Preparing process for calcium carbonate crystal whisker

A technology of calcium carbonate whisker and preparation process, which is applied in the directions of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of difficult to mix uniformly, poor economic benefit and the like, and achieves short preparation period, low cost and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

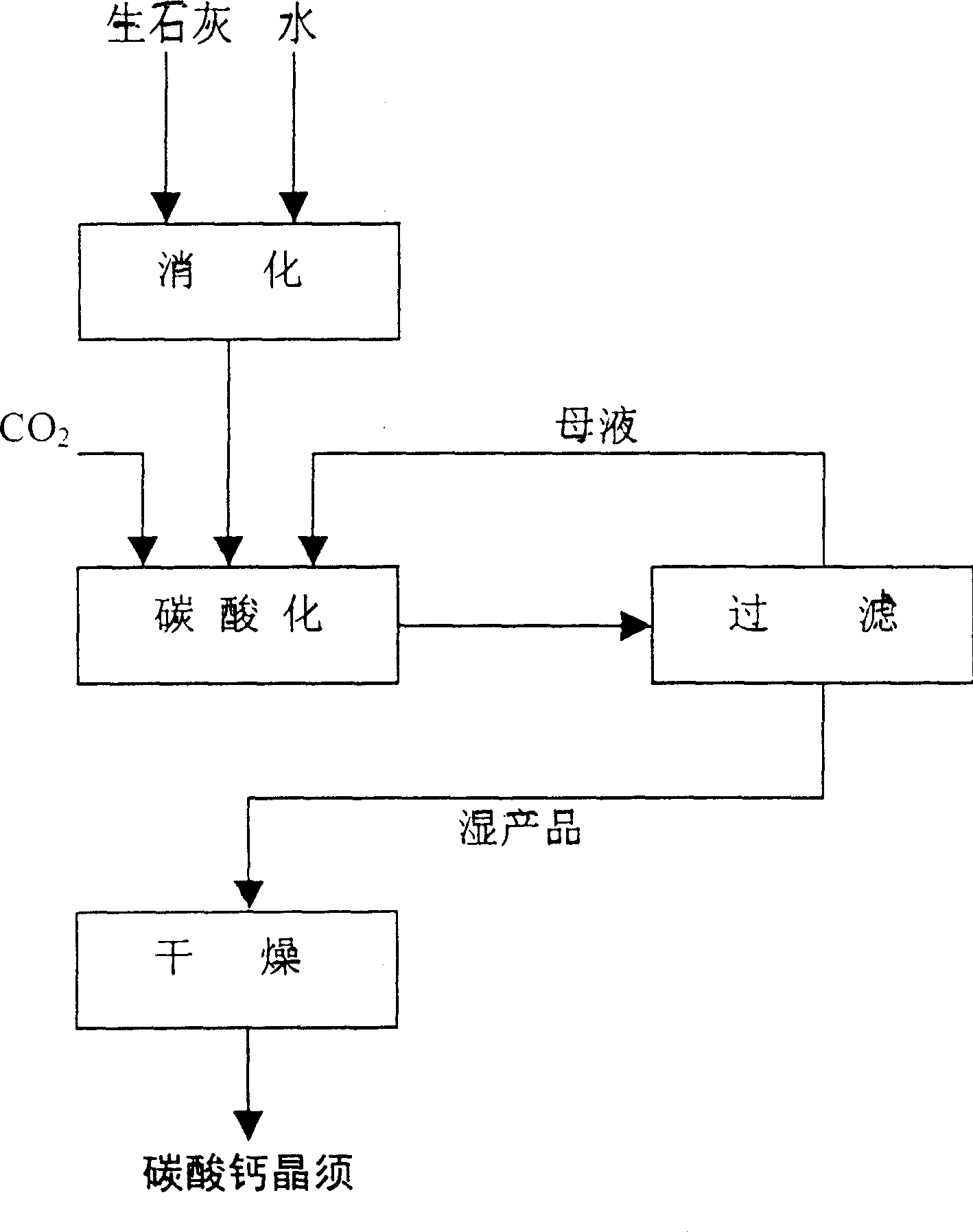

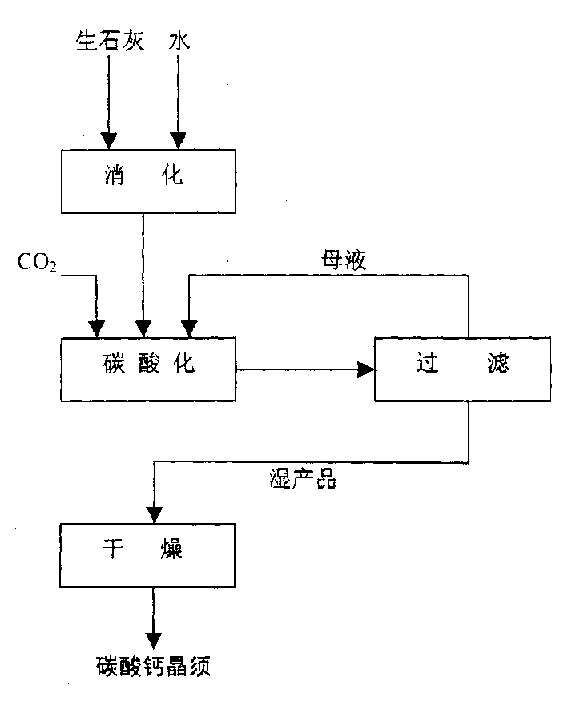

Image

Examples

Embodiment Construction

[0021] A preparation method for calcium carbonate whiskers, comprising the following process steps: (1) putting 2.1 kilograms of quicklime into 10 kilograms of water, stirring to make it fully mixed, making quicklime slurry, and standing for several minutes; (2) taking Dissolve 4.3 kg of magnesium chloride raw material in 90 kg of water to make a magnesium chloride solution with a concentration of 4-5% as a reaction environment and catalyst, and add it to the bubbling stirring tank for stirring, and then add the quicklime slurry made by the above process to the drum (3) Heating the reaction solution to 70-90° C., passing the dioxygen gas into the reaction solution for 2-6 hours from the gas distributor below the stirring tank to fully carbonize the reaction solution; (4 ) The reaction product is filtered, washed and dried by a centrifuge to obtain a calcium carbonate whisker product; the filtered mother liquor is sent to the reactor for repeated use, and its concentration is me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com