Method for preparing calcium-based oxygen carrier

An oxygen carrier and calcium-based technology, applied in chemical instruments and methods, fuel additives, petroleum industry, etc., can solve the problems of low mechanical strength and high price, and achieve the effect of high mechanical strength, low price and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

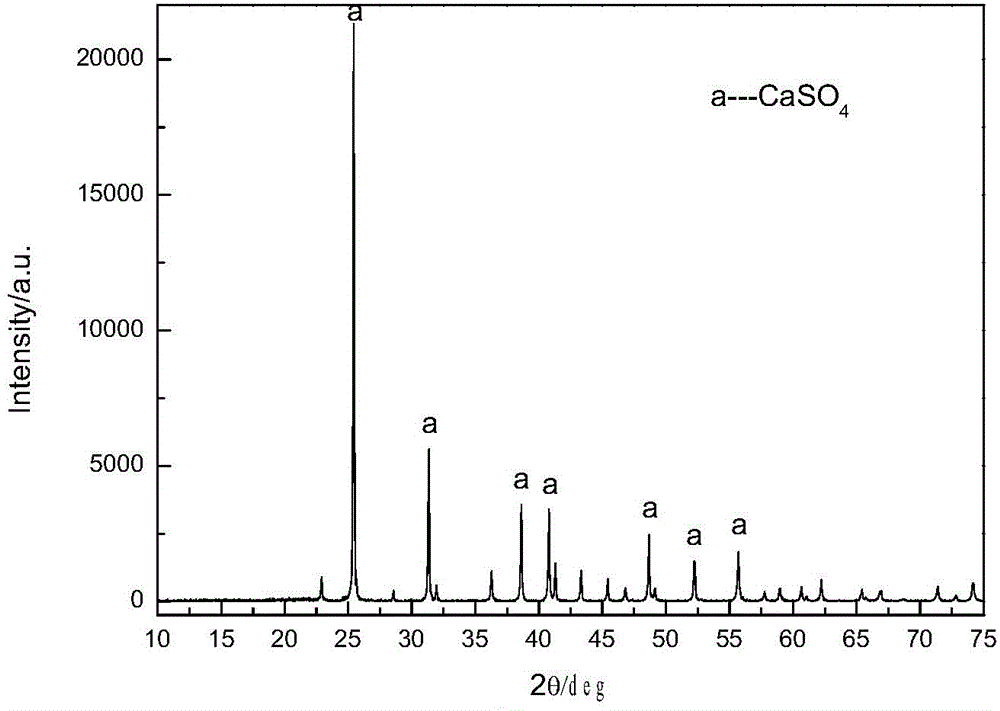

[0016] 40g calcium sulfate (CaSO 4 ) particles, 40ml silica sol and 10 large and small grinding balls are put into the ball mill jar together. Set the rotational speed of the ball mill to 200r / min, and the milling time to 6h. The product collected after ball milling was extruded into strips with a needle tube and other forming tools, and dried at room temperature for 12 hours. Finally, the shaped product is placed in a muffle furnace at 800° C. for calcination for 5 hours to obtain a strip-shaped oxygen carrier with an inert carrier loading of 50% (see figure 1 ).

[0017] The mechanical strength of the obtained oxygen carrier with a diameter of 2mm and a length of 4mm can reach 45.65N, and its mechanical strength is measured according to the average compressive strength of particles in GB 102012-88; at the same time, pure sulfuric acid without adding inert components is prepared under the same conditions The mechanical strength of calcium oxygen carrier is 0N.

Embodiment 2

[0019] 50g calcium sulfate (CaSO 4 ) particles, 50ml silica sol and 10 large and small grinding balls are put into the ball mill jar together. Set the rotational speed of the ball mill to 200r / min, and the milling time to 6h. The product collected after ball milling was extruded into strips with a needle tube and other forming tools, and dried at room temperature for 12 hours. Finally, the shaped product was placed in a muffle furnace at 800° C. for calcination for 5 hours to obtain a strip-shaped oxygen carrier with an inert carrier loading of 50%.

[0020] The mechanical strength of the obtained oxygen carrier can reach 45.65N, and the mechanical strength of the pure calcium sulfate oxygen carrier without adding inert components prepared under the same conditions is 0N.

Embodiment 3

[0022] 50g calcium sulfate (CaSO 4 ) particles, 10ml of silica sol, 20ml of deionized water and 10 large and small balls are put into the ball mill jar together. Set the rotational speed of the ball mill to 200r / min, and the milling time to 6h. The product collected after ball milling was extruded into strips with a needle tube and other forming tools, and dried at room temperature for 12 hours. Finally, the shaped product was placed in a muffle furnace at 800° C. for calcination for 5 hours to obtain a strip-shaped oxygen carrier with an inert carrier loading of 16.7%.

[0023] The mechanical strength of the obtained oxygen carrier can reach 13N, and the mechanical strength of the pure calcium sulfate oxygen carrier without adding inert components prepared under the same conditions is 0N.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com