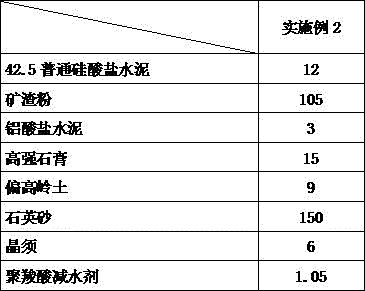

Patents

Literature

274 results about "Calcium carbonate crystals" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

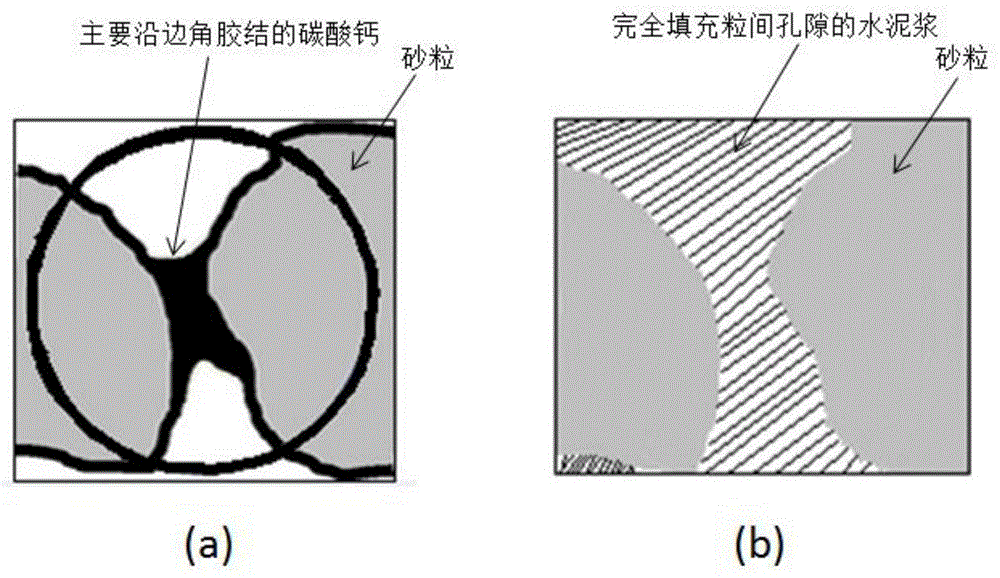

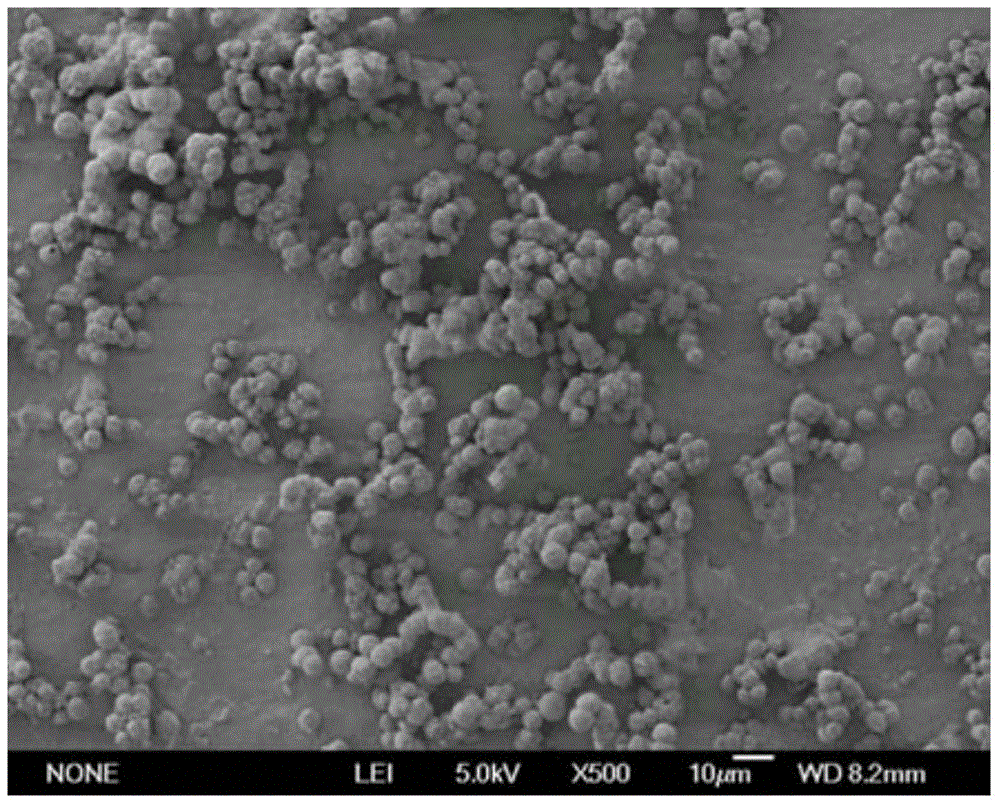

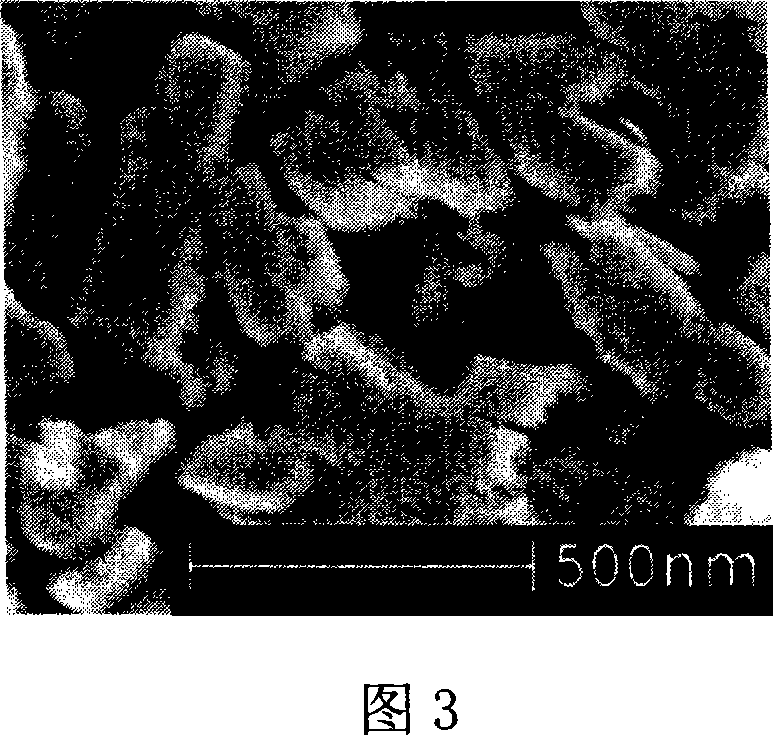

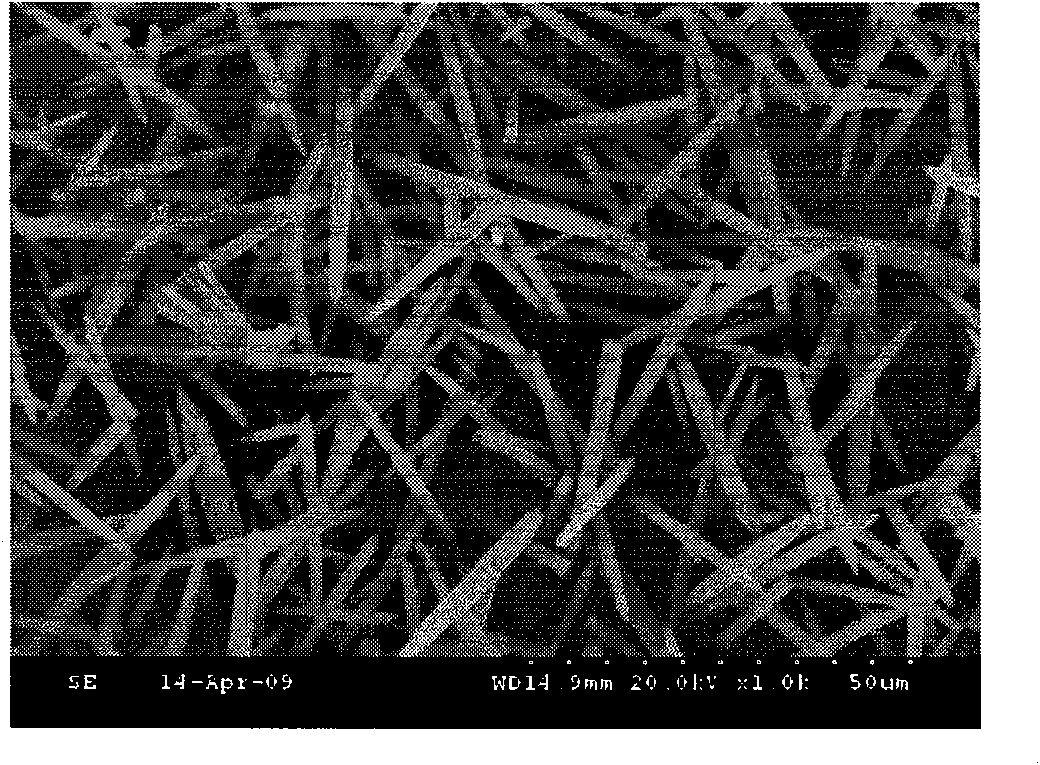

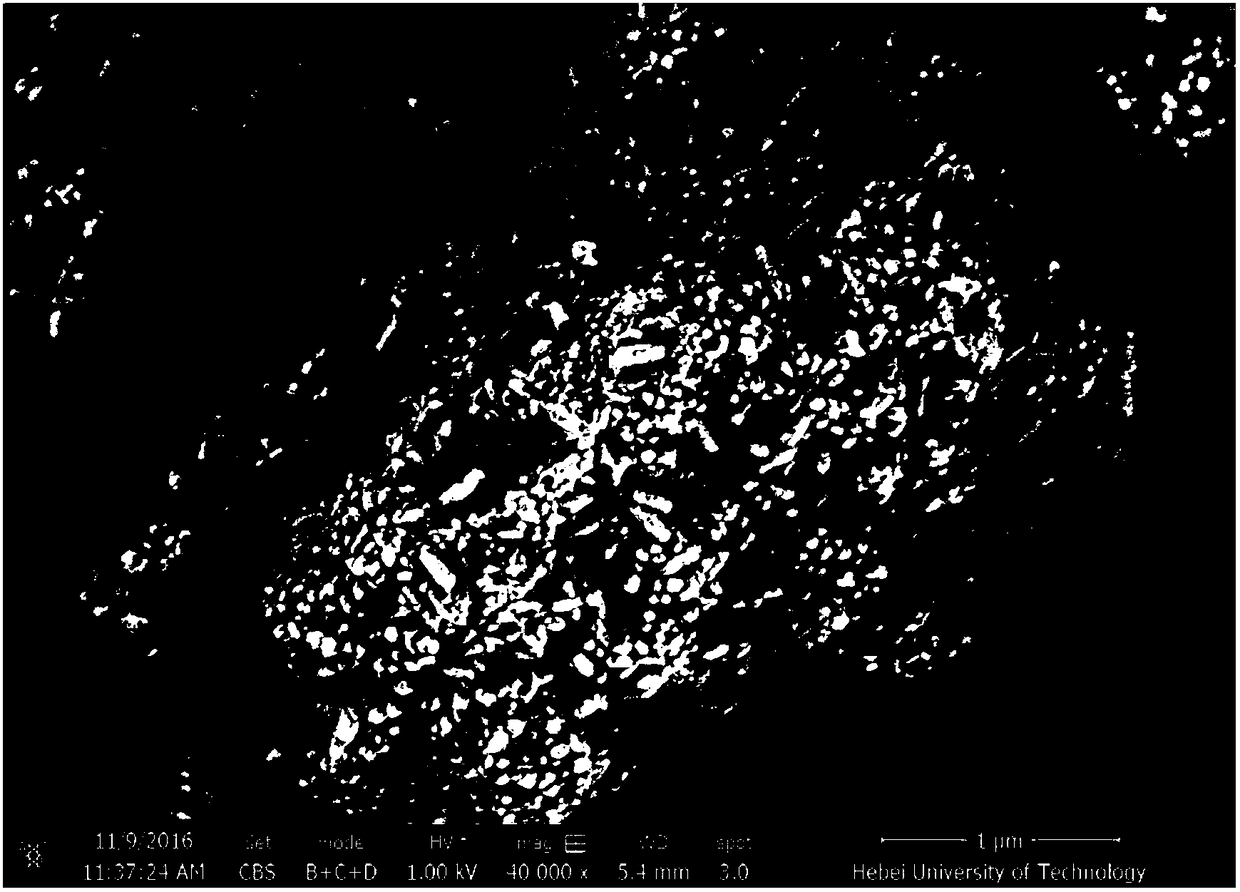

Calcium carbonate crystals are large circular crystals with radial striations with smooth surfaces. Smaller versions form pairs and tetrads. The crystals are slightly brown. Other forms are the dumb-bell, oval and tetrad forms, which are seen in the background.

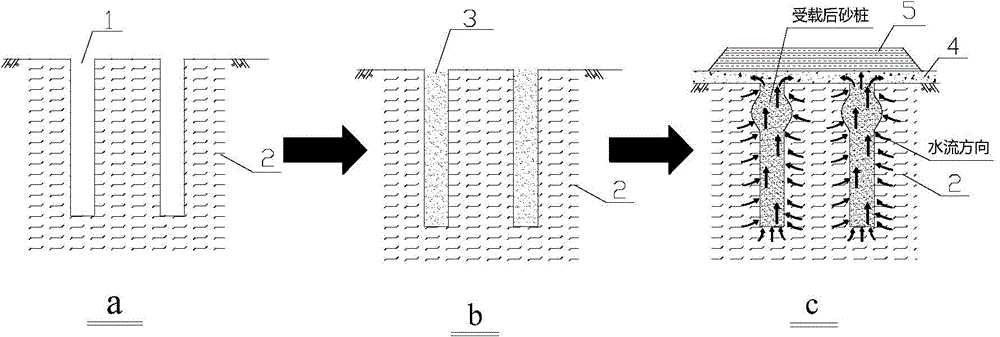

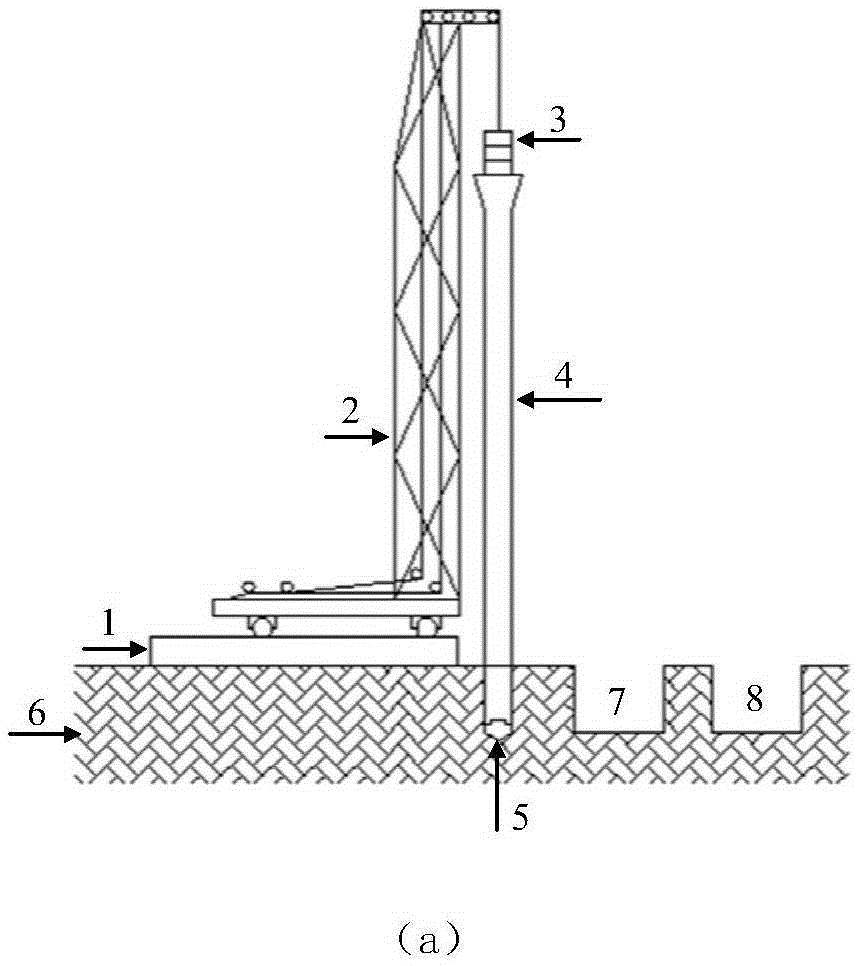

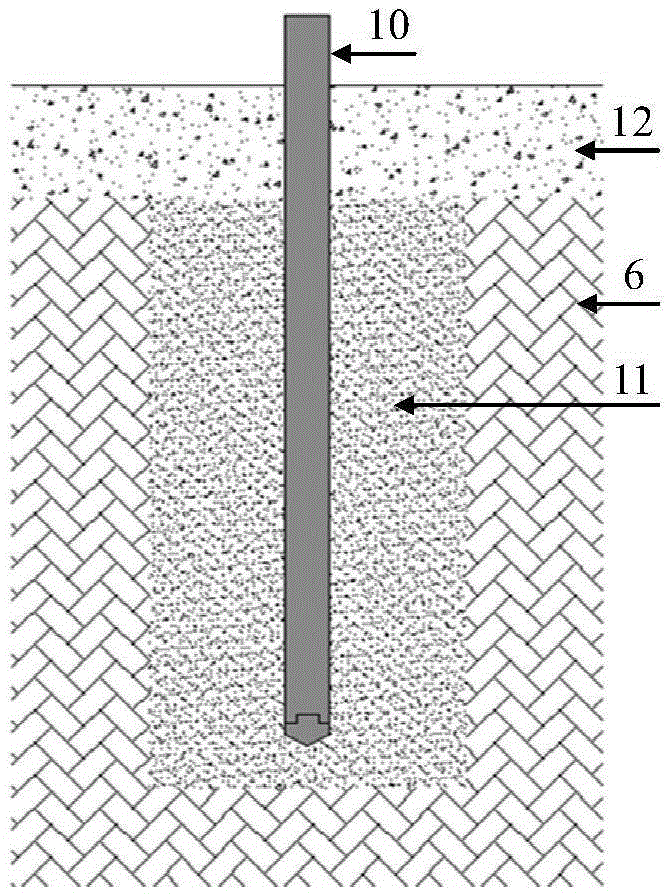

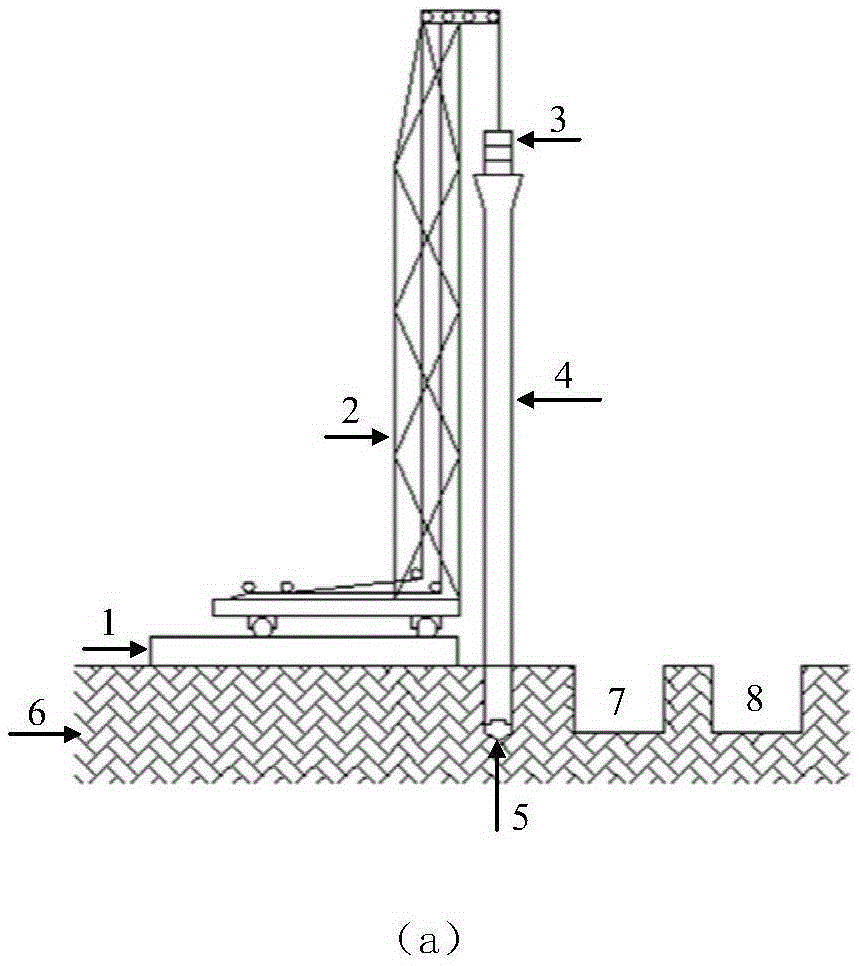

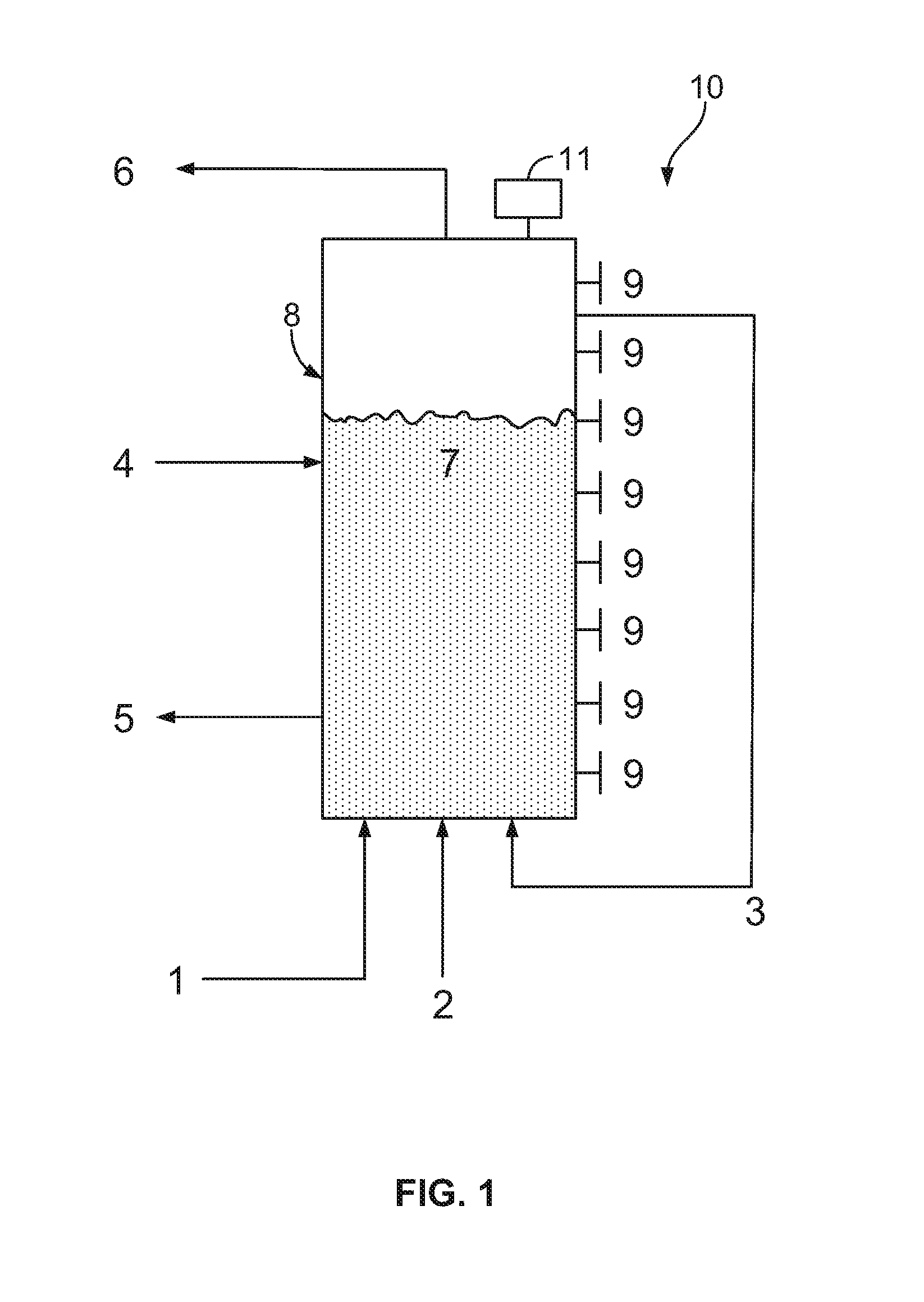

Method for soft soil foundation treatment through microorganism grouting sand drain

InactiveCN104631430AImprove vertical load carrying capacityPermeability changeOrganic fertilisersSoil conditioning compositionsSoil scienceSalt solution

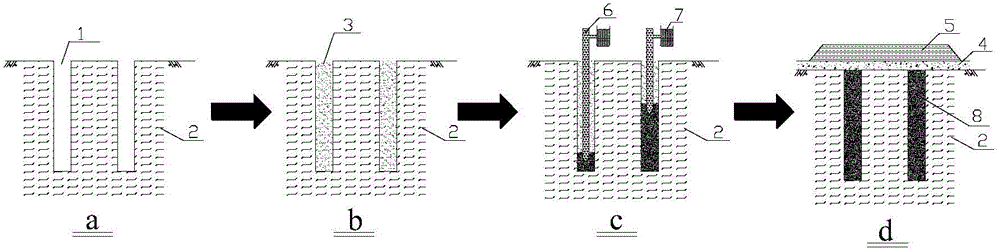

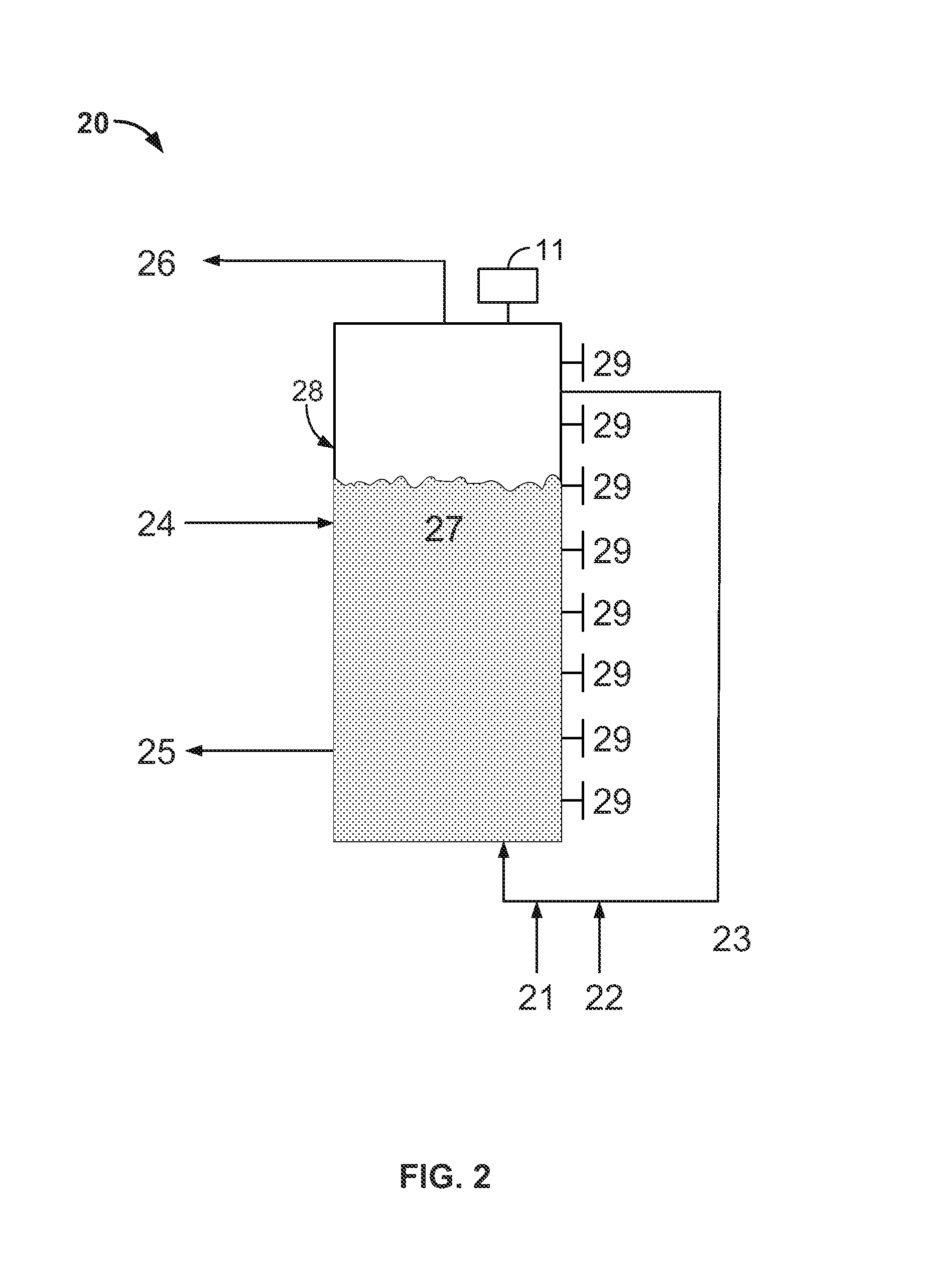

Disclosed is a method for soft soil foundation treatment through microorganism grouting sand drain. The method comprises the steps that a, a pile hole 1 is formed in a soft soil foundation to be treated, and sand is poured into the pile hole 1 to form a sand pile; b, a urease-producing microorganism solution 9 and a nutritive salt solution 10 are sequentially and evenly injected into the sand pile through a grouting tube 6, sand cementation is achieved through the microorganism induction calcium carbonate crystal technology, the concentration of the urease-producing microorganism solution 9 and the concentration of the nutritive salt solution 10 are controlled, sand in the pile body forms a specific cementation mode, and the good water permeable characteristic is ensured; c, after the microorganism grouting solidification sand pile is formed, a flexible water permeable sand cushion 4 is laid on the top of the foundation jointly formed by the sand oil and pile space soil 2, prepressing loads 5 are exerted on the top of the flexible water permeable sand cushion 4, pore water in the pile space soil 2 is made to be drained along a drainage channel formed by the sand pile and the sand cushion, the pile space soil is solidified, and the composite foundation with the high bearing capacity is formed jointly through the soft soil obtained after drainage and solidification are carried out on the microorganism grouting sand pile and the flexible water permeable sand cushion covering the soft soil.

Owner:NANJING FORESTRY UNIV

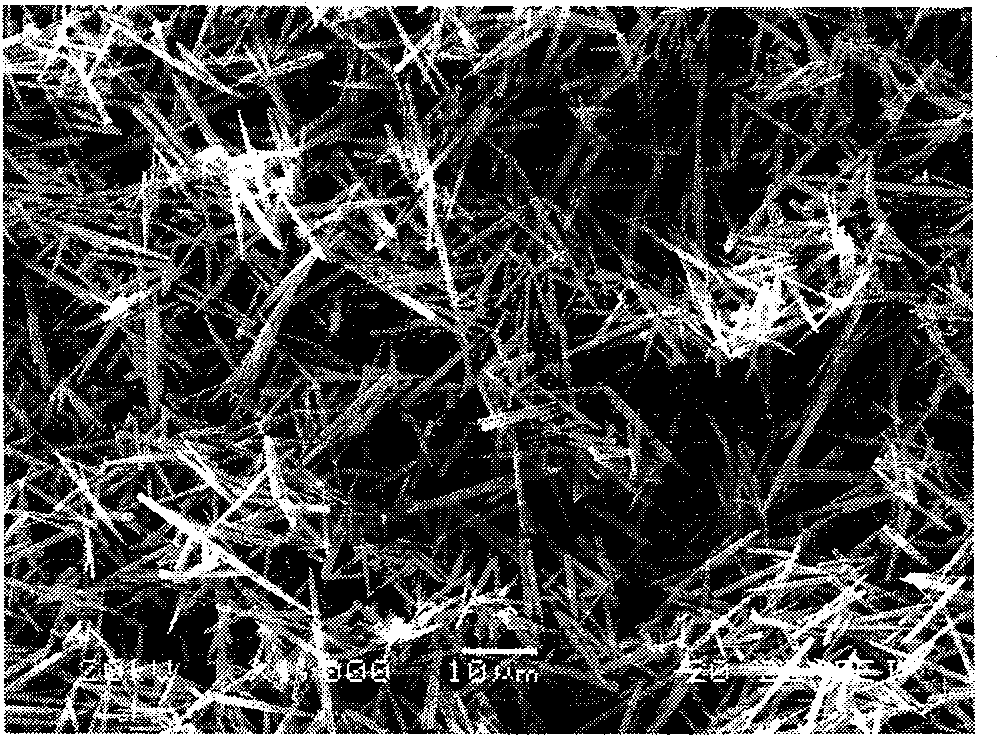

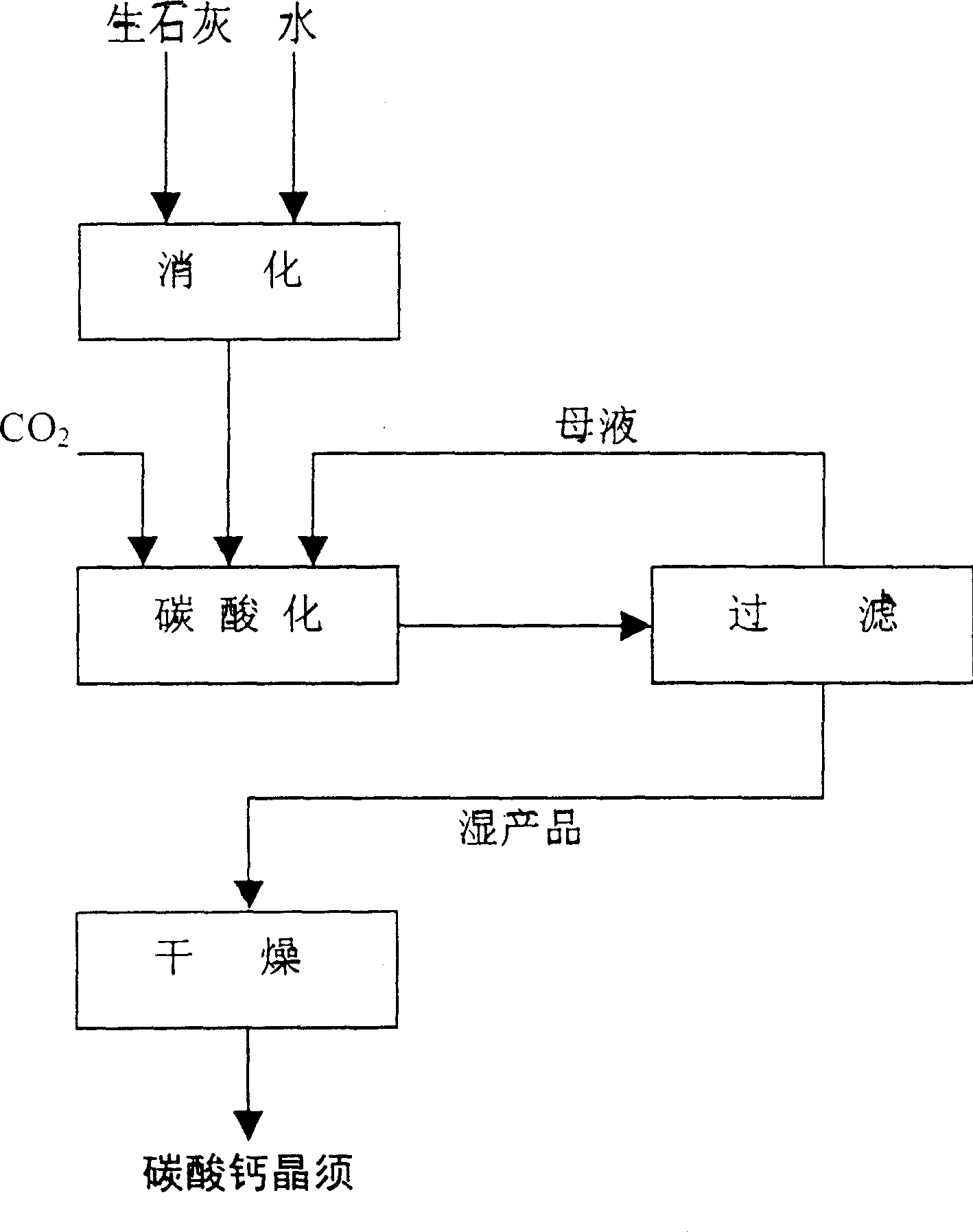

Single dispersing micron chopped fiber-like aragonite type calcium carbonate and preparation method thereof

InactiveCN1631792ASimple methodThe method is simple and controllableCalcium/strontium/barium carbonatesSolubilityPrinting ink

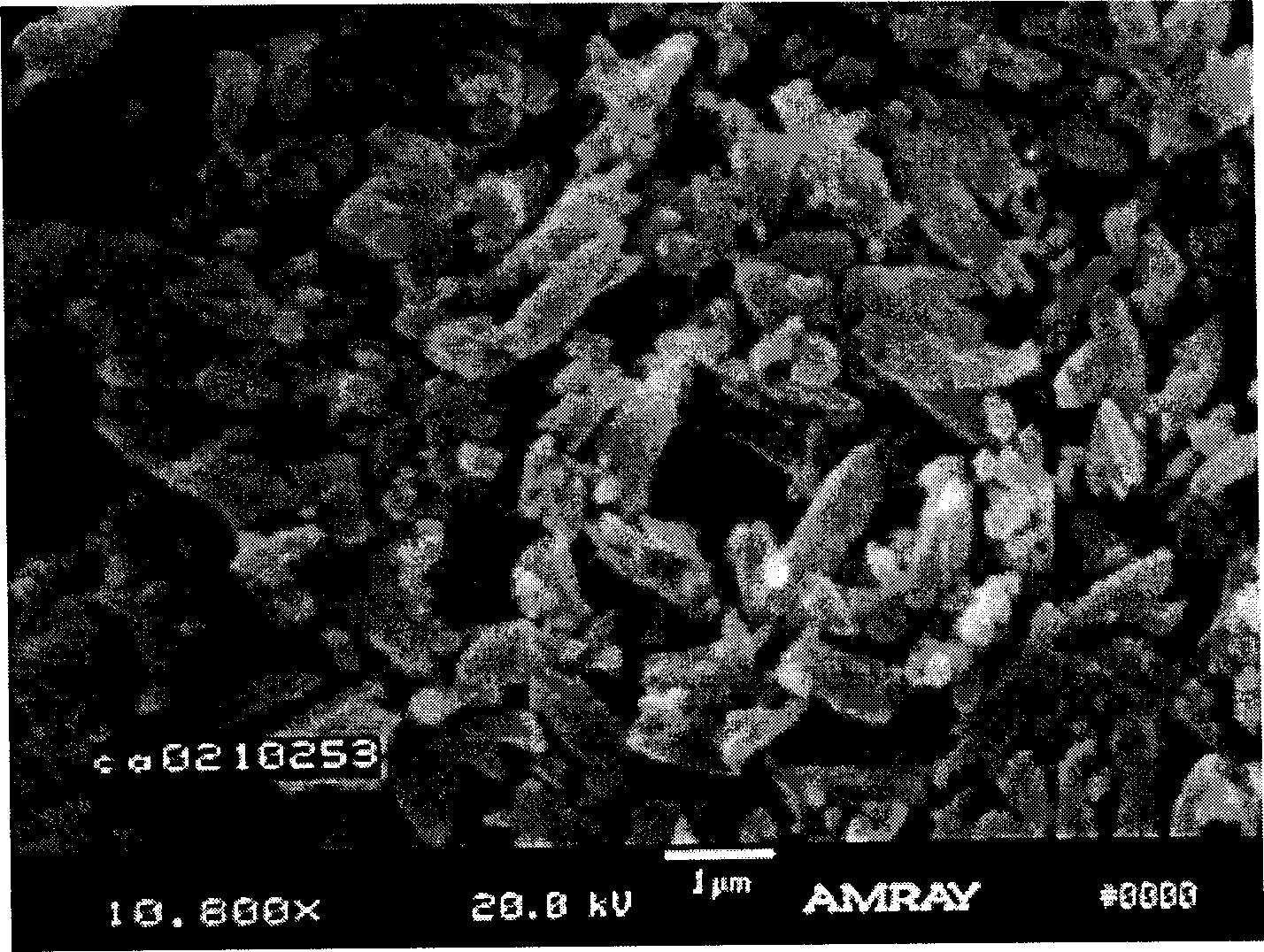

The invention relates to a single-distributive micron short fiber-typed vaterite calcium carbonate and its preparing method. The calcium carbonate crystal is needle short fiber-typed, its length is 2-8 micron and width is 0.3-1.5 micron, the ratio of length and diameter is 5-10, its content of vaterite calcium carbonate is larger than 90% with small particle on the surface of. The preparing method includes mix the aqueous solution of carbonate containing water soluble organic solvent with aqueous solution of calcium salt also containing that, make use of the different dissolubility of carbonate and calcium salt in water soluble organic solvent and water, and the different solvation to calcium ion, compound the product. The calcium carbonate has remarkable single distribution, large ratio of length and diameter, high activity of surface, suitable for coating on paper, filling plastic, coating, printing ink and paper, as well as the raw material for calcium preparations.

Owner:ZHEJIANG UNIV

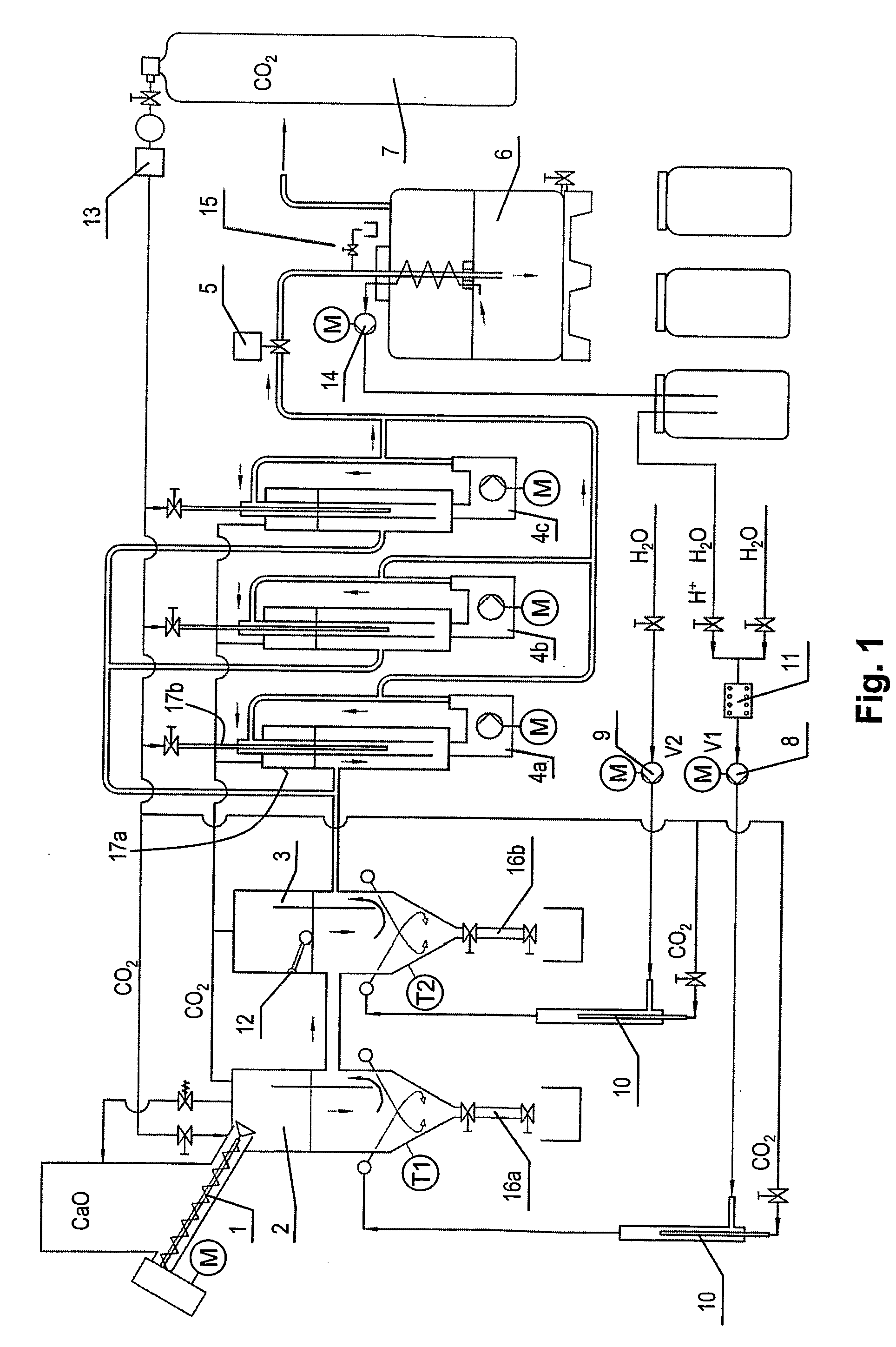

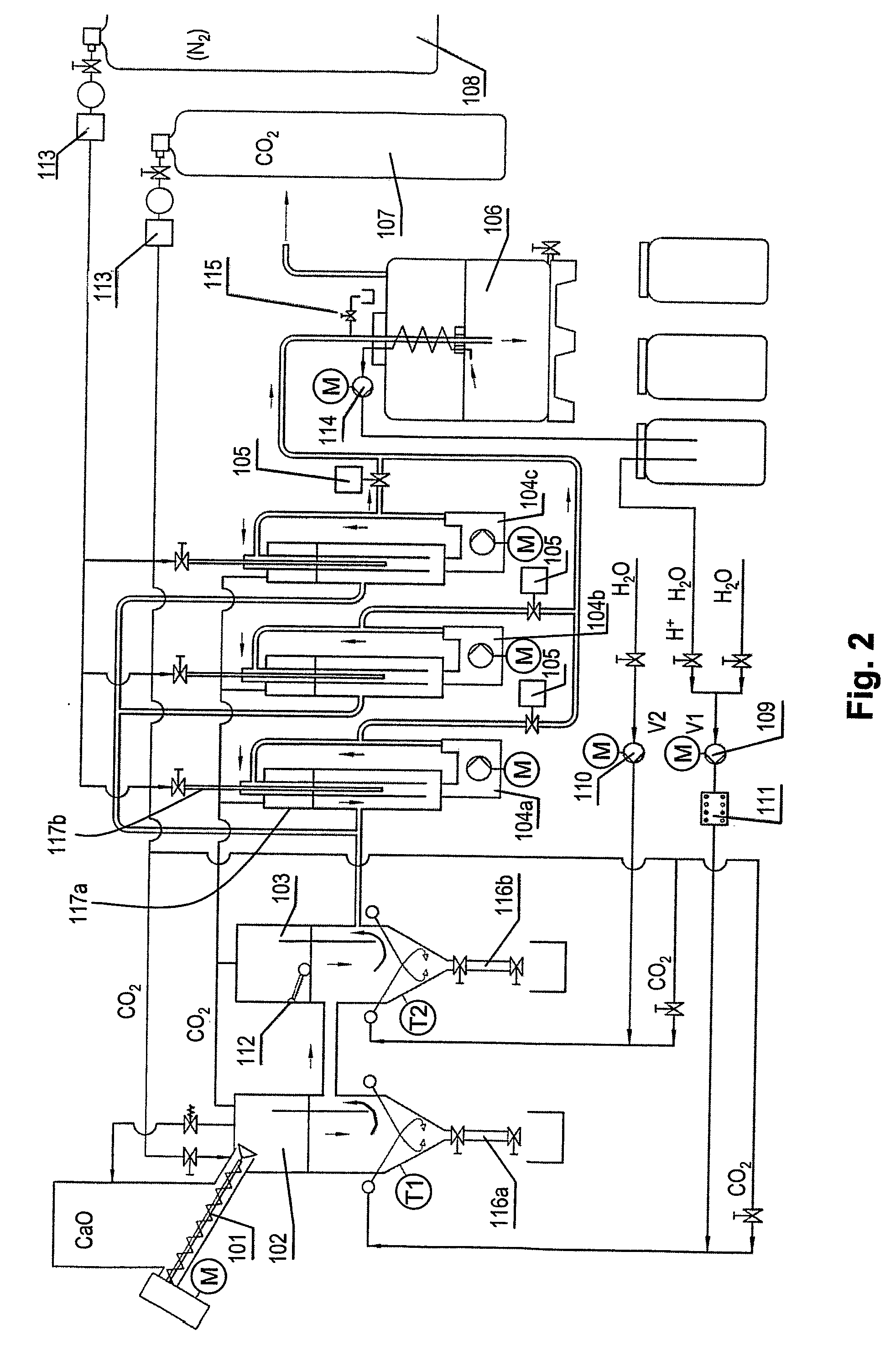

Process and apparatus for producing suspensions of solid matter

InactiveUS20090081112A1Short processing timeUse minimizedCalcium/strontium/barium carbonatesMaterial nanotechnologyCalcium hydroxideSolid mass

Method for producing nanosized calcium hydroxide crystals or particles, according to which method the calcium oxide-bearing initial material is brought into contact with carbon dioxide in the aqueous phase. Calcium carbonate crystals or particles are produced in a mixture, the pH of which is below 7. Using the present invention, it is possible to combine the two stages of producing CaCO3 particles into one entity, in which case the overall processing time is shortened and the use of external energy is minimized.

Owner:NORDKALK ABP

Prepn of transparent nanometer calcium carbonate for high-grade lithographic ink

InactiveCN1332207AImprove qualityControl rateInorganic pigment treatmentInksCarbonizationSurface charges

Through carbonization in Ca(OH)2 suspension by leading-in kiln gas containing CO2; controlling the nucleation rate of calcium carbonate crystal nucleus by the temperature of Ca(OH)2 suspension and the CO2 flow rate; controlling the growth rate of crystal faces by adding crystal form regulator; adding dispersant to regulate surface charge; and liquid phase surface coating dispersed cubic nanometercalcium carbonate grains, transparent nanometer calcium carbonate material for ink is prepared, which has size of 15-40 nm, GSD of 1.57, specific surface area greater than 35 sq m / g, ink oil absorption of 0.4 g / g and no coagulation. The calcium carbonate material may be used to produce transparent ink for high grade lithography.

Owner:倪海兵 +1

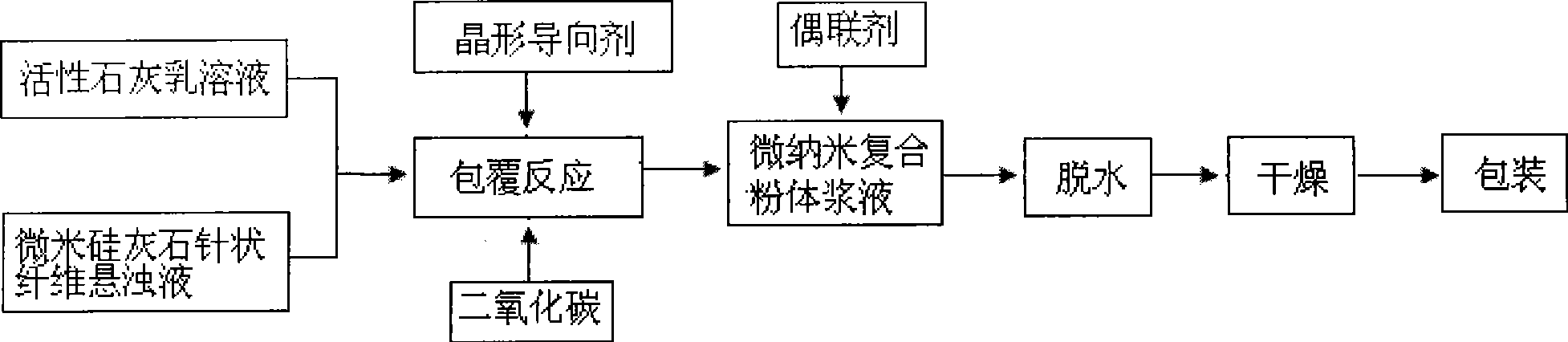

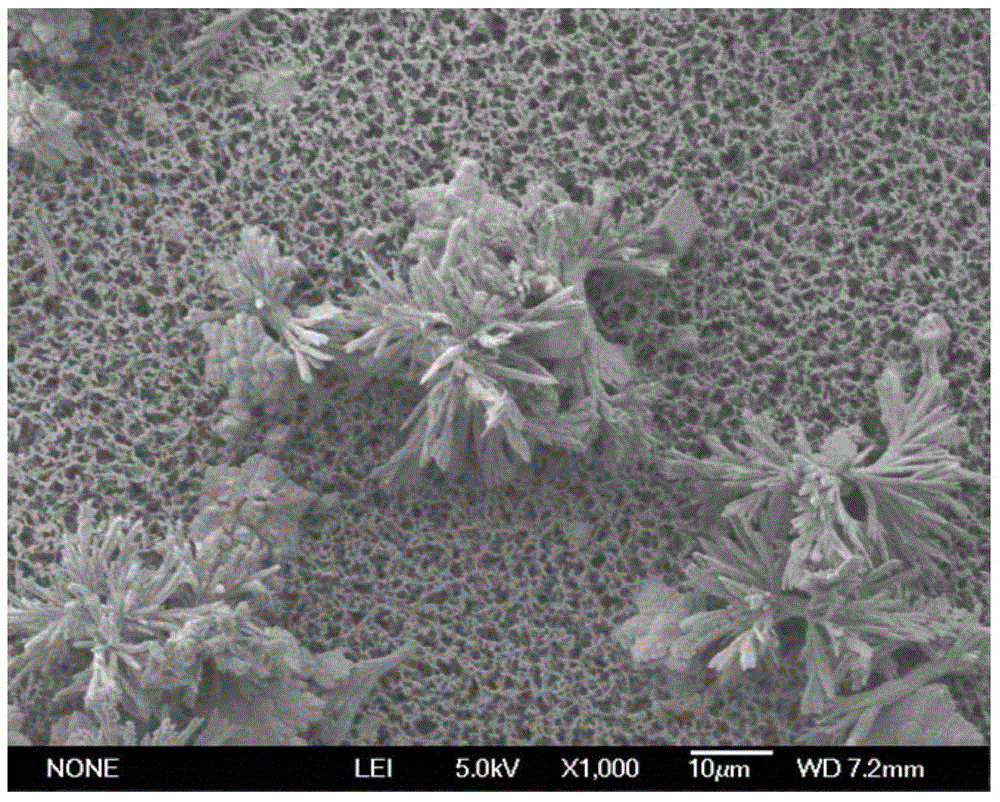

Grammite raphioid fibre crystal-nano calcium carbonate micro-nano composite powder material and production method

InactiveCN101498052AHigh surface energyHigh chemical activityPolycrystalline material growthAfter-treatment detailsMicro nanoFiber crystal

The invention relates to a surface modified product of an acicular wollastonite crystal and a production method thereof. The product is micro-nano composite powder by coating a nanometer calcium carbonate crystal on the surface of the acicular wollastonite fiber crystal. The method comprises the following steps: firstly, preparing an active lime milk solution and an acicular wollastonite fiber solution; compounding the two solutions into a suspension; adding a crystalline directing agent to the suspension and filling CO2 gas for a coating reaction so that the nanometer calcium carbonate crystal gradually grows on the surface of an acicular aedelforsite fiber, and the micro-nano composite powder by coating a nanometer calcium carbonate crystal on wollastonite is obtained; and coating a layer of coupling agent on the surface of the micro-nano composite powder to obtain the acicular wollastonite fiber crystal-nanometer calcium carbonate crystal-coupling agent composite powder material. The product keeps the superior characteristics of the acicular wollastonite crystal and the nanometer calcium carbonate crystal, improves the surface energy and the chemical activity of wollastonite composite particles and can be well stuck with organic polymers so as to form a favorable interface and improve the bonding force between fillings and basal bodies, such as plastics, pulp, and the like.

Owner:颜鑫 +3

Inflaming retarding high-temperature-resisting foam concrete and preparation method thereof

The invention discloses inflaming retarding high-temperature-resisting foam concrete and a preparation method thereof. The concrete is prepared by mixing a gel material, heat-resisting aggregates, a liquid-state composition, an admixture and a foaming agent, wherein the gel material is slag silicate cement and grade-I fly ash; the heat-resisting aggregates comprise vitrified micro-beads, crushed clay clinkers, nano clay and corundum sand; the liquid-state composition comprises a water reducing agent, water and acrylic resin; and the admixture comprises phosphate, an inorganic fire retardant, glass fibers and calcium carbonate crystal whiskers. The inflaming retarding high-temperature-resisting foam concrete prepared by the preparation method has the advantages of small density, relatively high strength, low heat conductivity coefficient, good heat insulation performance and the like; and the combustion performance is grade A, and the fireproof limit can reach 4 hours so that the inflaming retarding high-temperature-resisting foam concrete is a fireproof heat-insulation material with a good comprehensive performance.

Owner:CHINA MCC17 GRP +1

Method for preparing brake block by calcium carbonate crystal whisker

InactiveCN101205456AImprove high temperature resistanceReduce decomposition rateOther chemical processesPorosityDecomposition

The invention relates to a method for preparing a brake sheet through adopting calcium carbonate crystal whisker, belonging to the friction material field, wherein the following raw materials of corresponding part by weight are adopted: 5 to 15 portions of adhesive which adopts phenol formaldehyde resin, 20 to 30 portions of reinforcing material which is obtained through mixing steel fiber or ceramic fiber with one or several of aramid fiber, mineral fiber and glass fiber, 1 to 15 portions of grinding agent which comprises one or combination of several of aluminum sesquioxide, ferric oxide, magnesium oxide and friction powder, 5 to 15 portions of lubricant which comprises one or combination of several of graphite, molybdenum disulfide and mica, 5 to 15 portions of stabilizer calcium carbonate crystal whisker, and 30 to 50 portions of filler which comprises one or combination of several of barium sulfate, potassium titanate and magnesium oxide. The brake sheet, which is made through the method, can effectively increase porosity and improve the high-temperature resistance of material, thereby lowering the decomposition rate of organic material at a high temperature; meanwhile, the brake sheet can slow down the gaseous escape speed on a friction surface during fading, thereby reducing fading rate and the change rate of friction coefficient at high speed to less than 10 percent.

Owner:信义集团公司

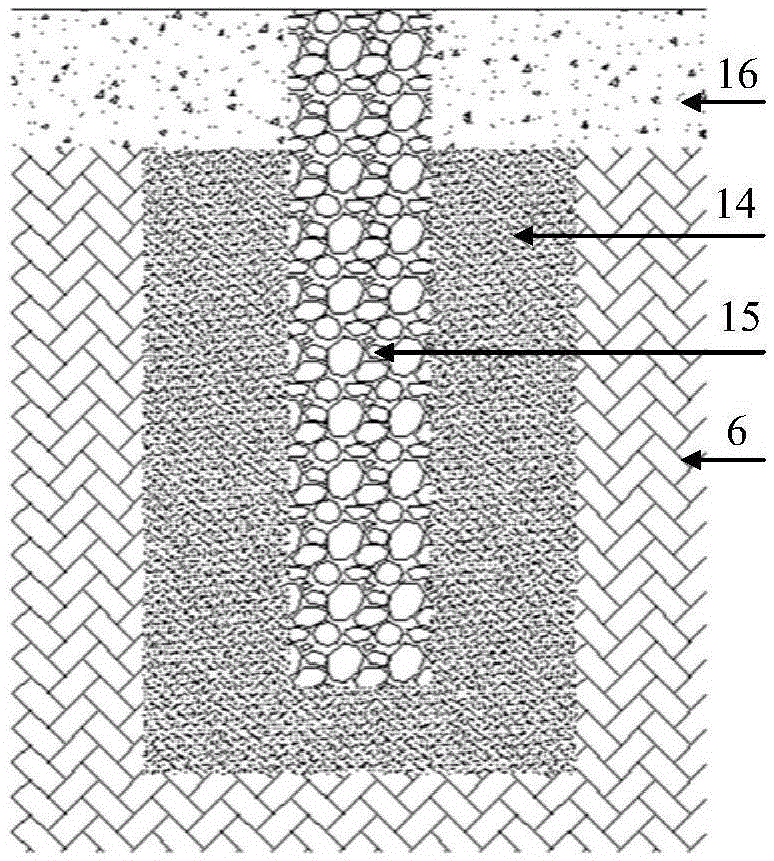

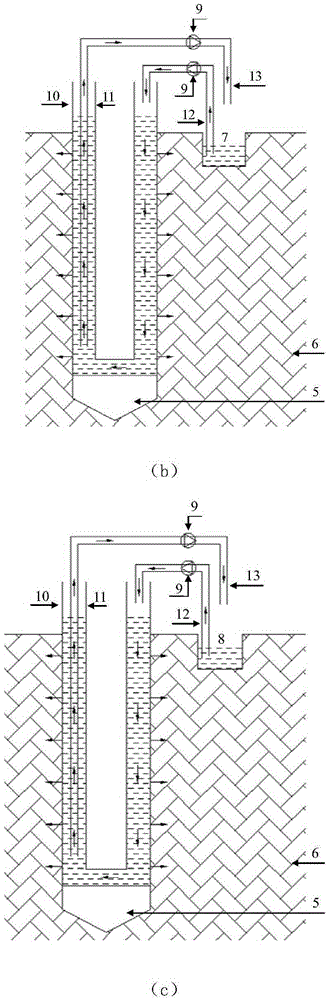

Composite foundation with discrete material pile restrained through microorganism soil solidification and construction method

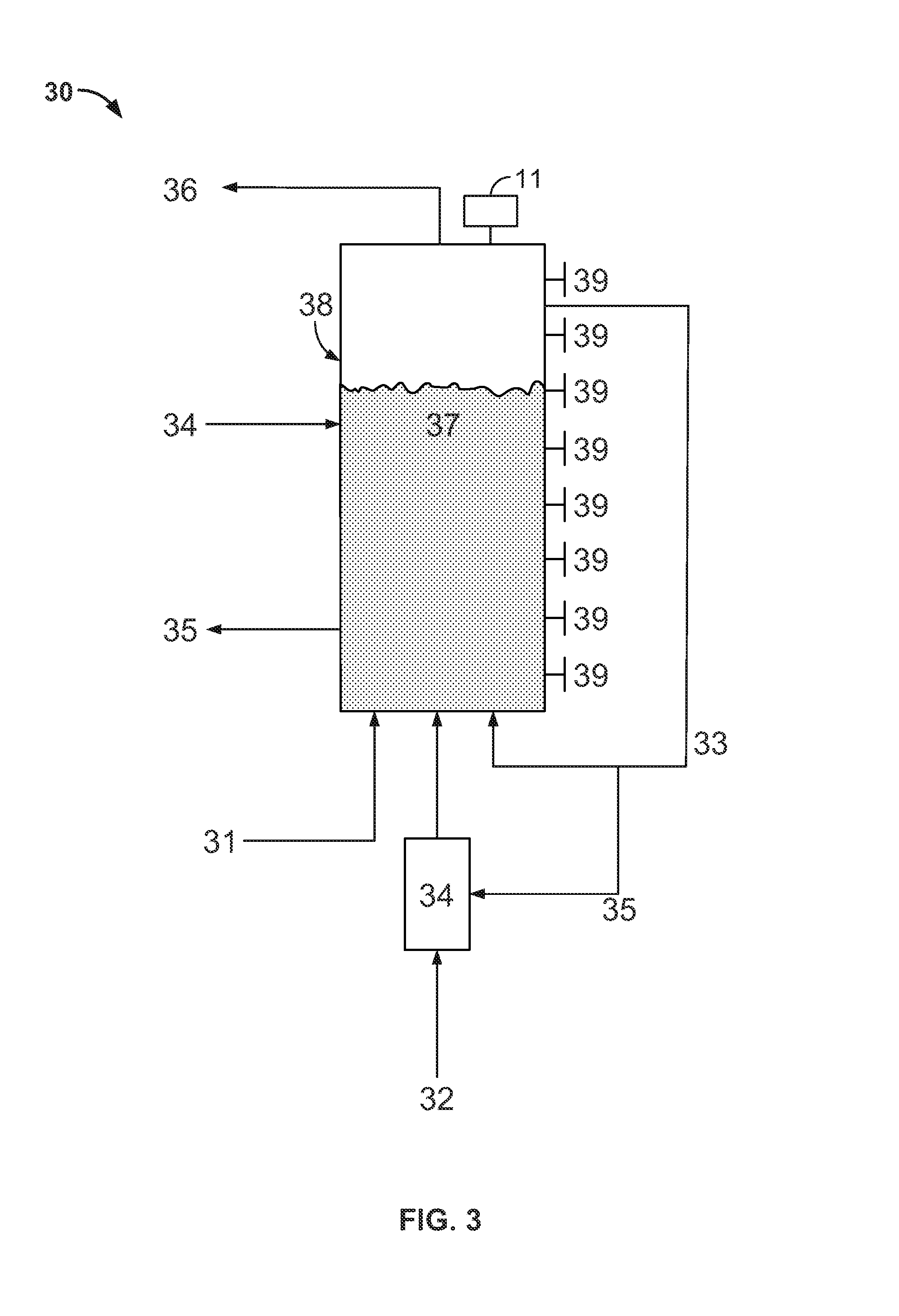

ActiveCN105386436AImprove bearing capacityIncrease profitBuilding constructionsOrganic fertilisersMicroorganismSoil science

The invention relates to a composite foundation with a discrete material pile restrained through microorganism soil solidification and a construction method. The construction method includes the steps that a, a pile pipe is pressed into a foundation body; b, meanwhile, microorganism bacterium liquid is injected into a gap between an inner steel sleeve and an outer steel sleeve and diffused into the foundation body around the pile; c, the microorganism bacterium liquid is pumped out, a cementing solution is injected and diffused into the foundation body around the pile and reacts with the microorganism bacterium liquid to generate calcium carbonate crystals, and loose sandy soil or floury soil is cemented; d, the step b and the step c are repeated until the soil around the pile meets reinforcement requirements; e, discrete materials are poured into a hole of the inner steel sleeve; and f, a bed course is laid, so that the composite foundation is formed. According to the composite foundation with the discrete material pile restrained through microorganism soil solidification, the microorganism bacterium liquid and the cementing solution react to generate calcium carbonate so as to solidify the soil around the pile, so that the strength of the soil around the pile is improved, and the discrete material pile is protected against the problems of different pile diameters, bulging damage, pile hole caving and the like; the microorganism solidified soil and the pile can be combined to bear loads, and thus the bearing capacity of the single pile is improved.

Owner:NANJING FORESTRY UNIV

Calcium carbonate surface modifying method

InactiveCN101914311AGood dispersionGood compatibilityPigment treatment with non-polymer organic compoundsSlurryCarbon chain

The invention discloses a calcium carbonate surface modifying method, which comprises the following steps of: adding a surface treatment agent into slurry obtained after the carbonation reaction of light calcium carbonate or precipitated calcium carbonate, wherein the treatment agent consists of unsaturated long carbon chain plant oil and a cosolvent; stirring at a high speed of 500 to 1,200rpm for 0.5 to 2h to perform surface treatment on the calcium carbonate; and obtaining the finished product of modified calcium carbonate by dewatering, drying, crushing and packaging the calcium carbonate emulsion after the reaction. The surface treatment agent of the invention has high dispersion in water at normal temperature, uniformly acts on the surfaces of calcium carbonate grains under the action of a high-speed shearing force, physical absorption and the hydroxyl on the calcium carbonate surface and restrains the crystal growth and secondary aggregation of the calcium carbonate, so that the modified calcium carbonate has uniform aperture, high dispersion, high affinity with organic high polymer and high filling property. In the invention, when the liquid surface treatment agent is used, the modification reaction process of the calcium carbonate needs no heating and is low in energy consumption and environmentally-friendly.

Owner:ZHEJIANG CHANGSHAN JINXIONG

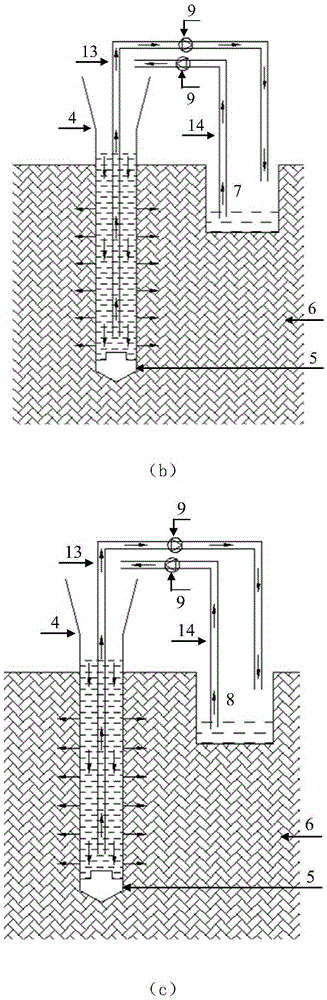

Microorganism soil-reinforcement cement fly-ash gravel (CFG) pile composite foundation and construction method

ActiveCN105386433AHigh strengthImprove bearing capacityBulkheads/pilesSoil preservationMicroorganismAggregate (composite)

The invention discloses a microorganism soil-reinforcement cement fly-ash gravel (CFG) pile composite foundation and a construction method. The construction method comprises the steps that a, a pile pipe is pressed into a foundation; b, microorganism bacterium liquid is injected into the pile pipe at the same time, and the microorganism bacterium liquid is made to diffuse towards the foundation around the pile pipe; c, the microorganism bacterium liquid is pumped out, and a cementing solution is injected into the pile pipe and made to diffuse to the foundation around the pile pipe and reacts with the microorganism bacterium liquid to generate calcium carbonate crystals, and incompact sandy soil or floury soil is cemented; d, the step b and the step c are executed repeatedly till the soil around the pile pipe meets the reinforcement requirement; e, pipe-drawing pile formation is conducted while cement-ash stabilized aggregates are poured; and f, a bed course is laid, so that the CFG pile composite foundation is formed. According to the microorganism soil-reinforcement CFG pile, the soil around the pile pipe is reinforced through calcium carbonate generated through reaction between the microorganism bacterium liquid and the cementing solution, so that the strength of the soil around the pile pipe is improved, and the quality problems of necking, pile breakage, soil carrying and the like in the pile forming process are solved; in addition, a reinforced soil body can be combined with a pile for bearing, and the bearing capacity of the single pile is effectively improved.

Owner:NANJING FORESTRY UNIV

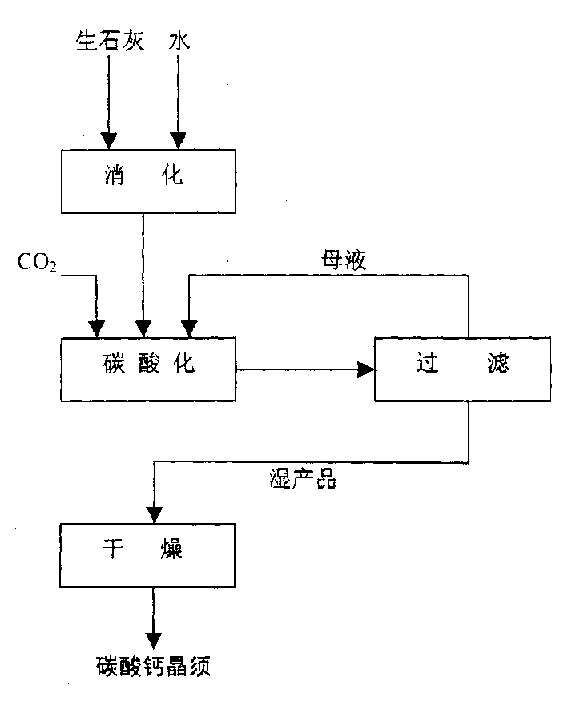

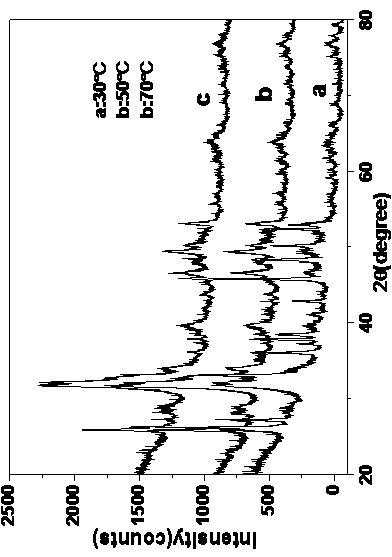

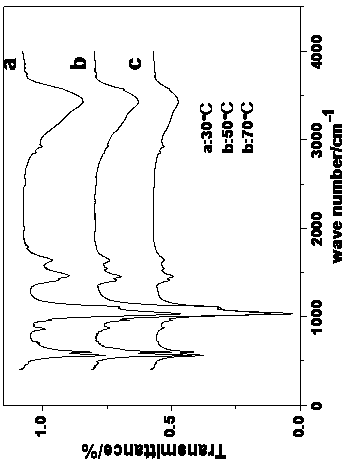

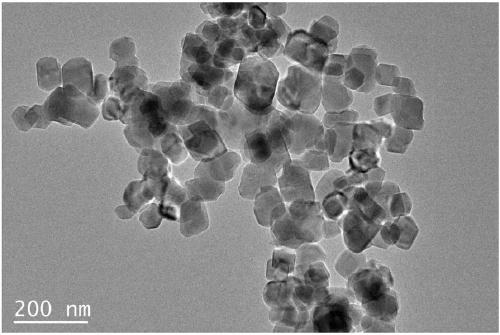

Preparation method of morphology controllable calcium carbonate based on temperature control

ActiveCN104692437ASimple processWide range of raw materialsCalcium/strontium/barium carbonatesCalcium crystalsTemperature control

The invention relates to a preparation method of morphology controllable calcium carbonate based on temperature control. The preparation method of the morphology controllable calcium carbonate based on the temperature control comprises the following steps: introducing a solution containing carbonate or gas such as CO2 which can generate carbonate or a gas mixture containing CO2 into a solution containing calcium ions at the temperature of 10-100 DEG C, initiating precipitation reaction, obtaining a precipitate mixture several minutes later, and drying at room temperature, so that micron-sized calcium carbonate crystals with specific morphology are obtained. The calcium carbonate obtained by adopting the preparation method is good in correspondence between morphology and reaction temperature, and the correspondence is independent of type of a reactant; the obtained calcium carbonate crystals are well dispersed and uniform in sized; meanwhile, control of crystal form is efficient and stable; besides, by adopting a temperature control process, one-step synthesis, simplicity and practicability are realized, and industrial cost is low, so that the preparation method of the morphology controllable calcium carbonate based on the temperature control can be widely applied to batch preparation of calcium carbonate in different morphologies.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

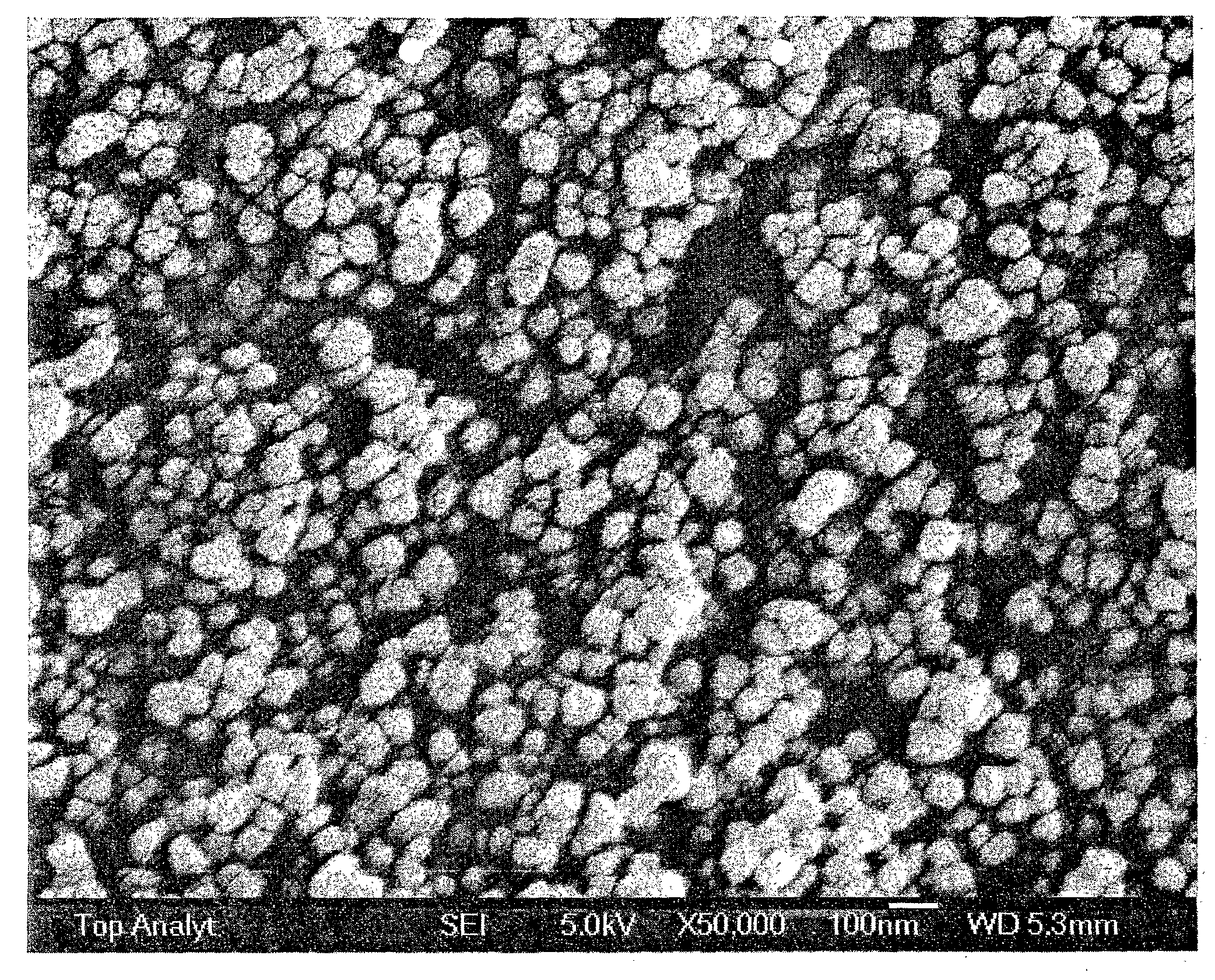

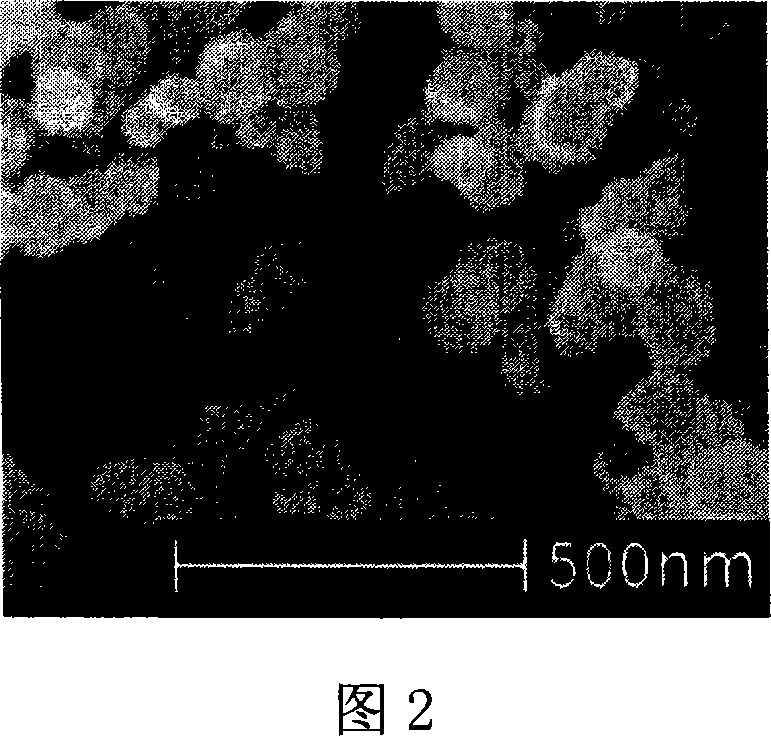

Production of high-purity spherical nano-calcium carbonate

ActiveCN101074106ACrystalline form intactHigh purityCalcium/strontium/barium carbonatesCalcium hydroxideChloride

Production of high-purity spherical calcium carbonate is carried out by taking calcium chloride as chlorine source, taking mixture of calcium hydroxide and polyacrylamide as impurity remover, reacting it with sodium hydroxide, bubbling while carburizing by pure carbon dioxide, growing calcium carbonate crystal grain fast and enlarging. It has excellent purity, activity and dispersion, it simplifies and optimizes process, shortens reactive time and saves energy resources, it costs low and has no environmental pollution.

Owner:仙桃市中星电子材料有限公司

Method for fixing CO2 in industrial waste gas by using calcium-based bulk industrial solid waste phosphogypsum through strengthening and carbonating

InactiveCN102627309AReduce miningLow costCalcium/strontium/barium carbonatesAmmonium sulfatesPhosphogypsumSlurry

The invention discloses a method for fixing CO2 in industrial waste gas by using calcium-based bulk industrial solid waste phosphogypsum through strengthening and carbonating. The method comprises the following steps of: firstly, washing phosphogypsum with hot water to remove water-soluble impurities; secondly, adding the phosphogypsum cleaned in the first step in ammonia water for carrying out alkali-dissolved reaction to leach part of calcium ions; thirdly, adding a solid-liquid mixer generated in the second step into an airtight reactor, introducing CO2 waste gas for carrying out a gas-liquid-solid multi-phase CO2 carbonated fixing reaction to generate a calcium carbonate crystal, filtering, separating, washing and drying to obtain crystalline calcium carbonate; and fourthly, adding crystallized mother solution obtained in the third step in sulfuric acid and neutralizing to neutral and carrying out evaporating, concentrating, slurry spraying and granulating, drying and screening to obtain a granular ammonium sulfate product. According to the method disclosed by the invention, two valuable products are generated by using two wastes, so that the production cost of raw materials is reduced and the value of products is improved; and the method has the advantages of easiness in industrialization, better economic benefit, social benefit and industrial application prospect.

Owner:中化化肥有限公司重庆磷复肥工程技术研究中心

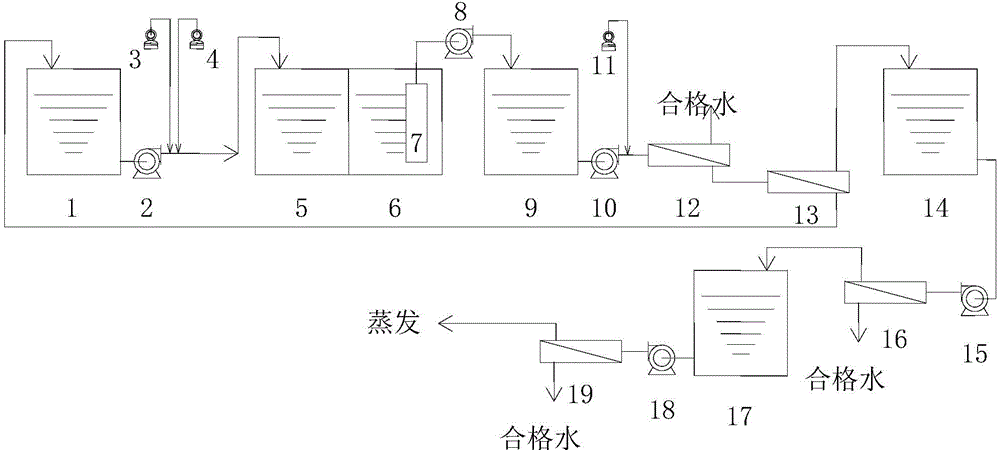

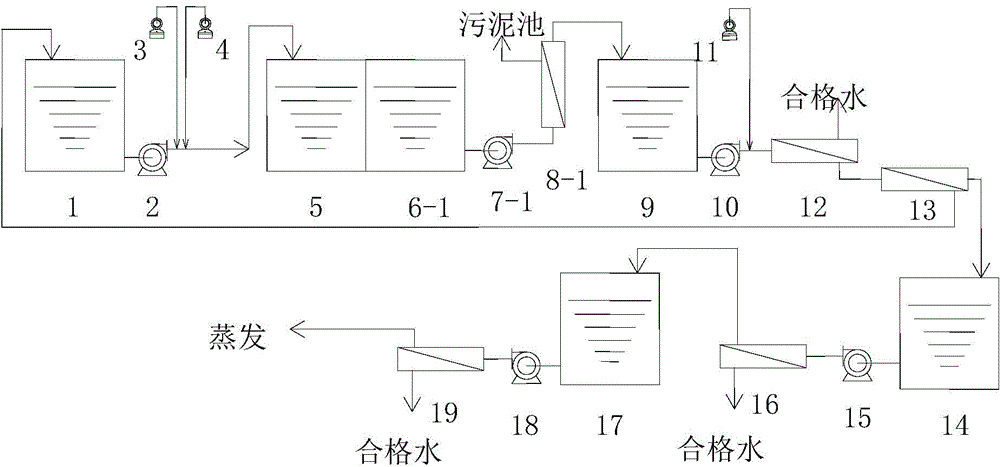

Method for treating reverse osmosis concentrated water and circulating wastewater by whole membrane method

ActiveCN104609610AReduce hardnessReduce salt contentScale removal and water softeningTreatment involving filtrationWater qualityProduced water

The invention discloses a method for treating reverse osmosis concentrated water and circulating wastewater by a whole membrane method, and belongs to the technical field of wastewater treatment and reclaimed water reuse. The method disclosed by the invention comprises the following steps: regulating the water amount and the water quality of wastewater by using a regulating tank; adding alkali to react with magnesium and calcium ions in a reaction tank to generate crystals of magnesium hydroxide and calcium carbonate; adding a mixed solution into a ceramic membrane filtering device; after the crystals of the magnesium hydroxide and calcium carbonate are filtered by a ceramic membrane, performing filter-pressing processing on a concentrated solution by using a plate frame; regulating the filtrate by adding an acid, and adding the regulated filtrate into a first-stage reverse osmosis device; recycling reverse osmosis pure water; adding the reverse osmosis pure water into a nano-filter; returning the concentrated water which is subjected to nano-filtration to the regulating tank; concentrating the water produced by the nano-filtration by using a second-stage reverse osmosis device; recycling the reverse osmosis produced water; further concentrating the concentrated water in a forward osmosis device; recycling the water produced by the forward osmosis; evaporating a trace amount of remaining concentrated water in an evaporator, and using the trace amount of remaining concentrated water in other ways, so as to finally realize zero emission of the wastewater.

Owner:山东泰禾环保科技股份有限公司

One-step carbonization process of preparing cubic calcium carbonate of 80-100 nm size

InactiveCN1361063AImprove electrical performanceImprove flame retardant performanceCalcium/strontium/barium carbonatesCalcium hydroxideEmulsion

Into calcium hydroxide emulsion of 10-12 wt% concentration and at 20-25 deg.c, compound crystal form controlling agent is added while stirring, and then the mixture is transferred into a bubbling carbonating tower for carbonization for 50-70 min while introducing CO2 gas in the rate of 50-80 1 / min. Kg calcium hydroxide and cold water to control the temperature not higher than 60 deg.c until the pH value being reduced to 7-8. Through the one-step carbonization process, cubic calcium carbonate of 80-100 nm size is prepared. The said process is suitable for use in industrial production and has low production cost and high production efficiency, and the product has excellent dispersant characteristic and may be widely used, especially in producing silicon rubber product.

Owner:GUANGZHOU GBS HIGH TECH & IND

Method for preparing calcium carbonate crystal whisker with controllable shape

InactiveCN101684570AHigh purityImprove qualityCalcium/strontium/barium carbonatesPolycrystalline material growthWhiskersChloride

Owner:成都市蜀阳硼业化工有限公司

Method for producing light active calcium carbonate

InactiveCN1456508AUniform particle sizeGood dispersionCalcium/strontium/barium carbonatesPigmenting treatmentDispersityWater insoluble

A process for preparing the light active calcium carbonate includes such steps as before or during carbonating reaction in the process for preparing light or precipitated calcium carbonate, adding the surfactant prepared from water-insoluble salt of fatty acid, alcohol or ether type surface wetting agent and water, carbonating reacting to obtain calcium carbonate emulsion, dewatering, drying and pulverizing. Its advantages are high granular uniformity, dispersity and thermal stability, and good affinity to organic high polymer.

Owner:ZHEJIANG CHANGSHAN JINXIONG

Method for preparing flaky calcite calcium carbonate crystal

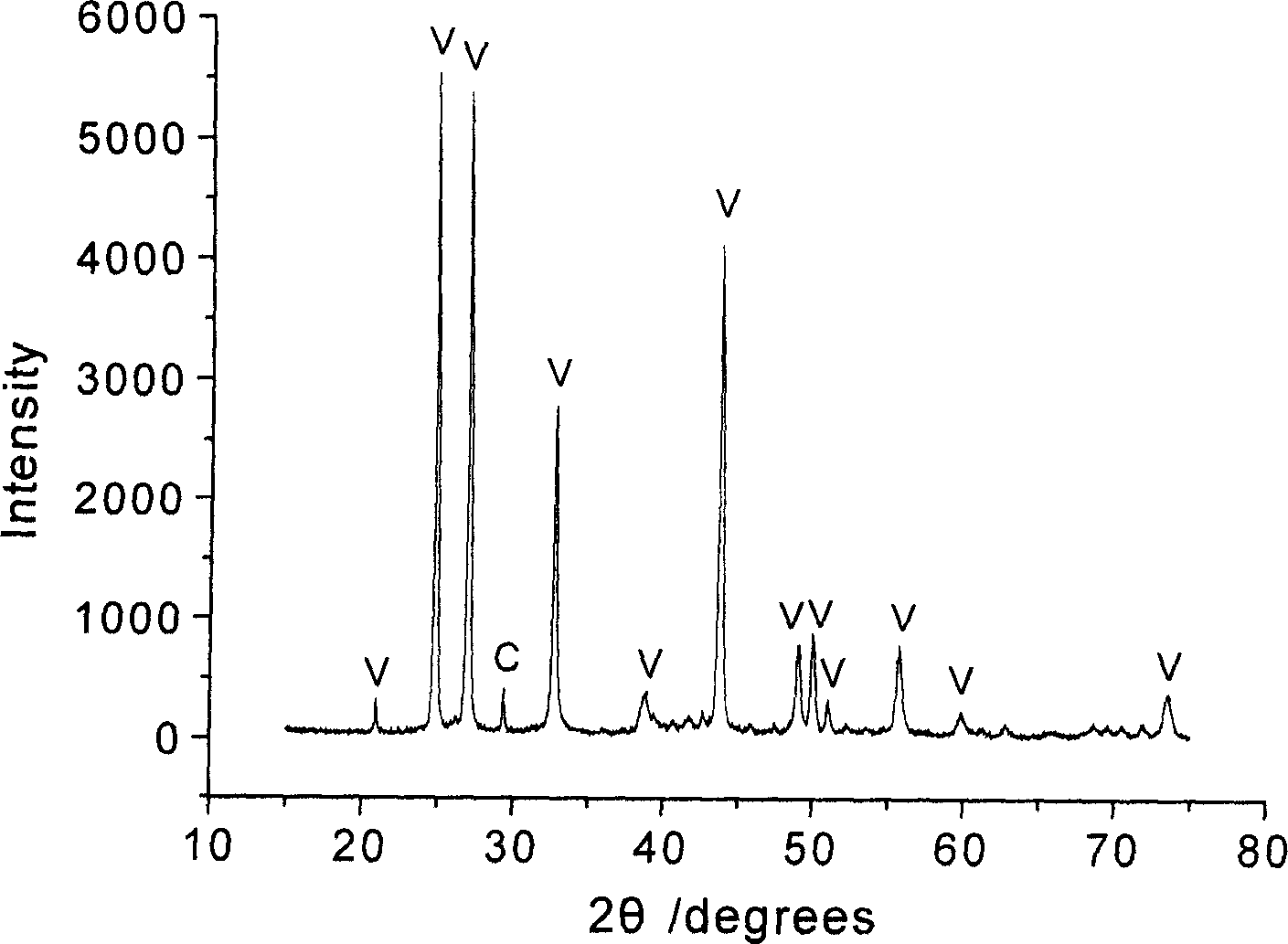

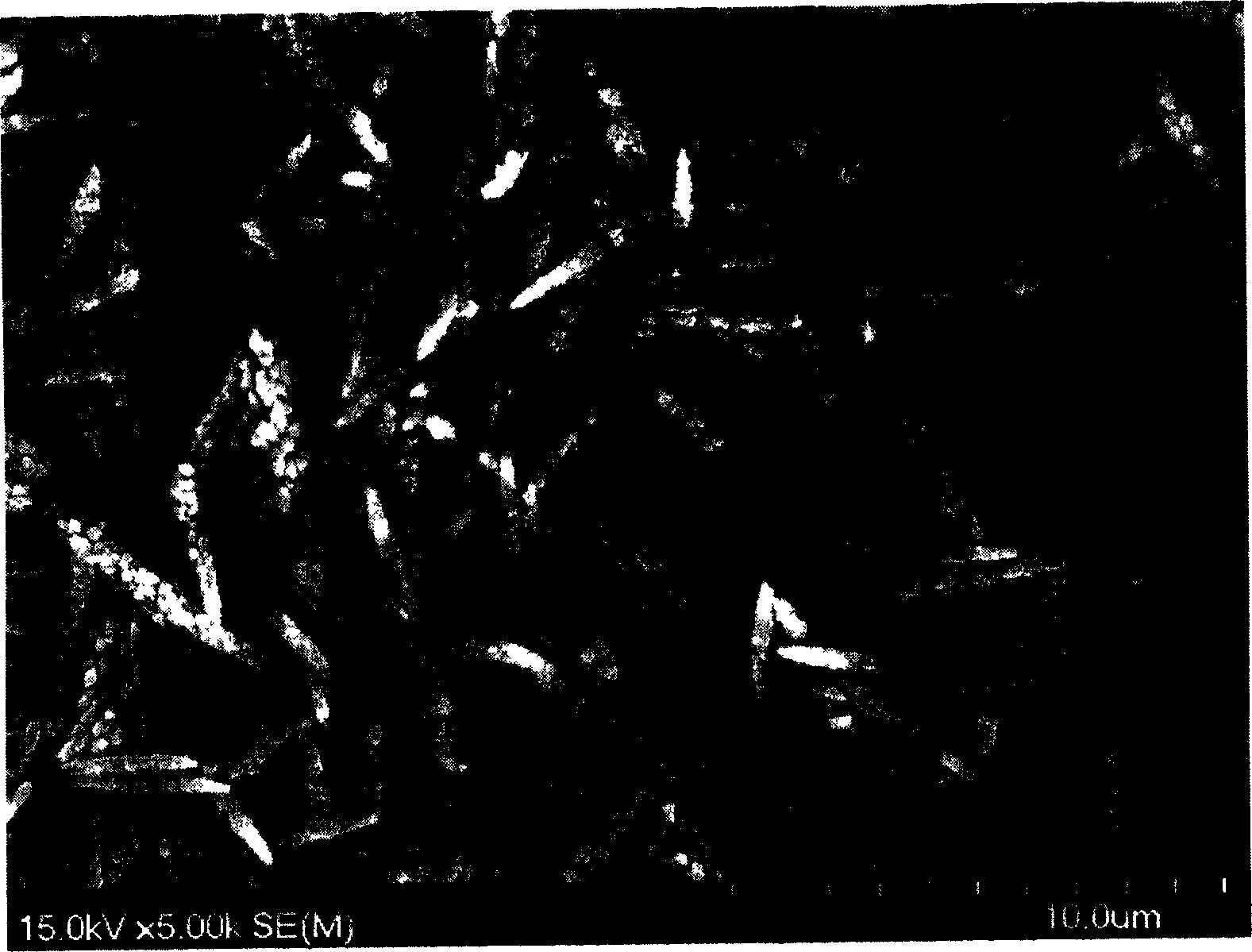

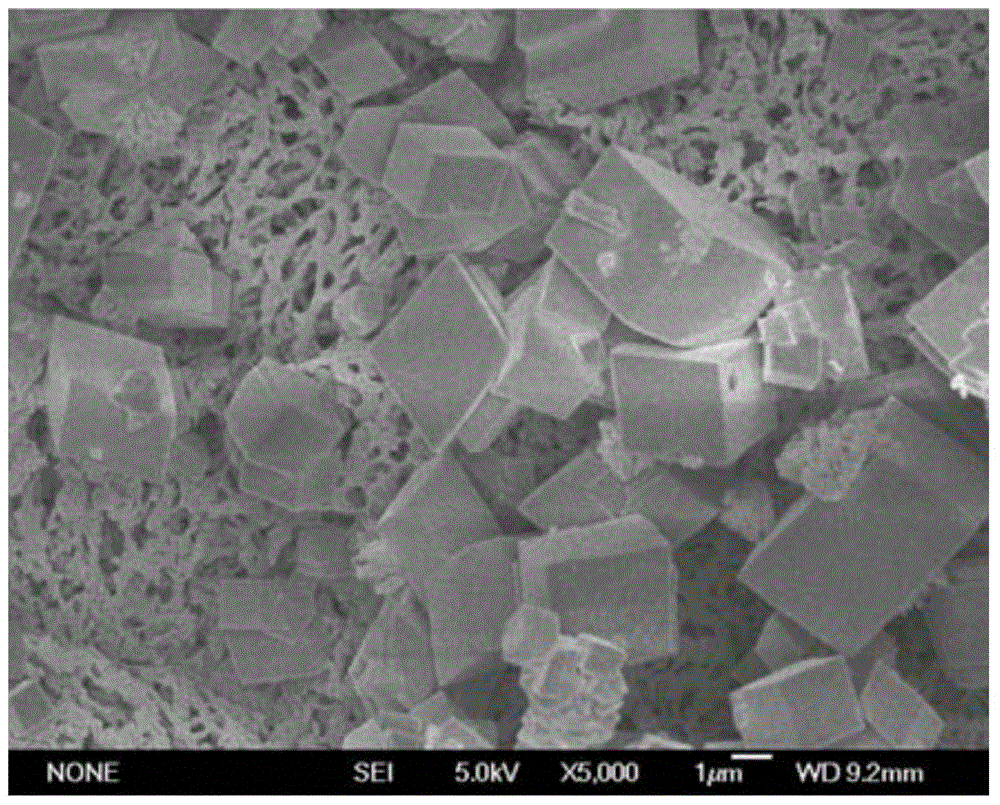

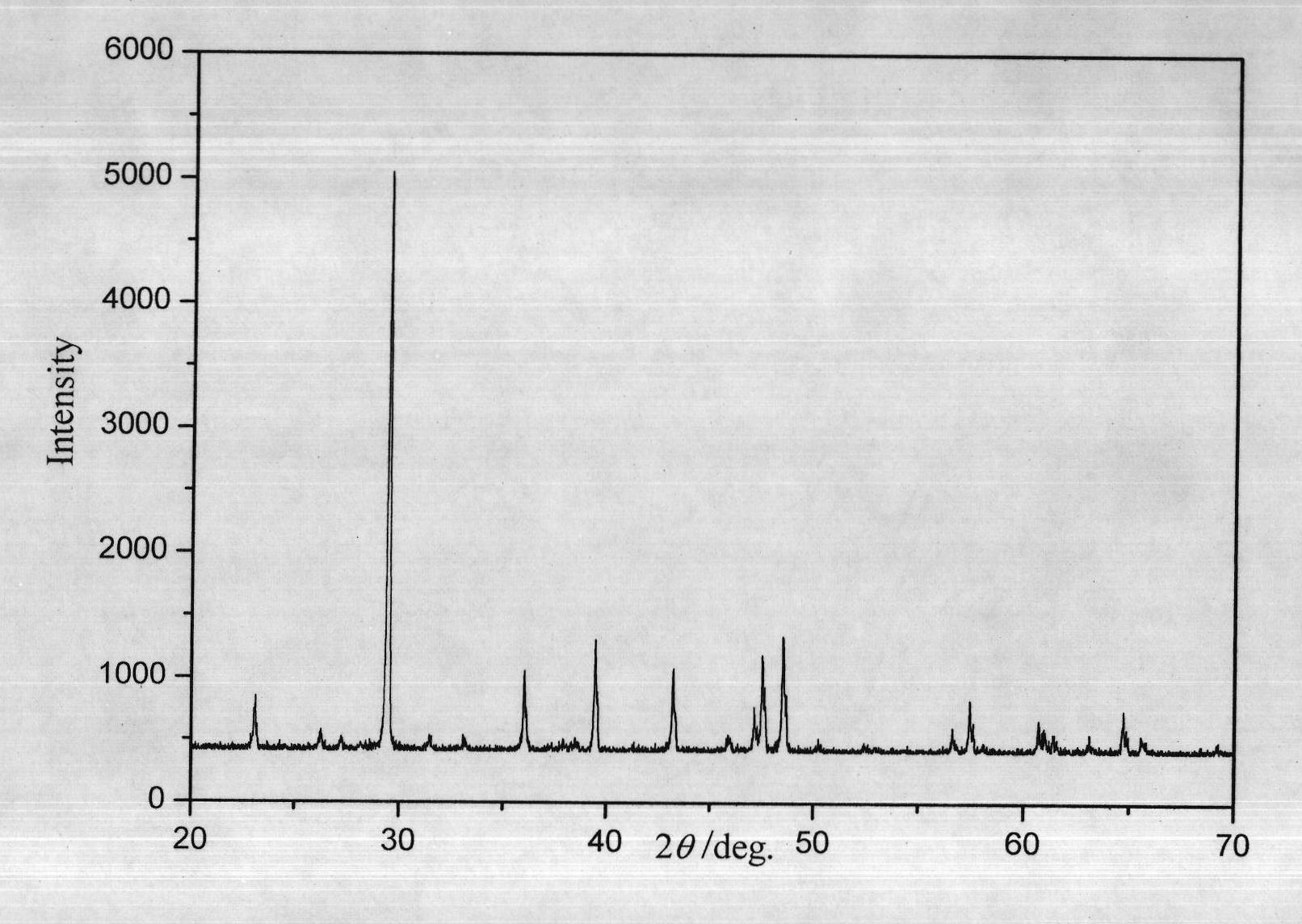

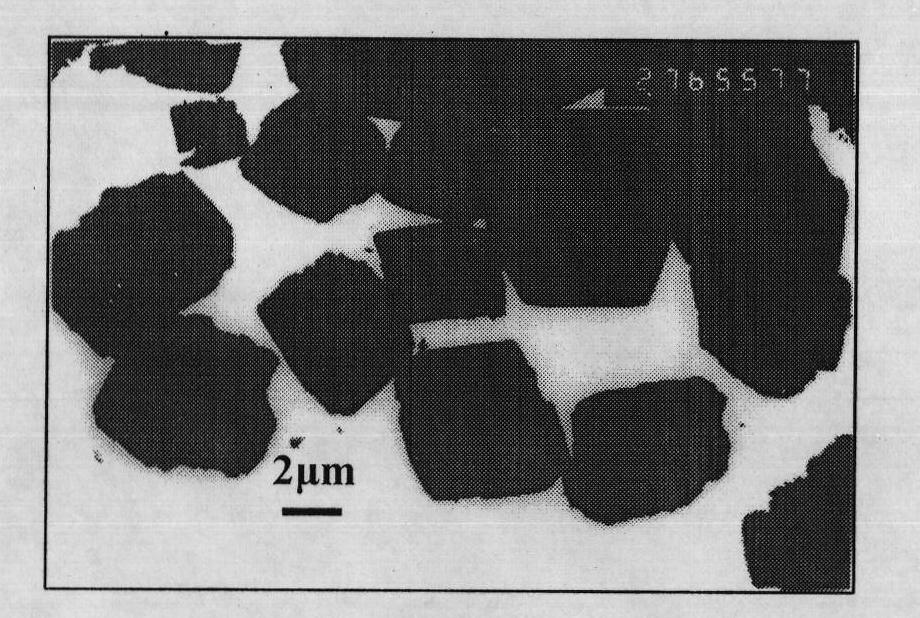

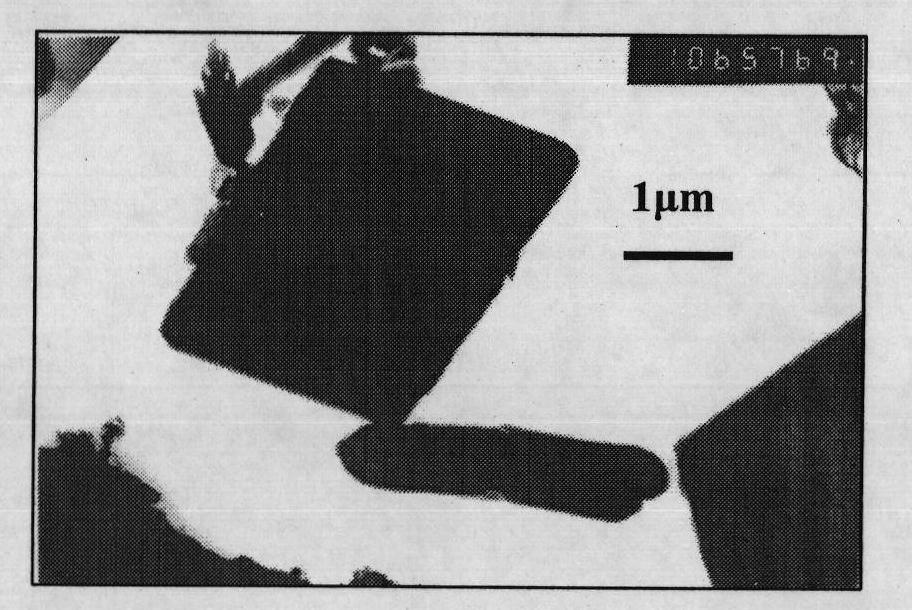

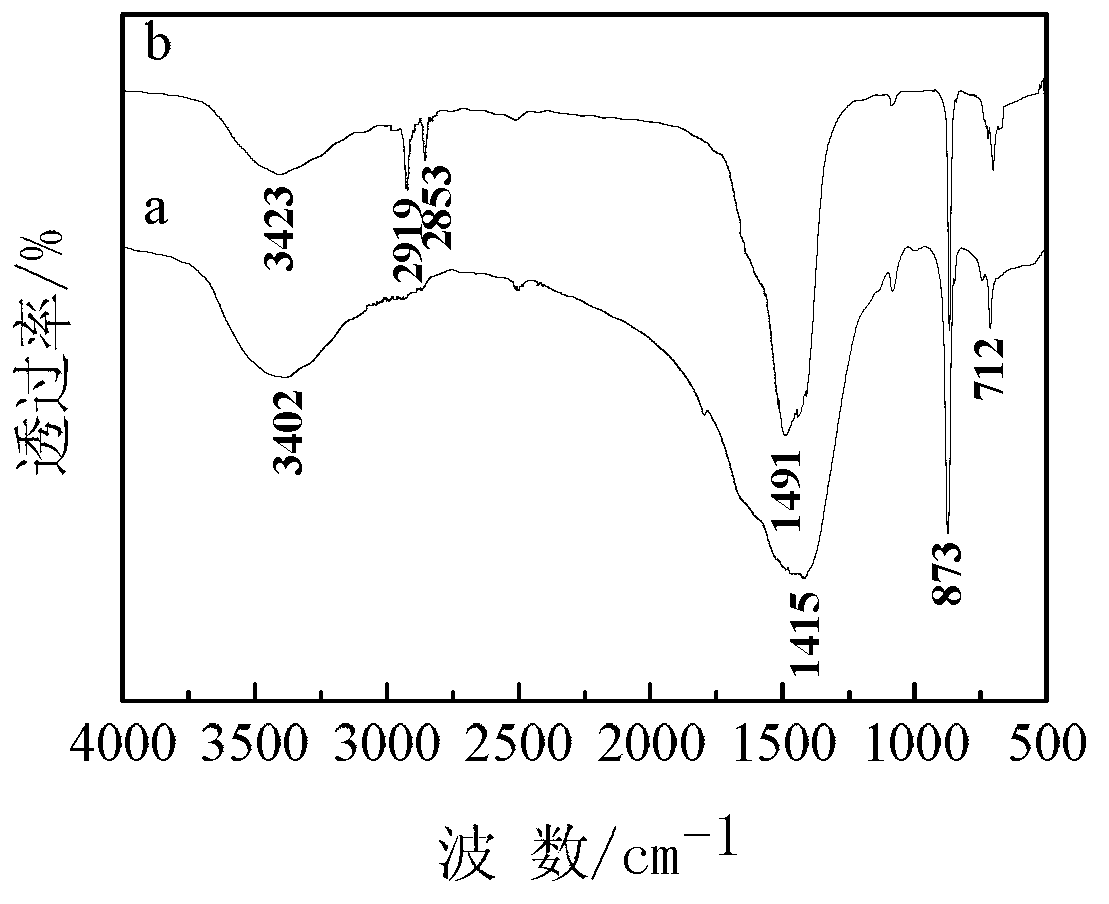

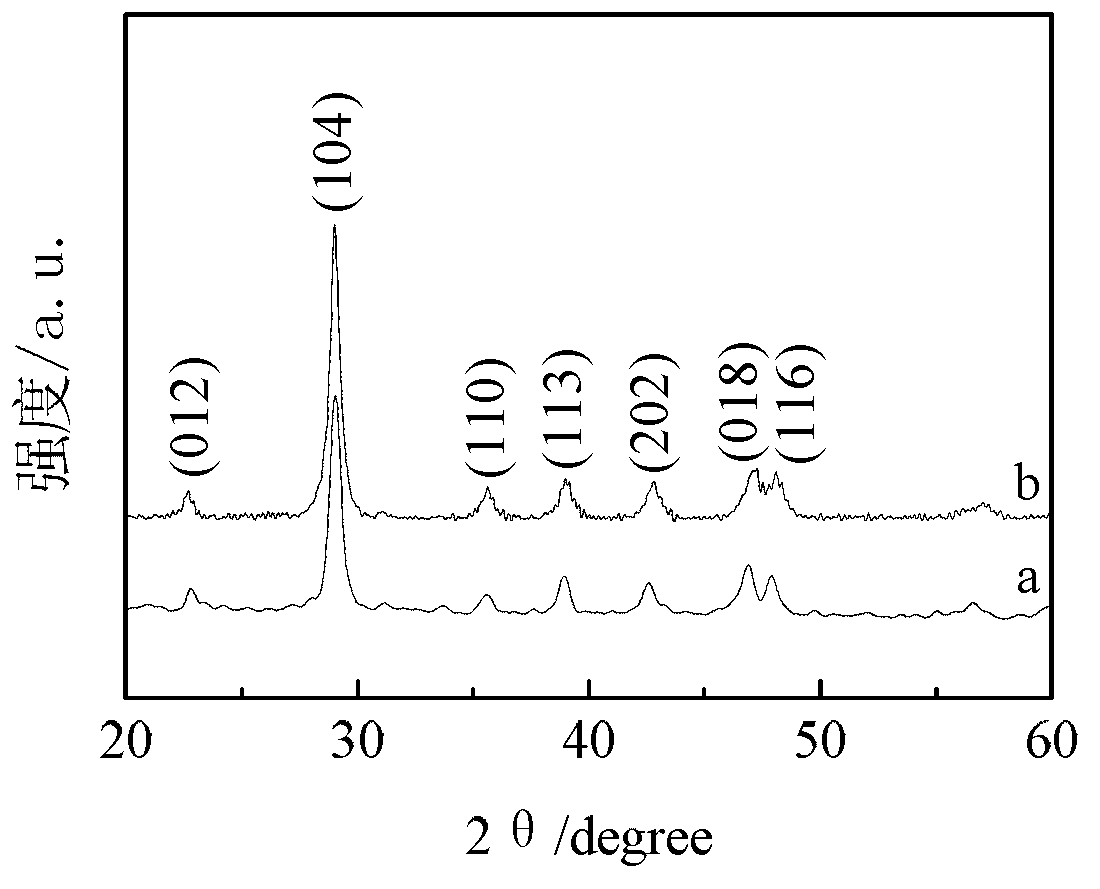

InactiveCN101935866ALow priceEasy to getCalcium/strontium/barium carbonatesPolycrystalline material growthX-rayScanning electron microscope

The invention relates to a method for preparing a flaky calcite calcium carbonate crystal, which comprises the following steps of: according to the substance amount ratio of calcium chloride to sodium carbonate as 1.4-1.8:1, adding boric acid or oxalic acid as a crystal shape control agent accounting for 0.8-4.2 percent of the mass of the sodium carbonate into 0.52-3.96mol / L of sodium carbonate solution, and controlling the solution temperature to be 40-90 DEG C; taking 1.24-6.32mol / L of calcium chloride solution, and controlling the solution temperature to be 40-90 DEG C; dropwise adding the calcium chloride solution into the sodium carbonate solution, stirring as dropwise adding, then stirring at constant temperature for 0.5-2 hours, settling at room temperature for 12-36 hours, and filtering to obtain precipitates; and repeatedly washing the precipitates with water to be neutral, removing adsorbed chloride ions, then filtering, and carrying out vacuum drying at the temperature of 40-80 DEG C to prepare the flaky calcite calcium carbonate crystal. A product is confirmed as a calcite crystal through X-ray diffraction analysis; and a scanning electron microscope result shows that the crystal is regularly flaky. The method has the advantages of low cost, simple process and regular product appearance.

Owner:HENAN UNIV OF URBAN CONSTR

Method for preparing assembled type building high-adhesive force polymer environmental-friendly spraying decoration mortar

The invention discloses a method for preparing assembled type building high-adhesive force polymer environmental-friendly spraying decoration mortar. The method comprises the following steps: uniformly mixing ordinary Portland cement, sulfate aluminum cement, quartz sand, calcium carbonate crystal whisker, an organic silicon coupling reagent, lignin fiber and basalt fiber, so as to obtain a mixed material A; uniformly mixing and stirring a silicon sol modified polyacrylic emulsion, cellulose ether, water and a thixotropic agent so as to obtain a mixed material B; and uniformly mixing the mixed material A and the mixed material B, thereby obtaining the high-adhesive force polymer environmental-friendly spraying decoration mortar. The spraying decoration mortar prepared by using the method is high in adhesive strength, good in weather resistance, excellent in mechanical property and environmental-friendly and non-toxic.

Owner:SHAOXING YISHENG MORTAR

Preparing process for calcium carbonate crystal whisker

InactiveCN1552959AQuality improvementHigh yieldPolycrystalline material growthSingle crystal growth detailsPolymer scienceWhiskers

Owner:青海海兴科技开发有限公司

Preparation method of hydroxyapatite nanosheets

InactiveCN103991856ASimple requirementsReduce manufacturing costMaterial nanotechnologyPhosphorus compoundsWater bathsSolubility

The invention relates to a preparation method of hydroxyapatite nanosheets, which comprises the following step: by using shell powder or egg shells as a calcium source, ammonium phosphate as a phosphorus source and water as a solvent, reacting at 30-70 DEG C to obtain the hydroxyapatite nanosheets. According to the method, the reaction occurs at lower temperature, the prepared shell calcium carbonate crystal grains have favorable crystallinity and obvious oriented preferential growth shape, are sheet-shaped, and have low solubility in the water solution. In the reaction process, calcium carbonate crystal grain dissolution, hydroxyapatite recrystallization and hydroxyapatite grain growth are performed, the calcium carbonate sheet-like crystal grains gradually grow into the hydroxyapatite nanosheets. The method has simple requirements for reactors, and can perform production only by using a glass container, a stirrer, a thermostatic water bath box and other low-temperature reactors; and the production process is easy to operate and does not need any high-temperature high-pressure apparatus, thereby effectively lowering the production cost of hydroxyapatite.

Owner:HUAIHAI INST OF TECH +2

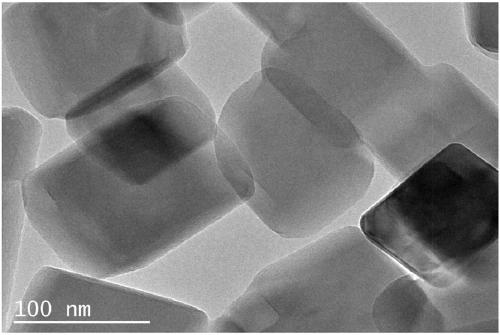

Preparation method for rice-grain-shaped light calcium carbonate

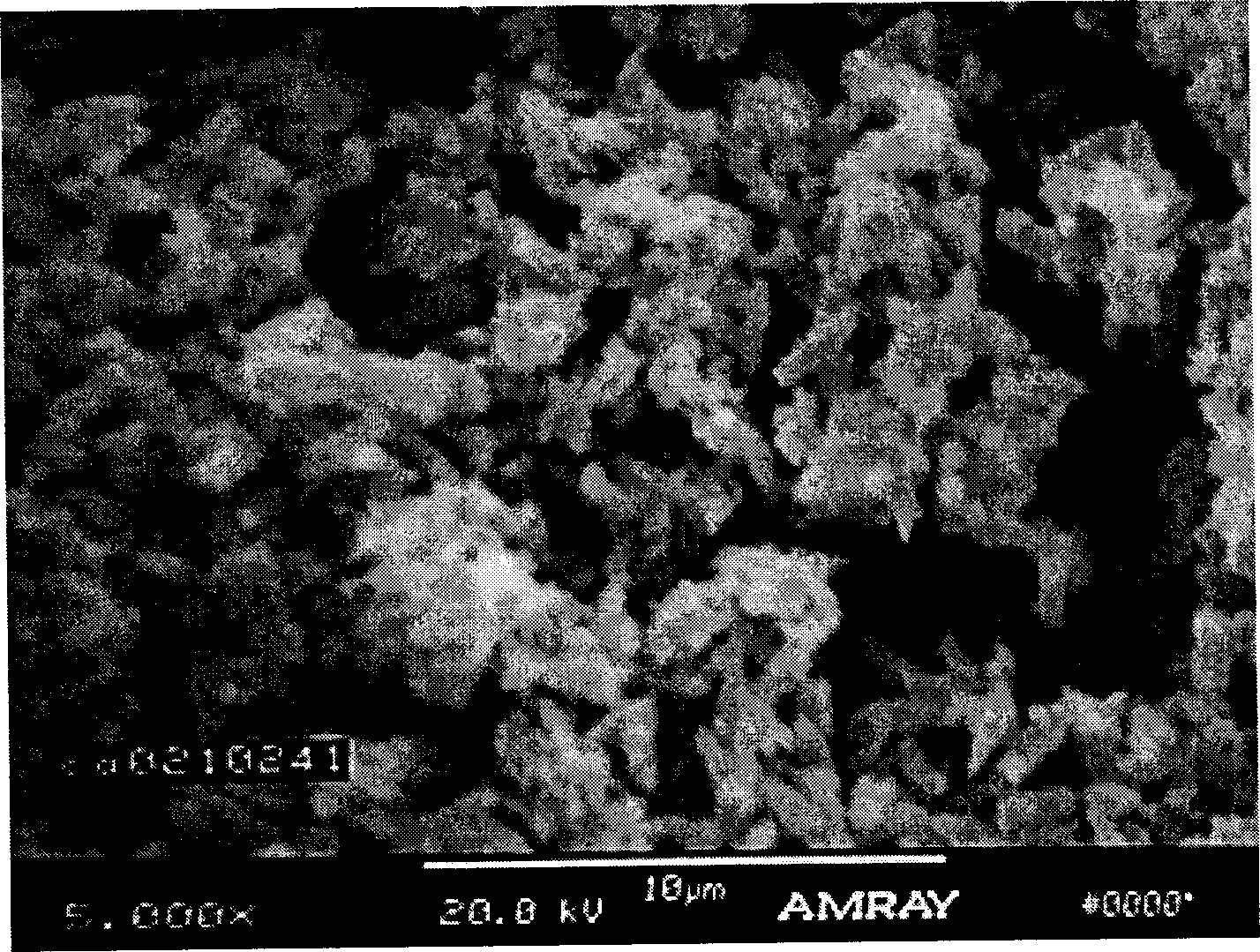

ActiveCN108083314ALarge specific surface areaGood dispersionCalcium/strontium/barium carbonatesNanotechnologyLongest DiameterCarbonization

The invention discloses a preparation method for rice-grain-shaped light calcium carbonate. The preparation method comprises the following steps: calcining lime stones with natural gas, adding digesting water to complete digesting reaction, performing screening, impurity-removal and ageing, adding a crystal form controller, introducing lime kiln kiln-gas to perform carbonization, pumping into a homogenizing tank to perform re-aging, and introducing purified, cooled and compressed lime kiln kiln-gas to perform secondary carbonation reaction, thereby preparing calcium carbonate slurry; and adding a modifying agent into the calcium carbonate slurry and stirring, and performing filter-pressing and dehydrating, drying, crushing and grading, thereby obtaining the rice-grain-shaped light calciumcarbonate. The light calcium carbonate crystal form prepared by the preparation method is rice-grain-shaped, has a long diameter of 150-200 nm, a short diameter of 30-50 nm, a BET specific surface area of 20-22 m<2> / g, a small length-diameter ratio, a high specific surface area and good dispersion, and can be used for manufacturing food and cosmetics; and moreover, the process is simple and feasible, the cost is low, the price is low, and the economic benefits are relatively good.

Owner:山东宇信纳米科技有限公司

Calcium carbonate crystal whisker reinforced high performance brake disc

InactiveCN101440849AHigh temperature resistanceWear-resistantOther chemical processesFriction liningThermal fatigueAdhesive

The invention relates to a calcium carbonate whisker reinforced high-performance brake disc. The compositions of the brake disc in percentage by weight are: 10 to 20 percent of calcium carbonate whisker, 10 to 15 percent of adhesive, 20 to 30 percent of mineral fiber, 15 to 25 percent of graphite, 2 to 5 percent of high-temperature adhesive, 1 to 3 percent of aramid reinforced fiber, 5 to 10 percent of friction-increasing material and the balance being mineral fillings. The brake disc does not contain substances harmful to human body, and has the characteristics of high temperature resistance, abrasion resistance, soft material and good toughness, and so on. Moreover, the brake disc has the advantages that even at high temperature of between 300 and 350 DEG C, the brake disc can still maintain higher friction coefficient and lower abrasion rate with the average hardness value equal to 35HRM; the brake disc can resist frequent thermal changes and has excellent thermal fatigue resistance and long service life; and the material can be recycled and the brake disc has high recycling rate; in addition, the brake disc has abundant raw material sources and low cost.

Owner:江西元邦摩擦材料有限责任公司

Preparation method of rod-like calcite type calcium carbonate crystals

InactiveCN103253693AControl grain sizeImprove controllabilityCalcium/strontium/barium carbonatesWater bathsAlcohol

The invention discloses a preparation method of rod-like calcite type calcium carbonate crystals, relating to a preparation method for calcium carbonate crystals and aiming at solving the technical problems that an existing preparation method of the rod-like calcite type calcium carbonate crystals is complicated, and high in cost, and the sizes of crystal particles cannot be well controlled. The preparation method disclosed by the invention comprises the steps of: I. placing a Ca(OH)2 solution into a thermostatic water bath cauldron, and introducing CO2 gas under the stirring condition; II. adding a PASP (Sodium of Polyaspartic Acid) solution with certain concentration into the solution, reacting for certain time, and then stopping the introduction of the CO2 gas; and III. washing the obtain samples respectively with deionized water and absolute ethyl alcohol, leaching, and carrying out vacuum drying for certain time under certain thermostatic condition to obtain the calcium carbonate crystals. The rod-like calcite type calcium carbonate crystals can be produced into plastics absorbed by the environment when being applied to plastic materials.

Owner:HEILONGJIANG UNIV

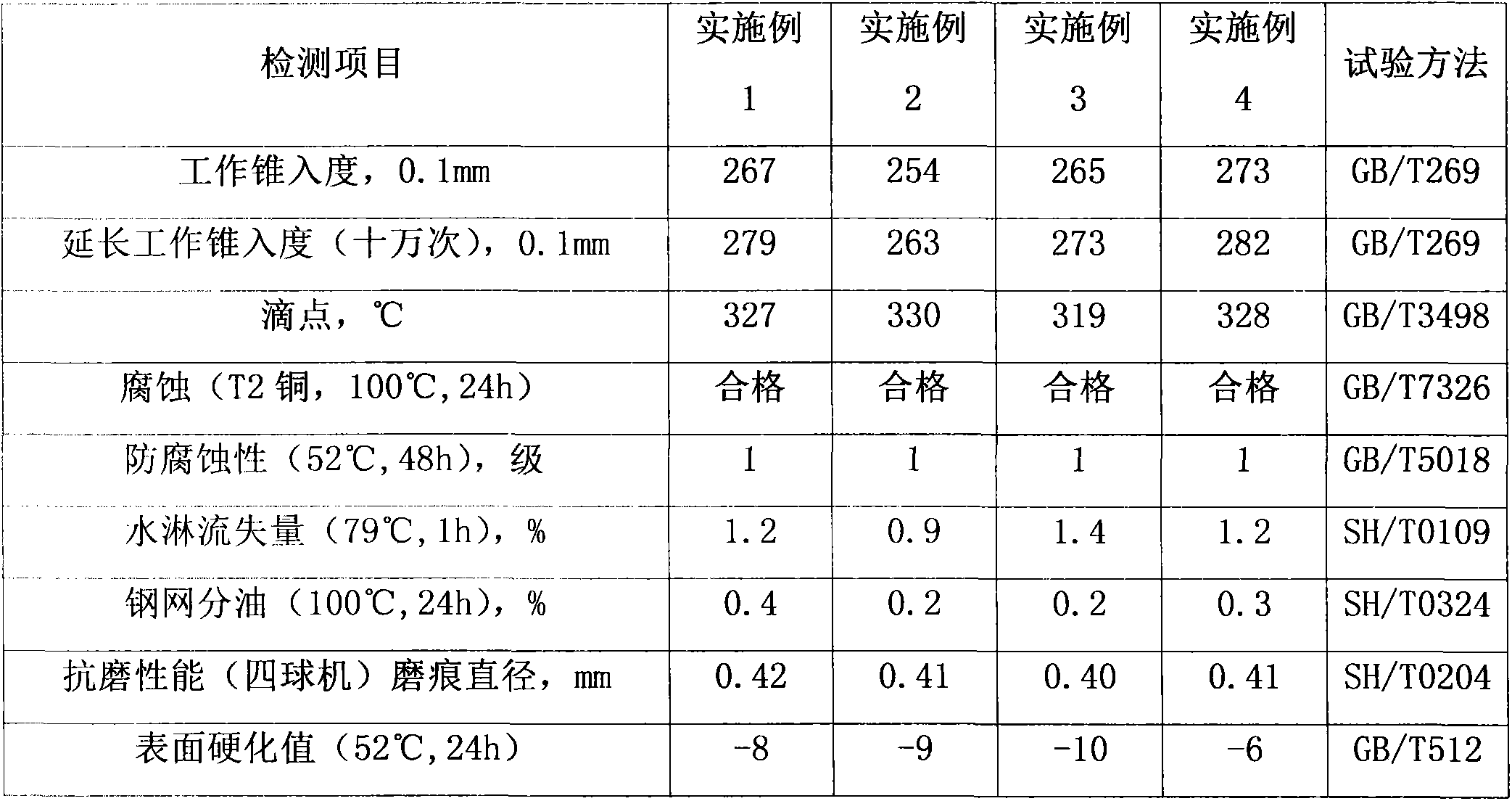

High-performance calcium sulfonate complex grease and preparation method thereof

InactiveCN103952215AHigh temperature resistantWater resistantLubricant compositionSulfonateCalcium hydroxide

The invention relates to high-performance calcium sulfonate complex grease and a preparation method thereof. The calcium sulfonate complex grease is prepared from the following raw materials: high-base-number calcium sulfonate, base oil, lauric acid, low-molecular-weight alcohol, high-purity water, boric acid, calcium hydroxide, an antioxidant, and an HL functional additive. The high-performance calcium sulfonate complex grease has the characteristics of being resistant to high temperature, resistant to water, and outstanding in extreme-pressure antiwear property, particularly realizing the uniform distribution of converted calcium carbonate crystal grain, ensuring stable structure, and also solving the problem of surface hardening.

Owner:青州市东能润滑油脂有限公司

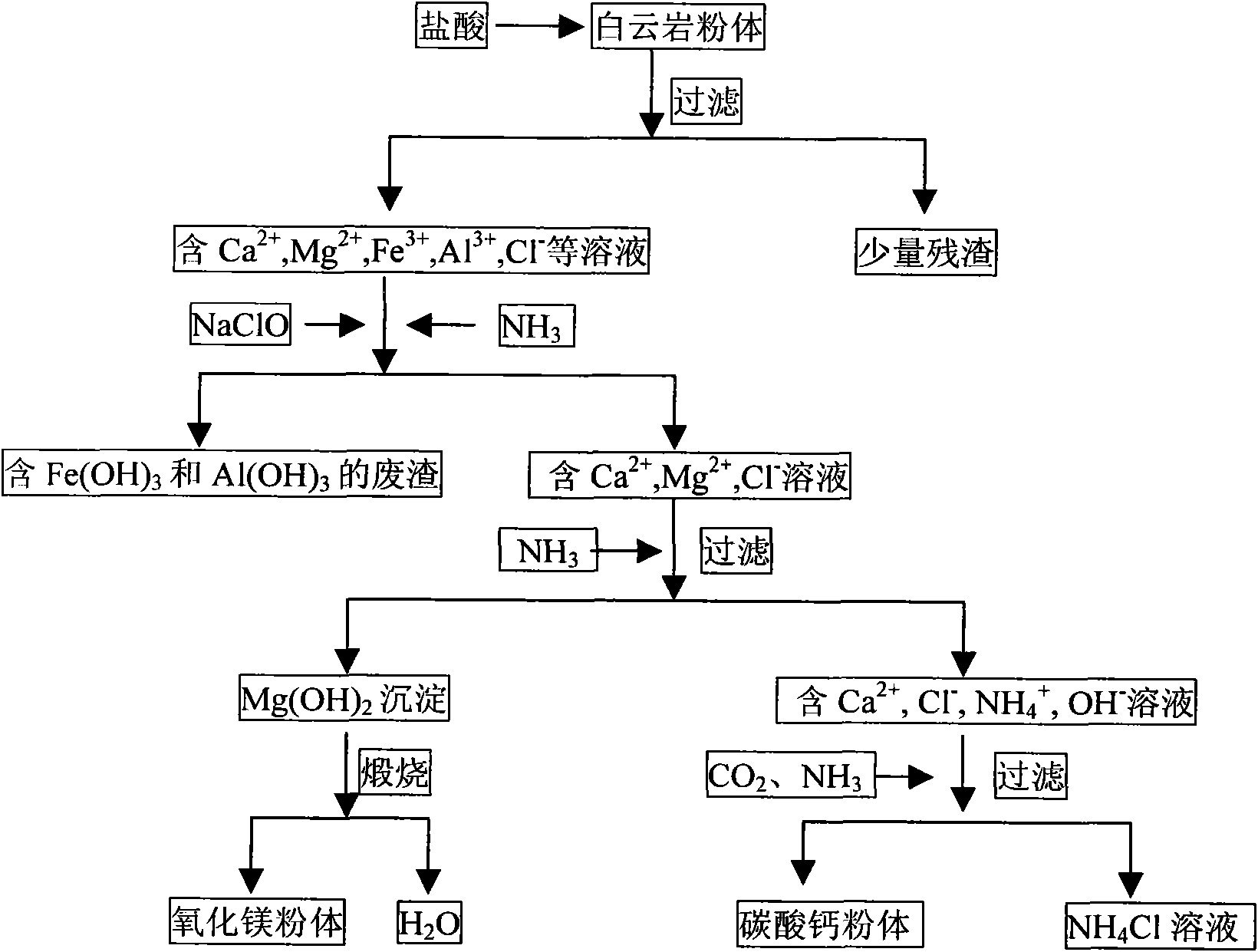

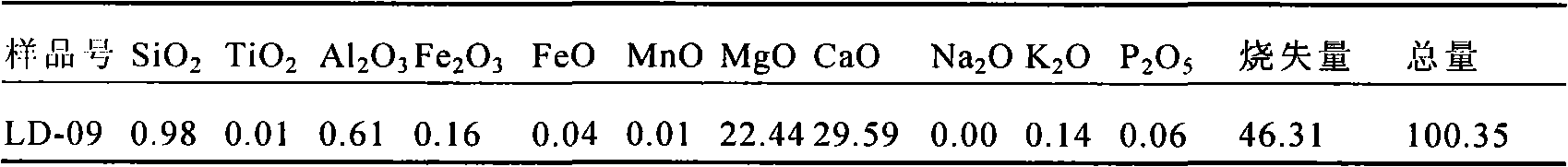

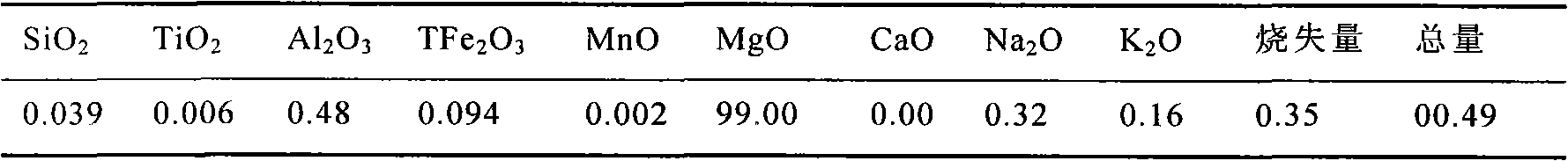

Process for preparing light magnesium oxide and calcium carbonate powder by utilizing dolomite acid method

ActiveCN102001693AReasonable process designReduce energy consumptionCalcium/strontium/barium carbonatesMagnesiaResource utilizationCarbonization

The invention relates to a process for preparing light magnesium oxide and calcium carbonate powder by utilizing a dolomite acid method, which comprises: dolomite is crushed and pulverized into powder; the powder is dissolved by utilizing hydrochloric acid to be prepared into a solution with key components of MgCl2 and CaCl2; the pH value is adjusted, the ions of Fe3<+>, Al3<+> and the like in the solution are eliminated, and the solution becomes a pure MgCl2 and CaCl2 solution; ammonia is introduced into the solution to react so that Mg2<+> is converted into Mg(OH)2 precipitations, and the light magnesium oxide powder is prepared through filtering, washing, drying and calcining; the filtrate is prepared into calcium carbonate crystals through continuous ammonia introduction and carbonization; and the calcium carbonate crystals are dried to prepare the light calcium carbonate powder. The process has the advantages that the design is reasonable; the energy consumption is low; the purities of the prepared light magnesium oxide and the calcium carbonate are above 98%; the resource utilization ratio of the dolomite is larger than 95%; and the process is worthy of being popularized and implemented.

Owner:昊青薪材(北京)技术有限公司

Recovering a caustic solution via calcium carbonate crystal aggregates

ActiveUS20150329369A1Reduce porosityHigh hardnessCalcium/strontium/barium carbonatesPulp liquor regenerationFluidized bedSlurry

Techniques for growing crystalline calcium carbonate solids such that the crystalline calcium carbonate solids include a volume of 0.0005 mm3 to 5 mm3, include a slaker to react quicklime (CaO) and a low carbonate content fluid to yield a slurry of primarily slaked lime (Ca(OH)2); a fluidized-bed reactive crystallizer that encloses a solid bed mass and includes an input for a slurry of primarily slaked lime, an input for an alkaline solution and carbonate, and an output for crystalline calcium carbonate solids that include particles and an alkaline carbonate solution; a dewatering apparatus that includes an input coupled to the crystallizer and an output to discharge a plurality of separate streams that each include a portion of the crystalline calcium carbonate solids and alkaline carbonate solution; and a seed transfer apparatus to deliver seed material into the crystallizer to maintain a consistent mass of seed material.

Owner:CARBON ENG LTD

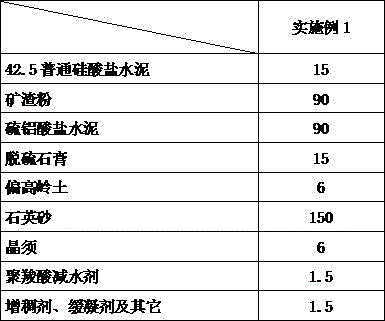

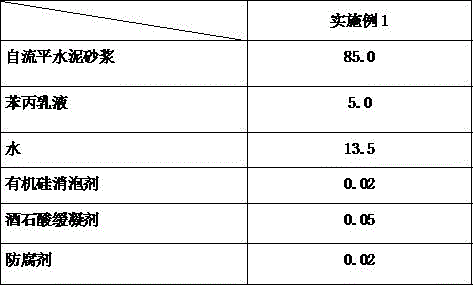

Whisker reinforcement-based self-leveling cement mortar and application thereof

The invention discloses whisker reinforcement-based self-leveling cement mortar. The whisker reinforcement-based self-leveling cement mortar comprises the following components in parts by weight: 10 to 20 parts of ordinary Portland cement, 50 to 150 parts of slag powder, 3 to 20 parts of special cement, 10 to 20 parts of gypsum, 5 to 10 parts of metakaolin, 100 to 160 parts of quartz sand, 1 to 10 parts of a crystal whisker and 1 to 1.5 parts of a water-reducing agent, wherein the special cement adopts sulphoaluminate cement or aluminate cement; the gypsum adopts one of or a mixture of more than two of high-strength gypsum, fluorgypsum, desulfurized gypsum and citric acid gypsum; and the crystal whisker adopts one of or a mixture of more than two of gypsum crystal whiskers, a magnesium hydroxide crystal whisker, a magnesium oxide crystal whisker, an ettringite crystal whisker and a calcium carbonate crystal whisker. A terrace prepared from the whisker reinforcement-based self-leveling cement mortar has high surface hardness and high anti-compression and anti-bending strength, and can meet the wear-resistant requirement of most occasions.

Owner:江苏蓝圈新材料股份有限公司

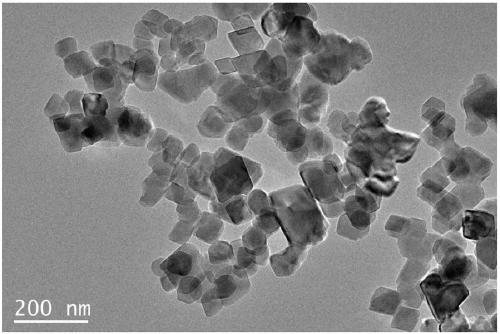

Preparation method of nano calcium carbonate for MS glue

InactiveCN109650431ADetermining performanceThe process steps are the sameCalcium/strontium/barium carbonatesNon-macromolecular adhesive additivesCarbonizationSlurry

The invention discloses a preparation method of nano calcium carbonate for MS glue, which comprises the following steps: removing impurities from calcium hydroxide (Ca (OH) 2) slurry obtained after the digestion reaction of quicklime (CaO) and water (H2O), preserving heat and aging, adding a crystal form control agent, performing primary carbonization synthesis reaction with the washed kiln gas containing carbon dioxide (CO2), adding a post-treatment agent, aging for a certain time, performing secondary carbonization synthesis reaction with the washed kiln gas containing carbon dioxide (CO2) to obtain calcium carbonate (CaCO3) cooked slurry, adding a modifier into the cooked slurry, performing filter pressing dehydration, drying, crushing and grading after the reaction is finished to obtain the nano calcium carbonate for MS glue. The nano calcium carbonate crystal prepared by the method is a standard cube, and the crystal is mono-disperse, and the average particle diameter is only 100-150nm, and the specific surface area is 16-18m <2 > / g, and the nano calcium carbonate crystal is used for MS glue, and the thixotropy is good, and the extrusion property is good, and the storage stability is good, and the surface finish after gluing is good, and the tensile strength is high, and the elongation is high and the bonding property is also good. The preparation method of nano calcium carbonate for MS glue has the advantages of simple and feasible process, low cost, low price and better economic benefit.

Owner:卢氏国嵩莱纳米科技有限公司

Method for regulating growth of calcium carbonate crystal grains by using pulping black liquor lignin

InactiveCN103435082AExpand the range of organic matter sourcesIn line with the policy of developing circular economyCalcium/strontium/barium carbonatesEnvironmental resistancePrill

The invention discloses a method for regulating growth of calcium carbonate crystal grains by using pulping black liquor lignin. According to the biological mineralization principle, by softwood pulping black liquor lignin as an organic matrix, the lignin concentration, system temperature, system pH value, crystallizing time and other technological parameters are changed and regulated to prepare calcium carbonate crystal grains with different shapes and sizes to satisfy the application demands of different technical fields. The technique disclosed by the invention is quick, efficient and environment-friendly; the softwood pulping black liquor lignin is introduced into the raw materials for preparing calcium carbonate crystal grains with different shapes and sizes as the organic regulation matrix, thereby sufficiently and reasonably utilizing the waste resources in paper making industry, and reducing the pollution load of the pulping black liquor onto the natural environment and the treatment cost of the paper making enterprise; and the prepared calcium carbonate crystal grains can be widely used in industries of paper making, rubber and the like, and has important environmental benefit and economic value.

Owner:ZHEJIANG SCI-TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com