Device system and method for gradient absorption of copper slag waste heat based on coal gasification reaction

A technology of coal gasification and copper slag, applied in gasification process, granular/powder fuel gasification, chemical industry and other directions, can solve problems such as environmental pollution, improve energy quality and achieve the effect of clean utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

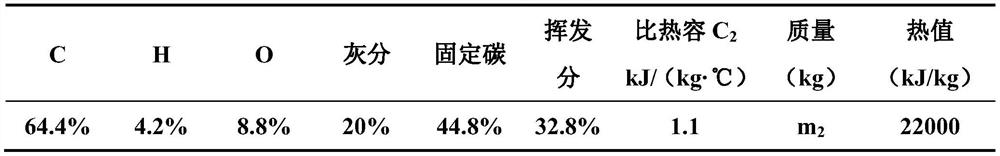

[0068] C=64.4% in the coal powder that this example adopts, H=4.2%, O=8.8%, ash content=20%, volatile matter content=32.8%, fixed carbon content=44.8%, coal powder specific heat capacity C 2 = 1.1 kJ / (kg·°C).

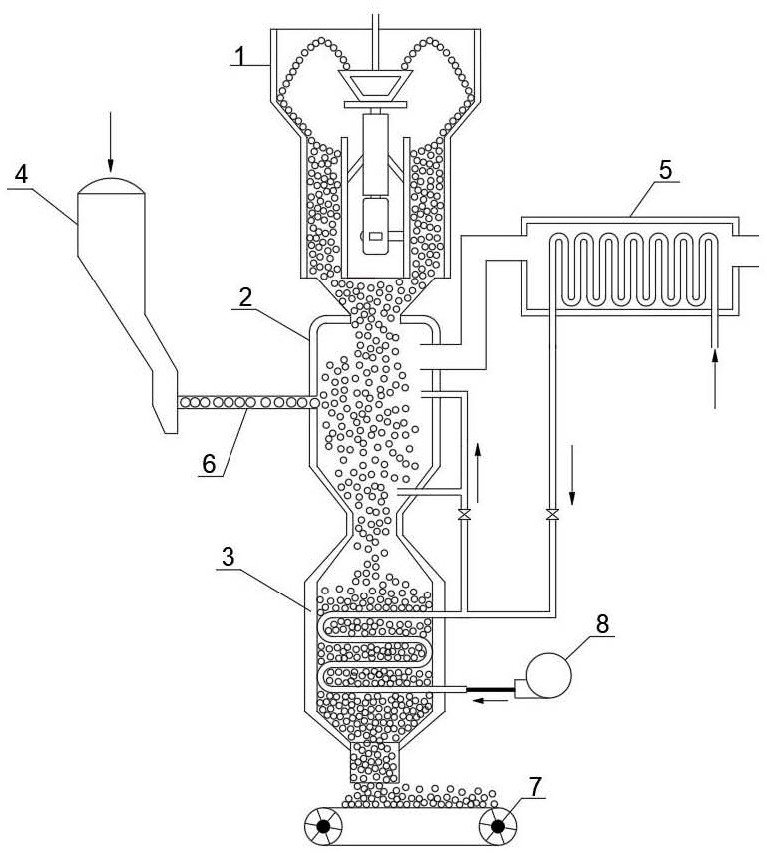

[0069] A device system and method for cascade absorption of copper slag waste heat based on coal gasification reaction. The structure is as follows: figure 2 As shown, it includes a dry granulation device 1, a gasification furnace 2, a waste heat boiler 3 and auxiliary equipment. The gasification furnace 2 is mainly composed of a furnace body, a feeding device and a synthesis gas processing device 5. The feeding device has a pulverized coal storage bin 4 and a screw feeder 6 .

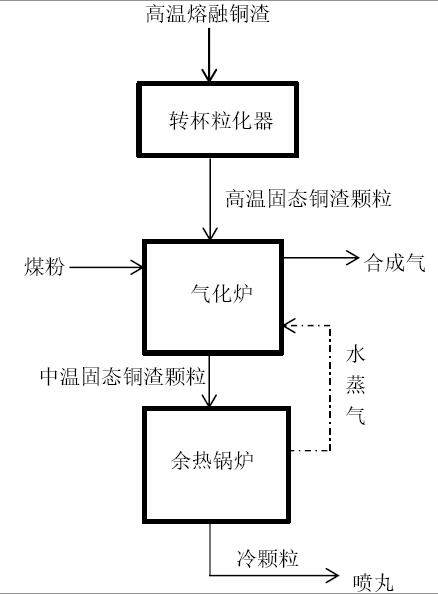

[0070] The method for recovering copper slag cascade waste heat by using the above-mentioned device, the process flow chart is as follows figure 1 shown. The process is mainly composed of granulation, gasification and waste heat utilization of waste heat boiler. The main raw materials of ga...

Embodiment 2

[0079] This example adopts the above-mentioned device to carry out the method for copper slag cascade waste heat recovery, and the process flow chart is as follows figure 1 As shown, the structure is shown in Figure 2. Specific steps are as follows:

[0080] (1) Copper slag granulation

[0081] The high-temperature copper slag in the molten state enters the dry granulation device 1, where it is transformed into spherical high-temperature particles at 1100°C due to the centrifugal force and surface tension in the dry granulation device 1, and then enters the gasifier 2.

[0082] (2) Waste heat recovery of high temperature copper slag particles

[0083] The high-temperature copper slag particles at 1000°C enter the gasifier 2, and the pulverized coal enters the gasifier 2 from the screw feeder 6 through the pulverized coal storage bin 4. The high-temperature copper slag particles move from top to bottom in the gasifier 2, and the gasification reaction quickly absorbs the heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific heat capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com