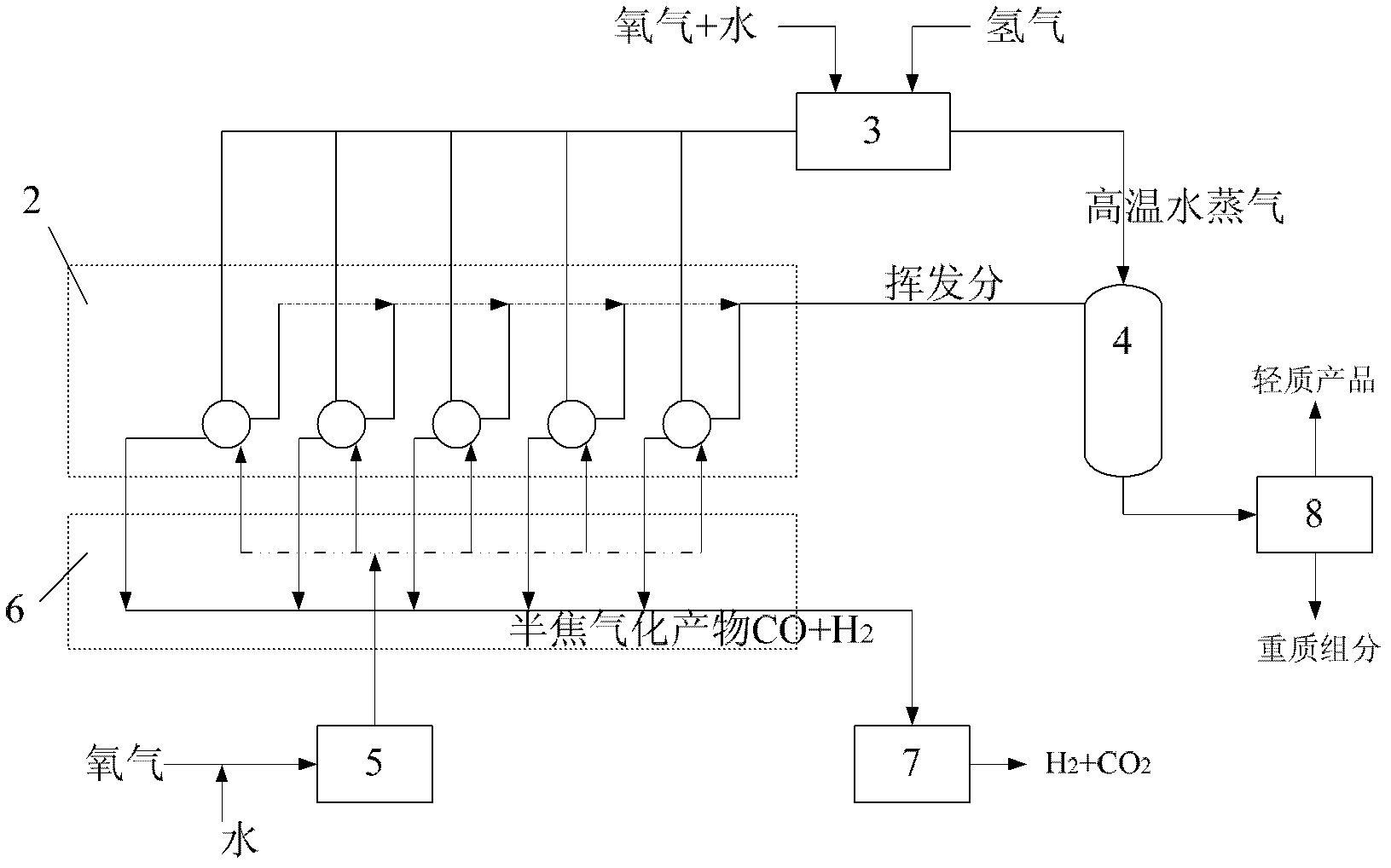

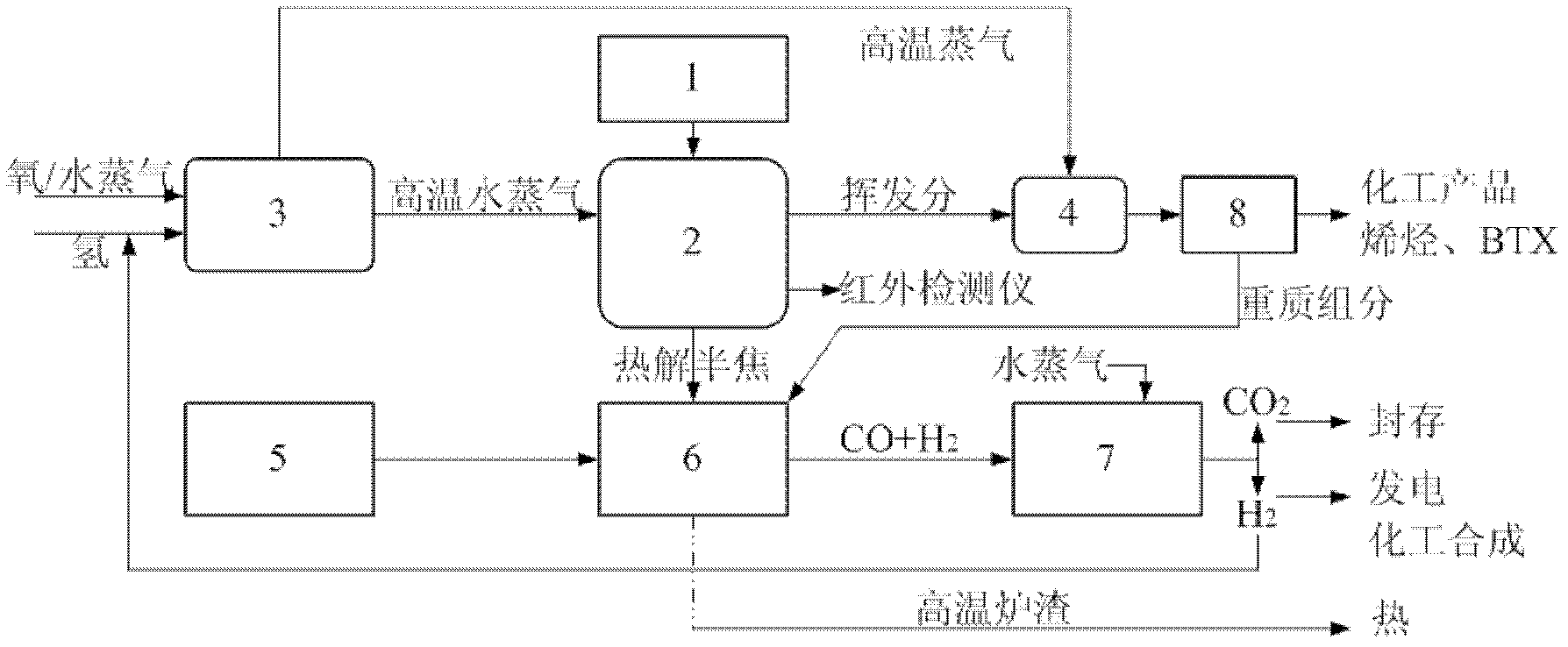

High-temperature water vapor pyrolysis-cracking-gasification device and method for solid fuel

A high-temperature water vapor and solid fuel technology, which is applied in the fields of gasification comprehensive utilization, solid combustion pyrolysis, and pyrolysis, can solve the problems of low tar yield, high content of heavy tar components, increased system and technical complexity, etc. problems, to achieve the effect of saving hydrogen consumption and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Raw material: a kind of bituminous coal with high volatile content, pellet particle size is 20-30mm

[0059] Features: Simulated moving bed pyrolysis reactor

Embodiment 2

[0063] Raw material: a kind of lignite with high volatile content, particle size less than 3mm

[0064] Features: Fluidized bed pyrolysis reactor

[0065] method of execution:

[0066]The coal sample is crushed to less than 3 mm, dried and sent to the feeder; then the material is sent to the fluidized bed pyrolysis reactor; under the high-temperature water vapor generated by the combustion of oxygen and a little excess hydrogen from the hydrogen-oxygen combustion controller Pyrolysis occurs under the action; through the infrared detector connected to the exhaust port of the pyrolyzer, the CO concentration at the outlet is detected in real time, and the average residence time of pulverized coal is adjusted to avoid the gasification reaction of semi-coke under the action of high-temperature water vapor. The thermal state of the volatile matter discharged from the pyrolyzer is directly sent to the thermal cracking reactor, where it is cracked with the high-temperature steam fro...

Embodiment 3

[0068] Raw material: Bituminous coal with high volatile content, pellet particle size of 20-30 mm

[0069] Features: fixed bed pyrolysis reactor

[0070] method of execution:

[0071] The coal sample is crushed and made into coal pellets of a size of 20 mm, which are dried and sent to the feeder; then the coal pellets are sent into a fixed-bed pyrolysis reactor (two pyrolysis reactors in parallel, used alternately); The hydrogen-oxygen combustion controller pyrolyzes under the action of high-temperature water vapor produced by combustion of oxygen and a little excess hydrogen; during the reaction process, the CO concentration at the outlet is detected by an infrared detector connected to the exhaust port of the pyrolyzer; when When the CO concentration starts to rise, stop the reaction in the pyrolyzer to avoid the gasification reaction between semi-coke and high-temperature water vapor; switch the valve so that high-temperature water vapor passes through another pyrolysis r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com