Patents

Literature

65results about How to "Realize clean utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for recovering vanadium in vanadium-titanium magnetite ore

ActiveCN102703688ARealize comprehensive utilizationAvoid recyclingProcess efficiency improvementAdhesiveMagnetite

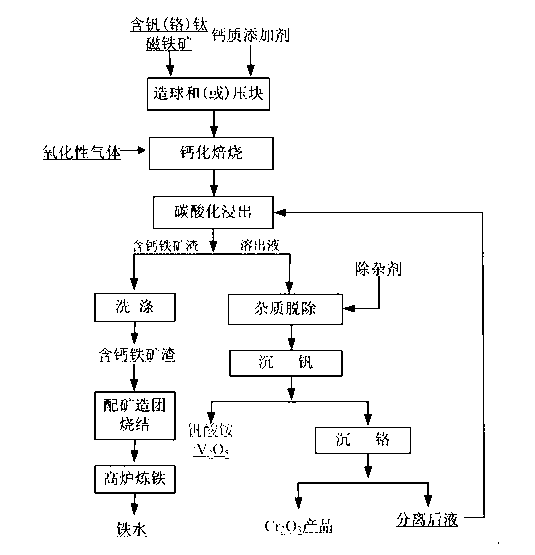

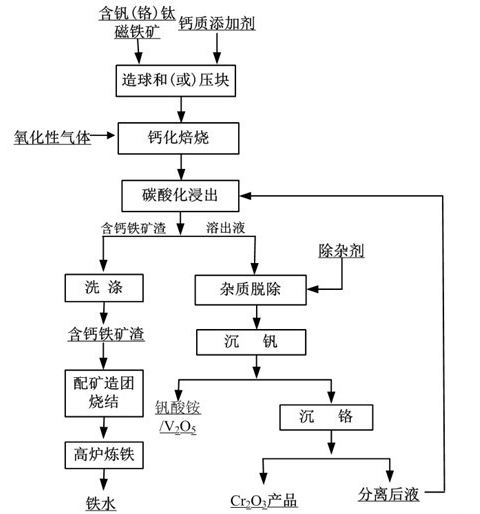

The invention discloses a method for recovering vanadium in vanadium-titanium magnetite ore. The method comprises the process steps of: (1) mixing, pelletizing or briquetting, vanadium-titanium magnetite ore, a calcium additive and an adhesive, drying and oxidizing roasting to obtain roasting clinker; (2) performing carbonation leaching on the roasting clinker by utilizing leaching solution containing CO3<2->, and performing solid-liquid separation to obtain calcium-contained iron ore slag and chrome-vanadium-contained dissolving solution; and (3) adding a reagent with NH4+ into the dissolving solution for ammonia settlement, so as to obtain ammonia vanadate, or adding acid liquor into the dissolving solution, and directly acidifying to obtain V2O5. By adopting calcified roasting-carbonation leaching, the vanadium in the vanadium-titanium magnetite ore is recovered, obtained sintered pellets containing the calcium-contained iron ore slag can be directly applied to blast furnace smelting; and therefore, the problem of recovering the vanadium in the vanadium-titanium magnetite ore is effectively solved, and subsequent blast furnace smelting is not influenced. After the vanadium is recovered by using the method, chromium can be recovered from obtained crystallizing mother solution; and therefore, the vanadium-titanium magnetite ore is effectively and comprehensively utilized.

Owner:HEBEI IRON AND STEEL

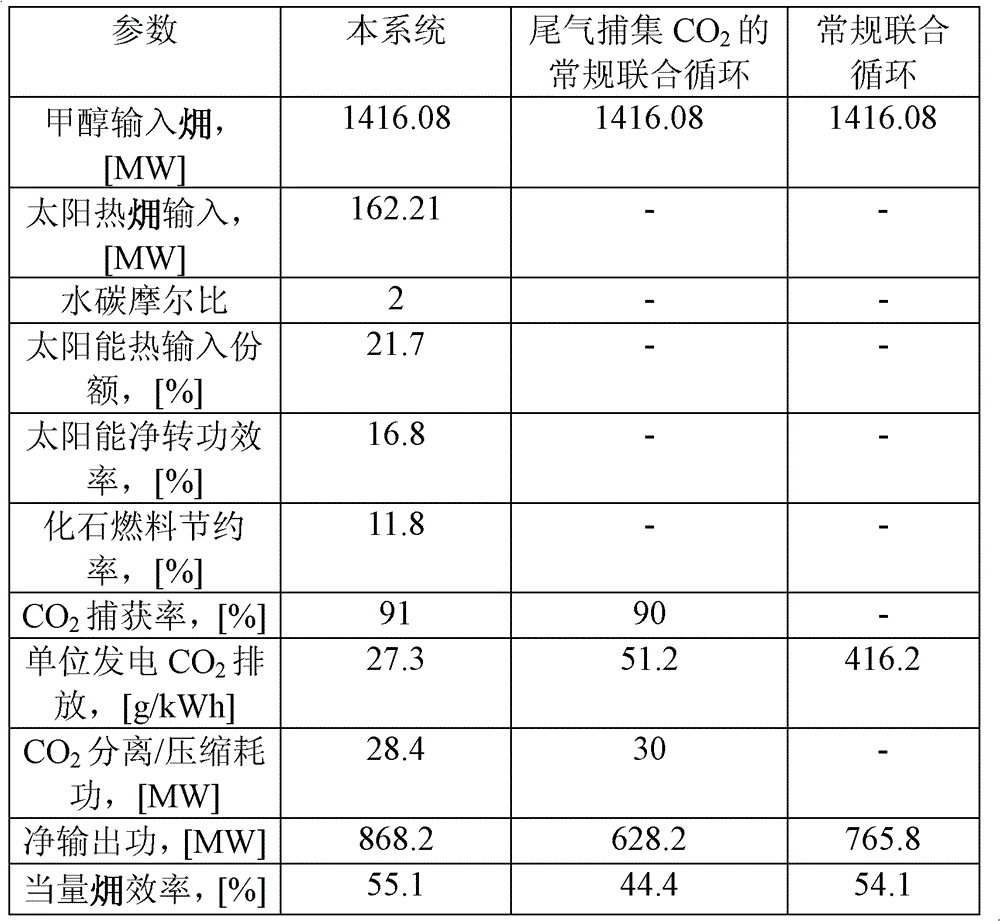

Low-CO2-emisison solar energy and methanol complementary thermodynamic cycle system and method

InactiveCN102797650AEfficient thermal power conversionSave energyHydrogenFrom solar energySteam reformingSyngas

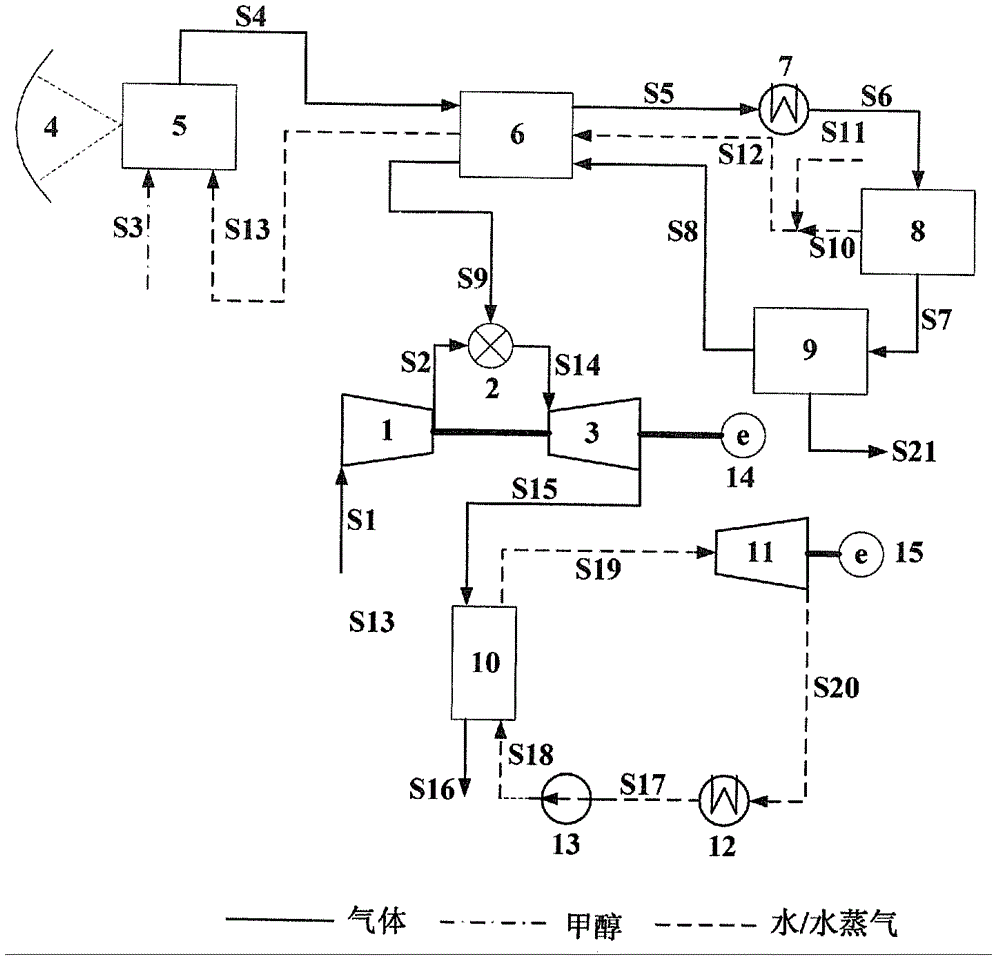

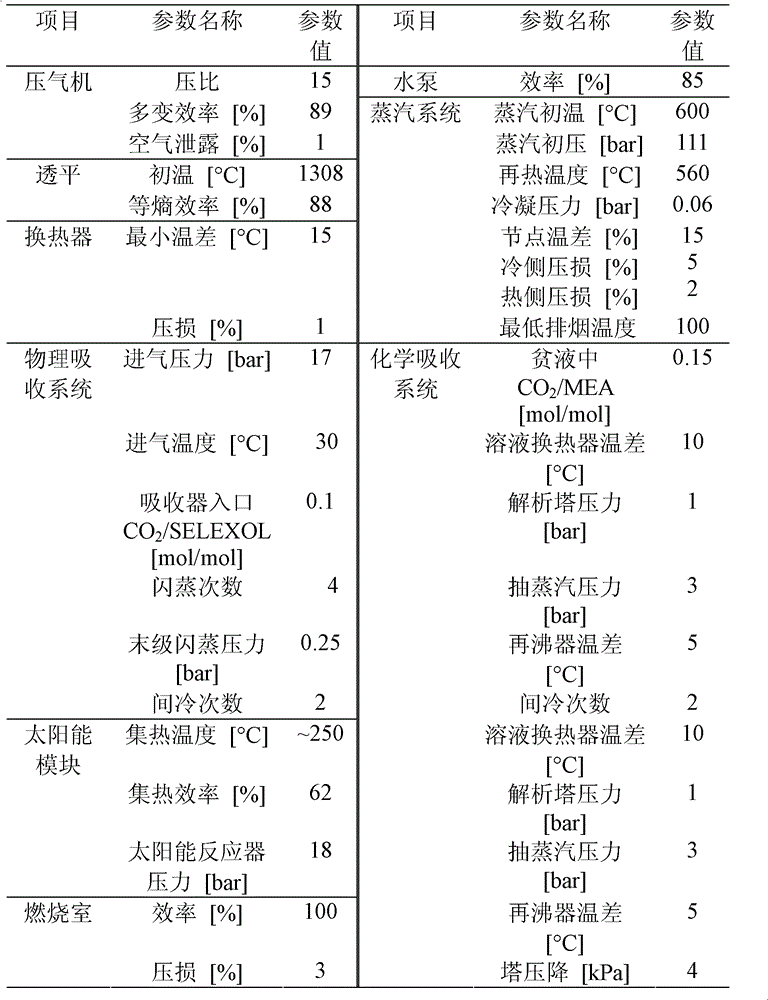

The invention discloses a low-CO2-emisison solar energy and methanol complementary thermodynamic cycle system and a low-CO2-emisison solar energy and methanol complementary thermodynamic cycle method. A solar energy grade is improved in combination with an efficient combined cycle system. The method comprises the following steps of: providing methanol / steam reforming reaction heat by using intermediate-and-low temperature solar energy, and converting a fuel into synthesis gas in which H2 and CO2 with the approximate molar ratio of 3:1 are used as main ingredients, so that low-grade solar energy is converted into synthesis gas chemical energy; separating the CO2 by using an absorption unit; and performing heat-into-power conversion on the decarburized clean fuel in an efficient combined cycle process. The introduction of the solar energy is combined with the separation of the CO2, so that the consumption of fossil energy is reduced, and the fuel can be utilized cleanly. By the method, the clean conversion efficiency of the solar energy is 16.8 percent, the equivalent efficiency of the system is 55.1 percent which is 1 percent higher than that of the conventional combined cycle process, and the conservation rate of a fossil fuel can reach 11.8 percent; and the discharge capacity of the CO2 can be reduced at low energy consumption, so that the fossil fuel is saved, and the intermediate-and-low temperature solar energy can be subjected to efficient heat-into-power conversion and can be complemented with the fossil fuel.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

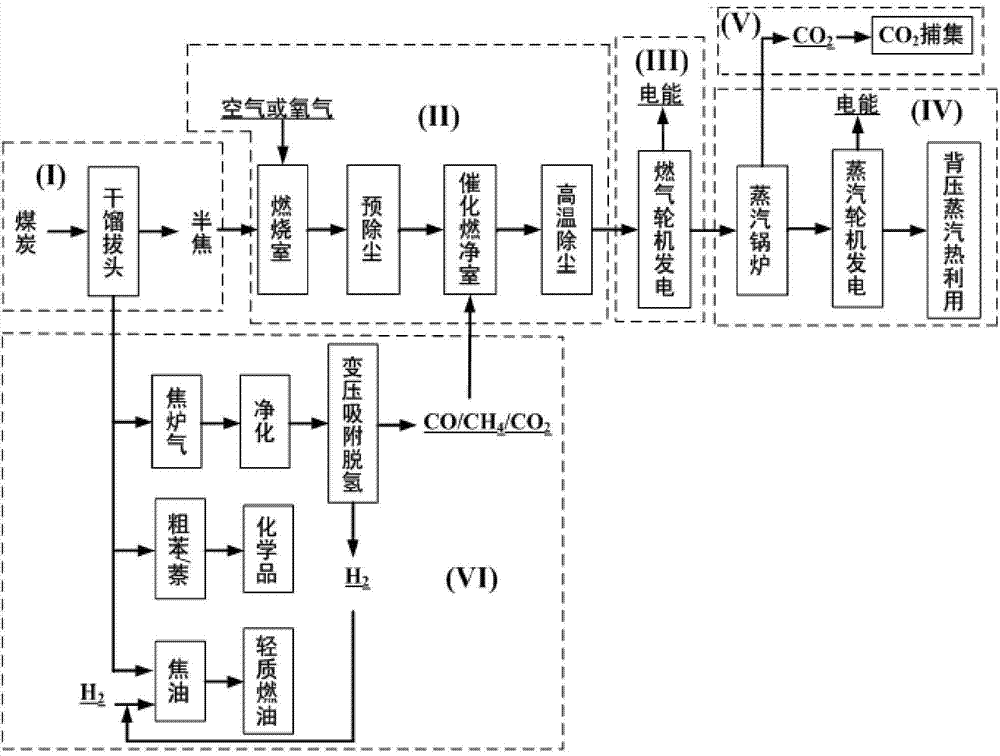

Efficient and clean utilization technology for highly volatile young coal

ActiveCN102965131AEfficient use ofHigh value-added utilizationHydrogen separationEnergy inputTrappingFuel oil

The invention relates to an efficient and clean utilization technology for highly volatile young coal. By means of integrated innovation of the following six technological modules: ''a young coal dry distillation topping process, a system for preparation of a high temperature gas turbine working medium by semi-coke oxygen-enriched direct combustion, gas-fired power generation, supercritical / ultra supercritical power generation, CO2 trapping, and a dry distillation topping gaseous product high-value utilization technique'', especially the method for preparation of high-temperature and high-pressure fuel gas meeting the gas turbine working medium purity requirement directly by semi-coke oxygen-enriched direct combustion without lowering temperature to remove dust and impurities, thermodynamic-chemical full-value clean utilization of coal can be realized. The power generation efficiency can reach over 60%. Compared with the IGCC (integrated gasification combined cycle) technology, the invention substitutes semi-coke oxygen-enriched direct combustion for a coal gasification process needing large investment, develops a high temperature dust removal technology, and makes full use of the useful work of high temperature fuel gas. The invention has the characteristics of less investment, simple process, and high power generation efficiency, etc., and also generates benzene, naphthalene, fuel oil and other high value-added chemicals as byproducts.

Owner:金涌

Method for preparing pulp for making natural-color packaging paperboards by using corn straw raw material

InactiveCN109629282AReduce consumptionEfficient removalPretreatment with water/steamPretreatment with alkaline reacting compoundsCardboardFiber

The invention relates to a method for preparing pulp for making natural-color packaging paperboards by using a corn straw raw material. The corn straw raw material is pretreated to separate most leaves and piths of corn straw and then is pulped by adopting a chemical mechanical method, and prepared paper pulp can replace waste paper pulp to be used for making corrugated raw paper or cardboard paper and other natural-color packaging paperboards. The method is characterized in that the structural characteristics of different components such as leaves, piths and straw skin in the corn straw raw material are fully utilized, the leaves and piths with smaller fiber contents are turned into powder or granules and the straw with higher fiber content is turned into dense sheets in the pretreatmentprocess, and then the extruded powder or granular leaves and piths are separated through screening for preparation of fodders or bio-organic fertilizers; the straw skin raw material without leaves andpiths is pulped by adopting the chemical mechanical method, and the organic waste generated in the preparation and pulping process can be used for preparing the fodders or bio-organic fertilizers.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

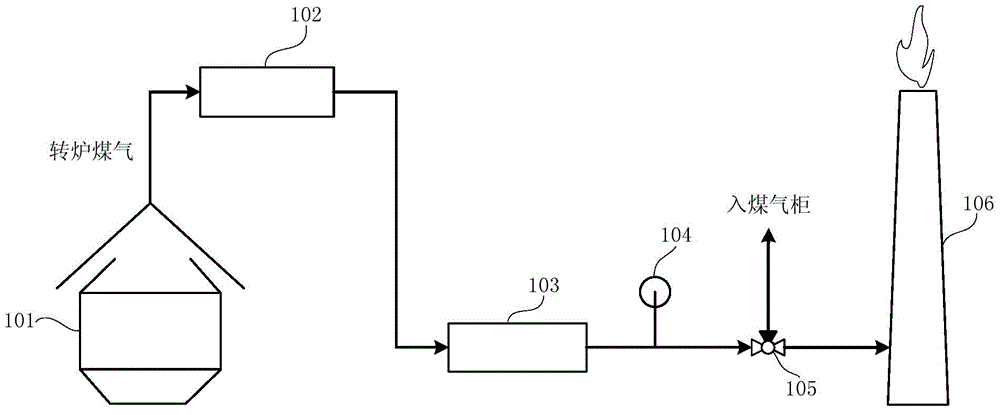

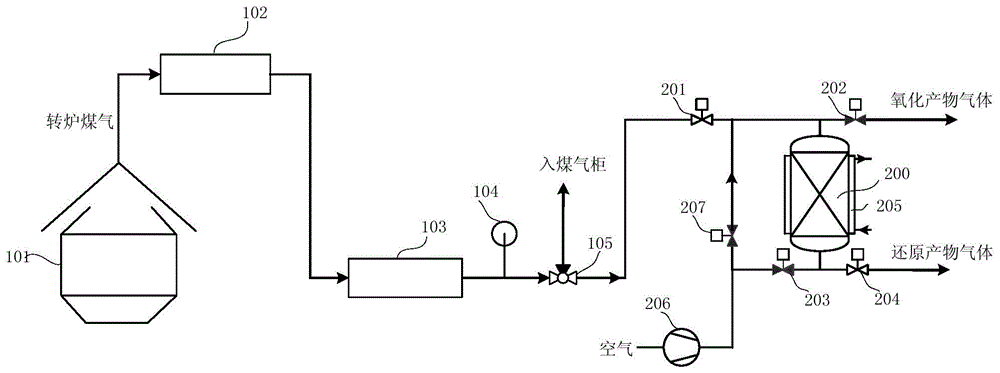

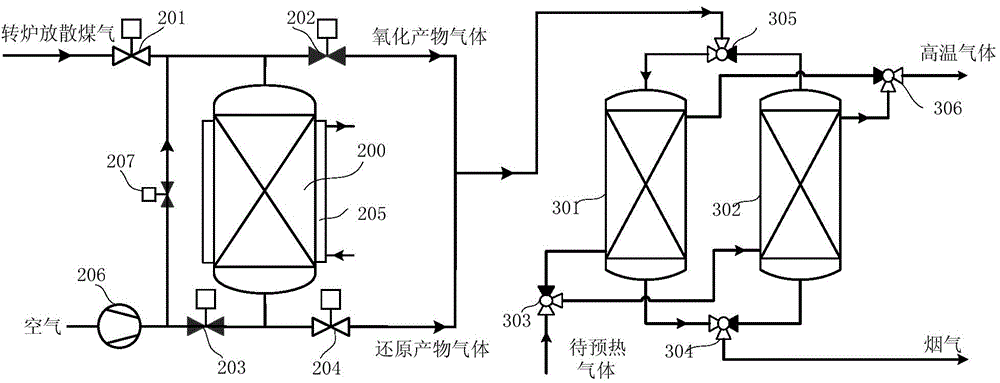

Diffused gas utilizing system and method

ActiveCN105299652AEfficient use ofRealize continuous energy supplyManufacturing convertersIndirect carbon-dioxide mitigationMetalChemistry

The invention relates to a diffused gas utilizing system and method. The diffused gas utilizing system comprises a chemical-looping combustion reactor. The chemical-looping combustion reactor is filled with metal oxygen carriers. Diffused gas is fed into the chemical-looping combustion reactor and reacts on the oxygen carriers. The oxygen carriers are mainly composed of Fe-based oxygen carriers, and Cu-based carriers are added according to a certain proportion. The flowing direction of the diffused gas and the flowing direction of air in the chemical-looping combustion reactor are made opposite through switching of a valve, so that the problem that the diffused gas cannot be used easily due to the facts that the potential safety hazards are large and the diffused gas is exhausted intermittently is solved, and accordingly safe, clean and efficient utilization of the diffused gas is achieved.

Owner:UNIV OF SCI & TECH BEIJING +1

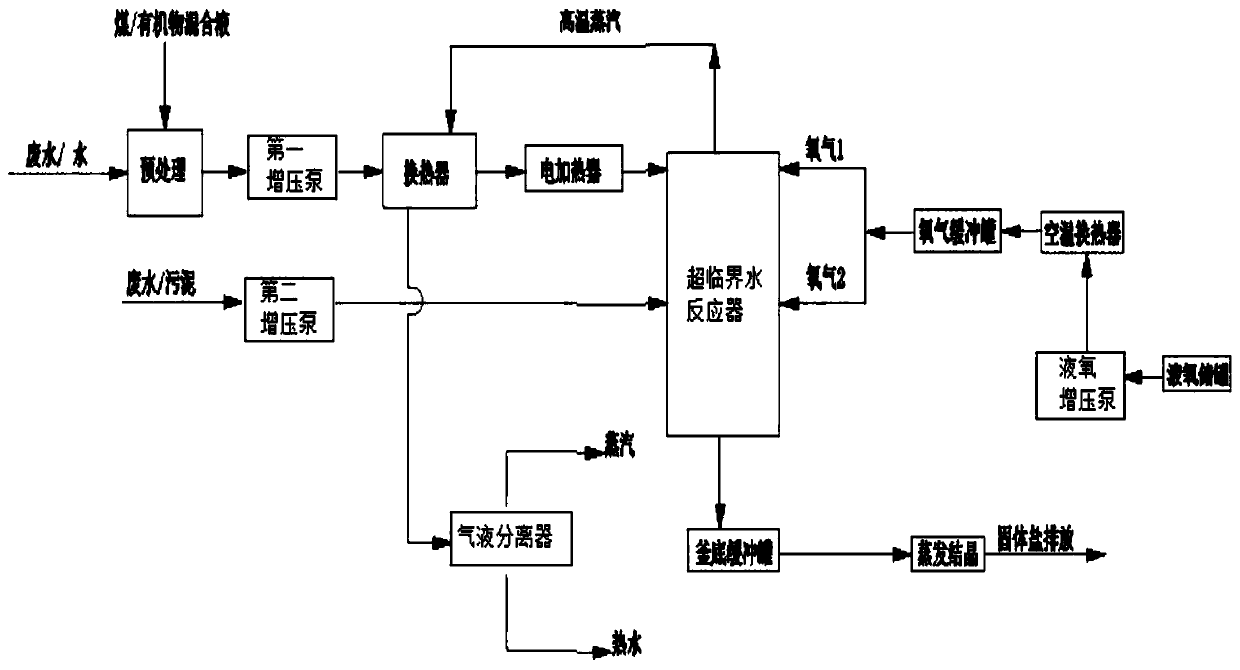

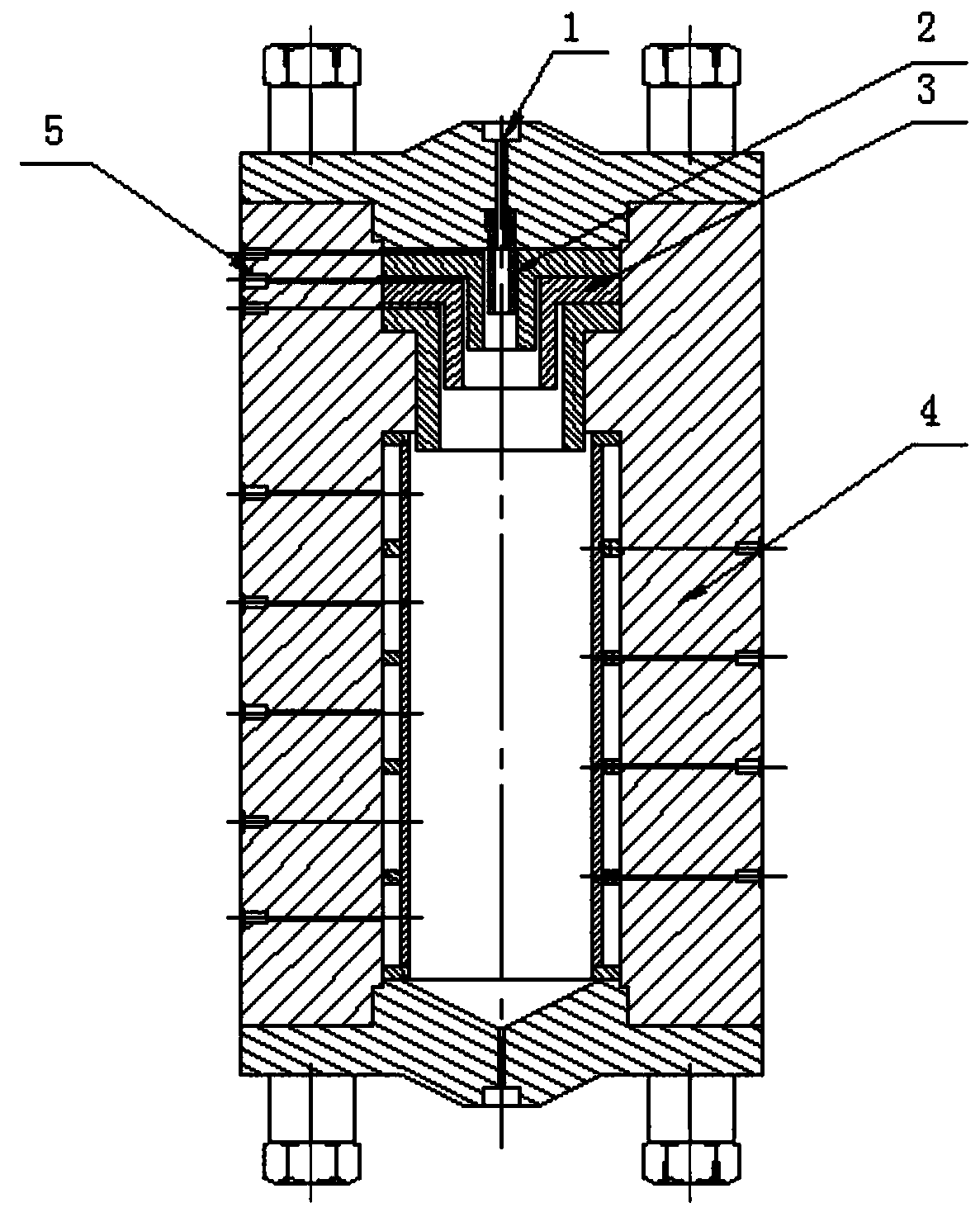

Wastewater and sludge treatment system and method using coal and organic matter as raw materials

PendingCN110510726ARealize clean utilizationNo secondary pollutionSludge treatment by oxidationSpecific water treatment objectivesHigh concentrationIndustrial waste water

The invention relates to a wastewater and sludge treatment system taking coal and organic matters as raw materials, the wastewater and sludge treatment system comprises a coal and organic matter mixedmaterial pretreatment unit; a liquid pressurizing unit; an oxygen supply unit; a supercritical water oxidation reaction unit; an evaporation crystallization unit; a heat recycling unit; a gas-liquidseparation unit and a waste heat utilization unit. The supercritical water oxidation reaction unit comprises a supercritical water oxidation reactor, wherein a liquid inlet of the supercritical wateroxidation reactor is connected with a coal and organic matter mixed liquid outlet of the coal and organic matter mixed material pretreatment unit, a first oxygen inlet is communicated into the supercritical water oxidation reactor after being merged with the liquid inlet, and a second oxygen inlet is communicated into the supercritical water oxidation reactor after being merged with a wastewater / sludge inlet. The waste water and sludge treatment system and process using coal and organic matters as raw materials have wide application range, high efficiency and zero pollution discharge, can realize energy and resource recovery at the same time, and are particularly suitable for industrial waste water, sludge, high-concentration organic waste water and hazardous waste treatment.

Owner:碧流天能(北京)科技股份有限公司

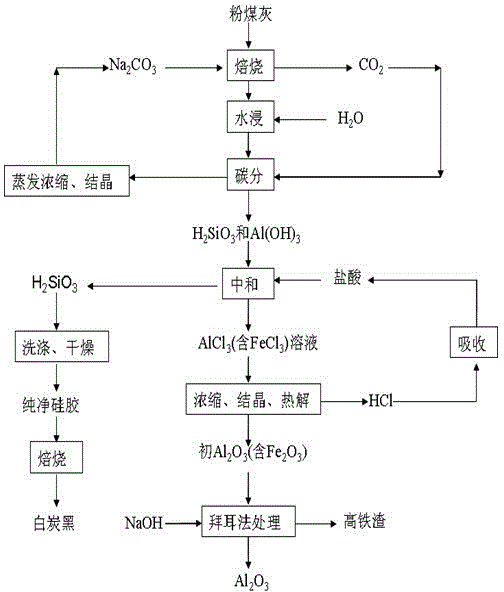

Method for processing fly ash

InactiveCN104445307ARealize comprehensive high-value utilizationIncrease added valueSilicaSolid waste disposalAluminium chlorideAluminium hydroxide

The invention relates to a method for processing fly ash, which comprises the following steps: adding sodium carbonate in the ground fly ash for roasting, then leaching by using water, leaching liquid carbon to obtain silica gel and aluminium hydroxide; neutralizing silica gel and aluminium hydroxide by hydrochloric acid, filtering to obtain the silica gel, processing and calcining to obtain white carbon black; performing evaporative concentration on the obtained aluminium chloride solution, crystallizing to obtain the aluminium chloride crystals, performing pyrolysis on the crystals to obtain initial alumina; and processing the initial alumina by a barer process to obtain the metallurgical-grade alumina and high iron slag, wherein the high iron slag can be a raw material for ironmaking. According to the invention, extraction for useful elements such as aluminium, silicon and iron in the fly ash can be realized, recovery rate can reach more than 90%, residue amount after extraction accounts for lower than 10% of mount of fly ash, carbon dioxide, acid and alkali required in the invention can be recovered and used, zero discharge can be realized during a whole technical process, and no secondary pollution can be generated on environment.

Owner:GUIYANG AL-MG DESIGN & RES INST

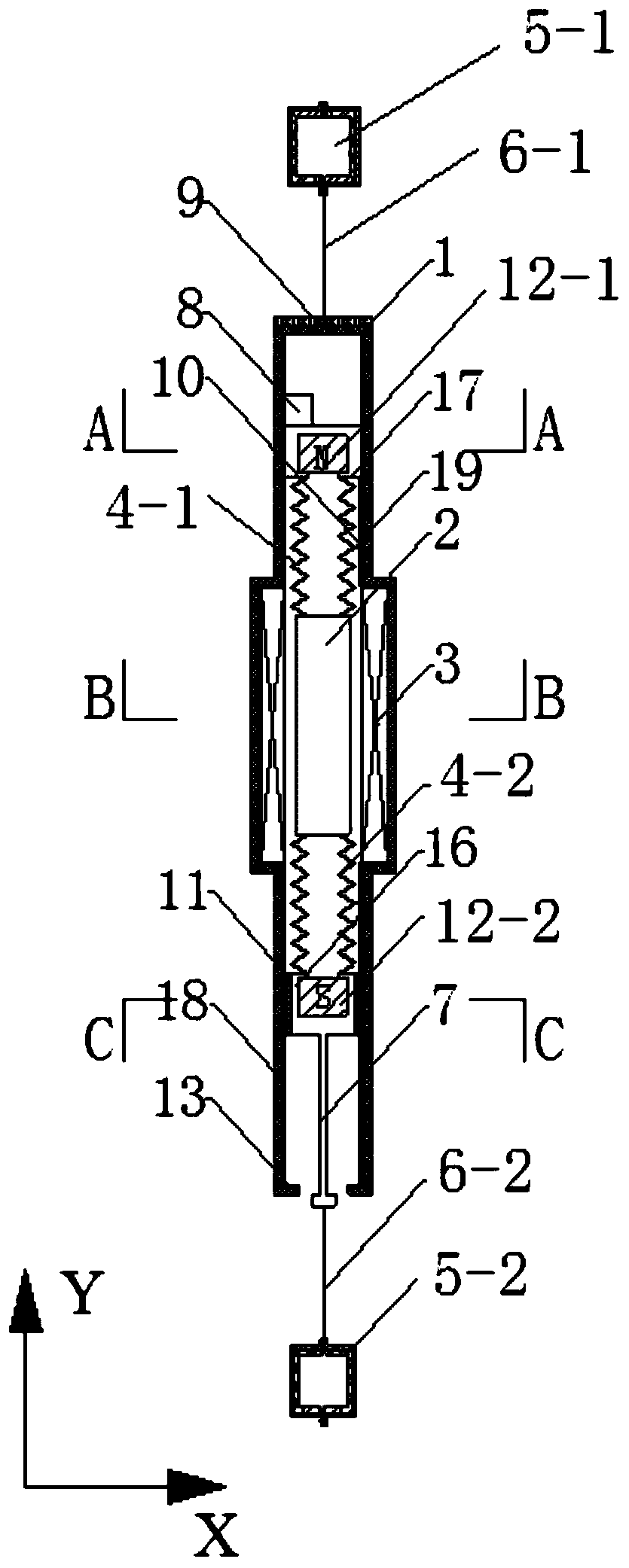

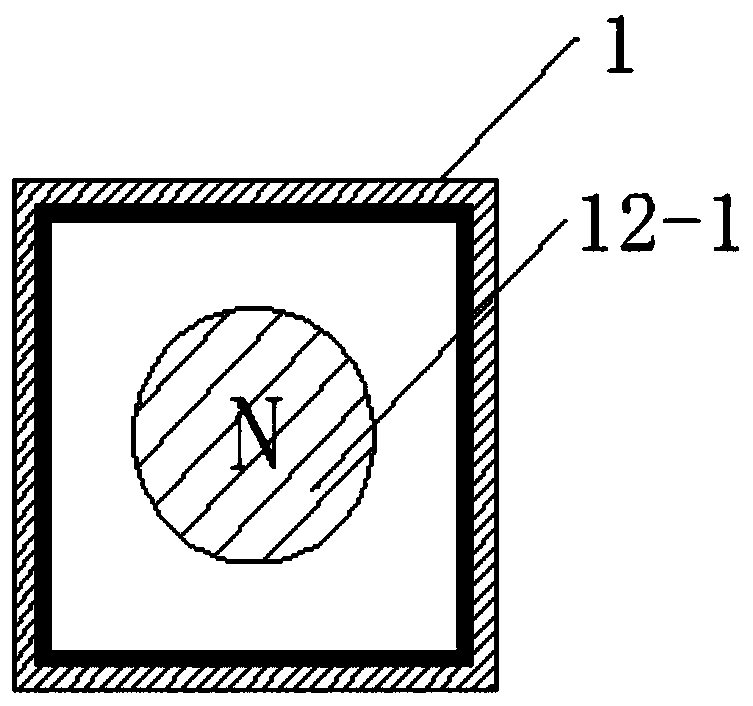

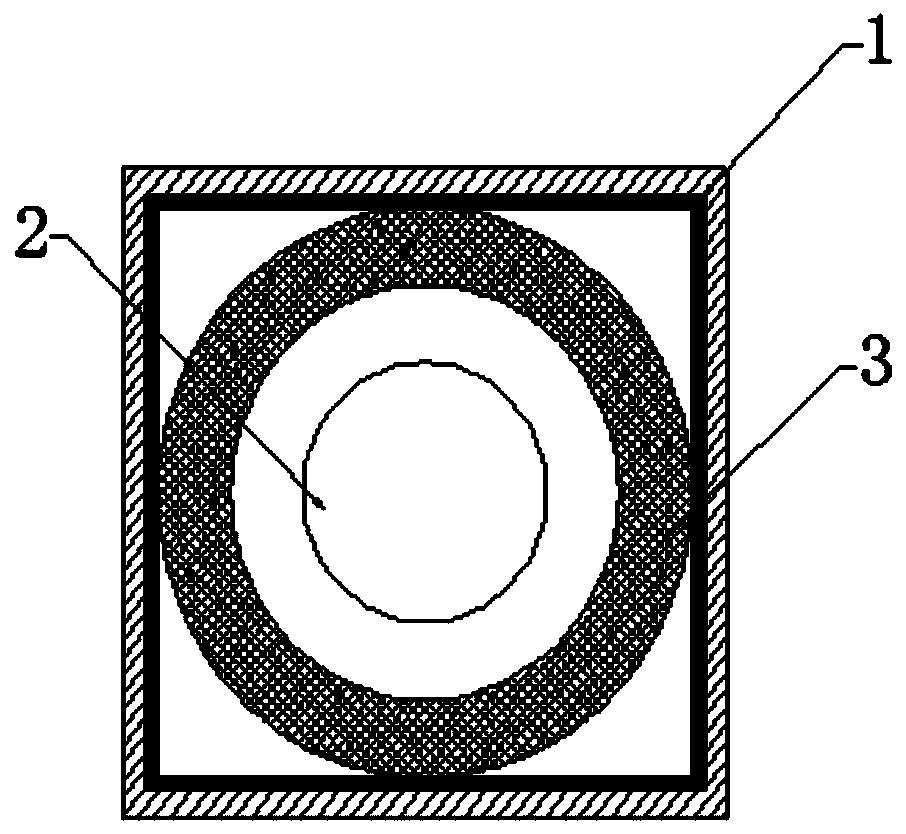

Self-adaptive electromagnetic energy dissipation anti-galloping vibration damping device

InactiveCN109818322AGive full play to its own energy consumption performanceImprove control effectMaintaining distance between parallel conductorsDevices for damping mechanical oscillationsClosed loopMagnetic poles

The invention discloses a self-adaptive electromagnetic energy dissipation anti-galloping vibration damping device which comprises an outer box body, wherein an iron core is arranged in the outer boxbody, the top of the iron core is connected with a mounting piece fixed on the inner wall of the outer box body through a first elastic device, the bottom of the iron core is connected with a piston through a second elastic device, and the piston can move up and down relative to the outer box body; a permanent magnetic pole is arranged in the mounting piece, a permanent magnetic pole is installedin the piston, and the polarities of the two permanent magnetic poles are opposite; a magnet exciting coil is arranged in a gap formed by the iron core and the outer box body, and is connected with acontroller mounted in the box body and a power supply mounted in the outer box body in series to form a closed loop; an upper clamping device connected with the outer box body is arranged above the outer box body, and a lower clamping device connected with the piston is arranged below the outer box body; a displacement monitor is installed on the inner wall of the outer box body and used for monitoring displacement of the first elastic device and the second elastic device; and the displacement monitor is connected with a pre-controller.

Owner:SHANDONG UNIV

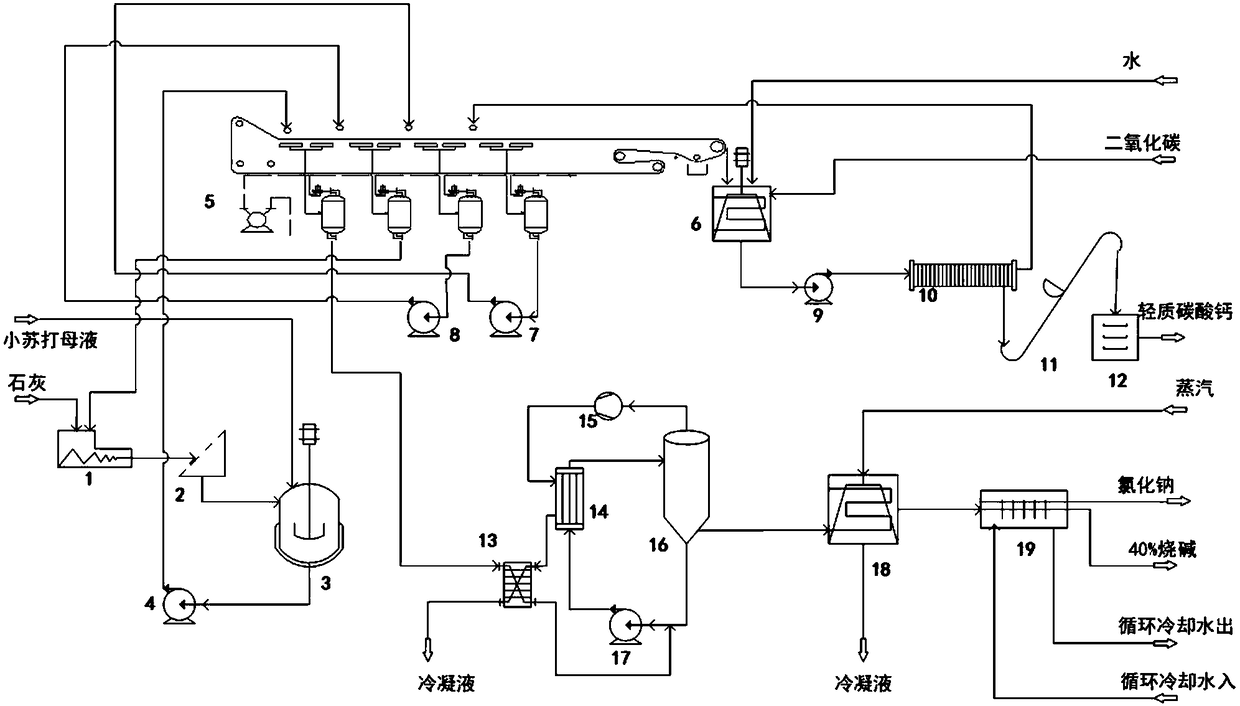

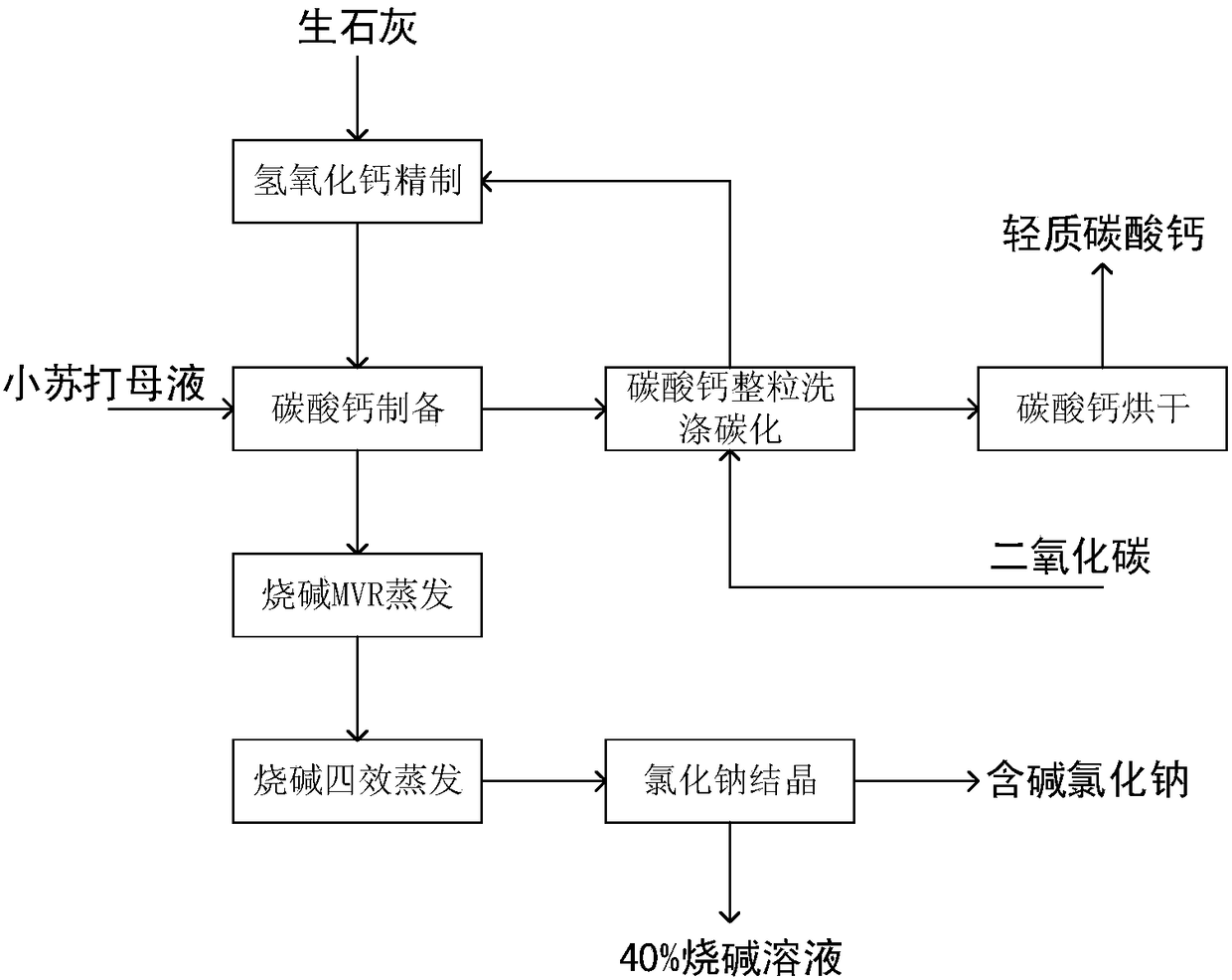

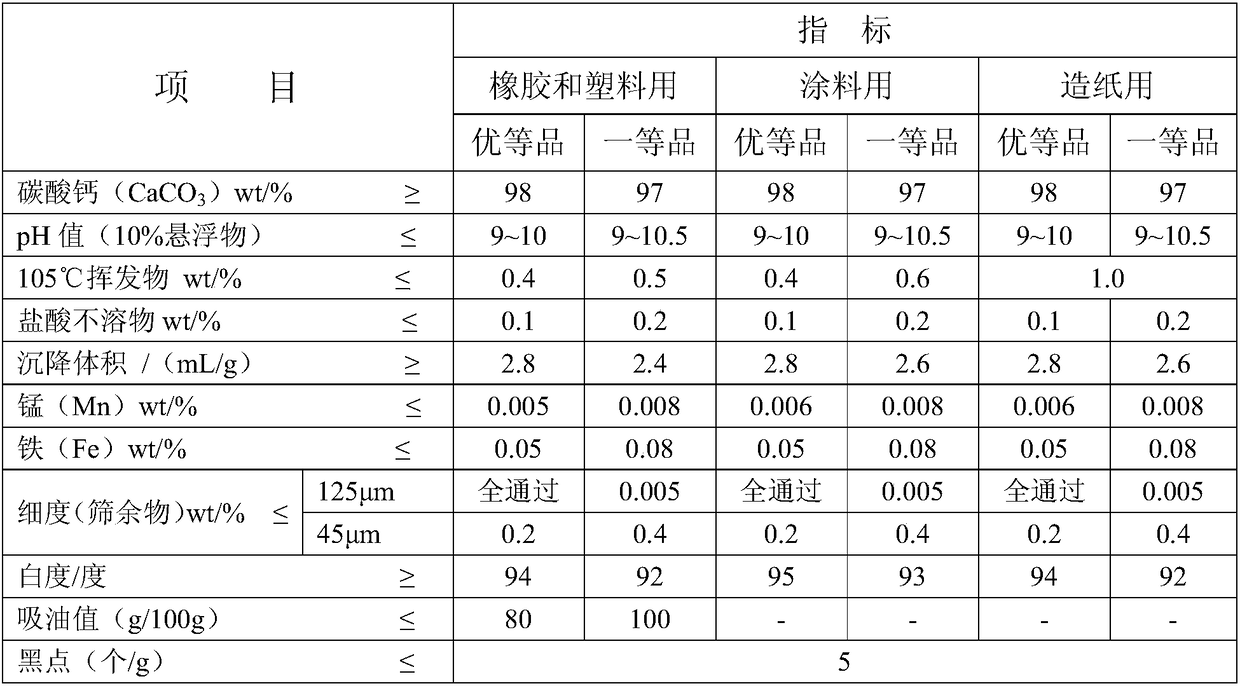

Trona sodium bicarbonate mother liquor resource utilization system and treatment method thereof

ActiveCN108439448ARealize clean utilizationSimple processCalcium/strontium/barium carbonatesProductsSodium bicarbonateResource utilization

The invention discloses a trona sodium bicarbonate mother liquor resource utilization system and a treatment method thereof. The system comprises a lime slaking unit, a causticizing reaction unit, a slurry separation unit, a calcium carbonate size stabilization carbonation unit, a calcium carbonate separation and drying unit, a caustic soda evaporation unit and a crystallization separation unit. The lime slaking unit is respectively connected to a quick lime feeding pipeline and the causticizing reaction unit; the causticizing reaction unit is respectively connected to a trona sodium bicarbonate mother liquor feeding pipeline, the lime slaking unit and the slurry separation unit; the slurry separation unit is respectively connected to the causticizing reaction unit, the calcium carbonate size stabilization carbonation unit and the caustic soda evaporation unit; the calcium carbonate size stabilization carbonation unit is respectively connected to a water feeding pipeline, a carbon dioxide feeding pipeline, the slurry separation unit and the calcium carbonate separation and drying unit; the caustic soda evaporation unit is respectively connected to the slurry separation unit and thecrystallization separation unit. The system and method provided by the invention do not produce solid waste, and are trona sodium bicarbonate mother liquor clean production technology.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

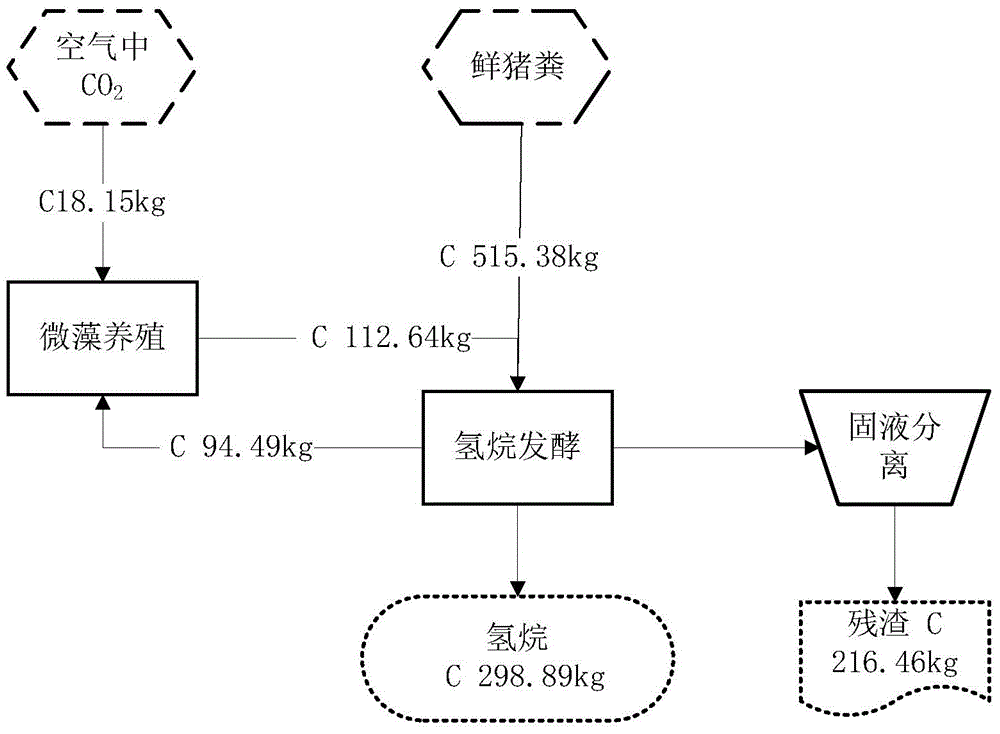

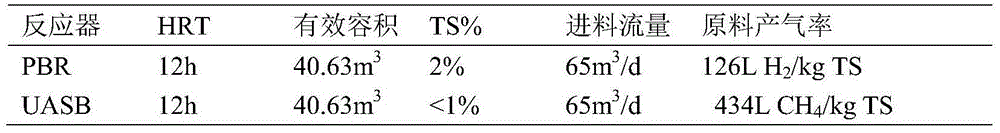

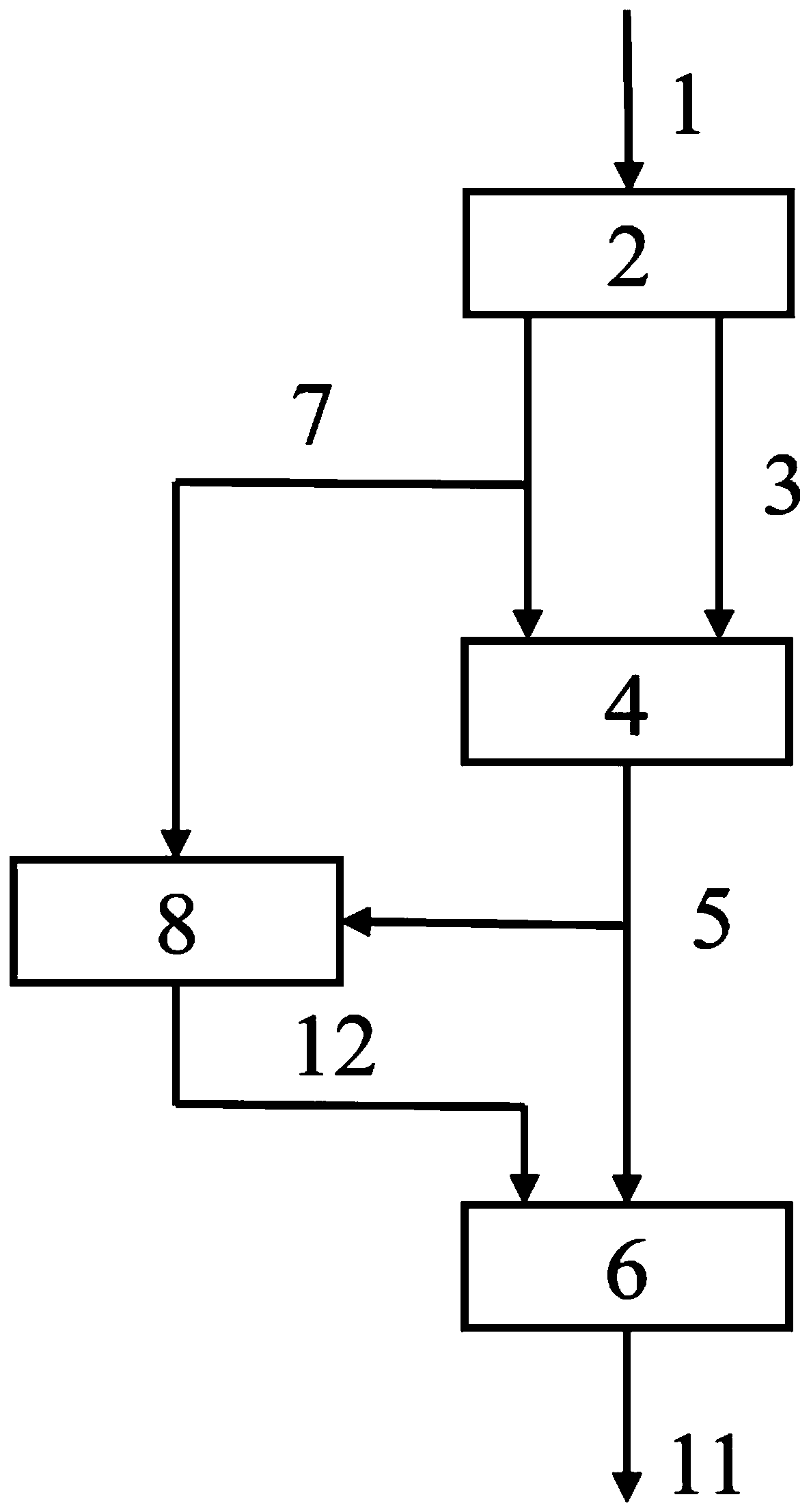

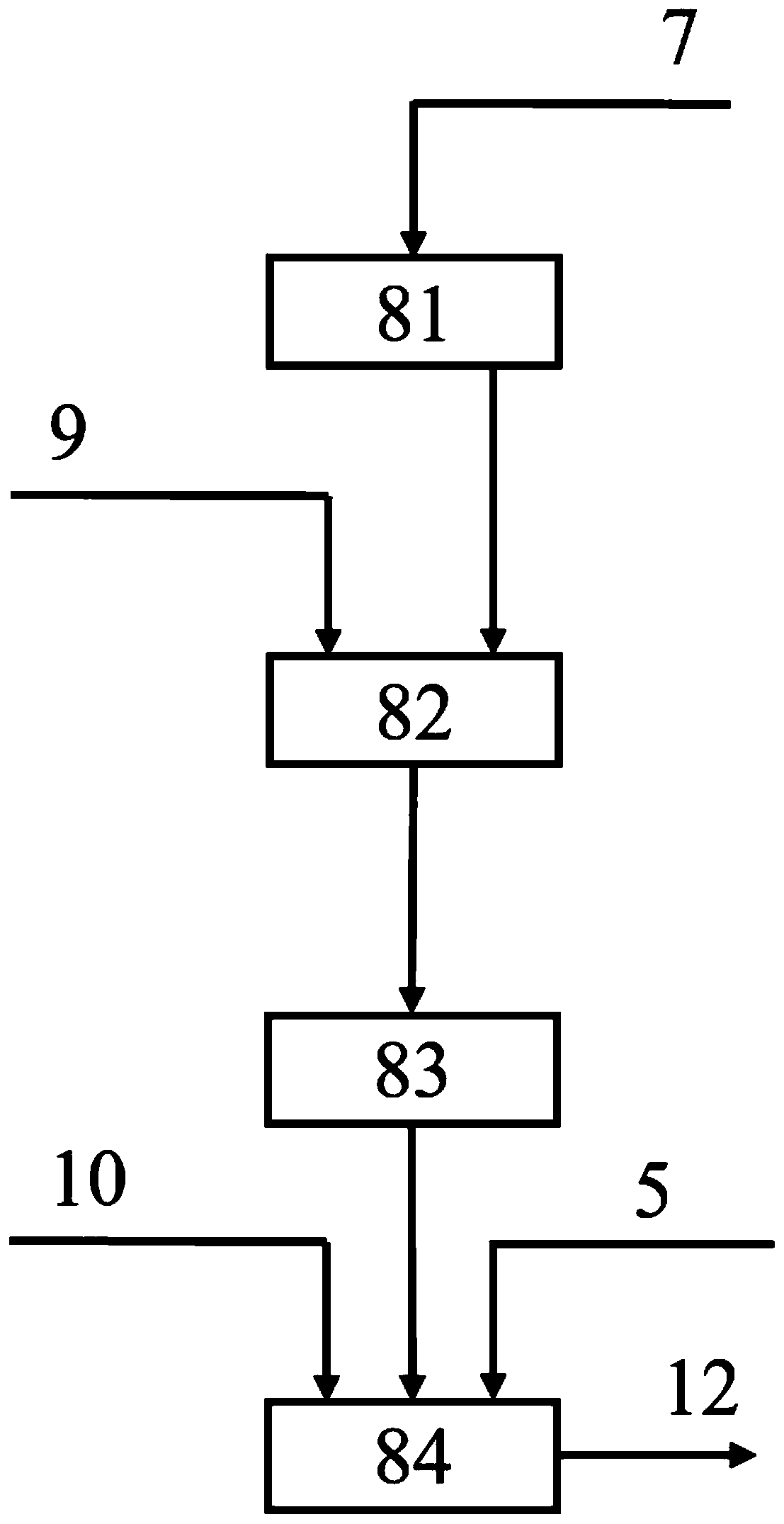

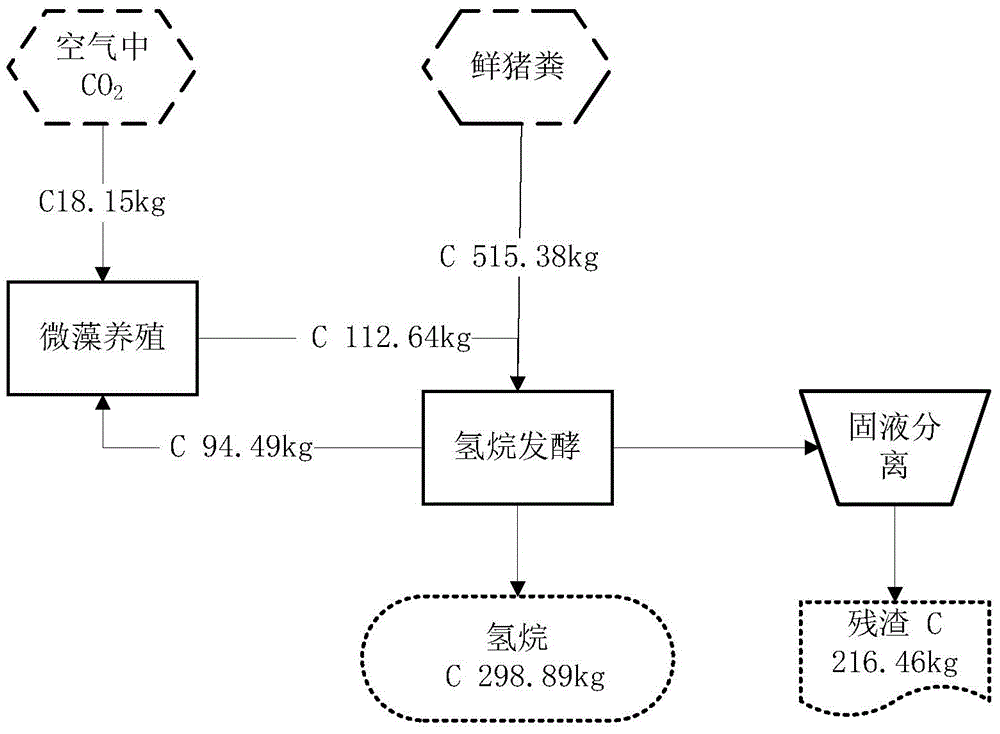

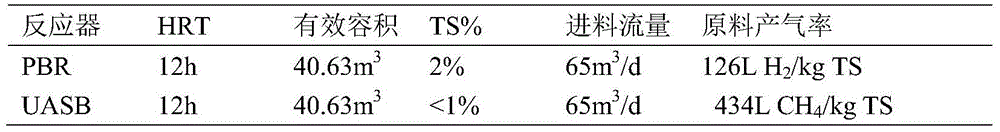

Organic waste treatment method in hydrogen alkane fermentation coupling microalgae breeding

ActiveCN103981220AImprove photosynthesis efficiencyReduce pollutionUnicellular algaeEnergy inputAlkaneNew energy

The invention discloses an organic waste treatment method in hydrogen alkane fermentation coupling microalgae breeding, and belongs to the technical fields of environmental protection and new energy. The method comprises the following steps: (1) preparing hydrogen through anaerobic fermentation; (2) preparing methane through anaerobic fermentation of residues; (3) applying hydrogen alkane generated to heat supply and power generation or to sale as vehicle fuel after being purified; (4) preprocessing fermentation liquor; (5) by taking the processed fermentation liquor as a matrix, breeding microalgae through carbon dioxide in hydrogen alkane generated by fermentation and carbon dioxide generated by burning the hydrogen alkane; and (6) mixing the collected microalgae with organic waste, and turning to the step of fermenting again. The method disclosed by the invention, through hydrogen and methane fermentation steps, improves waste treatment efficiency and energy recovery rate; the fermented liquid, through a nitrogen and phosphorus removal process of algae, functions as purifying; a sewage discharge indicator is achieved on an aspect of nitrogen and phosphorus, and the algae can serve as a raw material of anaerobic fermentation to continuously produce biological hydrogen alkane; and environment value added energy is realized.

Owner:CHINA AGRI UNIV

Method for preparing methane-rich gas by utilizing wastes

ActiveCN111363570AMild preparation conditionsEasy to operateGaseous fuelsSpecial form destructive distillationCatalytic reformingPtru catalyst

The invention provides a method for preparing methane-rich gas from waste, which comprises the following steps: 1. putting waste in a pyrolysis reactor, and carrying out pyrolysis at 400-700 DEG C toobtain a solid-phase product semicoke and volatile matters, 2, carrying out catalytic reforming on the volatile matters in a reforming reactor by using 60-75% of semicoke to obtain synthesis gas richin hydrogen and CO / CO2, loading active components on 25-40% of semicoke in a catalyst preparation system, and carrying out roasting and activation to obtain a catalyst, and 3, feeding the synthesis gas and a catalyst into a methanation reactor for a reaction, so that methane-rich gas is obtained, wherein the concentration of methane in the methane-rich gas is higher than 35%, and the concentrationof H2 in the methane-rich gas is lower than 20%. According to the method, the catalyst is prepared on the basis of the semicoke, the pyrolysis reforming product from the waste is adjusted into the gas rich in methane, subsequent utilization is facilitated, the method has important practical significance and value, thorough clean utilization of the waste is achieved, and the quality and efficiencyof waste recycled energy are improved.

Owner:TONGJI UNIV

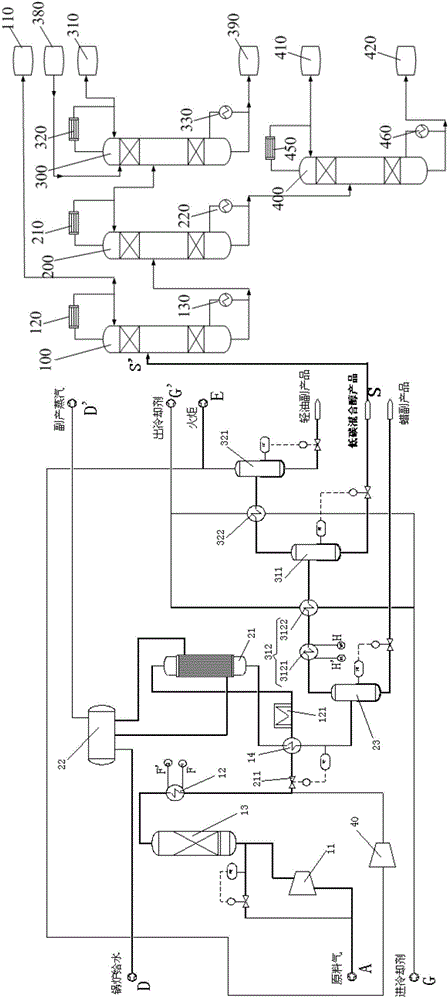

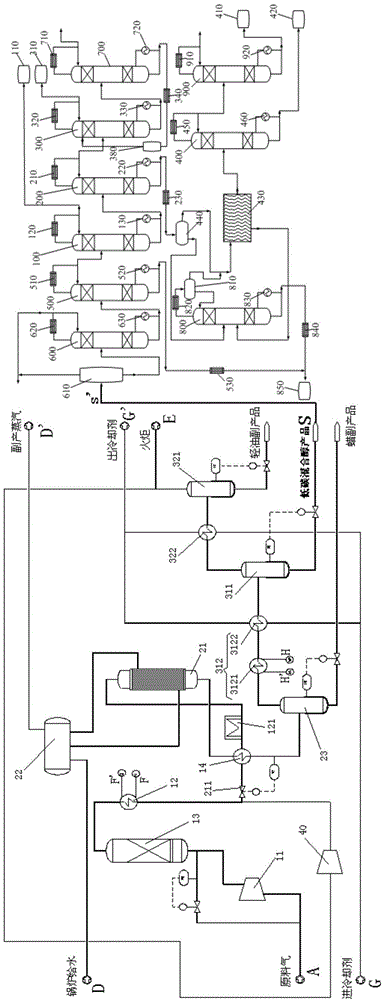

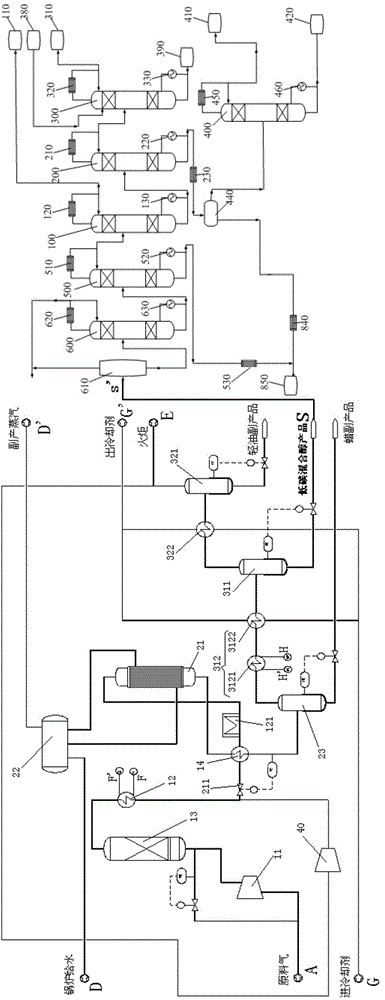

Joint production system and joint production process for synthesizing and separating low-carbon mixed alcohol

ActiveCN104529704ARealize clean utilizationReduce dependencyOrganic compound preparationHydroxy compound separation/purificationN-Propyl alcoholAlcohol synthesis

The invention provides a joint production system and a joint production process for synthesizing and separating low-carbon mixed alcohol. The joint production system for synthesizing and separating the low-carbon mixed alcohol comprises a low-carbon mixed alcohol synthesis subsystem and a low-carbon mixed alcohol separation subsystem, wherein the low-carbon mixed alcohol synthesis subsystem comprises a raw gas treatment module, a low-carbon alcohol synthesis module and a product treatment module which are communicated with one another in order, and the product treatment module comprises a low-carbon alcohol separation part which comprises a low-carbon alcohol separator and is provided with a low-carbon mixed alcohol outlet for draining a low-carbon mixed alcohol product; and the low-carbon mixed alcohol separation subsystem comprises a methanol rectifying tower, an ethanol rectifying tower, an extraction rectifying tower and an n-propyl alcohol rectifying tower. By adopting the system and the process provided by the invention, the problem of production technical difficulty during synthesis of the low-carbon mixed alcohol by using a raw material synthetic gas in the prior art is solved, and meanwhile, the problem of poor separation effect of the low-carbon mixed alcohol is solved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

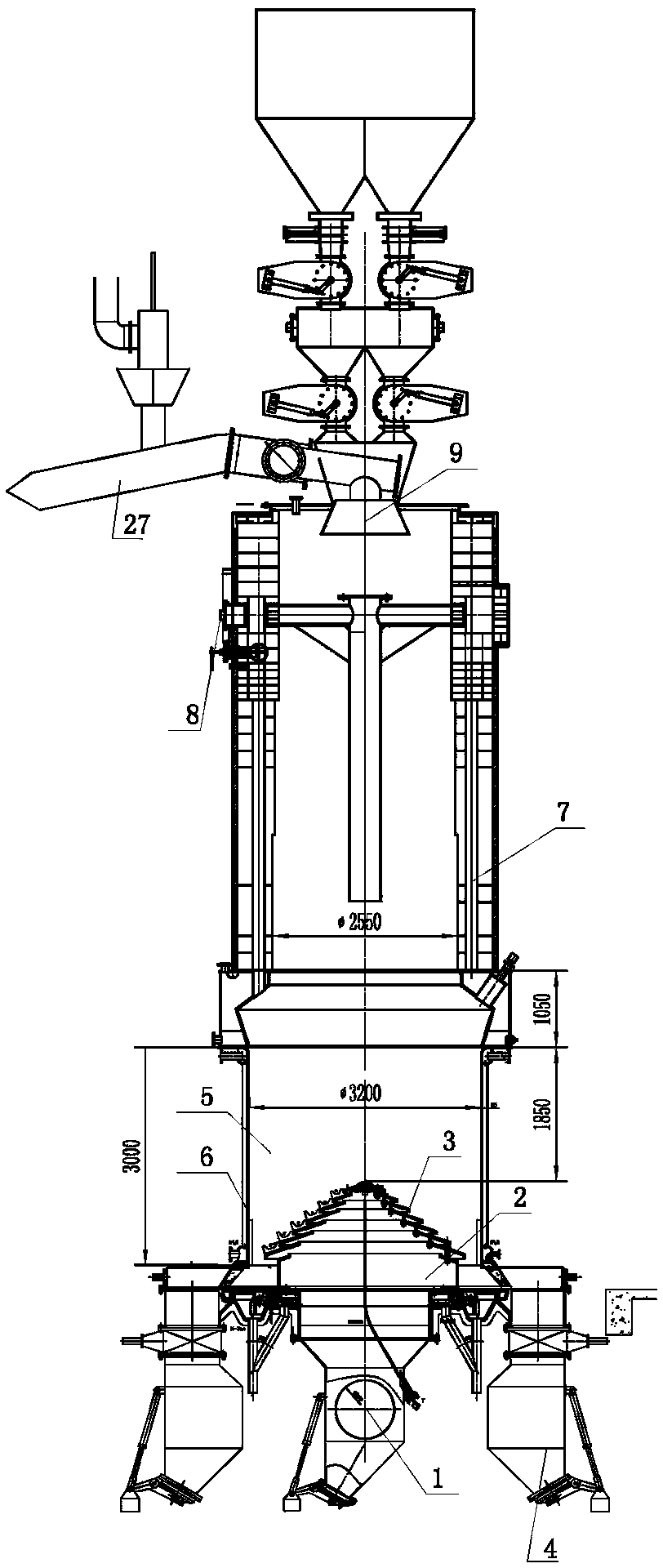

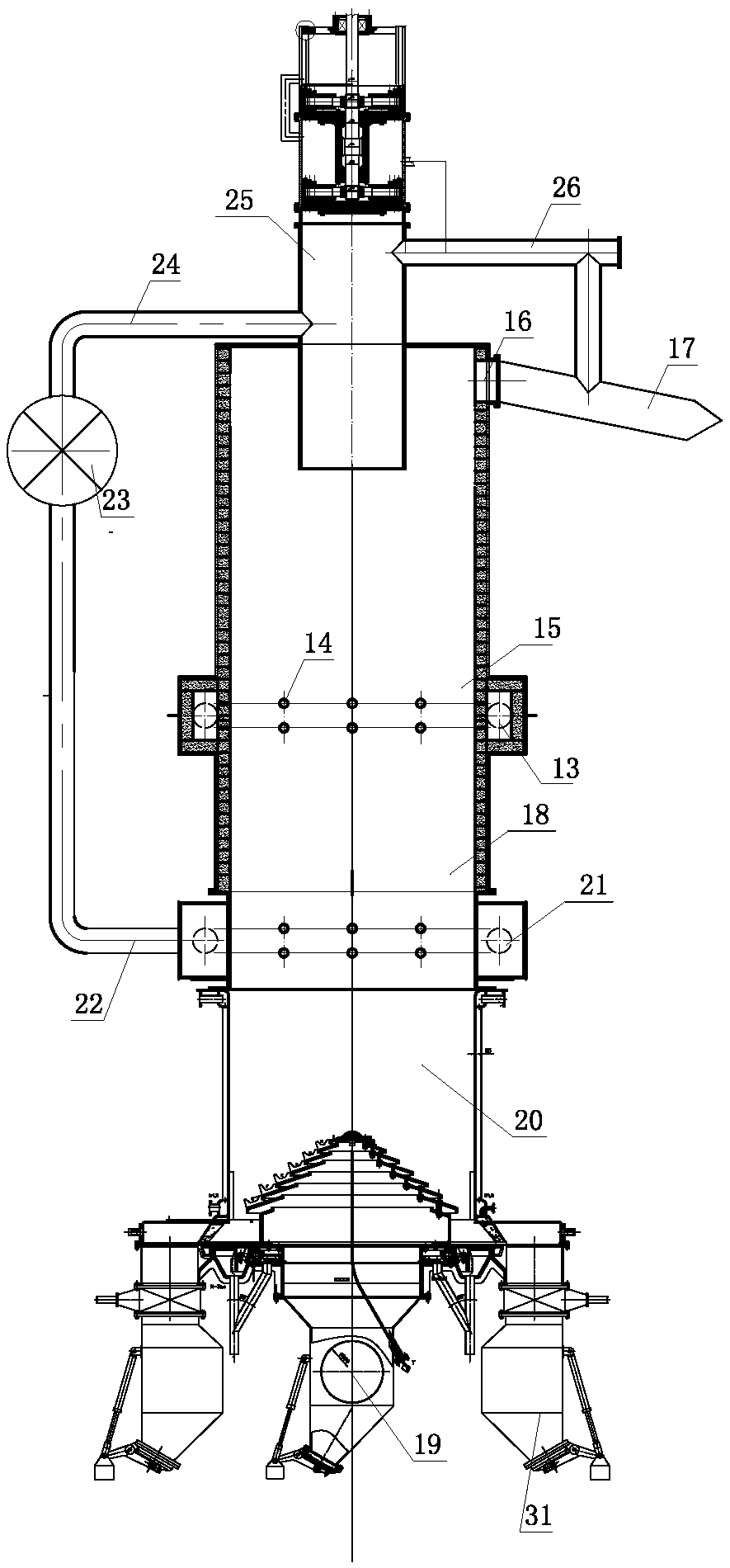

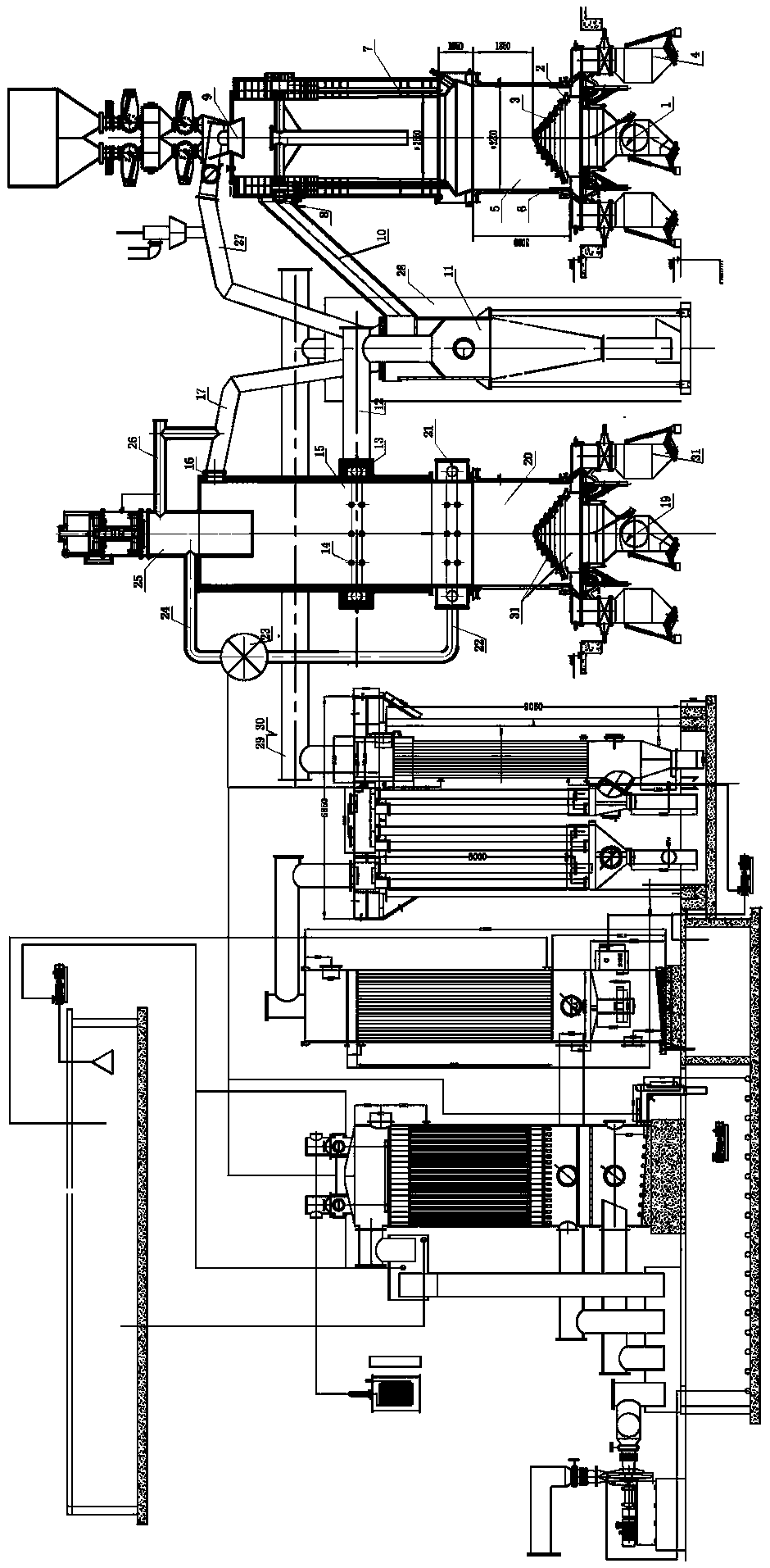

Dry distillation method of connecting Ramsbottom carbon dry distillation furnace with double-section gasification furnace and using high-temperature coal gas to replace combustion supporting gas

ActiveCN107227177AEasy to useRealize clean utilizationCoke quenchingDirect heating destructive distillationSlagHearth

The invention provides a method. According to the method, dry distillation crushed coal and slack coal are mainly milled and kneaded; extracted -15 to 30mm of cylindrical particles are used as major materials; small pea coal is used as auxiliary materials; coal is crushed by a sieve opening being 30mm; 5 to 30 mm of small-particle lump coal is separated out and is used for sealing a strong-force slag crushing double-section furnace to realize the gasification for replacing the gasification of lump coal gasification being 3 to 5cm and 3 to 8cm; the coal gasification raw material sources are expanded and increased. The rest crushed coal and slack coal being smaller than 5mm after the separation are milled and kneaded; the extruded cylindrical particles are fed into a Ramsbottom carbon dry distillation furnace to produce particular Ramsbottom carbon. The method has the advantages that the finished product rate is high; the crushing is little; cleanness is realized; the moisture content is low; the produced Ramsbottom carbon adapts to the use by various scattered bituminous coal-fired boilers, bituminous coal furnaces and stoves; the exhaust pollution of the bituminous coal firing is fundamentally solved.

Owner:孔令增

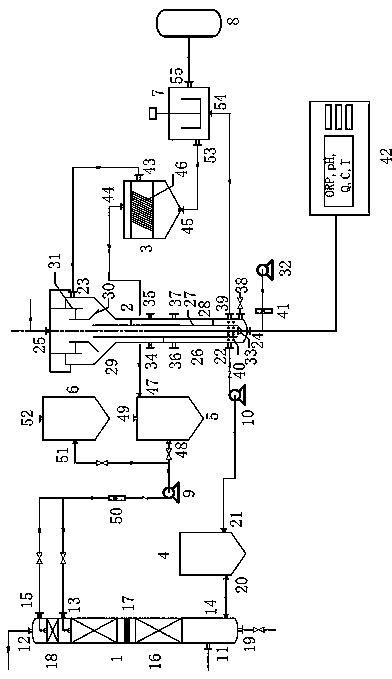

Skid-mounted microorganism desulfurization and sulphur recovery apparatus

InactiveCN105505495AAvoid safety hazardsHydrophilicBioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismTower

The invention relates to a skid-mounted microorganism desulfurization and sulphur recovery apparatus, which comprises an absorption tower, a bioreactor, a settling tank, a pregnant solution tank, a barren solution tank, a clear water tank, a centrifuge, a sulphur recovery tank, a barren solution pump, a pregnant solution pump and other equipment, wherein the top portion of the absorption tower, the barren solution tank and the clear water tank are connected through the barren solution pump and pipelines, the bottom portion of the pregnant solution tank and the bottom portion of the bioreactor are connected through the pregnant solution pump and a pipeline, the top portion of the bioreactor and the settling tank are connected through a pipeline, the top portion of the settling tank and the barren solution tank are connected through a pipeline, the bottom portion of the settling tank and the centrifuge are connected through a pipeline, and the centrifuge, the sulphur recovery tank and the bioreactor are connected through pipelines. The skid-mounted microorganism desulfurization and sulphur recovery apparatus of the present invention has advantages of simple structure, easy operation, stable and safe operation, high automation degree, high desulfurization efficiency, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

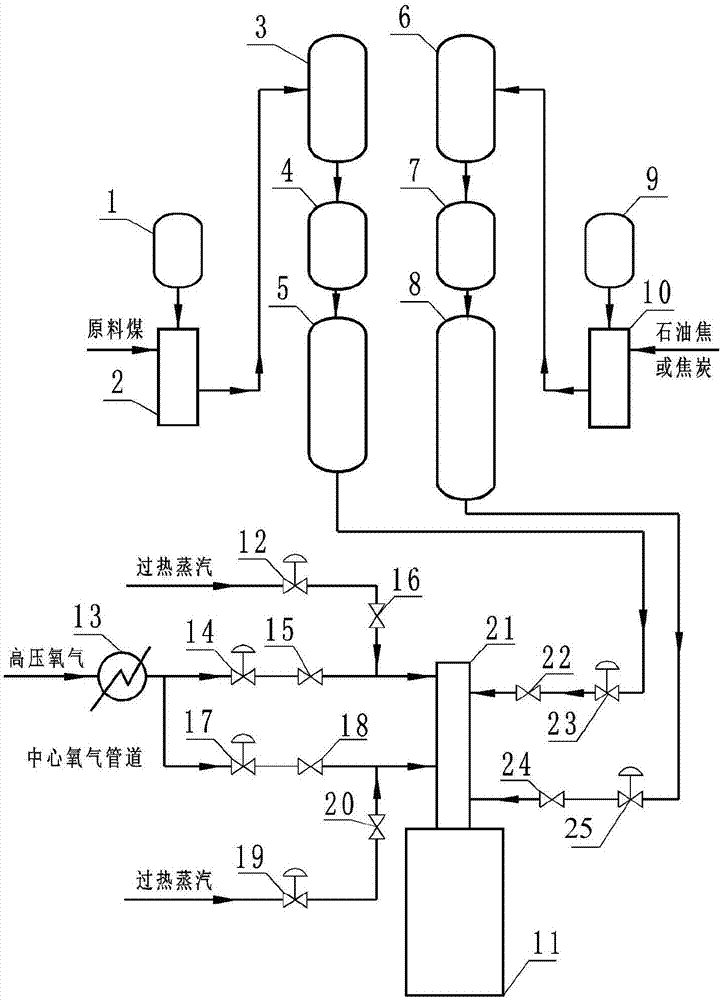

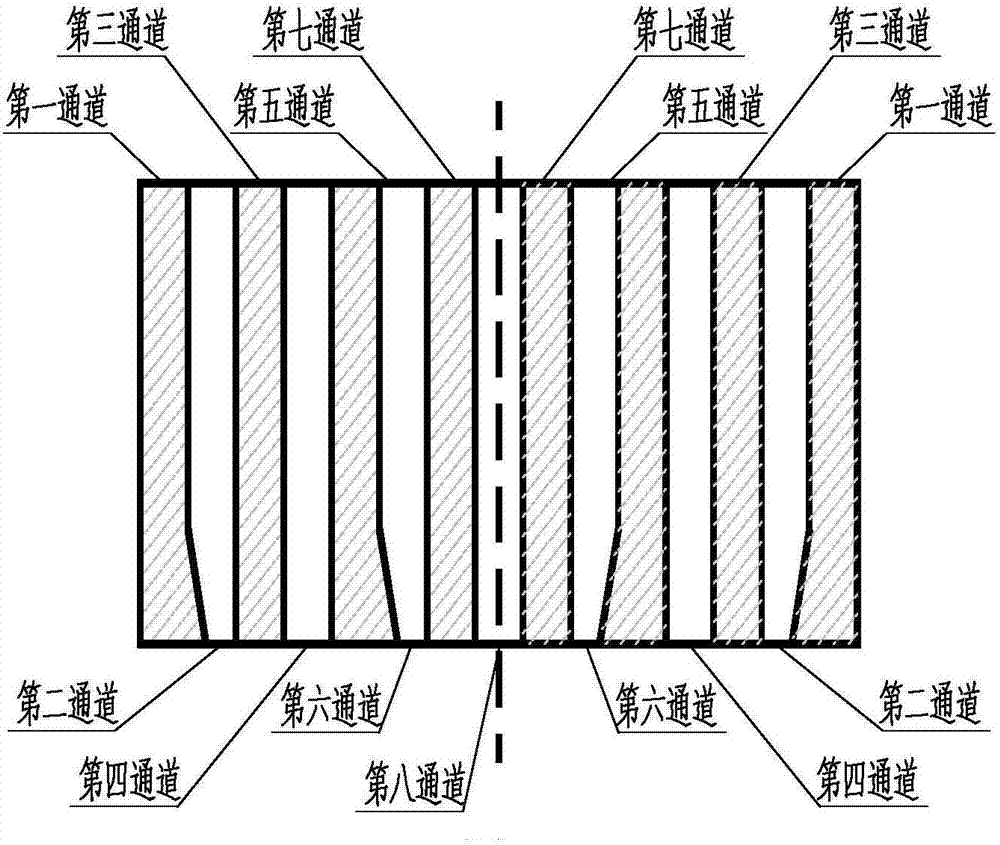

Gasification system and gasification method for pulverized coal and blending combustion combustible materials

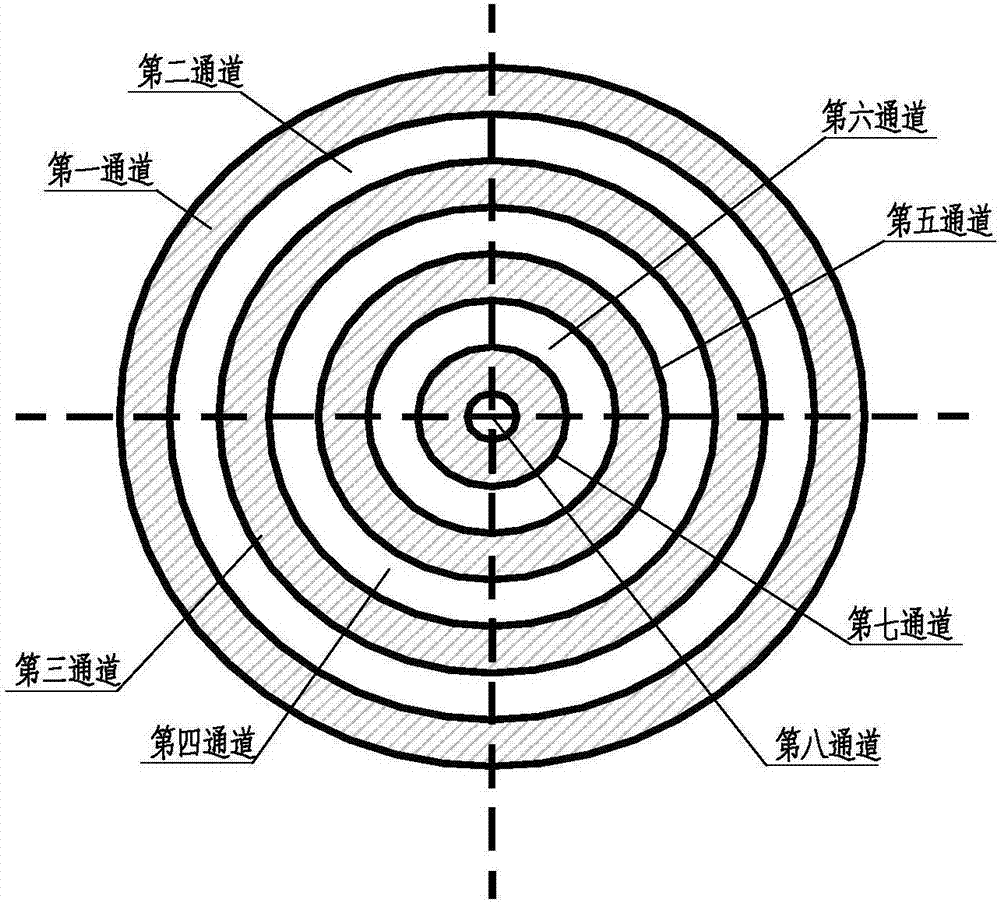

PendingCN107118805ARealize large-scaleRealize online maintenanceGasification processes detailsGranular/pulverulent flues gasificationSyngasCombustion

The invention provides a gasification system and a gasification method for pulverized coal and blending combustion combustible materials. The gasification system comprises a feeding system, a multi-channel gasification burner and a pulverized coal gasifier, wherein the multi-channel gasification burner is provided with eight channels which are concentrically arranged; the pulverized coal, the blending combustion combustible materials and oxygen respectively enter respective channels of the multi-channel gasification burner through the feeding system; the ratio of the oxygen to the coal in each layer can be adjusted separately to achieve the effect of controlling the temperature respectively; the carbon conversion rate can be improved, and components of effective gas in syngas can be improved; in addition, the large-scale gasification of the pulverized coal can be realized, and the gasification of low-rank coal and mixed combustion of coal with different characteristics can be realized.

Owner:CHANGZHENG ENG

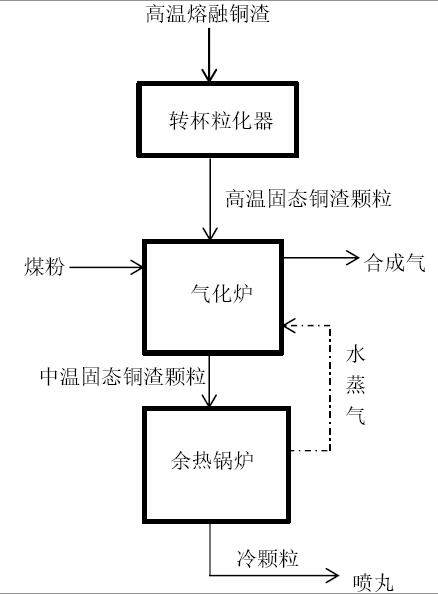

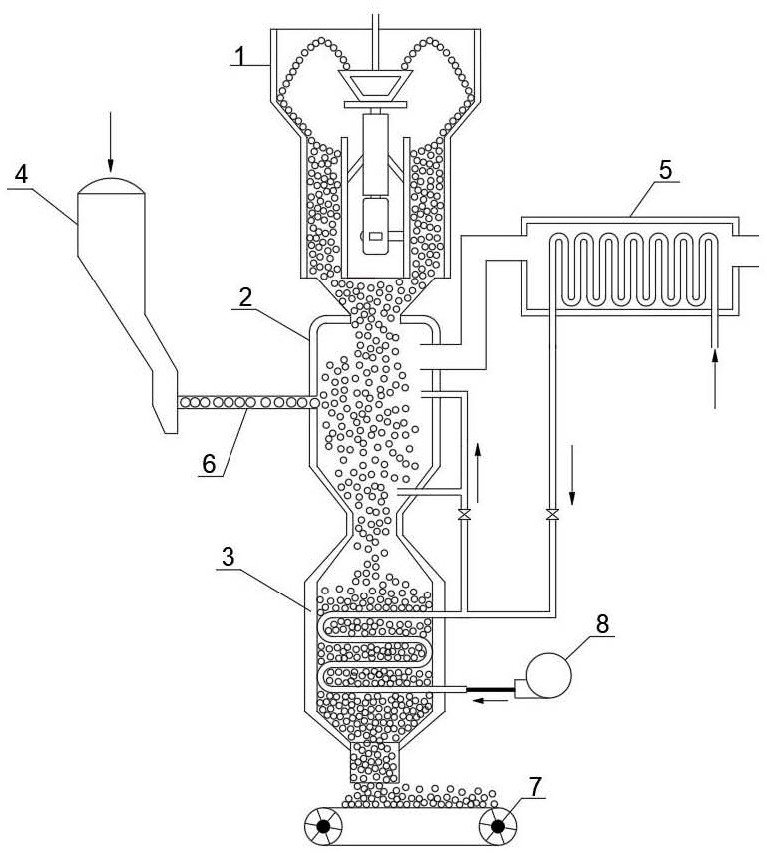

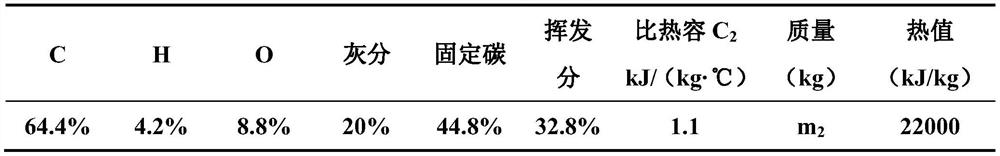

Device system and method for gradient absorption of copper slag waste heat based on coal gasification reaction

PendingCN111733322AEmission reductionSolve resource processingEnergy inputGasification processes detailsSyngasMetallurgy

The invention discloses a device system and method for gradient absorption of copper slag waste heat based on a coal gasification reaction. The method comprises the steps of carrying out copper slag granulation, carrying out the coal gasification reaction, carrying out waste heat recovery through a waste heat boiler and the like. The method specifically comprises the following steps that copper slag is prepared into high-temperature spherical slag particles, and the slag particles gradually provide heat for the coal gasification reaction and the waste heat boiler process; pulverized coal is subjected to heat exchange with the slag particles and is subjected to the gasification reaction under the action of a water vapor and a gasifying agent to absorb the heat of the slag particles so as togenerate synthesis gas containing CO, H2 and CH4; and cold water absorbs heat through heat exchange with the slag particles and is converted into water vapor to serve as the gasifying agent for the gasification reaction. According to the device system and method, the solid slag particle waste heat recovery efficiency is improved to 75% or above, and meanwhile high resource utilization of the coaland copper slag is achieved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Method for simultaneously producing collagens, chicken oil and high-calcium powder through using chicken bones

InactiveCN103263024ARealize clean utilizationNo emissionsFermentationEdible oils/fatsEnzymatic hydrolysisWastewater

The invention discloses a method for simultaneously producing collagens, chicken oil and high-calcium powder through using chicken bones. The method comprises a step of raw material treatment, a step of chicken oil separation, a step of chicken oil preparation, a step of two-step enzymatic hydrolysis, a step of high-calcium powder separation, and a step of collagen preparation. The method which utilizes the above six steps has the advantages of realization of the clean comprehensive utilization of the chicken bones, clean, green and pollution-free production process, no wastewater discharge, improvement of the quality of the collagens, suitableness for the large-scale industrialized production, and substantial economic and social benefits.

Owner:贝尔特(烟台)海洋生物科技有限公司

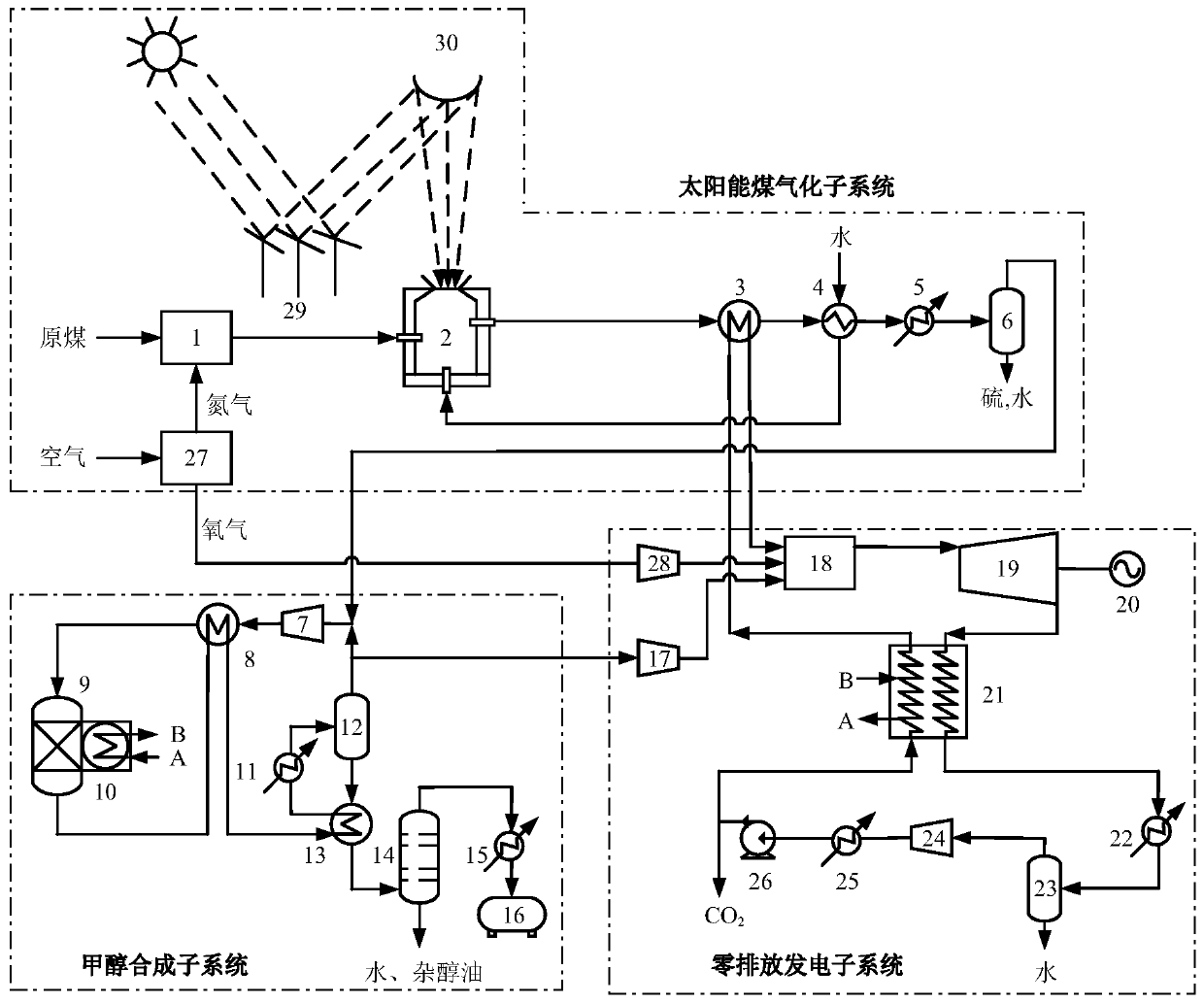

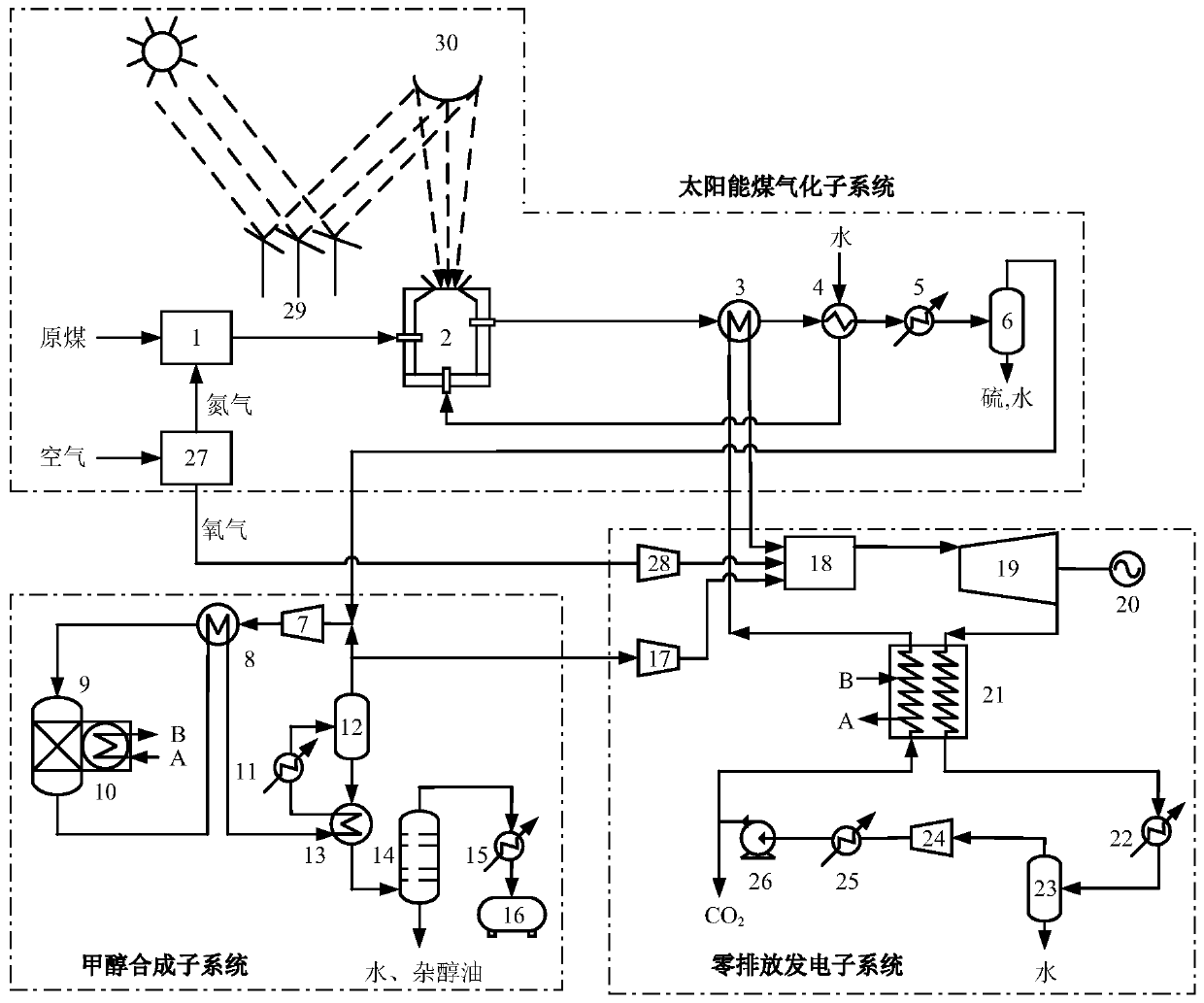

Solar-driven coal gasification methanol synthesis and zero-emission power generation combined system

InactiveCN111140359AImprove utilization efficiencyEfficient couplingOrganic compound preparationEnergy inputCombustion chamberSolar power

The invention discloses a solar-driven coal gasification methanol synthesis and zero-emission power generation combined system in the field of clean utilization of coals. The system mainly comprises asolar coal gasification sub-system, a methanol synthesis sub-system and a zero-emission power genration sub-system. The three sub-systems are connected with an oxygen compressor, a synthesis gas compressor and a combustor through an air separation unit and a purifying separation device, the three sub-systems are organically connected to form the combined system. In the system, condensed solar power provides energy for the coal gasification process, the produced synthesis gas is fed into a methanol synthesis reactor to synthesize methanol, purge gas from an outlet of the reactor is fed into the combustor, the purge gas and the oxyge generatged from the air separation unit are burnt, supercritical carbon dioxide is directly heated and driven to generate power, and a product of combustion can be separated from tail gas to achieve zero emission. Waste heat generated in the working process is recycled by heating a circulating working medium, generating steam and drying raw coal. The comprehensive utilizationrate of the energy source is improved, and it is achieved that graded utilization of the coal and clean power generation coordinatively develop.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

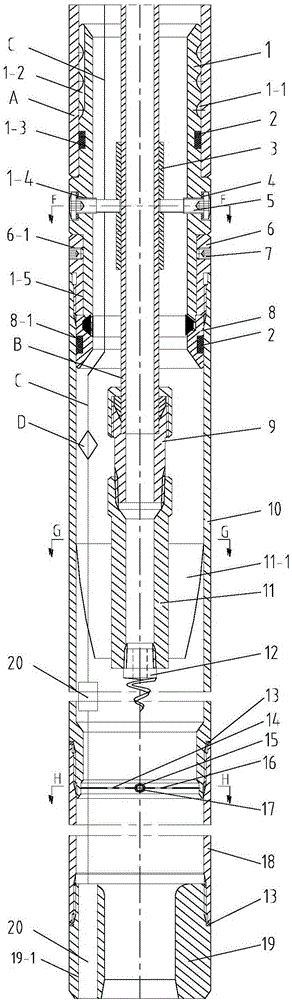

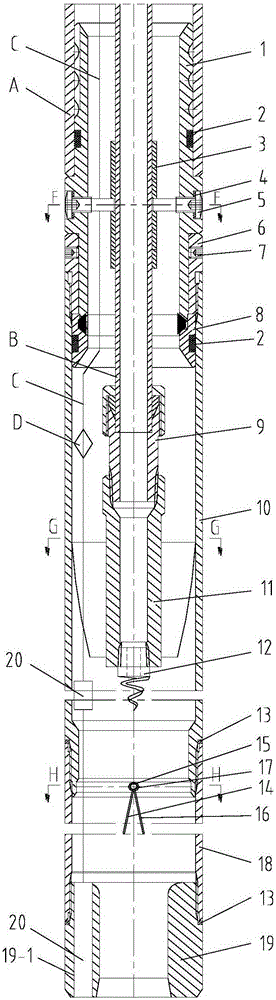

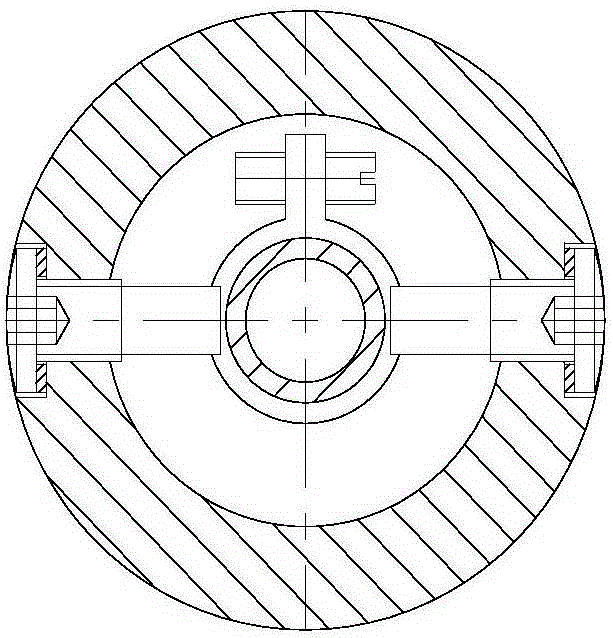

Central water tube gasifying and coal mining device

ActiveCN105178935APrevent axial movementRealize clean utilizationConstructionsCoal gasificationUpper jointWork cycle

The invention discloses a central water tube gasifying and coal mining device. The central water tube gasifying and coal mining device comprises an outer ring subassembly and an inner ring subassembly, wherein the outer ring subassembly comprises an upper joint, a sealing ring, an upper outer barrel, a lower outer barrel and a shower nozzle; a pressing ring groove is formed in the upper end of the upper joint; a fixing screw is arranged in the middle of the upper joint; a swivel nut is arranged at the lower end of the upper joint; the bottom of the upper joint and the sealing ring are positioned in a welded manner; the upper outer barrel is in the shape of a hollow cylinder; the upper end of the upper outer barrel is in threaded connection with the swivel nut; a valve mechanism is arranged on the bottom of the upper outer barrel; the lower outer barrel is in the shape of a hollow cylinder; the upper end of the lower outer barrel is connected with the lower end of the upper outer barrel; the lower end of the lower outer barrel is connected with the shower nozzle; the inner ring subassembly comprises a water delivery tube, a cutting sleeve straight-through terminal joint, a middle water tube and an atomizing nozzle; hose clamps are arranged on the water delivery tube pairwise; a fixing screw is inserted in the hose clamps arranged pairwise, and is used for limiting axial movement of the water delivery tube; and a plurality of helical blades which are used for producing circles on delivered oxygen are uniformly distributed on the outer surface of the middle water tube in the peripheral direction. The central water tube gasifying and coal mining device has the advantages of simple structure, high temperature resistance, oxidation resistance, long descent continuous working period and the like.

Owner:JIANGHAN MASCH RES INST LTD CO OF CNPC +1

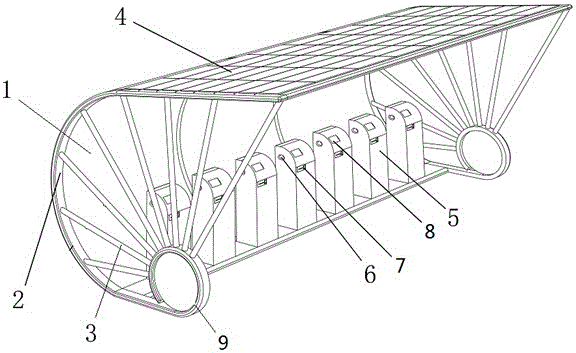

Pavilion type solar charging station for electric bicycles

InactiveCN105118176ARealize the clean utilization of energyImprove convenienceApparatus for hiring articlesCharging stationElectric bicycle

The invention discloses a pavilion type solar charging station for electric bicycles. The pavilion type solar charging station comprises an arc-shaped pavilion cover, wherein arc-shaped pipe racks are mounted at two ends of the arc-shaped pavilion cover; a group of support rods are arranged in each arc-shaped pipe rack; a solar cell panel is mounted at the top of the arc-shaped pavilion cover; a group of charging piles and storage battery packs are mounted on a bottom plate of the arc-shaped pavilion cover; a positive pole and a negative pole of the solar cell panel are connected with one end of each wire, the other end of the wire penetrates through inside of each arc-shaped pipe rack and is connected with a positive pole and a negative pole of each storage battery pack to form a loop, and the charging piles are connected in parallel in the loop. According to the pavilion type solar charging station for the electric bicycles, solar energy is adopted as an electric power source of the charging station for the electric bicycles, wire laying is not needed, the charging station becomes movable, further, construction of the charging station cannot affect projects of municipal administration, electric power and the like of a city, materials can be obtained from local sources, that is, local solar energy resources can be utilized for photovoltaic conversion, and convenience is improved while the cleaning utilization of energy is realized.

Owner:GUIZHOU UNIV

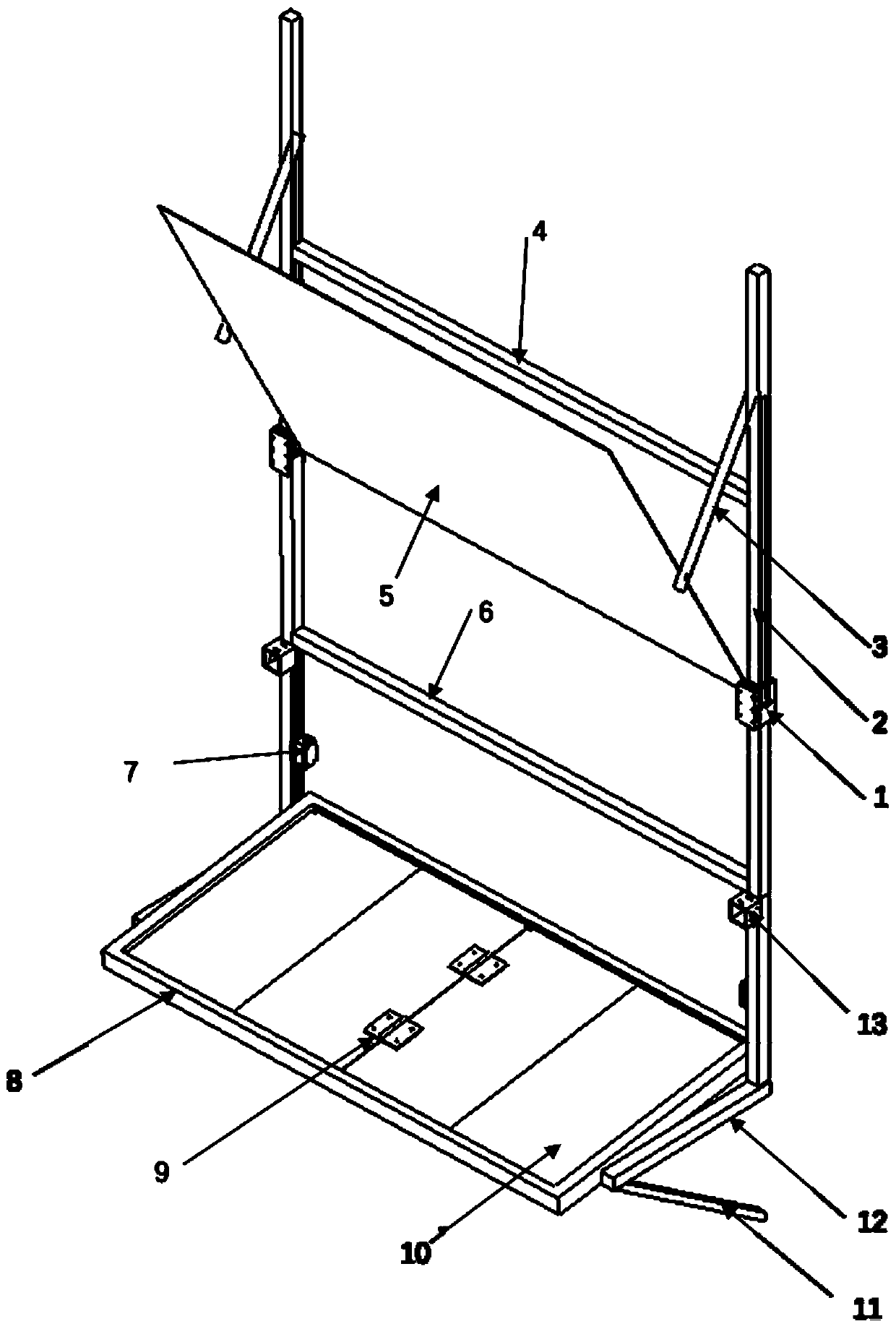

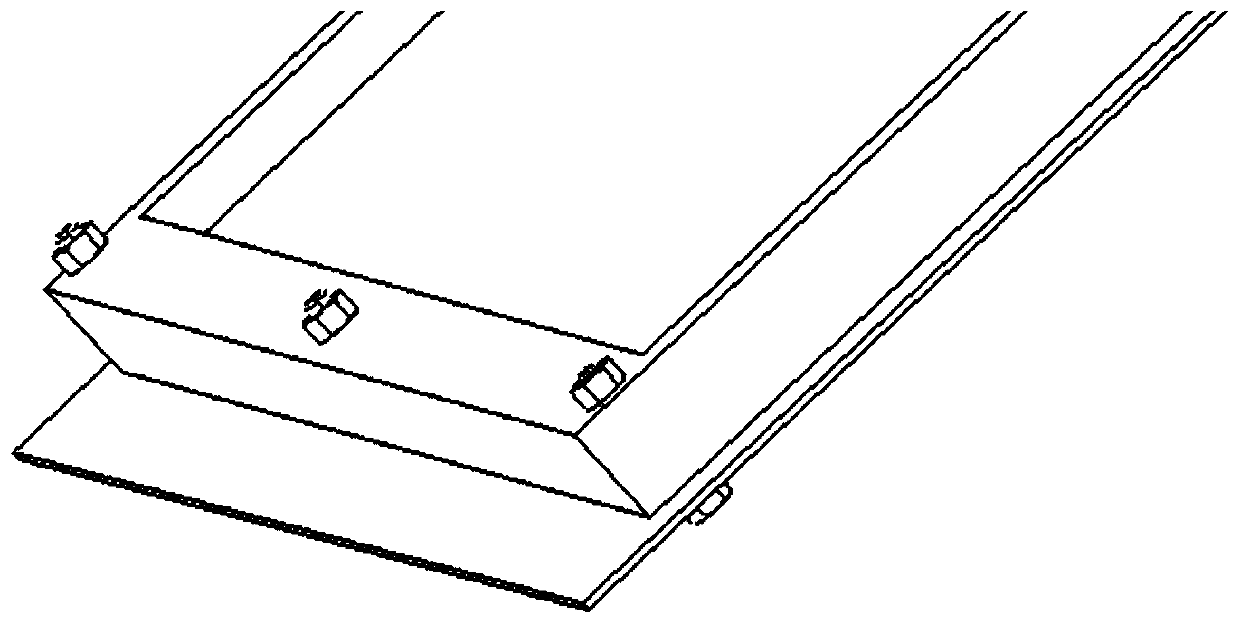

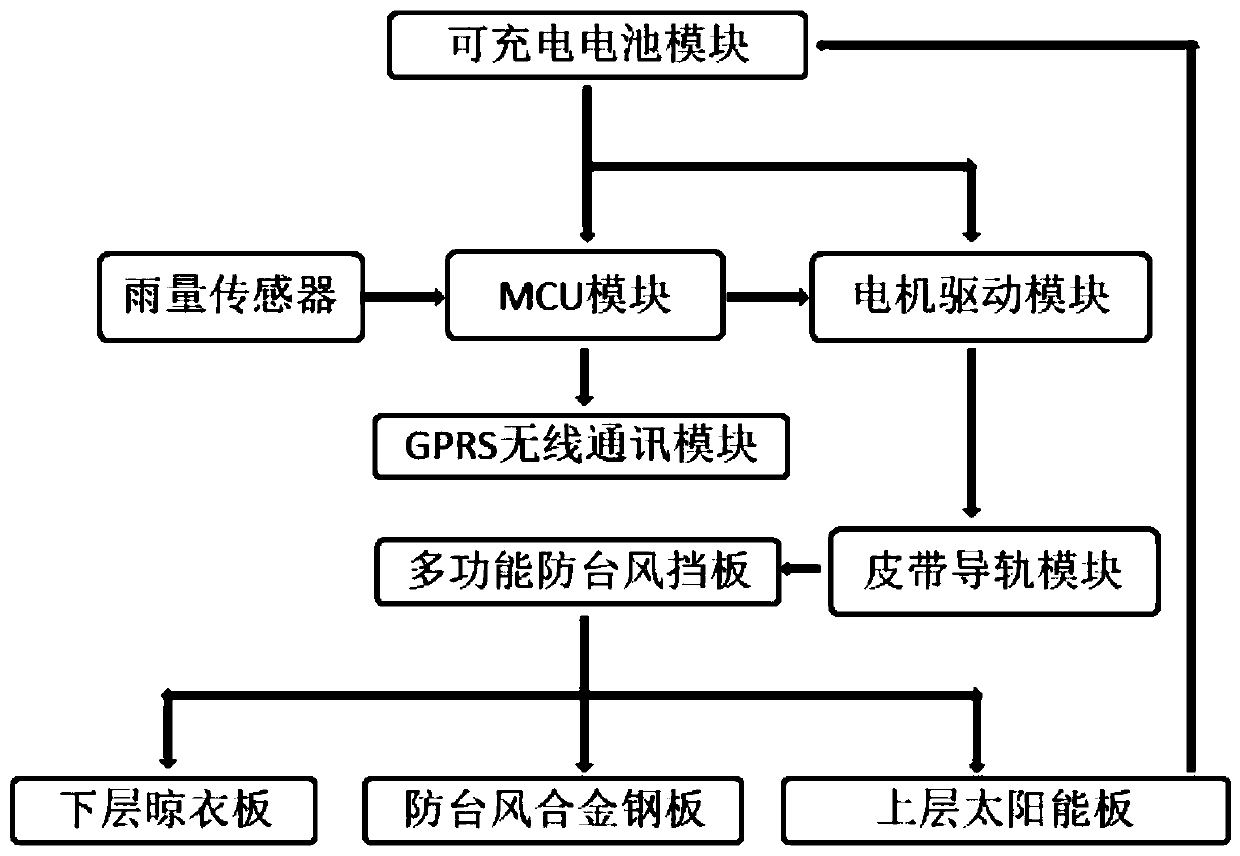

Multifunctional anti-typhoon and clothes airing device and anti-typhoon method thereof

ActiveCN111593537APlay a blocking roleAvoid destructionHurricane shuttersOther drying apparatusControl theoryMechanical engineering

The invention discloses a multifunctional anti-typhoon and clothes airing device and an anti-typhoon method thereof. The device comprises a first anti-typhoon mechanism, a second anti-typhoon mechanism, a wind speed sensor, a rain sensor and a controller. The first anti-typhoon mechanism comprises at least one second electric sliding block, two first guide rods, two first limiting rods and a windproof baffle. The second anti-typhoon mechanism comprises at least one second electric sliding block, two second guide rods, a framework and a floatable protection plate. The wind speed sensor is usedfor detecting the real-time wind speed, and the rain sensor is used for detecting the rainwater quantity. The controller is used for judging whether typhoon weather and rainy weather happen or not according to the real-time wind speed and the rainwater quantity, and the windproof baffle, the framework and the protection plate are driven by the first electric sliding blocks and the second electricsliding blocks to move so as to prevent wind and rain. By means of the device, the windproof effect is achieved, integrity of inner window bodies can be effectively guaranteed when typhoons come, a protection function is achieved, the device is used as other functions under good weather conditions, space is saved, and the device can be used for airing clothes.

Owner:HEFEI UNIV OF TECH

Combined production system for synthesis and separation of low-carbon mixed alcohols and its combined production process

ActiveCN104529704BRealize clean utilizationReduce dependencyOrganic compound preparationHydroxy compound separation/purificationN-Propyl alcoholAlcohol synthesis

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Method for treating slime water by employing coal gangue-based flocculant

InactiveCN106830240AIncrease productionRealize clean utilizationWaste water treatment from quariesWater treatment parameter controlCoal chemical industryMuffle furnace

The invention discloses a method for treating slime water by employing a coal gangue-based flocculant and belongs to the field of coal chemical industry. The method comprises the following steps of (1) crushing and sieving coal gangue, roasting in a muffle furnace and quickly cooling to obtain an activated material; (2) adding the coal gangue to dilute sulphuric acid, stirring evenly, and heating and curing the coal gangue in the muffle furnace to obtain the coal gangue-based flocculant; and (3) mixing the coal gangue-based flocculant and slime water for a period of time, standing and taking supernate to obtain treated slime water. The slime water is treated by using the coal gangue-based flocculant, clean production and comprehensive utilization of coal resources are achieved, the harm to the environment caused by the coal gangue is avoided to a great extent, local materials are adopted, wastes are changed into treasures, and the problem of high-mud slime water of a coal cleaning plant is difficult to treat is solved.

Owner:TAIYUAN UNIV OF TECH

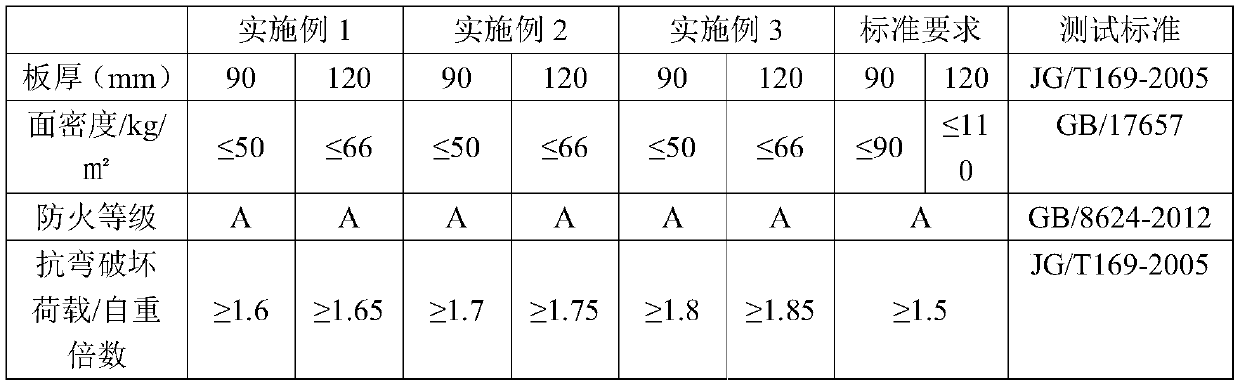

Light partition board prepared from coal slurry and preparation method of light partition board

The invention belongs to the technical field of building materials, and particularly relates to a light partition board prepared from coal slurry and a preparation method of the light partition board.The light partition board comprises the following components: water, a cement additive, a waterproof agent, short fibers, active slag powder, calcium oxide, coal slurry and Portland cement. A prepared partition wall has the properties of light weight, high strength, environmental protection performance, heat insulation, sound insulation, water resistance, stable size, good impact resistance, highcarbonization resistance, A-grade fire prevention performance and the like. Water-containing coal slime produced in a coal washing and dressing plant is adopted, and water contained in the coal slimeis used as mixing water for preparing slurry of light partition board products, so the problems of high energy consumption, high pollution and cost increase caused by drying in a drying forming process in the prior art are solved; a new path for coal slime utilization is developed for coal washing enterprises, and the problems of land resource waste, hidden environmental pollution danger and thelike caused by coal slime accumulation are further eliminated.

Owner:广州科源新材料有限公司

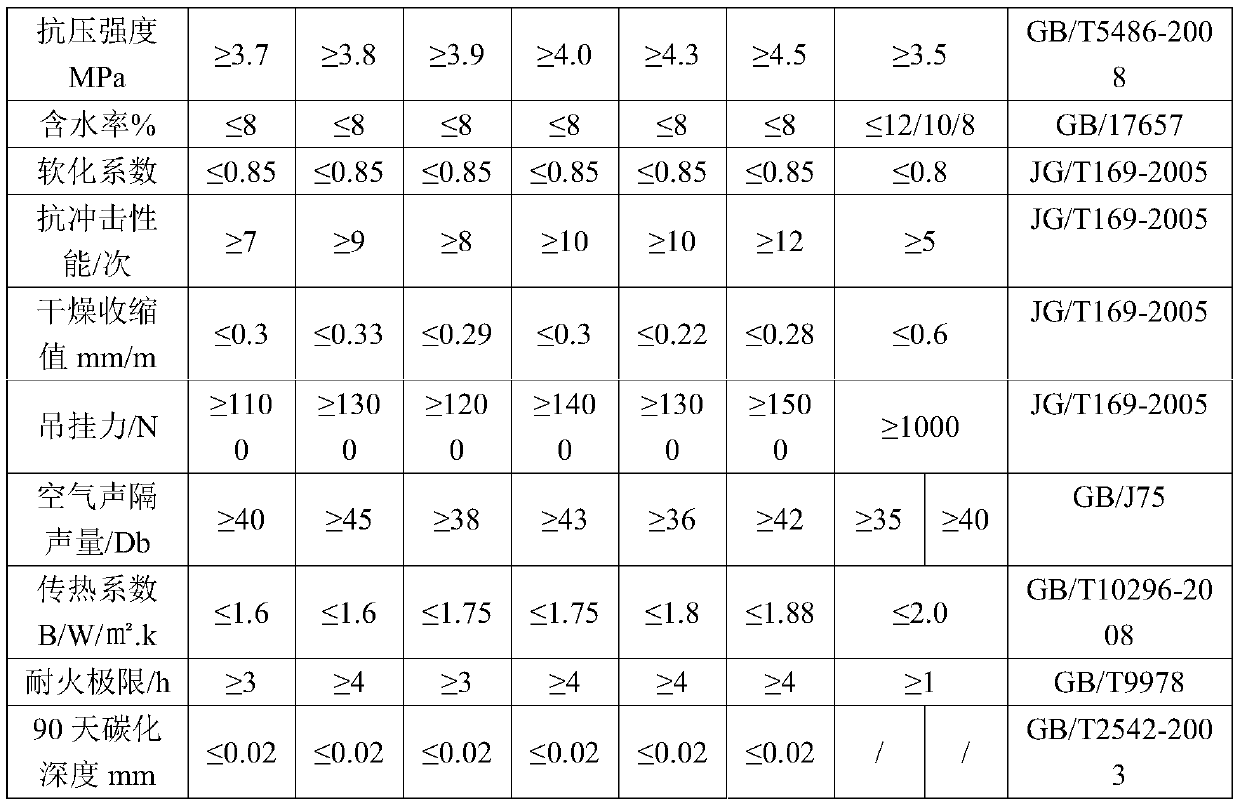

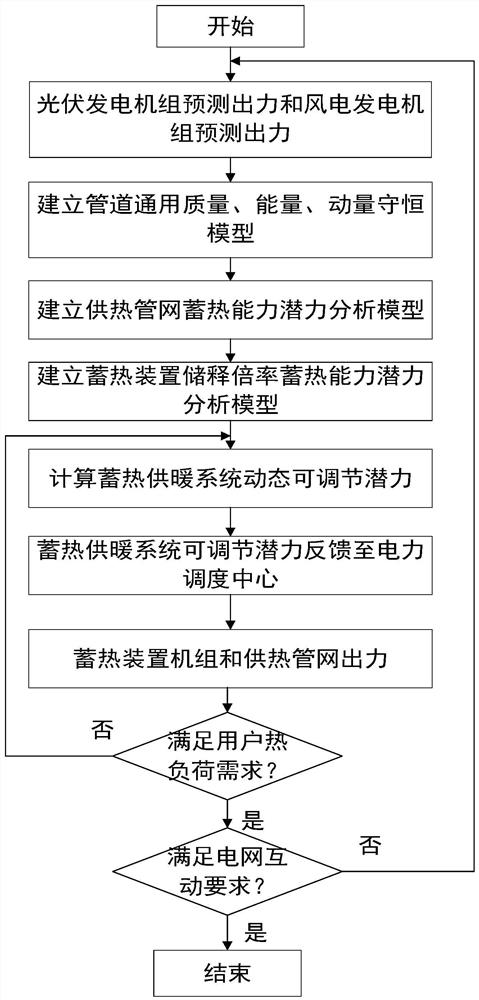

Dynamic adjustable potential analysis method and system for heat storage and supply system

ActiveCN112101648APromote digestionRealize clean utilizationLighting and heating apparatusForecastingNew energyHeat balance

The invention discloses a dynamic adjustable potential analysis method and system for a heat storage and supply system. The method comprises the following steps: predicting output of a photovoltaic generator set and predicting output of a wind power generator set; establishing a general mass, energy and momentum conservation model for heat storage and supply, and establishing a general pipeline outward heat release model, a heat release coefficient model and a general pipeline metal wall heat balance model; establishing a heat supply pipe network heat storage capacity potential analysis modelthrough the above models; establishing a heat storage capacity potential analysis model for the heat storage device storage and release multiplying power to obtain the dynamic adjustable potential ofthe heat storage and supply system; feeding the predicted output of the photovoltaic generator set, the predicted output of the wind power generator set and the dynamic adjustable potential of the heat storage and supply system back to a power dispatching center, so that the power dispatching center adjusts the output of the heat storage and supply system. Thus, renewable energy output is consumedto the maximum extent, the heat load requirement of users is met, and interaction between the heat storage and supply system and a power grid is achieved. According to the method, new energy consumption is promoted, and the requirement for safe and stable operation of a power grid is met.

Owner:NARI TECH CO LTD +3

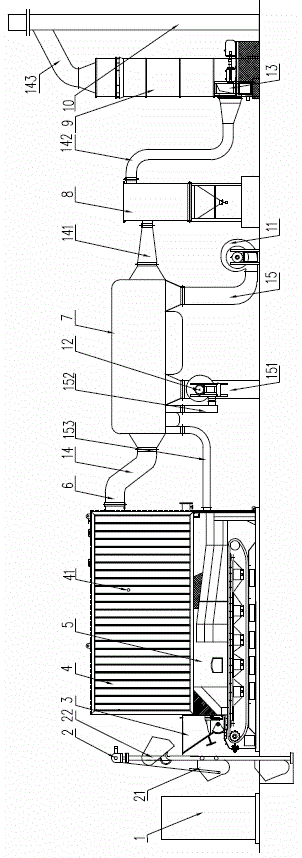

Novel environment-protecting and energy-saving industrial boiler system

InactiveCN104864387ALower exhaust gas temperatureImprove rationalitySolid fuel combustionIndirect carbon-dioxide mitigationAir preheaterCombustion chamber

The invention discloses a novel environment-protecting and energy-saving industrial boiler system. The system mainly consists of an electric control cabinet, a coal feeder, a combustion chamber, a furnace body, an air preheater, a multi-pipe dust remover, a water film dust remover and a chimney, wherein the lower part of the furnace body is the combustion chamber; the furnace body has a hearth temperature measuring port, and is provided with a smoke outlet in the back part; the combustion chamber is provided with a coal hopper at the front part and a secondary air port in the back part; the smoke outlet is connected with the air preheater by a smoke way I; the air preheater is connected with the multi-pipe dust remover by a smoke way II; the multi-pipe dust remover is connected with the lower part of the water film dust remover by a smoke way III; an air blower is connected with the air preheater by an air way I; one end of the an air way II is connected with the air preheater, and the other end is connected with an air chamber at the bottom of the combustion chamber; a secondary fan is connected with the air preheater by an air way III; and one end of an air way IV is connected with the air preheater, and the other end is connected with the secondary air port in the back part of the combustion chamber. The system can effectively reduce the boiler smoke discharge temperature, improve the system heat efficiency, realize the clean utilization of coals and control the displacements of atmospheric pollutants of sulfur dioxide, nitric oxide and industrial smoke dust in the fire coal control process.

Owner:王克文

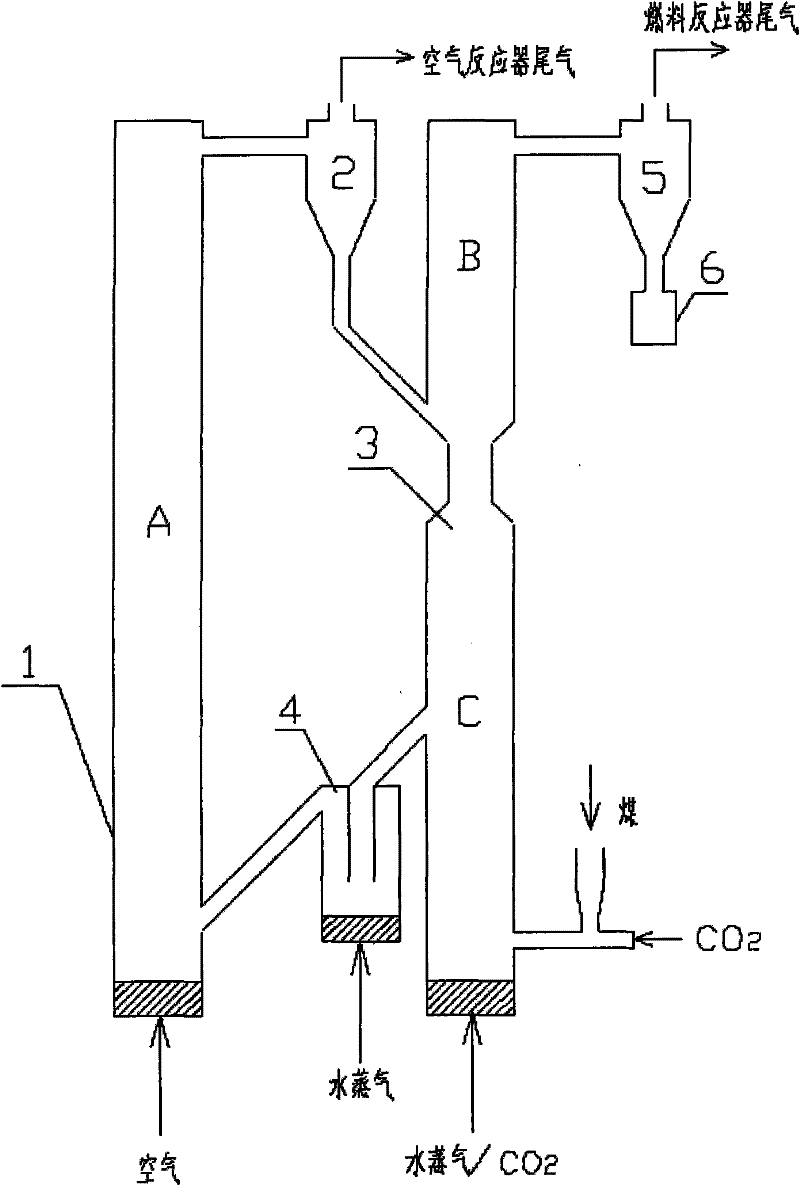

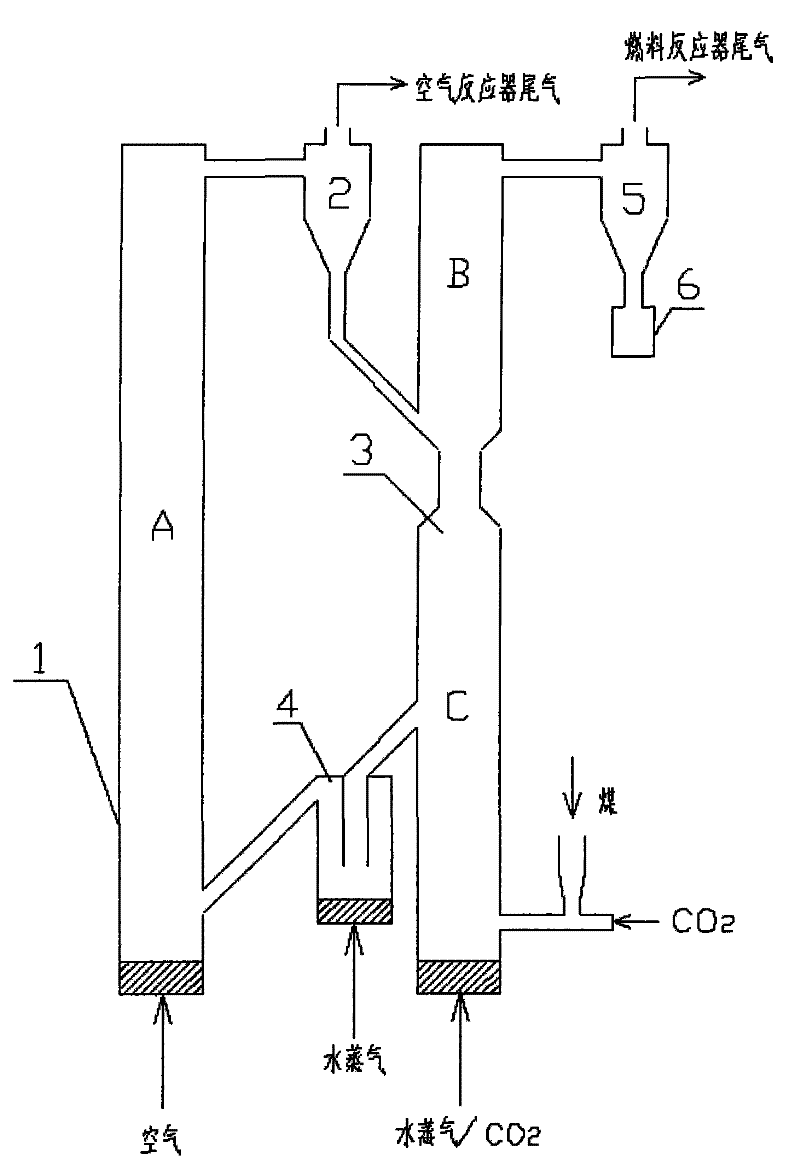

Pulverized coal combustion method and device with CO2 capture function

InactiveCN101666546BOvercoming many disadvantages such as low utilization efficiencyRealize clean utilizationExothermal chemical reaction heat productionExothermal chemical reactions for heatingHigh concentrationCyclone

The invention provides a pulverized coal combustion method with the function of capturing CO2, comprising the steps: CuFe2O4 is decomposed to generate O2 and oxygen vacancy ferrite CuFe2O4-delta (delta is no less than 0 but no more than 2); oxidation reaction is generated between the pulverized coal and the oxygen vacancy ferrite so as to generate CO2, H2O and non-condensed gas, wherein the oxidation reaction is generated between the non-condensed gas and O2 which is obtained by decomposition so as to generate CO2 and steam. The device for achieving the method comprises a loop which is formedby the communication of a fast fluidized bed, a first cyclone separator, a two-stage type bubbling fluidized bed, a U-type flow seal valve and the fast fluidized bed in sequence; and the bubbling fluidized bed is also communicated with a second cyclone separator which is communicated with an ash catching device. The pulverized coal combustion method with the function of capturing CO2 effectively combines a pure oxygen combustion technology of coal with a chemical chain combustion technology, not only lowers the preparation cost of the pure CO2, but also fully realizes the separation of the high-concentration CO2 after the coal reaction.

Owner:HUAZHONG UNIV OF SCI & TECH

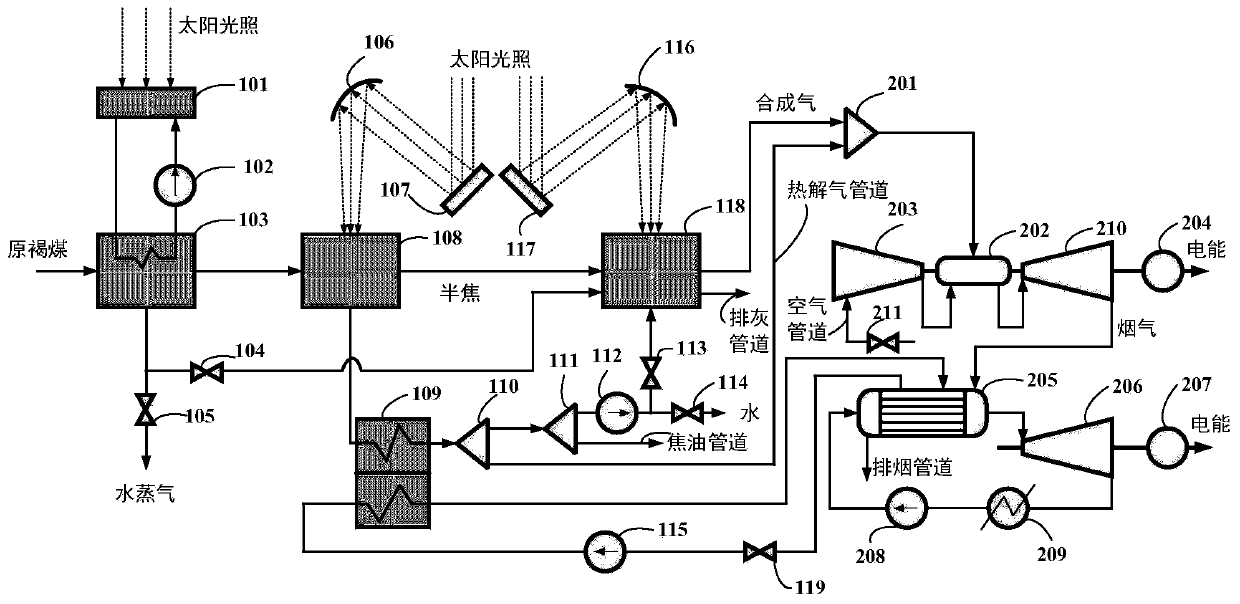

Solar-driven lignite multi-generation power generation system and operation method

InactiveCN110847991ARealize clean utilizationAchieve near-zero emissionsFrom solar energySteam engine plantsCombustion chamberCogeneration

The invention discloses a solar-driven lignite multi-generation power generation system and an operation method. The system comprises a steam dryer, a tower type solar pyrolyzer, a tower type solar gasifier, a mixer, a combustion chamber and a gas turbine which sequentially communicate, and further comprises a waste heat utilization system which is formed by sequentially communicating a waste heatboiler, a steam turbine, a condenser and a water pump; a tower type solar reflector field is used for focusing solar energy as a heat source of the tower type solar gasifier and the tower type solarpyrolyzer, and a groove type solar energy collector is used for focusing solar energy as a heat source of the steam dryer, and the purpose is that the heat sources of the tower type solar gasifier, the tower type solar pyrolyzer and the steam dryer are maintained at the optimal temperature on the basis of fully utilizing solar energy; and the water and waste steam flow entering the tower type solar gasifier are adjusted through waste steam regulating valves, and the purpose is that water and the semi-coke ratio in the tower type solar gasifier is guaranteed to maintain at an optimal value. Thesystem realizes the multi-cogeneration of electricity and tar, and is clean and efficient.

Owner:XI AN JIAOTONG UNIV

A method for processing organic waste by coupling hydrogenation fermentation with microalgae cultivation

ActiveCN103981220BImprove photosynthesis efficiencyReduce pollutionUnicellular algaeEnergy inputAlkaneNew energy

Owner:CHINA AGRI UNIV

Method for preparation of collagen feed and combined production of chicken oil and calcium powder

ActiveCN103919149AQuality improvementIncrease daily weight gainFungiAnimal feeding stuffBiotechnologyNutrition

The invention discloses a method for preparation of a collagen feed and combined production of chicken oil and calcium powder. The method is characterized by comprising the following steps: (1) raw material processing, (2) chicken oil preparation, (3) two step enzymolysis, (4) the preparation of soluble calcium powder, (5) the preparation of a collagen culture medium, (6) inoculation of a strain, and (7) fermentation for preparation of the fertilizer. According to the method, a two step composite enzymolysis technology is used, an enzymolysis protective agent is added in the enzymolysis process, the collagen quality is improved, and the good quality of the product is guaranteed. The soluble calcium is prepared by citric acid activation, so that the biological absorption rate of calcium is improved. By using of activated carbon for deodorization, the product content is improved, and at the same time the process time is shortened. The feed produced by the method contains the collagen, and has the advantages of being nutritional and healthy, capable of preventing and curing diseases, and improving the quality of meat. The production process is clean, green, non-pollution, and free of waste water discharge, and the clean comprehensive utilization of chicken bones is realized.

Owner:海宁市洛溪实业发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com