Polyethylene pipe conveying device

A conveying device, polyethylene pipe technology, applied in the direction of tubular objects, applications, household appliances, etc., to improve the quality of the factory and ensure the effect of cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

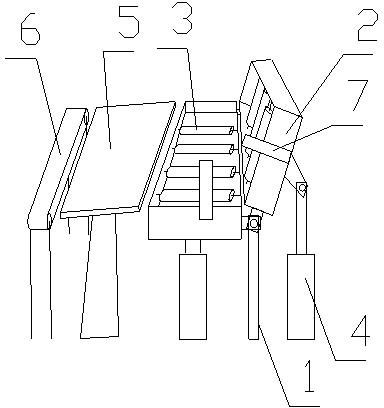

[0009] The polyethylene pipe conveying device includes a frame 1, two overturning frames 2, several conveying rollers 3, a transition plate 5, a conveyor belt 6, a pair of travel switches 7, and two overturning frame drive mechanisms 4, and one side of the two overturning frames 2 The sides are respectively hinged with the frame 1, there are two turning frame driving mechanisms 4 and are respectively connected with the turning frame 2, the conveying rollers 3 are evenly distributed in the turning frame 2, the transition plate 5 is obliquely arranged on one side of the turning frame 2, and the conveyor belt 6 Set on the other side of the transition plate 5, the travel switch 7 is set at the end of the turning frame, so that when the polyethylene pipe touches the travel switch 7, the corresponding production equipment stops outputting the polyethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com