Patents

Literature

722 results about "Sodium hydrogencarbonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The compound sodium hydrogen carbonate, also known as baking soda, sodium bicarbonate and bicarbonate of soda, is a white crystalline powder that is soluble in water. The chemical formula for sodium bicarbonate is NaHCO3.

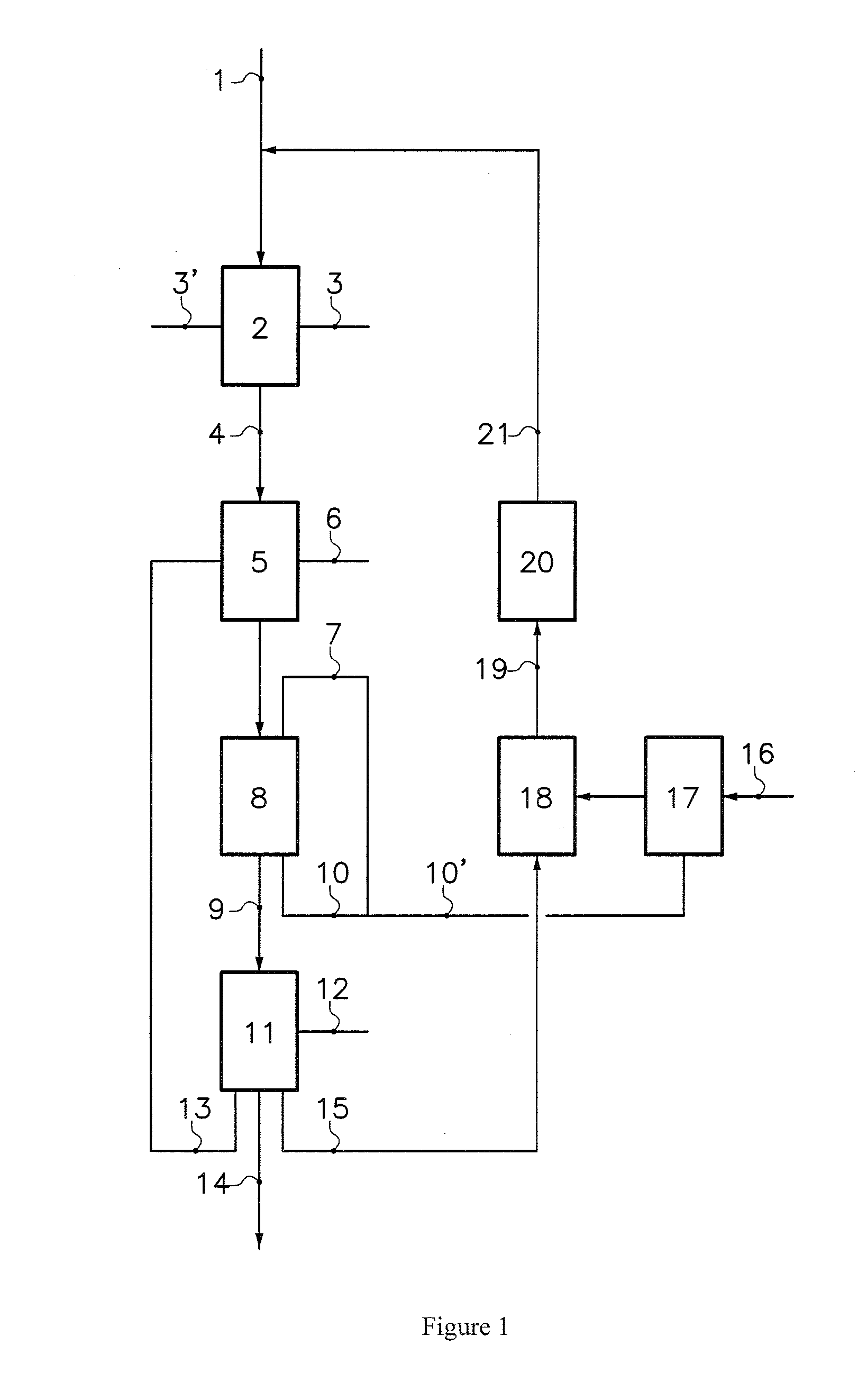

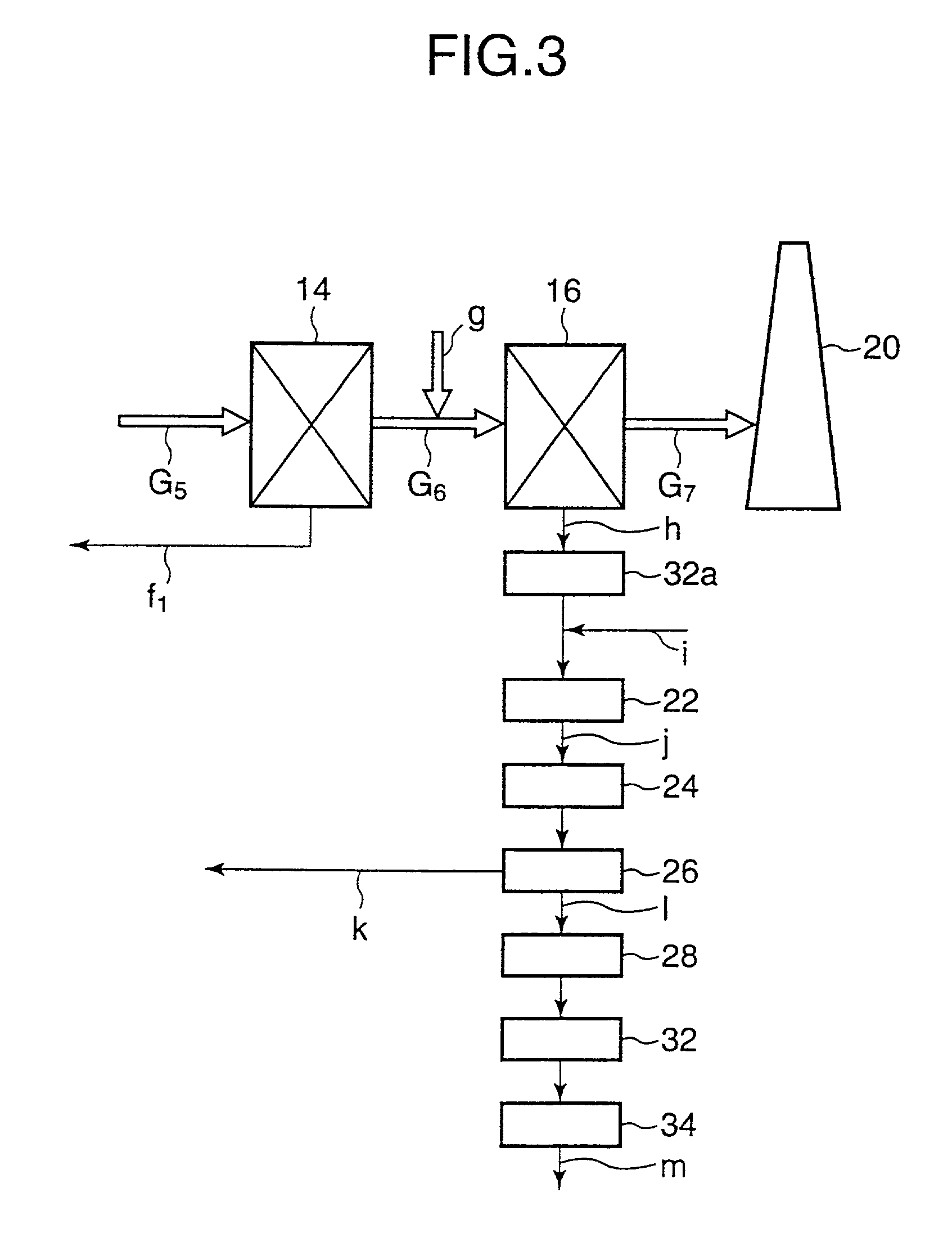

Process for producing sodium bicarbonate for flue gas desulphurization

InactiveUS20100290967A1Electrolysis componentsVolume/mass flow measurementSodium bicarbonateFlue gas

Process for producing sodium bicarbonate for purifying flue gases, according to which an aqueous solution containing sodium sulfate is subjected to electrodialysis to produce a sodium hydroxide solution and a sodium bisulfate solution, the sodium hydroxide solution being carbonated in order to obtain sodium bicarbonate.

Owner:SOLVAY SA

Organic selenium biologics and its preparation method, and method for producing selenium-rich vegetable using the same

InactiveCN1594234AIncrease multipleBio-organic fraction processingOrganic fertilisersSodium bicarbonateManganese

The invention discloses an organic selenium biologics and its preparation method, and method for producing selenium-rich vegetable using the same, wherein the preparation is prepared from water and the following components (by weight percentage) through mixing and fermentation, selenium dioxide : sodium hydrogen carbonate : methionine : brown sugar : carbamide : monobasic potassium phosphate : magnesium sulfate : manganese sulfate : calcium chloride = 35-45 : 35-45 : 10-20 : 45-55 : 1-10 : 1-10 : 1-4 : 1-4 : 1-10, the method of application comprises, diluting the organic selenium biologics to 50-200 times by charging water, spraying diluted organic selenium biologics liquid onto the vegetable leaves, stems or roots. The vegetable exerted by the organic selenium biologics contains rich selenium.

Owner:吴敦虎 +2

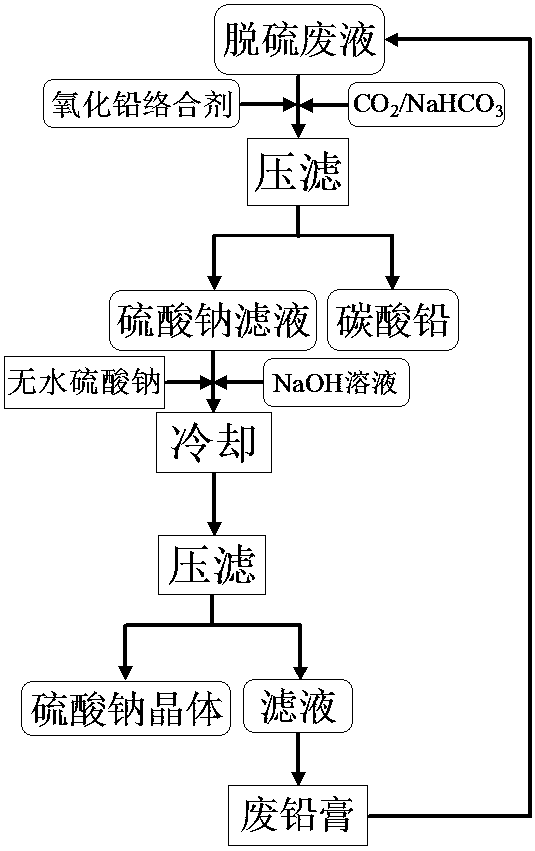

Method of recovering sodium sulfate from lead-bearing desulfurized waste liquid

ActiveCN103771459AStrong complexing abilityEliminate secondary pollutionAlkali metal sulfite/sulfate purificationLead carbonateLead oxide

The invention discloses a method of recovering sodium sulfate from a lead-bearing desulfurized waste liquid. The method is characterized by comprising the following steps: after adding a complexing agent into the lead plaster-bearing desulfurized waste liquid, forming a lead carbonate precipitate of lead complex ions in the liquor by adopting carbon dioxide or sodium hydrogen carbonate, and then carrying out solid-liquid separation to obtain a sodium sulfate filtrate and the lead carbonate precipitate; adding anhydrous sodium sulfate and sodium hydroxide into the sodium sulfate filtrate obtained by separating lead carbonate, and cooling at low temperature to separate out sodium sulfate crystals; and returning the filtrate without the sodium sulfate crystals again for desulfurization of lead oxide-bearing wastes.

Owner:BEIJING UNIV OF CHEM TECH

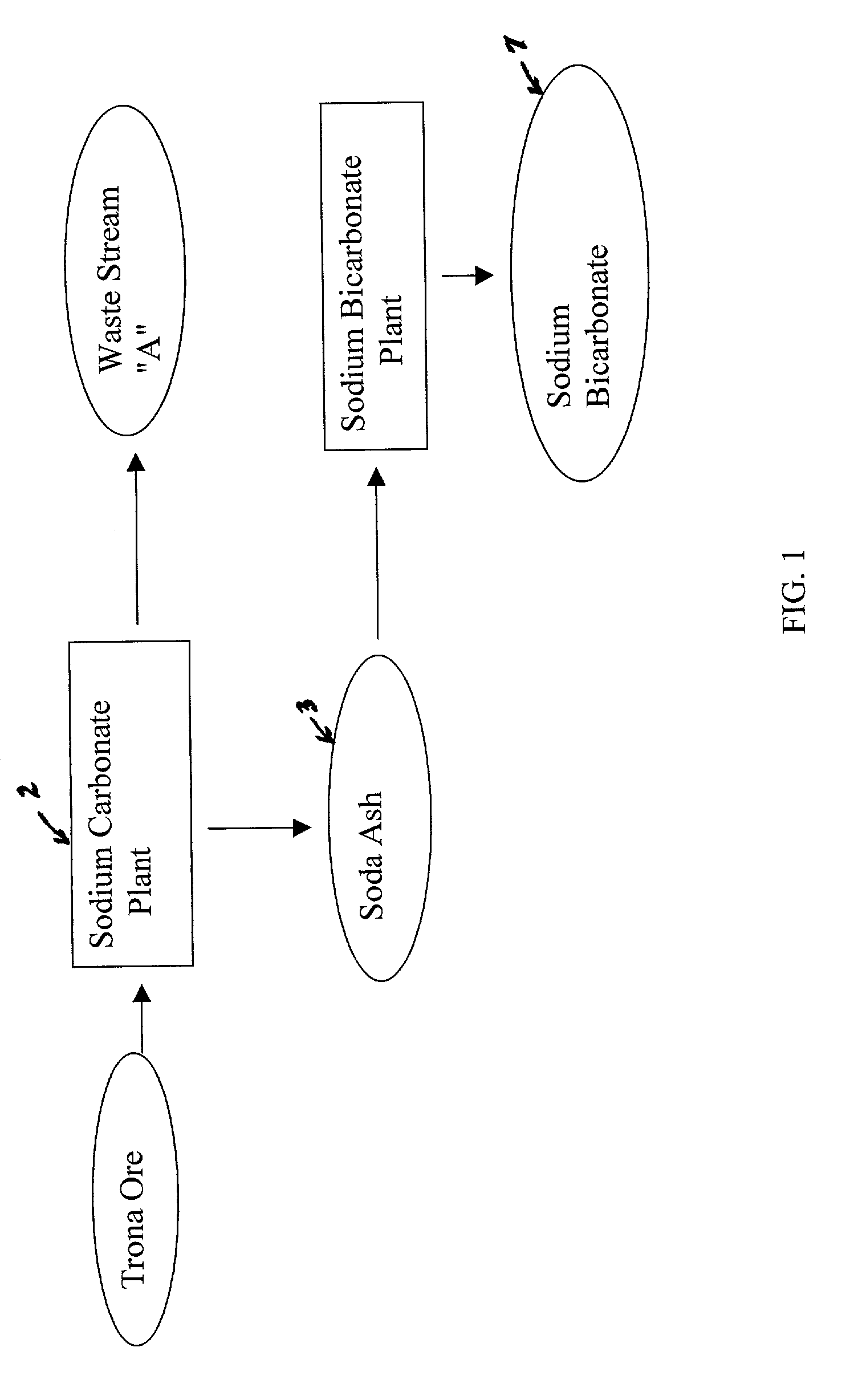

Sodium bicarbonate production method

InactiveUS20030017099A1Improvement in recovered sodium valuePromote recoveryBicarbonate preparationRubidium/caesium/francium compoundsEnvironmental engineeringSodium hydrogencarbonate

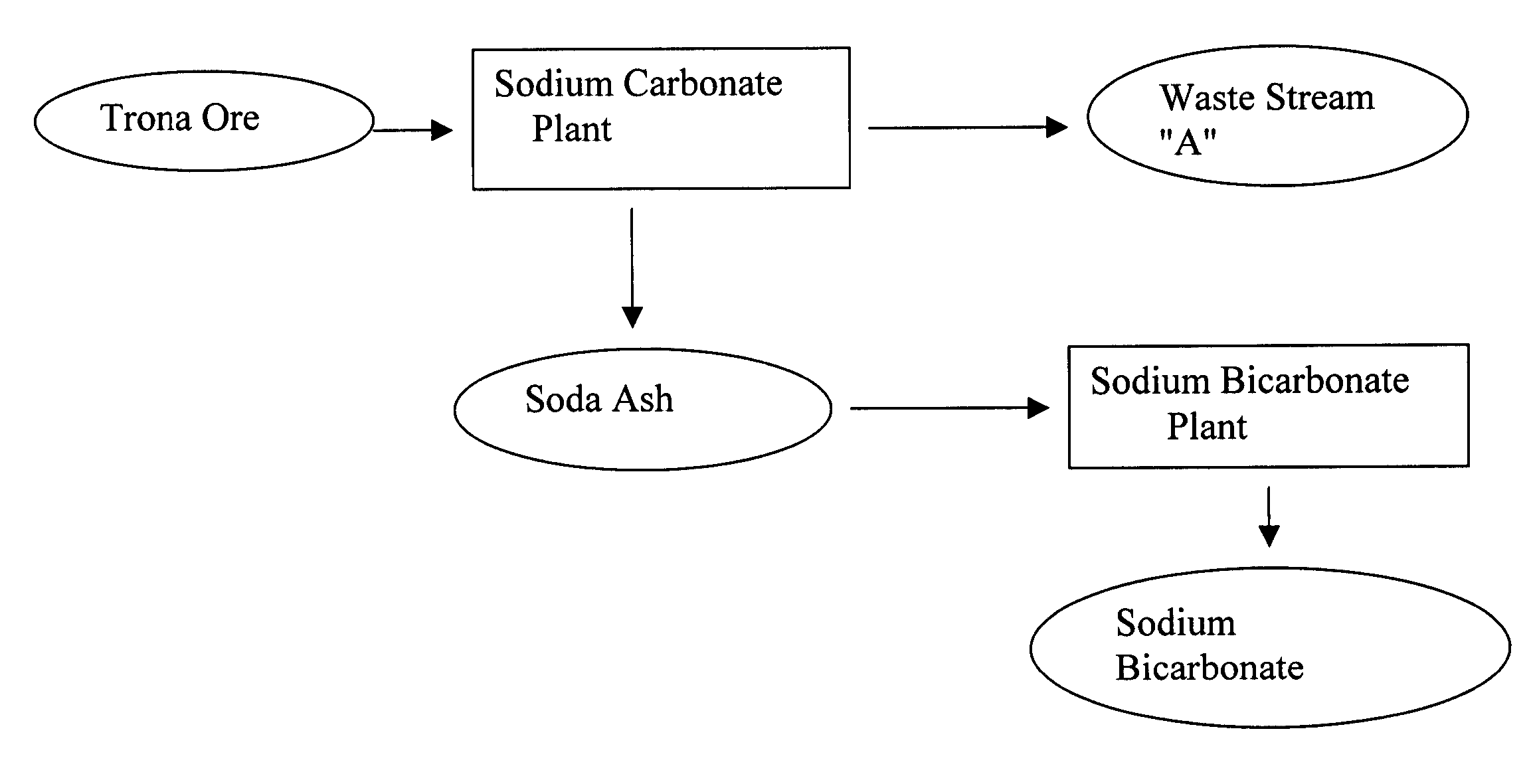

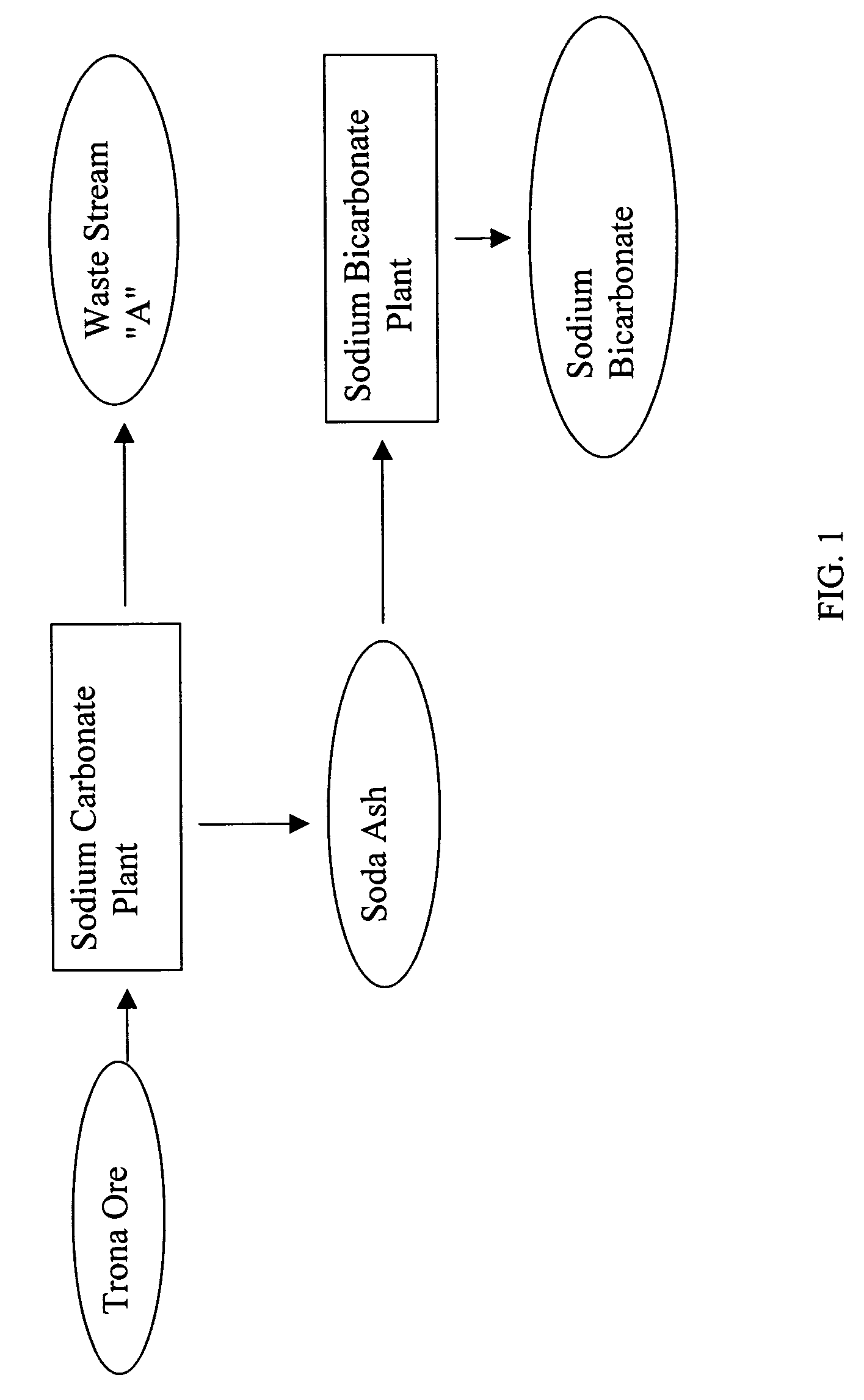

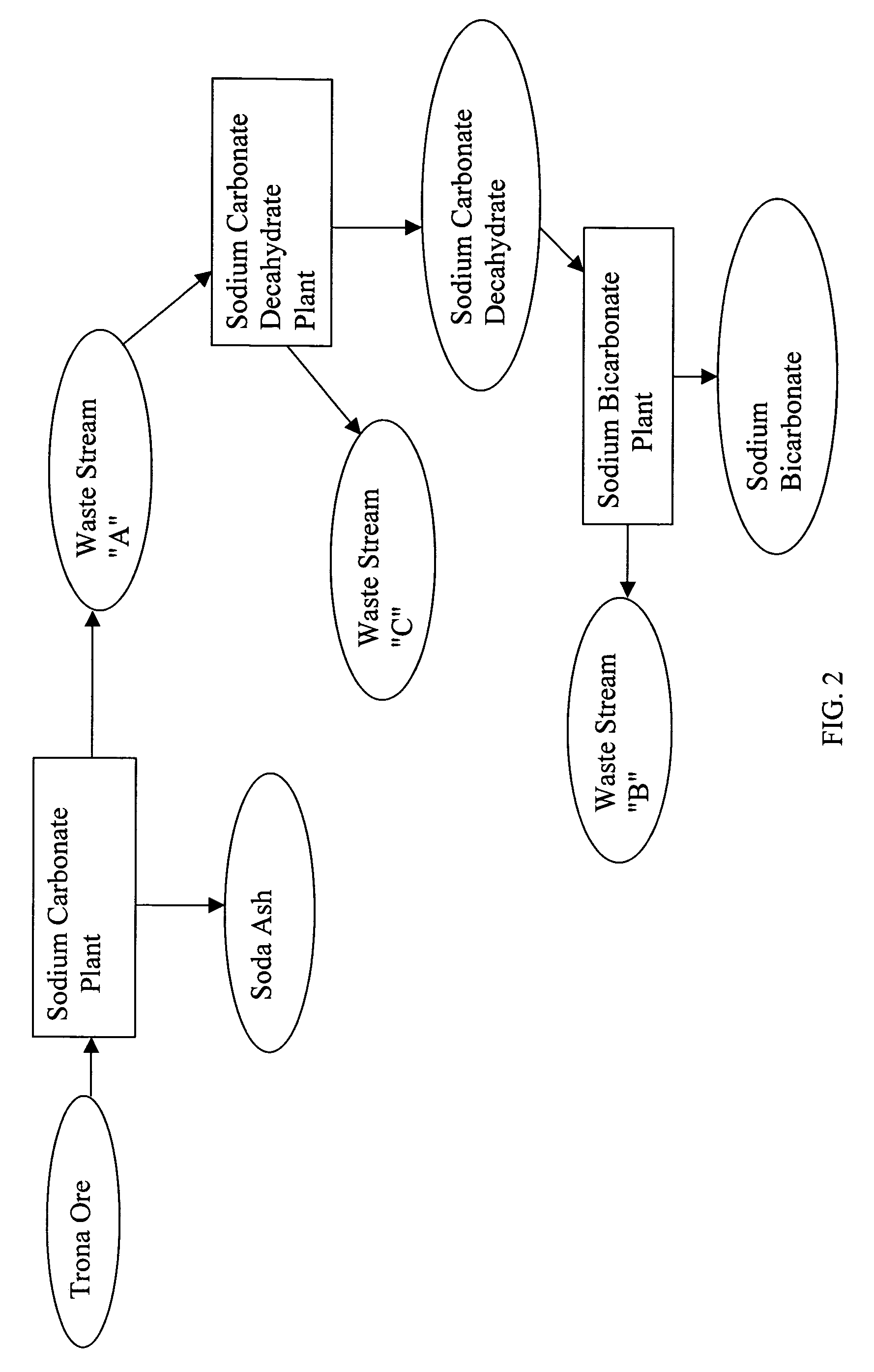

A method of producing additional sodium bicarbonate having a high degree of purity and obtaining a net reduction in effluent waste water, as compared to prior processes, when starting from trona ore is disclosed. The process entails utilizing the waste-water effluent stream from the conversion of trona ore to sodium carbonate as the feed for the conversion of sodium carbonate to sodium bicarbonate.

Owner:CHURCH & DWIGHT CO INC

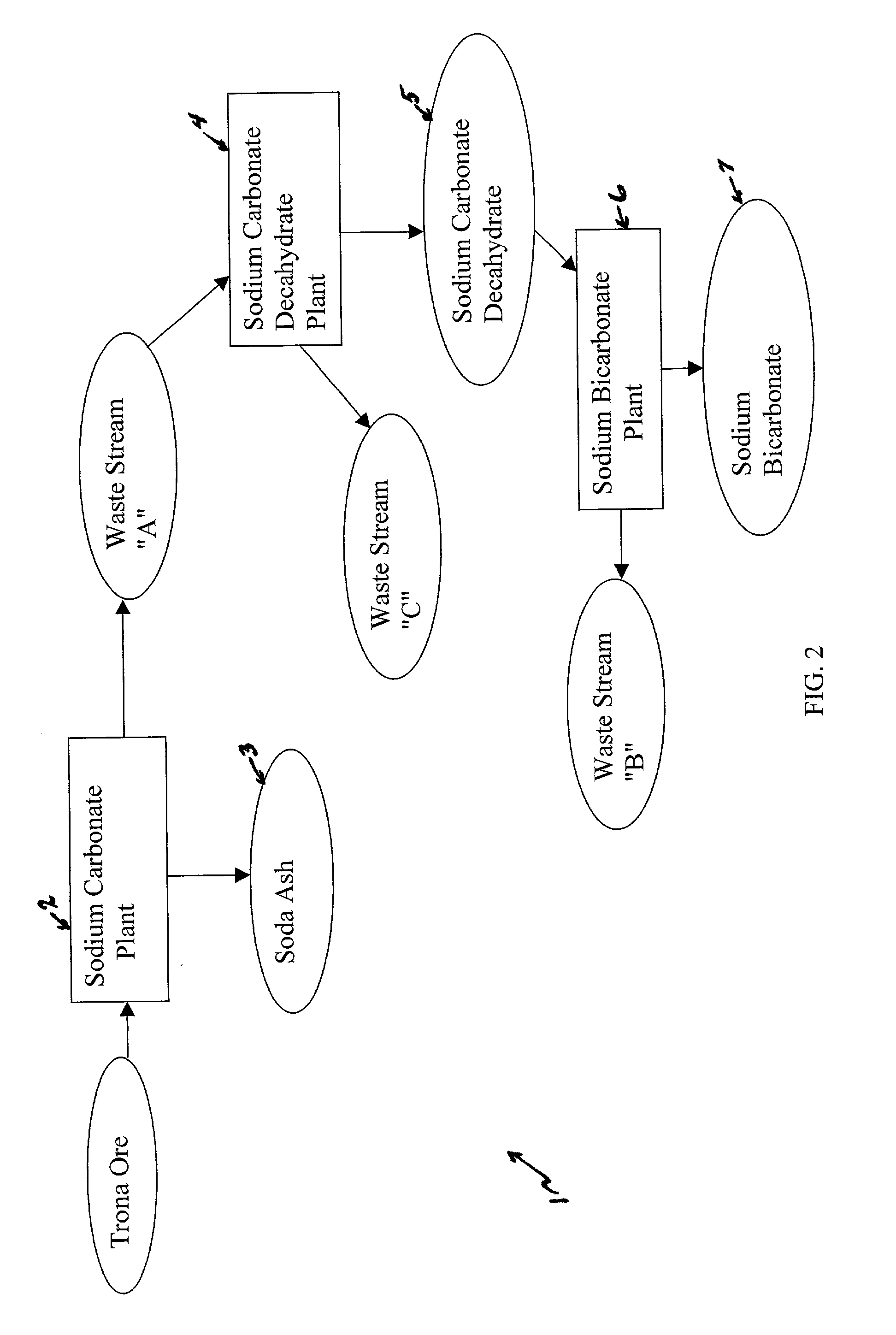

Sodium bicarbonate production method

InactiveUS20040057892A1Improvement in recovered sodium valuePromote recoveryBicarbonate preparationVarying alkali metal carbonate water contentWastewaterEngineering

A method of producing sodium bicarbonate having a high degree of purity and obtaining a net reduction in effluent waste water, as compared to prior processes, when starting from trona ore is disclosed. The process entails utilizing the waste-water effluent stream from the conversion of trona ore to sodium carbonate as the feed for the conversion of sodium carbonate to sodium bicarbonate.

Owner:CHURCH & DWIGHT CO INC

New process for co-producing ultra-fine white carbon black and calcium carbonate

InactiveCN101898776AAddress effectivenessImprove qualityCalcium/strontium/barium carbonatesSilicaPhysical chemistryCarbide

The invention provides a method for co-producing white carbon black and calcium carbonate. Carbide slag or lime and quartz sand are used as main raw materials. The method comprises the following steps of: introducing sodium silicate solution into carbon dioxide to obtain a mixture of white carbon black and sodium carbonate or sodium bicarbonate, filtering the solution, adding lime or carbide slag into the solution, preparing caustic soda and ultra-fine calcium carbonate by causticizing reaction, adding the quartz sand into the filtered dilute alkali liquor, and reacting the mixture under a heating band pressure to obtain sodium silicate solution so as to realize circulation and co-production.

Owner:BEIJING ZIGUANG YINGLI CHEM TECH CO LTD

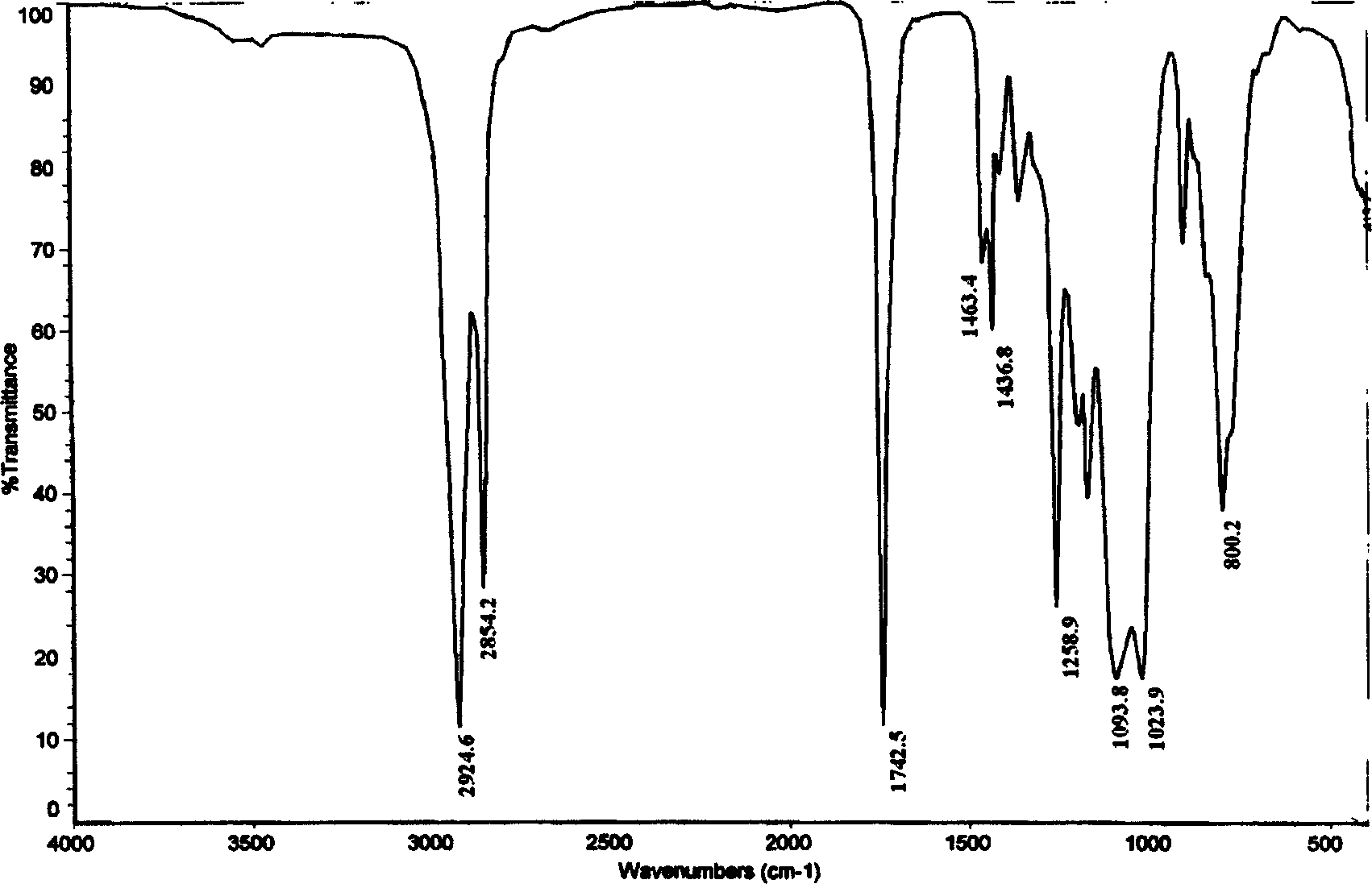

Preparation method for acidic silica sol in-situ modified acrylate emulsion

InactiveCN102604006AAvoid "secondary dispersion"Synthesis smoothlyCoatingsAcrylate esterSodium hydrogencarbonate

A preparation method for acidic silica sol in-situ modified acrylate emulsion includes the steps: firstly, diluting acidic silica sol with deionized water prior to adding small molecular alcohol, and then adding organo-siloxane with mixing to obtain modified acidic silica sol; then, utilizing the modified acidic silica sol, emulsifier, nuclear-layer monomers, deionized water and sodium bicarbonate to prepare seed pre-emulsion by means of pre-emulsification, adding the seed pre-emulsion into a reactor, heating up and adding initiator to initiate polymerization so that seed emulsion is prepared; and finally, adding emulsifier, shell monomers, initiator and deionized water into the reactor to prepare pre-emulsion by means of pre-emulsification, adding the pre-emulsion into the seed emulsion, replenishing initiator to hold, filtering after cooling to the normal temperature, and adjusting a pH (potential of hydrogen) value so that the modified acrylate emulsion is prepared. By the aid of the method, secondary dispersion of nano silica is avoided, stability of the emulsion is enhanced, and hardness, resistance to ultraviolet ageing and resistance to high temperature of an emulsion coating film are enhanced.

Owner:TAIYUAN UNIV OF TECH

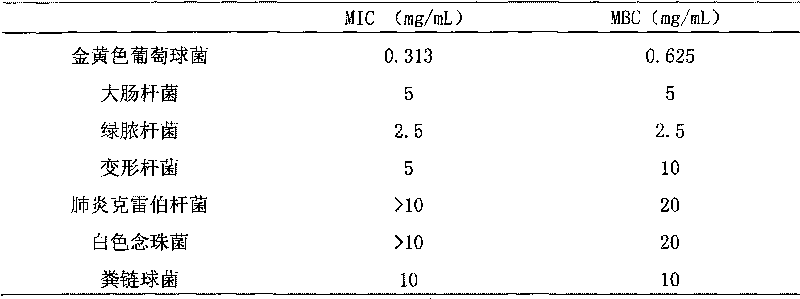

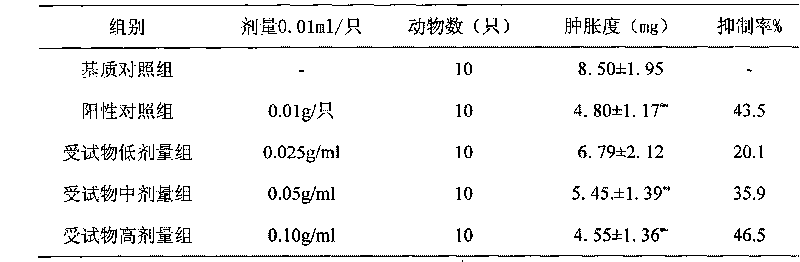

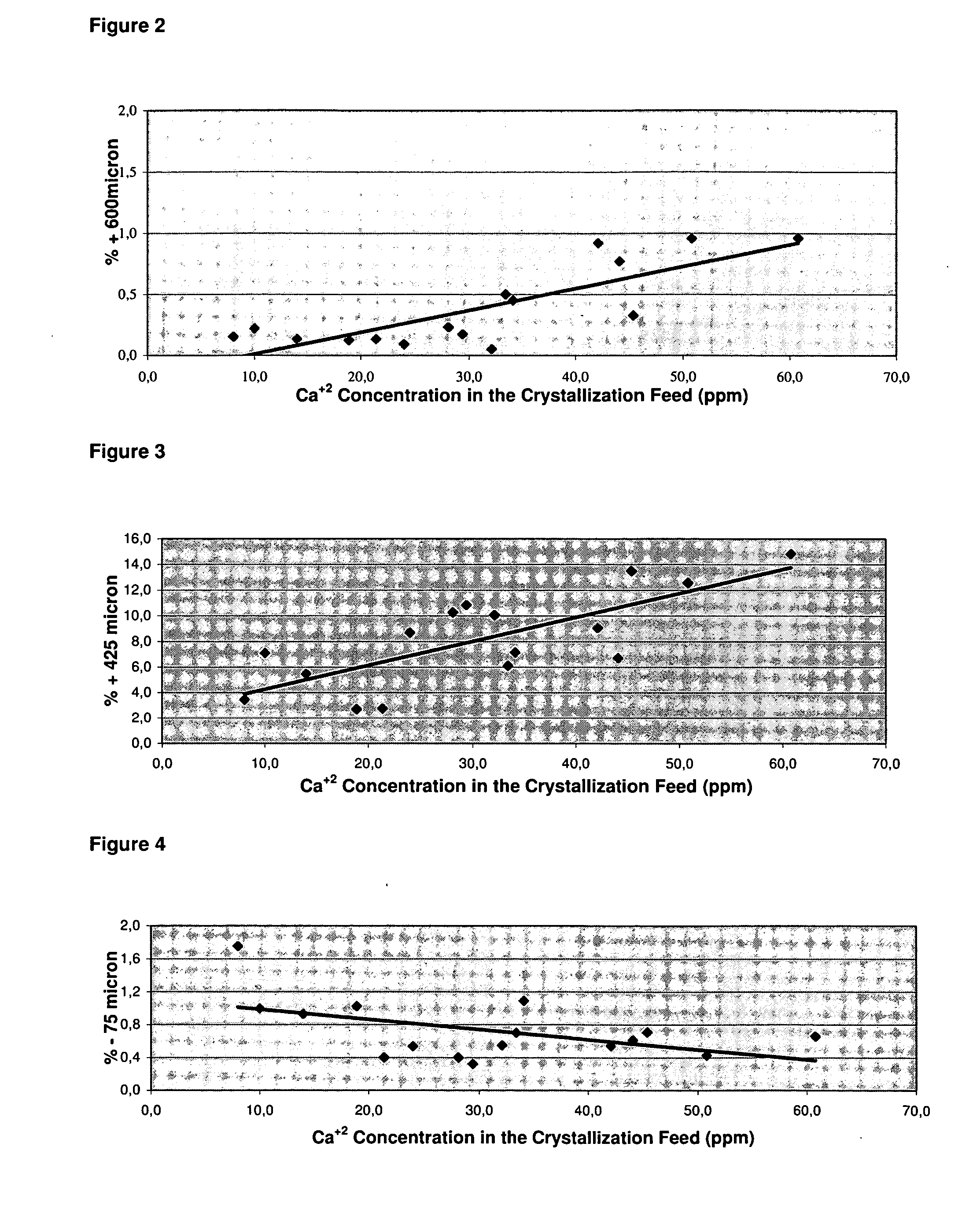

Pomegranate peel polyphenol antibiosis and antiphlogosis effervescent tablet as well as preparation method and application thereof

ActiveCN101700257AOvercome stabilityOvercoming patient carryAntibacterial agentsAntimycoticsSodium bicarbonateDisease

The invention relates to a pomegranate peel polyphenol antibiosis and antiphlogosis effervescent tablet as well as a preparation method and application thereof. The effervescent tablet is mainly prepared by raw material of pomegranate peel polyphenol, and auxiliary materials of sodium hydrogen carbonate, citric acid or tartaric acid, lactose, polyvinylpyrrolidone, magnesium stearate and superfine silica powder, has the functions of clearing heat, eliminating dampness, killing bugs and stopping itching, has strong suppression effect to women vagina pathogenic bacteria, features high safety, good stability, no obvious toxic or side effect, or drug tolerance, and provides convenience in using, carrying and storing for patients, is used for curing such diseases as vaginitis, vulvitis and the like caused by various trichomonad, epiphyte and bacteria, and can be used as preventability medicine for long-term use.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Sewage treating micro algae apparatus and process

InactiveCN101066807ALess investmentLow costBiological water/sewage treatmentSodium bicarbonateMagnesium salt

The present invention belongs to the field of environment protecting technology, and is especially sewage treating micro algae apparatus and process with high photosynthesis efficiency, high sewage treating efficiency and short sewage treating period. The sewage treating micro algae apparatus includes culture medium comprising carbon source of sodium carbonate, sodium bicarbonate, carbonic acid, CO2 or their mixture; nitrogen source of inorganic and / or organic nitrogen compound; phosphorus source of inorganic and / or organic iron compound; and inorganic salt selected from sodium salt, potassium salt, magnesium salt, etc. The present invention is used mainly for sewage treatment.

Owner:天津禄升海洋生物科技有限公司

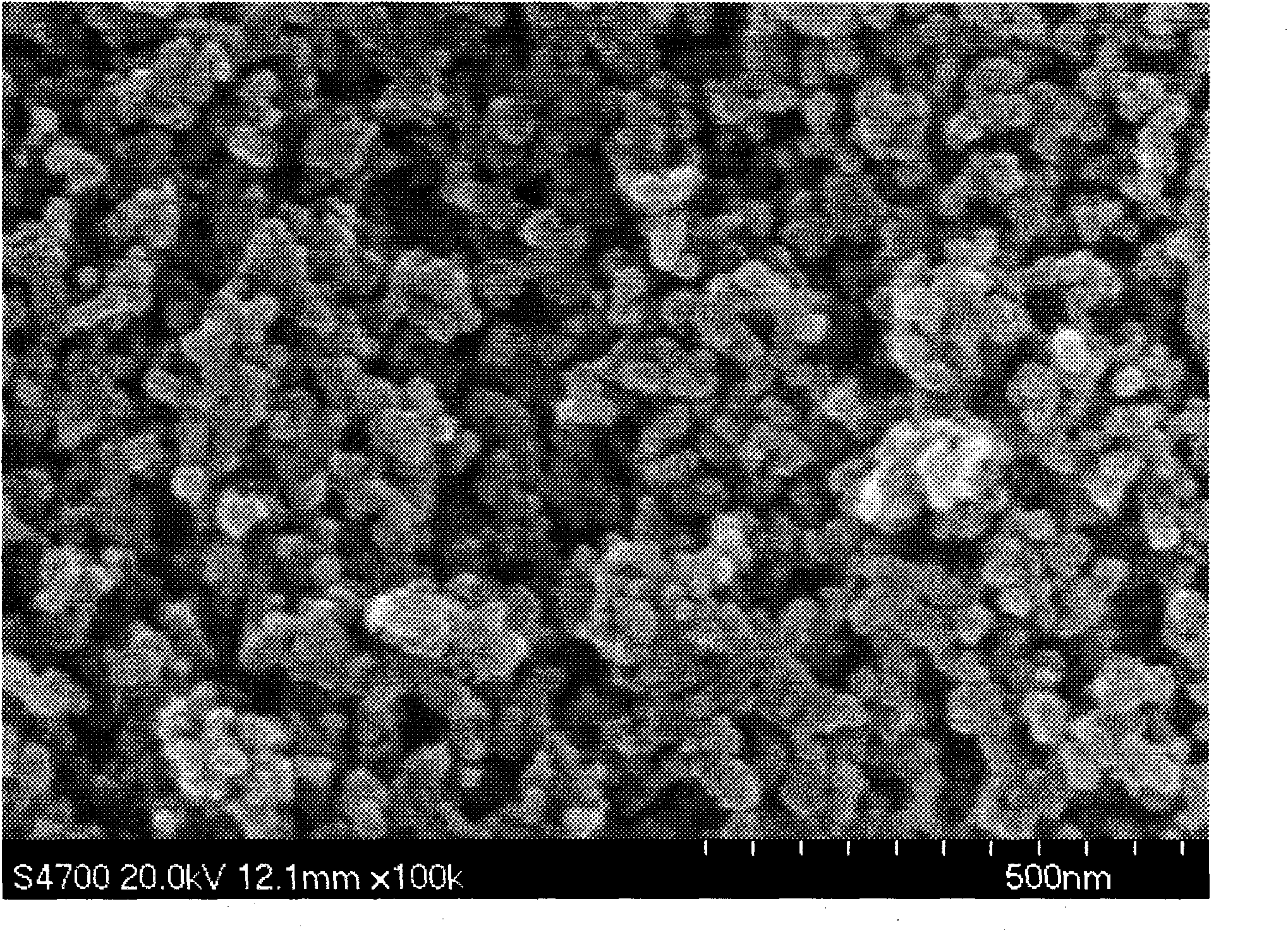

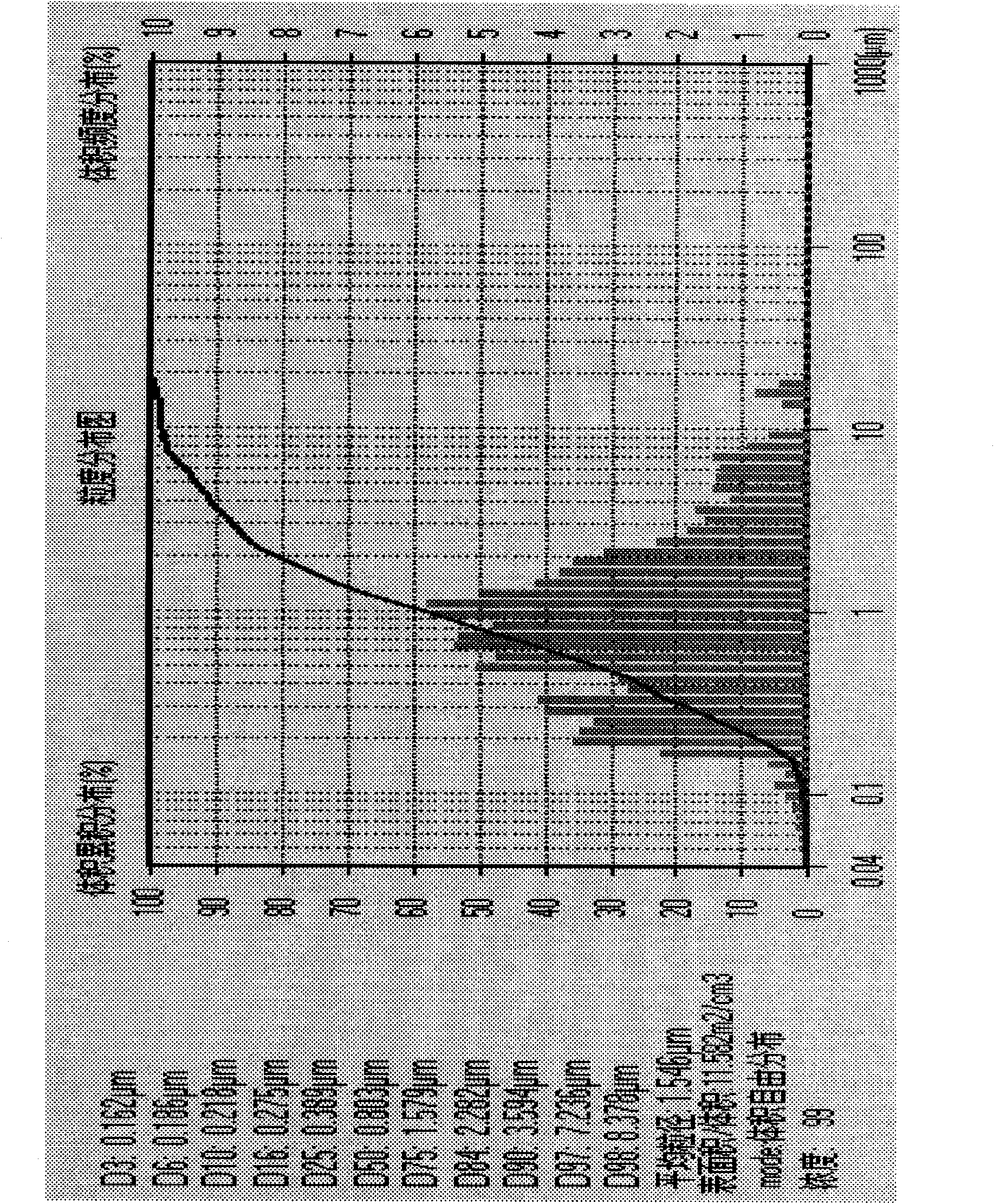

Preparation method of nano alumina material

The present invention relates to a nano alumina material, and its production method includes the following steps: using sodium aluminate and sodium hydrogen carbonate solutions to make them directly implement reaction, then filtering, dispersing, washing and adding acid to make beat-dispersion and ageing to obtain the transparent sol for preparing nano alumina material, and using said sol to directly produce nano alumina powder or nano alumina ceramic filter membrane.

Owner:SHANGHAI UNIV

Solid bath salt and the preparing method thereof

InactiveCN101061991APromote circulationGood curative effectCosmetic preparationsToilet preparationsSodium bicarbonateVitamin C

The invention discloses a solid bathing salt for washing, which comprises the following steps: allocating 50-70% baking soda, 12-18% salt cake, 7-8% common salt, 12-18% waterless citric acid, 0. 1-0. 3% vitamin E, 0. 5-1. 5% vitamin C and 0. 25-0. 4% essence; mixing evenly; pressing to each solid state shape; putting into water; dissolving swiftly; generating a great of carbon dioxide gas; dissolving into water; accelerating Na+, HCOH3, SO4-2, vitamin E, vitamin C and essence disperse into water; forming many nutritious component and chemical element. This invention possesses function of blood circulation acceleration, which can generate a great of nutritious components.

Owner:义乌市庆鹏化妆品有限公司

LDPE fishing net filament

InactiveCN103739907AWidely producedConjugated synthetic polymer artificial filamentsArtifical filament manufacturePhosphorous acidWear resistant

The invention relates to an LDPE (low-density polyethylene) fishing net filament, which comprises, by mass, 100 parts of LDPE; 0.3-0.5 part of UV-531; 0.3-0.5 part of DLTP; 0.3-0.5 part of zinc stearate; 0.5-1 part of barium stearate; 0.2-0.5 part of a light stabilizer; 10-15 parts of polybutadiene; 1-3 parts of carbon black; 5-10 parts of sodium hydrogen carbonate; 20-40 parts of butyl rubber; 20-40 parts of CPE; 2-3 parts of dibasic lead phosphite; and 25-45 parts of EVA. The product can tolerate a high temperature of 150-160DEG C and a low temperature of -30DEG C, has tensile strength of 10-20MPa, tensile elongation of 400-600%, and knot strength of 1.5-2MPa. Being light-fast and wear resistant, the product can be widely produced and be used for replacing existing materials continuously.

Owner:WUJIANG DONGXIN PLASTIC PACKAGING PLANT

Process for production of dense soda, light soda, sodium bicarbonate and sodium silicate from solutions containing bicarbonate

ActiveUS20060182675A1High processing flexibilityReduce product costBicarbonate preparationCrystallization separationBicarbonateSodium silicate

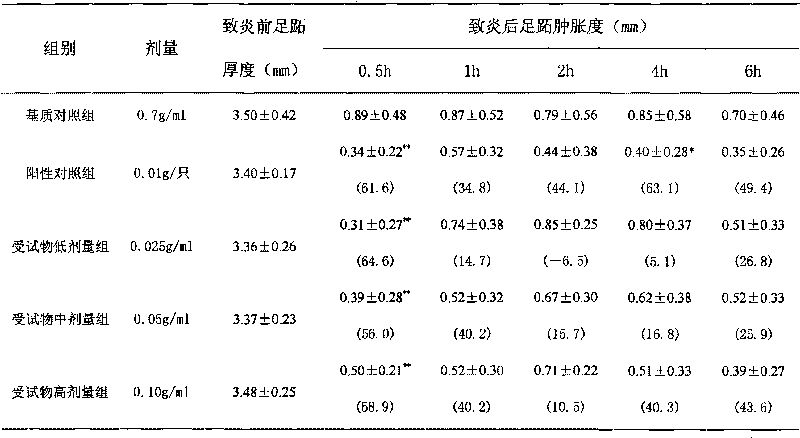

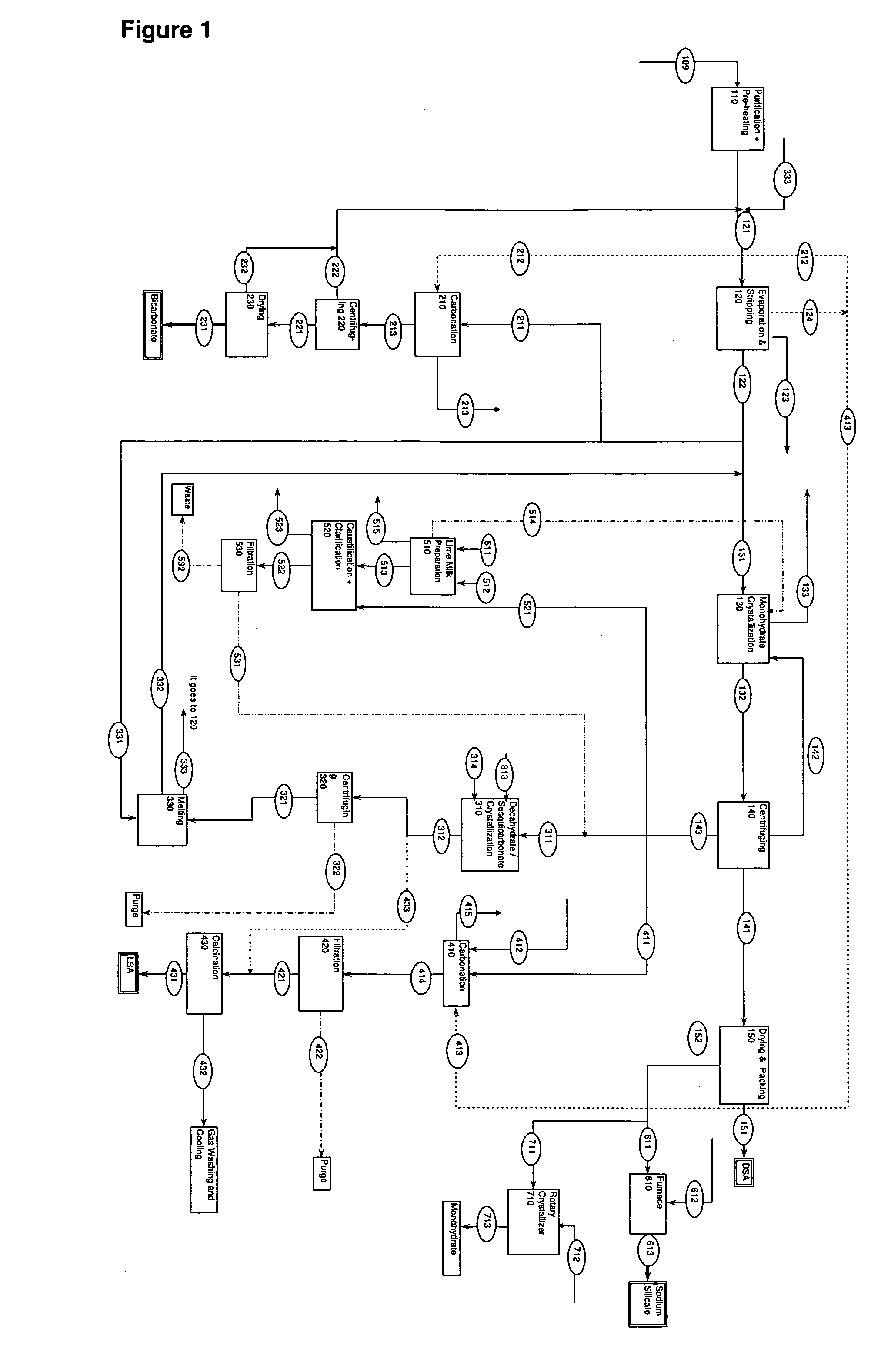

A process related to sodium chemicals production, including the processing of bicarbonate containing solutions obtained by solution mining of trona, nahcolite or wegscheiderite reserves and the lake waters containing bicarbonates, includes the steps of purification, evaporation-decarbonation, crystallization, centrifuging, and drying.

Owner:ETI SODA URETIM PAZARLAMA NAKLIYAT & ELEKTRIK URETIM SANAYI & TICARET A S

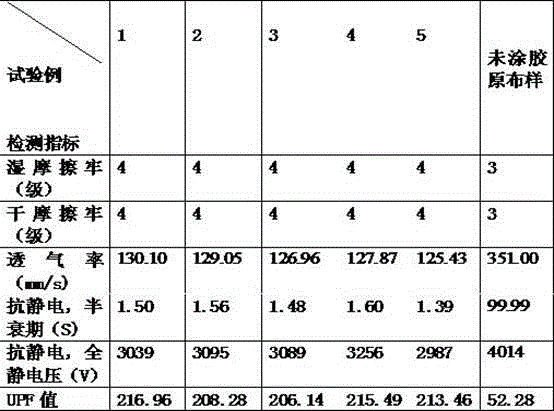

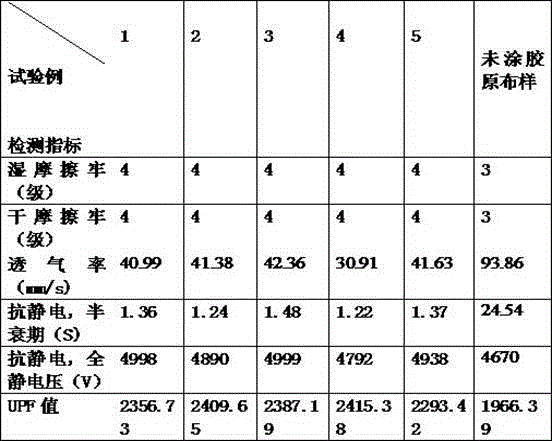

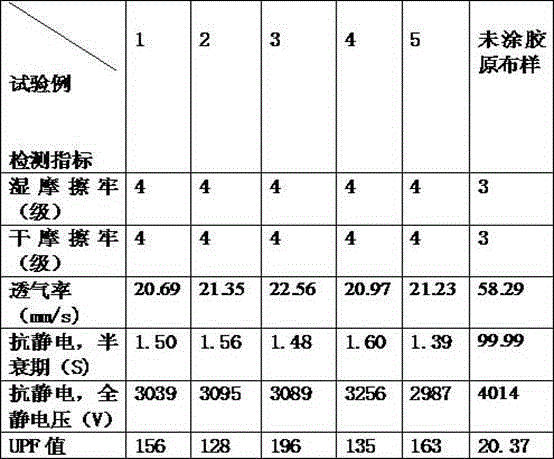

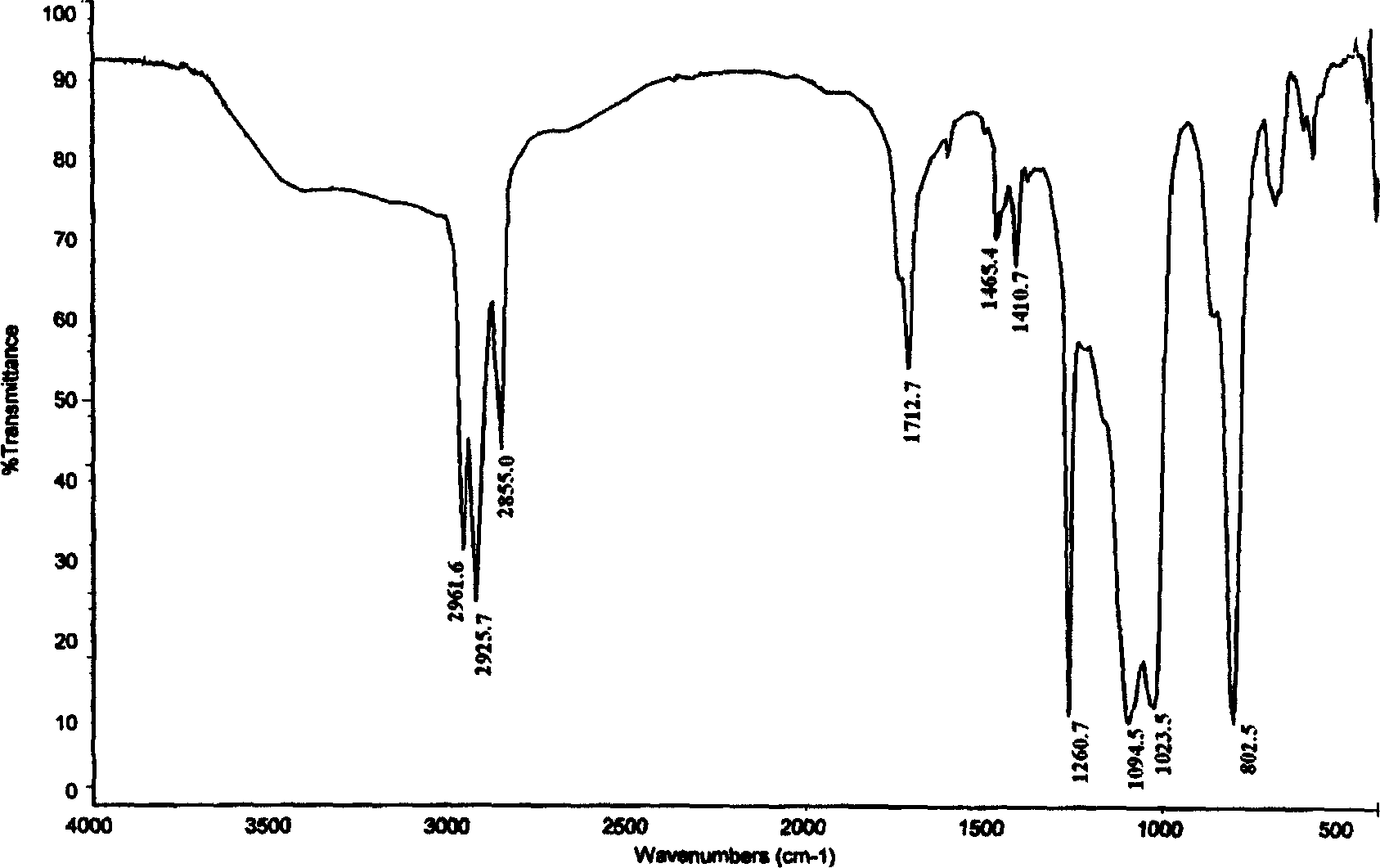

Breathable ultraviolet-resistant anti-static polyurethane resin coating adhesive and preparation method thereof

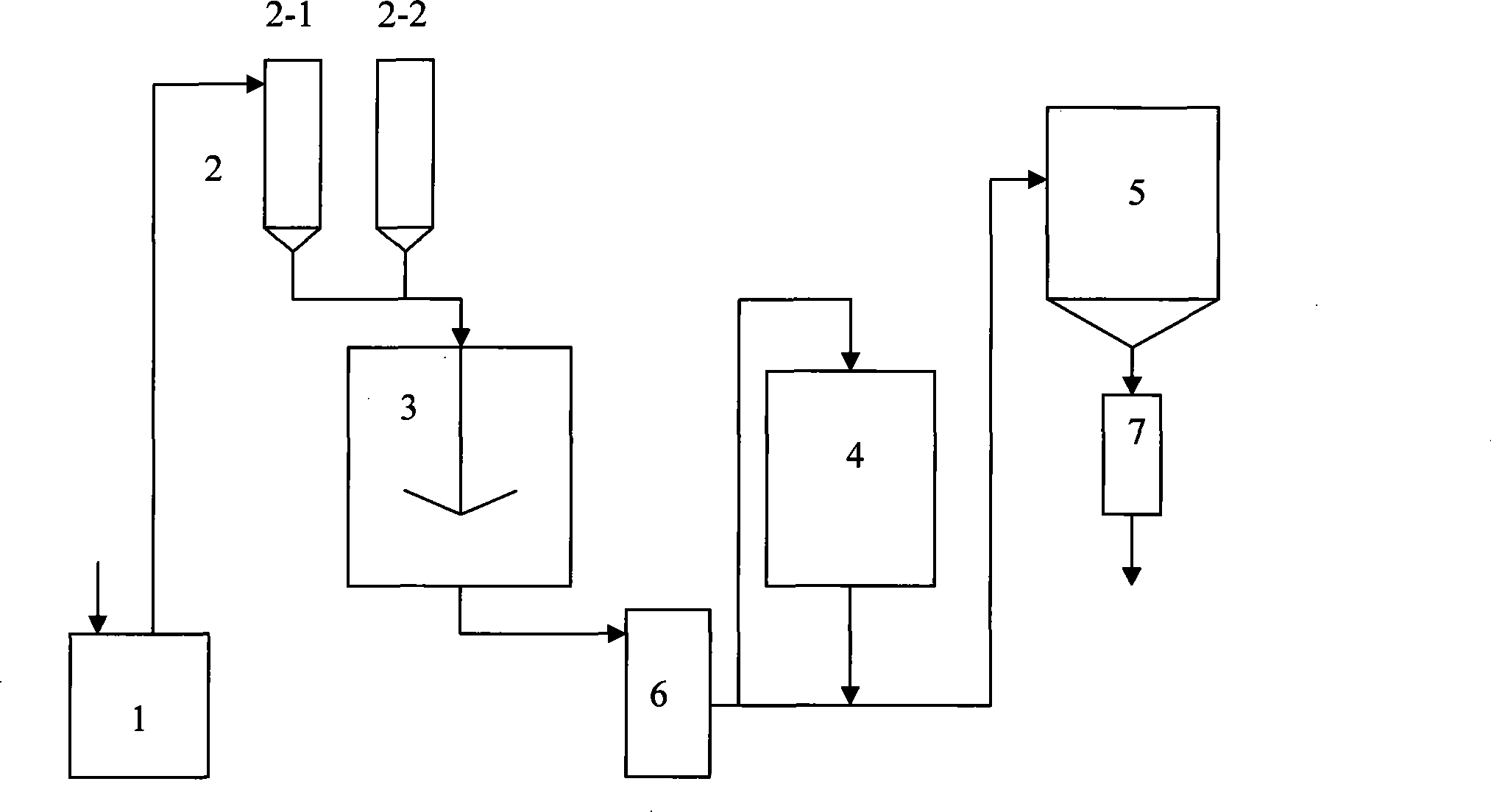

The invention is a breathable ultraviolet-resistant anti-static polyurethane resin coating adhesive and a preparation method thereof. The breathable ultraviolet-resistant anti-static polyurethane resin coating adhesive is prepared by compounding water-based breathable anti-static polyurethane resin, a blocked polyurethane crosslinking agent, nano zinc oxide and a thickening agent, wherein the water-based breathable anti-static polyurethane resin is prepared from components A, the blocked polyurethane crosslinking agent is prepared from components B, the components A comprise 50-200 parts of polyoxyethylene ether glycol, 50-200 parts of polyoxypropylene ether glycol, 1-5 parts of trimethylolpropane, 40-200 parts of polyisocyanate, 3-10 parts of a chain extender, 0.02-0.06 part of a catalyst, 30-60 parts of a solvent, 3-10 parts of sodium hydrogen carbonate, 3-10 parts of sodium hydrogen sulfite and 500-1,500 parts of deionized water, and the components B comprise 100-200 parts of 1.6-hexylidene diisocyanate trimer, 42-92 parts of acetone oxime or methyl ethyl methyl ethyl ketoxime, 0.02-0.06 part of a catalyst, 400-900 parts of a solvent and 30-80 parts of an ultraviolet-resistant additive. The breathable ultraviolet-resistant anti-static polyurethane resin coating adhesive has excellent air permeability, ultraviolet resistance and static resistance and has good dry and wet rubbing fastness.

Owner:LIAONING FIXED STAR FINE CHEM

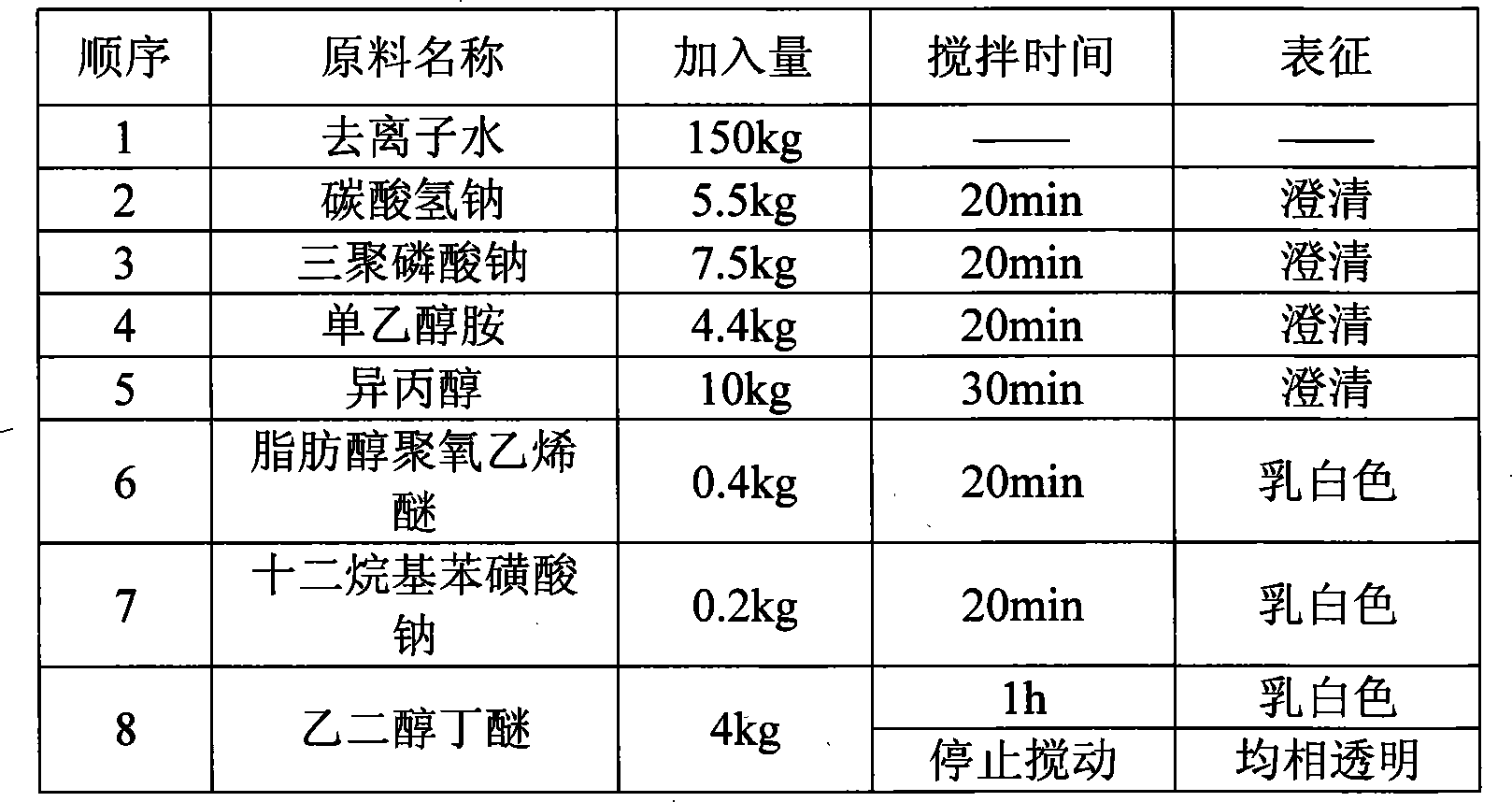

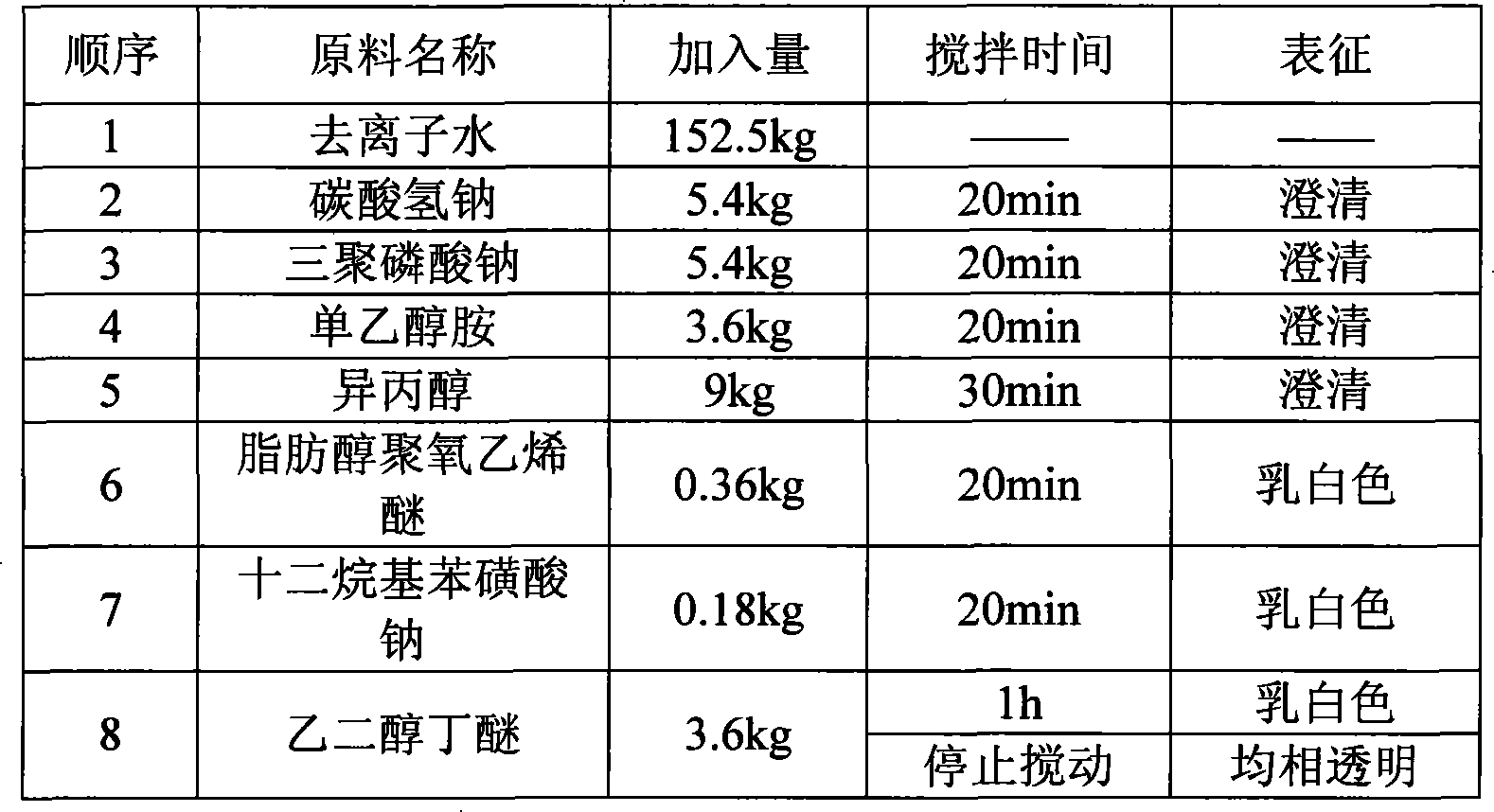

Electro-conductive glass substrate cleaning agent and preparation method thereof

InactiveCN101250465ASystem stabilityLower pHInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsSolubilityCleansing Agents

The invention discloses an electro-conductive glass base plate cleaning agent, which is formed by components with the following percentage by weight, baking soda 3-5%, sodium tripolyphosphate 3-5%, monoethanolamine 2-4%, isopropyl alcohol 5-10%, alkyl alcohol polyoxyethylene ether 0.2-0.4%, sodium dodecylbenzene sulfonate 0.1-0.5%, ethylene glycol monobutyl ether 2-5% and the rest is water. The process for preparation comprises the following steps: adding the above raw materials into an emulsion tank in turn, and then preparing the cleaning agent after mixing, homogenizing, cooling, exhausting and filtering. The electro-conductive glass base plate cleaning agent of the invention has low pH value, when in use, the electro-conductive glass base plate cleaning agent has microvesicle or has no bubbles, which has strong water solubility, the surface of glass has no residues and particulate matters after cleaning. The cleaning agent has excellent cleanness, nontoxic, nonirritant and easy biodegradation, which is easy to discharge and process discard solution. And the cleaning agent has the advantages of simple process for preparation, high yield, only little deposition and residue, low power consumption, convenient process and operation, easy automation, no environmental contamination and high economic benefit.

Owner:曹学增

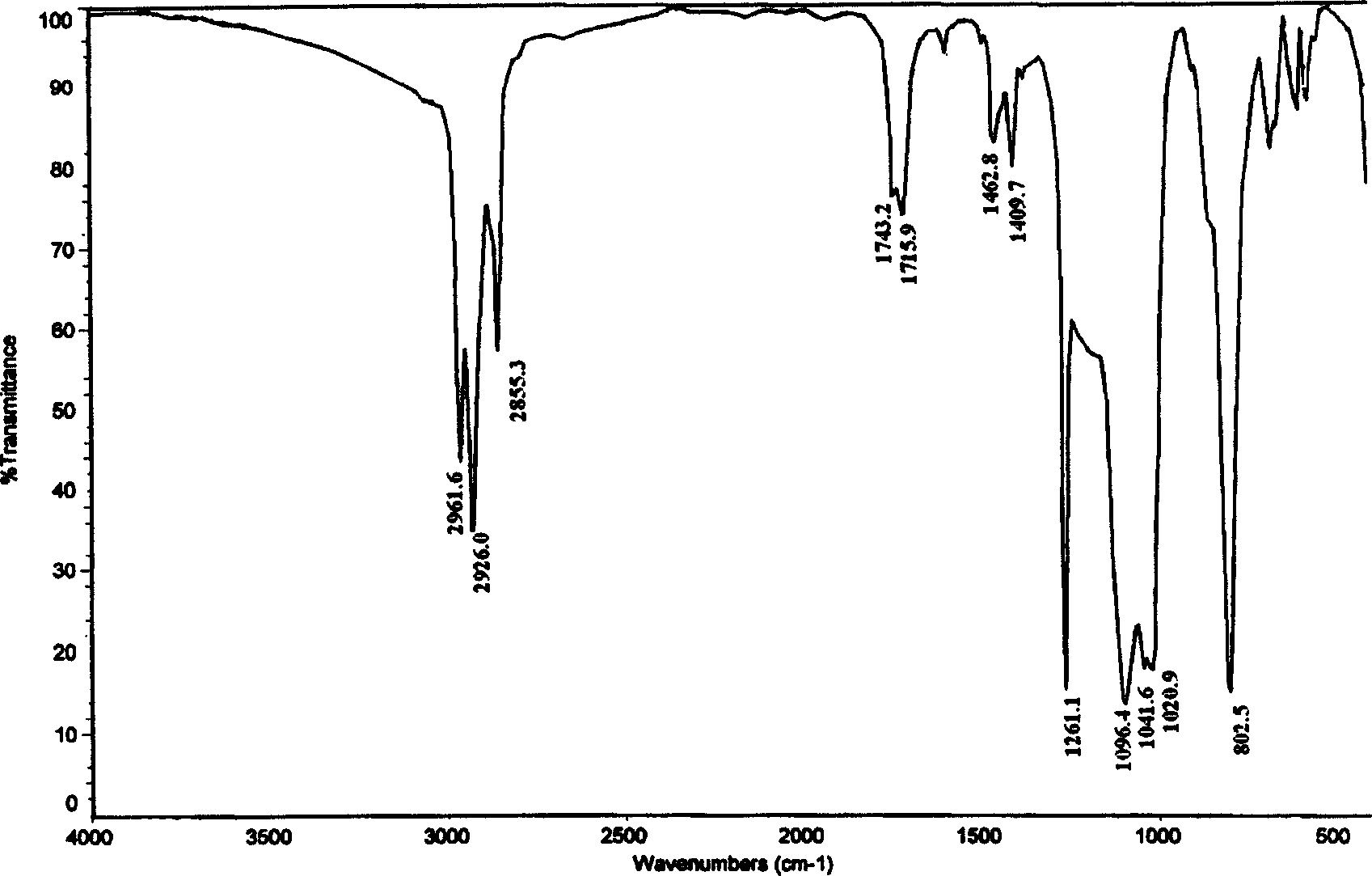

Preparation of carboxy silicon oil emulsion

Carboxy silicone latex emulsion is produced by: reacting the mixture of the ester group modified silicone oil, small molecular oxosilance, emulsifier, accelerating agent-dodecyl benzene sulflnic acid and water at 70-95deg.C for 5-15 hours, neutralizing by adding the sodium acid carbonate after the reactor is cooled. Its composition comprises (wt%): the use level of the ester group modified silicone oil and small molecular oxosilance is controlled by the termination product that the chain joint of organic silicon which contains carboxy has the 0.5-30% of all chain joint of organic silicon, 0.1-10% of the emolsifier, and 3-30% of the accelerating agent -dodecyl benzene sulflnic acid. It features: hydrolyzing of the ester group and polymerizing of oxosilance generate at the same time. Through the adjustment of the use level of dodecyl benzene sulflnic acid and non-ionic emolsifier, the grain size of the carboxy silicone oil latex emulsion can be modified, even the micro-latex emulsion will generate.

Owner:NANJING UNIV

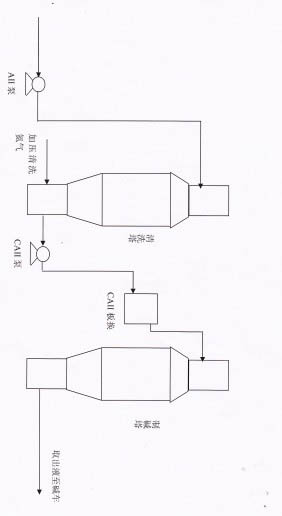

Method for preparing sodium carbonate by supplementing CO2 to flue gas

ActiveCN103588226AReduce investmentReduce power consumptionCarbonate preparationFlue gasCarbonization

The invention discloses a method for preparing sodium carbonate by supplementing CO2 to flue gas. The method comprises the following steps: carrying out de-dusting, desulfurizing and cooling on CO2-containing flue gas, increasing the pressure to be 0.05-0.35 MPa, directly filling the flue gas into the middle and the upper part of a sodium carbonate preparation carbonizing tower, producing a carbonation reaction, enabling a reaction product to continue to pass through the lower section of the carbonizing tower to finish the carbonation reaction with high-concentration CO2-containing gas to obtain sodium hydrogen carbonate, and calcining sodium hydrogen carbonate to obtain sodium carbonate. According to the method, during sodium carbonate production, the problem of CO2 deficiency is successfully solved, the equipment investment and the power consumption are greatly reduced, the CO2 emission is reduced, the utilization rate of sodium chloride is high, both the energy consumption and the cost are low, and the economic feasibility is high.

Owner:CHINA CHENGDA ENG

Wear-resistant ceramic material and preparation method thereof

The invention discloses a wear-resistant ceramic material and a preparation method thereof. The wear-resistant ceramic material comprises the following components in parts by weight: 65-70 parts of nano aluminum oxide, 10-15 parts of magnesium carbonate, 10-12 parts of kaolin, 5-12 parts of titanium diboride fibers, 5-8 parts of silicon carbide, 3-5 parts of sodium hydrogen carbonate, 5-7 parts of antimonous oxide and 3-5 parts of red mud. The invention further provides a preparation method of the wear-resistant ceramic material. The preparation method comprises the following steps: (1) weighing 10-15 parts of magnesium carbonate, 10-12 parts of kaolin, 5-12 parts of titanium diboride fibers, 5-8 parts of silicon carbide, 3-5 parts of sodium hydrogen carbonate, 5-7 parts of antimonous oxide and 3-5 parts of red mud and adding all the components into a high pressure homogenizer and uniformly mixing; (2) adding 65-70 parts of fully ball-milled nano aluminum oxide under an inertial atmosphere into the product obtained in the step (1), and raising the temperature to 700-710 DEG C to react for 1-2 hours; and (3) compressing and molding the product obtained in the step (2), heating to 1300-1350 DEG C at a temperature raising speed of 5 DEG C / minute, firing, insulating fro 2-4 hours, and cooling to obtain the wear-resistant ceramic material.

Owner:WUJIANG JIA BILLION ELECTRONICS TECH

Composite foamable agent and its preparation method

ActiveCN1907552AImproved dispersion and fluidityImprove liquidityTransportation and packagingMixingBicarbonateSodium bicarbonate

The invention relates to a composites foaming agent, which comprises inorganic foaming agent as bicarbonate and molecule screen, while the amount of molecule screen is 0.5-50 deals when the bicarbonate is 100 deals, wherein the bicarbonate can use baking soda, potassium acid carbonate, or ammonium acid carbonate or the mixture of them; and the preparation comprises: selecting the bicarbonate; breaking with machine or airflow; then mixing the inorganic foaming agent with molecule screen in the mixer; the invention has the advantages that: 1, it has better flow property and disperse property; it can effectively increase the foaming time and the contract rate of product; 3, it can foam the macromolecule polymer that sensitive to water; 4, the added macromolecule screen will not affect the property of macromolecule polymer.

Owner:HANGZHOU HI TECH FINE CHEM

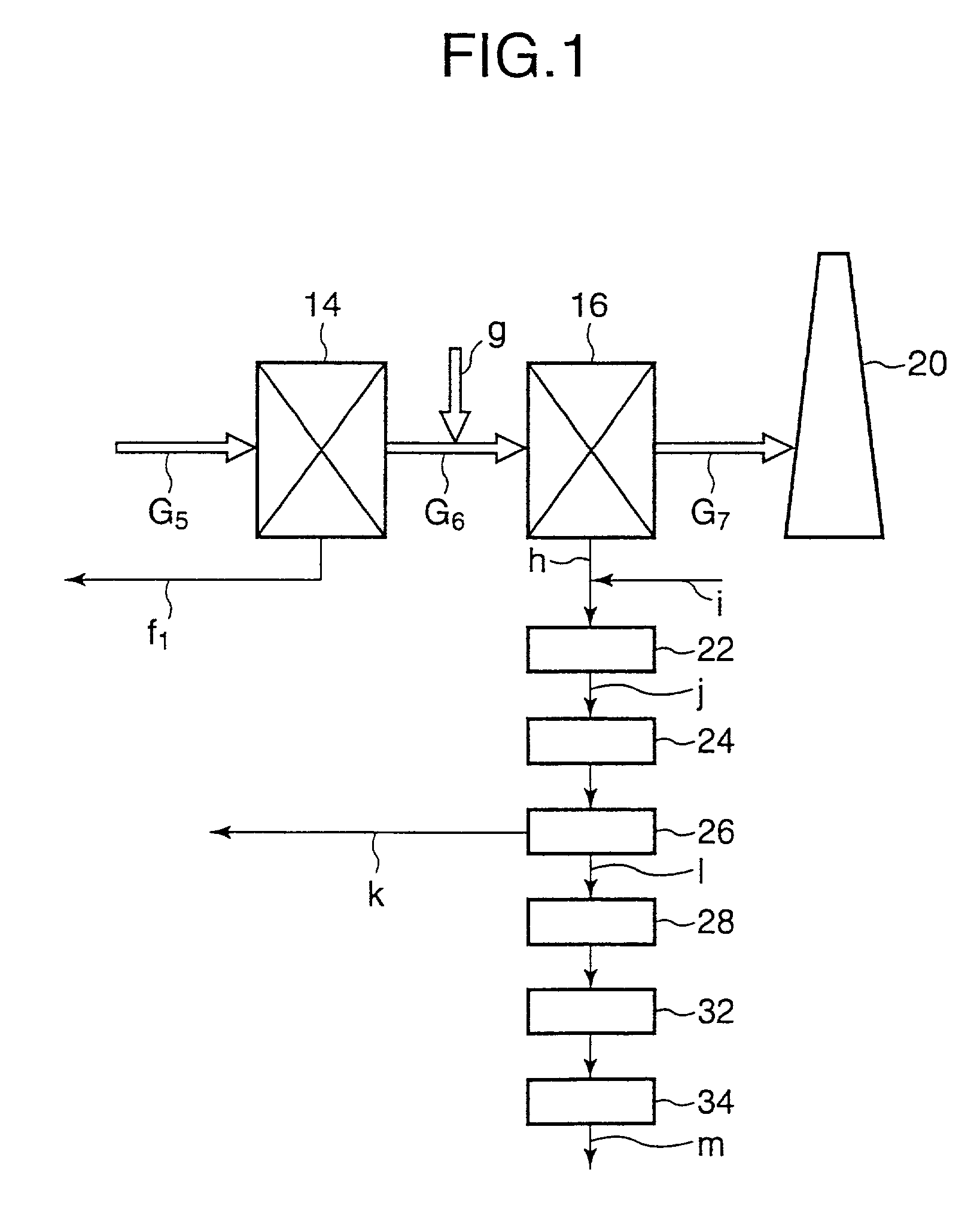

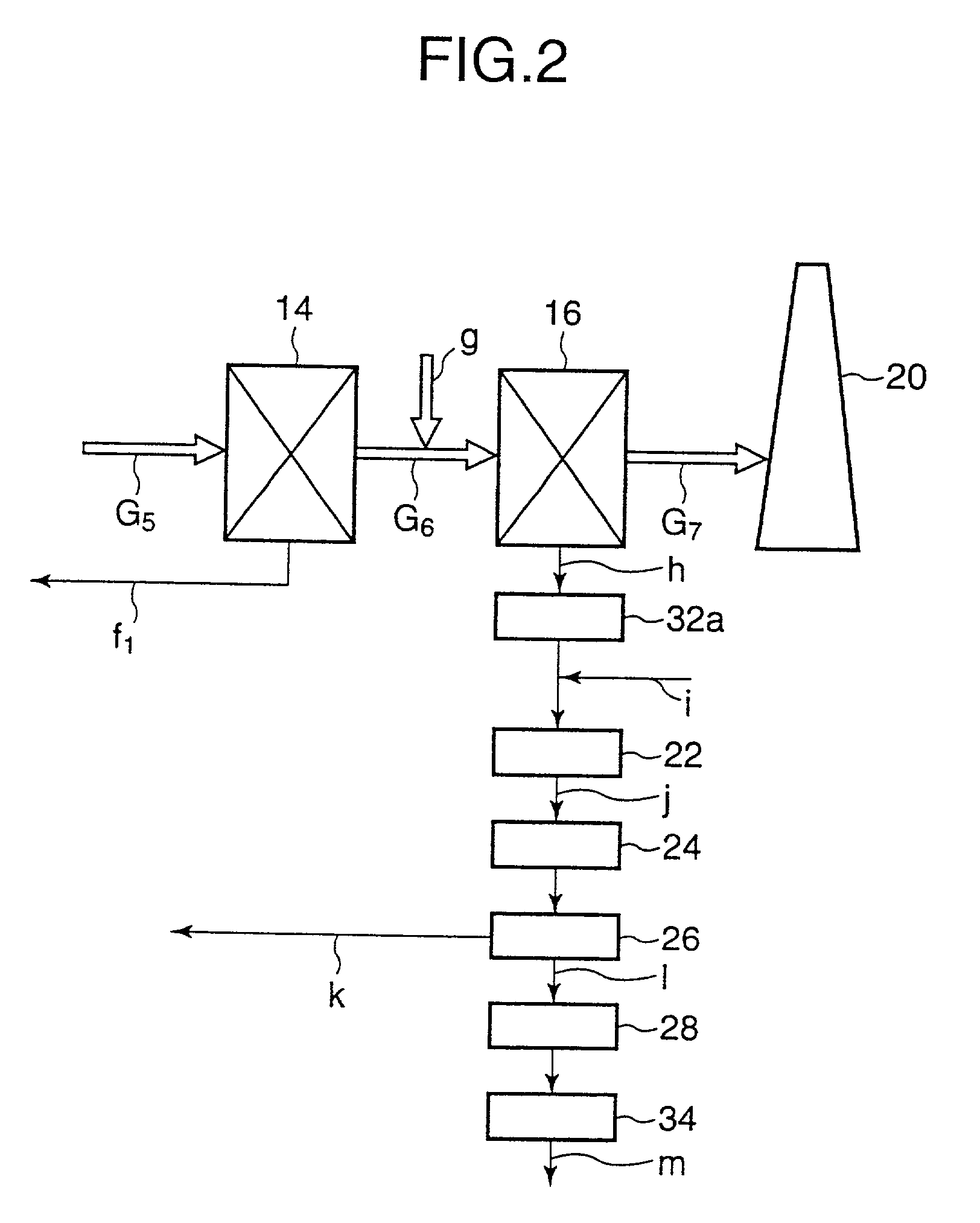

Sodium-based dechlorinating agent and waste treatment equipment

Owner:MITSUI ENG & SHIPBUILD CO LTD +1

Preparation method for high-purity esomeprazole sodium

ActiveCN103288801ASolve the prone to titanium complex suspensionSolve the difficulty of splittingOrganic chemistrySodium bicarbonateOmeprazole Sodium

The invention discloses a preparation method for high-purity esomeprazole sodium. The preparation method comprises the steps of: including and splitting esomeprazole sodium and D-(-)-diethyl tartrate, titanium iso-propylate, triethylamine and L-(+)-mandelic acid in the presence of a proper amount of water, and separating to obtain an inclusion complex; dissolving the inclusion complex with ethyl acetate, washing inclusion complex with sodium carbonate water solution, carrying out ammonia hydroxide eluting on an ethyl acetate layer, slowly regulating the pH value to 6-7 with glacial acetic acid, then extracting with dichloromethane, and concentrating to obtain crude esomeprazole free alkali product; carrying out silica gel adsorption and elution on the crude product to obtain a pure esomeprazole free alkali product; and enabling the pure product and the methanol-ethanol-acetonitrile solution of sodium hydroxide to form salt, and then crystallizing with isopropyl ether to obtain the high-purity esomeprazole sodium. According to the preparation method, the difficulties that when inclusion and splitting are carried out, the titanium complex suspension body are difficult to split and the ammonia complex of titanium is difficult to remove can be solved, the industrialization production can be realized, the industrialized production cost is low, the product purity is high, the yield is high, and no harmful gas is generated.

Owner:SICHUAN BAILI PHARM CO LTD

Blowing agent

InactiveUS20150267024A1Easy to processEasy to prepareOther chemical processesMixing methodsSodium bicarbonateHydrogen

The present invention relates to a new composition comprising 4,4′-oxybis(benzenesulfonylhydrazide) (OBSH) and sodium hydrogen carbonate (SBC), a process for the manufacturing thereof, and its use as blowing agent for the manufacturing of expanded thermoplastic materials and rubber compounds.

Owner:LANXESS LTD

Antibacterial PVC wood plastic plate and preparation method thereof

InactiveCN105038010AImprove impact resistanceImprove tensile propertiesSodium bicarbonateMicrocrystalline wax

The invention discloses an antibacterial PVC wood plastic plate. The antibacterial PVC wood plastic plate is prepared from, by weight, 100 parts of PVC-1300, 20-30 parts of PVC-1000, 10-20 parts of C 9 petroleum resin, 40-50 parts of modified nano calcium carbonate, 6-8 parts of corn straw powder, 0.5-1 part of AC foaming agents, 0.3-0.6 part of sodium bicarbonate, 1-3 parts of calcium and zinc stabilizers, 2-3 parts of silane coupling agents KH550, 2-3 parts of ACR, 0.2-0.5 part of microcrystalline wax, 0.2-0.5 part of stearic acid, 3-4 parts of PVC foaming regulators ZB-530, 4-5 parts of molybdenum oxide, 0.5-1.0 part of ammonium polyphosphate, 1-1.5 parts of zinc borate, 0.2-0.4 part of nanometer titanium dioxide and 3-4 parts of polyhexamethyleneguanidine phosphate. Extrusion shaping is performed through a conventional extruding machine. The PVC plate has good antibacterial performance, meanwhile has good impact resistance and tensile strength and has the advantages of being resistant to chemical corrosion and low in cost.

Owner:滁州远方车船装备工程有限公司

Method for preparing medicinal sterile sodium bicarbonate raw powder

InactiveCN101613119AQuality assuranceGuaranteed outputBicarbonate preparationSodium bicarbonateFiltration

The invention relates to a method for preparing medicinal sterile sodium bicarbonate raw powder, which comprises the following steps: (1) subjecting industrial sodium carbonate serving as a raw material to purification, dissolution in water, decarburization and membrane filtration; (2) introducing industrial carbon dioxide gas subjected to membrane treatment into solution of sterile sodium bicarbonate to carry out acidification, and controlling parameters such as flow rate, reaction time, terminal pH value and stirring speed; (3) adding ethanol liquid subjected to membrane treatment into solution in which reaction is finished to allow sodium bicarbonate crystals to precipitate gradually, adjusting stirring speed, and controlling crystallization time to allow the crystallization to be completed fully; and (4) filtering the solution by a crystal filter to obtain the product, and drying the product by using a vibratory drying machine to obtain a finished product that meets medicinal standards.

Owner:HARBIN PHARMA GRP CO LTD GENERAL PHARMA FACTORY

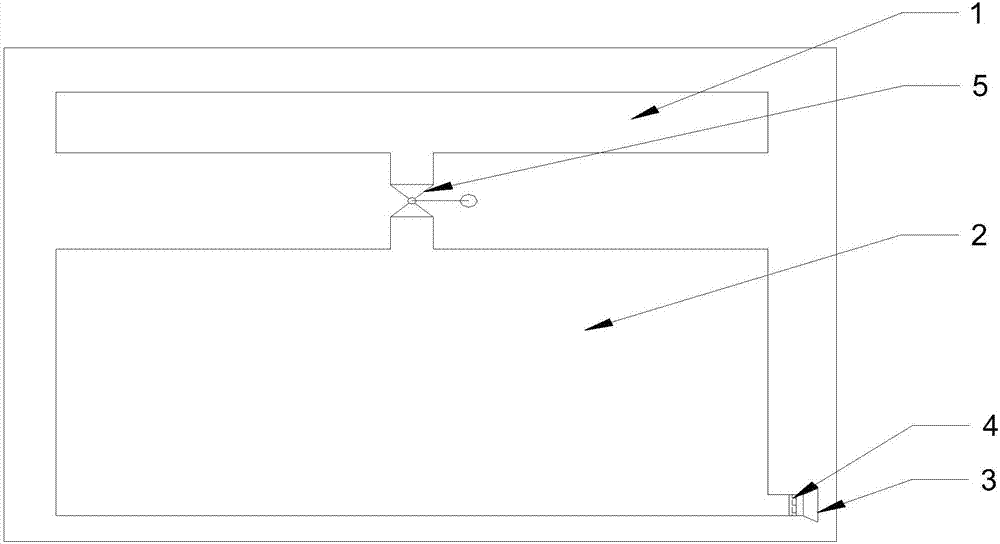

Domestic wall-mounted automatic chemical foam fire-fighting device

PendingCN107297044AGuarantee the safety of lifeEffective fire controlFire rescueChemical reactionAluminum sulphate

The invention discloses a domestic wall-mounted automatic chemical foam fire-fighting device. The domestic wall-mounted automatic chemical foam fire-fighting device comprises an upper container and a lower container, wherein the upper container and the lower container are filled with an aluminum sulfate solution and a sodium bicarbonate solution respectively; a plastic film is arranged between a nozzle and the lower container; the upper container is connected to the upper part of the lower container through a temperature sensing two-way valve. According to the device, the temperature sensing two-way valve is adopted as a starting device, and can be opened automatically when a fire occurs so that the upper container is communicated with the lower container, so that a chemical reaction occurs between the aluminum sulfate solution and the sodium bicarbonate solution, a carbon dioxide and foam mixed solution is automatically ejected, the effects of fire fighting and effective control of fire are reached, sufficient time is gained for fire rescue, and the life safety of users is guaranteed; moreover, the device is small in size and large in temperature selecting range, the device can be applicable to different sizes of spaces by adjusting the using amount of the mixed solution, full-automatic detection and action are adopted, and a fire-fighting function can be realized without the help of extra external force.

Owner:上海西良工程技术服务有限公司

Food fresh-keeping agent with function of oxygen absorption

The invention relates to a food fresh-keeping agent, in particular to a food fresh-keeping agent with the function of oxygen absorption. The food fresh-keeping agent is prepared from the following raw materials: 0.5-2 parts by weight of L-sodium ascorbate, 0.5-2 parts by weight of sodium hydrogen carbonate, 0.5-1 part by weight of zeolite, 1-10 parts by weight of ferrous sulfate (containing 7 kinds of crystal water), 1-3 parts by weight of sodium chloride (containing 2 kinds of crystal water) and 1-3 parts by weight of activated carbon. The food fresh-keeping agent has the advantages of scientific formula and simple preparation process and is suitable for keeping the fresh of breads, sausages, cakes, tea leaves, marine products, traditional Chinese medicine and the like. The food fresh-keeping agent is not directly doped in foods, is put in a food container together with a packing material, and can inhibit oxygen below 0.1% so as to inhibit the growth of bacteria without changing the color and the flavor of the foods. The food fresh-keeping agent is a safer food fresh-keeping agent.

Owner:冀登昌

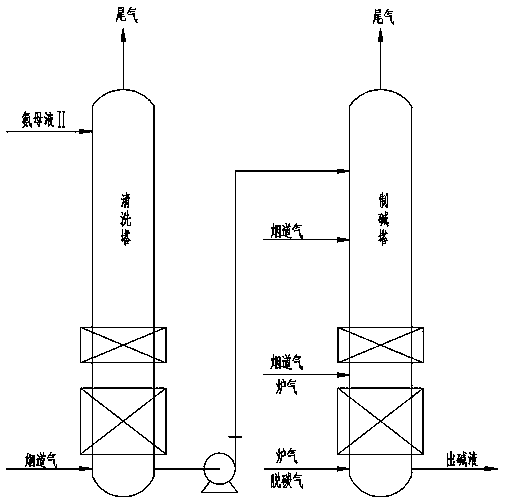

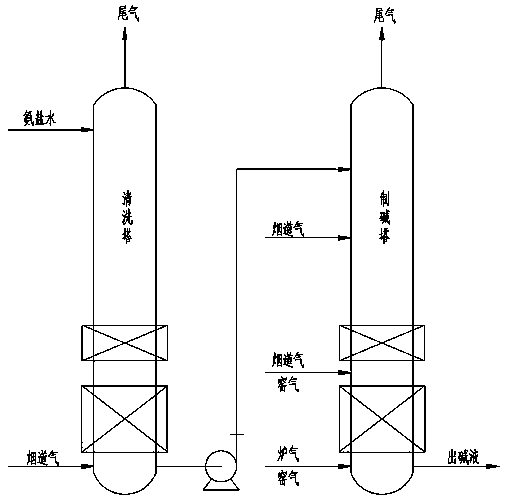

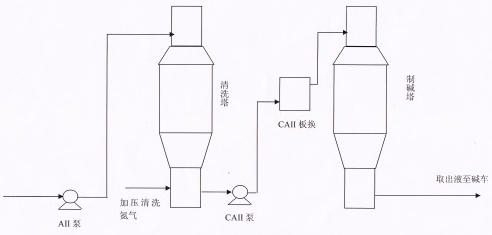

Carbonization cleaning process of carbonizer for producing heavy soda ash

InactiveCN102432041AImprove the degree of carbonization conversionRaise the temperature of IICarbonate preparationCooling towerCarbonization

Owner:SICHUAN HEBANG

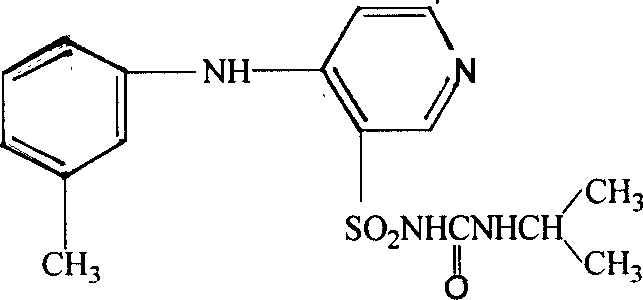

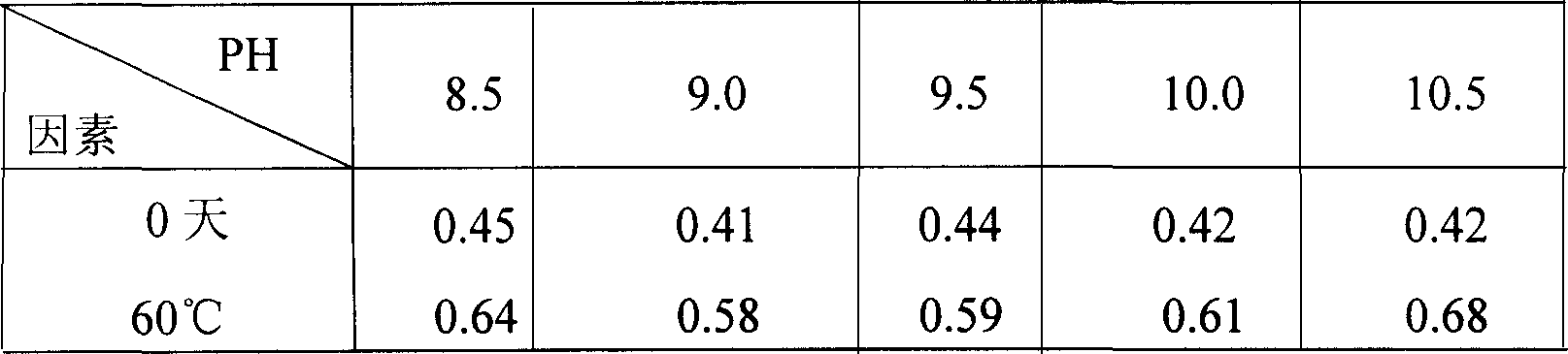

Torasemide freeze-drying preparation and prepn. method

A freeze-dried composition of torasemide features that it contains sodium hydrogen carbonate for higher solubility. Its preparing process is also disclosed.

Owner:南京海辰药业股份有限公司

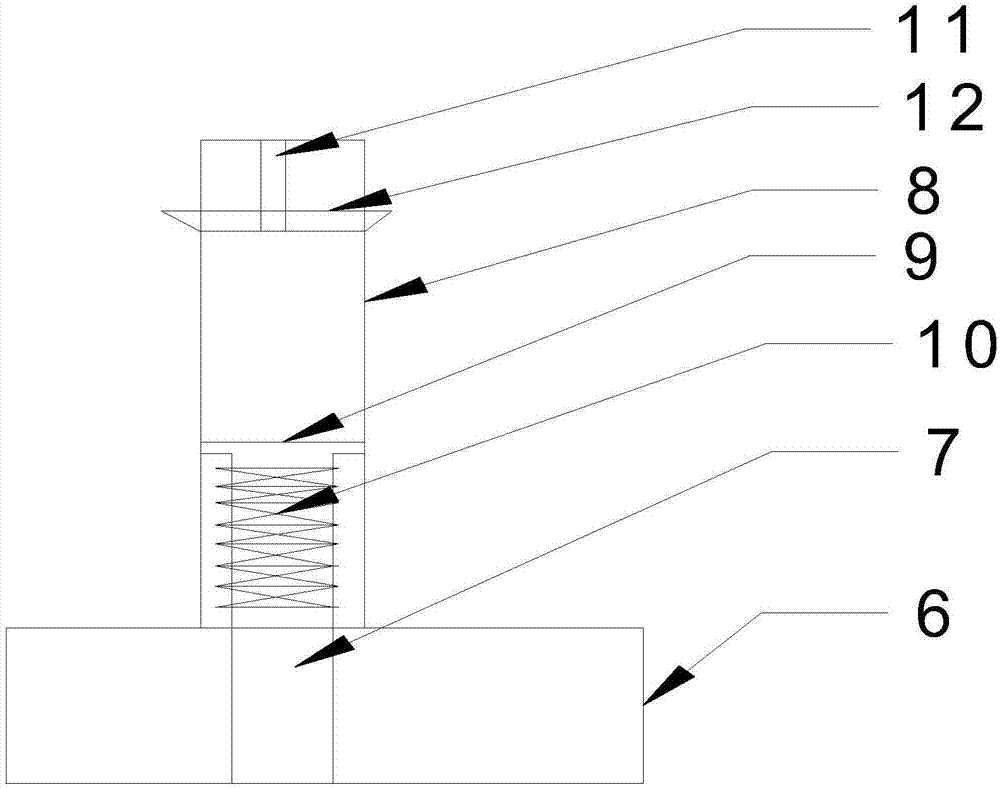

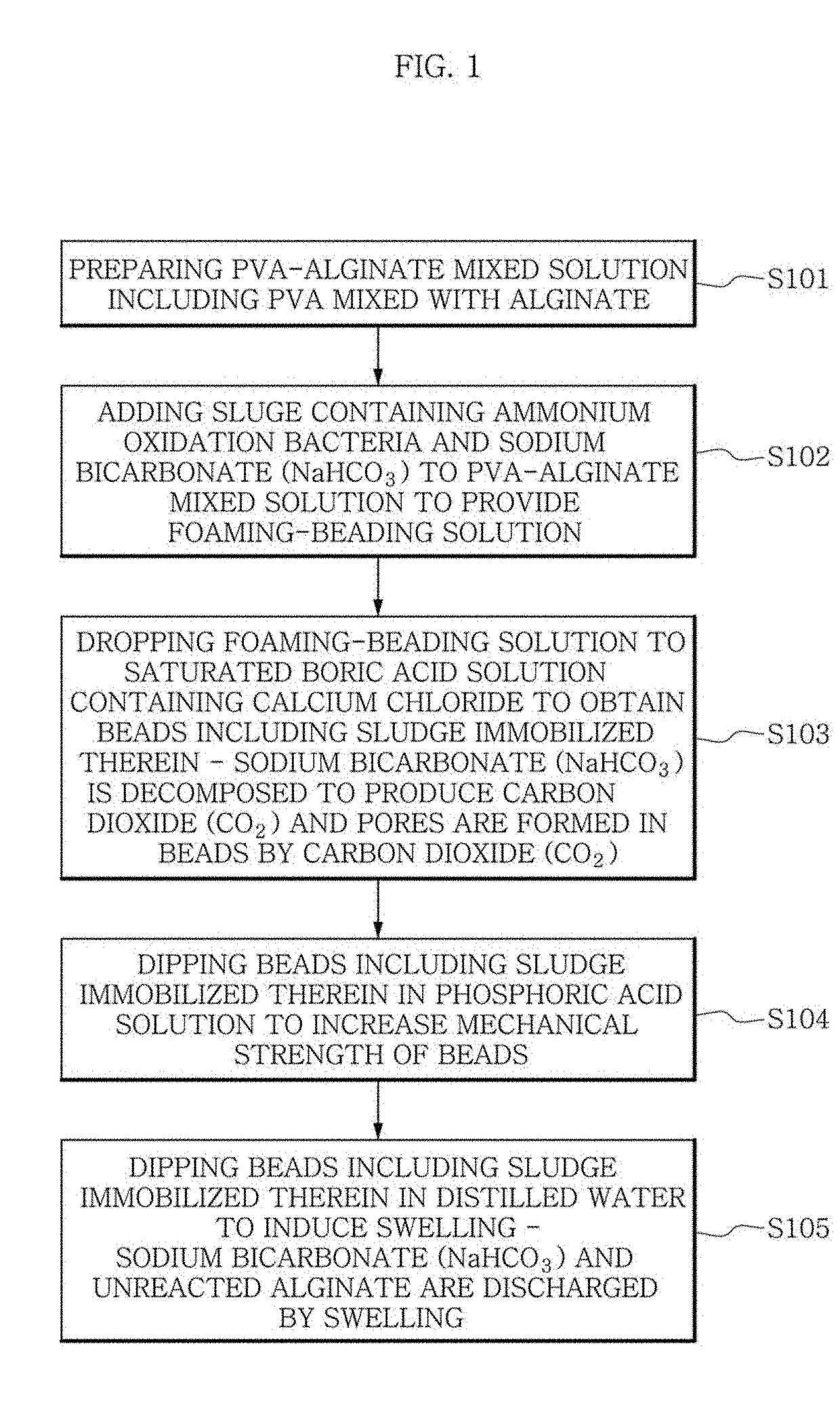

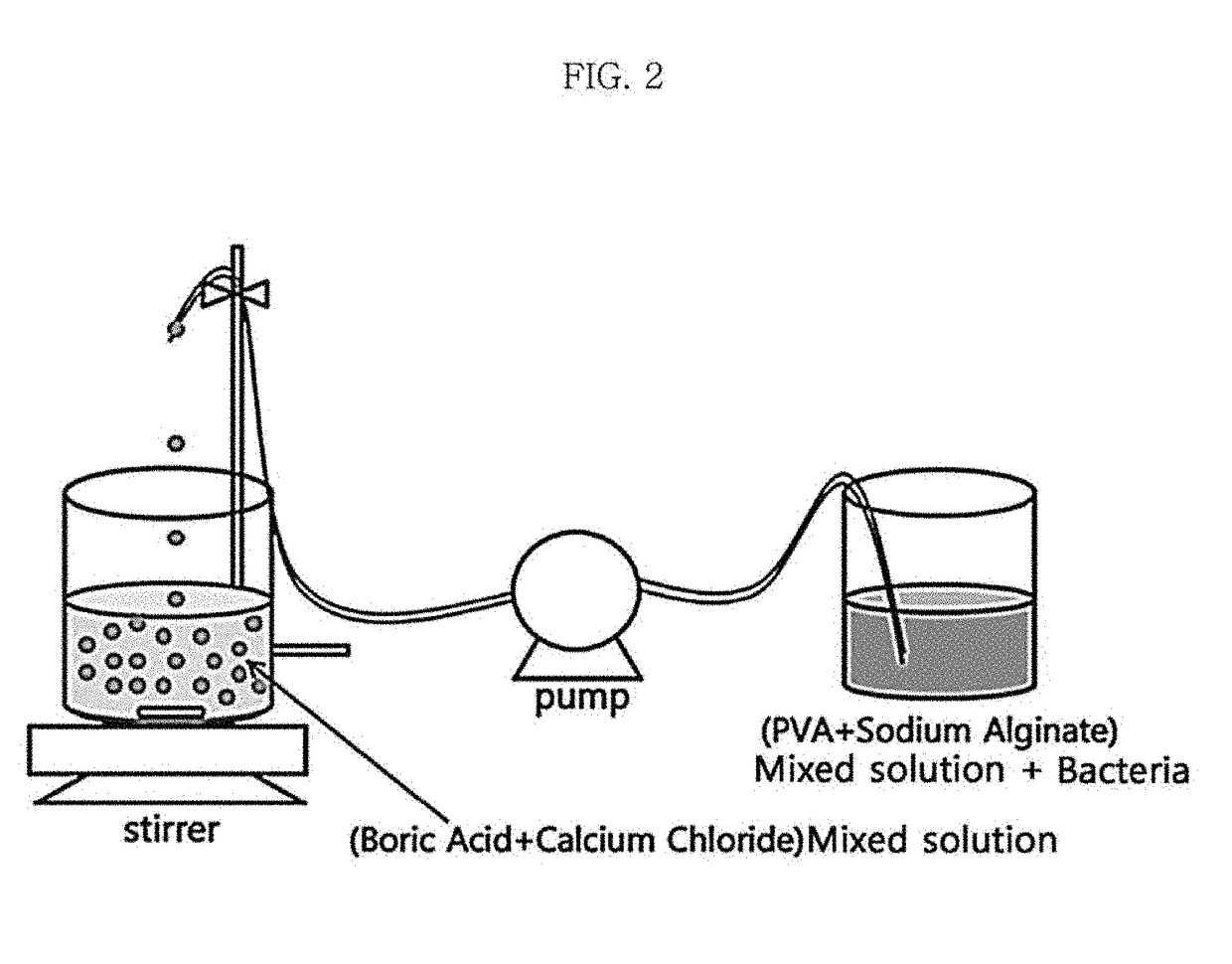

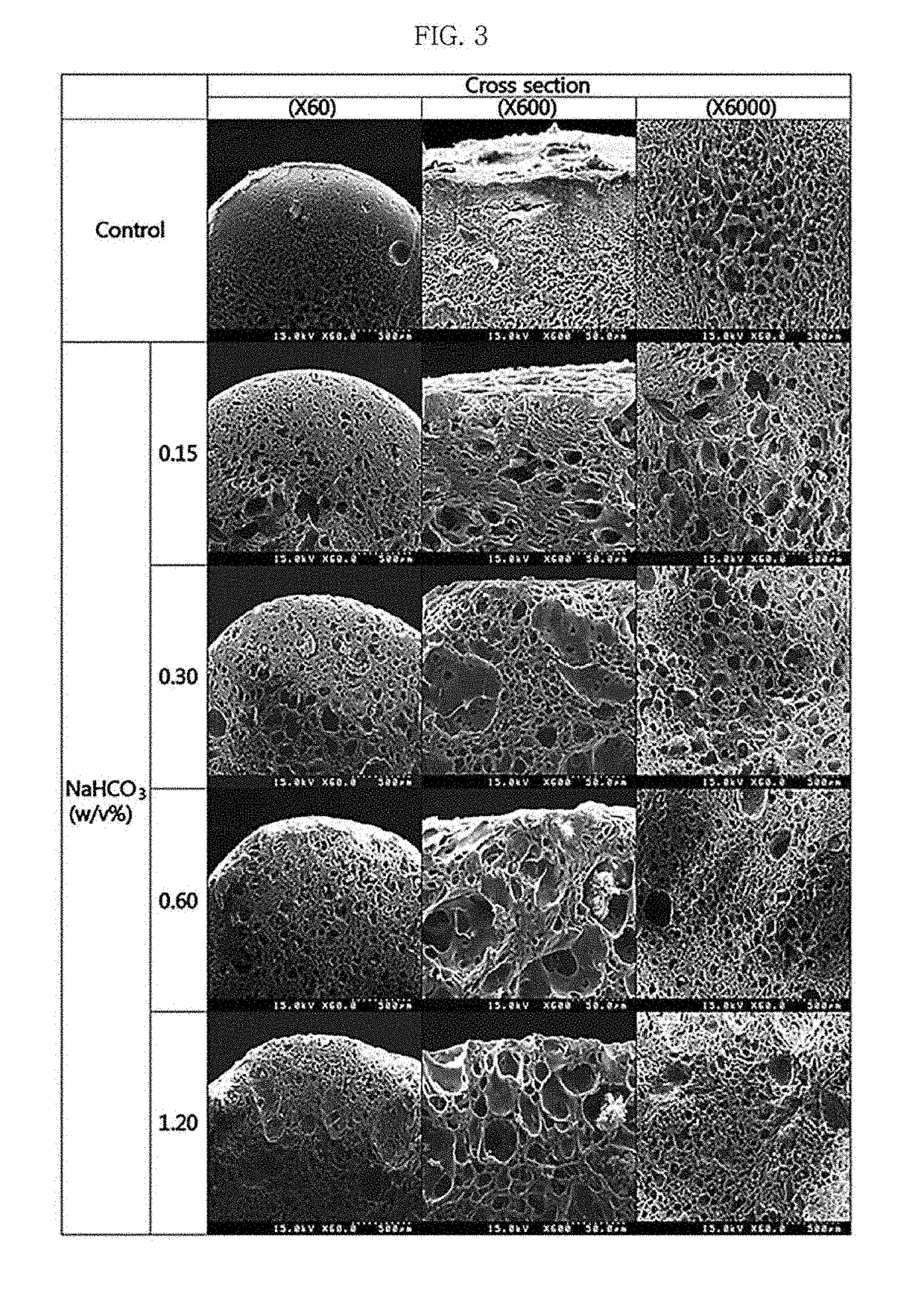

Carrier including ammonium oxidizing bacteria immobilized therein and method for preparing same

ActiveUS20170355979A1Improve gas permeabilityHigh strengthWater contaminantsTreatment with anaerobic digestion processesSodium bicarbonateSludge

Disclosed is a method for preparing the same. The method for preparing a carrier including ammonium oxidizing bacteria immobilized therein includes: preparing a PVA-alginate mixed solution containing PVA mixed with alginate; adding sludge containing ammonium oxidizing bacteria and sodium bicarbonate (NaHCO3) to the PVA-alginate mixed solution to obtain a foaming-beading solution; and dropping the foaming-beading solution to a saturated boric acid solution to obtain beads including sludge immobilized therein, wherein sodium bicarbonate (NaHCO3) is decomposed to produce carbon dioxide (CO2) which is discharged to the exterior of the beads to form pores in the beads, when the foaming-beading solution is dropped to the saturated boric acid solution to obtain beads including sludge immobilized therein.

Owner:KOREA INST OF SCI & TECH

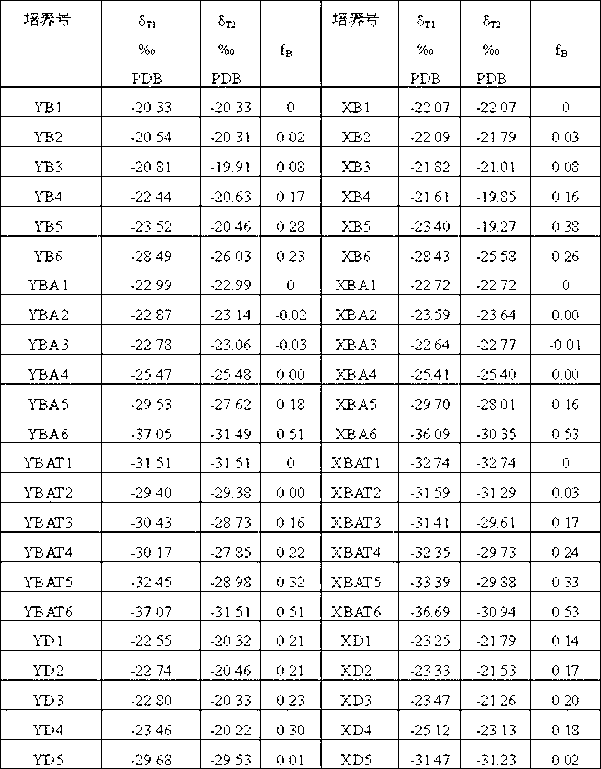

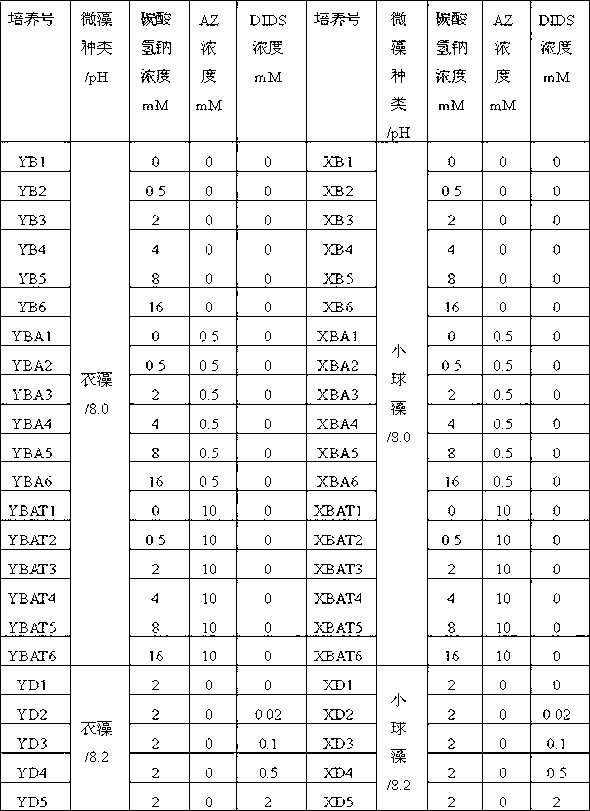

Method for quantifying microalgae using inorganic carbon approach

The invention discloses a method for quantifying a microalgae using an inorganic carbon approach. The prior art can not quantify microalgae using an inorganic carbon approach. The solving method comprises the following steps of: respectively adding two sodium bicarbonate of which the delta 13C value difference values are larger than 0.8% as an isotope label 1 and an isotope label 2 to cultivate microalgae to be tested in a nutrient solution; and respectively cultivating the microalgae to be tested for 4 days under the above condition and the cultivating condition of 16mM of sodium bicarbonate and 10mM of MAZ, testing the delta 13C values, computing the portion fB of the used and added inorganic carbon source under various microalgae cultivating conditions and the delta 13C value delta a of a microalgae body when a carbon dioxide approach in the atmosphere is completely used, and obtaining the portions of the two approaches in which the microalgae uses the inorganic carbon according to the obtained data. The method can quickly quantify the microalgae using inorganic carbon approach, and can develop a cultivating test under the complete same experiment condition to obtain the reliable data of the portion of the microalgae using inorganic carbon approach, which can not be achieved in the prior art.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com