Patents

Literature

32results about How to "Control spillover" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

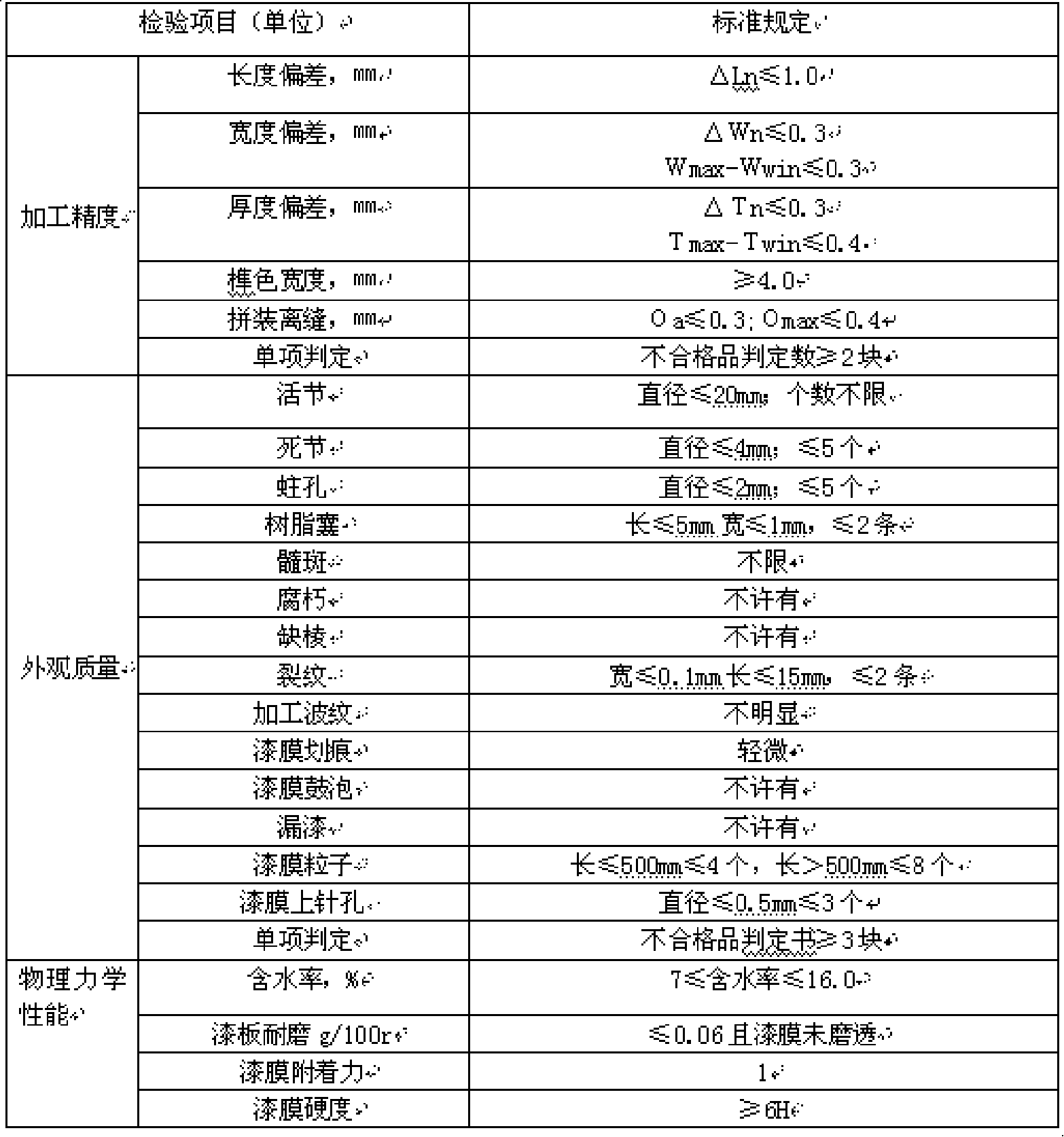

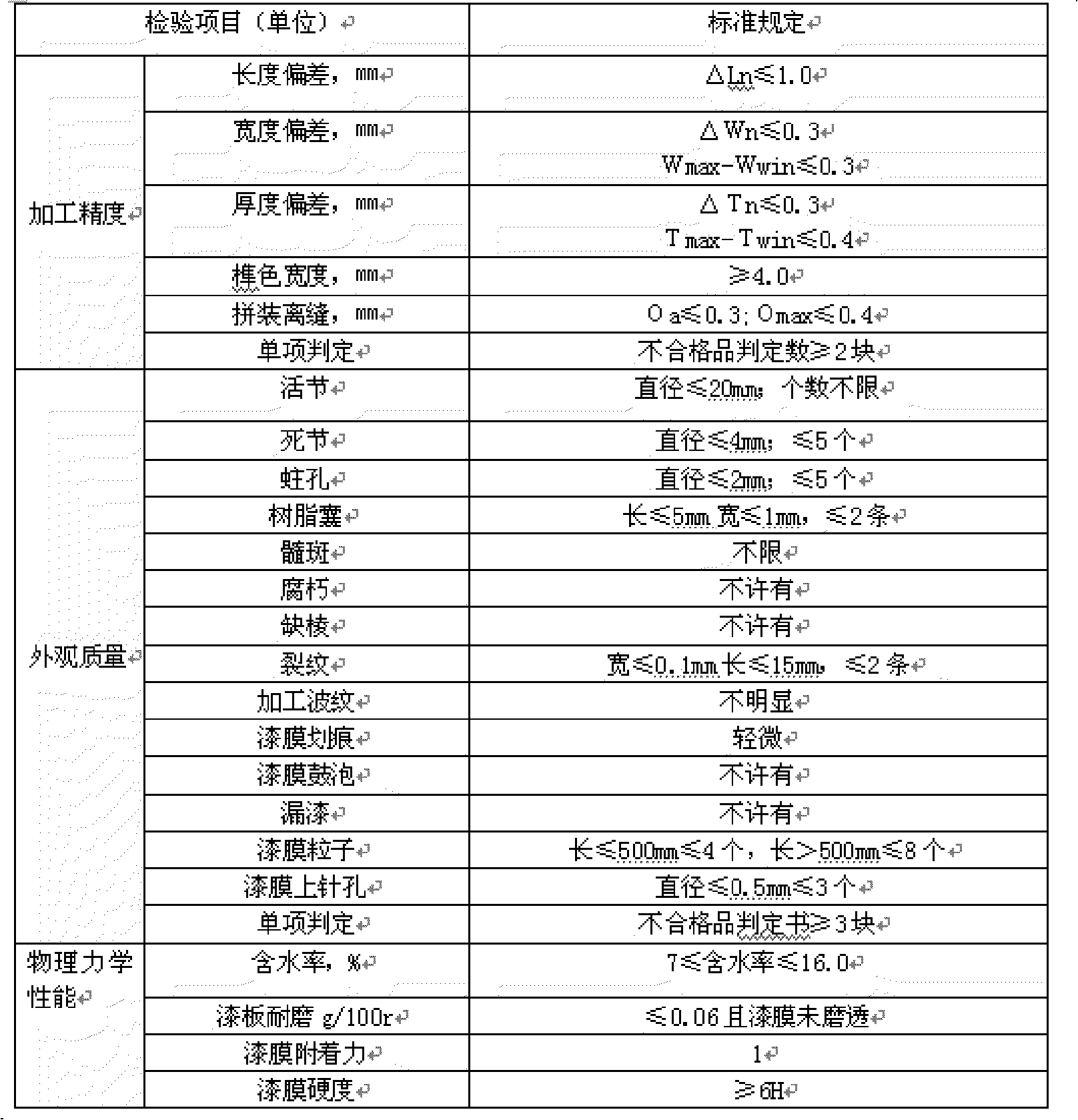

Method for producing wooden floor with platinum crystal surface

InactiveCN101301764ASolve the problem of insufficient adhesionIncrease pressureLiquid surface applicatorsWood treatment detailsPlatinumLacquer

The invention discloses a production method for a platinum crystal face wood floor, which comprises the production steps as follows: drying and curing of floor blank, blank processing, primer and paint painting. The invention adopts a vertical-lubrication penetration roller spraying technique, carries out the pre-heating disposal, drying disposal, balance disposal, humidifying treatment, temperature reduction kiln outgoing and curing to the floor blank, then processes the blank and paints the primer; the paint is then coated by adopting eight-bottom and four-surface so as to gain a finished product. The platinum crystal face wood floor prepared by the invention has the advantages that the paint adhesion of the tree with high grease (oil) content is improved; the floor has ultra-strong adhesion from the interior of the wood to the surface; a production process of eight-bottom and four-surface is adopted to combine an elastic, abration and friction resistance environmental protection paint; therefore, the surface filling of the floor is saturated, clear and natural, the chamfers are smoother and the wood floor is more scraping- resistant and wear-resistant; the one-off qualification rate of the product is improved and achieves 99.5 percent, thus improving the quality of the product.

Owner:浙江上臣家居科技有限公司

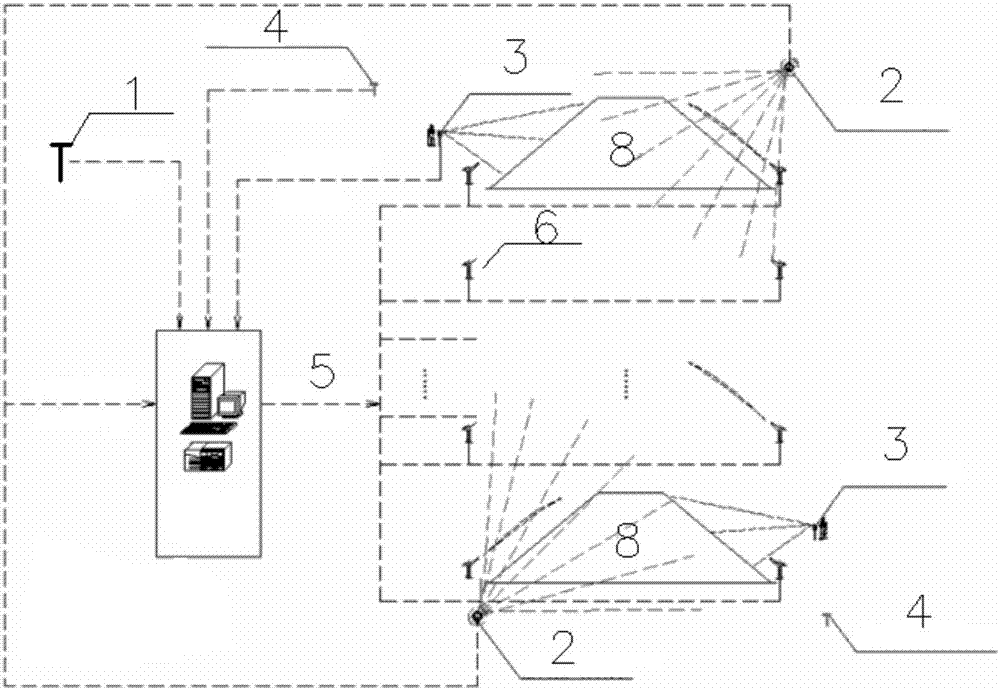

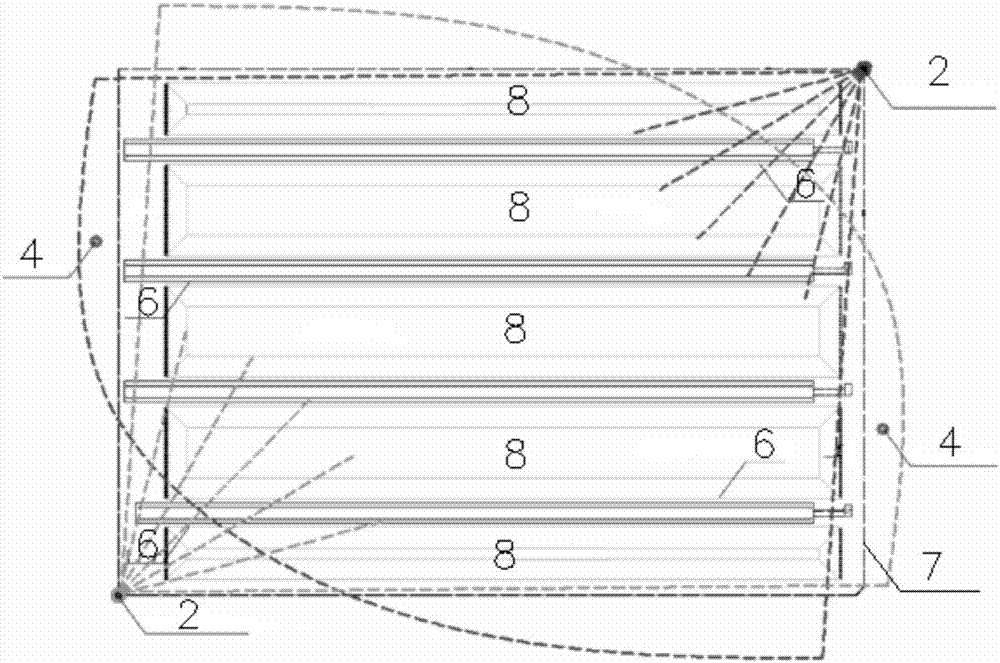

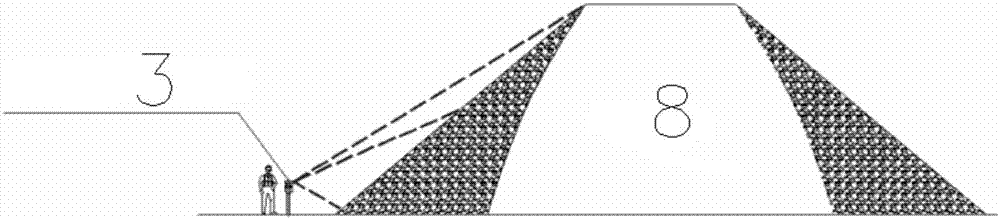

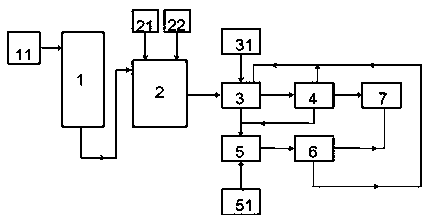

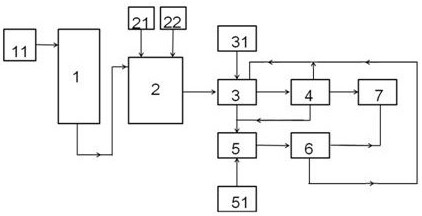

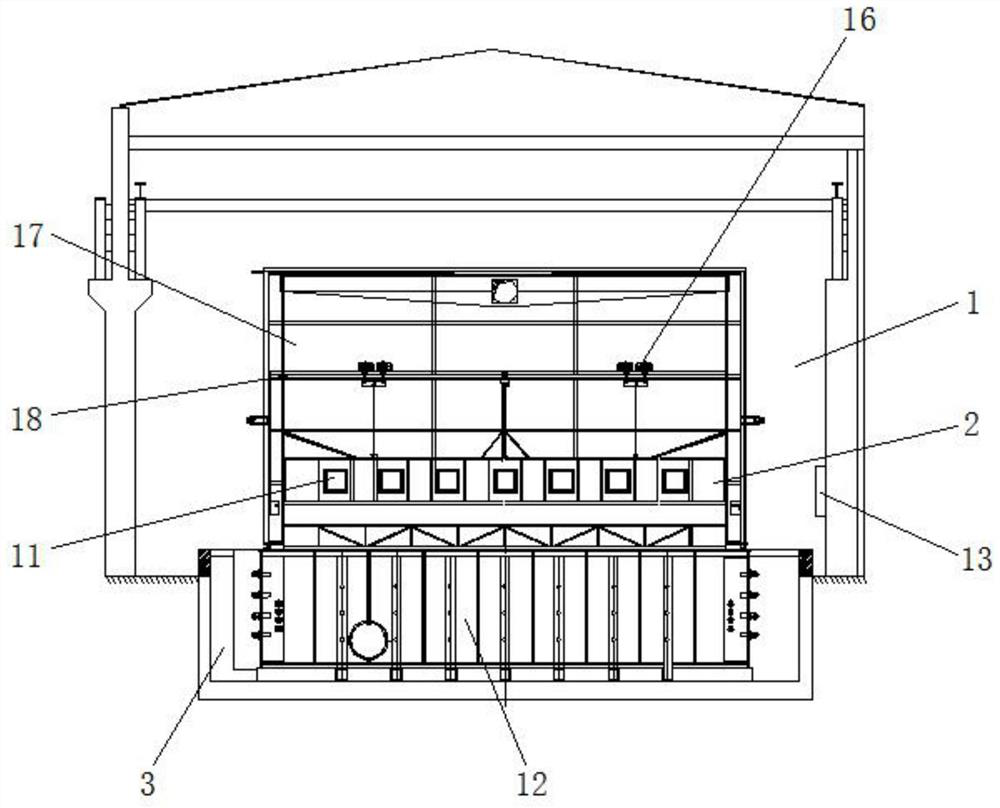

Automatic dust prevention and suppression system of coal storage yard

PendingCN107300903AAchieve dustproof effectControl spilloverTotal factory controlProgramme total factory controlSprinkler systemData acquisition

The invention relates to the technical field of environmental protection. An automatic dust prevention and suppression system of a coal storage yard comprises a water sprinkling system for the coal storage yard, and is characterized by further comprising a coal storage yard data acquisition system for acquiring environmental parameters of the coal storage yard, wherein the coal storage yard data acquisition system is connected with a signal processing system; the signal processing system is connected with the water sprinkling system through a control actuation system. According to the automatic dust prevention and suppression system of the coal storage yard, the environmental parameters such as the dust content and the moisture content of the storage yard can be mastered in real time through the coal storage yard data acquisition system, and a working state of the water sprinkling system is adjusted in real time through the signal processing system according to changes of the surrounding environmental parameters. The automatic dust prevention and suppression system of the coal storage yard realizes intelligent dust suppression of the coal storage yard, so that green and environmentally-friendly transformation and upgrading of the coal storage yard can be realized to push sustainable development of an enterprise with the coal storage yard.

Owner:CCCC THIRD HARBOR CONSULTANTS +1

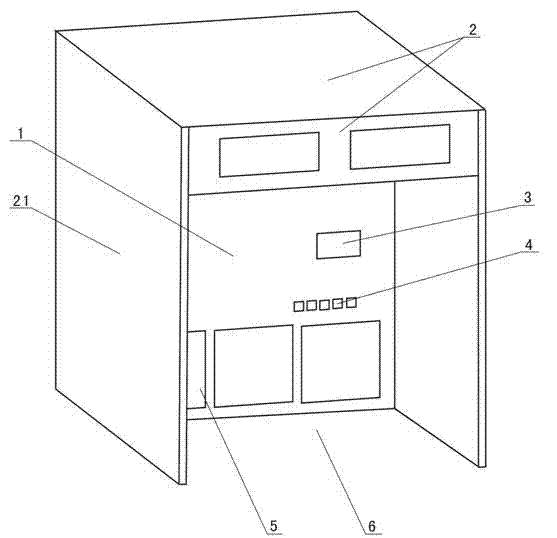

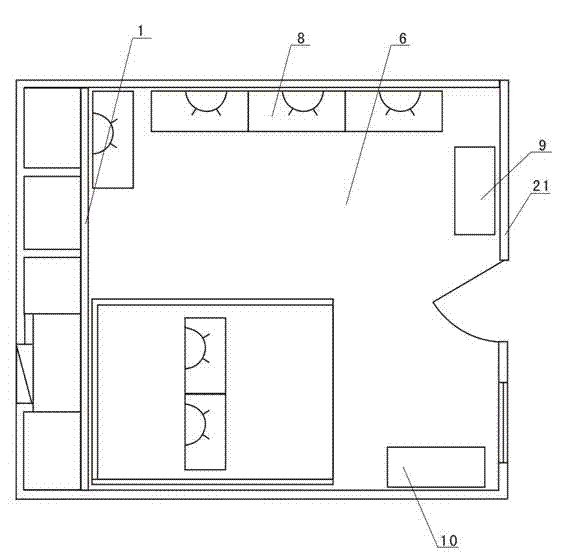

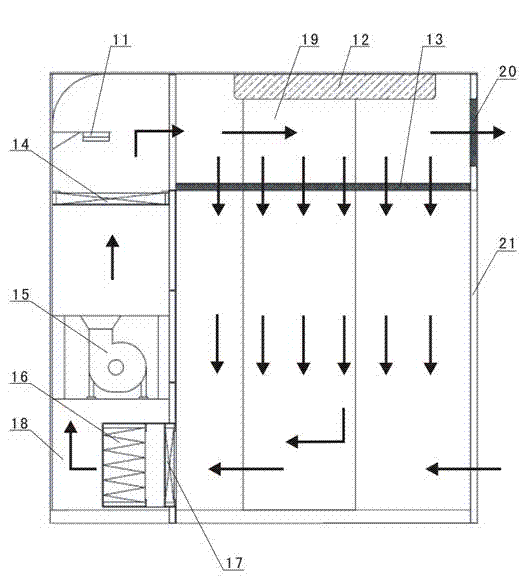

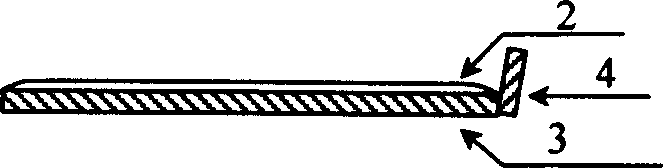

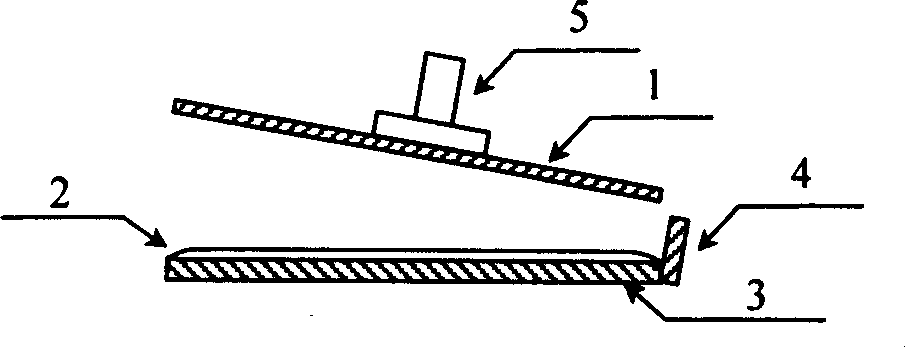

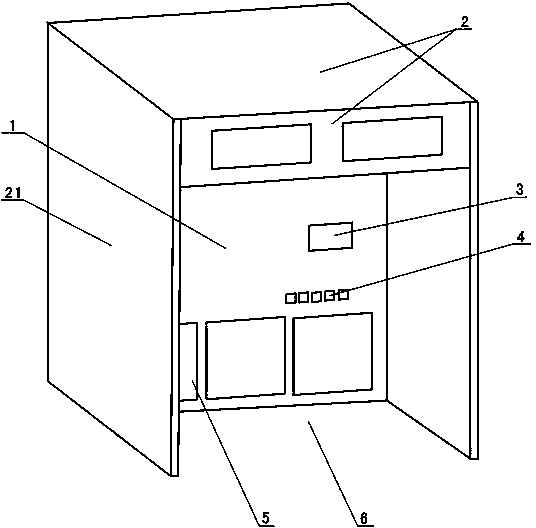

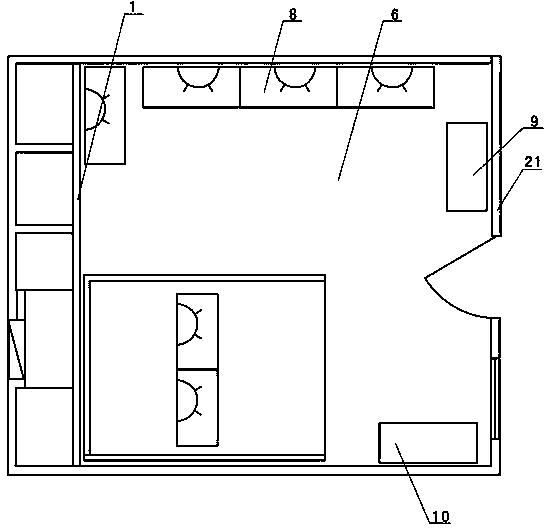

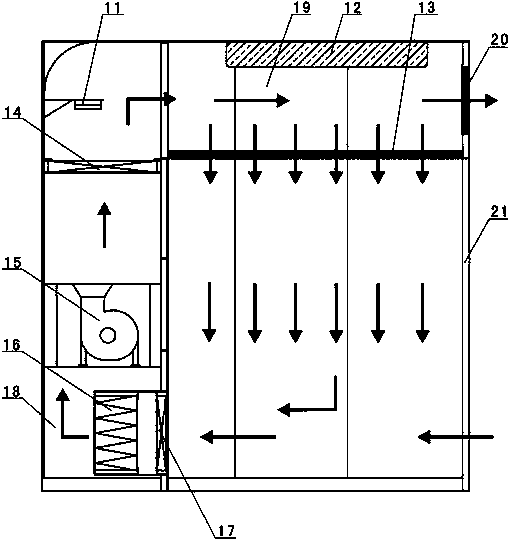

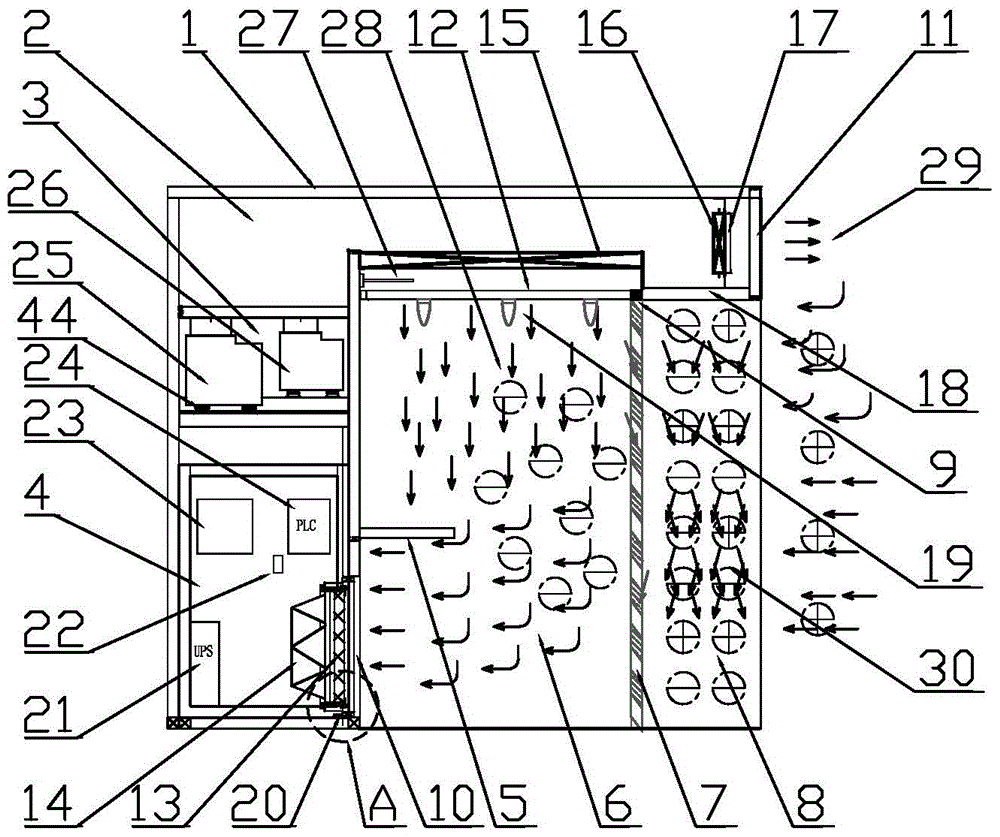

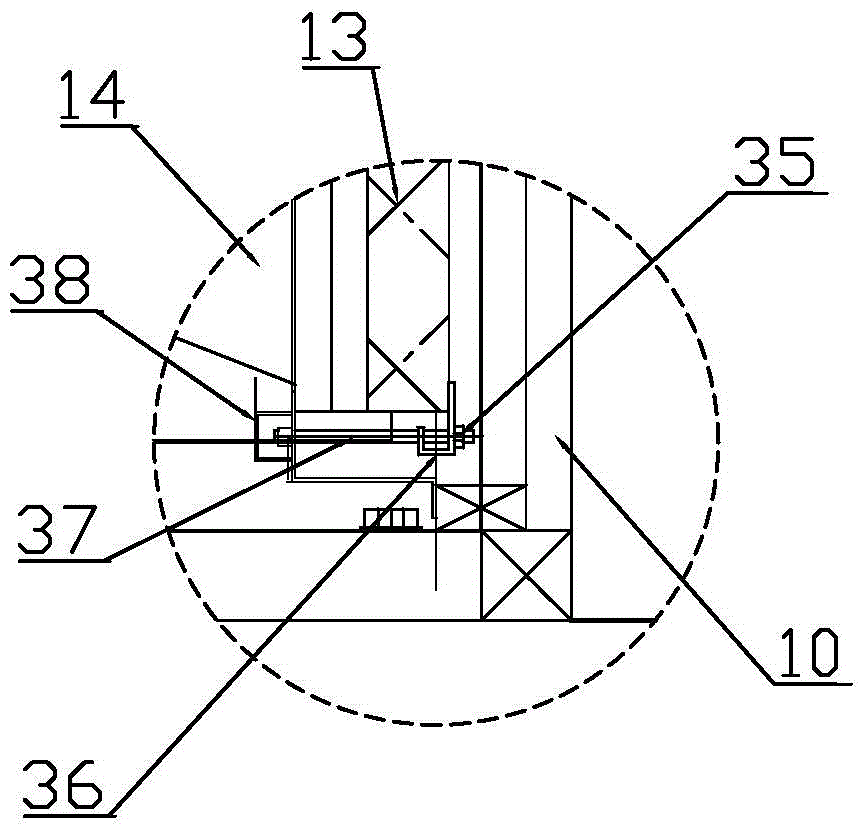

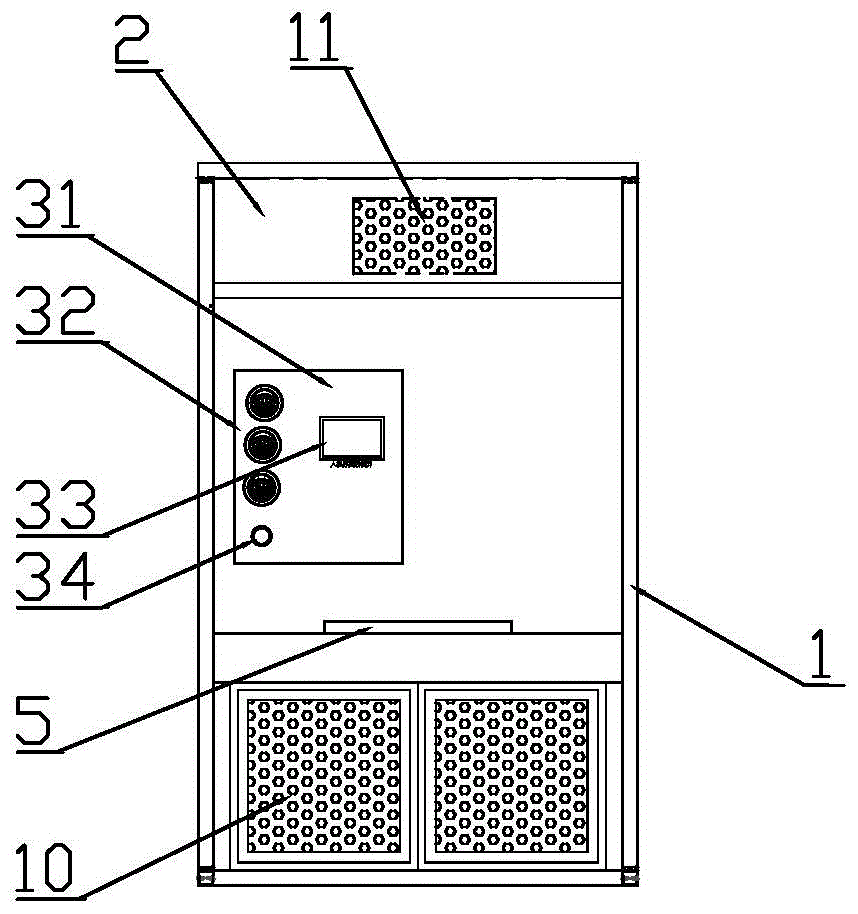

Digital intelligent integrated weighting chamber

ActiveCN102828627AImprove cleanlinessClean working environmentDispersed particle filtrationSpace heating and ventilation safety systemsExhaust valveFrequency conversion

The invention discloses a digital intelligent integrated weighting chamber which comprises a combined wall and an air processing system, wherein an operation space is arranged in the combined wall; in the air processing system, an inward air inlet is arranged on the lower part of the combined wall; a fresh air valve is mounted at the inward air inlet; an air return opening is arranged at the bottom of the operation space; an air inlet of a primary filter is communicated with the air return opening; air flues between the primary filter, a medium filter, a frequency conversion fan, a high-efficiency filter and a plenum chamber are connected in turn; the plenum chamber is arranged at the top of the operation space; a self-circulation flow-equalizing membrane is mounted at a self-circulation air outlet of the plenum chamber; an outer circulation flow-equalizing membrane is mounted at an outer circulation air outlet of the plenum chamber; an outward air outlet is arranged on the upper part of the combined wall; and an exhaust valve is mounted at the outward air outlet. According to the digital intelligent integrated weighting chamber, air is purified by multi-stage filters and the purified air is blown out at a constant speed by the self-circulation flow-equalizing membrane on the plenum chamber, and a high-cleanness working environment is formed in the operation space.

Owner:SICHUAN CHUANJING CLEAN TECH HLDG

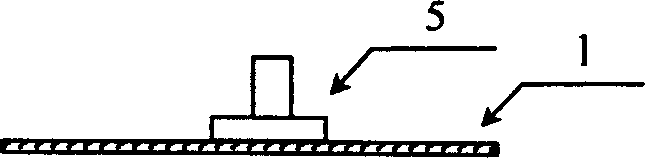

Automatic package method for solar battery sheet and anti-ratiation glass cover

InactiveCN1440083AControl spilloverAvoid pollutionFinal product manufactureSemiconductor devicesFree fallingOrthogonal coordinates

A method for automatically packaging a solar cell piece and a glass covering piece resistant against radiation is used for the solar cell in certain shapes and sizes. The method has the following steps: selecting the inclined packaging angle between the glass covering piece and the solar cell piece through an experiment, programming the moving traces of a packaging unit using a computer, determining the attitude of an absorbing disk which absorbs the glass covering piece, then downloading the documents of the moving traces and the controlling commands into the controller of a robot in orthogonal coordinate of three degrees of freedom so as to meet the specified requirements of the amount and size of the air bubbles using the packaging manner of free-falling body or inclined falling and ensure the relative positions between

Owner:SHANGHAI JIAO TONG UNIV

Vertical spinning dive pulverizer

InactiveCN101219408AIncrease production capacityExtended service lifeGrain treatmentsEngineeringPlunger

The invention relates to a vertical plunger pulverizer. A rotary main shaft of the pulverizer is vertically placed, a pulverizing chamber is divided into a grade-one pulverizing chamber and a grade-two pulverizing chamber that can pulverize soft and hard components of the materials respectively, which is more thoroughly pulverized than the existing technologies, thus reducing the pulverizing times due to re-pulverizing the oversized particles, saving time and improving the production ability of the machine. A hard abrasion resistant materials in an imbedded scaleboard of a shell can further improve the service life and security and stability of the machine; the size of particles can be adjusted according to different requirements; the invention is operated in a negative pressure, which effectively control the overflowing of the nanoids, and beneficial to environmental protection and generate small noise during the process.

Owner:汪大伟

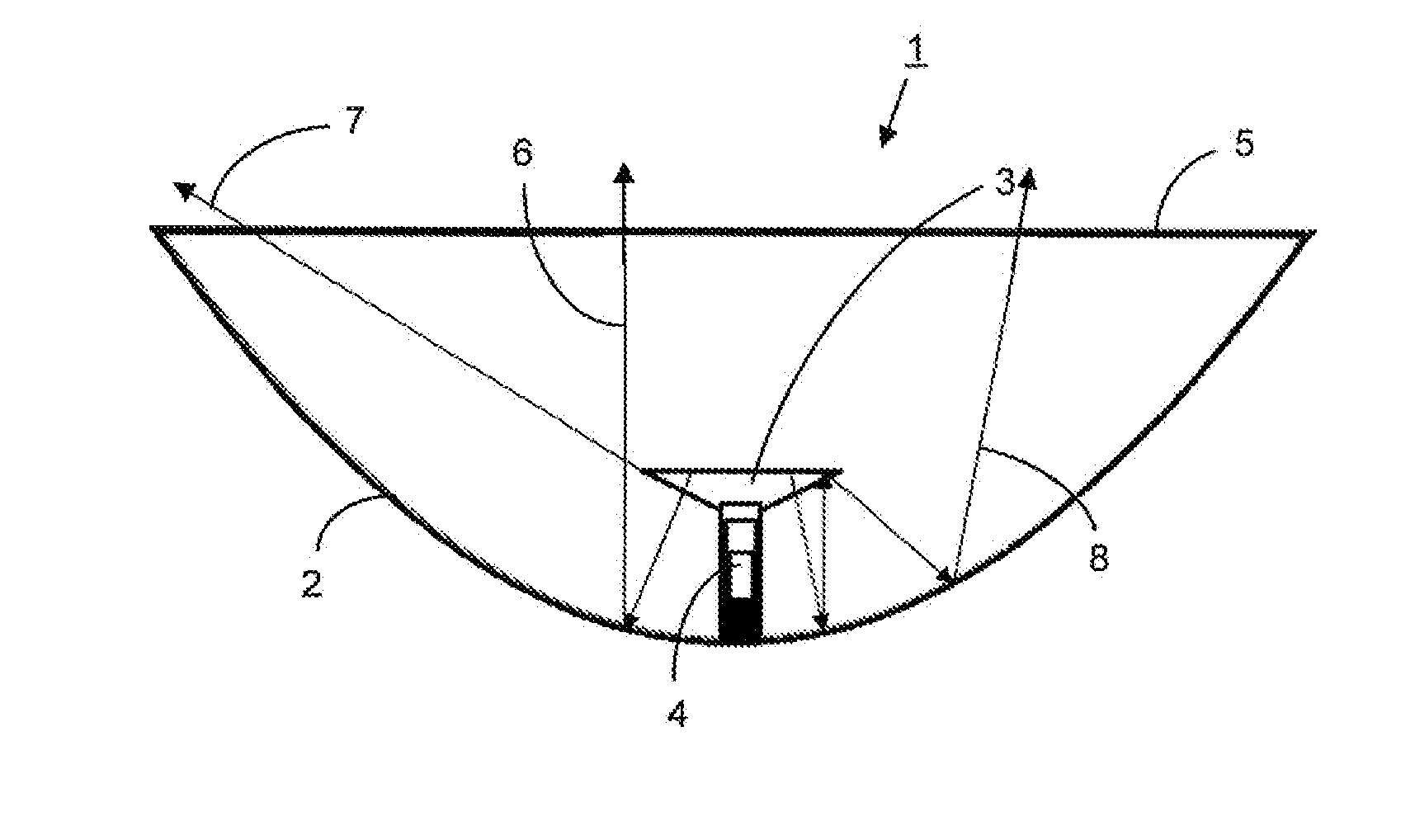

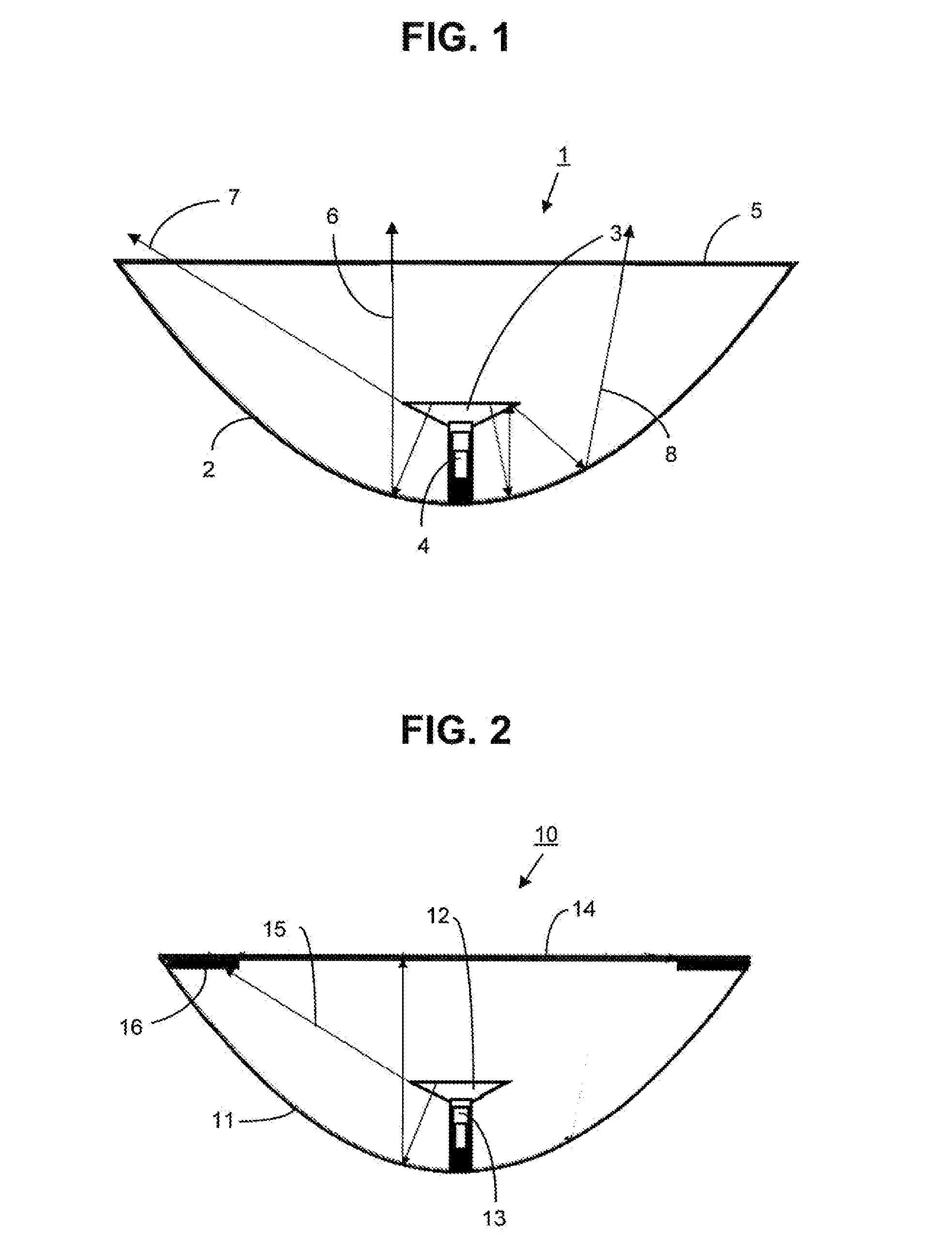

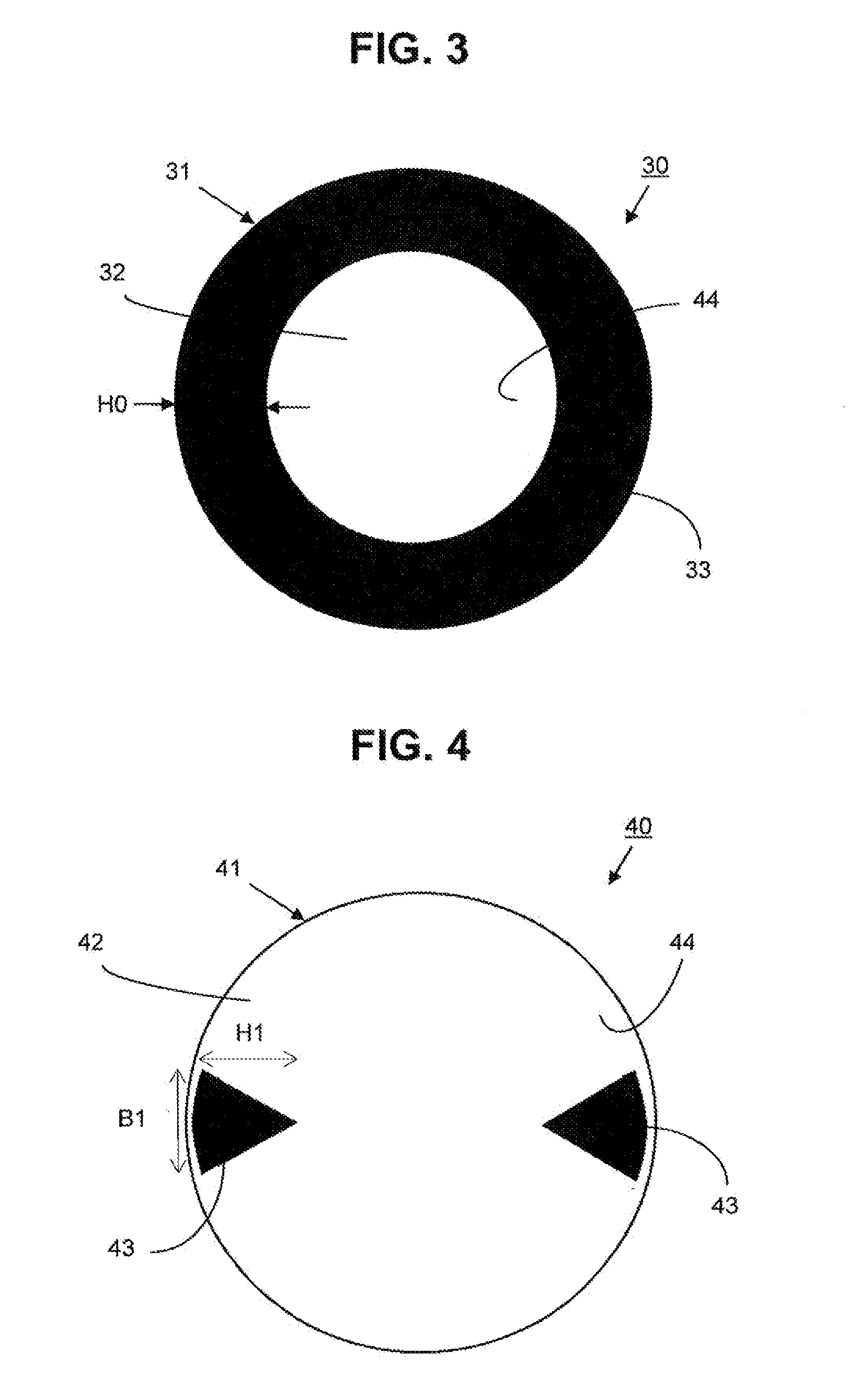

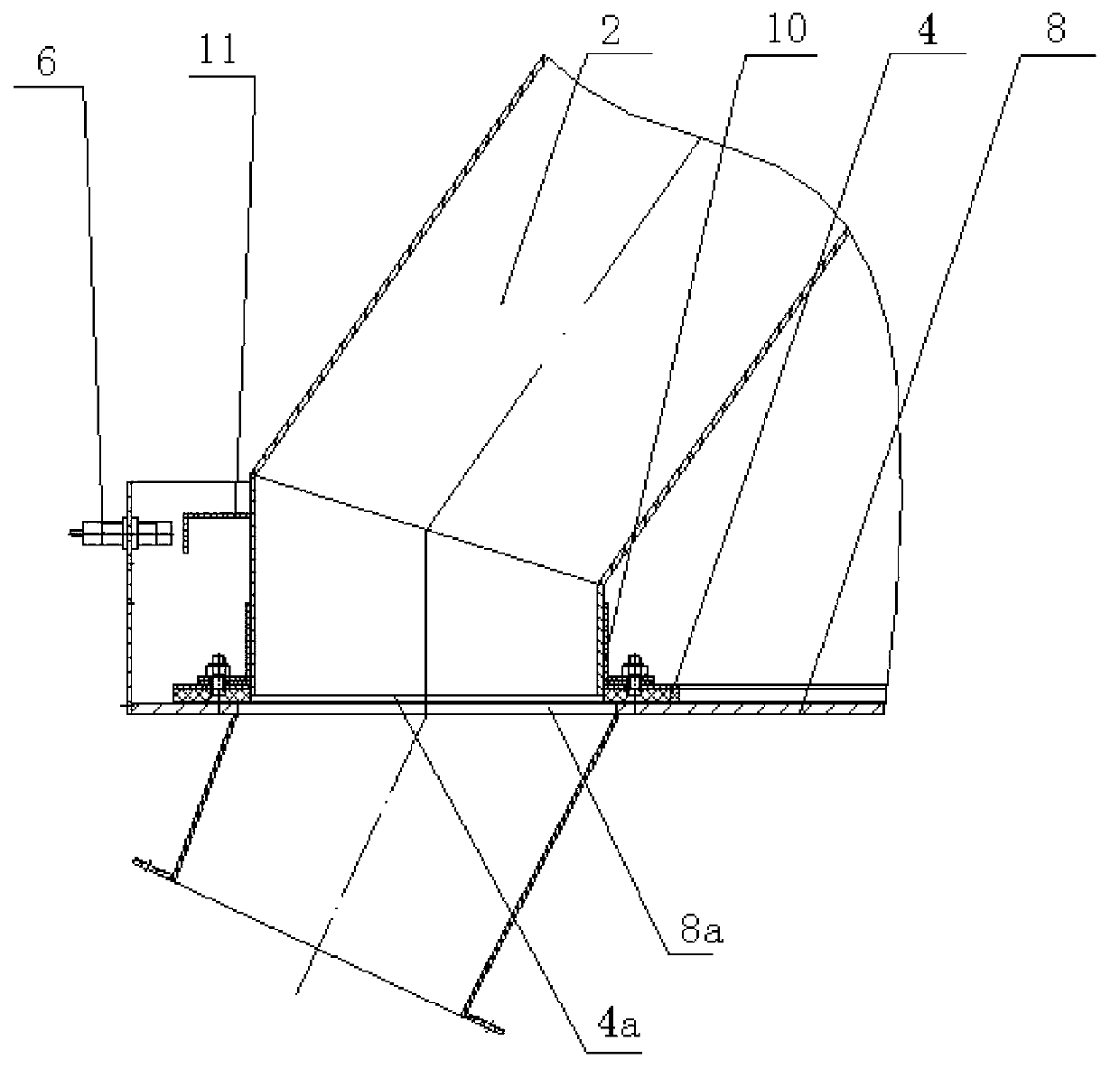

Radome for an antenna with a concave-reflector

ActiveUS20160087345A1Control spilloverMaintain performanceRadiating element housingsRadomeEngineering

Owner:ALCATEL LUCENT SHANGHAI BELL CO LTD

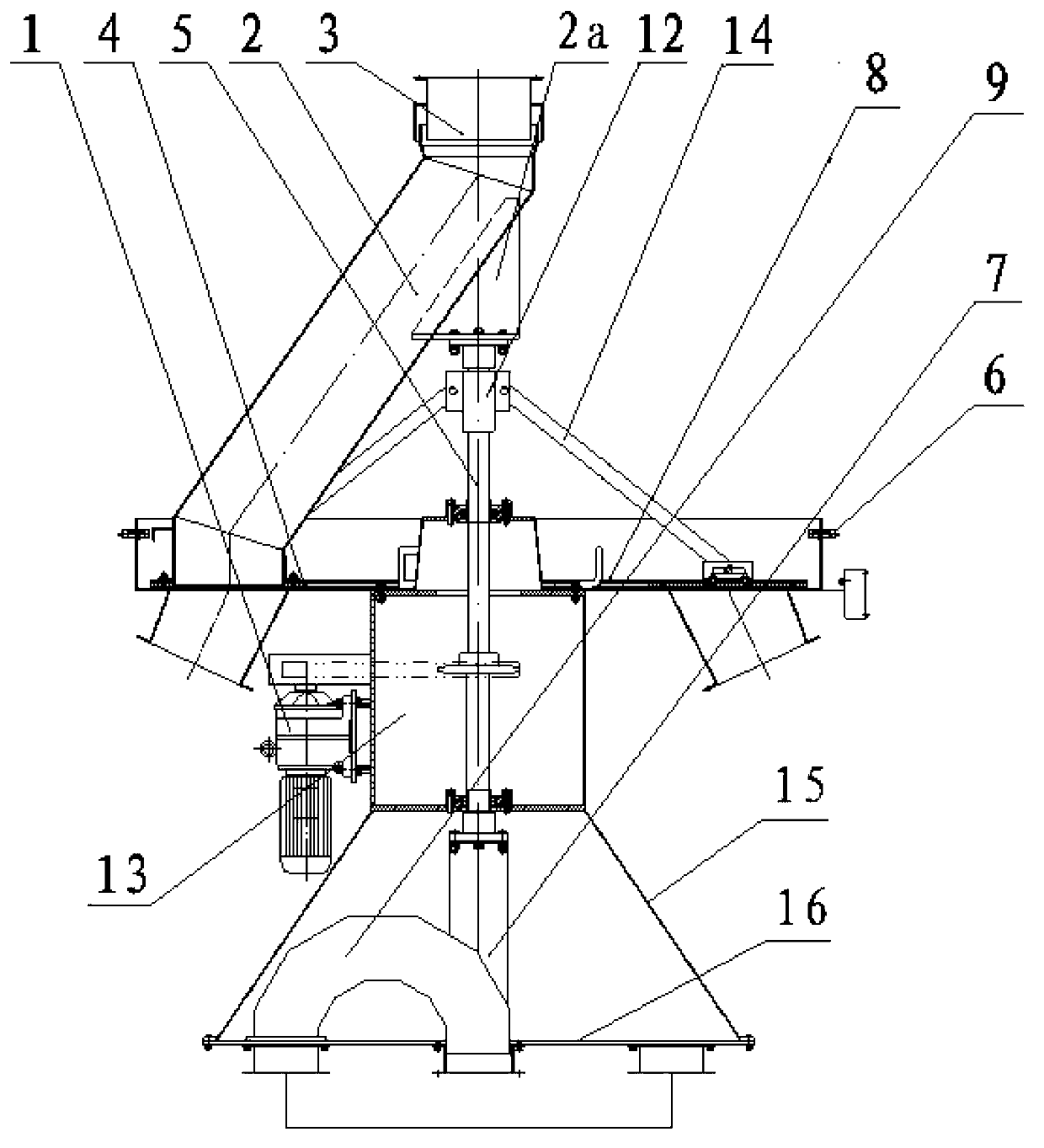

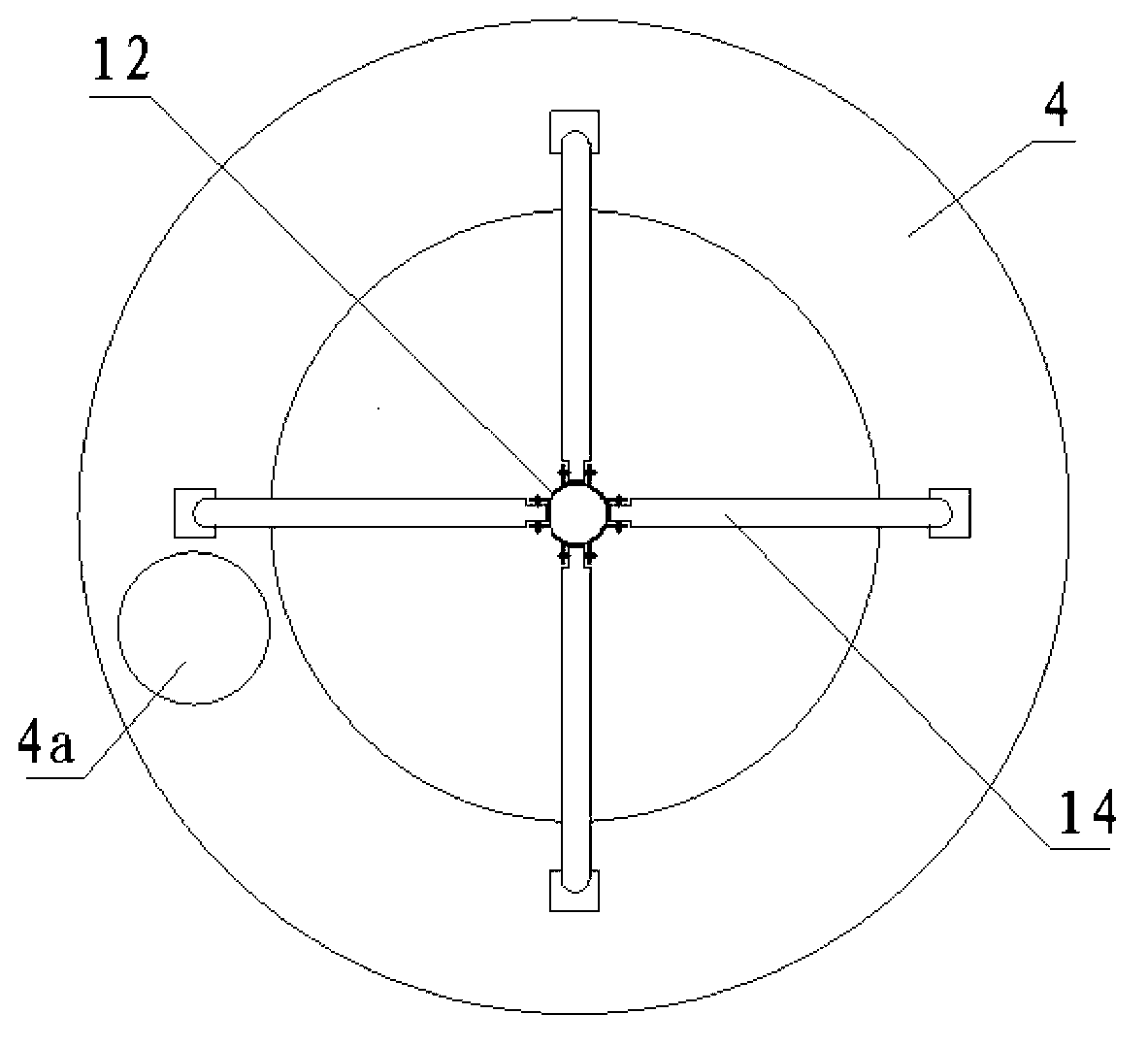

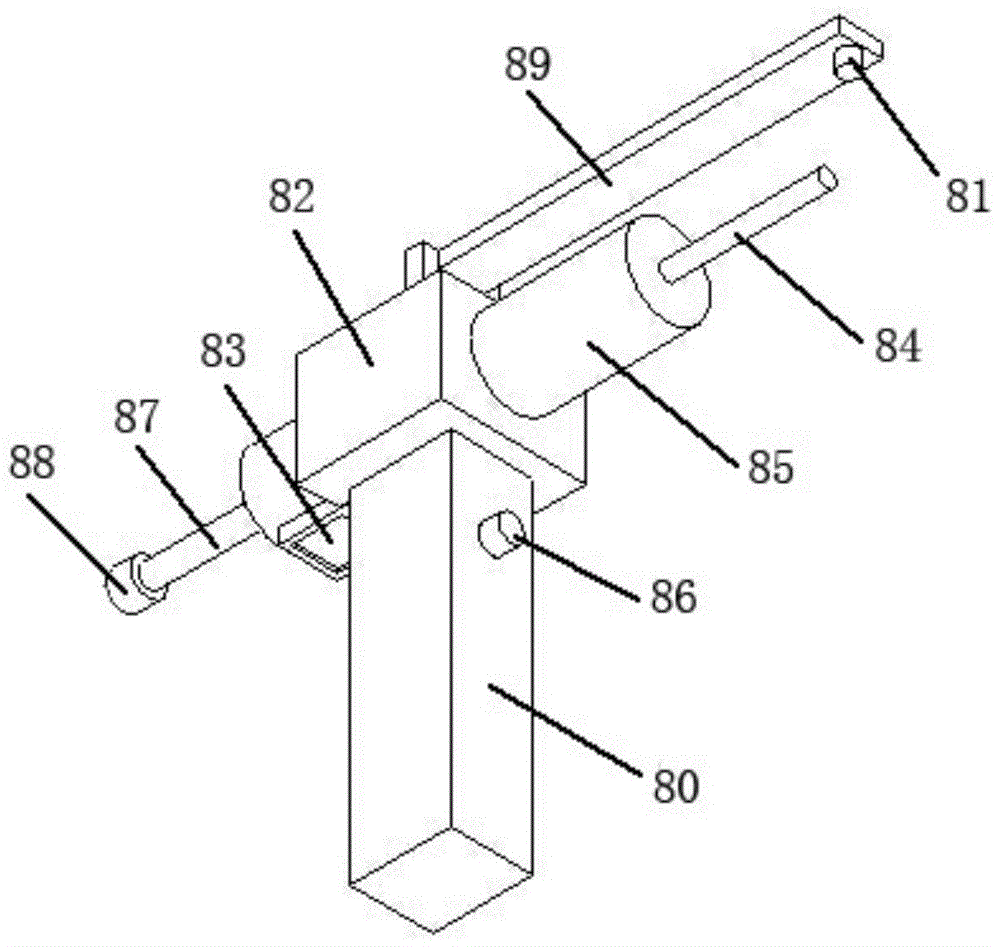

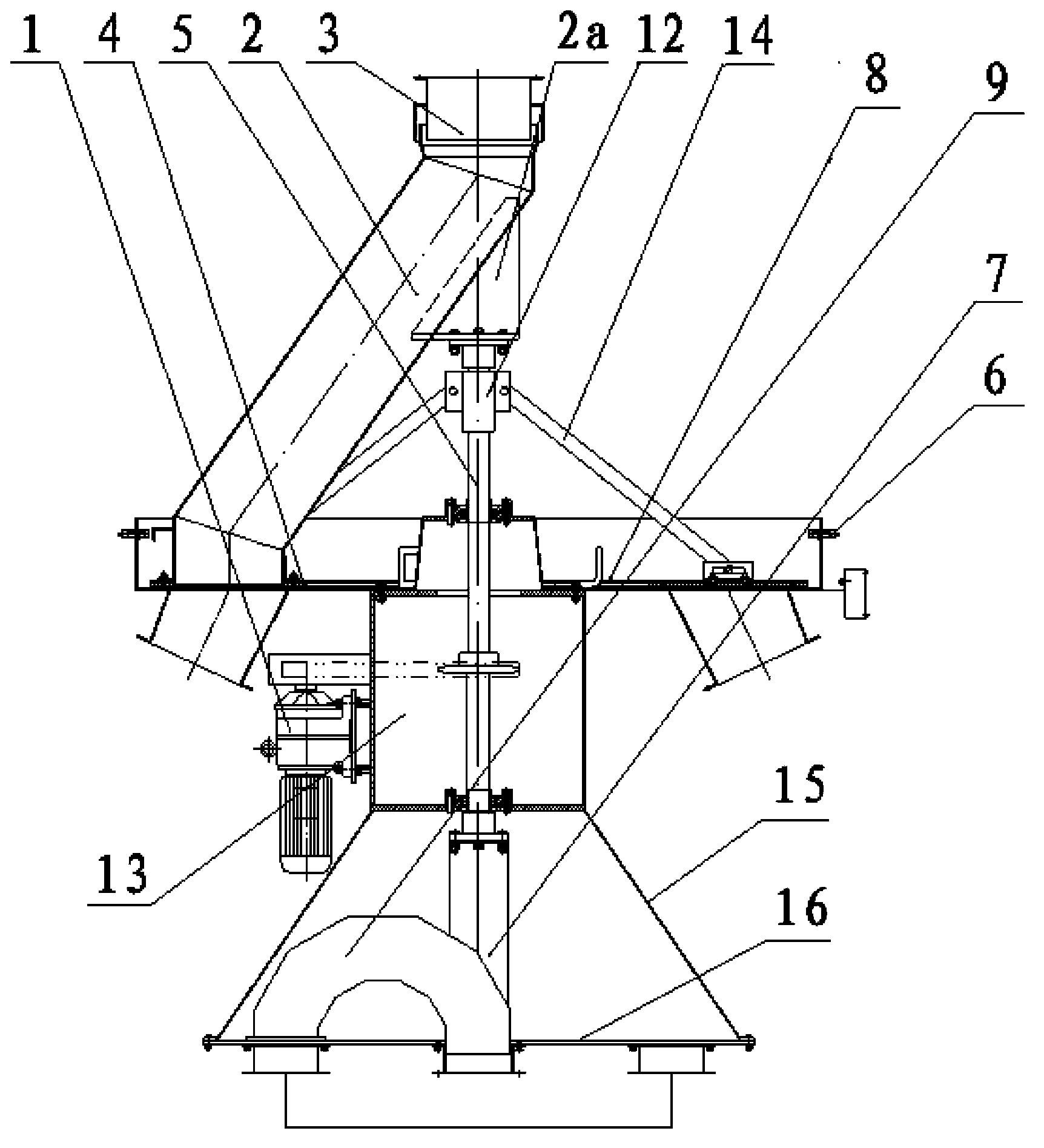

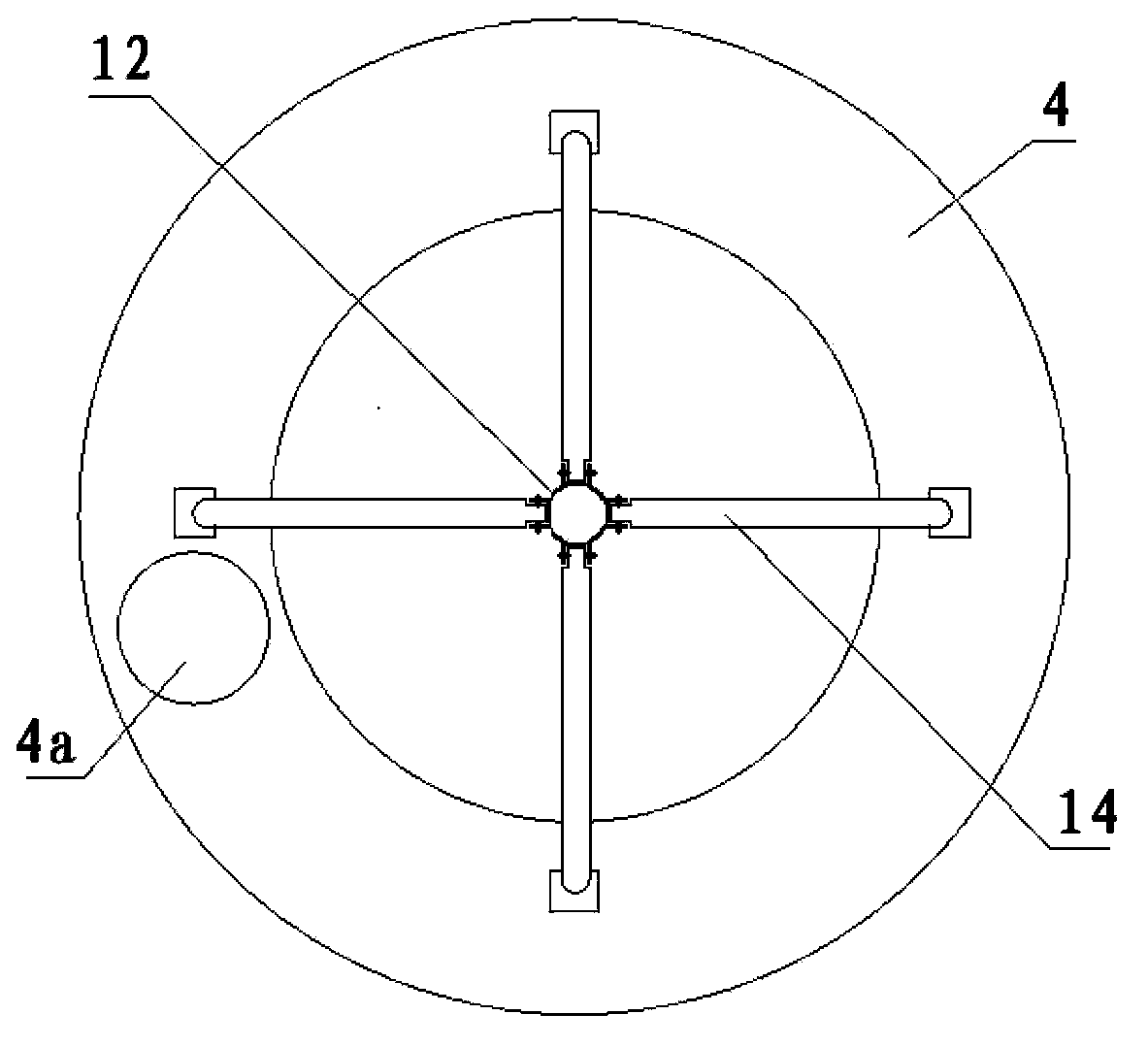

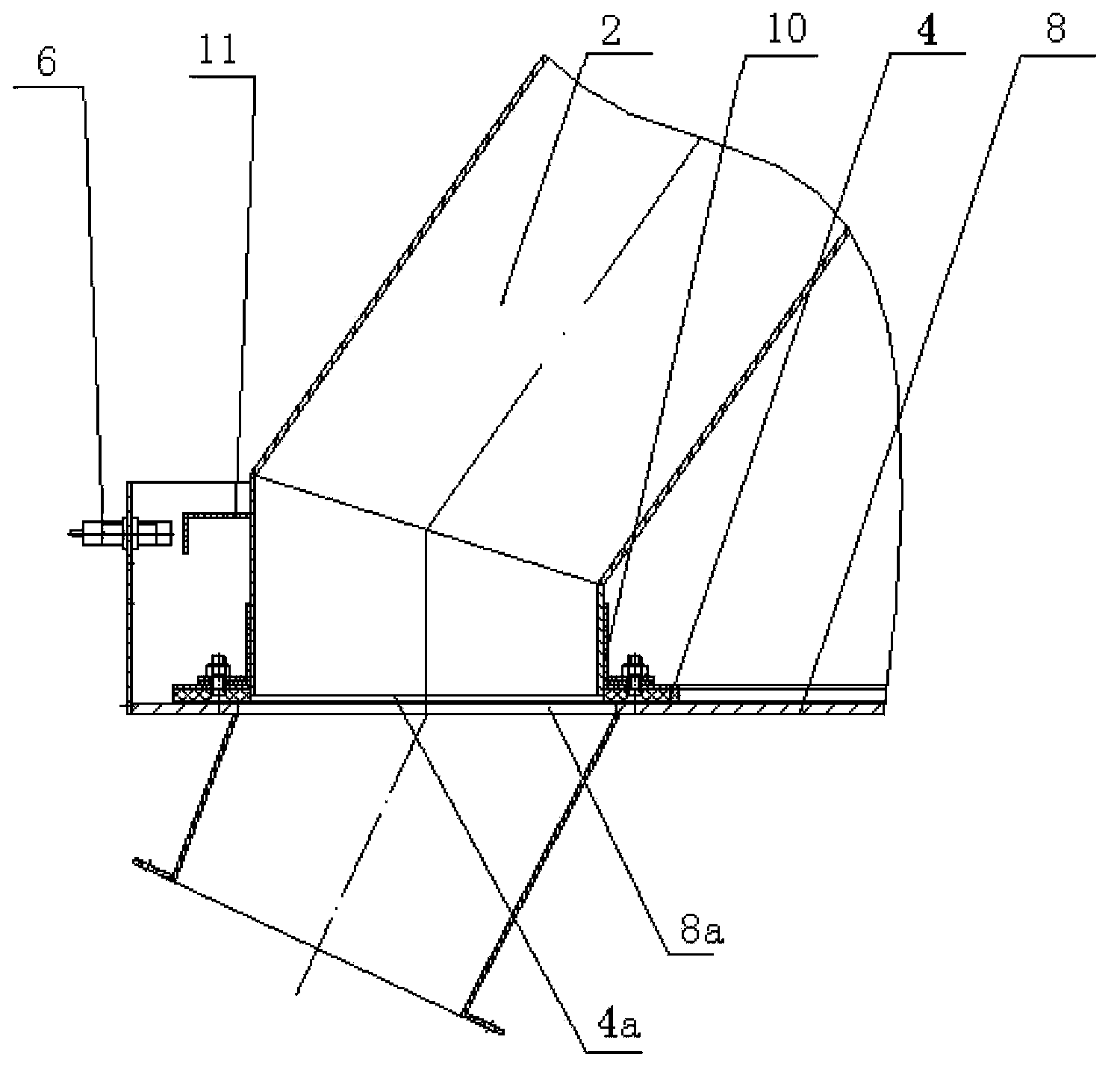

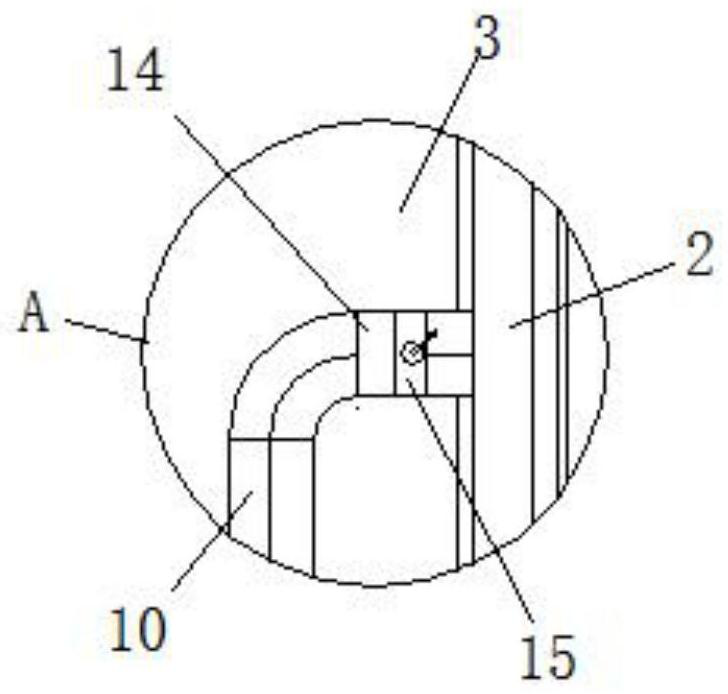

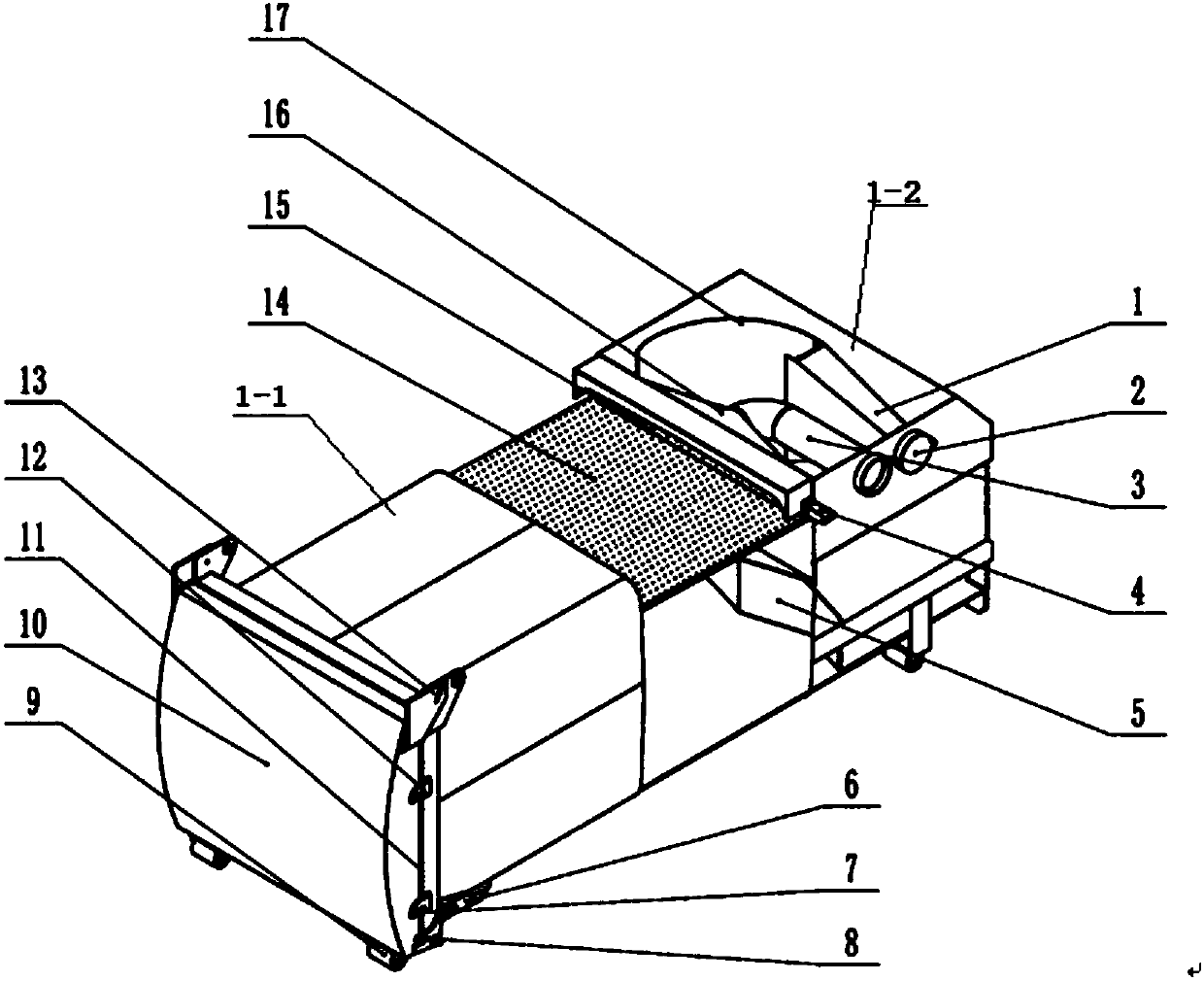

Rotary distributor with point-to-point feeding discharging and point-to-point dust absorption

The invention provides a rotary distributor with point-to-point feeding discharging and point-to-point dust absorption. The rotary distributor with point-to-point feeding discharging and point-to-point dust absorption comprises a feeding distribution platform component, a feeding articulated chute component and driving part of the feeding articulated chute component, and a column component used for installing the driving part. A shaft sleeve component is arranged on a main shaft of the driving part on the upper side of the feeding distribution platform. 3-4 umbrella type support bars are stretched from the shaft sleeve component in a sloping downward direction in an equal central angle mode. The lower ends of the support bars are connected with an annular rotating disc which is placed horizontally. The rotating disc is on the feeding distribution platform and matched with the feeding distribution platform gap. The radial width of the annular rotating disc covers a multi-position feeding distribution opening of the feeding distribution platform. A feeding discharging opening of the annular rotating disc is corresponding to a feeding discharging distribution opening of the feeding distribution platform. A lower port of an articulated chute of the feeding articulated chute component is connected with the feeding discharging opening of the annular rotating disc. A dedusting component is connected with the lower end of the main shaft of the driving part. The dedusting component comprises a dedusting component support connected with a flange at the lower end of the main shaft and a dust absorption bending pipe fixed on the dedusting component support. Two ports of the dust absorption bending pipe are respectively corresponding to a bunker dust absorption opening and a system dedusting opening.

Owner:HUBEI SANJIANG SPACE MECHANICAL & ELECTRICAL EQUIP

Technology for preparing calcium chloride by using waste slurry

ActiveCN110143607AAvoid environmental pollutionLow costCalcium/strontium/barium chloridesChemistryCalcium

The invention discloses a technology for preparing calcium chloride by using waste slurry. The technology comprises a hydrolysis process, a water-washing separation process, a precision filtration process and a product process, wherein the hydrolysis process comprises a dissolution tank and a reaction kettle; the water-washing separation process comprises a centrifugal separation apparatus; the precision filtration process comprises a first filtration apparatus, a waste slag storage tank and a second filtration apparatus; and the product process comprises a calcium chloride solution storage tank. According to the technology, quick lime or slaked lime which is alkaline in water is adopted to absorb hydrogen chloride gas generated by the hydrolysis process of the waste slurry, the overflow of the hydrogen chloride gas is effectively controlled, the problem of environmental pollution caused by hydrogen chloride in the waste slurry hydrolysis process is effectively avoided, the treatment cost of the waste slurry is reduced, and the waste slurry treatment efficiency is improved.

Owner:LUXI CHEM GRP

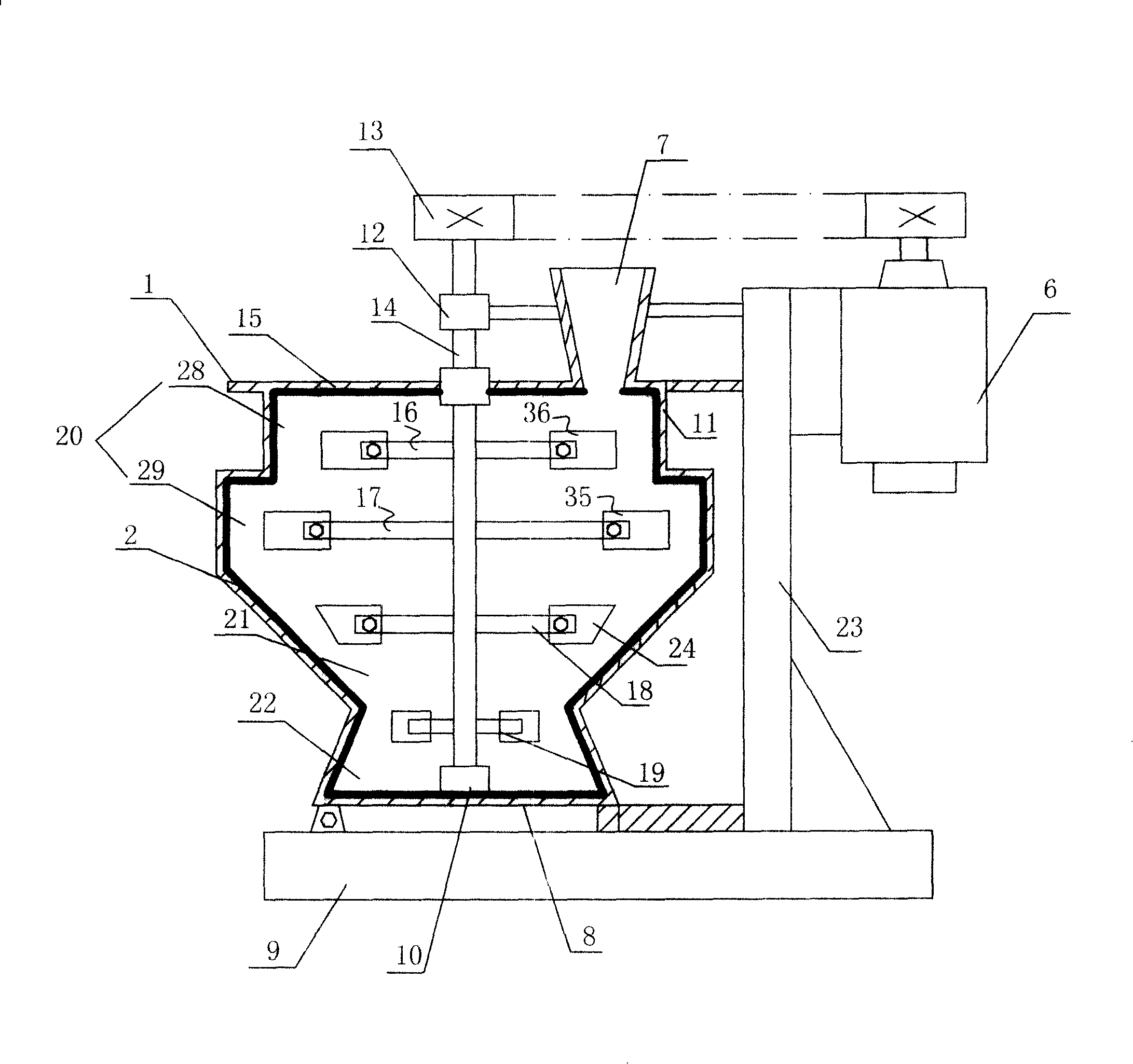

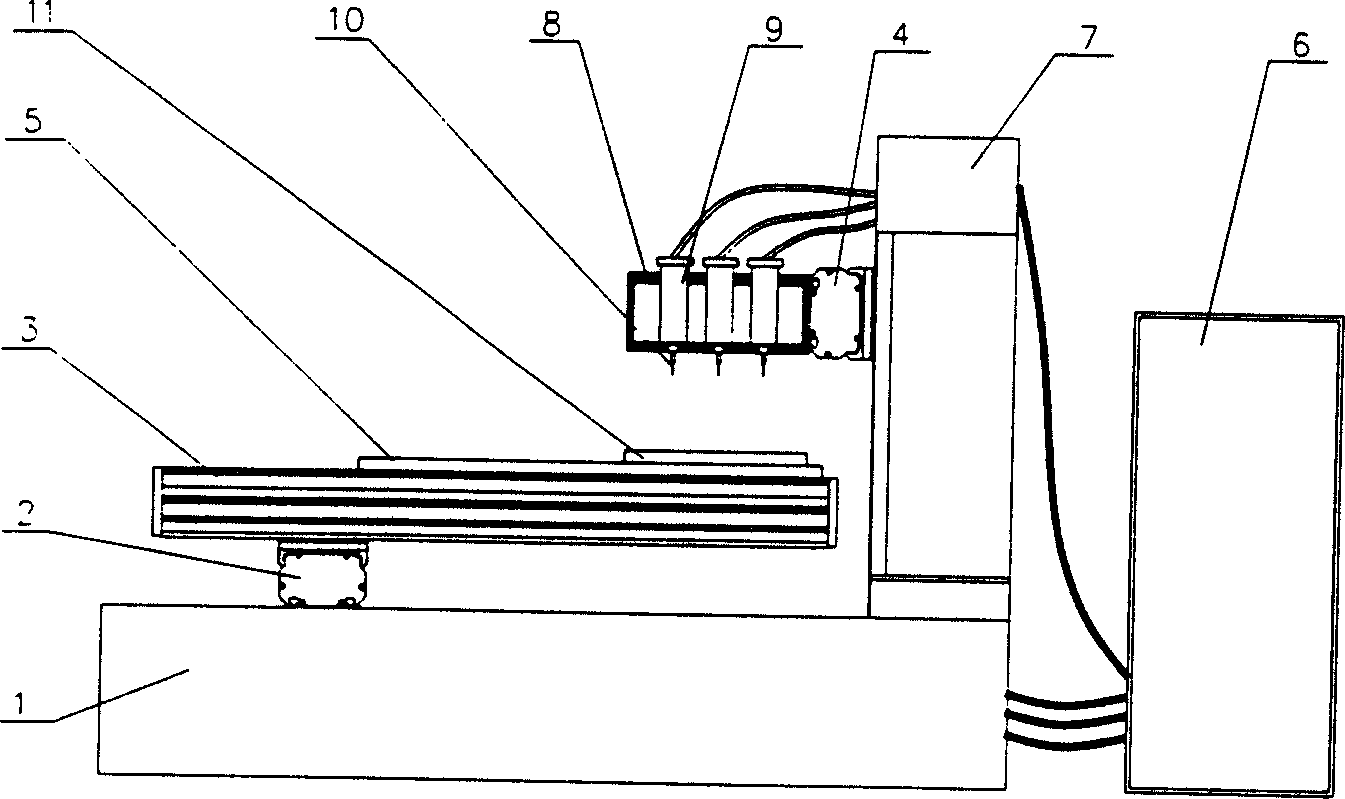

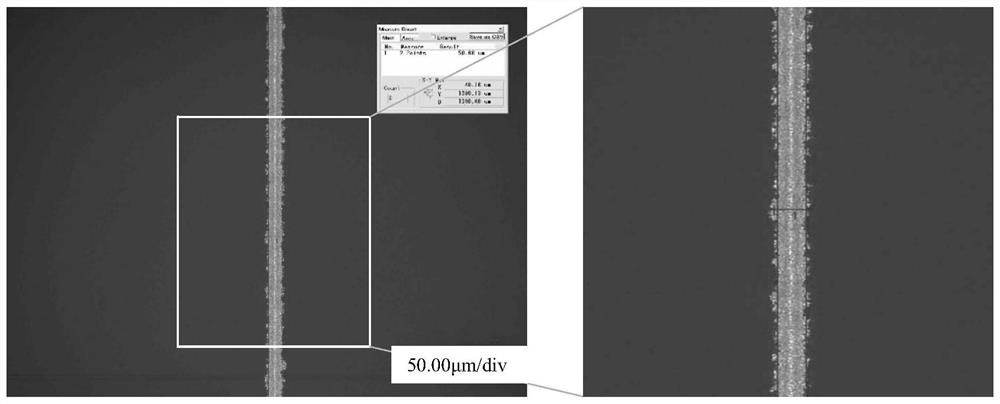

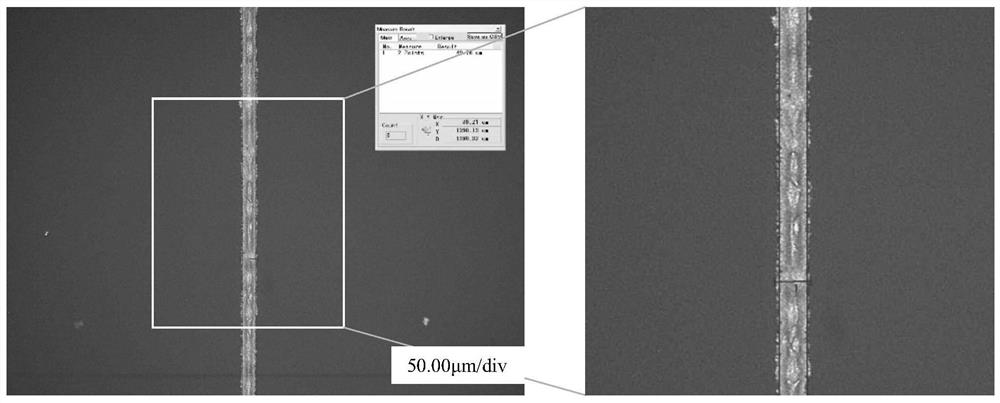

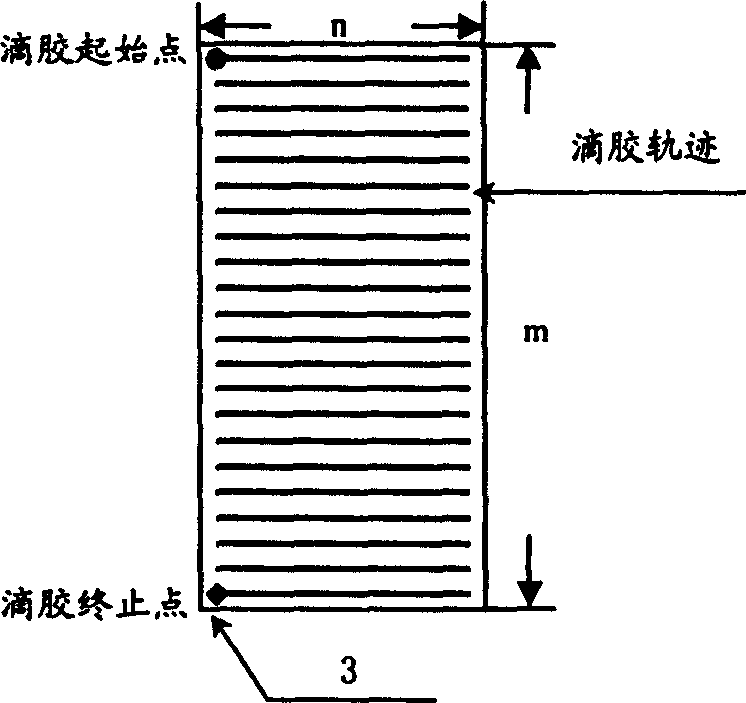

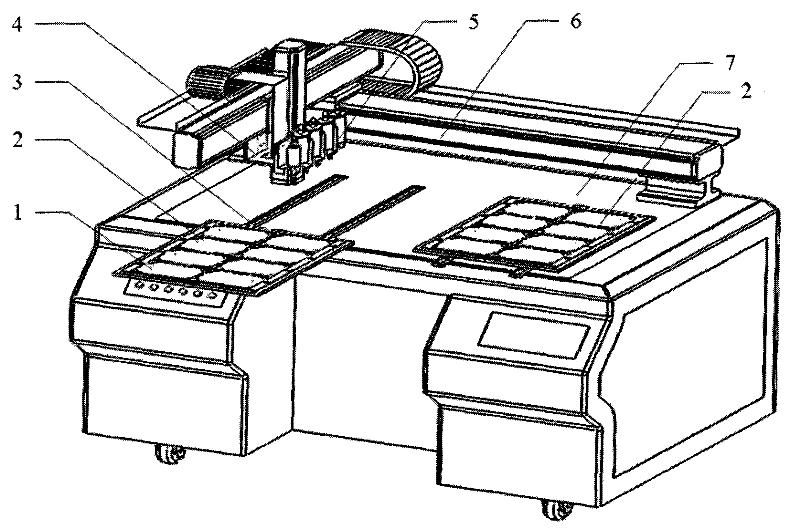

Automatic accurate coating mechanism of solar cell

InactiveCN1194822CControl thicknessReduce fragmentationLiquid surface applicatorsFinal product manufactureElectrical batteryEngineering

An automatic and precise resin coating mechanism for solar battery is composed of an automatic 3-freedom (X, Y and Z) moving unit, electric controller; resin dropping unit with electromagnetic valve,vacuum generator and multiple needles; and battery tray for holding solar batteries on it. Said battery tray is positioned on the bench of 3-freedom moxing unit which is controlled by said electric controller. Its advantages are precise control of the thickness of resin layer, no pollution, and high efficiency and percentage of finished products.

Owner:SHANGHAI JIAOTONG UNIV

Multifunctional sewage well device

InactiveCN103374968AAvoid spillingHas anti-odor and sewage discharge abilitySewerage structuresEnvironmental resource managementSewage

The invention relates to a multifunctional sewage well device, and belongs to the technical field of urban construction design. Deodorization, pollution discharge, flood prevention and anti-freezing road pedestrian safety capacity of an urban sewage well can be improved. The technical scheme includes that the multifunctional sewage well device comprises an integrated framework structure and an automatic sealed ball blow-down system, the integrated framework structure comprises an automatic blow-down system for a spring lifting well bore comprising at least two or three vertically lifting blow-down well bore groups with springs, and the lifting blow-down well bore groups are connected with rotatable lifting automatic blow-down sealed balls. The multifunctional sewage well device is applied to urban construction and manufacture.

Owner:武国贵

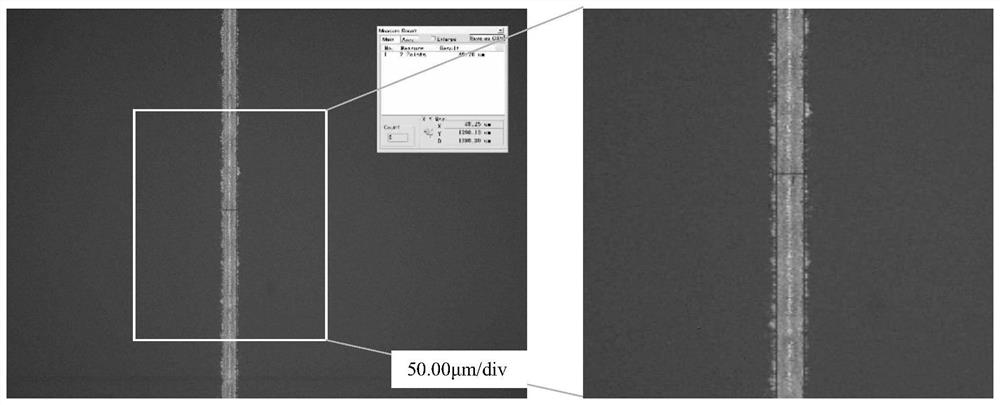

Solar cell grid line slurry, preparation method thereof and solar cell

PendingCN113035408AReduce contact resistanceImprove photoelectric conversion efficiencyNon-conductive material with dispersed conductive materialPhotovoltaic energy generationPolymer resinSolar battery

The invention belongs to the technical field of solar cells, and particularly relates to solar cell grid line slurry which comprises 65%-94% of conductive filler, 0.5%-15% of polymer resin, 0.1%-10% of curing agent, 5.0%-25% of solvent and 0.4%-10% of an auxiliary agent. The auxiliary agent is selected from at least one of a curing accelerator, an alcohol acid diester auxiliary agent and a silicon-containing auxiliary agent. According to the solar cell grid line slurry, the content of conductive filling factors is high, the contact resistance of printed grid lines and the cell is small, the line width is narrow, the height-width ratio is high, and the effective light absorption area of the solar cell is effectively prevented from being reduced, so that the efficiency of the cell is improved.

Owner:SHENZHEN BAROY NEW MATERIAL TECH CO LTD

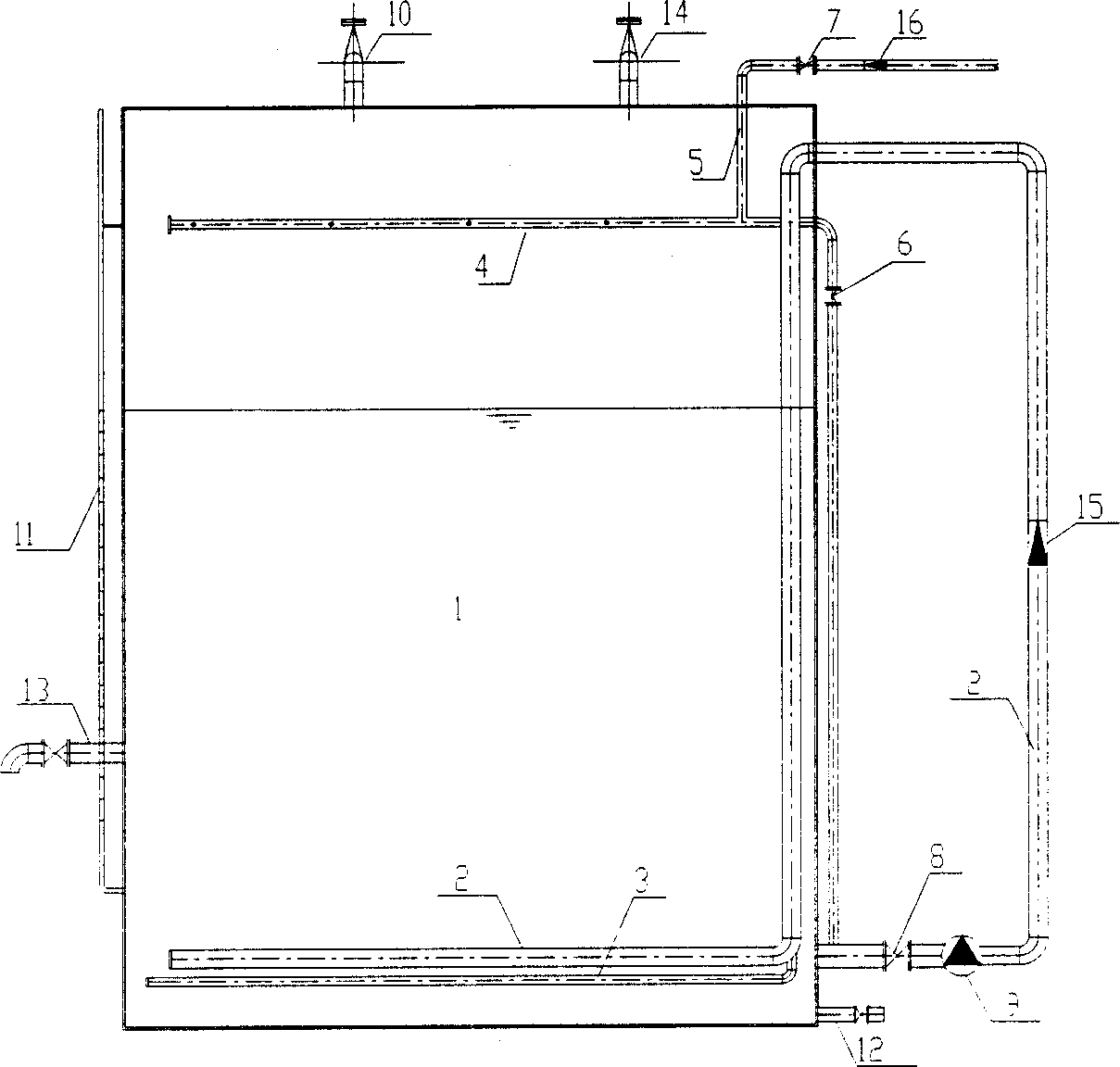

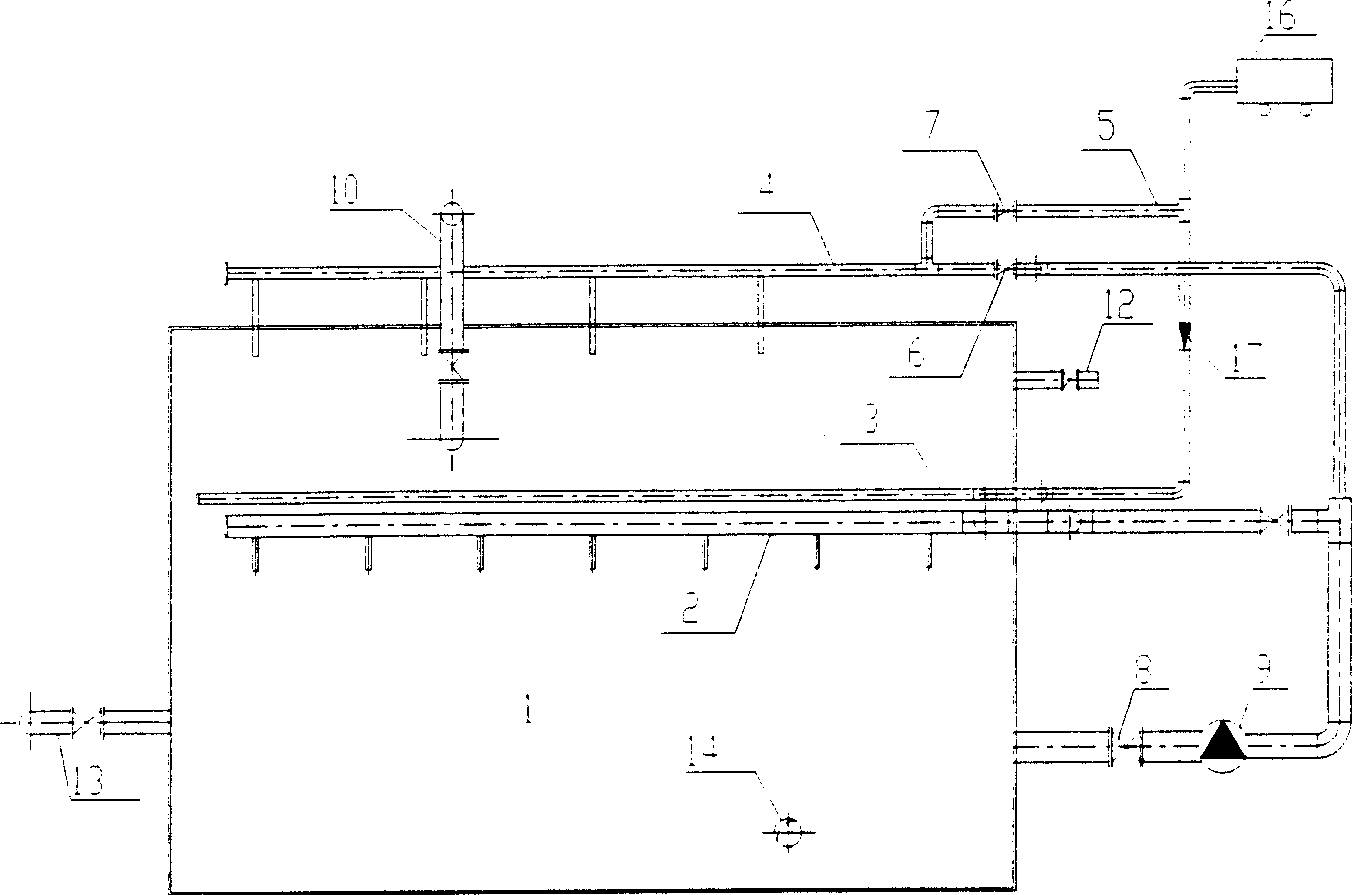

High temperature aerobic digestion device for sludge

InactiveCN1242933CReduce the energy consumption of high temperature aerobic digestionSimple structureSustainable biological treatmentBiological water/sewage treatmentSludgeOxygen

The high temperature aerobic sludge digesting apparatus has sludge circulating system comprising sludge circulating pipeline, sludge circulating bump and sludge flowmeter; sludge aerating system comprising aerating pipeline, aerating bump and gas flowmeter; and digesting pond covered with heat insulting material. The sludge jetting section of the sludge circulating pipeline is set horizontally in the bottom of the digesting pond, the aerating section of the aerating pipeline is set below the sludge jetting section, sludge defoaming pipeline is located below the gas exhausting pipeline, the gas valve of the defoaming pipeline is connected to the aerating pipeline, and liquid sludge valve is connected to the sludge circulating pipeline. The present invention has separated sludge aerating system and sludge circulating system, conventional aerating process and direct defoaming.

Owner:SHANGHAI JIAO TONG UNIV +1

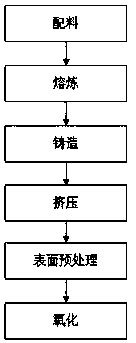

Aluminum-based brazing material and manufacturing process thereof

InactiveCN109794704AHigh strengthImprove performanceWelding/cutting media/materialsSoldering mediaImpuritySolder material

The invention relates to an aluminum-based brazing material. The aluminum-based brazing material is characterized by comprising, by mass, 9.0-9.5% of Si, 0.6% of Fe, 0.2% of Cu, 0.1% of Mn, 1.6-1.9% of Mg, 0.2% of Zn, no greater than 0.15% of other impurities in total, and the balance Al, specifically, the amount of each single impurity of the other impurities is no greater than 0.05%. The sagging, spillover and pseudo soldering of the brazing material are effectively controlled; the qualified rate is increased; and the cost is reduced.

Owner:镇江龙源铝业有限公司

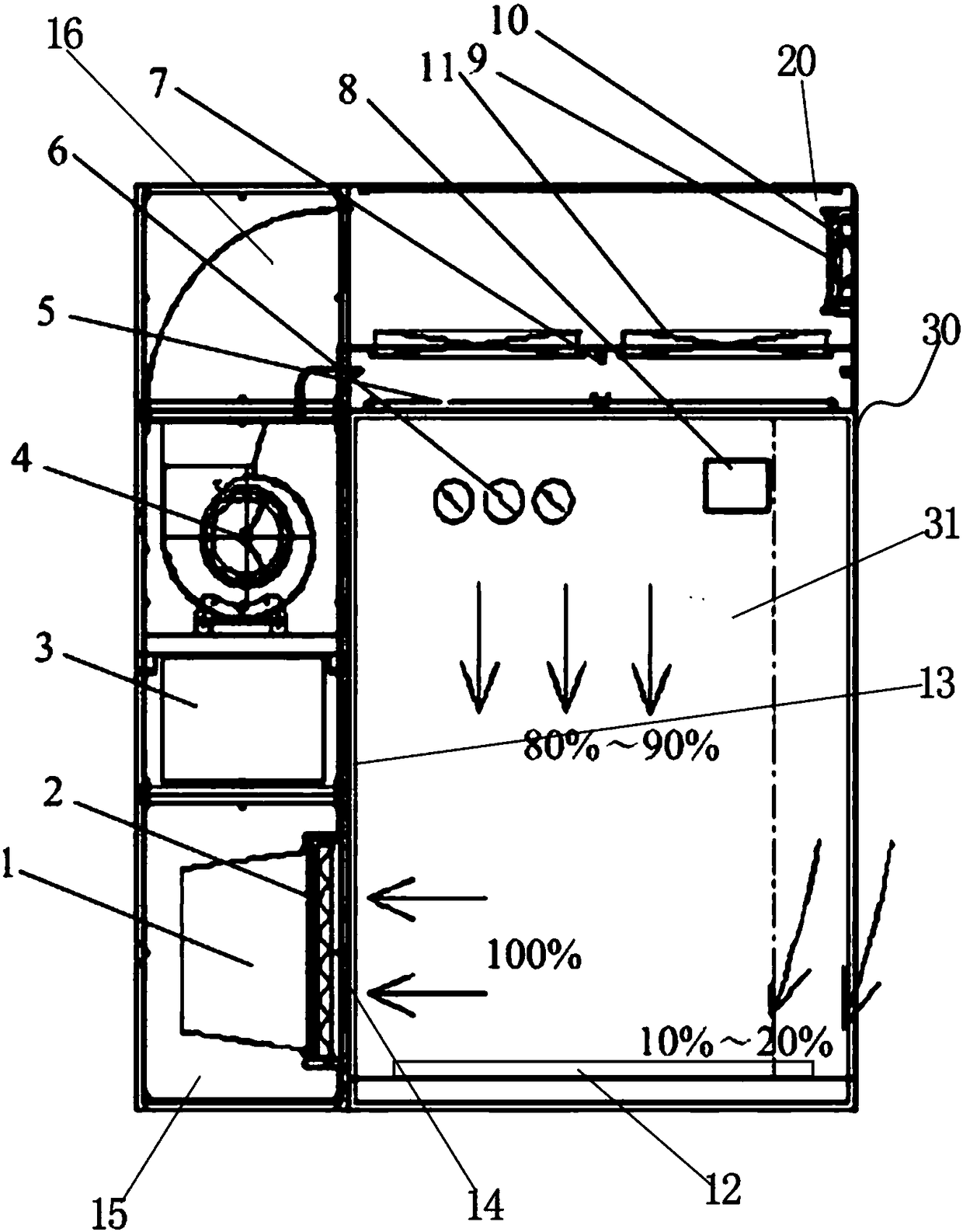

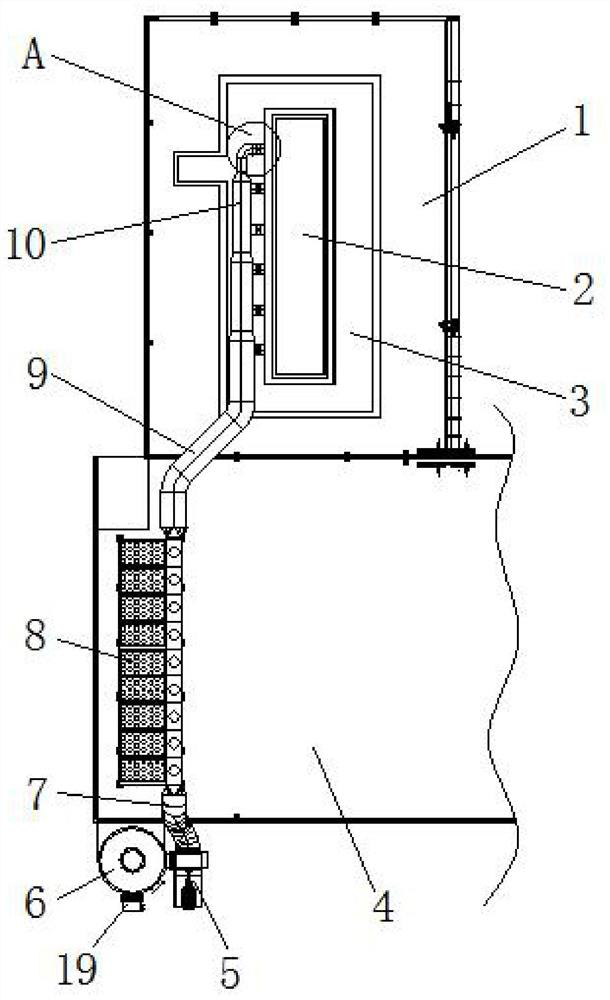

Negative-pressure weighing device and weighing method

InactiveCN108593060AControl spilloverControlled riseDispersed particle filtrationWeighing apparatus using fluid action balancingEngineeringMechanical engineering

The invention discloses a negative-pressure weighing device. The negative-pressure weighing device comprises a weighing box body; a weighing chamber is defined at the front part of the interior of theweighing box body; the bottom of the weighing chamber is provided with a weighing device; the rear part of the weighing chamber is provided with a back plate which plays a role of separation; the topof the weighing chamber is provided with a static pressure box; a filtering chamber is formed behind the back plate; the bottom of the back plate is provided with a filtering screen; the bottom of the filtering chamber is provided with a primary effect filter; the primary effect filter is corresponding to the filtering screen; the rear of the primary effect filter is provided with an intermediateeffect filter; the top surface of the intermediate effect filter is provided with a circulation fan; the circulation fan is connected with the static pressure box through an air pipe; the front sidesurface of the static pressure box is provided with a side air exhausting high-efficiency filter; the side air exhausting high-efficiency filter is provided with a regulating valve; and the bottom surface of the static pressure box is provided with a unidirectional flow high-efficiency filter. With the negative-pressure weighing device of the invention adopted, a dust removal requirement can be satisfied; dust overflow and rise can be controlled; the risk of dust cross-contamination can be avoided; the dust can be prevented from being inhaled by a human body and hurting the human body; the safety of an external environment and people in an indoor environment can be protected.

Owner:苏州天微至胜运动控制技术有限公司

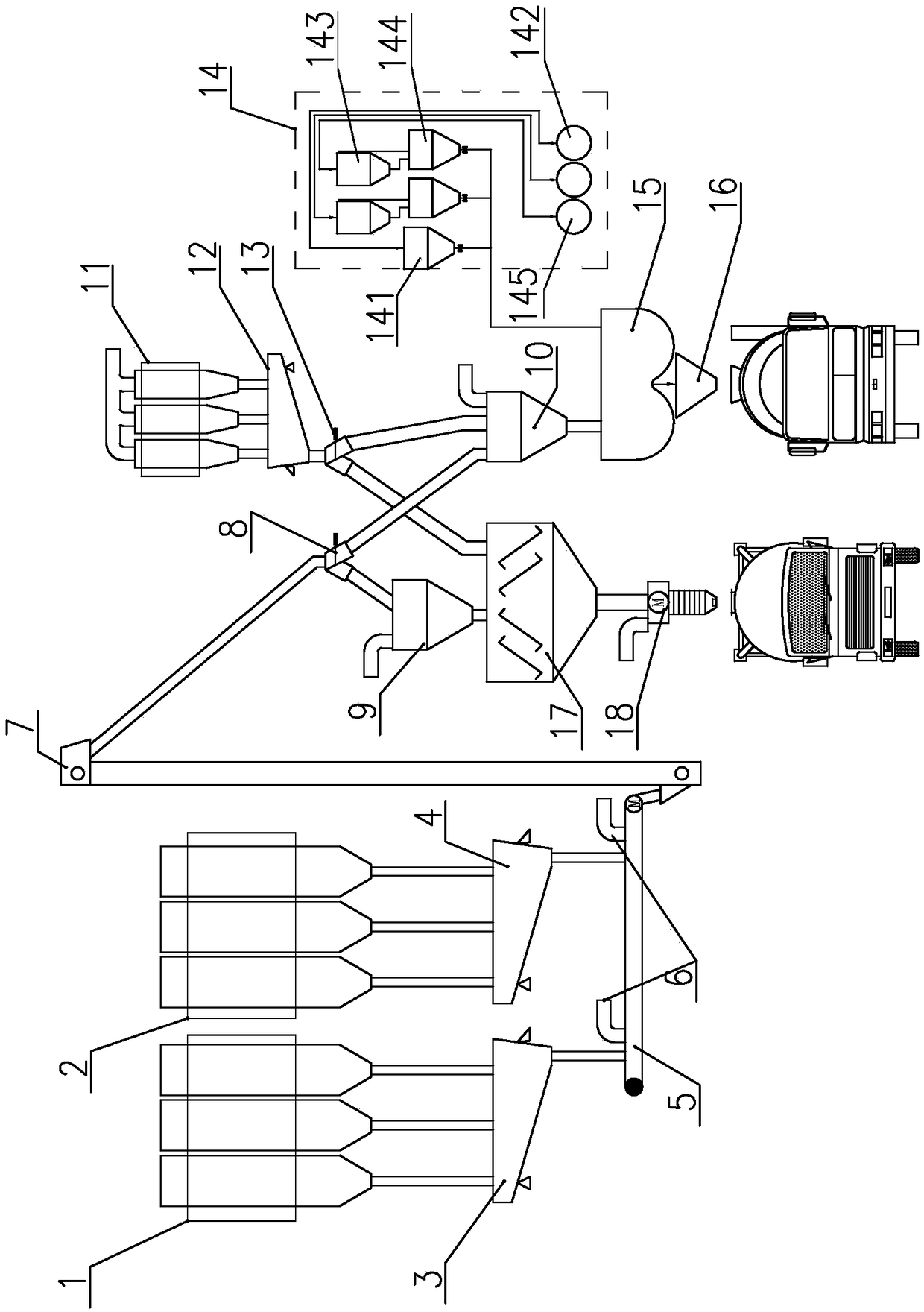

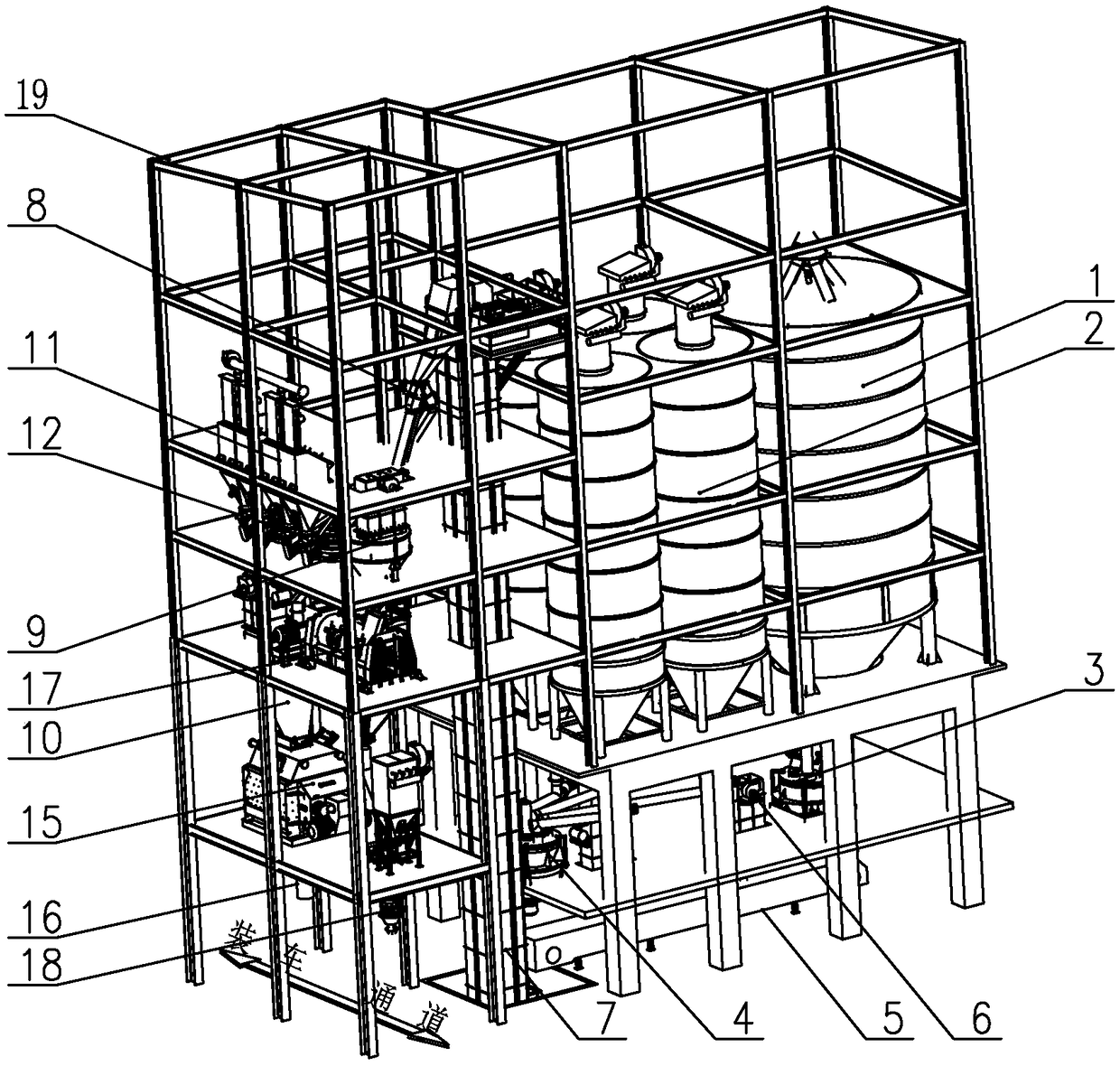

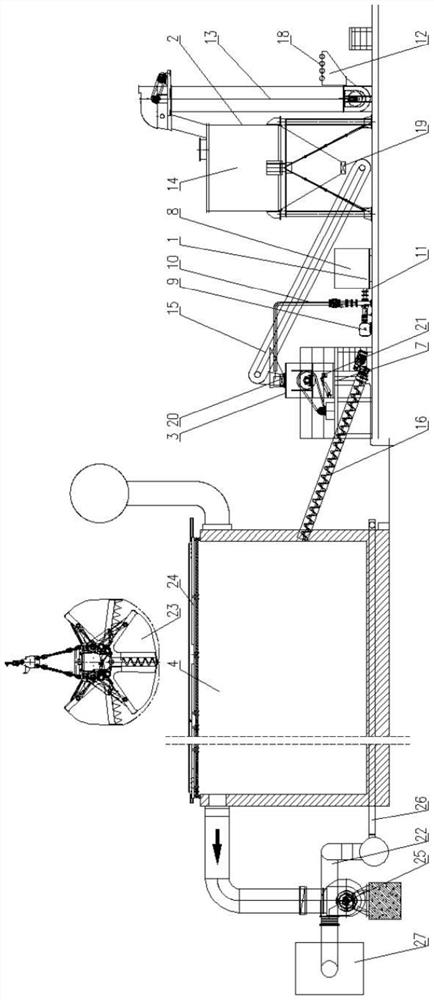

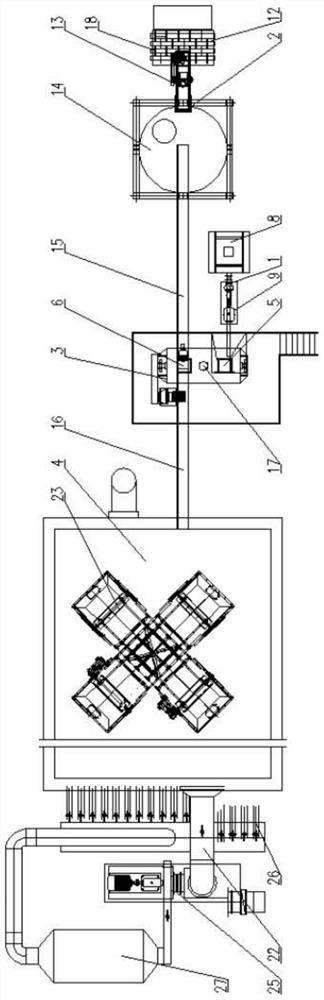

Dry and wet pre-mixed mortar production device

PendingCN109176893AControl spilloverPollution controlMixing operation plantDry mixingDistribution system

Disclosed is a dry and wet pre-mixed mortar production device. The dry and wet pre-mixed mortar production device comprises a main raw material storage and batching system, a metered material conveying and lifting system, a main raw material batching device, a dry mixing temporary storage hopper, a wet mixing temporary storage hopper, a solid admixture storage and batching system, a solid admixture distribution device, a wet-mixed mortar liquid distribution system, a wet mixing main machine and a dry mixing main machine. The dry and wet pre-mixed mortar production device effectively integratesprior two independent devices for producing dry-mixed mortar and wet-mixed mortar into one main building, and both the main raw material storage and batching system and the solid admixture storage and batching system are shared to maximize the utilization of raw material storage and batching.

Owner:FUJIAN SOUTHERN HIGHWAY MECHANICAL

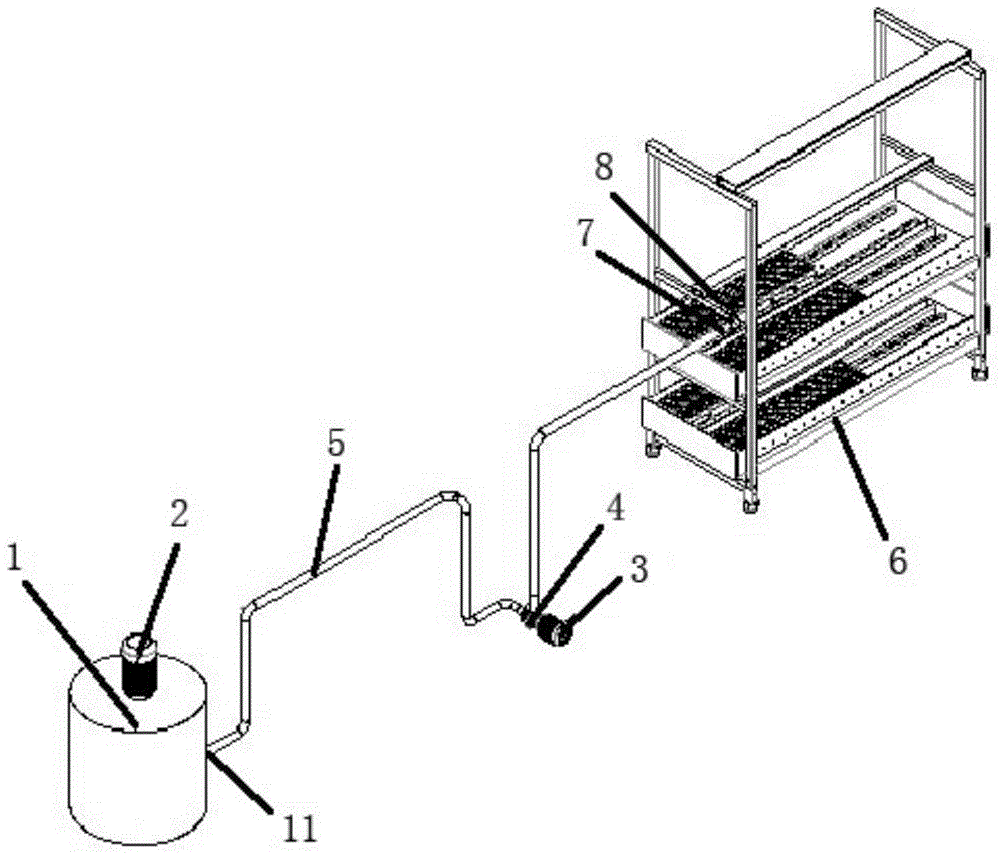

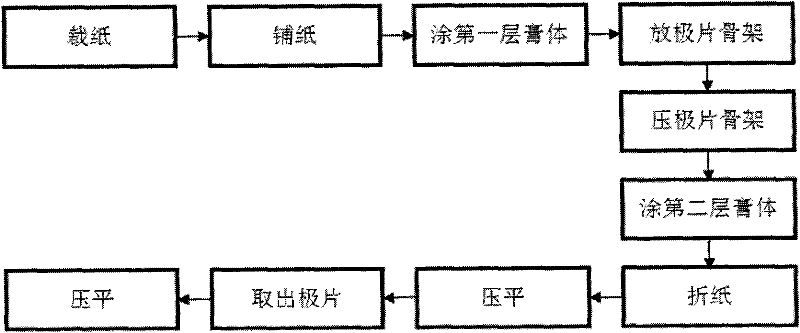

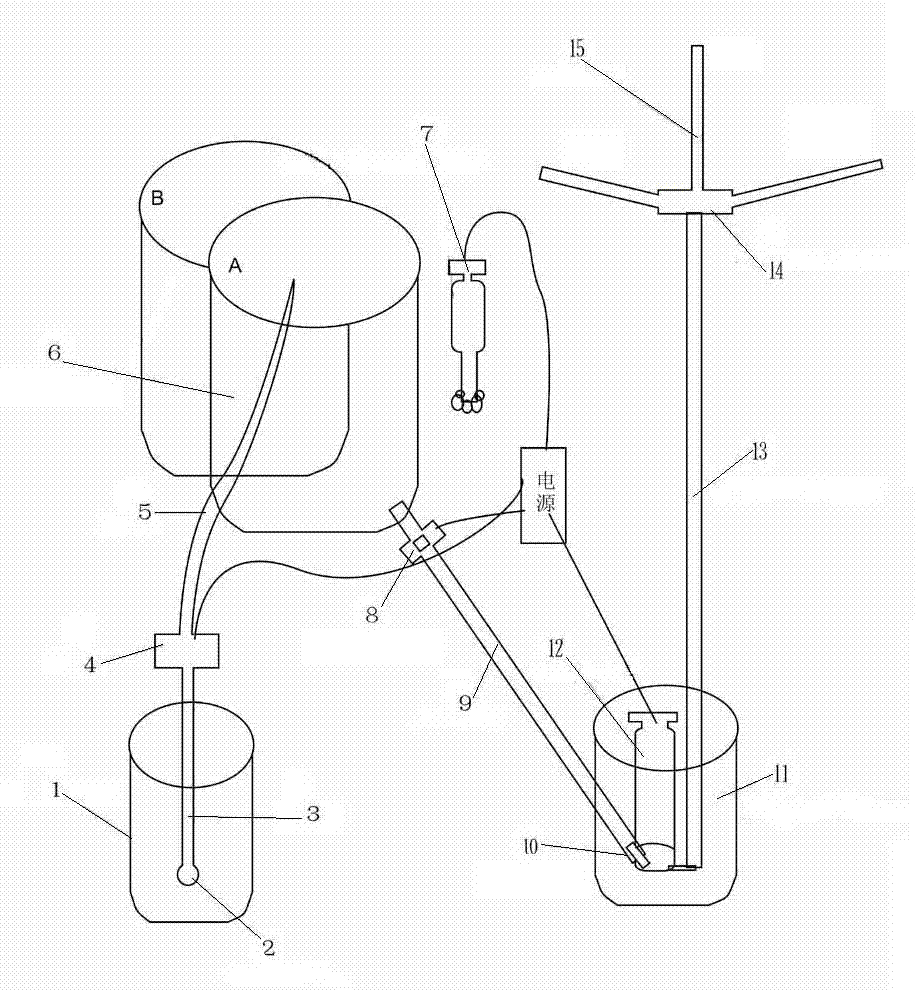

An automatic quantitative acid supplementation device for battery processing

ActiveCN104505487BGuaranteed Acid ConsistencyAvoid inconvenienceCell component detailsProcess engineeringControl valves

The invention discloses an automatic quantitative acid replenishing device for battery treatment, which comprises an acid liquid storage device and a charging frame. The acid equipment is connected by an acid delivery pipeline, a magnetic pump is installed in the middle of the acid delivery pipeline, and a pressure converter is installed on the magnetic pump, and a control valve is installed on the end of the acid delivery pipeline close to the acid supply equipment. The acid replenishing appliance includes the acid replenishing appliance body. The top of the acid replenishing appliance body is equipped with a flow meter, an acid injection pipe and an acid liquid introduction hose. There is an acid replenishment stopper between the acid injection pipe and the flow meter. Equipped with an infrared quantitative system, the infrared quantitative system is fixedly connected to the top of the flowmeter through a connecting plate. The invention guarantees the consistency of the acid content of the acid replenishing battery and effectively solves the inconvenience caused by the irregular turnover of the electrolyte used for acid replenishment at any time, solves the safety hazard and quality problems caused by the overflow of acid liquid, and effectively controls the cost of raw materials waste.

Owner:CHAOWEI POWER CO LTD

A technology for preparing calcium chloride by using waste slurry

ActiveCN110143607BControl spilloverSolve pollutionCalcium/strontium/barium chloridesFiltrationSlurry

Owner:LUXI CHEM GRP

System and process for preparing fertilizer from biogas residues and sludge

The invention discloses a biogas residue and sludge fertilizer preparation system and process, and belongs to the technical field of environmental protection. The device comprises a biogas residue and sludge receiving system, a straw auxiliary material storage system, a mixing device and a biomass drying bin, a biogas residue and sludge inlet and a straw auxiliary material inlet are formed in the top of the mixing device, a mixture discharge port is formed in the bottom of the mixing device, the biogas residue and sludge receiving system is composed of a biogas residue transfer container, a screw pump and a conveying pipeline, and the discharge port is reserved in the bottom of the biogas residue transfer container. Biogas residue sludge is conveyed to a biogas residue sludge inlet in the top of the mixing equipment through a screw pump and a conveying pipeline. According to the method, the industrial situation that kitchen biogas residues are single in disposal and low in resource utilization rate is solved, meanwhile, organic fertilizer returning is an important link for achieving an ecological cycle system, a new way is sought for resource utilization of kitchen waste end products, environmental protection pressure is relieved, resource saving and circular economy development are promoted, and the method has a wide application prospect. The current green, environment-friendly and low-carbon development concepts are met.

Owner:SHANGHAI LIMING RESOURCE REUSE

Rotary distributor with point-to-point feeding discharging and point-to-point dust absorption

The invention provides a rotary distributor with point-to-point feeding discharging and point-to-point dust absorption. The rotary distributor with point-to-point feeding discharging and point-to-point dust absorption comprises a feeding distribution platform component, a feeding articulated chute component and driving part of the feeding articulated chute component, and a column component used for installing the driving part. A shaft sleeve component is arranged on a main shaft of the driving part on the upper side of the feeding distribution platform. 3-4 umbrella type support bars are stretched from the shaft sleeve component in a sloping downward direction in an equal central angle mode. The lower ends of the support bars are connected with an annular rotating disc which is placed horizontally. The rotating disc is on the feeding distribution platform and matched with the feeding distribution platform gap. The radial width of the annular rotating disc covers a multi-position feeding distribution opening of the feeding distribution platform. A feeding discharging opening of the annular rotating disc is corresponding to a feeding discharging distribution opening of the feeding distribution platform. A lower port of an articulated chute of the feeding articulated chute component is connected with the feeding discharging opening of the annular rotating disc. A dedusting component is connected with the lower end of the main shaft of the driving part. The dedusting component comprises a dedusting component support connected with a flange at the lower end of the main shaft and a dust absorption bending pipe fixed on the dedusting component support. Two ports of the dust absorption bending pipe are respectively corresponding to a bunker dust absorption opening and a system dedusting opening.

Owner:HUBEI SANJIANG SPACE MECHANICAL & ELECTRICAL EQUIP

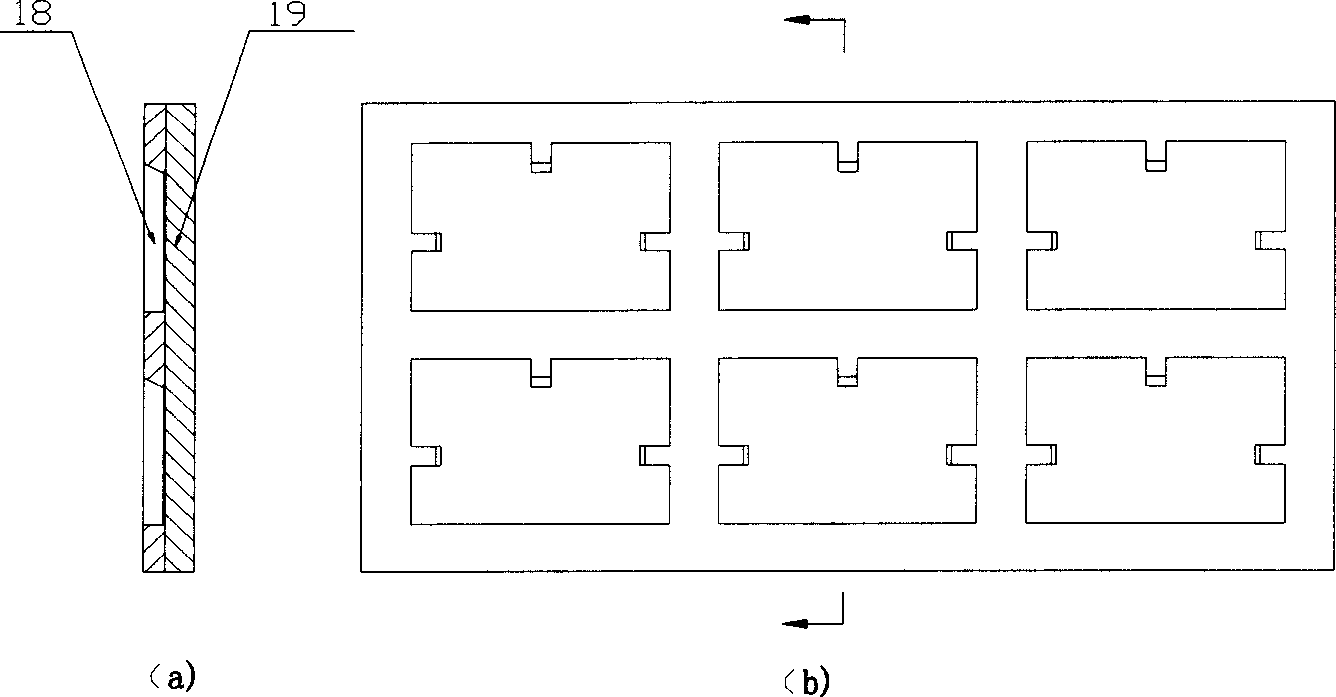

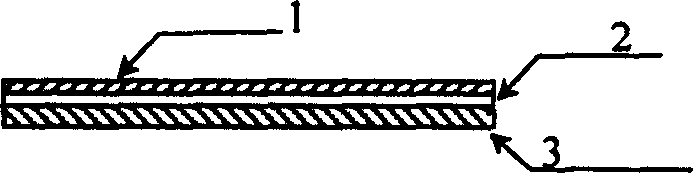

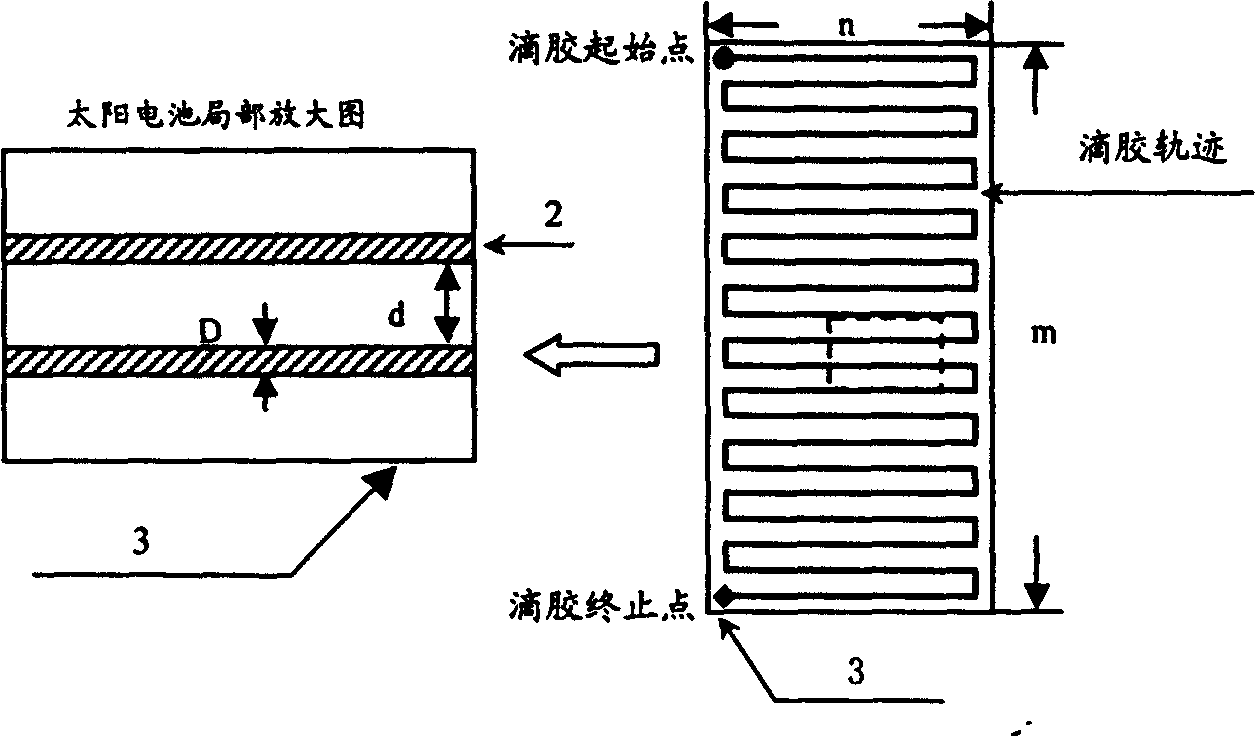

Glue layer thickness controlable continuous glue-dropping process for packing solar cell

InactiveCN1203539CPrecise thickness controlPrecise control of spillageLiquid surface applicatorsFinal product manufactureElectrical batteryEngineering

In the continuous glue-dropping process for packing solar cell with glue layer in controllable thickness, the glue-dropping path for robot is programmed in computer for some solar cell with certain shape and sizes to determine the distance between two lines of path and the edge distance of cell; and the path file is then downloaded into the controller of three-free dimension rectangular coordinate robot white selecting proper glue-dropping syringe and controlling glue-dropping pressure to different parameter range and glue thickness to complete the glue-dropping process. Via regulating relevant parameters, the present invention can control the glue thickness precisely, control the overflow of glue and avoid the contamination of glue to the cell.

Owner:SHANGHAI JIAOTONG UNIV

Digital intelligent integrated weighting chamber

ActiveCN102828627BImprove cleanlinessClean working environmentSpace heating and ventilation safety systemsDispersed particle filtrationExhaust valveFrequency conversion

The invention discloses a digital intelligent integrated weighting chamber which comprises a combined wall and an air processing system, wherein an operation space is arranged in the combined wall; in the air processing system, an inward air inlet is arranged on the lower part of the combined wall; a fresh air valve is mounted at the inward air inlet; an air return opening is arranged at the bottom of the operation space; an air inlet of a primary filter is communicated with the air return opening; air flues between the primary filter, a medium filter, a frequency conversion fan, a high-efficiency filter and a plenum chamber are connected in turn; the plenum chamber is arranged at the top of the operation space; a self-circulation flow-equalizing membrane is mounted at a self-circulation air outlet of the plenum chamber; an outer circulation flow-equalizing membrane is mounted at an outer circulation air outlet of the plenum chamber; an outward air outlet is arranged on the upper part of the combined wall; and an exhaust valve is mounted at the outward air outlet. According to the digital intelligent integrated weighting chamber, air is purified by multi-stage filters and the purified air is blown out at a constant speed by the self-circulation flow-equalizing membrane on the plenum chamber, and a high-cleanness working environment is formed in the operation space.

Owner:SICHUAN CHUANJING CLEAN TECH HLDG

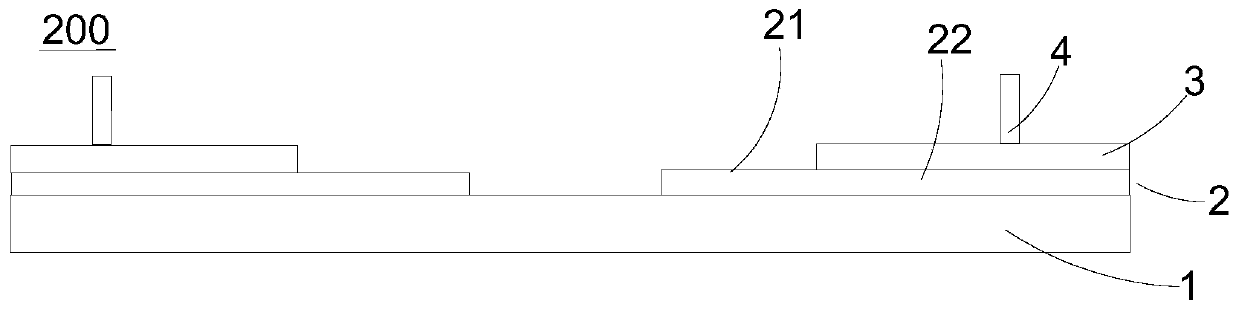

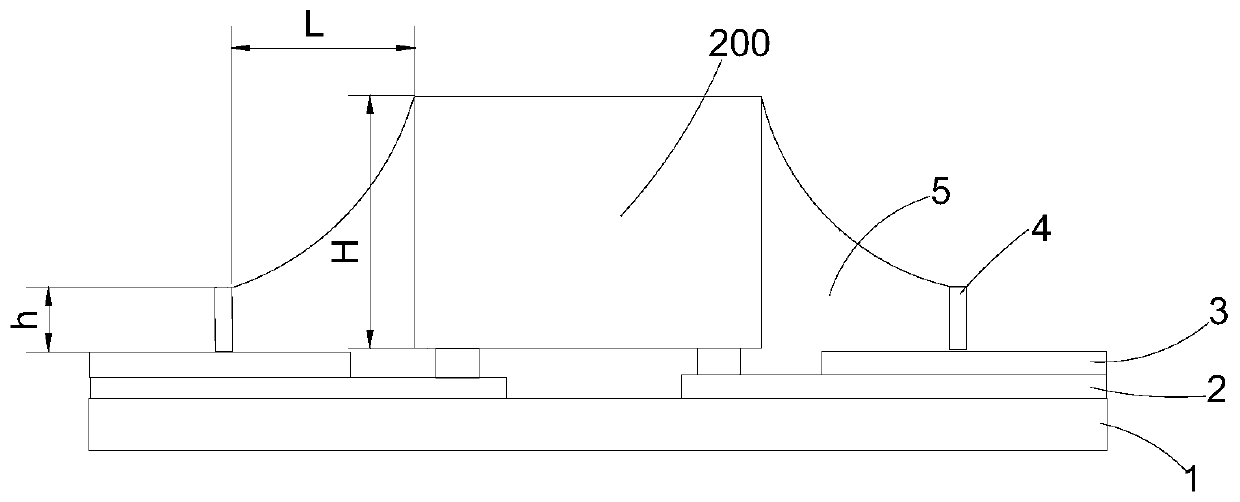

Flip chip packaging structure and packaging method

ActiveCN111508910ARealize setting shapingReduce widthSemiconductor/solid-state device detailsSolid-state devicesFlexible circuitsMechanical engineering

The invention discloses a flip chip packaging structure and a packaging method. The flip chip packaging structure comprises a flexible circuit board and a flip chip installed on the flexible circuit board. The flexible circuit board comprises a base layer, a circuit layer and a protective layer, wherein the circuit layer and the protective layer are arranged on the surface of the base layer; the side, provided with a flip chip, of the flexible circuit board is provided with a blocking body which is arranged on the protective layer and protrudes in the direction away from the protective layer;a sealant layer is arranged between the blocking body and the flip chip; the height h of the blocking body is not less than H-L; L represents the distance from the blocking body to the flip chip; H represents the vertical distance between the top of the sealant layer and the protective layer. The flow of the sealant is limited between the blocking body and the flip chip through the arrangement ofthe blocking body, so that the width of the sealant layer on the protective layer is effectively controlled, and the overflow of the sealant layer is effectively controlled.

Owner:CHIPMORE TECH CORP LTD +1

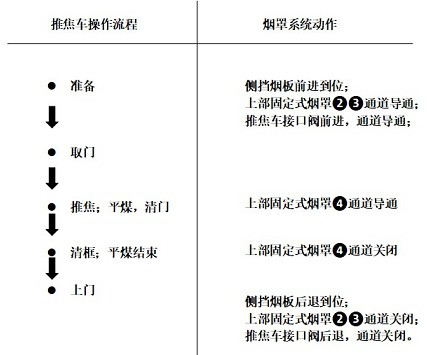

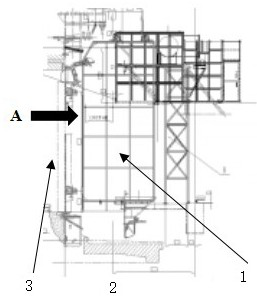

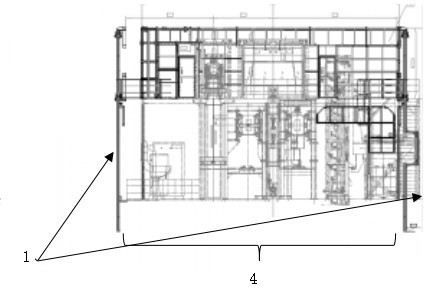

Efficient dust removal smoke hood for coke pusher of coke oven

ActiveCN114606014AGuaranteed collectionImprove integrityHuman health protectionCoke oven safety devicesThermodynamicsDust control

The invention relates to the technical field of coke oven vehicles, in particular to an efficient dust removal smoke hood of a 7.63 coke oven coke pusher. The invention discloses an efficient dust removal smoke hood for a coke pusher of a coke oven. Side smoke baffles are additionally arranged on the two sides of the coke pusher; (2) using a fixed smoke hood at the top of the coke pusher; (3) smoke dust at the top of the Nth coke pushing oven number and the top of the oven door of the (N-2) th coke pushing oven number is collected in an interface valve mode; and (4) the fixed smoke hood of the coke pusher is a hollow smoke hood with an interlayer, and holes are only formed in the local part of a smoke dust accumulation area. Negative pressure is uniformly distributed according to a smoke dust accumulation area through the interlayer type smoke hood of the coke pusher, and 100% collection of smoke dust in the span of the coke pusher is guaranteed.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

A kind of negative pressure weighing cover

ActiveCN104499735BEnsure high cleanliness environmentAvoid cross contaminationLighting and heating apparatusSpace heating and ventilation detailsWork zoneContamination

The invention discloses a negative pressure weighing cover. The negative pressure weighing cover is built by splicing and assembling an aluminum profile and a composite wall and comprises an upper box body, a machine room, a lower box body, a working area, a protection area and a supervision system. The supervision system is arranged on a control panel; a primarily efficient filter and a middle efficient filter are arranged on an air returning plate of the inner side of the lower box body; a UPS is arranged on the bottom corner of the lower box body; the machine room is provided with a main fan and a direct-current fan; an efficient filer A and an efficient filter B are arranged in the upper box body; the efficient filter A is sealed through a liquid seal trough, and an air outlet of the efficient filter A is provided with a flow equalizing diaphragm plate and a high-speed wind plate; and the high-speed wind plate is communicated with a high-speed wind curtain. A buffer partition plate is arranged in the upper box body. A double-area structure of the working area and the protection area is adopted, and the vertical one-way airflow and the double-side efficient filters are utilized, so that internal circulation and partial discharge of the working area are kept, negative pressure in the working area is made to prevent cross contamination, and external environment and safety of indoor personnel are protected.

Owner:苏州悠远环境科技有限公司

Galvanization collecting equipment

PendingCN111841177AEfficient collectionAvoid pollutionHot-dipping/immersion processesGas treatmentDust controlProcess engineering

The invention discloses galvanization collecting equipment which comprises a hot galvanizing room and a dedusting room, a hot galvanizing pot foundation pit is arranged in the middle of the bottom ofthe hot galvanizing room; a hot galvanizing pot is arranged at the bottom in the hot galvanizing pot foundation pit; supporting frames are arranged at the two ends of the top of the hot galvanizing pot foundation pit, sliding rails are symmetrically arranged in the middles of the two ends of the interior of each supporting frame, electric hoists are arranged on the two sides of the interiors of the two sets of sliding rails, a smoke suction hood is arranged at the output ends of the two sets of electric hoists jointly, and bin gates are evenly arranged at the two ends and the two sides of thesmoke suction hood. According to the equipment, zinc smoke generated in the workpiece plating process is treated in a centralized collection mode, the hot galvanizing pot adopts fully-closed zinc smoke collection equipment, 100% zinc smoke collection can be achieved, environmental pollution caused by zinc smoke leakage is effectively avoided, and meanwhile a good working environment is created forworkers.

Owner:青岛龙程昊宇工贸有限公司

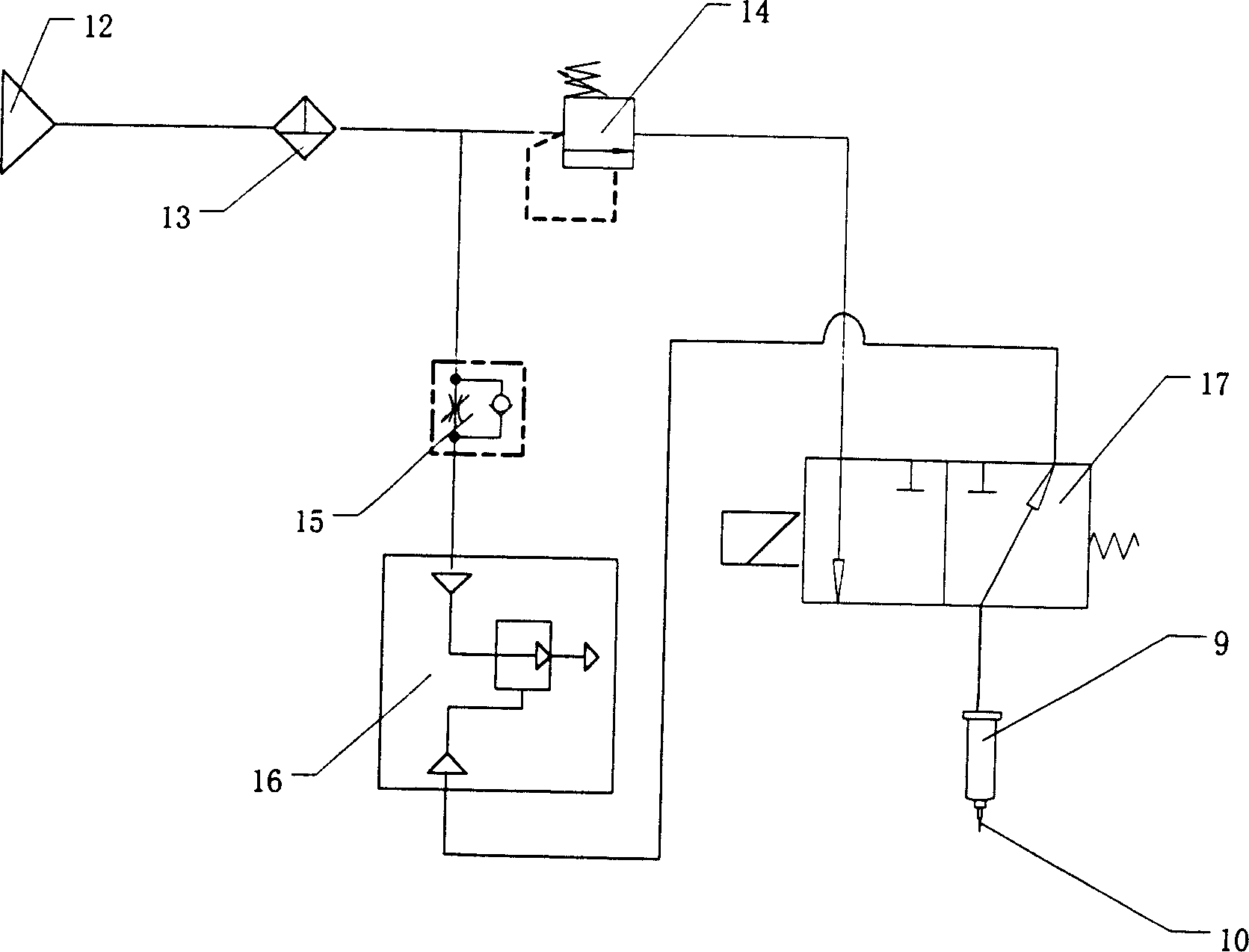

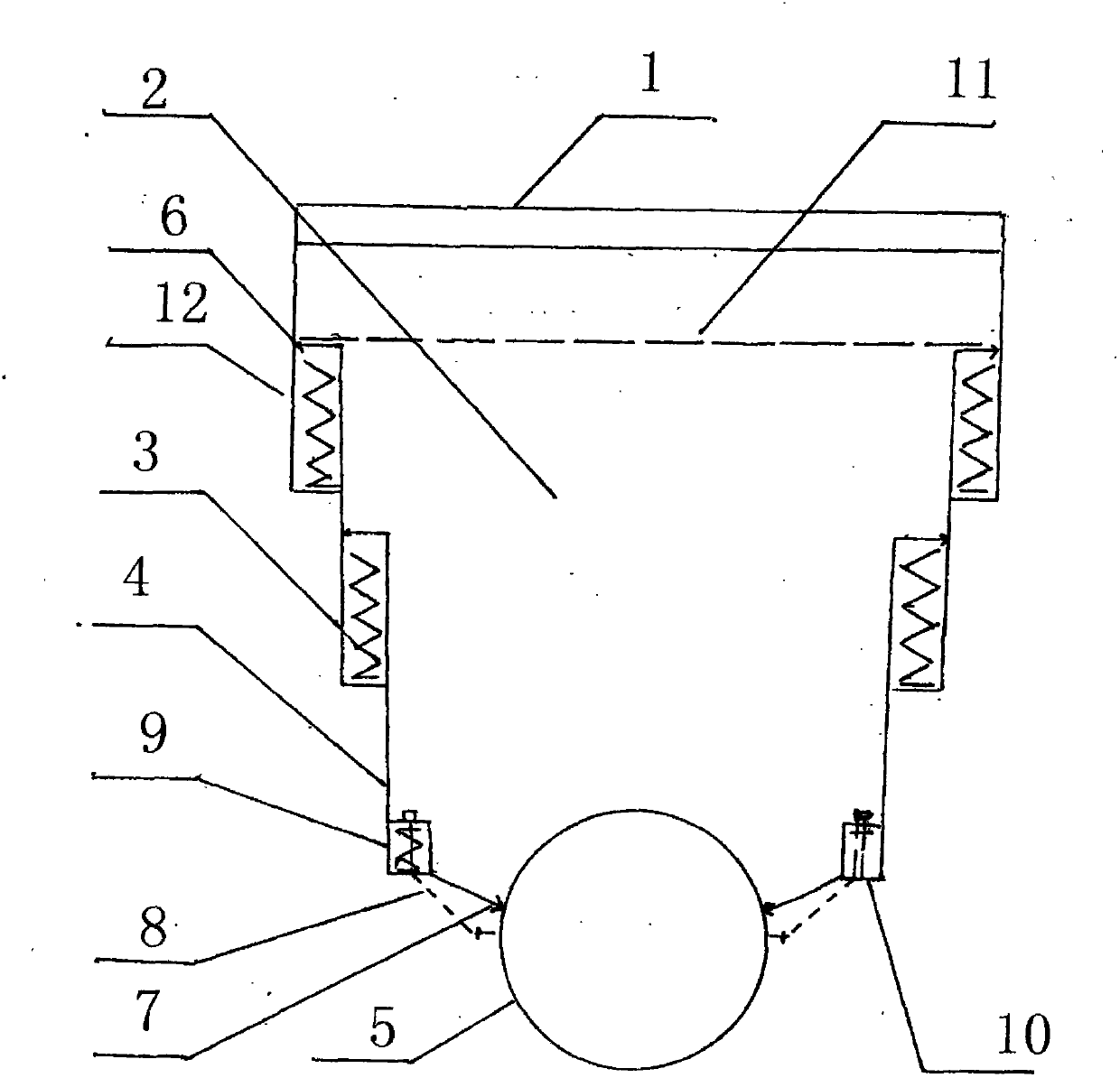

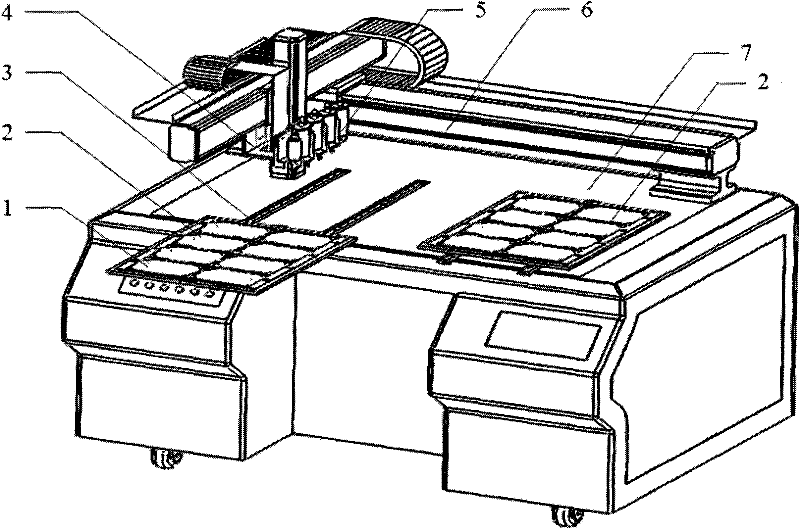

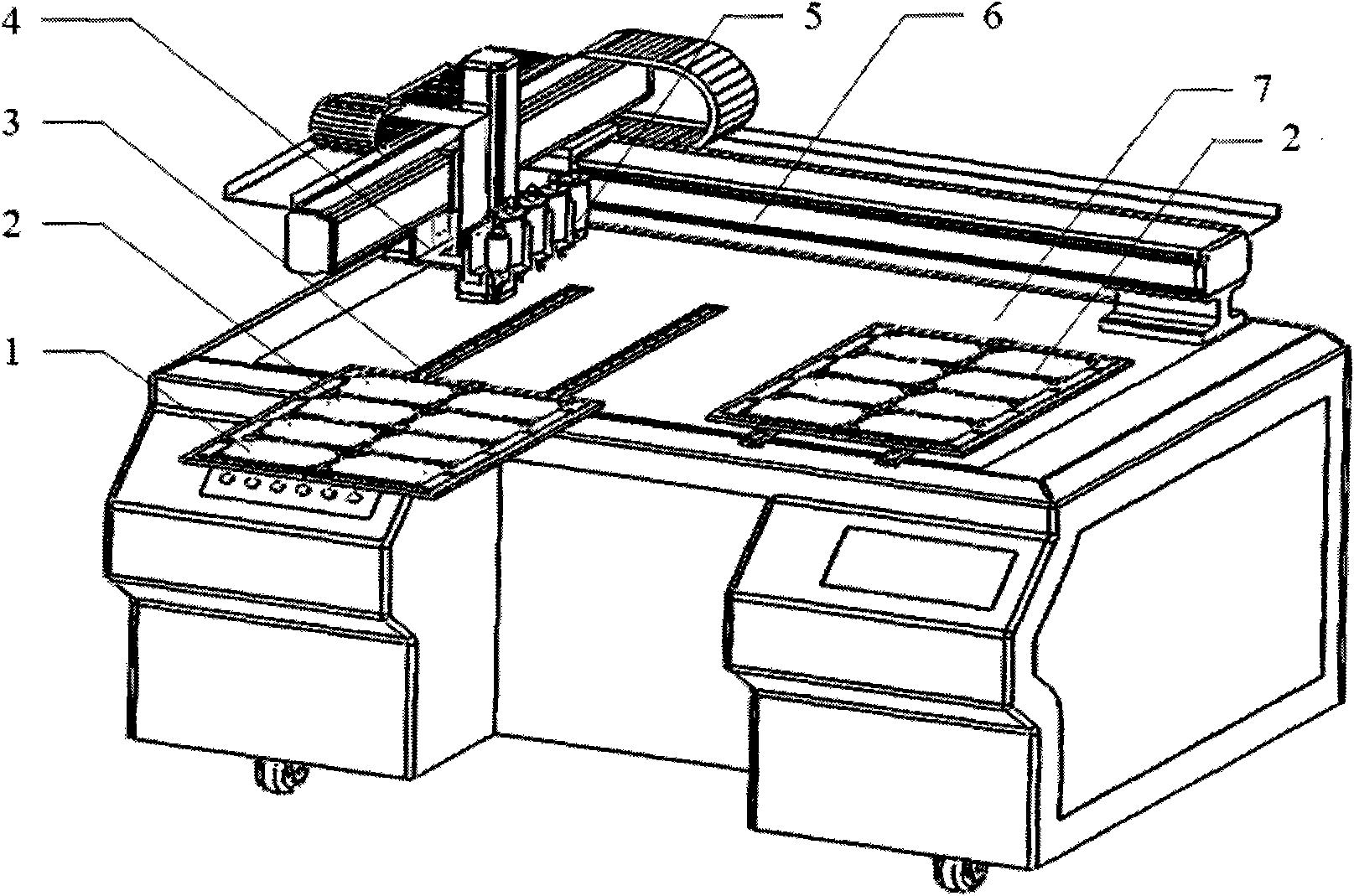

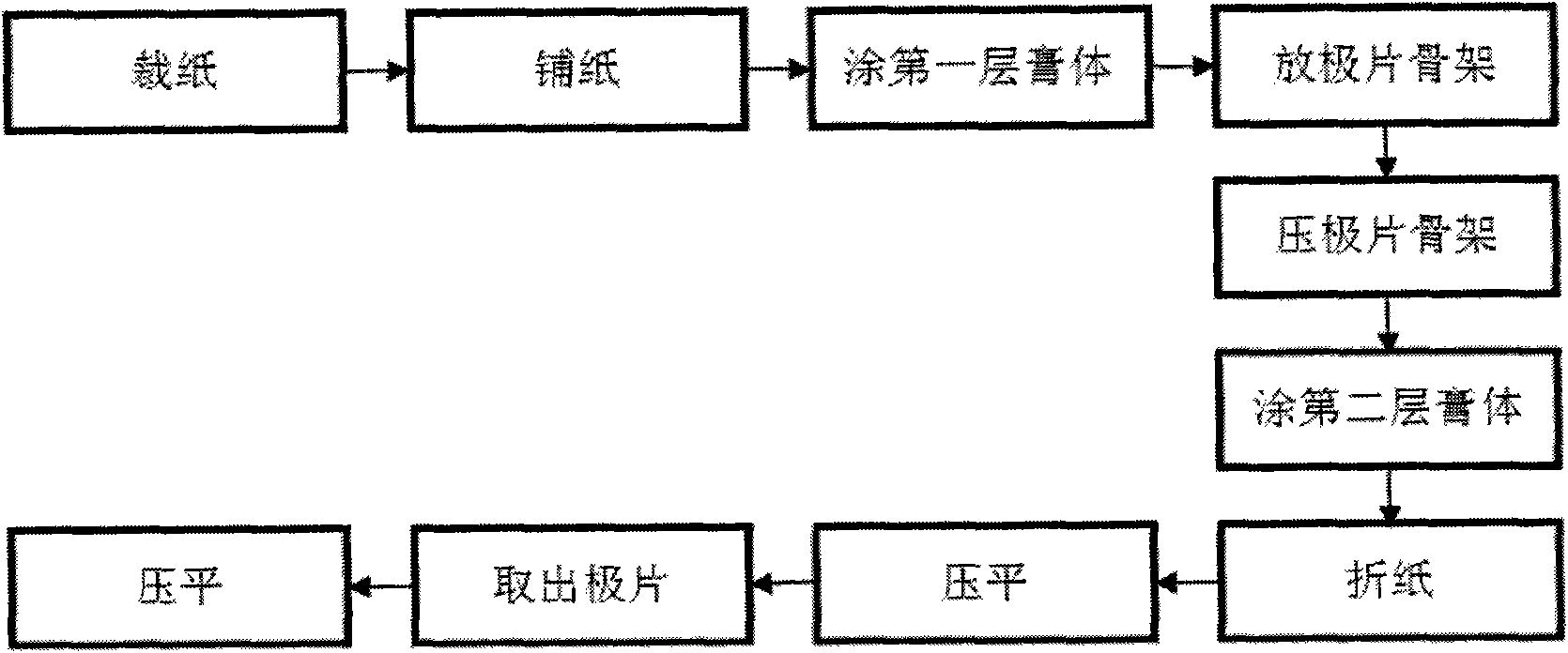

Space zinc-silver battery cathode plate module forming device and method thereof

InactiveCN101567446BEvenly distributedControl spilloverAlkaline accumulator electrodesCartesian coordinate robotEngineering

The invention discloses a space zinc-silver battery cathode plate module forming device and a method thereof in the technical field of battery preparation. The device comprises an end plate, a pressedcompact, a plurality of paste control valves, a three freedom degree cartesian coordinate robot and a working platform, wherein the end plate is movably arranged on the working platform through a lead rail; and the plurality of paste control valves are arranged on the movable arm of the three freedom degree cartesian coordinate robot. The double-layer paste coated by the method is uniformly arranged, thus improving the performance of the batteries, prolonging the service life, and simultaneously and effectively controlling the paste from spilling out, thereby avoiding the pollution of the paste to the batteries. The space zinc-silver battery cathode plate module forming device and the method thereof replace the operation technique of the existing space zinc-silver battery cathode plate module which is completely and manually formed, and greatly improve the precision, yield and efficiency.

Owner:上海交睿机器人科技有限公司

Method for producing wooden floor with platinum crystal surface

InactiveCN101301764BSolve the problem of insufficient adhesionIncrease pressureLiquid surface applicatorsWood treatment detailsPlatinumWear resistant

The invention discloses a production method for a platinum crystal face wood floor, which comprises the production steps as follows: drying and curing of floor blank, blank processing, primer and paint painting. The invention adopts a vertical-lubrication penetration roller spraying technique, carries out the pre-heating disposal, drying disposal, balance disposal, humidifying treatment, temperature reduction kiln outgoing and curing to the floor blank, then processes the blank and paints the primer; the paint is then coated by adopting eight-bottom and four-surface so as to gain a finished product. The platinum crystal face wood floor prepared by the invention has the advantages that the paint adhesion of the tree with high grease (oil) content is improved; the floor has ultra-strong adhesion from the interior of the wood to the surface; a production process of eight-bottom and four-surface is adopted to combine an elastic, abration and friction resistance environmental protection paint; therefore, the surface filling of the floor is saturated, clear and natural, the chamfers are smoother and the wood floor is more scraping- resistant and wear-resistant; the one-off qualificationrate of the product is improved and achieves 99.5 percent, thus improving the quality of the product.

Owner:浙江上臣家居科技有限公司

An irrigation device and method for large-scale no-tillage planting of mustard and mustard in Italian poplar forests

ActiveCN102972139BControl spilloverBalance in and outPressurised distribution of liquid fertiliserAgriculture gas emission reductionShunt DeviceHand held

The invention discloses an irrigation rig and an irrigation method of large-scale no-tillage planted pickled mustard root and leaf mustard in an Italian poplar forest. The irrigation rig is characterized by comprising a fixed diversion rubber bucket, a water conduit ball head, a water conduit, a self-sucking pump, a water outlet pipe, two high fertilizer-liquid containers used by turns, a hand-held electric mixer, a spilled fertilizer tube switch, a spilled fertilizer tube, a spilled fertilizer tube joint steel tube, a fixed diversion fertilizer-liquid rubber bucket, a high-pressure diving pump, a diversion fertilizer-liquid pressure water pipe, a shunting device and an operating hose. The irrigation rig and the irrigation method, which are simple to operate, good in drought-resisting fertilization effect, low in cost, high in work efficiency, and suitable for large-scale tillage planting and planting of the pickled mustard roots and the leaf mustards of Italian poplar forests in remote beaches in rivers and lakes, are provided by the invention.

Owner:刘立武

Pneumatic garbage collection and separation compression transfer box

ActiveCN105883268BImprove sealingControl spilloverGas current separationRefuse receptaclesRefuse collectionWaste collection

The invention provides a pneumatic transfer box for garbage collection, separation and compression. The function of integrating material-gas separation, compression and recycling is achieved. Seal of a box body is optimized. Overflow of bad smell, sewage and garbage in the box body is controlled. Total intelligence and automation are achieved. The simplest design and treatment method is adopted, and the machine fault rate is greatly reduced.

Owner:ZHEJIANG YISHUNTONG TECH CO LTD

Space zinc-silver battery cathode plate module forming device and method thereof

InactiveCN101567446AEvenly distributedControl spilloverAlkaline accumulator electrodesElectrical batteryCartesian coordinate robot

The invention discloses a space zinc-silver battery cathode plate module forming device and a method thereof in the technical field of battery preparation. The device comprises an end plate, a pressed compact, a plurality of paste control valves, a three freedom degree cartesian coordinate robot and a working platform, wherein the end plate is movably arranged on the working platform through a lead rail; and the plurality of paste control valves are arranged on the movable arm of the three freedom degree cartesian coordinate robot. The double-layer paste coated by the method is uniformly arranged, thus improving the performance of the batteries, prolonging the service life, and simultaneously and effectively controlling the paste from spilling out, thereby avoiding the pollution of the paste to the batteries. The space zinc-silver battery cathode plate module forming device and the method thereof replace the operation technique of the existing space zinc-silver battery cathode plate module which is completely and manually formed, and greatly improve the precision, yield and efficiency.

Owner:上海交睿机器人科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com