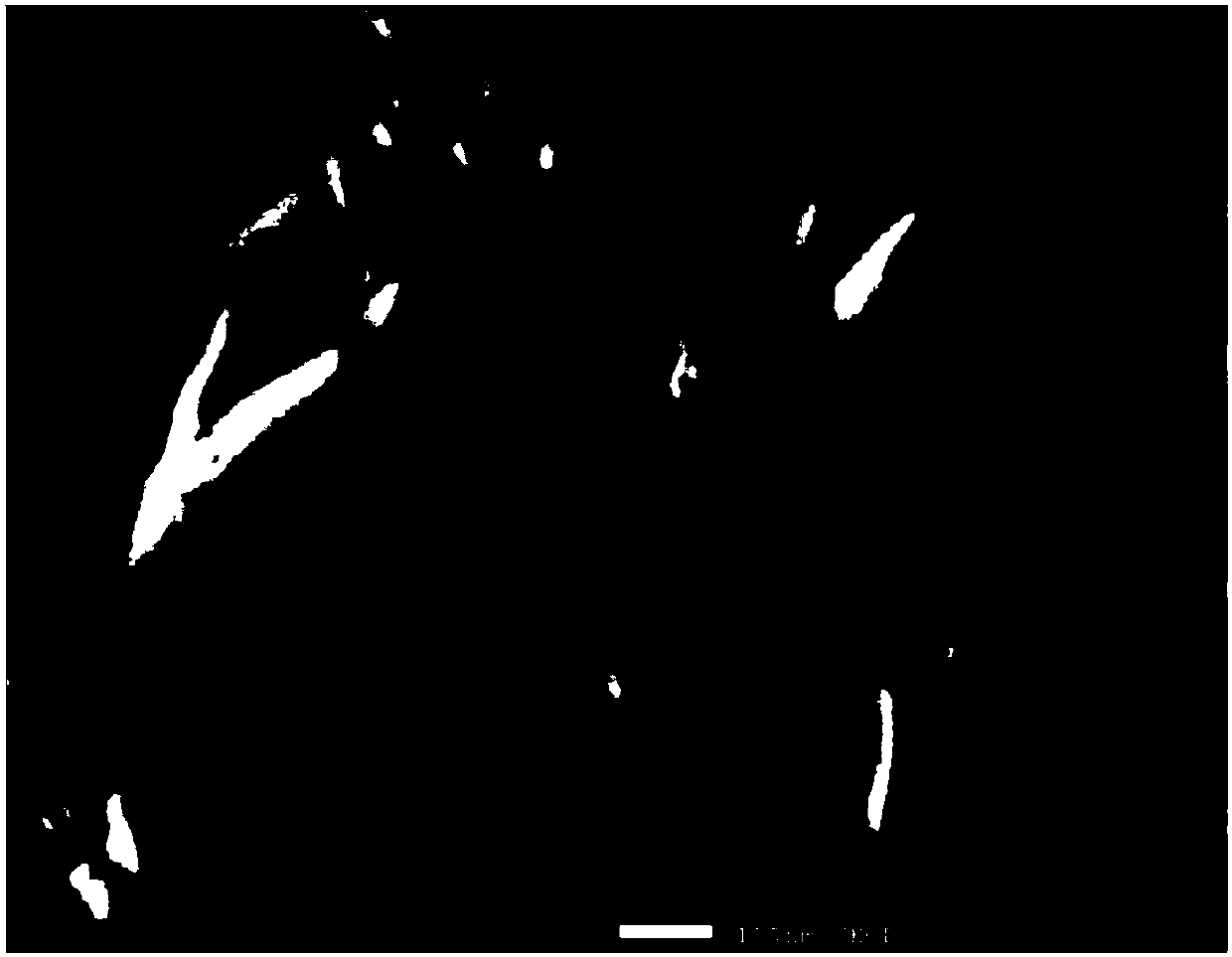

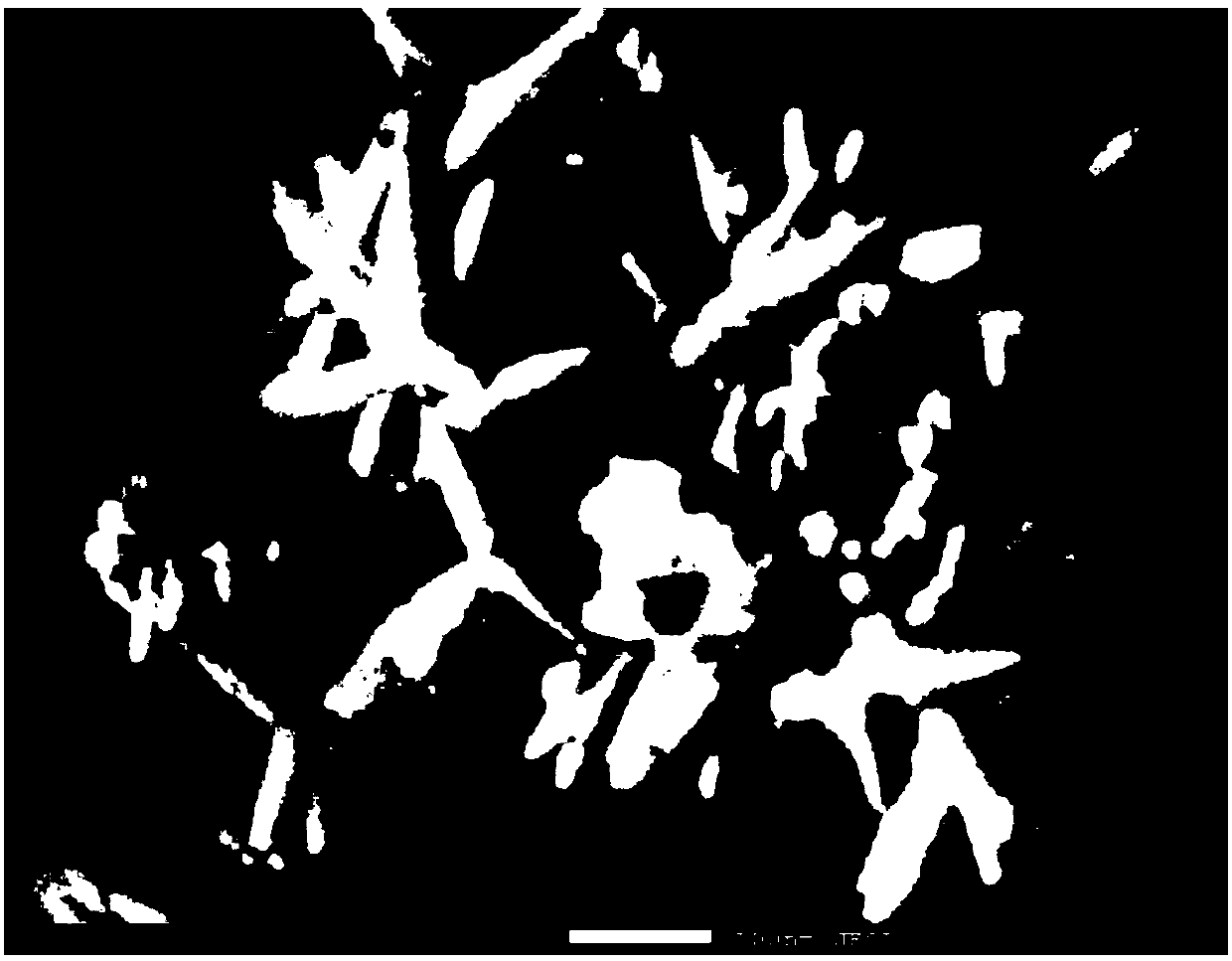

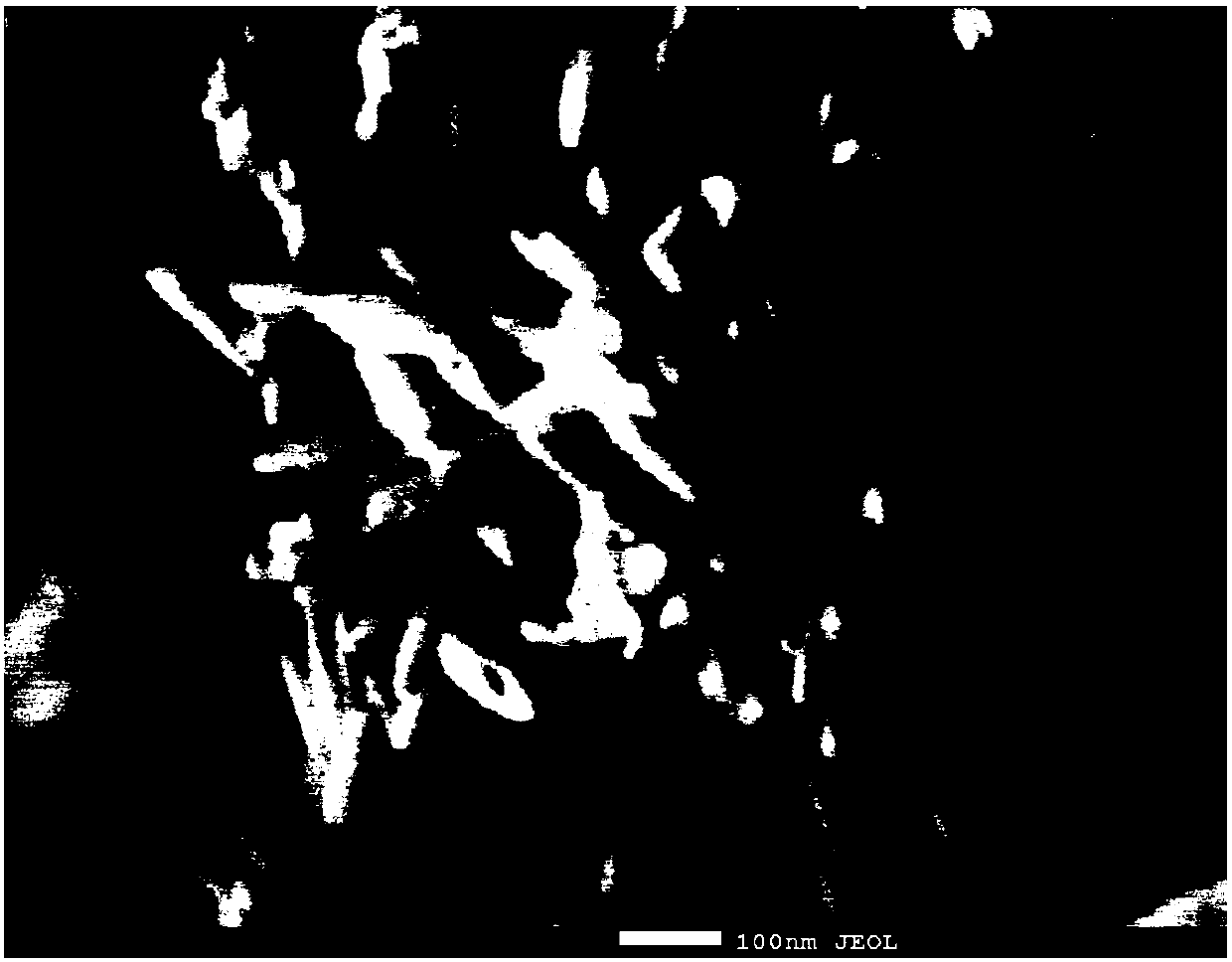

Preparation method of nano spindle precipitated calcium carbonate

A technology for precipitating calcium carbonate and spindles, applied in the direction of calcium carbonate/strontium/barium, nanotechnology, etc., can solve the problems of easy agglomeration, deterioration, and poor dispersion, and achieve simple process flow, good economic benefits, and good dispersion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The limestone is crushed to a size of 40×120mm by a jaw crusher, and then conveyed to the top hopper of the mechanical shaft kiln by a conveyor belt. The calcination is carried out in a mechanized vertical kiln, the calcination temperature is controlled between 950-1150°C, the ratio of limestone and anthracite is 10:1.1, and the calcination time is 20h;

[0032] The calcined lime is sieved to remove coal slag and small lime powder, and the obtained high-quality block lime enters the rotary digester for lime digestion. The temperature of the water for digesting lime is controlled at about 40°C, and the water consumption is 5 times the mass of lime. The primary lime slurry contains some coarse slag, and impurities are removed through a 40-mesh vibrating screen, a hydrocyclone, a 100-mesh vibrating screen and a 300-mesh vibrating sieve to obtain a refined lime milk Ca(OH)2 slurry.

[0033] Grind the refined milk of lime with a peeling machine, the grinding medium is zirco...

Embodiment 2

[0036] The limestone is crushed to a size of 40×120mm by a jaw crusher, and then conveyed to the top hopper of the mechanical shaft kiln by a conveyor belt. The calcination is carried out in a mechanized vertical kiln, the calcination temperature is controlled between 950-1150°C, the ratio of limestone and anthracite is 10:0.85, and the calcination time is 30h;

[0037] The calcined lime is sieved to remove coal slag and small lime powder, and the obtained high-quality block lime enters the rotary digester for lime digestion. The temperature of water for digesting lime is controlled at about 60°C, and the water consumption is 6 times of lime mass. The primary lime slurry contains some coarse slag, and impurities are removed through a 40-mesh vibrating screen, a hydrocyclone, a 100-mesh vibrating screen and a 300-mesh vibrating sieve to obtain a refined lime milk Ca(OH)2 slurry.

[0038] Grind the refined milk of lime with a peeling machine, the grinding medium is 3mm zirconiu...

Embodiment 3

[0041] The limestone is crushed to a size of 40×120mm by a jaw crusher, and then conveyed to the top hopper of the mechanical shaft kiln by a conveyor belt. The calcination is carried out in a mechanized vertical kiln, the calcination temperature is controlled between 950-1150°C, the ratio of limestone and anthracite is 10:1.0, and the calcination time is 24 hours;

[0042] The calcined lime is sieved to remove coal slag and small lime powder, and the obtained high-quality block lime enters the rotary digester for lime digestion. The temperature of water for digesting lime is controlled at about 50°C, and the water consumption is 5 times of lime mass. The primary lime slurry contains some coarse slag, and impurities are removed through a 40-mesh vibrating screen, a hydrocyclone, a 100-mesh vibrating screen and a 300-mesh vibrating sieve to obtain a refined lime milk Ca(OH)2 slurry.

[0043] Grind the refined milk of lime with a peeling machine, the grinding medium is zirconiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com