Patents

Literature

498 results about "Precipitated calcium carbonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Precipitated calcium carbonate (PCC), pre-dispersed in slurry form, is a common filler material for latex gloves with the aim of achieving maximum saving in material and production costs.

Paper coating pigments

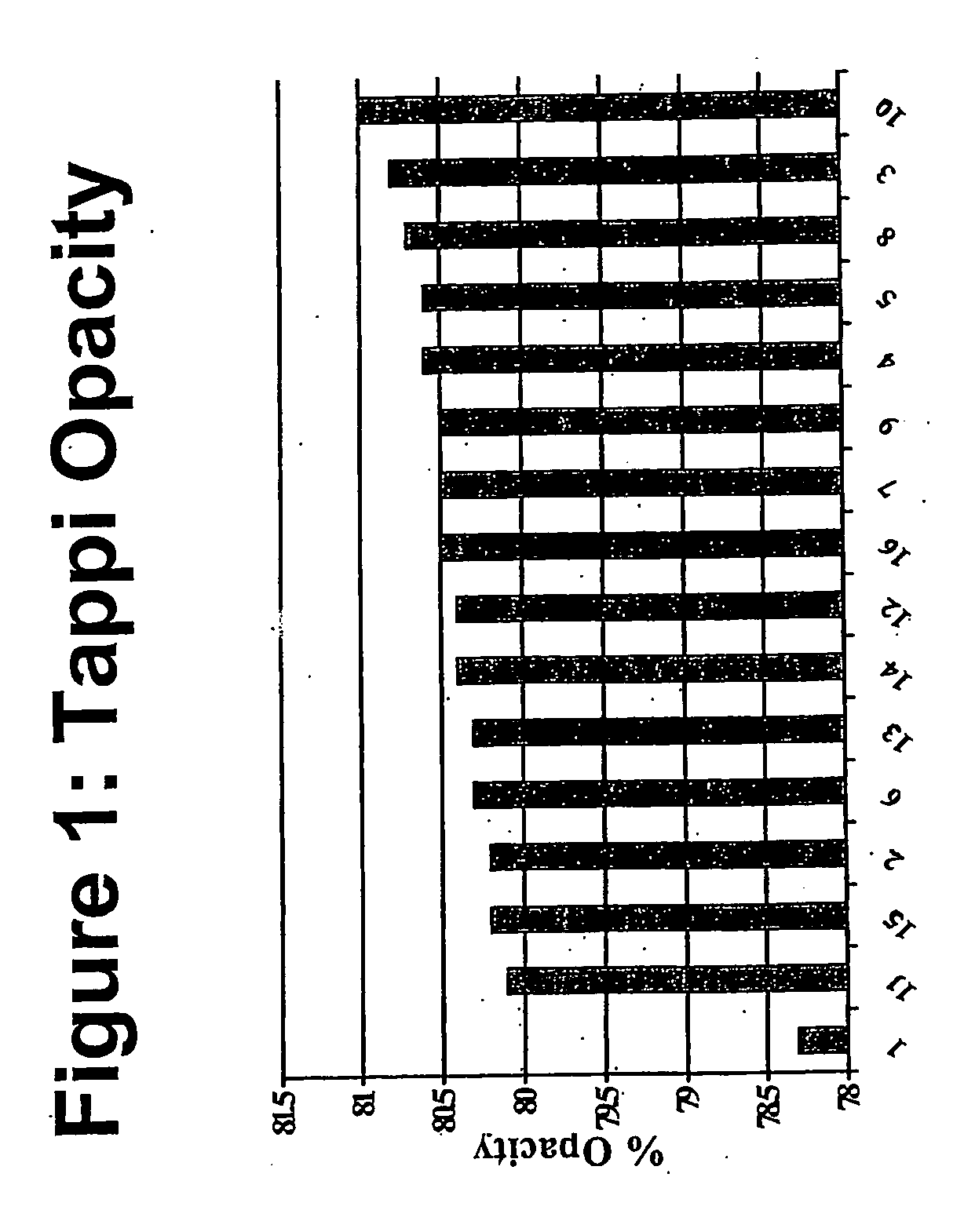

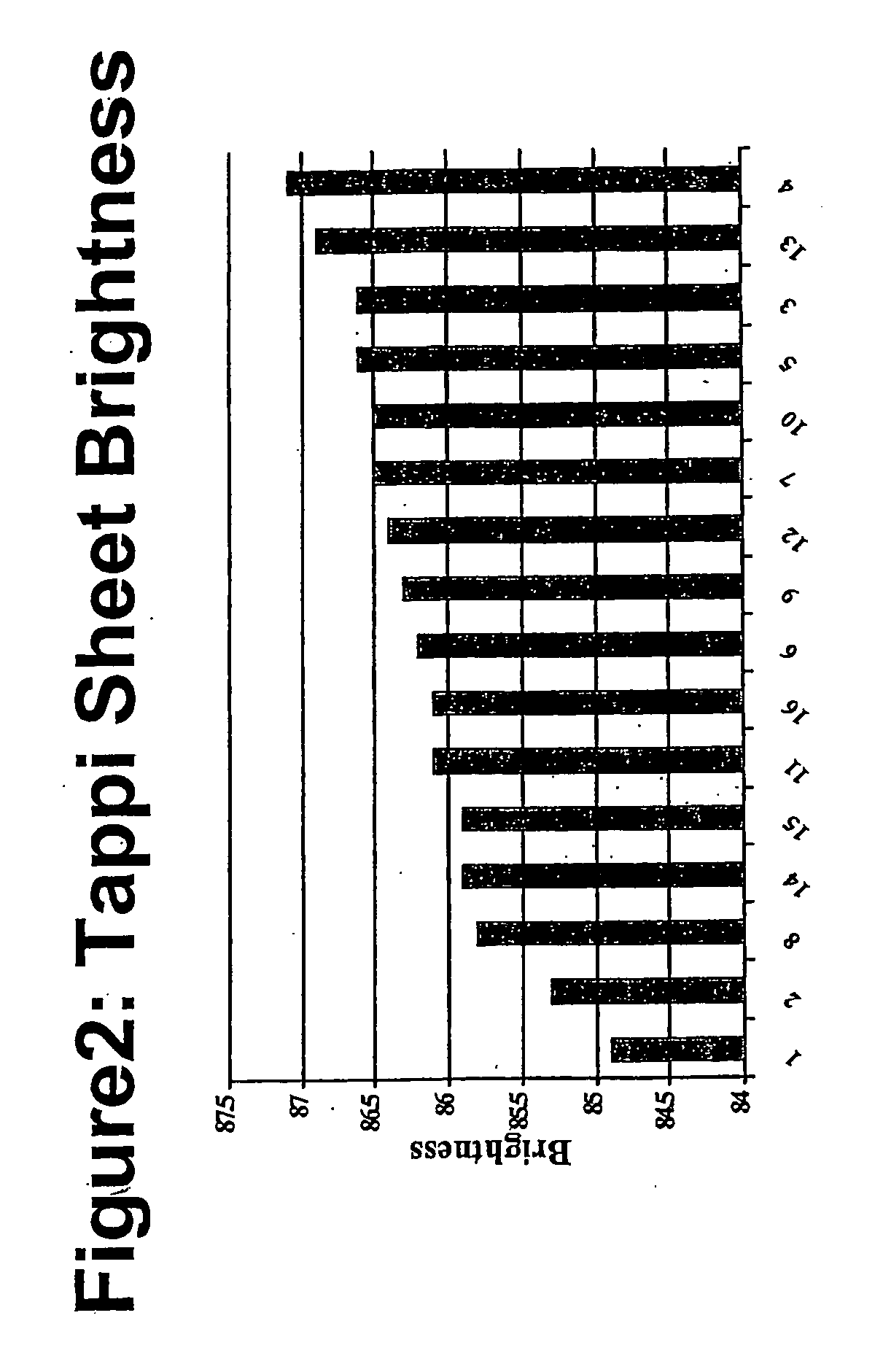

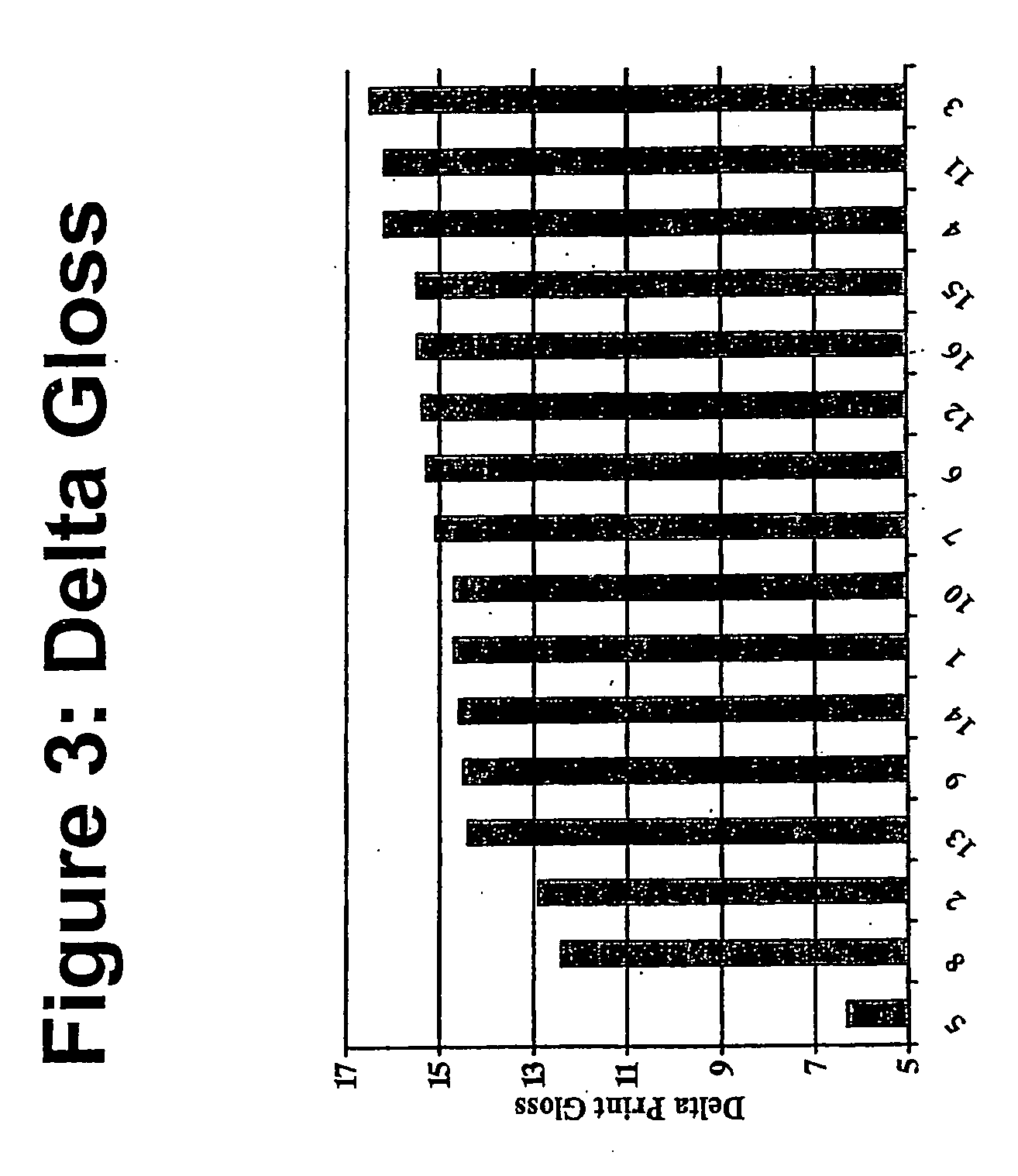

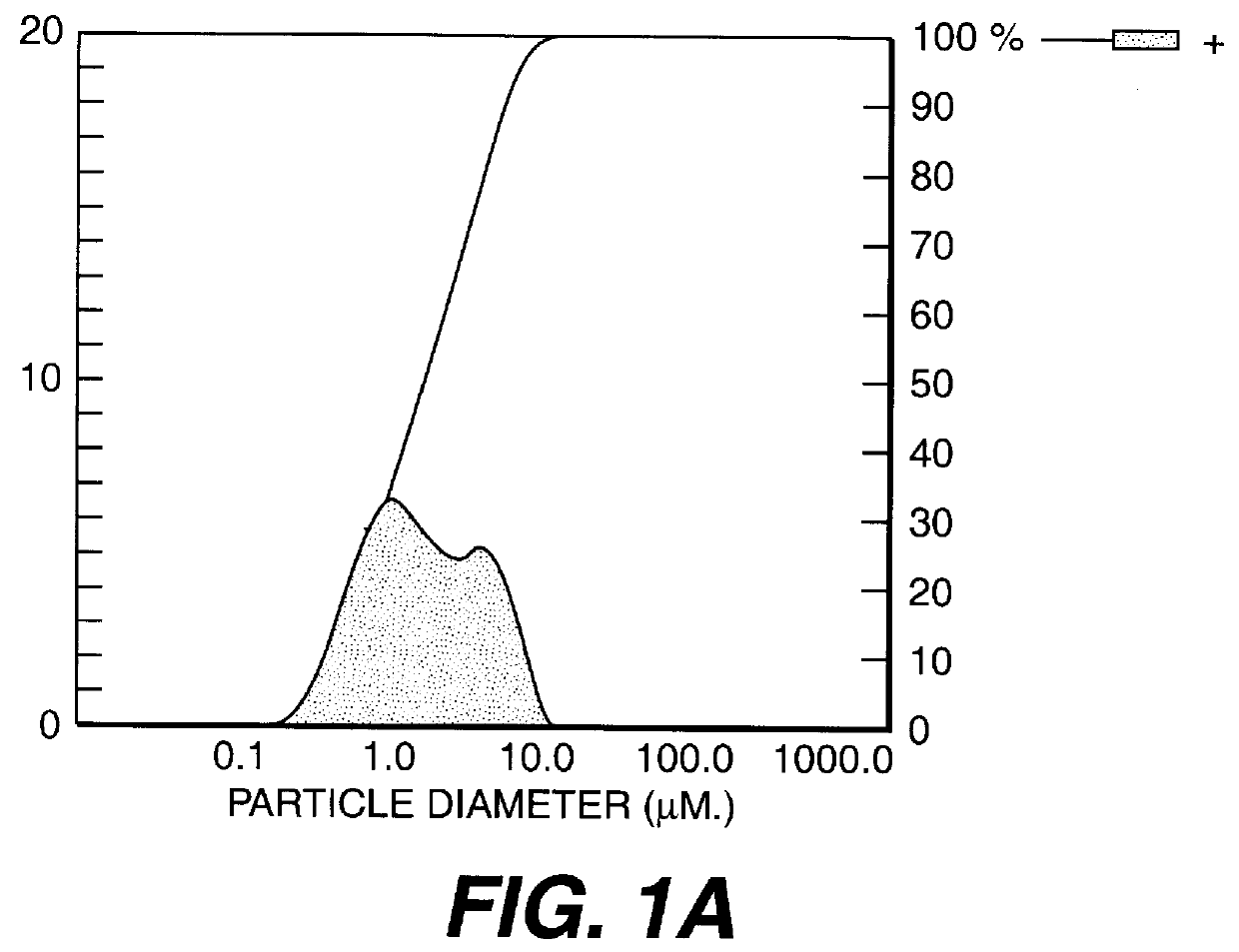

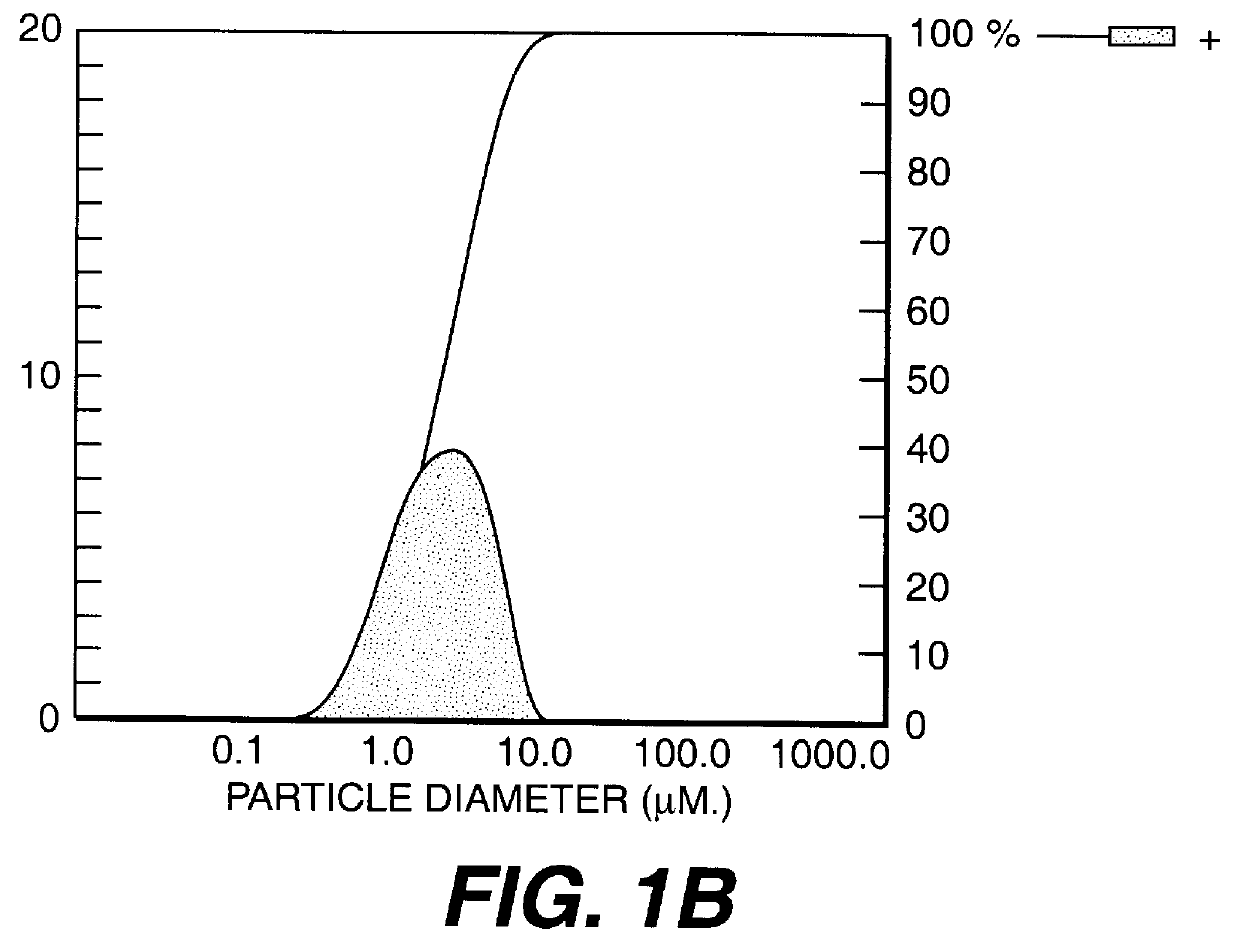

InactiveUS20060292305A1Increase steepnessImprove smoothnessCalcium/strontium/barium carbonatesPigmenting treatmentParticulatesPrecipitated calcium carbonate

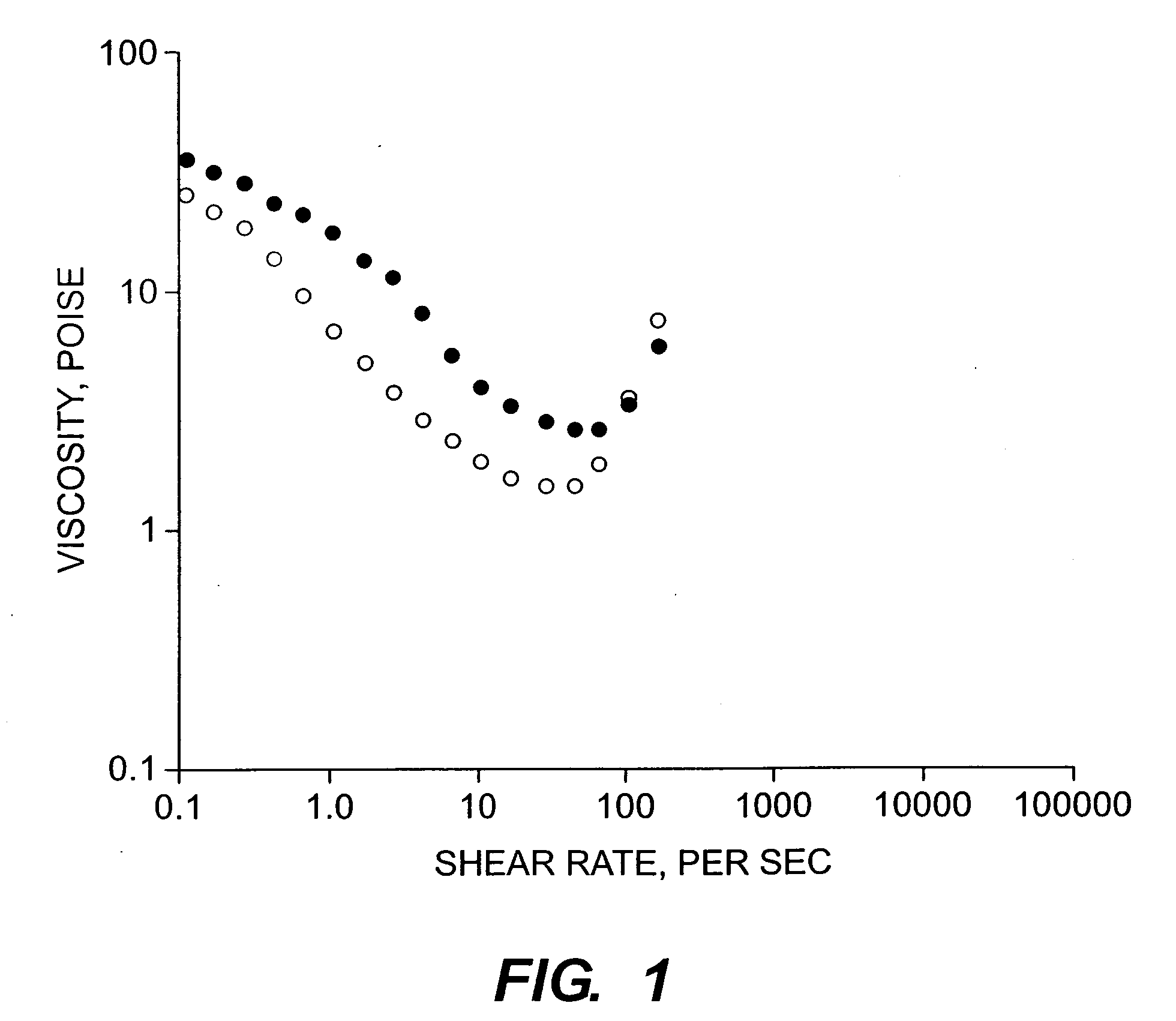

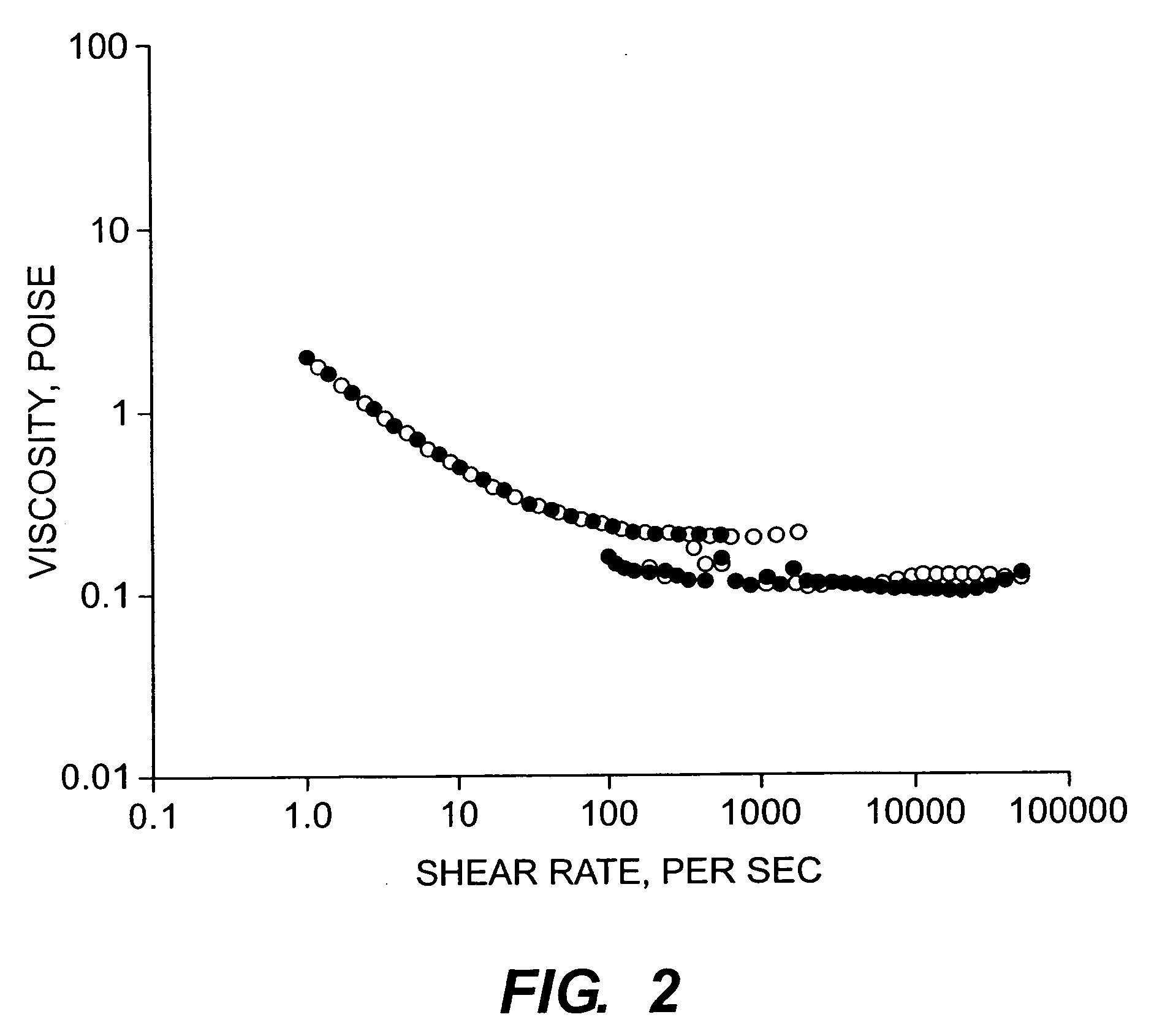

The present disclosure relates to a coating composition for use in producing a coating on paper and other substrates comprising an aqueous suspension of a particulate pigment together with a binder, wherein the particulate pigment comprises a mixture of: a first pigment component comprising particulate ground calcium carbonate (GCC) having a particle size distribution (psd) steepness factor ranging from about 30 to about 45; and a second pigment component comprising particulate precipitated calcium carbonate (PCC) having a psd steepness factor ranging from about 55 to about 75. The particulate pigment may optionally further include a particulate kaolin clay.

Owner:IMERYS PIGMENTS INC

Oral Care Composition Comprising Arginine and Calcium Carbonate

InactiveUS20130224270A1Inhibiting and reducing accumulationDiminishing acid levelCosmetic preparationsToilet preparationsPrecipitated calcium carbonateMedicine

This invention relates to oral care compositions comprising a basic amino acid or salt thereof, and an abrasive system comprising natural calcium carbonate and precipitated calcium carbonate; and to methods of using and of making these compositions.

Owner:COLGATE PALMOLIVE CO

Calcium carbonate precipitation method

InactiveUS6036933ACalcium/strontium/barium carbonatesMagnesium carbonatesNitratePrecipitated calcium carbonate

PCT No. PCT / GB96 / 00488 Sec. 371 Date Oct. 22, 1997 Sec. 102(e) Date Oct. 22, 1997 PCT Filed Mar. 1, 1996 PCT Pub. No. WO96 / 26902 PCT Pub. Date Sep. 6, 1996A method for producing precipitated calcium carbonate by reacting an aqueous solution of calcium nitrate [Ca(NO3)2] with an aqueous solution of ammonium carbonate [(NH4)2CO3] and allowing calcium carbonate to precipitate from the resultant mixture containing nitrate [NH4NO3] in the mother liquor, the process being characterized in that: (i) the calcium nitrate [Ca(NO3)2)] solution utilized in the processes is prepared by slaking lime [CaO] in water in the presence of ammonium nitrate [NH4NO3] to form calcium nitrate [Ca(NO3)2] and ammonium hydroxide [NH4OH] in solution, filtering the solution to render it solids free, and heating the filtrate to dissociate the ammonium hydroxide [NH4OH] and to drive ammonia gas [NH3] from the solution; (ii) the ammonium carbonate (NH4)2CO3 solution utilized is prepared by absorbing ammonia gas [NH3] and carbon dioxide gas [CO2] in water, the ammonia gas preferably being derived from the step in (i) above in which the Ca(NO3)2 solution is heated; and (iii) the ammonium nitrate used is derived from the precipitation phase during which calcium carbonate is precipitated from the mother liquor containing ammonium nitrate.

Owner:PRETORIA PORTLAND CEMENT COMPANY +1

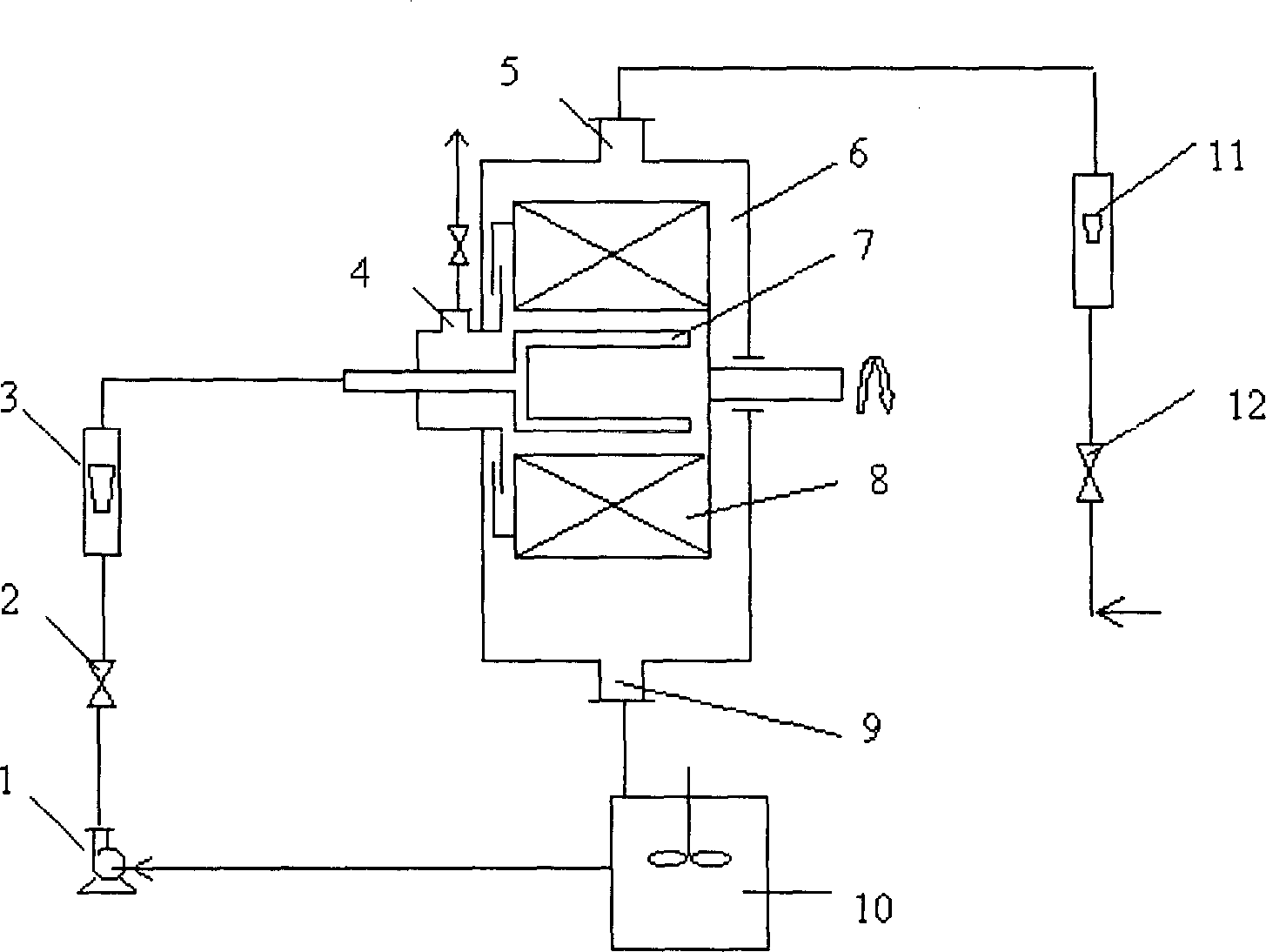

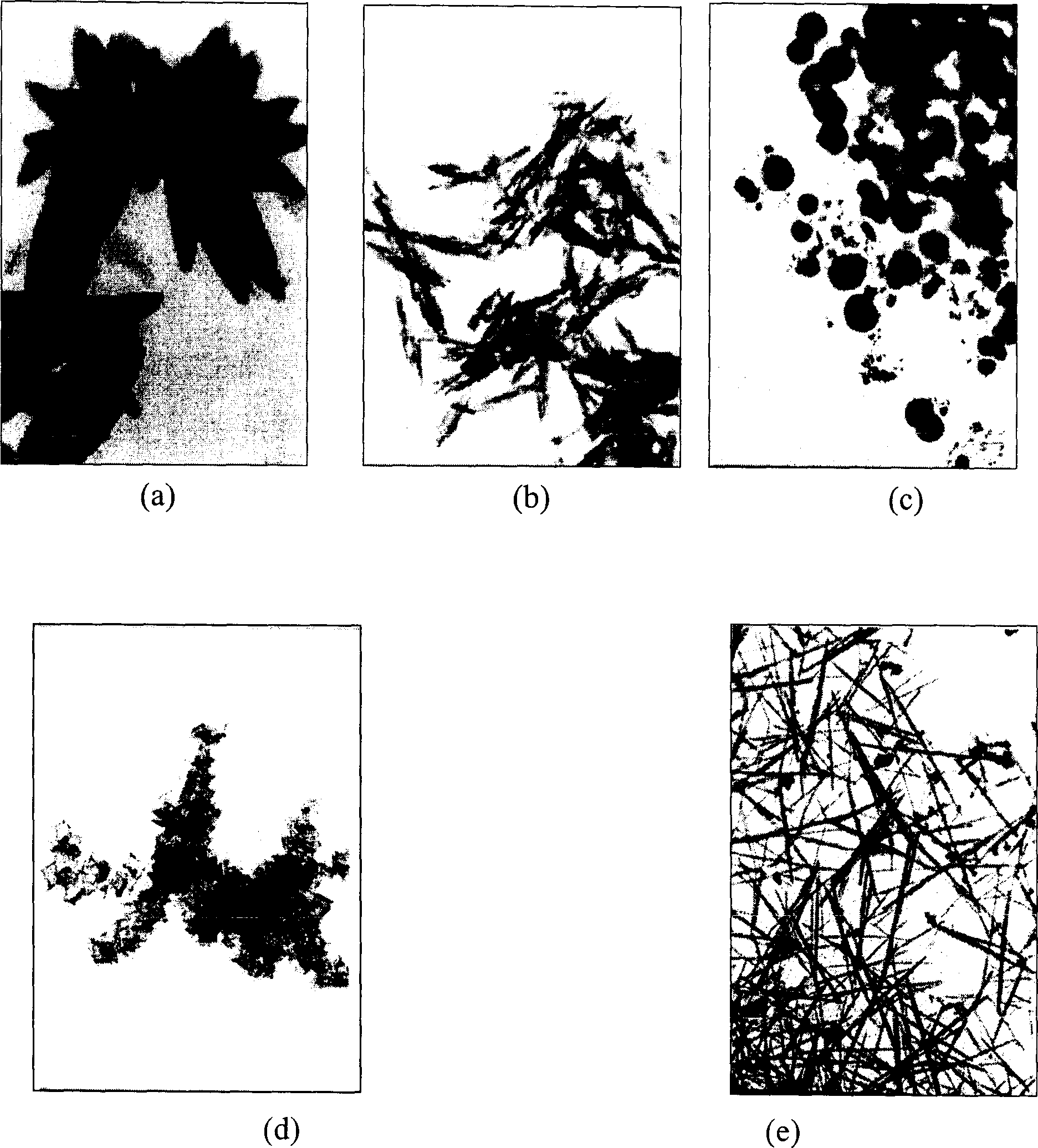

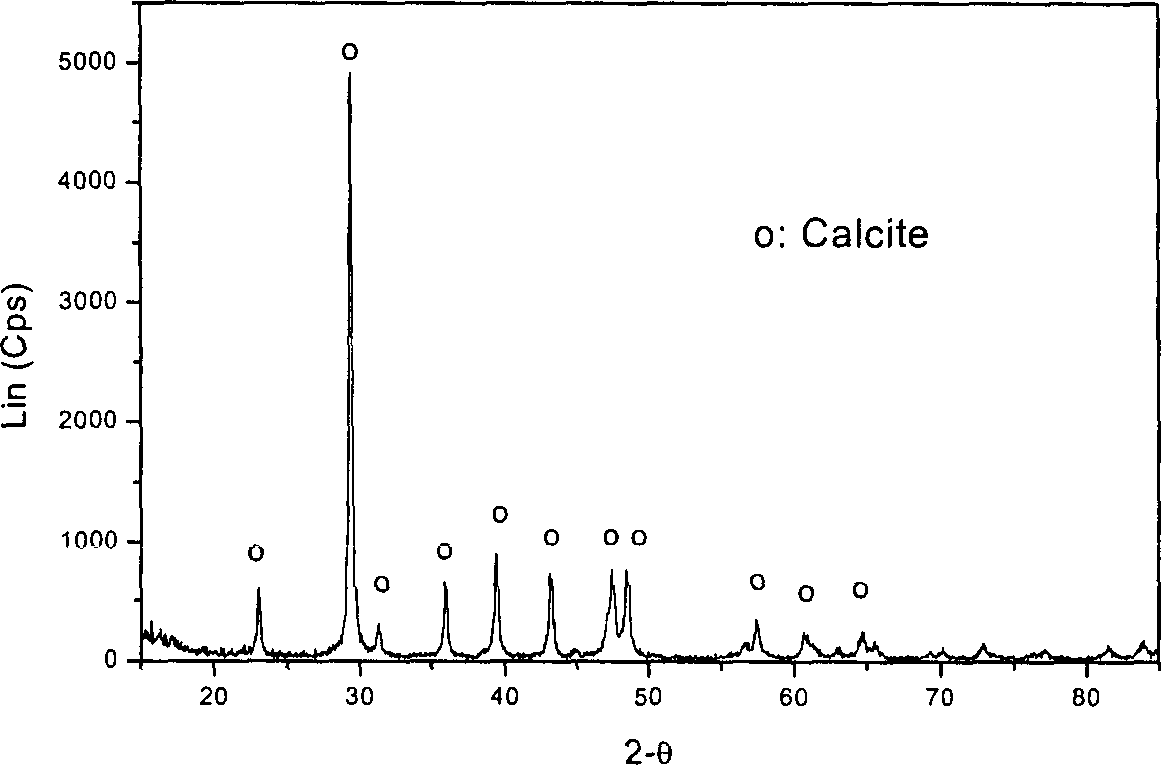

Method for preparing calcium carbonate with actual forms

InactiveCN1429772AEasy to shapeThe shape is obviously better than that of the prior art productsCalcium/strontium/barium carbonatesCalcium hydroxideField conditions

A process for preparing calcium carbonate with actual forms (such as spindle, petal, needle, flake, ball fibre, etc.) features that in the supergravity field condition of rotating bed and under the existance of crystal form controlling agent and crystal seeds, the suspension of calcium hydroxide and CO2-contained raw gas take part in carbonifying reaction. Its advantage is controllable granularity and form.

Owner:NANOMATERIALS TECH PTE +1

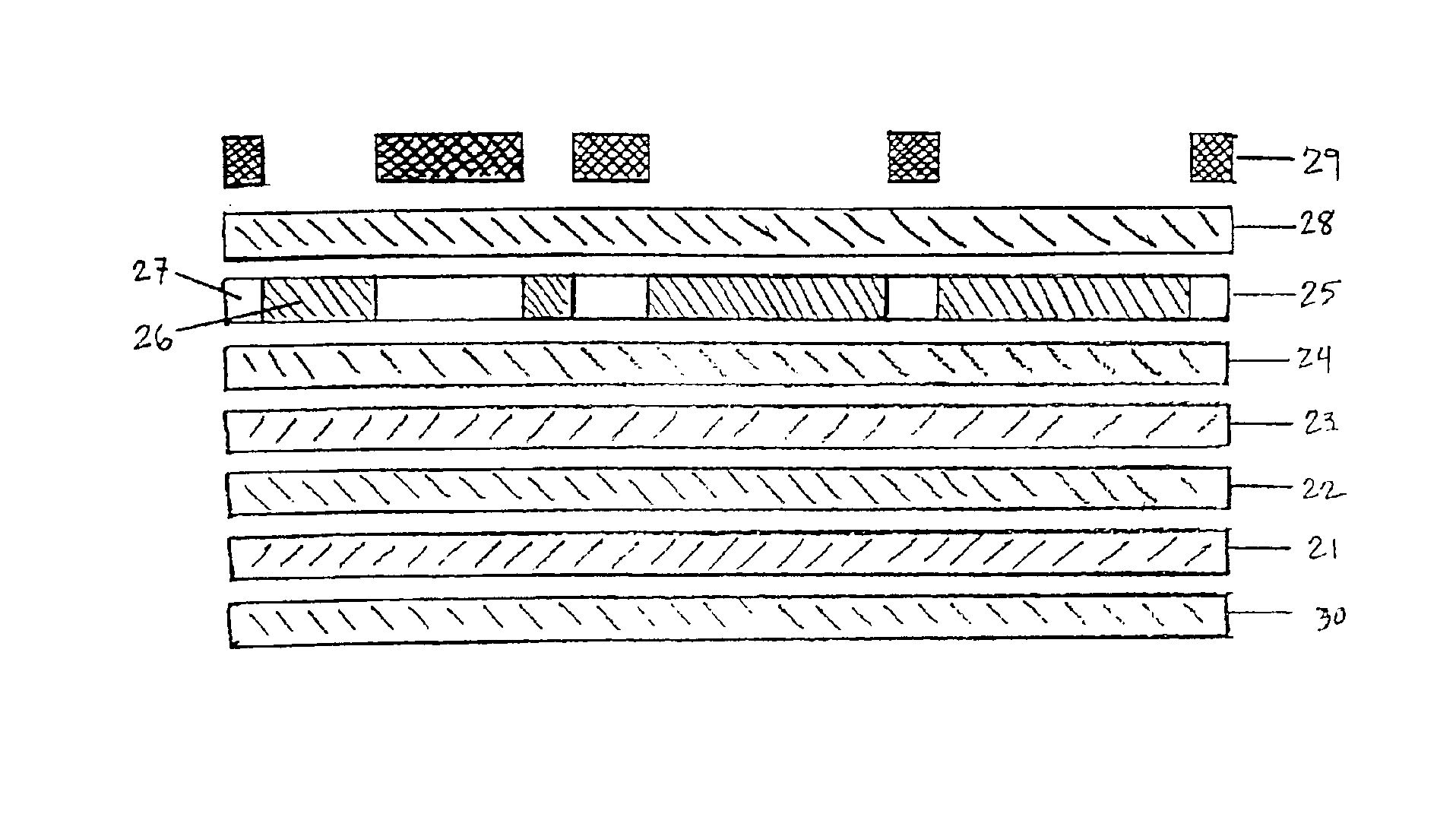

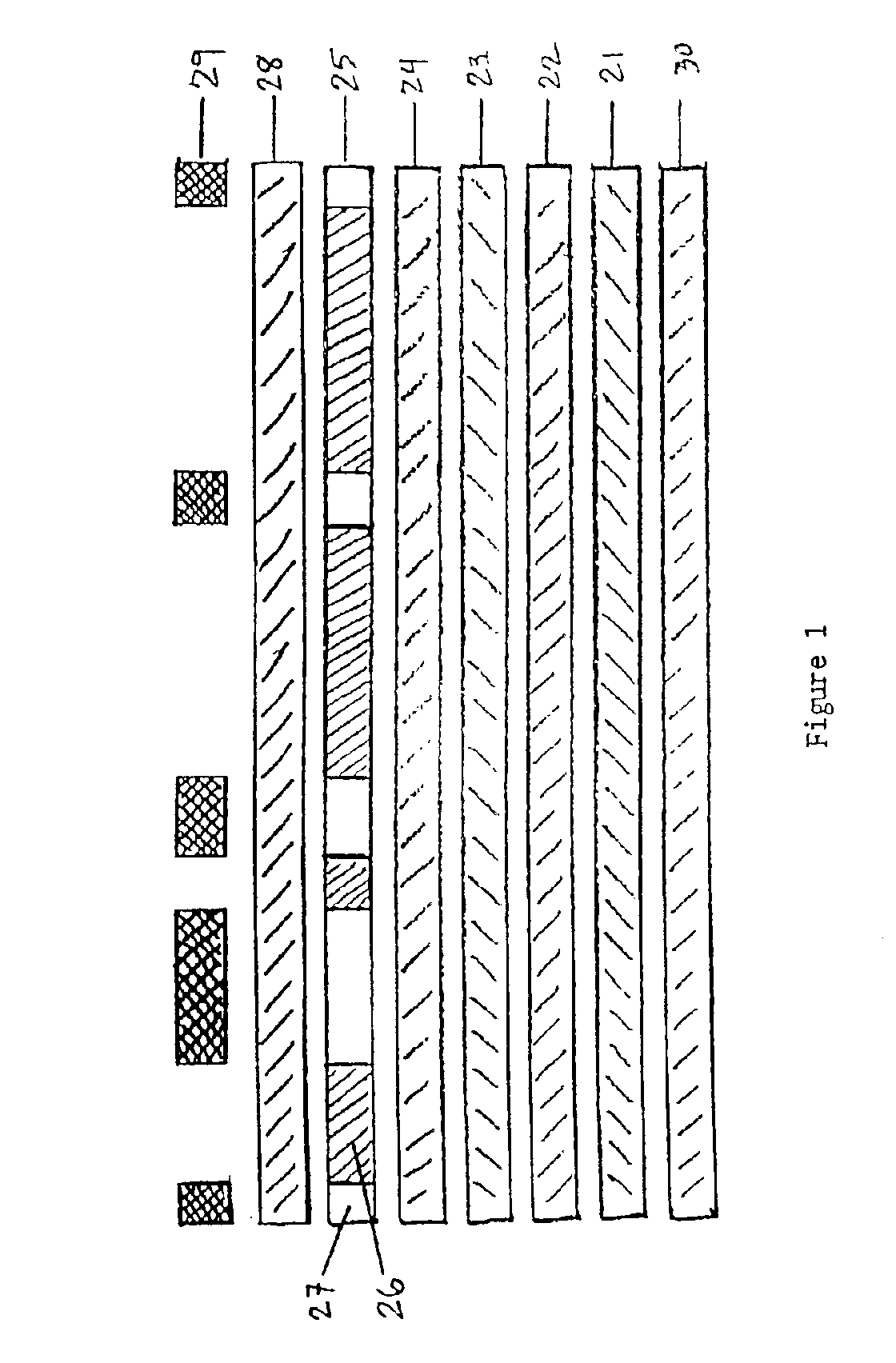

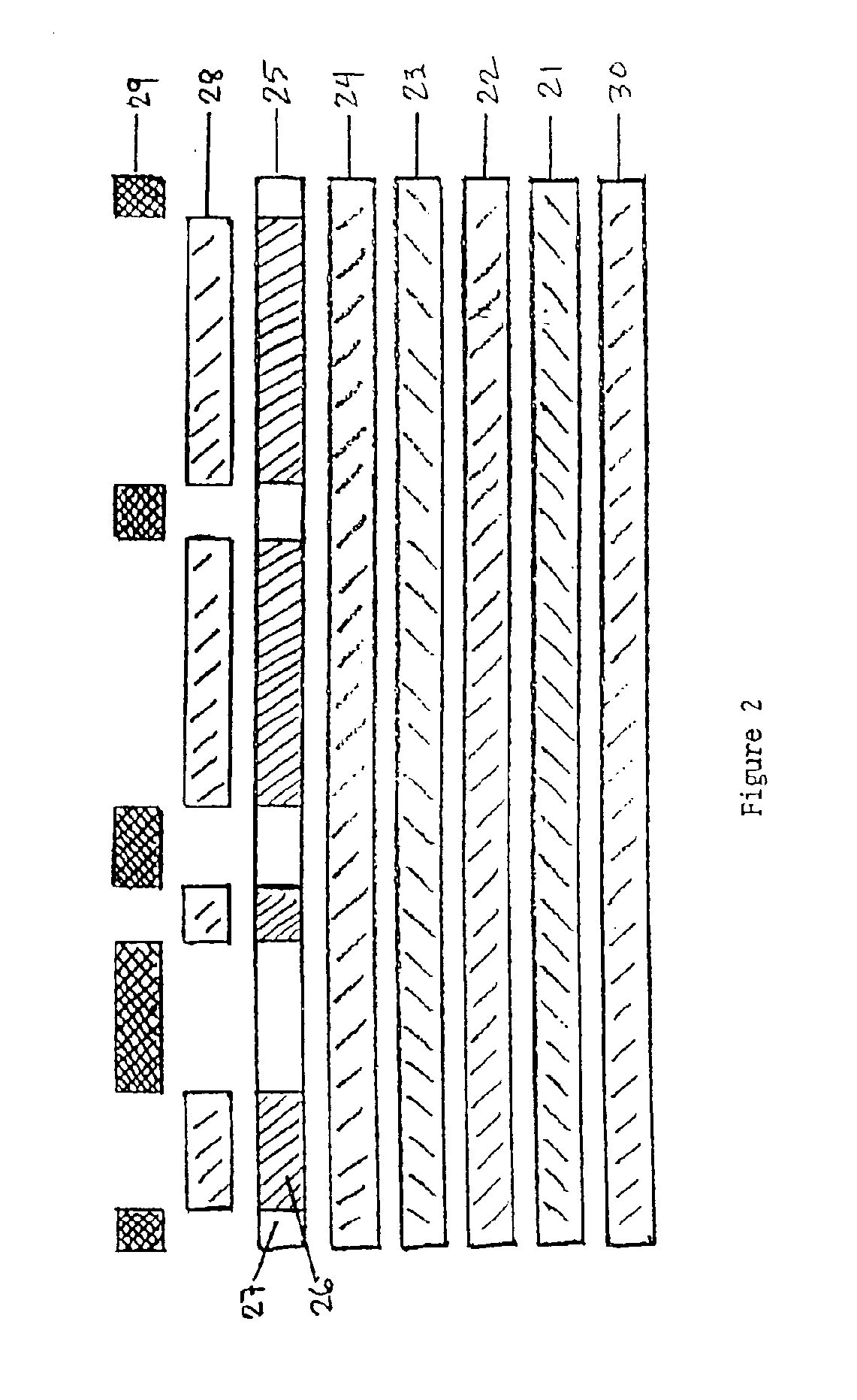

Image transfer material with image receiving layer and heat transfer process using the same

InactiveUS6869910B2Cost efficientDecorative surface effectsAblative recordingWater dispersiblePrecipitated calcium carbonate

An image transfer sheet, having a support sheet, an optional barrier layer on the support sheet, at least one heat release layer on the optional barrier layer or on the support sheet, an image receiving layer on the heat release layer, an optional image layer on the image receiving layer, an optional non-water-dispersible polymer layer on the image layer, and an optional transfer blocking overcoat layer on the optional polymer layer or the image layer, is used in a dry heat transfer process to transfer an image to a receptor element. The image receiving layer of the present invention is a precipitated calcium carbonate (PCC)-containing image receiving layer, a polyvinylpyrrolidone (PVP)-containing image receiving layer, or an image receiving layer containing both PCC and PVP (PCC / PVP).

Owner:SCHWENDIMANN JODI

Stabilized vaterite

InactiveUS20050106110A1Calcium/strontium/barium carbonatesCosmetic preparationsPrecipitated calcium carbonateChemistry

A precipitated calcium carbonate provides excellent cleaning properties without being excessively abrasive. The precipitated calcium carbonate has a vaterite crystalline form, a primary particle size of about 0.2 μm to about 3 μm, and an aggregate particle size of less than about 4 μm.

Owner:LIU SUNG TSUEN

Method and apparatus for production of precipitated calcium carbonate and silicate compounds in common process equipment

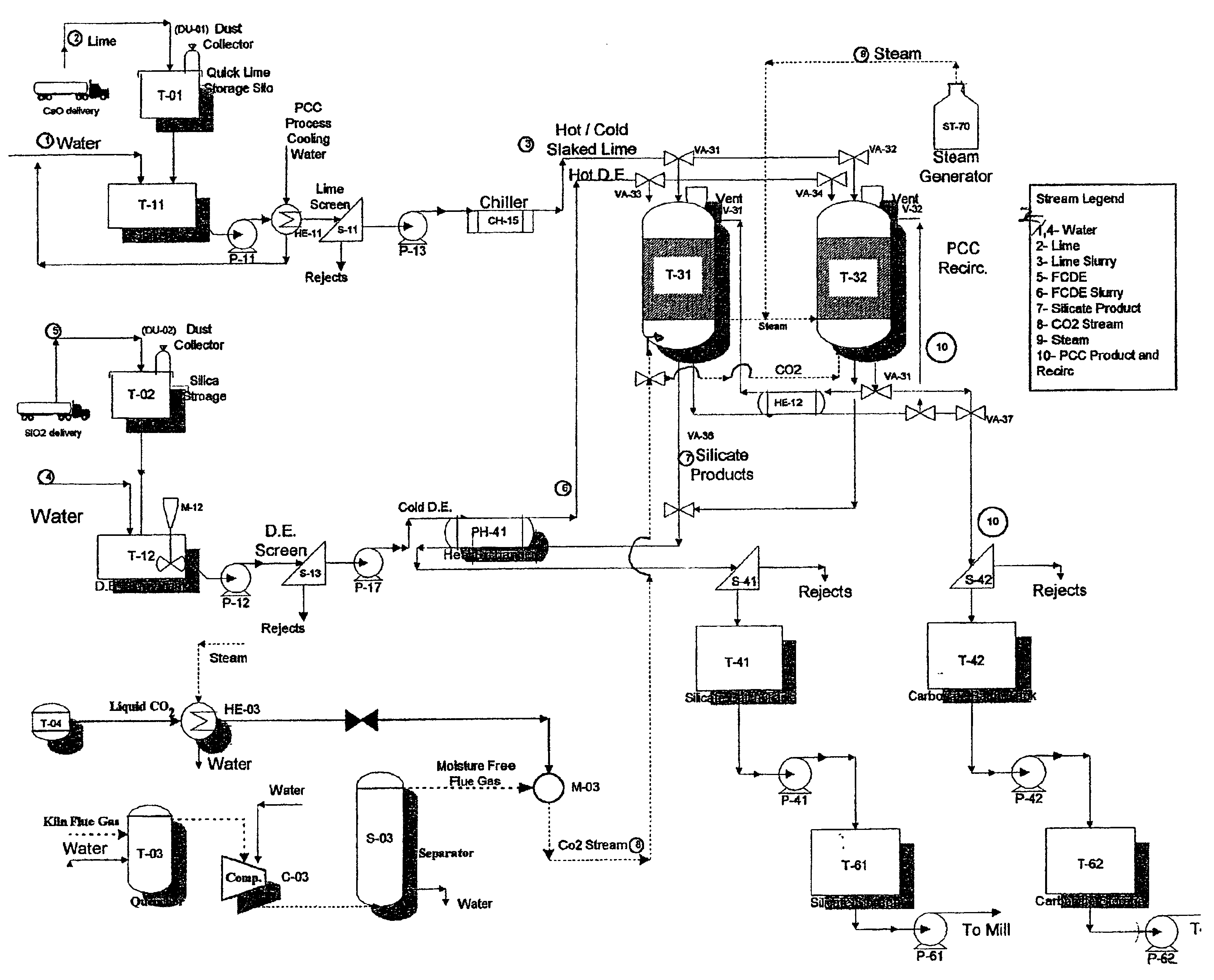

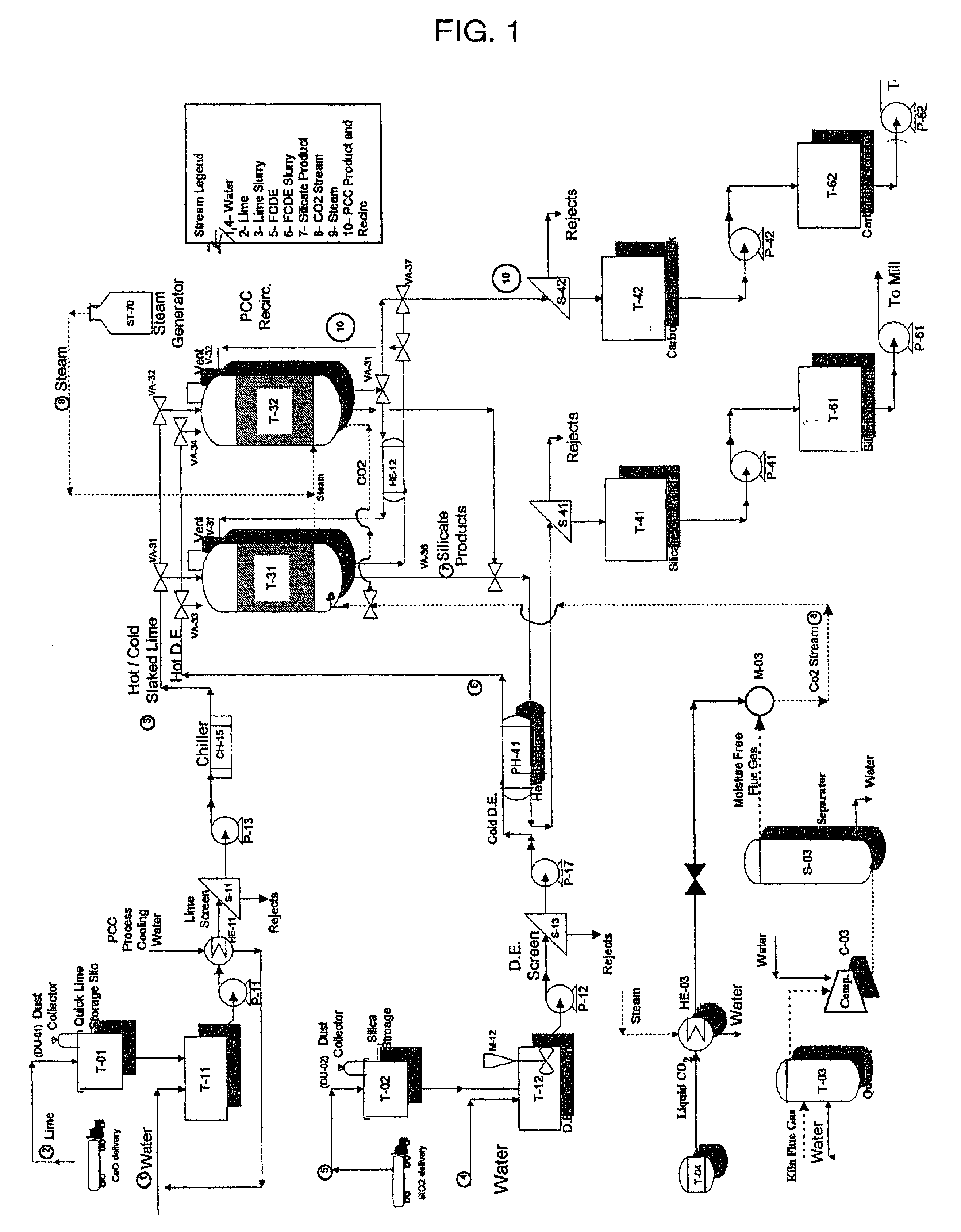

InactiveUS7048900B2Increase brightnessHigh opacityCalcium/strontium/barium carbonatesPulp liquors combustionCalcium silicateProcess equipment

A method and apparatus for the production of calcium carbonate and calcium silicate in common superatmospheric reactors. Multiple reactors can be provided for switching production between reactors, and advantageously utilizing process waste heat. On site production of both PCC and Calcium Silicate Hydrates is thus achieved in a paper mill.

Owner:PACIFIC NANO PROD

Acid stabilized calcium carbonate an method of making it

InactiveUS7033428B2Calcium/strontium/barium carbonatesPigmenting treatmentPrecipitated calcium carbonateWater soluble

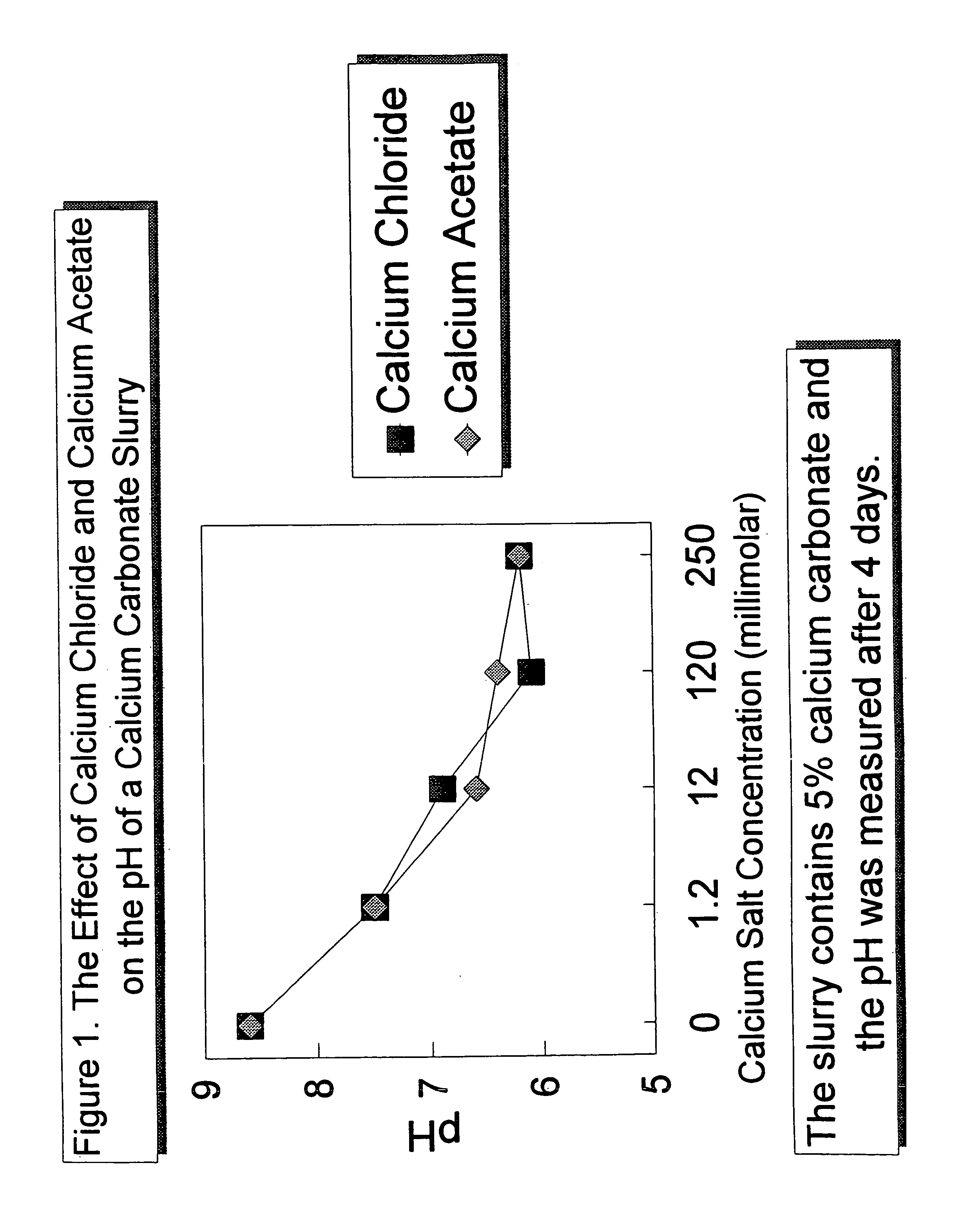

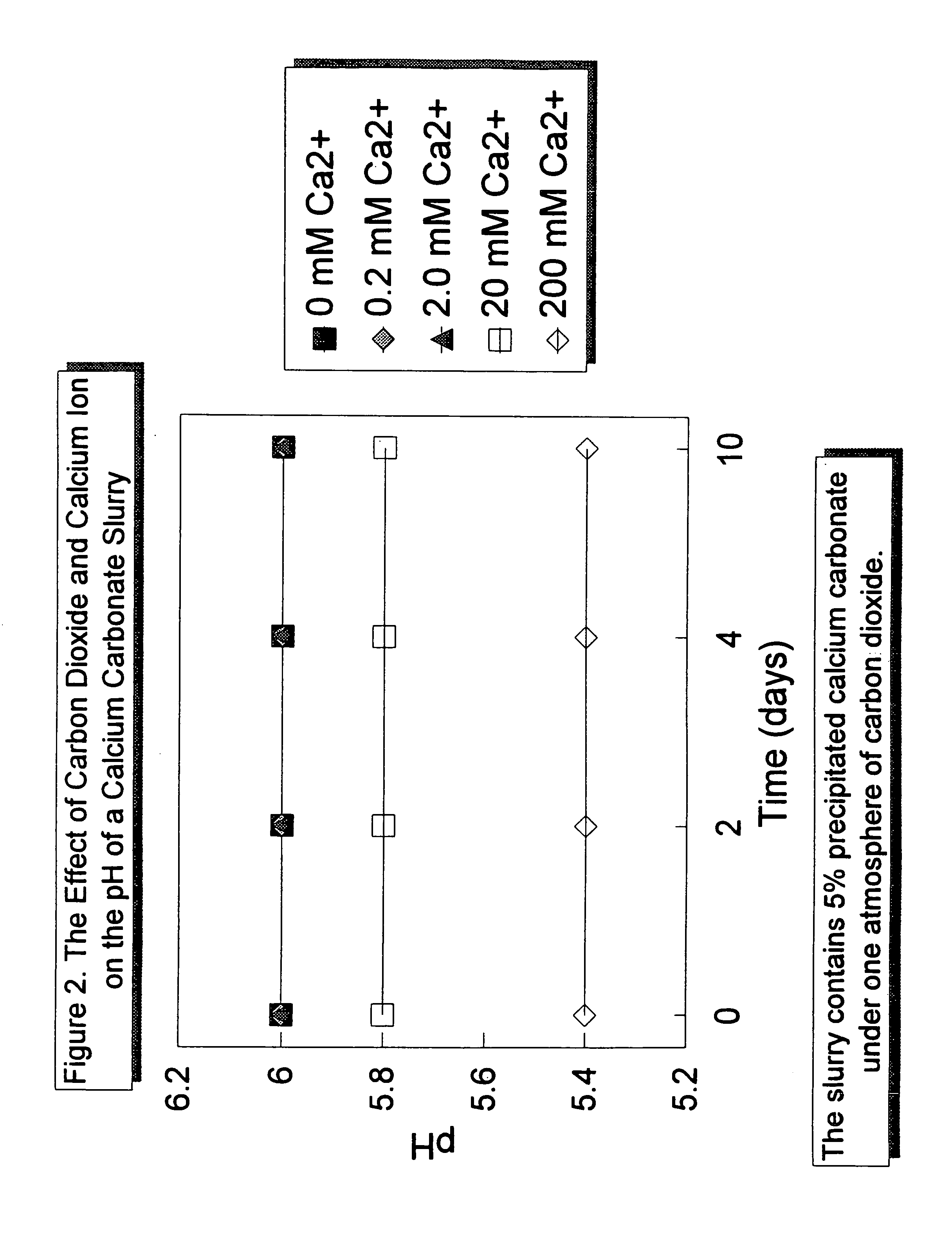

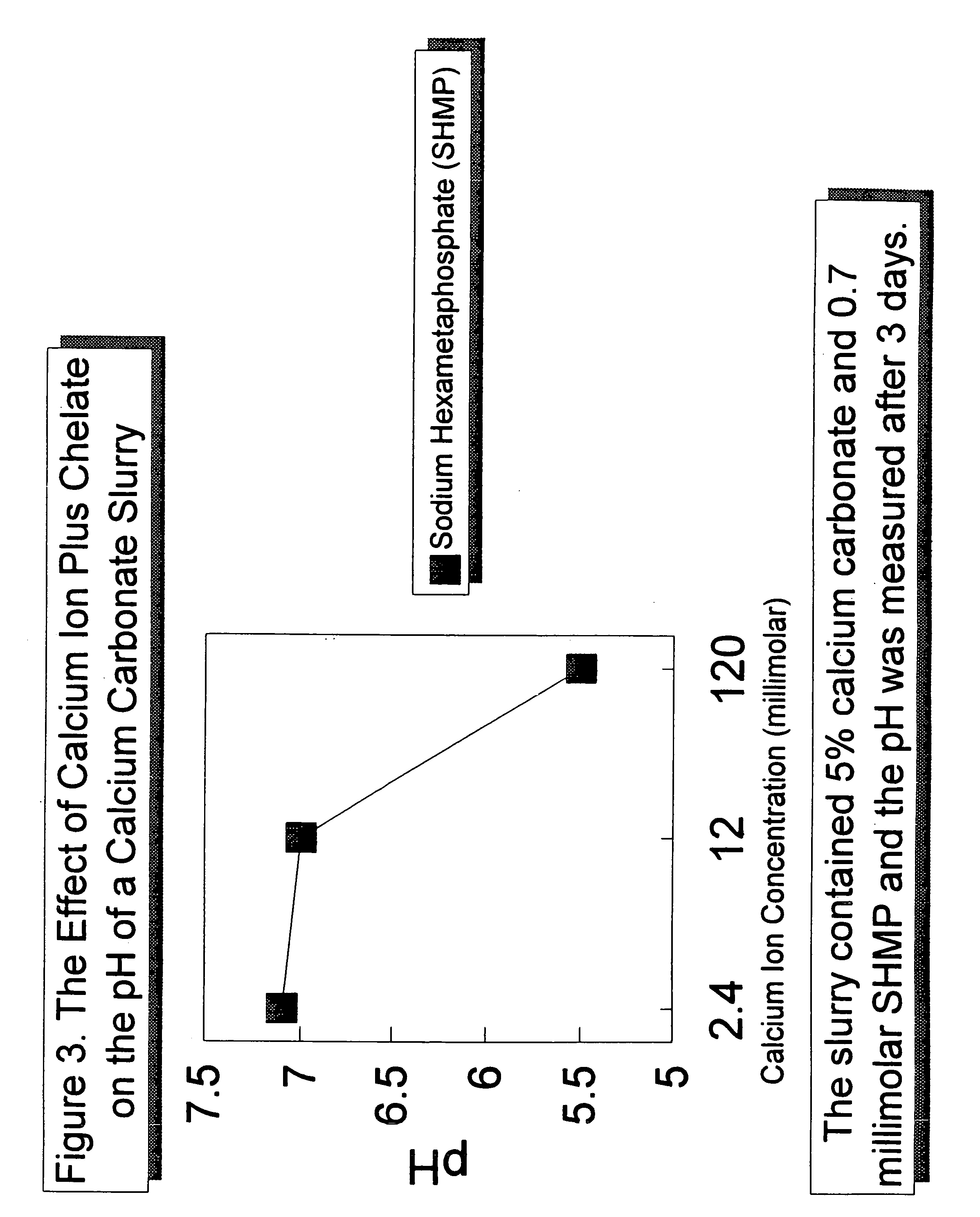

The present invention relates to an acid-stabilized calcium carbonate slurry having a pH of less than 7, preferably between about 6 and about 7, containing water, calcium carbonate, preferably precipitated calcium carbonate, and an acid-stabilizer of a water soluble calcium salt, a weak acid, a chelating agent, a weak acid capable of chelating calcium ion, or a mixture thereof. The acid-stabilizer is present in an amount sufficient to provide an aqueous calcium carbonate slurry having an increased calcium ion concentration and an acidic pH. In a typical acid-stabilized calcium carbonate slurry of the invention, the acid-stabilizer is present in an amount sufficient to provide a calcium ion concentration of about 1 millimolar to about 5 molar, preferably from about 1 to about 120 millimolar. The invention also relates to a method of making the acid-stabilized calcium carbonate slurry of the invention, to a method of forming a filled paper, that includes the step of adding the acid-stabilized calcium carbonate slurry of the invention to a papermaking pulp in a process for making acid paper, and to a filled paper produced according to the method of the invention.

Owner:MINERALS TECH

Inkjet recording media

InactiveUS20070218222A1Increase ink capacityExtended drying timeDuplicating/marking methodsPrecipitated calcium carbonateRecording media

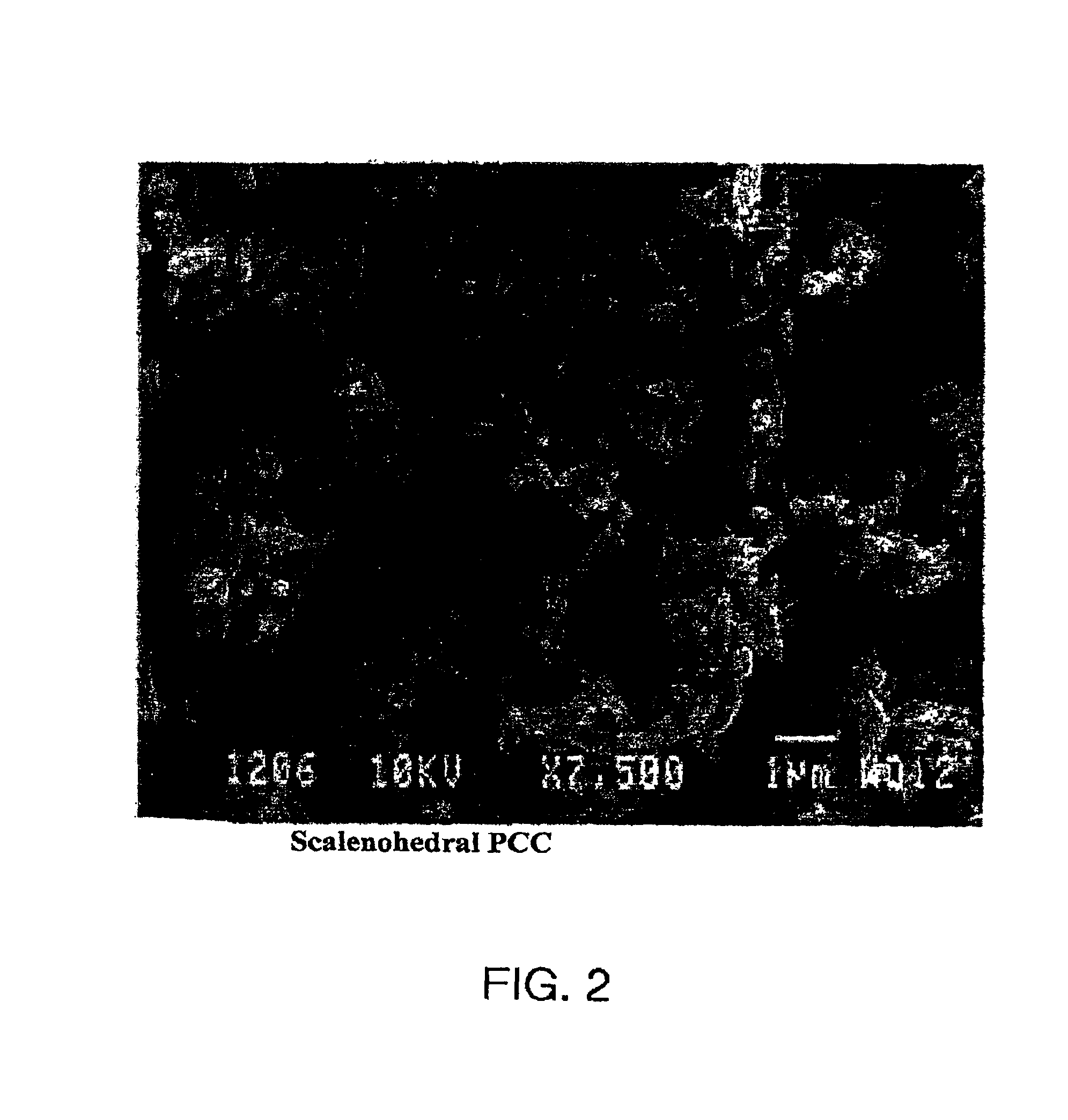

The invention relates generally to the field of inkjet recording media and inkjet printing methods. More specifically, the invention relates to a porous base layer of an inkjet recording element, the base layer comprises precipitated calcium carbonate having scalenohedral morphology and ground calcium carbonate.

Owner:EASTMAN KODAK CO

In situ precipitation of calcium carbonate (CaCO3) by indigenous microorganisms to improve mechanical properties of a geomaterial

A method for increasing the concentration of calcium carbonate in a geomaterial that contains indigenous microorganisms capable of hydrolyzing urea to ammonia, which method includes enriching the geomaterial with a source of nutrients, adding urea to the geomaterial which is hydrolyzed to ammonia and which raises the pH of the geomaterial, and adding a source of calcium ions to the geomaterial. Carbonate ions obtained by the hydrolysis of the urea combine with calcium ions to form calcium carbonate.

Owner:UNIVERSITY OF IDAHO

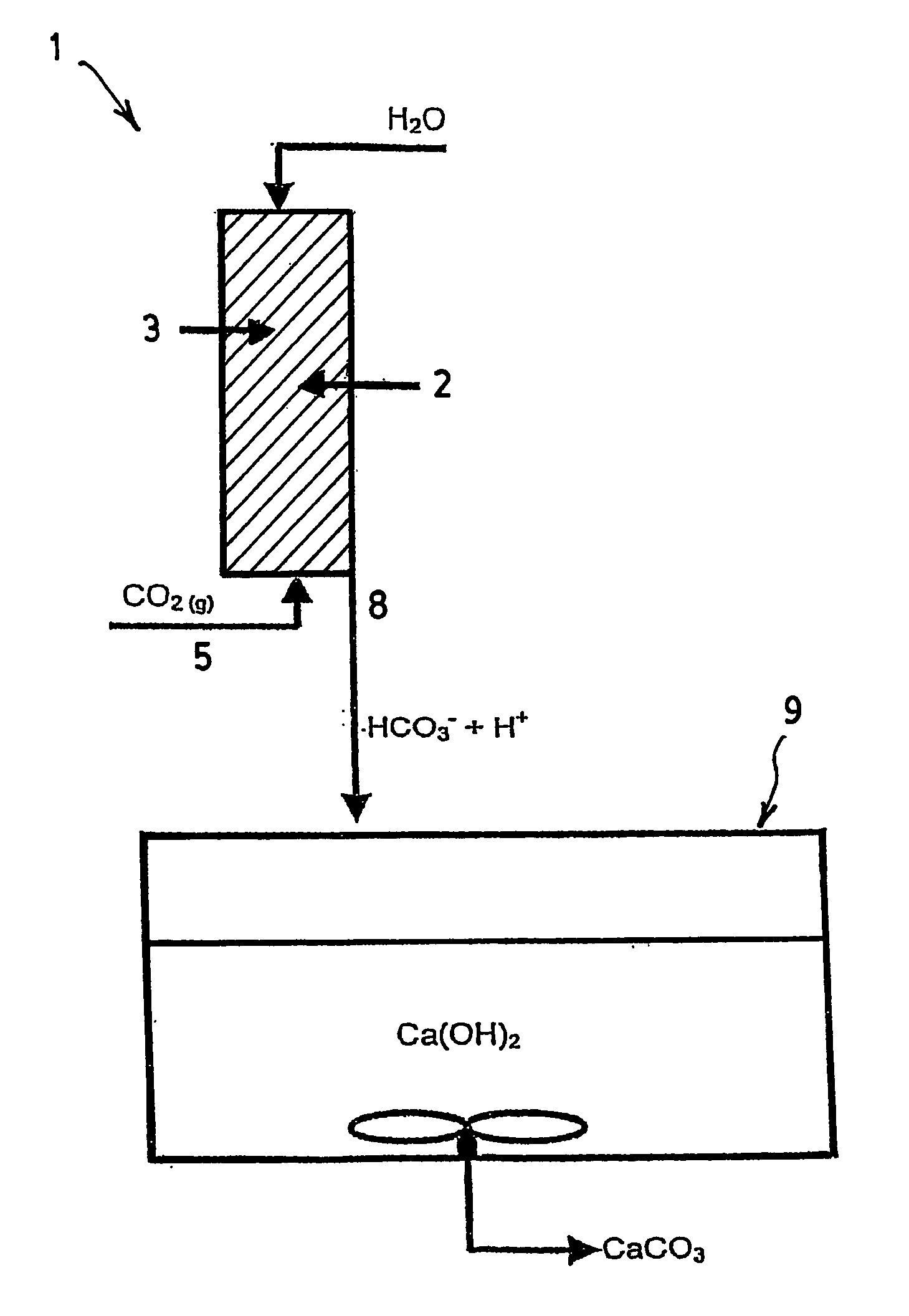

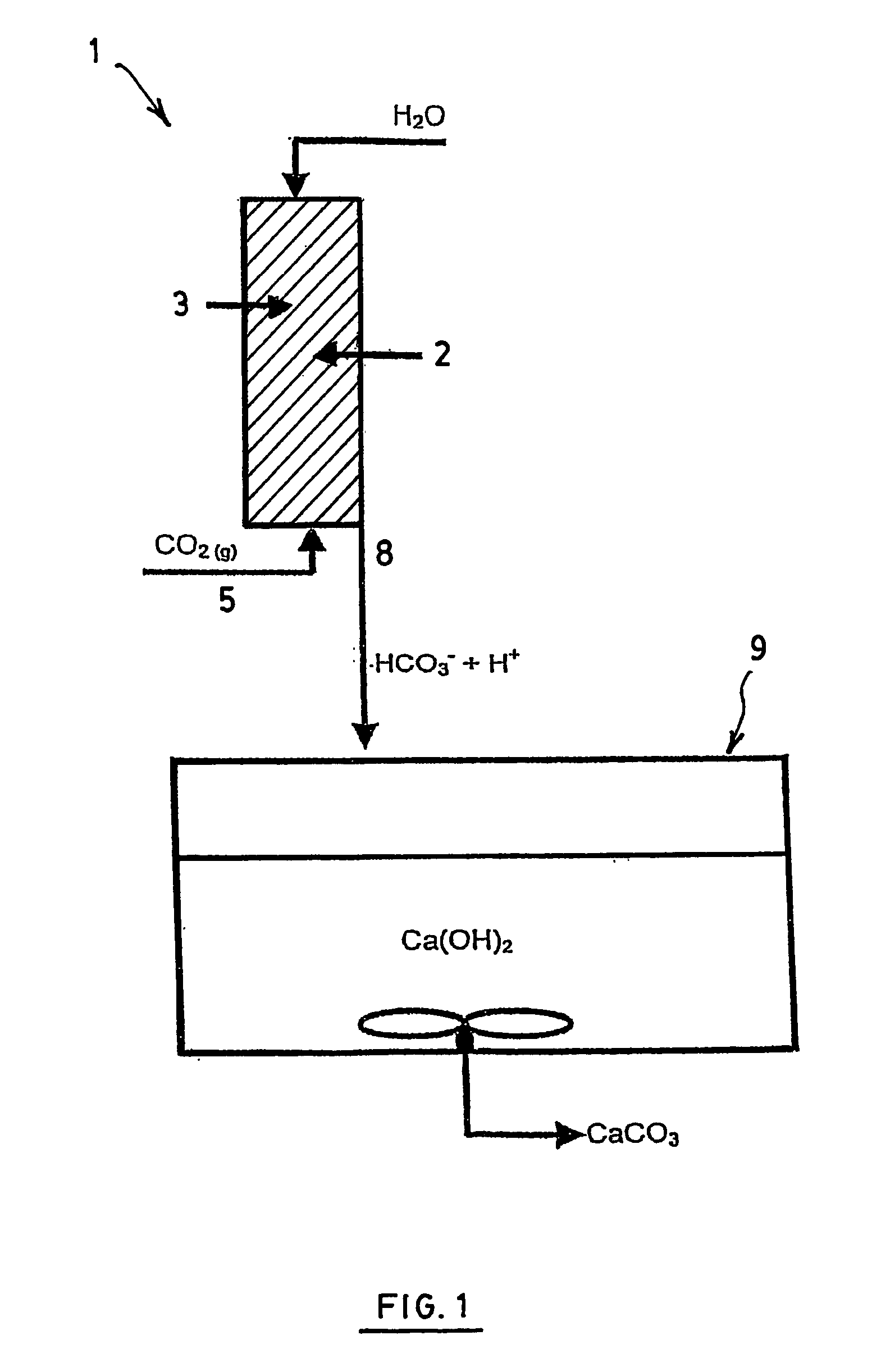

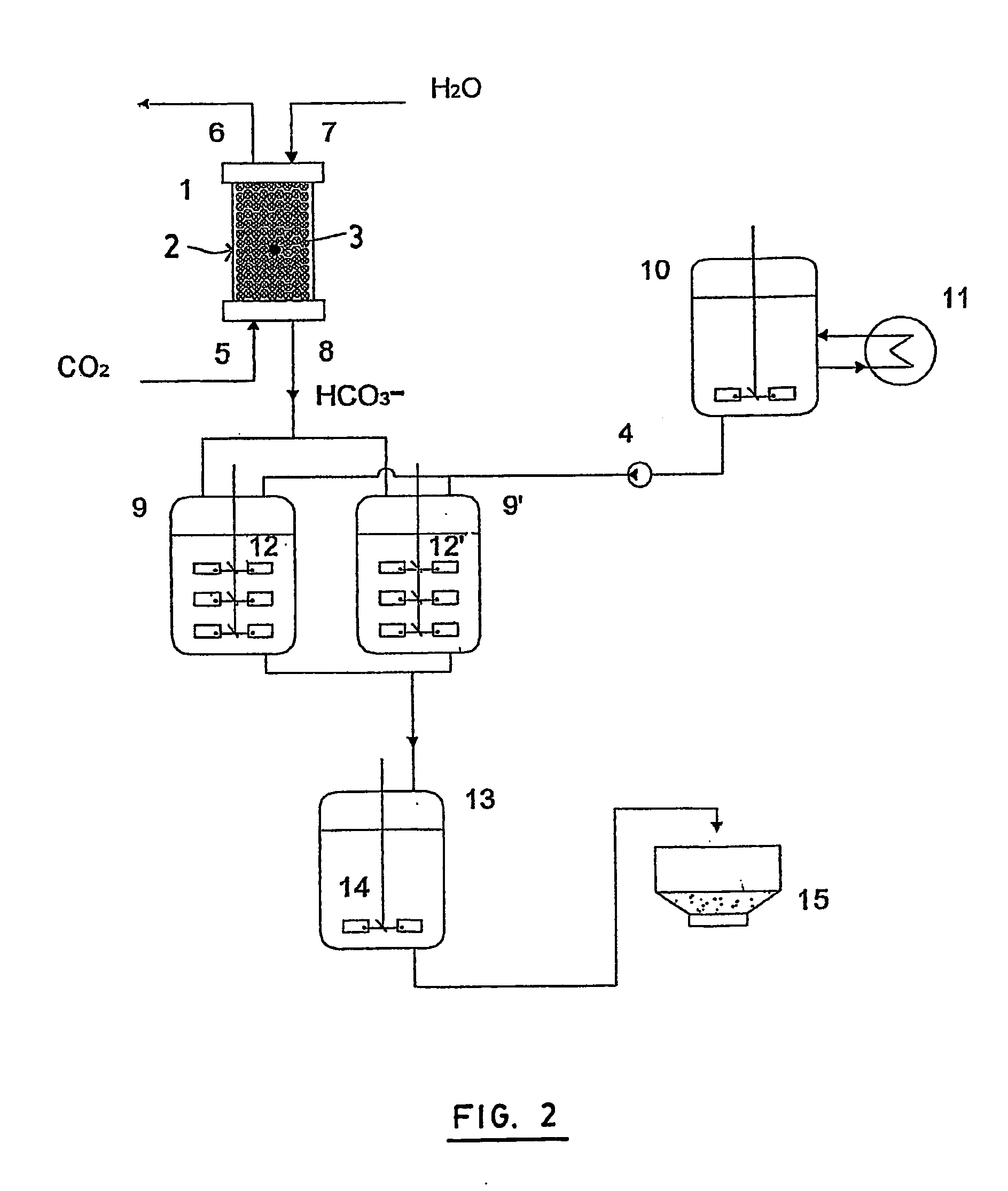

Process and an apparatus for producing calcium carbonate via an enzymatic pathway

InactiveUS20060128004A1High yieldHigh constantBioreactor/fermenter combinationsBiological substance pretreatmentsPrecipitated calcium carbonateAqueous solution

The invention relates to a method for improving the production yield of precipitated calcium carbonate (PCC). The improvement resides in the use of an enzymatic bioreactor that supplies HCO3 into the reaction enabling to produce PCC without bubbling gaseous carbon dioxide in the aqueous solution. The present invention has an industrial applicability, namely in the pulp and paper industry.

Owner:CO2 SOLUTION

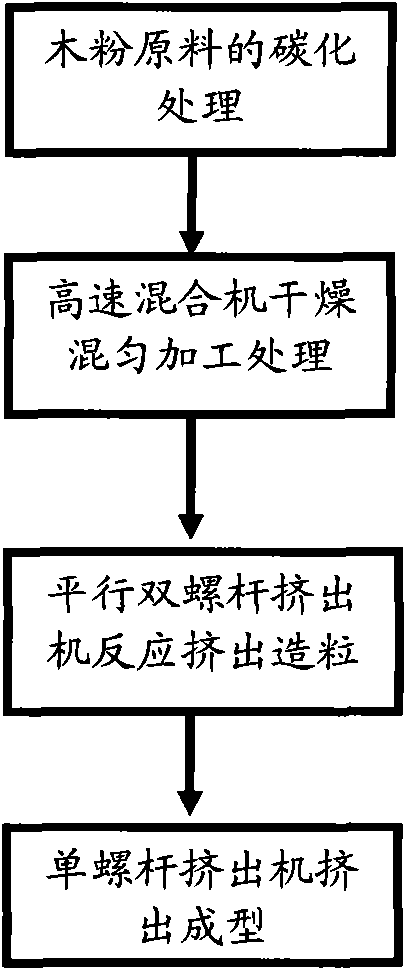

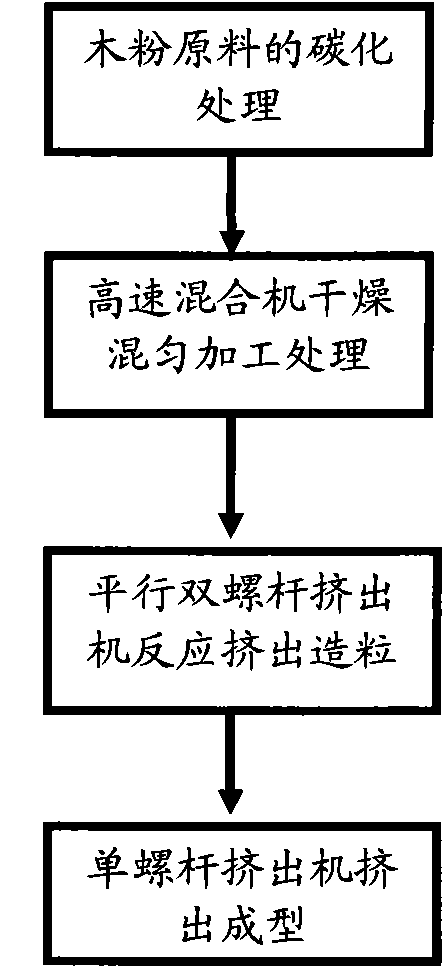

Wood-plastic composite for walls and preparation method thereof

The invention discloses a wood-plastic composite for walls, comprising the following components by mass: 68-78 parts of wood flour, 20-25 parts of PE plastics, 2-4 parts of coupling agents, 0.1-0.2 part of antioxidant and 2-5 parts of precipitated calcium carbonate-silicone oil. The invention also discloses a preparation method of the wood-plastic composite for walls. The quantity of the PE plastics in the formula of the wood-plastic composite is 20-25%, which is half as much as 50% of plastics in the common wood-plastic material, thus greatly saving the plastics and lowering the production cost, meanwhile, the prepared wood-plastic composite has the characteristics of high strength, creep resistance, good processability, low moisture rate and high weatherability.

Owner:姚喜智

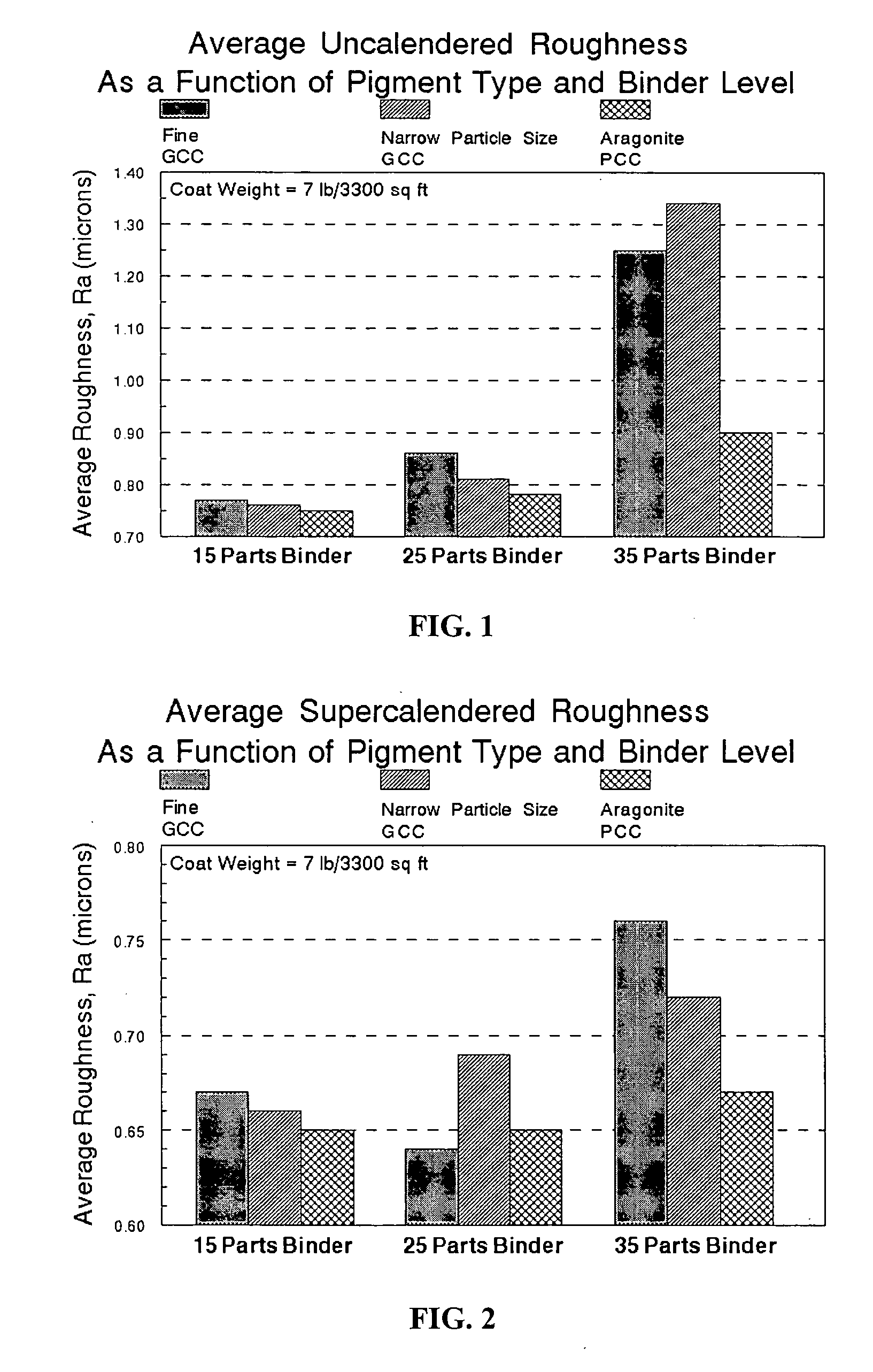

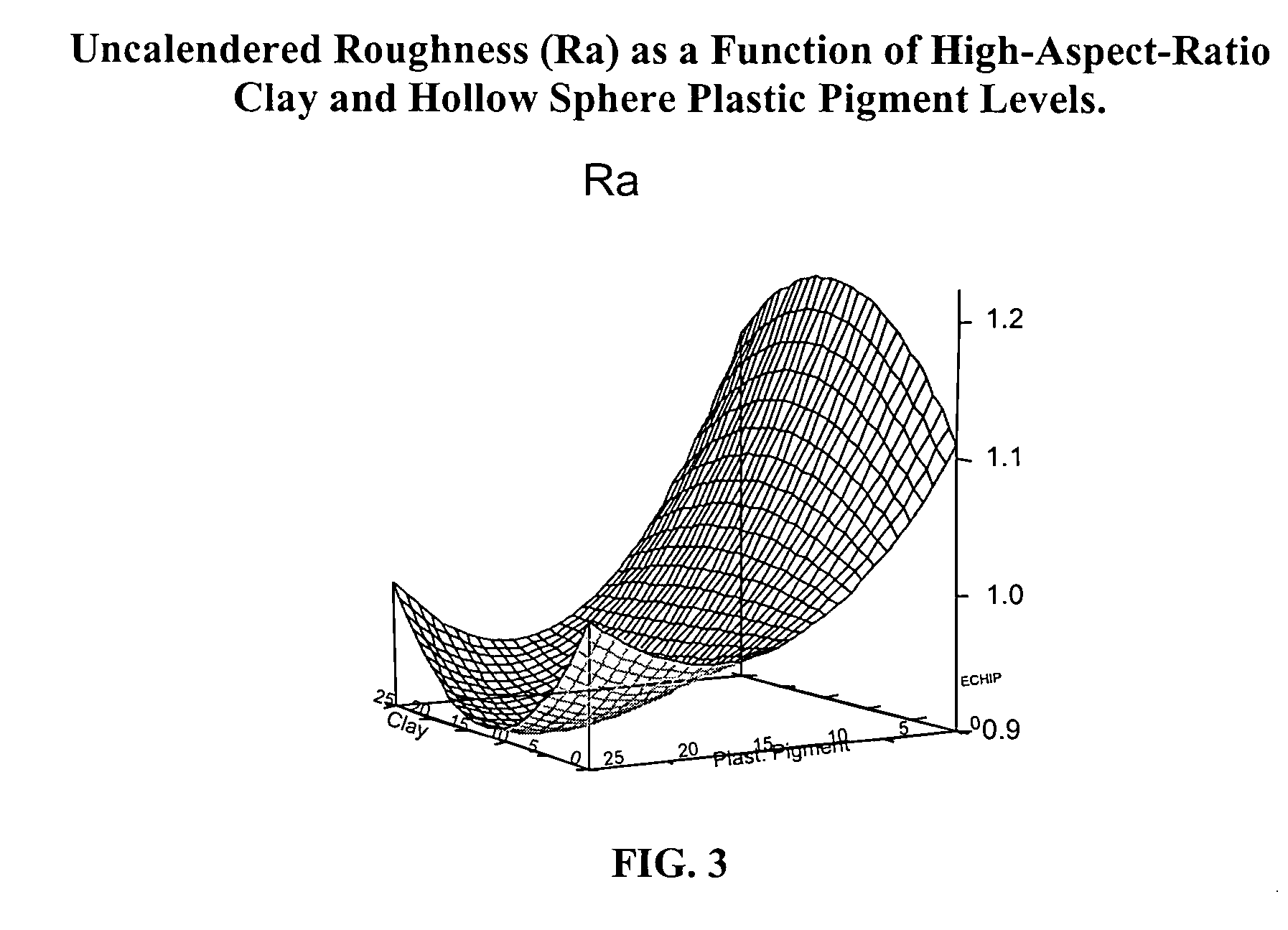

Pigment selection for photographic base stock

InactiveUS20050031805A1Photosensitive material auxillary/base layersCoatingsPrecipitated calcium carbonatePigment

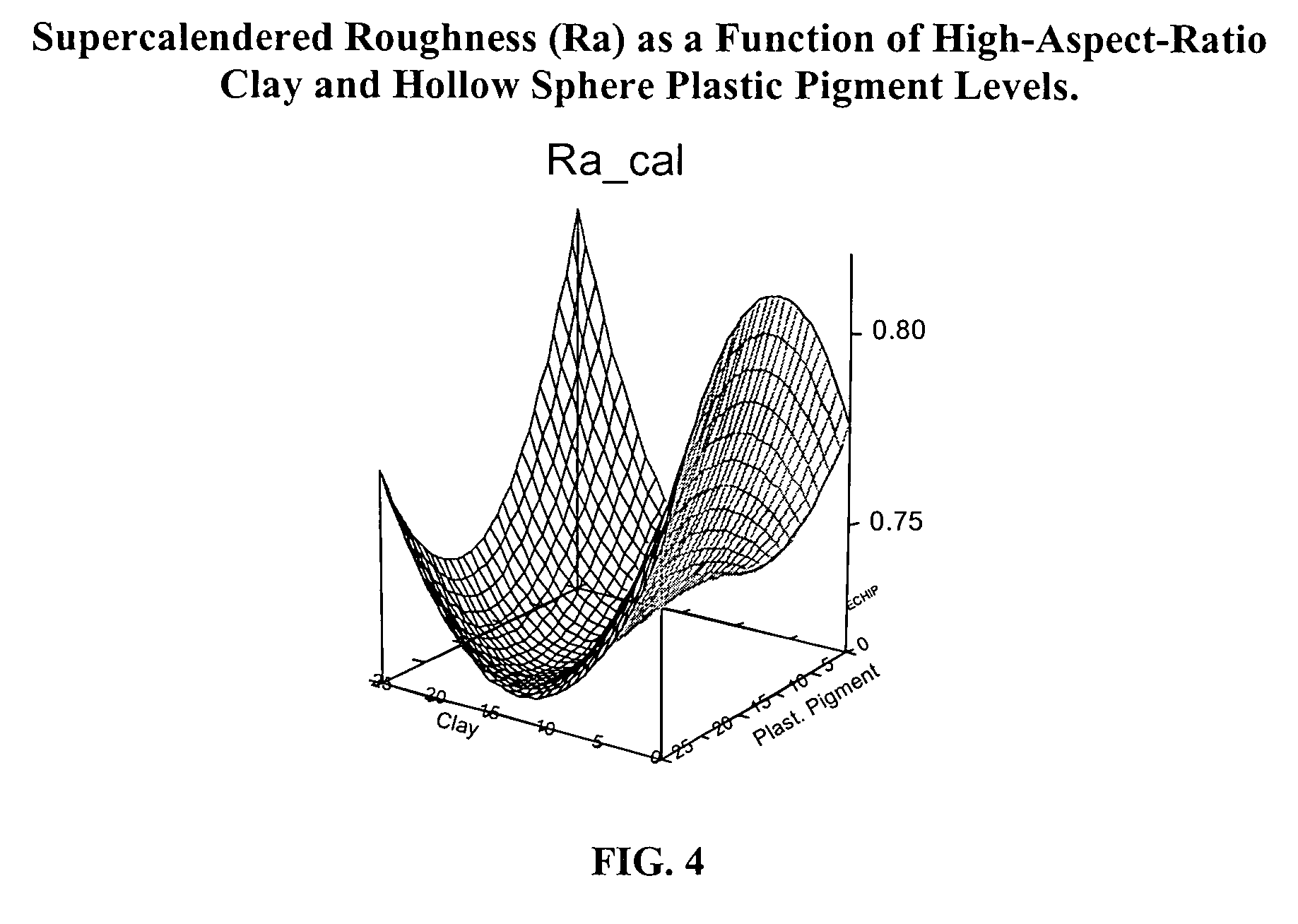

A coated paper, particularly useful as a photobase paper, includes a pigment coating on at least one side thereof wherein the pigment coating comprises aragonite precipitated calcium carbonate, hollow sphere pigment and, optionally high-aspect-ratio clay, with aspect ratio in the range of about 50 to about 100 and mixtures thereof. Methods for manufacturing the coated paper having a roughness of no more than 3 microns are also described.

Owner:NEWPAGE CORP

Pulp-grinding method for improving fibre brooming and application thereof in papermaking

InactiveCN101691700AEnhance brooming effectHigh strengthOther chemical processesPulp beating/refining methodsSodium BentonitePrecipitated calcium carbonate

The invention discloses a pulp-grinding method for improving fibre brooming, comprising the following steps: adding rigid filler to the pulp before grinding, and grinding after mixing the rigid filler and the pulp fibre, wherein the additive amount of the rigid filler accounts for 1%-30% of the total mass of the pulp; the rigid filler is any one or the mixture of several types of PCC, GCC, Talc, titanium pigment and bentonite of filler grade; and the rigid filler can also be fibrous mineral fibre. The adoption of the pulp-grinding method can improve devillicate brooming degree of the fibre, improve paper strength and interweaving, or can improve the ash content of paper and reduce fibre consumption under the condition of maintaining a considerable paper strength, and can reduce production cost and reduce the grinding energy consumption while protecting the environment.

Owner:GOLD EAST PAPER JIANGSU

Hatchery eggshell waste processing method and device

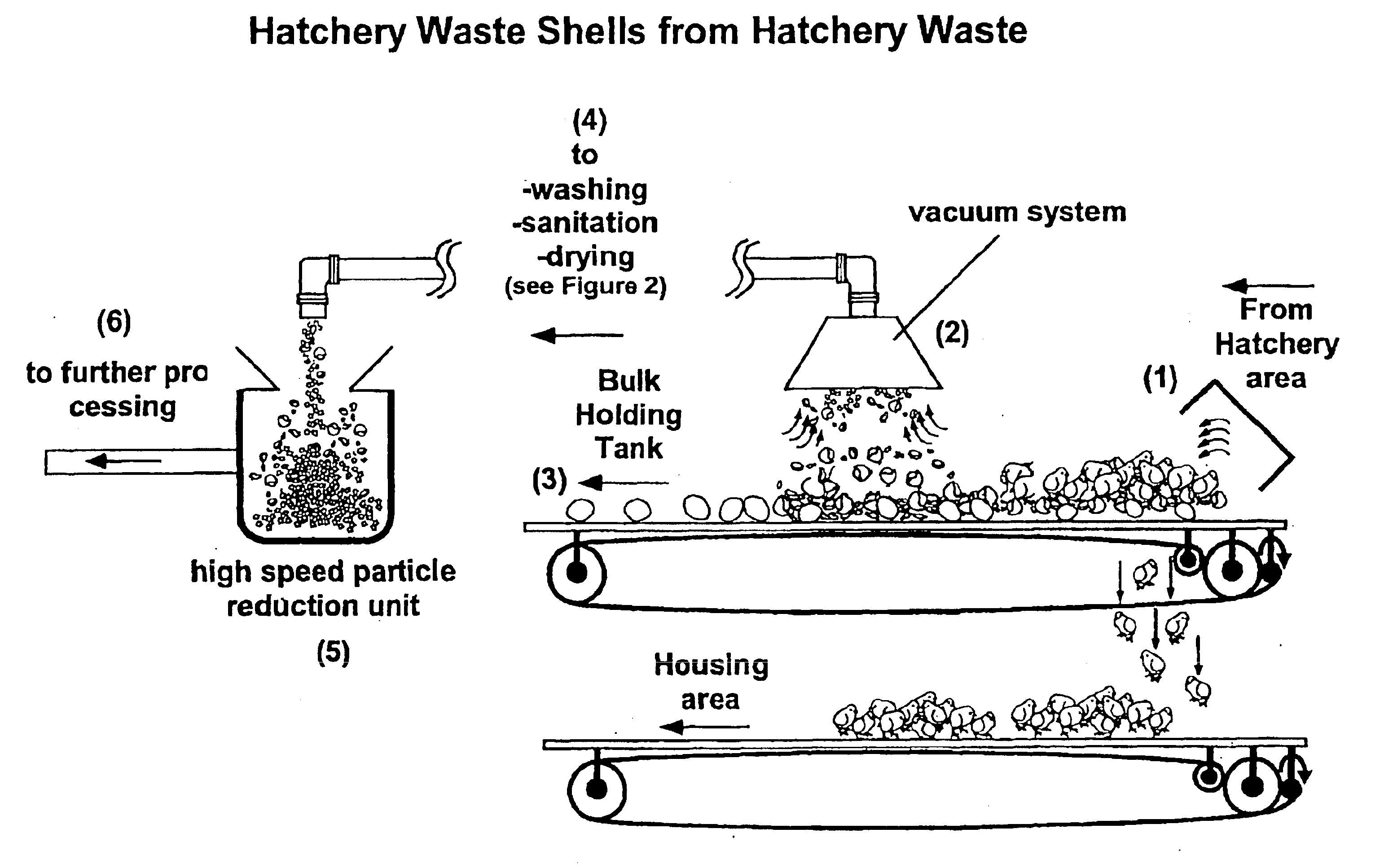

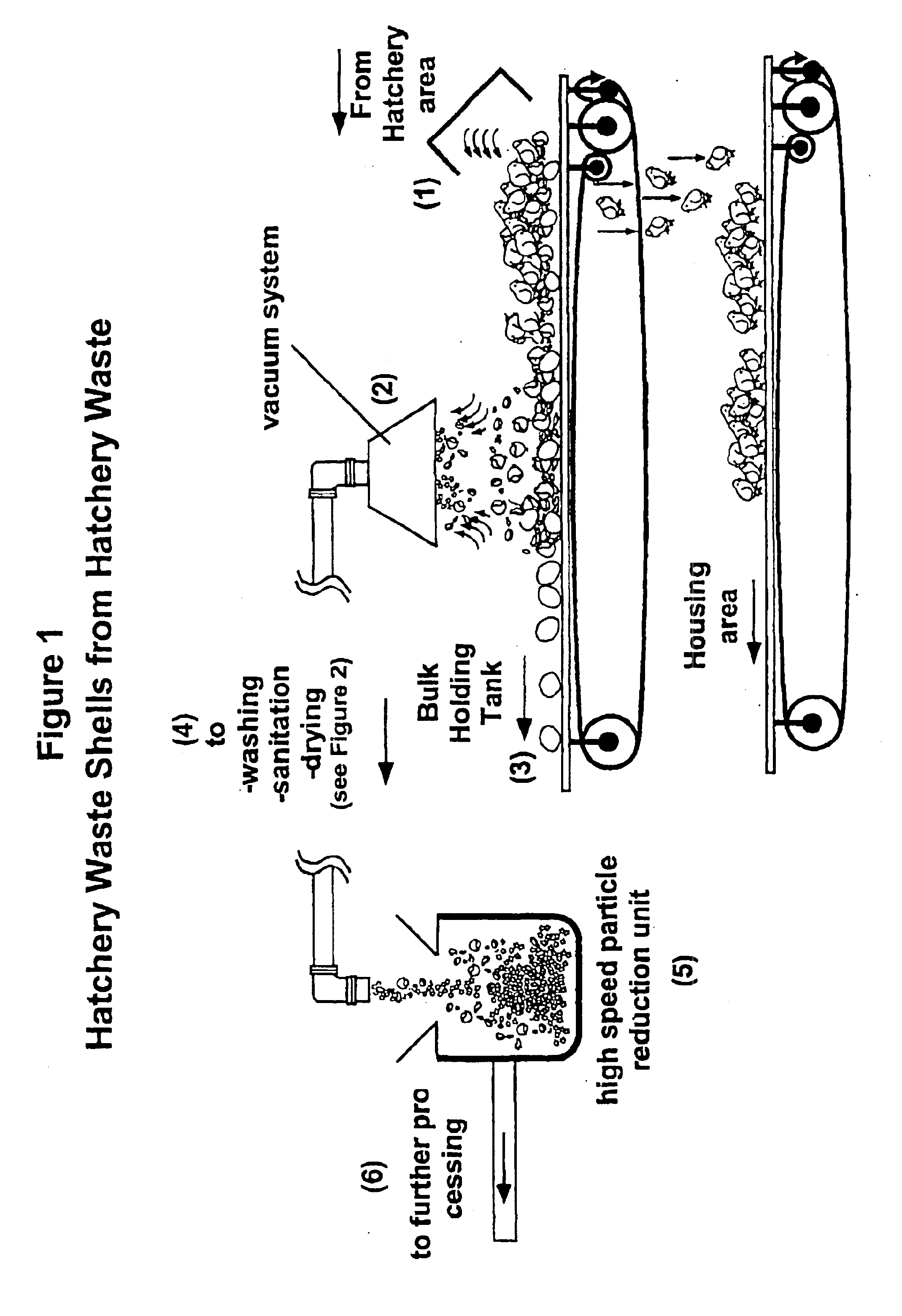

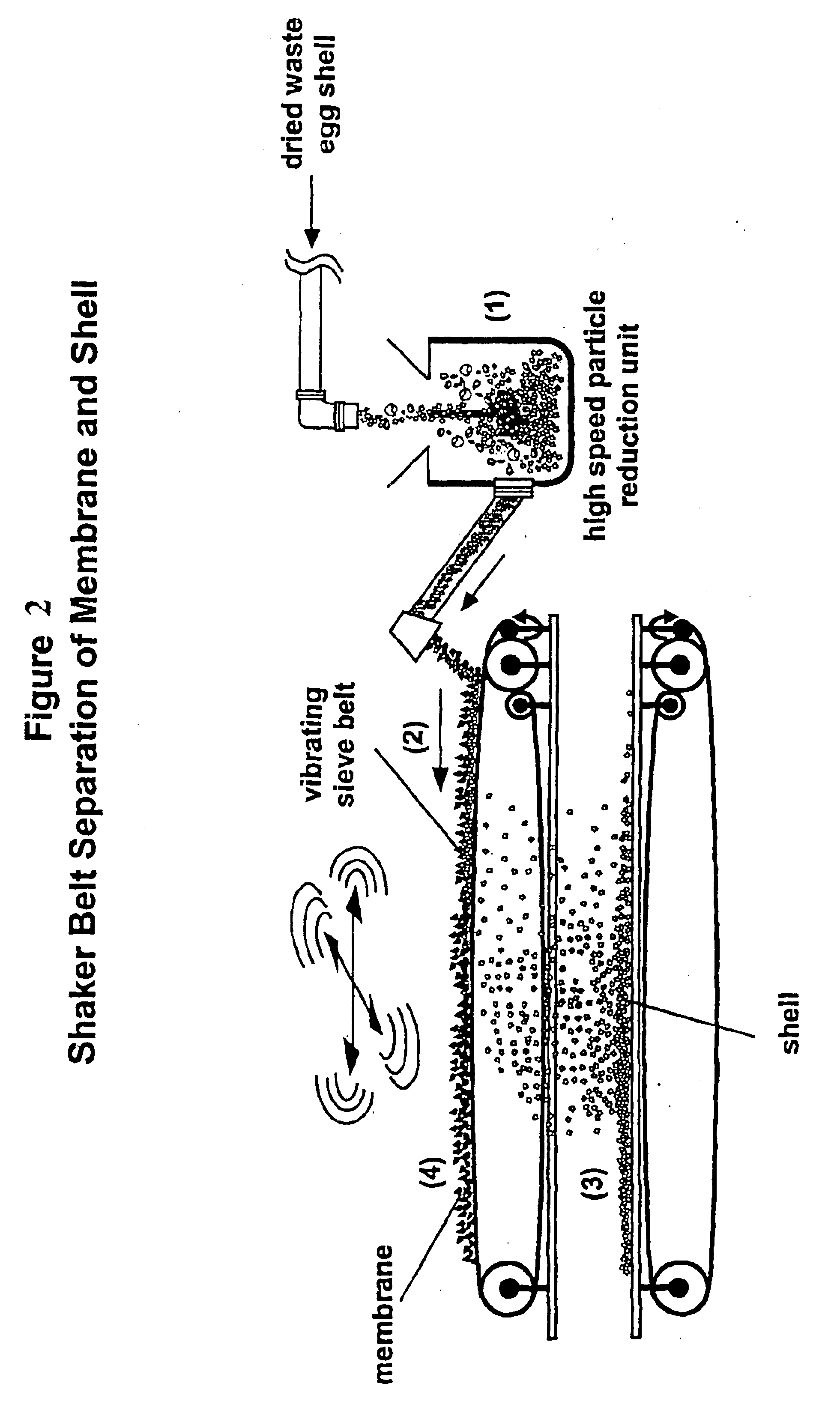

InactiveUS6899294B2Reduce environmental impactEconomic benefitVitamin food ingredientsPeptide/protein ingredientsWaste processingEggshell

A method and apparatus for separating the organic membrane portion of waste egg shells from the hard inorganic mineral portion thereof, so that each can be used or further processed as desired, thereby addressing the environmental and economic issues associated with disposing of waste egg shells. The membrane and shell are separated by first processing waste eggshells so as to yield small waste eggshell particles. During this processing, the waste eggshell particles are at least slightly abraded, whereby the linking structure between the membrane and shell is at least partially disrupted. Thereafter, the waste eggshell particles are conveyed to a device, which isolates the two components based on their size and weight differences. The methods listed above can provide products from the eggshell waste including precipitated calcium carbonate, membrane, protein, amino acids, collagen and other important components.

Owner:PENN STATE RES FOUND

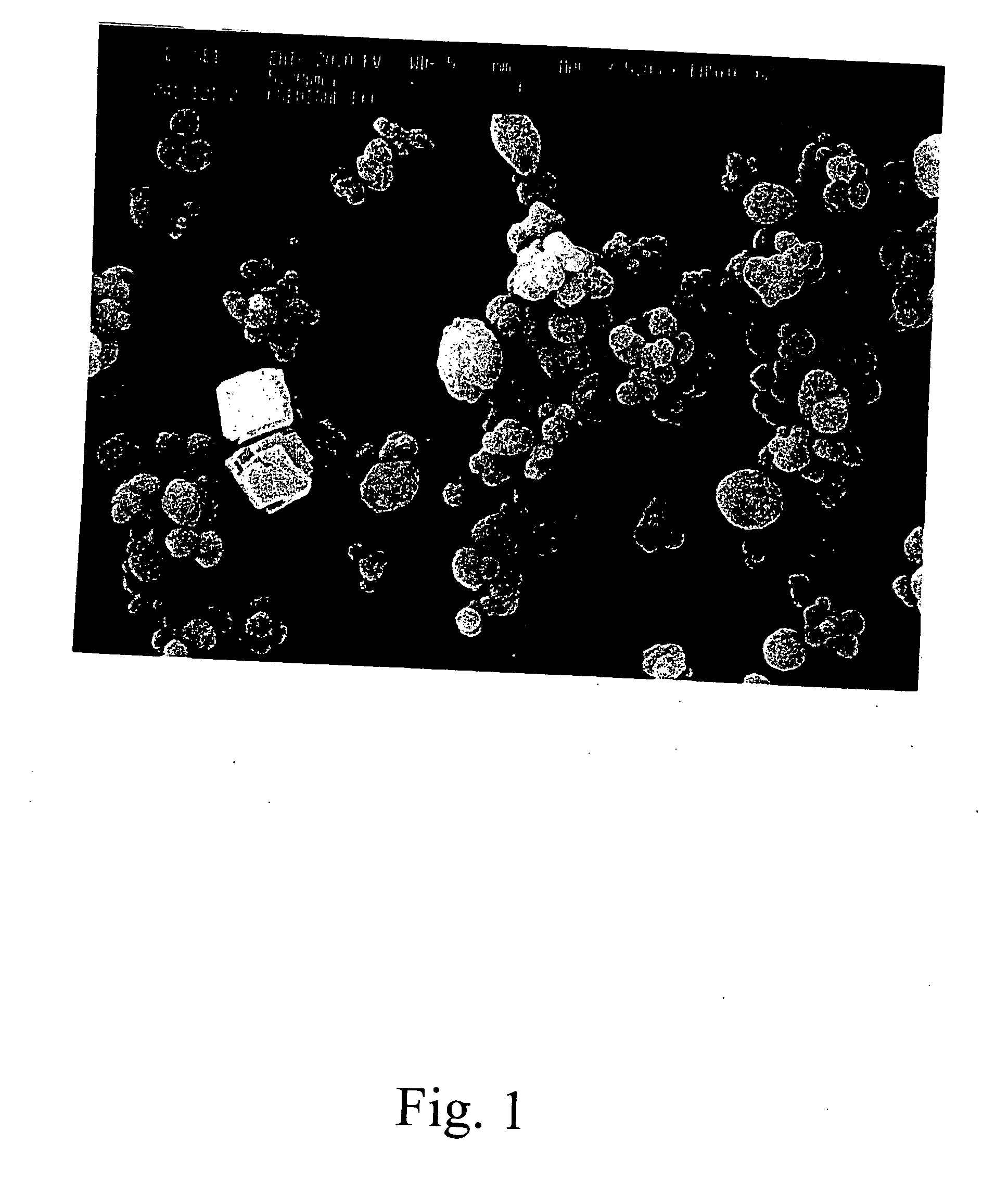

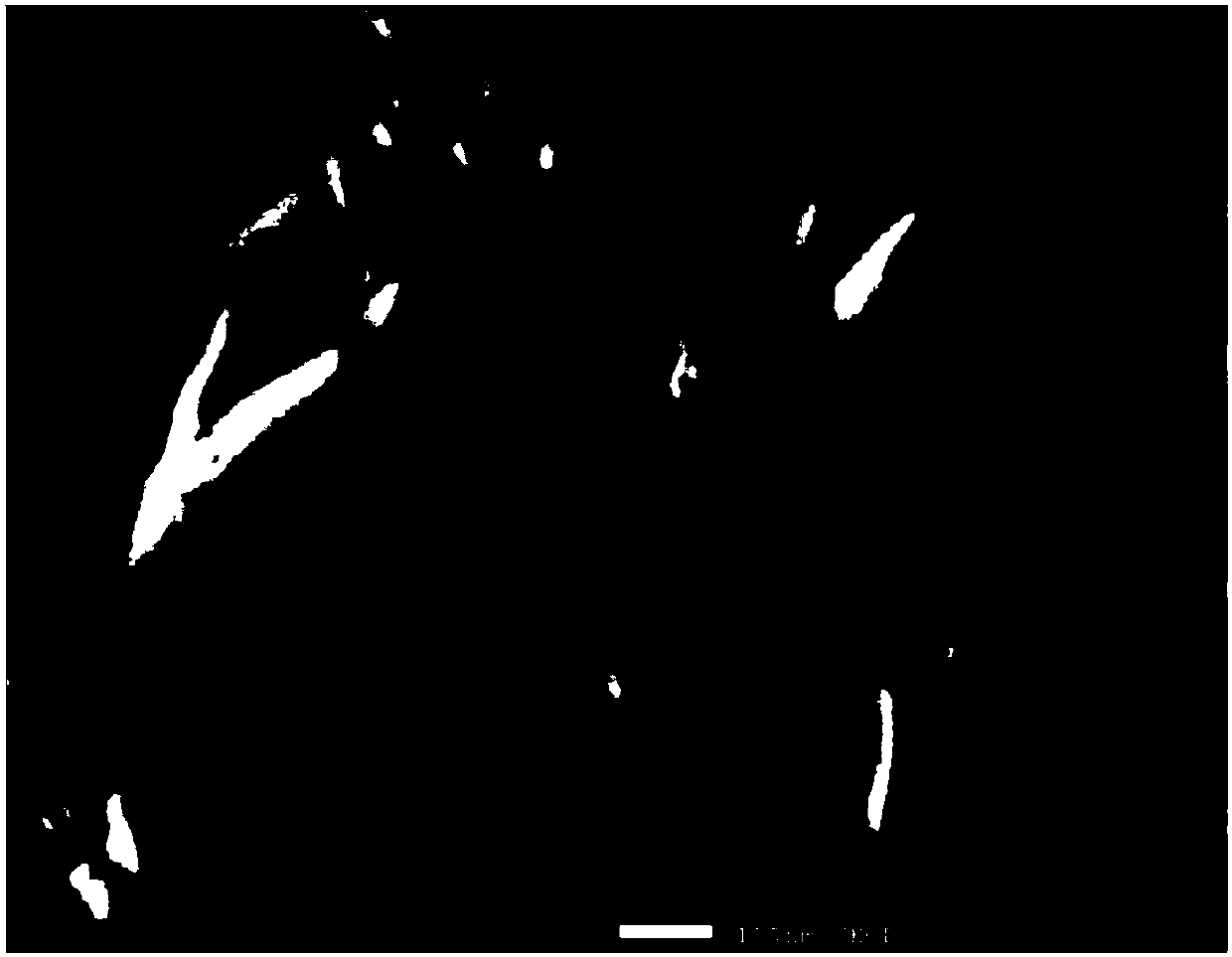

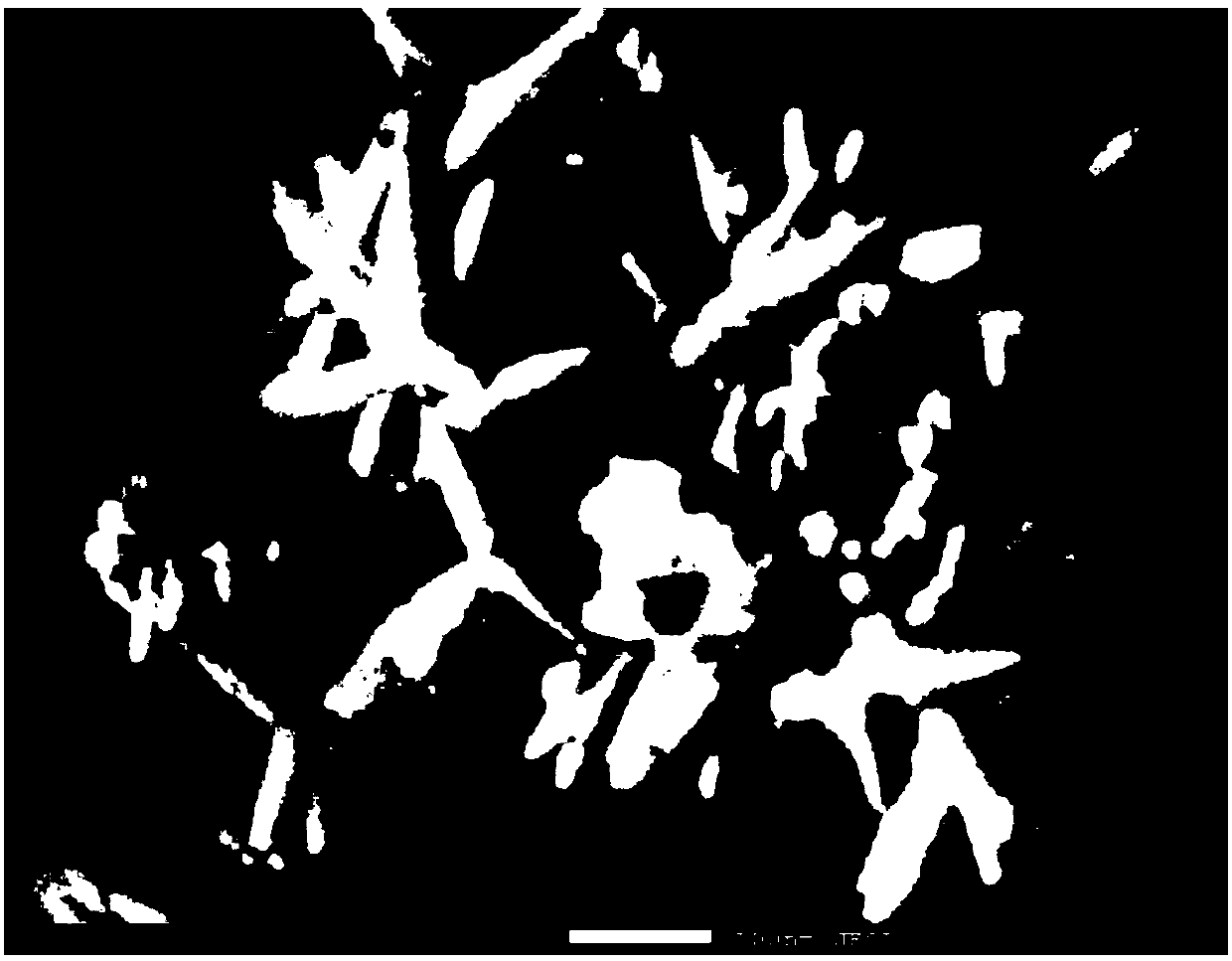

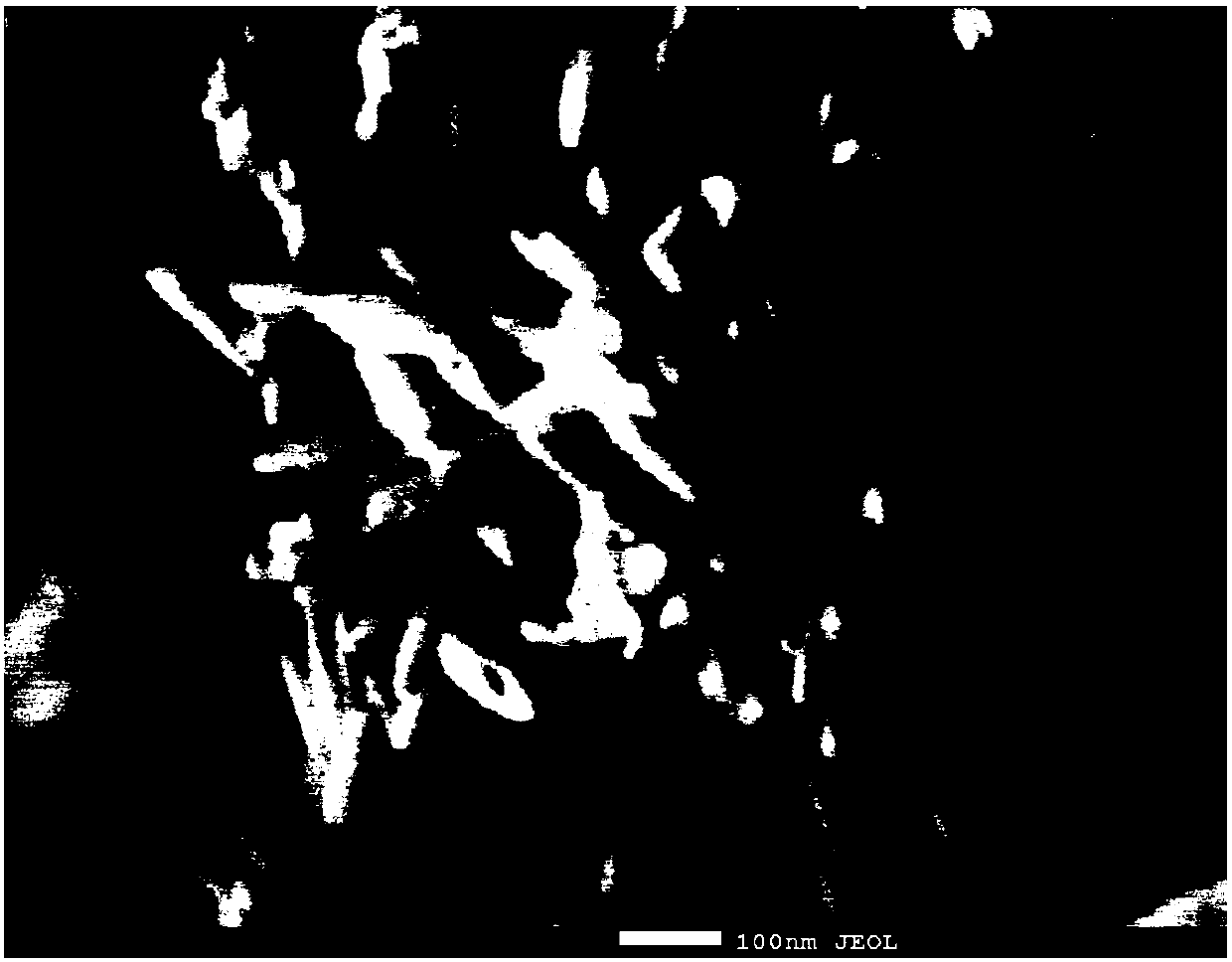

Precipitated calcium carbonate and method for the production thereof

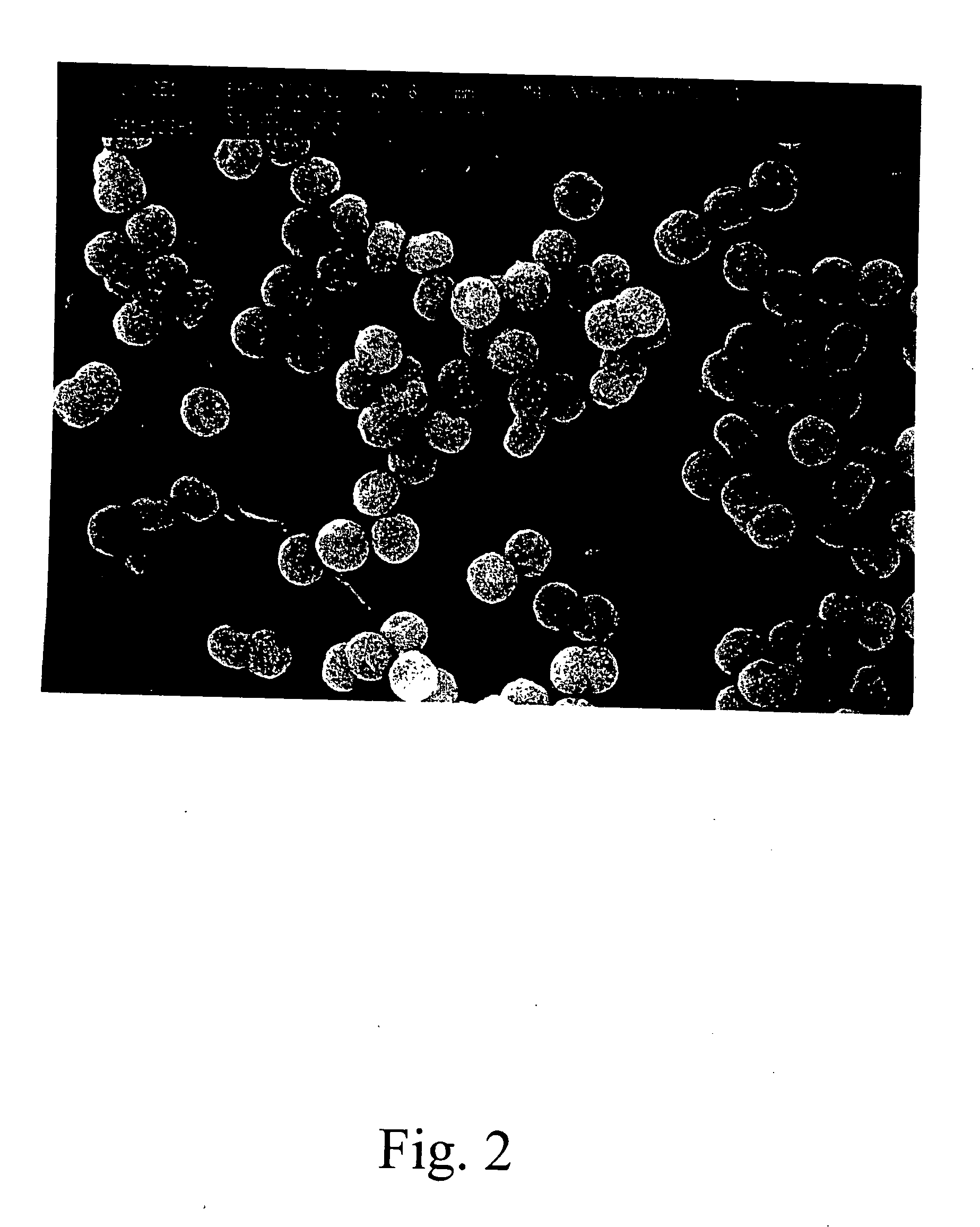

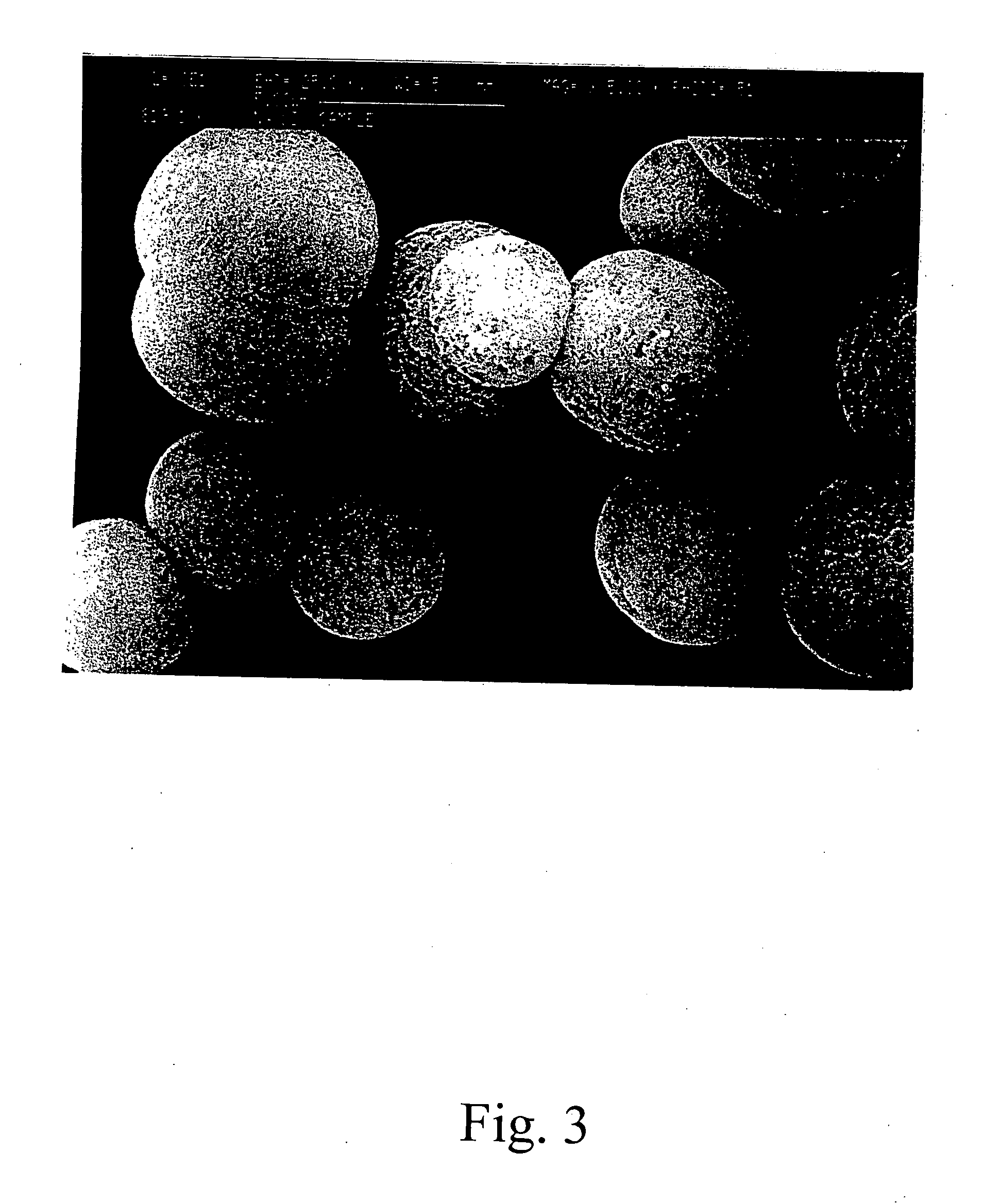

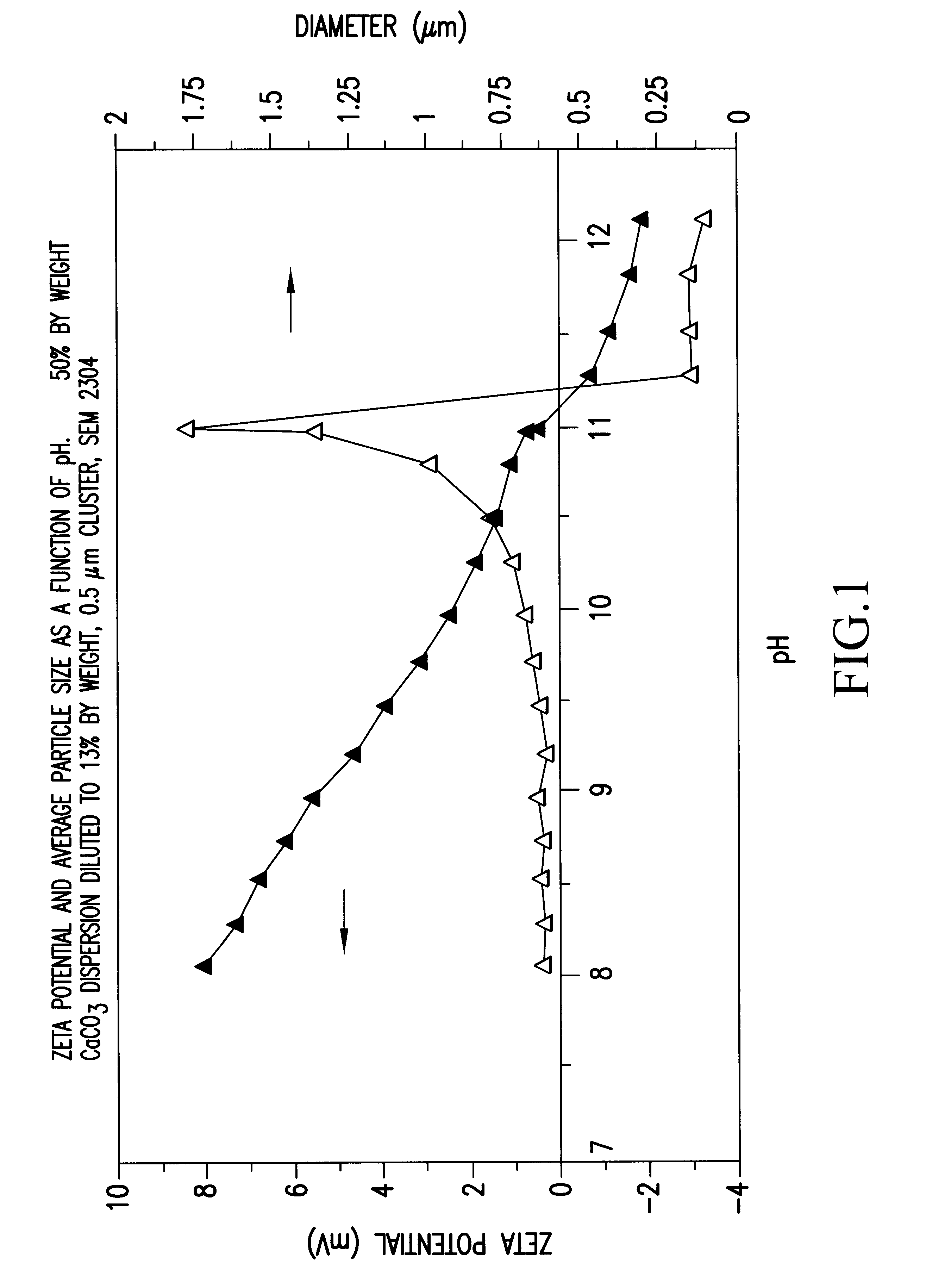

InactiveUS6602484B1High opacityIncrease reflectionCalcium/strontium/barium carbonatesMaterial nanotechnologyPrecipitated calcium carbonateSlurry

The invention concerns precipitated calcium carbonate products containing polynuclear regular agglomerates having a number of calcium carbonate particles (aggregates) attached to each other and having a particle size of about 40 to 200 nm. According to the invention, these products are prepared by adjusting the Z potential of the calcium carbonate suspension to -1 . . . -20 mV by adjusting the pH of the suspension to 6.5 . . . 9.5. The pH of the calcium carbonate slurry obtained by causticizing is adjusted to a desired value in a box filter, where after the suspension is stirred by a heavy-duty mixer such that it is subjected to differences of about 50 to 200 m / s in peripheral speed. The products according to the invention have good opacity and are very well suited for coating paper.

Owner:FP PIGMENTS

Method and device for loading a fibrous stock suspension

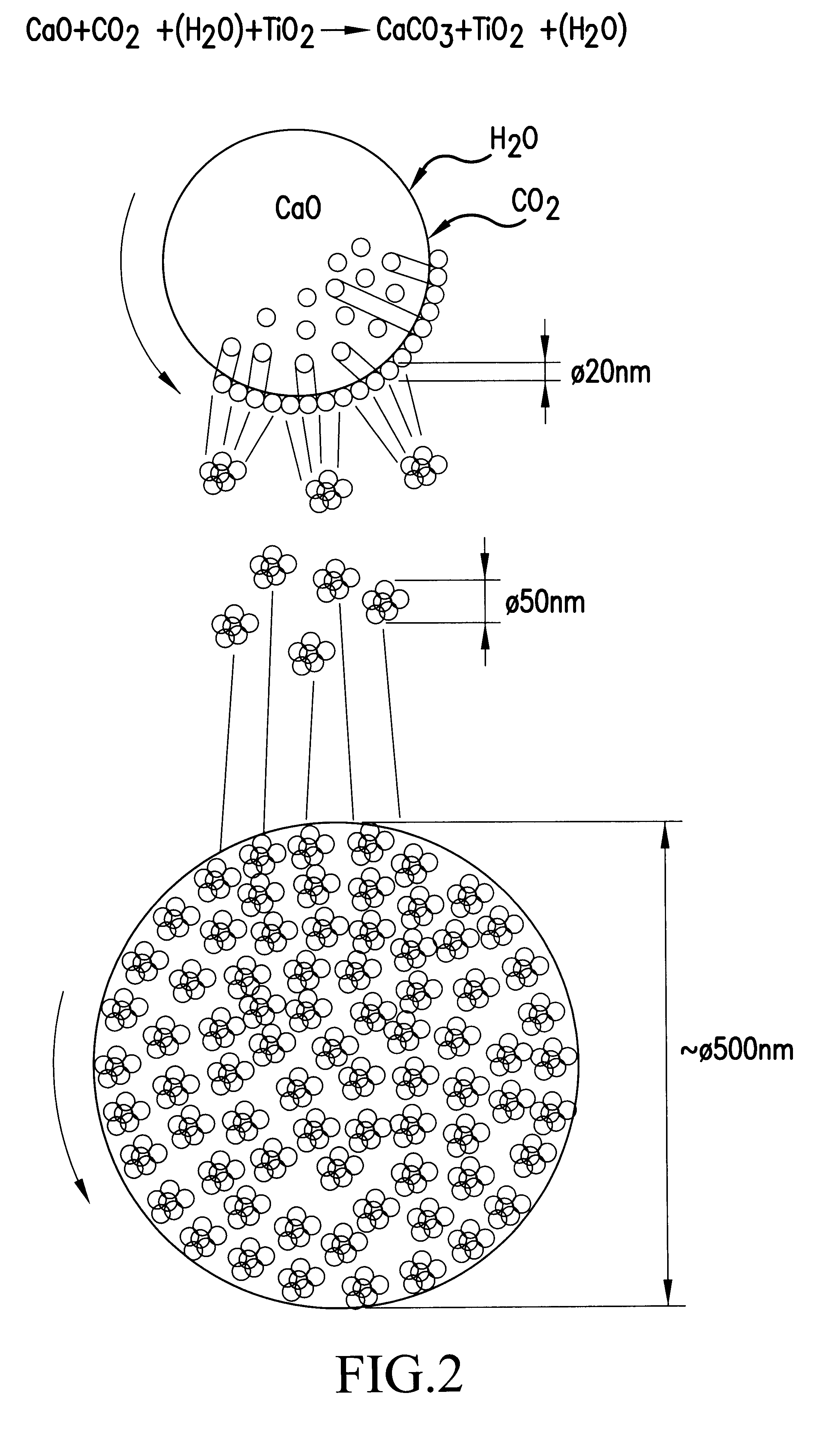

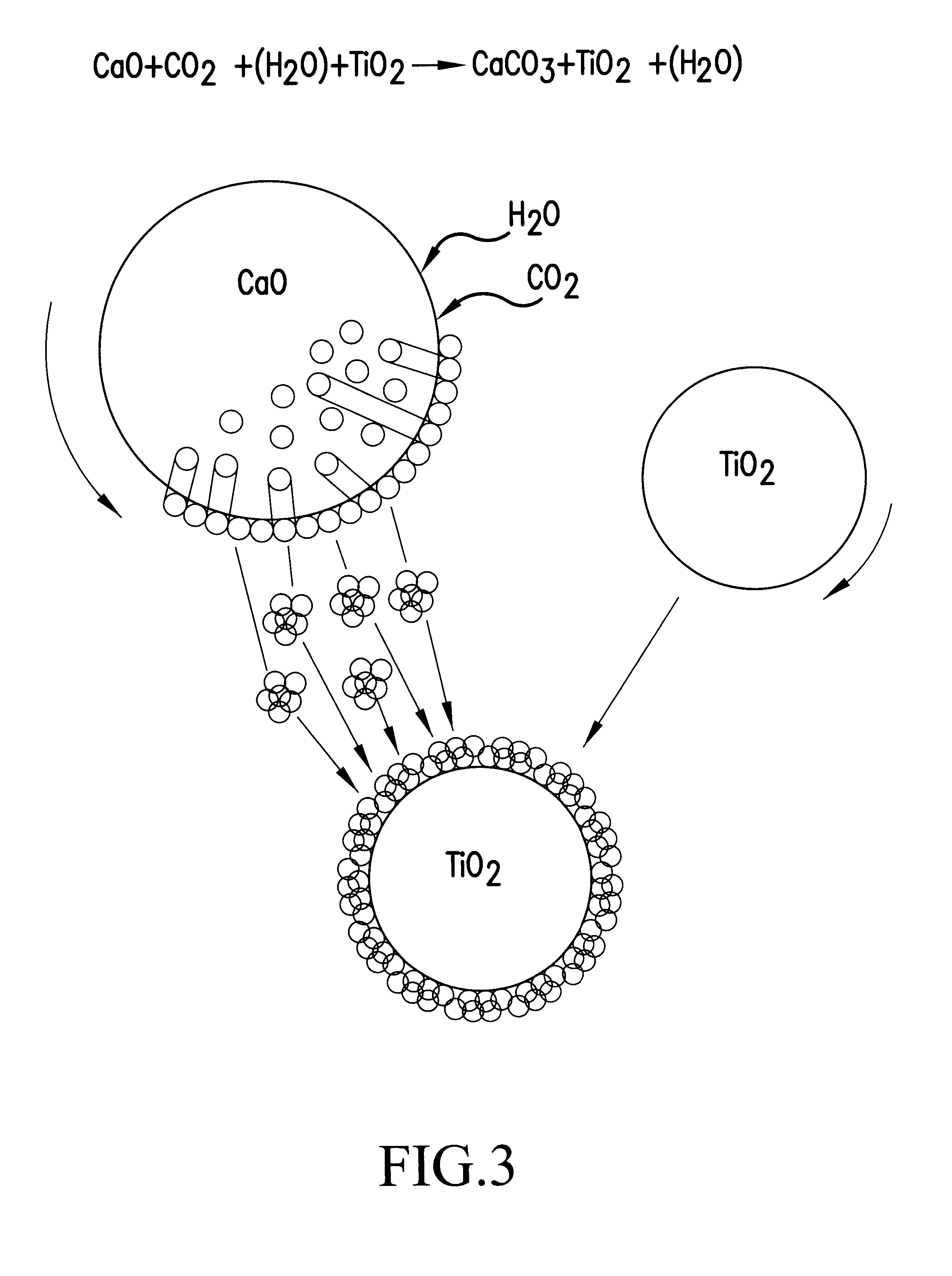

InactiveUS20070151681A1Improve featuresImprove dehydration propertiesCellulosic pulp after-treatmentNatural cellulose pulp/paperCalcium hydroxidePrecipitated calcium carbonate

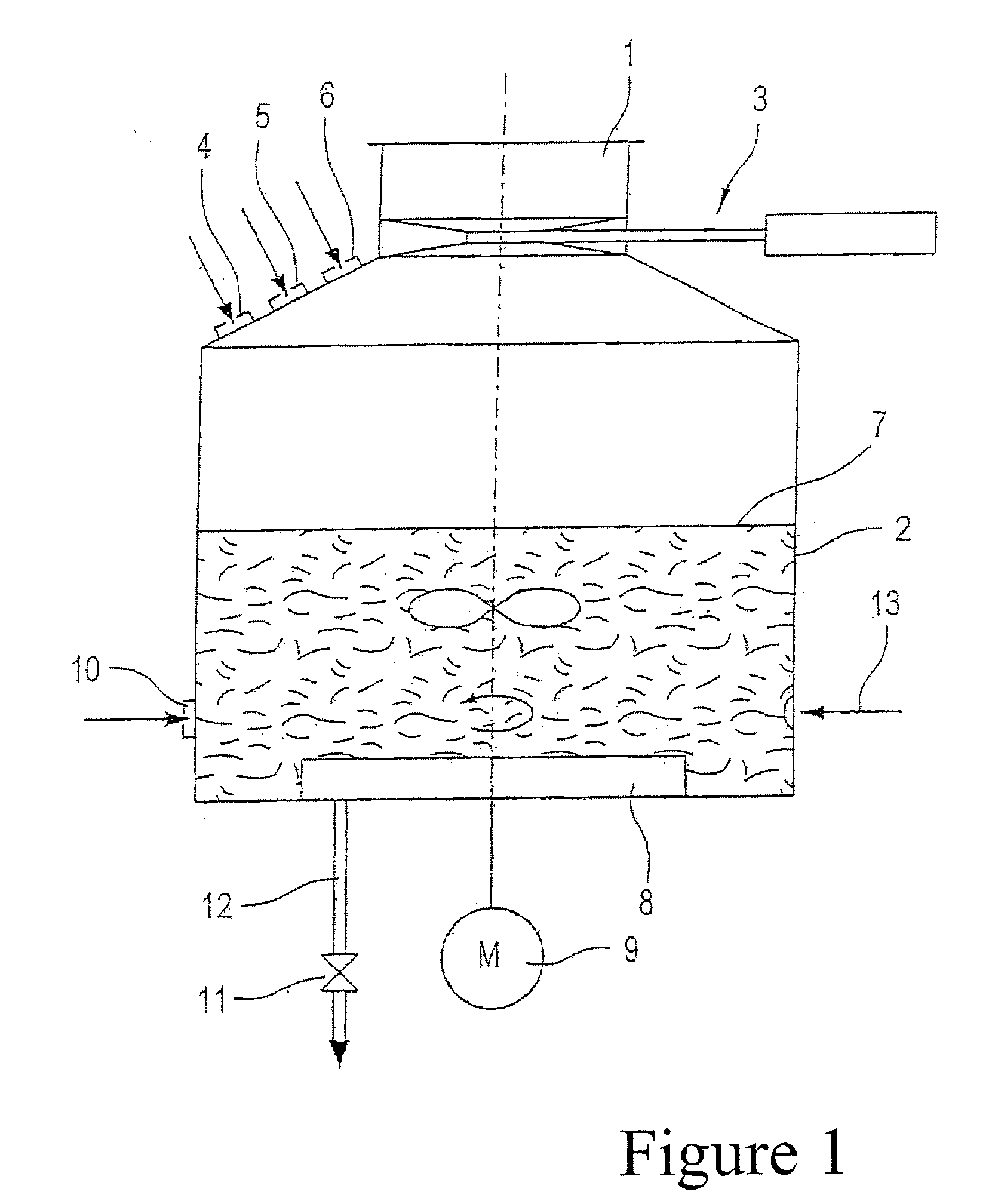

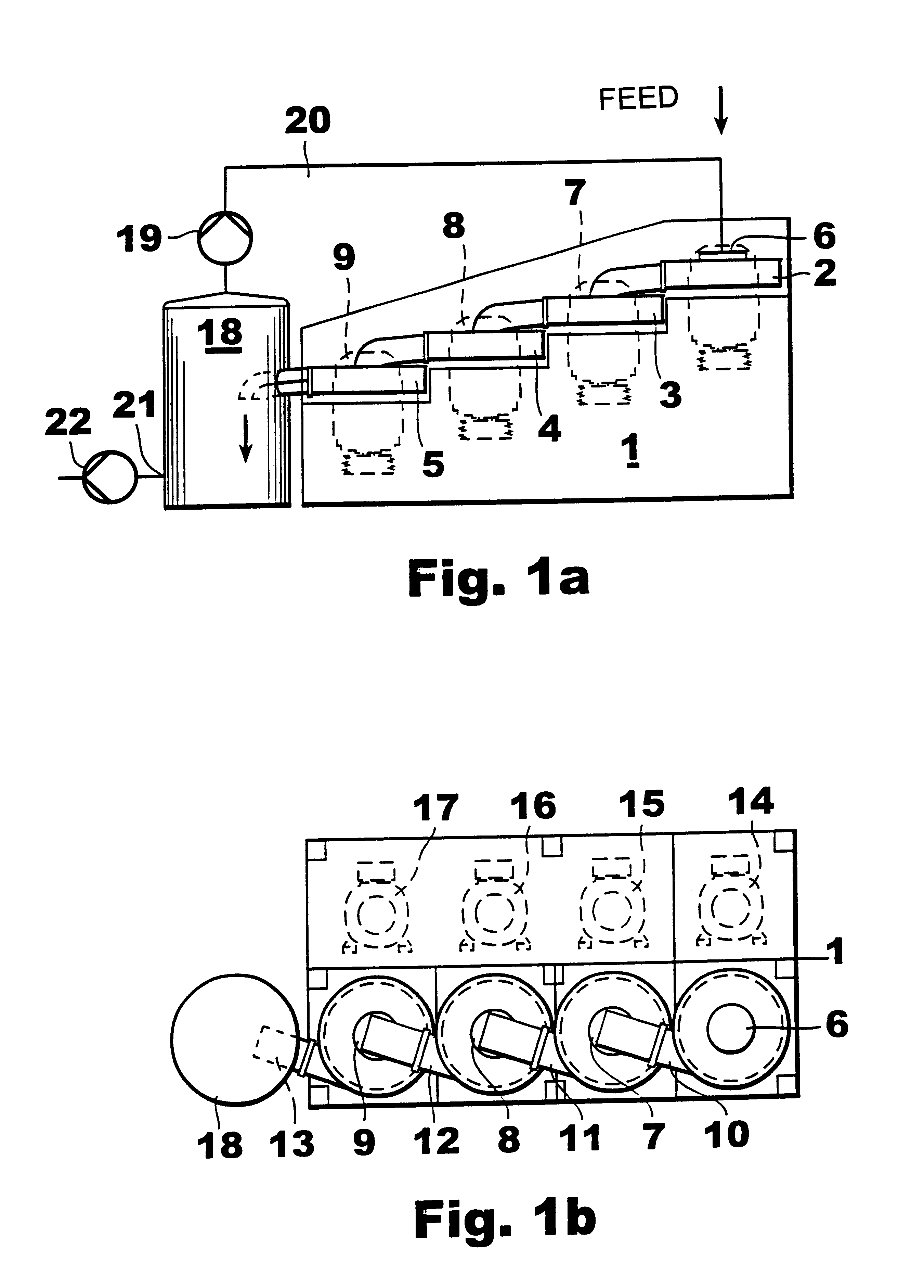

The present invention relates to a method and a device for loading a fibrous stock suspension including a plurality of cellulose fibers with calcium carbonate. The method includes adding calcium hydroxide in liquid or dry form and / or calcium oxide into the fibrous stock suspension, adding carbon dioxide into the fibrous stock suspension, and precipitating calcium carbonate from calcium hydroxide through carbon dioxide in a pressurized vessel.

Owner:VOITH PATENT GMBH

Inkjet recording media comprising precipitated calcium carbonate

InactiveUS20070134450A1Increase ink capacityExtended drying timeCoatingsThermographyPrecipitated calcium carbonateRecording media

The invention relates generally to the field of inkjet recording media and inkjet printing methods. More specifically, the invention relates to a porous base layer of an inkjet recording element, the base layer comprising precipitated calcium carbonate having scalenohedral morphology.

Owner:EASTMAN KODAK CO

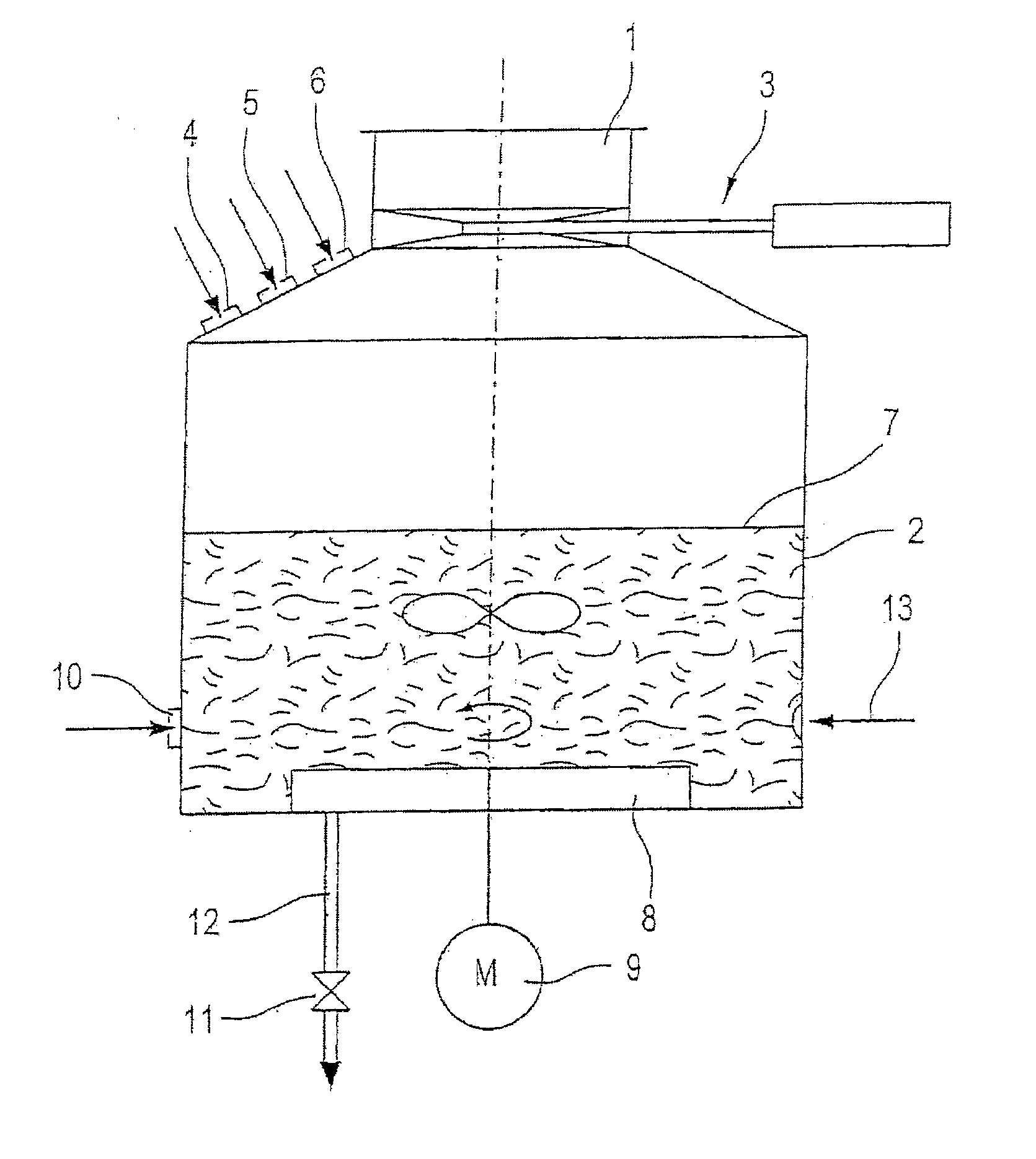

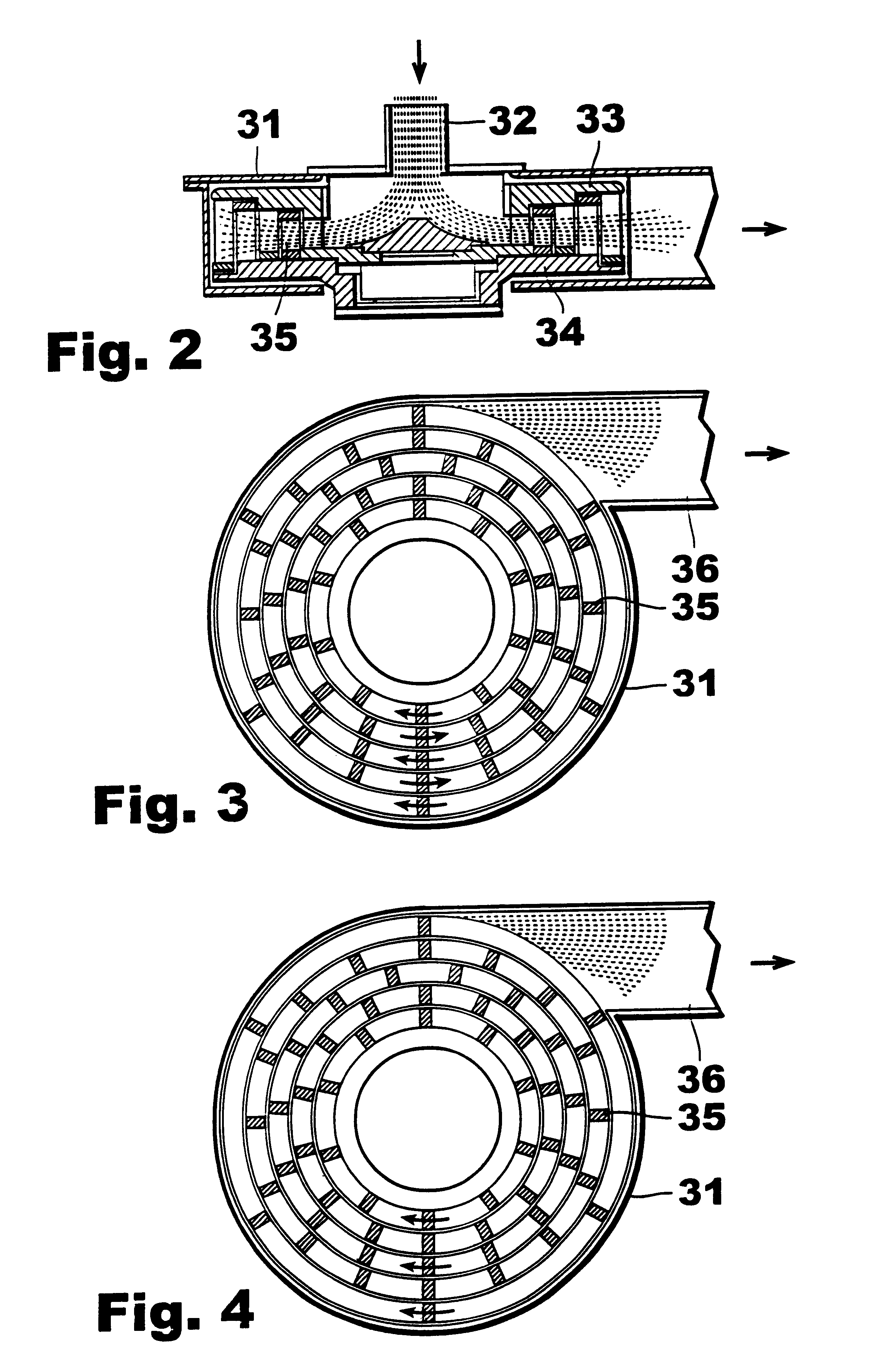

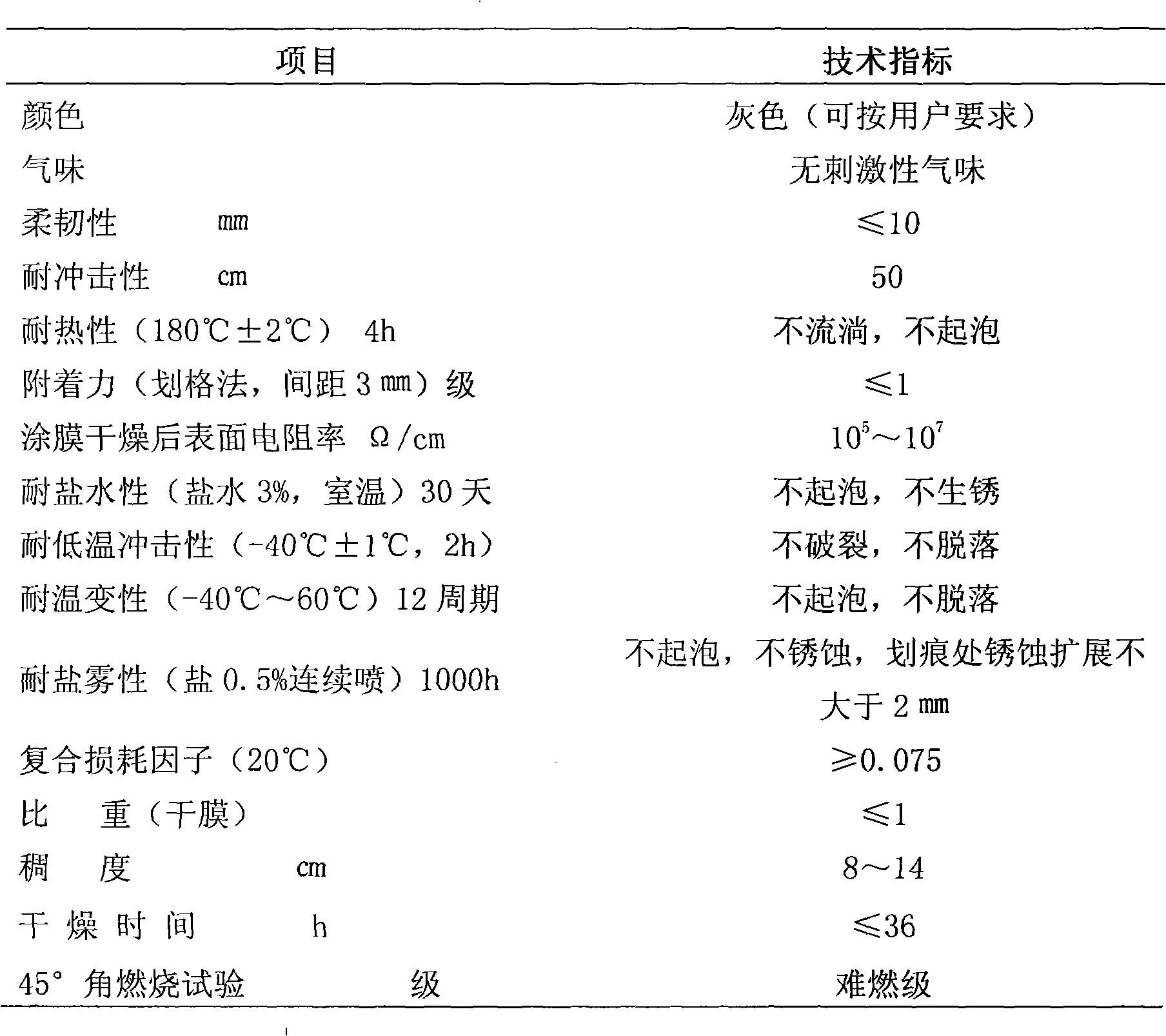

Apparatus and process for the preparation of precipitated calcium carbonate

A process and an apparatus for the preparation of precipitated calcium carbonates calcium hydroxide using gaseous carbon dioxide, whereby the carbonation is performed in a gaseous phase by mixing calcium-hydroxide-containing liquor mist with the carbon dioxide gas in a turbulence having an energy intensity in excess of 1000 kW / m3. The reaction is advantageously carried out in an apparatus, comprising at least two serially arranged pin mills having one or more rotatable vane rings which can be used to impose a great energy intensity on the material which is fed into the apparatus, whereby the first pin mill is provided with at least an inlet for slaked lime and carbon dioxide and an outlet for the reaction product, and the second pin mill is provided with an inlet for the product from the previous mill and an outlet for the reaction product. Carbonating is extremely swift. The residence time of the reaction is even less than 1 second. Due to the high energy intensity, carbonation may be performed at high solids contents.

Owner:FP PIGMENTS

Calcium carbonate surface modifying method

InactiveCN101914311AGood dispersionGood compatibilityPigment treatment with non-polymer organic compoundsSlurryCarbon chain

The invention discloses a calcium carbonate surface modifying method, which comprises the following steps of: adding a surface treatment agent into slurry obtained after the carbonation reaction of light calcium carbonate or precipitated calcium carbonate, wherein the treatment agent consists of unsaturated long carbon chain plant oil and a cosolvent; stirring at a high speed of 500 to 1,200rpm for 0.5 to 2h to perform surface treatment on the calcium carbonate; and obtaining the finished product of modified calcium carbonate by dewatering, drying, crushing and packaging the calcium carbonate emulsion after the reaction. The surface treatment agent of the invention has high dispersion in water at normal temperature, uniformly acts on the surfaces of calcium carbonate grains under the action of a high-speed shearing force, physical absorption and the hydroxyl on the calcium carbonate surface and restrains the crystal growth and secondary aggregation of the calcium carbonate, so that the modified calcium carbonate has uniform aperture, high dispersion, high affinity with organic high polymer and high filling property. In the invention, when the liquid surface treatment agent is used, the modification reaction process of the calcium carbonate needs no heating and is low in energy consumption and environmentally-friendly.

Owner:ZHEJIANG CHANGSHAN JINXIONG

In situ precipitation of calcium carbonate (CaCO3) by indigenous microorganisms to improve mechanical properties of a geomaterial

A method for increasing the concentration of calcium carbonate in a geomaterial that contains indigenous microorganisms capable of hydrolyzing urea to ammonia, which method includes enriching the geomaterial with a source of nutrients, adding urea to the geomaterial which is hydrolyzed to ammonia and which raises the pH of the geomaterial, and adding a source of calcium ions to the geomaterial. Carbonate ions obtained by the hydrolysis of the urea combine with calcium ions to form calcium carbonate.

Owner:UNIVERSITY OF IDAHO

Pharmaceutical composition

A pharmaceutical composition comprising 1.5 parts by weight powdered fennel, 2.0 parts by weight powdered rhubarb, 1.0 part by weight powdered glycyrrhiza, 2.0 parts by weight powdered phellodendron bark, 1.0 part by weight powdered zedoary, 1.5 parts by weight powdered picrasma wood, 1.0 part by weight powdered matricaria chamomilla, 1.5 parts by weight powdered geranium herb, 1.0 part by weight powdered ginseng, 1.5 parts by weight powdered citrus unshiu peel, 1.0 part by weight powdered scutellaria root, 1.0 part by weight powdered magnolia bark, 2.0 parts by weight powdered oyster shell, 1.0 part by weight powdered cyperus rhizome, 2.0 parts by weight powdered platycodon root, 2.0 parts by weight powdered melia azedarach, 1.0 part by weight powdered cnidium rhizome, 2.0 parts by weight sodium bicarbonate and 4.0 parts by weight precipitated calcium carbonate in 30 parts by weight of the composition.

Owner:NAKAMORI PHARMA

Process for producing inkjet recording medium

InactiveUS20060168811A1Excellent inkjet recording printabilityAdaptable to high speed coatingWriting implementsMetal-working apparatusPrecipitated calcium carbonateSilicon dioxide

A method for manufacturing an inkjet recording medium comprising the steps of: applying a coating color containing a pigment and a binder as major components to at least one side of a base material using a transfer roll coater, subsequently drying coating layer to form an ink absorbing layer, wherein Hercules viscosity of coating color is 5 m Pa·s to 30 m Pa·s and pigment contains a synthetic silica having an oil absorption of 90 ml / 10 g to 200 ml / 100 g, a BET specific surface area of 45 m2 / g to 200 m2 / g and an average particle diameter of 1.0 μm to 3.0 μm and / or a precipitated calcium carbonate-silica composite having an oil absorption of 100 ml / 10 g to 250 ml / 100 g, a BET specific surface area of 5 m2 / g to 150 m2 / g and an average particle diameter of 1.0 μm to 10 μm.

Owner:NIPPON PAPER IND CO LTD

Antibacterial interior wall latex paint

InactiveCN101555378ALow VOC contentLow costAntifouling/underwater paintsPaints with biocidesLow speedSecondary component

The invention discloses an antibacterial interior wall latex paint, which mainly comprises the following components of: deionized water, pure acrylic emulsion, titanium pigment, French chalk, calcium carbonate, precipitated calcium carbonate, kaolin, meerschaum powder and cyhalothrin; all the main components are matched with secondary components of hydroxyethyl cellulose, a dispersant, a defoaming agent, an antibacterial additive, a nano anti-fouling agent, a thickening agent, a leveling agent and the like and mixed into a single component formula, preabsorbed, mixed and stirred in a dispersing kettle with high-low speed, and carries out adjustment of pH value and filtering and package, and then the antibacterial interior wall latex paint is obtained. The antibacterial interior wall latex paint integrates the three functions of low VOC content, desinsection and antibacterium, and has cleaning resistance, high environmental conservation, low cost, convenient construction, long service life and wide market prospect.

Owner:北京虹霞正升装饰装修工程有限责任公司

Water-soluble conducting polyaniline static-free damping paint and preparation method thereof

InactiveCN101633809ANo pollutionWide damping temperature rangeAntifouling/underwater paintsPaints with biocidesWater basedVibration absorption

The invention relates to a water-soluble conducting polyaniline static-free damping paint and a preparation method thereof, belonging to a static-free damping paint. The water-soluble conducting polyaniline static-free damping paint contains the following raw materials in portions by weight: 20-40 portions of basic materials commixed by styrene-acrylic emulsion and water-based elastic acrylic emulsion dedicated for the water-based damping paint; 20-50 portions of fillers being several ones of lamellar mica powder, precipitated calcium carbonate, zinc phosphate, talc powder, titanium pigment, precipitated barium sulfate and silica sand; 25-50 portions of static-free fillers being water-soluble conducting polyaniline solution; 1-5 portions of fire retardants; and 2-6 portions of film forming assistants. The invention has the advantages that water-soluble emulsions are used as basic materials to ensure that the paint has such features as no position, no smell, incombustibility, no environmental pollution and easy construction; excellent damping effect and vibration-absorption effect are guaranteed; besides, as water-soluble conducting polyaniline solution is used as the static-free filler, the water-soluble conducting polyaniline static-free damping paint has the static-free function not available in the damping paint.

Owner:JILIN ZHENGJI TECH DEV

Split resistant putty powder and producing process

The invention relates to a crack resistant lacquer putty powder and a manufacturing technique thereof. The invention is characterized in that the crack resistant lacquer putty powder is prepared by the raw materials with the weight percentage: 30-50% of ground calcium carbonate, 5-10% of precipitated calcium carbonate, 20-35% of quartz sand, 20-30% of white cement, 0.5-1% of methyl cellulose, 1-3% of swell soil, 0.5-1% of titanium pigment, 0.5-1% of rubber powder and 0.5-1.5% of vegetable fiber. The manufacturing technique is completed according to the steps: the ground calcium carbonate is ground and processed, the quartz sand is screened, and then the vegetable fiber is processed; the raw materials are put into an agitating tank to be stirred and mixed, and the mixed powder material is filled into bags after being exhausted. The invention has the characteristics of high strength, good water resisting property, non-toxicity, odourlessness, yellowing resistance and the like; as being prepared by water, the crack resistant lacquer putty powder is easy to construct and leveled by sand; under the condition of large humidity and temperature difference change, the constructed wall does not craze and fall off, has no phenomenon of sand buckle, and is long in service life.

Owner:张鼎赛

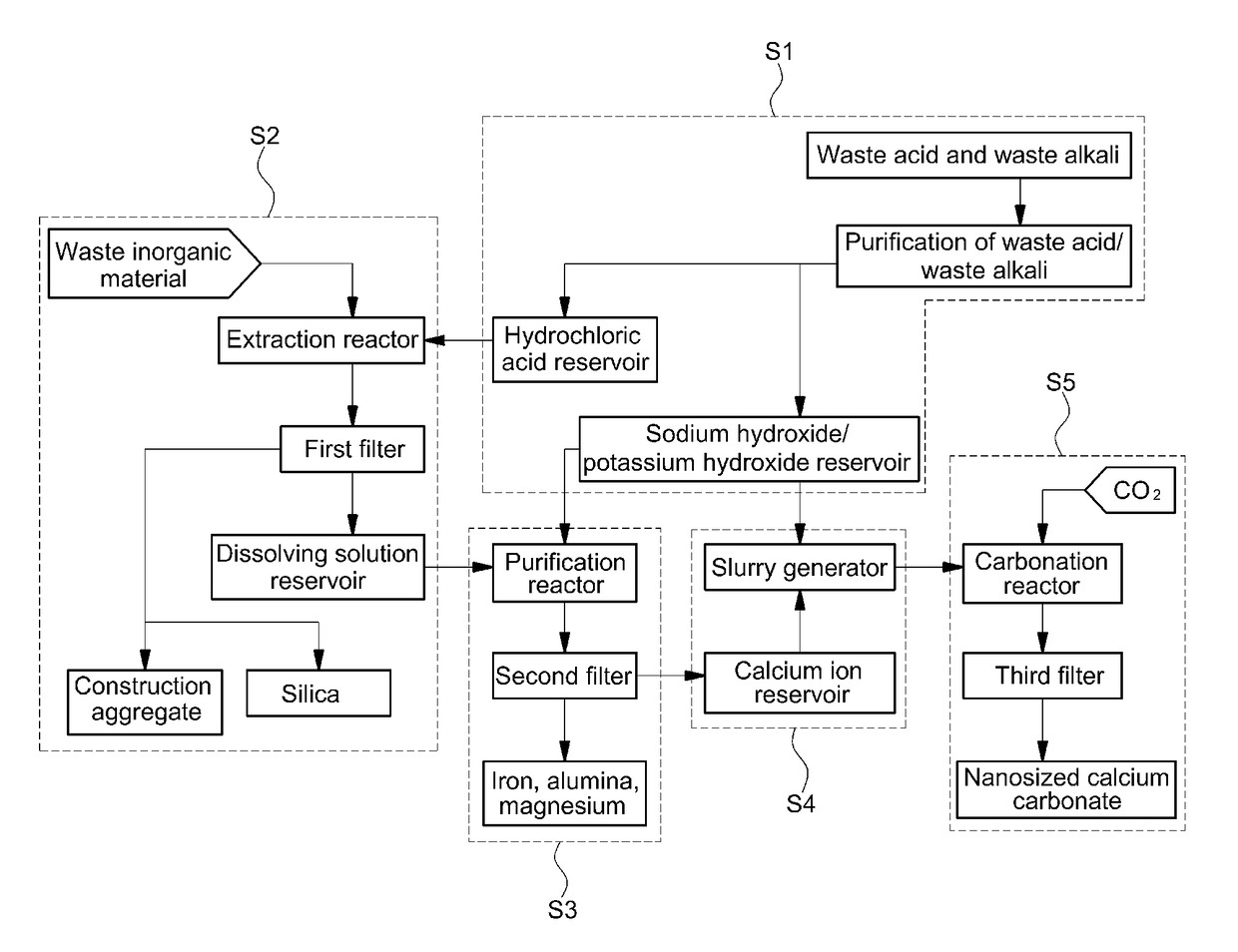

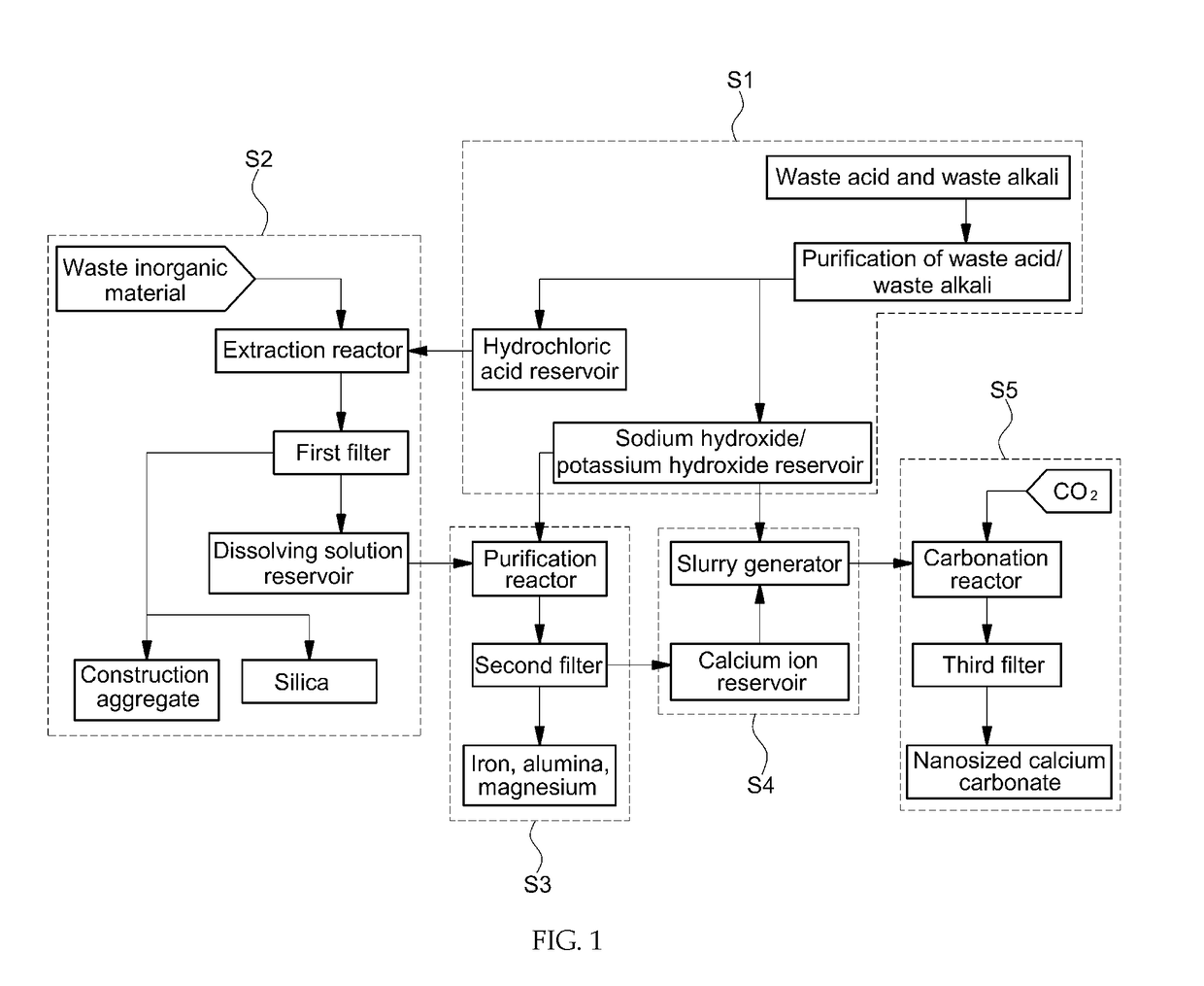

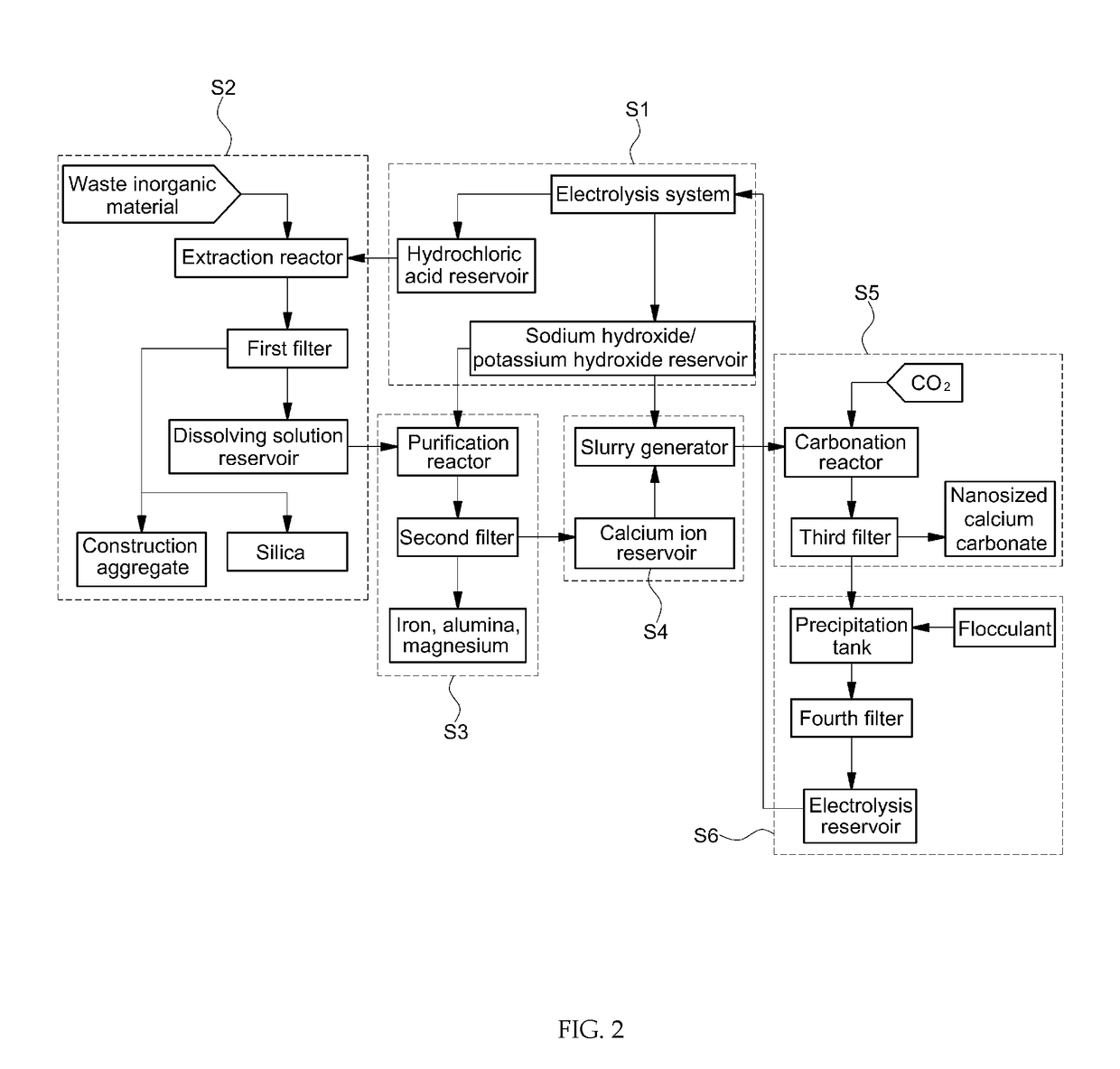

Preparation method of calcium carbonate with high purity from inorganic materials containing alkali metals or alkali earth metals

ActiveUS20170240432A1Low production costEconomical efficiencyCalcium/strontium/barium carbonatesProcess efficiency improvementAlkali ionsAlkaline earth metal

The present invention relates to a method and a process of preparing precipitated calcium carbonate of high purity by extracting calcium ion contained in an alkali ion-containing inorganic material such as mineral, steelmaking slag and waste concrete with the use of an acidic aqueous solution, separating other metal ions from the extracted solution, preparing an alkaline earth metal hydroxide using an alkaline aqueous solution and then contacting the same with carbon dioxide.

Owner:KOREA INST OF SCI & TECH

Method for cultivating agrocybe aegerita by using light industrial waste residues

InactiveCN102007847ARich in nutrientsReduce outputHorticultureFertilizer mixturesBiotechnologyNutrition

The invention belongs to the field of edible fungi production, and discloses a method for cultivating agrocybe aegerita by using light industrial waste residues. The method comprises the following steps of: collecting and treating the light industrial waste residues; preparing the prescription of a culture medium, and preparing and fermenting the culture medium; bagging and sealing the culture medium; sterilizing and inoculating the culture medium; cultivating mycelia; opening bags to show out the agrocybe aegerita; and managing the agrocybe aegerita growing period. The method is characterized in that: the light industrial waste residues comprise vinegar residues, wine dregs, sugar dust and manioc wastes; and 1 to 4 types of the light industrial waste residues are selected at random and are mixed with a small amount of cotton seed hulls, wood dust, corn flour, bran and precipitated calcium carbonate according to certain proportion to prepare a composite culture medium which is used for replacing the cotton seed hulls to cultivate the agrocybe aegerita, wherein the water content of the culture medium is 55 to 65 percent, and the pH is between 6.5 and 8. The light industrial waste residues is rich in nutrition, low in price and wide in source, so the method can reduce the production cost of the agrocybe aegerita, improve the economic benefit of cultivators by 25 to 30 percent, and not only can reduce pollution to the environment caused by organic wastes, but also can change waste into valuable and turn harmful into beneficial.

Owner:镇江市京口区瑞京农业科技示范园

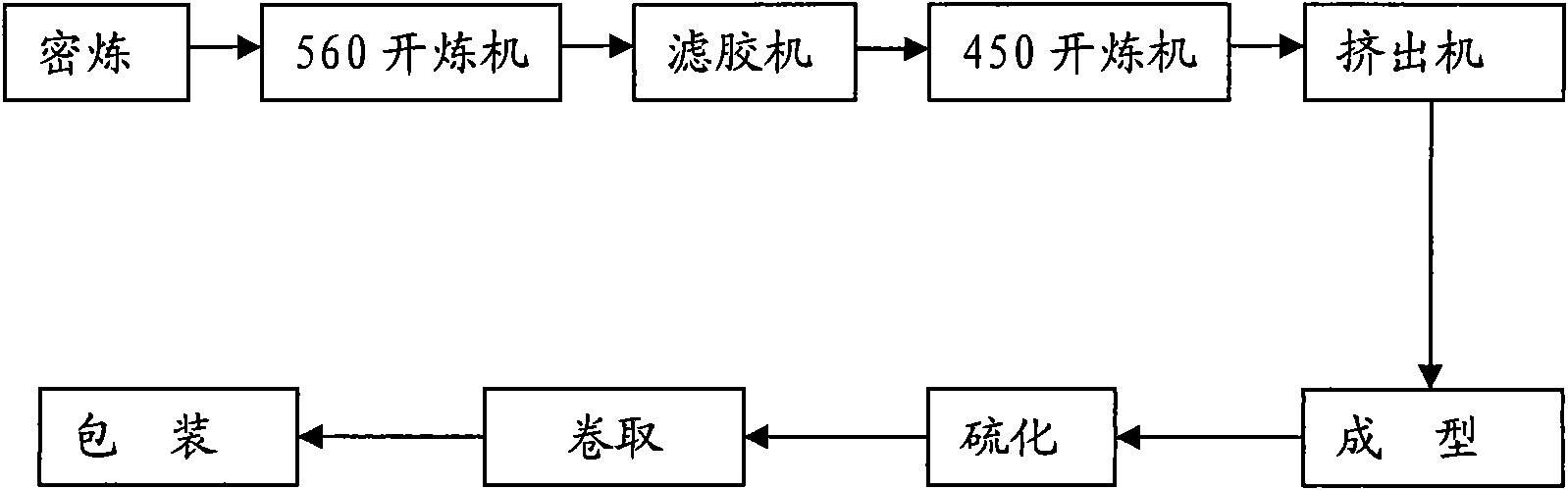

Method for preparing a TZ-SBSEC welding type rubber waterproof sheet

InactiveCN101585951ASolving Cold Bonding ProblemsWith solderable functionPolymer sciencePrecipitated calcium carbonate

The invention discloses a method for preparing a TZ-SBSEC welding type rubber waterproof sheet. The TZ-SBSEC welding type rubber waterproof sheet consists of SBS (1401), EPDM (4770), CPE (135A), precipitated calcium carbonate, carbon black N330, DOP, a modifier TP-10, sulfur, an age inhibiter RD, an age inhibitor 4010, and TMTD. The preparation method comprises the following steps: adding the SBS, the EPDM and the CPE according to formula proportion into a banbury mixer at a banburying temperature of between 90 and 105 DEG C for 30 min; orderly adding the modifier TP-10, the age inhibiter RD, the age inhibitor 4010 for banburying at the same banburying temperature for 1.5min; finally adding the precipitated calcium carbonate, the carbon black N330 and the DOP at a banburying temperature of between 135 and 145 DEG C for 9 min for even banburying, and discharging; performing rubber reversing on an S(X)K-560 rubber mixing machine, reducing the temperature to less than or equal to 90 DEG C, and discharging strips; filtering impurities by a rubber strainer, performing thinning and mixing on a 450 mill mixer, and discharging strips after even mixing; performing extrusion molding by an extruder, and vulcanizing the formed coiled material in a 20m continuous vulcanizing boiler at 160 DEG C and 0.3MPa; and finally rolling and packaging. The method solves the problem of cold adhesion in construction of the rubber waterproof sheet, and makes the rubber waterproof sheet form an integral waterproof layer.

Owner:曹天志 +2

Preparation method of nano spindle precipitated calcium carbonate

InactiveCN107555459AGood dispersionObvious reinforcement and toughening effectCalcium/strontium/barium carbonatesNanotechnologyDispersityPrecipitated calcium carbonate

The invention relates to a method for preparing nano-grade spindle precipitated calcium carbonate. The method comprises the following steps: (1) preparing calcium oxide, namely a lime semi-finished product; (2) preparing refined lime milk Ca(OH)2 slurry; (3) processing calcium carbonate slurry; (5) carrying out press filtering, drying, crushing and grading on the calcium carbonate slurry to obtaina nano-grade spindle precipitated calcium carbonate product. Compared with a precipitated calcium carbonate preparation technology in the prior art, the method provided by the invention has the advantages and beneficial effects that 1, the nano-grade spindle precipitated calcium carbonate is prepared for the first time; 2, the product has good dispersity and has a remarkable reinforcing and toughening effect in a plastic processing industry at the same time; 3, the method has the advantages of simple technical flow, small investment and good economic benefits.

Owner:青阳县泰鑫新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com