Patents

Literature

352 results about "Fuzzy pid control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

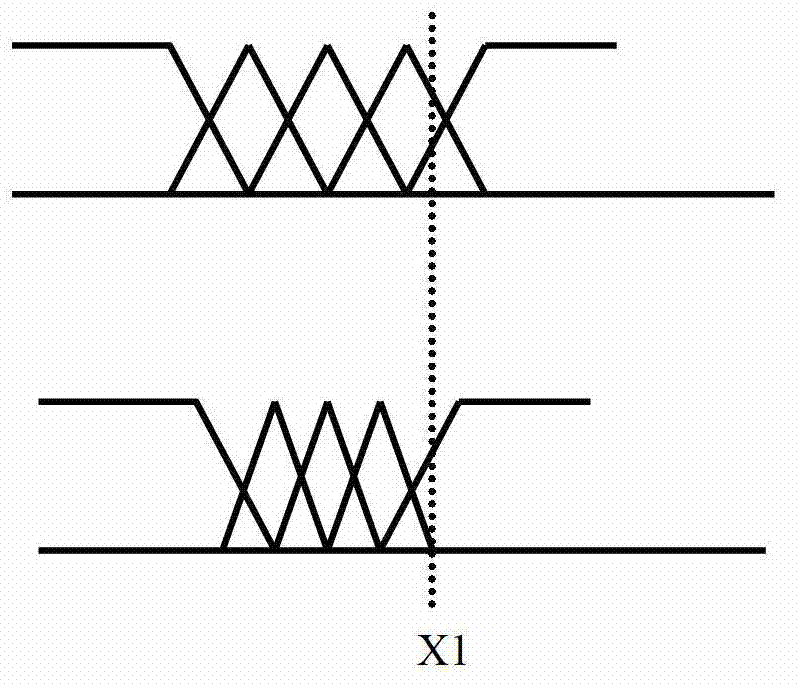

Control method for motion stability and outline machining precision of multi-shaft linkage numerical control system

ActiveCN102681489AAchieve smooth motionRealization errorNumerical controlFuzzy pid controlControl system

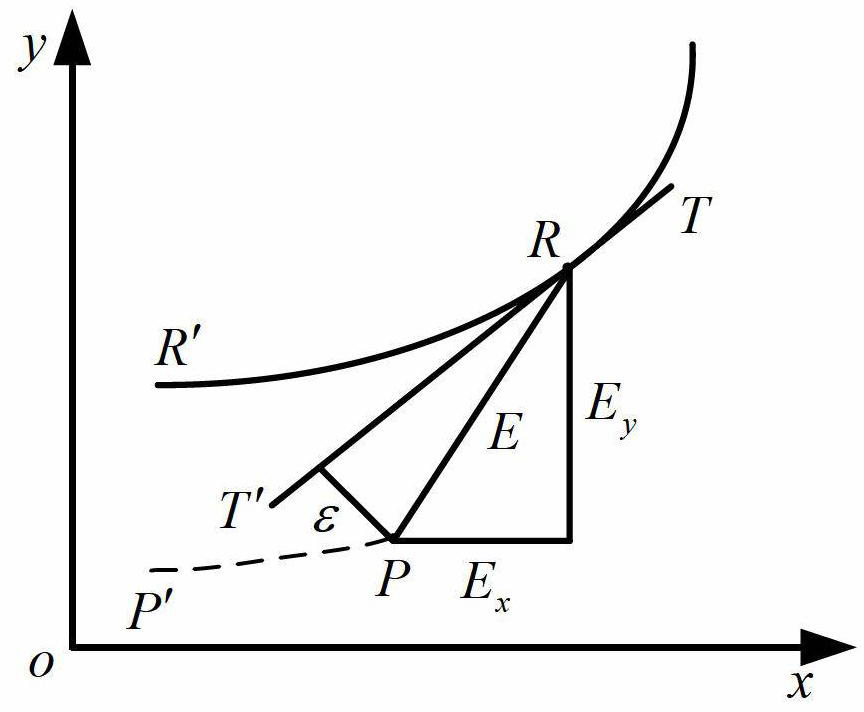

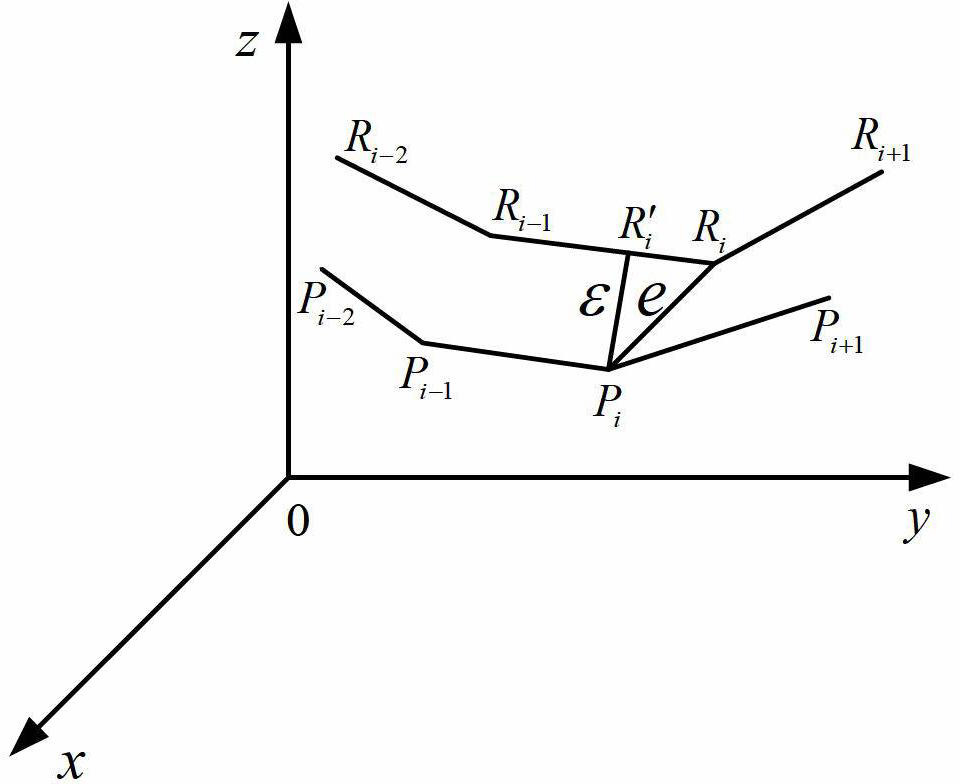

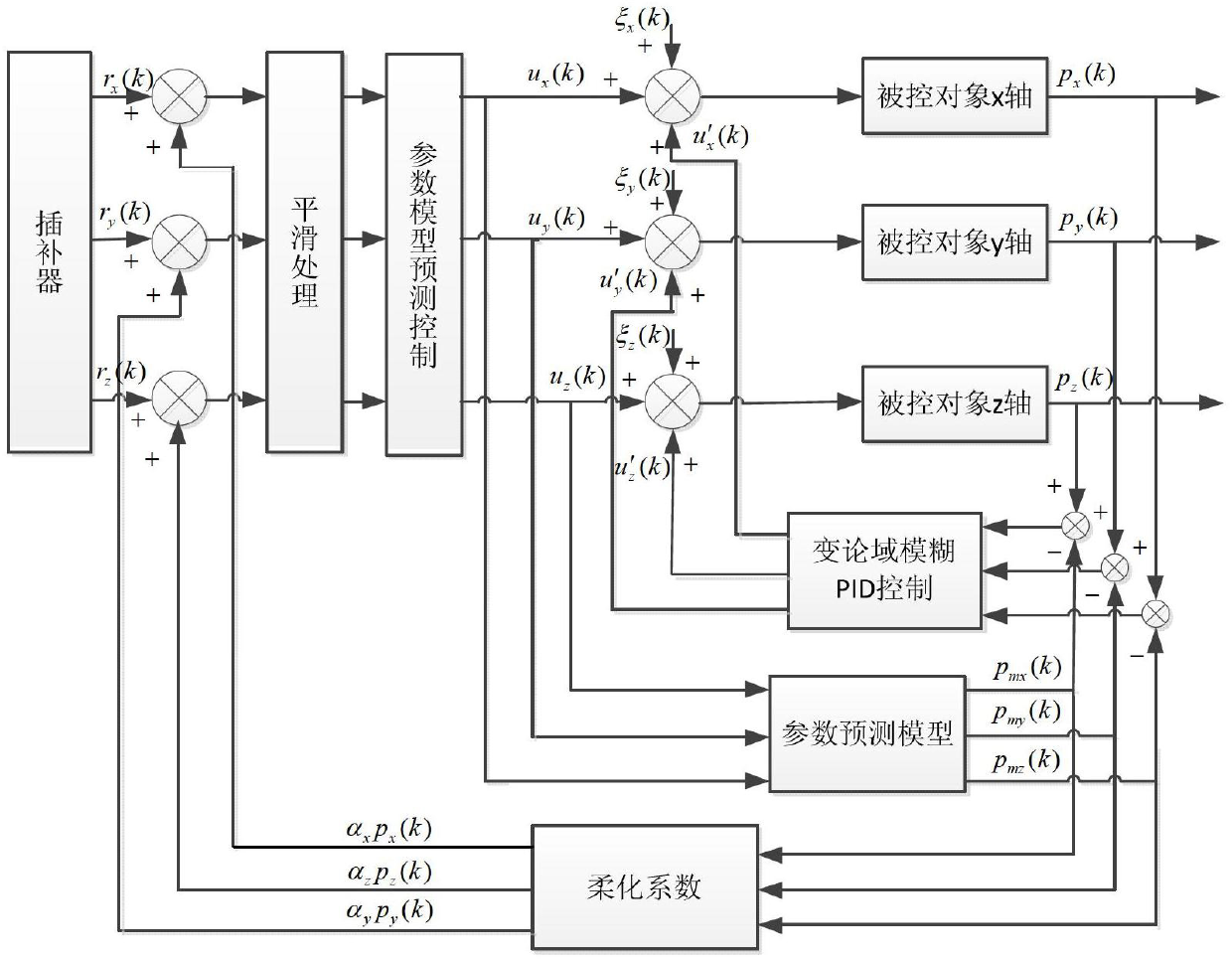

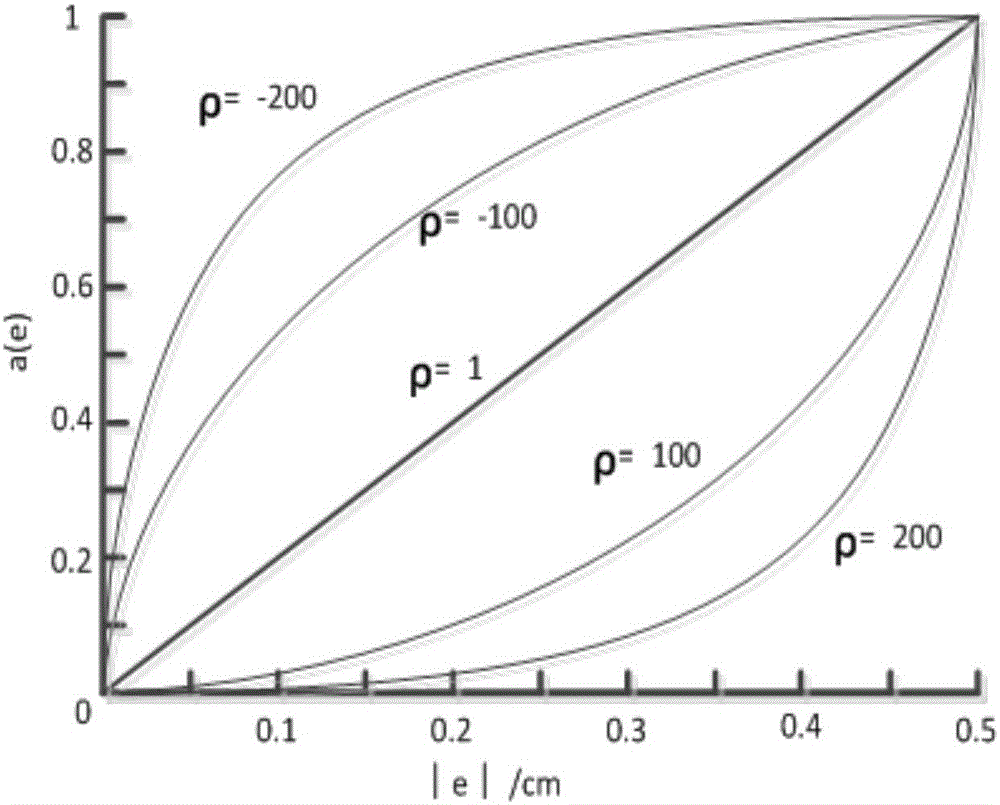

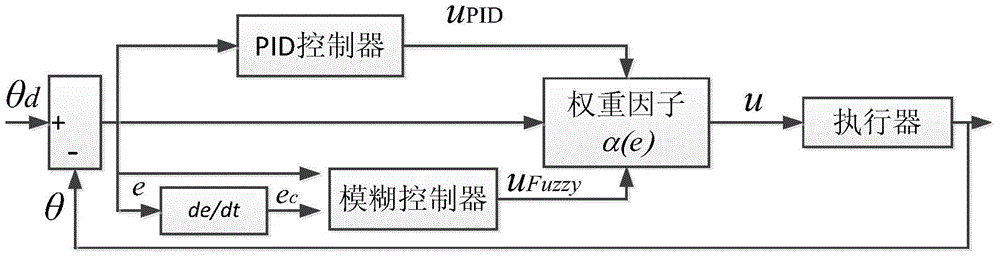

The invention discloses a control method for motion stability and outline machining precision of a multi-shaft linkage numerical control system. The control method achieves control on the motion stability and outline machining errors of the multi-shaft linkage numerical control system by using a compound control mode of multi-shaft parameter module predictive control and non-linear self-adaptive fuzzy proportional-integral-derivative (PID) control. Simultaneously, error module calculating efficiency is improved by building an outline error module, a speed error module and an acceleration error module. By means of performance optimization indexes, tracking errors, outline errors, speed errors and acceleration errors of the system are minimum, and control performance of a multi-shaft servo control system is improved. Multi-shaft parameter module predicative control increment is solved through a simplified calculating module so as to meet real-time requirements of the control system. Robust property of the multi-shaft linkage numerical control system is improved by adopting the non-linear self-adaptive fuzzy PID control method. The control method effectively improves the motion stability and outline machining precision of the multi-shaft linkage numerical control system.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

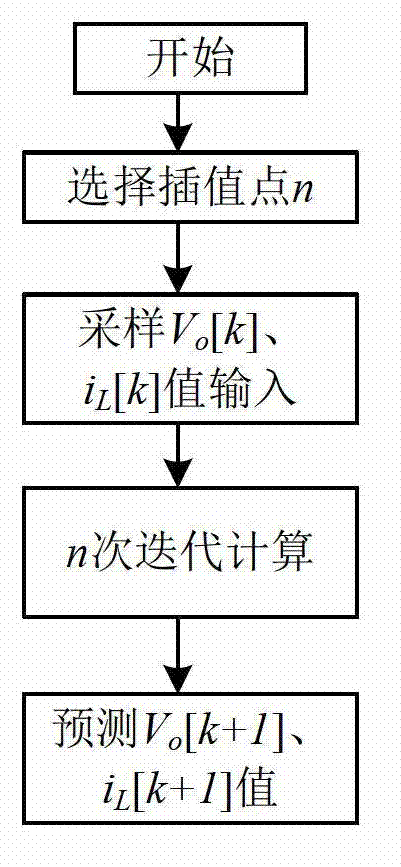

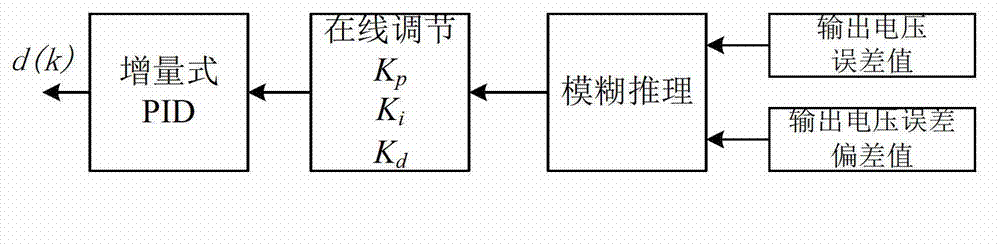

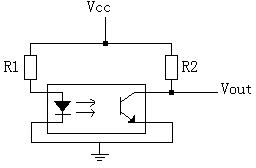

Fast transient response digital switch converter and control method of fast transient response digital switch converter

InactiveCN103051186AImproving the ability to respond to transient changesReduce Control LagDc-dc conversionElectric variable regulationProportion integration differentiationFuzzy pid control

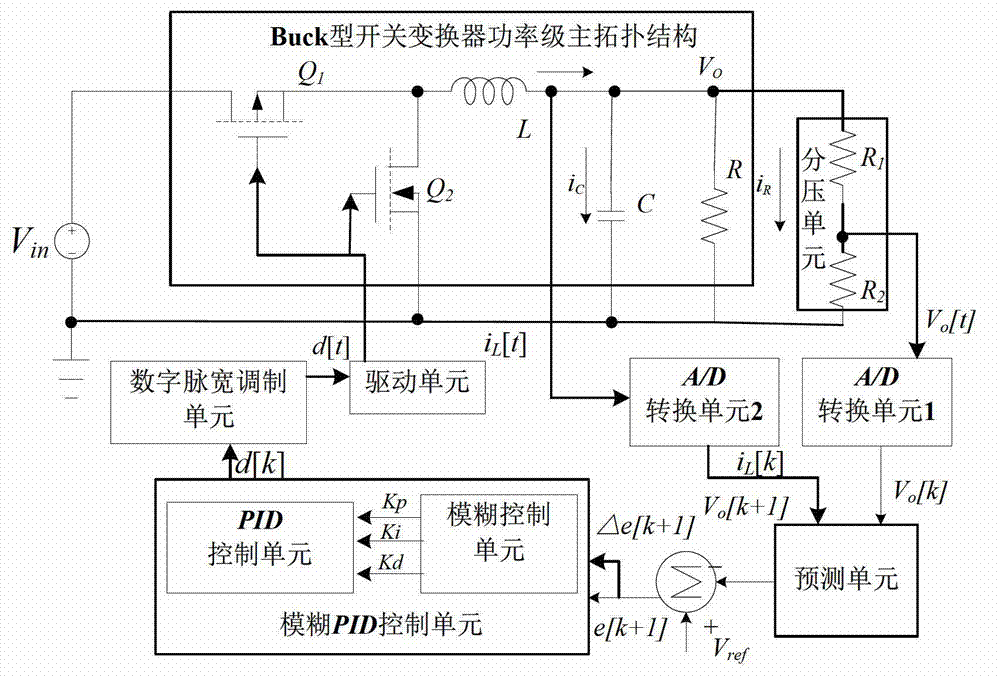

The invention provides a digital switch converter with fast transient response capability. The digital switch converter comprises a Buck type switch converter power level main topology structure, an A / D (analog-to-digital) sampling conversion unit, a prediction control unit, a fuzzy PID (proportion integration differentiation) control unit, a DPWM (digital pulse width modulation) unit and a driving unit, wherein the A / D sampling conversion unit respectively samples the analog output voltage value and the analog inductor current value of the sampling switch converter and converts analog signals into digital signals, the prediction control unit predicts the next switch period output voltage value according to the A / D sampling digital signal value combined with the Buck type switch converter main topology structure, the fuzzy PID control unit determines the switch period duty ratio according to the output voltage error value and the output voltage error deviation value, and the DPWM unit and the driving unit output the corresponding on-off state of a power tube of the PWM driving switch converter according to the duty ratio for regulating the output voltage value.

Owner:SOUTHEAST UNIV

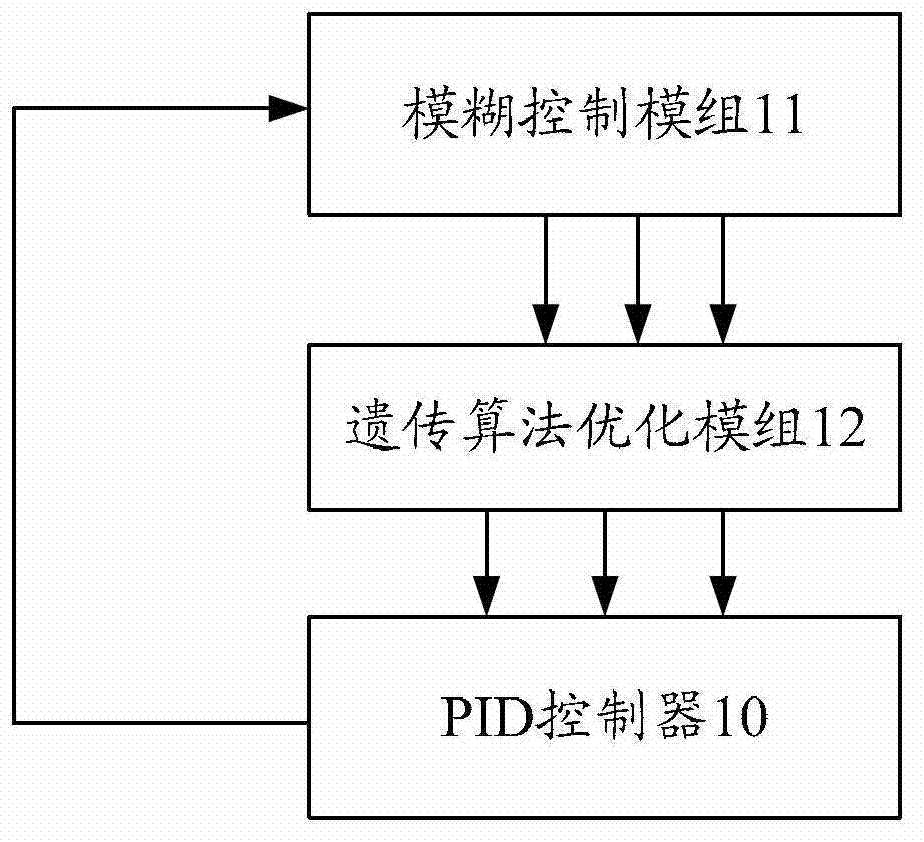

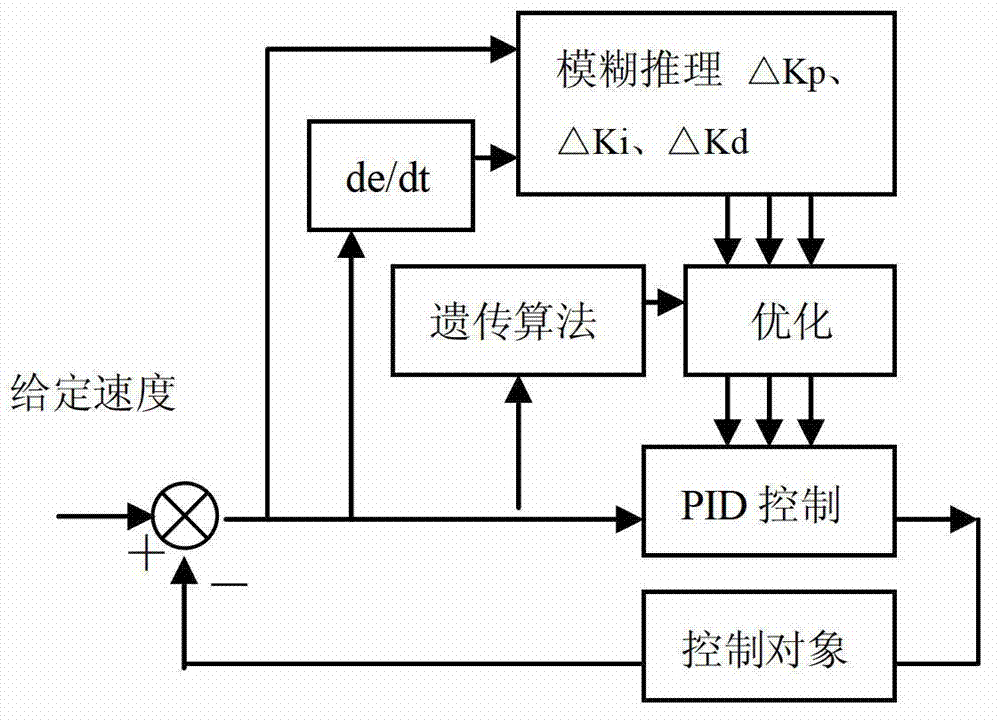

Fuzzy PID (Proportion Integration Differentiation) controller based on genetic algorithm and control method thereof

InactiveCN102968055AIncrease dynamicsImprove static performanceControllers with particular characteristicsProportion integration differentiationFuzzy pid control

The invention discloses a fuzzy PID (Proportion Integration Differentiation) controller based on genetic algorithm and a control method thereof. The control method comprises the following steps in sequence: controlling a controlled object by a fuzzy control algorithm; dynamically generating three parameters of the PID controller in an online manner; selecting a proper fitness function by virtue of the genetic algorithm; searching based on the fitness function of each individual in the population; increasing the speed of convergence of the genetic algorithm; calculating to obtain the optimal solution; and further optimizing three basic parameters output in the fuzzy control. By adopting the control method, dynamic and static performances of a control system can be improved while the accuracy in control detection is ensured.

Owner:SHANGHAI DIANJI UNIV

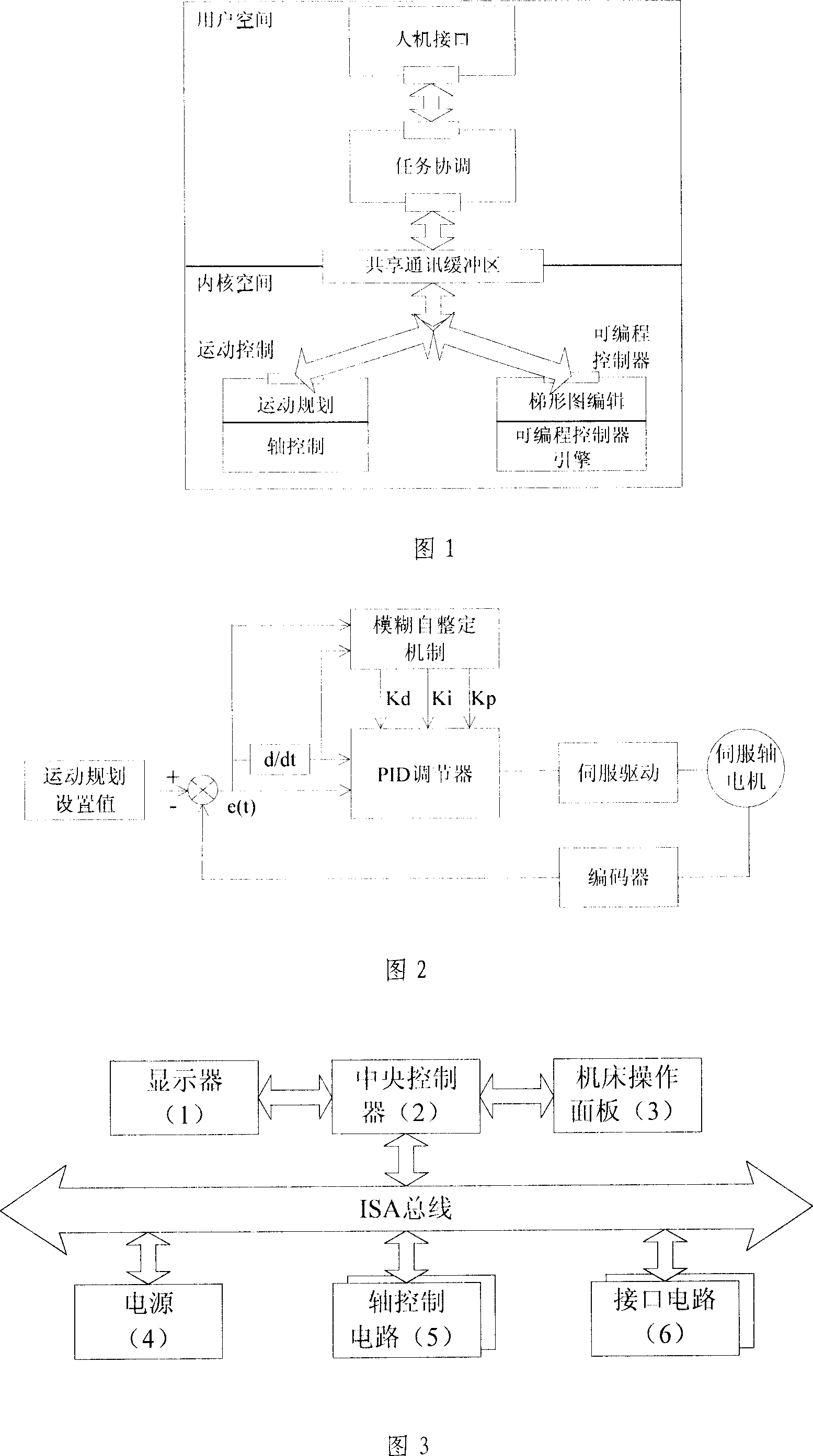

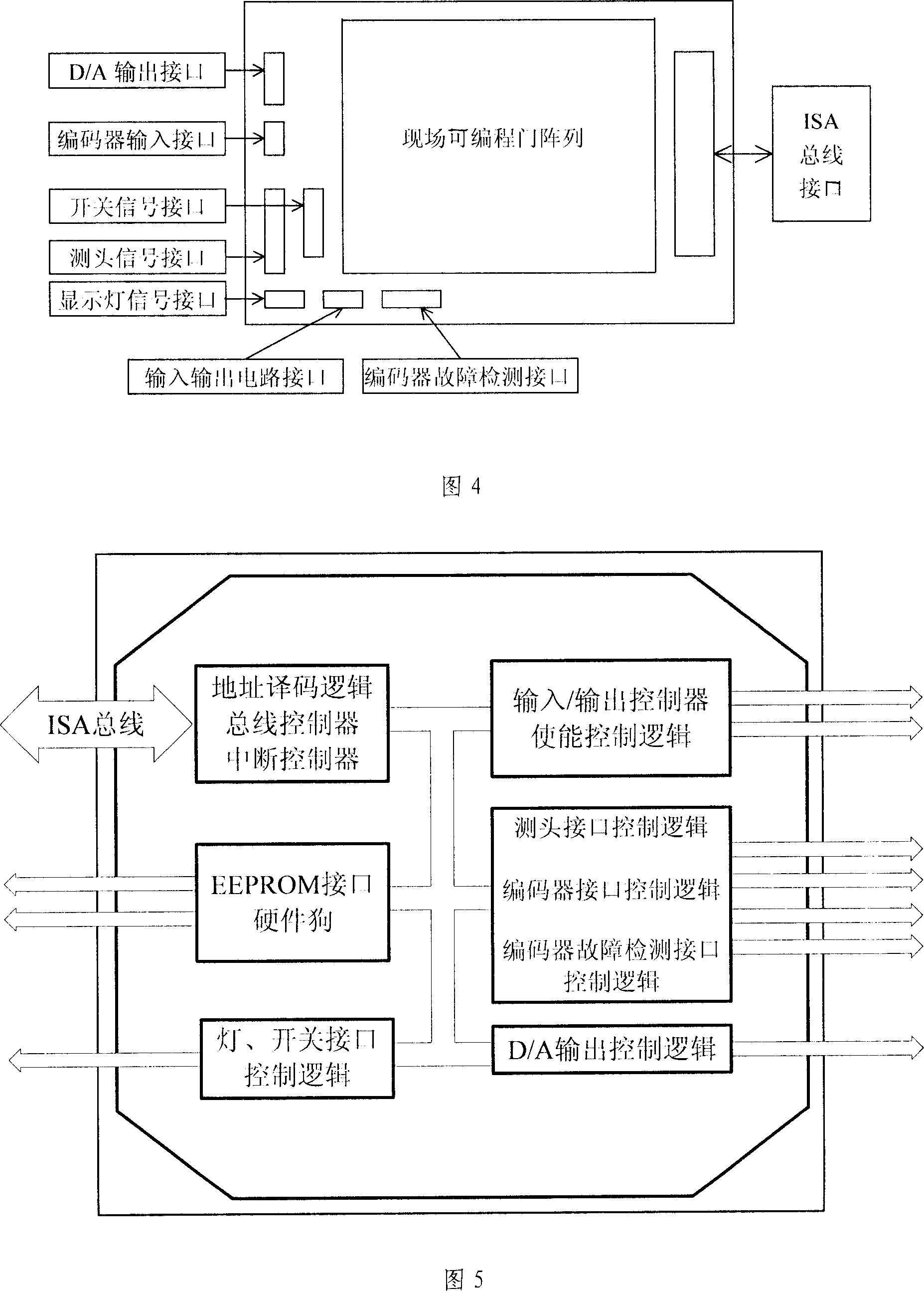

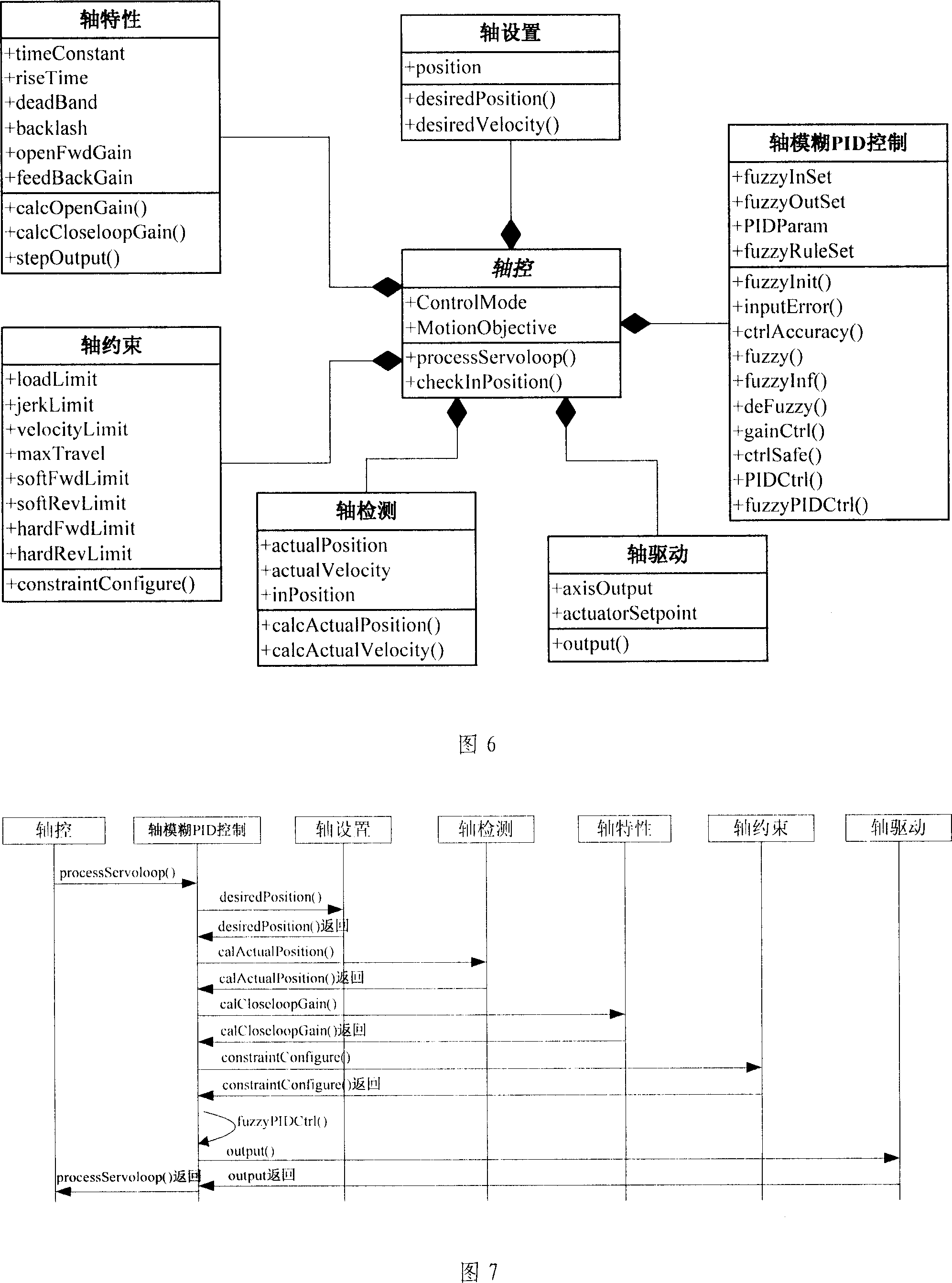

Fuzzy PID control method and execution apparatus of numerical control machine

ActiveCN1952819AHigh control precisionAvoid static errorNumerical controlAdaptive controlNumerical controlDigital control

This invention discloses a digital control machine fuzzy PID control method and its realization device, which adopts human to machine interface, task transfer, movement control and programmable controller to load the movement control and programmable controller onto inner space of system and to load interface, task transfer part onto system user space interacting through common communication buffer area; the movement control comprises movement plan and axis control parts to form process machine servo axis movement by use of fuzzy PID control method to determine axis control parameters for stable control.

Owner:中国科学院沈阳计算技术研究所有限公司

Diesel engine variable-altitude boost pressure control method

ActiveCN105673191APrevent surgeAvoid turbo overspeedInternal combustion piston enginesGas compressorOptimal control

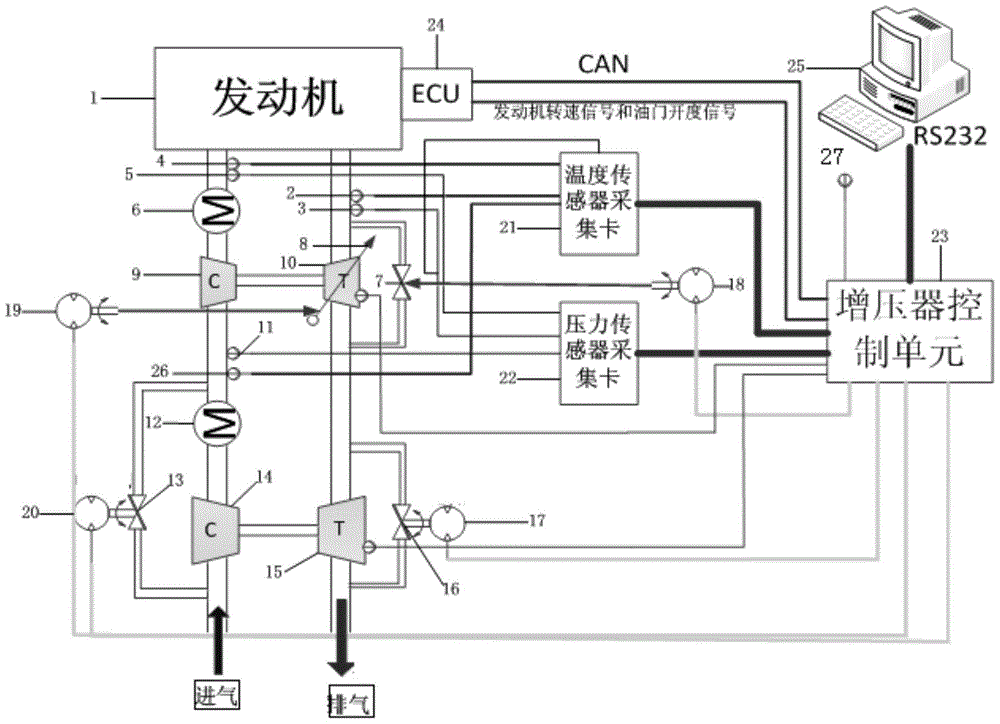

Disclosed is a diesel engine variable-altitude boost pressure control method. Through a two-level adjustable booster controller ECU, according to change of altitude, diesel engine rotation speed and loads, opening of a high-pressure stage VGT vane of a two-level adjustable booster and opening of a high-pressure stage turbine regulating valve and a low-pressure stage turbine regulating valve are controlled in real time, optimal control is conducted on boost pressure in a variable-altitude and variable-working-condition mode, and the purpose that in the 0 m-5500 m altitude range, all performance indicators of a diesel engine are always kept the same as the performance under the plain conditions is achieved. The mode that feedforward control and fuzzy PID control are combined is adopted for the diesel engine variable-altitude boost pressure control method, and the boost pressure can be adjusted in real time according to change of altitude and working conditions of the diesel engine, so that the requirements for best power performance and fuel economy in the steady state working condition and the transient state working condition are met, the objective that power of the diesel engine at the altitude 5500 m fixed point is recovered to 95% or above that on plains is achieved, turbo lag is relieved, and pumping loss work is reduced. Meanwhile, the problems of gas compressor surges, turbine overspeed, excessively high turbine-front discharge temperature and the like are avoided.

Owner:MILITARY TRANSPORTATION UNIV PLA

Hoisting load anti-swing control device, method, system and engineering machinery

ActiveCN103663143AOffset interferenceAvoid swingingLoad-engaging elementsFuzzy pid controlPid control algorithm

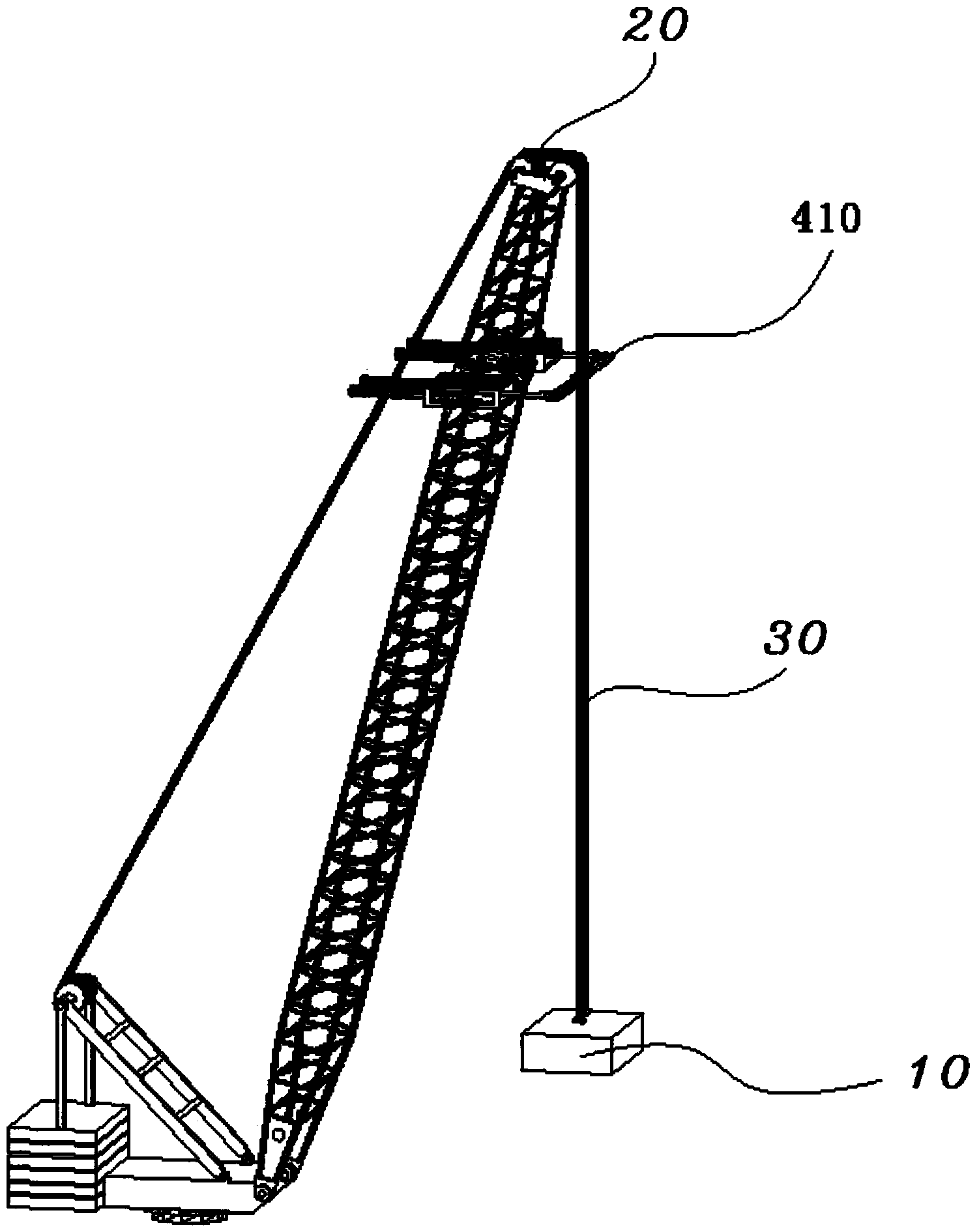

The invention discloses a hoisting load anti-swing control device, method, system and engineering machinery. The hoisting load is hoisted by a cantilever crane through a lifting rope. The hoisting load anti-swing control device comprises a receiving device and a control device, wherein the receiving device is used for receiving the horizontal position of the top end of the cantilever crane and / or receiving the tilt angel of the hoisting load and the rate of the tilt angle; the control device is used for carrying out one of the followings: when the horizontal position of the top end changes, controlling an anti-swing device to compensate the horizontal displacement of part of the lifting rope so as to enable the horizontal position not to change before the horizontal position of the top end of the cantilever crane changes; when the tilt angle and rate of the tilt angle of the hoisting load are greater than the preset values, adopting fuzzy PID control algorithms to enable the anti-swing device to control the horizontal displacement of part of the lifting rope so as to restrain the tilt angle and the rate of the tilt angle. Through the adoption of the technical scheme, various interferences can be counteracted, greater swing can be restrained, and higher positioning precision can be reached.

Owner:ZOOMLION HEAVY IND CO LTD

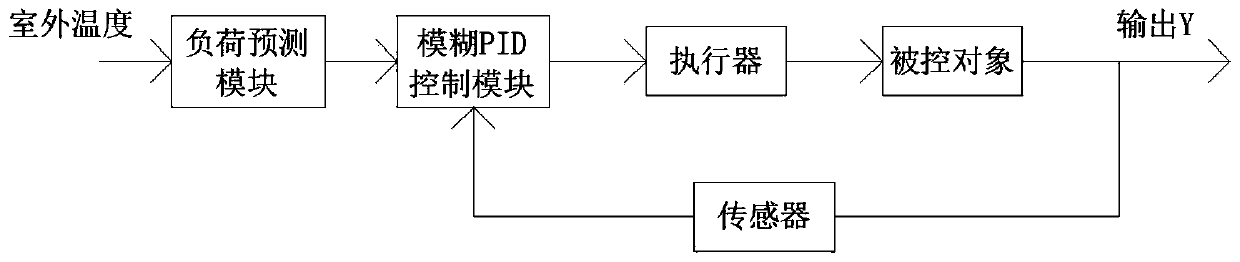

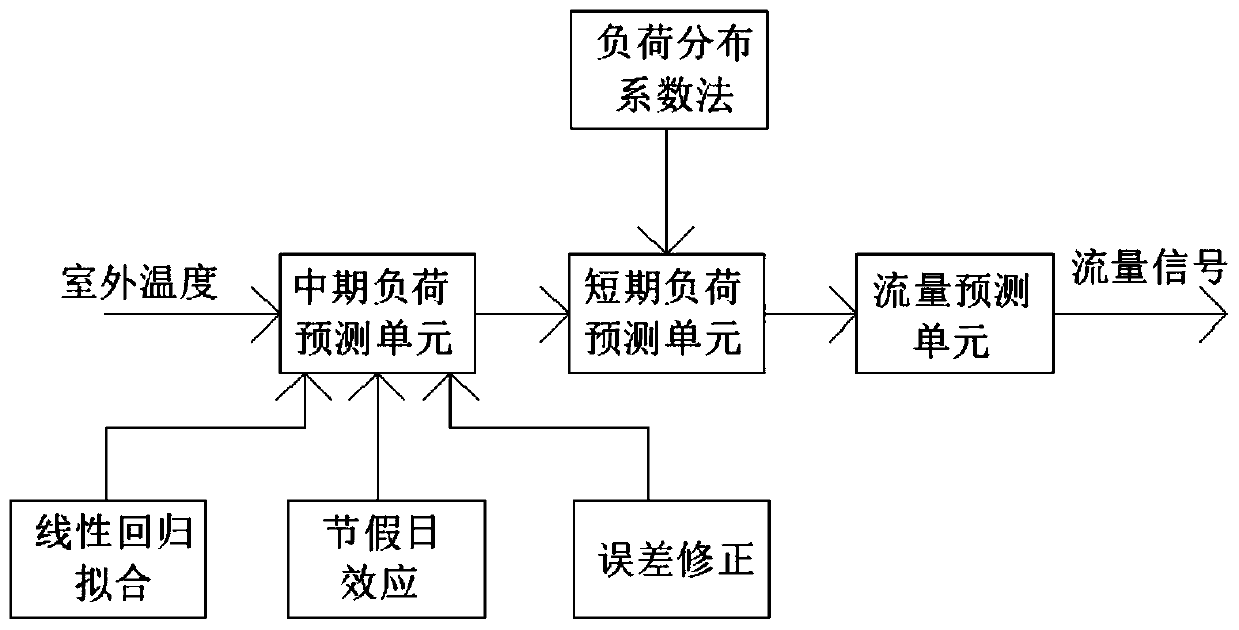

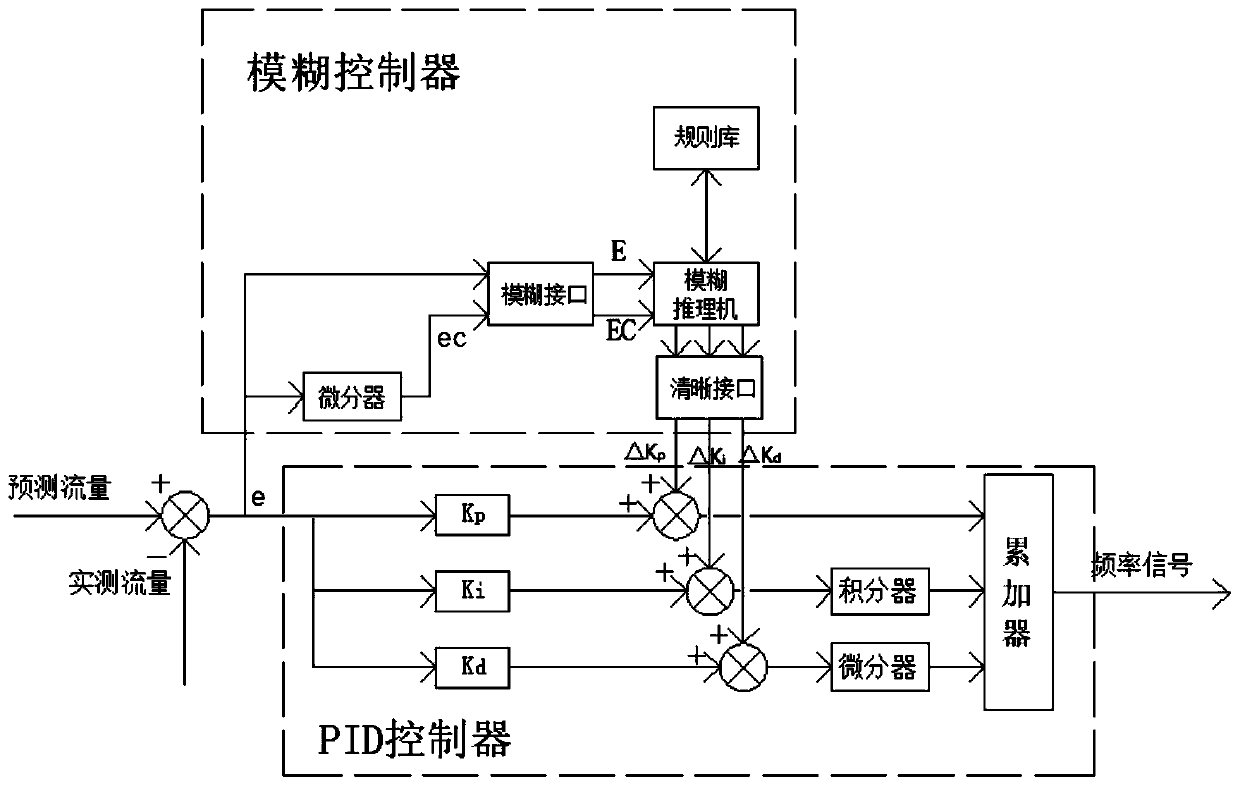

Refrigeration house temperature feedforward-fuzzy control system based on dynamic load variation and control method

ActiveCN109708258AAccurate predictionImprove controlMechanical apparatusSpace heating and ventilation safety systemsFrequency changerTraffic prediction

The invention discloses a central air conditioning fuzzy PID control system based on load prediction control. The system comprises a load prediction module, a fuzzy PID control module, an executor, acontrolled object and a sensor. The load prediction module is composed of three load prediction units including the medium-term load prediction unit, the short-term load prediction unit and the flow prediction unit. A load prediction controller calculates the required chilled water flow of a current chilled water system according to history operating data and an outdoor temperature, then the required frequency of a chilled water pump is calculated by means of the intelligent fuzzy PID control system, finally, the rotating speed of the water pump is changed through a water pump frequency changer, variable flow control of central air conditioning chilled water is completed, and therefore, the system has the energy-saving benefit. By means of the refrigeration house temperature feedforward-fuzzy control system based on dynamic load variation and the control method, the phenomena that temperature control through a traditional central air conditioning system chilled water control scheme lags, and the control precision is not high are avoided, early response of a flow control system is achieved, and the performance of a central air conditioning system is guaranteed.

Owner:NANJING DARSY ENERGY TECH CO LTD

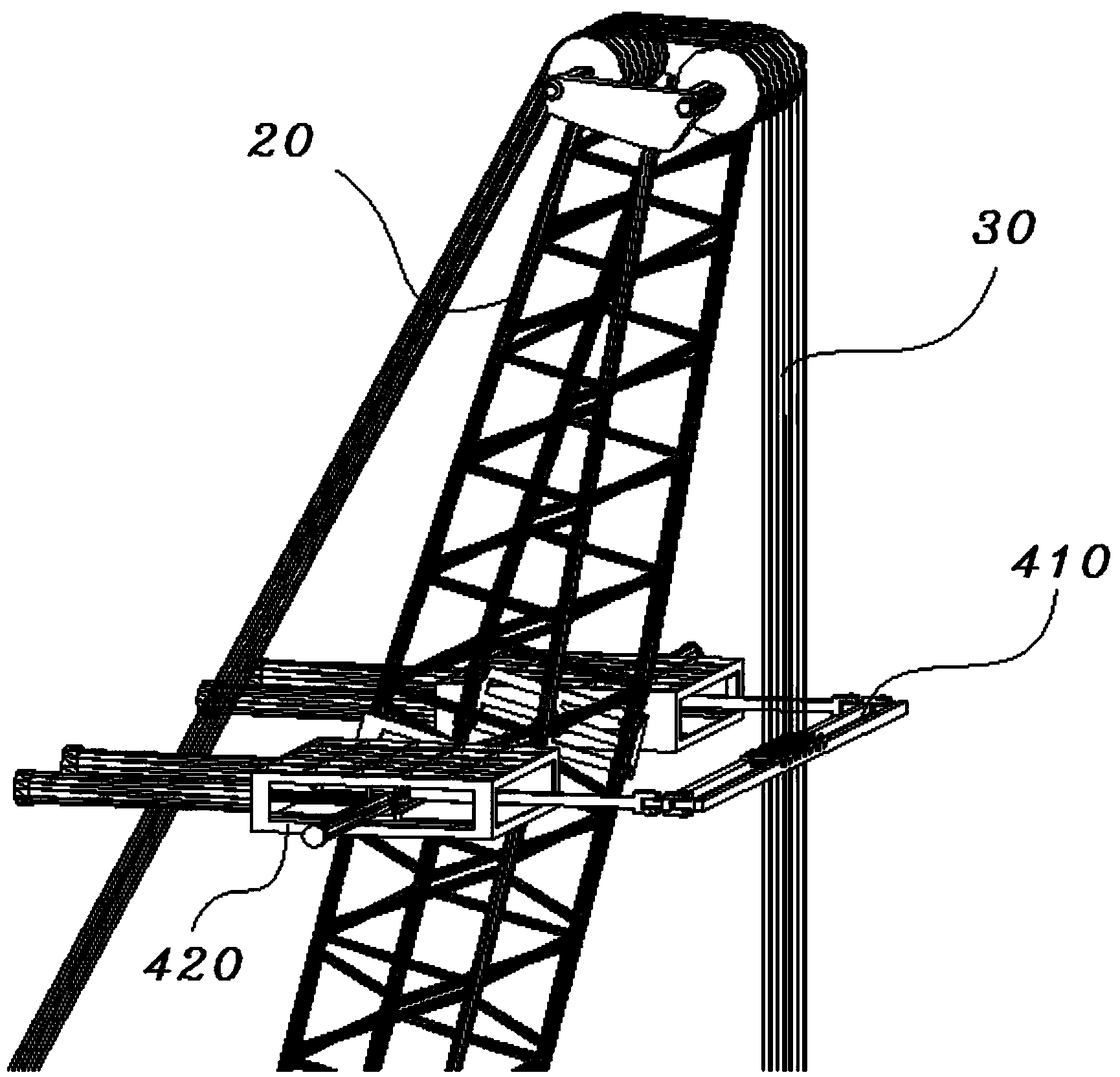

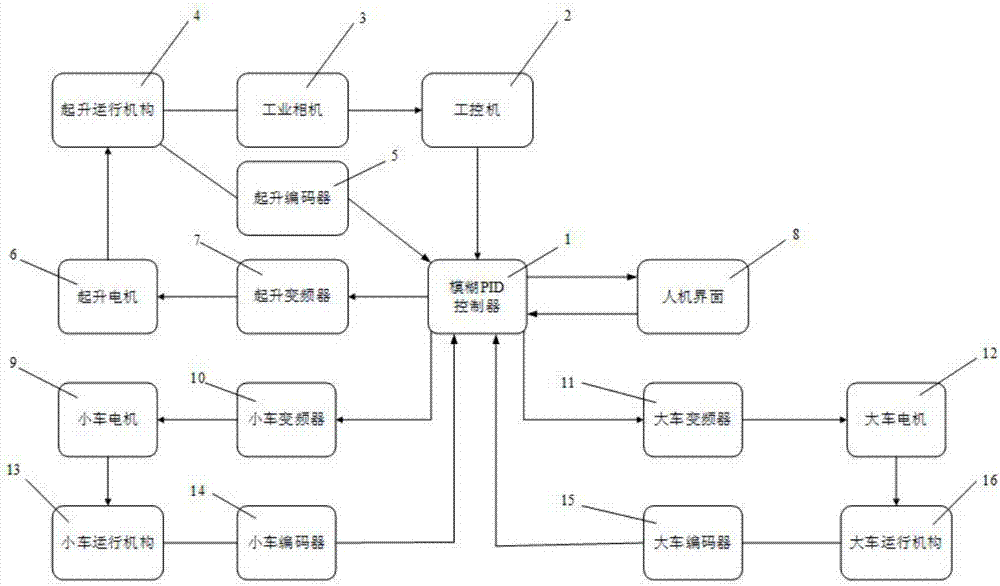

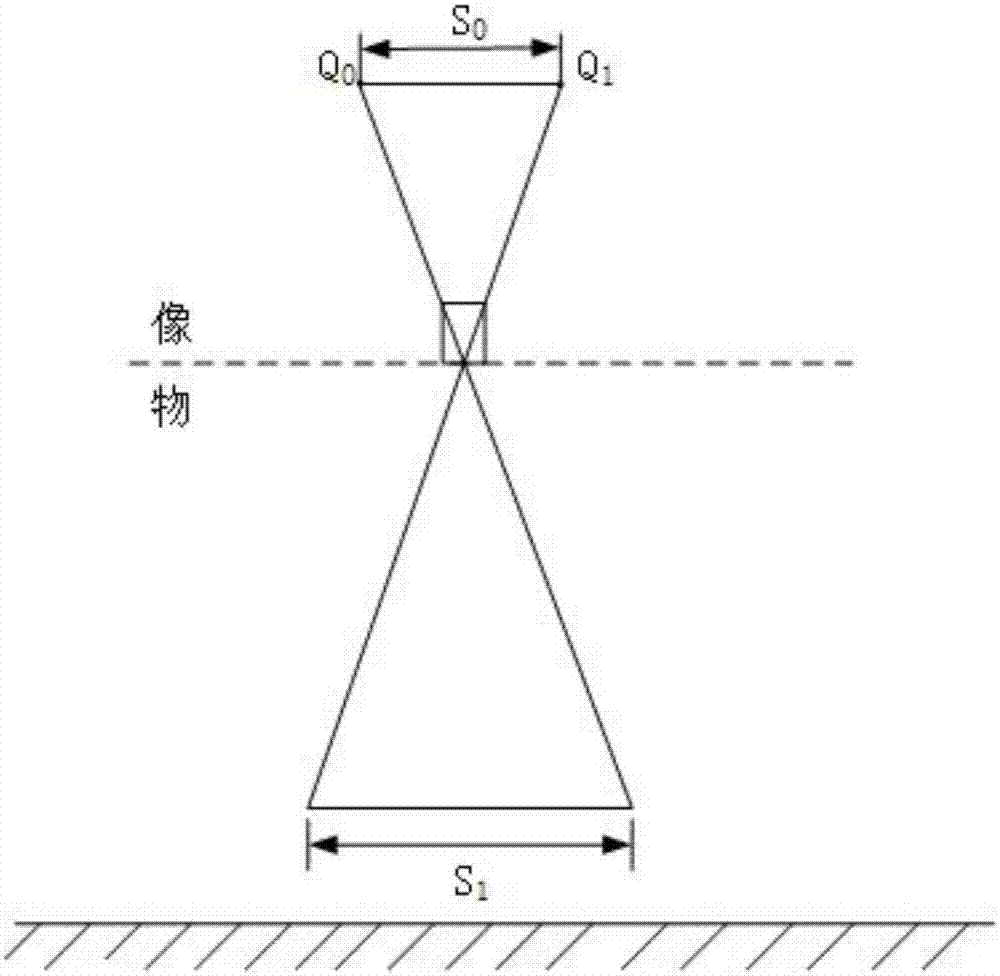

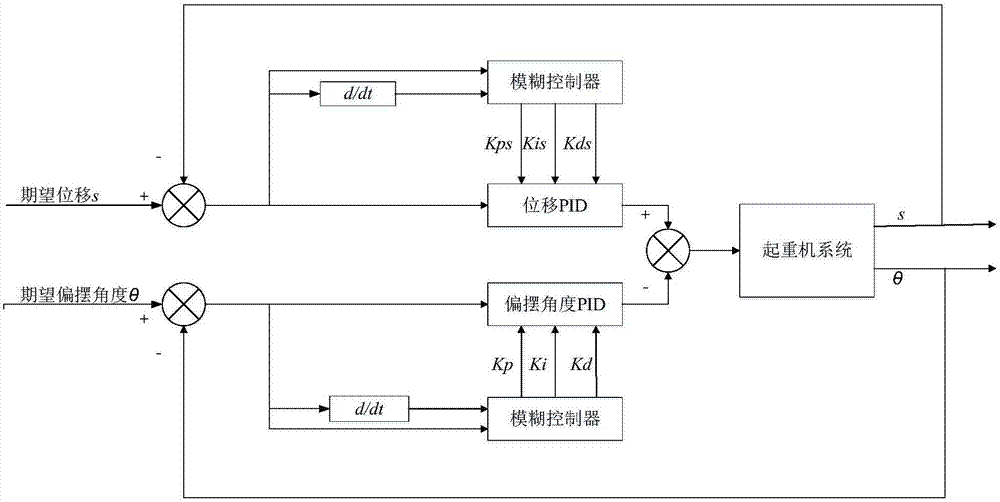

Intelligent anti-swinging crane control system and method based on fuzzy PID control

ActiveCN107487717ARealize real-time monitoringImprove the ability to resist external interferenceLoad-engaging elementsAdaptive controlHuman–machine interfaceControl system

The invention discloses an intelligent anti-swinging crane control system based on fuzzy PID control. The intelligent anti-swinging crane control system based on fuzzy PID control comprises a fuzzy PID controller, an industrial personal computer, an industrial camera, a lifting encoder, a human-computer interface, a trolley encoder and a gantry encoder. The human-computer interface is connected with the fuzzy PID controller. The industrial camera is installed on the lower side of a lifting operation mechanism. The lifting encoder is installed at one end of a lifting winding drum. The trolley encoder and the gantry encoder are installed on a trolley and a gantry correspondingly. The crane comprises the lifting operation mechanism, a trolley operation mechanism and a gantry operation mechanism. The lifting operation mechanism is connected with a lifting motor and a lifting frequency converter. The trolley operation mechanism is connected with a trolley motor and a trolley frequency converter. The gantry operation mechanism is connected with a gantry motor and a gantry frequency converter. The lifting frequency converter, the trolley frequency converter and the gantry frequency converter are connected with the fuzzy PID controller. The invention further discloses an intelligent anti-swinging crane control method based on fuzzy PID control. By the adoption of the intelligent anti-swinging crane control system and method based on fuzzy PID control, accurate control over the movement displacements of the gantry and the trolley of the crane and effective control over the swinging angle of a load can be achieved.

Owner:WUHAN UNIV OF TECH

Air-conditioning control technique with variable air quantity based on enthalpy value control

InactiveCN101672509ARealize intelligenceSpace heating and ventilation safety systemsLighting and heating apparatusAir volumeControl signal

The invention relates to a novel air-conditioning control technique with variable air quantity based on enthalpy value control, which comprises a pressure relevant type end device control part and a fuzzy PID control part. The technique concretely comprises a PID controller, a parameter self-calibration module, a fuzzy database, an air return valve, an air delivery valve, an air-conditioning end with variable air quantity, a humiture sensor and an air enthalpy value operation module. The humiture sensor collects indoor humiture signals Tr and phi r, the indoor humiture signals are transformedinto an executable standard electric signal by a variable delivery link, the electric signal is delivered into the air enthalpy value operation module, an enthalpy value representing indoor humiture properties is obtained by calculation, and the enthalpy value is compared with a set enthalpy value. After comparison, a bias and a bias change rate are regulated and calibrated by the fuzzy control module, and a timely and accurate control signal is sent to the air delivery valve or the air return valve positioned at the end, thereby changing the air quantity so as to achieve the purpose of regulating the humiture in a room. The invention has intellectualized control and shorter response regulation time and realizes the purpose of energy saving of an air-conditioning host machine.

Owner:DONGGUAN GUANGDA REFRIGERATION

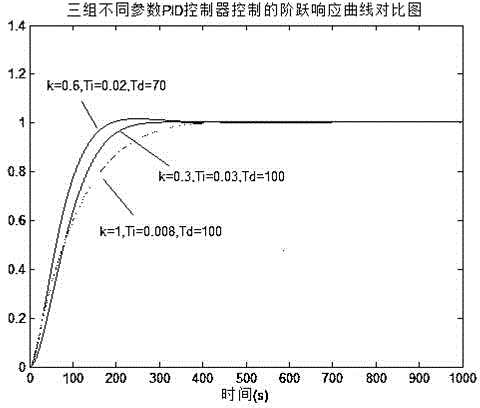

Method for controlling PID controller route based on fuzzy control

InactiveCN103995535AReduce power consumptionImprove efficiencyPosition/course control in two dimensionsDefuzzificationFuzzy pid control

The invention discloses a method for controlling a PID controller route based on fuzzy control. The method comprises the steps that on the basis of a motor PID controller, a route correcting strategy based on the fuzzy control idea is integrated, fuzzy PID controlled quantities of delta Kp, delta Ki and delta Kd are obtained by detecting deviation and the deviation regulating rate, after the fuzzy PID controlled quantities are received by the PID controller, the fuzzy PID controlled quantities are subjected to defuzzification to be adjusted to be three precise controlled quantities of Kp, Ki and Kd. Accordingly, a motor of self-tracking equipment is controlled, and the purpose of correcting the route is achieved.

Owner:SUZHOU INST OF INDAL TECH

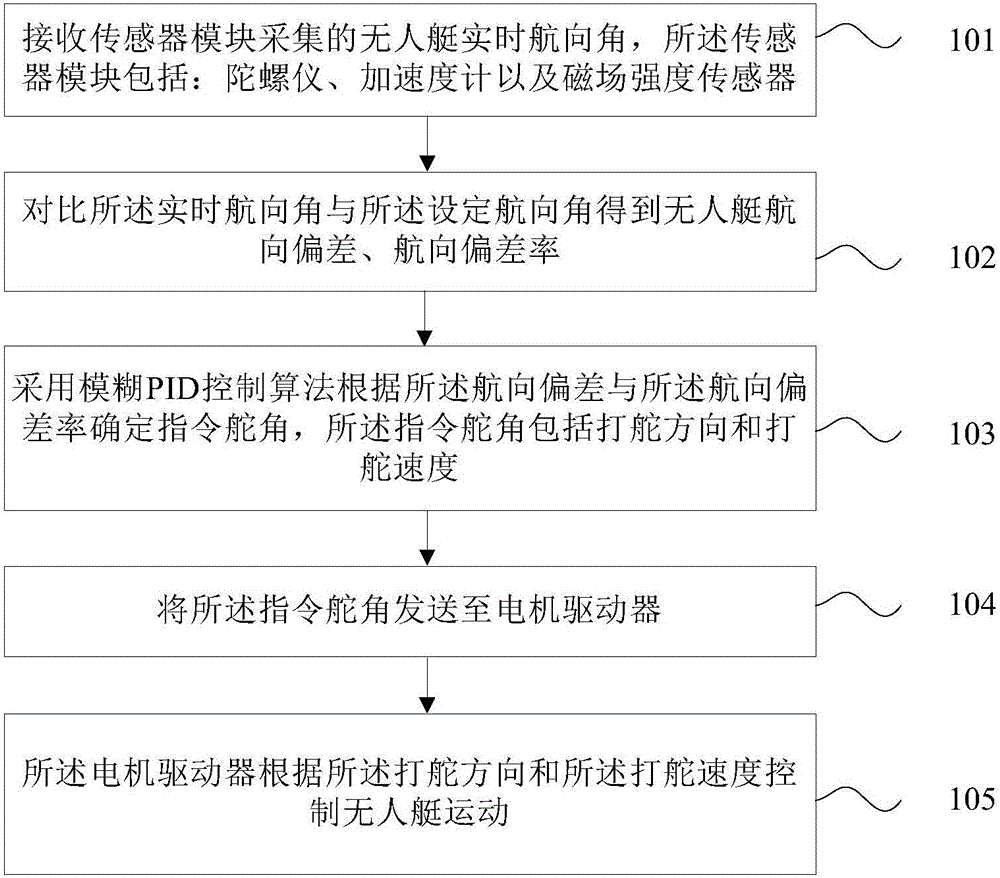

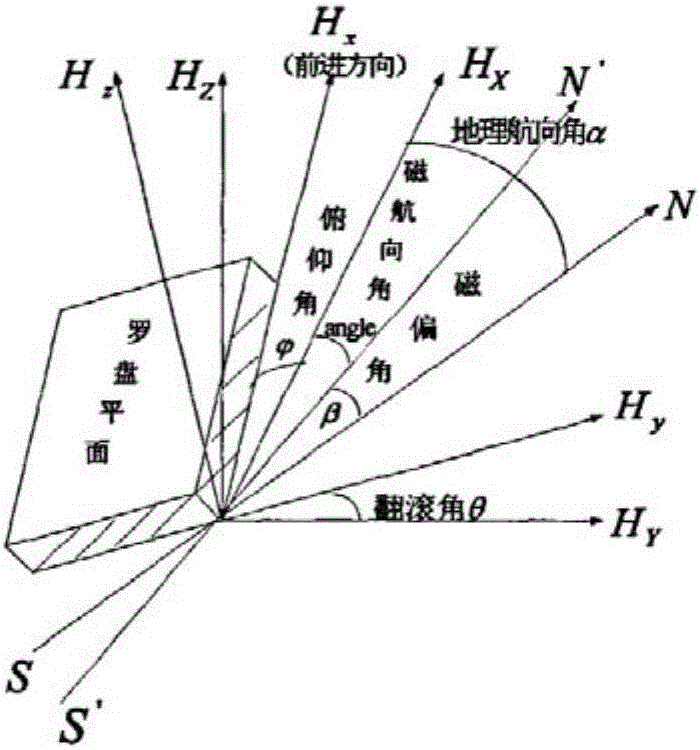

Unmanned surface vehicle course motion control method

The present invention provides an unmanned surface vehicle course motion control method. The method comprises the steps of receiving an unmanned surface vehicle real-time course angle acquired by a sensor module, wherein the sensor module comprises a gyroscope, an accelerometer and a magnetic field intensity sensor; comparing the real-time course angle and a set course angle to obtain an unmanned surface vehicle course deviation and a course deviation ratio; adopting a fuzzy PID control algorithm to determine an instruction rudder angle according to the course deviation and the course deviation ratio, wherein the instruction rudder angle comprises a steering direction and a steering speed; sending the instruction rudder angle to a motor driver; using the motor driver to control the unmanned surface vehicle motion according to the steering direction and the steering speed. The unmanned surface vehicle course motion control method of the present invention realizes the unmanned surface vehicle course control, and enables the steady-state performance, the dynamic performance and the control precision of the unmanned surface vehicle course motion to be improved and the course control adjustment time to be reduced.

Owner:DALIAN MARITIME UNIVERSITY

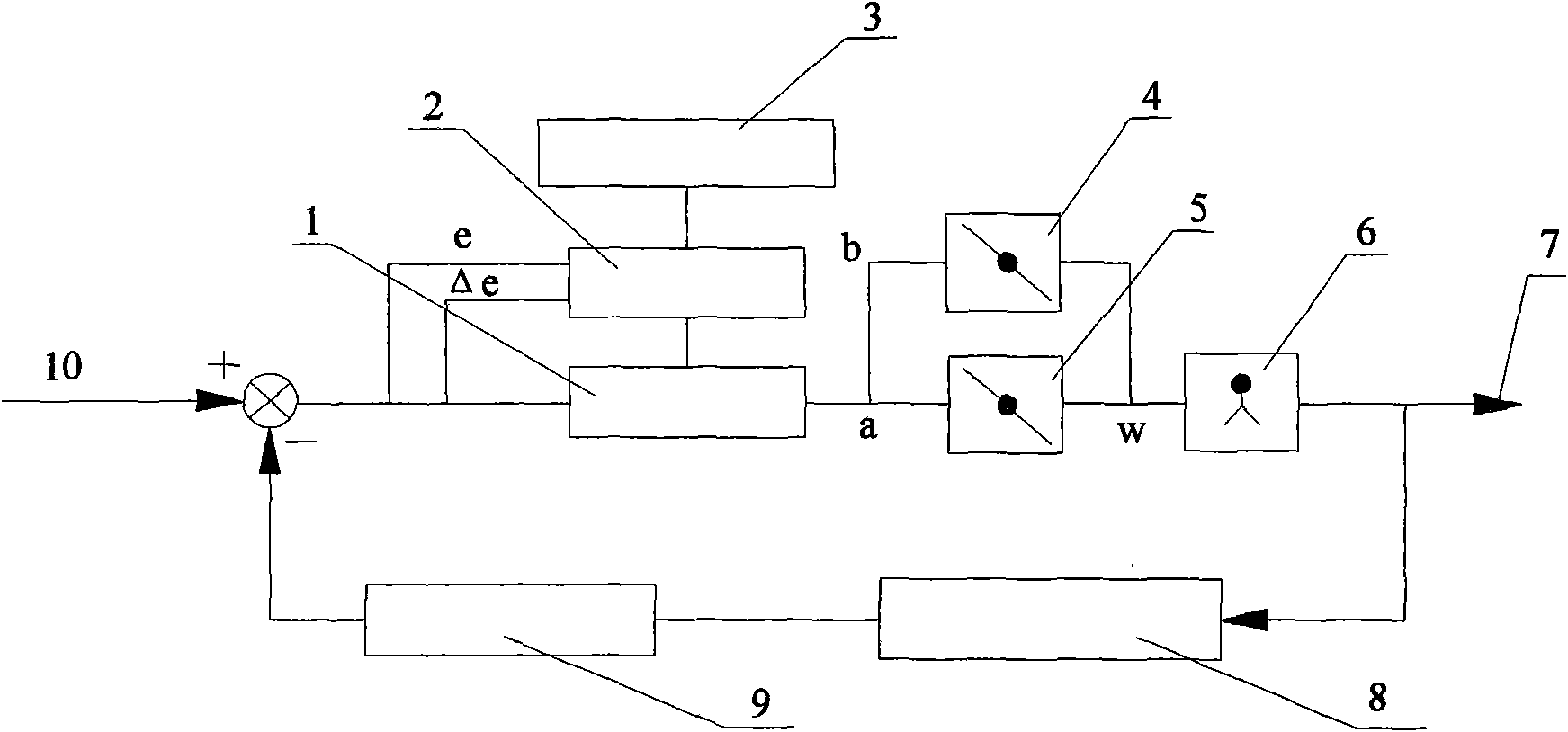

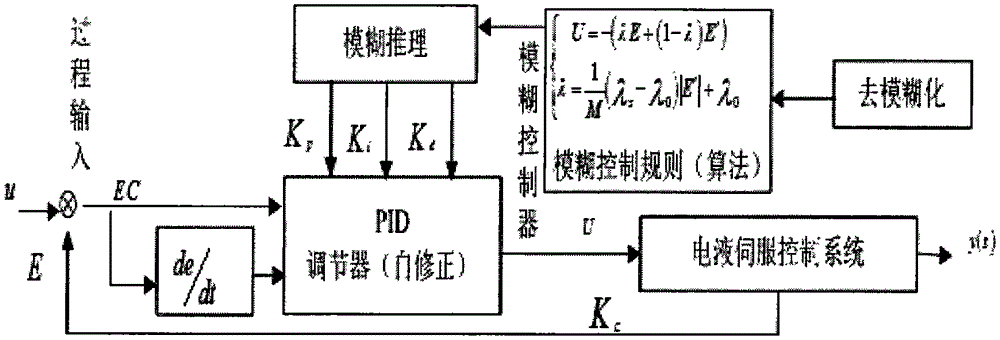

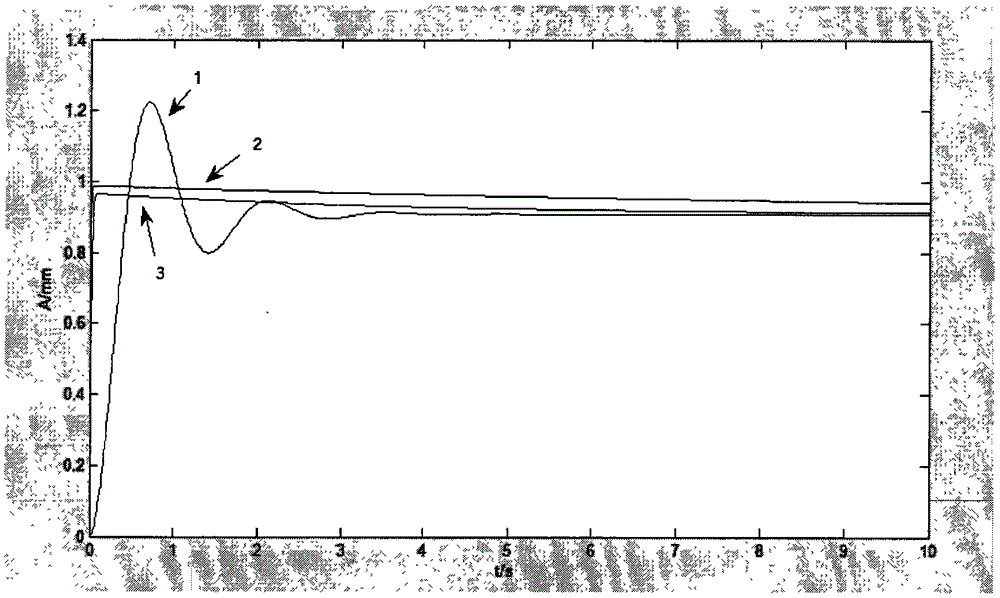

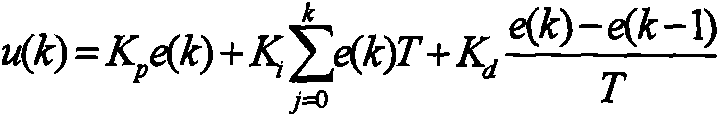

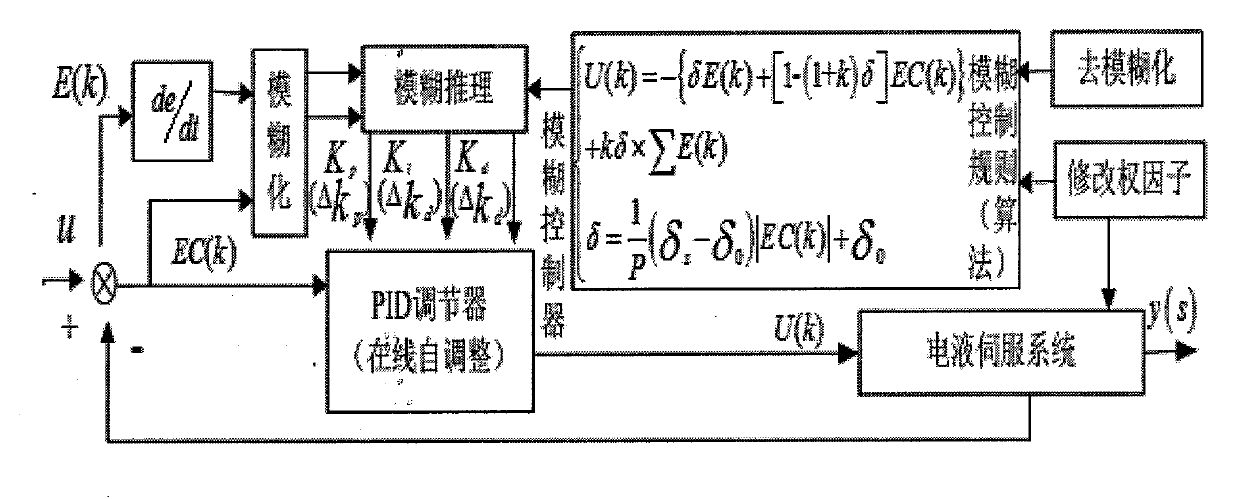

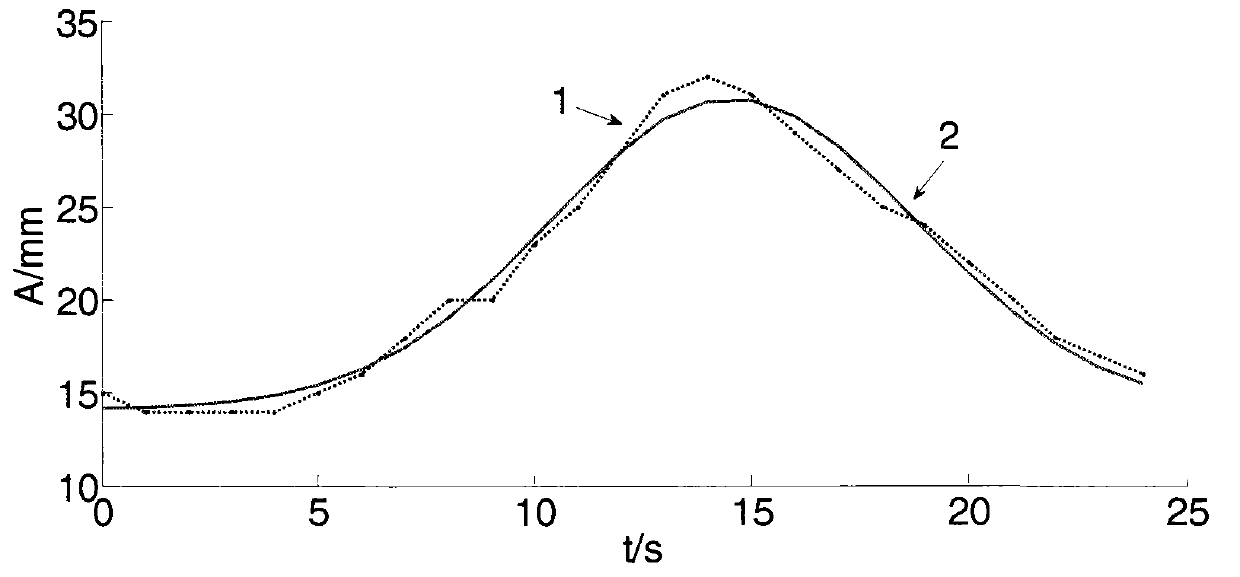

Electro hydraulic servo system self-correction fuzzy PID control method

The invention discloses an electro hydraulic servo system self-correction fuzzy PID control method. In the prior art, the problems that error accuracy is not high and stability and adaptability are not high exist. According to the self-correction fuzzy PID control method, an electro hydraulic servo control mechanism serves as a controlled object, a feedback value of the controlled object and the error E and the error change rate EC of a target value serve as input of a fuzzy PID controller, appropriate fuzzy control rules are set, parameter self-correction is conducted on PID parameters including Kp, Ki and Kd through a fuzzy reasoning method, the requirements of E and EC on PID parameter control at different moments can be met, the variable quantities including delta kp, delta ki and delta kd of PID controller parameter values are output, and the PID parameters are corrected on line according to the self-correction fuzzy control rules. The electro hydraulic servo system self-correction fuzzy PID control method overcomes the disadvantages caused by manual PID parameter correction, online real-time self-correction is achieved for the PID parameters, high robustness is achieved for system parameter correction, and therefore error accuracy and stability of the system are improved, and high application value is achieved.

Owner:张万军

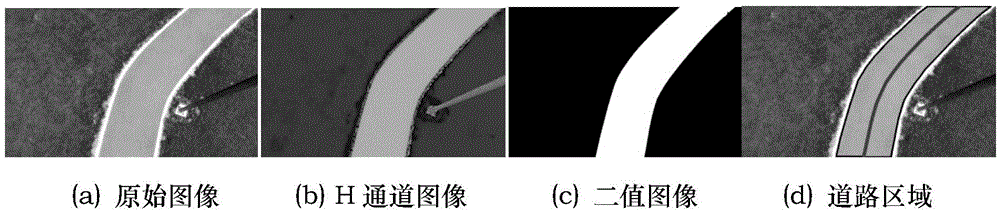

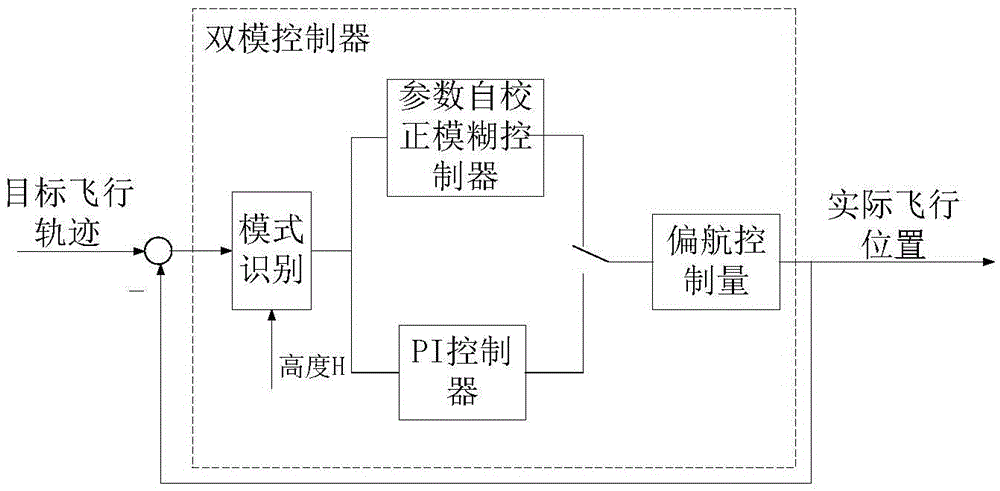

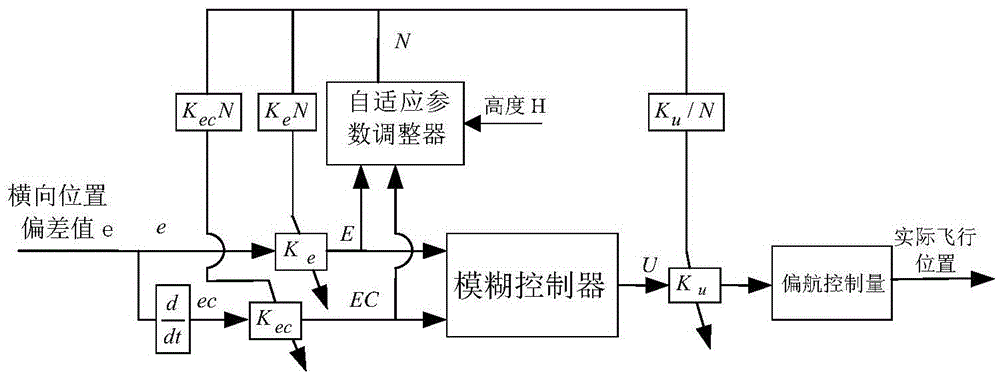

Intelligent road tour inspection control method for multi-rotor-wing unmanned aerial vehicle

ActiveCN105549603AInspection is accurateEliminate Steady State ErrorAttitude controlDual modeRoad surface

The invention discloses an intelligent road tour inspection control method for a multi-rotor-wing unmanned aerial vehicle. The method includes the steps of: 1. an airborne holder image sensor is controlled through a holder control unit, and the image sensor is vertically downward, and obtains information of an image right under an unmanned aerial vehicle; 2. road surface image information is obtained through the image sensor carried by the unmanned aerial vehicle, and a road central line is obtained through image processing and extraction; and 3. a deviation value of the road central line obtained by extraction and the actual position of the unmanned aerial vehicle is utilized to perform flight control of the unmanned aerial vehicle. At the same time, to reduce coupling of control, after control bottom layer driving is designed, only pitching and yaw control of the unmanned aerial vehicle is performed. For pitching control, constant-speed flight is adopted; and for yaw control, dual-mode parameter self-correcting fuzzy PID control is adopted. The intelligent road tour inspection control method applies the unmanned aerial vehicle to perform road tour inspection, and can reduce to a great extent cost of road tour inspection which is performed by applying a patrol vehicle at present, the visual field range of tour inspection is wide, and the control method is not limited by the road traffic condition.

Owner:BEIHANG UNIV

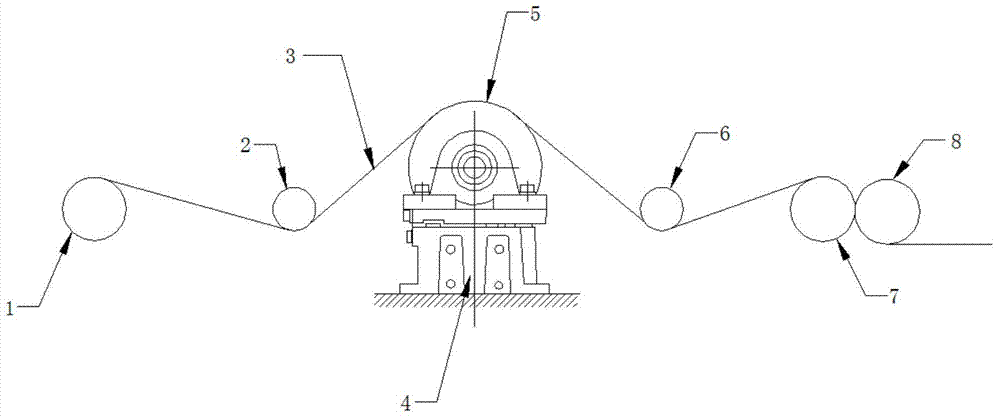

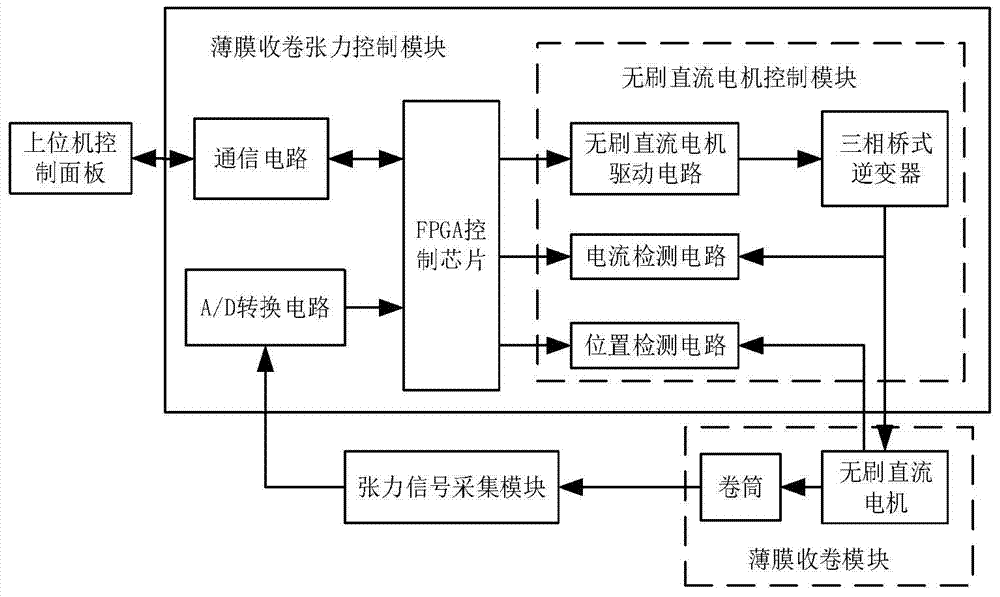

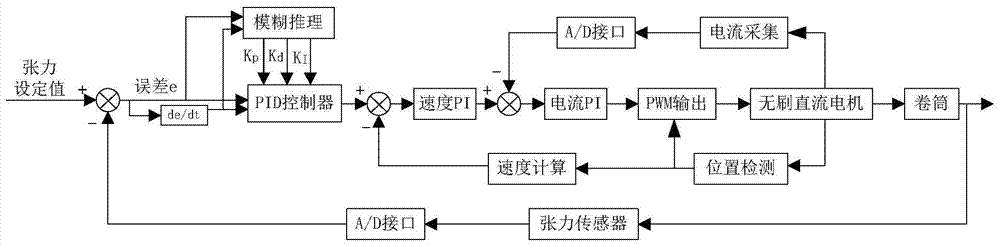

FPGA-based thin film rolling tension control system and method

InactiveCN104709748AImprove stabilityImprove parallel processing capabilitiesWebs handlingControl signalProgrammable logic device

The invention discloses an FPGA-based thin film rolling tension control system and method. The system comprises a tension signal collection module, a thin film rolling tension control module, a thin film rolling module and an upper computer operation panel. A programmable logic device FPGA controls a chip to achieve a fuzzy PID control algorithm, the speed controlled quantity of a brushless direct current motor is obtained, a double closed-loop control algorithm of the brushless direct current motor is combined, then signals are controlled to be correspondingly changed and adjusted when tension changes in the rolling process of a thin film, and constant control over the tension in the rolling process of the thin film can be achieved through real-time collection of tension of the thin film by utilization of the fuzzy PID control algorithm; the development cost is low, the integration level of the system is high, the steady state performance is good, the response speed is high, the control precision is high, and adaptability is high.

Owner:XI AN JIAOTONG UNIV

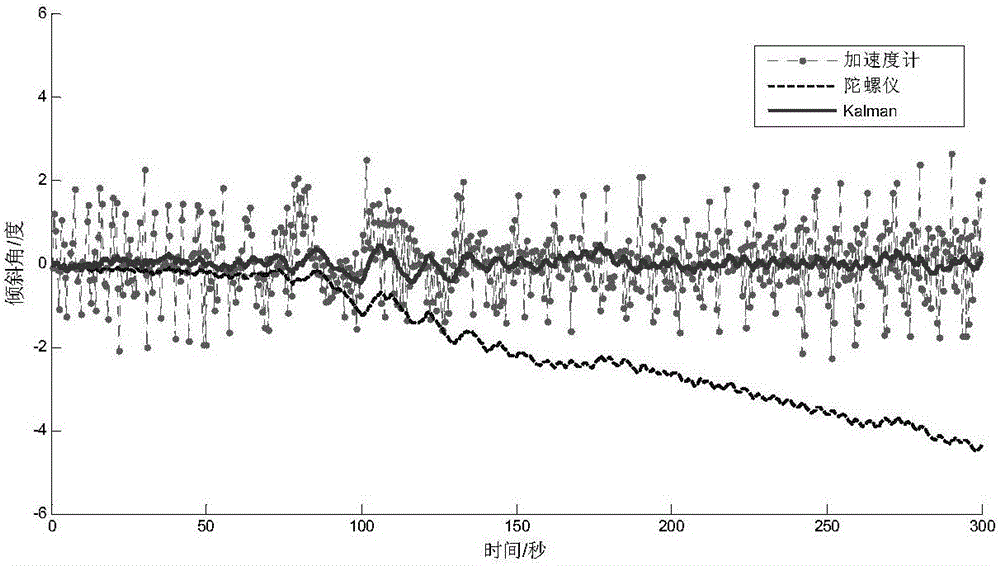

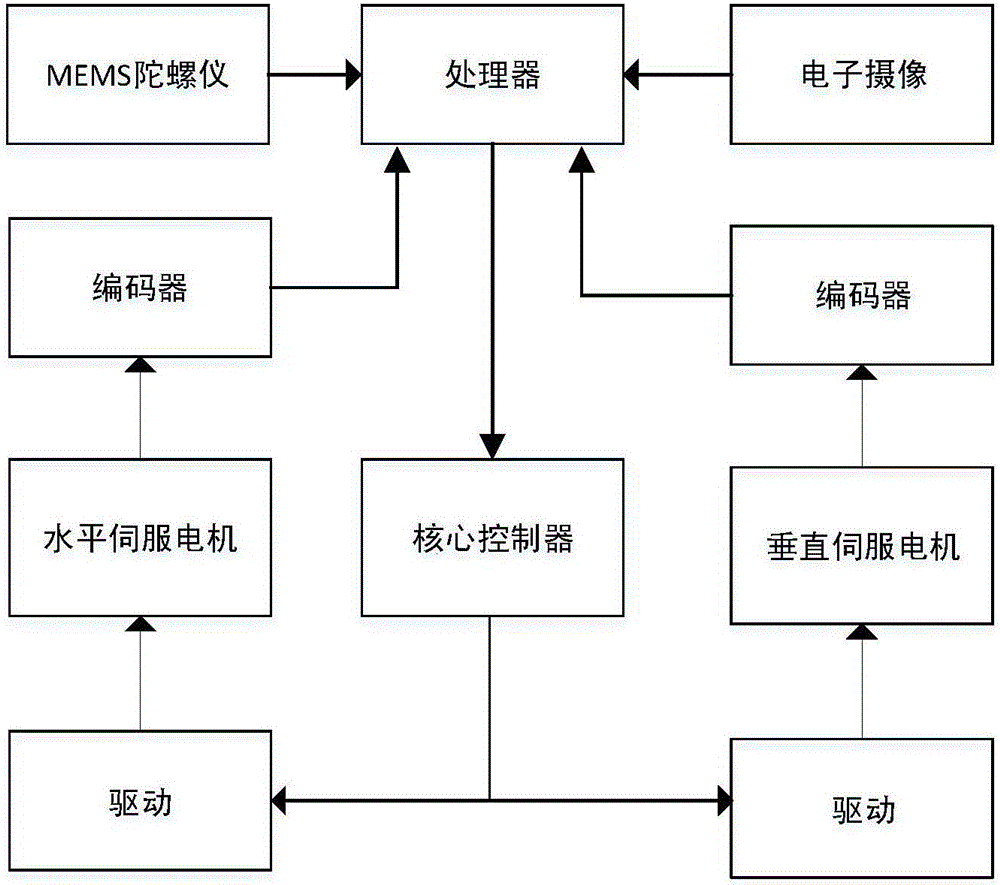

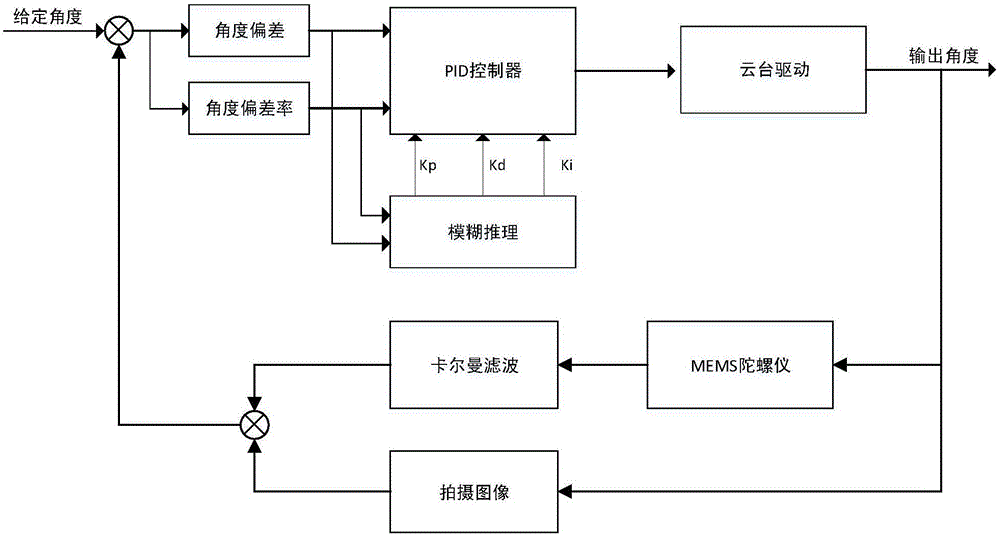

Head real-time control system and method for small unmanned aerial vehicle for land survey

ActiveCN106200693AReduce difficultyGood precisionControl using feedbackReal-time Control SystemAttitude control

The invention discloses a head real-time control system and method for a small unmanned aerial vehicle for a land survey. The head real-time control system comprises a head three-axis drive system, a video camera, an MEMS sensor, a processor and a core controller; the core controller controls the head three-axis drive system to conduct adjustment according to the angle, needing to be adjusted, of the head three-axis device system, wherein the angle is obtained through the processor. According to the head real-time control system and method for the small unmanned aerial vehicle for the land survey, the unmanned aerial vehicle for aerial surveying can meet ideal precision requirements in flight attitude control and head stability control; particularly, a unique online image angle calculation method is added, a head is controlled really according to actually photographed image features, and the unmanned aerial vehicle can adapt to various complex environments; meanwhile, fuzzy PID control is combined with self-adaptive Kalman filter, a stable image can be obtained, and therefore the difficulty of post processing of the image is reduced.

Owner:SOUTHEAST UNIV

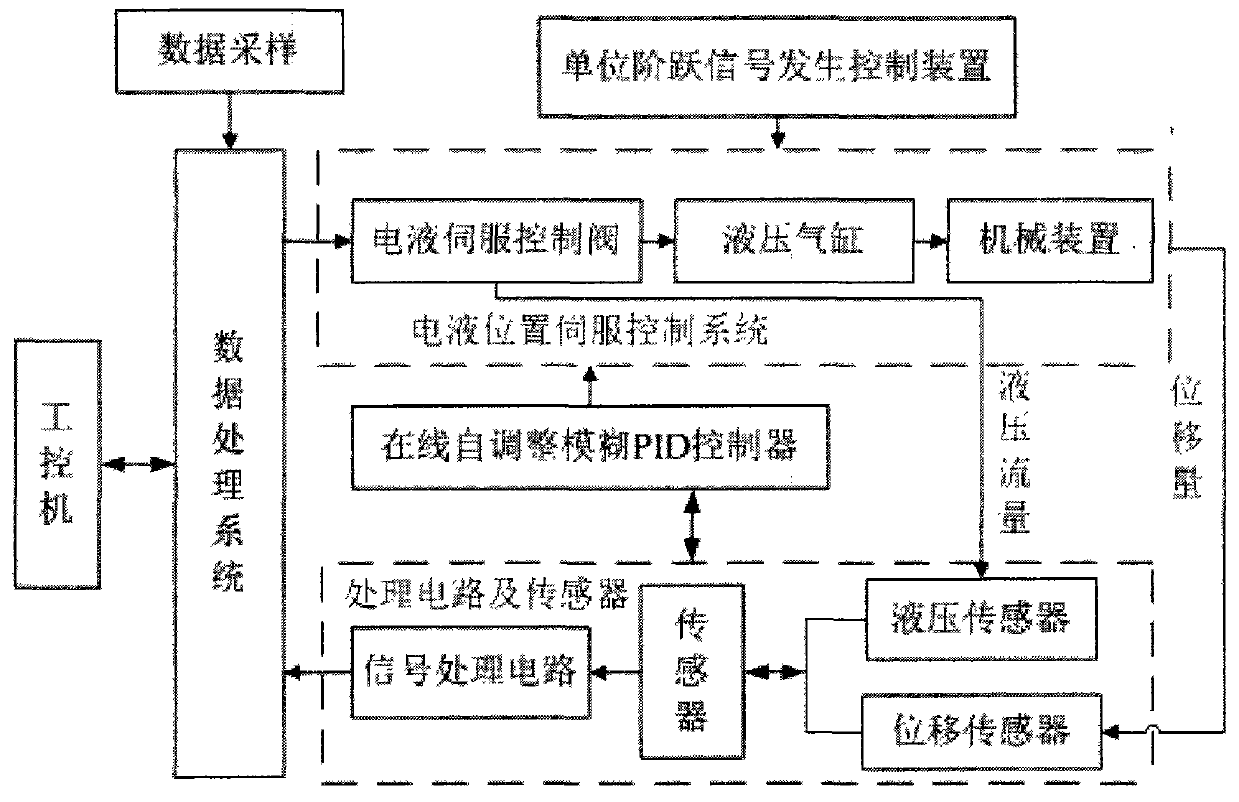

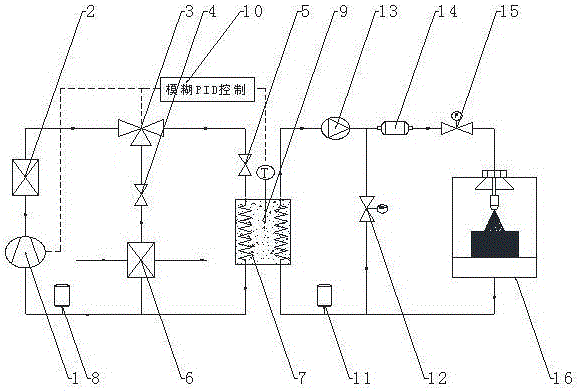

Test system and control method for electro-hydraulic servo online self-adjusting fuzzy PID control

InactiveCN104199283AHigh control precisionReduce vibrationControllers with particular characteristicsData processing systemTest efficiency

The invention discloses a test system for electro-hydraulic servo online self-adjusting fuzzy PID control and an online self-adjusting fuzzy PID control method for an electro-hydraulic servo position system. The test system for the electro-hydraulic servo online self-adjusting fuzzy PID control comprises an industrial personal computer, a data processing system, an electro-hydraulic servo control system, an online self-adjusting fuzzy PID controller, a processing circuit and a sensor. Different sensor signals in the sensor pass through the processing circuit, digital signals are gathered, and the online self-adjusting fuzzy PID control is performed through an electro-hydraulic servo system to realize the test control for the electro-hydraulic servo system. The test system for the electro-hydraulic servo online self-adjusting fuzzy PID control is featured with high test efficiency, good stability, strong practicability and the like, realizes the online real-time regulation for PID parameters and has strong identification performance and robustness for the online system parameter self-adjusting, and accordingly the system test precision and stability are improved, and the economical benefit and social benefit are good.

Owner:张万军

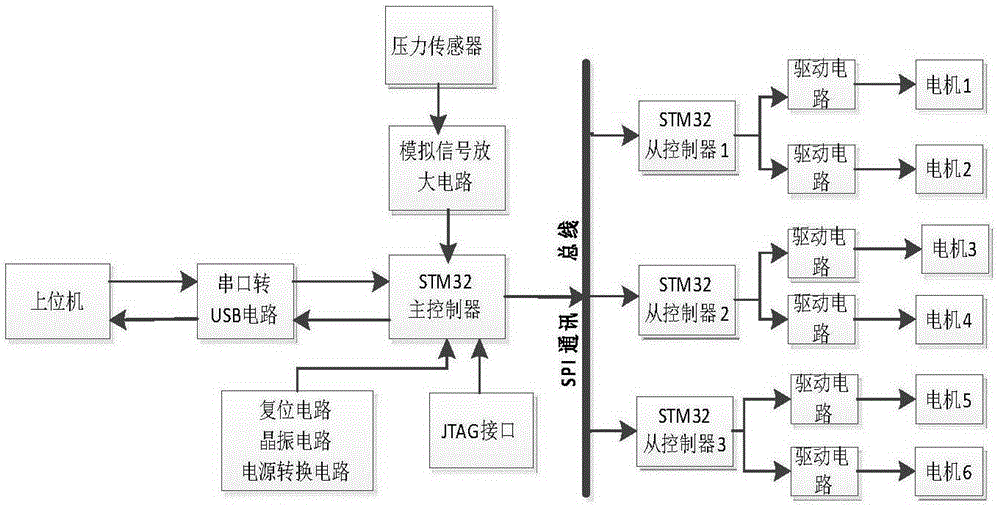

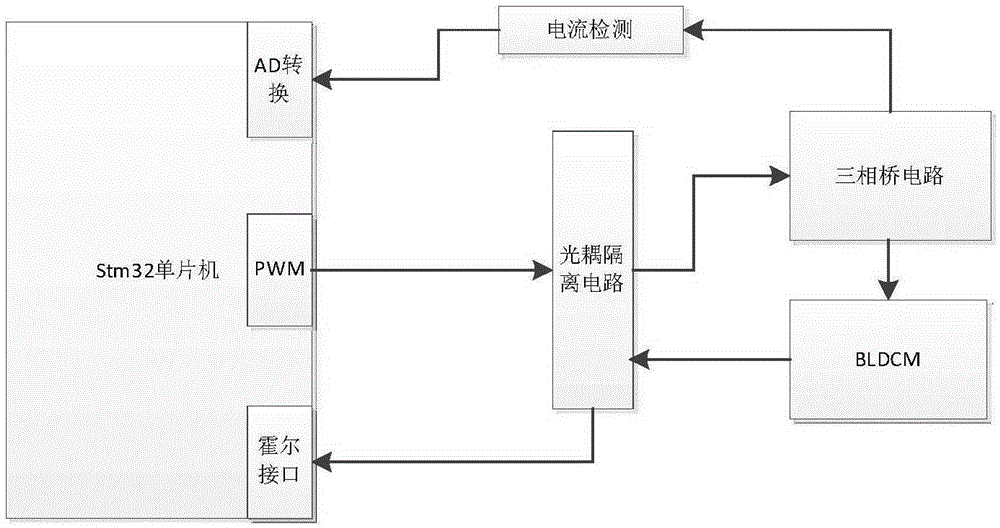

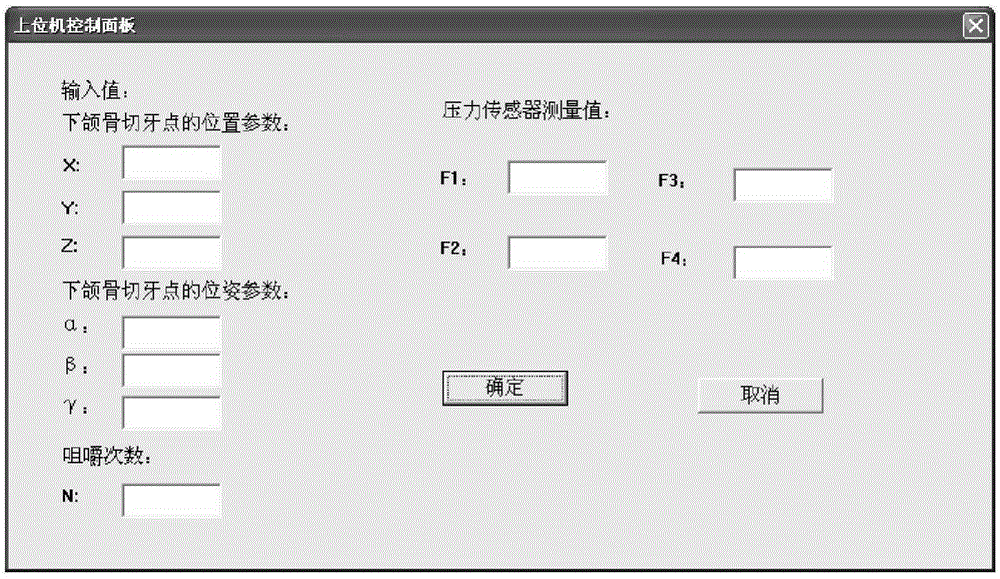

Six-degree-of-freedom chewing robot control system

InactiveCN105204394ASmall sizeIncrease in sizeProgramme controlComputer controlFuzzy pid controlControl system

The invention provides a six-degree-of-freedom chewing robot control system, and aims at solving problems that conventional point-to-point cubic polynomial interpolation is high in the required torque and relatively large in the required equipment size. Each chewing robot has problems of individual difference and symmetry of six driving rods due to the factor of machining accuracy of the robot so that consistent PID control parameters are difficult to obtain. The following scheme is adopted: step one: the movement tracks of each branch rod of the chewing robot are planned, telescoping of each driving rod is solved through the position and the posture of incisor points, and the expected position and speed of each driving rod are solved through a path passing point cubic polynomial interpolation method; and step two: the chewing process of the robot is controlled according to the movement tracks of each branch rod, and the chewing process includes three phases of opening, closing and occlusion; and fuzzy control is used in the opening and closing phases, and fuzzy PID control is used in the occlusion phase.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

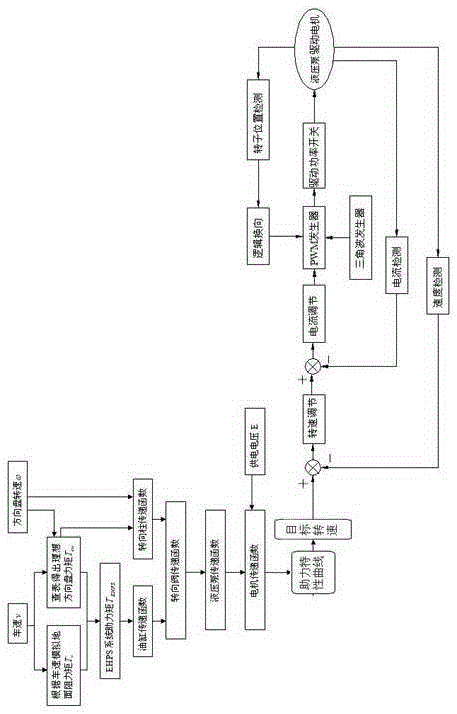

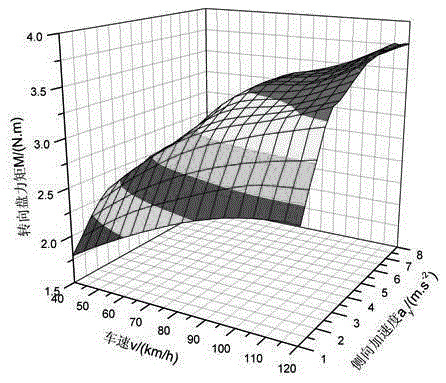

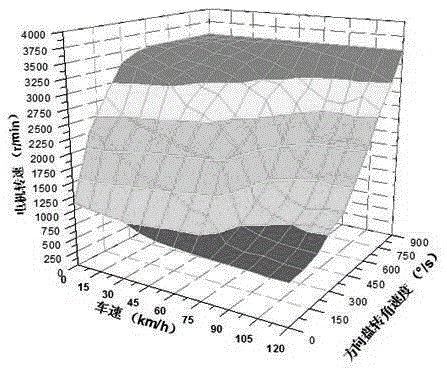

Automobile electric hydraulic power steering system control method

InactiveCN105253192ASatisfy handling stabilitySatisfy the lightness of steering manipulationFluid steeringClosed loopDrive motor

The invention discloses an automobile electric hydraulic power steering system control method. A controller collects a vehicle speed signal and a steering wheel angle speed signal, and a motor target speed value is determined by an assistance characteristic curve determined by vehicle parameters and EHPS system parameters according to a steering wheel torque preferred by a driver and a variation curve of lateral acceleration and travel speed. By virtue of a double closed loop control system of outer ring rotational speed control and inner ring current control, the revolving speed of an oil pump-driven motor is subjected to self-adaptive fuzzy PID control, the target speed of an oil pump-driving motor is controlled, and the output flow of a hydraulic oil pump is indirectly controlled, so the relaxation and convenience of directional steering and steering hand feeling are satisfied, the purpose of energy consumption reduction is also achieved, and the manipulation and safety of automobile driving are effectively improved.

Owner:YANCHENG YANHAI TRACTOR MFG

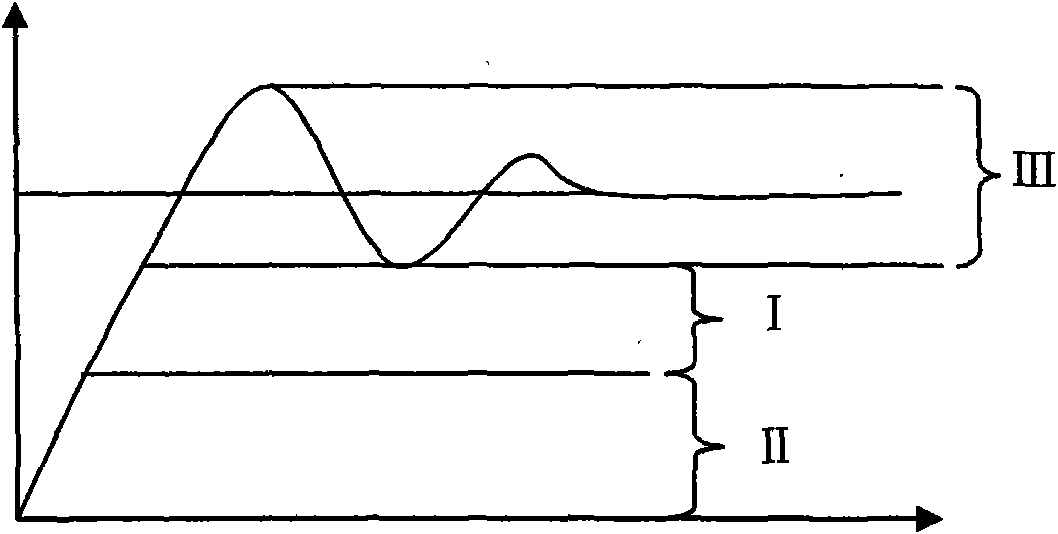

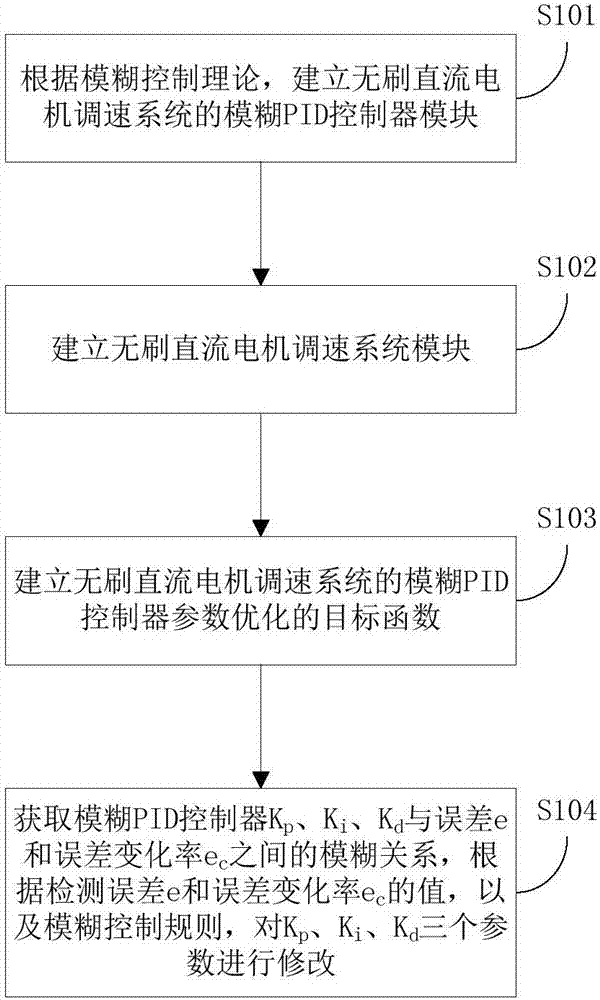

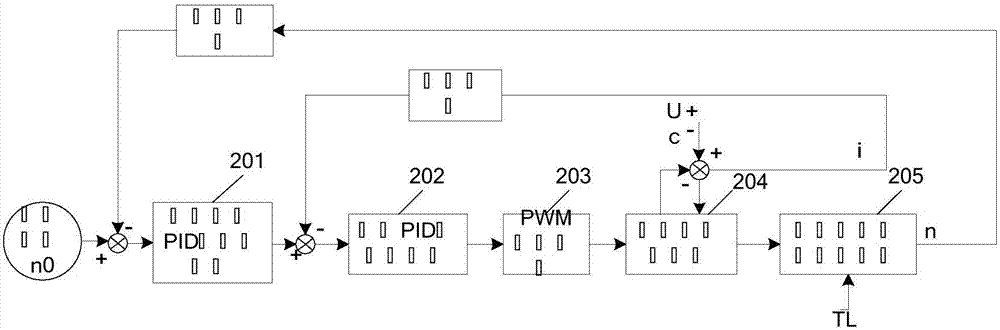

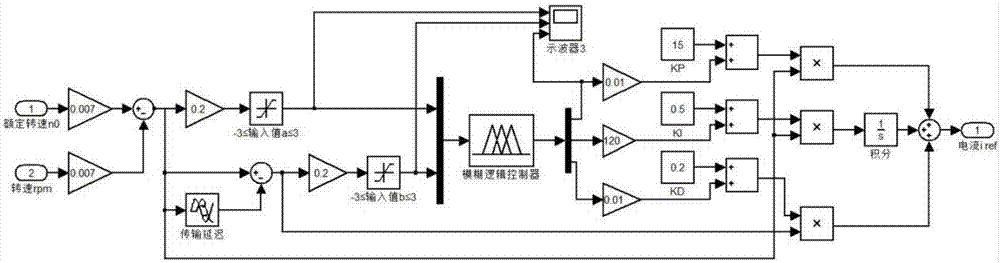

Brushless DC motor fuzzy PID control speed regulation system and method

InactiveCN107508506AImprove anti-interference abilityImprove robustnessSingle motor speed/torque controlFuzzy pid controlFuzzy pid

The invention provides a brushless DC motor fuzzy PID control speed regulation system and method. The method comprises steps of according to the fuzzy control theory, establishing a fuzzy PID controller module of a brushless DC motor speed regulation system; establishing a brushless DC motor speed regulation system module; establishing the objective function of fuzzy PID controller parameter optimization of the brushless DC motor speed regulation system; and obtaining the fuzzy relation between the fuzzy PID controller Kp, Ki, Kd and the error e and the error rate of change ec, and according to the values of the error e and the error rate of change ec, and fuzzy control rules, modifying the three parameters Kp, Ki, Kd. The invention also correspondingly provides a fuzzy control device. The method of the invention adopts the fuzzy PID control for the speed regulation in the PID control system, and has the advantages of good dynamic performance, fast rising speed, small overshoot and good robustness.

Owner:HARBIN UNIV OF SCI & TECH

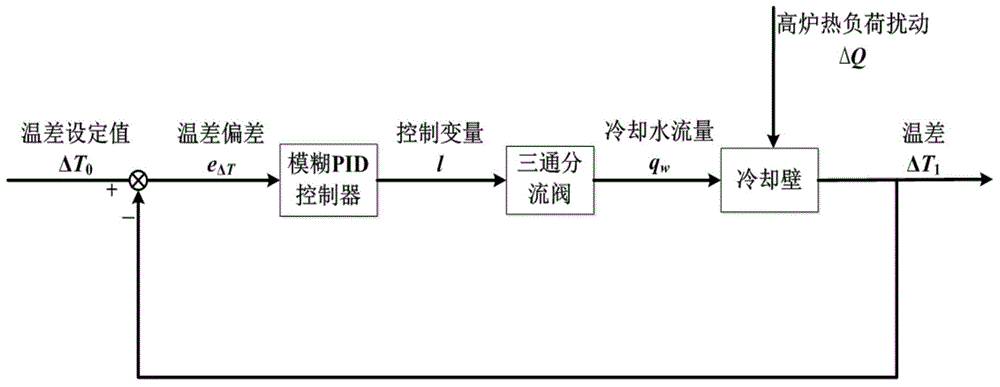

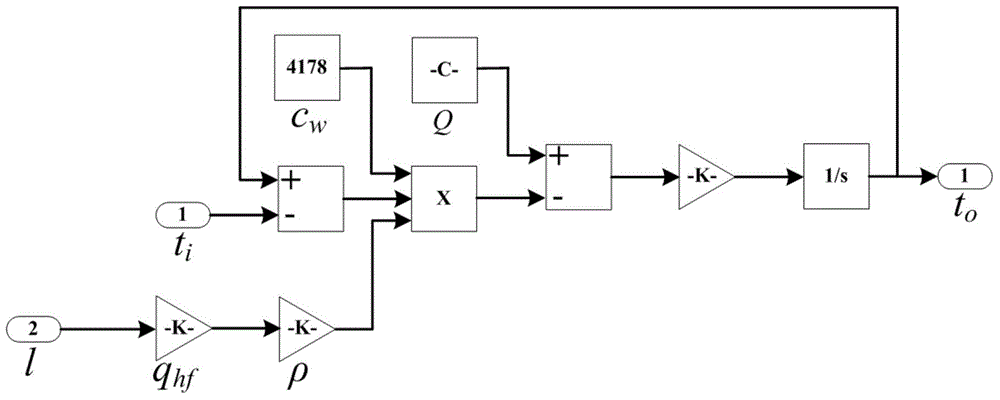

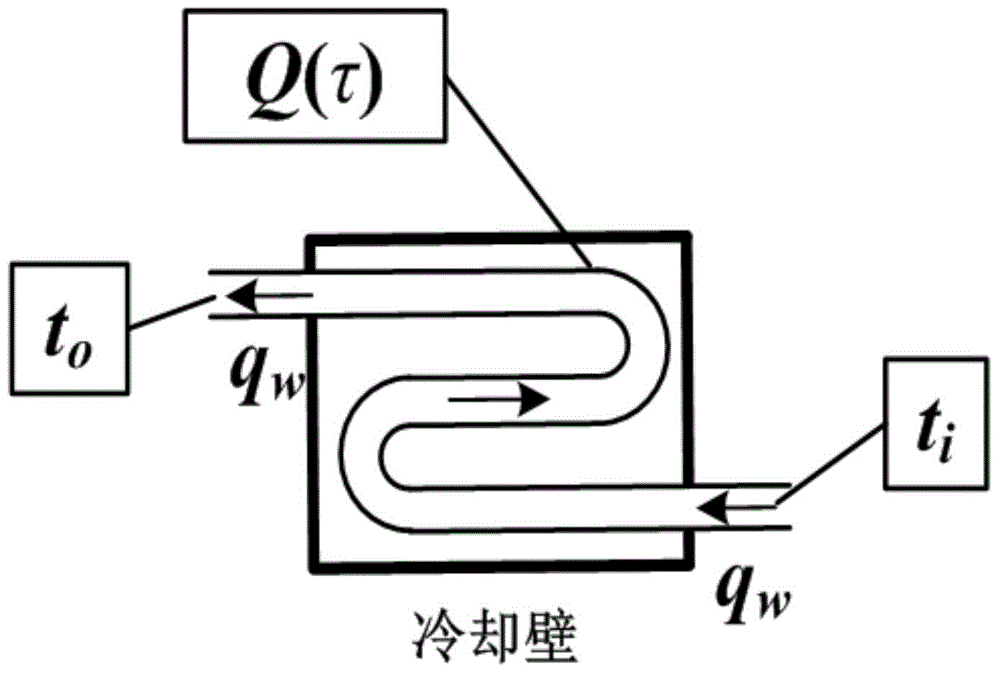

Furnace cooling intensity control method based on vague PID control

ActiveCN104898433ARealize automatic controlReduce volatilityCooling devicesAdaptive controlClosed loopSoft water

The present invention discloses a furnace cooling intensity control method based on vague PID control, and belongs to the technical field of furnace cooling control. The control method is based on the heat transfer theory and the engineering thermodynamics. A novel furnace water supply cooling method is provided; a diverging three-way valve serves as an executing mechanism; advantages of conventional PID control and vague control are combined; according to nonlinearity, obsoleteness and possible uncertain factors of a furnace cooling intensity control method and operating characteristics of a furnace closed-loop soft water circulating cooling system, PID parameter self-tuning inference rules are established, and opening of the diverging three-way valve is adjusted, thereby controlling cooling wall cooling intensity; in comparison with those in the prior art, real-time control of the cooling intensity is realized, control accuracy and stability are also raised, and manpower consumption is reduced.

Owner:马鞍山市安工大智能装备技术研究院有限公司

Airborne evaporation cycle refrigeration comprehensive heat management system and method and application thereof

InactiveCN106642855ADomestic cooling apparatusRefrigeration safety arrangementEvaporationEngineering

The invention relates to an airborne evaporation cycle refrigeration comprehensive heat management system and a method and application thereof and belongs to the airborne equipment cooling field. The airborne evaporation cycle refrigeration comprehensive heat management system comprises a high heat flow heating element spraying cooling cycle sub-system and an evaporation refrigeration cycle sub-system; and the airborne evaporation cycle refrigeration comprehensive heat management system further comprises a phase change heat exchanger (7) connected with the high heat flow heating element spraying cooling cycle sub-system and the evaporation refrigeration cycle sub-system, and a fuzzy PID control system (10). According to the system, by means of the fuzzy PID control system, the influences of heat inertia are considered, and the cold energy is fully utilized to perform cold storage for a phase change material; and by means of frequency conversion of a compressor, the purpose that one evaporation cycle refrigeration system is used to provide the cold energy for a refrigeration space and an airborne high heat flow heating element at the same is achieved, the system is integrated, the cold energy of the evaporation cycle refrigeration system is comprehensively managed, the heat load of the refrigeration space and the heat load of the airborne high heat flow element are reasonably matched, the weight of the system is greatly reduced, and the airborne equipment requirement is met.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

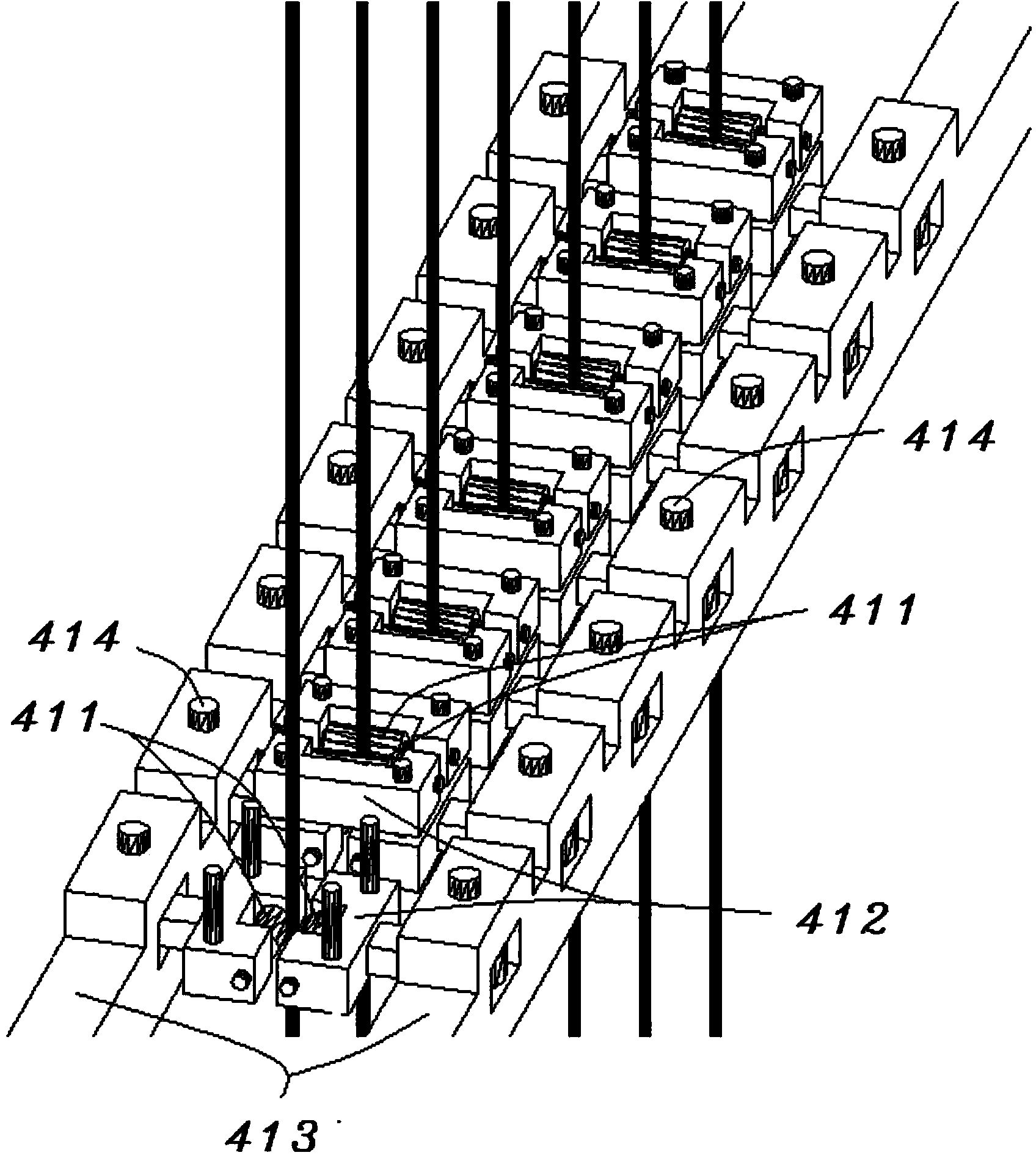

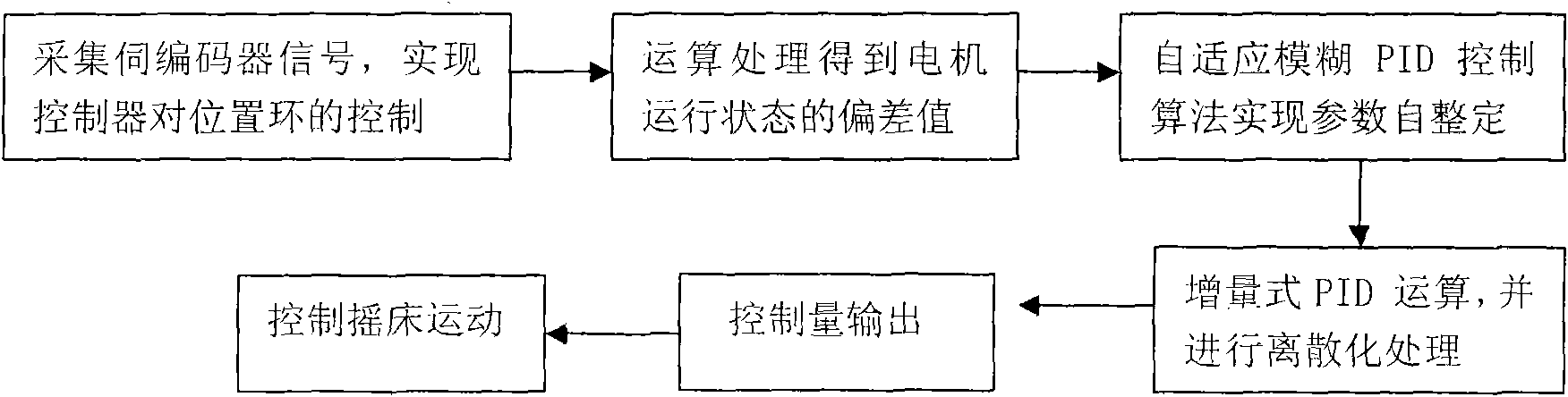

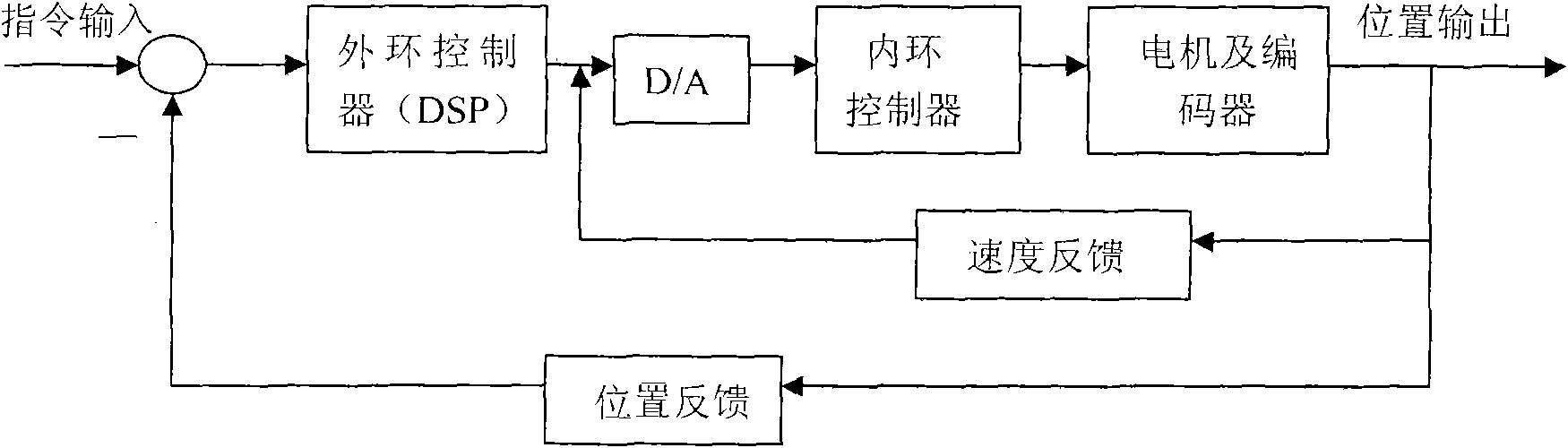

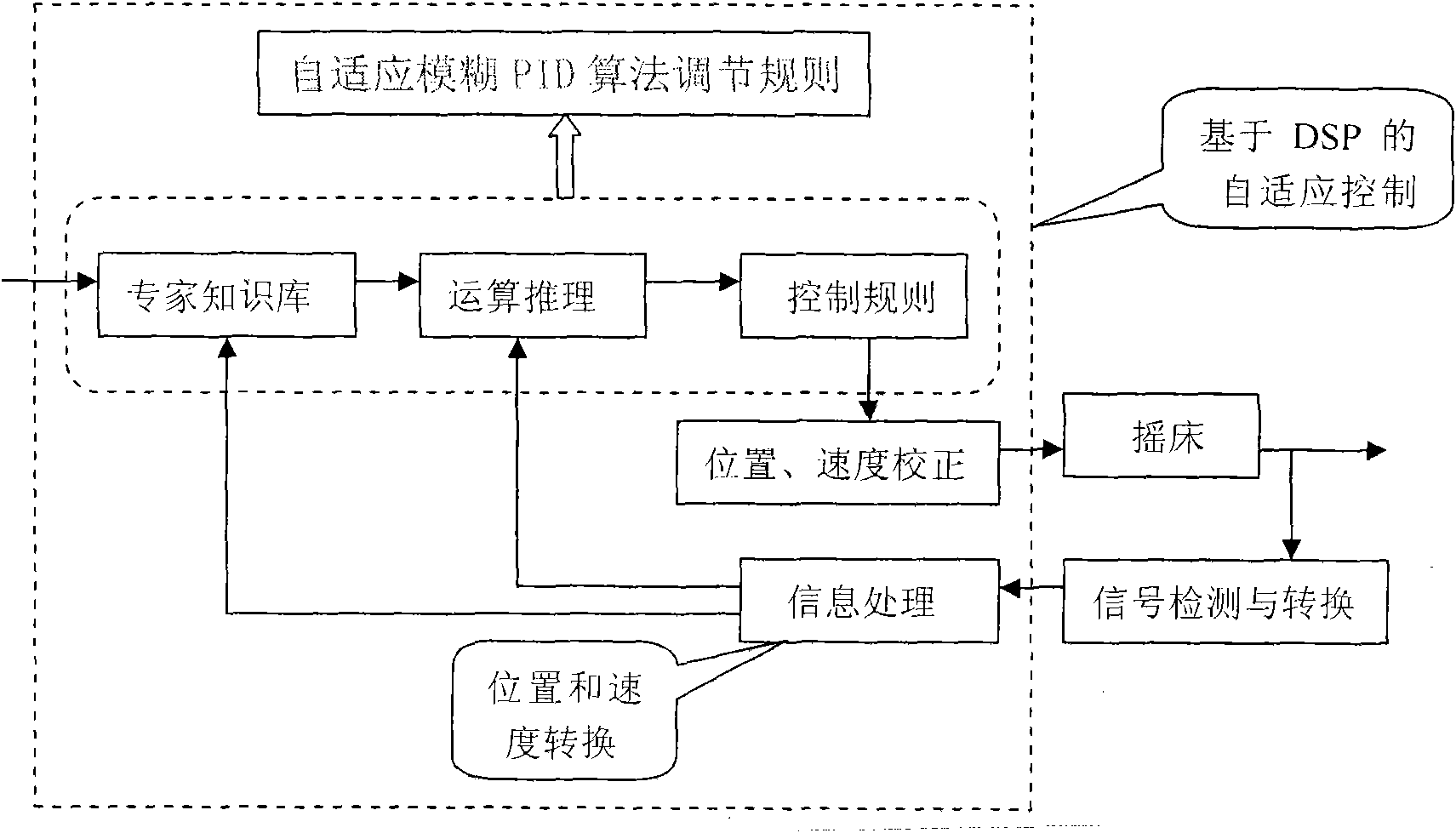

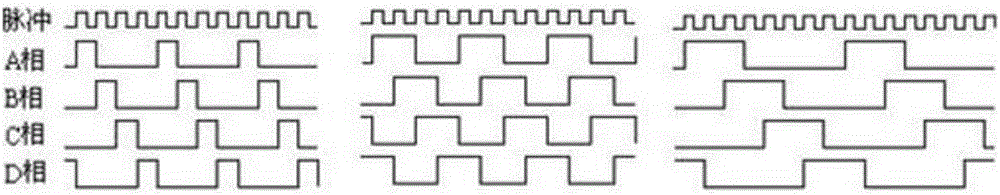

Method for controlling operations of shaker of computerized flat knitting machine

InactiveCN101655704AAutomatically correct running errorsRun accuratelyNumerical controlFuzzy pid controlPid control algorithm

The invention belongs to the technical field of computerized flat knitting machines, in particular to a method for controlling operations of a shaker of a computerized flat knitting machine. The method comprises the following steps: collecting real-time operation information of a servo motor; inputting the obtained operation information of the servo motor into an information processor to calculate; calculating an offset value in the step (2) by adopting an adaptive fuzzy PID control algorithm so as to obtain current revised data and then inputting the revised data into a program controller; calculating current Kp, Ki and Kd values by utilizing a fuzzy self-tuning rule and carrying out discretization processing through an incremental PID calculation; and outputting control signals to the servo motor by the program controller according to a control program to realize the automatic operation error correction and the precise operation control of the shaker. The invention can avoid needle transferring and connecting deviations and ensure that the computerized flat knitting machine works in an optimal state all the time, thereby solving the problem of unstable precision of the shaker inan operation process of the computerized flat knitting machine.

Owner:HANGZHOU COMFIRMWARE TECH CO LTD

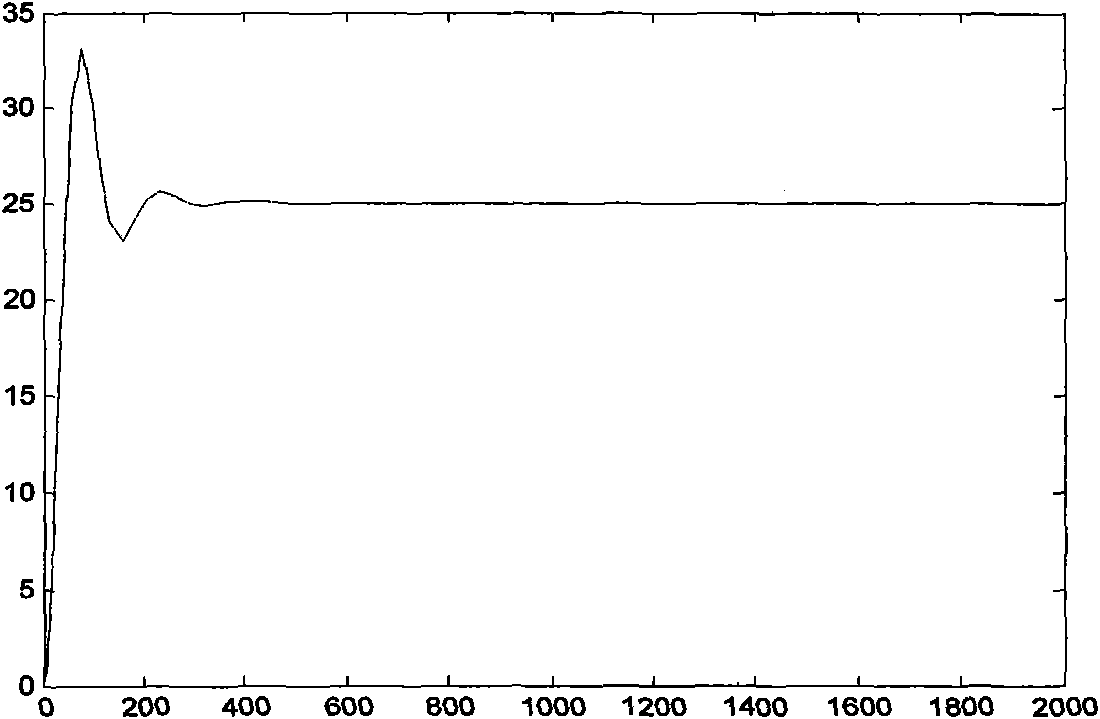

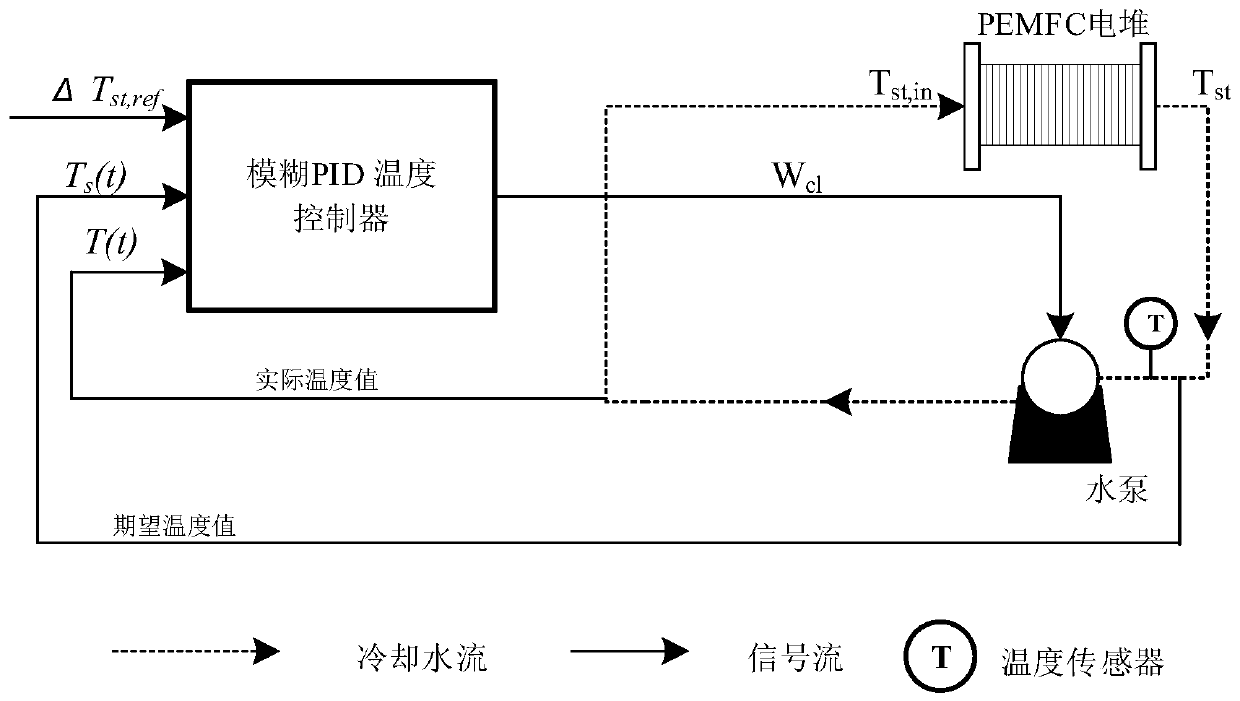

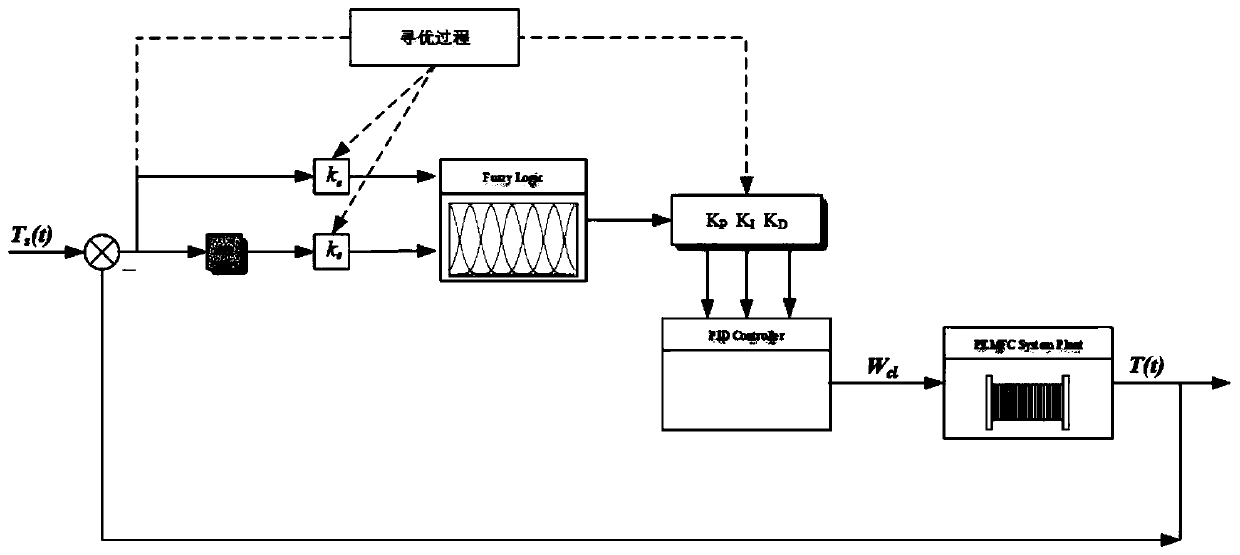

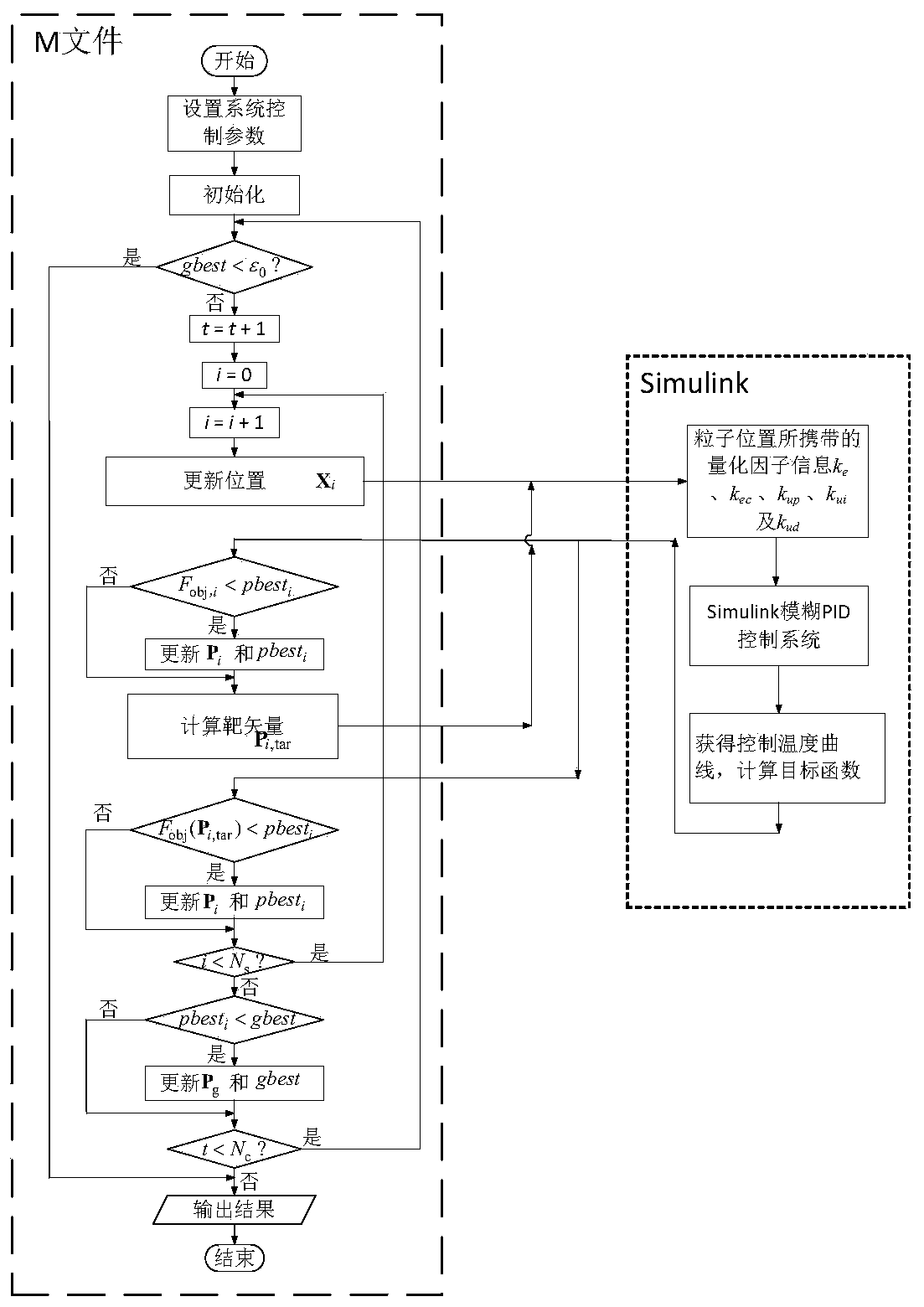

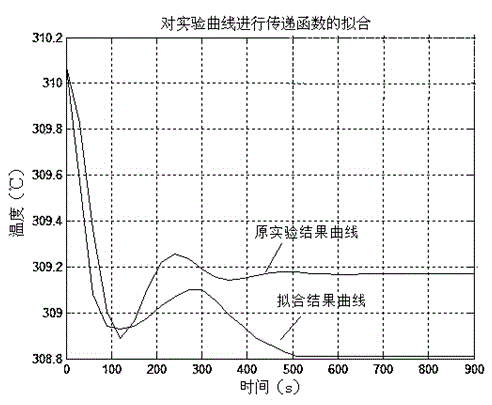

Improved particle swarm optimization fuzzy PID fuel cell temperature control method

ActiveCN111129548AMake up for dependencyMake up for shortcomings in engineering experienceFuel cell controlTemperature controlFuel cells

The invention discloses an improved particle swarm optimization fuzzy PID fuel cell temperature control method. The method comprises the following steps: establishing a fuel cell dynamic model based on an MATLAB / Simulink simulation platform, and obtaining output power and corresponding temperature of a fuel cell through the fuel cell dynamic model; designing a fuzzy PID temperature controller forthe fuel cell dynamic model, and controlling an error and an error change rate of an expected temperature value and an actual temperature value by using the controller to obtain a parameter adjustmentamount of the fuzzy PID temperature controller; optimizing a quantization factor and a scaling factor in the fuzzy PID temperature controller by adopting an improved particle swarm algorithm; and assigning the optimized quantization factor and scaling factor to a fuzzy PID temperature controller so as to control the temperature of the fuel cell in real time. According to the method, improved particle swarm optimization fuzzy PID control is utilized, a control strategy is set according to a control experience rule, the method has the advantages of being high in robustness, high in response speed and the like, and it is ensured that the PEMFC stack is maintained at a fixed temperature.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

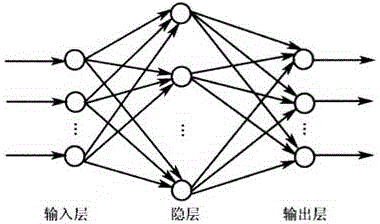

Method for controlling temperatures of reactors of pressurized water reactor nuclear power stations by aid of RBF (radial basis function) neural networks

ActiveCN104102782AIncreased level of controlConvenient researchBiological neural network modelsSpecial data processing applicationsPressurized water reactorMathematical model

The invention relates to a method for controlling temperatures of reactors of pressurized water reactor nuclear power stations by the aid of RBF (radial basis function) neural networks. The method is used for controlling the temperatures of the reactors of 900MW pressurized water reactor nuclear station units by the aid of the RBF neural networks, and includes testing characteristics of reactor temperature control systems on pressurized water reactor nuclear power unit simulation test platforms; fitting analytic and transfer functions of the systems according to data acquired from tests, solving the reactor temperature transfer functions and building high-precision mathematical models; designing traditional PID (proportion, integration and differentiation) controllers and controlling the temperatures of the reactors. The method has the advantages that the RBF neural networks are combined with the traditional PID controllers on the basis of the traditional PID controllers, so that the temperatures of the reactors can be compositely controlled, and obvious control effects can be realized as compared with control effects of the traditional PID control and fuzzy PID control; the method has high practical application value in the aspect of reactor temperature control, research and application of advanced intelligent control on nuclear power units can be promoted, and accordingly the control level on the units can be improved.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

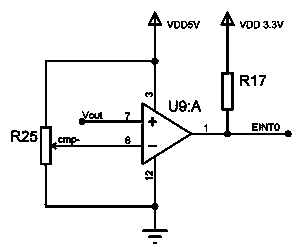

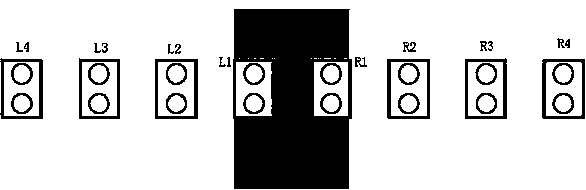

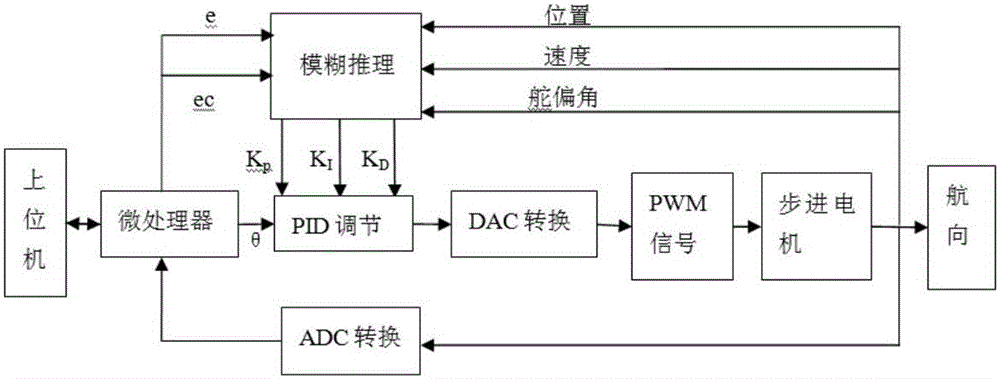

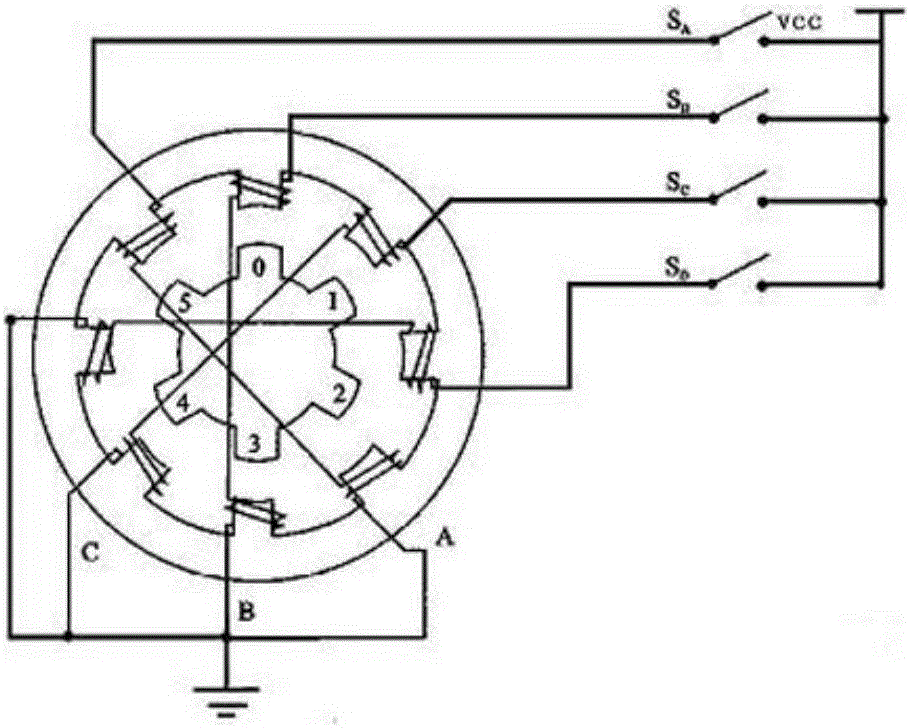

Fuzzy PID algorithm based ship course controller

InactiveCN105955269AEasy to controlReduce output errorPosition/course control in two dimensionsFuzzy pid controlPid control algorithm

The invention discloses a ship course controller based on a fuzzy PID algorithm. The controller includes: an input unit for obtaining an ideal rudder angle deflection according to the rudder deflection angle required by the ship and the output of a stepping motor drive unit; The digital conversion unit is used for digital-to-analog conversion and analog-to-digital conversion; the fuzzy parameter correction unit is used to perform fuzzy parameter correction according to the output of the stepper motor drive unit and the ideal rudder angle deflection; the PID adjustment unit is used to correct the fuzzy parameter according to the fuzzy parameter correction unit and The output of the stepper motor drive unit is adjusted by PID; the PWM signal output unit is used to output the PWM waveform for controlling the work of the stepper motor according to the output of the PID adjustment unit; the stepper motor drive unit is used to drive the stepper motor to control the course of the ship , and feed back the position, speed and rudder angle of the ship in real time. The invention aims at adopting the fuzzy PID control algorithm to realize the self-adaptive control of the ship steering gear.

Owner:WUHAN UNIV OF TECH

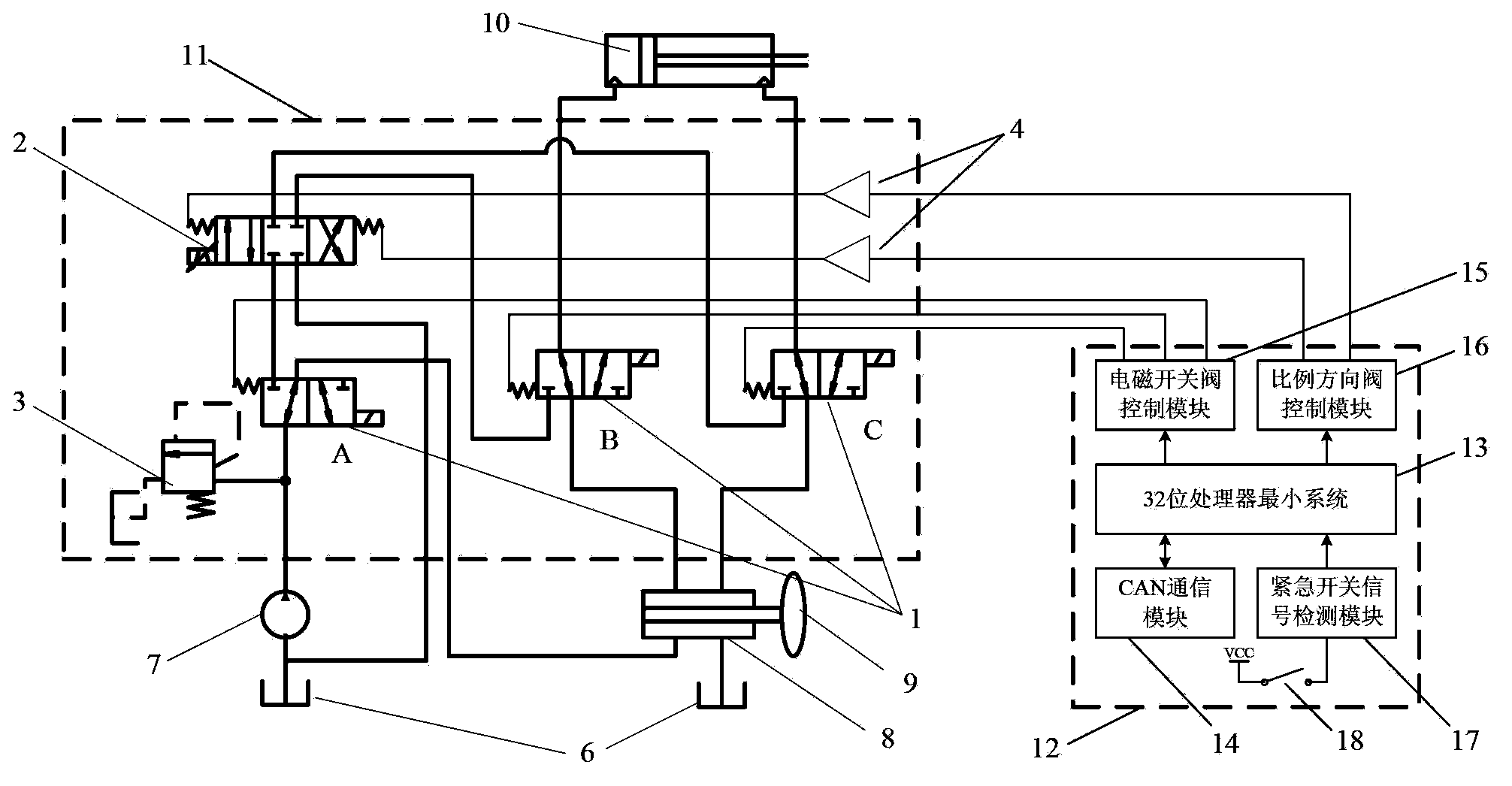

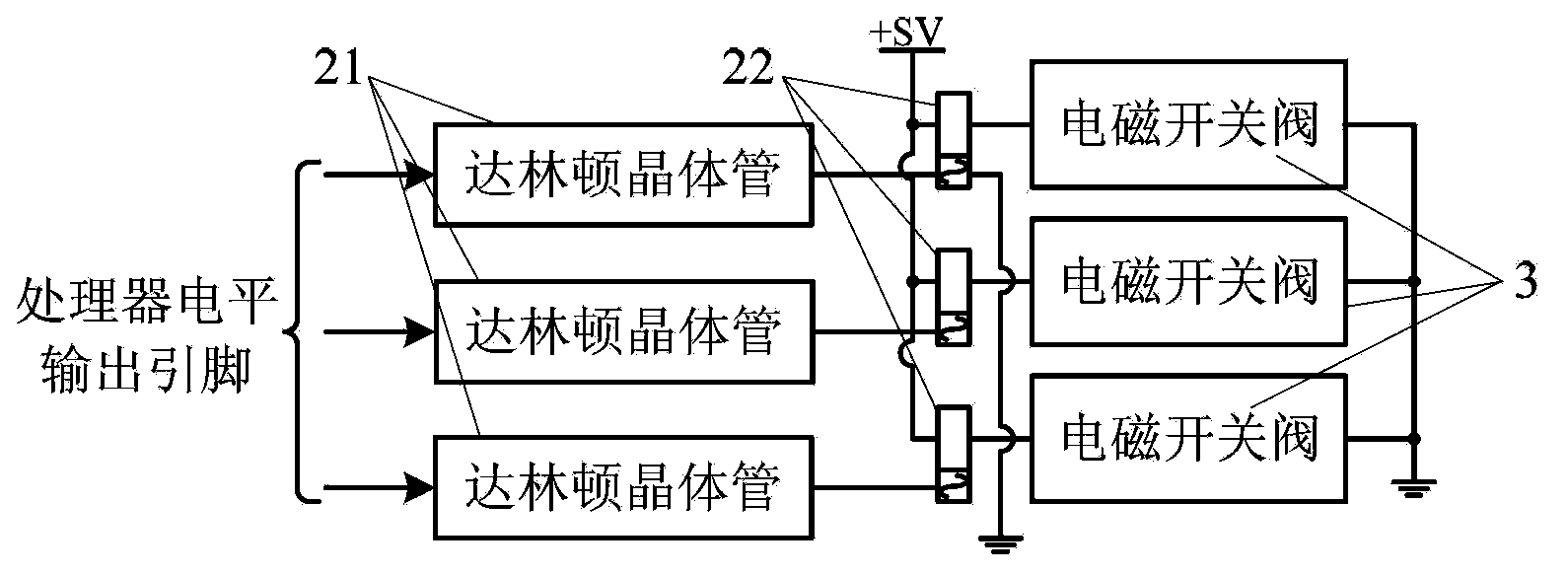

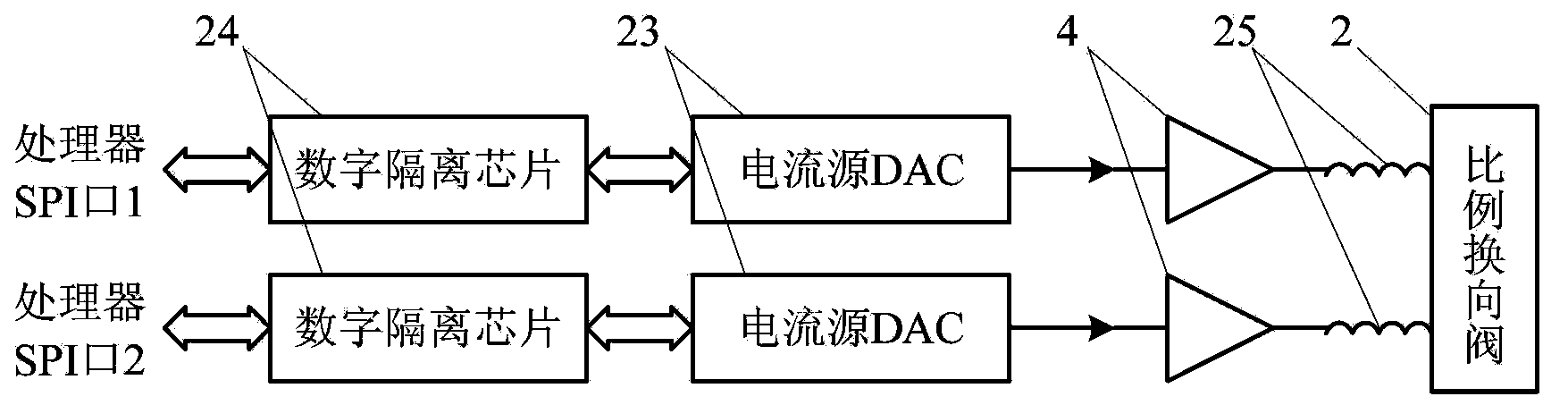

Hydraulic agricultural machine automatic steering control device and control method

ActiveCN103895698ASimple accessFacilitate failure analysisSteering linkagesFluid steeringAutomatic Generation ControlAutomatic steering

The invention relates to a hydraulic agricultural machine automatic steering control device which is characterized in that a controller and a hydraulic drive module which are connected are included. A control method comprises the following steps that the controller receives a start command of an upper computer to control an electromagnetic switch valve in the hydraulic drive module to be closed to enable an agricultural machine to switch to an automatic steering mode; the controller carries out self-adaptation fuzzy PID control according to an angle set value in a steering angle set command, a steering angle measuring angle from a sensor and an agricultural machine speed measuring value; obtained controlled quantity of the flow direction and flow is output to a proportional reversing valve of the hydraulic drive module to achieve automatic steering control. According to the hydraulic agricultural machine automatic steering control method with the self-adaptation fuzzy PID control method as a core, the problems of dead zones, equilibration and errors caused by asymmetric characters of a vehicle hydraulic steering system can be well solved, and automatic steering control precision is improved.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Direct current speed control mothed based on fuzzy PID control

InactiveCN106452248ASuppress nonlinearityMonitor changesElectronic commutation motor controlVector control systemsSelf-tuningFuzzy pid control

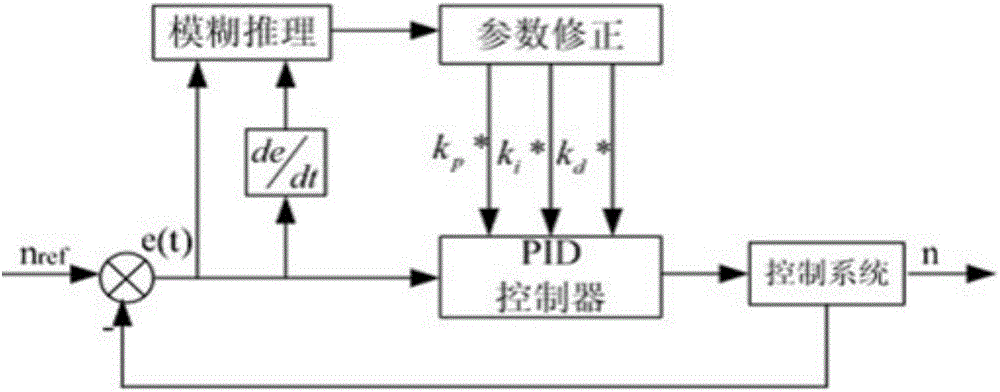

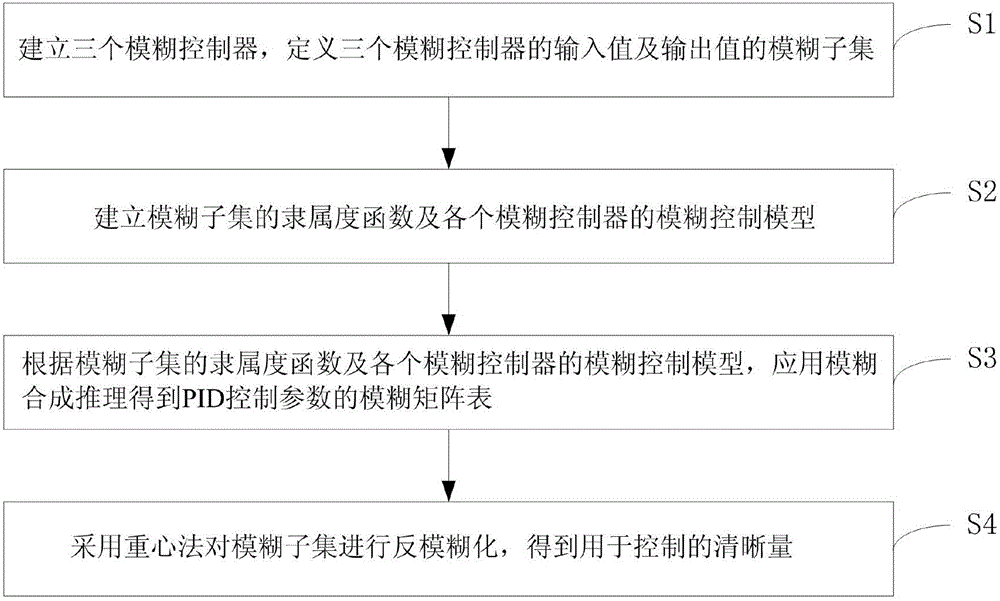

The invention provides a direct current speed control mothed based on fuzzy PID control, comprises the following steps: first, an actual rotation rate of the motor n and a rotation rate deviation e of a preset speed nref and a change rate of deviation ec are figured out, and then are fuzzified; after fuzzy, e and ec are controlled by fuzzy control rules reasoning, kp, ki and kd are acquired through fuzzification resolution. In the control process, a conventional PID controller parameter is modified online real-timely and finally rotation rate of the brushless direct current motor is adjusted by the traditional PID controller. The fuzzy control of the invention does not need to rely on the precise mathematical model of a controlled object so the invention is more stable in the control, and the non-linearity of the controlled object can be effectively suppressed; In the control process, the changes and real-time feedback of the parameter can be continuously monitored by the fuzzy PID self-tuning to idealize the control effect.

Owner:HUNAN UNIV OF TECH

Electric power steering system and control method

ActiveCN104828132AHigh precisionImprove stabilitySteering linkagesAutomatic steering controlElectric power steeringElectricity

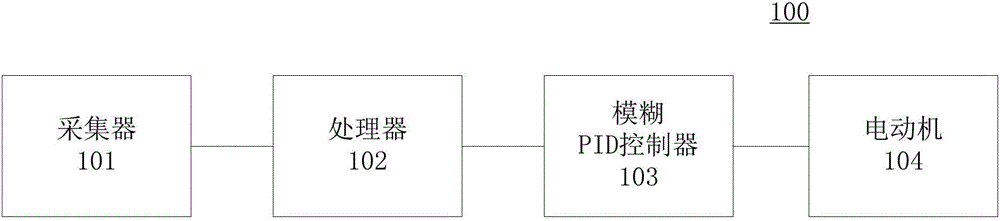

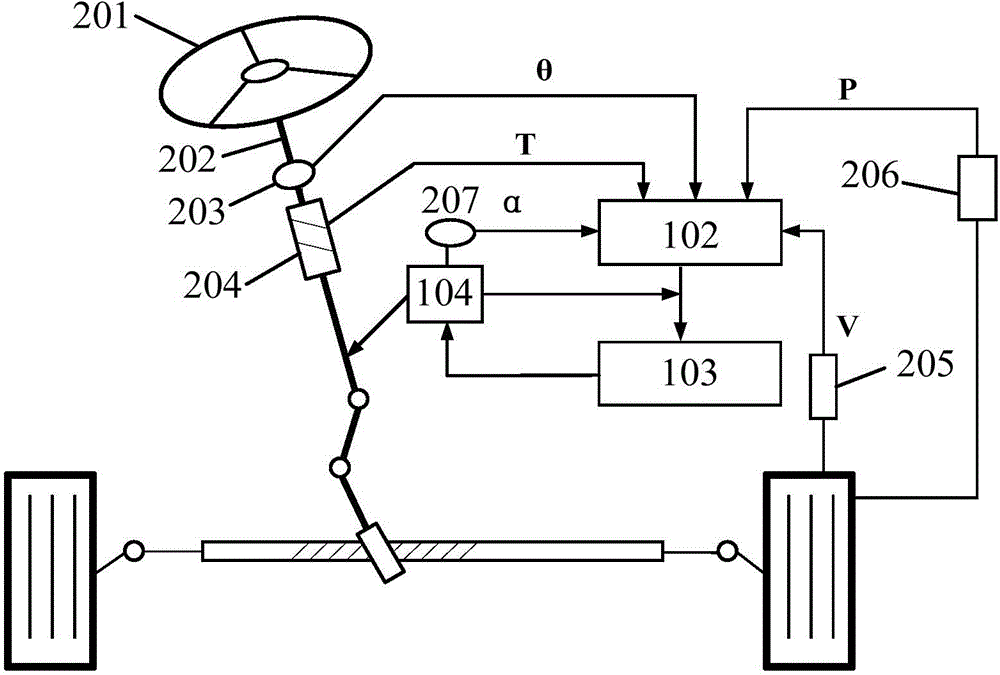

The invention discloses an electric power steering system and a control method. The electric power steering system comprises a collector, a processor, a fuzzy PID controller and a motor, wherein the collector is used for collecting manual torque applied to a steering wheel and the current speed of the vehicle; the processor is connected with the collector for receiving the manual torque and the speed, acquiring expected target steering torque applying to the steering mechanism after the motor is power-on according to the manual torque, the speed and the preset steering control strategy, and further acquiring target current needed when the motor outputs the target steering torque; the fuzzy PID controller is connected with the output end of the processor for receiving the target current and the present current of the motor, adopting fuzzy PID control algorithm to adjust the output current of the fuzzy PID controller according to the target current and the present current of the motor until the present current is the same as the target current; and the motor is used for controlling the steering mechanism according to the output current of the fuzzy PID controller. Accuracy and stability of the electric power steering system are enhanced.

Owner:BEIQI FOTON MOTOR CO LTD

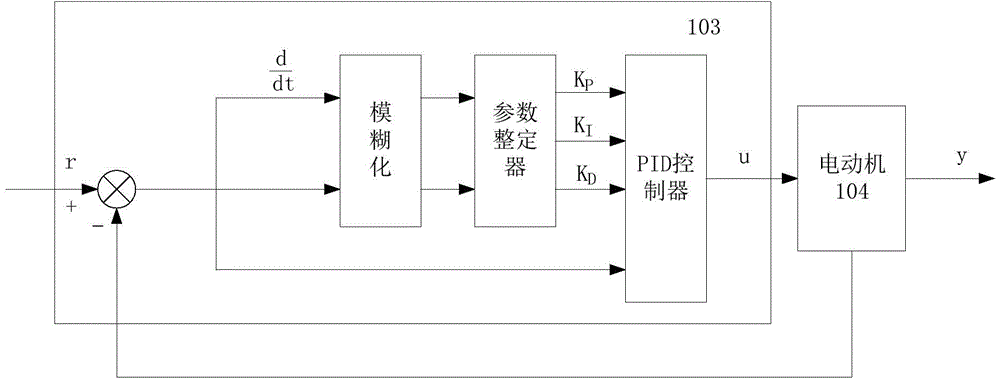

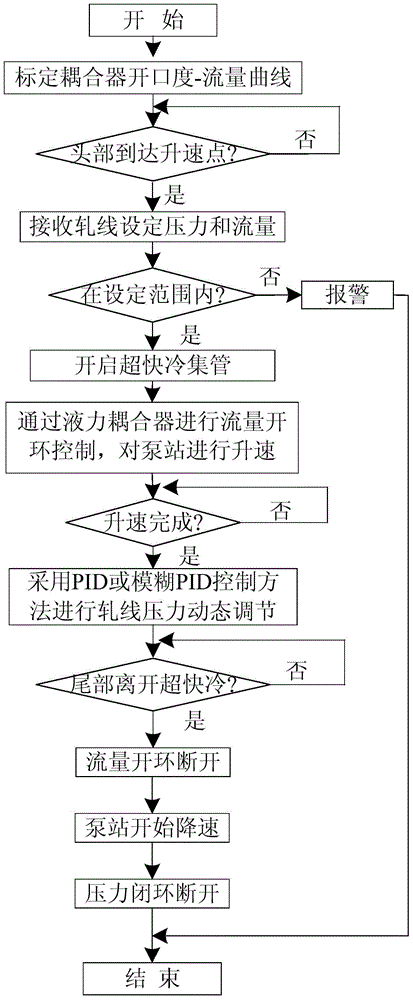

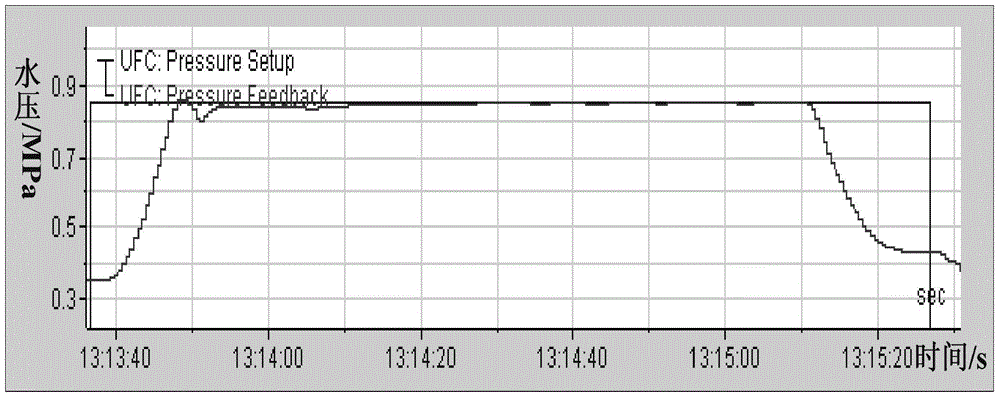

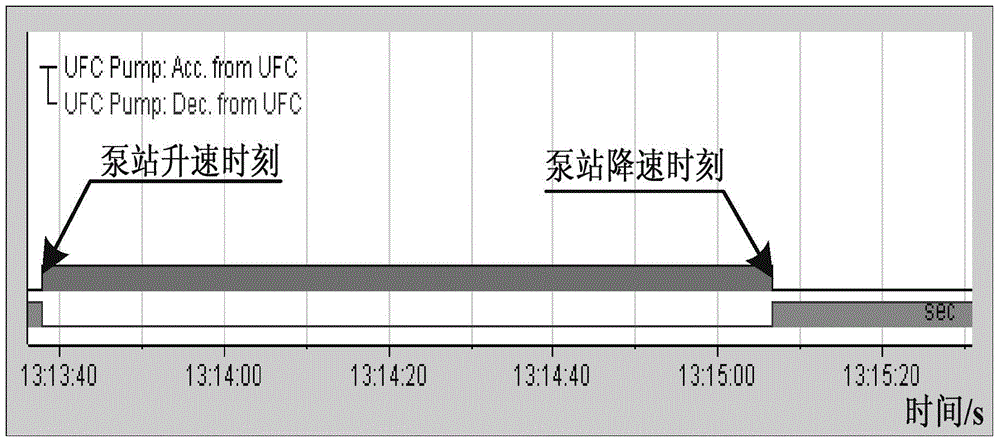

Water supply control method of hot continuous rolling line ultra fast cooling system

ActiveCN103605390ASolve stressFix stability issuesSimultaneous control of multiple variablesLoop controlFuzzy pid control

The invention relates to a water supply control method of a hot continuous rolling line ultra fast cooling system and belongs to the technical field of hot-rolled strip steel rolling. The water supply control method includes the following steps that: step one: the opening degree of a hydraulic coupler, namely, the flow curve of a pump station, is calibrated; step two: whether a strip steel head portion achieves a speed rise point is judged, if the strip steel head portion achieves the speed rise point, a rolling line transmits set pressure and total flow to the pump station, and step three is executed, otherwise, the step two is executed; step three: whether the set pressure and the set total flow which are transmitted to the pump station by the rolling line satisfy a set range is judged, if the set pressure and the set total flow satisfy the set range, an ultra fast cooling header is opened, and flow open-loop control and speed increase are performed on the pump station, and step four is executed, otherwise, alarming is performed; step four: whether the process of the speed increase is completed or not is judged, if the process of the speed increase is completed, a fuzzy PID control method is adopted to perform rolling line pressure dynamic regulation, otherwise, the step four is executed; and step five: whether a strip steel tail portion leaves an ultra fast cooling area is judged, if the strip steel tail portion leaves the ultra fast cooling area, the flow open-loop control is disconnected, the speed of the pump station is decreased to base speed, and a rolling line pressure dynamic regulation closed loop is disconnected, otherwise, the step five is executed.

Owner:NORTHEASTERN UNIV

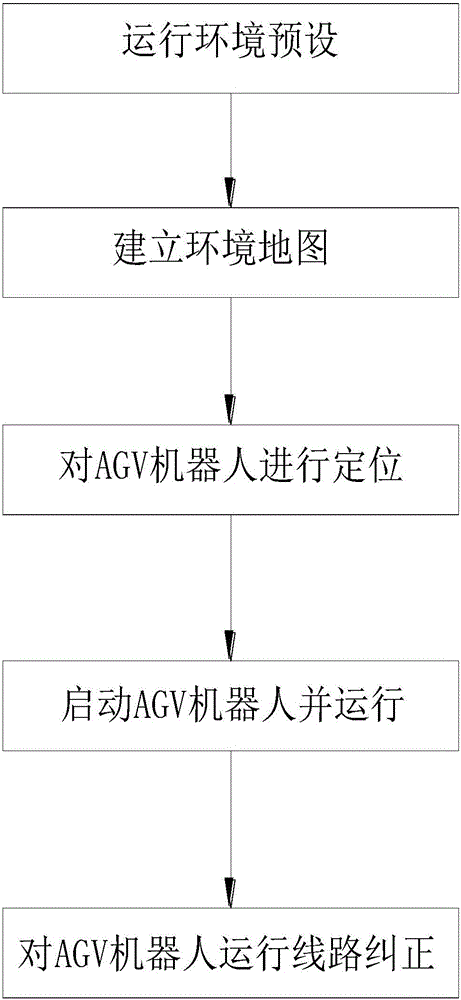

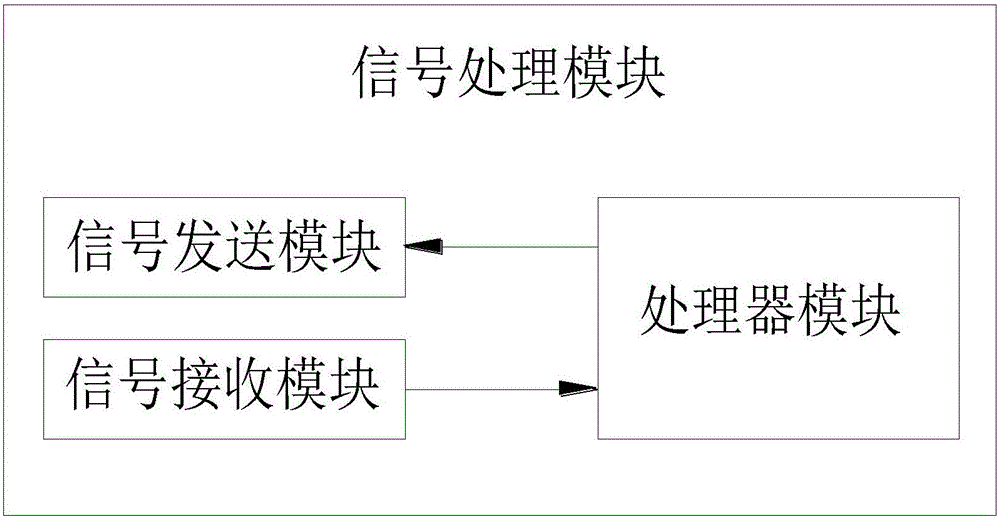

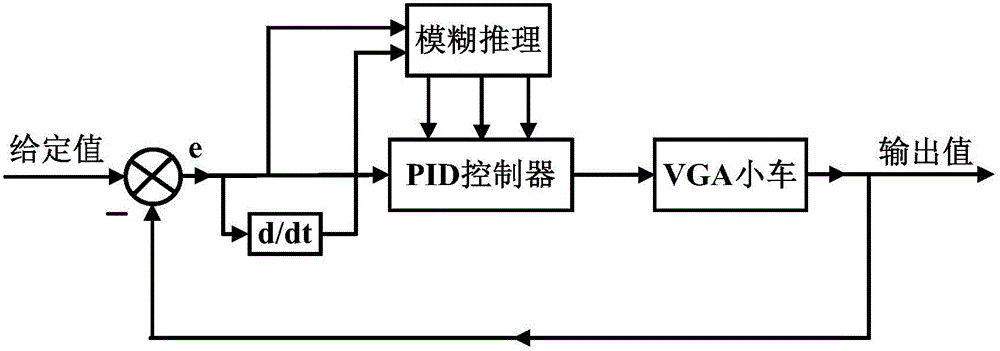

Algorithm for positioning control of automatic guided vehicle (AGV) robot based on fuzzy proportion integration differentiation (PID)

InactiveCN105759825AImprove response speedHigh precisionPosition/course control in two dimensionsVehiclesProportion integration differentiationFuzzy pid control

The invention discloses an algorithm for positioning control of an automatic guided vehicle (AGV) robot based on fuzzy proportion integration differentiation (PID). The algorithm comprises the following steps: a step S1 of operating environment presetting; a step S2 of establishment of an environmental map; a step S3 of AGV robot positioning; a step S4 of AGV robot line operation; and a step S5 of AGV robot operation line correction. The algorithm is more suitable for control over the AGV robot; through a mode of adding the fuzzy PID control, the response speed and control operation accuracy of the AGV robot can be improved, and the AGV robot positioning accuracy is higher.

Owner:刘学良

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com