Patents

Literature

572 results about "Coal storage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

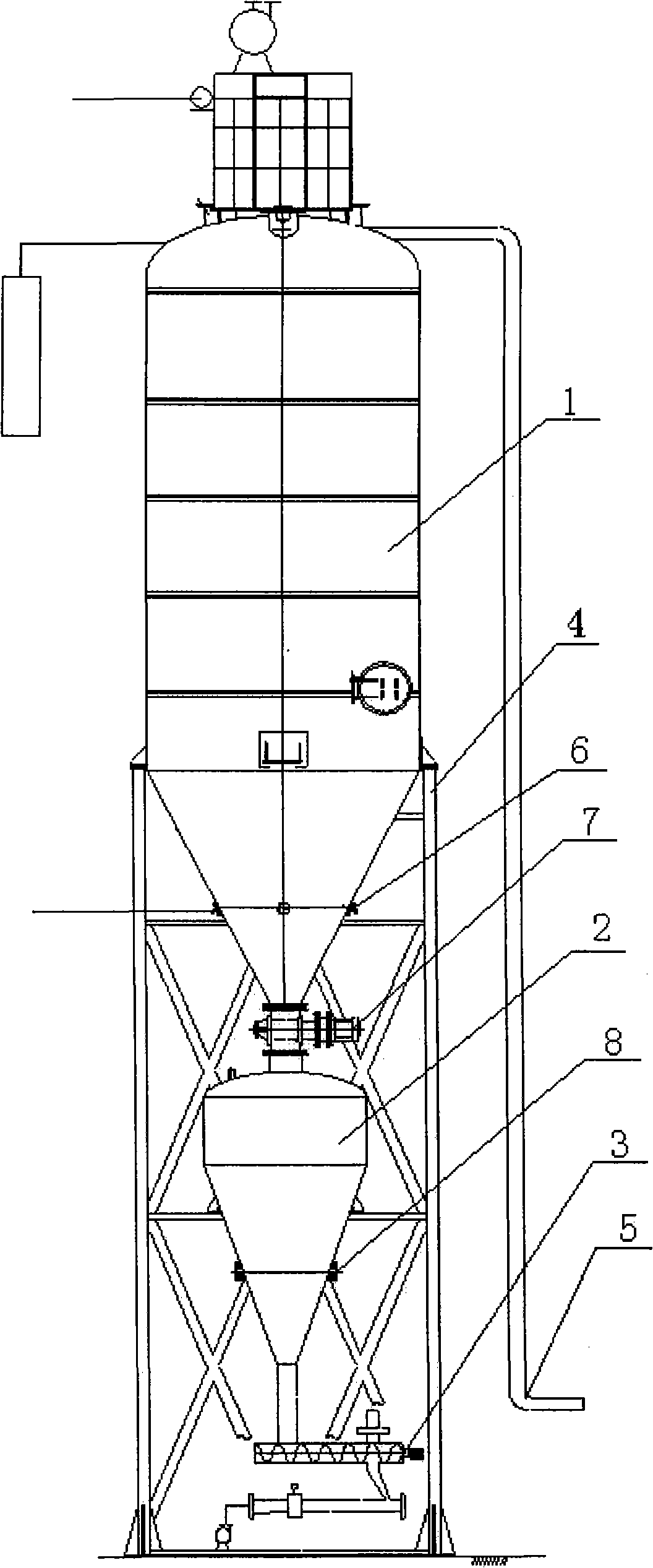

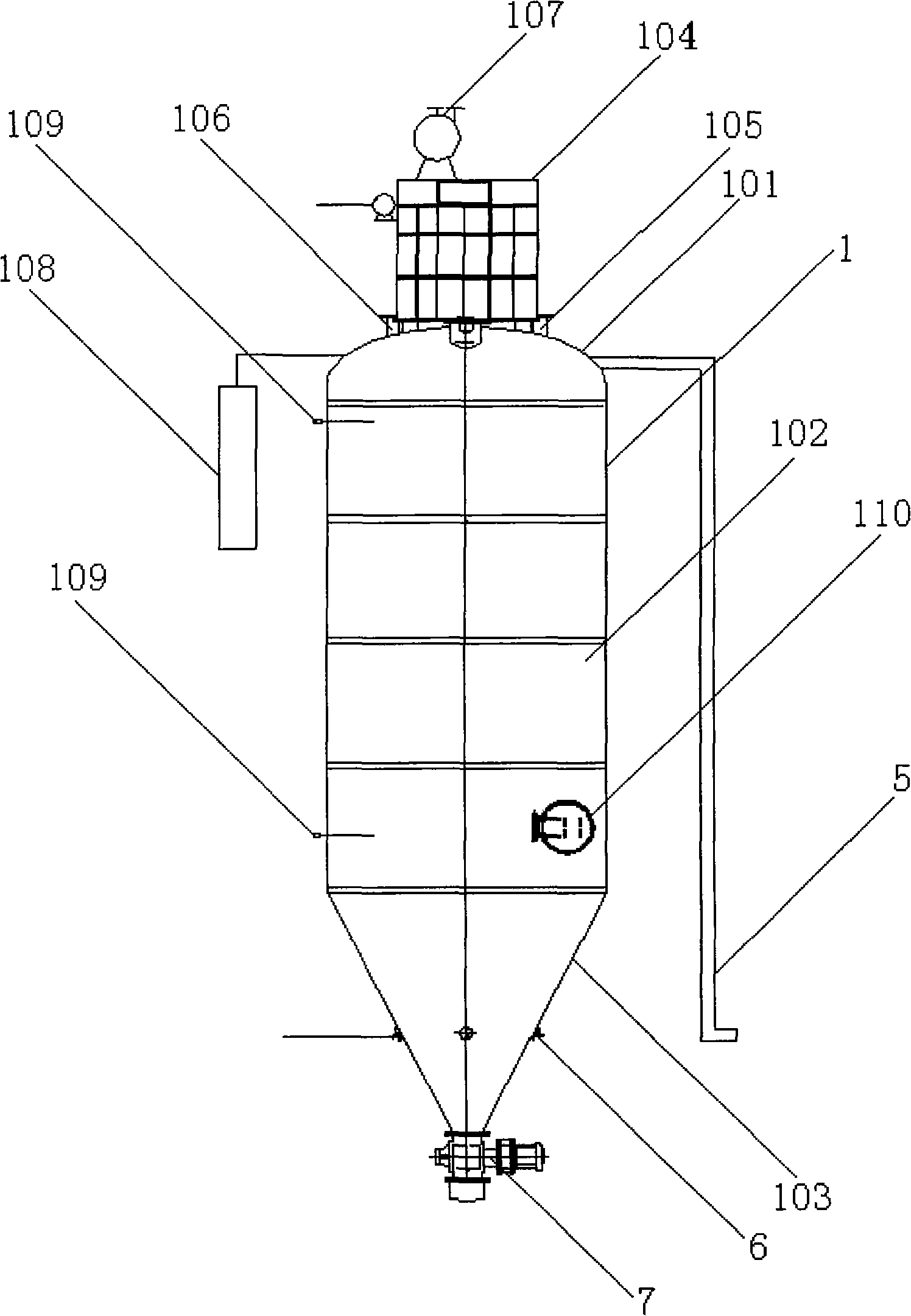

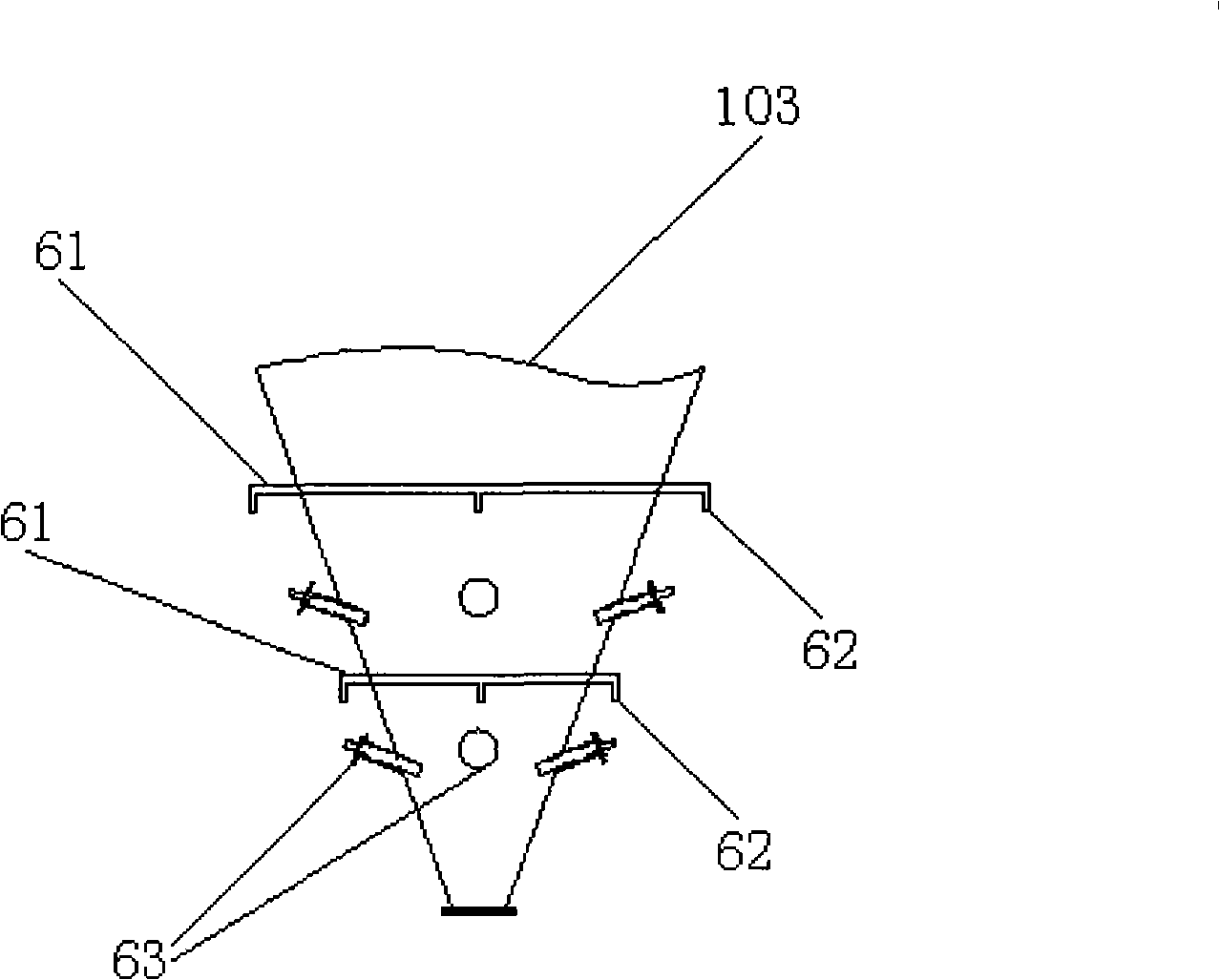

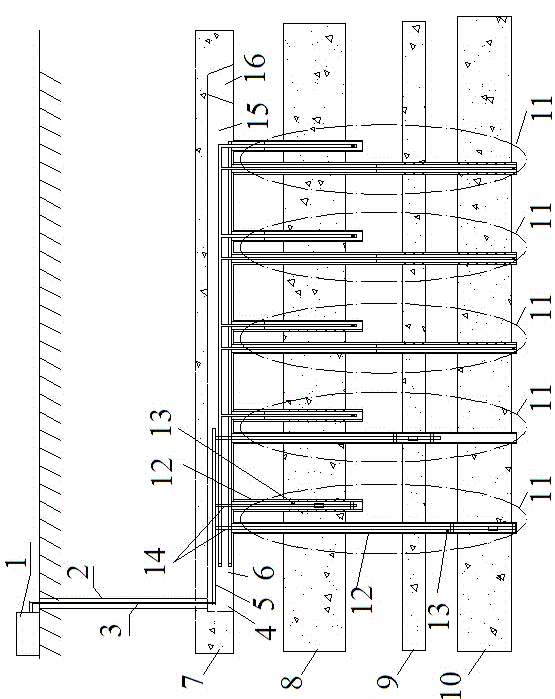

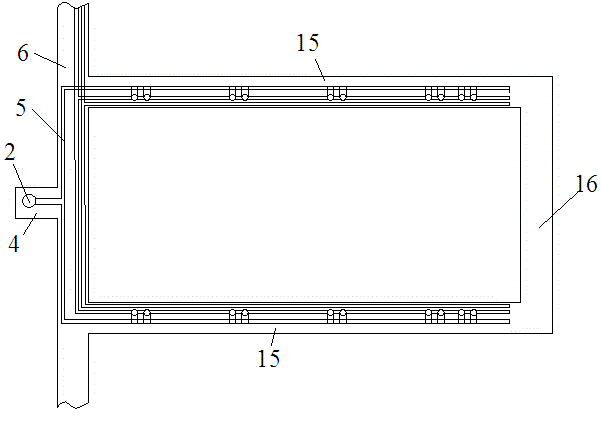

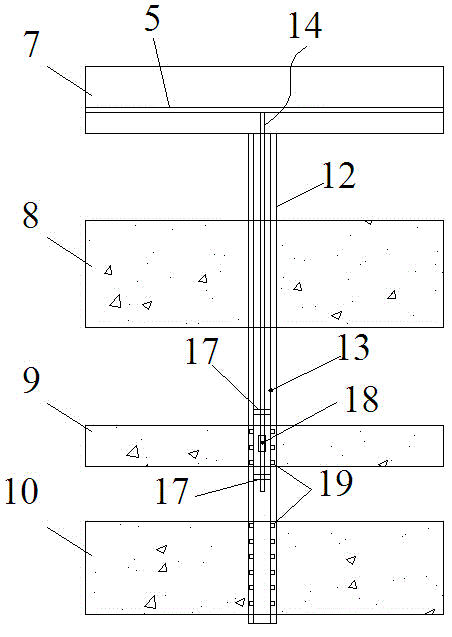

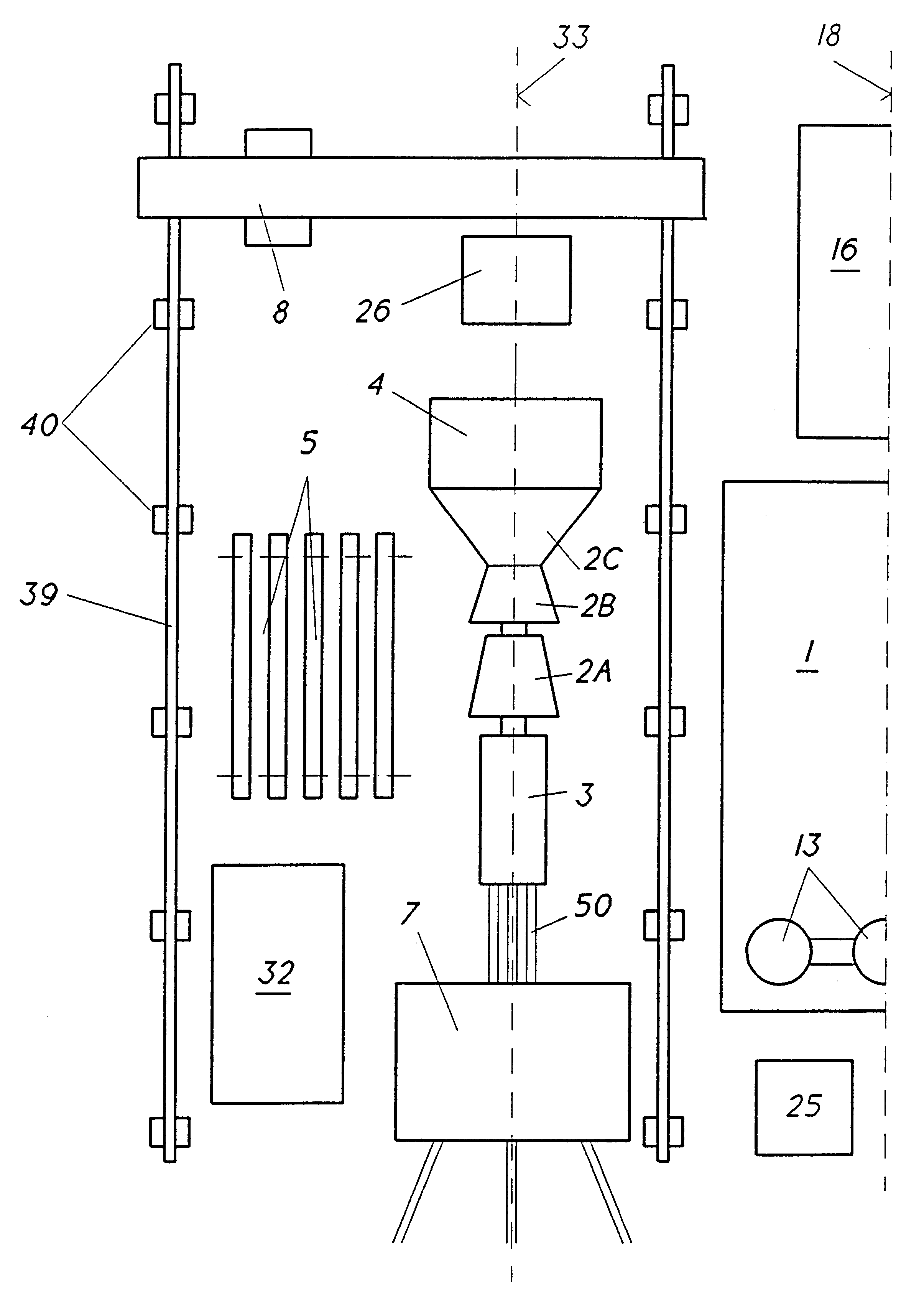

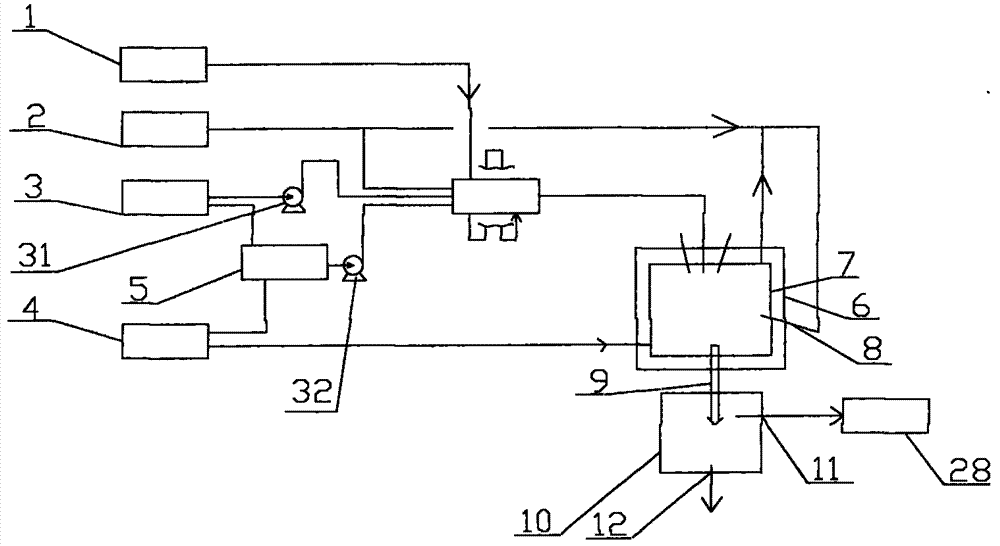

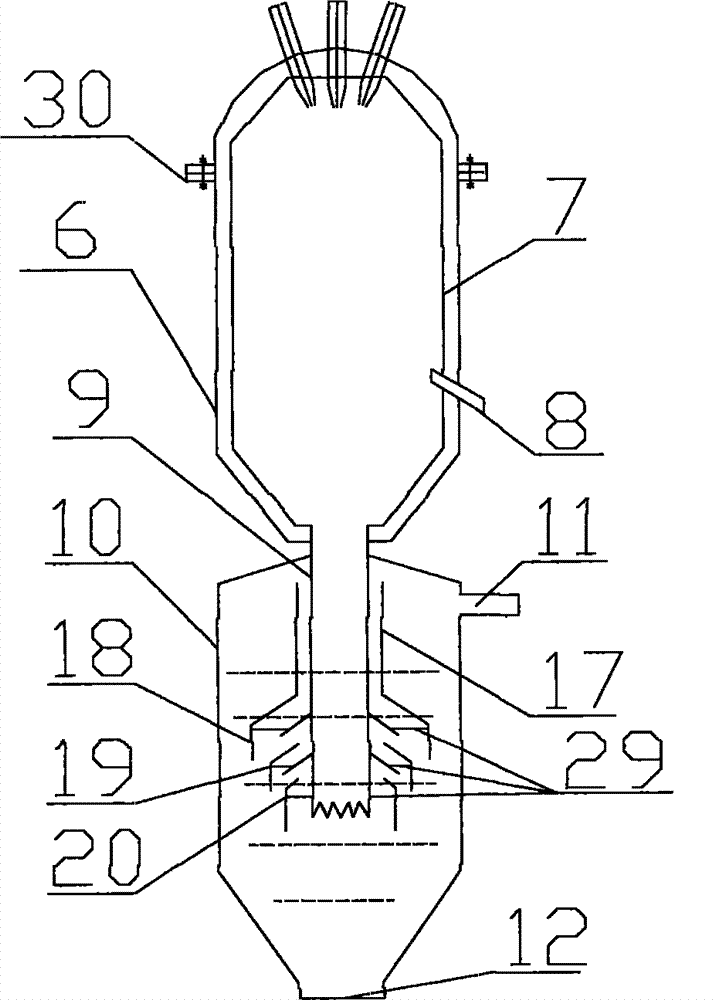

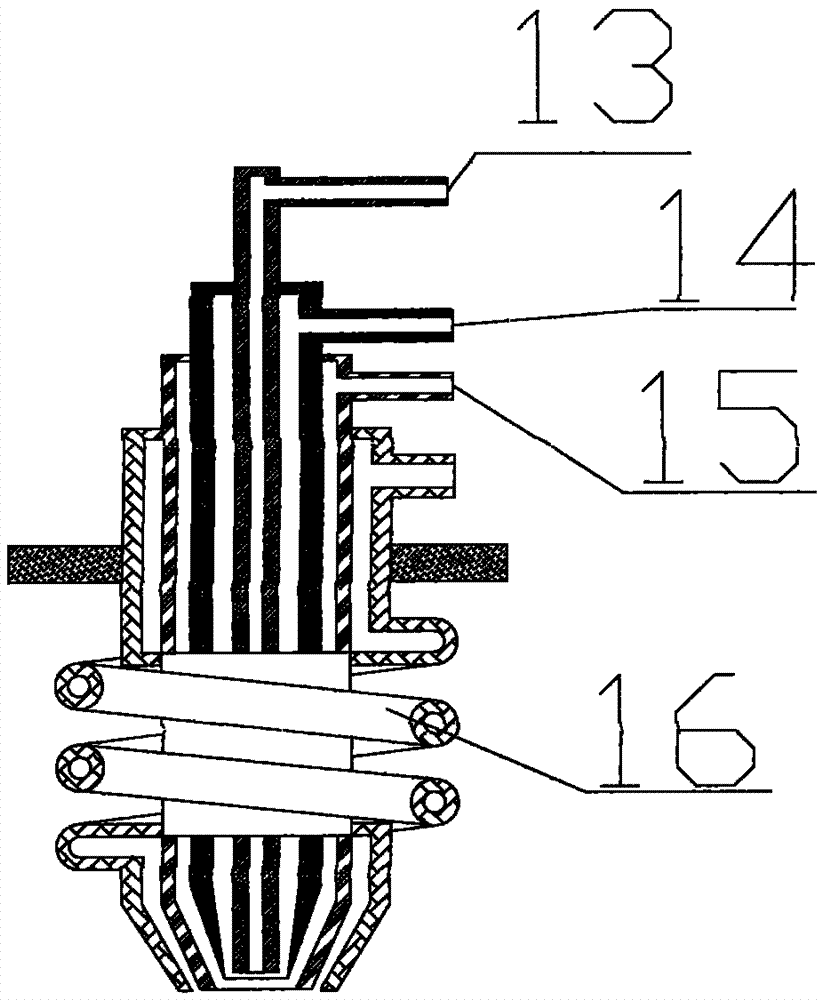

Combined coal powder storage and supply system

The invention relates to a combined coal powder storage and supply system which comprises a coal powder storage tank, a weighing coal powder supply silo, a pulse-free coal powder supply device and a support; the coal powder storage tank is vertically arranged at the top of the support, the weighing coal powder supply silo is vertically arranged on the support below the coal powder storage tank, the pulse-free coal powder supply device is arranged below a discharging opening of the weighing coal powder supply silo, and a flexible connector in the center at the top of a sealing head of the weighing coal powder supply silo is connected with a discharging opening of the coal powder storage tank through a rotary valve; and a fluidization component is arranged on the outer wall of a conical hopper of the coal powder storage tank, and a coal powder anti-arching stirring device is arranged on a hopper of the weighing coal powder supply silo. The invention has compact structure, reasonable layout, automatic feeding and stable supply and can solve the problems frequently existing in the ordinary coal storage silo and the supply silo of birdnesting, bridging, rat hole, channeling, wall build-up, breakage, self combustion, and the like; and the invention can be widely used in any situation where the small and medium-sized industrial coal powder boilers are required.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

Environment-friendly flame-retardant high-molecular gel inhibitor for preventing coal from spontaneously combusting of coal mine

InactiveCN101793160AReduced propensity to spontaneous combustionPrevent spontaneous combustionOther chemical processesDust removalSpontaneous combustionSurface-active agents

The invention discloses an environment-friendly flame-retardant high-molecular gel inhibitor for preventing coal from spontaneously combusting of coal mine, which takes water as a solvent and comprises the following components with percentage concentration by weight: 7-10 percent of high-molecular base material, 0.1-0.5 percent of inorganic inhibitor, 0.1-0.5 percent of flame retardant agent, 0.01-0.5 percent of surface active agent and 0.1-3 percent of reinforcing agent. The environment-friendly flame-retardant high-molecular gel inhibitor has the advantages of simple operation, good wall-absorbing property and inhibiting effect, flame retardant property and environment protection; a coating layer can bear the action of flame for a plurality of times and has large mechanical strength, and a coating film is stable and does not fall off in the humid environment. In the process of coal mining, the inhibitor solution is sprayed to superficial coal and combustible areas behind a coal-mining working surface and the spontaneous combustion tendency of coal can be reduced, therefore, the environment-friendly flame-retardant high-molecular gel inhibitor prevents the spontaneous combustion of coal thoroughly and is applicable to the operation under a mine and coal storage.

Owner:BEIJING UNIV OF TECH +2

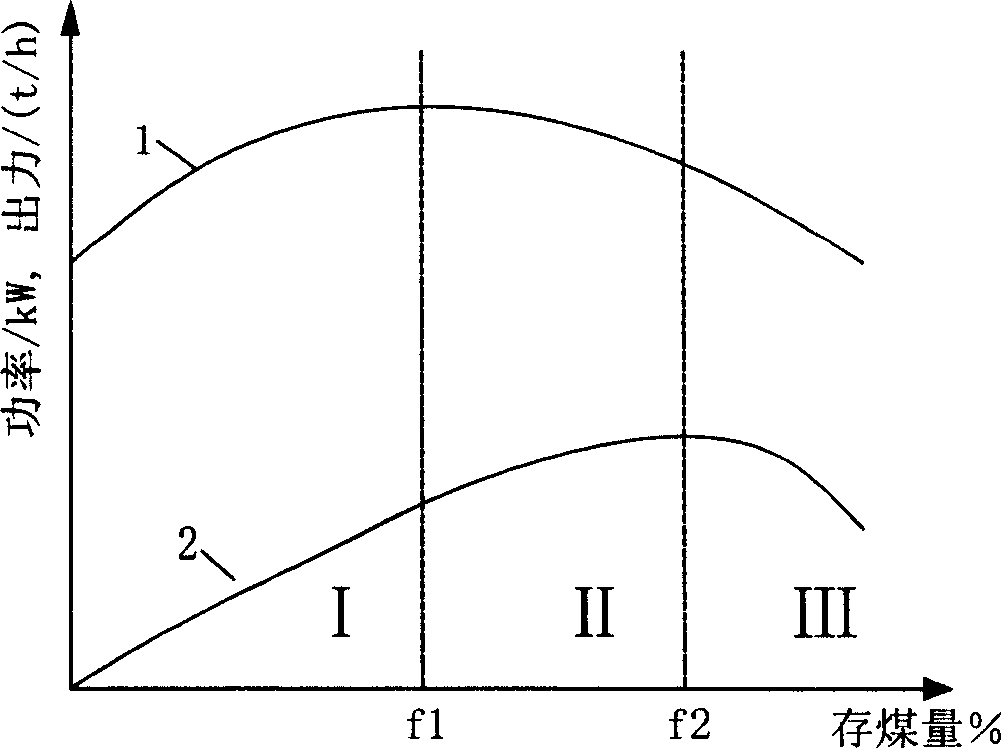

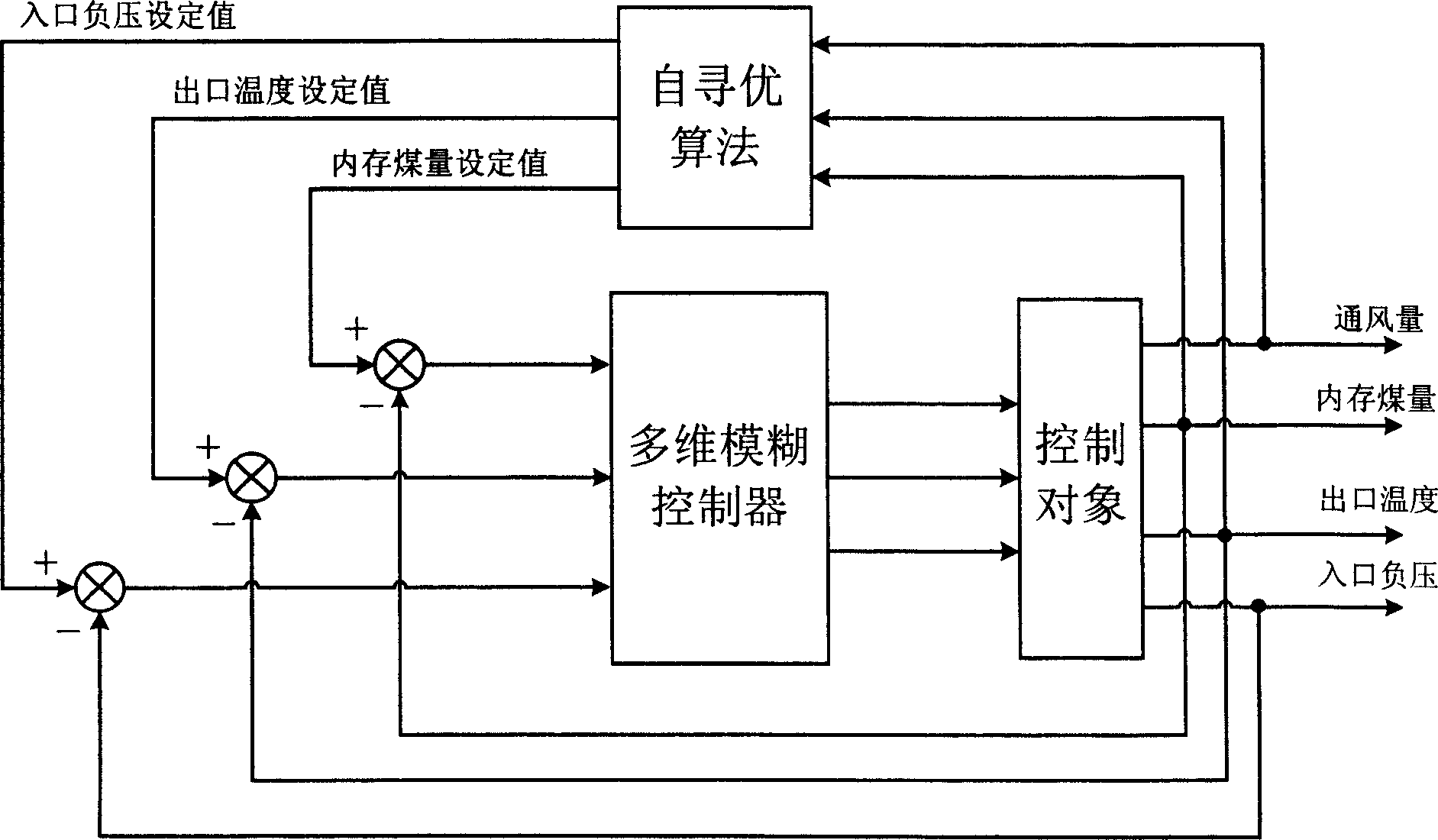

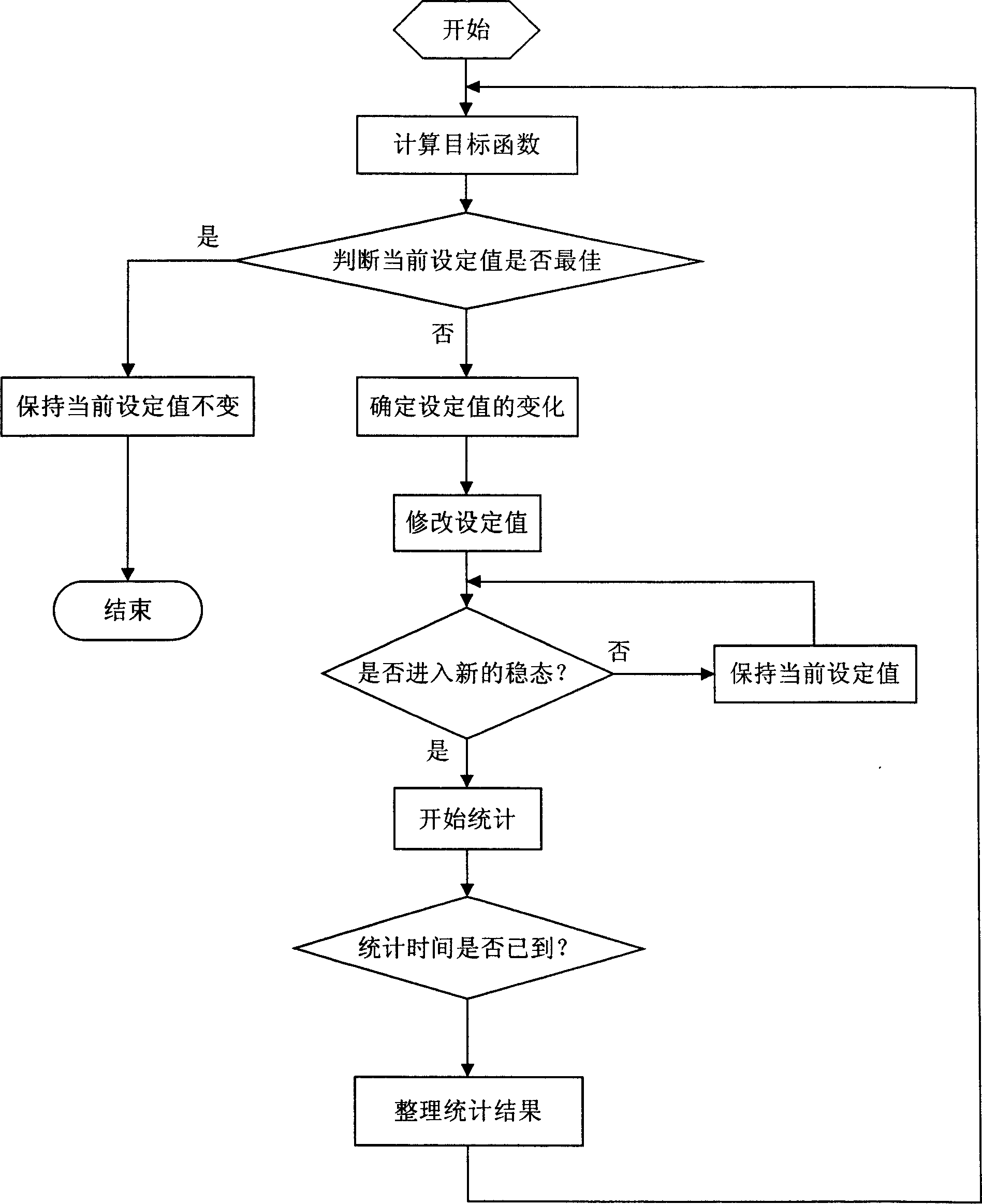

Powder-making system automatic control method for heat engine plant steel ball coal grinding mill

The automatic control method for steel ball coal mill in thermal power plant adopts a double-layer control structure, including an upper layer of self optimizing algorithm and a lower layer of multidimensional fuzzy control algorithm. The self optimizing algorithm finds out the optimal inside coal storage quantity inside the coal mill, the optimal outlet temperature of the coal mill and the optimal inlet negative pressure value of the coal mill as the controlling set values; and the multidimensional fuzzy control algorithm realizes the automatic regulation of the coal feed quantity, the hot air valve opening, and the recirculating air valve opening or the cold air valve opening, so as to ensure the safe and reliable running of the steel ball coal mill system in optimal mode.

Owner:XI AN JIAOTONG UNIV +1

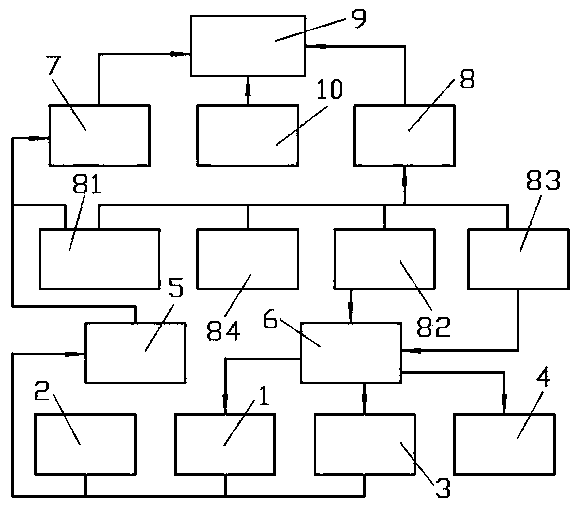

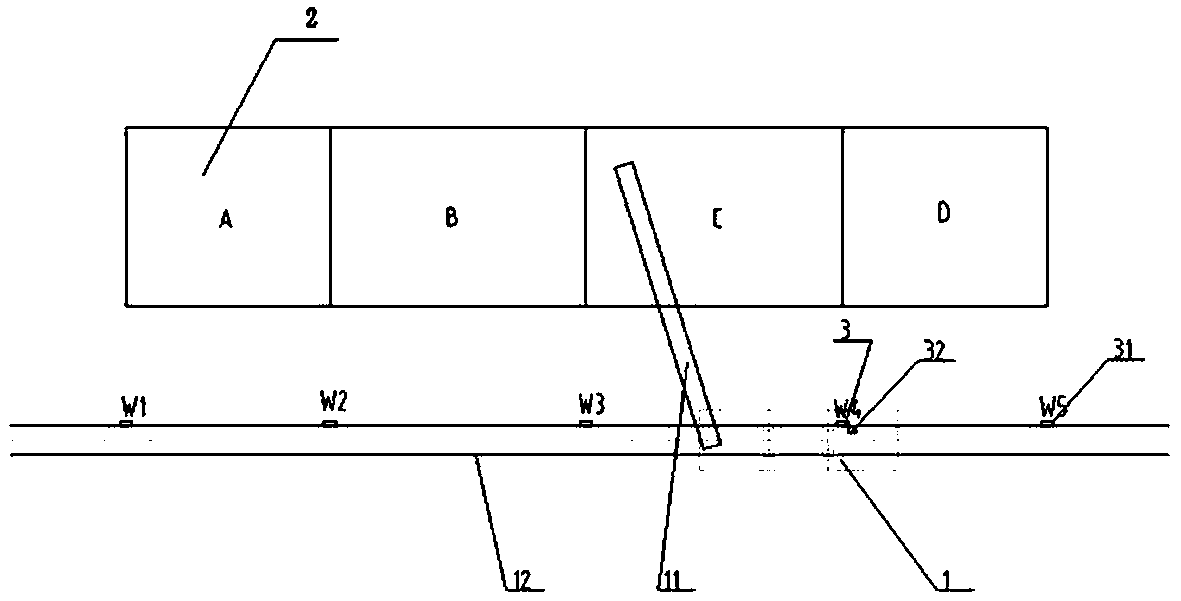

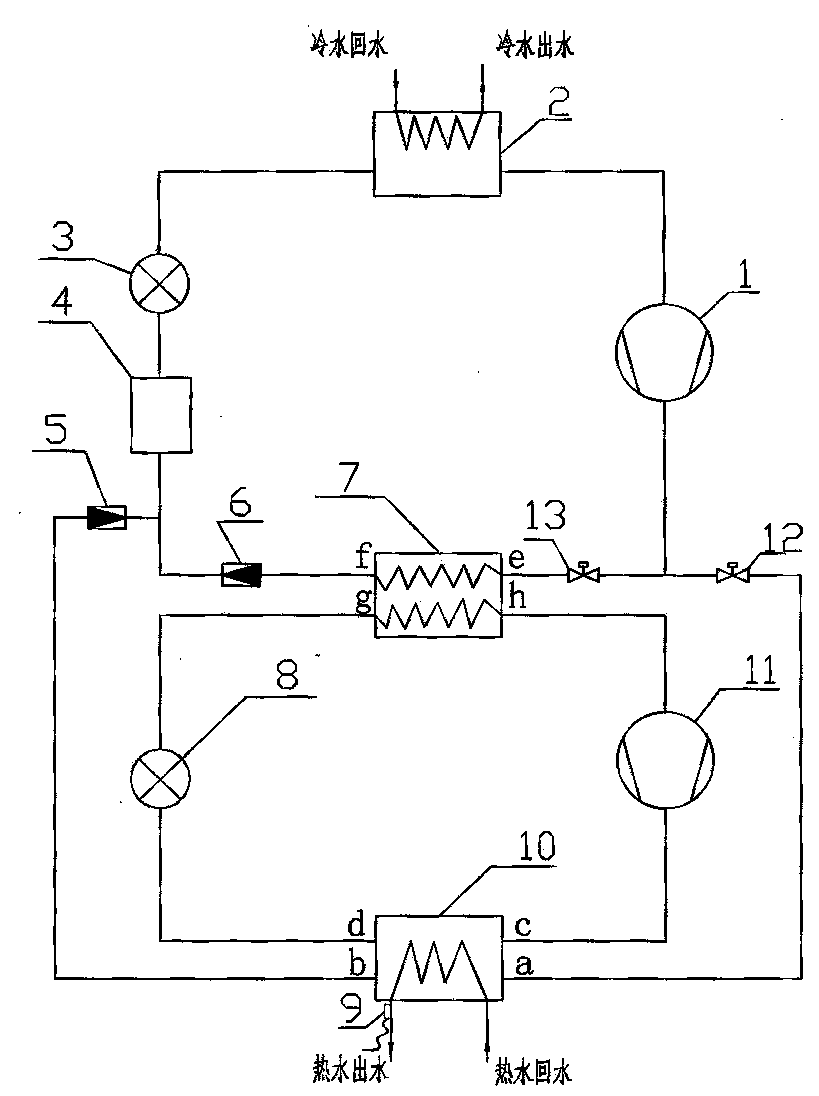

Coal-fired power plant coal yard refined management system and control method thereof

ActiveCN103455901AFast and accurate deliveryAccurate accessSystems intergating technologiesLogisticsInformatizationData acquisition

The invention relates to a coal-fired power plant coal yard refined management system and a control method of the coal-fired power plant coal yard refined management system. The coal-fired power plant coal yard refined management system is characterized by comprising a laser disc coal instrument, an intelligent temperature monitoring meter, a metering device, a stacker-reclaimer, a data acquisition unit, a controller, a data server, an application server and a computer client side. The application server comprises a coal database management module, a real-time stock management module, a coal storage management module and a heat loss evaluation and control module. The control method is characterized by including the following steps that coal pile outline data points and digital signs in a coal yard field are acquired according to the laser disc coal instrument, and three-dimensional reconstruction of coal piles is completed based on a VC++ and OpenGL platform; when coal is transported to a factory, information is input to the coal database management module through an input port in the computer client side. According to the coal-fired power plant coal yard refined management system and the control method, the informatization and intelligentization method is adopted, information is quickly and accurately transmitted, and coal heat loss is reduced.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Method for extracting gas from bedding level fractured well of ground coal seam roof

InactiveCN102080526ARealize multiple uses in one wellEasy extractionSurveyFluid removalPrincipal stressHydraulic fracturing

The invention provides a method for extracting gas from a bedding level fractured well of a ground coal seam roof, orderly comprising the following steps: selecting a coal storage layer with the gas content more than 8 m<3> / t; determining fissure zone position generated by extracting the coal layer, taking the rock formation at 3-7 m of the middle lower part of the fissure zone as the level construction layer; determining positions of the well opening and kickoff points according to landing points of the level segment; and realizing large curvature radius increased slanting, wherein the drilling position is parallel to a gate road at a coal stope working surface or vertical to the largest principal stress direction, and the length of the level segment is less than or equal to the strike length of the working surface; the well structure adopts a three-part structure; the level segment can be an uncased hole or a lower sleeve tube which is an emission hole; the level segment is constructed in the selected rock layer; the level segment uses an open hole packer or a sleeve tube packer for performing hydraulic fracture in segments; a drainage and extracting apparatus is arranged for extracting the ground gas by a virtual storage layer; and the negative pressure extracting is exchanged between the middle and last phase, thereby realizing multiple functions of the well. The method in the invention improves the extracting efficiency of the ground drilling well, realizes area outburst elimination, and reduces the gas disasters to the maximum limit.

Owner:HENAN POLYTECHNIC UNIV

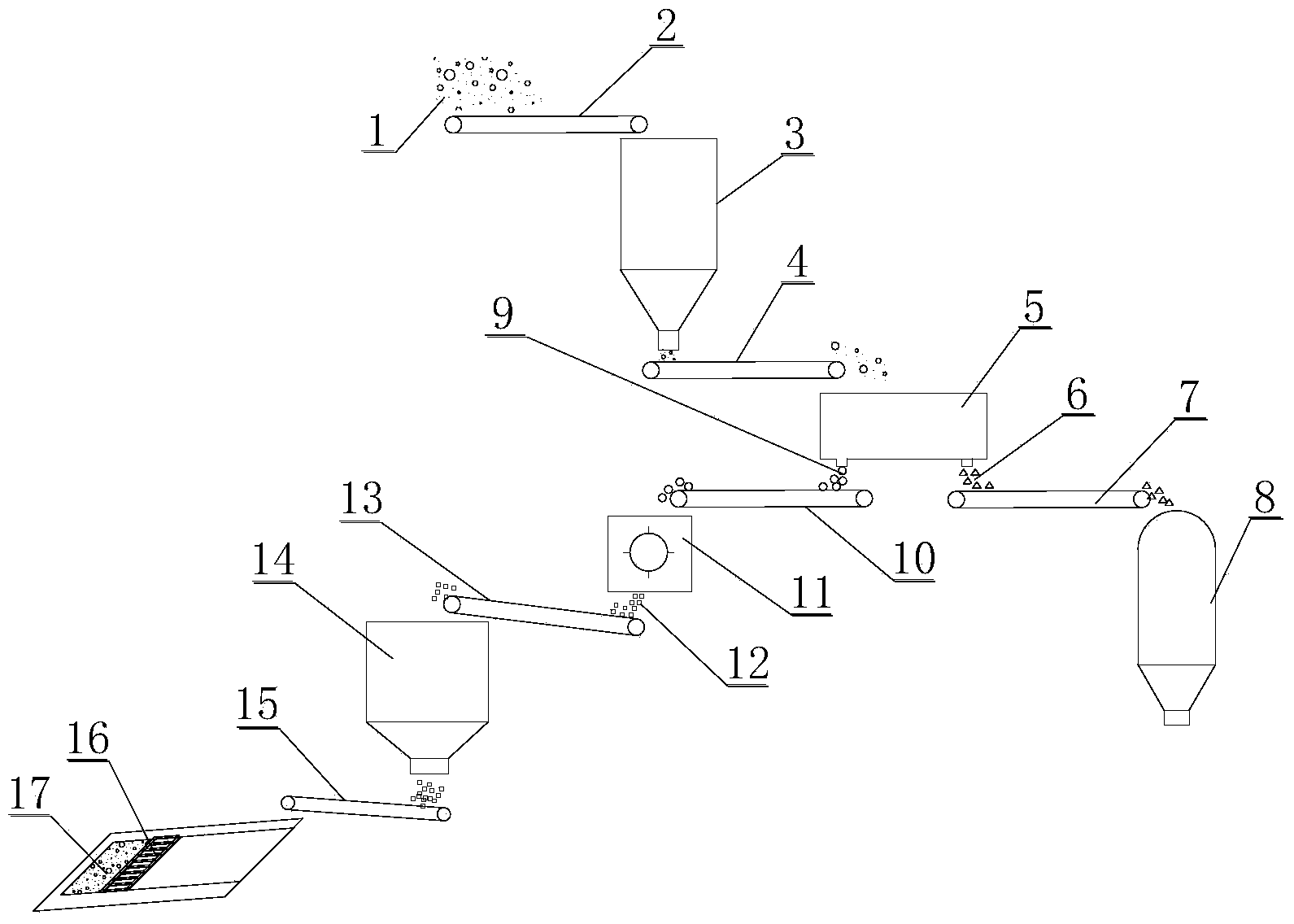

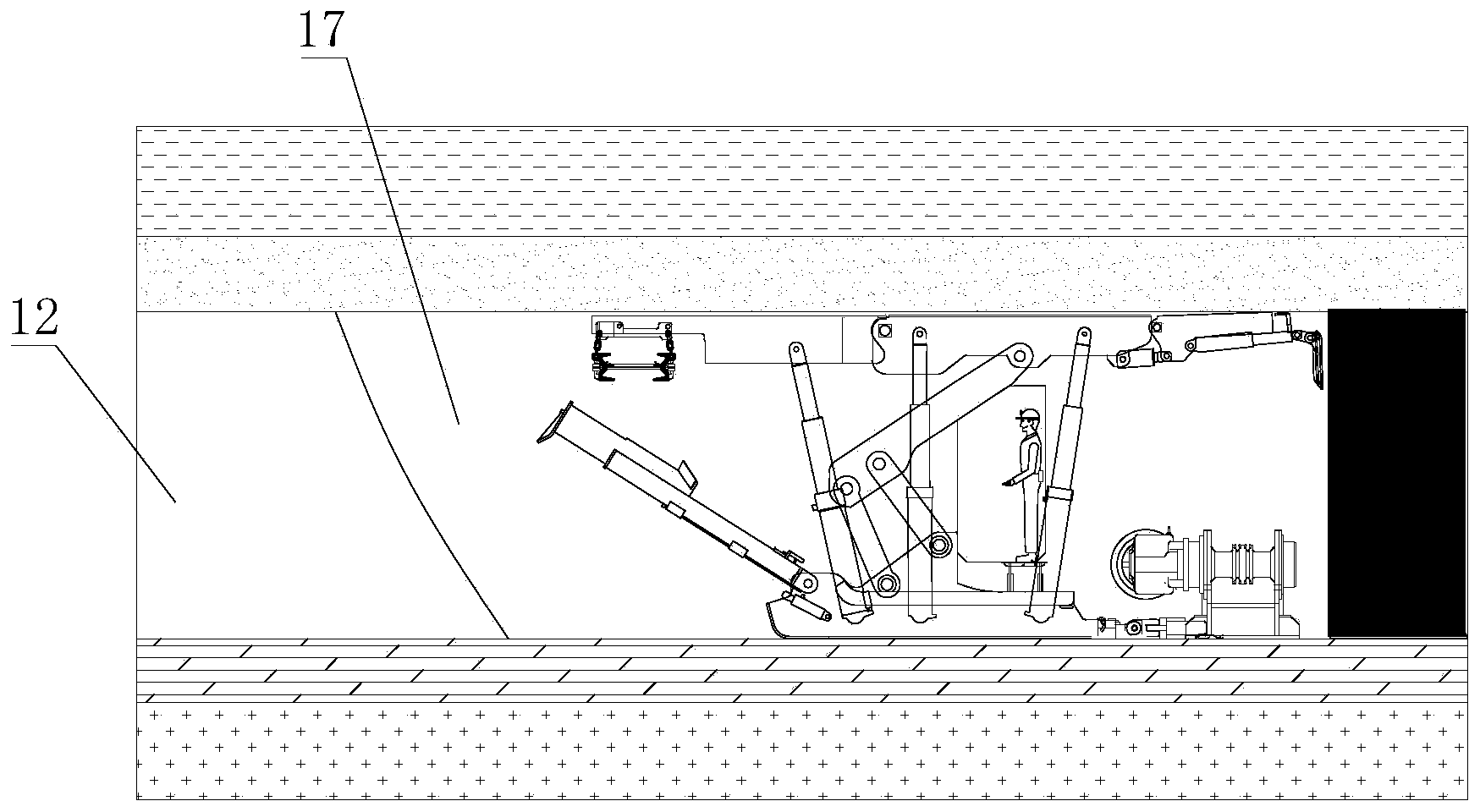

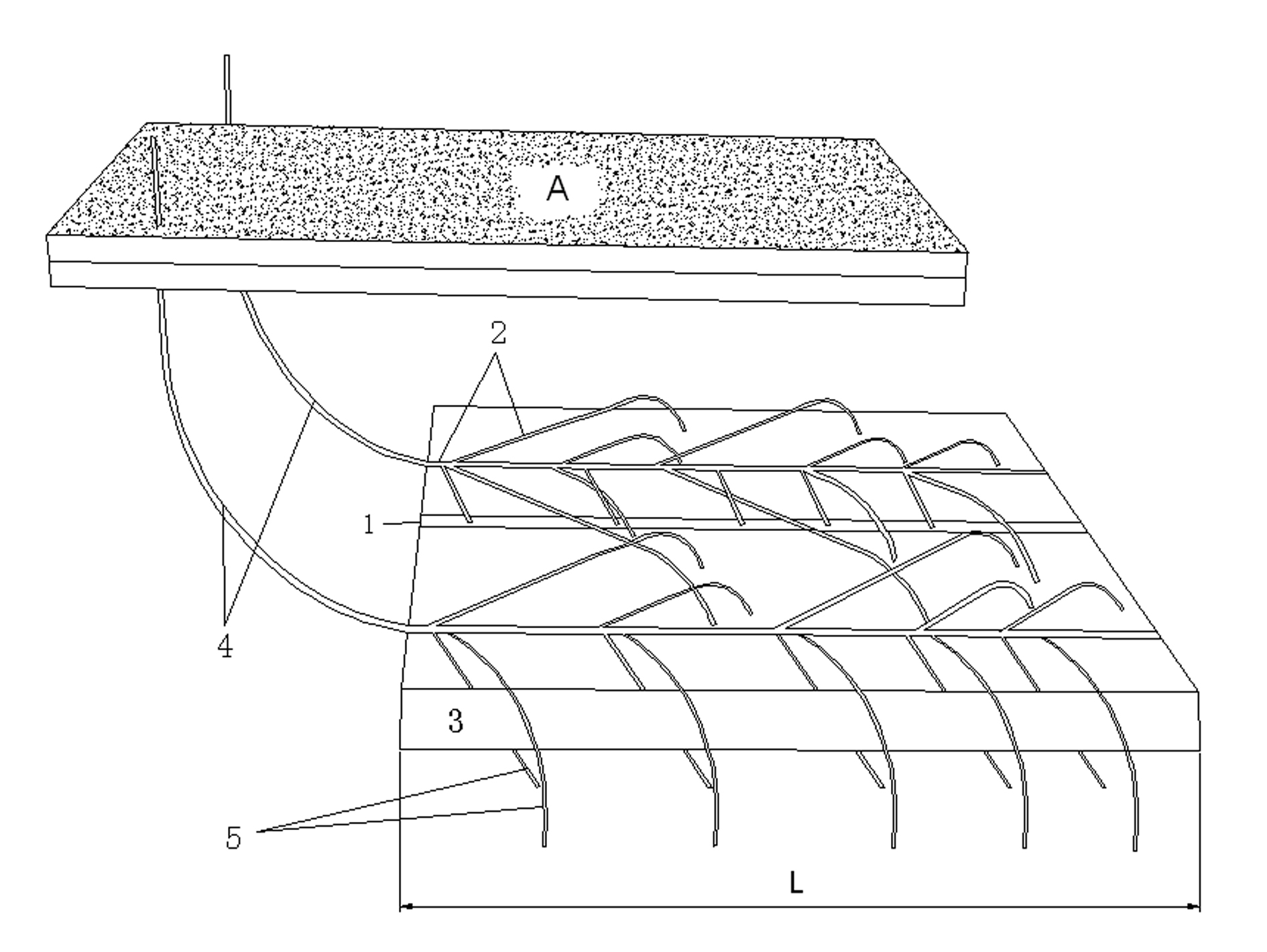

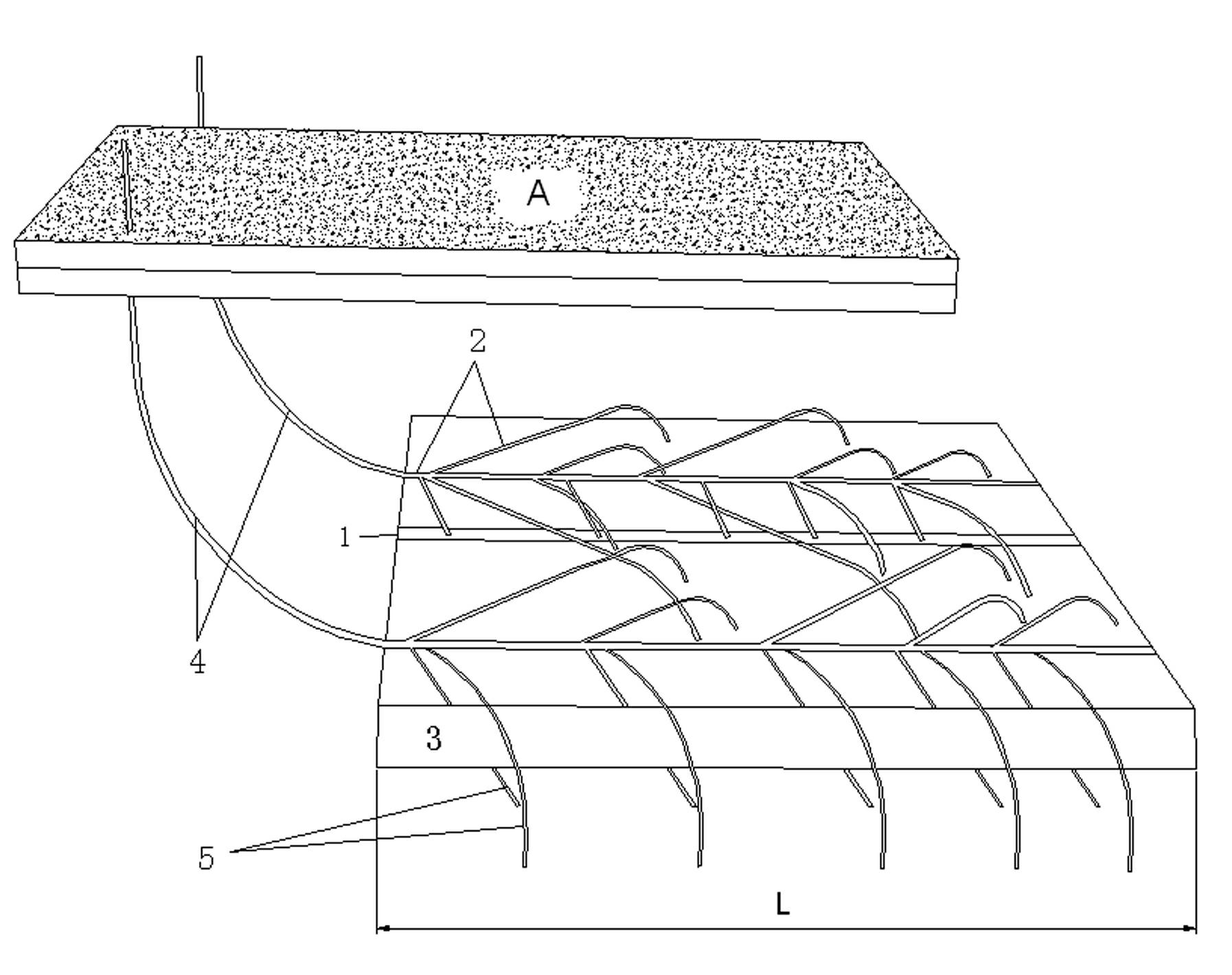

Coal mine underground mining, dress and filling integral method

InactiveCN104033153ASolve lifting problemsRealize no MasuiUnderground miningSurface miningCoal storagePollution

The invention discloses a coal mine underground mining, dress and filling integral method, which comprises the following steps that: a raw coal belt conveyor, a raw coal cabin, a raw coal feeding belt conveyor, a washing system, a cleaned coal belt conveyor, an underground coal storage cabin, a washed coal gangue belt conveyor, a digging coal gangue belt conveyor, a crushing machine, a coal gangue feeding belt conveyor, a coal gangue cabin and a filling coal belt conveyor are adopted; underground mined raw coal is subjected to dressing by washing by the washing system; cleaned coal subjected to dressing by washing is conveyed into the underground coal storage cabin and is hoisted onto the ground; and washed coal gangue obtained after the dressing by washing is crushed by the crushing machine and is then conveyed to a solid filling coal mining work surface for mine goaf filling. The mining, dress and filling integral method has the advantages that the safe and efficient exploitation under a railway, a water body and a building is realized; the mine auxiliary hosting pressure is reduced; the coal quality is improved; and the problems of ground occupation, pollution and the like caused by coal gangue discharge onto the ground are solved.

Owner:CHINA UNIV OF MINING & TECH

Method for extracting gas from coal seam roof complex branched well

InactiveCN102080518AExtraction time aheadReduce extraction timeFluid removalDirectional drillingCoal storageFissure

The invention relates to a method for extracting gas from a coal seam roof complex branched well, which comprises the following steps of: selecting a coal storage layer with the gas content larger than 8m<3> / t; determining the machine tunnel and the tail tunnel positions excavated by a working surface to be prepared, as the position of a horizontal well section of a complex branched well; confirming the layer position in which a fissure zone generated due to coal mining is located; respectively distributing the horizontal well section above a machine tunnel and a tail tunnel; confirming the positions of a well opening and a deflection point and realizing the angle gain of a large-curvature radius; by adopting a three-opening structure on a well body structure and adopting naked-eye structures for both the horizontal well and the branched wells, constructing a horizontal well section in a selected rock stratum; constructing the branched wells at both sides of the horizontal well section; constructing a downward branched well on the horizontal well section and drilling through the coal storage layer; installing extracting equipment for extracting gas; carrying out negative pressure extraction in the medium and later extracting phases for realizing one well with multiple purposes; and inspecting effects. The method is favorable for reducing the gas content, creating condition for safely and efficiently carrying out coal tunnel excavation and coal mining and really realizing one well with multiple purposes at the coal mining phase.

Owner:HENAN POLYTECHNIC UNIV

Combined separated layer fracturing, grouping and layer-combining mining method for coal bed well group

ActiveCN104806217AAffect production capacityGuaranteed scope of influenceFluid removalGas removalGeomorphologyHydraulic fracturing

The invention discloses a combined separated layer fracturing, grouping and layer-combining mining method for a coal bed well group. The method comprises the following steps of: (1) arranging a roadway, and digging an mining roadway in a top coal bed or a coal bed top plate; (2) establishing a fracturing pump room on the ground, constructing vertical wells and connection roadways, and enabling the connection roadway to be connected with the vertical wells and the roadway in the top coal bed; (3) paving high-pressure resistant pipelines; (4) constructing downwards in the roadway of the top coal bed to form a test drill hole, testing physic parameters of each coal bed below the top coal bed through the testing drill hole; (5) grouping the multiple coal beds below the top coal bed based on the physic characteristics of a coal storage layer; (6) implementing a fracturing and mining unit. The combined separated layer fracturing, grouping and layer-combining mining method for the coal bed well group ensures scope of influence of hydraulic fracturing, reduces cost taken for digging wells, can efficiently avoid mutual interference of fluid flowing among coal storage layers due to too great difference of physic characteristics of the storage layers.

Owner:HENAN POLYTECHNIC UNIV

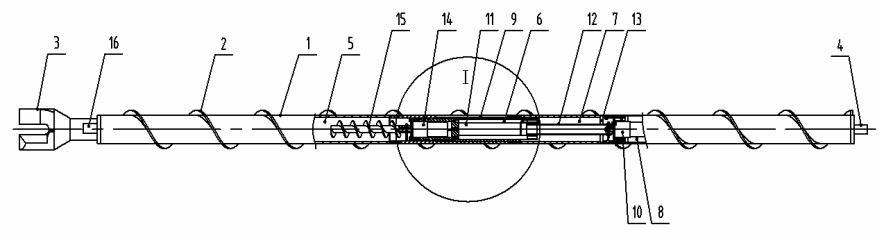

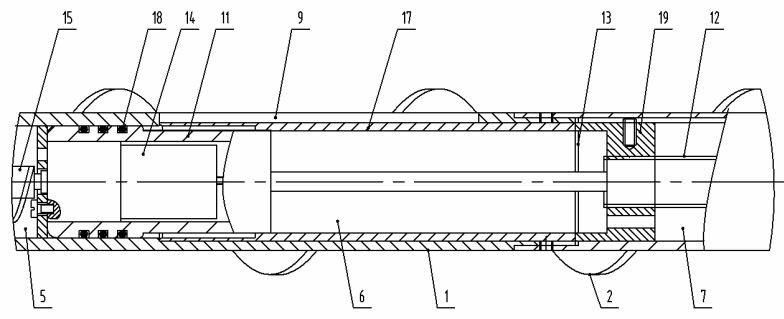

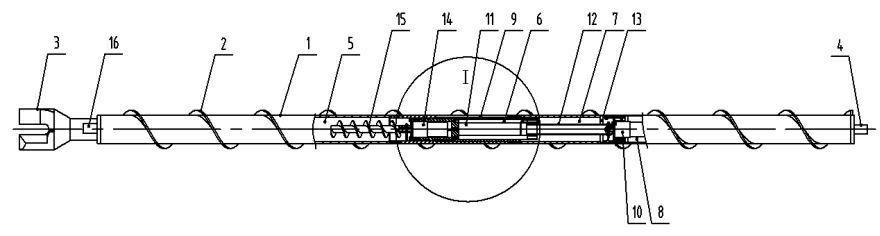

On-site sealed sampling device for coal bed gas

InactiveCN102103041ARealize in-situ seal acquisitionPrinciples of ScienceWithdrawing sample devicesPush and pullCoal mine methane

The invention discloses an on-site sealed sampling device for coal bed gas. The device comprises a hollow long rod piece, wherein the outer circumference of the long rod piece is provided with a spiral convex edge; a coal storage cabin, a closed cabin, a transmission cabin and a power and control cabin are arranged in the long rod piece from front to back respectively; the closed cabin is provided with a coal inlet; a reciprocating push and pull mechanism is arranged in the transmission cabin; a micro power speed reducing motor for providing power for the reciprocating push and pull mechanism is arranged in the power and control cabin; the front end of the reciprocating push and pull mechanism is in transmission connection with a piston sliding sleeve device for opening and closing the coal inlet; and the front end of the coal storage cabin is provided with a gas resolution hole. The device is mainly used for a sampling link before the process of measuring the content of the gas in a laboratory, has high practical value and is easy to popularize and apply, the on-site sealed acquisition of a coal sample and the gas is realized, underground resolution is not needed, loss amount is not required to be calculated in the process of measuring the content of the gas, and reliable basic parameters are provided for related fields of coal mine gas prevention and control and the like.

Owner:HENAN POLYTECHNIC UNIV

A coal seam fracturing fluid system

InactiveCN102287176ARapid gel breaking and flowbackReduce harmFluid removalDrilling compositionChlorine dioxideFracturing fluid

The invention relates to a method for pressing crack a coal bed pressing crack liquid, which sequentially comprises the following steps of: (1) selecting high-viscosity pressing crack liquid types used for the coal bed hydraulic cracking; (2) carrying out glue breaking experiments on pressing crack liquid adopted by chlorine dioxide indoors under the condition of the coal bed temperature and determining the minimum concentration of the chlorine dioxide; (3) determining the total quality of the chlorine dioxide according to the quantity of the pressing crack liquid and the concentration of the chlorine dioxide; (4) carrying out hydraulic pressing crack according to a procedure of prepad liquid, sand containing liquid and replacing liquid, wherein the chlorine dioxide added in the prepad liquid accounts for 70 percent, the chlorine dioxide added in the replacing liquid accounts for 30 percent, and not less than 10m<3> of active water or clean water is pumped and injected among the prepad liquid, the replacing liquid and the sand containing liquid for being used as isolation liquid; (5) starting to do pressing crack liquid backflow after the waiting for 2 to 4 hours from the completion of the hydraulic pressing crack; and (6) checking effects with the main indexes including the pressing crack liquid backflow quantity, the viscosity and the damage degree of the pressing crack liquid on the coal bed. The coal bed pressing crack liquid system has the advantages that the high-viscosity pressing crack liquid can realize fast glue breaking backflow at the coal bed temperature, and the damage to the coal storage layer is reduced.

Owner:HENAN POLYTECHNIC UNIV

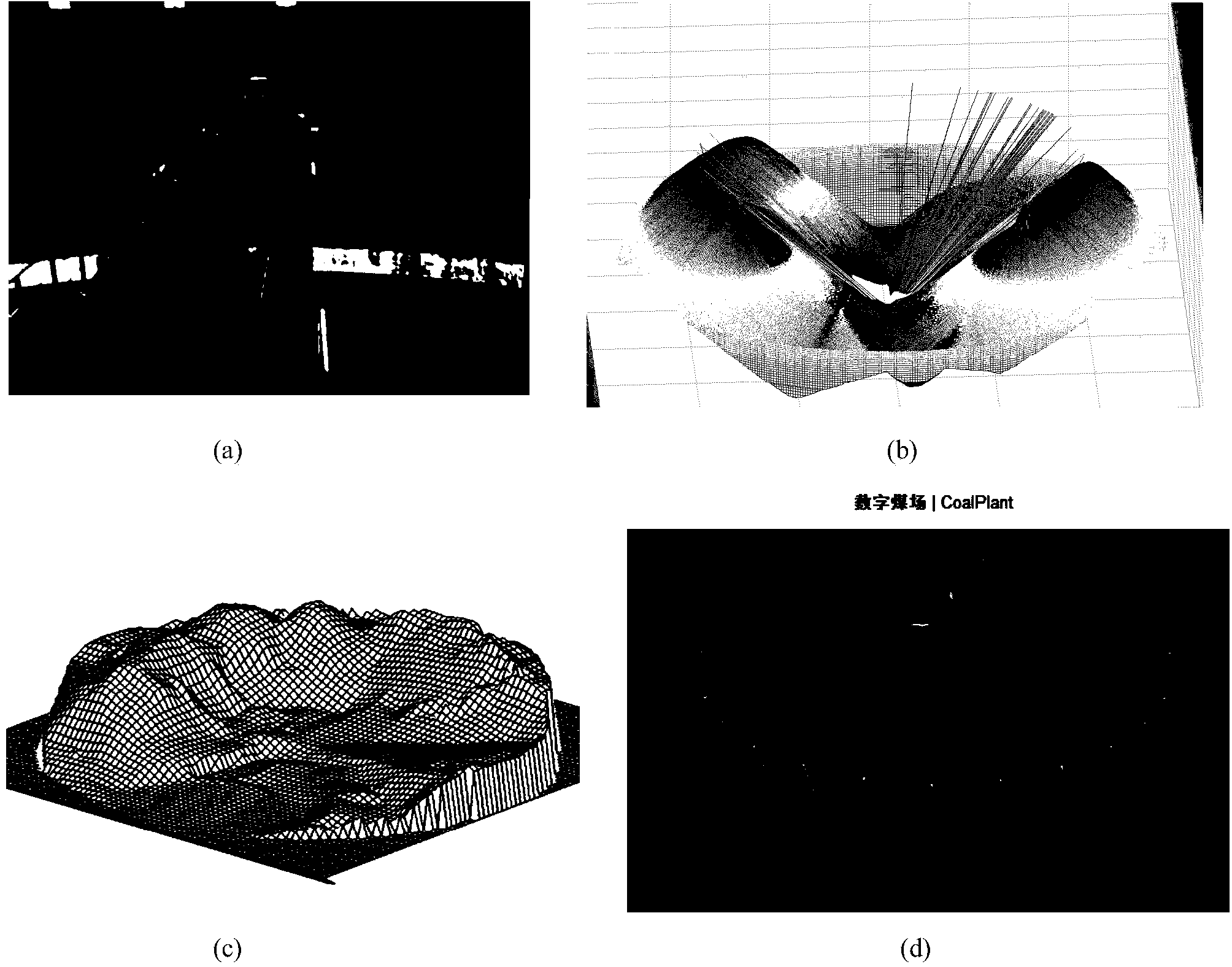

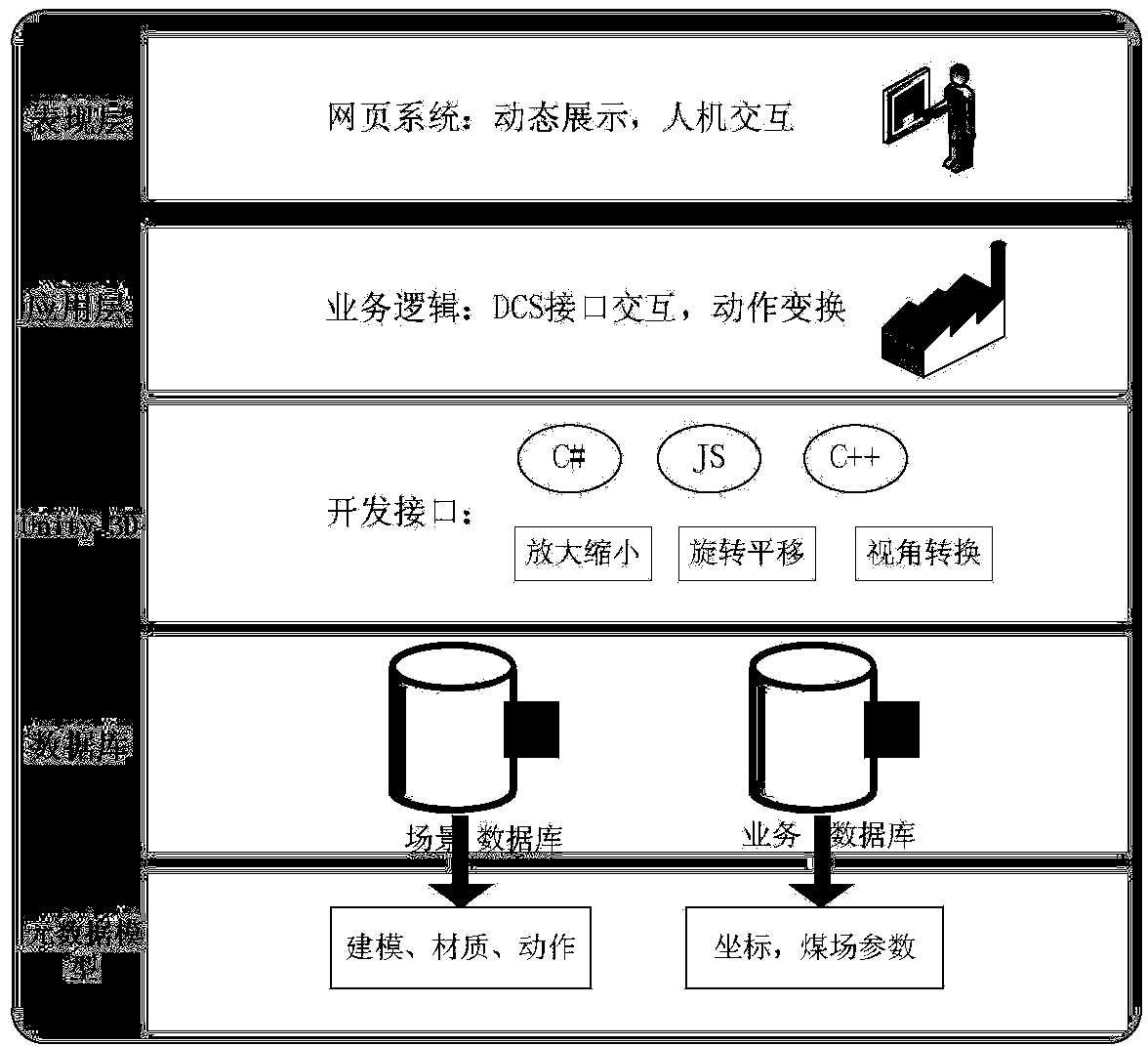

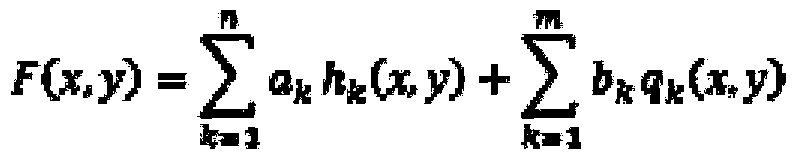

Unity3D-based circular coal yard three-dimensional (3D) intelligent visualization display platform

ActiveCN104392387AGuaranteed accuracy requirementsData processing applicationsDetails involving 3D image dataPoint cloudComputer graphics (images)

The invention relates to a Unity3D-based circular coal yard three-dimensional (3D) intelligent visualization display platform. Rapid and accurate checking of the inventory of a coal yard has great significance on cost accounting and scientific management of a power plant. The Unity3D-based circular coal yard 3D intelligent visualization display platform is characterized in that a 3D coal yard realization process involves generating 3D grid data according with coal yard reality through integrating point-cloud data scanned by a coal stocktaking instrument with daily coal sale data, generating a 3D stereogram by use of a Unity3D rendering technology, and then performing correction according real-time coal storage and consumption data according to a power plant DCS so as to improve the fitting precision of a drawn grid map and an actual coal yard shape. At the same time, a volume result of the coal yard inventory is given, the shape of the grid map is dynamically modified, and grid on-line 3D coal yard real-time updating is realized by use of a web technology. The Unity3D-based circular coal yard three-dimensional (3D) intelligent visualization display platform has the advantages of real-time performance, rapidness, low economic cost, high coal stocktaking precision and visual and clear interface.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

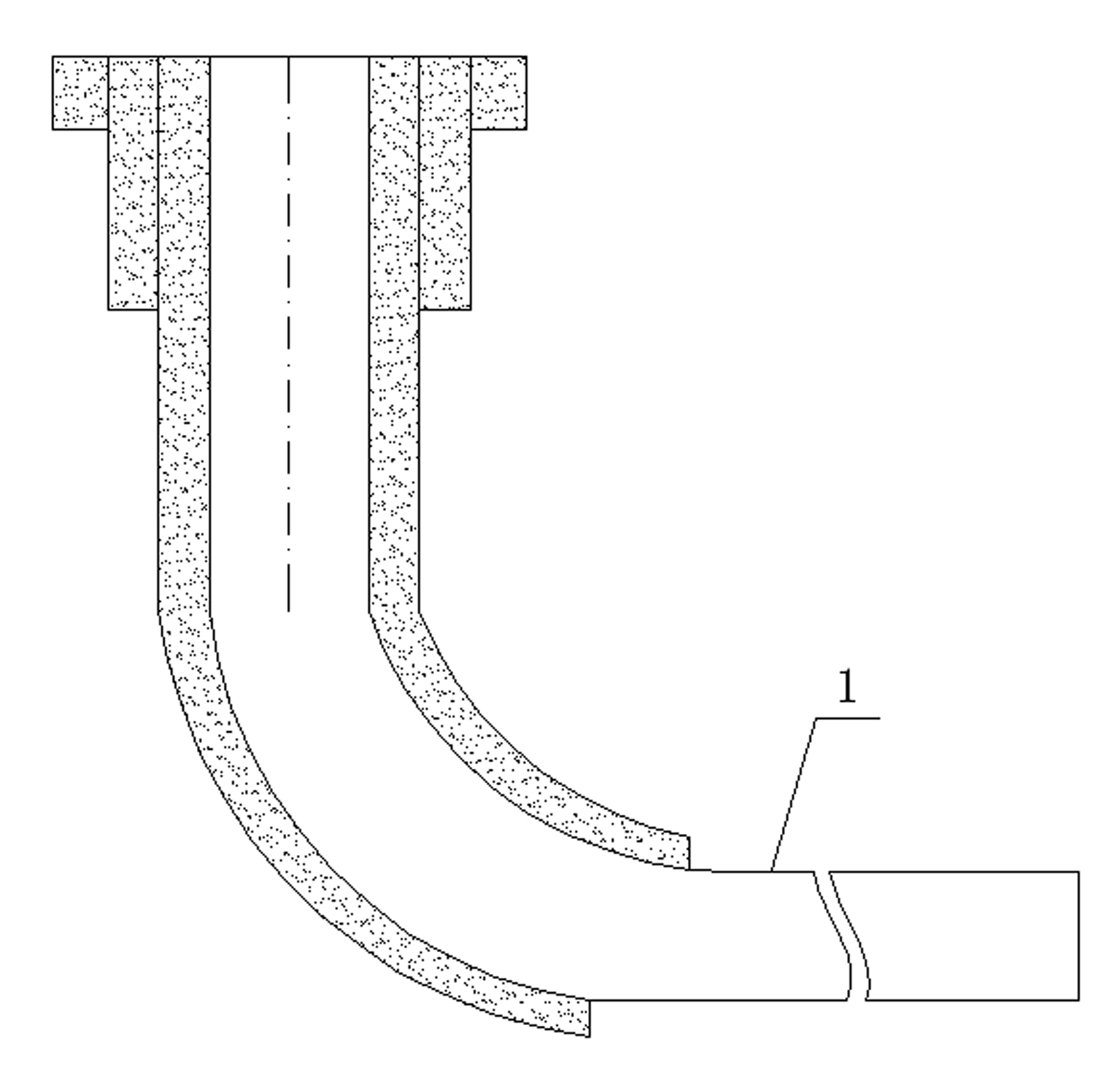

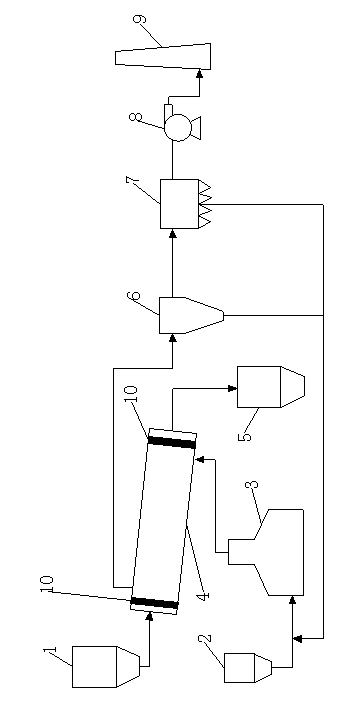

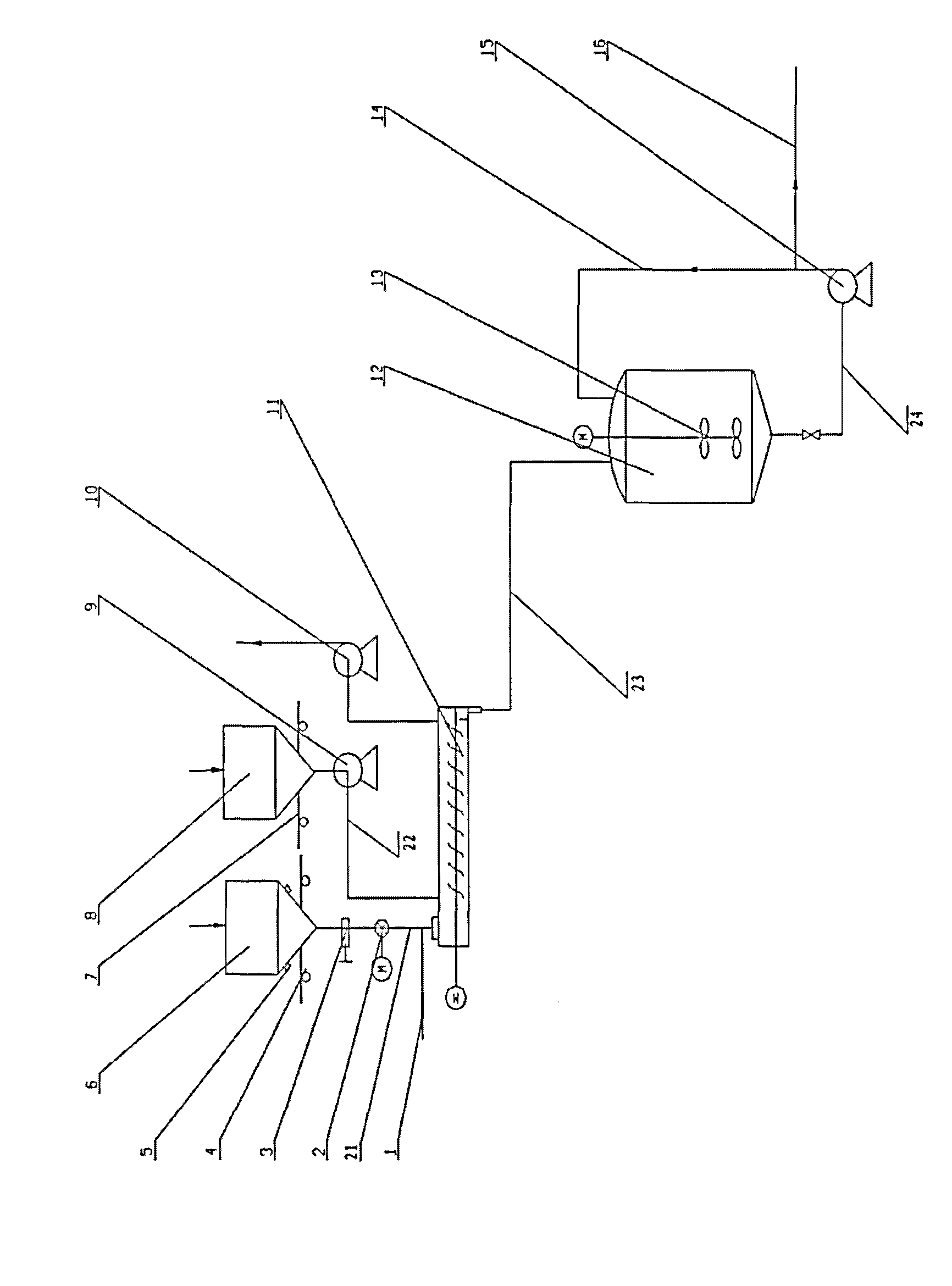

Efficient drying and quality-improving device and method for brown coal

The invention relates to an efficient drying and quality-improving device and method for brown coal. In the prior art, no efficient drying and quality-improving device or method for brown coal, which is used for improving the utilization value of the brown coal, exists. The efficient drying and quality-improving device is characterized by comprising a coal storage bin, a fuel bin, a hot blast stove, a cylinder-type dryer, a product bin, a cyclone dust collector, an electrical dust collector and a plurality of pipelines, wherein both the product bin and the coal storage bin are connected with the cylinder-type dryer; the cylinder-type dryer is connected with the cyclone dust collector; and the cyclone dust collector, the electrical dust collector, the fuel bin are all connected with the hot blast stove. The method is characterized in that the raw material of the brown coal is conveyed into the cylinder-type dryer from the coal storage bin; the hot blast stove generates high-temperature flue gas at the temperature of 700-900 DEG C, and the flue gas is conveyed into the cylinder-type dryer; the raw material of the brown coal is dried by the high-temperature flue gas and conveyed into the product bin from the cylinder-type dryer for sealing and cooling, so that the finished product of the brown coal is obtained after cooling. According to the device and the method, the moisture in the brown coal can be reduced substantially, and a part of ash content in the brown coal can also be reduced, so that the utilization value of the brown coal can be improved.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Method for treating waste coking oven gas desulfurization solution

InactiveCN101798533AAvoid pollutionReduce corrosionGas purification by liquid washingLiquid wasteSpray nozzle

The invention relates to a method for treating waste coking oven gas desulfurization solution, comprising the following steps: (1) setting up a pipeline from a waste coking oven gas desulfurization solution tank (1) and to the top of a coal tower (3); (2) transporting the waste coking oven gas desulfurization solution to the top of the coal tower (3) by using a waste coking oven gas desulfurization solution pump (2); (3) arranging an annular spraying pipe (4) on the top of the coal tower (3), wherein each spraying branch pipe is provided with a valve and a spray nozzle; (4) spraying the waste coking oven gas desulfurization solution to all coal storage tanks which are arranged on the top of the coal tower (3) under the outlet pressure of the waste coking oven gas desulfurization solution pump (2), and mixing the waste coking oven gas desulfurization solution with coking coal; and (5) decomposing the waste coking oven gas desulfurization solution at the high temperature of 1100-1200 DEG C in a coking oven. The invention can solve the problem existing in the prior art that the waste coking oven gas desulfurization solution can be not treated harmlessly and thoroughly.

Owner:NINGBO IRON & STEEL

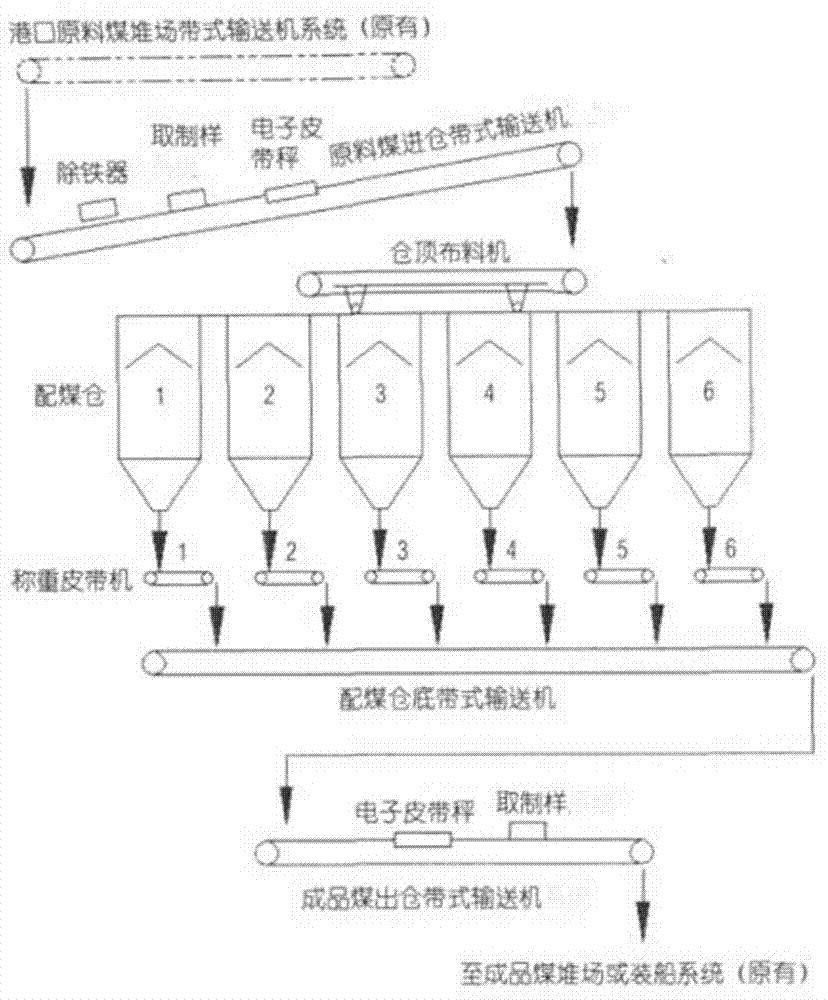

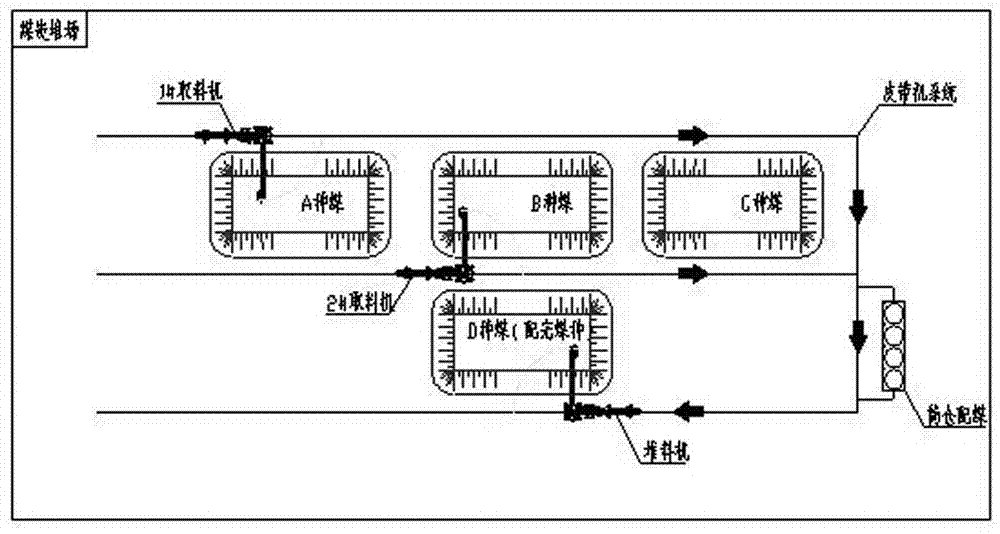

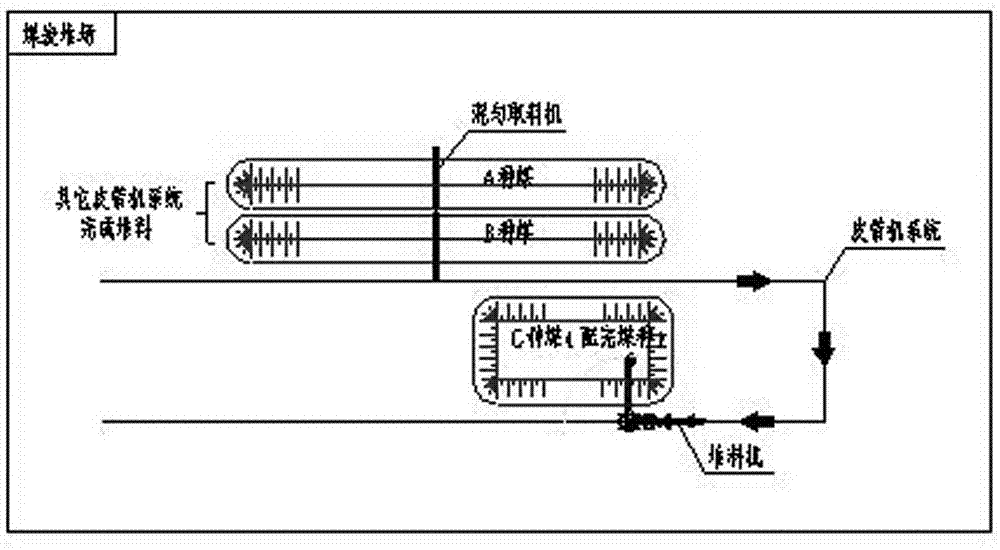

Accurate coal blending system of silo and coal blending method of accurate coal blending system

InactiveCN104773528AFulfill coal blending requirementsLoading/unloadingProcess engineeringMaterial distribution

The invention discloses an accurate coal blending system of a silo. The accurate coal blending system comprises a coal blending silo, a raw coal in-silo belt conveyor, a silo roof material distribution machine, a coal blending silo bottom belt conveyor, a metering device and a finished coal out-of-silo belt conveyor, wherein a coal inlet of the raw coal in-silo belt conveyor is connected to a storage yard coal blending system, a coal outlet of the raw coal in-silo belt conveyor is connected with a coal inlet of the silo roof material distribution machine, the coal blending silo comprises a plurality of silo tubes, a coal outlet of the silo roof material distribution machine is connected with coal inlets of the silo tubes, coal outlets of the silo tubes are connected with a coal inlet of the coal blending silo bottom belt conveyor, a coal outlet of the coal blending silo bottom belt conveyor is connected with a coal inlet of the finished coal out-of-silo belt conveyor, and a coal outlet of the finished coal out-of-silo belt conveyor is connected with a finished coal storage yard or a shipment system. According to the accurate coal blending system disclosed by the invention, high-accuracy coal blending requirements are met, meanwhile, the coal blending is not limited by the number of storage yard material taking devices, and the coal blending requirements on four or more than four coal types can be met.

Owner:浙江华电智能电站设备股份有限公司

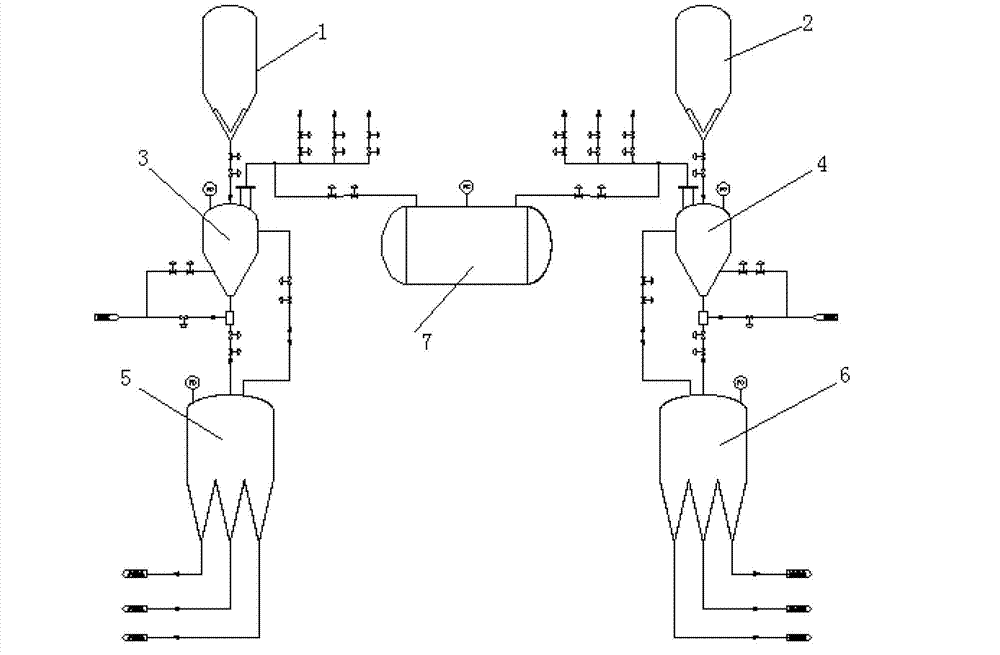

High pressure conveyance gas recovery method

The invention discloses a high pressure conveyance gas recovery method which comprises a first storage tank, a second storage tank, a first locking hopper, a second locking hopper, a first feeding tank, a second feeding tank and a gas coupling tank. After the first feeding tank (second feeding tank) correspondingly receives a batch of power from the first locking hopper (second locking hopper), the first locking hopper (second locking hopper) is separated from the first feeding tank (second feeding tank). The first locking hopper is opened for equalizing pressure with a communication valve of the gas coupling tank, after pressure is balanced, the second locking hopper is opened for equalizing pressure with the communication valve of the gas coupling tank. When pressure of the first locking hopper, the gas coupling tank and the second locking hopper is balanced, the gas coupling tank is isolated, gases are discharged into a powdered coal storage tank so that a filter is used for discharging pressure of the first locking hopper, and meanwhile, pressure conveyance gases are used for punching the second locking hopper. According to the high pressure conveyance gas recovery method, conveyance gases can be partly recycled, energy dissipation is reduced, and recovery use ratio of conveyance gases is 50% compared with a single system.

Owner:ANHUI JINMEI ZHONGNENG CHEM IND

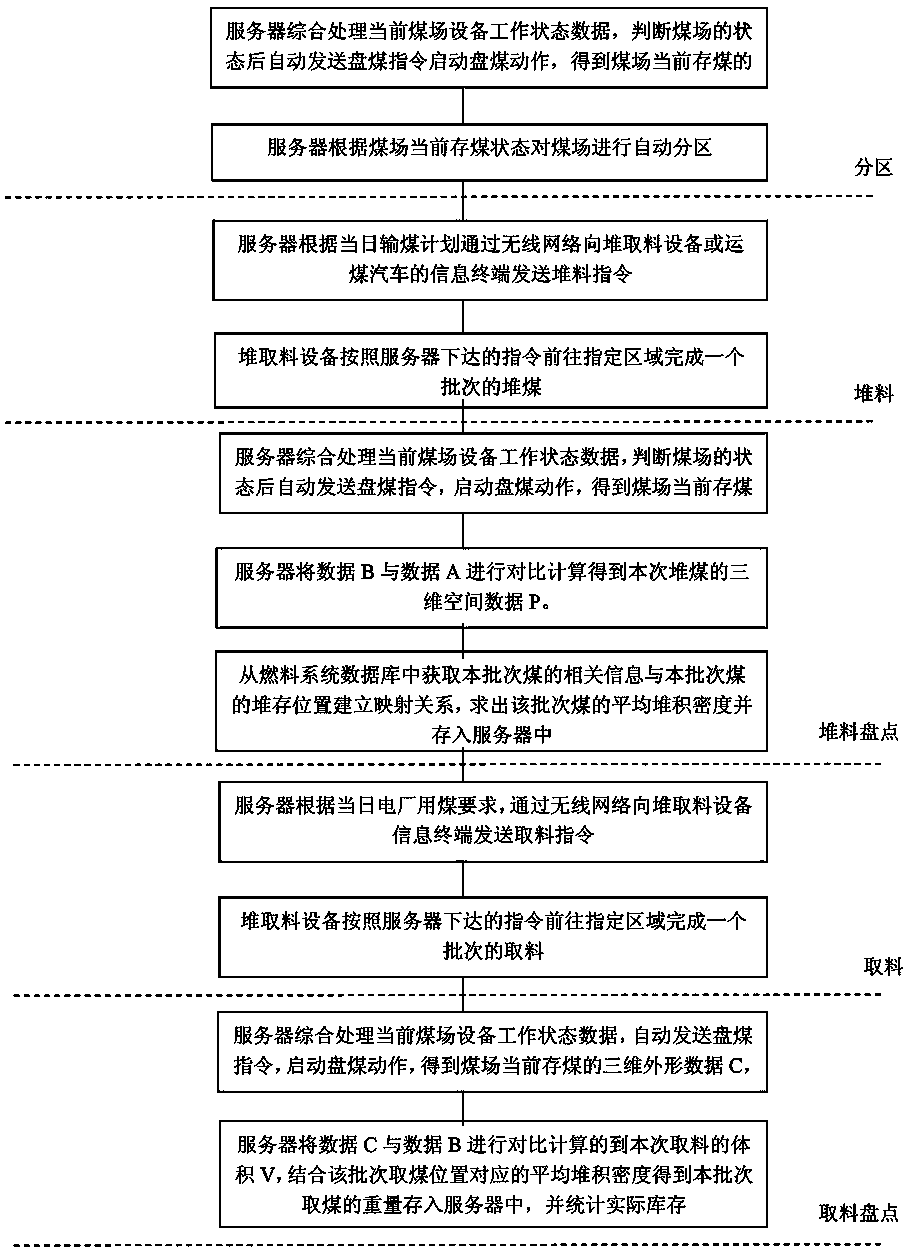

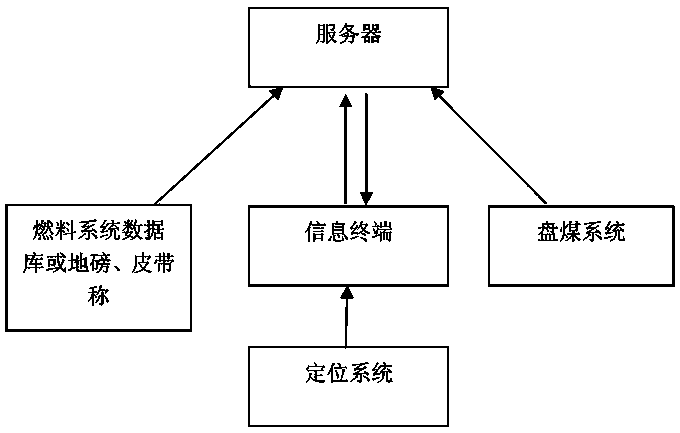

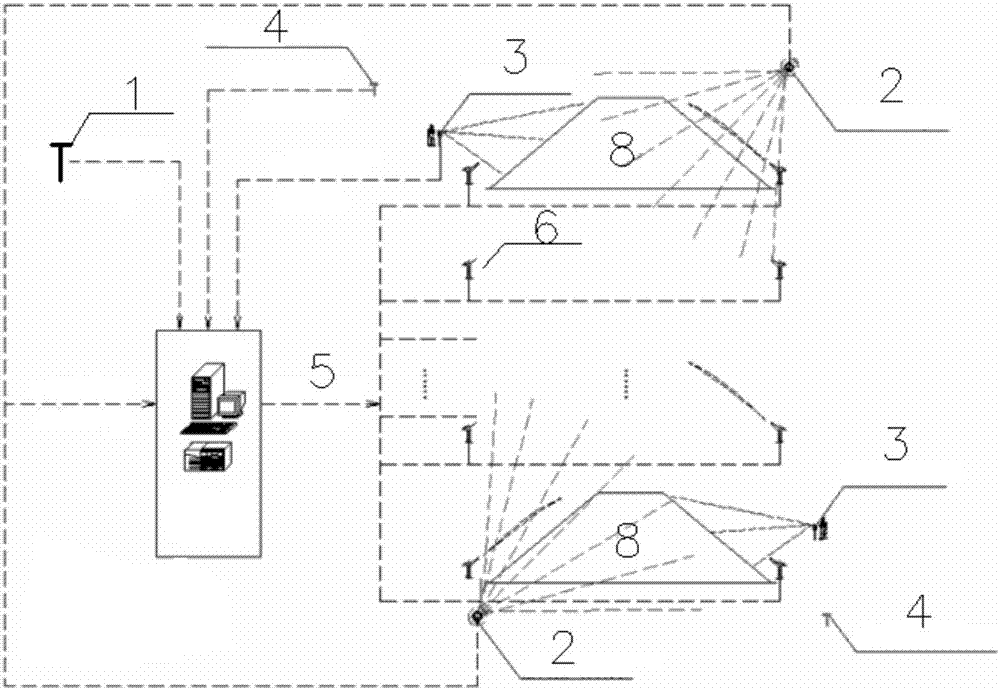

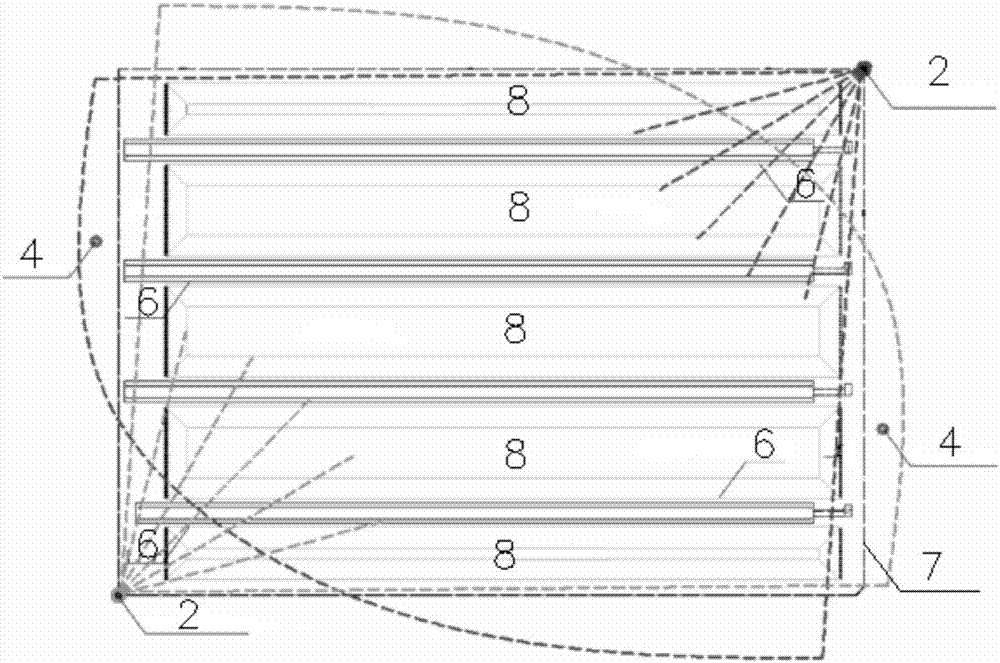

An intelligent coal yard monitoring method and a monitoring system

InactiveCN109242226AAccurate dataReduce manual interventionTransmission systemsParticular environment based servicesMonitoring systemEngineering

The invention discloses an intelligent coal yard monitoring method and system. The steps of the method are as follows: S1, dividing the coal yard into regions; S2, stockpiling material: the coal material is piled in different areas according to the actual needs according to the divided areas; S3, stockpile counting: the coal is divided into storage spaces according to the batches, the stacking density is calculated, and all the information of the batch of coal is related to the stacking position; S4, reclaiming material: reclaiming material in different regions according to requirements from the designated area of the stacking yard; S5, retrieval counting: the actual coal retrieval amount of this batch of coal retrieval is counted once, and the current coal storage state of the coal yard is counted and determined. The system is used to implement the method described above. The invention has the advantages of high automation degree, realizing intelligent real-time monitoring, good monitoring effect and the like.

Owner:HUNAN SUNDY SCI & TECH DEV

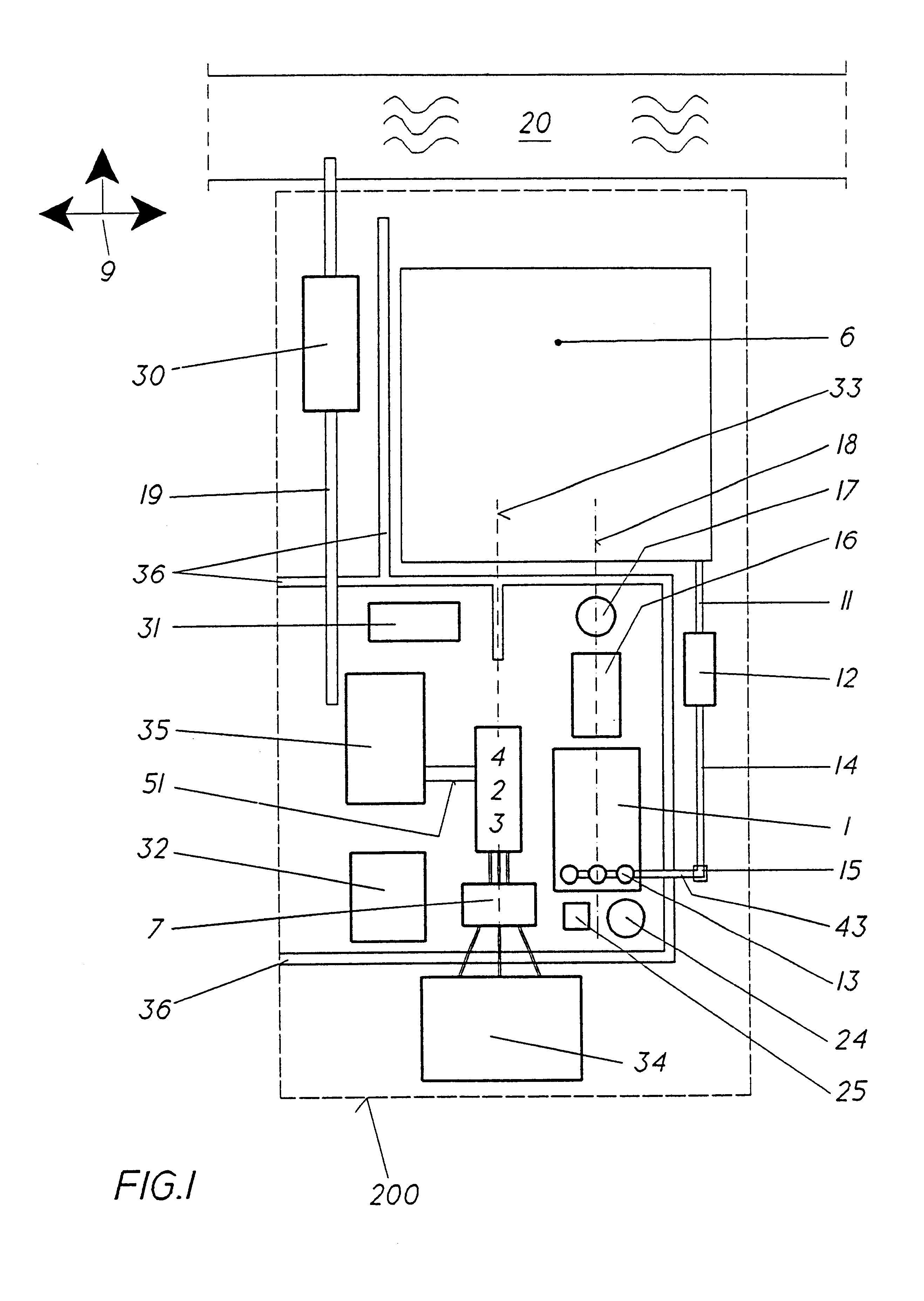

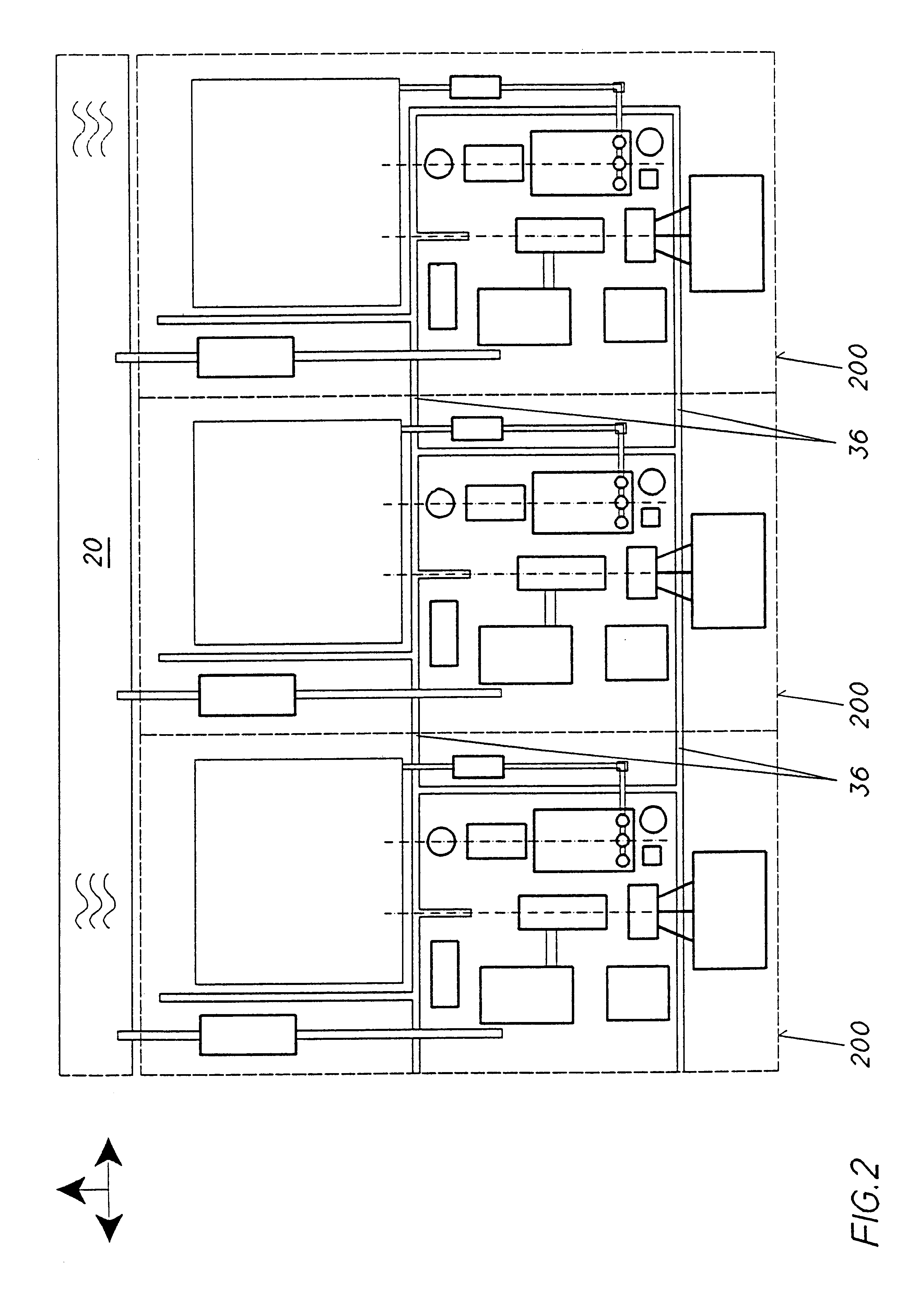

Steam power plant

The invention relates to a steam power plant which consists essentially of a steam generator (1), a turbo group comprising a condensing steam turbine (2) and generator (3), a water-cooled condenser (4) and a bled-steam-heated preheating system. In said steam power plant all components, including the fuel storage area (6), are situated at ground level and in the open air. The turbo group (2, 3) and the condenser (4), the preheating system with associated pumps and the transformers (7) are arranged such that a gantry crane is able to pass over them. The steam generator (1), flue gas cleaning system (16) and the chimney (17) are positioned in a row along a common flue gas axis (18) and the turbo group (2, 3) arranged in the immediate vicinity and parallel thereto. As seen from the main wind direction (9), the coal storage area (6) is positioned downwind from the turbo group (2, 3) and the steam generator (1).

Owner:GENERAL ELECTRIC TECH GMBH

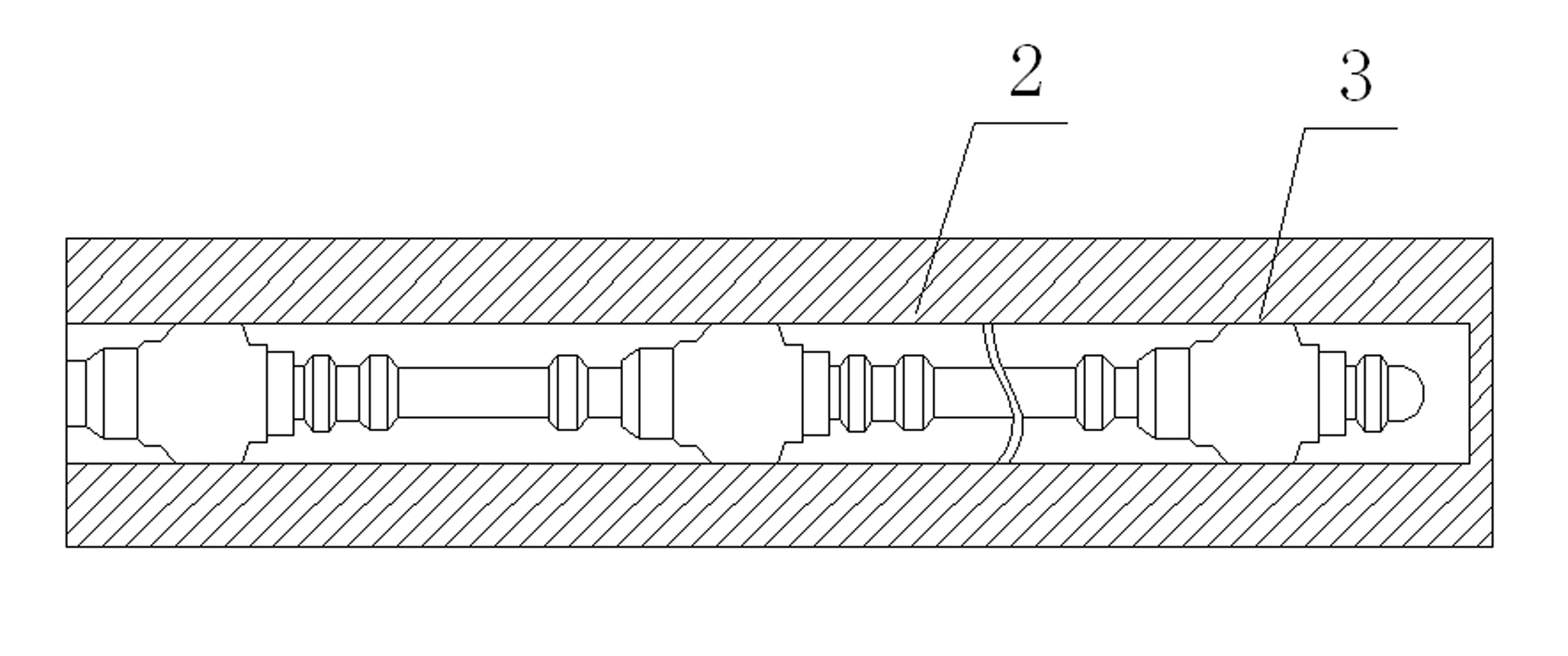

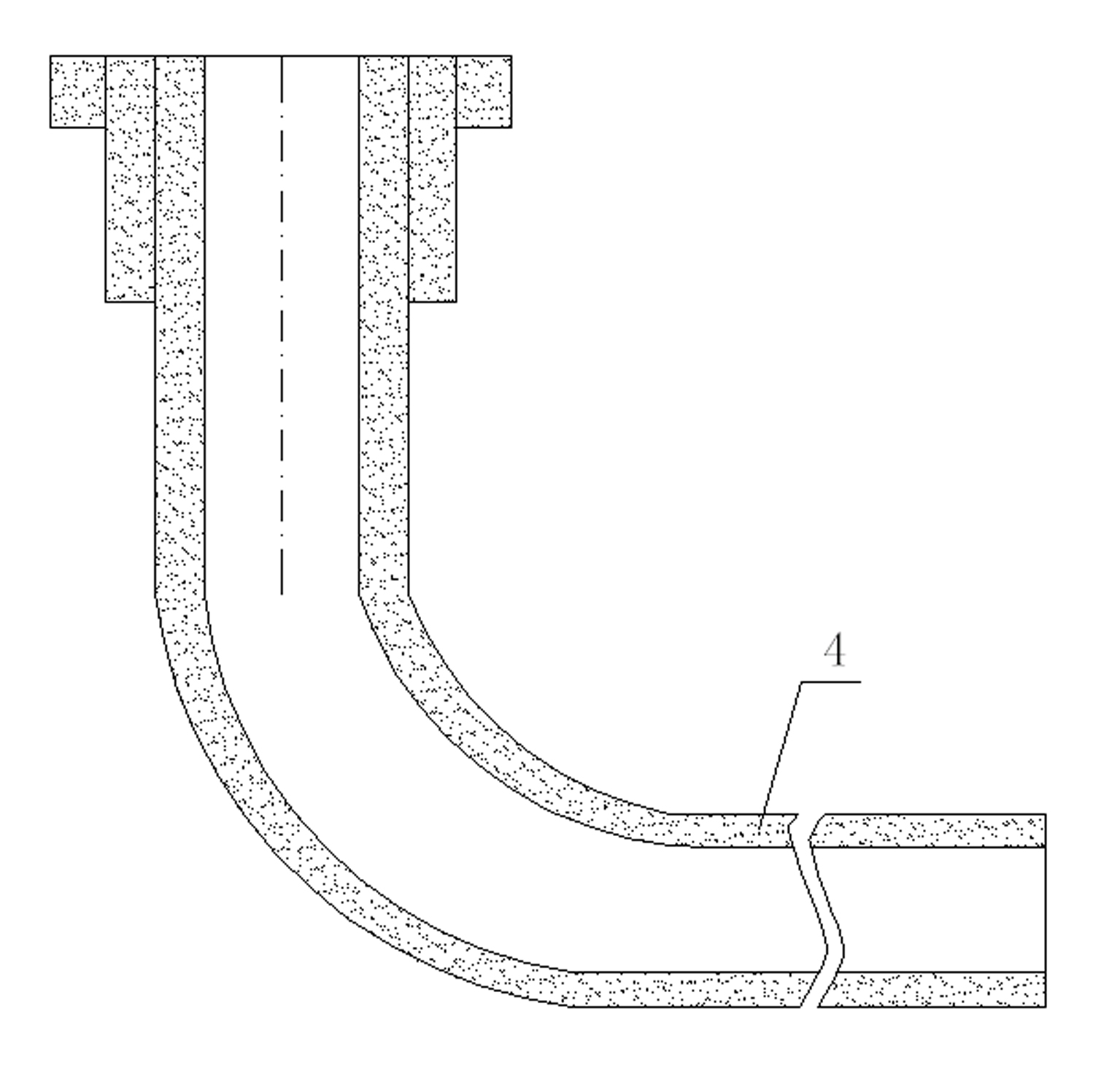

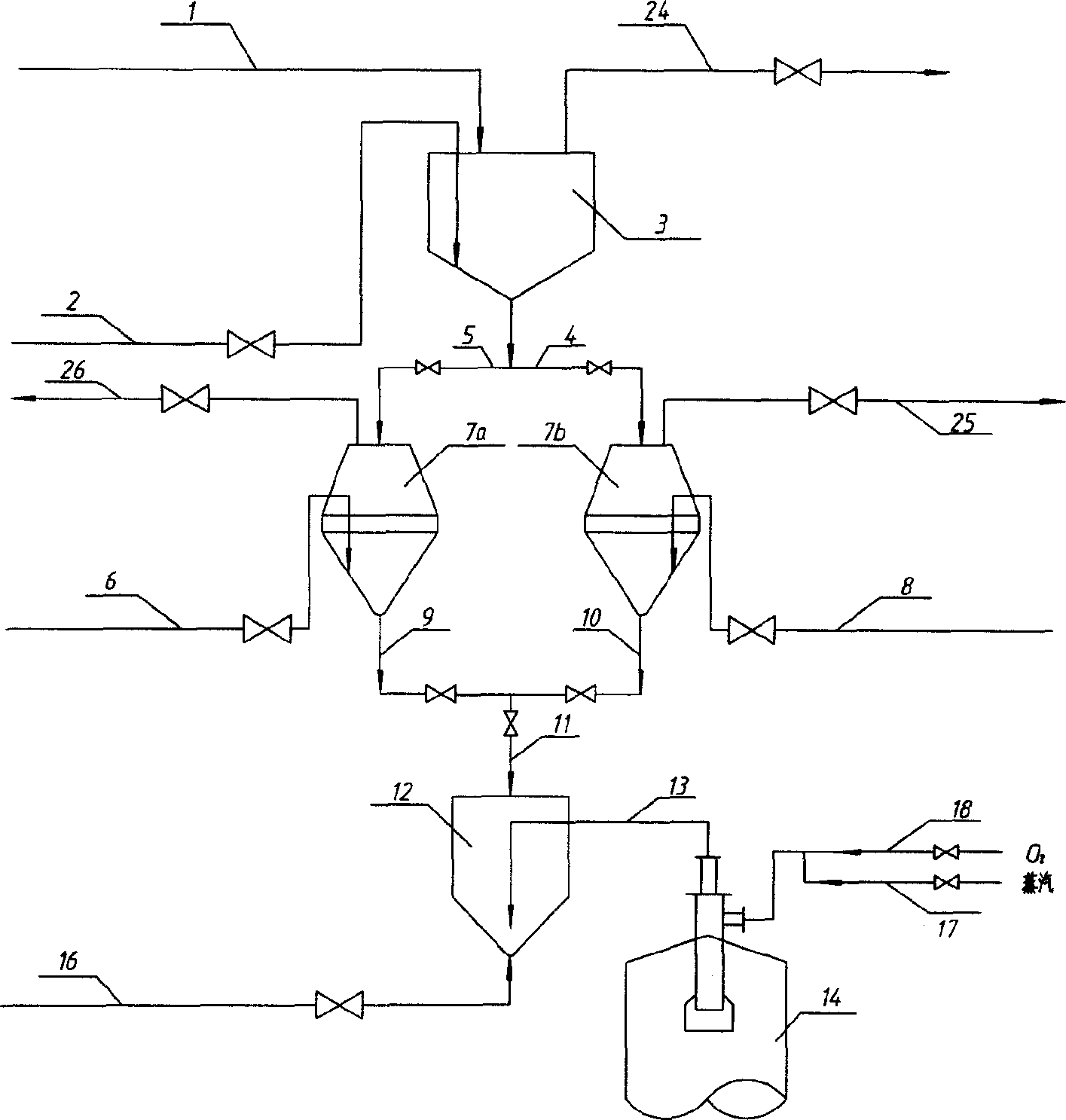

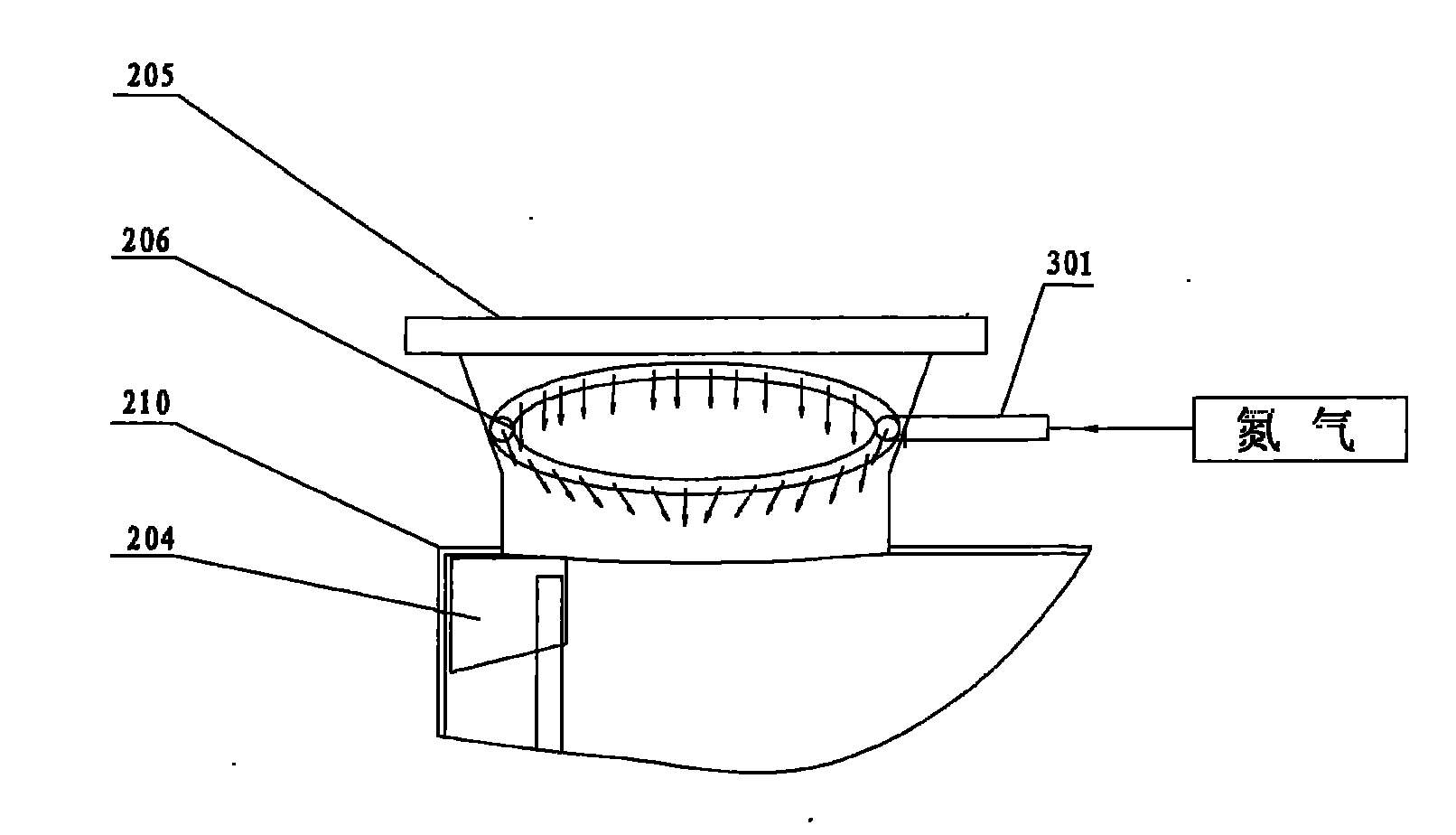

Safety sealing and air flow conveying method for fine coal gasification process

ActiveCN1702149AHigh active ingredientQuality is not affectedGranular/pulverulent flues gasificationRational useSyngas

The invention relates to a method for safety seal and flow delivery in the technique of the gasification of dust coal. It uses choke damp or flue gas to pressurize and seal safely the dust coal storage bin, and then uses choke damp to lock bucket the dust coal and to pressurize the dust coal feed bin, in order to transport the dust coal to gasification stove, temperature of said choke damp using to pressurize the feed bin being from normal temperature to less than 100 Deg. C, and pressure being 0.1-6.9 MPa. Using the specified choke damp to substitute nitrogen as power carrier of air conveying doesn't leaven the quality of the prepared synthetic gas or increase the content of nitrogen except the nitrogen carried by coal, available composition of the gas being high; using choke damp to substitute nitrogen as the gas for safety seal realizes the rational use of resource, for the limited choke damp carried with dust coal can generate non-catalytic reaction and getting corresponding product gas after it into gasification stove.

Owner:成都市通用工程技术有限责任公司

Environmentally-friendly multifunctional dust suppressant and preparation method thereof

InactiveCN103059347AReasonable formulaEasy to buy raw materialsOther chemical processesGlycerolCopper sulfate

The invention discloses an environmentally-friendly multifunctional dust suppressant and a preparation method thereof. The environmentally-friendly multifunctional dust suppressant comprises the materials in percentage by weight: 0.05-2.50% of carboxymethylcellulose, 0.05-2.50% of chitosan, 0.1-0.5% of acetic acid, 0.25-1.00% of glycerol, 0.05-0.15% of sodium alkyl benzene sulfonate, 0.01-0.05% of copper sulfate, 2-20% of magnesium chloride and the balance of water. The dust suppressant provided by the invention is remarkable in dust suppressant and loss preventative effect. Compared with other dust suppressants, the preparation method has the following advantages: the machining process is simple and convenient, the cost is lower, the dust suppressant time is long, the performance cost ratio is high, and the components are independent. The liquor of the dust suppressant is free from any toxic and side effects and corrosive effect, and the dust suppressant can be biodegradable and is free from any secondary pollution. The dust suppressant provided by the invention can be widely applied to the fields of construction sites, cement plants and coal storage and transportation and dust suppression.

Owner:青岛清泽环保有限公司

Preparation method of control agent for coal dust pollution

InactiveCN101575500ALow costWide variety of sourcesOther chemical processesBuilding constructionsPolyvinyl alcoholDust control

The invention relates to a preparation method of a control agent for coal dust pollution. The preparation method adopts the components with the following weight portions: 1 to 3 portions of polyvinyl alcohol (PVA), 2 to 3 portions of industrial starch, 1 to 1.5 portions of glutinous rice flour, 85 to 95 portions of water, 1 to 2 portions of polyoxyethylene nonylphenol ether and 1 to 2 portions of sodium humate. The control agent is prepared by mixing and evenly stirring the materials. The sodium humate contains 40 percent to 60 percent of humic acid and 10 percent to 20 percent of natrium. The control agent is characterized by low cost, wide material source, stable performance, wide application, innocuity and harmlessness, low corrosion rate, no odor and the like, as well as high inhibition rate, remarkable dust suppression effect, good frost resistance performance and the like. The technique that blending the control agent and spraying the control agent on the surface are combined is adopted in large-sized coal mines, ports and coal storage in China, thus realizing dust control and flame retardancy during production, storing and transporting processes of coals.

Owner:SHIJIAZHUANG XINBANGER ENERGY SAVING TECH CO LTD

Automatic dust prevention and suppression system of coal storage yard

PendingCN107300903AAchieve dustproof effectControl spilloverTotal factory controlProgramme total factory controlSprinkler systemData acquisition

The invention relates to the technical field of environmental protection. An automatic dust prevention and suppression system of a coal storage yard comprises a water sprinkling system for the coal storage yard, and is characterized by further comprising a coal storage yard data acquisition system for acquiring environmental parameters of the coal storage yard, wherein the coal storage yard data acquisition system is connected with a signal processing system; the signal processing system is connected with the water sprinkling system through a control actuation system. According to the automatic dust prevention and suppression system of the coal storage yard, the environmental parameters such as the dust content and the moisture content of the storage yard can be mastered in real time through the coal storage yard data acquisition system, and a working state of the water sprinkling system is adjusted in real time through the signal processing system according to changes of the surrounding environmental parameters. The automatic dust prevention and suppression system of the coal storage yard realizes intelligent dust suppression of the coal storage yard, so that green and environmentally-friendly transformation and upgrading of the coal storage yard can be realized to push sustainable development of an enterprise with the coal storage yard.

Owner:CCCC THIRD HARBOR CONSULTANTS +1

Steam coal preparation technique with low coal slime yield

The invention relates to a steam coal preparation technique with low coal slime yield, comprising the following steps of: (1) storing the raw coal of steam coal in a horizontal cabin, wherein the height of coal storage is less than 10 m; (2) crushing the raw coal less than 200 nm by using a grading crusher; (3) feeding the raw coal into a bolting mill for milling after crushing, wherein the coal with big screening size enters a lump coal washing system for washing, the fine coal powder with small size is then sieved, and the fine powder less than 6 nm after sieving directly enters a product cabin; and the remaining slack coal enters a non-pressure dense media swirler for washing and de-liming. The technique can wash all the steam coal with relatively lower cost; the coal slime yield is reduced; and the calorific value of washed steam coal product is increased.

Owner:CHINA SHENHUA ENERGY CO LTD

Oily dust preventive composition, preparation method and purpose for preventing dust from flying

ActiveCN103254872AKeep healthyComfortable environmentOther chemical processesDust removalEvaporationVolumetric Mass Density

The invention provides an oily liquid and oil state dust preventive composition, a preparation method and purpose for preventing dust from flying. The dust preventive composition comprises the following components per 100 parts by weigh of oily solution: 50-80 parts by weight of oily liquid acrylamide copolymerized high-molecules prepared by copolymerization of acrylamide monomers, and 2.0-10.0 parts by weight of surfactant with emulsification and dispersion functions, and 5.0-30.0 parts by weight of hygroscopic oil with dispersion and moisture evaporation inhibition function, and 0.2-10.0 parts by weight of one or two kinds of natural high-molecules with good dust adhesion strength or adhesion maintenance force. In the yellow sand region, tunnel, subway, mine, coal storage field, sand storage field, road and building sit with many dust, and a certain amount of dust composition can be diluted and stirred in water for sprinkling, because of differences of adsorption, viscosity, density and polarity, after the composition is coated on flying dust surface, the dust, the granular form dust and fine dust and other dusts can be prevented from flying.

Owner:清乾科技(佛山市)有限公司

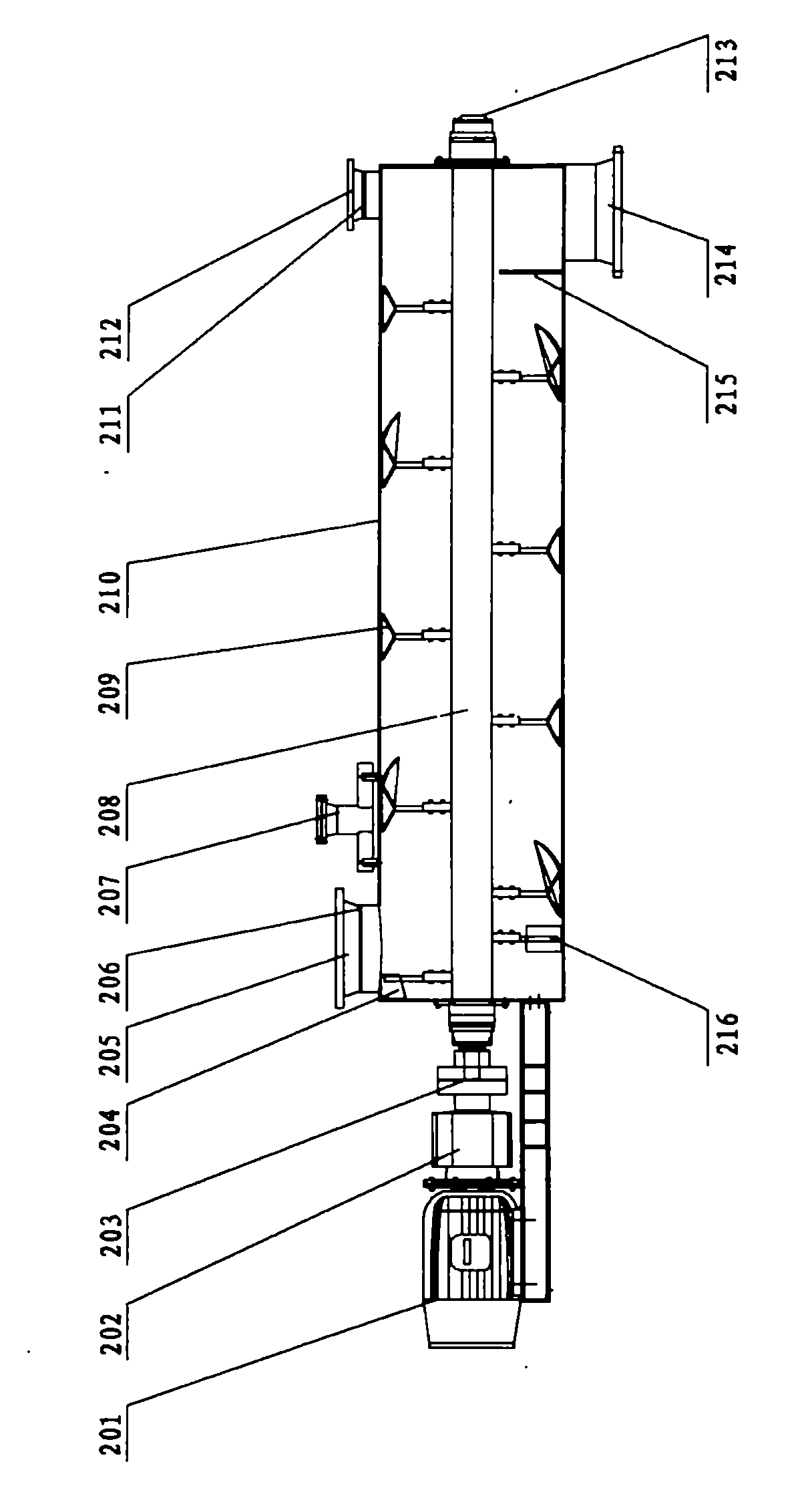

Preparation method of high-temperature oil-coal slurry

InactiveCN101829515ASolve the technical problem that it is difficult to completely dissolve in oil-coal slurrySolve the blockageMixing methodsRotary stirring mixersGranularityEngineering

The invention relates to a preparation method of high-temperature oil-coal slurry, which comprises the following steps of: (1) conveying pulverized coal from a pulverized coal storage tank into a horizontal solid-liquid mixer through a pulverized coal feeding hole to mix with solvent oil which is sprayed in from a high-temperature solvent tank through a liquid feeding hole, discharging the pulverized coal through a discharging hole of the horizontal solid-liquid mixer and conveying to a coal slurry stirring kettle; (2) further homogenizing the oil-coal slurry in the coal slurry stirring kettle under the action of a stirring paddle; and (3) extracting the oil-coal slurry from the coal slurry stirring kettle through a coal slurry discharging pipeline, wherein one part of the oil-coal slurry is returned to the coal slurry stirring kettle by the coal slurry discharging pipeline, and the rest is conveyed to a downstream liquefaction reaction system by a reaction material conveying pipeline. The method can solve the problem that coal particles of small granularity are hardly and fully dispersed in the solvent oil to form even high-temperature oil-coal slurry, and can be used for rapidly preparing qualified coal slurry and continuously producing coal slurry by a coil liquefaction reaction.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

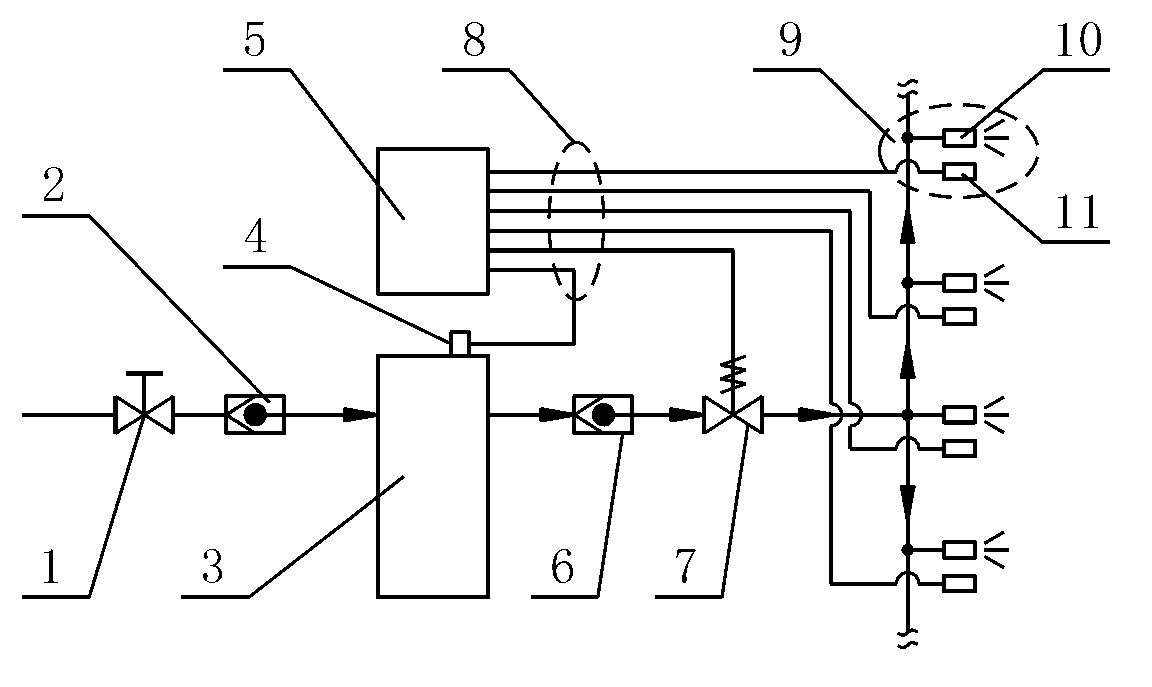

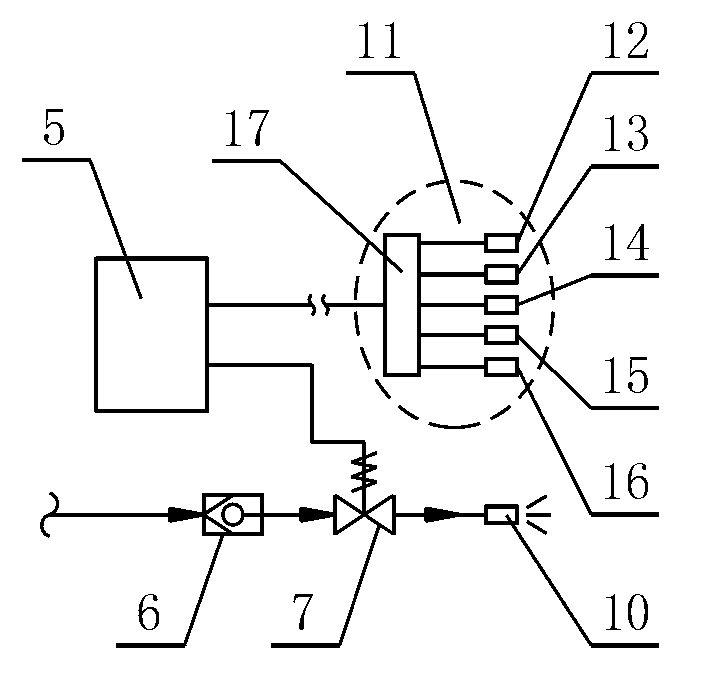

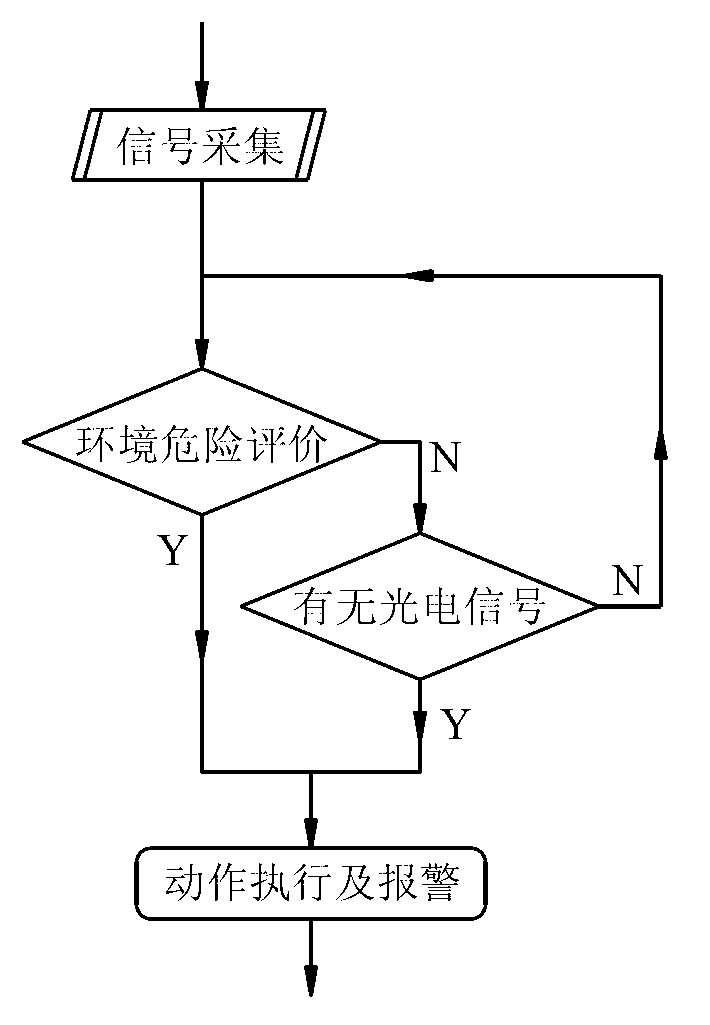

A system and a method for active fire extinguishing and explosion suppression in coal mine workplaces

ActiveCN103285541AIncreases the probability of successful execution of explosion suppressionSimple structureFire rescueActive monitoringGas composition

A system and a method for active fire extinguishing and explosion suppression in coal mine workplaces are especially suitable for monitoring, early warning, and actively inserting and inhibiting in spaces that are prone to fire and explosion hazards, and the spaces comprise coal mine workplaces that generate gas and coal dust, and gas and coal dust accumulated areas in coal storage bunkers, and the like. Quantitative evaluation of environmental space explosion hazard degrees is obtained by the system through active monitoring and comprehensive evaluating of a plurality of parameters such as gas composition, dust concentrations, ambient temperature, photoelectric signals, etc. in a working environment, thereby providing theory criteria for action execution of explosion suppression mechanisms. According to the invention, real-time monitoring of environmental parameters of gas and coal dust in workplaces and advanced quantitative determination of explosion hazard degrees are realized, and therefore effective explosion suppression measures are adopted proactively before an explosion hazard occurs, and the probability of successful execution of explosion suppression is increased.

Owner:CHINA UNIV OF MINING & TECH

Environment-friendly dust-removing air supply sprayer provided with silencer

ActiveCN102357438AExtended service lifeIncreasing the thicknessPump componentsUsing liquid separation agentSprayerDust emission

The invention discloses a dust-removing air supply sprayer provided with a silencer, belonging to the technical field of an air supply sprayer. The environment-friendly dust-removing air supply sprayer provided with the silencer has the technical key points that the environment-friendly dust-removing air supply sprayer comprises an axial flow fan; an air outlet arranged in front of the axial flow fan is connected with a spray cylinder; a silencing ring is sheathed in the spray cylinder; the external diameter of the silencing ring is less than the internal diameter of the spray cylinder; a silencing area is formed between the spray cylinder and the silencing ring; and the silencing area is internally filled with sound absorption cotton. The invention aims at providing the dust-removing air supply sprayer provided with the silencer, which is compact in structure and good in use effect; and the environment-friendly dust-removing air supply sprayer is used for removing and inhibiting dust for the dust pollution caused by a large open coal mine and fugitive dust emission pollution caused by coal storage yard, transportation, crushing and the like.

Owner:广东风华环保设备股份有限公司

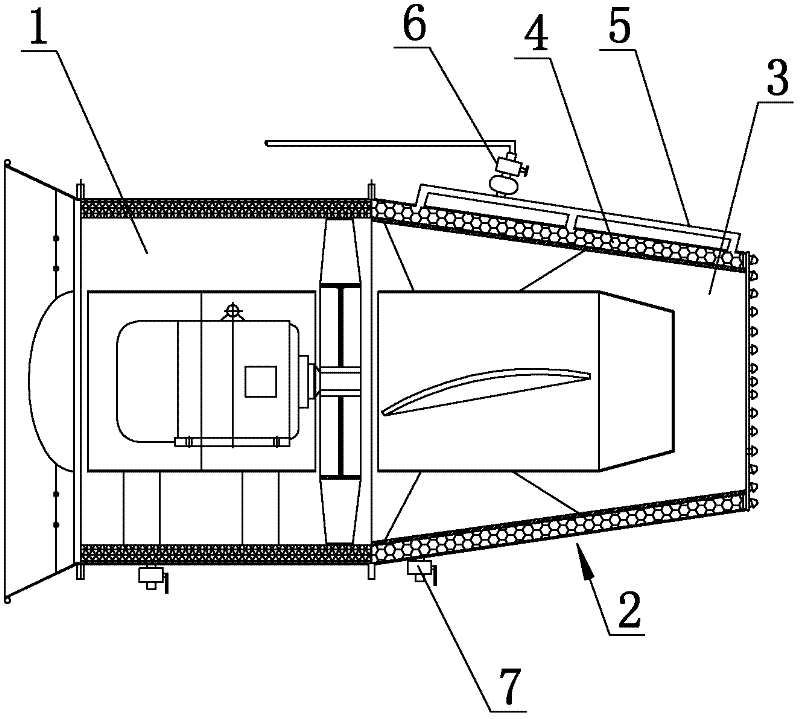

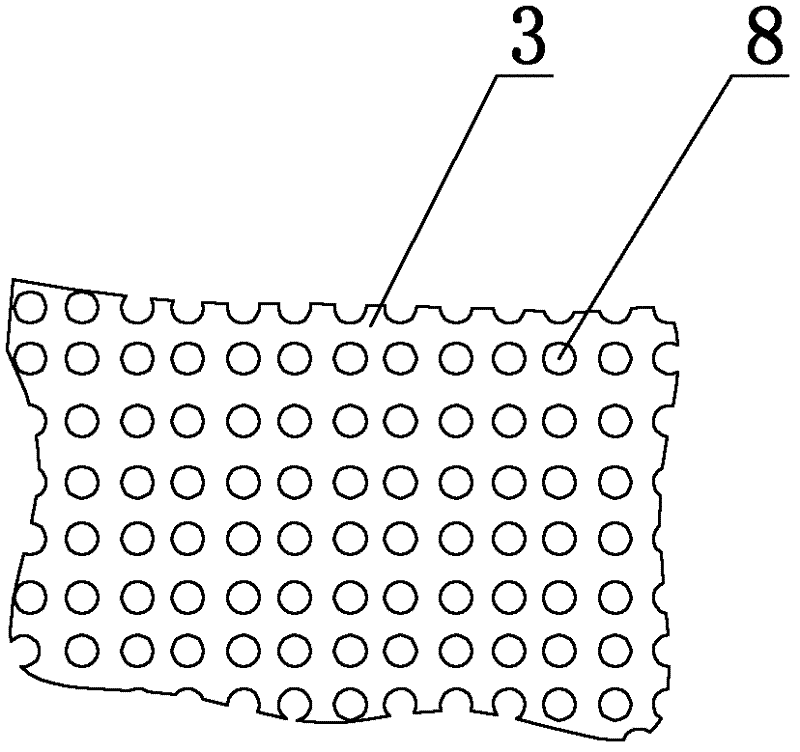

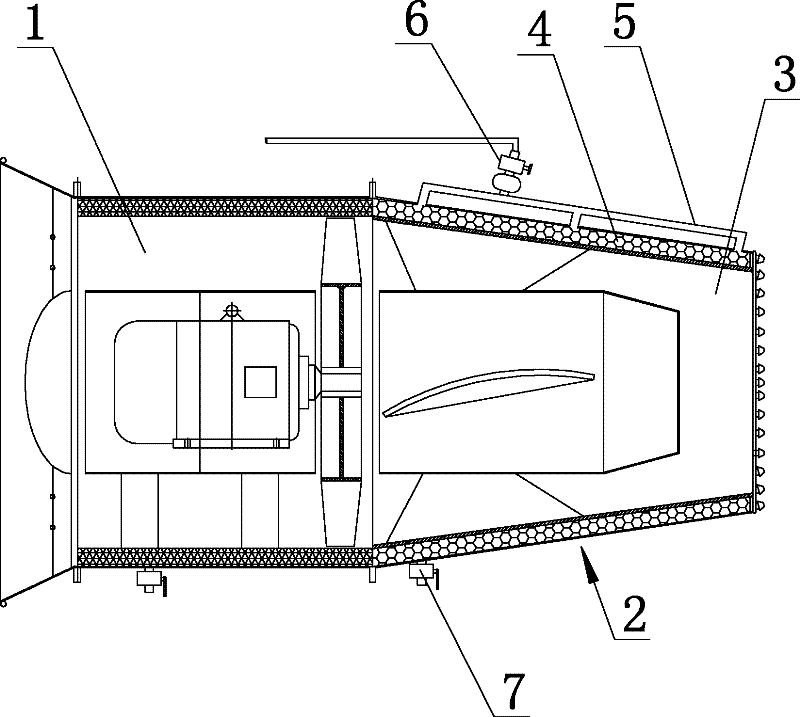

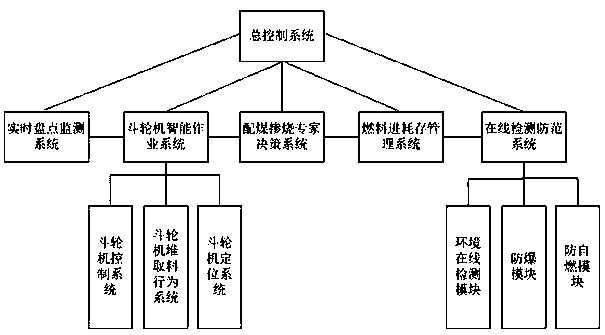

Digital coal yard intelligent control scheme based on GPU computing

ActiveCN108919761APrecise positioningUnmanned operationCo-operative working arrangementsLogisticsSpontaneous combustionLaser scanning

The invention discloses a digital coal yard intelligent control scheme based on GPU computing. The digital coal yard intelligent control scheme comprises a master control system, a real-time inventorymonitoring system, a bucket intelligent operation system, an coal blending mix-burning expert decision-making system, a fuel input and consumption management system and an online detection and prevention system. The digital coal yard intelligent control scheme is characterized in that the master control system is located in a master control room, is composed of a parallel computer group and performs big data calculation by using a GPU; the real-time inventory monitoring system acquires 4D data of a coal pile through laser scanning and transmits the 4D data to the master control system for coal pile parameter identification and judgment, and then simulates to generate a dynamic and visible 4D model; the bucket intelligent operation system performs the collection and transmission of data such as mass, temperature, humidity, heat, impurity of the coal pile and the position of a bucket through an intelligent chip reading device; the coal blending mix-burning expert decision-making systemis used for calculating a blending scheme according to the current situation of coal storage in a coal yard to form a cost optimization ranking table; the fuel input and consumption management systemperforms storage and coding by a SQL Server database, and the calculation amount is output to the master control system for deployment; and the online detection and prevention system comprises an environmental online detection module, an explosion-proof module and an anti-spontaneous combustion module. The digital coal yard intelligent control scheme based on GPU computing uses the system integration and heterogeneous data fusion technology to realize the fusion and sharing of relational data, real-time data and spatial data.

Owner:HUNAN CHANGZHONG MACHINERY

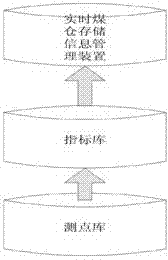

Method and system for displaying fired coal quality in real time

InactiveCN104765743AAvoid Burnout AccidentsDoes not affect calculationData processing applicationsSpecial data processing applicationsSafety instrumented systemStart time

The invention discloses a method for displaying fired coal quality in real time. The method comprises the following steps: searching for demanded measured point data from an SIS (Safety Instrumented System) system by a measured point base via a thermal power plant system and storing searched demanded measured point data; analyzing demands by an index base according to working conditions, acquiring one or more measured point data from the measured point base, calculating index data according to an index formula and measured data acquired from the measured point base, and transmitting the generated index data to a typical working condition index database; in real time processing and updating coal storage information of each coal bunker by a real-time coal storage information management device according to the index data, wherein the coal storage information involves in beginning and terminating time of coal bed formation; acquiring the corresponding coal quality information of the coal bed including real-time fired coal by matching the beginning and terminating time with the manually inputted coal supply information, thereby obtaining the real-time fired coal heat value of the coal bunker. According to the displaying method, coal quality conditions at present and after some time can be absolutely clear.

Owner:ZHEJIANG DATANG WUSHASHAN POWER GENERATION CO LTD

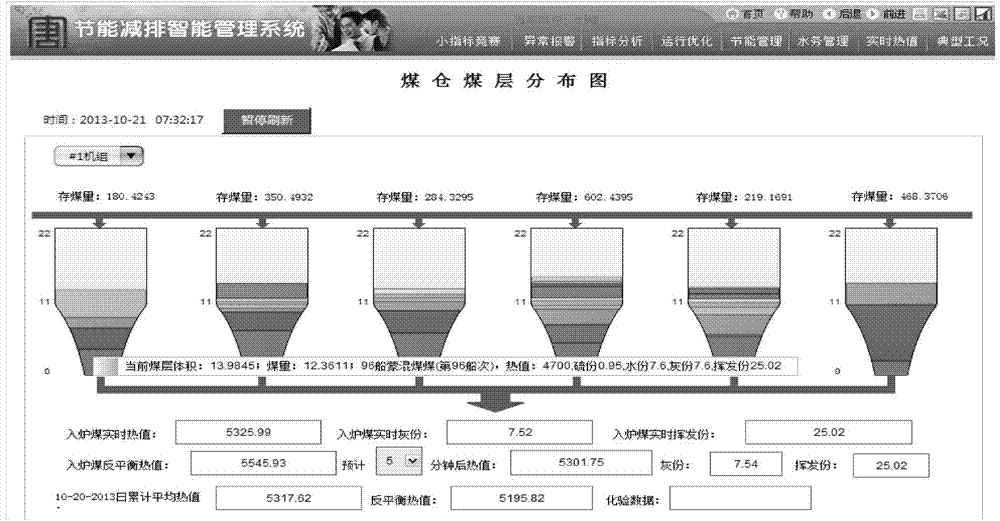

High-temperature water source heat pump unit

InactiveCN103697613AReduce shipping costsSave the cost of coal storage siteFluid heatersCompression machines with cascade operationEnvironmental resistanceSlag

Disclosed is a high-temperature water source heat pump unit. Single-step compression refrigeration cycle and cascaded refrigeration cycle combined linkage technology is adopted, temperature of outgoing water of the unit can be increased to be higher than 85 DEG C by utilizing a low-temperature heat source to lower a compression ratio of the unit under a high-temperature working condition, efficiency of the unit is improved, working conditions of compressors are improved, and running reliability of the unit under the high-temperature working condition is guaranteed. The high-temperature water source heat pump unit is composed of a first compressor, a first heat exchanger, a first throttling element, a liquid storage device, a first one-way valve, a second one-way valve, an intermediate heat exchanger, a first electromagnetic valve, a second electromagnetic valve, a second compressor, a second throttling element, a second heat exchanger and a connecting pipeline. By the high-temperature water source heat pump unit, high environmental-protection benefit and economic benefit can be achieved, waste gas and waste residues of a coal fired boiler are avoided from polluting surrounding environment, and coal transporting cost, coal storage site cost, dedusting cost, coal slag transporting and processing cost and the like are omitted; investment in building a heating system is saved, and the high-temperature water source heat pump unit is especially suitable for being used for building a central air conditioning heating system in northern cold areas.

Owner:JINGUODA TECH HUNAN

Coal gasification device and process capable of combusting organic effluent sewage

ActiveCN103695039AAvoid parkingIncrease reaction spaceCombined combustion mitigationGranular/pulverulent flues gasificationCoal waterCombustor

The invention belongs to a coal gasification device and process capable of combusting organic effluent sewage. The coal gasification device comprises an organic effluent sewage storage tank, an oxygen storage tank, a dry pulverized coal storage tank and a water storage tank, wherein the dry pulverized coal storage tank and the water storage tank are respectively connected with the inlet of a coal water slurry storage tank, outlets of the organic effluent sewage storage tank, the oxygen storage tank, the dry pulverized coal storage tank and the coal water slurry storage tank are respectively connected with a burner part at the top of a combustor; the burner part is connected with the interior of a membrane type water cooling film, the oxygen storage tank is connected with an oxygen and gas increasing nozzle arranged at the middle of the combustor through a pipeline, the water storage tank is connected with the inlet of the membrane type water cooling wall, a connecting cylinder is arranged at the bottom of the combustor, penetrates through the top of a water cooler and is arranged at the inner-upper part of the water cooler, a synthetic gas outlet is formed in the upper part of one side of the water cooler, a deslagging hole is formed in the lower part of the water cooler, and a multilayer baffling boosting cylinder is arranged at the outer part of the connecting cylinder. The coal gasification device has the advantages of strong coal type adaptability, high coal gasification efficiency, and cleanness and good quality of synthetic gas, and is capable of treating the organic effluent sewage.

Owner:HENAN XINLIANXIN FERTILIZER +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com