Method and device for loading a fibrous stock suspension

a technology of fibrous stock and calcium carbonate, which is applied in the direction of liquid chemical processes, thin-film liquid gas reaction processes, gas-gas reaction processes, etc., can solve the problems that print particles including flexo-ink cannot be removed through a floatation process, or can only be removed with great difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

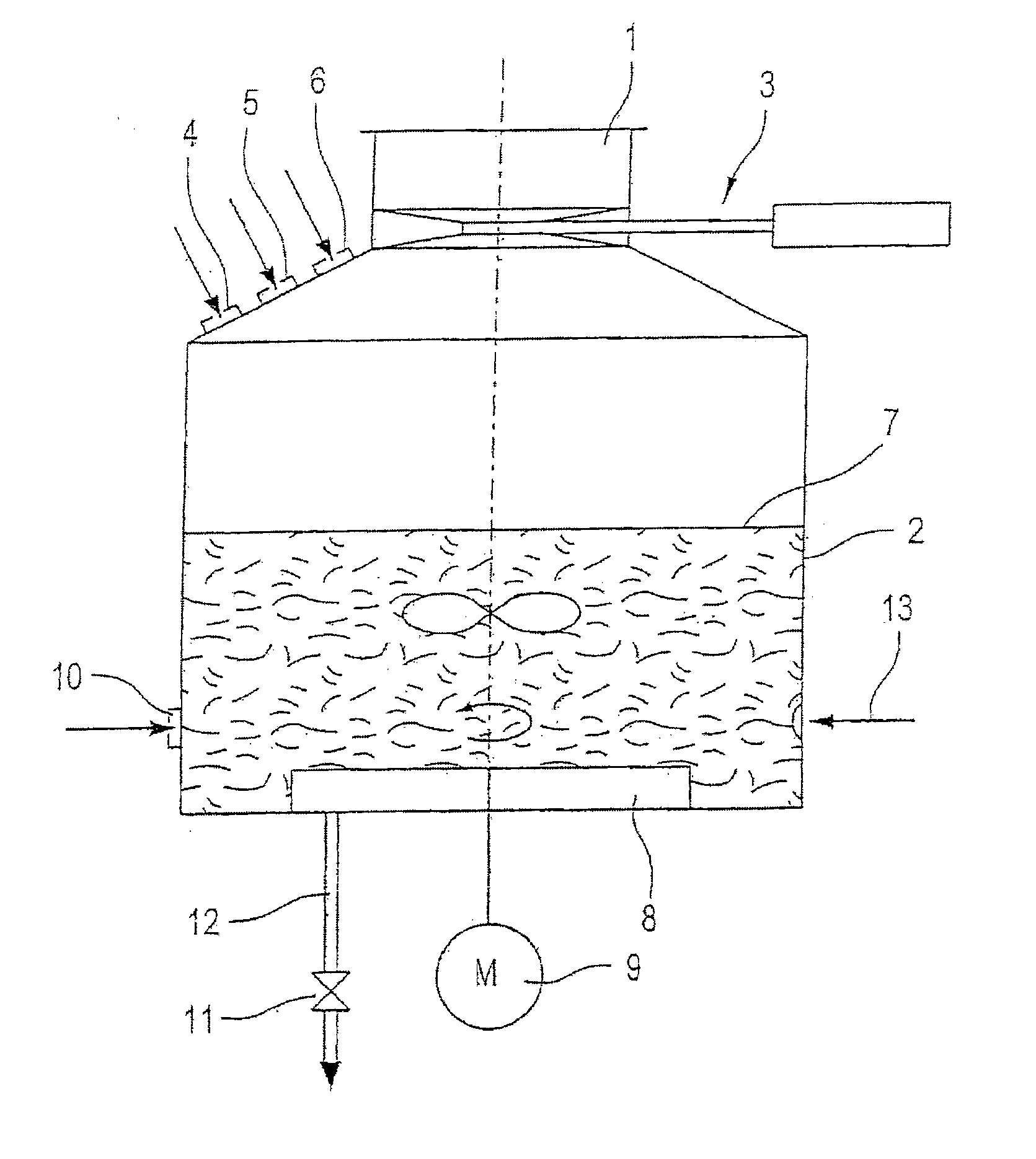

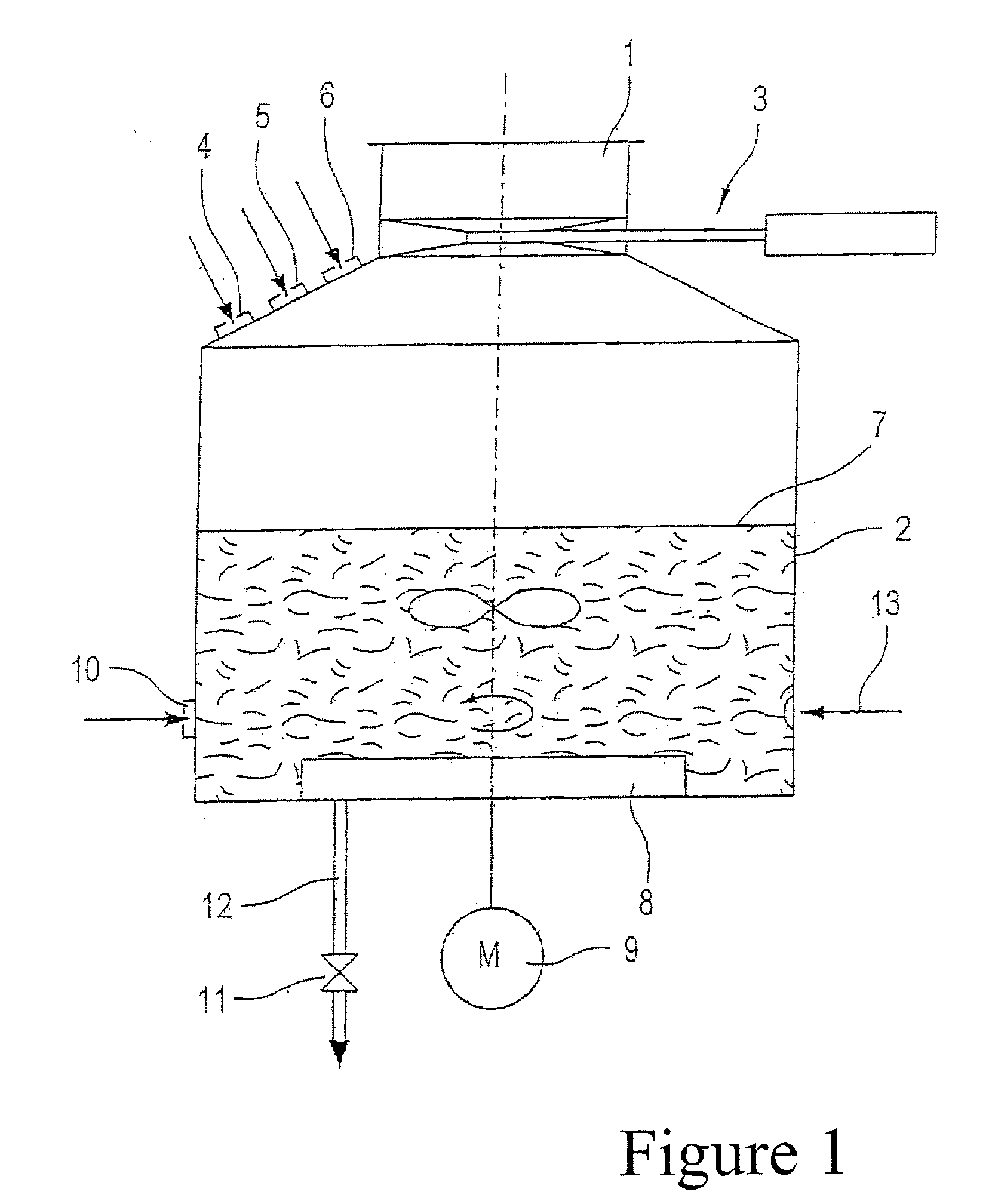

[0043] Referring now to the drawing, there is shown a fiber raw material which is supplied to a pressure vessel 2 through a supply pipe 1. In order to be able to establish and limit the supply volume a sluice 3 which is opened and closed via a motor driven closing mechanism is located between the supply pipe 1 and the pressure vessel 2.

[0044] Dilution water, calcium hydroxide in liquid or solid form or calcium oxide or chemicals are added through additional supply line connections 4, 5, 6 so that, if the raw fiber stock was initially supplied to a fill level 7, a filling of the pressure container 2 above this fill level 7 is formed, including the calcium hydroxide which serves the fiber loading process, together with the water and / or the dilution water in which it is dissolved.

[0045] In order to mix the fiber raw stock with the calcium hydroxide so that this penetrates into the fibers, a rotor 8 is supplied which includes a propeller wheel or similar device at the bottom and / or at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com