Patents

Literature

207 results about "Rotating furnace" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

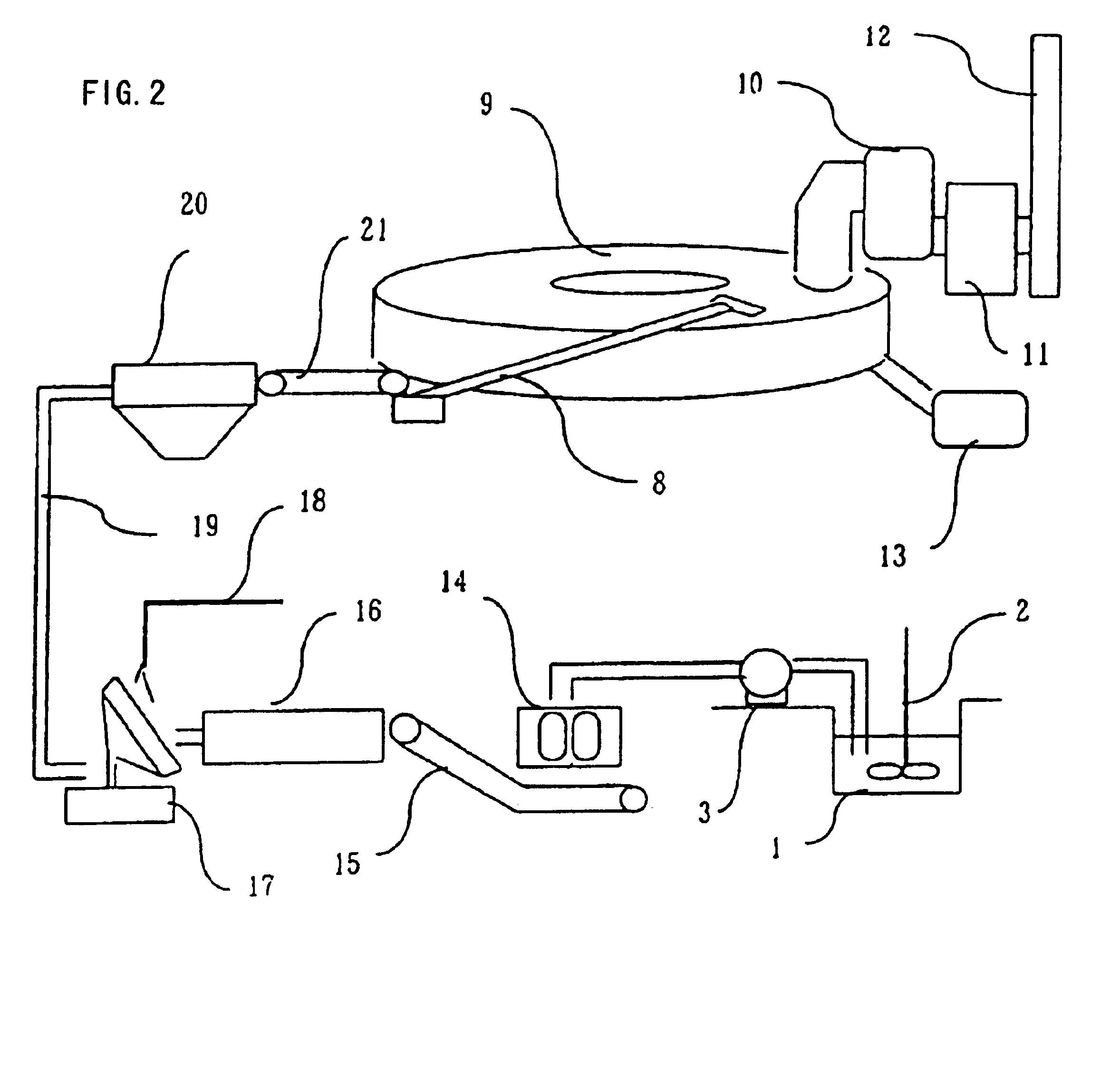

A rotating furnace is a device for making solid objects which have concave surfaces that are segments of axially symmetrical paraboloids. Usually, the objects are made of glass. The furnace makes use of the fact, which was known already to Newton, that the centrifugal-force-induced shape of the top surface of a spinning liquid is a concave paraboloid, identical to the shape of a reflecting telescope's primary focusing mirror.

Iron production method of operation in a rotary hearth furnace and improved furnace apparatus

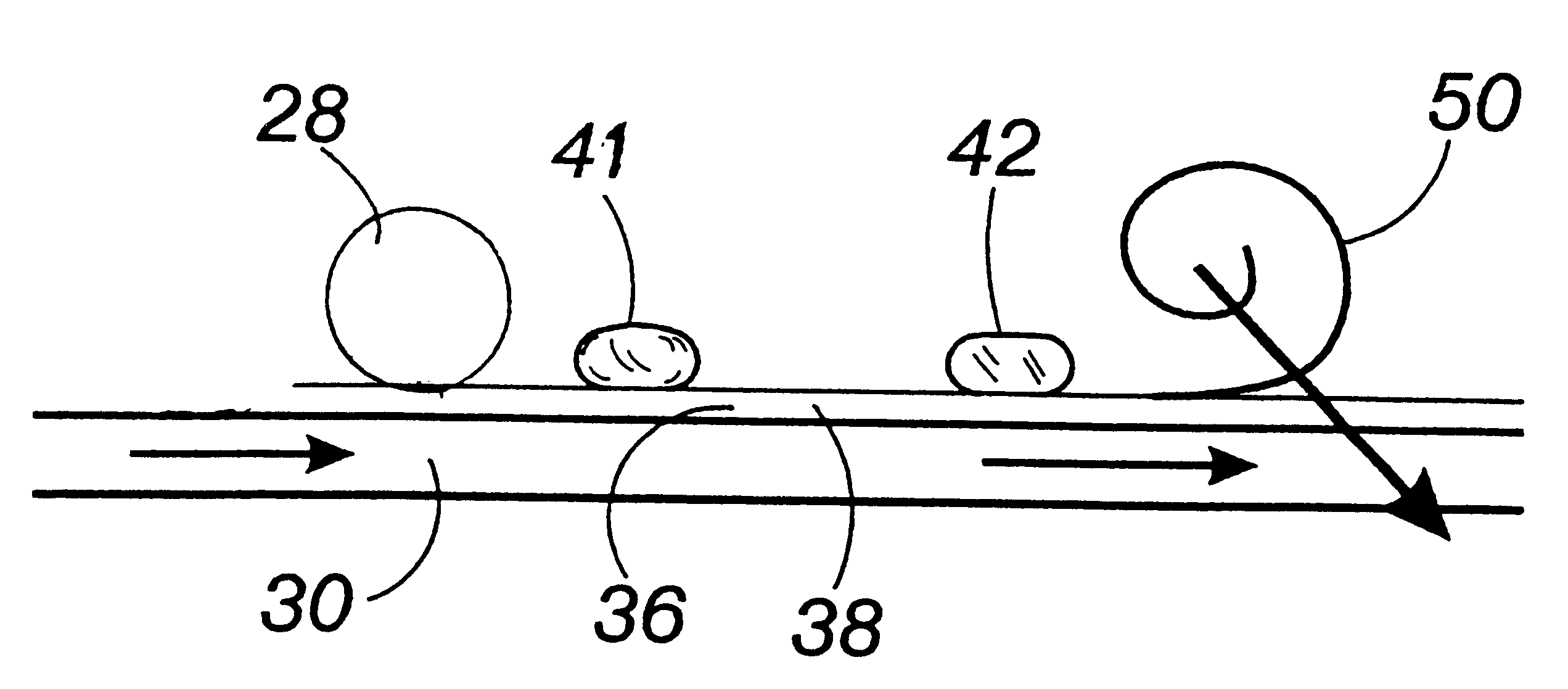

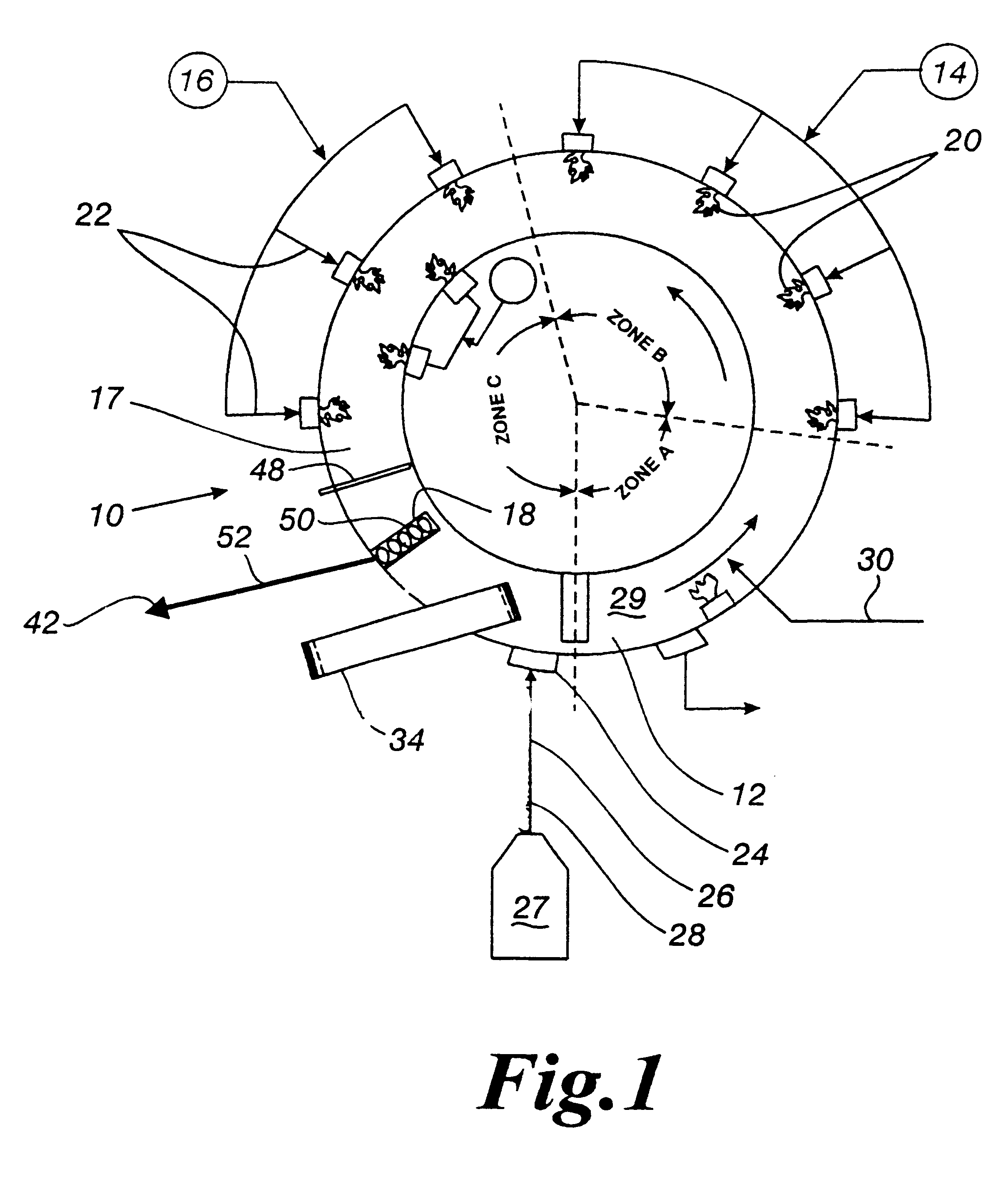

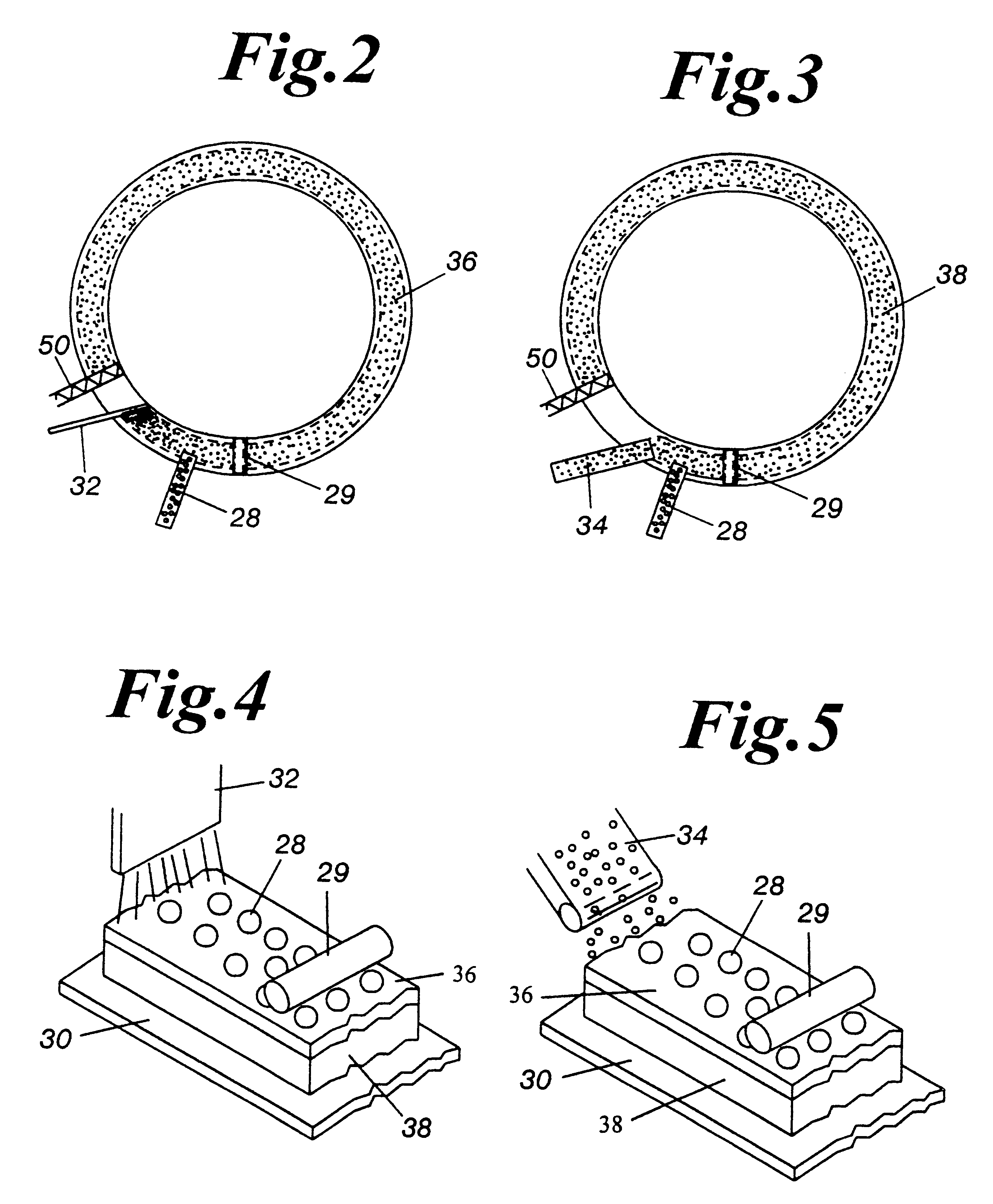

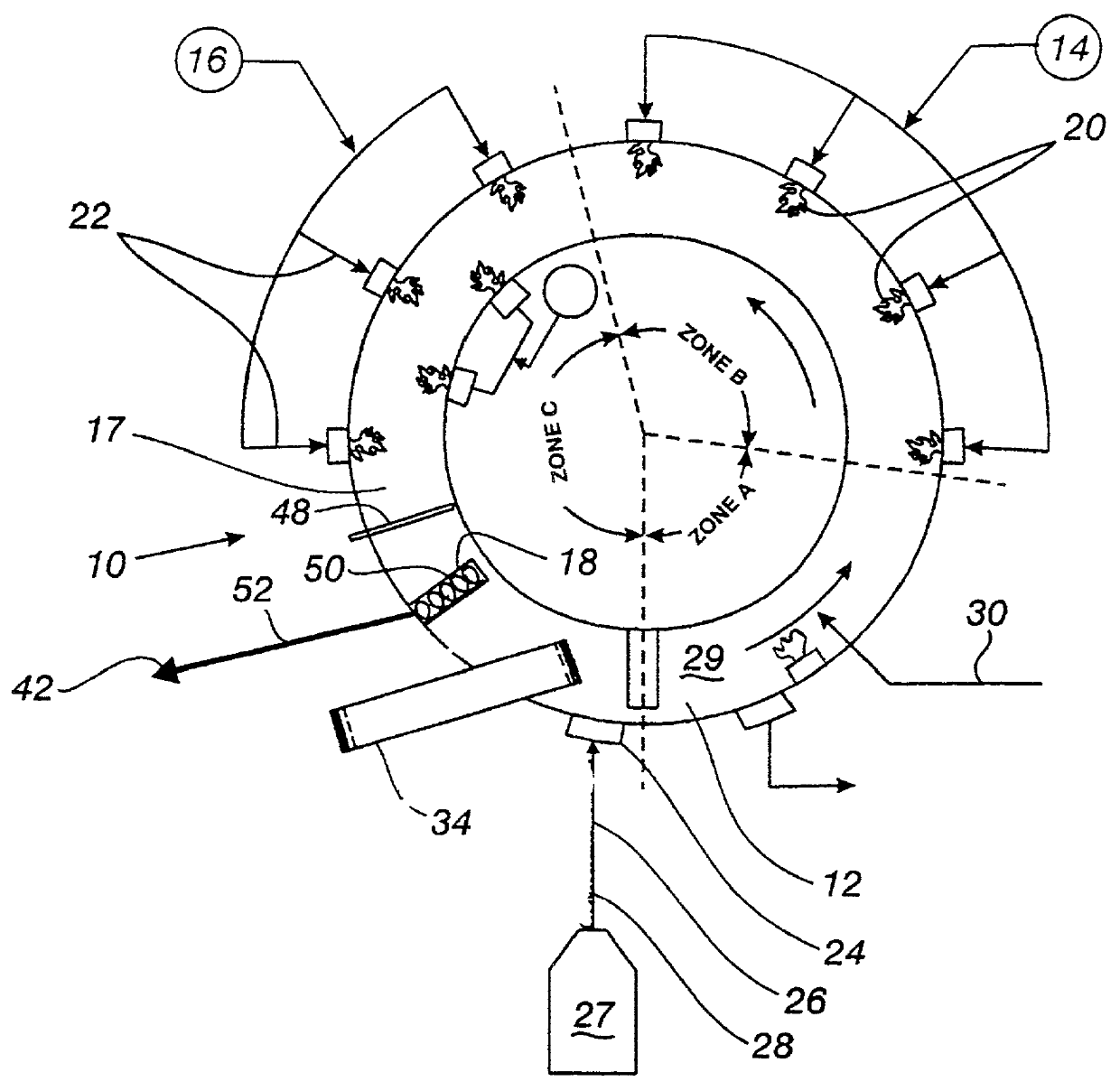

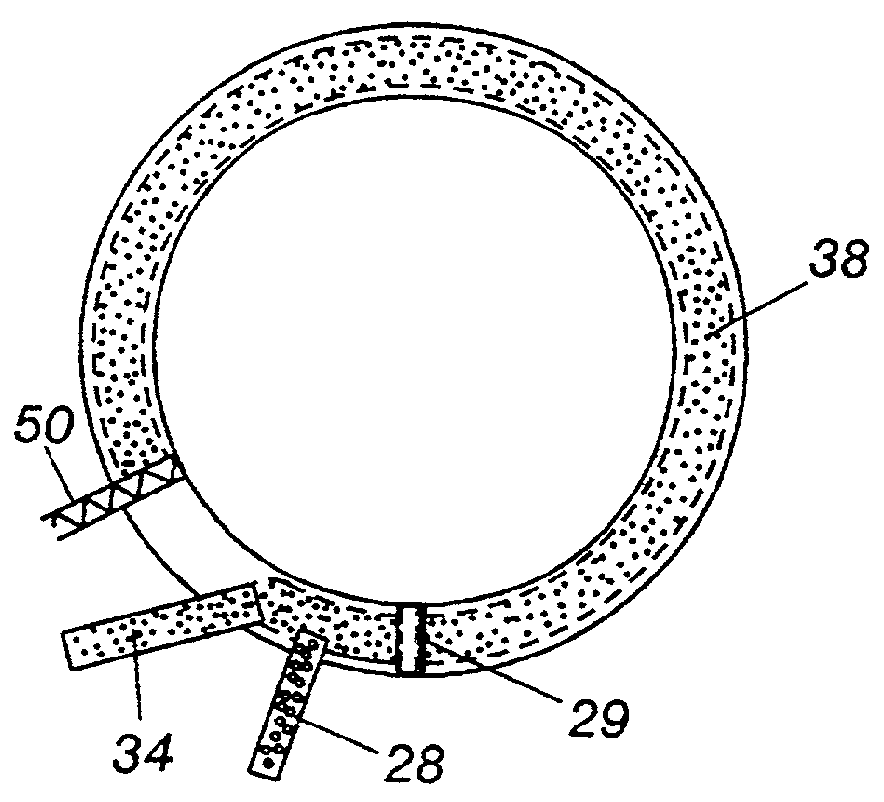

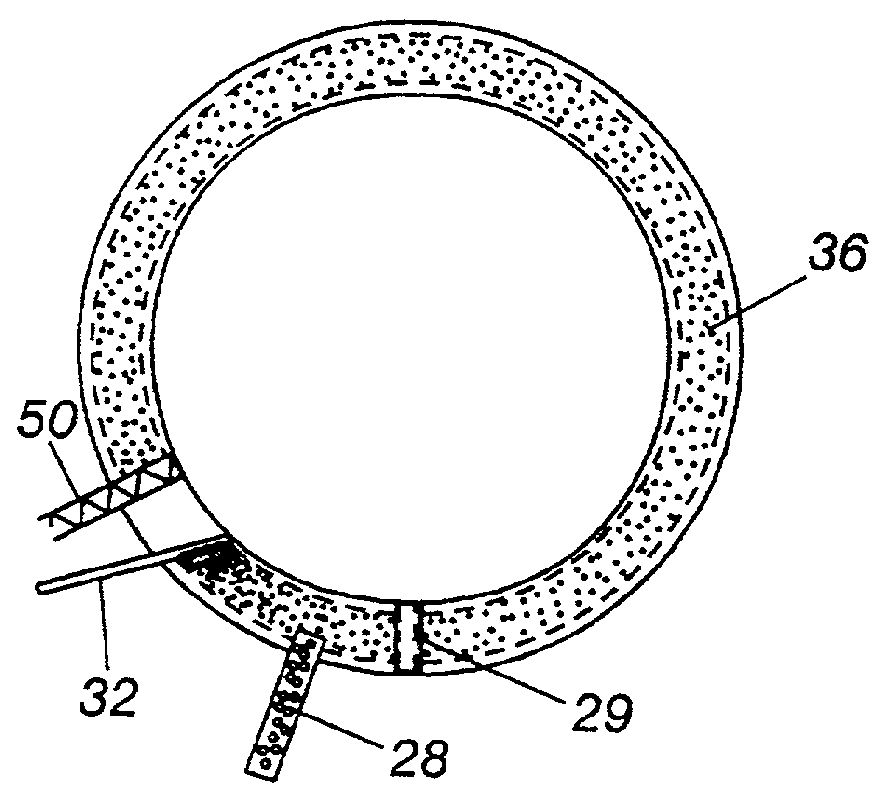

The present invention is an apparatus and method for the direct reduction of iron oxide utilizing a rotary hearth furnace to form a high purity carbon-containing iron metal button. The hearth layer may be a refractory or a vitreous hearth layer of iron oxide, carbon, and silica compounds. Additionally, coating materials may be introduced onto the refractory or vitreous hearth layer before iron oxide ore and carbon materials are added, with the coating materials preventing attack of the molten iron on the hearth layer. The coating materials may include compounds of carbon, iron oxide, silicon oxide, magnesium oxide, and / or aluminum oxide. The coating materials may be placed as a solid or a slurry on the hearth layer and heated, which provides a protective layer onto which the iron oxide ores and carbon materials are placed. The iron oxide is reduced and forms molten globules of high purity iron and residual carbon, which remain separate from the hearth layer. An improved apparatus includes a cooling plate that is placed in close proximity with the refractory or vitreous hearth layer, cooling the molten globules to form iron metal buttons that are removed from the hearth layer. The improvements due to the present apparatus and method of operation provide high purity iron and carbon solid buttons, which are separate from slag particulates, and discharged without significant loss of iron product to the interior surfaces of the furnace.

Owner:MIDREX INT B V ROTTERDAM

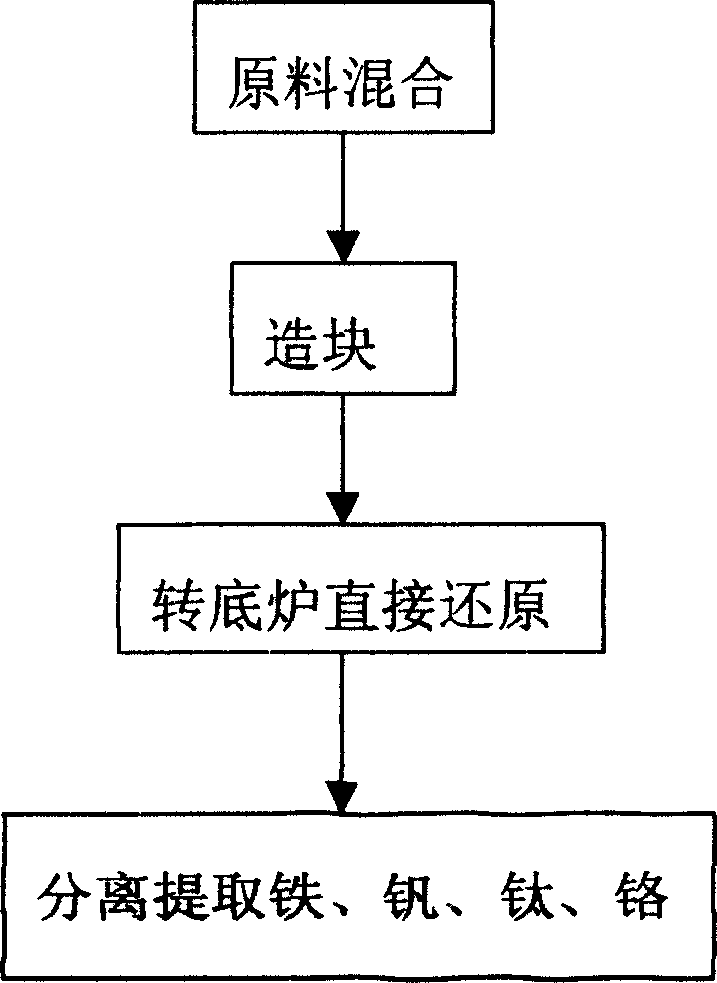

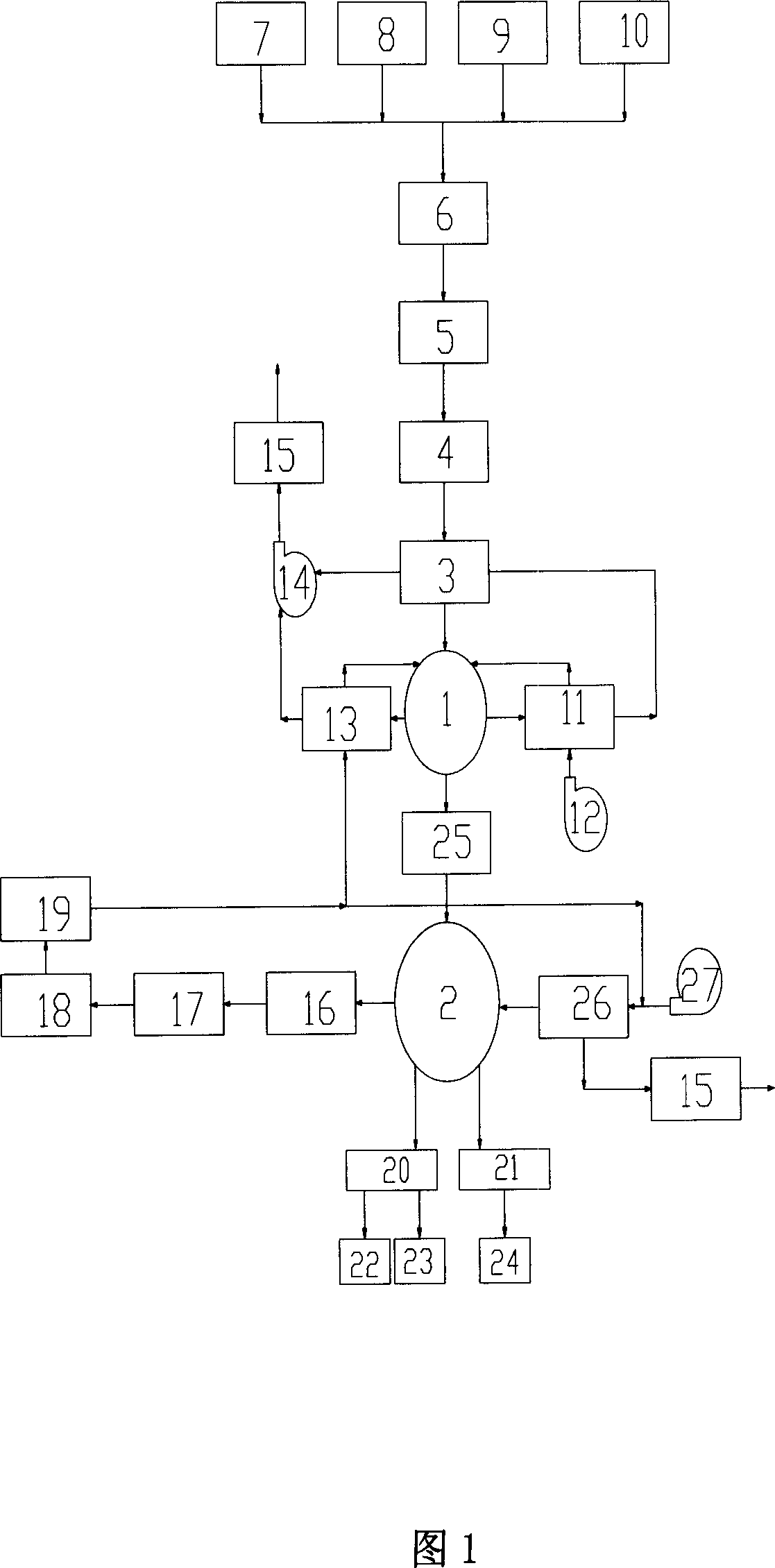

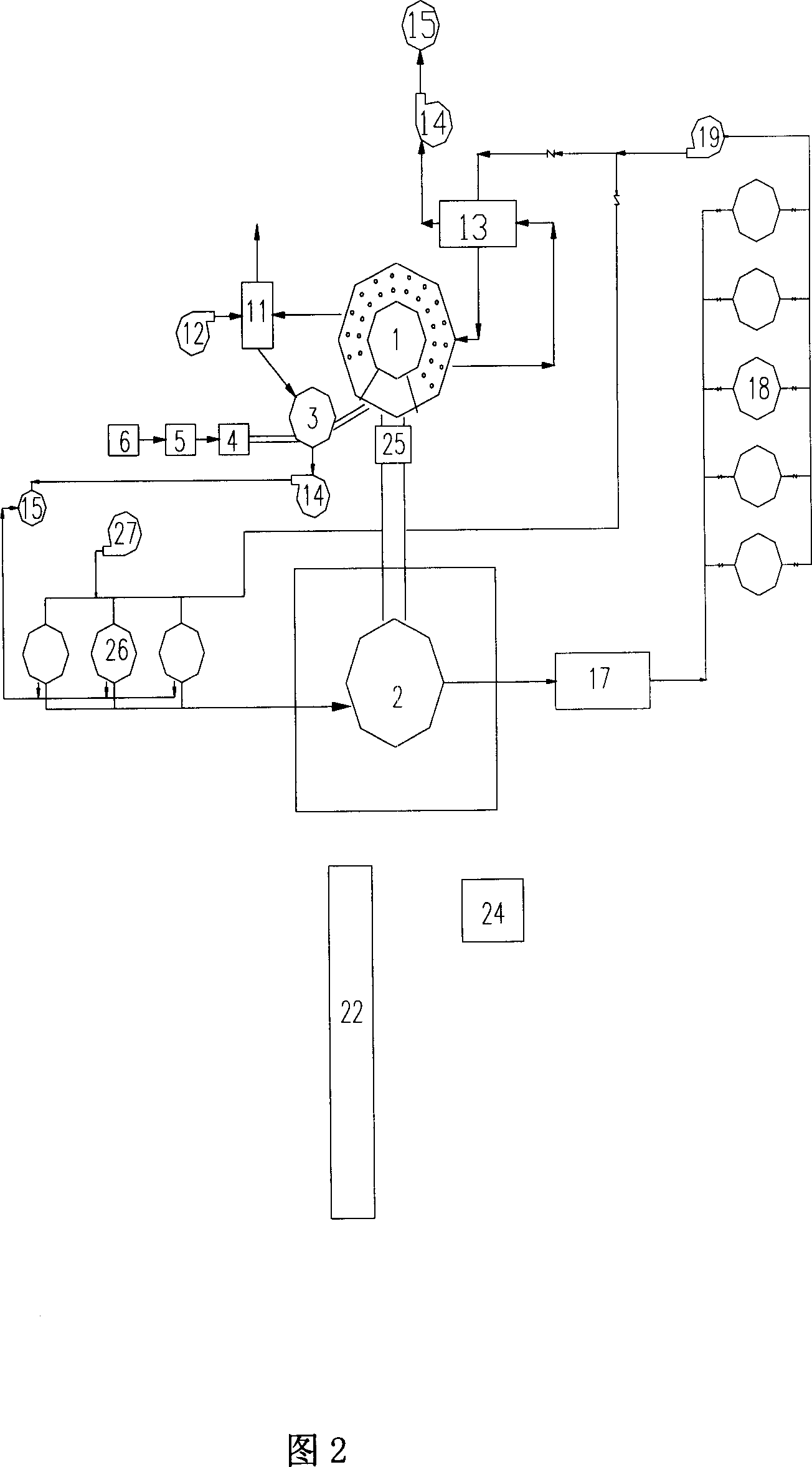

Method for separating and extracting metal element from varadium-titanium magnetite

InactiveCN1641045AFast reduction reactionShort recovery timeRecycling and recovery technologiesProcess efficiency improvementSlagAdhesive

The technological process of separating and extracting metal elements from V-Ti iron ore includes the steps of: agglomerating ore powder of mixing V-Ti iron ore powder, reductant, additives and adhesive, pressing the mixture into 10-25 mm diameter agglomerates and drying at 80-90 deg.c; reducing inside one bottom rotating furnace to obtain metal products; smelting the metal products in an electric furnace to obtain molten iron and V-Ti slag component, and smelting the V-Ti slag component to obtain V-Cr oxide and Ti slag as the material for producing titanium while. The present invention has high reduction temperature, fast reduction speed, short reduction time, high production efficiency, high metal and V-Ti recovering rate and less environmental pollution.

Owner:SICHUAN LOMON MINING & METALLURGY

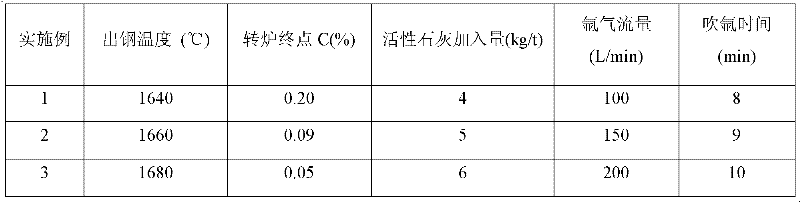

Method for producing strong annealed steel hot-rolled sheet coil

ActiveCN101121992ANo investment requiredHigh strengthTemperature control deviceManufacturing convertersSlagManganese oxide

The invention discloses a method of manufacturing a tough steel hot rolled strip coil. The molten steel, waste steel, chromic oxide and molybdenum oxide are mixed into a rotating furnace, and a fluxing medium is added in; the manganese oxide or manganese ore is added in at the earlier stage of blowing; the manganese oxide or manganese ore and the reducing agent are added in by the end of blowing, and nitrogen or argon is blew from bottom during the whole process; tapping is conducted when the components and the temperature of the molten steel are appropriate; during tapping, the composite deoxygener and the reducing desulfurating refining slag are added in the molten steel during tapping, and nitrogen or argon is blew from bottom of a steel ladle during the whole process. The steel ladle adds the metal aluminum in the molten steel from the CAS position to conduct deep deoxidation and microalloying; and then the increasing nitrogen agent, vanadium iron and ferrocolumbium are added in, and nitrogen or argon blowing is kept. The steel ladle is sent to the position of an LF refining furnace, the lime and reducing desulfurating refining slag are added in the LF refining furnace, argon is blew, electricity is supplied, the temperature is raised and argon is blew again, and the calcium line and the boron filament are fed at the later stage of refining; CSP is supplied for continuous casting, and the charging temperature of a cast slab is is more than 950DEG C; the heating temperature, the initial billet temperature, the rolling finishing temperature and the coiling temperature are well controlled. The tough steel hot rolled strip coil manufactured with the method has high strength and good tenacity.

Owner:湖南华菱涟钢特种新材料有限公司 +1

Iron production method of operation in a rotary hearth furnace and improved furnace apparatus

The present invention is an apparatus and method for the direct reduction of iron oxide utilizing a rotary hearth furnace to form a high purity carbon-containing iron metal button. The hearth layer may be a refractory or a vitreous hearth layer of iron oxide, carbon, and silica compounds. Additionally, coating materials may be introduced onto the refractory or vitreous hearth layer before iron oxide ore and carbon materials are added, with the coating materials preventing attack of the molten iron on the hearth layer. The coating materials may include compounds of carbon, iron oxide, silicon oxide, magnesium oxide, and / or aluminum oxide. The coating materials may be placed as a solid or a slurry on the hearth layer and heated, which provides a protective layer onto which the iron oxide ores and carbon materials are placed. The iron oxide is reduced and forms molten globules of high purity iron and residual carbon, which remain separate from the hearth layer. An improved apparatus includes a cooling plate that is placed in close proximity with the refractory or vitreous hearth layer, cooling the molten globules to form iron metal buttons that are removed from the hearth layer. The improvements due to the present apparatus and method of operation provide high purity iron and carbon solid buttons, which are separate from slag particulates, and discharged without significant loss of iron product to the interior surfaces of the furnace.

Owner:MIDREX INT B V ROTTERDAM

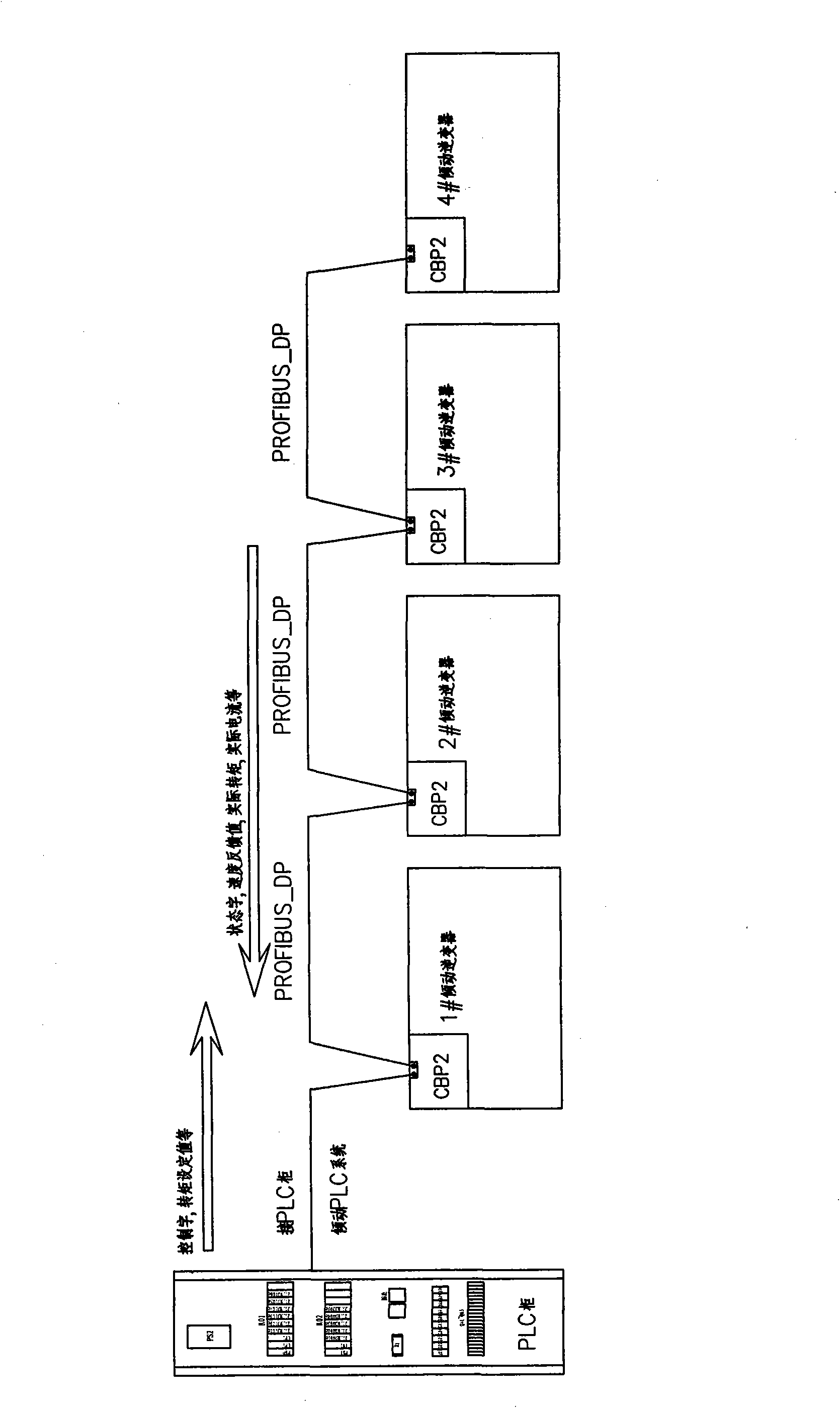

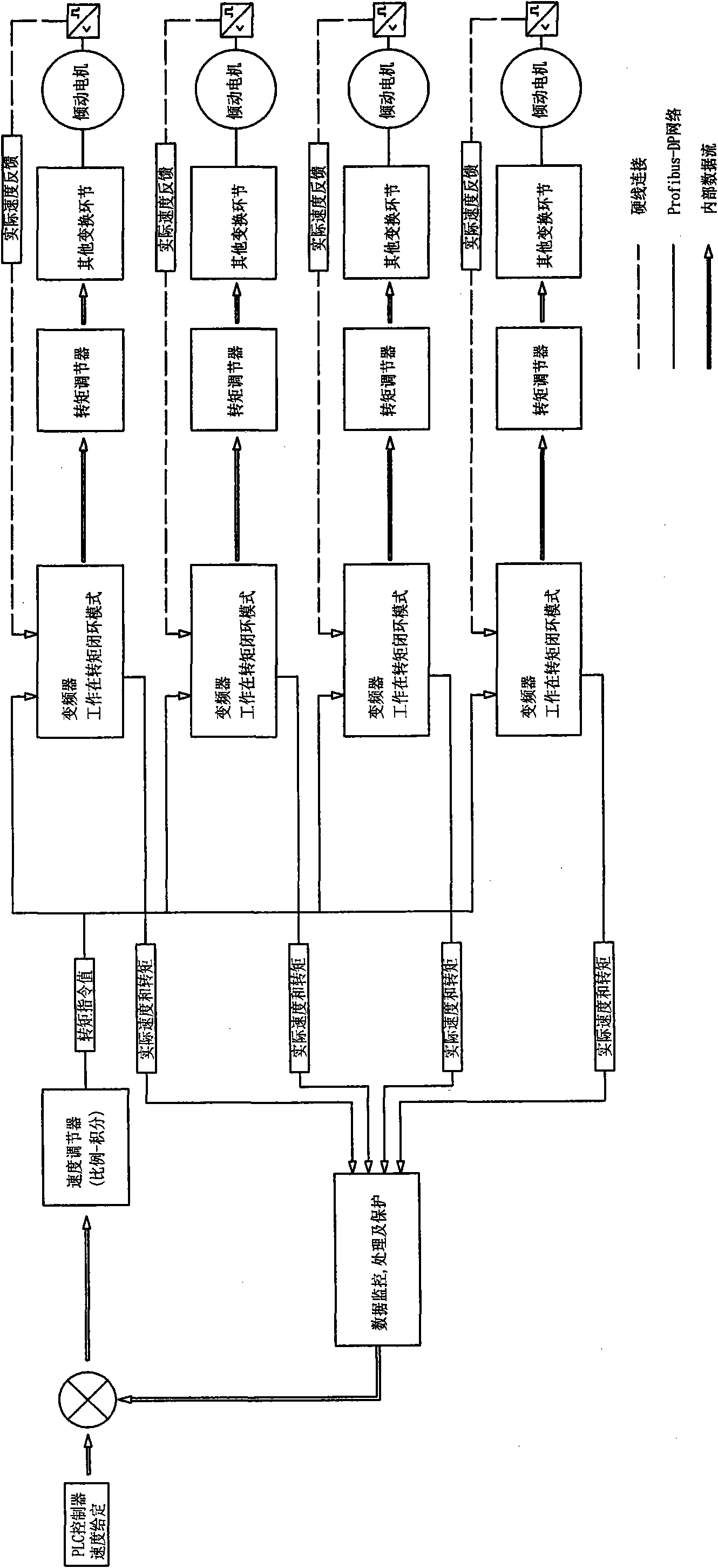

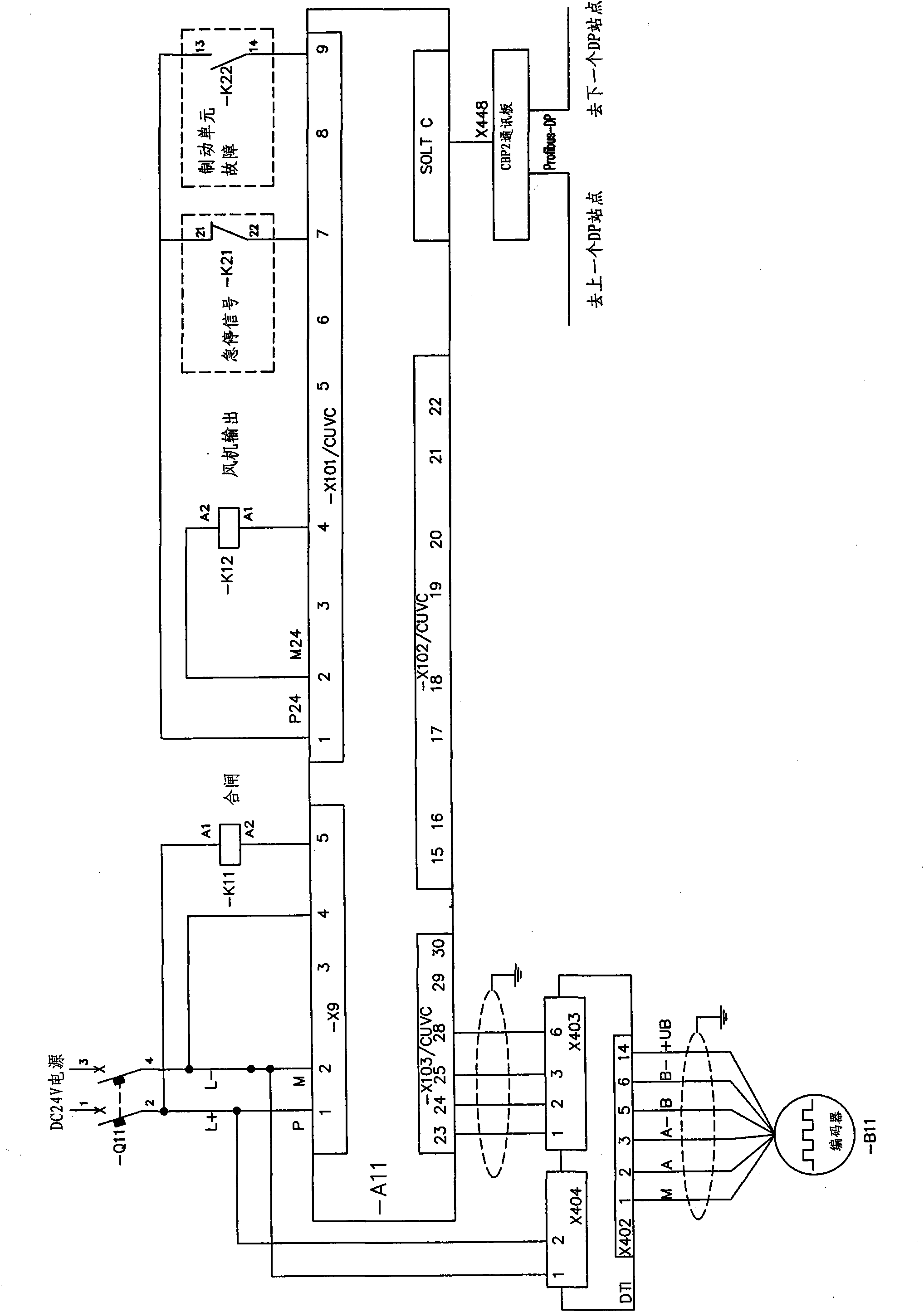

Electric transmission control method of tilting of rotating furnace

InactiveCN101798615AExtended service lifeReduce the amount of manual maintenanceManufacturing convertersTotal factory controlFrequency changerControl system

The invention provides an electric transmission control method of tilting of a rotating furnace, comprising the following steps that: 1) a network is configured, and then a control system is operated; 2) a PLC controller sends a torque instruction value to frequency converters which then adjust motors corresponding thereto according to the instruction; 3) a tilting speed encoder detects actual speed values of all the motors and feedbacks the actual speed values to the frequency converters; 4) the frequency converters send the actual rotating speed and the torque values of all the motors by the network to the PLC controller, and the PLC controller judges that all the frequency converters are in normal state according to data; and 5) the PLC controller obtains a speed feedback value of the current system after analysis and operation, and then the PLC controller sends the torque instrument value to four frequency converters after calculation of a speed regulator of the PLC controller. The electric transmission control method leads transmission equipment to be in good working state, thus being capable of prolonging the service life of machines.

Owner:WISDRI ENG & RES INC LTD

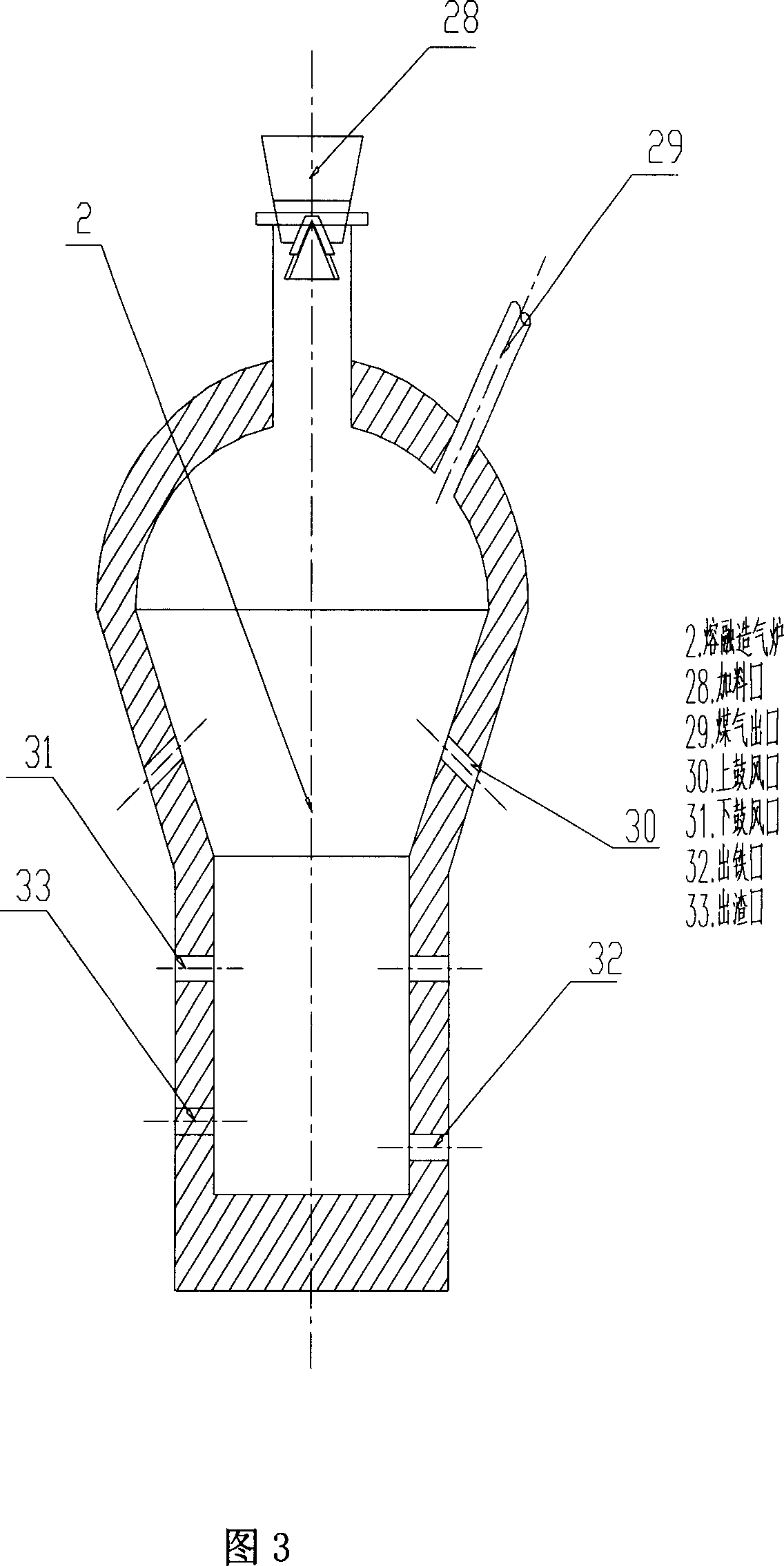

Fuse reducing iron-smelting process for rotating furnace

InactiveCN1940092ALatent heat utilizationReduce energy consumptionRotary drum furnacesGas emission reductionSmelting processSelf reduction

An iron smelting process by rotating-furnace melt and reduction is carried out by mixing iron-mine powder with powdered coal to obtain self-reduction palletizing, taking it as raw material, pre-reducing by rotating-furnace to obtain metal pellet with conversion rate >80%, heating, packing it into melt gas maker, finally reducing and melting while separating out iron slag to obtain liquefied iron and gas and utilizing it for hot-air furnace and rotating-furnace gas. It has no environmental pollution, and no need for oxygen and natural gas.

Owner:万天骥

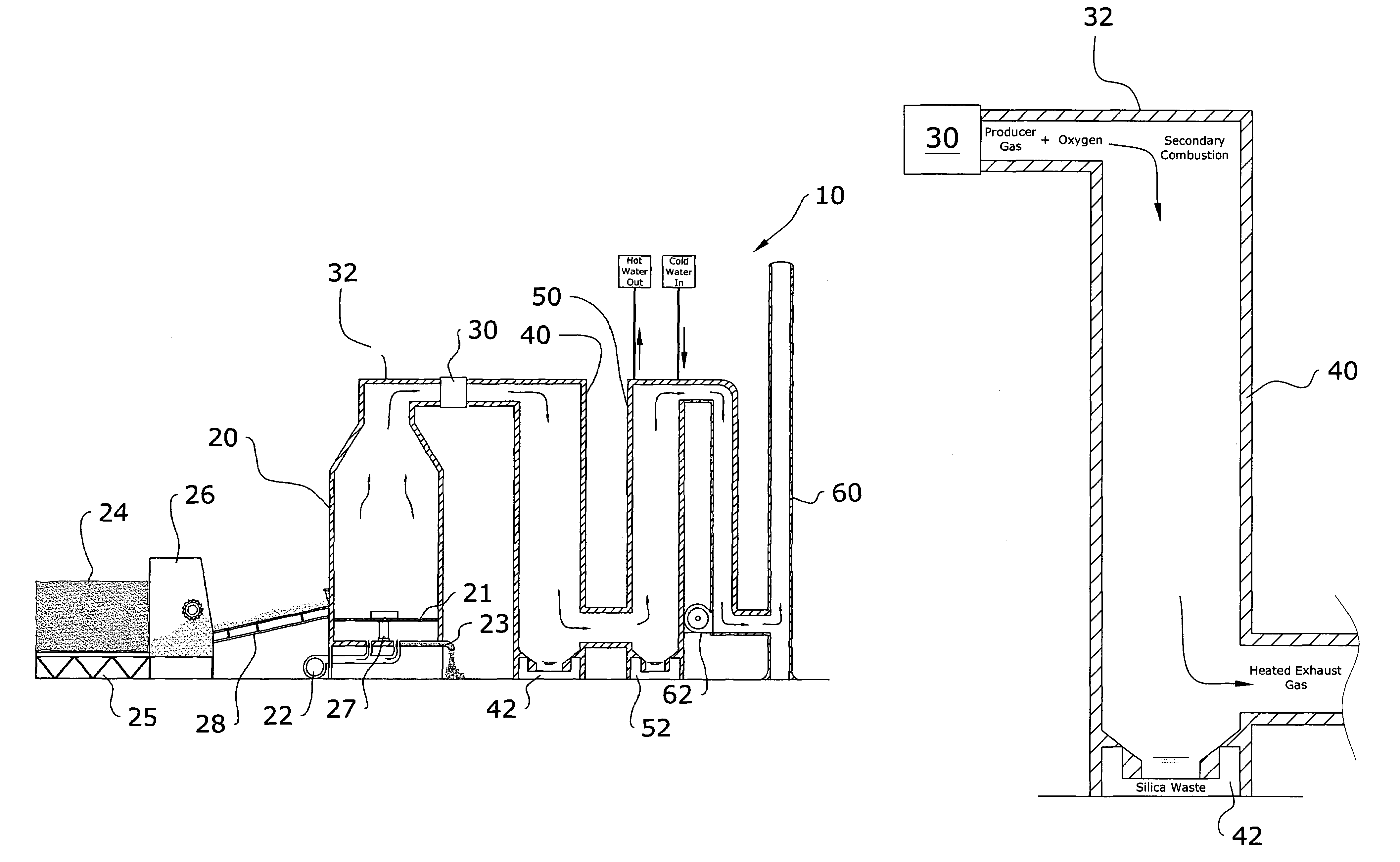

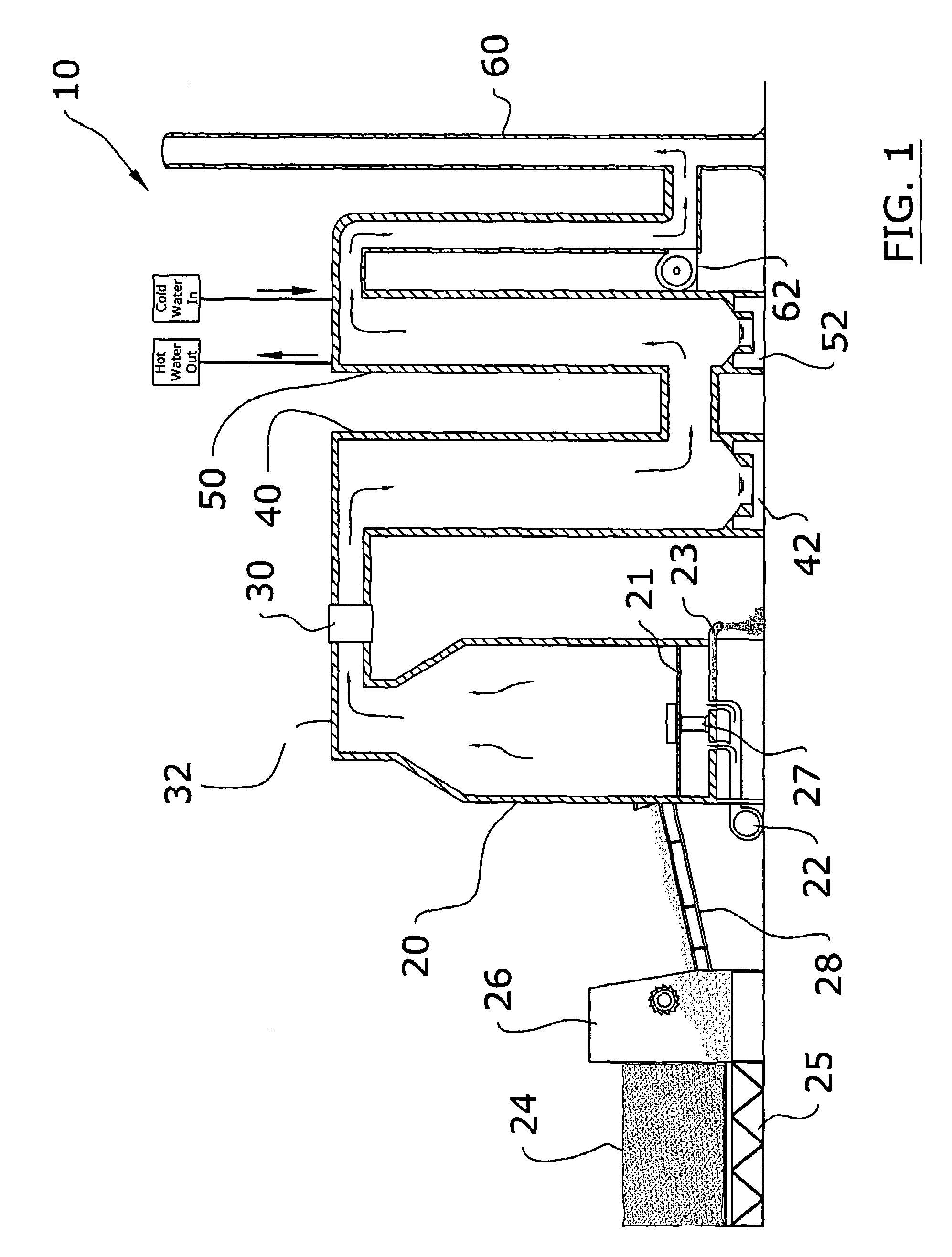

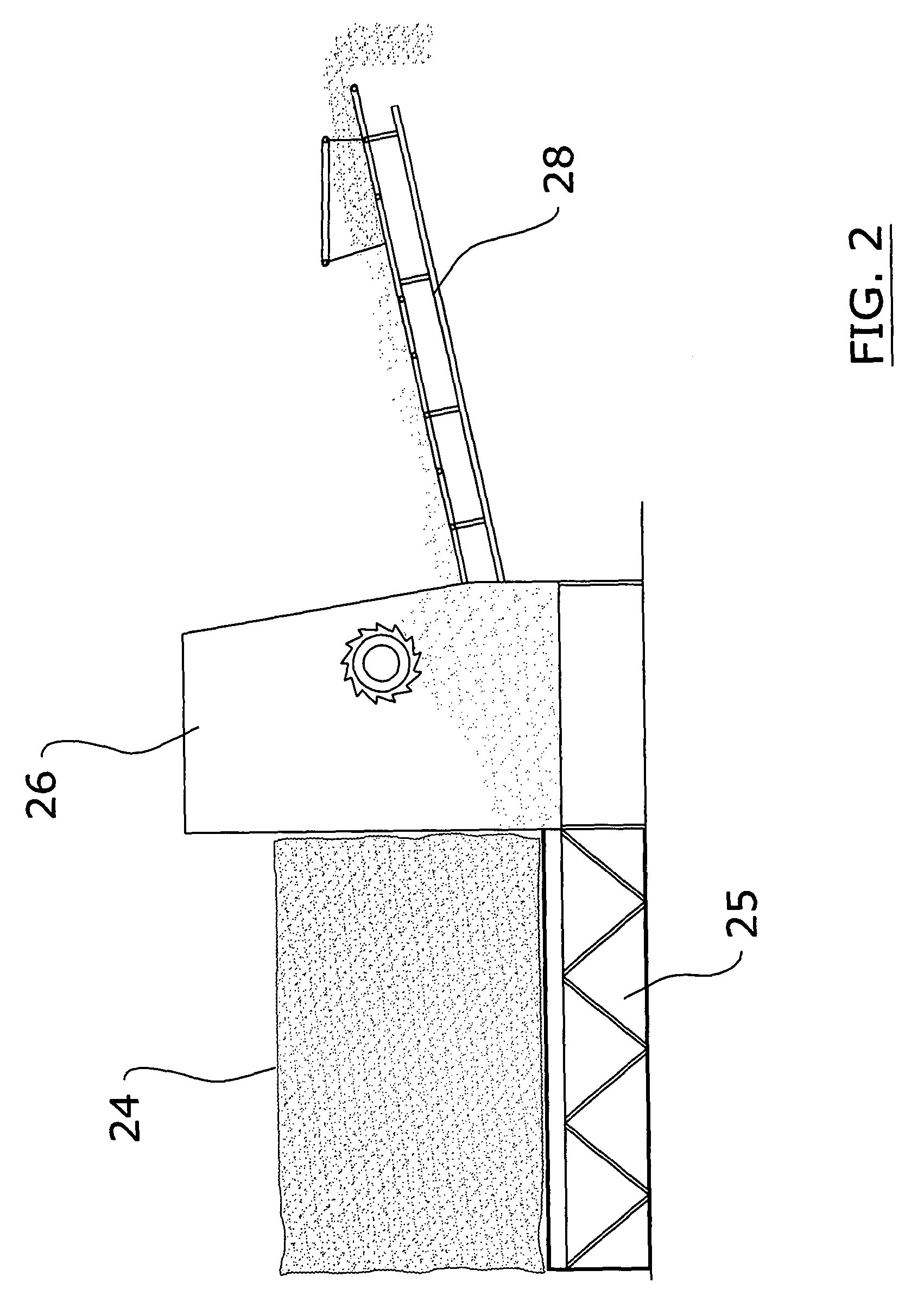

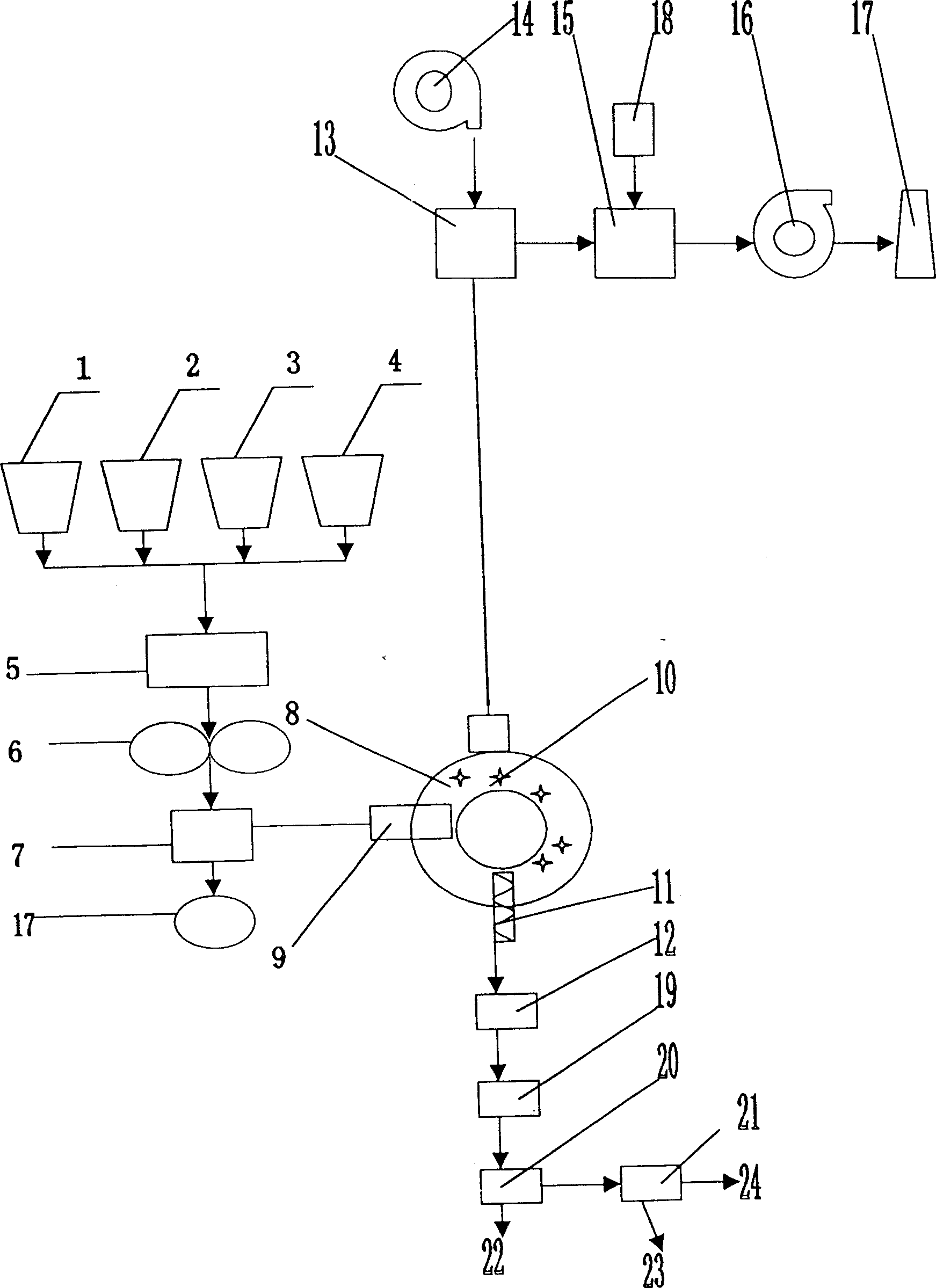

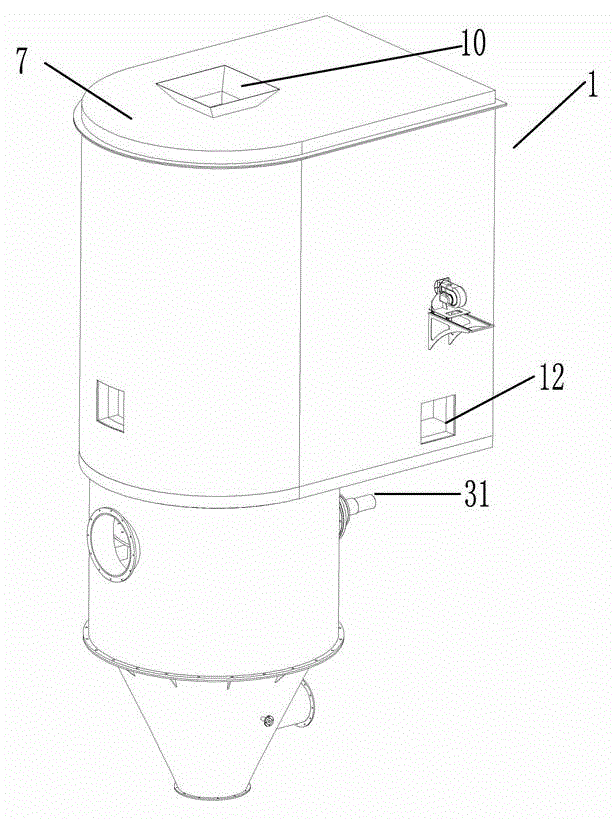

Biomass gasification system

InactiveUS7228806B2Reduce maintenanceEfficiently extracting heat energyPulverulent fuel combustion burnersSolid fuel combustionCombustion chamberOxygen

A biomass gasification system for efficiently extracting heat energy from biomass material. The biomass gasification system includes a primary combustion chamber, a rotating grate within the primary combustion chamber for supporting the biomass during gasification, a feeder unit in communication with the primary combustion chamber for delivering biomass, a secondary combustion chamber fluidly connected to the primary combustion chamber, an oxygen mixer positioned between the primary combustion chamber and the secondary combustion chamber, a heat exchanger and an exhaust stack.

Owner:INNOVAAT COM INT INC

Method for smelting high-chromium steel and high-chromium steel

The invention provides a method for smelting high-chromium steel, which comprises the steps of: primarily smelting molten iron in a rotating furnace; tapping molten steel after the primary smelting into a steel ladle, adding high carbon ferrochrome in the tapping progress, thus enabling Cr content in the molten steel to reach 1.8-2.4 wt%; refining the steel ladle by an LF furnace, adding low carbon ferrochrome in the steel ladle refining progress by the LF furnace, wherein, on the basis of addition amount of chromium, a weight ratio of the low carbon ferrochrome to the high carbon ferrochromeis (1: 2) to (1: 3.5); and carrying out RH vacuum refining upon molten steel after steel ladle refining by the LF furnace. The invention further provides high-chromium steel smelted by the method forsmelting the high-chromium steel disclosed by the invention. Through the technical proposal, the method disclosed by the invention fully considers the influence to temperature and carbon composition of the molten steel due to addition of chromium alloy, and is good for matching of production rhythm among working procedures, so that production can be carried out smoothly. In addition, through the method disclosed by the invention, yield of the chromium is high, and high-chromium steel with a higher Cr content is obtained in an economical manner.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

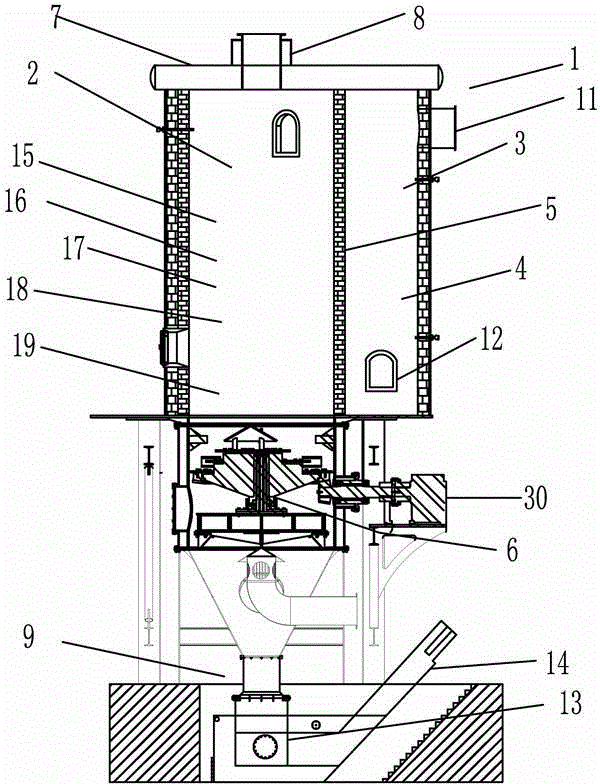

Vertical shaft multiple incinerator for refuse pyrolysis, gasification and fusion

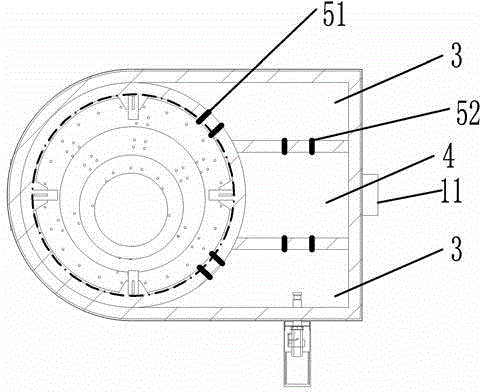

The invention discloses a vertical shaft multiple incinerator for pyrolysis, gasification and fusion. The vertical shaft multiple incinerator for pyrolysis, gasification and fusion comprises a vertical coaxial structure incinerator body, a main combustion chamber and a secondary combustion chamber outside the main combustion chamber are arranged in the incinerator body, the main combustion chamber and the secondary combustion chamber are of a horizontal multiple coaxial structure, an annular fusion combustion hearth is arranged between the main combustion chamber and the secondary combustion chamber, a high temperature fusion wall and a rotary fire grate are arranged in the combustion hearth, a shaft-less spiral conveying discharging device is arranged on an incinerator cover on the top of the incinerator body, a deslagging mechanism is arranged on the lower portion of the incinerator body, and a driving device of the rotary fire grate is arranged outside the incinerator body. The vertical shaft multiple incinerator for refuse pyrolysis, gasification and fusion is stable in combustion and reliable in operation; because smoke can stay for a long time at high temperature, it can be guaranteed that dioxin pollutants in the smoke can be fully decomposed and the smoke reaching the standard is discharged; because combustion assisting agents do not need to be added, operation cost is low and floor area is small.

Owner:广东昕旺环保科技发展有限公司

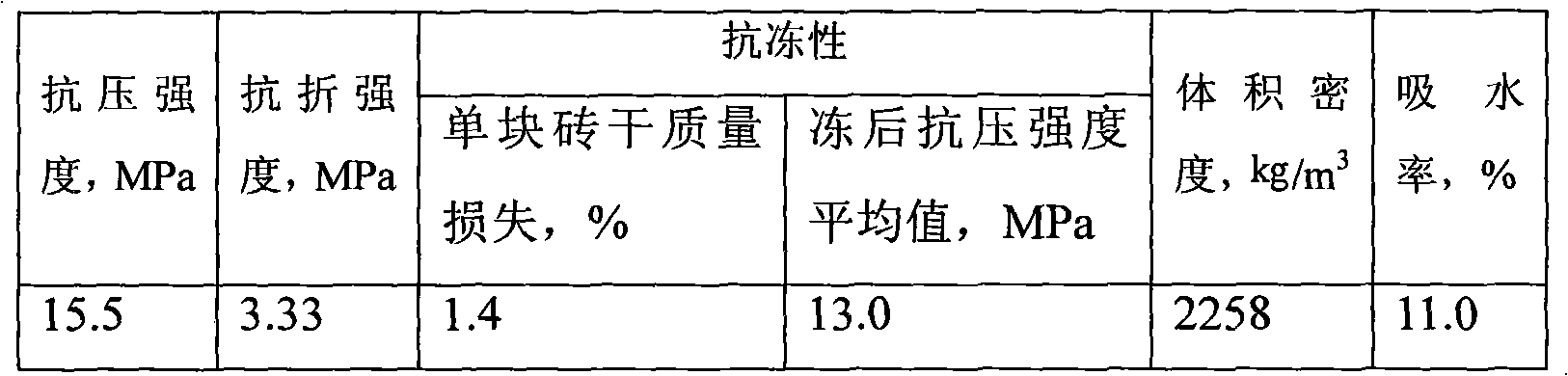

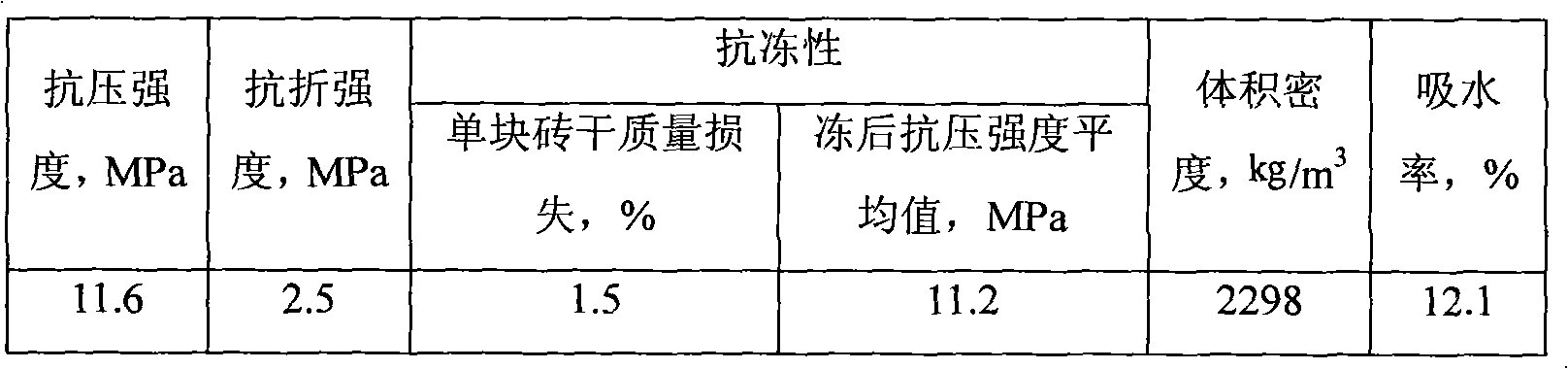

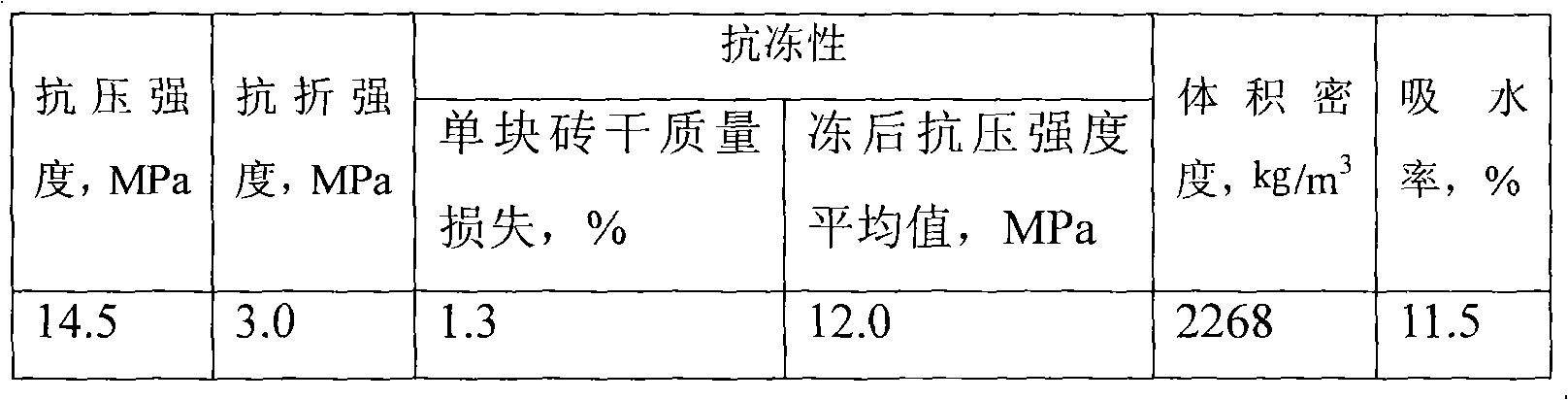

Method for producing baking-free slag bricks by using steel slag sludge of rotating furnace

ActiveCN101927524AReduce free calcium oxide contentLow iron contentSolid waste managementMixing operation control apparatusBrickSlag

The invention relates to a method for producing baking-free slag bricks by using steel slag sludge of a rotating furnace. The bricks are produced by taking tailings and tailing sludge of the rotating furnace as raw materials, taking slag silicate cement as an auxiliary material, adding a small amount of water into the raw materials and the auxiliary material, stirring the raw materials and the auxiliary material to uniformly mix the raw materials and the auxiliary material, pressing the mixture on a brick press, and naturally curing the pressed mixture. The bricks comprise the following compoennts in part by weight: 20 to 50 parts of tailings of the rotating furnace, 50 to 80 parts of tailing sludge of the rotating furnace and 0 to 5 parts of slag silicate cement. The adding amount of the added water is 0 to 5 percent of the total weight of the raw materials. The baking-free bricks are produced by taking the tailings and the tailing sludge of the rotating furnace as main raw materials, adding a small amount of slag silicate cement and water into the main raw materials, and pressing the mixture. The raw materials do not need to be treated and can be directly used and the mouled product is naturally cured, so that the energy is saved; and no any equipment is added, so that the problem that the tailings of the rotating furnace and the tailing sludge of the rotating furnace occupy space and pollute environment is solved by producing the baking-free slag bricks.

Owner:鞍钢绿色资源科技有限公司

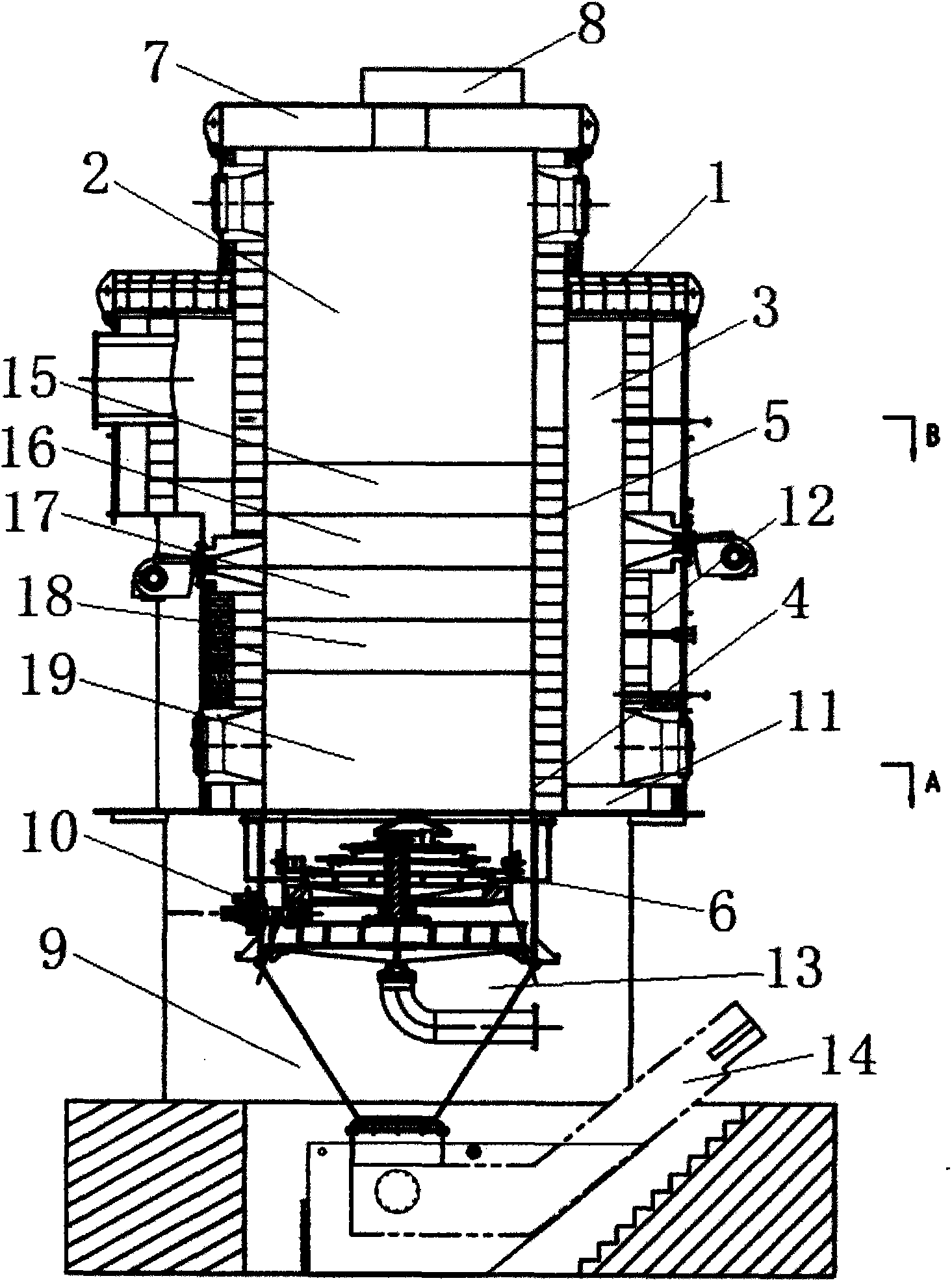

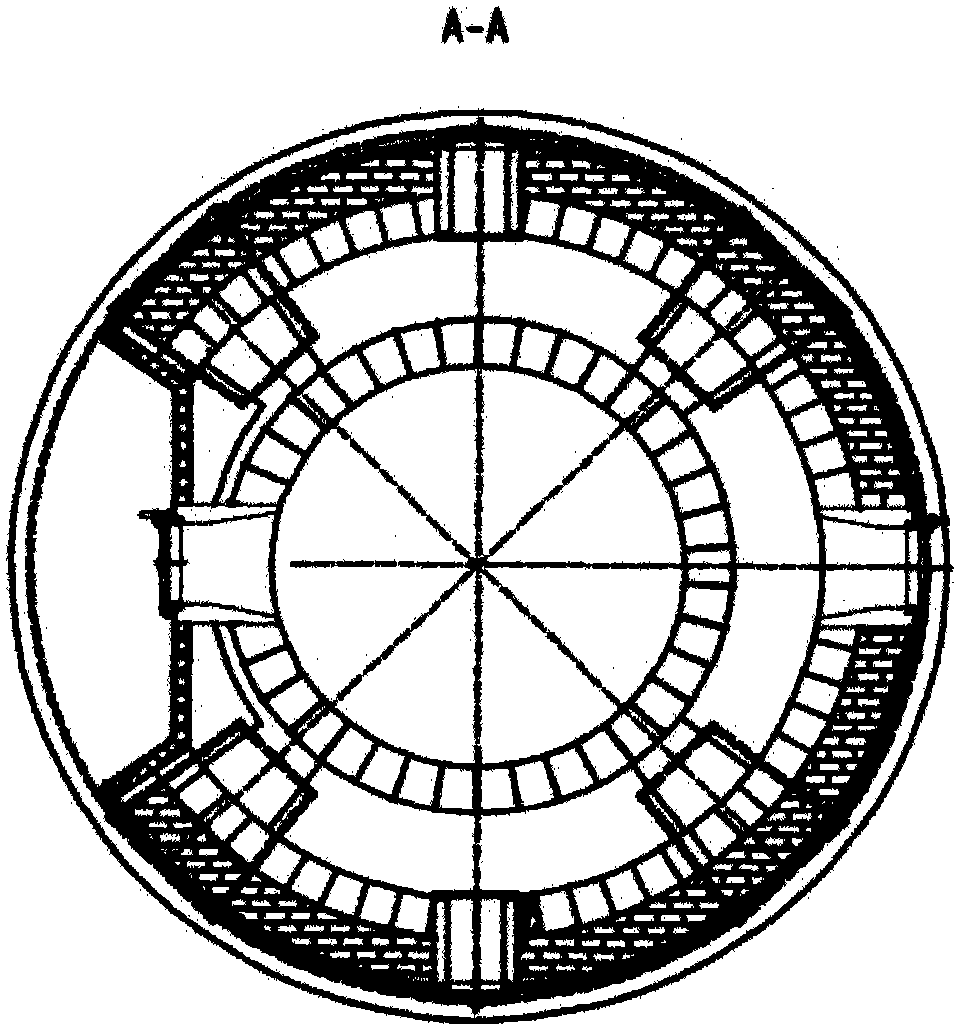

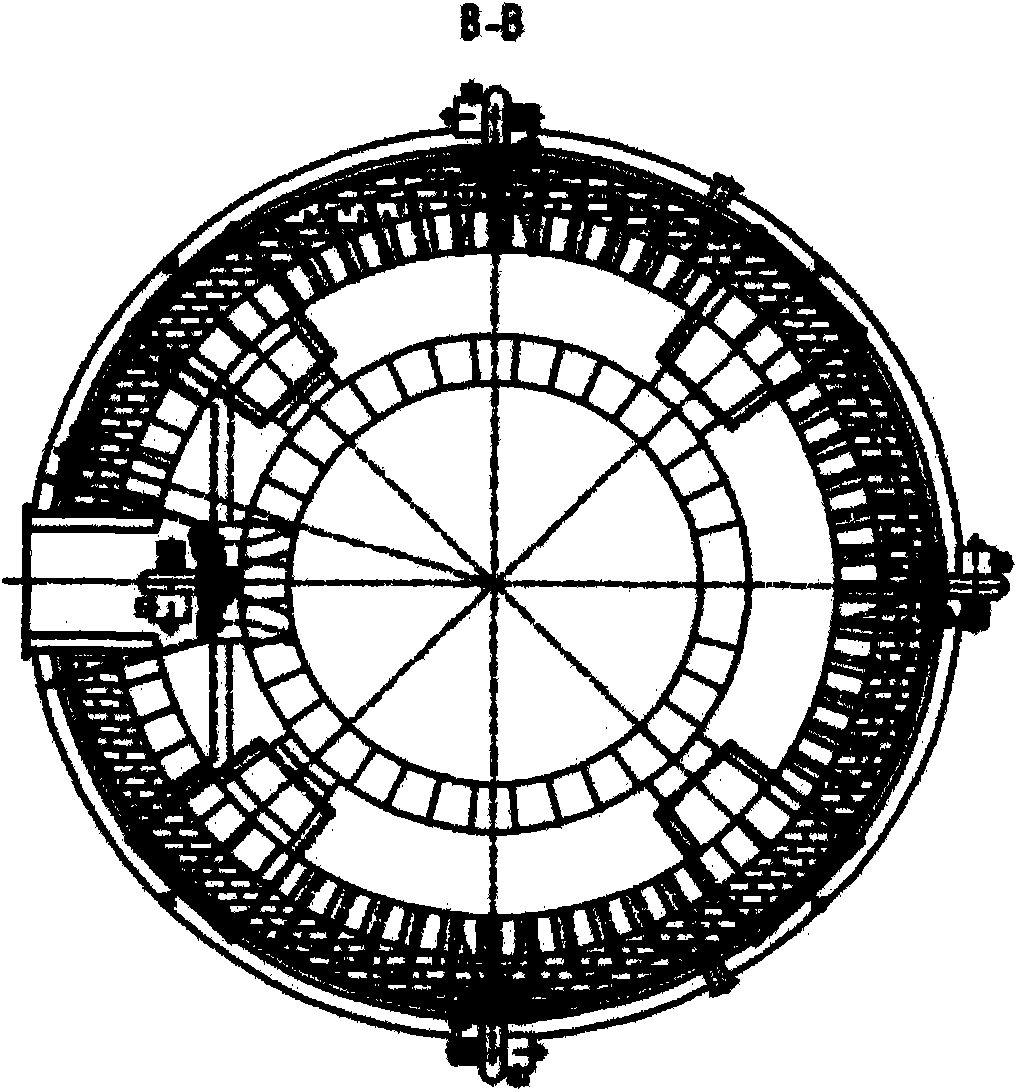

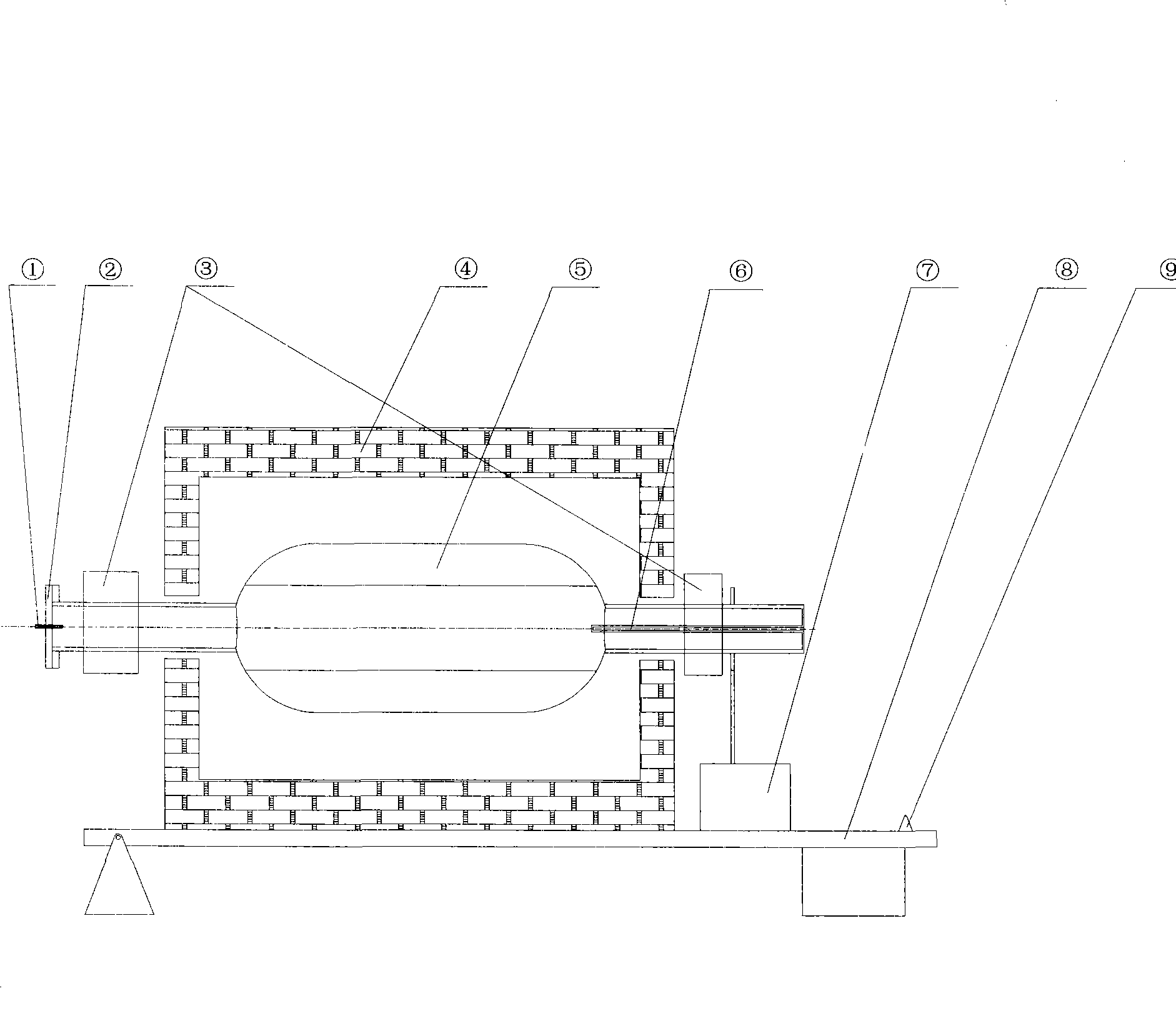

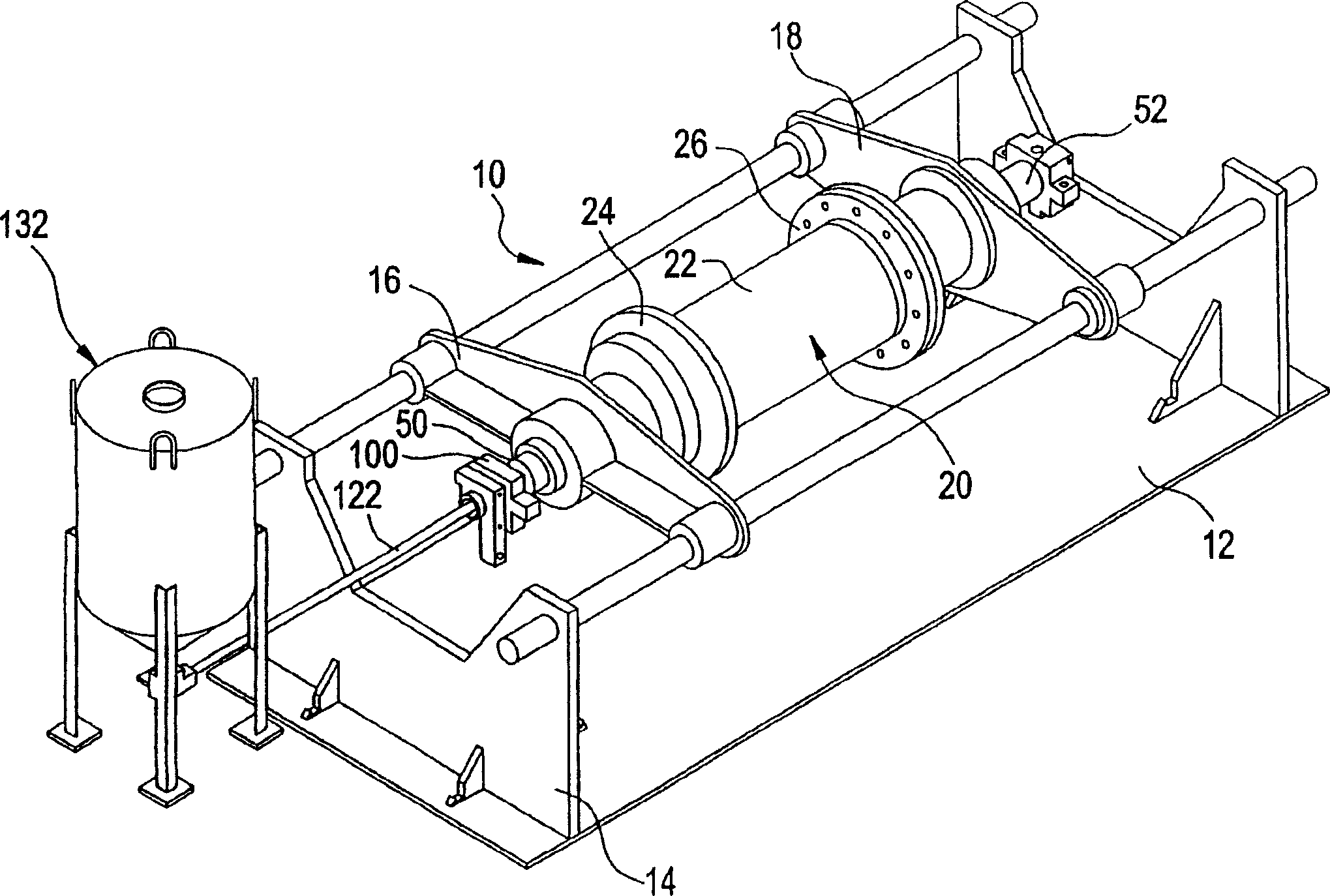

Design and structure for controllable atmosphere rotating furnace for oxidizing albronze alloy powder

ActiveCN101392987AFully contactedIncrease productivityRotary drum furnacesElectrical resistance and conductanceDifferential pressure

The invention provides a gas atmosphere controllable revolving furnace structure for the oxygen distribution in the oxidation of copper-aluminum alloy powder, which mainly consists of an air inlet(pumping) pipe, a roller cover, water cooling sleeves, a resistance furnace, rollers, an electrothermal couple pipe, a transmission mechanism, a furnace body bracket and a lifting hook, wherein the resistance furnace is fixed on the furnace body bracket, one end of the furnace body bracket is provided with the lifting hook and is supported by a lower end platform, the other end of the furnace body bracket is provided with a lower end triangular support which can rotate around the triangular support; the inside of the resistance furnace is provided with the roller rotating around the resistance furnace, two ends of the roller(5) arranged outside the resistance furnace are additionally provided with the water cooling sleeves, and the extension end of the roller, which is close to the triangular support end, is provided with the electrothermal couple pipe and is also provided with the transmission mechanism making the rollers rotate. The revolving furnace structure has the advantages that the production efficiency is high; and during the rotation of the rollers, power is fully contacted with the gas atmosphere, and the oxidation time is reduced by increasing the oxygen differential pressure in the rollers. The oxidation time is one-tenth of the oven baking time, so that the oxidation time is shortened.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Production method of steel for 82 B steel stranded wires

ActiveCN102211159ARealize cleaner productionProduction organizationManufacturing convertersOxygen contentImpurity

The invention discloses a production method of steel for 82 B steel stranded wires, belonging to the field of metallurgy. In the production method, the steel for the 82 B steel stranded wires is produced by adopting the process flow comprising the following steps of: rotating furnace primary smelting, LF (Low Frequency) refining, RH (Relative Humidity) refining and continuous casting and pouring of a large square billet, wherein the tail end of a solidification end is dynamically and lightly downwards pressed in the procedure of the continuous casting and pouring of the large square billet. According to the production method disclosed by the invention, technologies, i.e. rotating furnace whole-course bottom argon blowing, argon blowing after tapping, RH vacuum degassing, impurity removal,crystallizer electromagnetic stirring, and the like, are adopted in the process flow, and therefore the clean production of the steel for the 82 B steel stranded wires is realized; an antegrade production organization is achieved; obtained components and the quality of casting blanks all meet the requirements for steel grades, and the total oxygen content (T[O]) in the steel is less than 0.0020 percent; and wire breakage does not appear in the wire drawing process of a product, and therefore the wire broken rate of the wire drawing process is reduced.

Owner:PANZHIHUA IRON AND STEEL +2

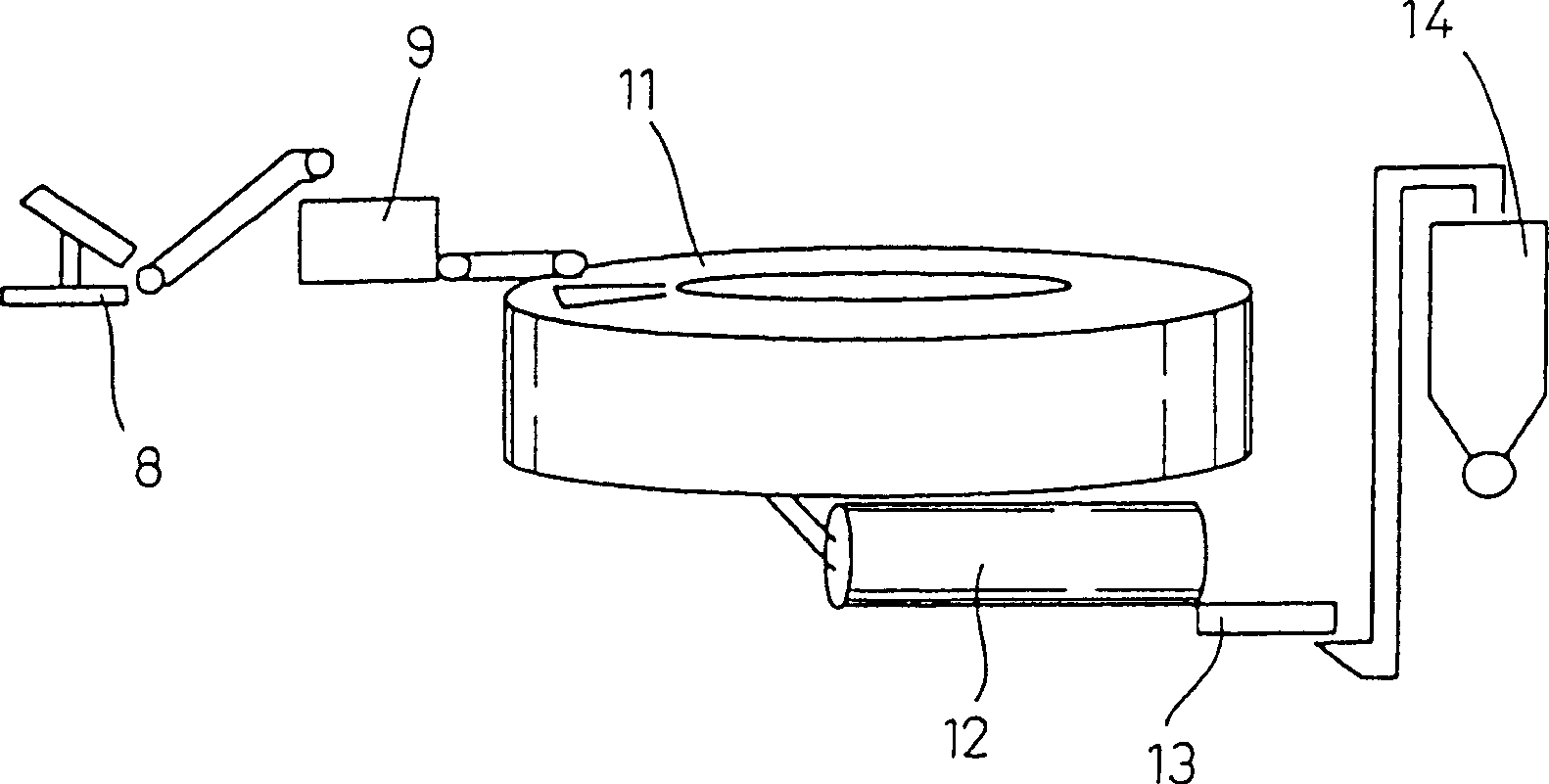

Facility for reducing metal oxide, method for operating the facilities and moldings as raw material to be charged to reduction furnace

The present invention provides a reducing furnace of the rotary hearth-type and a method for reducing a metal oxide simplified in the process from dehydration to molding, according to which a moisture-rich powdery raw material is reduced at low cost. The present invention also provides an operation method whereby dusts or sludge generated in the refining or processing of metal are economically recycled.A powdery mixture having a moisture content of 100% or higher relative to the total mass of a metal oxide-containing powder and a carbon-containing powder is made into a slurry and mixed by stirring. Thereafter, the slurry is dehydrated to a moisture content of 16 to 26% and compression-molded into articles. The cylindrical or granular shaped articles having a thickness or diameter of 30 mm or less thus obtained are fed to a zone the atmospheric temperature of which is 1170° C. or lower in the furnace and reduced through calcination by a rotary hearth reducing furnace thereby to provide a metal.

Owner:NIPPON STEEL CORP

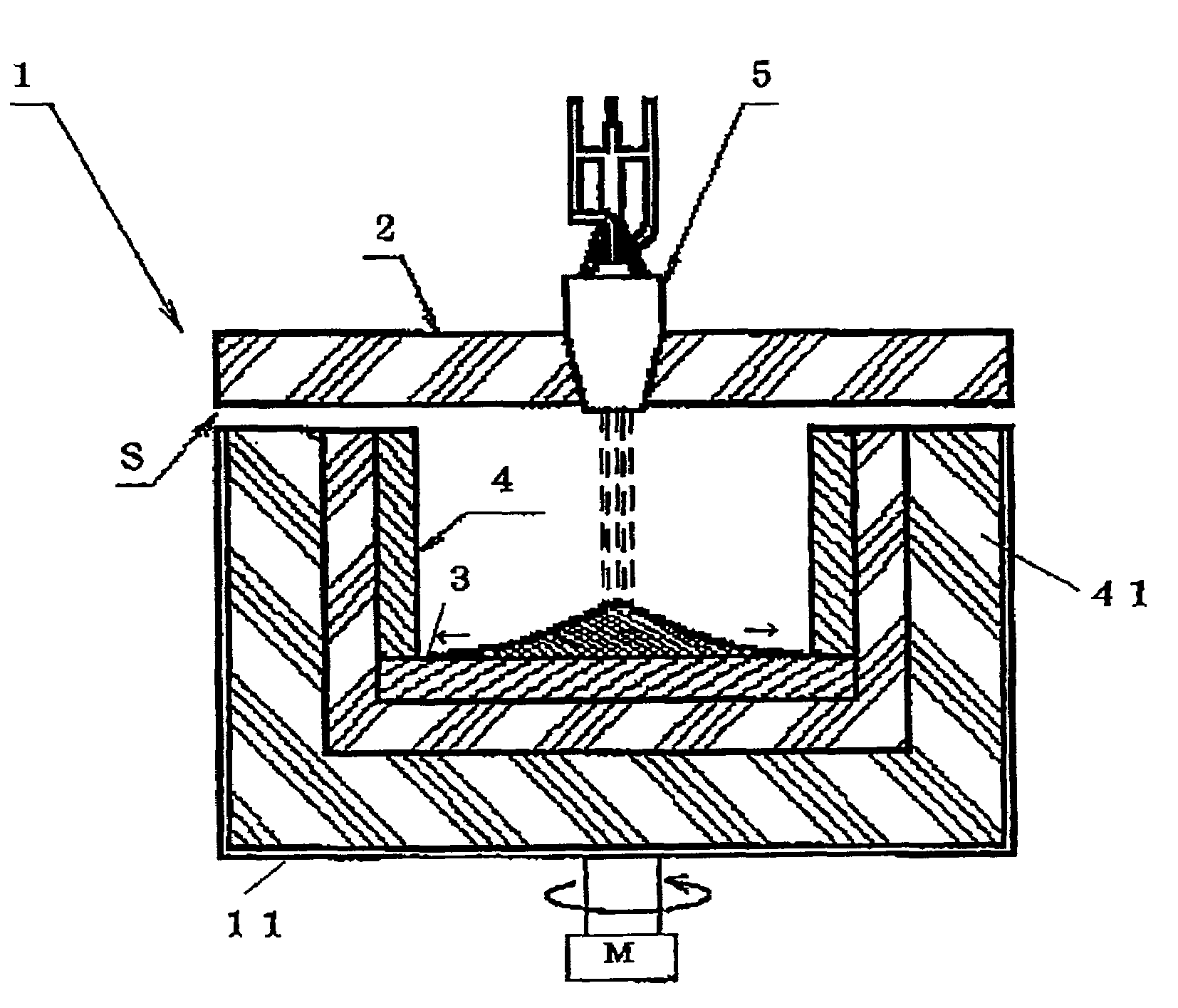

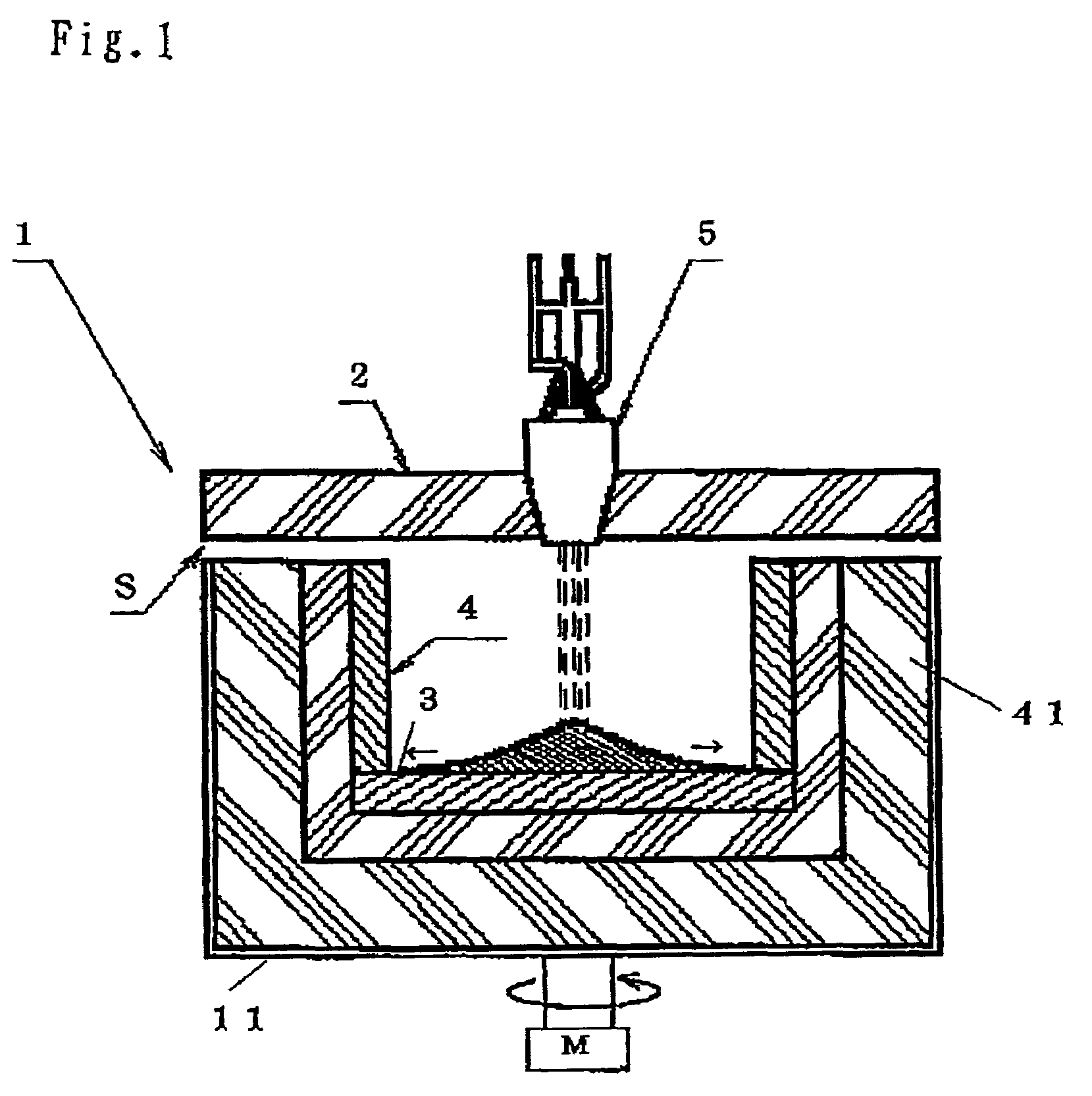

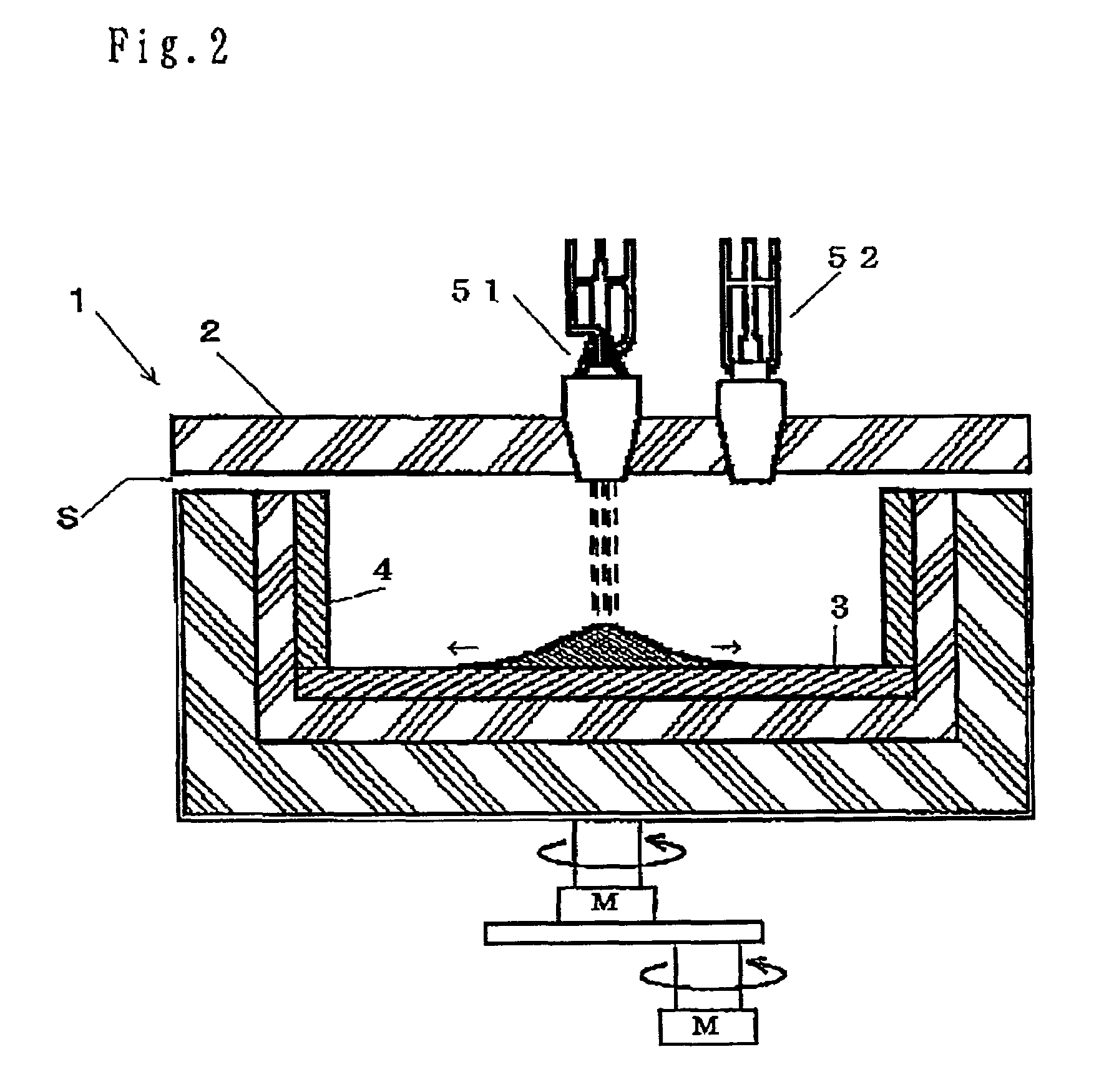

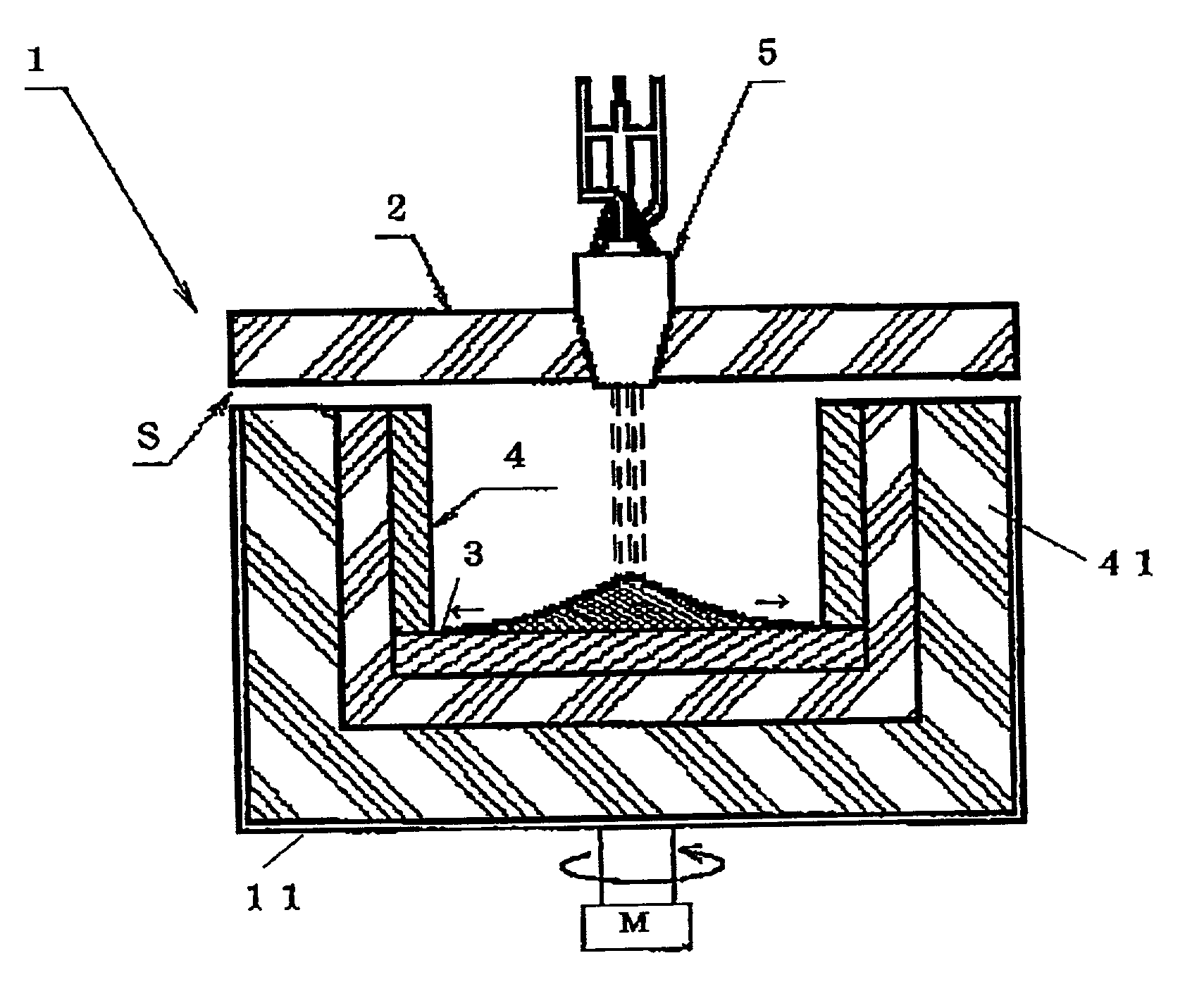

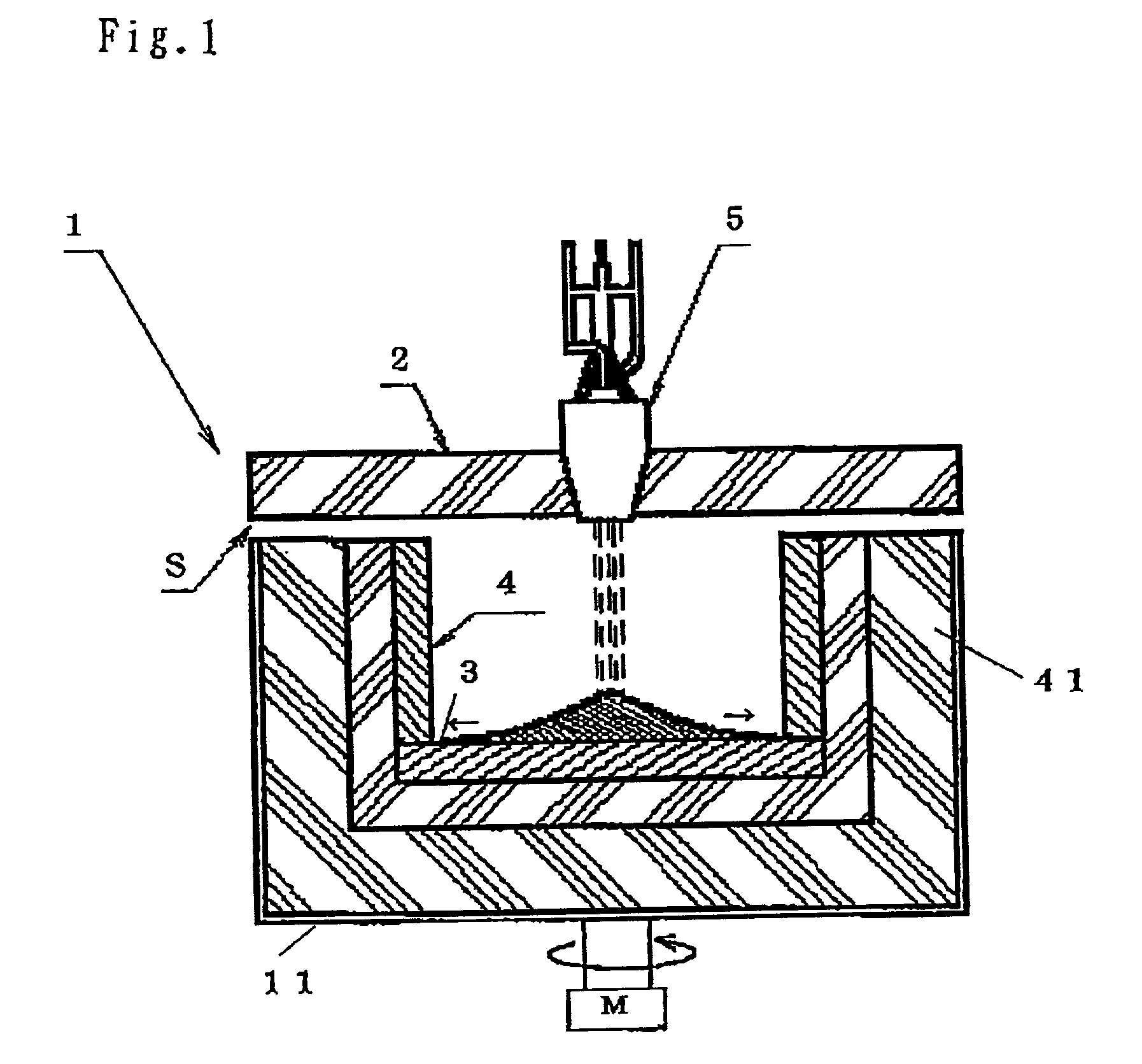

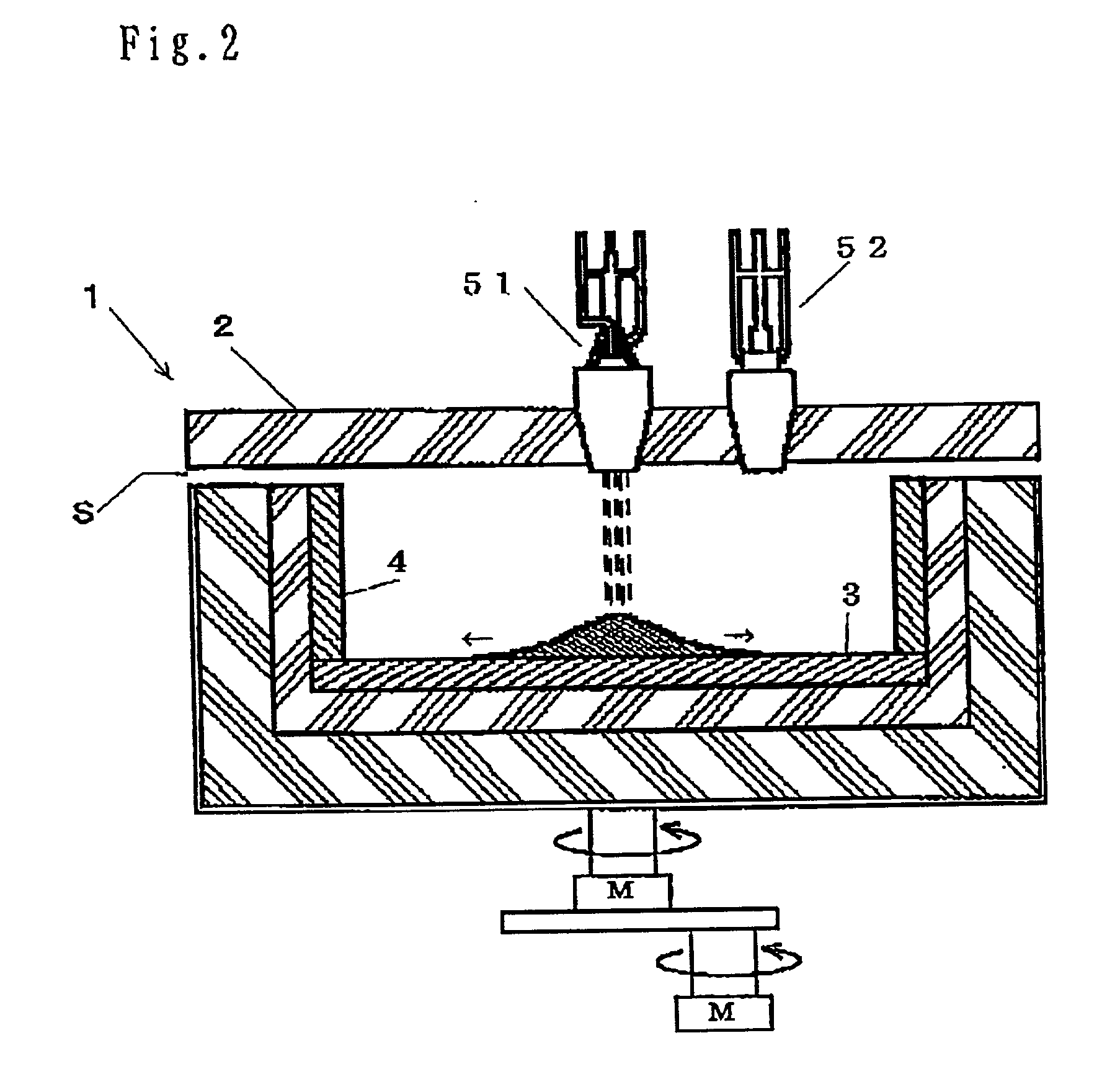

Method for manufacturing quartz glass ingot

InactiveUS7305852B2Inhibition formationAvoid excessGlass furnace apparatusGlass drawing apparatusCombustorHydrogen

The invention provides a method for manufacturing a large scale quartz glass slab ingot in a flame hydrolysis reaction in a furnace, including the steps of rotating the furnace, depositing a fused silica on a furnace bed, and extending the deposit outwardly by heating and rotation of the furnace, thereby a quartz glass slab ingot is obtained. A quartz glass burner is installed at the ceiling of the furnace, hydrogen gas supplied to the burner flows down along the tapered wall of the oxygen chamber and is ejected into the outer casing. Part of the hydrogen gas is deflected to the center of the burner and mixed with the oxygen just after the ejection from the oxygen gas nozzles. Thereby, the flame is formed smoothly and the thermal efficiency is improved. The flame becomes wide enough and the silica powder transported by the hydrogen gas is uniformly fused by the flame and heat capacity of the fused silica.

Owner:TOSOH QUARTZ

Coal base hot-air rotary hearth furnace melting reduction iron-smelting method

The coal base hot-air bottom-rotating furnace melt-reduction iron-smelting method for producing bead iron includes the following steps: using iron ore powder, coal powder, flux and adhesive to pelletize, in the coal base hot-air bottom-rotating furnace make the above-mentioned pellets be molten and reduced, cooling reduced material, breaking and seiving so as to implement said invented method. Inthe obtained bead-iron the iron content is 93-96%, carbon content is 2.5-3.5%, sulfur content is less than 0.08% and silicon content is less than 0.3%. Said invented bead-iron is suitable for smelting steel as raw material in electric arc furnace.

Owner:万天骥

Method for producing precipitated calcium carbonate

InactiveCN101648723AIncrease productionQuality improvementCalcium/strontium/barium carbonatesCalcium hydroxidePrecipitated calcium carbonate

The invention discloses a method for producing precipitated calcium carbonate, which comprises the following steps: crushing a limestone raw material; calcining the crushed limestone raw material after screening and water scrubbing; obtaining calcium oxide (CaO) after calcining; preparing calcium hydroxide by ashing the calcium oxide (CaO); generating liquid calcium carbonate by carbonizing the calcium hydroxide; and preparing calcium carbonate by dewatering and drying, wherein the drying method adopts an internally heated rotating furnace combining with a controllable temperature furnace in fluid bed, so the drying process has the advantages of no pollution, fast drying speed and good quality.

Owner:徐铭

Novel pyrolysis gasification melting environment-friendly furnace and method for processing wastes of novel pyrolysis gasification melting environment-friendly furnace

The invention provides a novel pyrolysis gasification melting environment-friendly furnace, which comprises a furnace body, a driving mechanism and a slag discharge mechanism, wherein a material inlet is arranged on a furnace cover which is arranged on the top end of the furnace body, a first and a second combustion process chambers are arranged on the upper portion of the furnace body, a rotating furnace grate is arranged on the lower portion of the furnace body, the bottom end of the furnace body is respectively connected with the slag discharge mechanism and an air supply port, the rotating furnace grate is fixedly connected with the driving mechanism through a driving mechanism interface, the first and the second combustion process chambers are adjacently arranged on the same horizontal plane, are insulated through a high temperature thermal conductive wall, and are communicated through a first connecting channel, the upper portion of the first combustion process chamber is communicated with the material inlet, the lower portion of the first combustion process chamber is communicated with the position of the rotating furnace grate, and a flue is arranged on the upper portion of a shell of the second combustion process chamber. The invention further provides a method for processing wastes of the novel pyrolysis gasification melting environment-friendly furnace. The novel pyrolysis gasification melting environment-friendly furnace and the method for processing the wastes of the novel pyrolysis gasification melting environment-friendly furnace can completely pyrolyze smoke during the combustion process, and prevents poisonous and harmful ingredients in the smoke from overflowing.

Owner:广东昕旺环保科技发展有限公司

Method for manufacturing quartz glass ingot and a manufacturing apparatus

The invention provides a method for manufacturing quartz glass large scale slab ingot in a flame hydrolysis reaction in a furnace, including the steps of rotating the furnace, depositing a fused silica on a furnace bed, and extending the deposit outwardly by heating and rotation of the furnace, thereby a quartz glass slab ingot is obtained. A quartz glass burner is installed at the ceiling of the furnace, hydrogen gas supplied to the burner is flowing down along the tapered wall of the oxygen chamber and being ejected into the outer casing part of the hydrogen gas is deflected to the center of the burner, and mixed with the oxygen just after the ejecton from the oxygen gas nozzles thereby the flame is formed smoothly and the thermal efficiency is improved, The flame becomes wide enough and the silica powder transported by the hydrogen gas is uniformly fused by the flame and heat capacity of the fused silica.

Owner:TOSOH QUARTZ

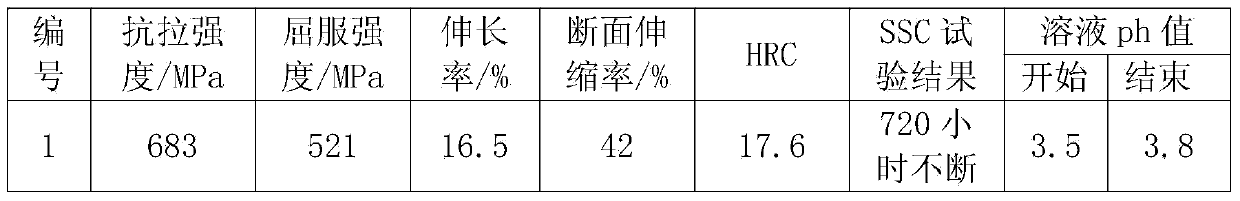

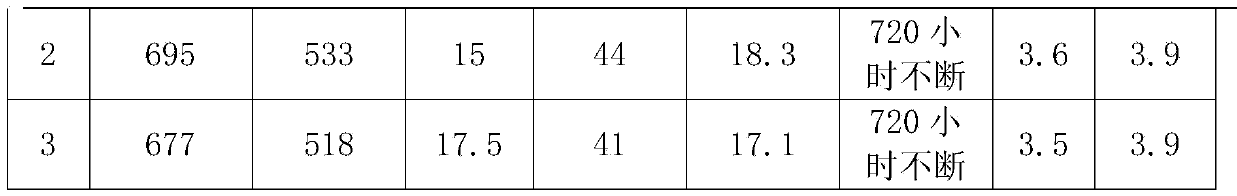

Wire rod production technology for ocean hose capable of resisting high pressure and high-concentration acid corrosion

The invention relates to a wire rod production technology for an ocean hose capable of resisting high pressure and high-concentration acid corrosion. Smelting components are as follows in percentage by weight: 0.05-0.15 percent of C, 0.20-0.50 percent of Si, 0.5-1.0 percent of Mn, 0.70-1.20 percent of Cr, 0.30-0.50 percent of Mo, 0.05-0.12 percent of Ti and 0.02-0.04 percent of Al. When a rotating furnace smelts 1 / 4 steel amount, the sequence of adding alloy materials is that steel core aluminum, BaAlSi, low-carbon ferromanganese, low-carbon ferrochromium and ferrosilicon; the refining basicity of white slag is 5.5-6.5; the degree of superheat of an intermediate ladle is 20+ / -5 DEG C; the pull speed is 2.2-2.5m / min; high-wire rolling heating temperature is 1,080-1,160 DEG C; the rolling starting temperature is 960-1,040 DEG C; the finish rolling temperature is 920-980 DEG C; the rolling speed is 80-95m / s; the spinning temperature is 850-900 DEG C; the cooling speed of Steyr controlled cooling is 4-5 DEG C / S. A wire rod produced by the technology disclosed bythe invention has the anti-corrosion steel tensile strength of more than or equal to 600MPa, the yield strength of more than or equal to 500MPa and the ductility of more than or equal to 15 percent, can conform to both H2S corrosion and CO2 corrosion and can resist corrosion under composite action of H2S and CO2; the loading force of stress corrosion test is 0.90 the yield strength.

Owner:TIANJIN IRON & STEEL GRP

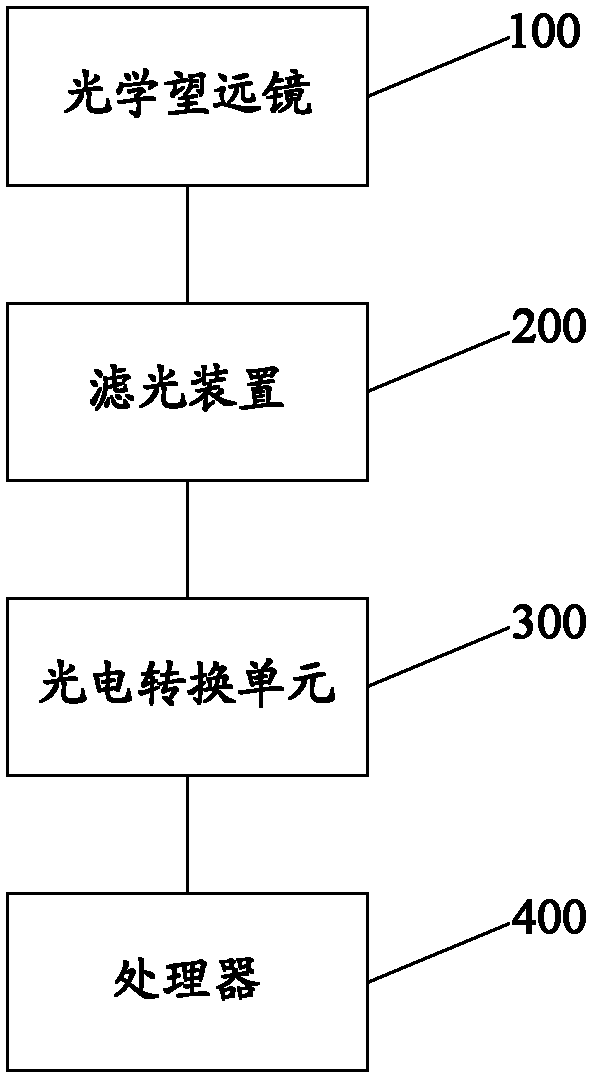

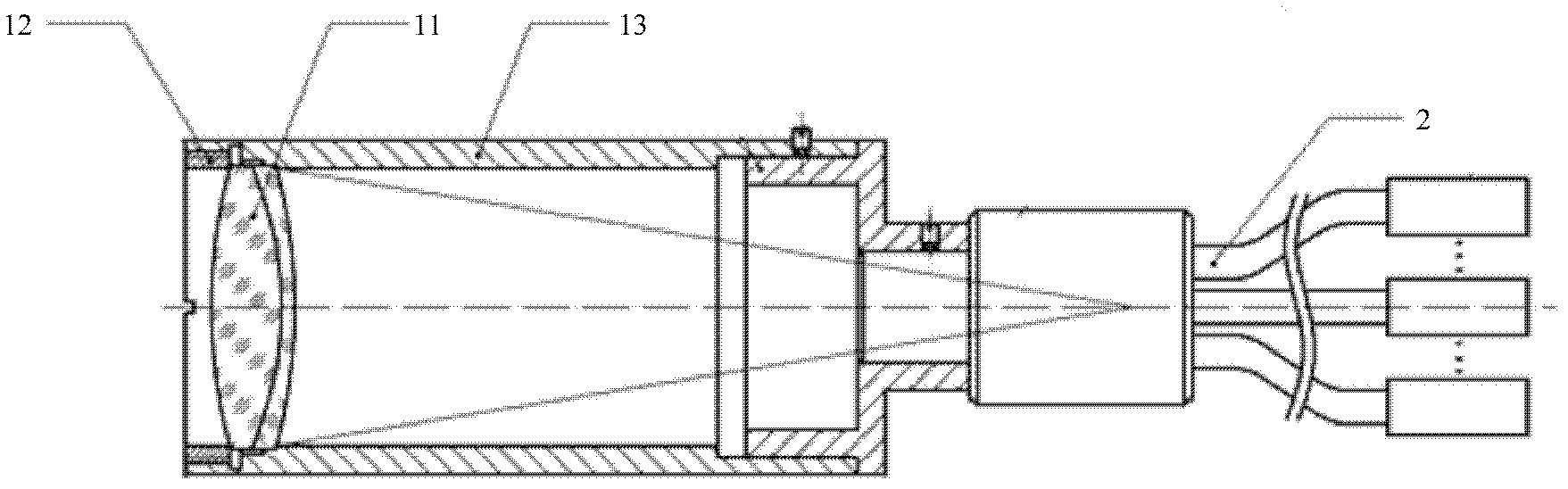

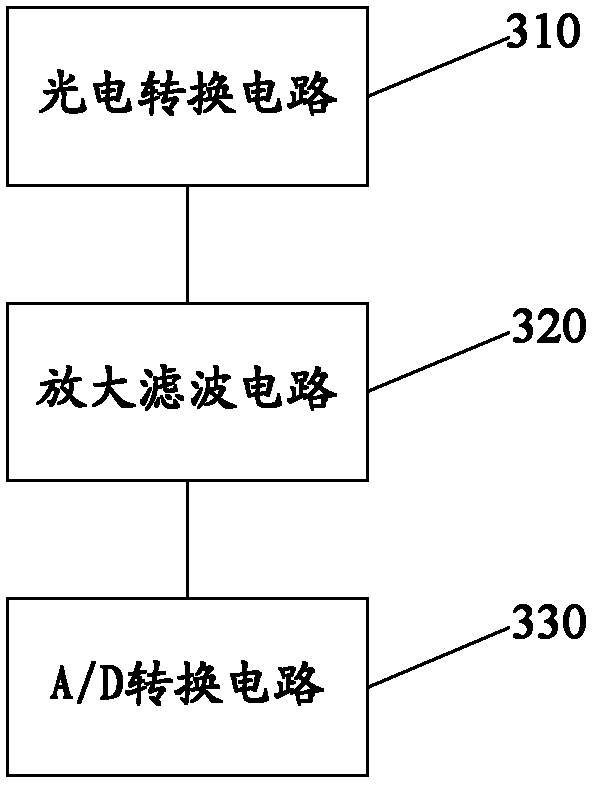

Rotating furnace molten steel temperature measurement device

ActiveCN102605137AOvercome the harsh environmentExtended service lifeThermometers using physical/chemical changesManufacturing convertersEngineeringPhotoelectric conversion

The invention discloses a rotating furnace molten steel temperature measurement device which comprises an optical telescope, a light-filtering device, a photoelectric conversion unit and a processor, wherein the optical telescope is connected with the light-filtering device and used for sending the obtained spectral information into the light-filtering device for filtering so as to obtain the filtered spectral information; the light-filtering device is connected with the photoelectric conversion unit and used for sending the filtered spectral information into the photoelectric conversion unit and converting the filtered spectral information into an electrical signal; and the photoelectric conversion unit is connected with the processor and used for sending the electrical signal into the processor for computing so as to obtain the rotating furnace molten steel temperature information corresponding to the electrical signal. According to the rotating furnace molten steel temperature measurement device, the optical telescope is used for acquiring the spectral information of the flame at a furnace mouth from a long distance in real time, and the light intensity value corresponding to the spectral information can be obtained according to the spectral information, so that the severe high temperature environment of the furnace mouth can be avoided, the service life of the device is prolonged, the device is convenient to install and maintain and is not limited by the size of a rotating furnace, and the cost is effectively reduced.

Owner:HUNAN RAMON SCI & TECH

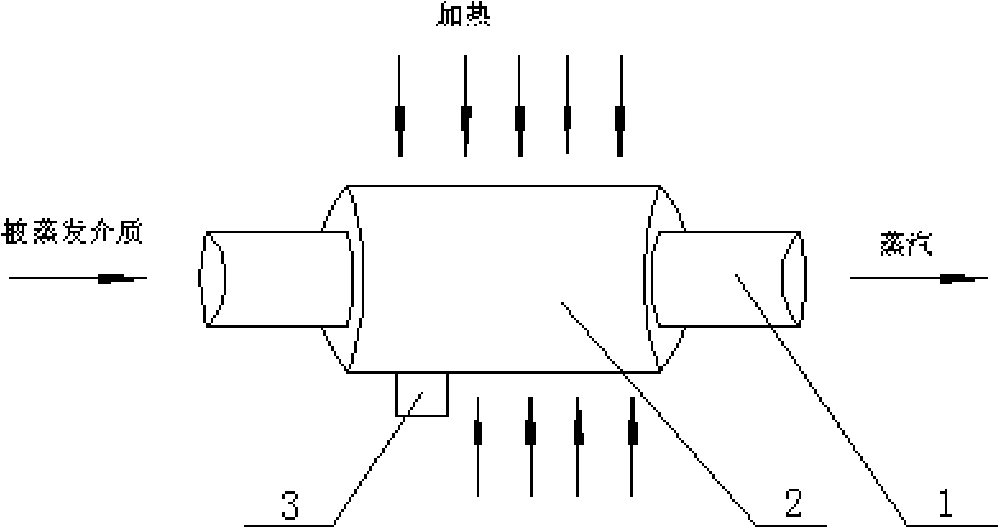

Evaporator

InactiveCN101507882AReduce transmissionThe heat release coefficient drops rapidlyEvaporationPlate heat exchangerFlue gas

The invention discloses an evaporator, which comprises a heating chamber and a heat exchanger arranged in the heating chamber. The evaporator is characterized in that the heating chamber is provided with a high-temperature gas inlet and a gas outlet; the inside of the heating chamber is provided with a heat exchange cylinder, and both ends of the heat exchange cylinder are provided with a hollow shaft which is communicated with the inside of the heat exchange cylinder respectively, wherein the two hollow shafts are coaxial; and the cylinder wall of the heat exchange cylinder is provided with a discharge port which can be opened and closed, and the outside of the heating chamber is provided with a driving device which drives the heat exchange cylinder to rotate through a transmission part. Evaporated media in the evaporator are directly heated in the rotating heat exchange cylinder, and bubbles generated by evaporating water in the evaporated media can be quickly exhausted so as to ensure that bubble cores with high heat release coefficients are evaporated. Moreover, in the production process of akali sulphide, high-temperature waste flue gas exhausted by a rotating furnace can be directly utilized so as to achieve the aims of saving energy and reducing emission.

Owner:眉山市津鑫机电有限公司

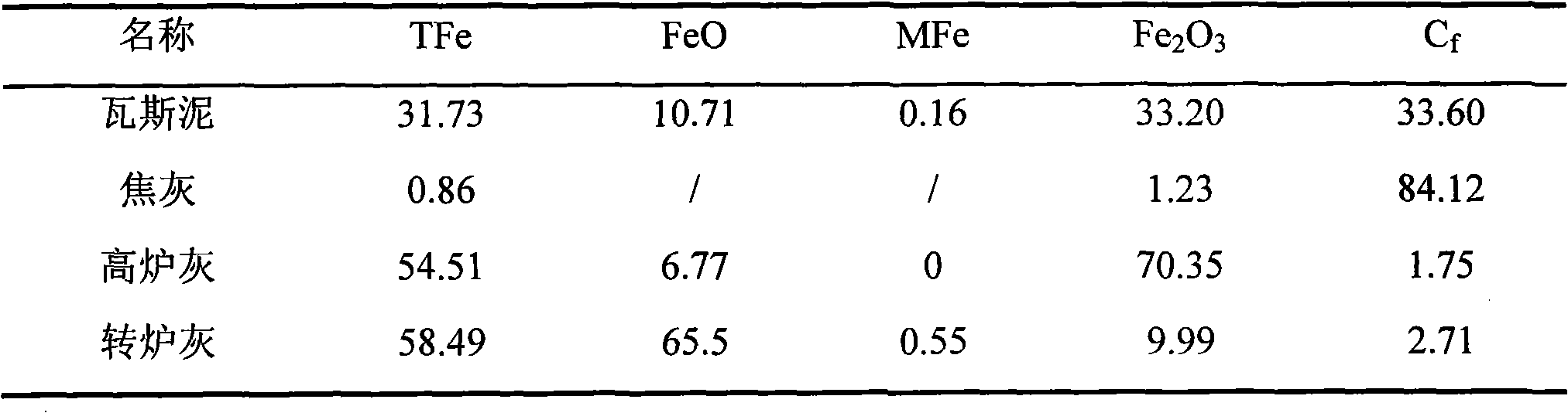

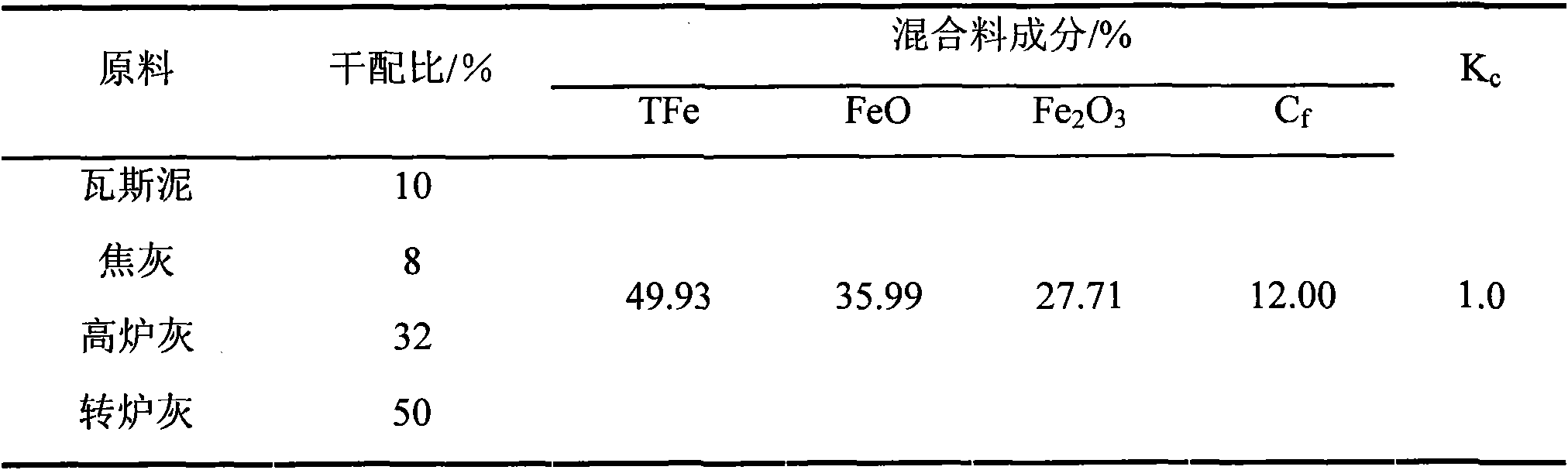

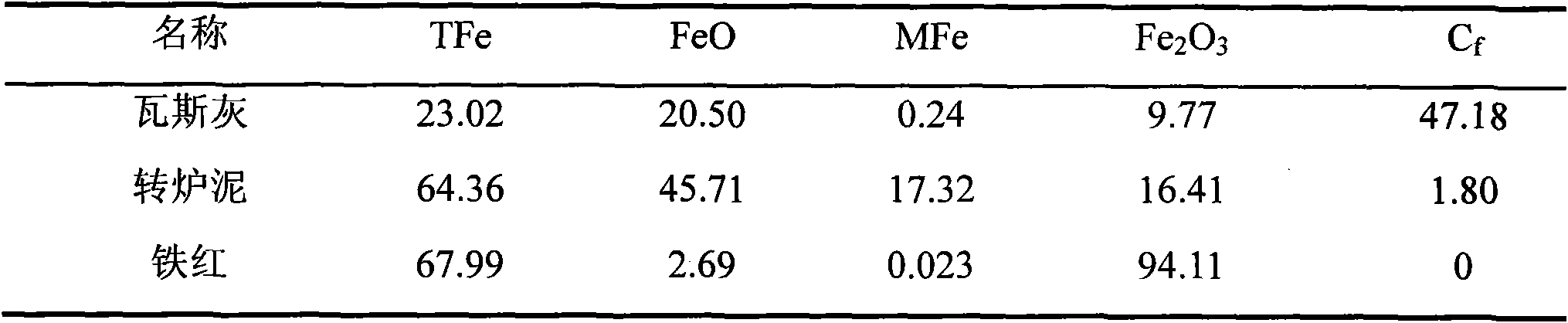

Method for comprehensively treating and utilizing dust sludge

ActiveCN102031361ALow melting pointSimplified processing facilitiesProcess efficiency improvementSteelmakingGranularity

The invention provides a method for comprehensively treating and utilizing dust sludge. The method comprises the following steps of: (1) dispensing: carrying out dispensing calculation according to main ingredients of various iron-containing dust sludge to ensure that the excess coefficient of the content of free carbon reaches 1.0-1.8; (2) mixing: uniformly mixing materials by using mixing equipment; (3) molding: pressing the mixed material into a dust sludge block mass with a granularity of 5-15mm by using molding equipment; (4) drying: drying the molded dust sludge block mass at a temperature below 300 DEG C; (5) charging: after steel-making molten iron in a molten iron pot is blended into a rotating furnace, putting the dust sludge block mass into the hollow molten iron pot through charging equipment according to a weight determined by calculation, preheating and partially reducing the dust sludge block mass by utilizing the molten iron pot and the heat of residual molten iron in the molten iron pot, and sufficiently reducing by utilizing the heat of a large quantity of molten iron and a scouring and stirring effect after the molten iron pot loses iron; and (6) desulfurizing: moving the steel-making molten iron pot which finishes receiving the molten iron and is filled with the dust sludge block mass to a desulfurizing position to desulfurize, wherein after desulfurizing, the molten iron pot can be normally used for steel-making. The method can be used for treating any dust sludge materials without separating the iron dust sludge, ensures that all the iron dust sludge is utilized, simplifies the dust sludge treatment facility, reduces the enterprise cost and has obvious economic benefit and environmental protection benefit.

Owner:ANGANG STEEL CO LTD

Process for upgrading low-rank coal in an internally heating way with heated gas carrier

InactiveCN101701158ALower energy consumption ratioImprove thermal efficiencyDirect heating destructive distillationSolid fuelsFlue gasProduct gas

The invention discloses a process for upgrading low-rank coal in an internally heating way with the heated gas carrier, comprising the following steps: (1) the crushed and screened raw coal is added to a rotating furnace grate arranged at the bottom of a reactor through a raw coal feeding elephant trunk; (2) hypoxic heated gas enters the reactor from a heating gas inlet arranged below the reactor to directly contact the raw coal sample and transfer heat to the raw coal sample through a hole chiseled on the rotating furnace grate, and the hypoxic heated gas and the raw coal sample are dried and subjected to the pyrolysis reaction; and (3) after a certain time of reaction, with the rotation of the rotating furnace grate, the processed raw coal sample is fixed on a plow-type mechanical stirrer which is arranged above the rotating furnace grate and is pushed to a discharge opening, and the tail gases of the heated gas are discharged out of a gas exhausting opening. The invention uses the hypoxic cyclic flue gas as the heat source to distill the low-rank coal and ensures that the hypoxic cyclic flue gas directly exchanges heat with the solid low-rank coal, thereby having high thermal efficiency and low energy consumption ratio. In addition, the invention has low requirement for the size of the granules of the processed low-rank coal and wide application range and can effectively reduce the content of the dust in the tail gases to be good for the transportation of the final product.

Owner:HUNAN HUAYIN ENERGY TECH

Production method of pipeline steel

InactiveCN102644037AReduce manufacturing costUniform Deformation ElongationTemperature control deviceSheet steelHeating furnace

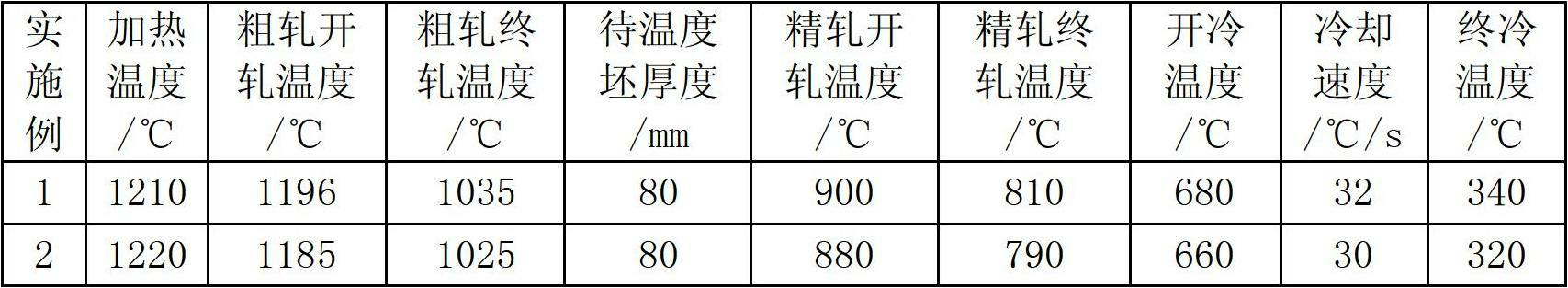

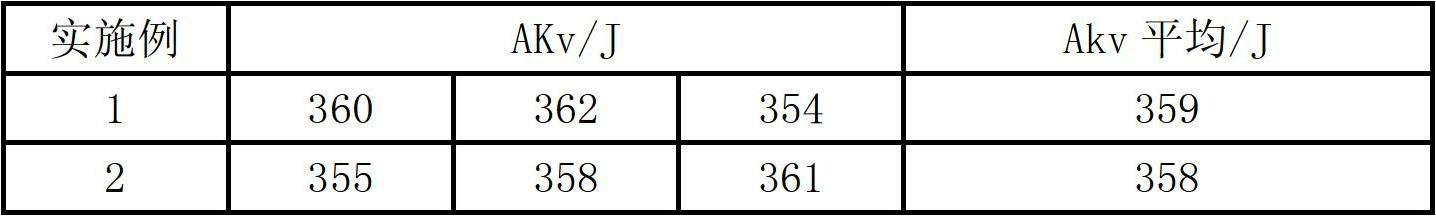

The invention relates to a production method of pipeline steel, which adopts the process route of: smelting in a rotating furnace, ladle furnace (LF) refining, vacuum degassing (VD), continuous casting, heating by a heating furnace, rough rolling, finish rolling, Mulpic cold control and finished product warehousing. The pipeline steel comprises the following alloying elements by mass percent: 0.03-0.06% of C, 0.20-0.35% of Si, 1.60-1.70% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.04-0.06% of Nb, 0.008-0.02% of Ti, 0.15-0.25% of Ni, 0.20-0.35% of Cr, 0.10-0.15% of Mo, less than or equal to 0.0003% of H, less than or equal to 0.005% of N, less than or equal to 0.0015% of O and the balance of Fe; and the technical method combining rough rolling, finish rolling and Mulpic cold control are carried out under the following conditions: the heating temperature of a billet is 1180-1230 DEG C, the first-stage blooming temperature is 1180-1220 DEG C, the accumulated deformation is more than or equal to 60% and the finish rolling temperature is 980-1060 DEG C; the second-stage blooming temperature of the billet is 880-900 DEG C, the finish rolling temperature is 780-810 DEG C and the accumulated deformation is more than or equal to 70%; air cooling relaxation is carried out on a rolled steel plate till the temperature is 650-680 DEG C, 40-60% of polygonal ferrite (PF) is separated out before the steel plate is cooled; and then, the steel plate is rapidly cooled by Mulpic, wherein the cooling speed is 30-35 DEG C / min, and the finish cooling temperature is 300-360 DEG C. The pipeline steel produced by the method is better in low strain ageing sensitivity and deformation resistance.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

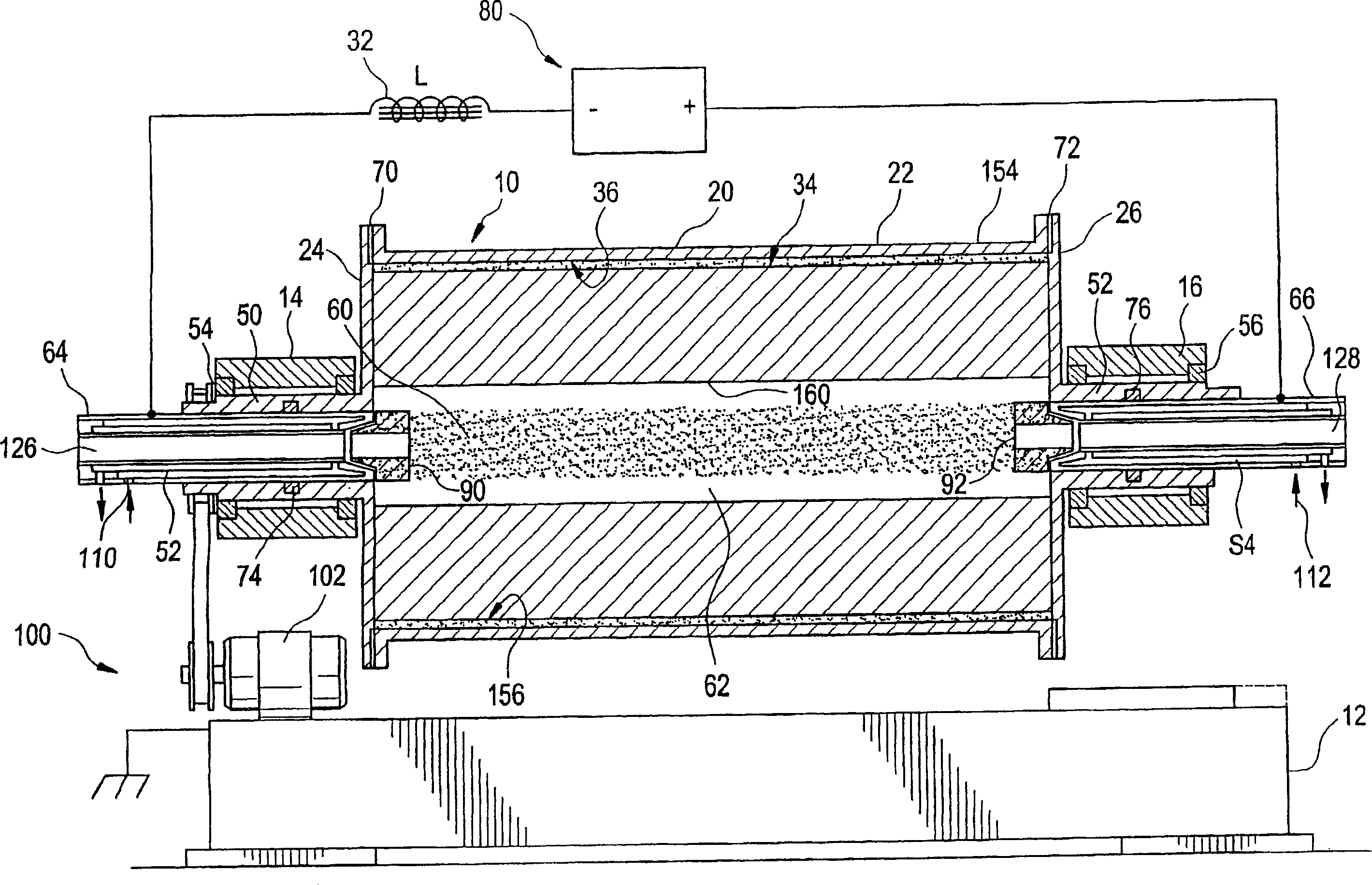

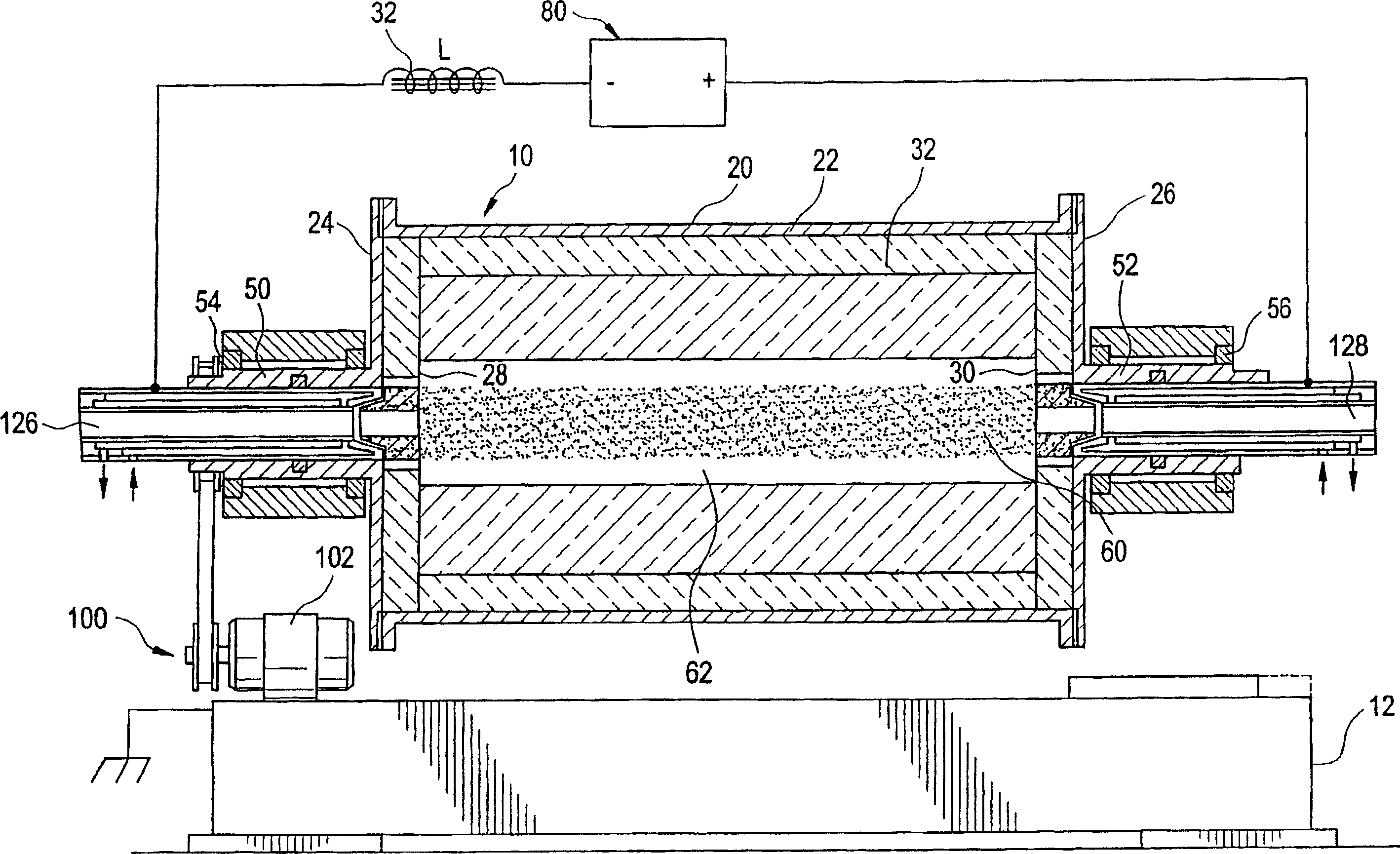

Fabrication of heavy walled silica tubing

A method for producing a silica glass body having a low bubble content includes melting silica sand in a chamber (62) of a rotating furnace housing (20) to form molten silica. Helium-containing gas is fed into the chamber, both during introduction of the sand and during the heating step. The helium diffuses more readily from the molten silica than other gases, resulting in lower bubble content. The furnace is heated by establishing a gas plasma arc (60) between spaced electrodes (64, 66) within the chamber.

Owner:GENERAL ELECTRIC CO

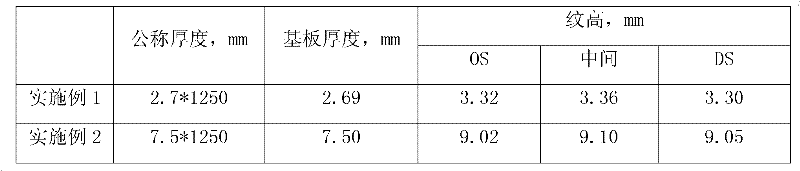

Method for producing checkered steel plate by applying CSP (Cast Steel Plate) process

ActiveCN102240675AGuaranteed performanceImprove surface qualityRoll force/gap control deviceTemperature control deviceSheet steelHigh intensity

The invention discloses a method for producing a checkered steel plate by applying a CSP (Cast Steel Plate) process. In the method, a rotating furnace for smelting, an LF (Low-Frequency) refining furnace and CSP continuous casting and rolling equipment are applied, and a controlled rolling and controlled cooling process is adopted. The checkered steel plate produced by applying the CSP process has the advantages of high strength, good forming property and accurate thickness precision, convexity, straightness and width of plate; and in addition, the product of the checkered steel plate has more uniform and stable property and higher longitudinal and horizontal precision.

Owner:MAANSHAN IRON & STEEL CO LTD

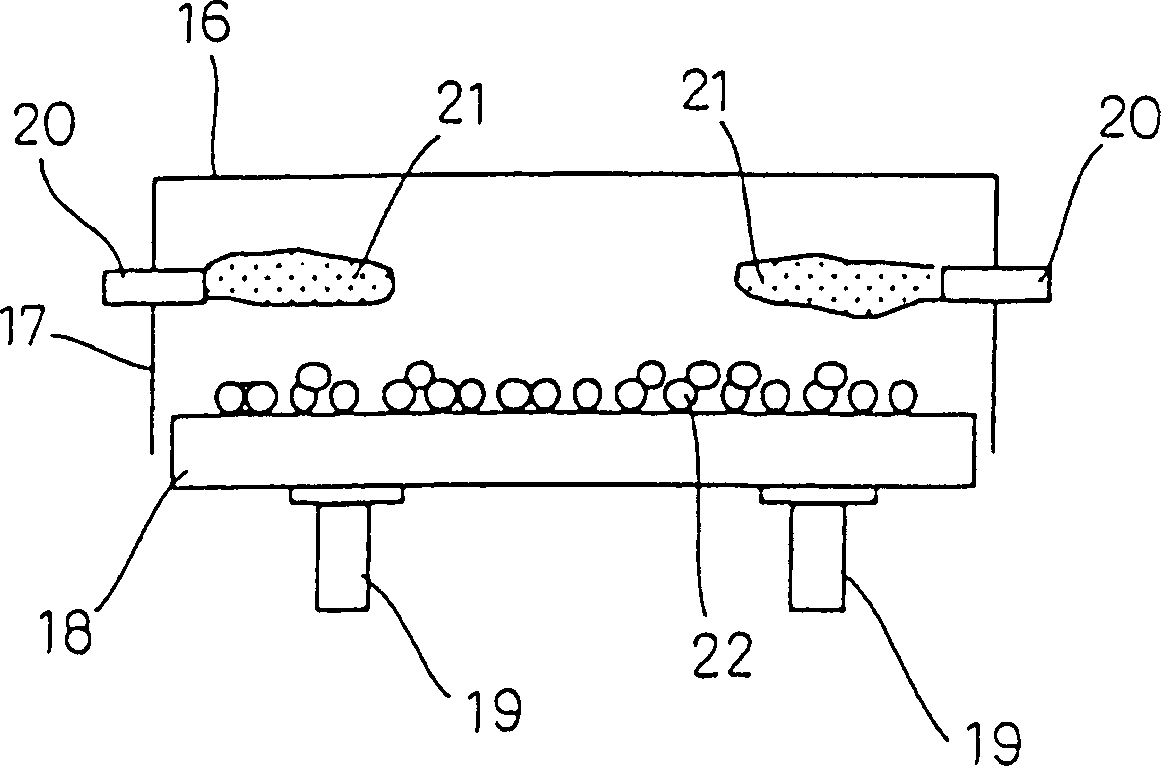

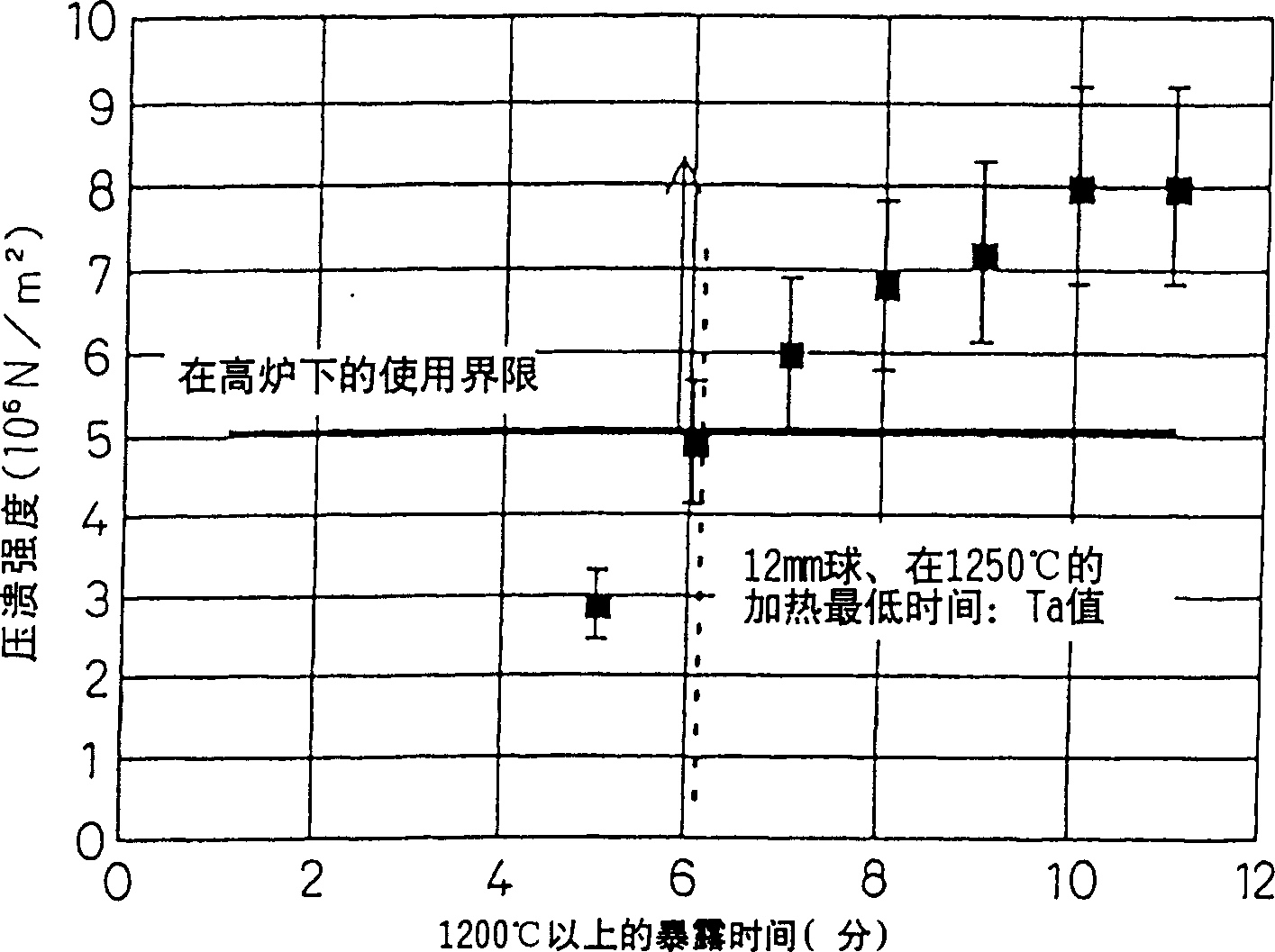

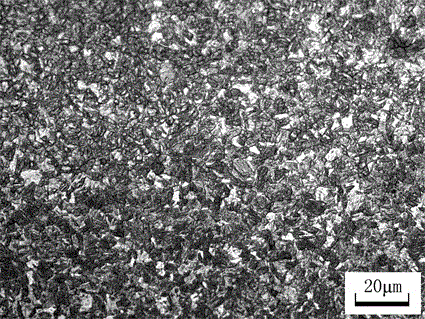

Method for producing reduced iron compact in rotary hearth reducing furnace, reduced iron compact, and method for producing pig iron using the same

There is provided a method of producing reduced iron compacts with high crushing strength, low powderization and a high reduction rate in a solid reduction-type firing reducing furnace such as a rotary hearth-type reducing furnace, as well as reduced iron compacts obtained by the method and a method of melt-reducing the reduced iron compacts in a blast furnace. In the method of producing reduced iron compacts, the atomic molar ratio of carbon to oxygen chemically combined with iron, manganese, nickel, zinc and lead, in raw material powder comprising a mixture of iron oxide-containing powder and carbon-containing powder, or the ferric oxide content of the raw material powder, is in a specified range, the compact is produced so as to give a porosity in a given range, and the compact is put on the hearth of a reducing furnace equipped with a rotating hearth and is heated for heating reduction by the heat from the combustion gas in the upper part of the furnace, for firing reduction at above a prescribed temperature.

Owner:NIPPON STEEL CORP

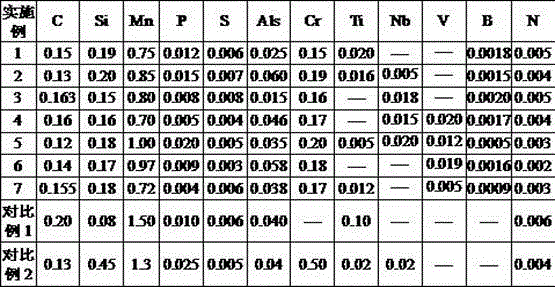

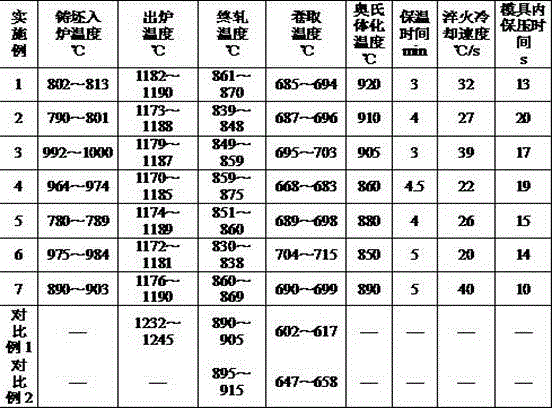

Thin thermoformed steel with tensile strength being not lower than 1100 MPa directly rolled by sheet billet and production method of thin thermoformed steel

The invention provides thin thermoformed steel with tensile strength being not lower than 1100 MPa directly rolled by a sheet billet. The thin thermoformed steel with tensile strength being not lower than 1100 MPa directly rolled by the sheet billet comprises the following components, in percentage by weight, 0.12-0.16% of C, 0.15-0.20% of Si, 0.7-1.0% of Mn, not higher than 0.02% of P, not higher than 0.008% of S, 0.015-0.060% of Als, 0.15-0.20% of Cr, 0.005-0.02% of Ti or 0.005-0.02% of Nb or 0.005-0.02% of V or a mixture mixed by more than two of the three components in any proportion, 0.0005-0.0020% of B and not higher than 0.005% of N. The production method of the thin thermoformed steel comprises the steps of desulfurizing molten iron; smelting the molten iron by an electric furnace smelting or a rotating furnace and refining the molten iron; performing continuous casting; performing descaling treatment before putting the molten iron into a soaking pit furnace; performing soaking; performing heating; performing high pressure water descaling before putting the molten iron into a rolling mill; performing rolling; performing cooling; performing coiling; performing austenitizing; performing mould stamping forming; and performing quenching. The steel is short in process, good in quality of product surface, high in accuracy of thickness, capable of meeting the quality requirements of cold-rolled products and realizing complicated deformation smoothly without resilience after deformation, and high in accuracy of part size.

Owner:武汉钢铁有限公司

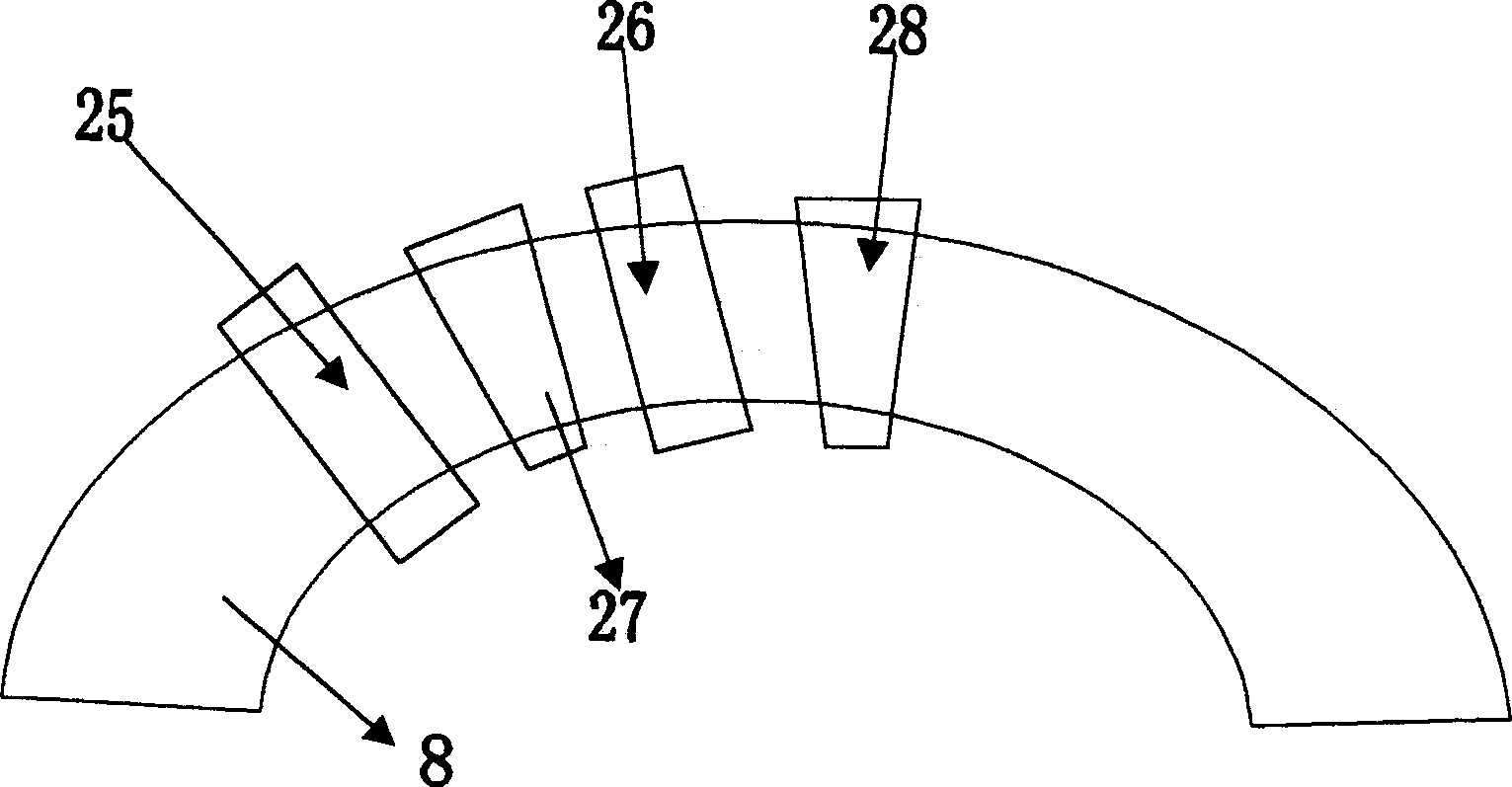

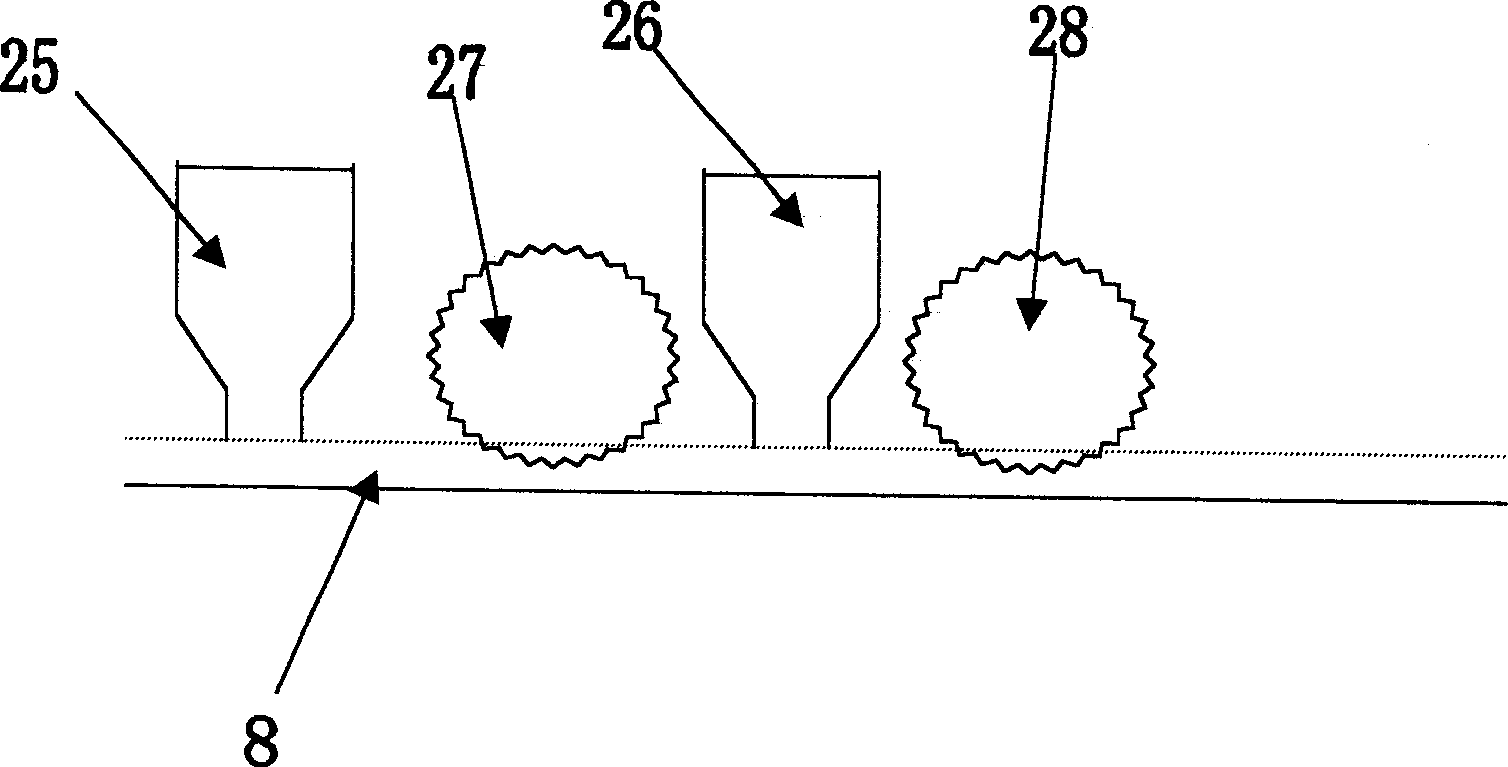

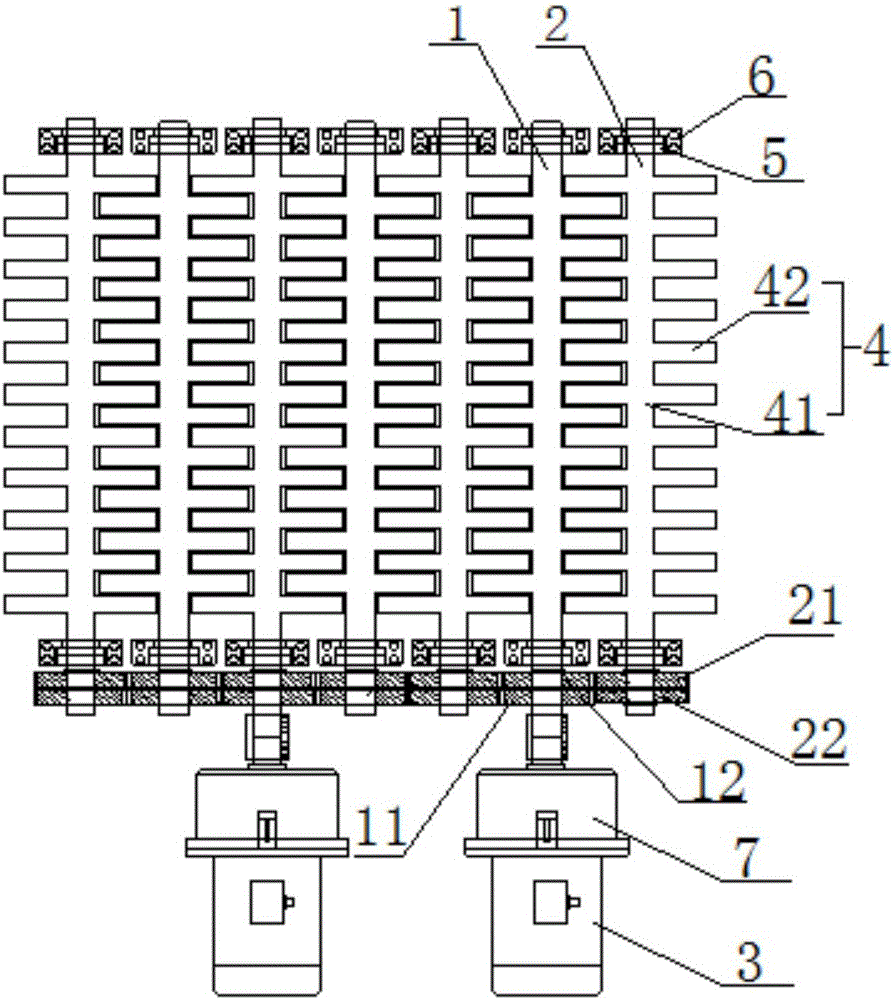

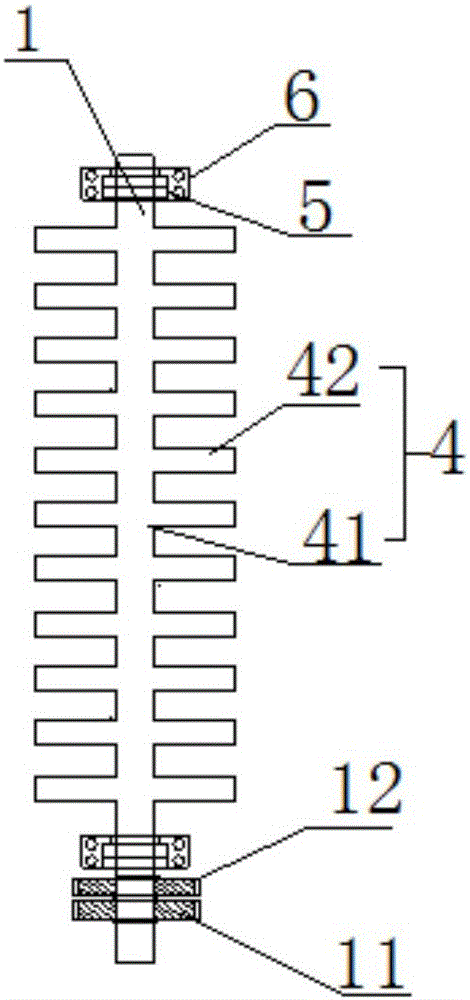

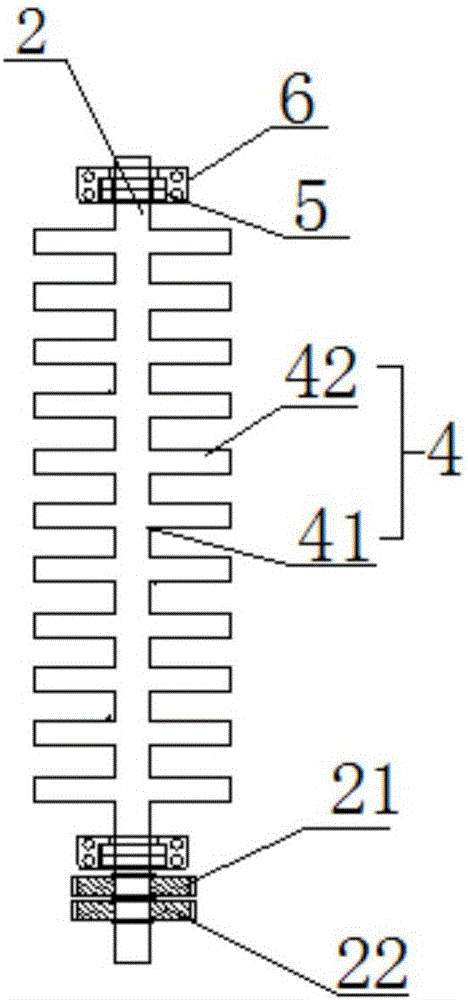

Rotary fire grate

PendingCN106705079ASmall form factorSave burning spaceRevolving grateRocking grateSpelunkingCombustion

The invention discloses a rotary fire grate. The rotary fire grate comprises installing bases, shaft plate sets A, shaft plate sets B and drive motors connected with the shaft plate sets A and the shaft plate sets B correspondingly. Tooth-shaped shaft plates of the shaft plate sets A and the shaft plate set B are distributed at intervals. The two ends of all the tooth-shaped shaft plates are connected to the corresponding installing bases in a pivoted mode. The tooth-shaped shaft plates are composed of rotary shafts and tooth-shaped plate bodies distributed in the axial directions of the corresponding rotary shafts symmetrically in an arrayed mode. A gear is fixed to the tooth-shaped shaft plate rotary shaft of each shaft plate set, and the tooth-shaped shaft plate rotary shaft of each shaft plate set is movably sleeved with a transition gear, wherein the gear is in engaged transmission with the transition gear. According to the rotary fire grate, stove ash and slag deposited after fuel combustion are timely cleared away, the single set of drive motors are used for repeatedly driving the tooth-shaped shaft plates to horizontally rotate around the corresponding shafts to form part of neutral positions, the phenomenon that integral fuel caving is caused and consequentially heat imbalance in a furnace is caused is avoided, and continuous operation of the combustion furnace is guaranteed through intermittent and intervallic rotation of the tooth-shaped shaft plates and timed instantaneous slag-discharging; and the space occupied by the fire grate is small during the static status or operating status of the fire grate, the overall appearance size of the combustion furance is compressed, and a combustion space in the combustion furnace is saved.

Owner:潘汉祥

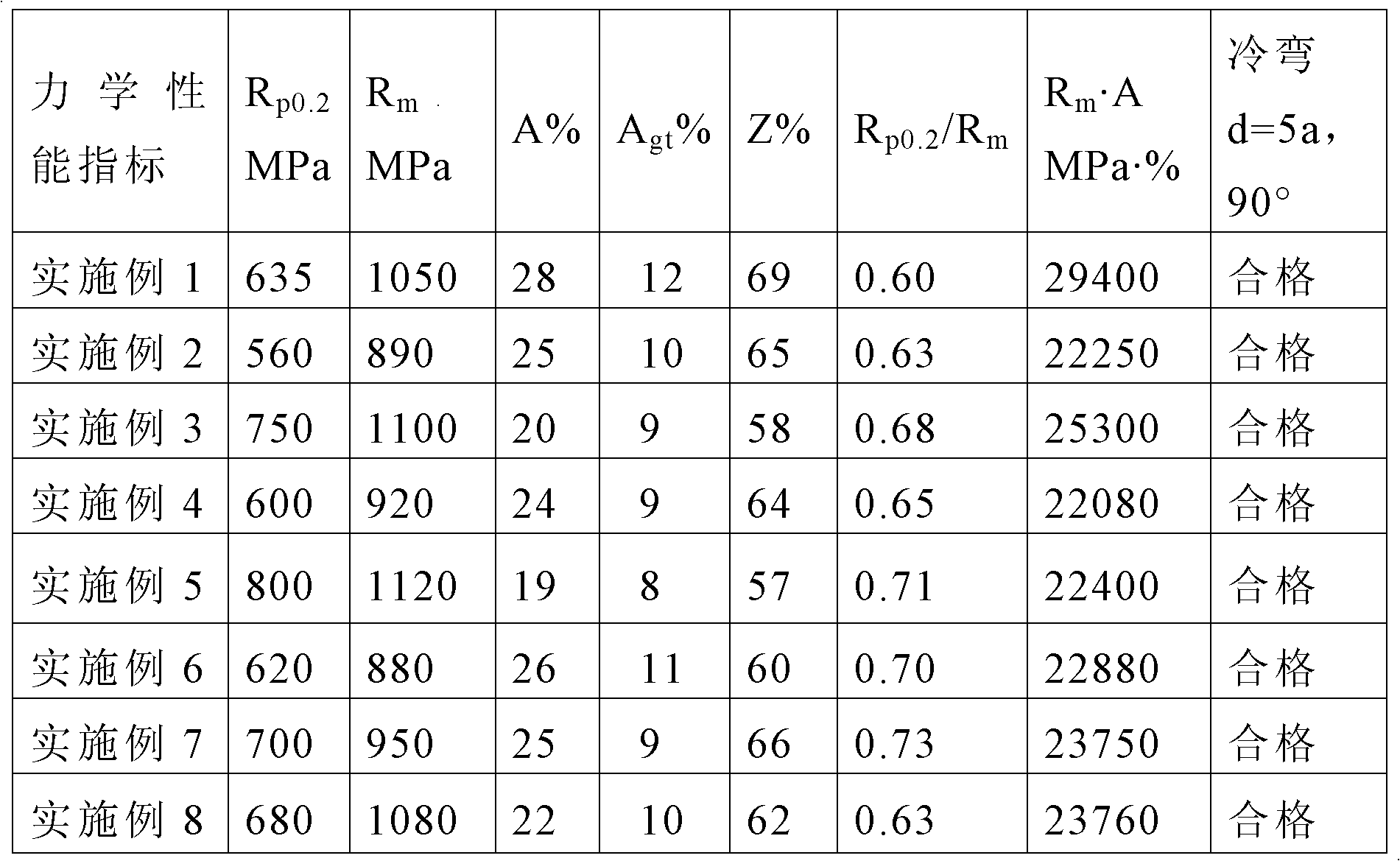

High-intensity quake-resistant steel bar for buildings and manufacturing method thereof

The invention discloses a high-intensity quake-resistant steel bar for buildings and a manufacturing method thereof. The steel bar for buildings comprises the following components in percentage by weight: 0.14-0.22 percent of C, 0.50-1.50 percent of Si, 1.00-1.60 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.020 percent of S, 0.10-1.30 percent of Al and the balance of Fe and inevitable impurities. The manufacturing method of the steel bar for buildings comprises the steps of pre-desulfurizing of molten iron, smelting in a rotating furnace, refining, continuous casting, continuous hot rolling and controlled cooling after rolling. Practices indicate that the high-intensity quake-resistant steel bar produced by adopting the manufacturing method has the characteristics of high intensity, low yield ratio, high-intensity plastic accumulation and superior quake resistance.

Owner:武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com