Patents

Literature

1017 results about "Calcium bicarbonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calcium bicarbonate, also called calcium hydrogen carbonate, has a chemical formula Ca(HCO₃)₂. The term does not refer to a known solid compound; it exists only in aqueous solution containing the calcium (Ca²⁺), bicarbonate (HCO⁻₃), and carbonate (CO²⁻₃) ions, together with dissolved carbon dioxide (CO₂). The relative concentrations of these carbon-containing species depend on the pH; bicarbonate predominates within the range 6.36–10.25 in fresh water.

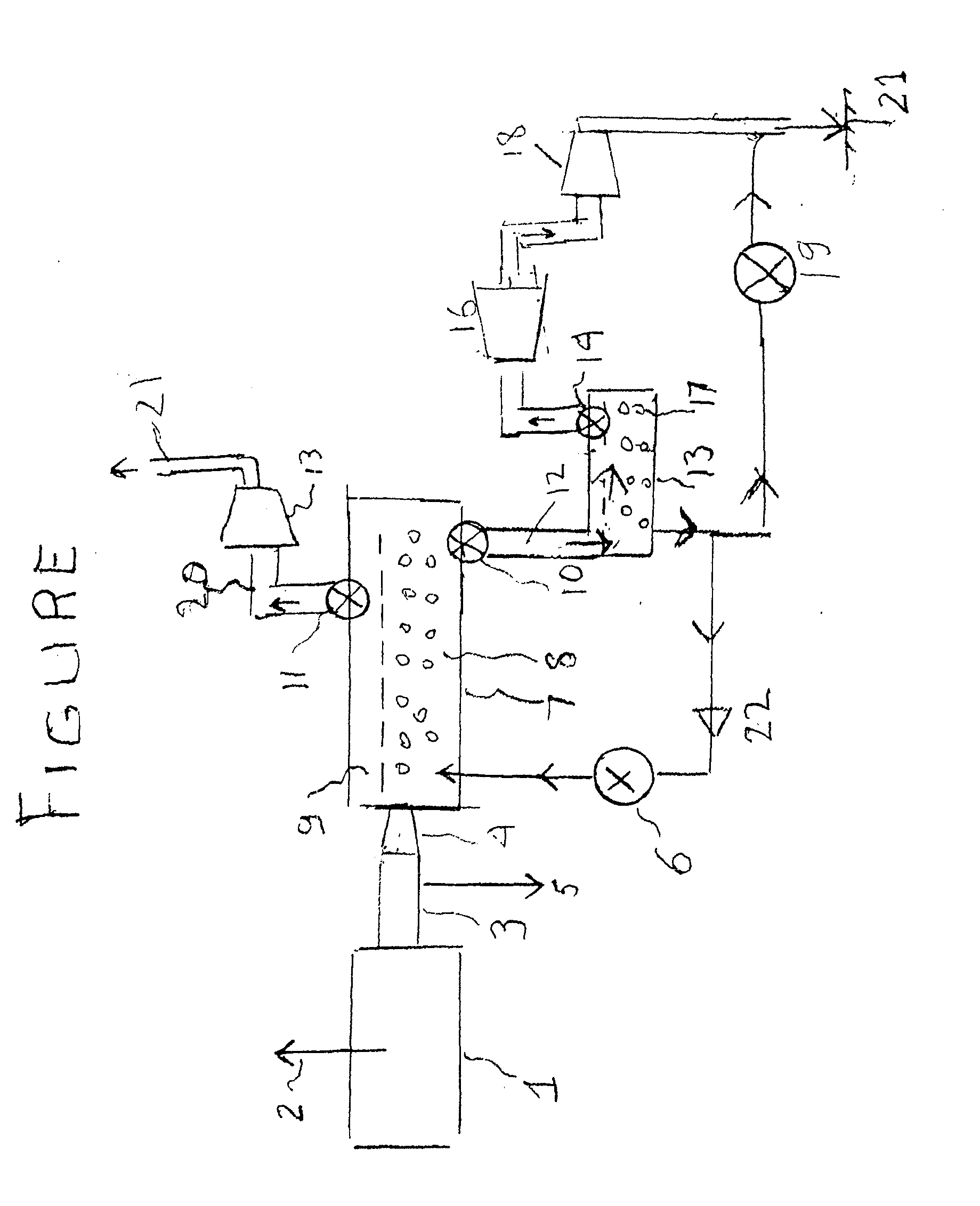

System and method for using carbon dioxide sequestered from seawater in the remineralization of process water

ActiveUS7771599B1Reduce scaleReduce inorganicLiquid degasificationGeneral water supply conservationSaline waterAlkalinity

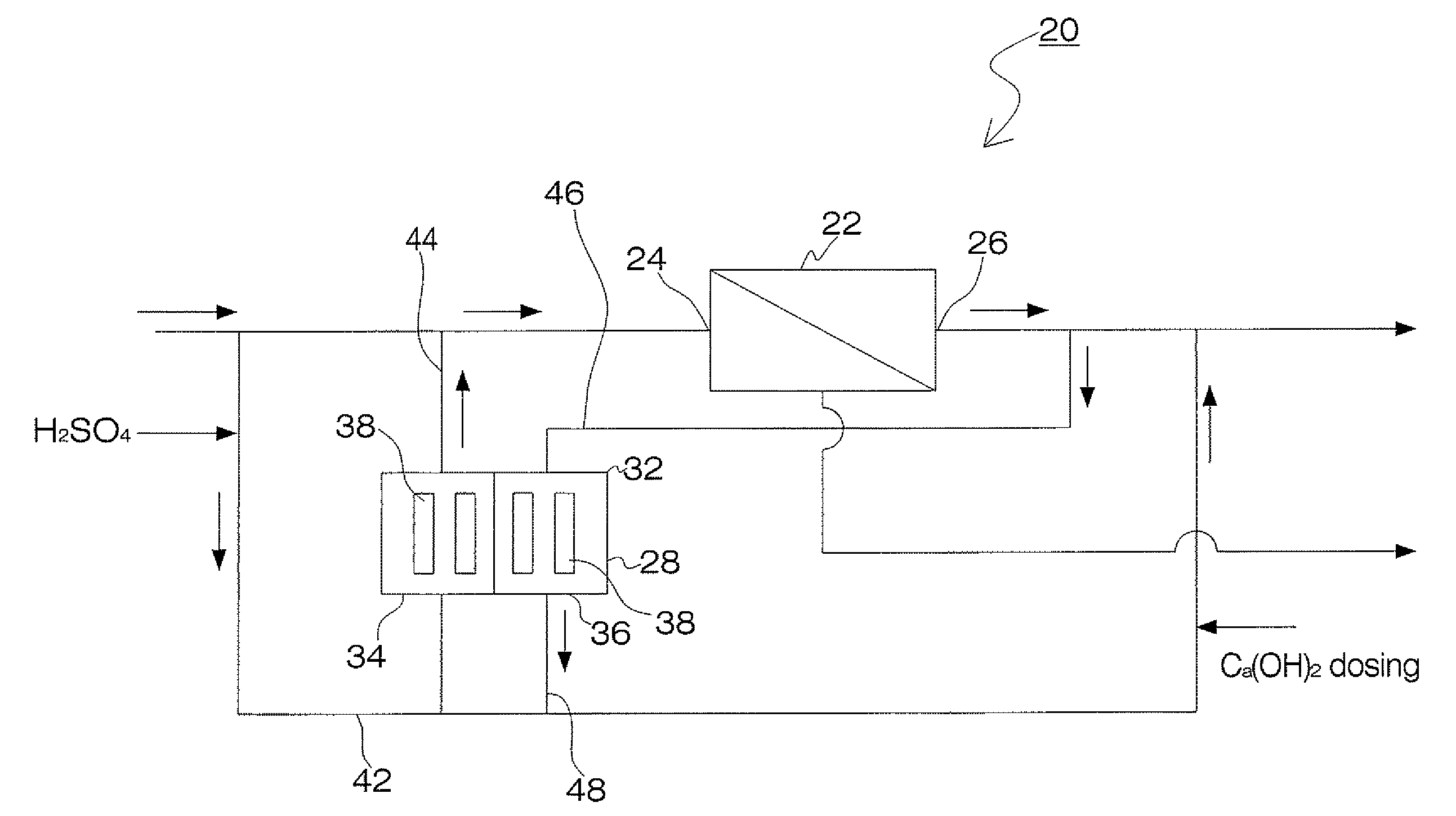

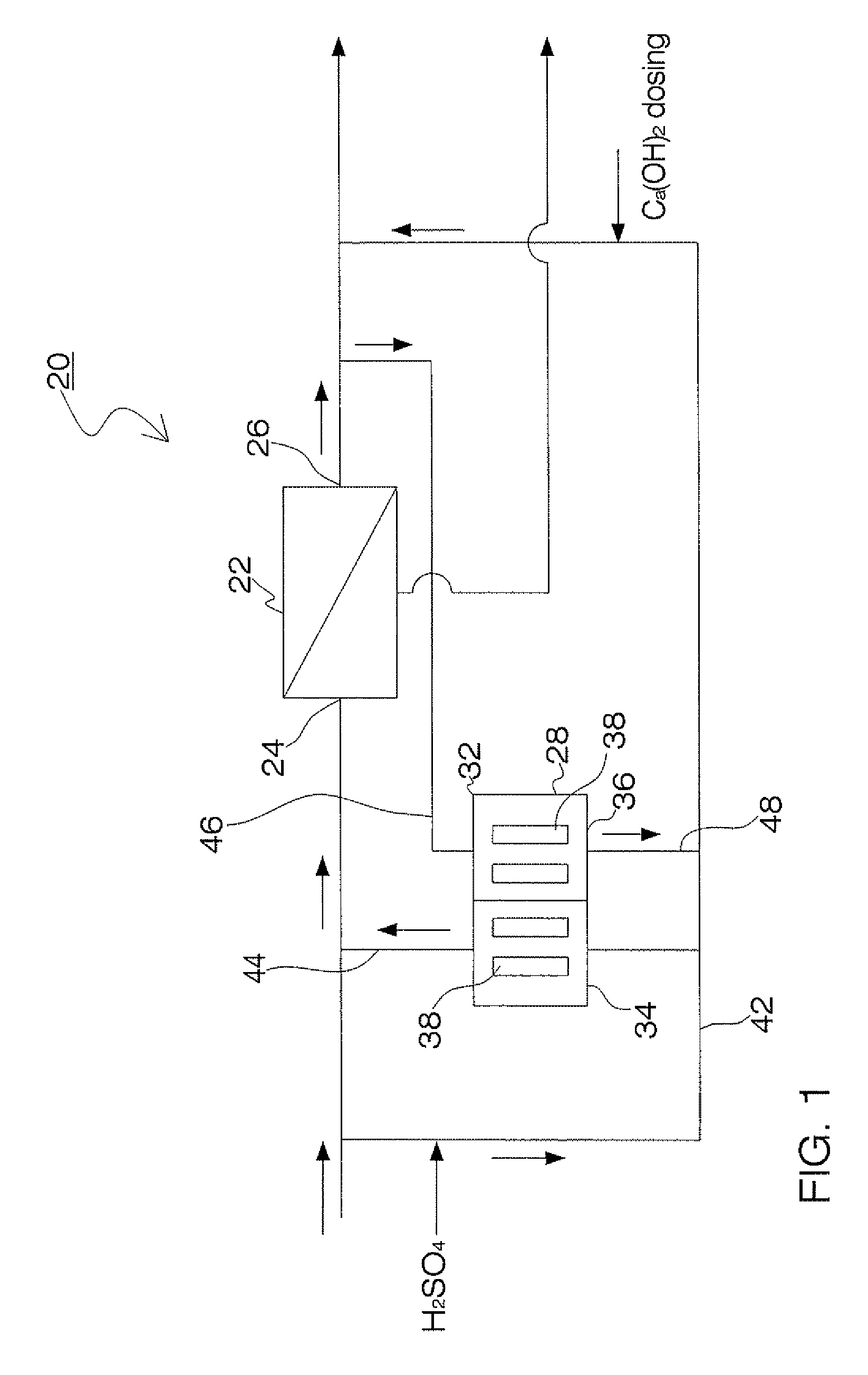

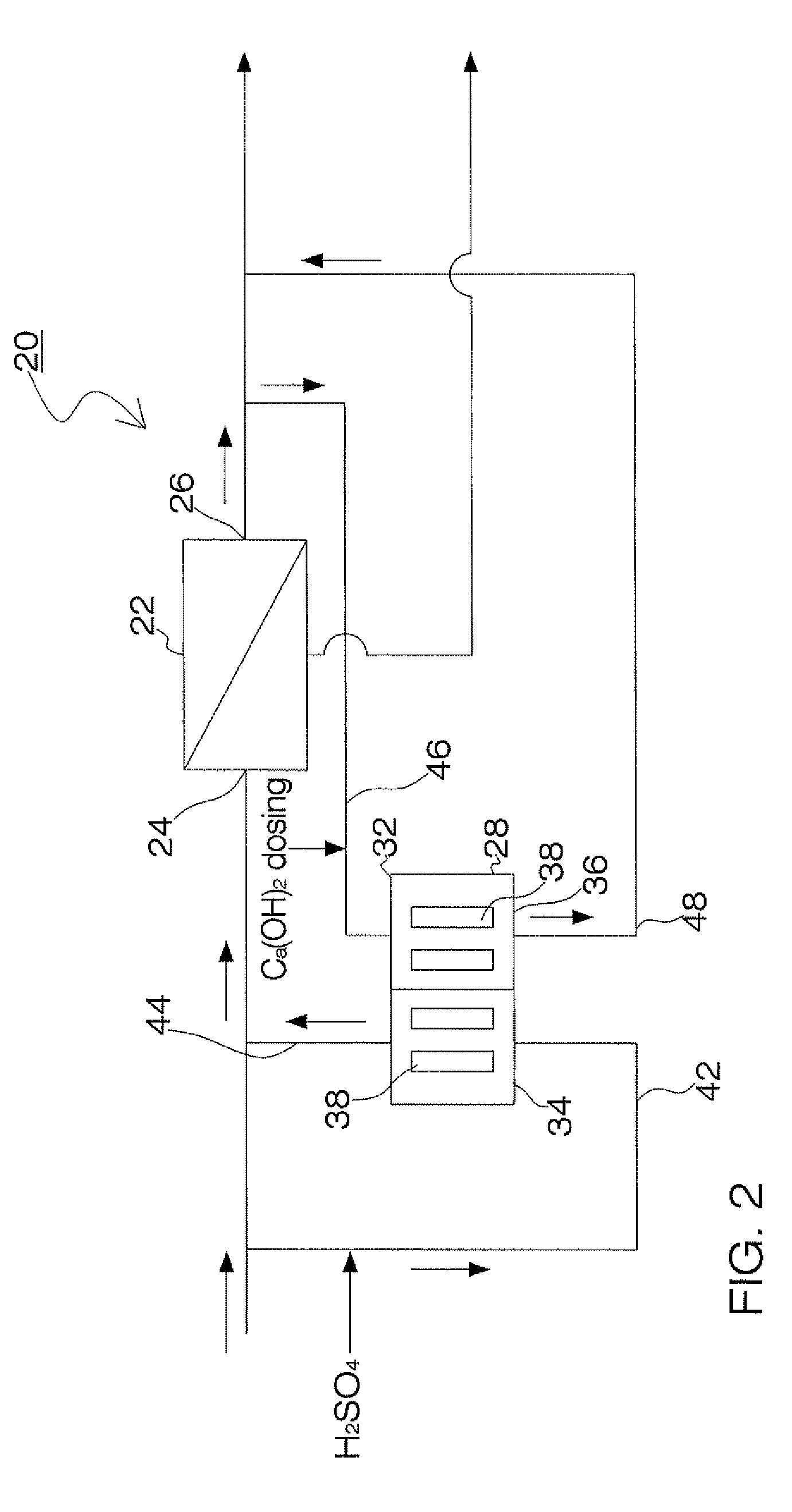

Disclosed is an improved method for the remineralization of process water in a desalination system. The method sequesters carbon dioxide gas (CO2) from seawater or concentrate (brine) of desalination process via a gas transfer membrane. The sequestered carbon dioxide gas (CO2) is thereafter used in the production of soluble calcium bicarbonate (Ca(HCO3)2). The calcium bicarbonate (Ca(HCO3)2) adds hardness and alkalinity to the resulting process water.

Owner:DOOSAN HEAVY IND & CONSTR CO LTD

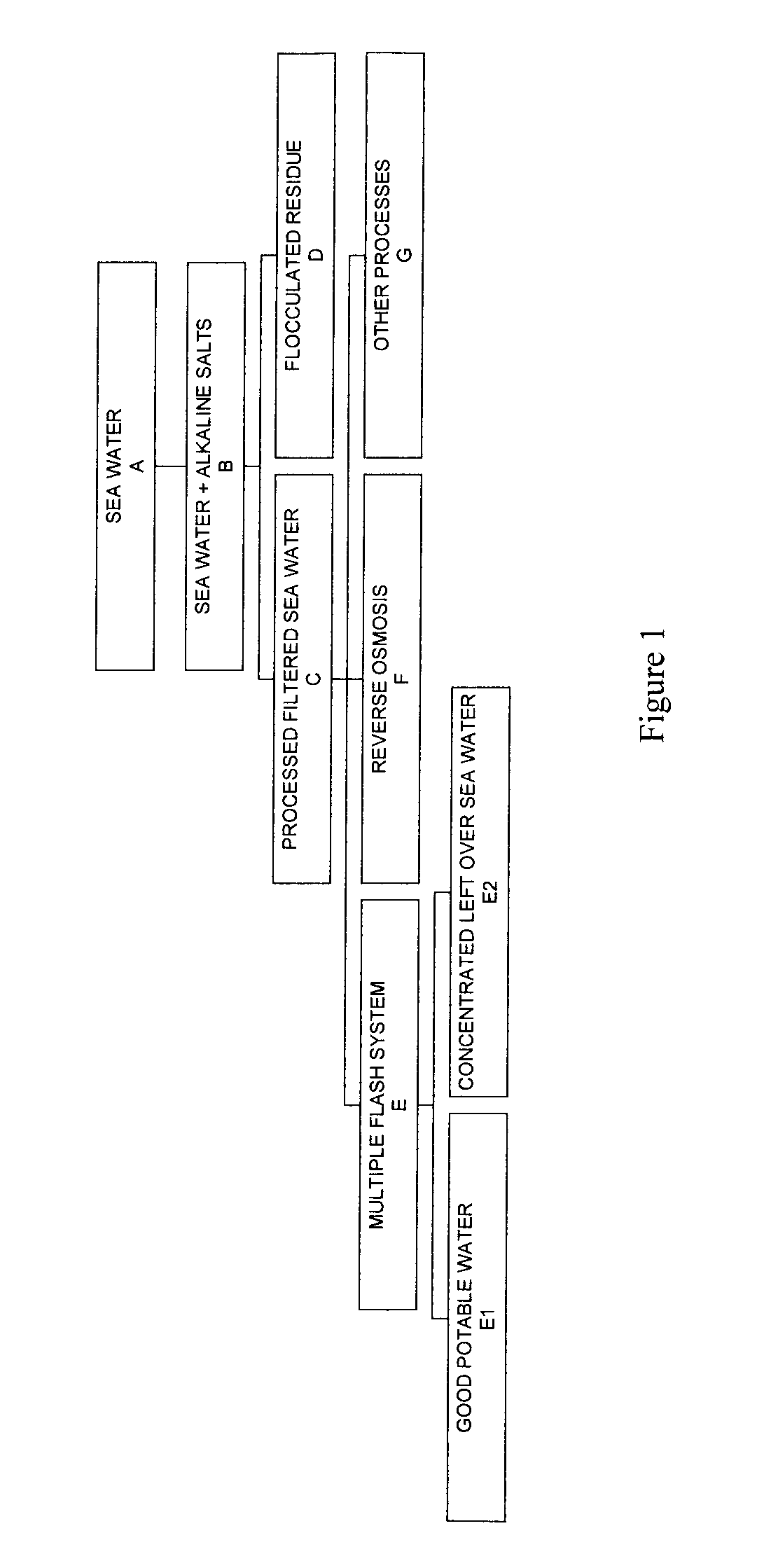

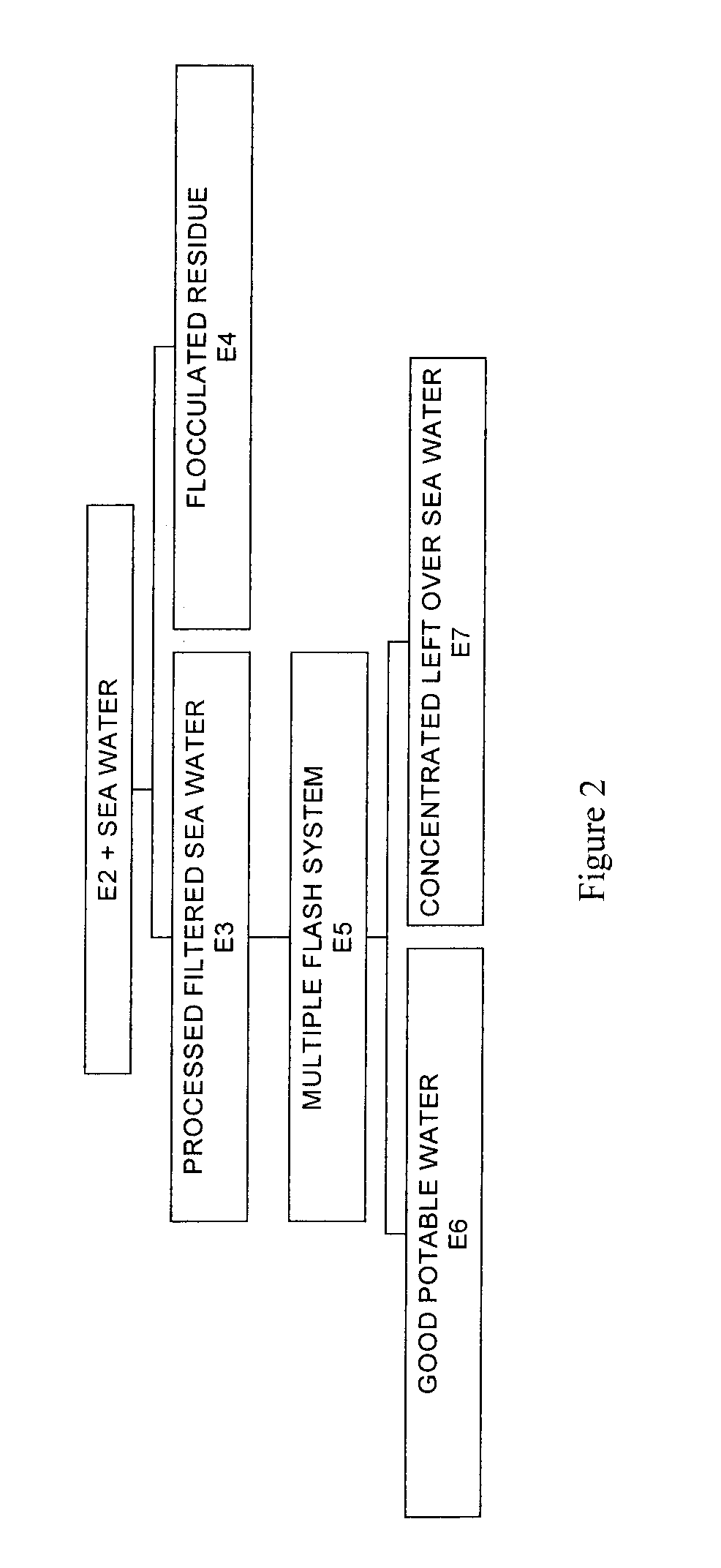

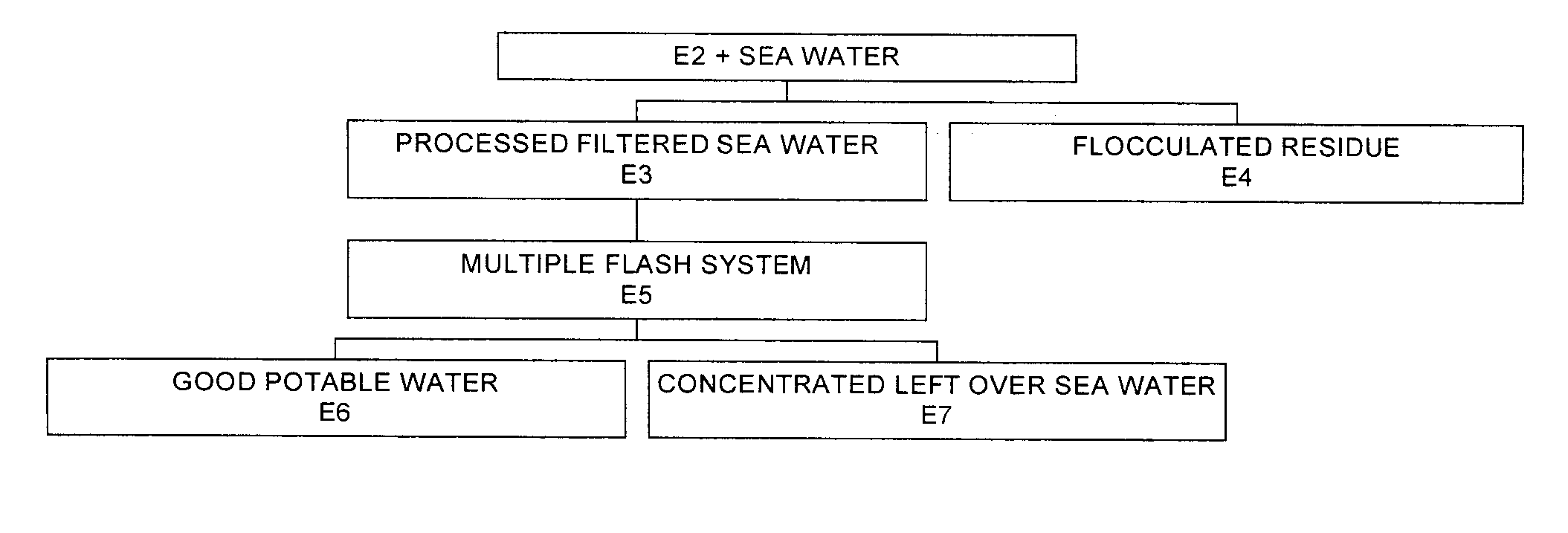

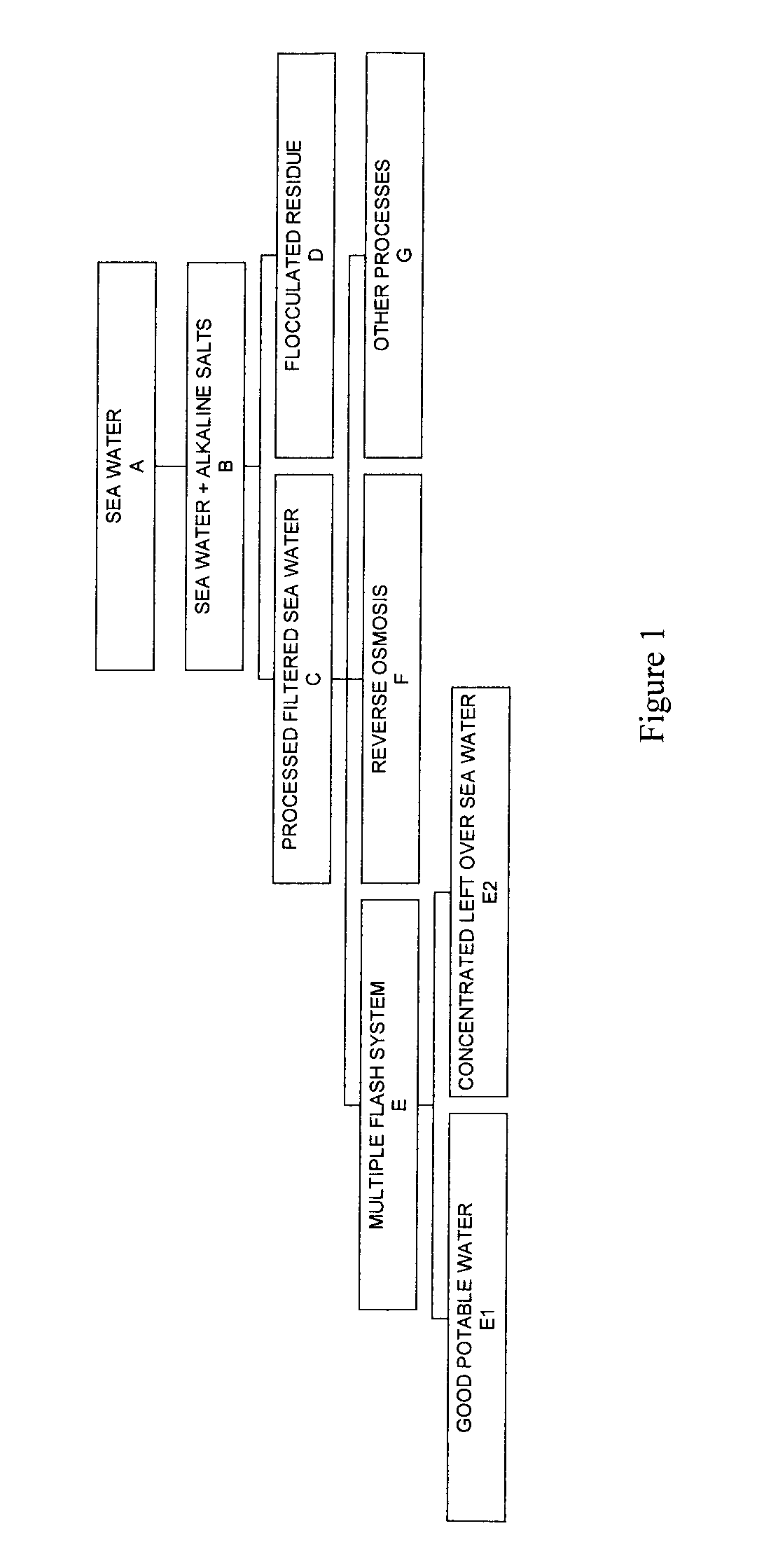

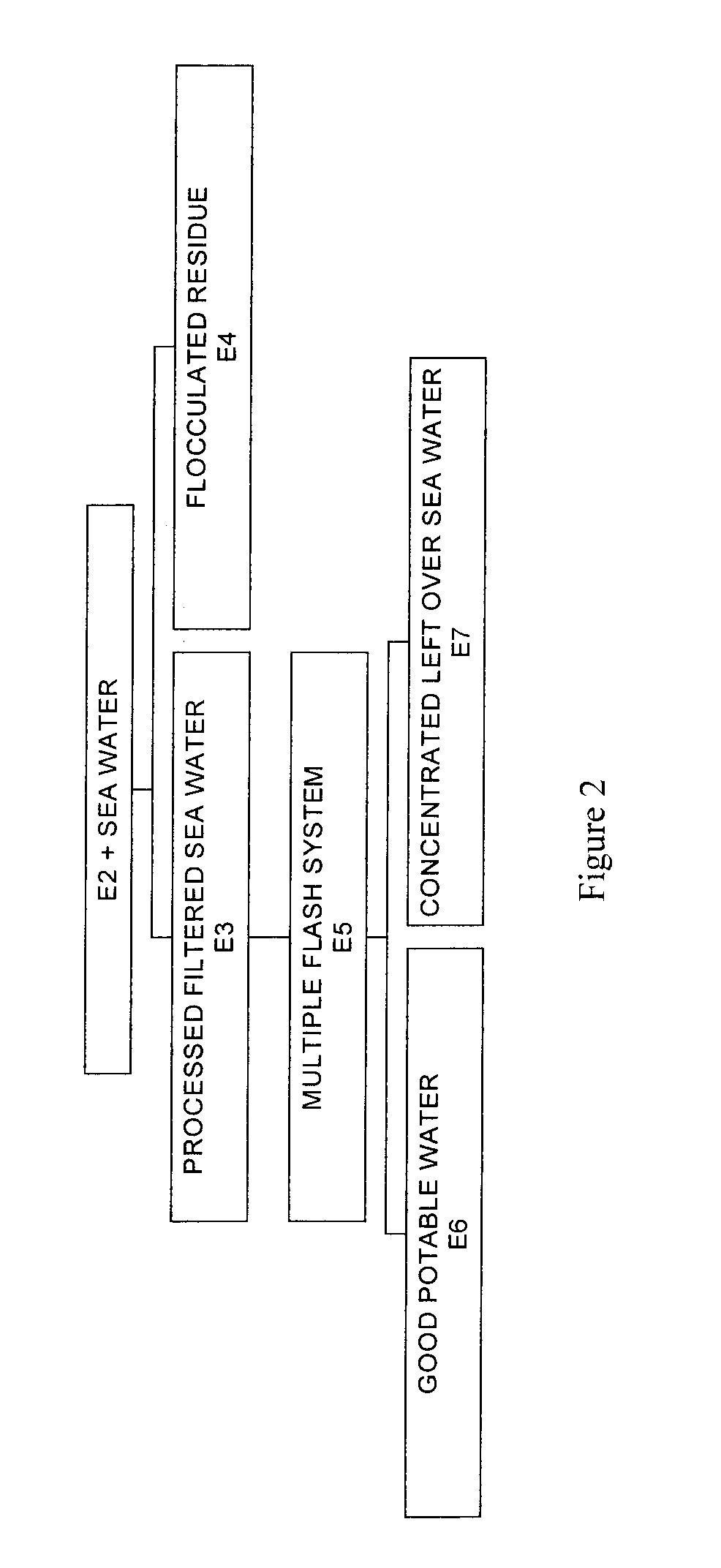

Process for pre-treating and desalinating sea water

ActiveUS20050098499A1Reduce maintenanceExtend equipment lifeGeneral water supply conservationSeawater treatmentCalcium bicarbonatePotassium hydroxide

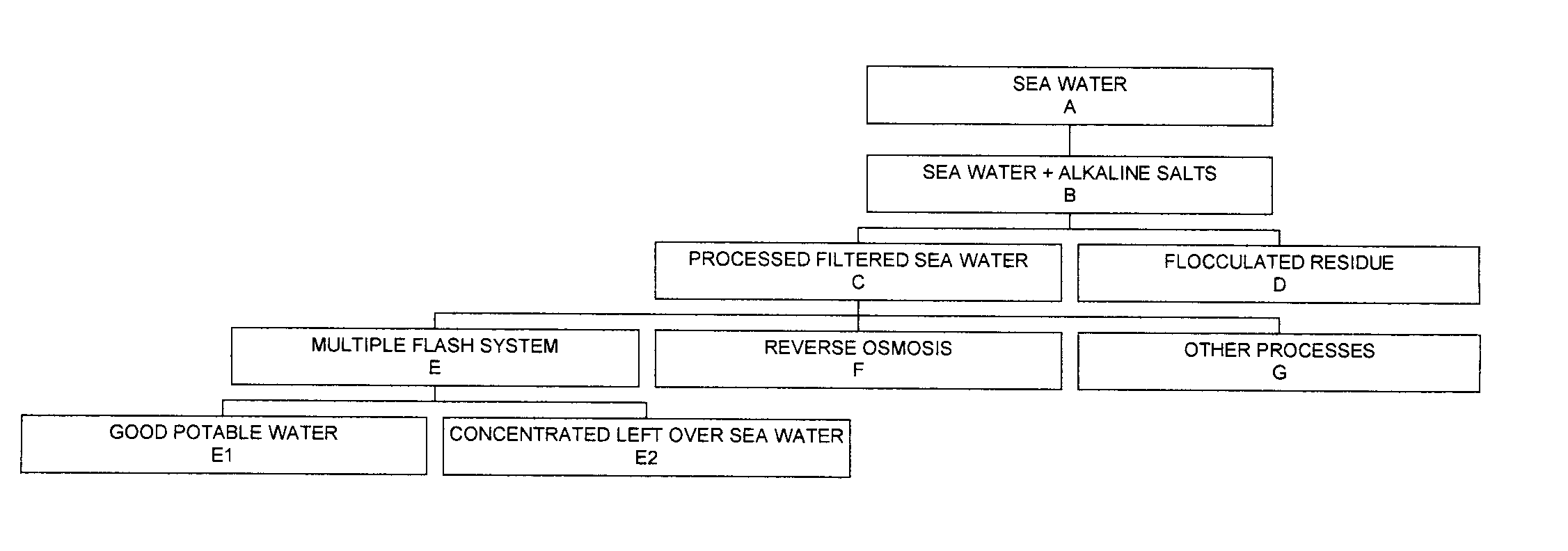

Water containing dissolved salts, such as calcium sulfate, calcium chloride, magnesium sulfate, magnesium chloride, sodium carbonate, sodium chloride, sodium sulfate, calcium bicarbonate, and mixtures thereof, is treated to reduce the concentration of those salts. About 0.1 to about 60 g / L of sodium hydroxide, sodium carbonate, potassium hydroxide, potassium carbonate, calcium hydroxide, calcium carbonate, aluminum hydroxide, aluminum sulfate, aluminum potassium sulfate, and mixtures thereof is added to the water, whereby a precipitate forms in the water. The precipitate is separated from said water and the water is desalinated using reverse osmosis, flash evaporation, or another method. The process is preferably performed by first adding calcium oxide or calcium hydroxide, separating the precipitate that forms, then adding sodium hydroxide and sodium carbonate to form a second precipitate.

Owner:HUSSAIN MOHAMMED AZAM

Process for pre-treating and desalinating sea water

ActiveUS7198722B2Extend equipment lifeReduce maintenanceGeneral water supply conservationSeawater treatmentCalcium bicarbonateReverse osmosis

Owner:HUSSAIN MOHAMMED AZAM

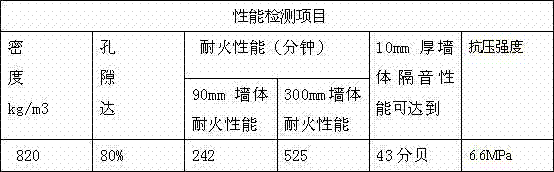

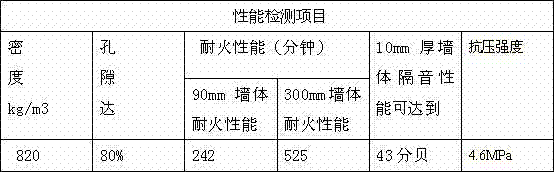

Acetylene sludge aerated concrete block and preparation method thereof

ActiveCN102875070ALow bulk densityGood heat insulationSolid waste managementCeramicwareSODIUM METAPHOSPHATEParaffin wax

The invention provides an acetylene sludge aerated concrete block, which is prepared by processing the following raw materials in part by weight: 20-30 parts of acetylene sludge, 25-30 parts of coal ash, 5-10 parts of cement, 4-6 parts of modified attapulgite, 5-10 parts of water treatment sludge, 5-10 parts of soda residue, 5-10 parts of light calcium powder, 10-15 parts of lime, triethanolamine, 4-5 parts of gypse, 0.02-0.08 part of aluminium powder, oxidized paraffin wax soap, 0.01-0.02 part of calcium bicarbonate, 2-3 parts of chelky slag, 1-2 parts of lignocellulose, 0.3-0.5 part of water glass, 0.03-0.05 part of borax, 1-2 parts of sodium hexametaphosphate, 1-2 parts of hydroxy propyl methyl cellulose sodium and 1-2 parts of superfine polyvinyl alcohol, wherein the weight of the triethanolamine is 0.1-0.3 percent of that of the lime, and the weight of the oxidized paraffin wax soap is 3-5 percent of that of the aluminium powder. According to the invention, the acetylene sludge is added into the raw materials of the aerated concrete block, and meanwhile other conventional additives and modified nano additives are added; the aerated concrete block is prepared by adopting a proper technology and is low in cost and good in performance; the circulating economy effect of changing waste into valuable is realized; the pollution is reduced; and the prepared aerated concrete block has the characteristics of light volume weight, high thermal insulation performance, good sound absorption effect and high strength and can be used for non-bearing or bearing wall bodies.

Owner:广东合盛建筑工程有限公司

Fragrant environment protection polyvinyl chloride granules

The invention discloses aromatic environment protective PVC granules which includes the components with the following weight portions: 100 weight portions of PVC resin; 8 weight portions to 40 weight portions of DOTP plasticizer; 10 weight portions to 40 weight portions of TOTM plasticizer; 2 weight portions to 12 weight portions of environment protective Ca / Zn thermal stabilizer; 0.1 weight portion to 1.5 weight portions of antioxidizer; 0 weight portion to 2.5 weight portions of polyethlene wax; 2 weight portions to 12 weight portions of plastic deodorant; 2 weight portions to 12 weight portions of aromatic essence, 0.5 weight portion to 3 weight portions of barium stearate; 0.1 weight portion to 3 weight portions of stearic acid; 3 weight portions to 20 weight portions of highly activated calcium bicarbonate filler; 0 weight portion to 10 weight portions of environment protective non-toxic flame retardant. The invention has the advantages that because all the raw materials in the prescription are safe and environment protective, the granulate is non-toxic, harmless and aromatic, has excellent performance, is environment protective, has no pollution and meets relevant provisions of the ROHS directive issued by European Union and the ''Management Method on Control of Electronic Information Product Pollution'' issued by China. The granule has wide scope of application, and is suitable to serve as the insulating material of wires and cables, floor leather material, sole material, toys for children and daily plastic products.

Owner:TBEA DEYANG CABLE CO LTD

Preparation method for zirconium-contained rare-earth composite oxide

ActiveCN102417352AExpand industrial applicationsHigh surface areaCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsChemical industryCalcium bicarbonate

The invention relates to a preparation method for a zirconium-contained rare-earth composite oxide. At a certain ratio, rare earth (cerium, yttrium, praseodymium or terbium) is mixed with zirconium to burden, or rare earth (cerium, yttrium, praseodymium or terbium) and zirconium are mixed with at least one of other metal ions (aluminum, barium, magnesium, strontium, titanium, manganese, ferrum, copper and hafnium) to burden. A magnesium bicarbonate or / and calcium bicarbonate aqueous solution prepared from raw materials of magnesium or / and calcium minerals or oxides and hydroxides by at least one working procedure of roasting, digesting, mixing size, carbonizing and the like can serve as a precipitator to carry out precipitation so as to obtain at least one of rare earth and zirconium composite carbonate and subcarbonate, and the at least one of rare earth and zirconium composite carbonate and subcarbonate is further roasted to obtain a zirconium-contained rare-earth composite oxide product. In the preparation method, cheap calcium or / and magnesium minerals or low-purity oxides and hydroxides can serve as initial raw materials to replace common chemical industry precipitators, such as ammonia water, ammonium bicarbonate, sodium carbonate, sodium hydroxide and the like, substances, such as magnesium, calcium, carbon dioxide and the like can be effectively circulated and utilized so as to greatly lower the production cost of the zirconium-contained rare-earth composite oxide, such as ceria-zirconia, yttrium zirconium, praseodymium zirconium, terbium zirconium and the like. In addition, in the production technology disclosed by the invention, no ammonia nitrogen wastewater, high-salinity wastewater and the like are generated, carbon dioxide greenhouse gas emission amount is reduced, the preparation technology is environmentally-friendly, and environment pollution is avoided.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Water curing reverse osmosis membrane chemical cleaning method

InactiveCN101224391AExtended service lifeEasy to cleanReverse osmosisCalcium bicarbonateReverse osmosis

The invention relates to a chemical cleaning method used for a water disposal reverse osmosis membrane, relating to a chemical cleaning method used for cleaning water disposal reverse osmosis membranes in the industrial water disposal process. The invention is characterized in that NaOH solution which contains EDTA is adopted to clean microorganism, organism and silicon dioxide, etc. pollutants on the reverse osmosis membrane; HCI solution is adopted to clean calcium bicarbonate and magnesium bicarbonate filth on the reverse osmosis membrane. By adopting the method of the invention, the reverse osmosis membrane used by captive power plant water disposal can be effectively cleaned in the alumina preparation process. The invention has better cleaning effect, reliable and practiced technique and convenient operation process.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

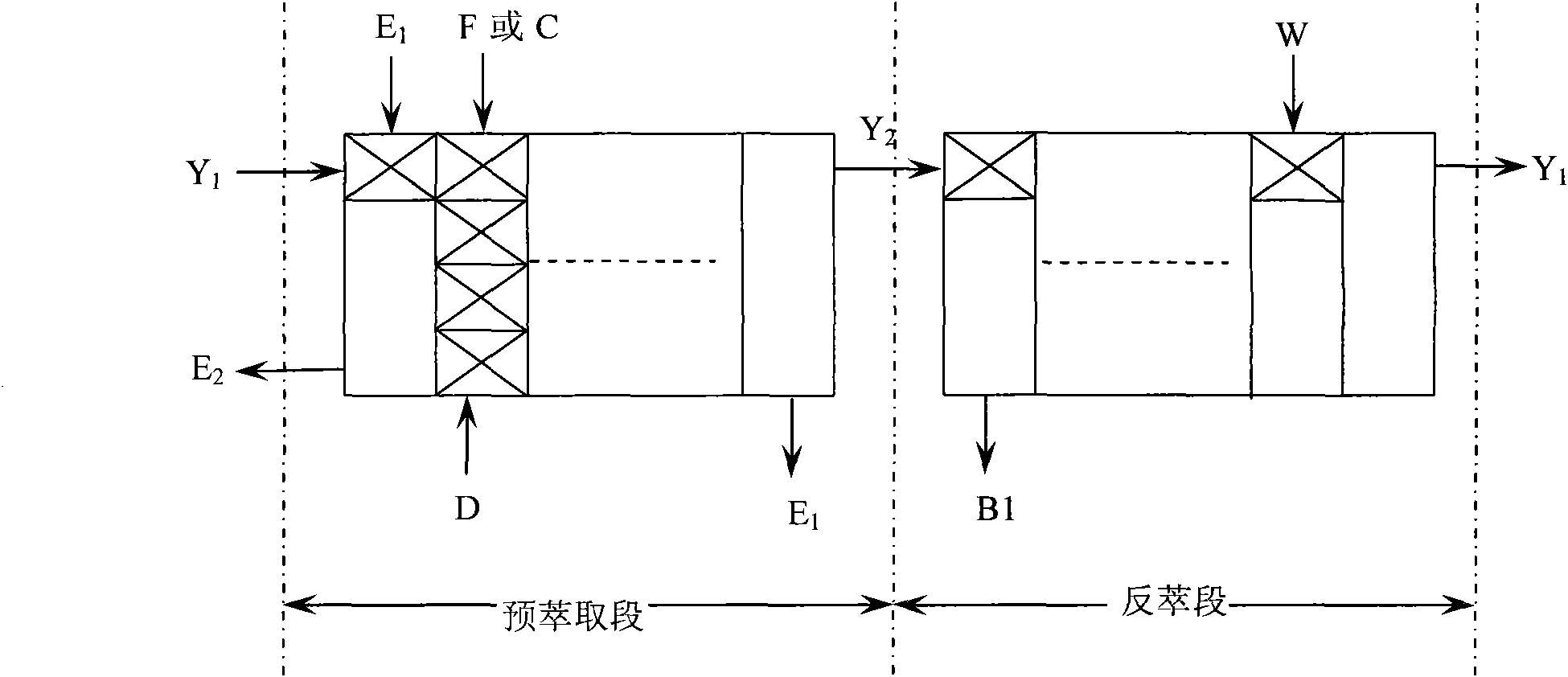

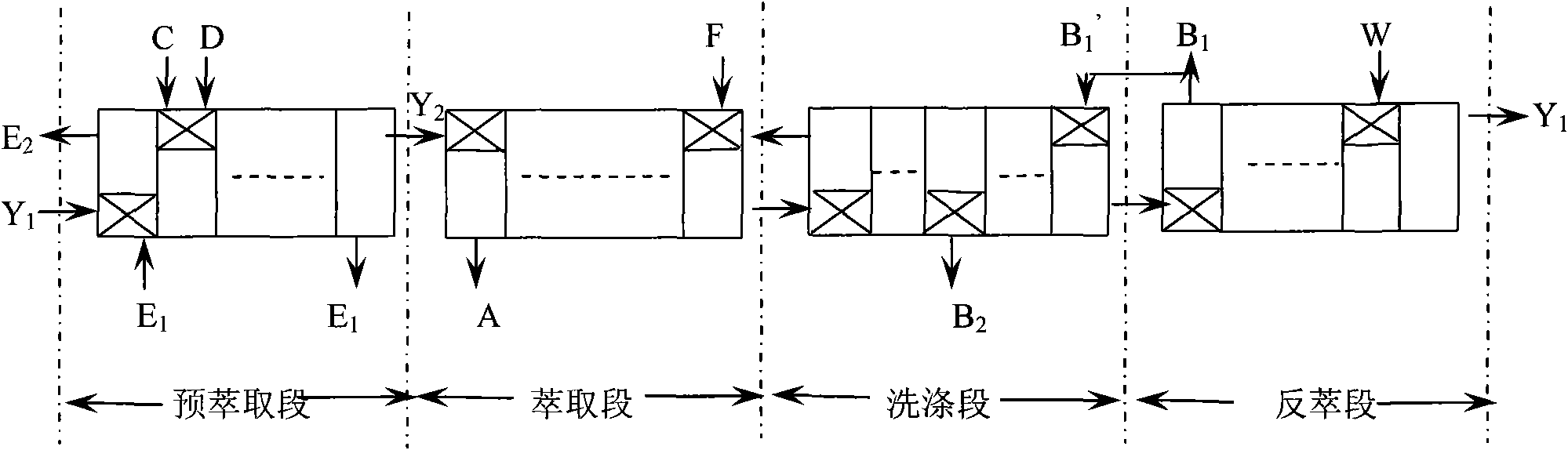

Process for separating rare-earth element by extraction

InactiveCN101781706ALow impurity contentEliminate pollutionProcess efficiency improvementRare-earth elementCalcium bicarbonate

The invention mixes and pre-extracts the mixed solution of acidic organic extractants such as P507, P204, C272, and naphthenic acid with magnesium bicarbonate and / or calcium bicarbonate solution and rare-earth solution. The rare-earth ions are extracted into the organic phase, then the loaded organic phase containing rare-earth ions are obtained through clarification, and can be used for the extract separation of the mixed rare-earth feed liquid. After a plurality of different levels of extraction, washing, stripping, single rare-earth compounds or rare-earth elements-containing enrichments can be obtained. The magnesium bicarbonate and / or calcium bicarbonate solution are prepared by roasting, digesting, carbonizing magnesite, limestone, calcite, dolomite and similar minerals, so that the content of impurities, such as silicon, iron, aluminum is lower. Ternary phase sediment is not produced in the pre-extraction and extraction separation process, so that the purity of the rare-earth products are not affected. The organic phase does not need ammonia saponification and does not produce ammonia-nitrogen wastewater. By adopting the invention, the production cost of rare-earth products is greatly lowered and the cost for three waste disposal is also greatly saved.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Method for processing production waste water of propylene oxide

InactiveCN101337745ARealize environmental protection and decontaminationCalcium/strontium/barium carbonatesWater/sewage treatment bu osmosis/dialysisEpoxyCalcium bicarbonate

A method for processing industrial wastewater of epoxy propane relates to a processing method of wastewater produced by epoxy propane, in particular to the treatment and the re-utilization of calcium chloride in wastewater. The invention provides a method for processing the industrial wastewater of the epoxy propane, which is used for processing and better utilizing the calcium oxide in the industrial waste water of the epoxy propane. The method comprises the following steps: firstly, generating calcium bicarbonate and calcium chloride by utilizing the reaction of ammonium bicarbonate and ammonium chloride; secondly, generating calcium carbonate precipitate, water and carbon dioxide through thermally decomposing the calcium bicarbonate; and thirdly, generating the calcium carbonate precipitate and the water by utilizing the reaction of calcium hydroxide in the wastewater and CO2 generated by thermally decomposing the calcium bicarbonate.

Owner:LIAONING DAZE ENVIRONMENT ENG

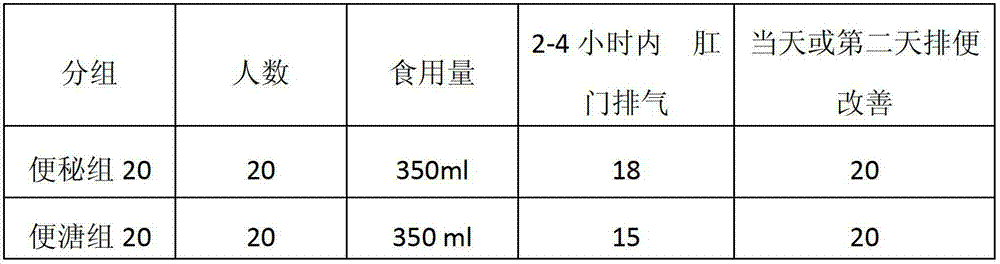

Gastrointestinal health preserving pulp and preparation method of gastrointestinal health preserving pulp

InactiveCN102813114ANo side effectsImprove gastrointestinal functionFood preparationCalcium bicarbonateSide effect

The invention belongs to the field of a health care product, and relates to gastrointestinal health preserving pulp and a preparation method of the gastrointestinal health preserving pulp. The gastrointestinal health preserving pulp is obtained through the following steps that 5 to 50 weight parts of corn, 5 to 20 weight parts of calcium carbonate or calcium bicarbonate, 5 to 20 weight parts of lupeose and 10 to 80 parts of other five-mixed-grain rice except the corn and edible traditional Chinese medical materials are weighed, the corn, other five-mixed-grain rice and the edible traditional Chinese medical materials are ground into pulp by a bean milk machine after the addition of a proper amount of water, then, the calcium carbonate or calcium bicarbonate and the lupeose are added, and the materials are uniformly mixed. The five-mixed-grain rice and the edible traditional Chinese medical materials are adopted to be compounded according to a specific mixing ratio, the obvious curative effect is realized on improving the gastrointestinal function, the raw material resources are sufficient, all ingredients have no toxic or side effect, and no matching contraindication exists.

Owner:吴志大

Mulberry compound fertilizer and preparation method thereof

The invention discloses a mulberry compound fertilizer, which is prepared from the following raw materials in parts by weight: 20-23 parts of urea, 24-28 parts of calcium superphosphate, 12-15 parts of humic acid, 13-16 parts of kieselguhr, 8-10 parts of tea shell powder, 3-4 parts of azedarach powder, 2-3 parts of garlic powder, 4-5 parts of carboxymethyl starch, 4-5 parts of calcium bicarbonate, 3-4 parts of ammonium molybdate, 5-6 parts of ferrous sulfate, 2-3 parts of copper sulfate, 1-2 parts of guar gum, 1-2 parts of zirconium oxide, 1-2 parts of methylcellulose, 3-4 parts of EM (effective microorganism) fungicide, 4-6 parts of film coating agent, and proper water. The fertilizer disclosed by the invention has the effects of inorganic and organic fertilizers; the nutrient elements required in the growth and development processes of mulberry can be reasonably configured, the growth requirements of the mulberry are met; the yield and the quality of the mulberry are improved, and the prepared fertilizer is not only quick to take effect, but also can slowly release the elements in the fertilizer; the property of the soil can be effectively improved by the added fungicide, and the utilization rate of the fertilizer is increased.

Owner:DANGTU COUNTY KEHUI TRADING

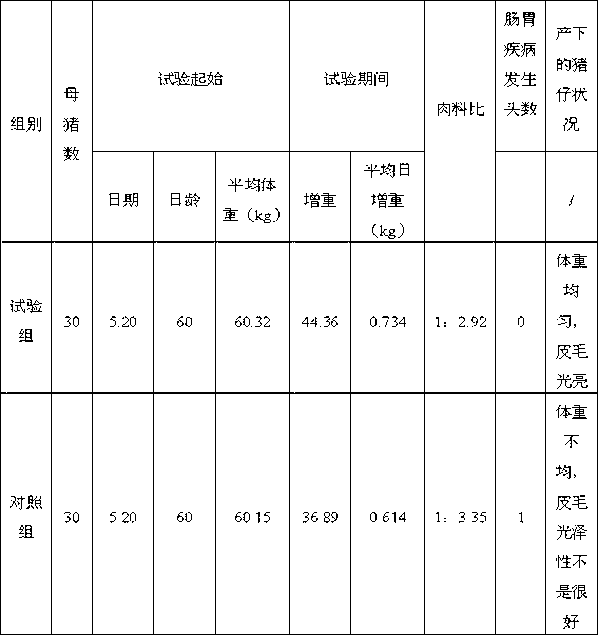

Feed for improving lean meat factor of fattening pig and preparation method of feed

ActiveCN103141708AMeeting nutritional needsImprove palatabilityFood processingAnimal feeding stuffBiotechnologyLean meat

The invention relates to a feed for improving the lean meat factor of a fattening pig. The feed for improving the lean meat factor of the fattening pig comprises the following materials: bean pulp, corn, peanut meal, bran, mountain flour, calcium bicarbonate, antioxidant, compound vitamin, compound microelement, salt, lysine and traditional Chinese medicine additive, wherein the traditional Chinese medicine additive comprises the following bulk drugs: astragalus mongholicus, medlar, poria cocos, herba epimedii, hawthorn, fennel, codonopsis pilosula, pericarpium citri reticulatae, ligusticum wallichii, liquorice, malt, rhizome atractylodis, quispualis indica, radix achyranthis bidentatae and dandelion. By adopting a new formula and the traditional Chinese medicine additive, the nutritional requirement of the fattening pigs is met, the palatability is good, the growth rate of lean-meat-type fattening pigs is high, the lean meat factor is high, the body type is plump, the anti-stress capability is strong, the meat is bright-colored and the drip loss is low. Besides, the feed has the advantages of little toxic and side effect, no drug tolerance, no residue and the like, and the side effect on the food safety is reduced.

Owner:菏泽新好饲料有限公司 +1

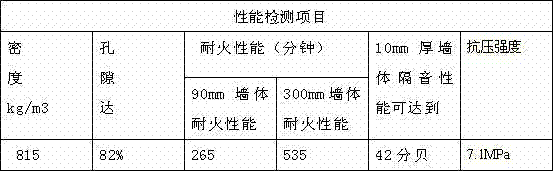

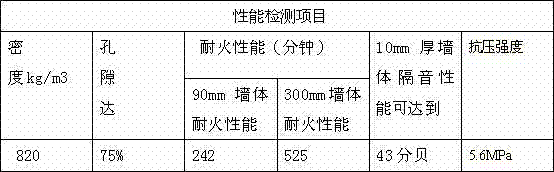

High-strength aerated concrete block

The invention discloses a high-strength aerated concrete block which is prepared from the following components in part by weight according to the conventional manufacturing process of the aerated concrete block: 28 to 32 parts of vanadiumore tailings, 5 to 10 parts of cement, 10 to 15 parts of quick lime, 5 to 10 parts of modified nanopowder, 5 to 10 parts of acetylene sludge, 3 to 5 parts of gypsum, 0.05 to 0.1 part of aluminum powder, 0.002 to 0.008 part of peregal, 0.03 to 0.08 part of calcium bicarbonate, 0.003 to 0.005 part of sodium carbonate, 0.5 to 0.8 part of calcium stearate, 0.3 to 0.5 part of zinc stearate, 0.01 to 0.03 part of sodium silicate, 0.05 to 0.1 part of hydroxypropyl methyl cellulose sodium, and proper amount of water. Through addition of nanopowder mineral powder, the volume weight of the brick is reduced, and meanwhile, the energy consumption is reduced. The high-strength aerated concrete block is good in heat insulation property and sound insulation property which are remarkably improved as compared with those of the conventional high-strength aerated concrete block. Meanwhile, the materials in a formula are optimized, so that the strength and the freezing resistance of the high-strength aerated concrete block are improved obviously.

Owner:沛县铸本混凝土有限公司

Chitosan oligosaccharide laying hen feed and preparation and use method thereof

ActiveCN102178107APromote growthGrowth inhibitionFood processingAnimal feeding stuffCalcium bicarbonateAnimal science

The invention provides chitosan oligosaccharide laying hen feed which is prepared from laying hen feed and a premix material in parts by weight. The laying hen feed is prepared from the following components in parts by weight: 62-64 parts of corn, 16-18 parts of bean pulp, 6-8 parts of rape seed dregs, 1-2 parts of fish meal, 1-2 parts of calcium bicarbonate, 3-4 parts of shell powder, 4-6 parts of talc powder, 0.4-0.6 part of soybean oil, 0.5-0.6 part of salt, 3-4 parts of wheat bran, 4-5 parts of sorghum flour and 3-4 parts of blood powder; and the premix material is prepared from the following components in parts by weight: 4-6 parts of laying hen vitamin, 3-5 parts of Vc, 20-22 parts of choline chloride, 1-2 parts of antioxidizing amine, 60-70 parts of protein powder and 1-2 parts of oligosaccharins. The chitosan oligosaccharide laying hen feed provided by the invention has the advantages of simple process and convenience in manufacture and use, and the oligosaccharins which is rich in chitosan oligosaccharide is added into the feed for feeding the laying hen so that the nutrition component of the obtained egg products contains the chitosan oligosaccharide.

Owner:QINGDAO TIANRUI ECOLOGICAL TECH

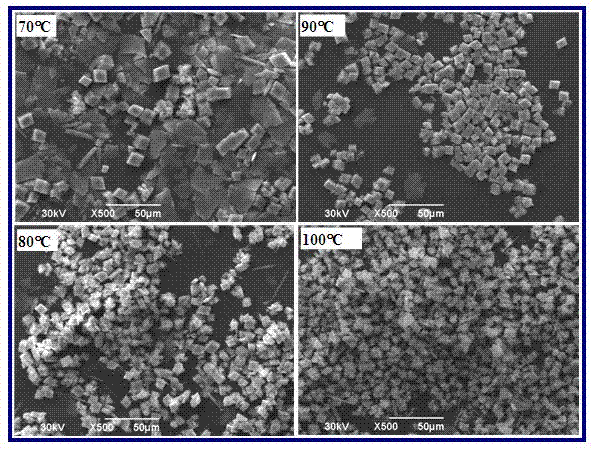

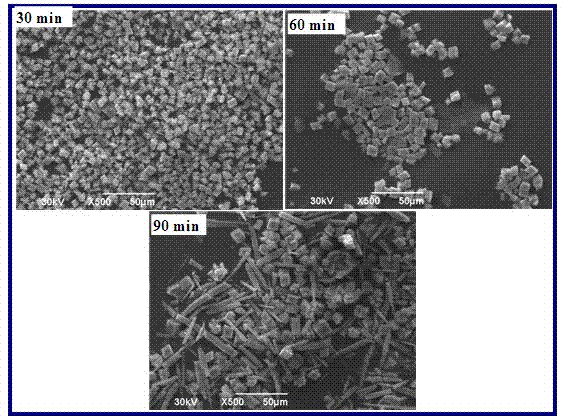

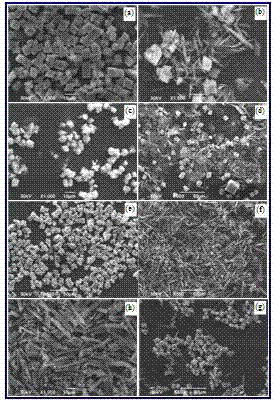

Method for preparing calcium carbonate powders of different structures and shapes

InactiveCN102757075AAdvances in preparation methodsAchieve diversificationCalcium/strontium/barium carbonatesNanotechnologyCalcium bicarbonateReaction temperature

The invention discloses a method for preparing calcium carbonate powders of different structures and shapes. The method comprises the following steps of: heating a calcium bicarbonate solution in different temperatures under the conditions of the participation of an additive or not, and resolving to generate calcium carbonate in different times. The crystal types of the calcium carbonate powders and the shapes of particles can be controlled through reaction temperatures and reaction times, and the diversification of the crystal types of the calcium carbonate powders and the shapes of particles can be particularly realized through the type and the amount of the additive.

Owner:HUBEI UNIV OF TECH

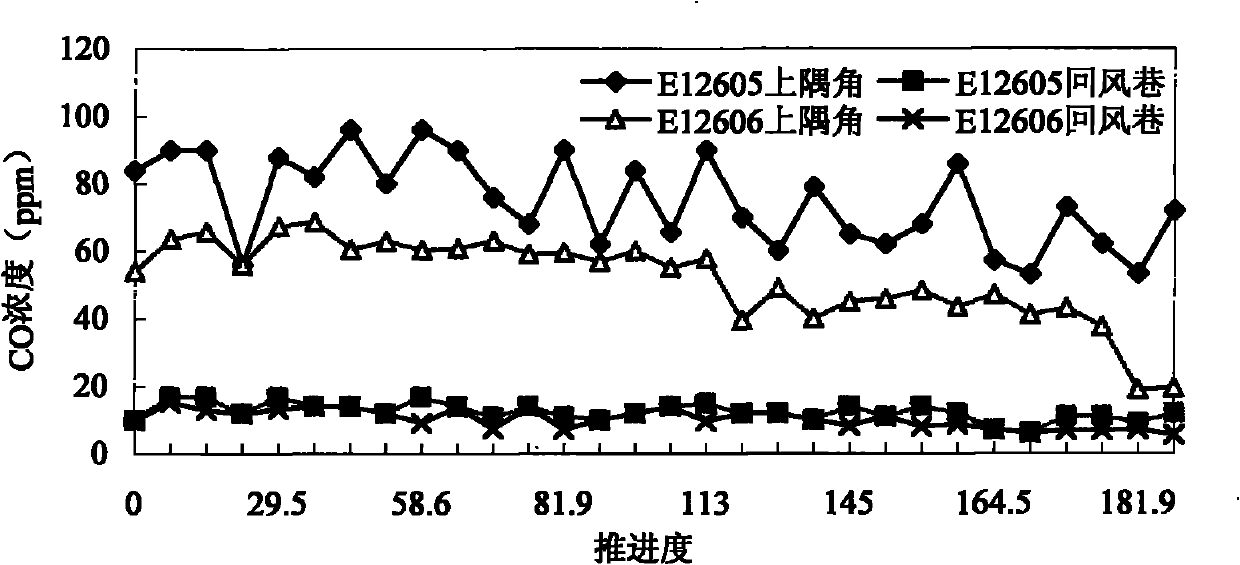

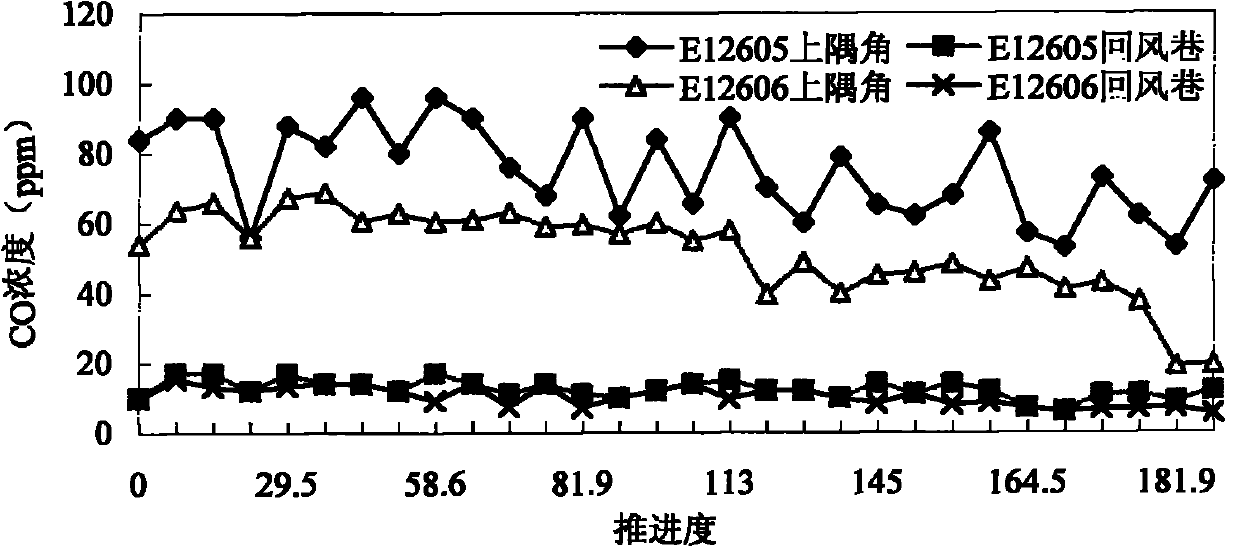

Inorganic salt type inhibitor for preventing and controlling spontaneous combustion of residual coal in goaf of coal mine

InactiveCN101766877AAvoid contactStop spontaneous combustionDust removalFire preventionSpontaneous combustionSodium bicarbonate

The invention discloses an inorganic salt type inhibitor for preventing and controlling spontaneous combustion of residual coal in a goaf of a coal mine, which belongs to the field of fire prevention and extinguishment in the goaf of the coal mine. The inorganic salt type inhibitor consists of sodium bicarbonate, calcium bicarbonate, calcium chloride, magnesium chloride, sodium chloride and zinc chloride according to a certain proportion by weight. The average inhibiting rate of the inorganic salt type inhibitor can achieve 85%, and the inhibiting effect is ideal. When in use, the inhibitor is covered on the surface of the residual coal in the goaf, thereby achieving the effects of preventing and controlling the spontaneous combustion of a coal layer in the region for a long time. The dusting method of the inorganic salt type inhibitor for fire prevention and extinguishment is safe and stable, the process flow is simple, the operation is convenient, the initial investment is low, and the using cost is relatively low. The fire prevention and extinguishment technology of the inorganic salt type inhibitor which has thermal instability and can release inert gas carbon dioxide has broad application prospects in the work of preventing and controlling the spontaneous combustion fire disasters of the coal layers. The inorganic salt type inhibitor is applicable to the fire prevention and extinguishment in the goaf of the coal mine.

Owner:UNIV OF SCI & TECH BEIJING

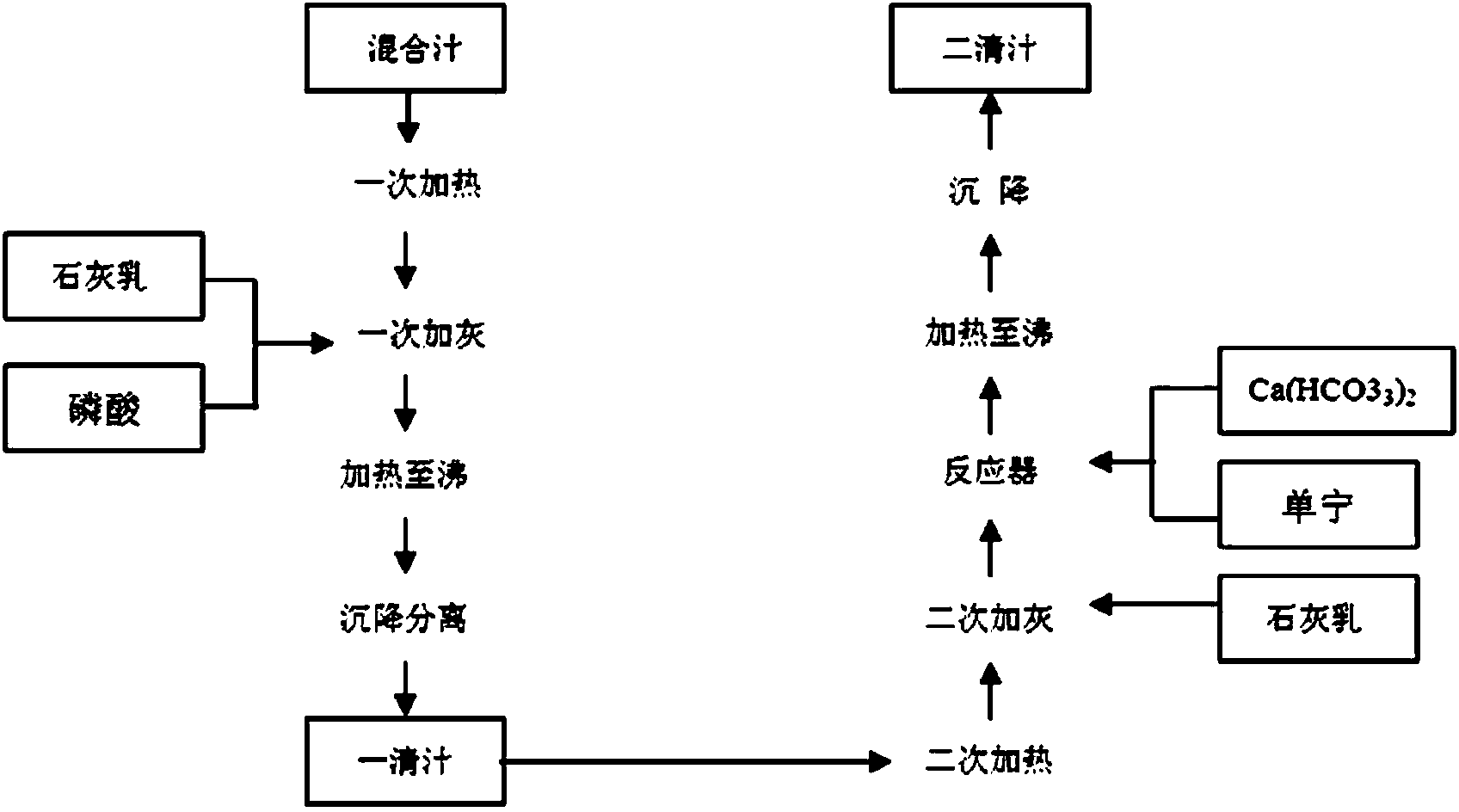

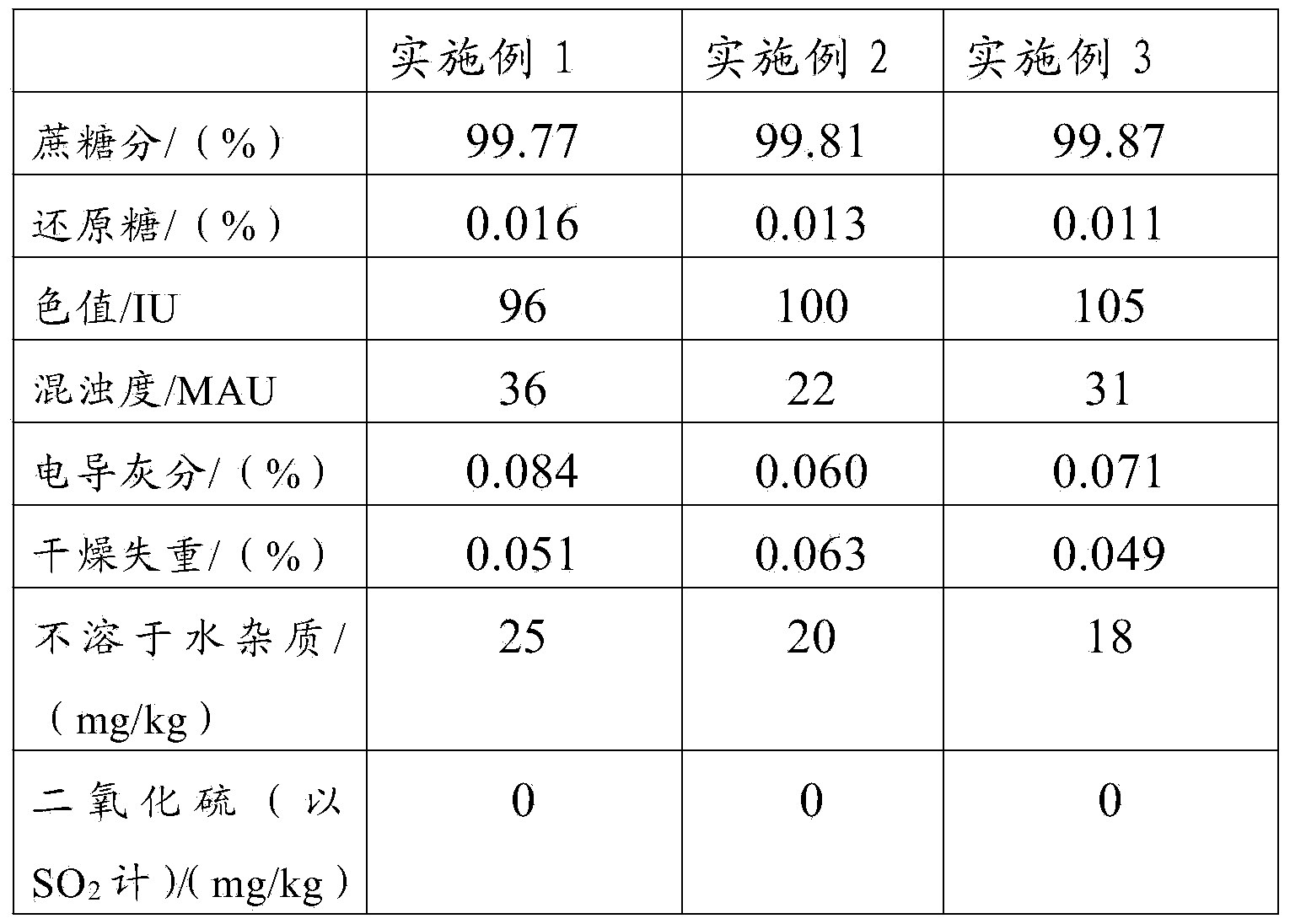

Sulfur-free clarifying method for cane sugar manufacture

ActiveCN103866052AAddress sugar containing SO

<sub>2</sub>

questionSolve containing SO

<sub>2</sub>

questionPurification using adsorption agentsCalcium bicarbonateFree sugar

The invention discloses a sulfur-free clarifying method for cane sugar manufacture. According to the method, lime milk, phosphoric acid, calcium bicarbonate and tannin are taken as clarifying agents, sugarcane mixed juice is taken as the raw material, after filtering by a sieve, primary clear juice is obtained through clarifying by a lime method, then the tannin and calcium bicarbonate are added for secondary clarifying, so as to obtain secondary clear juice. Sulfur-free sugar is produced without using SO2 in the whole process, so that the problem that domestic sugar has SO2 is solved thoroughly, the safety of the sugar is improved, and domestic sugar products are increased.

Owner:GUANGXI UNIV

Compound microbial fish fertilizer special for silver carp and preparation method thereof

InactiveCN103300248AFull of nutritionHigh in proteinAnimal feeding stuffBiotechnologyCalcium bicarbonate

The invention discloses a compound microbial fish fertilizer special for silver carp and a preparation method thereof. The compound microbial fish fertilizer special for silver carp comprises the following components in parts by weight: 0.5-0.8 part of silicate bacteria, 1-3 parts of streptococcus faecalis, 0.6-0.8 part of trichoderma sp, 2-5 parts of rhodopseudomonas palustris, 0.3-0.5 part of saccharomycetes, 50-60 parts of fishbone dust, 65-70 parts of vinegar residue powder, 50-55 parts of effluent precipitate, 40-60 parts of rice bran, 12-14 parts of brown sugar, 10-14 parts of table salt, 80-85 parts of pig manure, 45-55 parts of waste of a pig meat slaughter house, 60-65 parts of aquatic plants, 12-16 parts of calcium bicarbonate, 14-17 parts of urea, 1-3 parts of ferric citrate, 0.6-0.8 part of vitamin B1, 0.2-0.6 part of Vitamin B12, 1-3 parts of rheum officinale, 2-6 parts of Astragalus membranaceus and 4-7 parts of medicated leaven. The fertilizer disclosed by the invention can promote silver carp to grow quickly, the EPA content of fish is increased, the fish diseases are reduced, and the number of dead fish is reduced, and meanwhile, beneficial microorganisms in water are increased. Finally, both the quality and the weight of silver carp are improved.

Owner:苏州市阳澄湖现代农业发展有限公司

Physical separation and sequestration of carbon dioxide from the exhaust gases of fossil fuel combustion

InactiveUS20120058042A1Maximizes carbon dioxideEasy to separateCalcium/strontium/barium carbonatesOrganic chemistryCalcium bicarbonateNitrogen gas

Methods are provided for physically removing all the carbon dioxide from the combustion products of solid, liquid, and gaseous fossil fuels. The combustors operate without excess air to maximize the carbon dioxide at the exhaust, which is compressed with the nitrogen and mixed with pressurized water to dissolve the carbon dioxide in a chamber from which the nitrogen gas is removed. The solution is drained into a second lower pressure chamber from which the carbon dioxide re-evolves as a gas, which is then pressurized for sequestration in limestone formations as calcium bicarbonate. The water is recycled to repeat the separation process, and depressurization of the two gases recovers most of the compression energy.

Owner:ZAUDERER BERT

Boron slag aerated brick and preparation method thereof

The invention provides a boron slag aerated brick. The boron slag aerated brick is prepared from the raw materials: 20 to 30 weight parts of boron slag, 25 to 30 weight parts of coal ash, 5 to 10 weight parts of cement, 4 to 6 weight parts of modified sepiolite powder, 5 to 10 weight parts of powdered carbon, 5 to 10 weight parts of ceramics factory waste, 5 to 10 weight parts of calcium carbonate powder, 10 to 15 weight parts of lime, 0.1 to 0.3 weight percent of triethanolamine lime, 4 to 5 weight parts of gypsum, 0.02 to 0.08 weight part of aluminum powder, nekal which is 3 to 5 percent based on the weight of the aluminum powder, 0.01 to 0.02 weight part of calcium bicarbonate, 2 to 3 weight parts of volcanic rock, 1 to 2 parts of lignocellulose, 0.3 to 0.5 weight part of soda ash, 1 to2 weight parts of white emulsion, 1 to 2 weight parts of hydroxypropyl methyl cellulose sodium, and 1 to 2 weight parts of chitosan. Boron slag is added into the raw materials of the aerated brick, other conventional aids and modified aids are added, and the aerated brick processed by an appropriate process is low in cost, high in performance, achieves a cyclic economy effect of changing waste into wealth, and reduces pollution; and the processed aerated brick has the characteristics of light volume weight, high thermal insulation performance, good sound absorption effect and high intensity, and can be used for a non-load bearing wall body or a load bearing wall body.

Owner:任羚羊

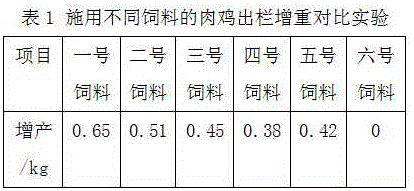

High-protein digestion promoting meat chicken feed and preparation method thereof

InactiveCN105767578AImprove immunityRich in trace elementsFood processingAnimal feeding stuffBiotechnologyCalcium bicarbonate

The present invention discloses a high-protein digestion promoting meat chicken feed. The meat chicken feed consists of the following raw materials: corn flour, soybean meal, wheat bran, grape peel dregs, fish meal, seaweed powder, earthworm powder, peanut meal, rice bran, bone meal, rapeseed cake, honey, silkworm chrysalis powder, calcium hydrogen phosphate, vitamin E, shell powder, vegetable oil, calcium bicarbonate, haws, radix sophorae flavescentis, pine needle powder, radix lsatidis, yeast powder and cellulase. The high-protein digestion promoting meat chicken feed is rich in proteins, starch, celluloses and trace elements. By adding the traditional Chinese medicinal ingredients, the meat chicken feed is excellent in promoting digestion and strengthening the immune system.

Owner:LIANYUNGANG HENGTU FARMING DEV CO LTD

High-protein feed for improving immunity of chickens for meat and preparation method of high-protein feed

InactiveCN106333128AImprove immunityRich in trace elementsFood processingAnimal feeding stuffBiotechnologyCalcium bicarbonate

The invention discloses high-protein feed for improving the immunity of chickens for meat. The high-protein feed comprises the following raw materials: corn flour, soybean pulp, wheat bran, grape peel dregs, fish meal, seaweed meal, earthworm powder, peanut meal, rice bran, bone meal, rape seed cakes, calcium hydrogen, corn protein, dicalcium phosphate, shell powder, plant oil, mountain flour, calcium bicarbonate, traditional Chinese medicine anti-disease additives, yeast powder, cellulase, premix and amino acid premix. The invention further discloses a preparation method of the high-protein feed for improving the immunity of the chickens for meat. The high-protein feed for improving the immunity of the chickens for meat, which is disclosed by the invention, is rich in protein, starch, cellulose and trace elements, and due to adoption of the traditional Chinese medicine anti-disease additives, the chicken feed disclosed by the invention is excellent in properties of promoting the digestion function and improving the immunity.

Owner:全椒县金凤凰禽业养殖专业合作社

Milking sow feed

ActiveCN104161222AKeep healthyPromote milk productionFood processingDigestive systemCalcium bicarbonateAnimal science

The invention provides a milking sow feed. The feed comprises the following components in parts by weight: 300-450 parts of corn, 180-250 parts of soybean meal, 15-22 parts of fish meal, 30-78 parts of bran, 8-15 parts of animal oil, 20-28 parts of carrots, 1-2 parts of calcium bicarbonate, 1-2 parts of lysine, 1-2 parts of methionine, 2-3 parts of choline, 0.1-0.15 part of biochemical fulvic acids, 0.01-0.015 part of salinomycin sodium, 6-10 parts of radix codonopsis, 10-16 parts of astragalus membranaceus, 3-8 parts of soup with pettitoes and lotus roots, 3-8 parts of Chinese pulsatilla roots, 3-6 parts of fungus umbellatus, 3-8 parts of poria cocos, 0.1-0.15 part of vitamins, 0.1-0.15 part of folic acids, and 0.1-0.15 part of pantothenic acids. The milking sow feed can improve milk yield, strengthen the immunity of newborn pigs, and effectively prevent and treat the diarrhoea of the newborn pigs.

Owner:SICHUAN GUOFENG ZHONGKE BIOTECH

Oil shale residue aerated brick and preparation method thereof

ActiveCN102875184AGood heat insulationImprove sound insulationSolid waste managementCeramicwareCelluloseCalcium bicarbonate

The invention provides an oil shale residue aerated brick. The oil shale residue aerated brick is prepared from the following raw materials: 20 to 30 weight parts of oil shale residue, 25 to 30 weight parts of coal ash, 5 to 10 weight parts of cement, 4 to 6 weight parts of modified attapulgite, 5 to 10 weight parts of mica powder, 5 to 10 weight parts of ceramics factory waste, 5 to 10 weight parts of calcium carbonate powder, 10 to 15 weight parts of lime, 0.1 to 0.3 weight percent of triethanolamine lime, 4 to 5 weight parts of gypsum, 0.02 to 0.08 weight part of aluminum powder, nekal which is 3 to 5 percent based on weight of aluminum powder, 0.01 to 0.02 weight part of calcium bicarbonate, 2 to 3 weight parts of volcanic rock, 1 to 2 weight parts of lignocellulose, 0.3 to 0.5 weight part of soda ash, 0.03 to 0.05 weight part of borax, 1 to 2 weight parts of sodium diacetate, 1 to 2 weight parts of hydroxypropyl methyl cellulose sodium, and 1 to 2 weight parts of superfine polyvinyl alcohol. The oil shale residues are added into the raw materials of the aerated brick, other conventional aids and modified nano aids are added, and the aerated brick which is processed by an appropriate process is low in cost and high in performance, achieves the cyclic economy effect of changing waste into wealth, and reduces pollution; and the processed aerated brick has the characteristics of light volume weight, high thermal insulation property, good sound absorption effect, and high intensity and can be used for a non-load bearing wall body or a load-bearing wall body.

Owner:深圳市嘉能新型环保建材有限公司

Fluorite slag aerated brick and preparation method thereof

ActiveCN102875186AGood heat insulationImprove sound insulationSolid waste managementCeramicwareParaffin waxCellulose

The invention provides a fluorite slag aerated brick which is prepared through processing raw materials in part by weight: 20 to 30 parts of fluorite slag, 25 to 30 parts of sand, 5 to 10 parts of cement, 4 to 6 parts of modified attapulgite, 5 to 10 parts of ceramsite, 5 to 10 parts of waste in ceramic factories, 5 to 10 parts of light calcium powder, 10 to 15 parts of lime, triethanolamine, 4 to 5 parts of gypsum, 0.02 to 0.08 part of aluminum powder, oxidized paraffin wax soap, 0.01 to 0.02 part of calcium bicarbonate, 2 to 3 parts of lava, 1 to 2 parts of lignocellulose, 0.3 to 0.5 part of sodium silicate, 0.03 to 0.05 part of borax, 1 to 2 parts of sodium hexametahposphate, 1 to 2 parts of hydroxypropyl methyl cellulose sodium, and 1 to 2 parts of superfine polyvinyl alcohol, wherein the weight of the triethanolamine is 0.1 to 0.3 percent of that of the lime, and the weight of the oxidized paraffin wax soap is 3 to 5 percent of that of the aluminum powder. Fluorite slag is added in the raw materials of the aerated brick, meanwhile, other conventional additives and modified nano additives are added, a proper process is adopted to manufacture the aerated brick, and the aerated brick is low in cost and good in performance, achieves the circular economy effect of turning waste into valuable, reduces the pollution, is light in weight, high in heat insulation property, good in sound-absorbing effect, and high in strength, and can be used as a non-bearing wall or a bearing wall.

Owner:山东未来城建筑工程有限公司

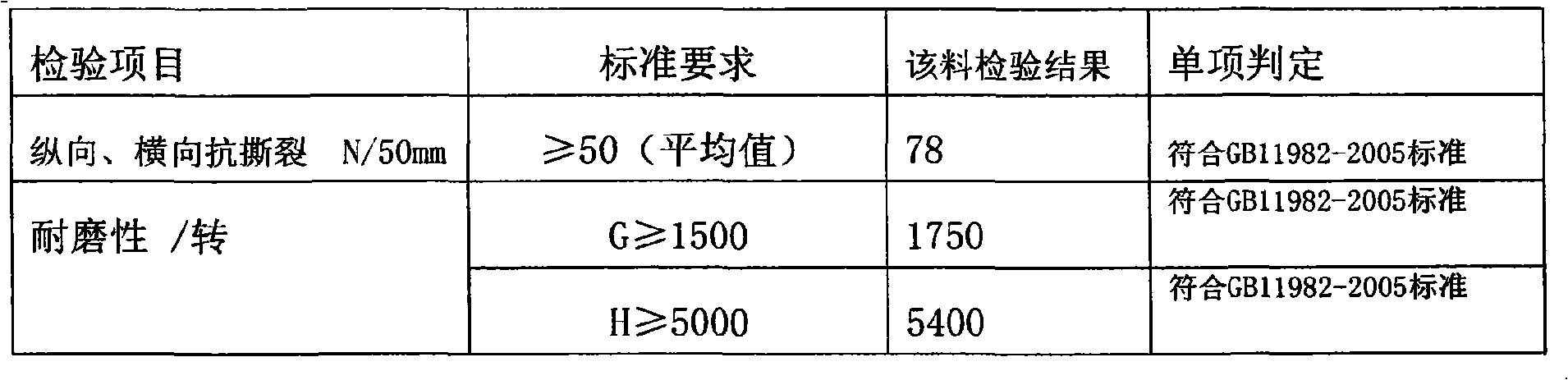

Fireproof insulating board for exterior wall and production method thereof

The invention discloses a fireproof insulating board for an exterior wall and a production method thereof and belongs to the technical field of building materials. The fireproof insulating board for the exterior wall is prepared from the following raw materials in parts by weight: 10-20 parts of phenolic resin, 20-40 parts of maize straws, 15-30 parts of silicate cement, 15-30 parts of water glass, 20-30 parts of diatomite, 10-20 parts of magnesium oxide, 10-20 parts of magnesium chloride, 5-15 parts of calcium hydrogen carbonate and 200-300 parts of water. The invention further provides a production method of the fireproof insulating board for the exterior wall. The production method comprises the following steps: mixing the raw materials; uniformly stirring; feeding into a die; rolling; demoulding; cutting; and maintaining. By taking phenolic resin and maize straws as a filling material, under the matching effect of other auxiliary materials, the fireproof insulating board for the exterior wall firm in structure, high in compression and fracture resistance, light in mass and safe to use is formed. The fireproof insulating board for the exterior wall reaches the demand of a level A fire protection standard and is good in insulating effect, low in cost and easy to industrialize.

Owner:昆山文创建筑装饰工程有限公司

Environment friendly bacteriostatic water color ink for tipping paper

ActiveCN101429364ABacteriostaticEnhance the antibacterial effect of the mediumInksWater basedCalcium bicarbonate

The invention provides an environment-friendly bacteriostatic water-based ink for tipping paper, which is characterized by consisting of the following raw materials in mass percentage: 45 to 55 percent of water, 3 to 10 percent of ethanol, 1 to 3 percent of antibacterial agent, 2 to 4 percent of anti-settling agent, 9 to 15 percent of titanium dioxide, 4 to 6 percent of calcium bicarbonate, 1 to 3 percent of GR organic dye, 5 to 10 percent of GR organic dye yellow, 1 to 3 percent of GR organic dye black, and 18 to 25 percent of binder. The environment-friendly bacteriostatic water-based ink can greatly reduce usage amount of ink and contents of arsenic, mercury and lead, prevents heavy metals such as the arsenic, the mercury, the lead, cadmium, nickel and chromium in a print from causing harm to human body, improves working environment, delays dispersing time of the antibacterial agent, increases antibacterial effect, has better viscosity stability and low inflammability, can simplify workload for printing and washing, and improves production efficiency.

Owner:楚雄市华丽包装实业有限责任公司

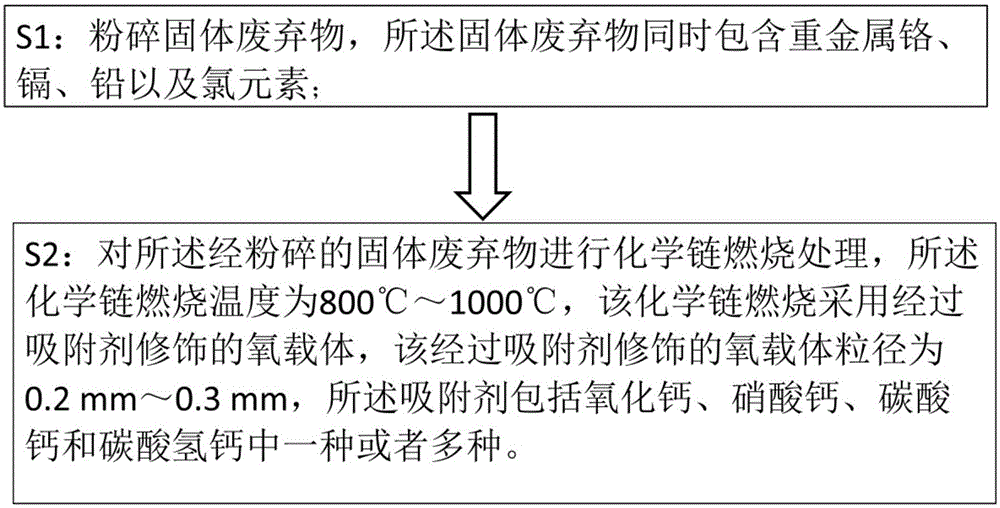

Method for stable volatilization of heavy metal chromium, cadmium and lead

InactiveCN105135447AAchieve fixationEasy to operateIndirect carbon-dioxide mitigationIncinerator apparatusCalcium bicarbonateSorbent

The invention discloses a method for stable volatilization of heavy metal chromium, cadmium and lead, and belongs to the technical field of harmlessness of solid wastes. The method comprises the following steps: S1, pulverizing the solid wastes, wherein the solid wastes comprise heavy metal chromium, cadmium and lead as well as a chlorine element; S2, performing chemical looping combustion treatment on the pulverized solid wastes, wherein the chemical looping combustion temperature is 800-1000 DEG C, an adsorbent-modified oxygen carrier is adopted in the chemical looping combustion process, the particle diameter of the adsorbent-modified oxygen carrier is 0.2-0.3 mm, and the adsorbent comprises one or more of calcium oxide, calcium nitrate, calcium carbonate and calcium bicarbonate. Through the adoption of the method, the problem in discharging of volatile chlorides of heavy metal chromium, cadmium and lead in a solid waste source utilization process in the prior art is solved.

Owner:HUAZHONG UNIV OF SCI & TECH

Feed for sow in late pregnancy and preparation method of feed

InactiveCN102987127AMeet nutritional needsImprove the immunityAnimal feeding stuffCalcium bicarbonateAdditive ingredient

The invention discloses a feed for a sow in late pregnancy. The feed comprises the following ingredients in parts by weight: 50-60 parts of corn, 10-15 parts of bran, 30-40 parts of fermented rice bran, 12-18 parts of dry fermented chicken manure, 3-4 parts of shell powder, 1-2 parts of yeast powder, 0.3-0.5 part of calcium bicarbonate, 3.2-3.8 parts of sugarcane leaf extract, 0.8-1.2 parts of litsea coreana powder, 0.1-0.3 part of charcoal, 3-8 parts of modified attapulgite, 0.3-0.5 part of salt, 2-3 parts of black soya bean, 3-4 parts of euphorbia thymifolia, 3-4 parts of Paederia scandens, 3-4 parts of Centella asiatica, 3-4 parts of Radix Boehmeriae, 1-3 parts of longan leaf, 4-5 parts of garlic, 0.2-0.4 part of bamboo leaf extract, 1-2 parts of banana peel freeze drying powder, 0.05-0.15 part of multi-vitamins, 0.4-0.6 part of premix compound, 3-5 parts of composite acidifier, 0.002-0.004 part of organic selenium, 0.10-0.20 part of lysine, and 0.10-0.20 part of aminoglutaric acid. The feed for the sow in late pregnancy disclosed by the invention is overall in nutrition; and the composite acidifier and the modified attapulgite are added, so as to improve the resistance of the sow and reduce the incidence rate. The produced piglet is high in survival rate, even in weight and bright in fur and feather.

Owner:HEFEI YONGSHENG POULTRY

Titanium calcium aluminate heat insulation refractory material and preparation method thereof

The invention relates to a titanium calcium aluminate heat insulation refractory material and a preparation method thereof. The titanium calcium aluminate heat insulation refractory material is characterized in that the method comprises the steps of blending a dodecyl dimethyl benzyl ammonium chloride (DDBAC) foaming agent, polyacrylamide, calcium hydrogen carbonate, tetrabutyl titanate and water, wherein the mass ratio of the DDBAC foaming agent to the polyacrylamide to the calcium hydrogen carbonate to the tetrabutyl titanate to the water is equal to 1: (0.5-1): (4-7): (3-6): (30-40); carrying out ultrasonic dispersion under the condition of water bath so as to prepare foaming liquid; blending the foaming liquid, rho-alumina micropowder and titanium-iron slag micropowder, wherein the mass ratio of the foaming liquid to the rho-alumina micropowder to the titanium-iron slag micropowder is equal to (50-60): (1-2): 100; mixing, stirring, molding, and carrying out vacuum freeze drying; putting the product into a muffle furnace, carrying out heat preservation at the temperature of 1450-1500 DEG C for 40-60min, and naturally cooling the product along with the furnace so as to obtain the titanium calcium aluminate heat insulation refractory material. The preparation method provided by the invention has the characteristics of being low in cost, simple in technology and high in rate of finished products; the prepared titanium calcium aluminate heat insulation refractory material is low in volume density, high in compression strength and small in heat conductivity coefficient.

Owner:WUHAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com