Patents

Literature

79 results about "Trona" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Trona (trisodium hydrogendicarbonate dihydrate, also sodium sesquicarbonate dihydrate, Na₂CO₃•NaHCO₃•2H₂O) is a non-marine evaporite mineral. It is mined as the primary source of sodium carbonate in the United States, where it has replaced the Solvay process used in most of the rest of the world for sodium carbonate production.

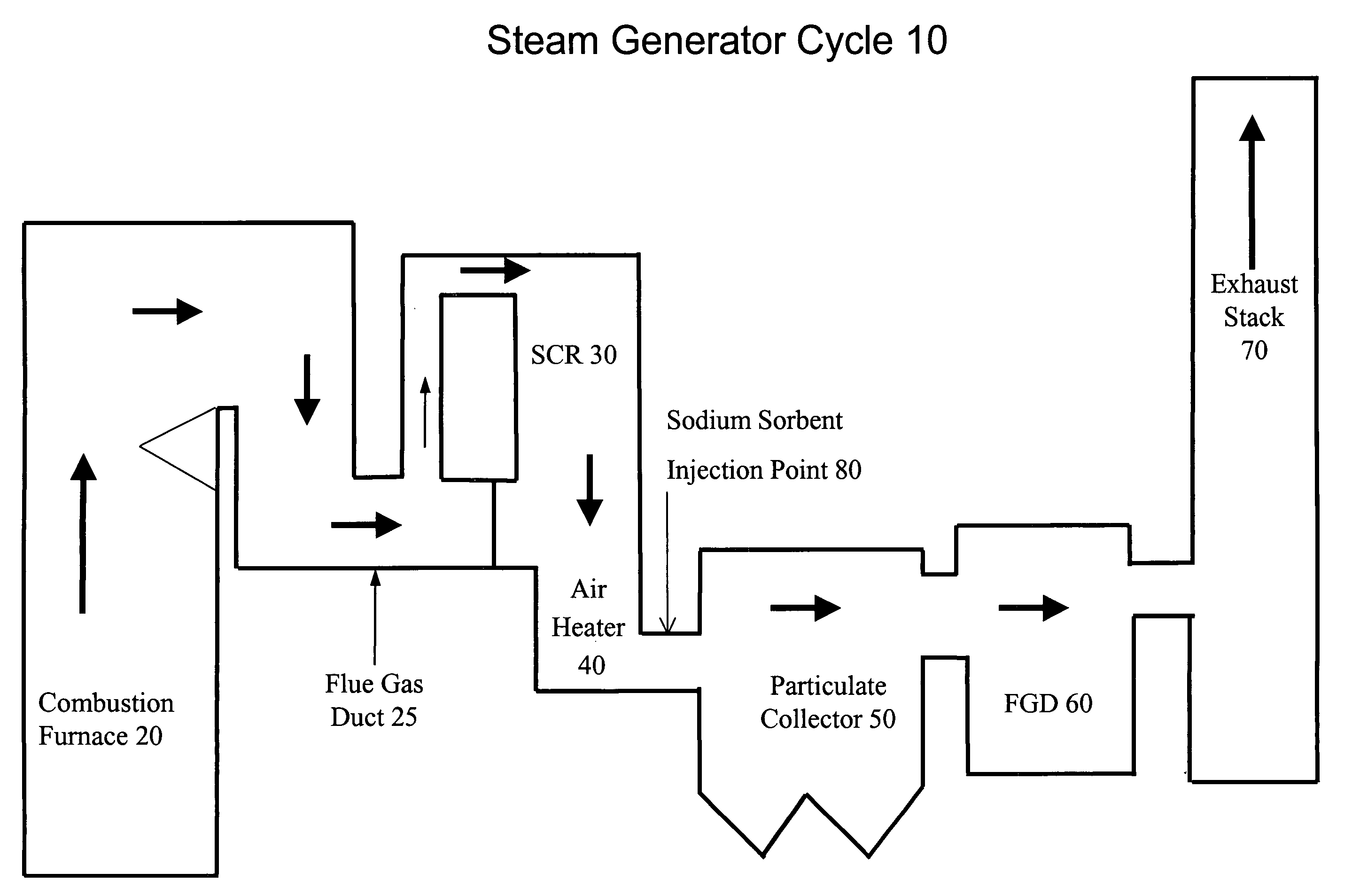

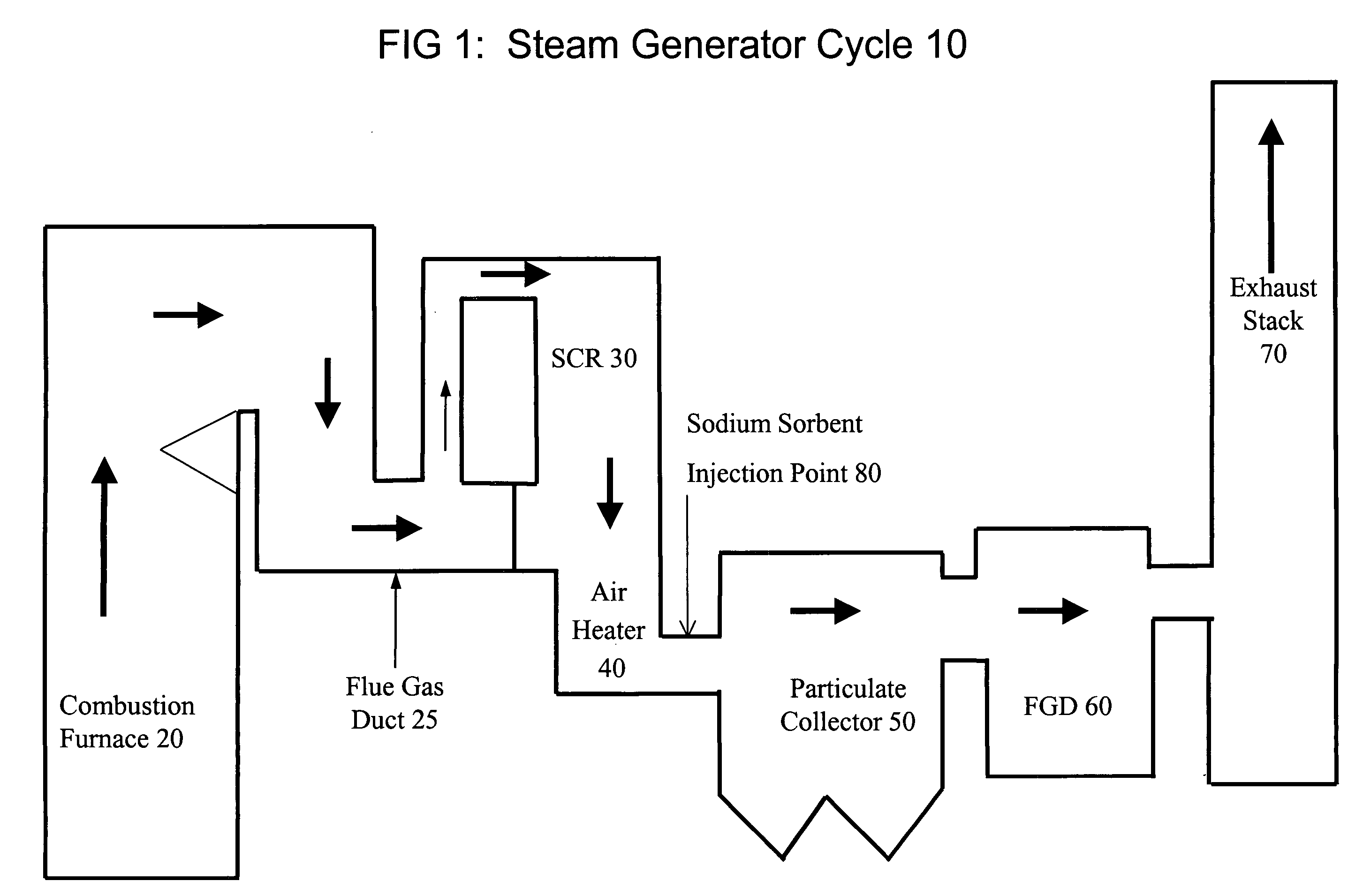

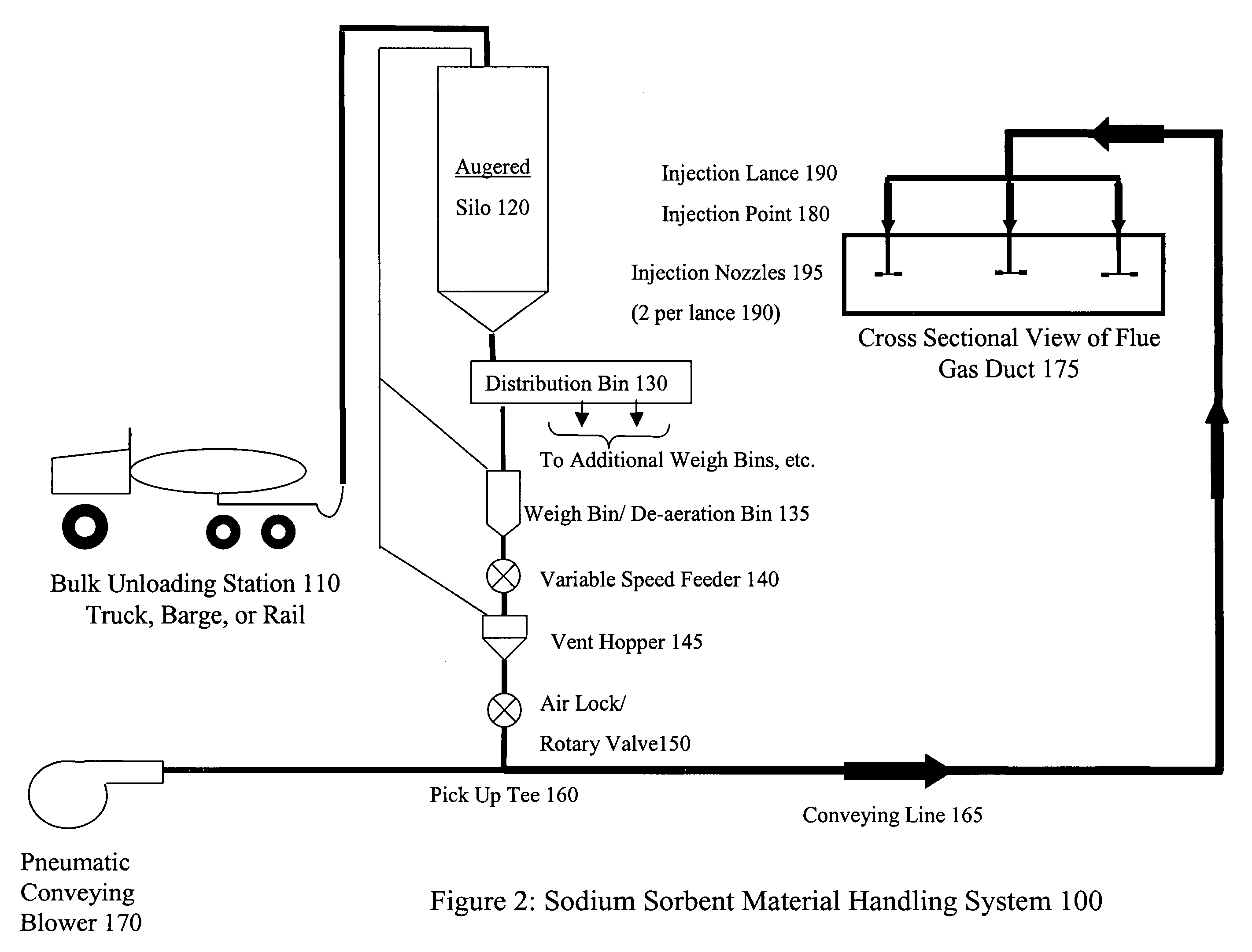

System and method for treating a flue gas stream

PendingUS20050201914A1Lower volume resistivityEfficient removalCombination devicesGas treatmentParticulatesDicarbonate

The present invention is a system and method for treating a flue gas stream to remove strong acid compounds selected from the group consisting of hydrofluoric acid (HF), hydrochloric acid (HCl), sulfuric acid (H2SO4), and sulfur trioxide (SO3) by injecting a sodium sorbent selected from the group consisting of sodium sesquicarbonate, sodium carbonate-bicarbonate, trona ore, mechanically refined trona ore, and trona into the flue gas stream, calcining substantially all of the sodium sorbent in the presence of the flue gas stream to form a soda ash, reducing the concentration of the at least one strong acid compound in the flue gas stream by reacting the at least one strong acid compound with the soda ash to form a sodium based by-product; and changing the chemistry of the flue gas stream to reduce the overall average resistivity of the particulate matter.

Owner:AMERICAN ELECTRIC POWER CO INC

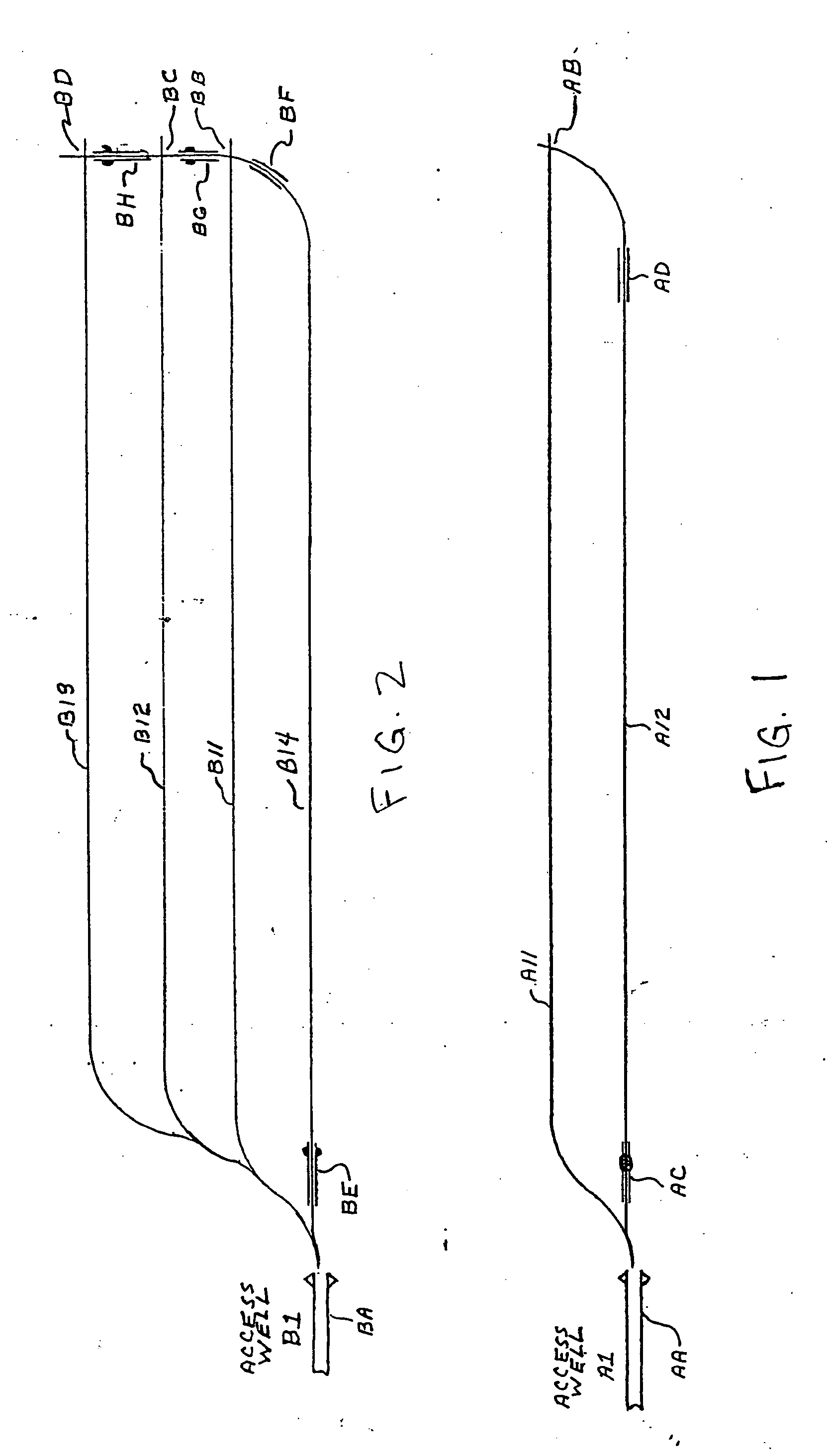

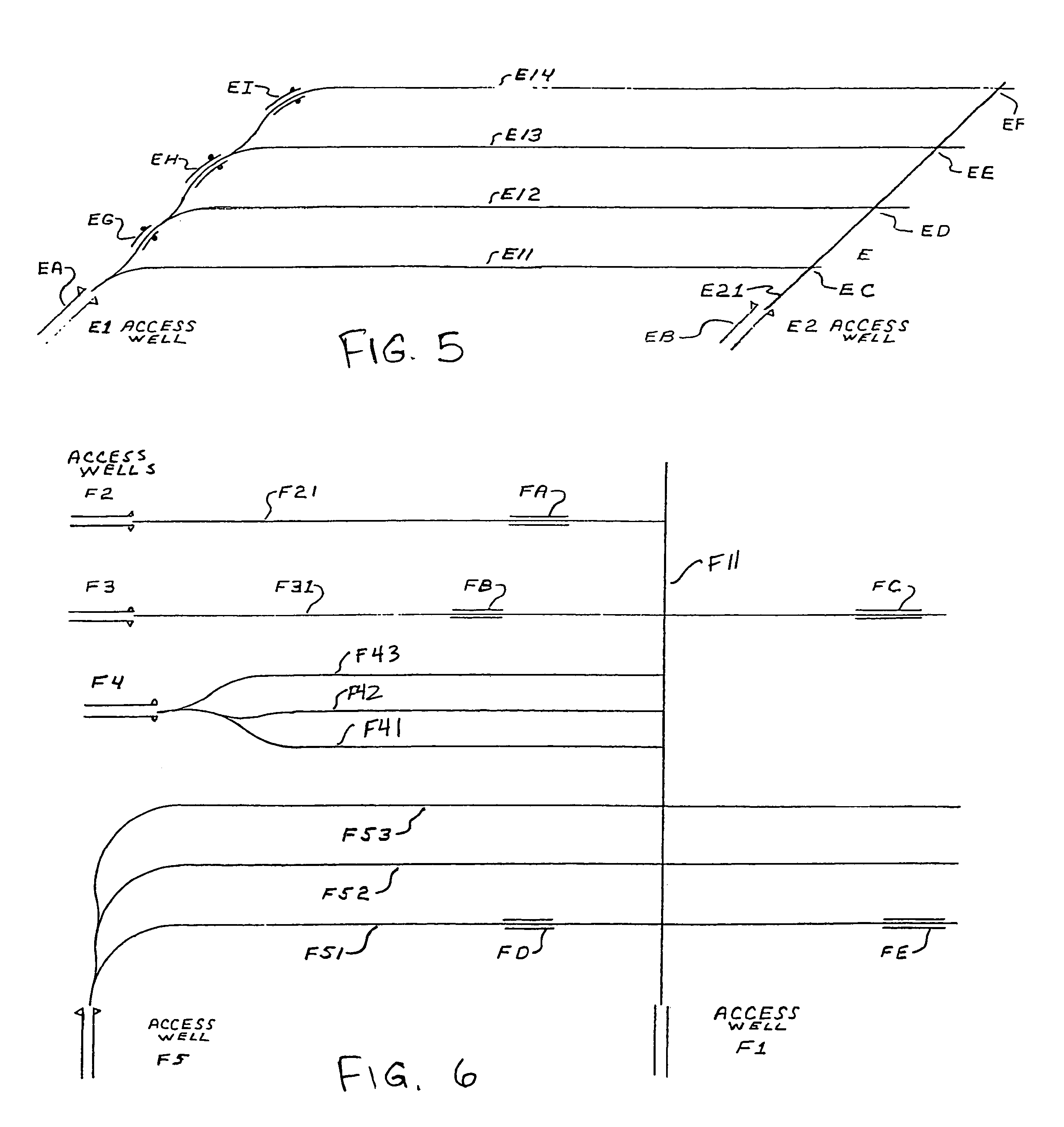

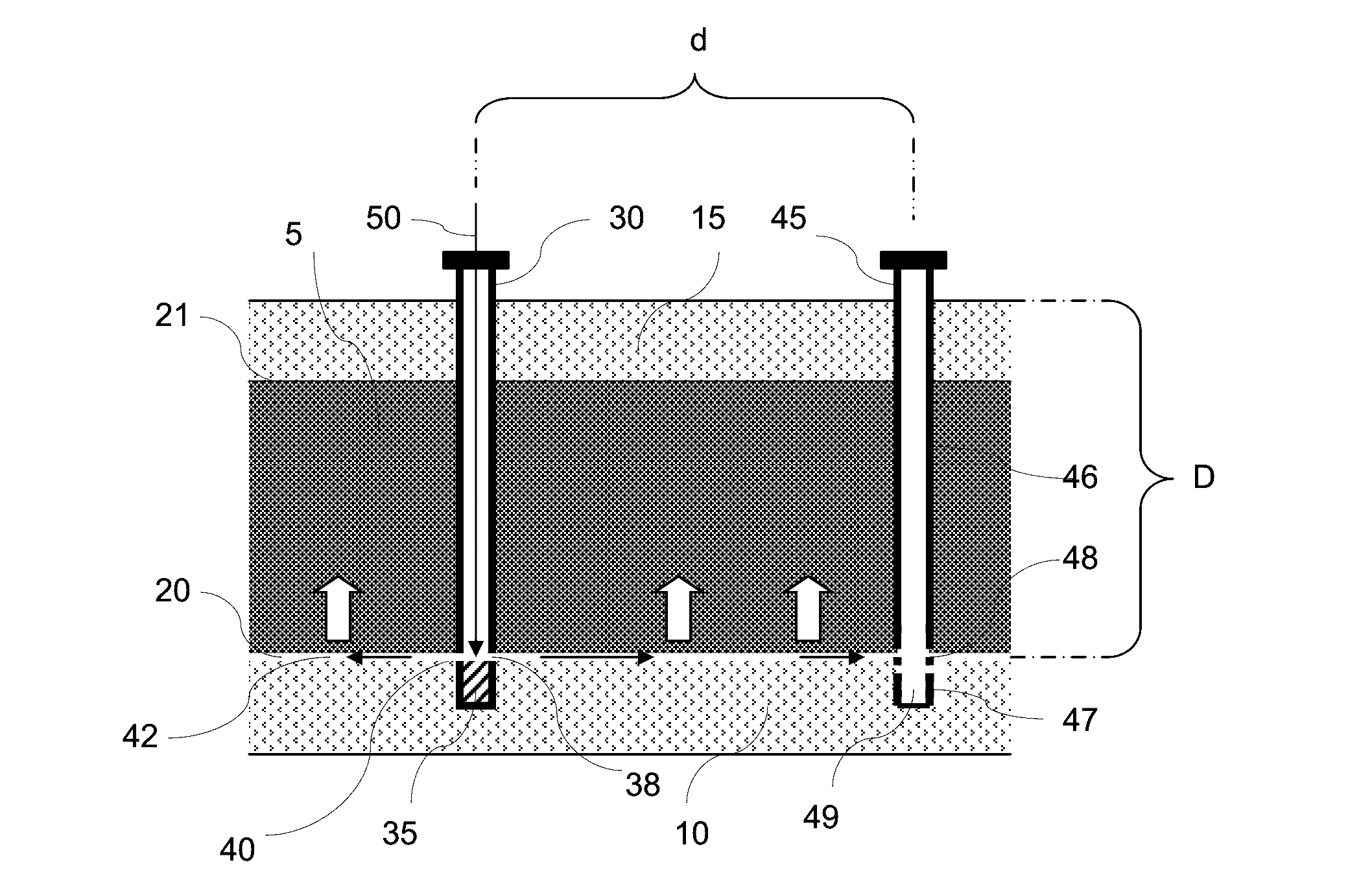

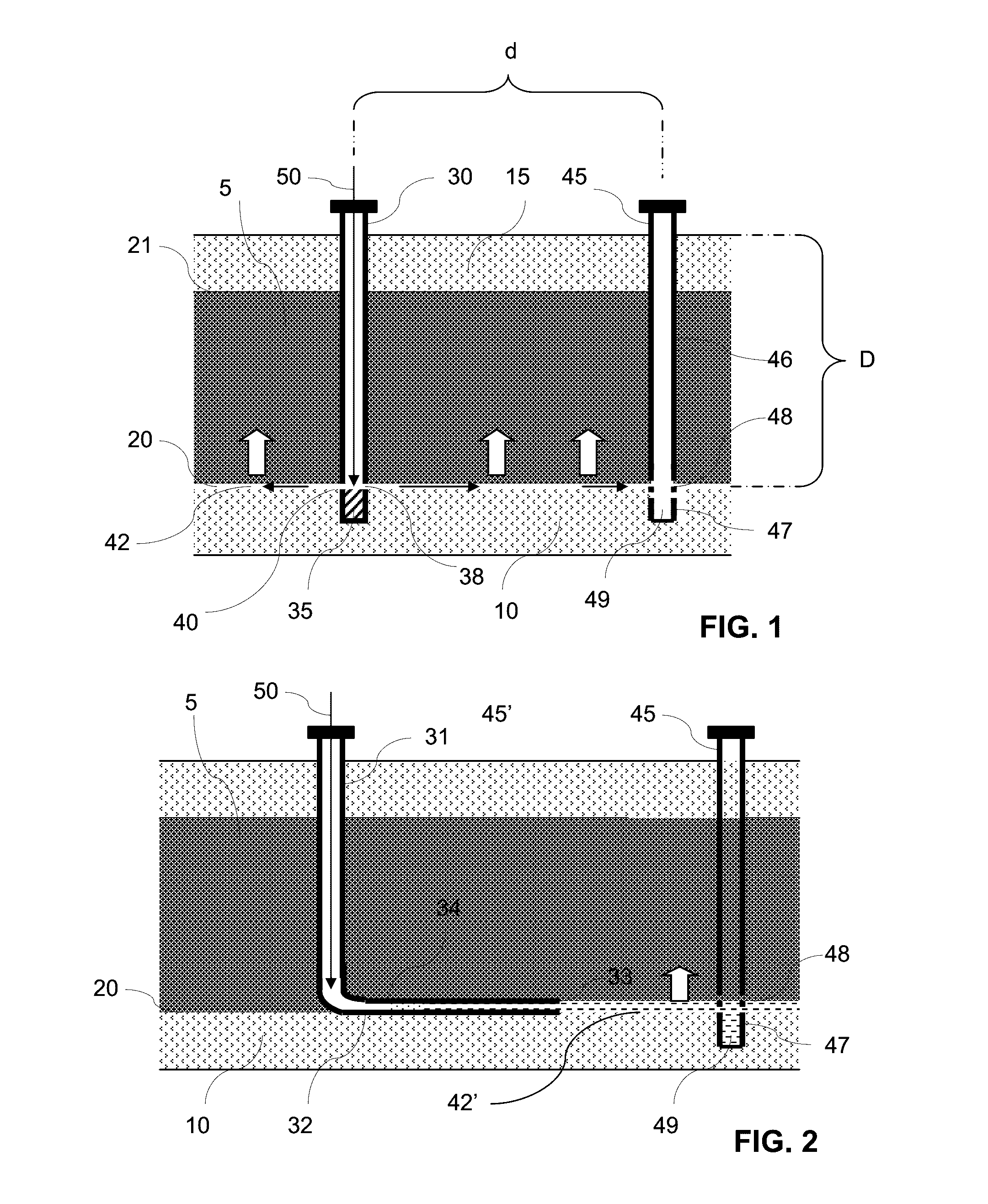

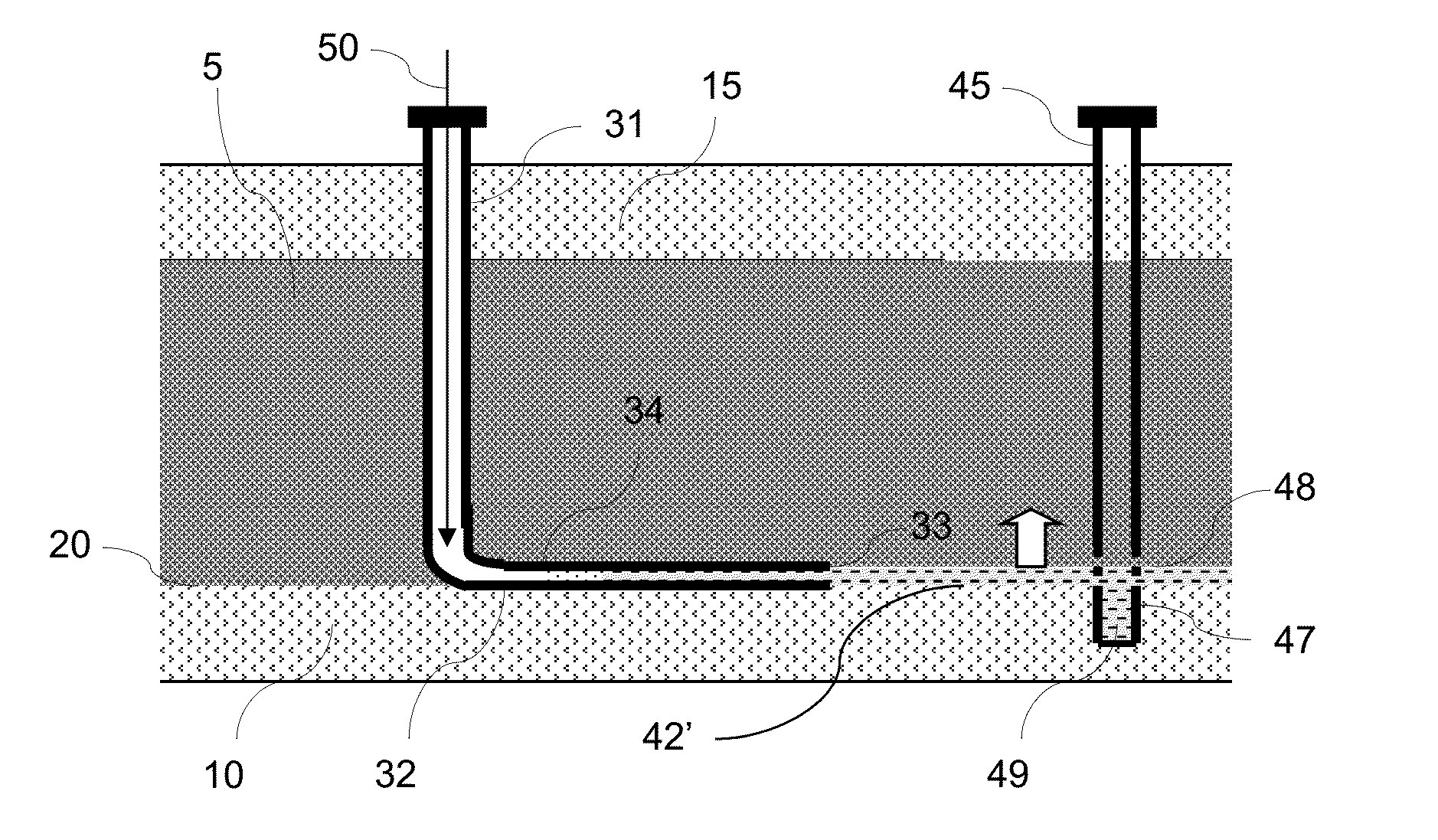

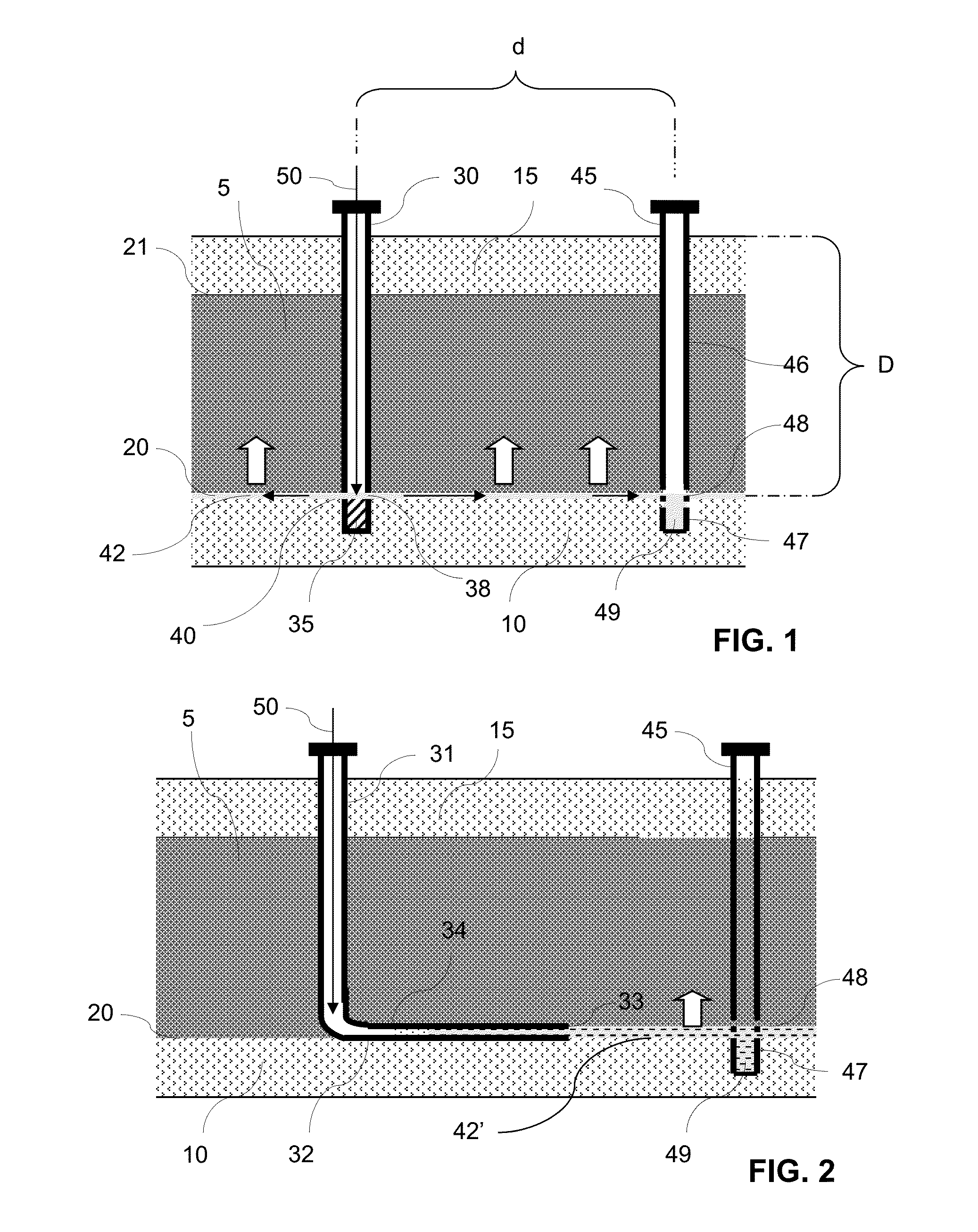

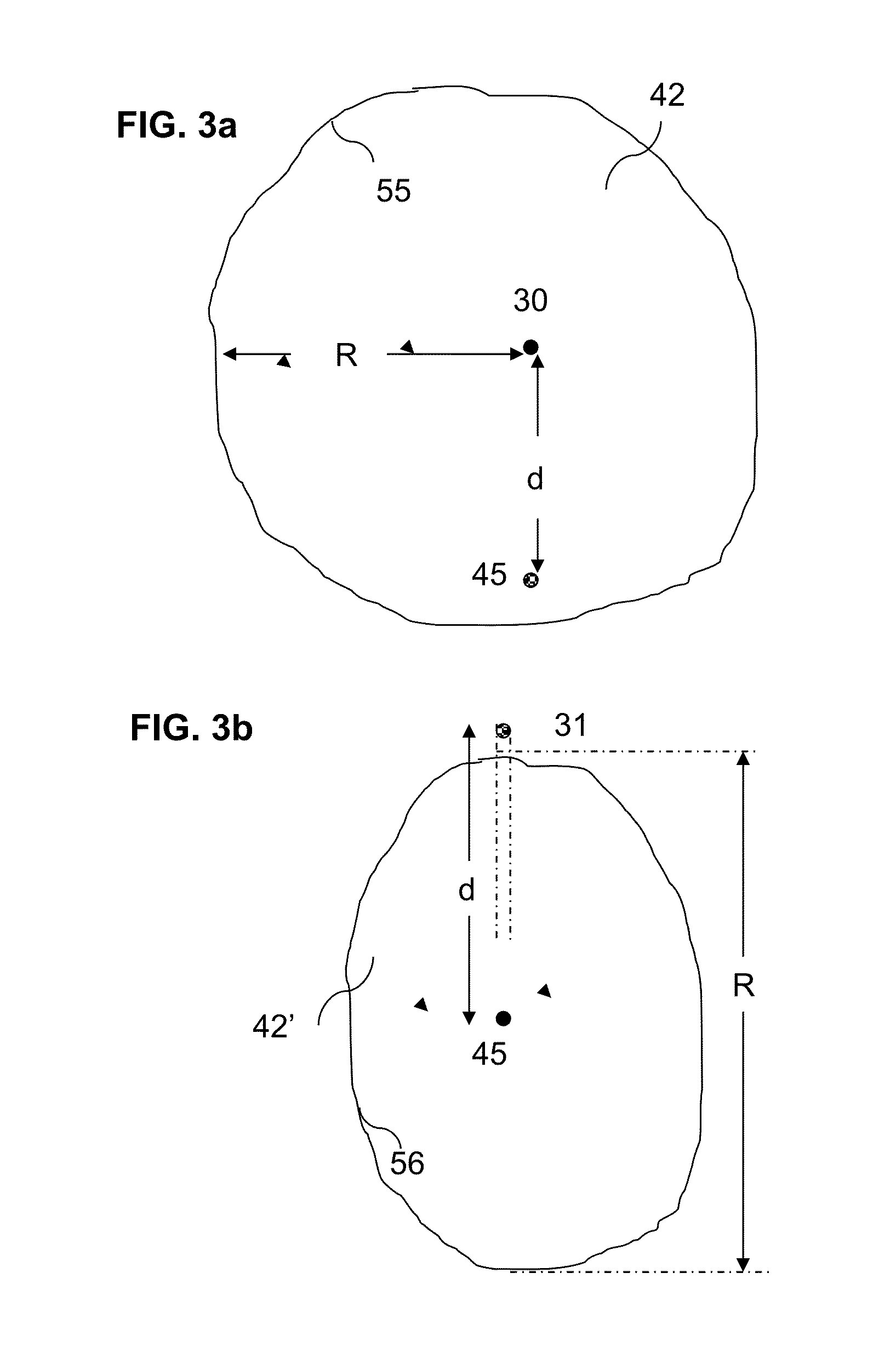

Methods for constructing underground borehole configurations and related solution mining methods

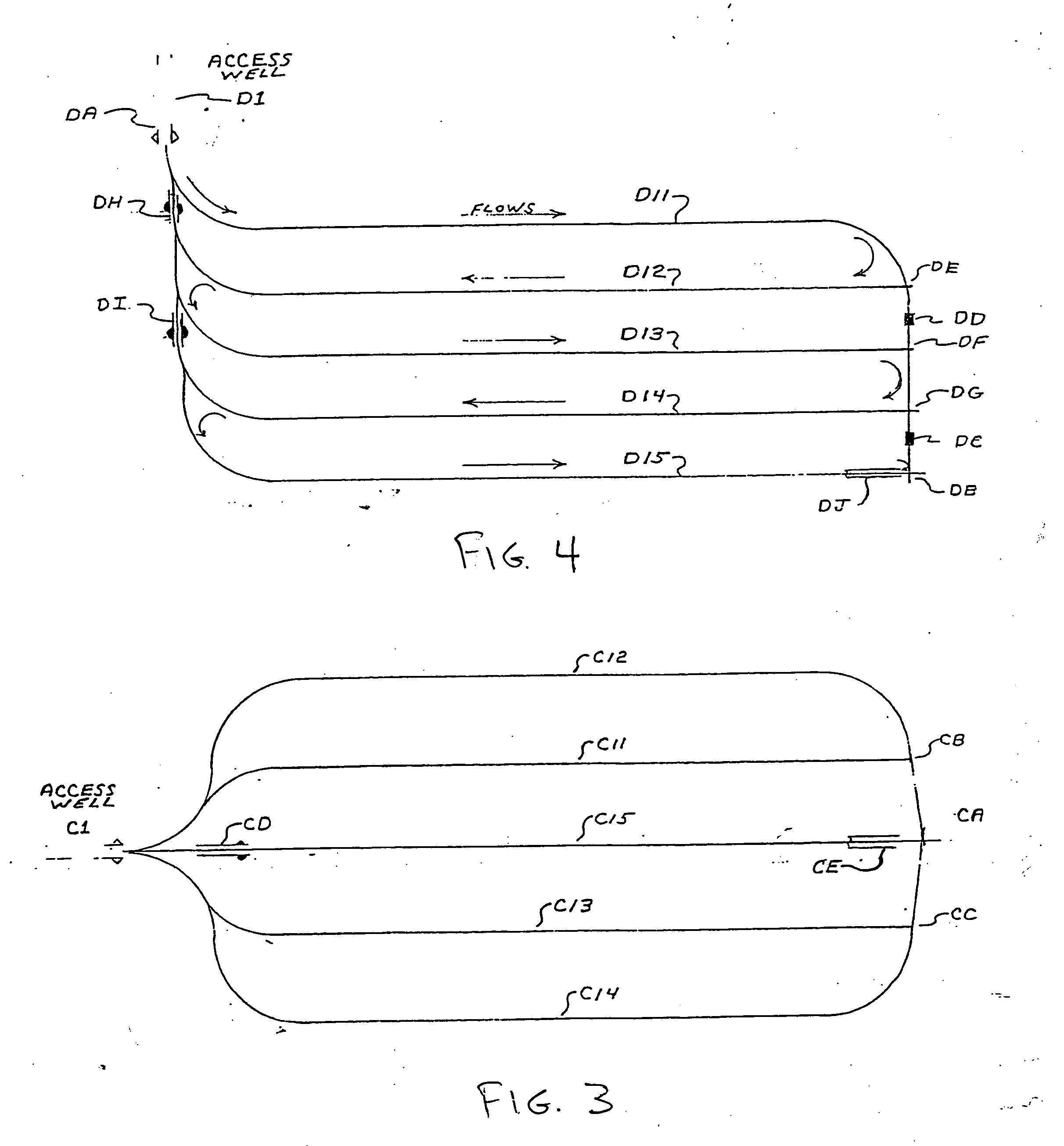

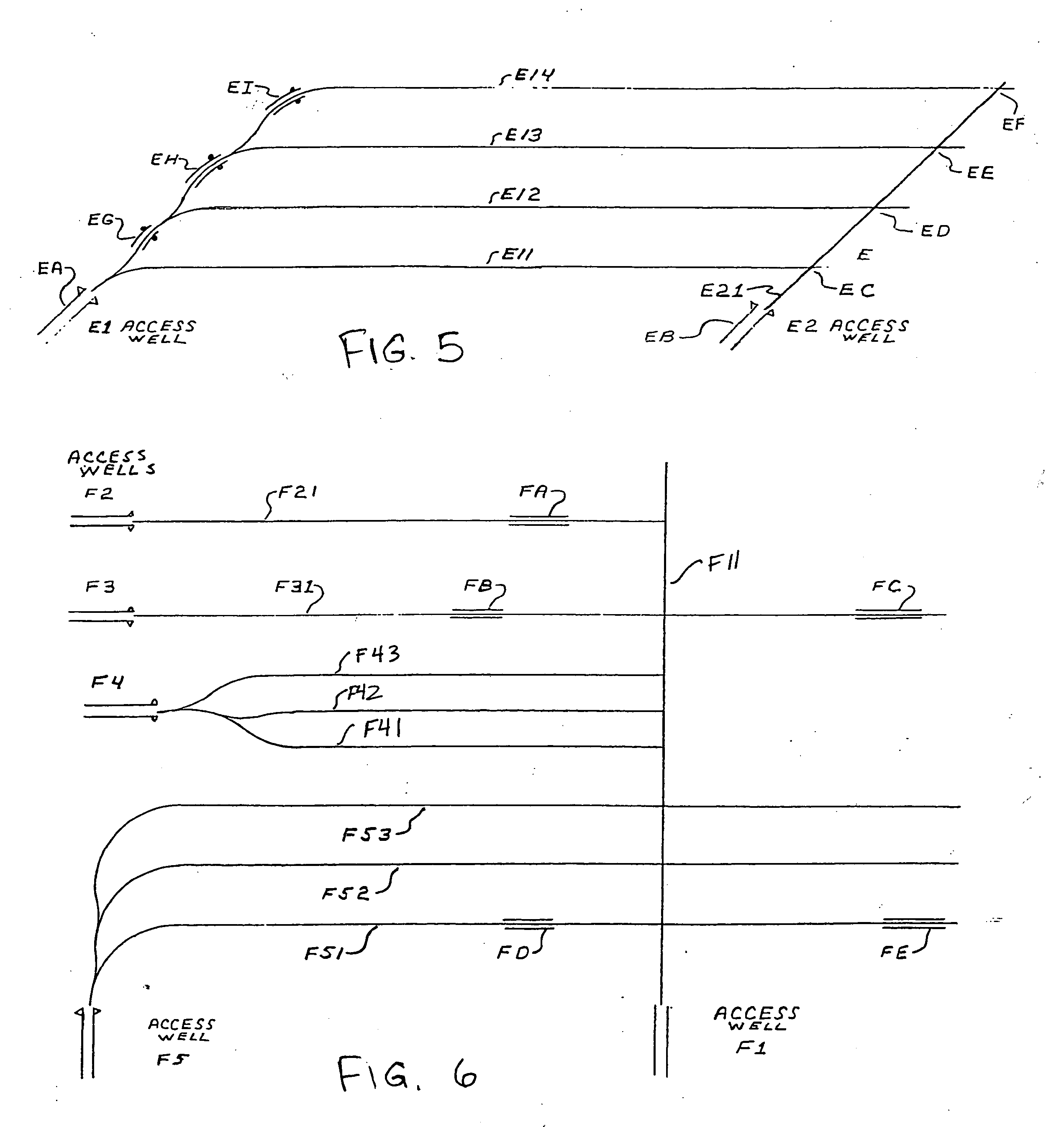

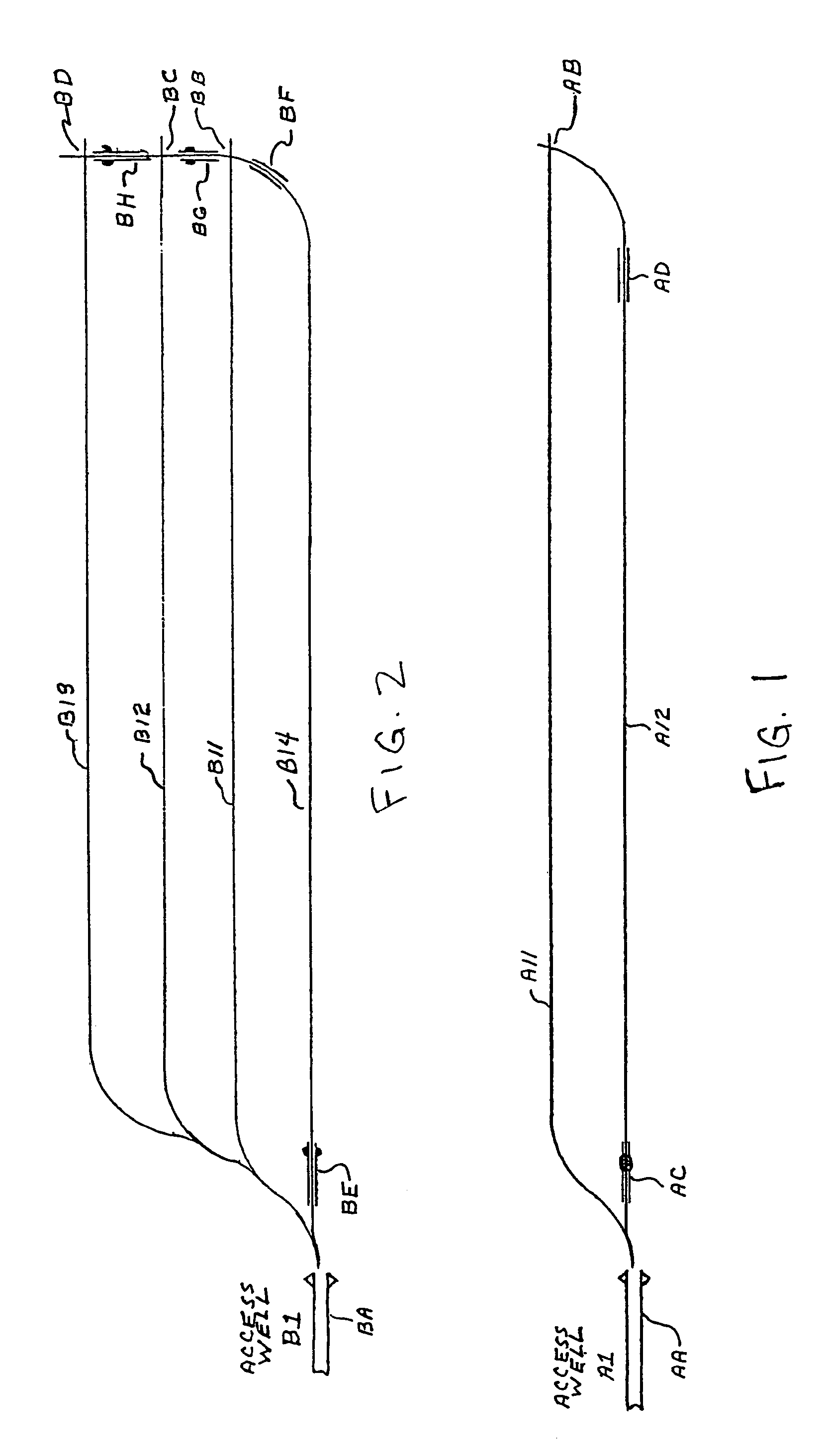

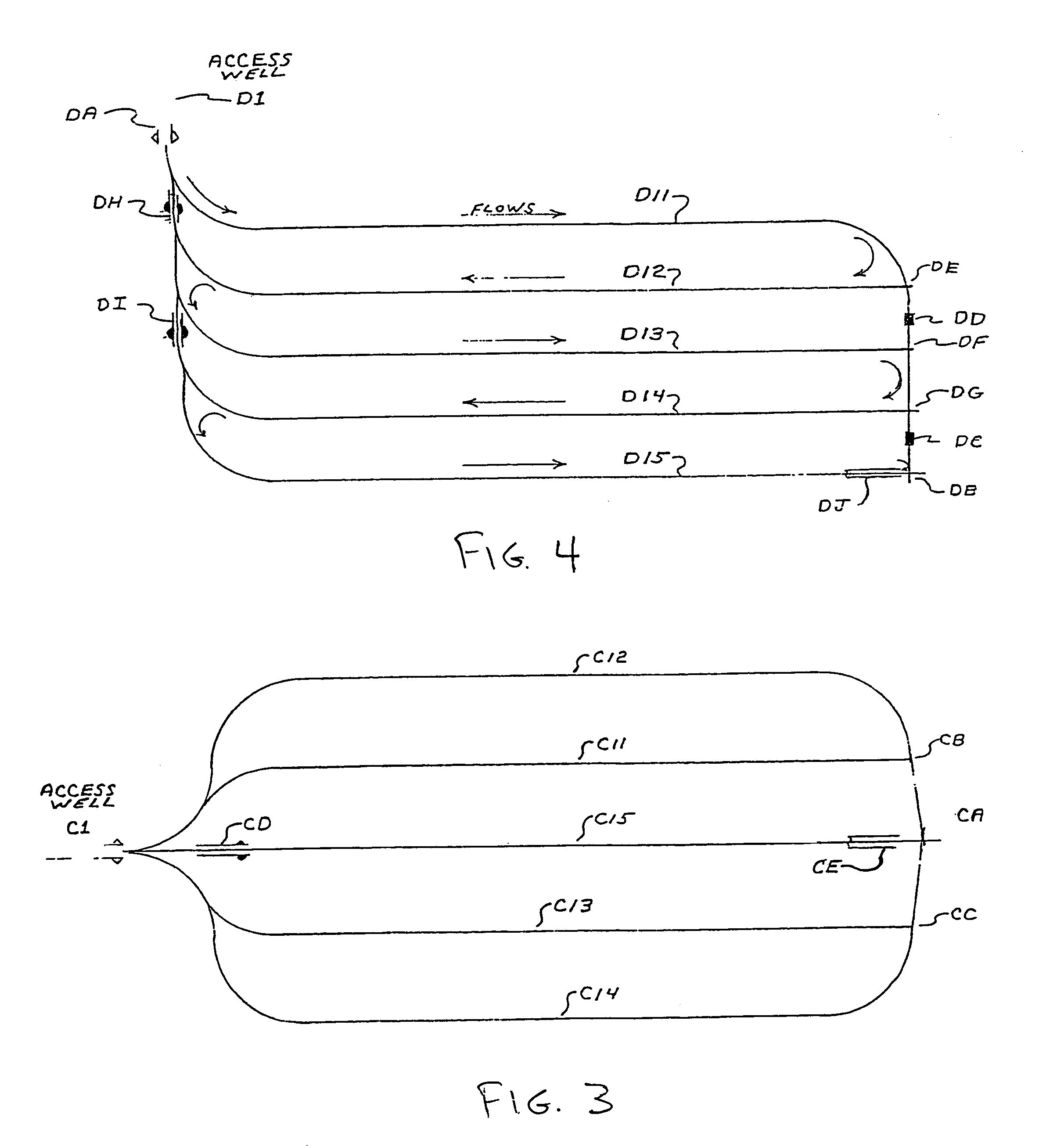

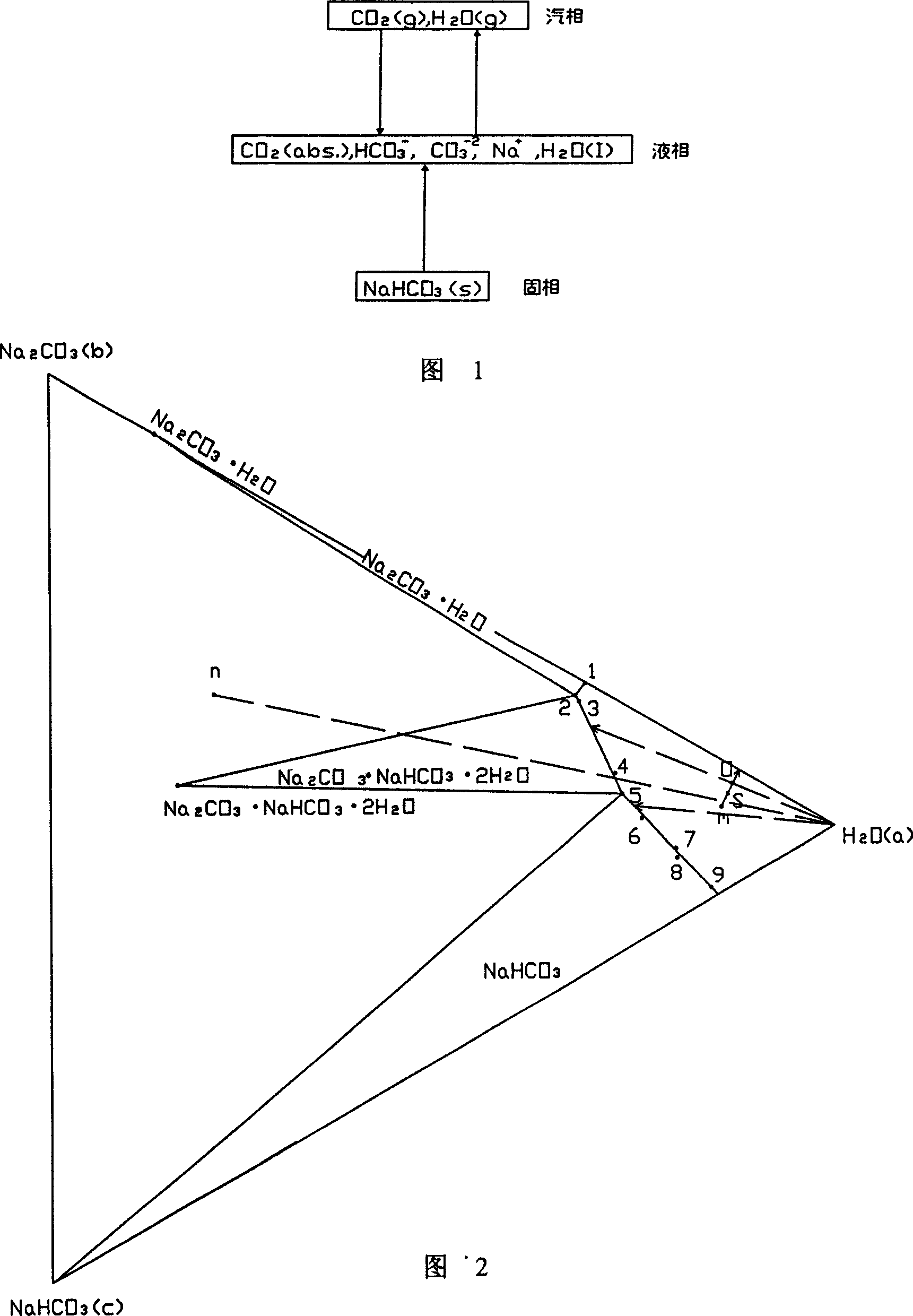

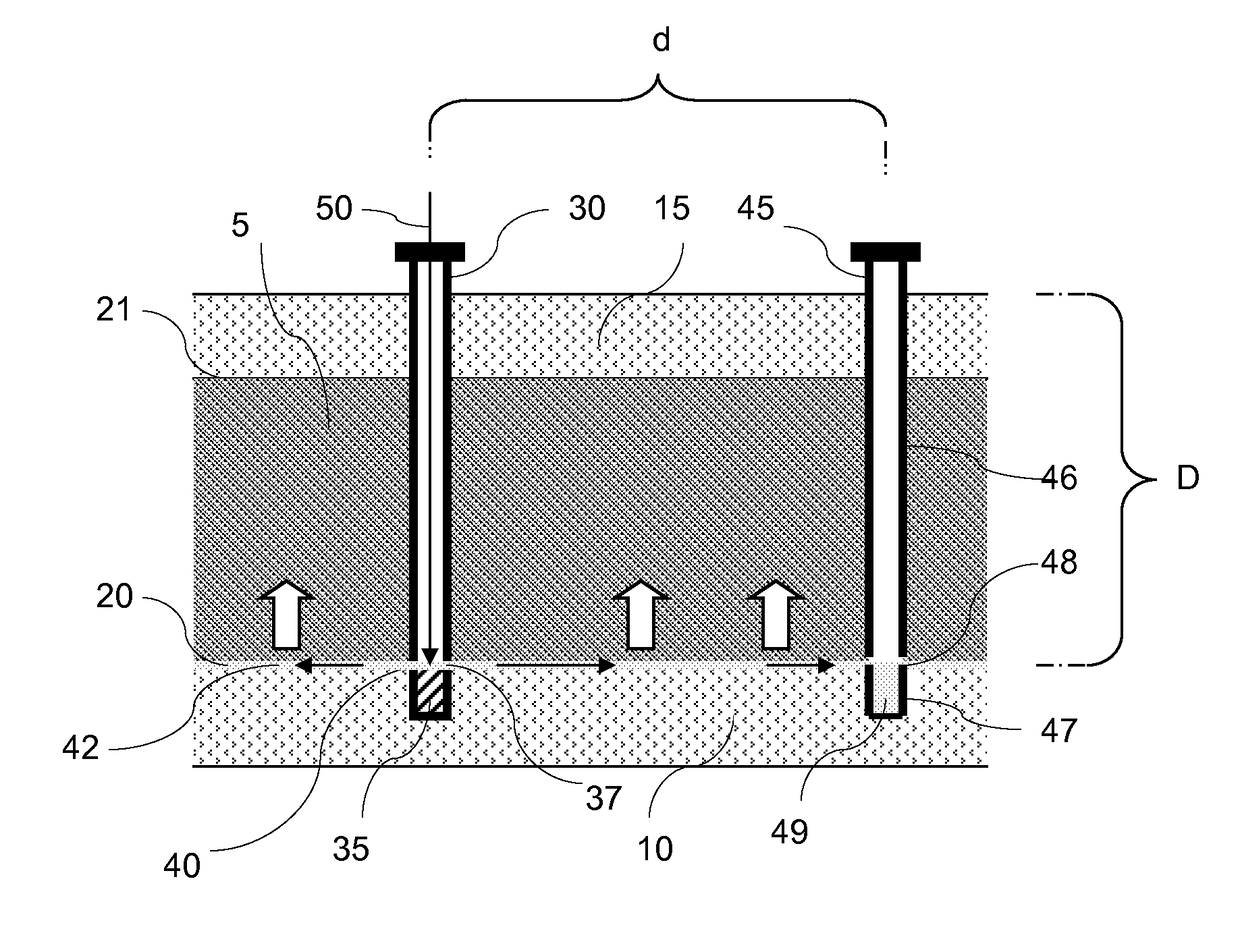

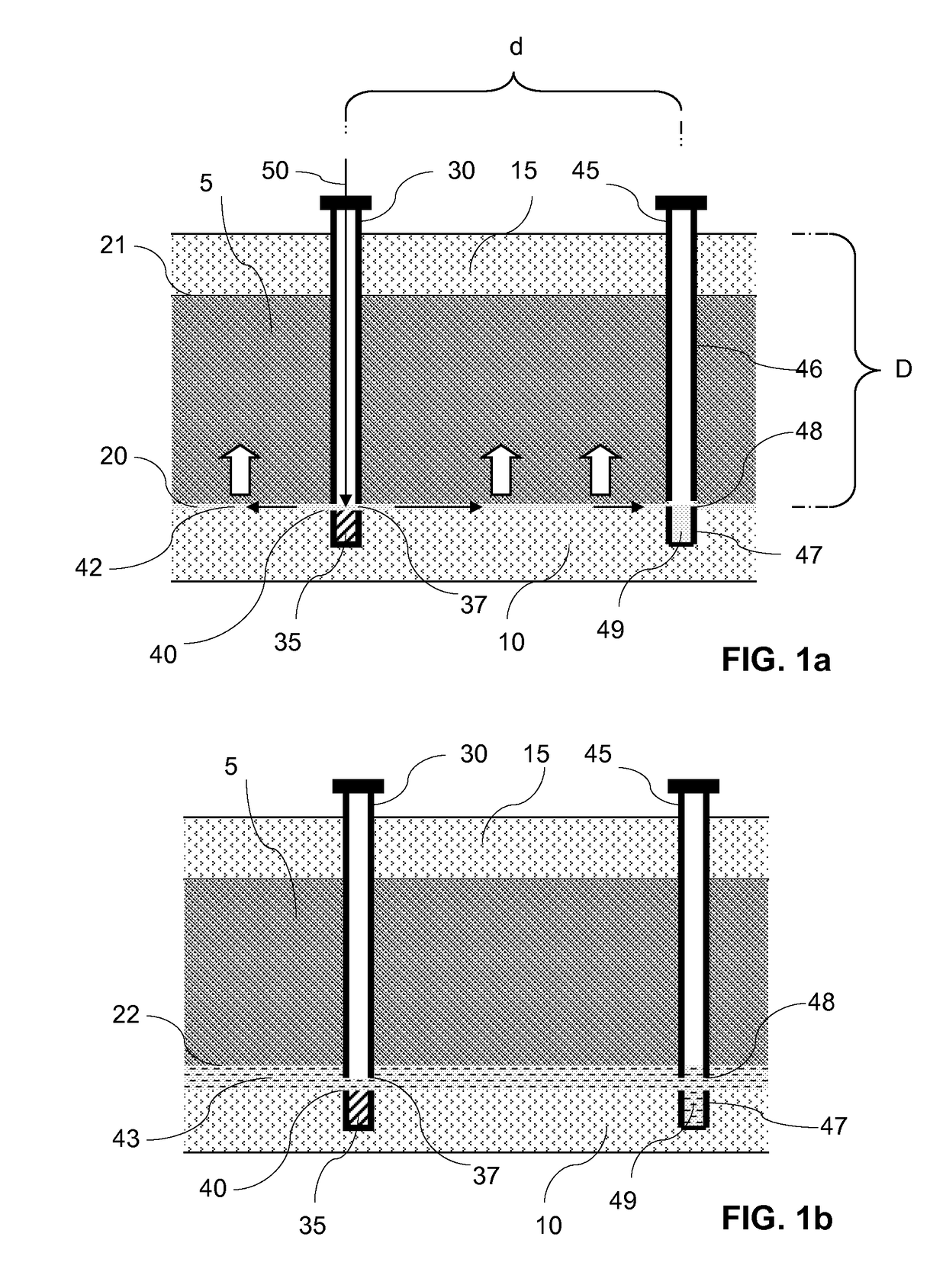

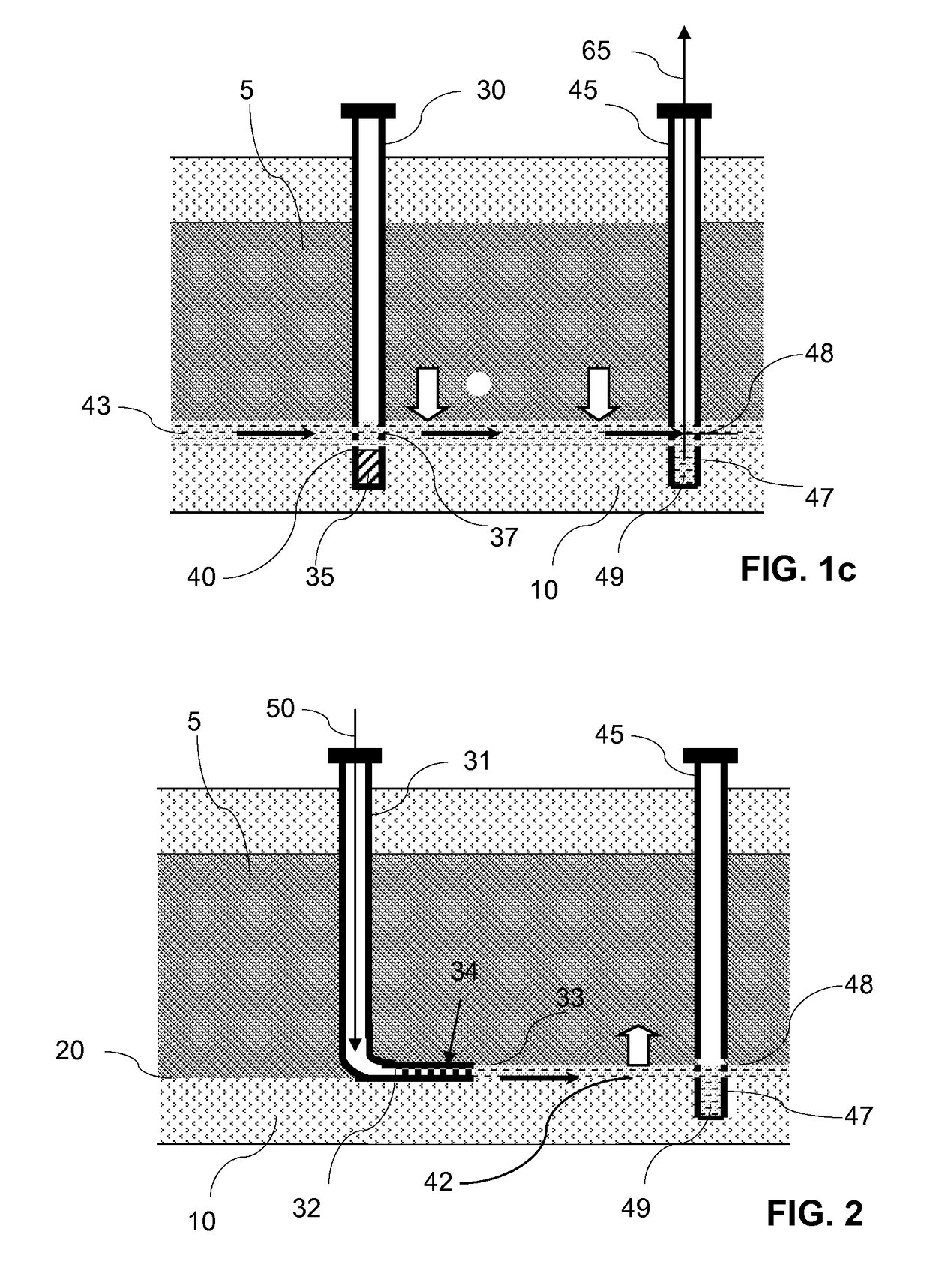

Disclosed are methods for solution mining of evaporite minerals, such as trona, comprising drilling an access well and at least two lateral boreholes; injecting a fluid; circulating the fluid through the lateral boreholes with a controlled fluid flow; and collecting a pregnant solution. Also disclosed are methods of solution mining that include injecting an aqueous solution into an underground trona cavity at a temperature sufficient to maintain at least a portion of the solution in the cavity in the Wegscheiderite solid phase region; removing aqueous solution from the cavity; and recovering alkaline values from the removed aqueous solution. Also disclosed are methods of solution mining that include injecting an aqueous solution into an underground trona cavity; removing aqueous solution from the cavity, wherein the temperature of the removed aqueous solution is at about the TWA point temperature; and recovering alkaline values from the removed aqueous solution.

Owner:SESQUI MINING

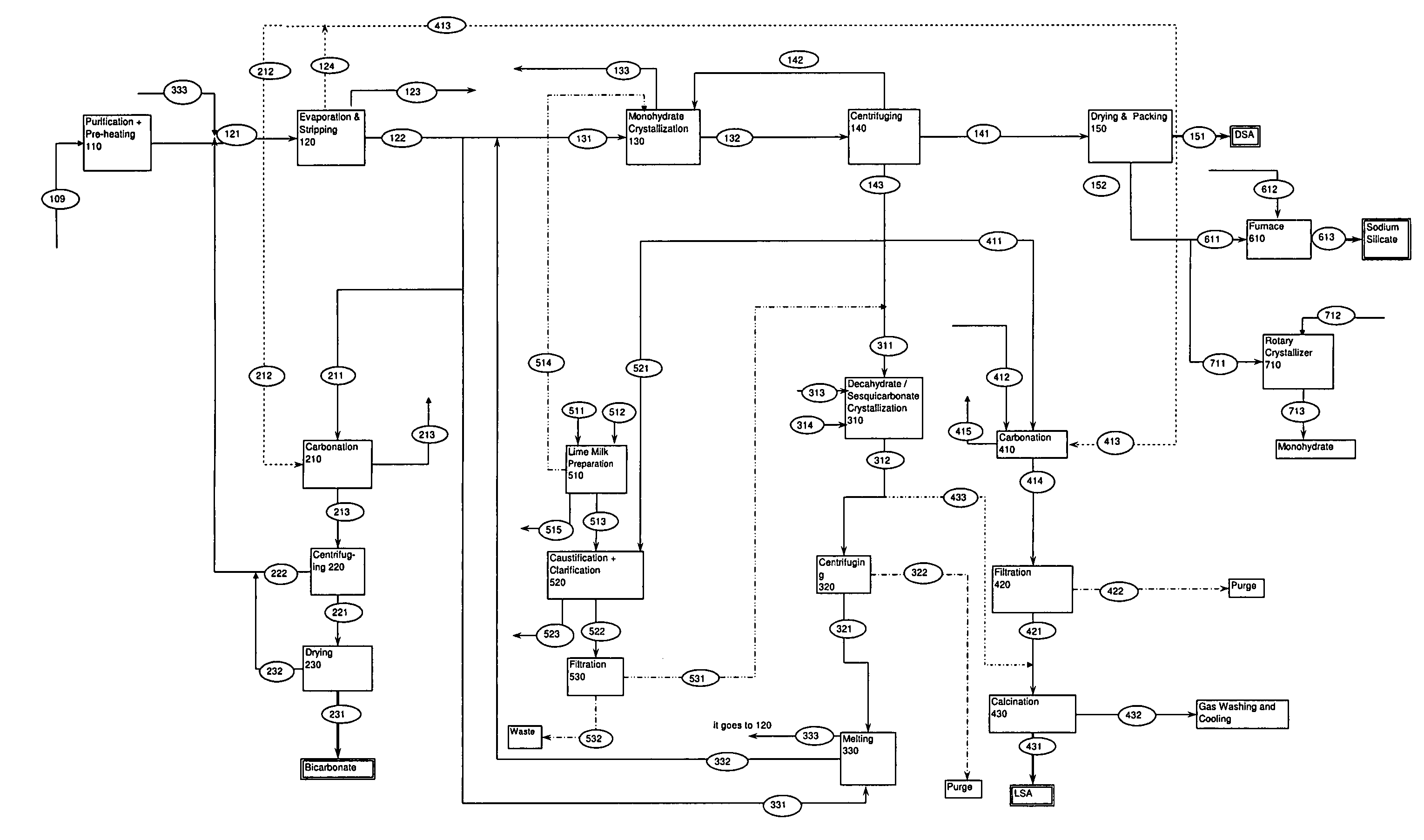

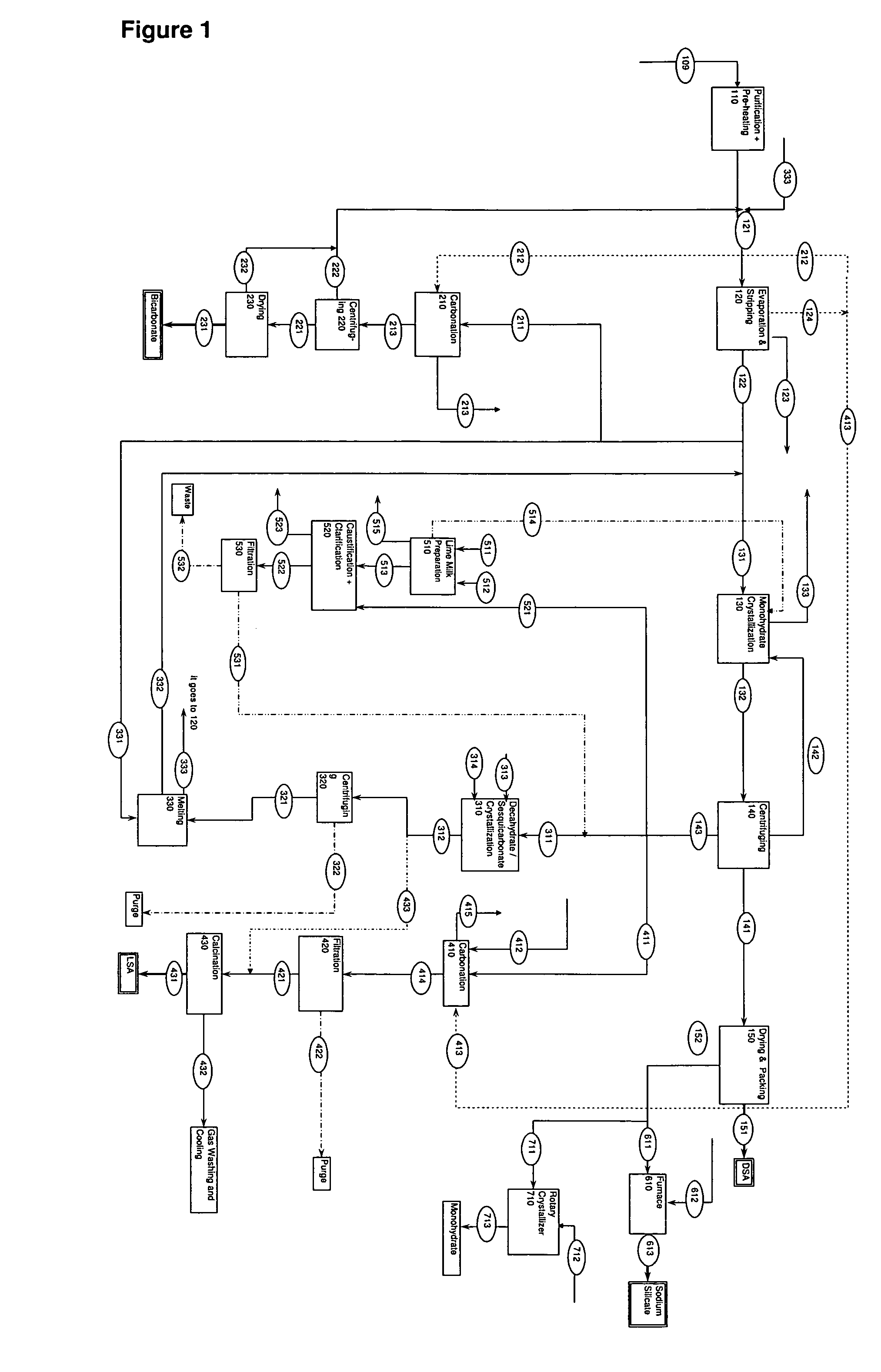

Process for production of dense soda, light soda, sodium bicarbonate and sodium silicate from solutions containing bicarbonate

ActiveUS7507388B2Processing requirementLow production costCrystallization separationAlkali metal silicatesSodium bicarbonateEvaporation

A process related to sodium chemicals production, including the processing of bicarbonate containing solutions obtained by solution mining of trona, nahcolite or wegscheiderite reserves and the lake waters containing bicarbonates, includes the steps of purification, evaporation-decarbonation, crystallization, centrifuging, and drying.

Owner:ETI SODA URETIM PAZARLAMA NAKLIYAT & ELEKTRIK URETIM SANAYI & TICARET A S

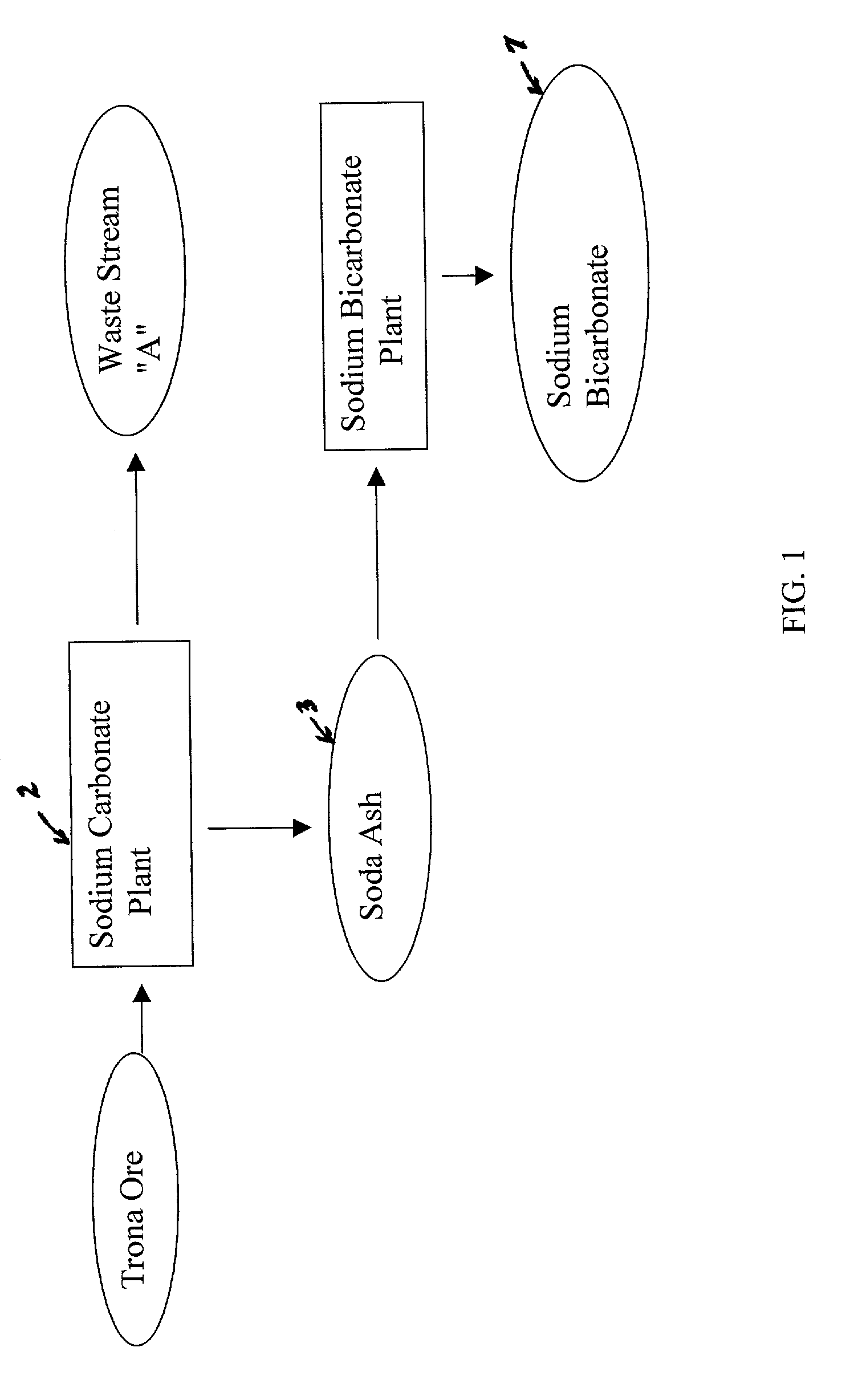

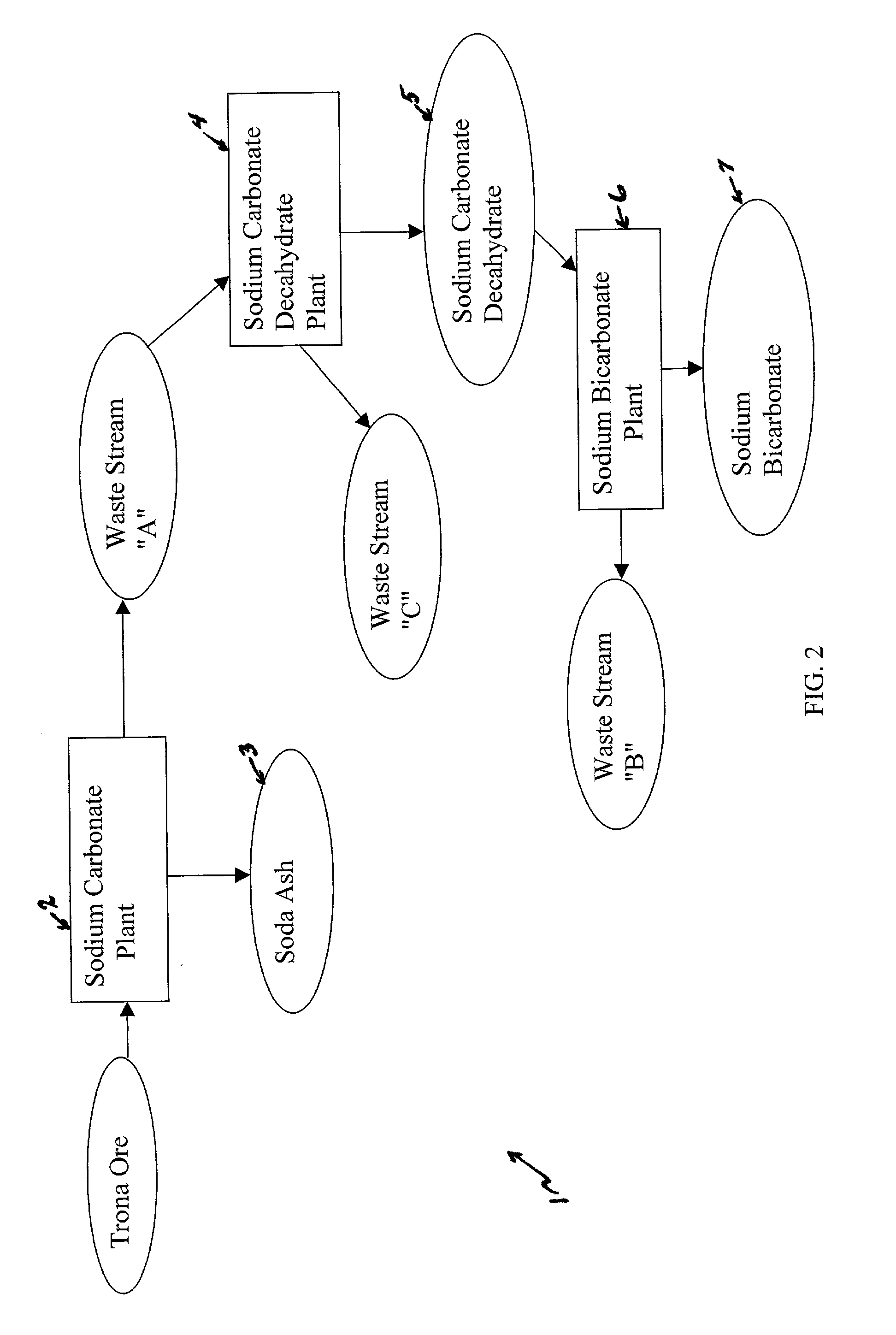

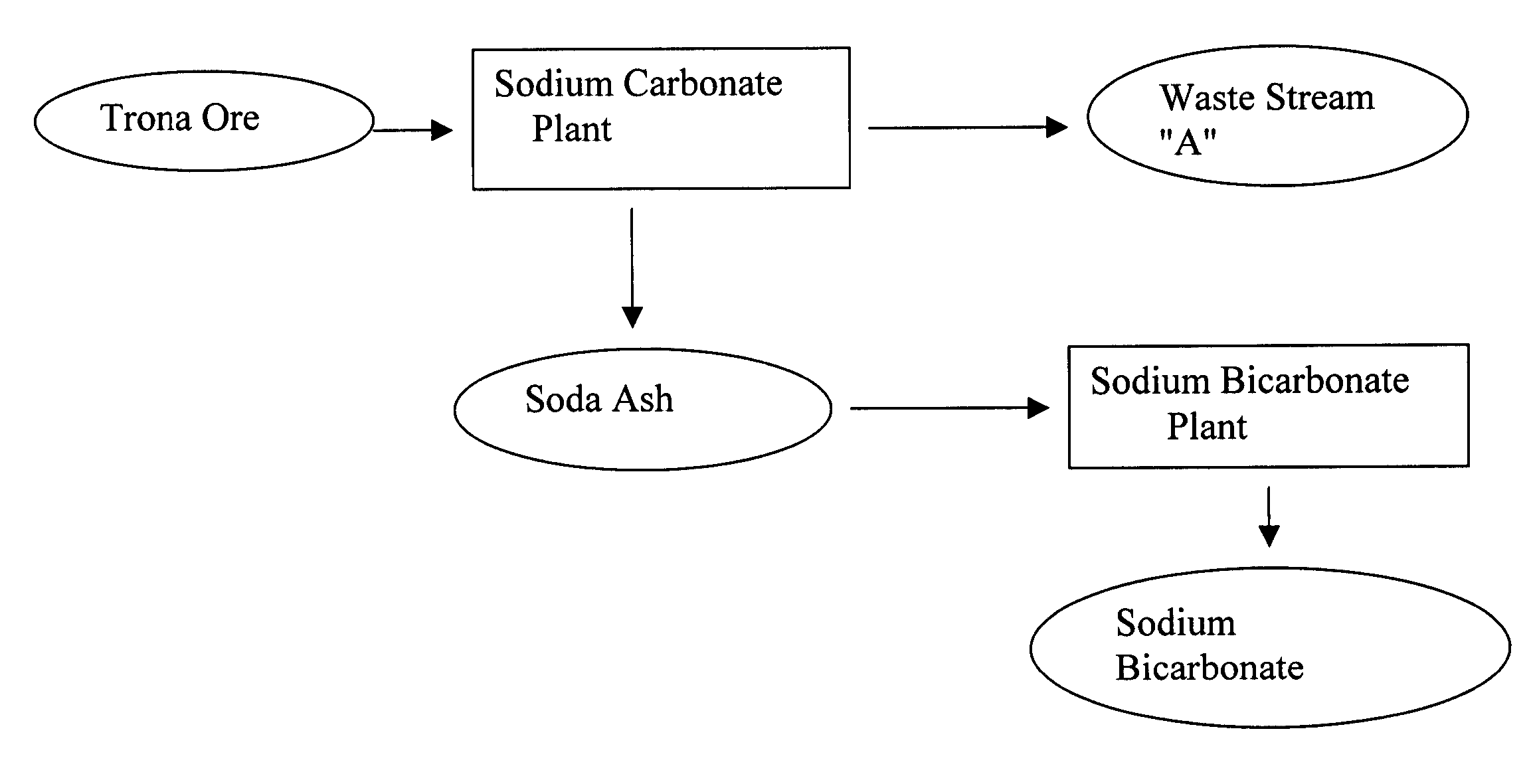

Sodium bicarbonate production method

InactiveUS20030017099A1Improvement in recovered sodium valuePromote recoveryBicarbonate preparationRubidium/caesium/francium compoundsEnvironmental engineeringSodium hydrogencarbonate

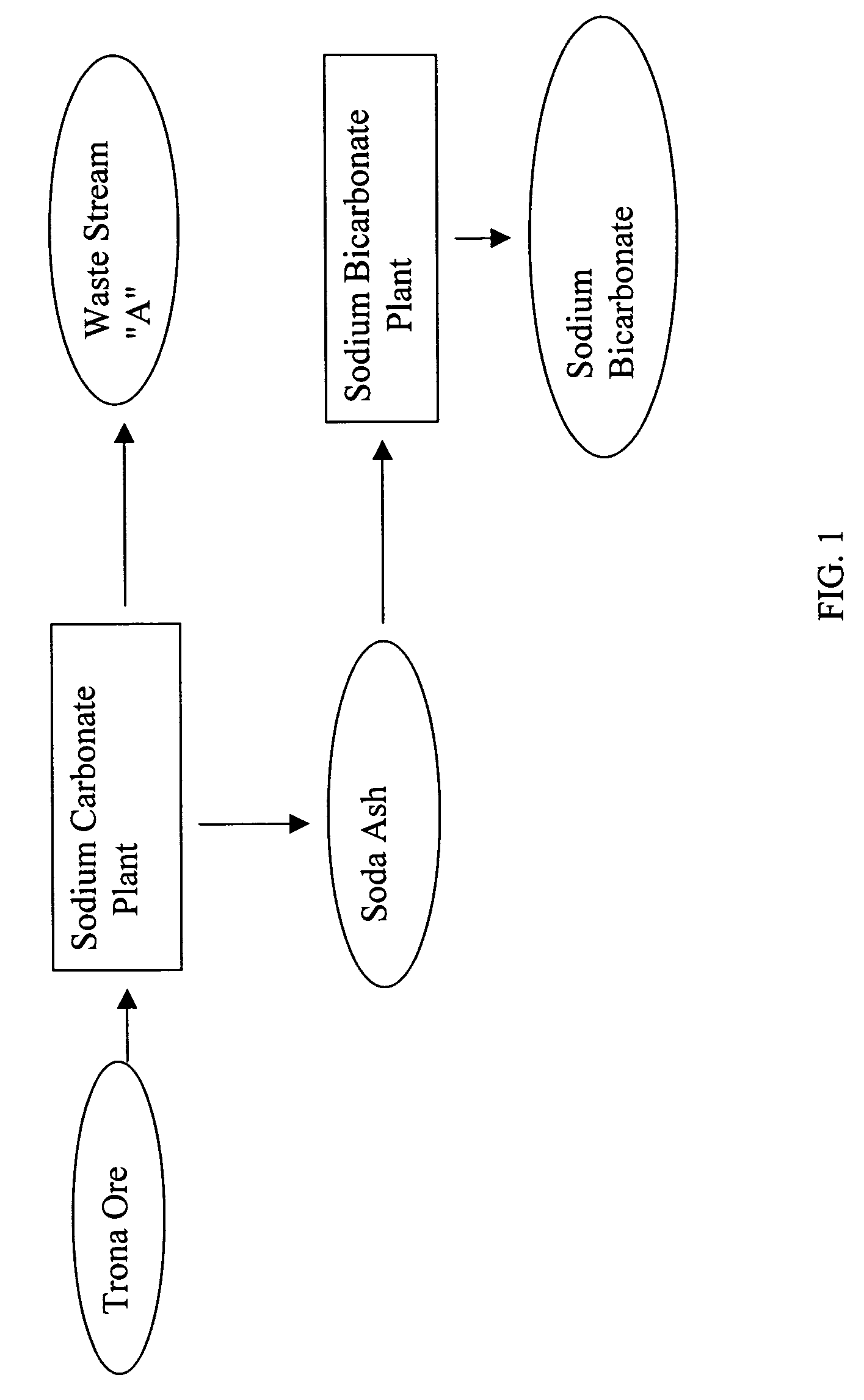

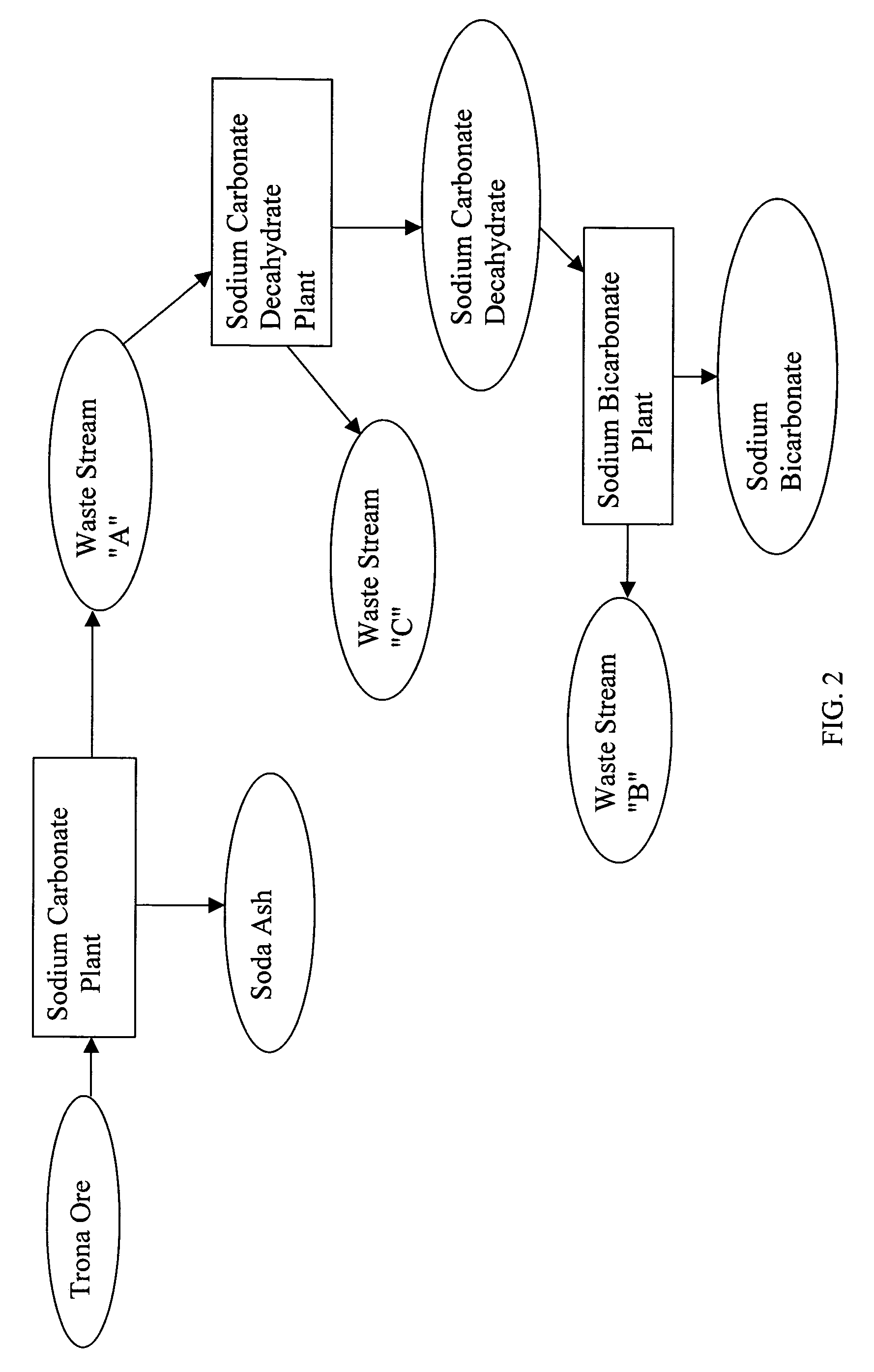

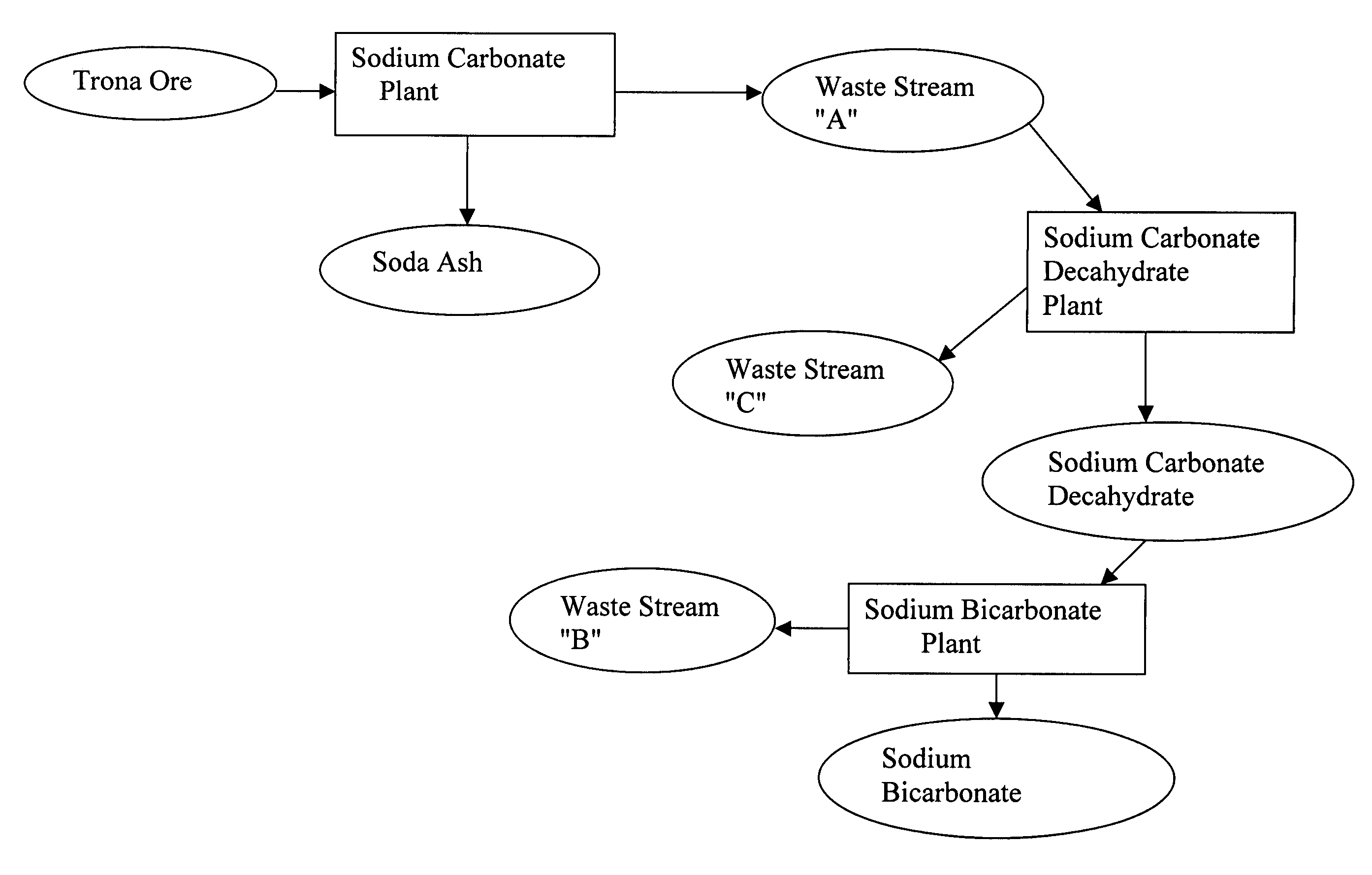

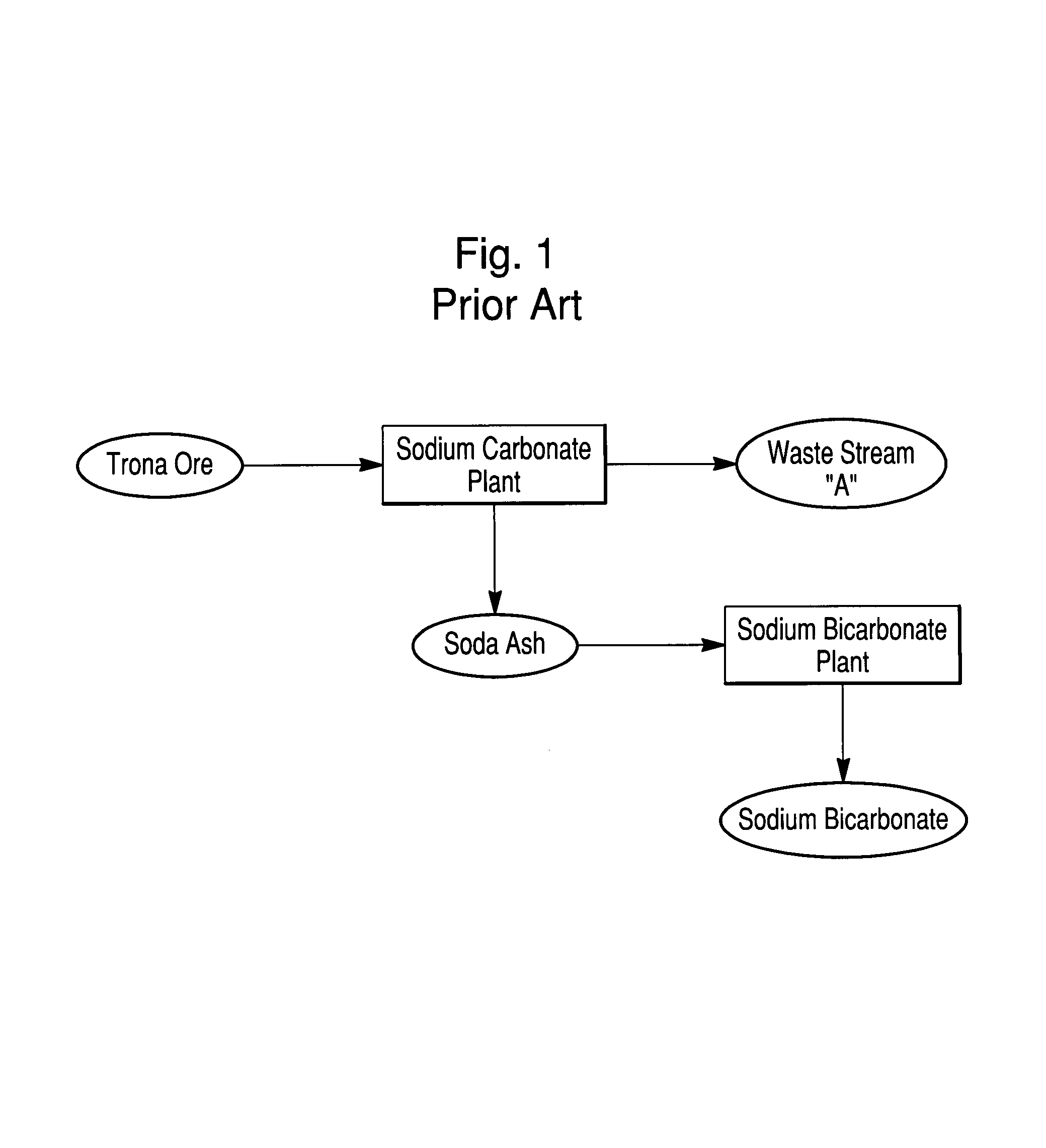

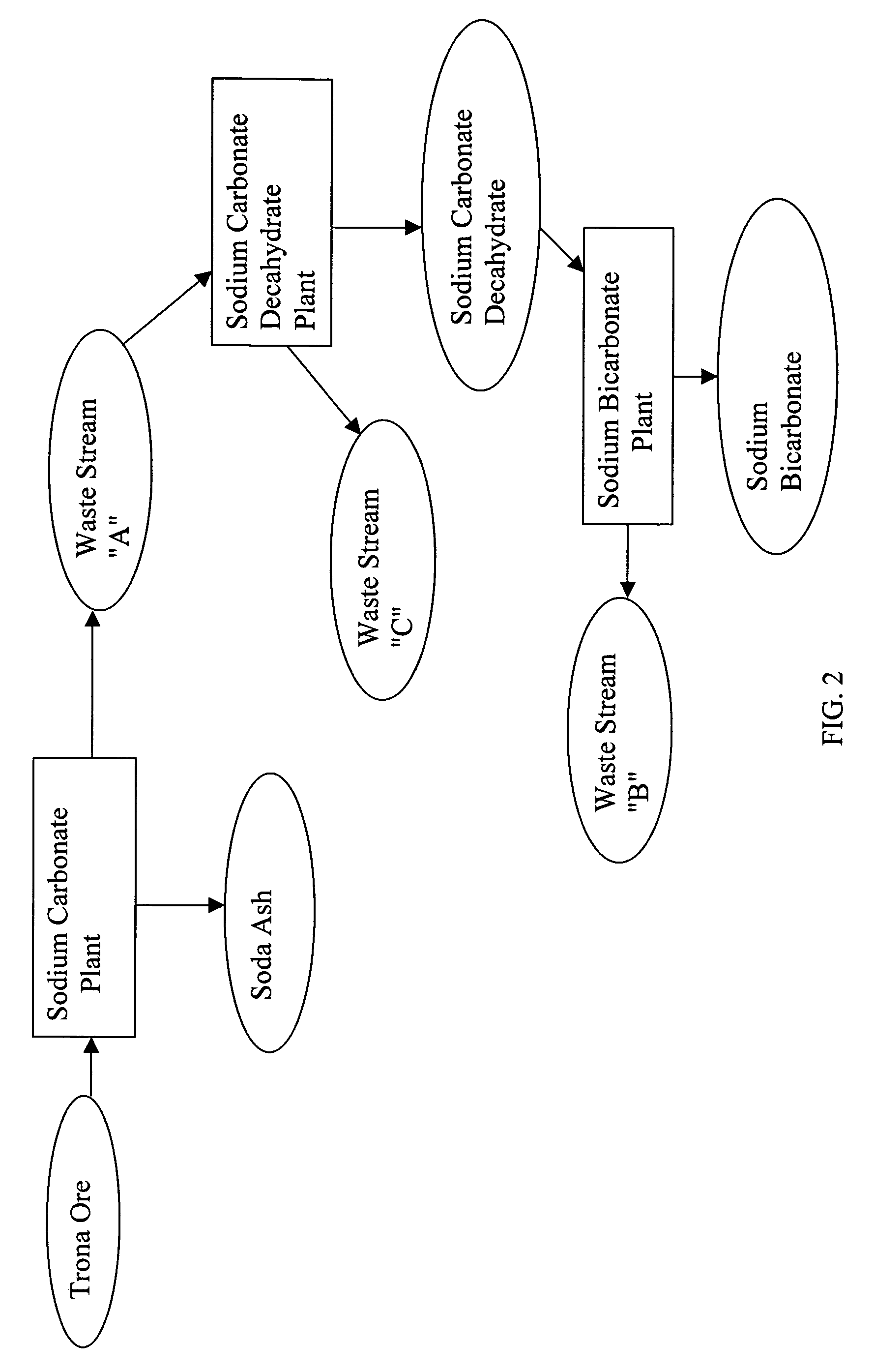

A method of producing additional sodium bicarbonate having a high degree of purity and obtaining a net reduction in effluent waste water, as compared to prior processes, when starting from trona ore is disclosed. The process entails utilizing the waste-water effluent stream from the conversion of trona ore to sodium carbonate as the feed for the conversion of sodium carbonate to sodium bicarbonate.

Owner:CHURCH & DWIGHT CO INC

Sodium bicarbonate production method

InactiveUS20040057892A1Improvement in recovered sodium valuePromote recoveryBicarbonate preparationVarying alkali metal carbonate water contentWastewaterEngineering

A method of producing sodium bicarbonate having a high degree of purity and obtaining a net reduction in effluent waste water, as compared to prior processes, when starting from trona ore is disclosed. The process entails utilizing the waste-water effluent stream from the conversion of trona ore to sodium carbonate as the feed for the conversion of sodium carbonate to sodium bicarbonate.

Owner:CHURCH & DWIGHT CO INC

Methods for constructing underground borehole configurations and related solution mining methods

Disclosed are methods for solution mining of evaporite minerals, such as trona, comprising drilling an access well and at least two lateral boreholes; injecting a fluid; circulating the fluid through the lateral boreholes with a controlled fluid flow; and collecting a pregnant solution. Also disclosed are methods of solution mining that include injecting an aqueous solution into an underground trona cavity at a temperature sufficient to maintain at least a portion of the solution in the cavity in the Wegscheiderite solid phase region; removing aqueous solution from the cavity; and recovering alkaline values from the removed aqueous solution. Also disclosed are methods of solution mining that include injecting an aqueous solution into an underground trona cavity; removing aqueous solution from the cavity, wherein the temperature of the removed aqueous solution is at about the TWA point temperature; and recovering alkaline values from the removed aqueous solution.

Owner:SESQUI MINING

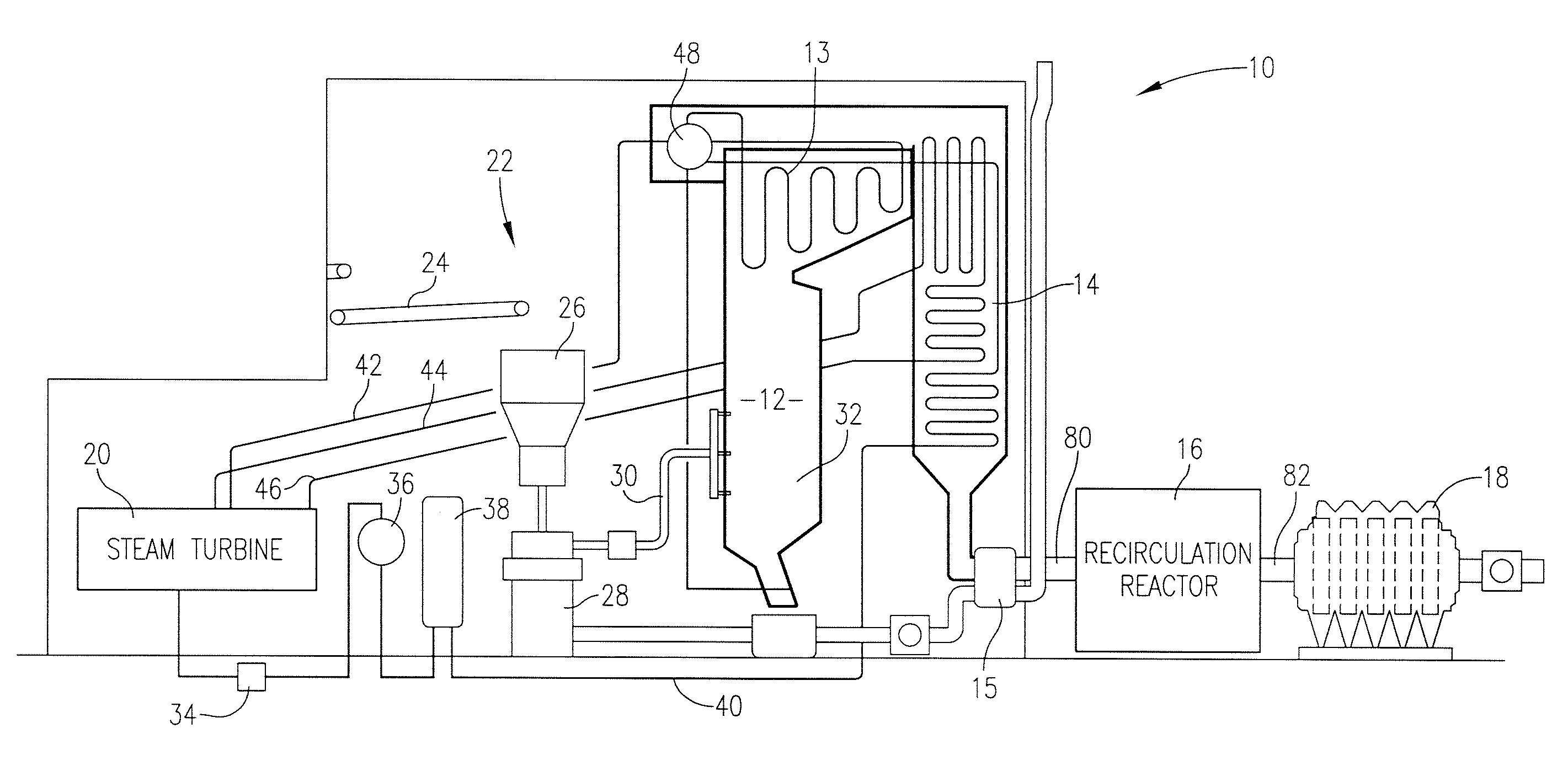

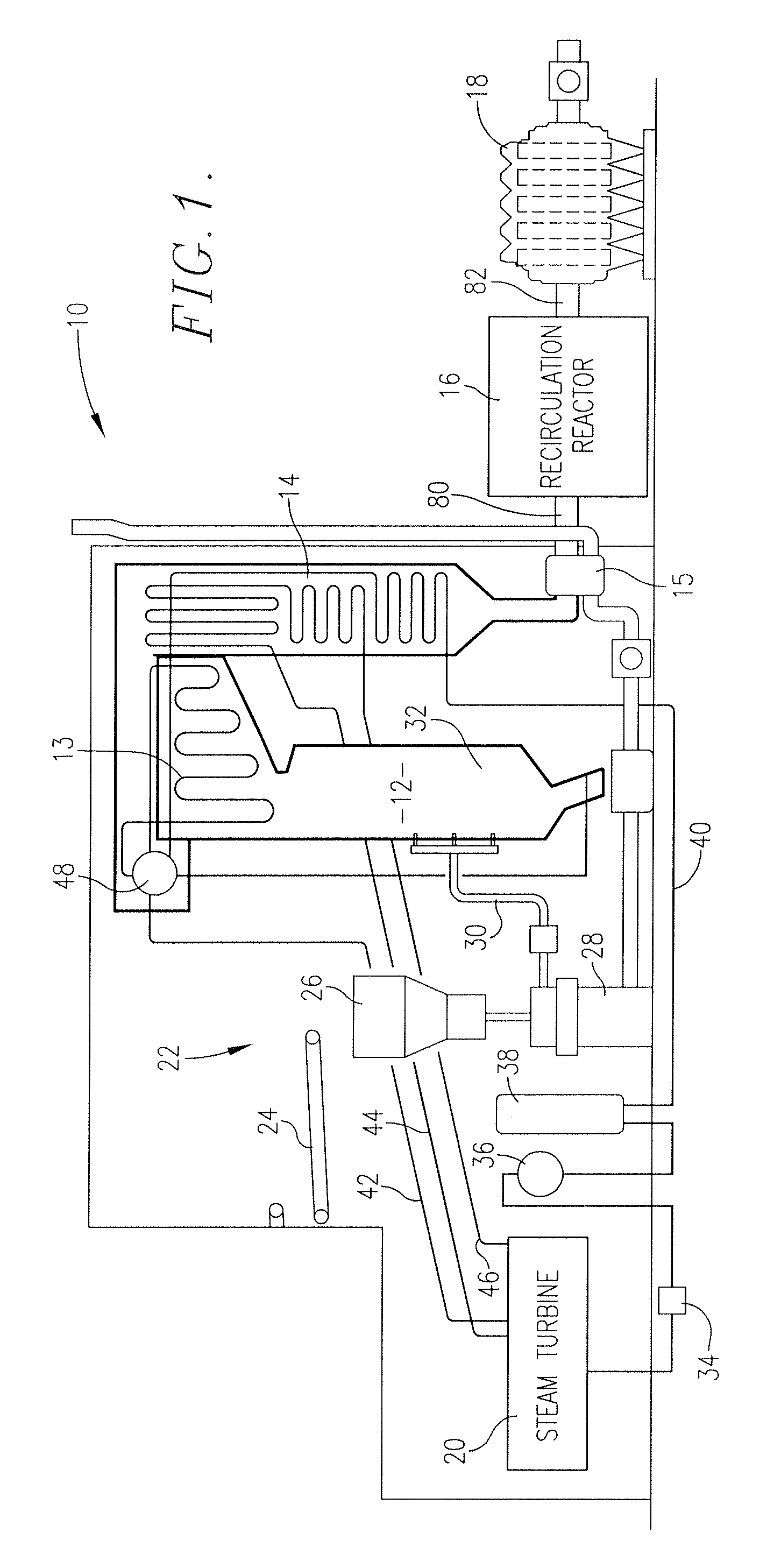

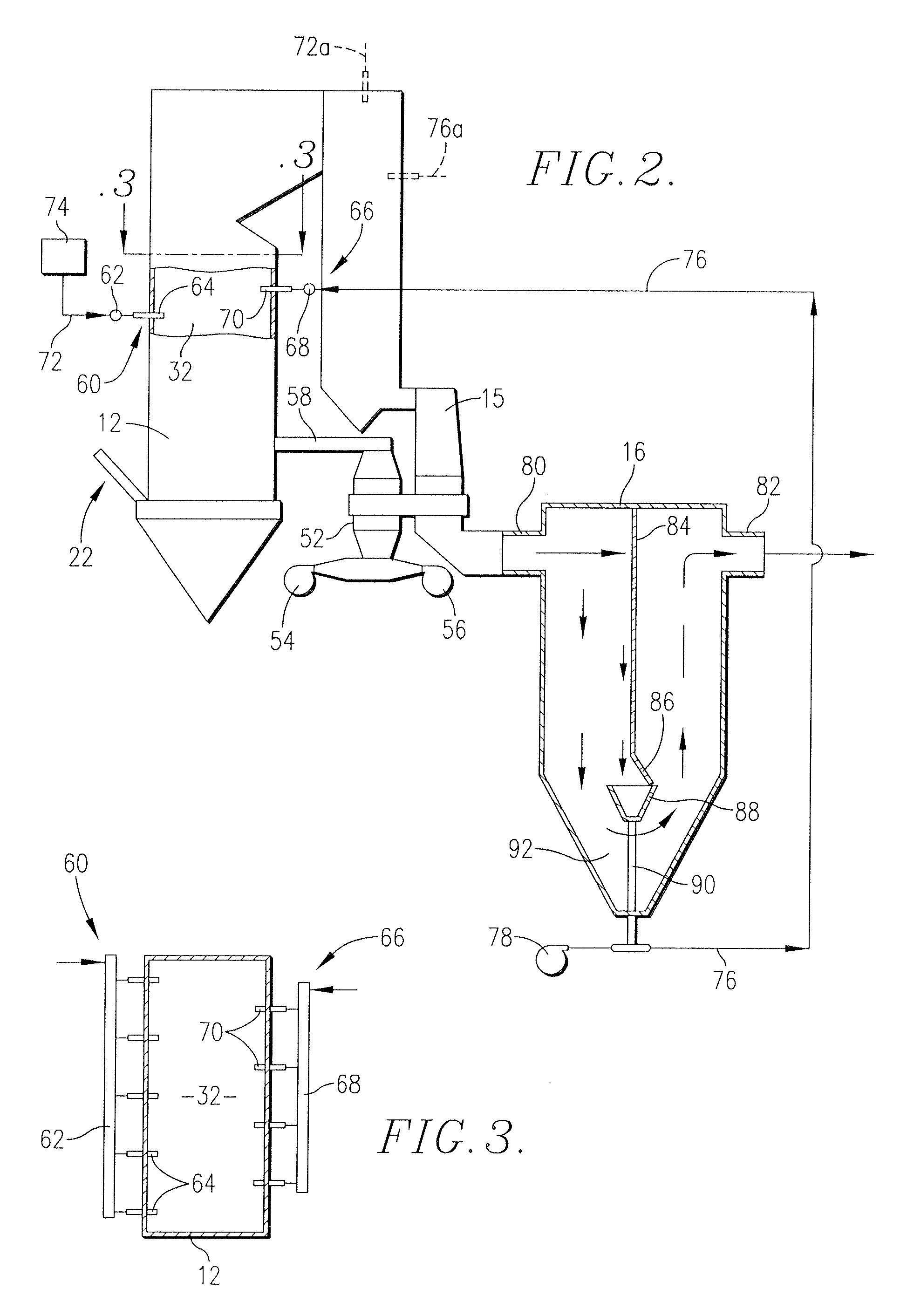

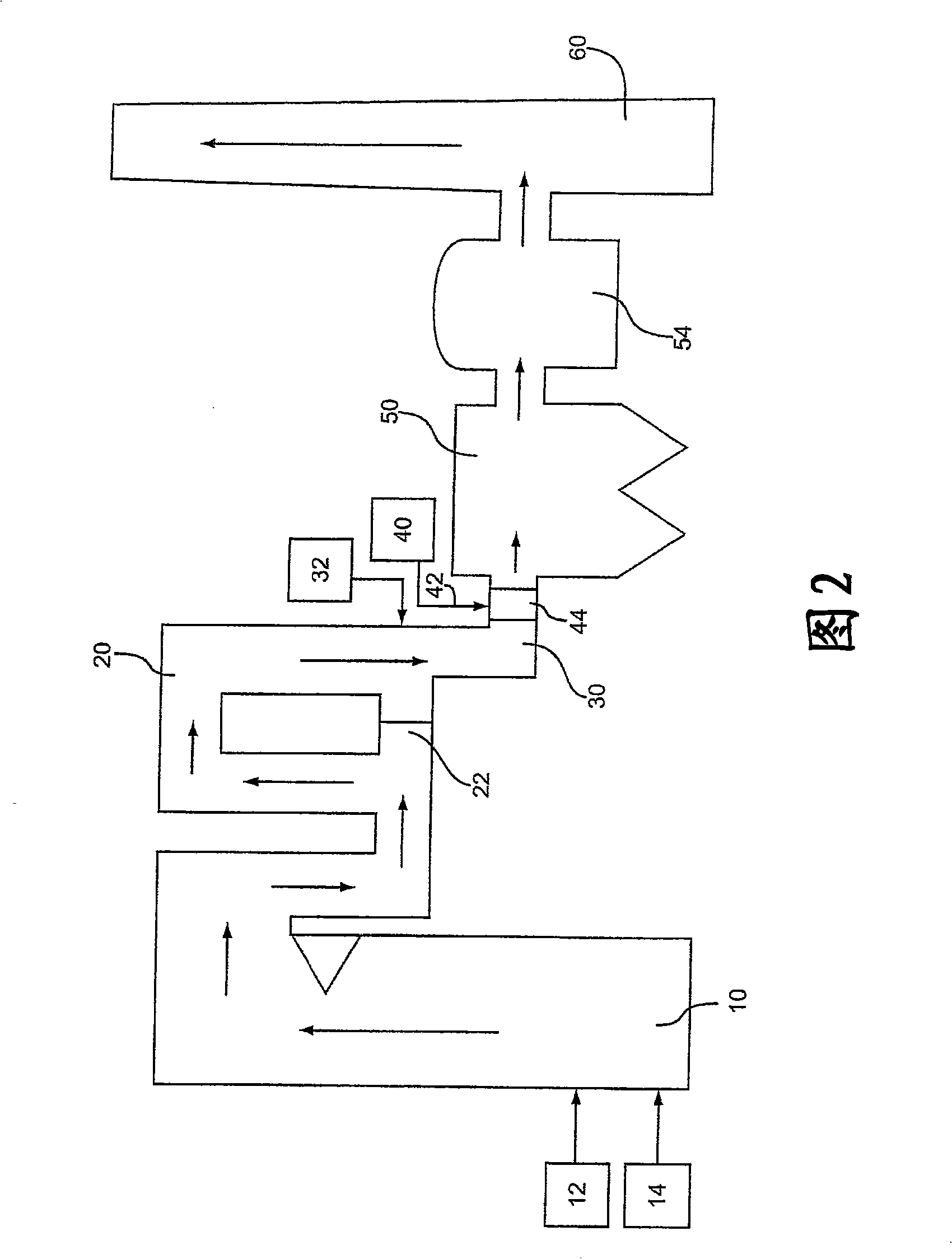

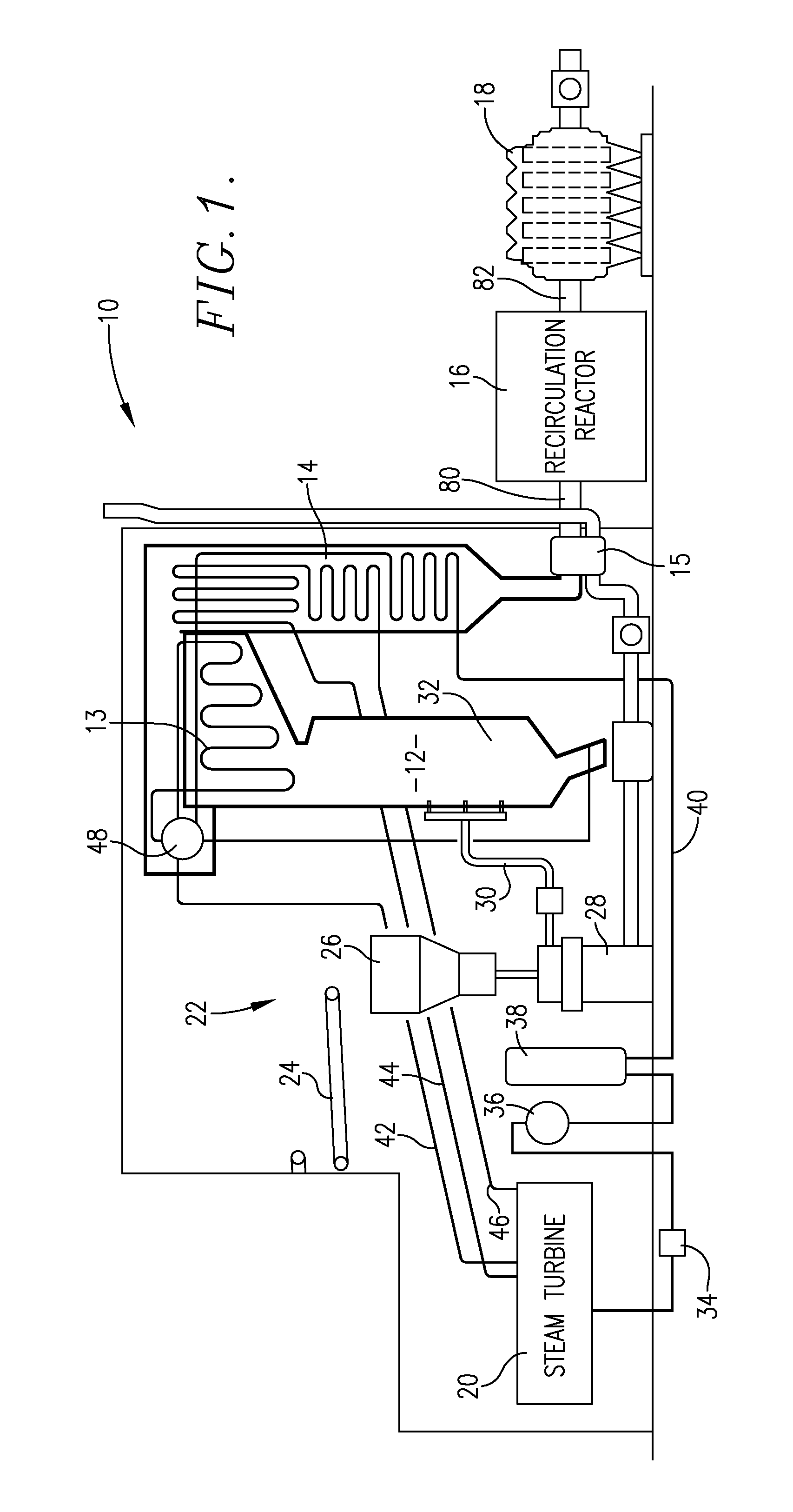

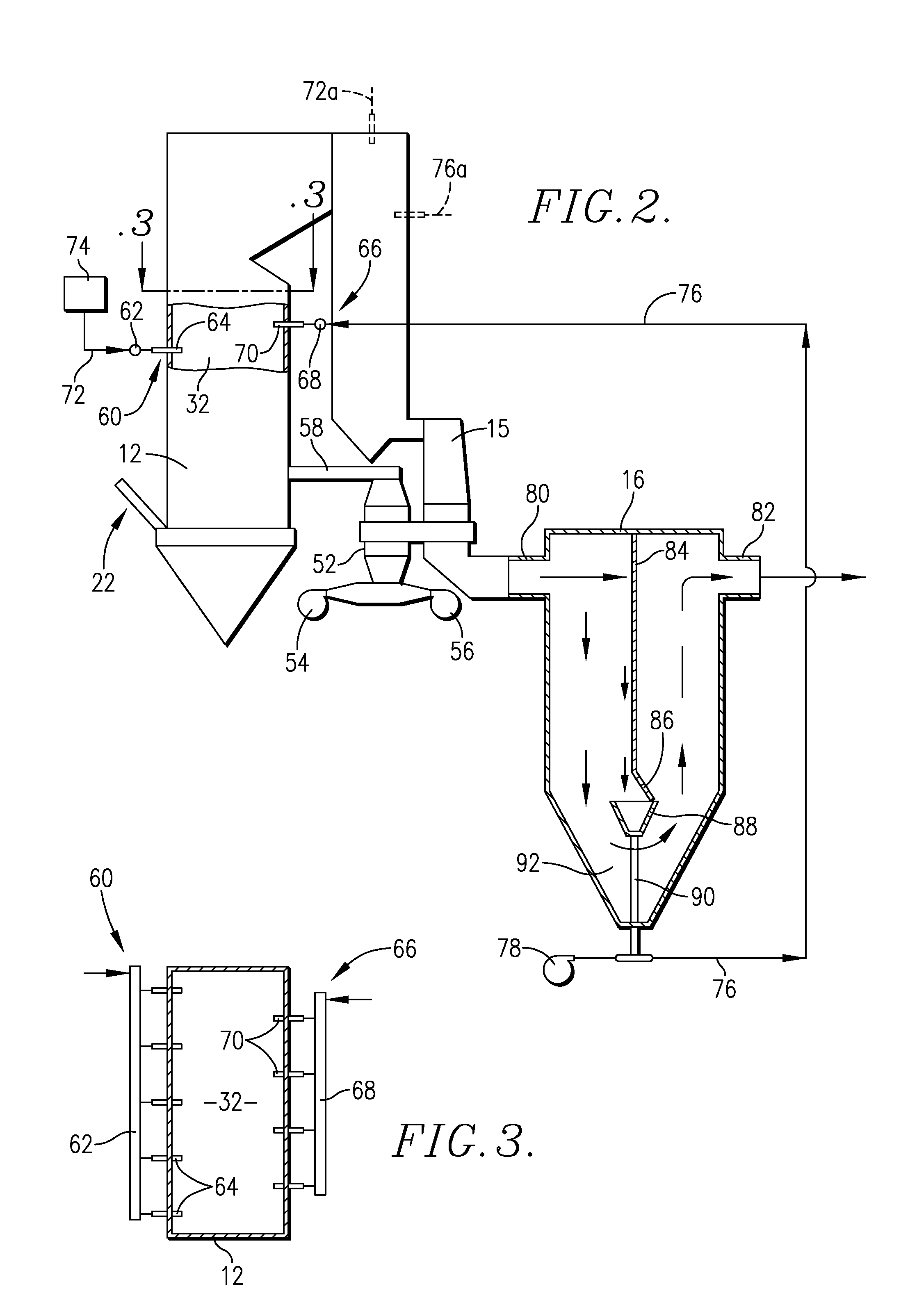

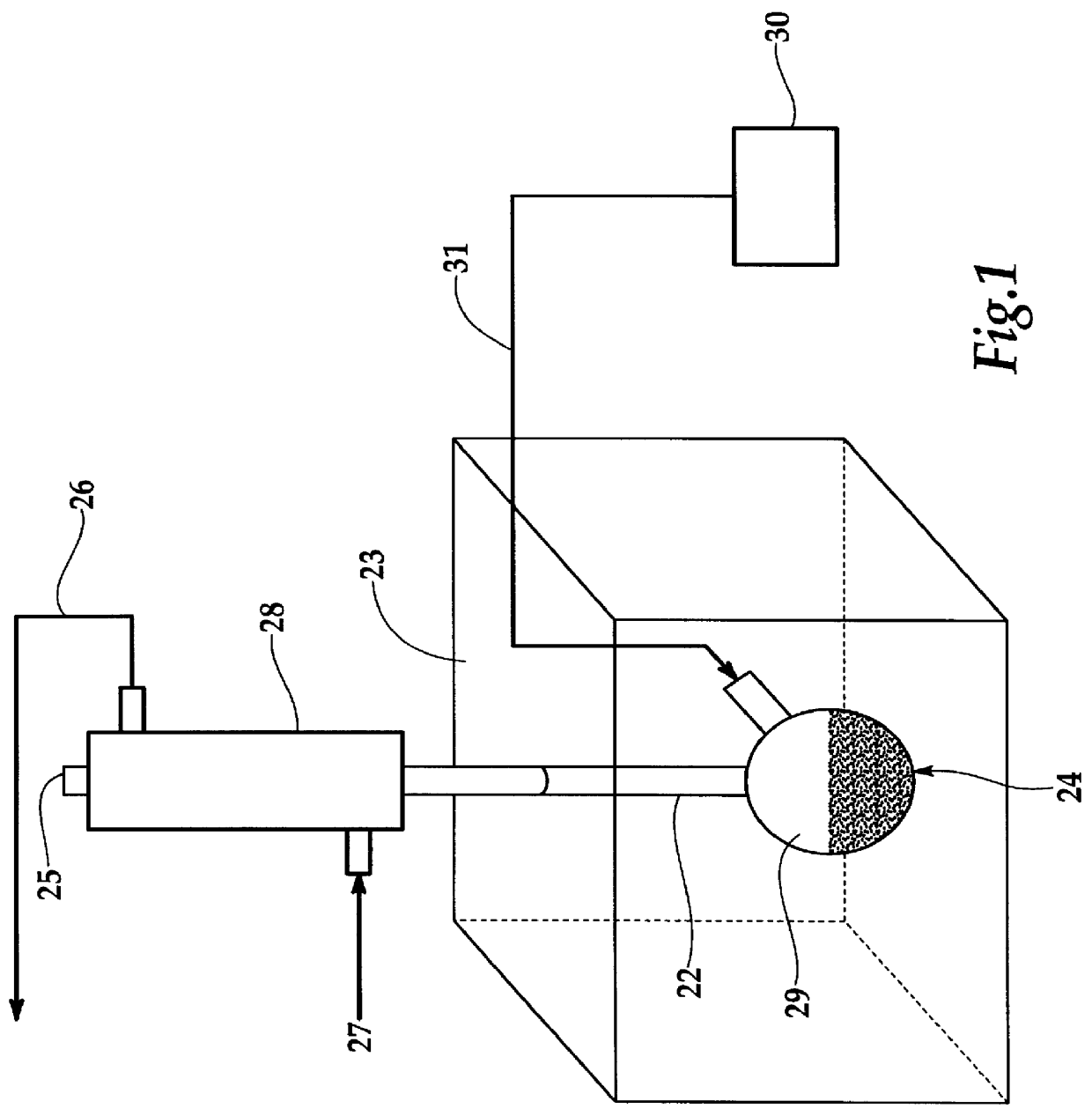

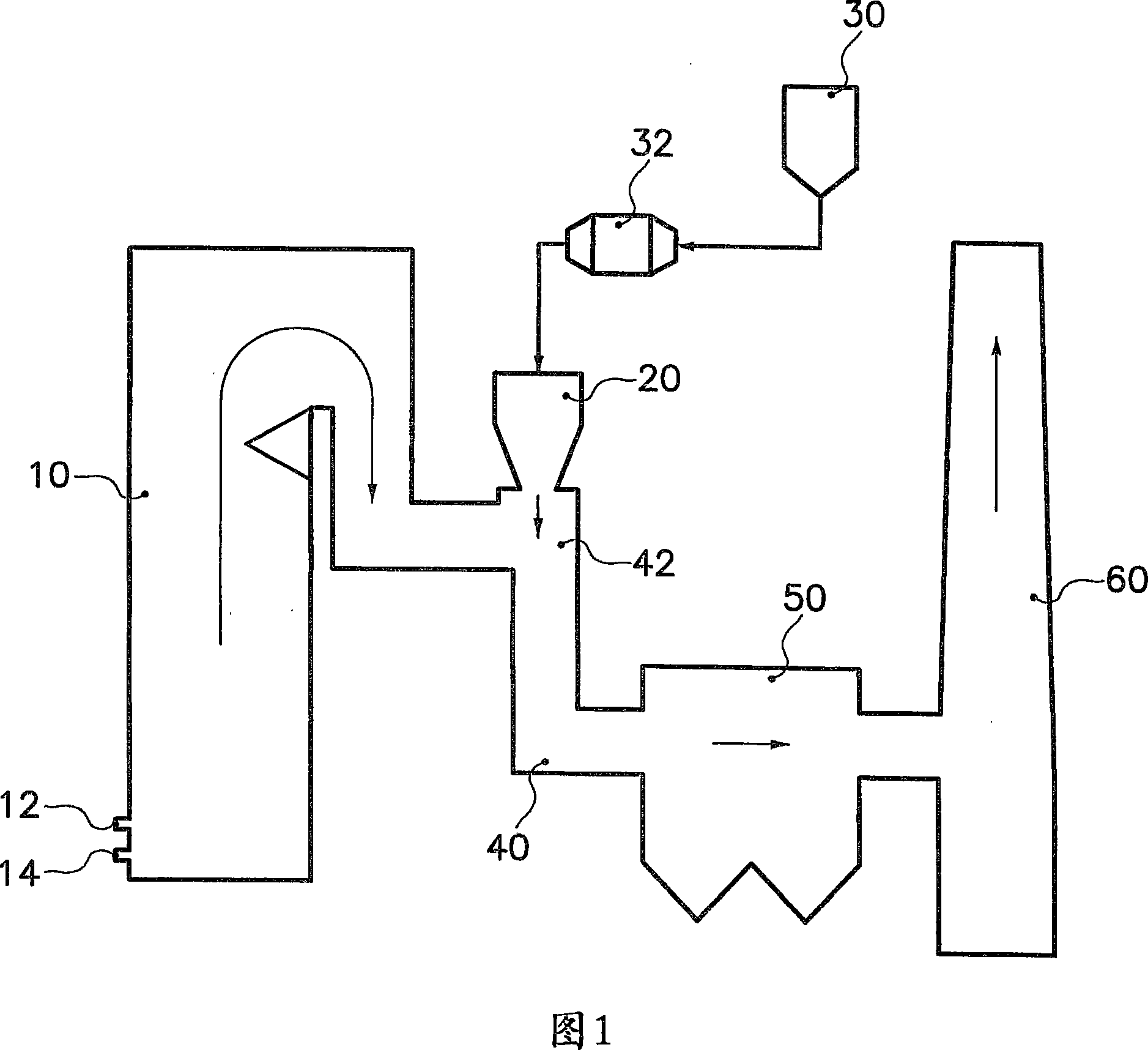

Pollution abatement process for fossil fuel-fired boilers

InactiveUS20100263577A1High degreeLow-cost operationGas treatmentSteam generation heating methodsParticulatesSodium bicarbonate

The present invention provides improved boiler assemblies (10) with enhanced pollution abatement properties through injection and recycling of particulate sorbent materials including sodium bicarbonate, trona, and mixtures thereof. The assemblies (10) include a boiler (12), economizer (14), air heater (15), and recirculation reactor (16). Fresh sorbent material is introduced via assembly (60) into the boiler assembly (10) at one or more injection locations, and serves to sorb NOx, SOx, and other pollutants in the flue gas. The flue gas and entrained sorbent material then pass through reactor (16) for separation of sorbent, which is then recycled for injection back into the assembly (10) upstream of reactor (16).The present invention can also be used in industrial applications where the same emissions are generated and are needed to be controlled. Examples of such applications are Cement and Lime Kilns.

Owner:INDAL ACCESSORIES

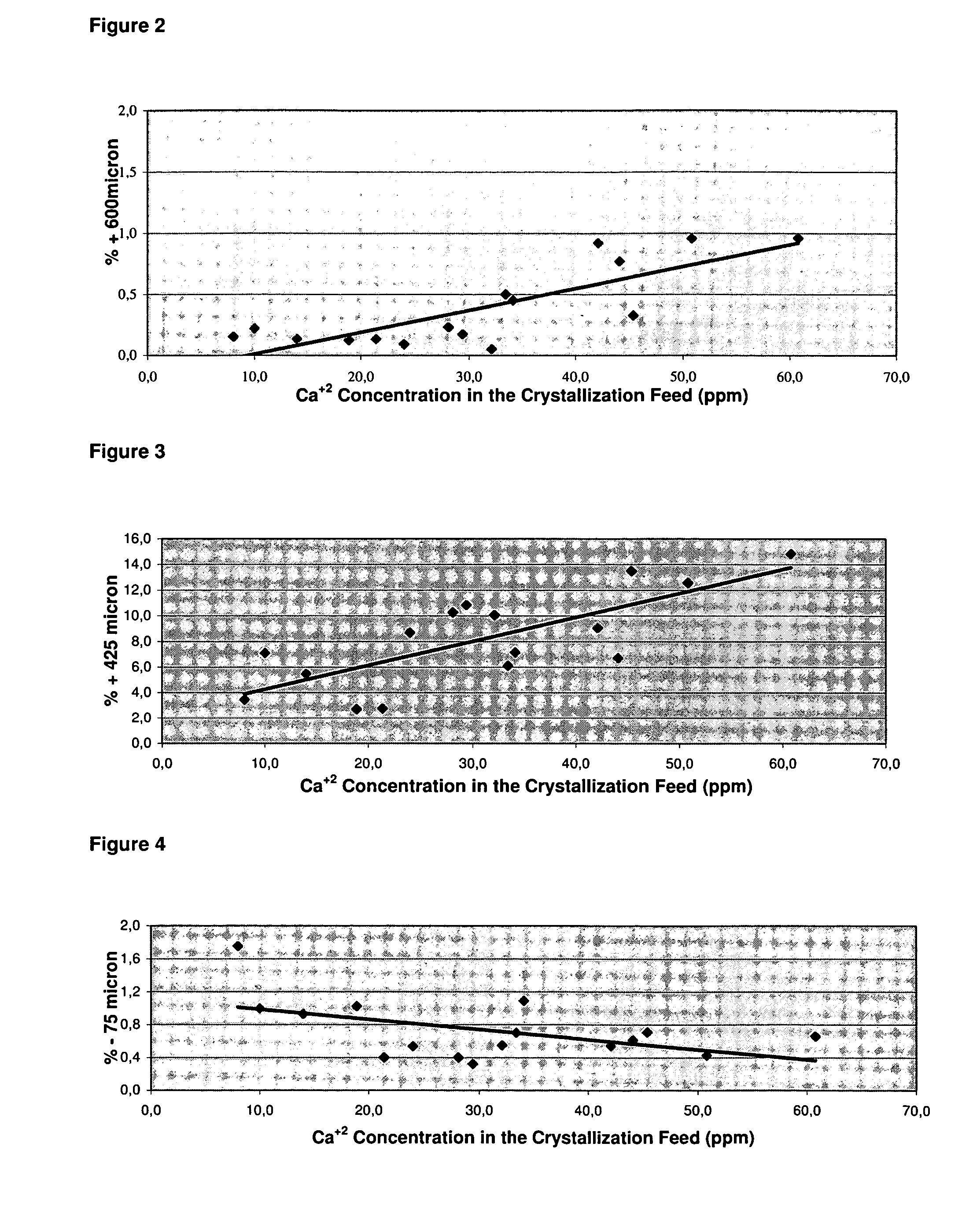

Removal of impurities in the production of crystalline sodium carbonate, bicarbonate, or sulfite

ActiveUS20100226840A1Reduce contentGood physical propertiesCrystallization separationAlkali metal sulfite/sulfate purificationSodium bicarbonateDicarbonate

A magnesium treatment for removing water-soluble impurities in a process for making crystalline sodium carbonate, bicarbonate, or sulfite. A waste comprising such impurities is treated with a magnesium compound to form water-insoluble matter which is removed to form a purified solution. The treatment may be performed on a solution which contains the waste and optionally dissolved calcined trona. The purified solution may be used as a feedstock to form crystalline soda ash, and / or used as a reactant to produce crystalline sodium sulfite or bicarbonate via reaction with SO2 or CO2. In preferred embodiments, the waste may comprise a purge or weak liquor, a reclaimed solid, or combinations thereof. The water-soluble impurities may be silicates and / or foam-causing impurities, and the waste may contain sodium bicarbonate, sodium sesquicarbonate, and / or one or more sodium carbonate hydrates, such as decahydrate.

Owner:SOLVAY CHEM INC

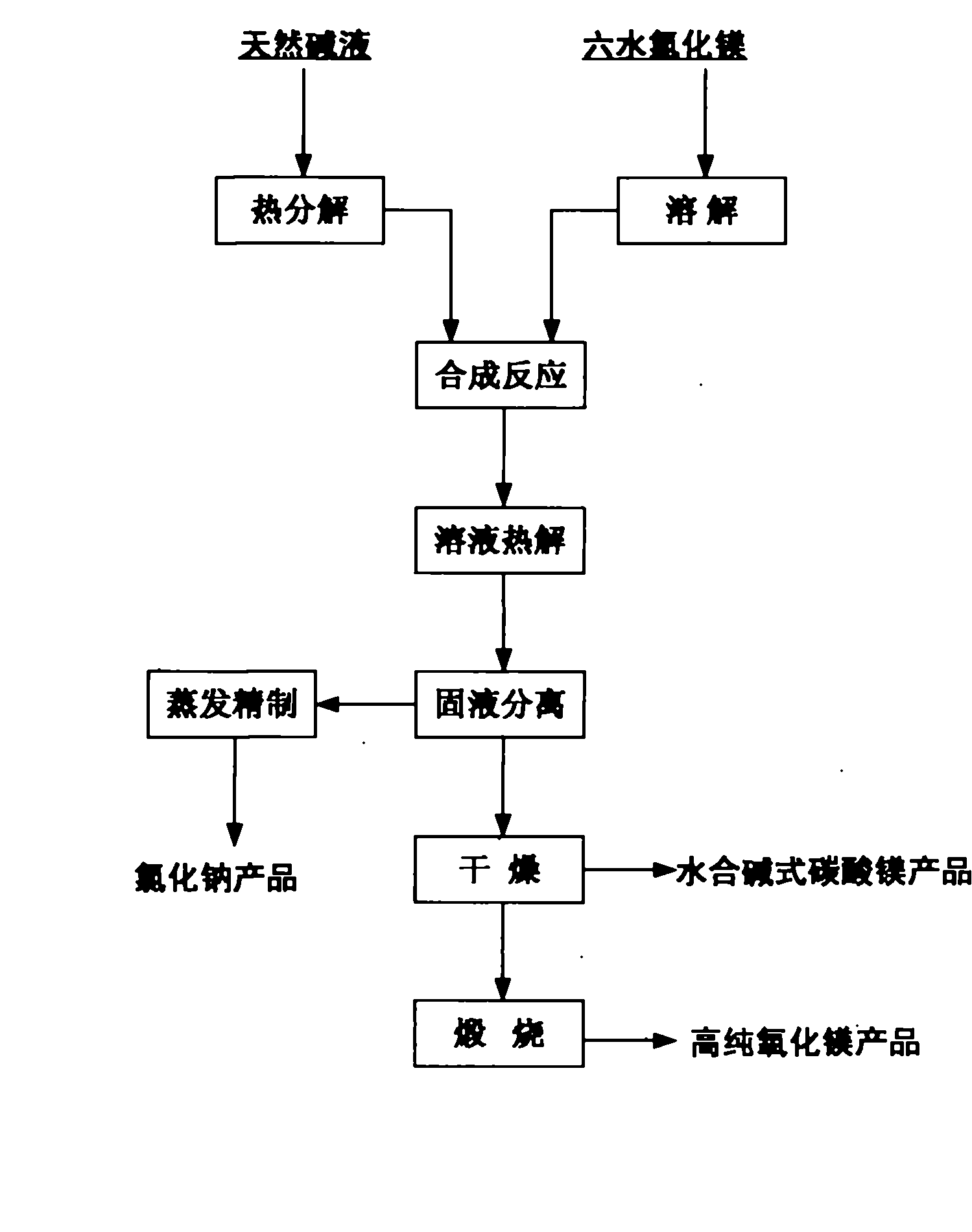

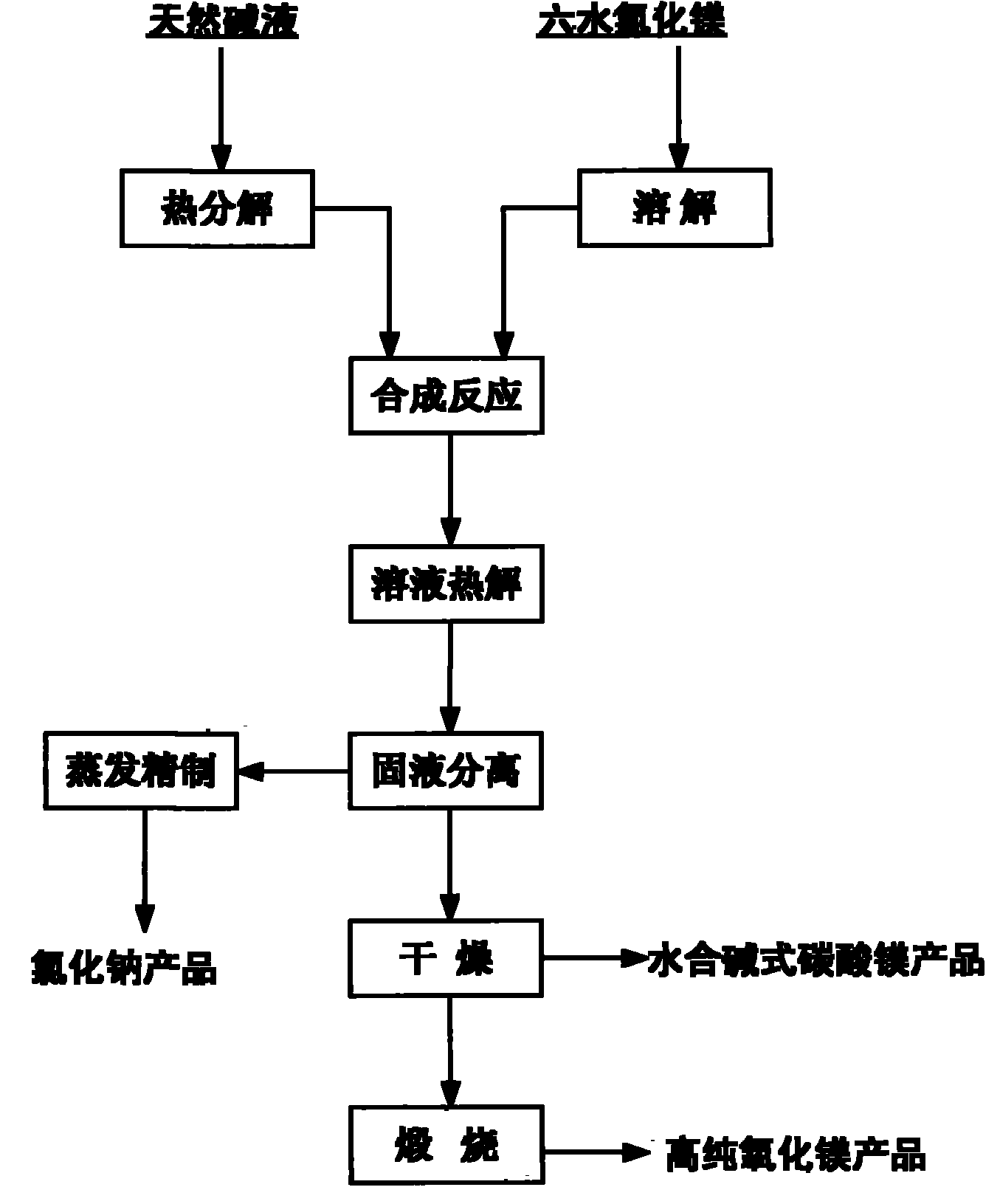

Method for preparing basic magnesium carbonate and high purity magnesium oxide with trona

ActiveCN102079533AAvoid evaporative concentrationPrevent crystallizationMagnesium carbonatesMagnesiaResource utilizationChloride

The invention belongs to the brine chemical engineering field and in particular to a method for preparing basic magnesium carbonate and high purity magnesium oxide with trona. In the method, magnesium chloride is used as a raw material, the brine of natural alkali is used as precipitation medium, the primary thermolysis of natural alkali is performed, the high temperature reaction of magnesium chloride solution is performed, hot water is used for washing to obtain hydrated basic magnesium carbonate of which magnesium chloride content is more than 42%, and the obtained solid intermediate product is calcined at high temperature to prepare high purity magnesium oxide of which purity is more than 98%. In the method in the invention, the advantages of the brine of natural alkali, namely low cost and high purity are utilized to prepare high purity magnesium oxide, thus the benefit of resource utilization can be increased, the brine of natural alkali can be used locally and the optimal industrial product with maximum benefit and technology can be obtained.

Owner:河南元亨精细化工有限公司

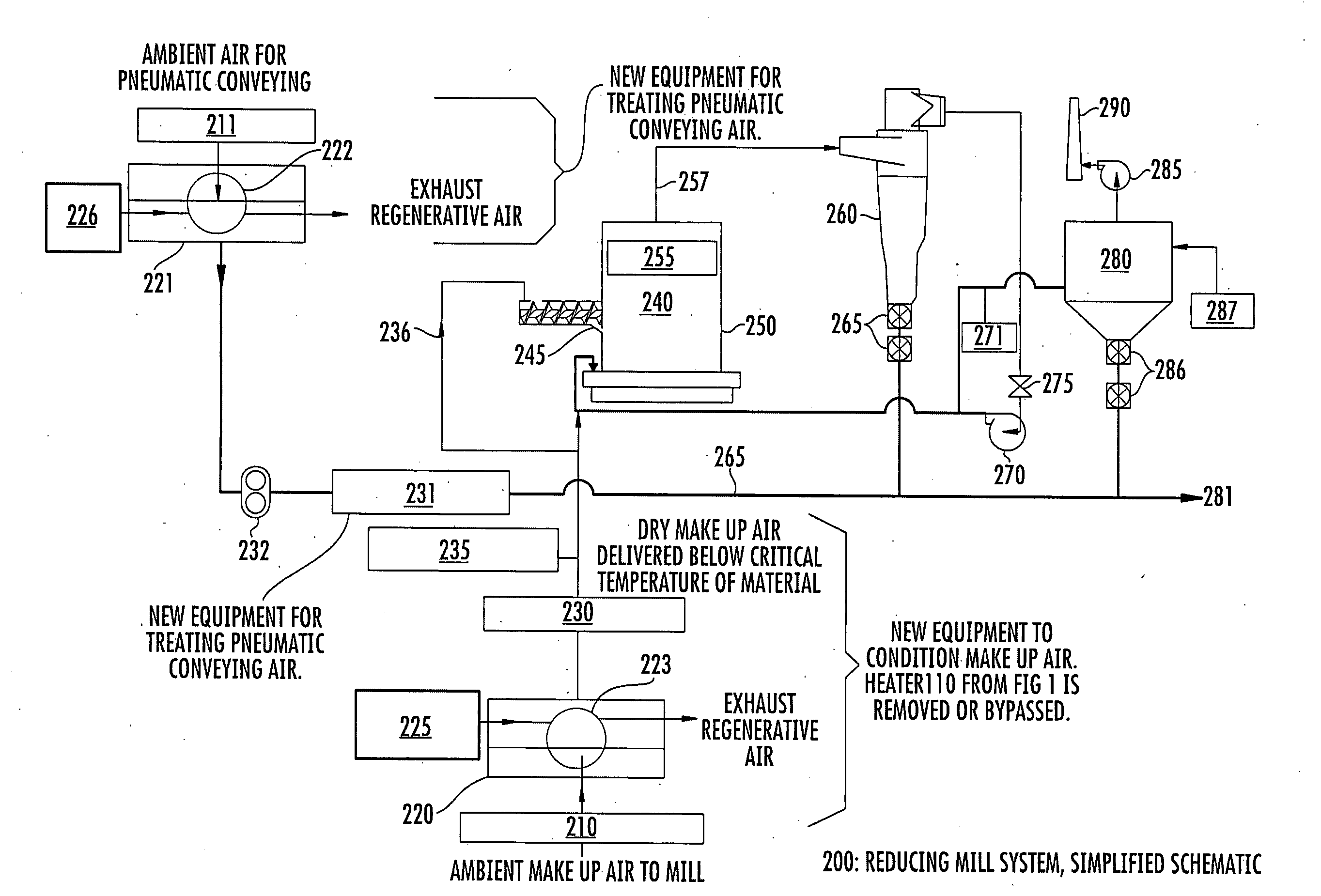

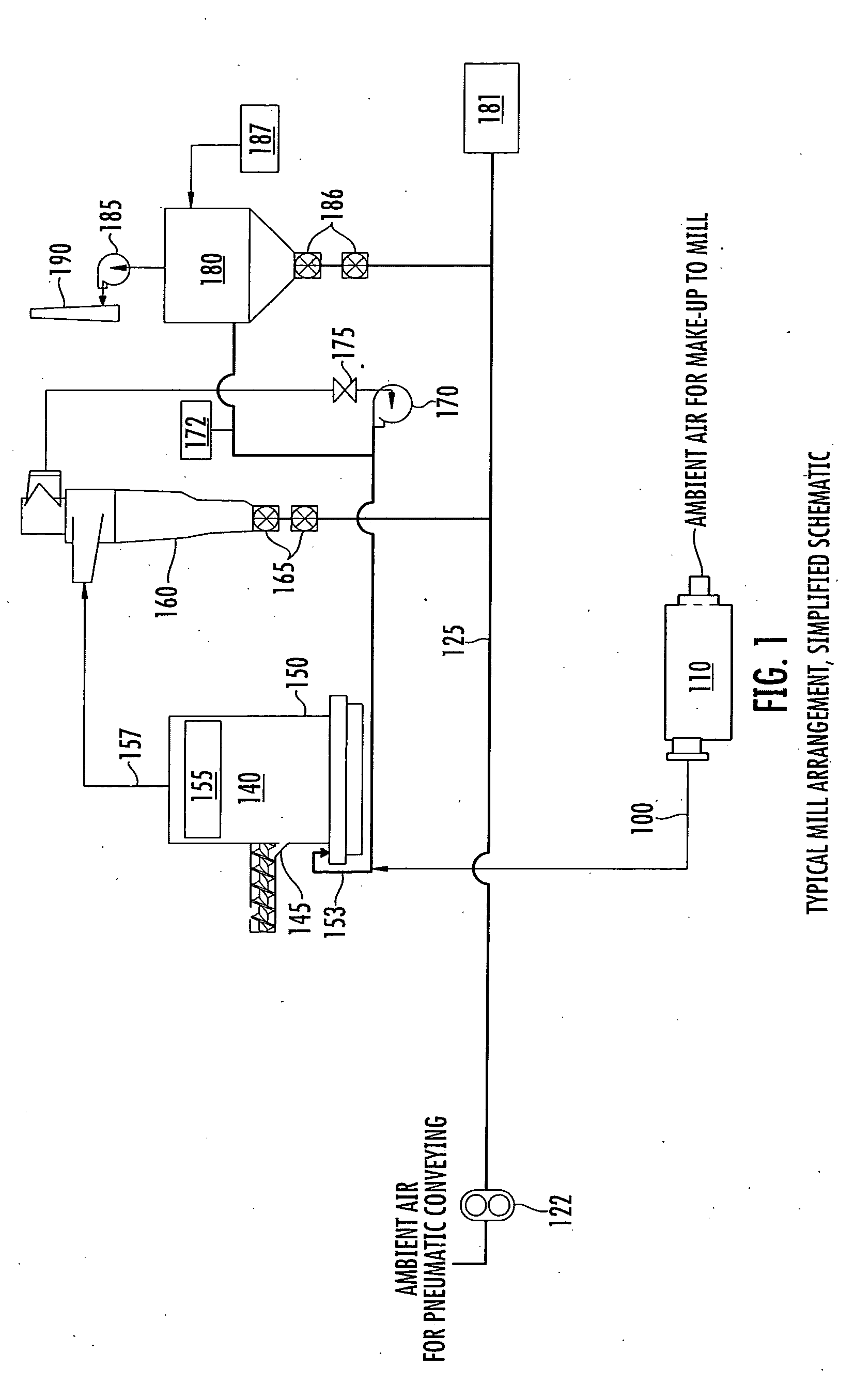

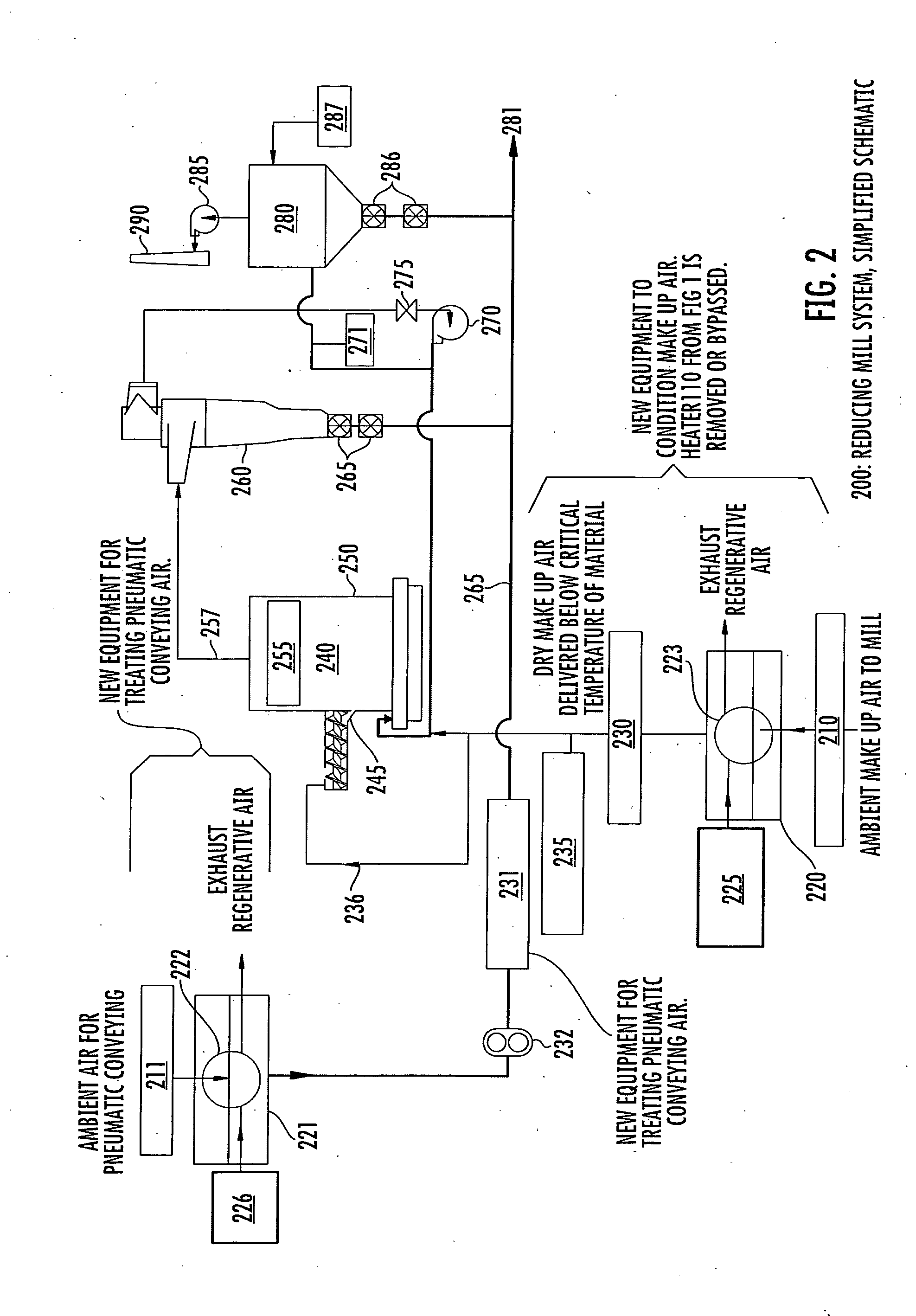

System and method for processing hygroscopic materials

InactiveUS20090212140A1Reduce humidityEasy to handleAlkali metal carbonatesSortingEngineeringPre treatment

The present invention is a system and method for reducing the size of a hygroscopic material while simultaneously drying the material at a relatively low temperature to a predetermined value during the reduction process. The present invention utilizes a preconditioning make-up air system to significantly dehumidify the make-up air to values in the range of 0.02 grains per pound of dry air while limiting the temperature of the make-up air exiting the preconditioning make-up air system to below a predetermined critical value. While not limited in its application to any one particular hygroscopic material, the present invention is particularly adapted to uses where the product is a temperature-sensitive, water adsorbing material such as sodium sesquicarbonate or trona ore.

Owner:AMERICAN ELECTRIC POWER CO INC

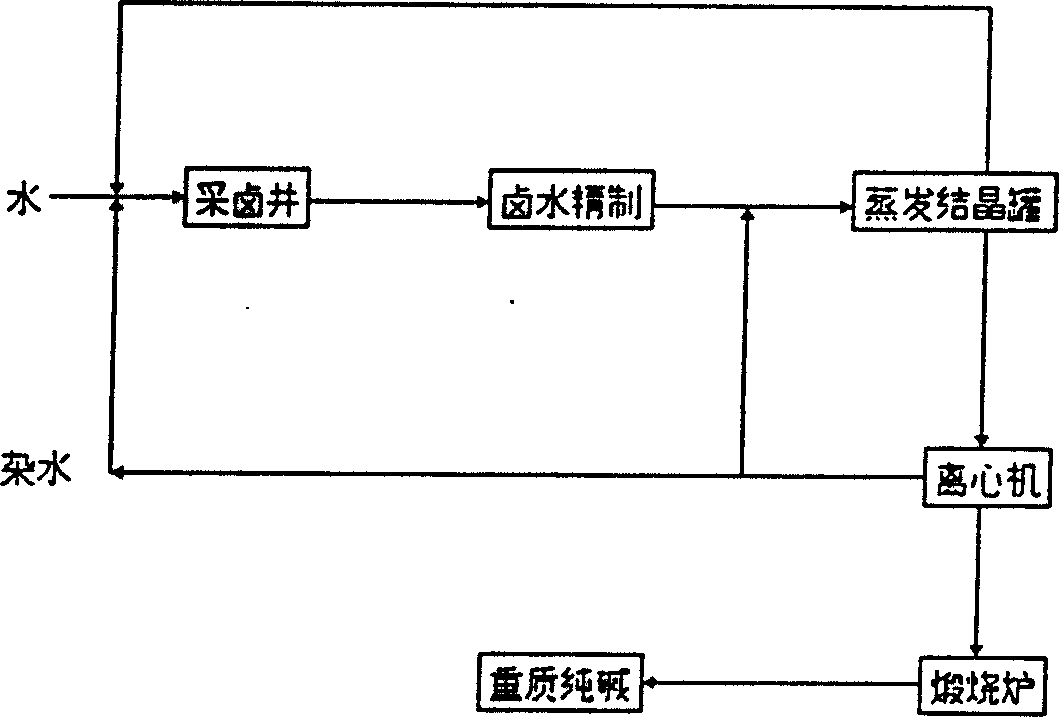

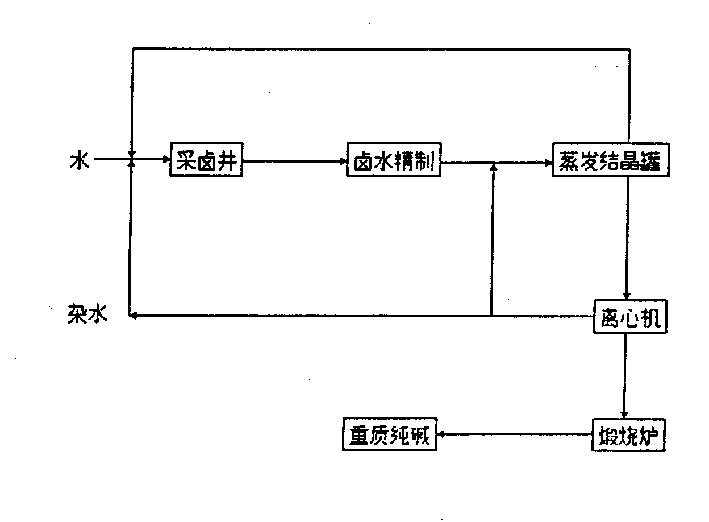

Process for preparing calcined soda by trona containing abundant sodium bicarbonate

The process for producing anhydrous sodium carbonate by utilizing natural alkali richly containing sodium hydrogen carbonate includes the following steps: purifying alkali bittern, feeding it into evaporation crystallization tank, introducing steam to make evaporation, concentration, wet decomposition (stripping) and crystallization so as to make most of sodium hydrogen carbonate in the alkali bittern be decomposed and converted into sodium carbonate, finally, in the crystallizer separating the sodium carbonate in the form of crystal carbonate and concentrated crystal soda mixed crystal from mother liquor, and calcining the mixed crystal to obtain invented product heavy anhydrous sodium carbonate whose stacking density is greater than 0.9.

Owner:INNER MONGOLIA YIKE SCI & TECH

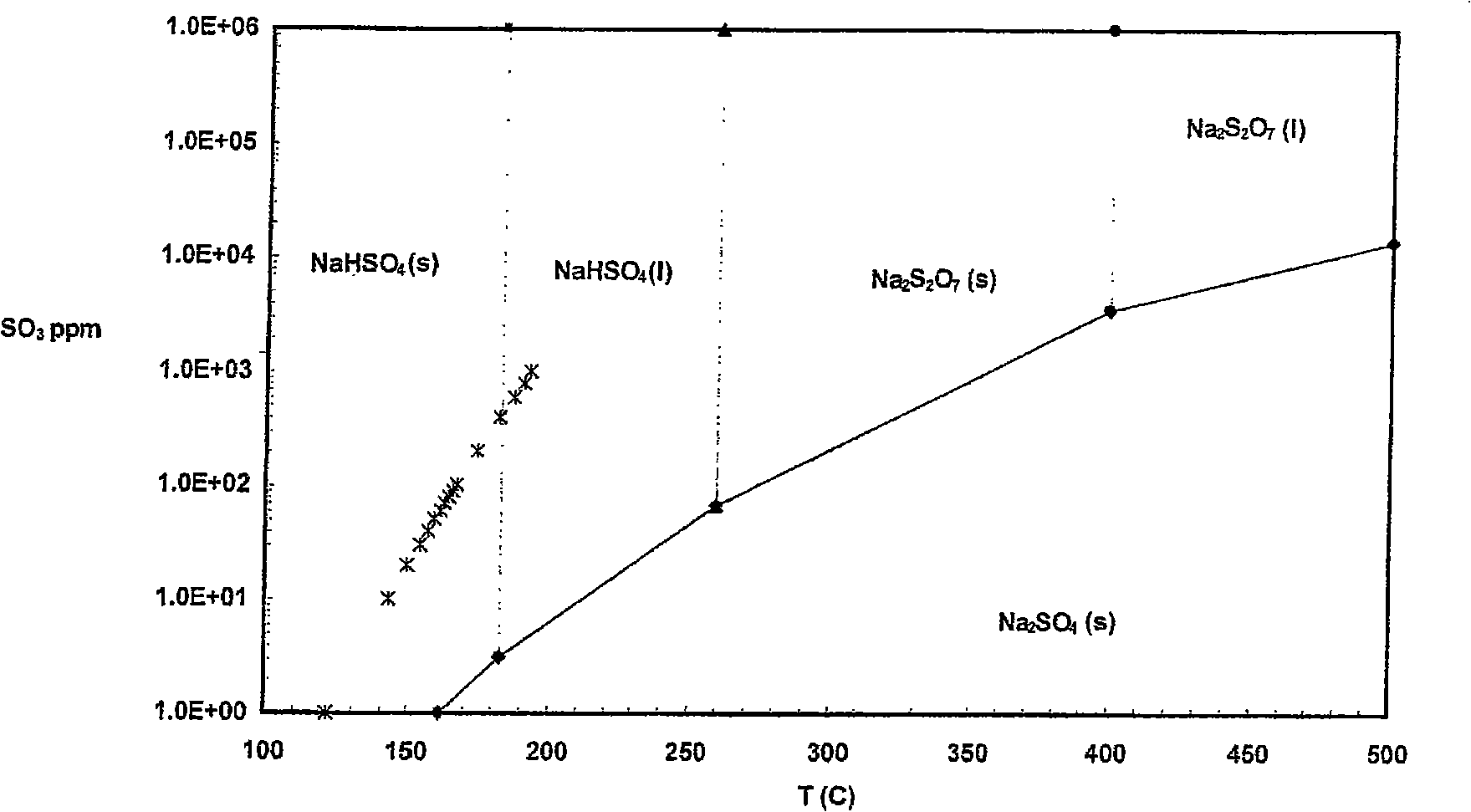

Sulfur trioxide removal from a flue gas stream

A method of removing SO3 from a flue gas stream having increased amounts of SO3 formed by a NOx removal system, includes injecting a sorbent composition into the flue gas stream. The sorbent composition includes an additive and a sodium sorbent such as mechanically refined trona or sodium bicarbonate. The additive is selected magnesium carbonate, calcium carbonate, magnesium hydroxide, calcium hydroxide, and mixtures thereof. The concentration of the SO3 in the flue gas stream is reduced and the formation of a liquid phase NaHSO4 reaction product is minimized.

Owner:SOLVAY CHEM INC

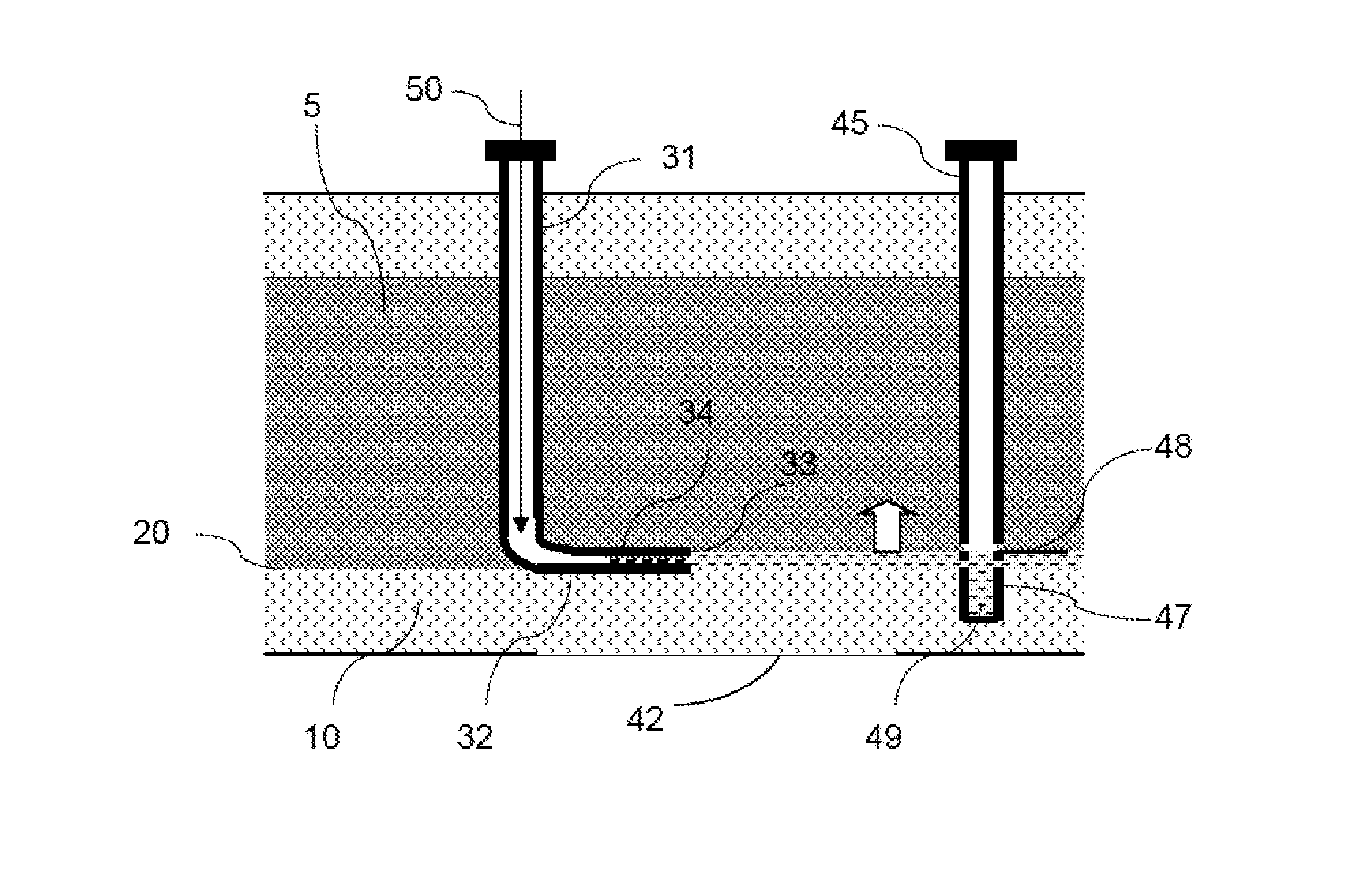

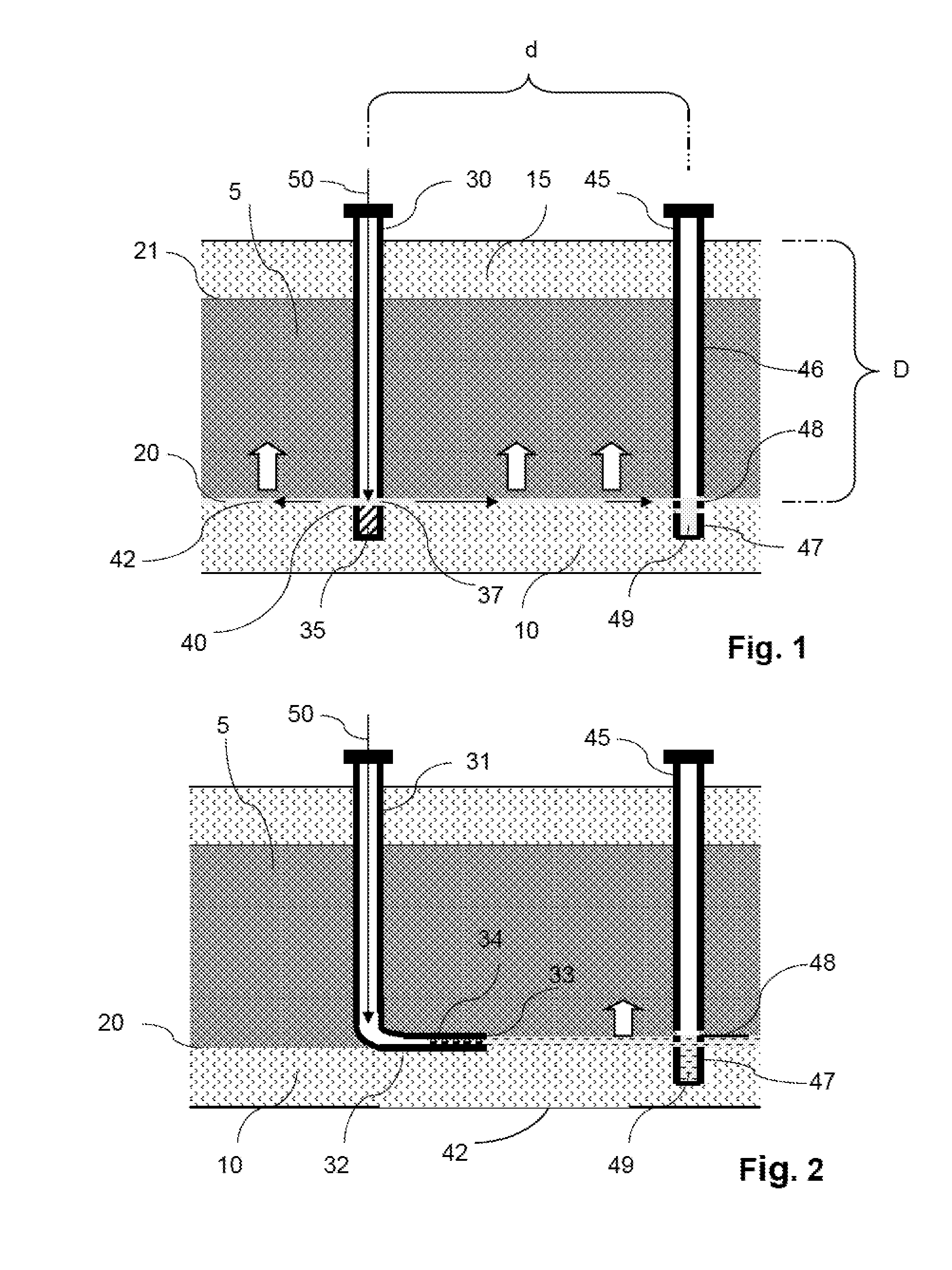

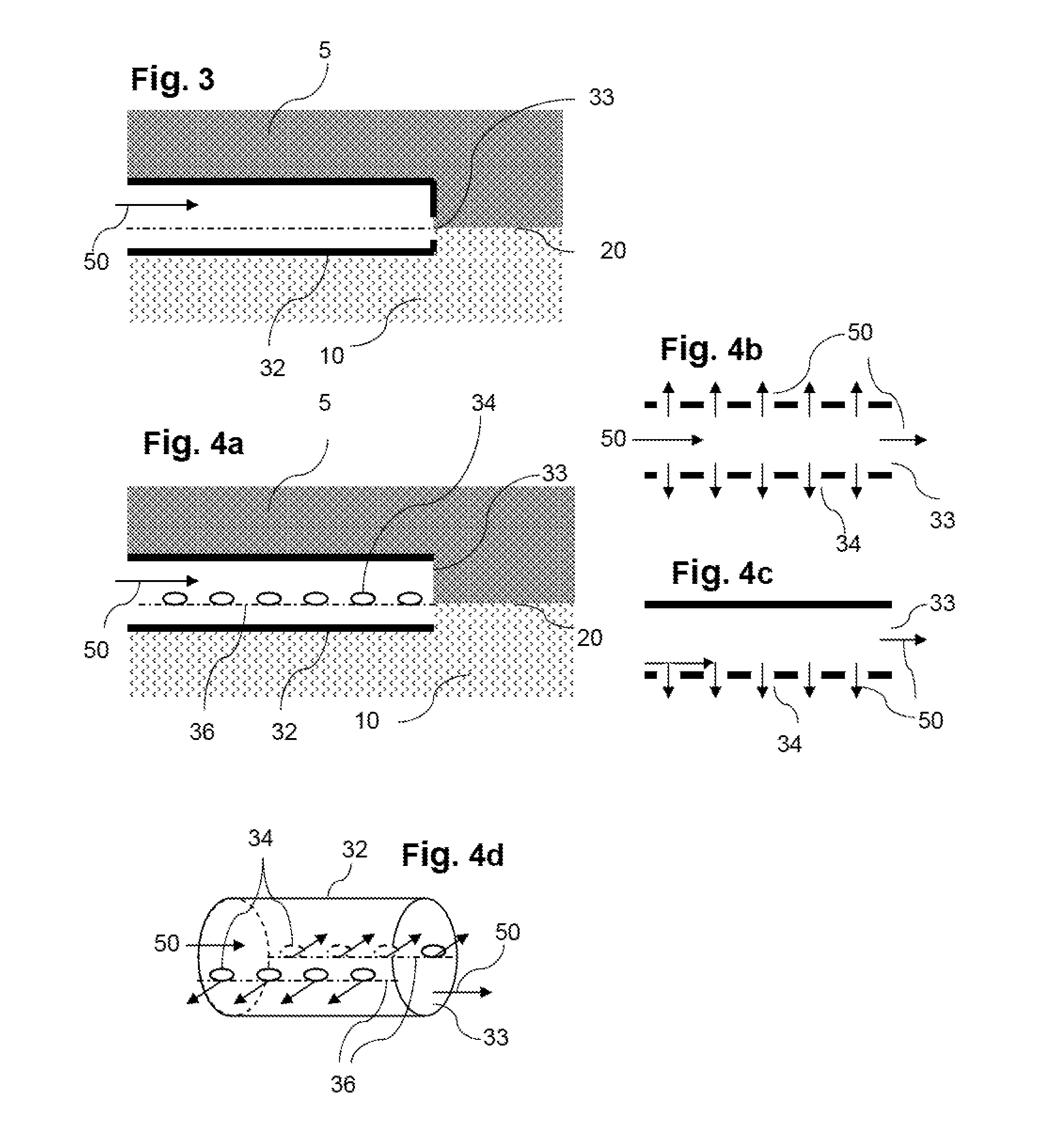

Multi-well solution mining exploitation of an evaporite mineral stratum

InactiveUS20160356157A1Avoids high vertical dissolutionDisloding machinesUnderground miningSodium bicarbonateSaline water

A method for in situ solution mining of a mineral from an underground evaporite stratum using a set of wells in fluid communication with at least one mineral cavity with some wells operated in solvent injection mode and other wells operated in brine production mode and optionally with some inactive wells, comprising switching the operation mode of one or more wells. The evaporite mineral preferably comprises trona. The at least one cavity is preferably formed by lithological displacement of the evaporite stratum at a weak interface with an underlying insoluble stratum by application of a lifting hydraulic pressure. The extracted brine can be processed to make valuable products such as soda ash and / or any derivatives thereof, rock salt, or potash. This method can provide more uniform dissolution of mineral in the cavity, can minimize flow channeling, can minimize sodium bicarbonate blinding for solution mining of incongruent trona ore, and / or may avoid uneven deposit of insolubles.

Owner:SOLVAY SA

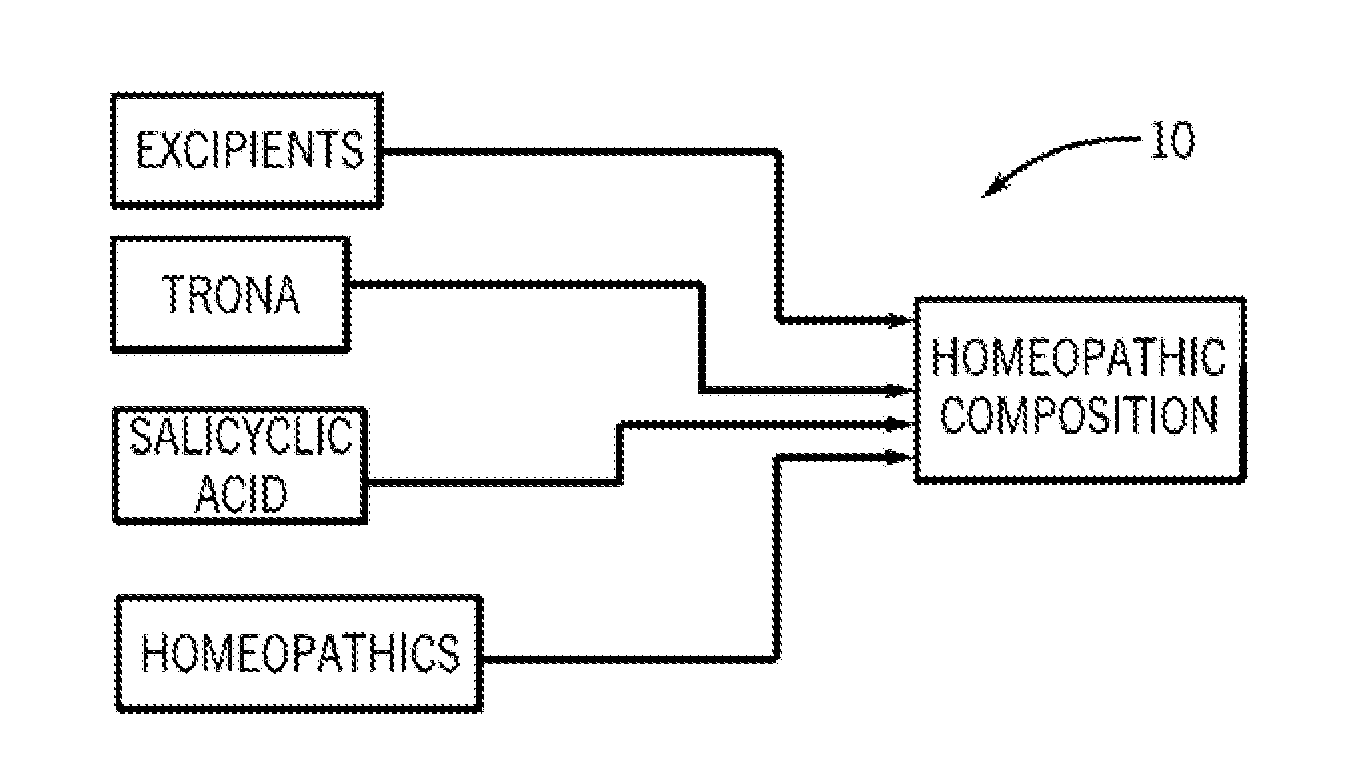

Homeopathic composition and method for the treatment of skin irritations and other skin diseases

Owner:JENSEN NED L +1

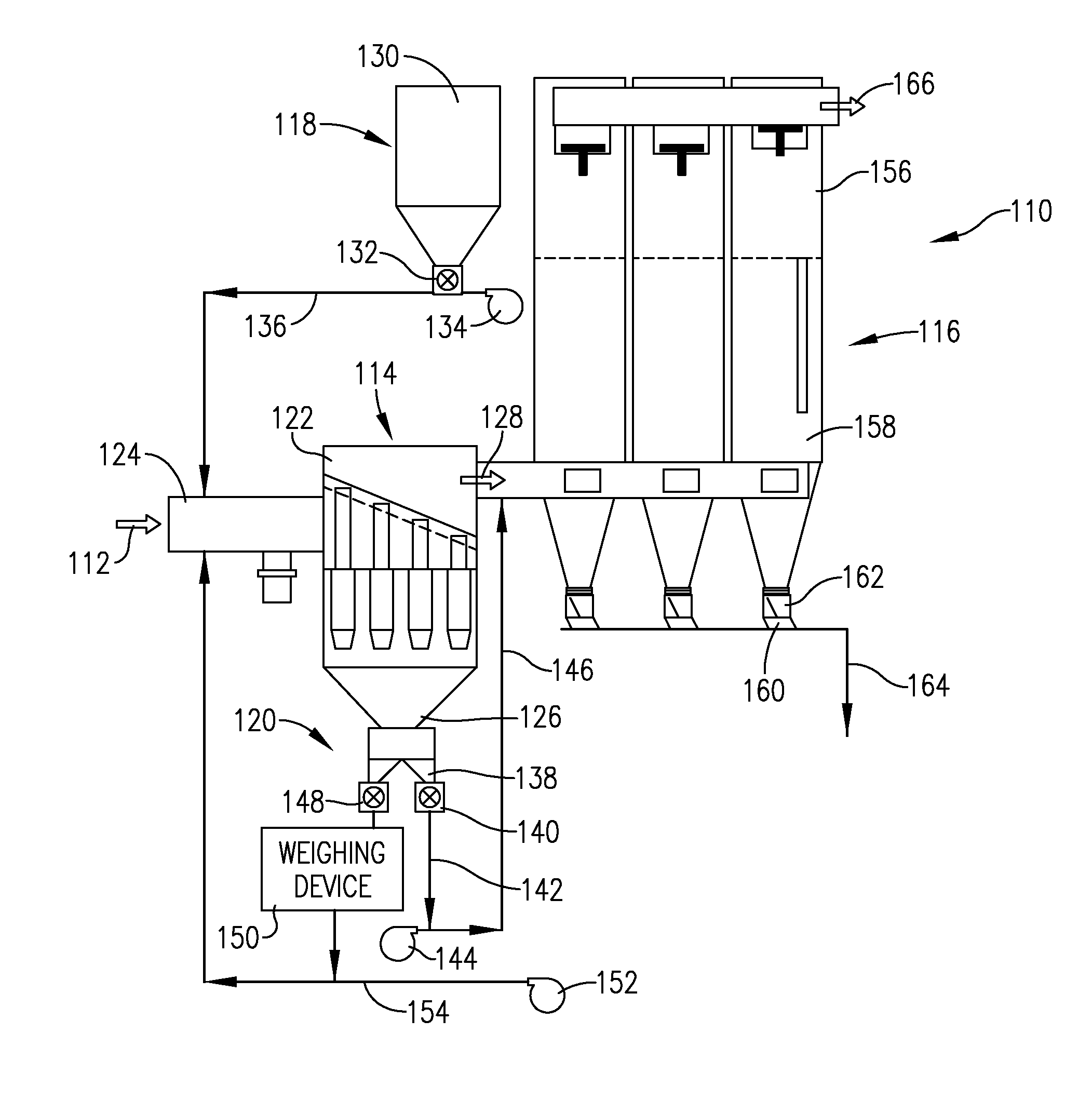

Pollution abatement process for fossil fuel-fired boilers

ActiveUS8695516B2High degreeLow-cost operationGas treatmentEmission preventionParticulatesSodium bicarbonate

The present invention provides improved boiler assemblies (10) with enhanced pollution abatement properties through injection and recycling of particulate sorbent materials including sodium bicarbonate, trona, and mixtures thereof. The assemblies (10) include a boiler (12), economizer (14), air heater (15), and recirculation reactor (16). Fresh sorbent material is introduced via assembly (60) into the boiler assembly (10) at one or more injection locations, and serves to sorb NOx, SOx, and other pollutants in the flue gas. The flue gas and entrained sorbent material then pass through reactor (16) for separation of sorbent, which is then recycled for injection back into the assembly (10) upstream of reactor (16). In another aspect, the invention provides pollution abatement apparatus (110) and methods employing an upstream recirculation reactor (114), a supply of fresh sorbent (118), and a downstream collector (116). In the reactor (114), fresh sorbent reacts with incoming hot flue gas (112) to generate a reduced pollutant flue gas (128) and a solids fraction including reacted sorbent and pollutants, and unreacted sorbent. Recirculation apparatus (120) provided between the reactor outlet (126) and reactor (114) serves to generate a substantially constant mass or volume flow rate of the reactor solids fraction, which minimizes the use of fresh sorbent and maximizes the pollution abatement efficiency of the apparatus (110).

Owner:INDAL ACCESSORIES

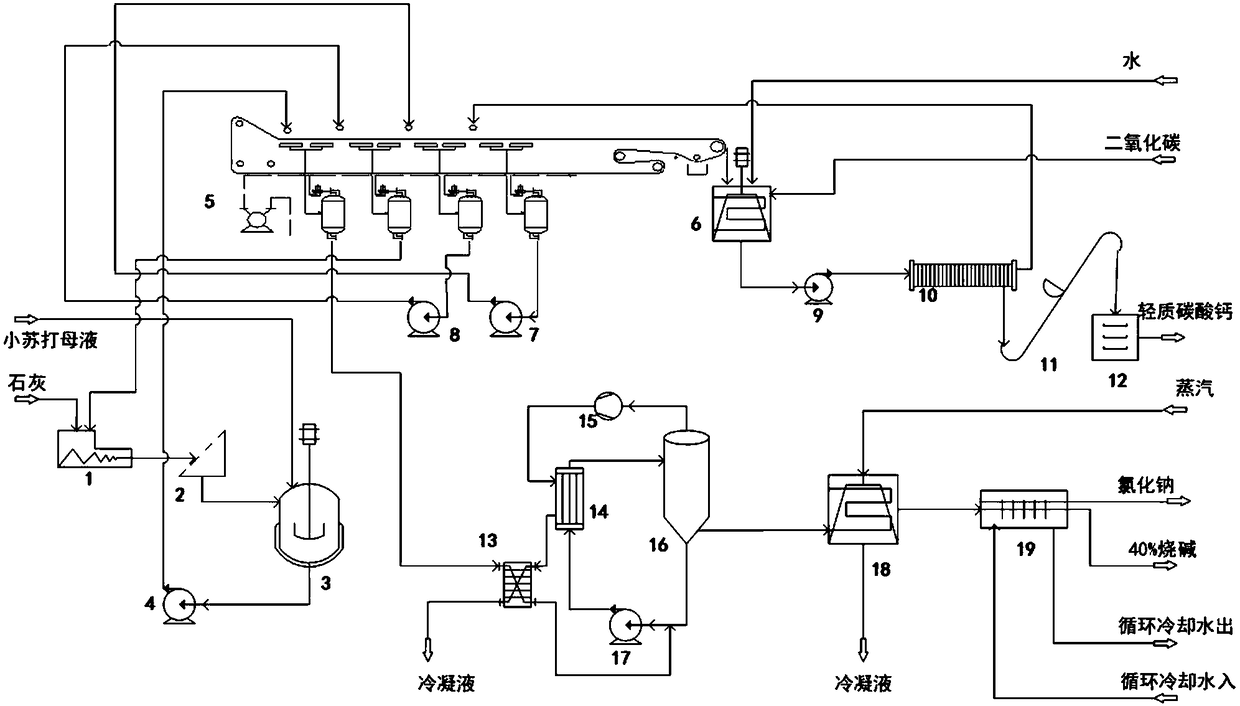

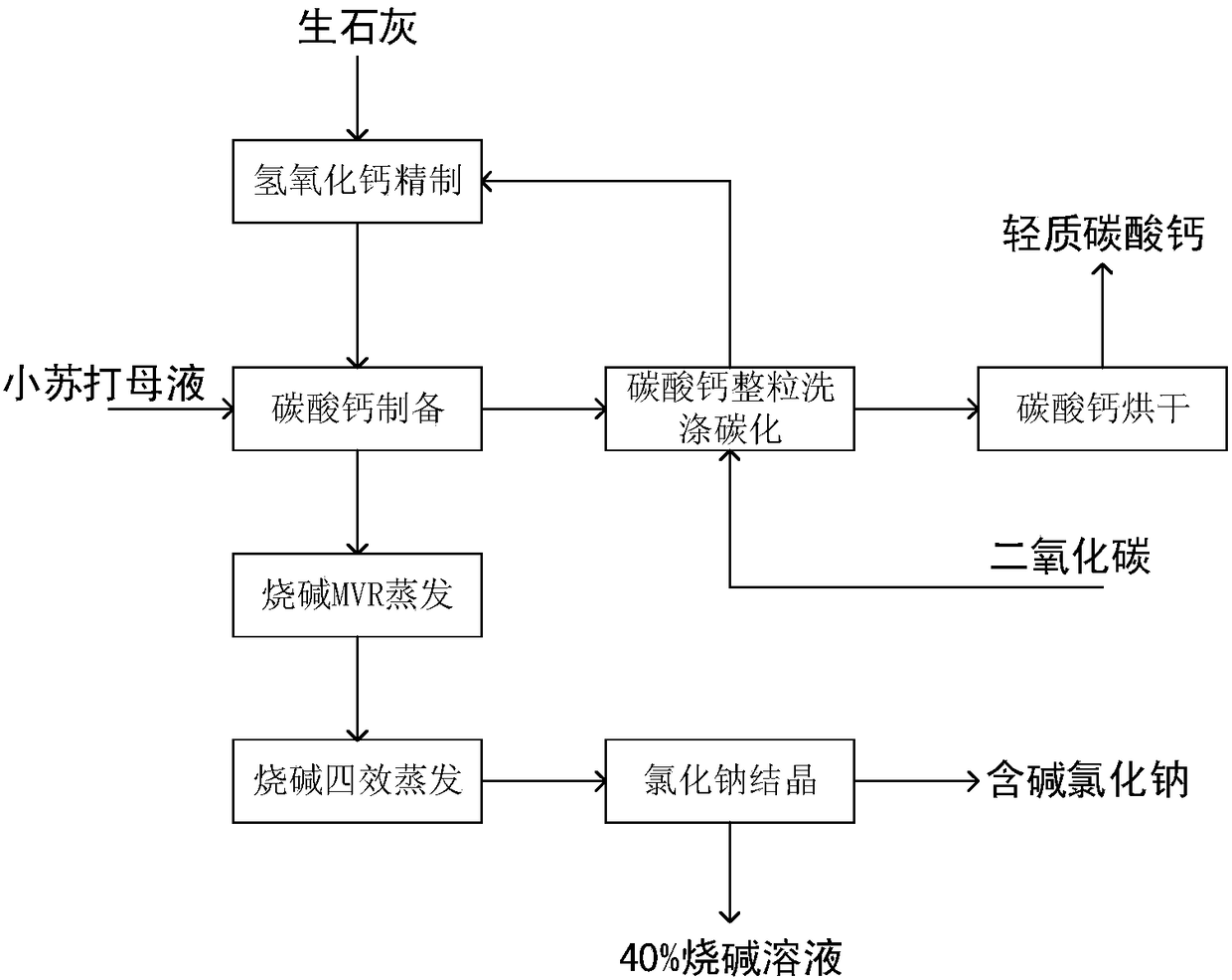

Trona sodium bicarbonate mother liquor resource utilization system and treatment method thereof

ActiveCN108439448ARealize clean utilizationSimple processCalcium/strontium/barium carbonatesProductsSodium bicarbonateResource utilization

The invention discloses a trona sodium bicarbonate mother liquor resource utilization system and a treatment method thereof. The system comprises a lime slaking unit, a causticizing reaction unit, a slurry separation unit, a calcium carbonate size stabilization carbonation unit, a calcium carbonate separation and drying unit, a caustic soda evaporation unit and a crystallization separation unit. The lime slaking unit is respectively connected to a quick lime feeding pipeline and the causticizing reaction unit; the causticizing reaction unit is respectively connected to a trona sodium bicarbonate mother liquor feeding pipeline, the lime slaking unit and the slurry separation unit; the slurry separation unit is respectively connected to the causticizing reaction unit, the calcium carbonate size stabilization carbonation unit and the caustic soda evaporation unit; the calcium carbonate size stabilization carbonation unit is respectively connected to a water feeding pipeline, a carbon dioxide feeding pipeline, the slurry separation unit and the calcium carbonate separation and drying unit; the caustic soda evaporation unit is respectively connected to the slurry separation unit and thecrystallization separation unit. The system and method provided by the invention do not produce solid waste, and are trona sodium bicarbonate mother liquor clean production technology.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Multi-well solution mining exploitation of an evaporite mineral stratum

ActiveUS20150260025A1Avoids high vertical dissolutionFluid removalAlkali metal oxides/hydroxidesSodium bicarbonateDissolution

A method for in situ solution mining of a mineral from an underground evaporite stratum using a set of wells in fluid communication with at least one mineral cavity with some wells operated in solvent injection mode and other wells operated in brine production mode and optionally with some inactive wells, comprising switching the operation mode of one or more wells. The evaporite mineral preferably comprises trona. The at least one cavity may be formed by directionally drilled uncased boreholes or by lithological displacement of the evaporite stratum at a weak interface with an underlying insoluble stratum by application of a lifting hydraulic pressure to create an interfacial gap. The extracted brine can be processed to make valuable products such as soda ash and / or any derivatives thereof. This method can provide more uniform dissolution of mineral in the cavity, minimize flow channeling, minimize sodium bicarbonate blinding for solution mining of incongruent trona ore, and / or may avoid uneven deposit of insolubles.

Owner:SOLVAY SA

Fly Ash and Fly Ash Leachate Treatment

InactiveUS20130315804A1Selenium/tellurium compundsPhosphorus sulfur/selenium/tellurium compoundsCombustionLitter

The present invention is directed to a process of treating fly ash and / or fly ash leachate to immobilize heavy metals contained in such fly ash and / or fly ash leachate, which process comprises treating such fly ash and / or fly ash leachate with a soluble ferrous compound under alkaline conditions. This process may be conducted in the absence of any pH modification, mixing (in the sense of a physical blending with a solid material), drying or heating steps, making it practical for treatment of alkaline fly ash (and other coal combustion by-products) which is currently stored in landfills or wet ash lagoons, particularly fly ash which has been recovered from flue gas streams treated with highly alkaline materials such as trona, bicarbonate or limestone and the like.

Owner:TRONOX ALKALI WYOMING CORP

Proppant material and its use in lithological displacement at trona-shale interface

A proppant material and its use for lithological displacement of an underground evaporite mineral stratum from a non-evaporite stratum, particularly of a trona stratum from a shale stratum. A lifting hydraulic pressure greater than the overburden pressure is applied at a weak strata interface, resulting in separating the strata and forming an interface gap with a mineral free-surface. The proppant is placed inside such gap as the gap is being formed or thereafter. The proppant may comprise tailings and / or particles containing an alkali compound, such as sodium hydroxide, trona, or soda ash particles. The proppant may comprise slow-water dissolving coated particles, particularly a slow-dissolving polymeric coating over a water-soluble alkali core. After propping the interface gap, the mineral from the formed mineral free-surface is dissolved by a production solvent, thereby enlarging the gap and forming a mineral cavity. The proppant preferably dissolves or degrades in the production solvent.

Owner:SOLVAY SA

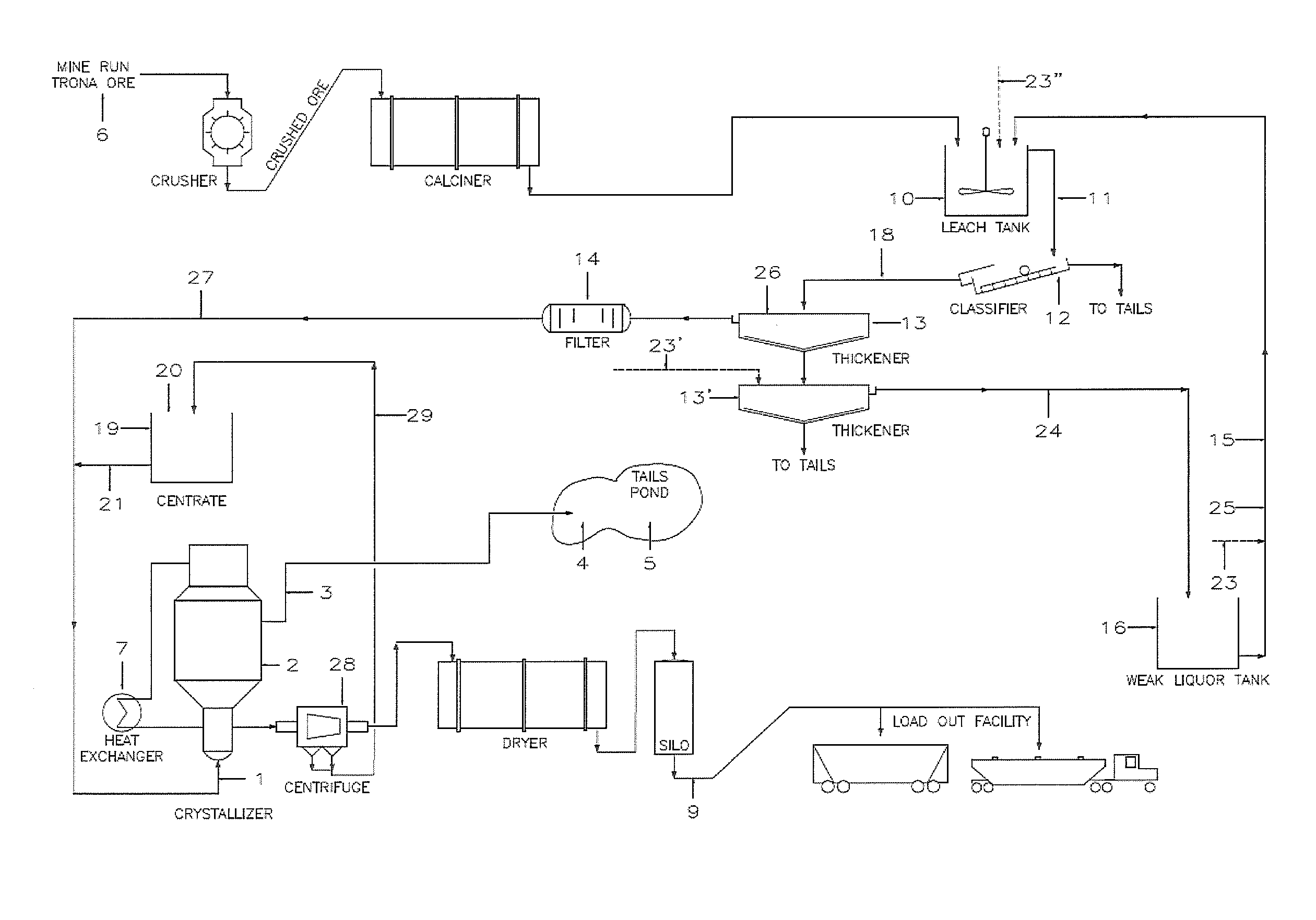

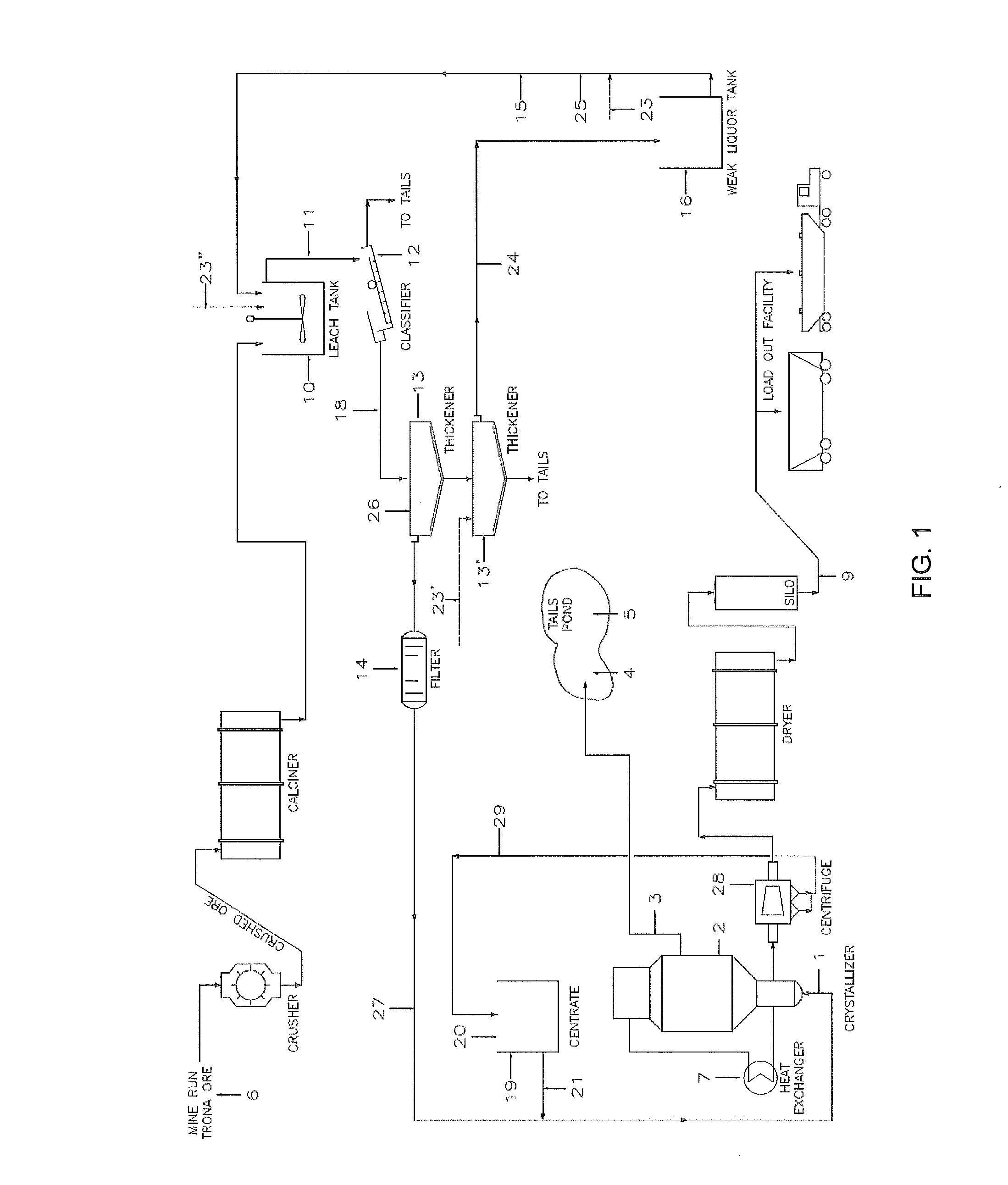

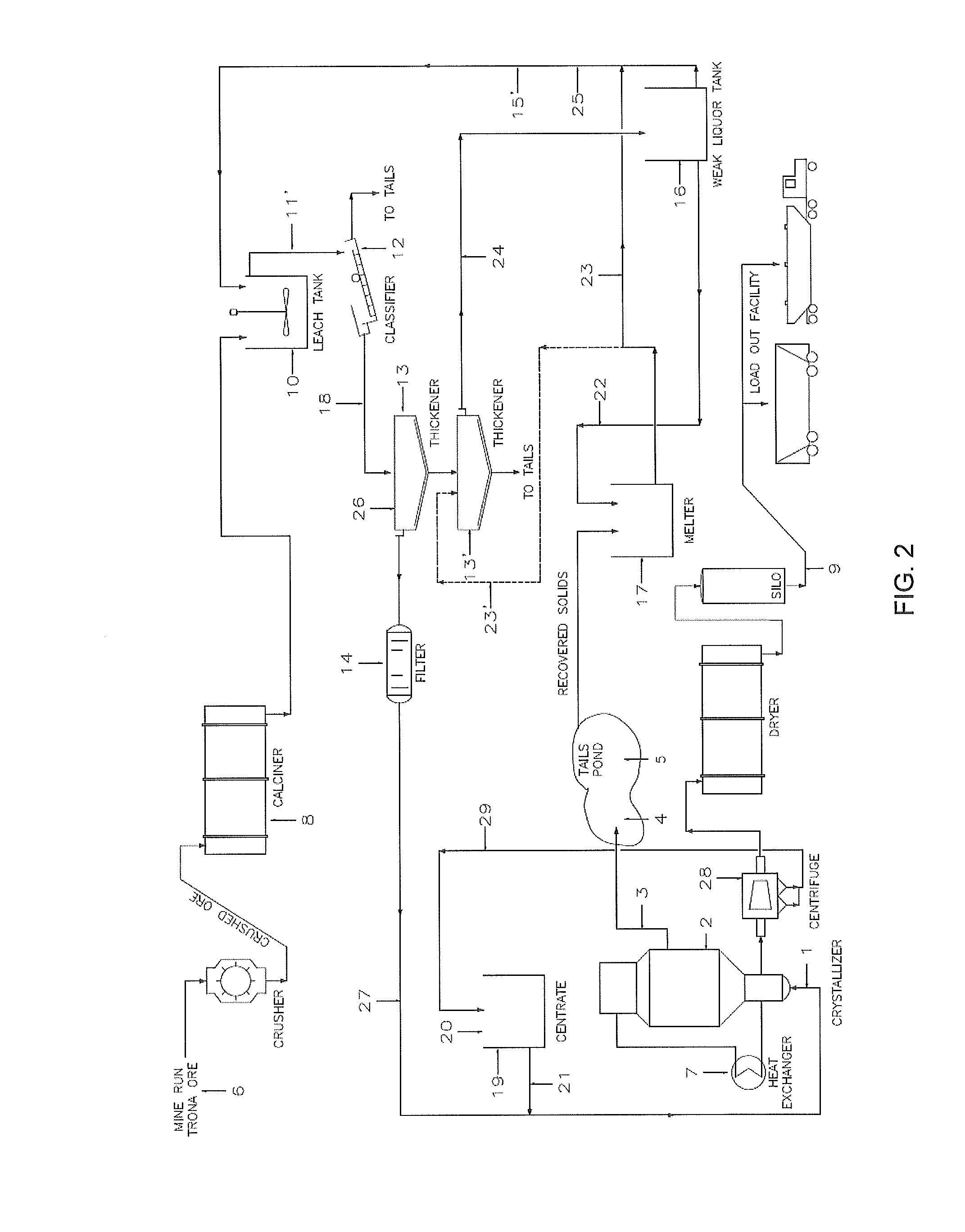

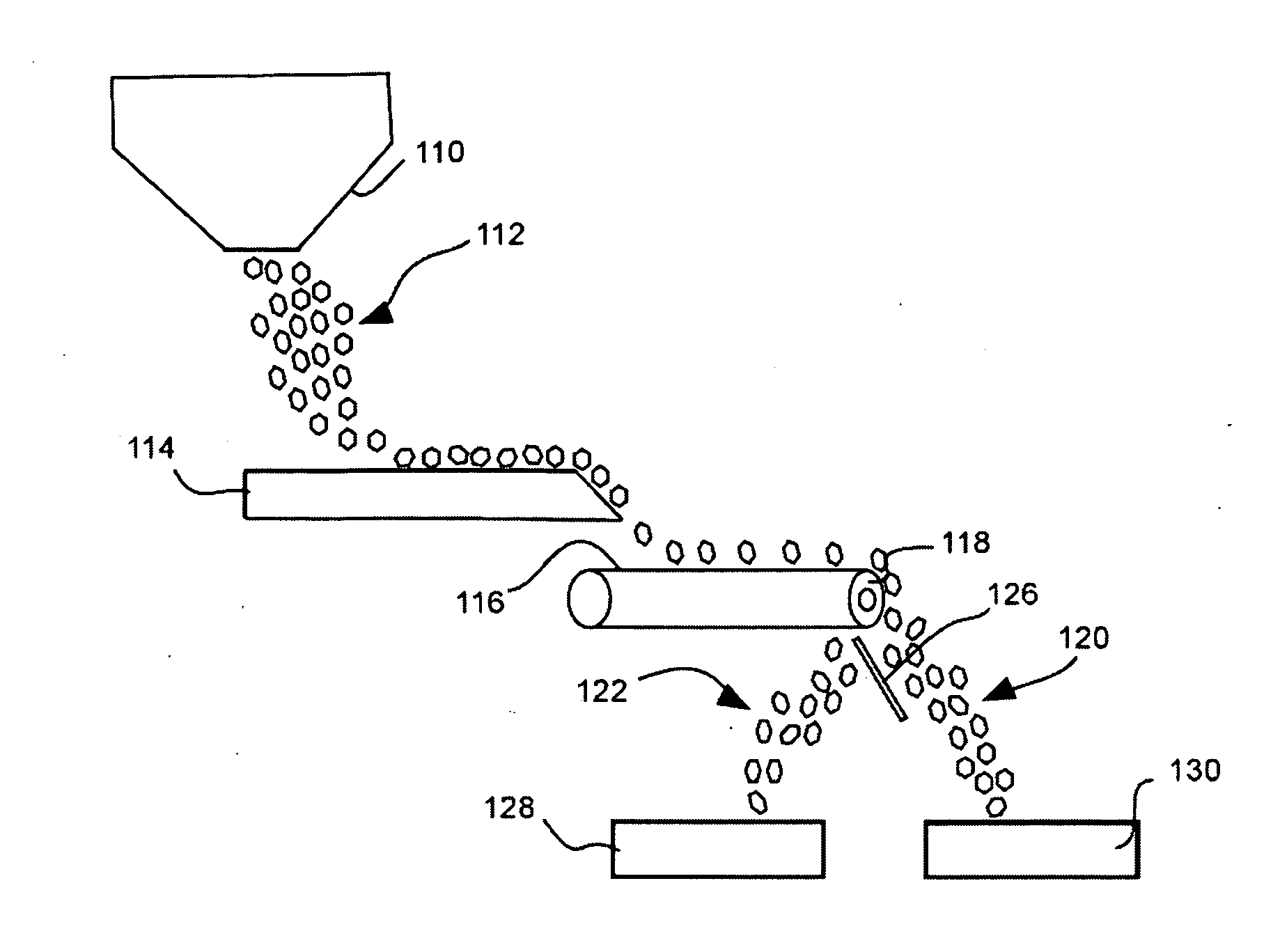

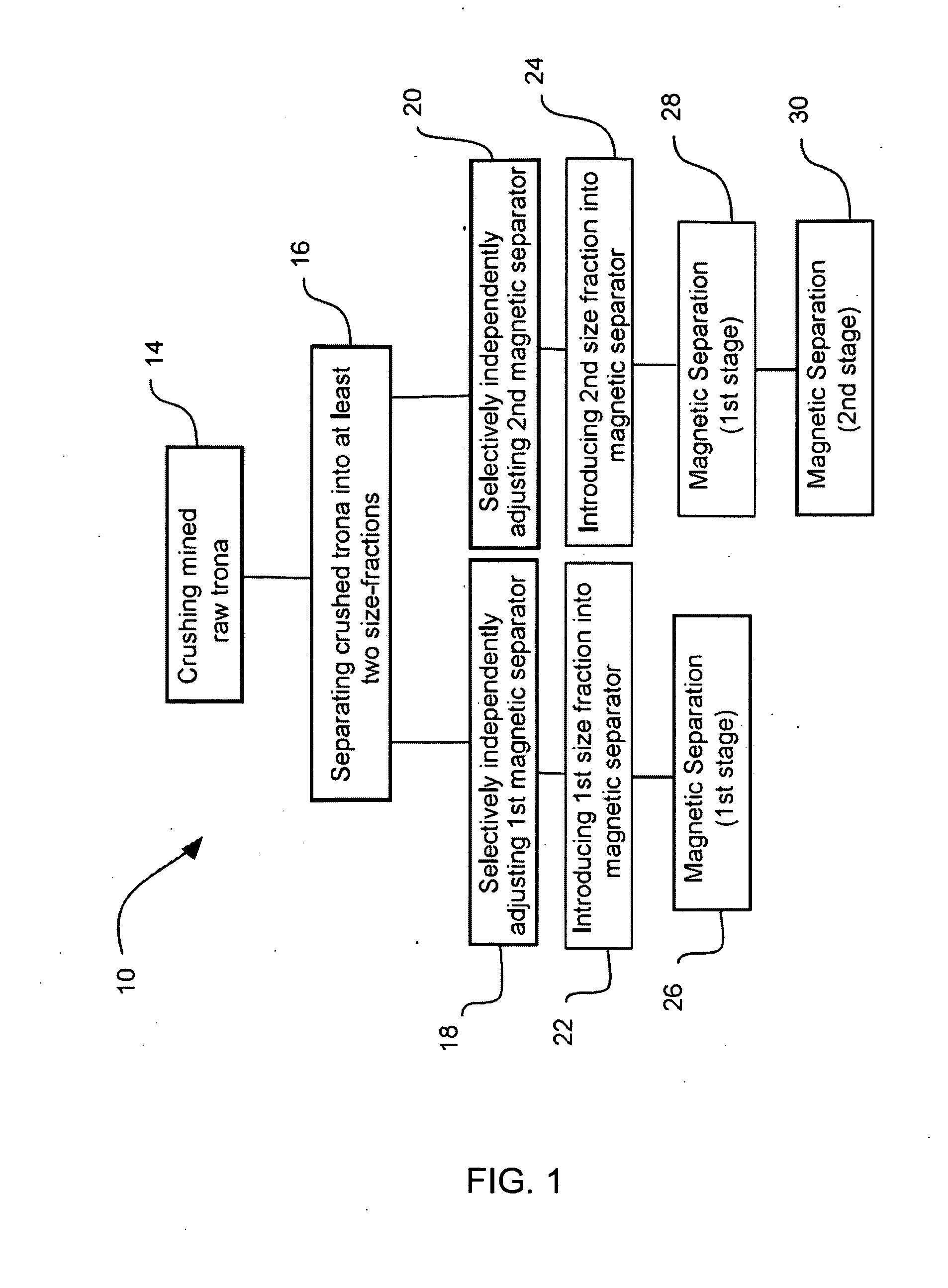

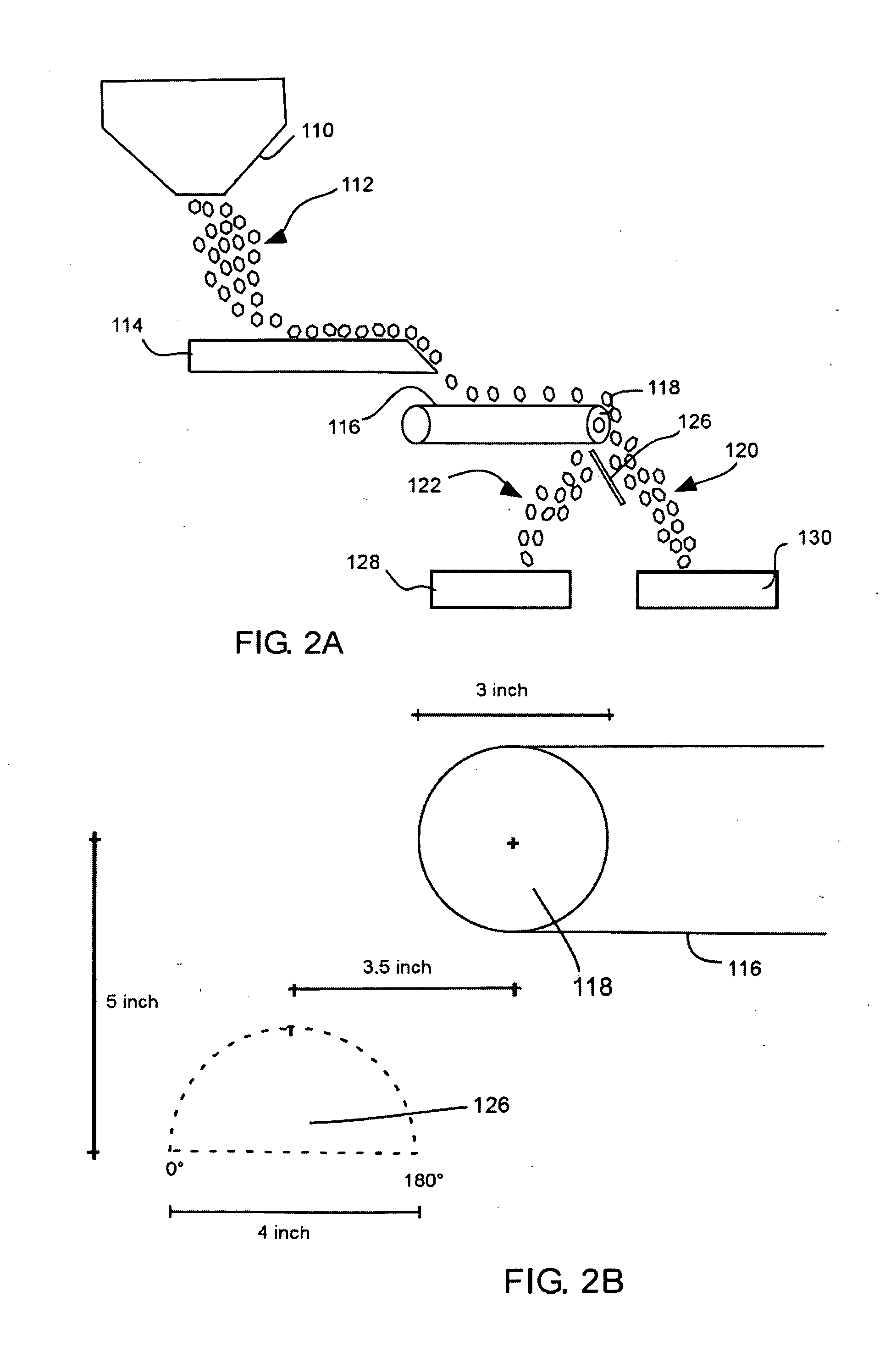

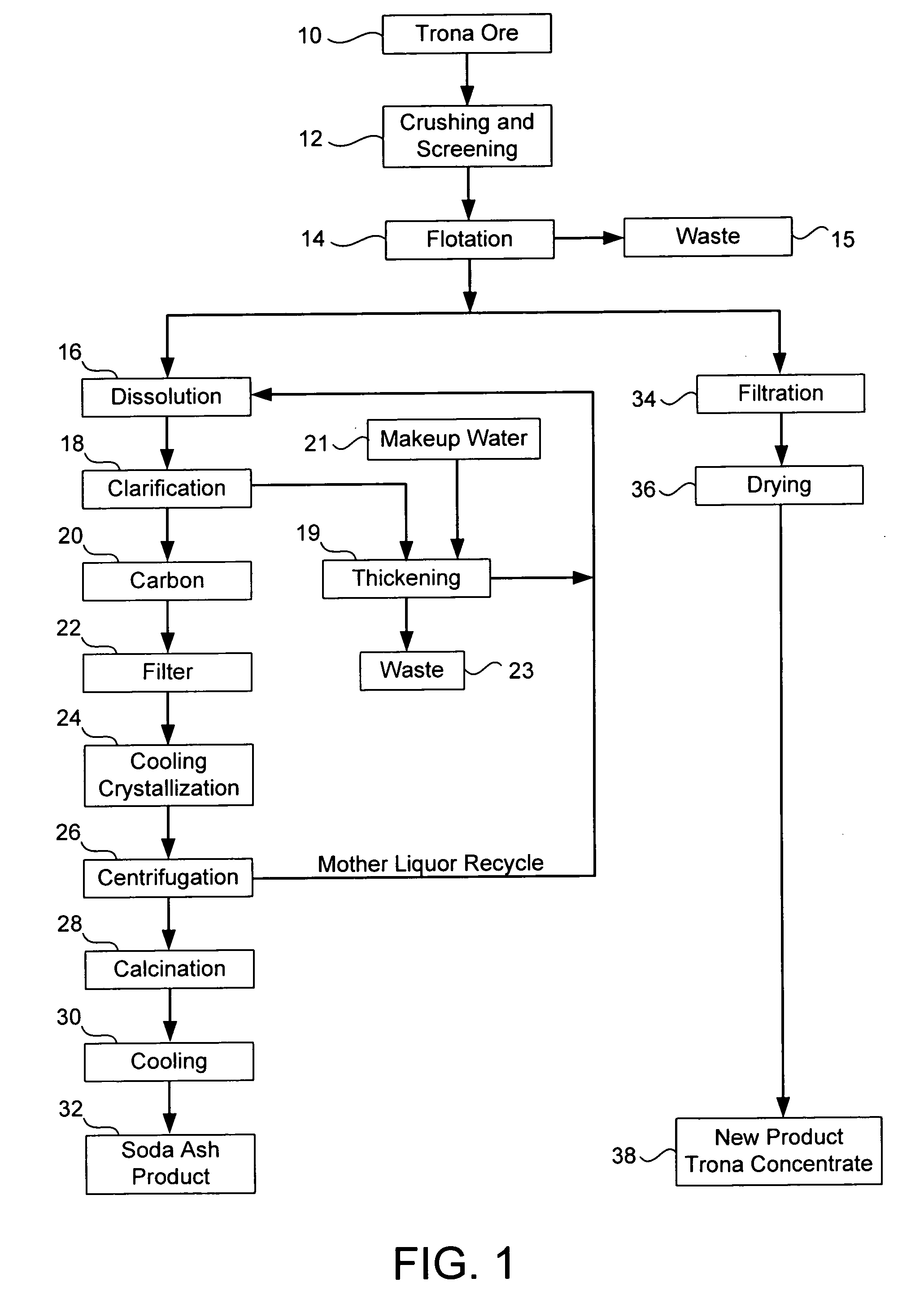

Systems and processes for producing high purity trona

InactiveUS20110272503A1Efficient separationFlotationAlkali metal carbonatesMagnetic separatorMagnetic separation

A process of producing high purity trona concentrate includes crushing a mined raw trona (14) to form a crushed raw trona, and separating the crushed raw trona into at least two size fractions (16), wherein a first size fraction is larger than a second size fraction. At least two magnetic separators can be selectively independently adjusted (18,20) to optimize magnetic separation of magnetic impurities from the size fractions. Each of the magnetic separators corresponds to one of the size fractions, which can be separately introduced into the corresponding magnetic separators (22,24) to undergo magnetic separation (26,28,30), which removes magnetic impurities from the size fractions. A first high purity dry trona and a second high purity dry trona may be recovered from the first and second size fractions, respectively. Each of the high purity dry tronas may be combined to form a magnetically purified dry trona.

Owner:UNIV OF UTAH RES FOUND

Removal of elements from coal fly ash

A method for removing elements, including heavy metals, from fly ash and from fly ash resulting from removal of SOx / NOx from flue gas using Na2CO3 / NaHCO3 / trona, is described. An aqueous suspension of the fly ash and / or a solution of the leachate from the fly ash is treated with dissolved ferrous compounds, such as FeSO4.7H2O and / or FeCl2.4H2O, at a chosen initial acidic pH, and the precipitation of the ferrous ions as the solution basifies sequesters the trace elements.

Owner:UNIVERSITY OF WYOMING

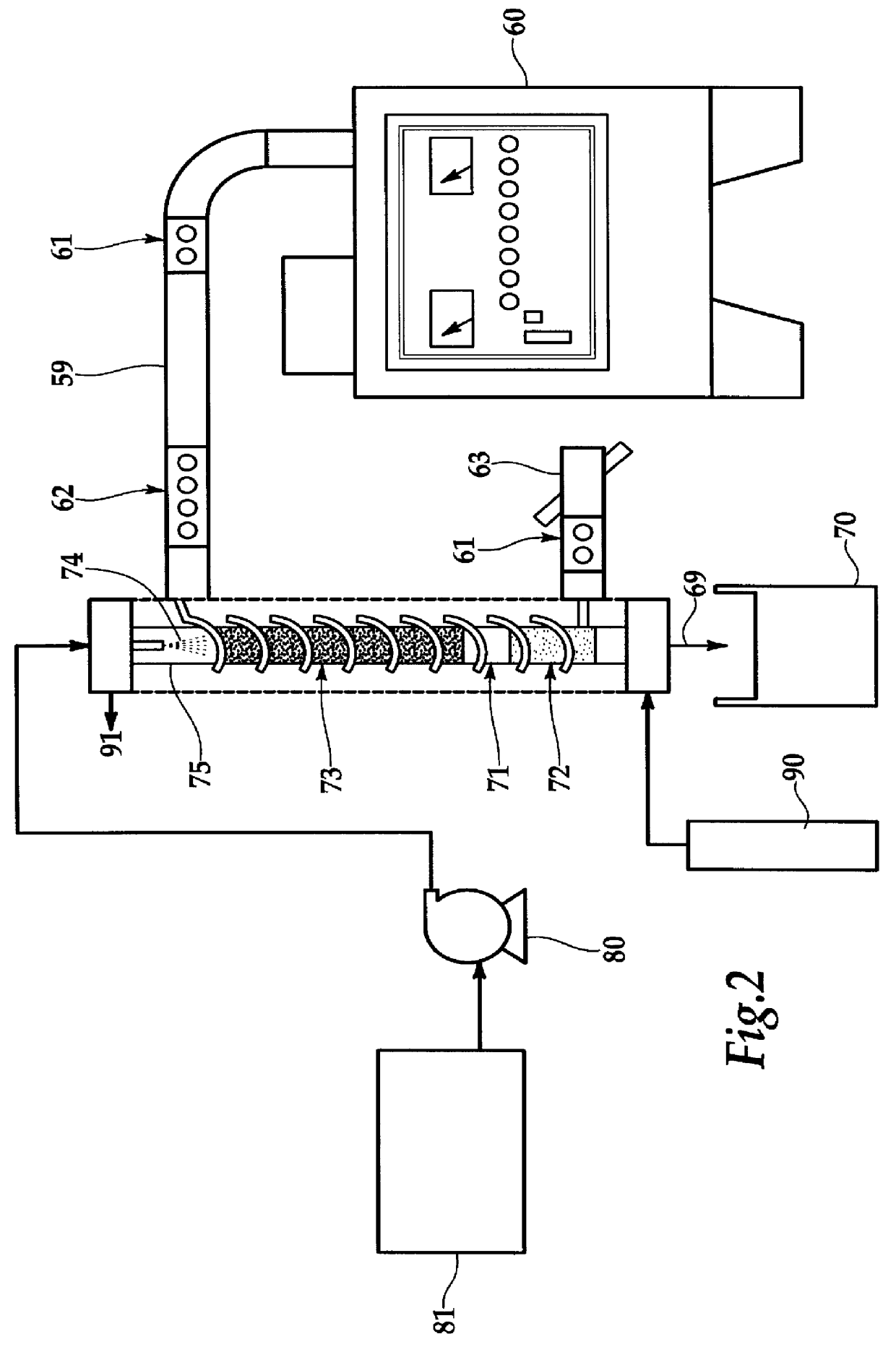

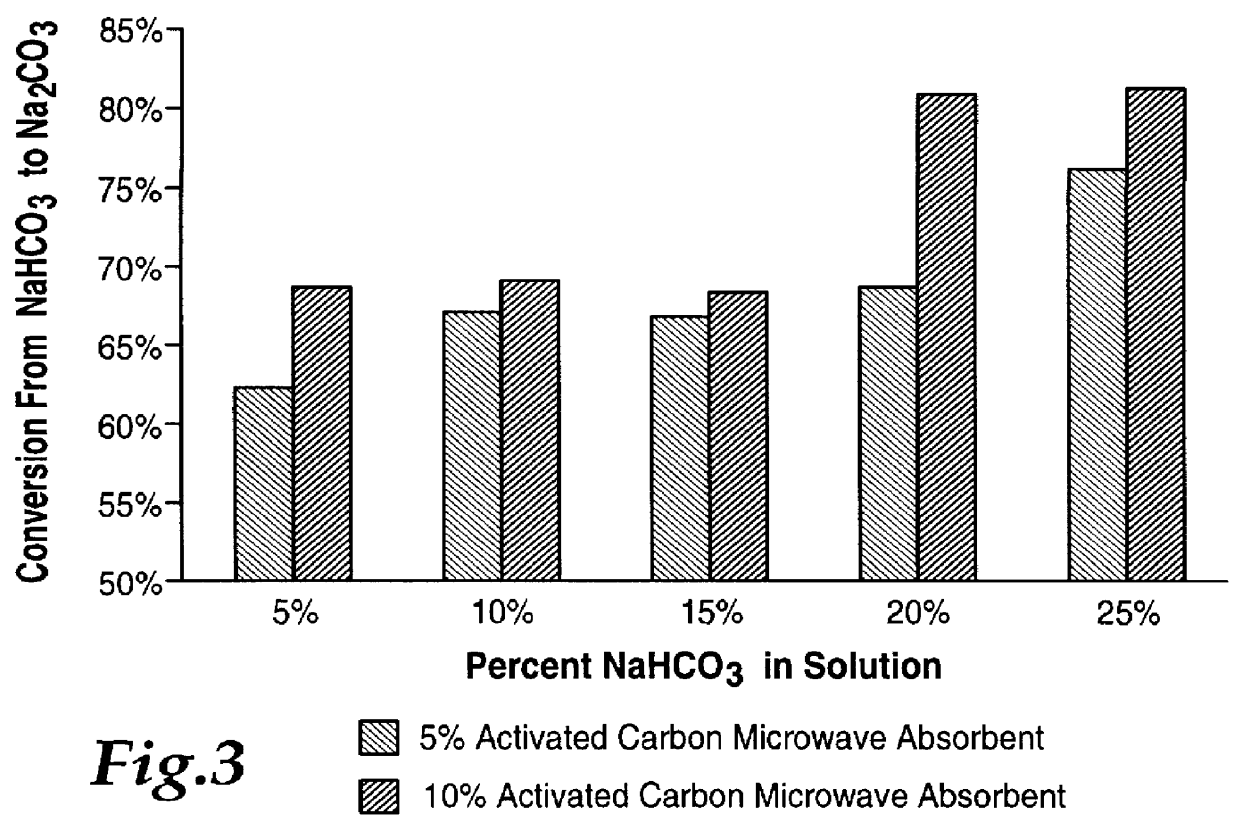

Process for microwave enhancement of gaseous decomposition reactions in solutions

InactiveUS6046376AEconomically viableEasy to solvePhysical/chemical process catalystsWater/sewage treatment by irradiationActivated carbonDecomposition

Gaseous decomposition from a solution is enhanced in the presence of activated carbon or its equivalent by radiofrequency energy in the microwave range. An important example is wet calcination using solutions containing bicarbonates, such as trona, where good conversion to carbonate is readily obtained. A further example is the excellent stabilization of solutions containing sulfites and bisulfites.

Owner:C MICRO SYST

Sodium bicarbonate production method

InactiveUS7255841B2Promote recoveryIncrease valueBicarbonate preparationVarying alkali metal carbonate water contentSodium bicarbonateWastewater

Owner:CHURCH & DWIGHT CO INC

Method for making spirulina alga culture solution

InactiveCN1594540AReduce formulation costsReduce manufacturing costUnicellular algaeCulture fluidPhosphor

The invention discloses a preparation method of spirulina culture solution, which comprises the steps : using natural trona bittern as basic material, determining natural trona bittern of nitrogen, phosphor, potassium content, employing spectrophotometric method or colorimetric estimation, then adding into HNO#-[3]solution, HCl solution, K#-[2]SO#-[4] and H#-[3]PO#-[4]solution to make containing 0.4-0.8g / L nitrogen, 0.07-0.1g / L phosphor, 0.3-1g / L potassium, adjusting PH to 8.5-10 using acid. The invention lowers the breeding cost dramatically due to the main fertilizer natural trona bittern and keeps the original nutrients of spirulina.

Owner:张德智

Batch solution mining using lithological displacement of an evaporite mineral stratum and mineral dissolution with stationary solvent

Batch initiation and / or exploitation phases of in situ solution mining of a mineral from an underground evaporite mineral stratum. The initiation phase may comprise a lifting step which employs a lithological displacement (lifting) of this stratum from an underlying non-evaporite stratum with application at the strata interface of a lifting hydraulic pressure greater than overburden pressure by a solvent suitable to dissolve the mineral; a soaking step for dissolution of mineral upon contact with stationary solvent, and a brine extraction step. The method may further comprise one or more exploitation phases carried out after the initiation phase. The exploitation phase may comprise a partial filing or filling step with the same solvent or different solvent than during lifting, another soaking step, and another brine extraction step. The lifting, cavity partial filing / filling, and brine extraction steps are being discontinuous. The evaporite mineral stratum preferably comprises trona.

Owner:SOLVAY SA

Purification of trona ores

The present invention is a trona concentrate and a process for floating gangue material from trona ore that comprises forming an emulsion, conditioning the trona ore at a high solids content in a saturated trona suspension, and then floating and removing the gangue material. The process for separating trona from gangue materials in trona ore can include emulsifying an oil in an aqueous solution to form an oil-in-water emulsion. A saturated trona suspension having a high solids content can also be formed having trona of a desired particle size. The undissolved trona in the saturated suspension can be conditioned by mixing the saturated suspension and the oil-in-water emulsion to form a conditioning solid suspension of trona and gangue material. A gas can be injected through the conditioning solid suspension to float the gangue material. Thus, the floated gangue material can be readily separated from the trona to form a purified trona concentrate without requirements of additional heat or other expensive processing steps.

Owner:UNIV OF UTAH RES FOUND

Lithological displacement of an evaporite mineral stratum

InactiveUS20160356140A1Inhibition of dissolutionSesquicarbonate preparationBicarbonate preparationOverburdenLithology

A lithological displacement of an underground evaporite mineral stratum from an underlying non-evaporite stratum comprising the application of a lifting hydraulic pressure of a fluid at a weak interface between the strata, resulting in lifting the overburden above the interface, separating the evaporite stratum from the underlying non-evaporite stratum and thus forming a mineral free-surface. The lifting hydraulic pressure is greater than the overburden pressure. The formed mineral free-surface is accessible for dissolution by a solvent. The fluid used for lifting may comprise a solvent suitable to dissolve the mineral. The evaporite mineral stratum preferably comprises trona, nahcolite, wegscheiderite, or combinations thereof.

Owner:SOLVAY SA

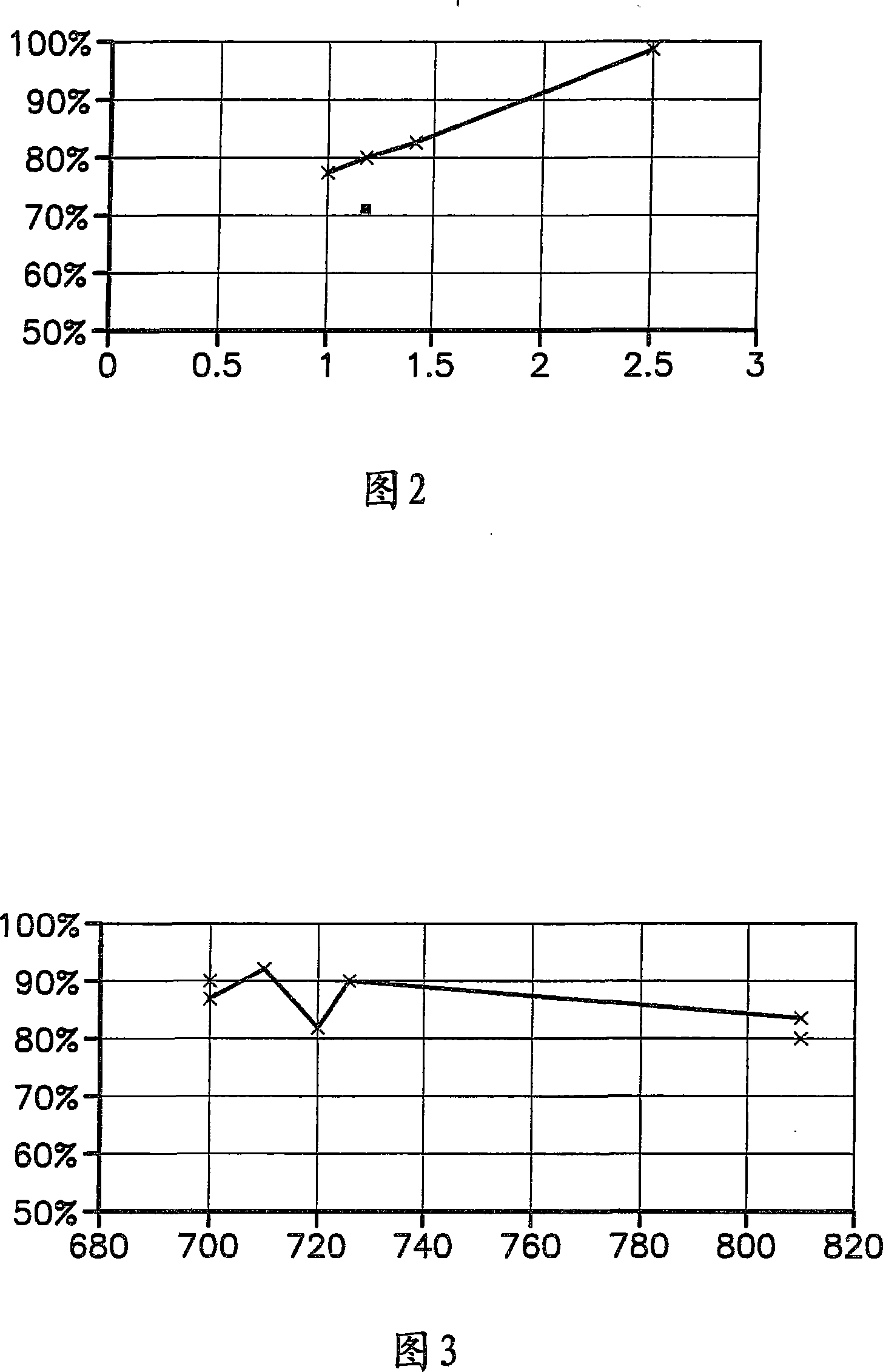

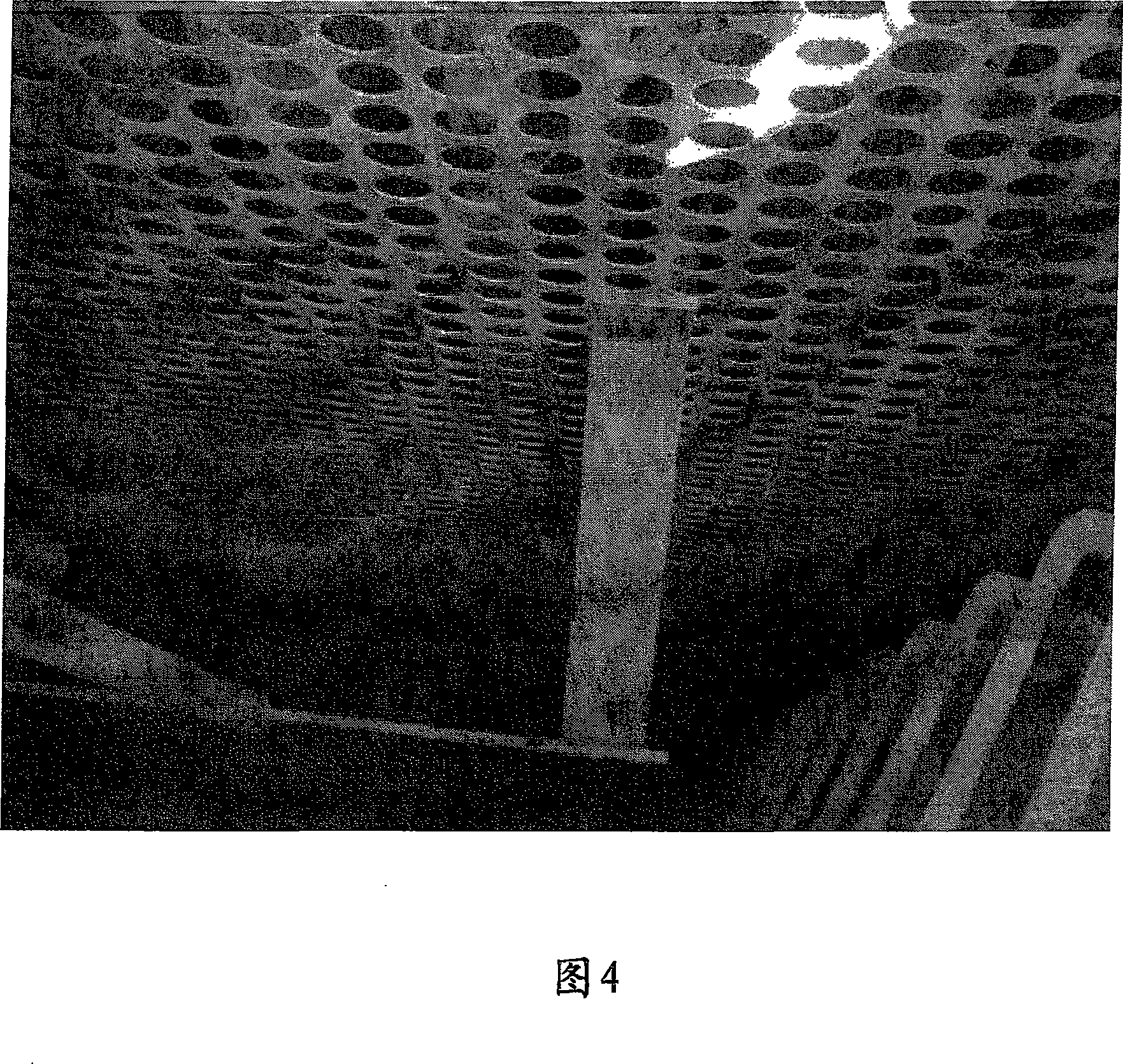

Method of removing sulfur dioxide from a flue gas stream

A method of removing SO2 from a flue gas stream containing SO2 comprising providing a source of trona and injecting the trona into the flue gas stream. The temperature of the flue gas is from about 600°F to about 900°F. Keep the trona in contact with the flue gas for a sufficient time to allow part of the trona to react with part of the SO2 to reduce the concentration of SO2 in the flue gas stream.

Owner:SOLVAY CHEM INC

Tibetan medicine composition for foot bath health care and preparation method of composition

InactiveCN106822256APromote circulationImprove immunityAntimycoticsAntipyreticExternal applicationTinospora sinensis

The invention discloses a Tibetan medicine composition for foot bath health care. The Tibetan medicine composition comprises, by weight, 55-65 parts of trona, 5-15 parts of olibanum, 5-15 parts of sweet wormwood herb and 15-25 parts of tinospora sinensis merr. The Tibetan medicine composition has the advantages that the Tibetan medicine composition is simple in raw materials and obvious in use effect, medicine effects are further improved by the aid of Tibetan medicines and foot bath, the Tibetan medicine composition solves the problems that orally-taken effects of traditional medicines are not obvious or external application medicines are palliative, and the composition effectively solves the problem of fester caused by foot bubbles.

Owner:旦增江白

Process for treating a gas contaminated by metals or organics compounds using a calcium-phosphate reactant comprising apatite

InactiveUS20180169573A1Reduce riskSolution value is not highGas treatmentOther chemical processesFuranPhosphate

Process for treating a gas contaminated by at least one element selected from the group consisting of heavy metals, organic compounds, and combinations thereof, wherein a calcium-phosphate reactant (reagent) particle comprising apatite is brought into contact with the contaminated gas at a temperature of at least 30° C. and preferably at most 1100° C. The metal(s) and / or organic compound(s) to be removed from the contaminated gas may be selected among the list of: Al, Ag, As, Ba, Be, Bi, Ce, Co, Cd, Cu, Cr, Fe, Hf, Hg, La, Li, Mg, Mn, Mo, Ni, Pb, Pd, Rb, Sb, Se, Sn, Sr, Th, Ti, U, V, Y, Zn, Zr, VOC, aromatic compounds, PAHs, dioxins, furans, or any mixture thereof. In such process, an alkaline compound particle comprising sodium bicarbonate, sodium carbonate, sodium sesquicarbonate (trona), quick lime, hydrated lime, lime stone or combinations thereof, may be further brought into contact with the contaminated gas.

Owner:SOLVAY SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com