Patents

Literature

1007 results about "Copper sulfide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Copper sulfides describe a family of chemical compounds and minerals with the formula CuSy. Both minerals and synthetic materials comprise these compounds. Some copper sulfides are economically important ores.

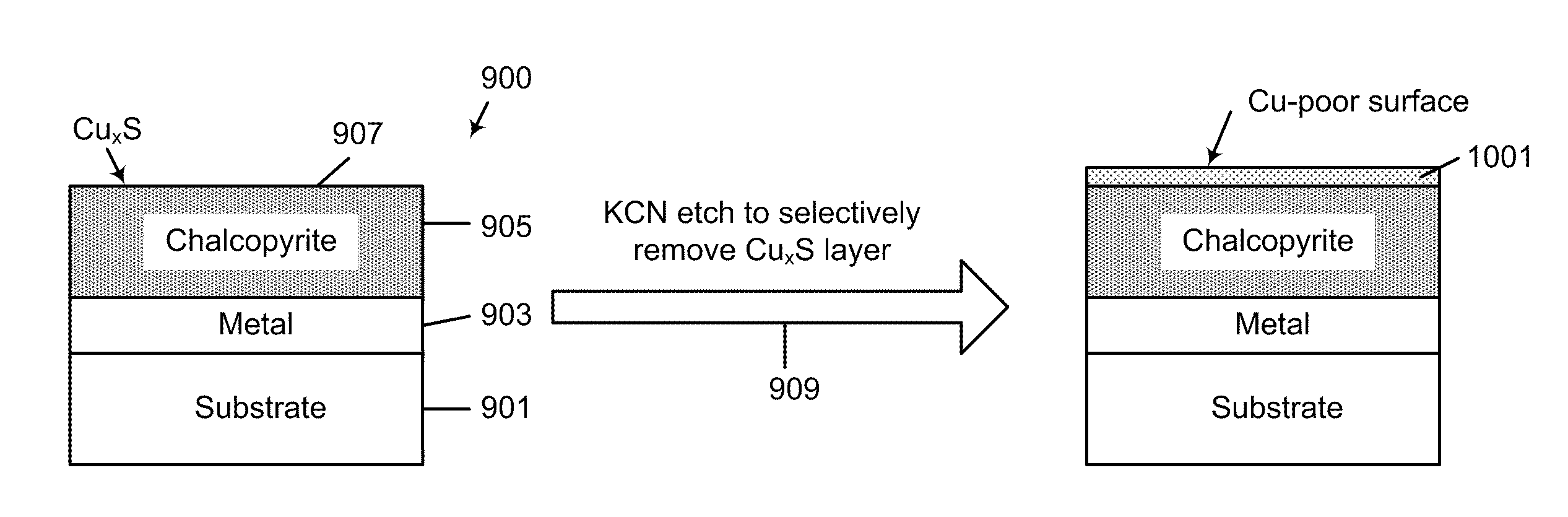

Sulfide species treatment of thin film photovoltaic cell and manufacturing method

ActiveUS8003430B1Toxic reductionAchieve benefitsSemiconductor/solid-state device manufacturingPhotovoltaic energy generationIndiumSulfur

A method for forming a thin film photovoltaic device. The method includes providing a transparent substrate comprising a surface region, forming a first electrode layer overlying the surface region, forming a copper layer overlying the first electrode layer and forming an indium layer overlying the copper layer to form a multi-layered structure. The multi-layered structure is subjected to a thermal treatment process in an environment containing a sulfur bearing species to forming a copper indium disulfide material. The copper indium disulfide material comprising a copper-to-indium atomic ratio ranging from about 1.2:1 to about 2:1 and a thickness of substantially copper sulfide material having a copper sulfide surface region. The thickness of the copper sulfide material is selectively removed to expose a surface region having a copper poor surface comprising a copper to indium atomic ratio of less than about 0.95:1. The method subjects the copper poor surface to a sulfide species to convert the copper poor surface from an n-type semiconductor characteristic to a p-type semiconductor characteristic. A window layer is formed overlying the copper indium disulfide material.

Owner:CM MFG

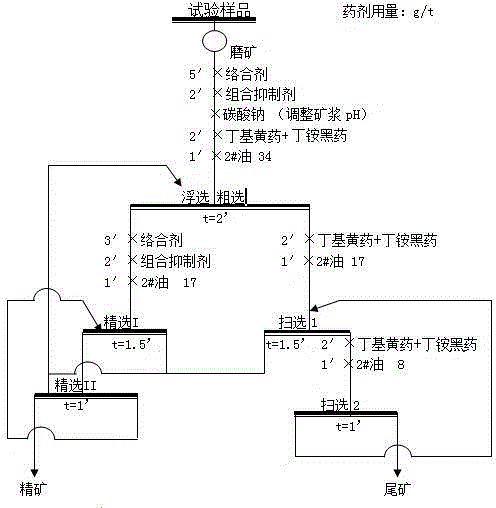

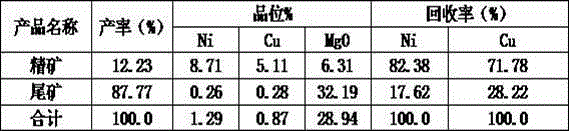

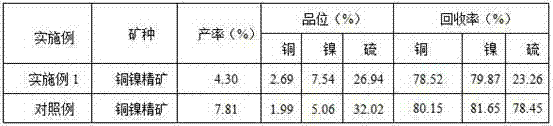

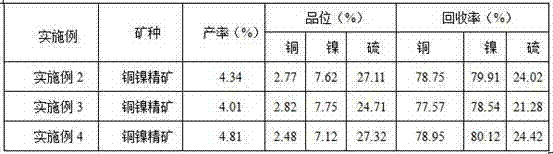

Method for reducing concentrate magnesium oxide content in copper-nickel sulfide ore flotation

The invention relates to a method for reducing concentrate magnesium oxide content in copper-nickel sulfide ore flotation. The method includes steps of firstly adding complexing agent oxalic acid, citric acid, tartaric acid, quadrol and EDTA (ethylene diamine tetraacetic acid), cleaning active ions of copper and nickel on the surface of magnesium-contained gangue mineral such as serpentine, removing flotation activity of sulfide ore collector such as xanthogenate, and adding composition agent to suppress gangue mineral. Ore pulp is treated by complexing agent, the flotation environment is improved, and floatability difference between copper-nickel sulfide mineral and magnesium-contained gangue mineral is increased. By combined inhibitor, serpentine and talc gangue mineral are suppressed, and magnesium-reducing effect is better; nickel recovery rate is increased to some extent as compared with that of actual production. Meanwhile, content of magnesium oxide in concentrate is reduced, and melting cost is lowered.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

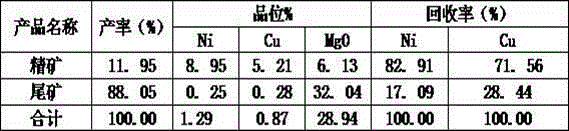

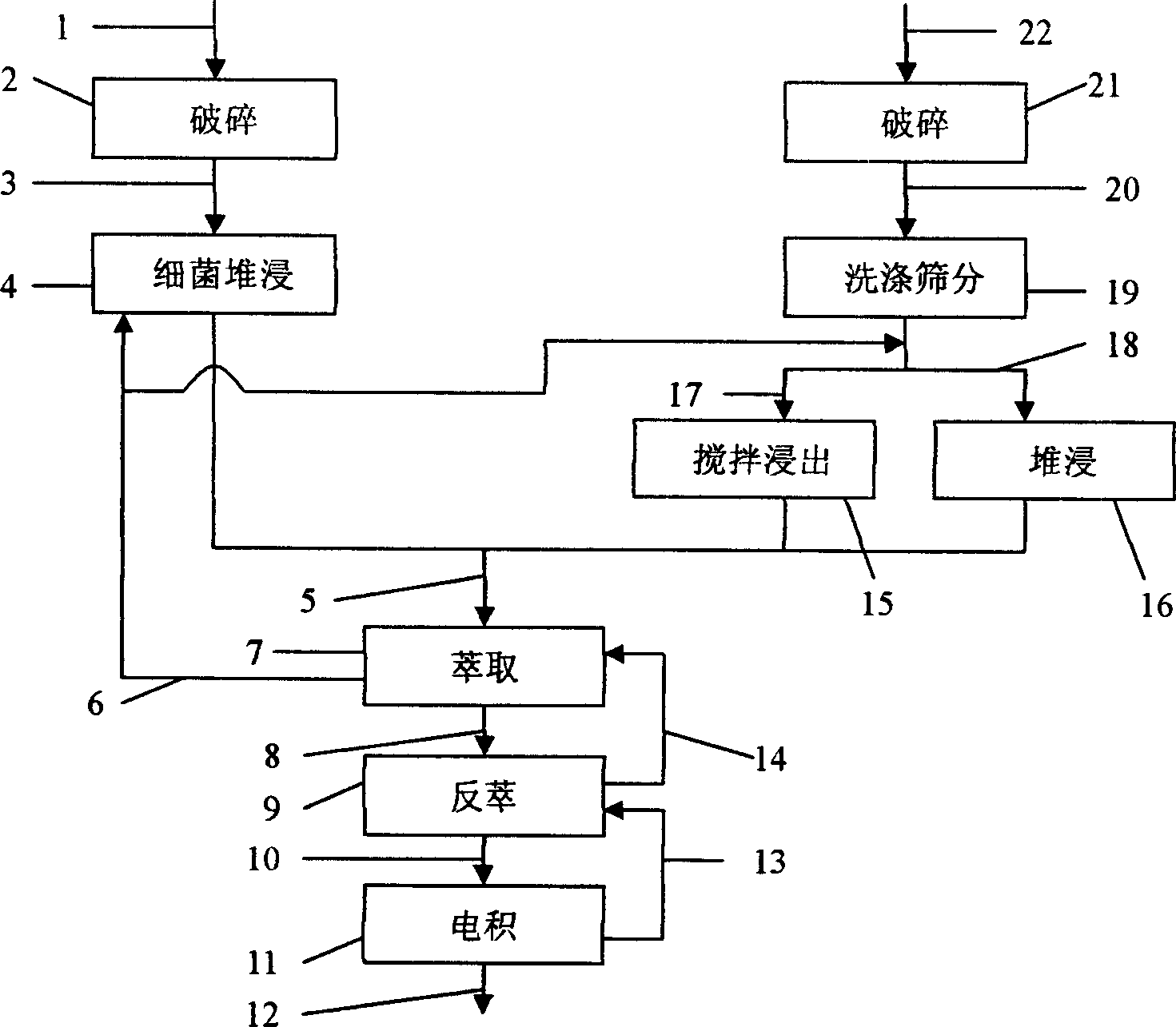

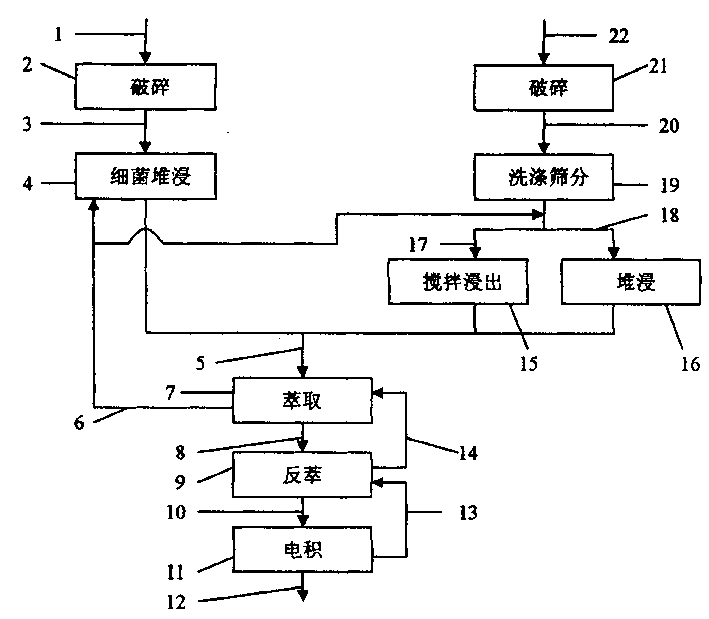

Method of leaching copper in copper containing pyrite using bacteria

InactiveCN1556230ASulfur content risesImprove qualityProcess efficiency improvementSulfideCopper sulfide

A process for extracting Cu from the Cu-contained pyrite by bacteria features that the electrochemical catalyzing action of bacteria to different sulfide ores is used sufficiently, that is, the low-potential copper sulfide is used as corrosion anode, the high-potential pyrite or gold-silver ore is used as cathode, the bacteria are used to promote the Galvanic ell effect between them, and for the residual pyrite, the special microspirobacteria are used to suppress its oxidization. Its extraction-out rate can reach more than 75% within 4 months.

Owner:湖南世纪垠天鑫业科技有限公司

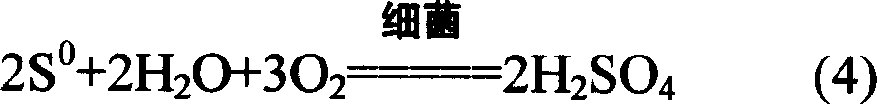

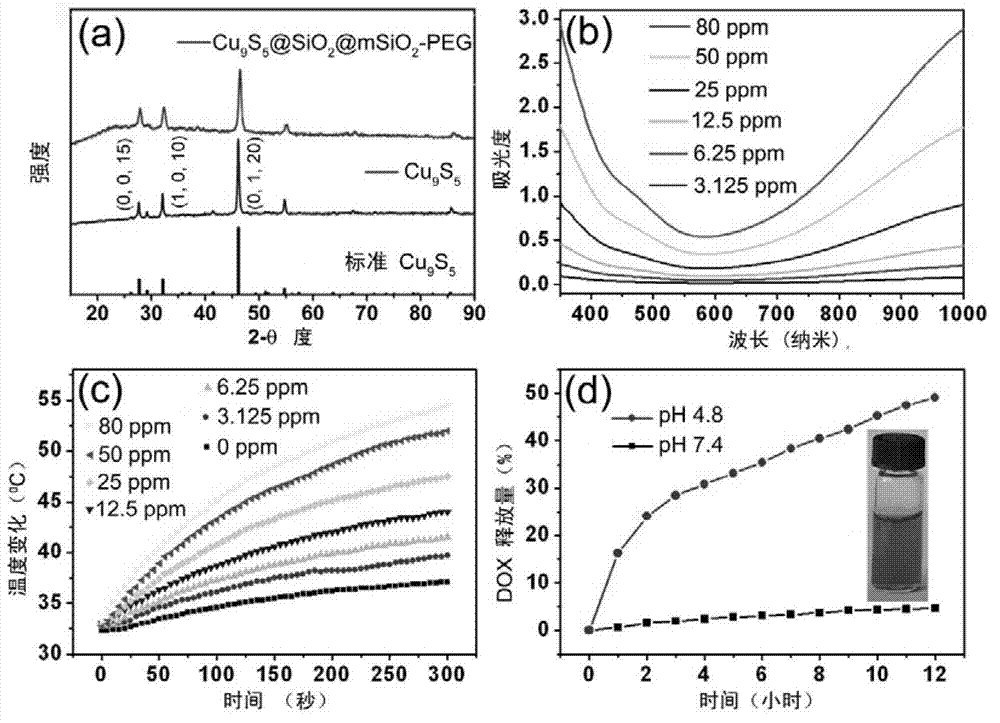

Copper sulfide/mesoporous silicon dioxide core-shell nano material as well as preparation method and application thereof

InactiveCN102961753AEffective photothermal ablationGuaranteed normal transmissionEnergy modified materialsPharmaceutical non-active ingredientsMesoporous silicaNitrogen gas

The invention relates to a copper sulfide / mesoporous silicon dioxide core-shell nano material as well as a preparation method and an application thereof. The chemical formula of the core-shell nano material is Cu9S5 / mSiO2-PEG. The preparation method comprises the following steps of: (1) raising the temperature of oleylamine under the protection of nitrogen; adding a mixed solution of copper dibutyldithiocarbamate and the oleylamine and dispersing the mixed solution into chloroform to prepare a D solution; (2) dissolving a surfactant into water; raising the temperature and adding the D solution to prepare an E solution; and (3) taking the E solution and adding ethanol; raising the temperature and adding an NaOH solution; immediately adding TEOS (Tetraethylorthosilicate) and reacting; adding PEG-silane; continually reacting and carrying out hydrothermal reaction; and adding into a scrubbing solution to centrifuge and wash to obtain the product. The copper sulfide / mesoporous silicon dioxide core-shell nano material is applied to near-infrared photo-thermal treatment, anti-cancer drugs, chemotherapy of tumors and infrared heat imaging. The nano material disclosed by the invention has very low cell toxicity and very high blood compatibility; and the united effects of thermal therapy and the chemotherapy are good.

Owner:DONGHUA UNIV

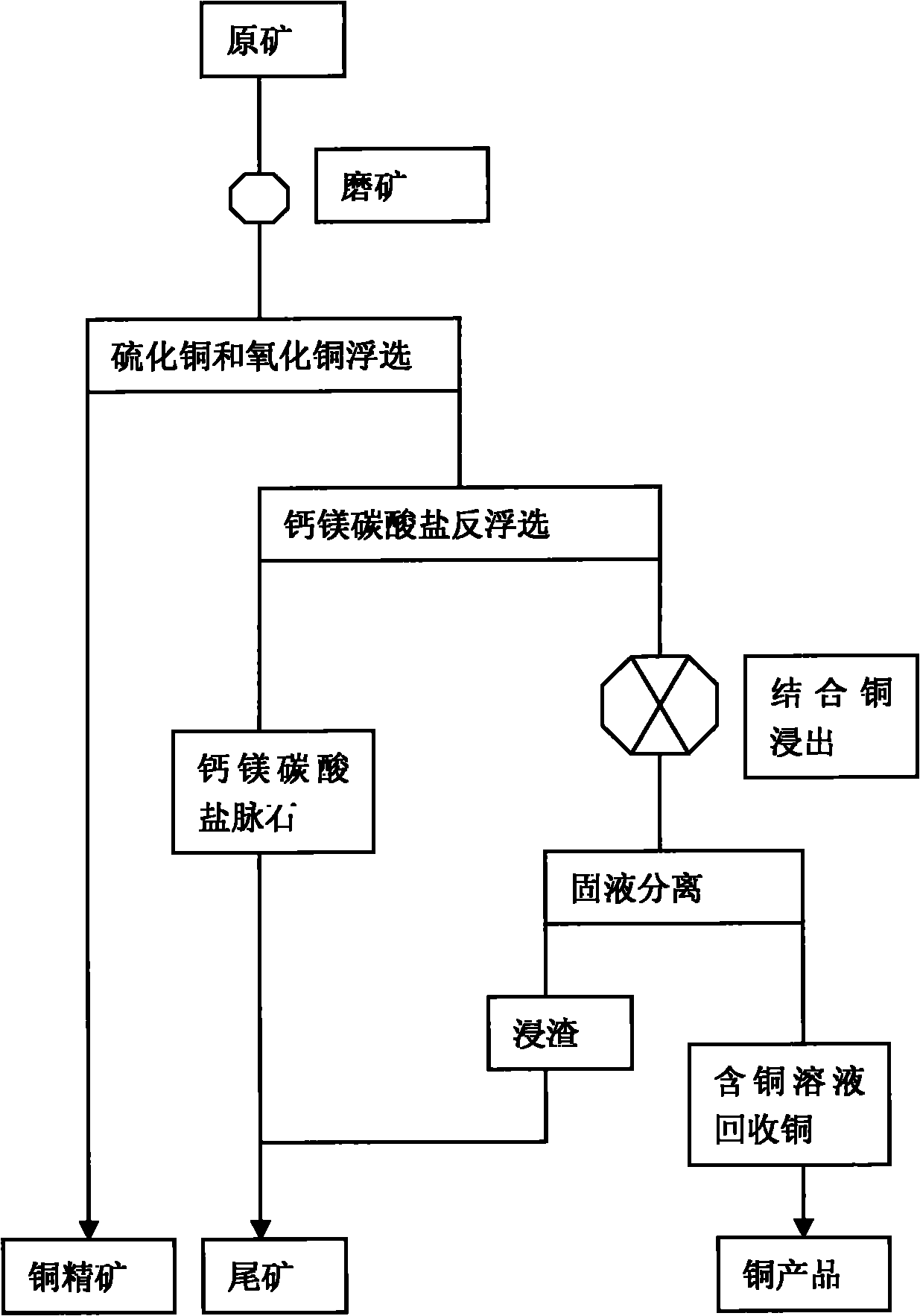

Flotation and metallurgy method of high-bonding-ratio carbonate gangue-type oxygen-sulfur mixed copper ore

ActiveCN101831559AAvoid lostReduce consumptionFlotationProcess efficiency improvementCopper oxideOxygen

The invention relates to a flotation and metallurgy method of high-bonding-ratio carbonate gangue-type oxygen-sulfur mixed copper ore. The flotation and metallurgy method comprises the following steps of: firstly, recovering copper sulfide minerals and free copper oxide minerals in the high-bonding-ratio oxygen-sulfur mixed copper ore with high calcium-magnesium carbonate gangue mineral content by flotation; carrying out reverse flotation on calcium-magnesium carbonate ore in tailings obtained after floatation with fatty acid to obtain middlings containing combined copper and less calcium-magnesium carbonate minerals; then, adding sulphuric acid and stirring to leach out combined copper; and processing a copper-contained solution obtained after solid-liquid separation to obtain a copper product by a metallurgy method. The method combines the flotation and the metallurgy for complementary advantages, efficiently recovers and utilizes high-bonding-ratio carbonate gangue-type oxygen-sulfur mixed copper ore resources incapable of being processed at present, lessens the emission of castoff, such as carbon dioxide, magnesium calcium sulfate, and the like and has favorable economic benefits and environmental benefits.

Owner:YUNNAN TIEFENG MINING CHEM NEW TECH CO LTD

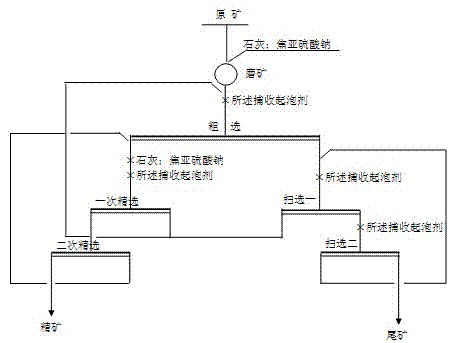

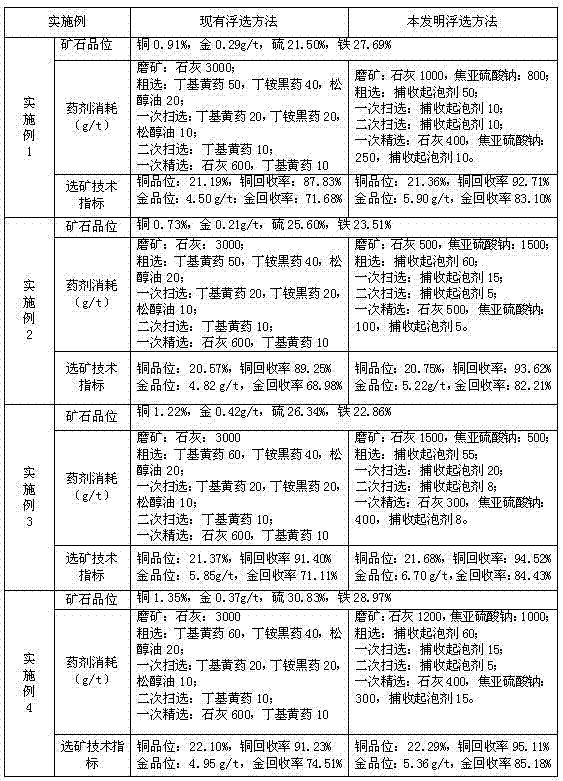

Method for floating high-sulfur gold-bearing copper ore

ActiveCN103691569AEnhanced inhibitory effectImprove beneficiation indexFlotationPropionitrileEthyl group

The invention discloses a method for floating high-sulfur gold-bearing copper ore, which aims at solving the problems that the existing beneficiation method is lower in copper and gold recovery rate under high-alkali condition, and problems that xanthate and black powder are adopted as high-sulfur gold-bearing copper ore collecting agents, the collecting power is stronger, the selectivity is poor, the separation difficulty of copper and sulfur can be aggravated and the consumption of inhibitors is increased. The method comprises the steps of by adopting lime and sodium metabisulfite as an ore pulp pH regulator and a pyrite inhibitor, and the mixture of isopropyl xanthogen propionitrile ester, black powder acid and ethyl dithiocarboxyl propionitrile ester according to certain proportion as a collecting foaming agent, carrying out ore grinding, rough concentration, primary scavenging, secondary scavenging, primary concentration, and secondary concentration on a crude ore, thus realizing the high-efficiency recovery on copper and gold in the high-sulfur gold-bearing copper ore. According to the method, through reasonable combination and addition of medicaments, the selective adsorption of the collecting agent on target mineral-copper pyrite and other copper sulfide minerals and gold minerals can be reinforced, and the copper recovery rate and the gold recovery rate can be improved.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

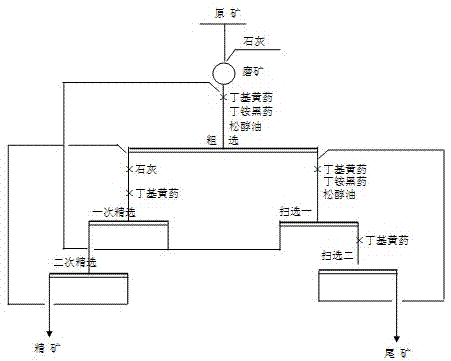

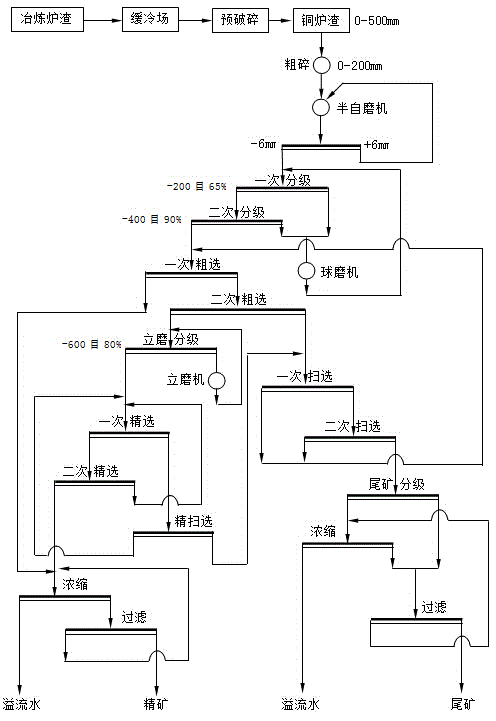

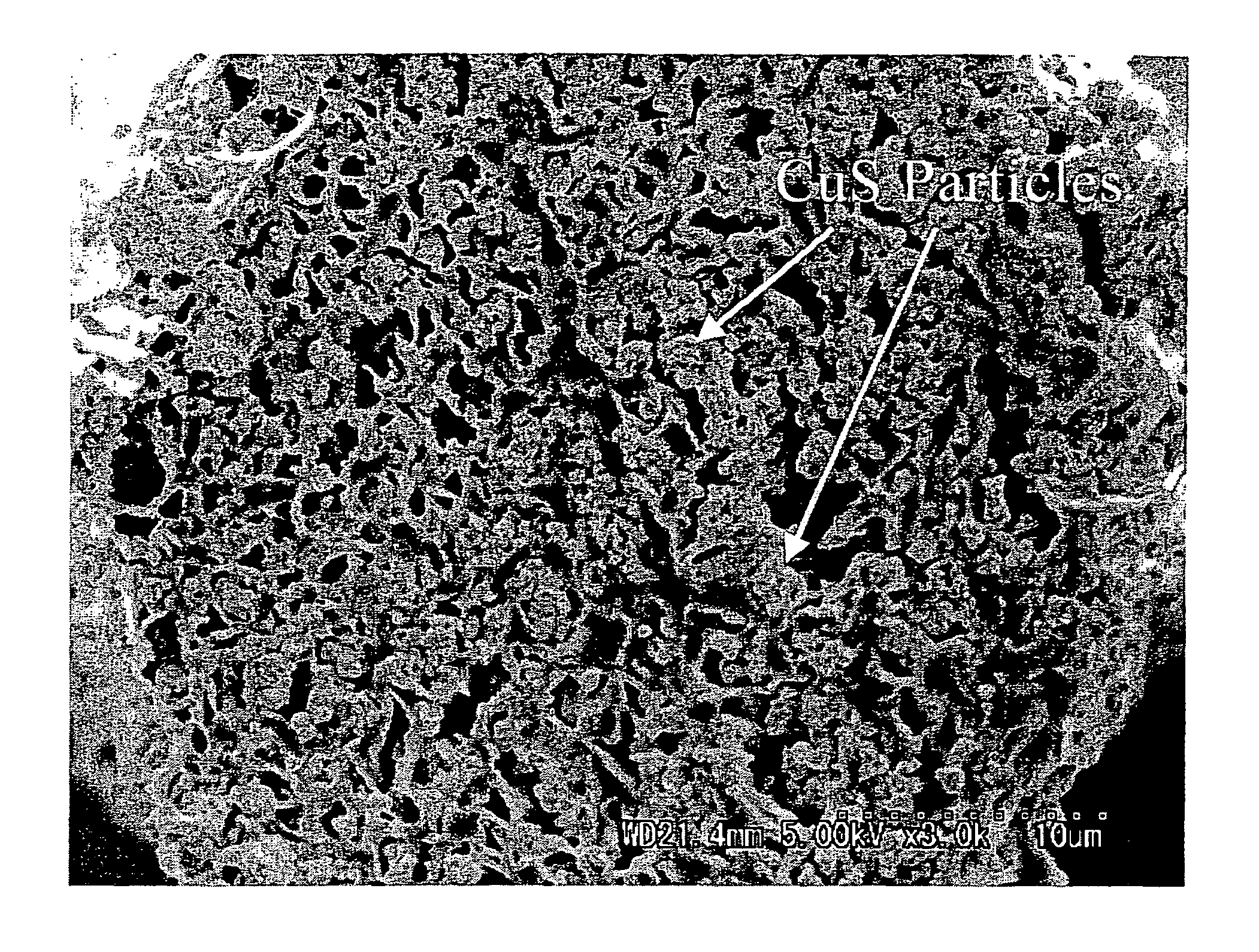

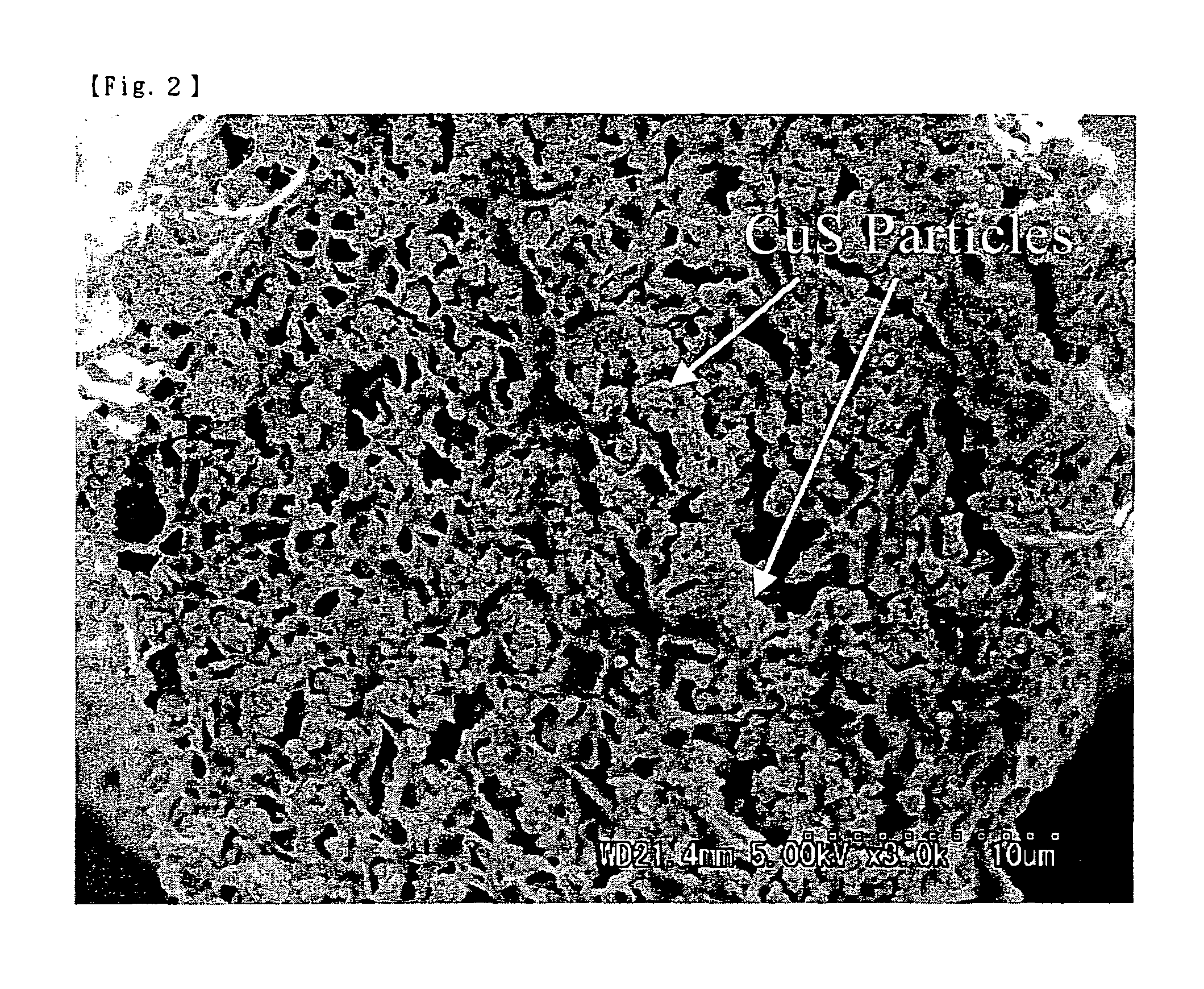

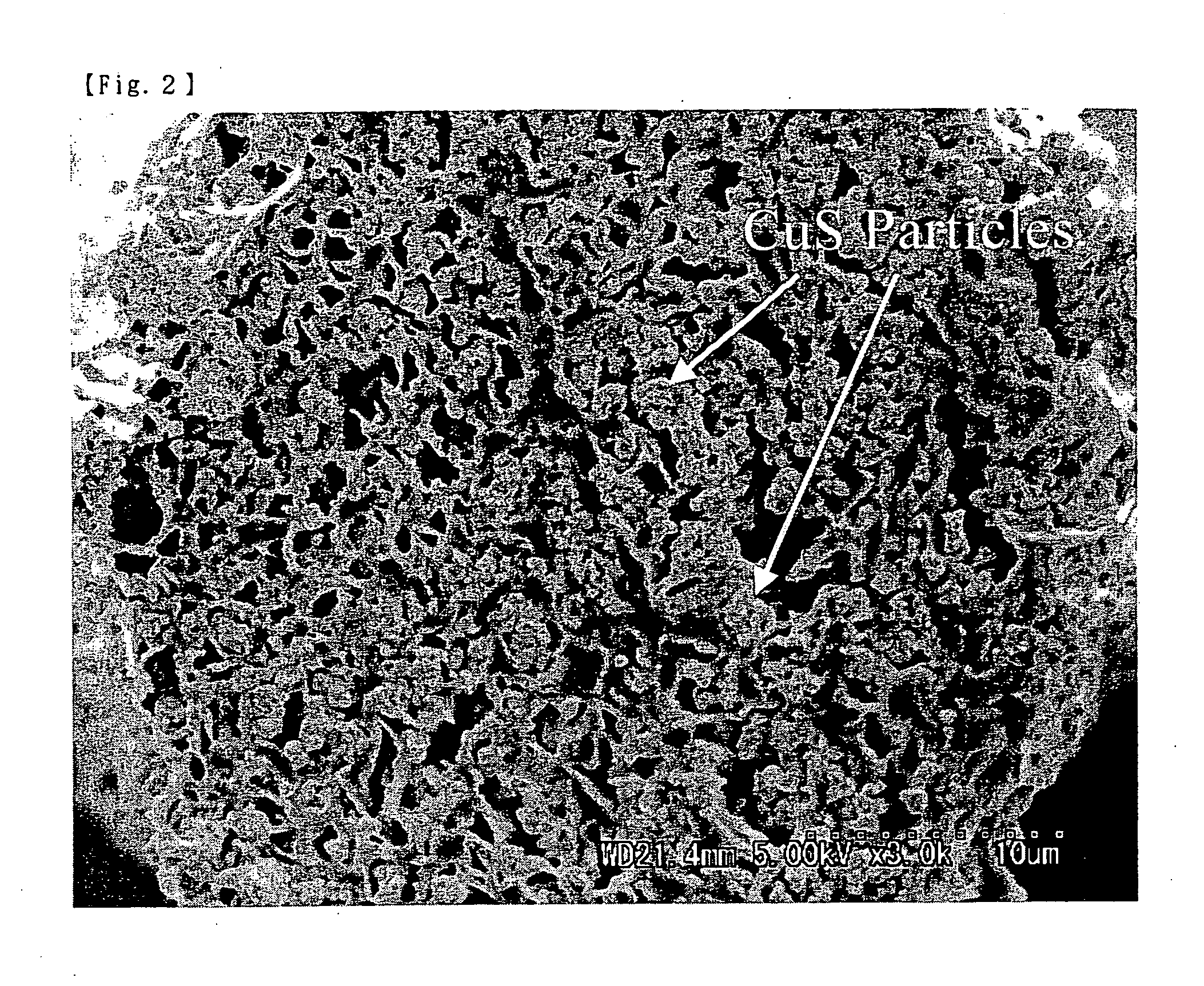

Copper furnace slag mineral processing process

InactiveCN104399573AExtend slow cooling timeIncrease collisionFlotationGrain treatmentsSlagEngineering

The present invention provides a copper furnace slag mineral processing process. According to the copper furnace slag mineral processing process, the slow cooling mode adopts centralized natural slow cooling for 12 h and spraying slow cooling for 60 h so as to prolong the slow cooling time of the slag ladle at a temperature of 1000-1250 DEG C, increase the opportunity of collision and growth of the copper matte particles, and easily achieve the crystallization development of the copper crystal, such that the recovery rate of the subsequent flotation operation is easily increased; the disseminated grain size of the copper sulfides in the furnace slag is fine, and for complete dissociation of the useful minerals, the stirring mill is adopted to carry out mineral grinding, ie., the crude concentrate is graded with a cyclone device, the setting sand after the grading is subjected to mineral grinding by adopting the stirring mill, the overflow after the grading is subjected to fine selection twice by adopting the flotation column, and the selected concentrate is directly adopted as the final concentrate, wherein the tailings being subjected to the one fine selection through the flotation column is sorted by adopting the flotation machine, and the tailings being subjected to the double fine selection through the flotation column cyclically returns. According to the present invention, the flotation machine, flotation column and vertical stirring mill combined process combining the machine, the column and the mill is adopted, such that the useful minerals with various particle sizes are easily recovered, and the metal recovery rate is efficiently increased.

Owner:广西金川有色金属有限公司

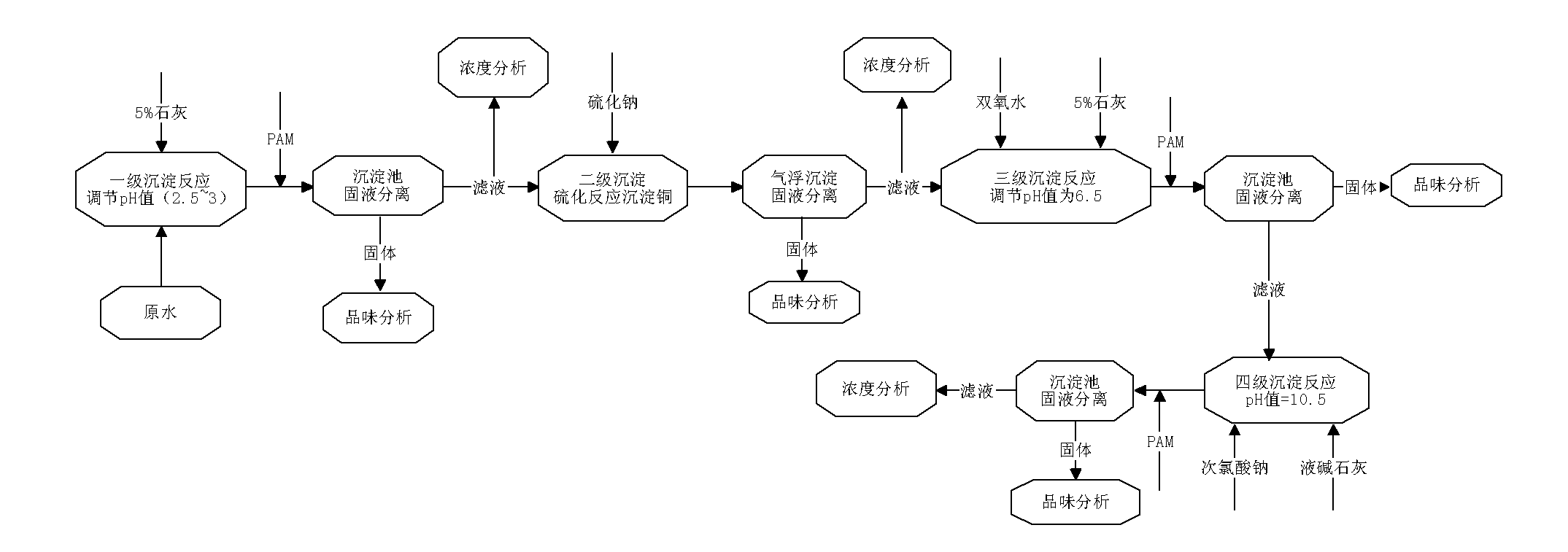

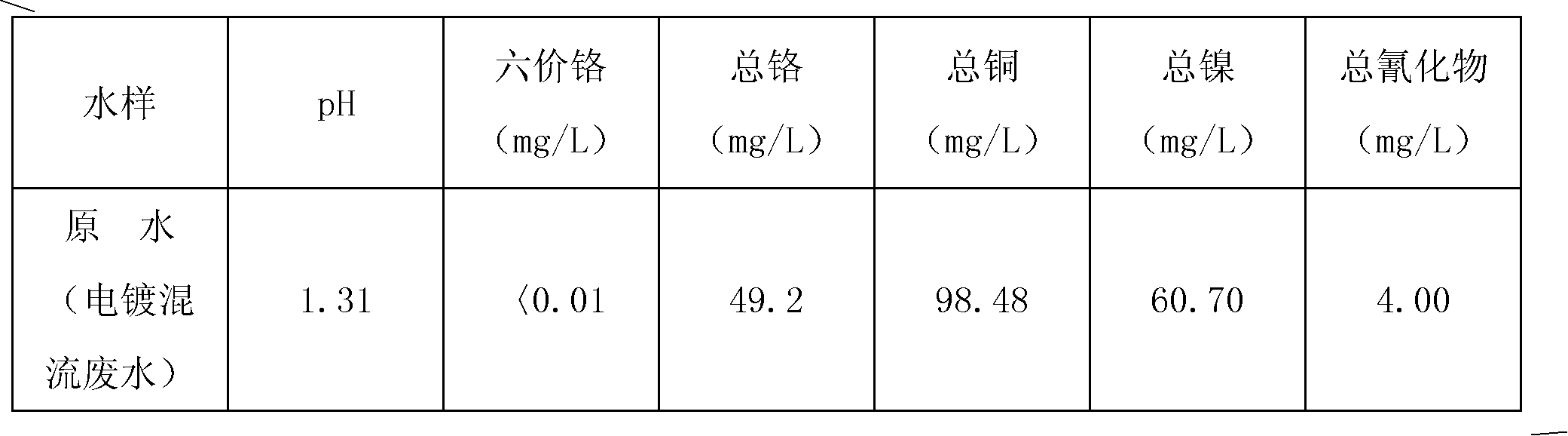

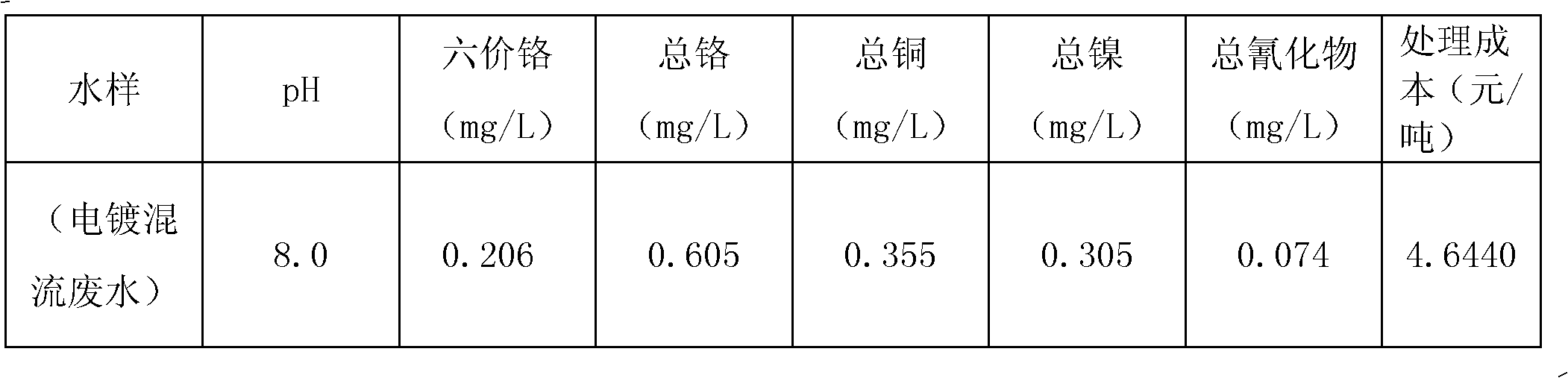

Recovery method of copper-nickel heavy metals in electroplated mixed-flow waste water

ActiveCN102557299AReduce lossesReduce loss rateWaste water treatment from metallurgical processMultistage water/sewage treatmentRecovery methodCopper sulfide

The invention relates to a recovery method of copper-nickel heavy metals in electroplated mixed-flow waste water. The recovery method comprises the following steps of: using lime to adjusting the pH value to be 2.5-3 in the electroplated mixed-flow waste water containing copper and nickel, adding a flocculating agent PAM (polyacrylamide), generating precipitate, and carrying out solid-liquid separation; then adding sodium sulfide, generating copper sulfide precipitate, and carrying out solid-liquid separation; then adding hydrogen peroxide for preventing complexation, using the lime to adjusting the pH value to be 6.5, simultaneously precipitating copper and chromium ions, adding the flocculating agent PAM, and carrying out solid-liquid separation; then using the lime to adjusting the pH value to be 10.5, simultaneously adding sodium hypochlorite for preventing complexation, generating precipitate containing nickel hydroxide, adding the flocculating agent PAM, carrying out solid-liquid separation, and recovering nickel mud; and finally, adjusting the pH value of the discharged water to be 8 by adding sulfuric acid, and realizing standard discharging. The recovery method has the advantages that the process is simple and convenient, the operation is easy, the recovery cost is low and the recovery rate is higher.

Owner:ZHEJIANG HI TECH ENVIRONMENTAL TECH

Method for melting copper by using waste copper and concentrate of copper sulfide as raw materials

The invention discloses a method for melting copper by using waste copper and concentrate of copper sulfide as raw materials. The method comprises the following steps of: in a mass ratio of the copper content of waste copper to the copper content of the concentrate of copper sulfide of 1:1.3-10, mixing the waste copper and the concentrate of copper sulfide, adding a raw material containing silicon dioxide into the mixture, recycling, continuously putting the mixture into a melting pond, adding fuel and controlling the temperature of the melt to be between 1,100 and 1,300 DEG C, charging oxygen-enriched air, of which the volume concentration is 23 to 85 percent, in the melting pond, and stirring and melting the materials in an oxidizing atmosphere in the melting pond until slag and copper matte are separated by melting; transferring the separated copper matte to an air refining procedure for air refining to obtain raw copper products; transferring the slag to a common electric furnace for melting to further lower the copper content of the slag to below 0.5 percent, and performing water quenching of the slag; and transferring smoke to an acid-making procedure for preparing sulfuric acid. By the method, a large amount of waste copper can be treated, and simultaneously due to the adoption of the waste copper, the slag type of the concentrate of copper sulfide in melting is improved.

Owner:XIZHI ELECTRONICS MATERIALS BRANCH YUNNAN COPPER IND GRP +3

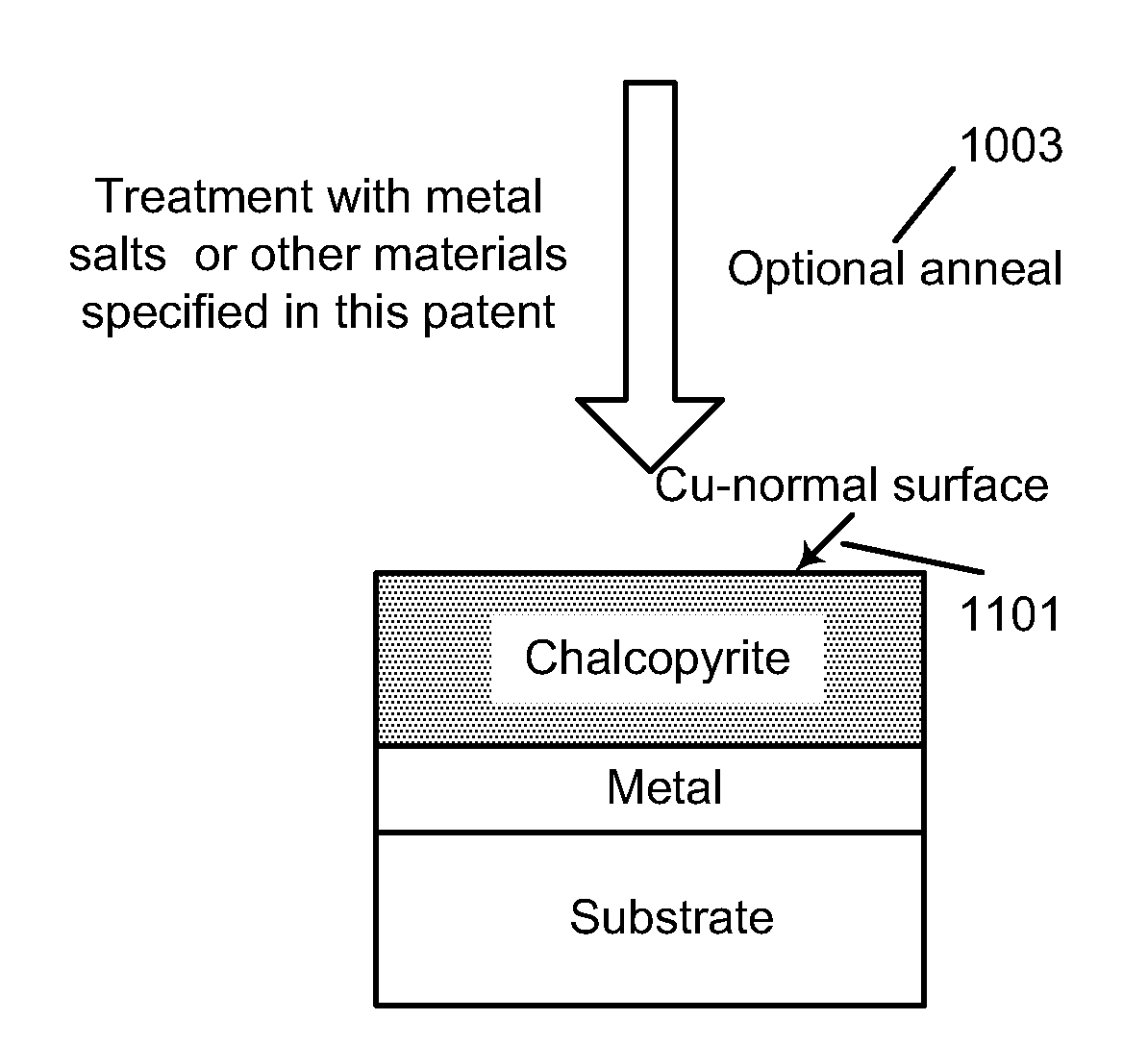

Metal species surface treatment of thin film photovoltaic cell and manufacturing method

A method for forming a thin film photovoltaic device. The method includes providing a transparent substrate including a surface region. A first electrode layer is formed overlying the surface region. A copper layer is formed overlying the first electrode layer and an indium layer overlying the copper layer to form a multi-layered structure. The method subjects at least the multi-layered structure to a thermal treatment process in an environment containing a sulfur bearing species and form a copper indium disulfide material. The copper indium disulfide material includes a thickness of substantially copper sulfide material. The thickness of the copper sulfide material is removed to expose a surface region having a copper poor surface characterized by a copper to indium atomic ratio of less than about 0.95:1. The method subjects the copper poor surface to a metal cation species to convert the copper poor surface from an n-type semiconductor characteristic to a p-type semiconductor characteristic. A window layer is formed overlying the copper indium disulfide material.

Owner:CM MFG

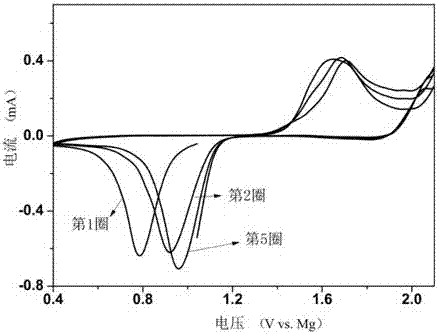

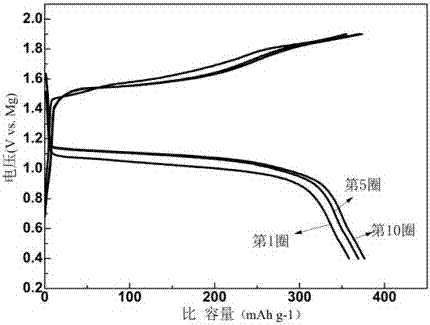

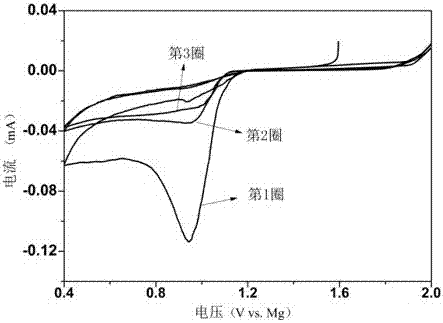

Sulfur/sulfide/copper ternary composite cathode and preparation and application thereof in magnesium-sulfur battery

ActiveCN106935796AGood capacity retentionImproved magnification performanceSecondary cellsPositive electrodesCopper foilCopper sulfide

The invention relates to the technical field of magnesium batteries, and discloses preparation and application of a sulfur / sulfide / copper ternary composite cathode in a magnesium-sulfur battery. The sulfur / sulfide / copper ternary composite cathode comprises sublimation sulfur, metal sulfide and metal copper foil. Meanwhile, the magnesium-sulfur battery is assembled by the sulfur / sulfide / copper ternary composite cathode, a magnesium ion electrolyte and a metal magnesium anode. The composite cathode not only can effectively bind polysulfide ions to the cathode region, thus suppressing a 'shuttle effect', but also generate a non-stoichiometric copper sulfide (CuxS, x<=2) interphase by means of dissolution of the metal copper foil, thus promoting the electrochemical conversion reaction of a discharging product MgS, significantly improving the charge and discharge capacity of the battery and improving the cycling stability of the magnesium-sulfur battery.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

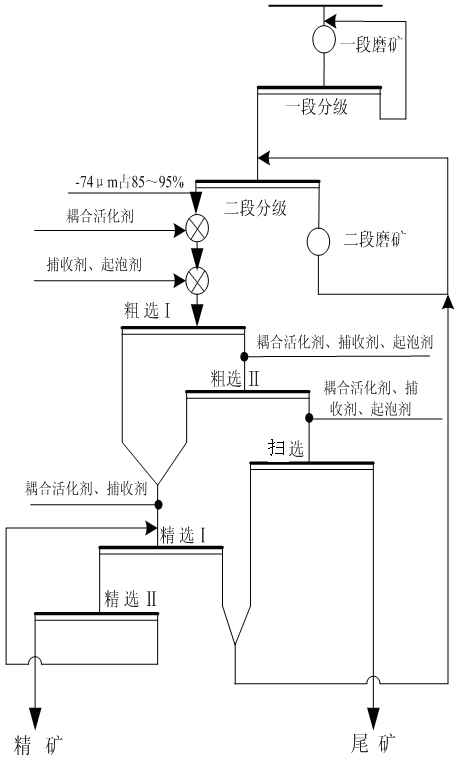

Ammonium-amine coupling activation method based on copper mineral sulfurization floatation system

Owner:KUNMING UNIV OF SCI & TECH

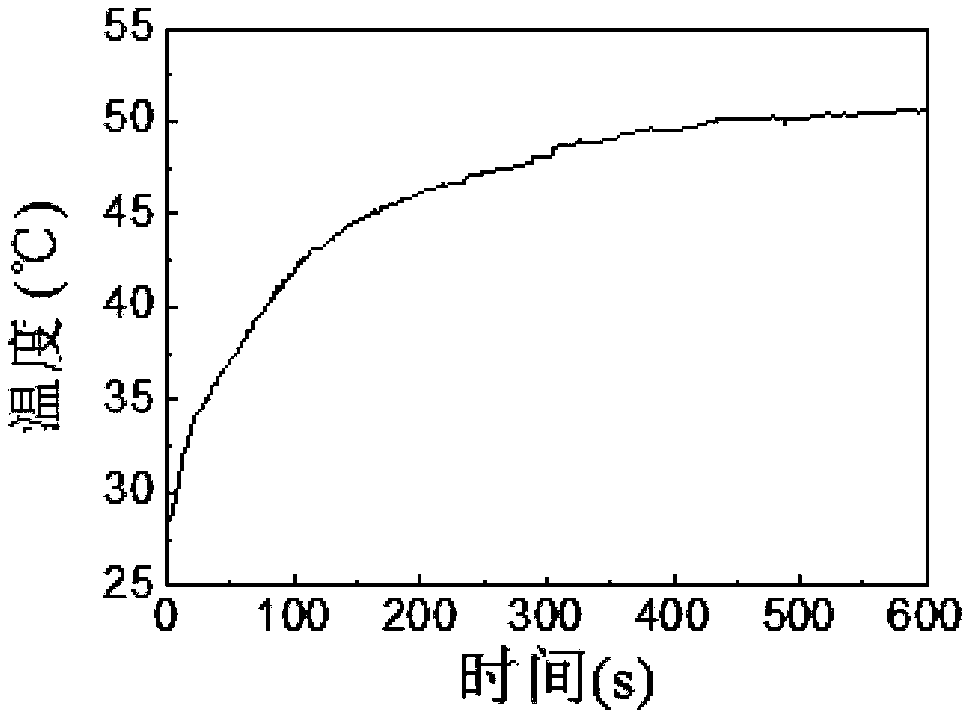

Preparation method of near-infrared light response hydrogel

ActiveCN103408708APromote breakthroughGood for healthEnergy modified materialsAerosol deliveryCross-linkCopper sulfide

The invention relates to a preparation method of near-infrared light response hydrogel. The method comprises the following steps: (1) adding a ligand into deionized water, stirring for dispersion, adding a soluble copper salt and a sulfate, carrying out a pre-reaction to obtain a mixed dispersion liquid, and enabling the mixed dispersion liquid to react for 8-24 hours to obtain copper sulfide; and (2) adding a cross-linking agent, a water soluble monomer, the copper sulfide obtained in the step (1), an initiator, and a catalyst into the deionized water to obtain a hydrogel polymerization liquid, and enabling the hydrogel polymerization liquid to polymerize at 0-50 DEG C for 1-48 hours to obtain the near-infrared light response hydrogel. The preparation method provided by the invention is simple in preparation process and large in raw material selection range; the temperature of the hydrogel under the radiation of the near-infrared light within the wavelength of 700-1100nm can be obviously increased, and therefore the hydrogel is high in application value; the method is simple in process, wide in raw material sources and quite low in cost, and has a high application value in the fields of thermal therapy treatment or intelligent devices.

Owner:DONGHUA UNIV

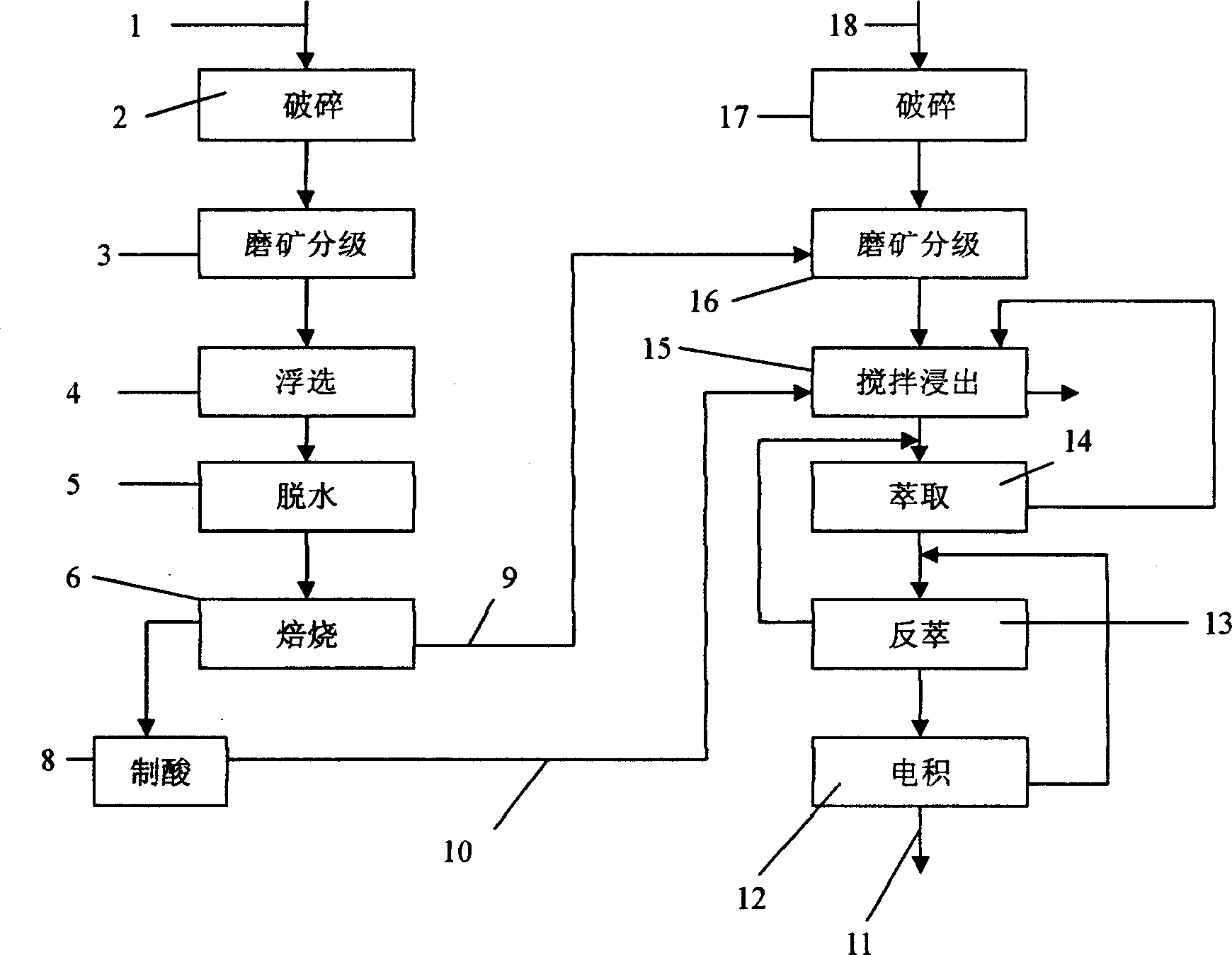

Method for extracting copper from mixed copper ores

InactiveCN1424413AEasy to stockpileImprove efficiencyProcess efficiency improvementPregnant leach solutionGranularity

A process for extracting copper from the mixture-type copper ore of copper sulfide ore and copper oxide ore includes such steps as respectively cracking, bacterial stacking extracting of one ore, washing, stirring and stacking extracting to another, extracting the extracted liquid, conventional back extracting to carried organic phase, and electrodepositing to obtain high-purity cathode copper. Its advantages are high recovery rate, low cost and no pollution.

Owner:ZIJIN MINING GROUP

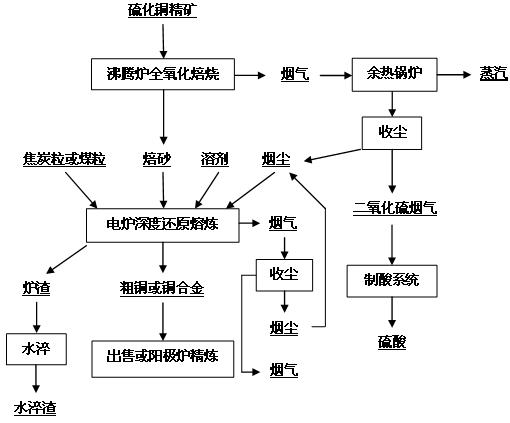

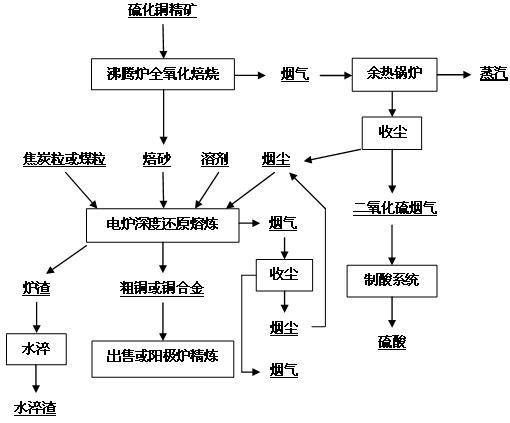

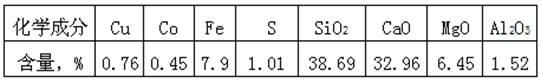

Method for smelting low-sulfur copper concentrate

InactiveCN102181662AShort processShort construction periodRotary drum furnacesCrucible furnacesPartial oxidationCopper oxide

The invention discloses a method for smelting low-sulfur copper concentrate, relating to copper concentrate, in particular to a method for producing rough copper or rough copper alloy from low-sulfur copper sulfide concentrate or copper sulfide concentrate comprising a part of copper oxide. The method is characterized by comprising the following smelting processes of: mixing sulfur or pyrite into the copper concentrate; performing boiling oxidizing roasting to produce calcine; performing reduction smelting on the calcine through an ore-smelting electric furnace to obtain rough copper or rough copper alloy; treating flue gas produced during the boiling oxidizing roasting and smelting of the ore-smelting electric furnace through a waste heat boiler, electrical dust collection and cloth bag dust collection; and feeding the treated flue gas into an acid making system to produce sulfuric acid. By adopting the method, the copper sulfide concentrate with low sulfur content and high silicon content or the copper sulfide concentrate comprising a part of the copper oxide, which cannot be subjected to self-heating matte smelting, can be treated; and the method has the advantages of a short process flow, less investment and a short construction period and is suitable for building small-scale copper smelting enterprises at electric power-rich areas.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Conductive polyvinyl alcohol fiber

InactiveUS7026049B2Improve conductivityIncreased durabilityElectroconductive/antistatic filament manufactureFibre treatmentFiberHeat resistance

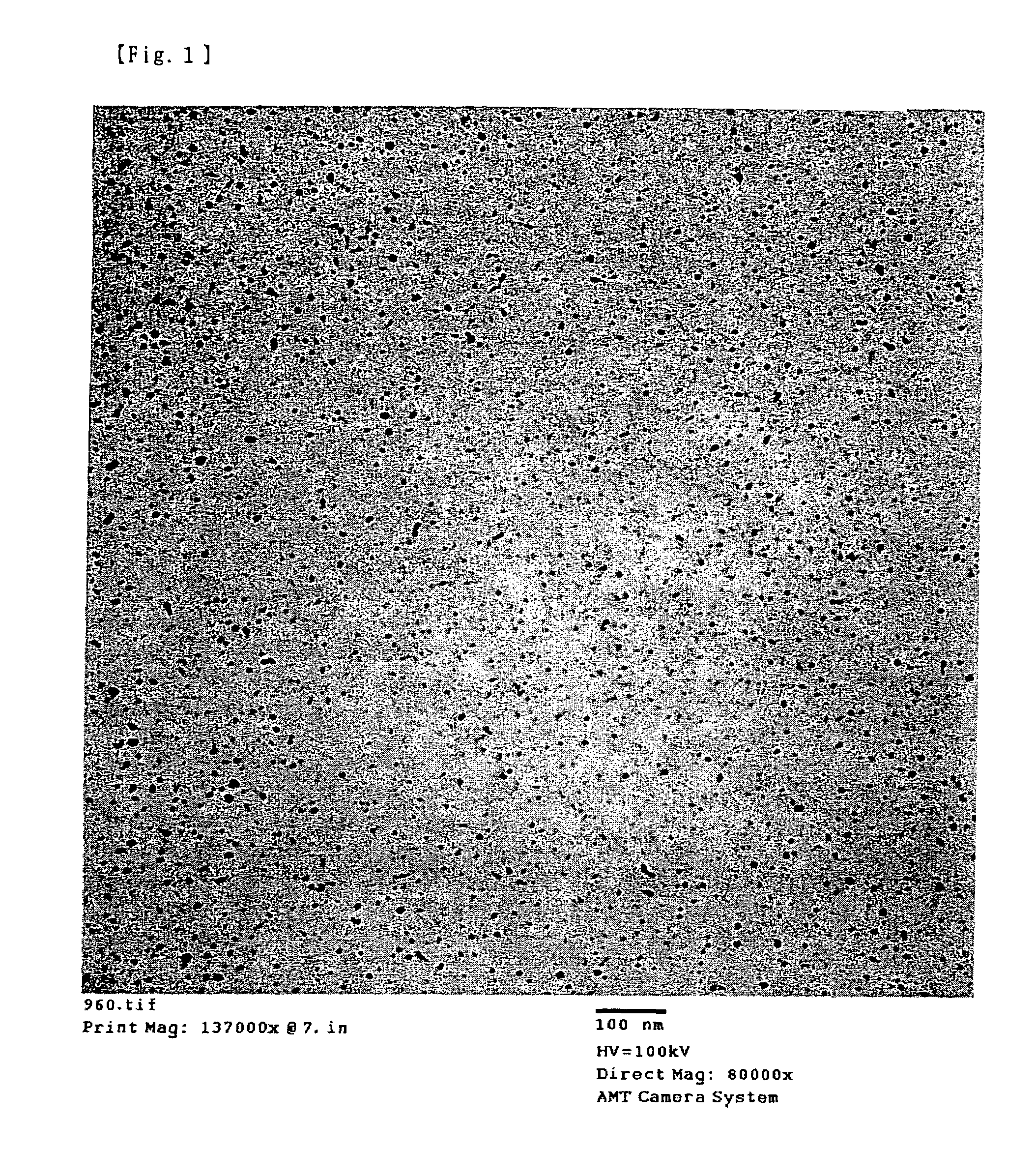

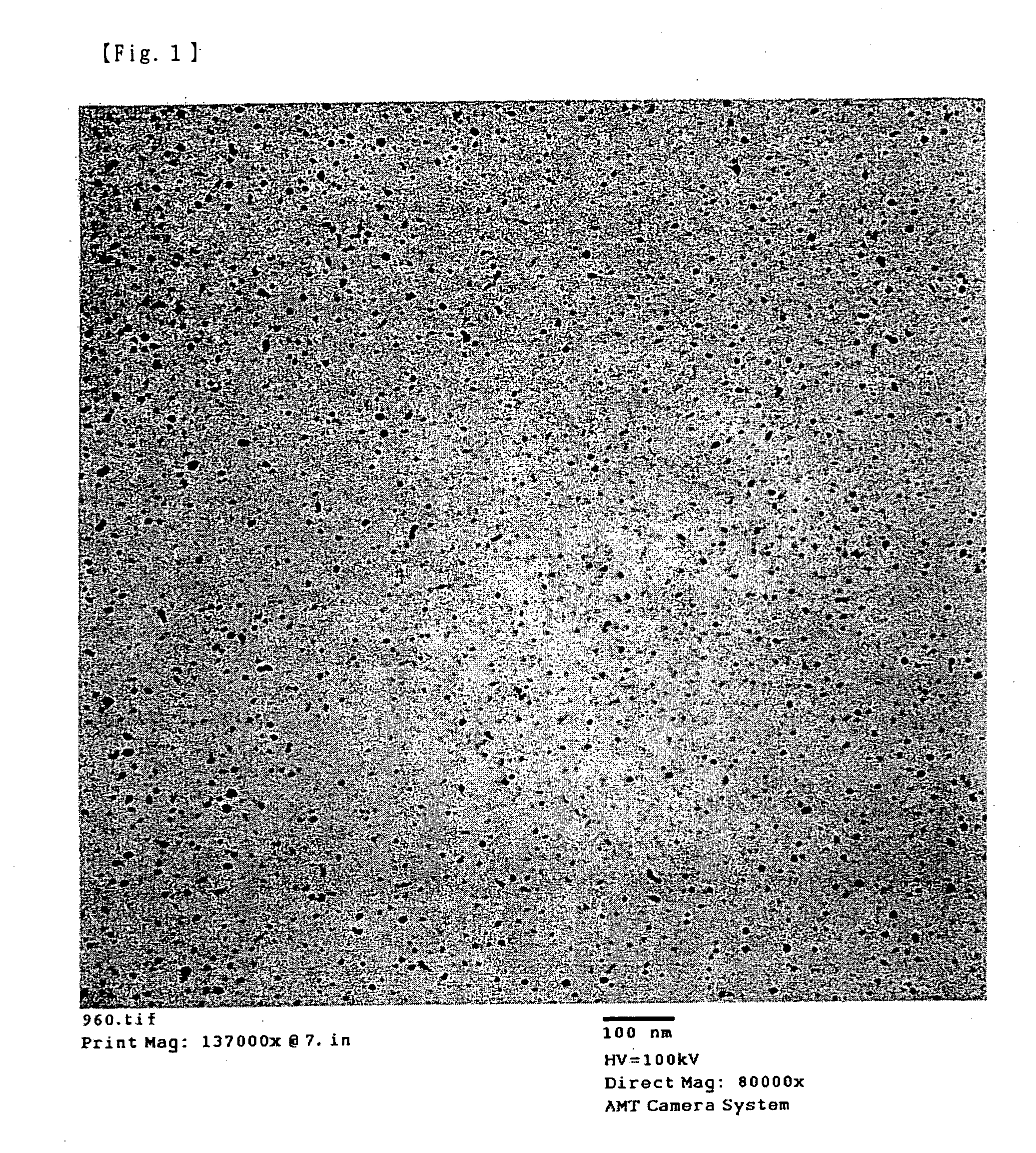

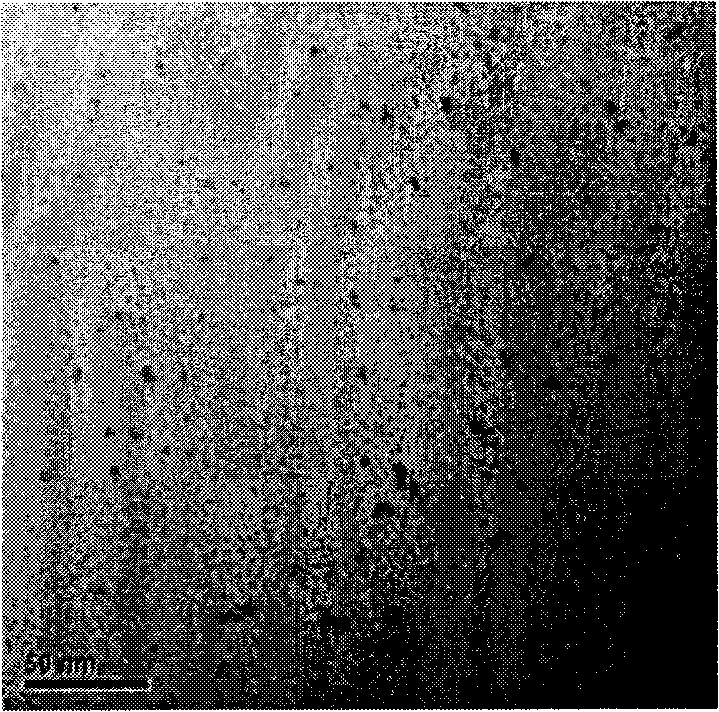

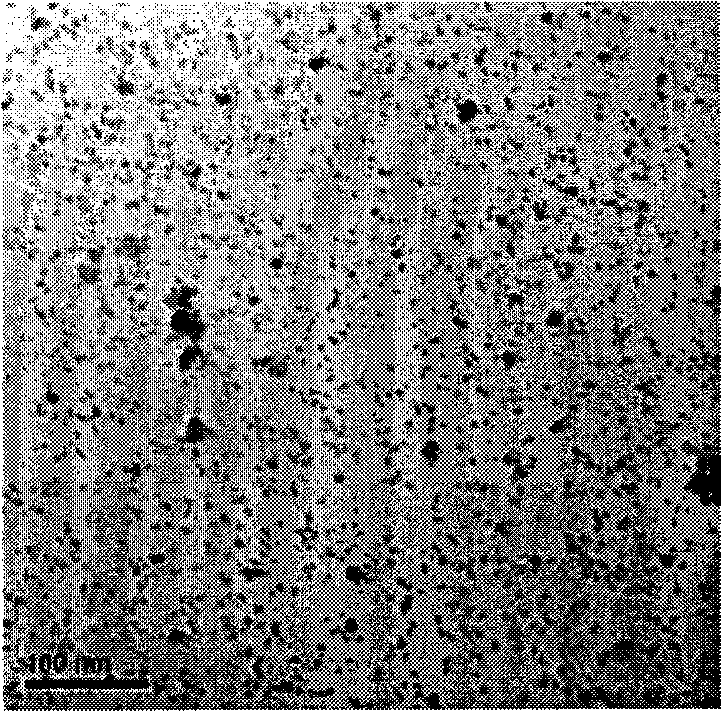

A conductive polyvinyl alcohol fiber having good mechanical properties and heat resistance contains a polyvinyl alcohol polymer and copper sulfide nano-particles having a mean particle size of at most 50 nm which are finely dispersed in the polymer. The content of the nano-particles in the fiber is at least 0.5% by mass / polyvinyl acohol polymer, and the degree of polymer orientation is at least 60%.

Owner:KURARAY CO LTD

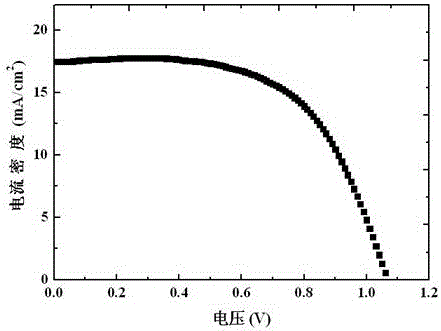

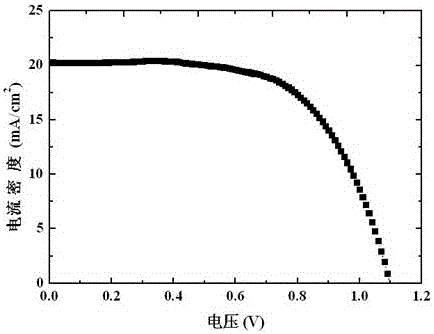

Perovskite solar cell based on Spiro-OMeTAD/CuxS composite hole transport layer and preparation method thereof

ActiveCN106025085AImprove photoelectric conversion efficiencyImprove stabilitySolid-state devicesSemiconductor/solid-state device manufacturingEvaporationCharge carrier mobility

The invention discloses a perovskite solar cell based on a Spiro-OMeTAD / CuxS composite hole transport layer and a preparation method thereof. The solar cell comprises a transparent conductive substrate, an oxide electron transport layer, a perovskite light absorption layer, a composite hole transport layer, and metal electrodes. The composite hole transport layer is obtained by the following steps: spin-coating a perovskite light absorption layer with a Spiro-OMeTAD layer, and depositing high-purity copper sulfide powder on the Spiro-OMeTAD layer through vacuum thermal evaporation to get a composite hole transport layer composed of a p-type CuxS film and a Spiro-OMeTAD layer, wherein 1<=x<=2. The hole carrier mobility of the composite hole transport layer can be up to 0.1cm<2>V.s<-1>, the composite hole transport layer is very hydrophobic, the contact angle is up to 92 degrees, and the water stability of devices is greatly improved. By employing the composite hole transport layer, the photoelectric conversion efficiency of planar perovskite film cells can be up to 14%, and the attenuation of devices after 1000-hour use is less than 10%, which are better than those of devices employing a Spiro-OMeTAD or CuxS hole transport layer alone.

Owner:WUHAN UNIV

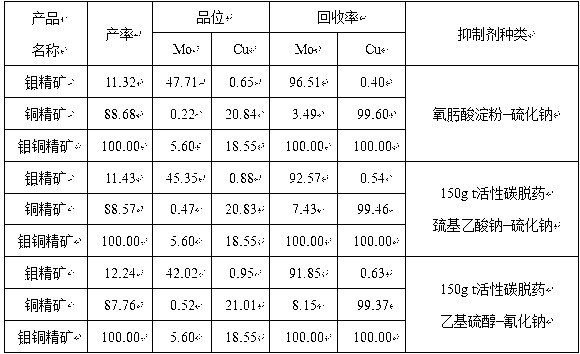

Method for flotation and separation of copper molybdenum sulphide bulk concentrates

The invention discloses a method for flotation and separation of copper molybdenum sulphide bulk concentrates and belongs to the technical field of mineral dressing. The method uses the copper molybdenum sulphide floated bulk concentrates as raw materials, adopts efficient environment-friendly copper ore inhibitor such as hydroxamic acid starch to inhibit copper sulphide ores, performs flotation of molybdenum sulphide ores and performs flotation and separation of copper and molybdenum. Oximido in the hydroxamic acid starch can be combined with active mass points Cu2+ on the surfaces of the copper sulphide ores to produce stable pentabasic chelate rings. Hydroxide radical and other polar radicals in a starch group at the other end of a chelate can be associated with water molecules through hydrogen bonds to enable the copper sulphide ores to be hydrophilic and inhibit the copper sulphide ores. In addition, the enormous hydrophilic water molecules of the hydroxamic acid starch can hide hydrophobic collecting agent molecules absorbed on the surfaces of copper ores, a collecting agent absorbed on the surfaces of the copper ores is not required to be removed, and the flotation and the separation of the copper molybdenum sulphide bulk concentrates do not need mechanical reagent removal or concentrated reagent removal. The hydroxamic acid starch serves as an inhibitor to inhibit the copper ores, sodium sulphide usage can be remarkably decreased, mechanical reagent removal or concentrated reagent removal is not needed, the chemical cost for the separation of the copper and the molybdenum is reduced, copper and molybdenum flotation and separation technological processes are simplified, good separation effect is obtained, and the method is environment-friendly and efficient.

Owner:HUNAN RES INST FOR NONFERROUS METALS

Preparation method of copper-zinc sulfide ore flotation separation inhibitor and application thereof

The invention provides a preparation method of a copper-zinc sulfide ore flotation separation inhibitor, comprising the following steps: adding 200-300ml of sulfuric acid solution the volume percentage content of which is 40-50% and 120-150g of pyrite smelting slag containing 40-50wt% of ferrum to a 500ml of three-neck flask at room temperature, stirring the obtained mixed solution with the speed of 60RPM for reacting for 4-6 hours, and filtering while being hot to obtain acid leaching liquid; and placing 200ml of the acid leaching liquid in a 500ml of three-neck flask, adding 50-60g of ferrous powder as a reducing agent, carrying out heating reflux reaction at the temperature of 75-85 DEG C for 1-2 hours, filtering the unreacted ferrous powder while being hot, transferring the obtained filtrate to an evaporation pan, evaporating and concentrating the filtrate into crystal at the constant temperature of 75-80 DEG C, filtering and drying while being hot to obtain white powder, that is, the zinc sulfide ore inhibitor. The preparation method has good inhibition effect on zinc ore so that copper-zinc associated ore can be effectively separated to obtain copper concentrate with higher quality; and the method adopts a small amount of agents, thus being nontoxic and pollution-free.

Owner:GUANGXI UNIV

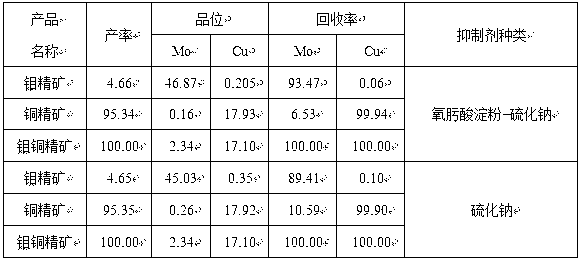

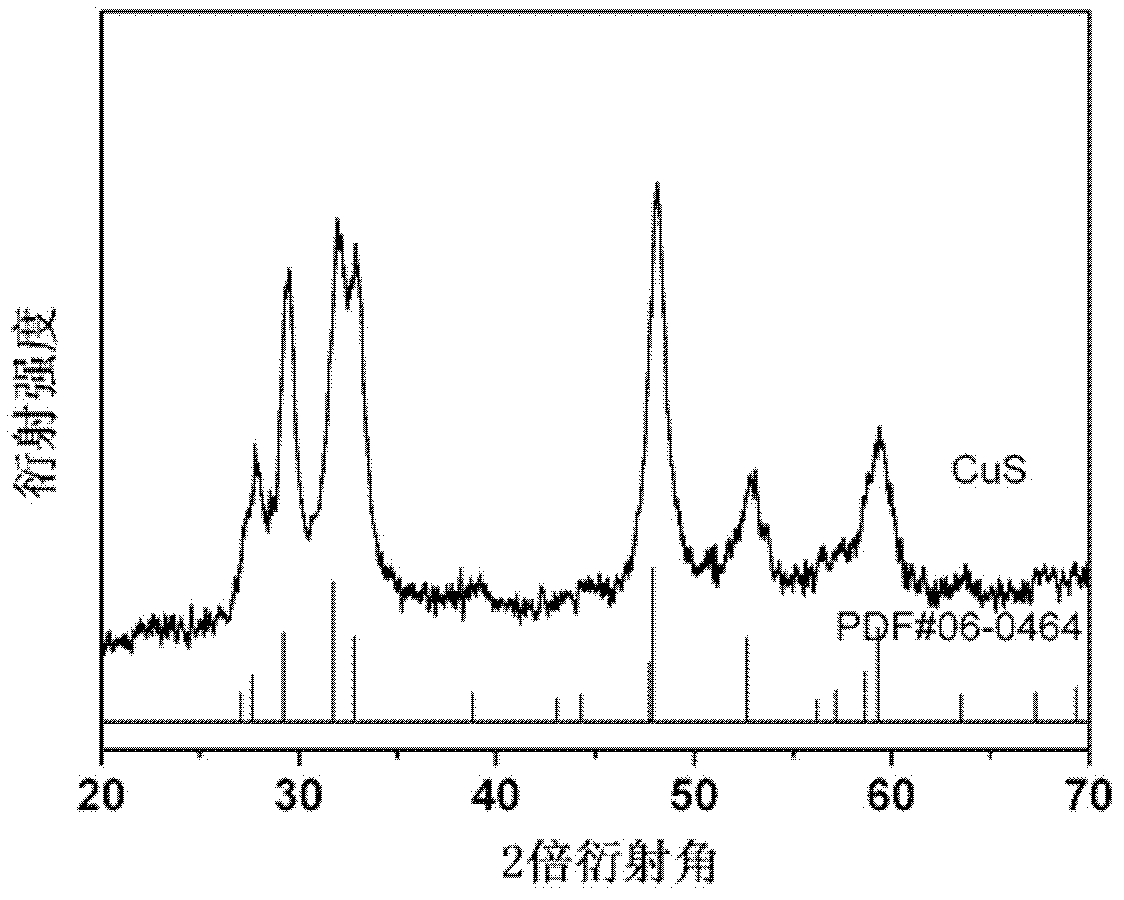

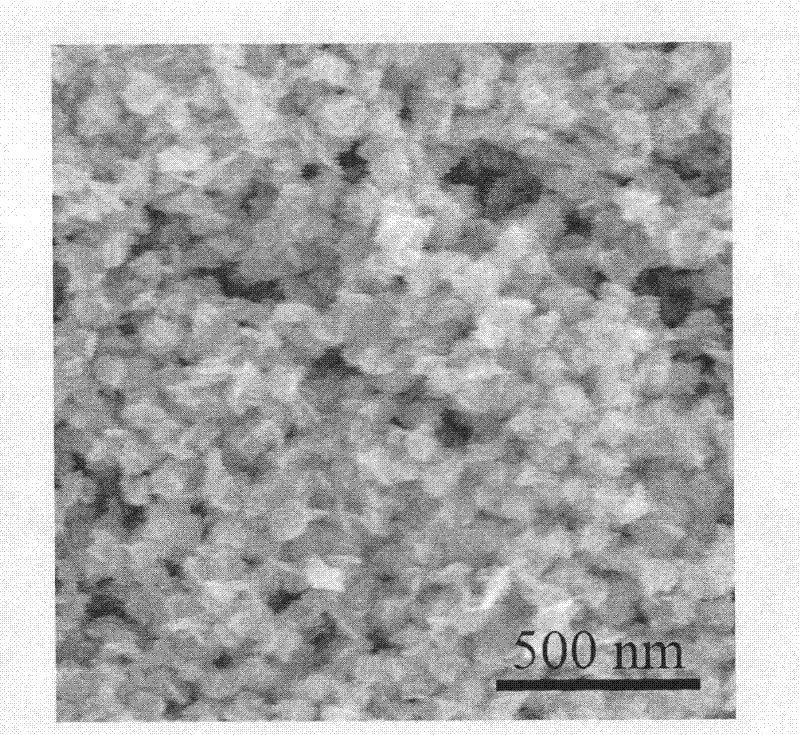

Preparation method of copper sulphide nano-powder with different stoichiometric ratios

InactiveCN102320647AStoichiometric ratio is easy to controlRaw materials are easy to getNanotechnologyCopper sulfidesArgon atmospherePhysical chemistry

The invention discloses a preparation method of copper sulphide nano-powder with different stoichiometric ratios, and belongs to the technical field of nanometer materials. The preparation method is characterized in that elemental copper powder (having a mass fraction above 99.9%) and elemental sulfur power (with a mass fraction above 99.8%) are utilized as raw materials and mixed according to a general chemical formula of Cu2-xS, wherein x is great than or equal to -0.5 and less than or equal to 1.5; and the mixture is subjected to ball-milling at a ball-milling rate of 100 to 425rpm in an argon atmosphere for 5 to 600 minutes to obtain stoichiometric ratio-adjustable single-phase copper sulphide nano-powder with particle sizes of 1 to 500 nanometers. The preparation method has the advantages of cheap and easily available raw materials, simple equipment, good operability of equipment, short process flow, convenience and quickness of large-scale production of copper sulphide nano-powder with different stoichiometric ratios, and wide application prospects.

Owner:UNIV OF SCI & TECH BEIJING

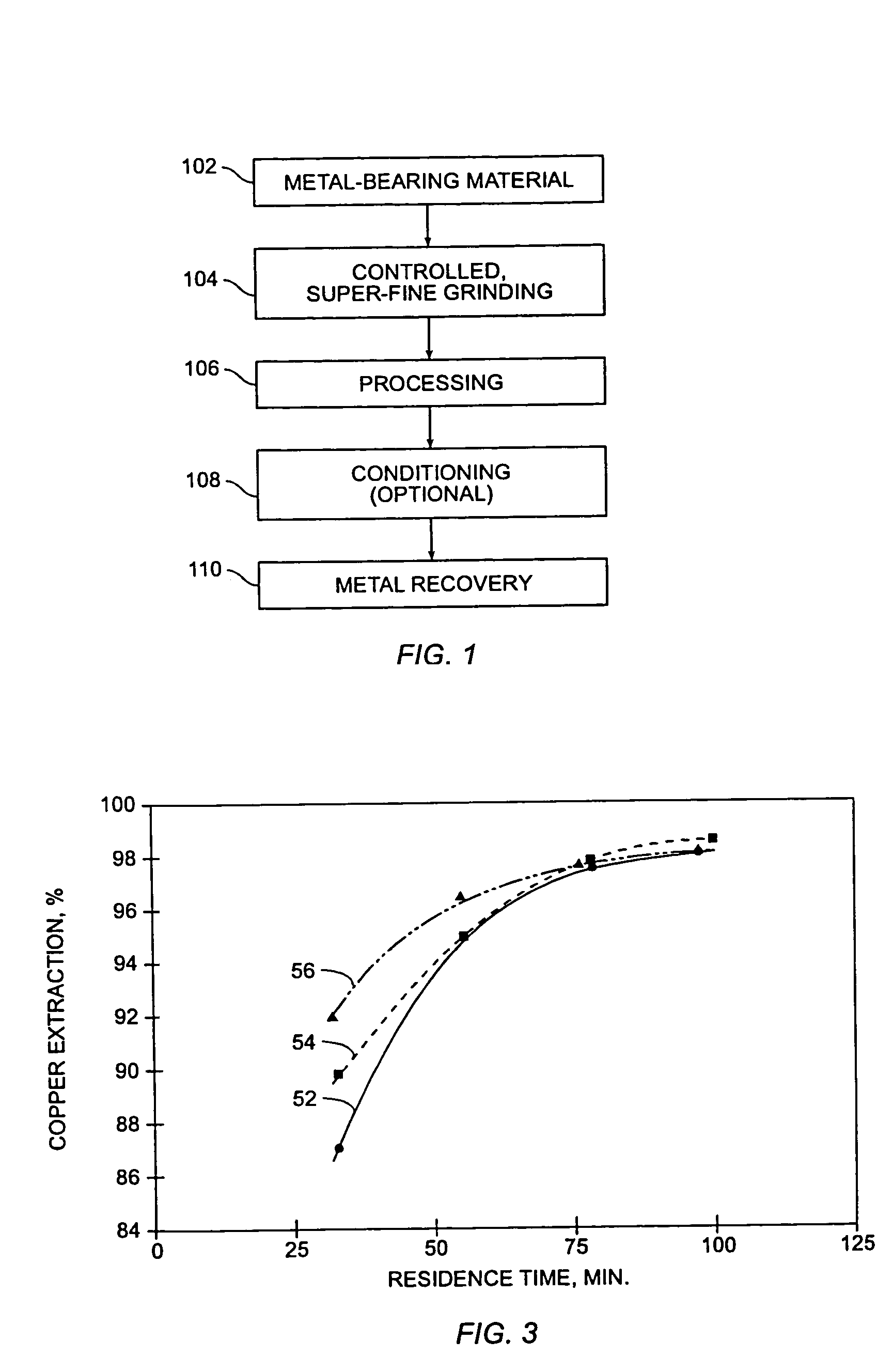

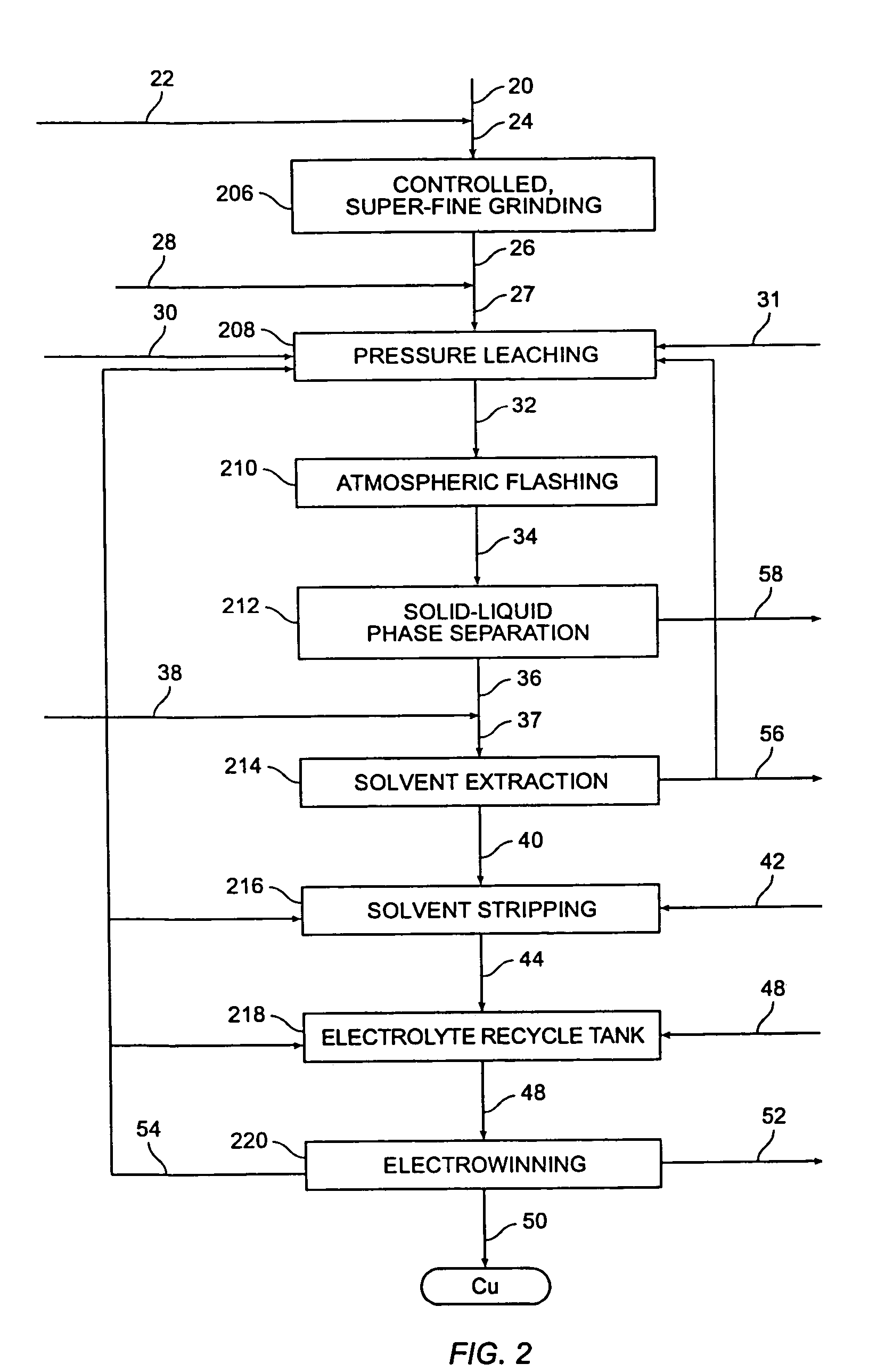

Method for recovery of metals from metal-containing materials using medium temperature pressure leaching

InactiveUS7341700B2Promote recoveryEnhanced metal value recoveryBiocideChromium compoundsRheniumMetallic materials

The present invention relates generally to a process for recovering copper and other metal values from metal-containing materials using controlled, super-fine grinding and medium temperature pressure leaching. Processes embodying aspects of the present invention may be beneficial for recovering a variety of metals such as copper, gold, silver, nickel, cobalt, molybdenum, rhenium, zinc, uranium, and platinum group metals, from metal-bearing materials, and find particular utility in connection with the extraction of copper from copper sulfide ores and concentrates.

Owner:FREEPORT MCMORAN COPPER & GOLD INC

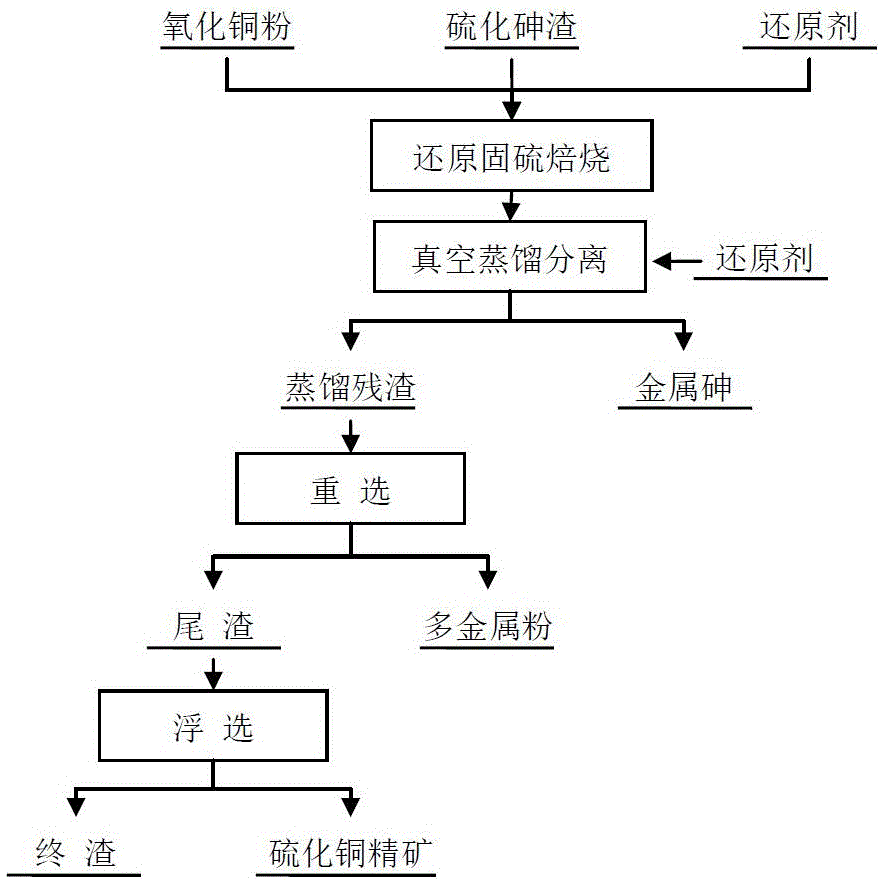

Method for metallic arsenic production directly through reducing sulfur-fixed roasting of arsenic sulfide residues

ActiveCN106756113AEfficient arsenic removalShort processProcess efficiency improvementDistillationCopper sulfide

The invention discloses a method for metallic arsenic production directly through reducing sulfur-fixed roasting of arsenic sulfide residues. The arsenic sulfide residues produced in the acidic wastewater purifying working procedure of a copper smelting plant serve as a raw material, meanwhile cupric oxide powder and a reducing agent are added, low-temperature reducing sulfur-fixed roasting is conducted after metallurgy calculation and ingredient mixing are conducted, and volatility of arsenic is utilized to enable roasted products to be subjected to vacuum separation in the reducing atmosphere so that the crude metal arsenic and distillation residues can be obtained; and distillation residues are subjected to a reselection technique for separation to obtain multi-metal powder and tailings, and the tailings are subjected to a flotation technique to obtain final residues and copper sulfide concentrates. According to the method for metallic arsenic production directly through reducing sulfur-fixed roasting of the arsenic sulfide residues, efficient arsenic removal of the arsenic sulfide residues can be achieved, harmless high-value products of the arsenic are directly produced, the process is short, energy consumption is low, the process is clean, and the direct recovery rate of the metal arsenic reaches up to 96.45%; and meanwhile, recovery of valuable metal existing in the arsenic sulfide residues is completed, and the cupric oxide powder is recovered in a high-quality copper sulfide concentrate mode finally.

Owner:广西河池鑫银环保科技有限公司

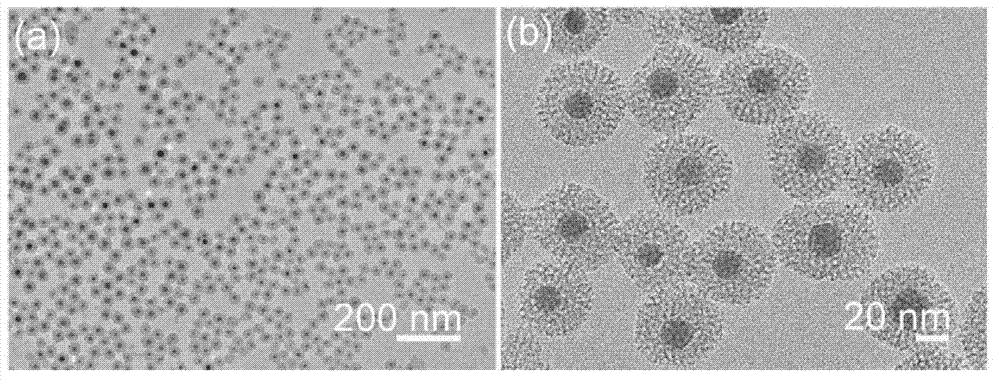

Pyrrhotite flotation inhibitor, preparation and application thereof as well as mineral processing method for copper-nickel sulfide

The invention provides an inhibitor for pyrrhotite flotation. The inhibitor comprises sodium carbonate, sodium pyrosulfite and triethylene tetramine, pyrrhotite in pulp can be effectively and selectively inhibited, meanwhile basically no affect is brought to the flotation of pentlandite and copper pyrite, and the inhibitor is particularly suitable for the flotation and separation of minerals difficult to select such as high content of pyrrhotite and low quality of cooper-nickel; and the invention further provides a preparation method and an application method of the inhibitor for pyrrhotite flotation, the operations are extremely simple and convenient, and excellent industrial prospect is provided.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

Nickel doped copper sulfide nano material as well as preparation method and application thereof

ActiveCN104548094AEnhanced magnetic resonance imagingFunctionalEnergy modified materialsNMR/MRI constrast preparationsTherapeutic effectCopper sulfide

The invention provides a nickel doped copper sulfide nano material. The chemical general formula of the nickel doped copper sulfide nano material is Cu1-xNixS, wherein CuS refers to a substrate, Ni<2+> refers to doping ions, and the value range of x is that x is larger than 0 and is smaller than or equal to 0.8; the nickel doped copper sulfide nano material provided by the invention is a multifunctional nano material and simultaneously has a magnetic resonance imaging function and a photothermal therapy effect, so that the nickel doped copper sulfide nano material can be used as a magnetic resonance imaging probe and a photothermal therapy reagent and is a nano material integrating detection and therapy. The invention further provides a preparation method and an application of the nickel doped copper sulfide nano material.

Owner:SHENZHEN INST OF ADVANCED TECH

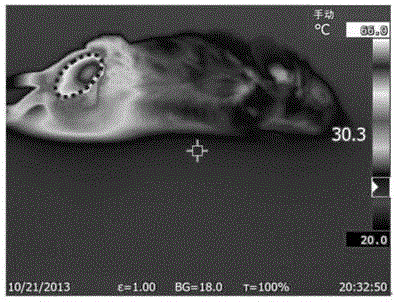

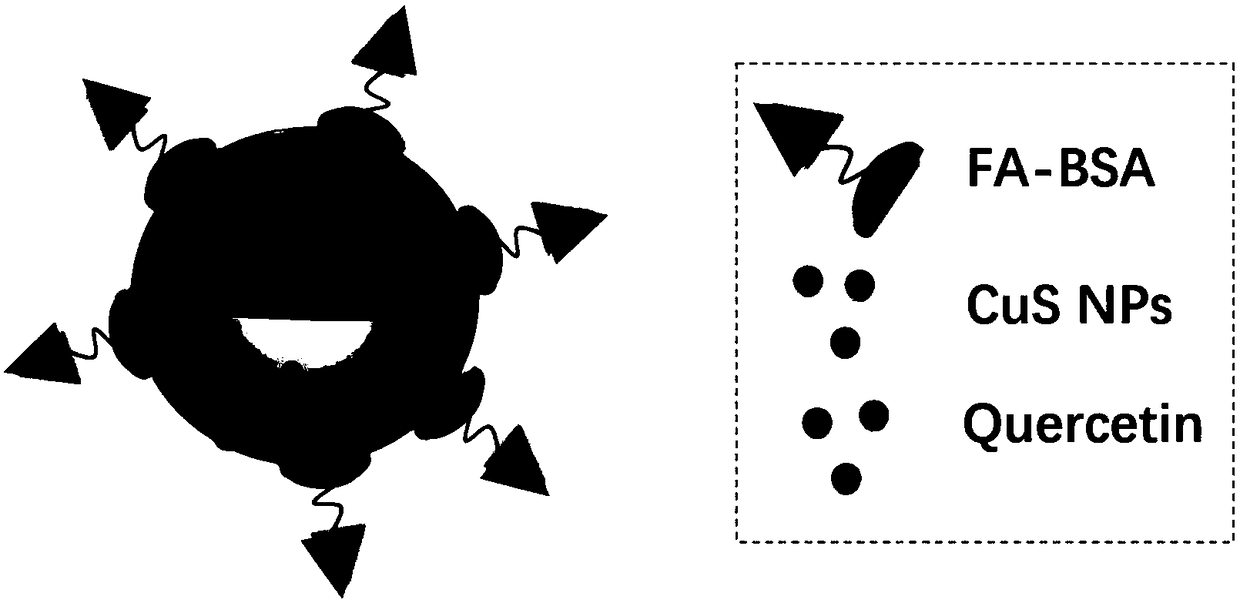

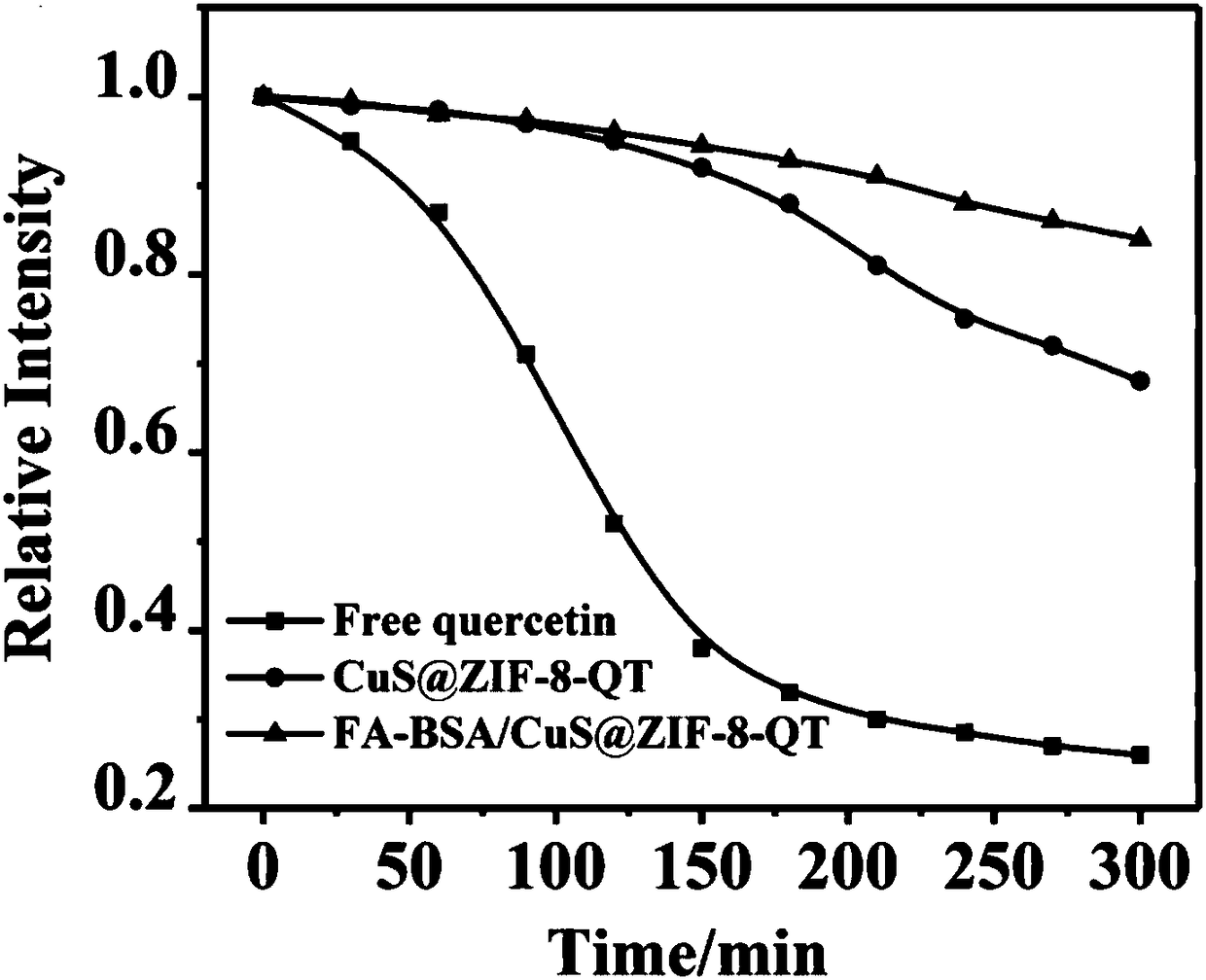

Quercetin drug-loading system based on copper sulphide-metal organic frame material

ActiveCN108524935AGood water solubilityGood chemical stabilityPowder deliveryOrganic active ingredientsSolubilityPharmaceutical formulation

The invention discloses a quercetin drug-loading system based on a copper sulphide-metal organic frame material. A metal organic frame zeolite imidazolate framework material (ZIF-8) is generated on the surfaces of copper sulphide nano-particles (CuS NPs) as a photothermal preparation to obtain a CuS@ZIF-8 carrier, quercetin is adsorbed into a carrier, and then is modified by a stabilizer and a targeting agent FA-BSA, and thus, a nano delivery system (FA-BSA / CuS@ ZIF-8) with a targeting active effect and pH response can be formed. The water solubility and the chemical stability of the quercetinare improved, good curative effect of treating tumors by combination of phototherapy and chemotherapy can further be played, meanwhile, drug can be rapidly released under the condition of low pH in atumor microenvironment, the tumor cell intake of a pharmaceutic preparation is further enhanced, and the quercetin drug-loading system based on the copper sulphide-metal organic frame material has low toxicity to normal cells, and is good in biological compatibility.

Owner:SHANDONG UNIV

Conductive polyvinyl alcohol fiber

InactiveUS20050181206A1Improve conductivityIncreased durabilityElectroconductive/antistatic filament manufactureFibre treatmentFiberPolymer science

A conductive polyvinyl alcohol fiber having good mechanical properties and heat resistance contains a polyvinyl alcohol polymer and copper sulfide nano-particles having a mean particle size of at most 50 nm which are finely dispersed in the polymer. The content of the nano-particles in the fiber is at least 0.5% by mass / polyvinyl acohol polymer, and the degree of polymer orientation is at least 60%.

Owner:KURARAY CO LTD

Preparation method of copper sulfide nano material

InactiveCN101559971AUniform sizeGood biocompatibilityNanostructure manufactureCopper sulfidesSulfurCopper sulfide

The invention relates to a preparation method of copper sulfide nano material, belonging to the technical field of nano composite material. The preparation method comprises the following steps of: preparing copper ion protein mixed solution; preparing copper-sulfur protein mixed solution; and carrying out centrifuge treatment and vacuum drying treatment. The method has simple and novel technique, little equipment quantity and low energy consumption and is environment-friendly.

Owner:SHANGHAI JIAO TONG UNIV

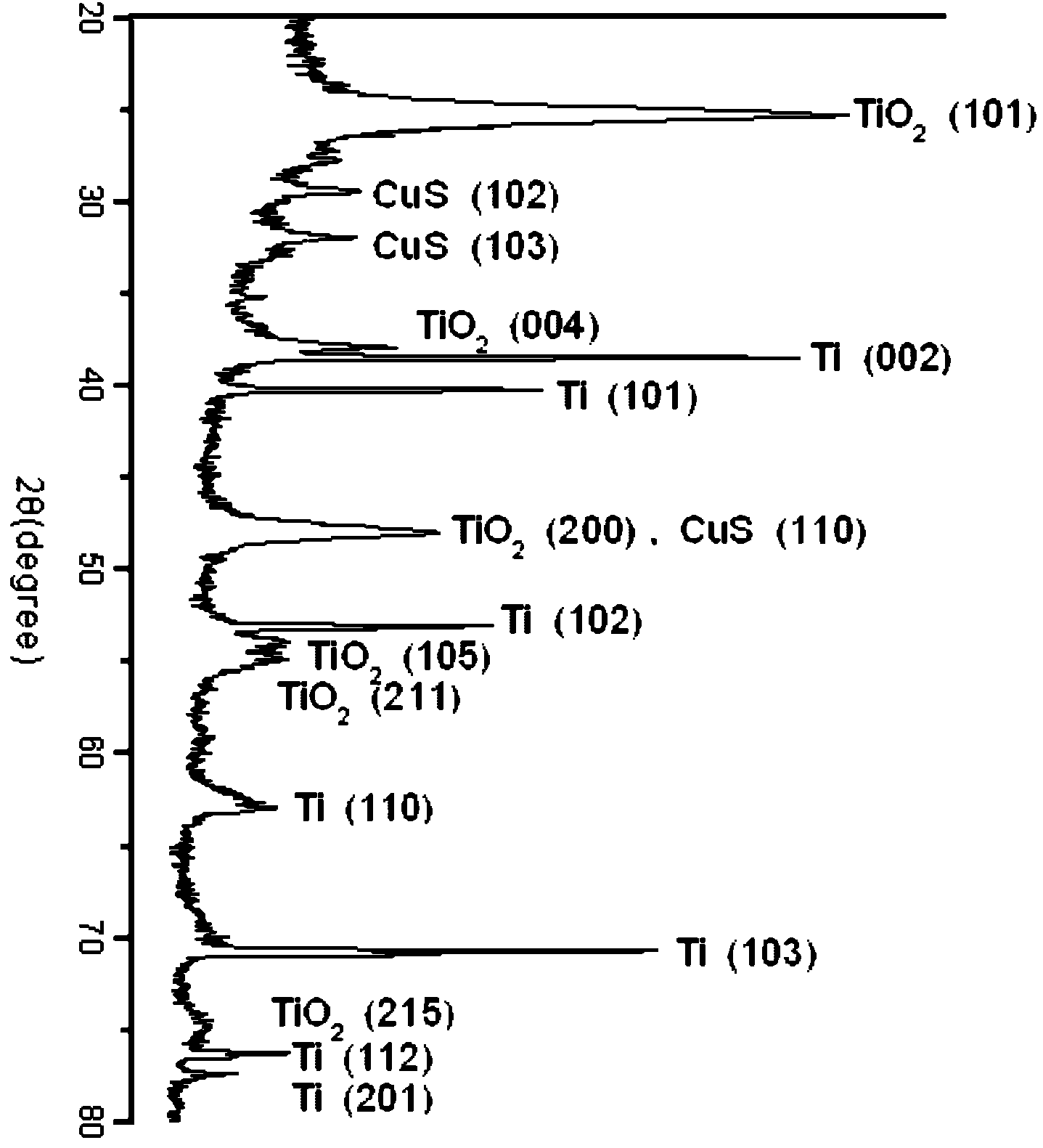

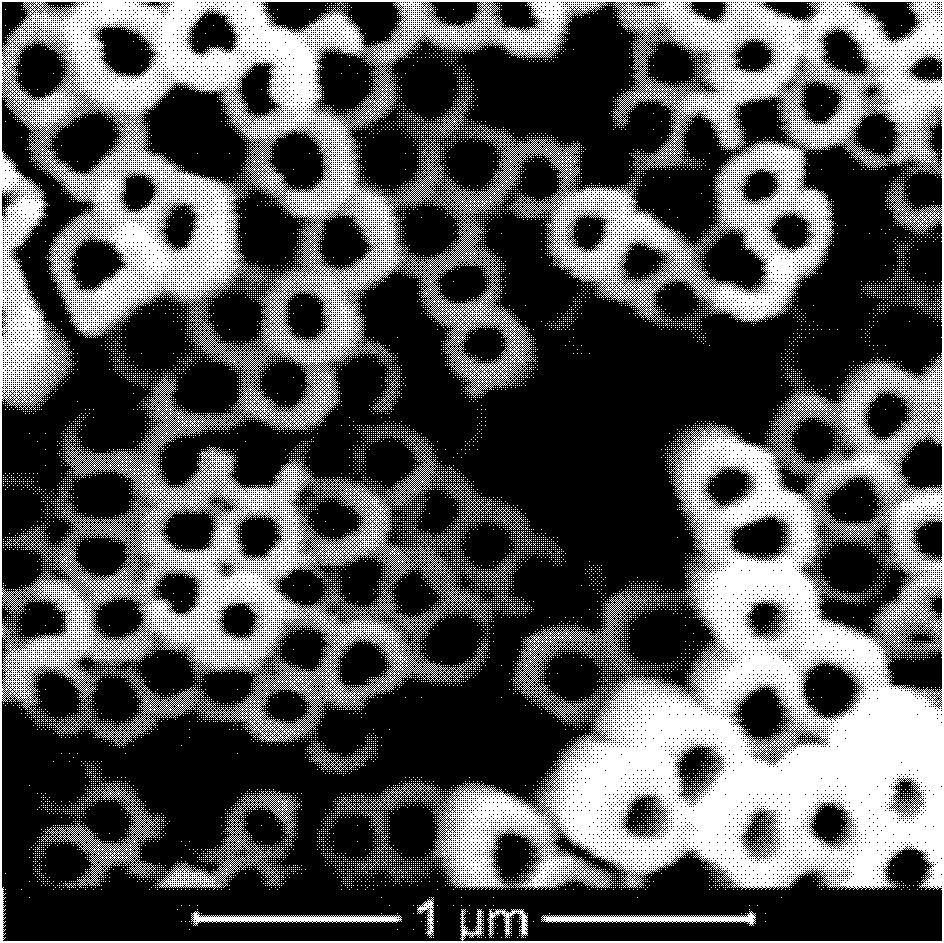

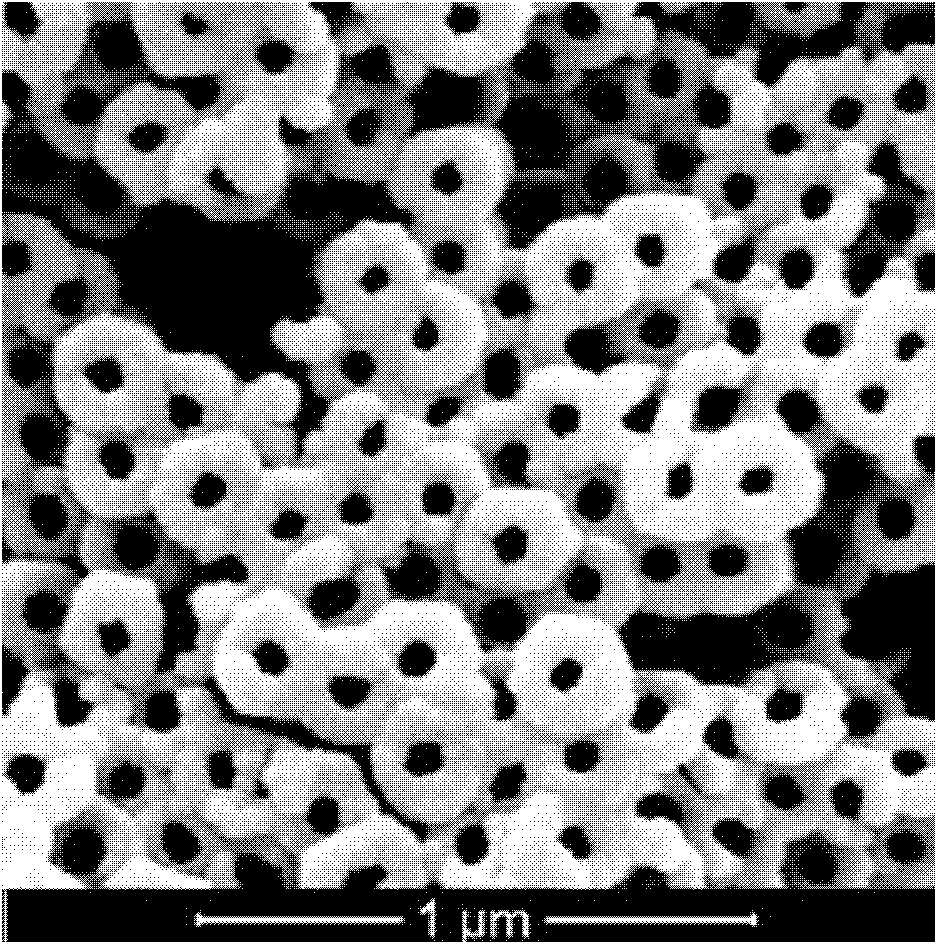

Method for preparing composite material of copper sulfide and titanium dioxide nano-tube

InactiveCN101899701APromote absorptionImprove utilizationSurface reaction electrolytic coatingSolar cellCopper sulfide

The invention provides a method for preparing a composite material of a copper sulfide and titanium dioxide nano-tube. The method comprises the following steps of putting a sanded titanium plate in acetone or absolute ethanol for ultrasonic cleaning, and is rinsed and aired with deionized water; anodizing a platinum plate serving as a cathode and the treated titanium plate serving as an anode in ethylene glycol solution with 0.25 weight percent of ammonium fluoride, namely a titanium dioxide nano-tube array grows on the surface of the titanium plate; putting the titanium plate growing the titanium dioxide nano-tube array in mixed solution filled with copper chloride and sodium thiosulfate, wherein molar concentrations of the copper chloride and the sodium thiosulfate in the mixed solution are the same, and are between 0.0025 and 0.01mol / L; and sealing the solution with an autoclave, heating the autoclave to the temperature of between 60 and 120 DEG C, and preserving the temperature for 12 to 24 hours. The nano composite material prepared by the method has high sunlight absorbing and utilizing capability, has good application prospect in the field of solar cells, and has simple manufacture process, low equipment requirement and low preparation cost.

Owner:SOUTHWEST JIAOTONG UNIV

Process of leaching gold

ActiveUS20090241735A1Improve efficiencyProcess efficiency improvementPregnant leach solutionChloride

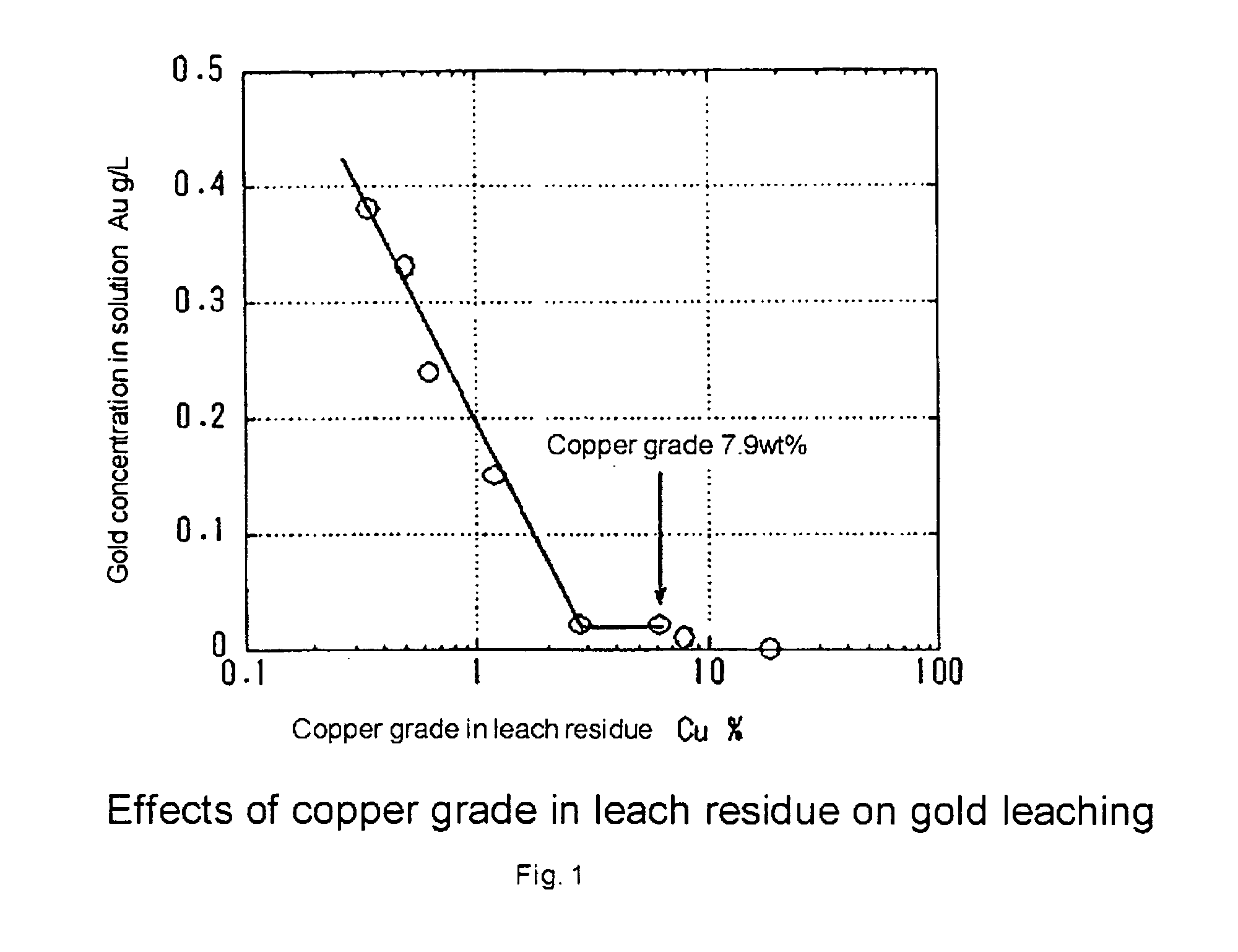

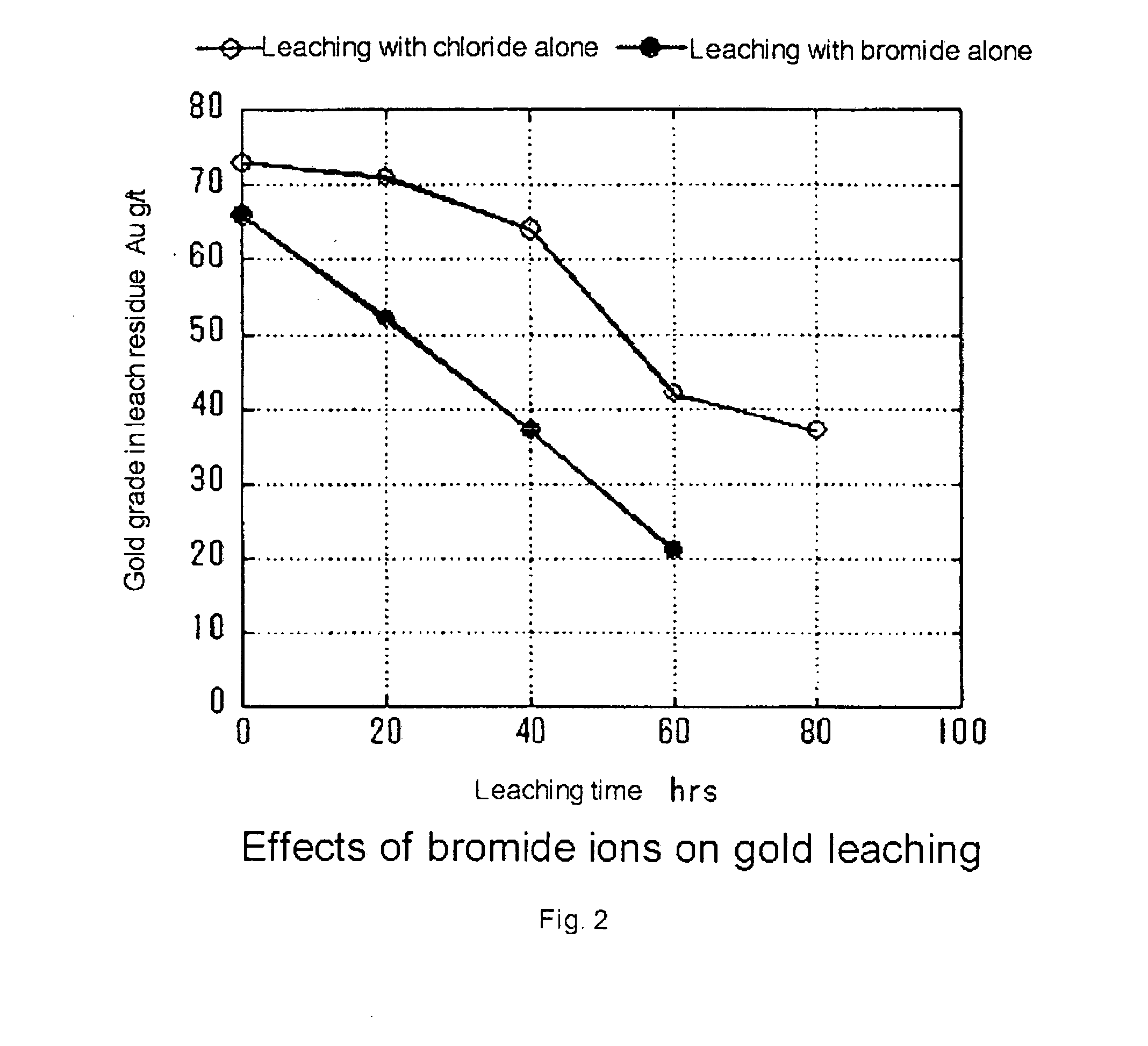

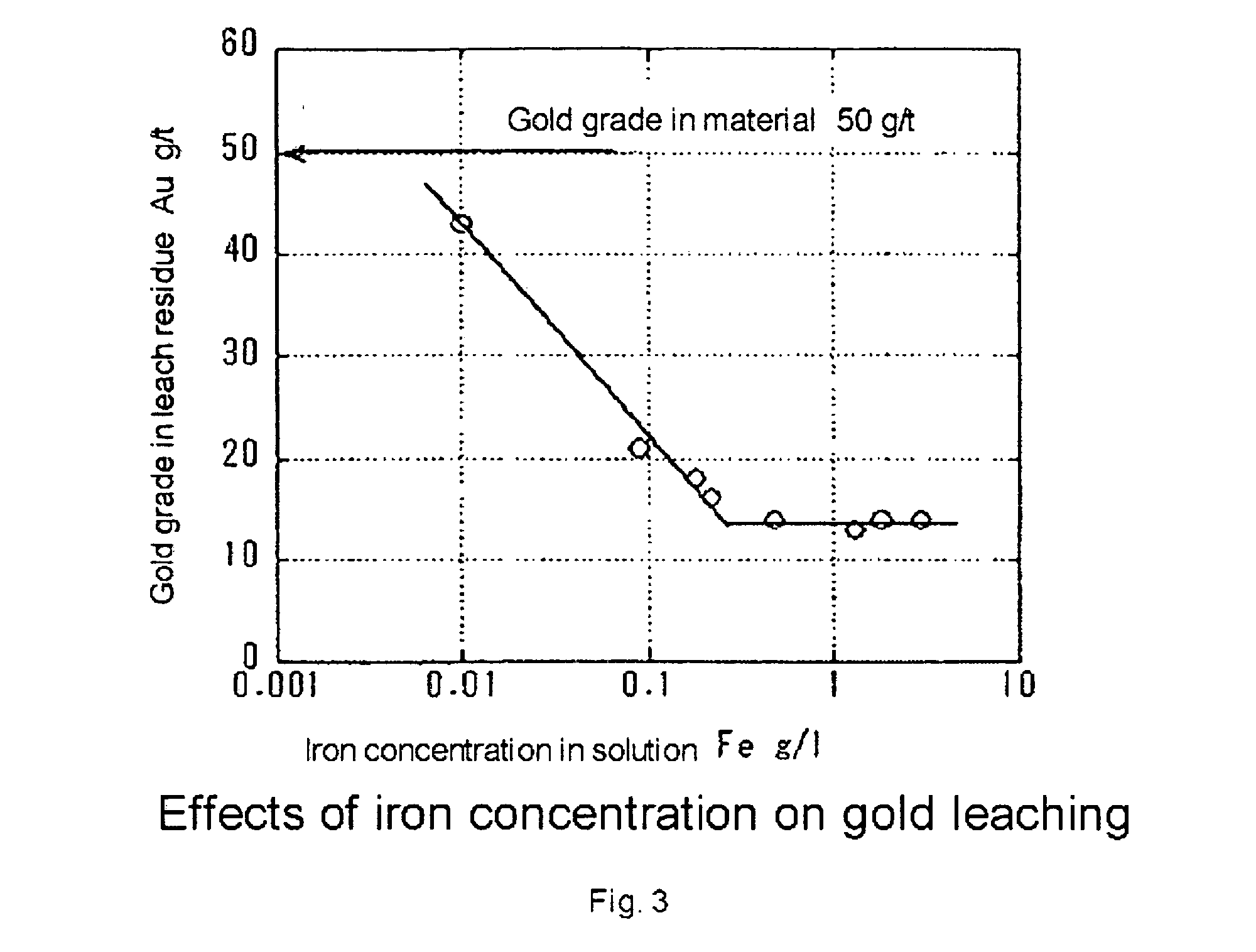

A process of leaching gold comprising the steps of: a) leaching copper from copper sulfide ore material that contains gold or contains silicate ore containing gold until the copper grade is reduced to 7.9 wt % or less; b) mixing the resulting material having a copper grade of 7.9 wt % or less with a gold leaching solution selected from the group consisting of a first solution containing chloride ions and ferric ions, and a second solution containing chloride ions and iron ions, the iron ions having been oxidized to trivalent ferric ions by air bubbled into the second solution; c) adjusting the pH of the gold leaching solution to 1.9 or less with stirring to leach at least gold in the material into the gold leaching solution by the oxidative activity of the ferric ions contained in the gold leaching solution, wherein the concentration of gold is reduced by selectively removing gold from part or all of the gold leaching solution during gold leaching. This process efficiently leaches at least copper and gold from a copper sulfide ore.

Owner:JX NIPPON MINING& METALS CORP

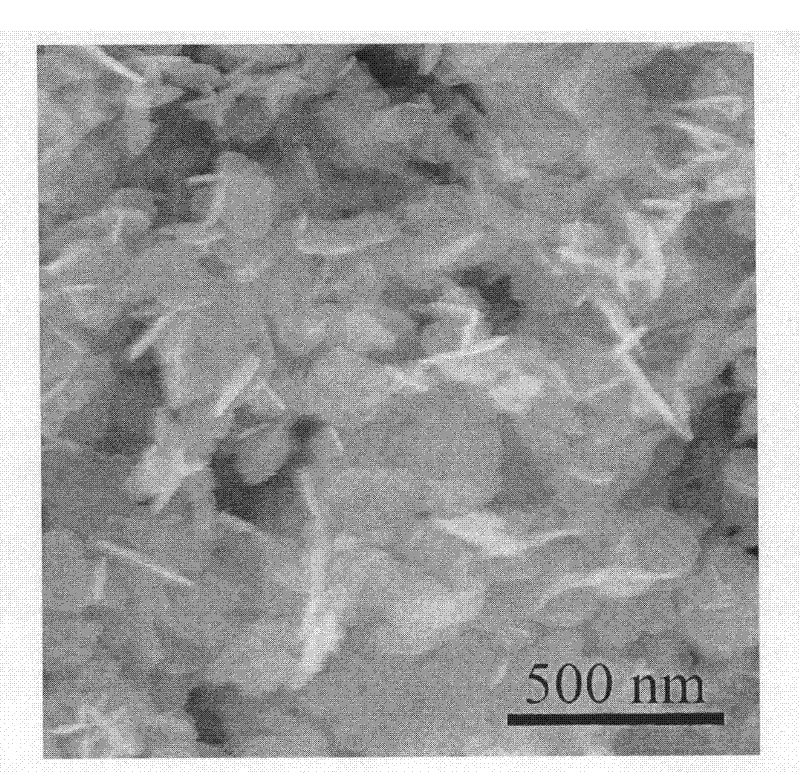

Method for preparing copper sulphide nanosheet

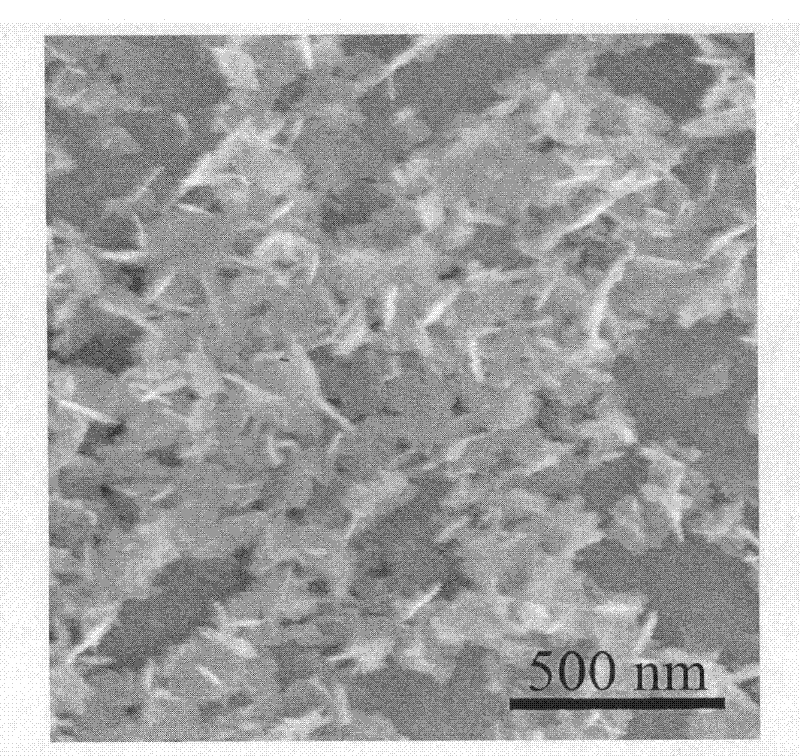

The invention discloses a method for preparing a copper sulphide nanosheet, comprising the following steps of: dissolving copper chloride and surfactant in deionized water to prepare a solution A; and dissolving thioacetamide in the deionized water to prepare a solution B; 2) mixing two solutions, i..e. the solution A and the solution B serving as a reaction solution to carry out water bath reaction to prepare a hexagon copper sulphide nanosheet; and controlling the side length of the copper sulphide nanosheet to be between 55 and 140nm and the thickness to be between 8 and 20nm through controlling a reaction condition. The method has the characteristics of easiness in acquisition of raw materials, simple equipment, low cost, simplicity in operation, effectiveness, quickness and the like; and the prepared copper sulphide nanosheet is ordered in appearance, high in dispersibility, yield rate and stability, controllable in sizes and suitable for large-scale industrial production. The prepared copper sulphide nanometer material has wide application prospect in the fields of light-emitting diodes, photochemical catalysts, flourescent materials, electrochemical batteries, sensors, lasers, solar batteries and the like.

Owner:CHONGQING UNIV OF ARTS & SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com