Automatic package method for solar battery sheet and anti-ratiation glass cover

A solar cell and cover glass technology, applied in the direction of circuits, electrical components, sustainable manufacturing/processing, etc., can solve the problems of high cost, pollution of cover glass and cells, difficult operation, etc., and achieve the number and size of bubbles Satisfaction, avoidance of damage to human health, avoidance of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

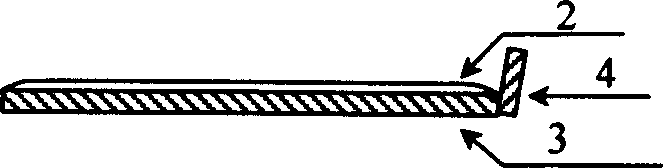

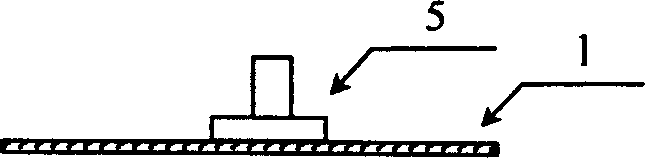

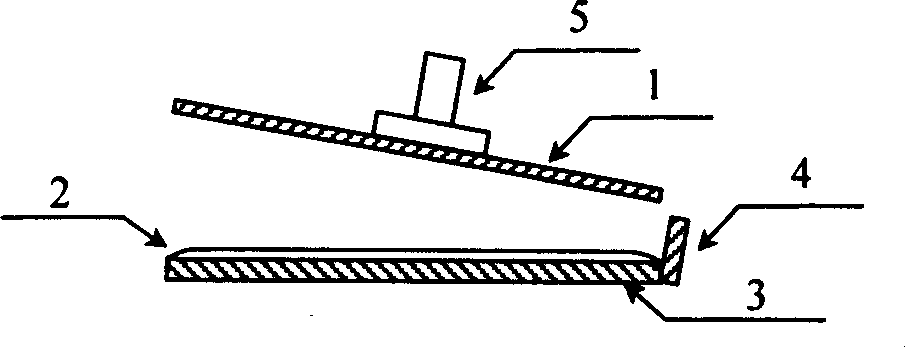

[0038] Such as figure 1 As shown, there is a uniform adhesive layer 2 on the solar cell 3, and a positioning block 4 is located on the right side of the solar cell 3. The thickness of the anti-radiation glass cover sheet 1 is 0.12mm, and the external dimension is 40.20×20.10mm; the thickness of the solar cell 3 is 0.20mm. The thickness of the adhesive layer 2 is less than 0.1 mm. The present invention utilizes the non-Newtonian fluid characteristics of the colloid, and through the uniform extrusion of the adhesive layer 2 through the slit formed between the glass cover sheet 1 and the solar cell sheet 3, the air between the glass cover sheet 1 and the adhesive layer 2 is naturally discharged , to achieve the control of packaging quality. The specific method is as follows:

[0039] At room temperature (15-25°C), measure the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com