Patents

Literature

191results about How to "Improve factory quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

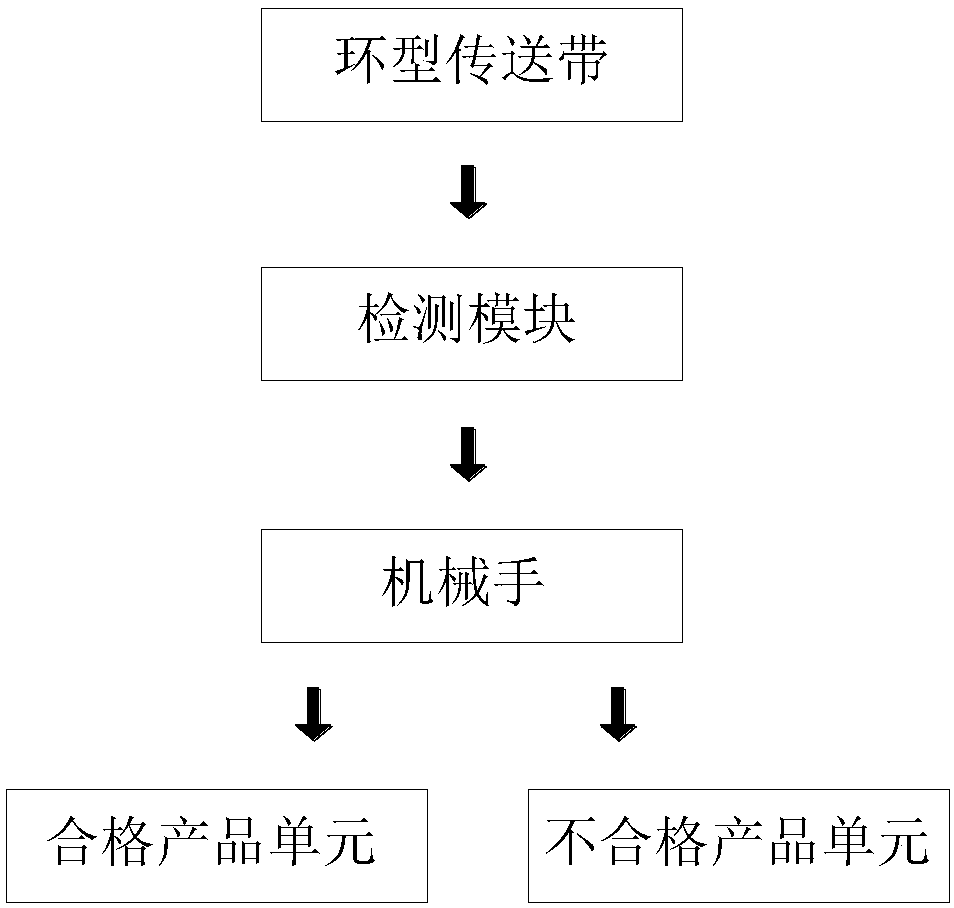

High-efficient detection system for injection molding product quality

InactiveCN108176601AQuality Efficient Detection EfficientEfficient detectionSortingInternal factorConveyor belt

The invention discloses a high-efficient detection system for injection molding product quality.N stations are uniformly arranged on an annular conveyor belt; a detection module is used for acquiringimage information of products on the n stations on the annular conveyor belt, analyzing the image information, and marking the products on the n stations as qualified products or unqualified products;a manipulator is used for conveying the qualified products marked by the detection module to a qualified product unit, and conveying the unqualified products marked by the detection module to an unqualified product unit; and the unqualified product unit is used for acquiring image information of the unqualified products, comparing the image information with preset image information to obtain defective kinds of the unqualified products, and marking the unqualified products according to the defective kinds. According to the high-efficient detection system for the injection molding product quality provided by the invention, a target product and multiple products in the same batch are compared and analyzed, and the occurrence of the phenomenon that the detection accuracy of the target productquality is reduced by the influences of an external environment and internal factors of an injection molding system can be effectively avoided, so that the injection molding product quality is high-efficiently detected.

Owner:QUANJIAO XIANGRUI PLASTIC

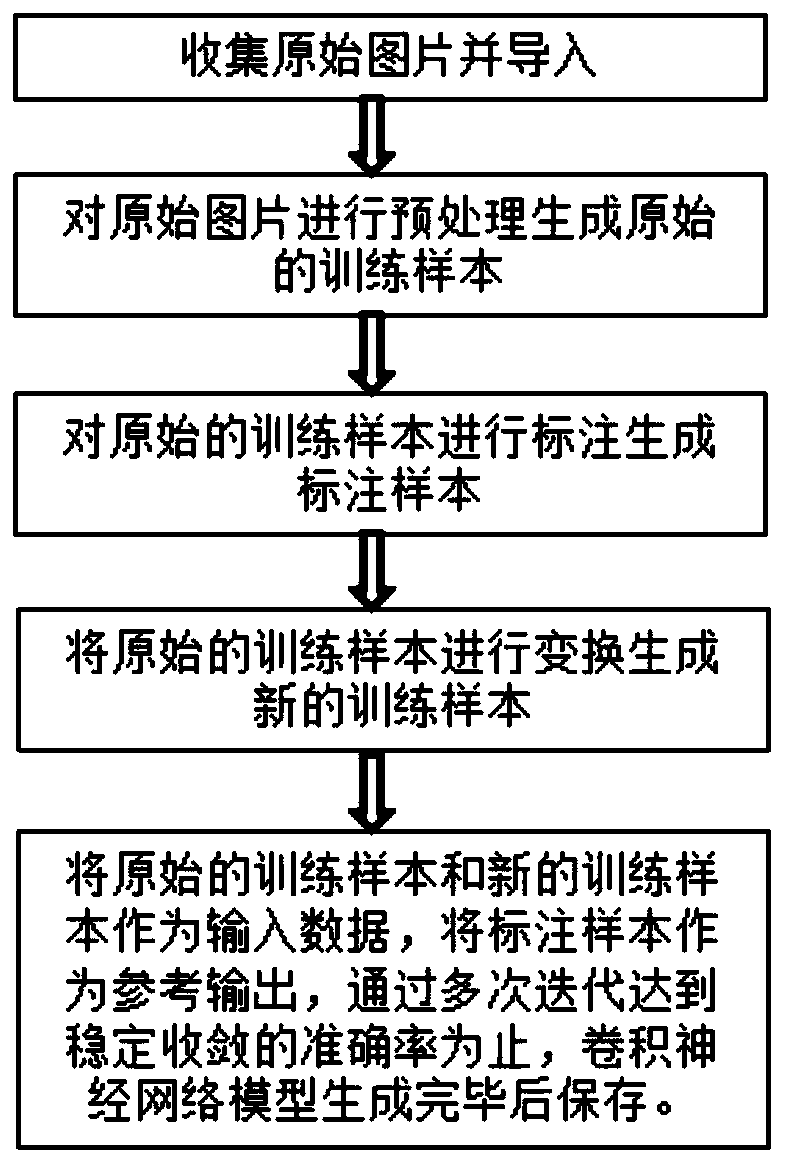

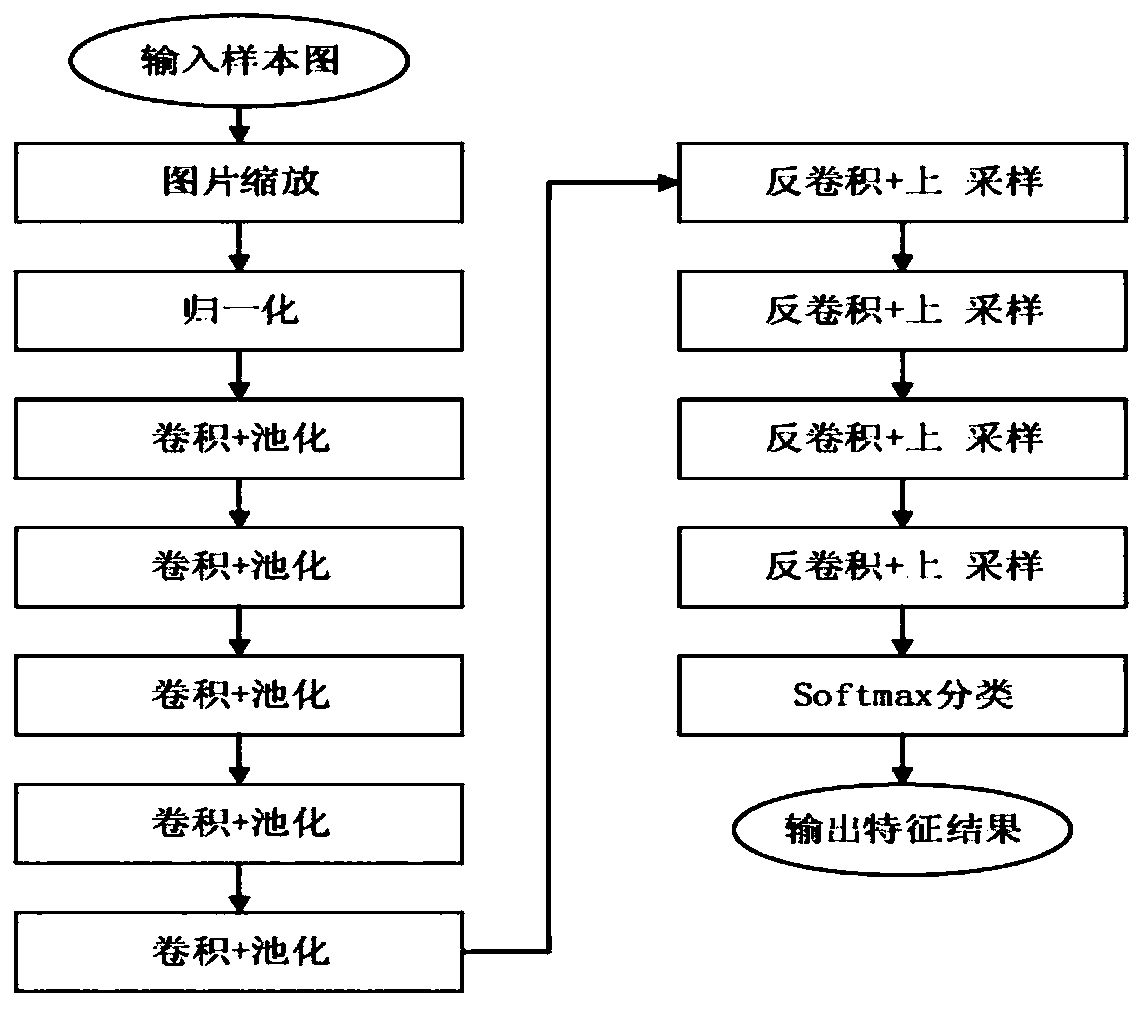

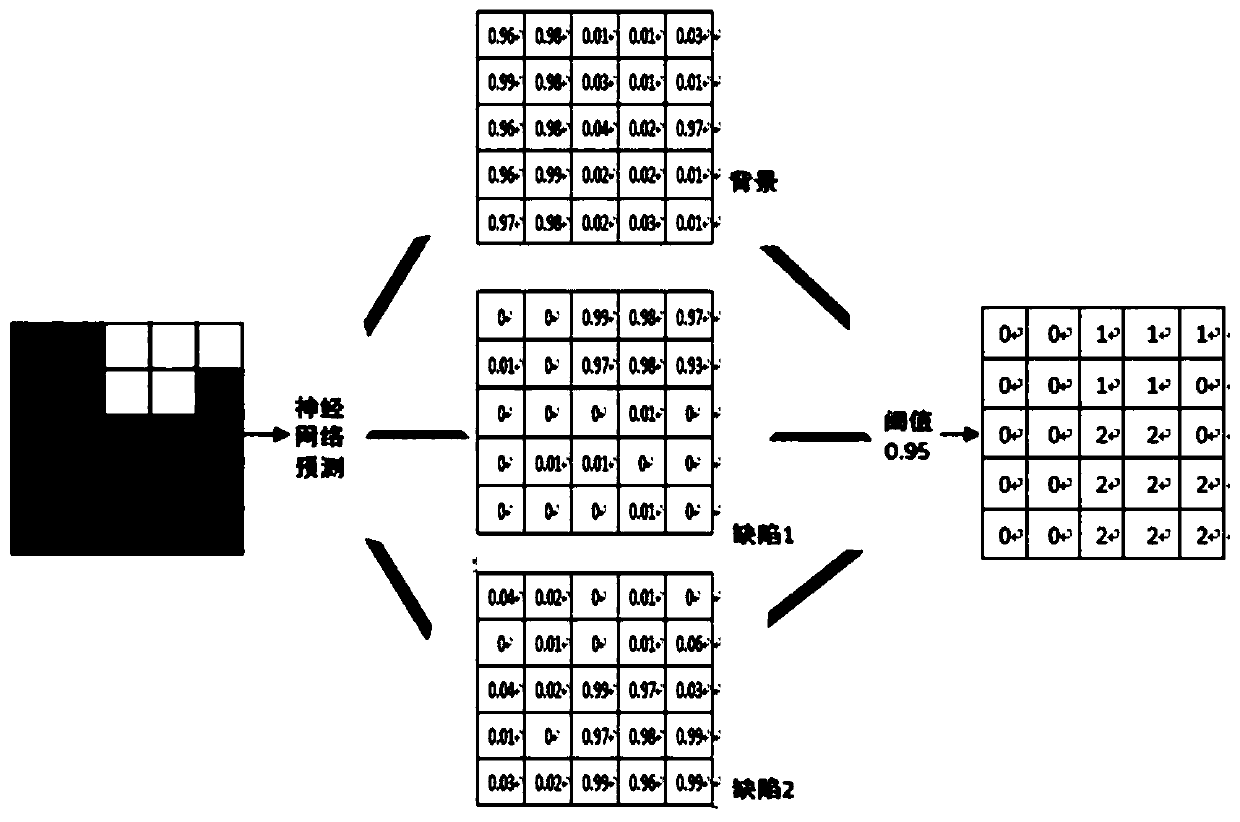

Method for constructing convolutional neural network model for surface defect detection and application thereof

PendingCN111582294AImprove factory qualityEnhance the imageCharacter and pattern recognitionOptically investigating flaws/contaminationEngineeringLow contrast

The invention discloses a method for constructing a convolutional neural network model for surface defect detection and application thereof. The method comprises the following steps: (1) collecting and importing an original picture; (2) preprocessing the original picture, and determining the preprocessed original picture as an original training sample and storing the original training sample; (3)labeling the original training sample to generate a labeled sample; (4) transforming the original training sample to generate a new training sample, and enhancing the training sample; and (5) taking the training sample as input data, marking the sample, carrying out corresponding processing, and taking the processed sample as reference output: after the convolutional neural network model is generated, storing the convolutional neural network model until the stable convergence accuracy is achieved through multiple iterations. According to the method, various adverse effects caused by interference factors such as random product defect form, complex texture and low contrast ratio under the condition that a small number of samples are input are overcome, so that the defect recognition rate isimproved.

Owner:慧泉智能科技(苏州)有限公司

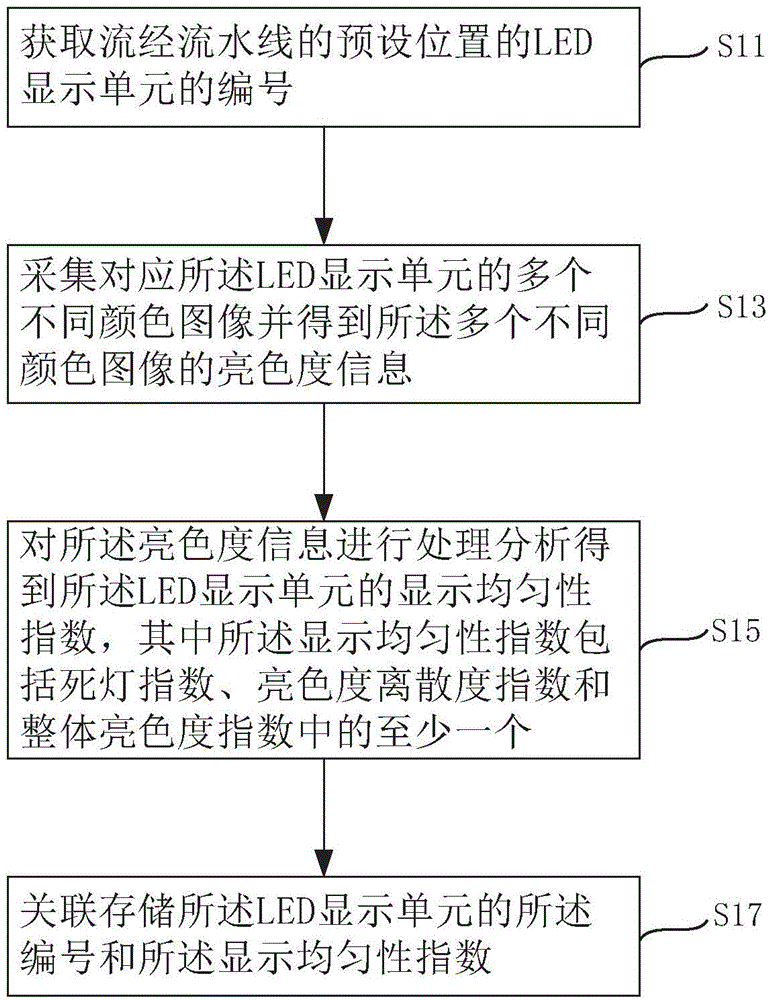

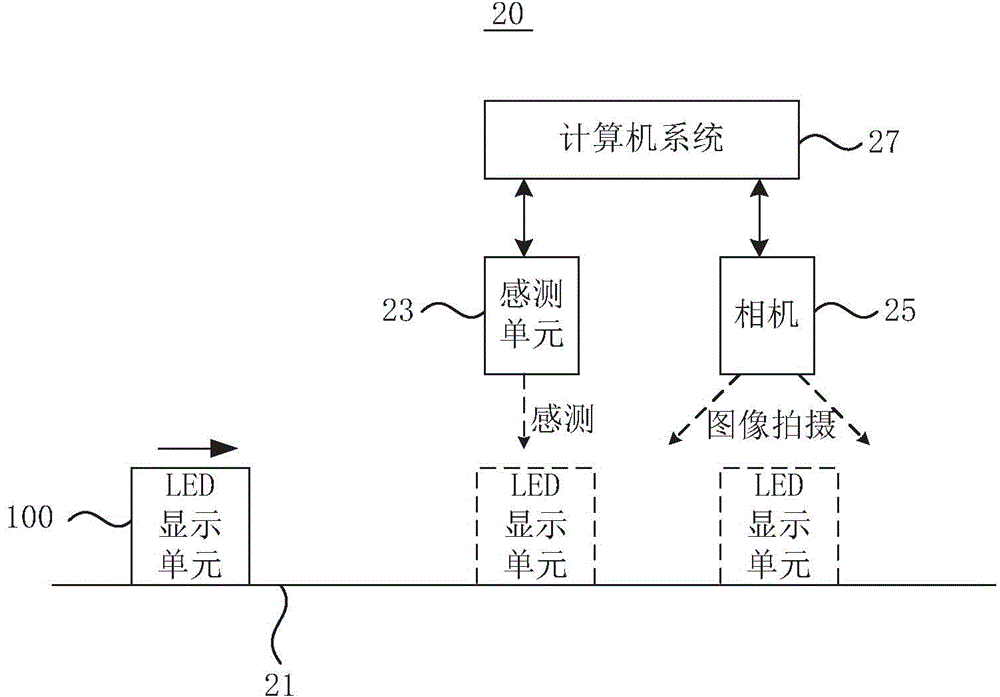

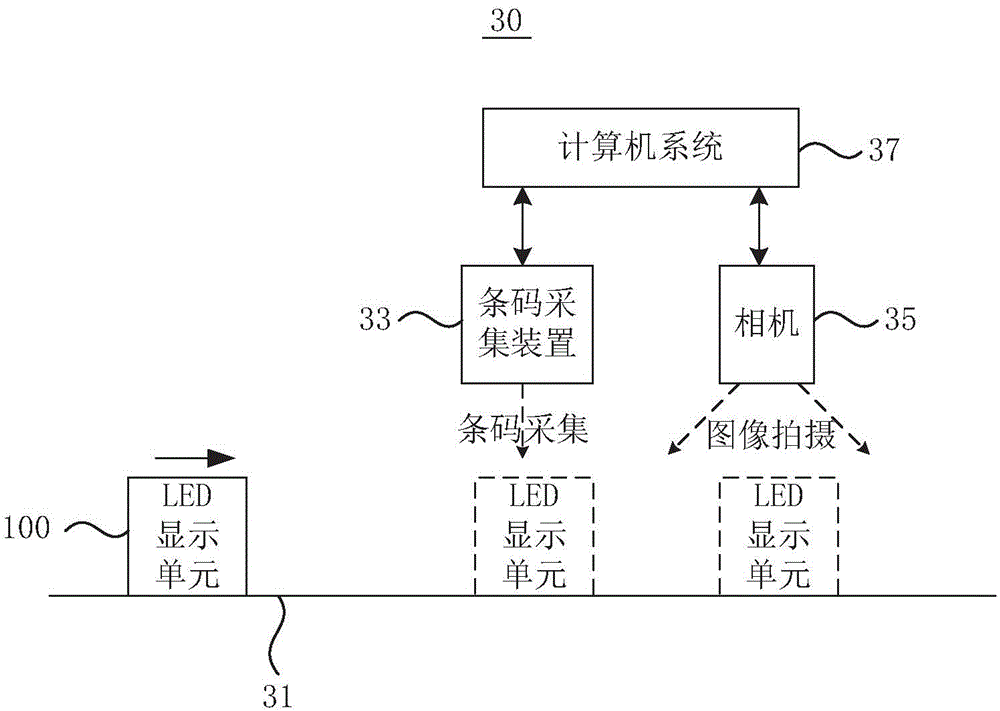

Assembly-line LED (light emitting diode) display unit uniformity detection method, system and device

InactiveCN104637425AImprove factory qualitySave manpower and material resourcesStatic indicating devicesMaterial resourcesAssembly line

The invention relates to an assembly-line LED (light emitting diode) display unit uniformity detection method, system and device. The method comprises the steps: (a) acquiring a serial number of an LED display unit flowing through a preset position of an assembly line; (b) acquiring multiple different color images of the corresponding LED display unit and obtaining brightness information of the multiple different color images; (c) processing and analyzing the brightness information to obtain a display uniformity index of the LED display unit, wherein the display uniformity index comprises one of a death lamp index, a brightness and chrominance dispersion index and overall brightness and chrominance index; (d) correlating and storing the serial number and the display uniformity index of the LED display unit. The display uniformity index is acquired by virtue of the assembly line way, so that the delivery quality of a product can be improved, reference information can be provided for the subsequent production, and the assembly-line LED display unit uniformity detection method also has characteristics that the manpower and material resource can be saved, the efficiency can be improved, the automation degree can be increased, and the like.

Owner:XIAN NOVASTAR TECH

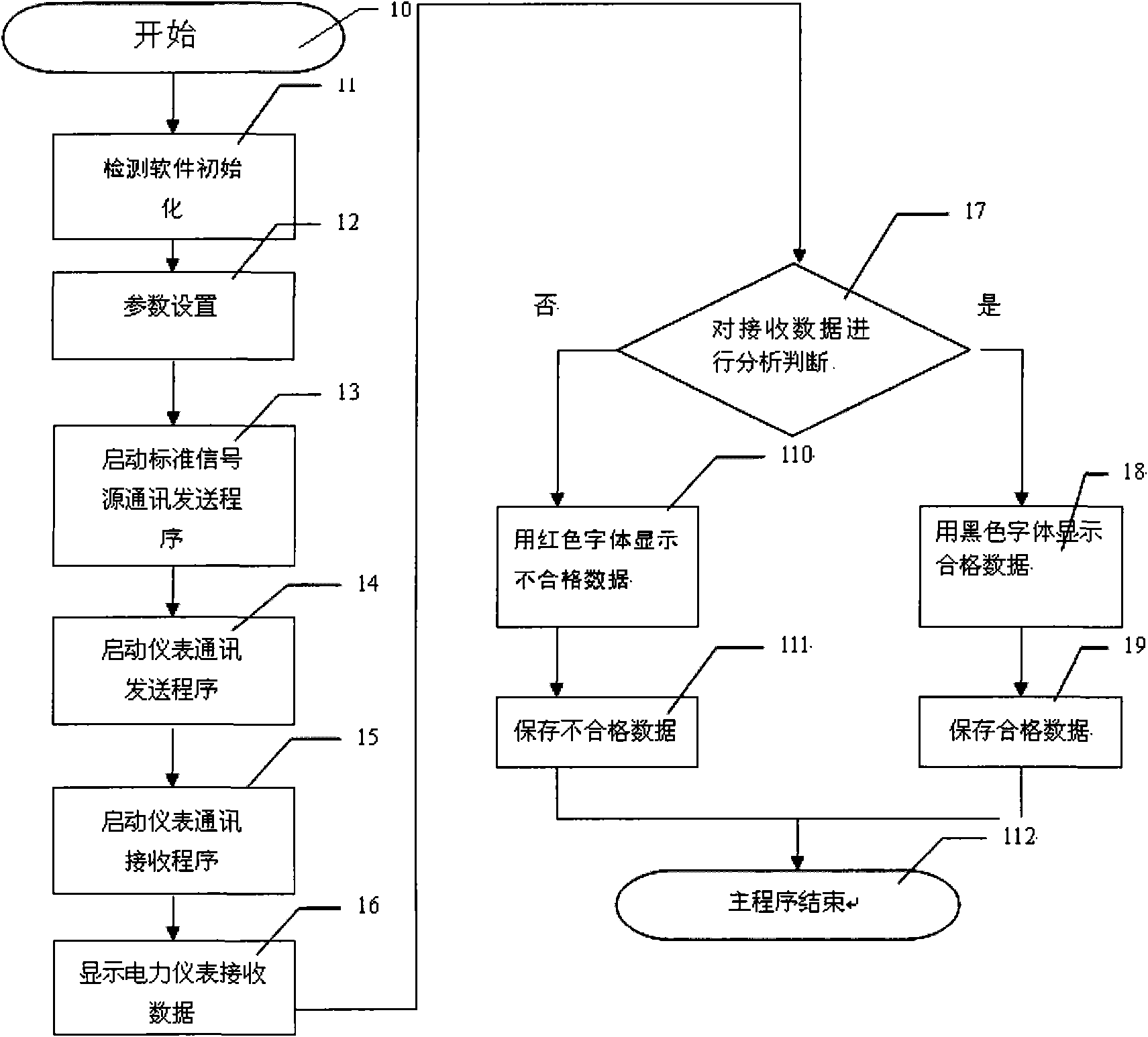

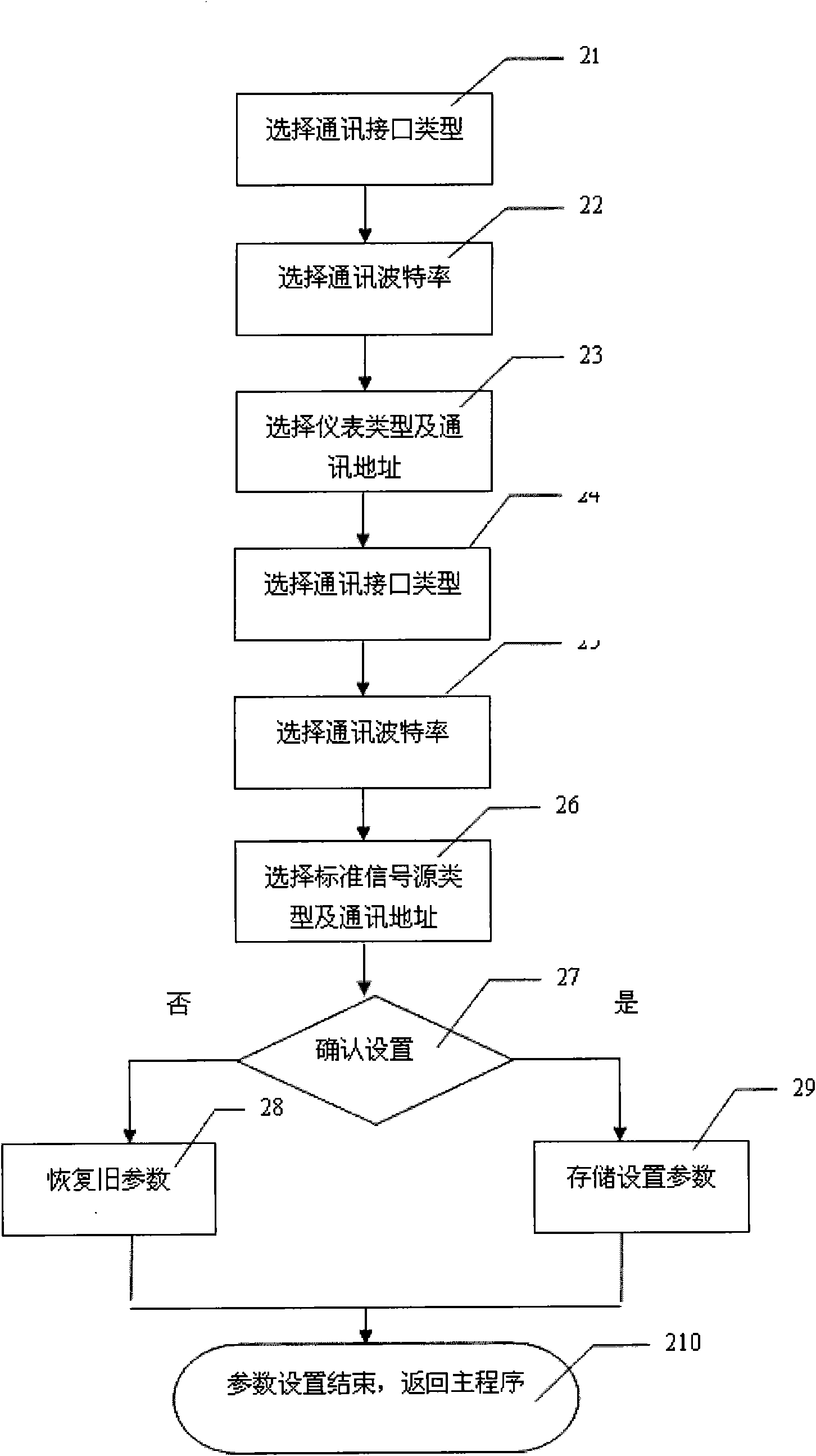

Automatic detection method of multifunctional electric meter

InactiveCN101930065AIncrease productivityImprove factory qualityElectric signal transmission systemsElectrical measurementsSignal sourceAutomatic testing

The invention discloses an automatic detection method of a multifunctional electric meter, which is characterized in that the multifunctional electric meter and a standard signal source are respectively connected with an upper computer, and the multifunction electric meter is detected by using detection software per se. By using the method, the invention has the advantages of improving the production efficiency and the outgoing quality of multifunctional electric meters, realizing automatic detection, lowering the production cost because the software has lower hardware requirement to the upper computer, and shortening the detection time and greatly improving the detection accuracy.

Owner:ANHUI XINLONG ELECTRICAL

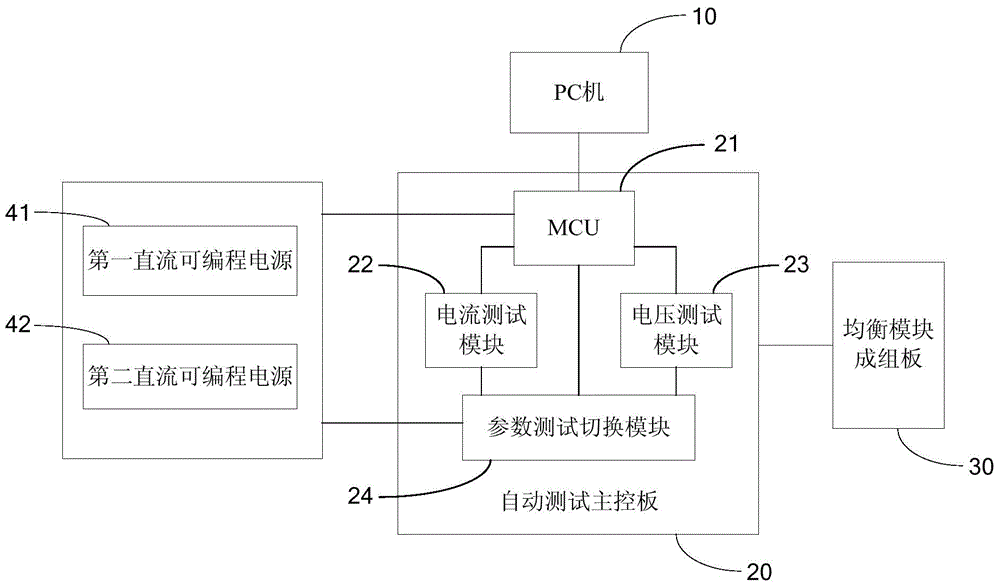

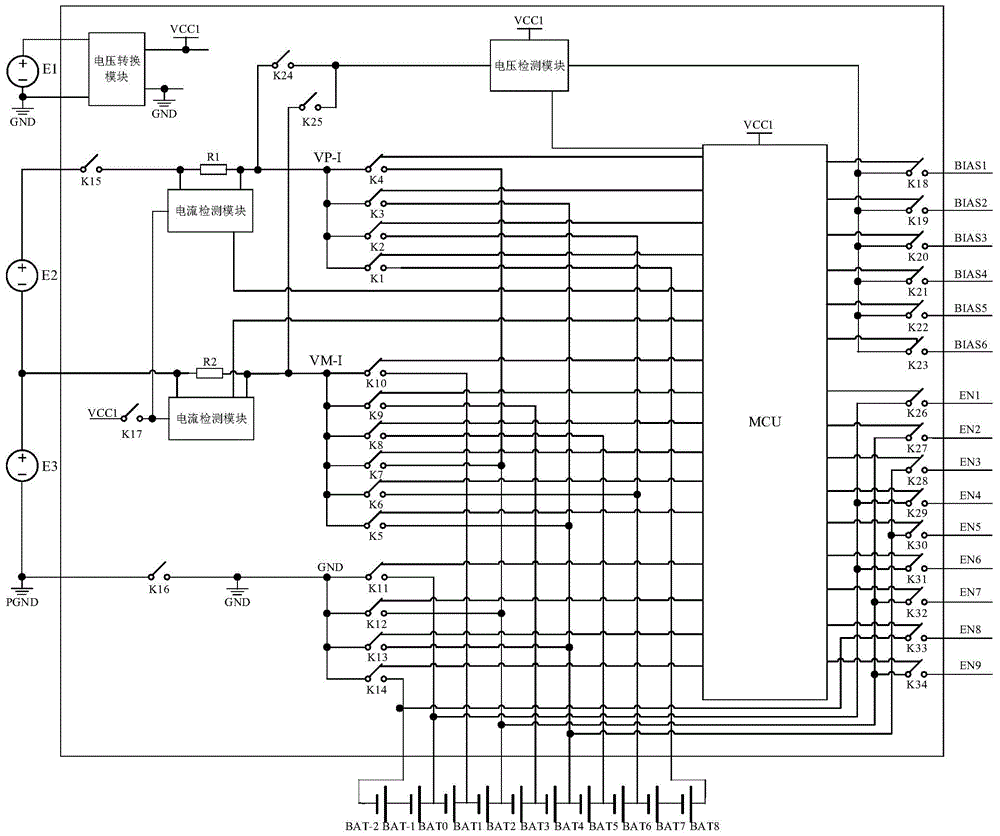

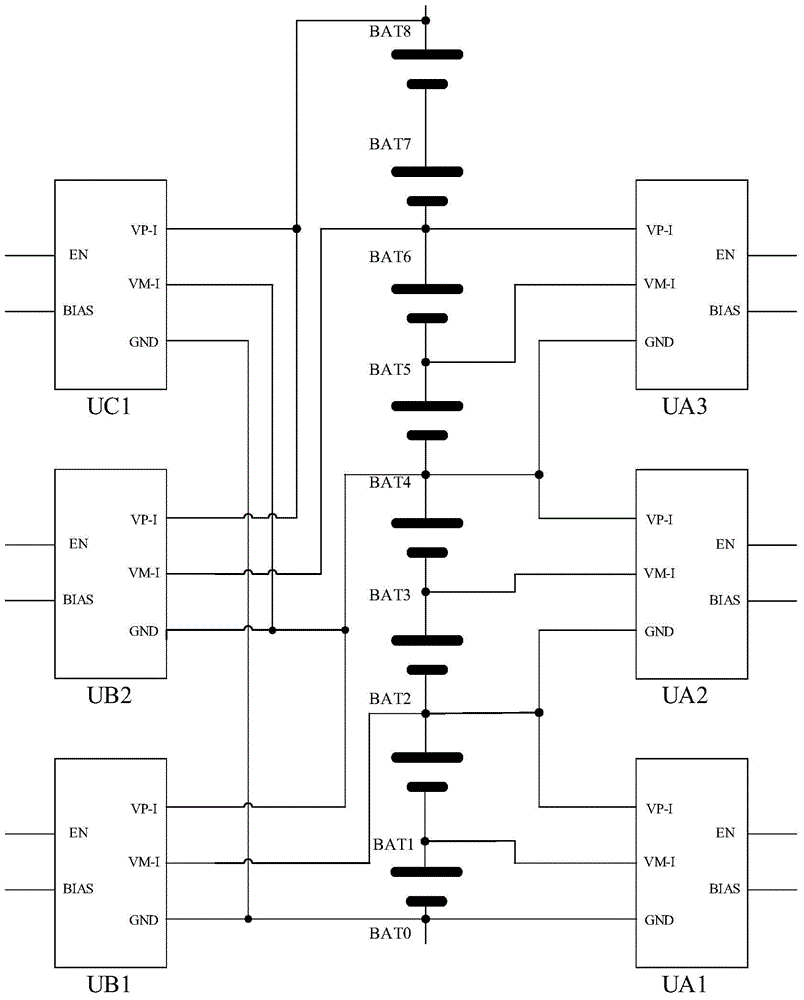

Automatic testing system for battery equalization module packing

ActiveCN104407302ASuit one's needsExtend your lifeBatteries circuit arrangementsElectrical testingPower flowElectrical battery

An automatic testing system for battery equalization module packing comprises a PC (personal computer), an automatic test main control panel, at least one direct-current programmable power supply and a test table for holding equalization module packing panels, wherein multiple equalization modules are connected with the inside of the test table, the automatic test main control panel is electrically connected with the PC, the at least one direct-current programmable power supply and the test table for holding the equalization module packing panels respectively, the automatic test main control panel controls control connection lines used for connection with the test table to be connected and disconnected, whether each equalization module passes a test is judged by testing changes of voltage and currents of each control connection line, and accordingly whether performance of the equalization modules on the packing panels is qualified in different states is tested. The measurement accuracy and efficiency of the automatic testing system in voltage, current and other data are multiplied compared with a traditional manual testing mode, and the quality of ex-factory products can be improved.

Owner:HANGZHOU BMSER TECH

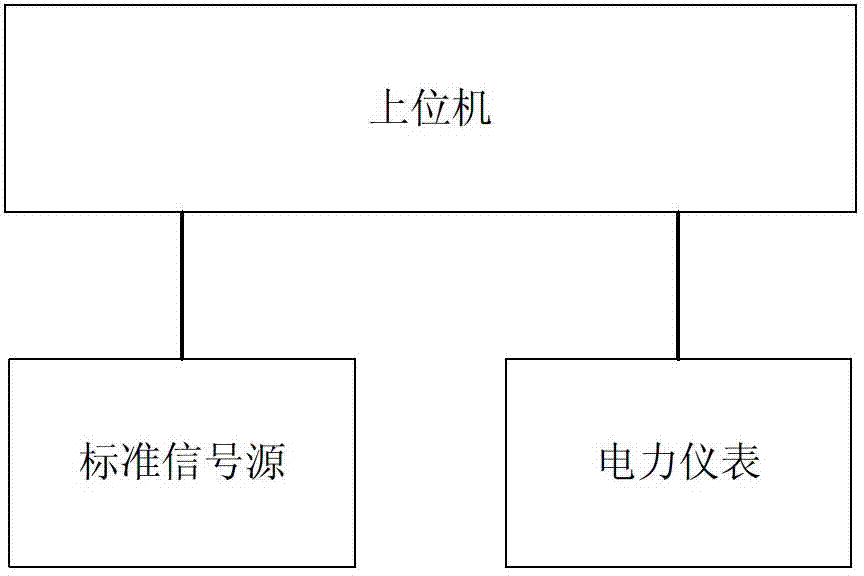

Power instrument detecting method

InactiveCN103048634AIncrease productivityImprove factory qualityElectrical measurementsEngineeringSignal source

The invention discloses an automatic detecting method for a multifunctional power instrument, which is characterized in that an upper computer is respectively connected with the multifunctional power instrument and a standard signal source; and the multifunctional power instrument is detected by utilizing a detection program of the multifunctional power instrument. The method has the advantages of improving production efficiency and outgoing quality of the multifunctional power instrument, implementing automatic detection, reducing production cost, shortening detecting time and greatly improving detection accuracy.

Owner:ANHUI HUININGELECTRIC INSTR & APPLIANCE GRP

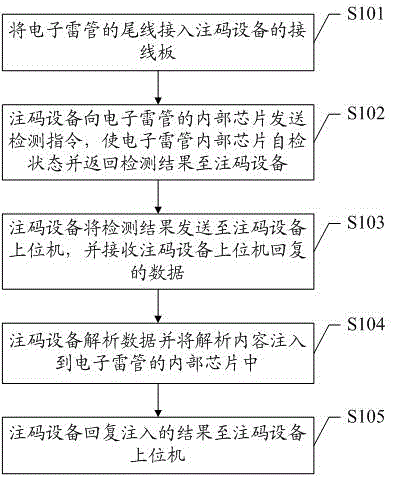

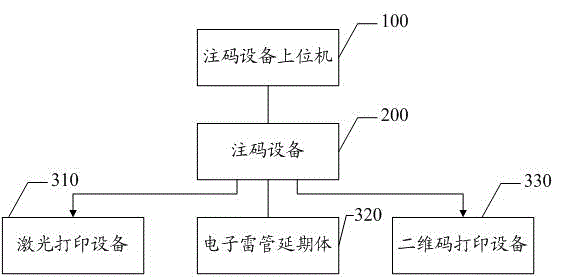

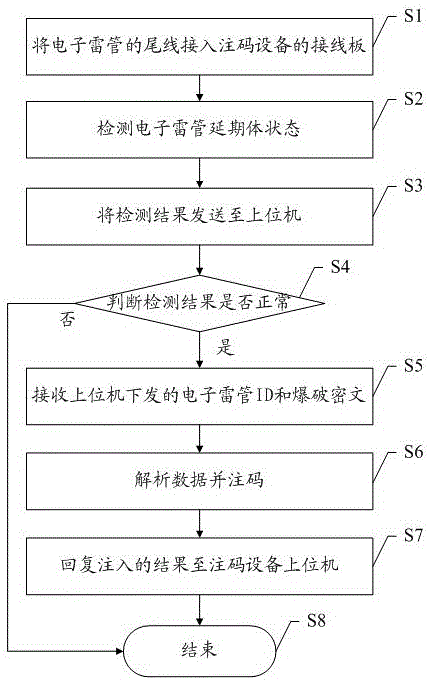

Code injection method and system for electronic detonator

InactiveCN105928424AImprove testing standardsImprove factory qualityDetecting faulty hardware by power-on testPrintingDetonatorCode injection

The invention discloses a code injection method and a code injection system for an electronic detonator. The code injection method comprises the following steps: A. the tail line of the electronic detonator is connected to a wiring board of code injection equipment; B. the code injection equipment sends a detection instruction to an inside chip of the electronic detonator, so that the inside chip of the electronic detonator enters a self-detection state and returns the detection result to the code injection equipment; C. the code injection equipment sends the detection result to an upper computer of the code injection equipment and receives data replied by the upper computer of the code injection equipment; D. the code injection equipment analyzes the data and injects the analysis content into the inside chip of the electronic detonator; and E. the code injection equipment replies the injected result to the upper computer of the code injection equipment. The method and the system can automatically detect whether the tail line of the electronic detonator is in contact with the wiring board in real time to detect and inject code, can improve the working efficiency, can improve the detection standard of electronic detonators leaving factory, can improve the delivery quality of the electronic detonators, and can guarantee good performance of the electronic detonators leaving factory.

Owner:XINJIANG CHUANGANDA ELECTRONICS TECH DEV

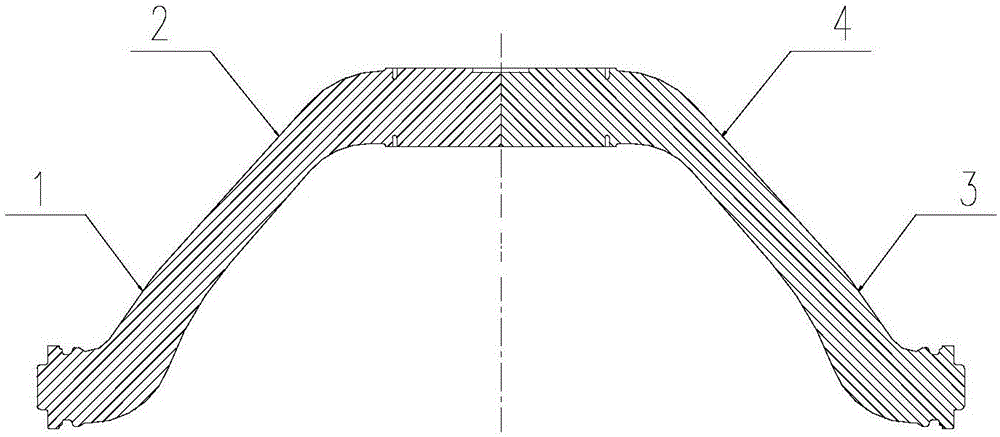

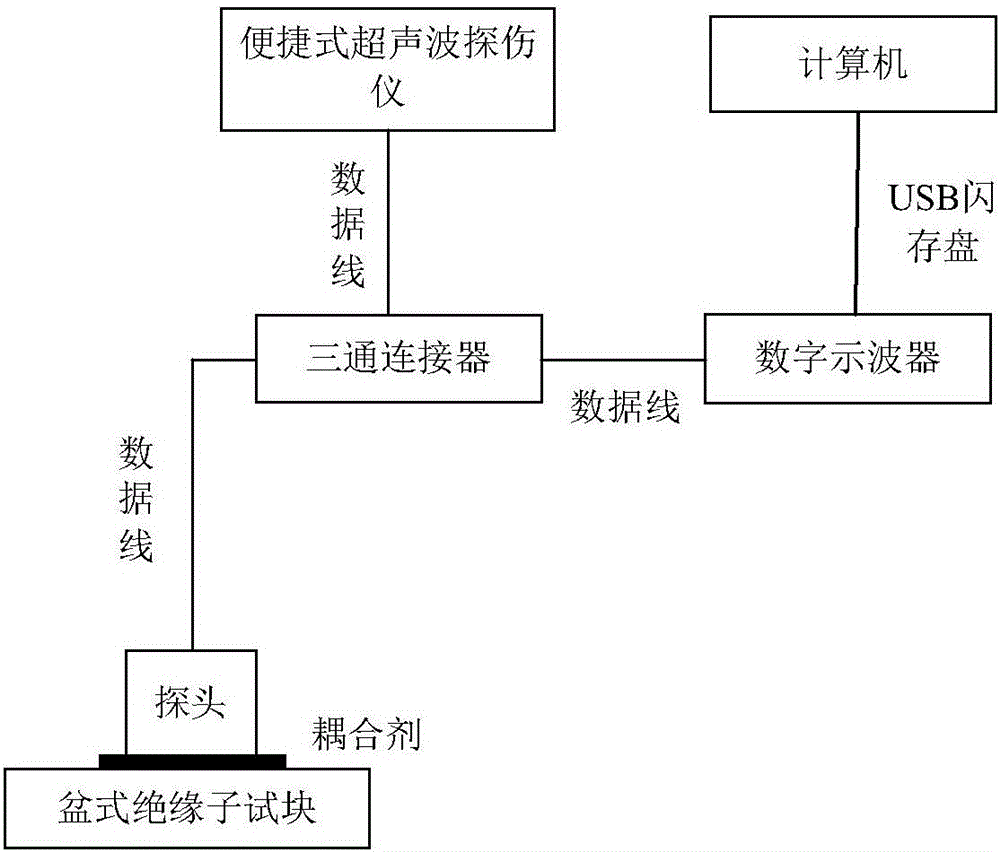

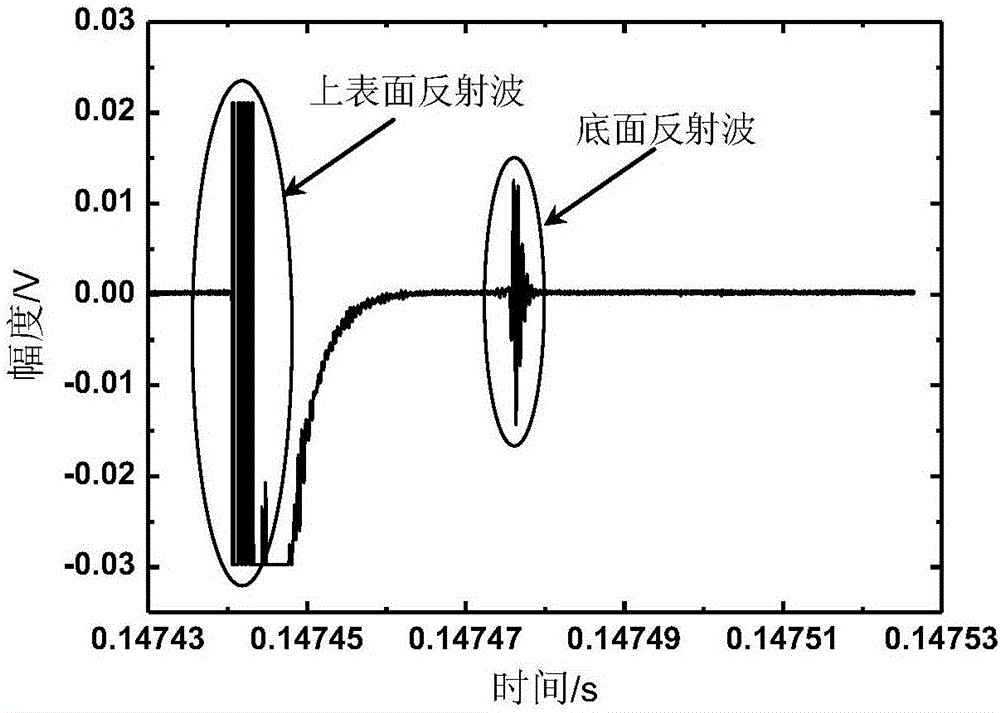

Nondestructive testing method and device for basin type insulator curing degree of high-voltage switch equipment

InactiveCN106645404ARealize non-destructive testingImprove factory qualityAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial heat developmentFast Fourier transformUltrasonic testing

The invention relates to a nondestructive testing method and device for basin type insulator curing degree of high-voltage switch equipment, wherein the nondestructive testing method comprises the following steps: transmitting an ultrasonic pulse to an insulator to be tested; obtaining an ultrasonic reflection signal at the lower bottom surface of the insulator to be tested; carrying out fast Fourier transform on the ultrasonic reflection signal, and calculating a power spectrum of the ultrasonic reflection signal; comparing the peak value of the power spectrum with a relational data base, thus obtaining the curing degree of the insulator to be tested; the relational data base is a corresponding relation of insulator curing degrees obtained by carrying out ultrasonic tests on insulator samples with different curing degrees and the power spectrum of the ultrasonic reflection signal at the lower bottom surface of the insulator. The method disclosed by the invention can effectively realize nondestructive testing on the overall curing degree of the basin type insulator.

Owner:PINGGAO GRP +1

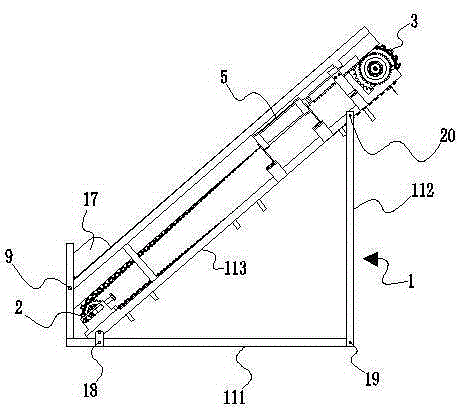

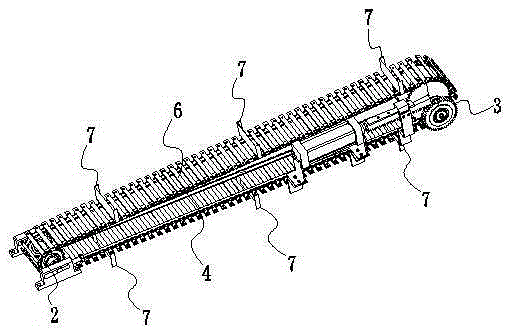

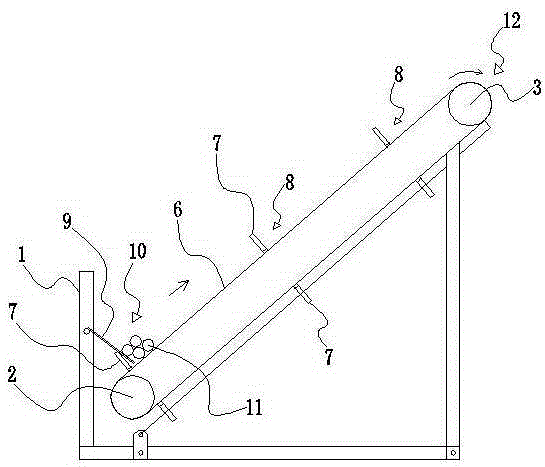

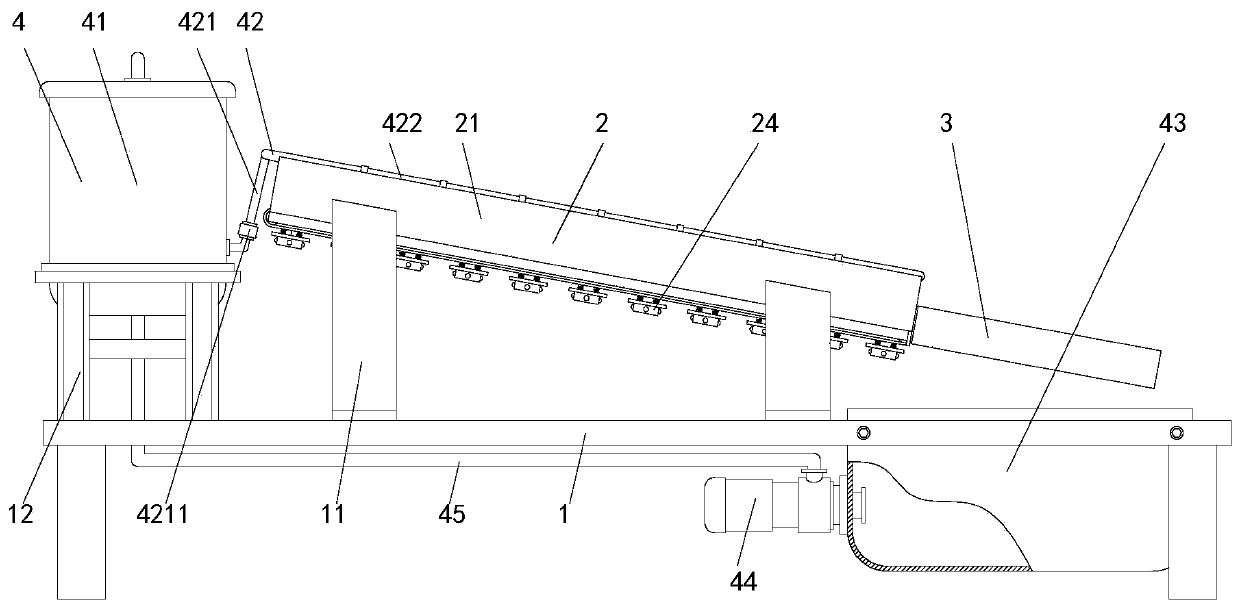

Pipe fitting unloading device and unloading method for malleable cast iron pipe fitting end facing machine

The invention discloses an unloading device and an unloading method for a malleable cast iron pipe fitting end facing machine. The unloading device comprises a rack and a sprocket-chain conveying component obliquely arranged on the rack, wherein the sprocket-chain conveying component comprises double driven sprockets, double driving sprockets and double chains, which are connected to the rack in a rotating manner, a driving device is arranged on the rack, a chain plate is arranged on the double chains, a plurality of lifting baffles are arranged on the double chains, a lifting space is formed between each lifting baffle and the chain plate, a blanking plate is connected to the rack, one end of the blanking plate is connected to the rack in a rotating manner, one of the plurality of lifting baffles is in contact with one side surface of the other end of the blanking plate and is pressed against the other end of the blanking plate so as to form a material waiting space, and the discharging position is positioned at the part of the double driving sprockets. During work, by using the plurality of lifting spaces sequentially penetrating through the material waiting space, pipe fittings in the material waiting space are sequentially conveyed to the discharging position, then fall in a bucker loader, and are transported away. The processing efficiency is improved.

Owner:ZHUZHOU KAIFENG IND

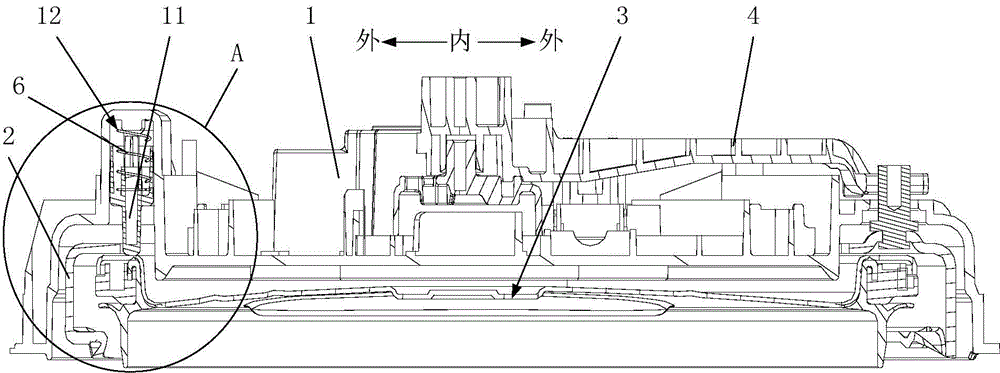

Automatic leakage detecting device for household air conditioner finished products

ActiveCN104215398ARealize the purpose of automatic sealing inspectionImprove factory qualityFluid-tightness measurementSensing by electromagnetic radiationIndustrial engineeringApplication actions

The invention relates to the field of sealability and leakage detecting equipment for household air conditioner finished products, in particular to an automatic leakage detecting device for household air conditioner finished products. The automatic leakage detecting device comprises a detection component, a retaining block component and a sensing component. The detection component is located on one side of the conveying direction of a conveying platform and comprises a leakage detection probe gun connected with a leakage detector probe suction gun and a pushing mechanism used for driving the leakage detection probe gun to perform reciprocating action along the specified direction. The retaining block component is located on the other side, relative to the side where the detection component is located, of the conveying platform, and the direction of force application action of the retaining block component on a to-be-detected packing box is opposite to that of acting force of the detection probe gun on the to-be-detected packing box. The sensing component comprises a sensing portion and a control portion, wherein the control portion receives signals of the sensing portion and controlling the pushing mechanism to act; the sensing portion detects in-place information of the to-be-detected packing box on the conveying platform; the control portion receives the signal and drives the pushing mechanism to perform specified pushing action. The automatic leakage detecting device is high in automation level, the requirements on sealability detection quality are met, and meanwhile, detection efficiency can be further improved.

Owner:HEFEI GENERAL MACHINERY RES INST +1

Double-sided synchronous spraying system for high polymer material

ActiveCN111632786AImprove processing efficiencyImprove factory qualityPretreated surfacesLiquid spraying apparatusMolecular materialsMechanical engineering

The invention discloses a double-sided synchronous spraying system for a high polymer material, and relates to the technical field of high polymer material spraying. A circulating type workpiece operation unit is fixedly installed at the top end of the interior of a spraying workshop, two sets of workpiece processing units are fixedly installed at the bottom end of the interior of the spraying workshop and located under the circulating type workpiece operation unit, the circulating type workpiece operation unit can drive a plurality of metal workpieces to do kidney-shaped circular motion. In the moving process of a plurality of metal workpieces, feeding, workpiece surface sweeping treatment, high polymer material spraying treatment, high polymer material hot air drying treatment and discharging can be achieved, the procedures can be sequentially carried out in order, the whole treatment process is free of a vacuum period, and therefore the machining efficiency of the metal plate-shapedworkpieces is improved, and in the whole spraying process, the double faces of each workpiece can be synchronously sprayed at a time, the workpieces do not need to be manually turned over, and time and labor are saved.

Owner:郑州中汇钛金属材料研究院有限公司

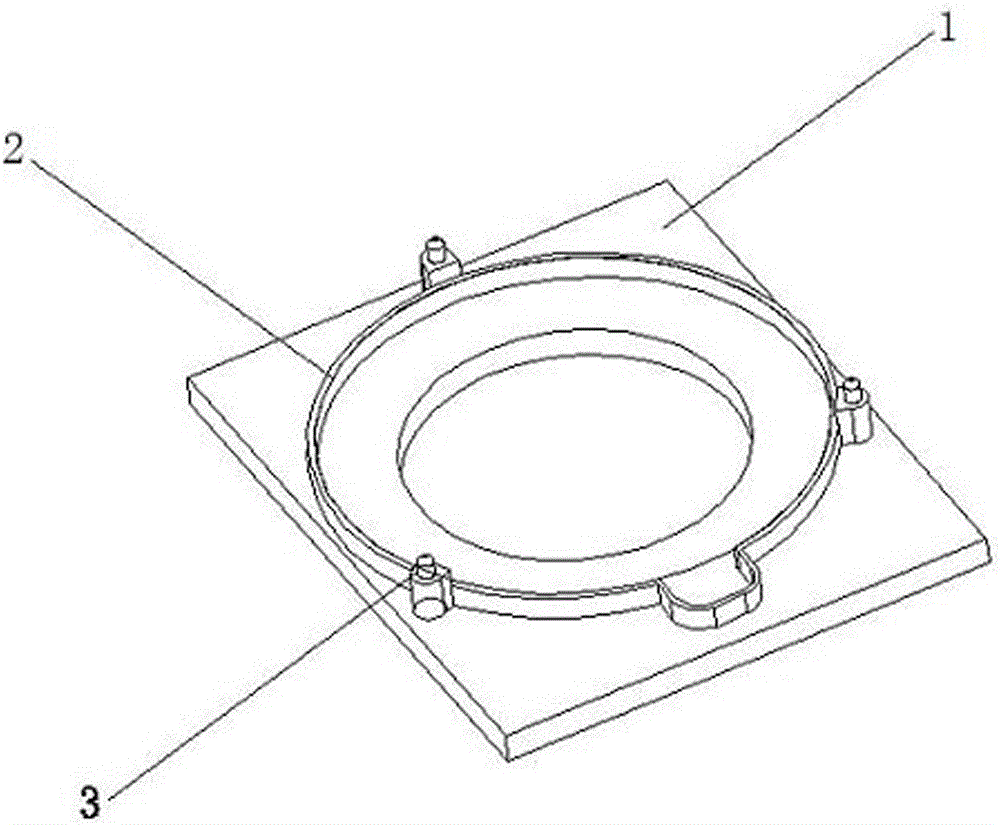

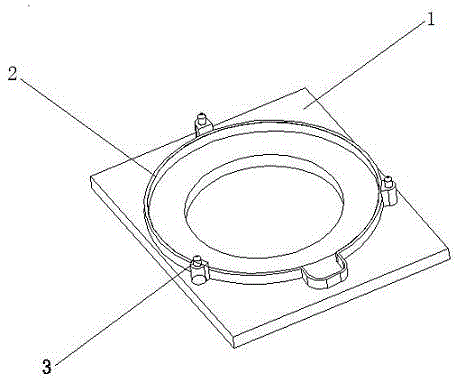

Detecting tool

InactiveCN105157504AMeet actual needsImprove detection efficiencyMechanical measuring arrangementsEngineeringSurface plate

The invention discloses a detecting tool, and relates to the technical field of automobile part machining. The detecting tool comprises a panel, a detection rib and detection pins, and is characterized in that the panel is provided with the detection rib, and the detection rib is provided with a plurality of detection pins. The detecting tool disclosed by the invention can carry out shaping on a flange plate, also can carry out detection on the flange plate, not only improves the outgoing quality of the flange plate, but also improves the detection efficiency of workers.

Owner:REFONE AUTO POWER

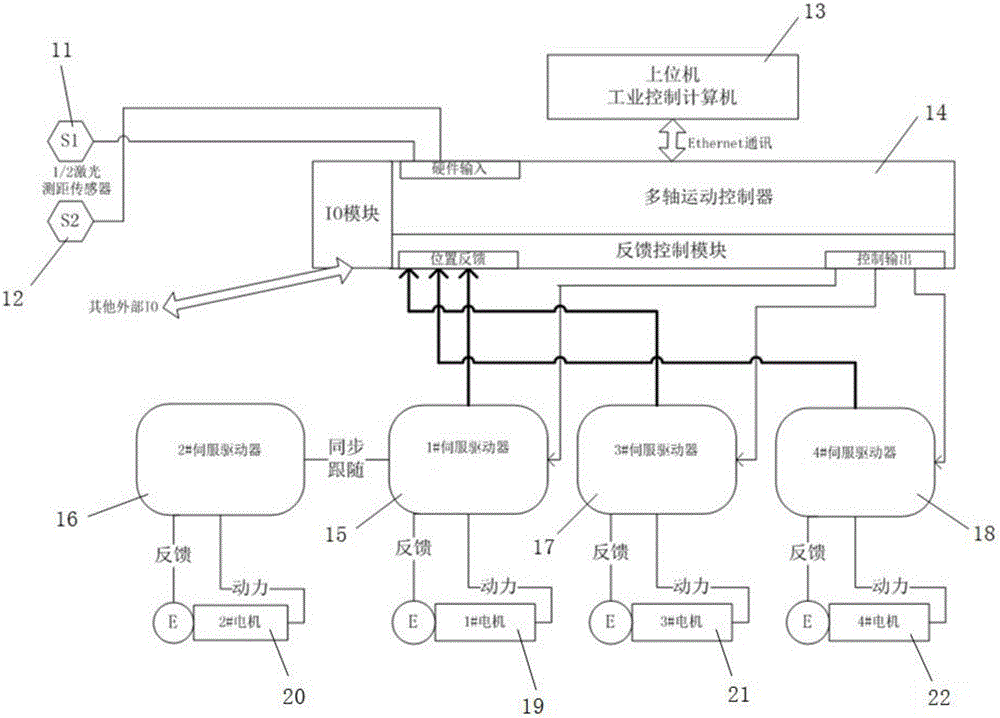

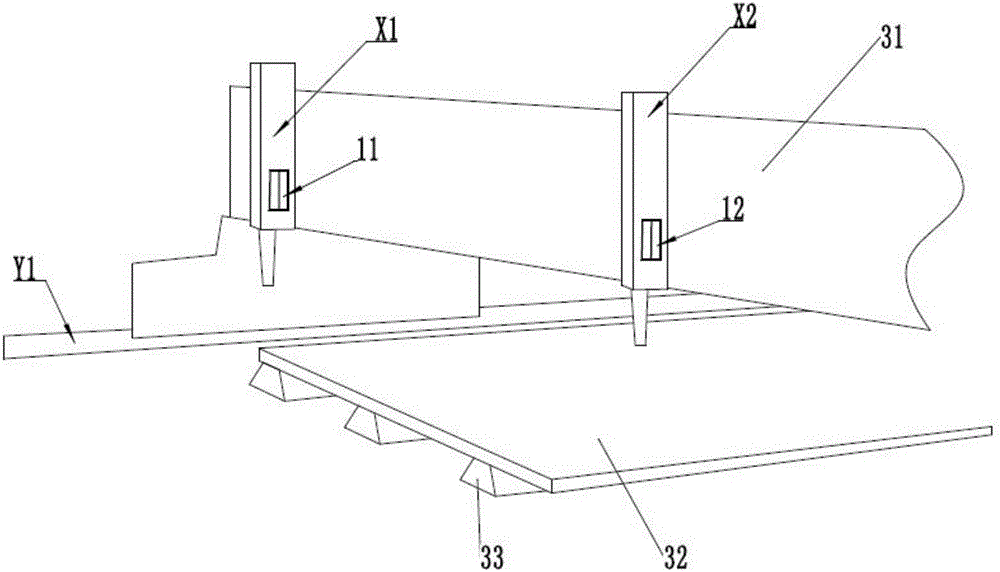

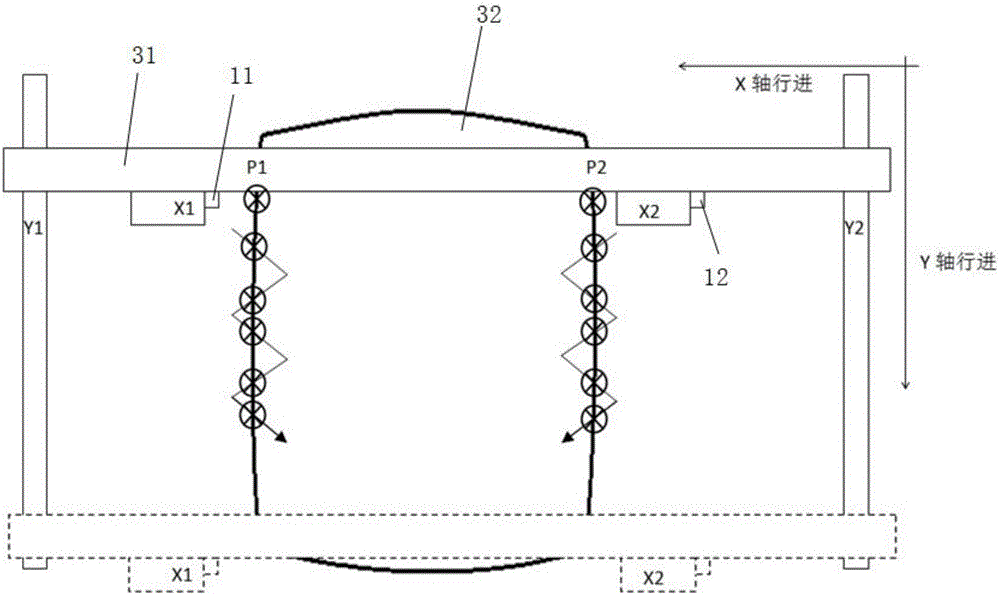

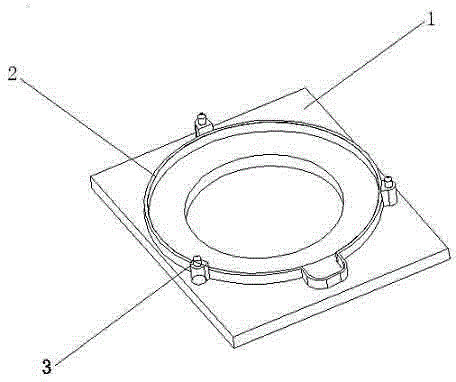

Steel plate edge scanning and cutting control system based on laser distance measuring sensors

ActiveCN106001847AAuto scanRealize cutting workWelding/soldering/cutting articlesMetal working apparatusLaser rangingControl system

The invention discloses a steel plate edge scanning and cutting control system based on laser distance measuring sensors. The steel plate edge scanning and cutting control system based on the laser distance measuring sensors comprises the first laser distance measuring sensor, the second laser distance measuring sensor, an upper computer industrial control computer, a multi-axis movement controller, a 1# servo driver, a 1# motor, a 3# servo driver, a 3# motor, a 4# servo driver and a 4# motor, wherein the first laser distance measuring sensor and the second laser distance measuring sensor are connected with the multi-axis movement controller; the upper computer industrial control computer is in communication connection with the multi-axis movement controller; the 1# motor is connected with the 1# servo driver; the 3# motor is connected with the 3# servo driver; the 4# motor is connected with the 4# servo driver; and the multi-axis movement controller is provided with a feedback control module, and the 1# servo driver, the 3# servo driver and the 4# servo driver are all connected with the feedback control module. The steel plate edge scanning and cutting control system based on the laser distance measuring sensors can carry out automatic scanning and cutting on steel plates, manpower is saved, and the precision and quality of the cut steel plates are high.

Owner:佛山市中菱智控科技有限公司

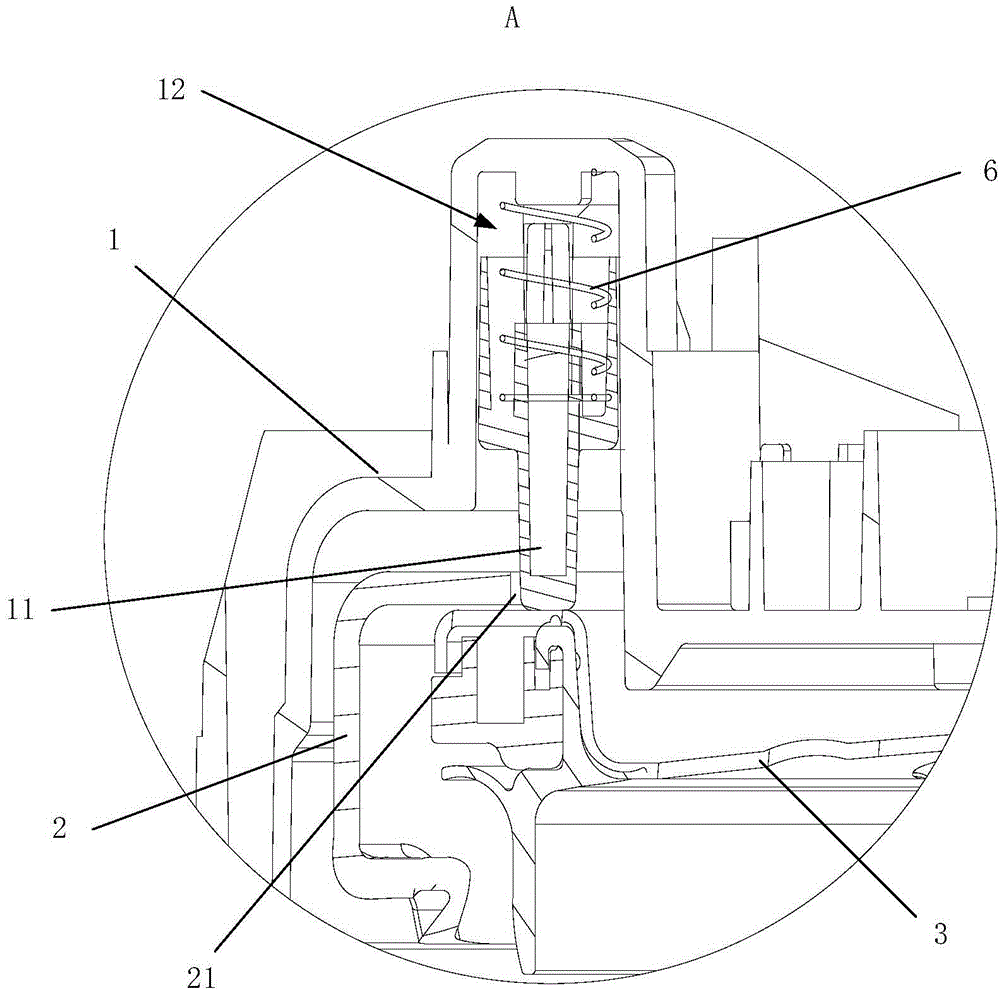

Automotive blower flange testing fixture

InactiveCN105571429AImprove factory qualityImprove detection efficiencyWork holdersMechanical measuring arrangementsTest efficiencyTest fixture

An automotive blower flange testing fixture relates to the technical field of automotive component processing. The automotive blower flange testing fixture comprises a panel, a testing rib and testing pins. The panel is provided with the testing rib on which a plurality of testing pins are arranged. The automotive blower flange testing fixture can fix a flange and furthermore can perform testing on the flange. Not only is outgoing quality of the flange improved, but also testing efficiency of a worker is improved.

Owner:HEFEI HONGTIAN MACHINERY MFG CO LTD

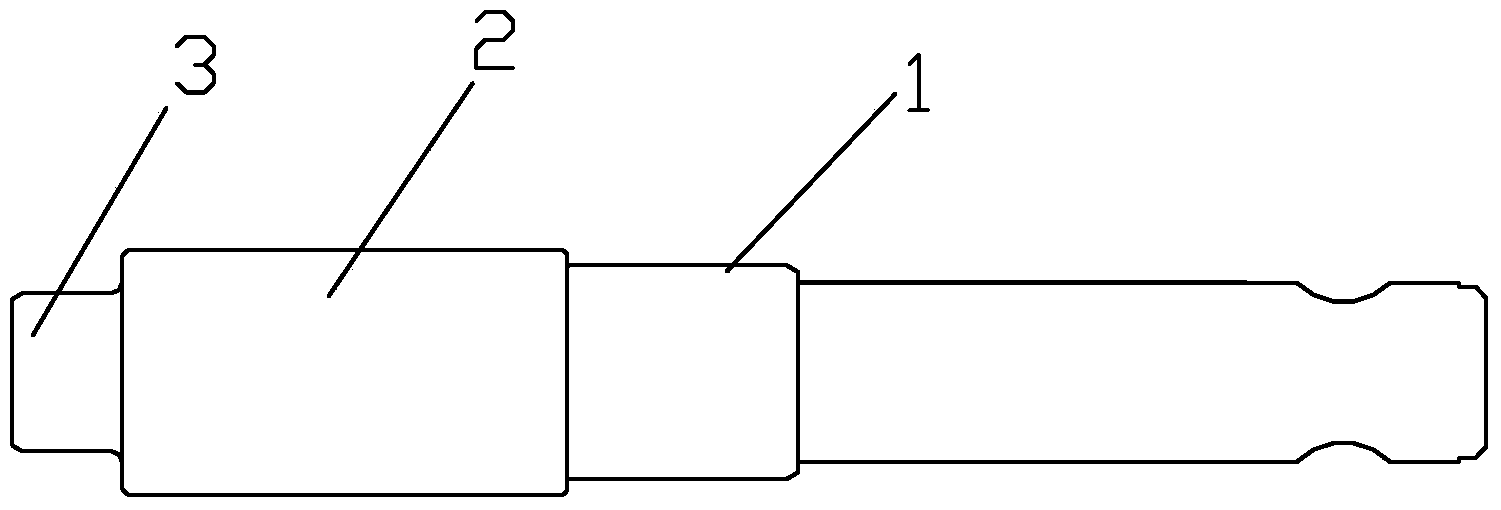

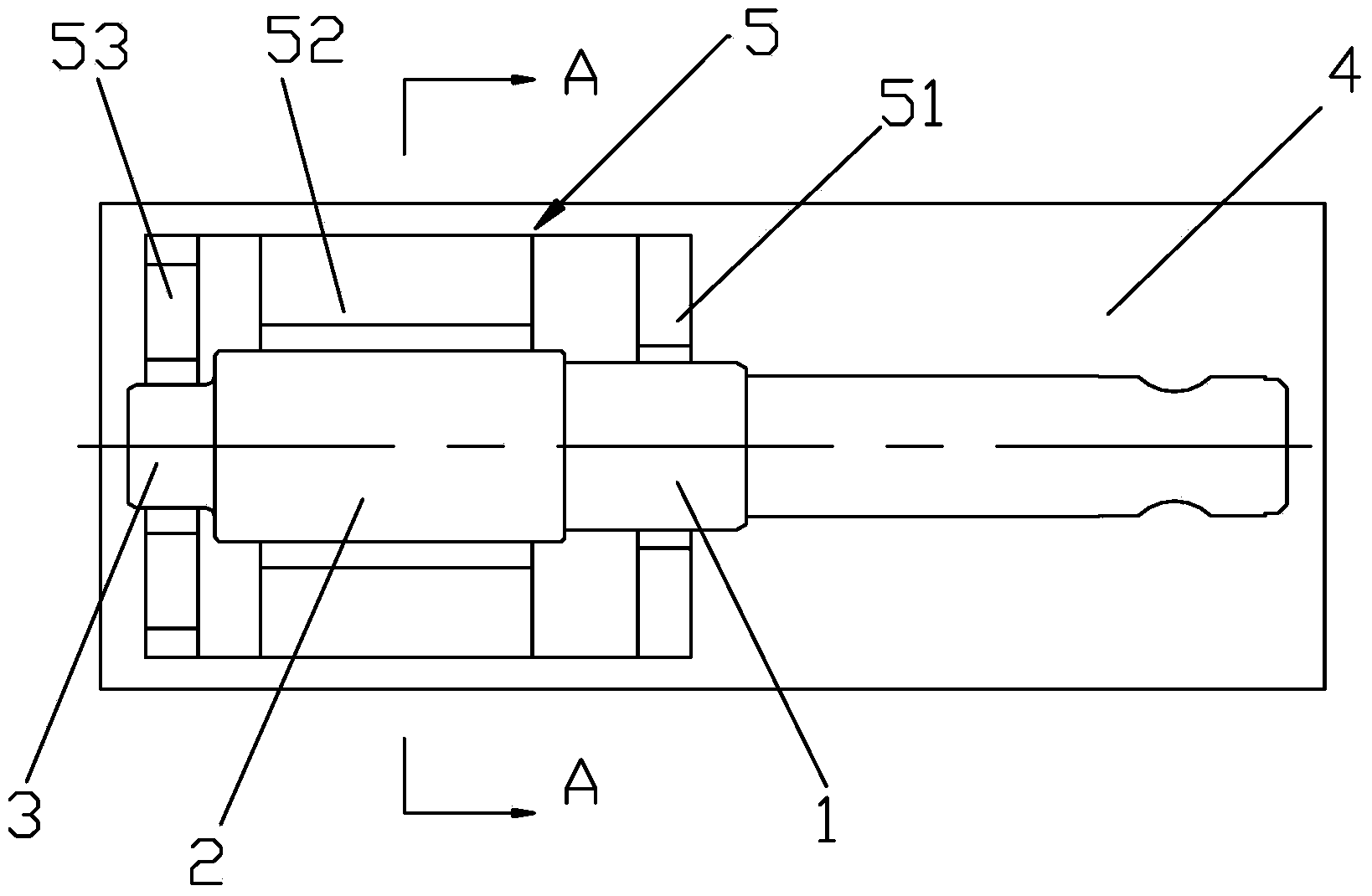

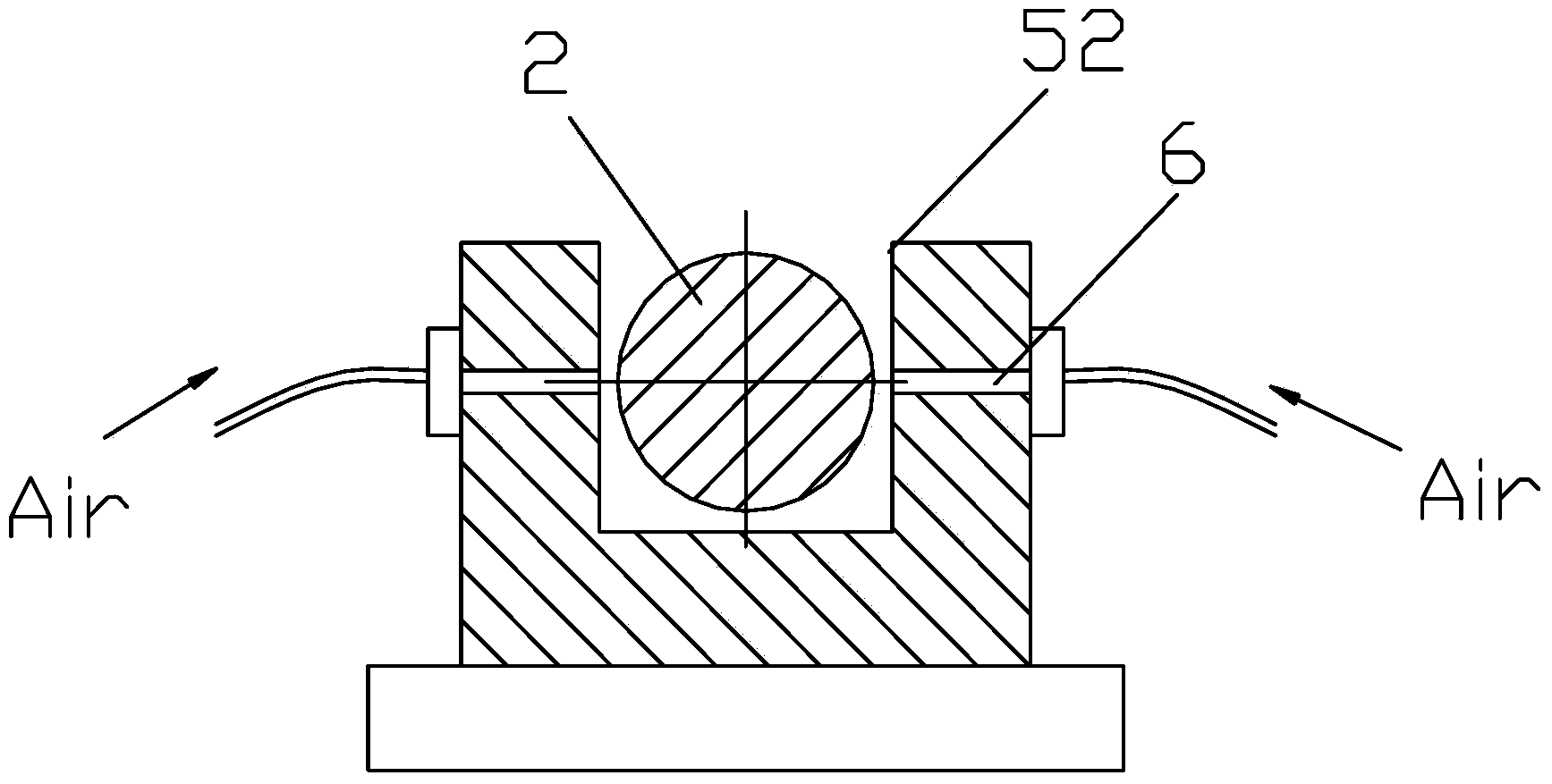

Automobile steering system input shaft outer diameter automatic detection device

InactiveCN103644867ADetection speedImprove detection accuracyUsing fluid meansEngineeringUltimate tensile strength

The invention provides an automobile steering system input shaft outer diameter automatic detection device. The automobile steering system input shaft outer diameter automatic detection device comprises a base. The base is provided with a measuring block. The measuring block is provided with a groove for placing an input shaft. Both of two sidewalls of the groove are provided with a first pneumatic nozzle hole, a second pneumatic nozzle hole and a third pneumatic nozzle hole which are arranged successively. When the input shaft is placed into the groove, the first pneumatic nozzle hole, the second pneumatic nozzle hole and the third pneumatic nozzle hole correspond to position of a first diameter portion, a second diameter portion and a third diameter portion separately, and the first pneumatic nozzle hole, the second pneumatic nozzle hole and the third pneumatic nozzle hole are connected with a pneumatic measuring apparatus separately. By adopting the input shaft outer diameter automatic detection device, the detection speed of the input shaft can be effectively improved, the labor intensity of testers can be reduced, the occurrence of errors can be prevented, and the detection accuracy of the input shaft can be effectively improved, so that the outgoing quality of the input shaft can be effectively improved.

Owner:GREEN PRECISION SUZHOU CO LTD

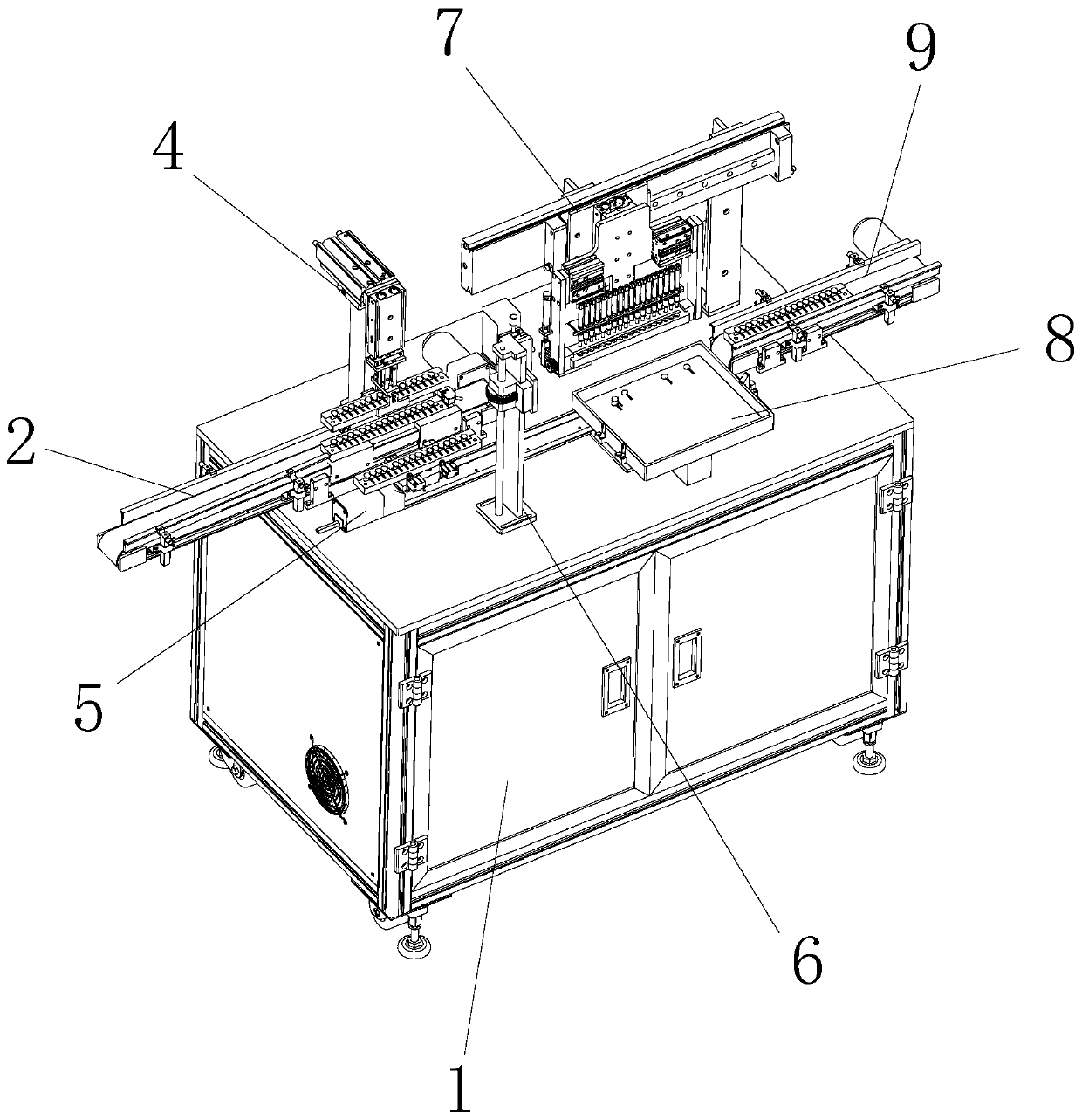

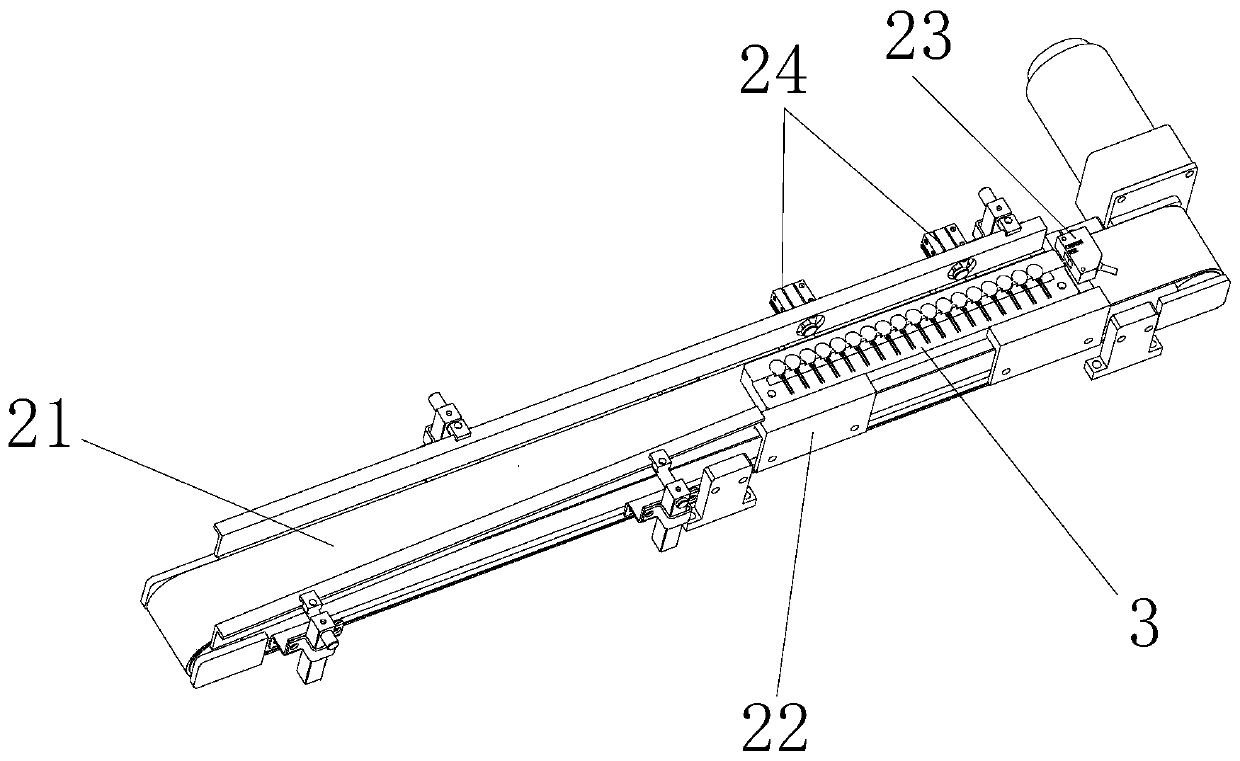

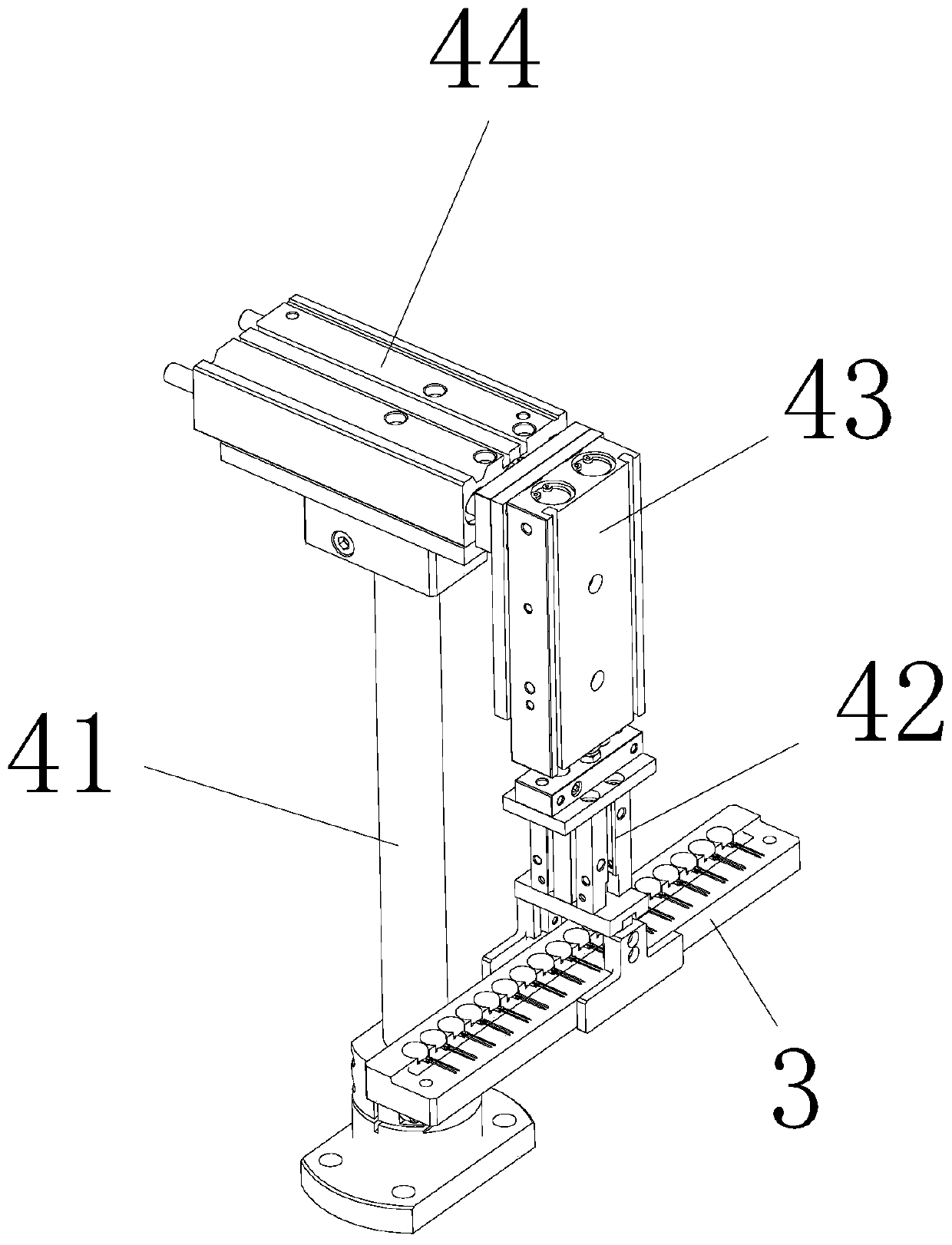

Device suitable for defect detection of mobile-phone flat motors and achievement method thereof

PendingCN109759342AHigh degree of automationAccelerate the efficiency of loading inspectionOptically investigating flaws/contaminationSortingEngineeringMobile phone

The invention discloses a device suitable for the defect detection of mobile-phone flat motors and an achievement method thereof, and belongs to the technical field of mobile-phone hardware detection.The device includes a frame, wherein the upward side of the frame is correspondingly connected with a feeding positioning mechanism, a transplanting mechanism, a step shifting mechanism, a CCD photographing detecting mechanism, a transplant removing mechanism, a defective-product collection mechanism and a second conveying mechanism. According to the device, the automatic feeding of the motors and the automatic detection of appearance defects are achieved, so that the factory quality of the motors is better, the detection speed is fast, the detection result is accurate, and the production efficiency is greatly improved.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

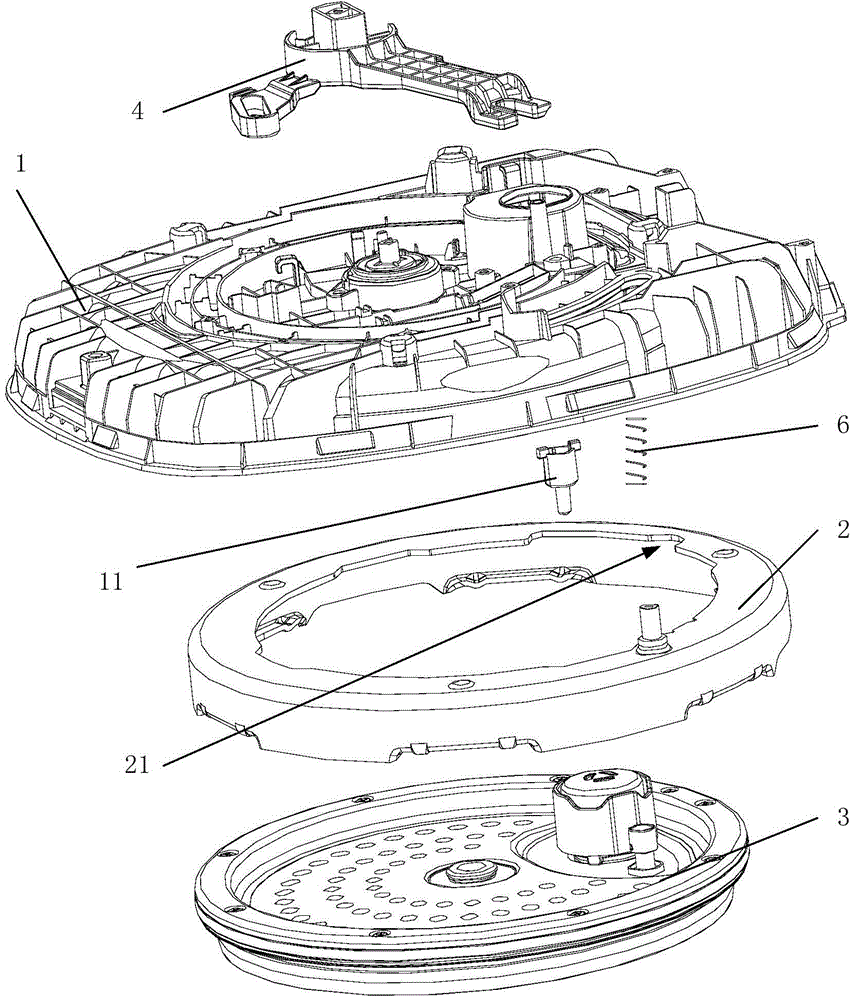

Electric pressure cooker and upper cover component thereof

The invention provides an electric pressure cooker and an upper cover component thereof. A detecting part is disposed on the inner cover of the upper cover component. A matching part is disposed on the lock of the upper cover component. When the cover plate of the electric pressure cooker is separated from the upper cover component, the detecting part is matched with the matching part to interfere the action, for driving the lock to rotate, of the connecting rod slider of the upper cover component; when the cover plate is assembled to the upper cover component, the detecting part is separated from the matching part to relieve the interference. By the upper cover component, the problem that the cover plate of the upper cover component is not mounted is solved effectively, product application safety is well guaranteed, and quality of electric pressure cookers leaving factories is increased at the same time.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Automobile air blower flange detecting tool

InactiveCN105571428AImprove factory qualityImprove detection efficiencyWork holdersMechanical measuring arrangementsAir blowerFlange

The invention discloses an automobile air blower flange detecting tool relating to the automobile component processing technology field. The automobile air blower flange detecting tool comprises a panel, a detecting band, and detecting pins. The panel is provided with the detecting band, which is provided with a plurality of detecting pins. The automobile air blower flange detecting tool can be used for the shaping and the detecting of the flange, and therefore the outgoing quality of the flange can be improved, and the detecting efficiency of the workers can be improved.

Owner:合肥光裕机械有限责任公司

Automatic colloidal coating gluing mechanism suitable for plastic plates

ActiveCN113070180AImprove gluing efficiencyAvoid confusionLiquid surface applicatorsSpraying apparatusStructural engineeringManufacturing engineering

The invention relates to the technical field of gluing, in particular to an automatic colloidal coating gluing mechanism suitable for plastic plates. The automatic colloidal coating gluing mechanism comprises a base and a processing table, and further comprises a controller, a feeding device, an impurity removal device and a spraying device, the feeding device comprises a lifting plate, a jacking assembly and a pushing assembly, and the impurity removal device comprises a rolling brush and a traction assembly; and the spraying device comprises a spray head, an extrusion assembly and a sliding assembly, a top plate is fixedly arranged at the top of the base, the sliding assembly is arranged at the bottom of the top plate, the spray head and the extrusion assembly are both arranged on the sliding assembly, and the jacking assembly, the pushing assembly and the extrusion assembly are electrically connected with the controller. The plates are prevented from being clamped effectively, and feeding efficiency is high; and meanwhile, the gluing surface can be cleaned before gluing, smooth gluing is guaranteed, bubbles are prevented from being generated, and it is guaranteed that follow-up products adhere to the gluing surface firmly.

Owner:深圳市广德盛科技有限公司

Automobile blower flange checking fixture

InactiveCN105571426AImprove factory qualityImprove detection efficiencyWork holdersMechanical measuring arrangementsFlangeAutomotive engineering

An automobile blower flange checking fixture relates to the technical field of automobile parts processing. The checking fixture comprises a panel, a detection rib, and detection pins. The detection rib is arranged on the panel, and the detection pins are arranged on the detection rib. The checking fixture can be used to finalize the design of a flange and detect the flange. The outgoing quality of flanges and the detection efficiency of workers are improved.

Owner:HEFEI KAIRUIDE NEW ENVIRONMENTAL PROTECTION BUILDING MATEIRAL CO LTD

Detection tool

InactiveCN104864789AMeet actual needsImprove detection efficiencyMechanical measuring arrangementsEngineeringFlange

The invention discloses a detection tool, and relates to the technical field of automobile part machining. The tool comprises a panel, a detection rib, and detection pins, wherein the panel is provided with the detection rib and the detection rib is provided with a plurality of detection pins. The tool can achieve the molding of a flange plate, also can detect the flange plate, improves the outgoing quality of the flange plate, and improves the detection efficiency of a worker.

Owner:合肥明华机电工程有限公司

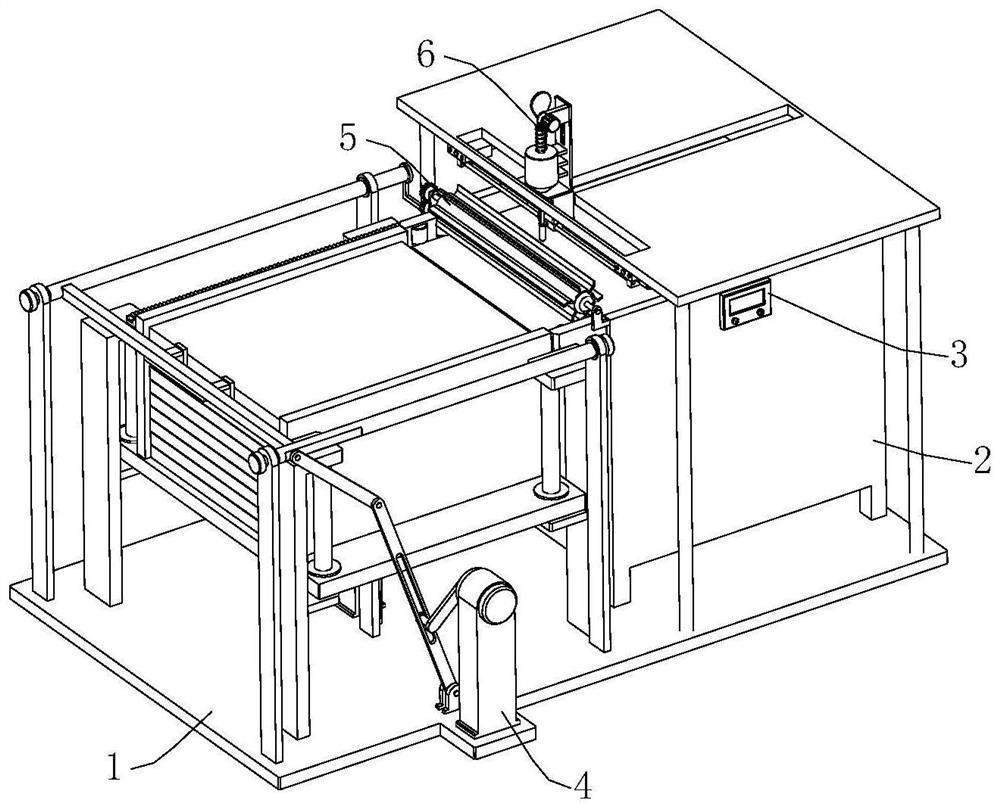

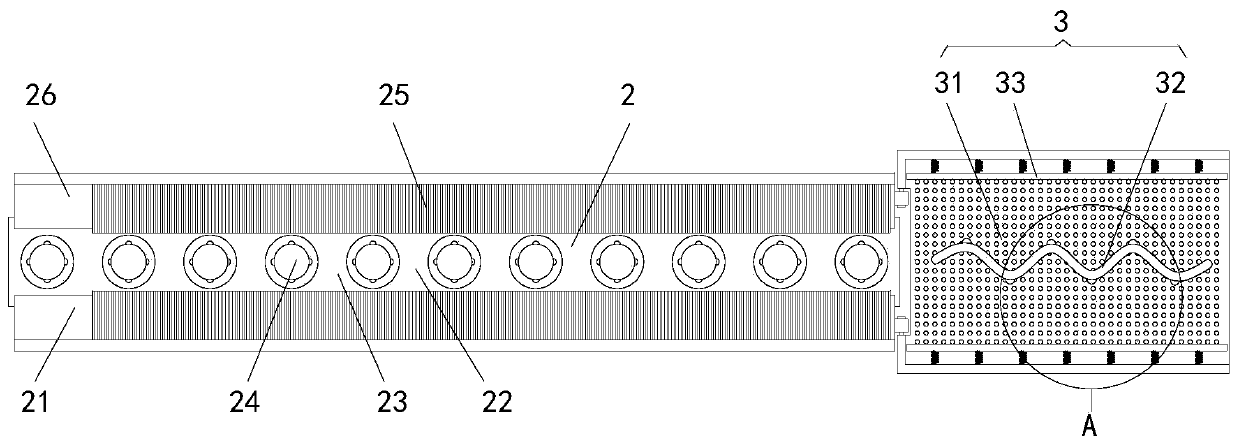

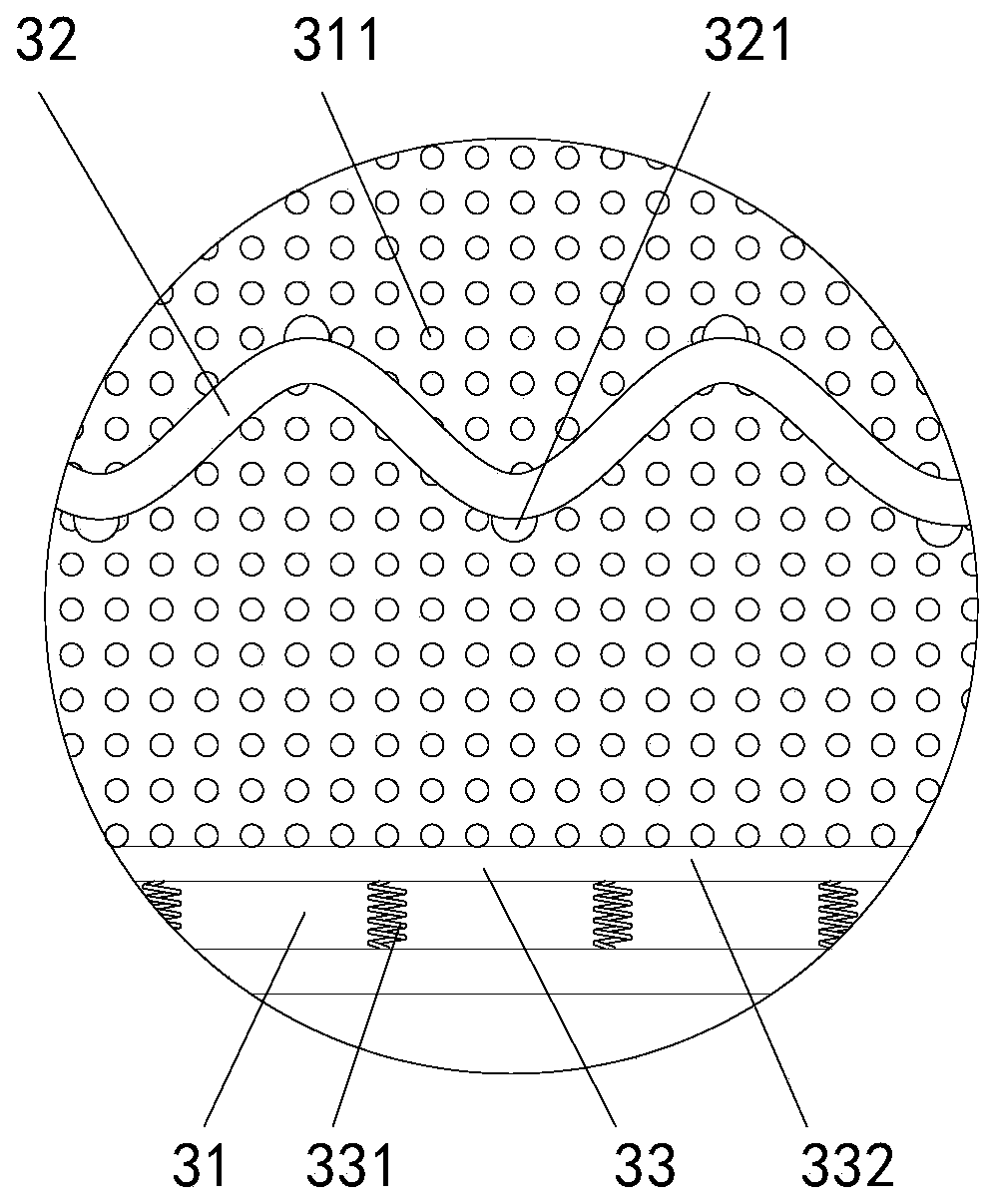

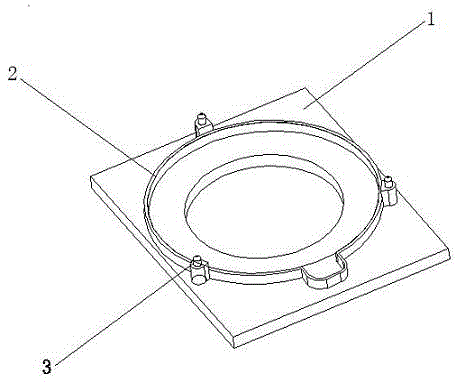

Production and manufacturing method of bearing

ActiveCN110355532AImprove the rotation effectReduce coefficient of frictionPretreated surfacesCoatingsSurface cleaningEngineering

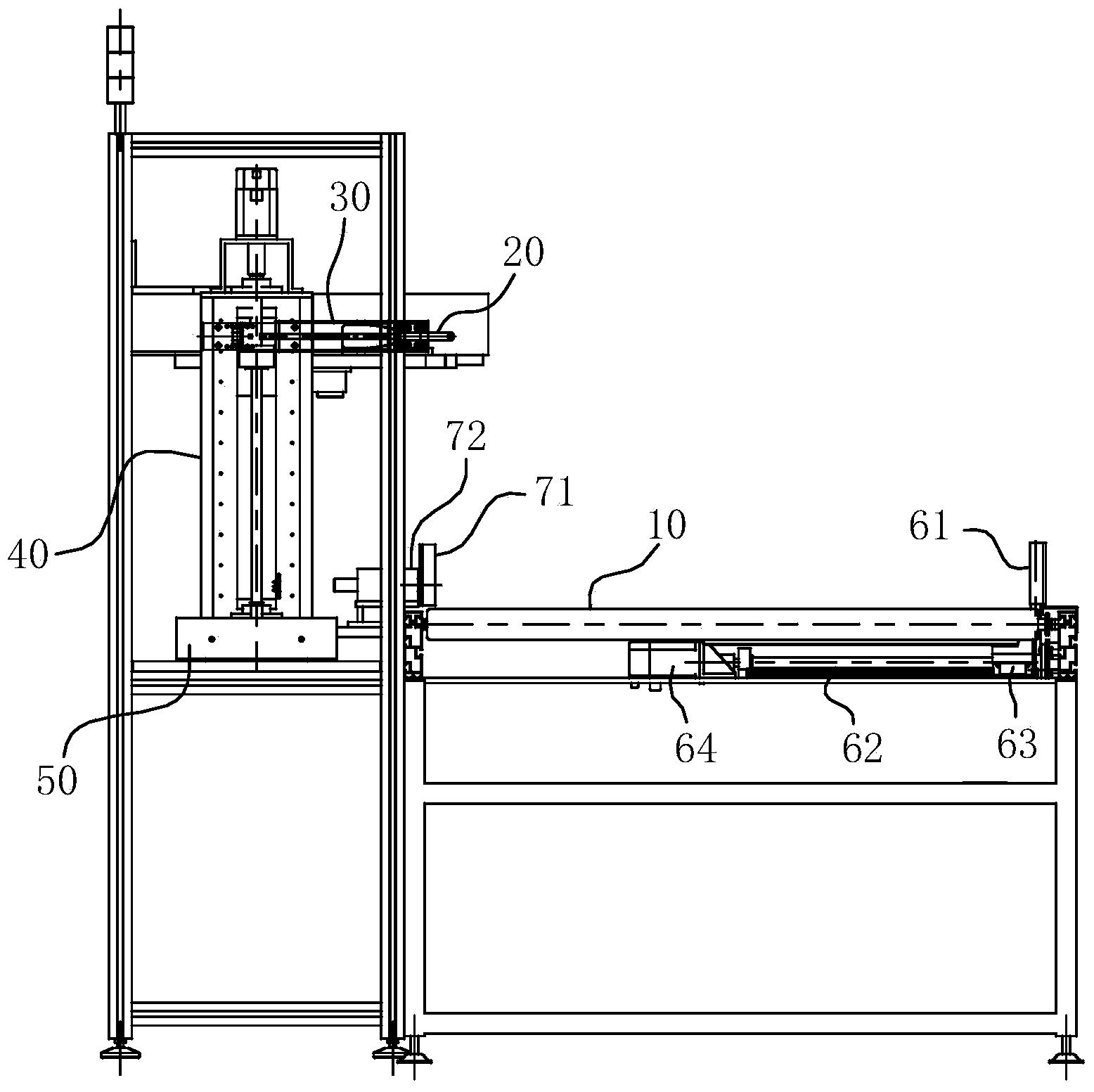

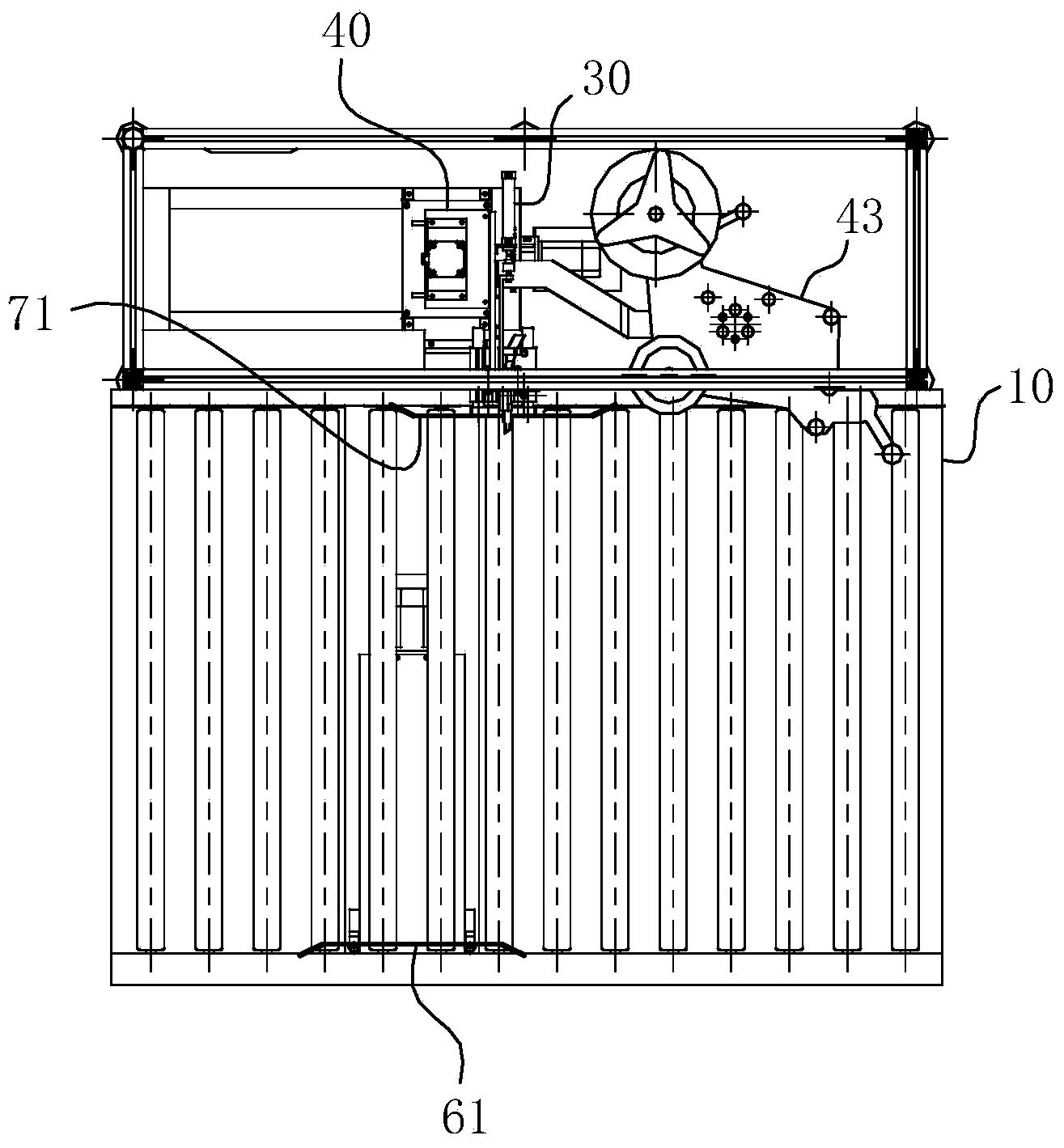

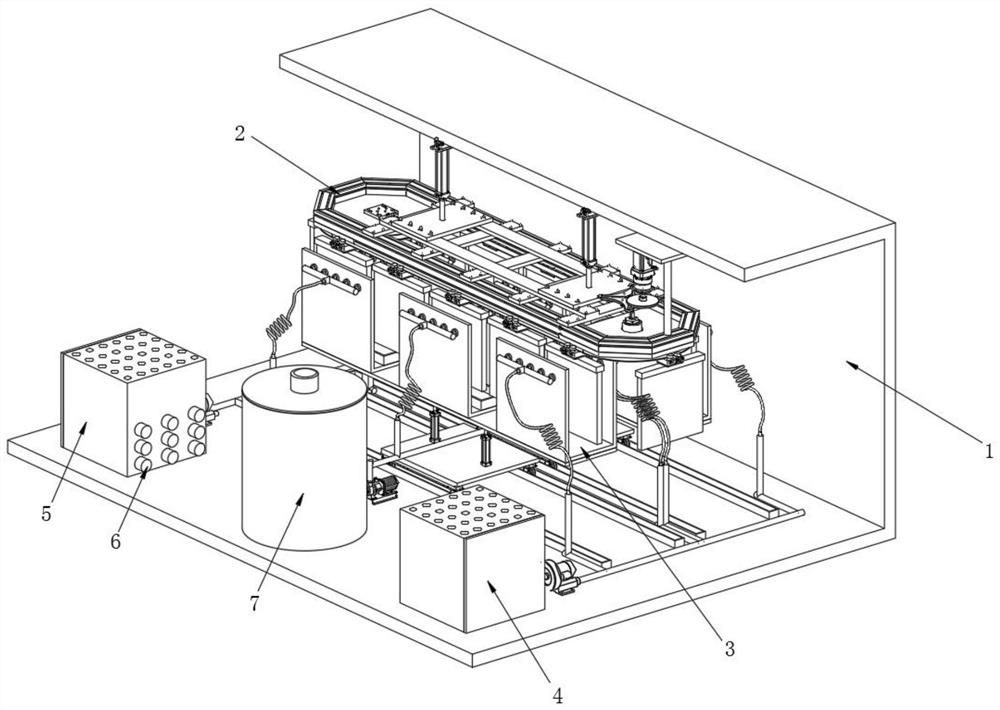

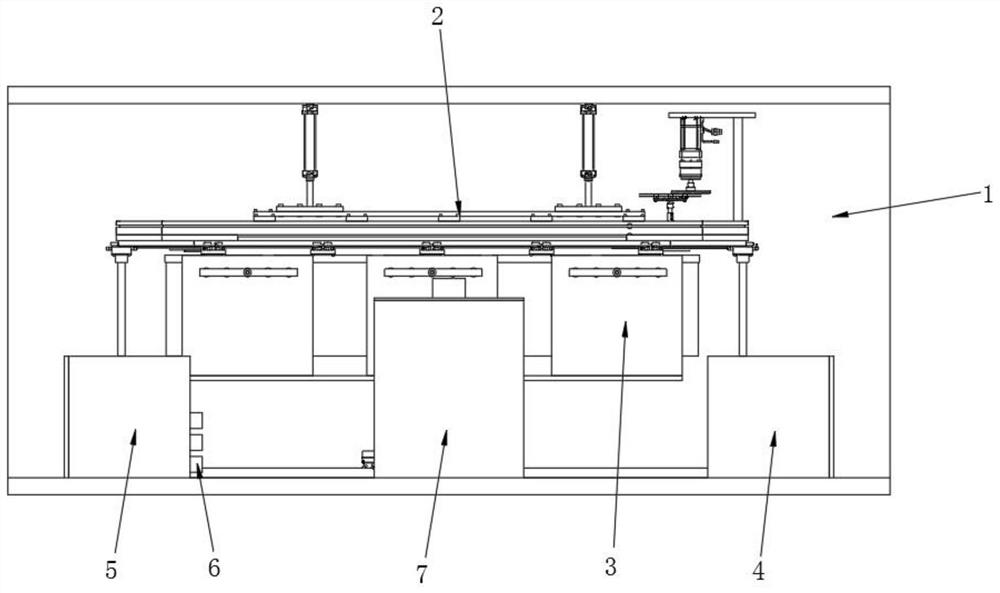

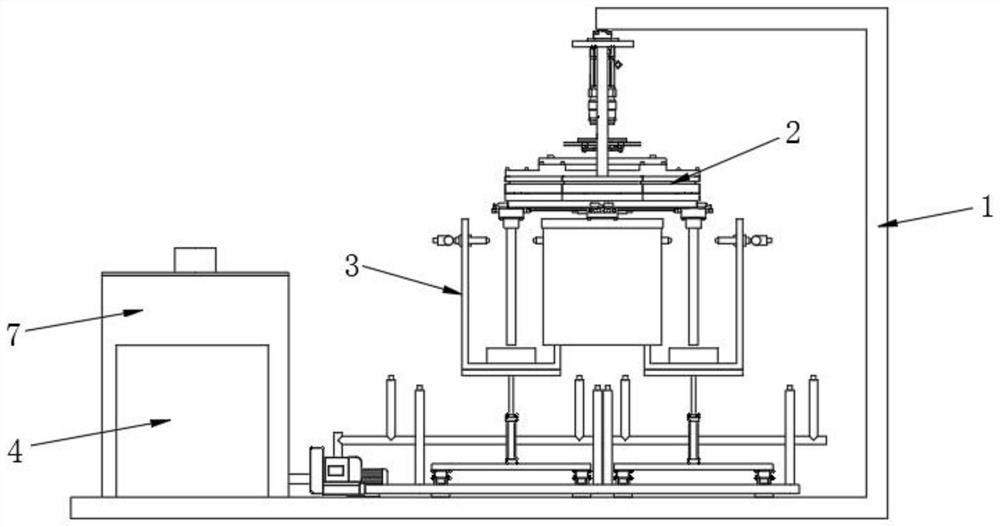

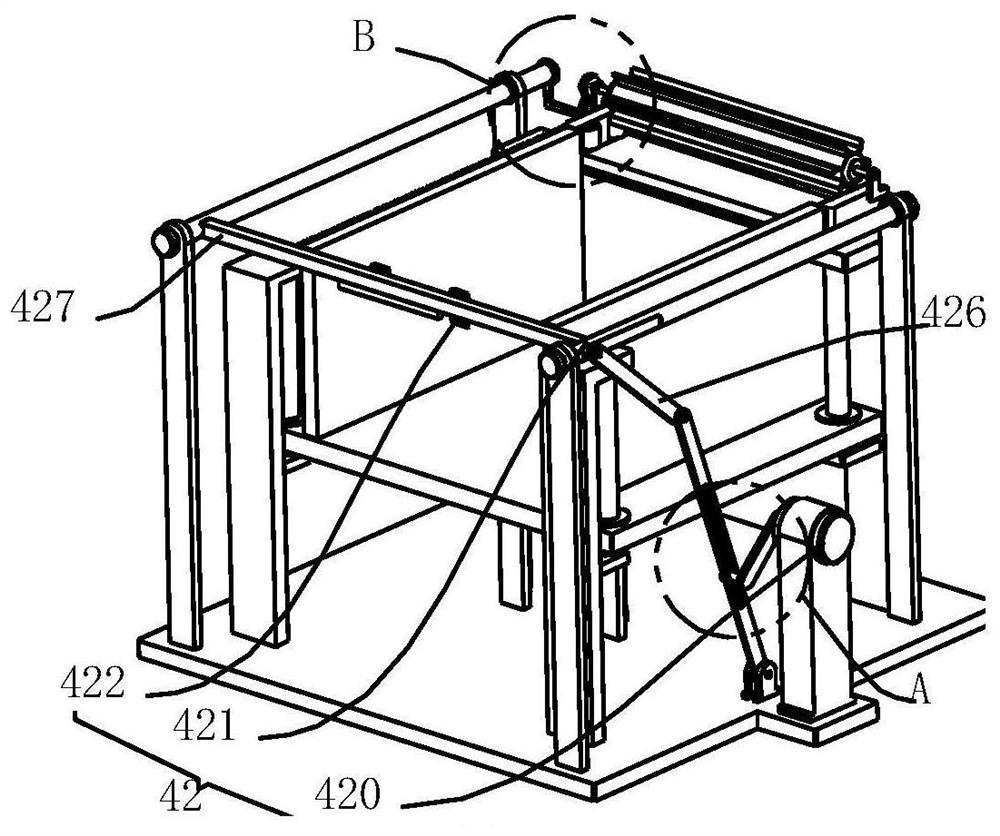

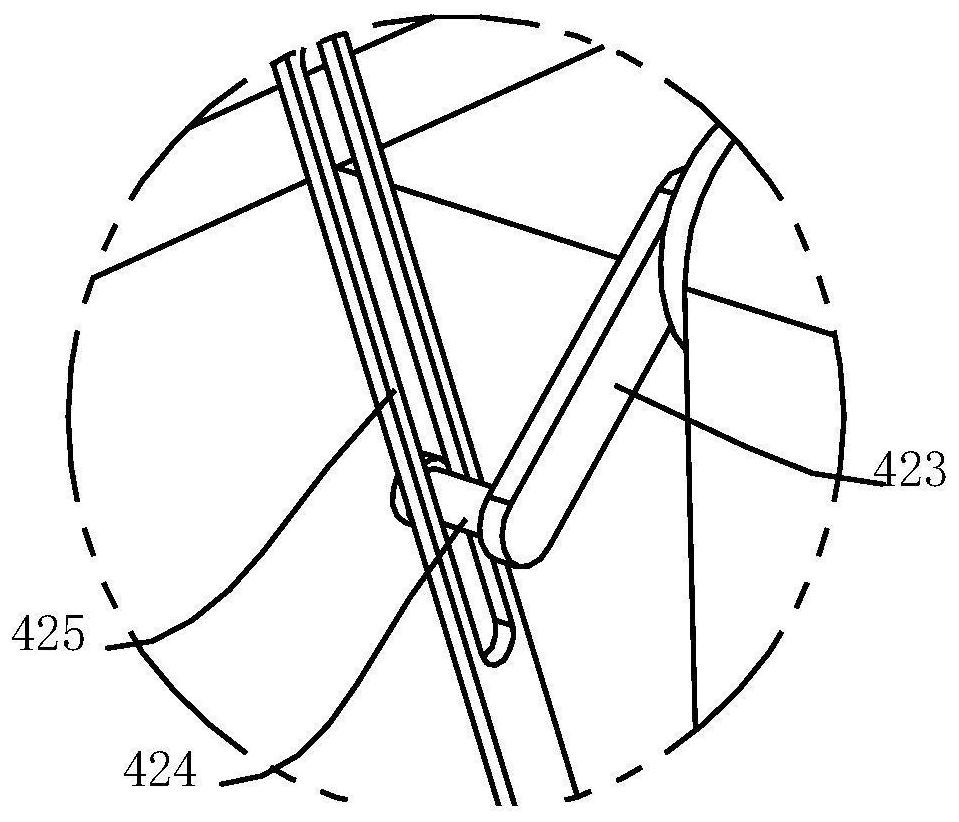

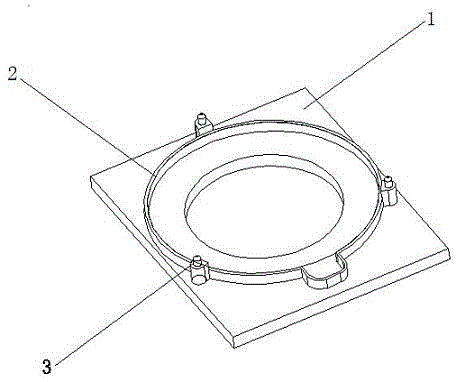

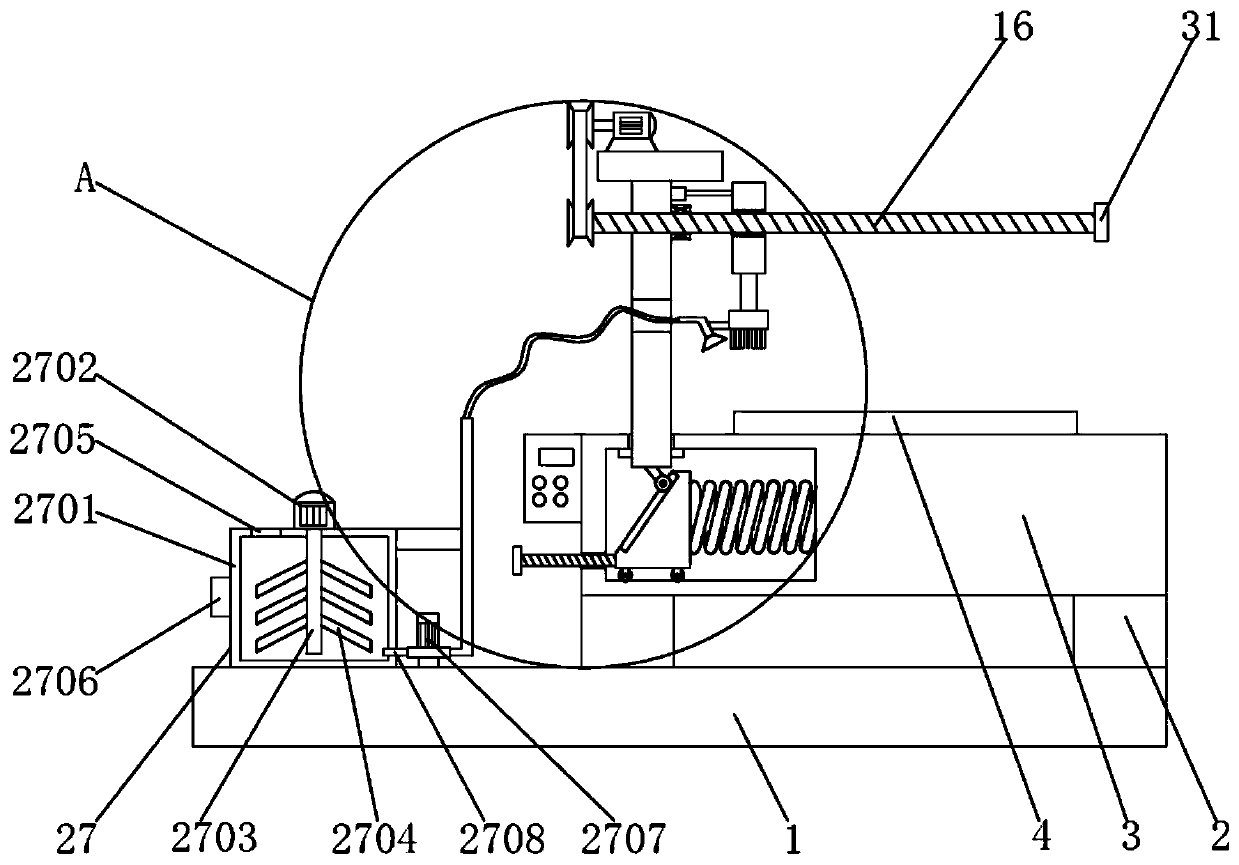

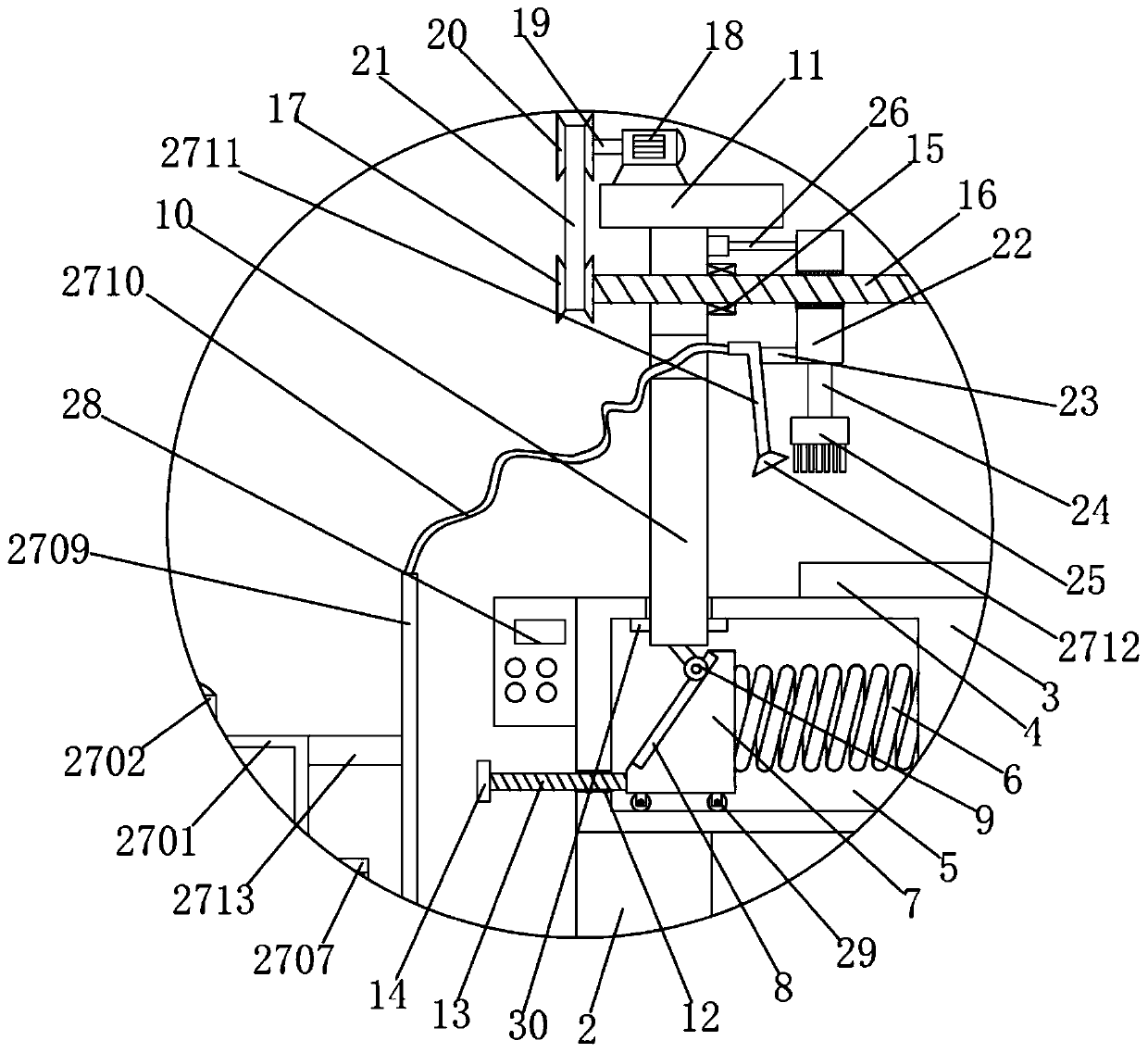

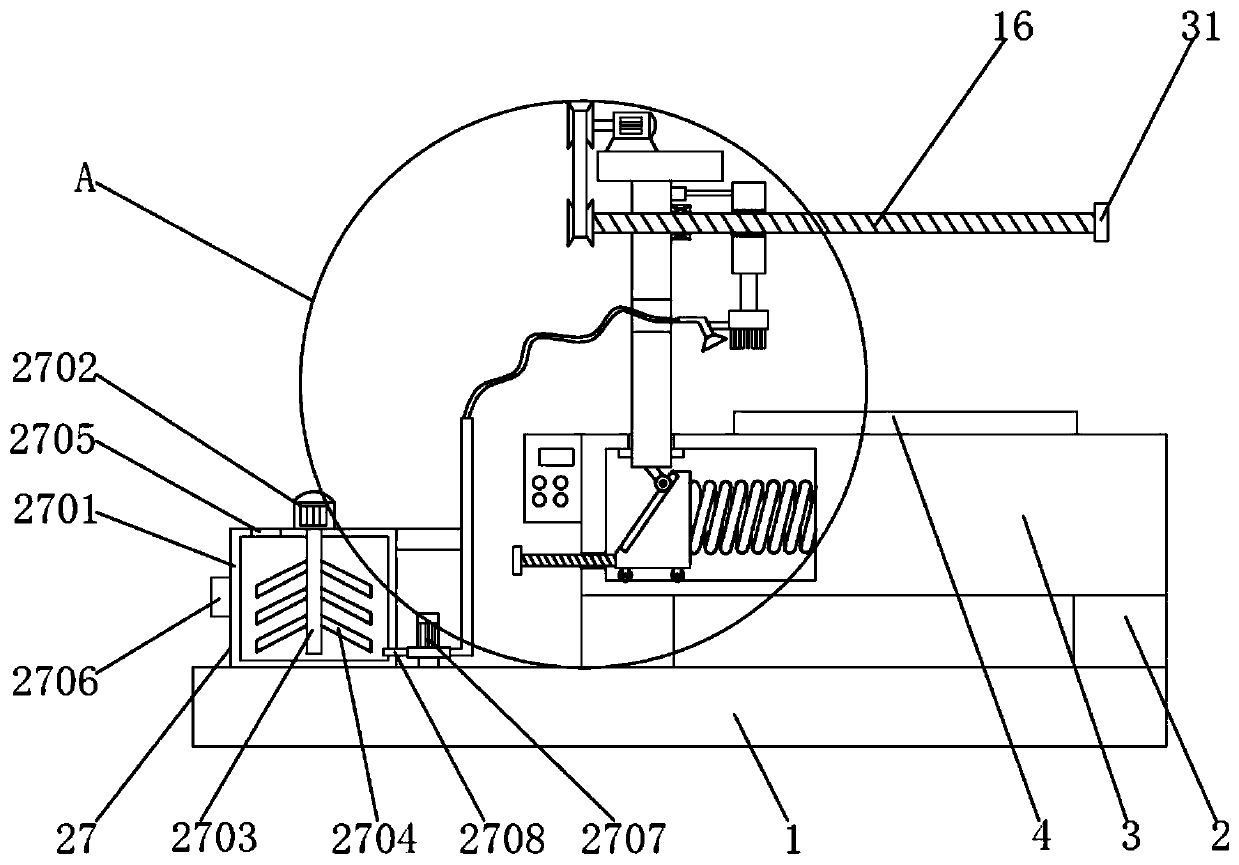

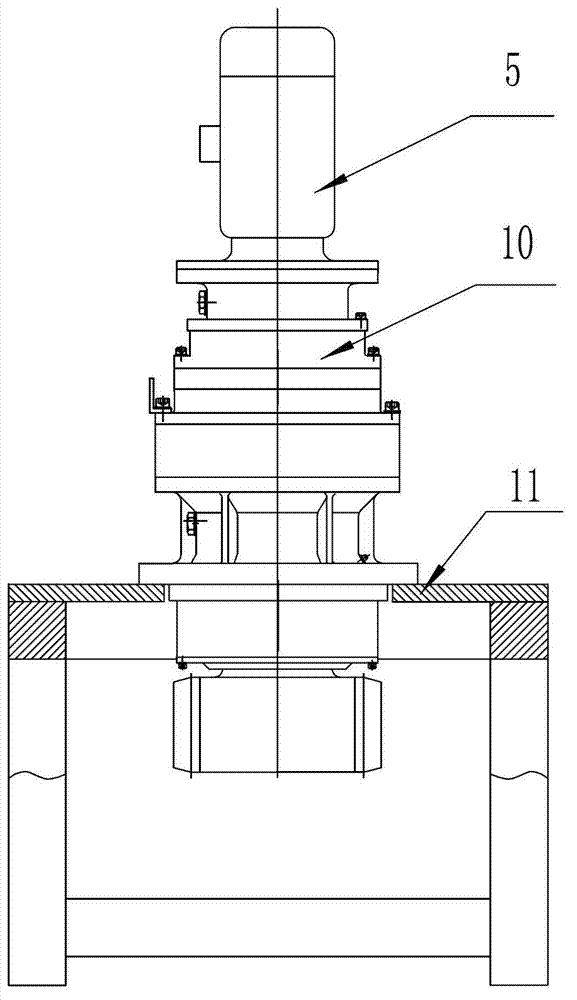

The invention discloses a production and manufacturing method of a bearing. The production and manufacturing method of the bearing particularly comprises the following steps: S1, performing surface cleaning treatment on a bearing outer ring, a bearing inner ring, a retainer and a roller which are processed through a machining mode; S2, assembling the bearing outer ring, the bearing inner ring, theretainer and the roller in the step S1; S3, manually putting finished product bearings in the step S1 on a limiting platform assembly (24) on a conveying belt sequentially, and fixing the finished product bearings; S4, performing lubricating treatment on the fixed finished product bearings through a lubricating channel assembly (2) and a circulating lubricating mechanism (4); and S5, performing lubricating oil draining treatment on the lubricated finished product bearings through a draining channel assembly (3) and packaging the drained finished product bearings. The bearing lubricating efficiency is improved, the labor intensity of workers is reduced and the lubricating effect is guaranteed; furthermore, reutilization of lubricating oil is realized.

Owner:HUANGSHAN ZHENYI PRECISION MACHINERY

Detecting tool

InactiveCN105571469AMeet actual needsImprove detection efficiencyMechanical counters/curvatures measurementsEngineeringFlange

The invention discloses a detecting tool relating to the automobile component processing technology field. The detecting tool comprises a panel, a detecting band, and detecting pins. The panel is provided with the detecting band, which is provided with a plurality of detecting pins. The detecting tool can be used for the shaping and the detecting of the flange, and therefore the outgoing quality of the flange can be improved, and the detecting efficiency of the workers can be improved.

Owner:合肥光裕机械有限责任公司

Workpiece painting device

InactiveCN111111978AReduce labor intensityImprove factory qualitySpraying apparatusDrive wheelRolling-element bearing

The invention discloses a workpiece painting device. The device comprises a bottom plate, and two supporting bases are fixedly connected to the right side of the top of the bottom plate. Through the cooperation among a cavity, a supporting spring, a trapezoidal block, a limiting sliding groove, a roller, a supporting column, a top plate, a threaded groove, a first threaded rod, a handle, a rollingbearing, a second threaded rod, a driven wheel, a forward and reverse motor, a forward and reverse rotating shaft, a driving wheel, a belt, a threaded sleeve, a fixing block, a connecting block, a brush, a telescopic rod, a paint spraying device, a stirring box, a stirring motor, a stirring rotating shaft, stirring blades, a heater, a conveying pump, a conveying hose, a paint spraying pipe and aspray head, the effect of high automation degree is achieved, manual painting is not needed, time and labor are saved, the labor intensity of workers is reduced, the painting quality is guaranteed, the situation of uneven painting is avoided, the ex-factory quality of workpieces is improved, and convenience is brought to manufacturers to sell, and great convenience is brought to manufacturers.

Owner:淮北德林机械设备有限公司

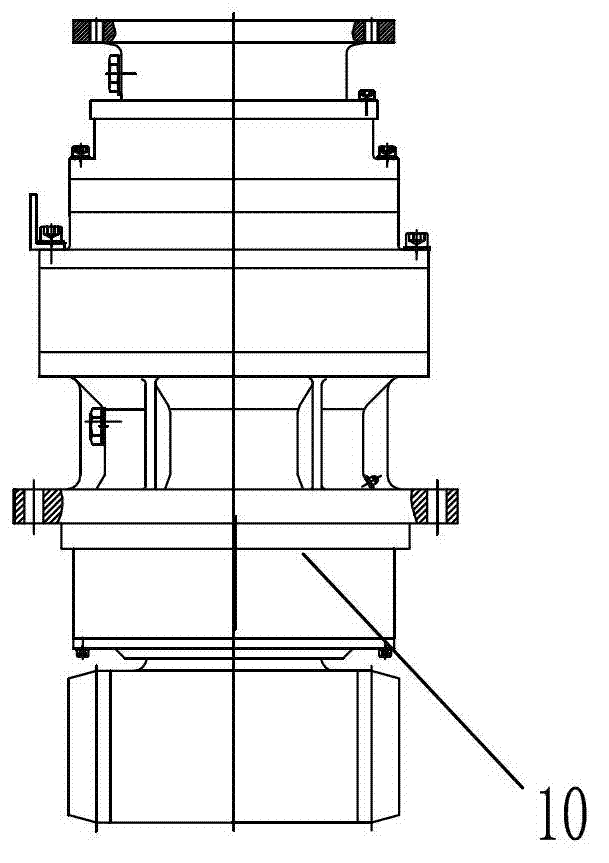

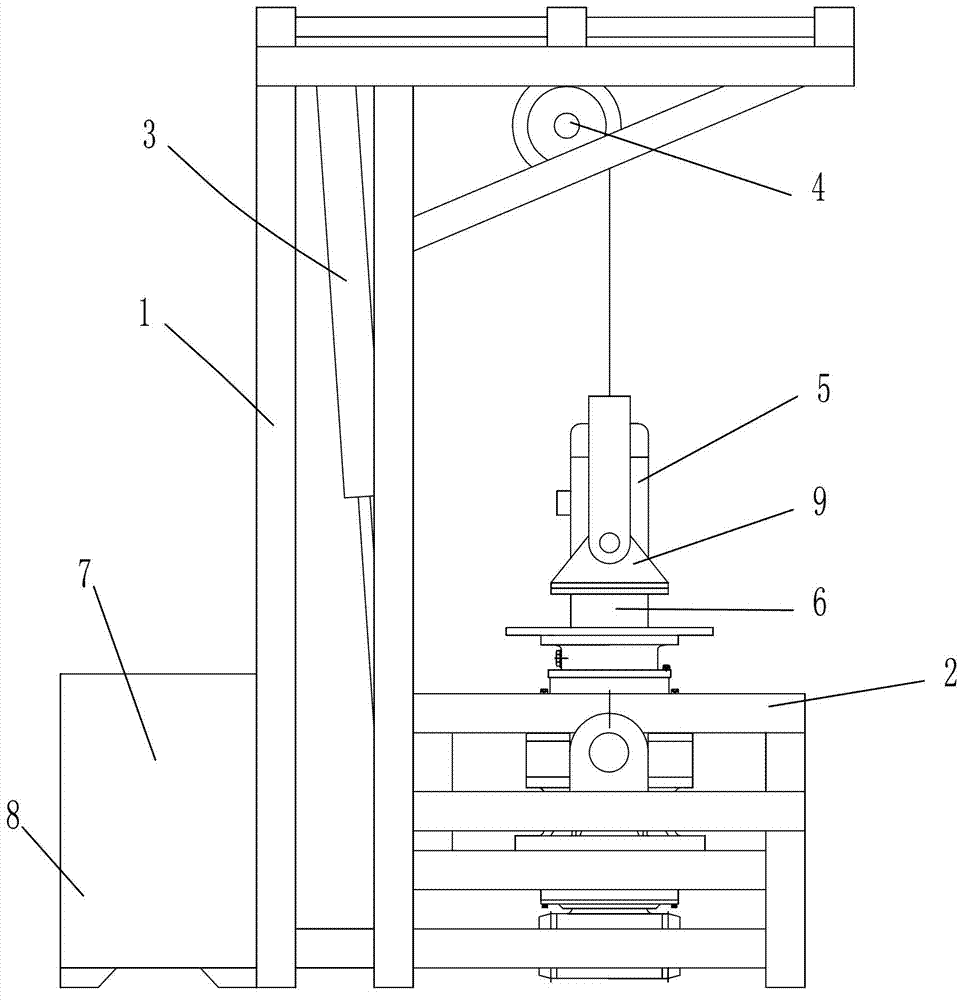

No-load test device for overturning of pitch-variable gearbox

ActiveCN103308303AEasy loading and unloadingEasy flip testMachine gearing/transmission testingDrive motorEngineering

The invention discloses a no-load test device for overturning of a pitch-variable gearbox. The no-load test device comprises a fixed rack, an overturning station, an air cylinder piston assembly, a balance crane and a driving motor, wherein the overturning station is hinged to the fixed rack through two first hinging shafts, the two first hinging shafts are positioned on the front and rear sides of the overturning station and are centred left and right, the overturning station is articulated with the lower end of a piston rod through a second hinging shaft, the second hinging shaft is positioned on the left side of the overturning station and centred front and back, the upper end of the piston rod extends into an air cylinder body, the upper end of the air cylinder body is hinged to the fixed rack, the lower end of the air cylinder body is suspended, the driving motor is arranged in a lifting frame, the lifting frame is suspended at the lower end of the balance crane, the balance crane is fixedly arranged above the overturning station, and the axes of the first hinging shafts and the second hinging shaft are parallel. According to the no-load test device, the pitch-variable gearbox to be tested can be automatically overturned in a range from 0 degrees to 90 degrees, so that the pitch-variable gearbox can be tested in an approximately real application condition.

Owner:CHONGQING GEARBOX

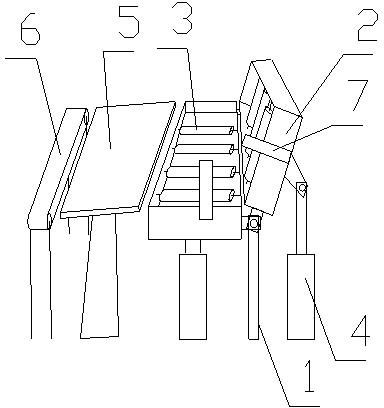

Polyethylene pipe conveying device

The invention relates to a polyethylene pipe conveying device. The polyethylene pipe conveying device comprises a rack, two overturning frames, a plurality of transfer rollers, a transition plate, a conveyor belt and two overturning frame driving mechanisms, wherein one of the side edges of the two overturning frames is respectively hinged with the rack, the two overturning frame driving mechanisms are respectively connected with the overturning frames, the transfer rollers are uniformly distributed in the overturning frames, the transition plate is obliquely arranged on one side of one overturning frame, and the conveyor belt is arranged on the other side of the transition plate. According to the polyethylene pipe conveying device provided by the invention, the two overturning frames are driven by a hydraulic rod, and in view of polyethylene pipes with different specifications, different angles are formed between the two overturning frames to ensure the stable output of the polyethylene pipes with different specifications, so as to ensure trim notches and improve the outgoing quality.

Owner:XINGHUA DONGXU MACHINERY

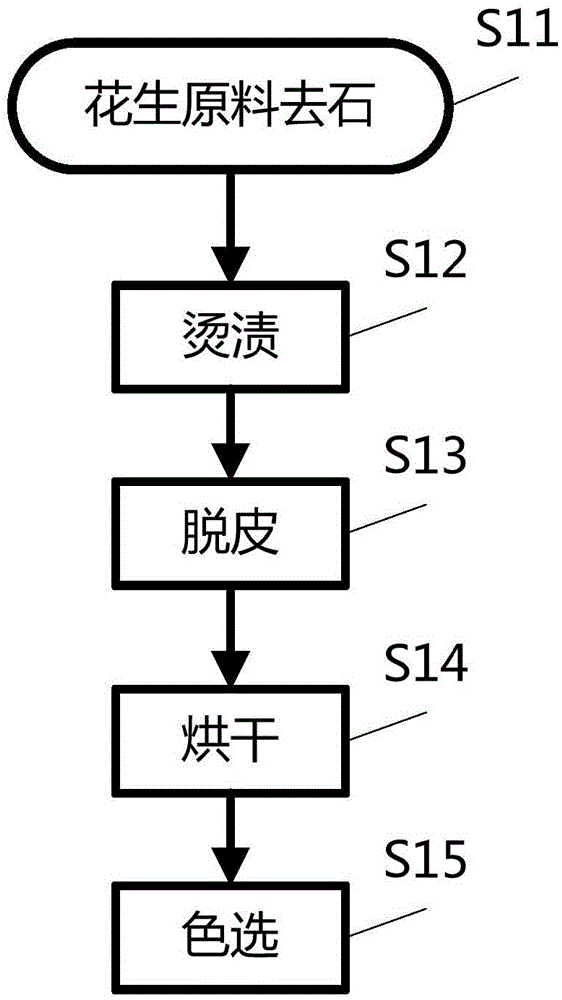

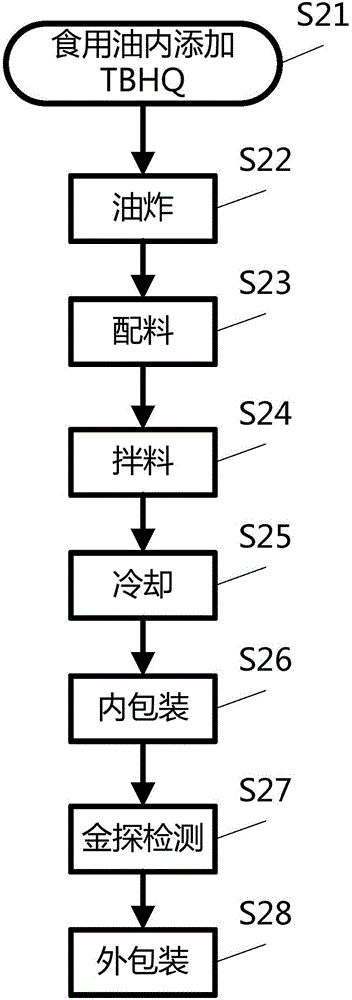

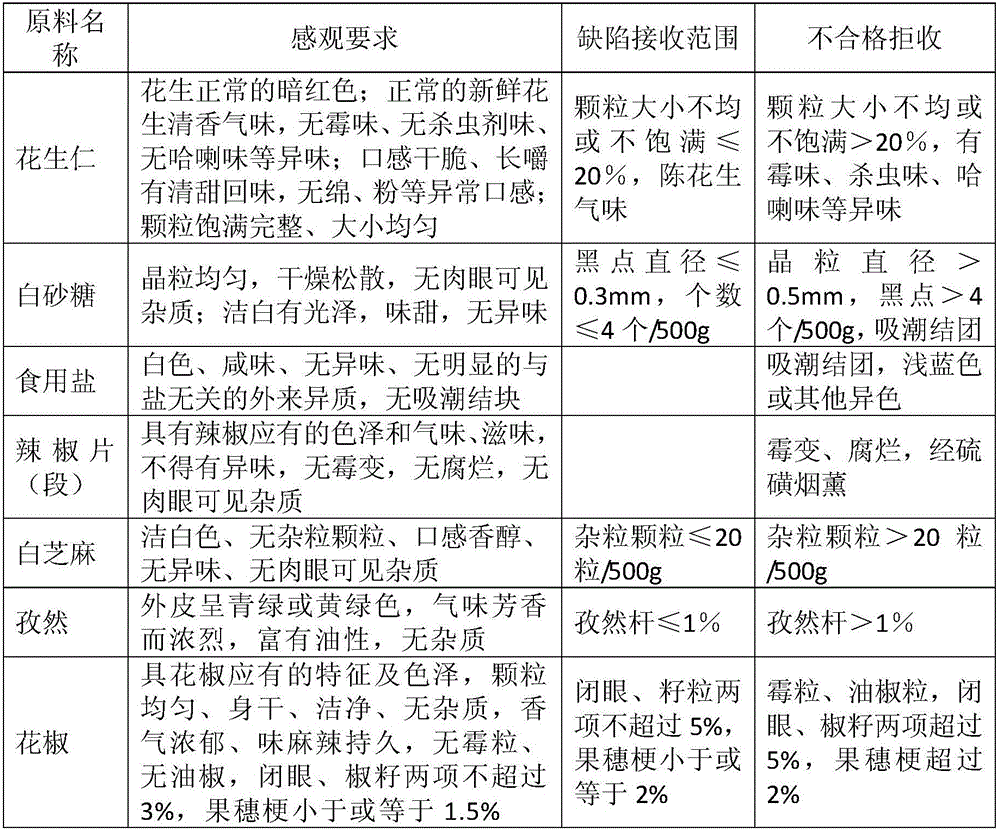

Processing technology of Xiaojiu peanut food

The invention discloses a processing technology of Xiaojiu peanut food. The processing technology comprises steps as follows: stone removing, heating and impregnating, peeling, drying, color sorting, frying, blending, mixing, cooling, inner packaging, metal detection, outer packaging and the like. The peanut food processed with the technology has appropriate salty and sweet flavor, tastes fragrant and crisp, and is healthy, safe and nutrient-rich.

Owner:东莞市傻二哥食品有限公司

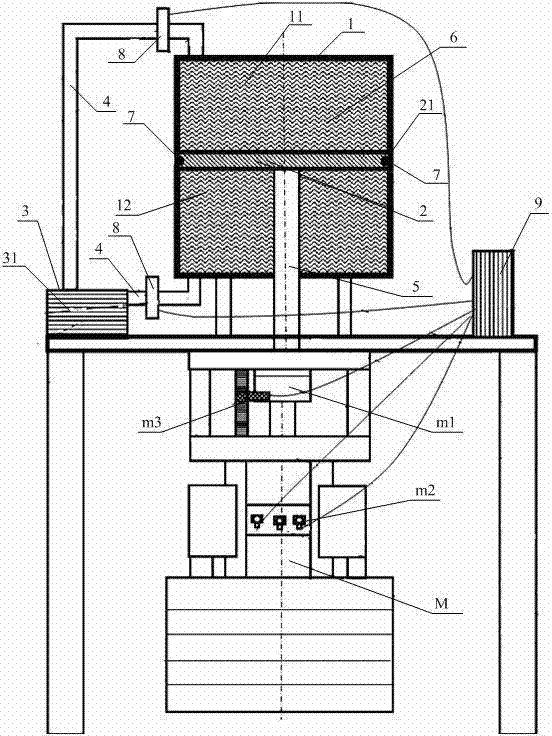

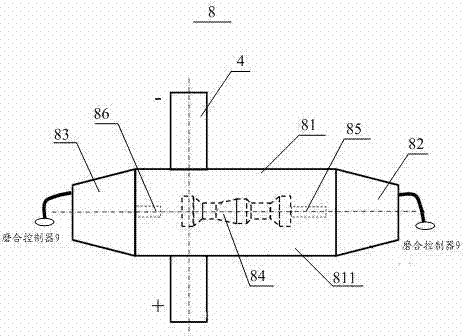

Running-in device of hydraulic operating mechanism used for high-pressure SF6 breaker

ActiveCN104733255ALow costFast implementationHigh-tension/heavy-dress switchesProtective switch operating/release mechanismsTime dynamicsPiston

The embodiment of the invention discloses a running-in device of a hydraulic operating mechanism used for a high-pressure SF6 breaker. The running-in device of the hydraulic operating mechanism used for the high-pressure SF6 breaker comprises a totally enclosed columnar box body, a piston, medium containing device, a driving connecting rod and damping mediums. The piston is embedded inside the box body, the outer surface of the piston is abutted against the inner wall of the box body, and the box body is divided into an upper cavity and a lower cavity by the piston, wherein the upper cavity and the lower cavity are not communicated with each other. The medium containing device is arranged outside the box body, the medium containing device is connected with the upper cavity and the lower cavity through two guide pipes, and the communication is achieved. One end of the driving connecting rod is placed inside the lower cavity and fixed on the piston, and the other end of the driving connecting rod is placed outside the box body and is matched with the hydraulic operating mechanism. The upper cavity and the lower cavity are filled with the damping mediums. When the driving connecting rod moves, the piston is driven to slide along the inner wall of the box body in the direction of facing or deviating from the lower cavity. According to the running-in device of the hydraulic operating mechanism used for the high-pressure SF6 breaker, the adaptability is high, aiming at the damping changing condition of various high-pressure SF6 breakers in the divide-shut braking process, the real-time dynamic closed-loop adjustment on the damping is achieved, the installing and fitting testing time of the hydraulic operating mechanism and the high-pressure SF6 breaker is shortened, and the delivering efficiency and the quality of the mechanism are improved.

Owner:SHENZHEN POWER SUPPLY BUREAU

Method of inscribed circle for testing synthesis precision of numerically controlled machine tool

InactiveCN1696634AImprove market competitivenessReflects the precision of the imputation workMeasurement/indication equipmentsStructural/machines measurementEngineeringTest material

A method for inspecting comprehensive accuracy of digital controlled machine tool by utilizing inscribed circle includes using runin method to work out regular polygon on testing material first, then working out a inscribed circle in the same nominal size as opposite side size of regular polygon and in tangency to regular polygon, finally obtaining comprehensive accuracy of machine tool according to symmetry situation and tangency situation of inscribed circle to regular polygon.

Owner:NANJING HIGH SPEED TRANSMISSION SK NUMERICAL CONTROL EQUIP

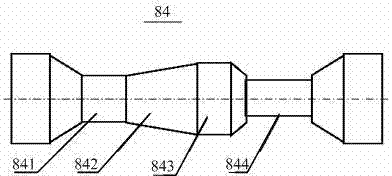

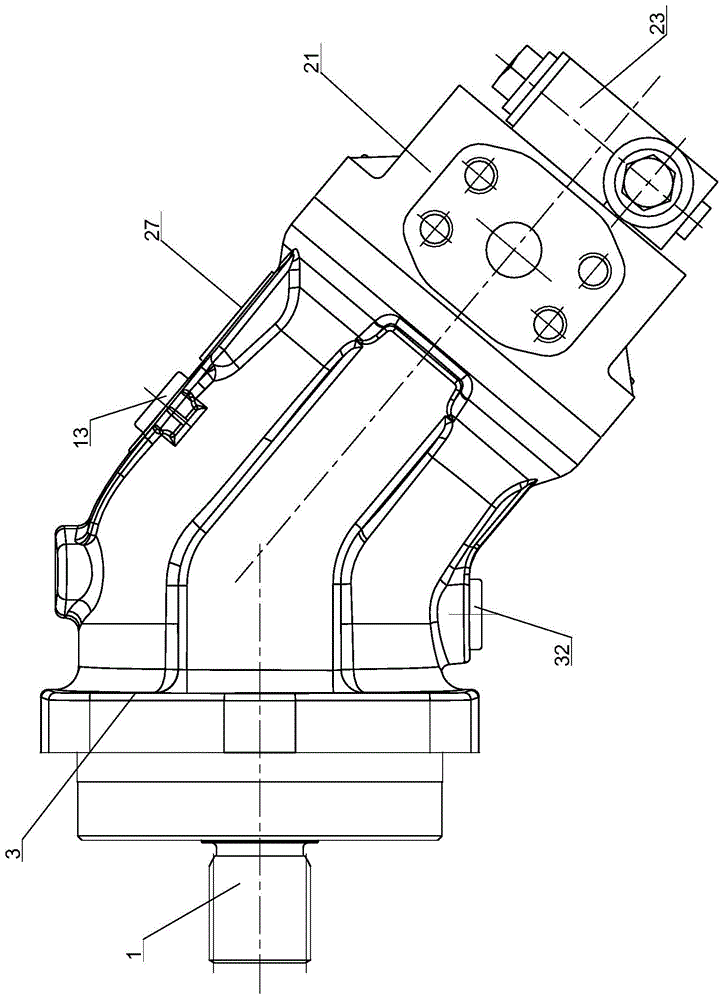

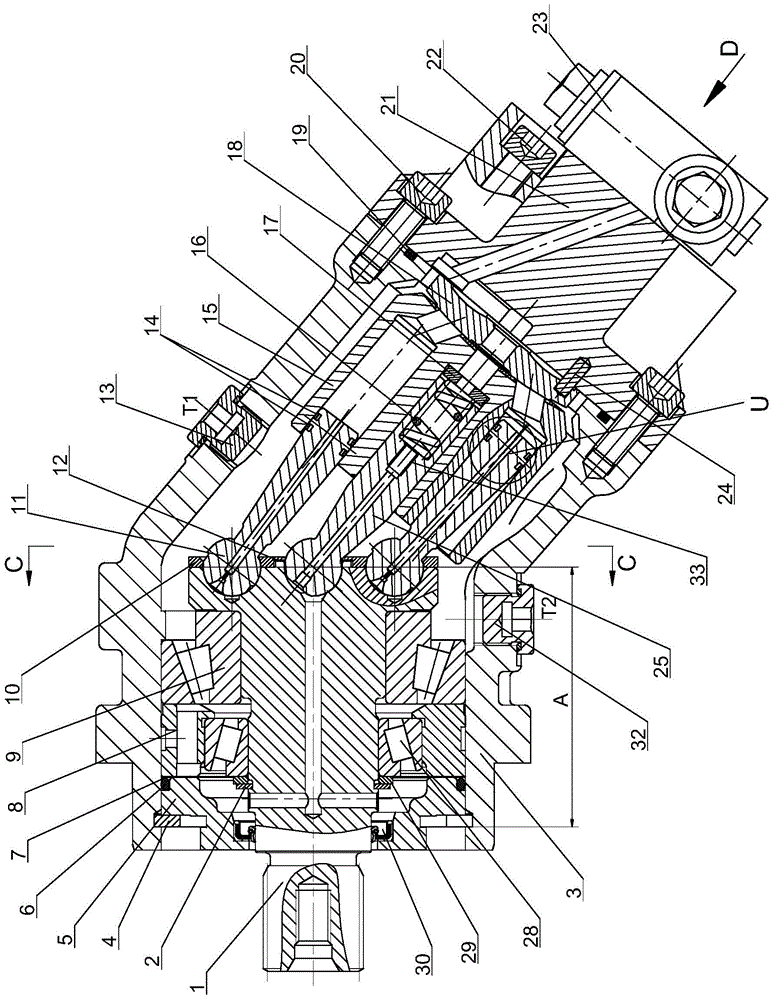

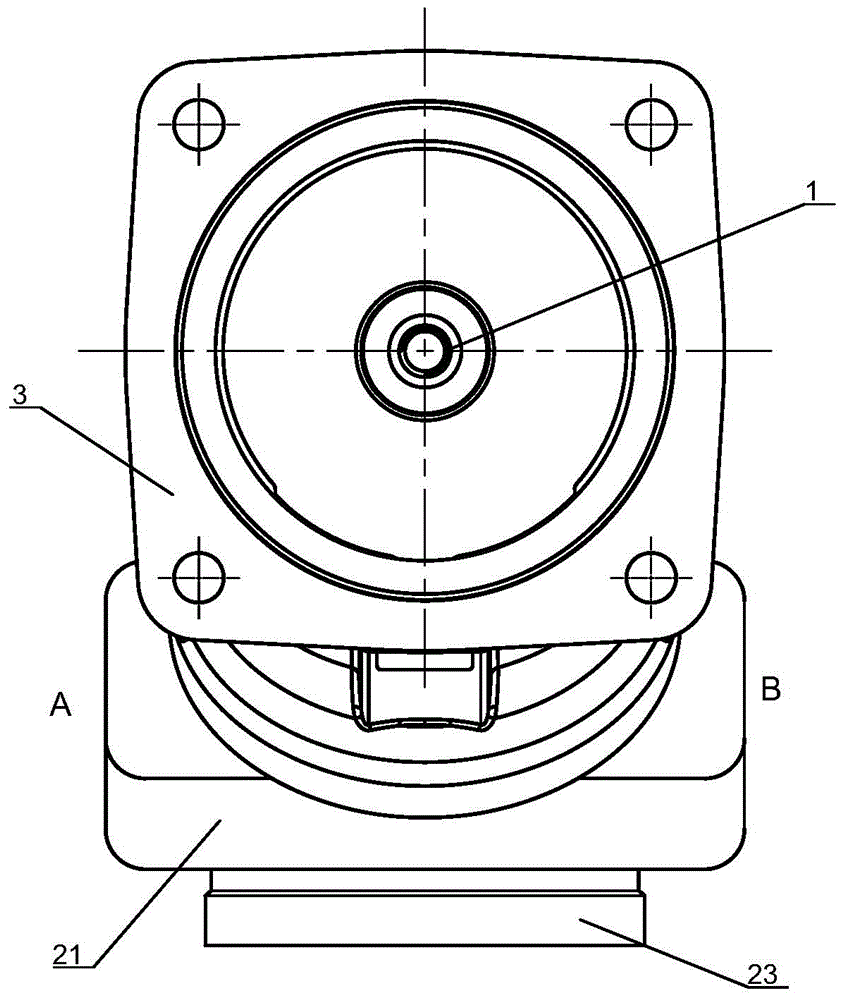

Improved hydraulic motor and assembly test method thereof

InactiveCN104405575AGood for heat dissipationImprove efficiencyReciprocating piston enginesRotary piston enginesIntermediate pressureDrive shaft

The invention discloses an improved hydraulic motor, a front end tapered roller bearing, a rear end tapered roller bearing and a driving shaft are installed by interference fit, an intermediate pressure ring is installed on the front end tapered roller bearing by interference fit, an oil groove radial channel arranged on the driving shaft is extended to the driving shaft front end to prompt the driving shaft to generate centrifugal force to improve the hydraulic energy to transform into mechanical energy efficiency; the intermediate pressure ring and an outer ring of the rear end tapered roller bearing are in interference fit with an inner hole of a motor casing; a bearing pressure cover is mounted in the motor casing, a plunger ring shrinks and sheathes a plunger, the plunger and a ball head end of a center connecting rod are respectively installed in the driving shaft, a cylindrical spring is installed in the center connecting rod for prevention of locking of the center connecting rod, the cylindrical spring and the axially uniformly distributed plunger are filled into a cylinder body, an oil distributing plate and the cylinder body spherical surface are fit, a spring seat is arranged in the end part of the center connecting rod; a rear end cover is installed in the motor casing end part, a positioning pin is inserted into the oil distributing plate, and a flush valve is tightly installed on the rear end cover end part in order to realize the automatic control of cooling.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com