Pyrrhotite flotation inhibitor, preparation and application thereof as well as mineral processing method for copper-nickel sulfide

A technology of copper-nickel sulfide ore and pyrrhotite, which is applied in flotation, solid separation, etc., can solve the problems of high recovery rate, adsorption influence, and difficult stability of reaction conditions, etc., and achieve shortened production time, improved grade, and separation The effect of the enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

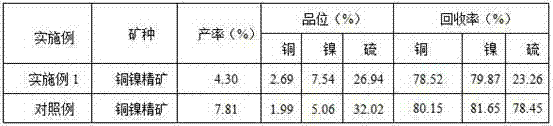

Embodiment 1

[0043] Embodiment 1 Get 20 parts by weight of solid sodium carbonate, 5 parts of sodium metabisulfite and 3 parts of triethylenetetramine to configure pyrrhotite inhibitor. In the inhibitor, the total weight of the three components accounts for 2% of the total weight of the inhibitor .

[0044] Specific steps:

[0045] (1) Rough selection and flotation - adding water to the ore material dissociated from the basic monomer to adjust the slurry to a solid mass fraction of 20% in the slurry, and a pH value of 5~6, and then adding 2000 g of sulfuric acid per ton of raw ore to the slurry ( That is, use 2000g of sulfuric acid per ton of raw ore), stir for 2 minutes, then add 100 g of butyl xanthate / ton of raw ore, stir for 1 minute, then add 30 g of butyl ammonium black medicine / ton of raw ore, and stir for 1 minute, then add foaming agent pinitol Oil 20 g / ton of raw ore, and stir for 1min, inflate and stir for 1min, scrape and bubble for 7min, and obtain copper-nickel coarse concen...

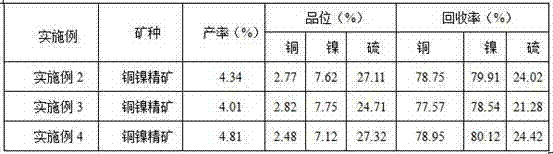

Embodiment 2

[0055] The operation of this embodiment is the same as that of Embodiment 1, the difference is:

[0056] When the inhibitor is prepared, 15 parts of solid sodium carbonate, 10 parts of sodium metabisulfite and 5 parts of triethylenetetramine are prepared in parts by weight. In the inhibitor, the total weight of the three components accounts for 5% of the total weight of the inhibitor.

[0057] When beneficiating:

[0058] In step (1), the solid mass fraction contained in the pulp is 30%, the pH value is 5~6, the dosage of sulfuric acid is 3000 g / ton of raw ore, the dosage of butyl xanthate is 150 g / ton of raw ore, and the amount of butyl ammonium black is medicinal The amount is 50 g / ton of raw ore, and the consumption of terpineol oil is 30 g / ton of raw ore;

[0059] In step (1), the amount of sulfuric acid used for the first screening of the tailings was 2000 g / ton of raw ore, the dosage of butyl xanthate was 55 g / ton of raw ore, and the dosage of butylamine black was 50 g / ...

Embodiment 3

[0064] The operation of this embodiment is the same as that of Embodiment 1, the difference is:

[0065] When the inhibitor is prepared, 30 parts of solid sodium carbonate, 7 parts of sodium metabisulfite and 4 parts of triethylenetetramine are prepared in parts by weight. In the inhibitor, the total weight of the three components accounts for 10% of the total weight of the inhibitor.

[0066] When beneficiating:

[0067] In step (1), the solid mass fraction contained in the ore pulp is 25%, the pH value is 5~6, the dosage of sulfuric acid is 5000 g / ton of raw ore, the dosage of butyl xanthate is 130 g / ton of raw ore, and butylammonium black is used for medicine The amount is 40 g / ton of raw ore, and the consumption of terpineol oil is 40 g / ton of raw ore;

[0068] In step (1), the amount of sulfuric acid used in the first sweeping of the tailings was 1700 g / ton of raw ore, the dosage of butyl xanthate was 45 g / ton of raw ore, and the dosage of butylamine black was 40 g / ton o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com