Patents

Literature

117 results about "Fragmentation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Medium chromium multielement alloy cast ball and cast segment oil quenching heat treatment technique

The invention discloses a medium chromium multielement alloy cast ball and cast segment oil quenching heat treatment technique, wherein the contained components are as follow: 1.7-3.1 of C, 0.3-1.0 ofSi, 0.3-1.0 of Mn, 5-10 of Cr, less than or equal to 0.09 of S, less than or equal to 0.08 of P, and trace of Mo, Ni, Nb, Cu, Y, B, V and Ti; cast medium chromium multielement alloy cast ball and cast segment are heated to 930-1050 DEG C, the temperature is kept for 1.5-3h followed by oil cooling treatment, when the surface temperature of medium chromium multielement alloy cast ball and cast segment are decreased to 100-250 DEG C, the product is moved off the oil tank to halt oil quenching, and the product is poured into an iron bucket, when the iron bucket is full the product is put into a tempering furnace for tempering treatment. The invention solves the problem of poor use quality as cast condition of the medium chromium multielement alloy cast ball and cast segment, in addition, theproduct has no crack, the hardness, toughness and antifatigue impact service life is improved, consumption is reduced, and the ball fragmentation rate is low, thus saving quantities of chromium alloyresource for the nation and reducing operation cost for the user.

Owner:宁国市南洋机械有限公司

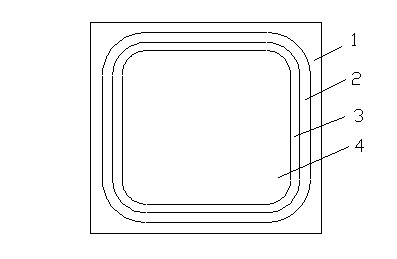

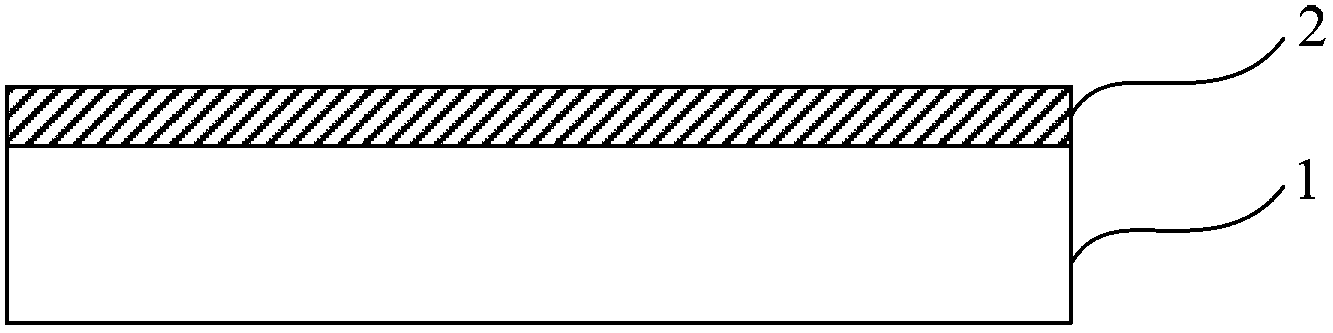

High-power planar junction bidirectional TVS diode chip and production method thereof

InactiveCN101916786AIncrease profitAvoid stressSemiconductor/solid-state device manufacturingSemiconductor devicesManufacturing technologyFragmentation rate

The invention discloses a high-power planar junction bidirectional TVS diode chip and a production method thereof, and relates to the technical field of manufacturing of a semiconductor device. The production method comprises the following steps of: protecting both surfaces of a silicon wafer with SiO2; photo-etching diffusion windows on the both surfaces; simultaneously forming P-type diffusion regions in the diffusion windows; and forming coated regions on the surfaces of the P-type diffusion regions. By adopting shallow junction diffusion, the process has the advantages of short diffusion time, long product life, high performance, no warping of the silicon wafer and low fragmentation rate of the product. Trenching is not needed during the production, so the utilization ratio of the silicon wafer and the current density of the product can be improved. Scribing is not performed on a glass passivation layer, so the stress of a glass passivation film can be prevented so as to contribute to ensuring firm structure, reducing leakage current, particularly the leakage current at the high temperature and improving the reliability of the product. By using a multilevel metallization mode, the coating can be finished at one time and has simple process and high reliability.

Owner:NANTONG MINICHIP MICRO ELECTRONICS

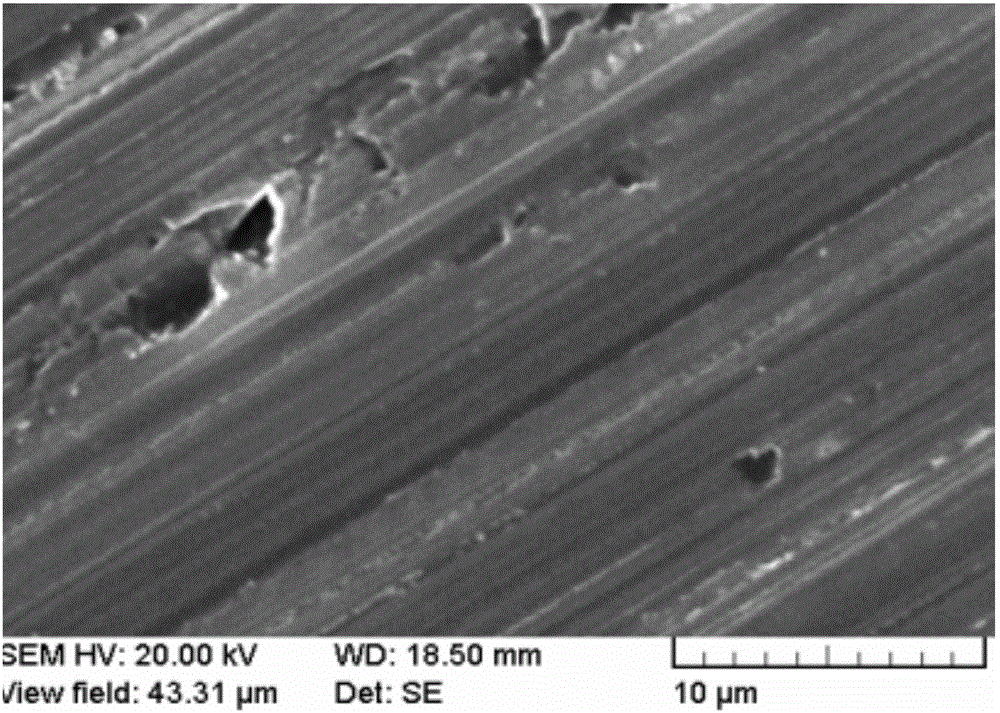

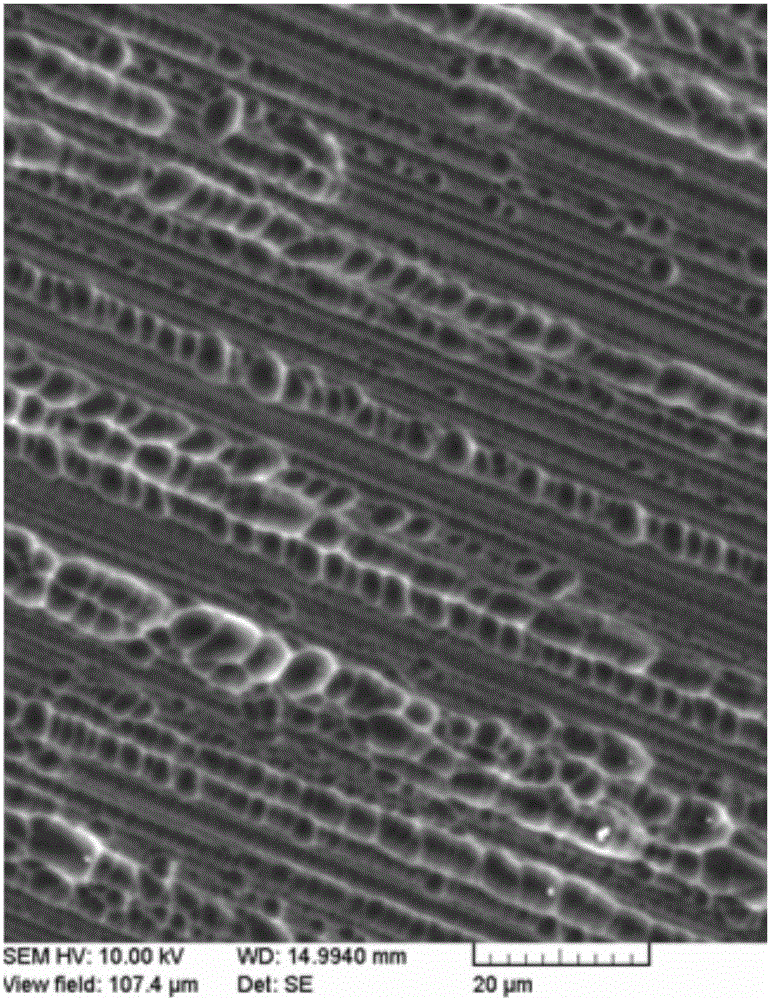

Texture etching method for single crystalline silicon solar cell

InactiveCN101431124AImprove conversion efficiencyIncrease short circuit currentFinal product manufactureSemiconductor devicesHydrofluoric acidEtching

The invention discloses a preparation method of a monocrystalline silicon solar cell texture, the process is as follows: a monocrystalline silicon wafer which is rinsed cleanly by pure water after the chemical pre-cleaning in the former step is put in an ultrasonic tank of an ultrasonic cleaning machine with the power of 1,800-2,400w and the frequency of 25-40kHz, mixed water solution with 1 percent-2 percent NaOH and 3 percent-6 percent isopropyl alcohol according to the weight percentage is prepared in the ultrasonic tank, the temperature of the mixed water solution is set to be 75-85 DEG C, the ultrasound time is 30-35min, then the monocrystalline silicon wafer is taken out and put in hydrochloric acid water solution with the volume percentage of 10 percent for soaking for 4-6min, hydrofluoric acid water solution with the volume percentage of 10 percent is further used for soaking for 4-6min after the rinsing, then deionized water is used for cleaning, and drying is finally carried out. The silicon wafer texture prepared by the preparation method is even and low in reflection rate; furthermore, the preparation method reduces the fragmentation rate and improves the production efficiency and the production capacity.

Owner:NINGBO ULICA SOLAR SCIENCE & TECHNOLOGY CO LTD

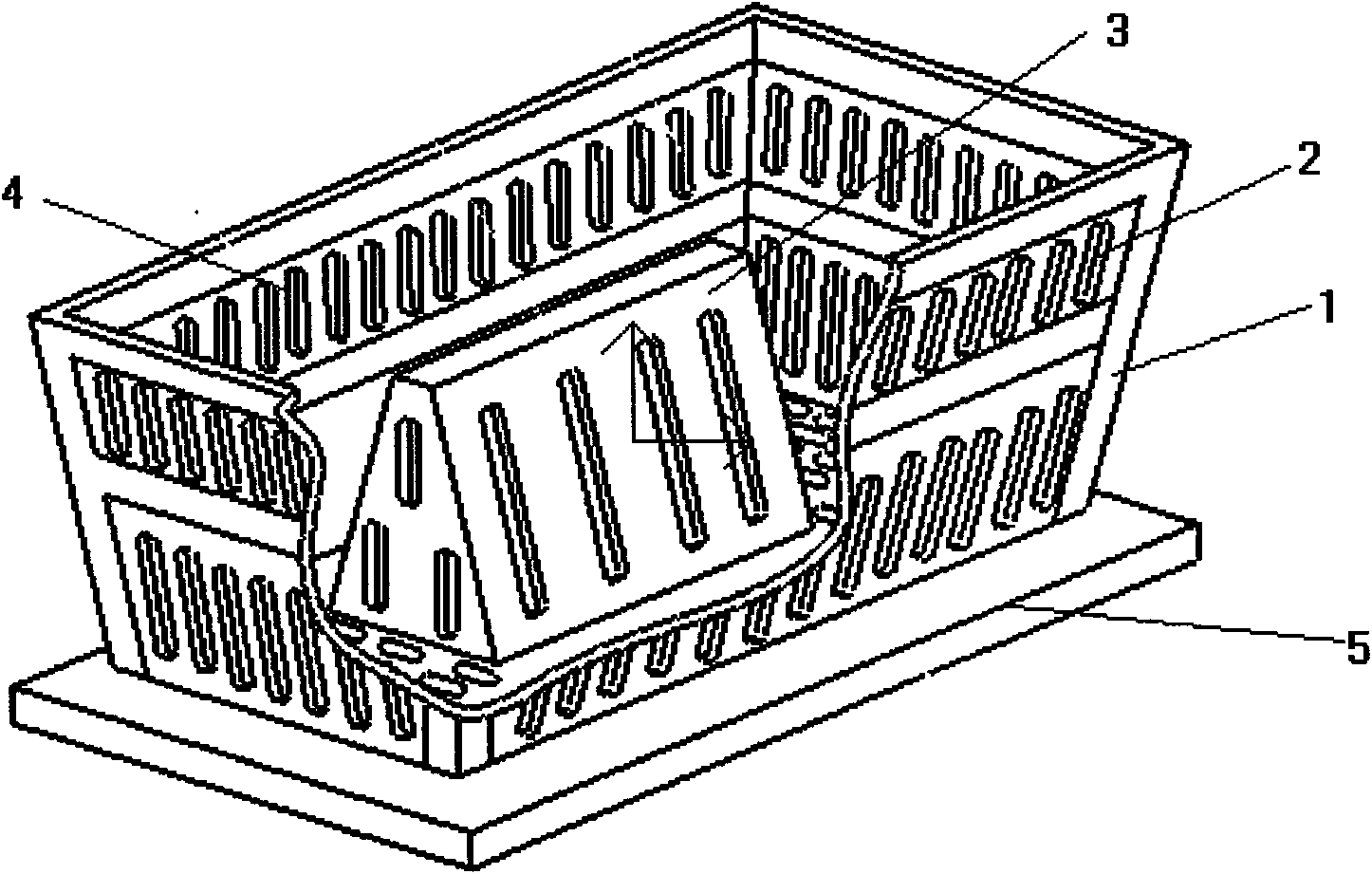

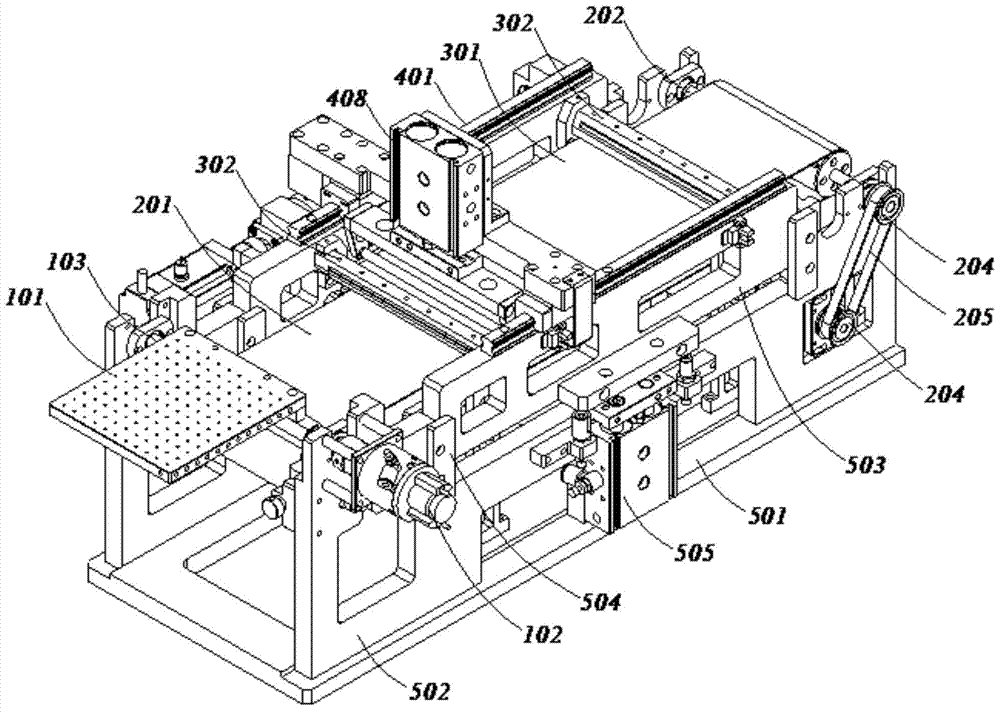

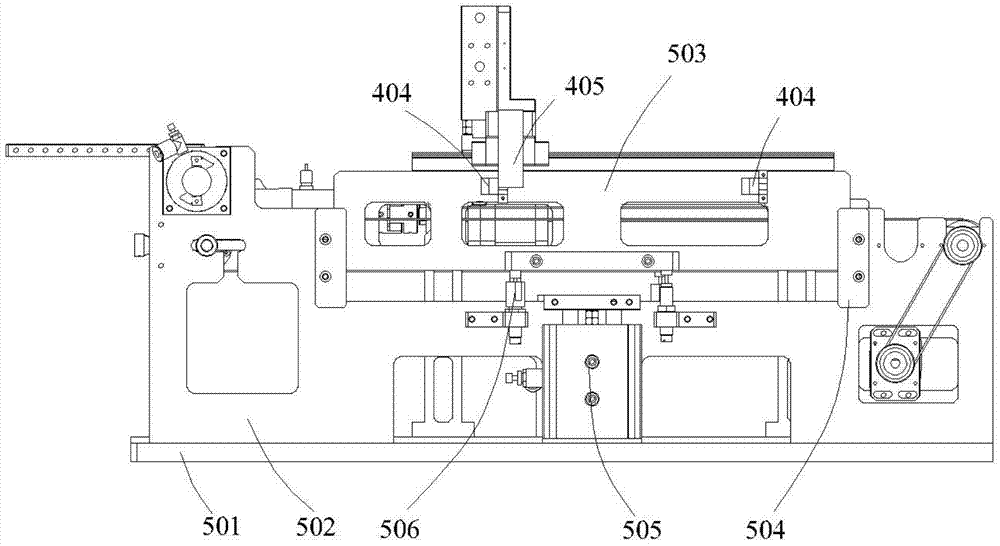

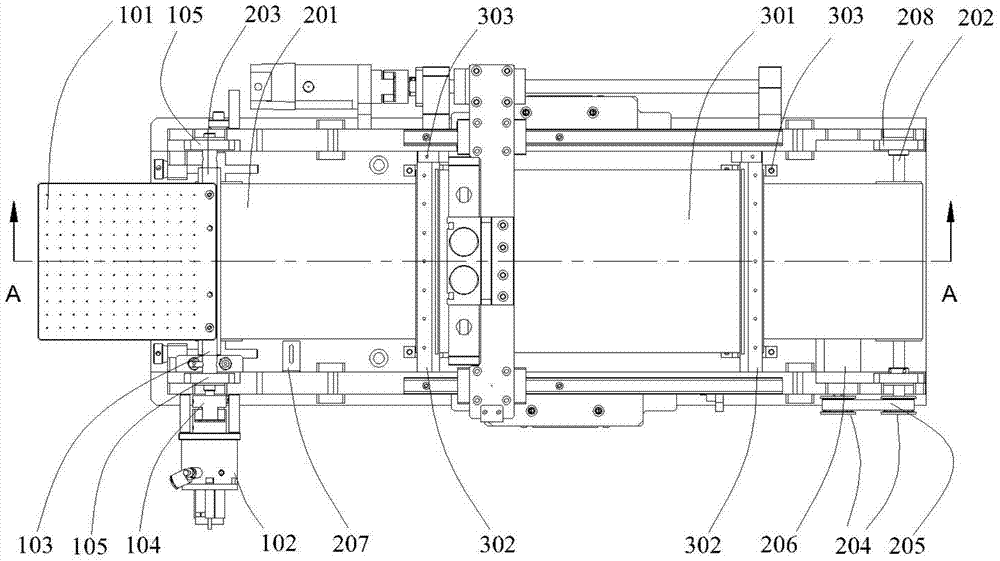

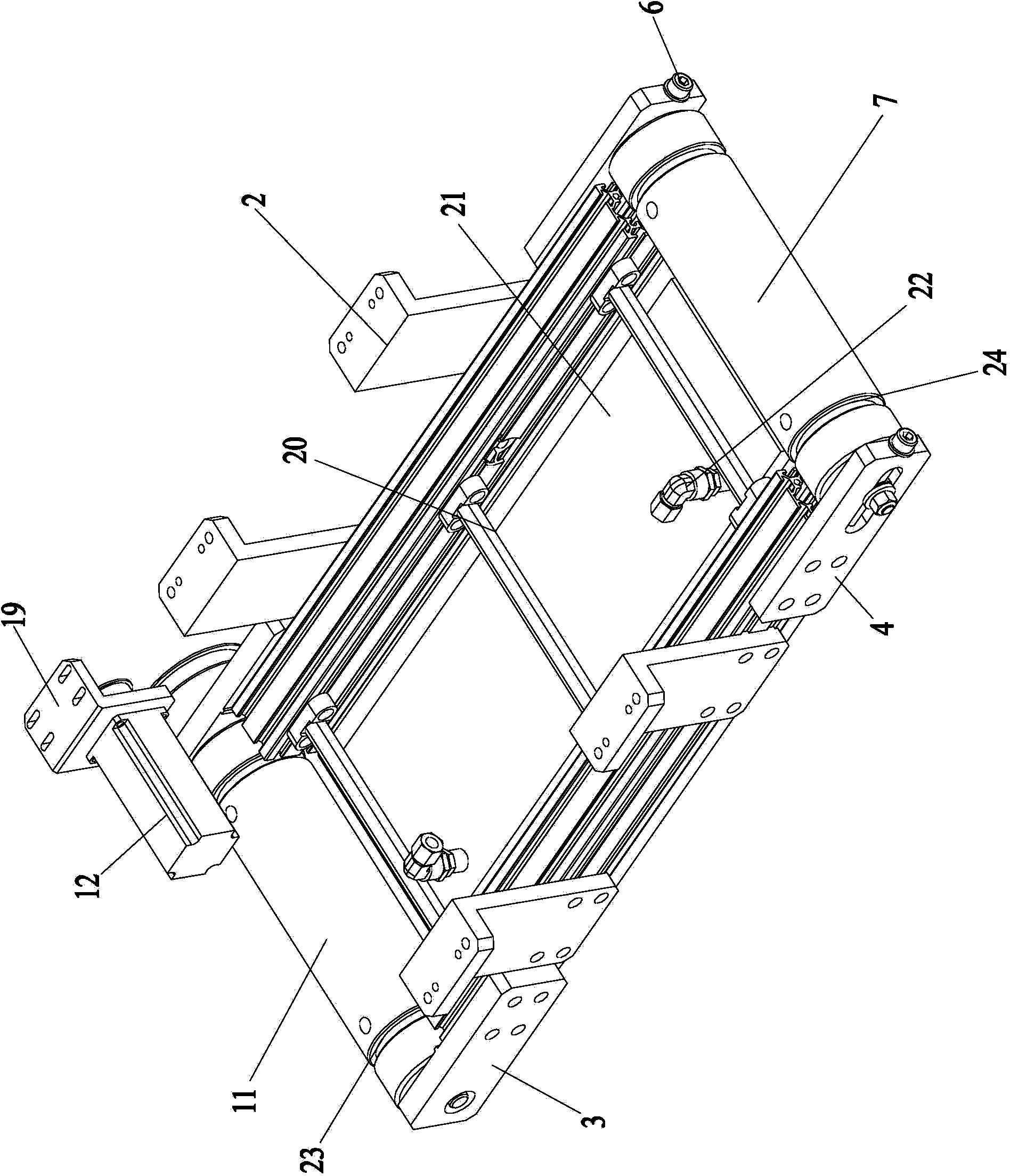

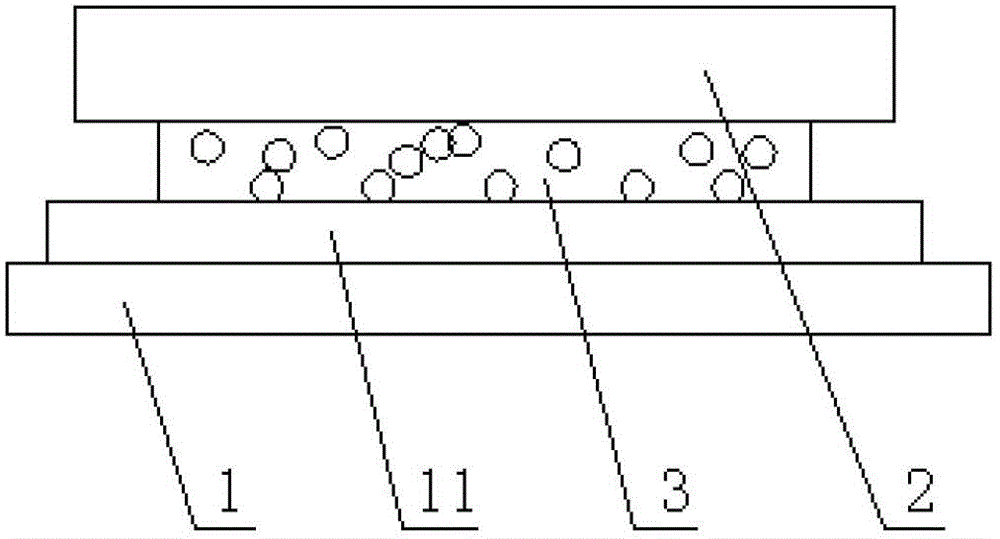

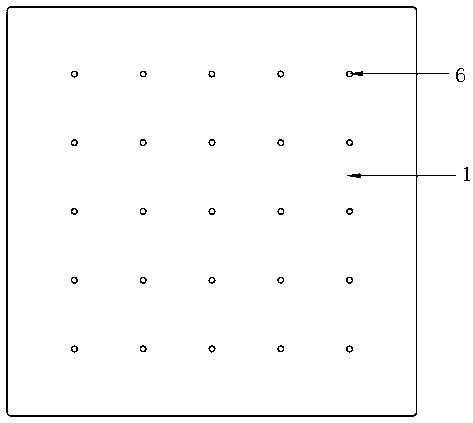

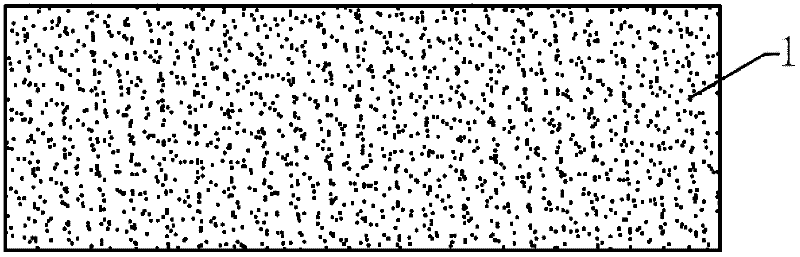

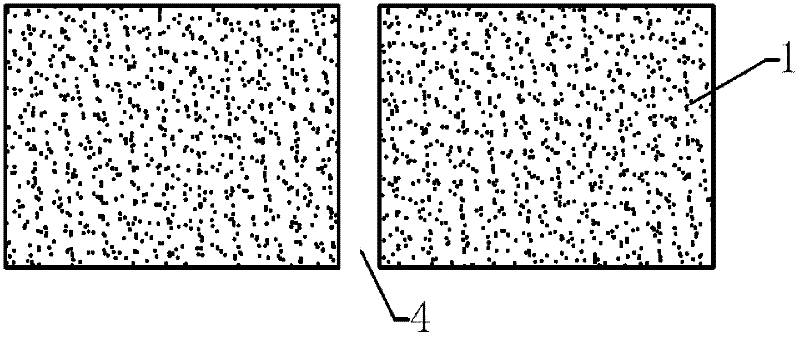

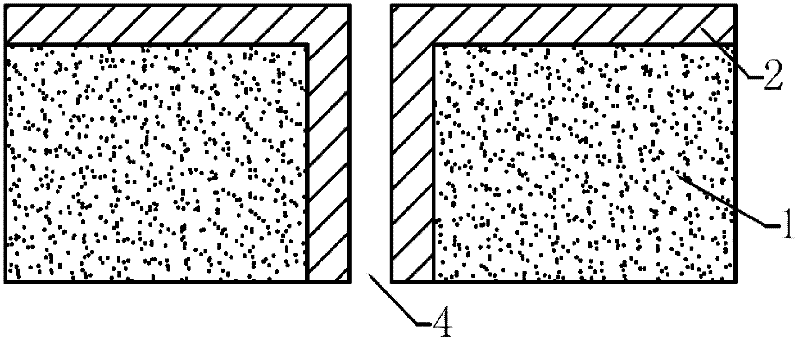

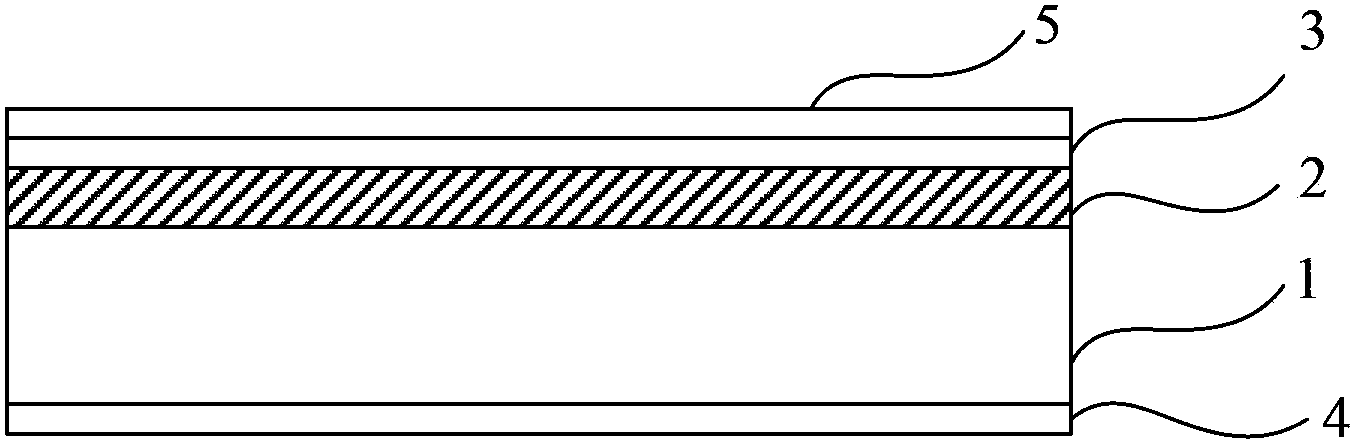

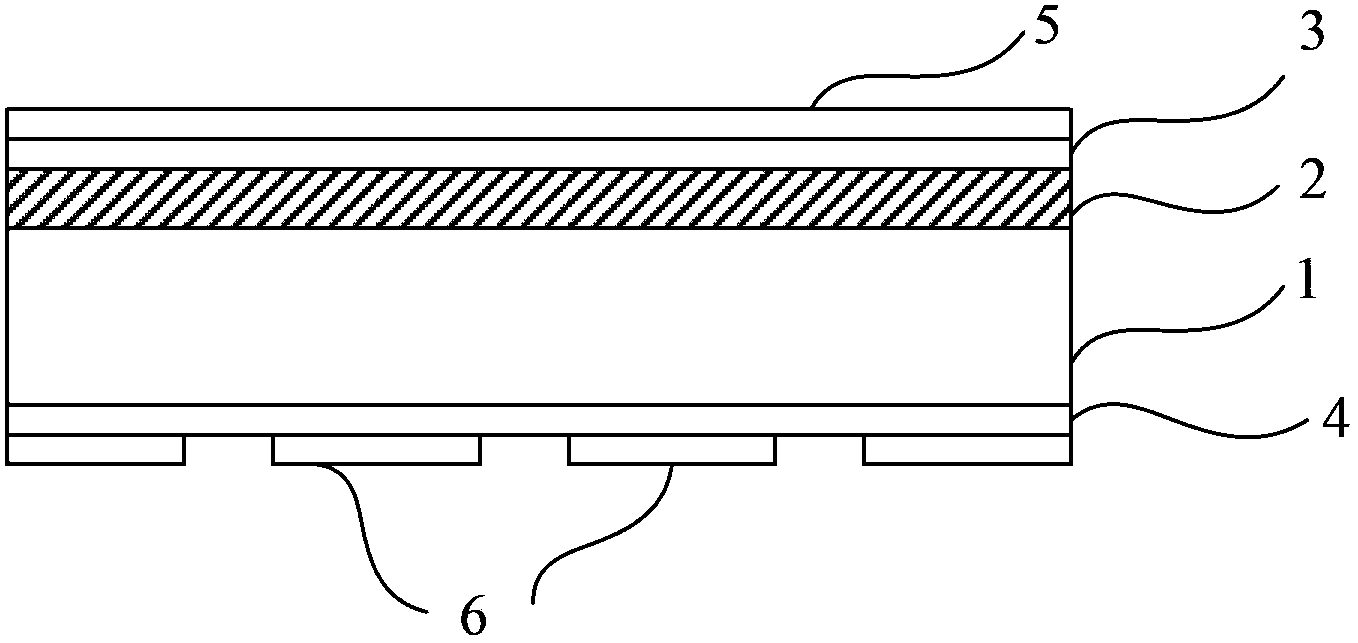

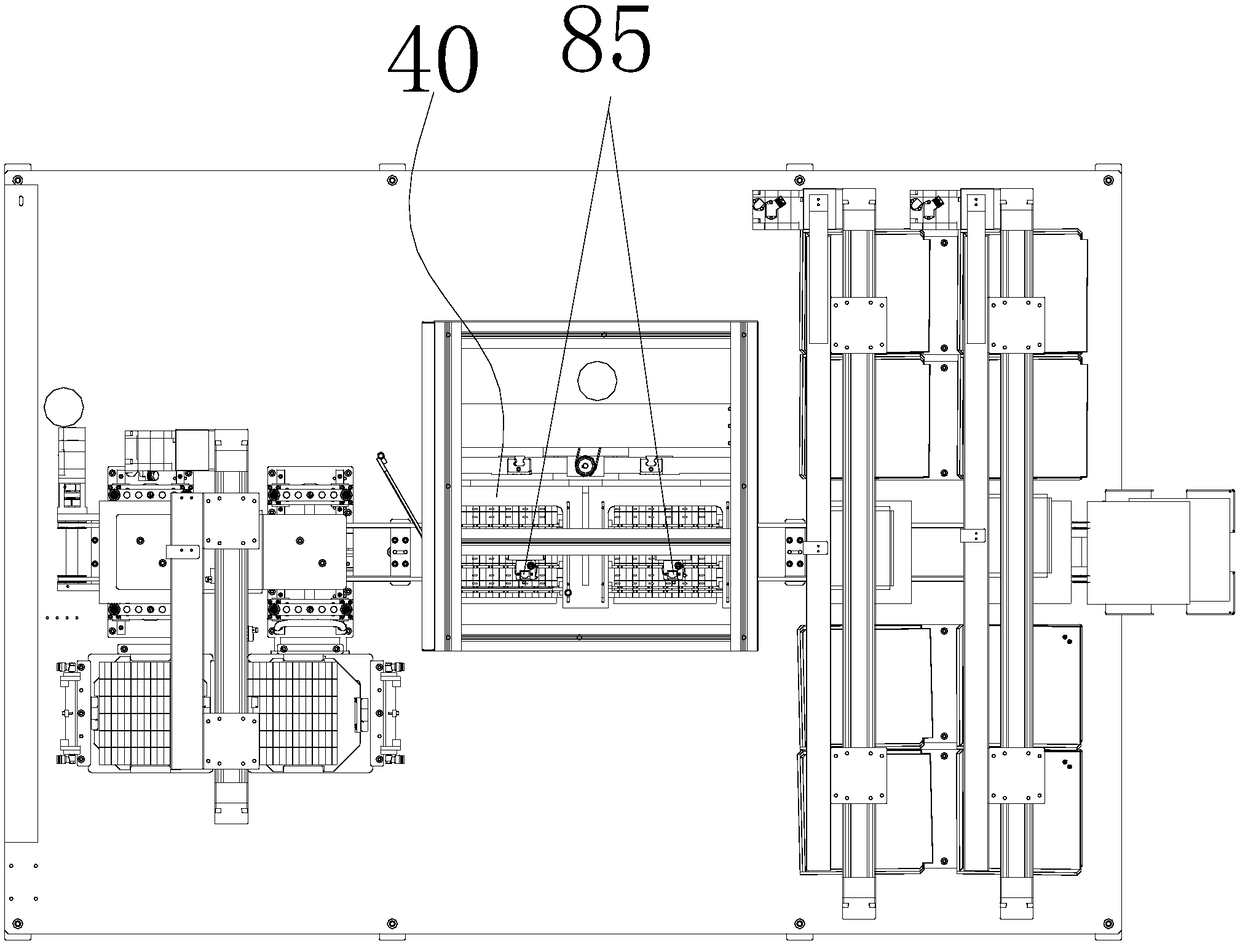

Cell splitting device and cell splitting method

InactiveCN104766821AImprove efficiencyGuaranteed accuracyFinal product manufactureSemiconductor/solid-state device manufacturingFragmentation rateEngineering

The invention relates to the technical field of crystalline silicon cell manufacturing, and discloses a cell splitting device and a cell splitting method. The device comprises a device body, a feeding device and a flexible belt conveying device which are arranged on the device body in sequence, a lifting device mounted on the device body and disposed at one side of the flexible belt conveying device, a flexible belt coating device mounted on the lifting device and disposed on the upper end of the flexible belt conveying device, and a roller rolling device mounted on the lifting device and disposed on the upper end of the flexible belt coating device. A pressing device for driving the roller rolling device to press the flexible belt coating device and a linear moving device for driving the roller rolling device to move along the conveying direction of the flexible belt conveying device are mounted on the roller rolling device. According to the invention, a cell is coated with two layers of flexible belts and is rolled by the roller rolling device, so that the cell is not broken or moved, the efficiency of cell splitting is improved, and the fragmentation rate is reduced.

Owner:HANS LASER TECH IND GRP CO LTD

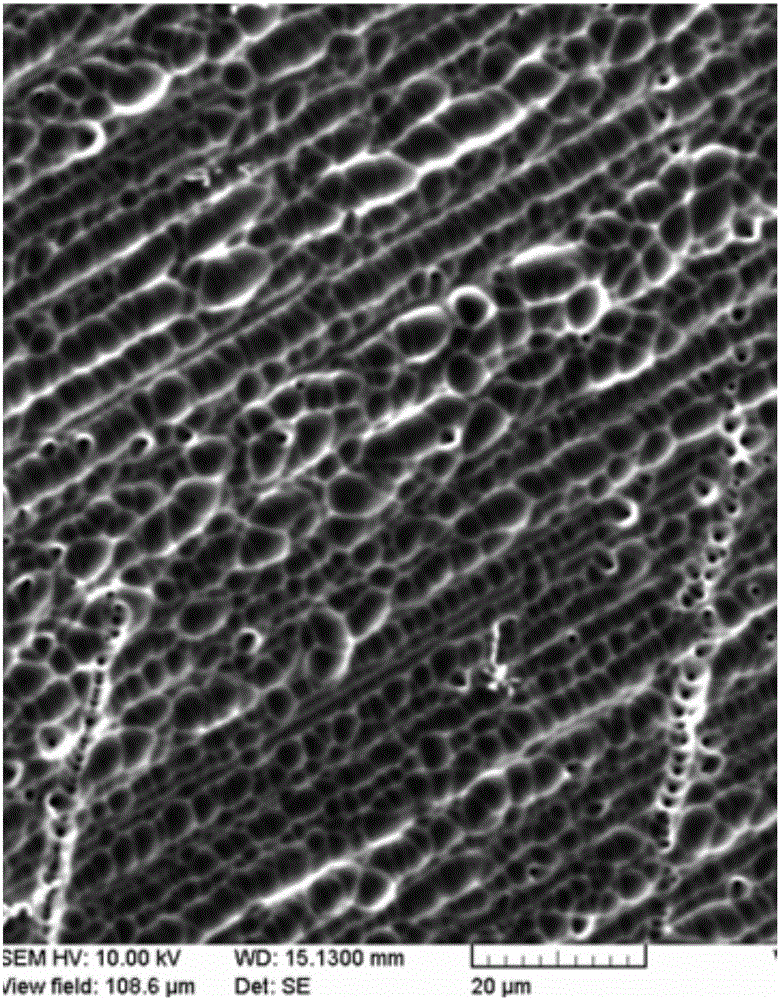

Auxiliary chemical composition used for monocrystalline silicon or polycrystalline silicon acidic texturization and application thereof

InactiveCN106521634AEasy to prepareEasy to useAfter-treatment detailsPhotovoltaic energy generationPolyolChemical composition

The invention provides an auxiliary chemical composition used for monocrystalline silicon or polycrystalline silicon acidic texturization. The auxiliary chemical composition includes: polysaccharide or its derivative, polyol or its derivative. The preparation and use method of the auxiliary chemical composition is simple and easy to implement, and has good repeatability. When used for diamond wire-cut monocrystalline silicon or polycrystalline silicon texturization, the auxiliary chemical composition can increase the texturization temperature, and at the same time can greatly improve the surface texturization uniformity, and the prepared silicon chip has the characteristics of low reflectivity, clean surface, low fragmentation rate, and uniform color after coating, thus greatly improving the photoelectric conversion efficiency of silicon cells.

Owner:湖州三峰能源科技有限公司

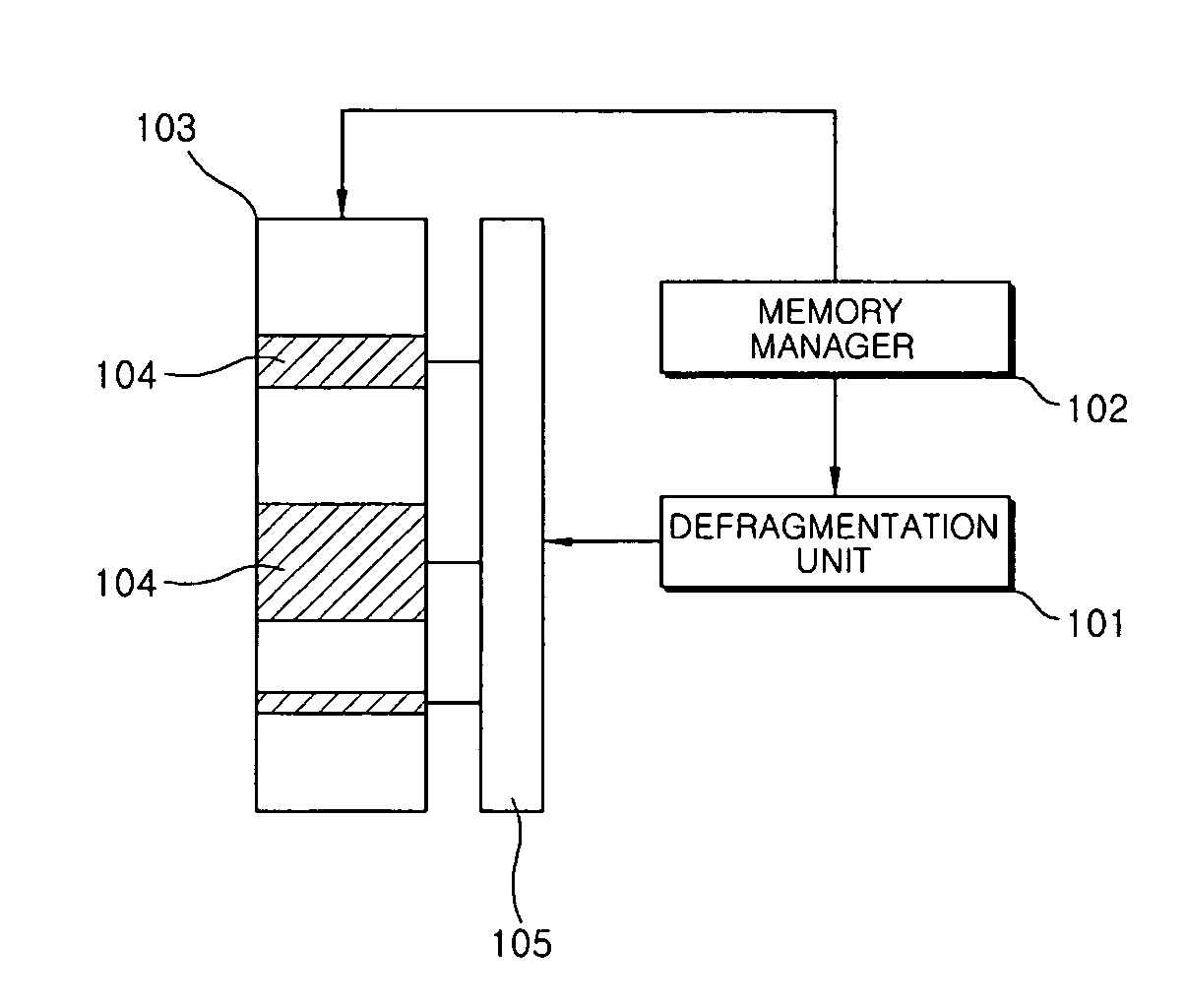

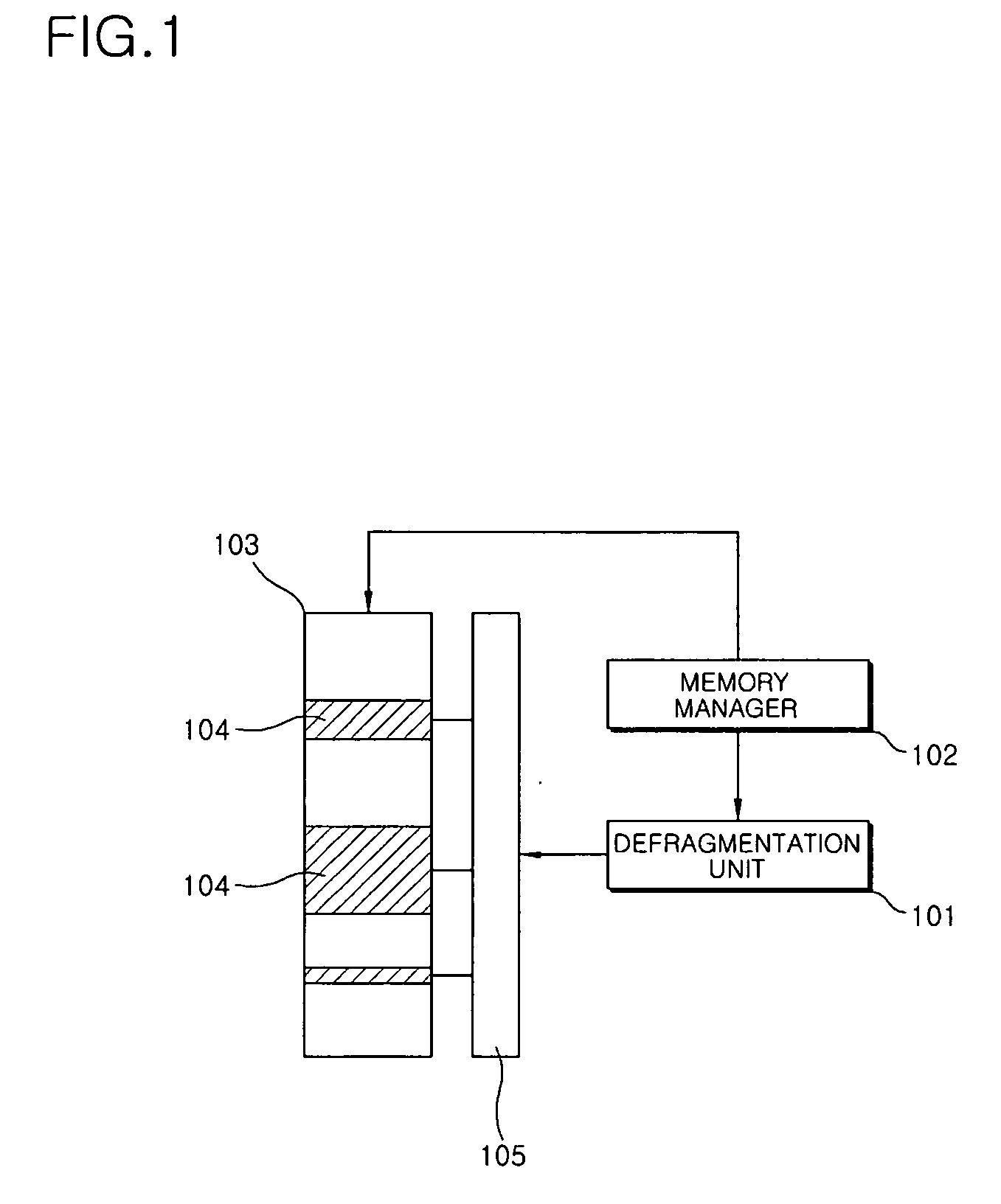

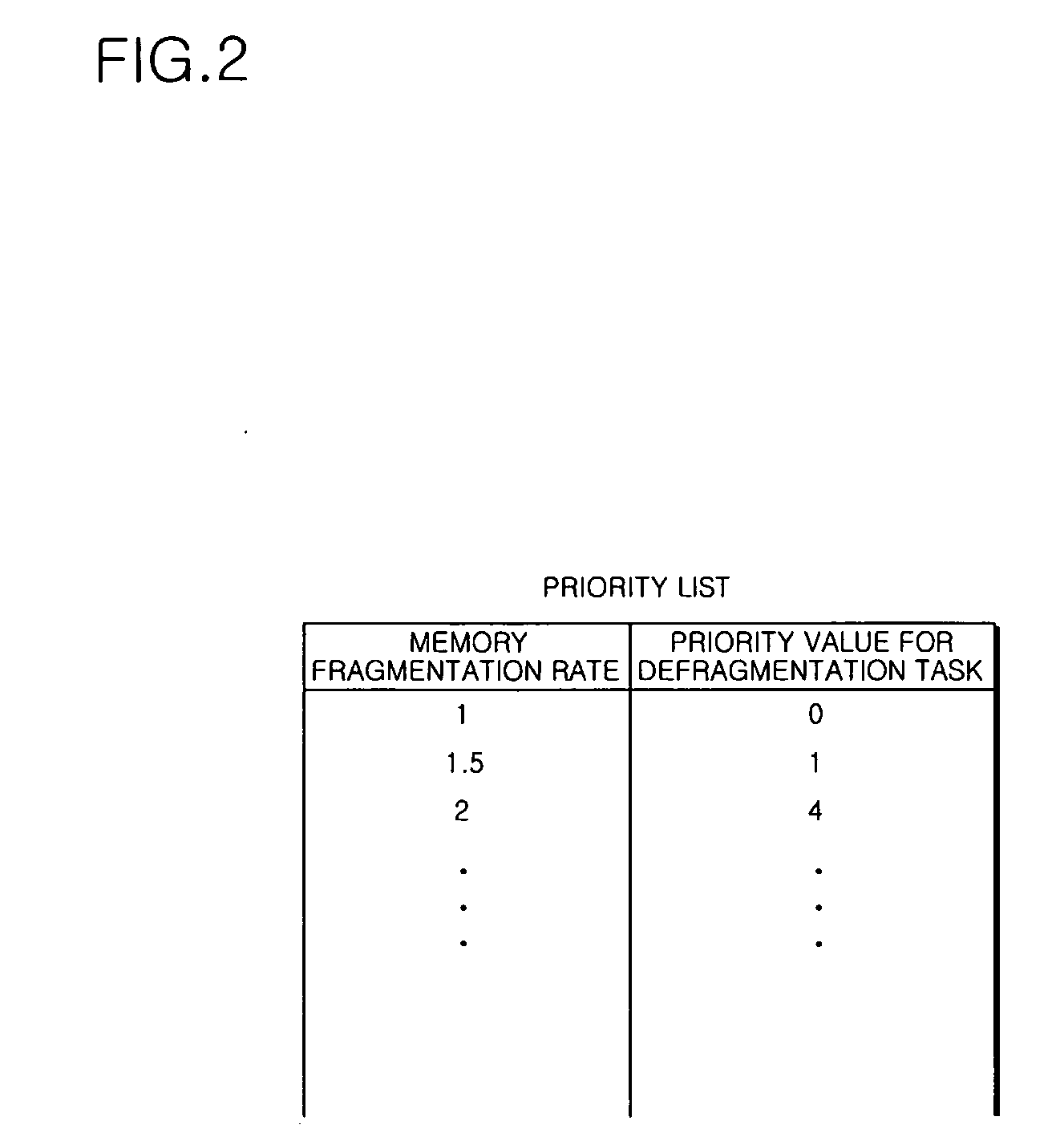

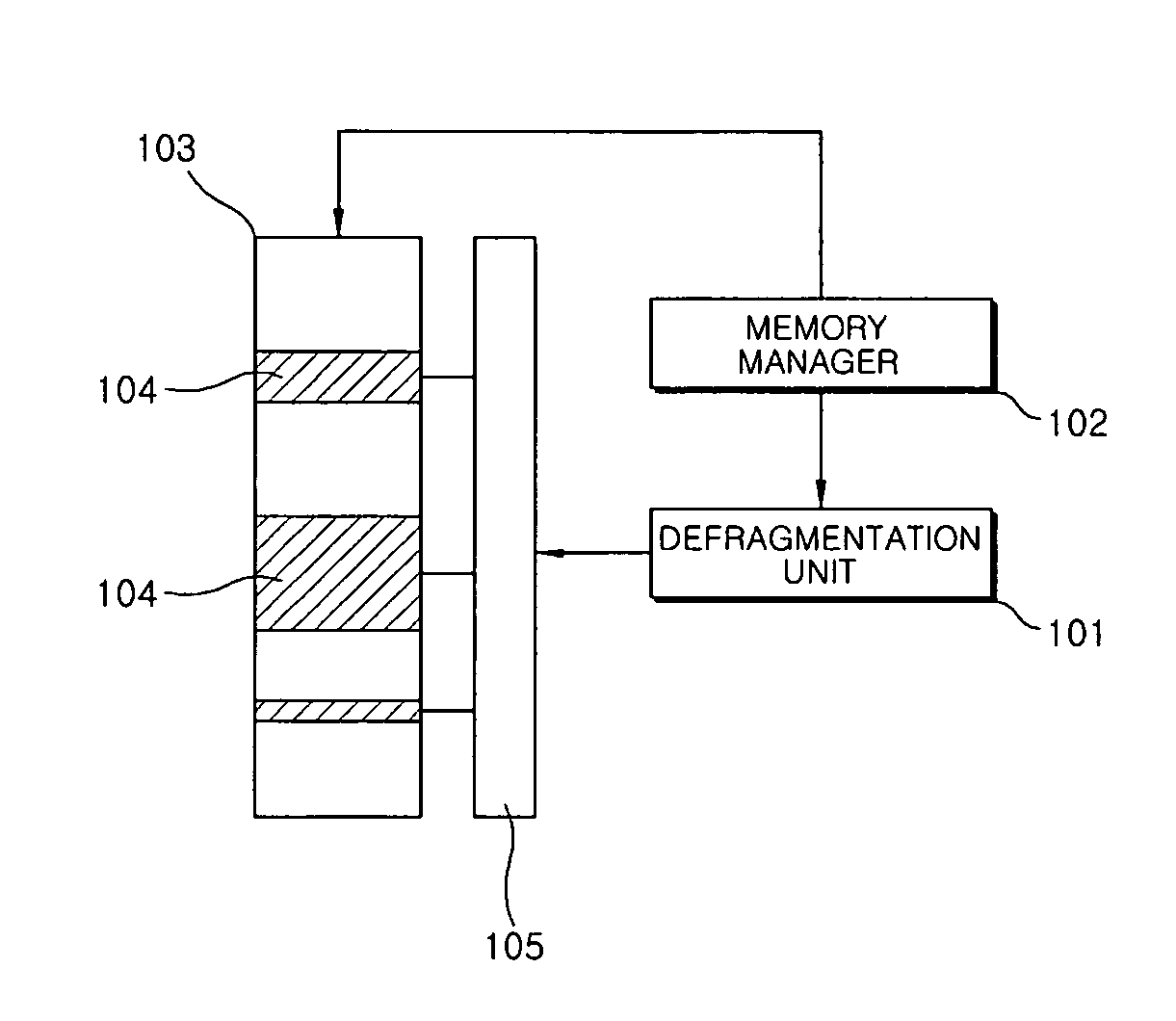

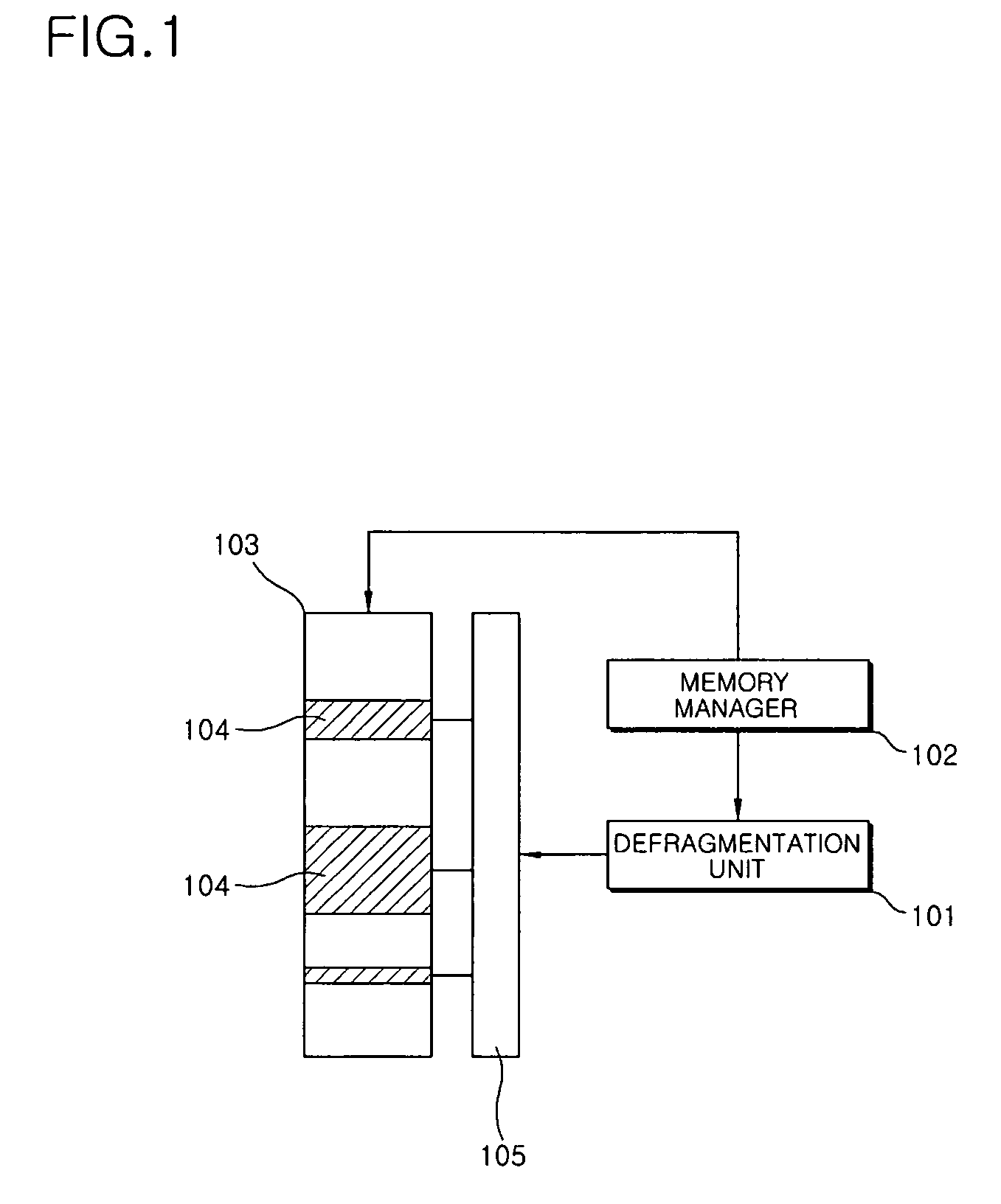

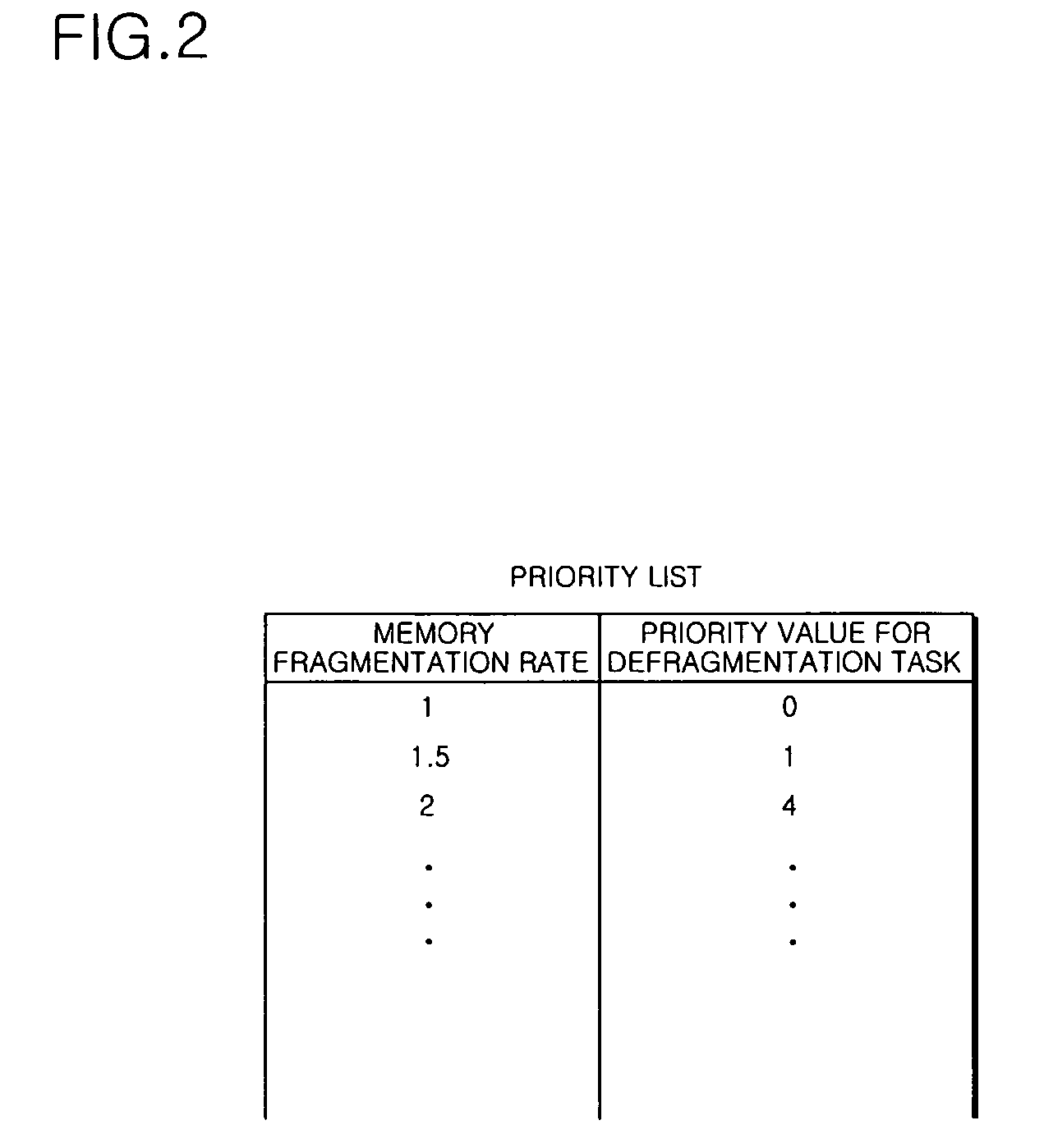

Apparatus for managing memory in real-time embedded system and method of allocating, deallocating and managing memory in real-time embedded system

An apparatus for managing memory in a real-time embedded system and a method of allocating, deallocating and managing memory in a real-time embedded system. The apparatus includes a defragmentation unit performing a defragmentation task according to a predetermined priority to collect together memory fragments, and a memory manager allocating or deallocating a predetermined area of memory upon request of a task, and calculating a memory fragmentation rate of the memory to determine a priority of the defragmentation task. The method of managing memory in a real-time embedded system includes determining whether the conditions under which the memory is used vary, and if the condition vary, calculating a memory fragmentation rate of the memory to determine a priority of the defragmentation task according to the memory fragmentation rate.

Owner:SAMSUNG ELECTRONICS CO LTD

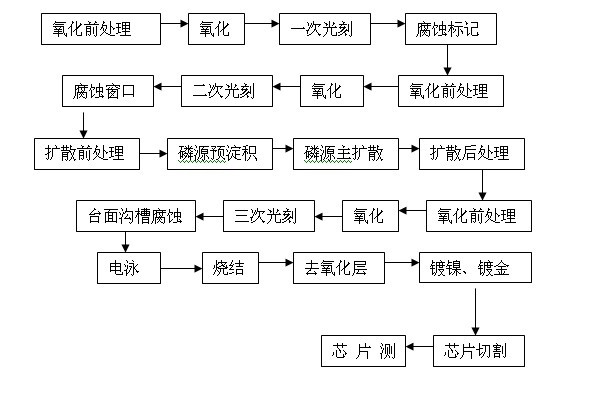

Chip for two-way voltage regulator diode DB3 and manufacturing technique thereof

ActiveCN102082093AImprove trigger abilityImproved pressure stabilityPhotomechanical apparatusSemiconductor/solid-state device manufacturingEtchingFragmentation rate

The invention relates to a manufacturing technique of a chip for a two-way voltage regulator diode DB3, wherein the two-way voltage regulator diode DB3 is a symmetrical diode with the structure of N<+> PN<+>. The resilience voltage is increased due to the adoption of a triple photolithographic process, the trigger capacity of the two-way voltage regulator diode is improved; due to the application of shallow mesa or trench etching, the fragmentation rate is reduced; and glass is passivated due to the adoption of an electrophoretic process, the withstand voltage stability and reliability of the two-way voltage regulator diode are improved. The manufacture technique of the chip for the two-way voltage regulator diode has the advantages of improving the breakdown voltage stability of the two-way voltage regulator diode DB3, enhancing the trigger capacity of the diode, reducing the high-temperature power consumption, prolonging the service life of the diode, and simultaneously improving the qualification rate.

Owner:TIANJIN ZHONGHUAN SEMICON CO LTD

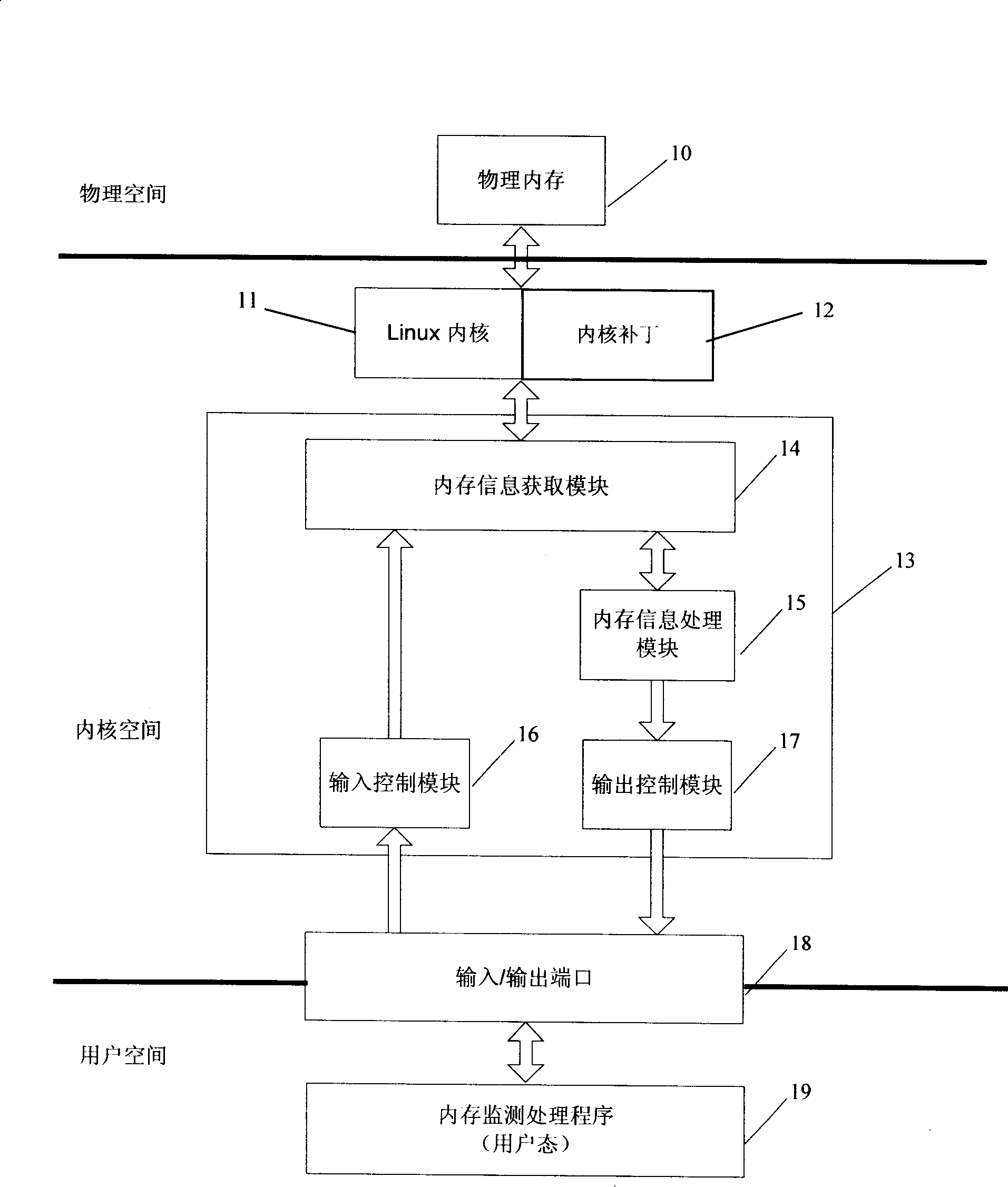

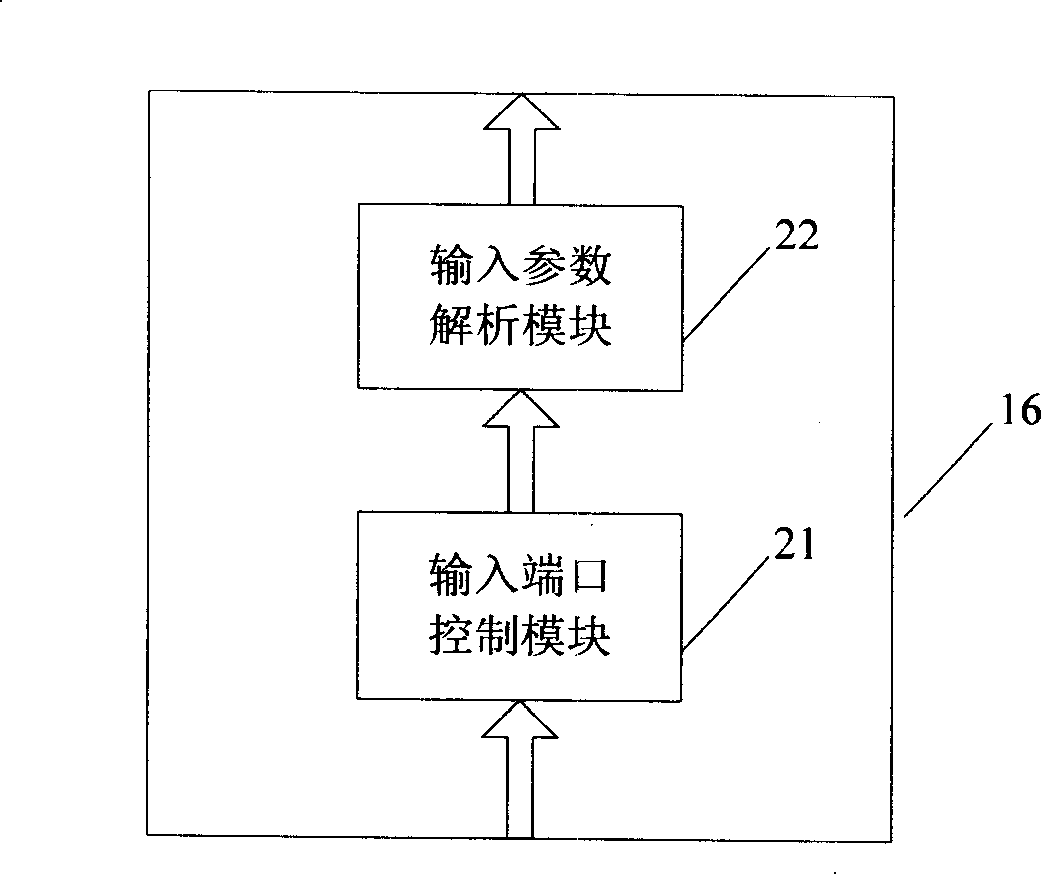

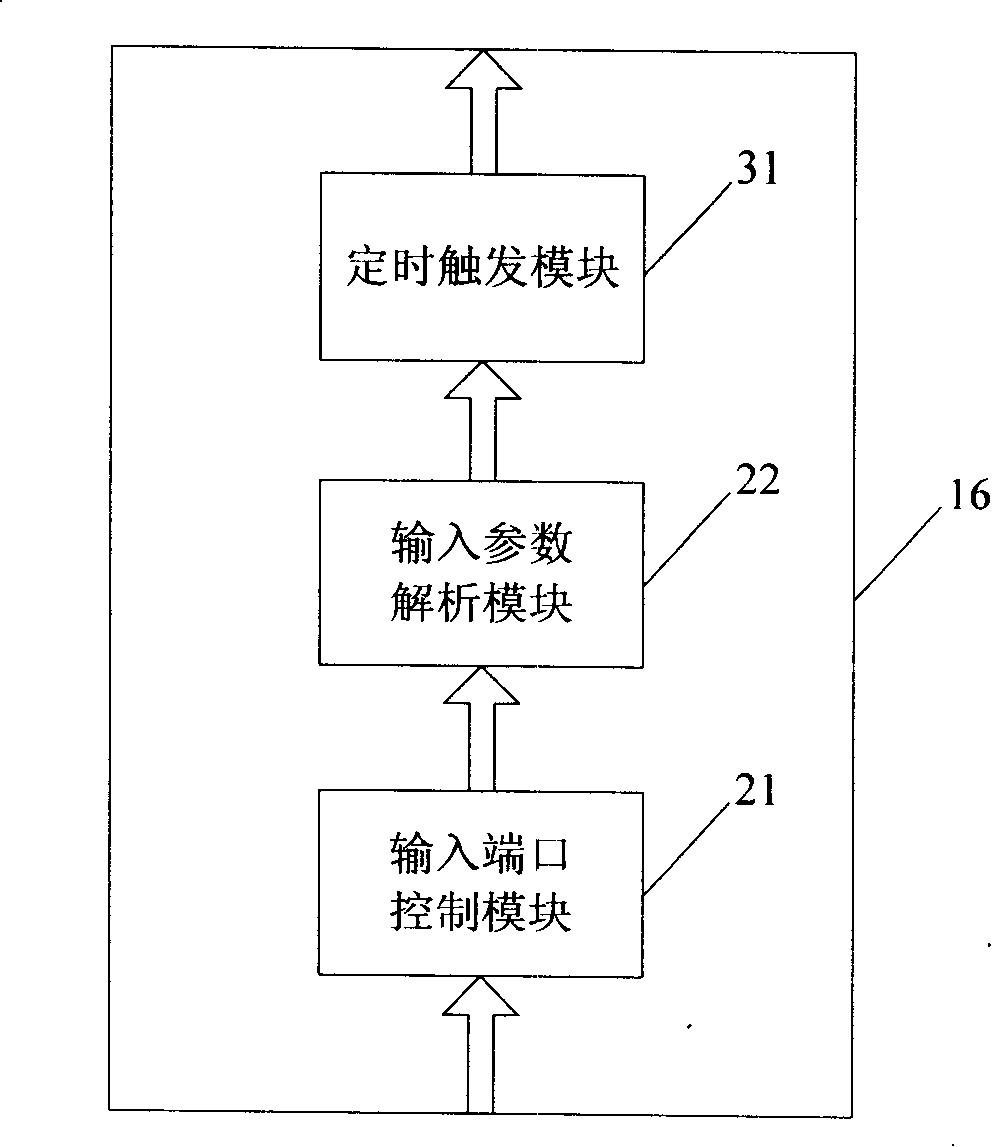

Physical memory information monitoring system of Linux platform

InactiveCN101221527ARealize monitoringImprove compatibilityHardware monitoringFragmentation rateGNU/Linux

The invention discloses a Linux platform physical memory information monitoring system, which can monitor use conditions of physical memories under a Linux platform and optimize use of Linux platform physical memory resources. By adoption of the means of kernel patching and a memory monitoring processing module, static monitoring and dynamic monitoring of overall conditions and detailed use conditions of the physical memories in the Linux platform can be performed and monitoring of the following physical memory information in the Linux platform is realized, for example, acquisition of the number of distributive designated stage memory blocks, acquisition of memory details to compute external fragmentation rate of the memories and so on, thereby the invention has good compatibility and suitability. The system of the invention is particularly suitable for an embedded type Linux platform, wherein, various memory resources are limited but complex memory operations are needed to be provided.

Owner:上海宇梦通信科技有限公司

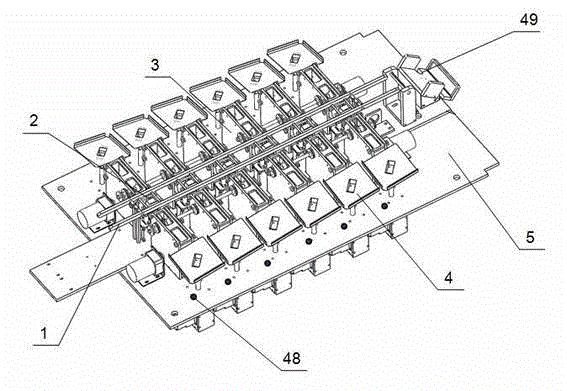

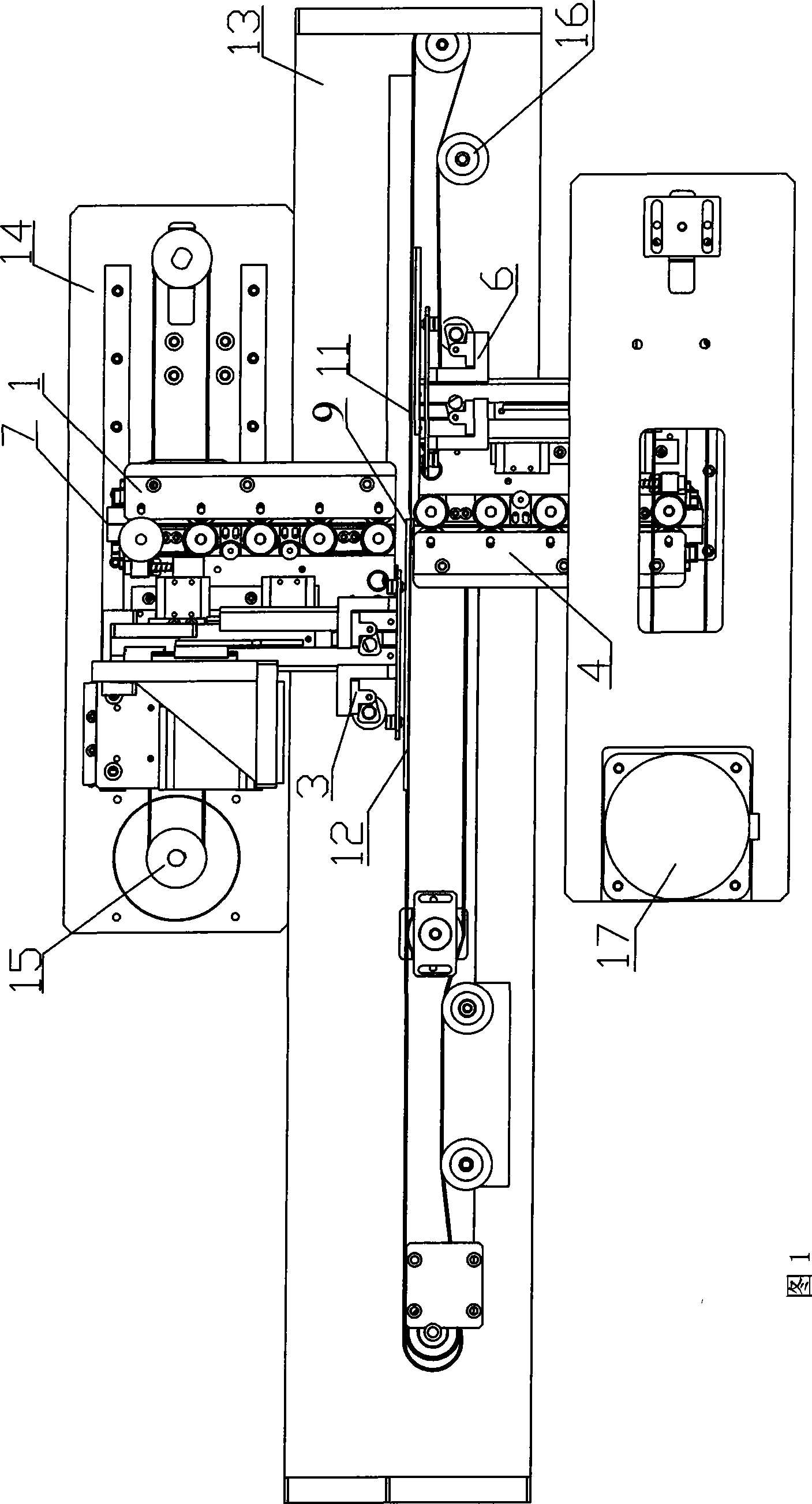

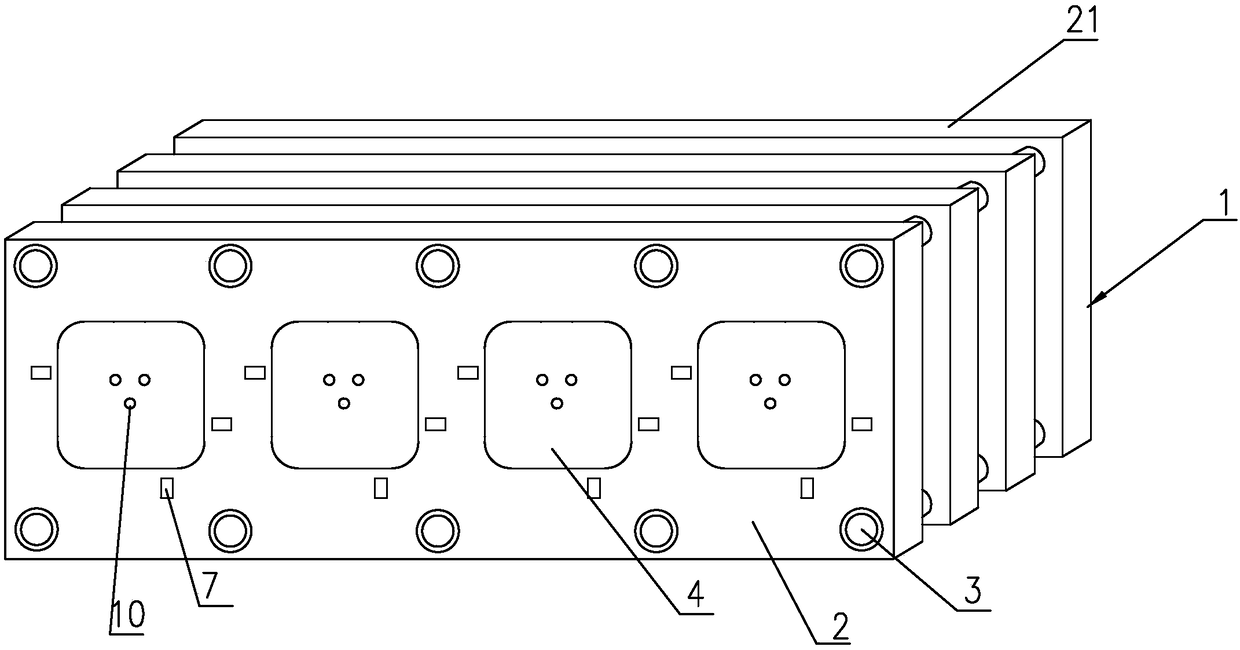

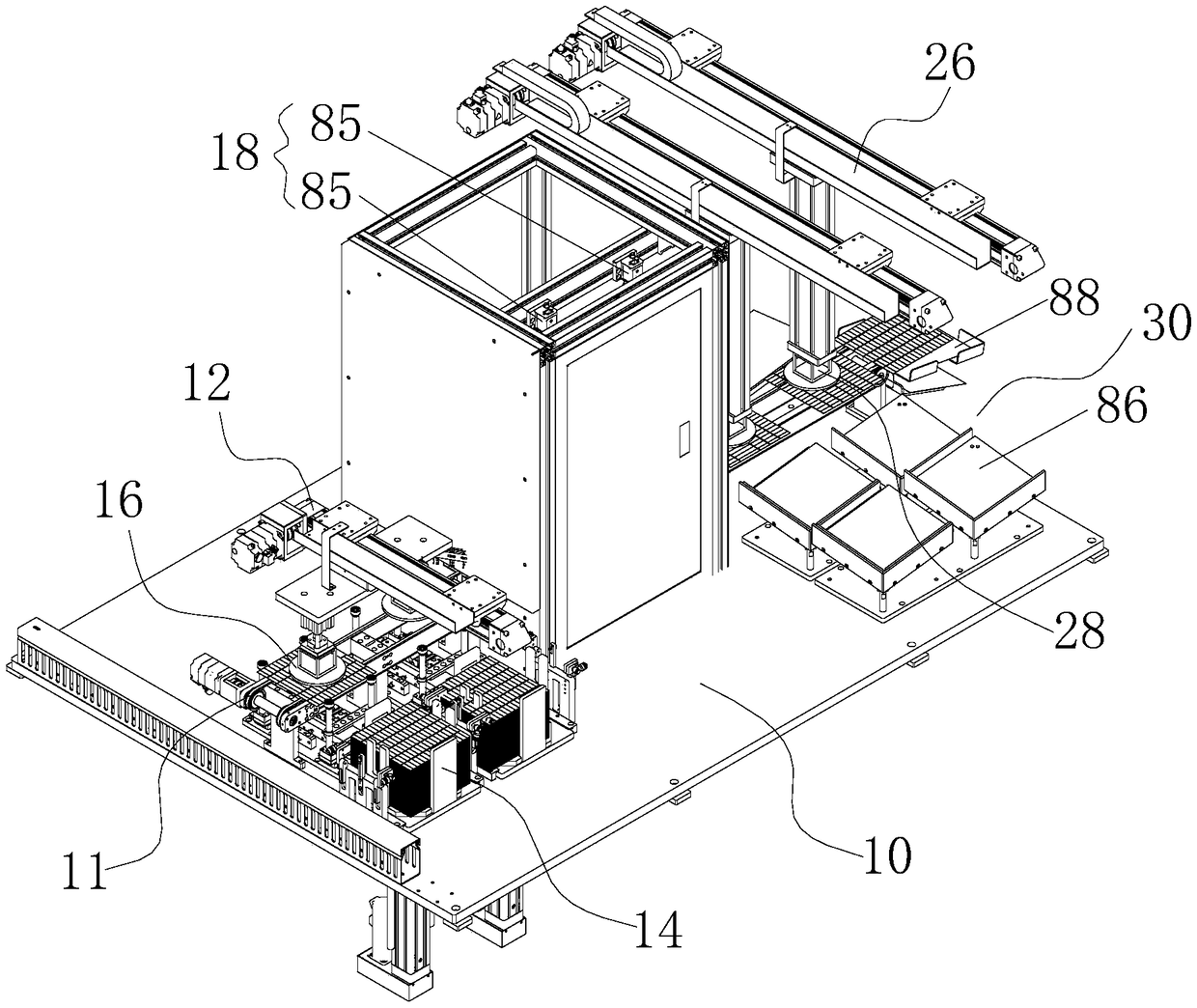

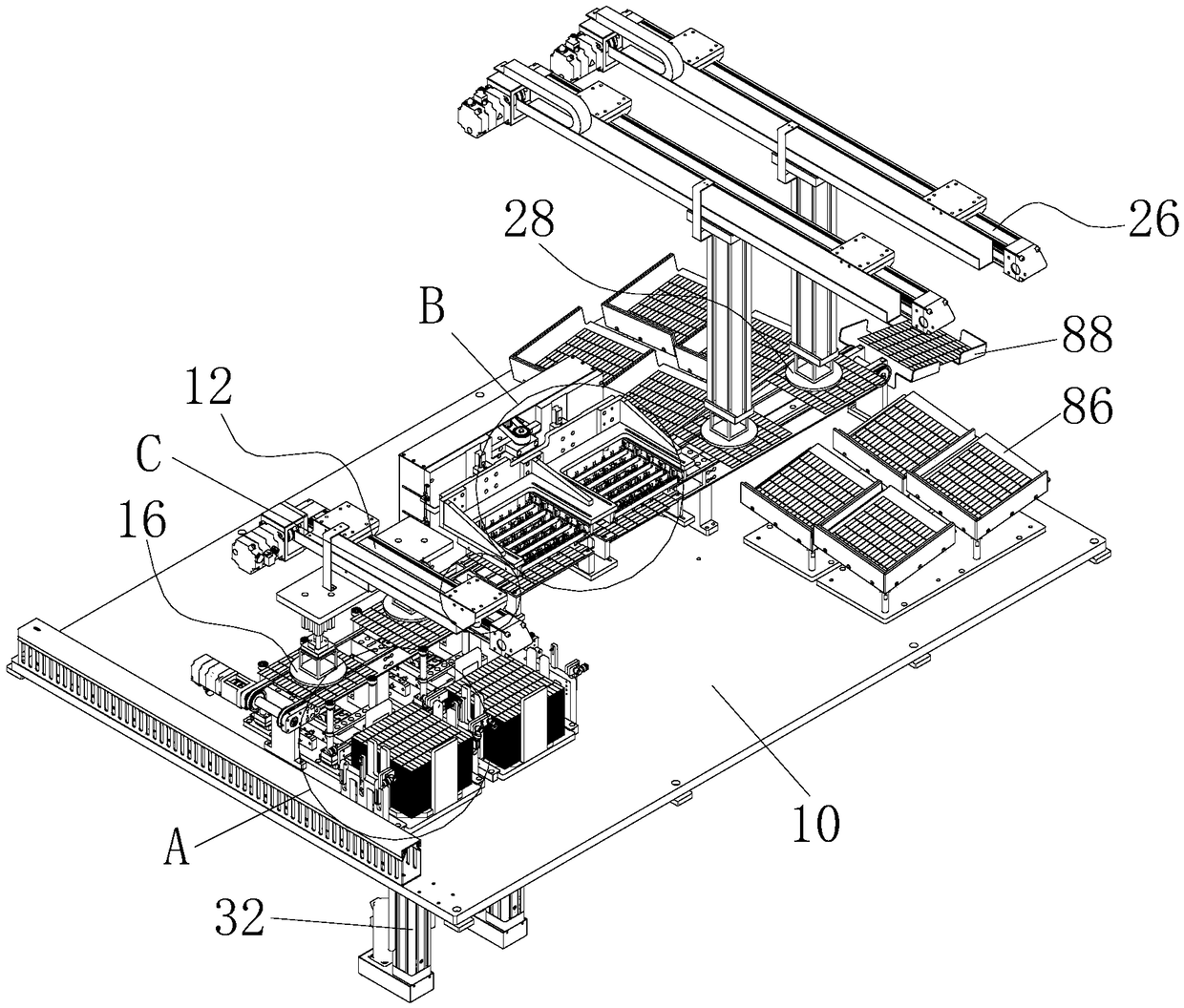

Blanking system for detecting and sorting silicon chip or cell

ActiveCN103949405ACompact structureReduce Fragmentation RateFinal product manufactureSortingElectrical batteryFragmentation rate

The invention relates to the solar energy photovoltaic equipment field, and concretely relates to a blanking system for detecting and sorting a silicon chip or a cell, which comprises a rectangular mounting plate, a main transmission mechanism capable of transmitting the silicon chip / cell along the length direction of a base plate is arranged at the end face of the base plate, a main conveyor belt sheet box is arranged at the transmission end of the main transmission mechanism, the sheet box elevating systems are respectively arranged at two sides of the main transmission mechanism, a vertical transmission mechanism capable of transmitting the silicon chip / cell to the sheet box elevating system along the width direction of the mounting plate is arranged between the main transmission mechanism and the sheet box elevating system; the main transmission mechanism comprises two parallel main conveyor belts, and a lifting-up sheet transmission mechanism used for lifting the silicon chip / cell and transmitting the silicon chip / cell to the vertical transmission mechanism. The blanking system can satisfy the detecting and sorting requirement of silicon chip / cell, a flexible cell and a high efficiency cell with high efficiency and low fragmentation rate.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

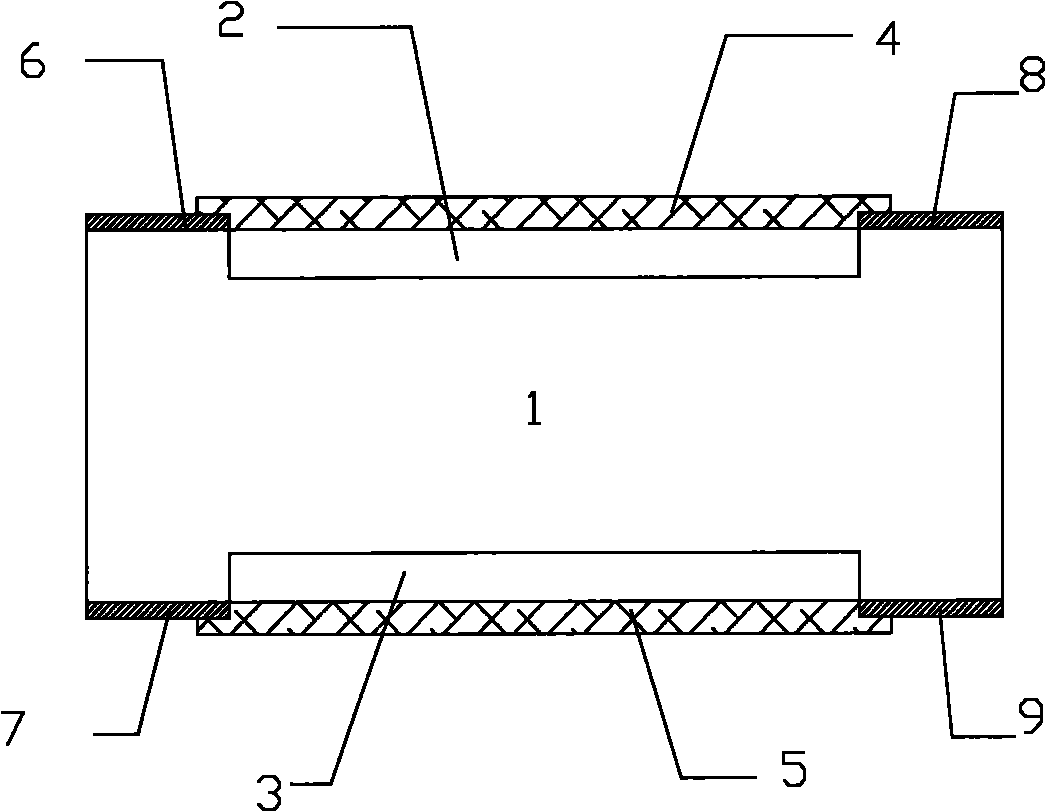

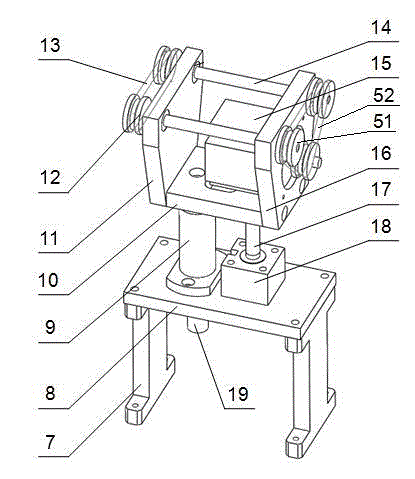

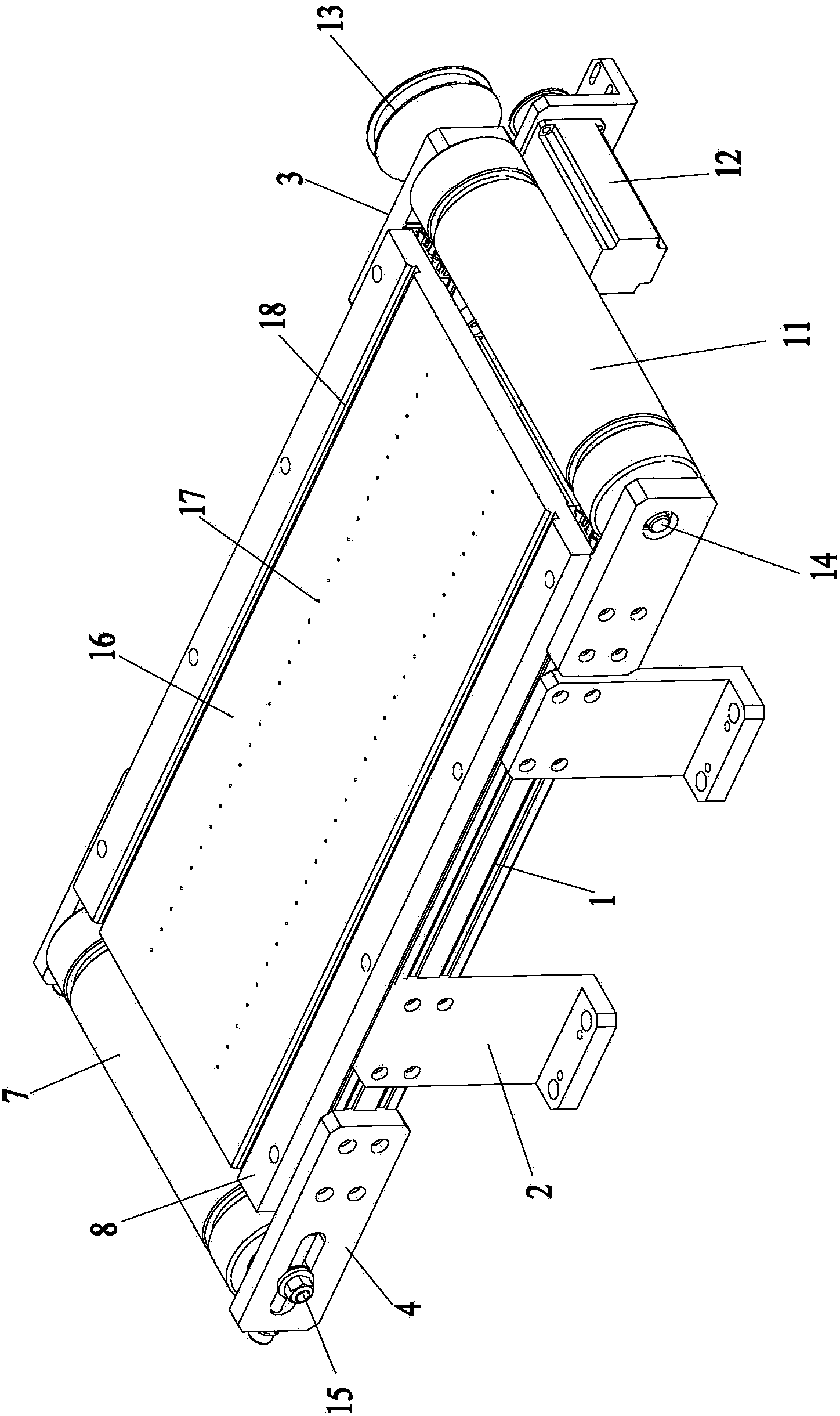

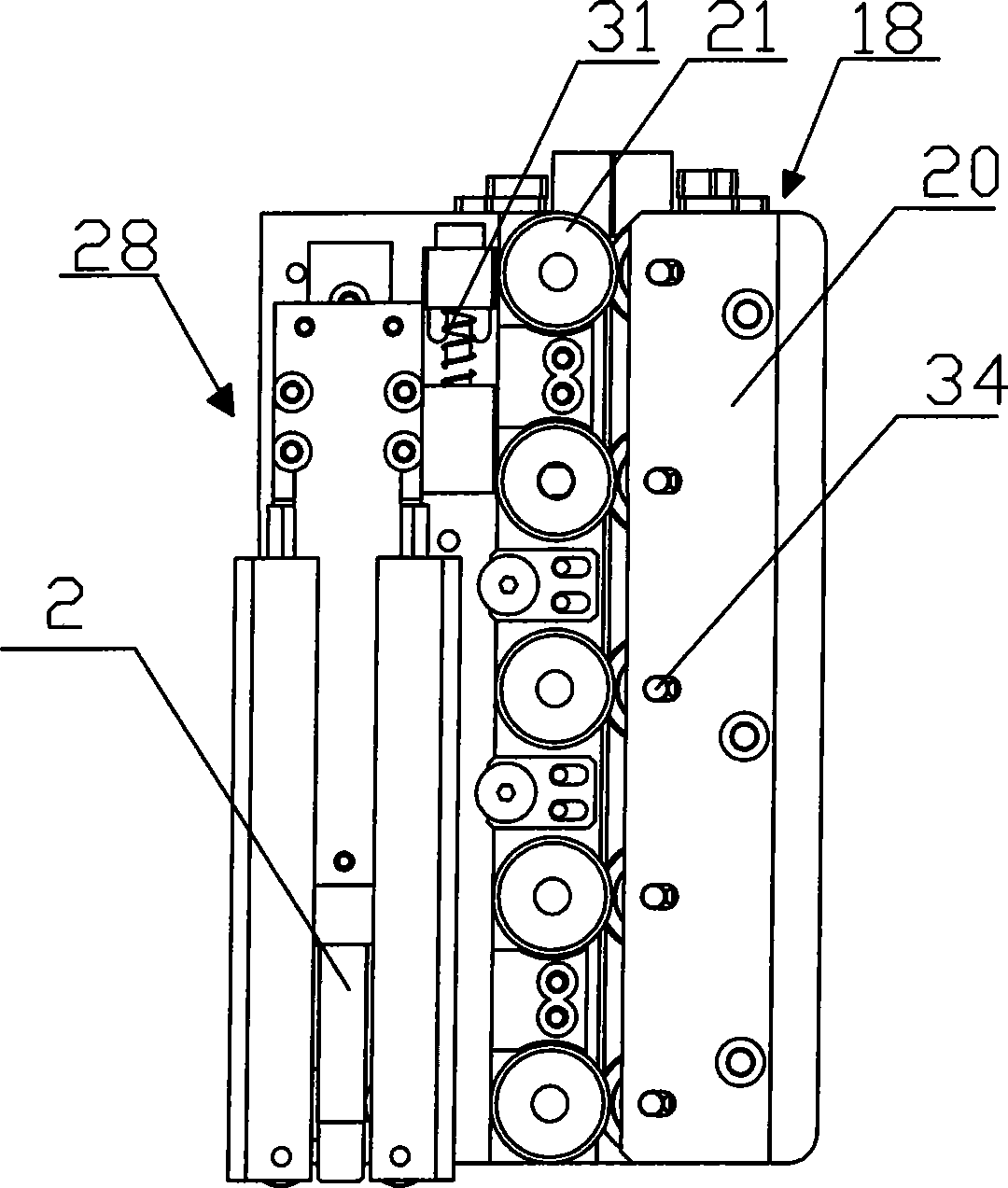

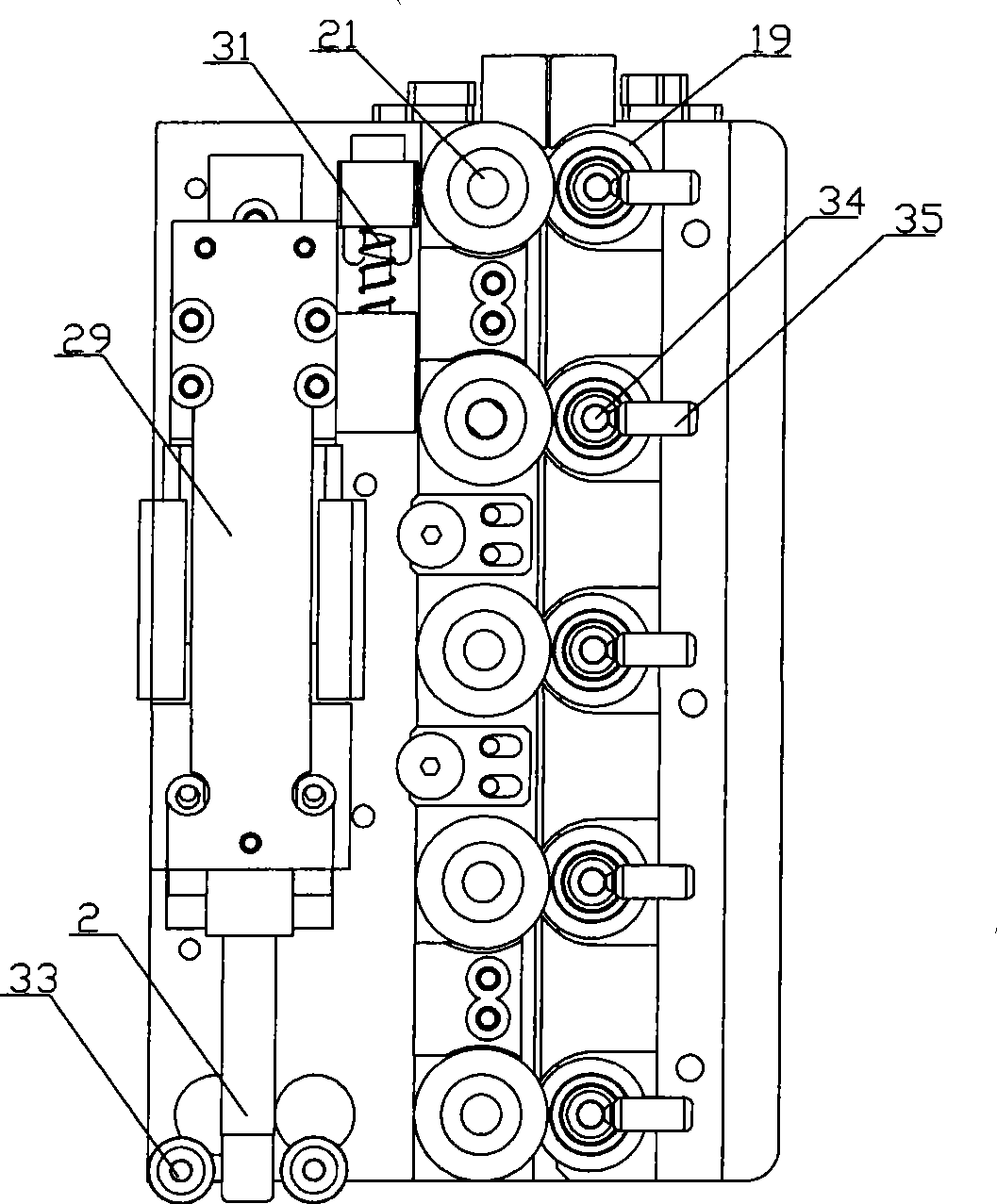

Battery piece feeding conveying mechanism for photovoltaic stringing welding machine

ActiveCN104299935AGuaranteed stabilityReduce Fragmentation RateSolid-state devicesSemiconductor/solid-state device manufacturingDrive wheelFragmentation rate

The invention belongs to the technical field of battery piece conveying and processing and relates to a feeding conveying mechanism, in particular to a battery piece feeding conveying mechanism for a photovoltaic stringing welding machine. According to the technical scheme, the battery piece feeding conveying mechanism for the photovoltaic stringing welding machine comprises a conveying rack, and the conveying rack is provided with a first rack end and a second rack end corresponding to the first rack end. Driving wheels are installed at the first rack end of the conveying rack, driven wheels are installed at the second rack end of the conveying rack, the driven wheels and the driving wheels are connected through a conveying belt installed on the conveying rack, a plurality of belt air holes penetrating through the conveying belt are formed in conveying belt, and the belt air holes can be communicated with a vacuum adsorption cavity in the conveying rack. The battery piece feeding conveying mechanism for the photovoltaic stringing welding machine is compact in structure, improves the feeding conveying efficiency, improves the capacity, reduces the fragmentation rate of battery piece feeding, shortens the generation cycle time and is safe and reliable.

Owner:WUXI SUNTECH POWER CO LTD

Method for packaging solar module

InactiveCN101562211AImprove conversion efficiencyReduce packaging costsFinal product manufactureSemiconductor devicesFragmentation rateEngineering

The invention discloses a method for packaging a solar module, comprising the serial connection of cell slices. A method for the serial connection of the cell slices is as follows: a traditional thin welding tape is welded and connected with a front electrode of one cell slice, then the welding tape is led from the front face to the back face of the other cell slice, and finally the welding tape and a back electrode of the cell slice are spliced together by a conducting adhesive tape. The method for packaging a solar module adopts the conducting adhesive tape to replace the traditional welding tape for the connection between every two cell slices, using no welding processes or less welding processes, thereby greatly lowering the fragmentation rate caused by bow action , greatly reducing the possibilities of subfissure and back electrode damage, improving the module conversion efficiency, saving the raw materials and lower the module packaging cost.

Owner:CEEG SHANGHAI SOLAR SCI & TECH

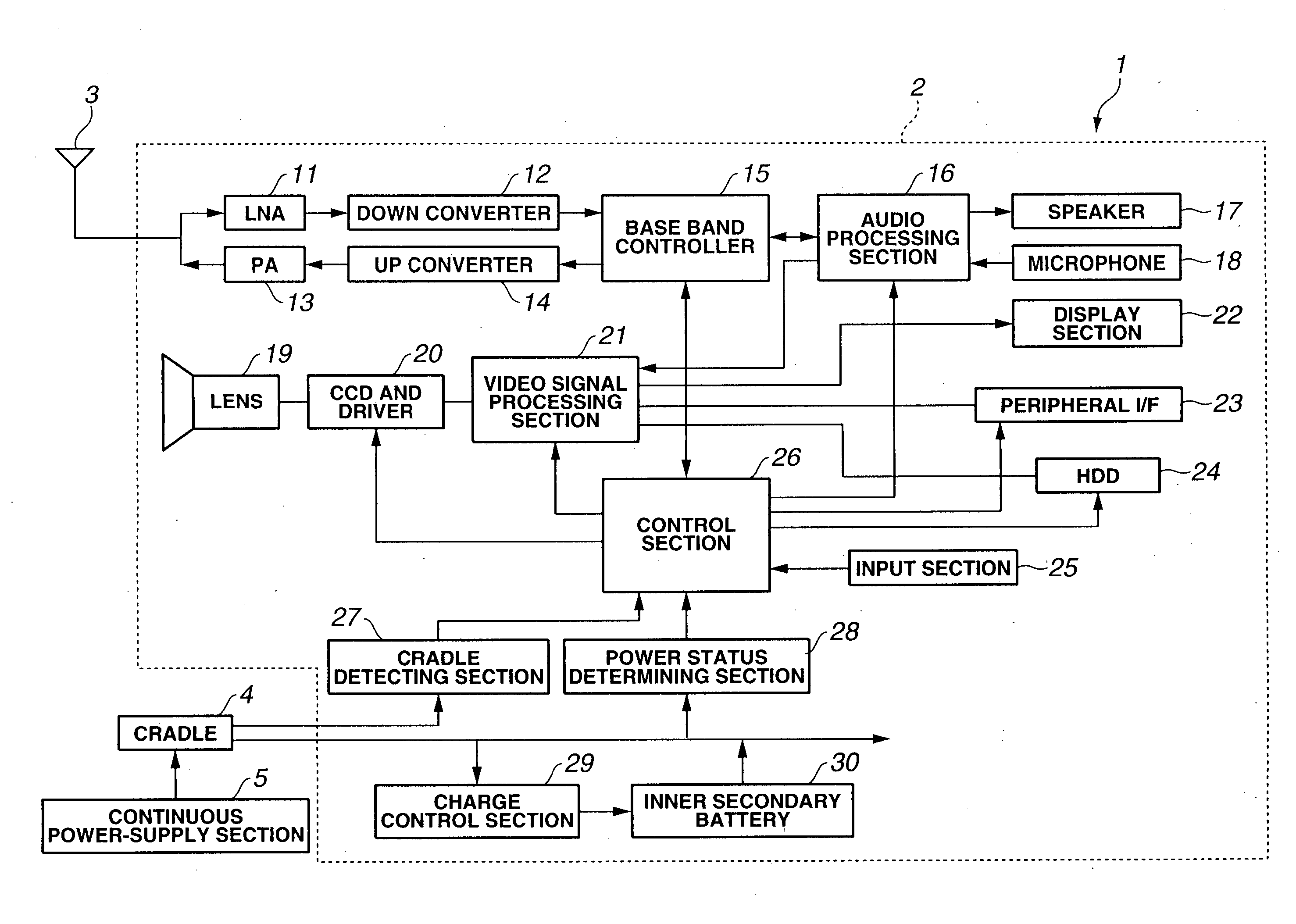

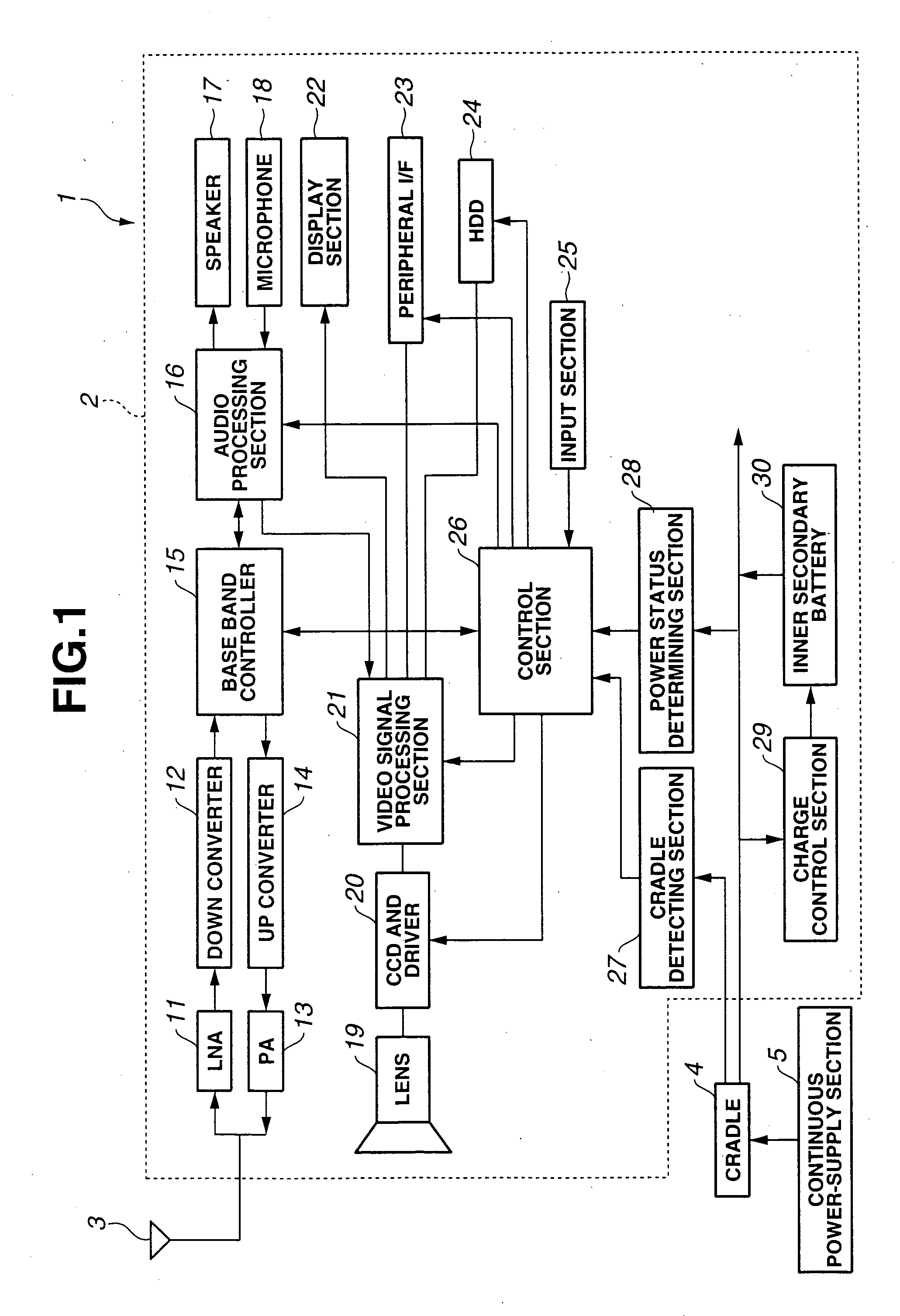

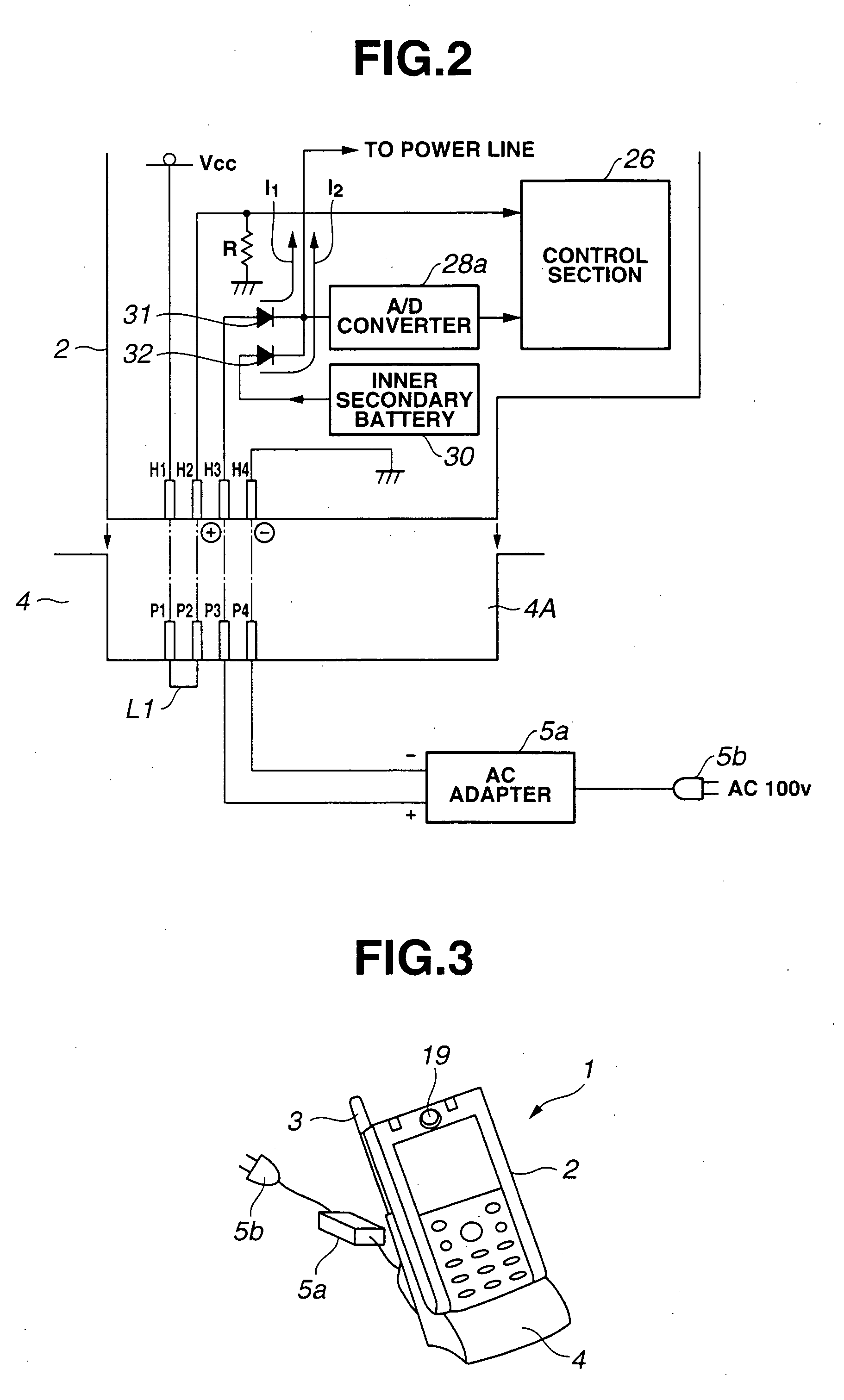

Recording device, recording method, and recording system

InactiveUS20050190483A1Avoid consumptionAvoid damageInput/output to record carriersFilamentary/web record carriersFragmentation rateElectrical battery

A recording device has a recording medium, such as an HDD, for recording information signals such as an audio signal and a video signal. When it is detected that the recording device is connected to a cradle serving as a power supply, the power supply supplies the continuous power to the recording device, and a fragmentation rate of the information signal recorded to the recording medium is a predetermined value or more, the defragmentation of the recording medium is automatically executed. Thus, the damage of the recording medium due to the vibrations and the unnecessary power-consumption of battery are prevented and the convenience of the automatic defragmentation is ensured.

Owner:KK TOSHIBA

Method for laying photovoltaic module

InactiveCN101826575AReduce thicknessImprove controllabilityFinal product manufactureSemiconductor devicesInfraredFragmentation rate

The invention provides a method for laying a photovoltaic module. The method comprises the following steps of: a) evaporating and plating a solder strip and a bus bar on a glass plate in vacuum; b) welding a battery plate set to the solder strip and the bus bar by using laser to obtain the glass plate welded with the battery plates; c) laying an EVA plate on the battery plate set; and d) laying a back plate on the EVA plate to obtain the laid battery plate. By using the method for laying the photovoltaic module provided by the invention, the glass plate and the battery plate are integrated into a whole; the glass plate is bonded to the battery plate without needing EVA; the thickness of the photovoltaic module is reduced; moreover, the fragments of the battery plate can be detected by using infrared ray after laying and the fragments do not need detecting again after lamination and formation, so that fragmentation rate is reduced and the controllability of the quality of the photovoltaic module is increased.

Owner:LIXIAN YINGLI NEW ENERGY CO LTD

Double side continuous series welding system for fragment crystal silicon chip and welding method thereof

InactiveCN101364620AImprove welding efficiencyImprove welding success rateFinal product manufactureSemiconductor/solid-state device manufacturingFragmentation rateEngineering

The invention discloses a double-surface continuous series welding system for a fragile crystal silicon chip and a welding method thereof. An upper fixing plate is arranged on the upper side of a bracket of the system; an upper welded component and a drive motor that drives the upper welded component to conduct parallel movement are arranged on the upper fixing plate; a transport mechanism that supports and transfers the welded crystal silicon chip is arranged on the lower side of the upper welded component on the bracket; an upper locating component for locating an upper welded crystal silicon chip and a solder strip is arranged on the upper side of the transport mechanism; a lower fixing plate is arranged on the lower side of the bracket corresponding to the upper side thereof; a lower welded component symmetrical to the upper fixing plate, and a drive motor that drives the lower welded component to conduct parallel movement are arranged on the lower side of the bracket; and a lower locating component for locating a lower welded crystal silicon chip and a solder strip is arranged on the lower side of the transport mechanism on the bracket. The welding method comprises the following steps: the crystal silicon chips are arranged; the solder strips are installed; each welding component operates; the solder strips are welded on the silicon chips by a welding device; after welding, the previous welded crystal silicon chip is removed and replaced by a new crystal silicon chip for continuous welding. The invention reduces the fragmentation rate and ensures high welding efficiency.

Owner:天津必利优科技发展有限公司

Monocrystalline silicon solar cell and its corrosion solution, texturing method and preparation method, and photovoltaic module

InactiveCN102277574AIntegrity guaranteedReduce Fragmentation RateAfter-treatment detailsFinal product manufactureFragmentation ratePotassium hydroxide

The invention provides etching liquid for a (111) crystal direction monocrystalline silicon solar cell, and the etching liquid comprises 3% by weight to 8% by weight of potassium hydroxide, 0.0005% by weight to 0.01% by weight of isopropanol, 2% by weight to 6% by weight of sodium silicate and the balance of pure water. The invention further provides a texturing method of the monocrystalline silicon solar cell, and the texturing method uses the etching liquid to etch a (111) crystal direction monocrystalline silicon chip at the temperature of 50 DEG C-70 DEG C. The invention further provides a preparation method of the monocrystalline silicon cell chip by applying the etching liquid and the texturing method, the monocrystalline silicon solar cell made of a (111) crystal direction matrix material and a photovoltaic component produced by the monocrystalline silicon cell. The (111) crystal direction monocrystalline silicon solar cell is higher in strength and low in fragmentation rate.

Owner:YINGLI ENERGY CHINA

Marking method for ingot casting polycrystalline silicon slice head and tail sequencing

InactiveCN102364699AFragmentation rate did not increaseSemiconductor/solid-state device manufacturingSemiconductor devicesFragmentation rateAdhesive

The invention relates to a marking method for ingot casting polycrystalline silicon slice head and tail sequencing, which comprises the following steps: 1) detecting: carrying out infrared and minority carrier lifetime detection on a squarely holed ingot casting polycrystalline silicon crystal bar; 2) cutting off: determining the cut-off position according to the infrared and minority carrier lifetime detection results so as to carry out cut-off processing; 3) marking: utilizing laser to draw lines for marking on the surface of the cut-off crystal bar; 4) surface burnishing: burnishing the surface of the marked crystal bar for polishing; 5) chamfering: chamfering the crystal bar after surface burnishing; 6) bar sticking: sticking the chamfered crystal bar onto a crystal holder through curing adhesive; and 7) slicing: curing the crystal bar for a period of time and then sending the crystal bar into a stock for slicing. The ingot casting polycrystalline silicon bar is sliced after being marked in the method disclosed by the invention, and finally the heads and tails of silicon slices are sequenced according to the positions of line marks at the edges of the silicon slices, so the positions of the silicon slices in the crystal bar can be clearly identified, and the fragmentation rate is not increased.

Owner:TRINA SOLAR CO LTD

A graphite boat for a crystalline silicon solar energy PERC battery and a saturation process thereof

PendingCN109244019AExtended service lifeImprove corrosion resistanceFinal product manufactureSemiconductor/solid-state device manufacturingFragmentation rateGraphite

The invention discloses a graphite boat for a crystalline silicon solar energy PERC battery and a saturation process thereof, wherein the graphite boat comprises a graphite boat body, and SiC films are plated on all surfaces of the graphite boat body. A SiC film is plate on that graphite boat in the graphite boat saturation process of the invention, The SiC film has good corrosion resistance, so it will not be corroded by nitrous oxide in the back passivation process, and the surface of the graphite boat can be smooth, which not only protects the graphite boat, prolongs the service life of thegraphite boat, but also ensures the uniformity of the back passivation film and reduces the fragmentation rate. At the same time, due to the excellent wear resistance of SiC film, the EL scratch caused by friction can be reduced, and the subsequent saturation process time is greatly shortened, so that the productivity of the machine is improved.

Owner:ZHEJIANG AIKO SOLAR ENERGY TECH CO LTD +1

Apparatus for managing memory in real-time embedded system and method of allocating, deallocating and managing memory in real-time embedded system

Owner:SAMSUNG ELECTRONICS CO LTD

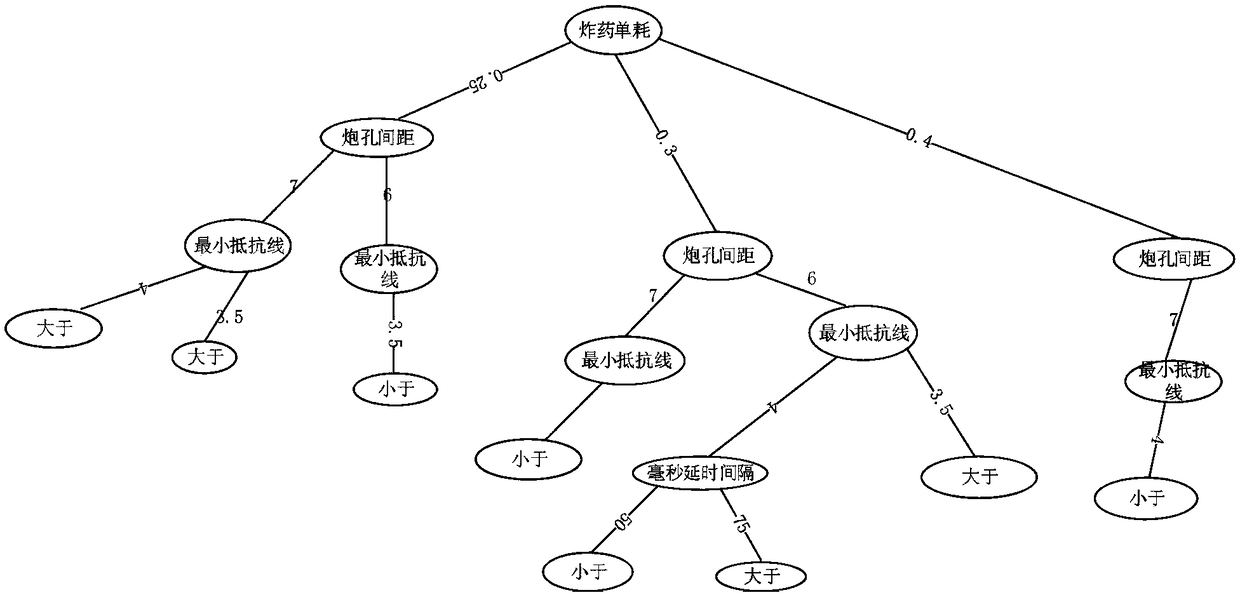

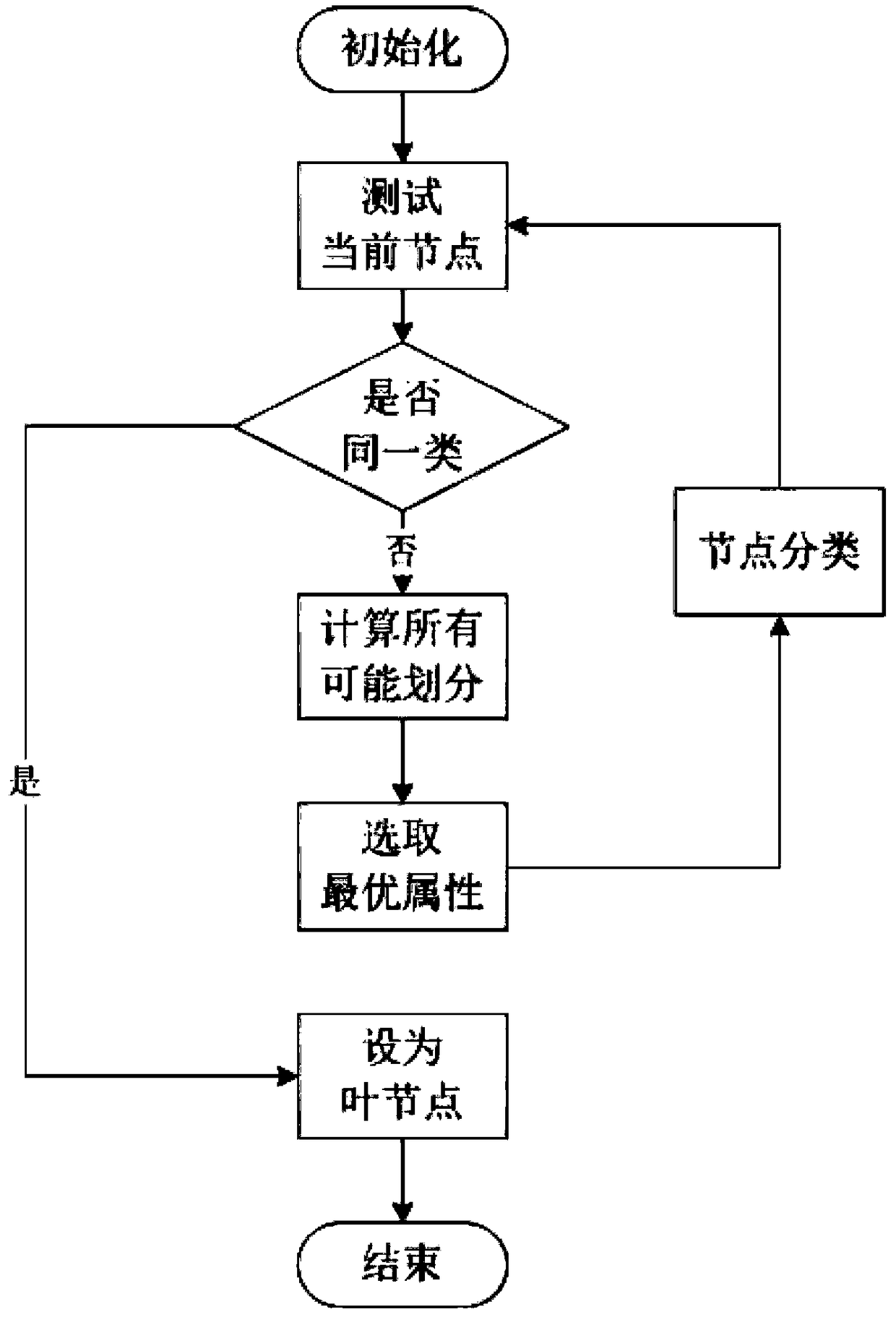

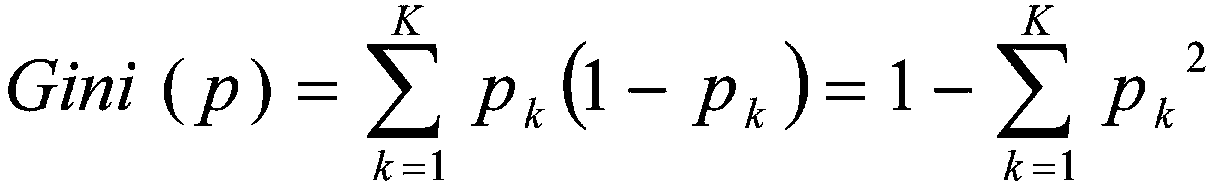

A blasting fragmentation prediction method based on cart tree regression algorithm

InactiveCN109146195AReduce chunk rateReduce secondary breakageForecastingComplex mathematical operationsFragmentation ratePredictive methods

The invention discloses a blasting fragmentation prediction method based on a cart tree regression algorithm. A CART decision tree model is constructed and trained by a CLS algorithm using the existing historical rock fragmentation related parameters as sample attributes. New rock fragmentation related parameters are collected and forecasted by the trained CART decision tree model. In accordance with that prior art, the invention firstly constructs a CART decision tree model and trains the CART decision tree model according to the related parameters of the historical rock fragmentation, then,the trained CART decision tree model can be used for predicting the blasting fragmentation. The invention prevents the occurrence of the blasting fragmentation accident from the root cause, reduces the large fragmentation rate generated in the blasting process, reduces the secondary fragmentation, improves the production efficiency and saves the blasting cost.

Owner:NORTH BLASTING TECH

Method for detecting edge red film of solar cell panel

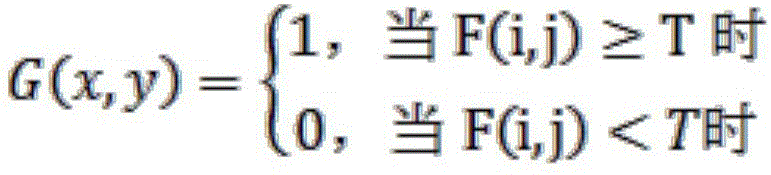

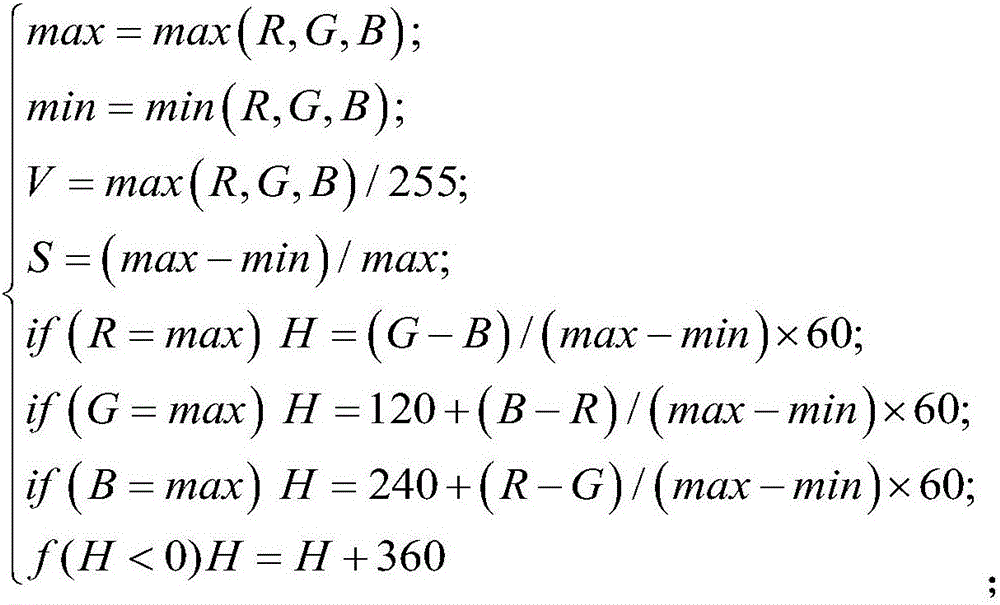

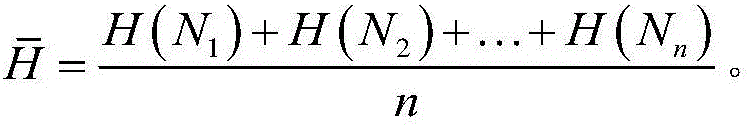

ActiveCN106057700AImprove appearance qualityReduce pollutionSemiconductor/solid-state device testing/measurementProduction rateCells panel

The invention discloses a method for detecting edge red film of a solar cell panel by using a machine vision detection system. The method comprises the following steps: acquiring the RGB image of a solar cell panel through the CCD camera of a machine vision detection system; generating a cell panel region through a back light source and extracting cell panel gate lines through an R channel; combining the two steps to remove external and white interference; and finally converting for an HSV model. According to the invention, an edge tonal variance based detection method is provided to calculate the color variance of the solar cell panel. When the color variance of the solar cell panel at the edge region represents the value determined as the disclosed figure, the solar cell panel is determined to be an edge red film. The method of the invention uses a machine vision system, adopts a detection method based on the image mean value and the image variance to select the edge red film of a solar cell panel, which replaces the traditional manual detection method, effectively improves the appearance quality of a cell panel and reduces labor intensity of manual work and the manual fragmentation rate, as well as the manual pollution to the cell, therefore, improving productivity.

Owner:HOHAI UNIV CHANGZHOU

Photovoltaic module and welding method of photovoltaic module

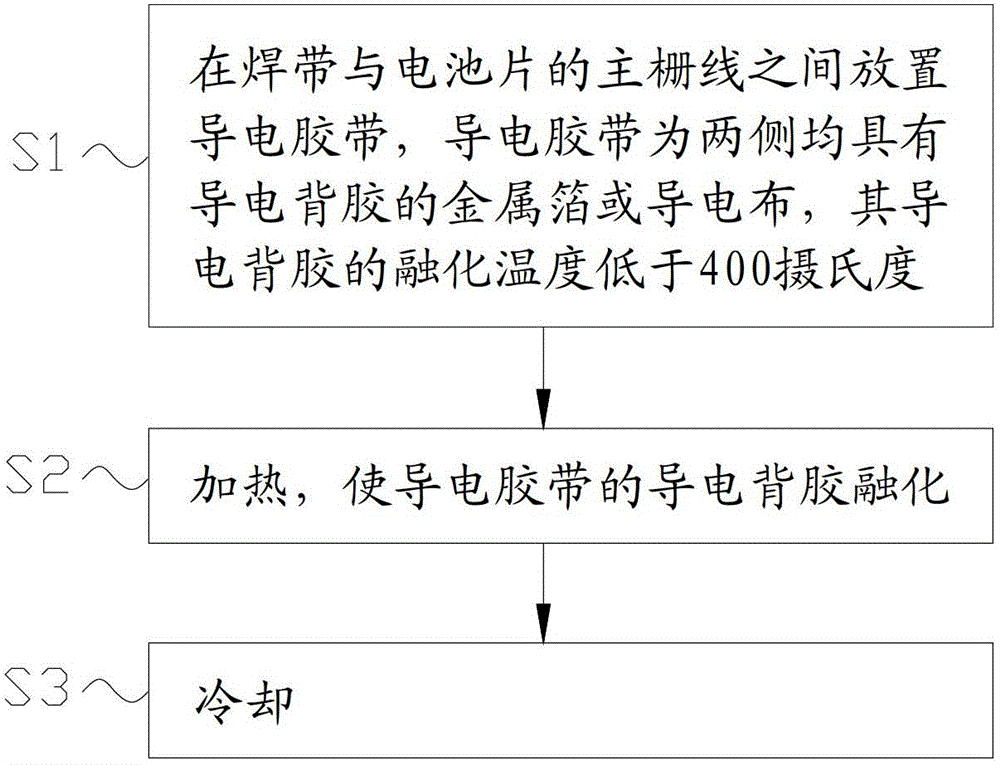

InactiveCN103144300AAchieve connectionAlleviate uneven swelling and shrinkingFinal product manufacturePhotovoltaic energy generationMetal foilFragmentation rate

The invention discloses a welding method of a photovoltaic module. The welding method comprises the steps of: placing a conductive tape between a welding strip and a main grid line of a battery piece, wherein the conductive tape is a metal foil or a piece of conductive cloth with two sides being provided with conductive back adhesive, and the melting temperature of the conductive back adhesive is below 400 DEG C; heating to enable the conductive back adhesive to be melted so as to bond the welding strip with the main grid line of the battery piece; and cooling to complete the welding process. During the welding process, the welding strip and the battery piece are bonded with each other by using the conductive tape, the temperature during the process is below 400 DEG C which is the welding temperature of the welding strip and the battery piece in the prior art, and the welding temperature in the welding process is lower than the welding temperature in the prior art to realize low-temperature bonding so as to relieve the phenomenon of uneven expansion and shrinkage between the welding strip and the battery piece, thus reducing stress generated in the welding process, and reducing the battery fragmentation rate in the welding process of the photovoltaic module. The invention also provides the photovoltaic module produced by using the welding method.

Owner:TIANJIN YINGLI NEW ENERGY RESOURCES

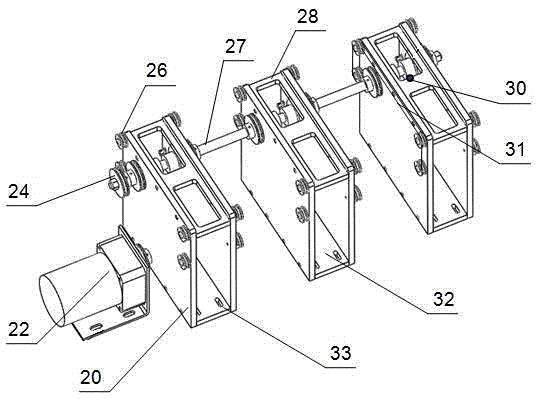

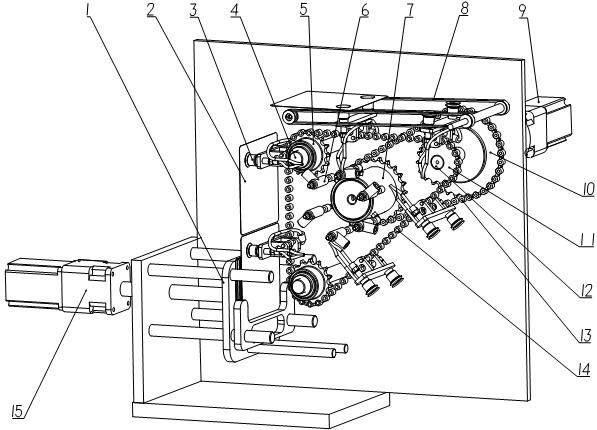

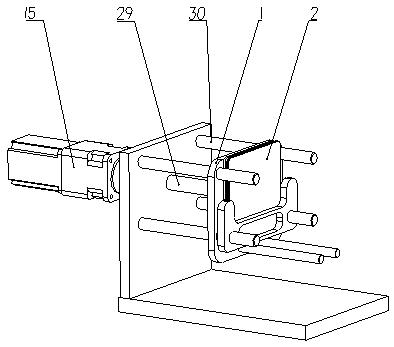

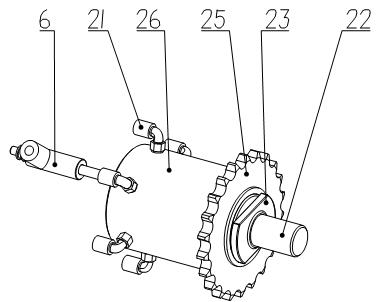

Solar silicon wafer automatic wafer separator based on cyclic distribution device and wafer separation method thereof

ActiveCN102427095AEfficient separationIncrease productivityFinal product manufactureConveyor partsFragmentation rateSilicon chip

The invention discloses a solar silicon wafer automatic wafer separator based on a cyclic distribution device, which comprises a feed system, a drive system and a cyclic distribution device. The cyclic distribution device is arranged on one side of the feed system, a distribution shaft sleeve of the cyclic distribution device is connected with a plurality of vacuum generators, and each vacuum generator corresponds to one suction head assembly so that the cyclic distribution device is provided with a plurality of stations; the drive system comprises two sets of chain drive devices driven by the same driving shaft, the chain drive device No.1 drives the vacuum generators to rotate by the distribution shaft sleeve of the cyclic distribution device, and the chain drive device No.2 drives eachsuction head assembly to rotate; and a horizontal conveyor belt assembly is fixedly arranged above the drive system. According to the solar silicon wafer automatic wafer separator based on the cyclicdistribution device, disclosed by the invention, on the premise of not damaging solar silicon wafers, the solar silicon wafers can be efficiently separated, and the fragmentation rate is reduced. Theinvention further discloses a wafer separation method of the solar silicon wafer automatic wafer separator based on the cyclic distribution device.

Owner:RES INST OF ZHEJIANG UNIV TAIZHOU

Automatic sand blasting device used for diamond wire polycrystalline silicon slices

ActiveCN106003447AChange the surface morphologyEasy to operateWorking accessoriesGrinding machinesAutomatic controlFragmentation rate

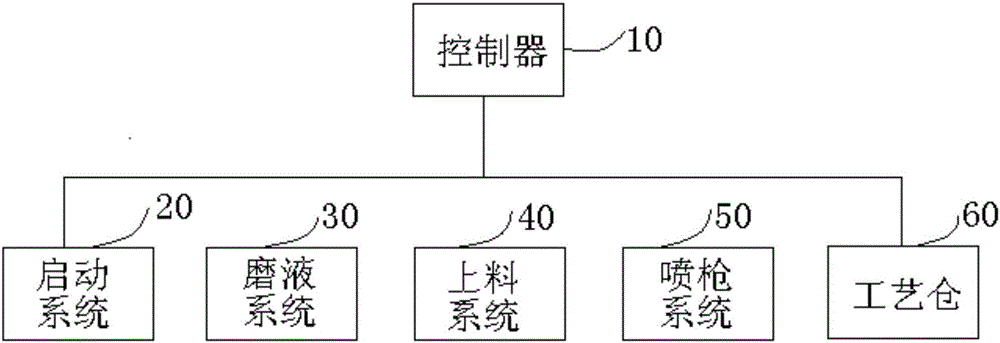

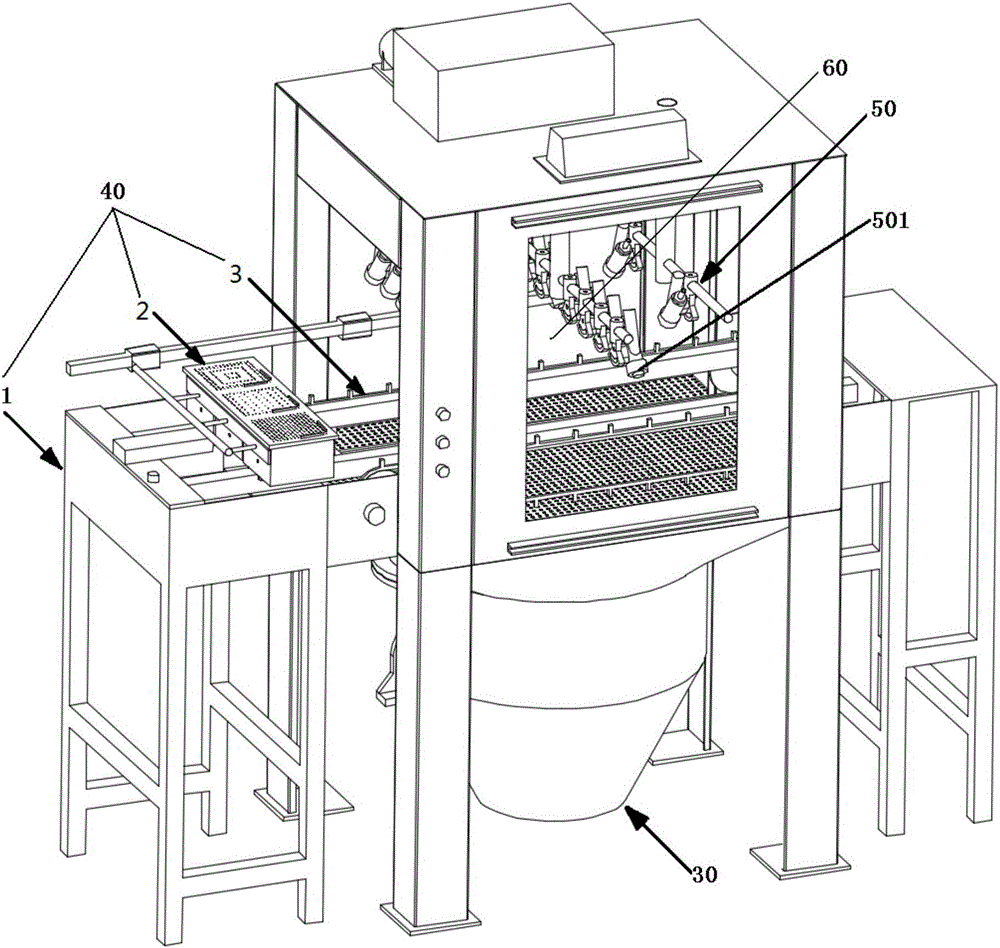

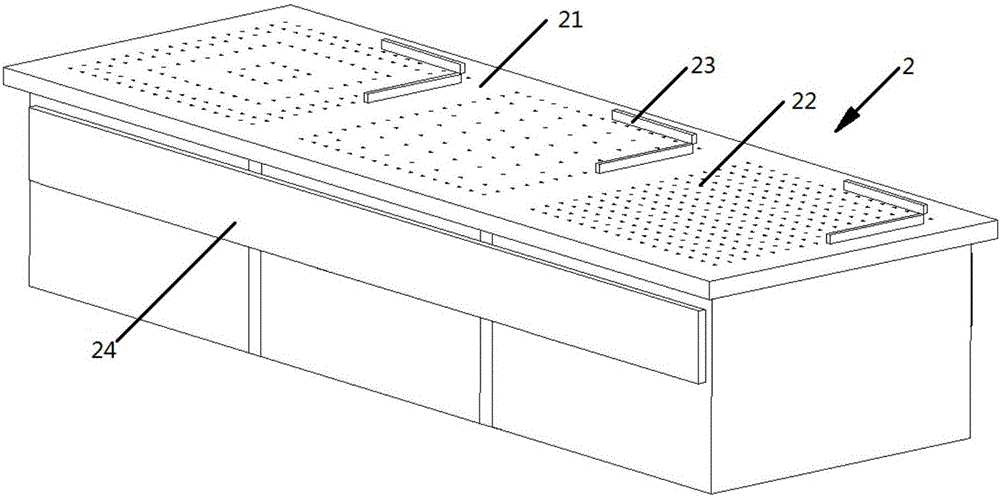

The invention discloses an automatic sand blasting device used for diamond wire polycrystalline silicon slices. The automatic sand blasting device comprises a starting system, a grinding fluid system, a spray gun system, a feeding system, a process bin and a controller. When an operation command input from the outside is a sand blasting command, the controller automatically controls the starting system, the grinding fluid system, the spray gun system and the feeding system to conduct sand blasting treatment on the surfaces of the diamond wire polycrystalline silicon slices. The automatic sand blasting device is easy to operate, high in processing precision and processing stability, low in fragmentation rate and high in production capacity. The surfaces of the diamond wire polycrystalline silicon slices are subjected to sand blasting treatment, and consequently the surface microtopography of the diamond wire polycrystalline silicon slices can be changed; and the diamond wire polycrystalline silicon slices subjected to surface treatment can be directly used for production of battery pieces.

Owner:BEIJING HEDEFENG MATERIAL TECH

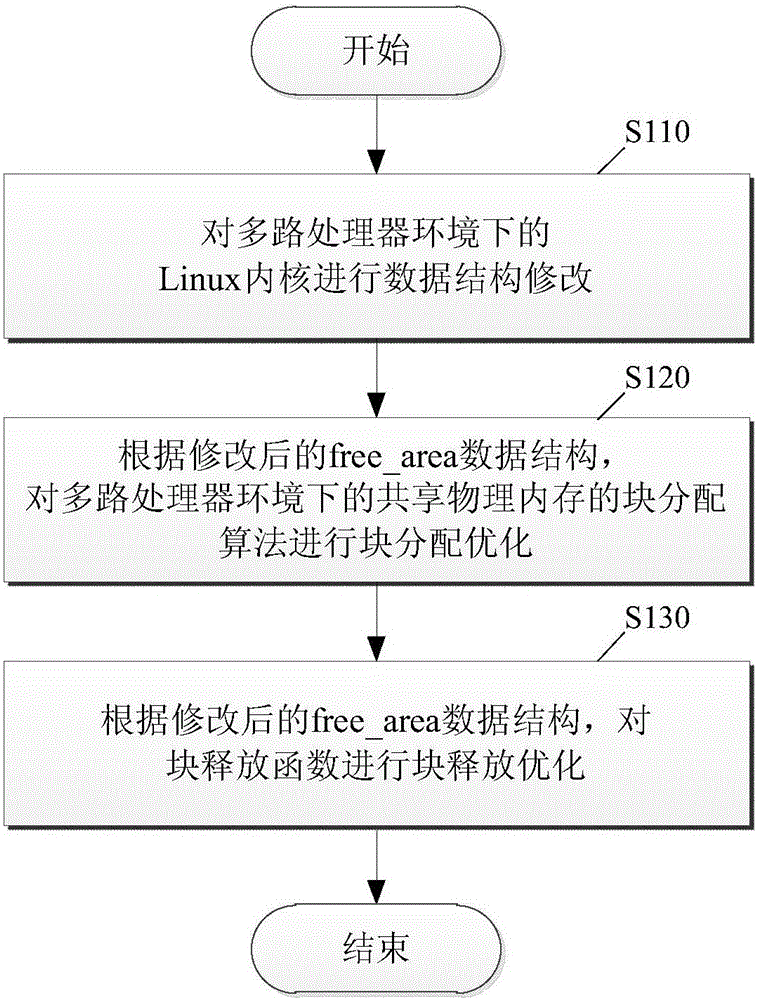

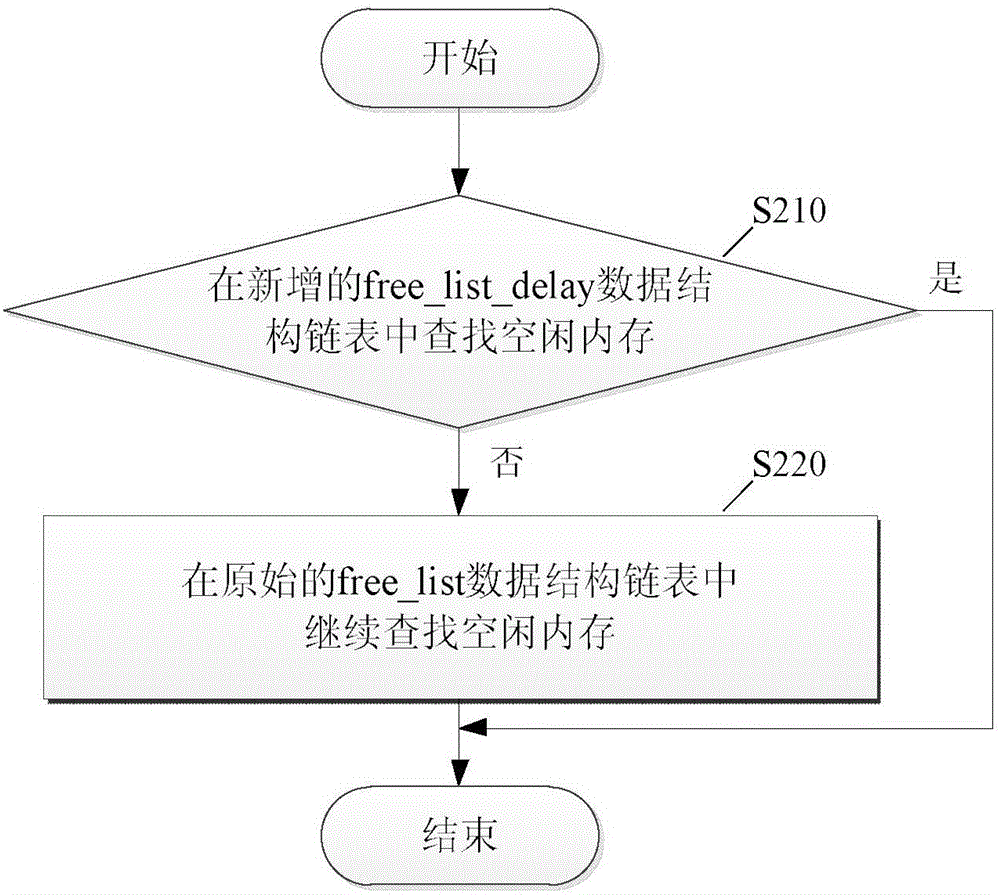

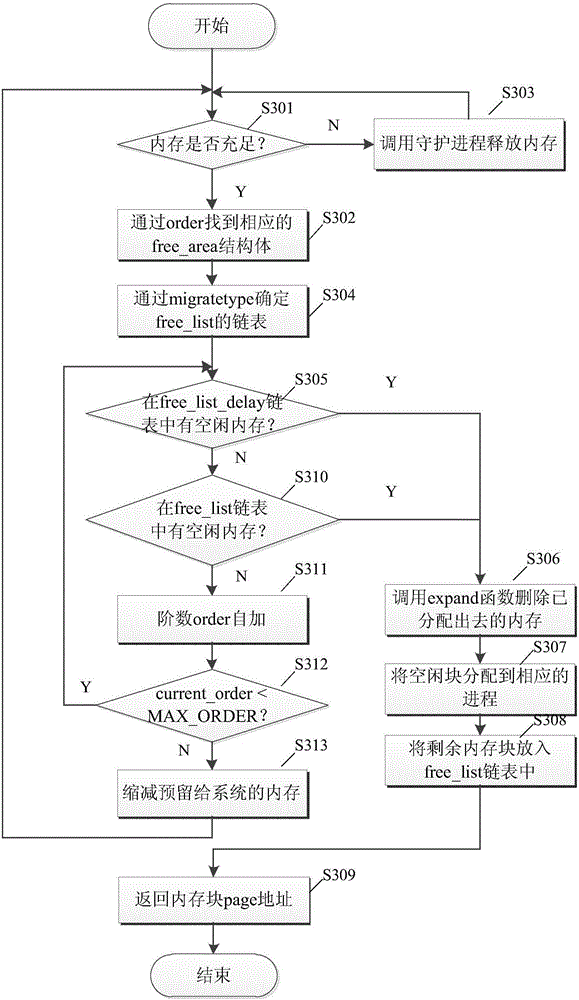

Shared memory optimization processing method and device based on multipath processor

InactiveCN106095577AReduce time overheadImprove efficiencyResource allocationFragmentation rateAllocation algorithm

The invention provides a shared memory optimization processing method and device based on a multipath processor. The shared memory optimization processing method based on the multipath processor is characterized by comprising the steps that data structure modification is conducted on a Linux kernel in a multipath processor environment, wherein data structure modification comprises the step of additionally arranging a data structure chain table in a free_area data structure; block allocation optimization is conducted on a block allocation algorithm of a shared physical memory in the multipath processor environment according to the modified free_area data structure; block release optimization is conducted on a block release function according to the modified free_area data structure. Compared with an existing partner algorithm, the method and device have the advantages that time consumption can be reduced, the usage efficiency of the physical memory is promoted, and the memory fragmentation rate is decreased.

Owner:NORTHEAST FORESTRY UNIVERSITY

Preparation method of MWT solar cell

InactiveCN110112230AEnsure conversion efficiencyEnsure costFinal product manufacturePhotovoltaic energy generationFragmentation rateSolar cell

The invention provides a preparation method of an MWT solar cell. According to the method, the production technical scheme of a double-sided MWT + cell is provided to ensure the basic conversion efficiency and cost advantages of the MWT + cell. The MWT + aluminum grid double-sided cell technology is applied to reduce the warpage problem caused by the sheet so that the fragmentation rate of the cell and the assembly process can be reduced; meanwhile, the MWT + double-sided cell technology effectively improves the conversion efficiency of the cell.

Owner:WUXI DEXIN SOLAR POWER

Preparation method for back contact type silicon solar cell

ActiveCN102403406AReduce holesAvoid shading lossFinal product manufactureSemiconductor devicesHeat conductingSilicon solar cell

The invention discloses a preparation method for back contact type silicon solar cell, which comprises the following steps of: (1) etching texture on the illuminated surface of silicon chips, and setting holes; (2) coating, diffusing and forming junctions on the illuminated surface of the silicon chips; forming PN junctions on the illuminated surface and in the holes; (3) setting transparent heat conducting film on the PN junctions on the illuminated surface and in the holes; (4) etching the circumference; plating antireflection films on the transparent heat conducting film on the illuminated surface of silicon chips; and (5) preparing through hole electrode, back metal electrode and back passivation field on the non-plating film surface of the silicon chips to obtain the back contact type silicon solar cell; and the through hole electrode is electrically communicated with the transparent conducting film. The illuminated surface of the back contact type silicon solar cell is not covered by electrode, so shading loss is avoided and the photoelectric conversion efficiency is greatly improved. The quantity of to-be-opened holes is greatly reduced so as to dramatically reduce the fragmentation rate and simplify the preparation processes.

Owner:CSI CELLS CO LTD +1

Manufacturing method for solar energy battery, and solar energy battery

InactiveCN103985779ARandom combinationImprove conversion efficiencyFinal product manufacturePhotovoltaic energy generationFragmentation rateOptoelectronics

The invention discloses a manufacturing method for a solar energy battery, and a solar energy battery. The method comprises: step S1, forming a PN structure on a substrate by use of an iron implantation mode; step S2, performing annealing processing on the PN structure, letting in oxygen during annealing so as to form oxide films on the front surface and the back surface of the substrate; step S3, arranging a mask layer on the back surface of the PN structure, an area not covered by the mask layer being an electrode area; and step S4, forming an electrode in the area not covered by the mask layer. According to the invention, the conventional two procedures of passivating and perforating are omitted, the process steps are simplified, and since an additional perforating step is unnecessary, the fragmentation rate is greatly reduced. Besides, by using the method, the adding of new process devices is unnecessary, thus the manufacturing cost is decreased.

Owner:KINGSTONE SEMICONDUCTOR LIMITED COMPANY

Solar cell sheet EL defect tester

ActiveCN109245719AImprove factory qualityFast testPhotovoltaic monitoringSemiconductor/solid-state device testing/measurementTest efficiencyFragmentation rate

The invention relates to a solar cell sheet EL defect testing machine, which includes a rack, a conveying mechanism mounted on the rack and a feeding mechanism, a test mechanism and a blanking mechanism arranged in order; A feeding mechanism includes at least one first horizontal linear module, at least one storage mechanism and at least one first vacuum adsorption mechanism; the storage mechanismis located on one side of the conveying mechanism, a first vacuum suction mechanism is mounted on the first horizontal linear module, the test mechanism comprises a camera assembly, a lifting mechanism, a probe assembly and a copper plate assembly mounted on the lifting mechanism, the probe assembly and the copper plate being arranged opposite each other in the vertical direction; the blanking mechanism comprising at least one second horizontal linear module, at least one second vacuum suction mechanism and a sorting assembly; the second vacuum suction mechanism being mounted on the second horizontal linear module. The invention is suitable for mass sampling inspection and full inspection of EL defects of battery sheets. The test speed is fast, lthe fragmentation rate is low; the invention can adopt to customers with different needs, is high in test efficiency, and has Extensibility.

Owner:SUZHOU MAKING INTELLIGENT EQUIP CO LTD

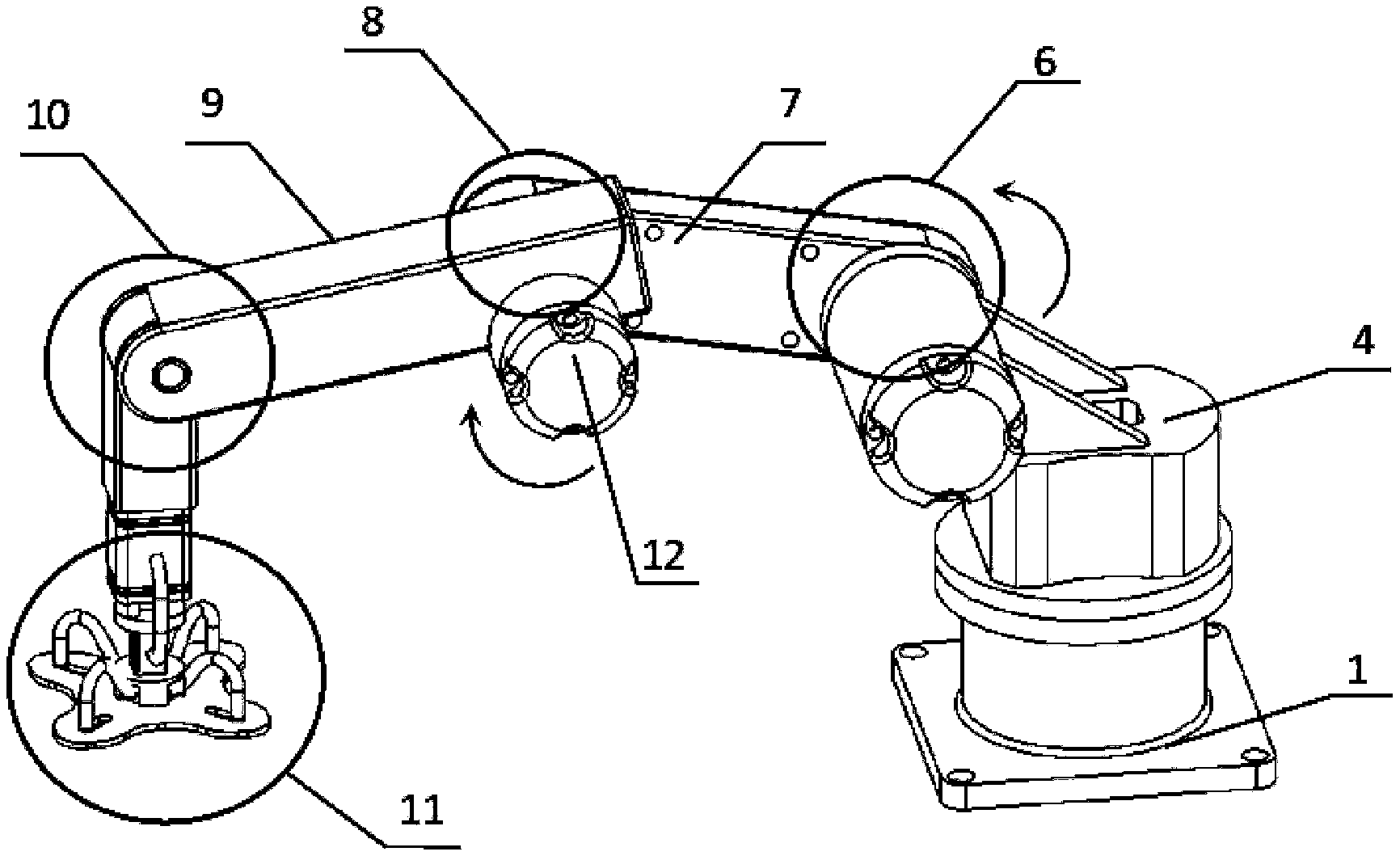

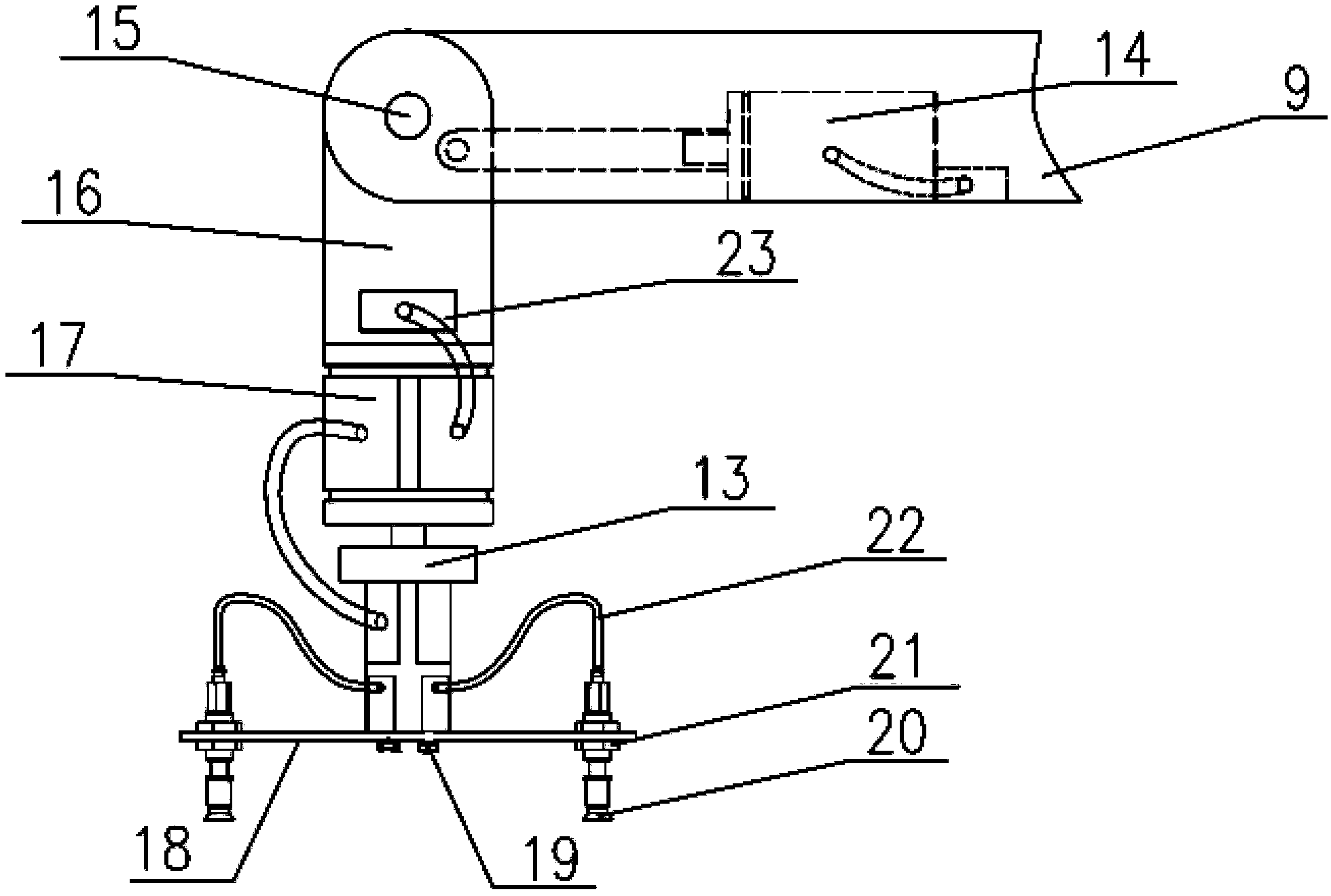

Silicon wafer fully-automatic feeding/discharging manipulator and movement trajectory control method thereof

ActiveCN103413773ASimple structureSmall footprintProgramme-controlled manipulatorFinal product manufactureProcess equipmentFragmentation rate

The invention discloses a silicon wafer fully-automatic feeding / discharging manipulator and a movement trajectory control method thereof. The silicon wafer fully-automatic feeding / discharging manipulator and the movement trajectory control method thereof are used for fully-automatic feeding / discharging in multi-channel chain-type texturing, chain-type cleaning and sintering devices. The manipulator of the invention comprises a mounting base, a shoulder joint, a big arm, a small arm and a gripper used for gripping silicon wafers to multichannel solar battery sheet process equipment; the swing of the big arm and the small arm is controlled through a motor, and parametric design and PID control are adopted to realize concise control of the movement trajectory of the manipulator. With the silicon wafer fully-automatic feeding / discharging manipulator and the movement trajectory control method thereof of the invention adopted, problems such as large occupied space, complex mechanism, low flexibility, slow response and high production cost of chain-type texturing, chain-type cleaning and sintering devices as well as problems of serious wear of silicon wafer surface, low conversion efficiency and high fragmentation rate can be solved.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

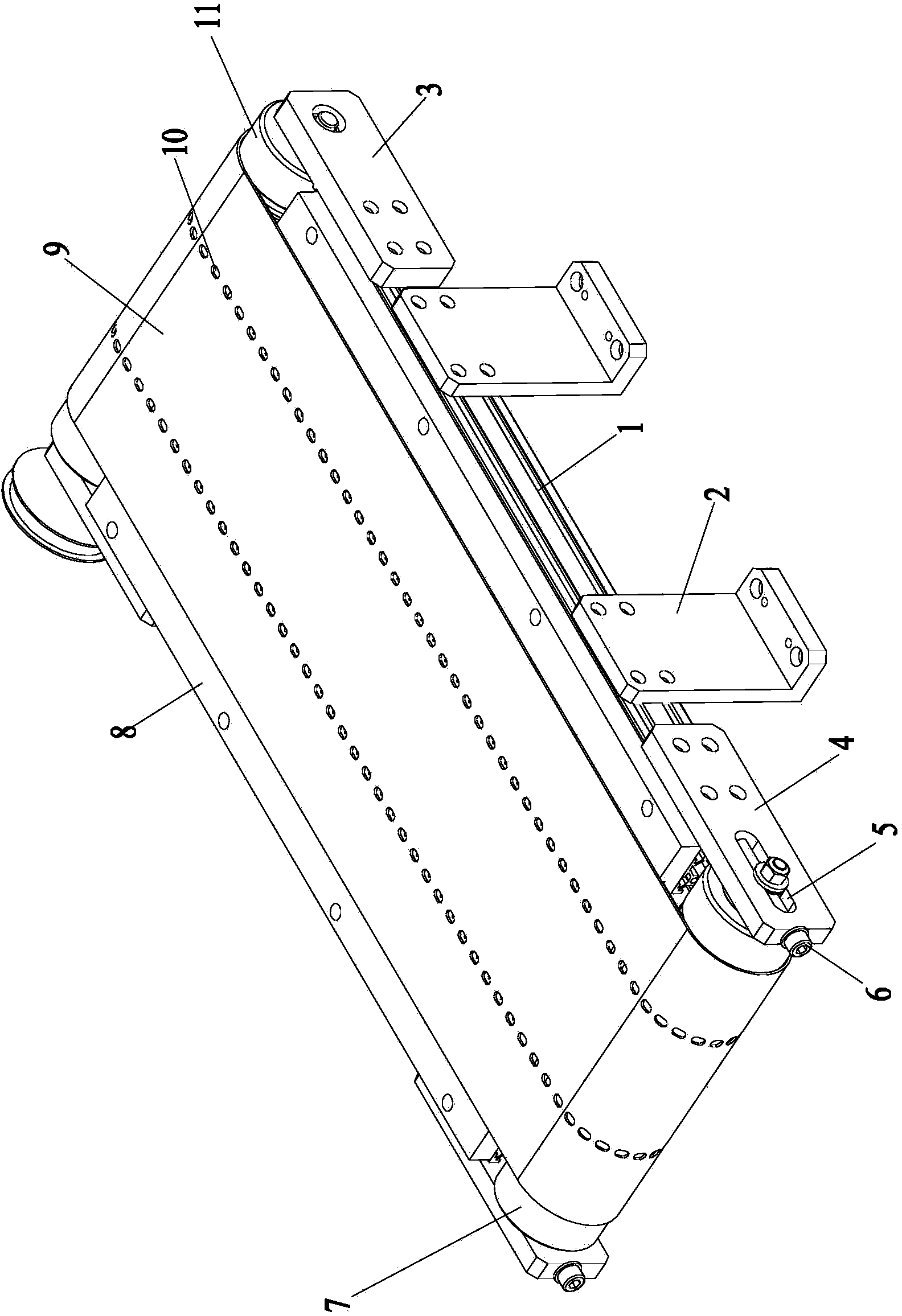

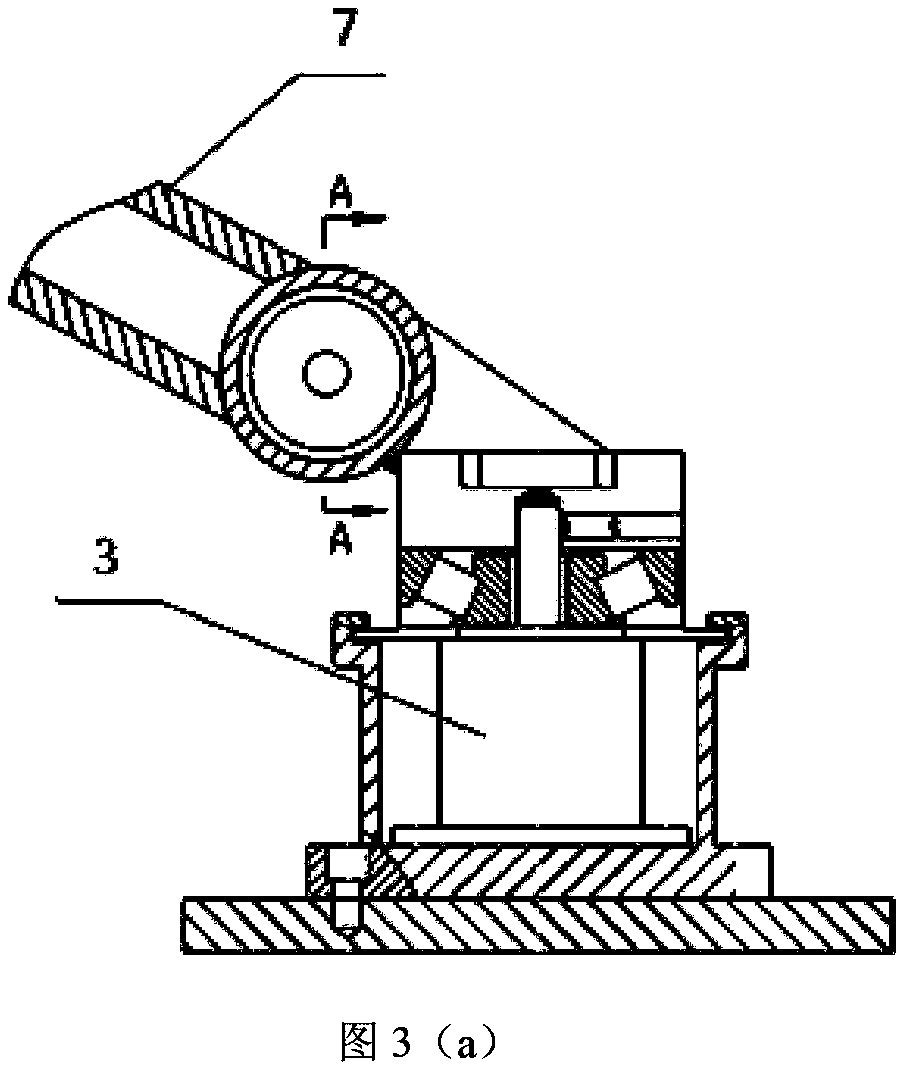

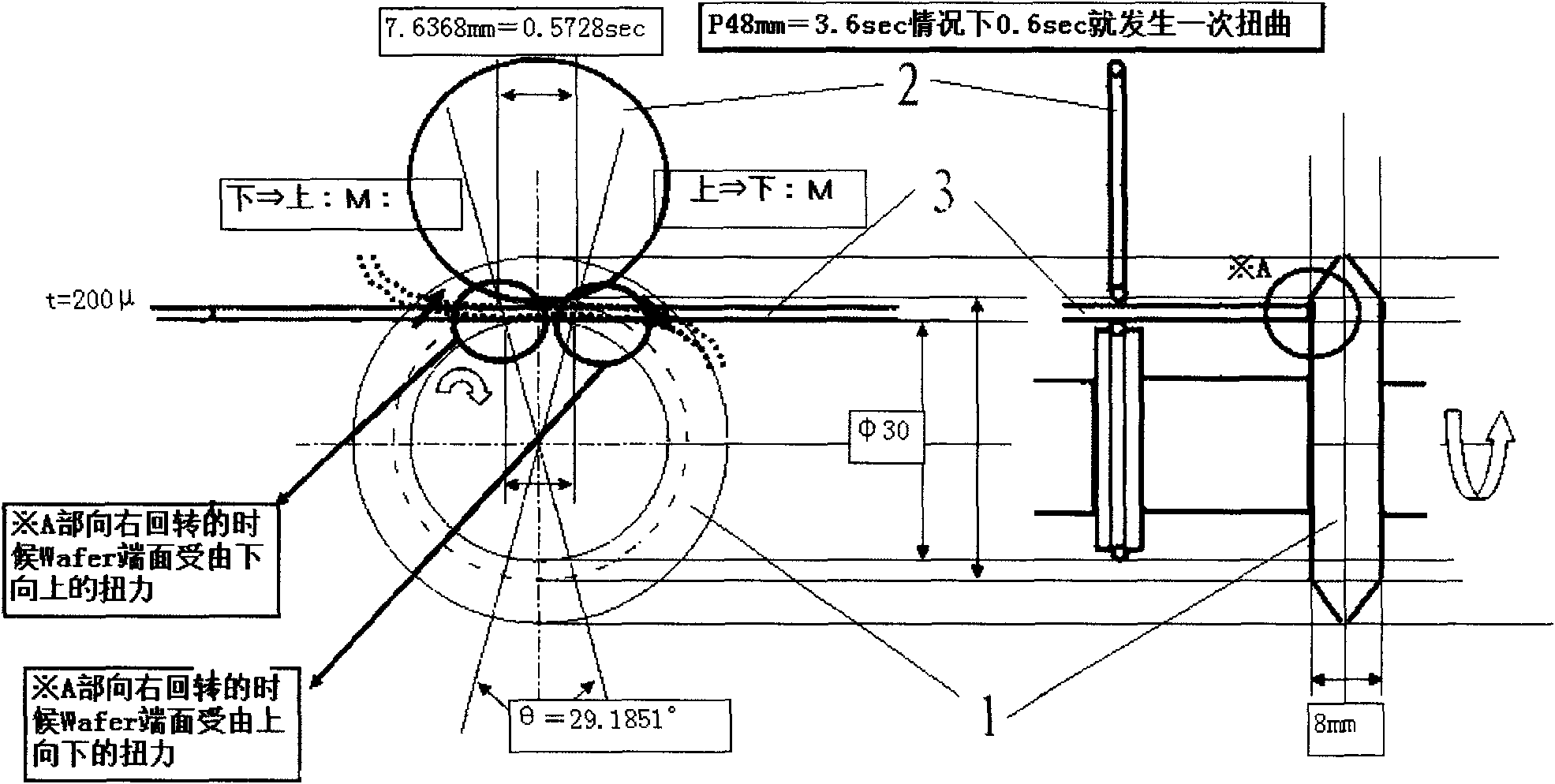

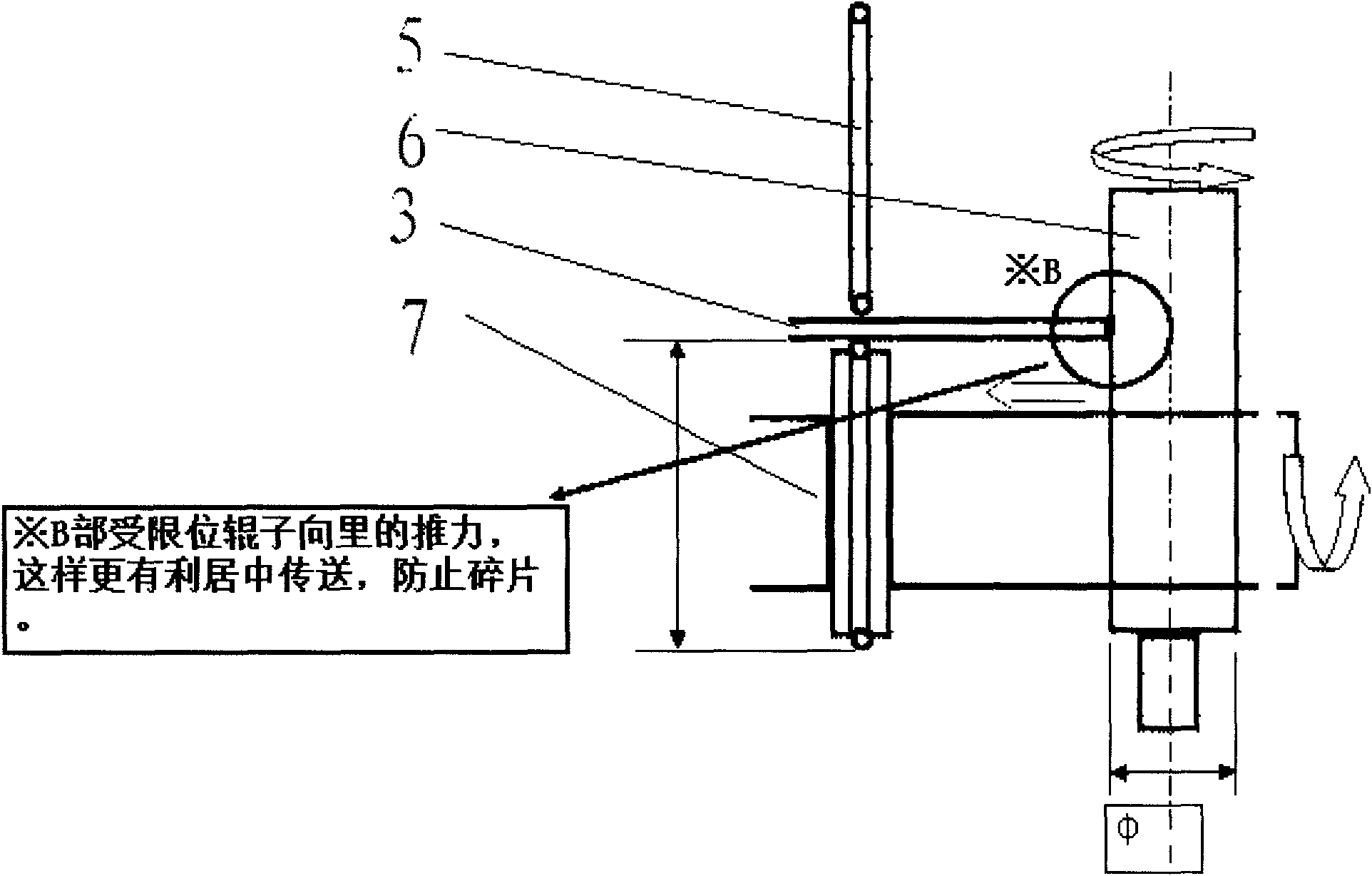

Method and device for reducing fragmentation rate by chain type texturing for multicrystalline solar cells

InactiveCN101640229AReduce incentivesFinal product manufactureSemiconductor devicesShear stressFree rotation

The invention relates to a method and a device for reducing fragmentation rate by chain type texturing for multicrystalline solar cells, a driving roller and limiting rollers are designed in a split manner, and the design of the limiting rollers leads the stress direction of a silicon wafer to be conductive to centralized transmission of the silicon wafer; the limiting rollers are arranged in thedirections which are vertical to the transmission direction of the silicon wafer, each limiting roller freely rotates around a shaft line thereof, when the silicon wafer touches the rollers, the generated friction force leads each roller to rotate around the shaft line thereof and leads the silicon wafer to move to a central line of the transmission; as the limiting rollers are arranged on both sides of the silicon wafer, the silicon wafer can move to the direction of the central line of the transmission no matter which side of the limiting rollers are touched by the silicon wafer, thereby playing the role of automatic deviation correction. The device has the advantages that the device changes the integral design of a conveying roller and the limiting rollers of the original scheme, removes alternating shear stress generated by friction of the limiting rollers and the silicon wafer, reduces an incentive of fragmentation of the silicon wafer and reduces the fragmentation rate to be within 2 per mill.

Owner:CHINA UNITED CLEANING TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com