Patents

Literature

160 results about "Excess hydrogen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Excess hydrogen can cause problems in a variety of industries. It can corrode semiconductors, electronics, and nuclear fuel sitting in storage. It also poses an explosion hazard. To remove this extra hydrogen, chemists can use an organic compound called a hydrogen getter that chemically binds to several hydrogen atoms.

Hydrogen production from carbonaceous material

InactiveUS6790430B1Avoid the needCalcium/strontium/barium carbonatesGas turbine plantsCalcinationExothermic reaction

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE +1

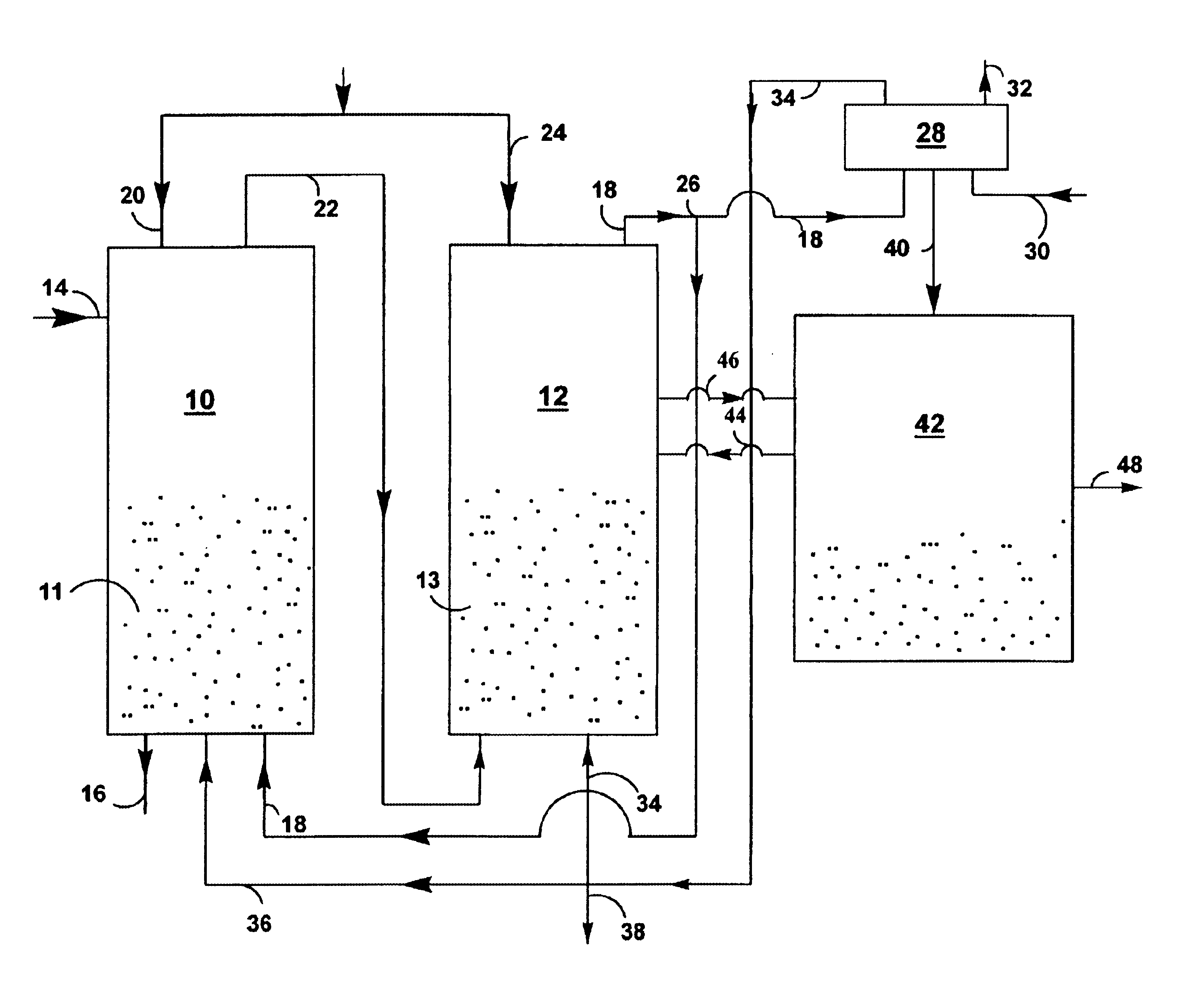

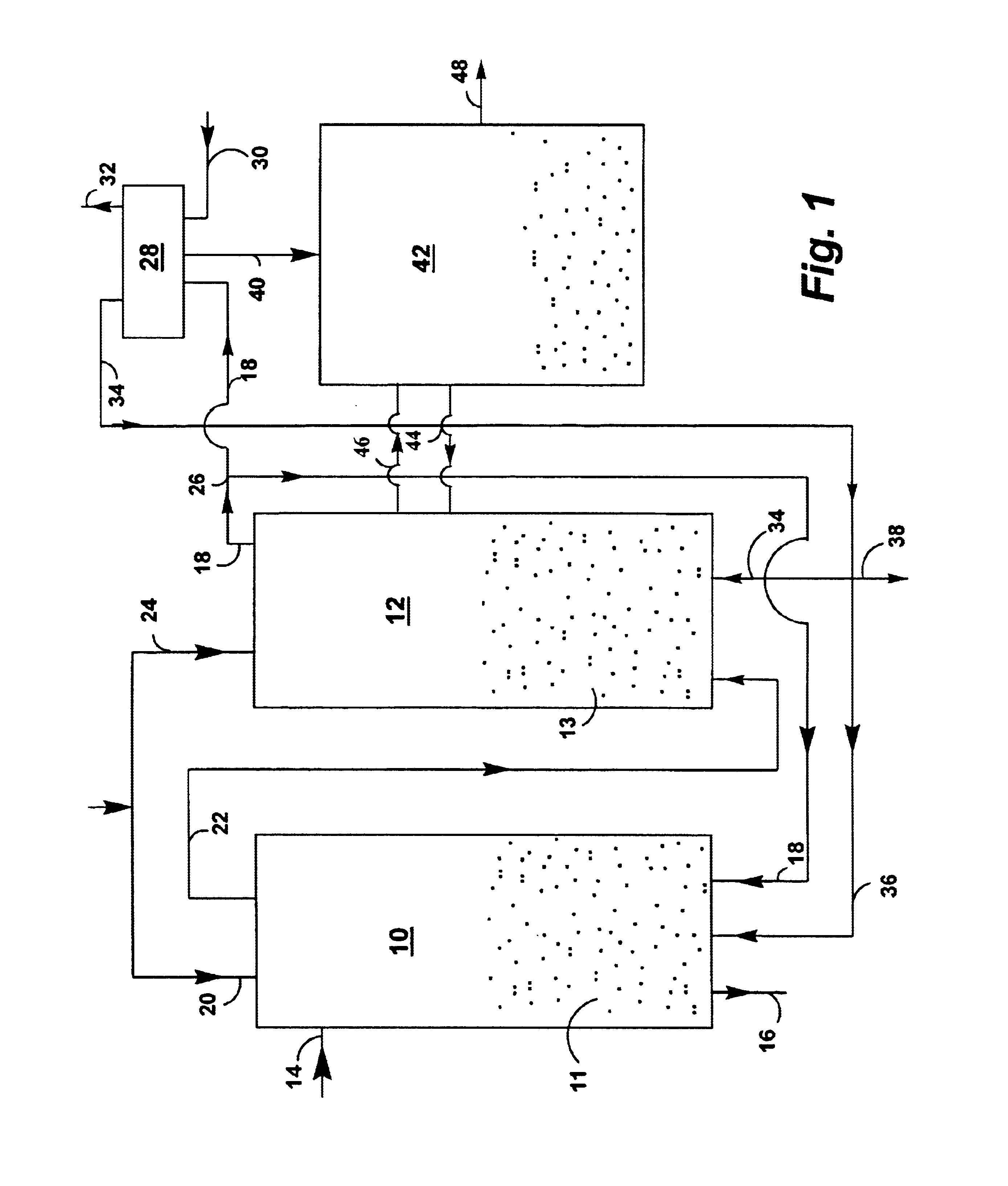

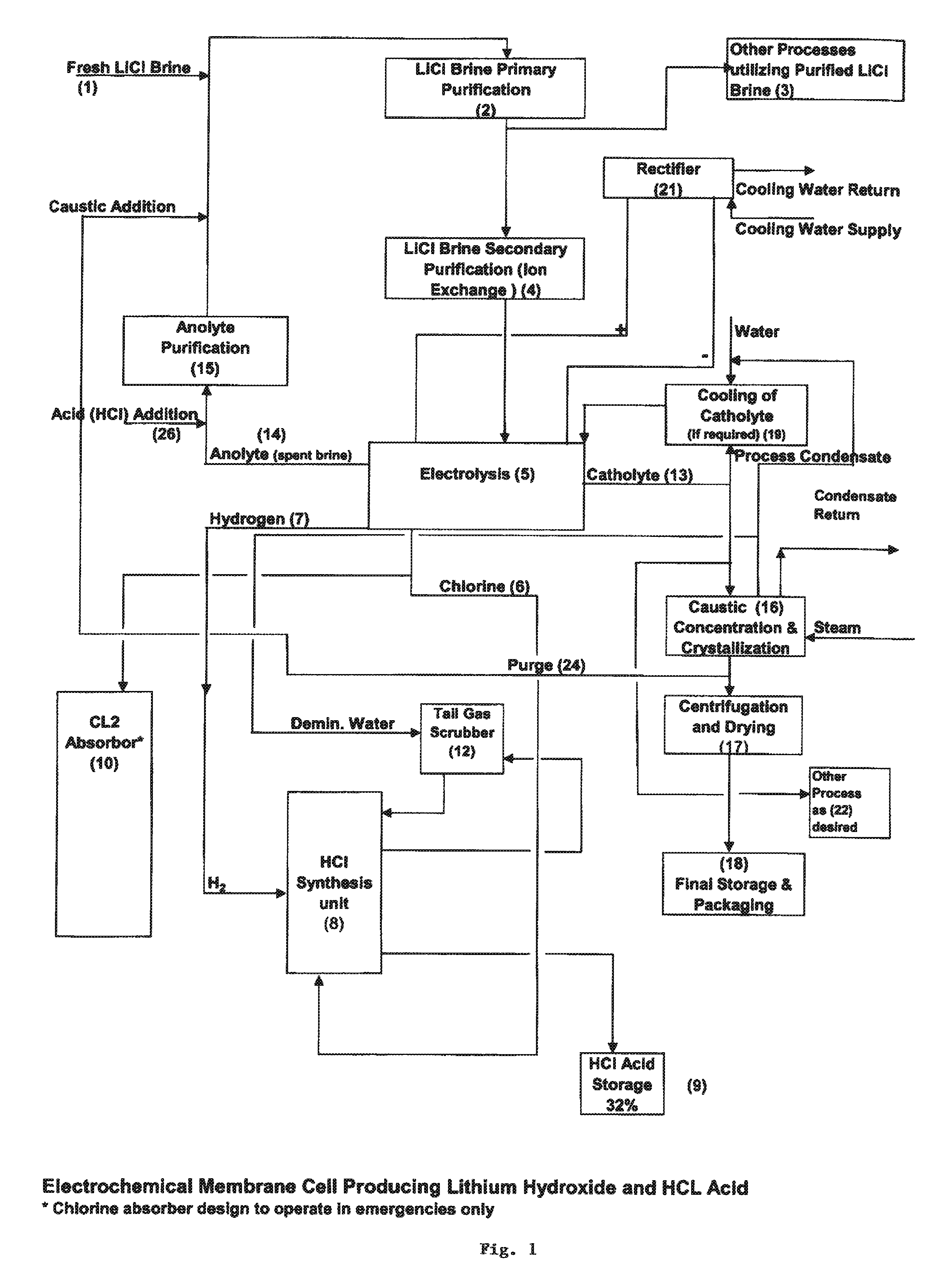

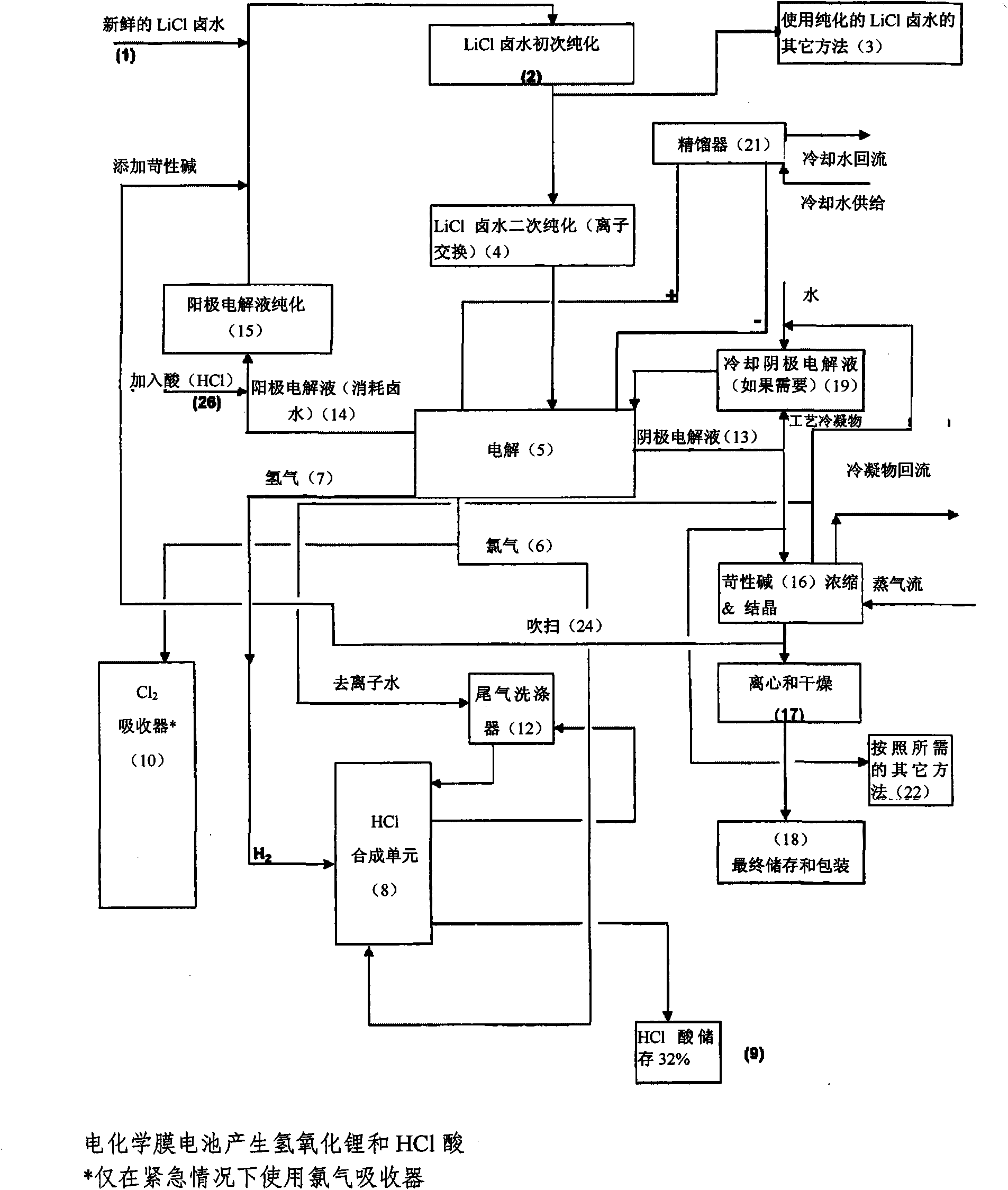

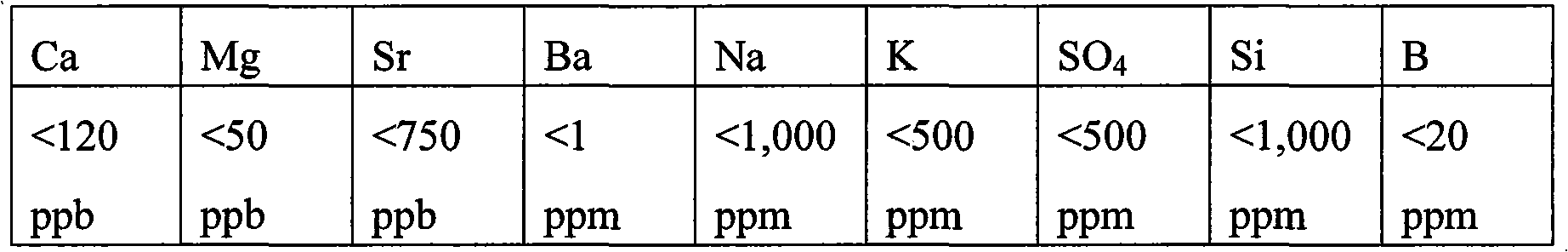

Method of making high purity lithium hydroxide and hydrochloric acid

InactiveUS20110044882A1Simple and economical processEasy to convertElectrolysis componentsEnergy inputElectrolysisIon exchange

The present invention relates to a process for producing high purity lithium hydroxide monohydrate, comprising following steps: concentrating a lithium containing brine; purifying the brine to remove or to reduce the concentrations of ions other than lithium; adjusting the pH of the brine to about 10.5 to 11 to further remove cations other than lithium, if necessary; neutralizing the brine with acid; purifying the brine to reduce the total concentration of calcium and magnesium to less than 150 ppb via ion exchange; electrolyzing the brine to generate a lithium hydroxide solution containing less than 150 ppb total calcium and magnesium, with chlorine and hydrogen gas as byproducts; producing hydrochloric acid via combustion of the chlorine gas with excess hydrogen and subsequent scrubbing of the resultant gas stream with purified water, if elected to do so; and concentrating and crystallizing the lithium hydroxide solution to produce lithium hydroxide monohydrate crystals.

Owner:ROCKWOOD LITHIUM INC

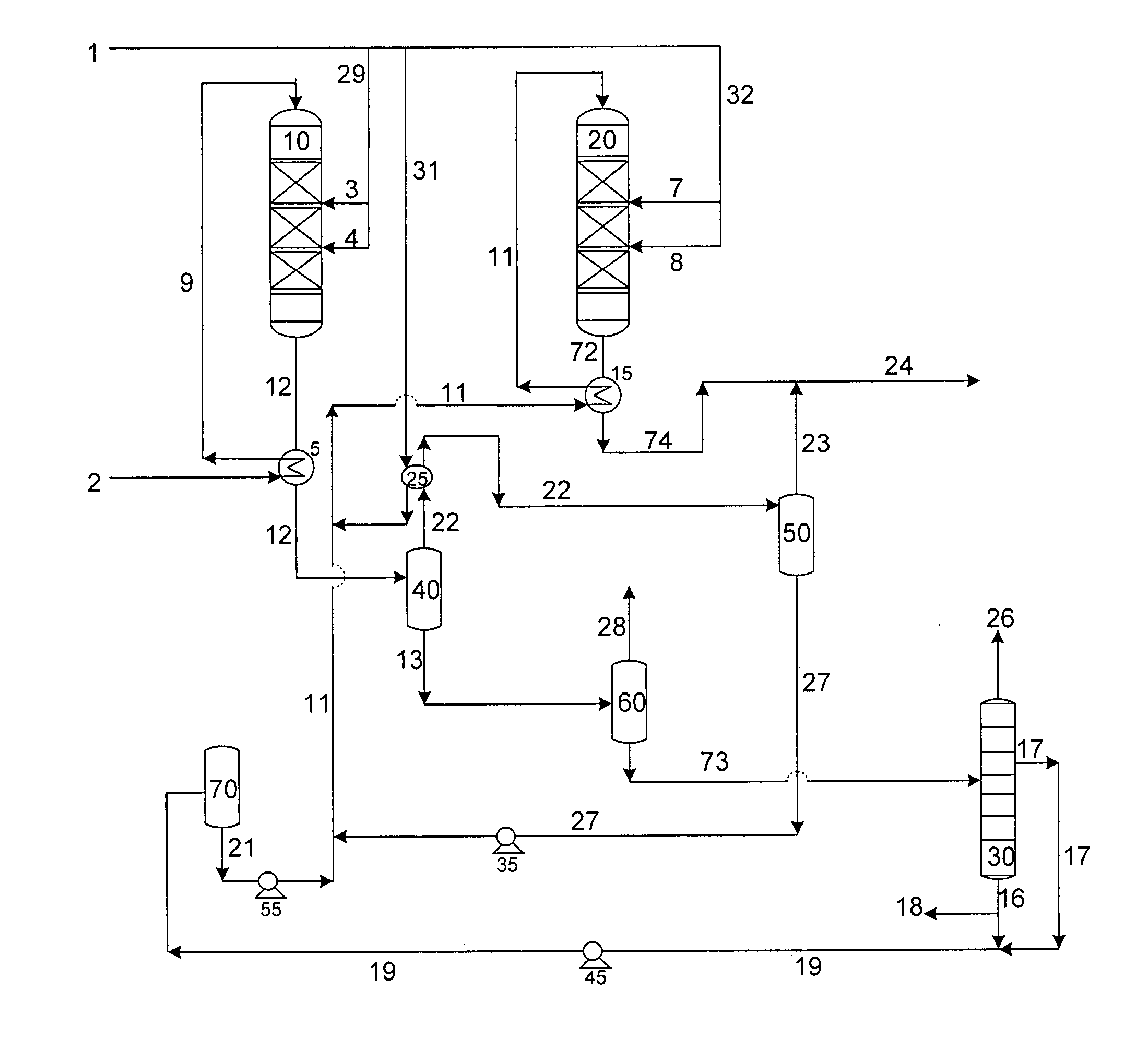

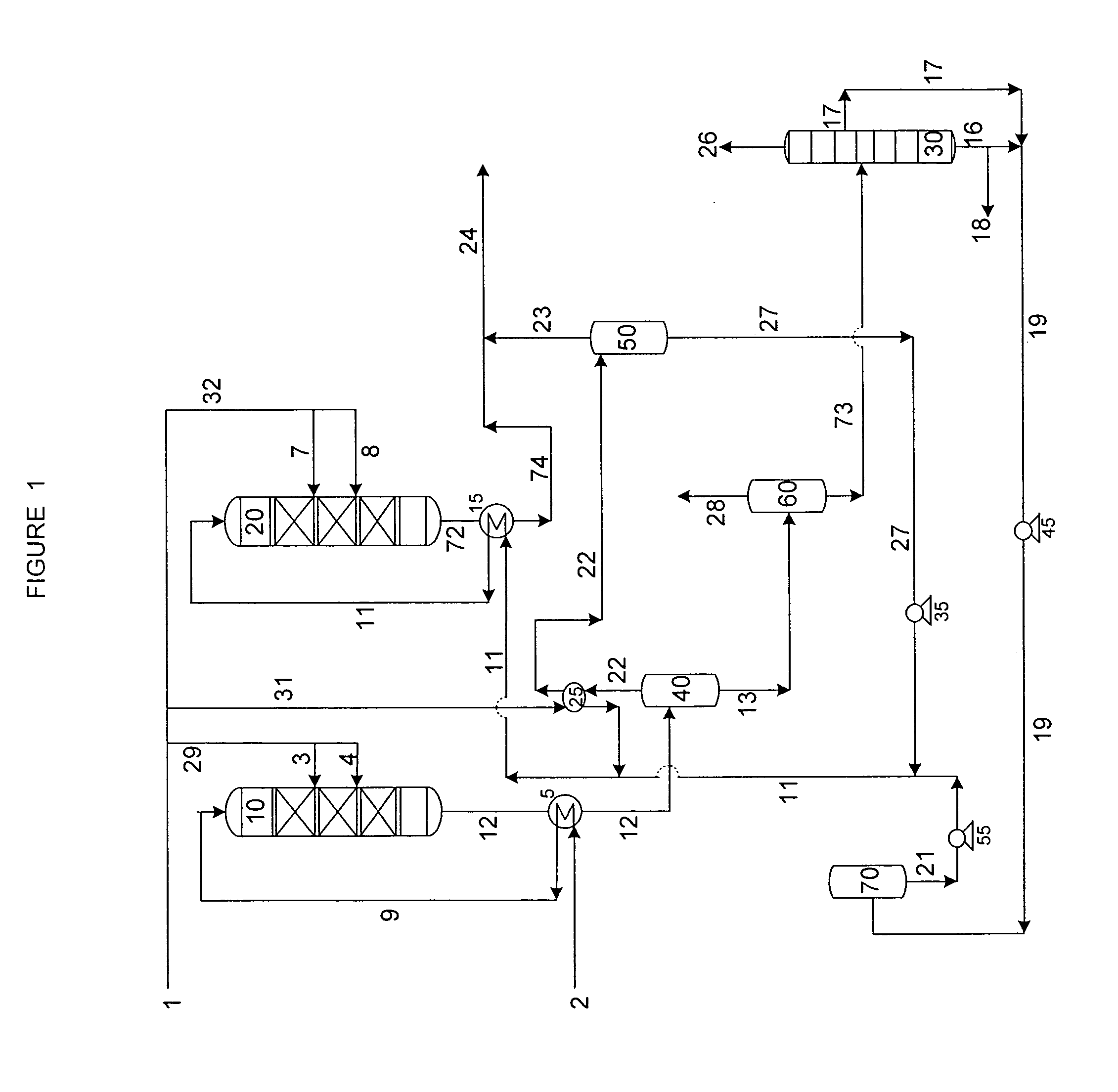

Targeted hydrogenation hydrocracking

InactiveUS20090159493A1Hydrocarbon oil crackingTreatment with hydrotreatment processesProcess engineeringEngineering

This invention is directed to a process scheme in which a partial conversion hydrocracking (HCR) unit, preferably preceded by a hydrotreating unit, feeds unconverted oil to a FCC (fluid catalytic cracking ) unit. Most refineries run the FCC unit at the full capacity for optimal asset utilization. During shutdowns of Residue Desulfurization unit(s) which feed an FCC unit, it is desirable to reduce the conversion in the FCC feed hydrocracker. In this way, the feed to FCC unit is maximized. Jet and Diesel products that conform to specifications may be produced during low conversion HCR operation. Furthermore, undesirable over-saturation of the unconverted oil (UCO) from the HCR unit feeding the FCC unit can be avoided. Excess hydrogen consumption can also be avoided. Normally, further aromatic saturation of the middle distillate products from a low conversion HCR is achieved in a separate, post treatment, unit.

Owner:CHEVROU USA INC

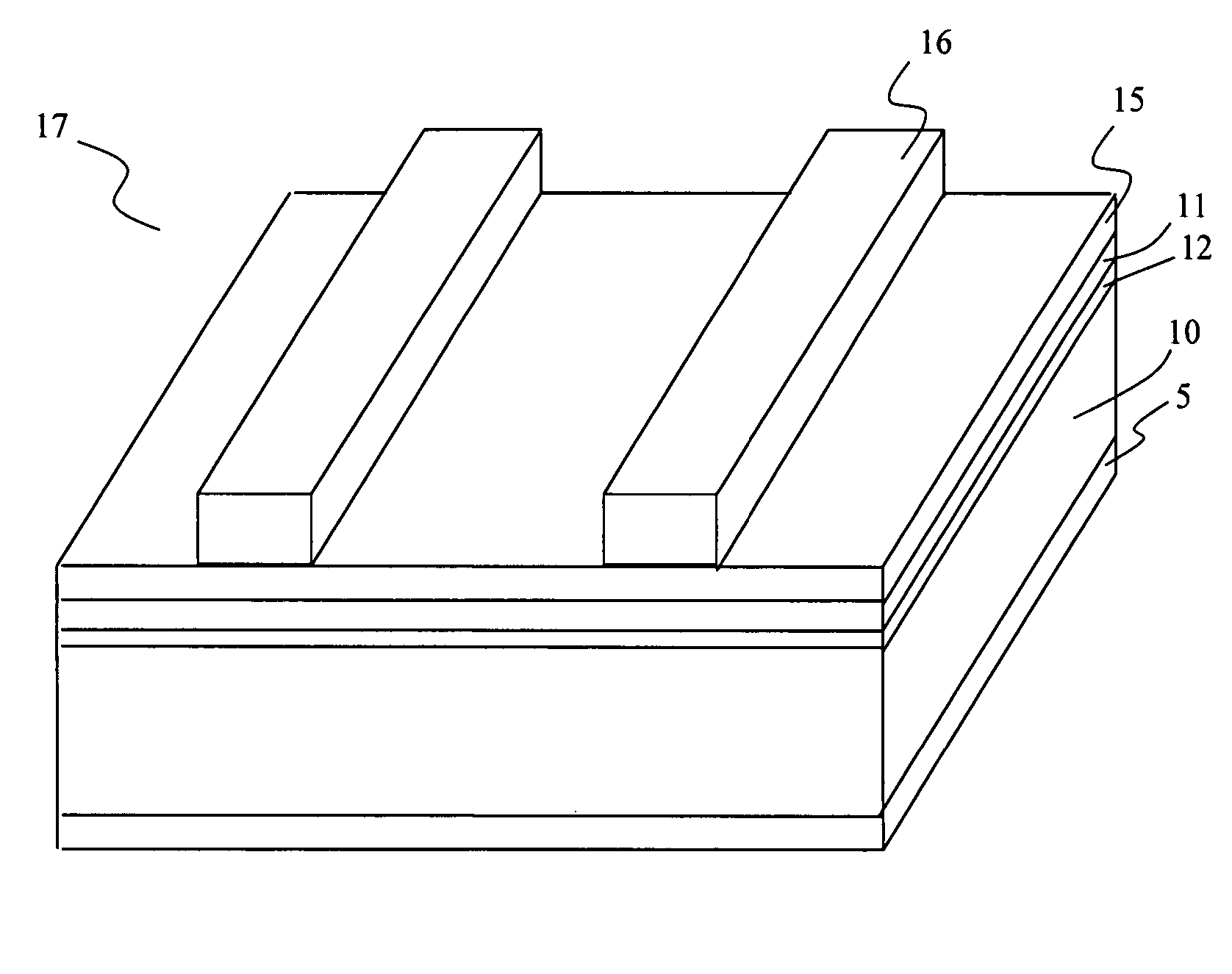

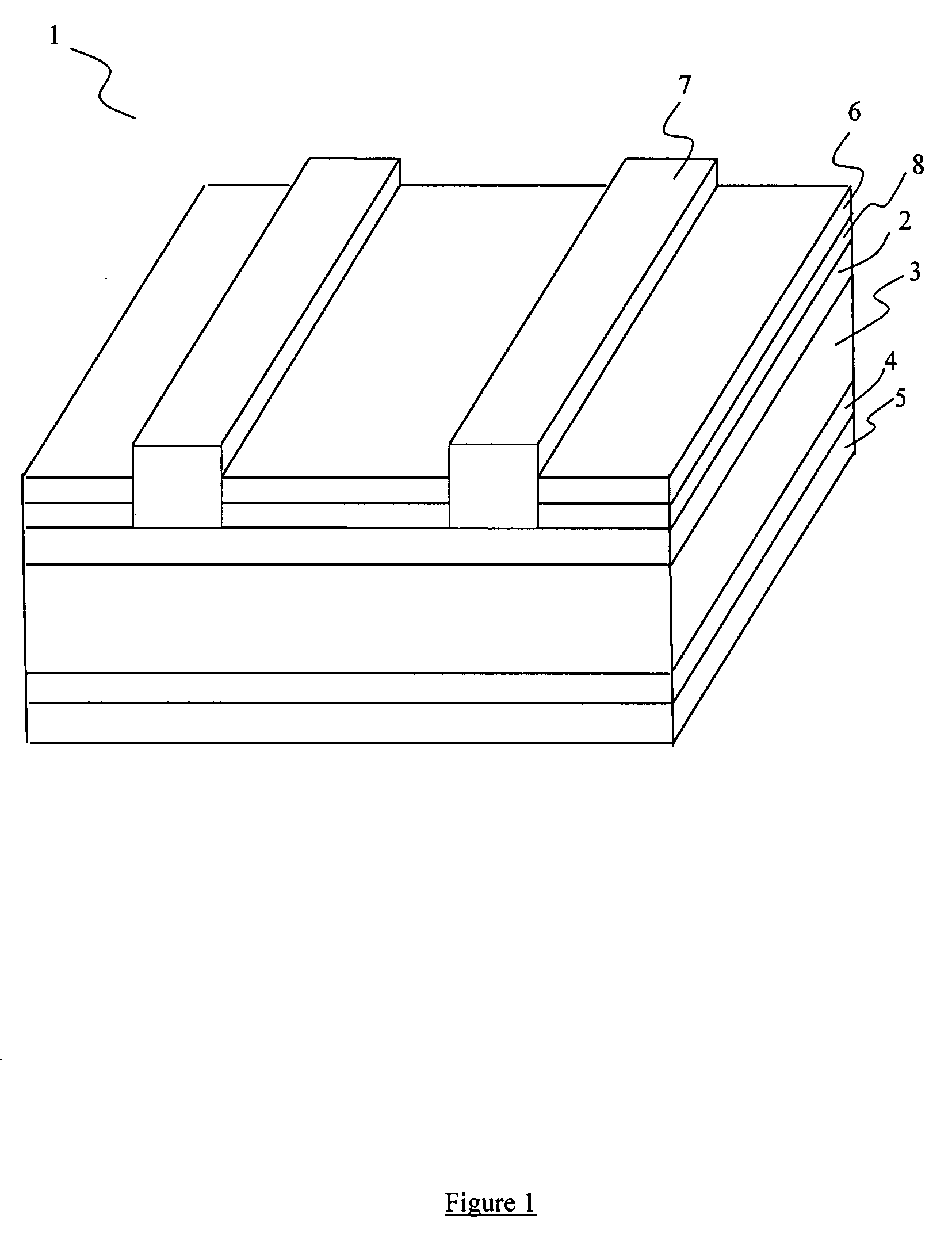

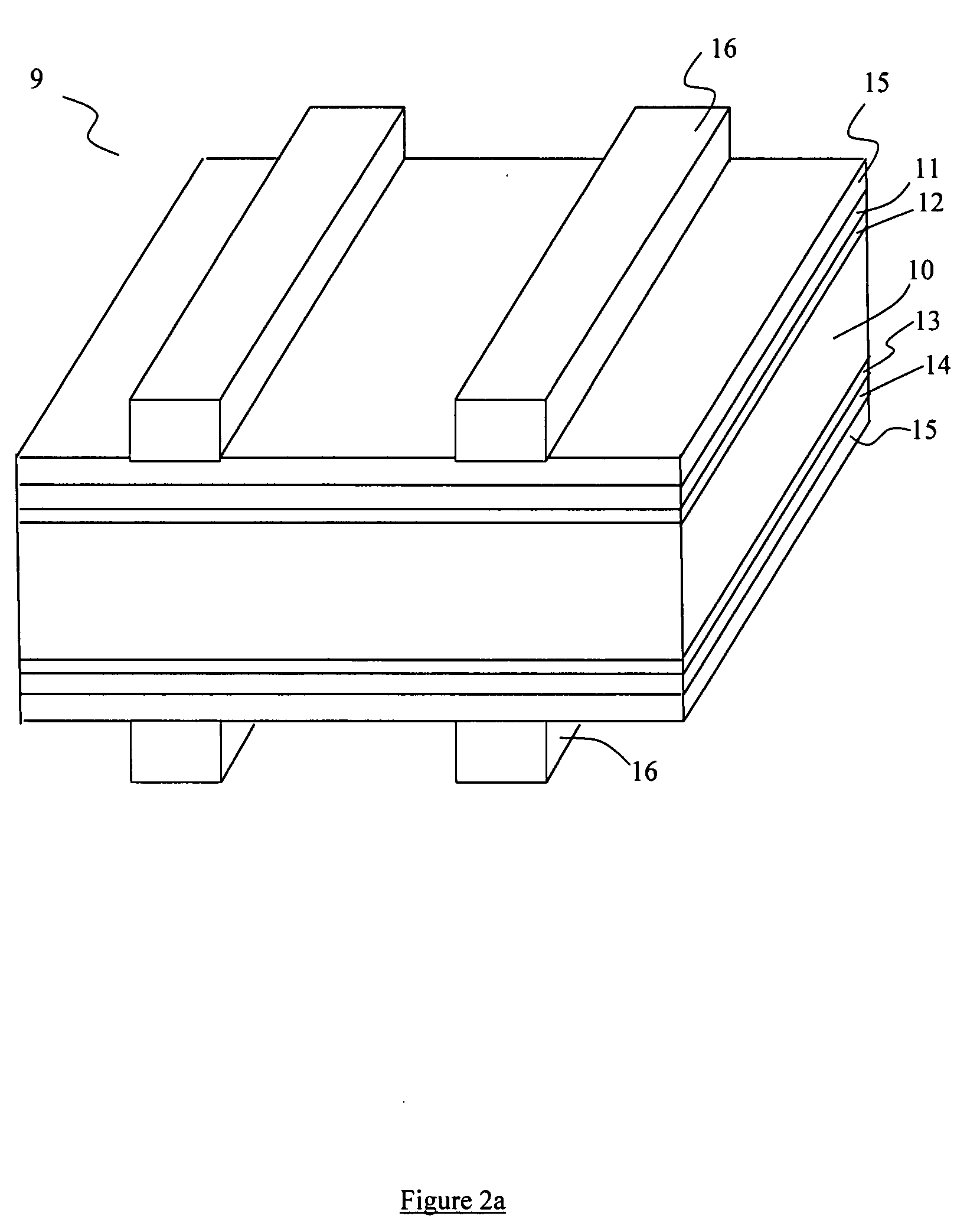

Low-temperature doping processes for silicon wafer devices

InactiveUS20080000521A1Quality improvementImprove concentrationPolycrystalline material growthFinal product manufactureGas phaseSystem configuration

A low temperature method and system configuration for depositing a doped silicon layer on a silicon substrate of a selected grade. The silicon substrate for functioning as a light absorber and the doped silicon layer for functioning as an emitter. The method comprises the acts of: positioning the silicon substrate in a chamber suitable for chemical vapour deposition of the doped silicon layer on the silicon substrate, an external surface of the silicon substrate suitable for promoting crystalline film growth; using a plurality of process parameters for adjusting growth of the doped silicon layer, the plurality of process parameters including a first process parameter of a process temperature for inhibiting diffusion of dopant atoms into the external surface of the silicon substrate, and a second process parameter of a hydrogen dilution level for providing excess hydrogen atoms to affect a layer crystallinity of the atomic structure of the doped silicon layer; exposing the external surface of the silicon substrate in the chamber to a vapour at appropriate ambient chemical vapour deposition conditions, the vapour including silicon atoms, dopant atoms and the excess hydrogen atoms, the atoms for use in growing the doped silicon layer; and originating growth of the doped silicon layer on the external surface to form an interface between the doped silicon layer and the silicon substrate, such that the doped silicon layer includes first atomic structural regions having a higher quality of the layer crystallinity next to the interface with adjacent second atomic structural regions having a lower quality of the layer crystallinity with increasing concentrations of crystal defects for increasing thickness of the doped silicon layer from the interface. The resultant silicon substrate and doped layer (or thin film) can be used in solar cell manufacturing.

Owner:SIVOTHTHAMAN SIVA +1

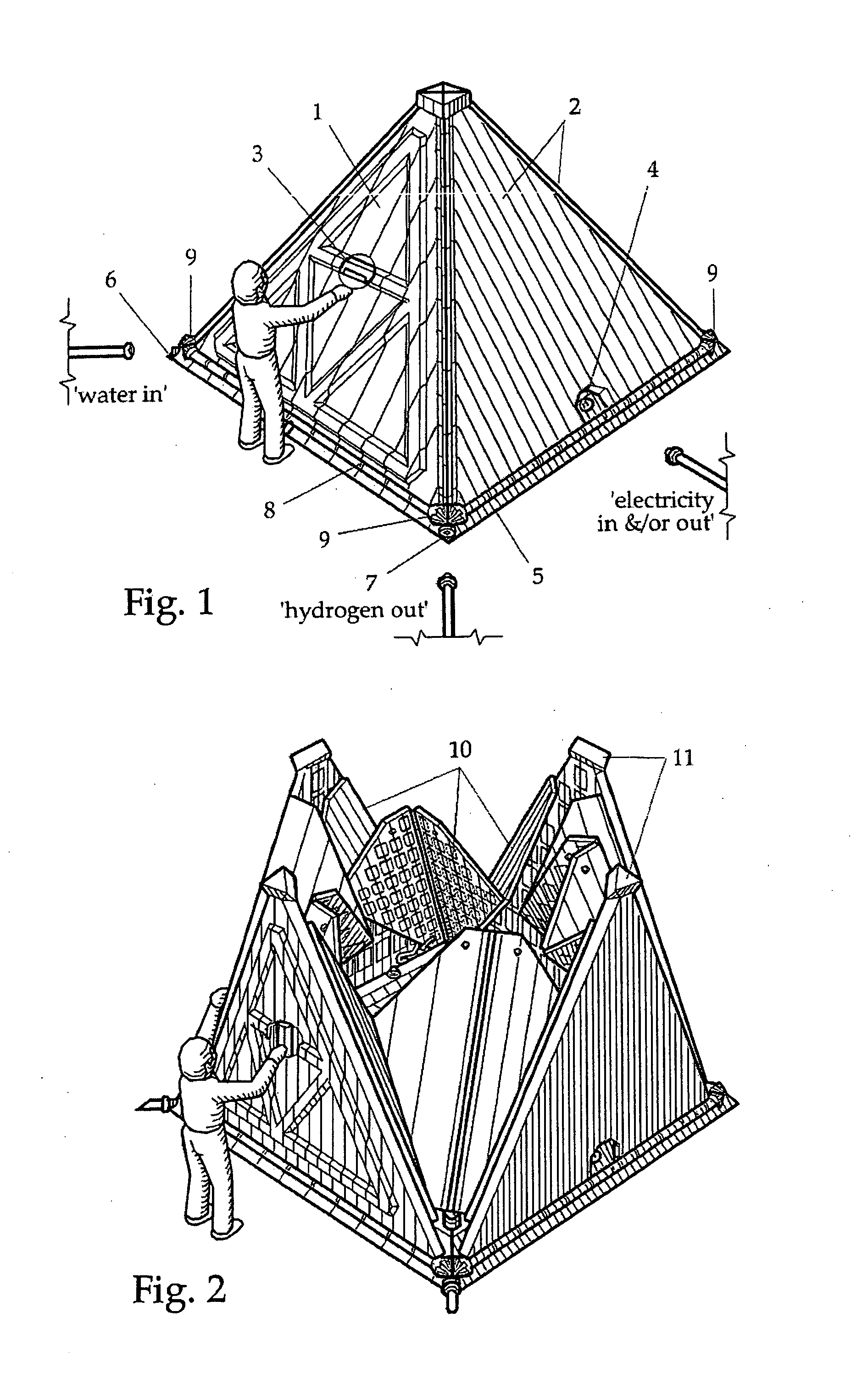

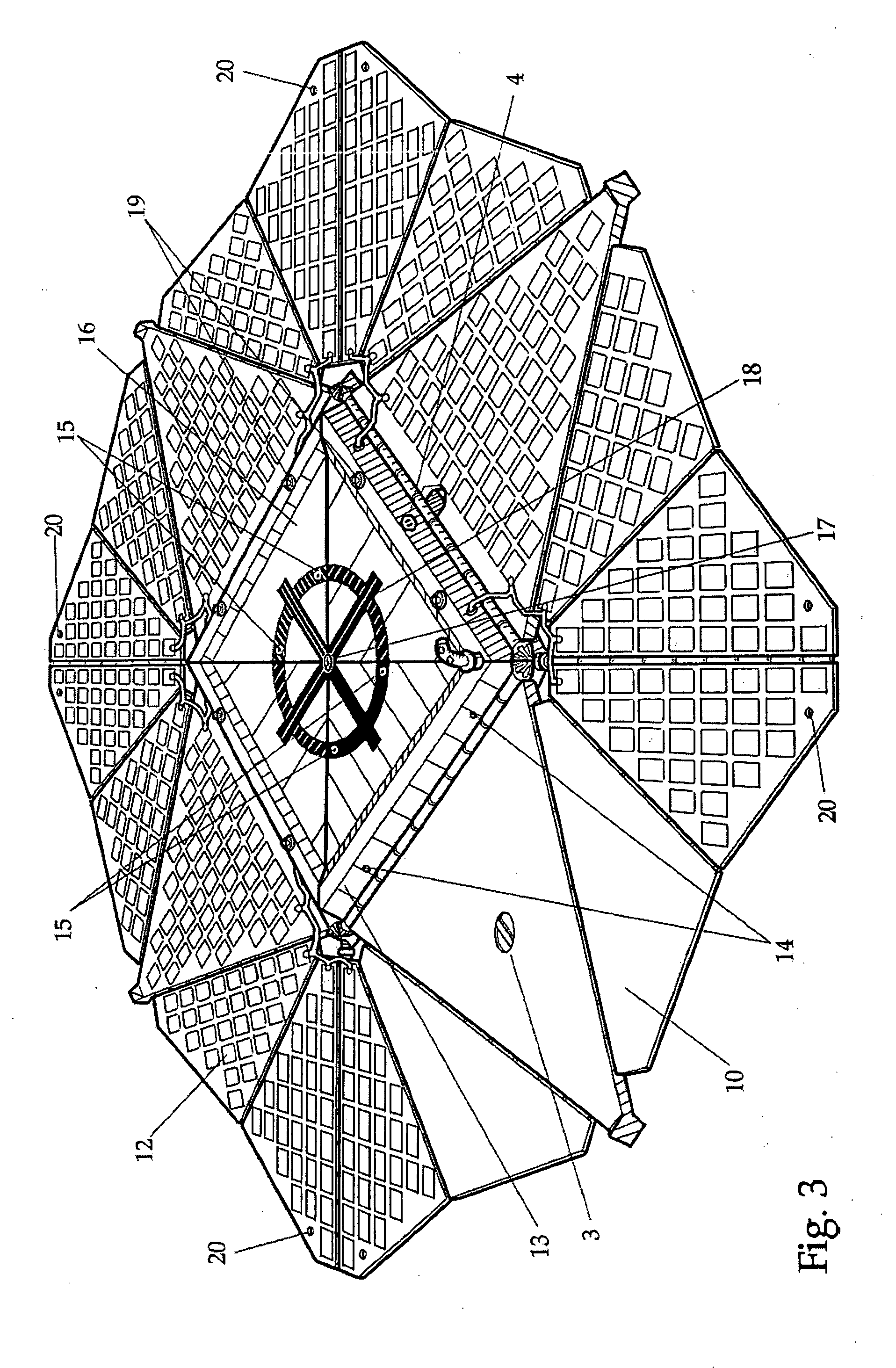

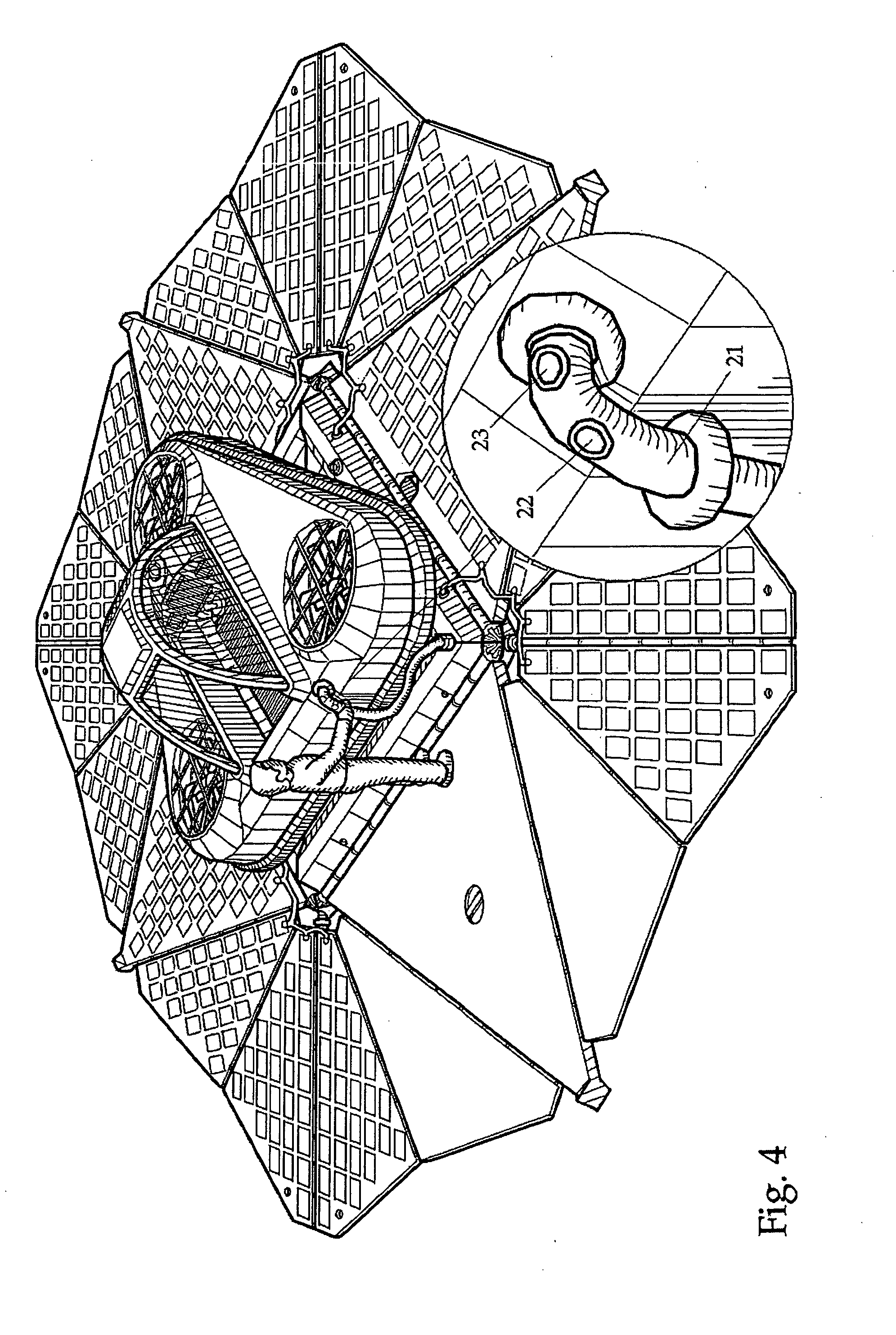

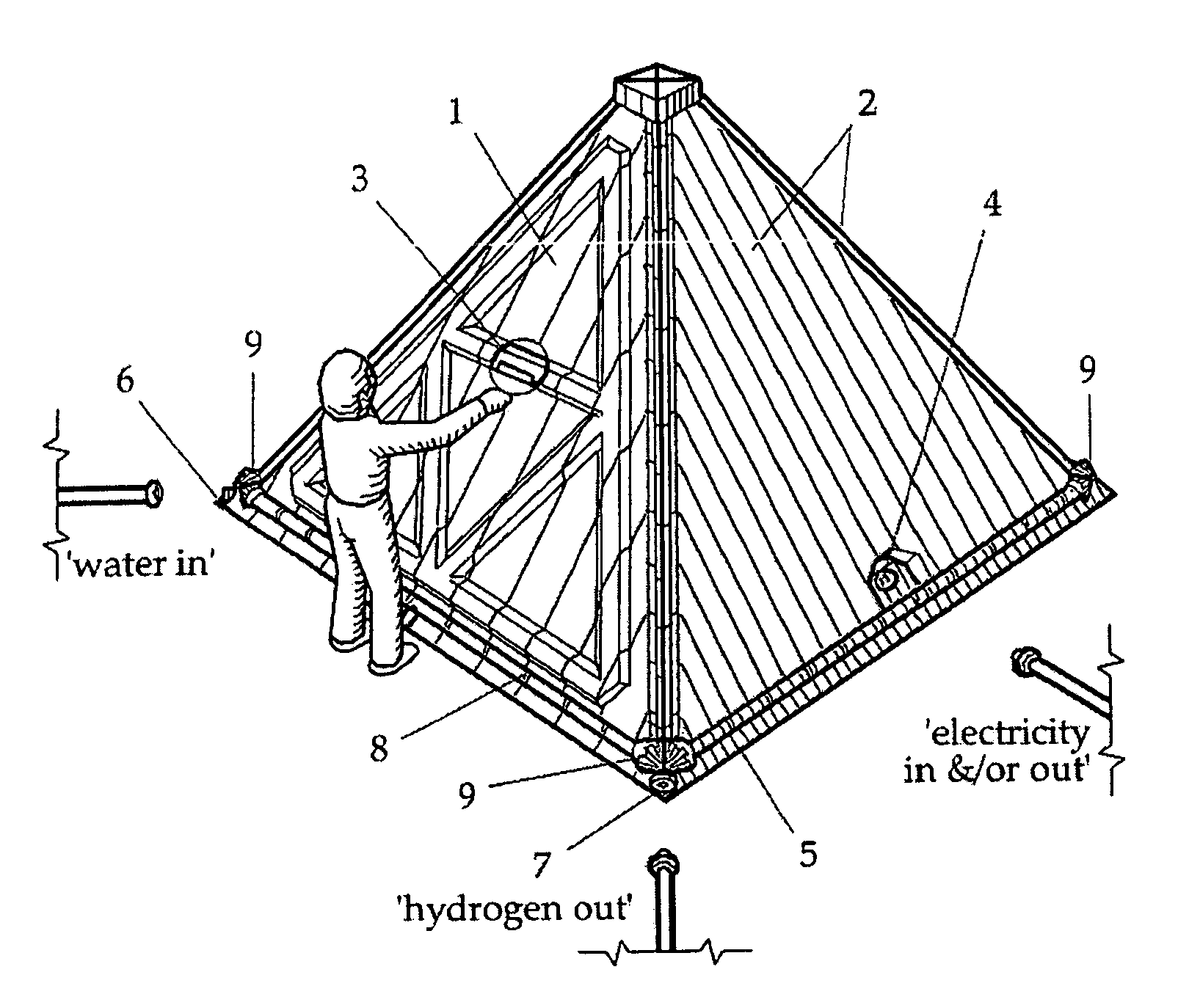

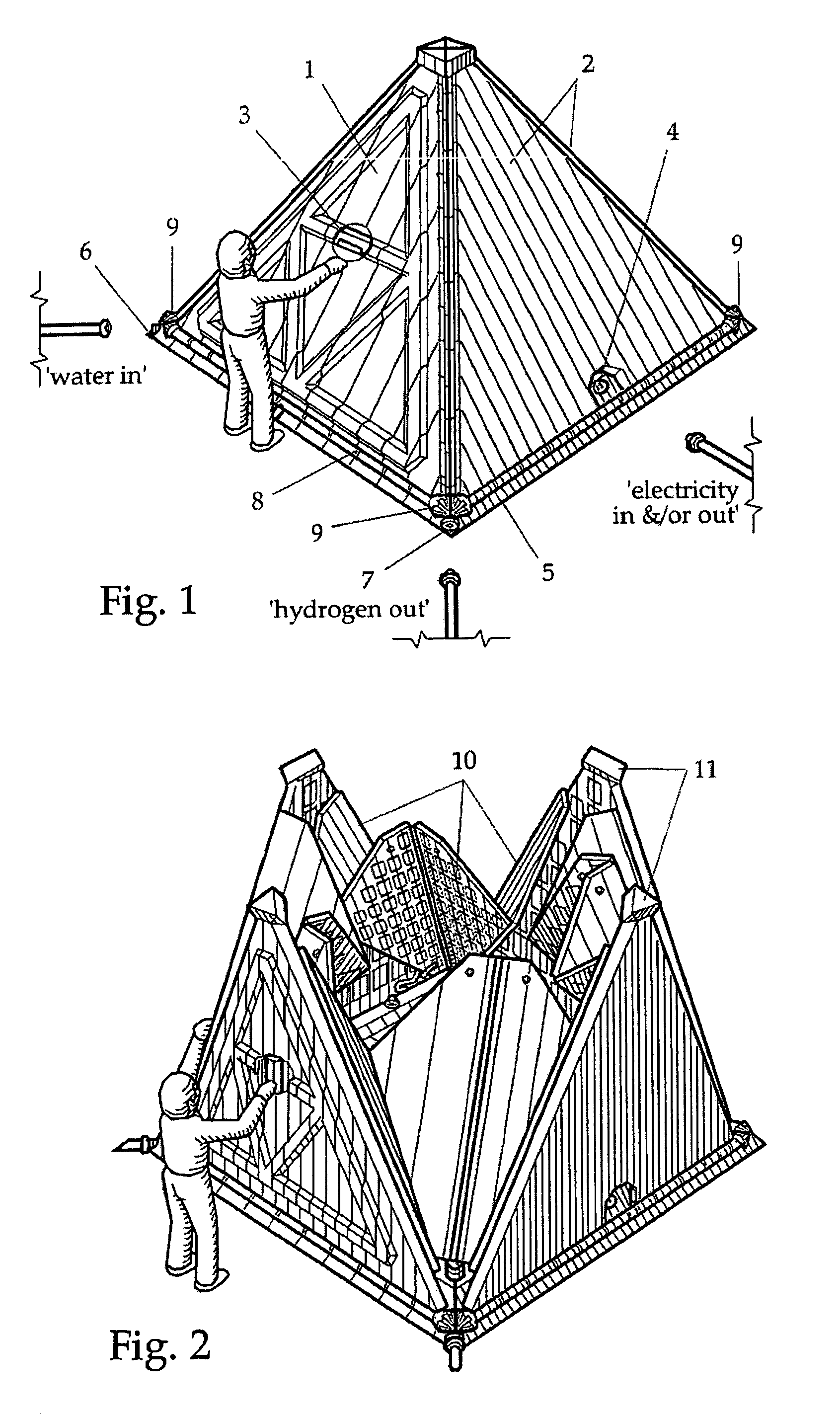

Personal renewable-energy fueling & storage station for electric-powered vehicles

InactiveUS20050231157A1Avoid delayAvoid traffic congestionBatteries circuit arrangementsRailway vehiclesExternal energyHydrogen fuel cell

A personal refueling station for a personal-sized electric vehicle has a polygonal base structure housing a refueling system and a plurality of flat panels hinged thereto which open to form a flat surface and close up to an upright pyramid for storage. The flat panels have solar PV arrays mounted on their inside surfaces which generate electricity from sunlight in the open position. The electricity is used to generate hydrogen for hydrogen-fuel-cell vehicles, or is stored for recharging non-hydrogen electric vehicles. Alternatively, hydrogen or electricity may be provided from an external renewable power source. The station can also have utility hookups to provide excess hydrogen or electricity to an external energy usage, such as a home, business, or other station. The personal refueling station has a compact design that can be installed at home or business locations. It is designed to accommodate a personal-use electric vehicle such as an electric car or cart or a personal VTOL hovercraft. It can be used in a stationary location or transported for remote use, as well as operated by remote control.

Owner:UFOZ

Method of making high purity lithium hydroxide and hydrochloric acid

The present invention relates to a process for producing high purity lithium hydroxide monohydrate, comprising following steps: concentrating a lithium containing brine; purifying the brine to remove or to reduce the concentrations of ions other than lithium; adjusting the pH of the brine to about 10.5 to 11 to further remove cations other than lithium, if necessary; neutralizing the brine with acid; purifying the brine to reduce the total concentration of calcium and magnesium to less than 150 ppb via ion exchange; electrolyzing the brine to generate a lithium hydroxide solution containing less than 150 ppb total calcium and magnesium, with chlorine and hydrogen gas as byproducts; producing hydrochloric acid via combustion of the chlorine gas with excess hydrogen and subsequent scrubbing of the resultant gas stream with purified water, if elected to do so; and concentrating and crystallizing the lithium hydroxide solution to produce lithium hydroxide monohydrate crystals.

Owner:ROCKWOOD LITHIUM INC

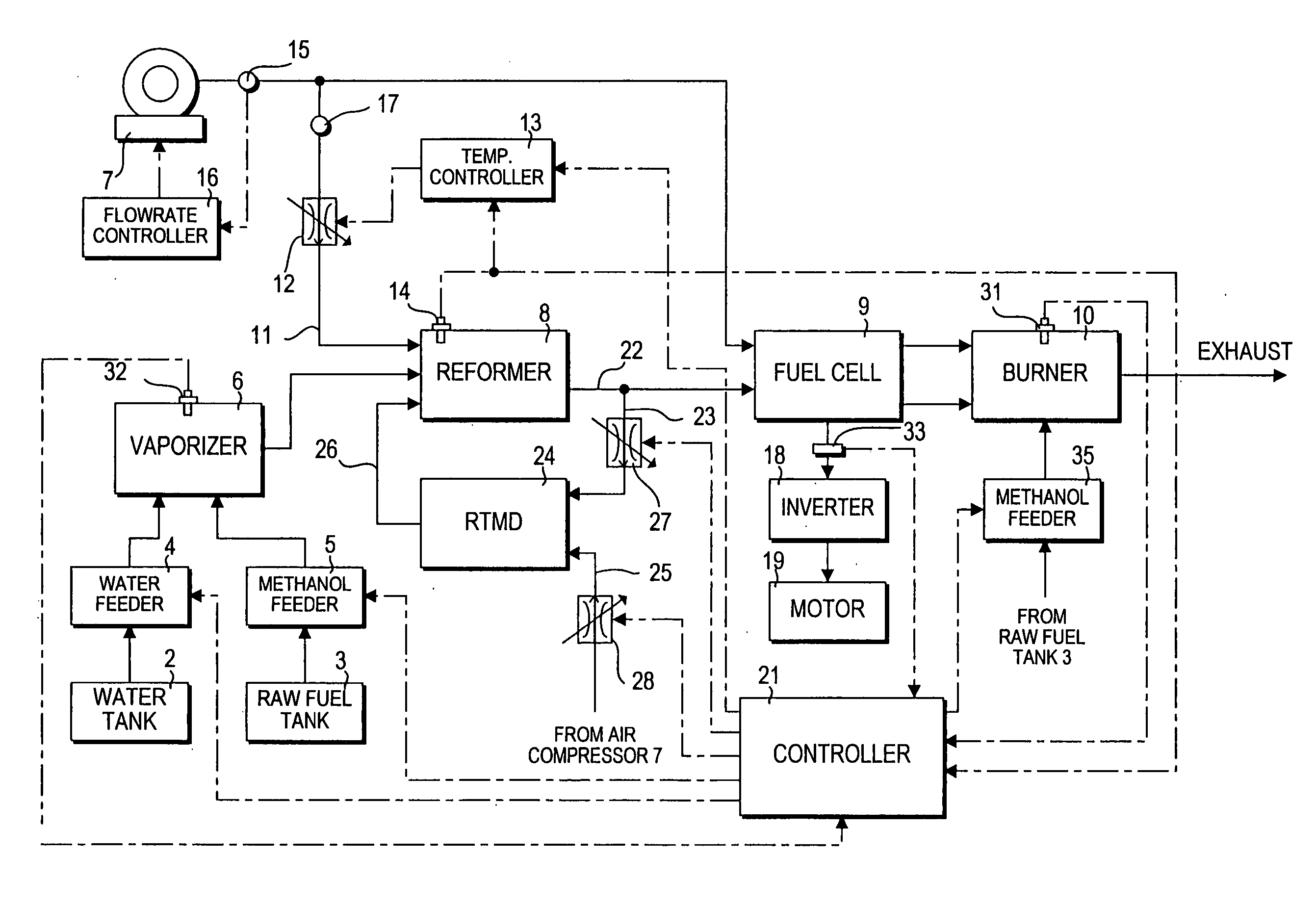

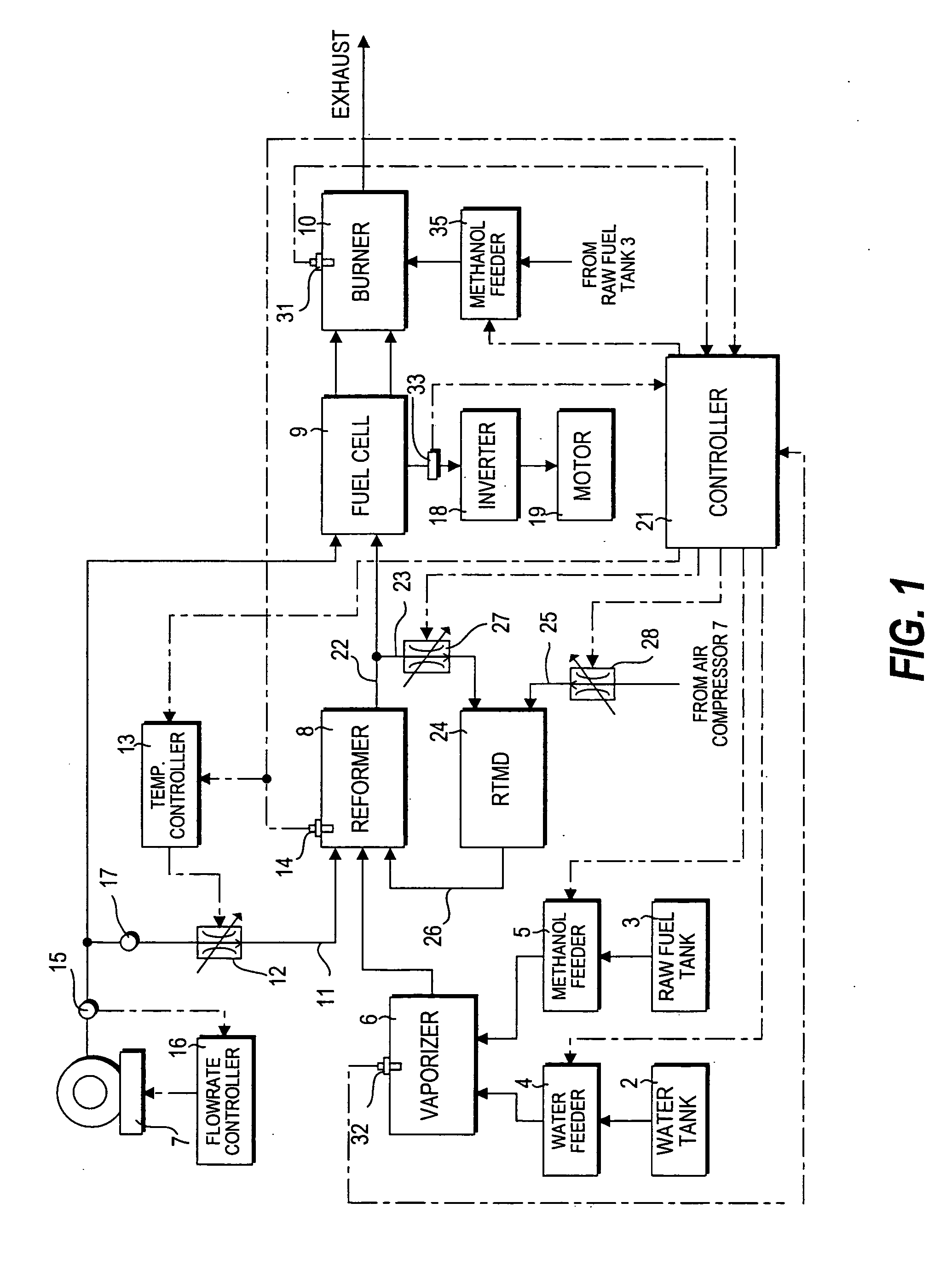

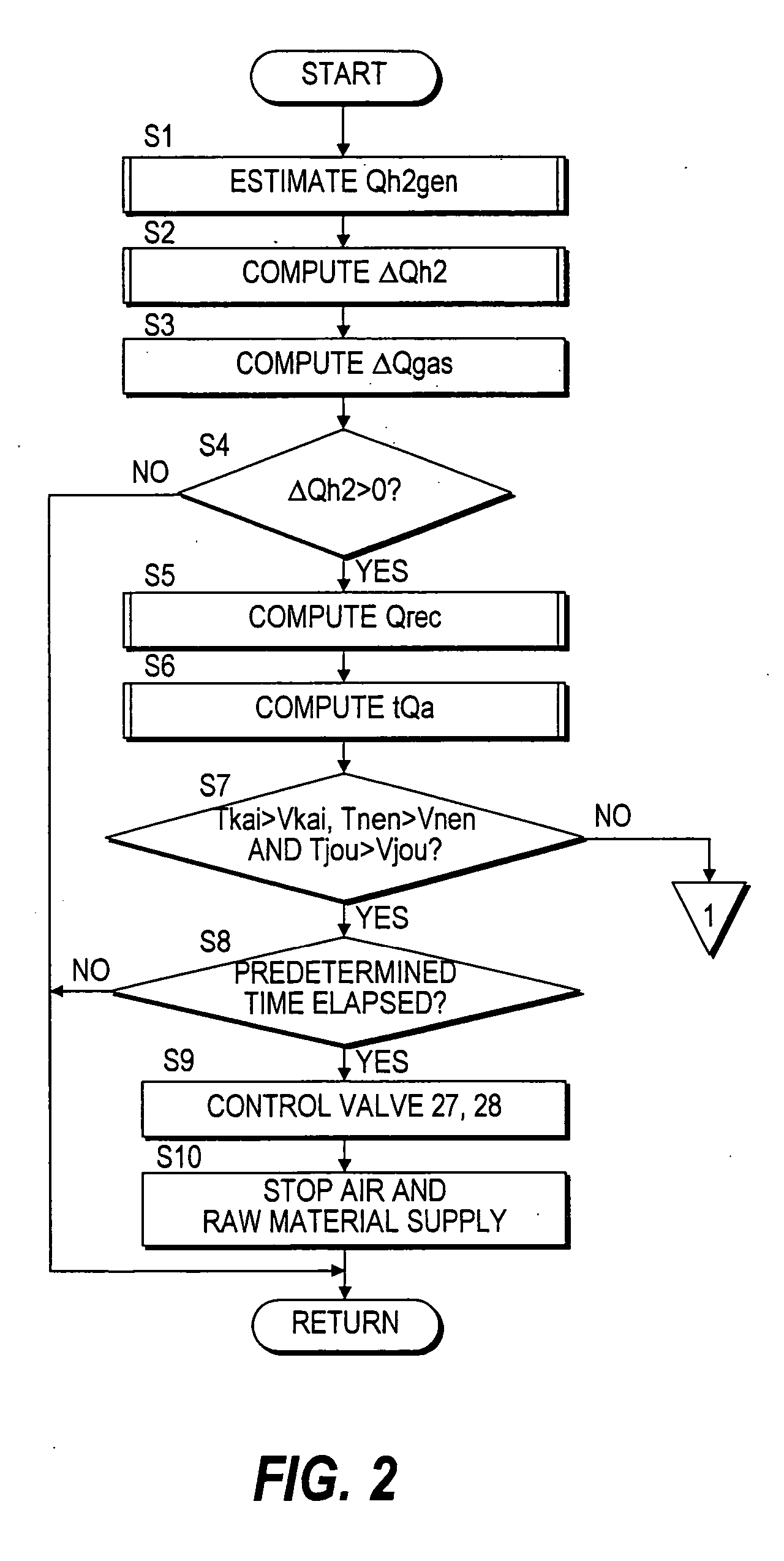

Fuel cell system and its control method

InactiveUS20050123812A1Quick buildFuel cell heat exchangeMotive system fuel cellsFuel cellsEngineering

A fuel cell system comprises a reformer (8) which produces reformate gas containing hydrogen using gas containing oxygen and raw material vapor, and a fuel cell (9) which generates power by reacting hydrogen in the reformate gas with oxygen. A controller (21) determines whether or not excess hydrogen has been produced by the reformer (8), and when it is determined that excess hydrogen was produced, burns the excess hydrogen to keep the reformer (8) warm.

Owner:NISSAN MOTOR CO LTD

Personal renewable-energy fueling and storage station for electric-powered vehicles

InactiveUS7248018B2Avoid congestionAvoid delayBatteries circuit arrangementsRailway vehiclesExternal energyHydrogen fuel cell

Owner:UFOZ

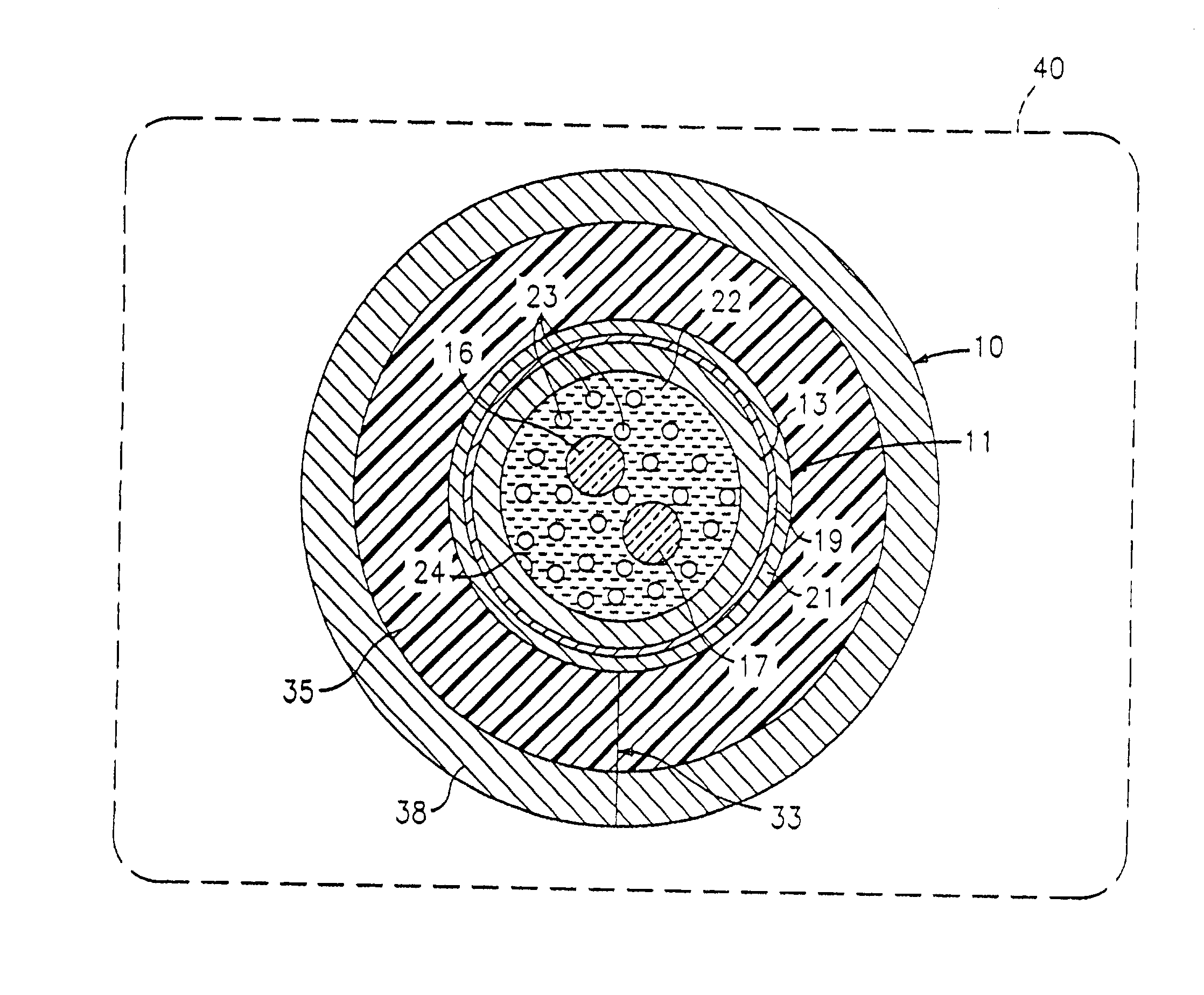

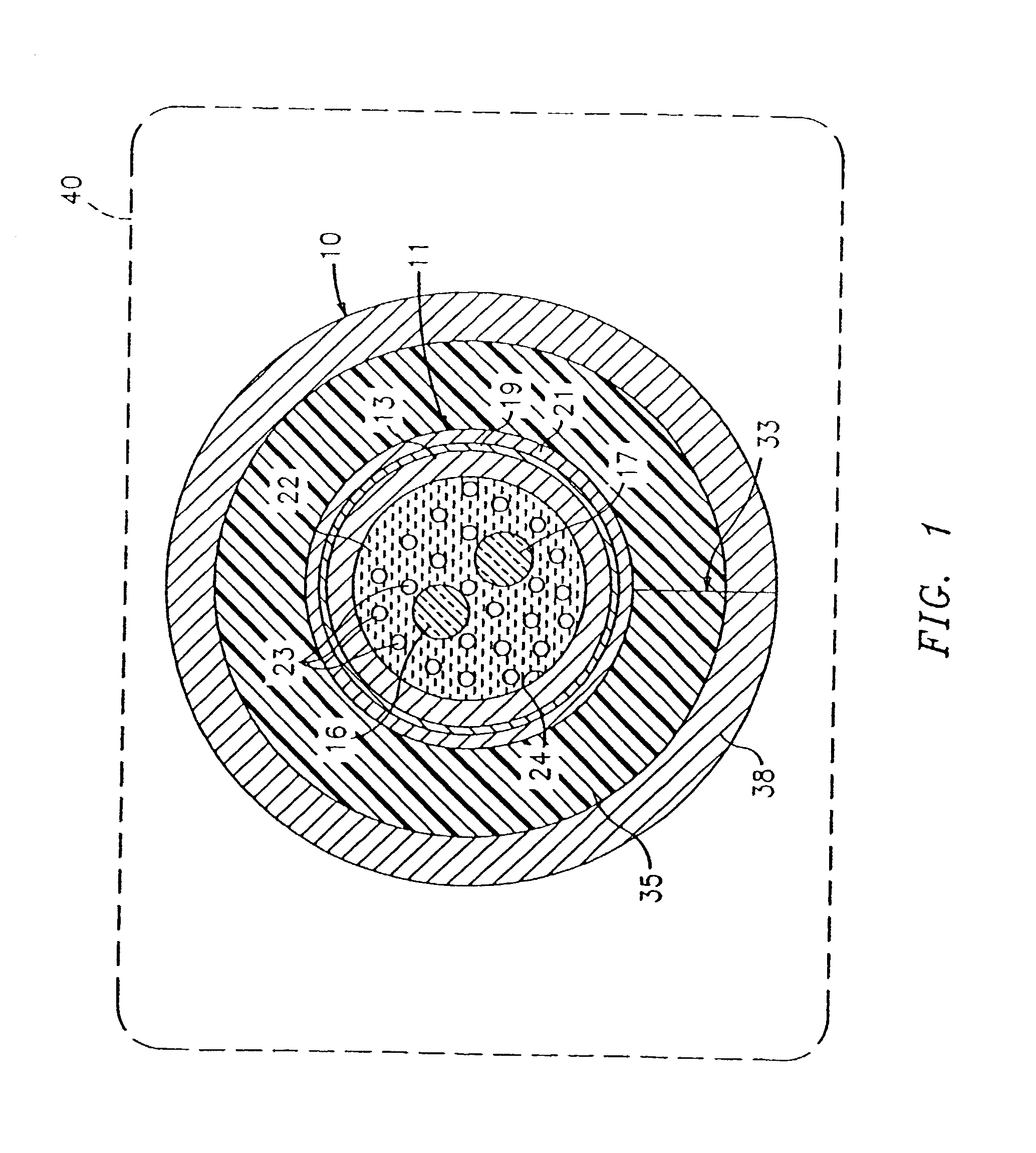

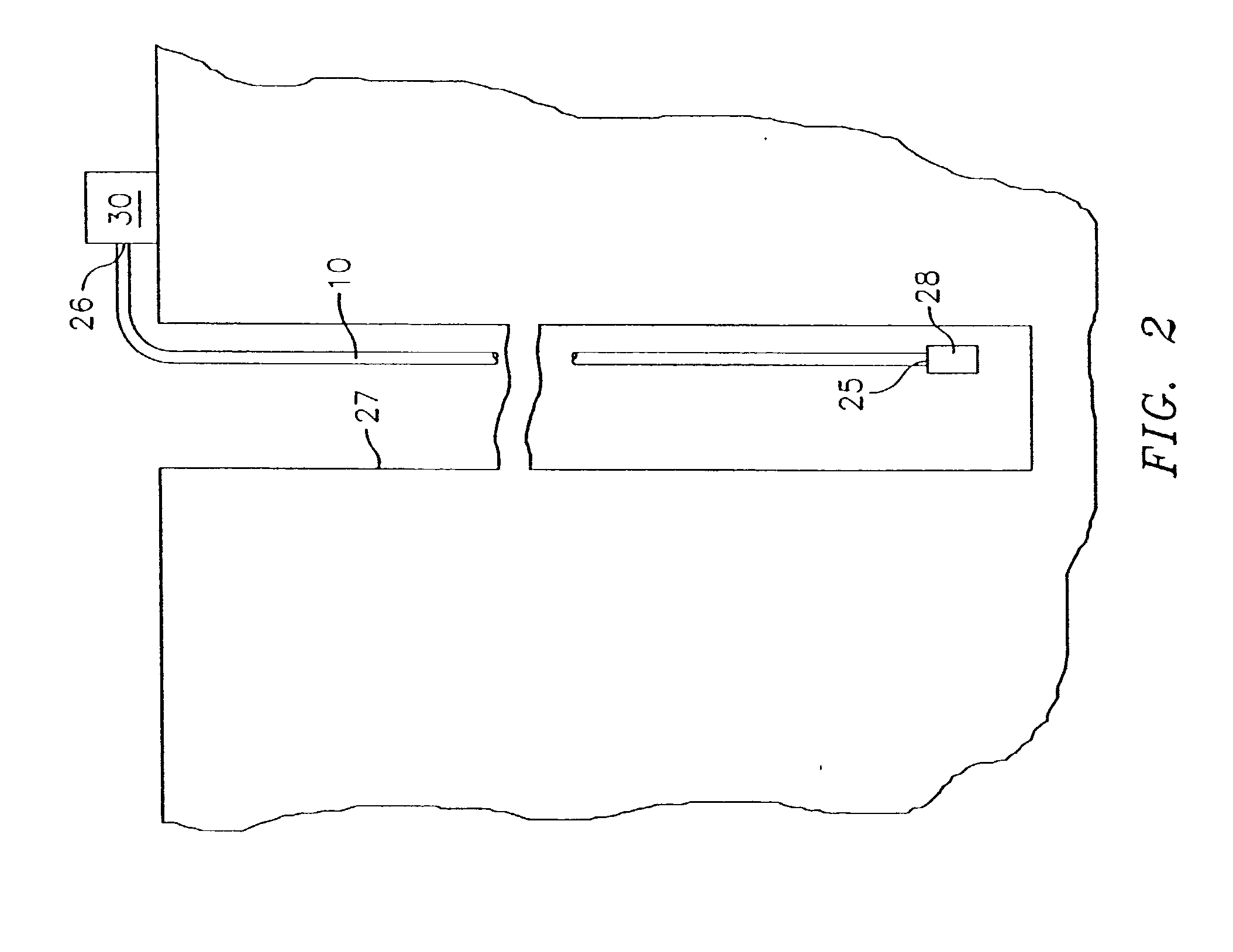

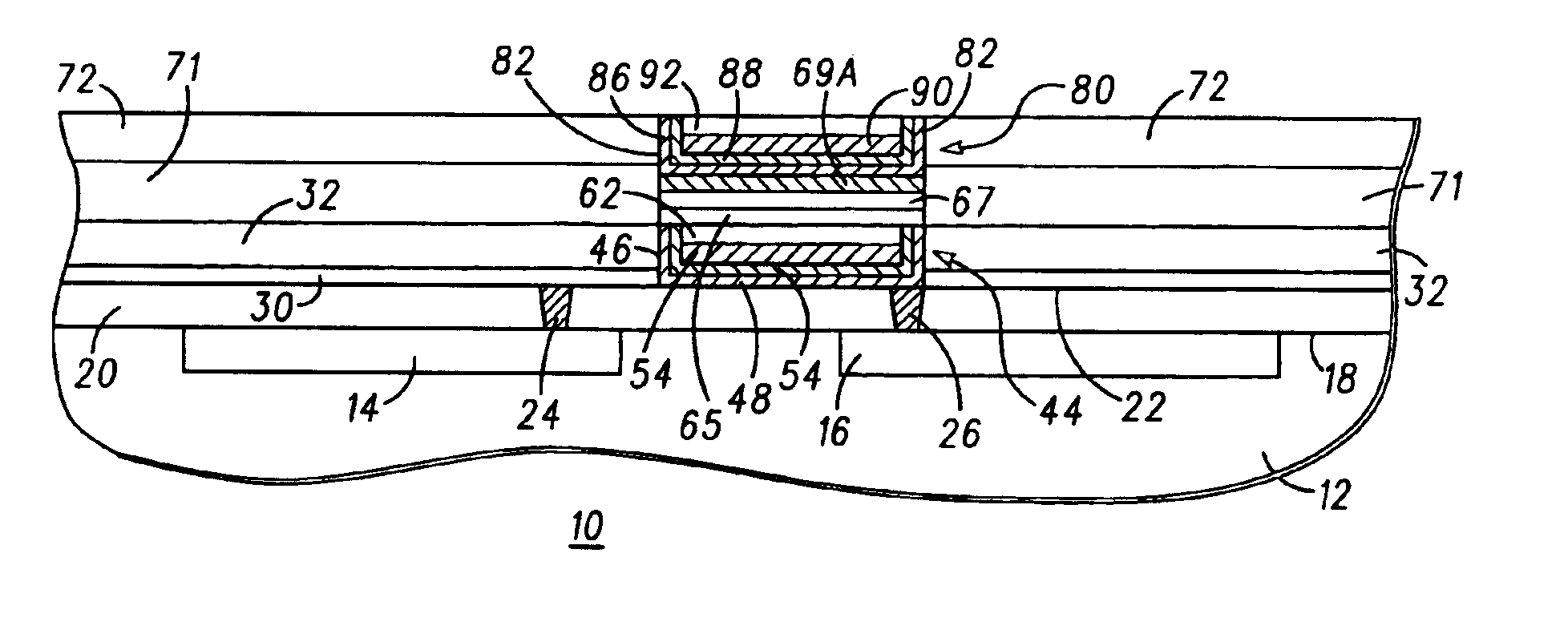

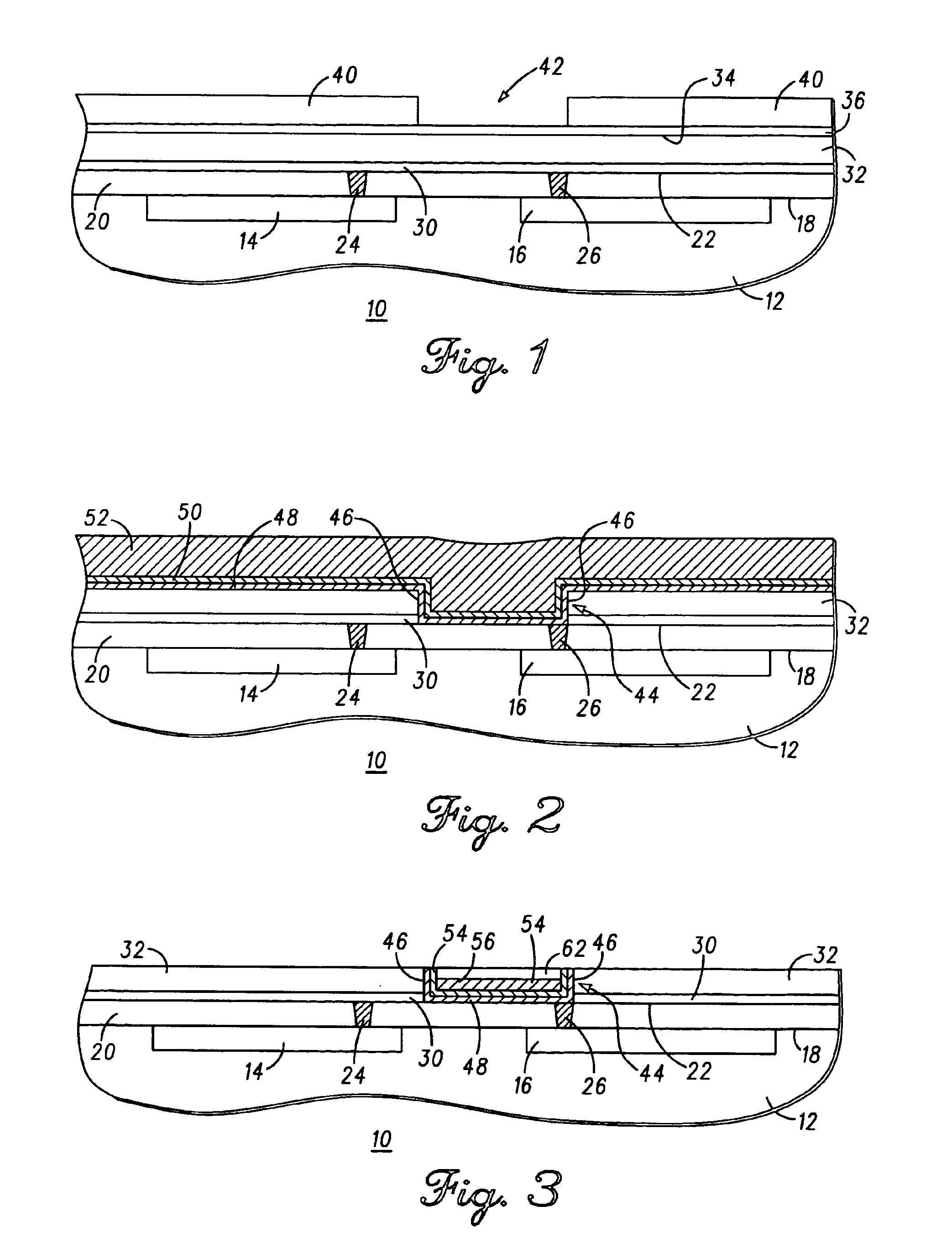

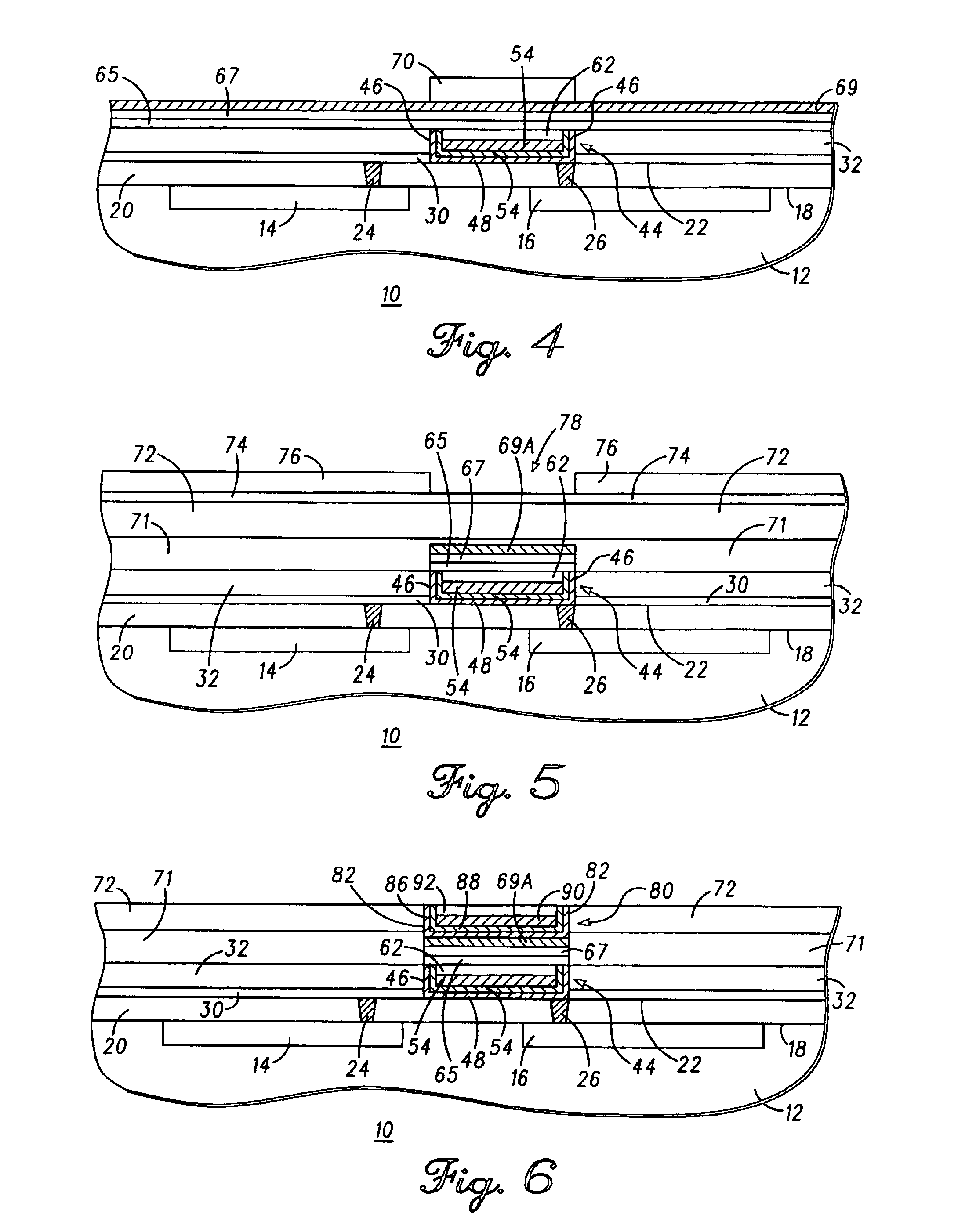

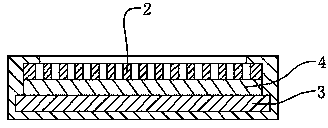

Optical fiber cable for use in harsh environments

A fiber optic cable includes a core and a surrounding protective layer. The core includes an inner tube having one or more optical fibers contained therein, and the surrounding protective layer includes an outer tube received over the inner tube, and a layer of buffer material positioned between the outer tube and the inner tube. The buffer material maintains the inner tube generally centrally located within the outer tube and providing a mechanical link between the inner tube and the outer tube to prevent relative movement therebetween. The inner tube may be coated with a low hydrogen permeability material to minimize the entrance of hydrogen into the inner tube. The low hydrogen permeability material may be coated with a protective layer of hard, scratch resistant material to protect the integrity of the low hydrogen permeability material. The area in the inner tube not occupied by the optical fibers may be filled with a filler material, the filler material being selected to have a sufficient viscosity to resist the shear forces applied to it as a result of the weight of the optical fibers within the tube while allowing movement of the optical fibers within the tube during spooling, deployment and handling of the cable to thereby prevent damage and microbending of the optical fibers. The filling material may be impregnated with a hydrogen absorbing / scavenging material to remove any excess hydrogen within the inner tube. The optical fibers have an excess length with respect to the inner tube, and the cable may include an outer jacket of a high temperature, protective material to protect the cable during handling and installation.

Owner:WEATHERFORD TECH HLDG LLC

Process for combined preparing methylic alcohol, natural gas for automobile and synthesis ammonia form industrial end gas rich in carbon and hydrogen

ActiveCN101284761AIncrease profitReduce complexityHydrocarbon from carbon oxidesOrganic compound preparationNitrogen gasEnergy expenditure

The invention discloses a method for coproducing methanol, natural gas for vehicles, and synthetic ammonia by using the hydrocarbon-rich industrial tail gas. The method is characterized in that the purified mixed raw material gas, namely a mixture of coke oven gas and carbide furnace gas, passes through a methanol synthesizer, a methanator, a pressure swing absorption and separation device and an ammonia synthesis reactor in sequence, to firstly separate the methanol; the separated methane can be used as the natural gas for vehicles; ammonia synthesis can be performed to the separated hydrogen gas and nitrogen; and pure hydrogen can be obtained by the excess hydrogen gas through pressure swing absorption after the ammonia synthesis is performed. Compared with prior art, the method has the advantages that the CH4 conversion is avoided, the CO transformation is avoided, and the air separation device is not provided. Therefore, the complexity of process is reduced, the useful component of the gas and the useful energy source can be comprehensively utilized in a cascade way, the raw material gas, the energy consumption, and the discharge amount of the carbon dioxide are all reduced, and the method develops a new way for the comprehensive utilization of the hydrocarbon-rich industrial tail gas of coke oven gas, carbide furnace gas, etc.

Owner:XIAN ORIGIN CHEM TECH

Method for manufacturing a memory element

A method for manufacturing the memory device by plasma decomposition of sulfur dioxide. A first copper electrode having a surface is provided. The surface of the first copper electrode may be made amorphous. A copper sulfide layer, CuxS, where 1≦x≦2, is disposed on the copper surface by decomposing sulfur dioxide in an ambient containing excess hydrogen. The copper sulfide layer may be is cuprous sulfide or cupric sulfide. A second copper electrode is coupled to the copper sulfide layer.

Owner:GLOBALFOUNDRIES INC

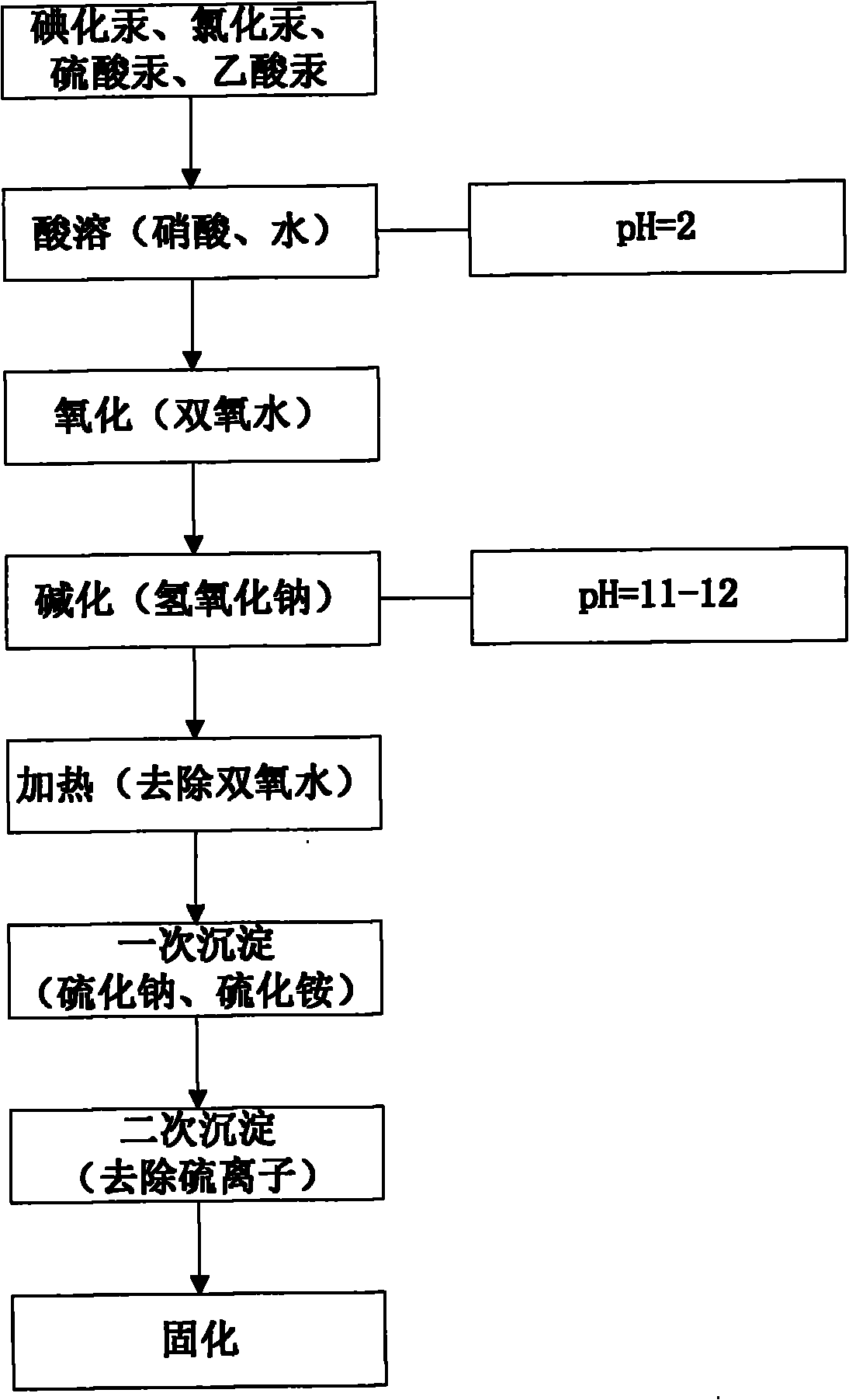

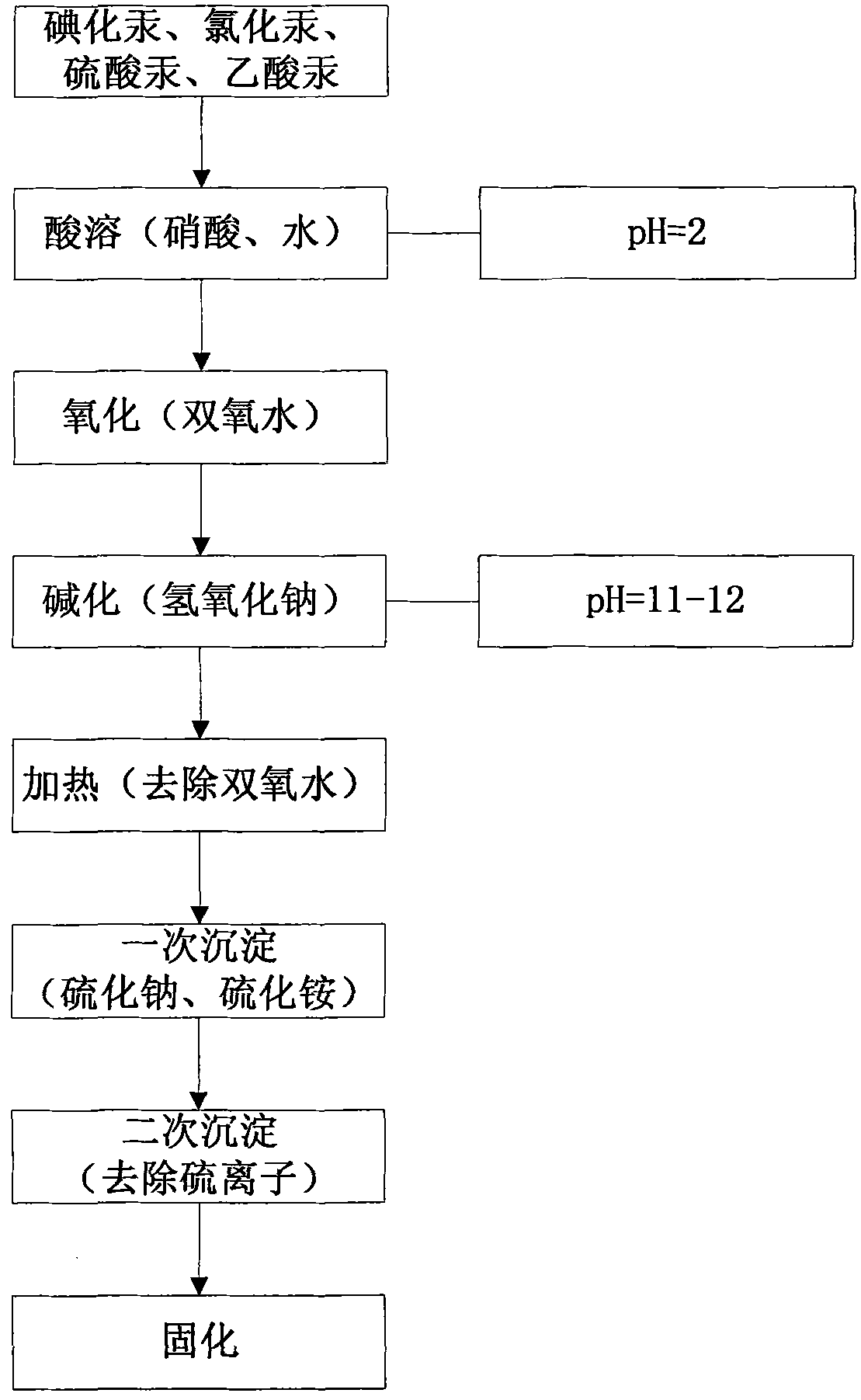

Harmless processing technology for waste dangerous chemical containing mercury

ActiveCN102247685ALow leaching toxicity concentrationAvoid Unpredictable Security RisksChemical protectionLiquid wasteChemical treatment

The invention provides a harmless processing technology for waste dangerous chemical containing mercury. The technology comprises the following steps: 1) adding waste containing mercury into water and adjusting a pH to less than 2; then adding hydrogen peroxide to converse all organic mercury in a reaction system to Hg<2+>; 2) adjusting a ph of the reaction system to 11-12 and heating to remove excess hydrogen peroxide; 3) adding compound sulfide to converse all Hg<2+> in the reaction system to HgS deposition, and adding ferrous salt to precipitate excess S<2->; 4) adding solidification materials into the depositions and a waste liquid from step 3) and carrying out solidification treatment to obtain a cement solidified body. The technology provided by the invention combines a chemical treatment and a cement solidification technology organically; and a mercury leaching toxicity of the obtained cement solidified body is less than 0.1mg / L to meet relevant national harmlessness standard.

Owner:浙江归零环保科技有限公司

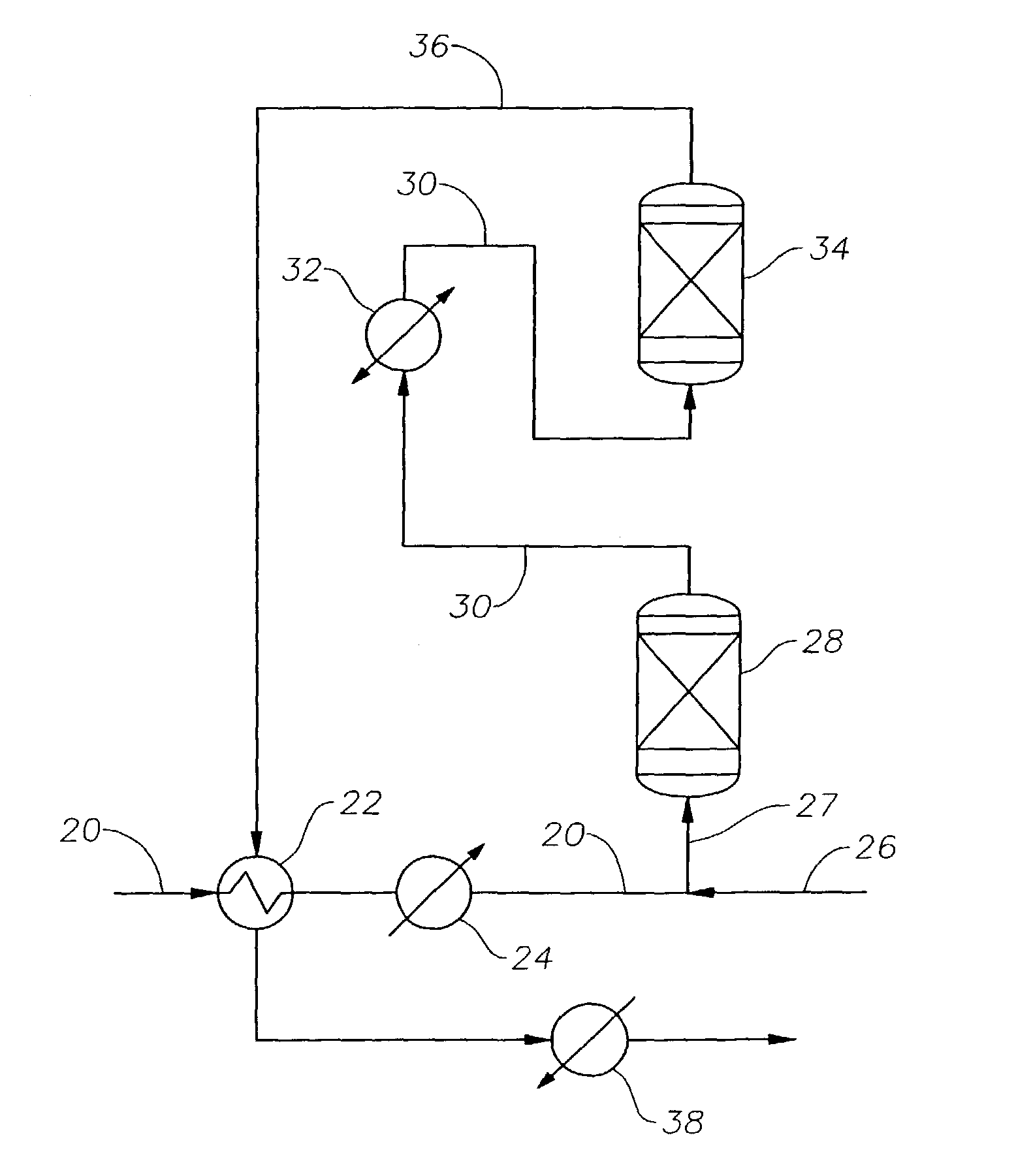

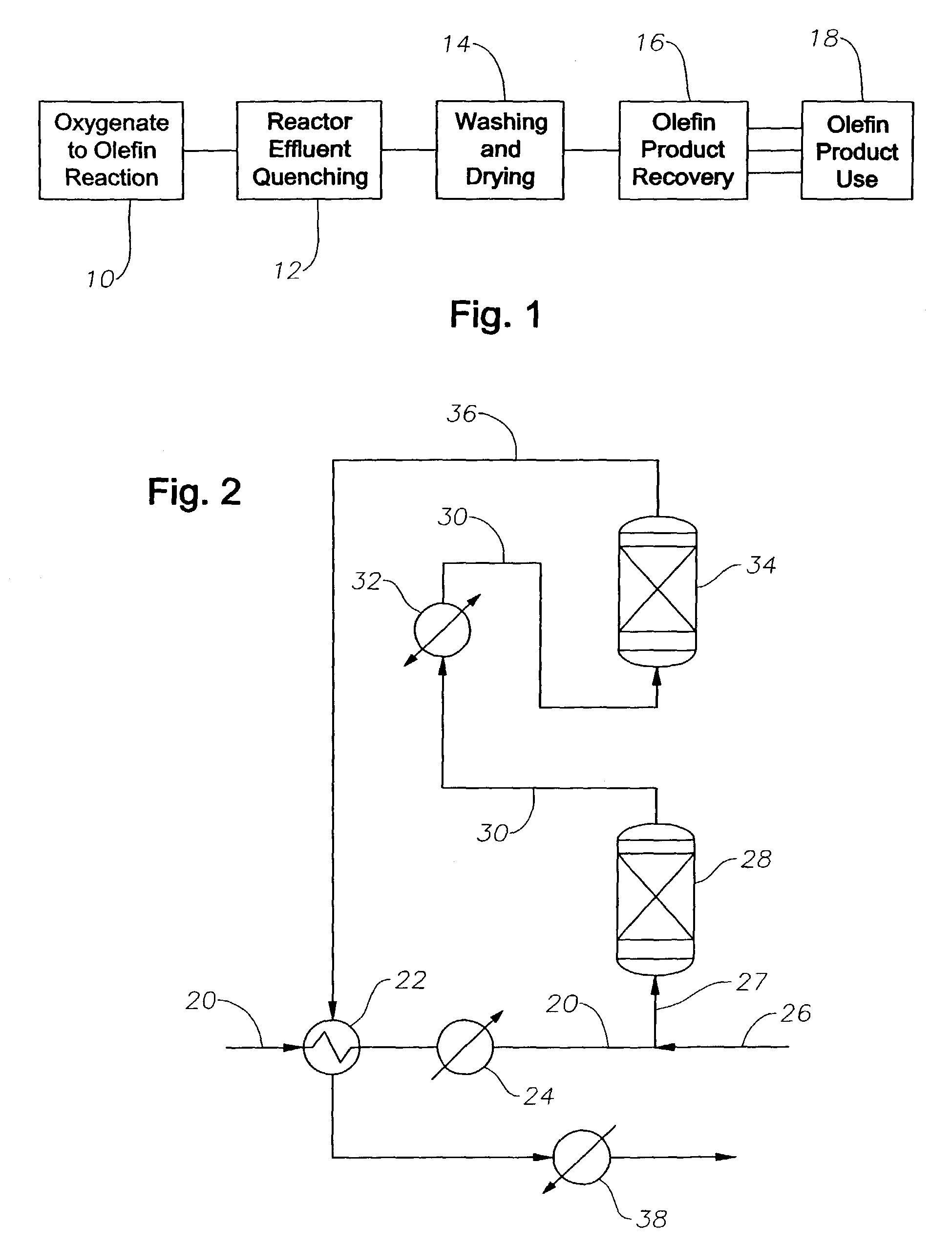

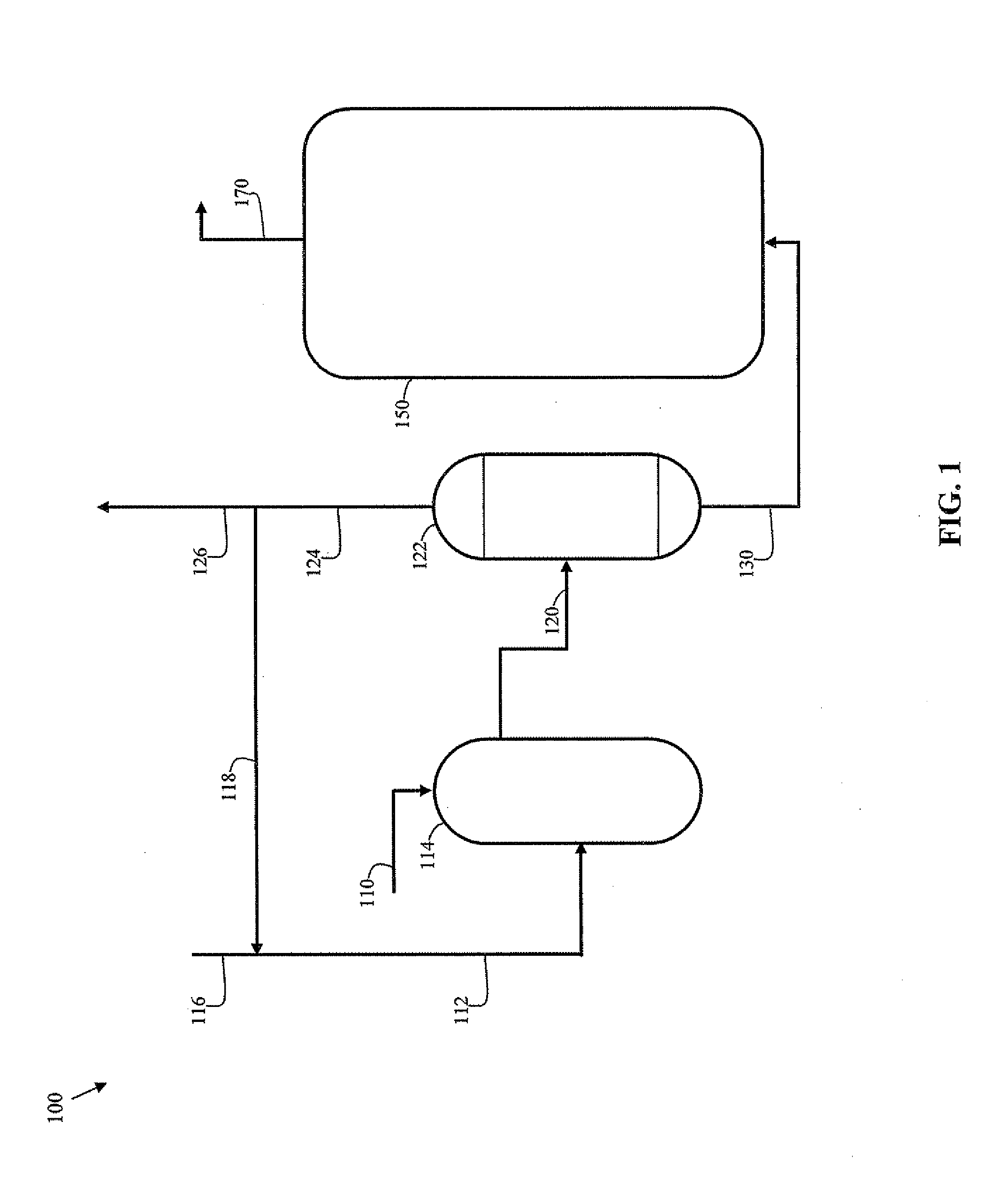

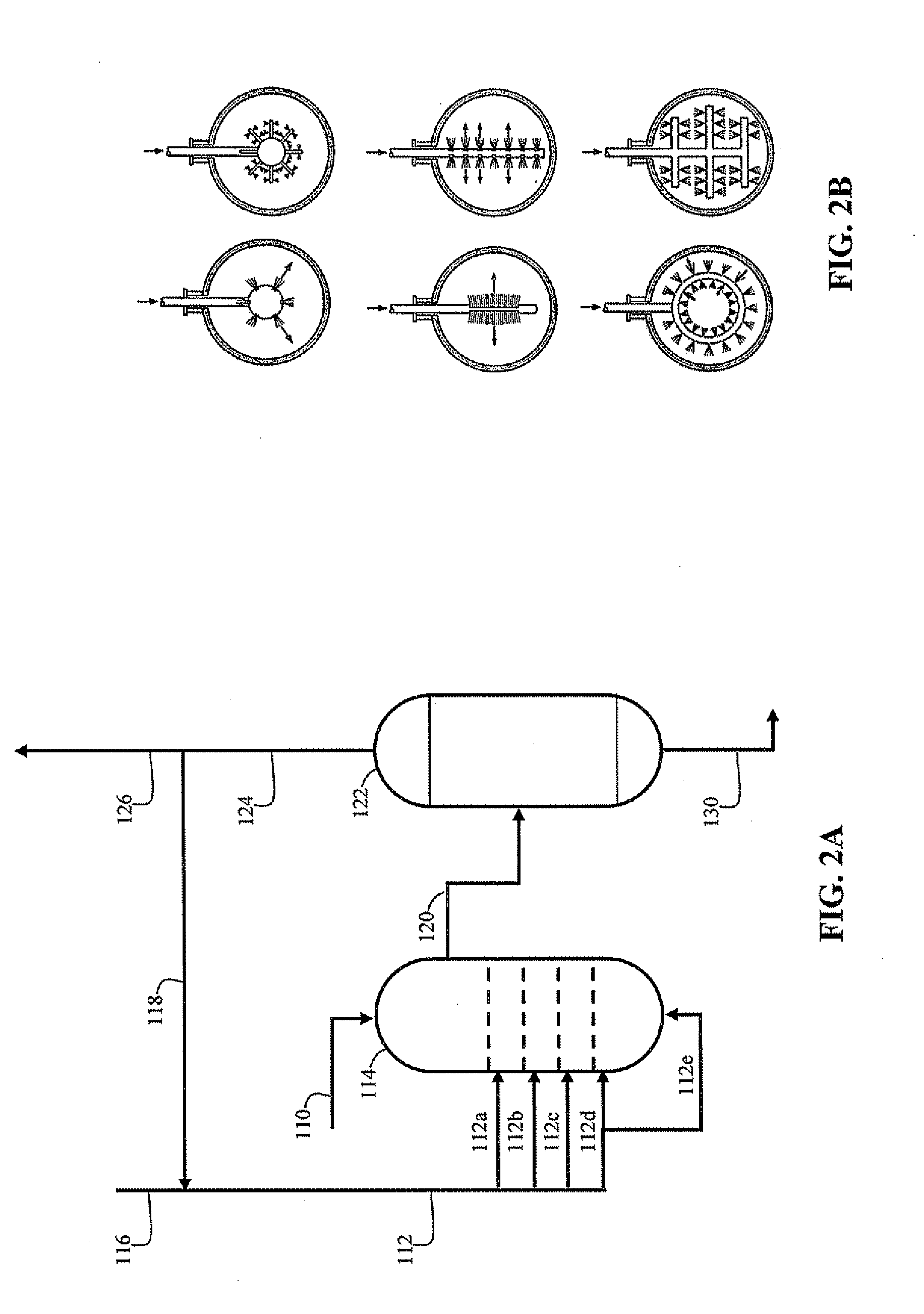

Process for removal of alkynes and/or dienes from an olefin stream

InactiveUS7115789B2Hydrocarbon by hydrogenationHydrocarbon purification/separationPtru catalystHydrogenation catalysis

The present invention is a process for removing alkynes and / or dienes from an olefin product stream withdrawn from an oxygenate-to-olefins reactor. The process comprises hydrogenating a first olefin stream that has alkynes and / or dienes in the presence of excess hydrogen and a first hydrogenation catalyst. The hydrogenation of the first olefin stream produces a second olefin stream that has unreacted hydrogen. The second olefin stream is contacted with a second hydrogenation catalyst producing a third olefin stream. The third olefin stream has low levels of hydrogen and alkynes and / or dienes.

Owner:EXXONMOBIL CHEM PAT INC

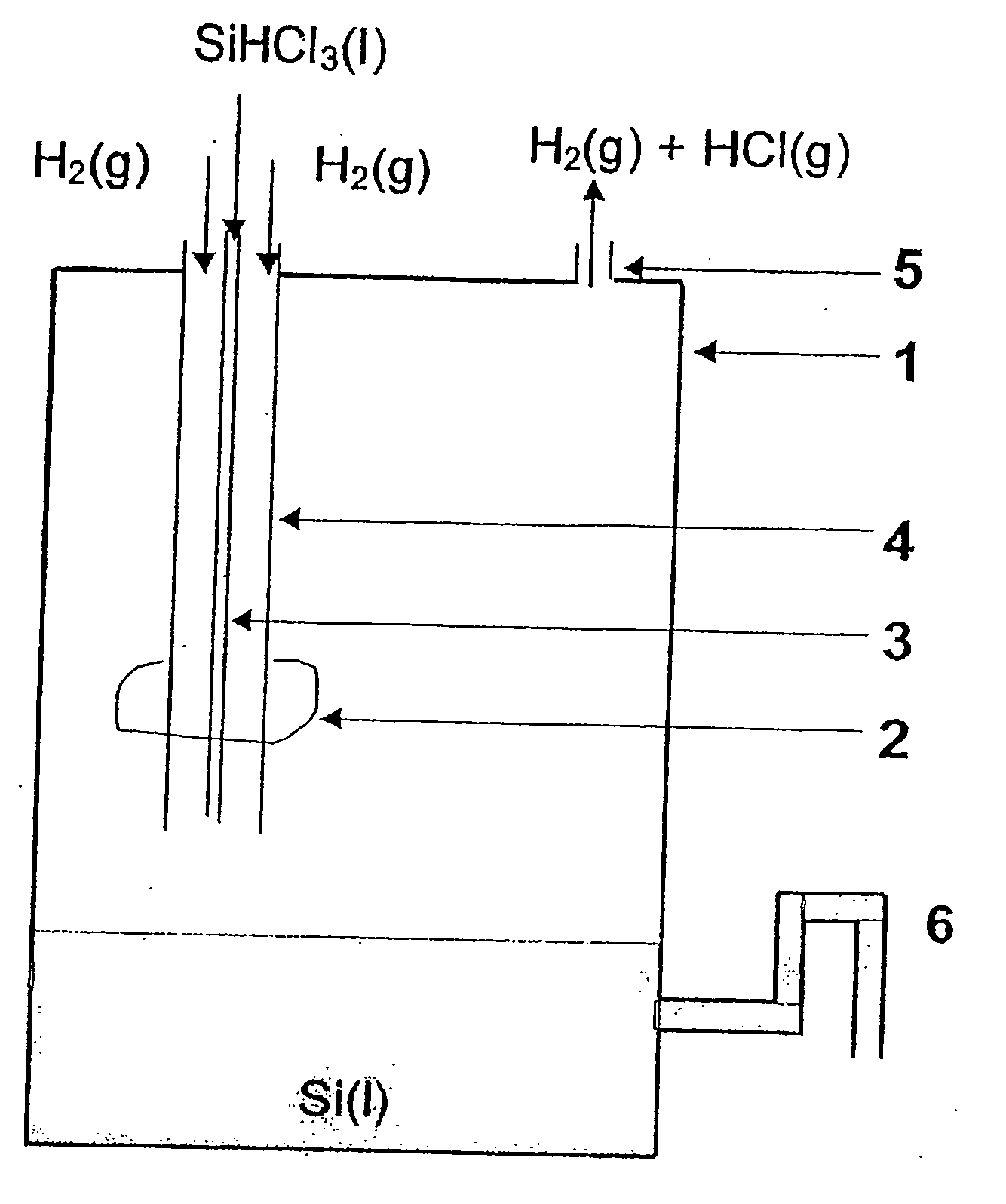

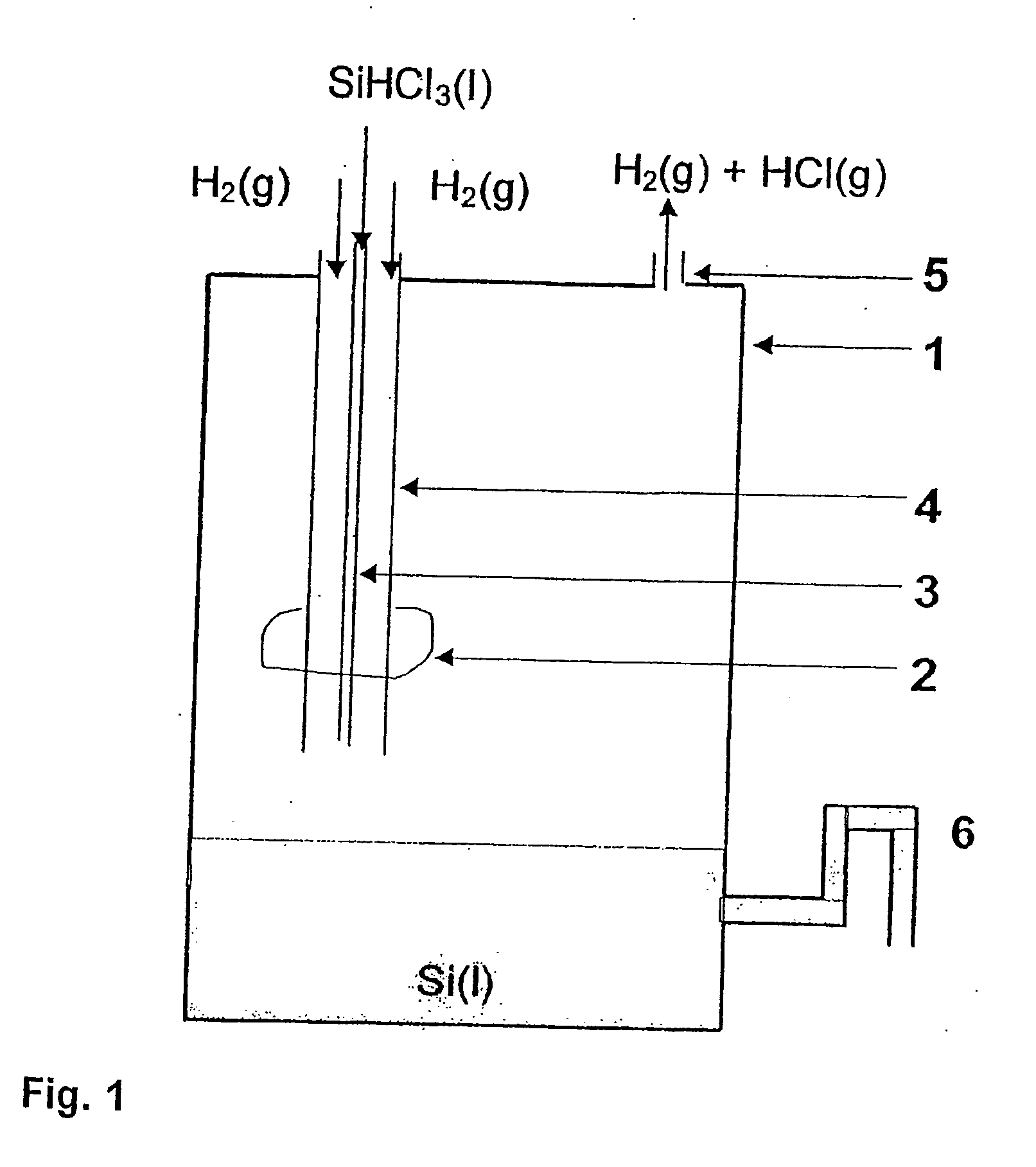

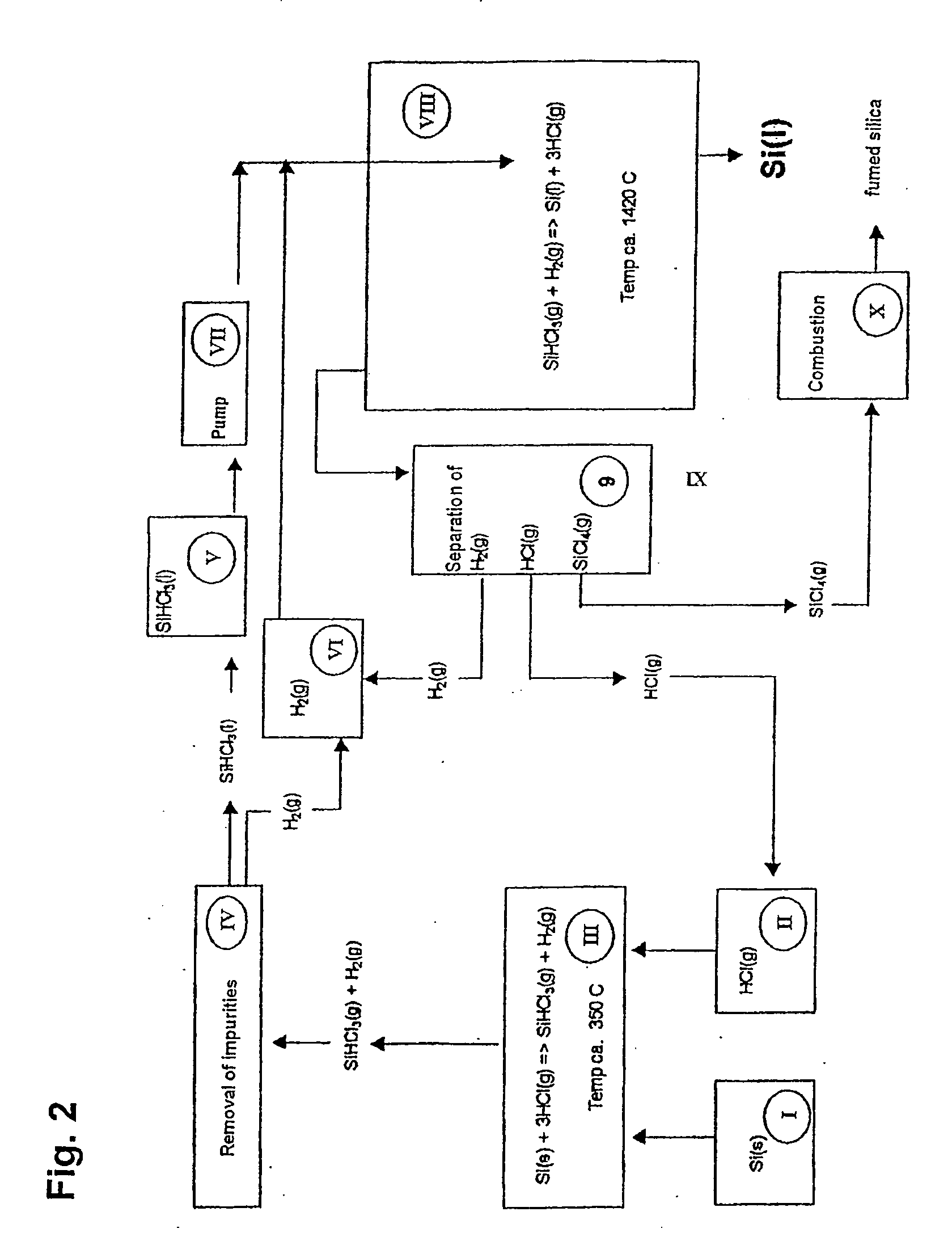

Production of high grade silicon, reactor, particle recapture tower and use of the aforementioned

Solar Grade Silicon is produced by decomposition of a silicon precursor, preferably trichlorosilane, in the presence of an excess of hydrogen gas, where the reactant are introduced in a reaction chamber whose lower portion is held at a temperature above the melting point of silicon and whose upper portion is held at ambient temperatures. The method is distinguished by the introduction of trichlorosilane through a feed pipe which is arranged coaxially inside an outer pipe for introducing hydrogen gas that functions as a cooling medium for the introduced fluid trichlorosilane. The silicon formed is collected in the lower portion of the reactor and removed through an outlet. Excess hydrogen and hydrogen chloride is withdrawn through an outlet and can, after purification, be used as reactants in the essentially closed system for the production of pure silicon from low grade silicon. Silicon particles in the off gases can be separated, melted and recycled using a particle recapture tower.

Owner:SOLAR GRADE SILICON

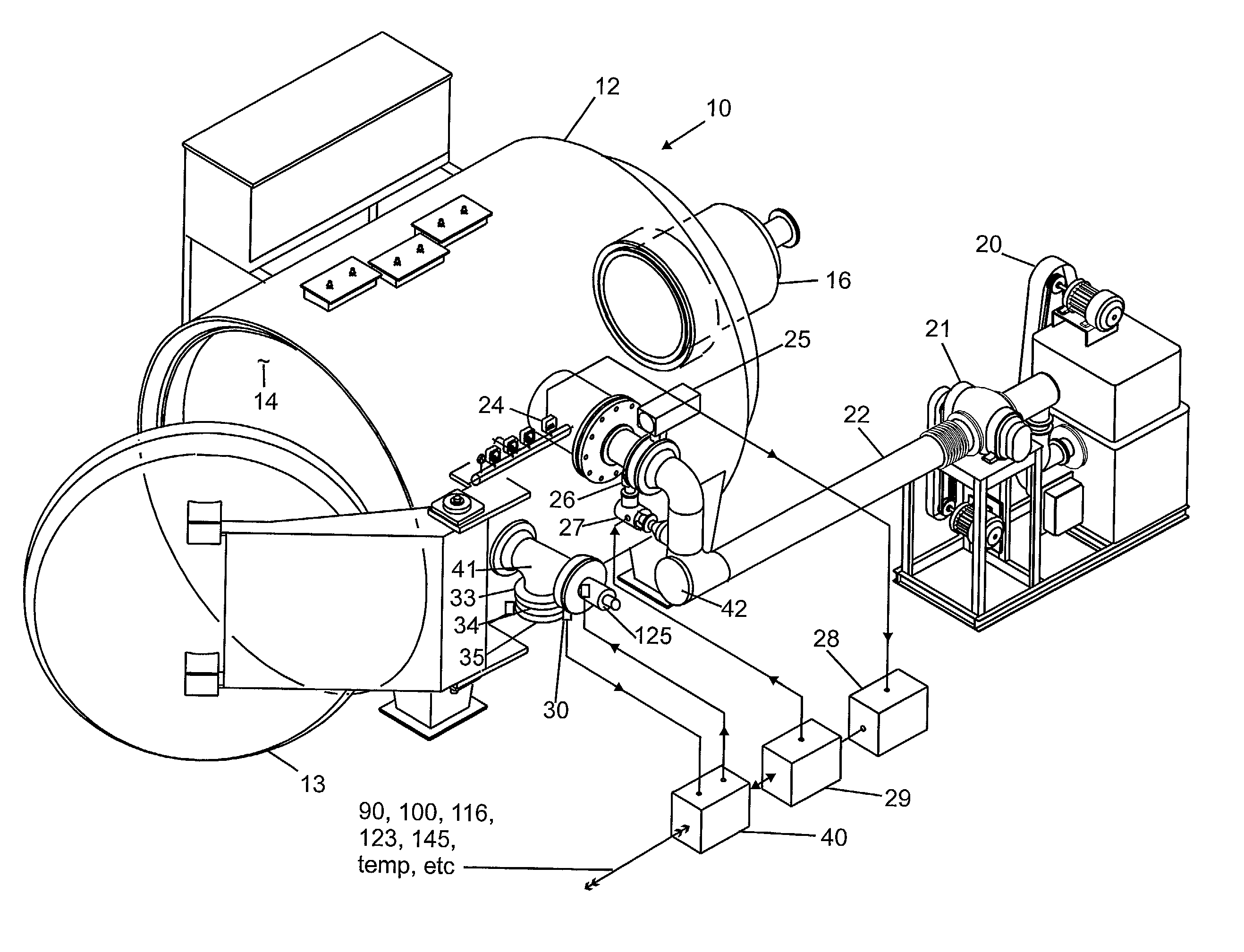

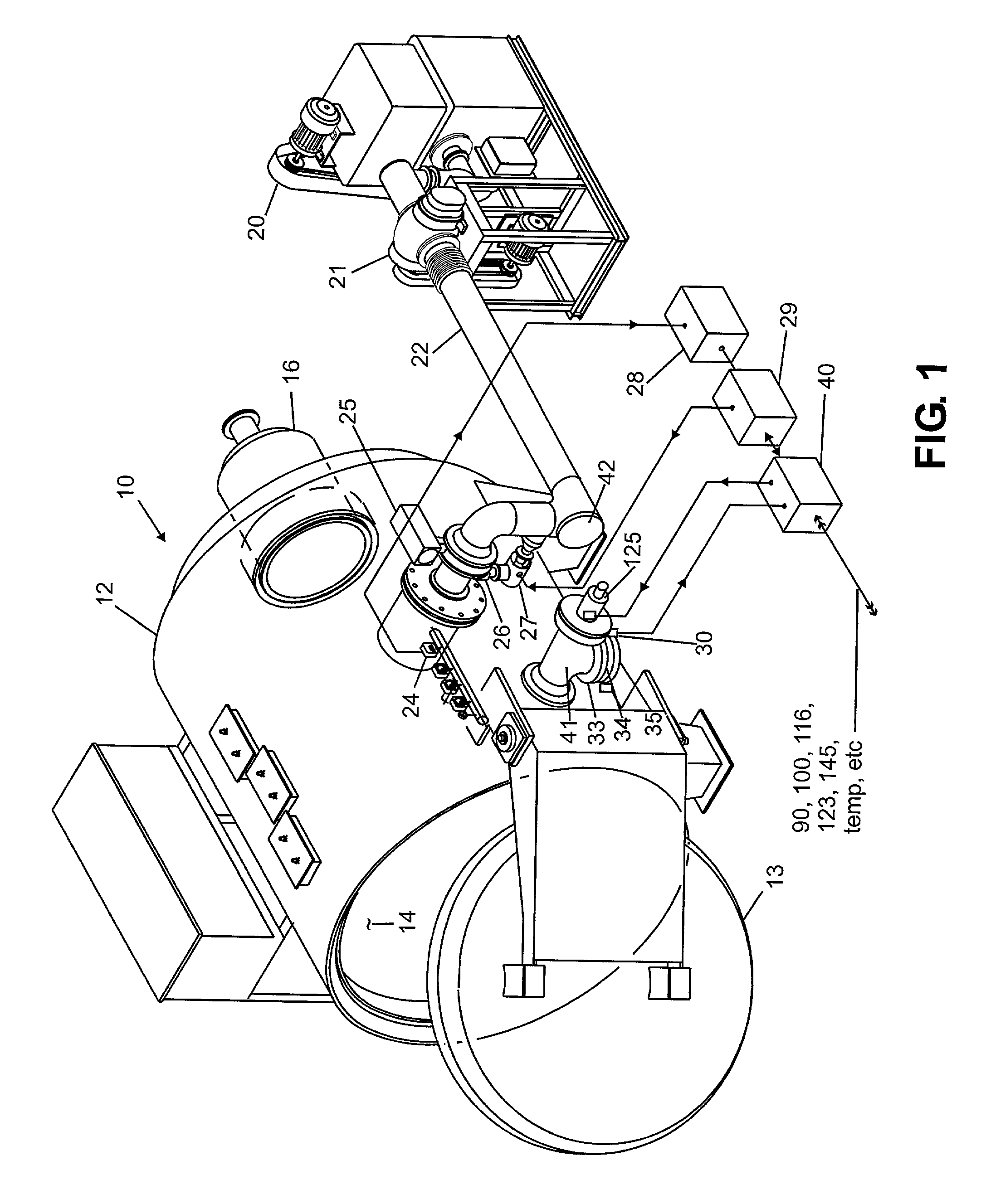

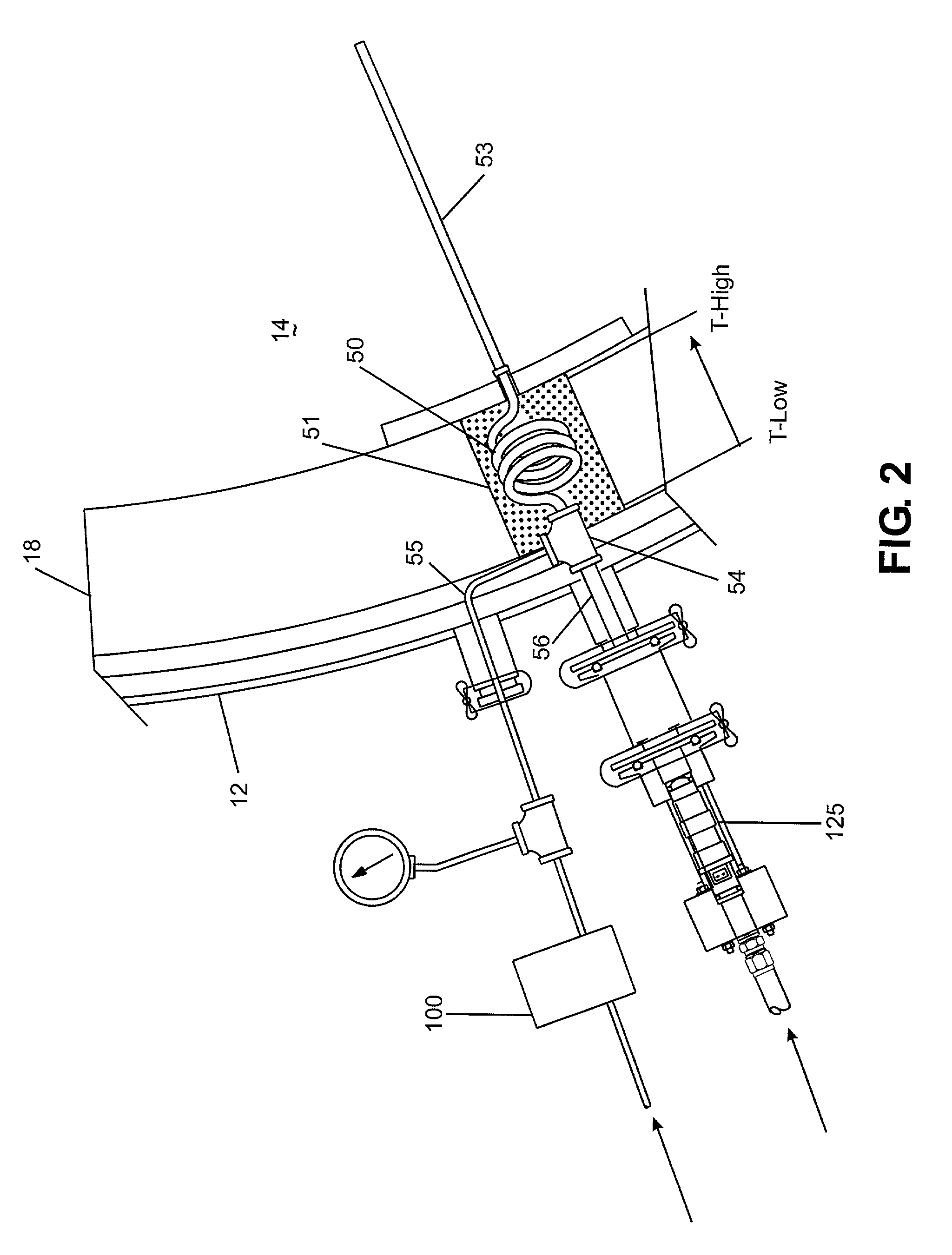

Vacuum carburizing with unsaturated aromatic hydrocarbons

ActiveUS7033446B2Easy to controlAccurate repeatabilitySolid state diffusion coatingAlkaneCarbon potential

Vacuum carburizing of ferrous workpieces is performed at low pressure in a vacuum furnace using an unsaturated aromatic such as benzene as the carburizing medium. The unsaturated aromatic is gas phase hydrogenated into a napthenes, such as cyclohexane, which is metered into the furnace chamber proper and functions as the carburizing gas. The furnace is constructed to be generally transparent to the napthenes so that cracking tends to occur at the workpiece which functions as a catalyst to minimize carbon deposits. The unsaturated aromatic is supplied in liquid form to fuel injectors which inject the liquid aromatic as a vapor at duty cycles and firing orders to produce a uniform dispersion of the hydrocarbon gas about the work resulting in uniform carburizing of the workpieces. An in-situ methane infrared sensor controls the process. Excess hydrogen beyond what is required to hydrogenate the aromatic is added to the furnace chamber to either assure full carbon potential and produce methane or to perform variable carburizing. Hydrogenation occurs in a hydrogenation coil in fluid communication with the furnace chamber with temperature for the reaction set by the position of the hydrogenation coil in the furnace insulation.

Owner:SURFACE COMBUSTION

Process for producing methanesulfonic acid

ActiveCN101219975AEfficient use ofEasy to produceSulfuric acid esters preparationAlkaline earth metalEvaporation

The invention discloses a preparation method for methanesulfonic acid. A water liquor or a solid mixture of a sulfite or a mixture of the sulfite and a bisulfite is reacted with a dimethyl sulfate to generate a methylsulfonate and a sulfate, and the mixture liquor of the reaction directly cools and precipitates a sulfate salt crystallization through concentration by adding a salting-out agent or a concentrated liquor; filtering and removing a dilute-methyl sulfonate liquor of the sulfate; a soluble alkaline earth salt can also be reused as a precipitant for further removing the remained sulfate ion; finally, the purified methylsulfonate liquor is concentrated to pulpiness or dry powder to be acidified by excess concentrated hydrochloric acid or excess hydrogen chloride gas is directly pumped in the purified methylsulfonate liquor to precipitate a sodium chloride crystallization. After filtering, the mixed acid liquor of hydrochloride and methanesulfonic acid can be gotten, which can get the highly-purified methanesulfonic acid after evaporation concentration, vacuum distillation and distillation. The materials of the invention can be gotten easily and the invention has simple techniques and low cost, which does no harm to the environment and is suitable to be used in industry.

Owner:HEBEI YANUO CHEM IND

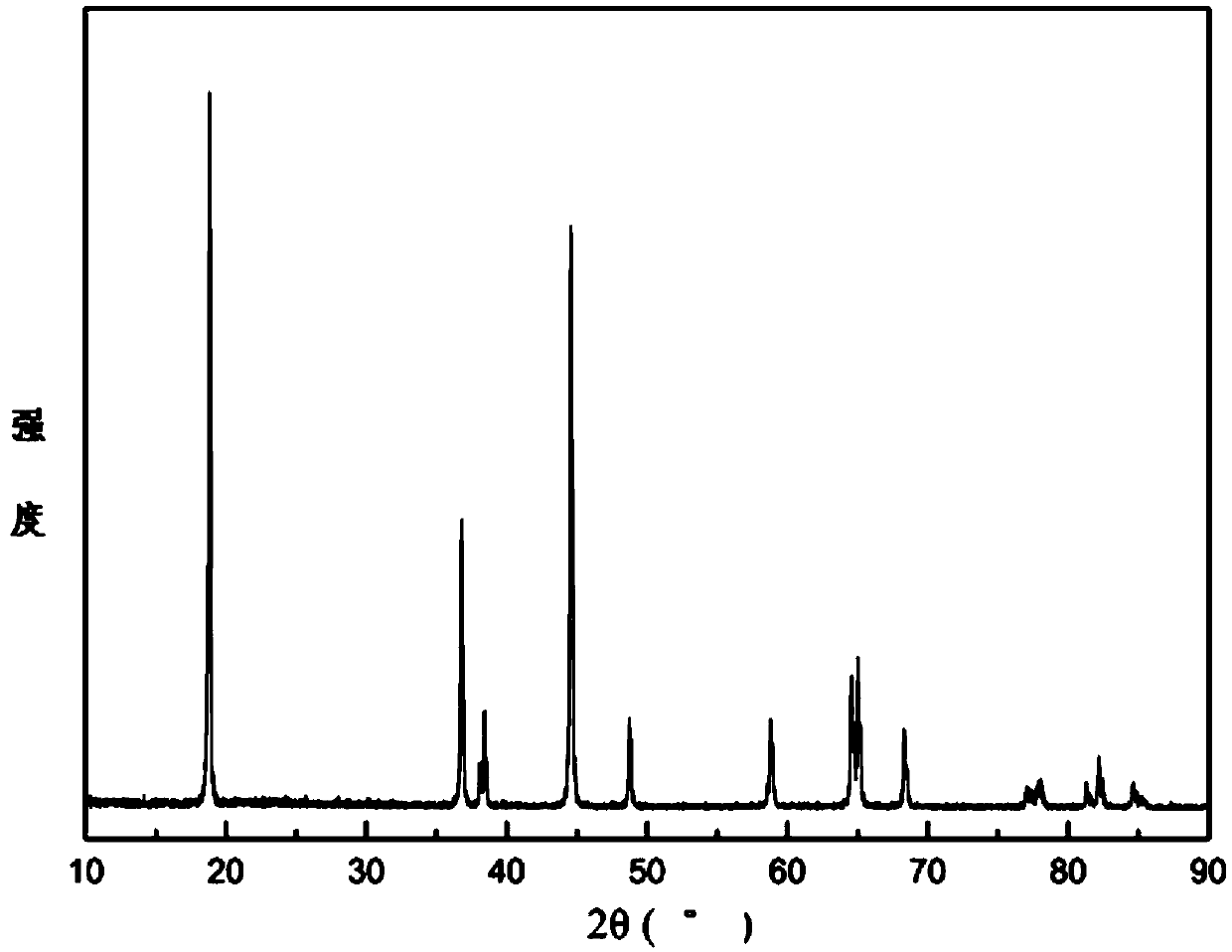

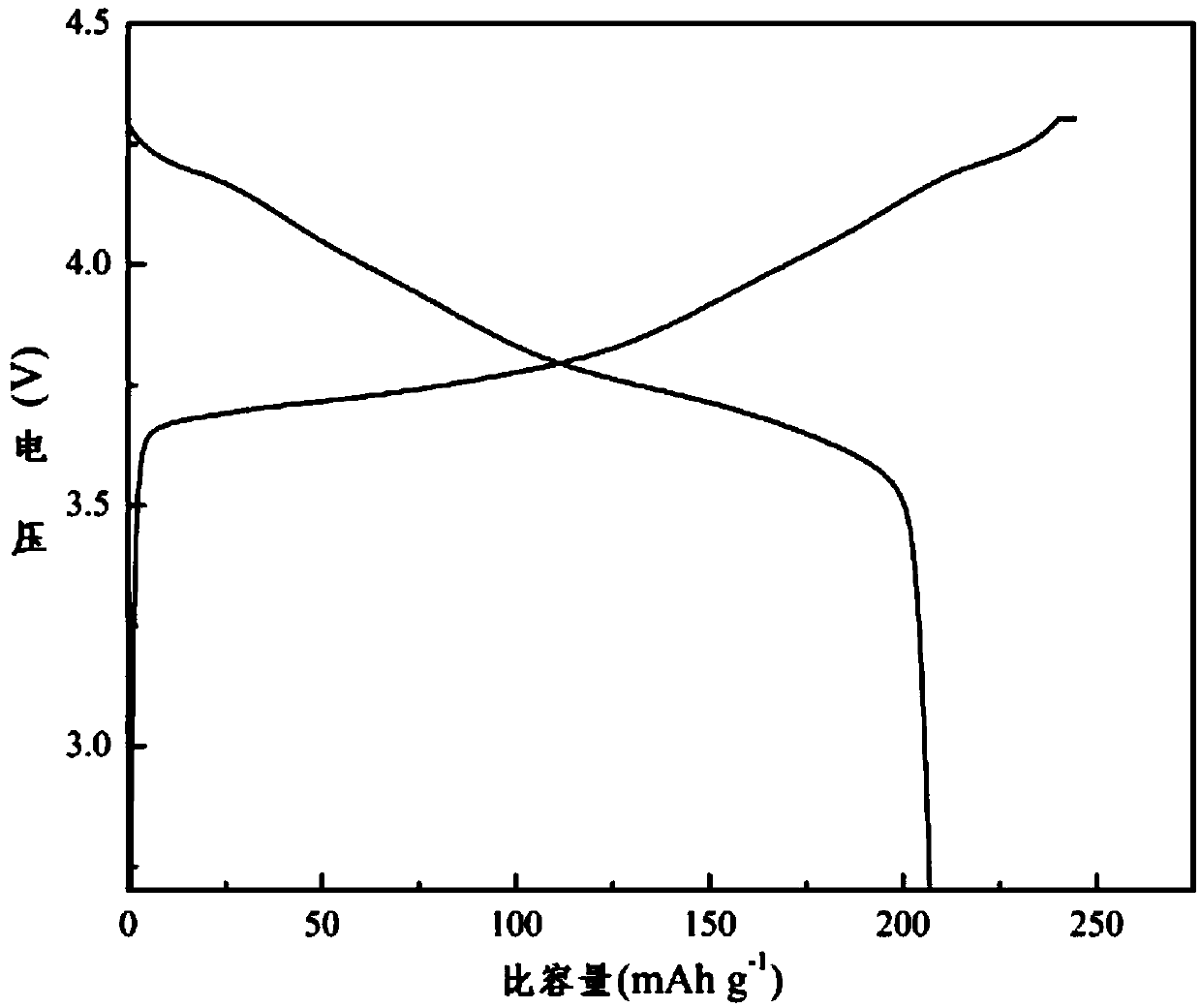

Ternary positive electrode material having porous structure and preparation method thereof

InactiveCN109546143ALarge specific surface areaImprove stabilityCell electrodesNickel saltLithium hydroxide

The invention discloses a ternary positive electrode material having a porous structure and a preparation method thereof. The chemical formula of the ternary positive electrode material is as follows:LiNixCoyMn1-x-yO2, wherein the x is larger than 0.5 and is less than 1, the y is larger than 0 and is less than 0.3, and x+y is less than 1. In addition, the preparation method of the ternary positive electrode material includes: step one, dissolving nickel salt, cobalt salt and manganese salt in a mixed solvent, adding urea to obtain mixed liquid, transferring the mixed liquid in a hydrothermalreactor, and carrying out reaction for 8 to 40h at a temperature of 120 to 240 DEG; after reaction completion, obtaining a product, carrying out filtering, washing and vacuum drying on the precut, andcarrying out preliminary calcining for 1 to 6 hours at a temperature of 400 to 600 DEG C to obtain an intermediate; and step two, carrying out sintering on the intermediate obtained at the step one and an excess amount of lithium hydroxide to obtain a spindle-shaped ternary positive electrode material having a porous structure. According to the invention, the process is simple; the reaction conditions can be controlled; the product quality is stable; the crystallinity is high; and the size is uniform. The obtained ternary positive electrode material has the high energy density and large specific surface area.

Owner:XIANGYA HOSPITAL CENT SOUTH UNIV

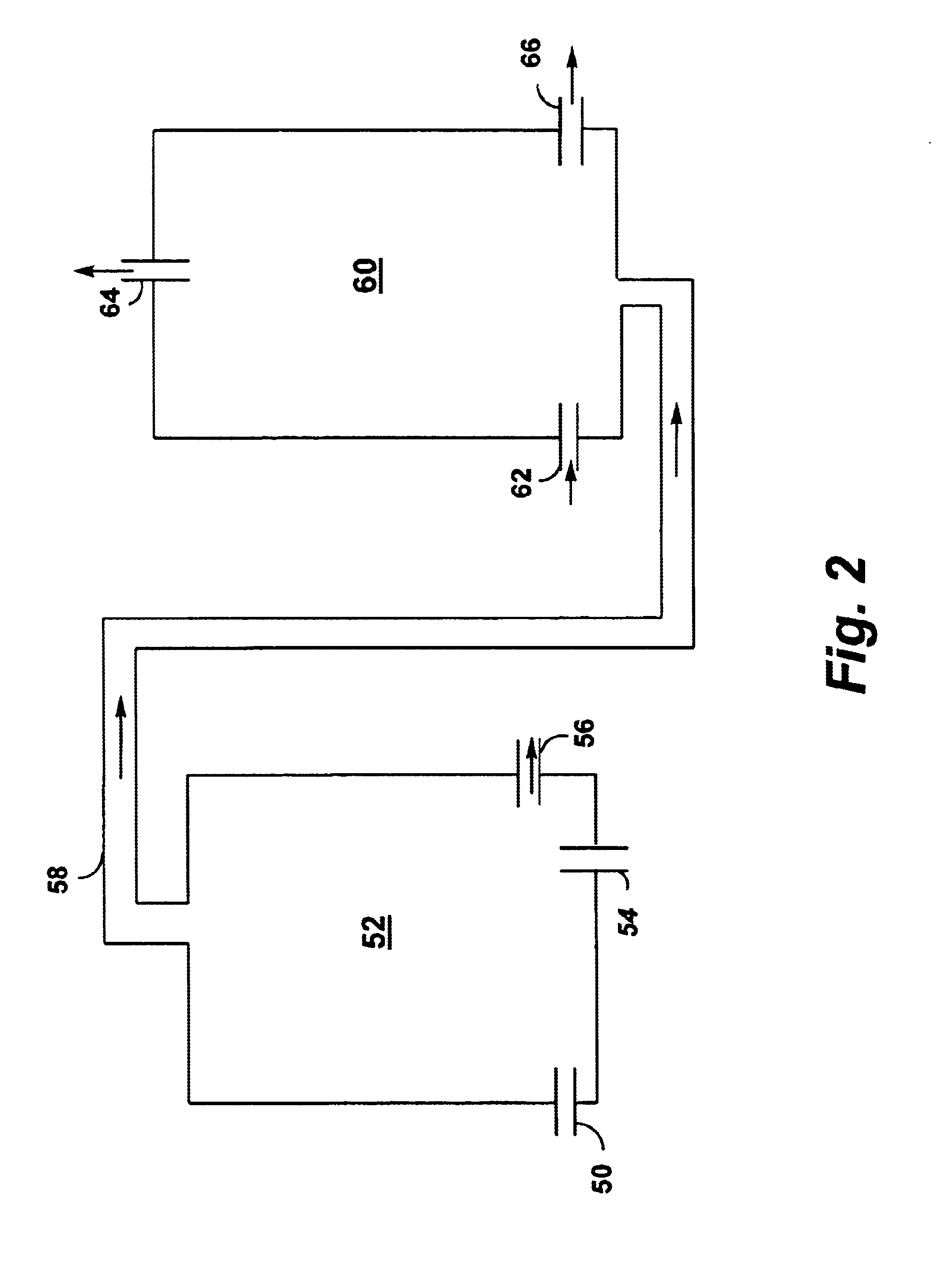

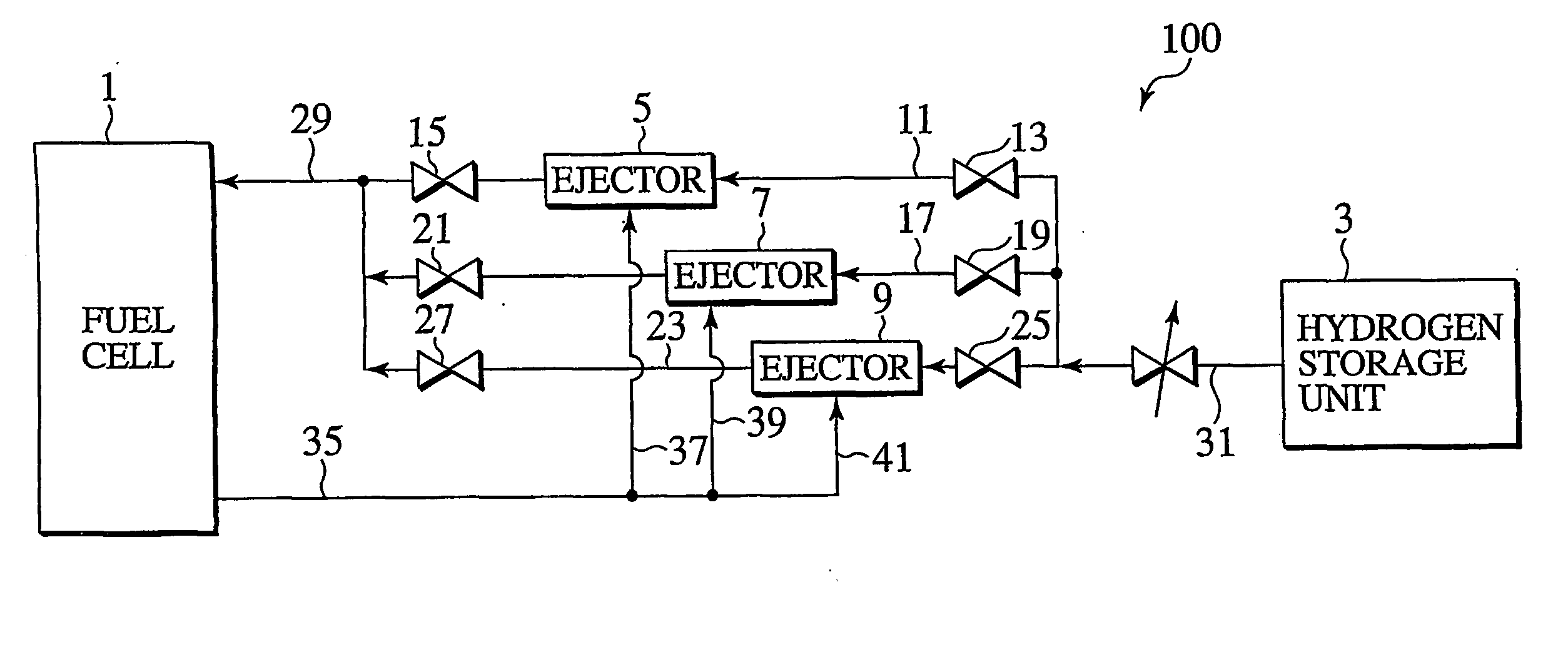

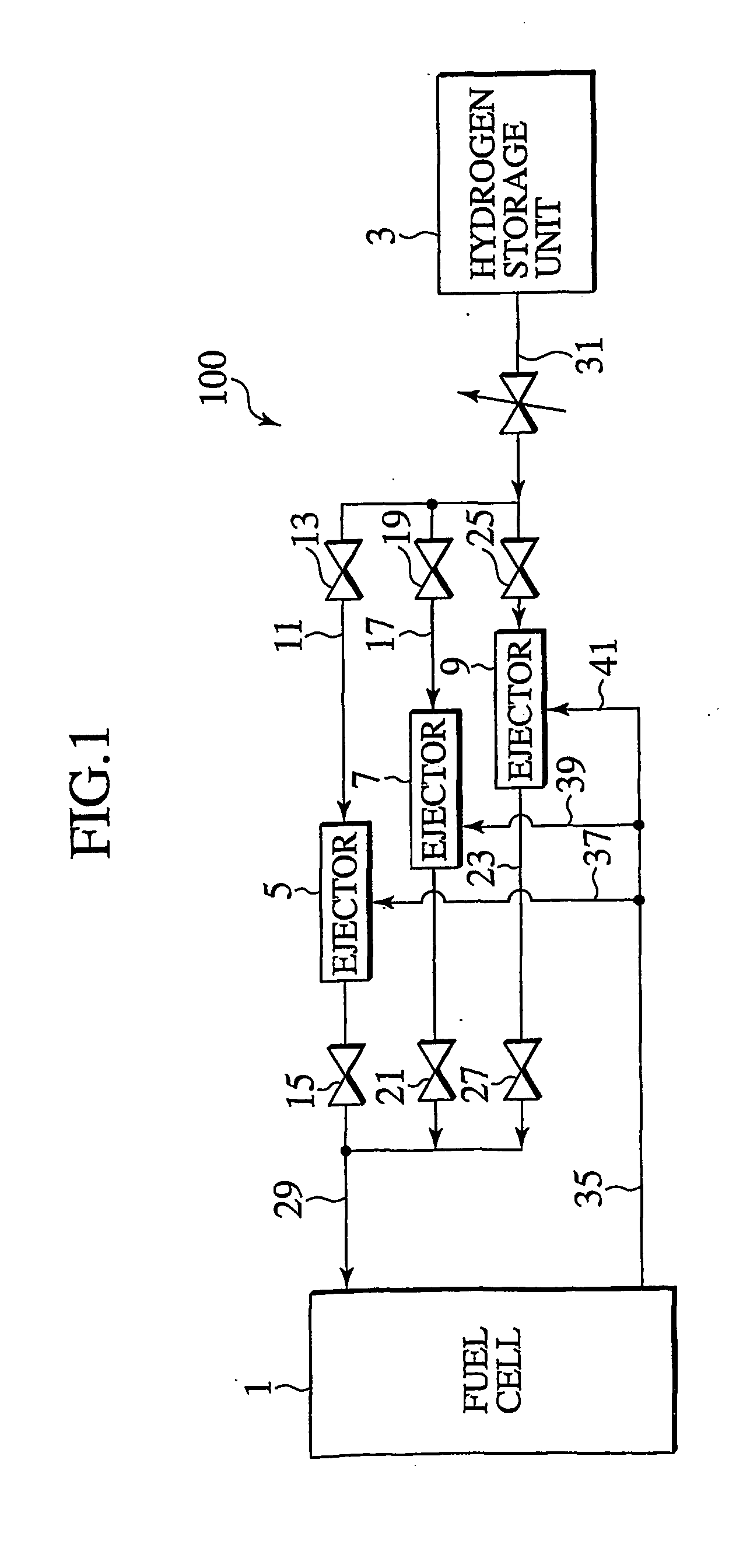

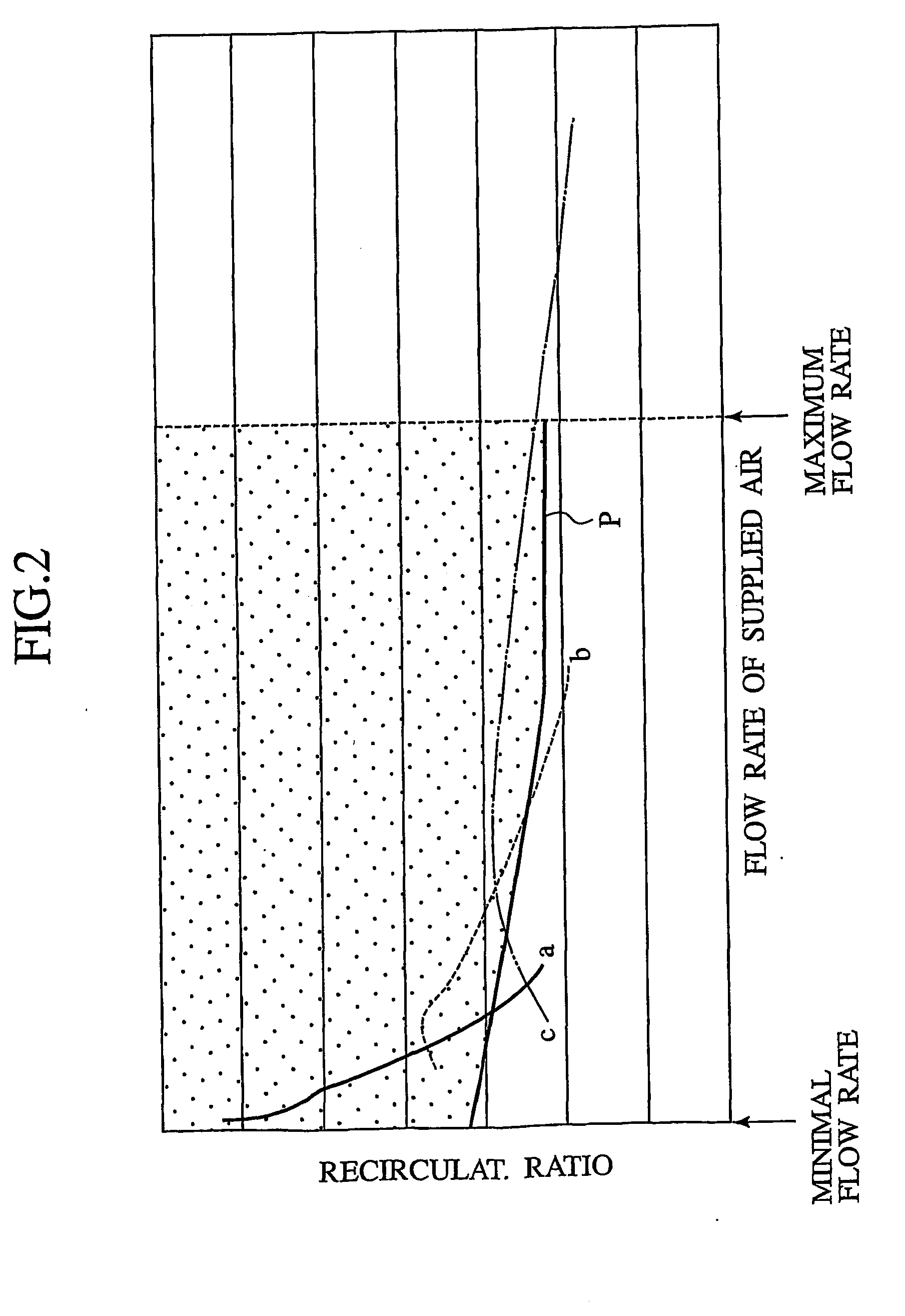

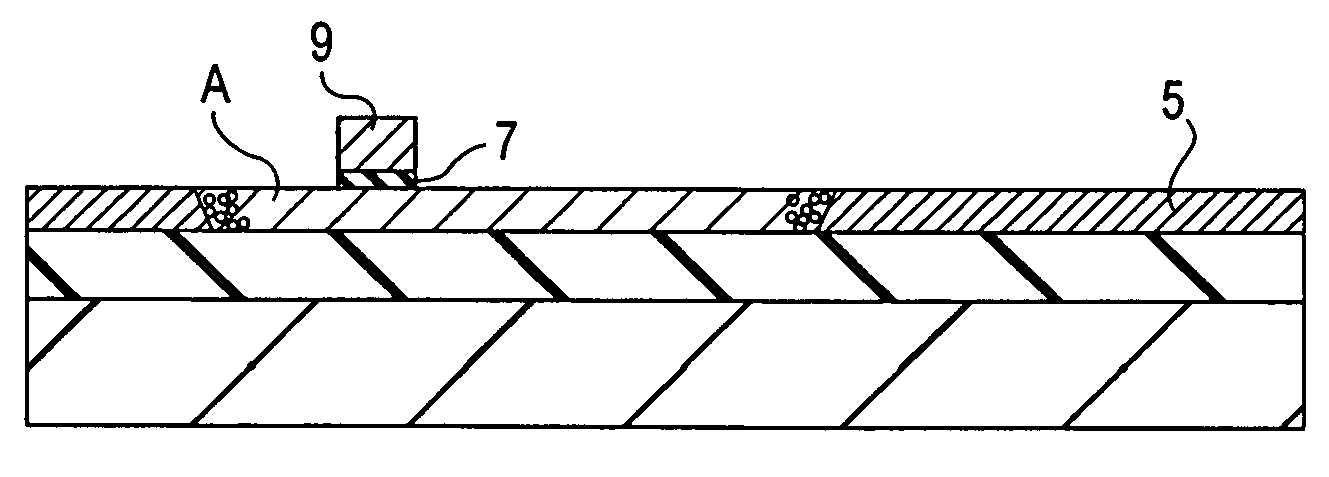

Fuel cell system

Three ejectors 5, 7, 9 with differences in specification are connected in parallel between a hydrogen storage unit 3 and a fuel cell 1. Respective ejectors 5, 7, 9 allow excess hydrogen, discharged from the fuel cell 1, to pass through a hydrogen recirculating common flow passage 35 and to be recirculated through three recirculation branch flow passages 37, 39, 41. Shut-off mechanisms 13, 15, 19, 21, 25, 27 are disposed at both upstream and downstream sides of the respective ejectors 5, 7, 9, with closing and opening of the shut-off mechanisms located at both the upstream and downstream sides of the respective ejectors 5, 7, 9 permitting the three ejectors 5, 7, 9 to be properly used.

Owner:NISSAN MOTOR CO LTD

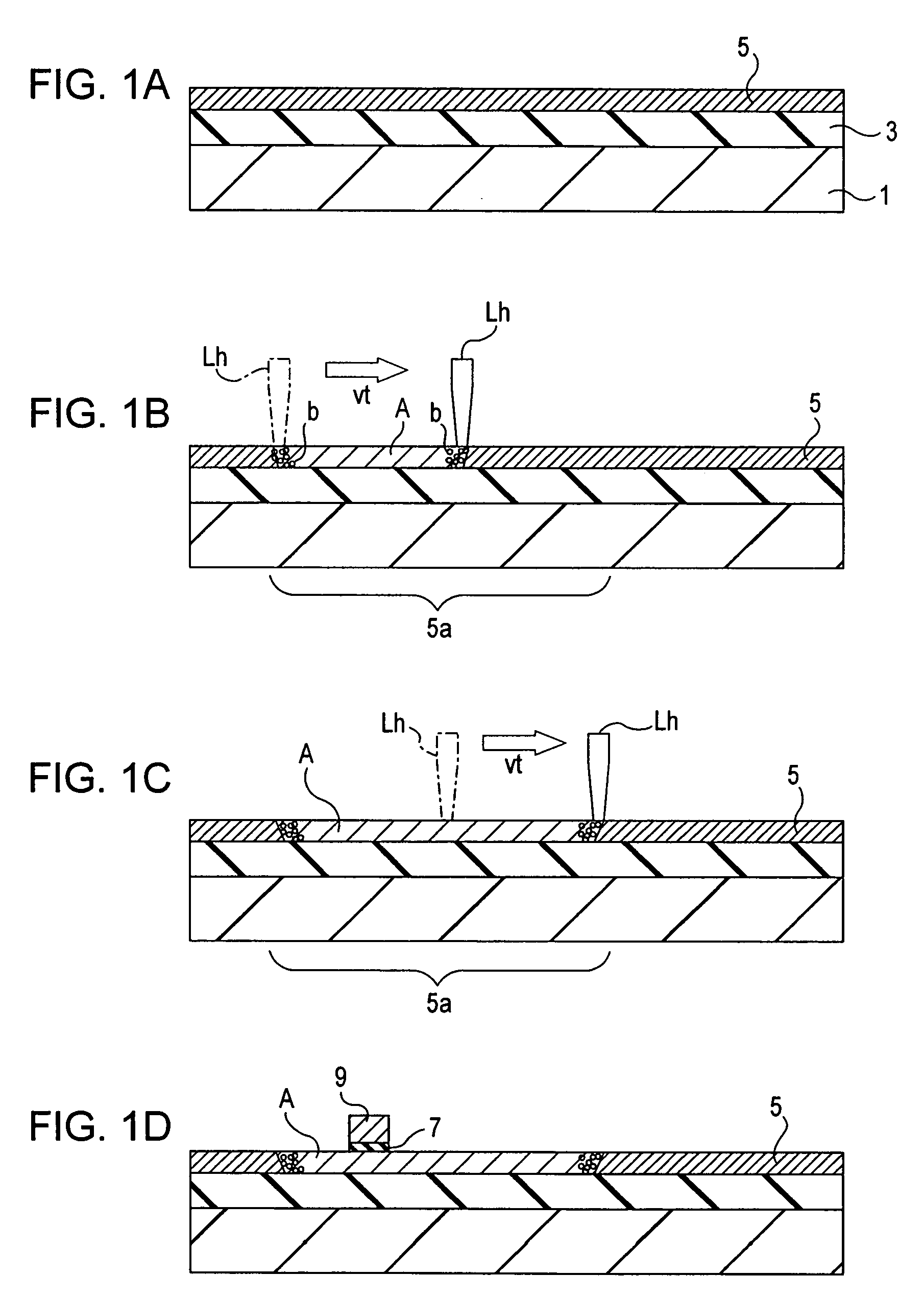

Method for making thin-film semiconductor device

InactiveUS20060079033A1Reduce processing temperatureSimplify the process stepsSolid-state devicesSemiconductor/solid-state device manufacturingLaser beamsSemiconductor thin films

A method for making a thin-film semiconductor device includes an annealing step of irradiating an amorphous semiconductor thin film with a laser beam so as to crystallize the amorphous semiconductor thin film. In the annealing step, the semiconductor thin film is continuously irradiated with the laser beam while shifting the position of the semiconductor thin film irradiated with the laser beam at a predetermined velocity so that excess hydrogen can be removed from the region irradiated with the laser beam without evaporating and expanding hydrogen ions in the semiconductor thin film.

Owner:JAPAN DISPLAY WEST

Vanadium-nitrogen alloy resolution method

InactiveCN101135617AEfficient and safe digestionFully digestedPreparing sample for investigationAlloy substratePhosphoric acid

The method relates to a Vanadium-Nitrogen alloy digestion method, belonging to the Vanadium-Nitrogen alloy detection field. The Vanadium-Nitrogen alloy digestion method comprises following steps: a) taking out the Vanadium-Nitrogen alloy to be tested from a sealed container; adding nitric acid to react until bubbles is free and the NO2 smoke is generated; b) adding hydrofluoric acid and phosphoric acid separately; then sealing them and using micro wave to clear up; c) adding hydrofluoric acid. The Vanadium-Nitrogen alloy digestion method realizes the digestion in effective, safe, fast and complete way for Vanadium-Nitrogen alloy substrate and all impurity element, and also can detect multiple elements, such as silicon, aluminum, calcium, magnesium, ferrum, chromium, titanium, arsenic, plumbum and the like at the same time according to a combination of modern precision analysis instruments, such as ICP-AES, ICP-MS, AAS and the like, so as to greatly improve the accuracy and precision degree of detection data, work efficiency and has broad market prospect in industrial application.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

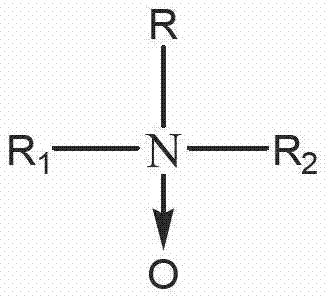

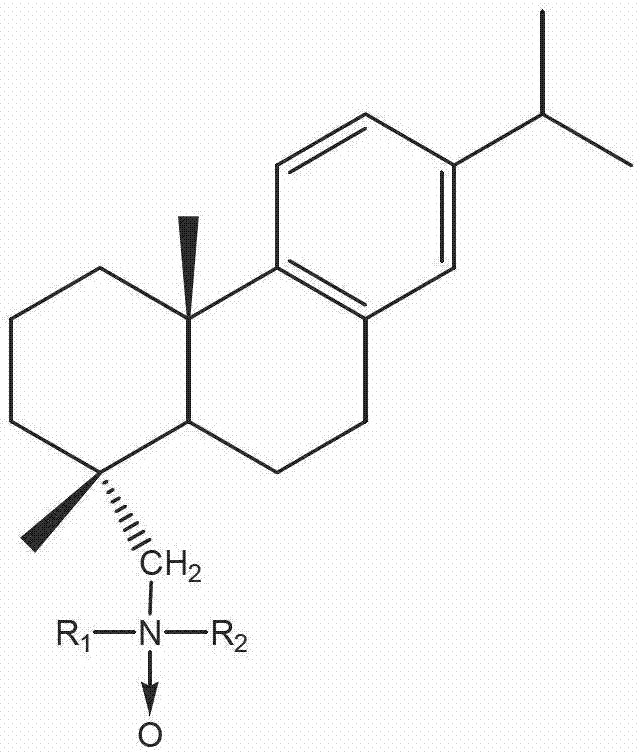

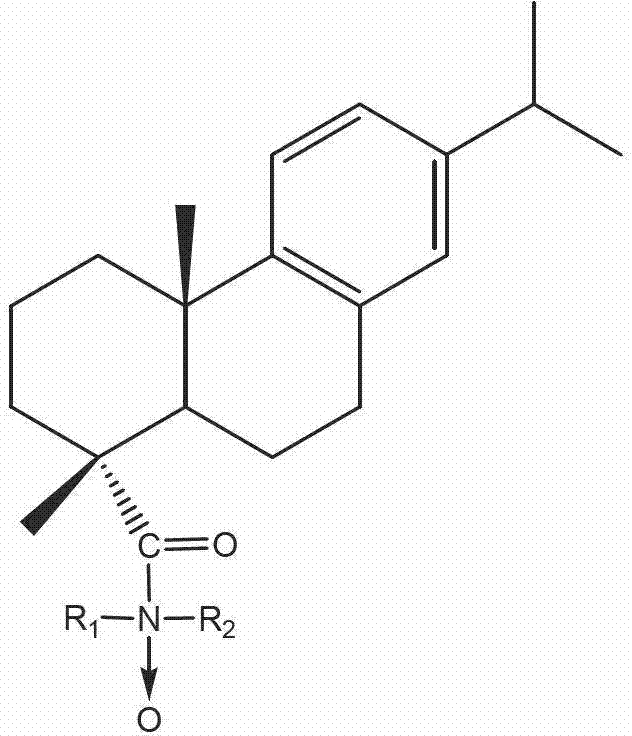

Tertiary amine oxide with rosinyl three-membered phenanthrene ring structure and preparation method of tertiary amine oxide

The invention discloses a tertiary amine oxide with a rosinyl three-membered phenanthrene ring structure and a preparation method of the tertiary amine oxide. The preparation method comprises the following steps of: (1) dissolving, namely mixing tertiary amine, an alcoholic solution or water and catalysts, heating the mixture to 50-60 DEG C, stirring and dissolving the mixture to obtain an alcoholic solution or an aqueous solution of the tertiary amine; (2) oxidizing reaction, namely mixing the alcoholic solution of the tertiary amine and hydrogen peroxide in a mole ratio of the tertiary amine to the hydrogen peroxide 1:(1-1.5), reacting the mixture for 12-25 hours at 65-80 DEG C, then adding disulfate and excess hydrogen peroxide to the mixture for reacting for 0.5-1 hour; and (3) separating and drying, namely steaming reaction products in a spinning manner, and drying the products in vacuum to obtain the tertiary amine oxide with the rosinyl three-membered phenanthrene ring structure. The tertiary amine oxide disclosed by the invention is high in electrolyte resistance and good in defoaming capability, has a good effect in hard water, and has good wetting and emulsifying performance. The preparation method is simple and practicable and is high in yield.

Owner:GUANGXI UNIV FOR NATITIES

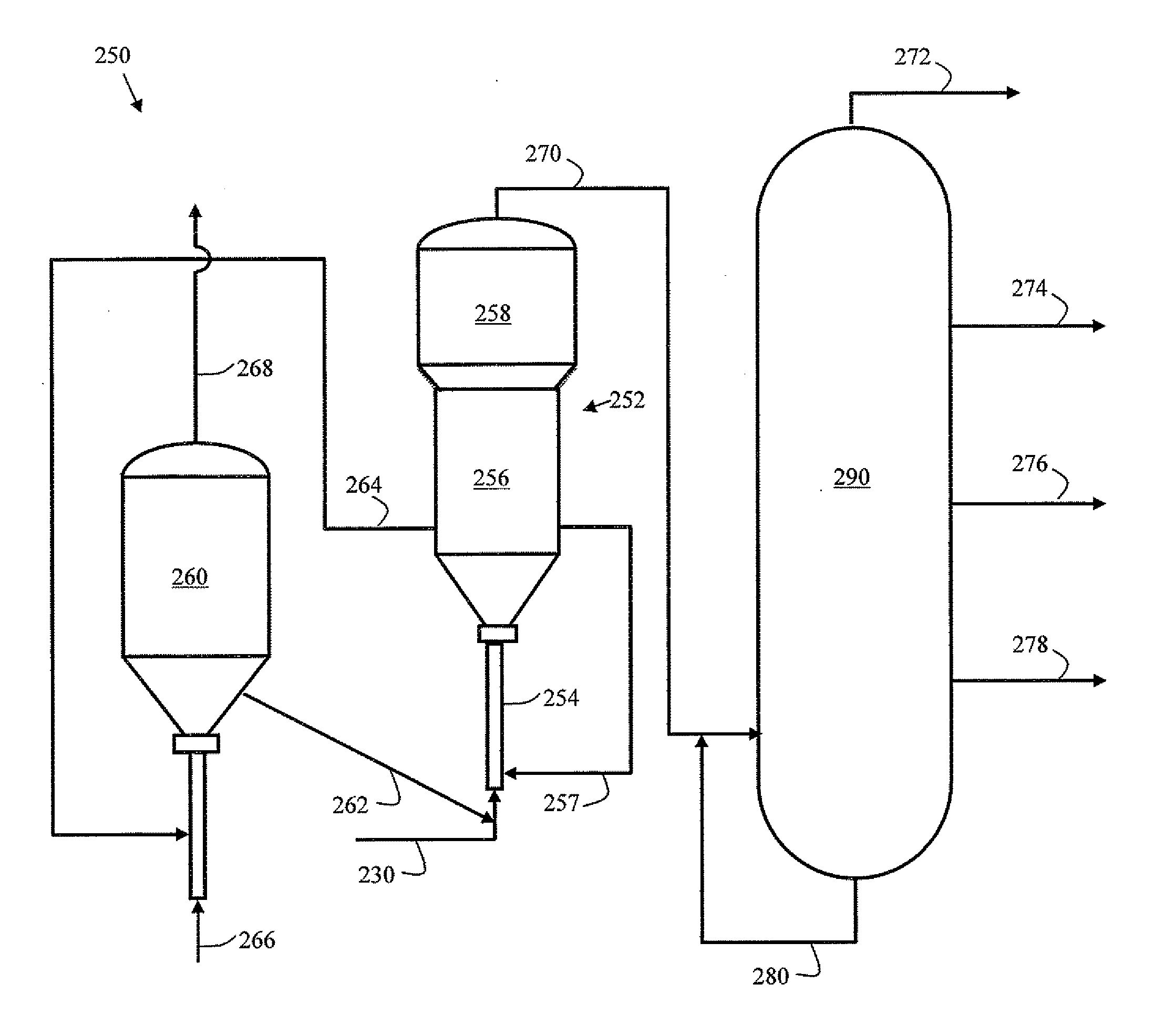

Hydrogen-enriched feedstock for fluidized catalytic cracking process

ActiveUS20130026067A1Reduce the amount requiredGood curative effectCatalytic crackingHydrocarbon oil crackingBoiling pointLiquid hydrocarbons

A process for catalytically cracking a hydrocarbon oil containing sulfur and / or nitrogen hydrocarbon constituents by dissolving excess hydrogen in the liquid hydrocarbon feedstock in a mixing zone at a temperature of 420° C. to 500° C. and a hydrogen-to-feedstock oil volumetric ratio of 300:1 to 3000:1, flashing the mixture to remove remaining hydrogen and any light components in the feed, introducing the hydrogen saturated hydrocarbon feed into an FCC reactor for contact with a catalyst suspension in a riser or downflow reactor to produce lower boiling hydrocarbon components which can be more efficiently and economically separated into lower molecular weight hydrocarbon products, hydrogen sulfide and ammonia gas and unreacted hydrogen in a separation zone. Hydrogen present in the liquid phase enhances the desulfurization and denitrification reactions which occur during the conversion process and allows for the removal of significantly more sulfur- and / or nitrogen-containing contaminants from the feedstock in an economical fashion.

Owner:SAUDI ARABIAN OIL CO

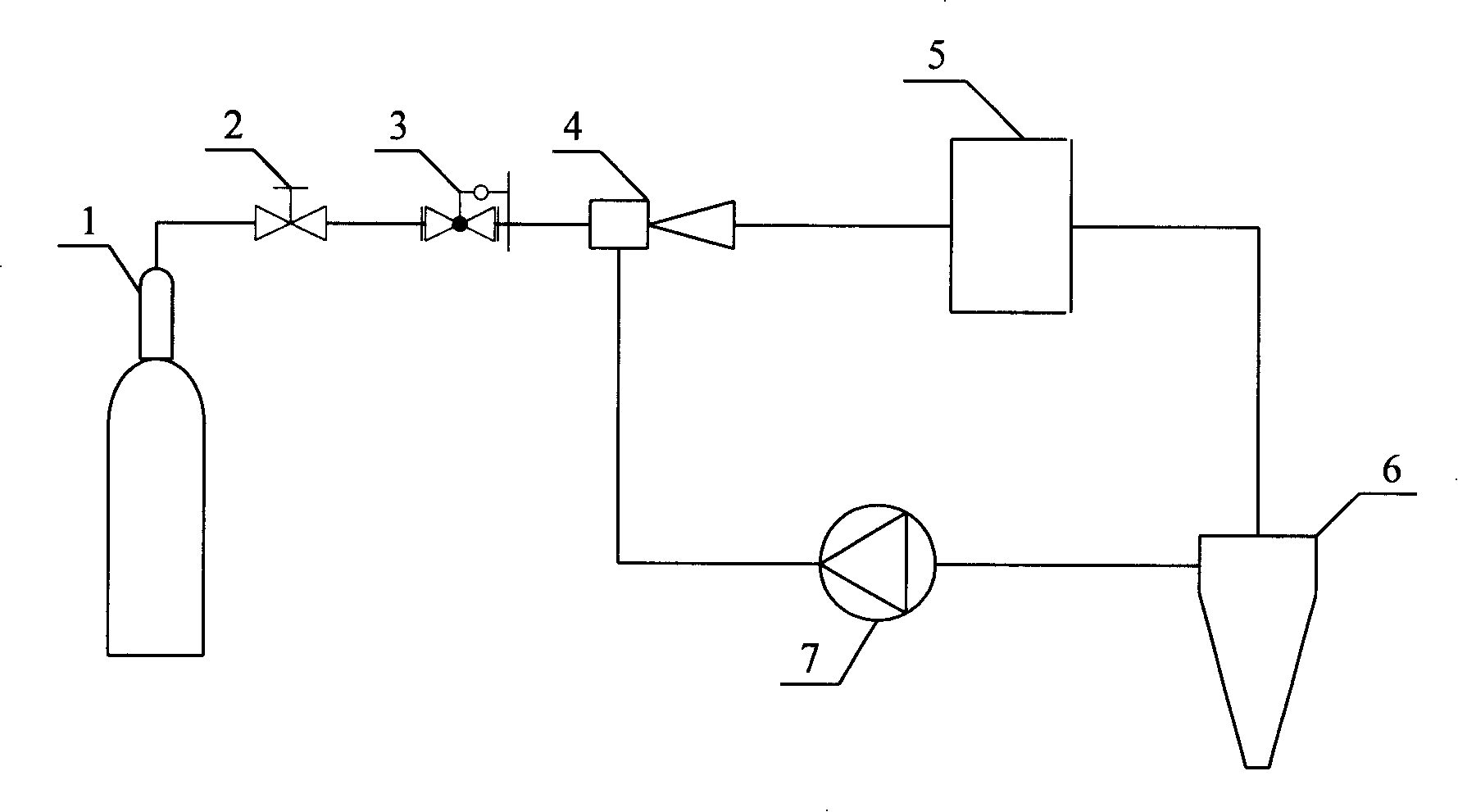

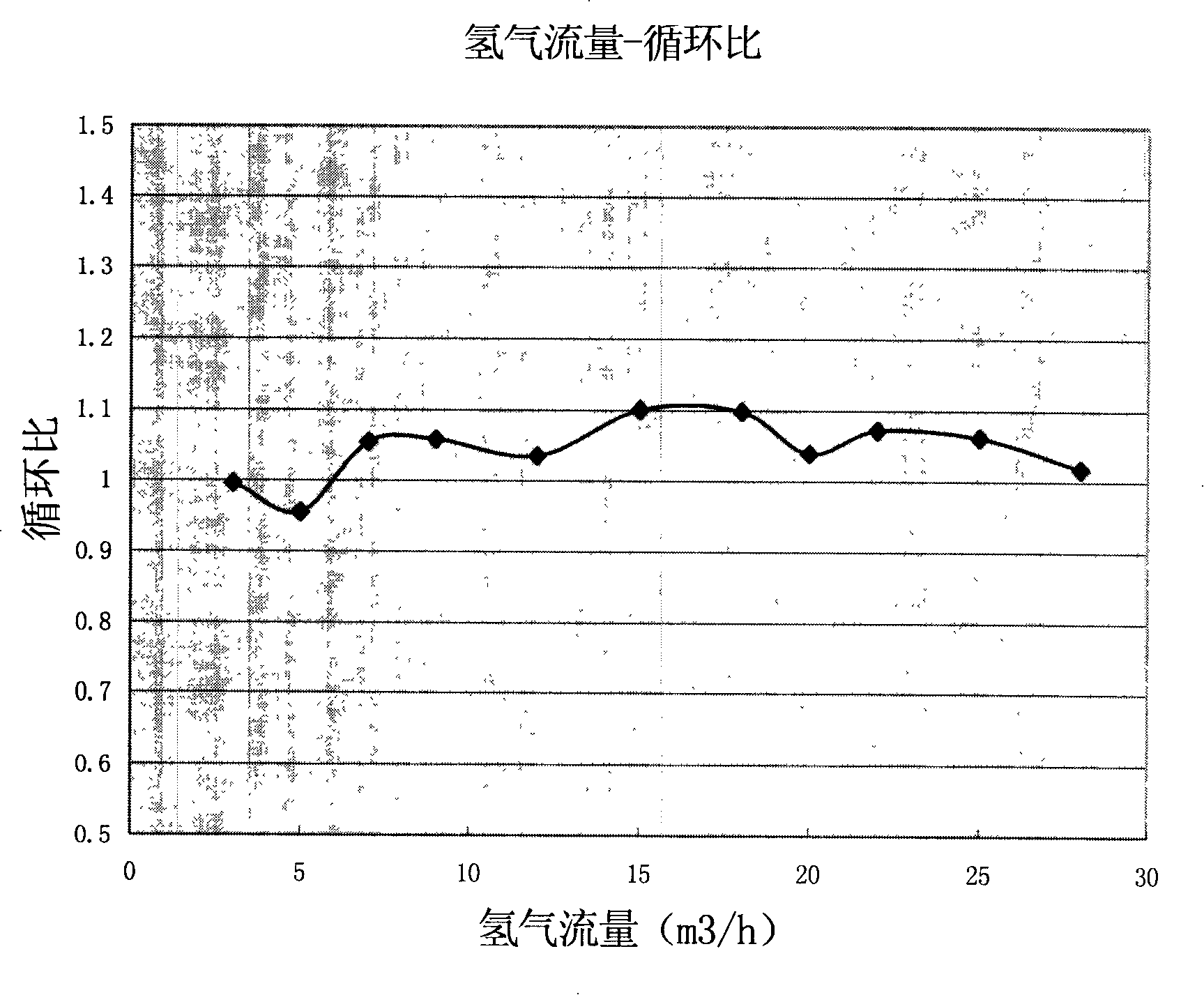

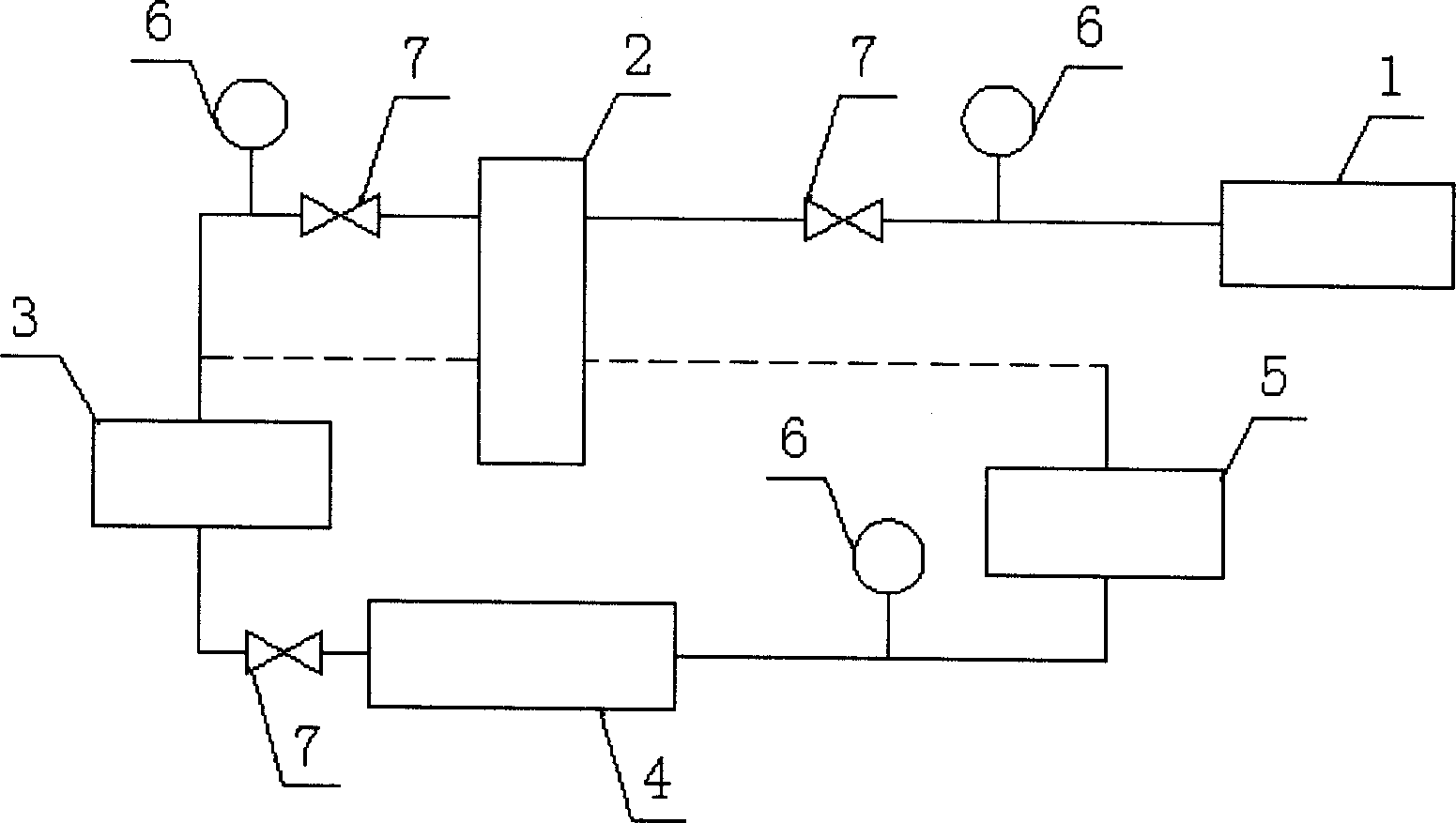

A fuel circulation method for fuel battery and special device

The invention relates to an engine system for a fuel cell, which is a fuel circulation method for the fuel cell and a special device. The high-pressure fuel hydrogen gas from a hydrogen gas source passes a pressure reducing valve to reduce the pressure, enters into a hydrogen gas sprayer, the hydrogen gas from the sprayer goes into a fuel cell, after reaction with the fuel cell, the over-dose hydrogen gas and water generation from the reaction enter into a water separator together, the hydrogen gas from the water separator gas outlet goes into an air blower inlet, and the hydrogen gas pressurized by the air blower enters into the sprayer gas induction inlet. The sprayer design point is the pressure and flow rate of the consumed hydrogen gas at the fuel cell nominal power, the air blower can regulate the speed, through the regulating the air blower rotary speed, the fuel hydrogen gas can maintain approximately constant circulation ratio within the scope of the fuel cell full power. The invention meets the requirements of the fuel cell to hydrogen gas circulation with relatively little energy consumption, which can carry the water of the product out of the cell, can sufficiently utilize the fuel hydrogen gas, and the fuel can be more uniformly distributed at each single section of the cell, thereby further improving the fuel cell life.

Owner:SUNRISE POWER CO LTD

Method for degrading kelp polysaccharide sulfate

The invention discloses a degradation method of kelp sulfated polysaccharide, which is characterized in that the kelp sulfate polysaccharide is firstly extracted and separated from kelp, and then degraded by hydrogen peroxide to obtain low molecular weight kelp sulfate polysaccharide. The method has fast degradation speed, very little reagent consumption, simple process, low cost, easy decomposition and removal of excess hydrogen peroxide, basically unchanged sulfuric acid group and total sugar content, concentrated molecular weight distribution, and controllable molecular weight range. Due to the bleaching effect of hydrogen peroxide, the obtained low molecular weight sulfated polysaccharide sample has a white appearance.

Owner:JINAN UNIVERSITY

Method for synthesizing succinic acid from maleic acid

ActiveCN102417445ALow reaction temperatureLess side effectsCarboxylic preparation by ozone oxidationButanedioic acidMaleopimaric acid

The invention discloses a method for synthesizing succinic acid from maleic acid. The method for synthesizing succinic acid from maleic acid comprises the following steps that 1, a catalyst is added into a fixed bed reactor; 2, hydrogen is fed into the fixed bed reactor so that the pressure is stabilized in a range of 5 to 35atm; the reaction system is heated to a temperature of 50 to 150 DEG C; and a maleic acid or maleate aqueous solution having a mass fraction of 1.0 to 25.0% passes through a catalyst bed layer at an airspeed of 0.01 to 5.00h<-1> and then enters into a liquid gathering tank, wherein in reaction, a feeding rate molar ratio of the hydrogen to the maleic acid or maleate aqueous solution is (3.0 to 15.0): 1; 3, reaction liquid obtained by the step 2 is cooled and filtered to form succinic acid or succinate and filtrate; 4, the obtained succinate is acidized and separated to produce succinic acid; and 5, the filtrate obtained by the step 3 is mixed with maleic acid and the excess hydrogen is recovered and recycled. The method for synthesizing succinic acid from maleic acid has the advantages of mild conditions, low cost and high product purity.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

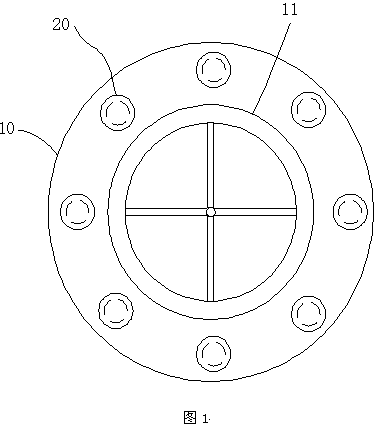

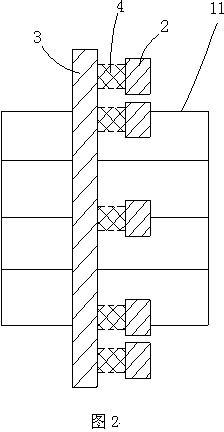

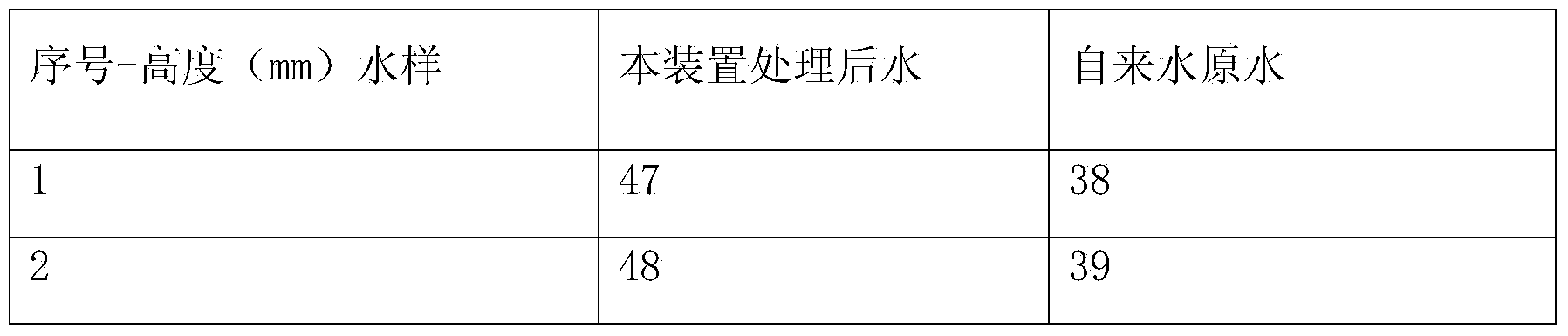

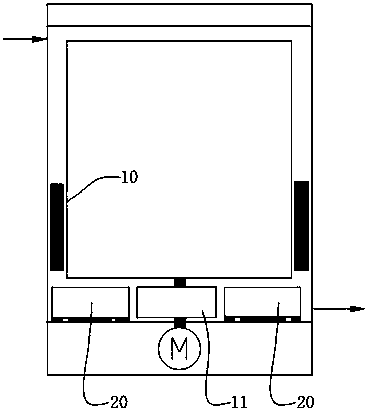

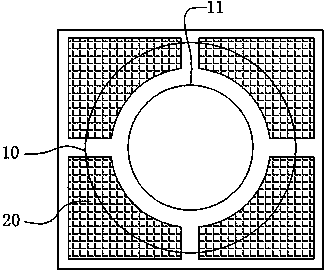

Excess hydrogen sterilization washing machine

ActiveCN103938412AImprove reducibilityHas the ability to sterilize and disinfectOther washing machinesWater/sewage treatmentElectrolysisProcess engineering

The invention relates to an excess hydrogen sterilization washing machine and belongs to the technical field of washing machines. The washing machine comprises a washing machine cylinder body. At least one electrolysis unit is arranged in the washing machine cylinder body. The electrolysis unit comprises a shell body which is provided with a water inlet and a water outlet respectively. At least one pair of a cathode and an anode is arranged in the shell body. A water permeable multi-hole membrane is clamped between the anode and the cathode without any gap. The area of the side face, opposite to the anode or the cathode, of the water permeable multi-hole membrane is smaller than the area of the side face, opposite to the water permeable multi-hole membrane, of the cathode or the anode. The washing machine can generate washing water which contains a large number of ultra-micro air bubbles and strong oxidation factors and has great reducibility, and accordingly the excess hydrogen sterilization washing machine is suitable for washing of clothes of women (especially pregnant women) and infants.

Owner:DALIAN SHUANGDI INNOVATIVE TECH RES INST

Excess hydrogen sterilization washing machine

ActiveCN103938413AImprove reaction efficiencyIncrease contact areaOther washing machinesLavatory sanitoryElectrolysisProcess engineering

The invention relates to an excess hydrogen sterilization washing machine and belongs to the technical field of washing machines. The washing machine comprises a washing machine cylinder body and an electrolysis power supply. At least one electrolysis unit is arranged in the washing machine cylinder body. The electrolysis unit comprises at least one pair of a cathode and an anode. The electrolysis power supply is used for providing power for the cathode and the anode. A water permeable membrane is arranged between the anode and the cathode which are paired. Water permeable hole diameters of the water permeable membrane are smaller than or equal to 2 mm and are larger than or equal to 1 mm. The washing machine can generate washing water which contains a large number of ultra-micro air bubbles and strong oxidation factors and has great reducibility, and accordingly the excess hydrogen sterilization washing machine is suitable for washing of clothes of women (especially pregnant women) and infants.

Owner:DALIAN SHUANGDI INNOVATIVE TECH RES INST

Method for synthesizing succinic acid from maleic acid

ActiveCN102417445BLow reaction temperatureLess side effectsCarboxylic preparation by ozone oxidationButanedioic acidMaleopimaric acid

The invention discloses a method for synthesizing succinic acid from maleic acid. The method for synthesizing succinic acid from maleic acid comprises the following steps that 1, a catalyst is added into a fixed bed reactor; 2, hydrogen is fed into the fixed bed reactor so that the pressure is stabilized in a range of 5 to 35atm; the reaction system is heated to a temperature of 50 to 150 DEG C; and a maleic acid or maleate aqueous solution having a mass fraction of 1.0 to 25.0% passes through a catalyst bed layer at an airspeed of 0.01 to 5.00h<-1> and then enters into a liquid gathering tank, wherein in reaction, a feeding rate molar ratio of the hydrogen to the maleic acid or maleate aqueous solution is (3.0 to 15.0): 1; 3, reaction liquid obtained by the step 2 is cooled and filtered to form succinic acid or succinate and filtrate; 4, the obtained succinate is acidized and separated to produce succinic acid; and 5, the filtrate obtained by the step 3 is mixed with maleic acid and the excess hydrogen is recovered and recycled. The method for synthesizing succinic acid from maleic acid has the advantages of mild conditions, low cost and high product purity.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

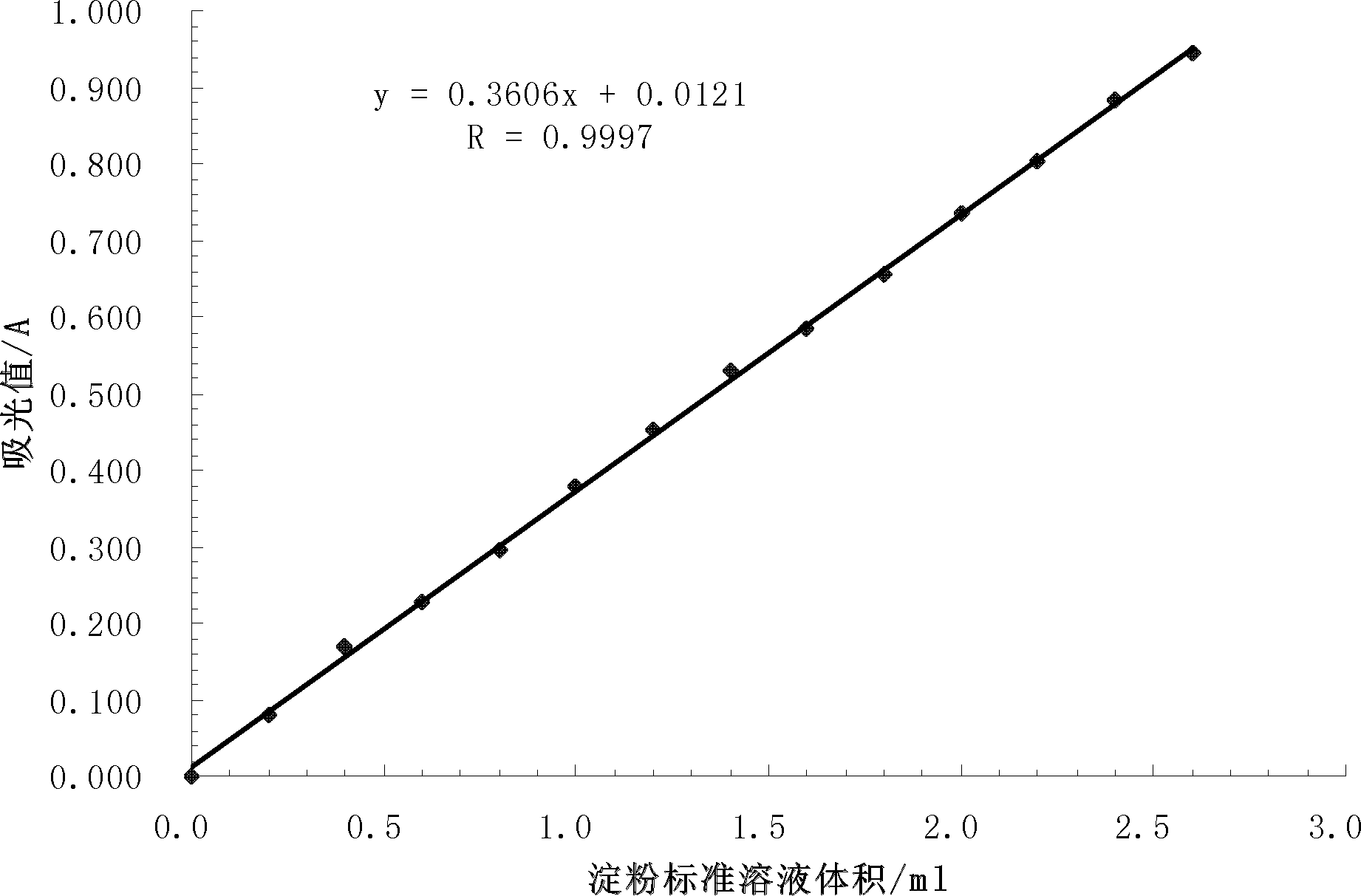

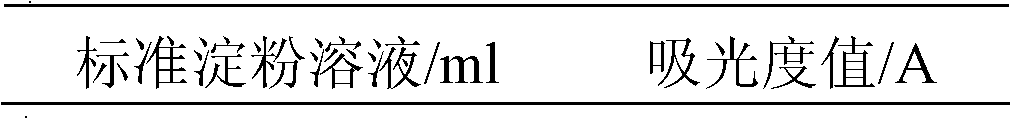

Method for measuring starch content of oceanic microalgae cell

InactiveCN102323261AImprove accuracySimple processMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationPetroleumPeroxide

The invention discloses a method for measuring starch content of an oceanic microalgae cell. In allusion to features of the substance composition of the oceanic microalgae cell, the method comprises the following steps of: firstly, degreasing, decolorizing and desugaring the microalgae cell by using ethanol, petroleum ether and 90% ethanol; secondly, taking a calcium nitrate solution with the concentration of 0.6-0.8g / ml as an extractant for extracting starch in the microalgae cell, and boiling for 15 to 30 minutes to sufficiently extract the starch in the microalgae cell; thirdly, oxidizing residual reducing sugar and residual pigment by using hydrogen peroxide, and boiling to remove the excess hydrogen peroxide; and finally, taking iodine as a color-developing agent, and directly measuring the starch content of the oceanic microalgae through spectrophotometry. Compared with the conventional method for measuring starch content of terrestrial plants, the method has the advantages of simple process, short experimental period, accurate result and good repeatability.

Owner:DALIAN UNIV

Non-power consumption hydrogen gas circulating method for fuel cell and its device

InactiveCN1767243ASuitable for medium and low pressure operationLow costFuel cellsFuel cellsHigh pressure hydrogen

The invention relates to a fuel cell non-powered consumption hydrogen gas circulating method and apparatus. The high pressure hydrogen gas of the hydrogen gas storage enters into the hydrogen gas circulating condenses pump driving end to drive the piston of the hydrogen gas circulating condenses pump to a certain position, then it enters into the buffer bucket and then the fuel cell pile, the excess hydrogen gas and the water generated by the reaction enters into the water-hydrogen separator and then the hydrogen gas circulating condenses pump condenses end, it enters into the buffer bucket after the forcing of the hydrogen gas circulating condenses pump, and then it mixes the hydrogen gas from the hydrogen gas circulating condenses pump driving end. The apparatus comprises a hydrogen gas storing bucket, a hydrogen gas circulating condenses pump, a buffer bucket, a fuel cell pile, and a water-hydrogen separator.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com