Patents

Literature

120results about How to "Join smoothly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

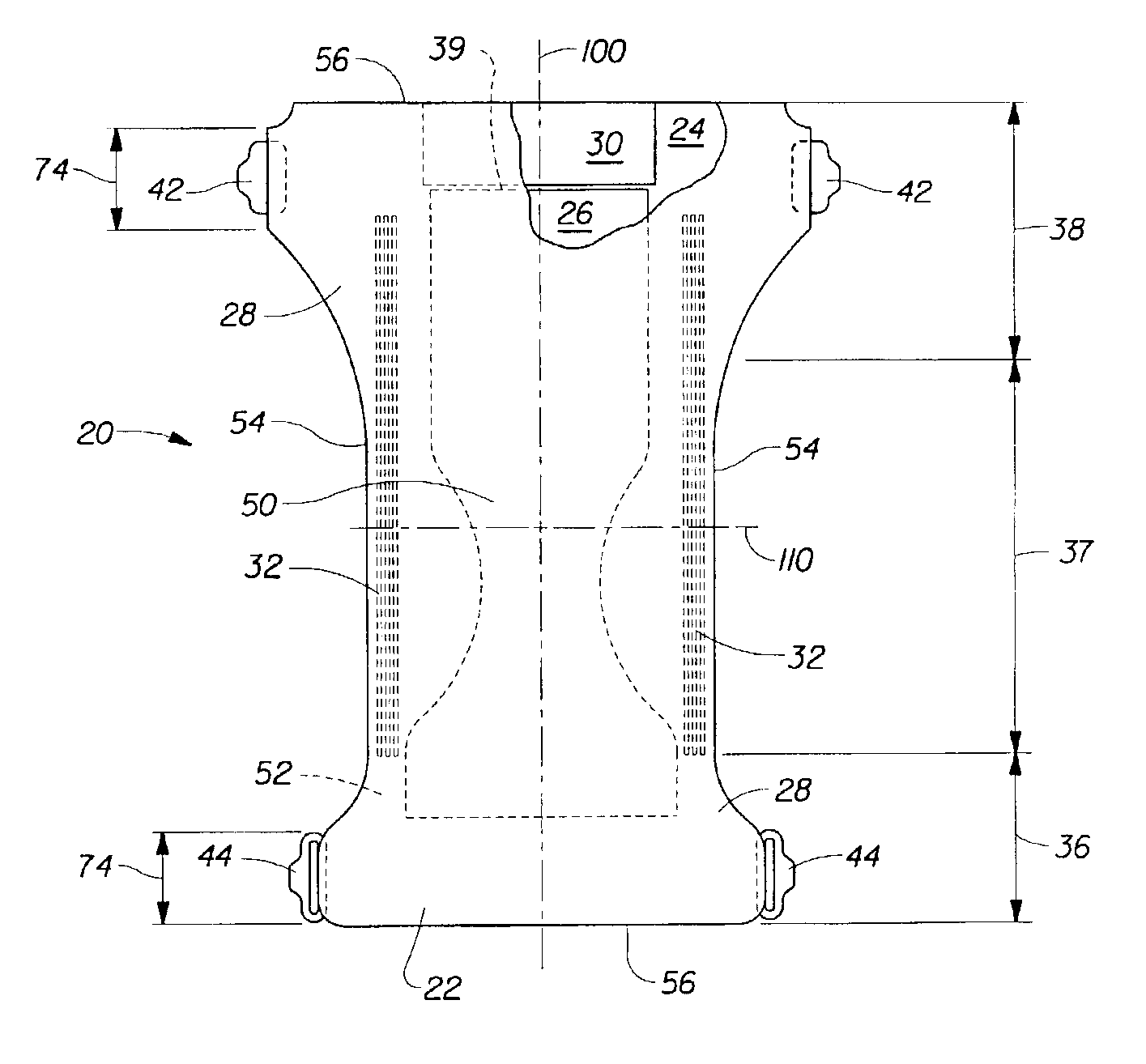

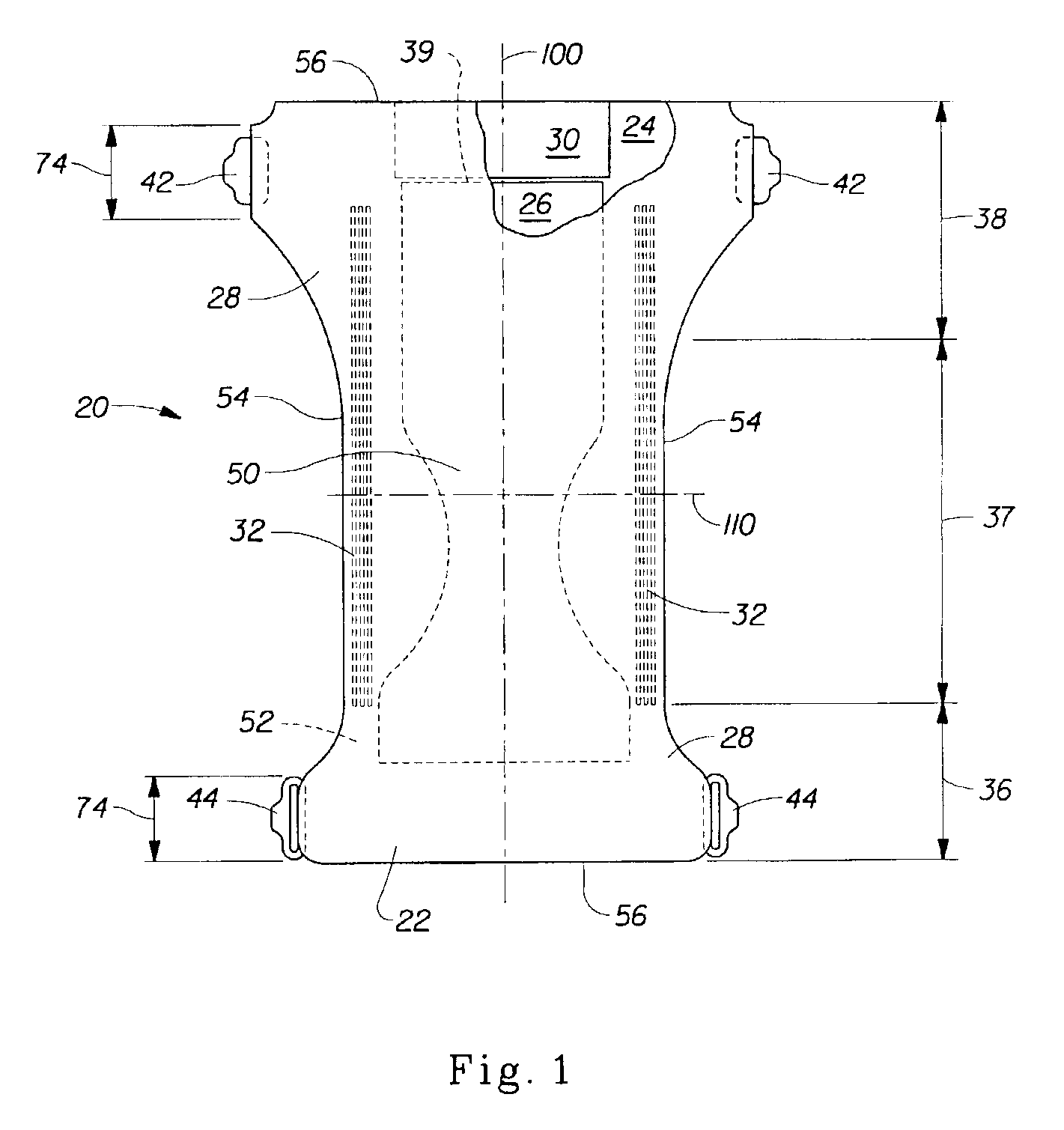

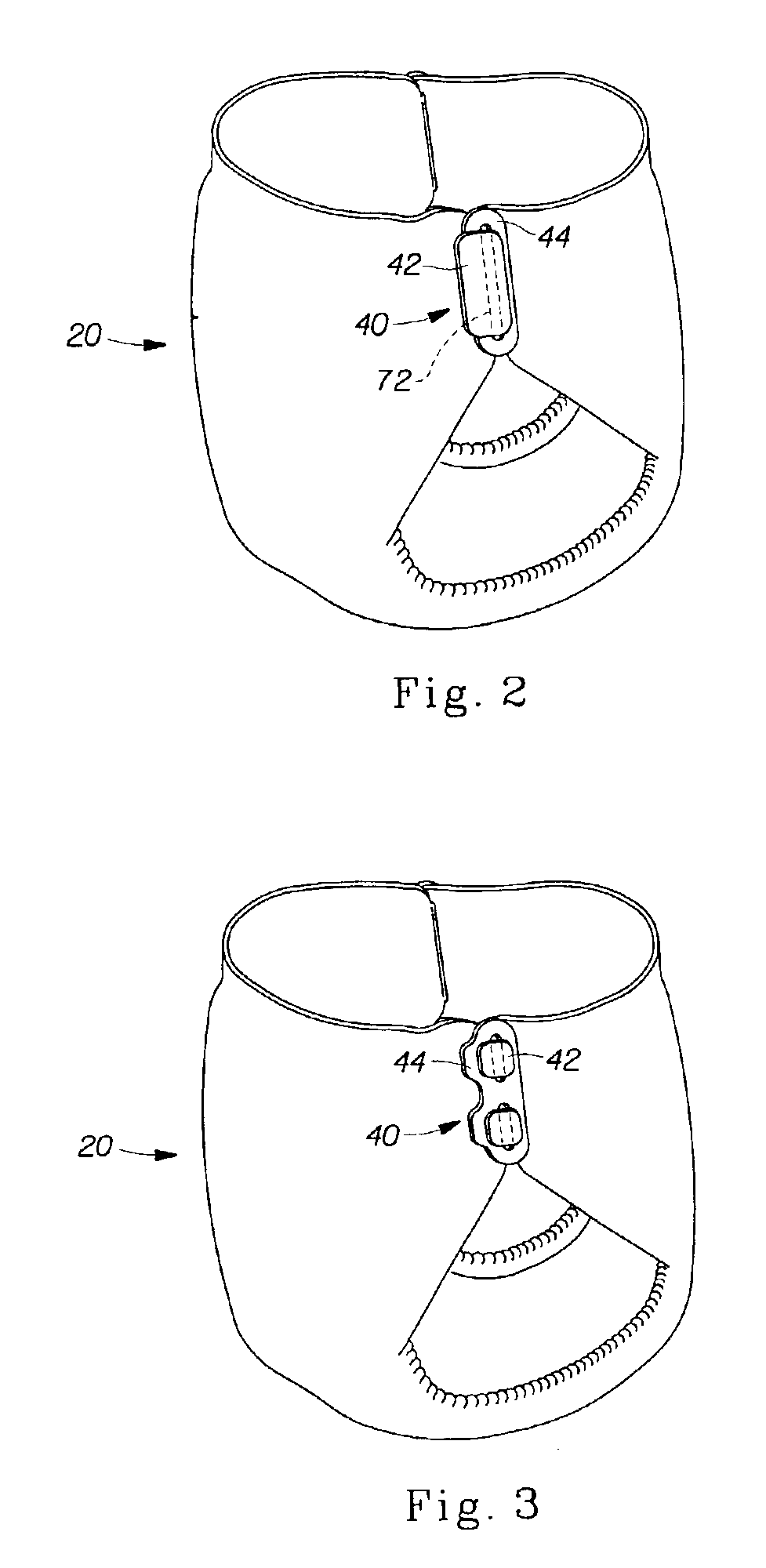

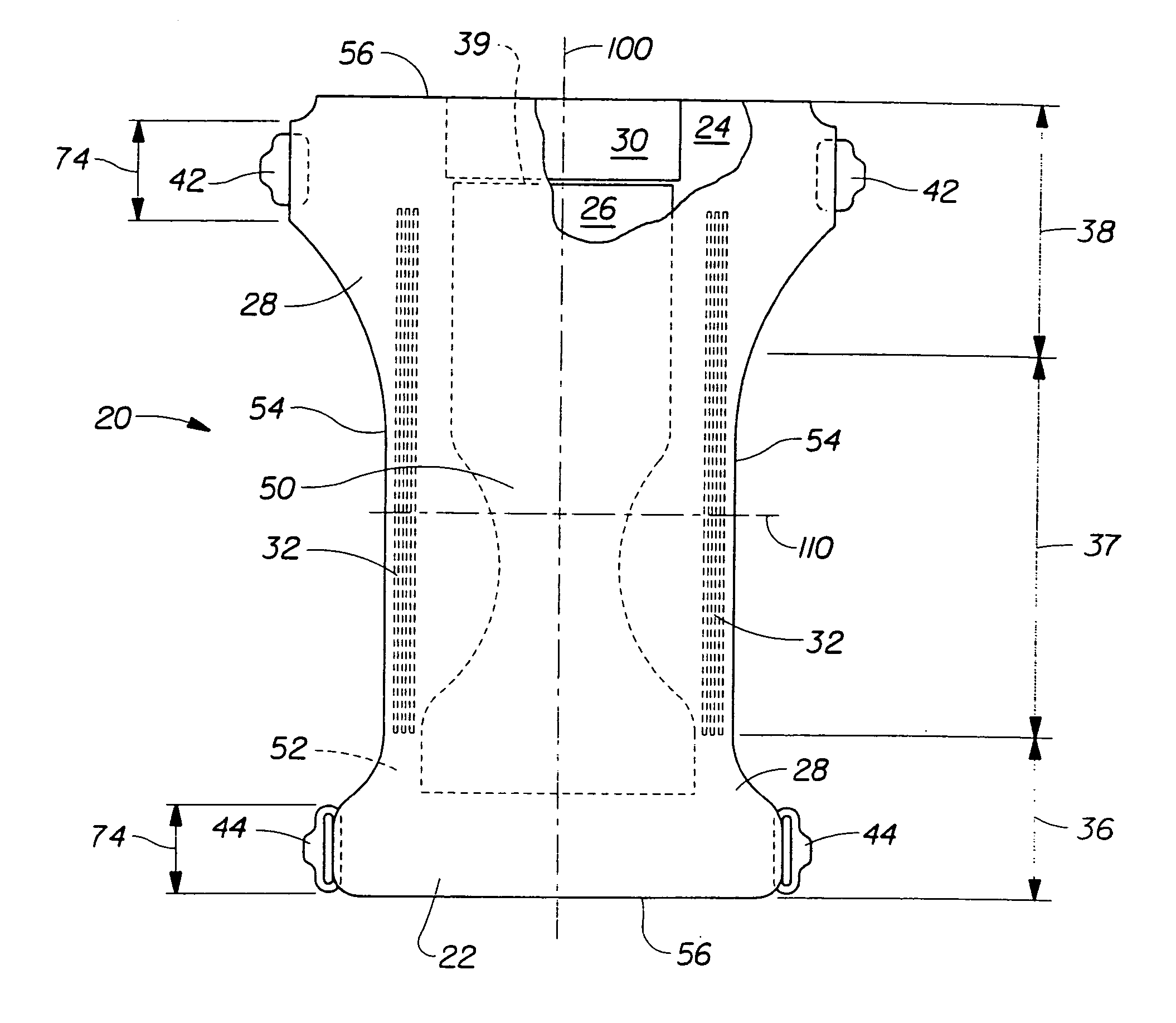

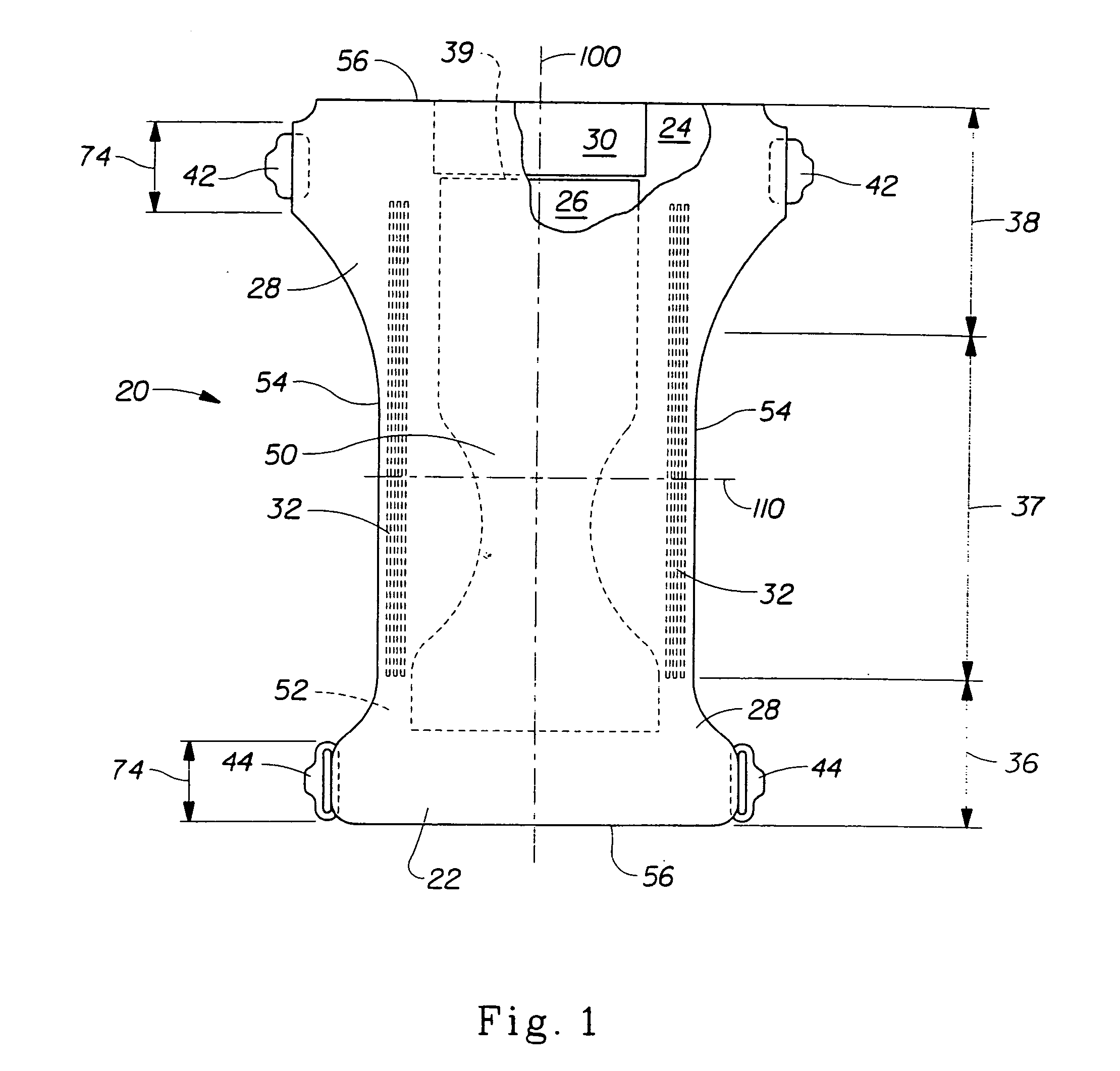

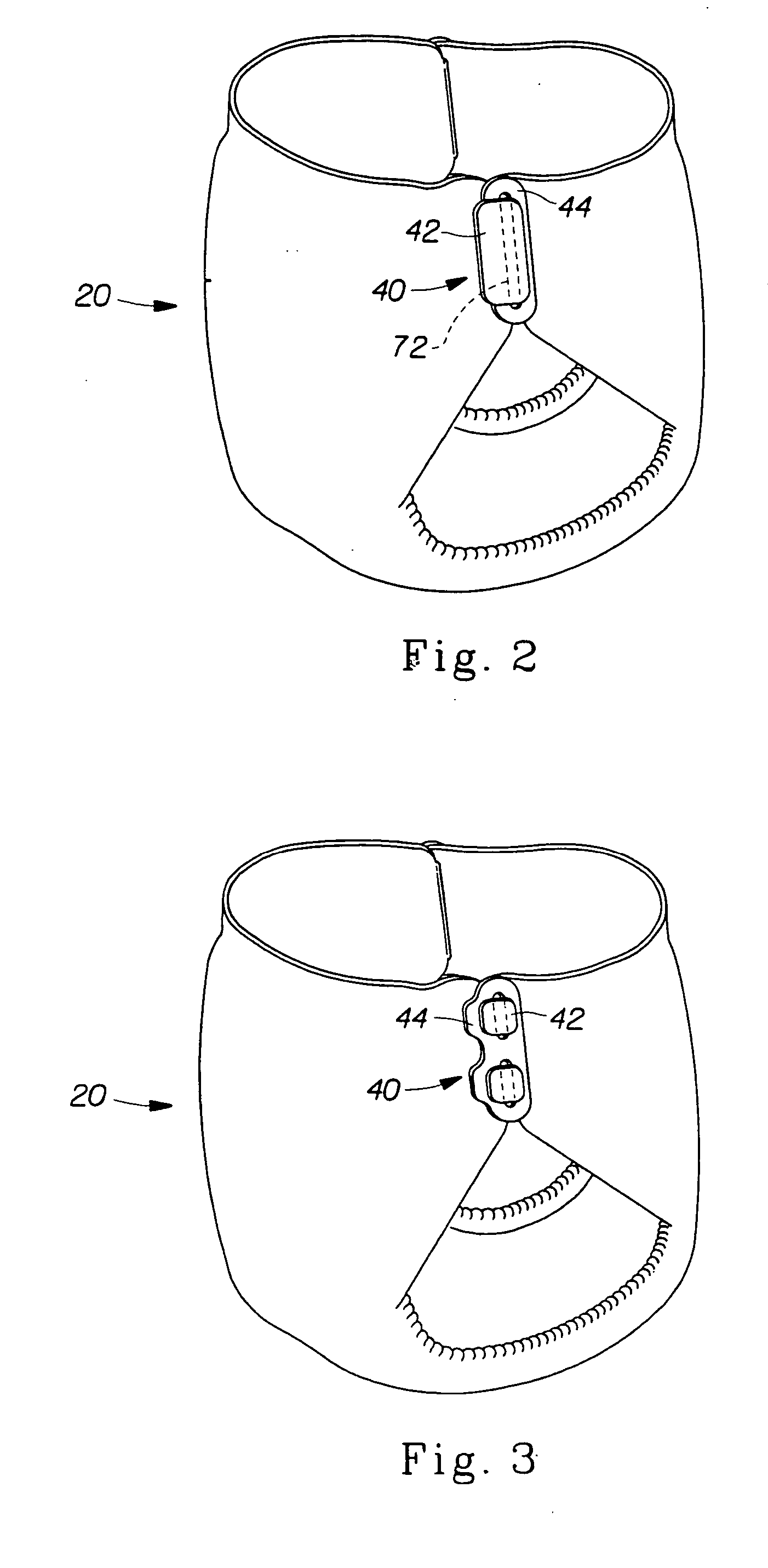

Absorbent article fastening device

Owner:THE PROCTER & GAMBLE COMPANY

Absorbent article fastening device

Owner:THE PROCTER & GAMBLE COMPANY

Sealing glass composition, sealing glass frit, and sealing glass sheet

A sealing glass composition which has an alkali metal oxide content kept down as much as possible, and can stably join metal or ceramic members together in a temperature range of 600 to 900° C. The sealing glass composition is used to join together members each selected from the group consisting of metal members and ceramic members, and comprises, as essential components, 20 to 50 mol % of SiO2, 1 to 9 mol % of Al2O3, 5 to 25 mol % of B2O3, 10 to 40 mol % of BaO, and 5 to 20 mol % of SrO. ZnO content is 0 to 10 mol %. An alkali metal oxide content is not more than 5 mol %. PbO is substantially not contained. The total content of MgO, CaO, SrO, BaO and ZnO is 30 to 50 mol %.

Owner:NIPPON SHEET GLASS CO LTD

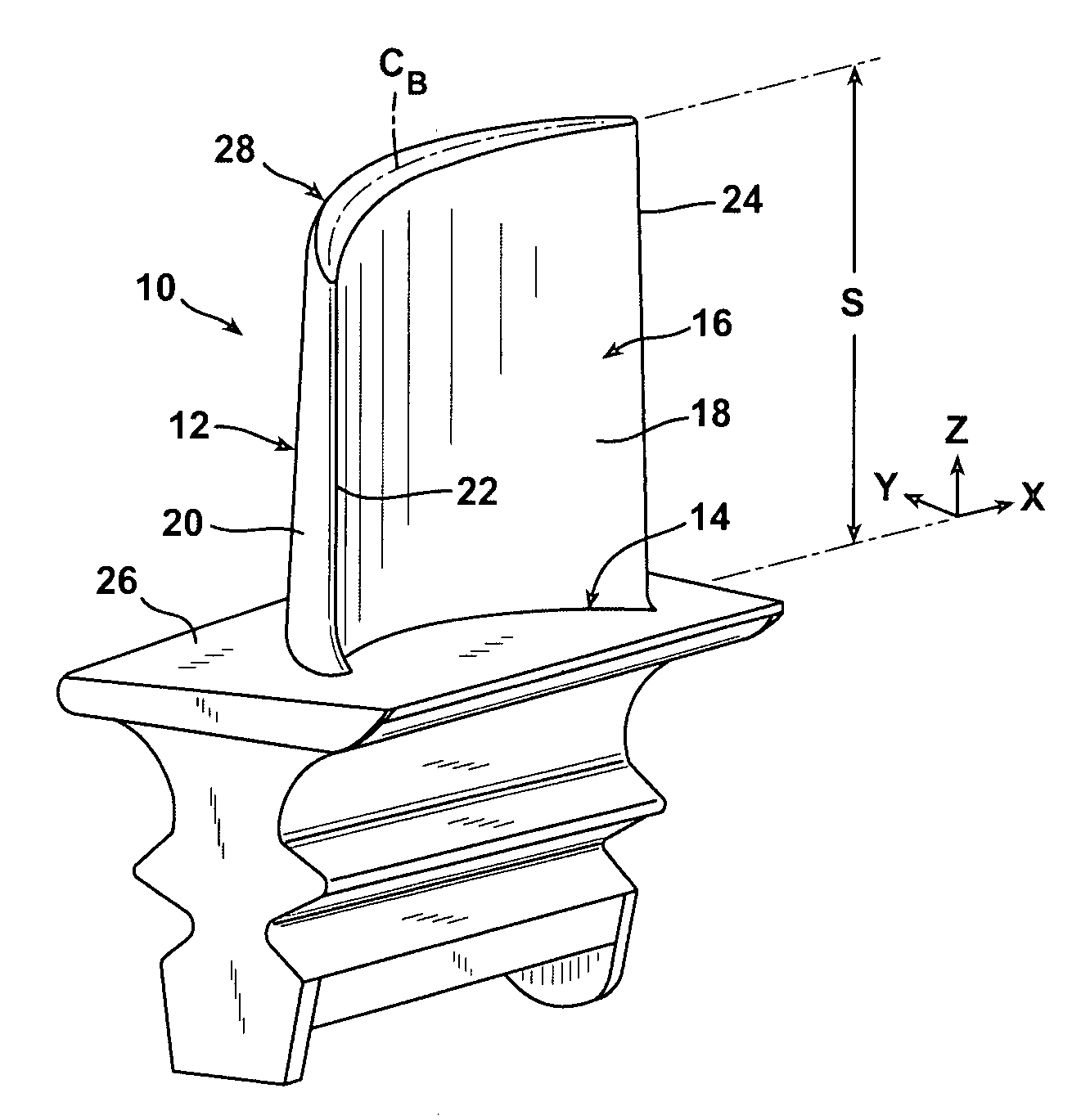

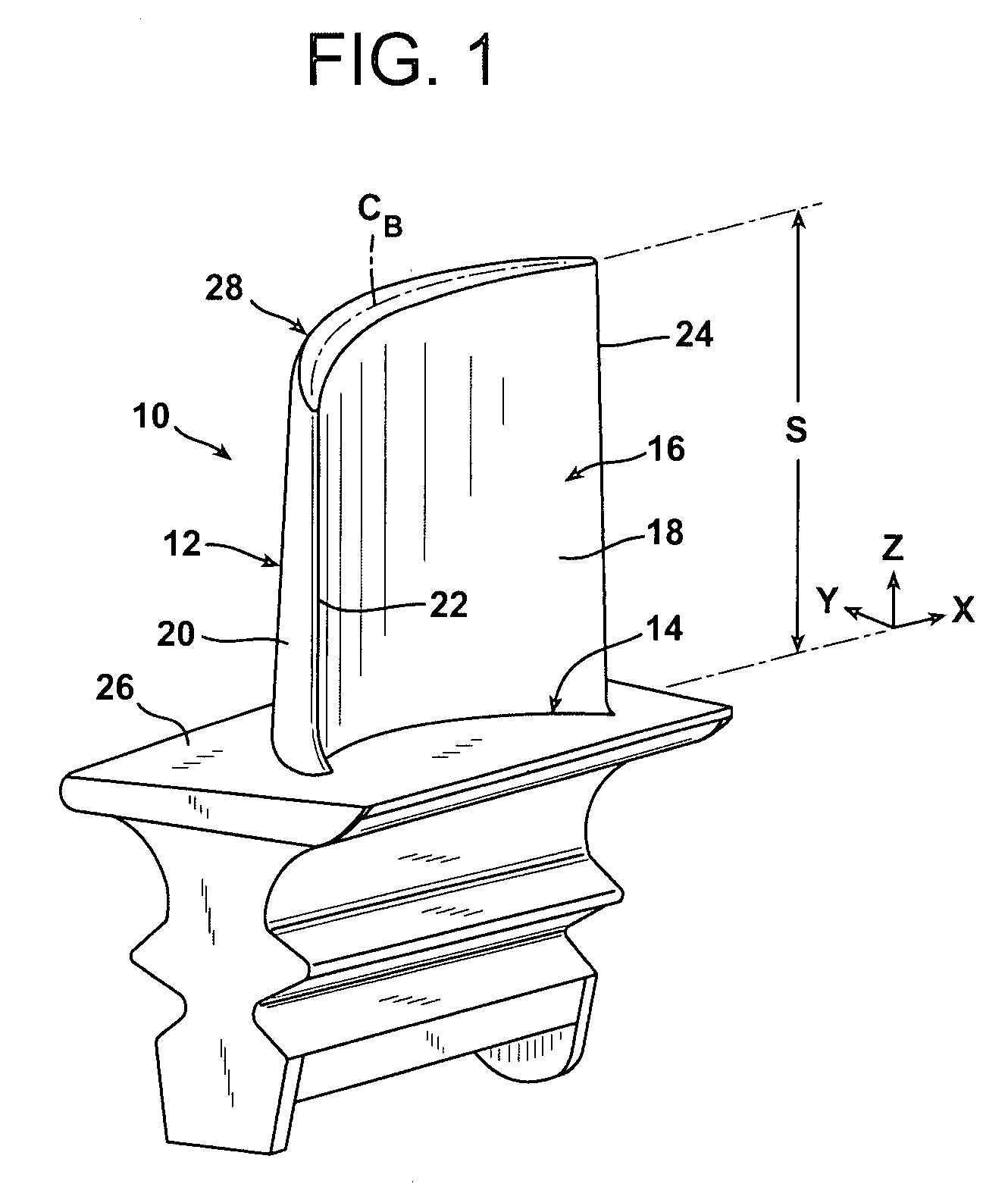

Airfoil shape and sidewall flowpath surfaces for a turbine nozzle

ActiveUS7001147B1Improve performanceJoin smoothlyEngine manufacturePump componentsEngineeringTurbine

Owner:IPSEN MFG IRELAND +1

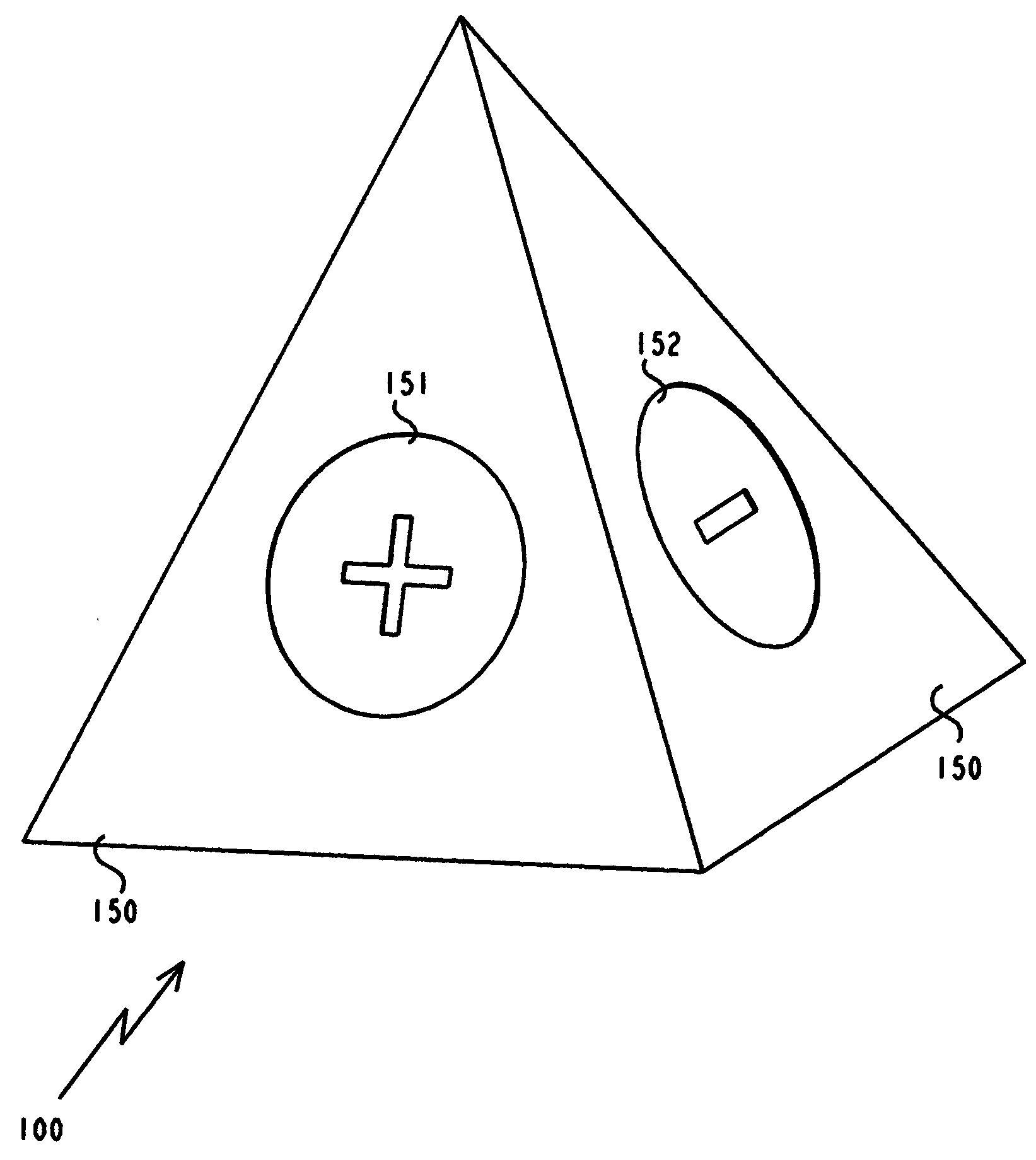

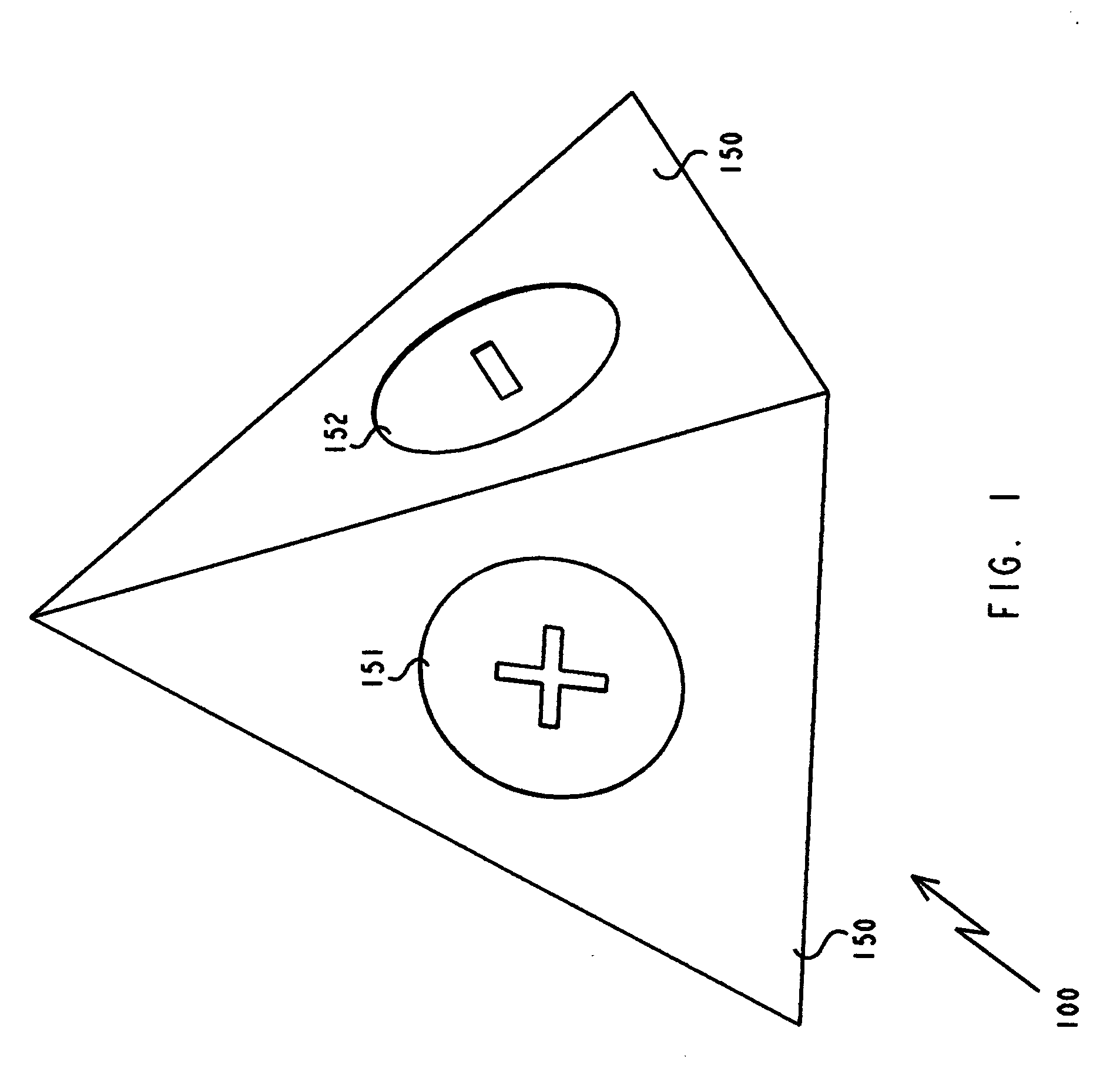

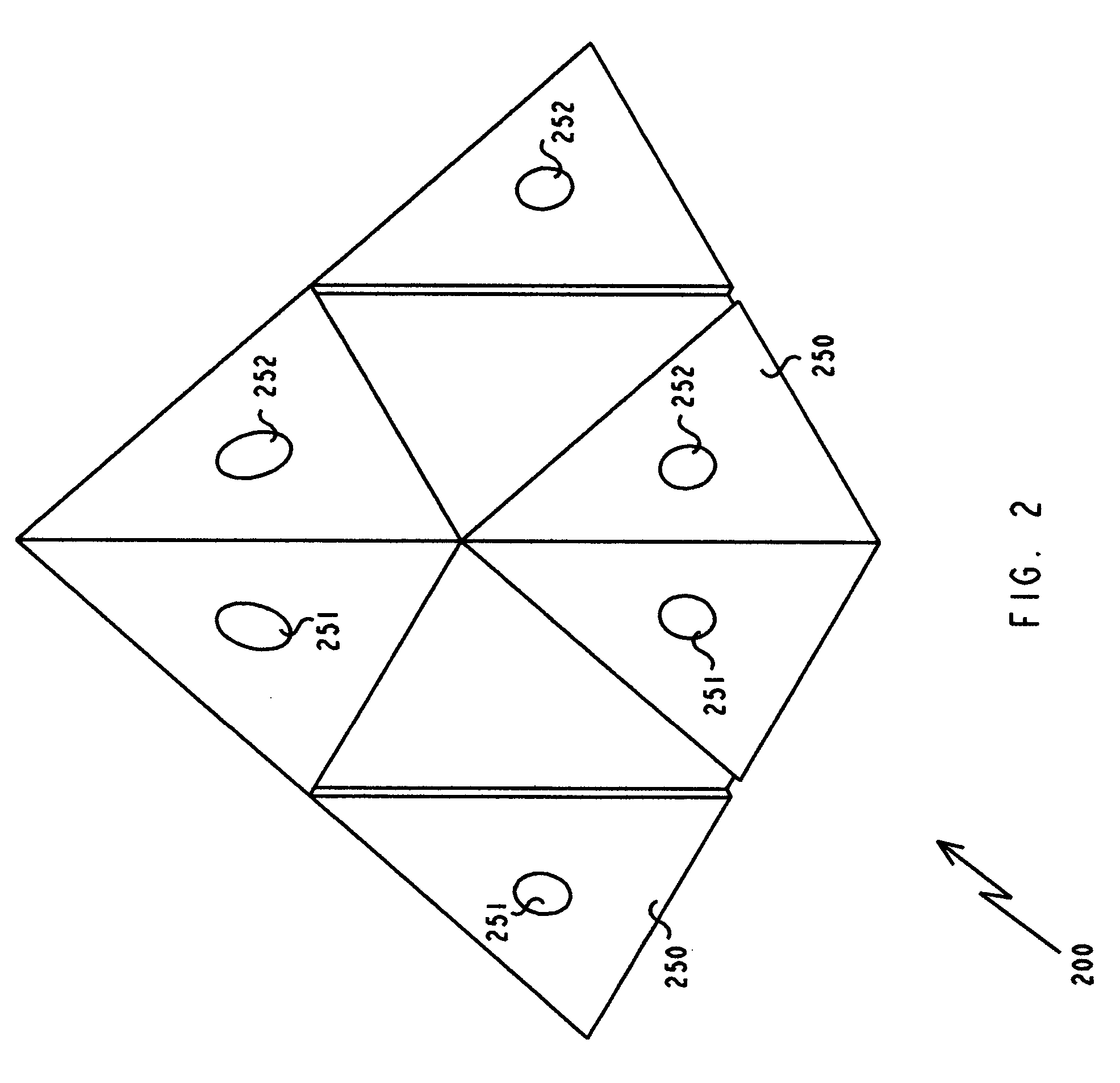

Sacred geometry educational entertainment system

Methods, devices and systems for teaching, learning and understanding sacred geometry concepts through magnetic modular toys comprising a plurality of triangular modular members assembled to form multidimensional hedrons and where in each triangular member includes a magnet such that adjacent members have opposite magnetic polarity facing each triangular member. Platonic solid shapes with interior magnets to hold forms together for construction of larger Platonic solids, geometry learning, and puzzle solving skills. Multidimensional hedrons include simple and small as ell as stellated tetrahedrons, octahedrons, icosahedrons and dodecahedrons.

Owner:FENTRESS WARREN SCOTT

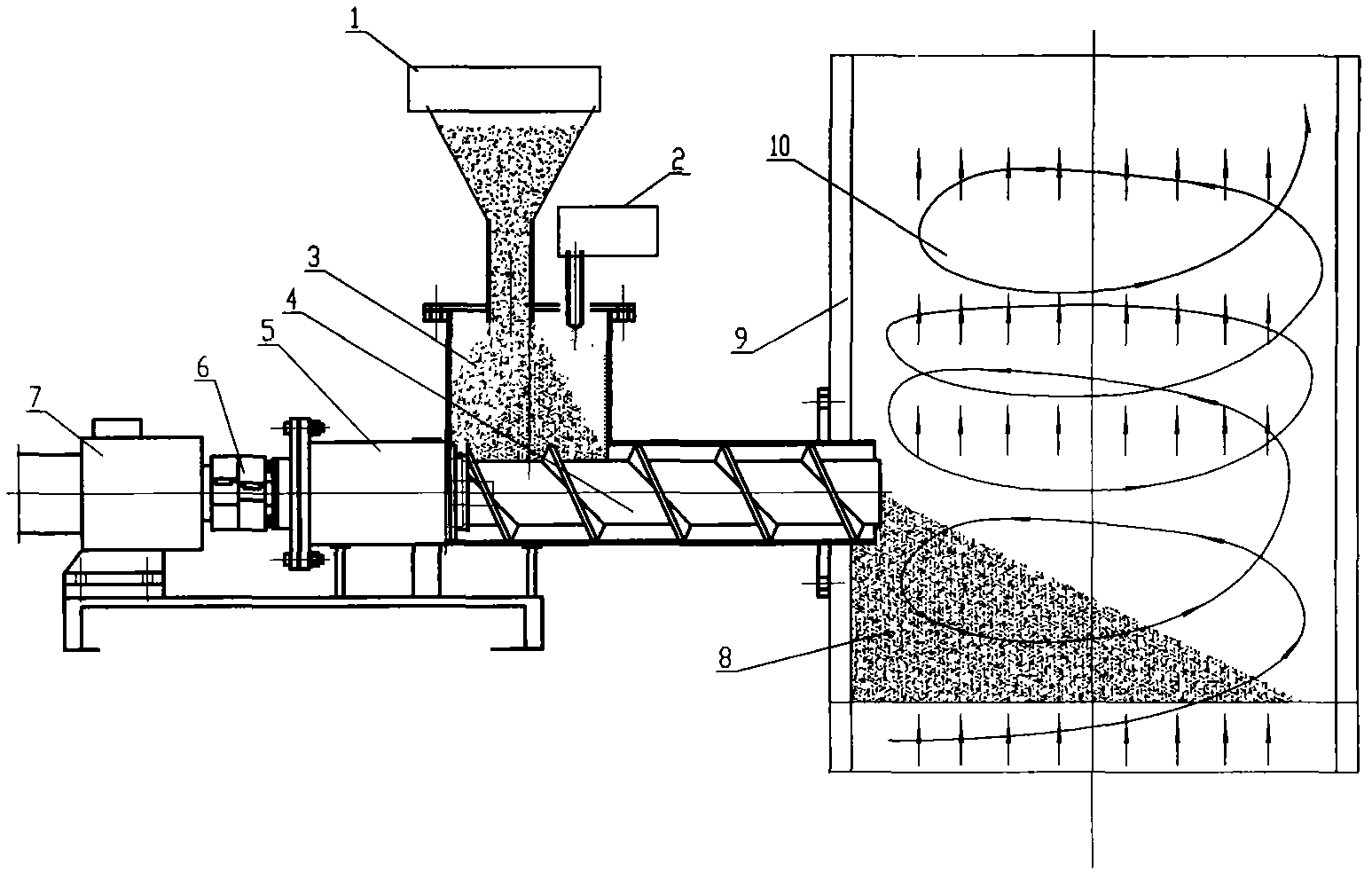

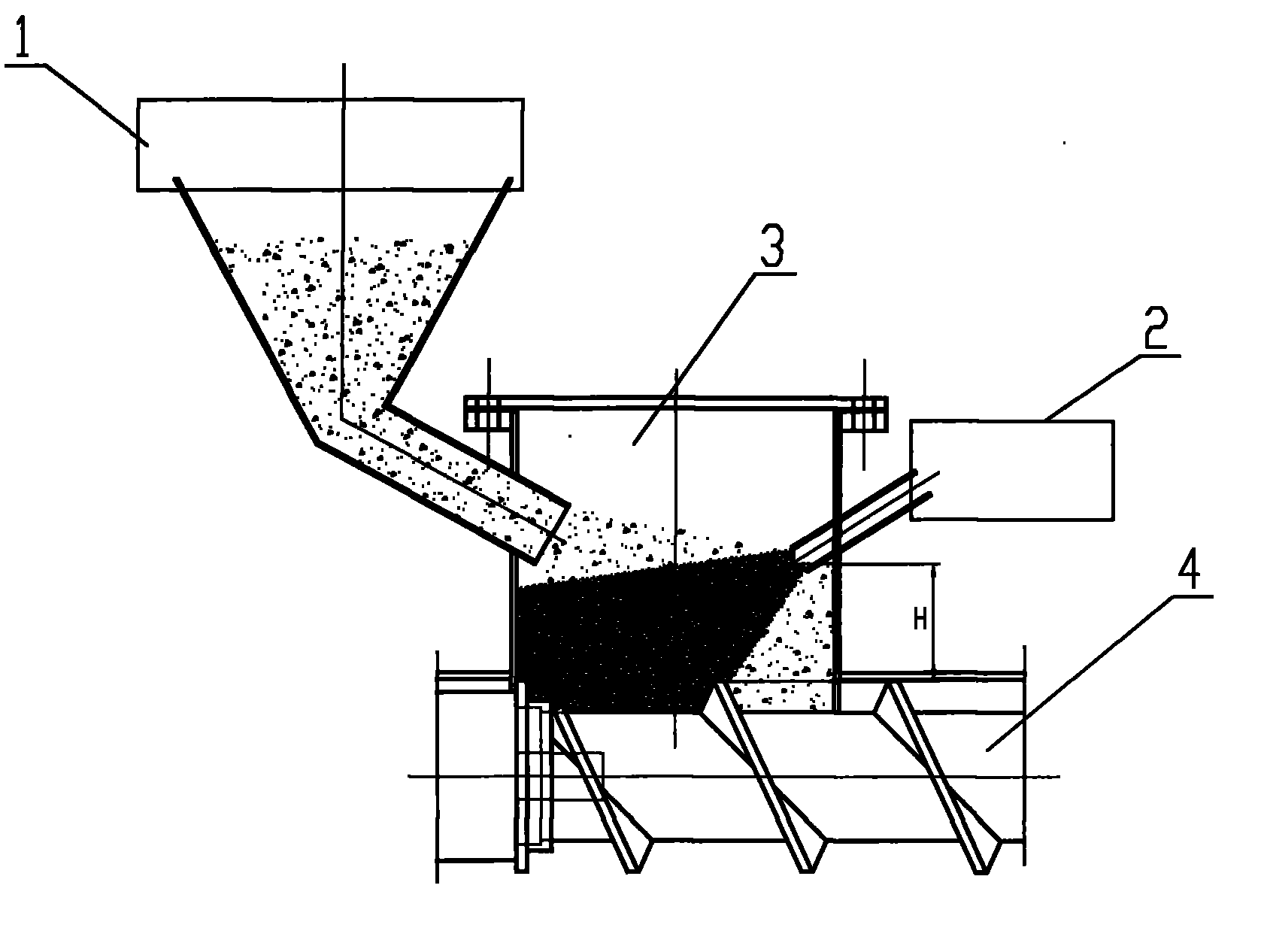

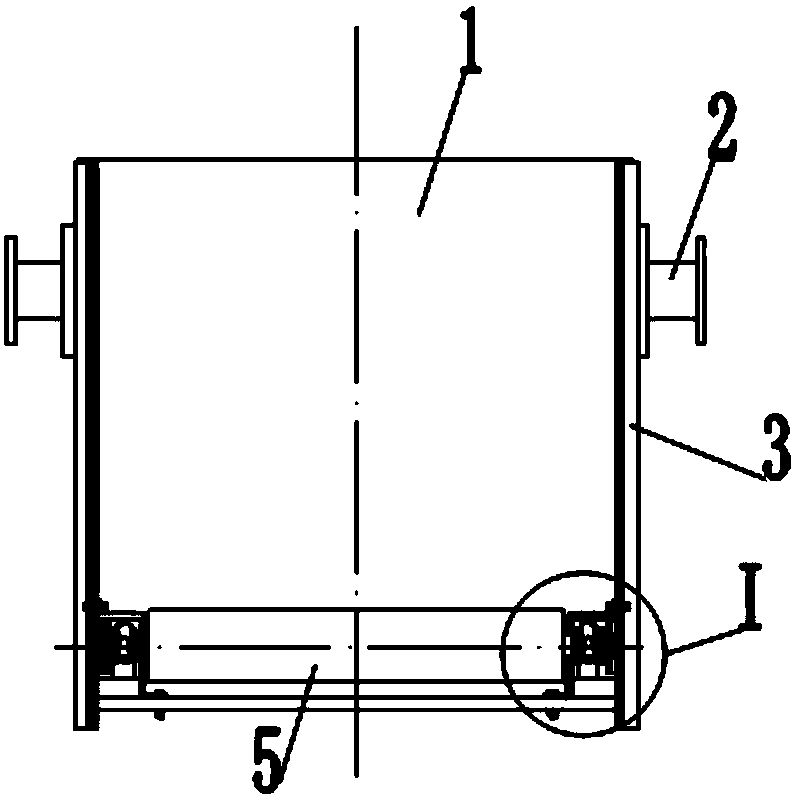

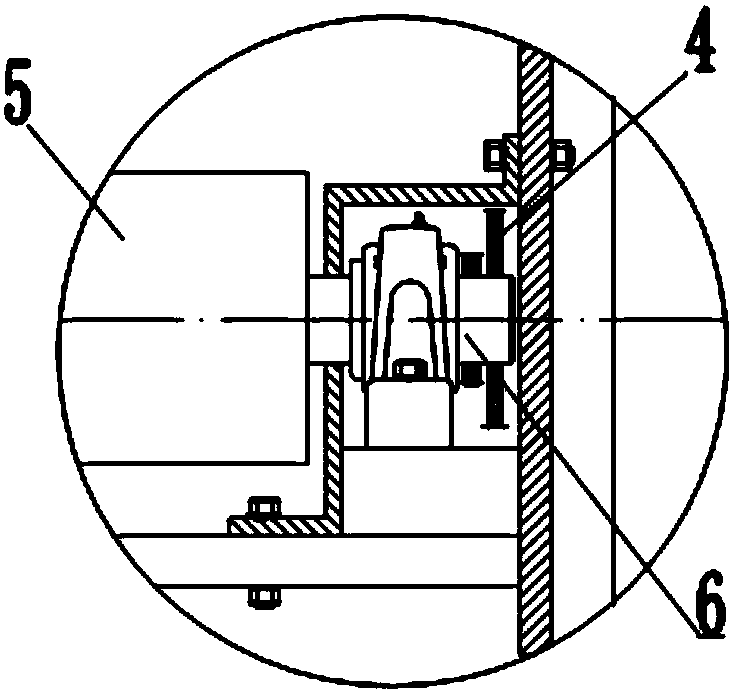

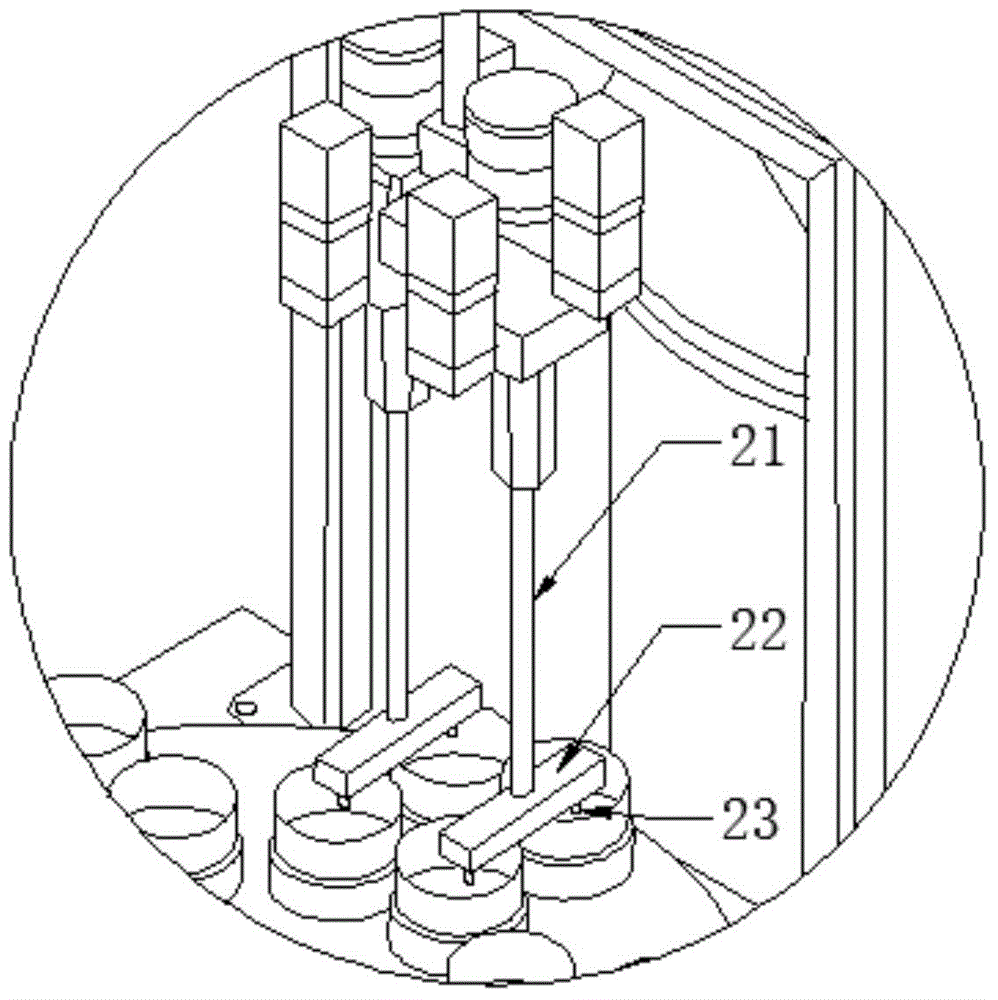

Catalyst successive impregnation equipment and method

ActiveCN102806109AImprove impregnation efficiencyImprove impregnation uniformityCatalyst activation/preparationEngineeringCatalyst support

The invention relates to catalyst successive impregnation equipment and a method. The catalyst successive impregnation equipment comprises a carrier continuous feeding system (1), an impregnation liquid conveying system (2), an impregnation chamber (3), a conveying part (4), a dryer (9) and a power system; the carrier continuous feeding system (1) and the impregnation liquid conveying system (2) are open in the impregnation chamber (3); the bottom of the impregnation chamber (3) is open at the initial end of the conveying part (4); the conveying part (4) is positioned between the impregnation chamber (3) and the dryer (9); an outlet at the tail end of the conveying part (4) is communicated with the dryer (9); and power is provided for the operation of the conveying part (4) by the power system. The invention also discloses the method applying the equipment. The catalyst successive impregnation equipment and the method which are provided by the invention can be used for carrying out catalyst carrier impregnation to prepare a catalyst; a catalyst carrier is continuously impregnated; the impregnation efficiency is high; the impregnation uniformity is good; and the catalyst carrier is crushed a little.

Owner:CHINA PETROLEUM & CHEM CORP +1

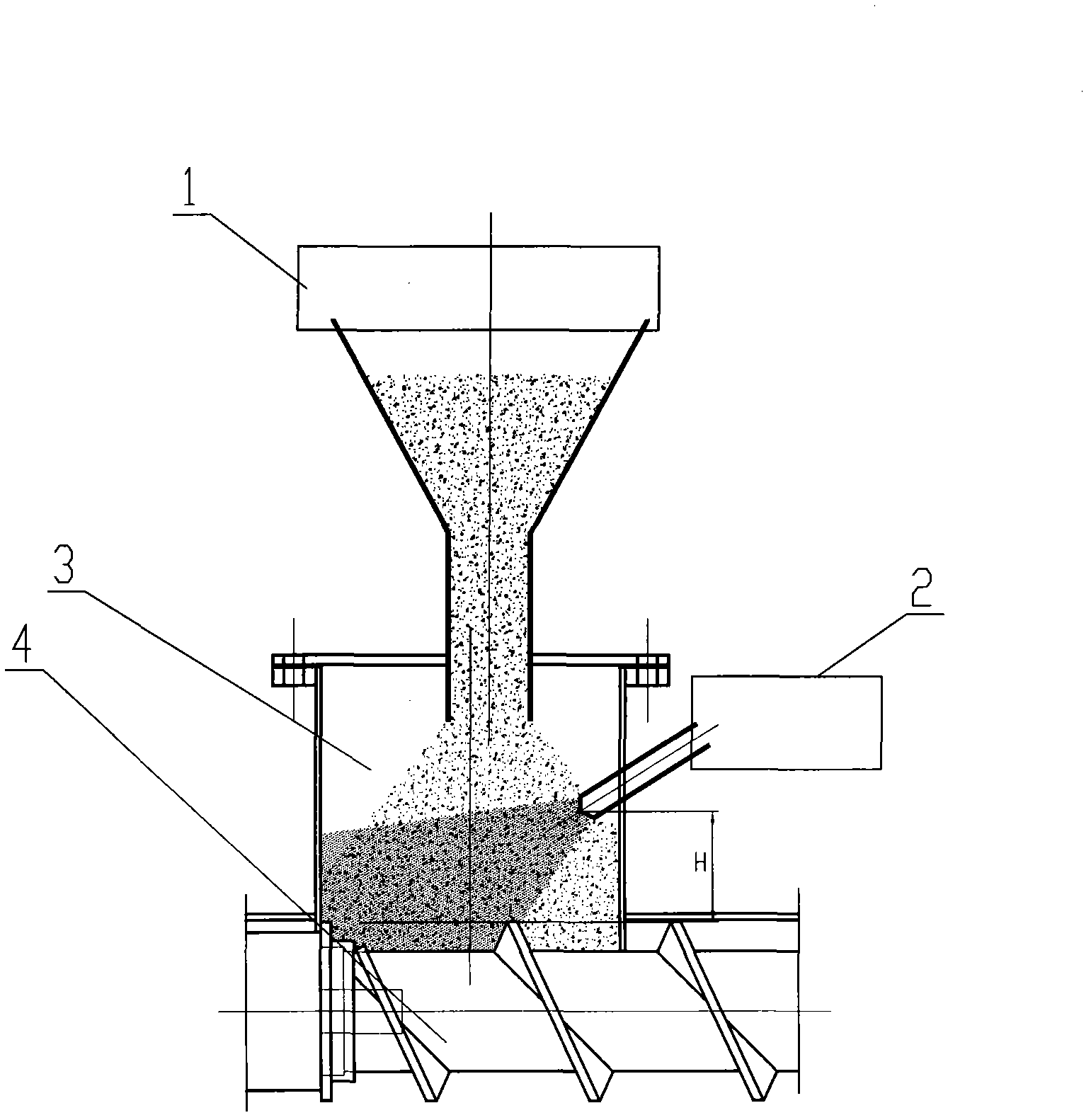

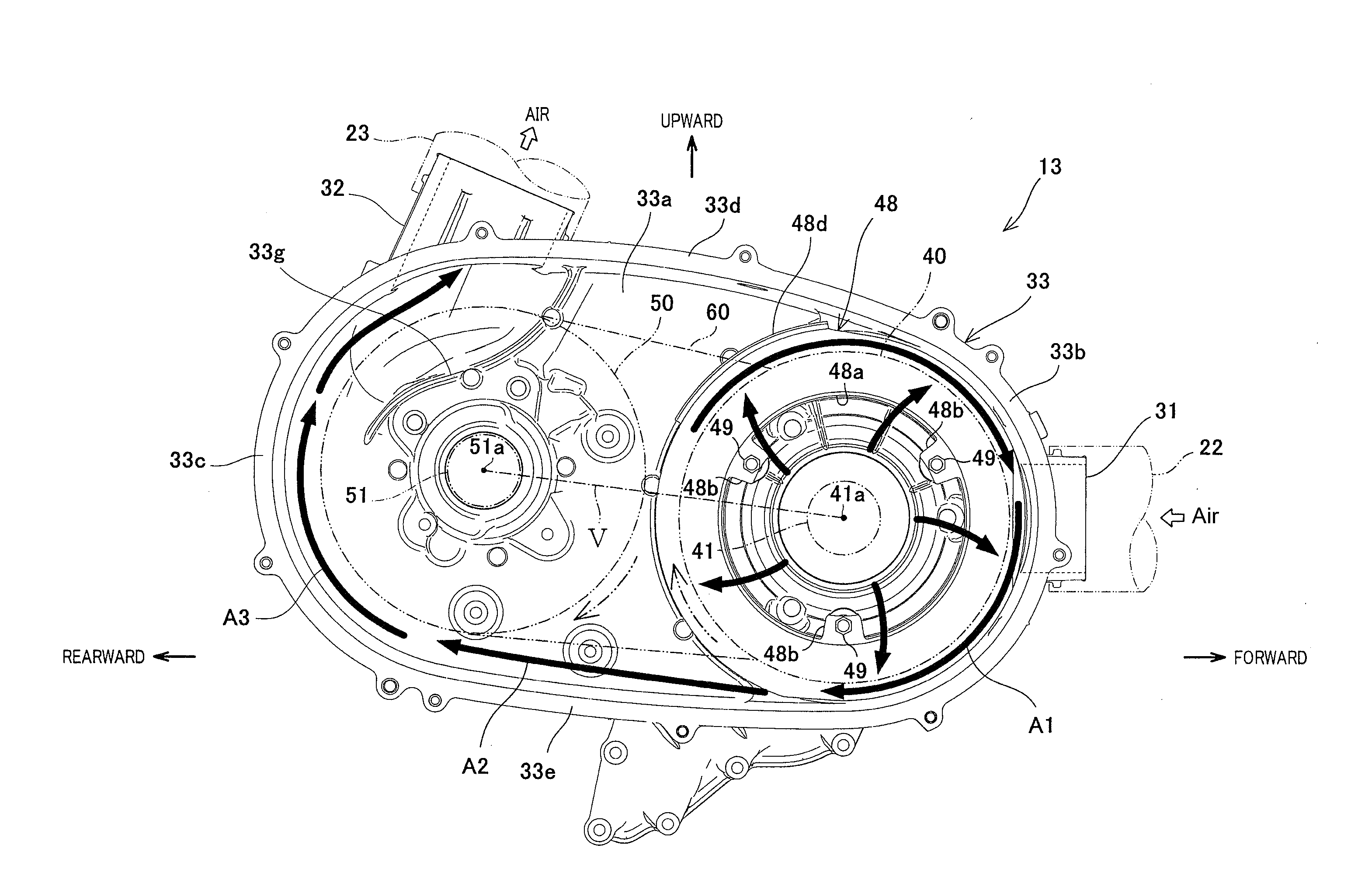

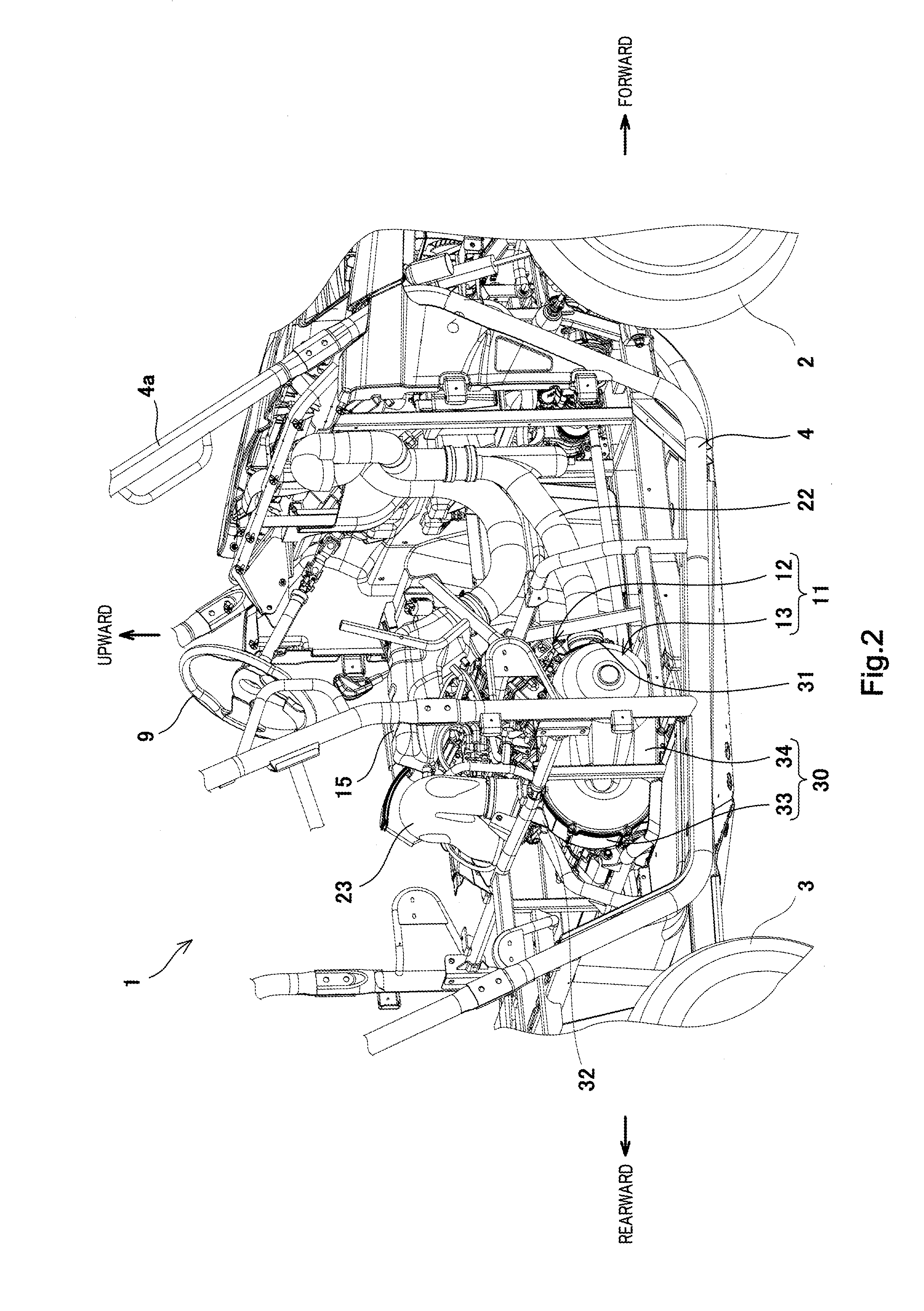

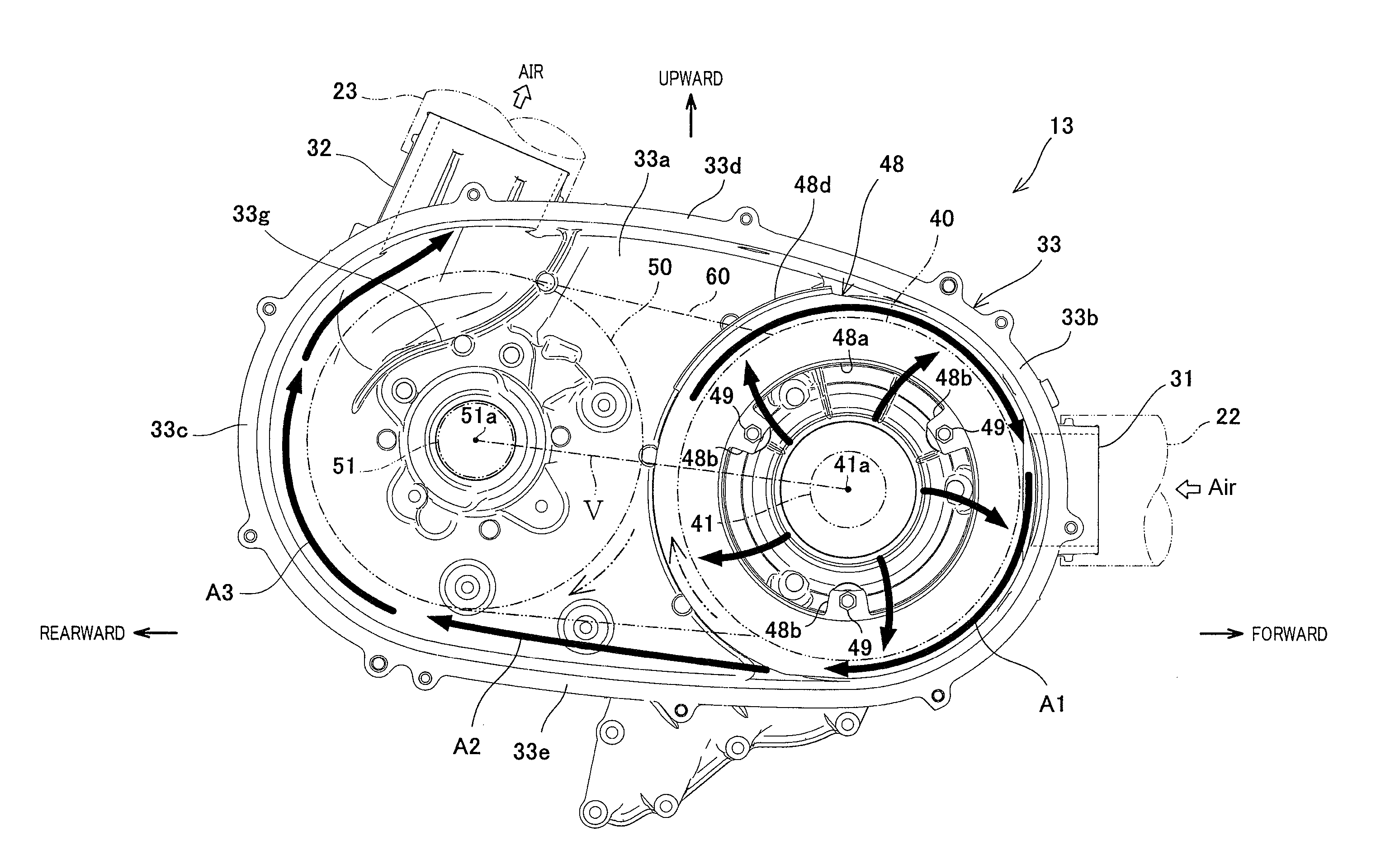

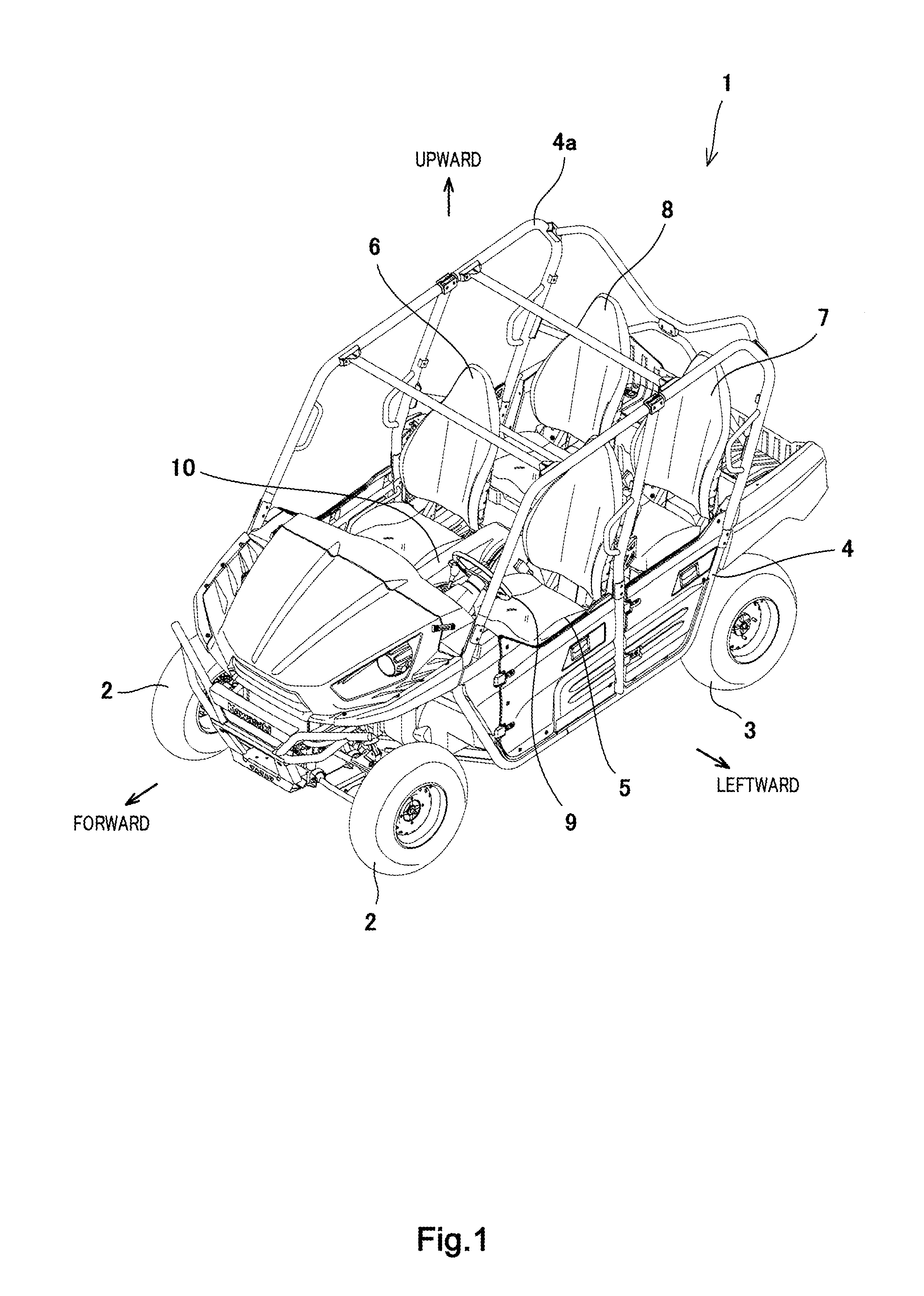

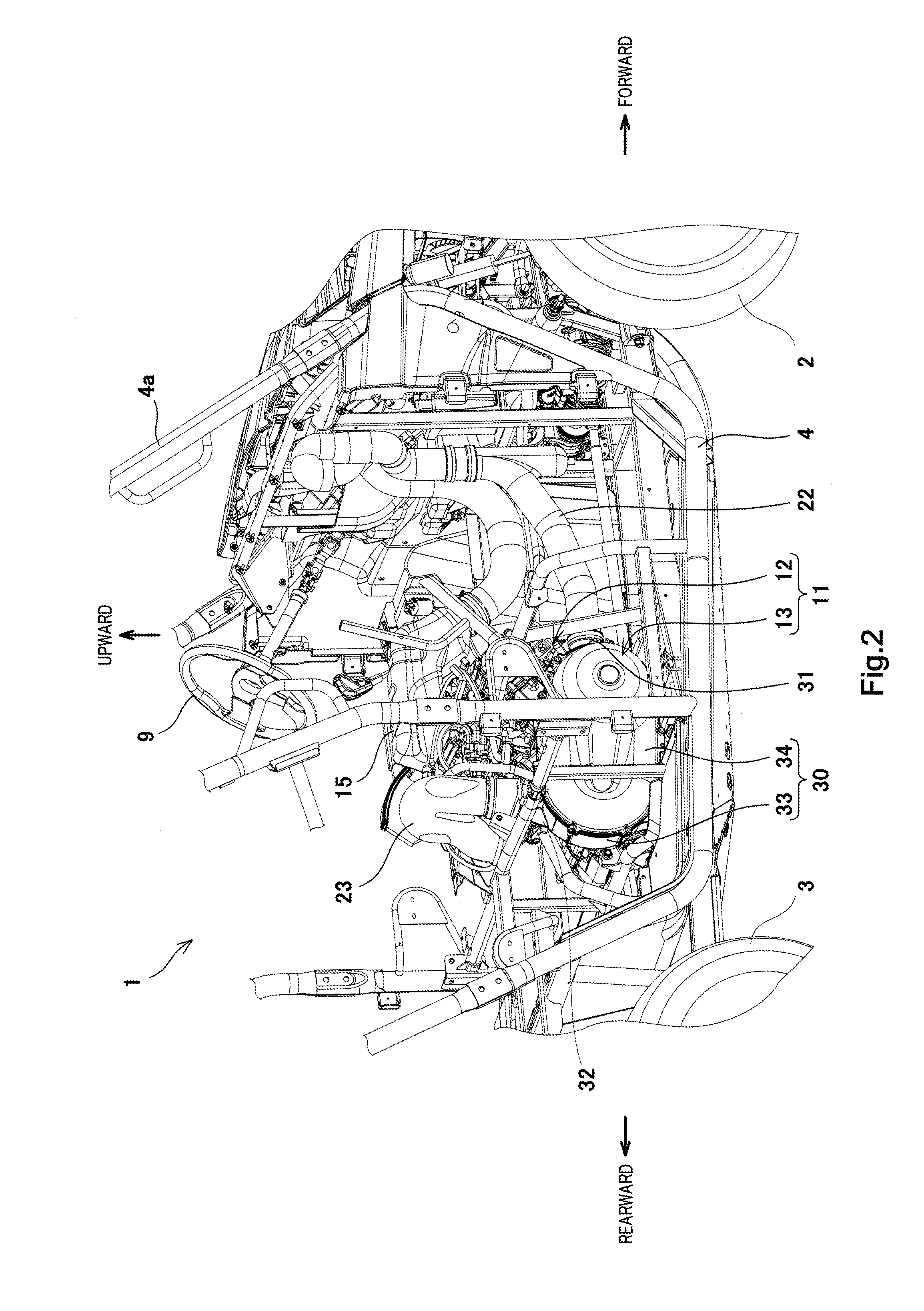

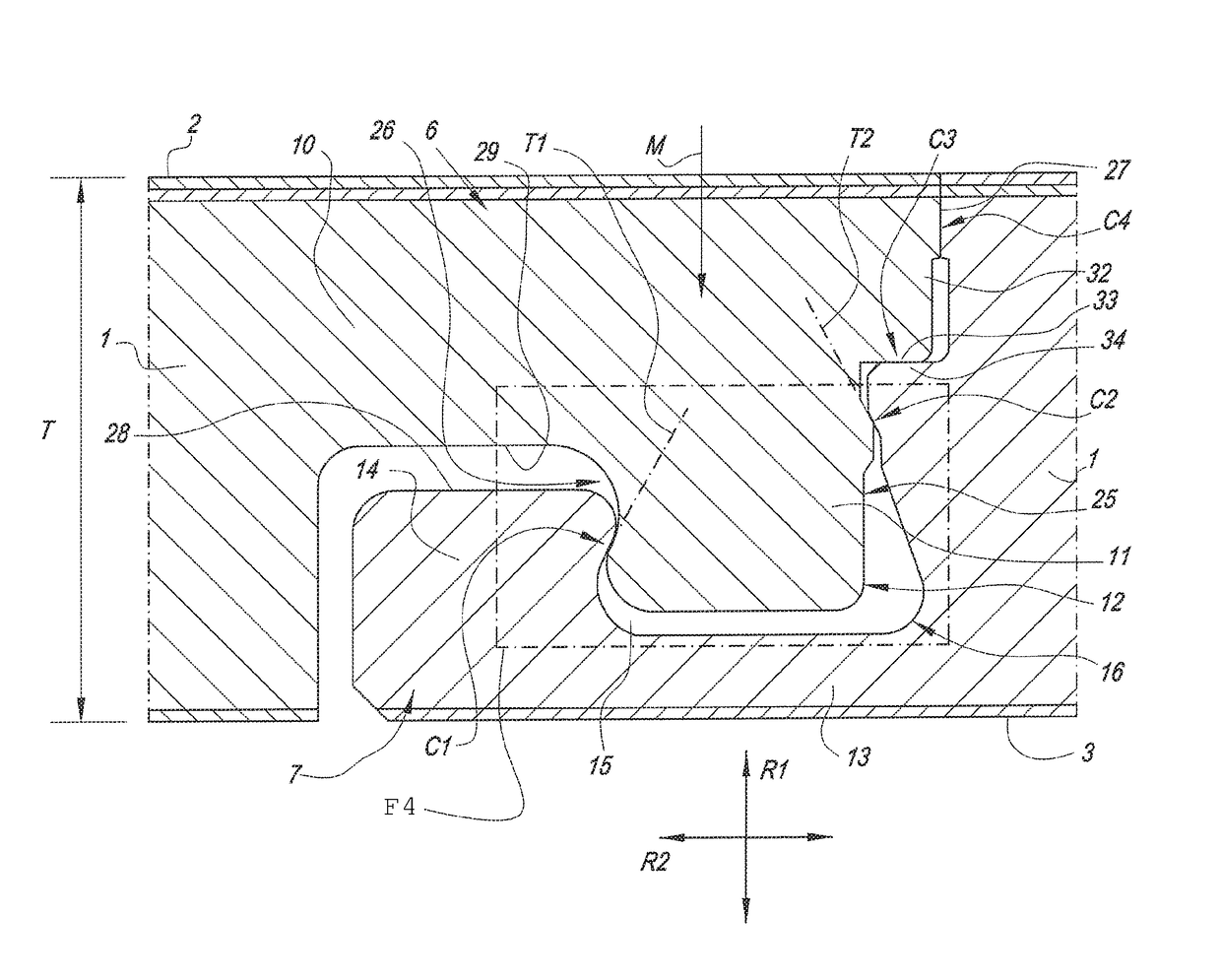

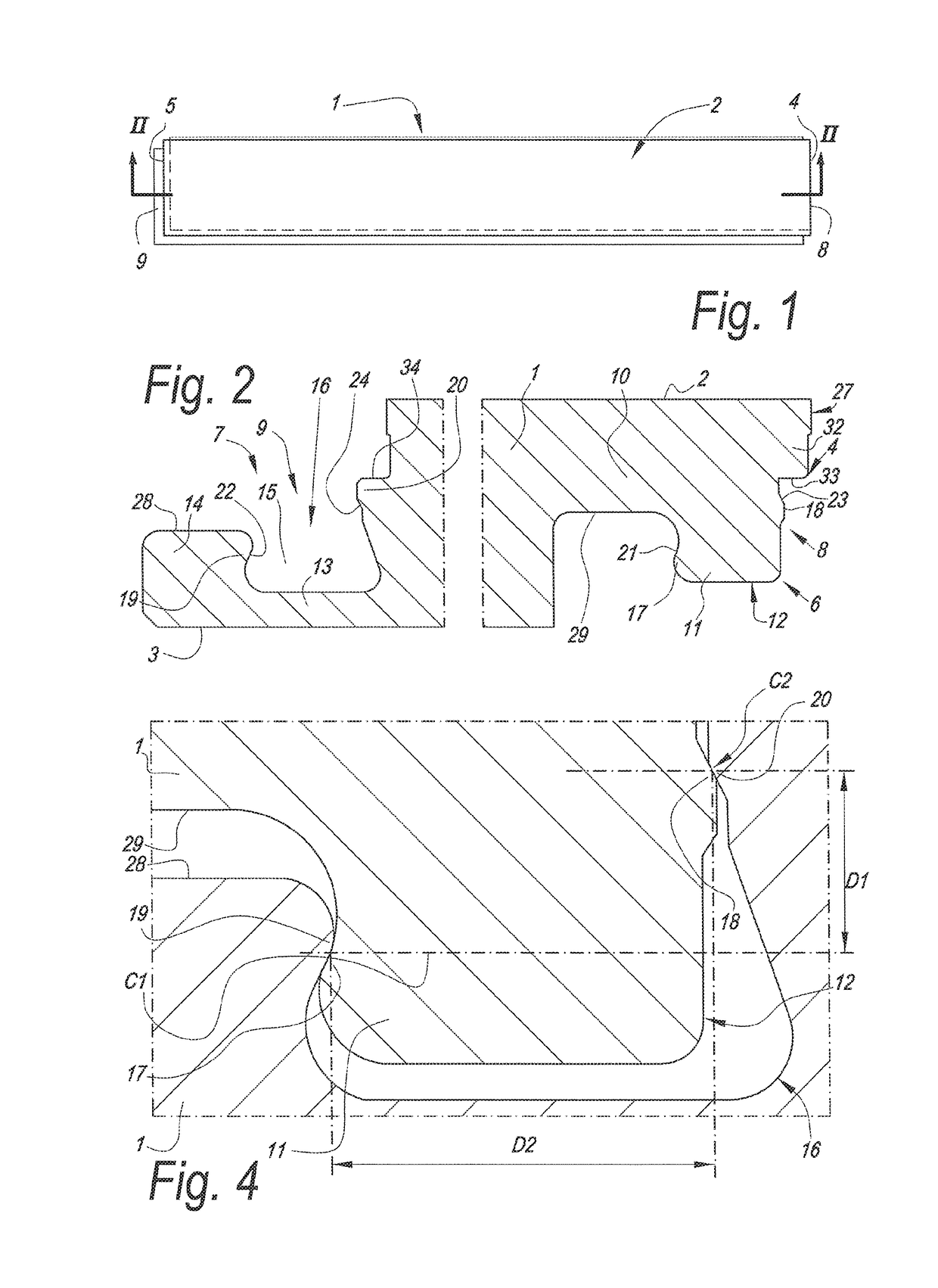

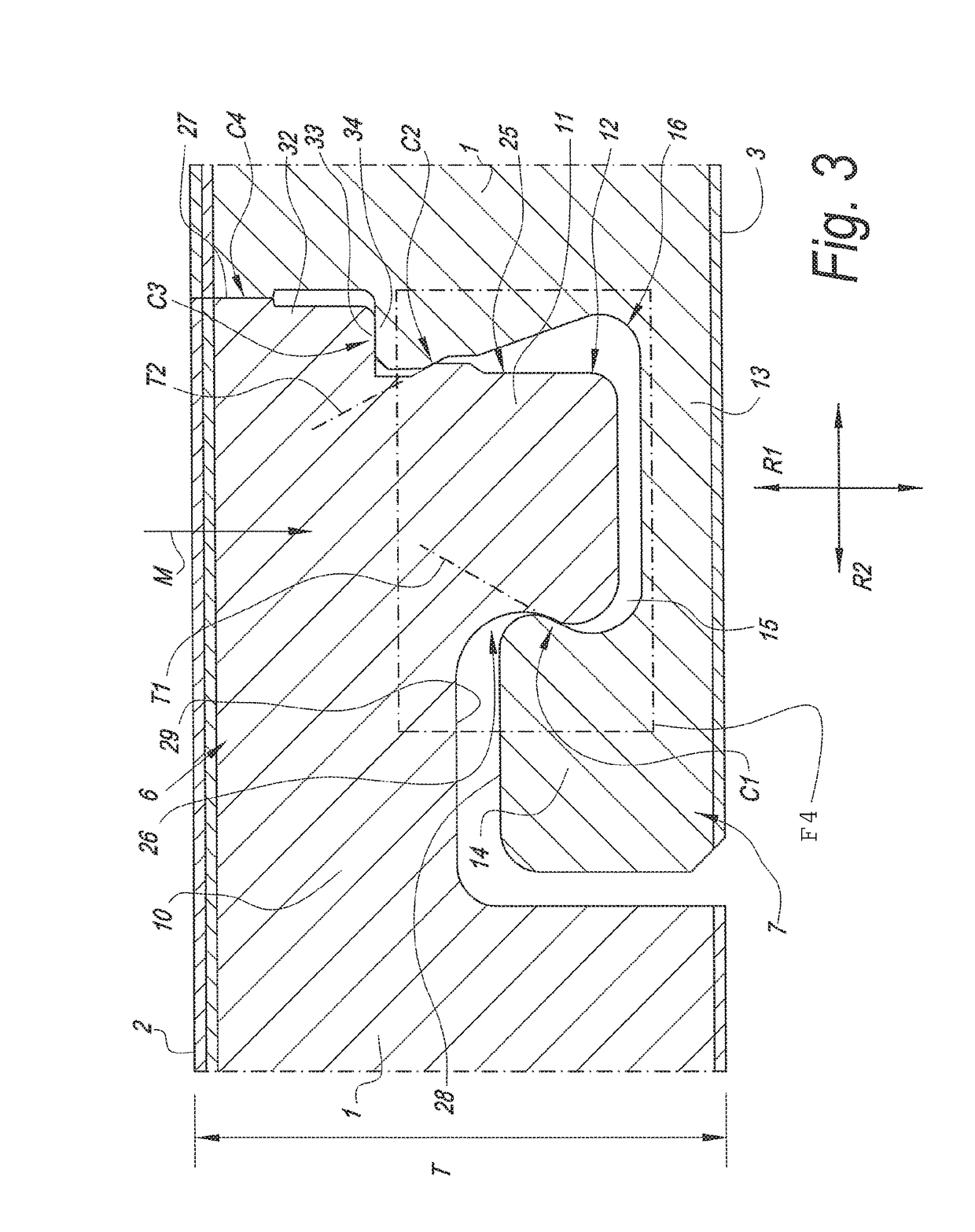

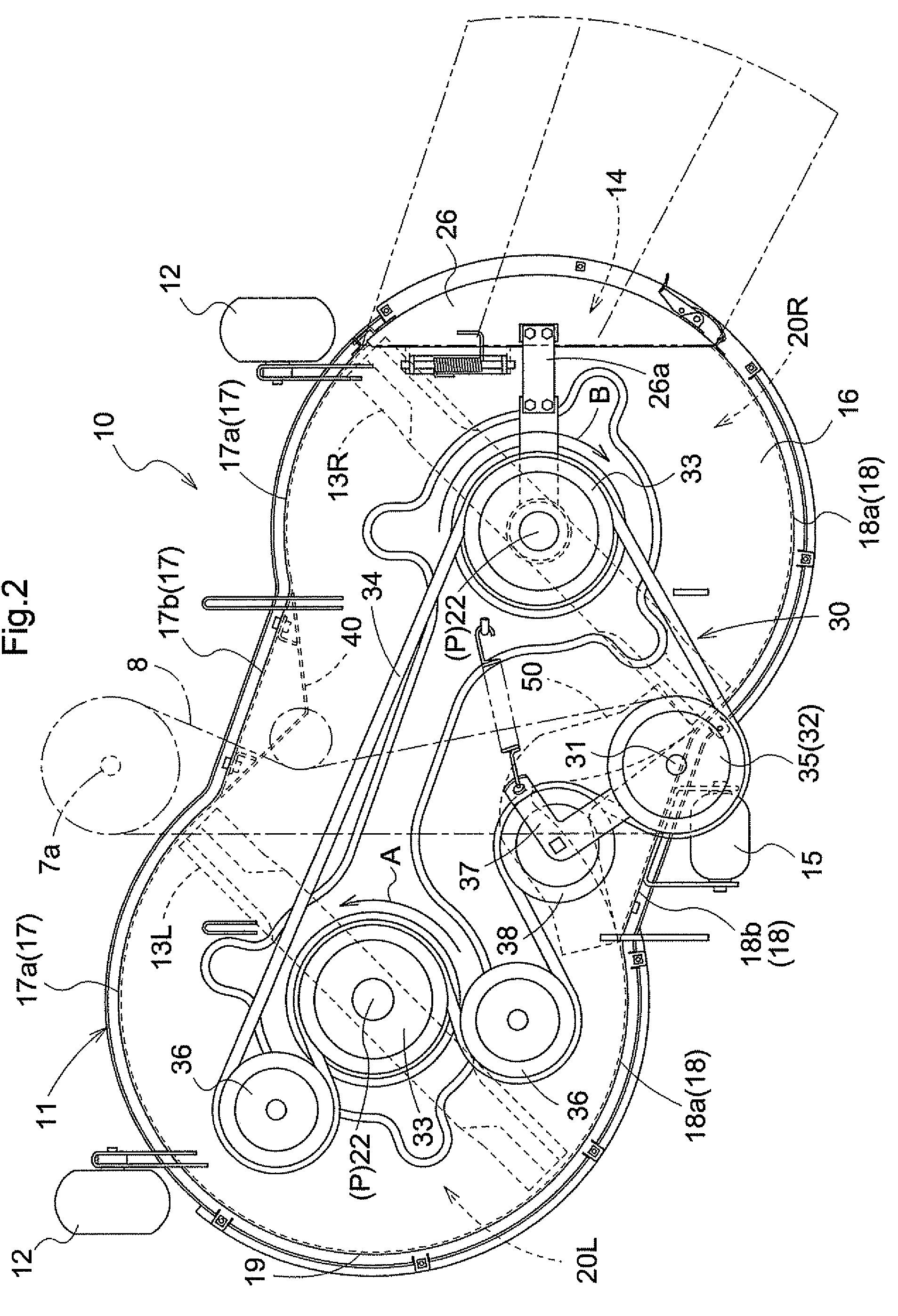

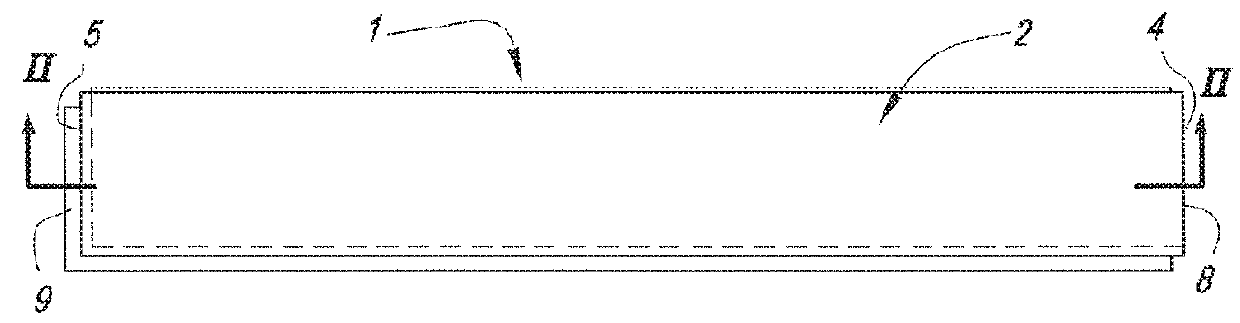

Belt Type Continuously Variable Transmisson

ActiveUS20130090199A1Improve cooling efficiencySuppressing interference with flowGear lubrication/coolingLine segmentEngineering

A belt-type continuously variable transmission comprises a drive pulley assembly mounted to a drive shaft; a driven pulley assembly mounted to a driven shaft; a belt connecting the two; and a case assembly for accommodating these components. The drive pulley assembly has fins for generating a flow of air moving toward an outer periphery of the drive pulley assembly. When viewed in an axial direction of the drive shaft, an air blocking plate is positioned at a forward side in a rotational direction of the drive pulley assembly relative to an imaginary line segment connecting a center axis of the drive pulley assembly to a center axis of the driven pulley assembly, between the drive pulley assembly and the driven pulley assembly such that the air blocking plate surrounds the outer periphery of the drive pulley assembly over a predetermined range.

Owner:KAWASAKI MOTORS LTD

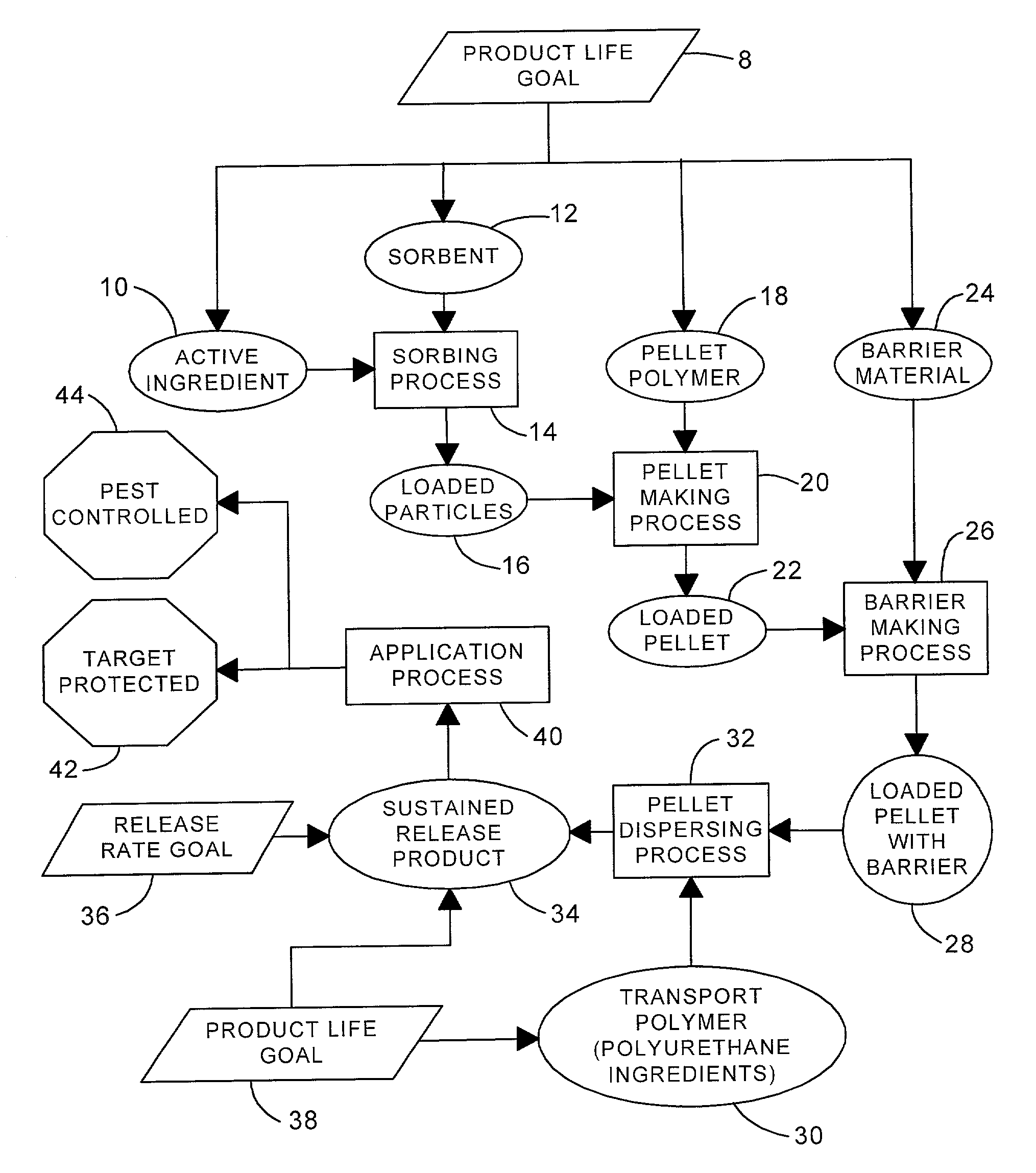

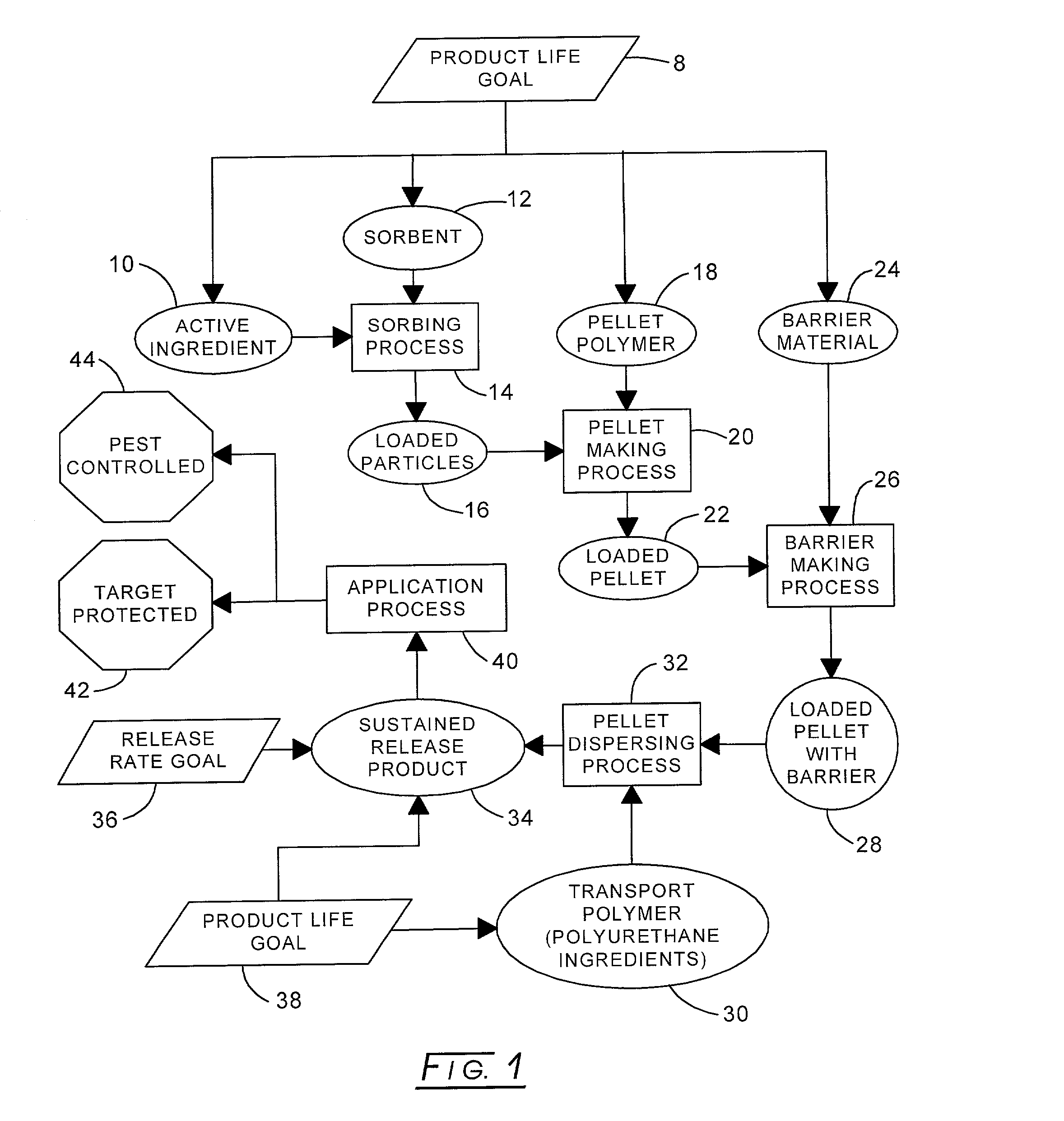

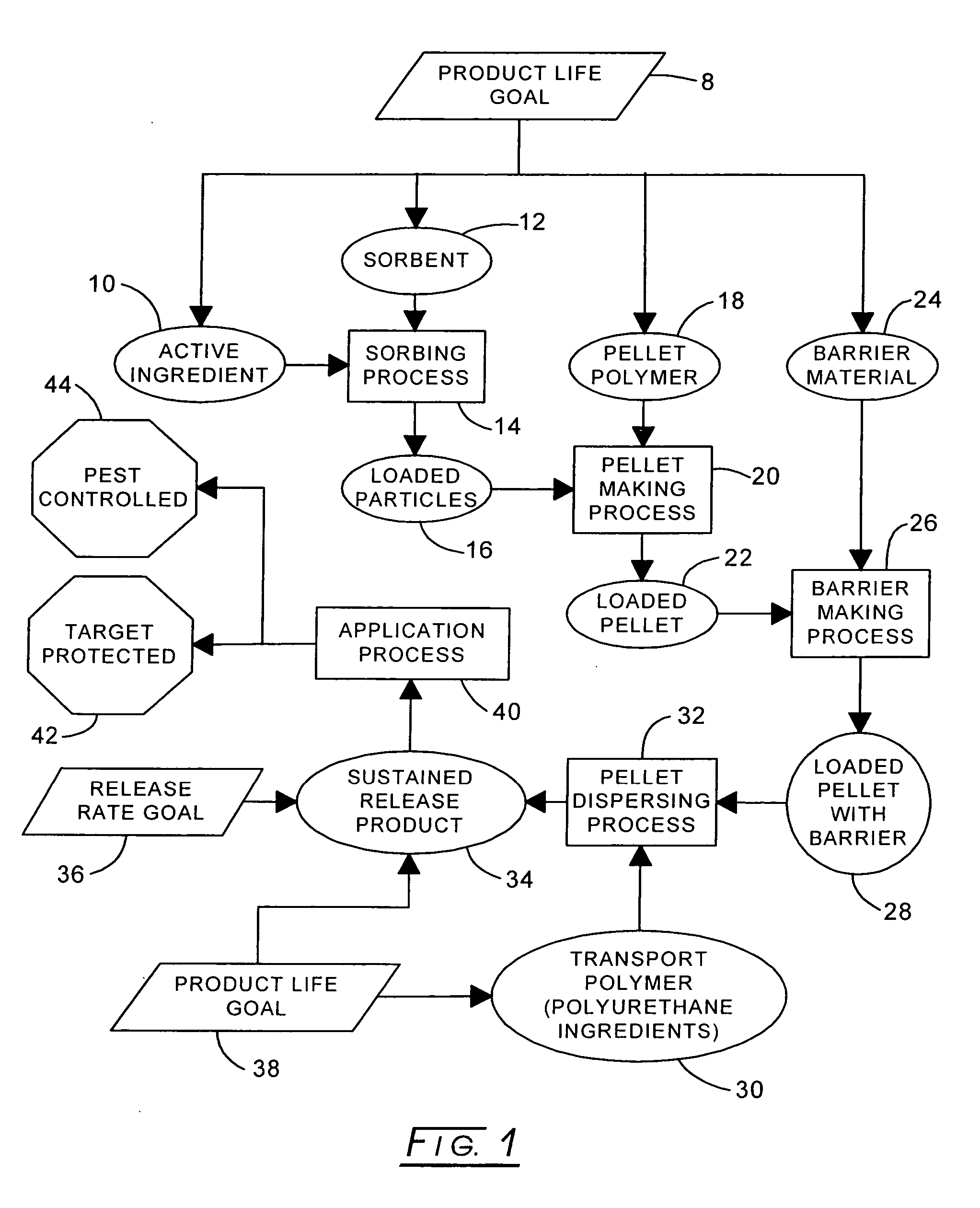

Sustained release pest control products and their applications

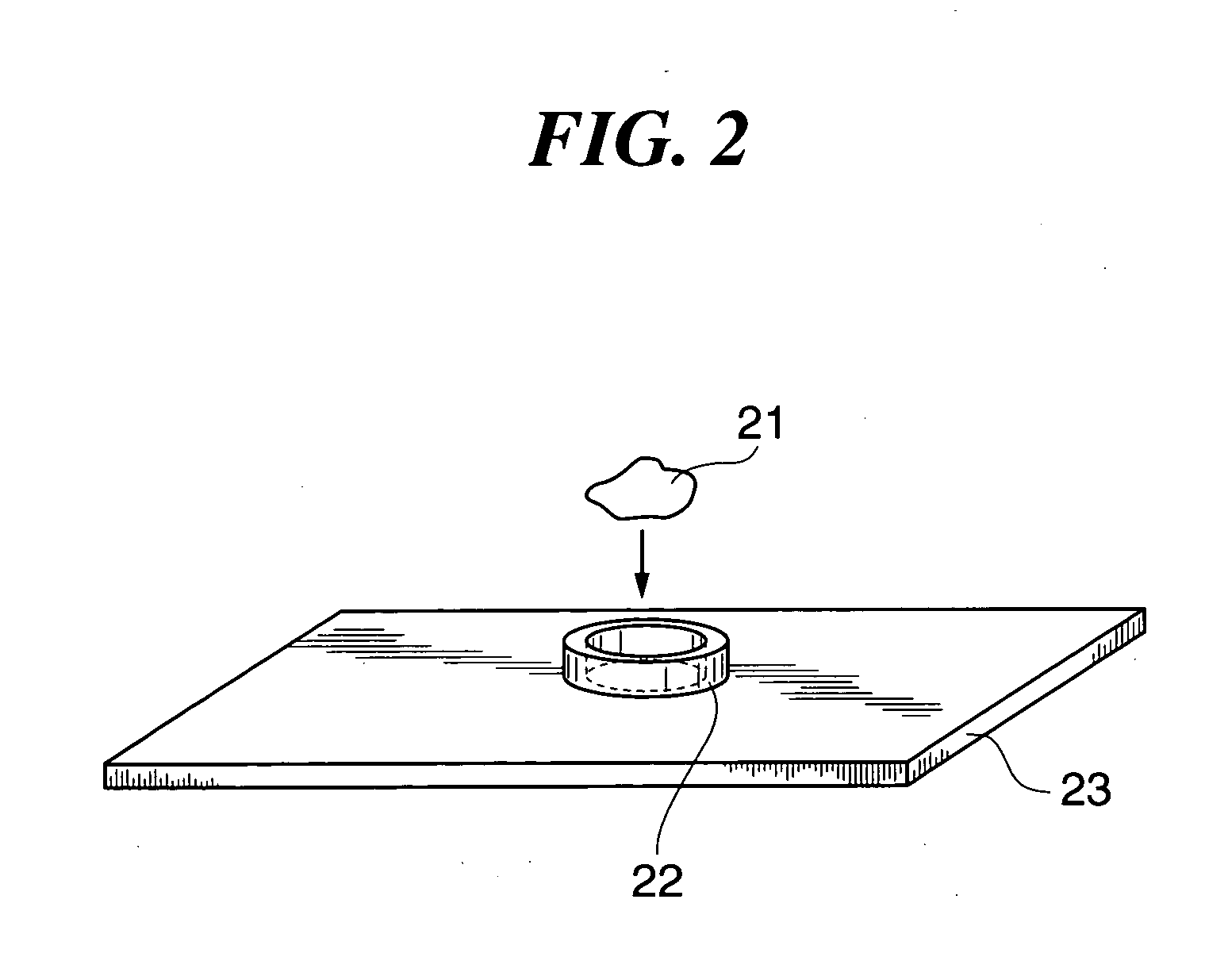

InactiveUS7056522B2Convenient and inexpensive methodReadily apparentBiocideLiquid surface applicatorsPolymer scienceSorbent

A method for applying a barrier to structures to prevent the infiltration of pest species (unwanted organisms) uses a (e.g., coating) composition formed from a polyurethane (e.g., film-forming) polymer system and a pellet comprising a pesticide incorporated into a sorbent and dispersed in the polyurethane polymer system. The composition protects the structure by application either to the structure or to a pathway that leads to the structure. Advantageous polymer systems include polyurethanes rich in urea linkages and predominating in aliphatic and alicyclic backbones.

Owner:BIOGUARD TECH

Sustained release pest control products and their applications

InactiveUS20060127435A1Convenient and inexpensive methodSlow release rateBiocideLiquid surface applicatorsPest controlColloid

A method for applying a barrier to a structure to prevent the infiltration of pest species includes providing a composition and associating the coating composition with the structure. The composition is formed from a polymer component having dispersed therein beads formed from colloidal clay and adsorbed pest control agent. Colloidal clays (e.g., nano-clays) adsorb more pest control agent that do standard clays and releases the adsorbed pest control agent at a slower rate than do standard clays.

Owner:BIOGUARD TECH

Belt type continuously variable transmission

ActiveUS8834307B2Suppressing interference with flowImprove cooling efficiencyGear lubrication/coolingDrive shaftEngineering

A belt-type continuously variable transmission comprises a drive pulley assembly mounted to a drive shaft; a driven pulley assembly mounted to a driven shaft; a belt connecting the two; and a case assembly for accommodating these components. The drive pulley assembly has fins for generating a flow of air moving toward an outer periphery of the drive pulley assembly. When viewed in an axial direction of the drive shaft, an air blocking plate is positioned at a forward side in a rotational direction of the drive pulley assembly relative to an imaginary line segment connecting a center axis of the drive pulley assembly to a center axis of the driven pulley assembly, between the drive pulley assembly and the driven pulley assembly such that the air blocking plate surrounds the outer periphery of the drive pulley assembly over a predetermined range.

Owner:KAWASAKI MOTORS LTD

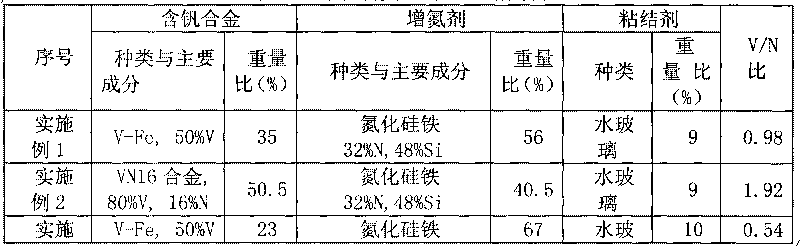

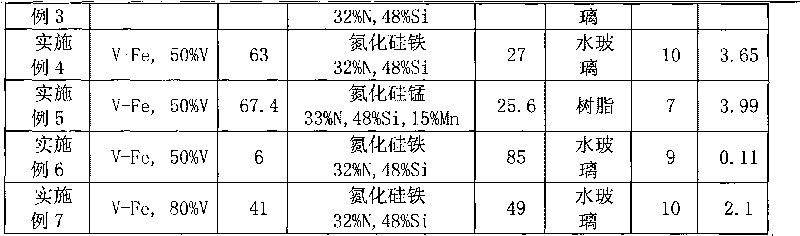

Vanadium-nitrogen additive for smelting microalloyed steel and method for preparing same

The invention discloses a vanadium-nitrogen additive for smelting microalloyed steel and a method for preparing same. The vanadium-nitrogen additive and the method are characterized in that the vanadium-nitrogen additive is uniformly mixed by vanadium-contained alloy powder, nitrogen increasing agent powder, and adhesive, wherein the mass ratio of the adhesive is 5-12%, the total mass ratio of the vanadium-contained alloy powder and the nitrogen increasing agent powder is 88-95%, and the ratio of V / N is controlled within 0.1-4. The method for preparing the vanadium-nitrogen additive used for smelting microalloyed steel comprises the following steps: mixing the vanadium-contained alloy powder and the nitrogen increasing agent powder by the weight percentage, mechanically and uniformly blending the mixed powders, subsequently adding 5-12% of the adhesive and uniformly mixing the powders again, finally mechanically forming blocks of spherule shapes or other shapes, and preparing the vanadium-nitrogen additive by drying the blocks. The ratio of V / N of molten steel can be controlled within 3.0-5.0 by the vanadium-nitrogen additive, the enhancement effect of the vanadium can be sufficiently played by utilizing the cheap nitrogen element, and the amount of the vanadium is reduced obviously.

Owner:MAANSHAN IRON & STEEL CO LTD

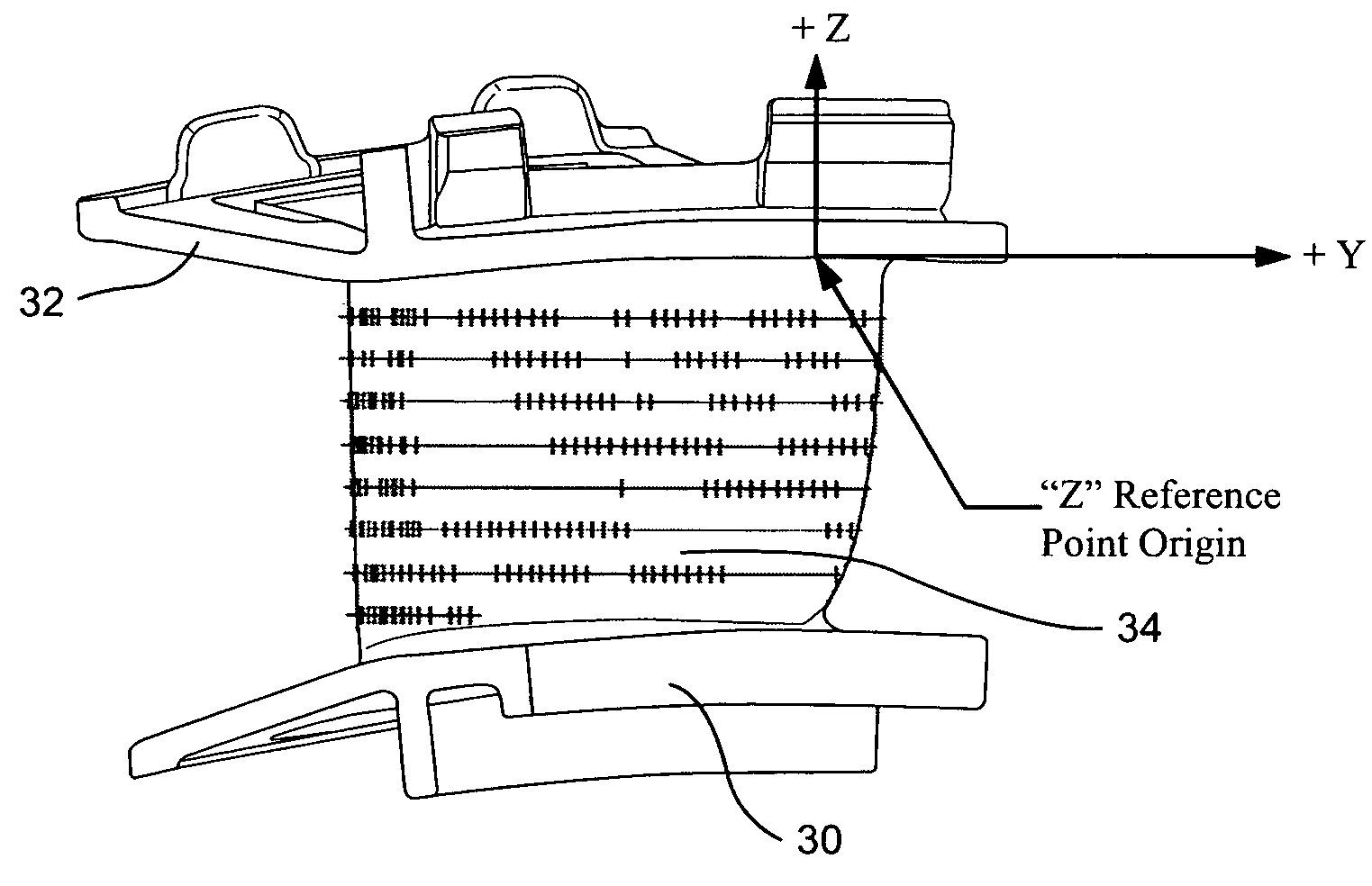

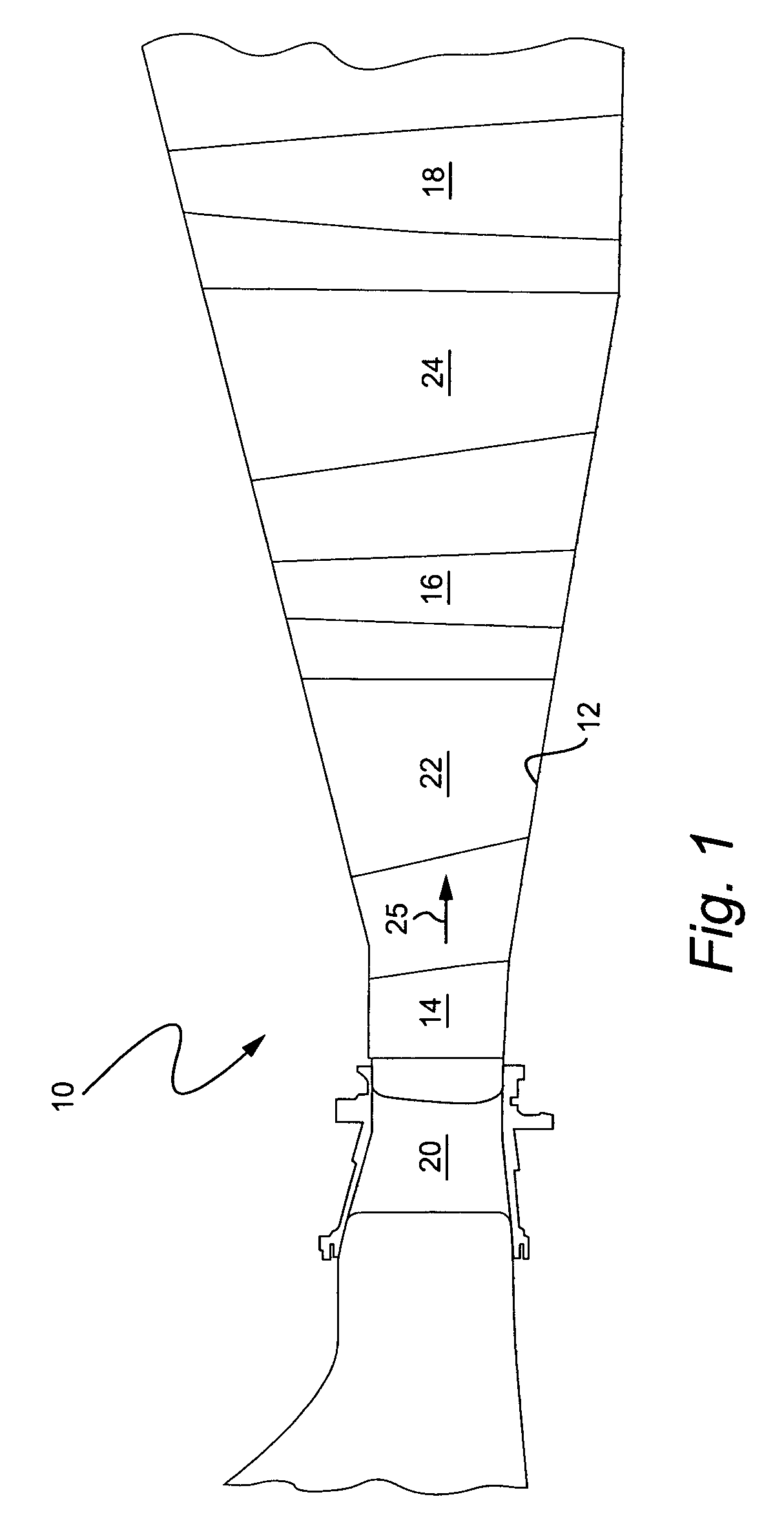

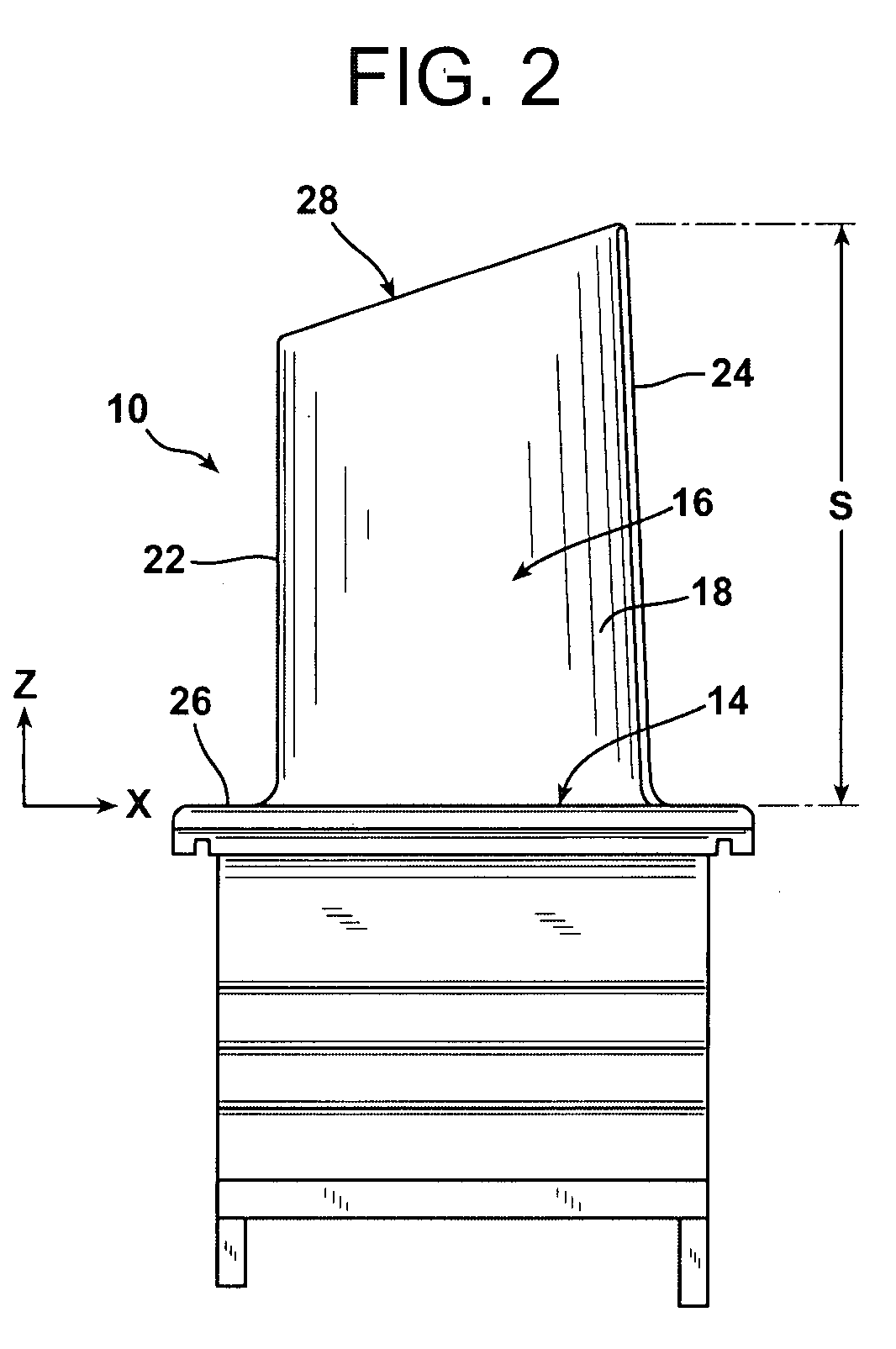

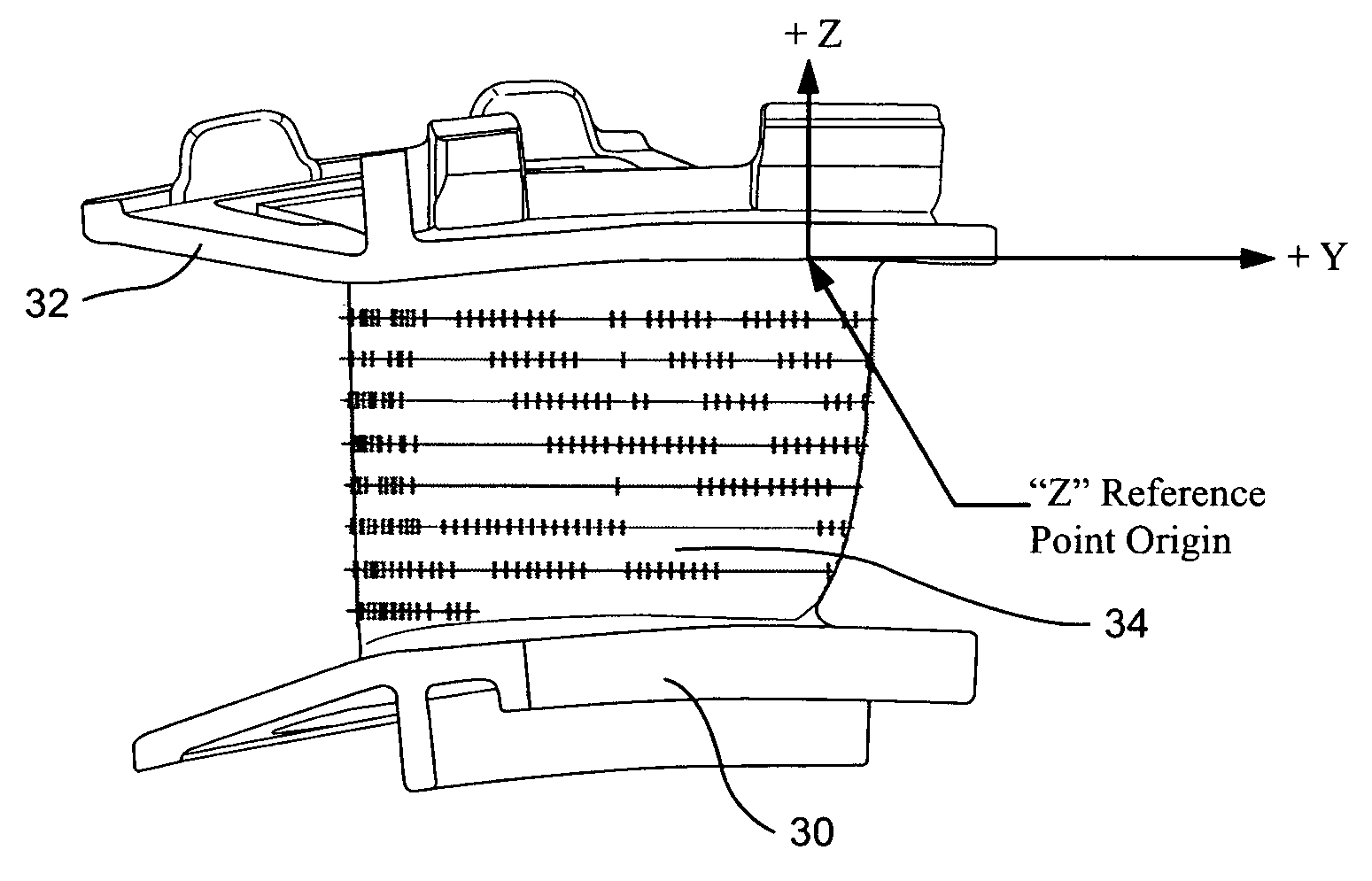

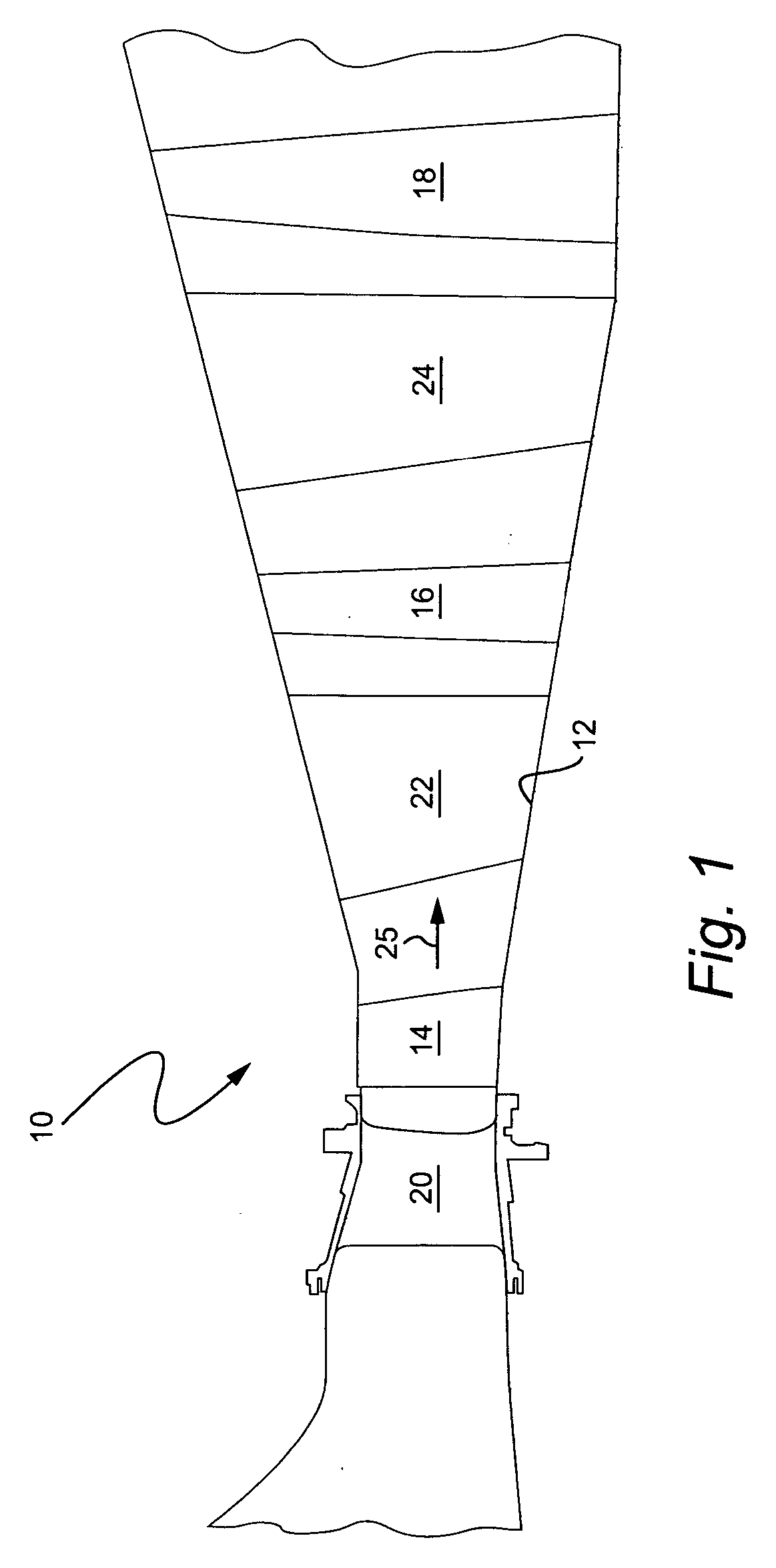

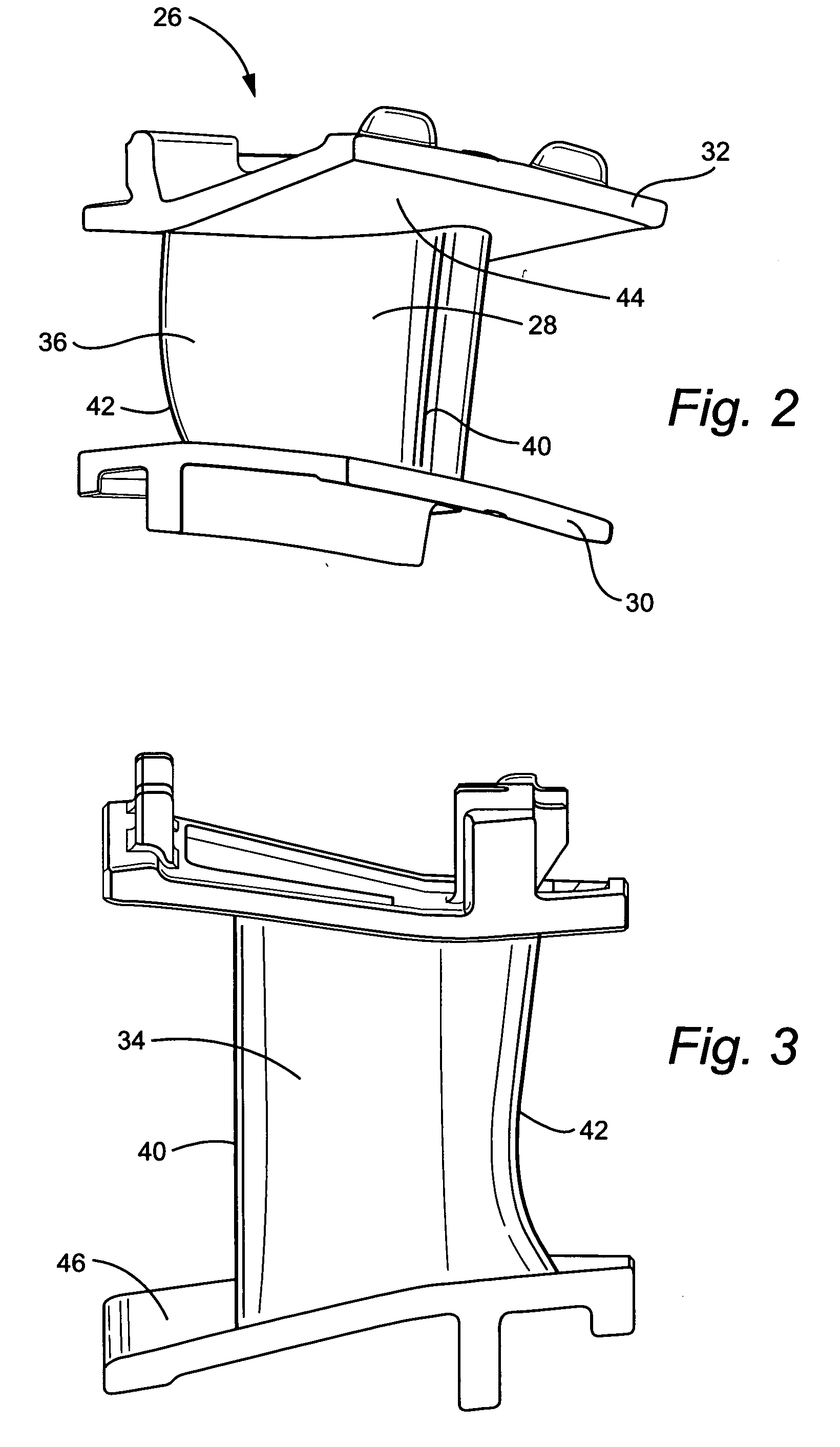

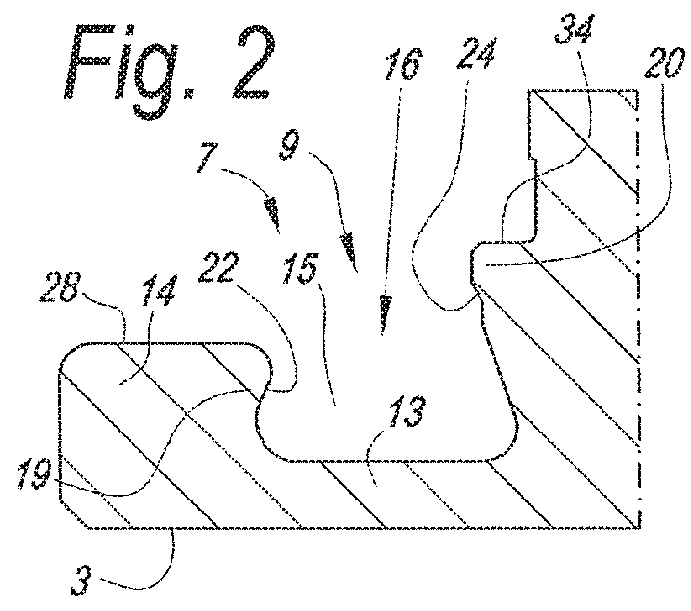

External profile for turbine blade airfoil

InactiveUS20080273984A1Join smoothlyEngine manufactureOther chemical processesLeading edgeTurbine blade

A turbine blade including an airfoil having a pressure sidewall and a suction sidewall joined together along an upstream leading edge and a downstream trailing edge. The leading edge and trailing edge are formed as substantially straight edges, and portions of the pressure sidewall and suction sidewall adjacent the trailing edge form substantially planar surfaces. The airfoil has an uncoated nominal profile substantially in accordance with Cartesian coordinate values of X, Y and Z set forth in Table 1 wherein Z represents a perpendicular distance from a plane normal to a radius of a turbine centerline and containing the X and Y values with the Z value commencing at zero in the X, Y plane at a radially innermost aerodynamic section of the airfoil, and X and Y represent coordinate values defining the airfoil profile at each distance Z which, when connected by smooth continuing arcs, define profile sections at each distance Z.

Owner:SIEMENS ENERGY INC

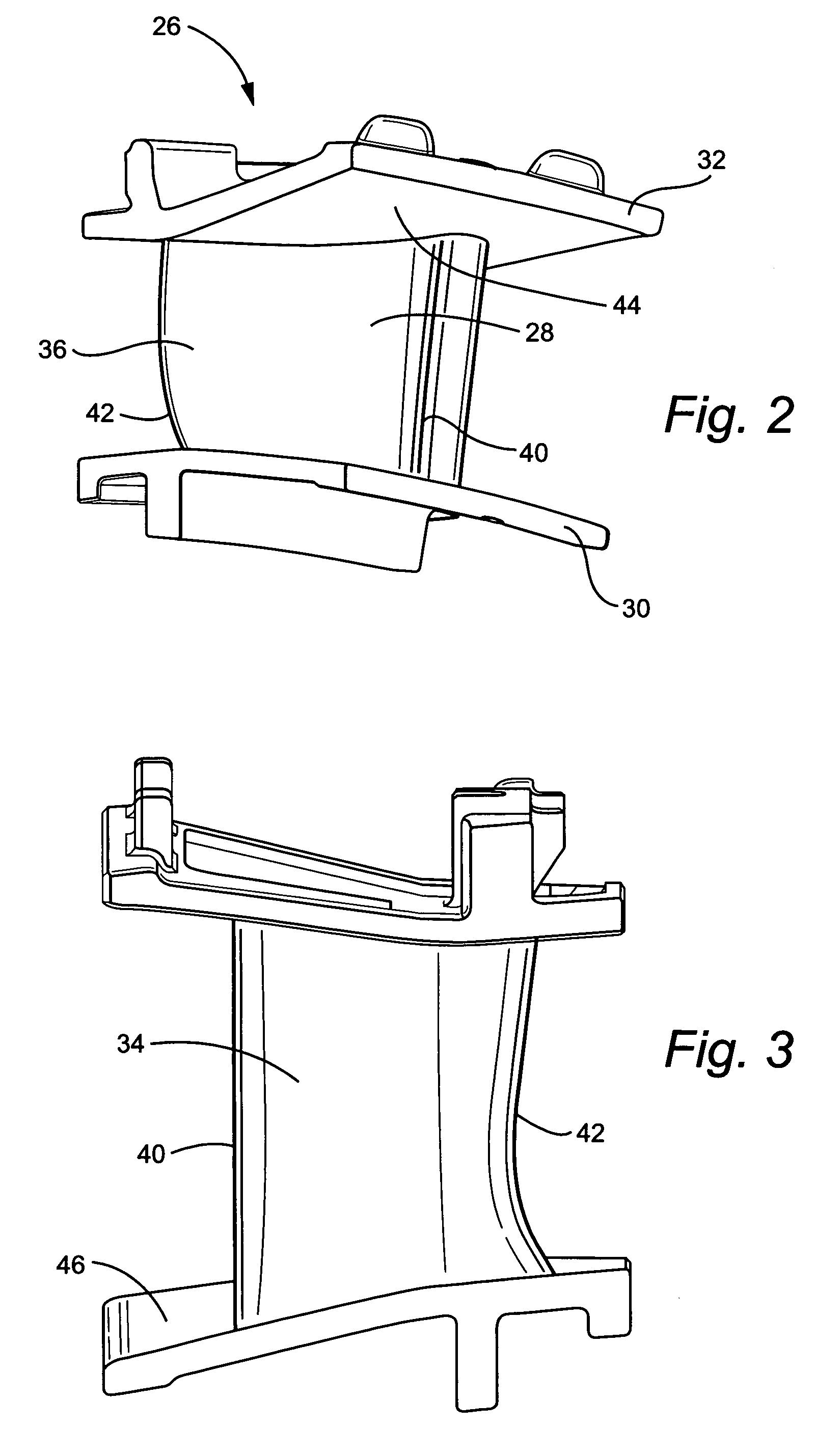

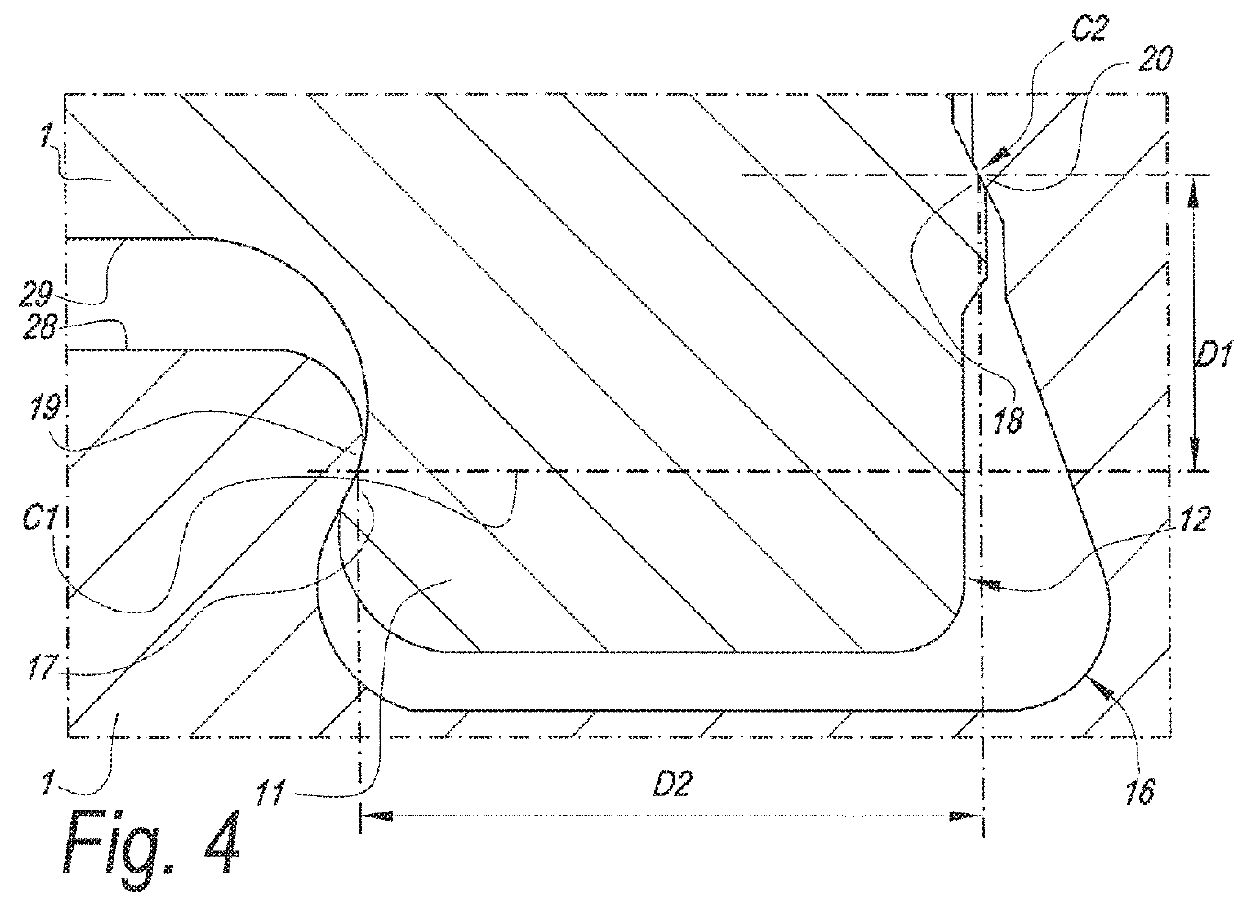

Airfoil shape and sidewall flowpath surfaces for a turbine nozzle

ActiveUS20060024159A1Improve performanceJoin smoothlyEngine manufacturePump componentsEngineeringNozzle

A turbine nozzle includes airfoil and sidewall surfaces. The airfoil and sidewall surfaces have profiles substantially in accordance with Cartesian coordinate values of X, Y and Z set forth in Tables I-IV for the pressure and suction sides of the airfoil, and the outer and inner sidewall surfaces, respectively. The X, Y and Z values are distances in inches. The X and Y values for the airfoil, when connected by smooth continuing arcs, define airfoil profile sections at each distance Z. The profile sections at the Z distances are joined smoothly with one another to form a complete airfoil shape. The X, Y and Z values of Tables III and IV define the outer and inner sidewall surfaces, respectively, of the gas flowpath.

Owner:IPSEN MFG IRELAND

Multi-crack fracturing control method for medium-depth coal beds

ActiveCN103244097AJoin smoothlyOvercoming poor sand-carrying abilityFluid removalFracturing fluidHigh pressure

The invention relates to an oil extraction process for oil fields, in particular to a multi-crack fracturing control method for medium-depth coal beds. The method comprises six steps of 1) preparation of a filtrate reduction fracturing fluid; 2) utilization of a high-pressure pump set; 3) utilization of a high-pressure pump set; 4) utilization of a high-pressure pump set; 5) phased utilization of a prepad liquid; and 6) ending of work. According to the multi-crack fracturing control method, prior conventional active-water sand fracturing method is changed through theoretical analysis and on-site verification, and the filtrate reduction fracturing fluid, the prepad liquid variable displacement technology, a multi-stage particle size slug technology, a reasonable mortar-sand ratio raising technology and the like are used, accordingly, difficulties such as large filter losses, poor sand carrying capabilities and excess leak-off of the fracturing liquid and high construction pressure during opening of natural cracks are overcome. Multi-crack is effectively prevented and treated through the means of the filtrate reduction fracturing fluid, and the prepad liquid variable displacement technology and the multi-stage particle size slug technology, so that the construction pressure is reduced, smooth adding of a propping agent is guaranteed, and the fracturing construction success rate is improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

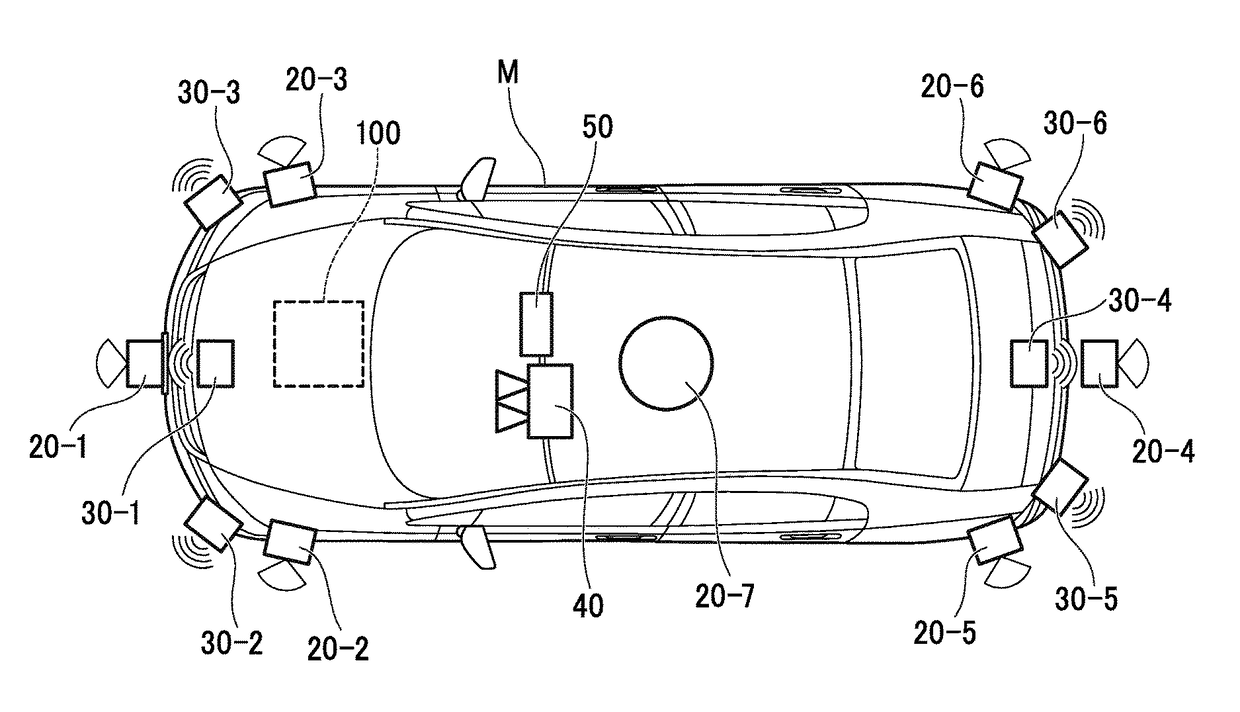

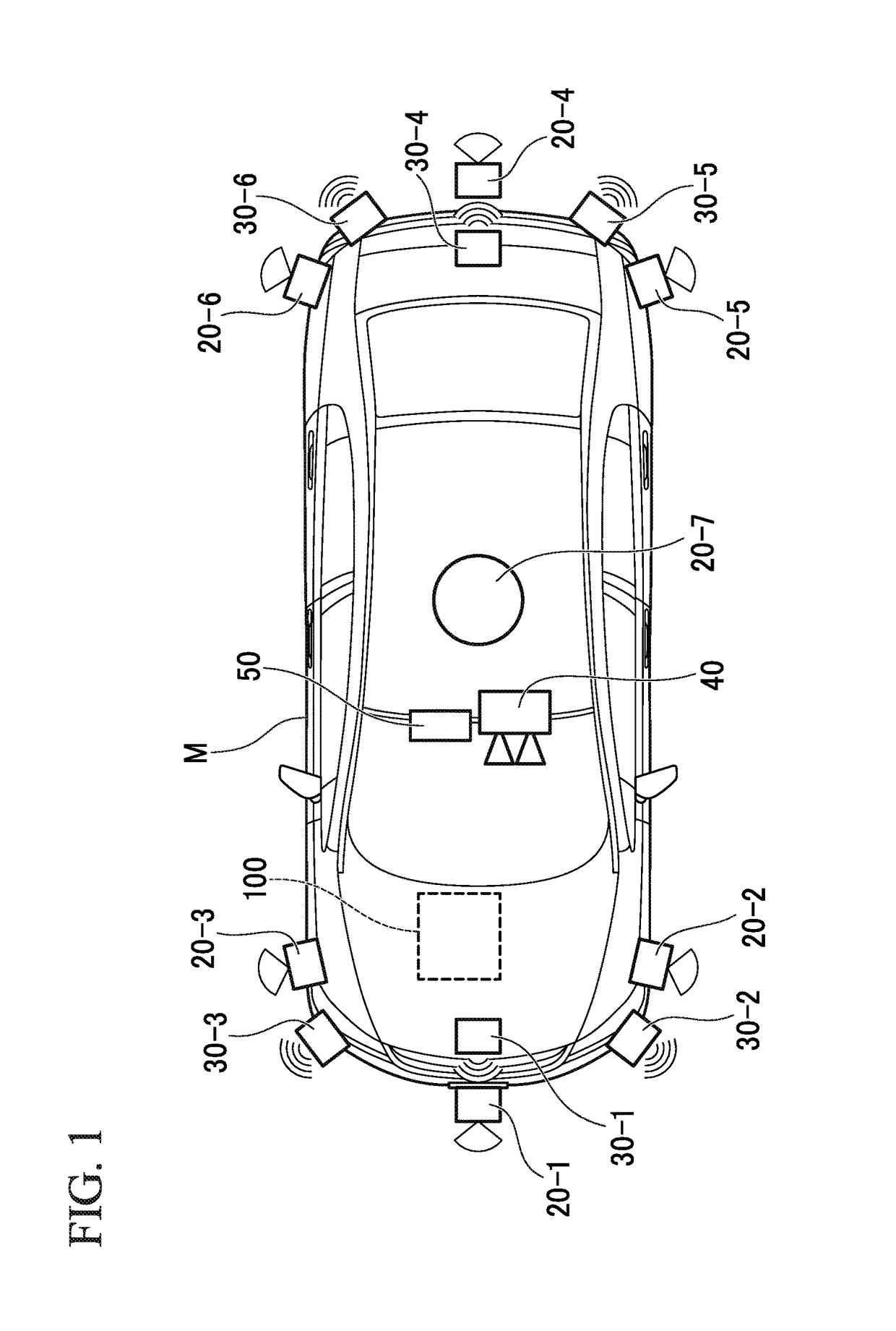

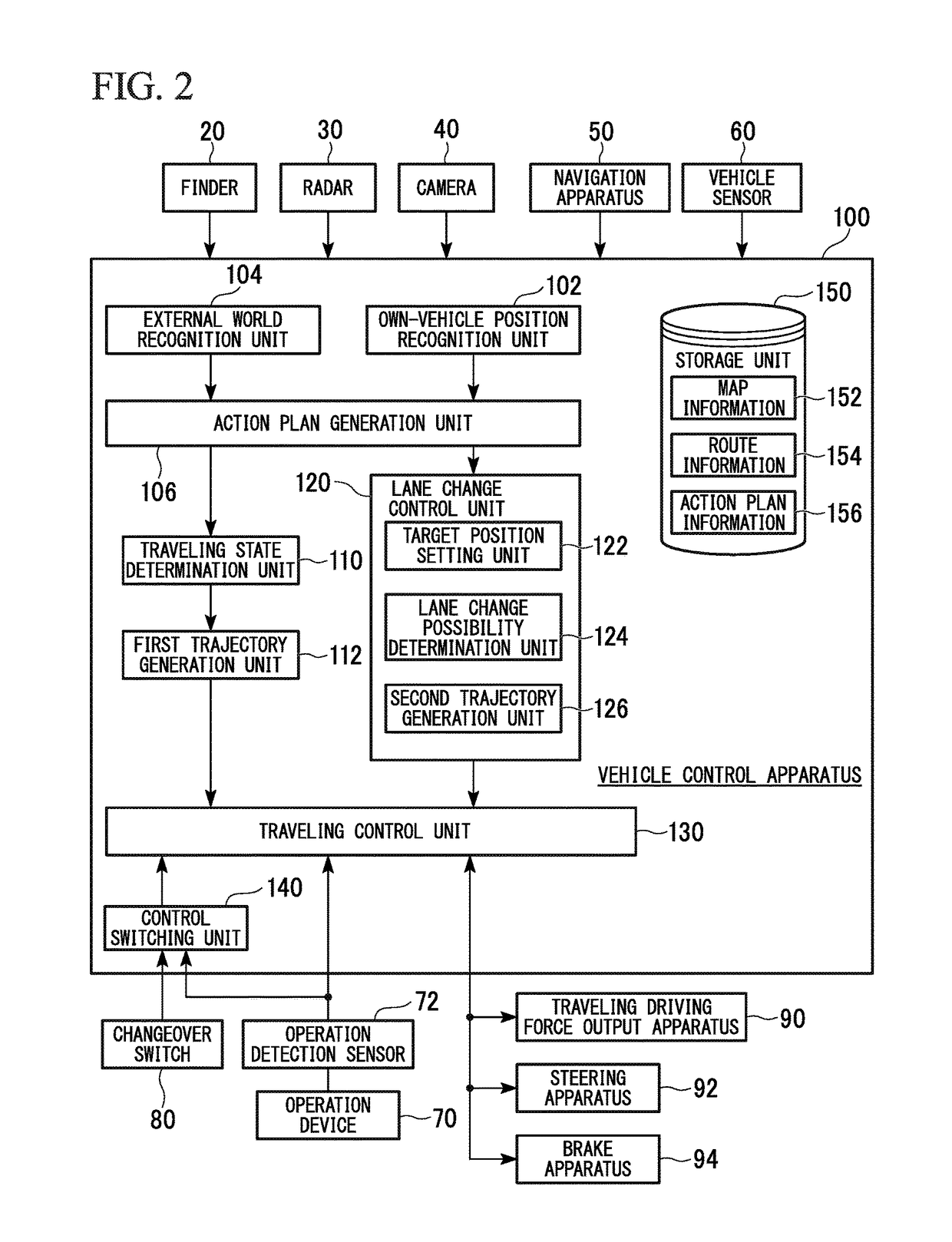

Vehicle control apparatus, vehicle control method, and vehicle control program

ActiveUS20170120912A1Improve securityImprove accuracyCruise controlExternal condition input parametersEngineeringVehicle control

A vehicle control apparatus includes a specification unit configured to specify a speed of an object located in front of an own vehicle and a distance between the object and the own vehicle, a calculation unit configured to calculate a target speed of the own vehicle on the basis of the speed of the object specified by the specification unit and a value based on the distance, and a traveling control unit configured to control traveling of the own vehicle on the basis of the target speed calculated by the calculation unit.

Owner:HONDA MOTOR CO LTD

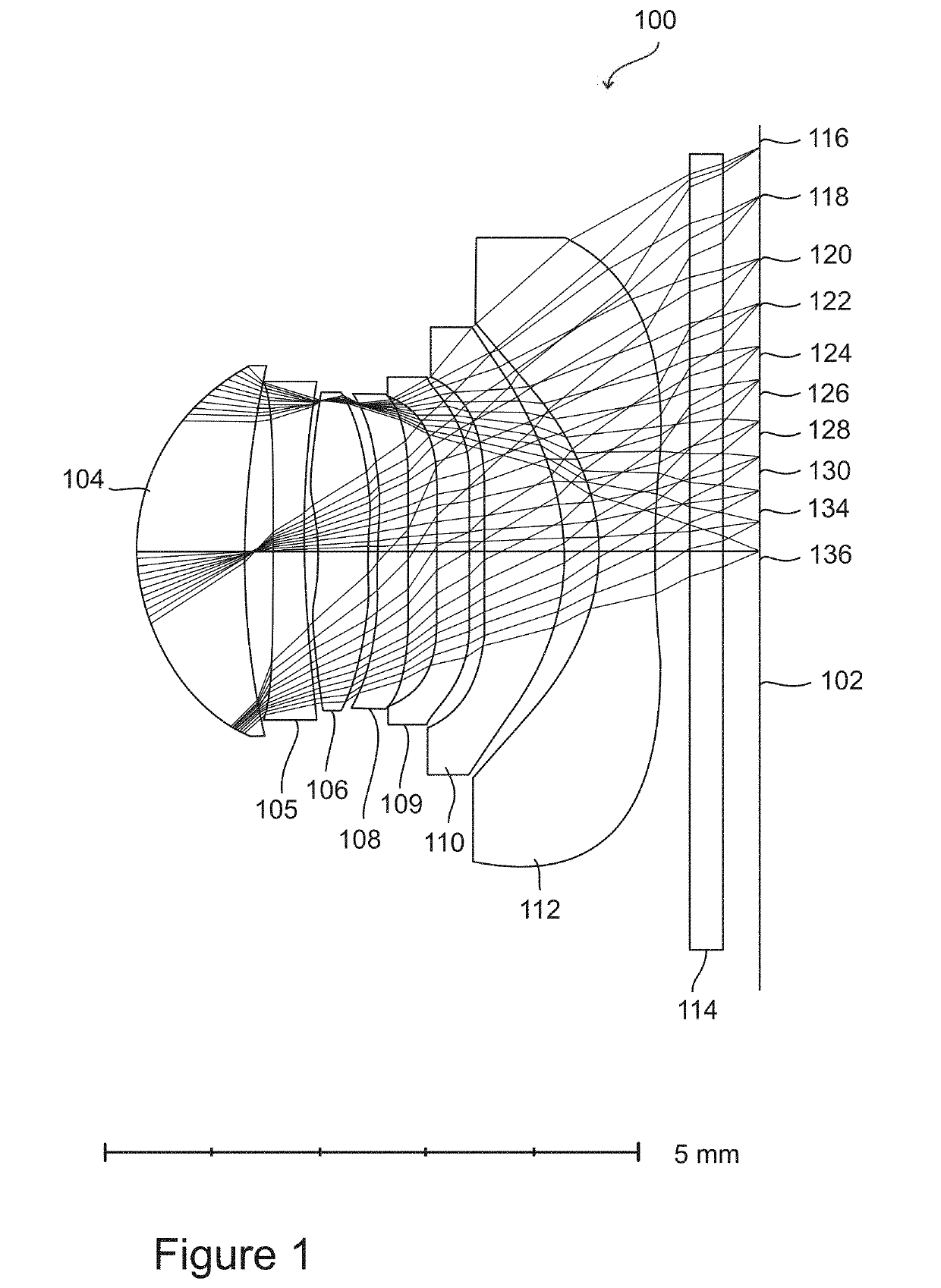

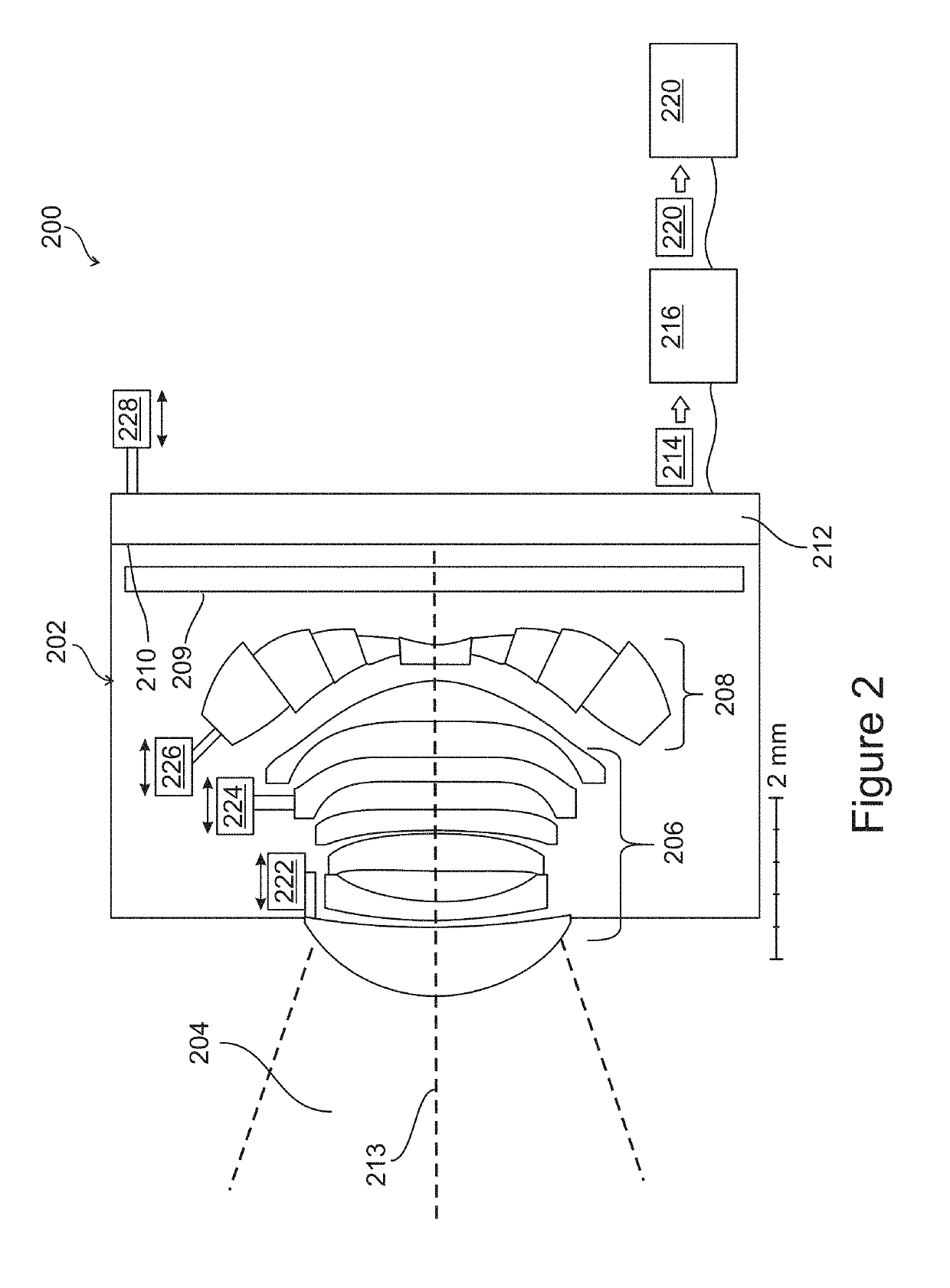

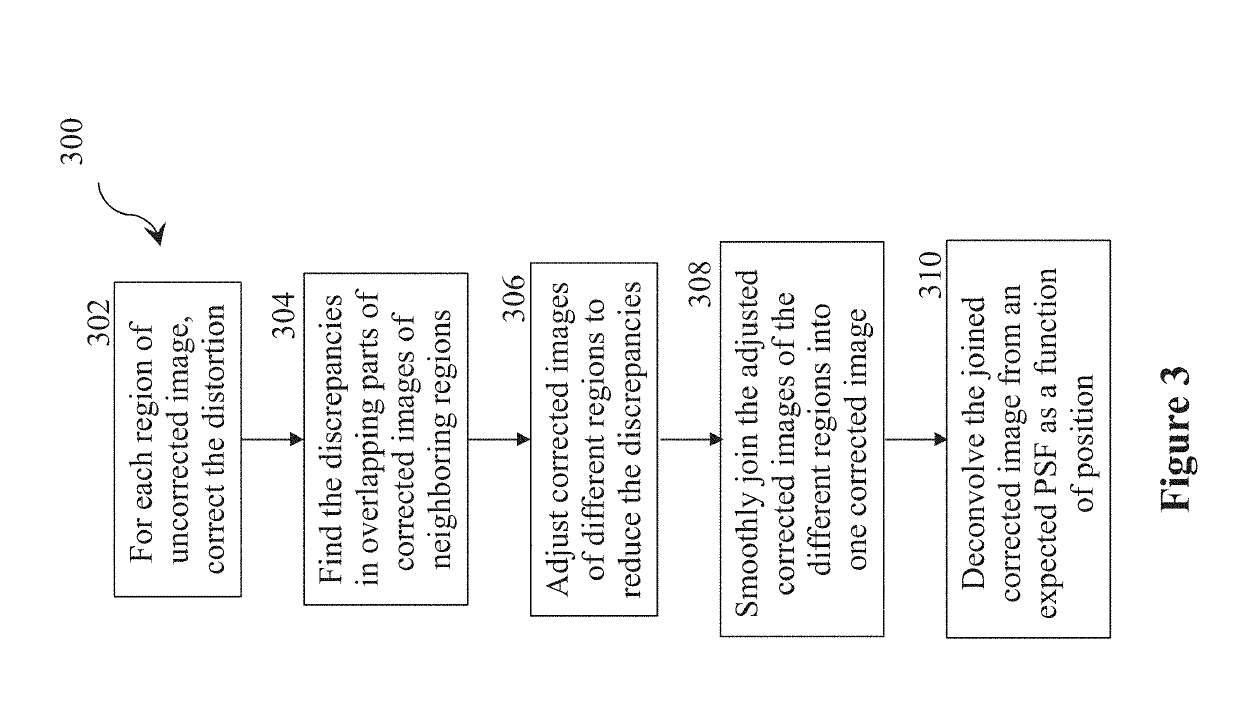

Lens design with tolerance of fabrication errors

ActiveUS20190107651A1Join smoothlyReduces and eliminates discontinuity in digital imageImage enhancementTelevision system detailsSensor arrayDigital image

An optical system that produces a digital image of a field of view, comprising:a) a sensor array of light sensors that produces an output signal indicating an intensity of light received by each light sensor;b) one or more optical elements that together project an image of the field of view onto the sensor array, including at least one sectioned optical element comprising a plurality of sections, at least two of the sections differing in one or both of size and shape, each section projecting onto the sensor array an image of only a portion of the field of view, the different sections projecting images of different portions of the field of view to non-overlapping regions of the sensor array.

Owner:IPHYSICIST

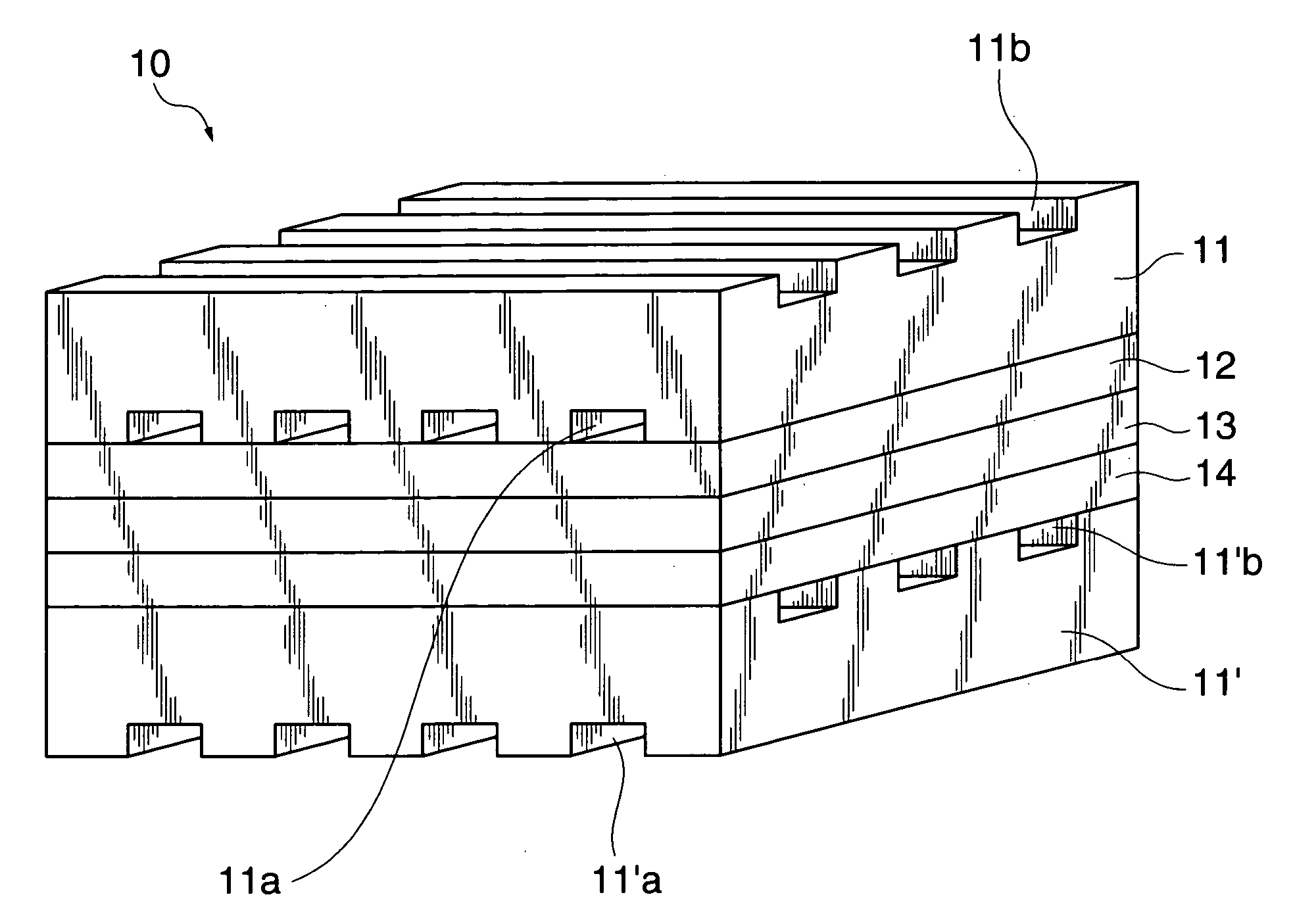

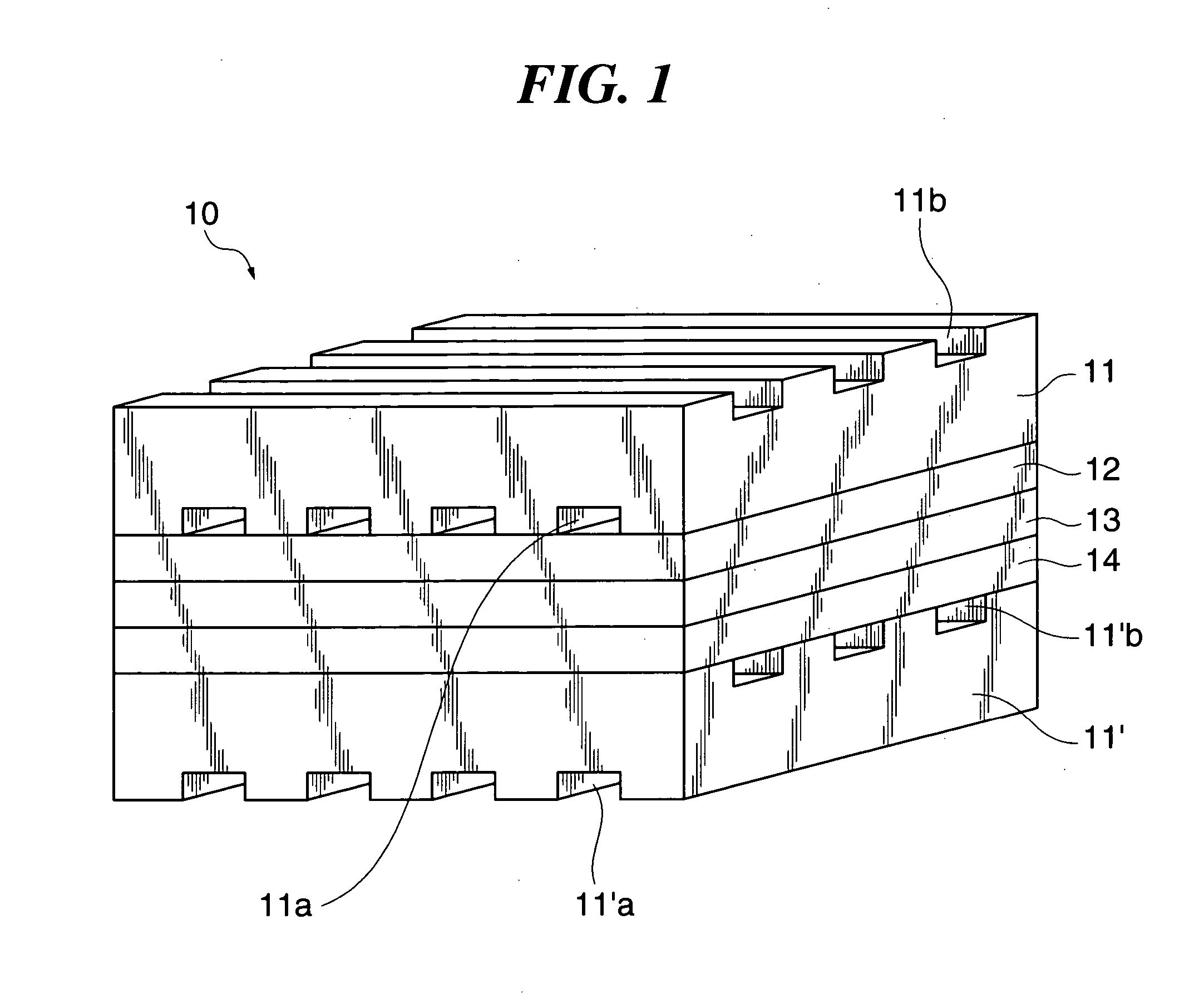

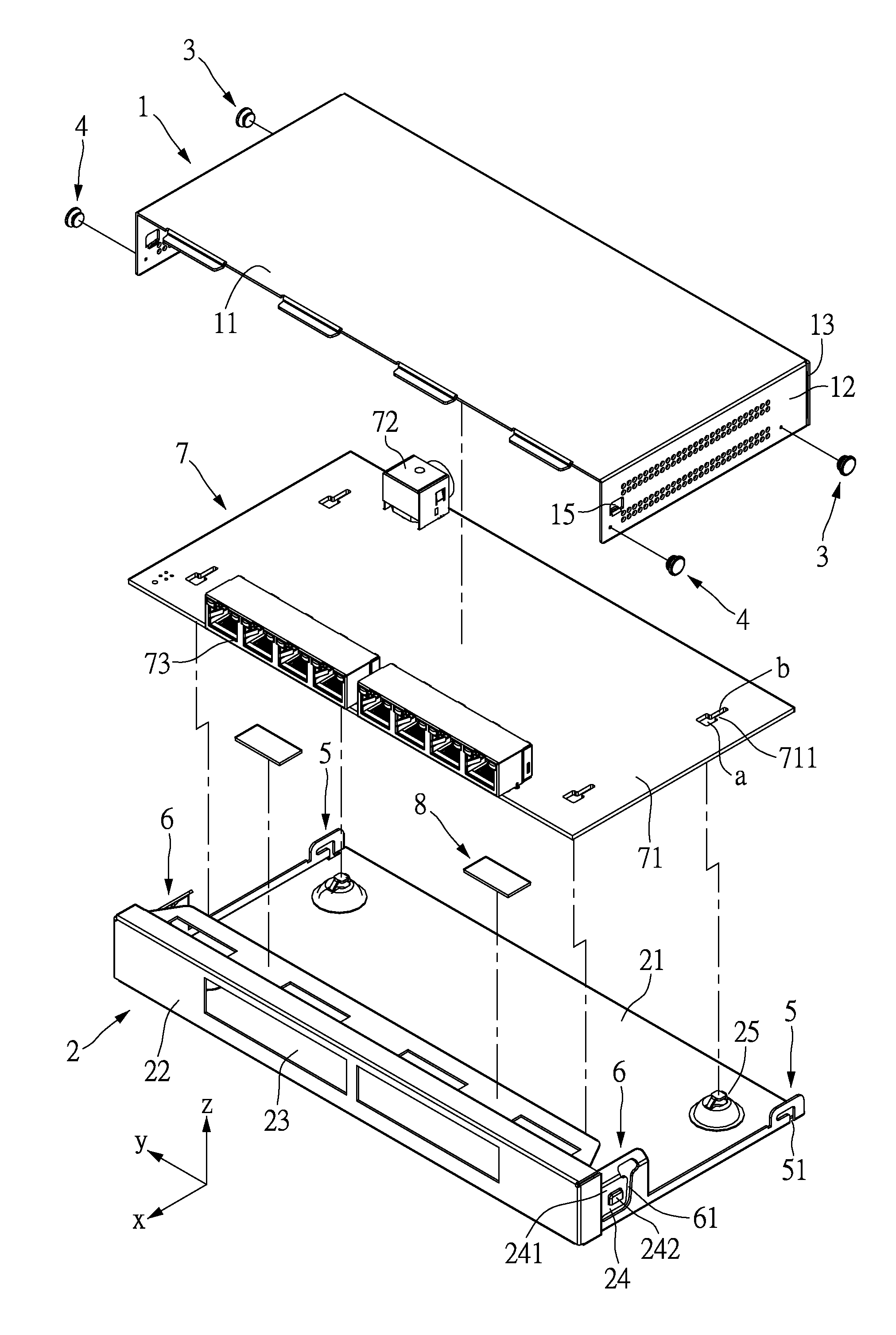

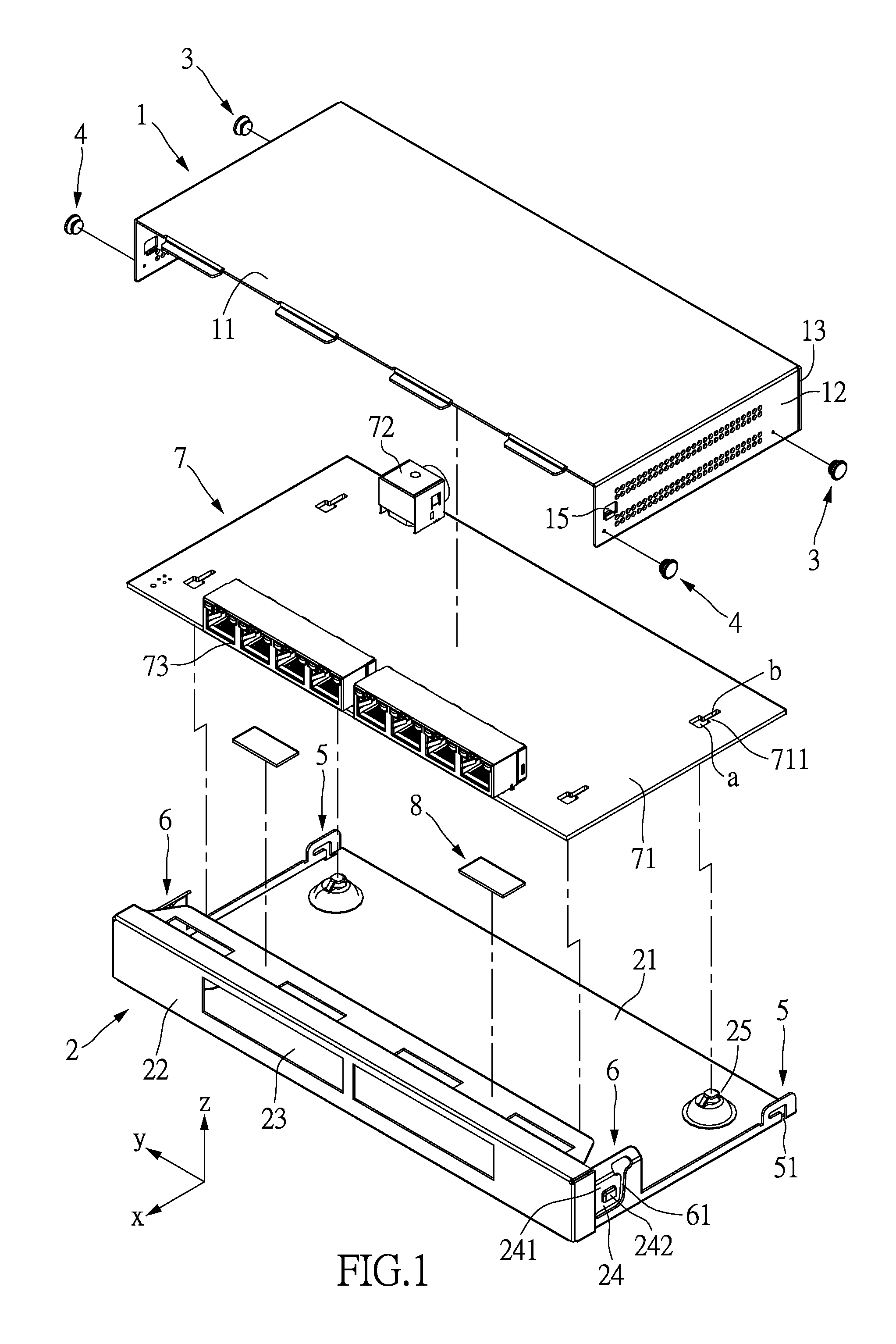

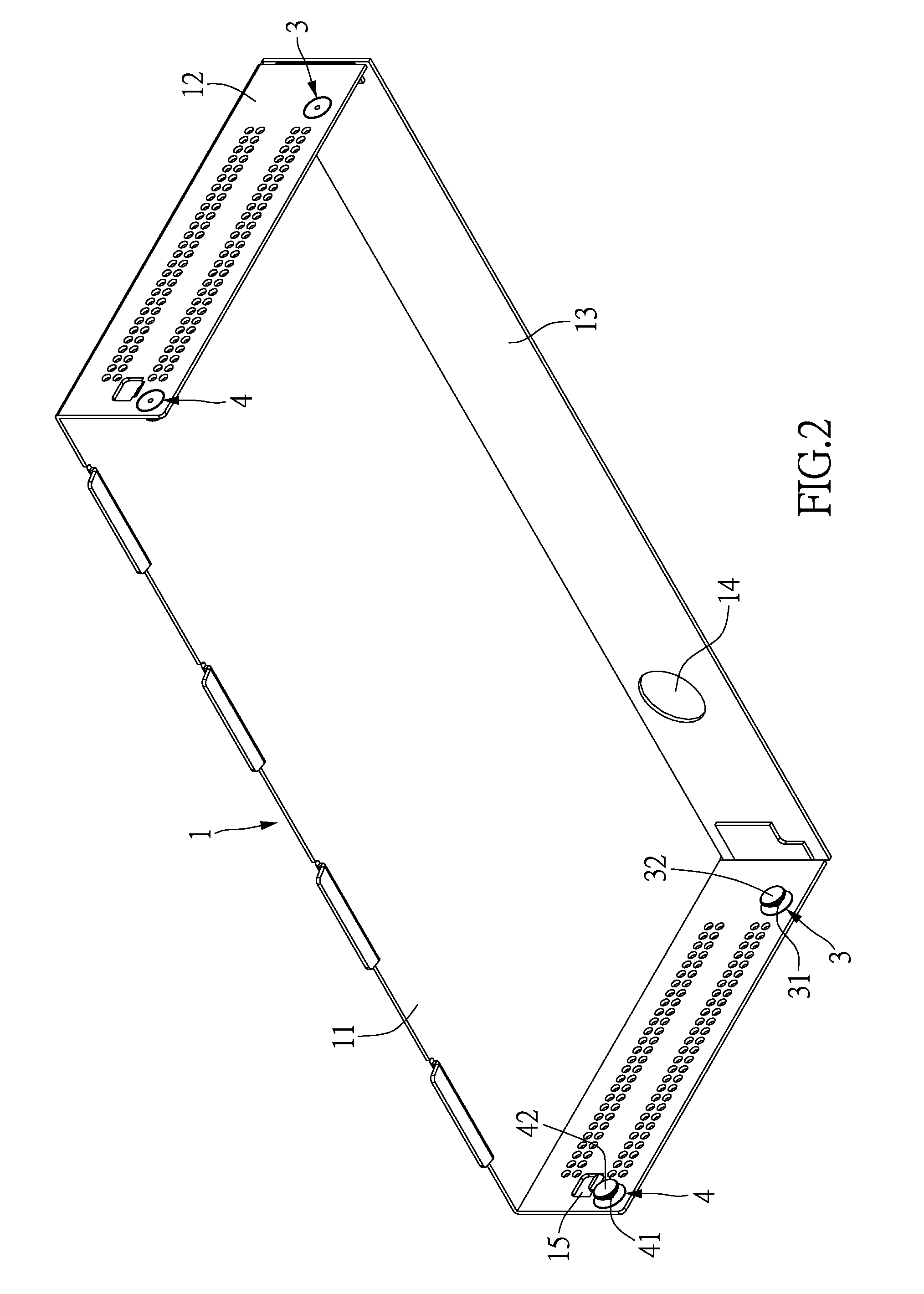

Housing assembly

InactiveUS20150289399A1Stably joined togetherSimple processClosed casingsDigital data processing detailsEngineeringElectrical and Electronics engineering

A housing assembly includes a first housing, a second housing, two first bolts, two second bolts, two first guiding rails and two second guiding rails. The first housing has a top board and two side boards. The second housing has a bottom board. The two first bolts and two second bolts are formed on the two side boards of the first housing. The two first guiding rails and two second guiding rails are formed on two sides of the bottom board of the second housing. Each first guiding rail has a first guiding groove, which includes a first vertical section, a first horizontal section, a first opening and a first fixing node. Each second guiding rail has a second guiding groove, which includes a second vertical section, a second horizontal section, a second opening and a second fixing node.

Owner:LITE ON ELECTRONICS (GUANGZHOU) LTD +1

Panel

ActiveUS20170138061A1Stable and reliable joint structureImprove compromiseSheet joiningFlooringEngineeringMechanical engineering

A panel, which, at two opposite edges, is provided with coupling parts that allow joining by a downward movement, said coupling parts including a male part that fits in a female part, wherein vertically active locking portions are provided at opposite sides of the male part and female part, wherein these locking portions are located at different distances from an upper side of the panels.

Owner:UNILIN NORDIC AB

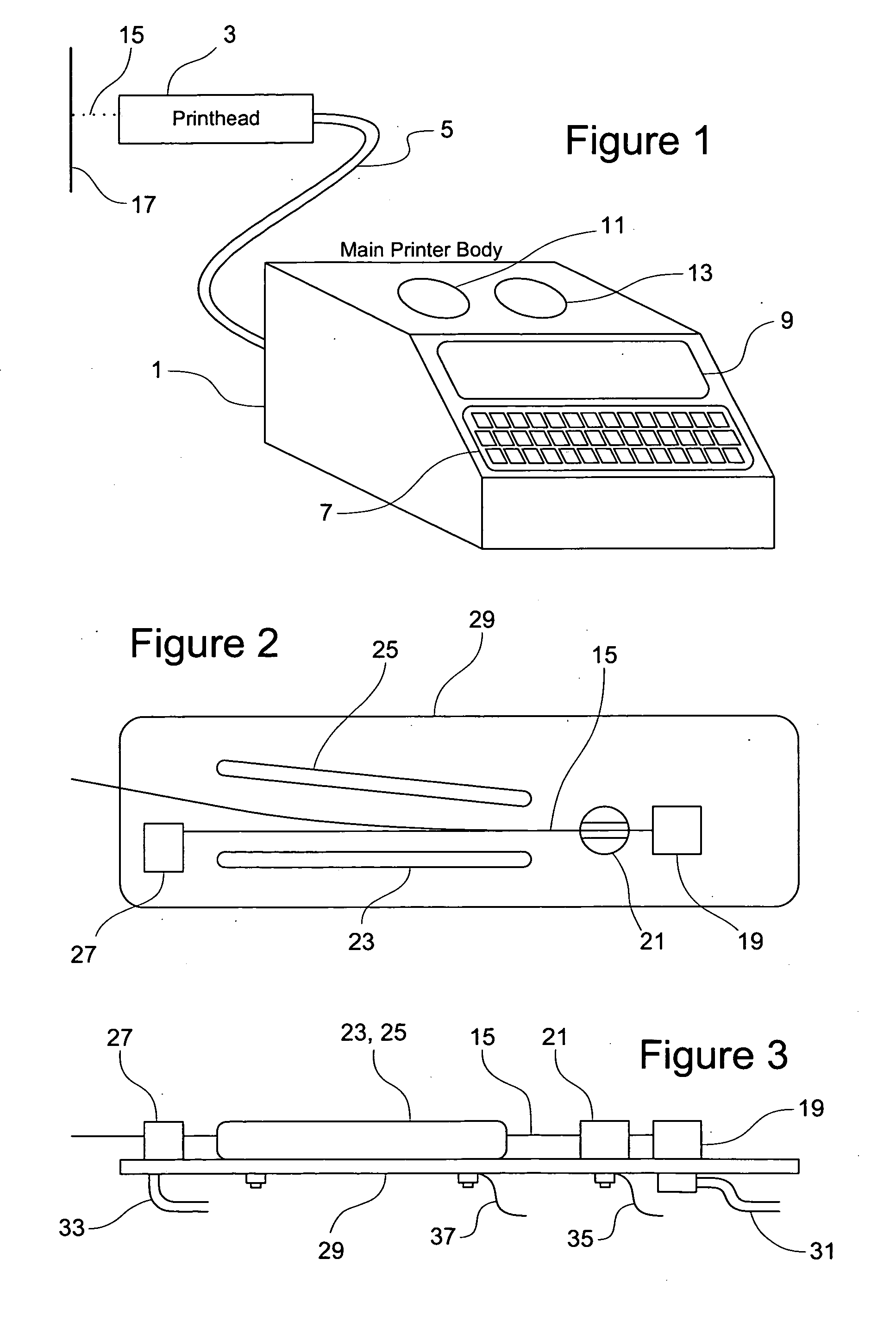

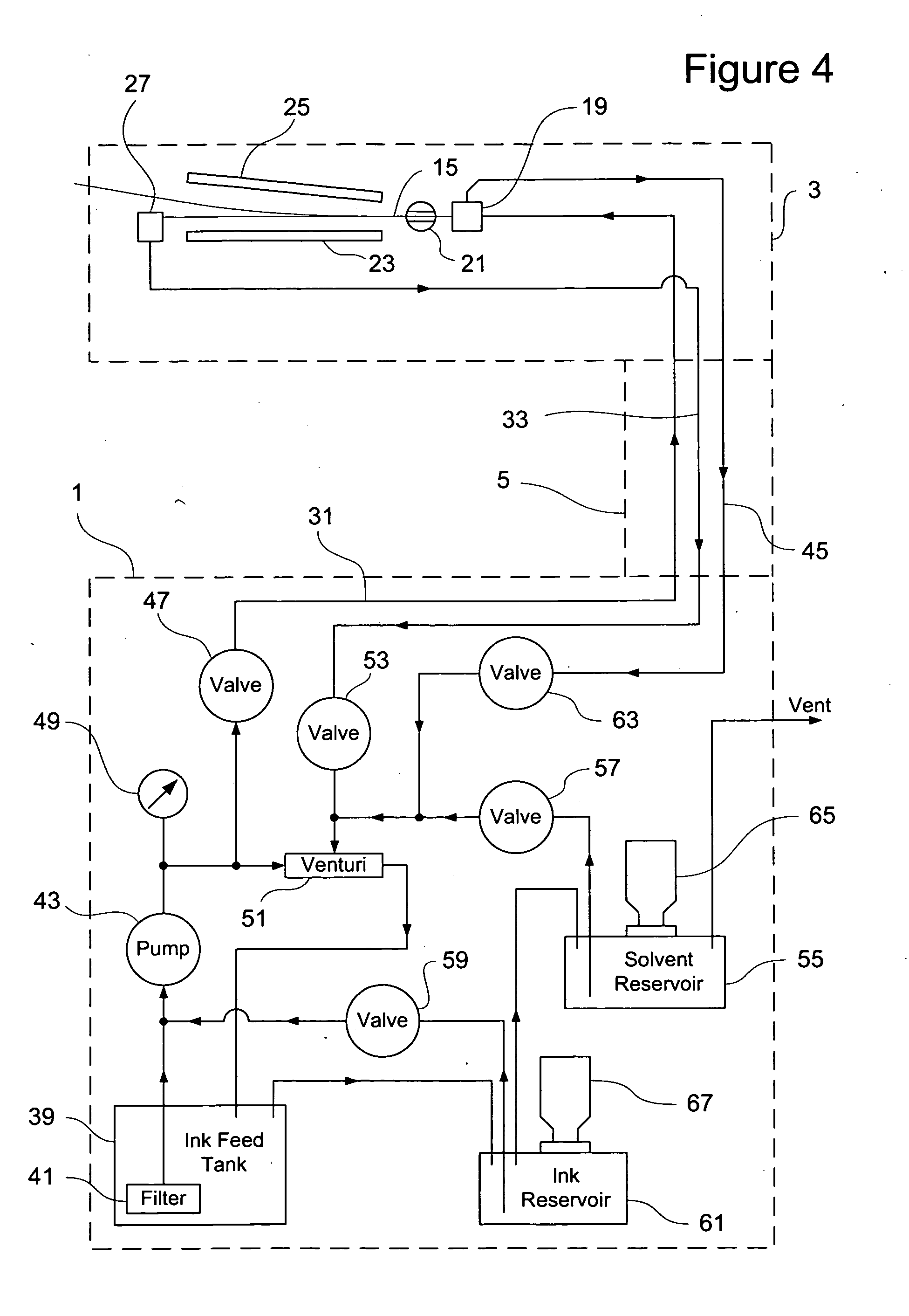

Inkjet printer

Owner:LINX PRINTING TECH

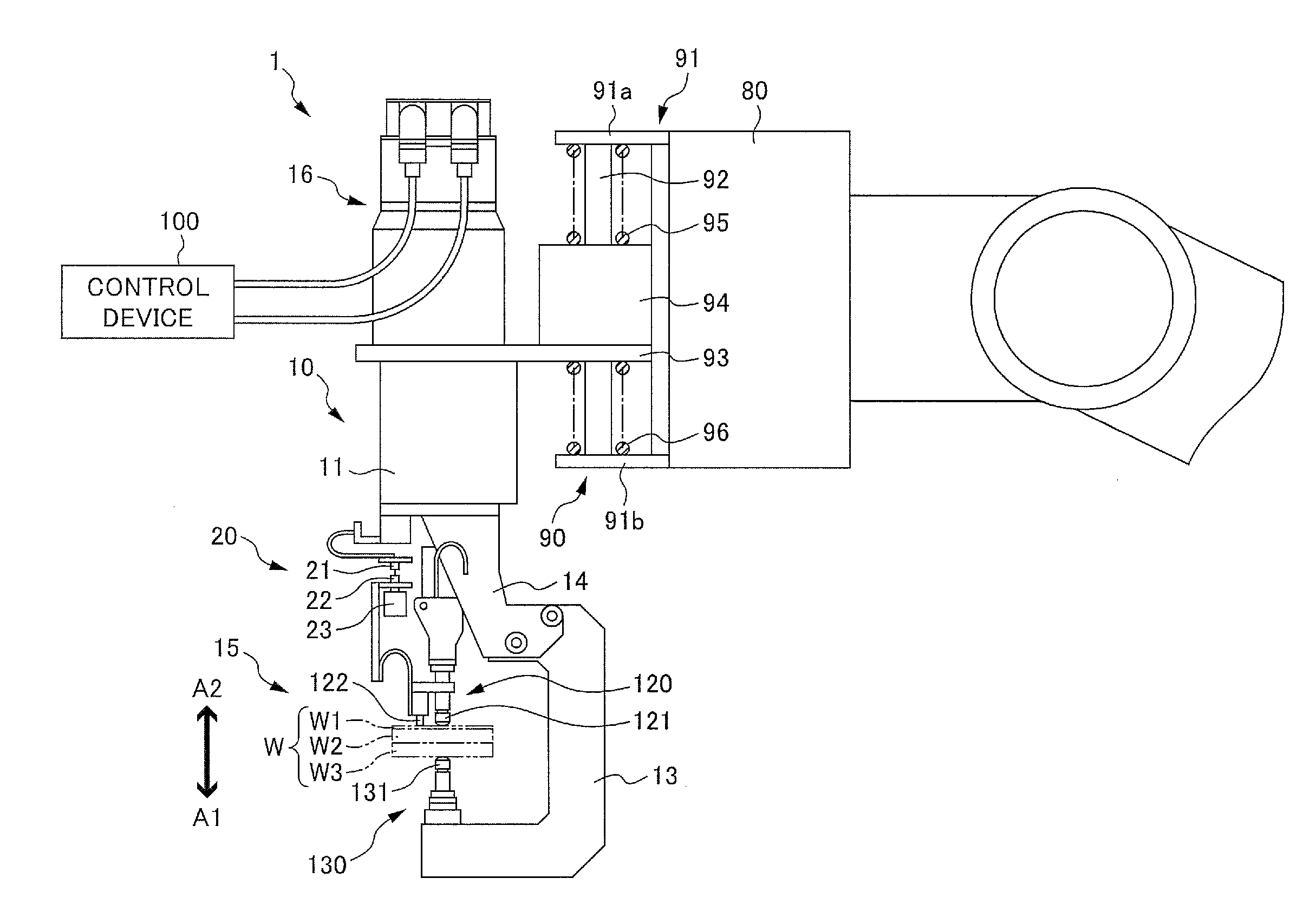

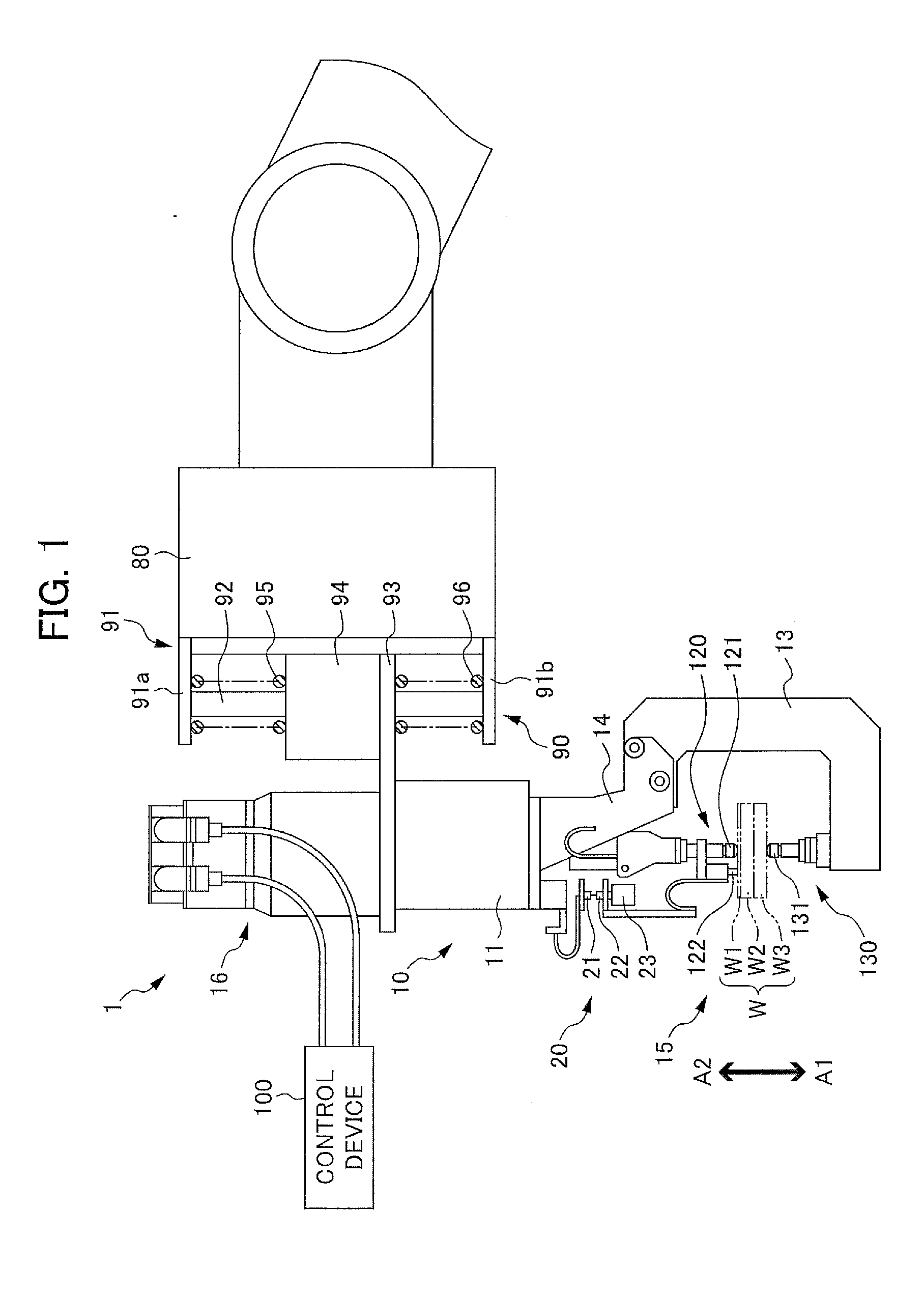

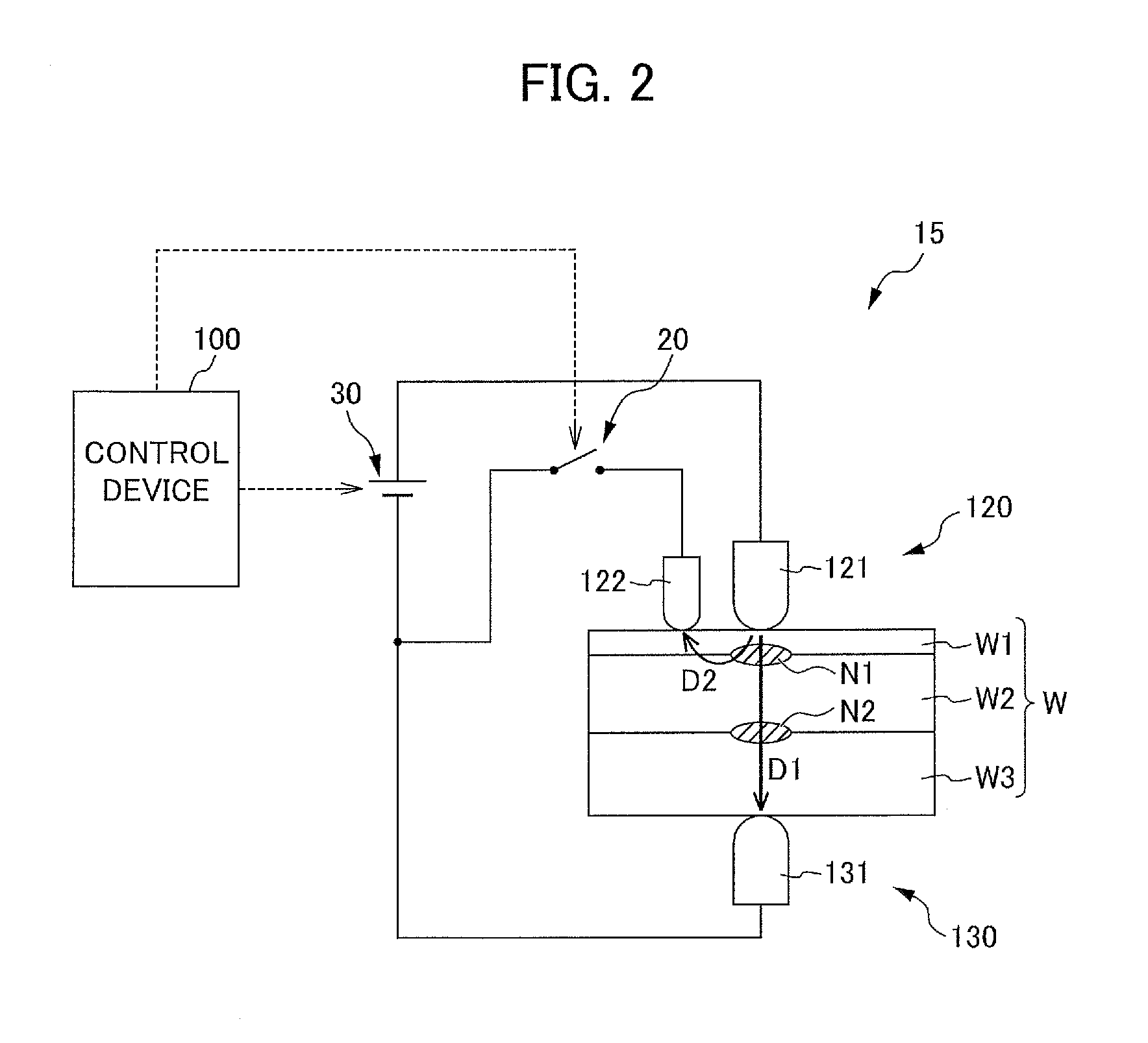

Switching electrode and resistance welding device using same, spot welding device and spot welding method

ActiveUS20150136742A1Small resistance valueLittle changeContact surface shape/structureOhmic-resistance electrodesEngineeringElectrical and Electronics engineering

The invention provides a switching electrode which has a small variation in resistance value even when a large amount of current is repeatedly cut off and can carry a stable amount of current even when it is continuously used. In the invention, the switching electrode is used in a switch which includes a first switching electrode tip (21) and a second switching electrode tip (22), brings the first switching electrode tip (21) and the second switching electrode tip (22) into surface contact with each other to carry a current, and separates the first switching electrode tip (21) and the second switching electrode tip (22) to cut off the current. At least one of contact surfaces of the first switching electrode tip (21) and the second switching electrode tip (22) is a flat surface having an uneven portion.

Owner:HONDA MOTOR CO LTD

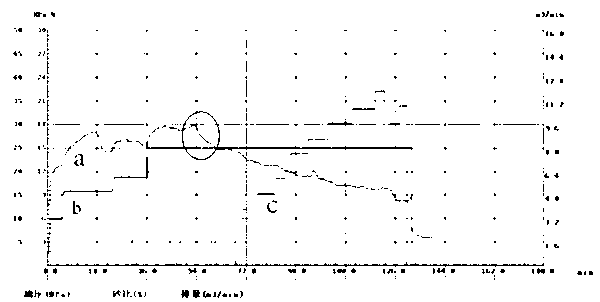

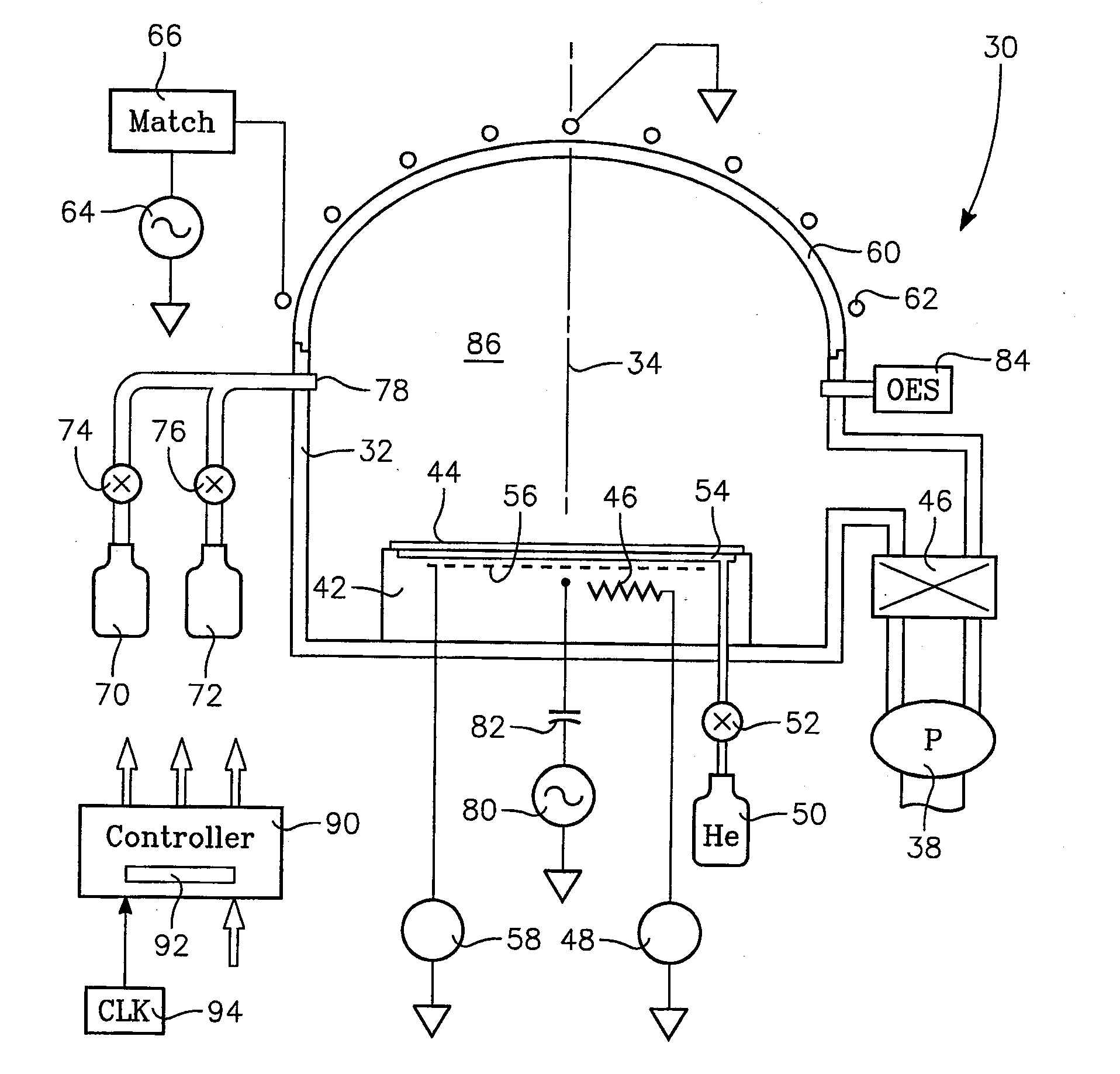

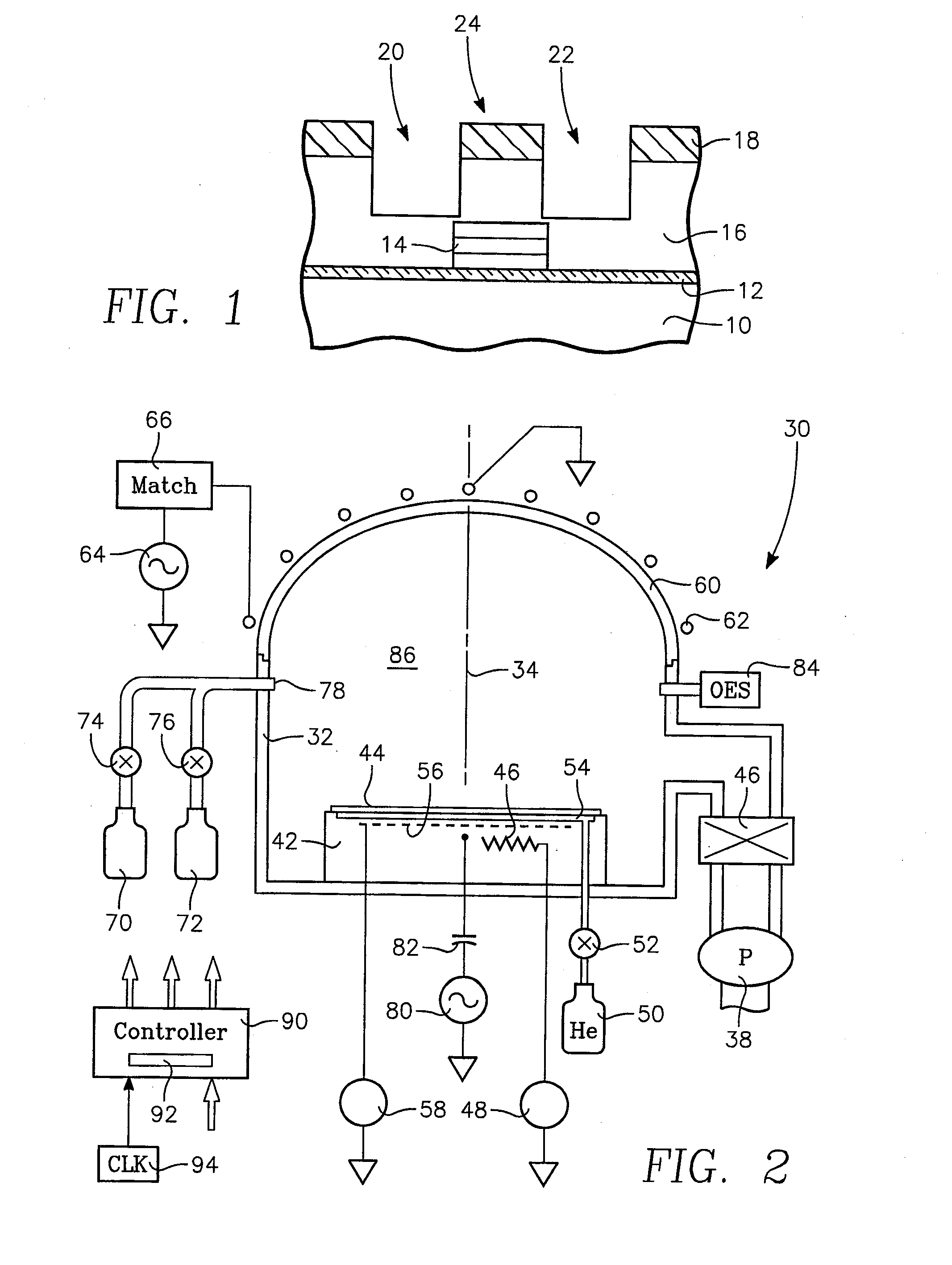

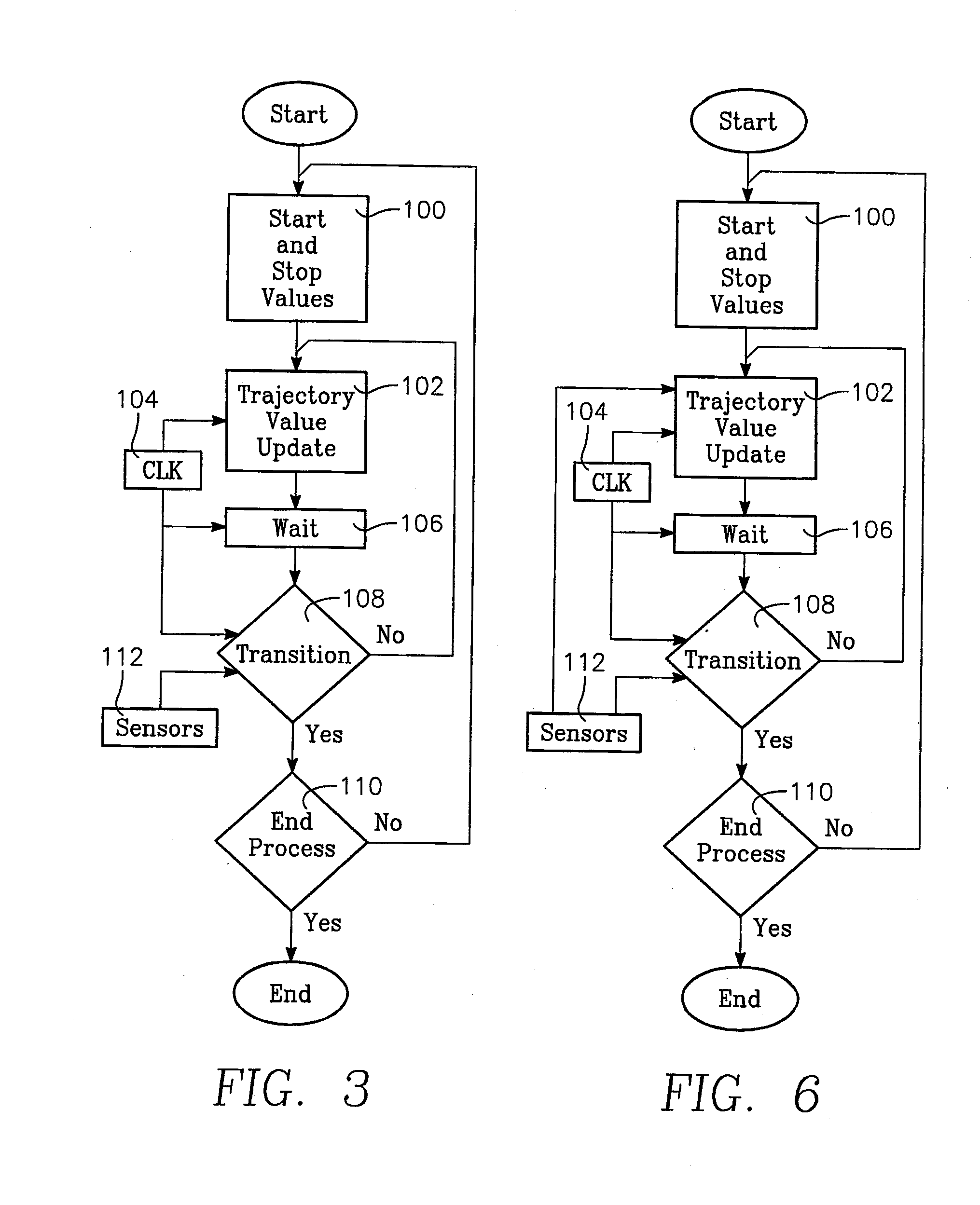

Trajectory based control of plasma processing

InactiveUS20090061544A1Join smoothlySemiconductor/solid-state device testing/measurementElectric discharge tubesEngineeringParameter control

A method of controlling a plasma processing according to trajectories connecting start and stop values of parameters controlling the plasma processing, for example, gas flow and power supplied to generate the plasma. The trajectories maybe based on equations including at least time as a variable. At set times within the processing, the values of the parameters are updated according to the predetermined trajectories. Sensors associated with the chamber may also adjust the trajectories, provide variables to the equations, and / or define the trajectories.

Owner:APPLIED MATERIALS INC

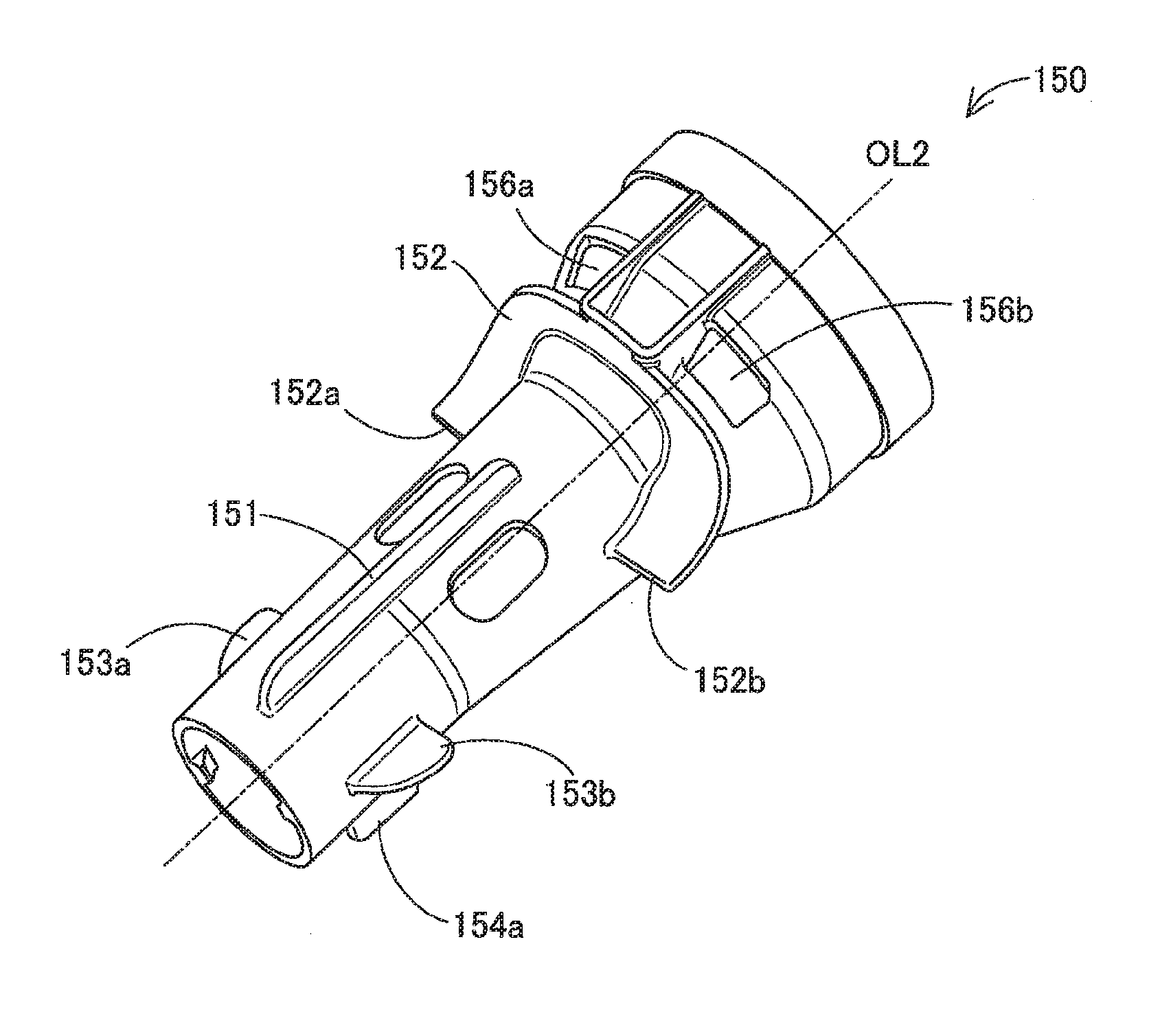

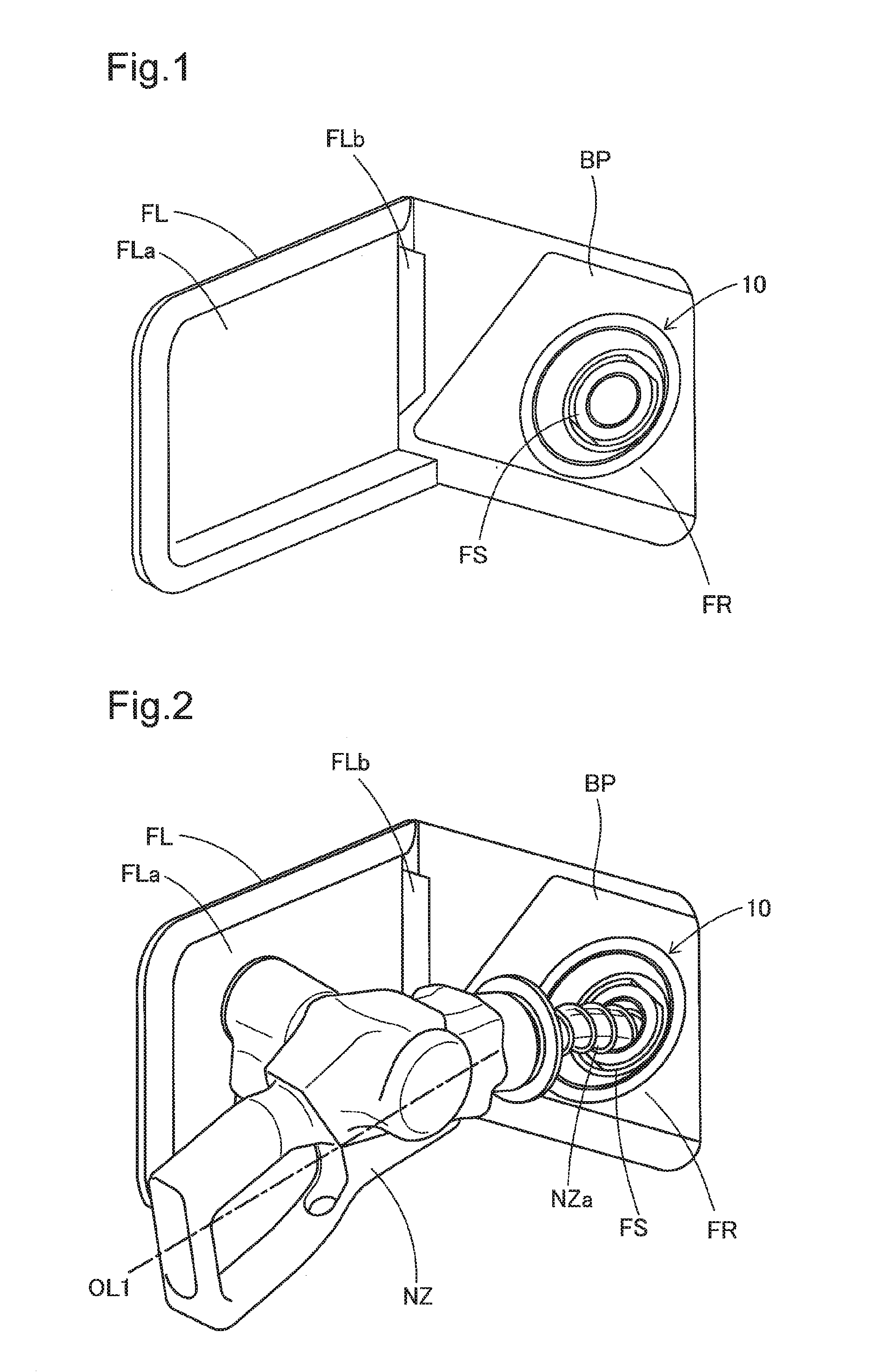

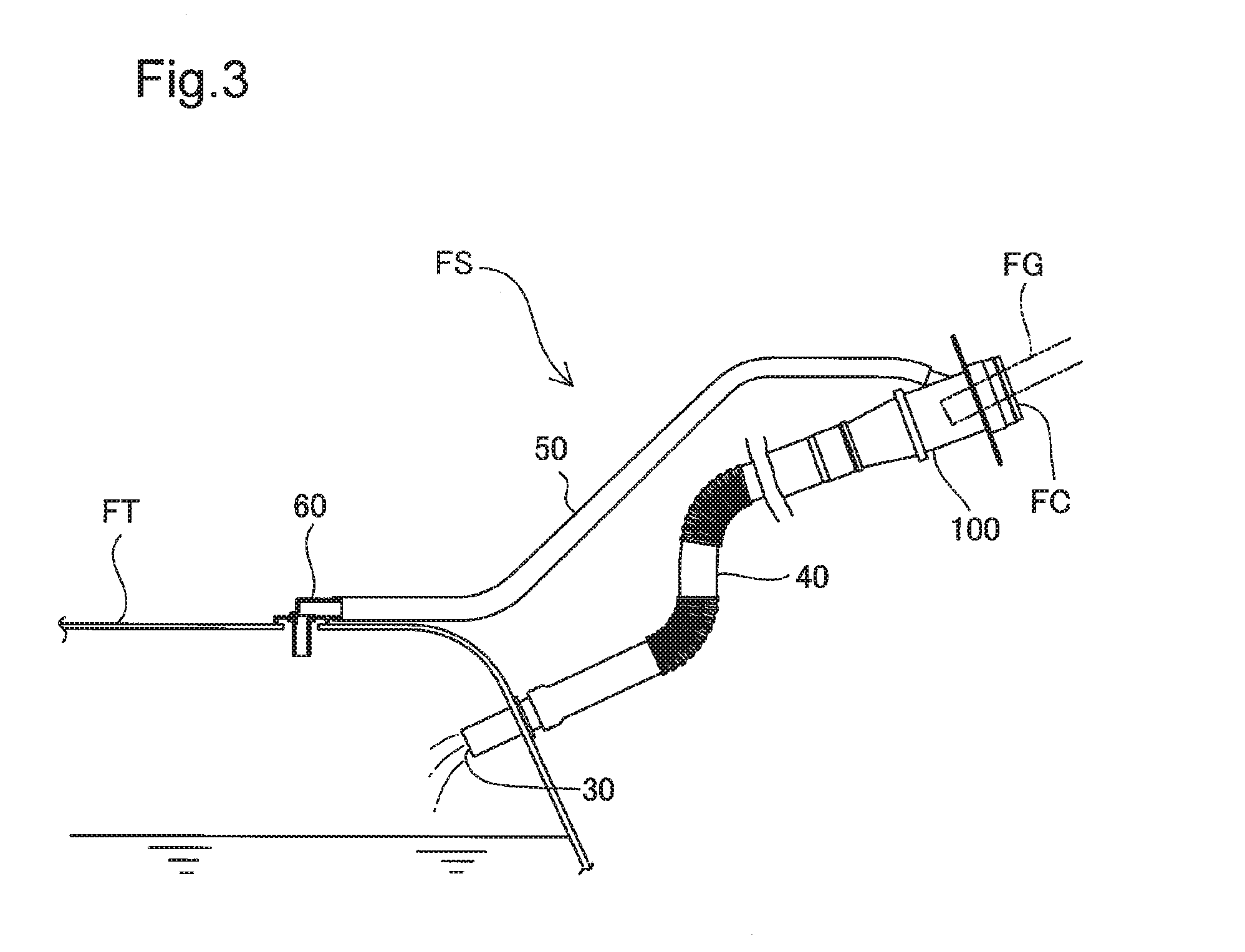

Fuel supply apparatus

ActiveUS20160272063A1Speed up the flowSuppress turbulenceMachines/enginesLiquid fuel feedersVaporizationFuel supply

An object is to provide a fuel supply apparatus that is configured to cause fuel vapor generated by vaporization of a fuel circulated in a fuel tank to be smoothly joined with the supplied fuel. The fuel supply apparatus comprises a filler neck body that is configured to include a hollow fuel passage-forming portion arranged to define a fuel passage and a breather port; a nozzle guide that is placed inside of the fuel passage-forming portion and is configured to introduce a fueling nozzle; a guide portion that is configured to introduce an inflow gas flowing in from the breather port, to the fuel passage via an outer circumferential space; and a rib that is provided between the guide portion and a lower end in the first direction of the nozzle guide and is configured to divide the inflow gas introduced through the fuel passage.

Owner:TOYODA GOSEI CO LTD +1

Sustained release pest control products and their applications

A method for applying a barrier to structures to prevent the infiltration of pest species (unwanted organisms) uses a (e.g., coating) composition formed from a polyurethane (e.g., film-forming) polymer system and a pellet comprising a pesticide incorporated into a sorbent and dispersed in the polyurethane polymer system. The composition protects the structure by application either to the structure or to a pathway that leads to the structure. Advantageous polymer systems include polyurethanes rich in urea linkages and predominating in aliphatic and alicyclic backbones.

Owner:BIOGUARD TECH

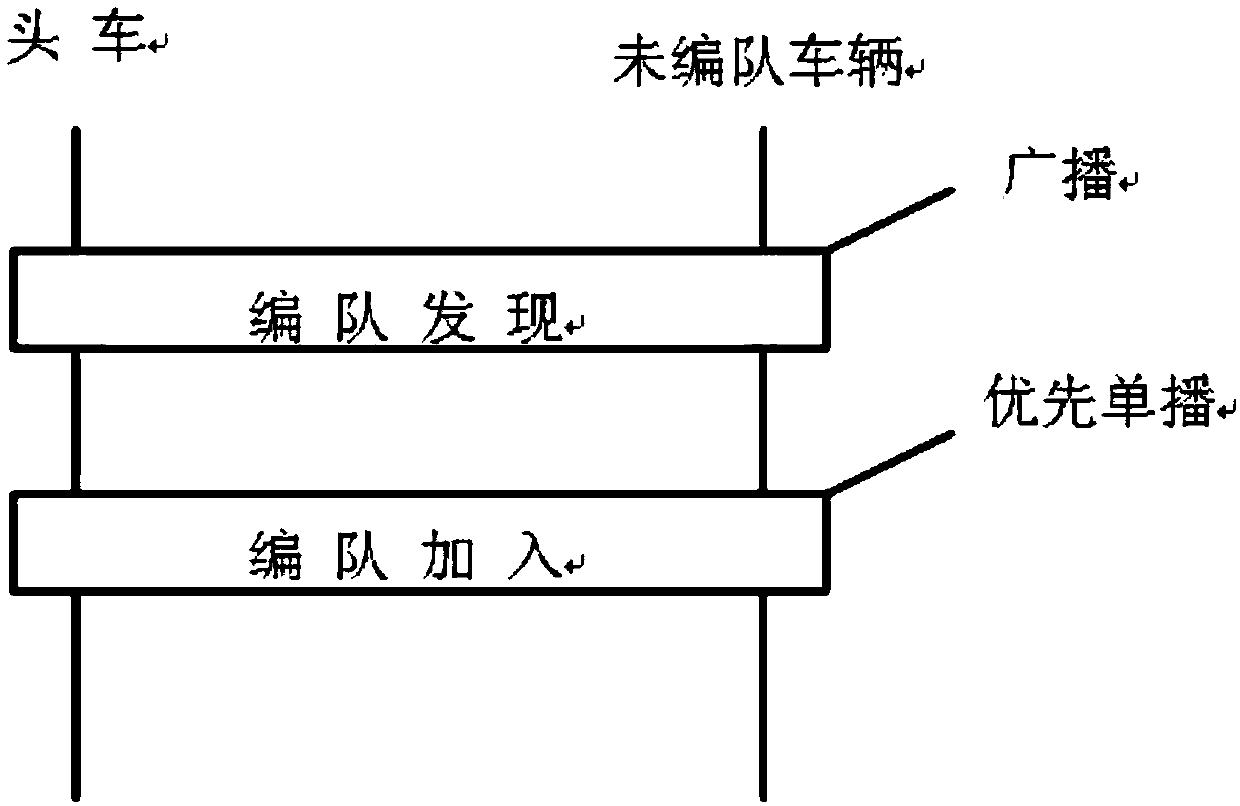

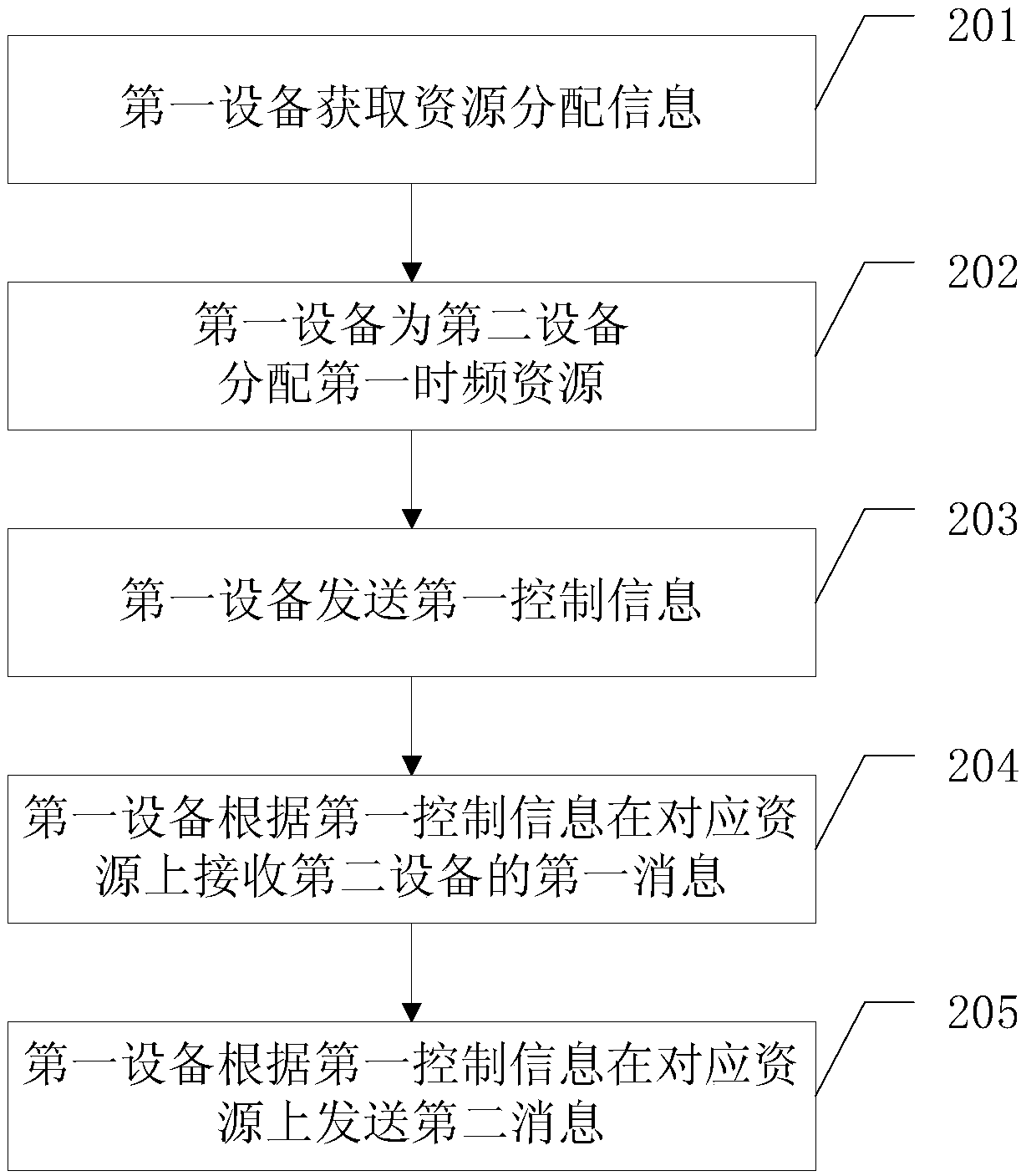

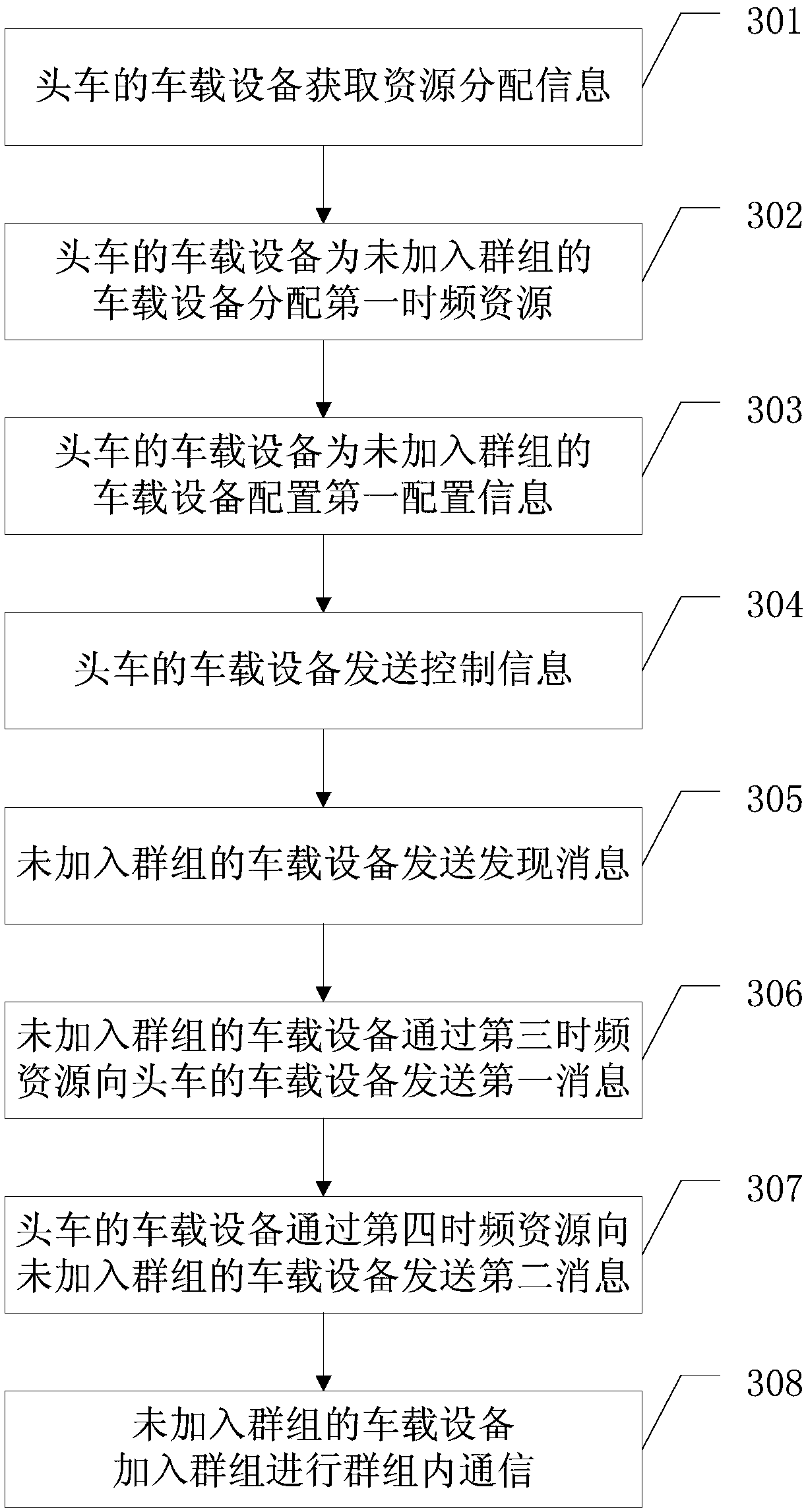

Resource allocation method and communication equipment

ActiveCN110545524AAvoid resource utilization conflictsAvoid confictParticular environment based servicesBroadcast service distributionResource allocationDistributed computing

The embodiment of the invention discloses a resource allocation method and communication equipment, which are used for allocating special reserved resources to the communication equipment which does not join a group so as to smoothly join the group. The method provided by the embodiment of the invention comprises the following steps: a first device configures first configuration information for asecond device, wherein the first configuration information is used for indicating a first time-frequency resource allocated by the first device, and the first time-frequency resource is different froma second time-frequency resource allocated by the first device to a third device in the same group, the first time-frequency resource comprises a third time-frequency resource and a fourth time-frequency resource, the third time-frequency resource is a time-frequency resource used when the first device receives a message sent by the second device, the fourth time-frequency resource is a time-frequency resource used when the first device sends the message to the second device, and the third time-frequency resource and the fourth time-frequency resource are different; and the first device sendscontrol information, wherein the control information comprises first configuration information.

Owner:HUAWEI TECH CO LTD

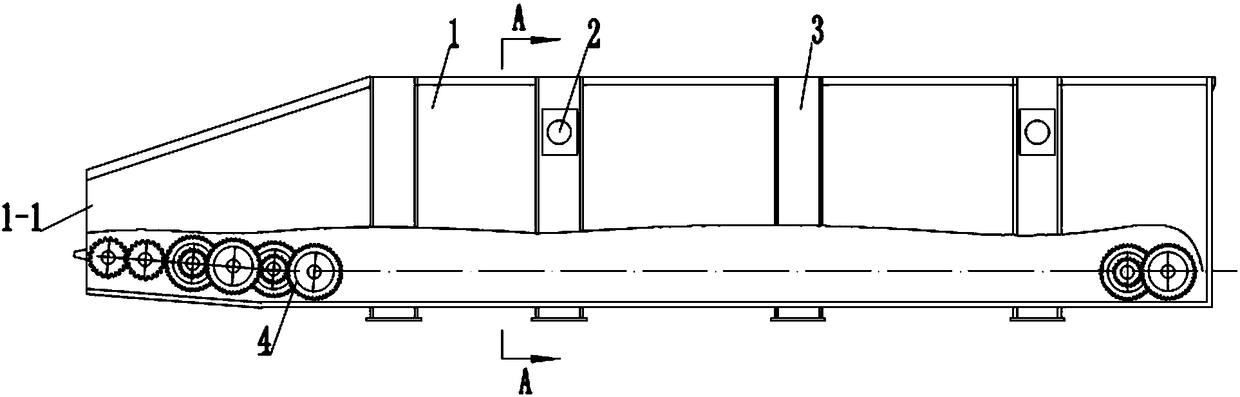

Rotating furnace scrap steel feeding hopper

PendingCN108085452AJoin smoothlyImprove the smoothness of joiningManufacturing convertersEngineeringScrap

The invention discloses a rotating furnace scrap steel feeding hopper, and belongs to the technical field of iron and steel smelting. The rotating furnace scrap steel feeding hopper comprises a box, four groups of lifting lugs and one group of reinforcing ribs, a discharging port is formed in the front end of the box, the reinforcing ribs are arranged outside two side walls of the box, and the lifting lugs are symmetrically and fixedly mounted on the front, the rear, the left and the right of the reinforcing ribs. The hopper is characterized in that one row of rollers are arranged at the bottom of the box and perpendicular to a center axis of the length direction of the bottom surface of the box, and one group of gears are arranged on the outer wall of first roller positioned at the discharging port of the box along a peripheral direction. The hopper solves the problem that scrap steel materials are stacked on a furnace opening in the feeding process, feeding smoothness of scrap steelis improved, and the feeding proportion of the scrap steel is increased.

Owner:TANGSHAN DELONG STEEL CO LTD

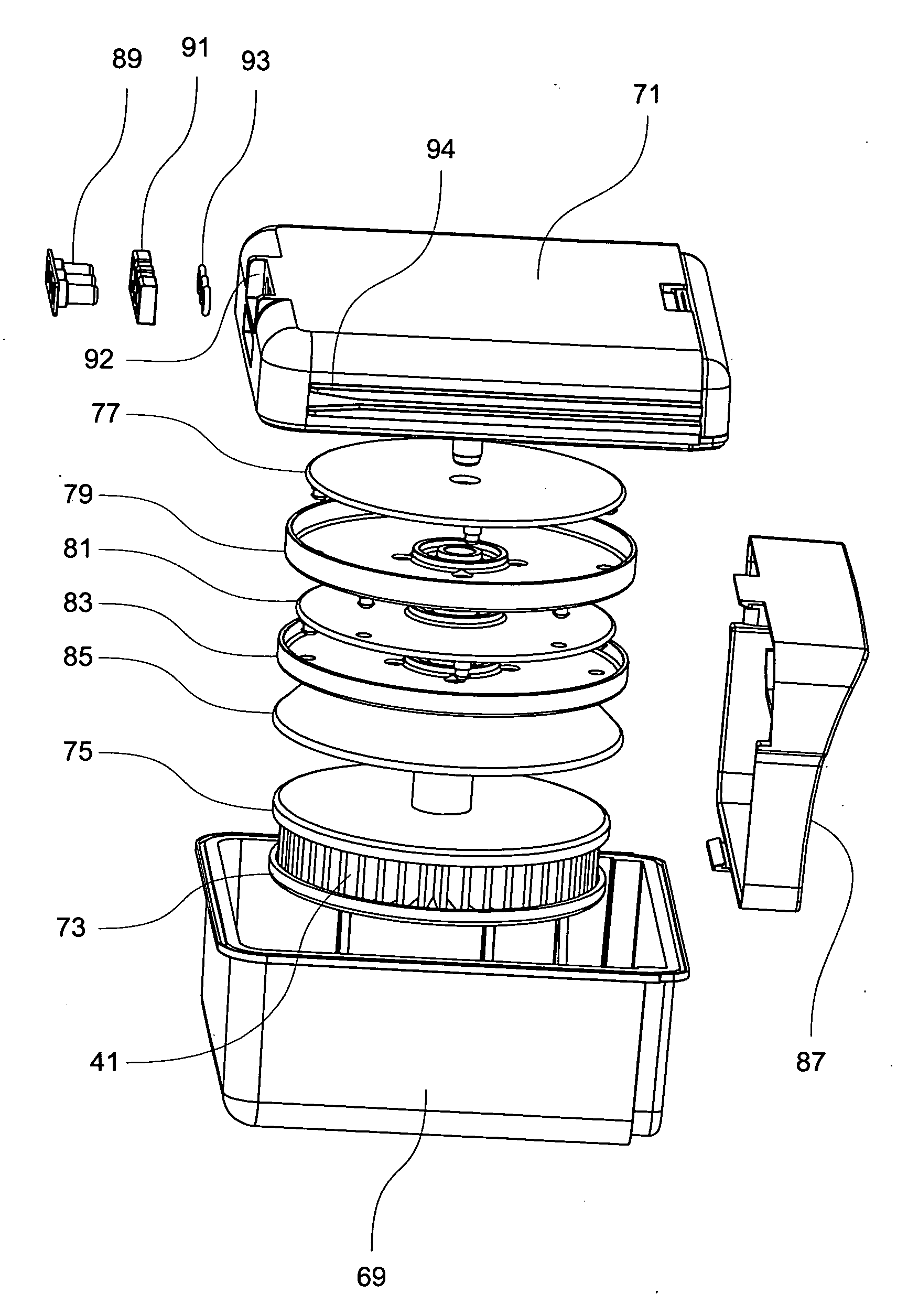

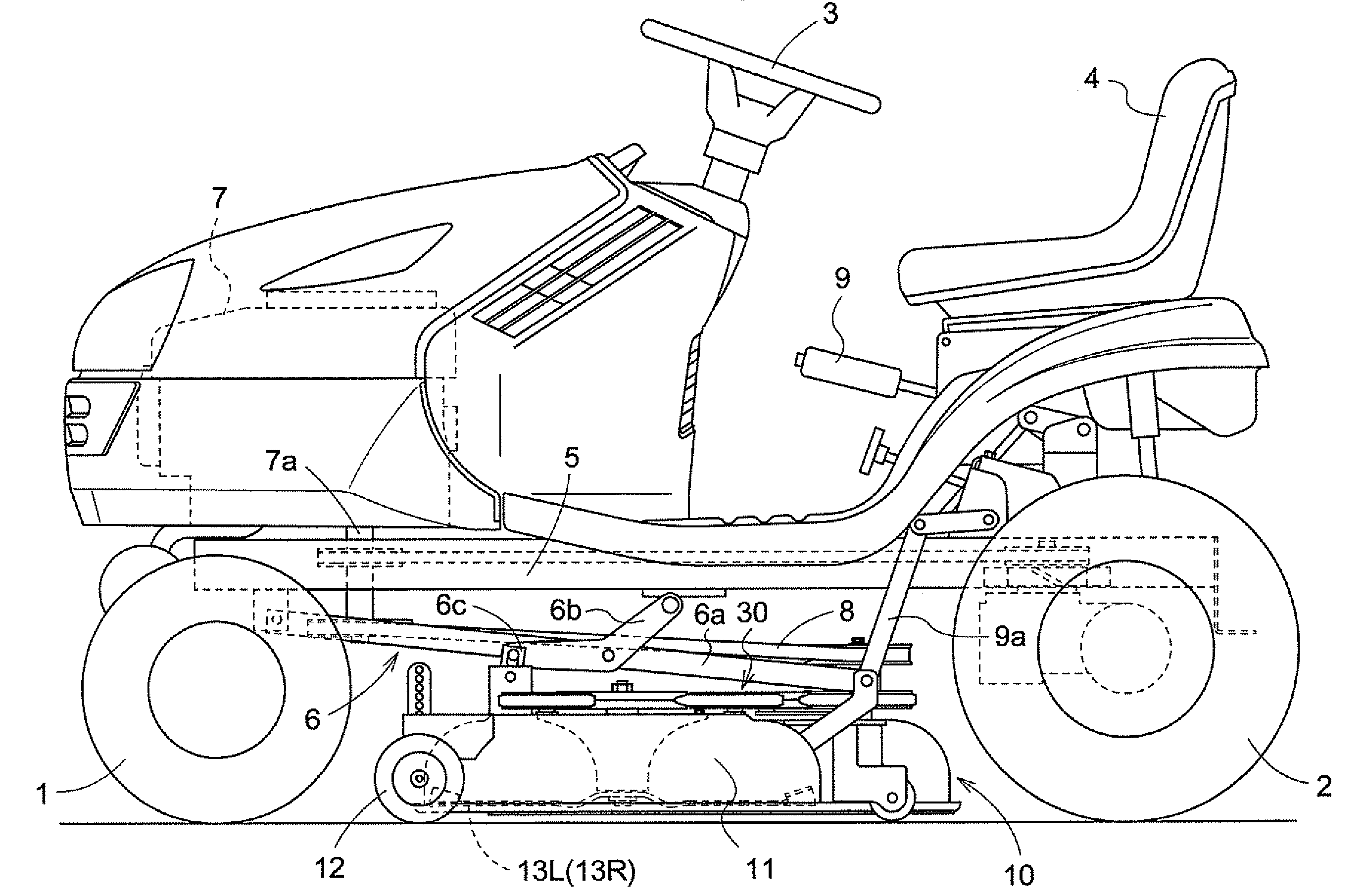

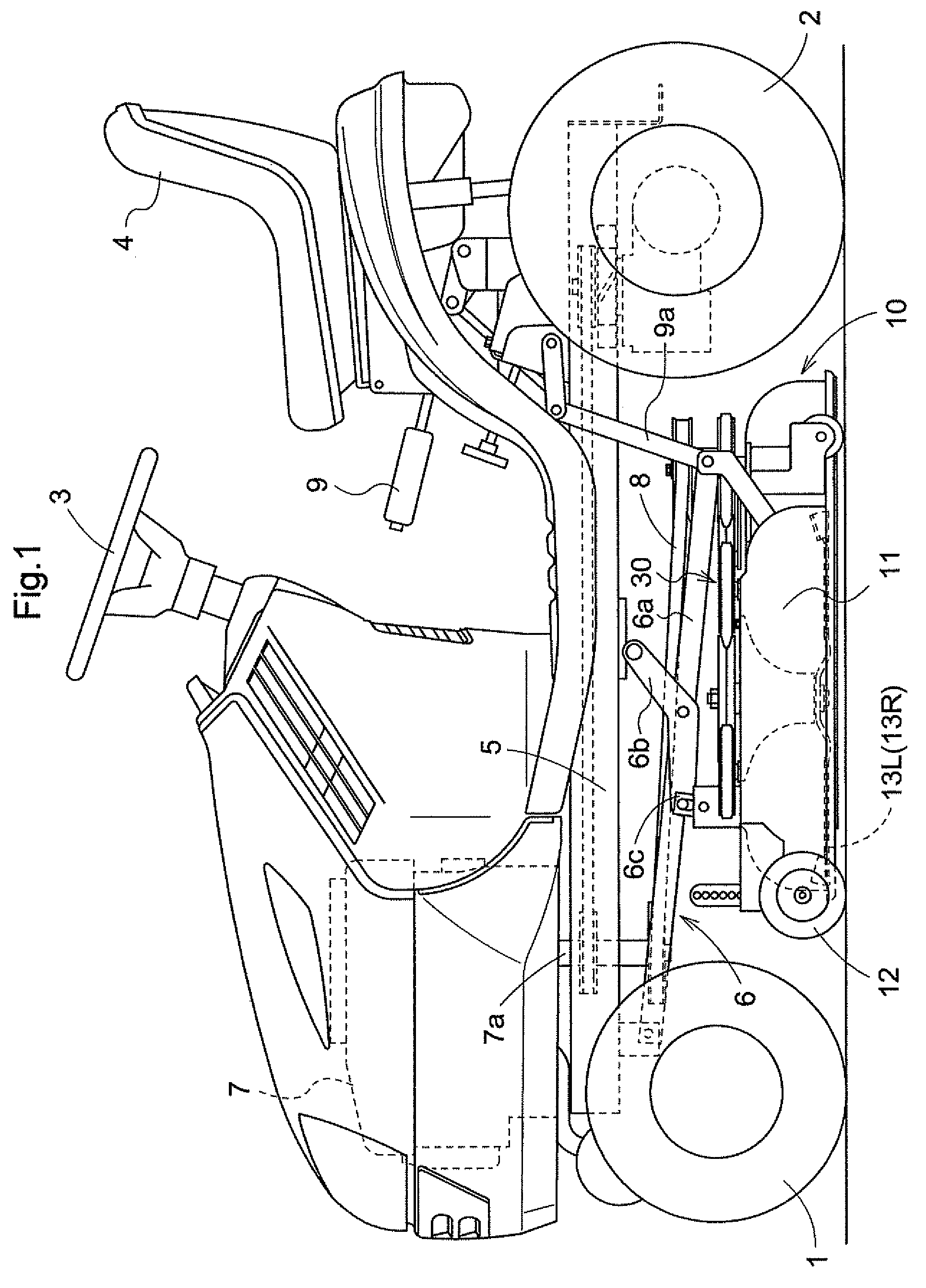

Mower unit

A mower unit includes a housing, a pair of cutting blades arranged inside the housing, each of the cutting blades being rotatable about a respective vertical axis supported by the housing, the cutting blades being driven to be rotated in opposite directions, and a baffle arranged generally between rotation regions of the cutting blades to guide air flows generated by the cutting blades. The baffle defines an upper baffle portion located adjacent an upper region of the housing, a lower baffle portion located adjacent a lower region of the housing, and an air passage formed for allowing the air flows to flow between the upper baffle portion and lower baffle portion.

Owner:KUBOTA LTD

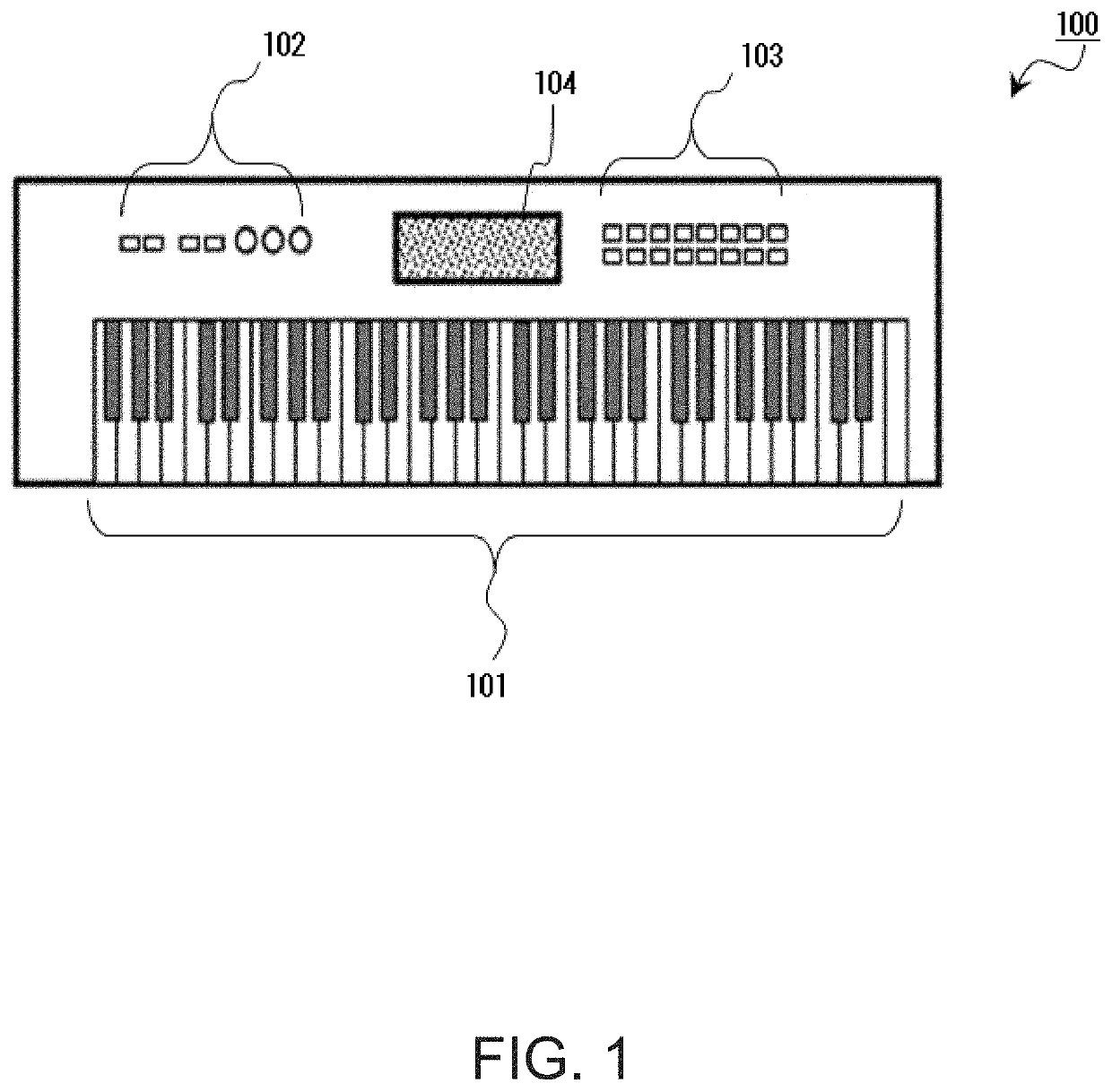

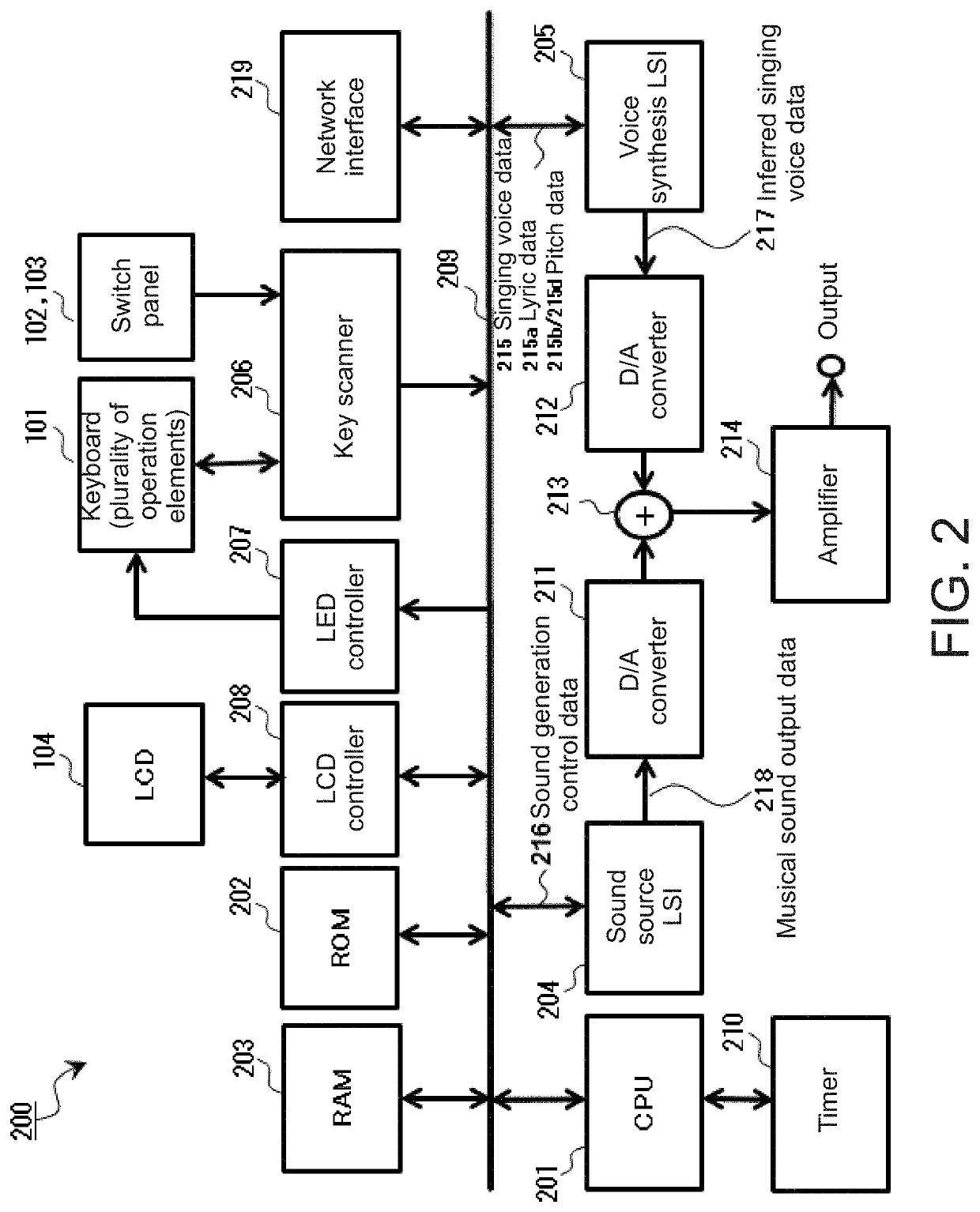

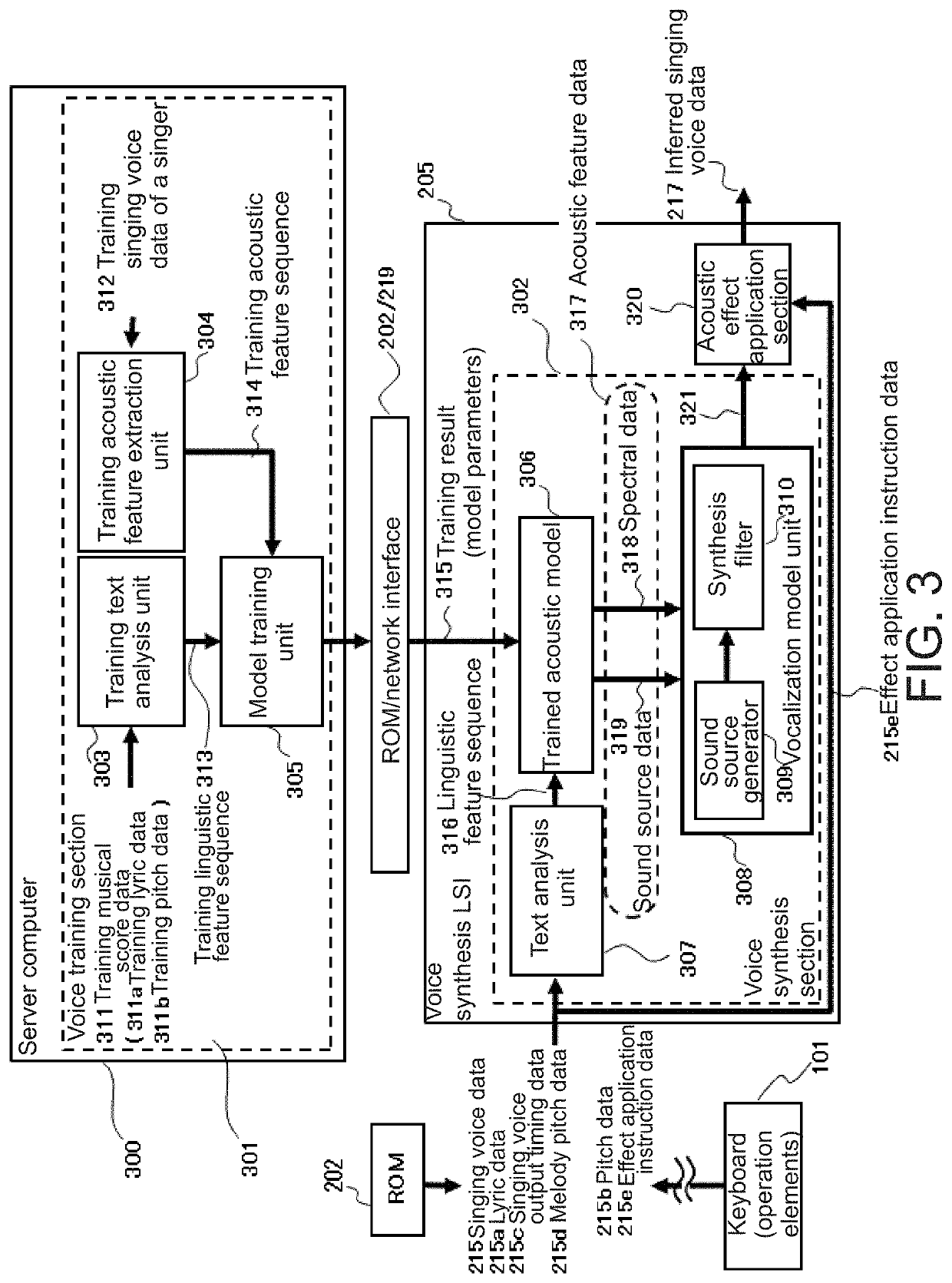

Electronic musical instrument, electronic musical instrument control method, and storage medium

ActiveUS20210012758A1Join smoothlyElectrophonic musical instrumentsNeural learning methodsElectronic instrumentEngineering

An electronic musical instrument includes: a memory that stores lyric data including lyrics for a plurality of timings, pitch data including pitches for said plurality of timings, and a trained model that has been trained and learned singing voice features of a singer; and at least one processor, wherein at each of said plurality of timings, the at least one processor: if the operation unit is not operated, obtains, from the trained model, a singing voice feature associated with a lyric indicated by the lyric data and a pitch indicated by the pitch data; if the operation unit is operated, obtains, from the trained model, a singing voice feature associated with the lyric indicated by the lyric data and a pitch indicated by the operation of the operation unit; and synthesizes and outputs singing voice data based on the obtained singing voice feature of the singer.

Owner:CASIO COMPUTER CO LTD

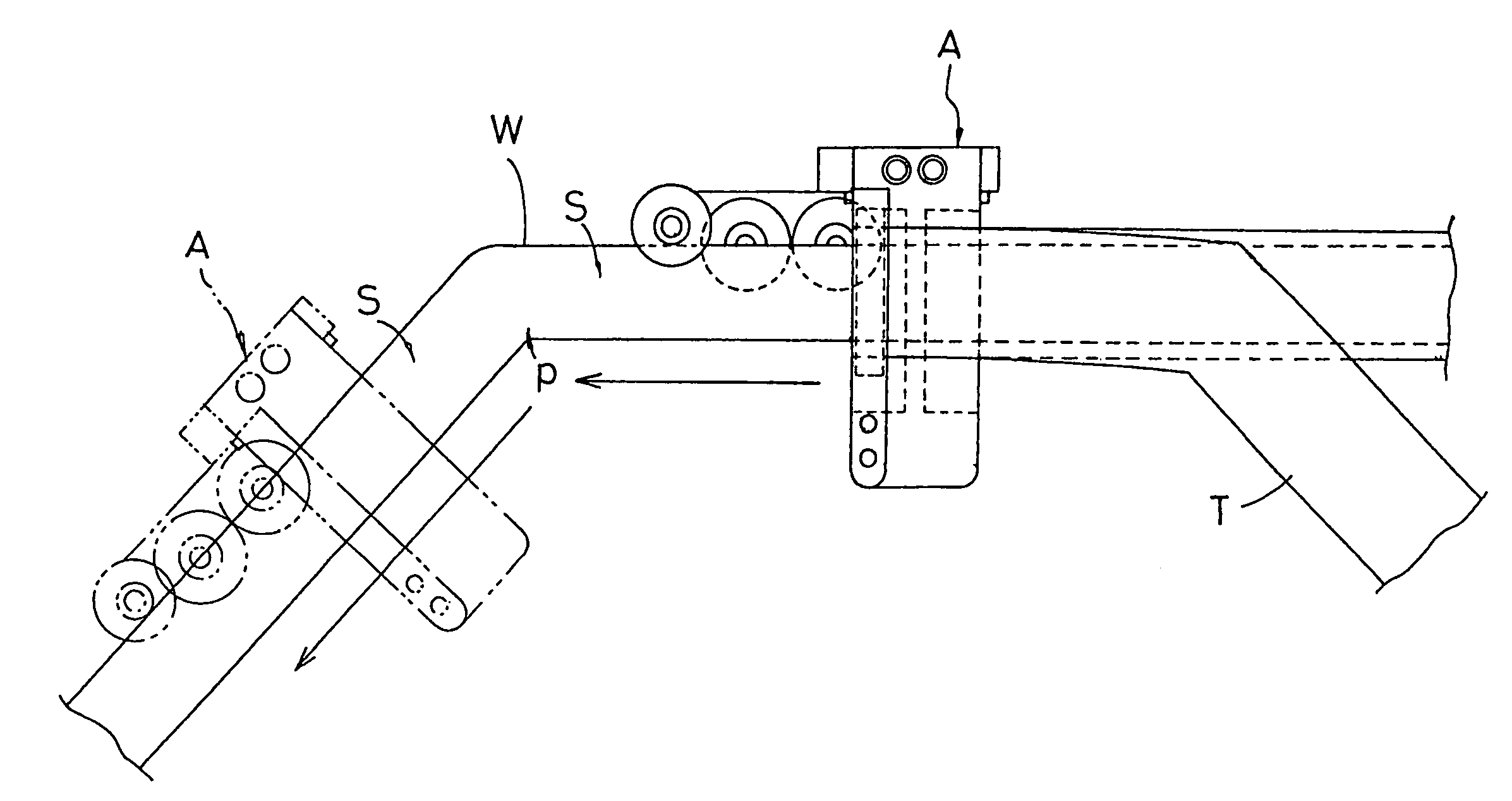

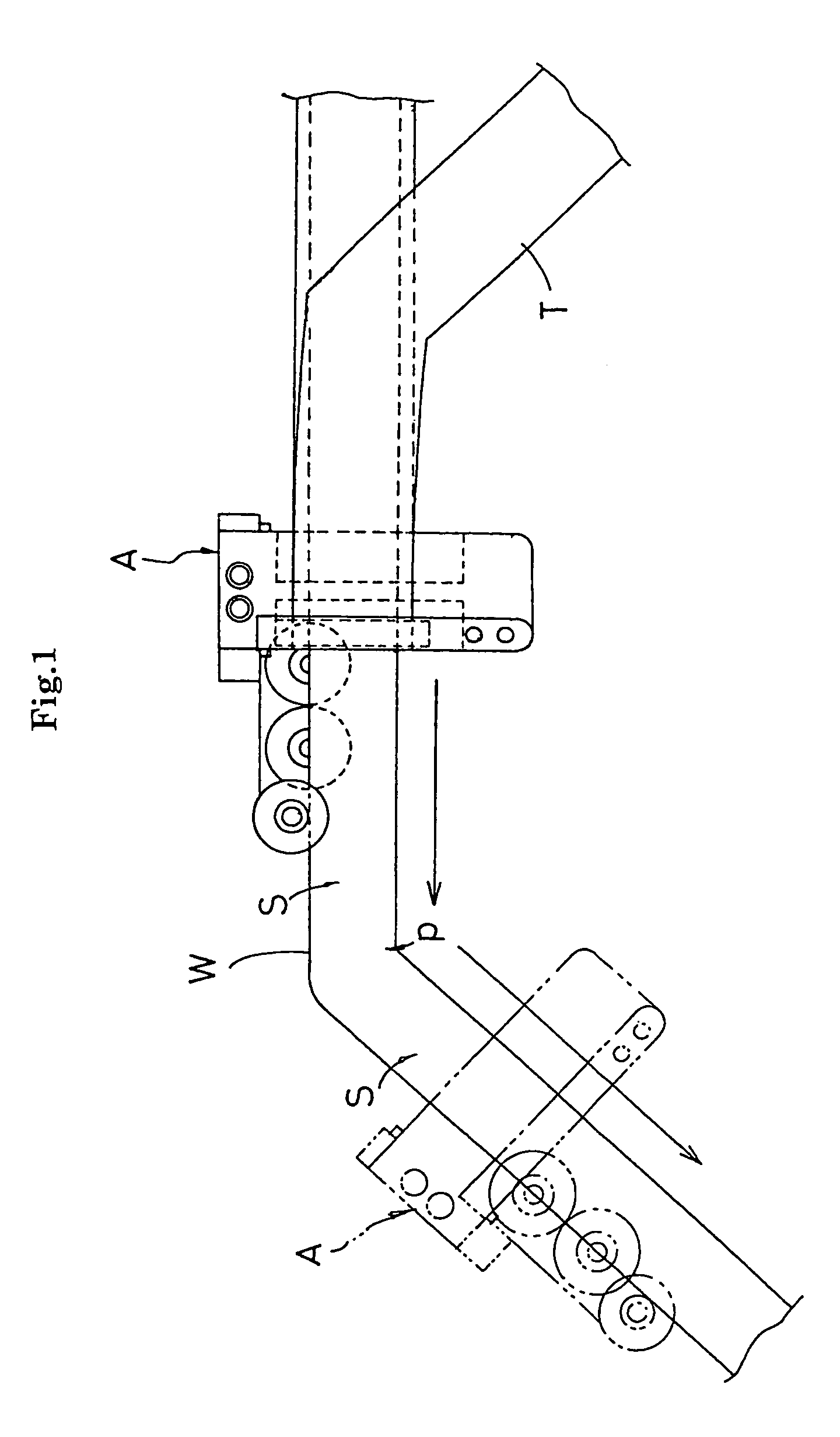

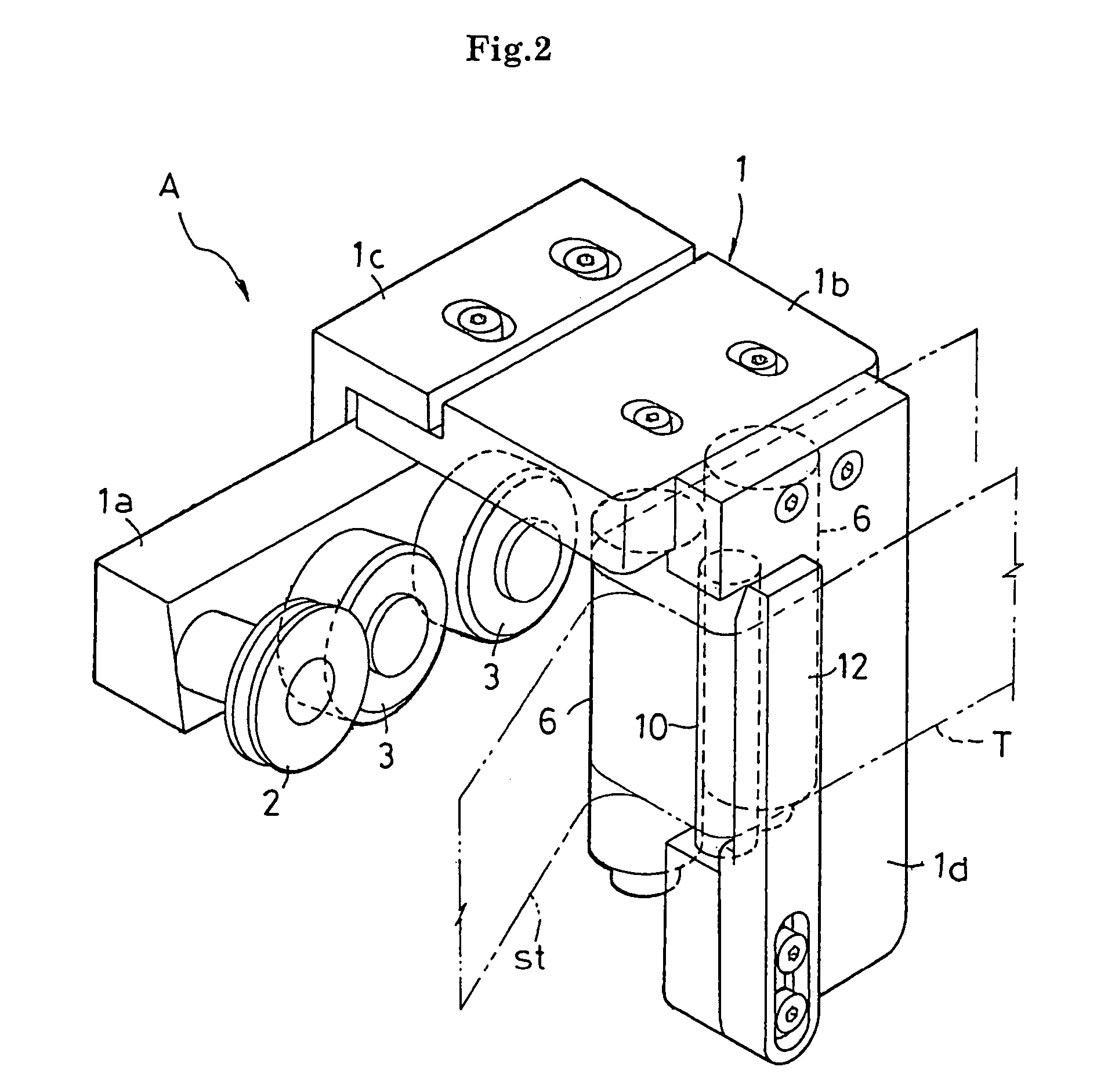

Method and apparatus for joining adhesive tape

An adhesive tape inserted into a tape inserting clearance defined between a tape supplying roller and a tape guide is supplied to joining rollers while being wound around the tape supplying roller under guidance. At the tape inserting clearance, one side edge of the adhesive tape is guided to a tape positioner in slide contact, to be positioned in a tape width direction, and further, the adhesive tape T is inserted and moved while allowing the tape to be moved toward the other side edge of the adhesive tape.

Owner:NITTO DENKO CORP

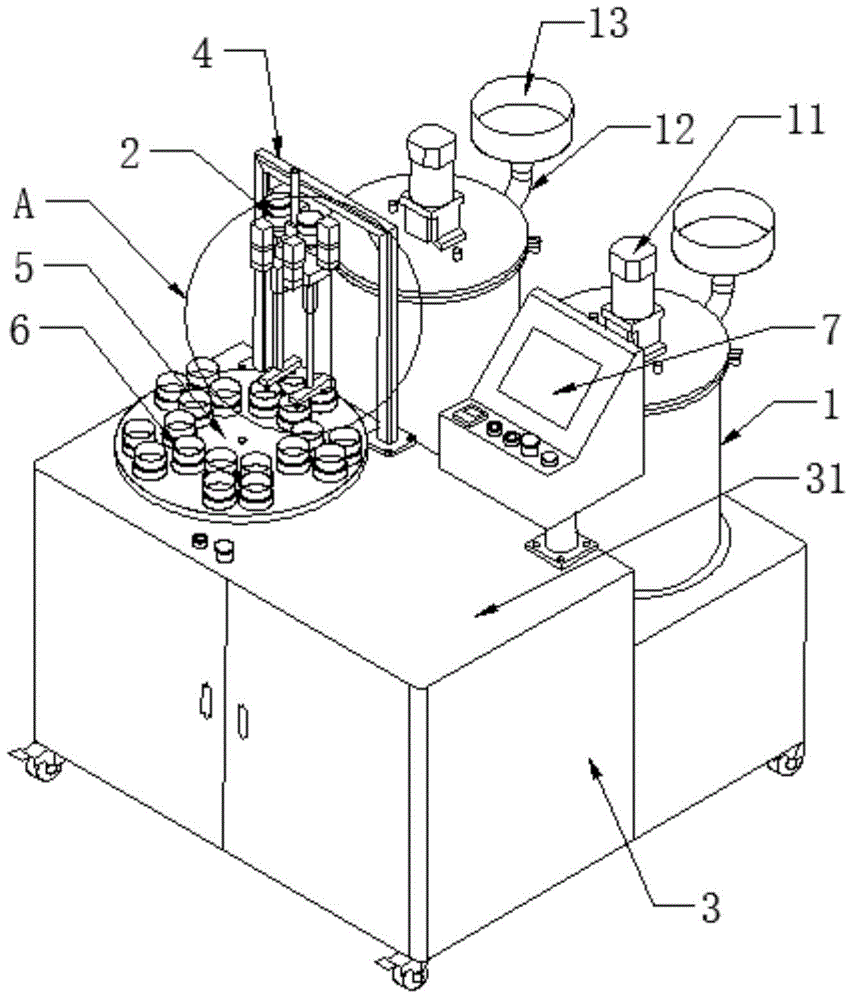

Automatic turnplate type glue preparation and injection machine

InactiveCN105983510AImprove single injection efficiencyAvoid cloggingLiquid surface applicatorsSpraying apparatusMachine controlFiltration

The invention discloses an automatic turnplate type glue preparation and injection machine which is provided with at least two charging barrels and at least one dynamic mixing glue injection head. The dynamic mixing glue injection head is provided with a plurality of feeding ports and a discharging port. The charging barrels communicate with the feeding ports in a one-to-one correspondence mode through feeding pipes. Each feeding pipe is provided with a metering pump and a feeding valve. At least one working turnplate is arranged on a working table and under the dynamic mixing glue injection head. The center of the working turnplate is connected with a motor and a reduction gearbox through a rotary shaft. The working turnplate is provided with a plurality of sets of positioning points. A glued piece is placed at each positioning point correspondingly. The multiple sets of positioning points are distributed in a radial shape around the center of the working turnplate. A control computer of the glue injection machine controls the dynamic mixing glue injection head, the metering pumps, the feeding valves and the motor. By the adoption of the automatic turnplate type glue preparation and injection machine, full automation, batch production and continuous production of glue preparation and glue injection in the ultra-filtration element glue sealing technique are achieved, the automation degree is high, the labor intensity is relieved, the labor cost is reduced, and the glue preparation and glue injection quality is improved.

Owner:KUNSHAN JINGCHENG MEMBRANE TECH CO LTD

Panel

ActiveUS9995045B2Reliable lockingJoin smoothlySheet joiningFlooringMechanical engineeringEngineering

Owner:UNILIN NORDIC AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com