Method for stable volatilization of heavy metal chromium, cadmium and lead

A heavy metal and volatile technology, applied in the fields of lead, fixed volatile heavy metal chromium, and cadmium, can solve problems such as difficult industrialization, complex process of removing heavy metals, and reduction of solid waste burnout, achieving strong process operability, Achieve recycling and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

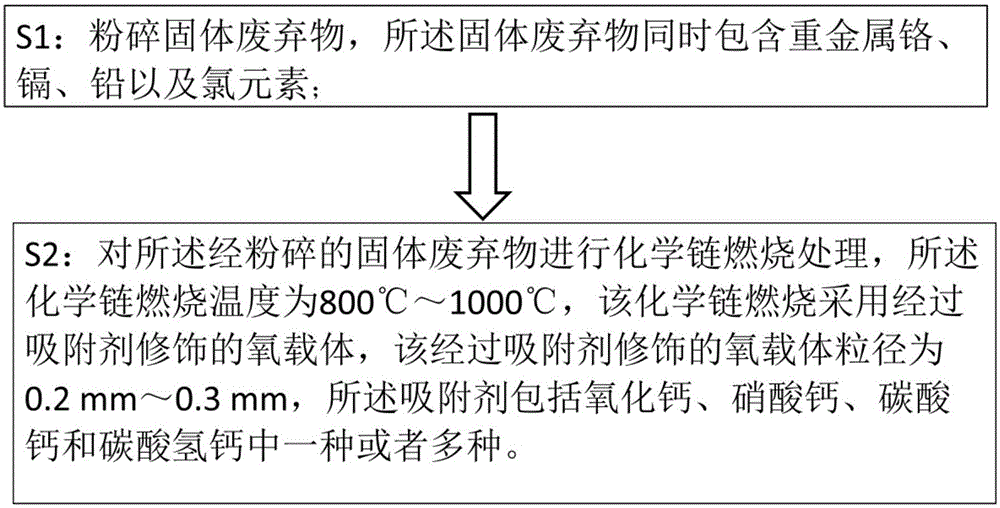

[0026] A method for utilizing solid waste energy and fixing volatile heavy metals chromium, cadmium and lead, comprising the following steps:

[0027] S1: Use a shredder to crush solid waste into solid fuel with a particle size of less than 1mm. The solid waste includes municipal solid waste, sludge, medical waste, industrial combustible waste, waste biomass and combustible waste containing volatile heavy metals chromium, cadmium, lead and Cl elements.

[0028] S2: Carry out chemical looping combustion utilization on the pulverized solid waste, the chemical looping combustion temperature is 850°C-1000°C, the chemical looping combustion uses an oxygen carrier modified by an adsorbent, the oxygen carrier is iron ore, The iron ore is crushed first, and then iron ore particles with a particle size of 0.2 mm to 0.3 mm are obtained by screening. The adsorbent used was Ca(NO 3 ) 2 , the Ca(NO 3 ) 2 Dissolved in deionized water, followed by wet impregnation modification of iron o...

Embodiment 2

[0033] S1: Use a shredder to crush solid waste into solid fuel with a particle size of less than 1mm. The solid waste includes municipal solid waste, sludge, medical waste, industrial combustible waste, waste biomass and combustible waste containing volatile heavy metals chromium, cadmium, lead and Cl elements.

[0034] S2: Perform chemical looping combustion on the pulverized solid waste, the temperature of the chemical looping combustion is 800°C-900°C, the chemical looping combustion uses an oxygen carrier modified by an adsorbent, the oxygen carrier is copper ore, The copper ore is pulverized first, and then the copper ore particles with a particle size of 0.2 mm to 0.3 mm are obtained by sieving. The adsorbent used was Ca(HCO 3 ) 2 , the Ca(HCO 3 ) 2 Dissolved in deionized water, then wet-impregnated copper ore particles. During the wet impregnation modification process, the mass percentage of adsorbent can be controlled, so as to prepare oxygen carriers with differe...

Embodiment 3

[0037] S1: Same as Example 2.

[0038] S2: Perform chemical looping combustion on the pulverized solid waste, the temperature of the chemical looping combustion is 800°C-900°C, the chemical looping combustion uses an oxygen carrier modified by an adsorbent, the oxygen carrier is copper ore, The copper ore is pulverized first, and then the copper ore particles with a particle size of 0.2 mm to 0.3 mm are obtained by sieving. The adsorbent used was Ca(HCO 3 ) 2 , the Ca(HCO 3 ) 2 Dissolved in deionized water, then modified by ultrasonic wet impregnation of copper ore particles. The mass percentage of adsorbent can be controlled in the process of ultrasonic wet impregnation modification, so as to prepare oxygen carriers with different adsorbent contents. In the chemical chain combustion process of solid waste, the adsorbent is used to absorb and fix chlorine element, so as to realize the role of fixing volatile heavy metals chromium, cadmium and lead in the process of solid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com