Patents

Literature

247 results about "Chemical looping combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

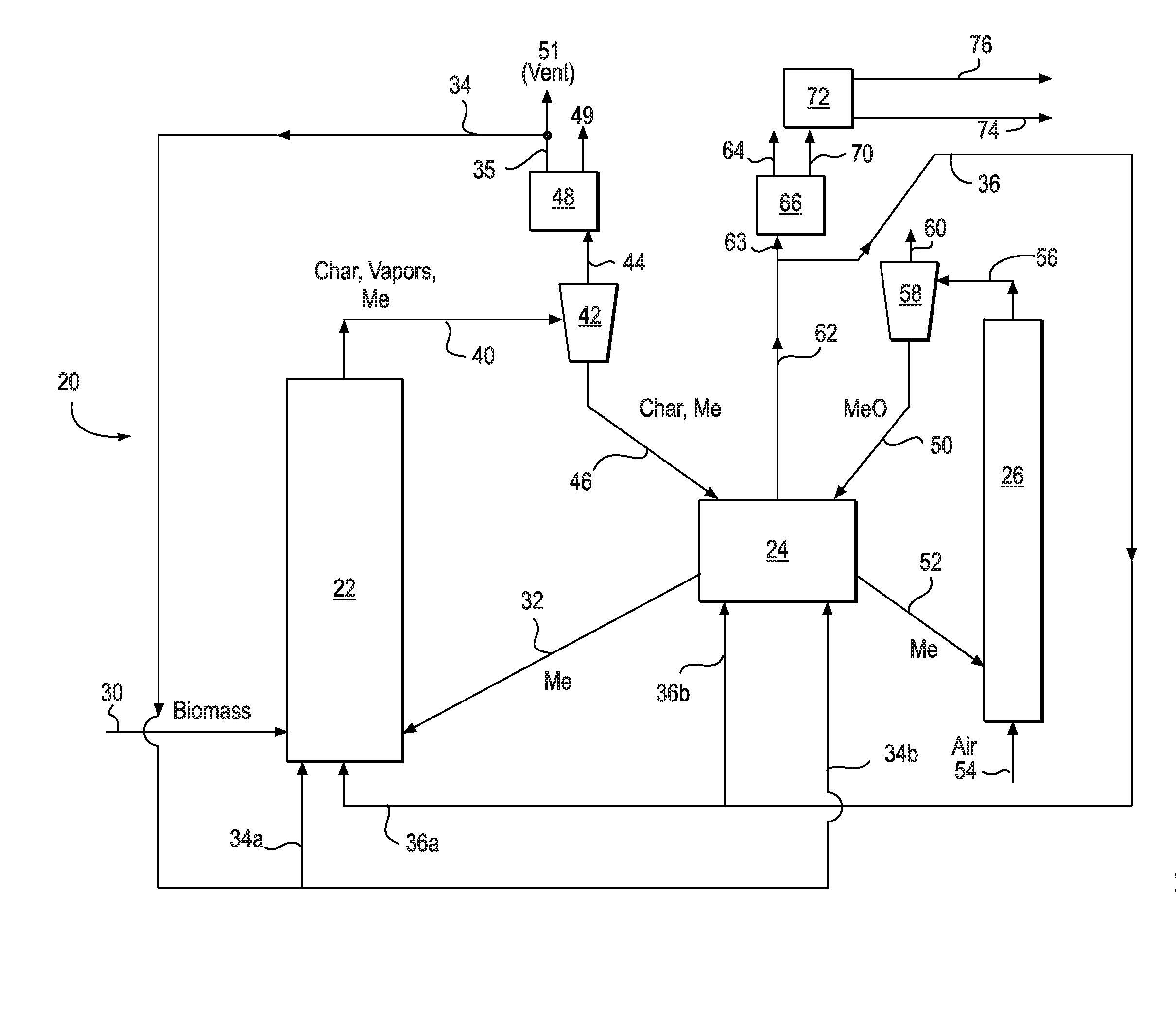

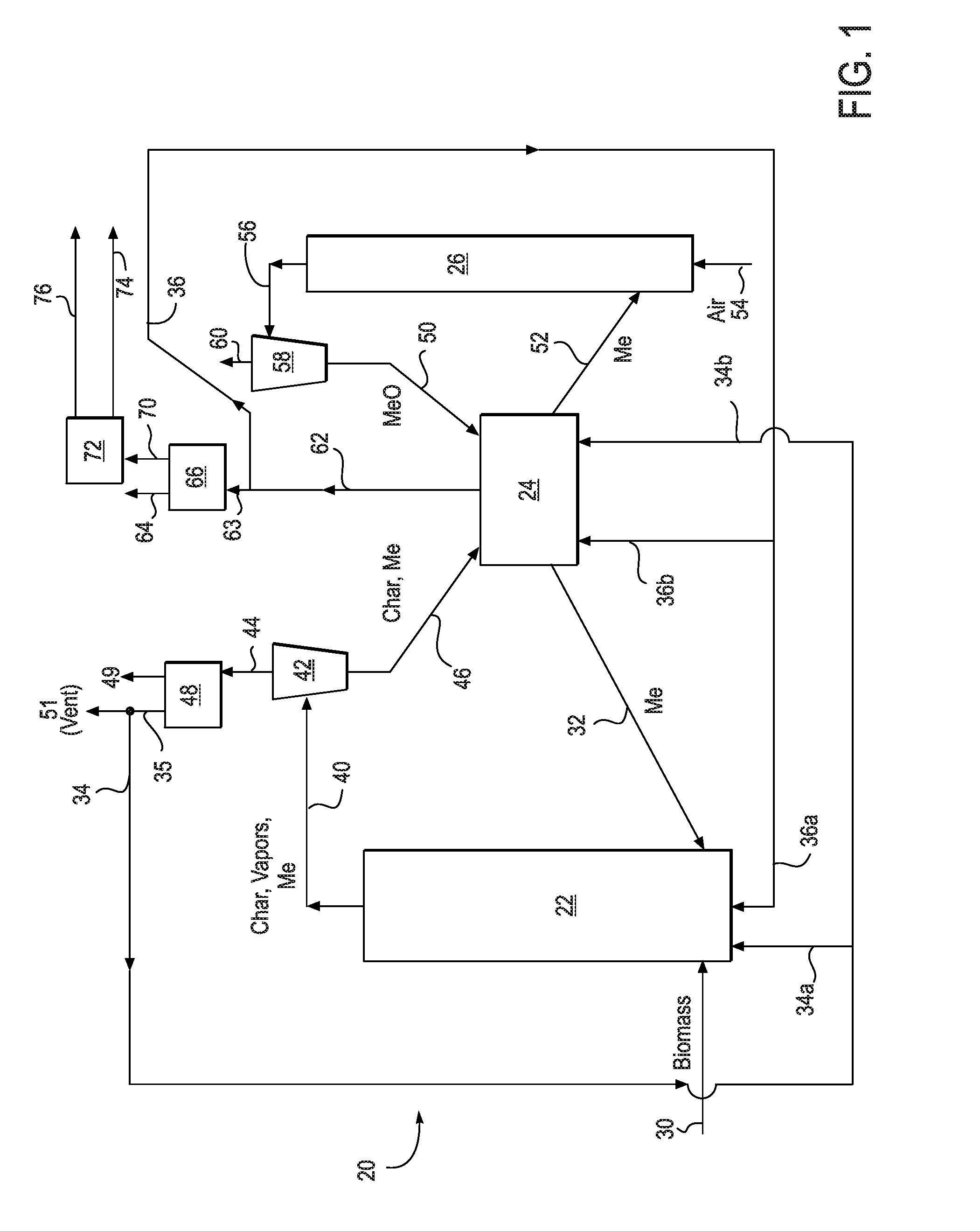

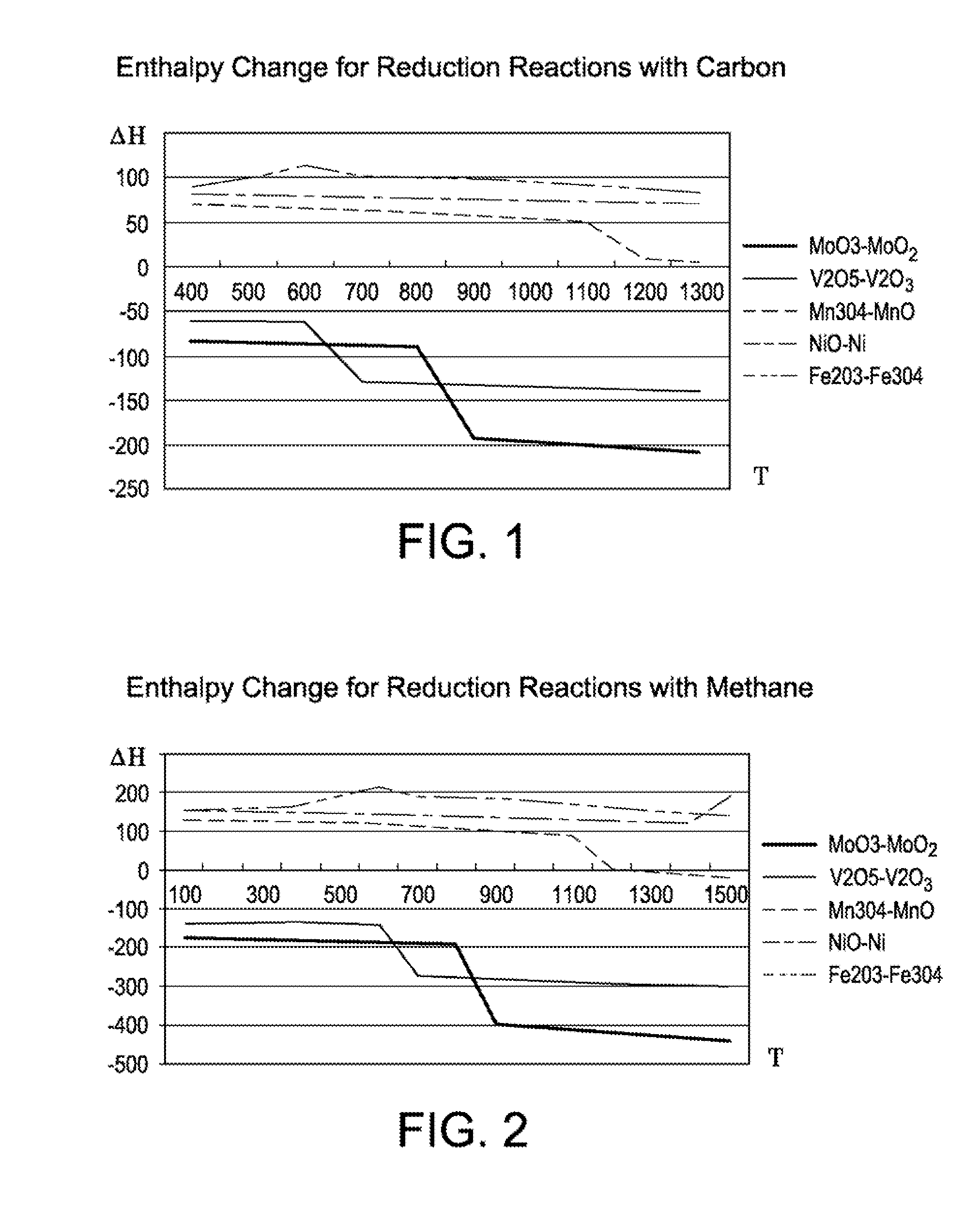

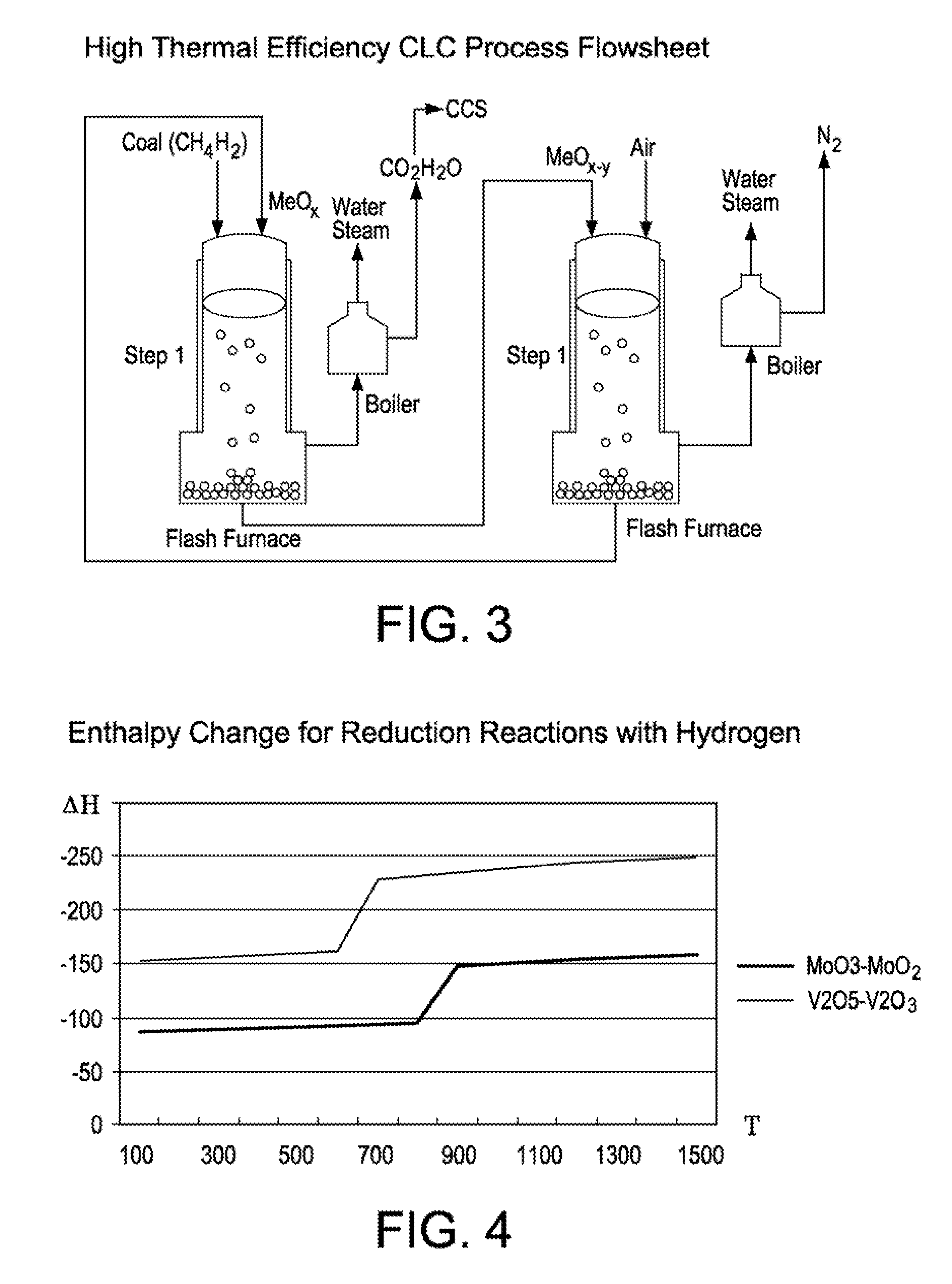

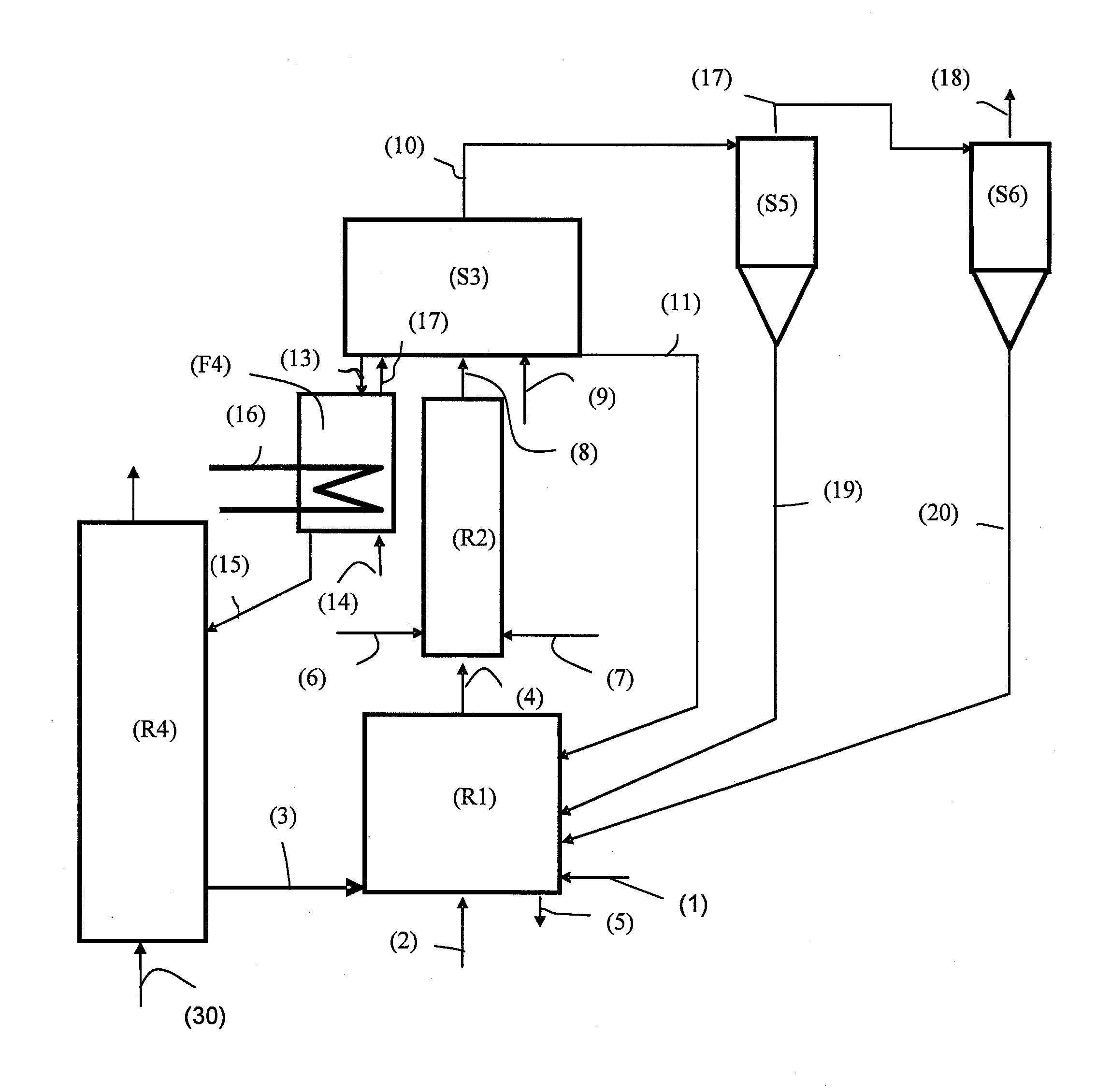

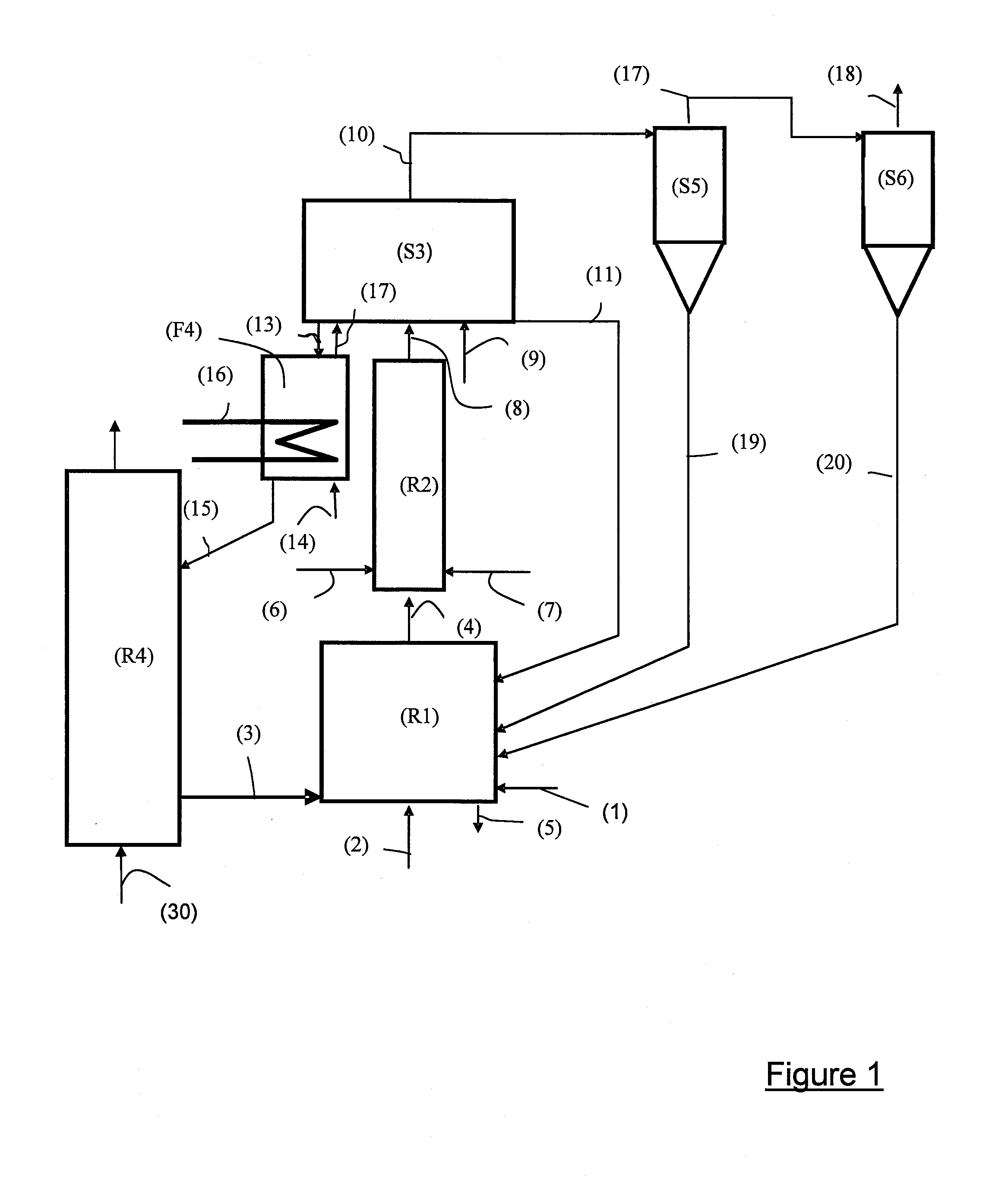

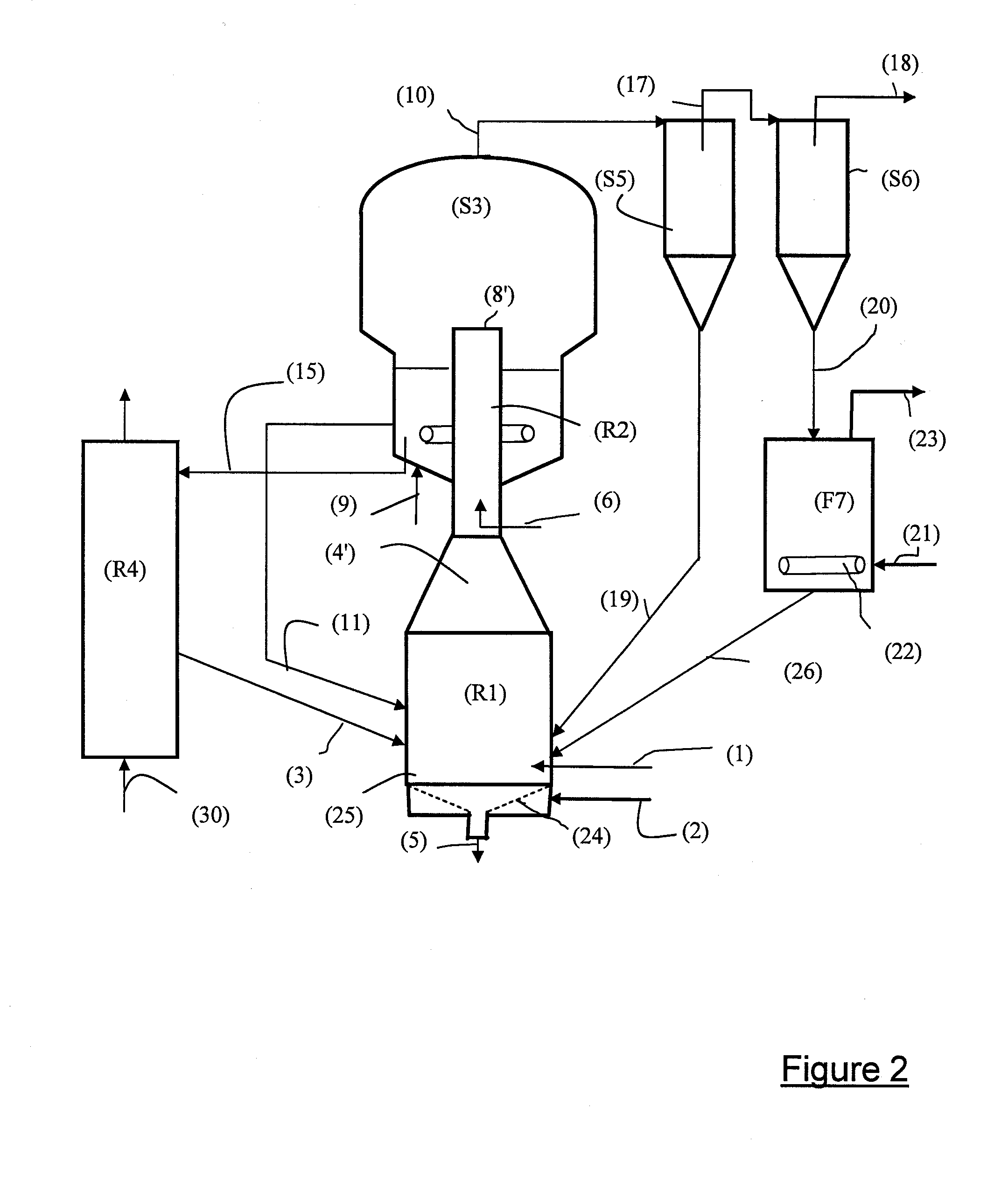

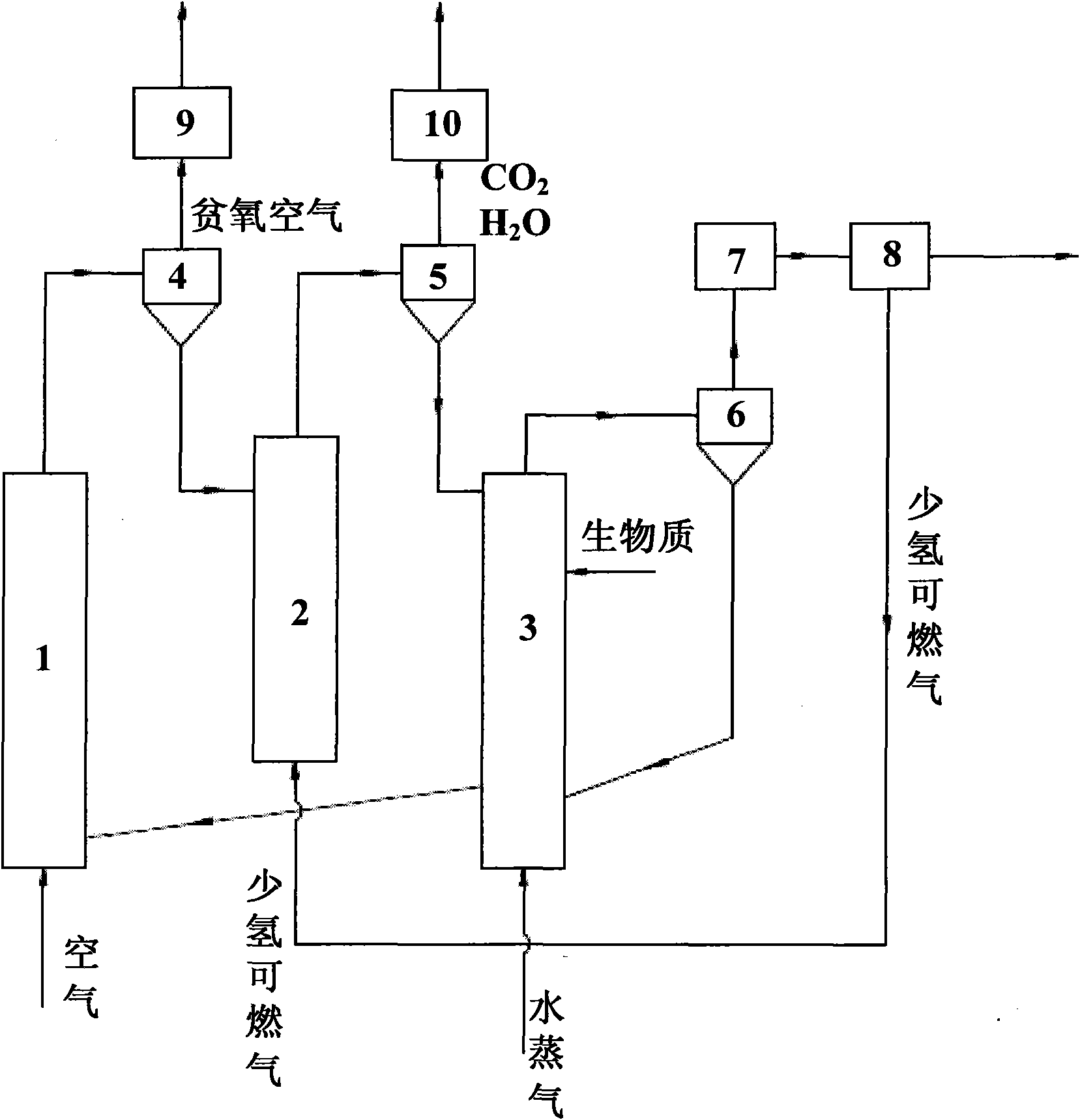

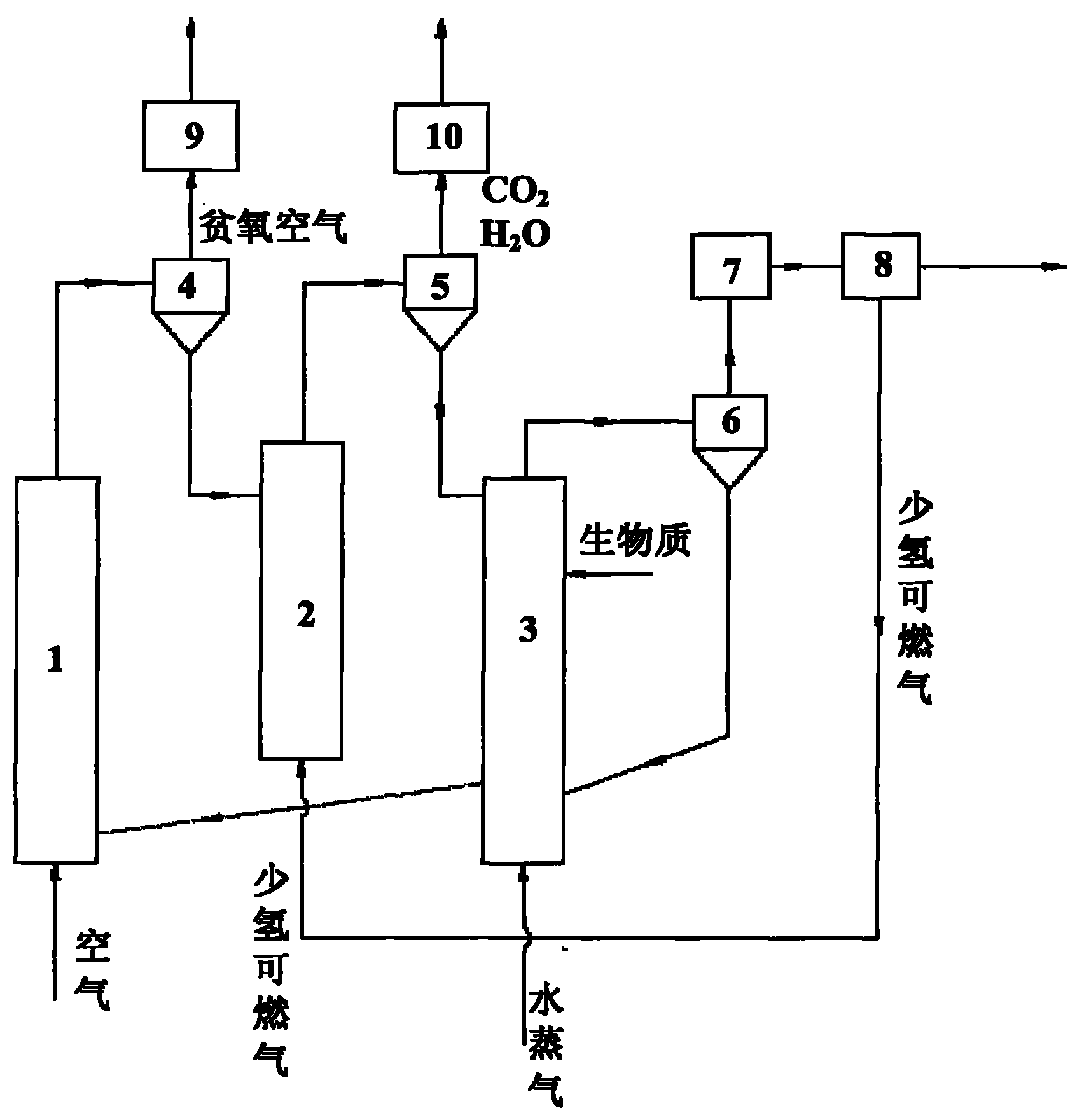

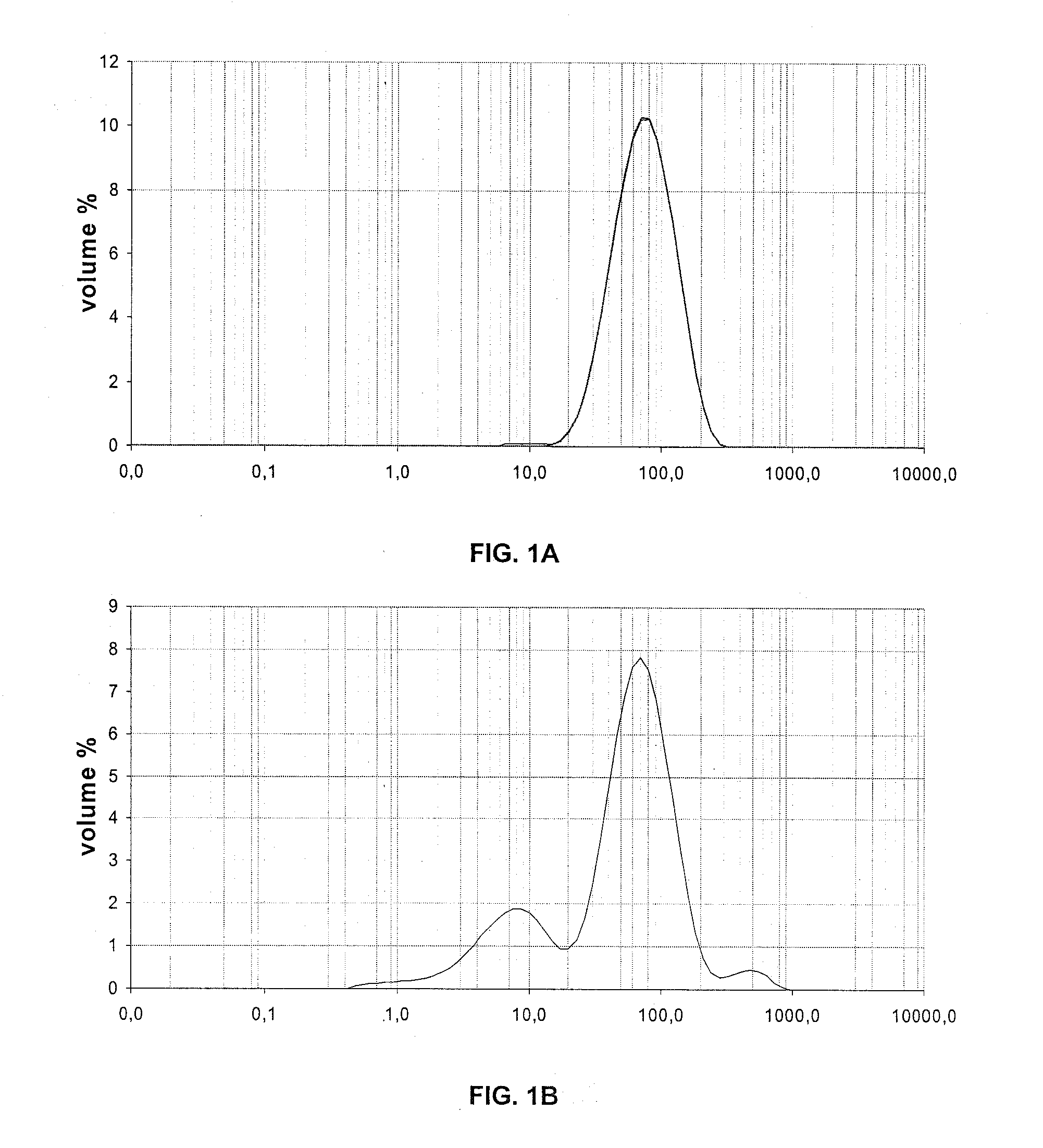

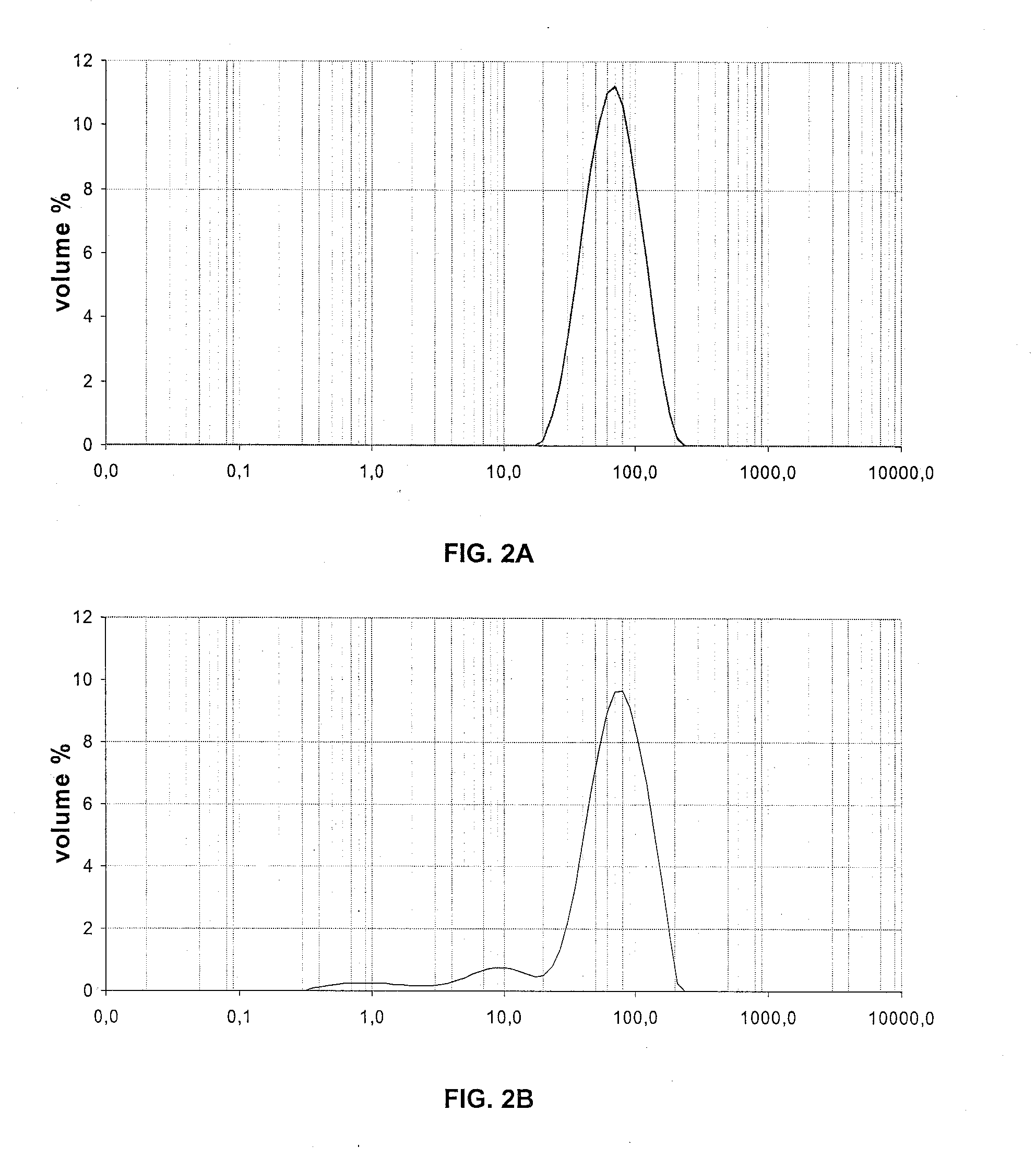

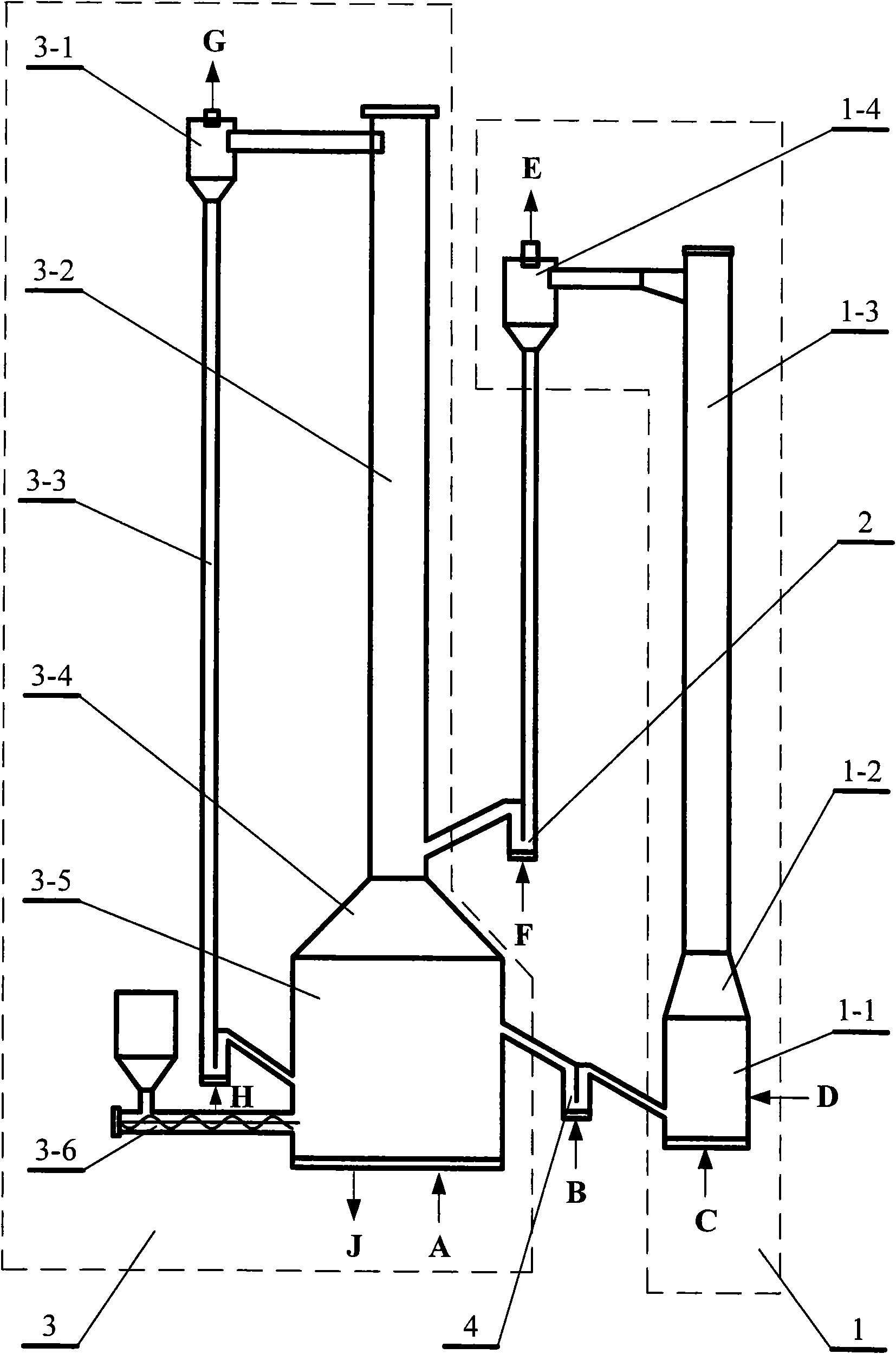

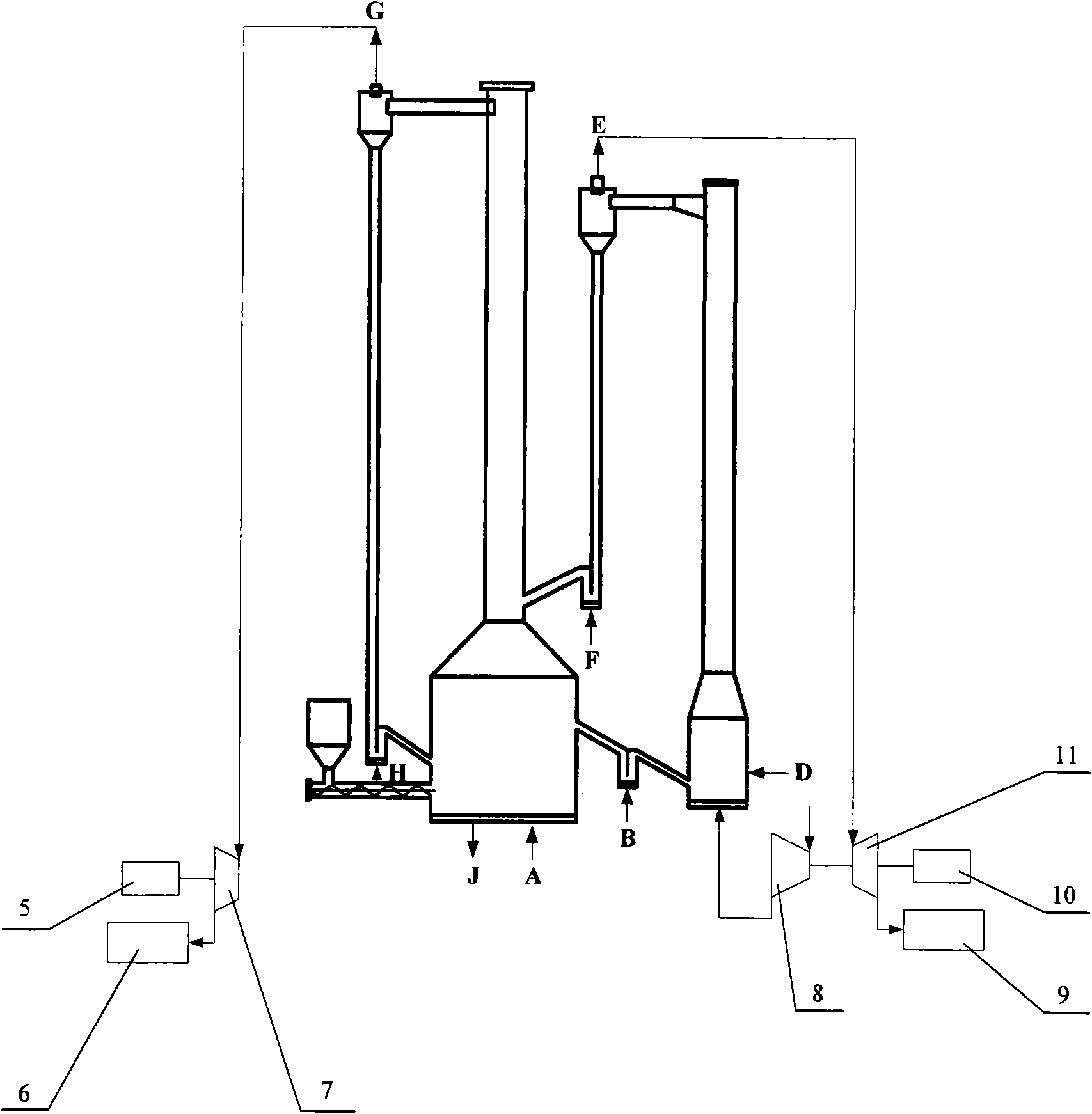

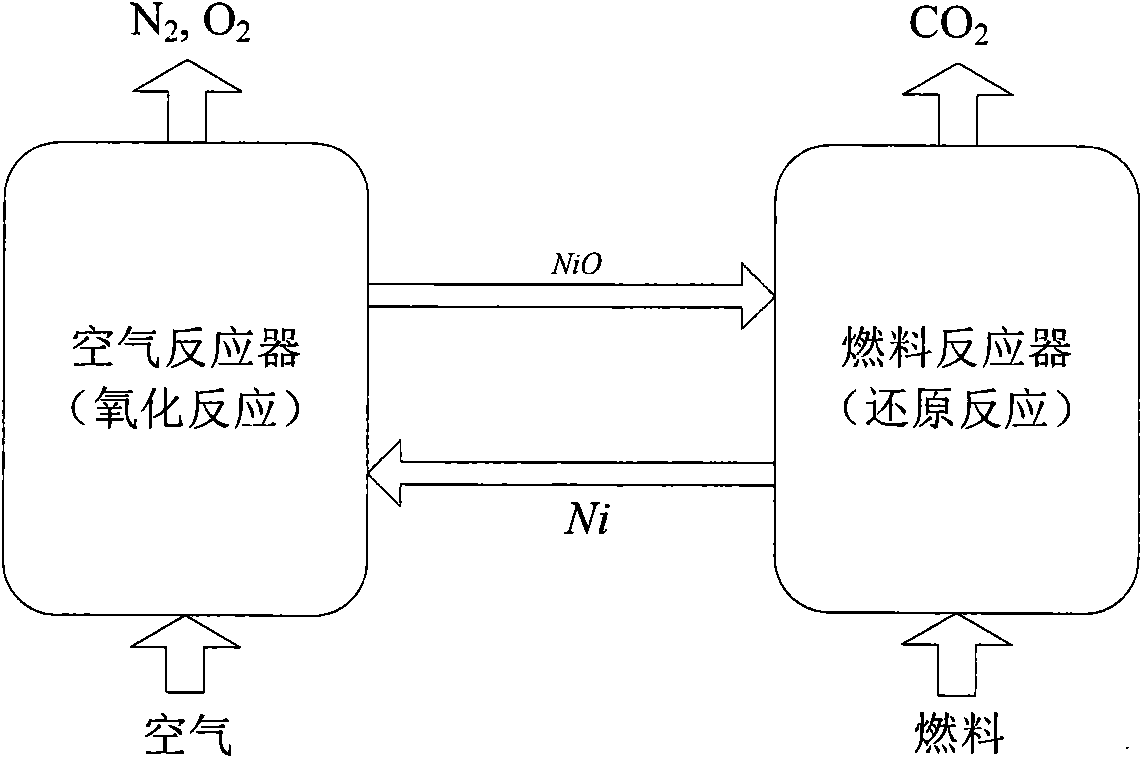

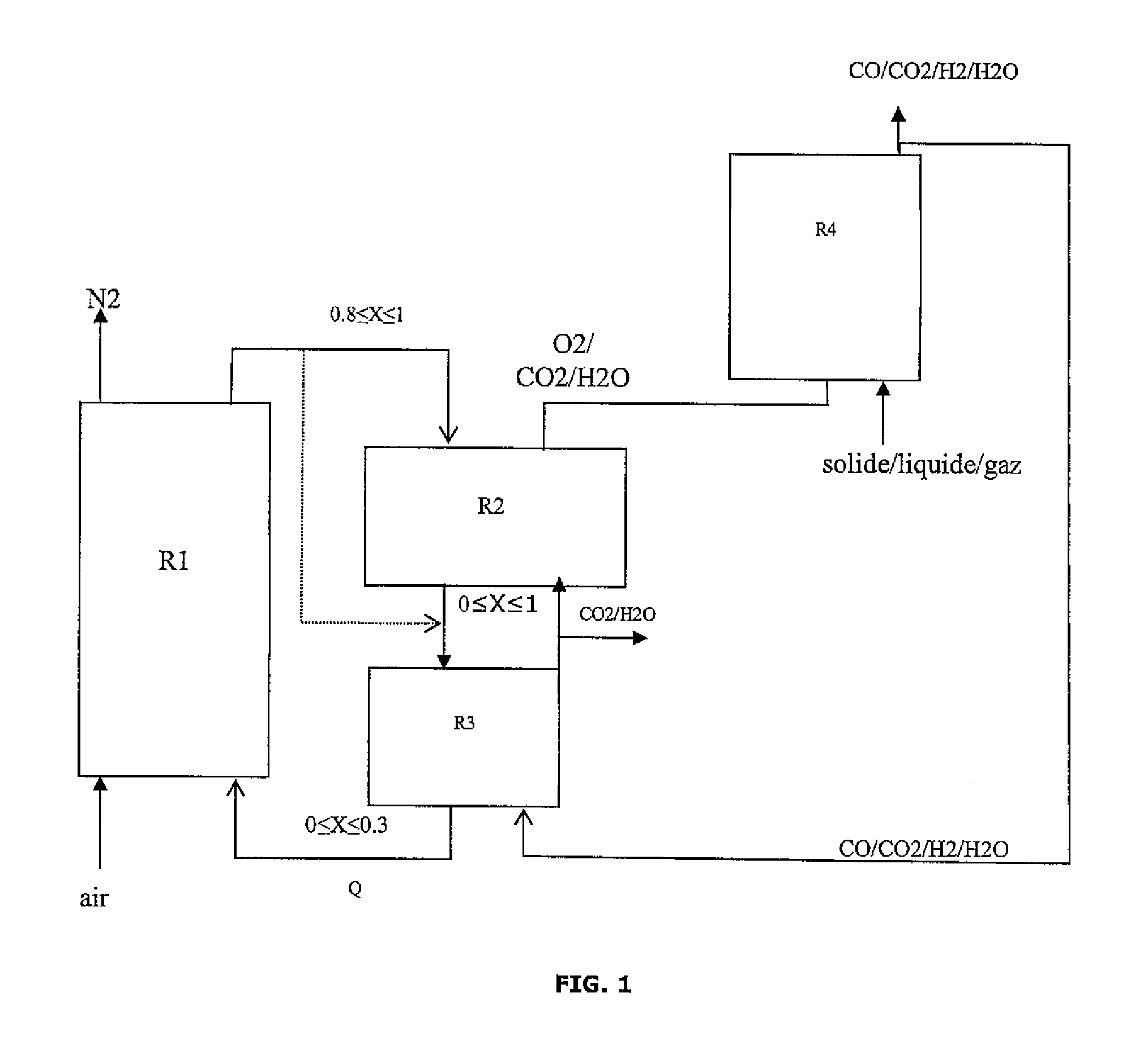

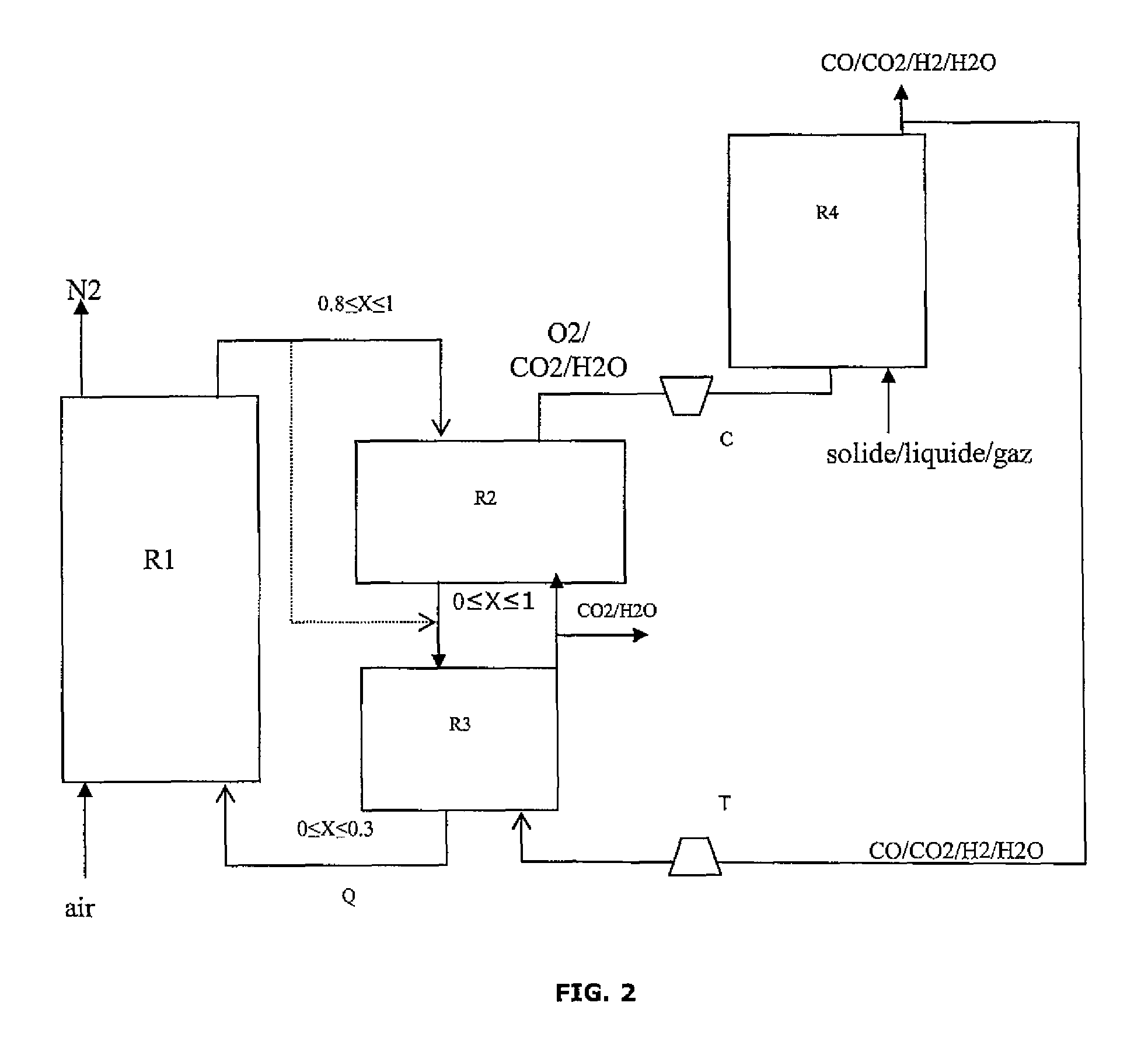

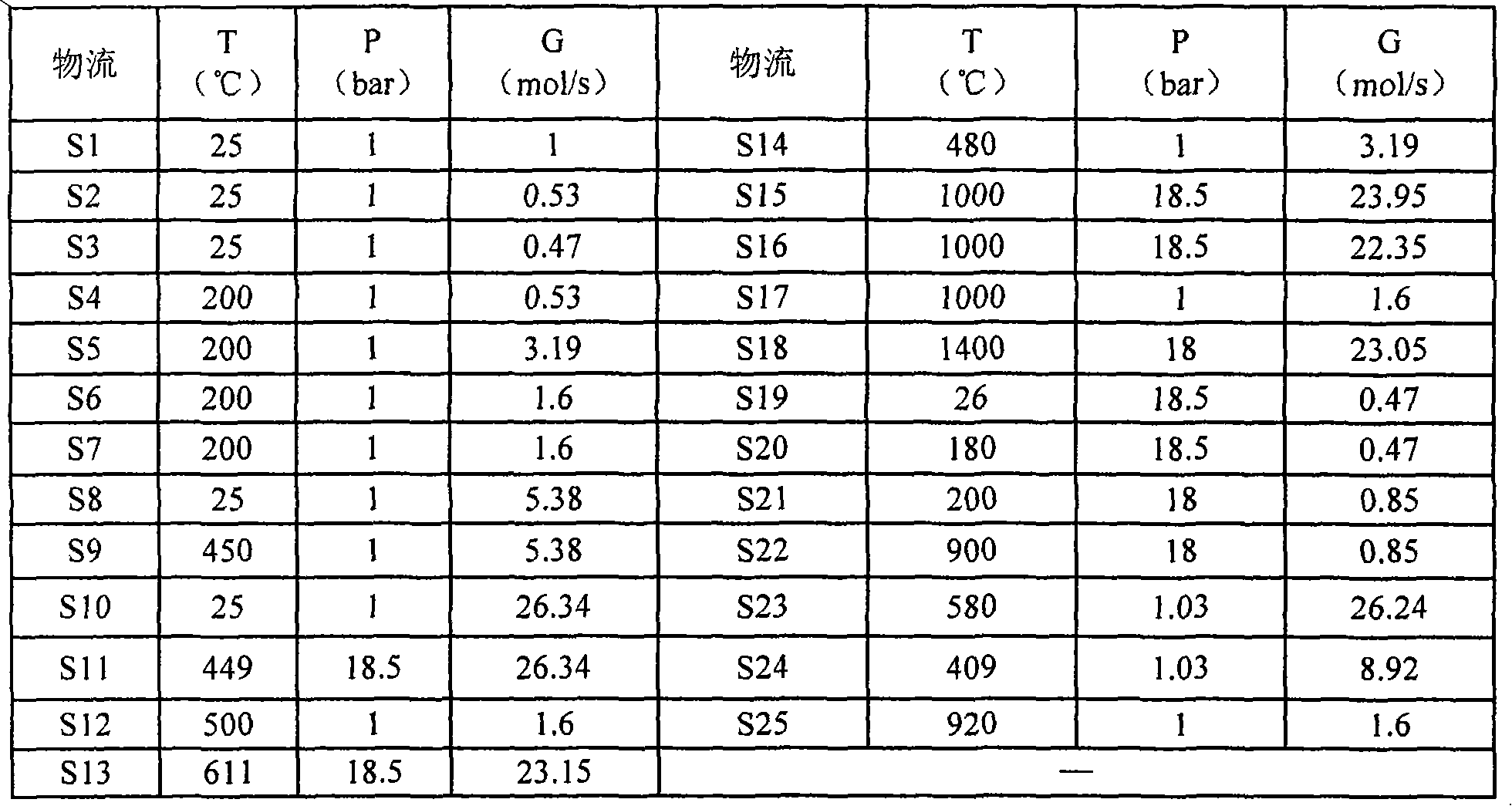

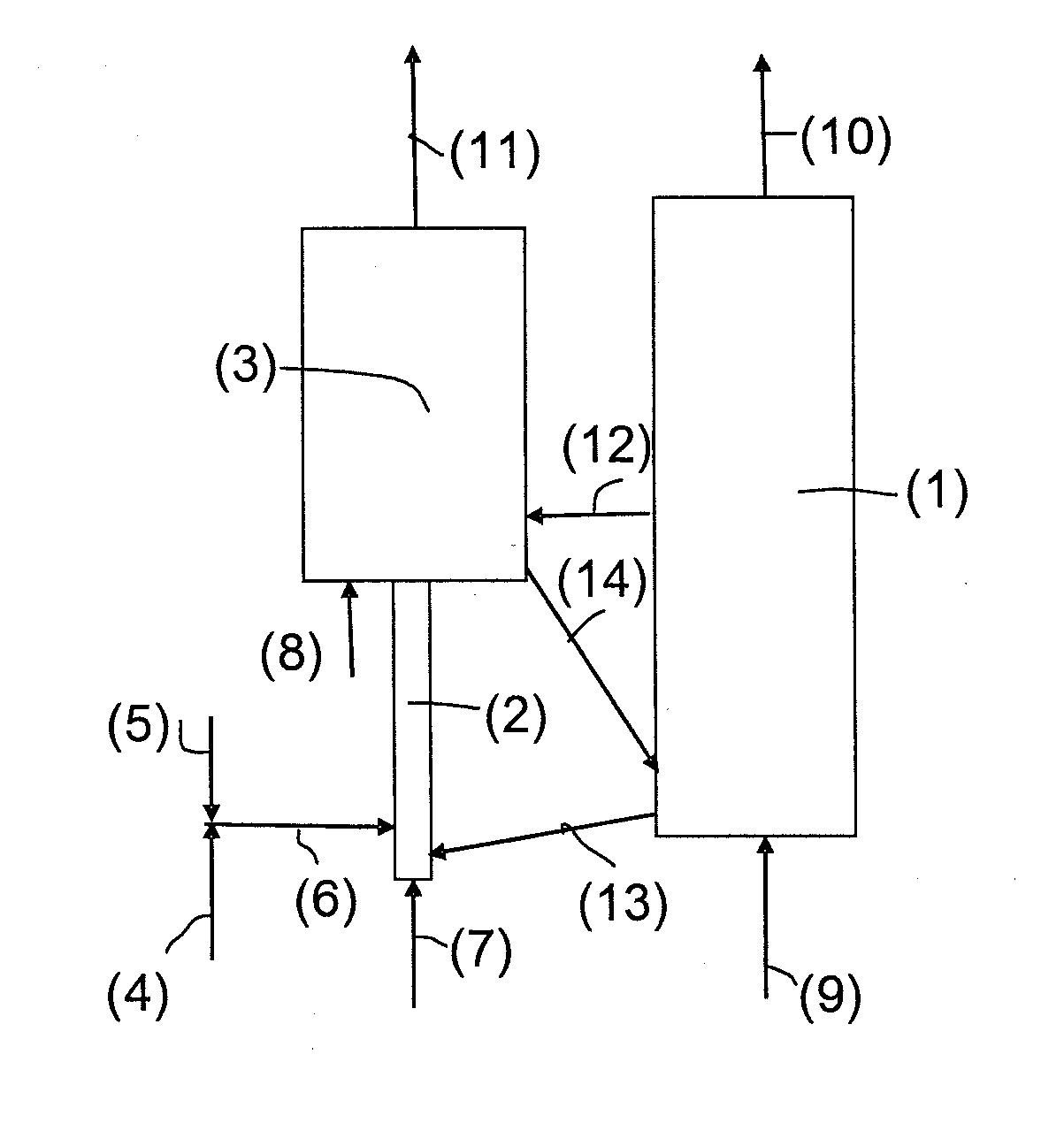

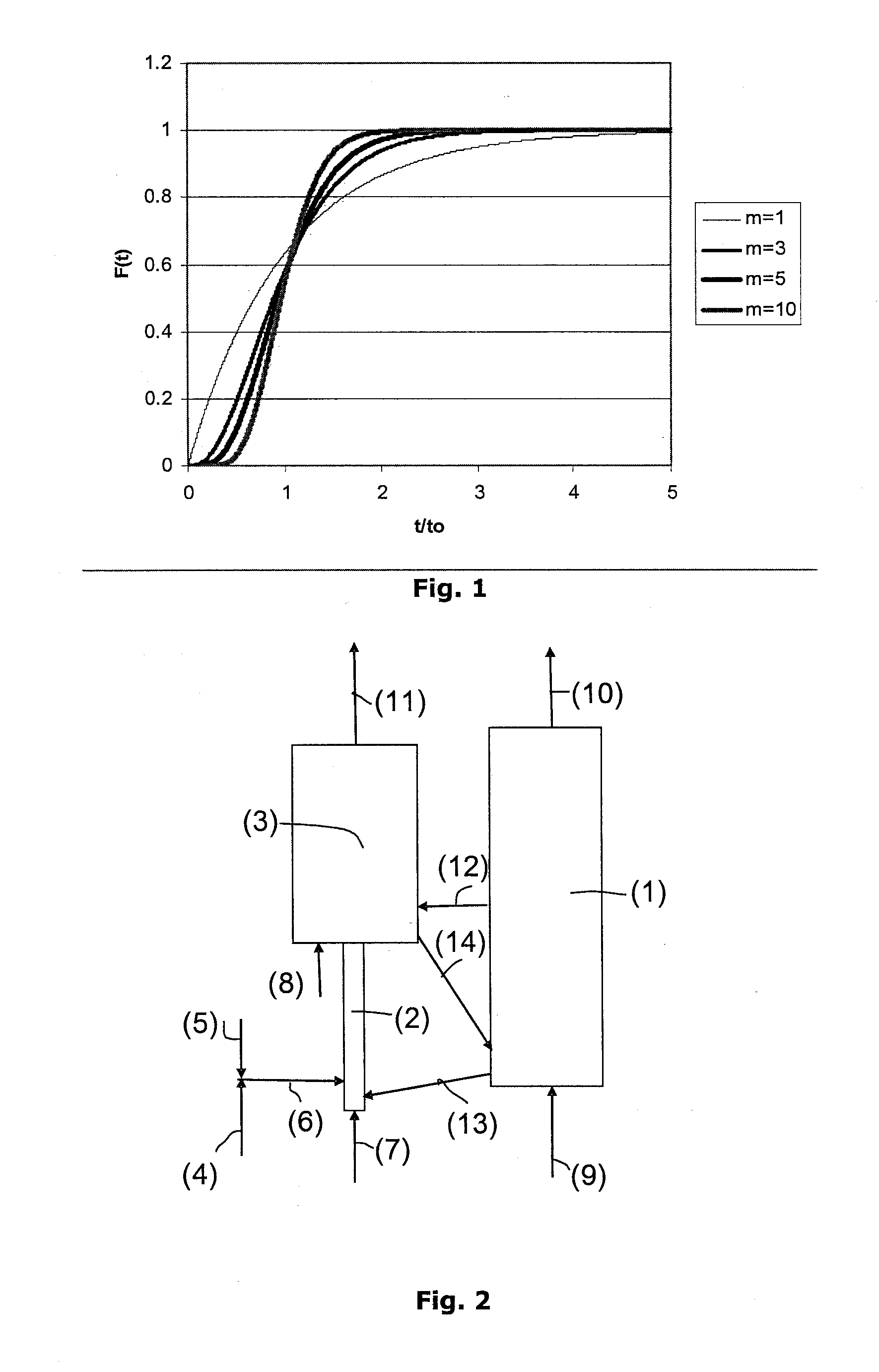

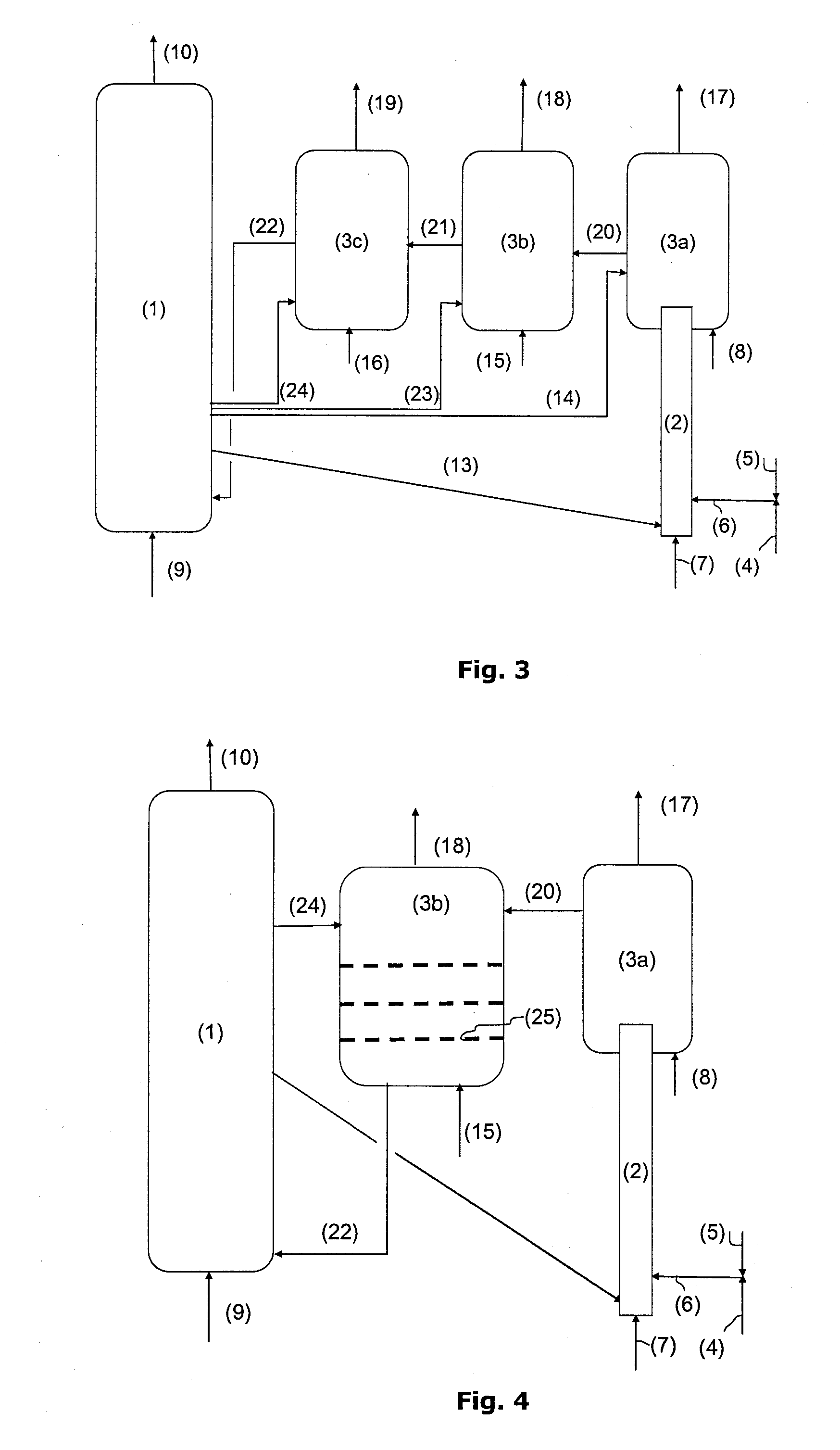

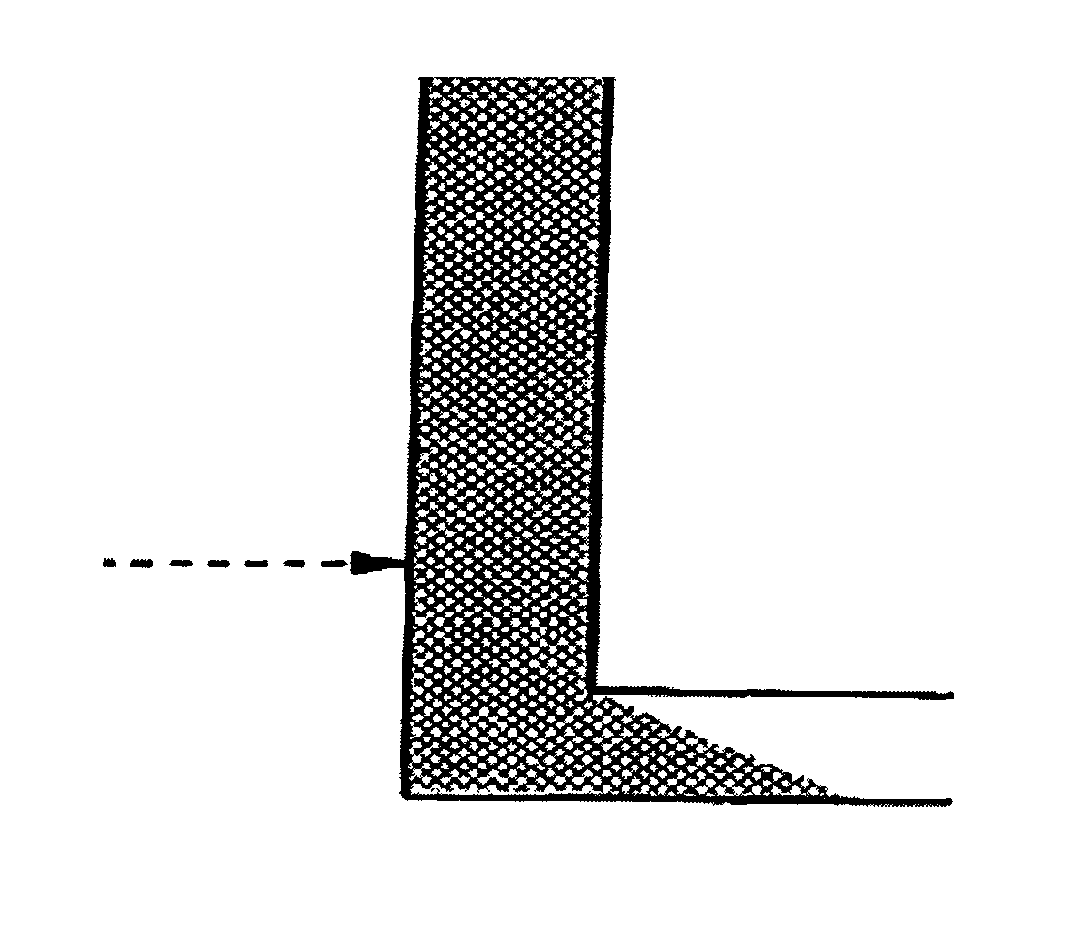

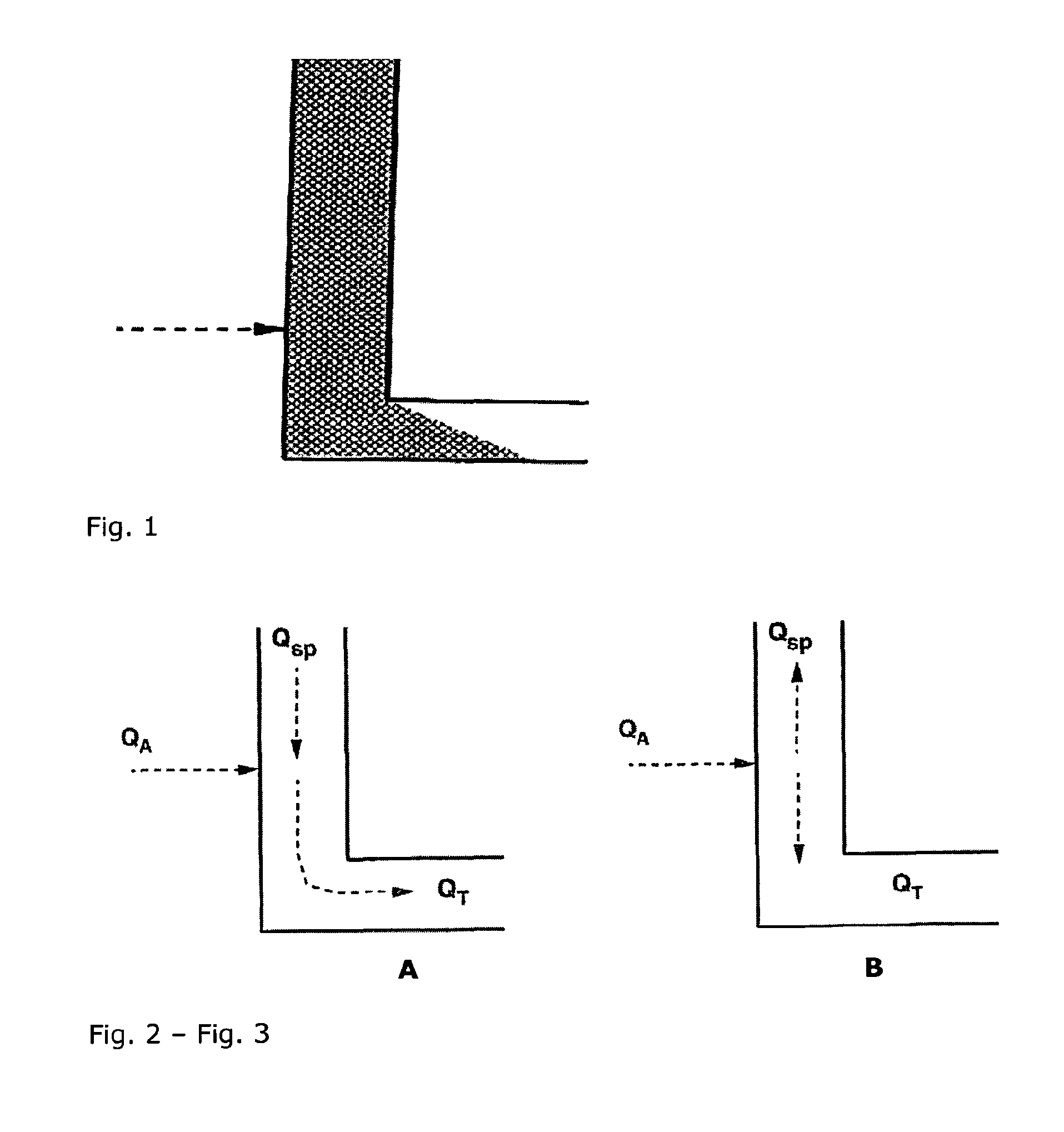

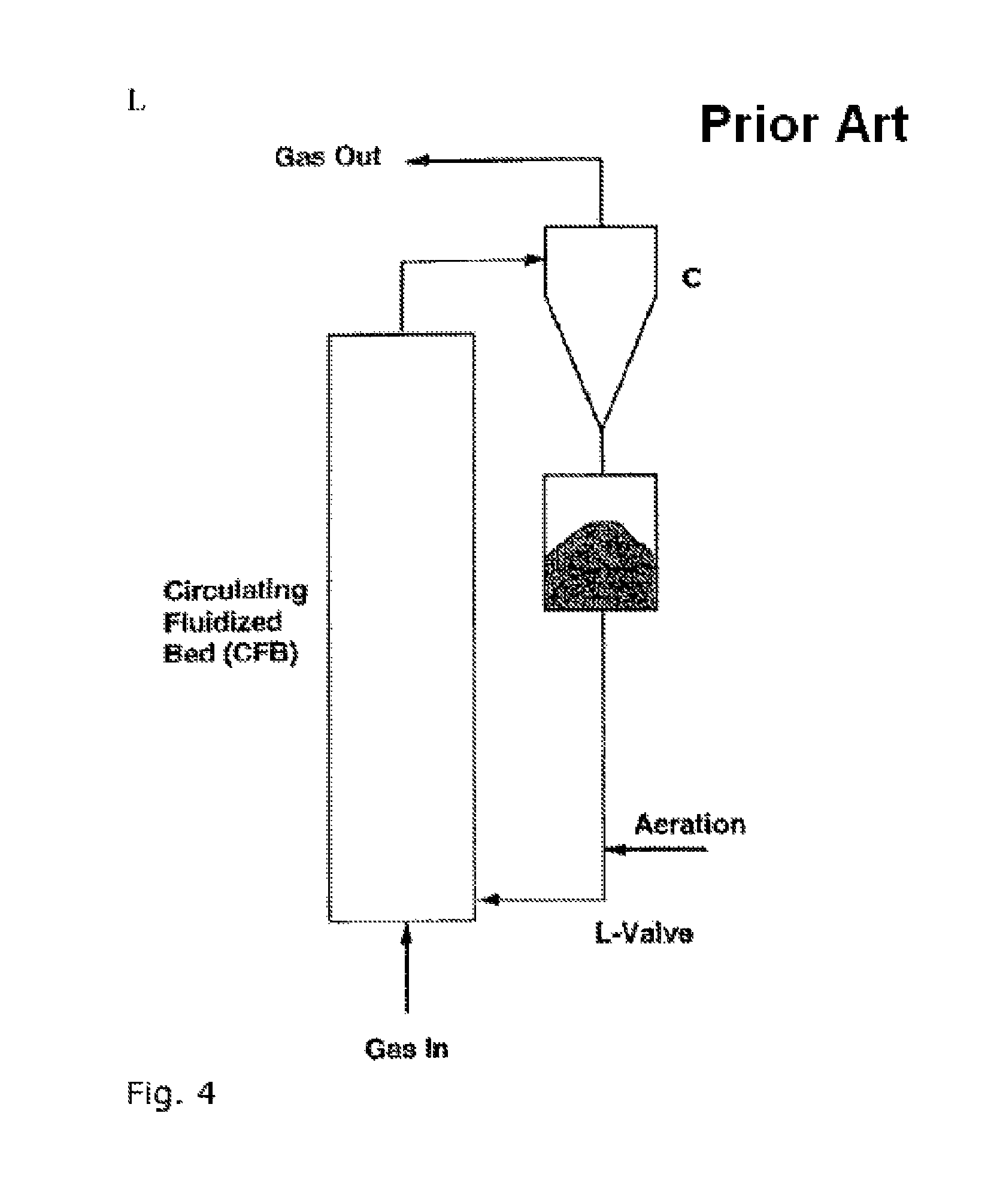

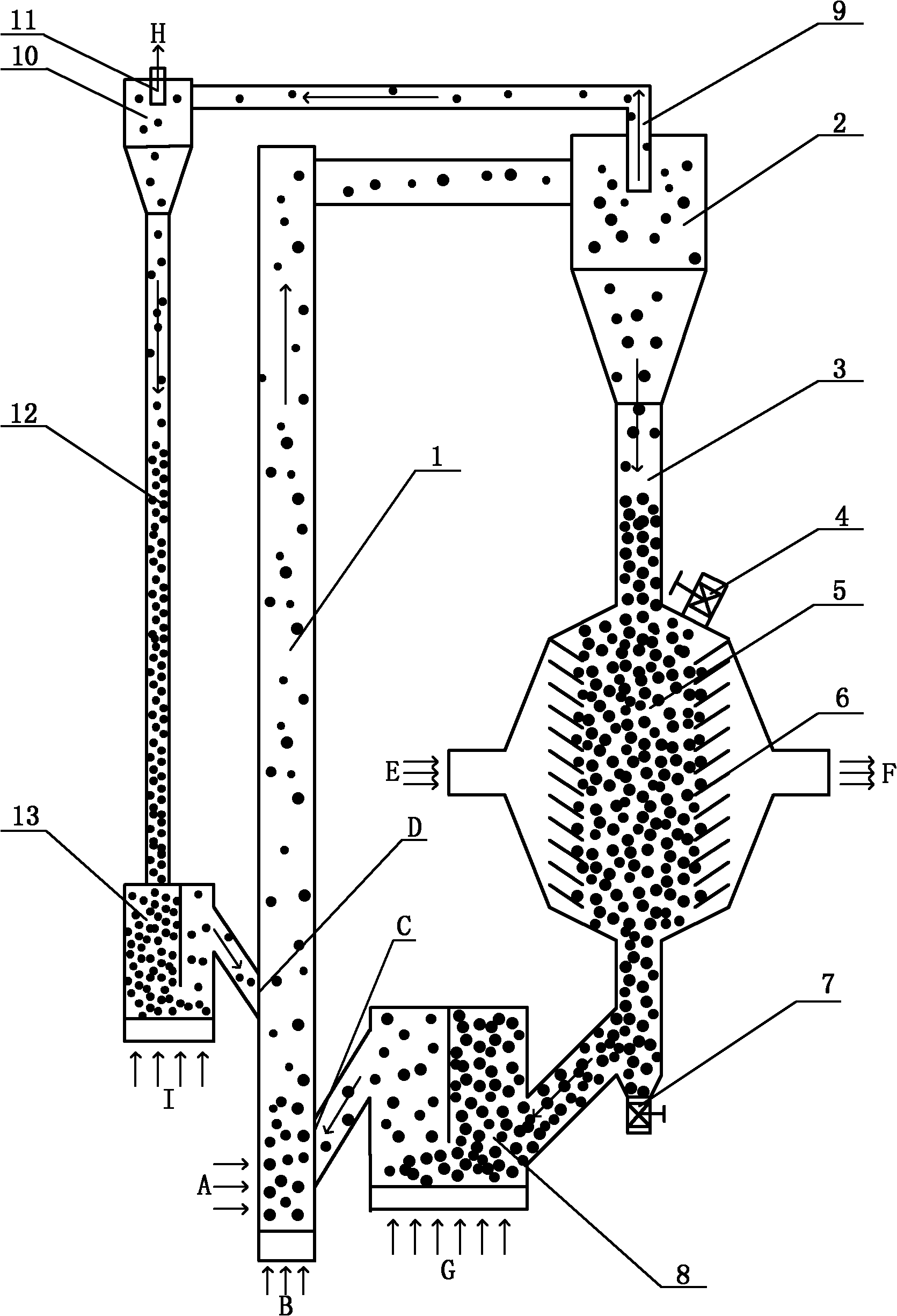

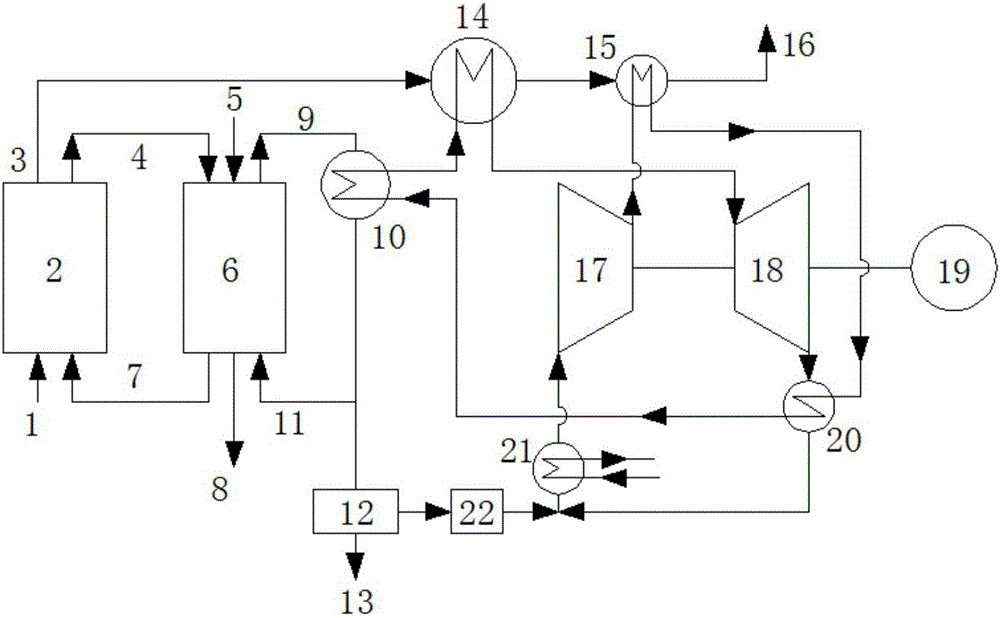

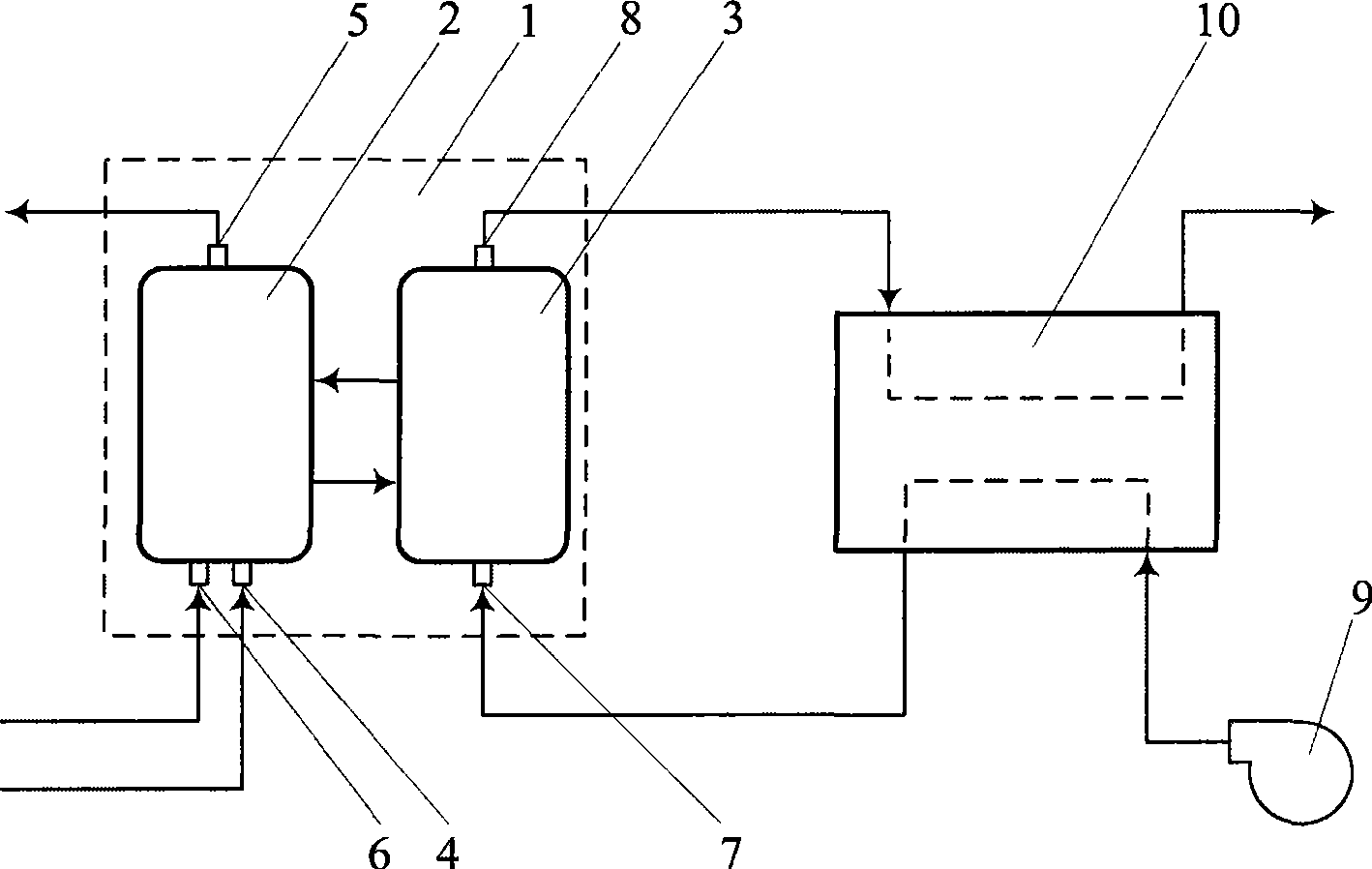

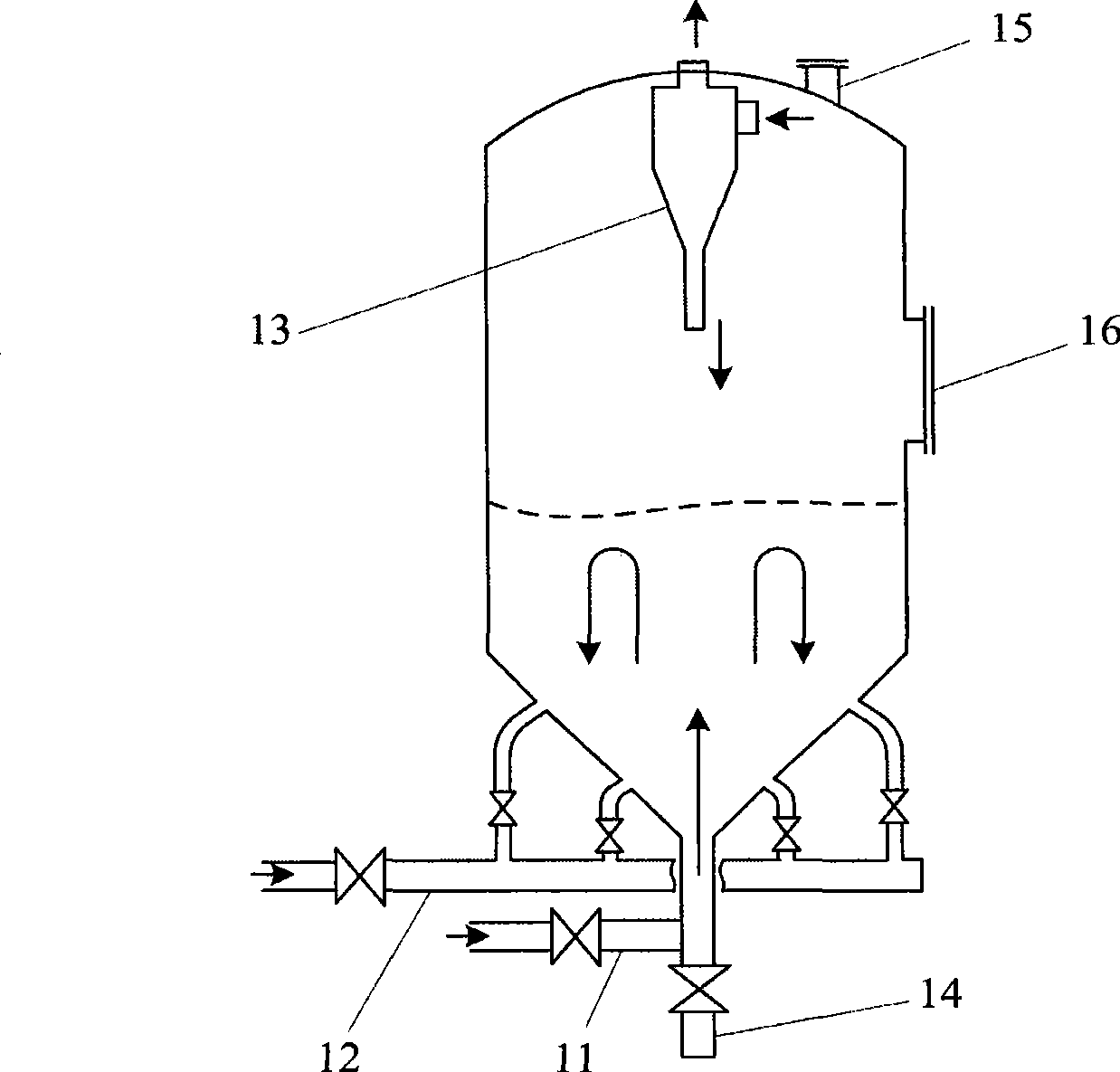

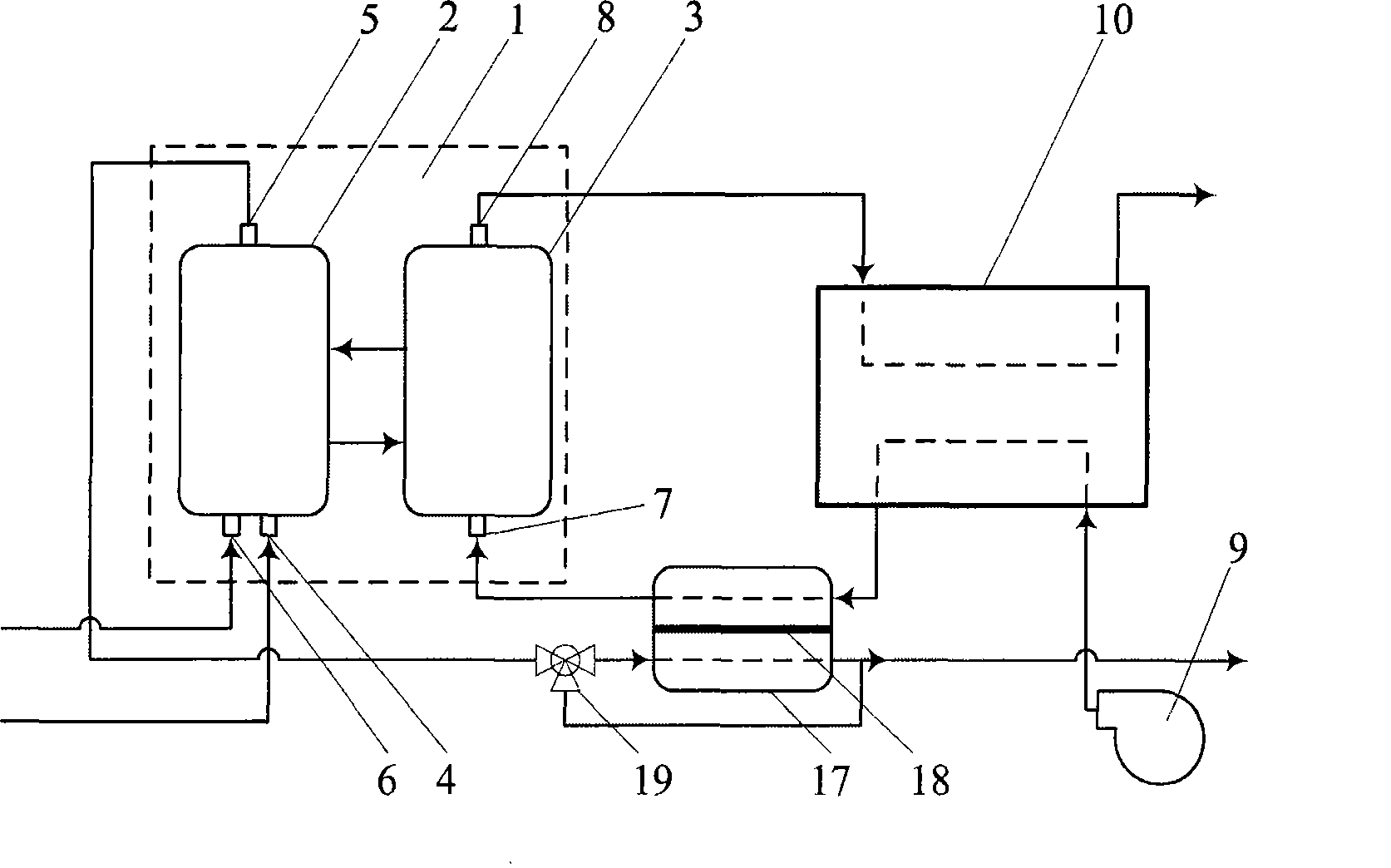

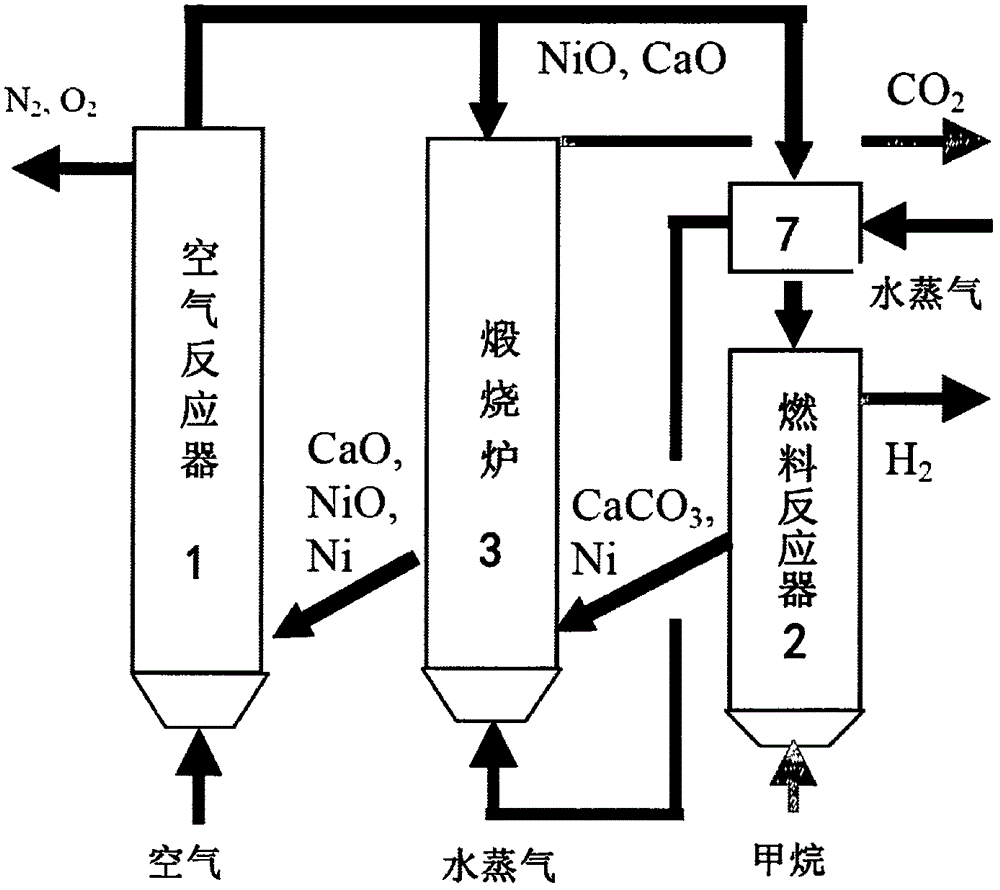

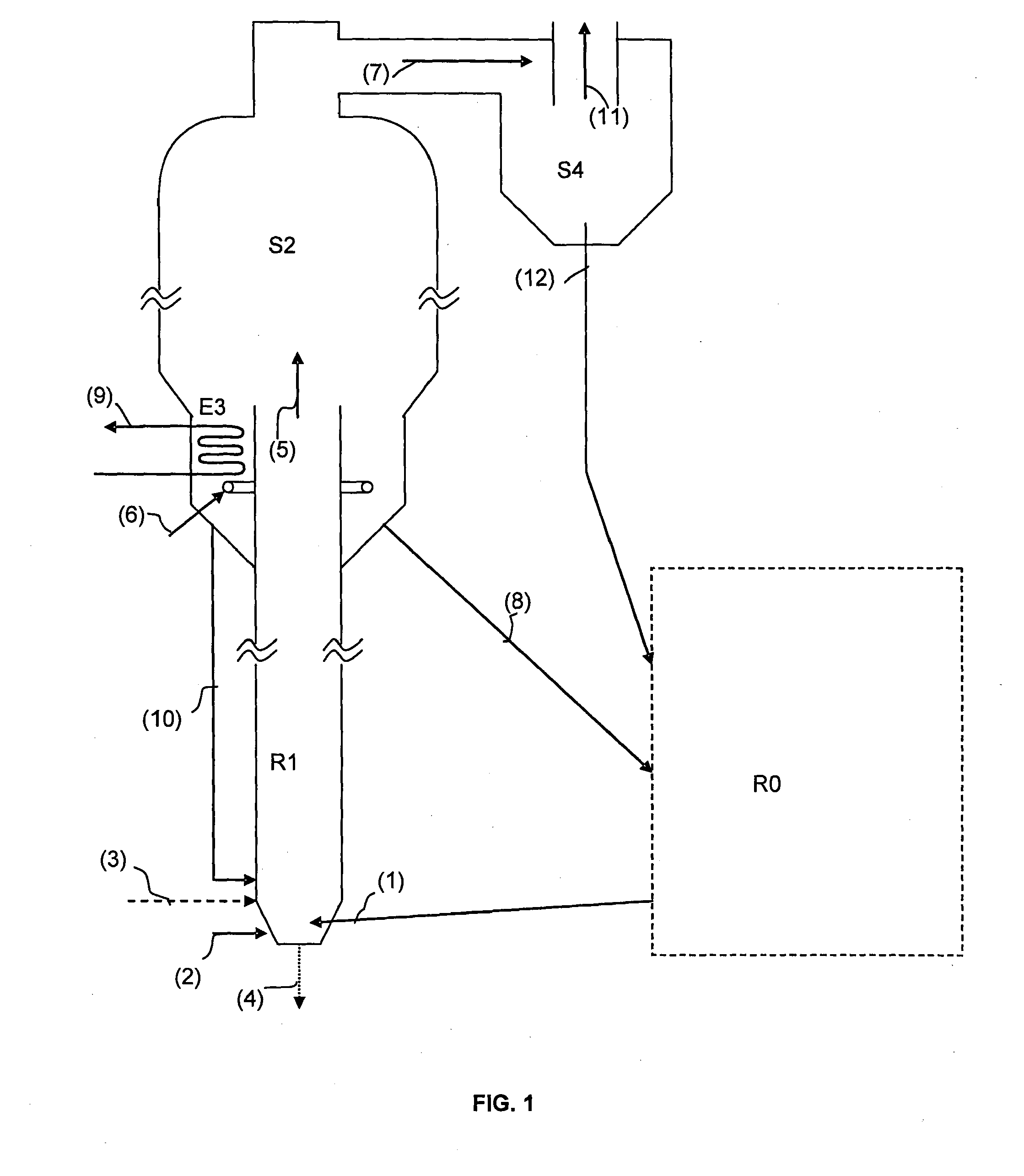

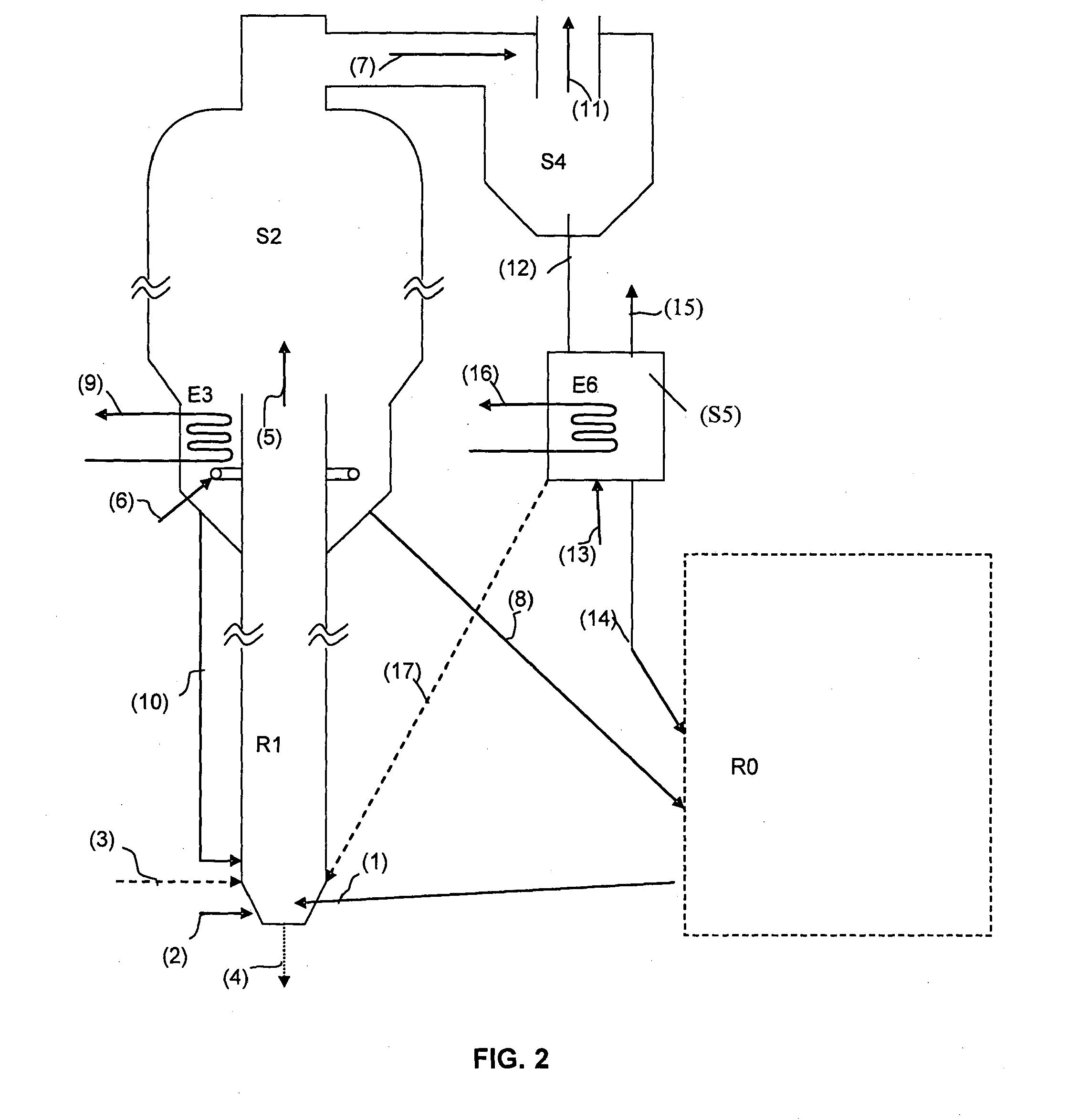

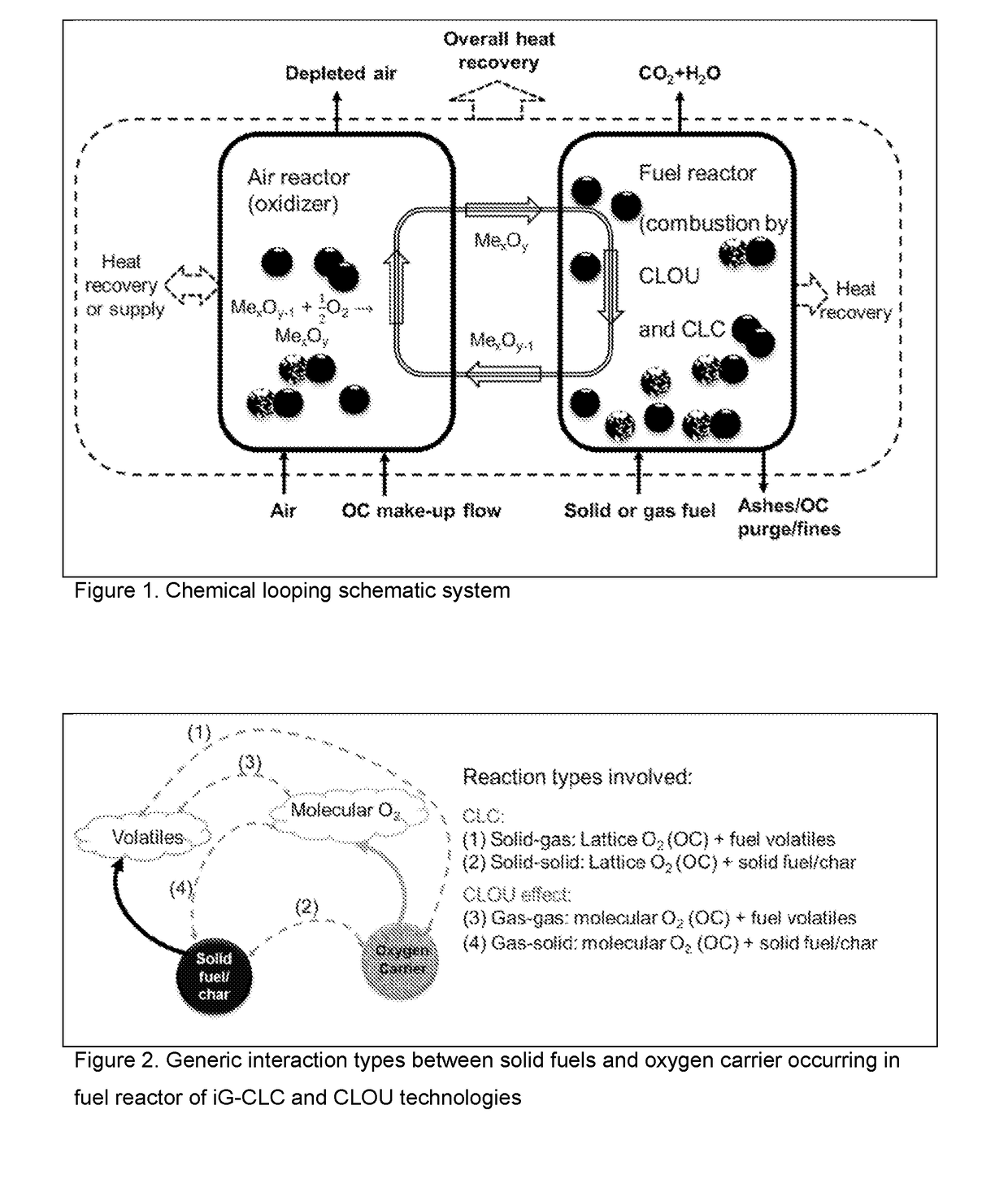

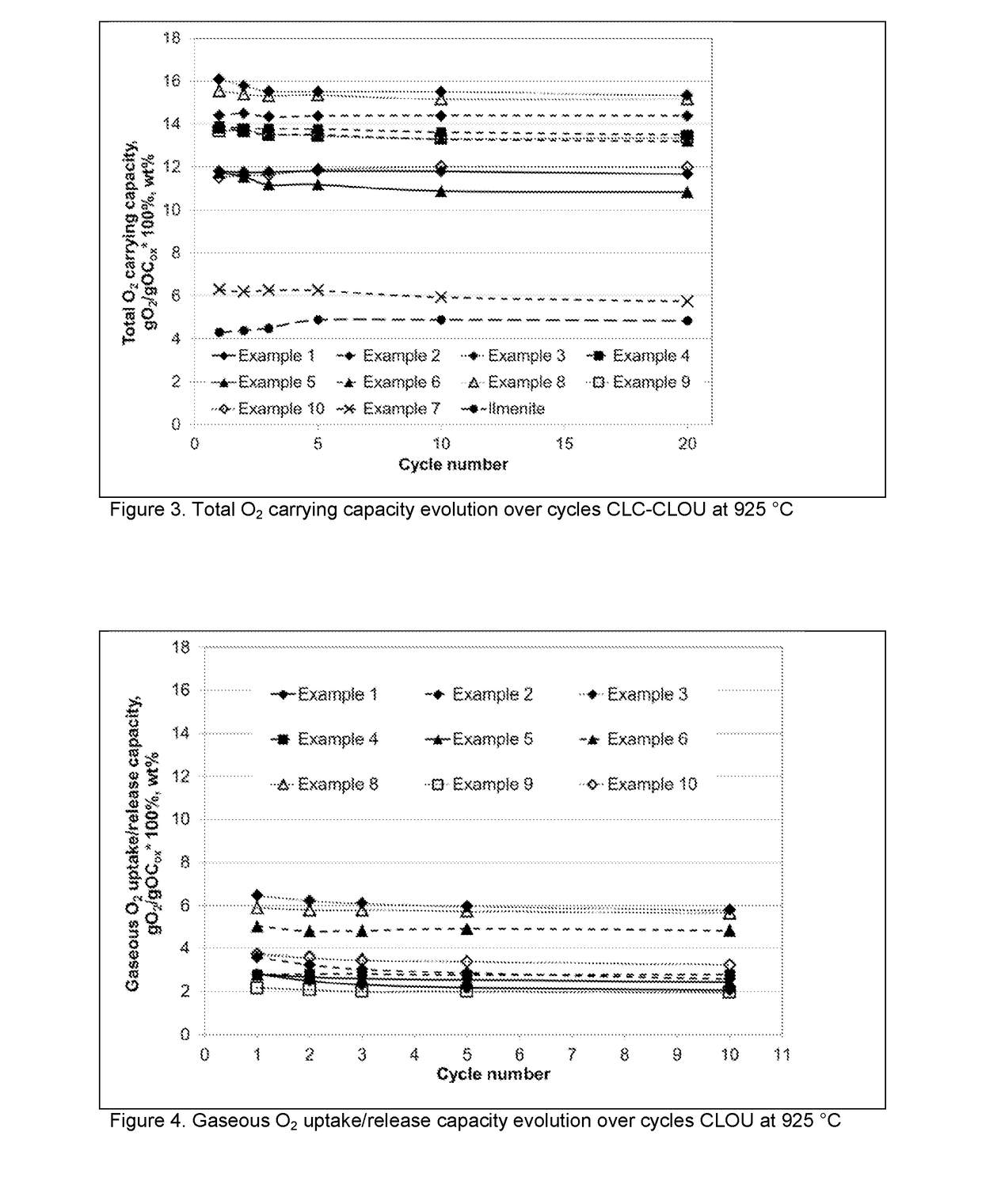

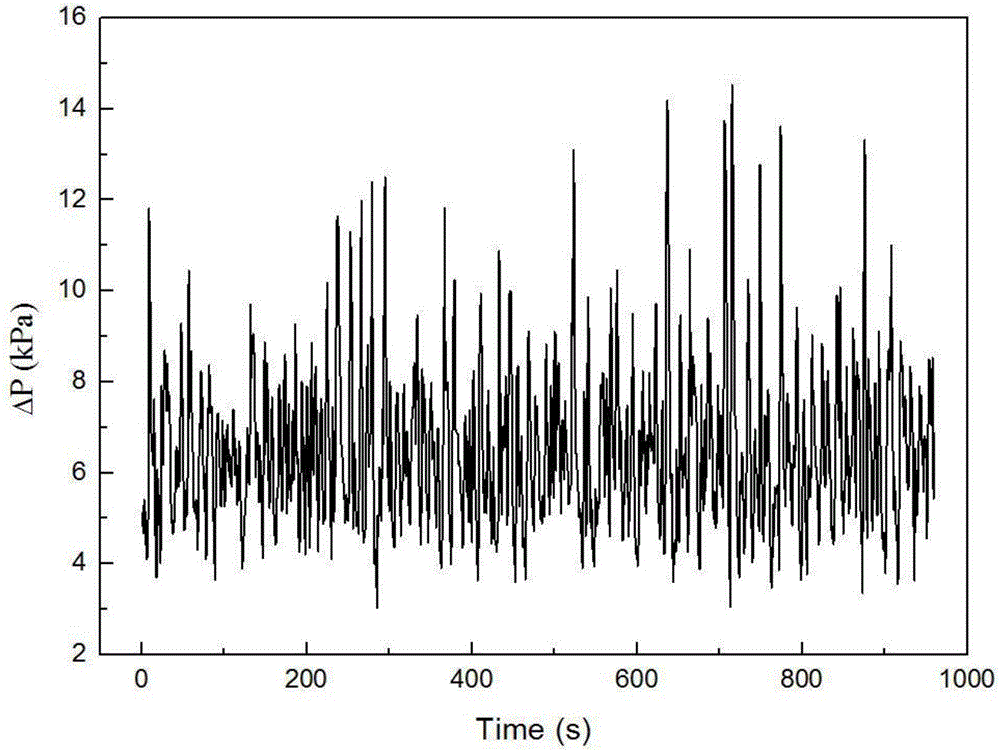

Chemical looping combustion (CLC) is a technological process typically employing a dual fluidized bed system. The CLC operated with an interconnected moving bed with a fluidized bed system has also been employed as a technology process. In CLC, a metal oxide is employed as a bed material providing the oxygen for combustion in the fuel reactor. The reduced metal is then transferred to the second bed (air reactor) and re-oxidized before being reintroduced back to the fuel reactor completing the loop. Fig 1 shows a simplified diagram of the CLC process. Fig 2 shows an example of a dual fluidized bed circulating reactor system and a moving bed-fluidized bed circulating reactor system.

Method and system for capturing carbon dioxide from biomass pyrolysis process

A system and method for biomass pyrolysis utilizing chemical looping combustion of a produced char to capture carbon dioxide is disclosed. The system includes a biomass pyrolysis reactor, a char combustor, and oxidation reactor and a separator for separating carbon dioxide from flue gas produced by the char combustion. The pyrolysis reactor pyrolyzes biomass in the presence of reduced metal oxide sorbents producing char and pyrolysis oil vapor. The char is separated and combusted in the char combustor, in the presence of oxidized metal oxide sorbents, into a gaseous stream of carbon dioxide and water vapor. The carbon dioxide and water are separated so that a stream of carbon dioxide may be captured. The oxidation reactor oxidizes, in the presence of air, a portion of reduced metal oxide sorbents into oxidized metal oxide sorbents that are looped back to the char combustor to provide oxygen for combustion. A second portion of the reduced metal oxide sorbents is recycled from the char combustor to the pyrolysis reactor to provide heat to drive the pyrolysis. Pyrolysis oil upgrading catalyst particles may be used in addition to the metal oxide sorbents as heat energy carrier particles to improve the quality of the pyrolysis oil vapors produced in the pyrolysis reactor. Also, the metal oxide sorbents may have metals incorporated therein which serve to upgrade the pyrolysis vapors produced during pyrolysis. Non-limiting examples of such metals include Ni, Mo, Co, Cr, W, Rh, Ir, Re, and Ru.

Owner:CHEVROU USA INC

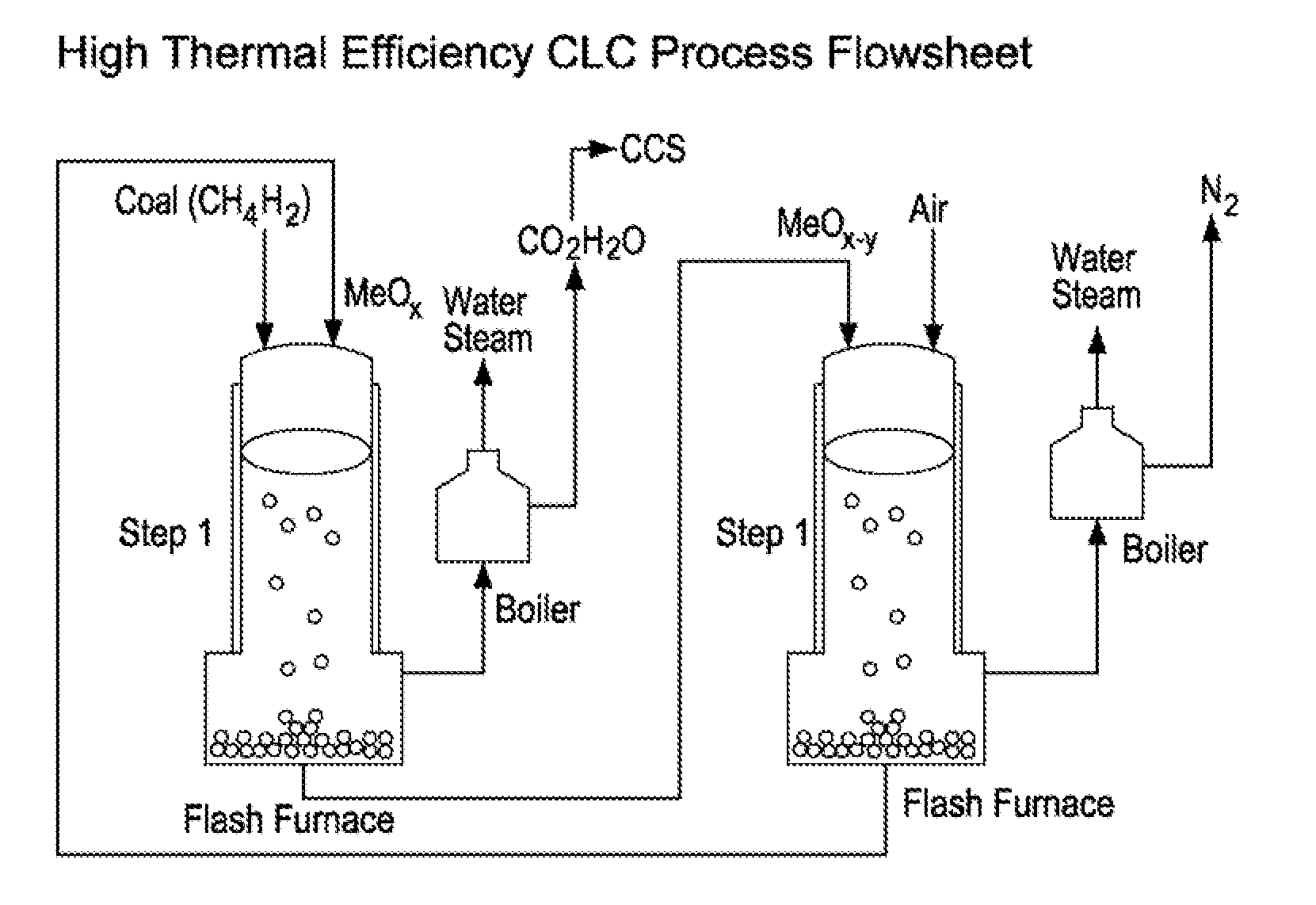

Process and apparatus for high energy efficiency chemical looping combustion

InactiveUS20110094226A1Liquid carbonaceous fuelsDirect carbon-dioxide mitigationHigh energyChemical measurement

Process and apparatus are provided for a high energy efficiency chemical combustion process. The process provides two reaction steps, both of which are exothermic. First, a reduced oxygen carrier is contacted with oxygen in a reactor to form an oxidized oxygen carrier, such as metal oxide or metal suboxide, and then the oxidized oxygen carrier is fed to a second reactor and combusted with a fuel. The reaction produces the reduced oxygen carrier and carbon dioxide. The reduced oxygen carrier from the second reactor is recycled back to said first reactor. Carbon monoxide can also be produced during the process depending on stoichiometric amounts of the reactants. Though the process can be performed in various types of reactor systems, one preferred embodiment is the flash furnace with the production of fly ash during combustion. The process is highly efficient and produces a large amount of usable work.

Owner:ORCHARD MATERIAL TECH

Chemical looping combustion method with a reaction zone including a gas-solid separation zone and plant using same

ActiveUS20130149650A1Small flowFluidized bed combustionFurnace componentsReaction zoneOxidation zone

The object of the invention is a combustion method for a solid feed using a chemical loop wherein an oxygen-carrying material circulates, said method comprising at least:contacting the solid feed particles in the presence of metallic oxide particles in a first reaction zone (R1) operating in dense fluidized bed mode,carrying out combustion of the gaseous effluents from first reaction zone (R1) in the presence of metallic oxide particles in a second reaction zone (R2),separating in a separation zone (S3) the unburnt particles and the metallic oxide particles within a mixture coming from second reaction zone (R2),re-oxidizing the metallic oxide particles in an oxidation zone (R4) prior to sending them back to first zone (R1).

Owner:TOTALENERGIES ONETECH +2

Biomass gasification hydrogen-producing system and method

InactiveCN101774542AReduce utilizationTo achieve hierarchical utilizationHydrogen productionGas solidHeat carrier

The invention discloses a biomass gasification hydrogen-producing system and a method, which belongs to the technical field of hydrogen production. Biomass gasification hydrogen production and chemical-looping combustion are combined to realize low-cost separation of carbon dioxide; and the fractional utilization of matter and energy is realized via the circulation among three beds with metal oxide as a heat carrier and an oxygen carrier. The system mainly comprises an air reactor, a fuel reactor, a moving bed gasifier, a gas-solid separation device, a gas purification device, a hydrogen separation device and a follow-up hydrogen-producing device. The system not only can realize hydrogen production, but also can realize hydrogen production with near zero emission of CO2, thereby realizing efficient cleaning and utilization of biomass.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Oxidation-reduction active mass and chemical-looping combustion method

InactiveUS20110054049A1Maximize productionIncrease mass flowCatalytic crackingCarbon compoundsOxidation-Reduction AgentRedox

The invention relates to a method for chemical-looping redox combustion on an active mass including a binder, in form of a fluidized-bed catalytic cracking catalyst containing silica and alumina, and a metal oxide active phase. The active mass is obtained by impregnating metal salts on a new or used catalytic cracking catalyst. Advantageously, the invention applies to the sphere of CO2 capture.

Owner:INST FR DU PETROLE +1

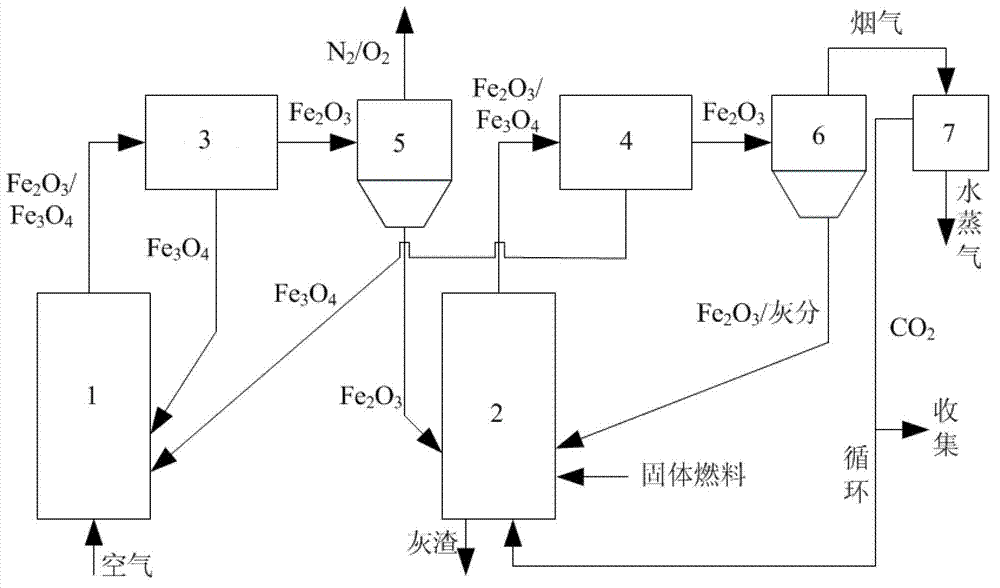

Method and device for burning chemistry chains based on iron or iron oxide

InactiveCN101672530AIncrease oxygen capacityHigh purityExothermal chemical reaction heat productionExothermal chemical reactions for heatingGas phaseWater vapor

The invention discloses a method and a device for burning chemistry chains based on iron or iron oxide, and the method comprises the following steps: placing iron or iron oxide in an air reactor fluidized bed; introducing fluidized air; obtaining Fe2O3 by reacting iron or iron oxide with oxygen in the introduced air; separating gas phase from solid phase by a separator; discharging the separated high-temperature oxygen-poor air from the top end of the separator; feeding the separated Fe2O3 in a fuel reactor fluidized bed via an overflow groove; feeding solid fuel in the fuel reactor fluidizedbed via a spiral feeder; generating synthesis gas by a gasification reaction in which the solid fuel reacts with the water vapour introduced from the bottom end of the fuel reactor; carrying out reduction reaction by reacting the synthesis gas or fuel with oxygen released by Fe2O3 to generate carbon dioxide; reducing Fe2O3 to FeO or Fe; returning to an air reactor fluidized bed via an overflow groove for further oxidation; and realizing cyclic usage. If gas fuel is used, the gas fuel is directly introduced in the fuel reactor.

Owner:SOUTHEAST UNIV

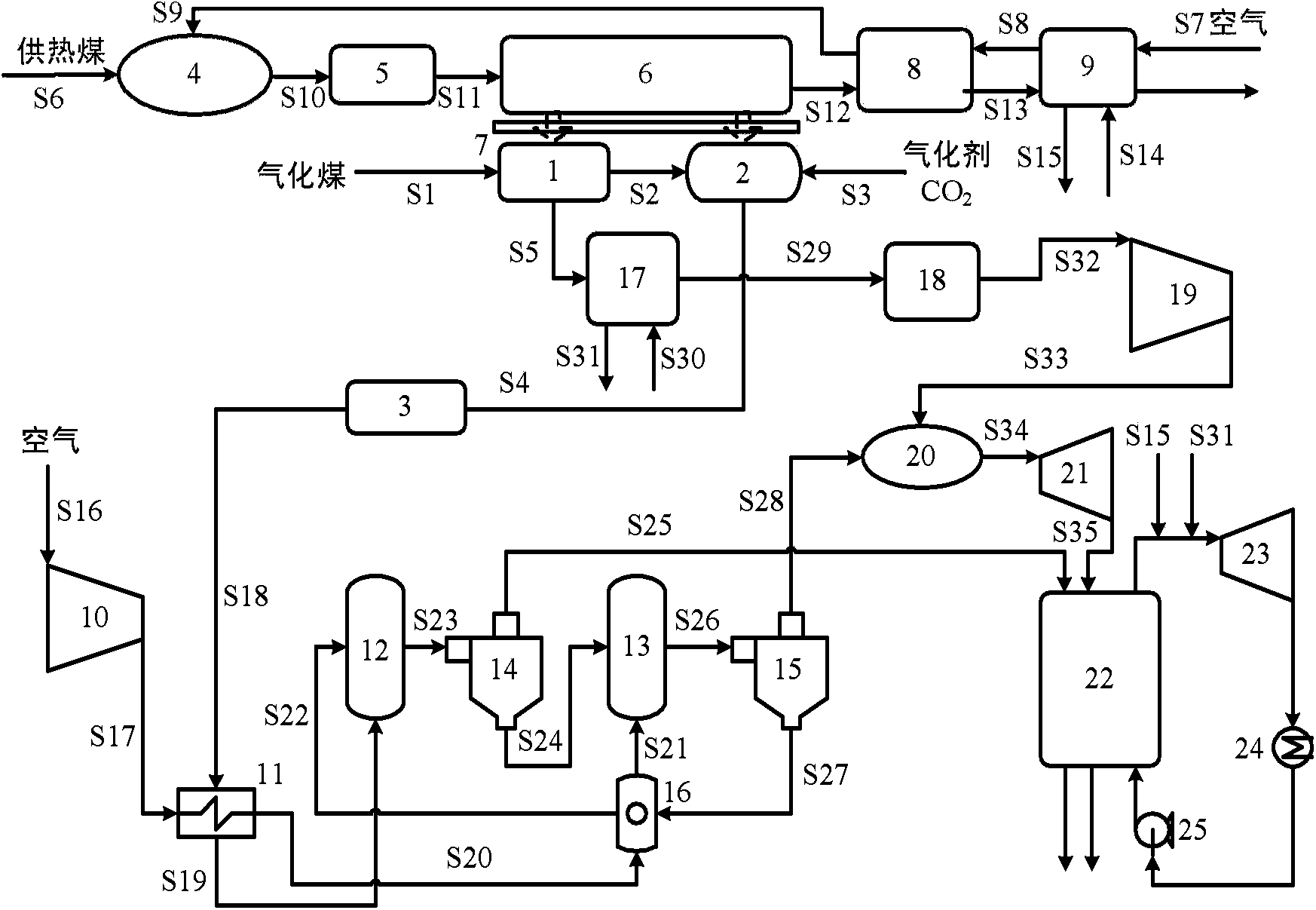

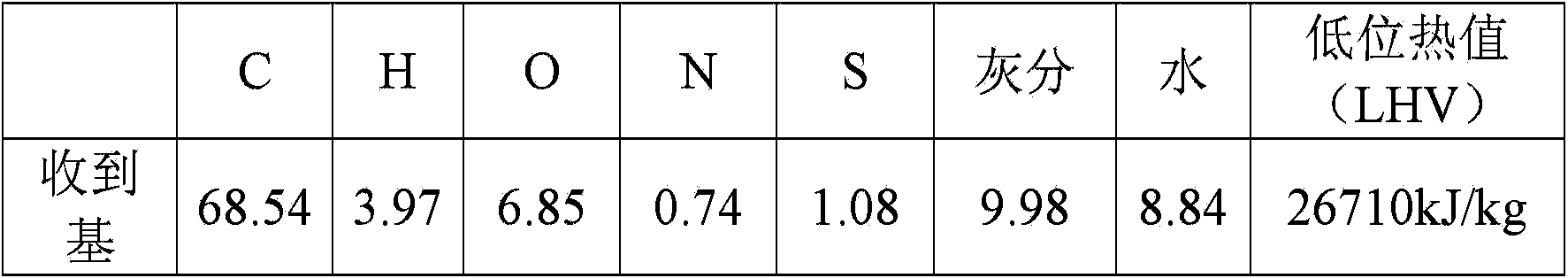

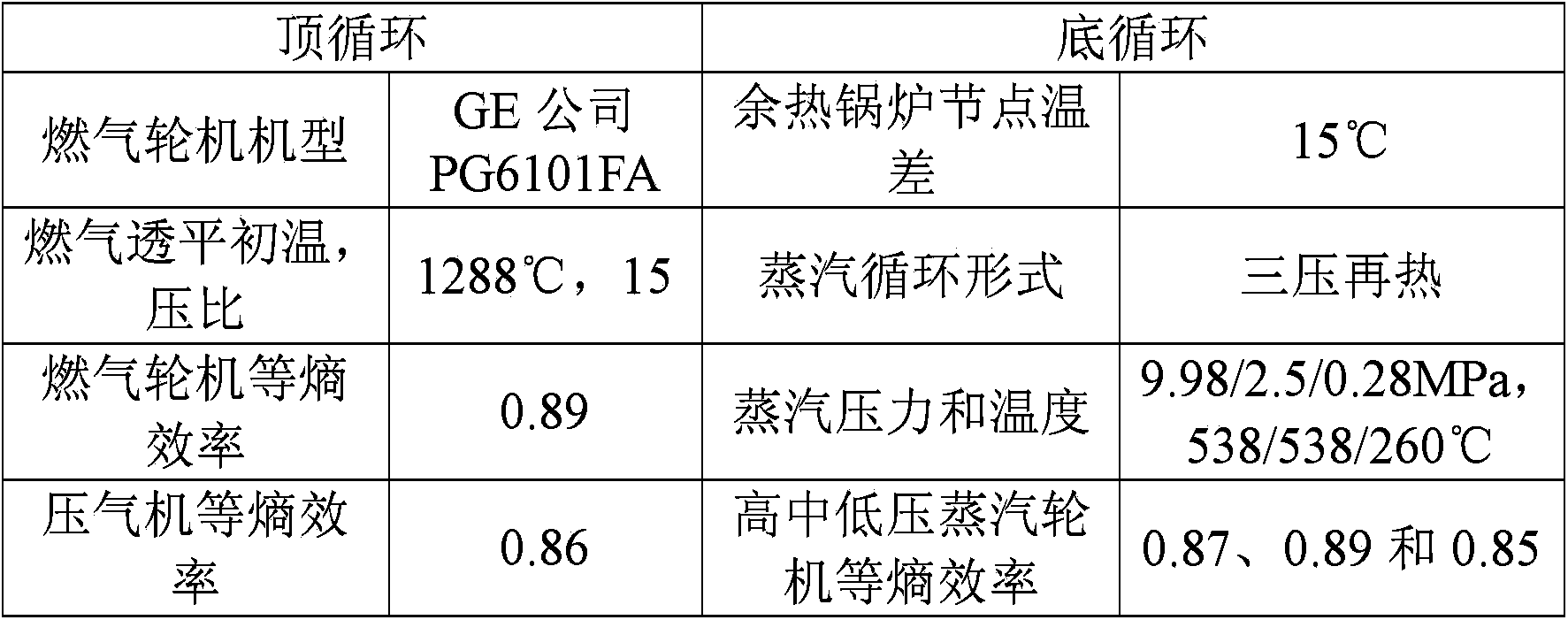

CO2 gas coke chemical-looping combustion power generating system and method

ActiveCN103758592ALess investmentReduce energy consumptionEnergy inputGas turbine plantsHydrogenWater vapor

The invention discloses a CO2 gas coke chemical-looping combustion power generating system and method. The system comprises a coal step gasification subsystem, a fire coal heating subsystem, a chemical-looping combustion subsystem and a power generating subsystem. According to the system and method, coal to be gasified is partially gasified through the carbonization process, coke oven gas and coarse coke are generated, then the coarse coke reacts with CO2 to generate CO, and therefore step gasification of hydrogen and carbon components of the coal is realized, moreover, an expensive air separating unit is omitted, and the system energy consumption is lowered; through chemical-looping combustion of the CO, losses in the combustion process is reduced, and the efficiency of the system is improved; through afterburning of the coke oven gas, energy waste of the coke oven gas is avoided, the temperature of a fuel gas turbine inlet is lowered, and the problem that in a chemical-looping combustion power system, due to circulation material limitation, the primary temperature of a fuel gas turbine inlet is low is solved. Due to the fact that CO2 generated in a chemical-looping combustion reduction reactor is not diluted by N2, CO2 zero-energy-consumption separation can be realized by removing steam through simple condensing.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

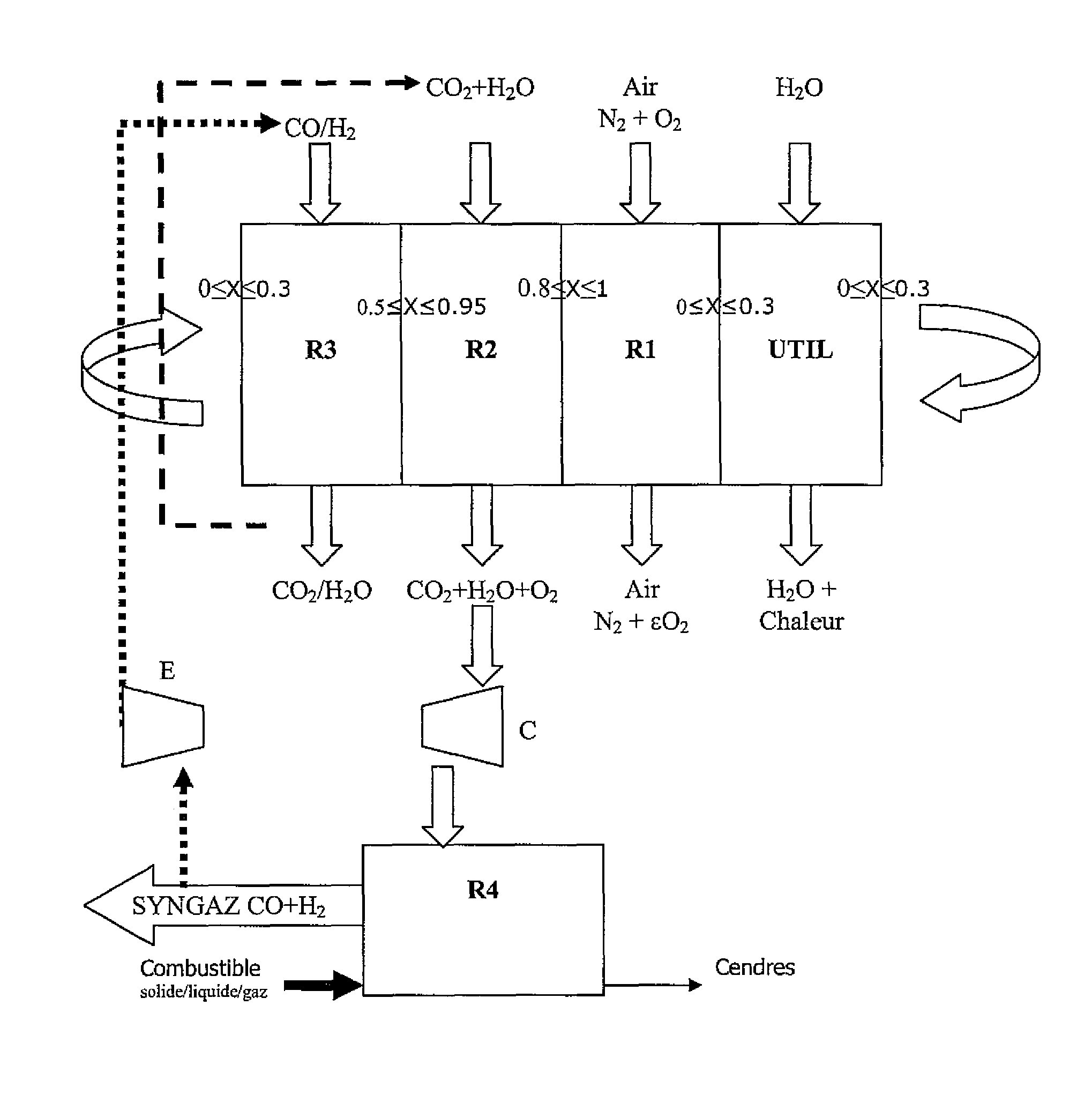

Integrated energy and/or synthesis gas production method by in-situ oxygen production, chemical looping combustion and gasification

The invention relates to an integrated method of in-situ oxygen production, chemical looping combustion and gasification of liquid, solid or gaseous fuels allowing combustion of coal, petroleum coke and / or liquid hydrocarbons and notably heavy and / or extra heavy or bituminous residues for production of synthesis gas under pressure and / or energy.

Owner:INST FR DU PETROLE

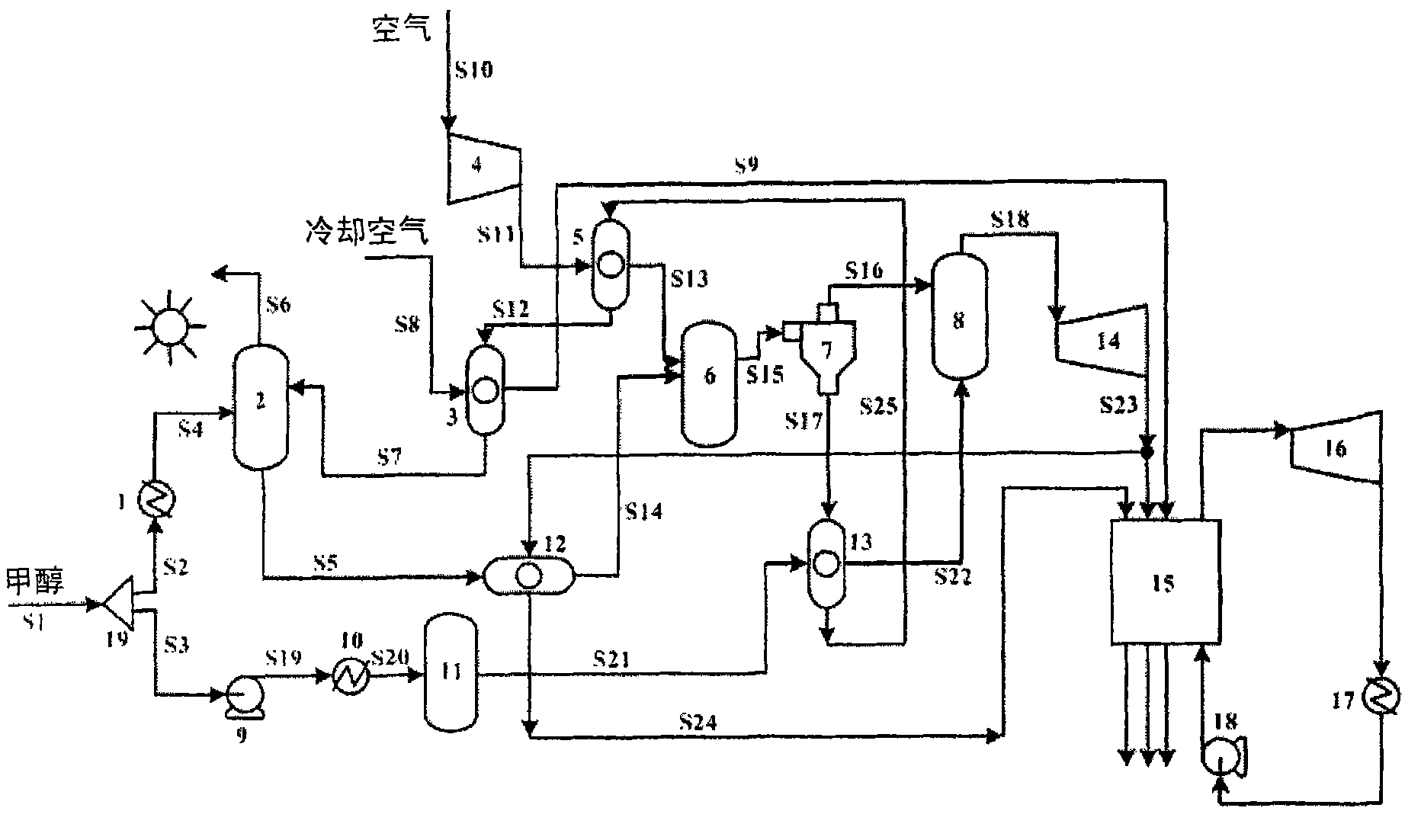

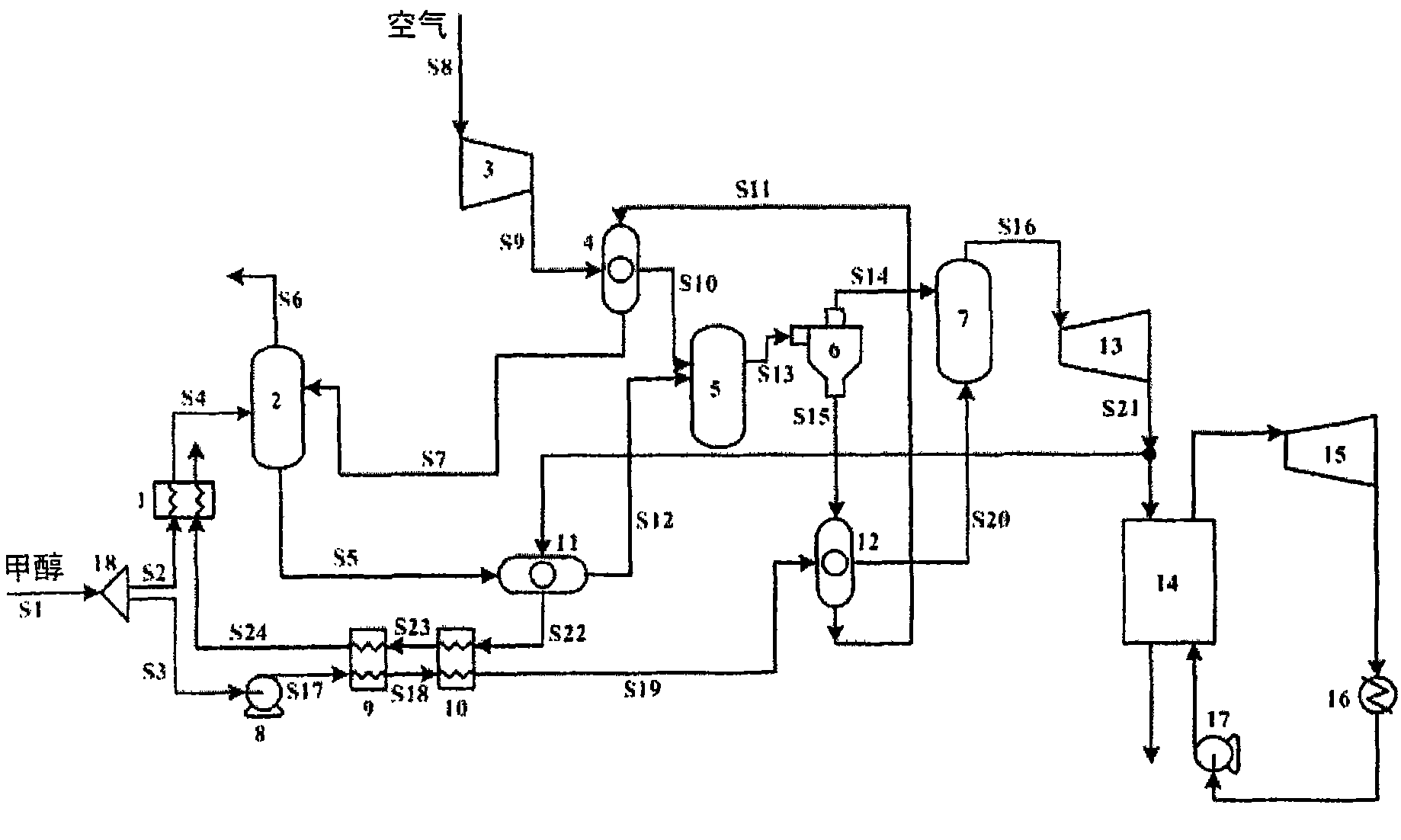

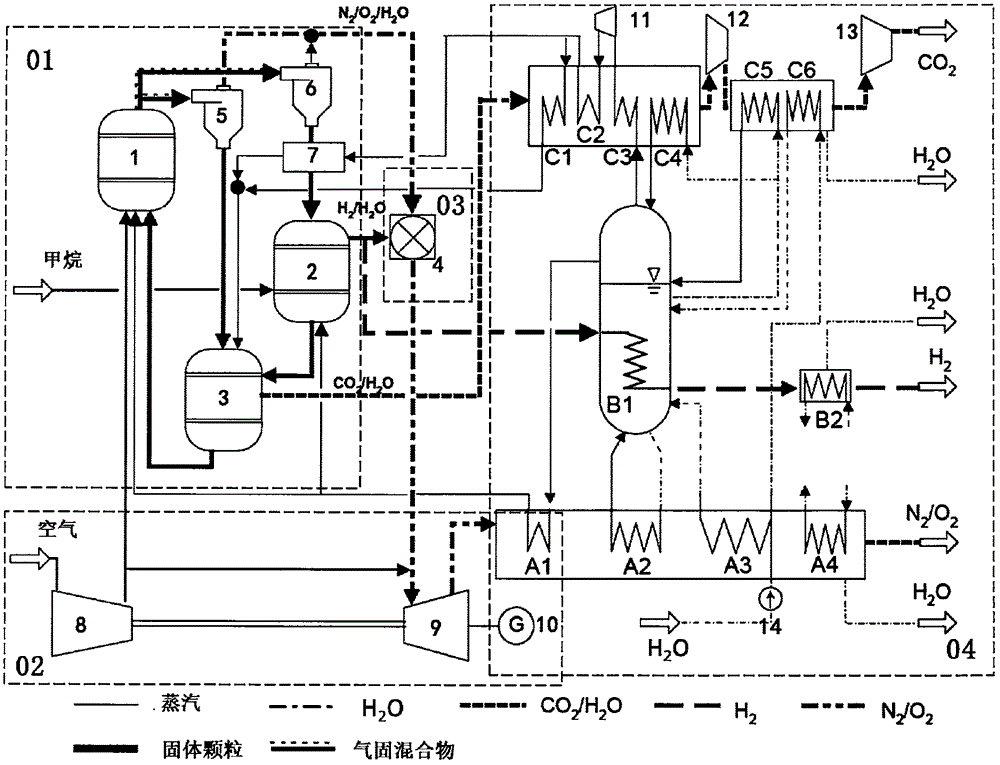

Solar energy and methanol fuel chemical-looping combustion power generation system and method

ActiveCN101888194ARealize cascade utilizationOvercoming the problem of low initial temperatureSteam engine plantsLight radiation electric generatorCombustion chamberChemical reaction

The invention relates to the technical fields of the solar thermal power generation and energy, in particular to a solar energy and methanol fuel chemical-looping combustion power generation system and method used for controlling CO2 emission. The intermediate-low temperature solar thermochemical process and the chemical-looping combustion power cycle are coupled organically to form the system ofthe invention. The system comprises a solar heat collecting-reduction reactor, a solar heat collecting-decomposition reactor, an oxidation reactor, an afterburning combustion chamber, a gas turbine, a steam turbine, an exhaust-heat boiler, a heat exchanger and the like. By using the device of the invention, the graded use of energy resources with different qualities can be realized; the zero-energy separation of CO2 can be realized through simple condensation; the combustion method can reduce the fuel grade to FeO grade, thus reducing the fuel loss in the combustion process and increasing theefficiency of the system; the solar thermochemical reaction is adopted to improve the grade of intermediate-low temperature solar energy; and afterburning is adopted so as to solve the problem that the gas turbine inlet has low initial temperature caused by the limit of the cycle material in the chemical-looping combustion power system.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Optimised method and device loop combustion on liquid hydrocarbon feedstock

InactiveUS20110171588A1Improve cooling effectEvenly distributedFluidized bed combustionCatalytic crackingLiquid hydrocarbonsImproved method

Owner:INST FR DU PETROLE +1

Chemical looping combustion method and plant with independent solid circulation control

ActiveUS8771549B2Hydrocarbon from carbon oxidesGasification processes detailsProcess engineeringReaction zone

The invention relates to an improved plant and method for chemical looping combustion of at least one hydrocarbon feed with independent control of the circulation of the solid active mass particles between the fluidized bed reaction zones, by means of one or more non-mechanical valves of L-valve type.

Owner:TOTALENERGIES ONETECH +2

Fuel coal chemical looping combustion CO2 separation method in coupling with pure oxygen gasification

ActiveCN105222129AIncrease temperatureIncrease reaction rateFluidized bed combustionIndirect carbon-dioxide mitigationWater vaporEngineering

The invention provides a fuel coal chemical looping combustion CO2 separation method in coupling with pure oxygen gasification. In a fuel reactor, a gasification agent (B) composed of water vapor and a small amount of oxygen enters from the bottom of a bed of a bubbling fluidized bed gasification furnace (1), the bed material (C) is coarse-grained inert material and performs fluidization movement under the action of the gasification agent and forms a dense phase zone; fine powdered coal (A) is added into the bubbling fluidized bed gasification furnace (1) from the dense phase zone and performs gasification reaction with the gasification agent (B), so as to form coal gas and unburned carbon (D); oxygen carrier particle (E) enters from the bottom of a lifting pipe (2) and reacts with the combustible components such as CO, H2 and CH4 in the coal gas, so as to generate CO2 and H2O. The flue gas composed of CO2, water vapor, uncompleted burned combustible gas and tiny amount of carbon-containing fine fly ash enters into a reburning chamber (13), wherein the combustible gas and the carbon in the fine fly ash perform combustion reaction with oxygen (J) from an oxygen inlet (14) of the reburning chamber, so as to generate CO2 and H2O.

Owner:SOUTHEAST UNIV

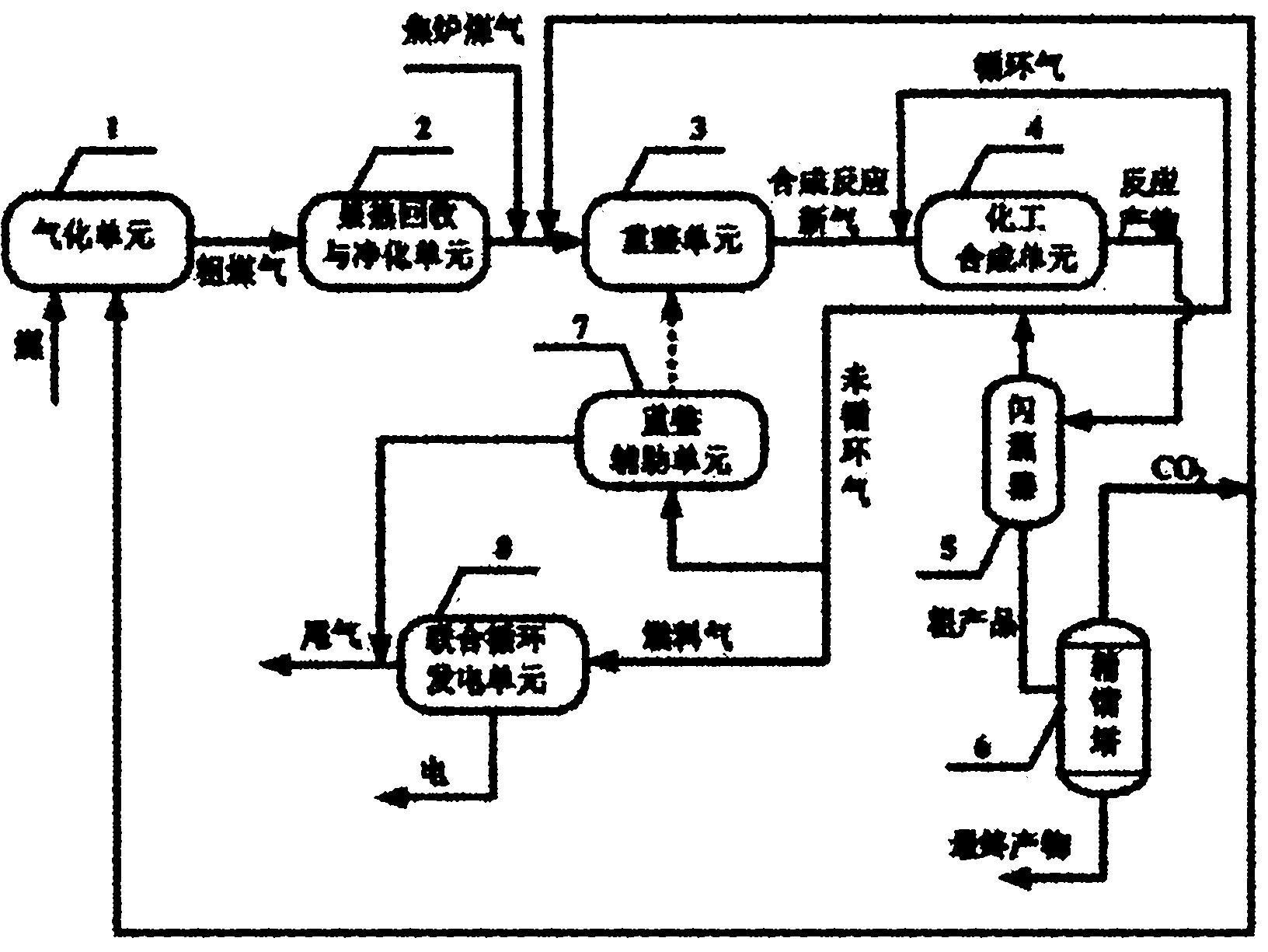

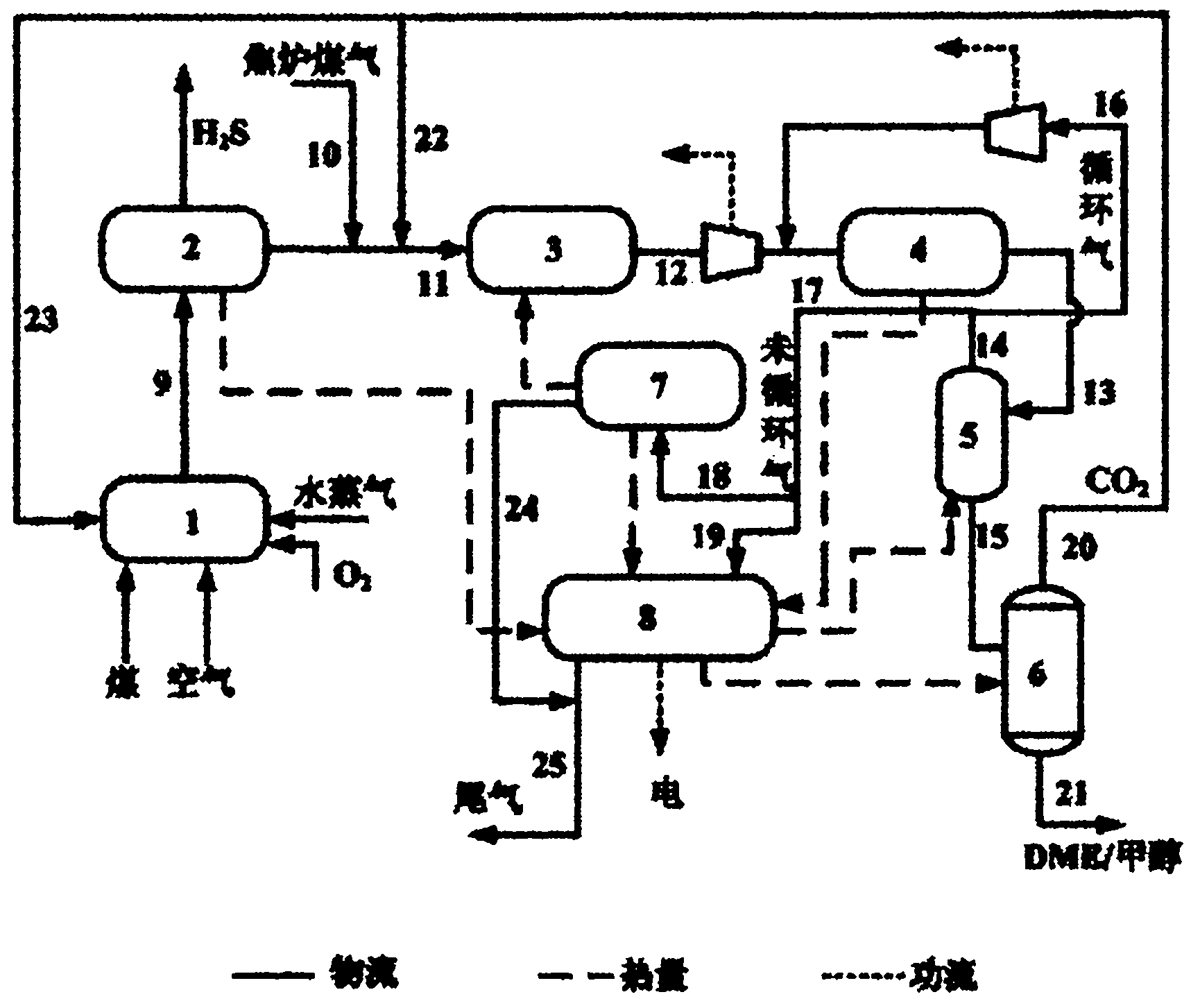

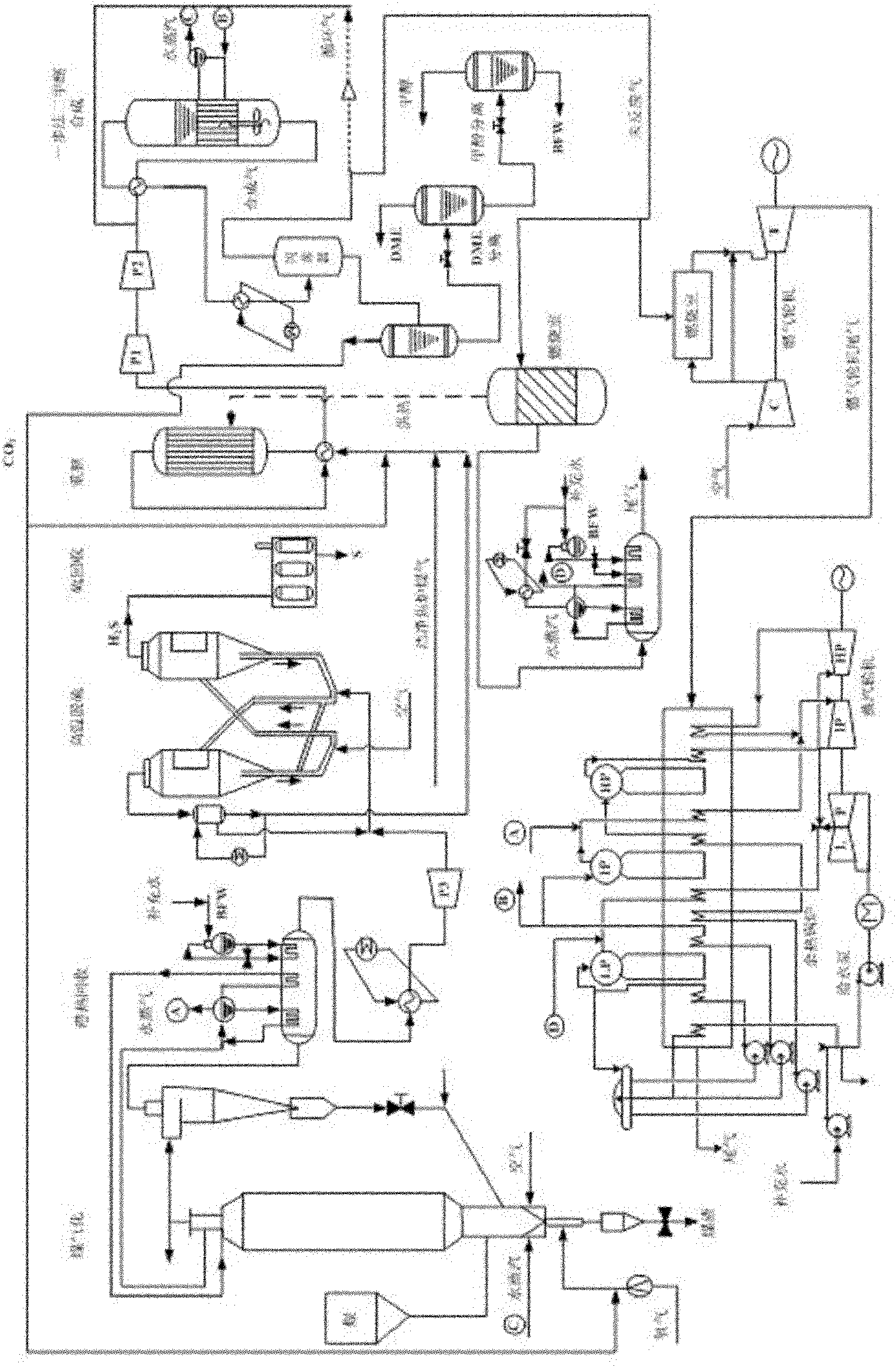

Chemical power poly-generation energy system and method for recycling CO2

ActiveCN102060662AReduce consumptionEmission reductionHydrogenOrganic compound preparationChemical synthesisHigh energy

The invention relates to the technical fields of energy sources and environment and discloses chemical power poly-generation energy system and method for recycling CO2. In the system, coal gas obtained by gasifying a carbon-rich raw material, and a hydrogen-rich raw material, namely, coke oven gas, are mixed and subjected to a reforming reaction and a chemical synthesis reaction to obtain a reaction product, the reaction product is processed in a flash evaporation process and a rectification process for separation to obtain CO2 gas and a final product, one part of the CO2 gas separated from a rectifying tower is delivered to take part in the gasification process of the carbon-rich raw material, and the other part of the CO2 is delivered to take part in the reforming reaction. By means of the system and the method provided by the invention, the CO2 separated in the rectifying process is used as feed gas to be directly recycled by the system so that a water gas shift reaction, chemical-looping combustion and other methods with higher energy-consumption performance for improving the chemical concentration of the CO2 are avoided, the problems of reduced energy system efficiency caused by the separation of CO2 and difficulties in transporting and storing large amount of CO2 are solved, and thus, a dual-effect production mode for energy-saving and environmental-protection utilization of resources is realized.

Owner:TAIYUAN UNIV OF TECH

CaO guided technology for producing hydrogen through steam reforming and chemical looping combustion of methane

InactiveCN103552983AFacilitate reformation reactionAchieve separationHydrogenSteam reformingProcess engineering

The invention discloses a CaO guided technology for producing hydrogen through steam reforming and chemical looping combustion of methane. The technology mainly comprises an air reactor, a fuel reactor, a reforming reactor and a calcinator. Methane and steam are taken as the raw materials for producing hydrogen, an oxygen carrier with NiO as the active component circulates continuously in the air reactor and the fuel reactor, the fuel methane can be completely oxidized by crystal oxygen provided by NiO, reducing-state Ni-based oxygen carrier is oxidized by air in the air reactor, a large quantity of heat released by oxidization is provided for the reforming reactor through wall heat transfer, CaO is added into the reforming reactor for absorbing CO2 generated in reaction, so as to enhance the reforming reaction to generate high-purity hydrogen, CaO adsorbs CO2 so as to form solid CaCO3 in the reforming reactor, and solid CaCO3 is pyrolyzed in the calcinator for CaO regeneration. Compared with the traditional methane steam reforming technology, the technology disclosed by the invention can be used for producing high-purity hydrogen at low temperature under normal pressure; the products at the outlet of the fuel reactor are only CO2 and H2O, so that high-purity CO2 can be obtained by condensing, the separation and collection technologies for CO2 are simplified, and the cost for producing hydrogen is sharply saved.

Owner:SOUTHWEST PETROLEUM UNIV

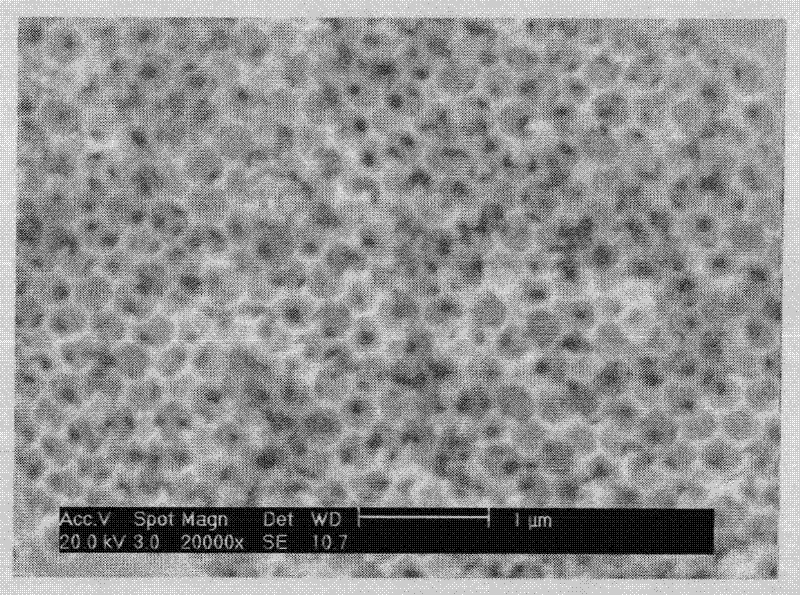

A kind of iron-based oxygen carrier based on fly ash-based porous ceramic membrane and its preparation method

InactiveCN102260569AHigh porosityLarge specific surface areaFuel additivesMaterials preparationBULK ACTIVE INGREDIENT

The invention belongs to the technical field of chemical looping combustion, and in particular relates to a novel iron-based oxygen carrier based on a fly ash-based porous ceramic membrane and a preparation method thereof. The present invention uses Fe2O3 as an active component and a fly ash-based porous ceramic membrane as a carrier to obtain an embedded loaded film-like iron-based oxygen carrier; in the oxygen carrier, the mass percentages of Fe2O3 and the carrier are respectively 5% to 50% and 50% to 95%. The iron-based oxygen carrier prepared by using fly ash-based porous ceramic membrane as a carrier has extremely large porosity and large specific surface area, which can make Fe2O3 highly dispersed, increase the reaction area, and avoid the high temperature of Fe2O3 The sintering of the inert fly ash-based porous ceramic membrane has stable performance at high temperatures and will not react with Fe2O3, which can avoid the loss of Fe2O3 and ensure the thermal stability of the new iron-based oxygen carrier; the preparation of raw materials has a wide range of sources, and the price Low cost, friendly to the environment and other advantages, suitable for large-scale promotion.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

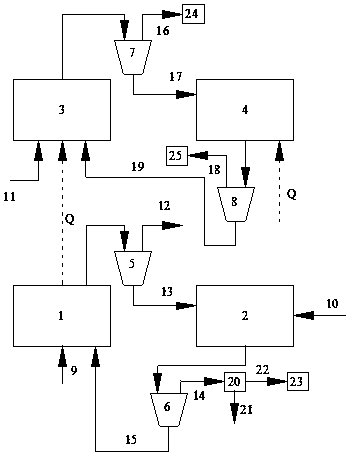

Device for separating carbon dioxide through chemical-looping combustion in coal pressurizing high-density recirculating fluidized bed

ActiveCN102087023AExtended staySolving the Response Matching ProblemFluidized bed combustionIndirect carbon-dioxide mitigationReaction rateMoving bed

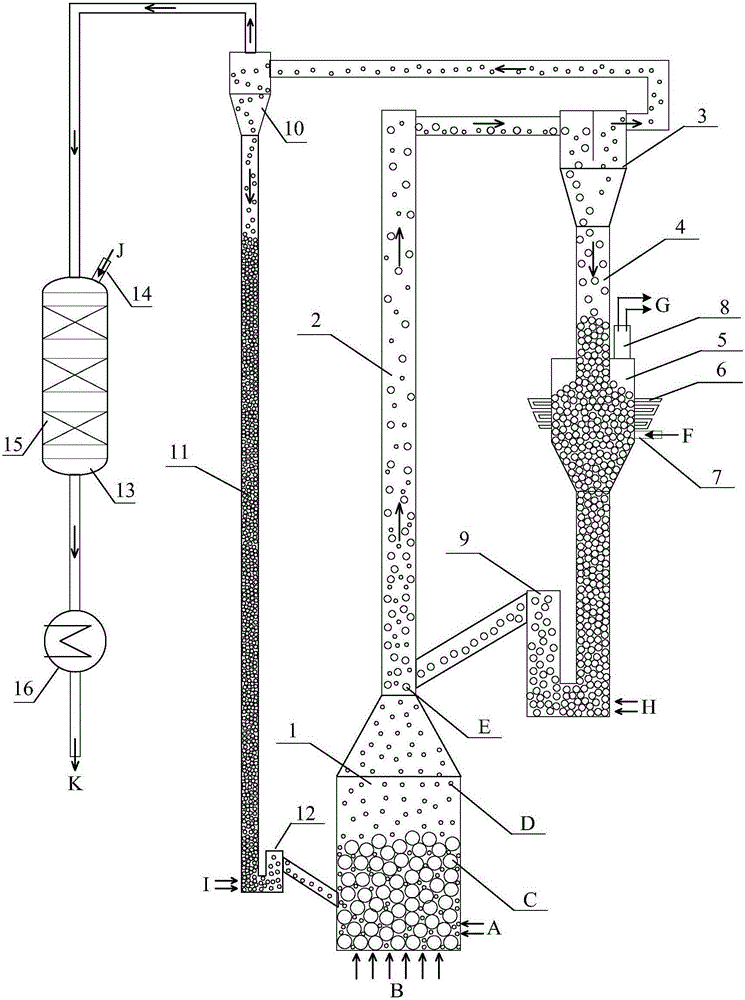

The invention discloses a device for separating carbon dioxide through chemical-looping combustion in a coal pressurizing high-density recirculating fluidized bed. Gasification reaction is carried out on coal particles and a gasification agent in a pressurizing high-density recirculating fluidized bed fuel reactor 1; and a gasification product and an oxygen carrier returning back to the fuel reactor 1 performs redox reaction to generate CO2 and H2O. The device comprises the pressurizing high-density recirculating fluidized bed fuel reactor (1), a primary cyclone separator (2), a primary dipleg (3), a fresh oxygen carrier particle feeder (4), a cross flow moving bed air reactor (5), a grid plate (6), an inactivation oxygen carrier discharging device (7), a primary material returner (8), a primary exhaust pipe (9), a secondary cyclone separator (10), a secondary exhaust pipe (11), a secondary dipleg (12) and a secondary material returner (13). By using the device in the invention, the reaction matching problem caused by the quantity grade difference existing in combustion and the oxygen carrier reaction rate is solved, thus the combustion efficiency of the coal, the separated CO2 concentration and the final gathering rate of the CO2 are greatly improved.

Owner:SOUTHEAST UNIV

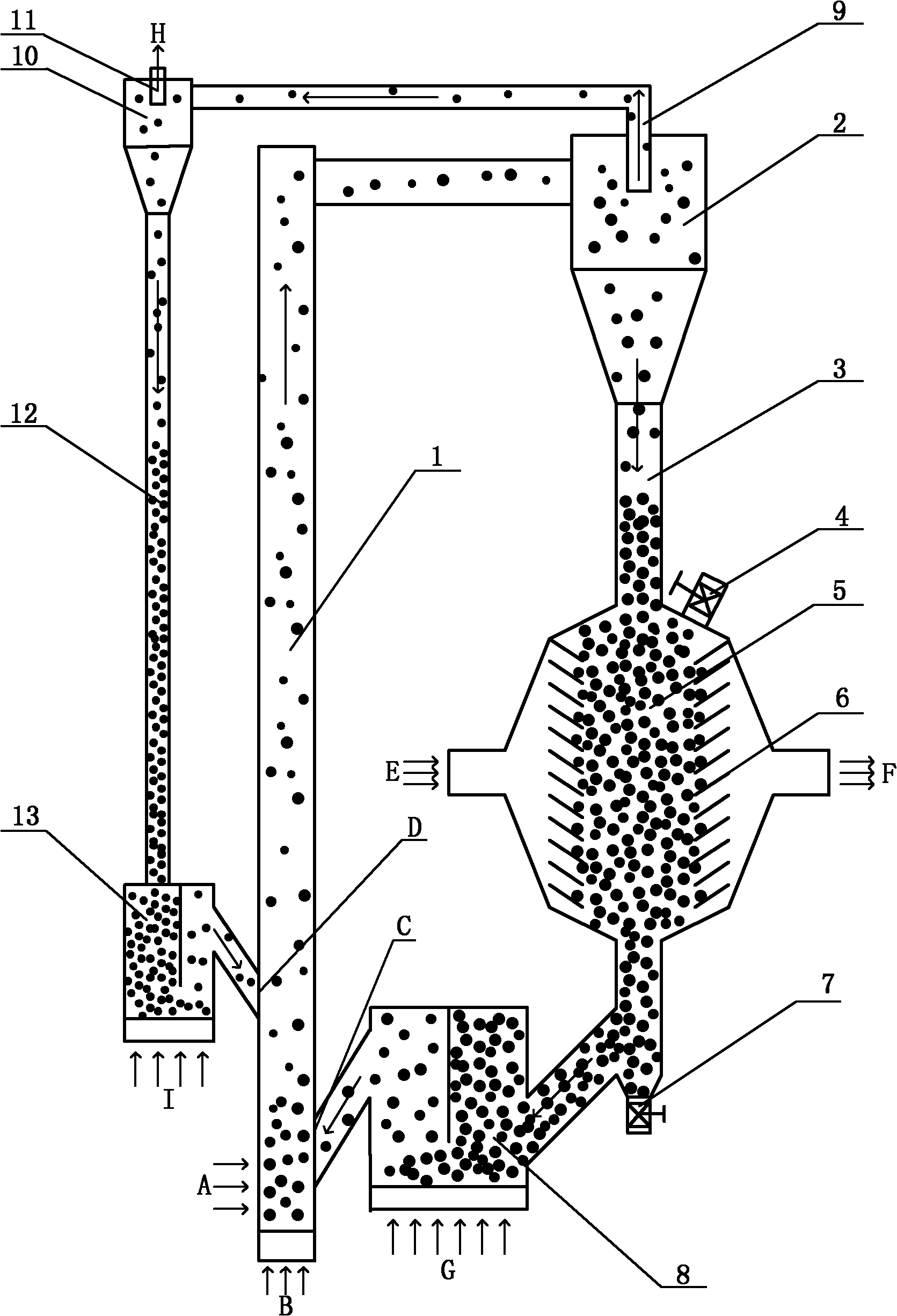

Method for stable volatilization of heavy metal chromium, cadmium and lead

InactiveCN105135447AAchieve fixationEasy to operateIndirect carbon-dioxide mitigationIncinerator apparatusCalcium bicarbonateSorbent

The invention discloses a method for stable volatilization of heavy metal chromium, cadmium and lead, and belongs to the technical field of harmlessness of solid wastes. The method comprises the following steps: S1, pulverizing the solid wastes, wherein the solid wastes comprise heavy metal chromium, cadmium and lead as well as a chlorine element; S2, performing chemical looping combustion treatment on the pulverized solid wastes, wherein the chemical looping combustion temperature is 800-1000 DEG C, an adsorbent-modified oxygen carrier is adopted in the chemical looping combustion process, the particle diameter of the adsorbent-modified oxygen carrier is 0.2-0.3 mm, and the adsorbent comprises one or more of calcium oxide, calcium nitrate, calcium carbonate and calcium bicarbonate. Through the adoption of the method, the problem in discharging of volatile chlorides of heavy metal chromium, cadmium and lead in a solid waste source utilization process in the prior art is solved.

Owner:HUAZHONG UNIV OF SCI & TECH

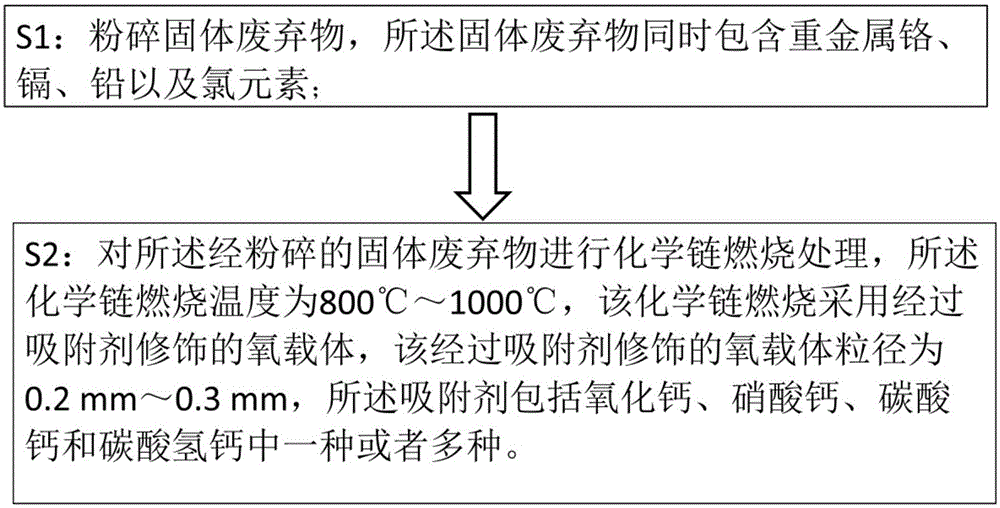

Indirect intermediate-temperature chemical energy storage device for solar heat on basis of chemical-looping combustion

InactiveCN103245087ARealize rational utilizationSimple structureSolar heating energySolar heat devicesHigh energyStorage tank

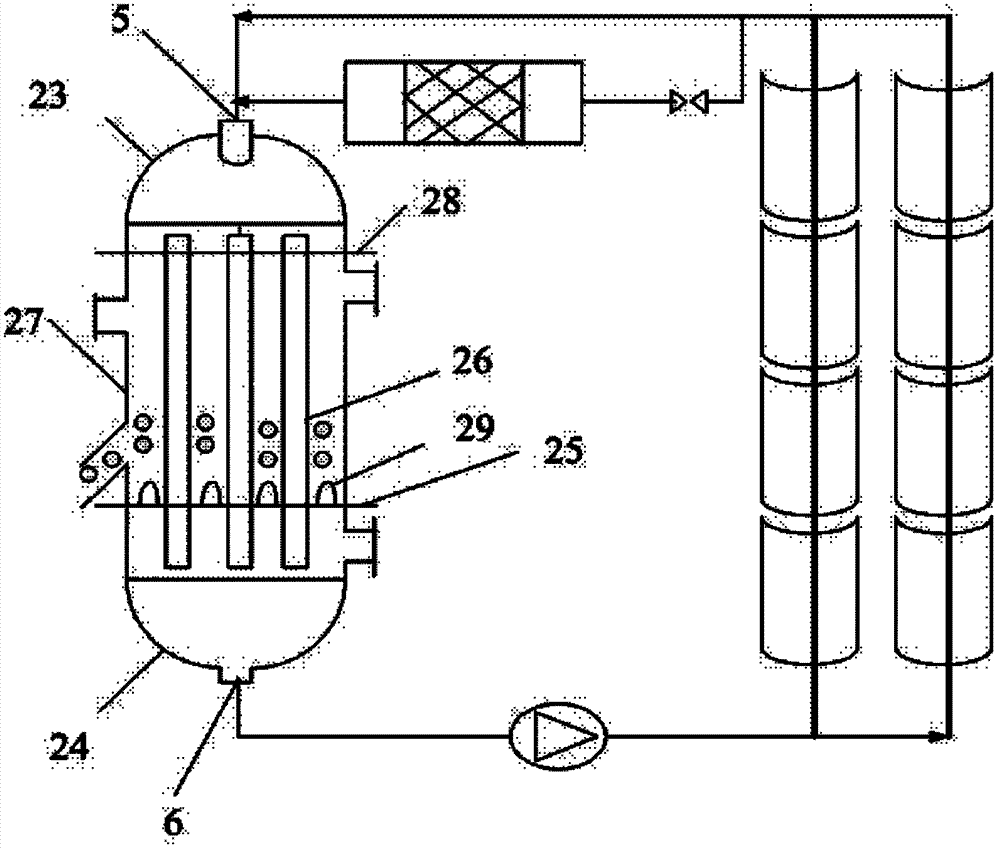

The invention discloses an indirect intermediate-temperature chemical energy storage device for solar heat on the basis of chemical-looping combustion. The indirect intermediate-temperature chemical energy storage device comprises parabolic trough condensers, line-focus reinforced heat collecting tubes, a shell and tube heat collecting reactor, a heat collecting fluid regulating valve, a heat collecting fluid standby storage tank, a gas-solid oxidation reactor, a gas distributing board, a gas-solid heat exchange device, a gas-solid separating device and a pressure pump. The line-focus reinforced heat collecting tubes and the shell and tube heat collecting reactor are connected with the pressure pump, the shell and tube heat collecting reactor and a return valve are connected with the gas-solid oxidation reactor, and the gas-solid oxidation reactor, the gas-solid separating device and the gas-solid heat exchange device are connected with the shell and tube heat collecting reactor. When solar energy is unavailable or the irradiation intensity of the solar energy is insufficient, the line-focus reinforced heat collecting tubes, the heat collecting fluid regulating valve, the heat collecting fluid standby storage tank and the shell and tube heat collecting reactor are connected with the pressure pump. The collected solar heat is stored in a metallic solid fuel form by the indirect intermediate-temperature chemical energy storage device, and the indirect intermediate-temperature chemical energy storage device has the advantages of high energy storage density, simple structure, flexibility in regulation and control and the like.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Oxygen carrier for methane chemical looping combustion and preparation method for oxygen carrier

The invention relates to an oxygen carrier for methane chemical looping combustion and a preparation method for the oxygen carrier. The oxygen carrier comprises Fe2O3, Al2O3, CeO2 and KNO3, wherein the mass ratio of the KNO3 to the (CeO2 + Fe2O3 + Al2O3) is (1-10)%: (99-90)%; the mass ratio of the CeO2 to the (Fe2O3 + Al2O3) is (1-20) %: (99-80)%; and the mass ratio of the Fe2O3 to the Al2O3 is (10-60) %: (90-40)%. The method comprises the following steps of: preparing a nitrate solution, adding aqueous ammonia serving as a precipitant for co-precipitation, performing suction filtration, washing, roasting, soaking in a potassium nitrate solution, drying, roasting, and thus obtaining the oxygen carrier for methane chemical looping combustion. The oxygen carrier has high CH4 conversion rate and quick conversion rate in full conversion reaction of methane, the reaction is full, the CO2 concentration of the product is high, and the method for preparing the oxygen carrier is simple and facilitates industrialization.

Owner:KUNMING UNIV OF SCI & TECH

Coal-based fuel chemical-looping combustion power generation system and method based on supercritical carbon dioxide

ActiveCN106438043AMake up for the leakLow costGas turbine plantsCombustion systemProcess engineering

The invention provides a coal-based fuel chemical-looping combustion power generation system and method based on supercritical carbon dioxide. Power generation efficiency is high, emission of nitrogen oxides is low, carbon dioxide is easy to gather, and furthermore, a chemical-looping combustion technology and supercritical carbon dioxide circular power generation are combined organically. The system comprises a chemical-looping combustion system and a supercritical carbon dioxide circular power generation system; the chemical-looping combustion system comprises an air reactor and a combustion reactor; and the supercritical carbon dioxide circular power generation system comprises a carbon dioxide turbine, a carbon dioxide compressor and a generator, and the carbon dioxide compressor and the generator are both connected with the driving end of the carbon dioxide turbine. The chemical-looping combustion technology and the supercritical carbon dioxide circular power generation are combined, while power generation is realized by supercritical carbon dioxide, the carbon dioxide is gathered and recycled, and part of the gathered carbon dioxide can also be supplemented into the supercritical carbon dioxide circular system after being pressurized to compensate for part of leakage in the circular system.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

Oxygen carrier of chemical-looping combustion and preparation method and application thereof

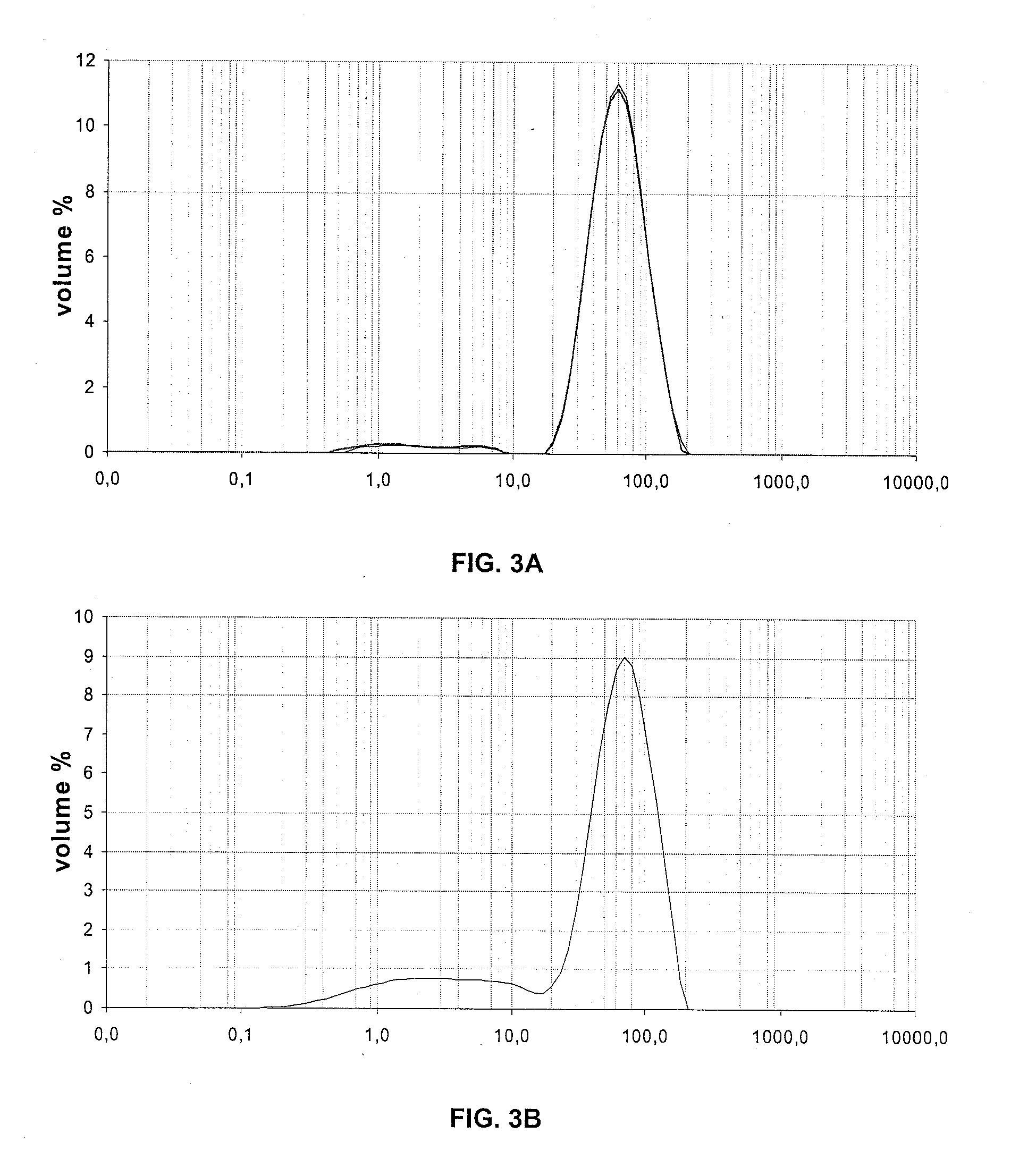

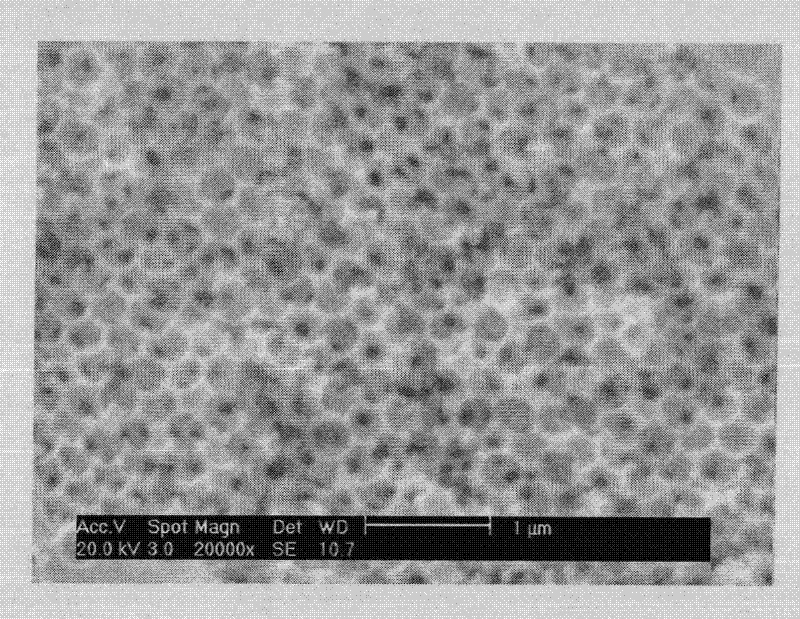

ActiveCN102443454AImprove stabilityFacilitated DiffusionFuel additivesActive componentEmulsion polymerization

The invention discloses an oxygen carrier of chemical-looping combustion and preparation method and application thereof; the oxygen carrier uses CeO2 as carrier and Fe2O3 as active component; the weight percentage of the active component Fe2O3 in the oxygen carrier is 5-30%; and the aperture of the oxygen carrier is 500nm-50um. The preparation method of the oxygen carrier comprises the following processes of: preparing template by emulsion polymerization method, preparing the macroporous CeO2 and loading the active component and the like. The oxygen carrier is applied to the chemical-looping combustion, wherein the reaction temperature in the air reactor is 500-1000 DEG C, the reaction temperature of the fuel reactor is 500-1000 DEG C, and the reaction pressure is constant pressure. The oxygen carrier of the invention has three-dimension ordered macroporous structure, uniform distribution of the active component and simple preparation method; and the oxygen carrier in the chemical-looping combustion has the advantages that the lamination of the reaction bed is reduced, the activity of the reaction bed is high and the diffusion effect of the reaction bed is good and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method and apparatus for producing and heating carbonaceous fuel gasifying agent

The invention discloses a method for producing and heating a gas agent which contains carbon fuel and a device thereof, pertaining to the gasification field of fuels containing carbon. Parts of syngas generated by a gasifier is combusted through chemical-looping combustion and the heat generated therefrom is recovered in a heat exchanger network, and under the condition that external H2O and / or CO2 is added, the H2O and CO2 mixed gas at enough high temperature and as large as possible flow is obtained and used as the gas agent; when the gas agent is lack of heat and has too low fractional conversion, O2 is transferred to the gas agent from gas containing the O2 through a peroxy-separator. The gas agent obtained by the method is sent to a ground gasifier or an underground gasifier to react with the fuels containing the carbon, and the syngas containing no N2 is obtained. By adjusting the composition of the gas agent, the composition of the syngas can be adjusted flexibly according to downstream requirements; the discharge of CO2 is low during the whole gasification process; the method relies little on environment and after a gasification system starts and works normally, the syngas can be obtained through the gasification of the fuels containing the carbon so as to provide energy for continuous production, and obtained intermediate material flow is favorable for doping the O2 into the gasifier.

Owner:张鹏

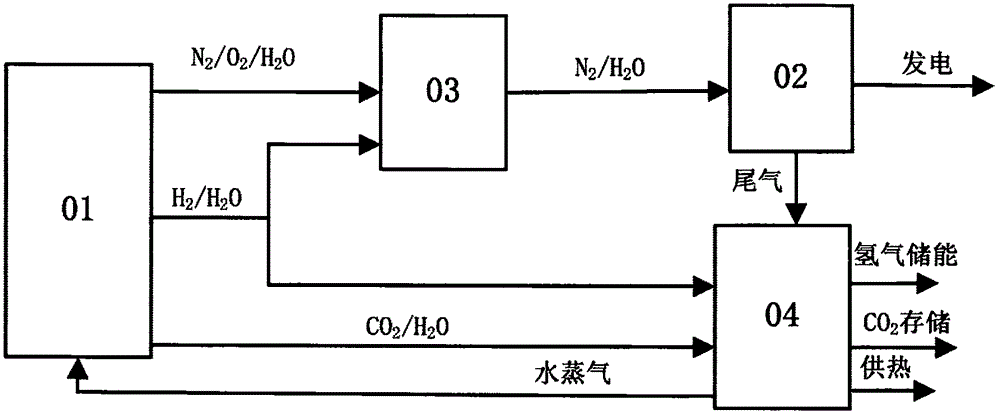

Chemical looping combustion-based hydrogen energy storage, combined heat and power generation and CO<2> capture system and method

ActiveCN106784936AImprove dynamic efficiencyEmission reductionFuel cell heat exchangeWater vaporCogeneration

The invention relates to a chemical looping combustion-based hydrogen energy storage, combined heat and power generation and CO<2> capture system and method. The system comprises a chemical looping combustion system, a gas turbine power generation system, an auxiliary combustion system and a waste heat recovery and utilization system, wherein the chemical looping combustion system is used for producing hydrogen and high-temperature gas, and realizing adsorption and separation of CO<2> in a combustion product; the gas turbine power generation system generates power by utilizing the high-temperature gas generated by the chemical looping combustion system or the auxiliary combustion system; the auxiliary combustion system is accessed under the condition of a relatively large power load, so that gas temperature of an inlet of a gas turbine is increased and the power generation efficiency is improved; and the waste heat recovery and utilization system can realize high, medium and low temperature gradient utilization of waste heat resources of the gas in the system, produce steam required in the system and supply heat. According to the system, an output ratio of power generation and hydrogen energy storage can be adjusted and controlled by controlling reaction conditions while CO<2> capture and heat supply are carried out, and production is carried out according to power demands, so that dynamic efficiency of energy utilization is improved.

Owner:NINGBO RUIXIN ENERGY TECH

Magnetic oxygen carrier based solid fuel chemical-looping combustion system and technology

ActiveCN102878552AEfficient separationFluidized bed combustionIndirect carbon-dioxide mitigationNuclear engineeringSolid fuel

The invention belongs to the technical field of chemical-looping combustion, and particularly relates to a magnetic oxygen carrier based solid fuel chemical-looping combustion system and technology. The system is based on the characteristic that during the oxidation-reduction reaction of an iron-based oxygen carrier, Fe2O3 in high valence state is nonmagnetic and Fe3O4 in low valence state is magnetic; and electromagnetic control devices are adopted to separate an oxygen carrier with Fe3O4 in low valence state from a fuel reactor and send the oxygen carrier to an air reactor, meanwhile separate an oxygen carrier with Fe2O3 in high valence state from the air reactor and sent the oxygen carrier to the fuel reactor, so that the chemical-looping combustion of coal, biological substances and other solid fuels is realized. Through adopting an electromagnetic separation device, the system not only realizes the efficient separation of the oxygen carrier and solid particles such as unburned solid fuels and burnout ash residues during the direct chemical-looping combustion of solid fuel, but also realizes the effective separation of Fe2O3 in high valence state and Fe3O4 in low valence state, so that the oxygen carrier is efficiently and fully utilized.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

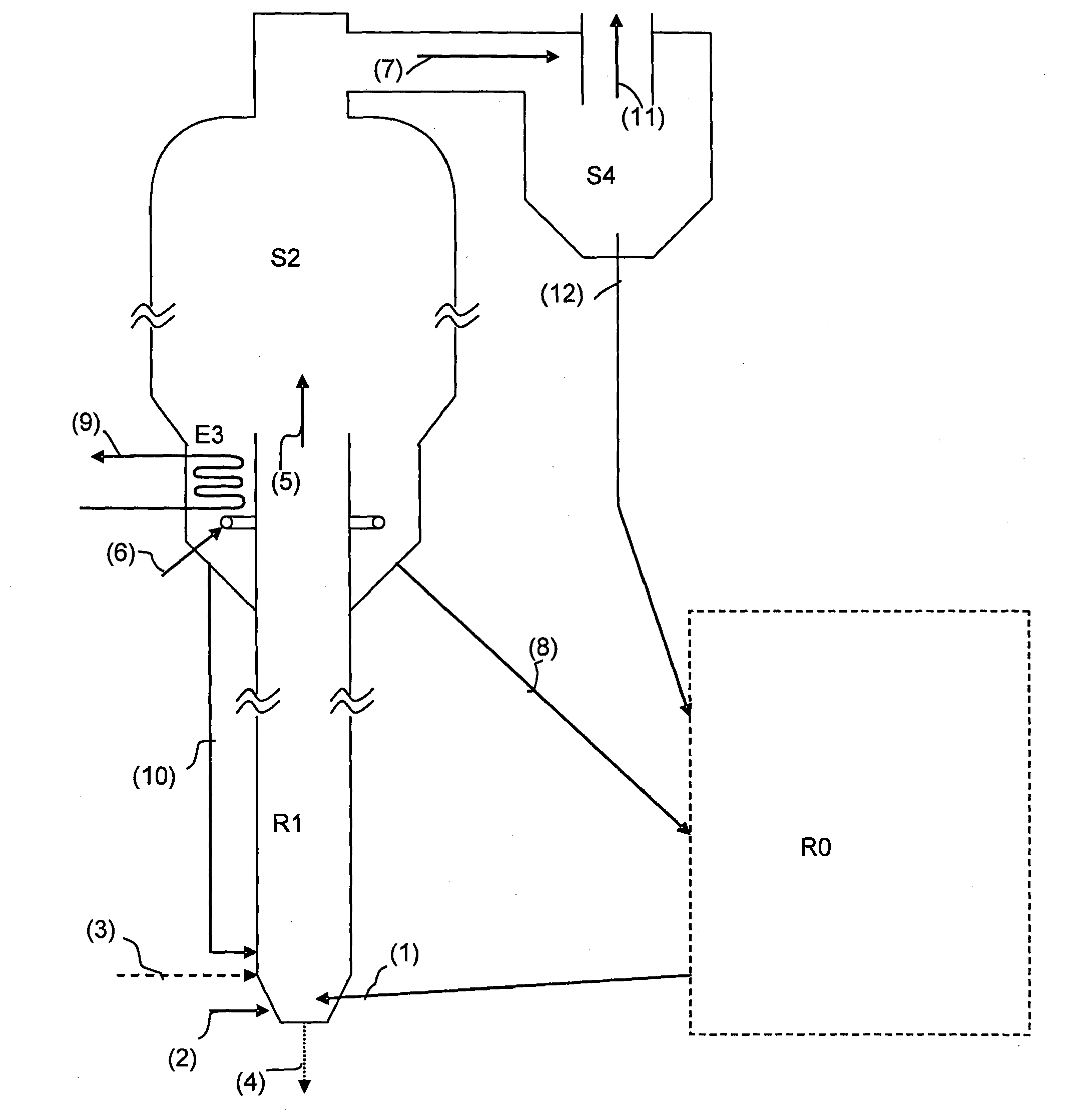

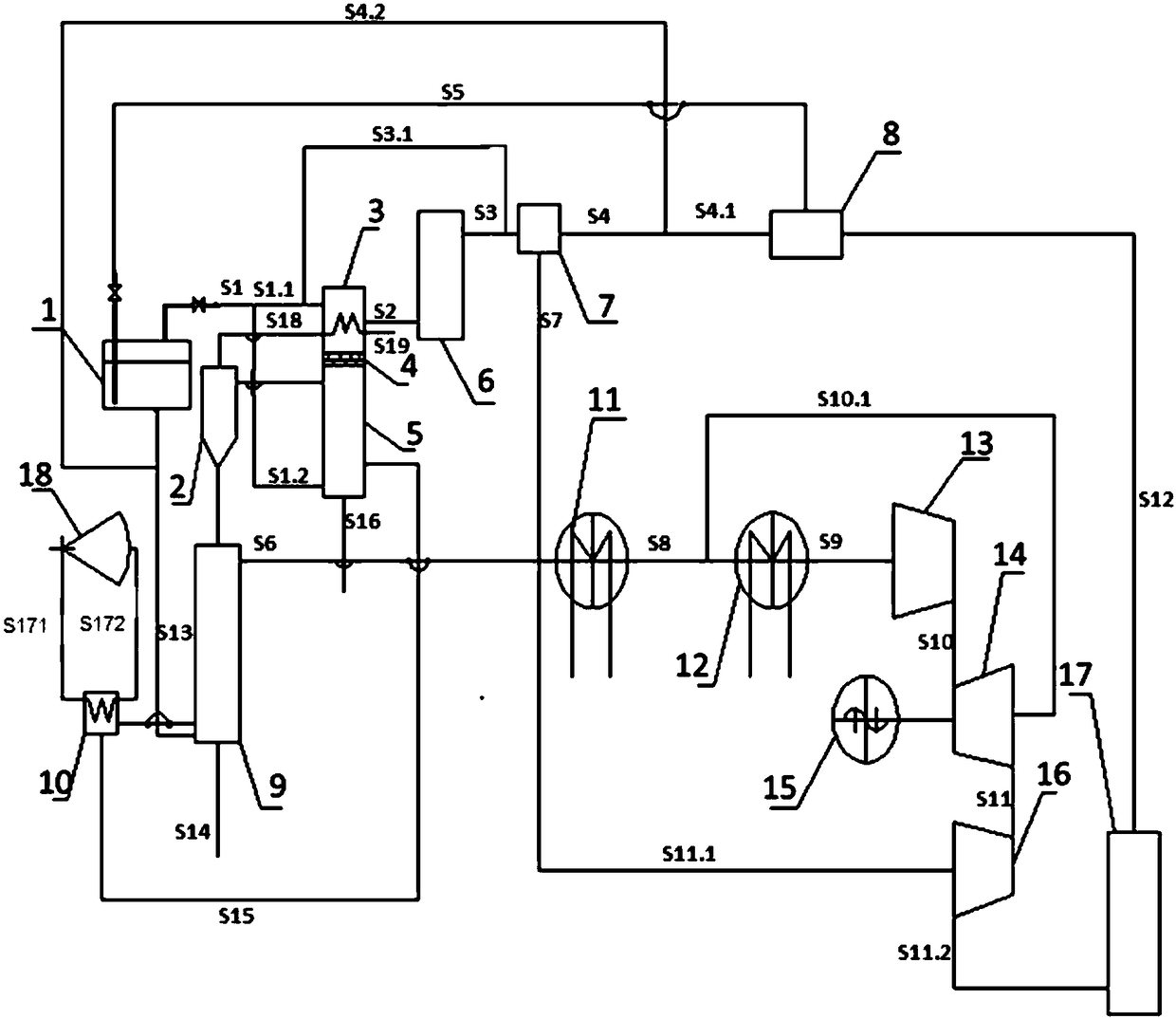

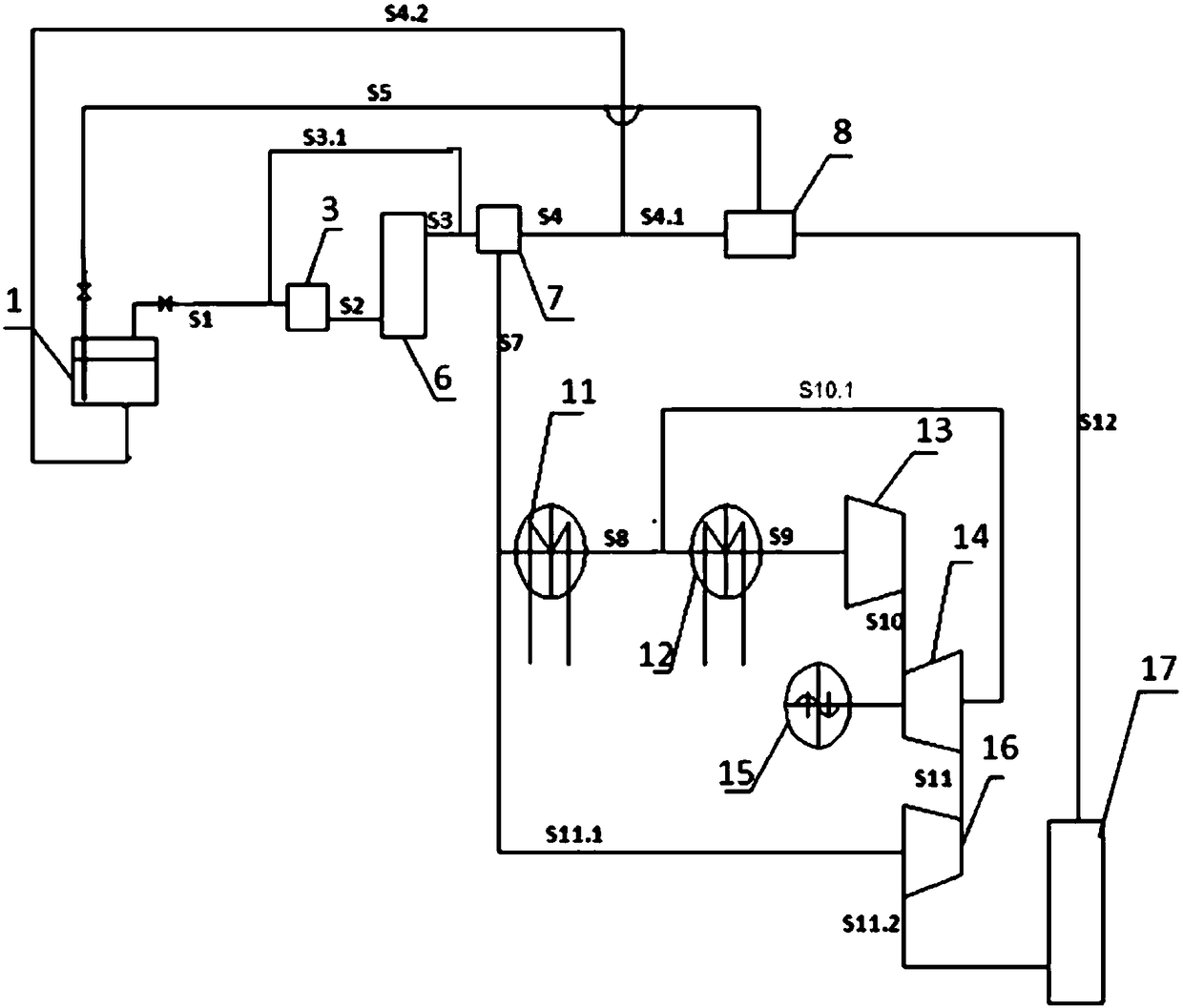

Chemical-looping combustion method with dilute phase removal of ashes and fines in the oxidationzone and plant using same

The invention relates to a method for chemical-looping combustion of a hydrocarbon-containing feedstock, comprising:contacting oxygen-carrying material particles coming from a reduction zone R0 with an oxidizing gas stream in a reactive oxidation zone R1,separating the fly ashes, the fines and the oxygen-carrying material particles within a mixture coming from zone R1 in a dilute phase separation zone S2, the driving force required for dilute phase elutriation in S2 being provided by the oxidizing gas stream from reactive oxidation zone R1. Optionally, partitioning is carried out in a dedusting zone S4, then possibly in a dense phase elutriation separation zone S5. The invention also relates to a chemical-looping combustion plant allowing said method to be implemented.

Owner:TOTALENERGIES ONETECH +2

Combined heat and power generation system based on solar energy integrated oxygen-enriched combustion and chemical looping combustion and working method thereof

InactiveCN108507188AReduce sinteringBig investmentBioreactor/fermenter combinationsSolar heating energyHigh energyPower cycle

The invention discloses a combined heat and power generation system based on solar energy integrated oxygen-enriched combustion and chemical looping combustion and a working method thereof. A solar thermal chemistry process and a fuel power cycle are organically coupled by the system, so that the step utilization of the solar energy is realized; on one hand, a reduced oxygen-carrying body is usedfor converting the solar energy into chemical energy to be stored in an oxygen-carrying body heat accumulator, necessary heat energy is provided for the chemical looping combustion; and on the one hand, the characteristic that the CO2 is released by absorbing CO2 through the photosynthesis of microalgae under light illumination is utilized, pure O2 is provided for the oxygen-enriched combustion, and secondary air is provided for an air reactor; in addition, by complementary integration of the oxygen-enriched combustion system and the chemical looping combustion system, and the reasonable and efficient utilization of the fuel is realized; and meanwhile, the pure CO2 generated through oxygen-enriched combustion and chemical looping combustion is used for pushing a turbine to generate electricity for heat supply, so that the problem of high energy consumption and high cost due to the fact that CO2 is trapped and separated is solved, the CO2 flue gas waste heat can be effectively utilized.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

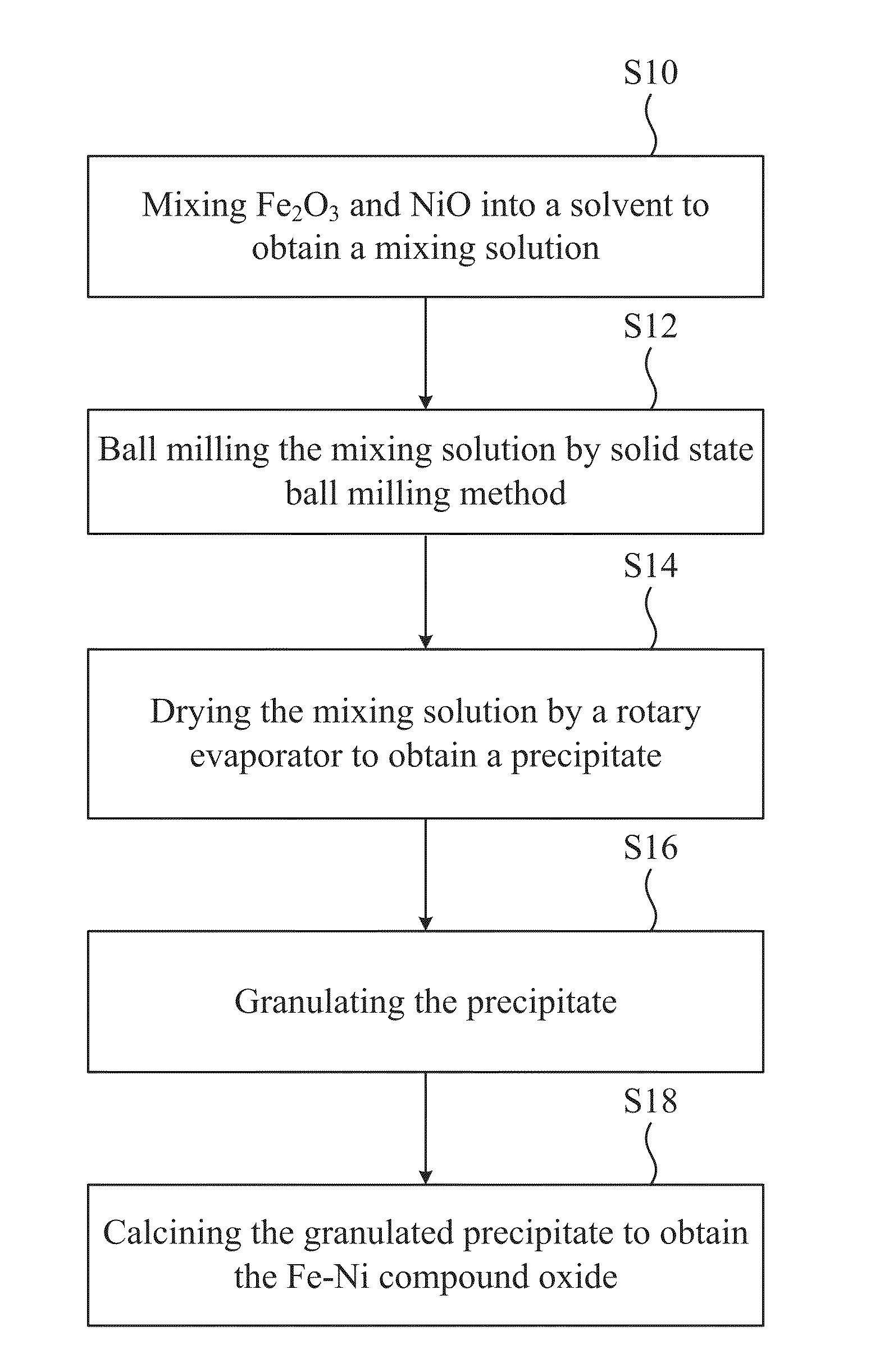

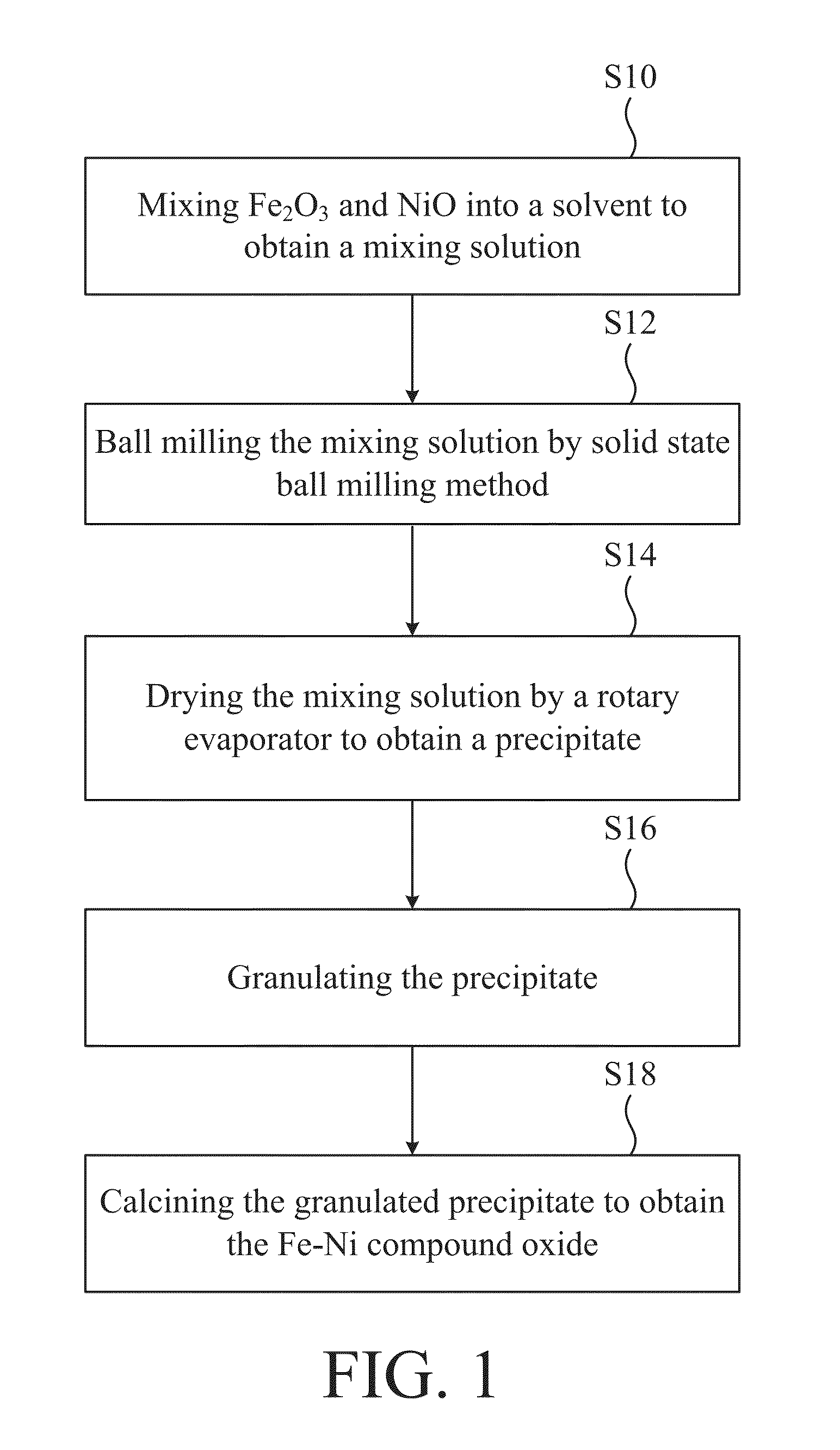

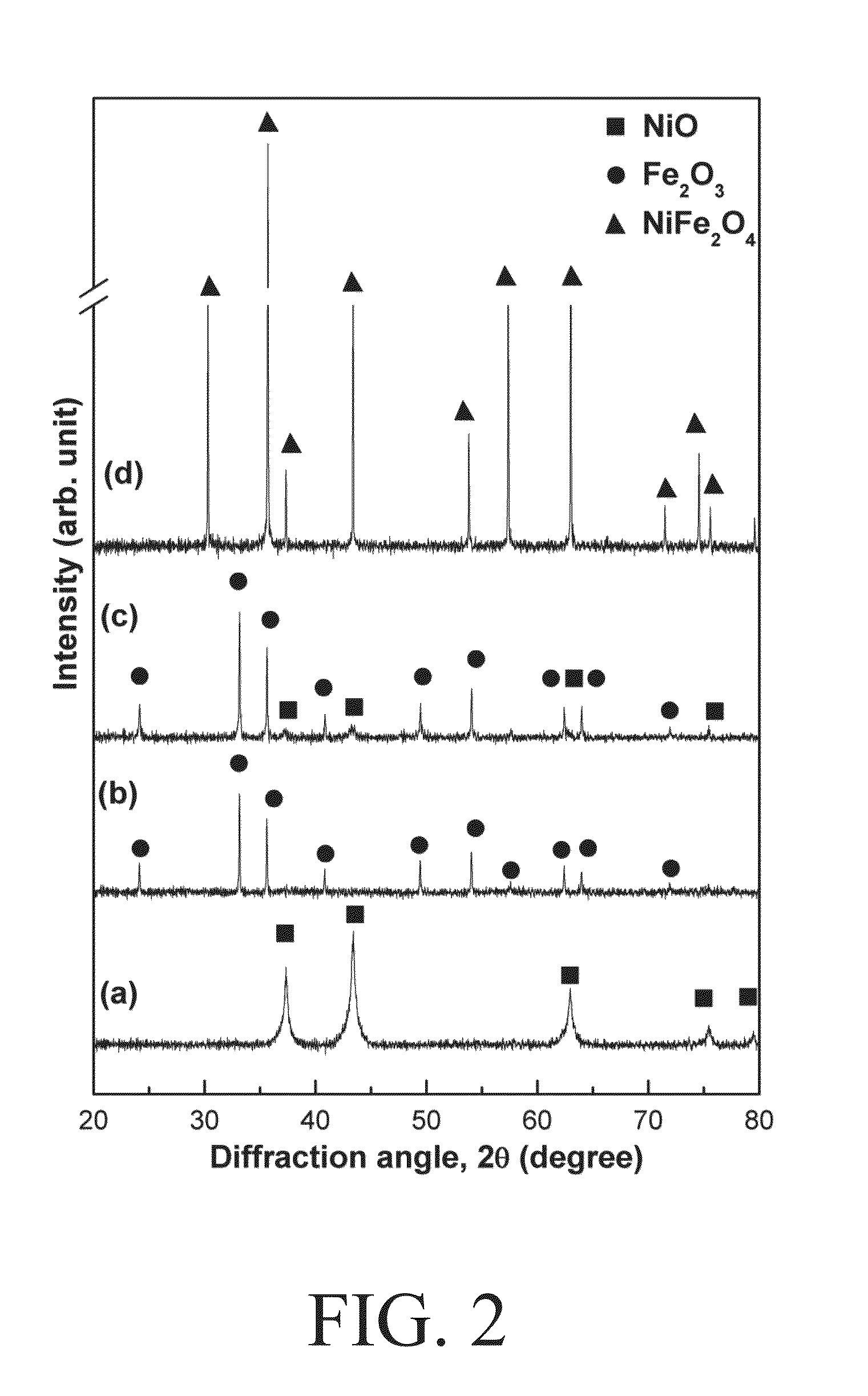

Fe-ni compound oxide for chemical looping combustion process and method of manufacturing the same

InactiveUS20130130032A1Increase oxidation rateProducing hydrogen gasMaterial nanotechnologyHydrogenReduction rateHydrogen

A Fe—Ni compound oxide is used as an oxygen carrier for chemical looping combustion process, wherein the structure of the Fe—Ni compound oxide is a single-phase spinel structure. The method for manufacturing the Fe—Ni compound oxide of the invention includes the following steps: mixing Fe2O3 and NiO to obtain a mixing solution and ball milling the mixing solution by the solid state ball milling method; drying the mixing solution to obtain a precipitate; granulating the precipitate and then calcining the granulated precipitate to obtain the Fe—Ni compound oxide. Accordingly, the Fe—Ni compound oxide manufactured by the method of the invention is provided with high oxidation rate and high reduction rate, and capable of keeping loops and producing hydrogen gas.

Owner:NATIONAL TSING HUA UNIVERSITY

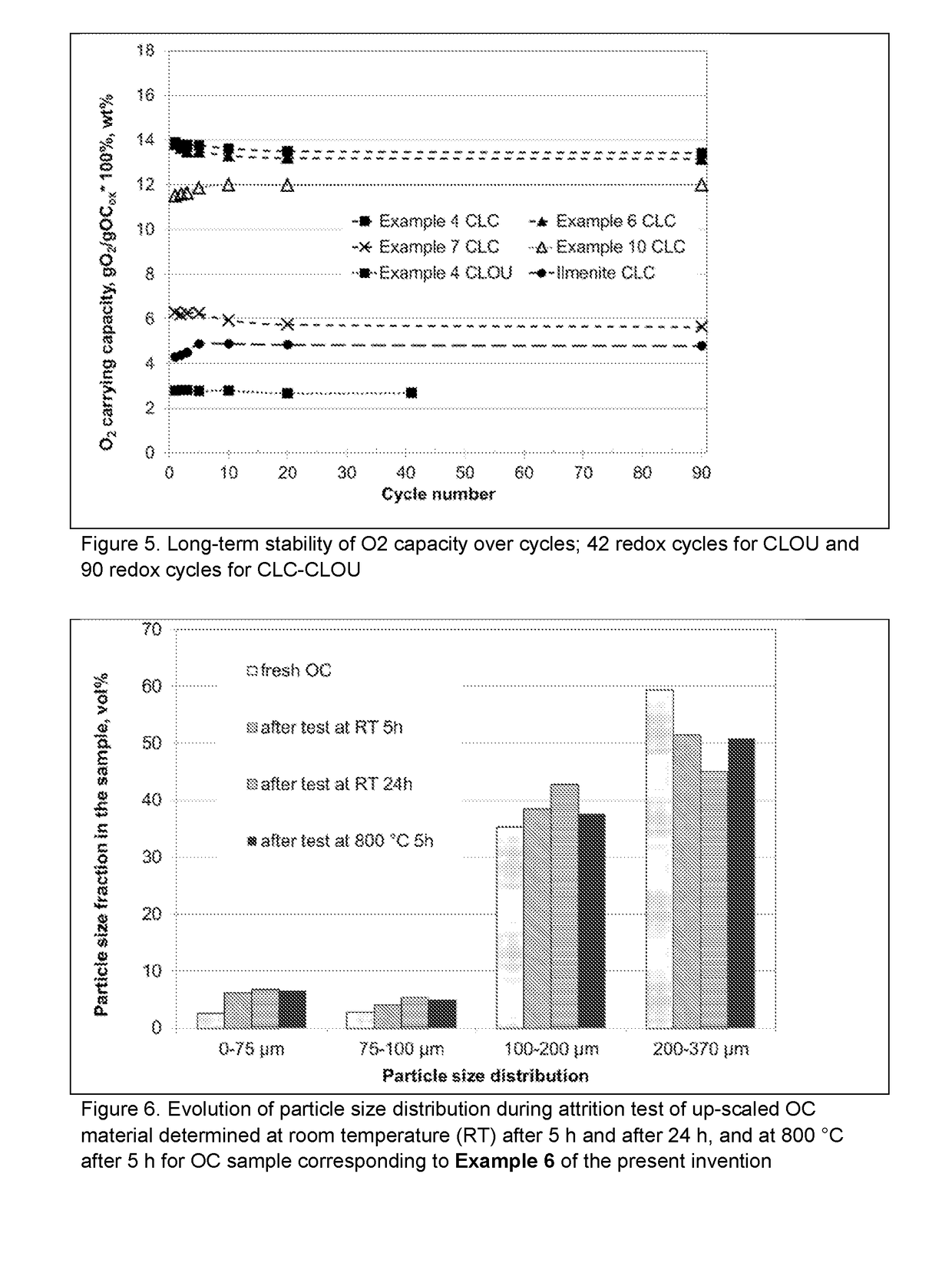

Sustainable Oxygen Carriers for Chemical Looping Combustion with Oxygen Uncoupling and Methods for Their Manufacture

InactiveUS20190003704A1Simple and scalable and cost-effective methodImprove mechanical stabilityFluidized bed combustionCatalytic crackingCarrying capacityCompound (substance)

An oxygen carrier (OC) for use in Chemical Looping technology with Oxygen Uncoupling (CLOU) for the combustion of carbonaceous fuels, in which commercial grade metal oxides selected from the group consisting of Cu, Mn, and Co oxides and mixtures thereof constitute a primary oxygen carrier component. The oxygen carrier contains, at least, a secondary oxygen carrier component which is comprised by low-value industrial materials which already contain metal oxides selected from the group consisting of Cu, Mn, Co, Fe, Ni oxides or mixtures thereof. The secondary oxygen carrier component has a minimum oxygen carrying capacity of 1 g of O2 per 100 g material in chemical looping reactions. Methods for the manufacture of the OC are also disclosed.

Owner:INSTITUTT FOR ENERGITEKNIKK

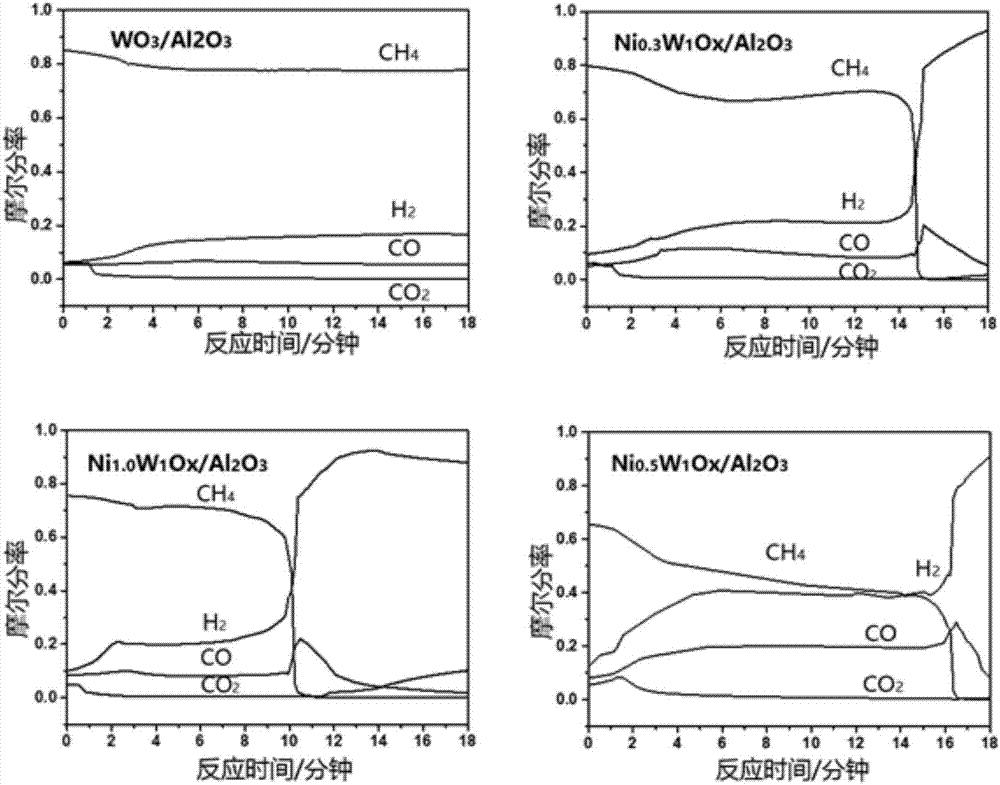

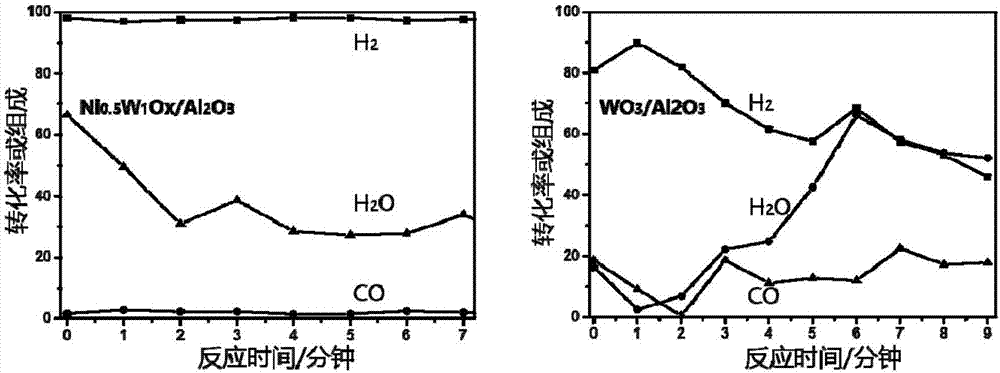

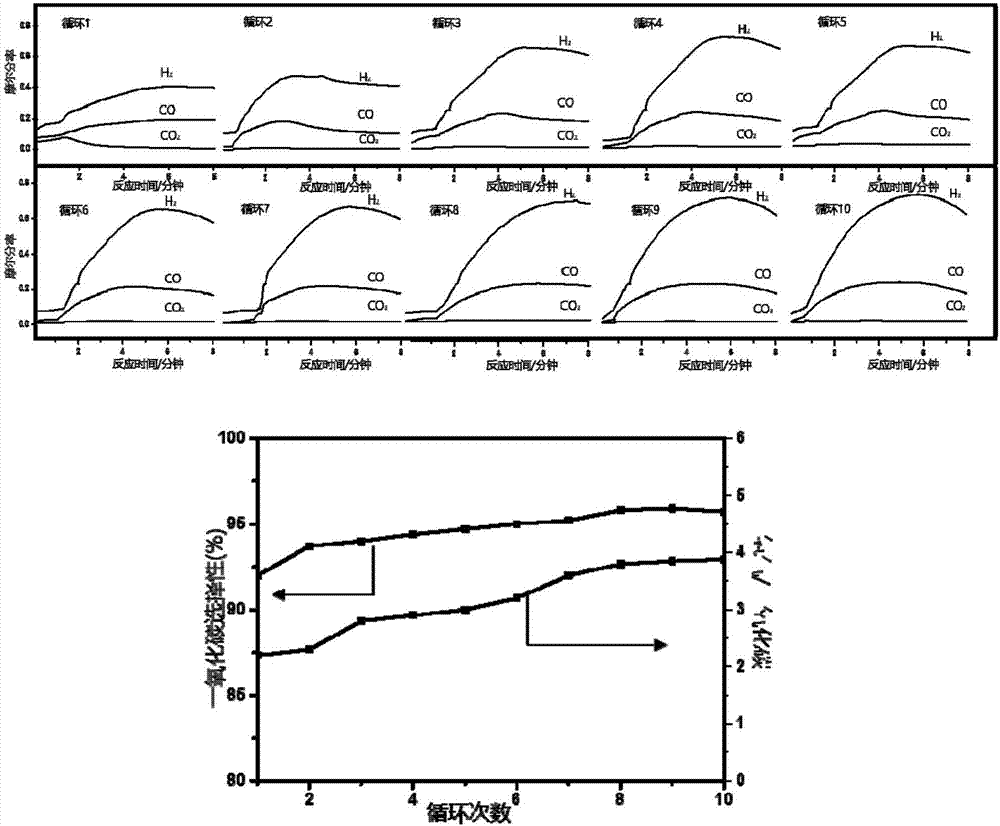

Supported nickel tungsten bimetallic composite oxide and preparation method and application thereof

The invention belongs to the technical field of chemical looping hydrogen, and discloses supported nickel tungsten bimetallic composite oxide and a preparation method and an application thereof. A molecular formula is NiyW1O3+y / Al2O3, y is 0.3-1; the preparation method comprises the following steps: completely mixing nickel nitrate hexahydrate, tungsten hexachloride and aluminum nitrate nonahydrate in ethanol according to proportion and then dissolving the materials; then dropping a NaOH aqueous solution and mixing with a mixture, after standing, performing centrifugal filtration on a flocculent precipitate and washing the material; and drying and roasting the material to obtain the product. The supported nickel tungsten bimetallic composite oxide can be used for tribed self-heating gasification with light alkane, and reforming and direct production of hydrogen and carbon dioxide. The advantages of chemical looping combustion, catalytic reforming and high purity hydrogen production by pyrolysis water, and self-heating reforming of a gas-solid counter current operation-type tribed reactor are combined, the coprecipitation preparation method having the advantages of simple operation and low cost is used, so that fuel can be directly converted to carbon dioxide and high purity hydrogen, and near-zero energy consumption in-situ separation of the product is realized.

Owner:TIANJIN UNIV

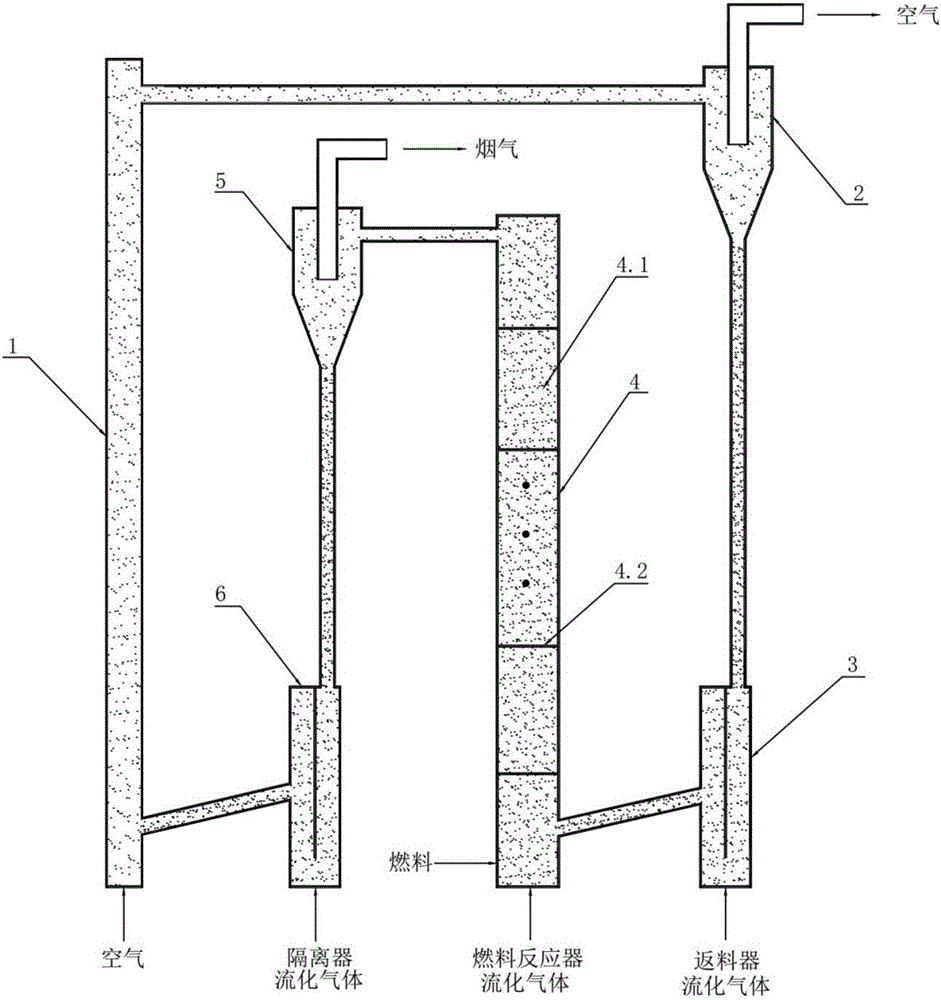

Chemical looping combustion device and method based on tower bubbling fluidized bed fuel reactor

ActiveCN106247323AImprove conversion efficiencyGuaranteed uptimeFluidized bed combustionIndirect carbon-dioxide mitigationCycloneOxidation state

The invention provides a chemical looping combustion device and method based on a tower bubbling fluidized bed fuel reactor. The device is a circulating loop composed of an air reactor, an air cyclone separator, a return feeder, the tower fuel reactor, a fuel cyclone separator and an isolator. The method includes the steps that fuel in the tower fuel reactor sequentially upward passes through small chambers divided by multiple independent air distribution partition boards in the height direction to be subjected to deep oxidation reaction with oxidation state oxygen carriers, the mixture is converted into CO2 and H2O to be discharged, reduction state oxygen carriers enter the air reactor through the fuel cyclone separator and the isolator for oxygen carrier regenerative reaction to generate oxidation state oxygen carriers, and the oxidation state oxygen carriers are separated through the air cyclone separator and then enter the fuel reactor through the return feeder; solid fuel is subjected to gasification reaction in the small chamber on the lower portion of the fuel reactor and then is subjected to oxidation reaction. By means of the device and method, the air-solid flow state in the fuel reactor can be effectively improved, and chemical looping combustion efficiency is improved.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com