Patents

Literature

306 results about "Oxygen-carrying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hemoglobin, the main oxygen-carrying molecule in red blood cells, carries both oxygen and carbon dioxide. However, the CO 2 bound to hemoglobin does not bind to the same site as oxygen. Instead, it combines with the N-terminal groups on the four globin chains.

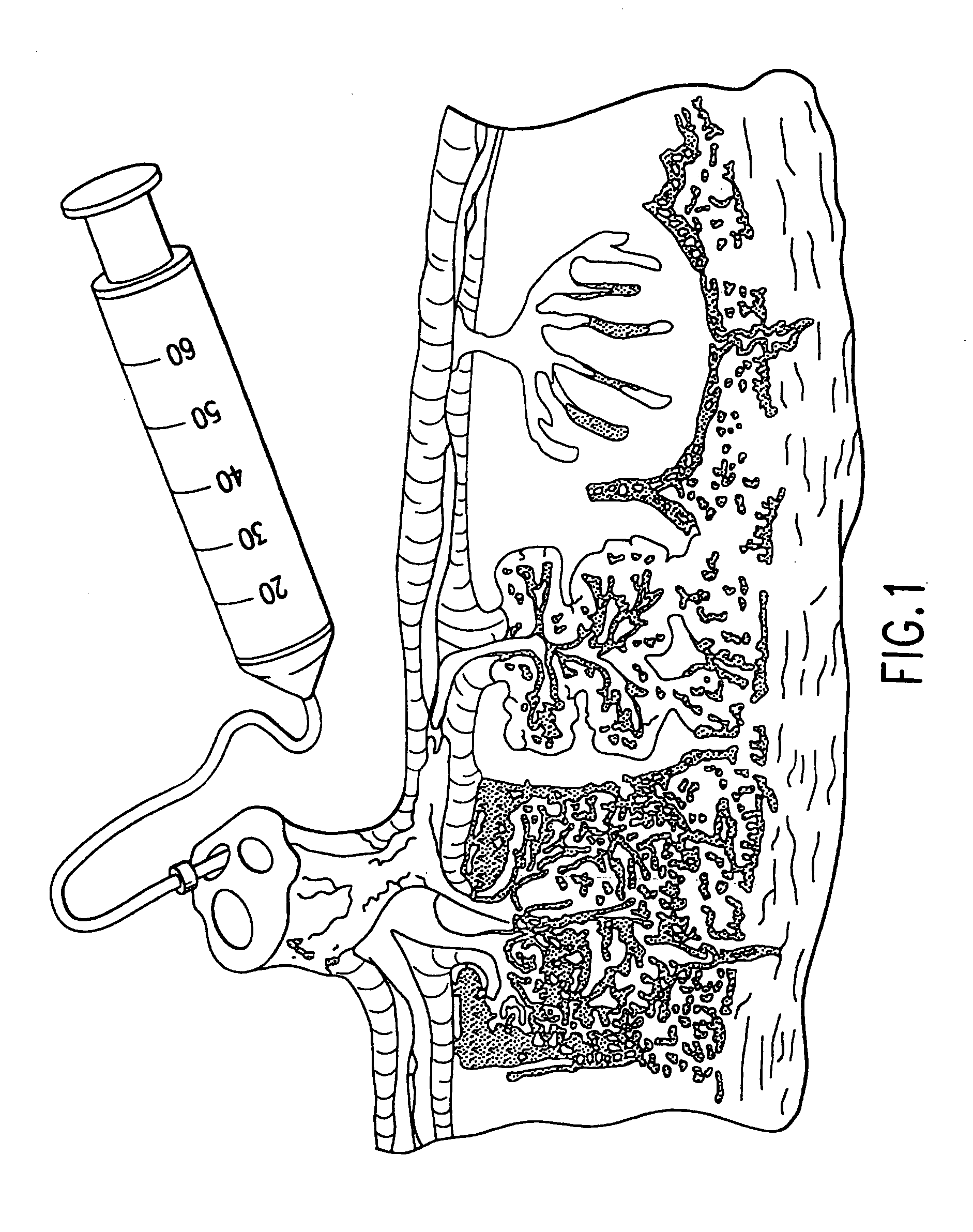

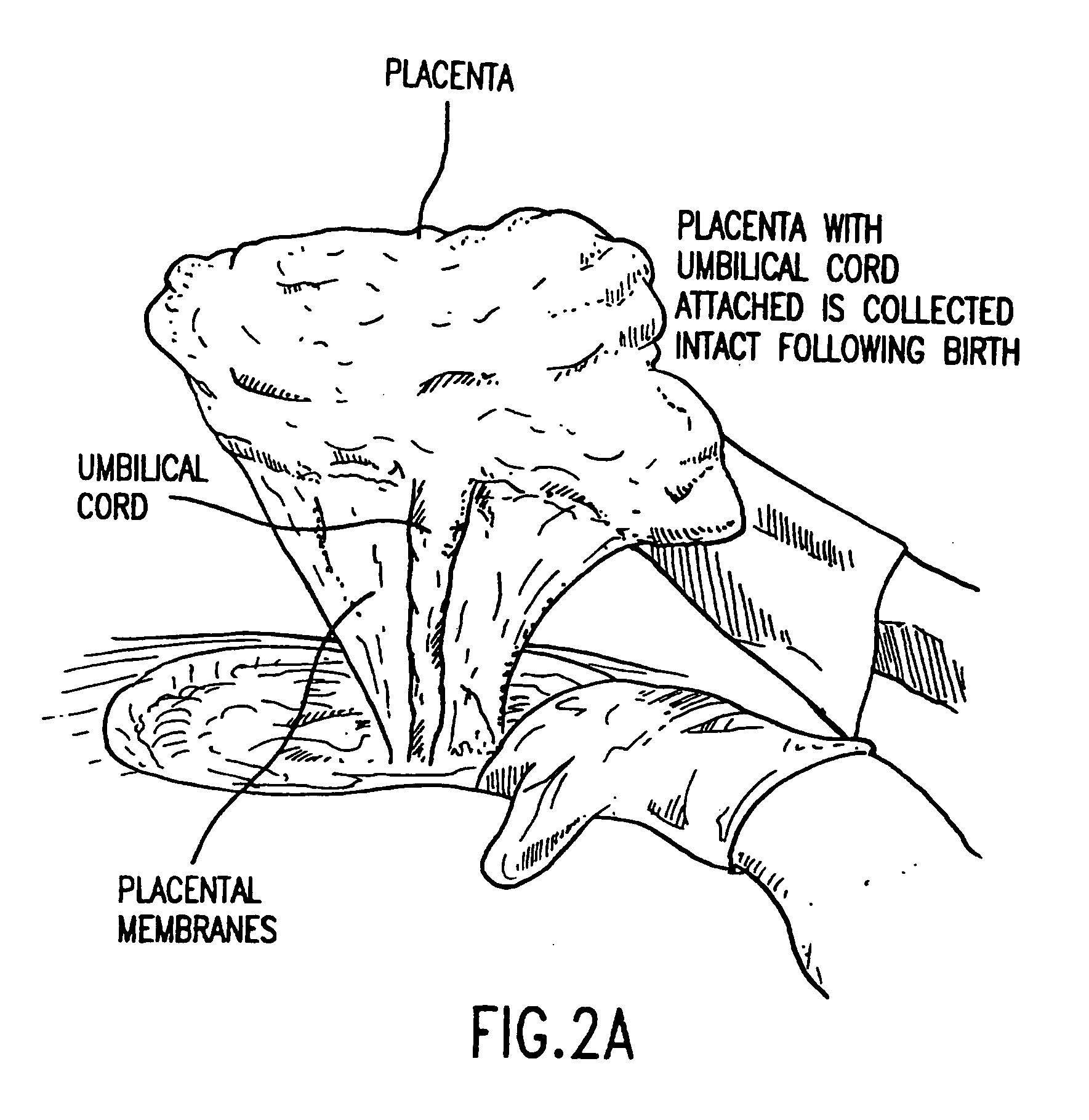

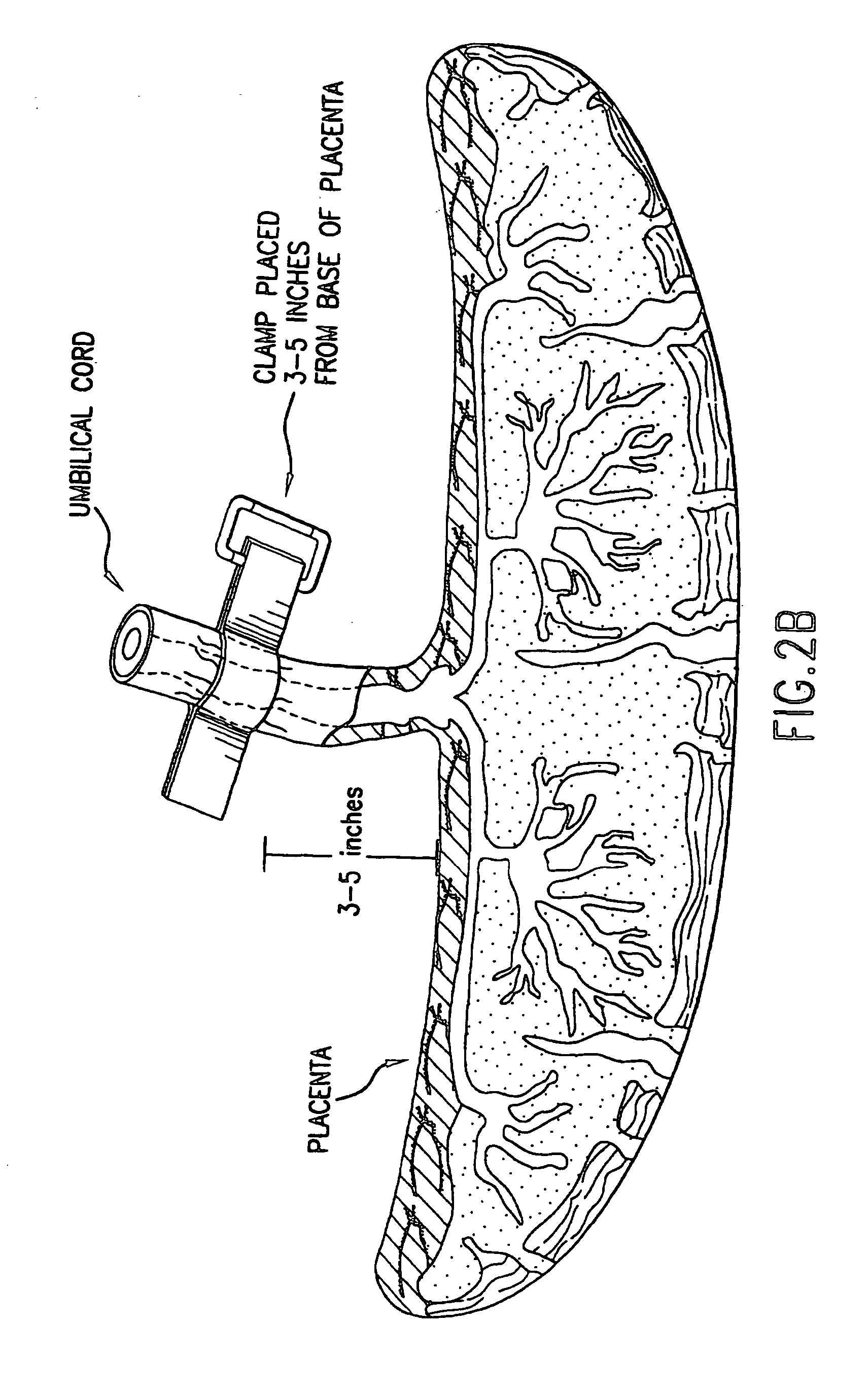

Composition for collecting and preserving placental stem cells and methods of using the composition

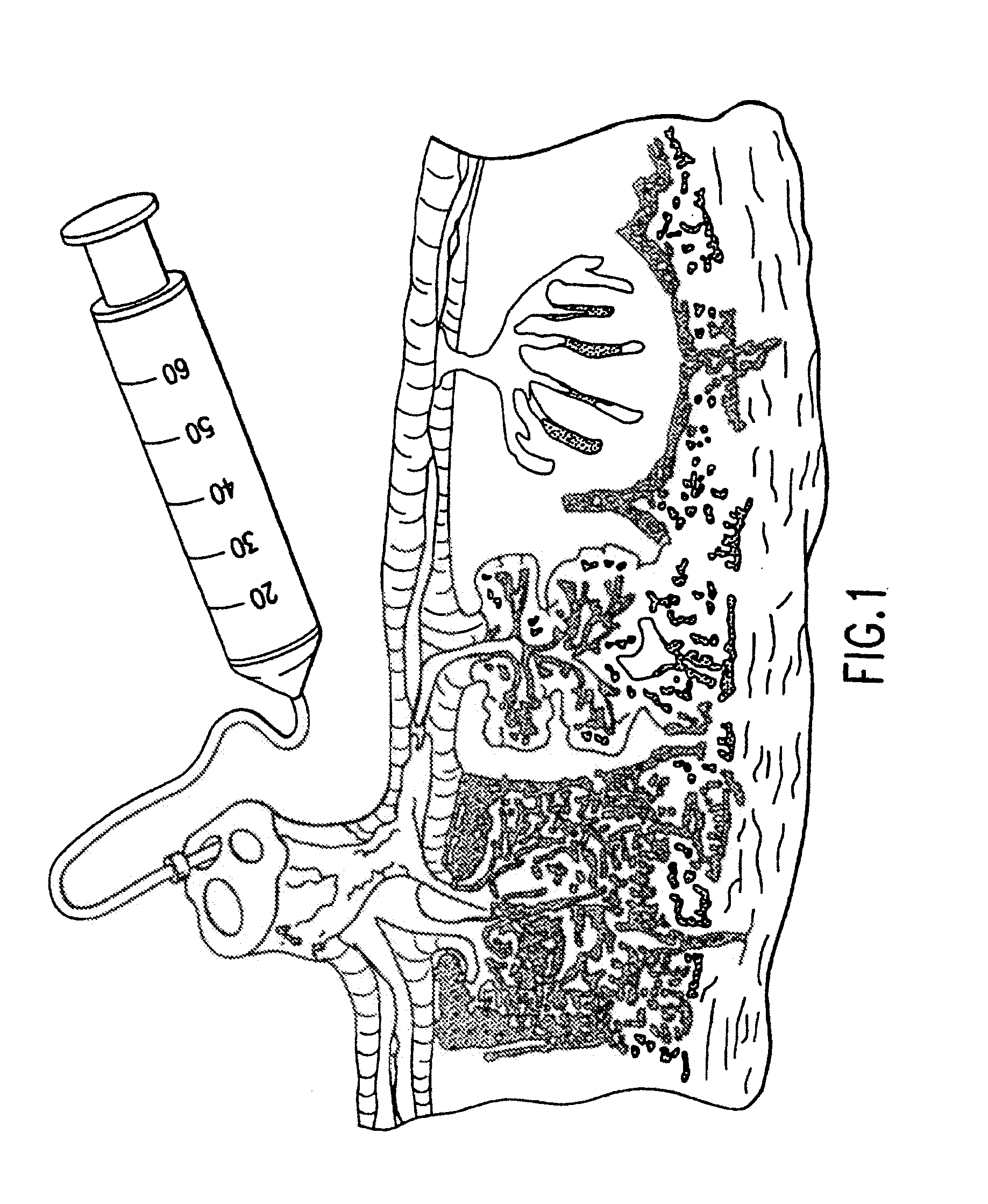

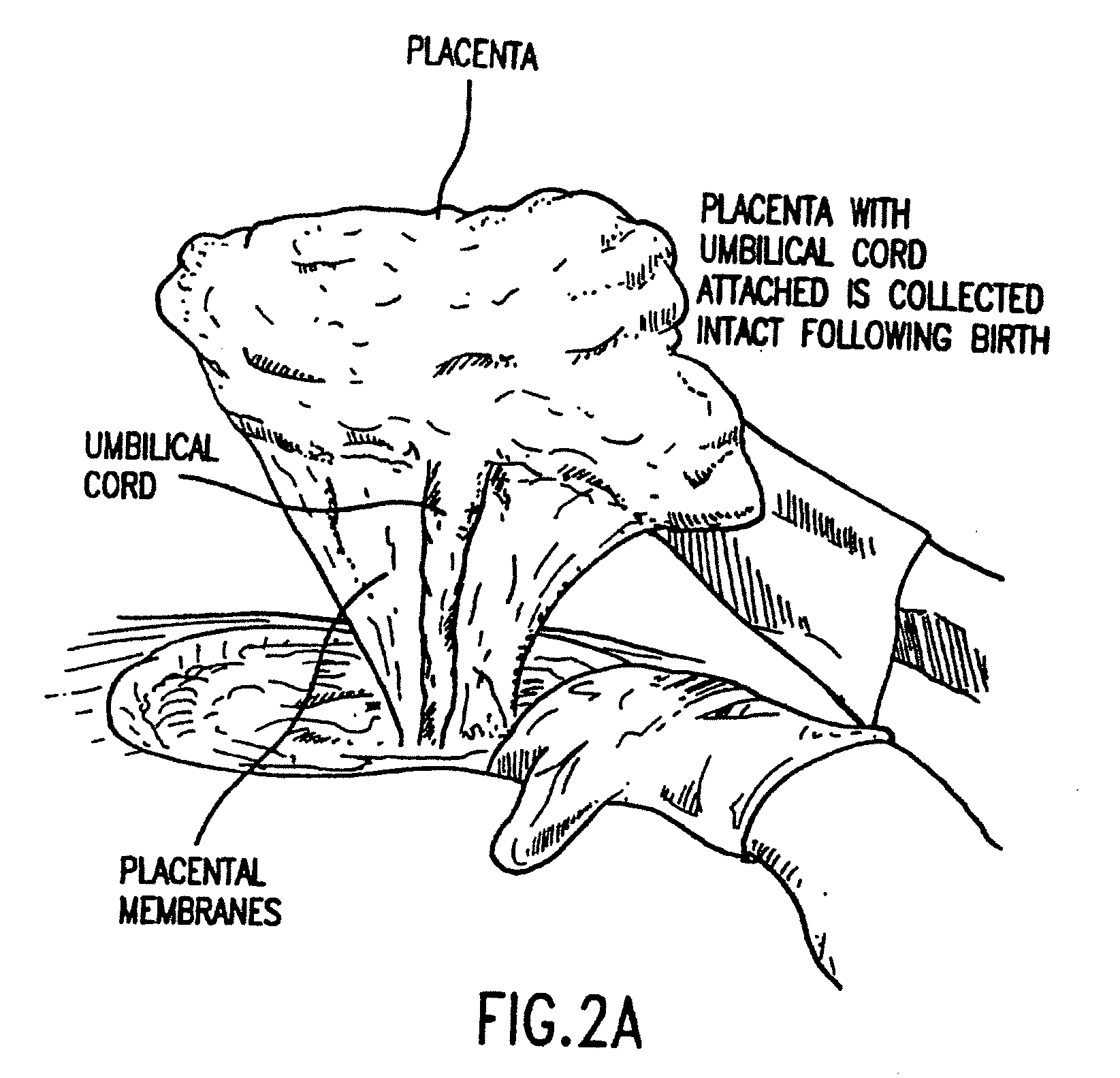

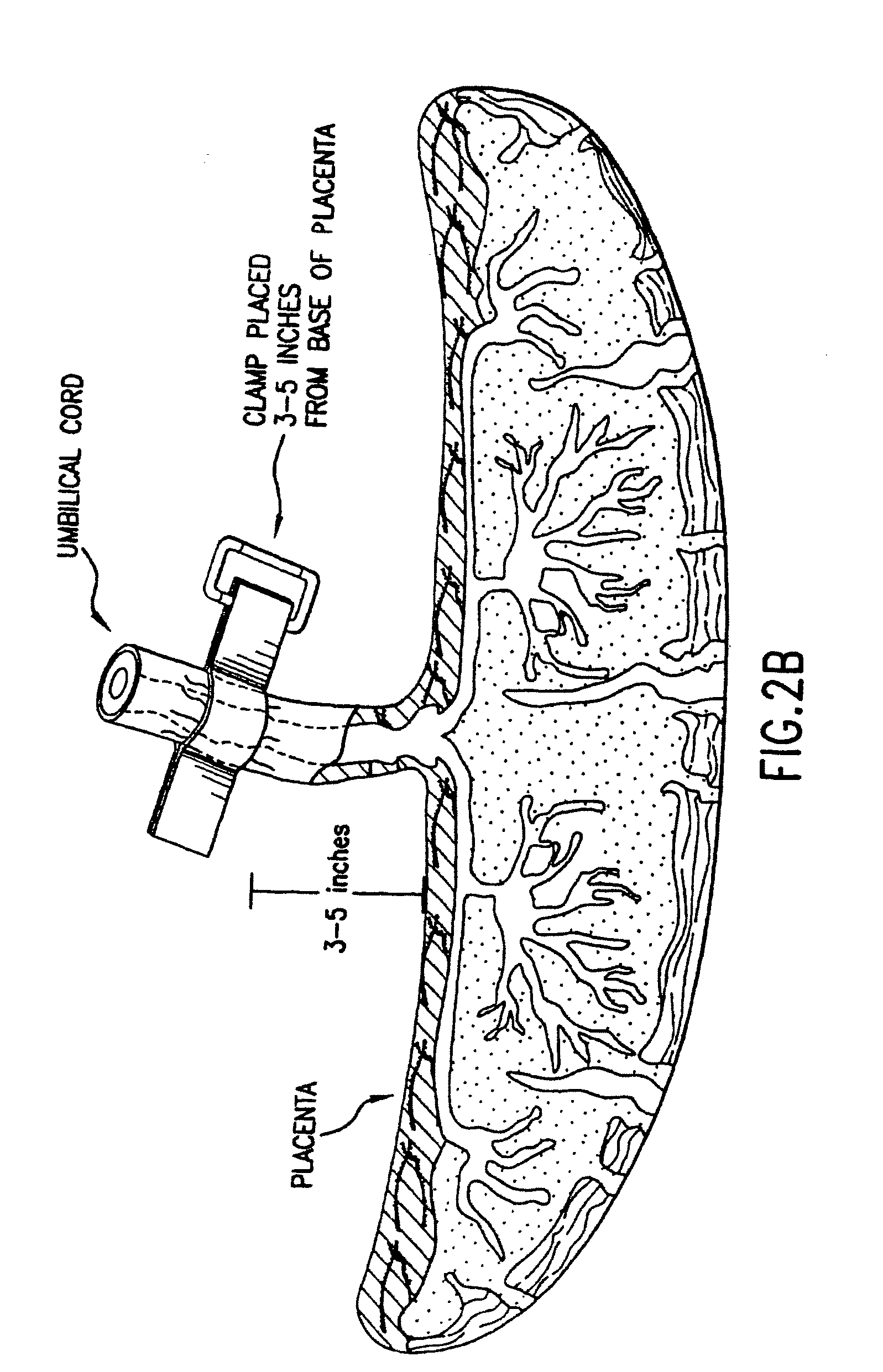

The present invention provides improved compositions and methods for the collection of stem cells from an organ, e.g., placenta. The invention provides a stem cell collection composition comprising an apoptosis inhibitor and, optionally, an enzyme such as a protease or mucolytic enzyme, vasodilator, necrosis inhibitor, oxygen-carrying perfluorocarbon, or an organ preserving compound. The invention provides methods of using the stem cell collection composition to collect stem cells and to preserve populations of stem cells.

Owner:CELULARITY INC

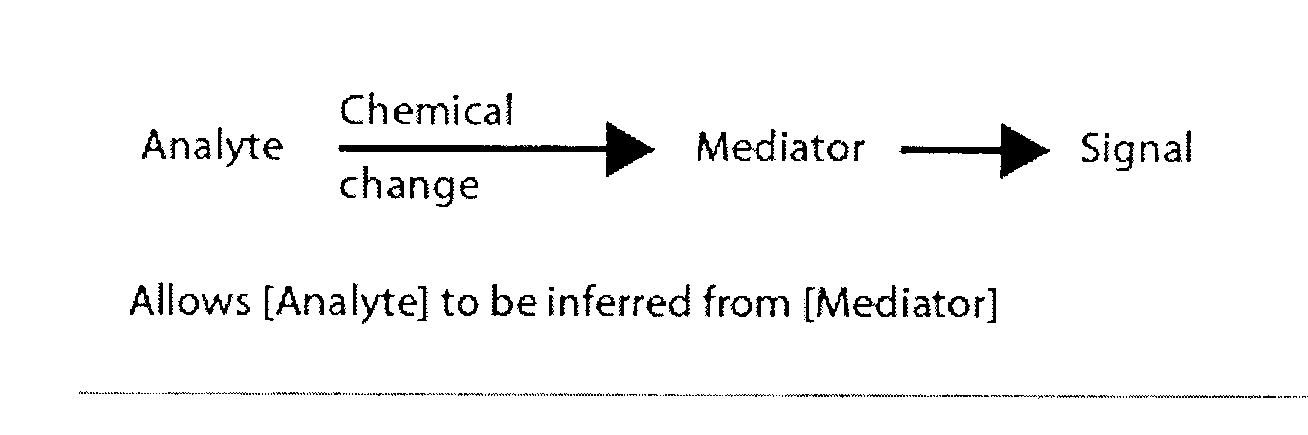

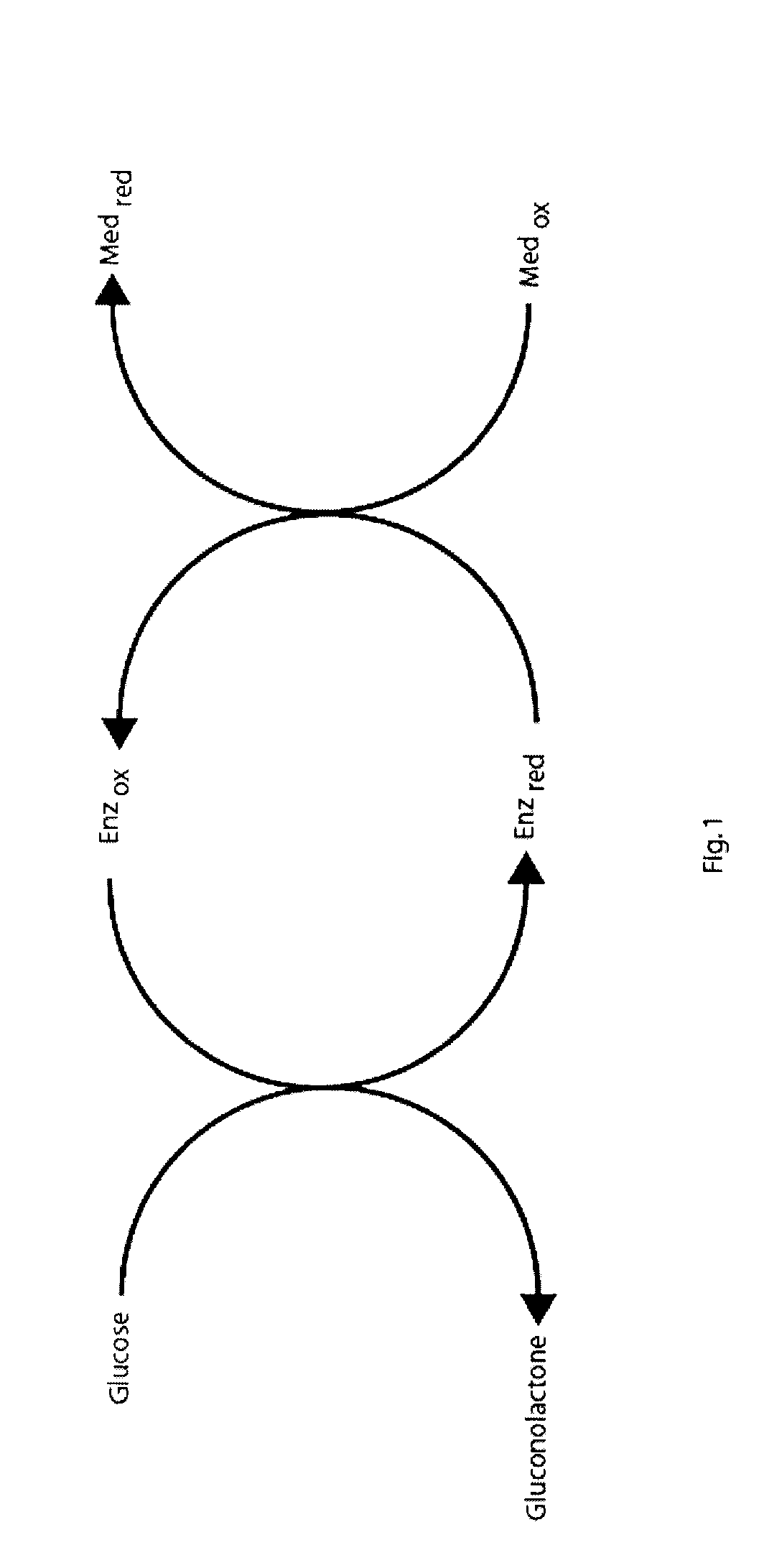

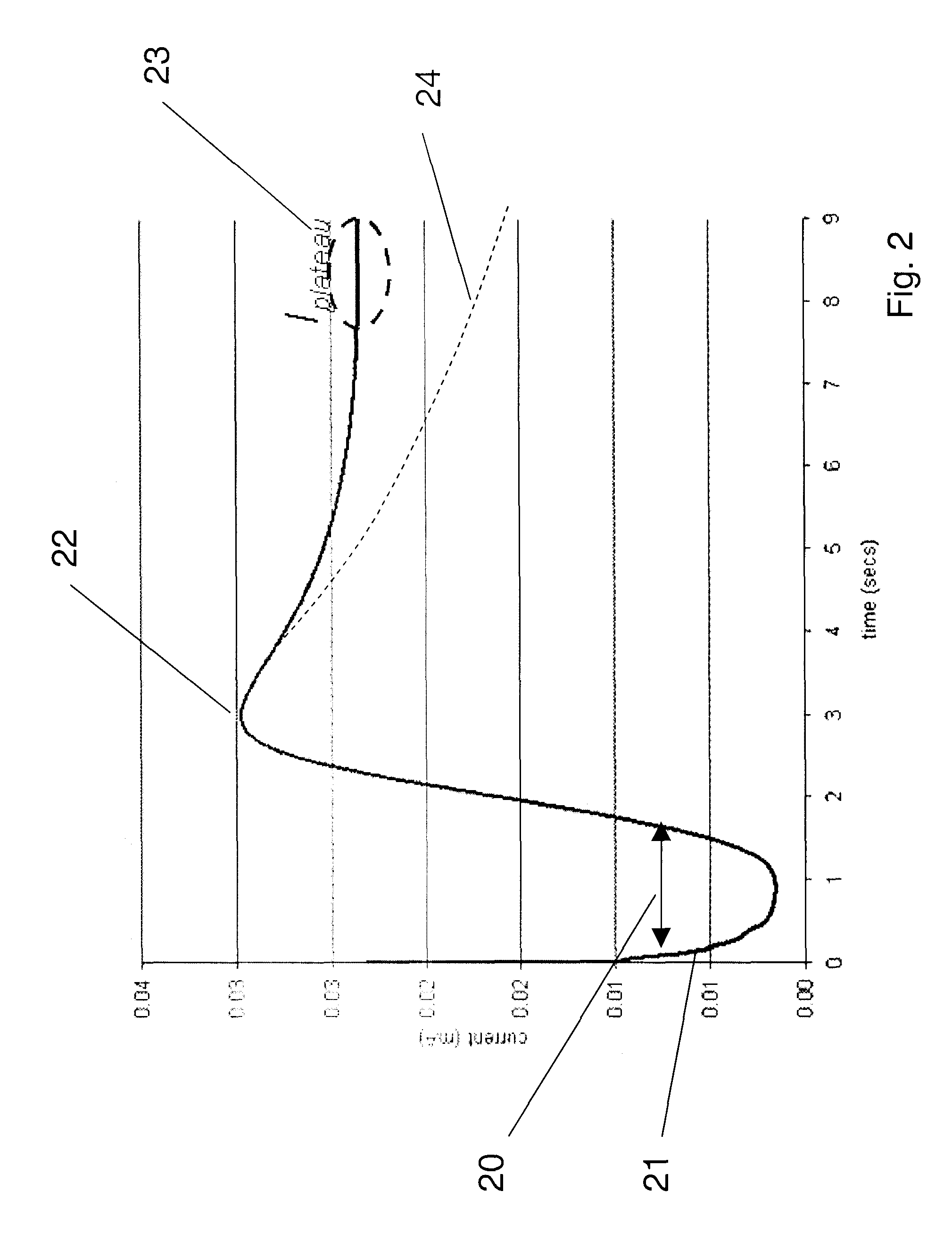

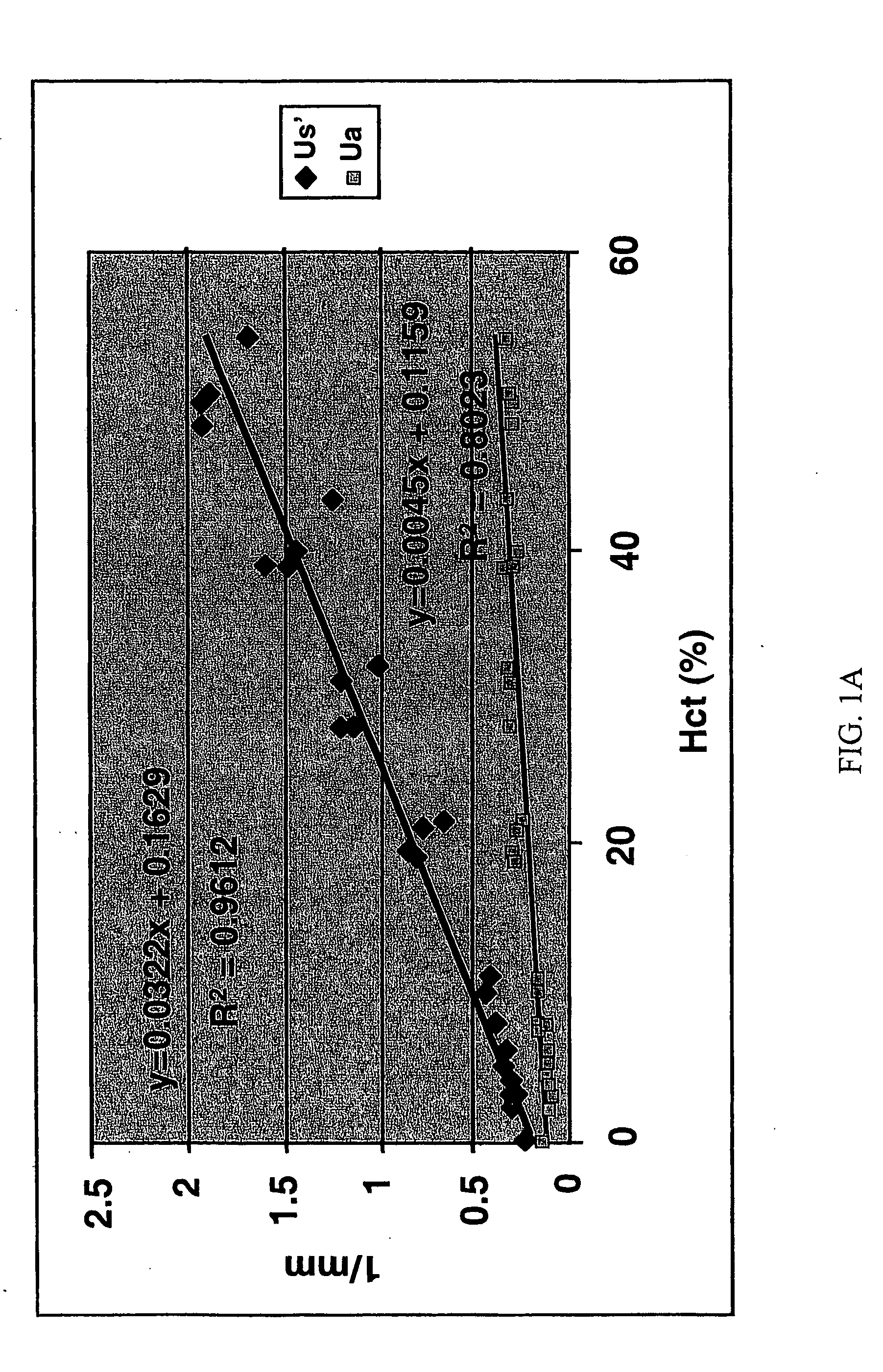

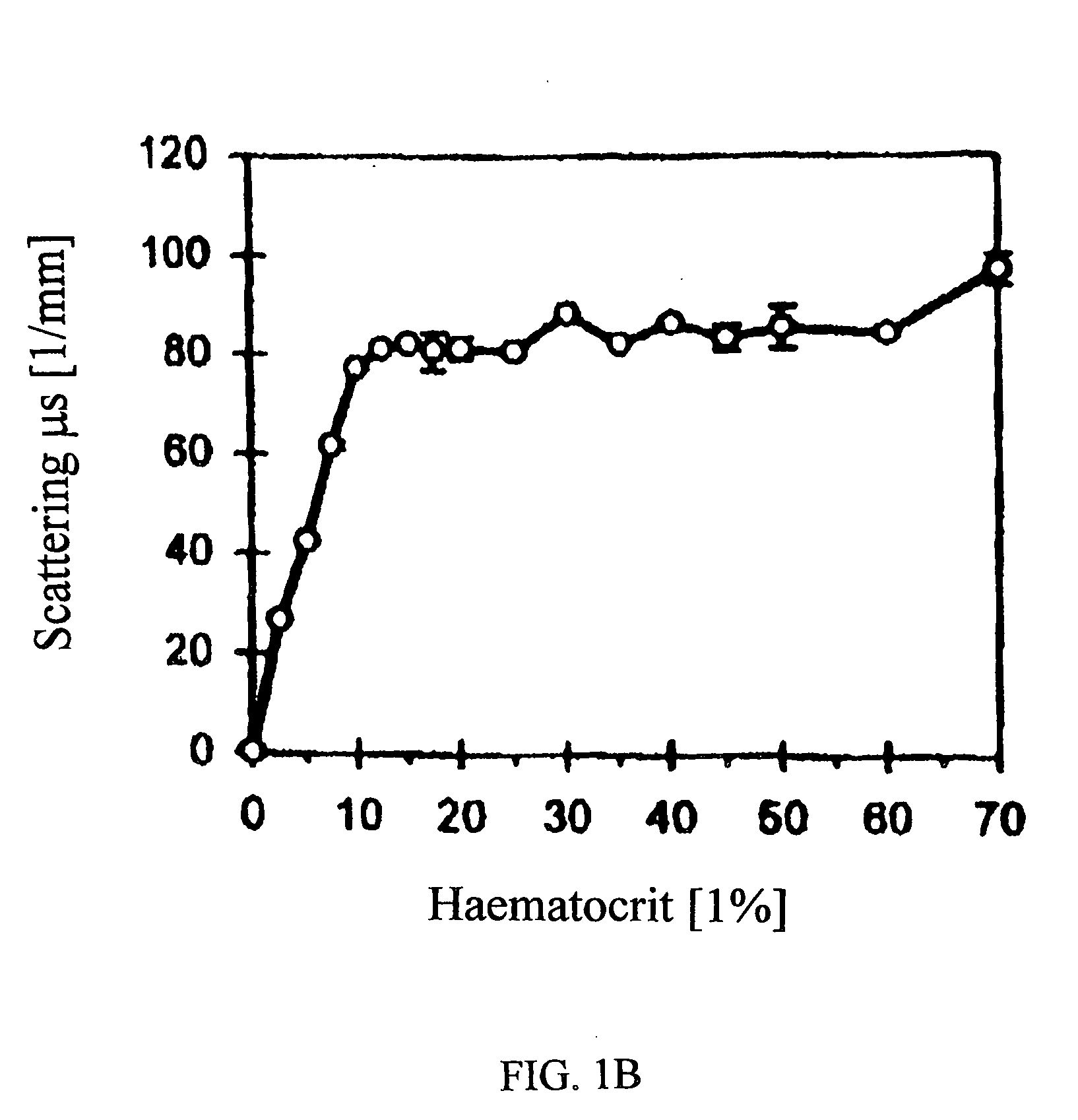

Analyte determination method and analyte meter

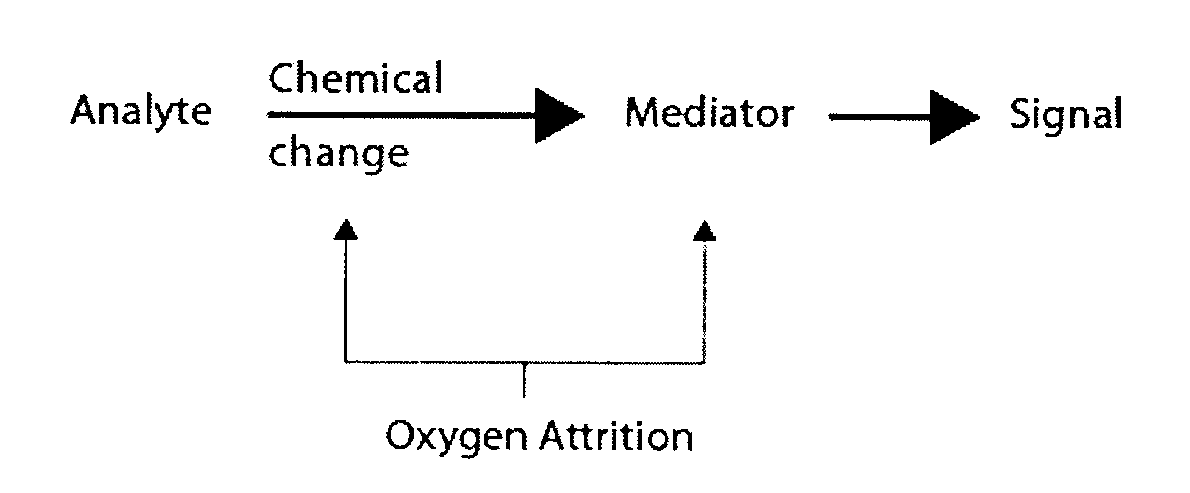

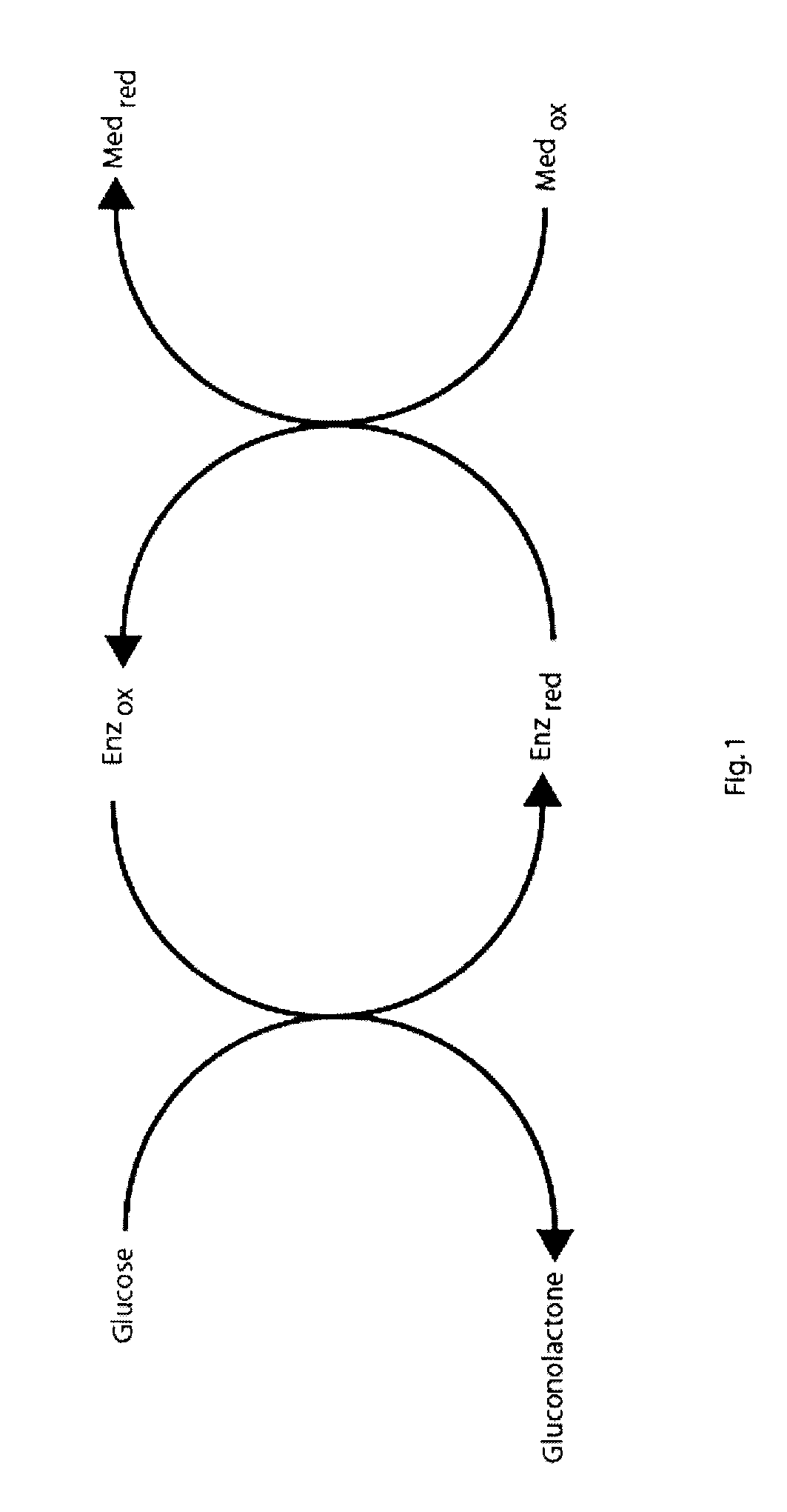

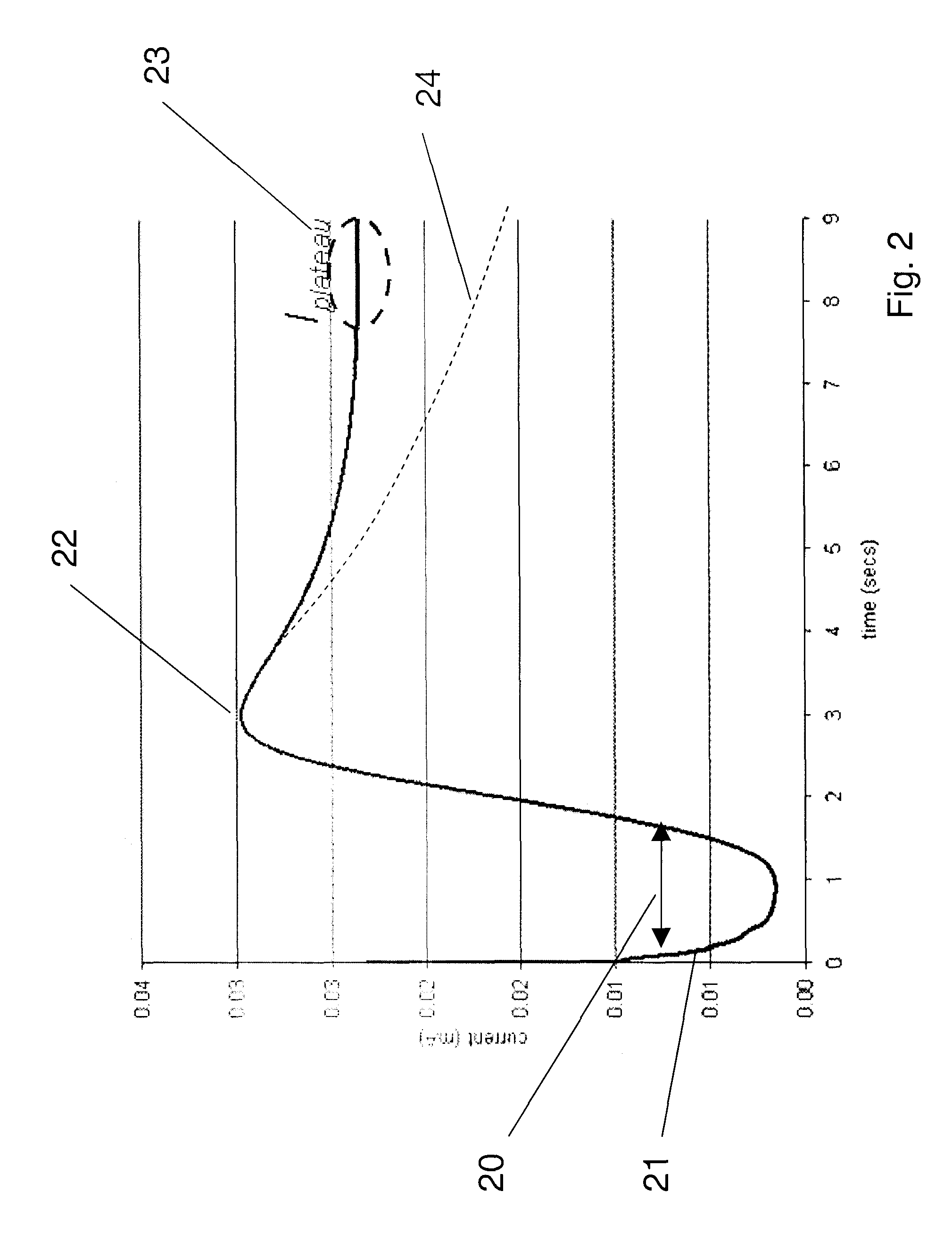

The presence of oxygen or red blood cells in a sample applied to an electrochemical test strip that makes use of a reduced mediator is corrected for by an additive correction factor that is determined as a function of the temperature of the sample and a measurement that reflects the oxygen carrying capacity of the sample. The measured oxygen carrying capacity can also be used to determine hematocrit and to distinguish between blood samples and control solutions applied to a test strip.

Owner:AGAMATRIX INC

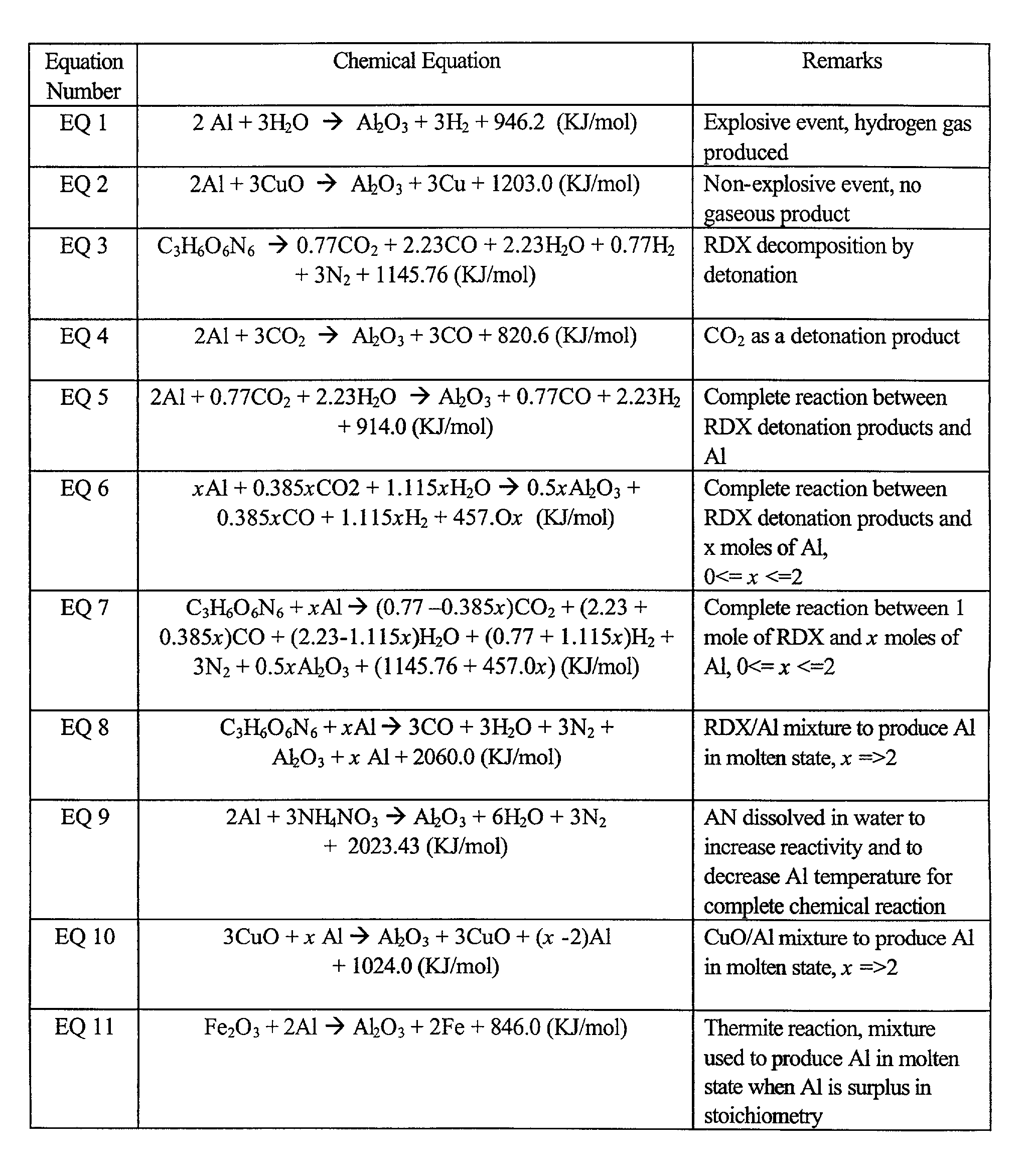

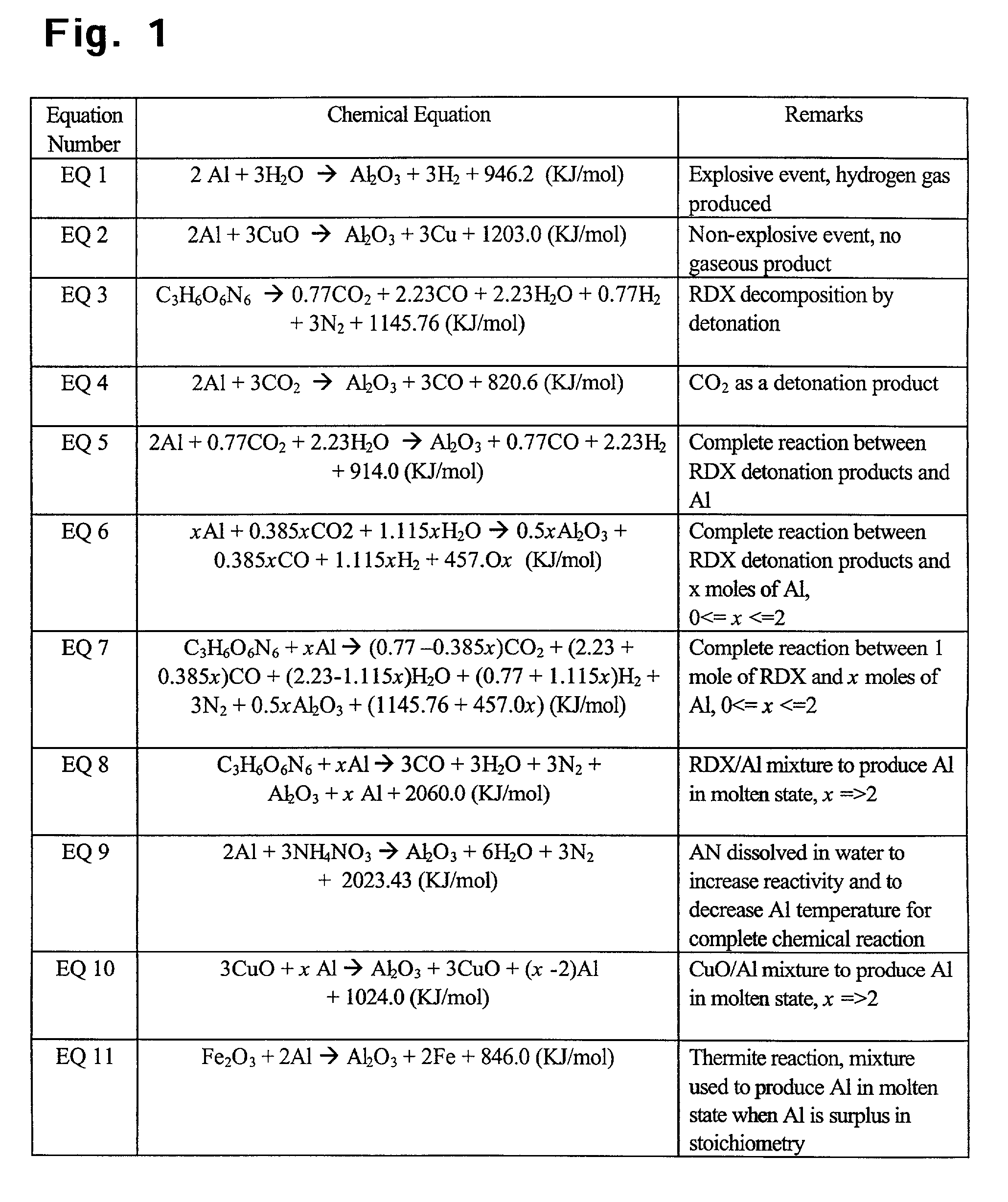

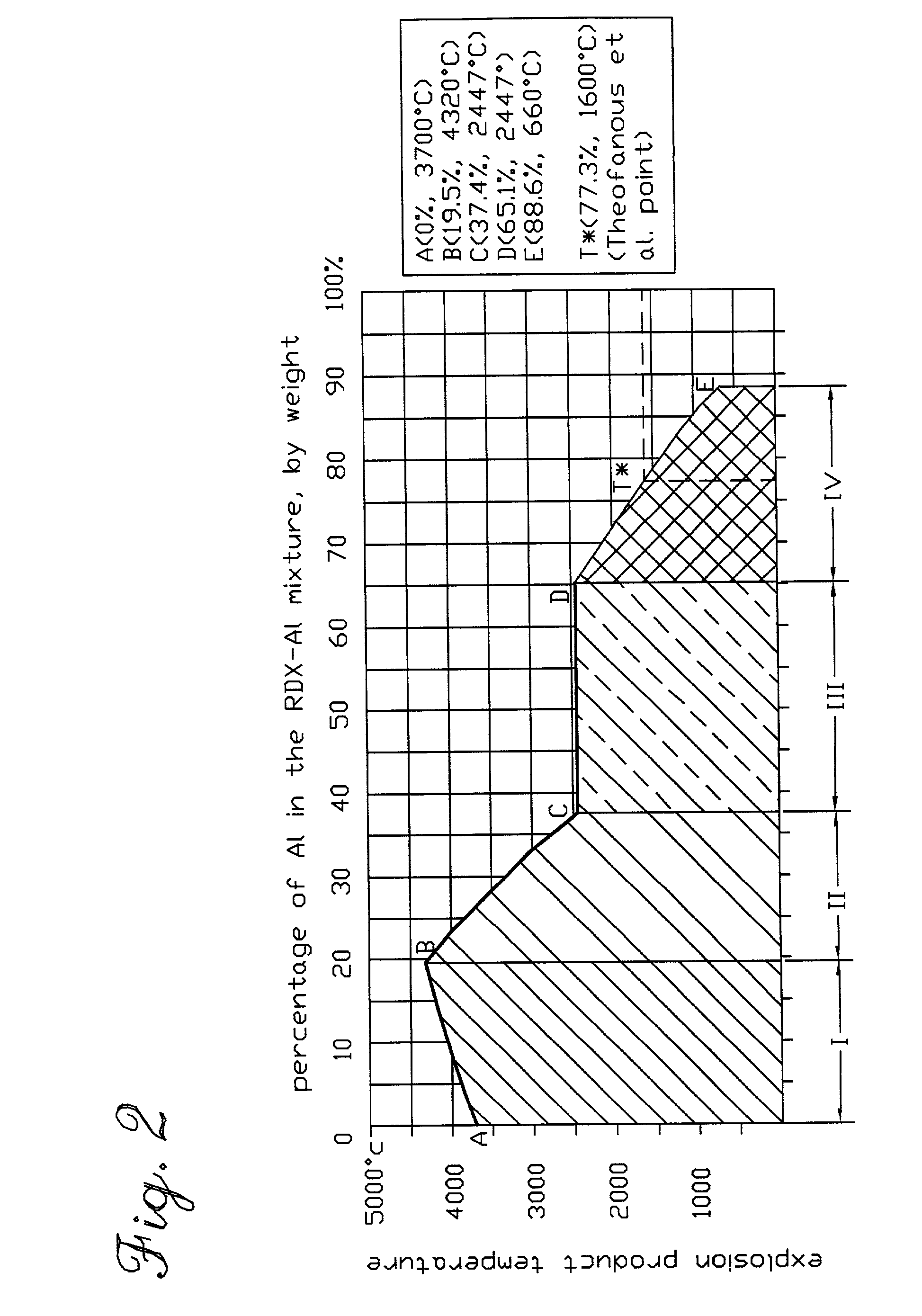

Use of aluminum in perforating and stimulating a subterranean formation and other engineering applications

InactiveUS7393423B2More energy outputImprove mechanical propertiesExplosive chargesBlasting cartridgesMolten stateThermal energy

A chemical reaction between molten aluminum and an oxygen carrier such as water to do useful work is disclosed, and in particular two chemical methods to obtain aluminum in its molten state. One is to detonate a HE / Al mixture with surplus Al in stoichiometry, and the other is to use an oxidizer / Al mixture with surplus Al in stoichiometry. Additionally, there is a physical method of shocking and heating Al using high temperature reaction products. The produced Al in its liquid form is forced to react with an oxygen carrying liquid (e.g. water), giving off heat and releasing hydrogen gas or other gaseous material. A water solution of some oxygen-rich chemicals (e.g. ammonium nitrate) can be advantageously used in place of water. A shaped charge is also disclosed having a liner that contains aluminum, propelled by a high explosive such as RDX or its mixture with aluminum powder. Some aluminum in its molten state is projected into the perforation and forced to react with water that also enters the perforation, creating another explosion, fracturing the crushed zone of the perforation and initializing cracks. Another shaped charge is shown having a liner of energetic material such as a mixture of aluminum powder and a metal oxide. Upon detonation, the collapsed liner carries kinetic and thermal energy. Also shown are methods to build and to detonate or fire explosive devices in an oxygen carrying liquid (e.g. water) to perforate and stimulate a hydrocarbon-bearing formation.

Owner:GEODYNAMICS

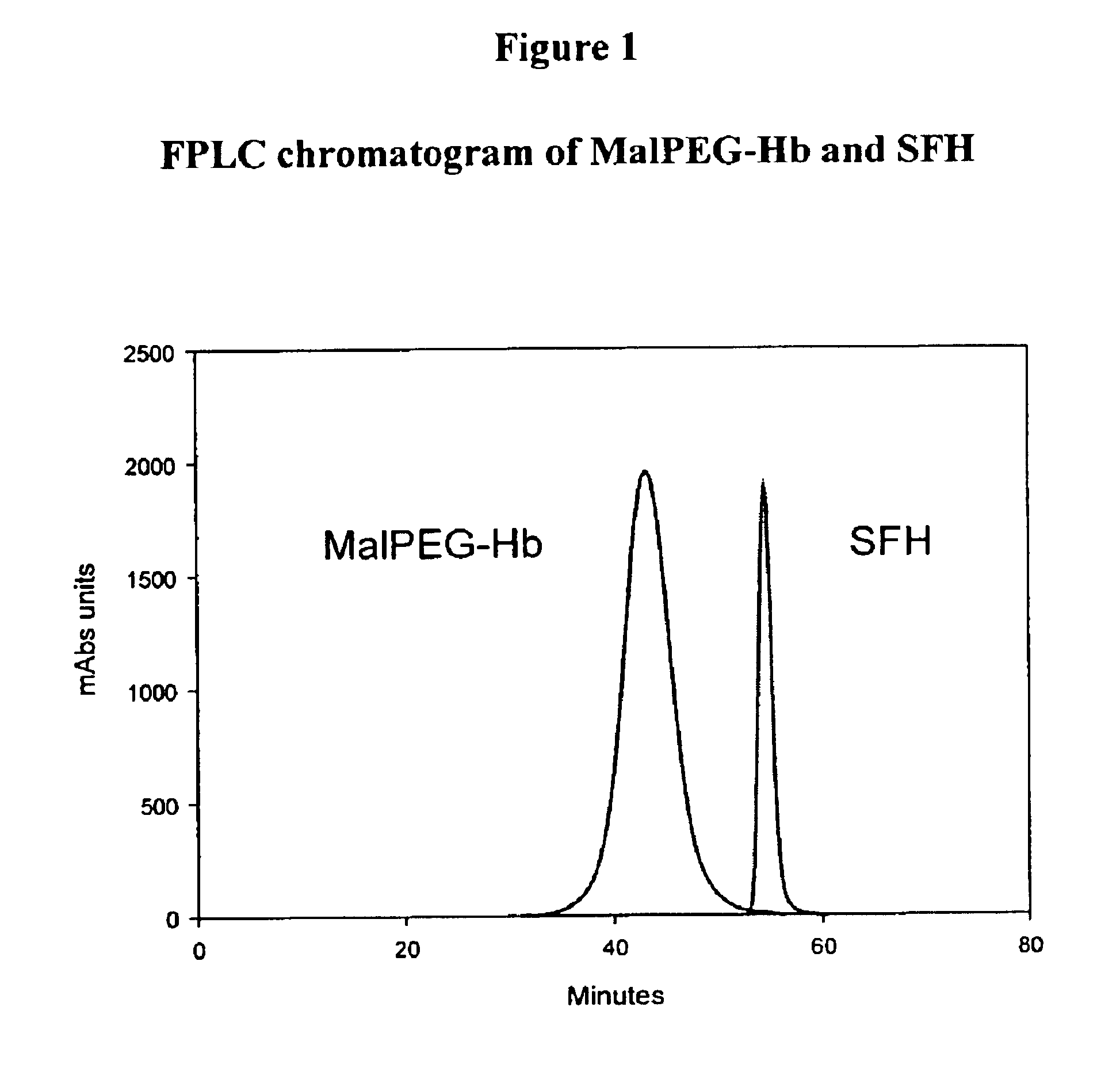

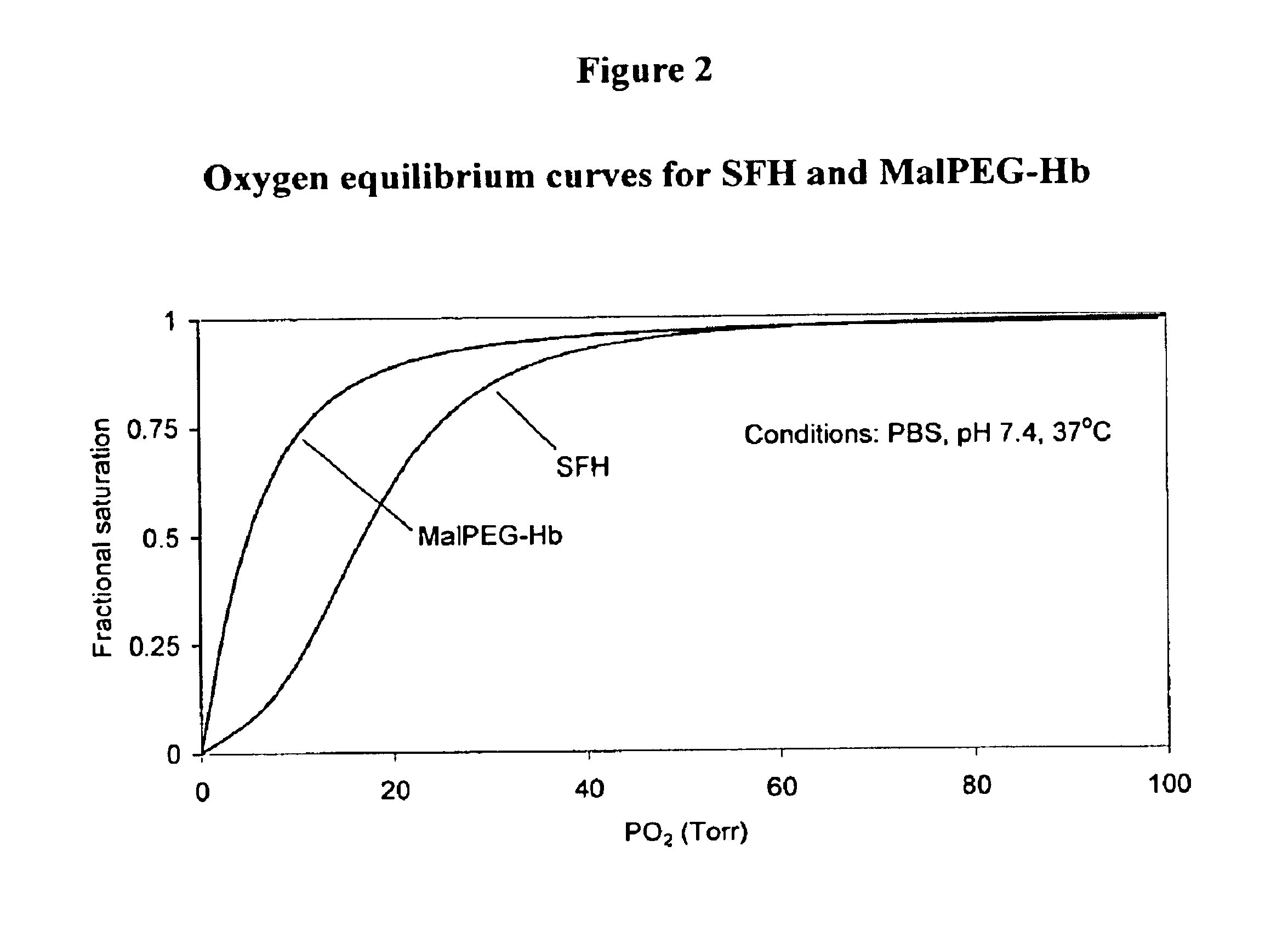

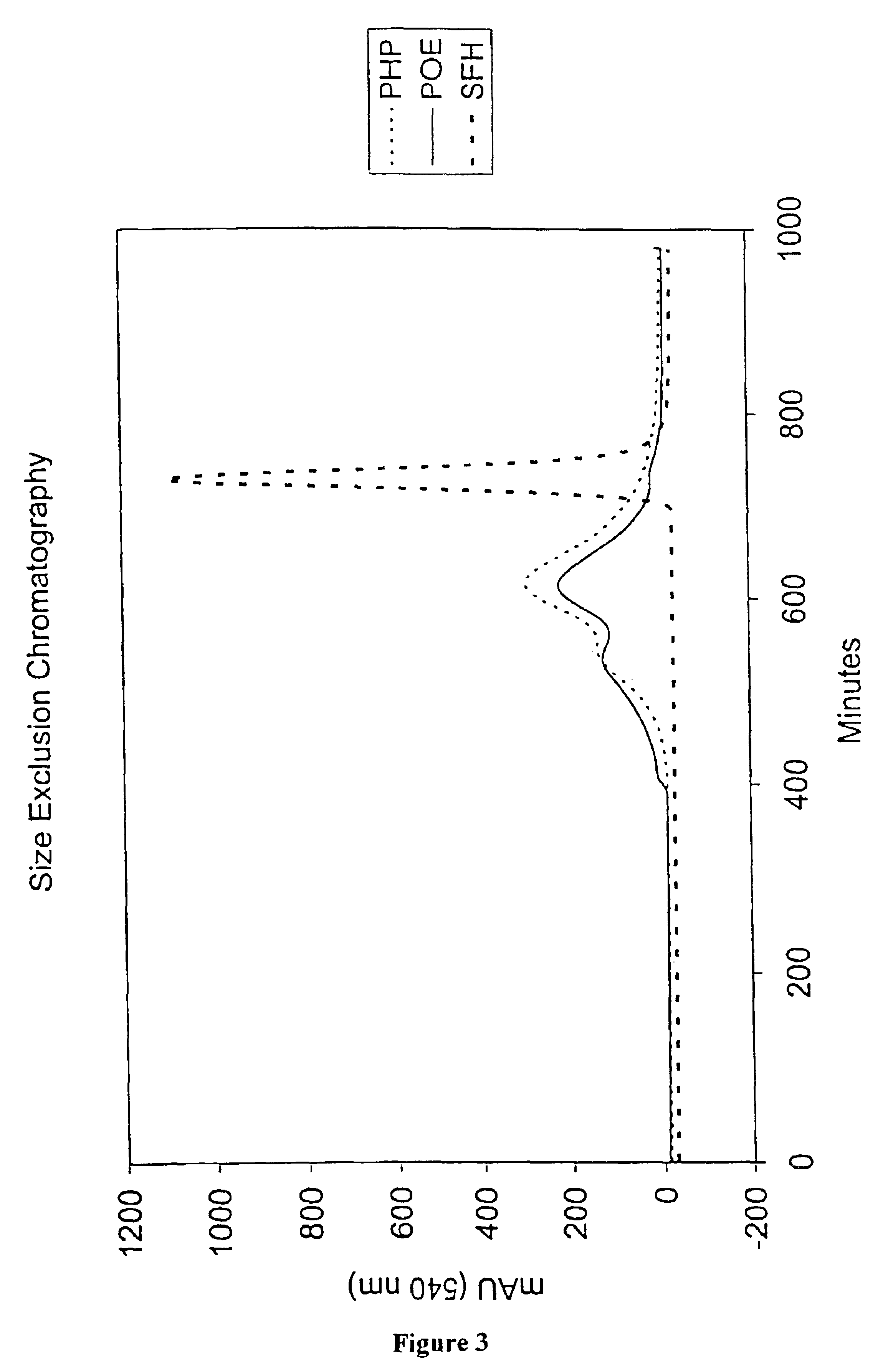

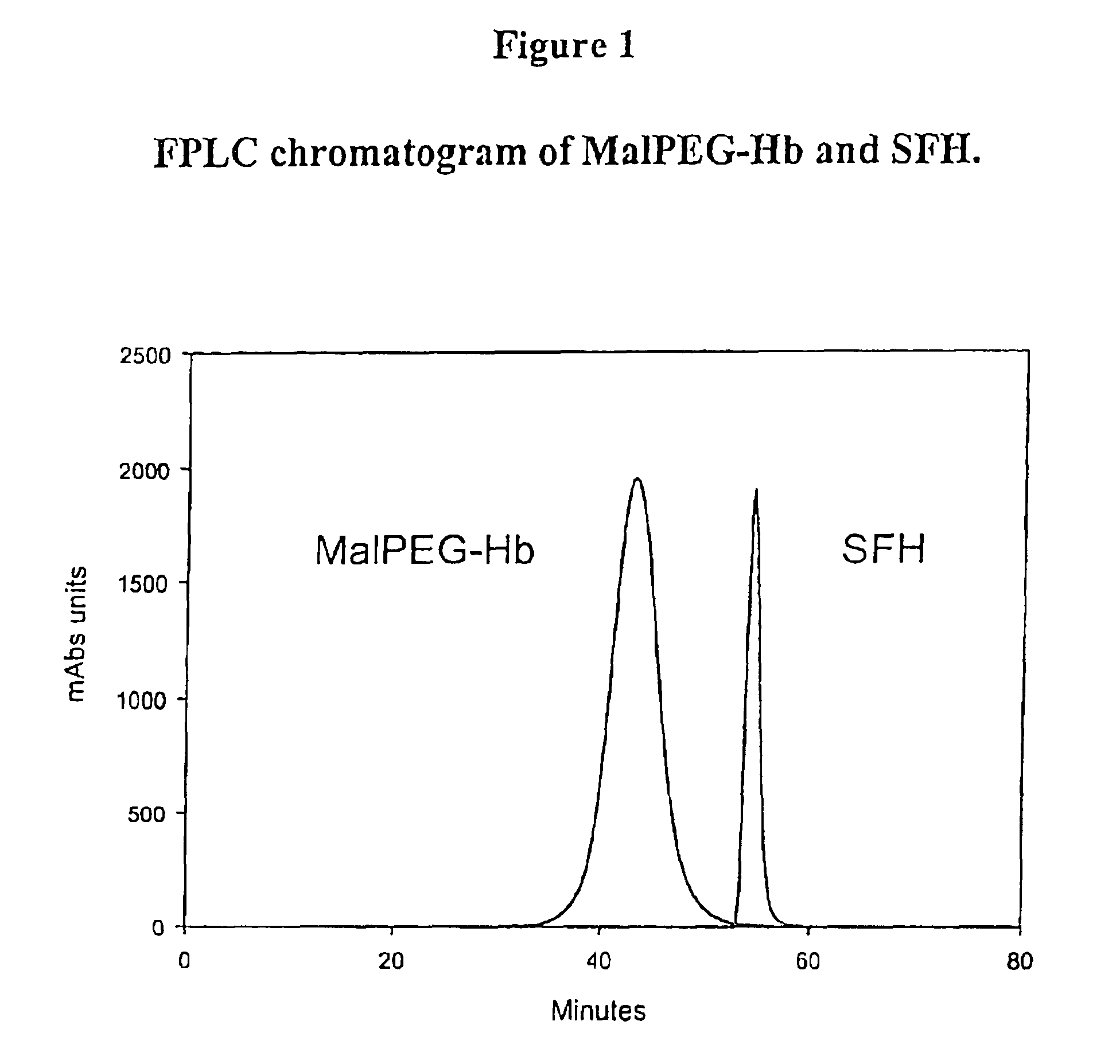

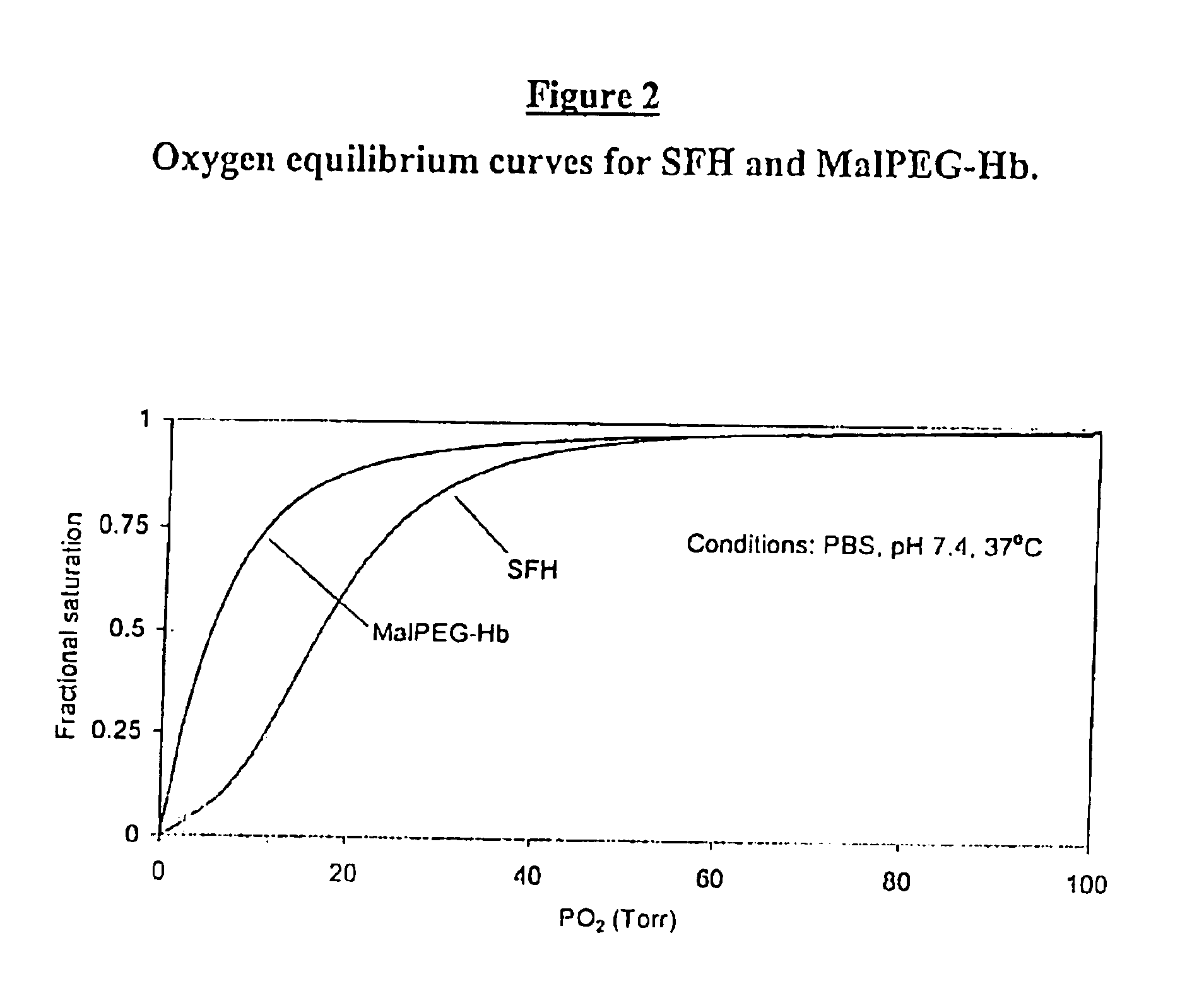

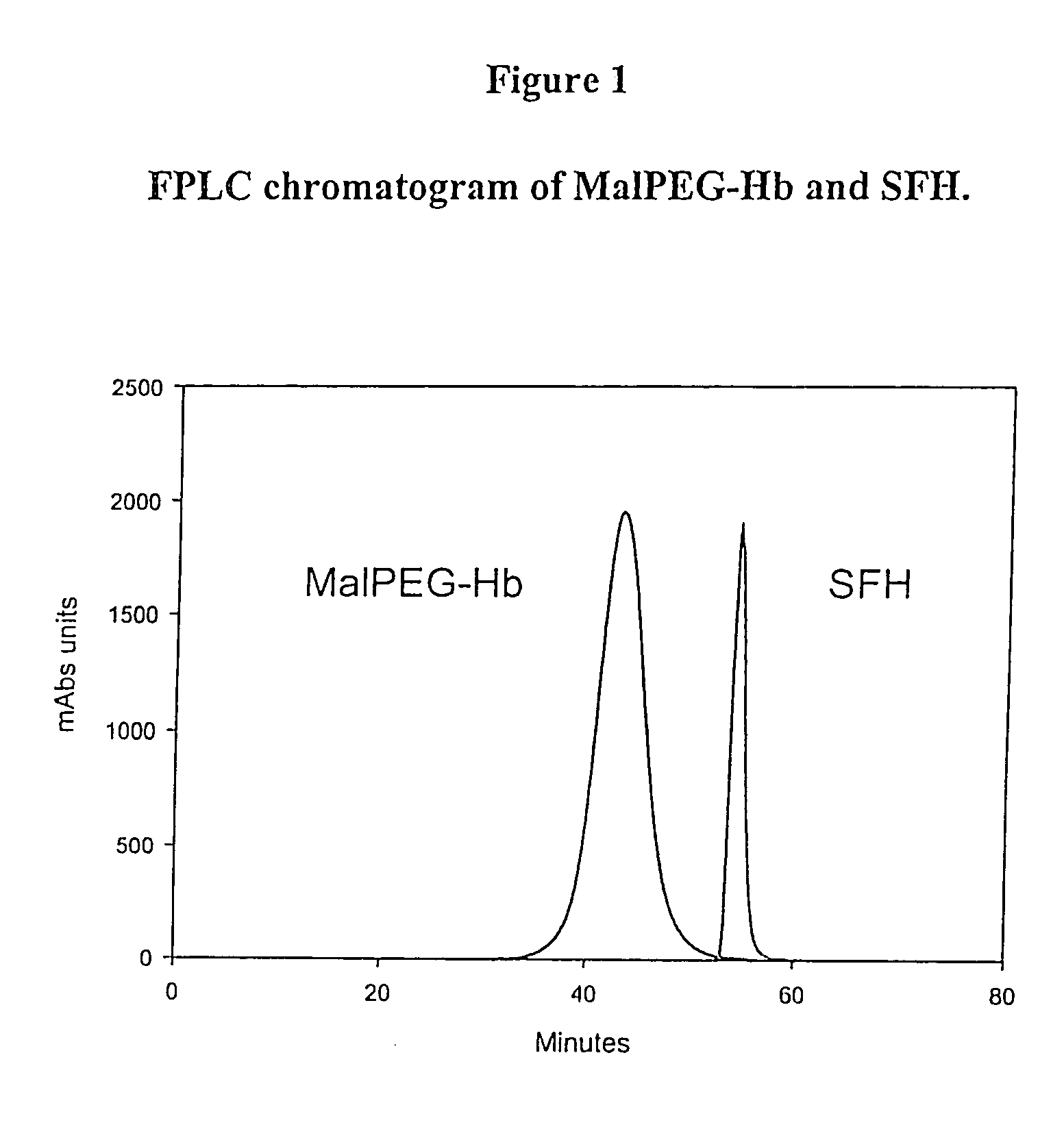

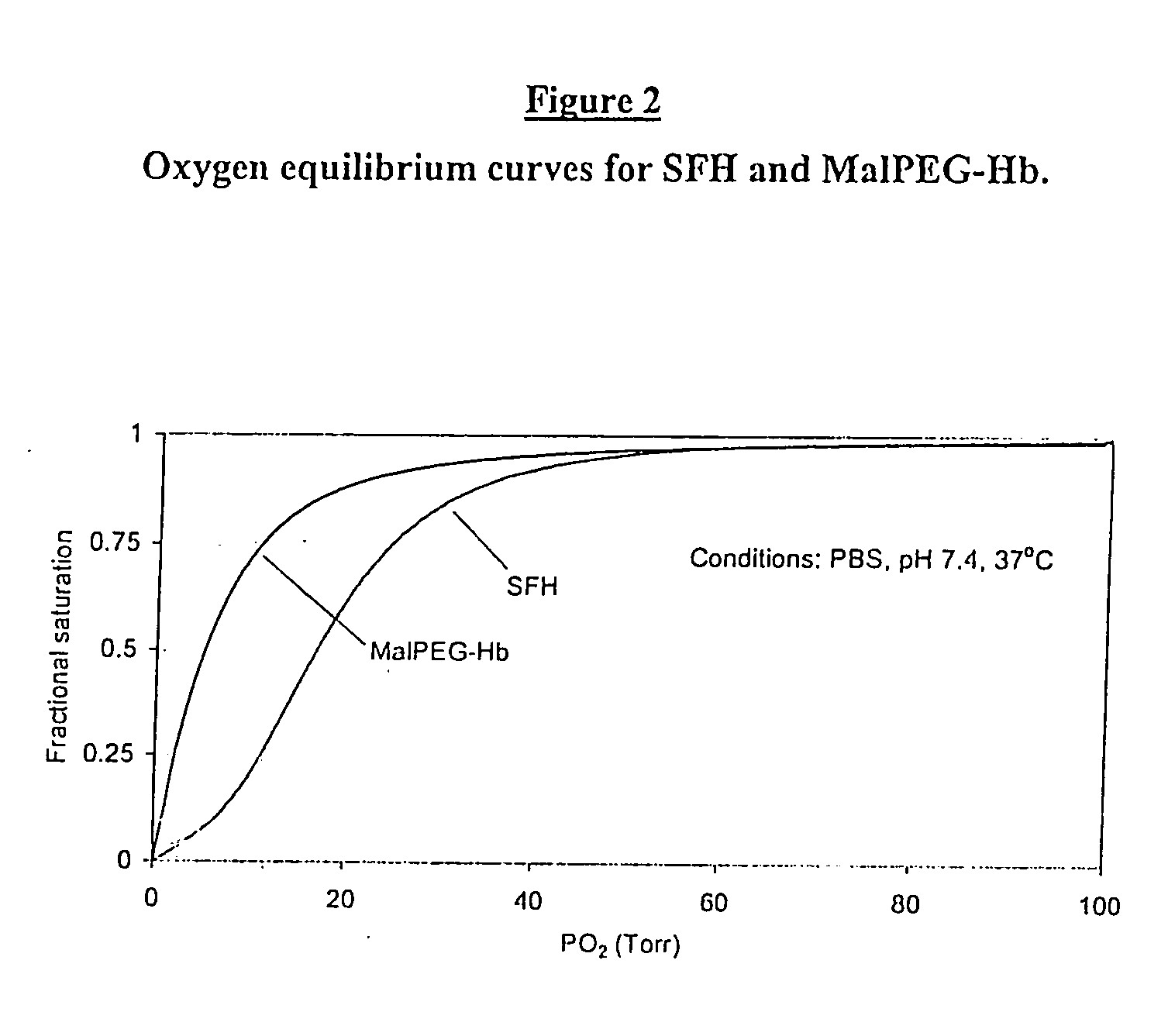

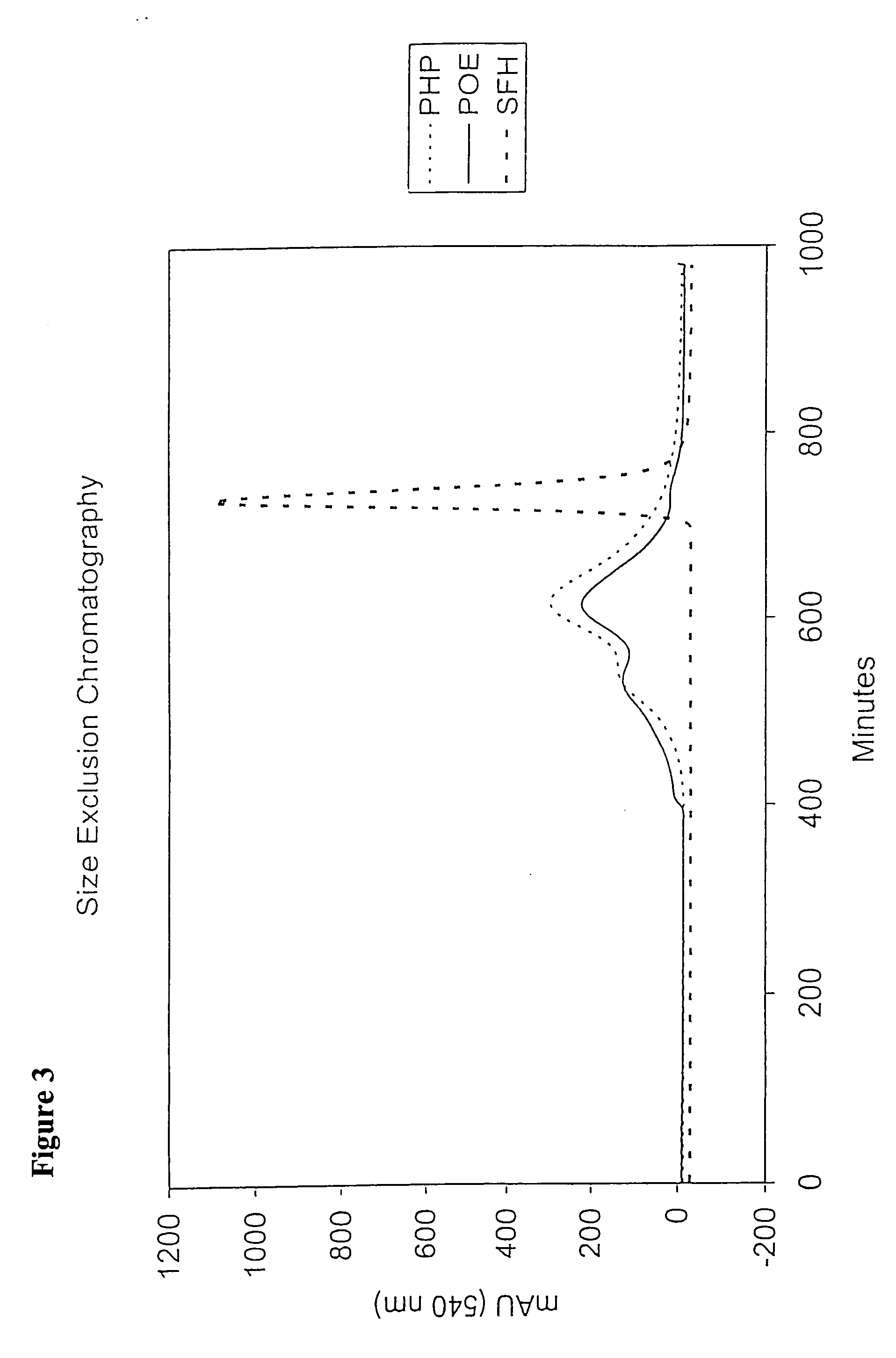

Methods for oxygen transport comprising a high oxygen affinity modified hemoglobin

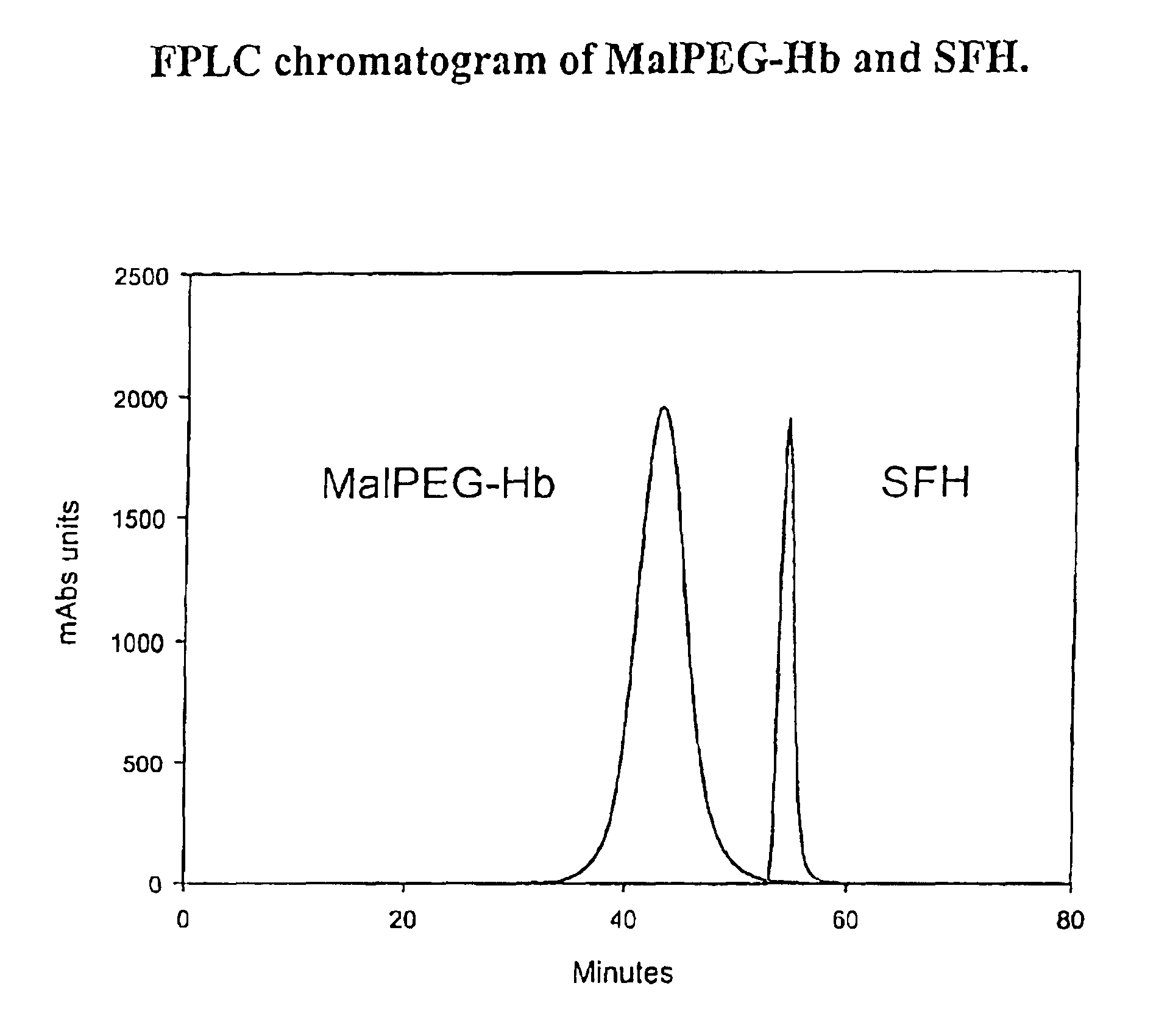

InactiveUS6844317B2Low toxicityImprove stabilityAntibacterial agentsBiocideWhole blood productOxygenated Hemoglobin

The present invention relates to blood products, and more particularly to compositions comprising a modified oxygenated hemoglobin having a high affinity for oxygen and methods for making such compositions. Such compositions according to the present invention have better stability to autooxidation and superior oxygen carrying characteristics.

Owner:SANGART INC

Composition for collecting and preserving placental stem cells and methods of using the composition

ActiveUS20100291679A1Cell culture active agentsNon-embryonic pluripotent stem cellsVascular dilatationBiology

The present invention provides improved compositions and methods for the collection of stem cells from an organ, e.g., placenta. The invention provides a stem cell collection composition comprising an apoptosis inhibitor and, optionally, an enzyme such as a protease or mucolytic enzyme, vasodilator, necrosis inhibitor, oxygen-carrying perfluorocarbon, or an organ preserving compound. The invention provides methods of using the stem cell collection composition to collect stem cells and to preserve populations of stem cells.

Owner:CELULARITY INC

Compositions for oxygen transport comprising a high oxygen affinity modified hemoglobin

InactiveUS6974795B2Earlier and safer intervention in patient treatmentLow toxicityPeptide/protein ingredientsMammal material medical ingredientsWhole blood productOxygenated Hemoglobin

The present invention relates to blood products, and more particularly to compositions comprising a modified oxygenated hemoglobin having a high affinity for oxygen and methods for making such compositions. Such compositions according to the present invention have better stability to autooxidation and superior oxygen carrying characteristics.

Owner:SANGART INC

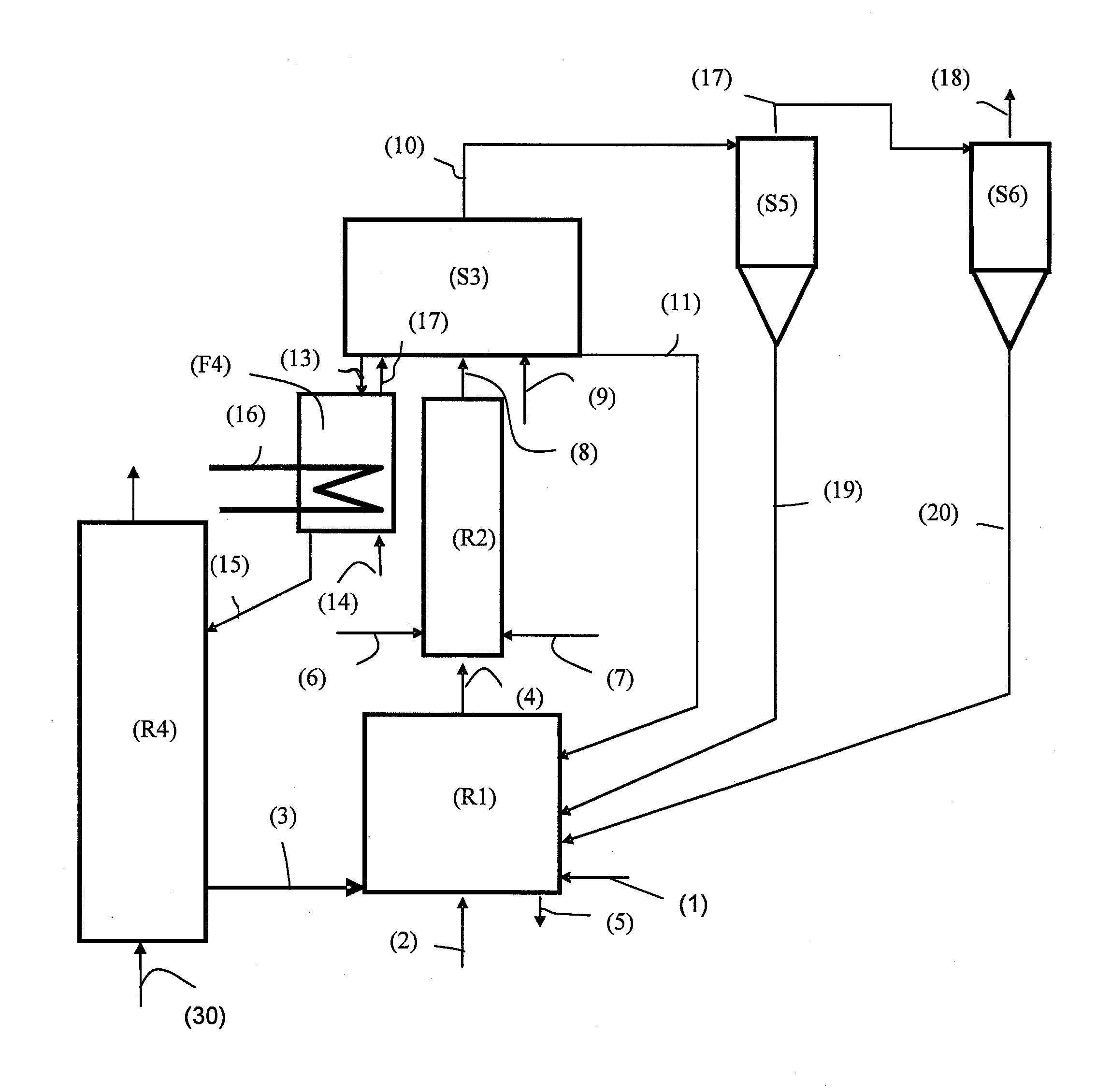

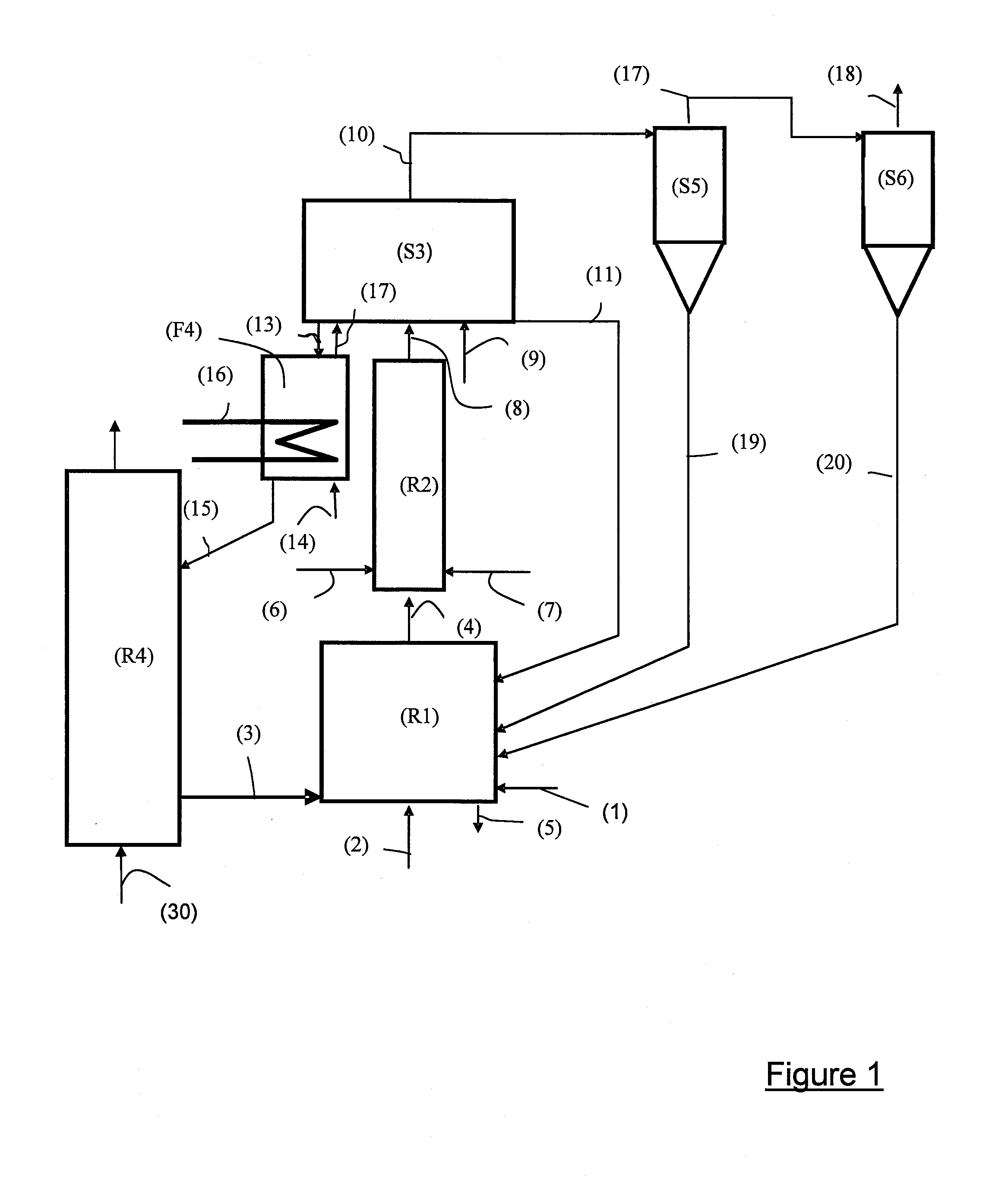

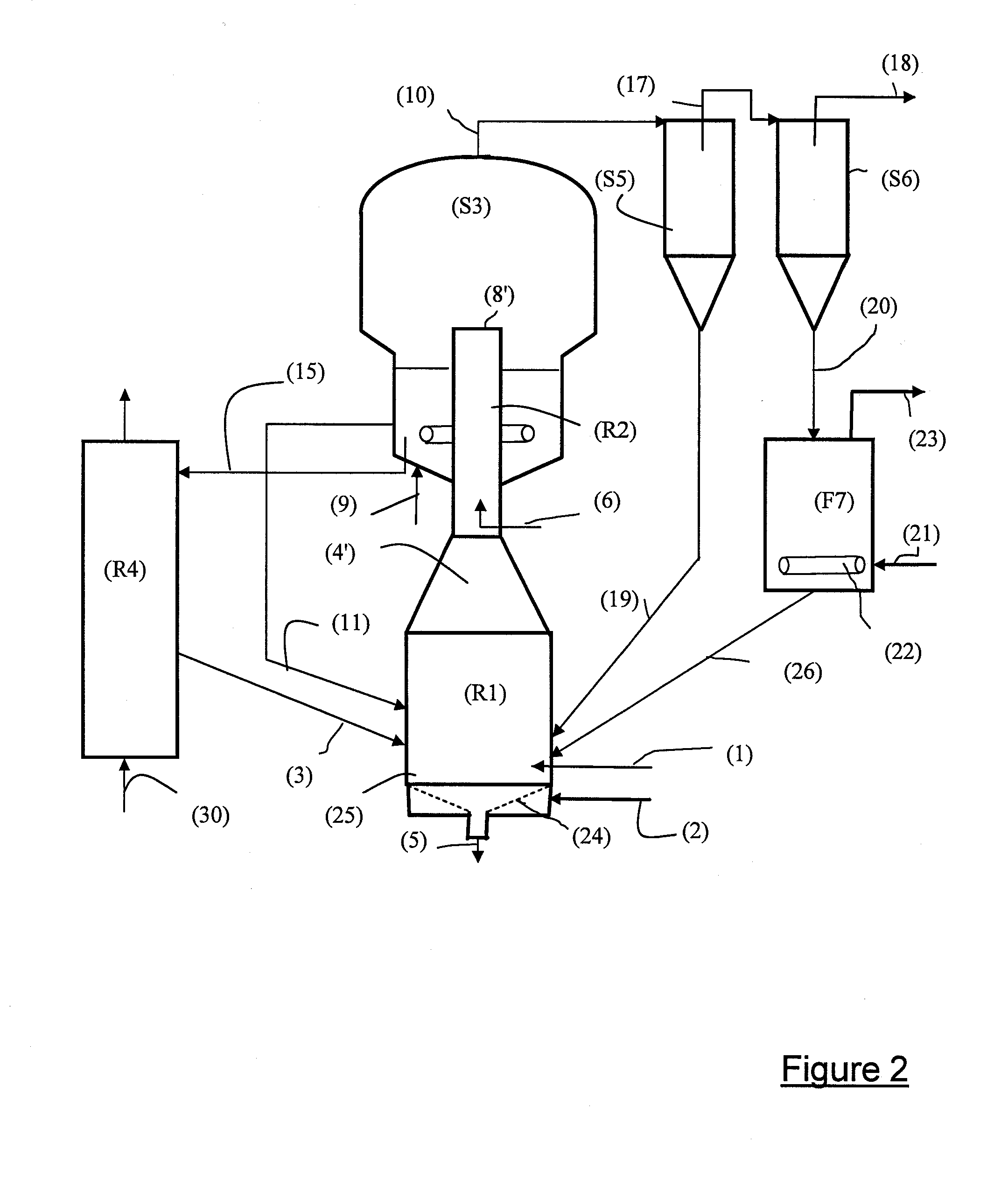

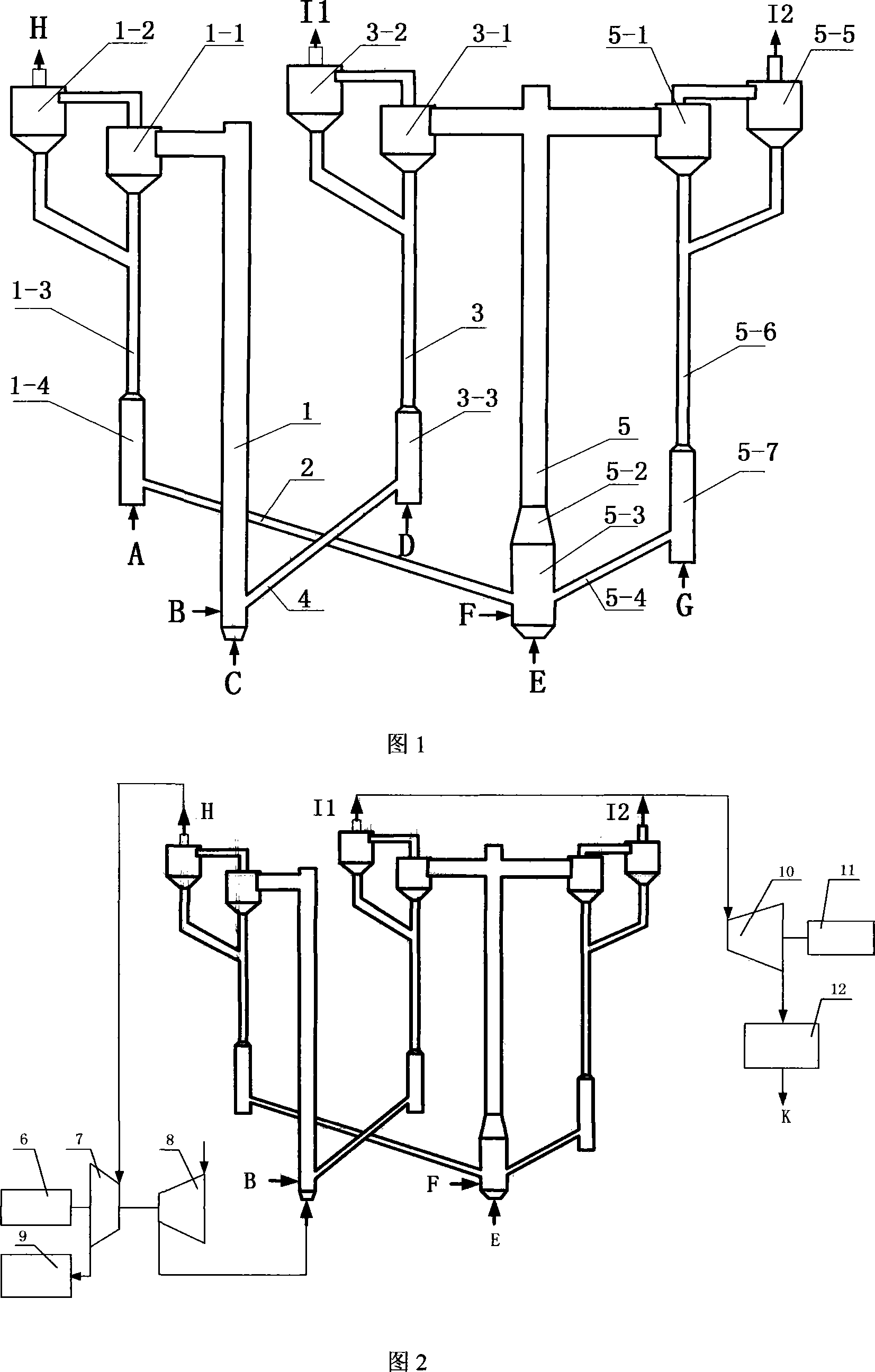

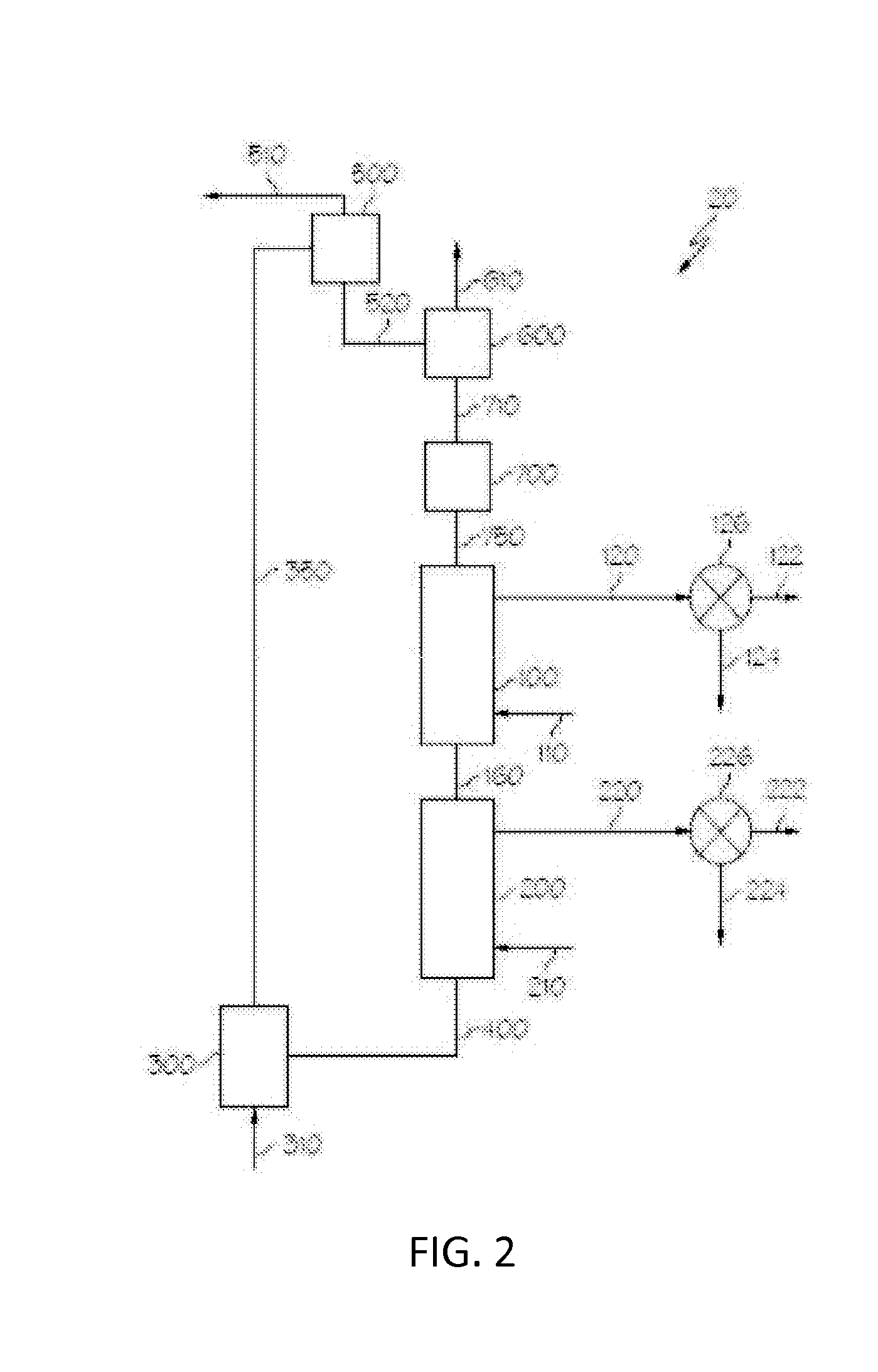

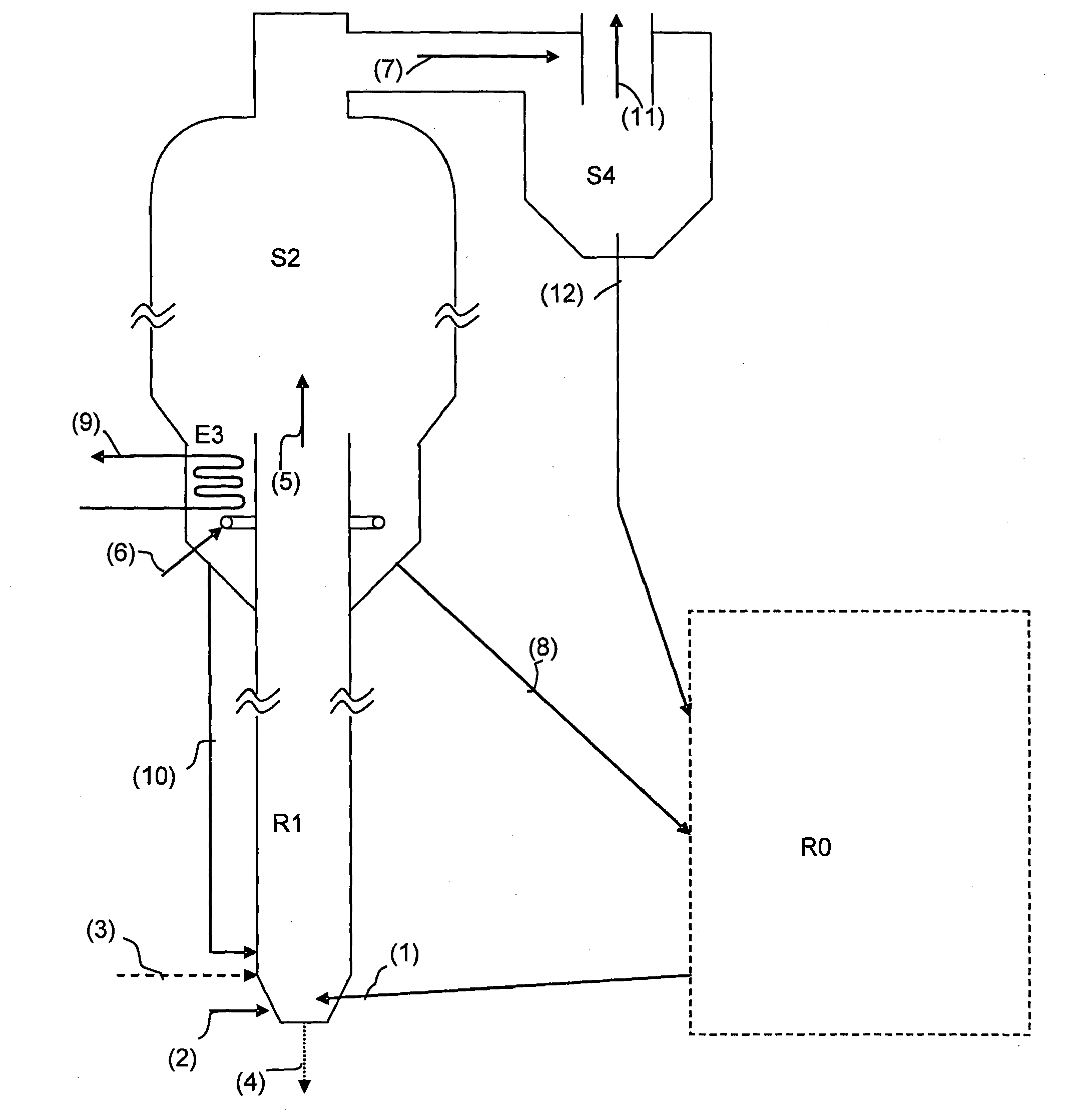

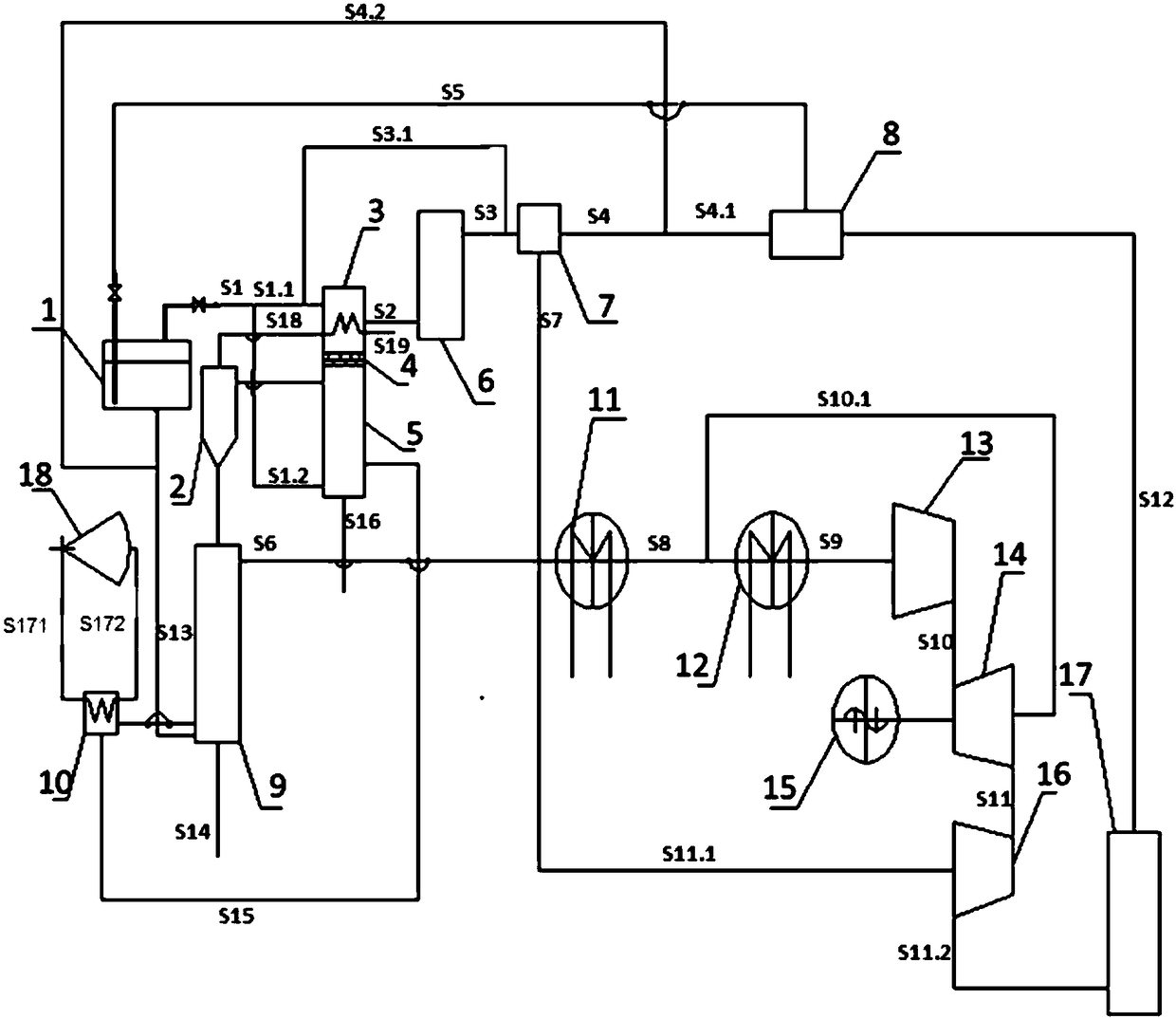

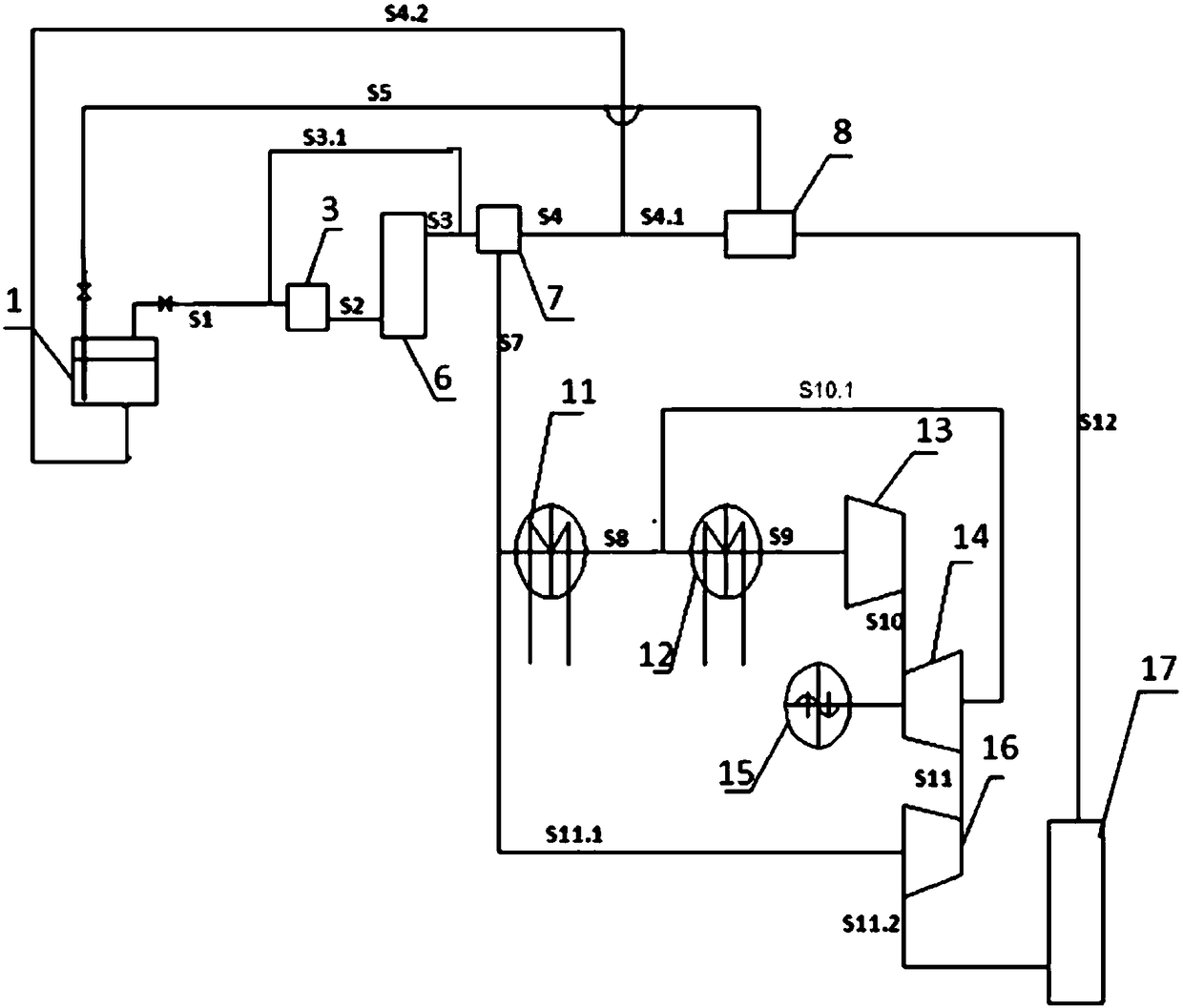

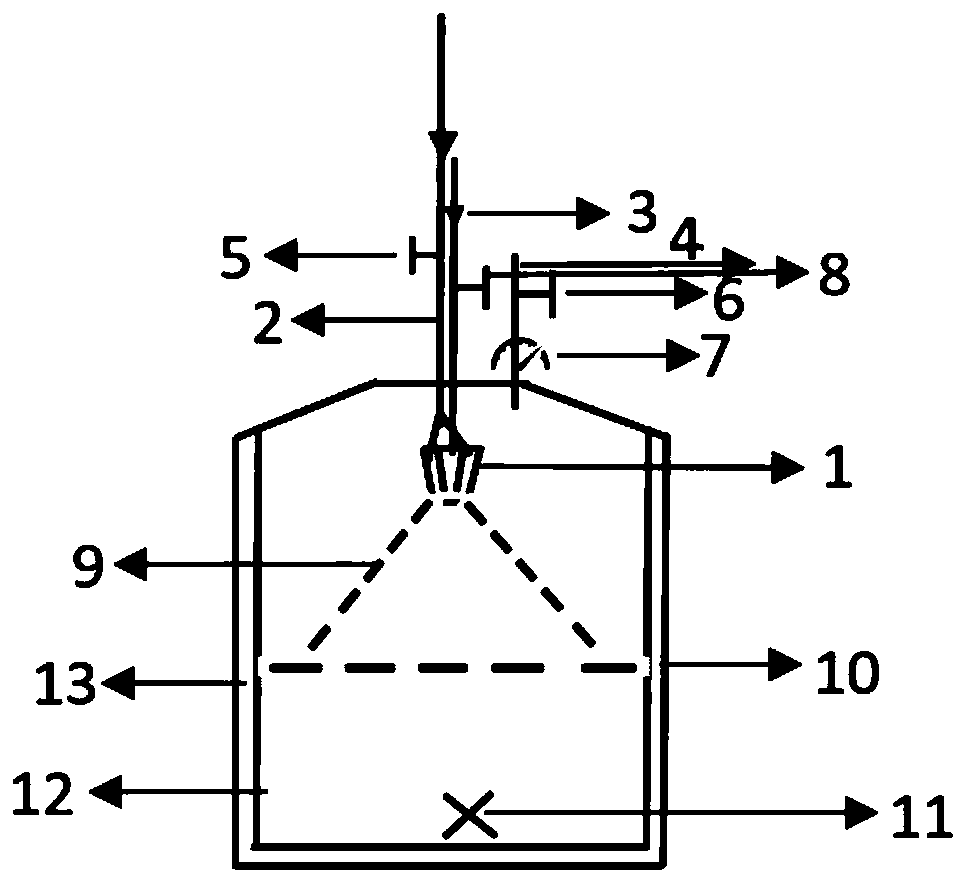

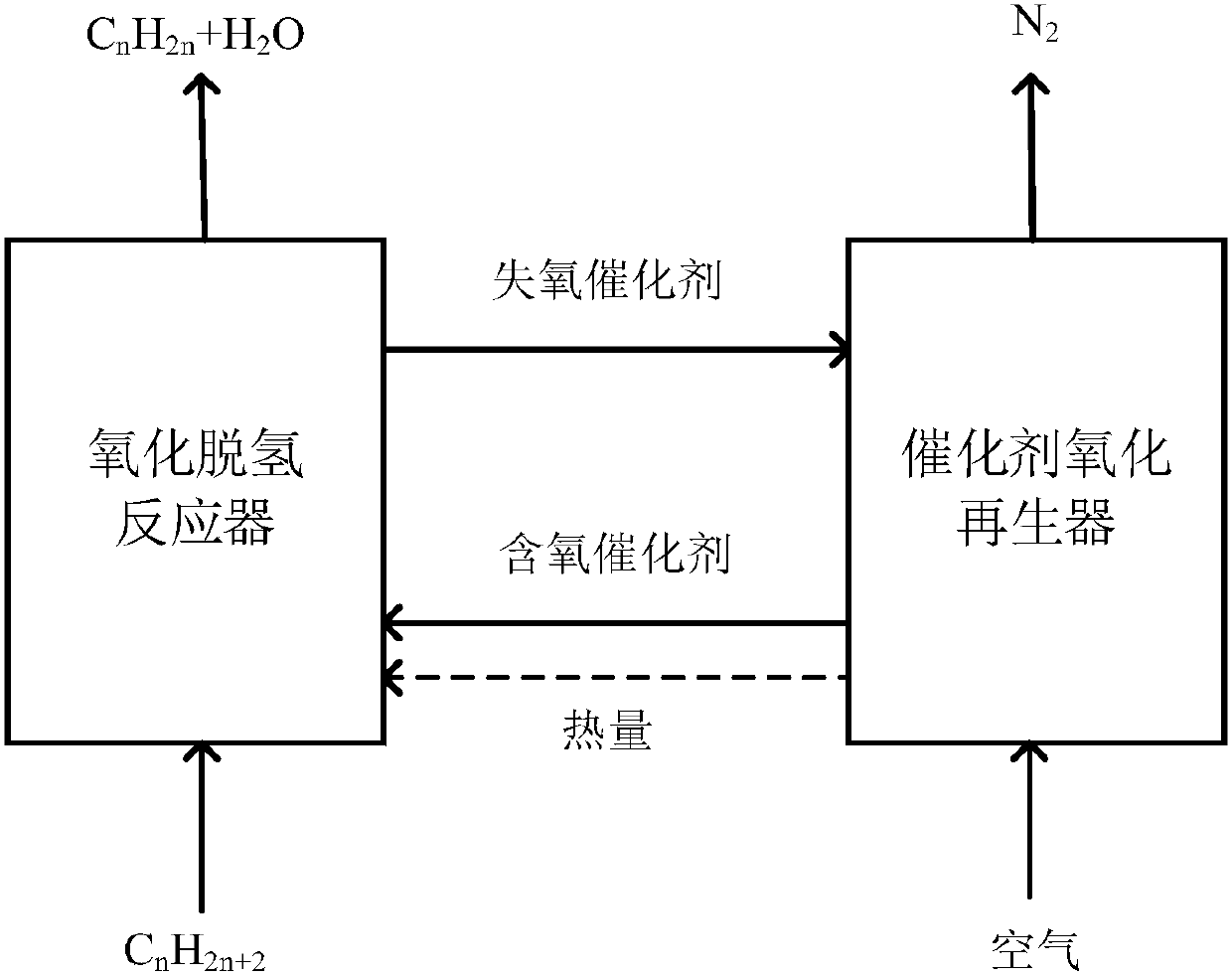

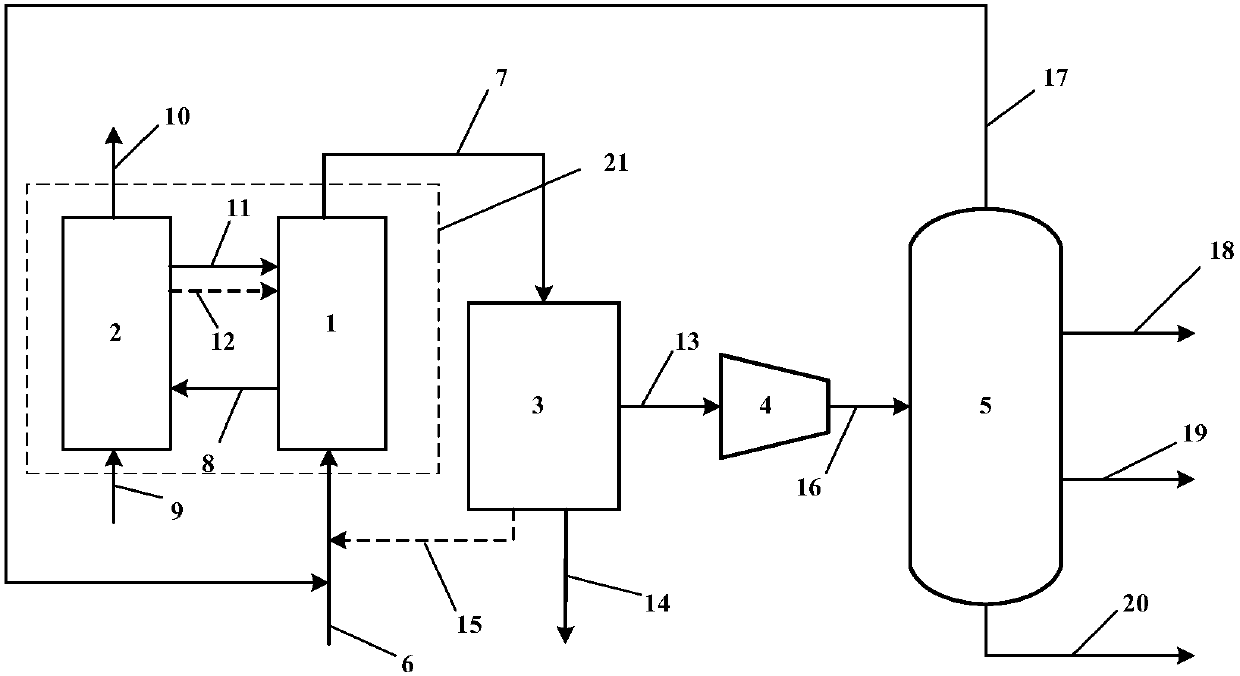

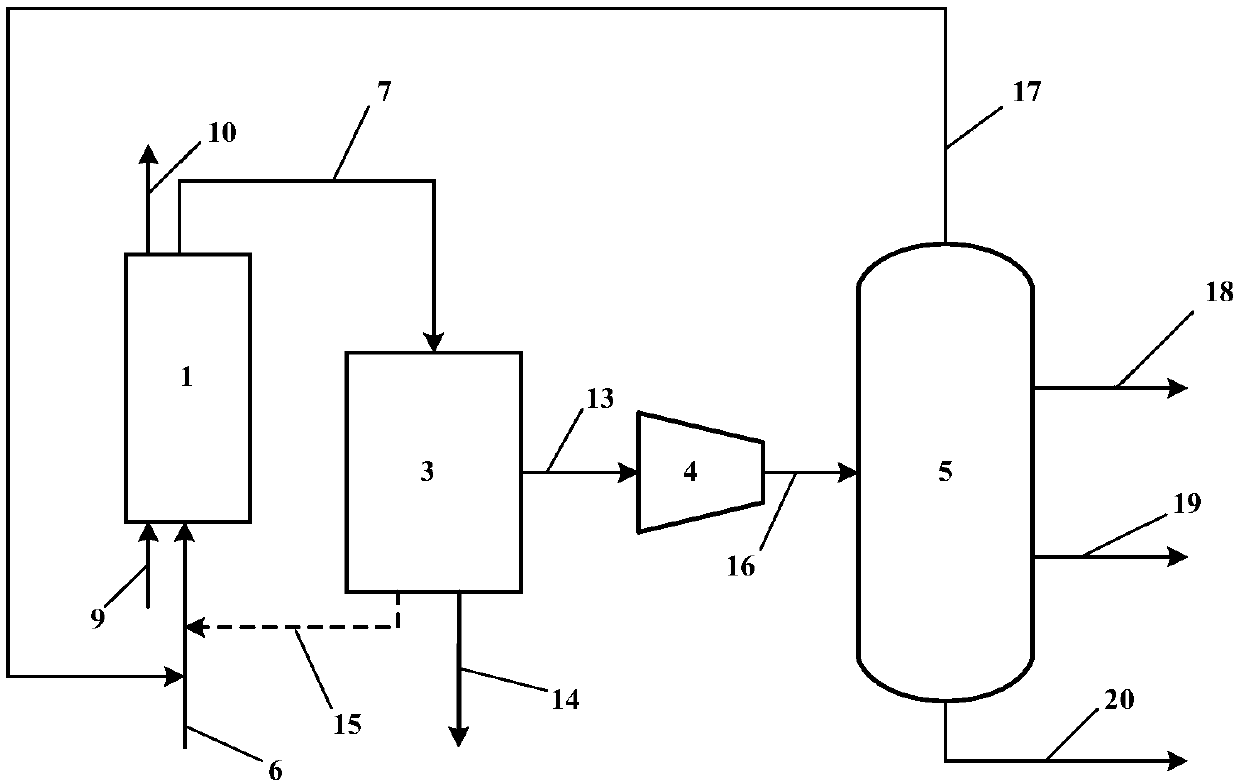

Chemical looping combustion method with a reaction zone including a gas-solid separation zone and plant using same

ActiveUS20130149650A1Small flowFluidized bed combustionFurnace componentsReaction zoneOxidation zone

The object of the invention is a combustion method for a solid feed using a chemical loop wherein an oxygen-carrying material circulates, said method comprising at least:contacting the solid feed particles in the presence of metallic oxide particles in a first reaction zone (R1) operating in dense fluidized bed mode,carrying out combustion of the gaseous effluents from first reaction zone (R1) in the presence of metallic oxide particles in a second reaction zone (R2),separating in a separation zone (S3) the unburnt particles and the metallic oxide particles within a mixture coming from second reaction zone (R2),re-oxidizing the metallic oxide particles in an oxidation zone (R4) prior to sending them back to first zone (R1).

Owner:TOTALENERGIES ONETECH +2

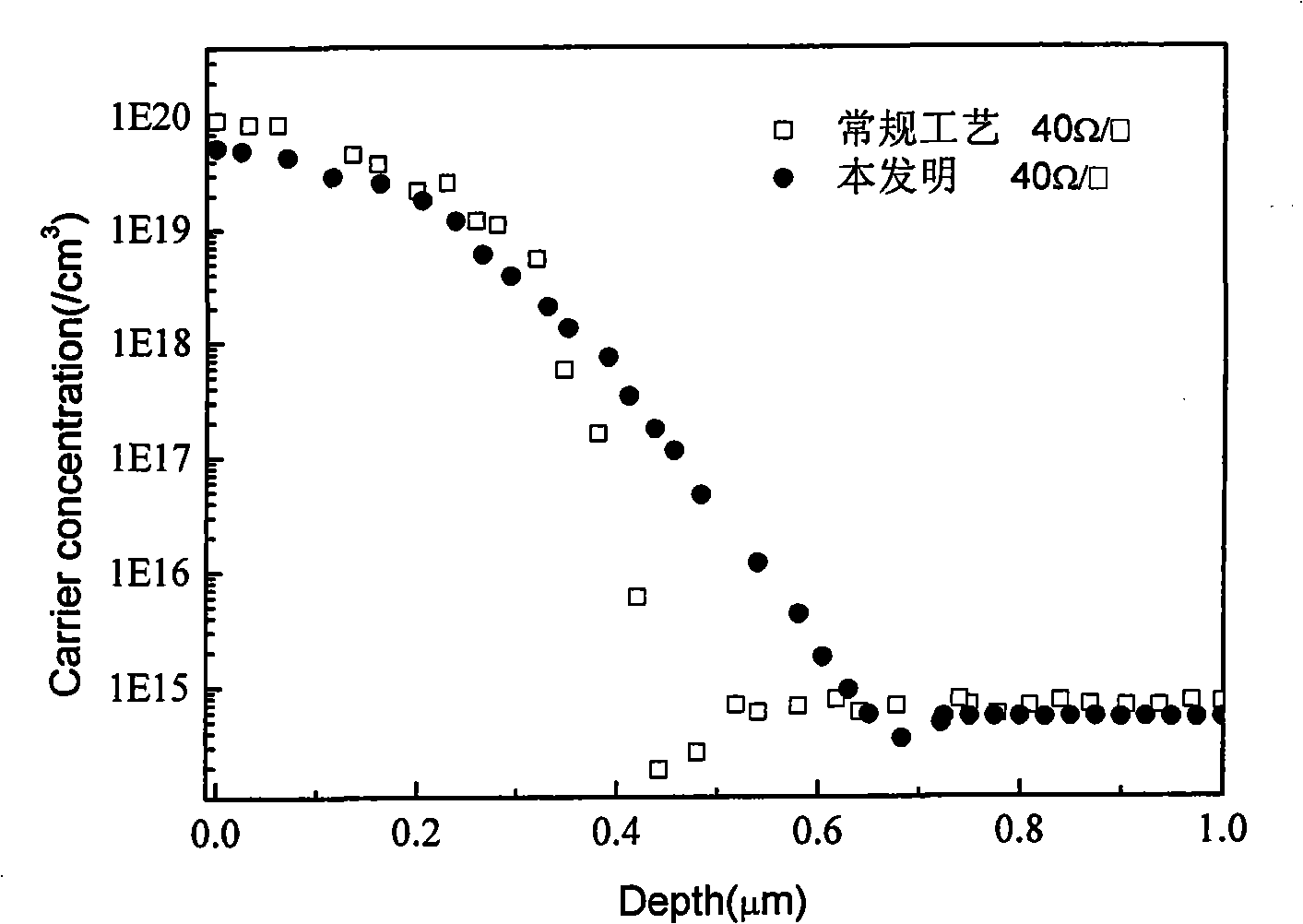

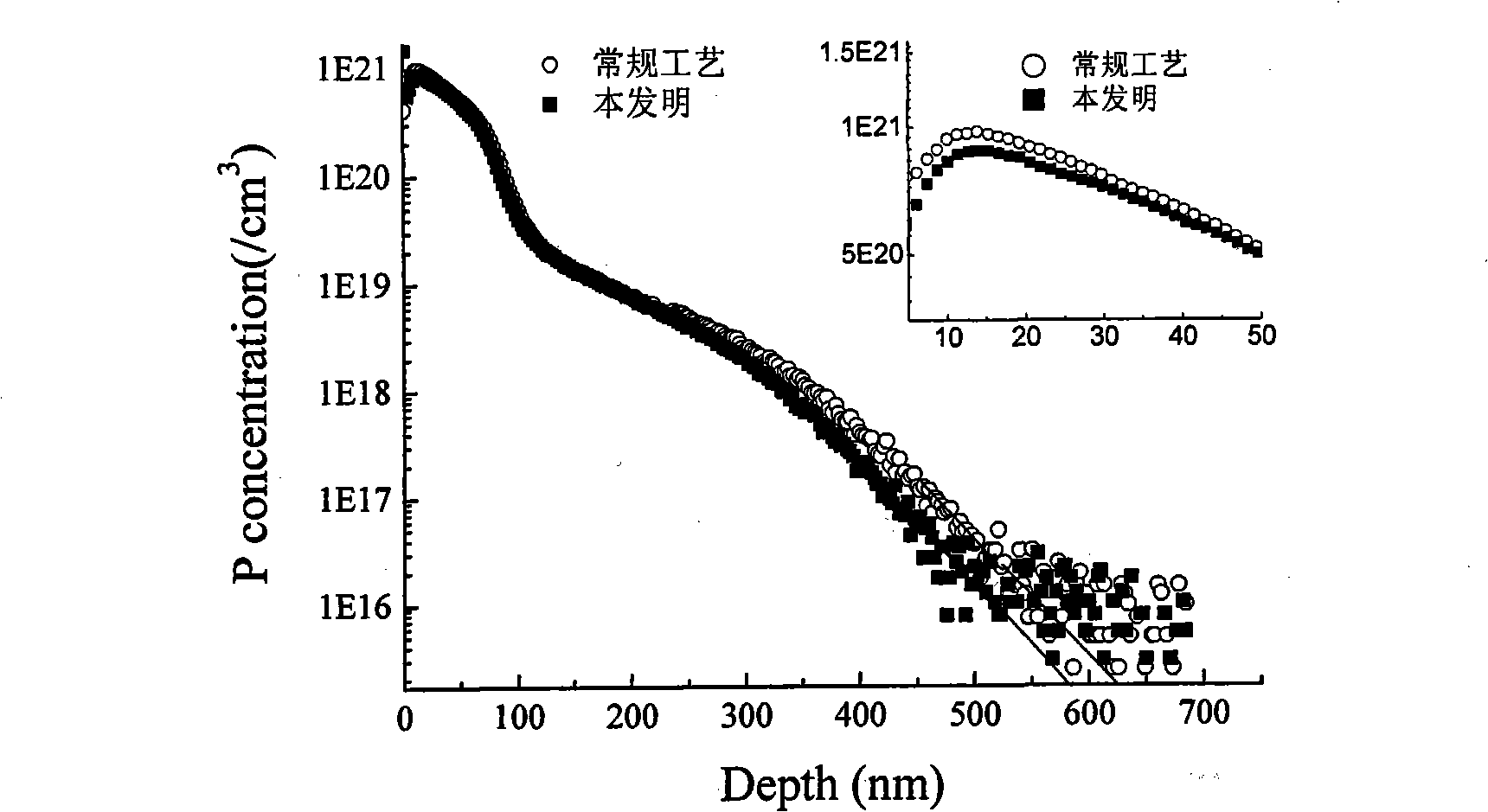

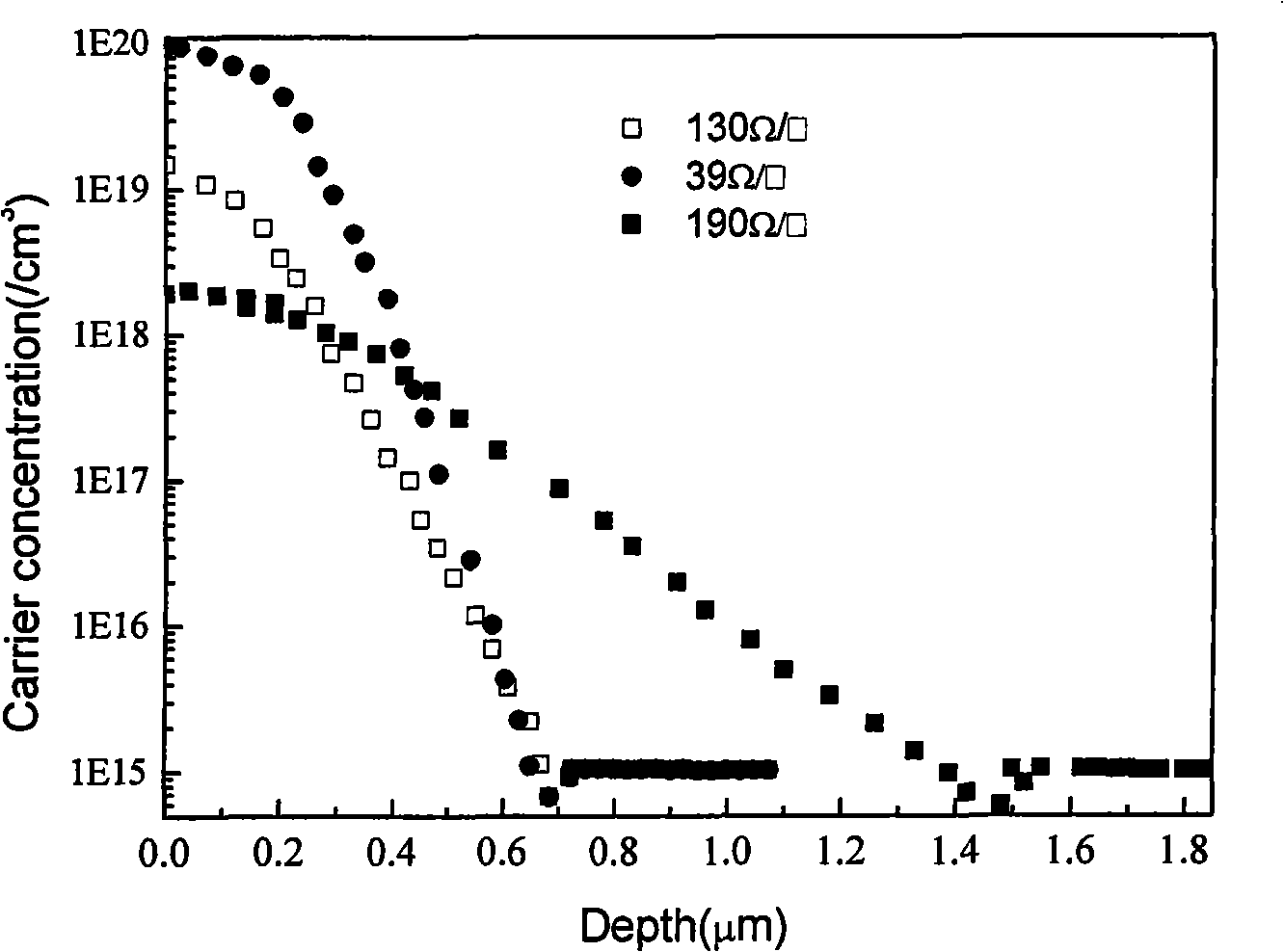

Diffusion technique for silicon solar cell emitter

InactiveCN101404309AAdjust doping concentrationControlling Surface Doping ConcentrationFinal product manufactureSemiconductor devicesElectrical resistance and conductanceDiffusion

The invention discloses a diffusion technique of a silicon solar cell emitter. The technique comprises the following steps: (1) low-temperature prediffussion is carried out: a silicon wafer is placed into a diffusion furnace and inlet with protective nitrogen as well as nitrogen and oxygen carrying a POCl3 source at the diffusion temperature of 800-840 DEG C for 10-50 minutes; (2) promoting diffusion at higher temperature: the nitrogen and the oxygen carrying a phosphorus source are cut off and the diffusion temperature is raised to 820-860 DEG C to promote the diffusion of phosphorus atoms in the course of rising and stabilizing the temperature for 10-40 minutes; and (3) the diffusion furnace is cooled and the silicon wafer is taken out. By adopting the technique, a moderate surface doping concentration and a thicker emitter doping curve can be achieved, therefore, the compound effect caused by the high surface doping concentration of the emitter is reduced, and short circuit current of the solar cell is enhanced. The technique can realize a broader range of square resistance distribution, and obtain a square resistance value meeting the contact with a metal electrode.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

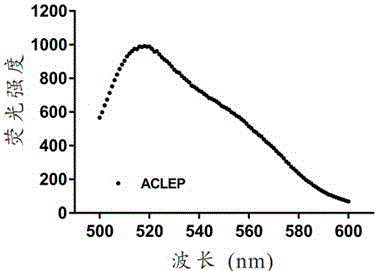

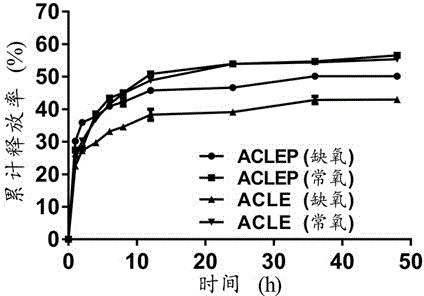

Novel photosensitive agent with function of carrying oxygen

InactiveCN101130082AOxygen-carrying functionEnhanced photodynamic effectMetabolism disorderAntineoplastic agentsPhotosensitizerMedicine

The invention discloses a new typed photosensitizer with oxygen-carrying function in the biological medical domain, which is the composition of oxygen-carrying material and photosensitizer to improve oxygen content in the target area and reinforce the optical dynamic effect of photosensitizer. The invention can be photosensitizer in the optical dynamic treating course and booster in the low strength / high strength focusing / non-focusing hypersonic treating course, which is fit for skin beauty, obesity and benign, malignant proliferative disease.

Owner:许川山

Analyte determination method and analyte meter

The presence of oxygen or red blood cells in a sample applied to an electrochemical test strip that makes use of a reduced mediator is corrected for by an additive correction factor that is determined as a function of the temperature of the sample and a measurement that reflects the oxygen carrying capacity of the sample. The measured oxygen carrying capacity can also be used to determine hematocrit and to distinguish between blood samples and control solutions applied to a test strip.

Owner:AGAMATRIX INC

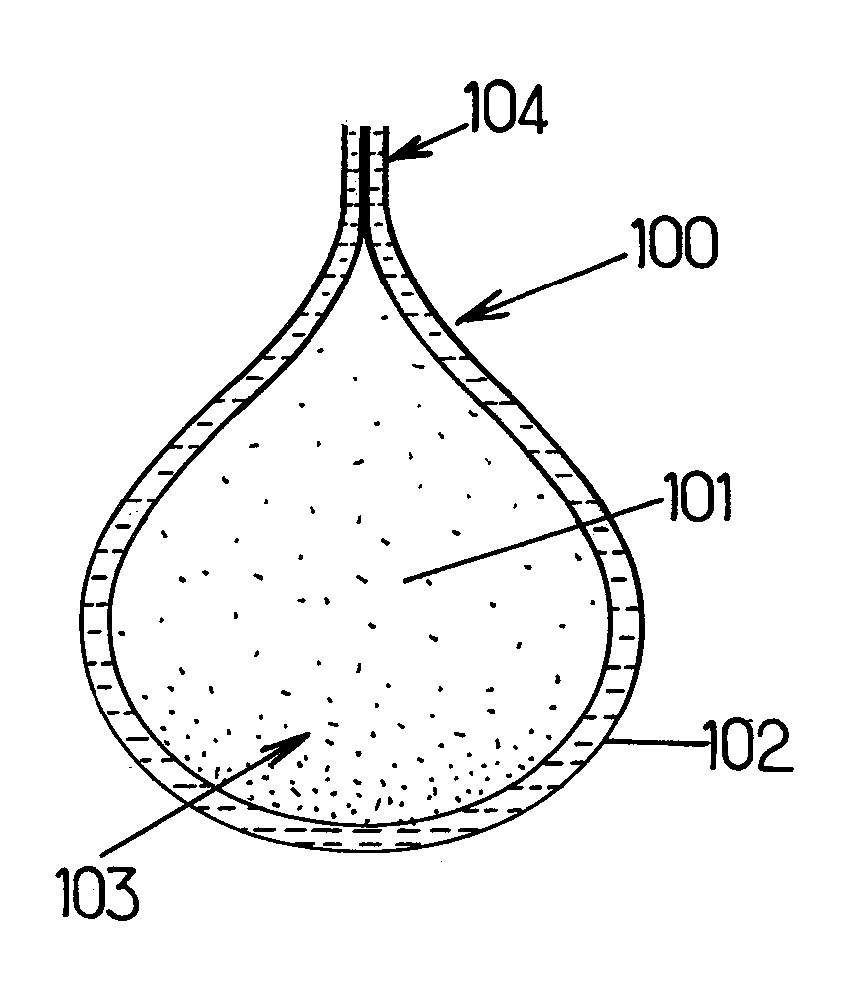

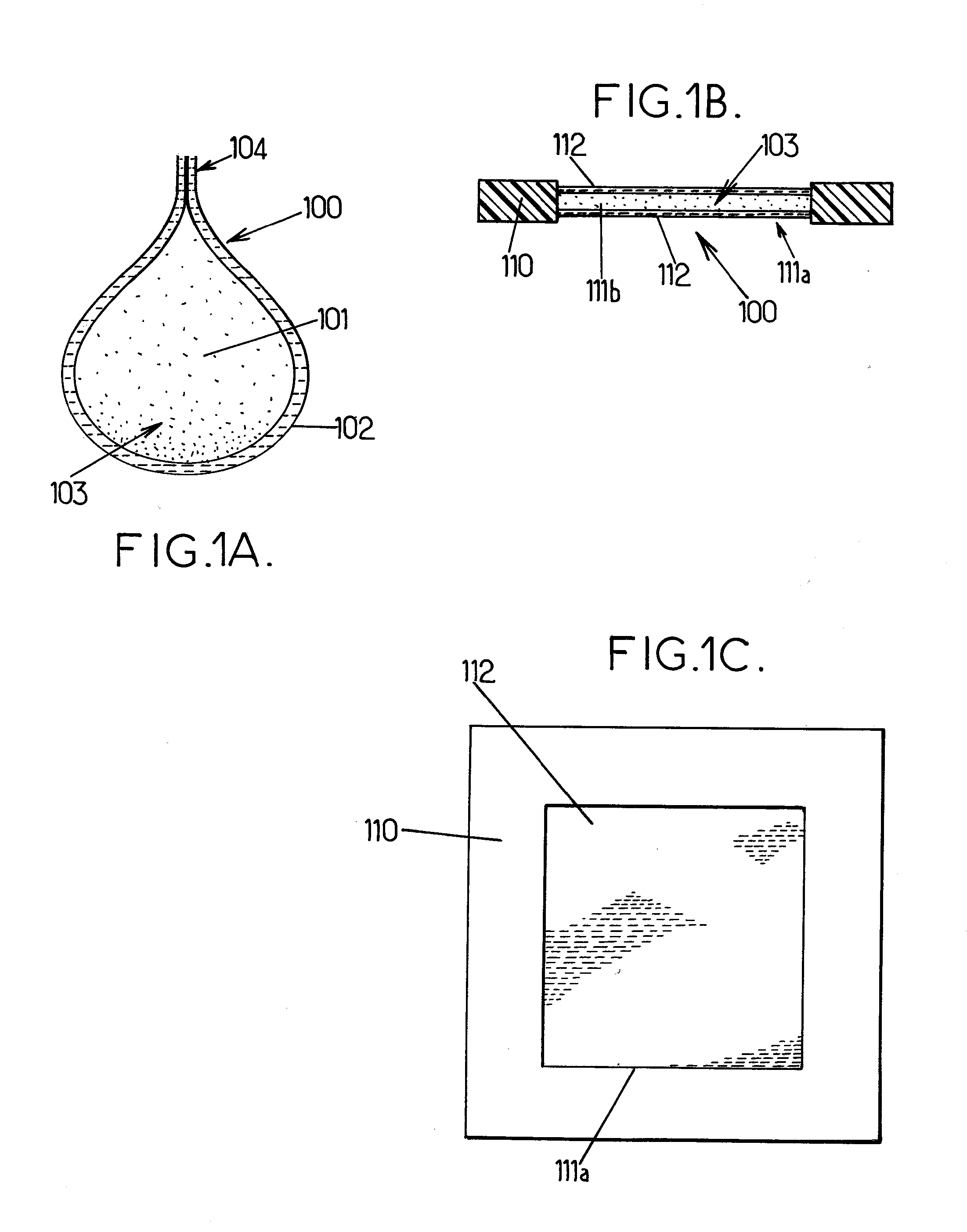

Bioreactor using oxygen-carrying molecules

The present invention relates to devices and bioreactors capable of delivering oxygen to a cell culture using oxygen-carrying molecules. The bioreactor comprises at least two chambers separated by an oxygen-permeable membrane. The oxygen-carrying molecules are chosen from extracellular hemoglobin isolated from worm belonging to Arenicoliolae family or Nereidiolae family.

Owner:HEMARINA

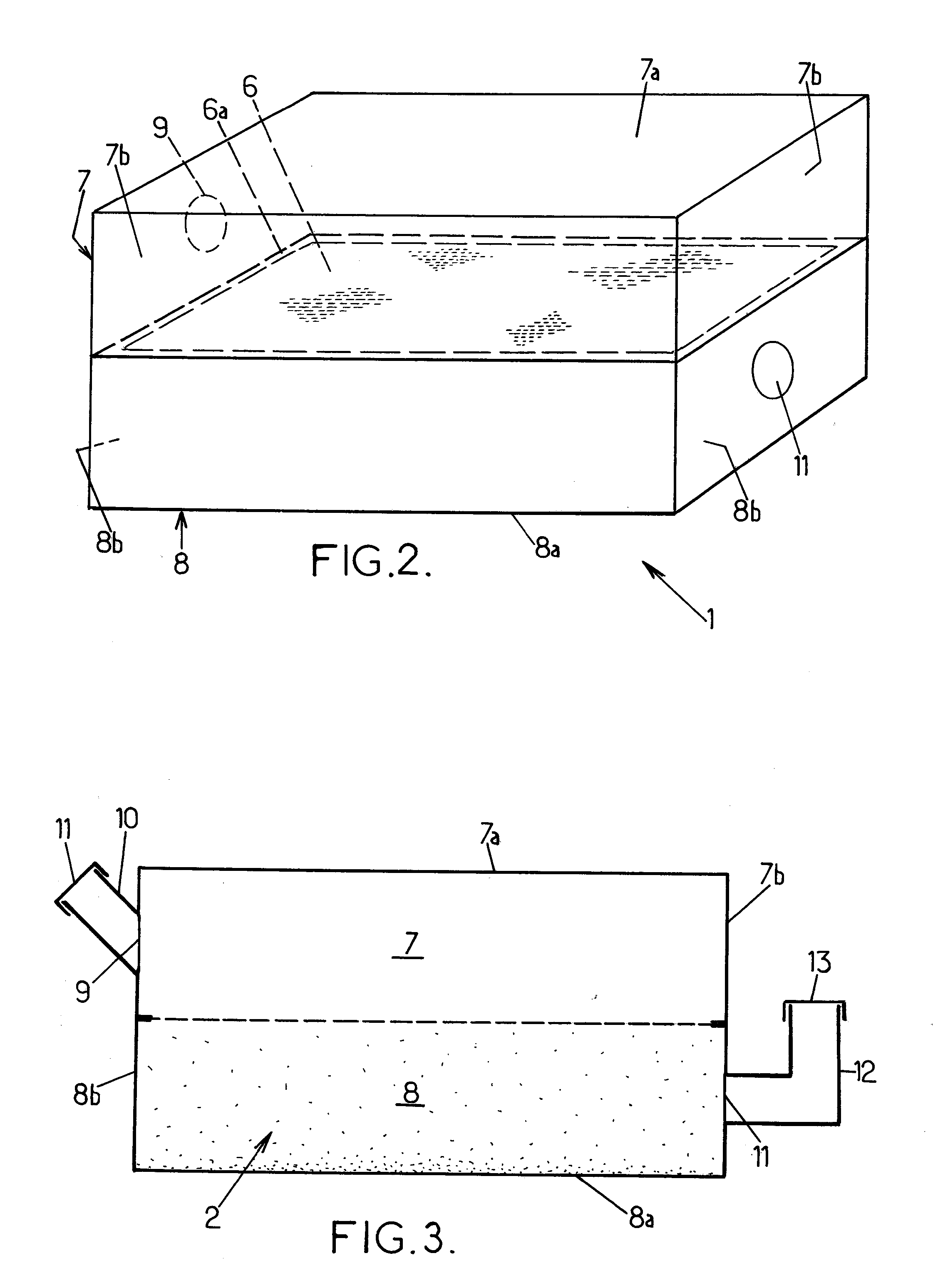

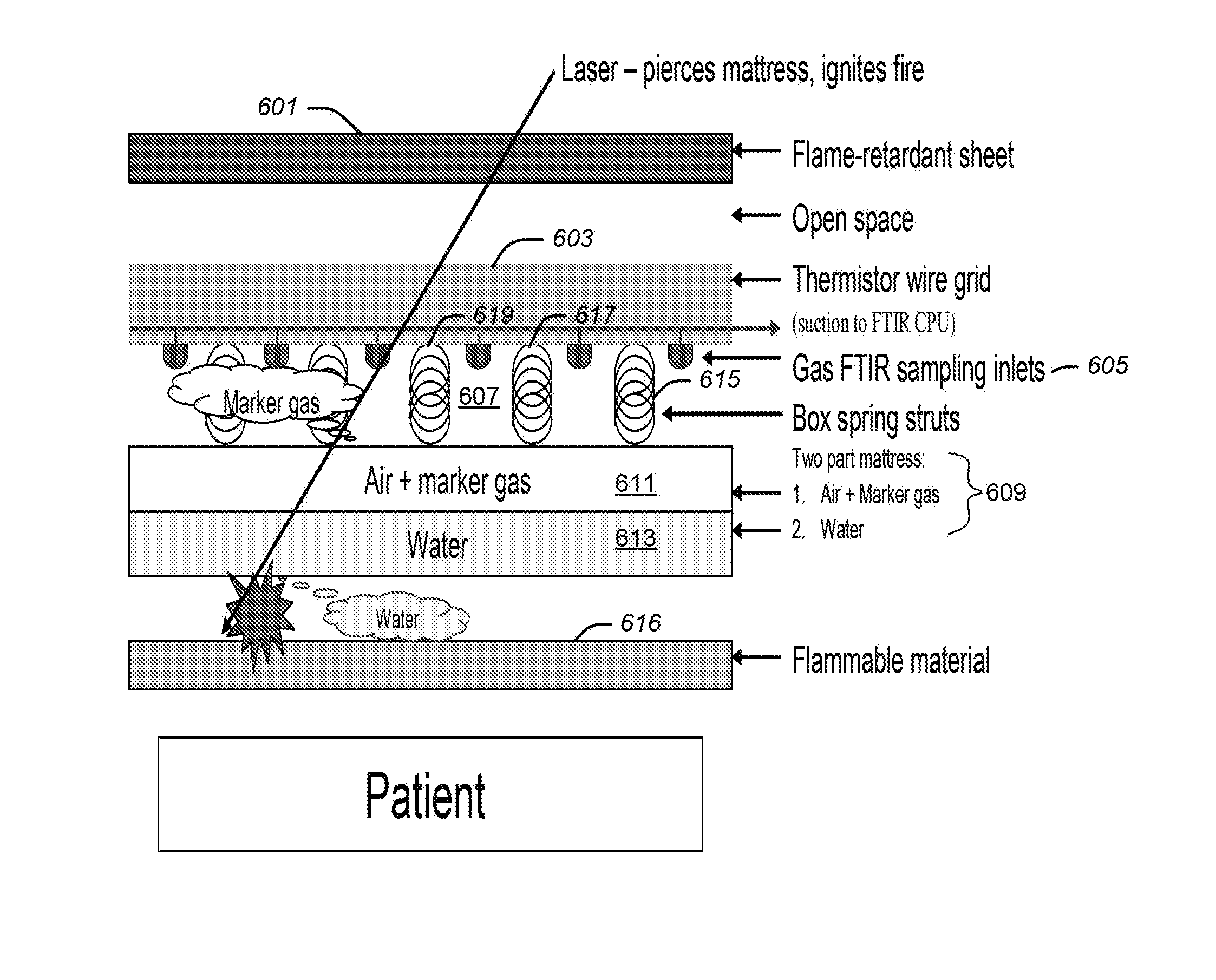

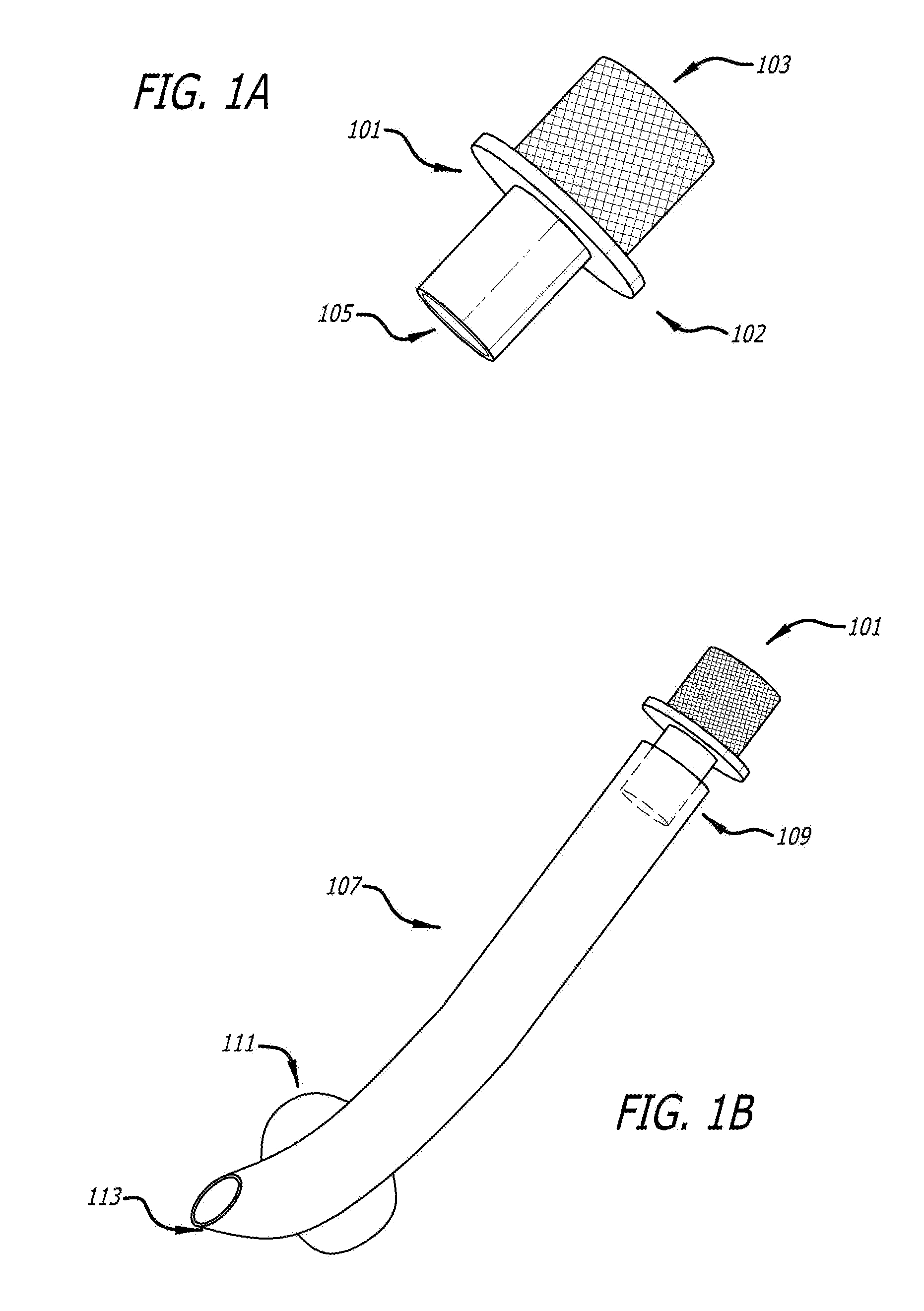

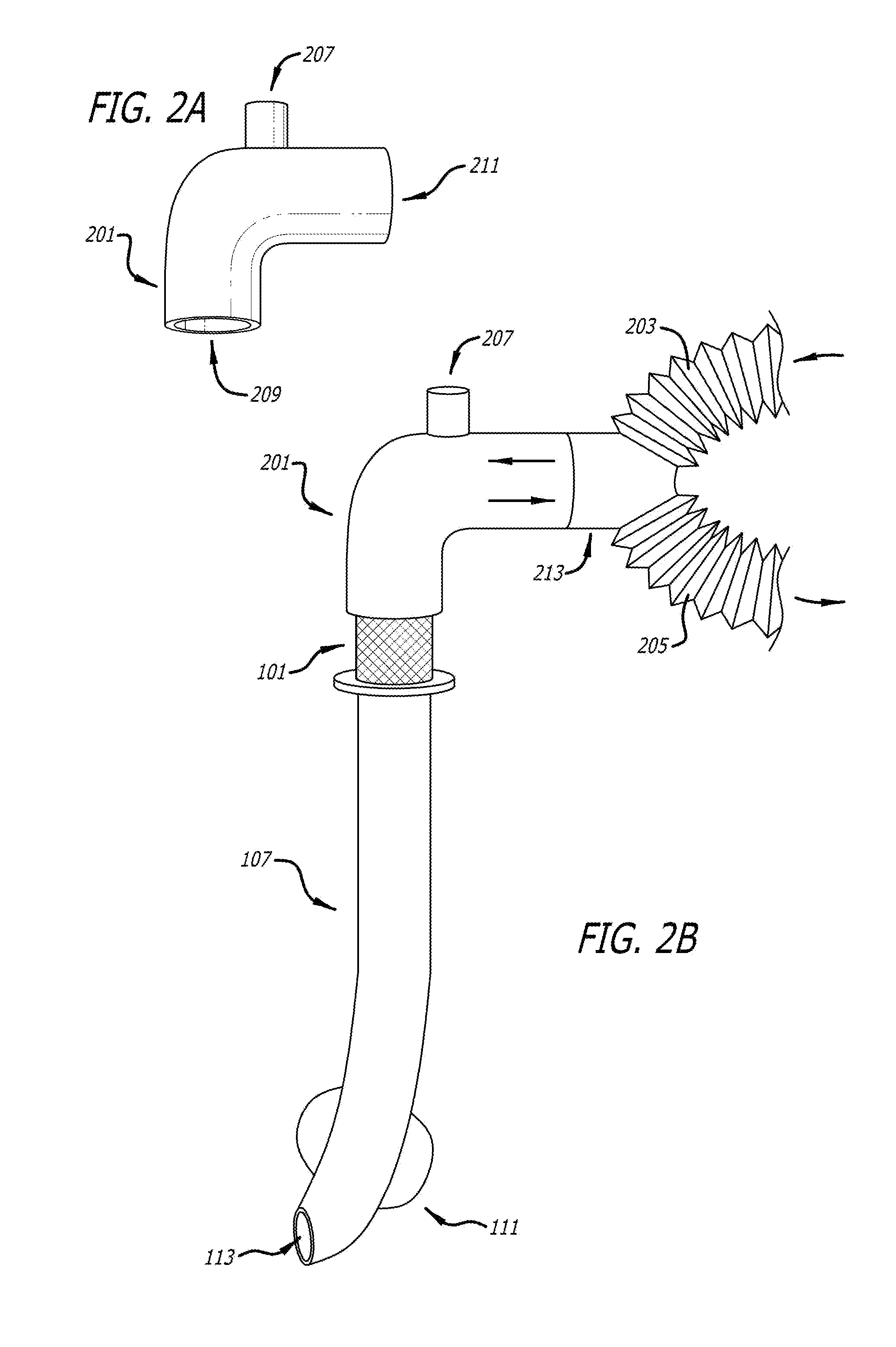

Detection and suppression of airway / drape fires during surgical procedures

InactiveUS20100300708A1Quality improvementRespiratory device testingDiagnosticsEmergency medicineSurgery procedure

Apparatus for oxygenating the airway of a patient may include a device for delivering an oxygen-carrying gas into the airway, a fire detection system configured to detect indications of an imminent or incipient fire in the airway, and a fire suppression system configured to suppress the imminent or incipient fire in the airway in response to detection of the fire in the airway by the fire detection system.A drape for use during surgery on a patient may include a sheet configured to cover an area of the patient during surgery, a fire detection system attached to the sheet and configured to detect indications of an imminent or incipient fire beneath the sheet, and a fire suppression system attached to the sheet and configured to suppress the imminent or incipient fire beneath the sheet in response to detection of the imminent or incipient fire by the fire detection system.

Owner:UNIV OF SOUTHERN CALIFORNIA

Catalyzer for preparing low carbon olefinic hydrocarbon through hydrocarbons catalytic oxidation cracking

ActiveCN101116827AReduce surface area carbonImprove conversion rateCatalytic crackingMolecular sieve catalystsCatalytic oxidationCracking reaction

A catalyst preparing light olefins from hydrocarbon catalytic oxidation cracking is provided. Weight percentage compositions of components in the catalyst are as follows: 10-100 percent by weight of an active component, and 0-90 percent by weight of a carrier, wherein the active component comprises oxygen-carrying type metal oxide and acid catalytic material. Weight percentage compositions of components in the active component are as follows: 10-99 percent by weight of the oxygen-carrying type metal oxide, and 1-90 percent by weight of the acid catalytic material. The hydrocarbon oil raw material is contacted with the above catalyst, proceeds with catalytic oxidation cracking reaction under the conditions of 500-800 DEG C, the water-oil ratio of 0-1.5 and the feeding quality space velocity of 1-500 h-1, and separates reaction logistics to obtain the target product of light olefins. The catalyst not only improves the conversion of raw materials, but also improves the yield and selectivity of ethylene, propylene and butane to different extent, and simultaneously reduces the carbon deposition on the catalyst surface.

Owner:CHINA PETROLEUM & CHEM CORP +1

External gel used for treating diabetic foot, and preparation method and application thereof

ActiveCN102949709AWon't scabPromote dissolutionOrganic active ingredientsNervous disorderGel preparationPh regulation

The invention relates to an external gel used for treating diabetic foot, and a preparation method and an application thereof. Specifically, the invention relates to an external gel preparation with oxygen-carrying and antibacterial materials, and containing recombinant human epidermal growth factor (rhEGF). The preparation basically comprises: a medicine component recombinant human epidermal growth factor (rhEGF), an oxygen-carrying material, an antibacterial material, a gel substrate, a stabilizing agent, a humectant, a penetration enhancing agent, a surfactant, and a pH regulation agent.

Owner:ZHANGJIAGANG IND TECH RES INST CO LTD DALIAN INST OF CHEM PHYSICS CHINESE ACADEMY OF SCI

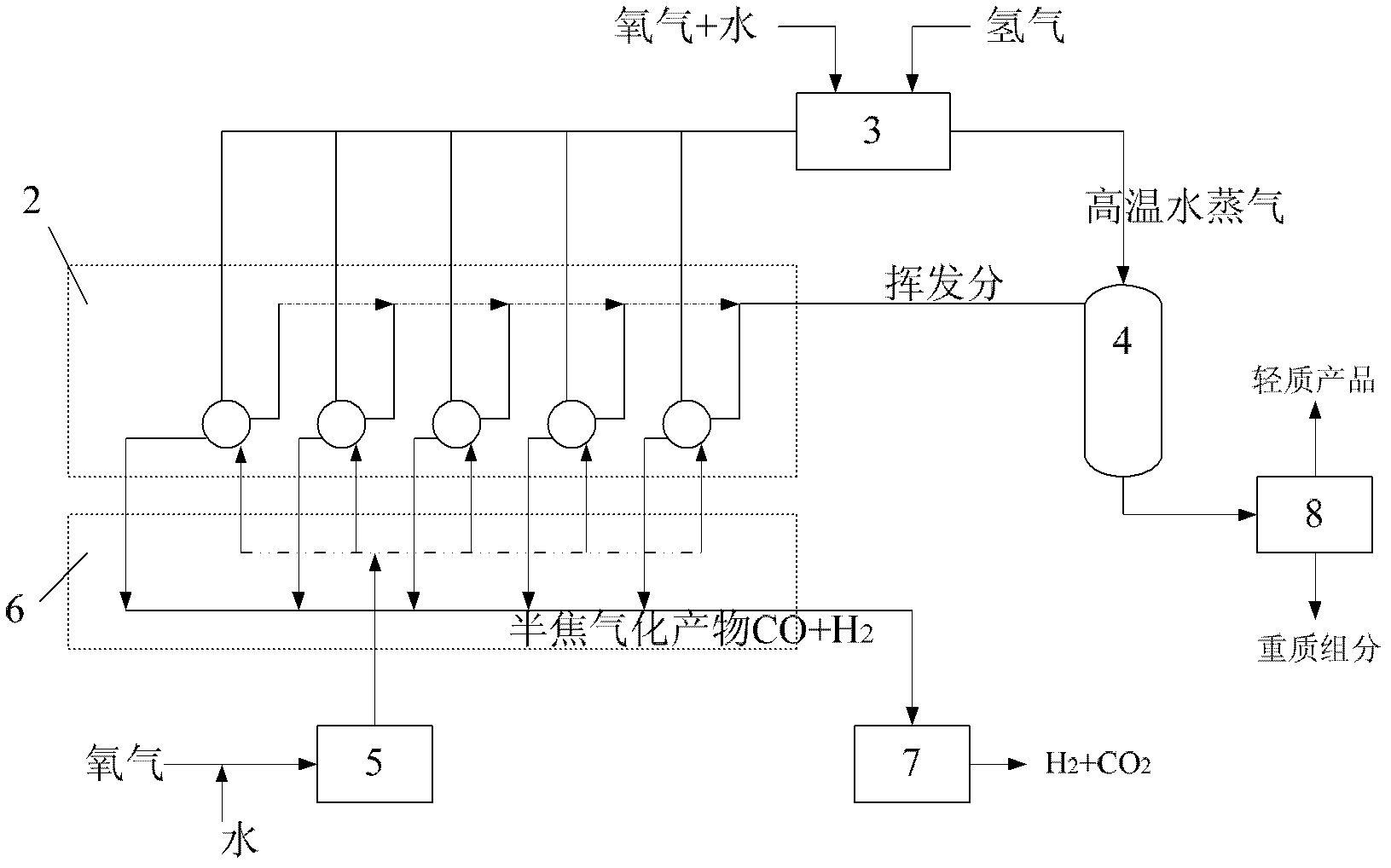

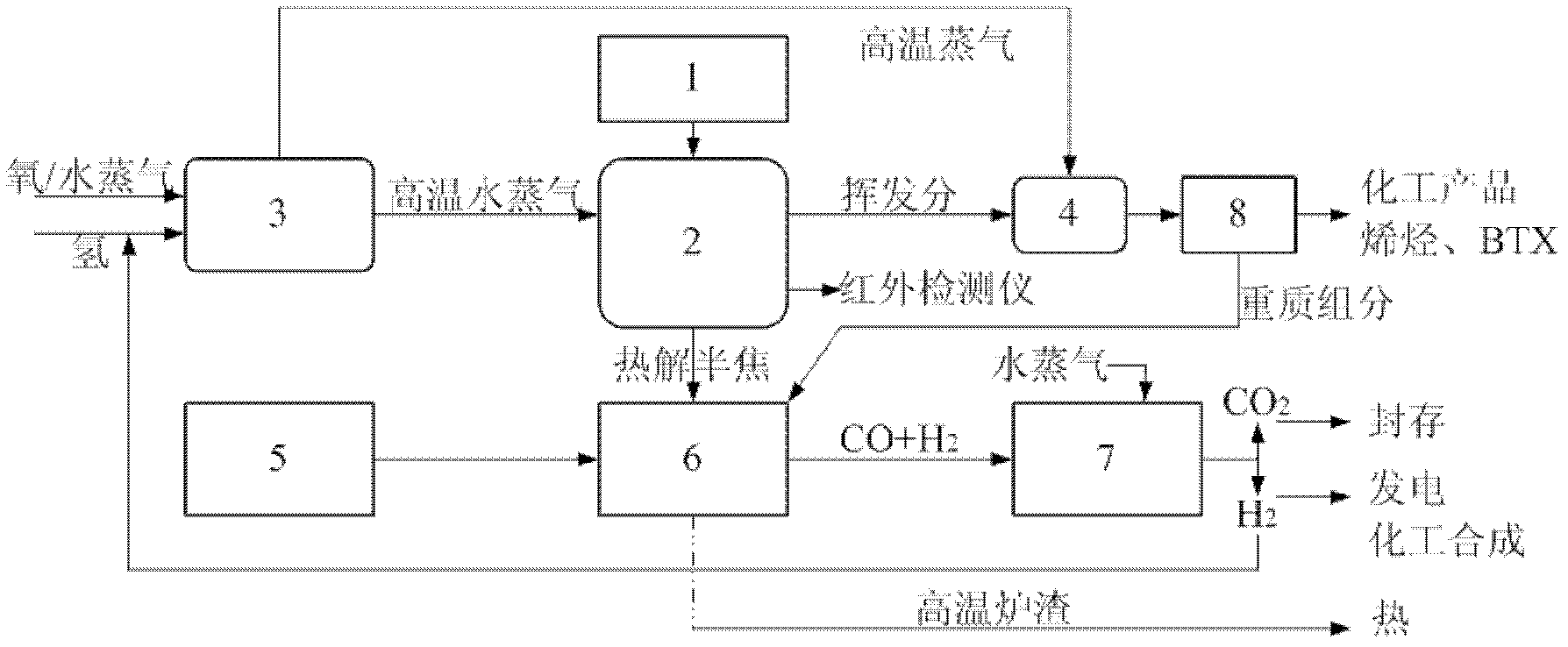

High-temperature water vapor pyrolysis-cracking-gasification device and method for solid fuel

ActiveCN102849676AReduce energy consumptionReduce hydrogen consumptionCarbon compoundsDirect heating destructive distillationHydrogenWater vapor

The invention relates to the comprehensive utilization field of a solid fuel, specifically to high-temperature water vapor pyrolysis-cracking-gasification device and method for the solid fuel. The method includes introducing the high-temperature water vapor generated by the combustion of O2 and H2 into the solid fuel for low-temperature pyrolysis, to separate out the volatile matter and obtain an oil gas product and pyrolysis semi-coke; performing thermal cracking to the oil gas product in hot state under the action of the high-temperature water vapor, and separating to obtain a lightweight product and a heavyweight component; gasifying the pyrolysis semi-coke and the heavyweight component under the action of oxygen-carrying high-temperature water vapor, to obtain water gas; and allowing the reaction between the water gas and water vapor, to obtain CO2 and H2, separating, storing the CO2, and using the H2 in power generation. The invention is characterized in that the high-temperature water vapor generated by hydrogen-oxygen combustion is used to provide heat; the oil gas product generated by the pyrolysis directly enters the thermal cracking reactor in hot state; higher-added value products, such as lightweight olefins and BTX, are obtained via the thermal cracking; and the clean and high-efficiency comprehensive utilization of the solid fuel is realized through fractional extraction.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Oxygen carrier gasifying combustion method for loading oxygen and device

The invention discloses an oxygen carrying gasification combustion method with an oxygen carrier as well as relevant apparatus; the method is characterized in that the oxygen carrier is arranged inside an air reactor fluidized bed; if fluidized air is fed, oxysome reacts with oxygen in the air before high-value metal oxide is heated to obtain; then, the oxide will be separated through a two-stage separator; the high-temperature oxygen denuded air, which is separated, is exhausted out of the upper-end of the separator; the separated oxygen carrier goes through a returning dipleg to enter a mixing and gasification chamber; in a circulation fluidized bed in the air reactor, an oxygen carrying reaction happens between the oxygen carrier and oxygen in the air: The oxygen carrier from the reaction flows into the dipleg after being separated by the two-stage separator, so that the oxygen carrier and the fuel can together enter the gasification chamber below the fuel reactor fluidized bed; in the gasification chamber, a gasification reaction happens to the fuel and the water vapour, so as to create a synthetic gas. Meanwhile, the oxygen carrier releases oxygen and a reduction reaction happens with a synthetic gas or a fuel, before carbon dioxide is gained.

Owner:SOUTHEAST UNIV

Sonosensitizer with oxygen-carrying function

InactiveCN101125203AOxygen-carrying functionEnhanced sonodynamic effectAntineoplastic agentsPharmaceutical active ingredientsHigh intensityOxygen content

The present invention pertains to the biomedical field, more particularly, the present invention relates to a sound-sensitive agent which has the oxygen carrying function. The sound-sensitive agent is a composition which is composed of the substances with the oxygen carrying function and the sound-sensitive substances. The present invention makes use of the substances with the oxygen carrying function to improve the oxygen content of the target area, strengthen the sonodynamic effect of the sound-sensitive substances and develop the safe and effective sound-sensitive agent. The sound-sensitive agent which has the oxygen carrying function can be used as the sound-sensitive agent during the sonodynamic treatment process and can be used as the synergistic agent during the low-intensity / high-intensity focused / non-focused ultrasound treatment process, so the present invention is applicable to the skin care, obesity, benign and malignant proliferative diseases.

Owner:许川山

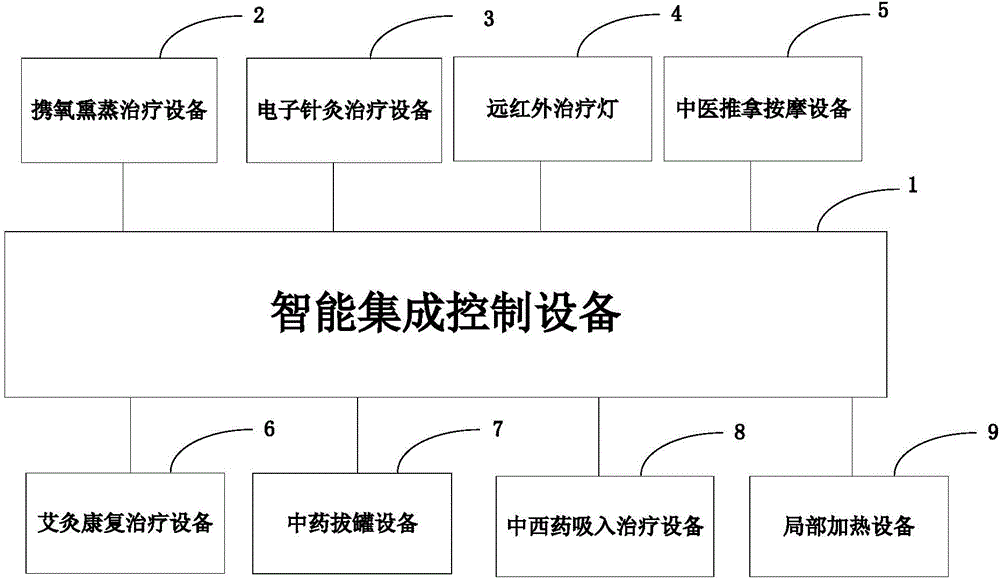

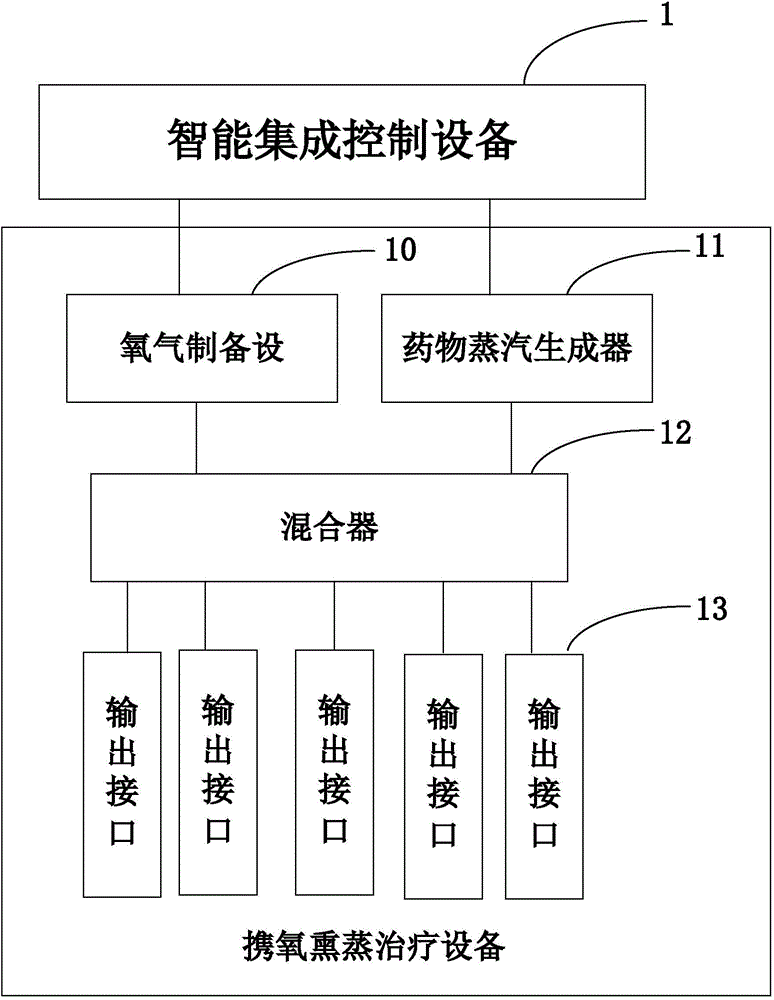

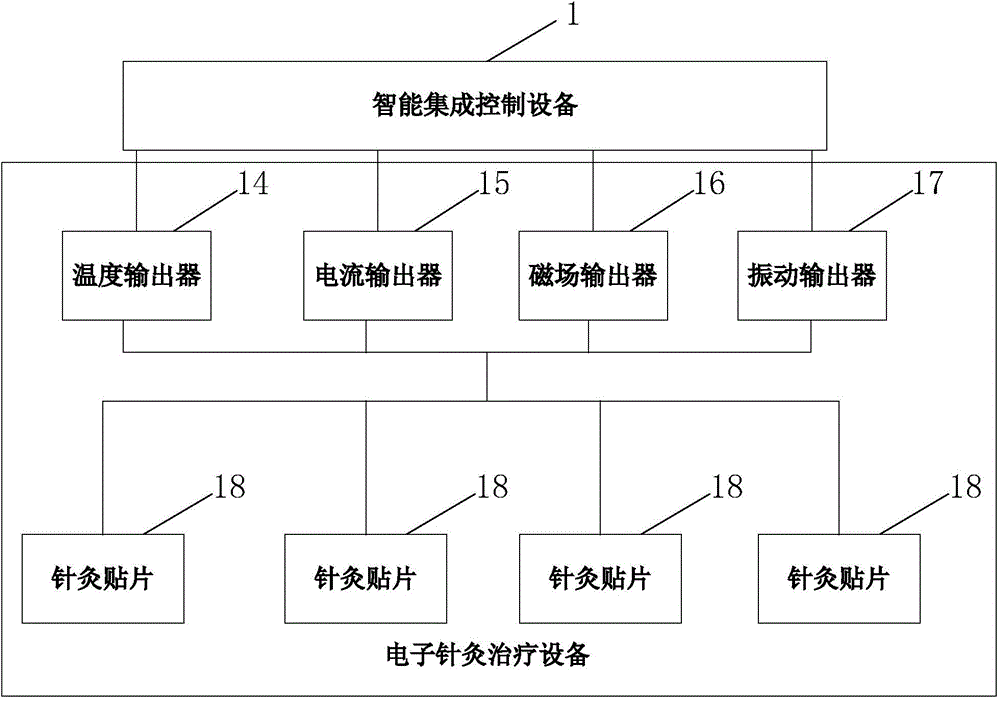

Multifunctional and intelligent traditional Chinese medical rehabilitation therapy robot

ActiveCN104146857AImprove sexual functionImprove practicalityDevices for heating/cooling reflex pointsMedical devicesDiseaseTherapeutic Devices

The invention provides a multifunctional and intelligent traditional Chinese medical rehabilitation therapy robot. The multifunctional and intelligent traditional Chinese medical rehabilitation therapy robot comprises intelligent integrated control equipment, oxygen-carrying fumigation therapy equipment, electronic acupuncture therapy equipment, a far infrared therapy lamp, traditional Chinese medical massage equipment, moxibustion rehabilitation equipment, traditional Chinese medical cupping therapy equipment, Chinese and western medicine inhalation therapy equipment and local heating therapy equipment. The oxygen-carrying fumigation therapy equipment, the electronic acupuncture therapy equipment, the far infrared therapy lamp, the traditional Chinese medical massage equipment, the moxibustion rehabilitation equipment, the traditional Chinese medical cupping therapy equipment, the Chinese and western medicine inhalation therapy equipment and the local heating therapy equipment are integrated and are connected to one another through intelligent integrated control equipment; various traditional Chinese medical rehabilitation therapy functions of the multifunctional and intelligent traditional Chinese medical rehabilitation therapy robot can be fulfilled; the multifunctional and intelligent traditional Chinese medical rehabilitation therapy robot can be used for treating diseases of a plurality of patients simultaneously and can also be used for treating various diseases of a patient; and the functionality and the practicality of a traditional Chinese medical therapy device are improved.

Owner:韩雪海

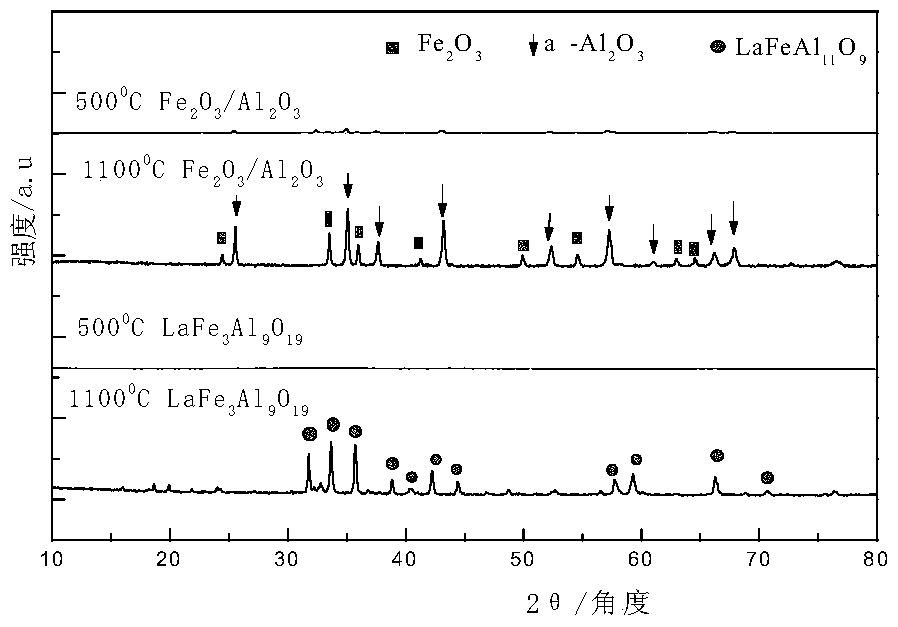

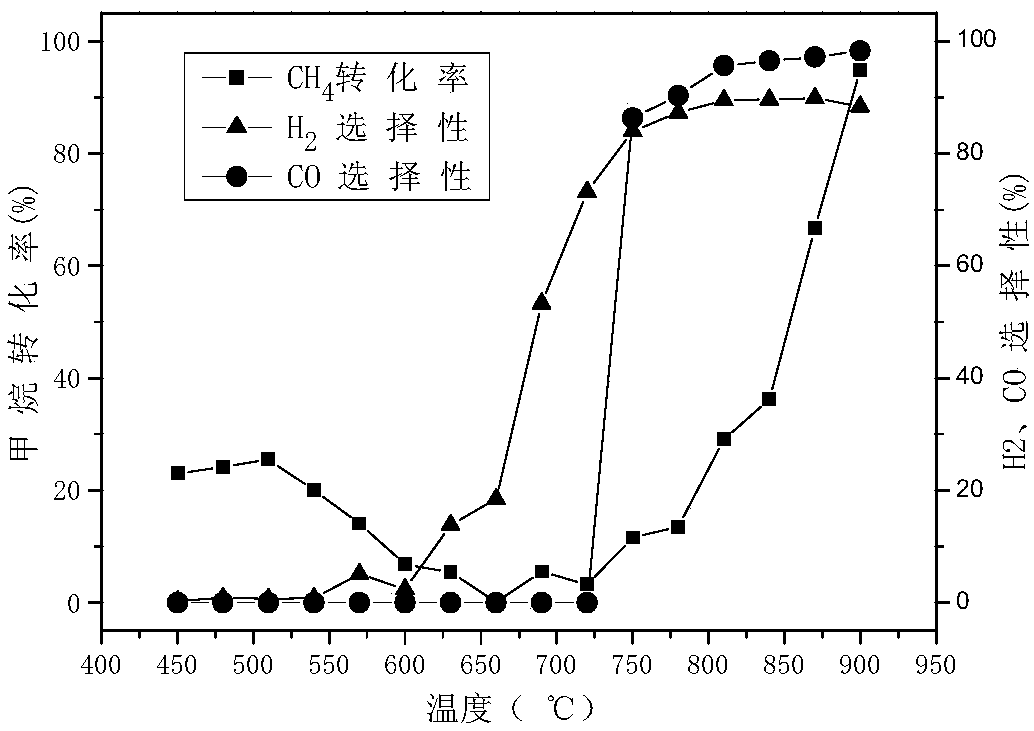

Oxygen carrier for chemical cycle dry gas reforming, and preparation method and application of oxygen carrier

ActiveCN105056955AEasy to prepareEase of industrial productionHydrogenMetal/metal-oxides/metal-hydroxide catalystsFiltrationRare earth

The invention provides an oxygen carrier for chemical looping dry gas reforming, and a preparation method and application of the oxygen carrier. The oxygen carrier is a composite metal oxide adopting a hexaaluminate structure, and has the general formula of AMxAl(12-x)O19, wherein A is rare earth metal lanthanum and / or barium, M is transition metal Fe, and x is greater than 0 or smaller than 5. The temperature of the oxygen carrier in a fuel reactor is 750-1000 DEG C, and the temperature of the oxygen carrier in an oxidation reactor is 750-1000 DEG C, and both of the reaction pressures are normal pressure. The preparation method comprises the following steps: using iron nitrate, aluminum nitrate, lanthanum nitrate and / or barium nitrate as a precursor to prepare a nitrate solution; adding ammonium carbonate as a precipitant for coprecipitation; performing suction filtration, washing, drying and roasting to obtain the oxygen carrier. The oxygen carrier has the advantages of being larger in oxygen-carrying rate, higher in reactivity, excellent in shock-resistant mechanical property and high temperature stability, environmental-friendly, low in cost and easy to prepare.

Owner:NORTHWEST UNIV(CN)

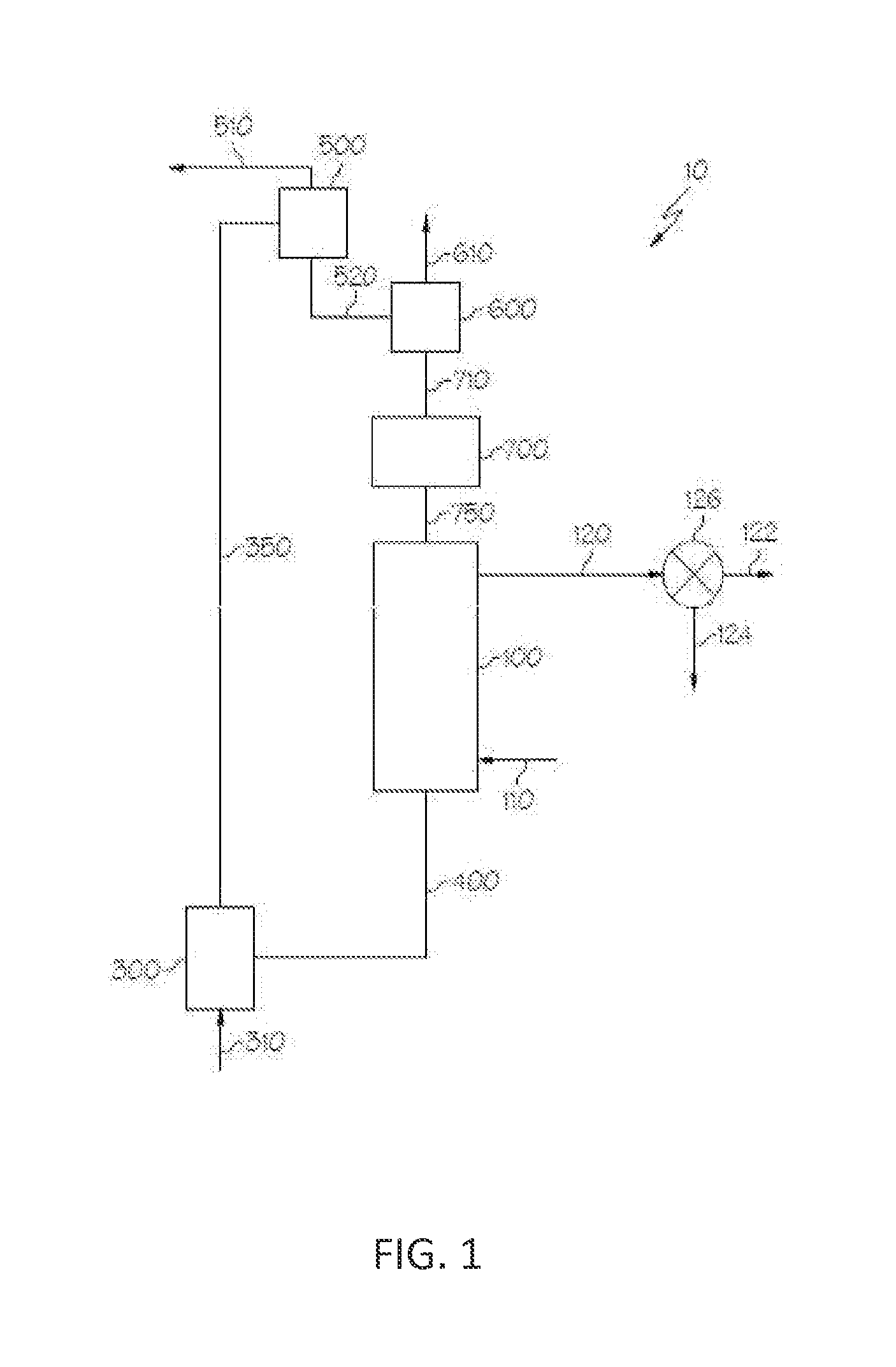

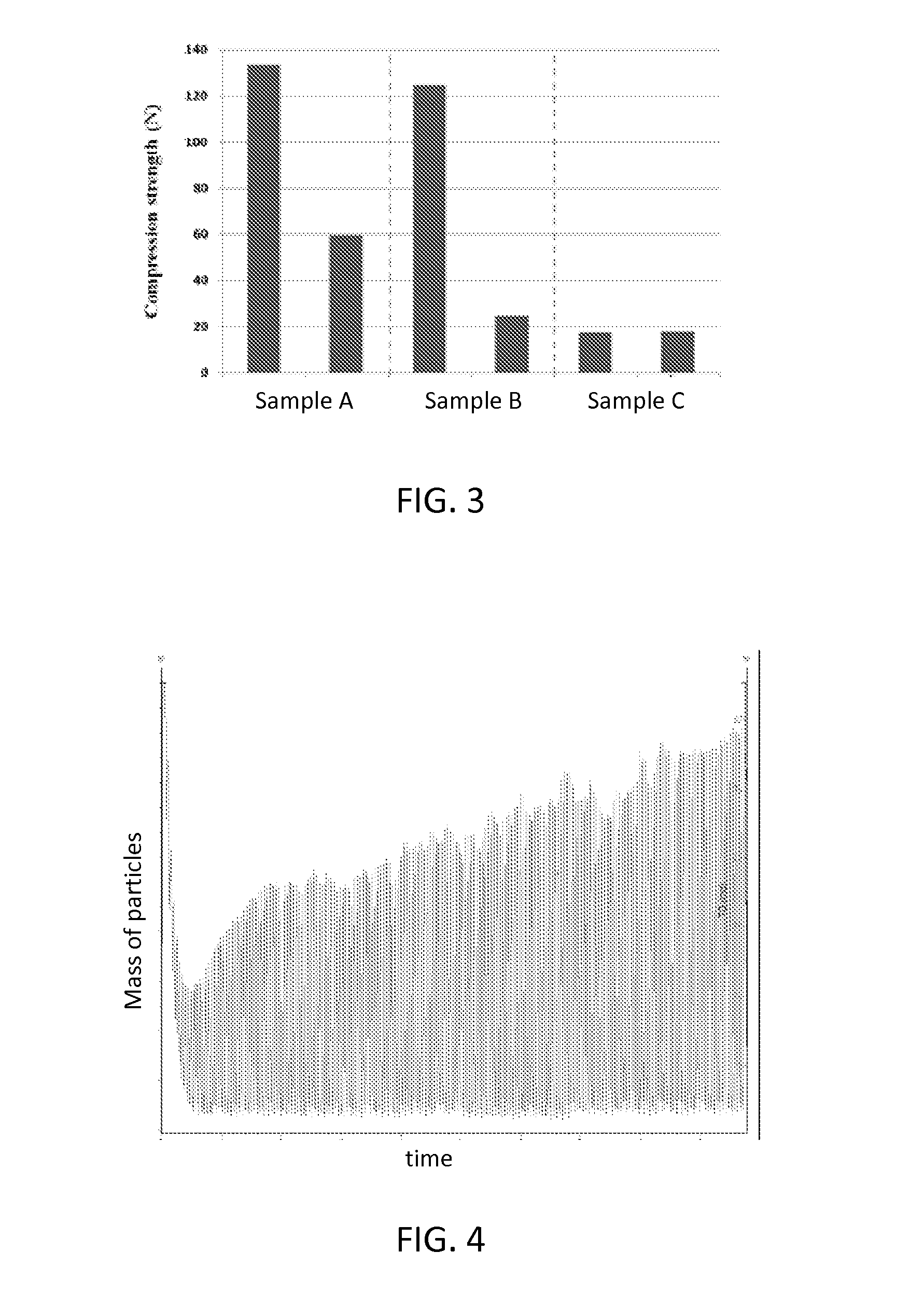

Oxygen carrying materials and methods for making the same

A method for producing an oxygen carrying material may include forming a mixture that includes powders of active mass precursor, support material precursor, and inert structure precursor, and producing the oxygen carrying material by heating the mixture at a temperature of greater than 1300° C. for a time sufficient to sinter the inert structure precursor to form a high-strength inert structure. The inert structure precursor may be one or more refractory ceramic components.

Owner:OHIO STATE INNOVATION FOUND

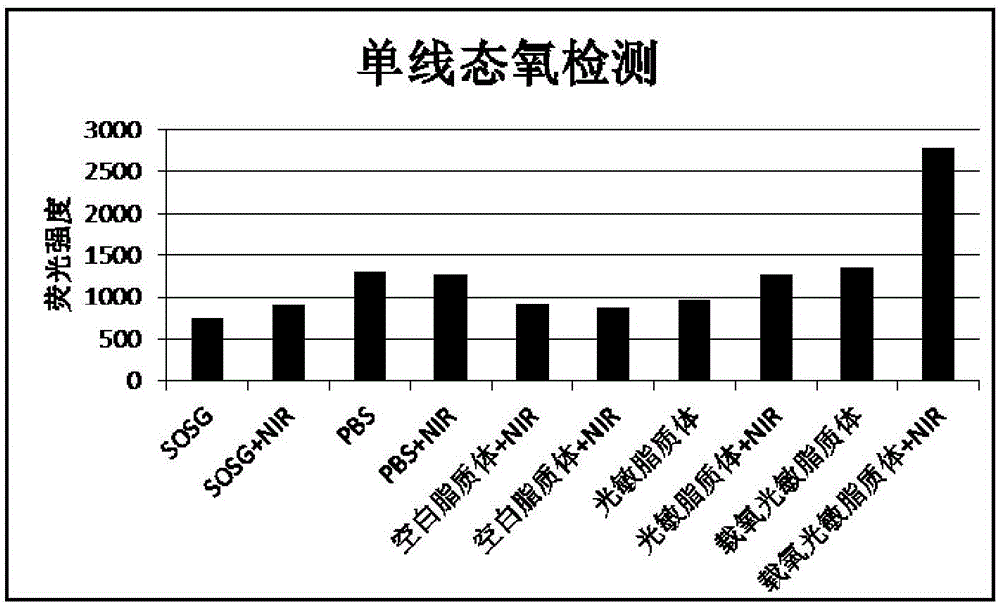

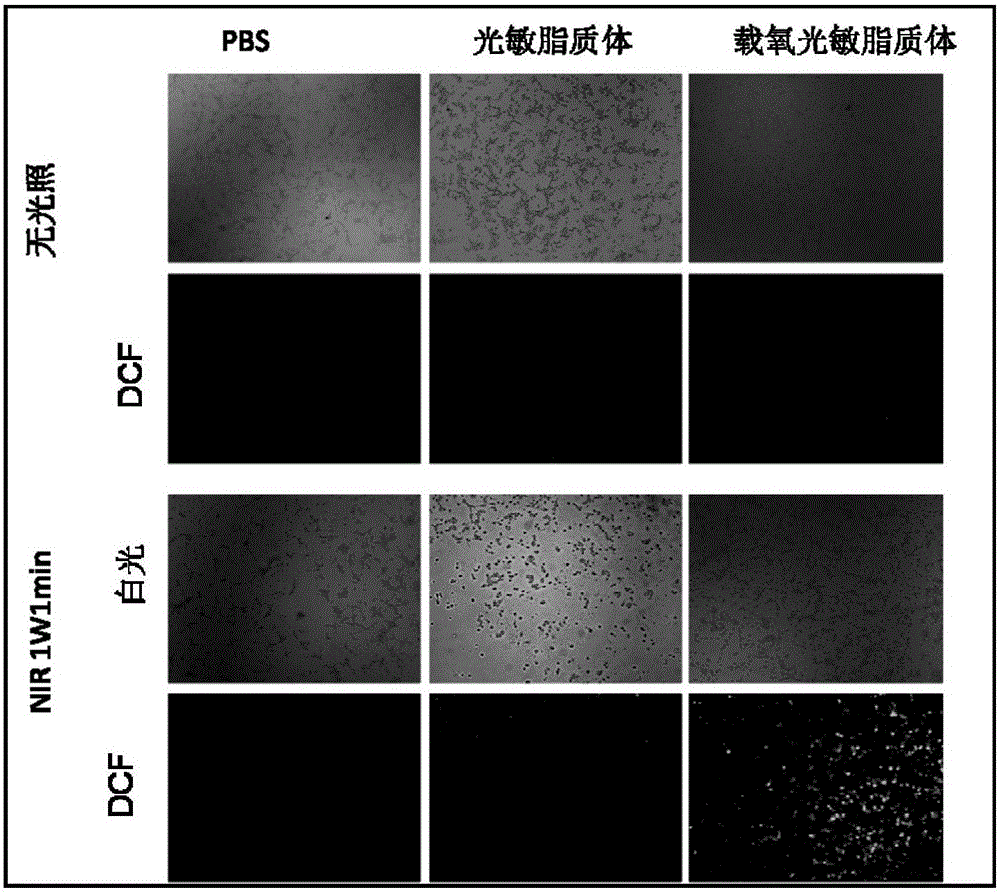

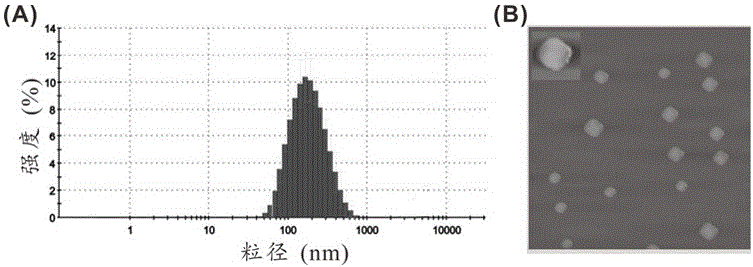

Oxygen-carrying enhanced photodynamic photosensitive liposome and preparation and application thereof

InactiveCN105997877AImprove the effect of chemotherapyImprove the effect of photodynamic therapyPeptide/protein ingredientsPhotodynamic therapyHydration reactionCholesterol

The invention provides a photosensitive liposome carrying oxygen to enhance photodynamics, which is composed of phospholipids, cholesterol, long-circulation materials, hemoglobin, and chemotherapeutic drugs and / or photosensitizers, each component is dissolved in an organic solvent, and the Steam to form a thin film, then add oxyhemoglobin solution, or a mixed solution of photosensitizers and / or chemotherapeutic drugs and oxyhemoglobin, and hydrate to obtain a multilayer liposome solution, which is obtained by ultrasonication and purification. The liposome of the present invention can simultaneously carry oxygen, chemotherapeutic drugs and / or photosensitizers to the tumor site, alleviate the hypoxic state of tumor cells, improve the sensitivity of tumor cells to chemotherapeutic drugs, inhibit tumor growth and metastasis, and can also Under the irradiation of near-infrared light, the photosensitizer in the liposome generates more singlet oxygen, resulting in an enhanced photodynamic therapy effect. The loaded drug molecules are released to realize remote control of drug release.

Owner:ZHEJIANG UNIV

Methods and compositions to reduce scattering of light during therapeutic and diagnostic imaging procedures

InactiveUS20050113678A1Reduce signal attenuationImprove image qualityDiagnostics using tomographySensorsBlood substituteIn vivo

Disclosed are improved methods and compositions for use in light-based in vivo imaging and treatment. The techniques described involve the use of low-scattering, oxygen-carrying blood substitutes in imaging and treatment methods, including OCT imaging. The invention has particular advantages in imaging within the cardiovascular system and highly vascularized or oxygen-dependent tissues.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

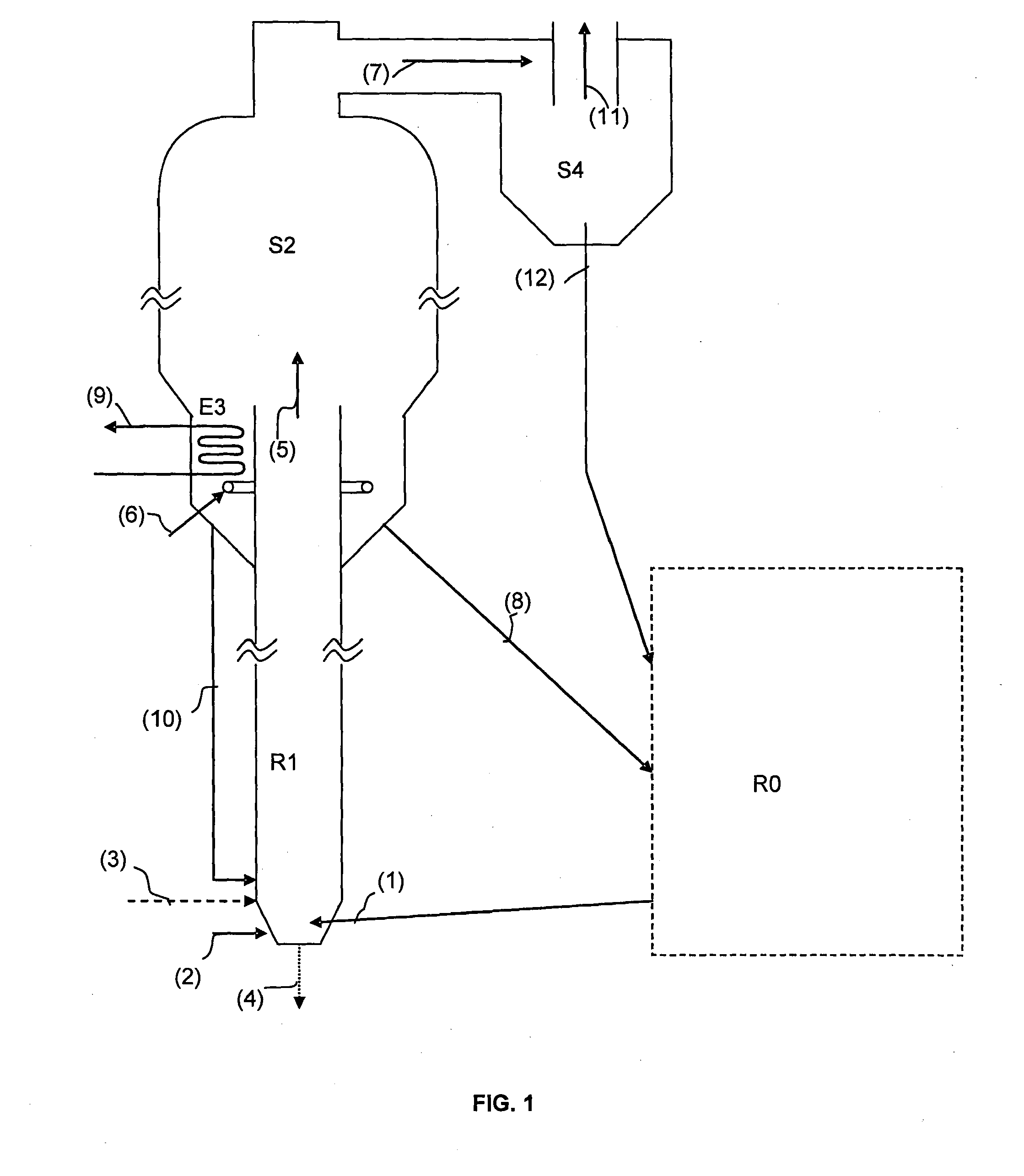

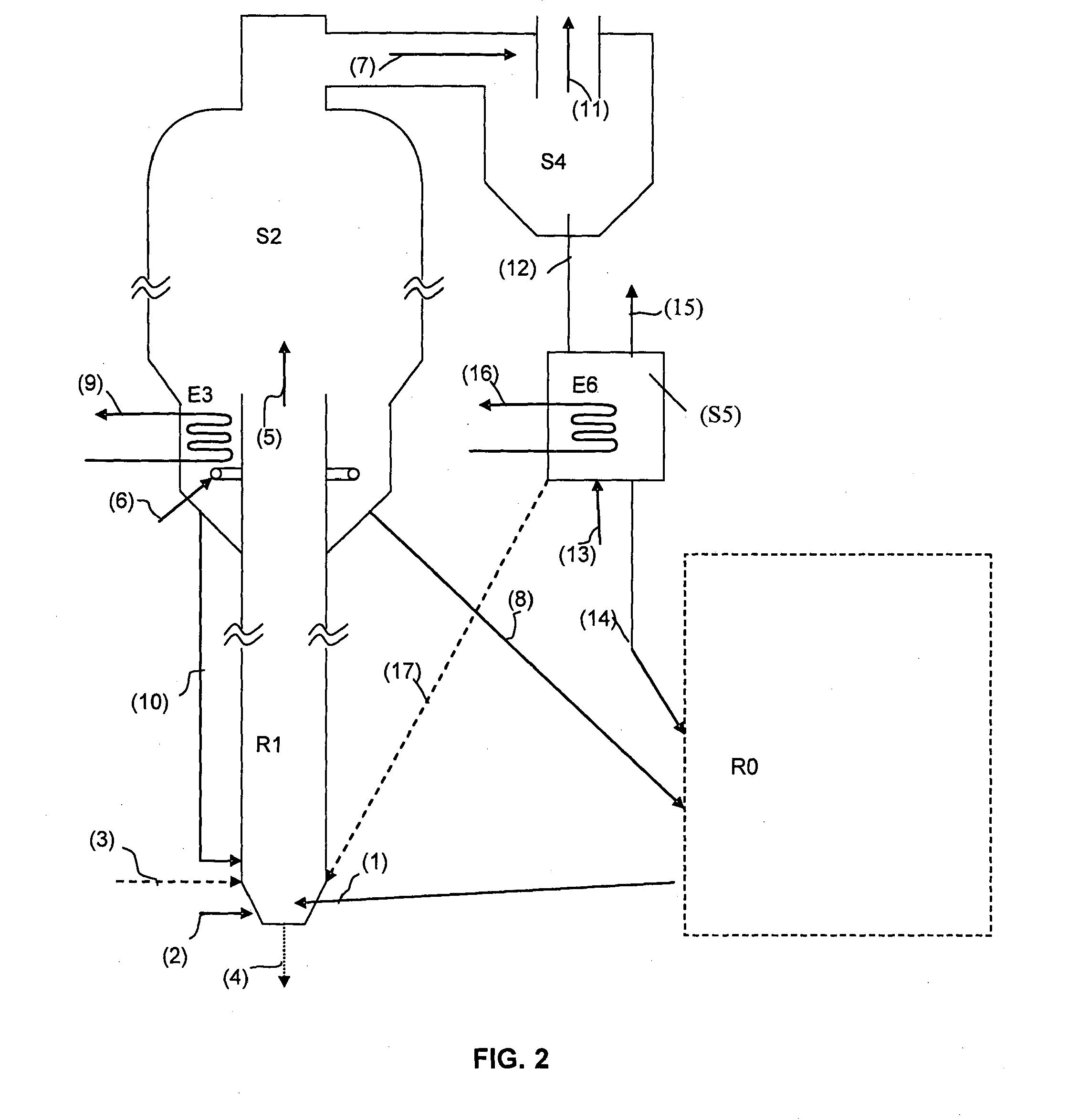

Chemical-looping combustion method with dilute phase removal of ashes and fines in the oxidationzone and plant using same

The invention relates to a method for chemical-looping combustion of a hydrocarbon-containing feedstock, comprising:contacting oxygen-carrying material particles coming from a reduction zone R0 with an oxidizing gas stream in a reactive oxidation zone R1,separating the fly ashes, the fines and the oxygen-carrying material particles within a mixture coming from zone R1 in a dilute phase separation zone S2, the driving force required for dilute phase elutriation in S2 being provided by the oxidizing gas stream from reactive oxidation zone R1. Optionally, partitioning is carried out in a dedusting zone S4, then possibly in a dense phase elutriation separation zone S5. The invention also relates to a chemical-looping combustion plant allowing said method to be implemented.

Owner:TOTALENERGIES ONETECH +2

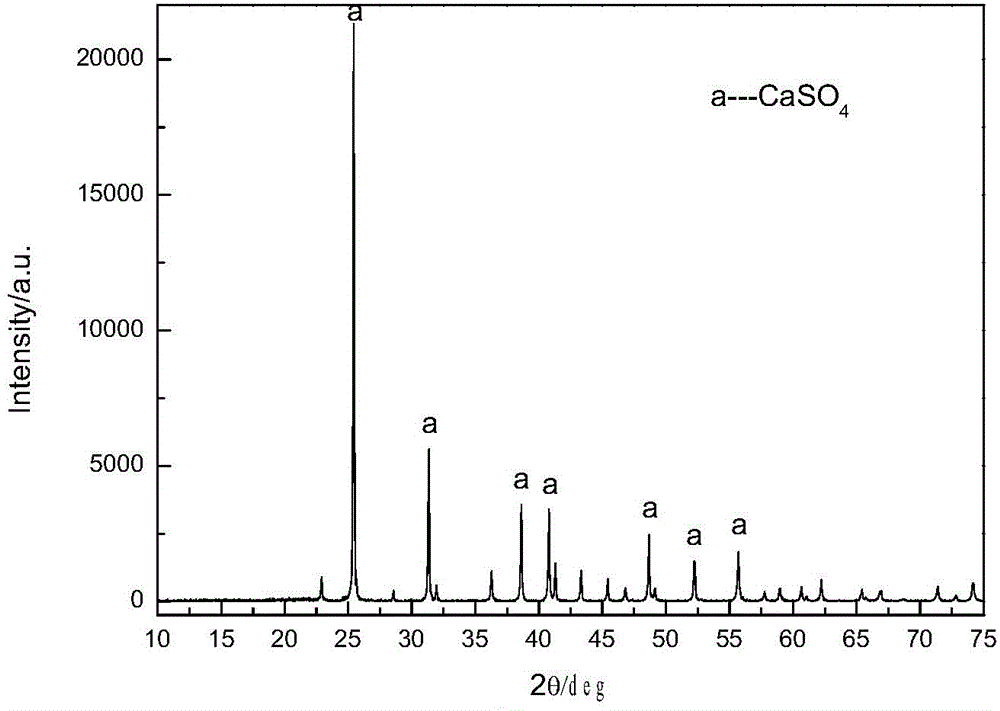

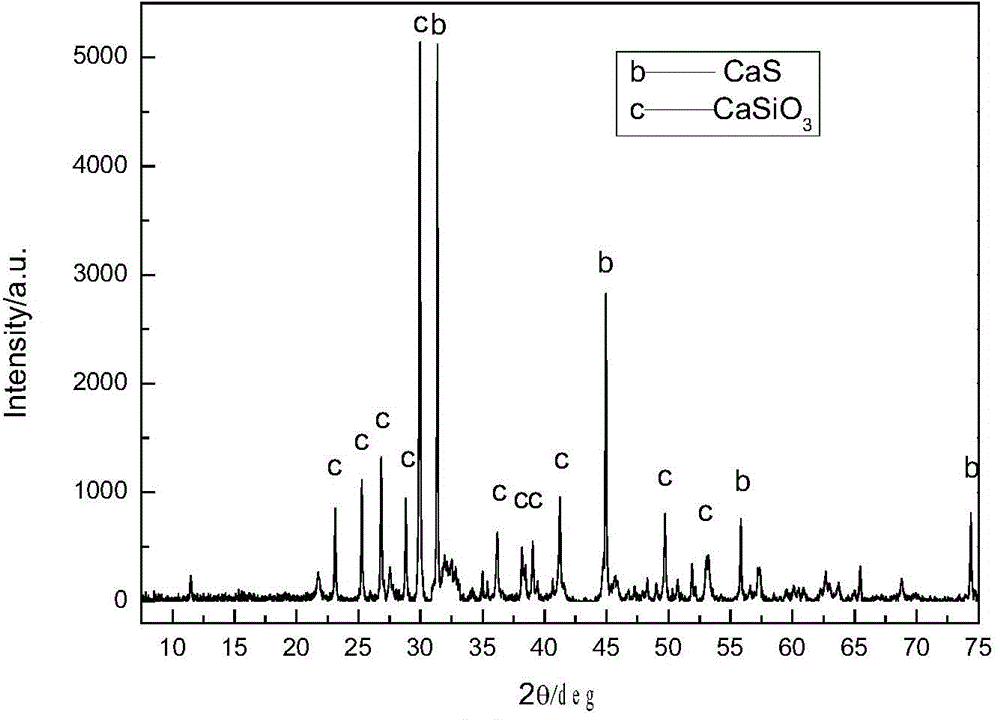

Method for preparing calcium-based oxygen carrier

ActiveCN104164273ALow priceHigh mechanical strengthPhysical/chemical process catalystsFuel additivesBall millChemistry

The invention belongs to the technical field of preparation of an oxygen carrier in a chemical chain combustion system, and particularly relates to a method for preparing a calcium-based oxygen carrier. The oxygen carrier is prepared by the following steps: with calcium sulfate as a main body material, and pseudo-boehmite, silica sol and the like as inert components, adding calcium sulfate powder, the inert components and a proper amount of water to a ball mill; fully mixing; and carrying out an extrusion forming process, a drying process and a calcining process to obtain a stripe oxygen carrier with certain mechanical strength. The method has the advantages of being simple in preparation method, and the prepared oxygen carrier is low in price, high in oxygen carrying capacity, high in mechanical strength and the like. According to the preparation method of the calcium-based oxygen carrier with industrial potential, provided by the invention, the problems that the oxygen carrier is difficult to mold and poor in mechanical strength in the prior art are solved.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

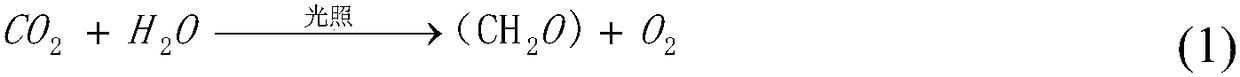

Combined heat and power generation system based on solar energy integrated oxygen-enriched combustion and chemical looping combustion and working method thereof

InactiveCN108507188AReduce sinteringBig investmentBioreactor/fermenter combinationsSolar heating energyHigh energyPower cycle

The invention discloses a combined heat and power generation system based on solar energy integrated oxygen-enriched combustion and chemical looping combustion and a working method thereof. A solar thermal chemistry process and a fuel power cycle are organically coupled by the system, so that the step utilization of the solar energy is realized; on one hand, a reduced oxygen-carrying body is usedfor converting the solar energy into chemical energy to be stored in an oxygen-carrying body heat accumulator, necessary heat energy is provided for the chemical looping combustion; and on the one hand, the characteristic that the CO2 is released by absorbing CO2 through the photosynthesis of microalgae under light illumination is utilized, pure O2 is provided for the oxygen-enriched combustion, and secondary air is provided for an air reactor; in addition, by complementary integration of the oxygen-enriched combustion system and the chemical looping combustion system, and the reasonable and efficient utilization of the fuel is realized; and meanwhile, the pure CO2 generated through oxygen-enriched combustion and chemical looping combustion is used for pushing a turbine to generate electricity for heat supply, so that the problem of high energy consumption and high cost due to the fact that CO2 is trapped and separated is solved, the CO2 flue gas waste heat can be effectively utilized.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

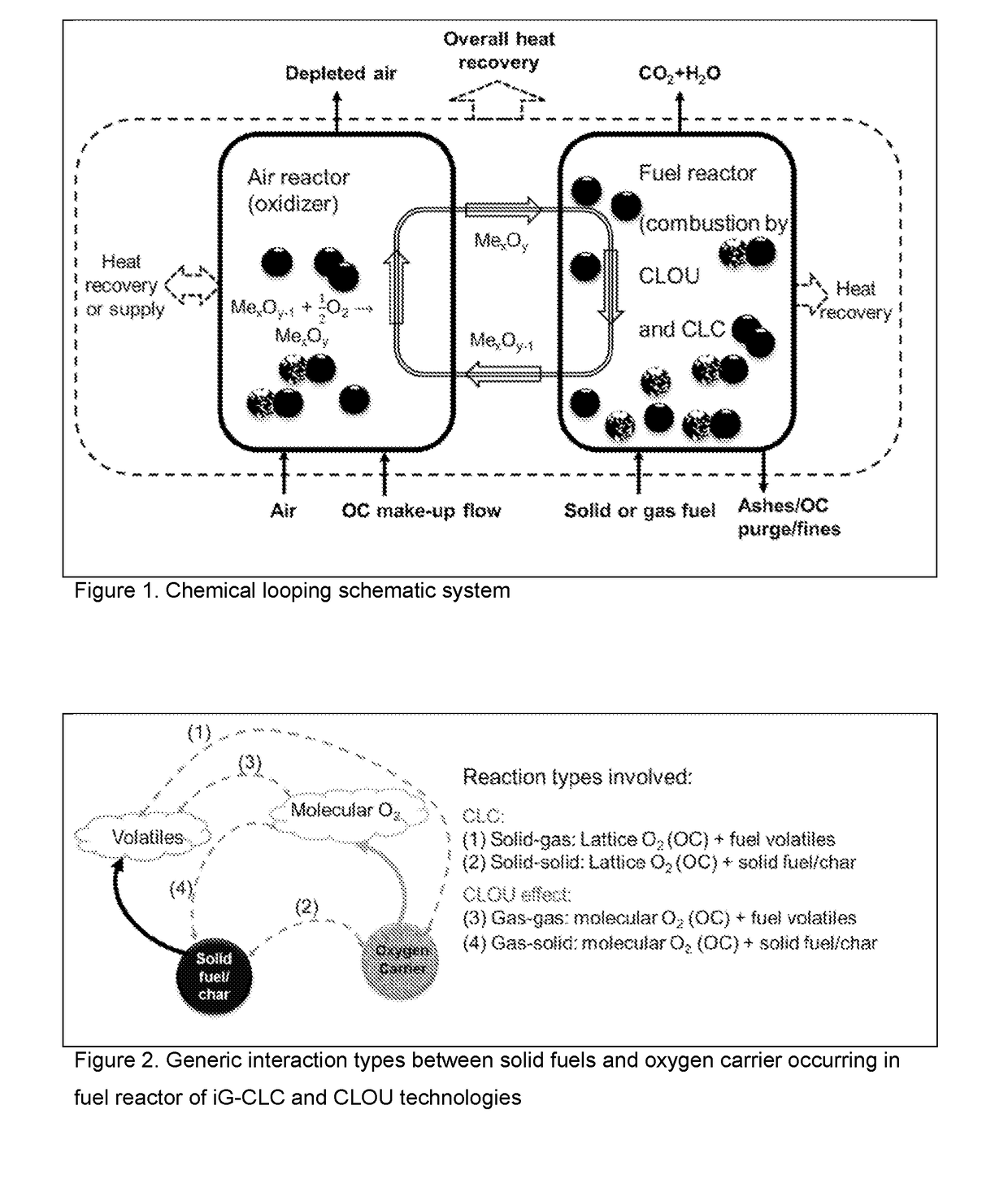

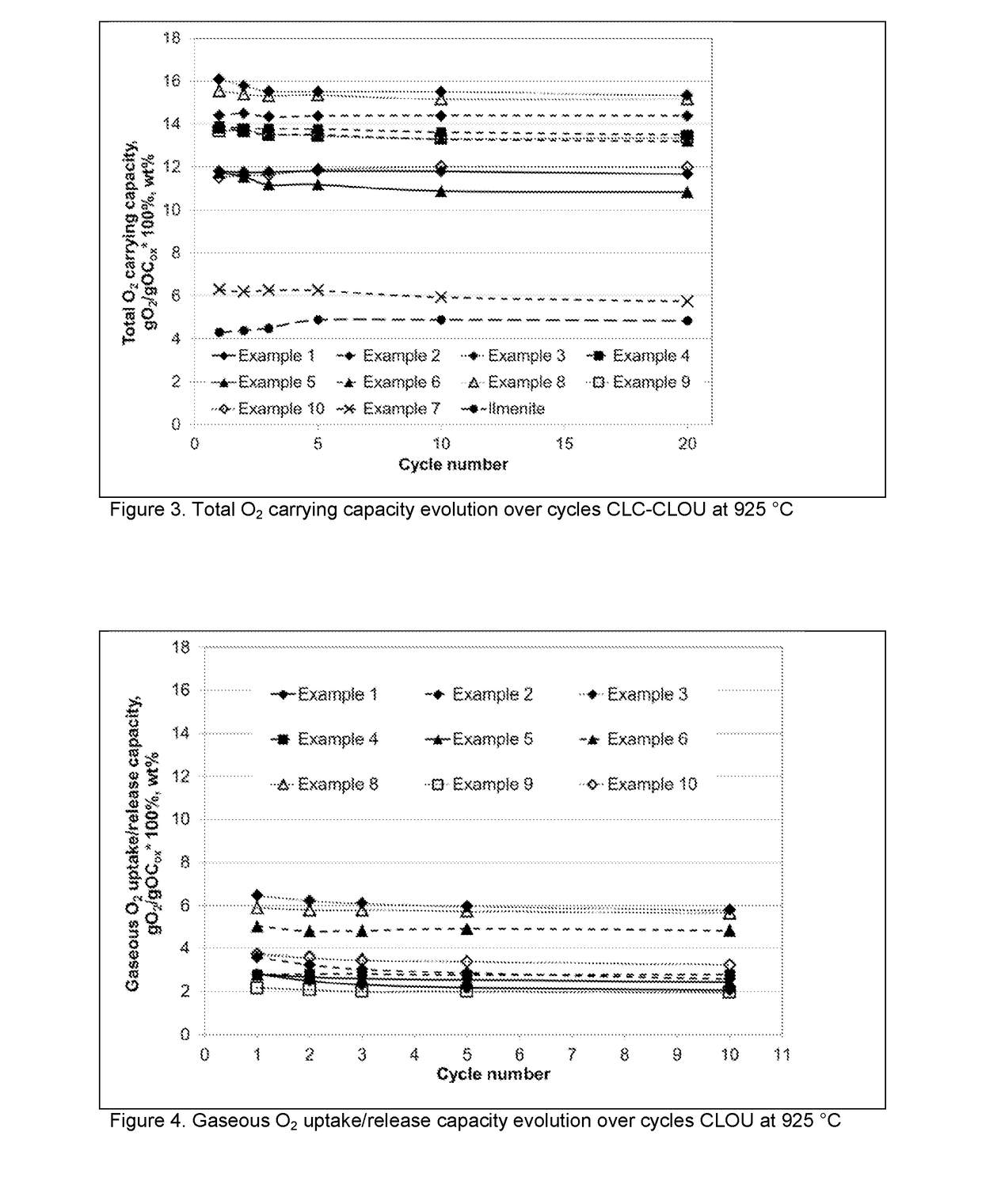

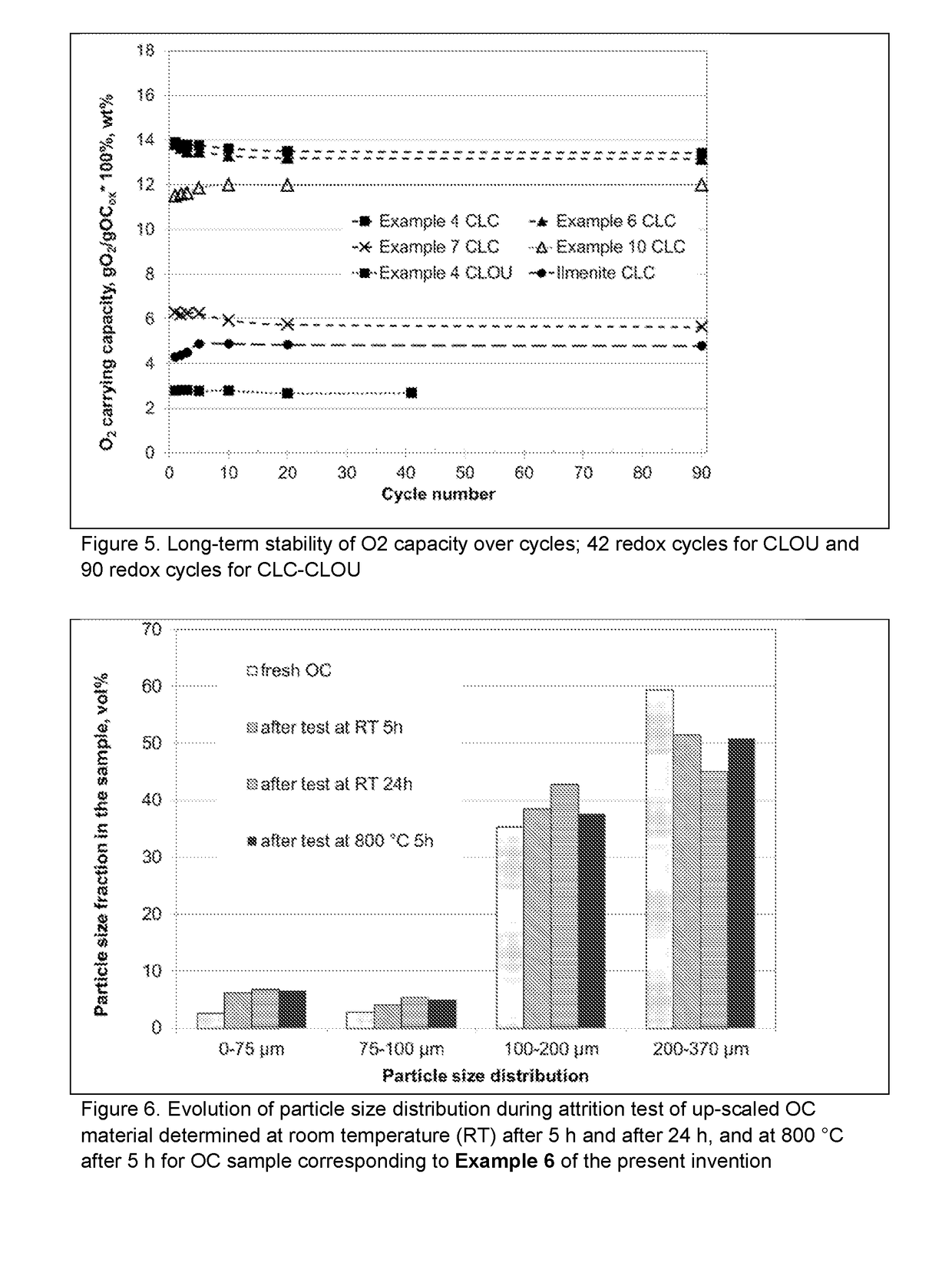

Sustainable Oxygen Carriers for Chemical Looping Combustion with Oxygen Uncoupling and Methods for Their Manufacture

InactiveUS20190003704A1Simple and scalable and cost-effective methodImprove mechanical stabilityFluidized bed combustionCatalytic crackingCarrying capacityCompound (substance)

An oxygen carrier (OC) for use in Chemical Looping technology with Oxygen Uncoupling (CLOU) for the combustion of carbonaceous fuels, in which commercial grade metal oxides selected from the group consisting of Cu, Mn, and Co oxides and mixtures thereof constitute a primary oxygen carrier component. The oxygen carrier contains, at least, a secondary oxygen carrier component which is comprised by low-value industrial materials which already contain metal oxides selected from the group consisting of Cu, Mn, Co, Fe, Ni oxides or mixtures thereof. The secondary oxygen carrier component has a minimum oxygen carrying capacity of 1 g of O2 per 100 g material in chemical looping reactions. Methods for the manufacture of the OC are also disclosed.

Owner:INSTITUTT FOR ENERGITEKNIKK

Cross-linked hemoglobin preparation method and organ perfusate comprising hemoglobin

InactiveCN110563836AIncrease join speedReduce complexityAntibody mimetics/scaffoldsHaemoglobins/myoglobinsLiquid ChangeCross-link

The invention discloses a cross-linked hemoglobin preparation method, wherein the preparation method comprises the following steps: a, diluting deoxidized hemoglobin, and adding the diluted deoxidizedhemoglobin into an anaerobic reactor; b, arranging an atomizer at the top of the anaerobic reactor, adding a cross-linking agent into the reactor through the atomizer, and carrying out a cross-linking reaction; and c, adding a reducing agent to terminate the cross-linking reaction, and removing the unreacted cross-linking agent and the terminating reducing agent in an ultrafiltration liquid changing manner to obtain the cross-linked hemoglobin. The cross-linked hemoglobin prepared by the preparation method contains low contents of macromolecules (greater than 500 kD) and micromolecules (lessthan 64 kD); by adding the cross-linked hemoglobin into organ perfusate, the phenomena of organ acidosis and lysosomal enzyme activation adverse consequences caused by lack of an oxygen carrying agentin conventional perfusate and cell damage caused by excessive free radicals generated during reperfusion can be solved, and the perfusate is quite simple and convenient to prepare, store, transport and use.

Owner:REDPHARM BEIJING BIOPHARMACEUTICAL INST CO LTD

Low-carbon alkane chemical chain oxydehydrogenation to olefin technology

InactiveCN108046973ALimit optionsHigh energy consumptionCatalyst regeneration/reactivationHydrocarbonsWater vaporLattice oxygen

The invention relates to a design of low-carbon alkane (C2-C5) chemical chain oxydehydrogenation to olefin technology. A catalyst adopted by the technology is a novel bifunctional catalyst, a metallicoxide with an oxygen-carrying function is used as an oxygen carrier to provide lattice oxygen for oxidative dehydrogenation, and a metal active ingredient with a dehydrogenation function is loaded onthe metallic oxide. According to the technology, a fixed bed, a circulating fluidized bed or a moving bed can be taken as a reactor, in the oxidative dehydrogenation process, the metal active ingredient can be taken as a dehydrogenation active center, the reaction of dehydrogenation of alkane to olefin is taken place in the reactor, the lattice oxygen carried by the oxygen carrier can be selectively reacted with H2 generated in the dehydrogenation to oxidize the H2 to steam, when the reaction is completed, the catalyst losing the lattice oxygen is oxidized and regenerated in the air to supplement the lattice oxygen while carbon deposit is removed, and the reactivity of the catalyst is recovered. Compared with a traditional technology, in situ oxidation is conducted on the H2 generated inthe dehydrogenation to greatly improve percent conversion of the alkane and olefin yield, demands of catalytic reaction and catalyst regeneration can be met simultaneously, the dehydrogenation can beconducted at a lower temperature, the oxidized and regenerated catalyst carries a large amount of heat which can be provided for the dehydrogenation to achieve an operation of self-heating in the dehydrogenation process, and energy consumption can be greatly reduced by means of the designs.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Compositions for oxygen transport comprising a high oxygen affinity modified hemoglobin

InactiveUS20050026816A1Earlier and safer intervention in patient treatmentLow toxicityPeptide/protein ingredientsMammal material medical ingredientsWhole blood productOxygenated Hemoglobin

The present invention relates to blood products, and more particularly to compositions comprising a modified oxygenated hemoglobin having a high affinity for oxygen and methods for making such compositions. Such compositions according to the present invention have better stability to autooxidation and superior oxygen carrying characteristics.

Owner:SANGART INC

Aptamer modified oxygen-carrying and medicine-carrying multifunctional liposome compound

InactiveCN106821985AEasy to prepareImprove stabilityOrganic active ingredientsInorganic active ingredientsDispersityTumor target

The invention discloses an aptamer modified oxygen-carrying and medicine-carrying multifunctional liposome compound. The compound contains a liposome, a chitosan derivative, an anti-cancer medicine and an oxygen-carrying body, wherein the liposome is prepared from lecithin and cholesterol, the chitosan derivative is fixed in the liposome and is fixed by a nucleic acid aptamer of a targeting epidermal growth factor receptor (EGFR), and the anti-cancer medicine and the oxygen-carrying body are entrapped in the liposome. The liposome compound can be prepared by virtue of a hydration film method, the method is simple and convenient, and obtained nano-particles have uniform particle sizes and good dispersity; and the liposome compound has good tumor targeting ability, presents a remarkable synergistic effect with medicine molecules and is capable of reversing drug resistance caused by hypoxia of tumor cells, and the tumor treatment efficiency is improved, and the liposome compound can be applied to the treatment of lung cancers.

Owner:FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com