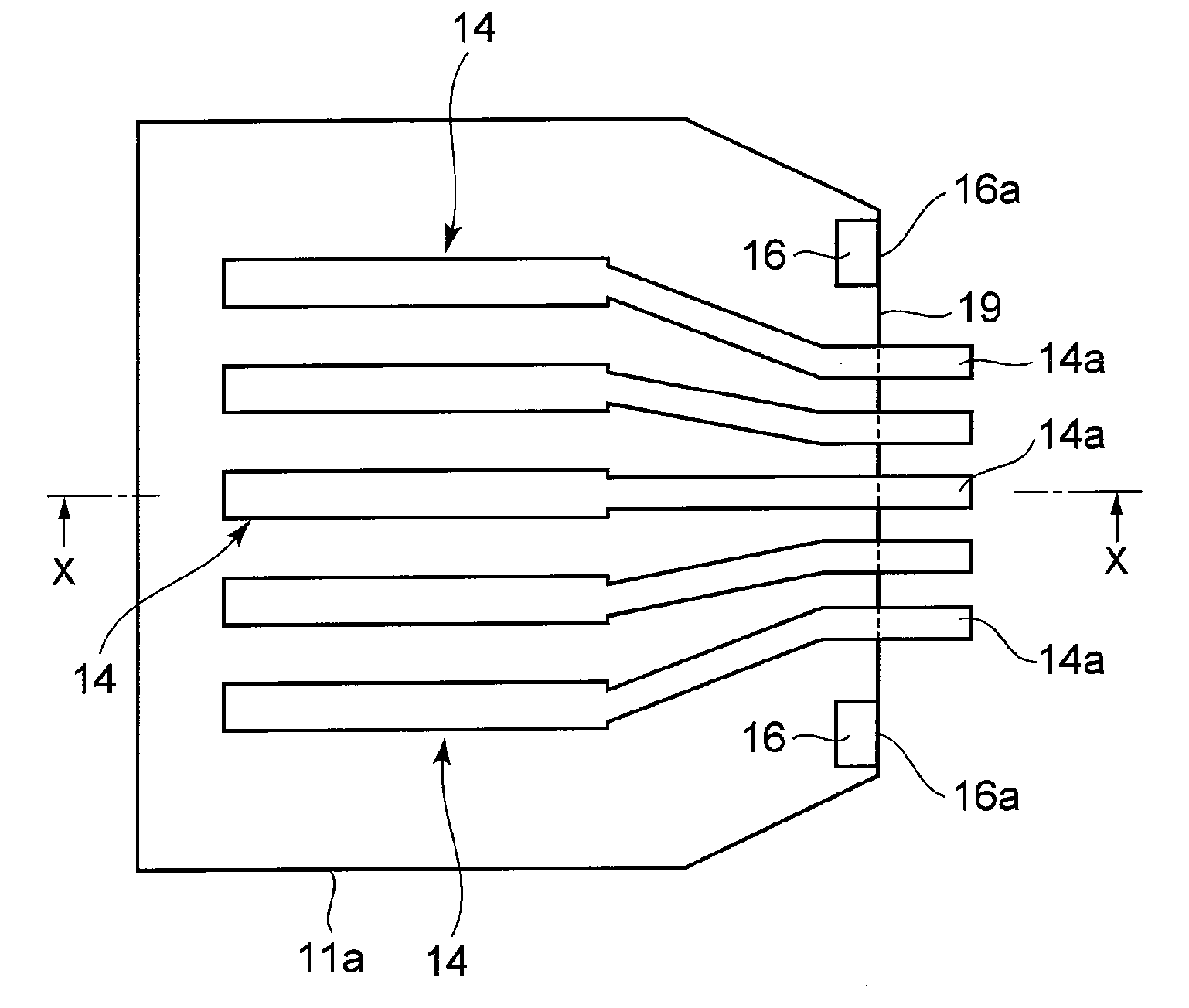

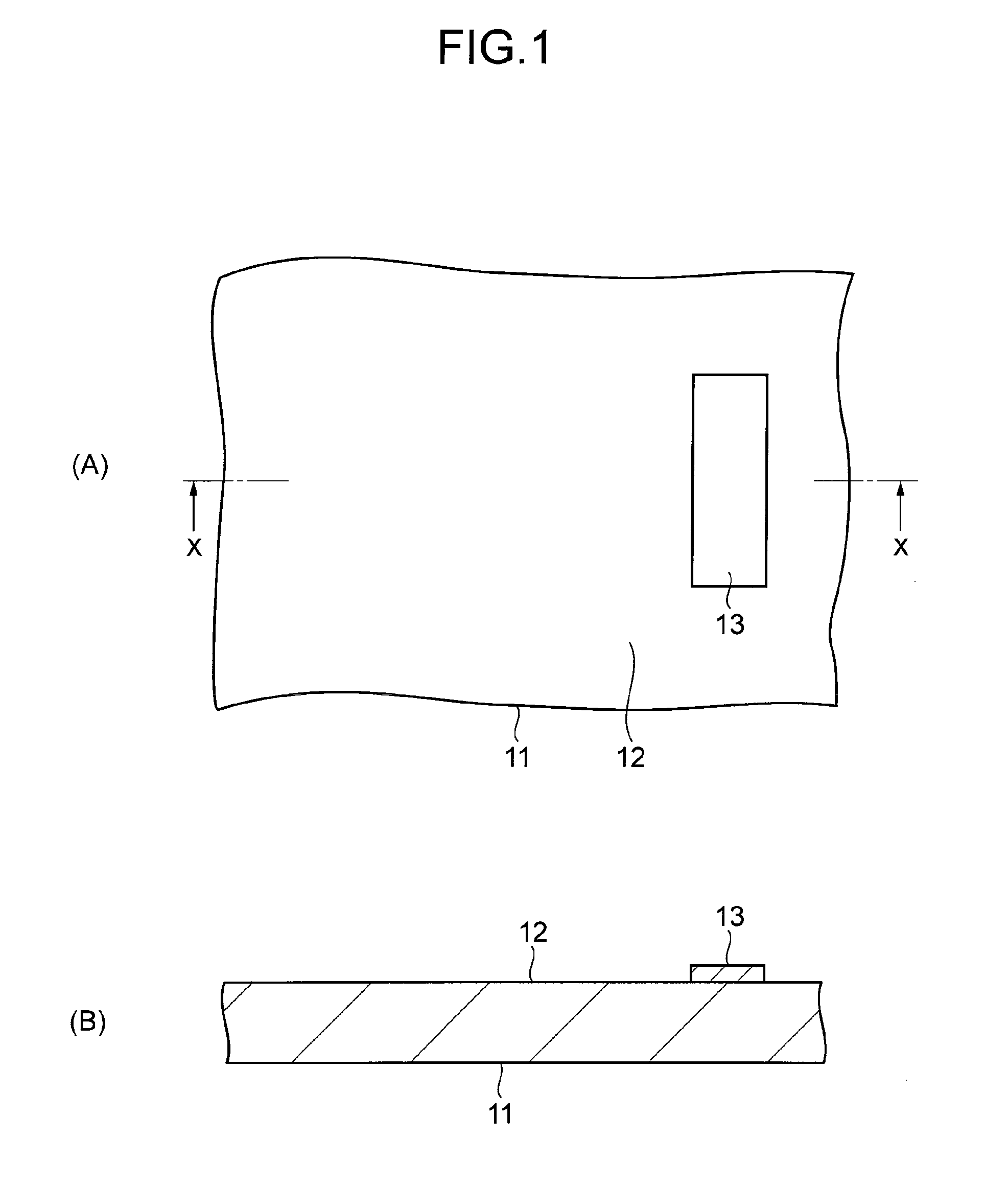

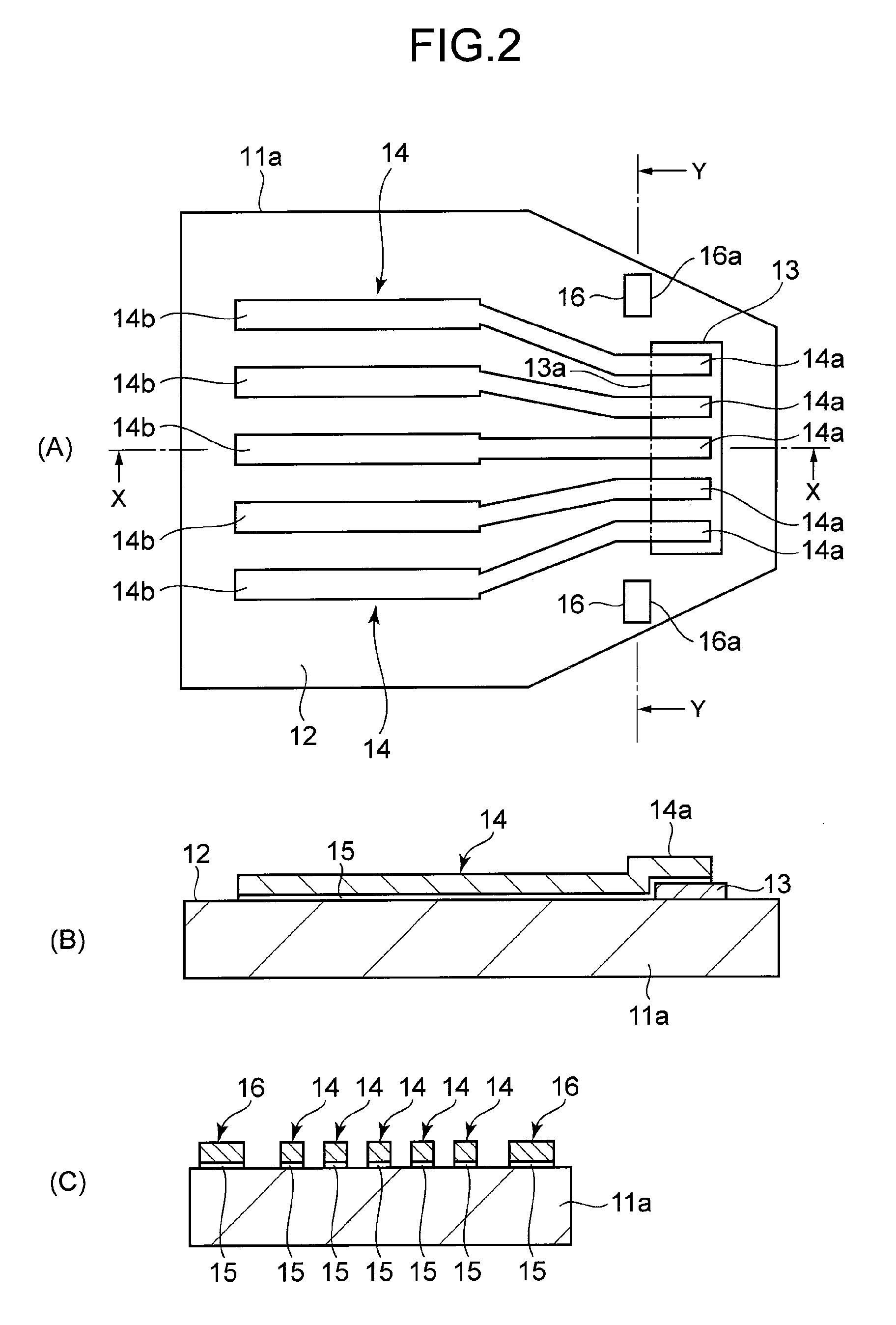

Manufacturing method for probe contact

InactiveUS20100050431A1Easy to controlLow costContact member manufacturingElectrical measurement instrument detailsStress concentrationPosition control

To make the fracturing position controlled conveniently with high precision when the substrate end of the probe contact is fractured and cut off.By compressing the front face of the substrate end portion with the pushing member, brittle fracture is generated on the substrate along the carved groove, and the substrate end portion is cut off from the substrate. The fracturing position in the above-mentioned fracturing is controlled so as to be along the fracturing position whose extension puts thereon the stress concentrating ends of two fracturing control structures. Here, the fracturing control structure is located with high positional precision on the front face of the substrate through the alignment technique of photolithography. In this way, resilient armatures constituted of the tips projected from the fracturing position coming to be the end of the substrate 11a can be stably formed with high precision.

Owner:YAMAICHI ELECTRONICS

Shale reservoir fracture control uniform expansion fracturing method

ActiveCN111878051AAdaptableStrong guidance for fracturing stimulation operationsFluid removalDesign optimisation/simulationMining engineeringFracturing fluid

The invention discloses a shale reservoir fracture control uniform expansion fracturing method, and belongs to the technical field of unconventional oil and gas reservoir development. The shale reservoir fracture control uniform expansion fracturing method particularly comprises three key methods and technologies of fracturing scheme design, optimum well entering material selection and field construction implementation. The method comprises the following steps of (1) fracturing scheme design: mainly comprising subsection design, perforation design, scale design and temporary plugging design; (2) optimum well entering material selection: mainly comprising optimum selection of a proppant and fracturing fluid; and (3) field construction implementation: mainly comprising two parts of temporaryplugging construction and sand adding mode. Compared with a box body transformation theory and a close cutting technology, the method disclosed by the invention has the advantages of being larger intransformation size, higher in crack complexity degree, better in reservoir stratum utilization efficiency and the like, besides, the adverse effect of casing deformation and pressure channeling on reservoir stratum yield increase transformation is greatly weakened, and the method is suitable for being applied and popularized in southern shale gas blocks in China and has good application prospects. A feasible technical means is provided for efficient development of the current shale gas well.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

System and method for testing biological effect of water under supercritical CO 2 phase change pulse

InactiveCN110440980AConforms to the transmission pathRapid change measurementShock waveUltrasound attenuation

The invention discloses a system for testing the biological effect of water under supercritical CO 2 phase change pulse. The system comprises a fracturing pipe and a data acquisition device, wherein the fracturing pipe is arranged in a rock stratum below a water surface, liquid CO 2 is filled in the fracturing pipe and is connected with a fracturing control system, and after the fracturing controlsystem sends out a control instruction, the fracturing pipe is heated instantly to enable liquid CO 2 to complete phase change fracturing so as to break the rock stratum; and the data acquisition device is arranged outside the rock stratum and at the radial position of the fracturing pipe and is used for acquiring water shock wave pressures at a plurality of positions when the rock stratum is cracked. The system and method for testing the biological effect of water under supercritical CO 2 phase change pulse, provided by the invention, have the advantages that: the water shock wave generatedwhen the rock stratum is cracked is collected by utilizing the pressure sensors which are arranged outside the rock stratum and are positioned at the radial position of the fracturing pipe and are simultaneously arranged in layers, the arrangement mode of the pressure sensors accords with the transmission path of the water shock wave, and a foundation is laid for establishing an shock pressure attenuation equation.

Owner:CHONGQING JIAOTONG UNIVERSITY

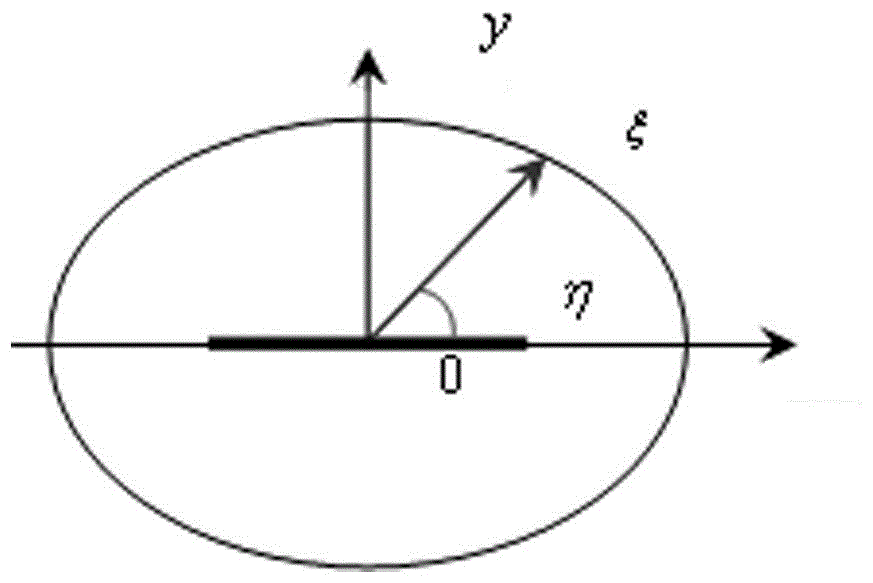

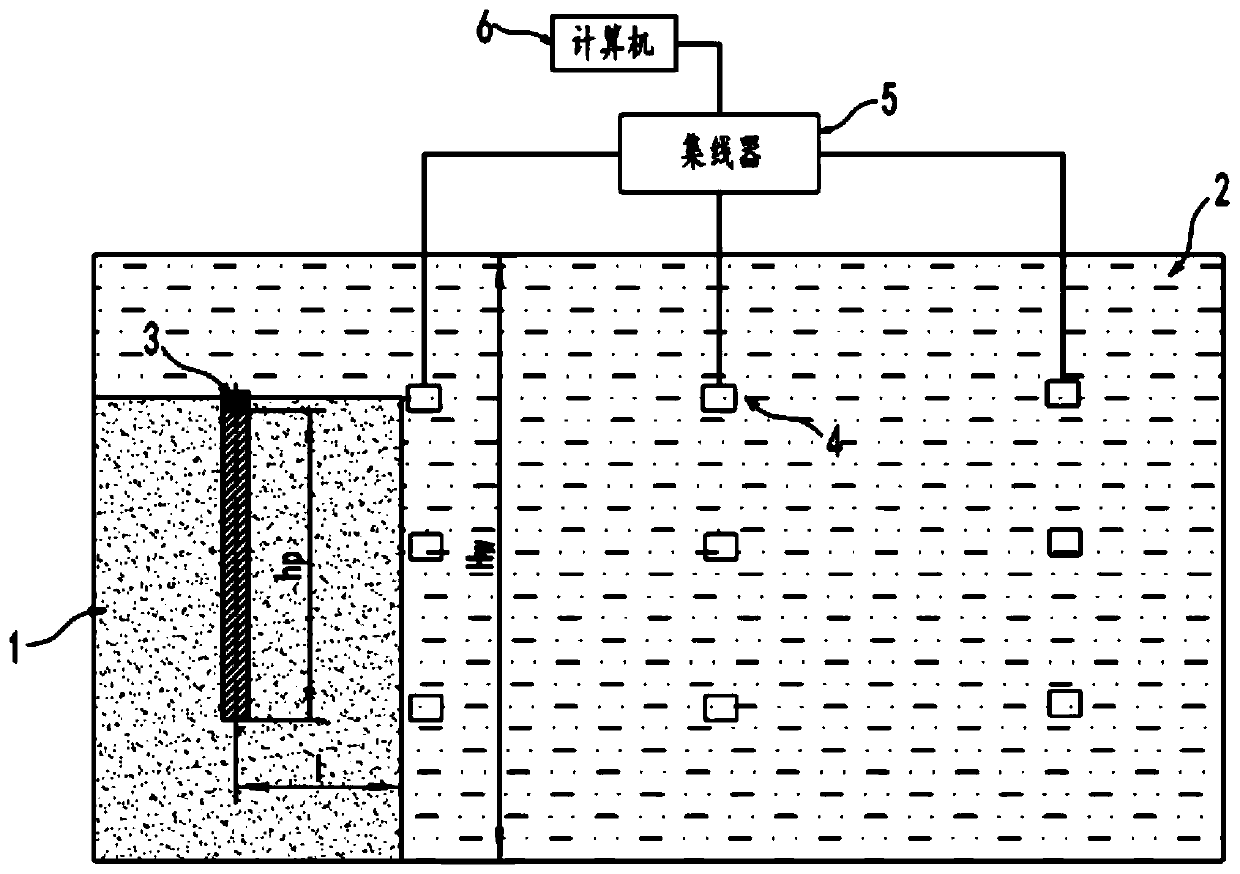

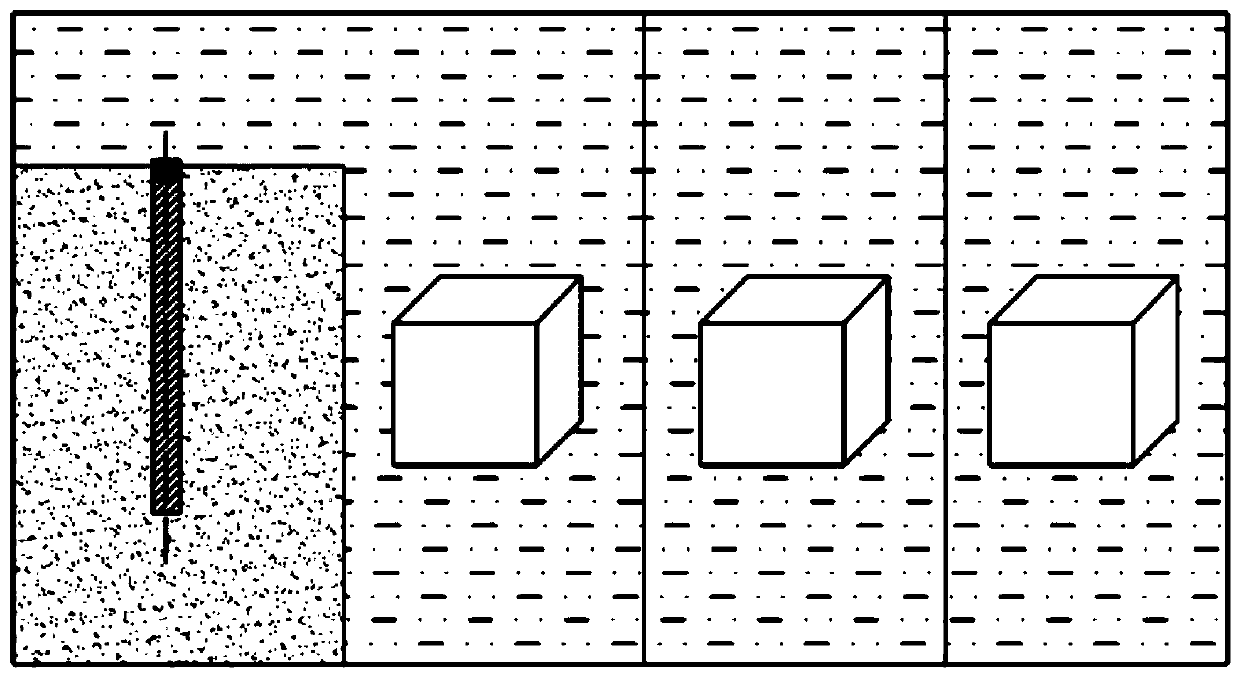

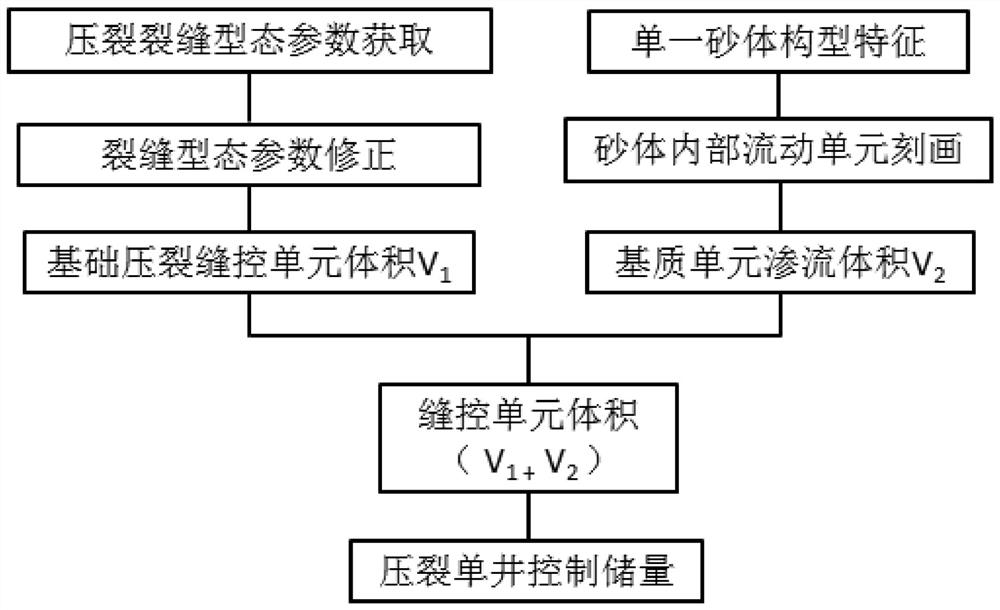

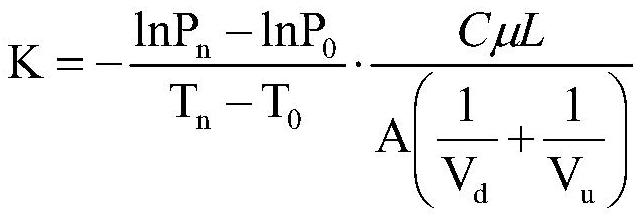

Method for calculating controlled reserves of fractured single well

PendingCN113177322ASolve technical problems with large calculation errorsOptimizing the rational production systemDesign optimisation/simulationSpecial data processing applicationsOil fieldEconomic benefits

The invention relates to a method for calculating controlled reserves of a fractured single well, which comprises the following steps of: establishing vertical and lateral configuration modes of a single sand body so as to obtain distribution characteristics of the single sand body in the vertical direction and the lateral direction; further determining seepage rule characteristics of fluid in different single sand bodies; obtaining the shape parameters and the three-dimensional airspace volume of the fractures in the single-well fractured interval; taking the sum of the volume V1 of the fracture control unit of the foundation fracturing fracture and the seepage volume V2 of the matrix unit as the volume V of the fracture control unit after single well fracturing; and calculating the control reserves in the fracture control unit volume V after single well fracturing by using a grid volume fraction method, and accumulating and obtaining the final control reserves of the fractured single well. According to the method provided by the invention, the oil field development scheme is formulated in a targeted manner, so that the reasonable production system of a single well is optimized, the crude oil recovery rate is improved, and the purpose of economic benefit development of low-permeability and ultra-low-permeability oil reservoirs is finally achieved.

Owner:SHAANXI YANCHANG PETROLEUM GRP

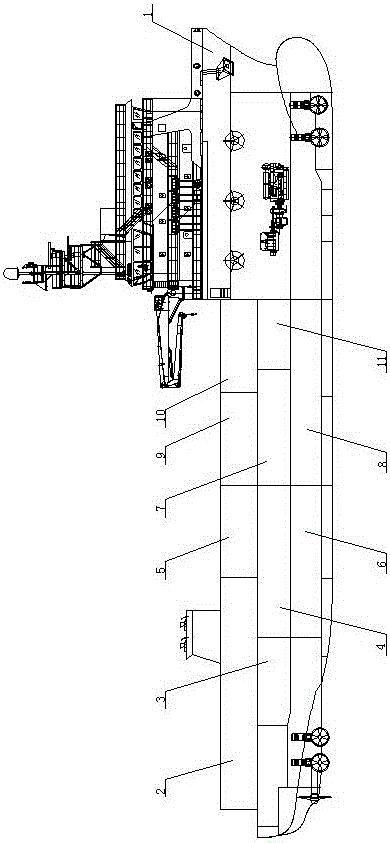

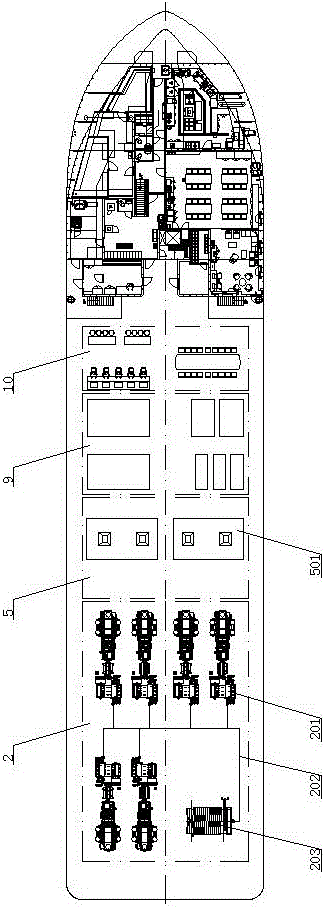

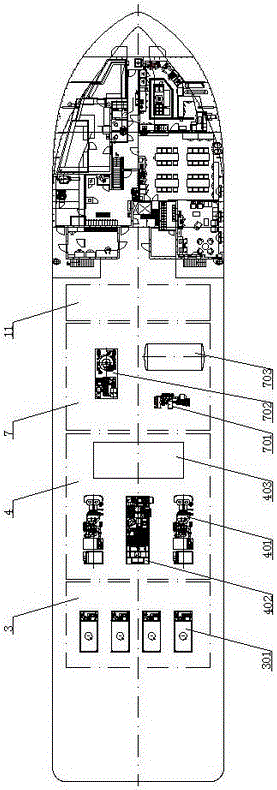

Fracturing vessel operating system

ActiveCN106050212AAchieve true integrationSolve the problem that large-scale offshore oil and gas stimulation operations cannot be carried outWaterborne vesselsFluid removalData acquisitionFracturing fluid

Disclosed is a fracturing vessel operating system which is characterized in that a high-pressure pumping area is used for supercharging and pumping prepared fracturing fluid or acid liquor to a wellhead device; a proppant storage area and a bulk material storage area are respectively used for storing proppant and dry powder additives for fracturing operation; a fracturing control cabinet is used for operational control and data acquisition for construction equipment; an acid liquor storage area, a clean water storage area and a liquid additive storage area are respectively used for storing liquid raw materials of acid liquor, clean water and additives for the fracturing operation; a fracturing fluid mixing area and an acid liquor mixing area are respectively used for preparing the fracturing fluid and the acid liquor for the fracturing operation; a mass laboratory, arranged on the first-layer under deck of the fracturing vessel and close to the bow, is used for monitoring mass of the prepared fracturing fluid and acid liquor. The fracturing vessel operating system is an integration of a fracturing operating system and a vessel, utilizes internal space of cabins completely, meets technological requirements for stimulation operations such as ocean acidification, fracturing and sand control, and overcomes the failure in offshore oil and gas stimulation operation in scale.

Owner:中石化四机石油机械有限公司 +1

Hydraulic fracturing and microwave fracturing combined anti-reflection shale experimental device and method

PendingCN113075112AAvoid damageImprove ductilityMaterial analysis using microwave meansMaterial strength using tensile/compressive forcesThermodynamicsAxial pressure

The invention discloses a hydraulic fracturing and microwave fracturing combined anti-reflection shale experimental device and method. The device comprises a triaxial pressure chamber unit, a confining pressure and axial pressure control unit, a hydraulic fracturing control unit, a microwave fracturing control unit and a permeation control unit. The method comprises the following steps: replacing a shale sample with a standard steel sample for volume calibration, and completing measurement of an upper permeation reference volume and a lower permeation reference volume through cooperation of the triaxial pressure chamber unit, the confining pressure and axial pressure control unit and the permeation control unit; dismantling the standard steel sample, installing the shale sample into a triaxial pressure chamber unit, and completing device connection; completing simulation of ground stress and formation temperature environment through the confining pressure and axial pressure control unit and a heater in the triaxial pressure chamber unit; completing hydraulic fracturing of the shale sample through the hydraulic fracturing control unit; completing microwave fracturing of the shale sample through the microwave fracturing control unit; completing permeation of the shale sample through the permeation control unit, and finally obtaining the permeability of the shale sample through calculation.

Owner:NORTHEASTERN UNIV

Fracturing tool

PendingCN113404477AImprove passabilityFacilitate large-scale processing and productionSurveyFluid removalFracturing fluidWell cementing

The invention provides a fracturing tool, and belongs to the field of fracturing well completion. Fracturing sliding sleeves are put into a well along with a casing pipe during well cementation and well completion, and each fracturing sliding sleeve corresponds to a required fracturing layer section. An intelligent dart body presets parameters on the ground by using a computer program, and is put into the well through a wellhead and pumped during fracturing, the intelligent dart body generates an electromagnetic pulse every time the intelligent dart body passes through one fracturing sliding sleeve, the intelligent dart body counts the number of the electromagnetic pulses to complete counting of the fracturing sliding sleeves, the intelligent dart body is controlled to be hung in the corresponding fracturing sliding sleeve according to the preset parameters, and a channel of a fracturing hole is opened under the hydraulic action, at the moment, a sealing device achieves sealing of the fracturing sliding sleeve and the intelligent dart body, and fracturing fluid forcibly passes through the fracturing hole of the fracturing sliding sleeve to achieve fracturing construction of the corresponding layer section. The electromagnetic counting control mode can be infinitely great in numerical value, the size specifications of the fracturing sliding sleeves and the intelligent dart body are unified, and the advantages of production and manufacturing and fracturing construction such as large-scale batch production and infinite multi-layer section fracturing control are facilitated.

Owner:SANY PETROLEUM INTELLIGENT EQUIP CO LTD

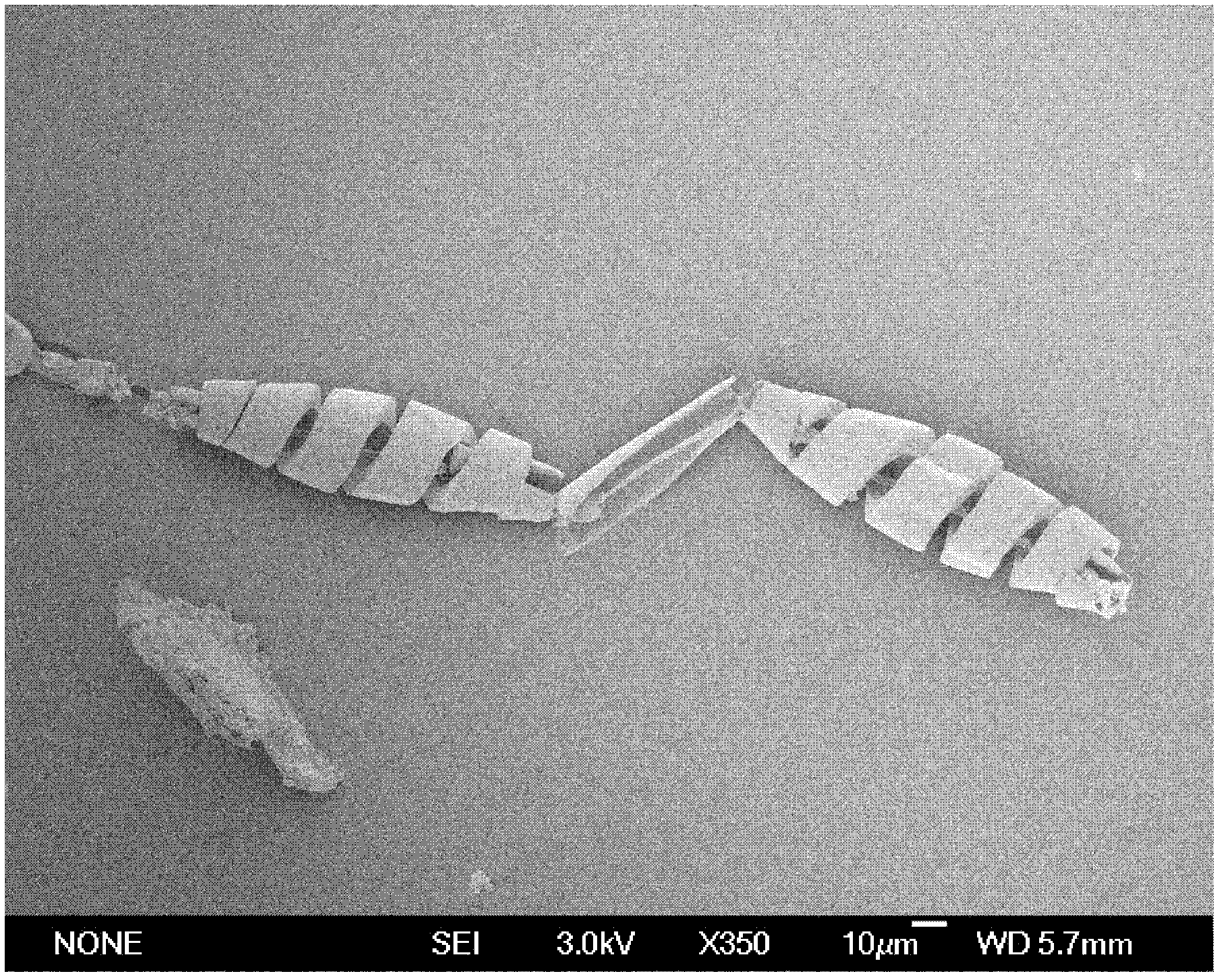

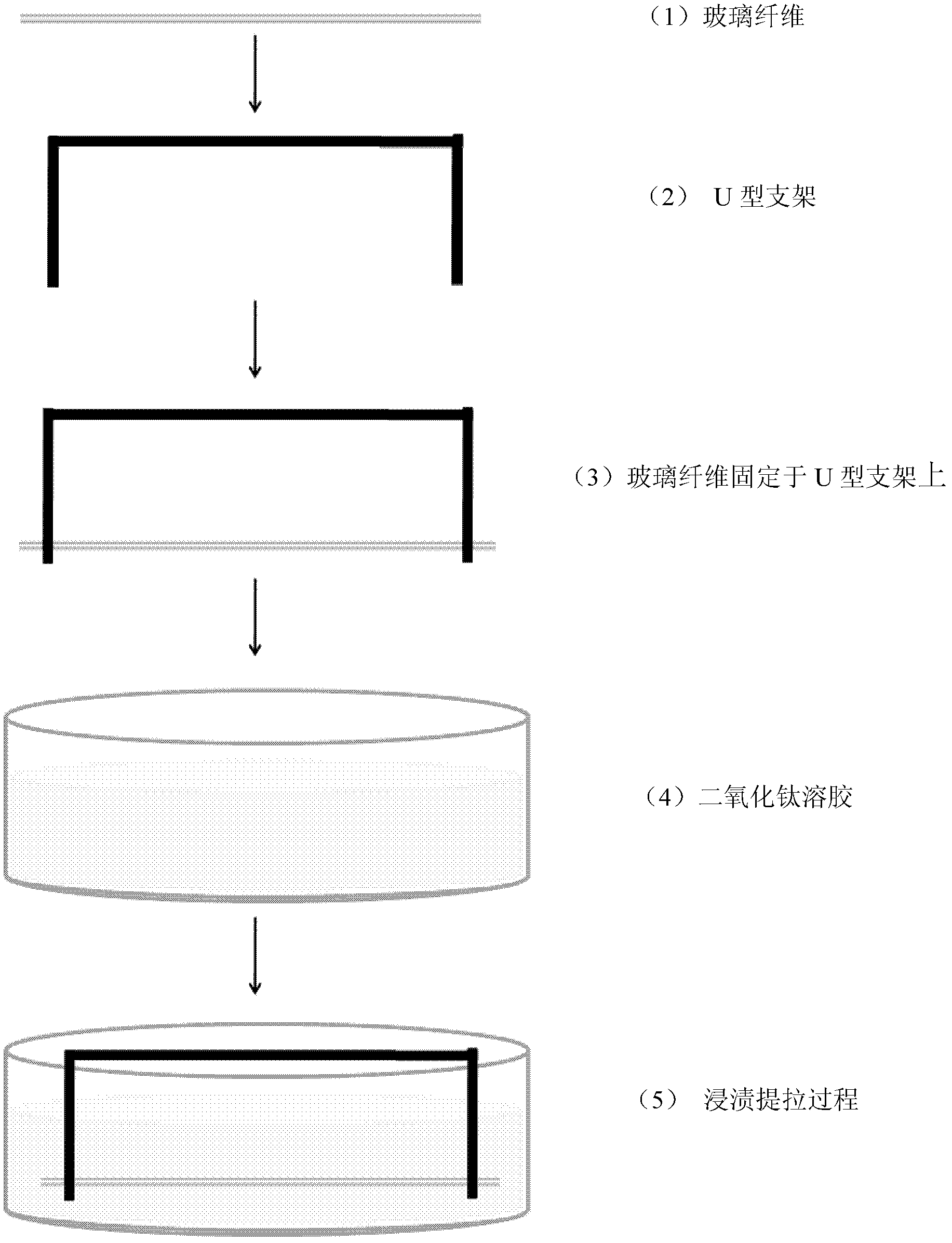

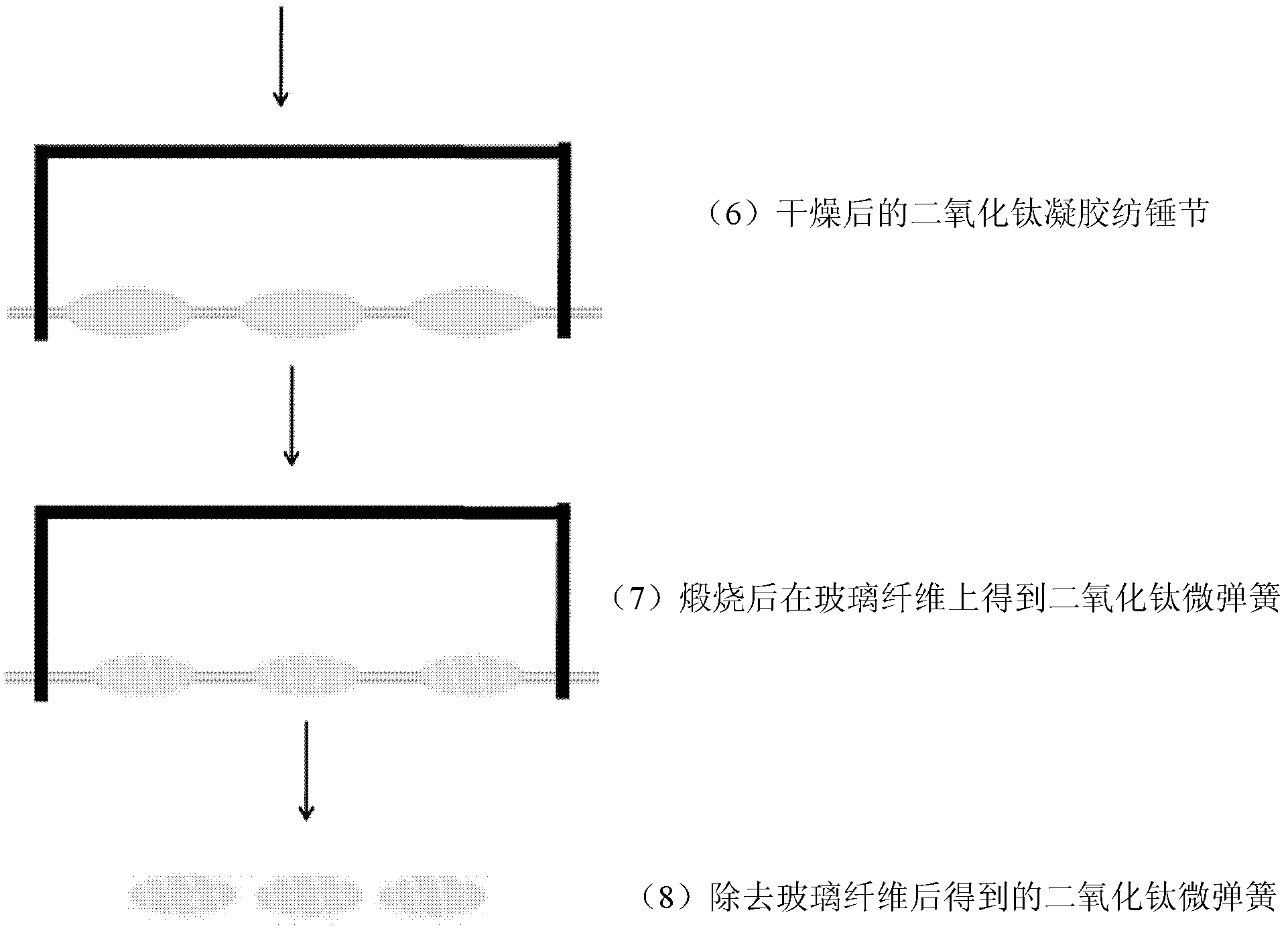

Method for manufacturing micro-spring

InactiveCN102515092AWide range of applicable materialsControllable shapeSpringsMicrostructural devicesFiberMicron scale

The invention relates to a method for manufacturing a micro-spring by using a fracture control method. According to the method disclosed by the invention, the micro-spring is manufactured on the basis of controlling three-dimensional fracture. The method comprises the following steps of: coating a layer of oxide sol on a hard fiber material of which the diameter is of a micron scale; forming a core-shell-structure spindle knot taking the hard fiber material as a core and the oxide sol as a shell by fracturing a liquid membrane of the oxide sol; and forming the core-shell-structure spindle knot taking the oxide sol as the shell when a solvent in an oxide sol shell layer of the spindle knot is volatilized. Because of a special core-shell structure and heterogeneous core-shell components of the spindle knot, the spindle knot not only has a weak core-shell interface, but also has different thermal expansion coefficients. When the spindle knot is subjected to heating treatment, a core-shell material with different thermal expansion coefficients generates a heat stress. Under the action of the heat stress, the weak interface of the spindle knot cracks, and then the regular micro-spring is formed on the shell layer.

Owner:INST OF CHEM CHINESE ACAD OF SCI

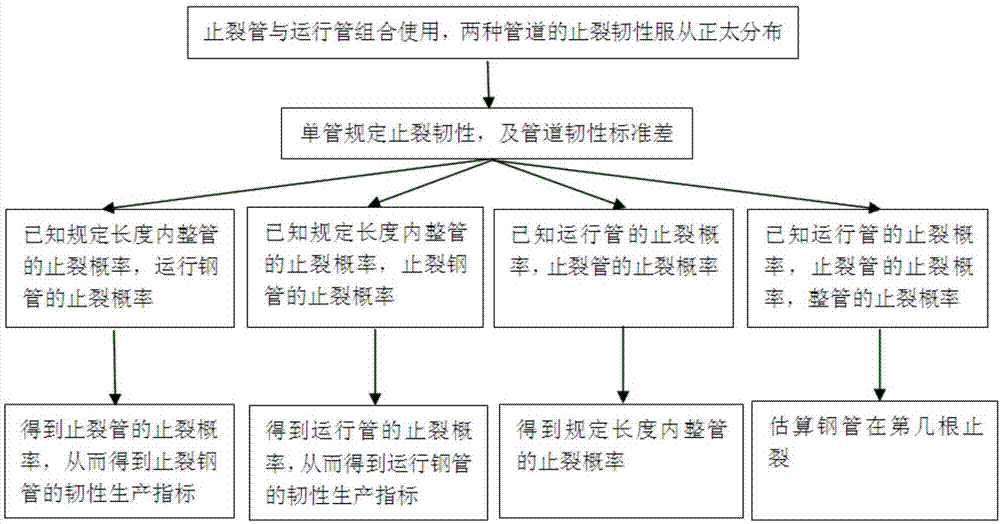

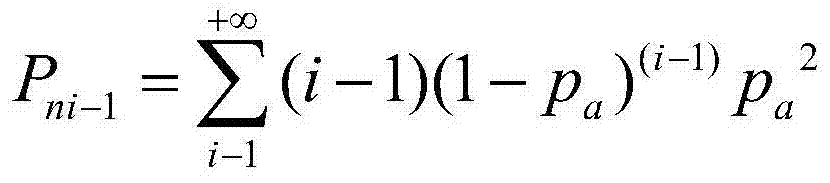

Fracture controllable natural gas pipeline and ductile fracture control method thereof

Disclosed are a fracture controllable natural gas pipeline and a ductile fracture control method thereof. The fracture controllable natural gas pipeline comprises i-1 operating pipes and a fracture stop pipe communicated with the (i-1)th operating pipe. According to the method, probability statistics of permutation and combination is performed to obtain a probability extended over the i-1 operating pipes; according to the probability P<ni-1> extending over the i-1 operating pipes and a probability P<c> wherein the operating pipe higher than a required pipe ductility is unable to be facture-stopped, and probabilities of the operating pipes unable to fracture-stopped are acquired; according to single-pipe fracture stop probability P of a fracture stop pipe and the probabilities of the operating pipes unable to fracture-stopped, a fracture stop probability of the fracture controllable natural gas pipeline is obtained; ductile fracture of the fracture controllable natural gas pipeline is controlled according to the fracture stop probability of the fracture controllable natural gas pipeline. The fracture controllable natural gas pipeline has good safety, and fracture of the fracture controllable natural gas pipeline can be controlled by acquiring the fracture stop probability of the fracture controllable natural gas pipeline and the ductility requirement thereof.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Simulation test device and method for multi-angle tilt drilling grouting technology for coal seam bottom plate under effect of pressure-bearing flowing water

ActiveCN109441441AEasy to observeOptimization of grouting processSealing/packingWater sourceOpen source

The invention discloses a simulation test device and method for a multi-angle tilt drilling grouting technology for a coal seam bottom plate under the effect of pressure-bearing flowing water. The simulation test device comprises a test rack, a pressure-bearing aquifer water source applying device, multi-angle drilling and different hole diameter fracture simulation devices and a grouting device;the test rack is used for bearing the multi-angle drilling and different hole diameter fracture simulation device; the multi-angle drilling and different hole diameter fracture simulation devices aredivided into multiple sets according to drilling angles and the sizes of fractures; the pressure-bearing aquifer water source applying device comprises a constant-pressure water pump, a water pressureadjusting valve, an open source fracture and sealed fracture control valve and a flowmeter; and the grouting device comprises a grouting machine, a safety valve, a slurry flushing valve, a grouting channel valve, a grouting hole selecting switch and a disassembly-free flushing valve. According to the simulation test device, simulation of a grouting process layout process, simulation of a dynamicprocess of slurry flowing to diffusion, simulation of drilling tilt angles to the slurry diffusion influence, and scenario simulation of precipitation and condensation mechanisms can be achieved.

Owner:NORTH CHINA INST OF SCI & TECH

Tower crane fracture control room life saving device based on information technology and operation method thereof

InactiveCN112479067ASmooth landingRescue time shortenedParachutesAlarmsMarine engineeringControl room

The invention discloses a tower crane fracture control room life saving device based on an information technology and an operation method thereof. The tower crane fracture control room life saving device comprises a tower crane, wherein a shell is fixedly arranged on the front side of the tower crane; a pop-up cavity with an upward opening is formed in the shell; guide columns are symmetrically and fixedly arranged at the left and right positions of the bottom wall of the pop-up cavity; guide blocks which are in sliding fit with the left and right side walls of the pop-up cavity are arranged on the guide columns; a pop-up block is fixedly arranged between the guide blocks; the bottom of the pop-up block is fixedly connected with the bottom wall of the pop-up cavity through two first springs; pistons which are fixed on the bottom wall of the pop-up cavity are symmetrically arranged at the left and right positions between the first springs; the pop-up block abuts against the pistons; when a control room is in the air, the gravity center of the control room is adjusted through a balancing weight; meanwhile, the control room is stabilized in the air through the matching of a parachuteand a stabilizing parachute; and then the resistance on the parachute is increased through drainage wind power, so that the control room slowly descends.

Owner:蒋来苟

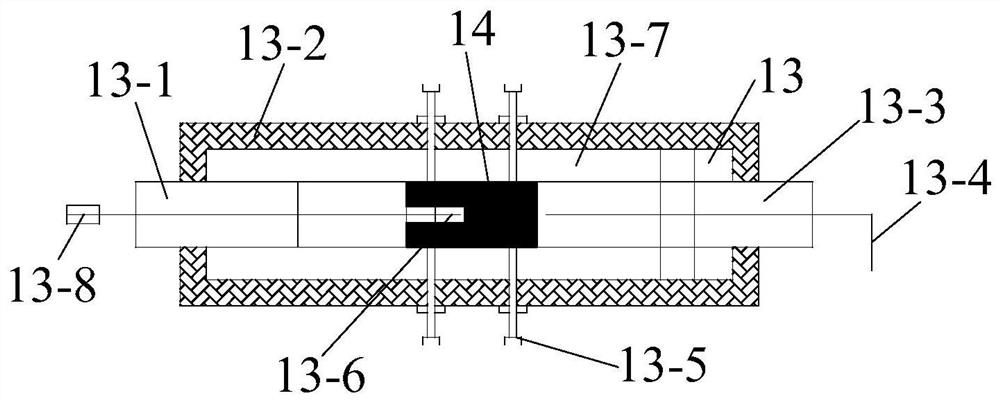

Control method of hydraulic fracturing of hard roof/top coal in cut hole

ActiveCN103527198BFacilitate OrientationReduce air leakageUnderground miningSurface miningHydraulic fracturingEngineering

The invention relates to a hydraulic fracturing control method of cut tight roof / top coal. The method comprises the following steps: constructing two rows of fracturing drill holes at intervals in the roof / top coal above an open-off cut by a drilling machine to a set depth, wherein one row of fracturing drill holes is close to a main upper of the open-off cut while the other row is close to an auxiliary upper of the open-off cut; constructing a row of anchor cable drill holes to the roof / top coal at the left and right ends of the open-off cut, respectively; or constructing rows of fracturing drill holes in different directions in a measure lane of the roof above the open-off cut; carrying out hydraulic fracturing on the drill holes, so that one or more cracks are generated on a rock body in a given plane to split the rock stratum to blocks or layers in certain shapes and sizes so as to damage the integrity of the rock and reduce the strength of the rock. Therefore, pressure of the roof in a large area and sudden extrusion of accumulated gases in a worked out section in an early mining stage on a coal face are prevented, air leak on the coal face is reduced, and the safety is ensured. Meanwhile, caving of top coal can be improved. The method is simple, convenient to construct, safe and reliable and good in effect.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com