Treatment method of papermaking PVA wastewater

A treatment method and technology for wastewater, which are applied in the process of wastewater treatment, water/sewage treatment, and water treatment parameter control. The effect of shortening the post-processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment provides a method for treating papermaking PVA wastewater, and the steps are as follows:

[0035] (1) Water quality of PVA waste liquid: PVA concentration is 5.4%, COD=98000~100000mg / L, 200ml PVA waste liquid is treated in a single test.

[0036] (2) Add sodium sulfate, borax, sodium carbonate, and sodium bicarbonate to the PVA waste liquid, stir at 30°C for 30 minutes, and measure the COD removal rate in the PVA waste liquid and the water content of the recovered PVA gel.

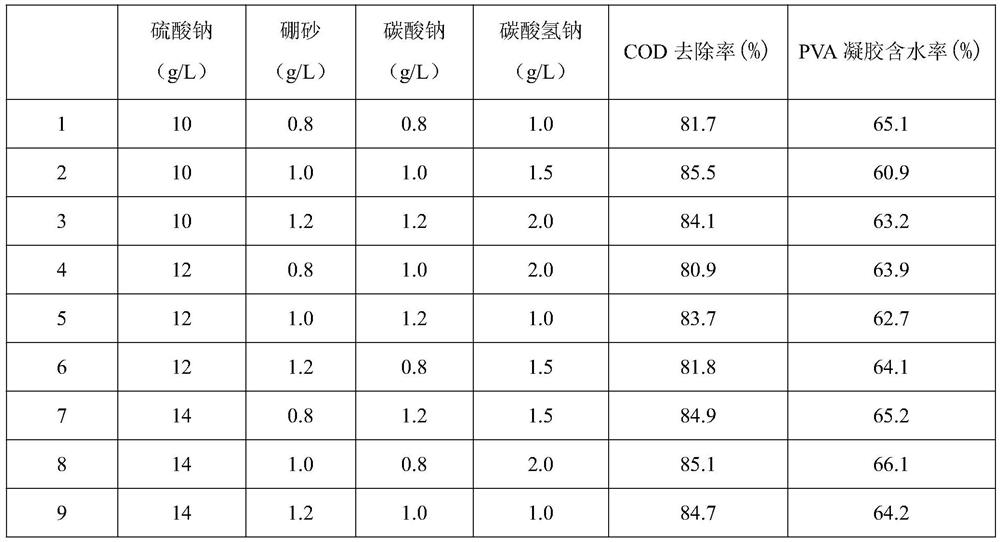

[0037] (3) Determine the optimal addition amount of the above substances according to the orthogonal experiment, and the results are shown in Table 2.

[0038] Table 2

[0039]

[0040] It can be seen from Table 2 above that when the addition amount of sodium sulfate is 10g / L, borax 1.0g / L, sodium carbonate 1.0g / L, sodium bicarbonate 1.5g / L, the removal rate of COD in PVA wastewater is higher, which is 85.5%, the water content of the recovered PVA gel is also low, at 60.9%.

Embodiment 2

[0042] In this example, the best solution obtained in Example 1 was used for testing, and the degree of polymerization of the obtained PVA gel was tested.

[0043] Under certain reaction conditions, the relative molecular mass of the recovered PVA is determined by the viscosity method. From the Mark equation, the average relative molecular mass M of the recovered PVA is equal to 83805, which is not large in absolute and relative deviation from the average value of the PVA puree. The performance impact is minimal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com