Patents

Literature

1836 results about "Model predictive control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

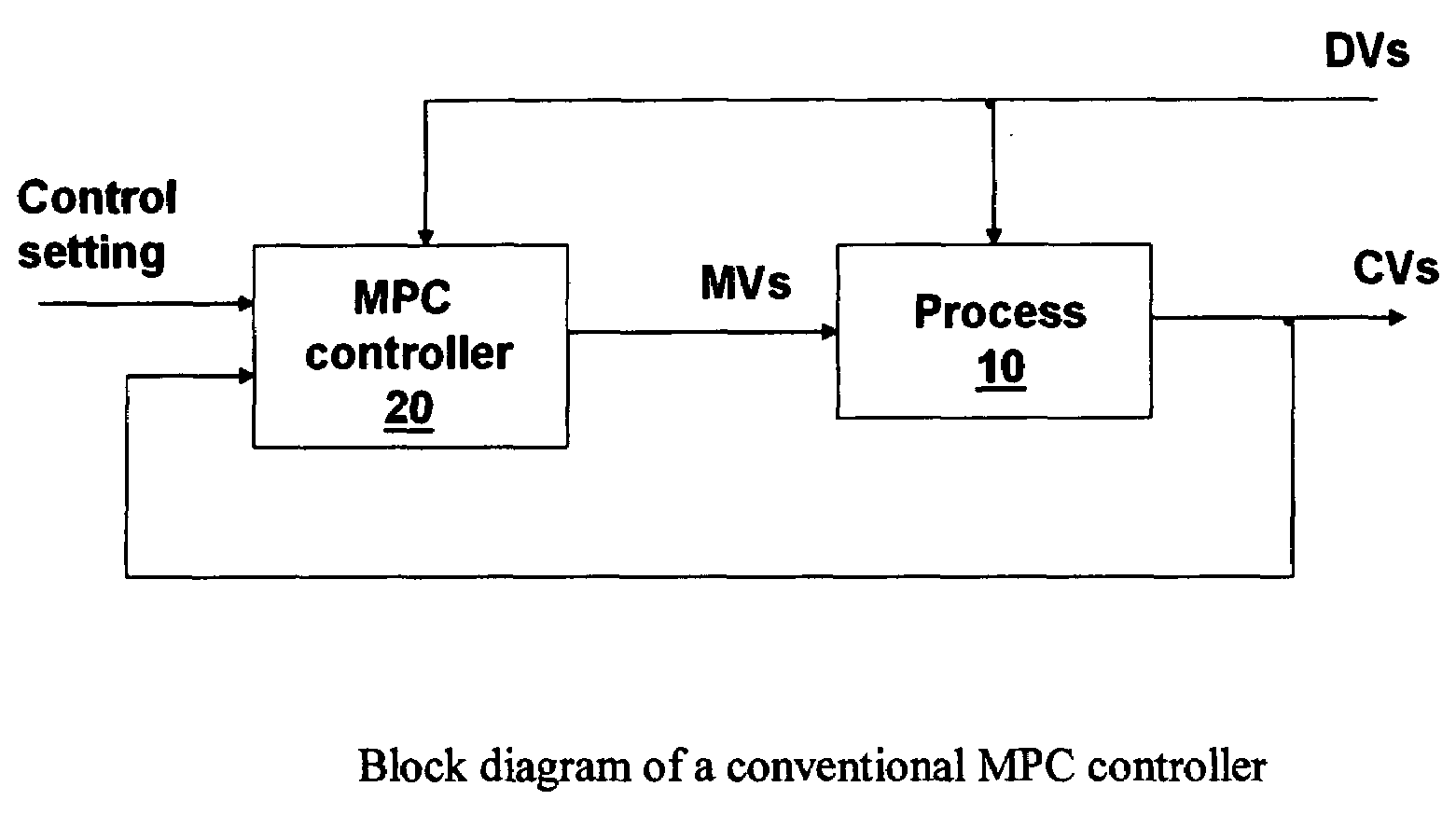

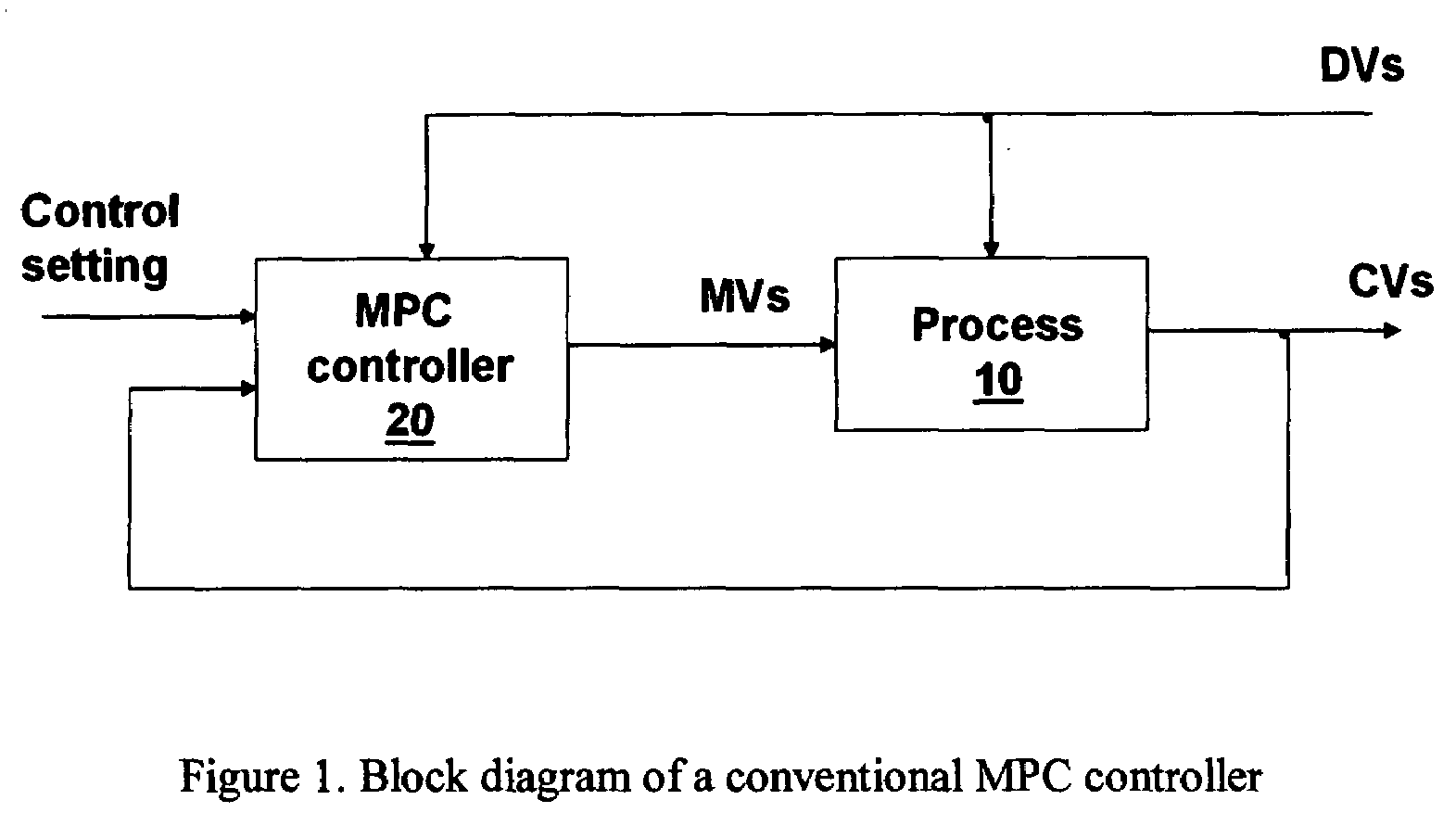

Model predictive control (MPC) is an advanced method of process control that is used to control a process while satisfying a set of constraints. It has been in use in the process industries in chemical plants and oil refineries since the 1980s. In recent years it has also been used in power system balancing models and in power electronics. Model predictive controllers rely on dynamic models of the process, most often linear empirical models obtained by system identification. The main advantage of MPC is the fact that it allows the current timeslot to be optimized, while keeping future timeslots in account. This is achieved by optimizing a finite time-horizon, but only implementing the current timeslot and then optimizing again, repeatedly, thus differing from Linear-Quadratic Regulator (LQR). Also MPC has the ability to anticipate future events and can take control actions accordingly. PID controllers do not have this predictive ability. MPC is nearly universally implemented as a digital control, although there is research into achieving faster response times with specially designed analog circuitry.

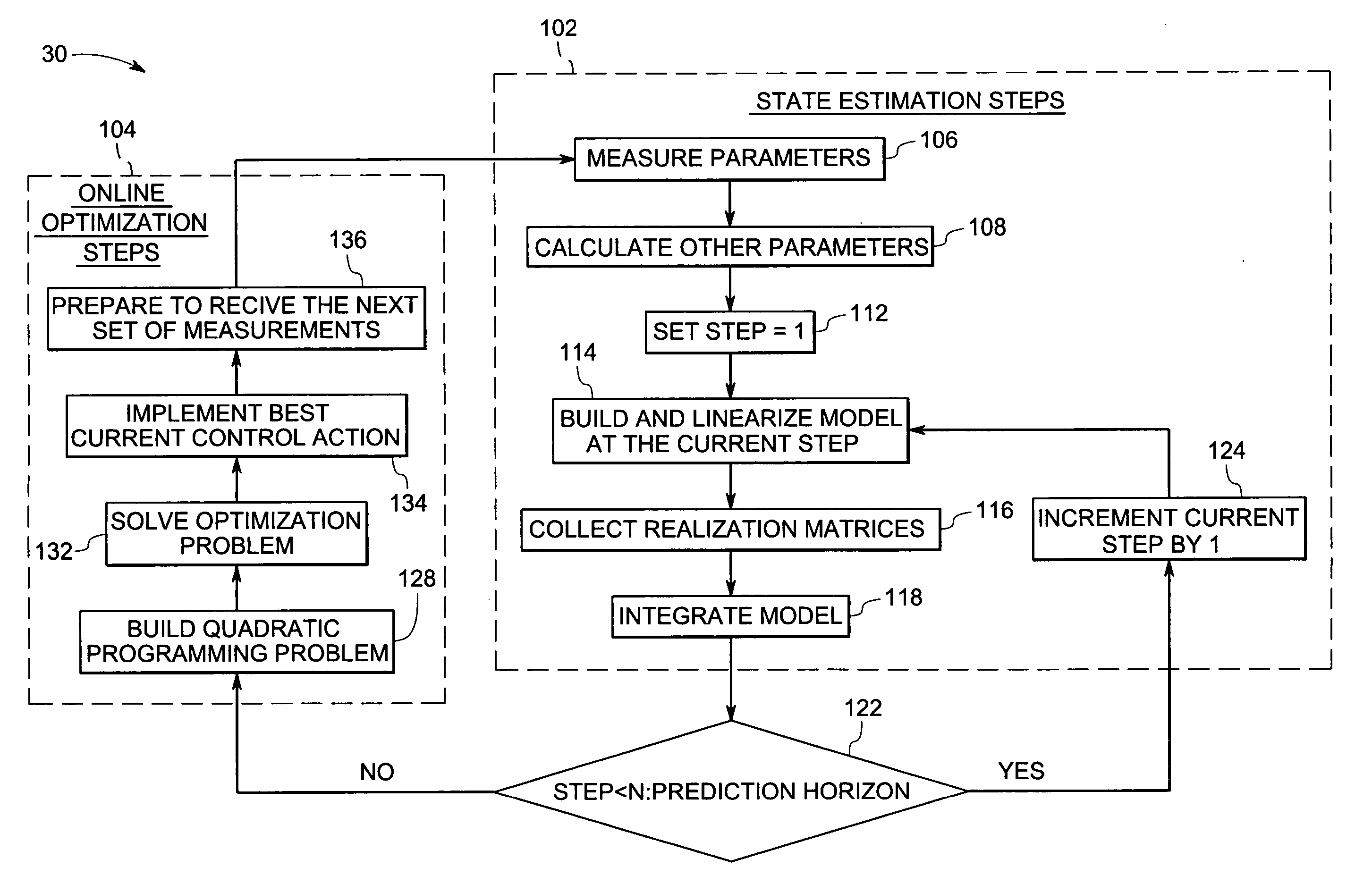

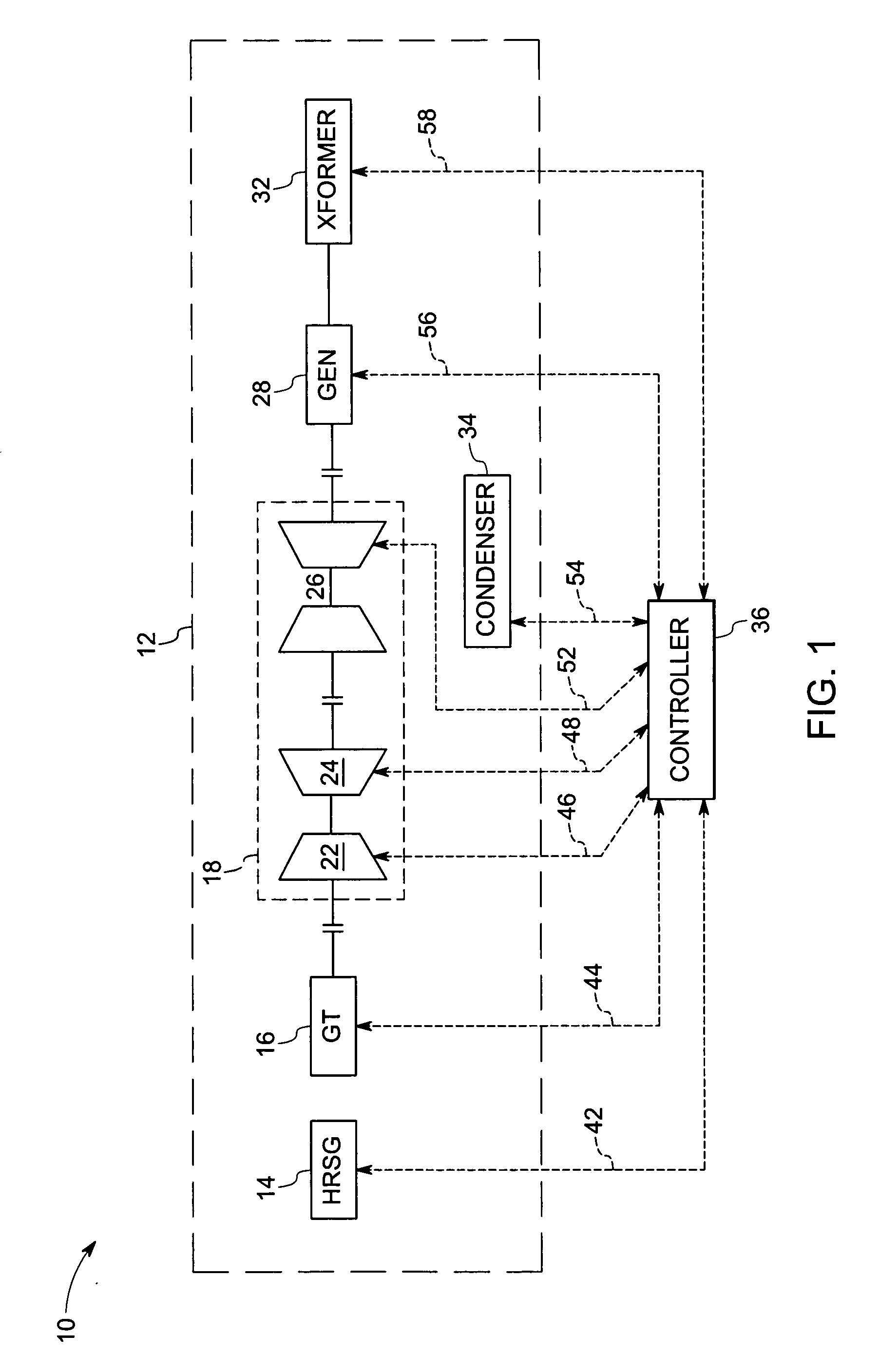

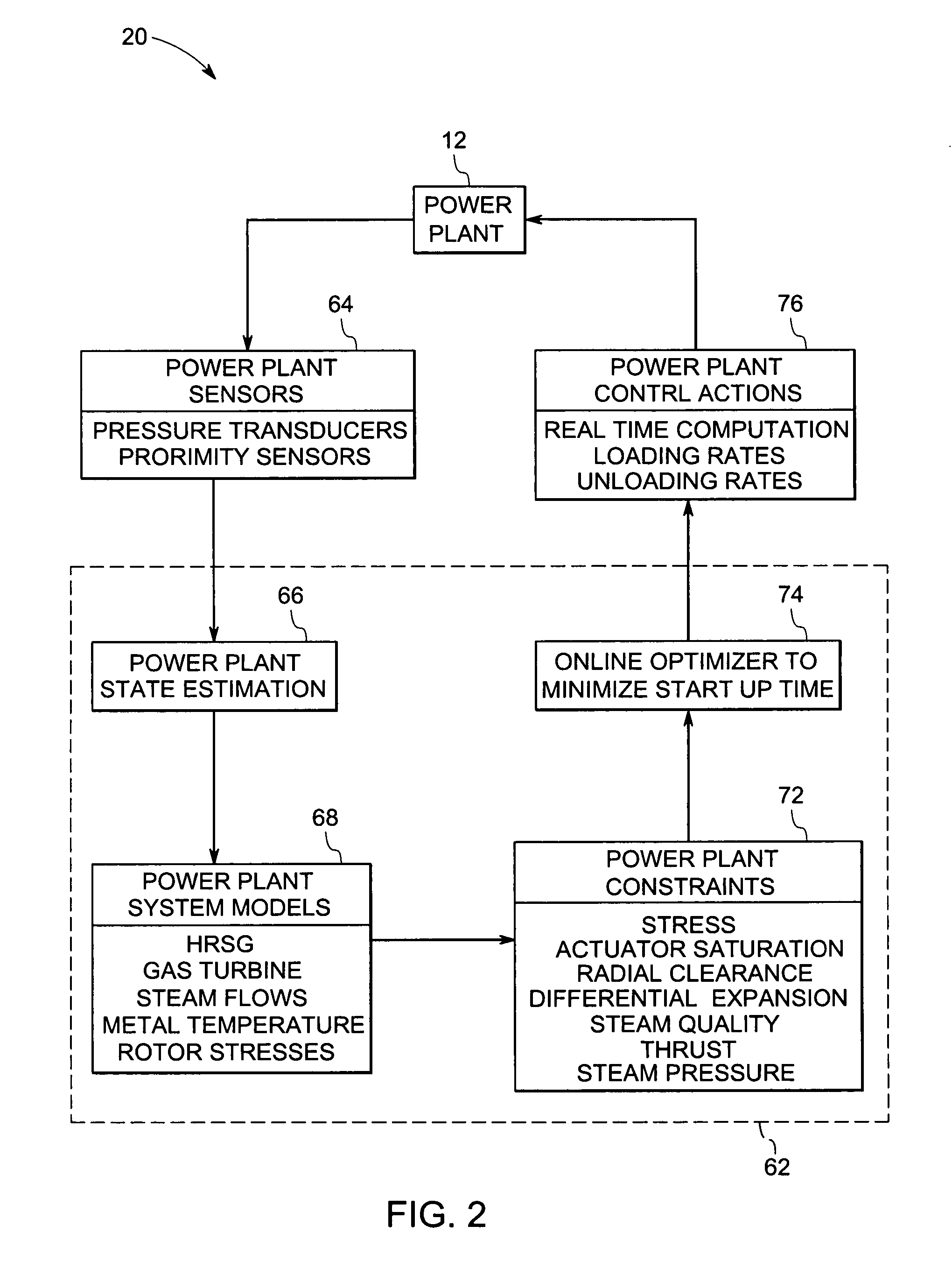

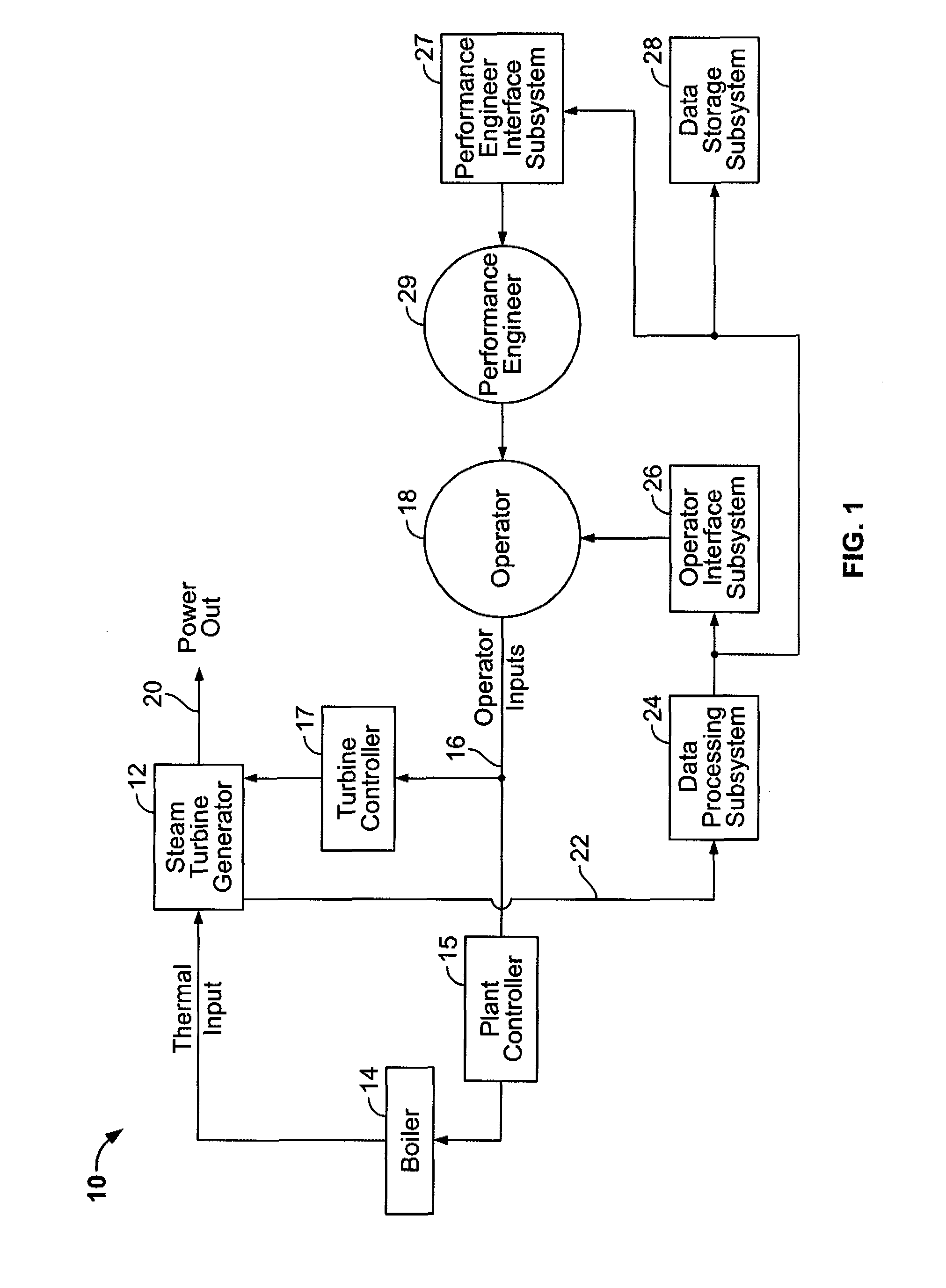

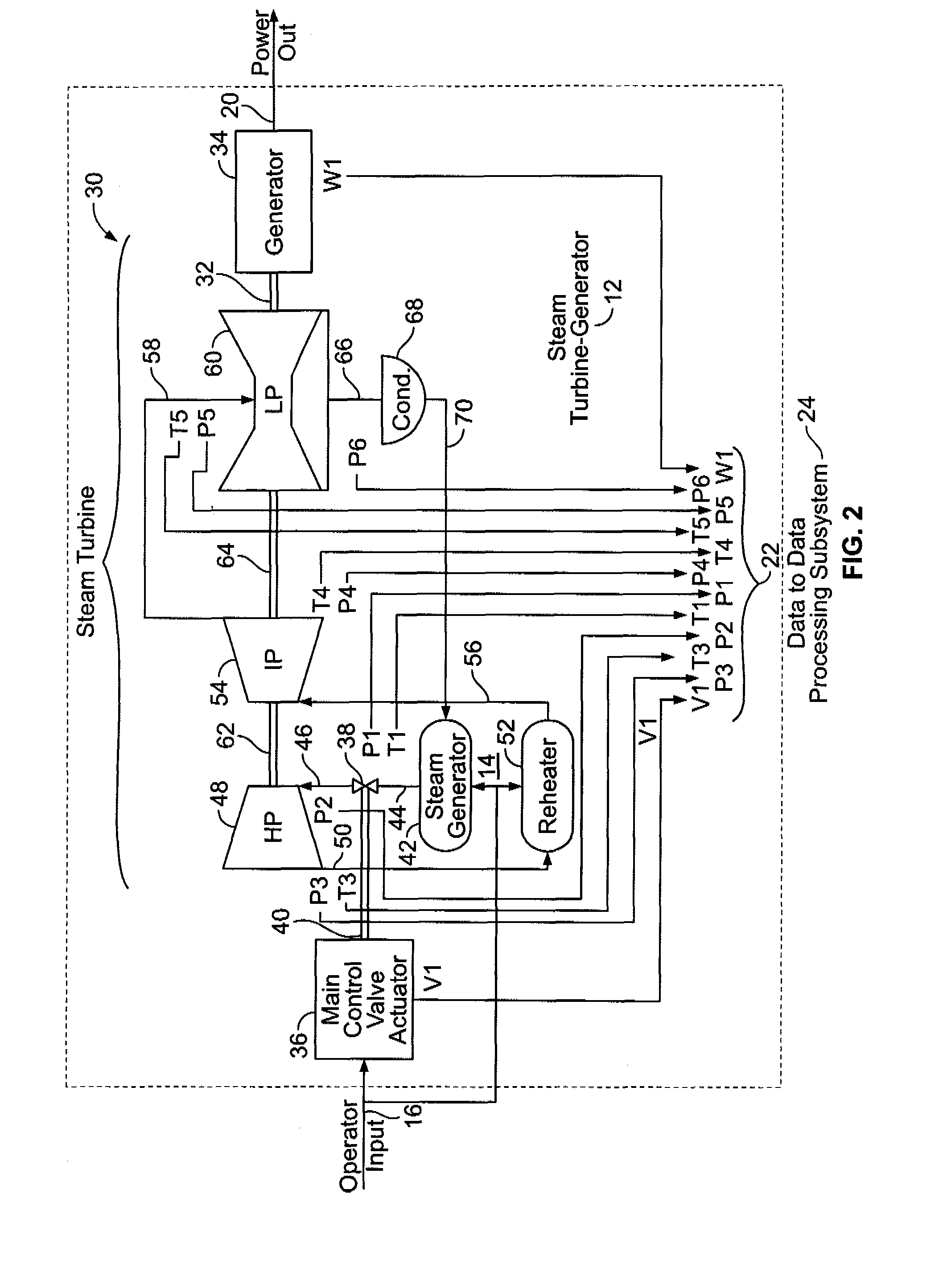

Method and system for model predictive control of a power plant

InactiveUS20070055392A1Improves performance criterionImproving performance criterionCombined combustion mitigationAdaptive controlPower stationModel predictive control

System and method for model predictive control of a power plant. The system includes a model for a number of power plant components and the model is adapted to predict behavior of the number of power plant components. The system also includes a controller that receives inputs corresponding to operational parameters of the power plant components and improves performance criteria of the power plant according to the model. There is also provided a method for controlling a power plant.

Owner:GENERAL ELECTRIC CO

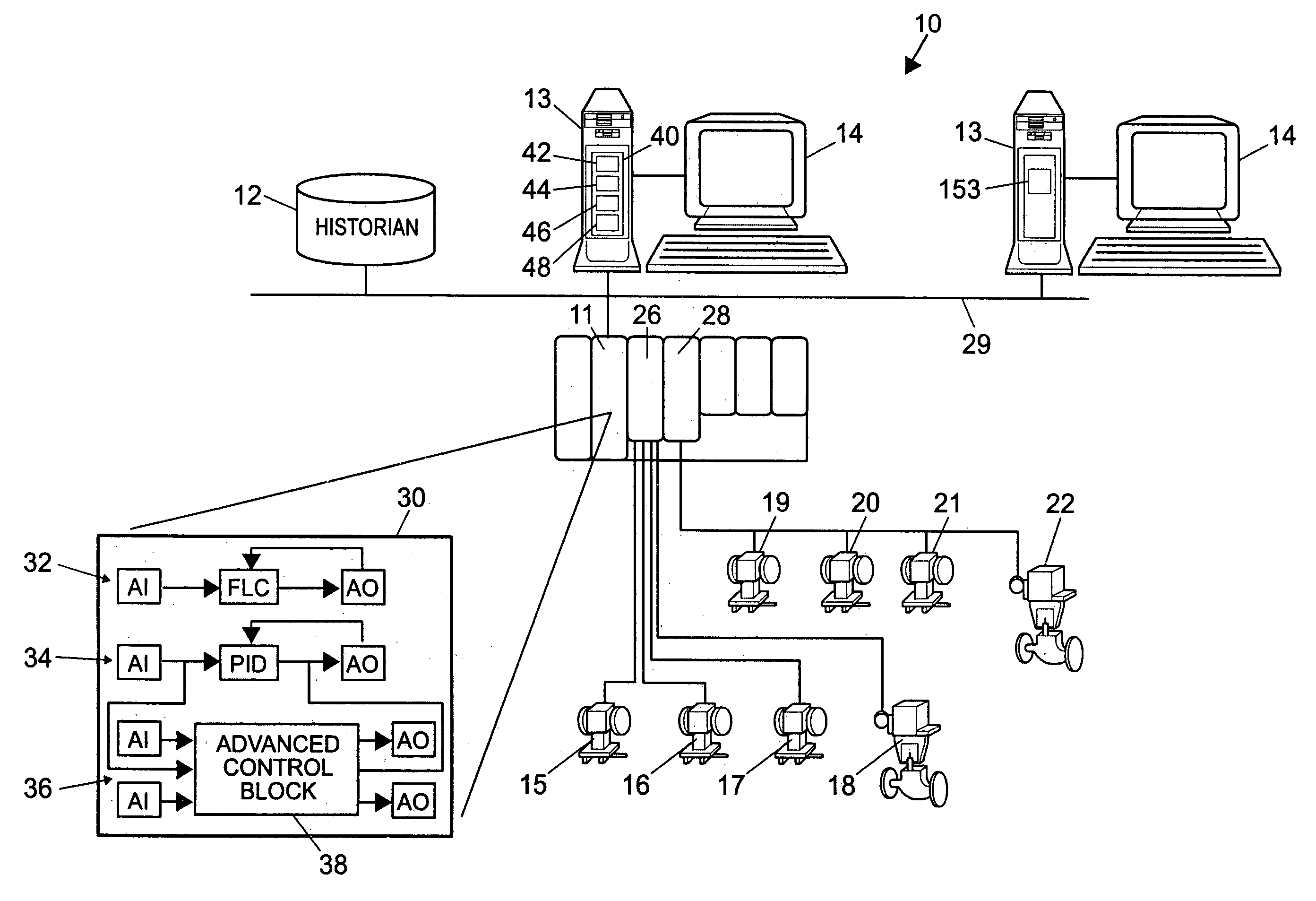

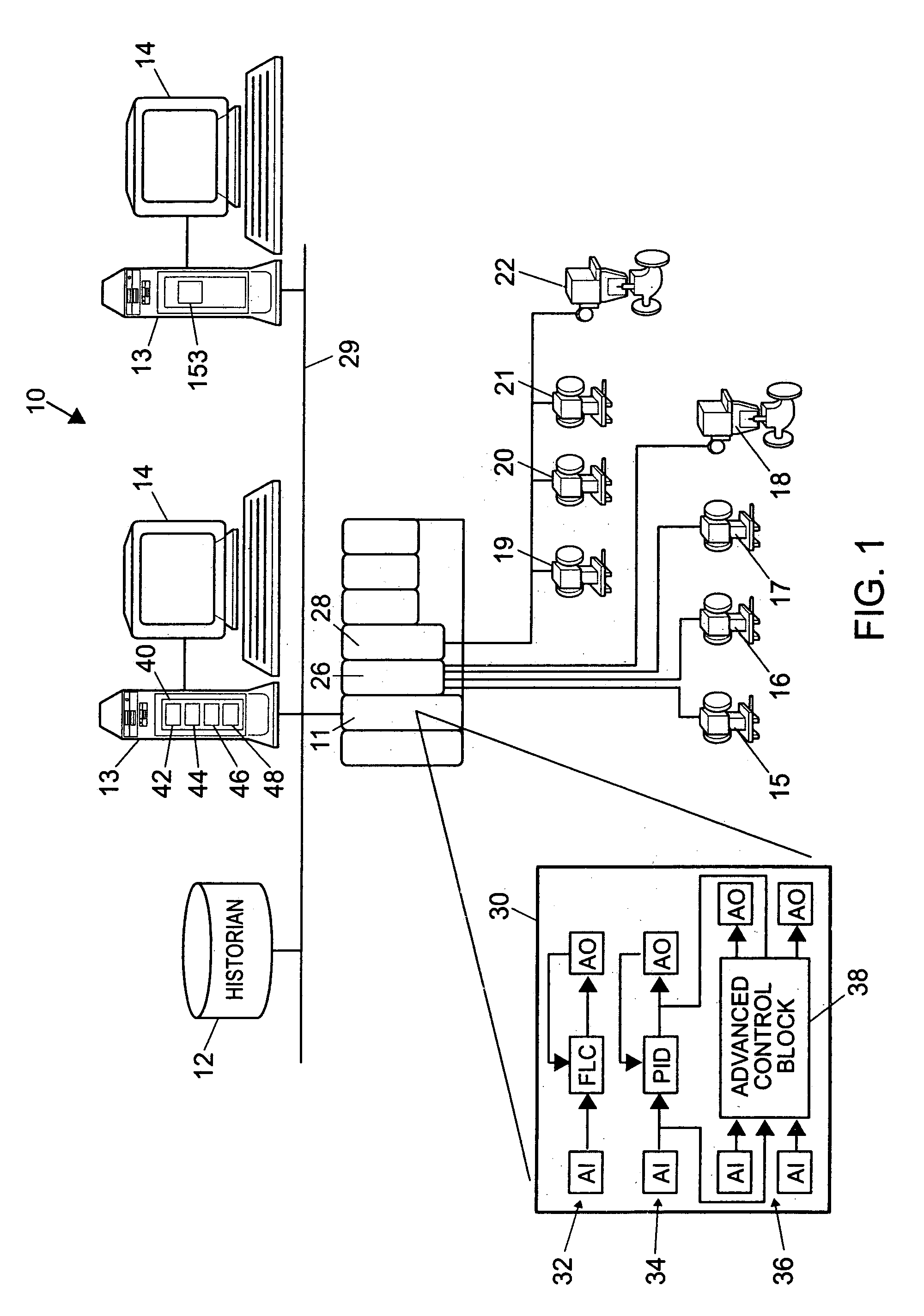

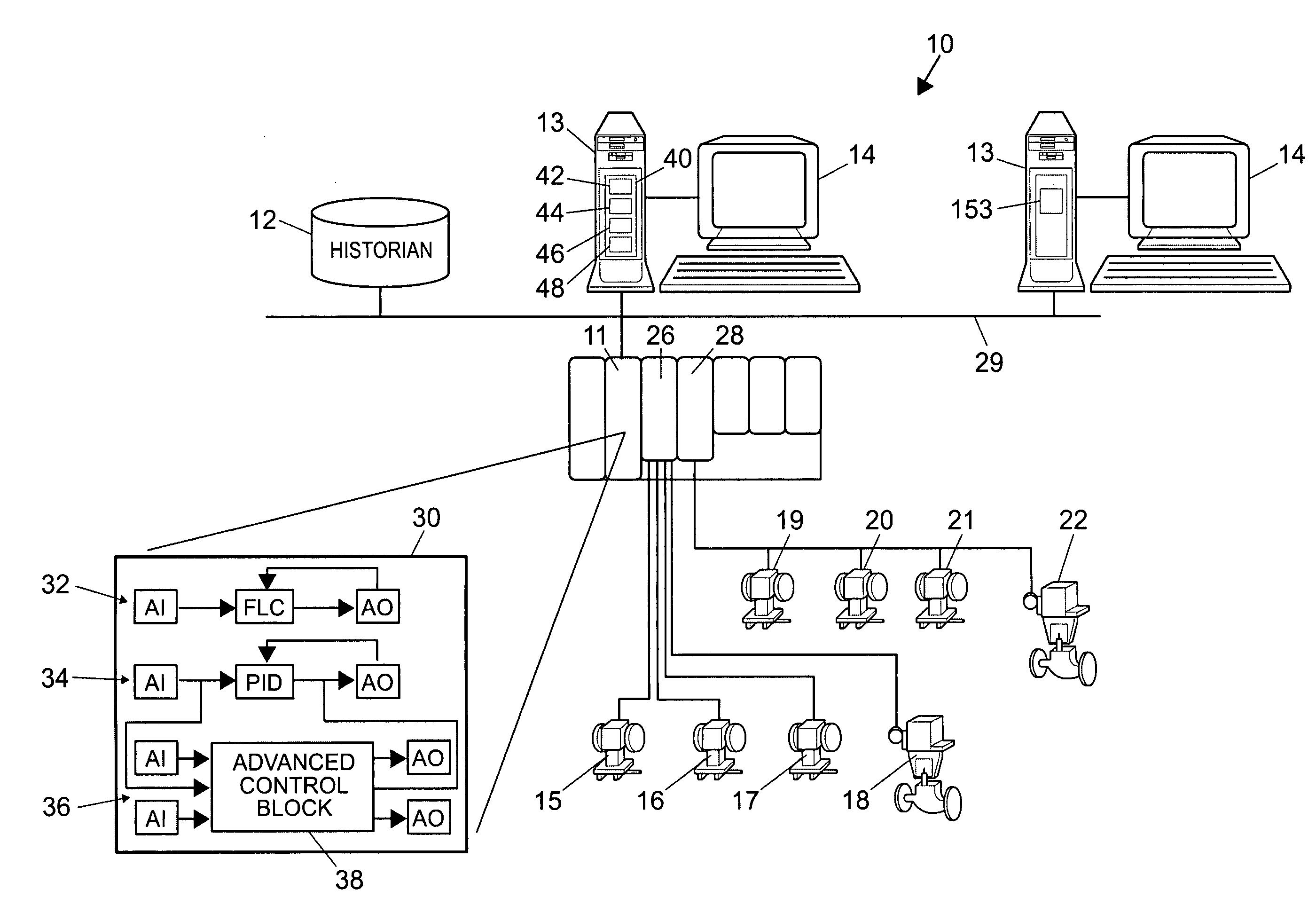

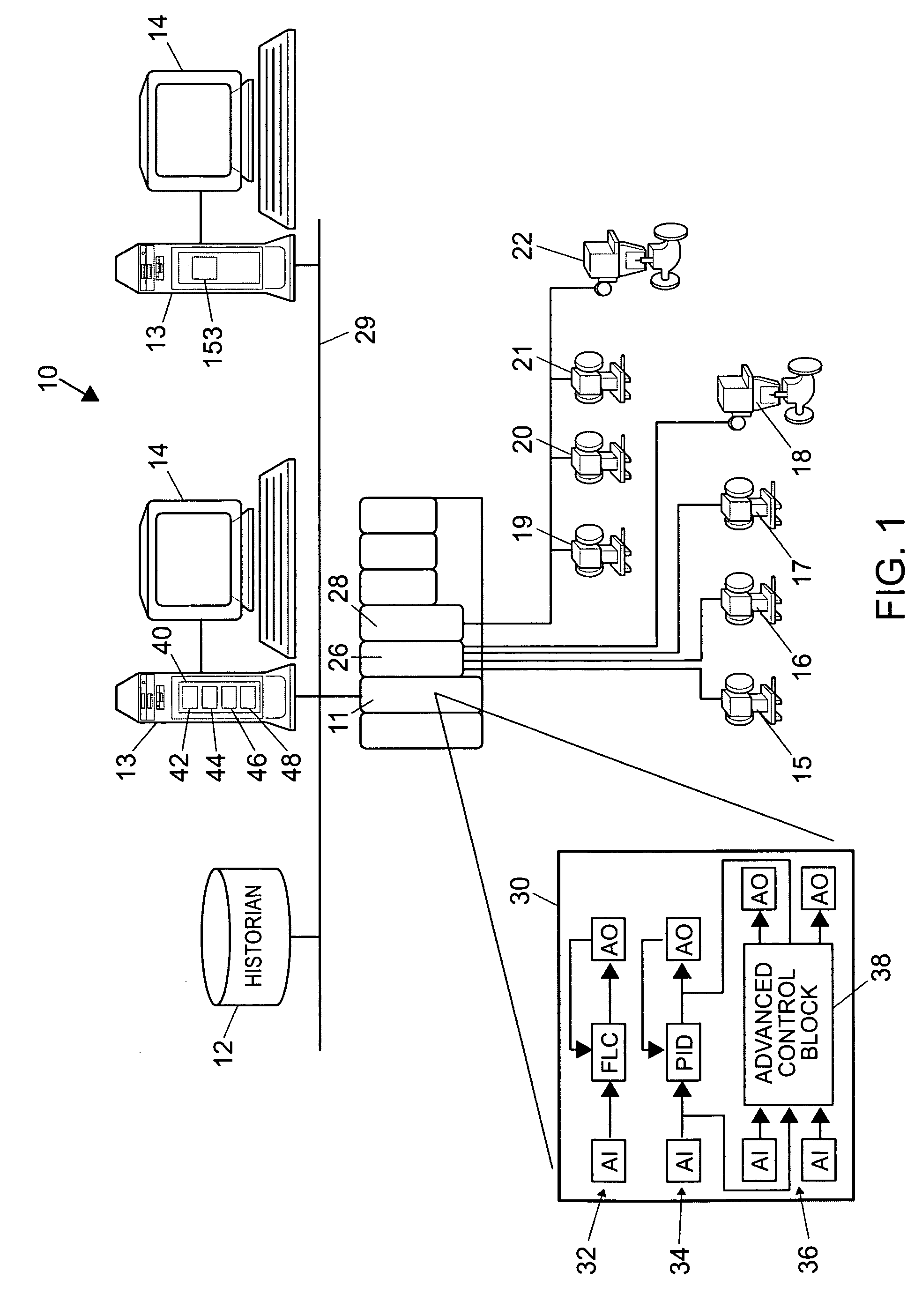

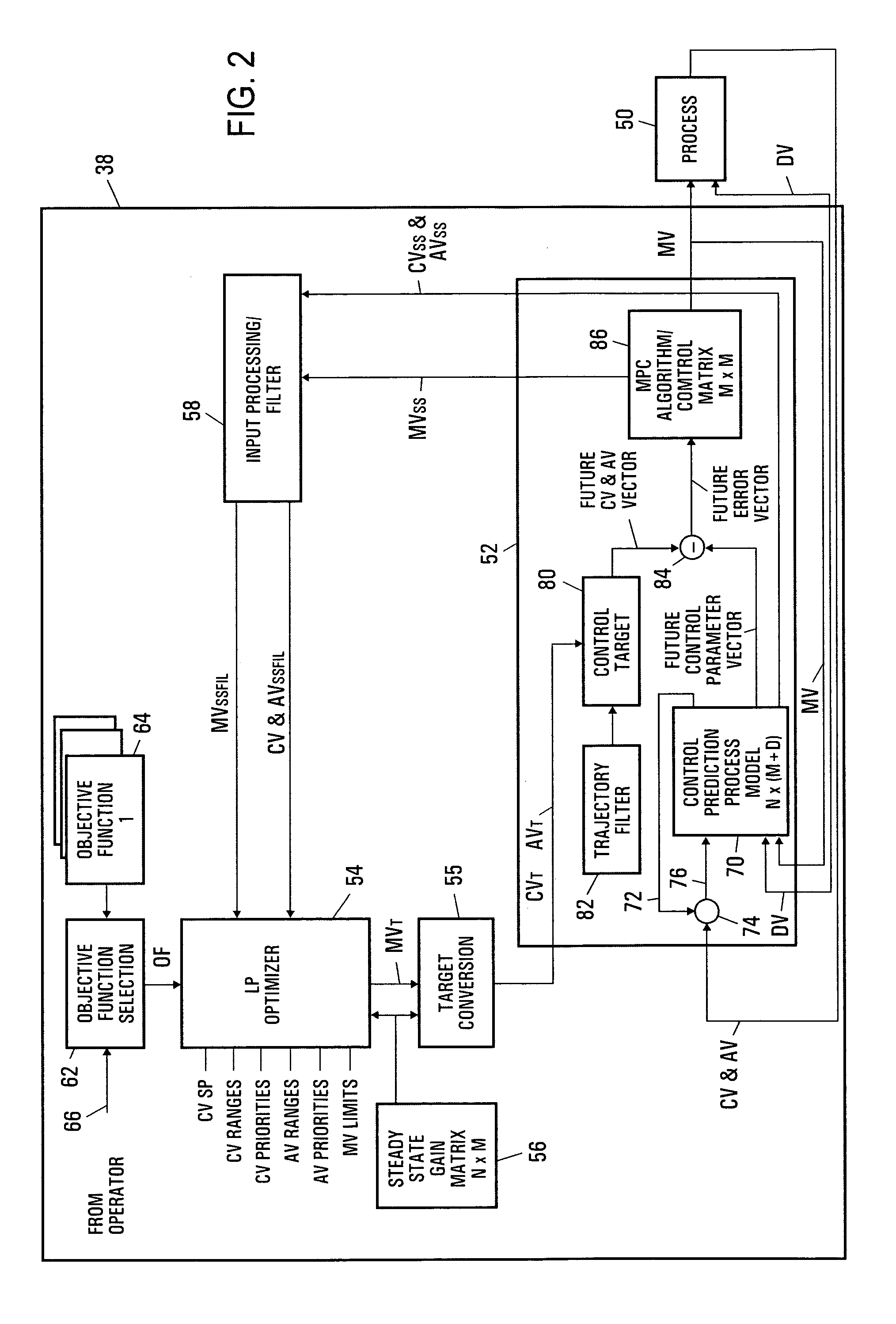

Integrated model predictive control and optimization within a process control system

InactiveUS7050863B2Minimize and maximize objective functionMaximize and minimize objective functionData processing applicationsElectric controllersConfiguration optimizationControl system

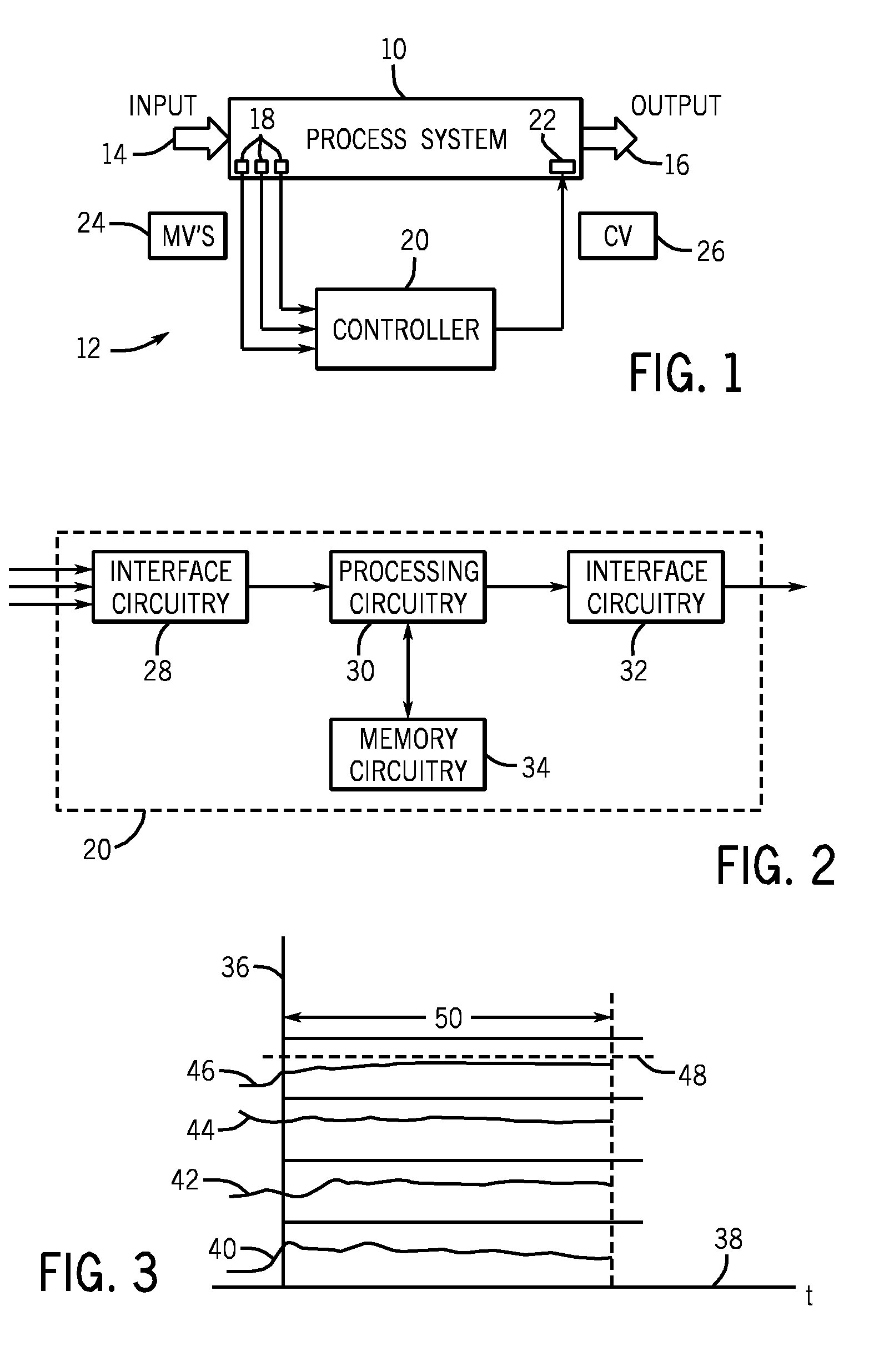

A process control configuration system is provided for use in creating or viewing an integrated optimization and control block that implements an optimization routine and a multiple-input / multiple-output control routine. The configuration system may enable a user to display or configure the optimizer or the control routine. A storage routine may store information pertaining to a plurality of control and auxiliary variables and to a plurality of manipulated variables to be used by the optimization routine and / or the control routine. A display routine may present a display to a user regarding the information pertaining to the plurality of control and auxiliary variables and to the plurality of manipulated variables.

Owner:FISHER-ROSEMOUNT SYST INC

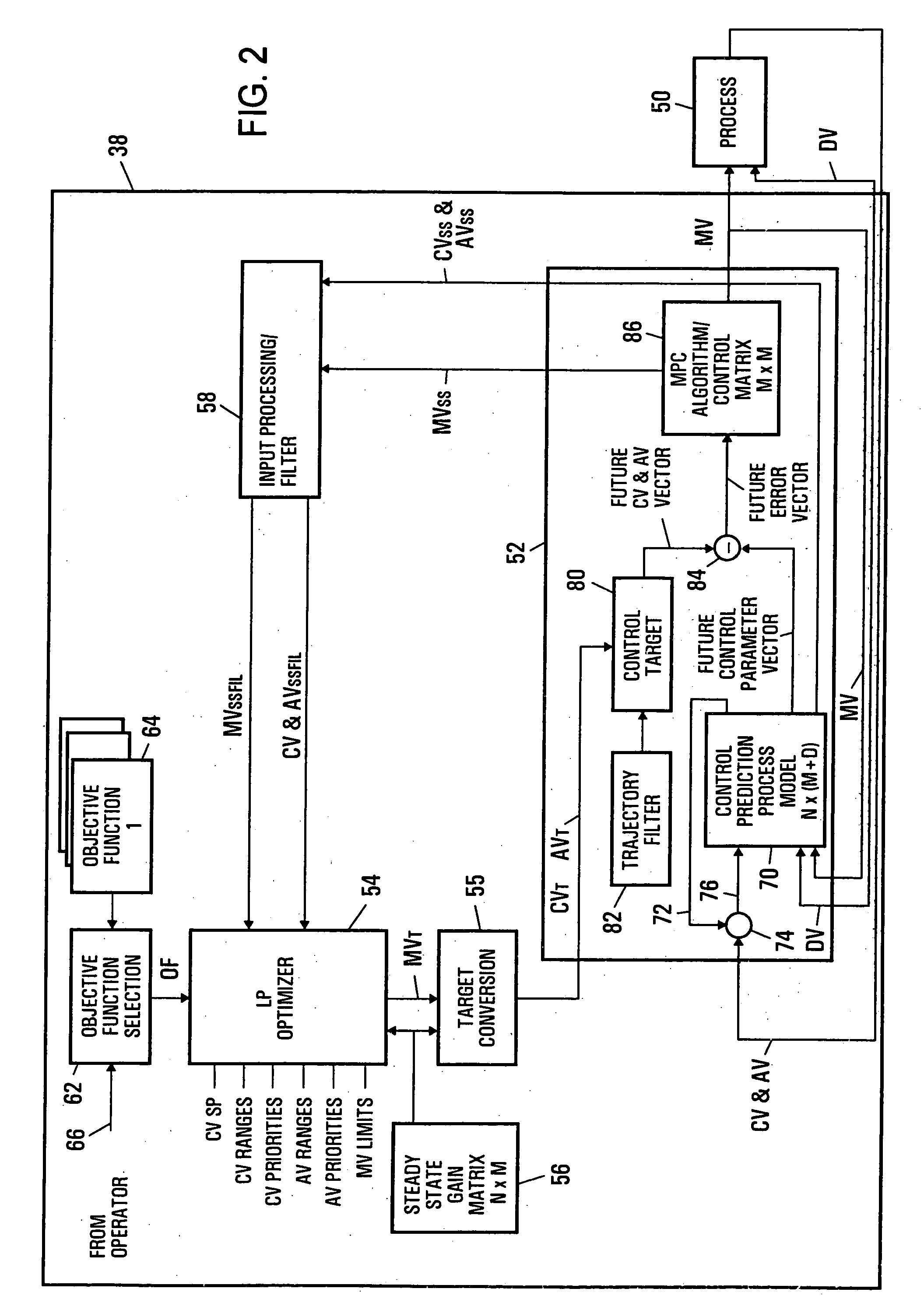

Integrated model predictive control and optimization within a process control system

InactiveUS7376472B2Simple calculationHigh gainData processing applicationsElectric controllersOperating pointControl system

An integrated optimization and control technique integrates an optimization procedure, such as a linear or quadratic programming optimization procedure, with advanced control, such as model predictive control, within a process plant in which the number of control and auxiliary variables can be greater than the number of manipulated variables within the process plant. The technique first determines a step response matrix defining the correlation between changes in the manipulated variables and each of the process variables that are used during optimization. A subset of the control variables and auxiliary variables is then selected to be used as inputs to a model predictive control routine used to perform control during operation of the process and a square M by M control matrix to be used by the model predictive control routine is generated. Thereafter, during each scan of the process controller, the optimizer routine calculates the optimal operating target of each of the complete set of control and auxiliary variables and provides the determined target operating points for each of the selected subset of control and auxiliary variables to the model predictive control routine as inputs. The model predictive control routine determines changes in the manipulated variables for use in controlling the process from the target and measured values for each of the subset of the control and auxiliary variables and the M by M control matrix.

Owner:FISHER-ROSEMOUNT SYST INC

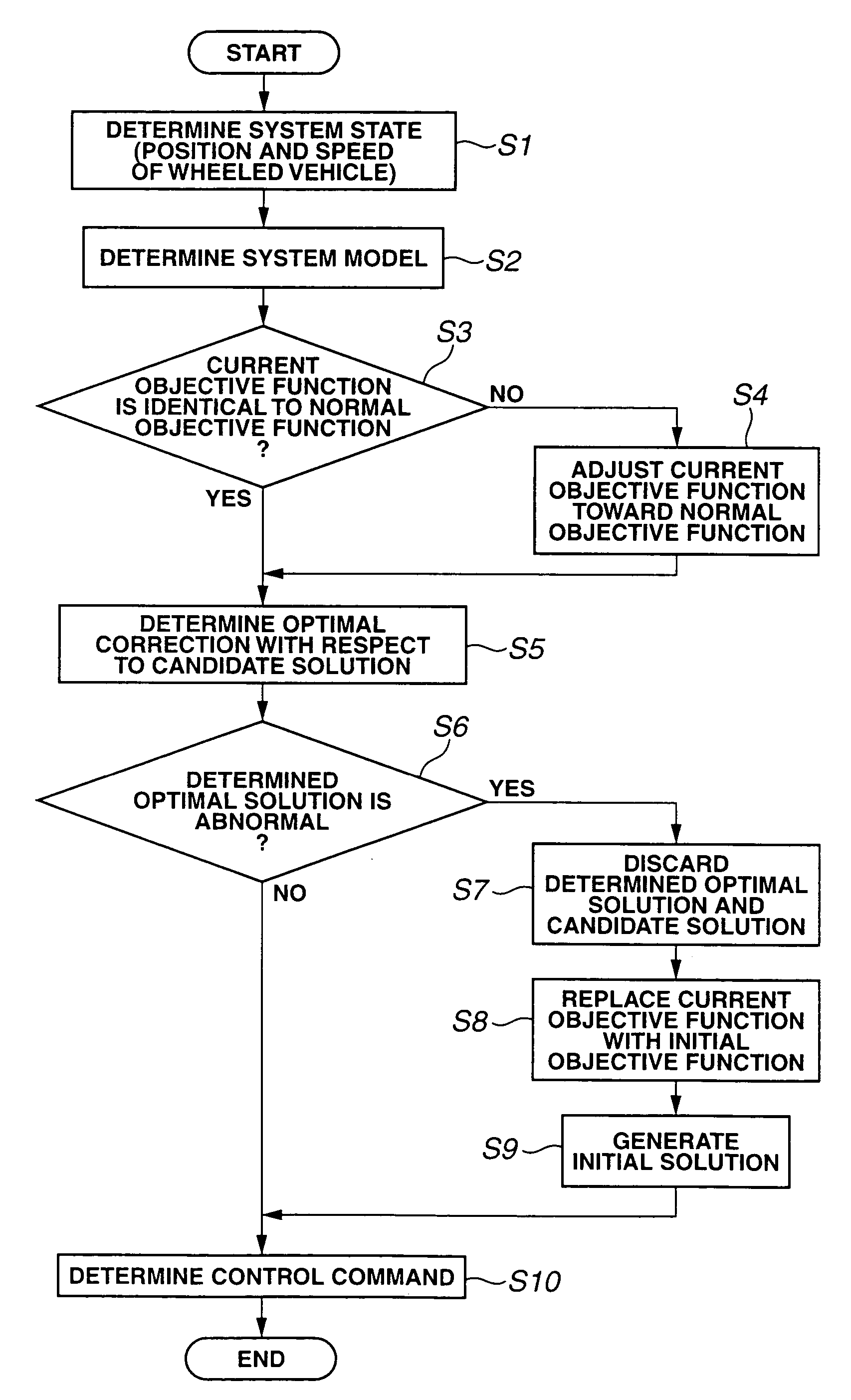

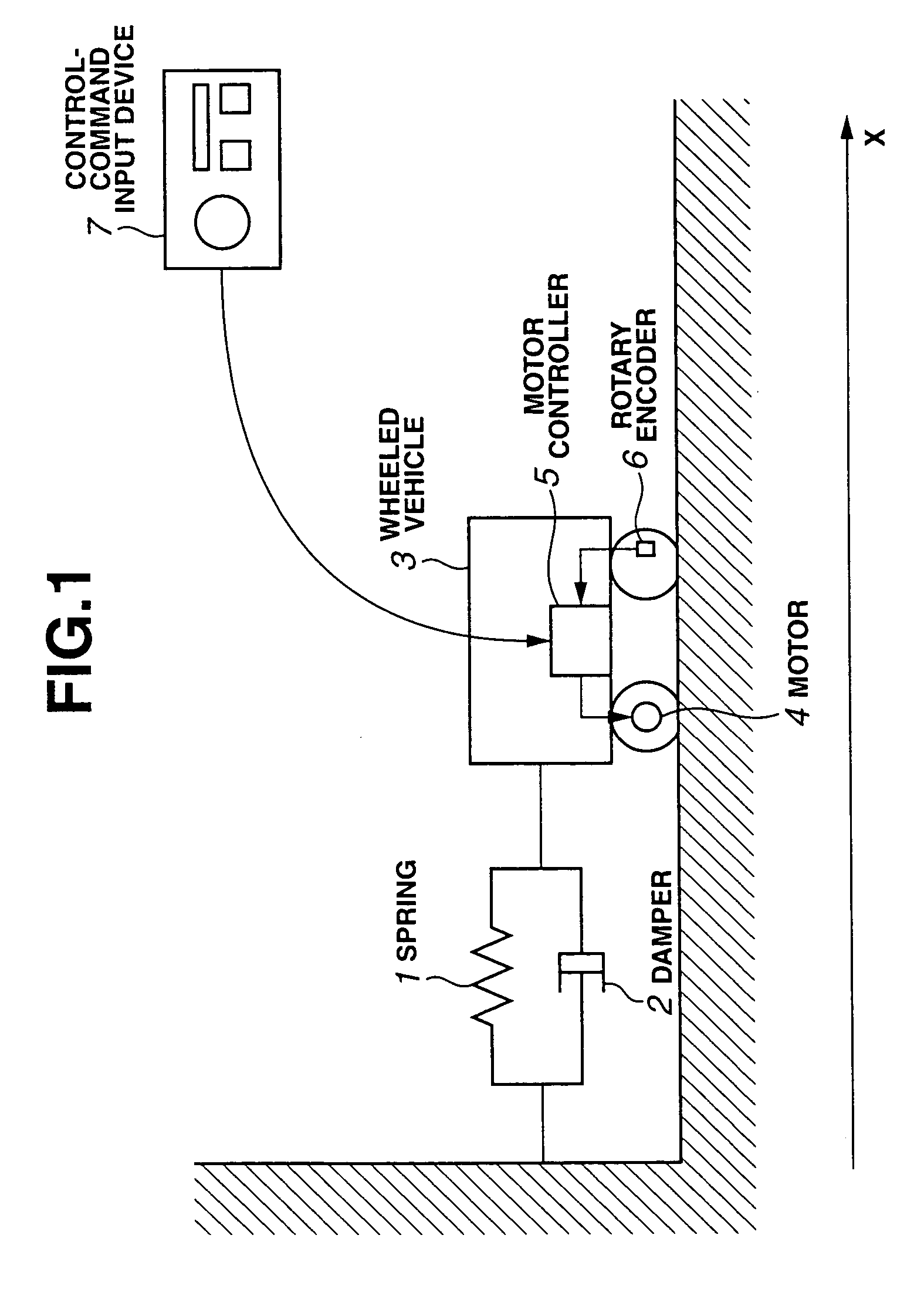

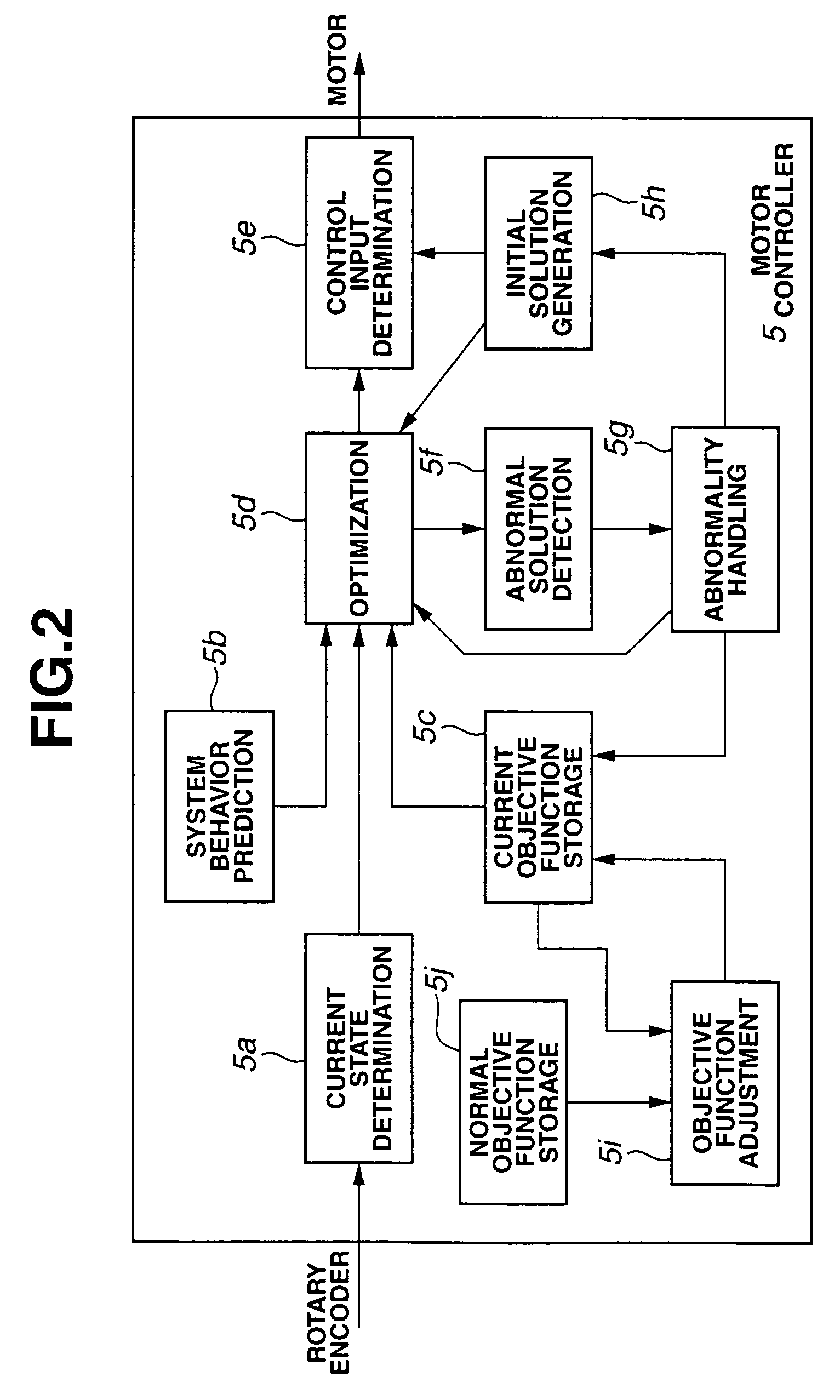

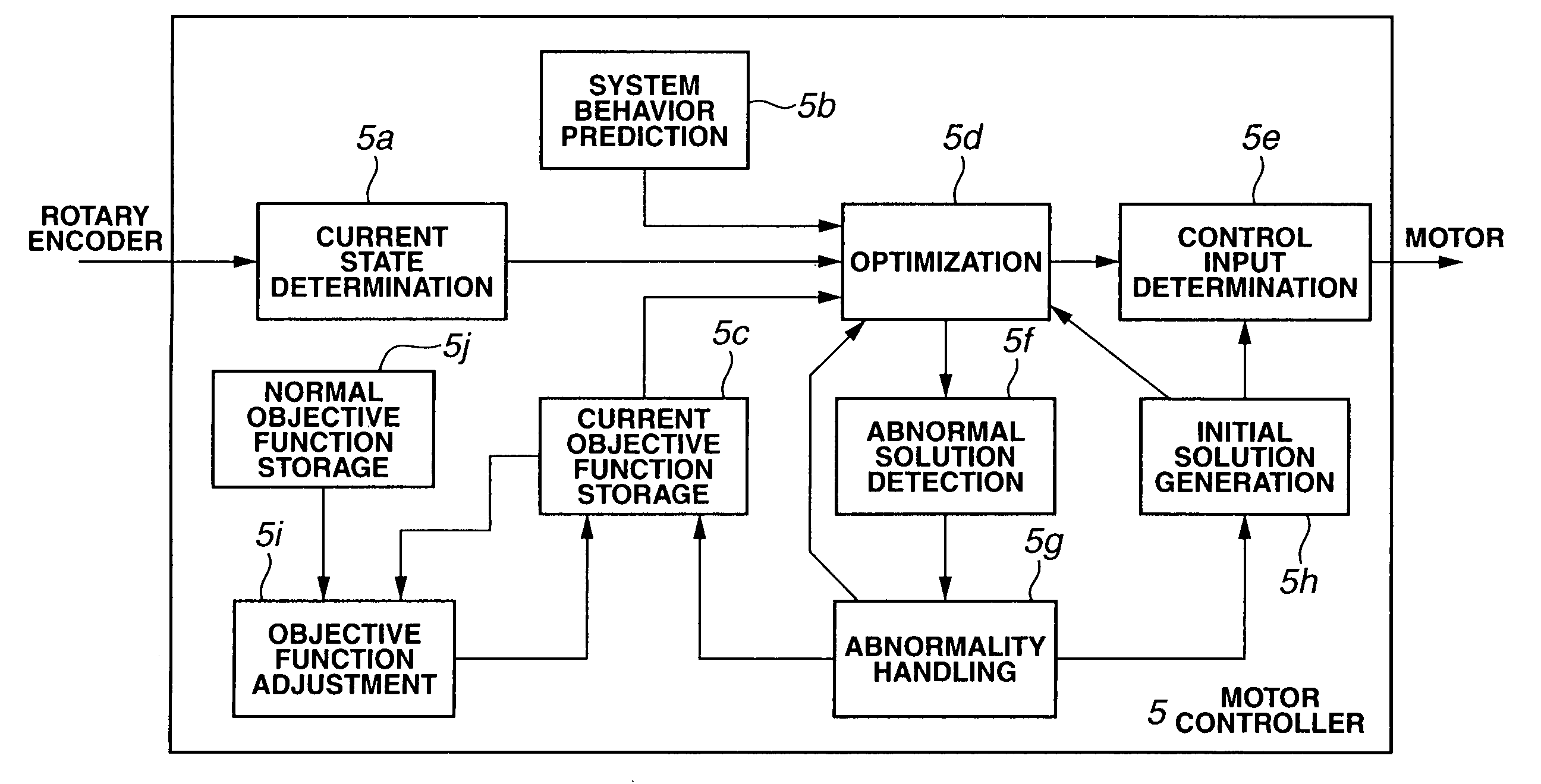

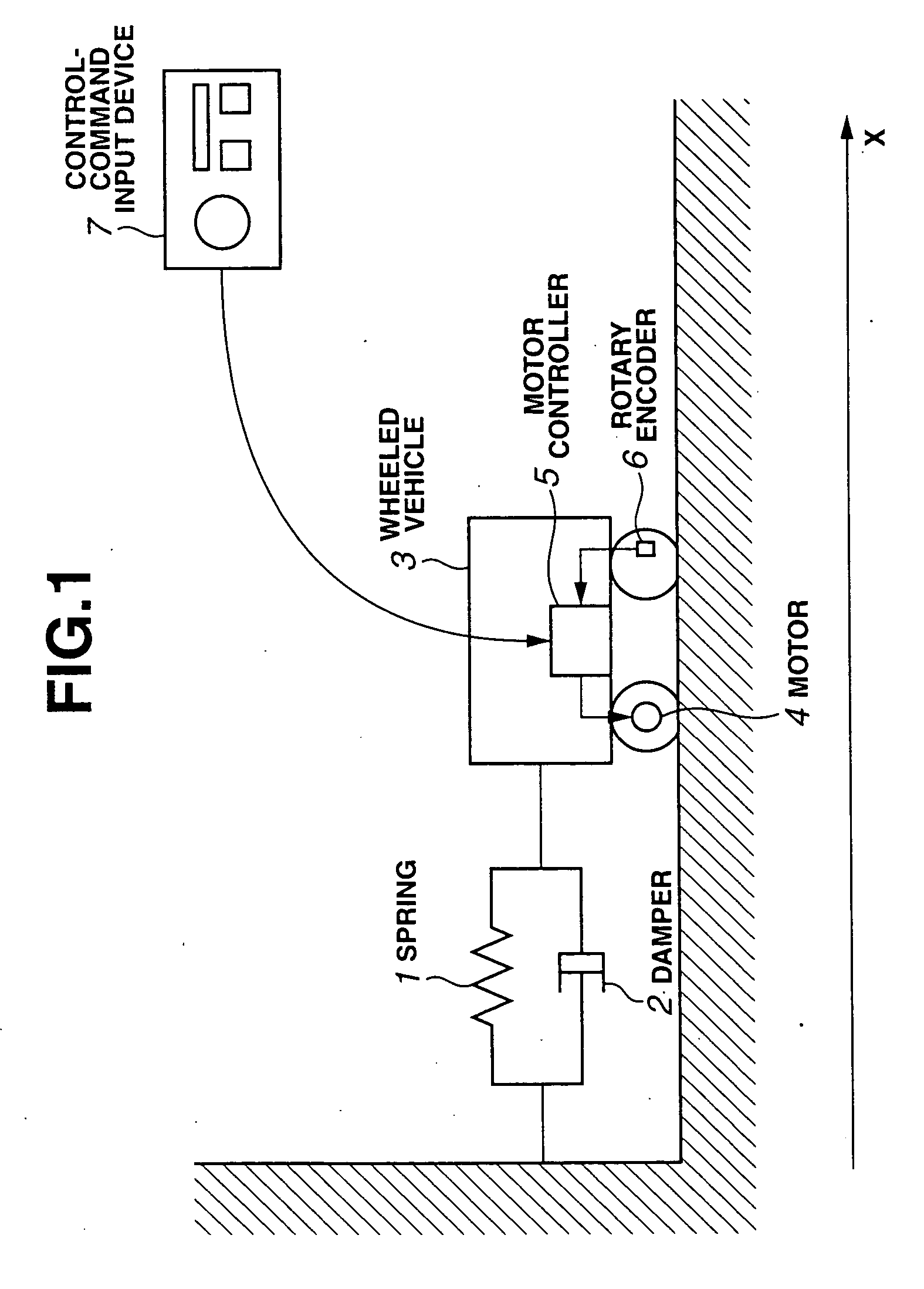

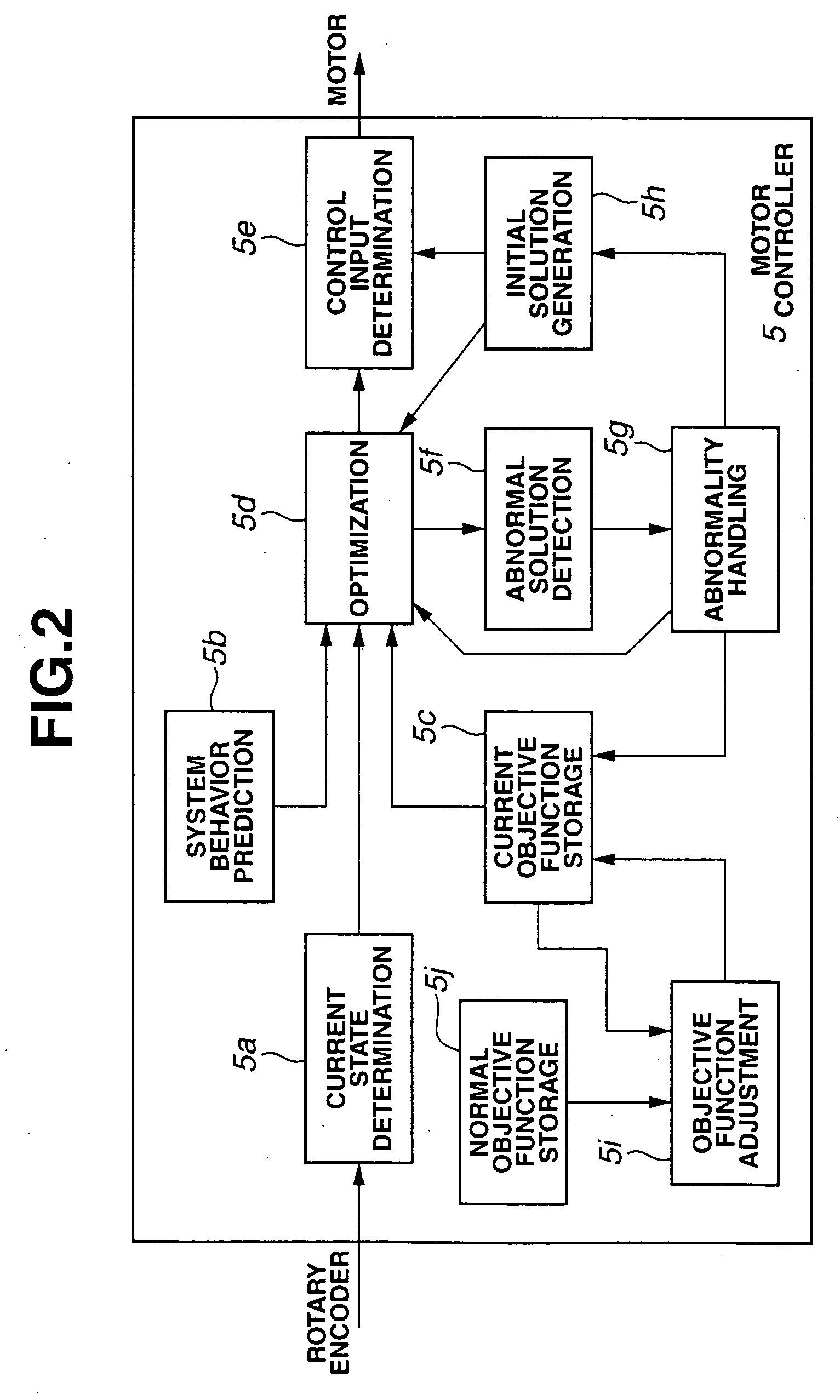

Model predictive control apparatus

InactiveUS7418372B2Quick responseAnalogue computers for vehiclesVehicle fittingsModel predictive controlEngineering

A model predictive control apparatus includes an initial solution generation section, an abnormality handling section, and an objective function adjustment section. The abnormality handling section performs initial solution generation when it is determined that performed optimization is abnormal. The initial solution generation section generates an initial optimal value of a future time series control input in accordance with an initial objective function, without reference to a candidate value of the time series control input. The objective function adjustment section adjusts the current objective function so that the current objective function varies stepwise with time toward the normal objective function when it is determined that the current objective function is different from the normal objective function.

Owner:NISSAN MOTOR CO LTD

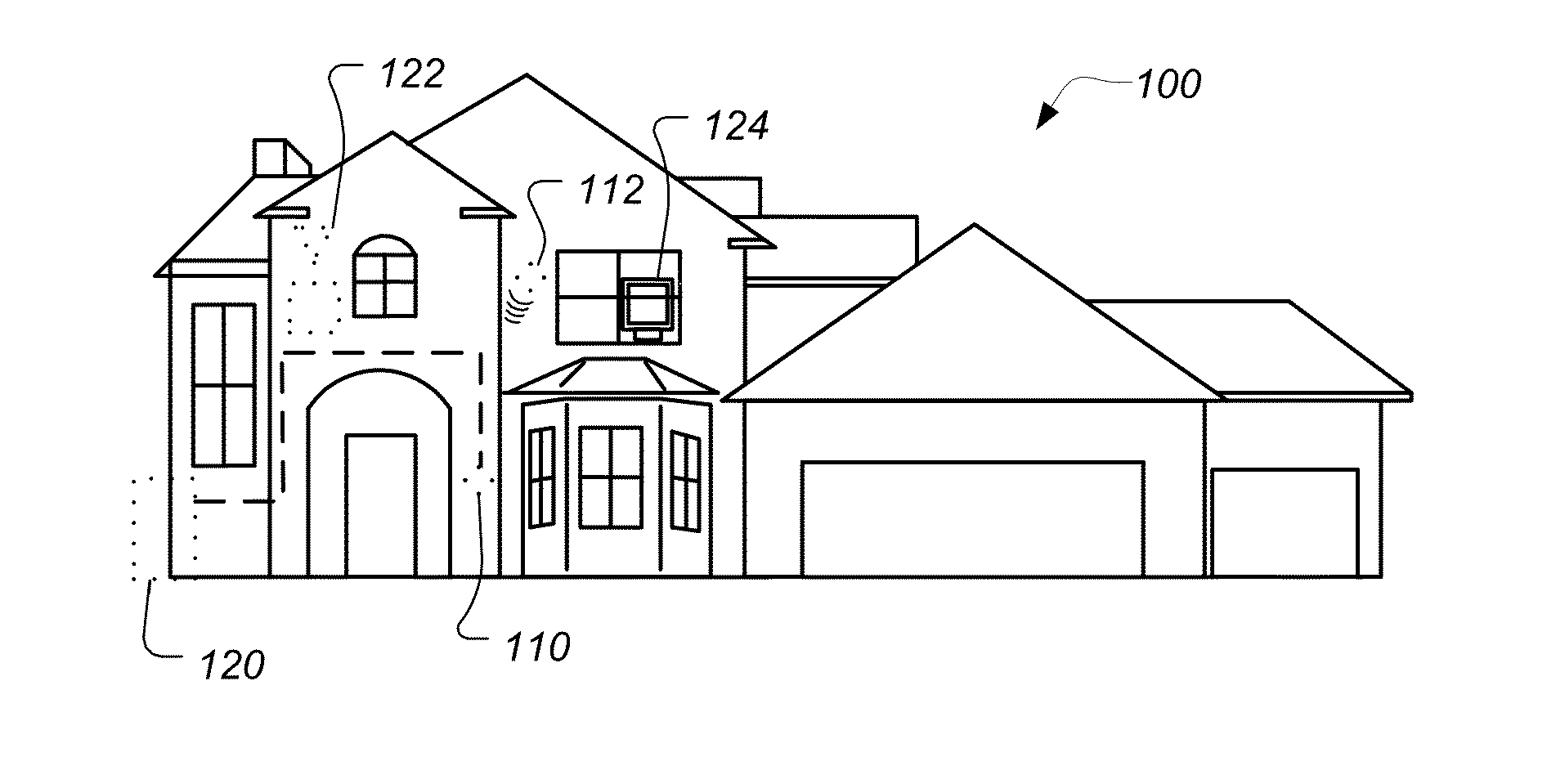

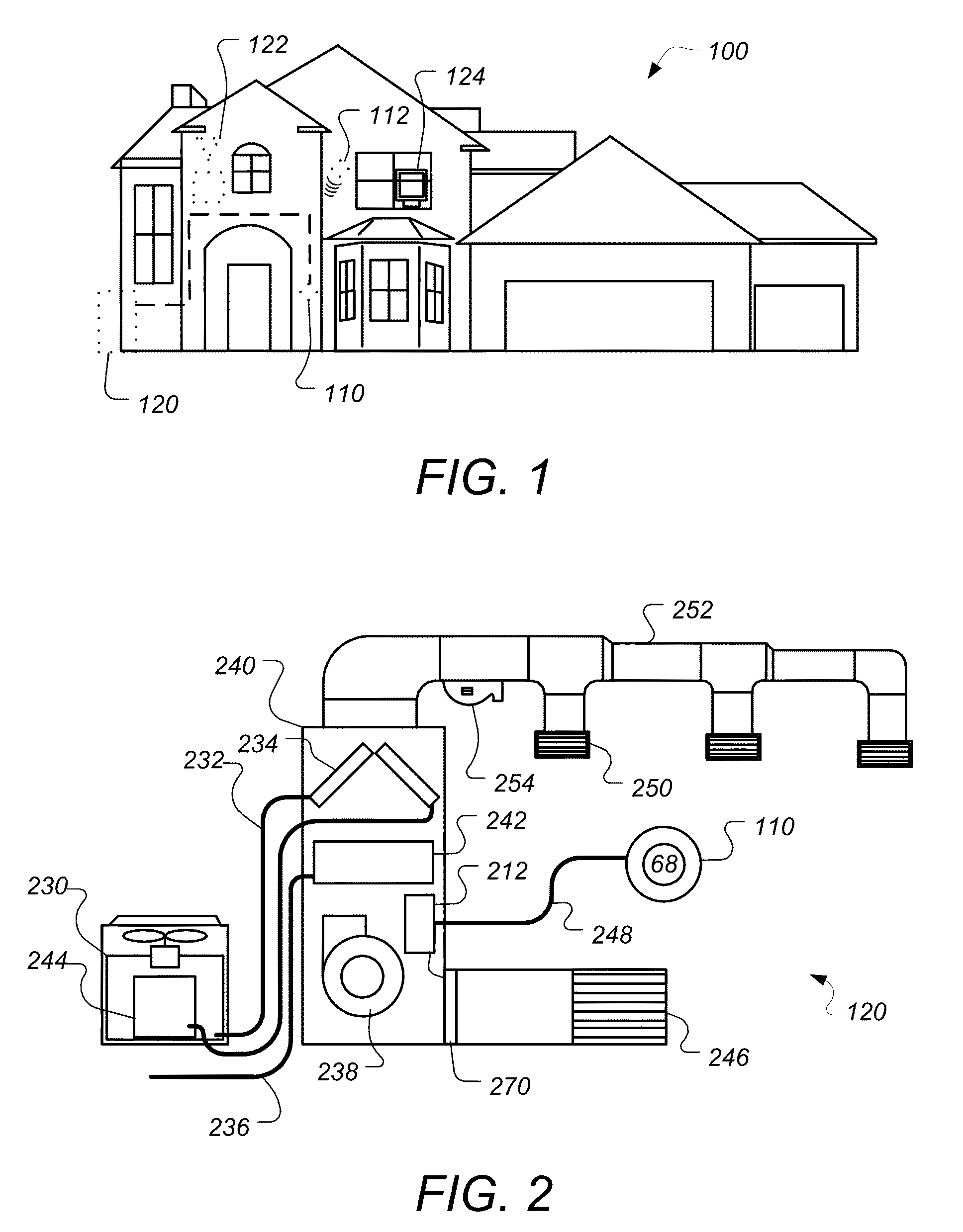

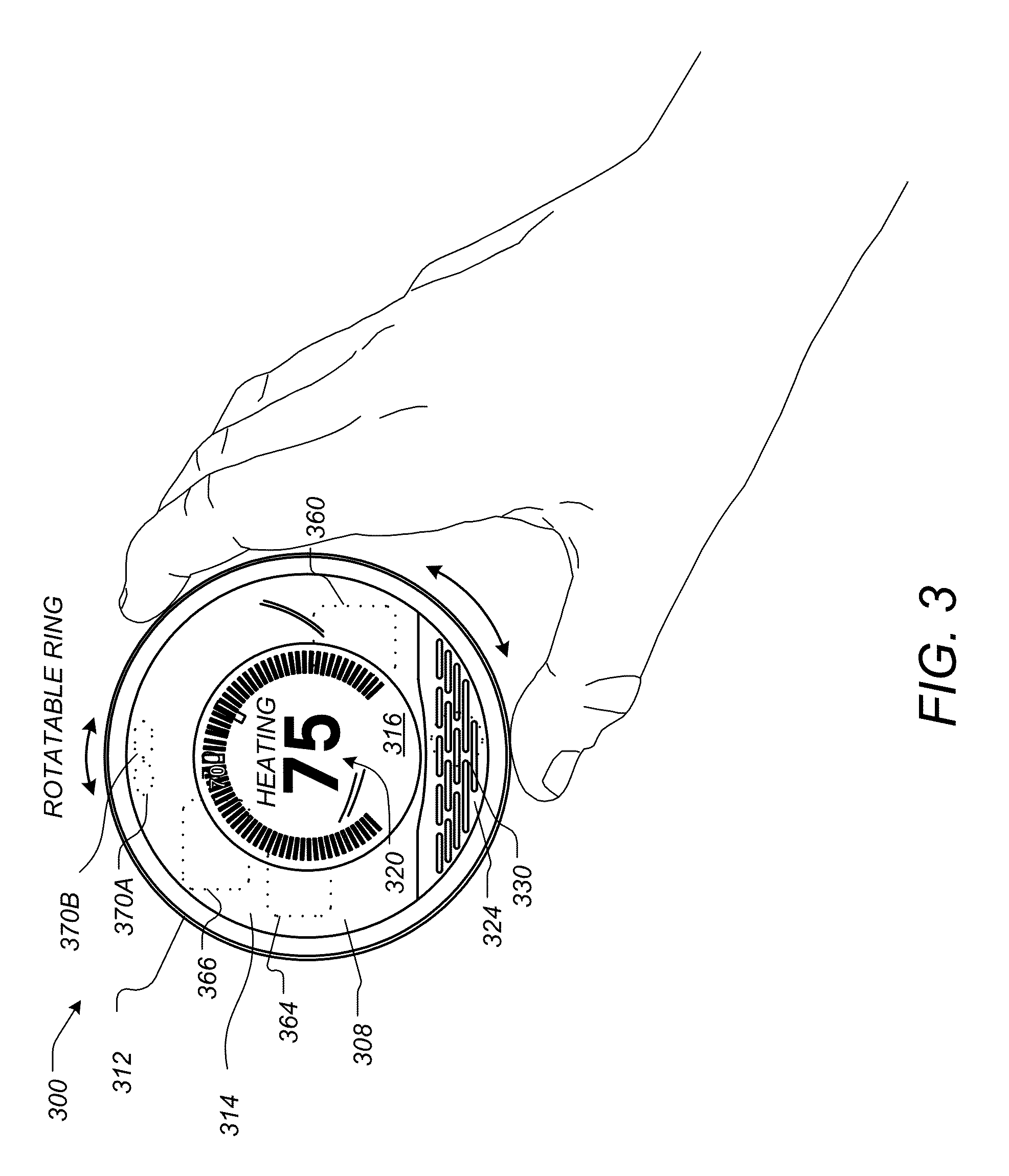

Radiant heating controls and methods for an environmental control system

ActiveUS8600561B1Function increaseIncrease valueMechanical apparatusStatic/dynamic balance measurementPrediction algorithmsOptimal control

Embodiments of the invention describe thermostats that use model predictive controls and related methods. A method of controlling a thermostat using a model predictive control may involve determining a parameterized model. The parameterized model may be used to predicted ambient temperature values for an enclosure. A set of radiant heating system control strategies may be selected for evaluation to determine an optimal control strategy from the set of control strategies. To determine the optimal control strategy, a predictive algorithm may be executed, in which each control strategy is applied to the parameterized model to predict an ambient temperature trajectory and each ambient temperature trajectory is processed in view of a predetermined assessment function. Processing the ambient temperature trajectory in this manner may involve minimizing a cost value associated with the ambient temperature trajectory. The radiant heating system may subsequently be controlled according to the selected optimal control strategy.

Owner:GOOGLE LLC

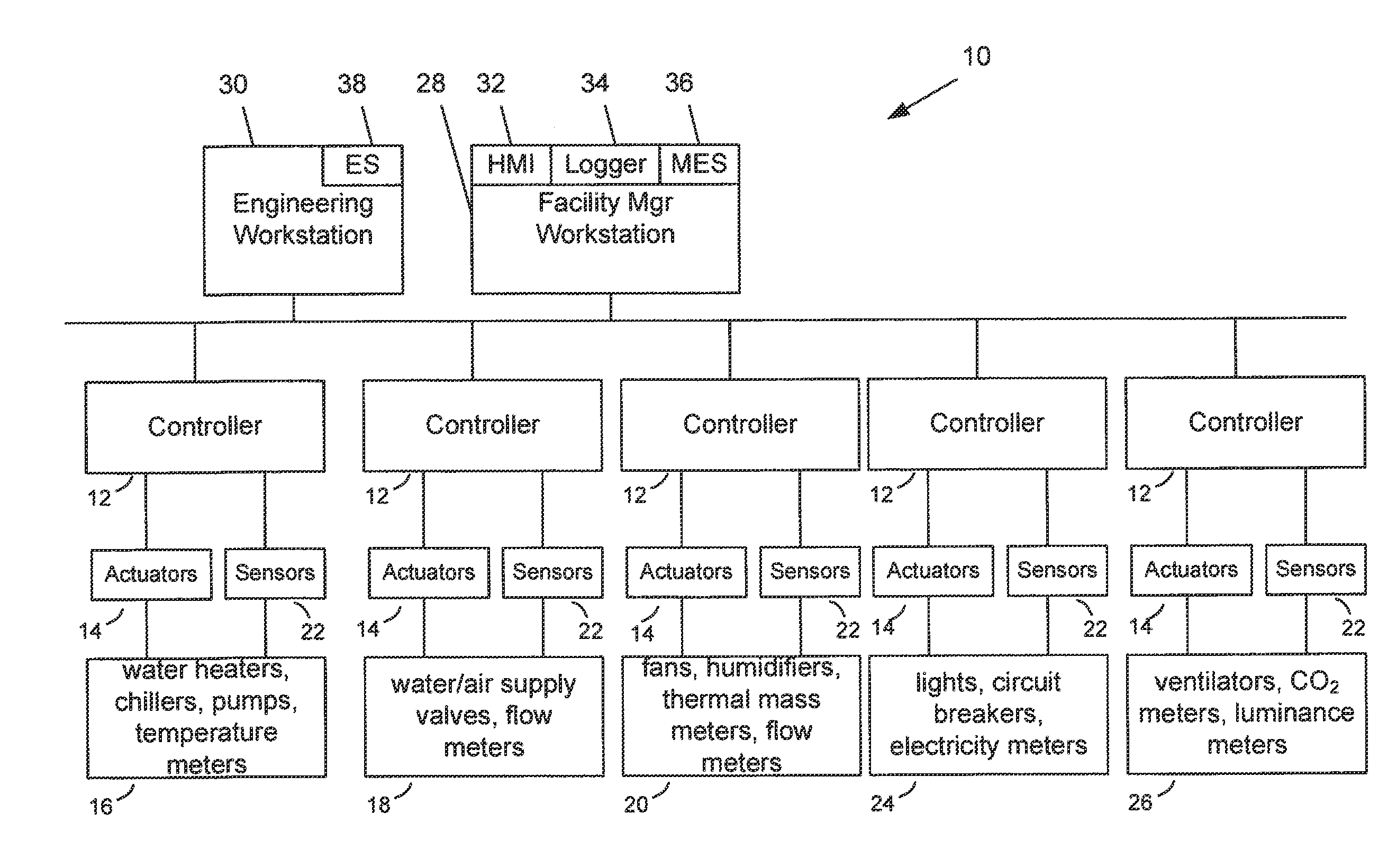

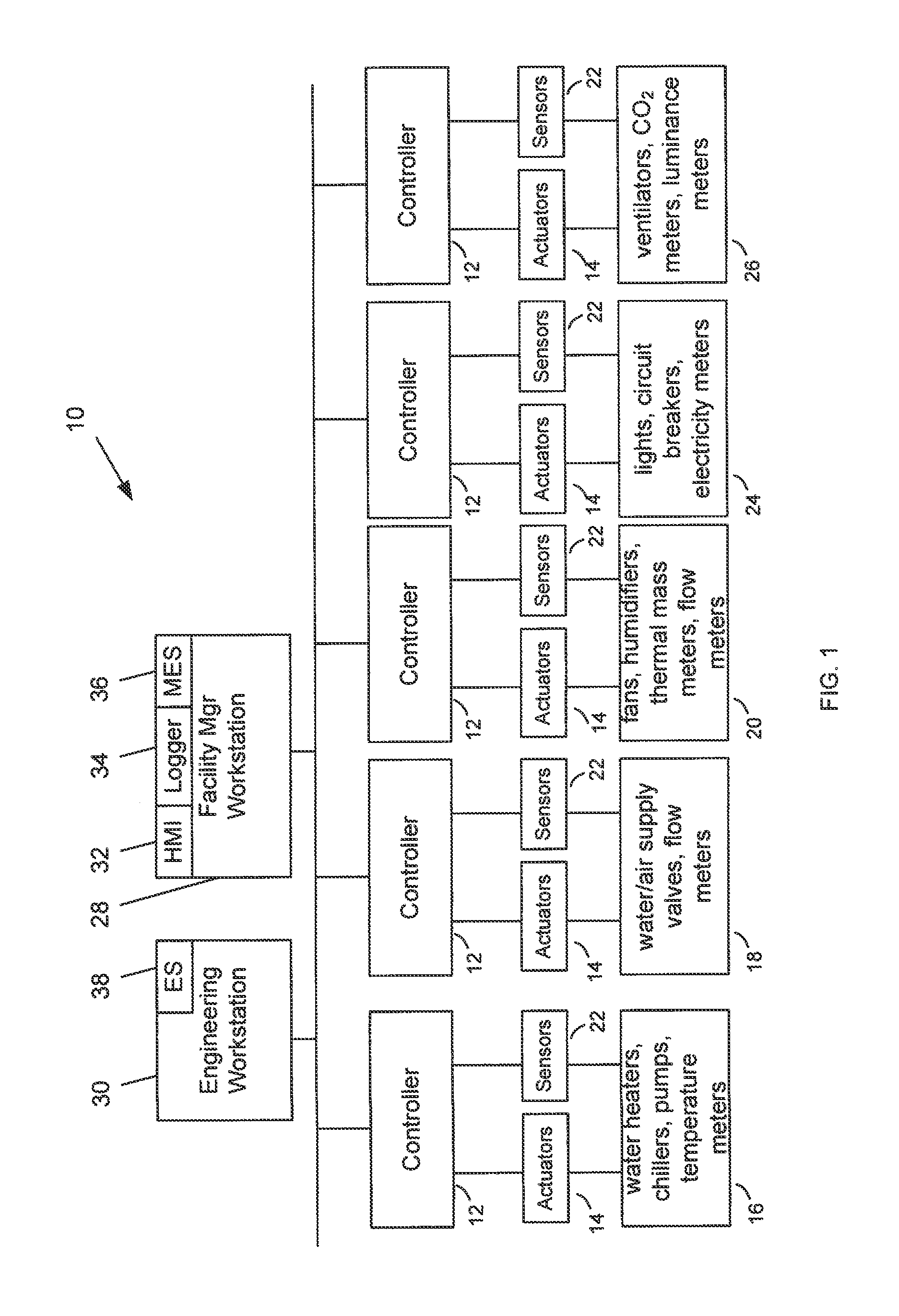

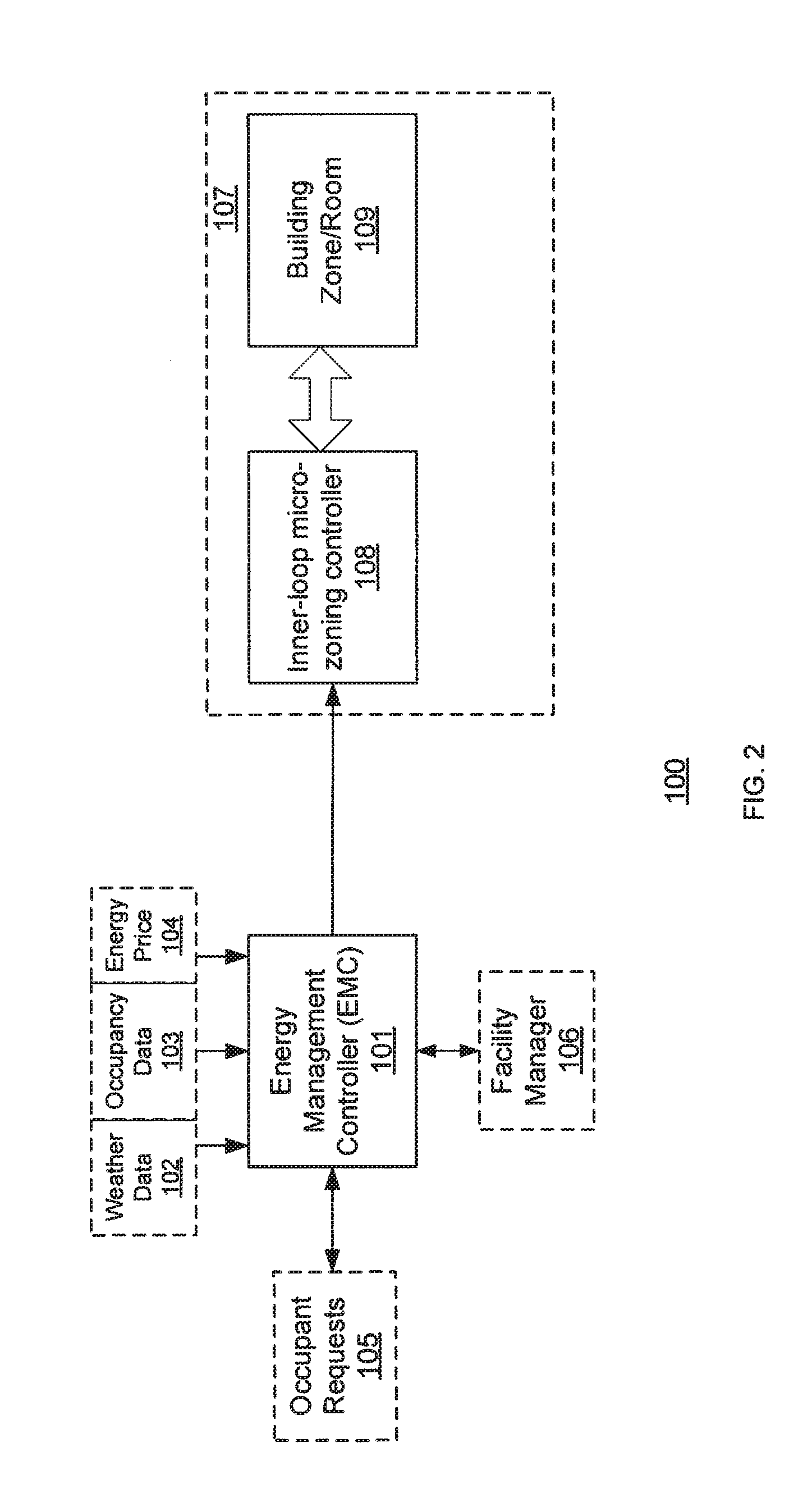

Cloud enabled building automation system

ActiveUS20130274940A1Optimize energy useLow costMechanical power/torque controlData processing applicationsControl signalOperating energy

A method of controlling energy consumption in a building. The method includes receiving occupant request data comprising a plurality of requests, wherein each of the plurality of requests corresponds to one of a plurality of zones in the building wherein the occupant request data is received via a cloud computing resource. The method also includes receiving weather data comprising at least one of current weather measurement data and weather forecast data wherein the weather data is received via a cloud computing resource. In addition, a facility management rule is received via a cloud computing resource. Further, the method includes generating a plurality of output control signals via cloud computing resource, wherein each of the plurality of output control signals is based on one of a plurality of requests and predicted occupant schedules, energy price data and the facility management rule. The control signals are generated by using simulation-based model predictive control method to determine a set of optimized control signals based on optimized energy use or optimized energy cost. The optimized control signals are transmitted to controllers.

Owner:SIEMENS AG

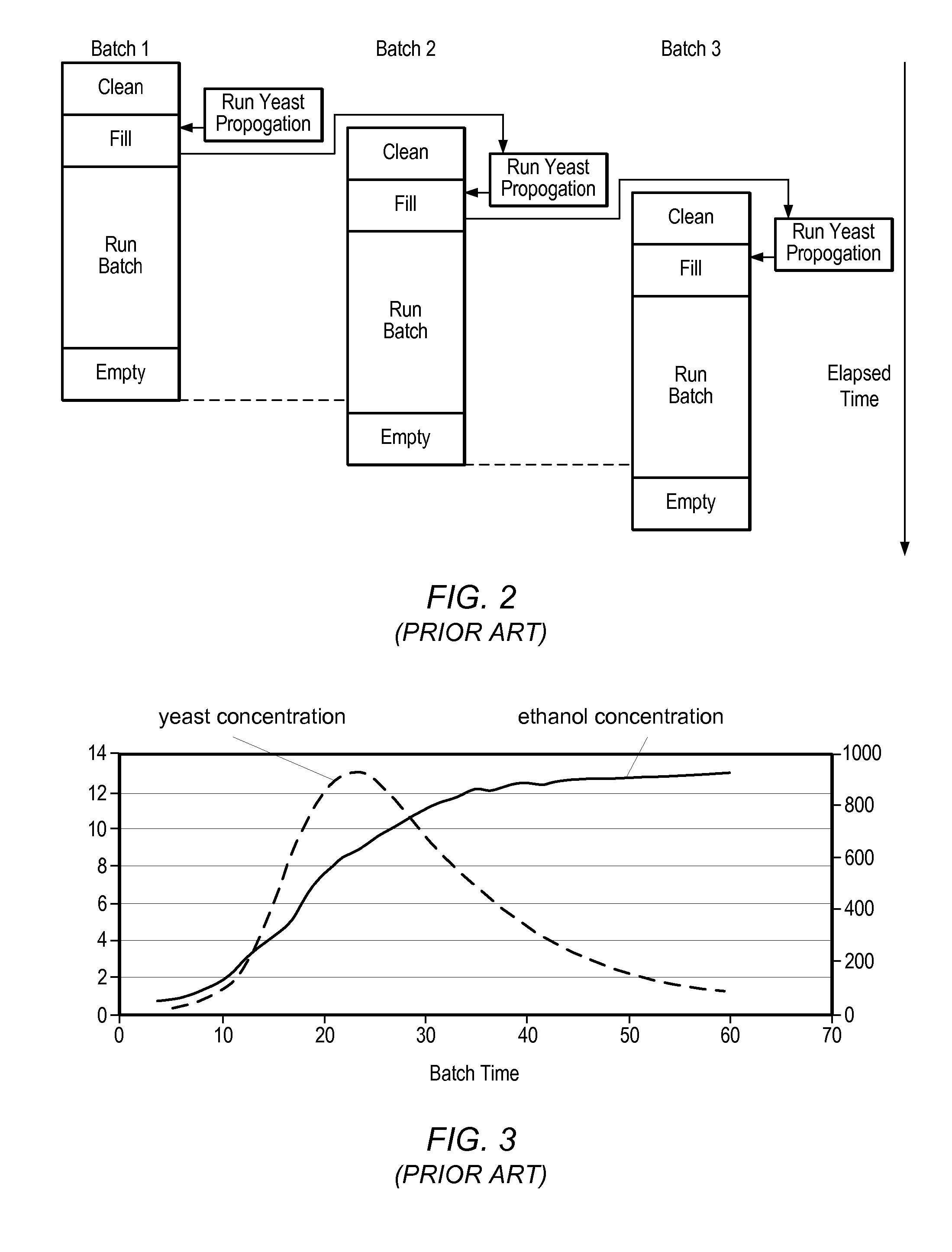

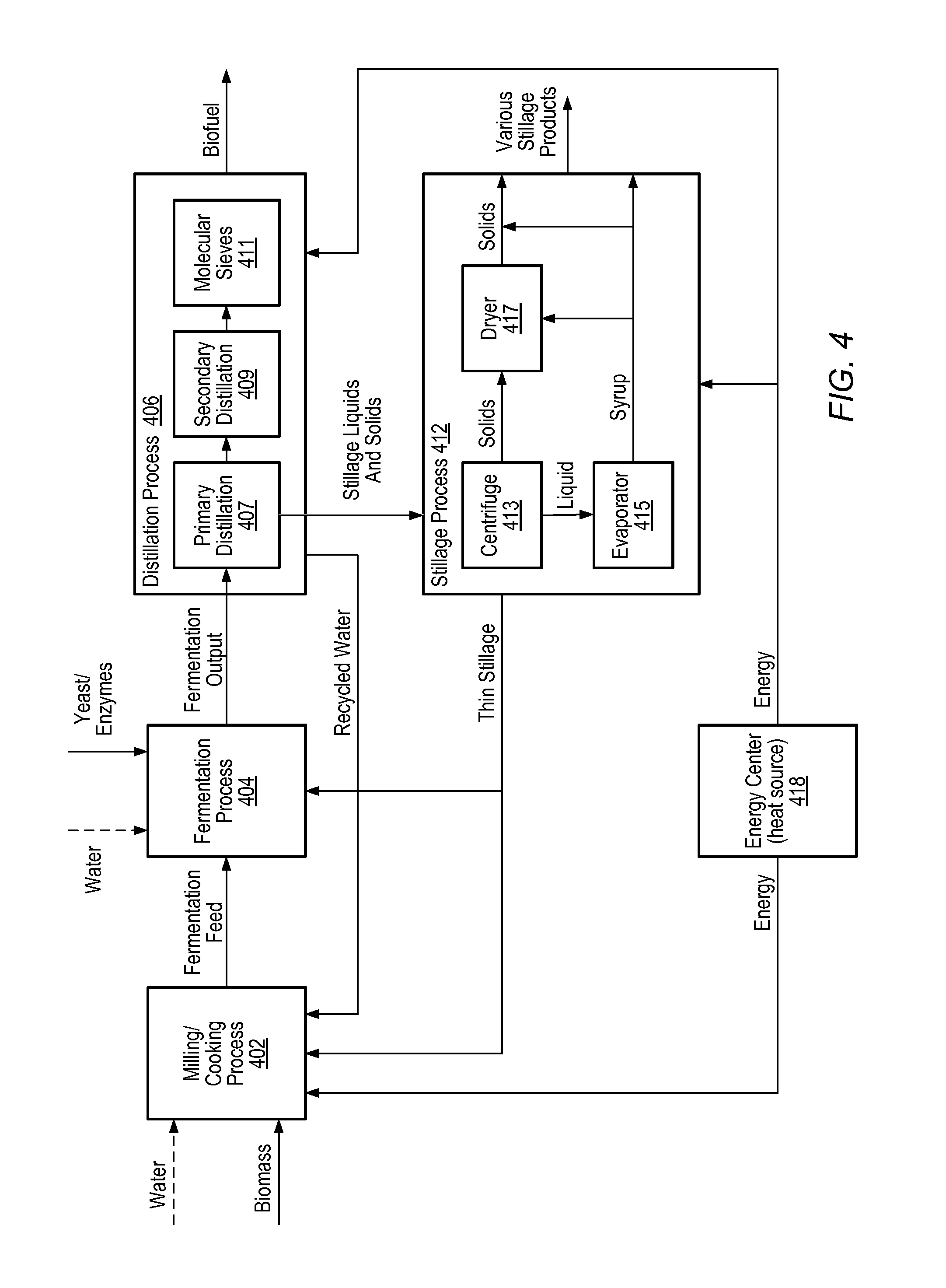

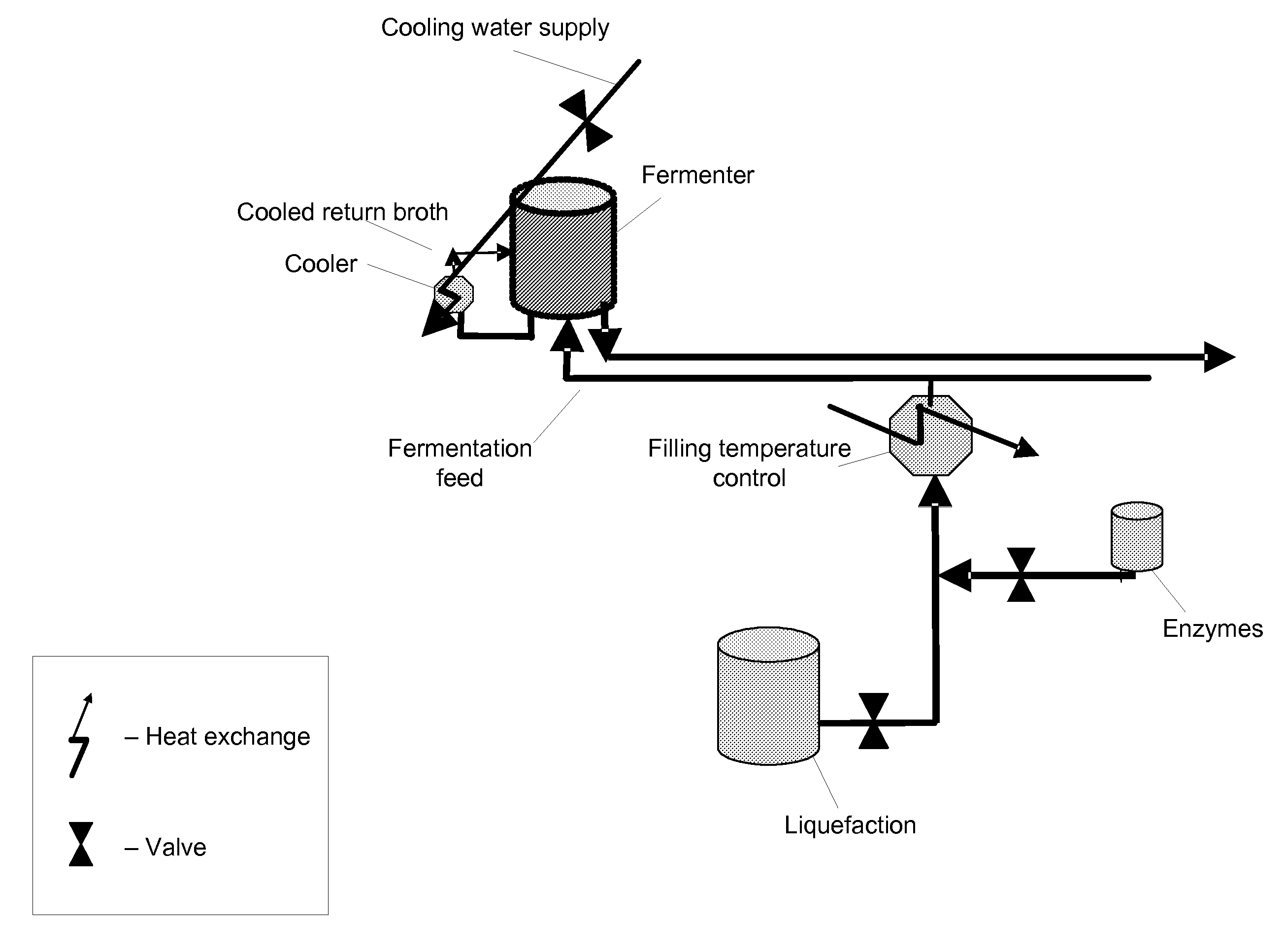

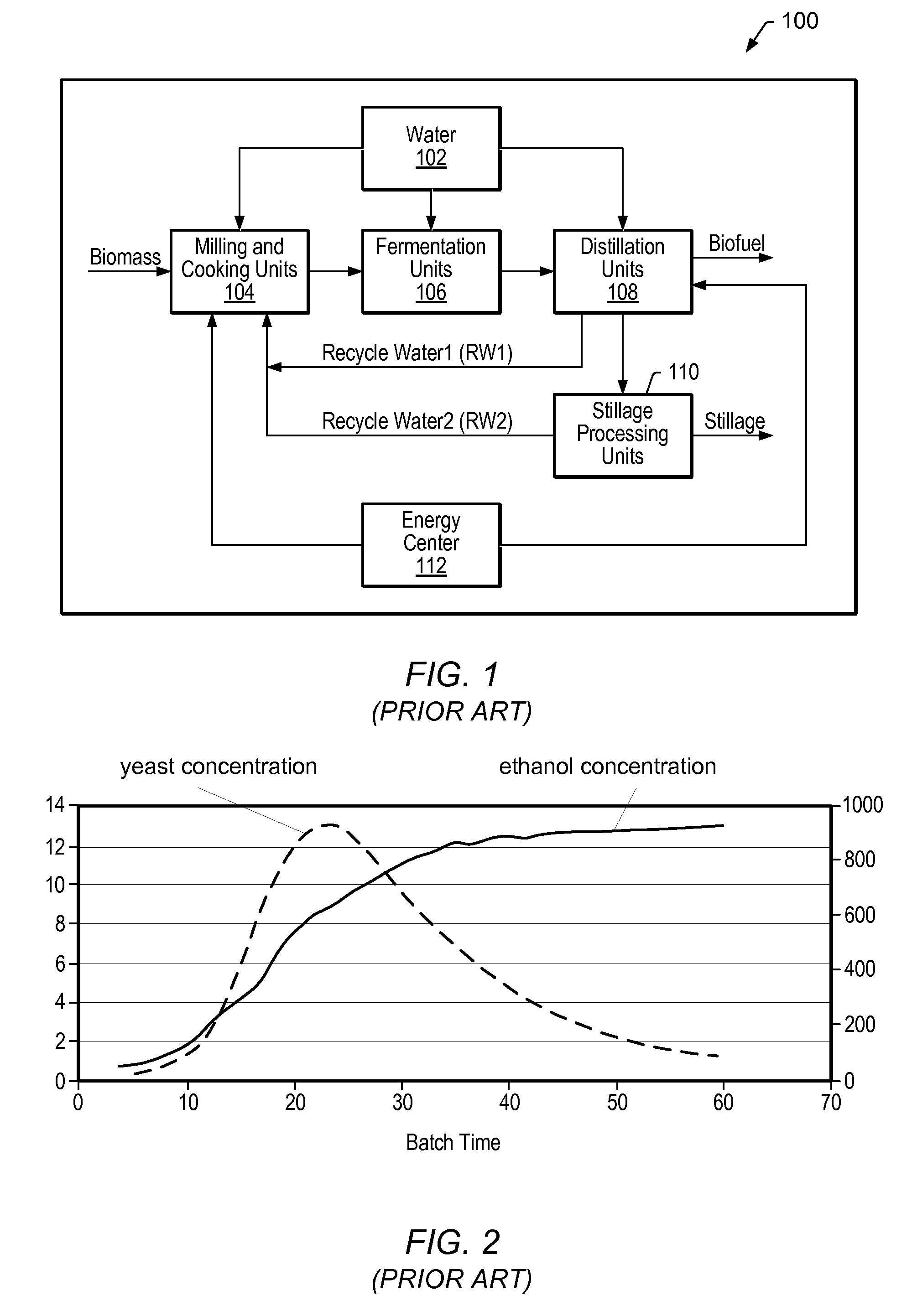

Model predictive control of fermentation in biofuel production

ActiveUS20080109100A1Easy to controlImprovement in biofuel yieldBiological substance pretreatmentsTemperatue controlHorizonBiofuel

System and method for managing batch fermentation in biofuel production. An optimizer executes a nonlinear multivariate predictive model of a batch fermentation process in accordance with an end of batch objective specifying a target end of batch biofuel concentration to determine an optimal batch trajectory over a temporal control horizon specifying a biofuel and / or sugar concentration trajectory over the batch fermentation process. A nonlinear control model for the batch fermentation process that includes the temporal control horizon driven by biofuel concentration during the batch fermentation process is executed per the determined optimal batch trajectory using received process information as input, thereby generating model output including target values for manipulated variables for the batch fermentation process, including batch fermentation temperature. The batch fermentation process is controlled per the target values to produce biofuel in accordance with the determined optimal batch trajectory, to substantially optimize the end of batch biofuel yield.

Owner:ROCKWELL AUTOMATION TECH

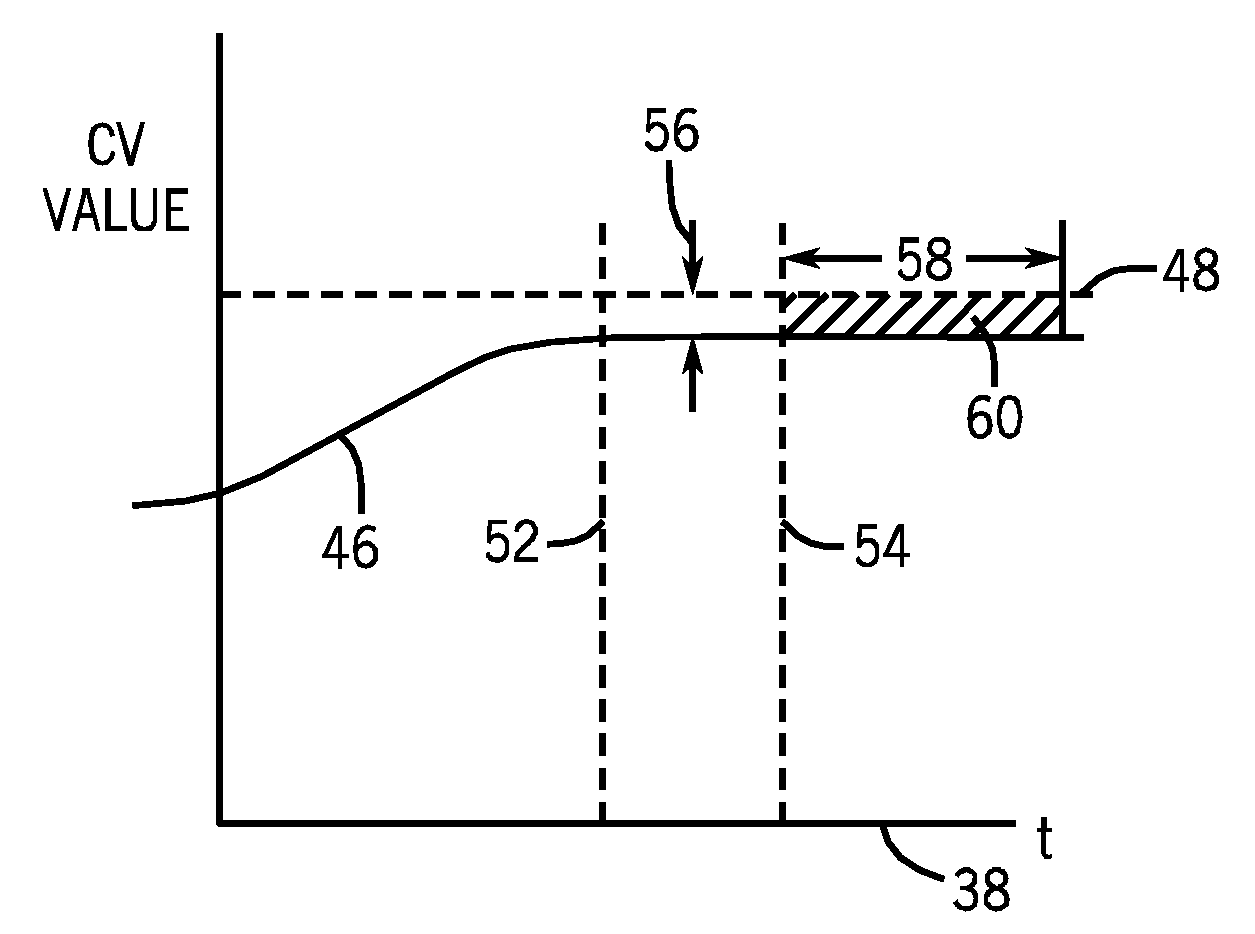

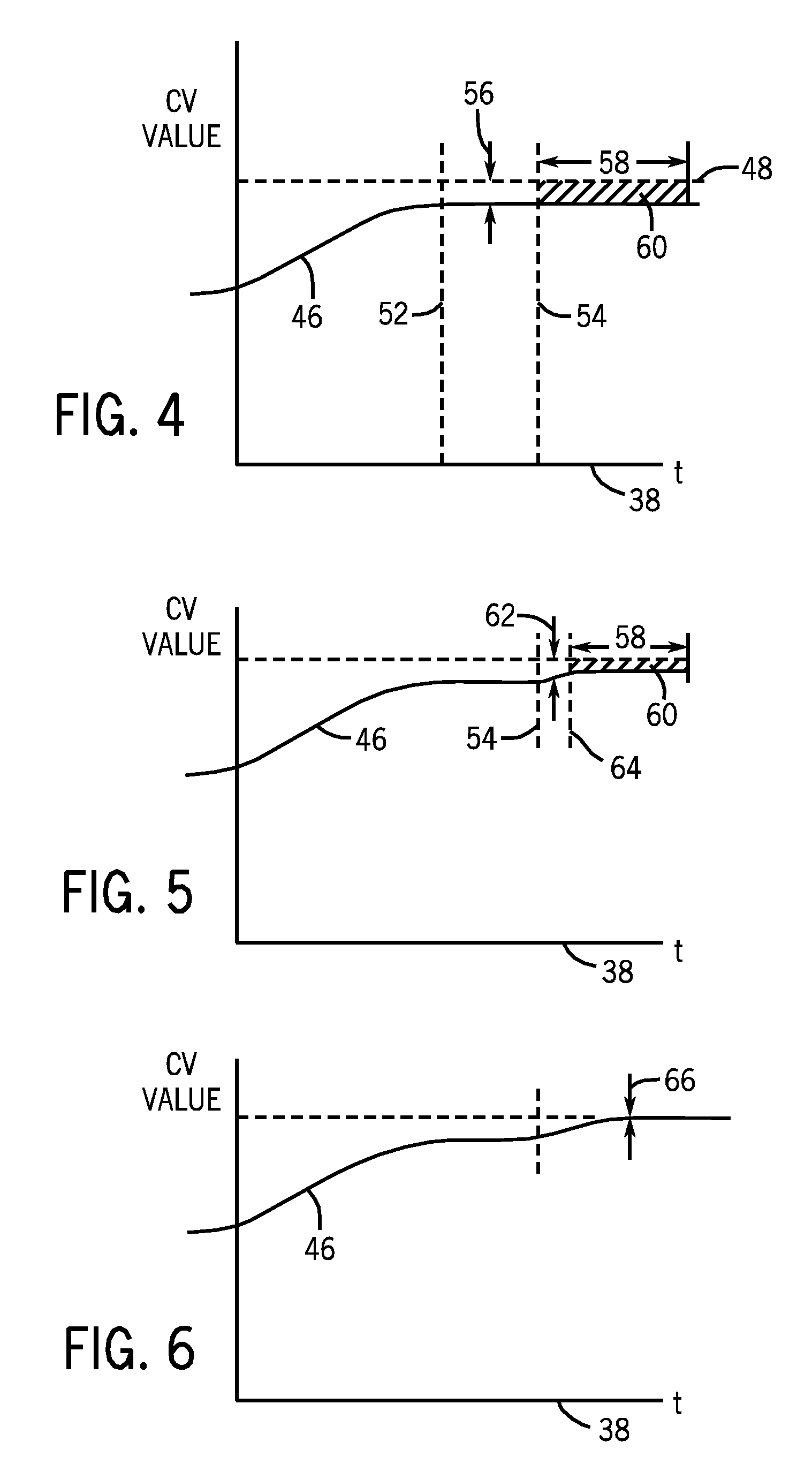

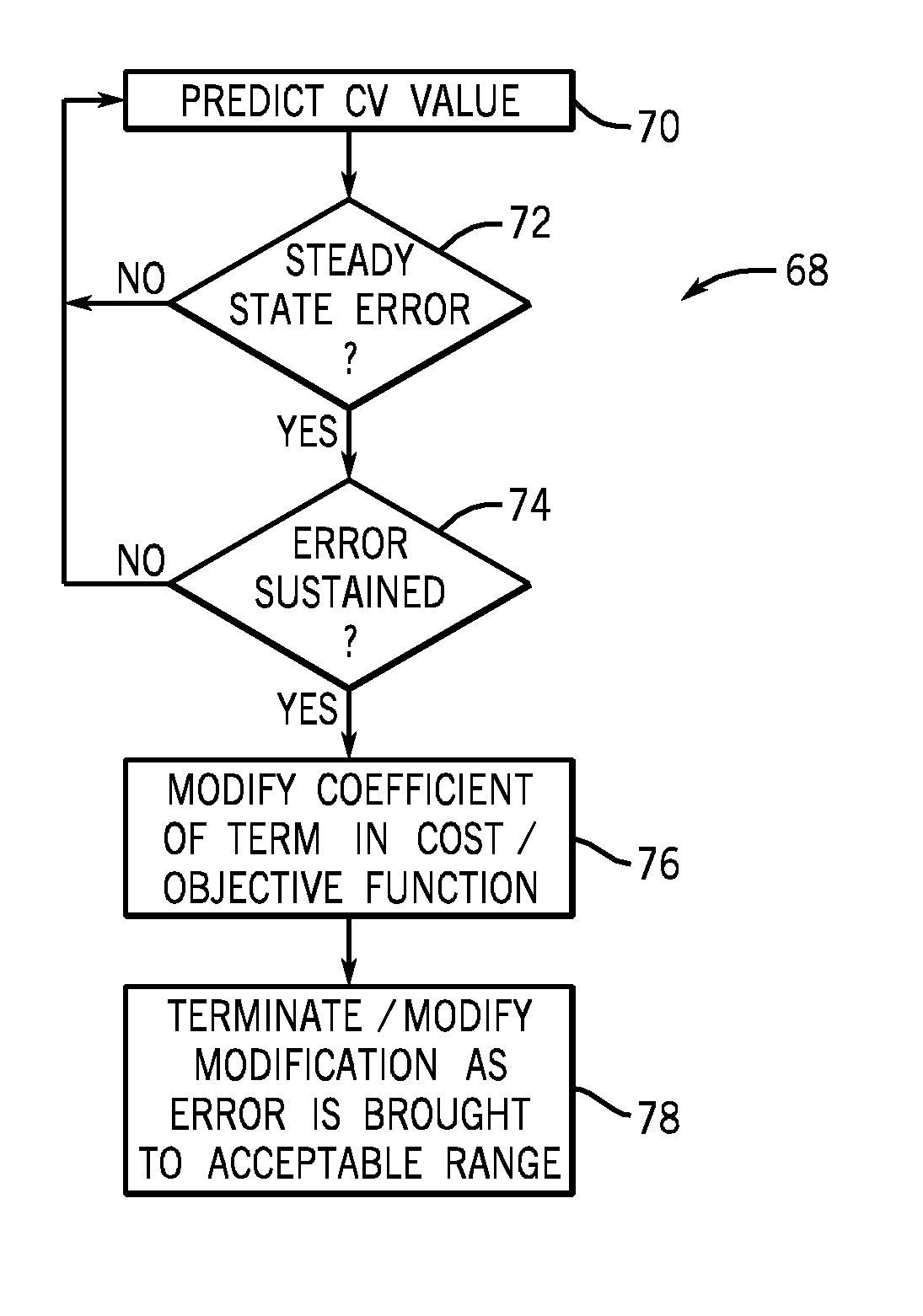

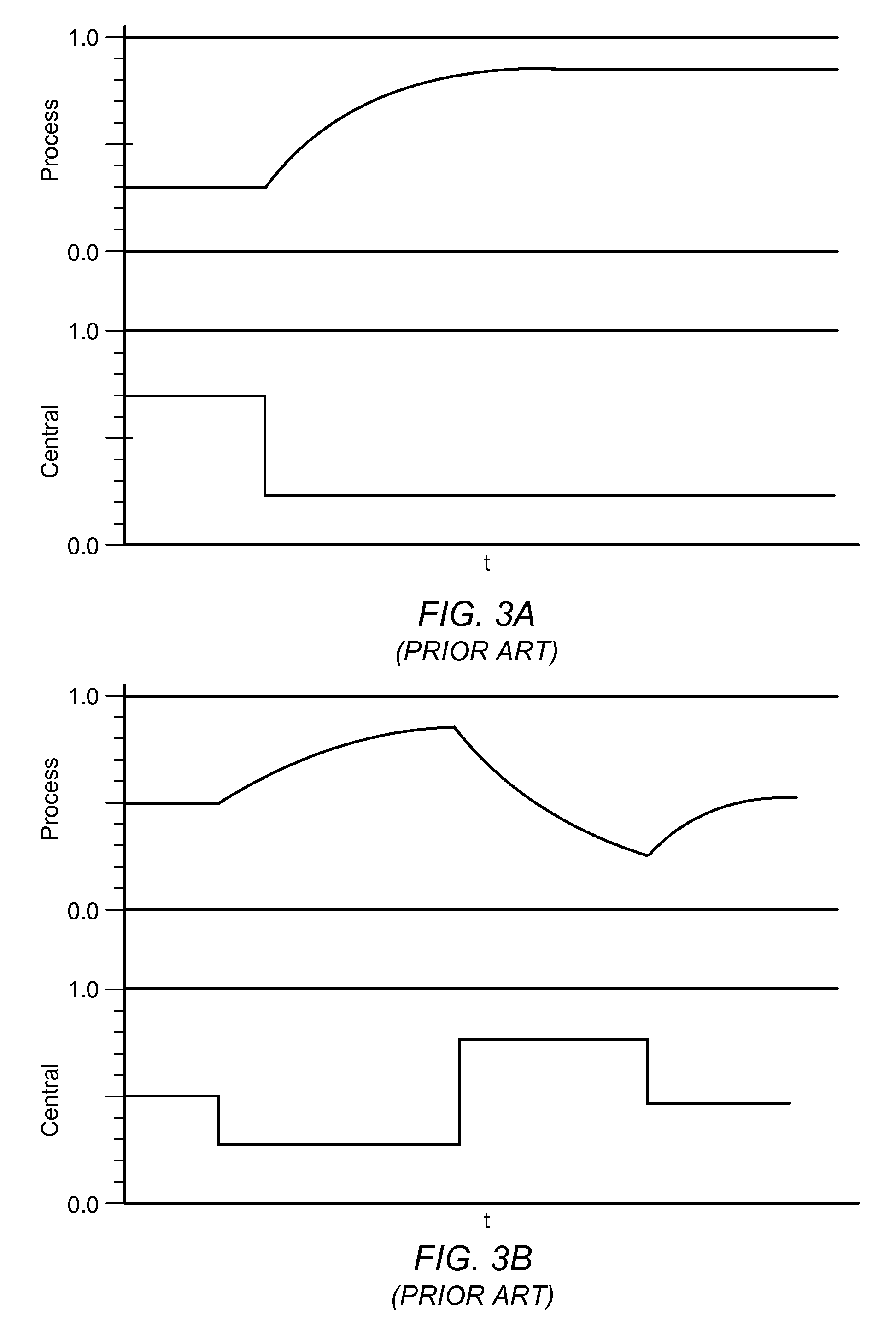

Model predictive control system and method for reduction of steady state error

ActiveUS8032235B2Reducing steady state errorReduce errorsElectric/magnetic detection for well-loggingPermeability/surface area analysisHorizonControl system

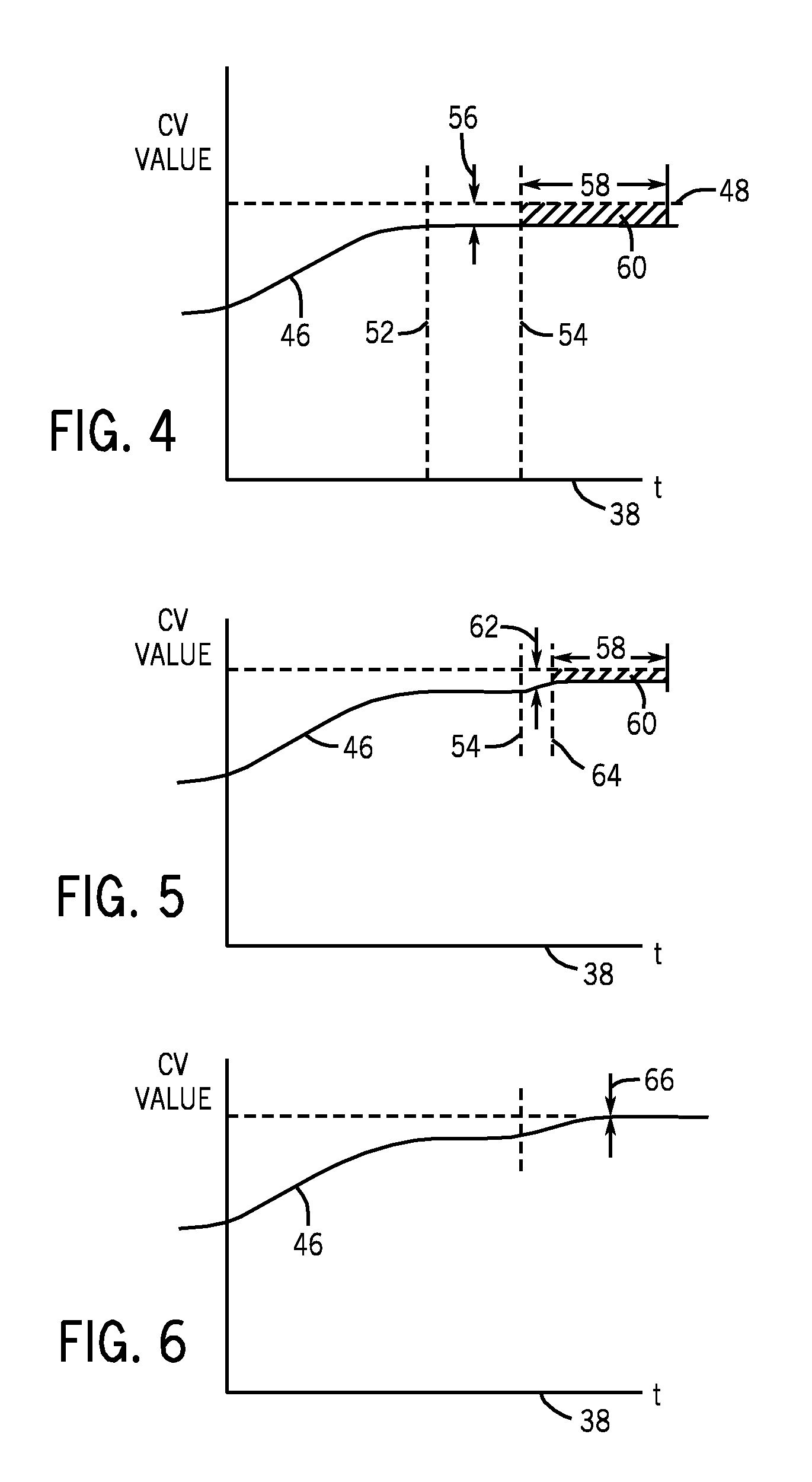

A technique is disclosed for reducing an error in a controlled variable via model predictive control. A predicted error in the controlled variable is determined for a forward-looking control horizon based upon measured or computed variables. The integral of the predicted error is computed. If the error or the integral exceed a tolerance for a determined time period, the model predictive control algorithm is modified to drive the error or the integral to within a tolerance. The modifications to the control algorithm may include changes to coefficients for terms based upon the error and / or the integral of the error.

Owner:ROCKWELL AUTOMATION TECH

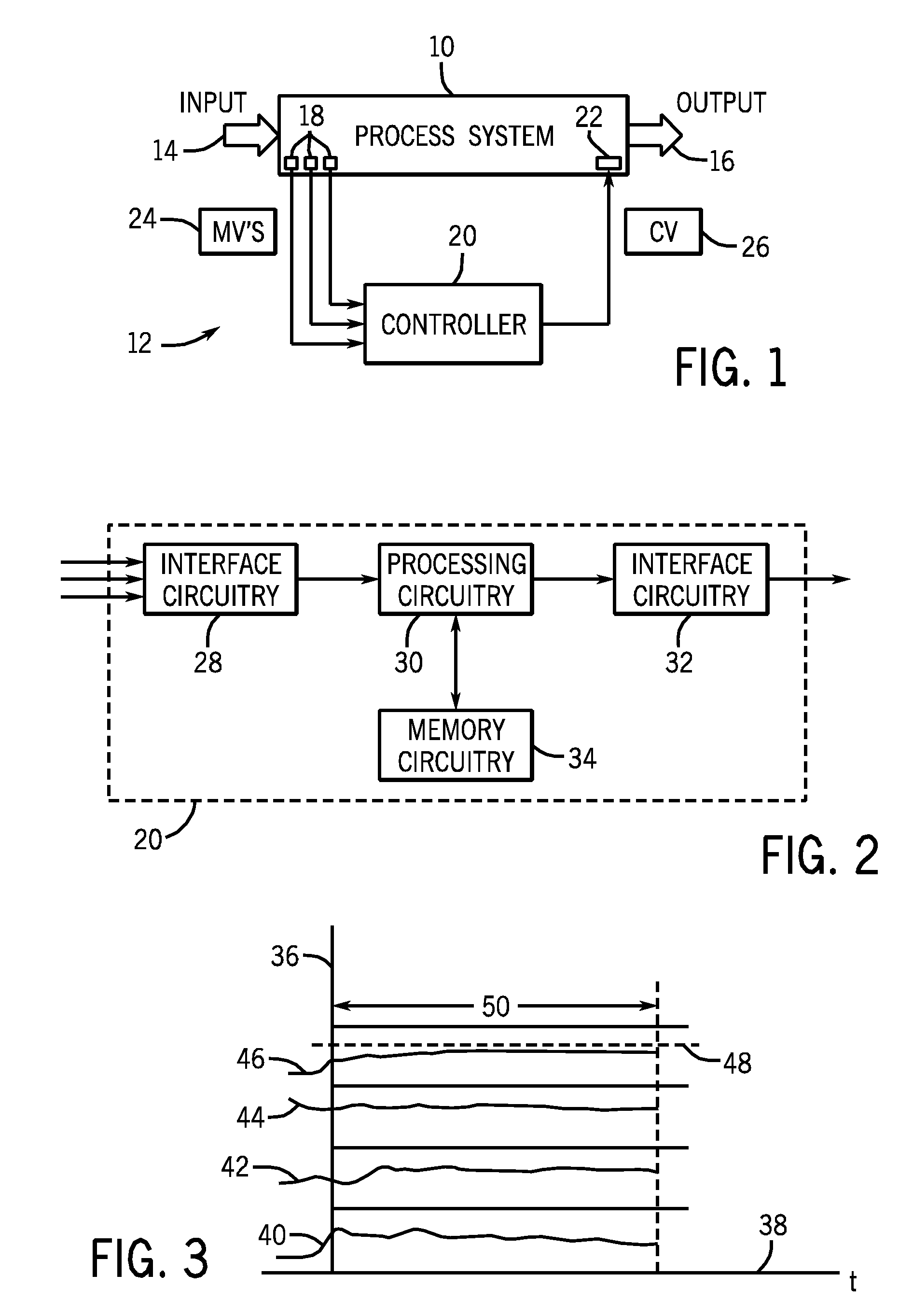

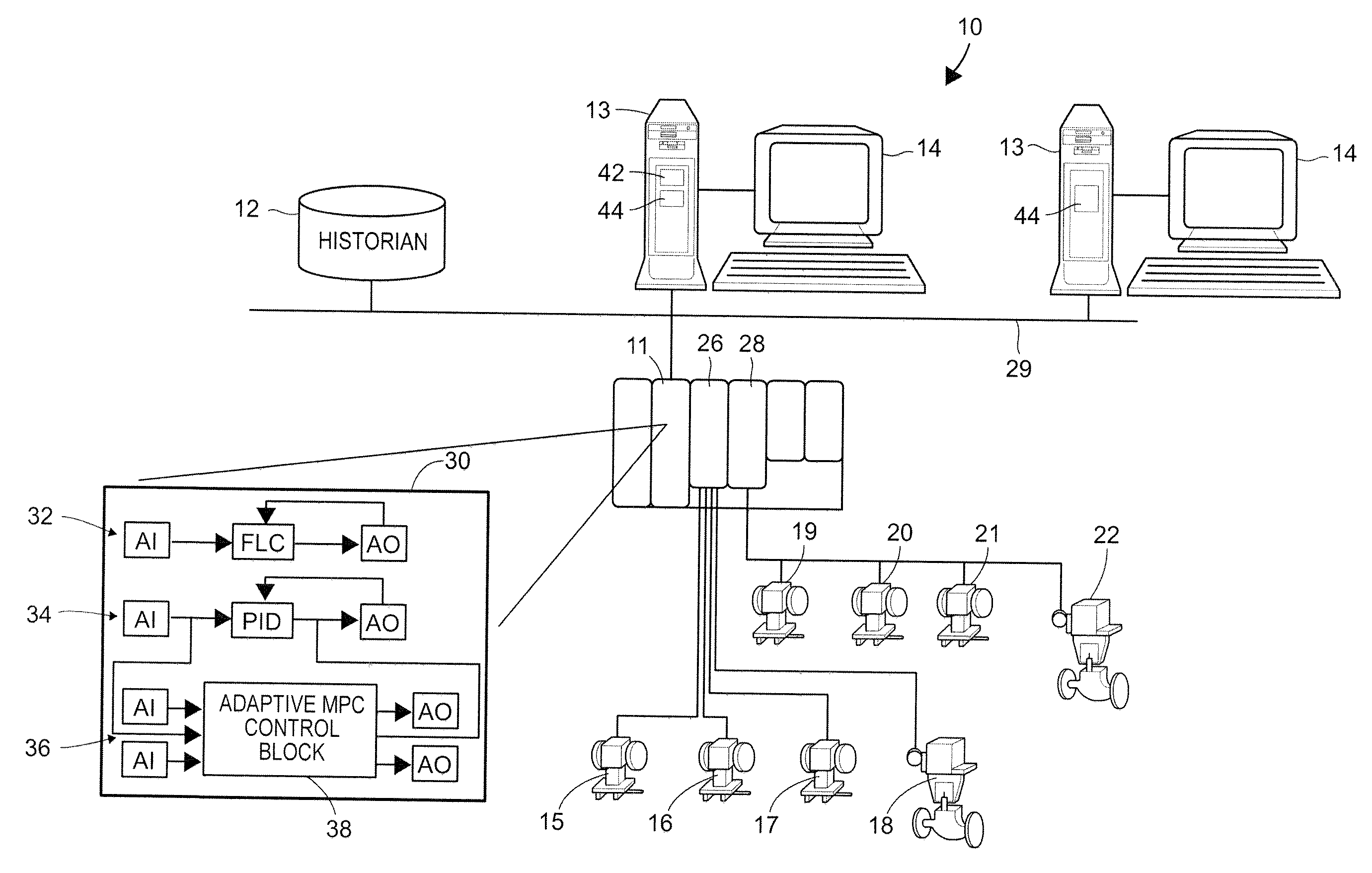

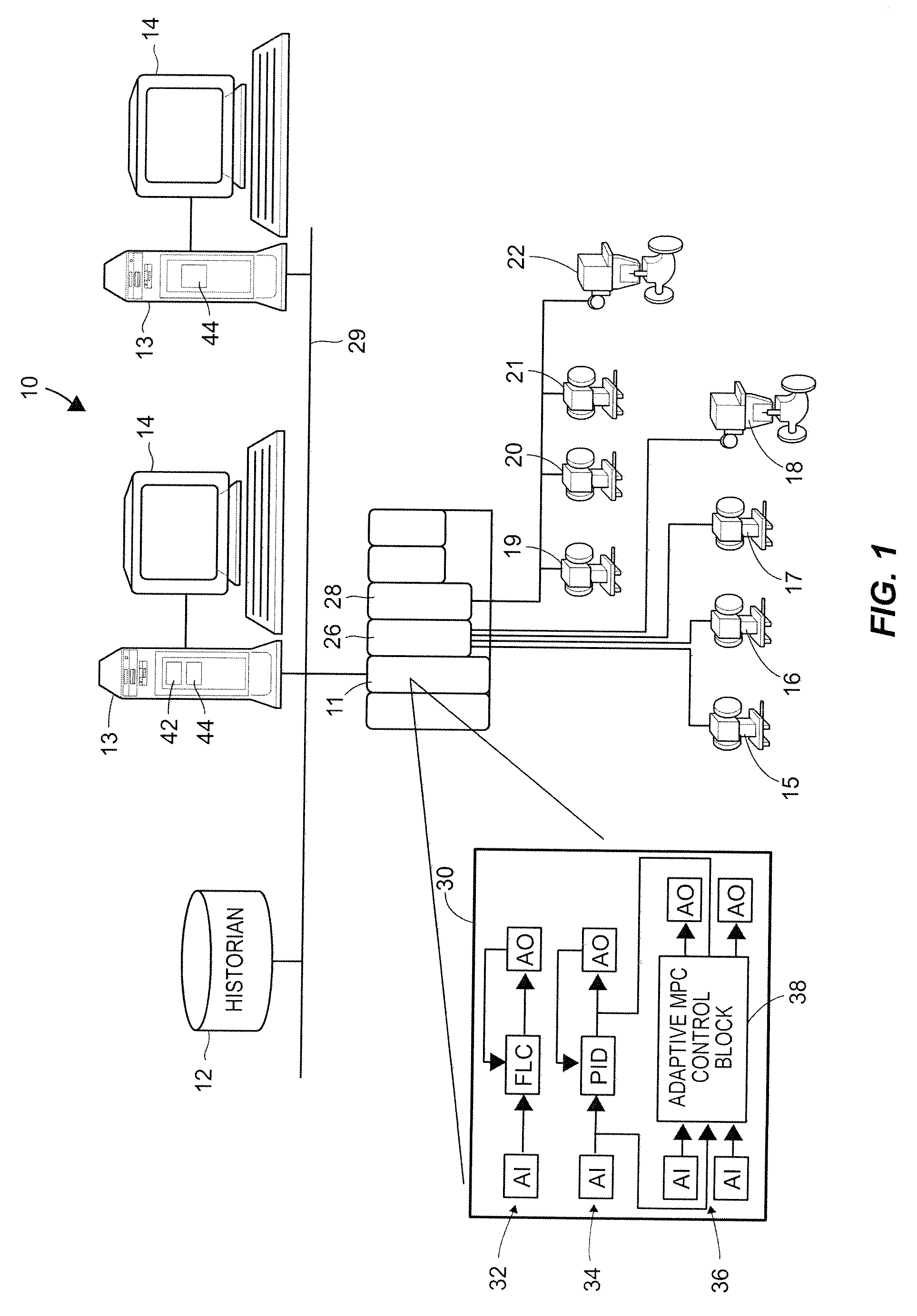

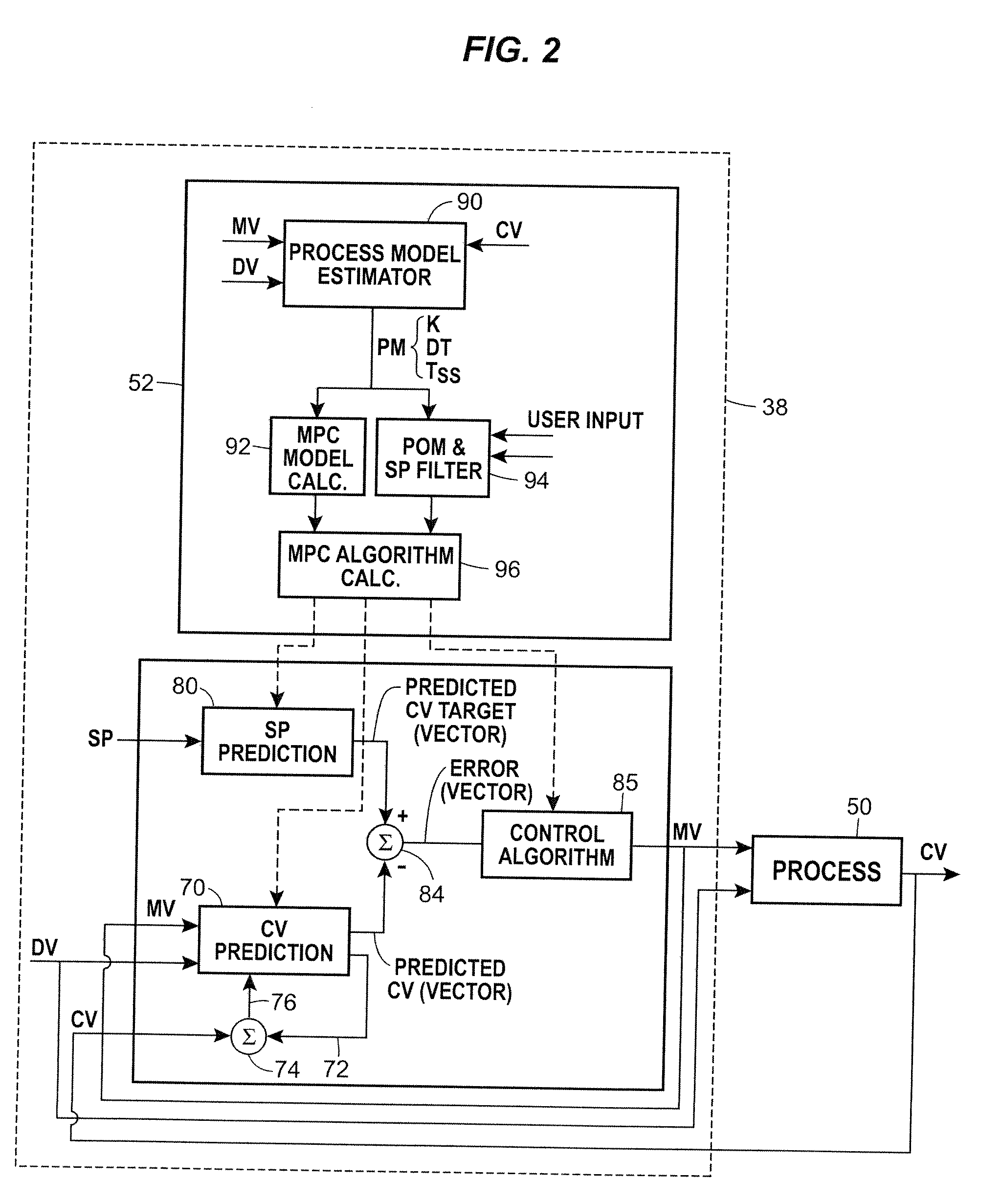

On-line adaptive model predictive control in a process control system

A method of creating and using an adaptive DMC type or other MPC controller includes using a model switching technique to periodically determine a process model, such as a parameterized process model, for a process loop on-line during operation of the process. The method then uses the process model to generate an MPC control model and creates and downloads an MPC controller algorithm to an MPC controller based on the new control model while the MPC controller is operating on-line. This technique, which is generally applicable to single-loop MPC controllers and is particularly useful in MPC controllers with a control horizon of one or two, enables an MPC controller to be adapted during the normal operation of the process, so as to change the process model on which the MPC controller is based to thereby account for process changes. The adaptive MPC controller is not computationally expensive and can therefore be easily implemented within a distributed controller of a process control system, while providing the same or in some cases better control than a PID controller, especially in dead time dominant process loops, and in process loops that are subject to process model mismatch within the process time to steady state.

Owner:FISHER-ROSEMOUNT SYST INC

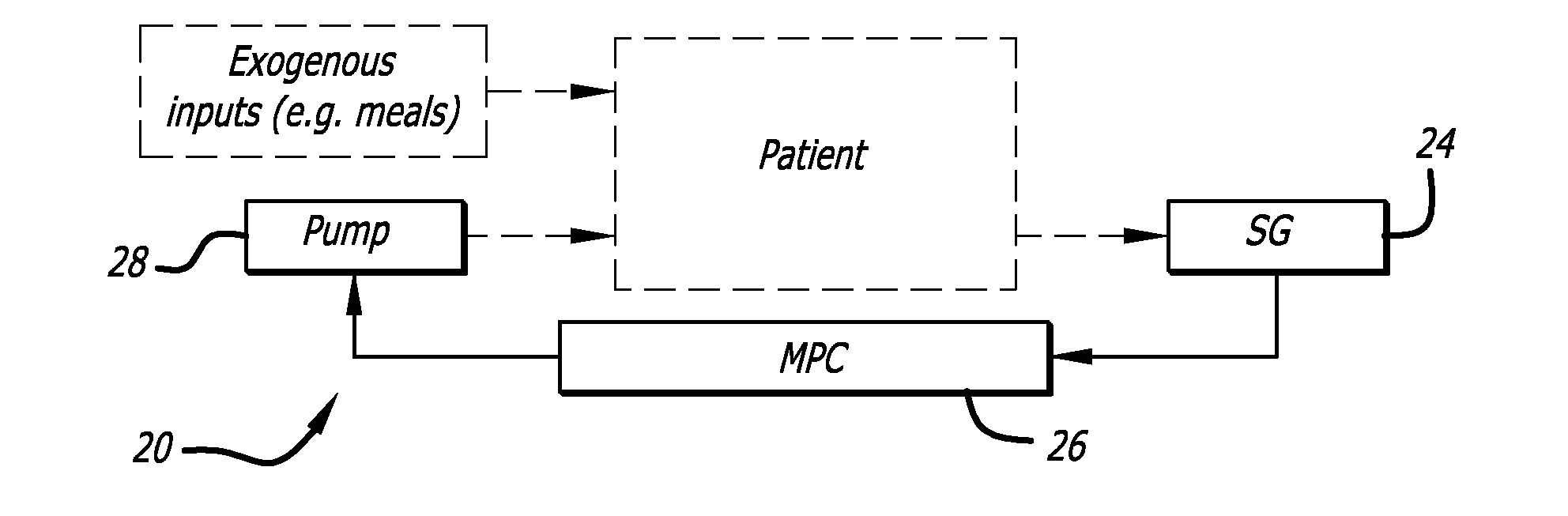

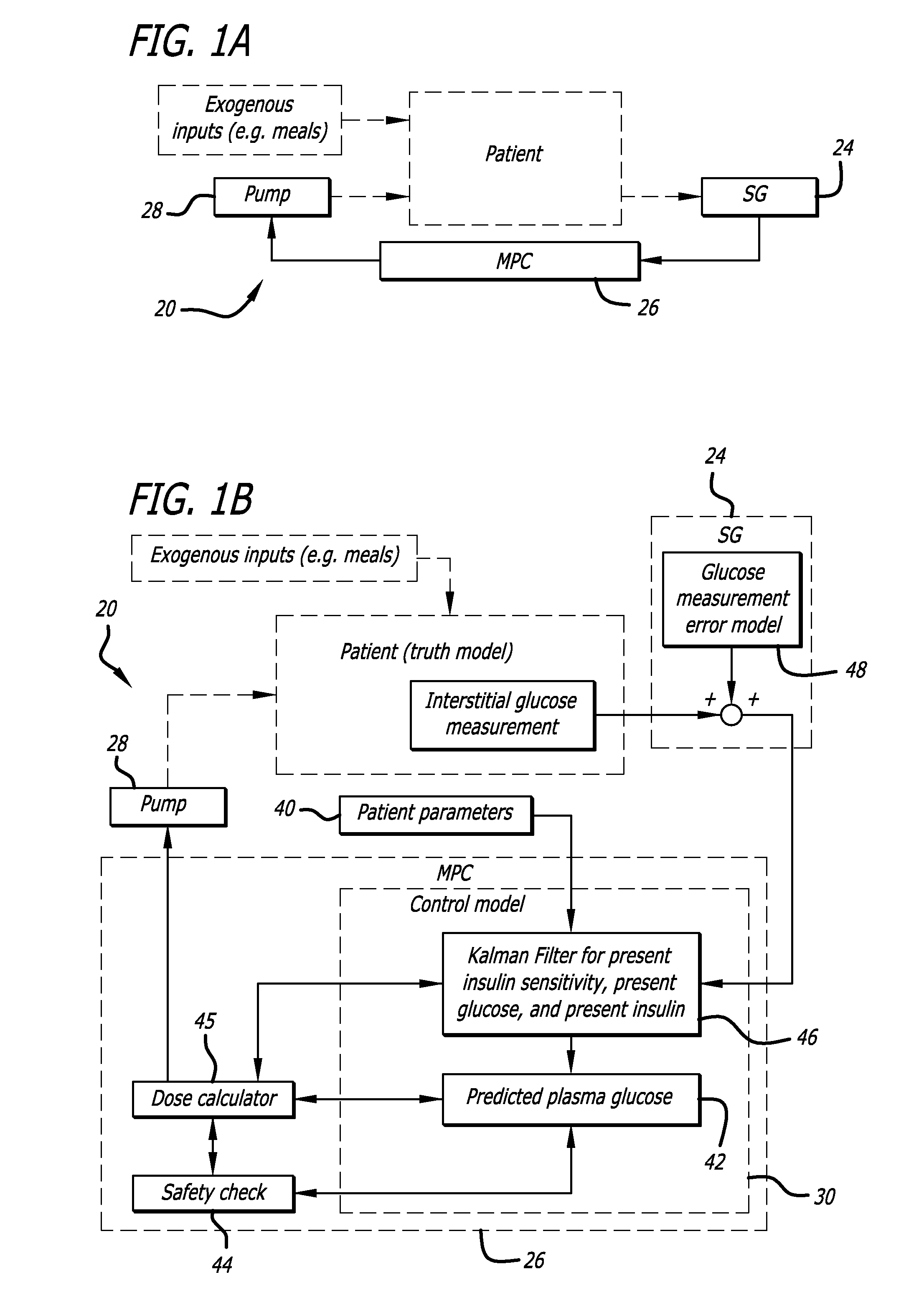

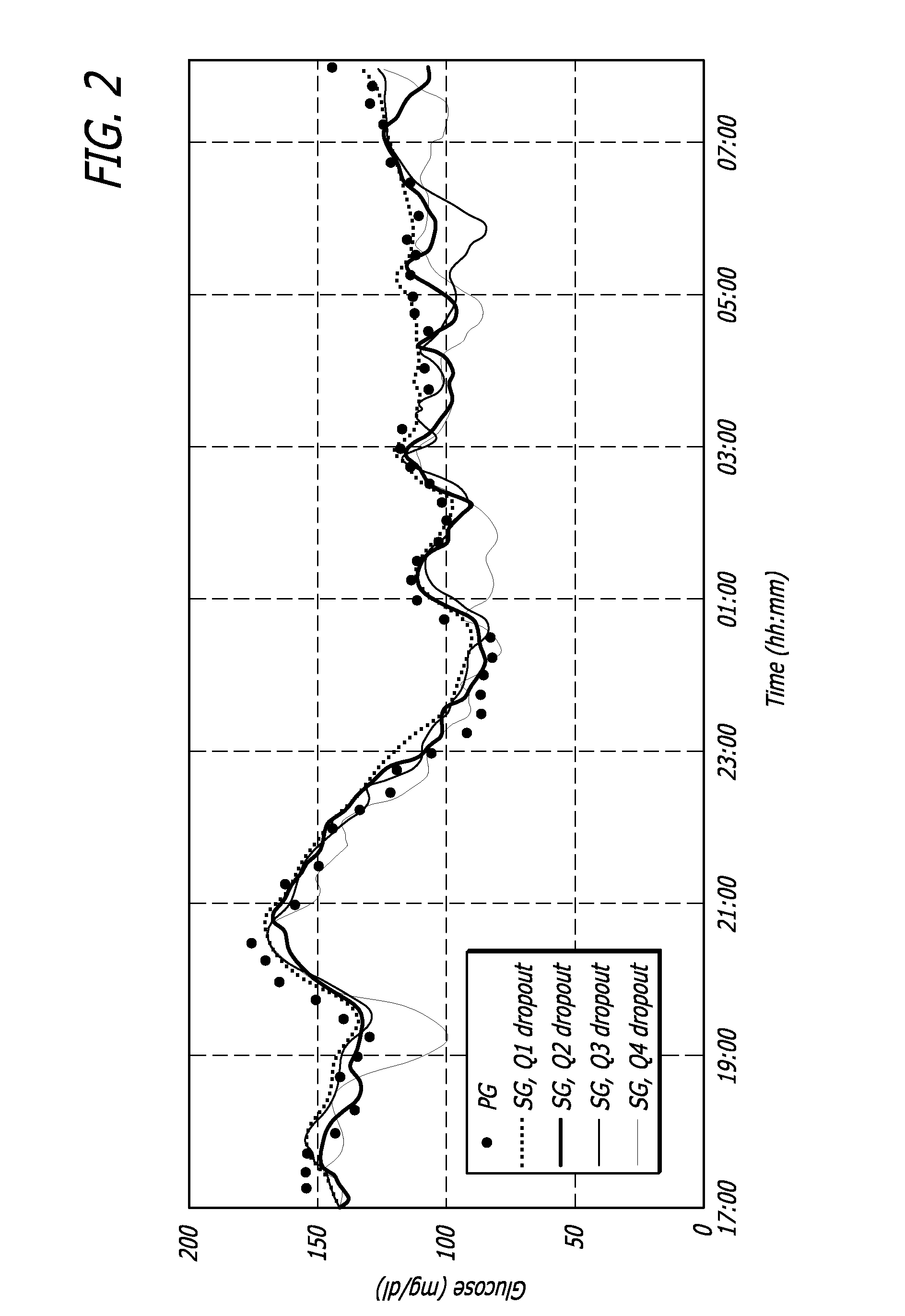

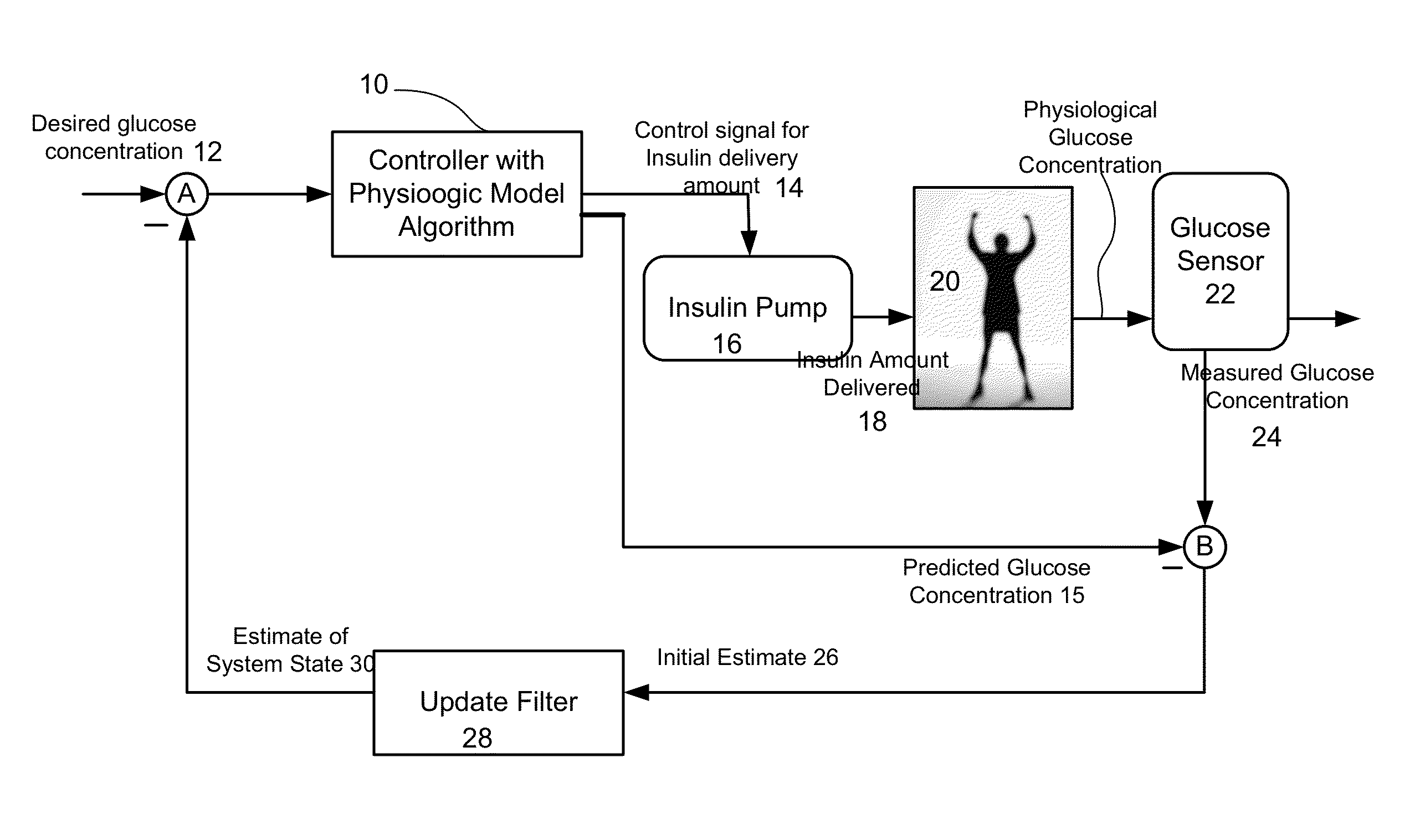

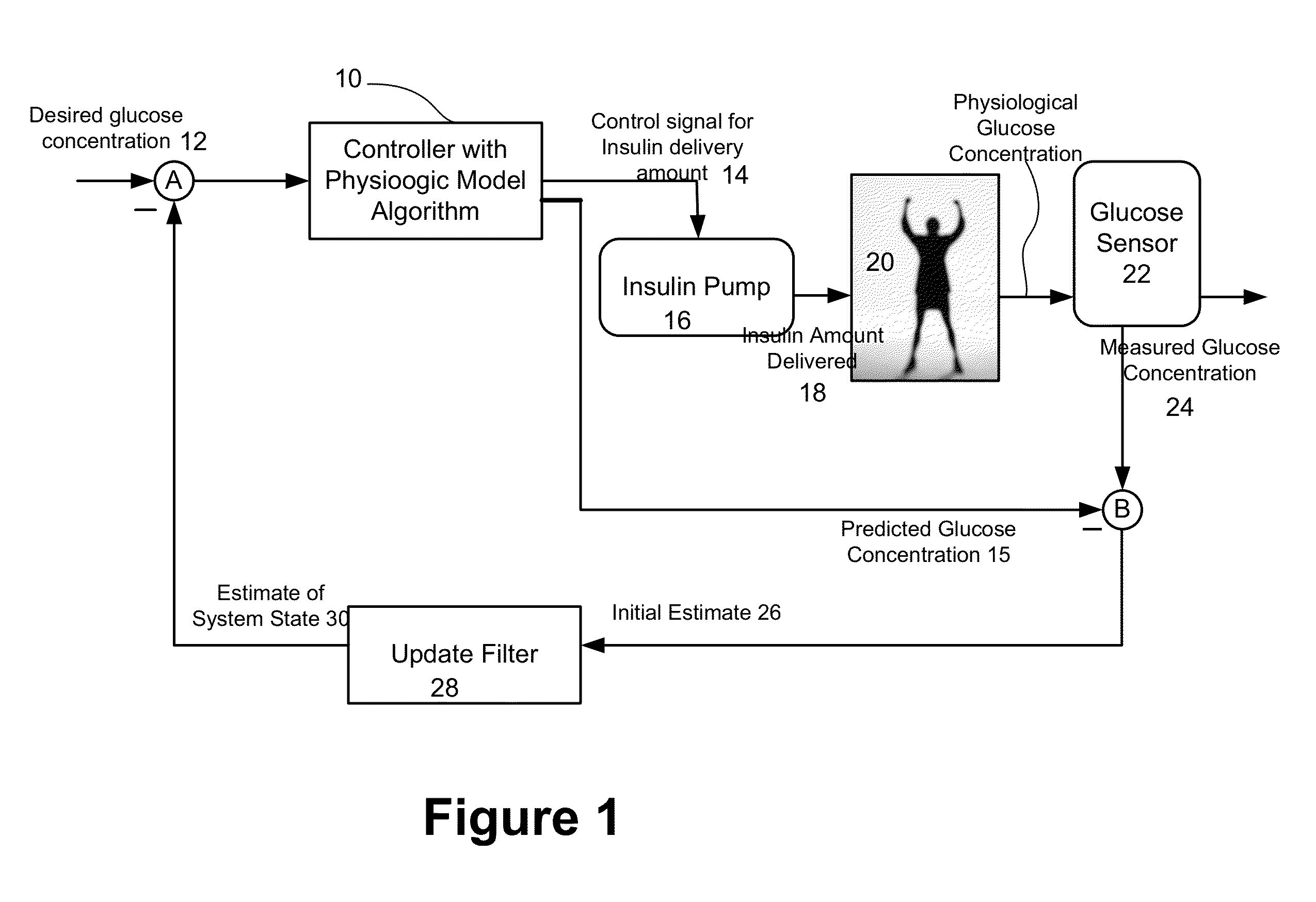

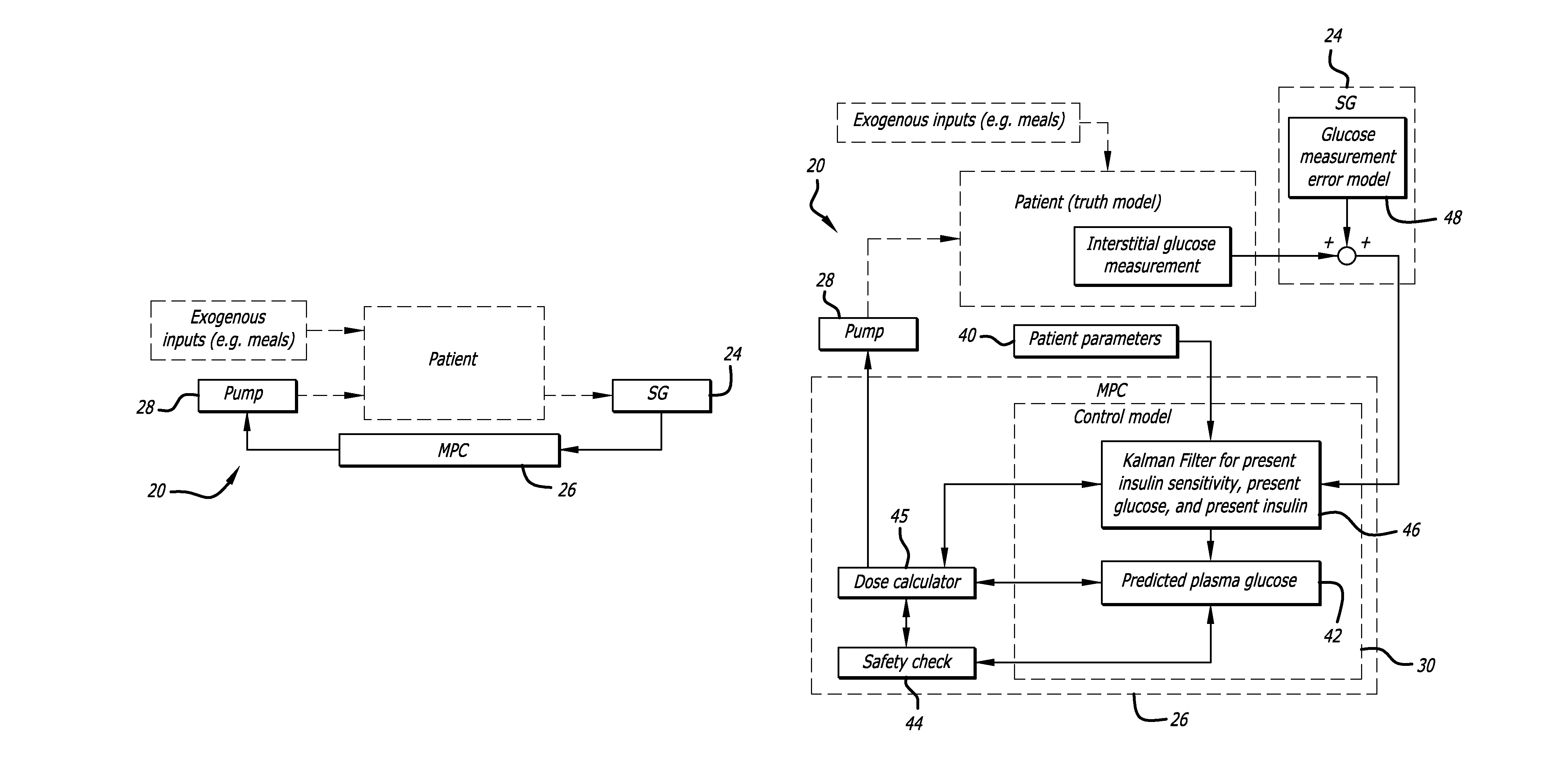

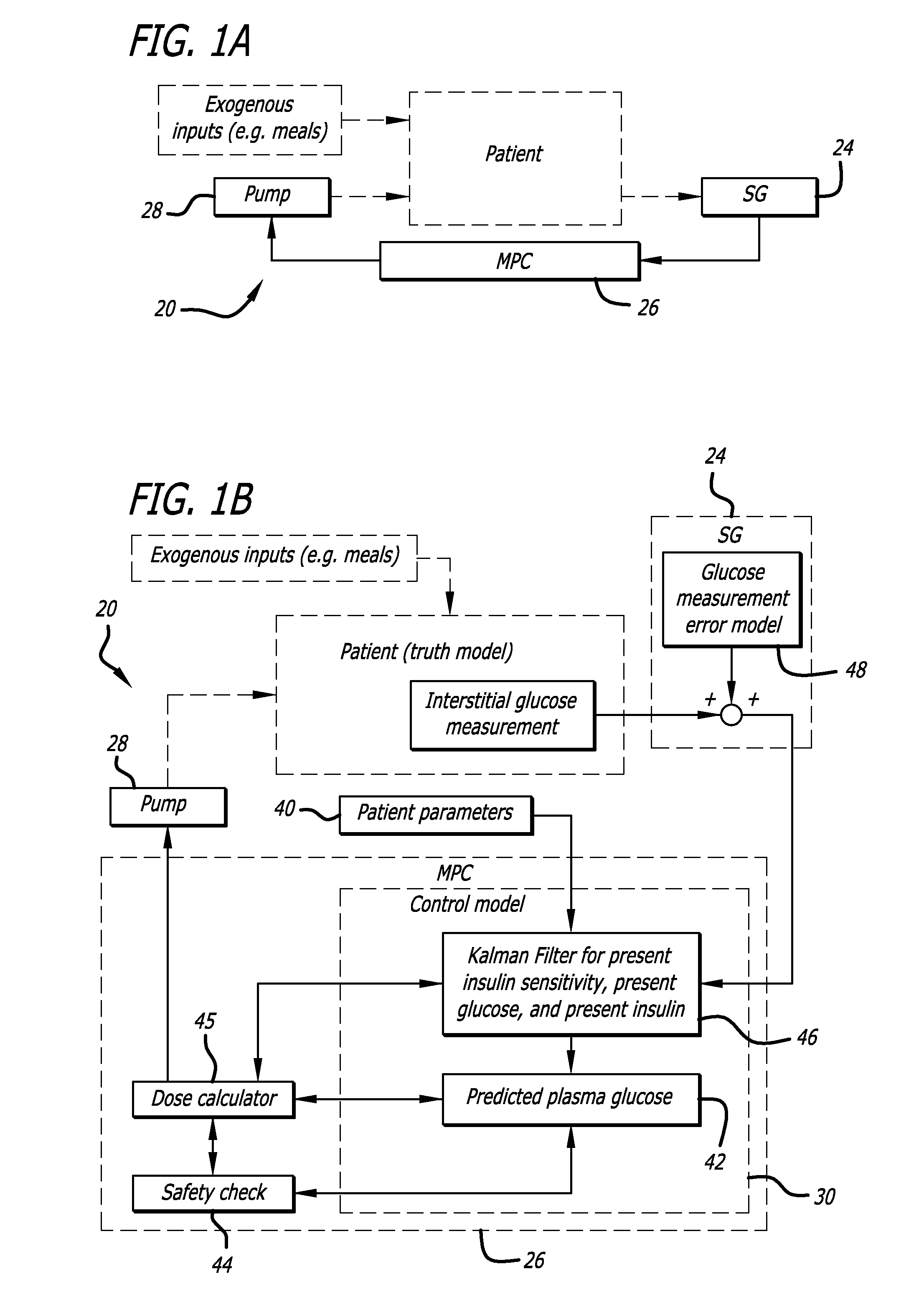

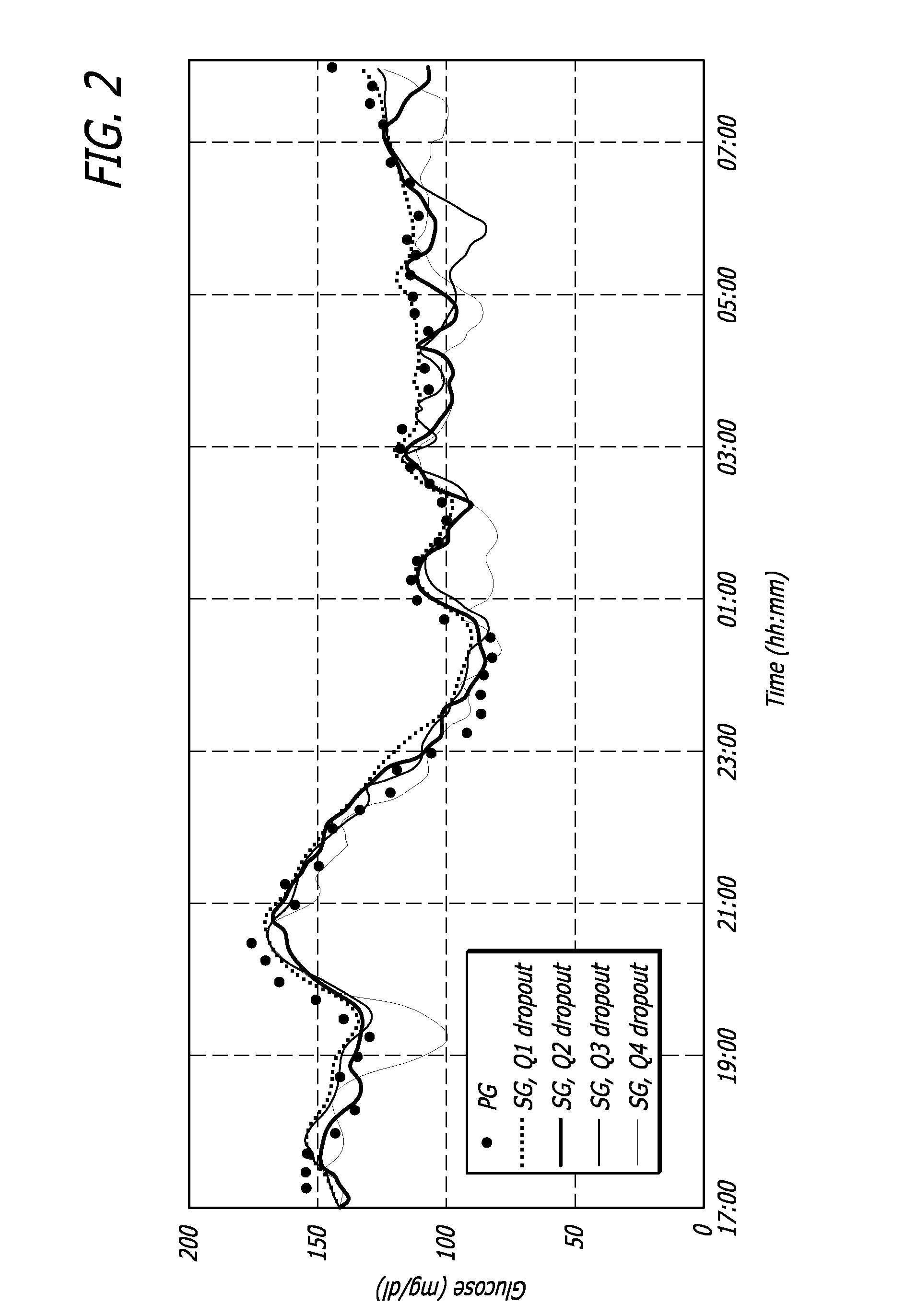

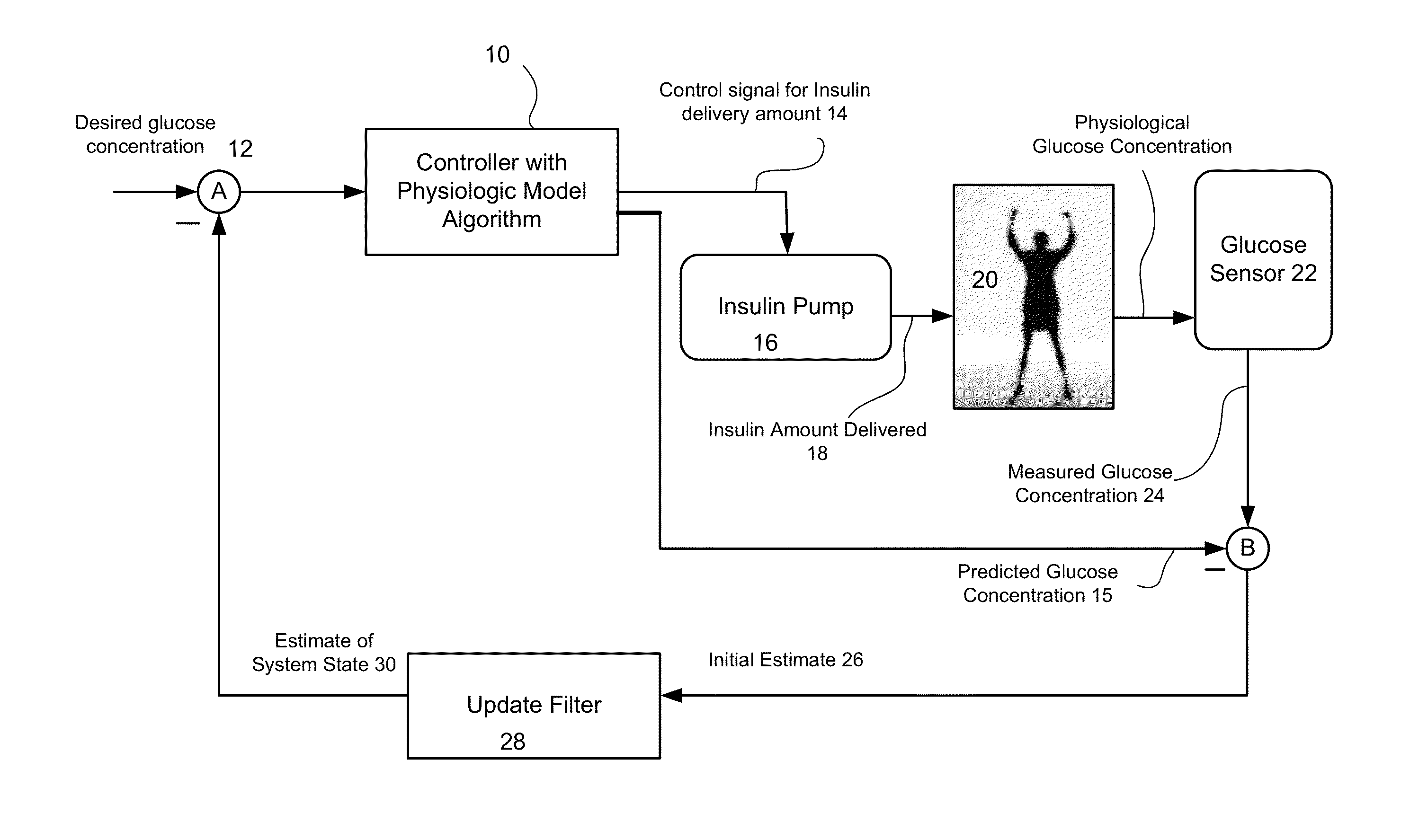

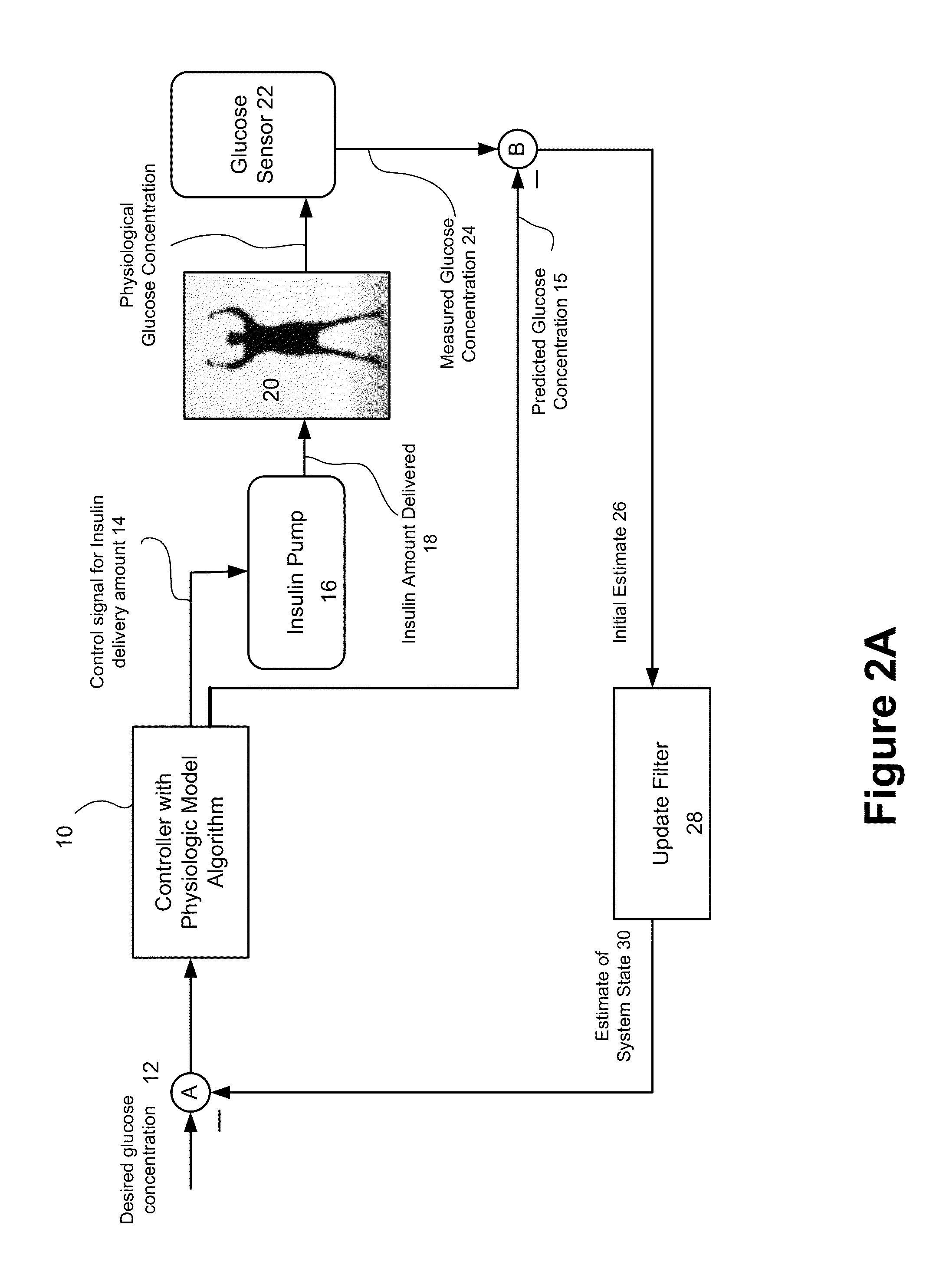

Overnight closed-loop insulin delivery with model predictive control and glucose measurement error model

ActiveUS20100280441A1Reducing insulin deliveryReduce deliveryDrug and medicationsMedical devicesGlucose sensorsClosed loop

A closed-loop system for insulin infusion overnight uses a model predictive control algorithm (“MPC”). Used with the MPC is a glucose measurement error model which was derived from actual glucose sensor error data. That sensor error data included both a sensor artifacts component, including dropouts, and a persistent error component, including calibration error, all of which was obtained experimentally from living subjects. The MPC algorithm advised on insulin infusion every fifteen minutes. Sensor glucose input to the MPC was obtained by combining model-calculated, noise-free interstitial glucose with experimentally-derived transient and persistent sensor artifacts associated with the FreeStyle Navigator® Continuous Glucose Monitor System (“FSN”). The incidence of severe and significant hypoglycemia reduced 2300- and 200-fold, respectively, during simulated overnight closed-loop control with the MPC algorithm using the glucose measurement error model suggesting that the continuous glucose monitoring technologies facilitate safe closed-loop insulin delivery.

Owner:CAMBRIDGE ENTERPRISE LTD +1

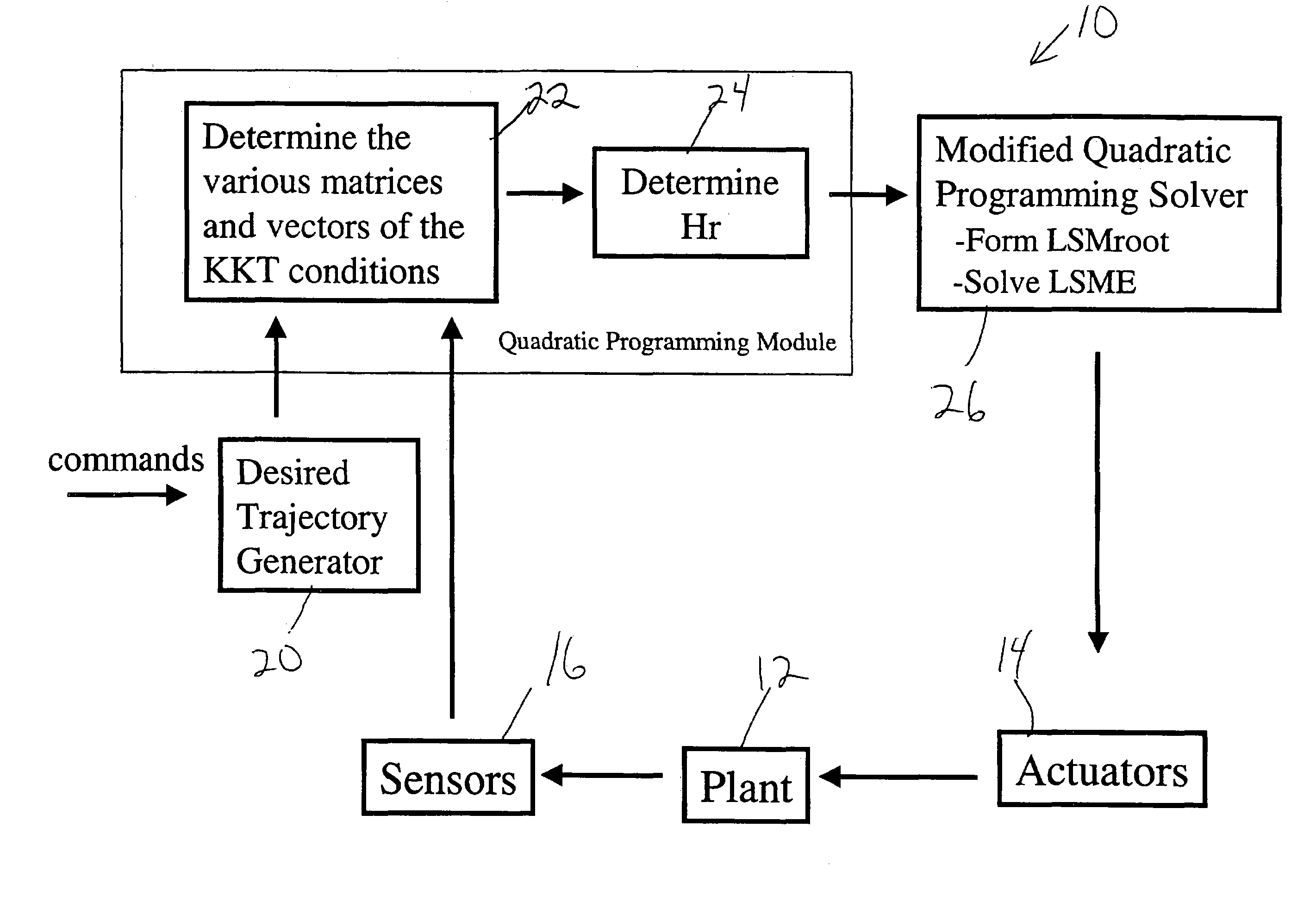

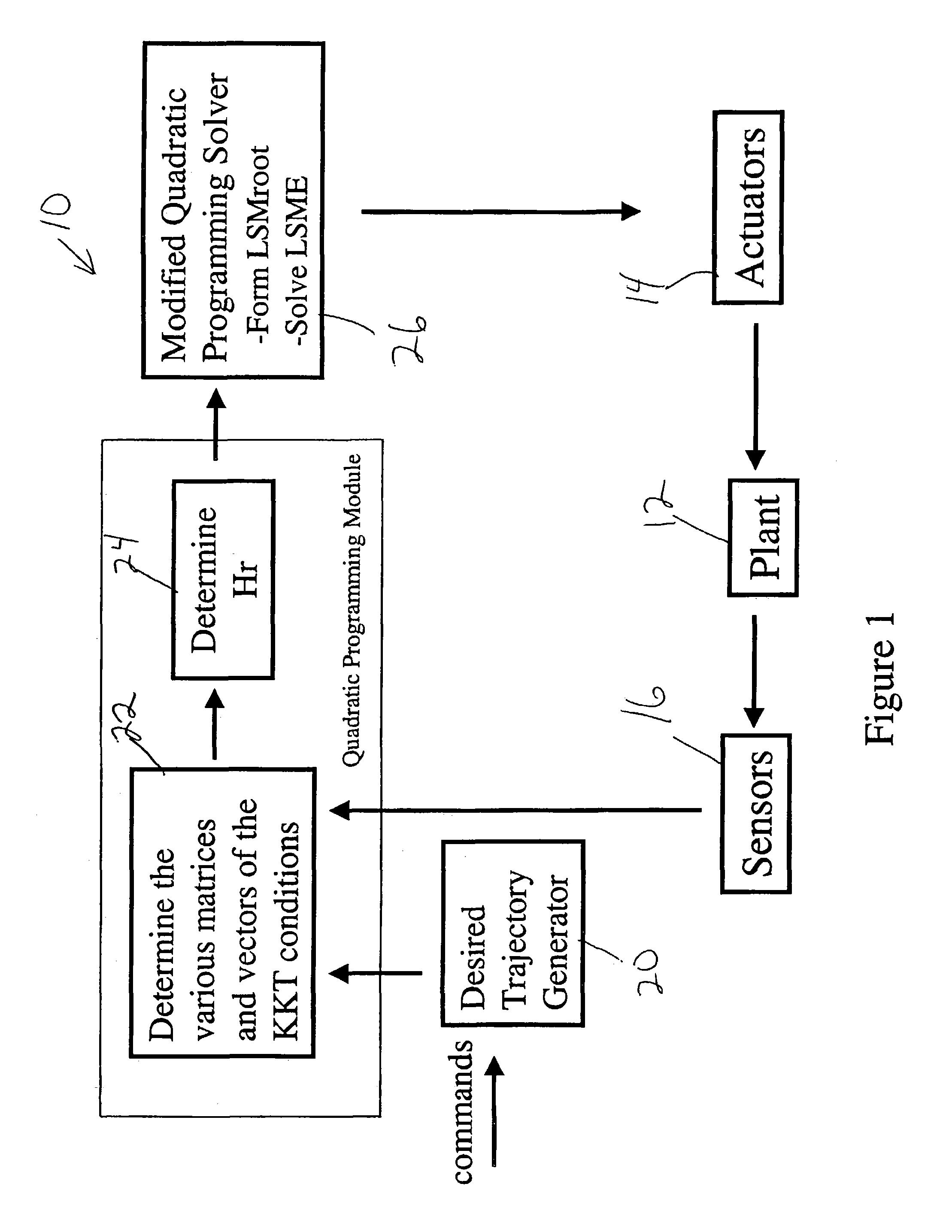

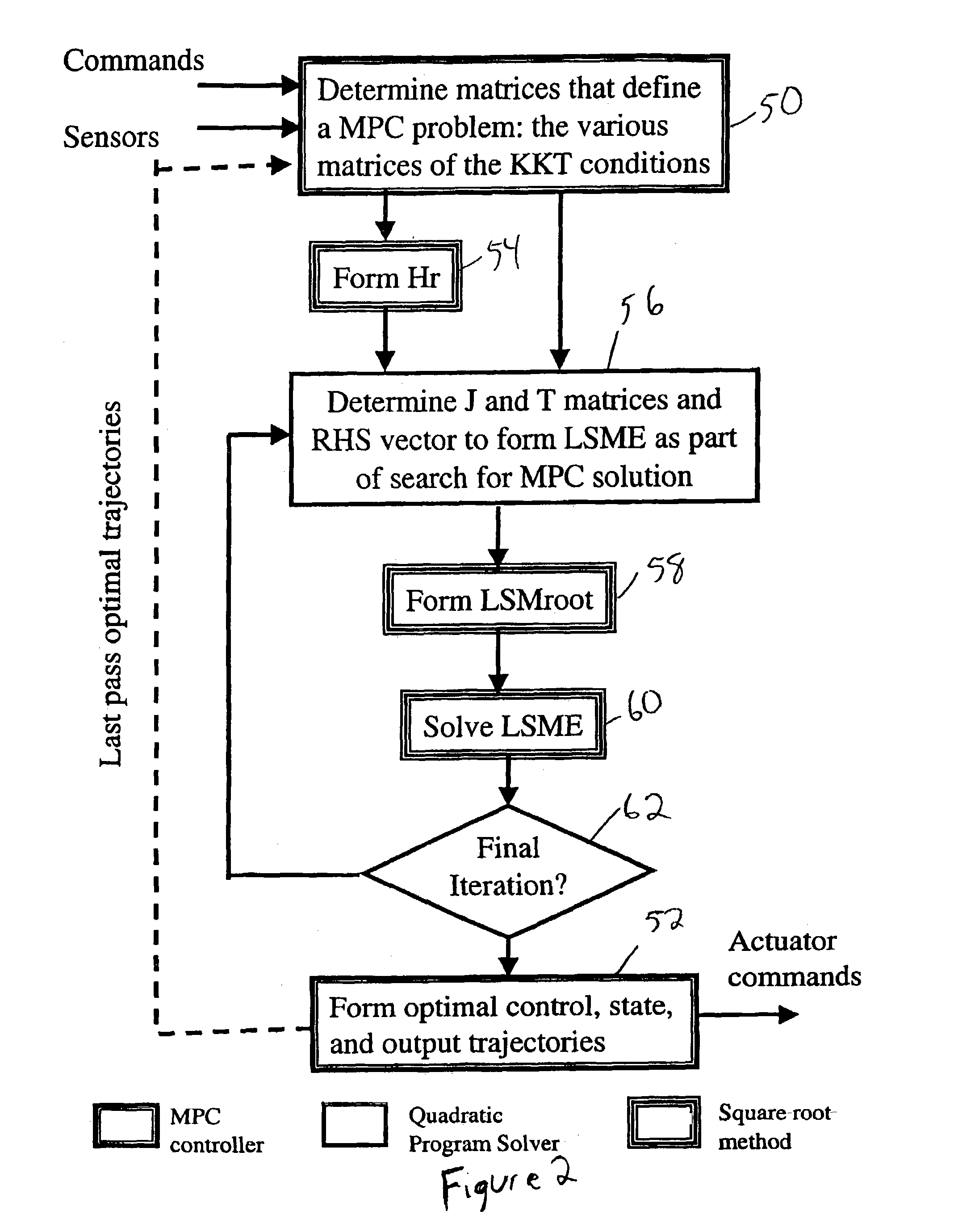

Square root method for computationally efficient model predictive control

ActiveUS7197485B2Lighten the computational burdenFast dynamicsSimulator controlDigital computer detailsAlgorithmModel predictive control

An efficient method for solving a model predictive control problem is described. A large sparse matrix equation is formed based upon the model predictive control problem. The square root of H, Hr, is then formed directly, without first forming H. A square root (LSMroot) of a large sparse matrix of the large sparse matrix equation is then formed using Hr in each of a plurality of iterations of a quadratic programming solver, without first forming the large sparse matrix and without recalculating Hr in each of the plurality of iterations. The solution of the large sparse matrix equation is completed based upon LSMroot.

Owner:RTX CORP

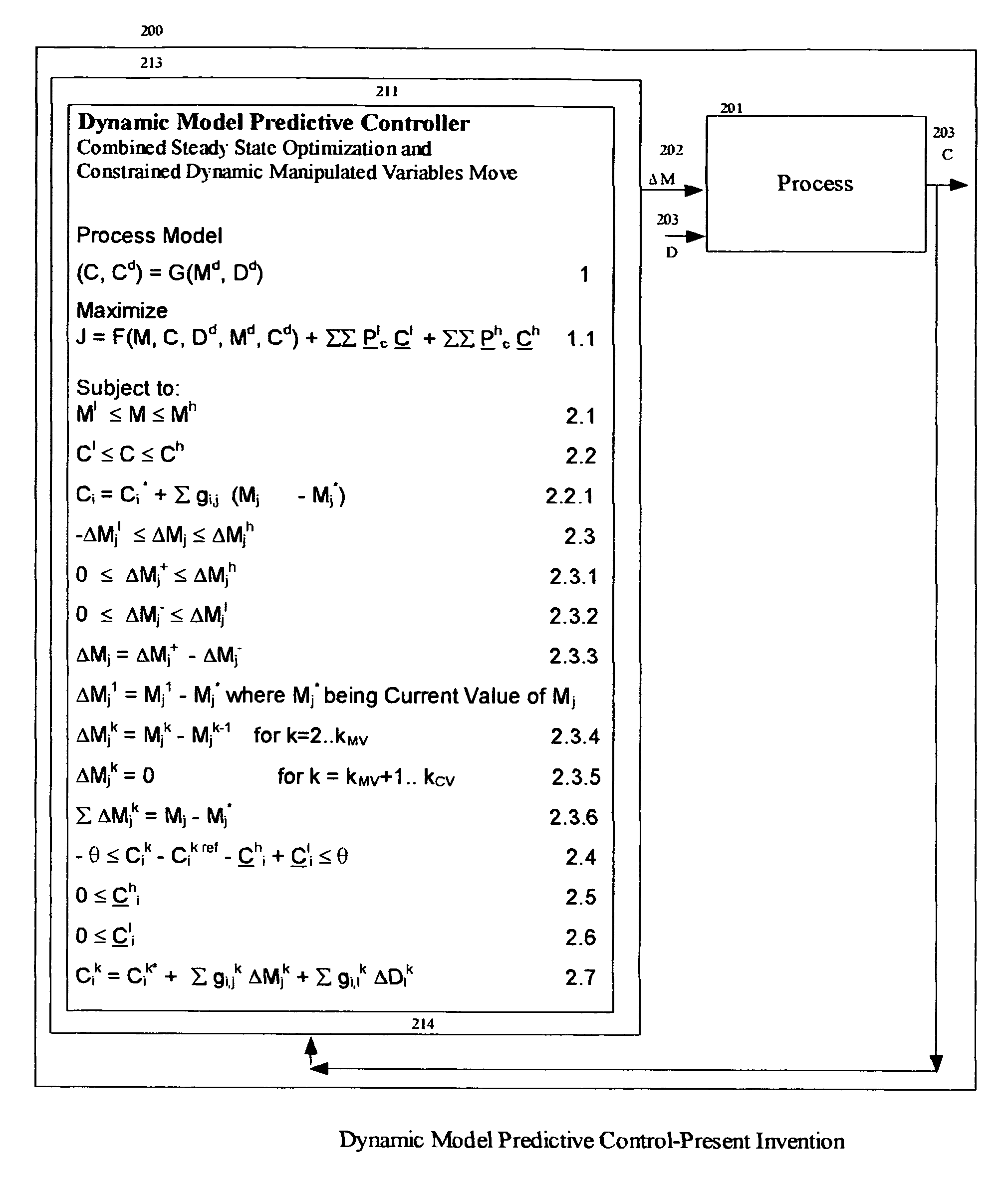

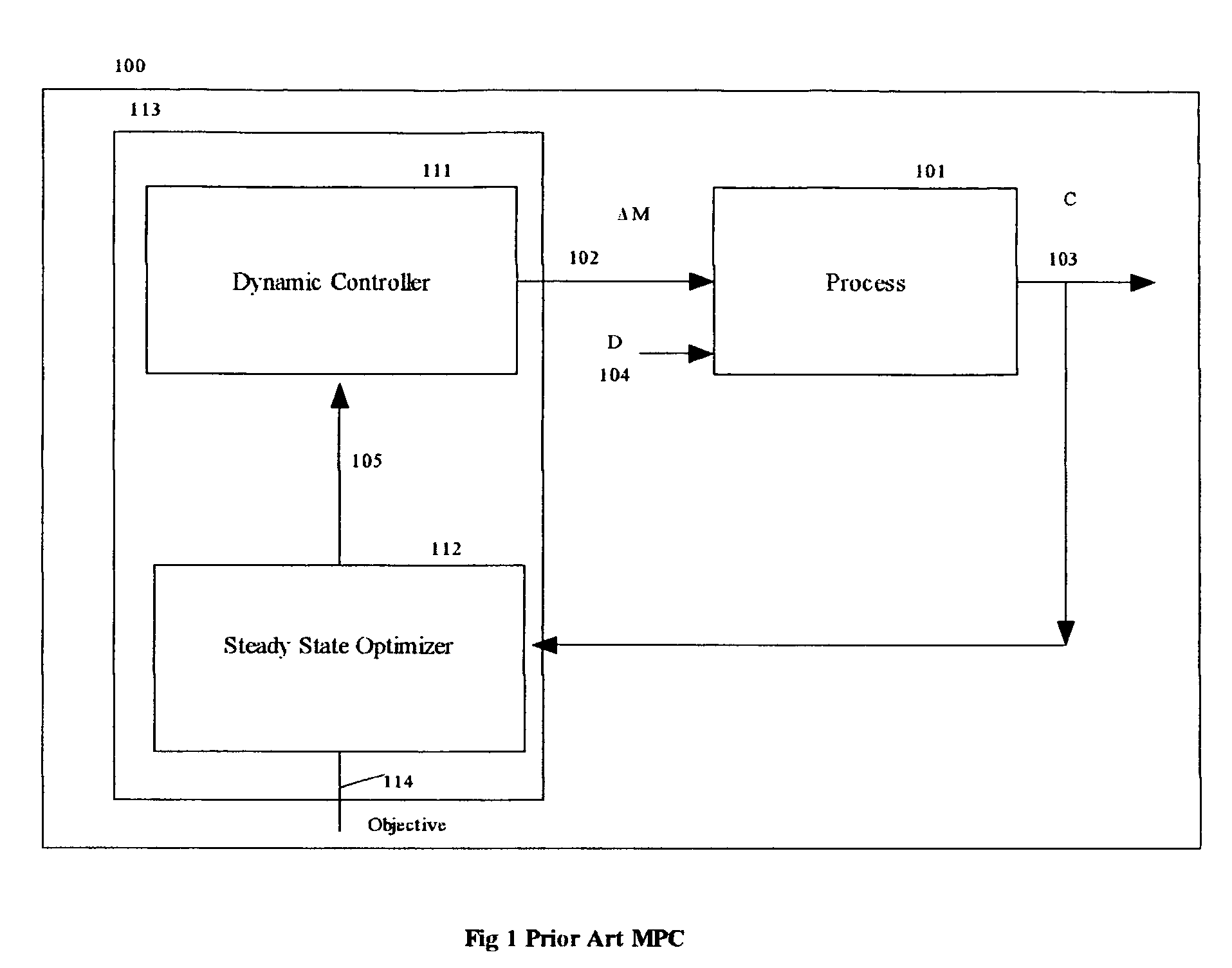

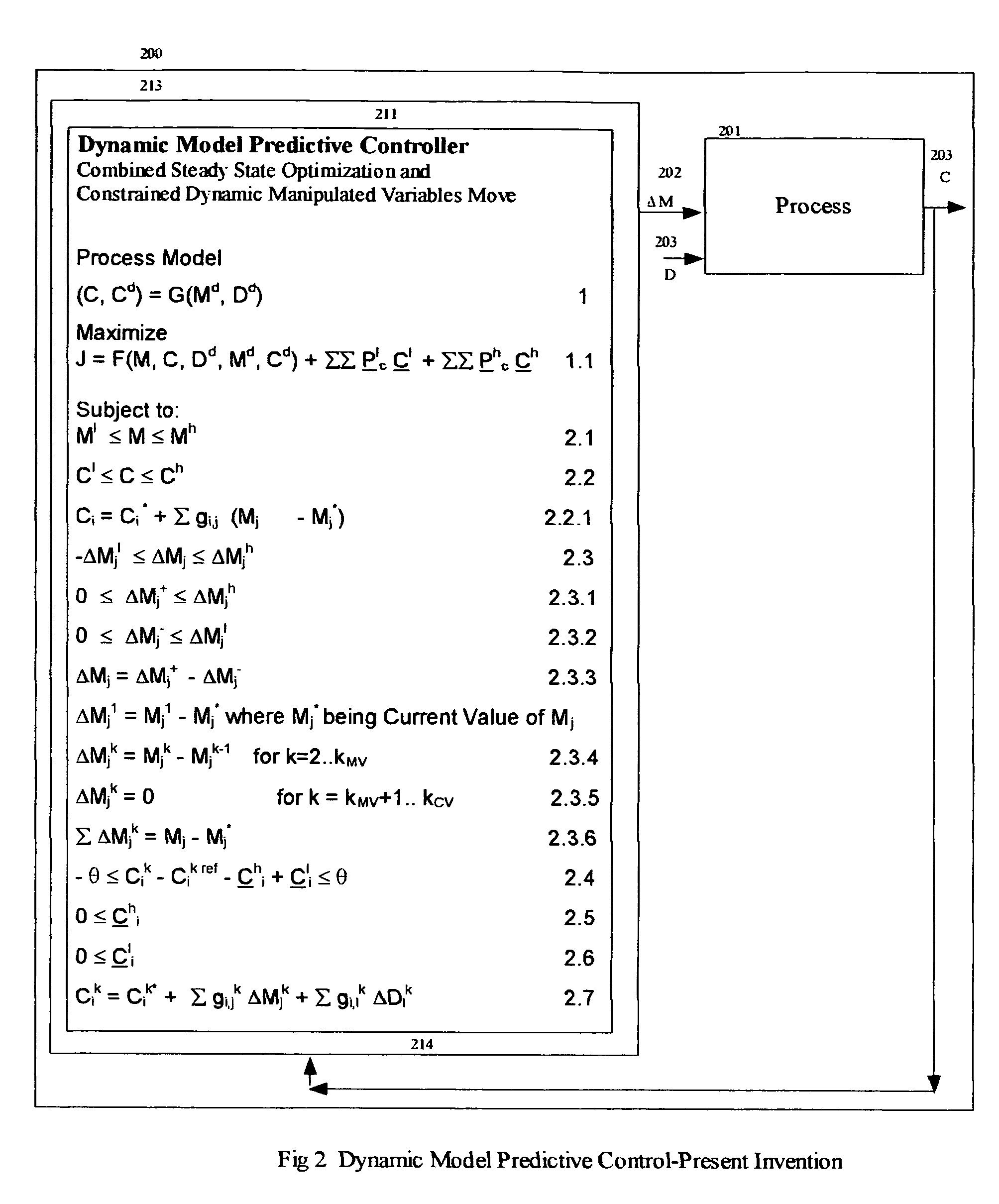

Dynamic model predictive control

InactiveUS7826909B2Improved and robust control performanceProgram control using stored programsDigital computer detailsDynamical optimizationDynamic models

A method of dynamic model predictive control is presented in which both steady state optimization and dynamic moves calculation of the manipulated variables are determined together as part of one optimization solution (211). The method combines steady state optimization and dynamic move calculation such that the steady state optimal targets are determined consistent with the dynamic moves and the resulting dynamic response of the process so that the controlled variables do not violate their low / high limits in both steady state and dynamically. The method utilizes what is described as high limit dynamic violation variables and low limit dynamic violation variables corresponding to each of the controlled variables. The method offers a unique capability of mixing a part dynamic optimization with a part steady state optimization as it relates to application of a large model predictive control under varying situations, in particular at or near constraints violations that can be done dynamically in real time for improved and robust control performance without having to change the controller tuning.

Owner:ATTARWALA FAKHRUDDIN T

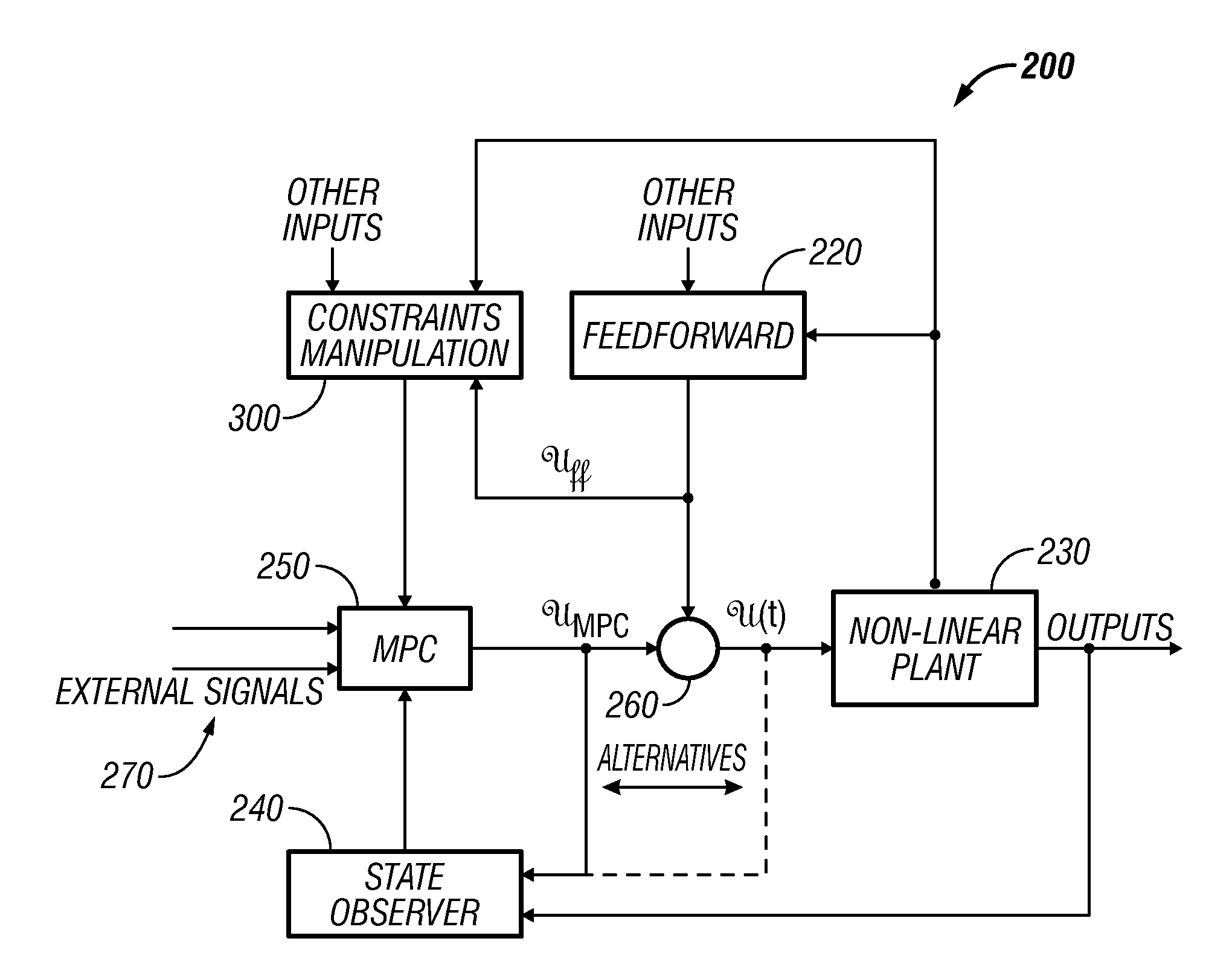

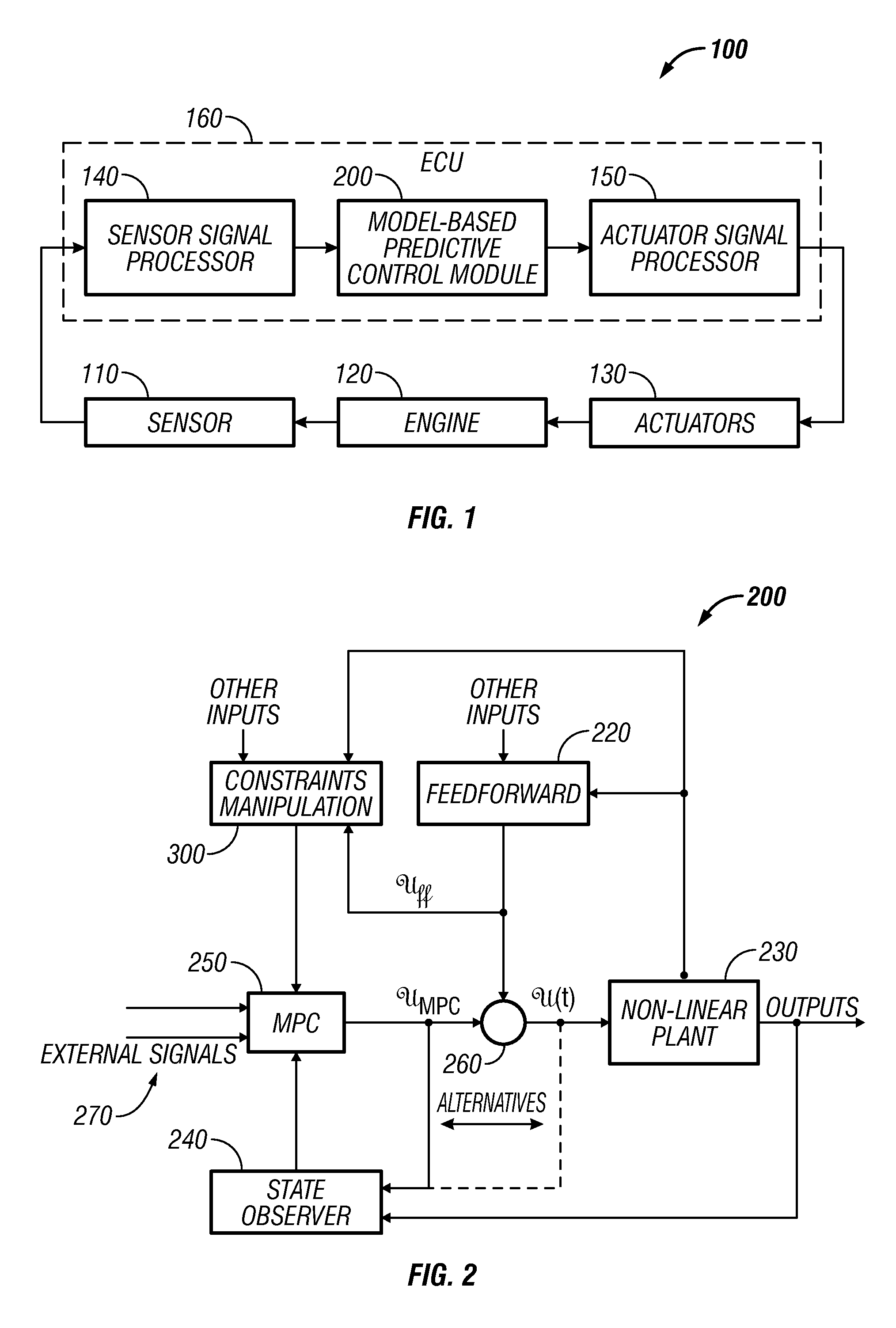

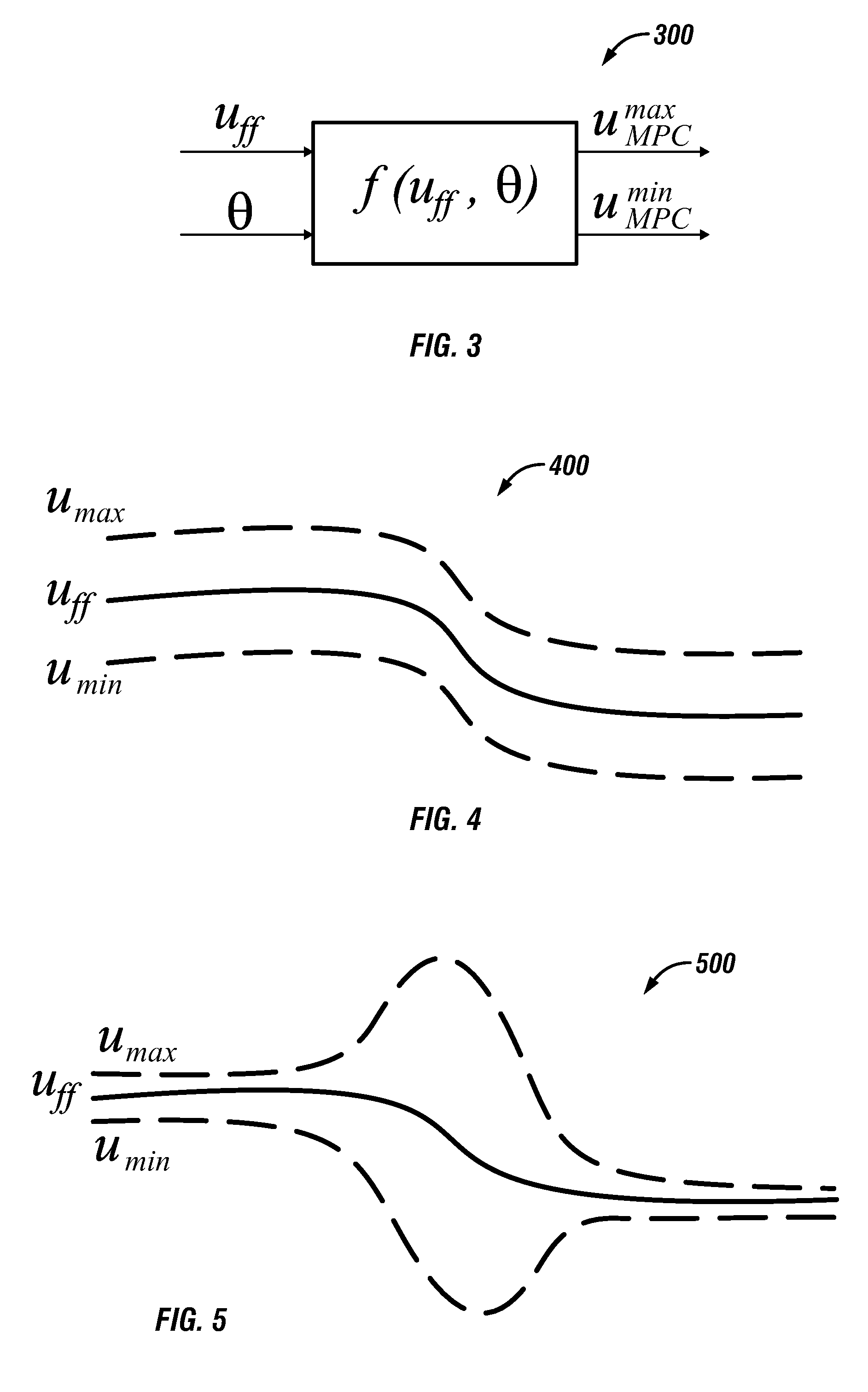

Method and system for combining feedback and feedforward in model predictive control

ActiveUS8145329B2Improve transient responseImprove performanceAdaptive controlState observerModel predictive control

A method and system for combining a feedback control and a feedforward control in a linear MPC to minimize effect of model uncertainty. An externally computed feedforward signal, which is more accurate and reliable, can be utilized in association with the MPC, A steady state relation between system parameters can be determined in order to compute the feedforward signal for a set of actuators associated with a non-linear system. A feedback MPC controller can then be designed. A state observer can be configured as an unknown input observer to estimate the effect of the feedforward signal. A strategy for manipulating the constraints of the MPC feedback signal can be implemented. A resulting control action for the actuators can be provided as a sum of corresponding feedback and feedforward signal while ensuring the constraints satisfaction.

Owner:JPMORGAN CHASE BANK N A AS ADMINISTATIVE AGENT

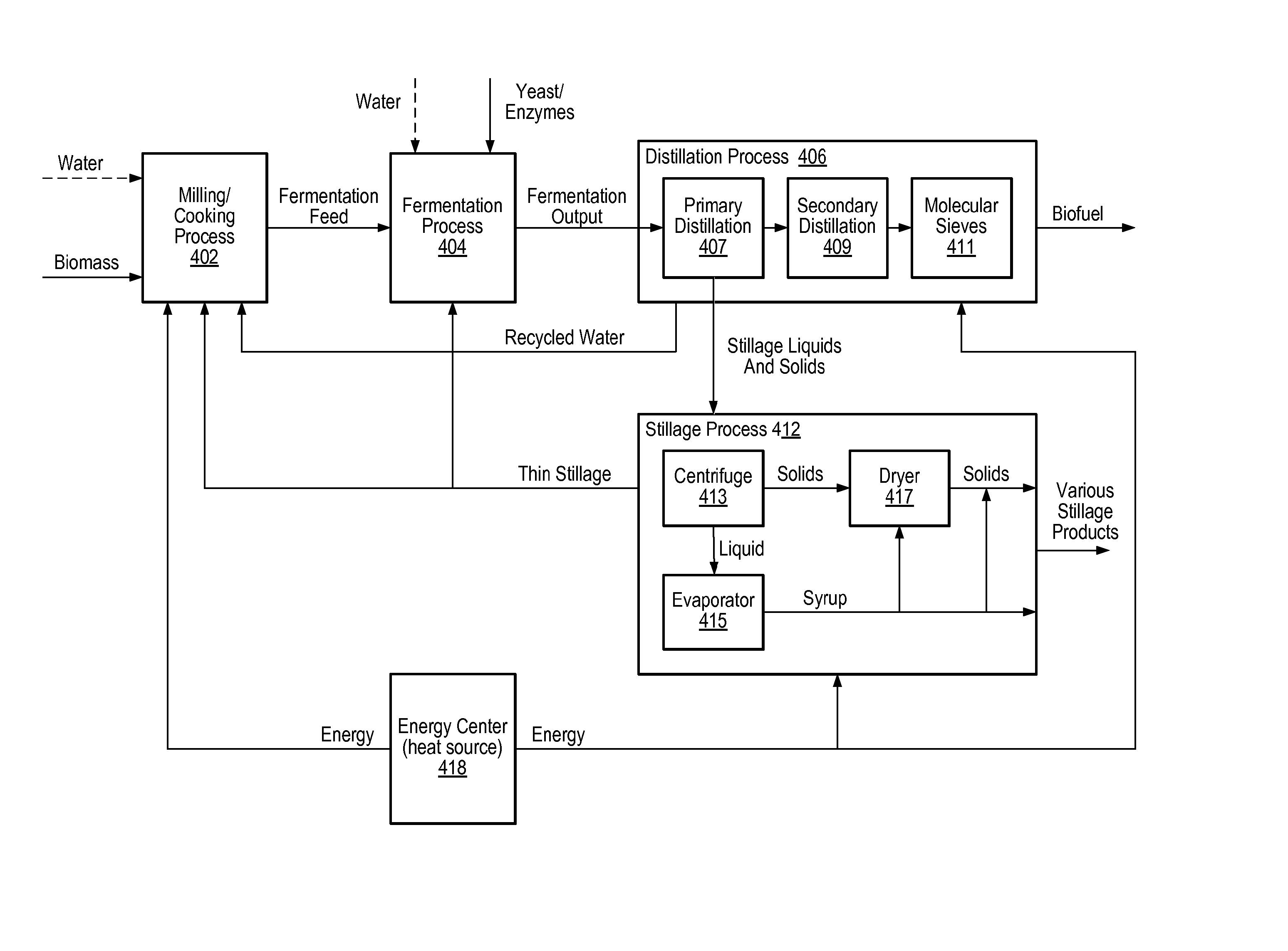

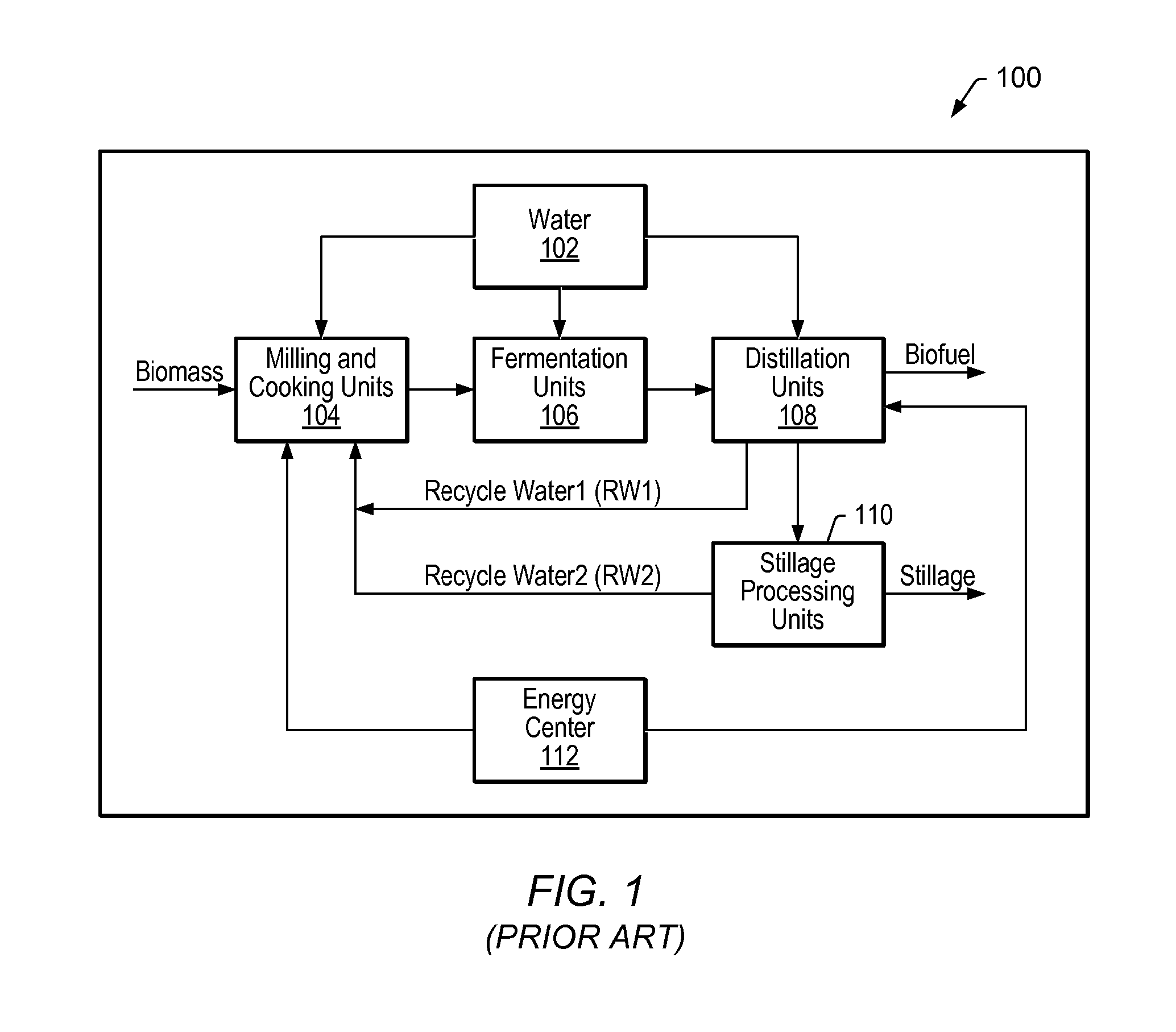

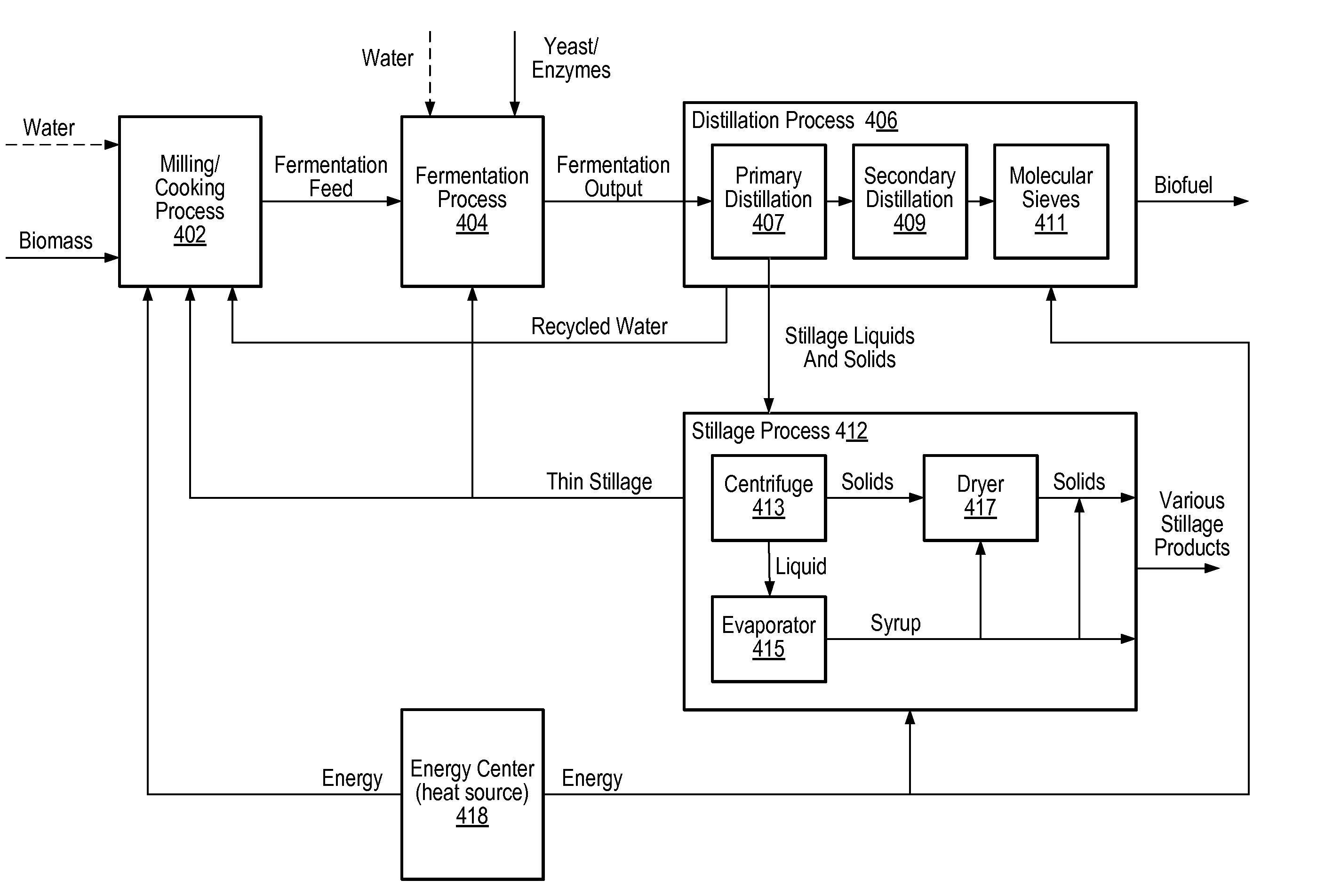

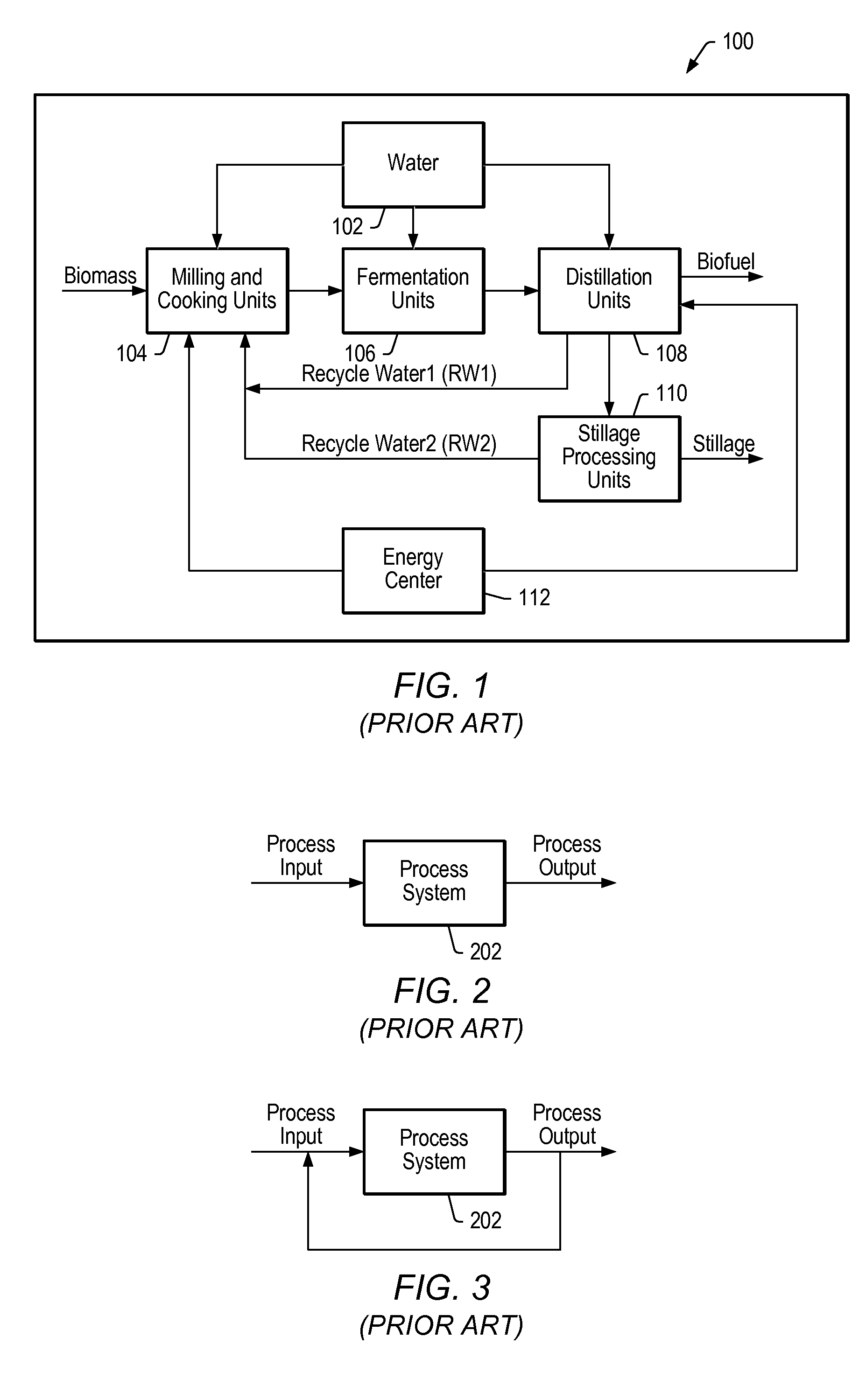

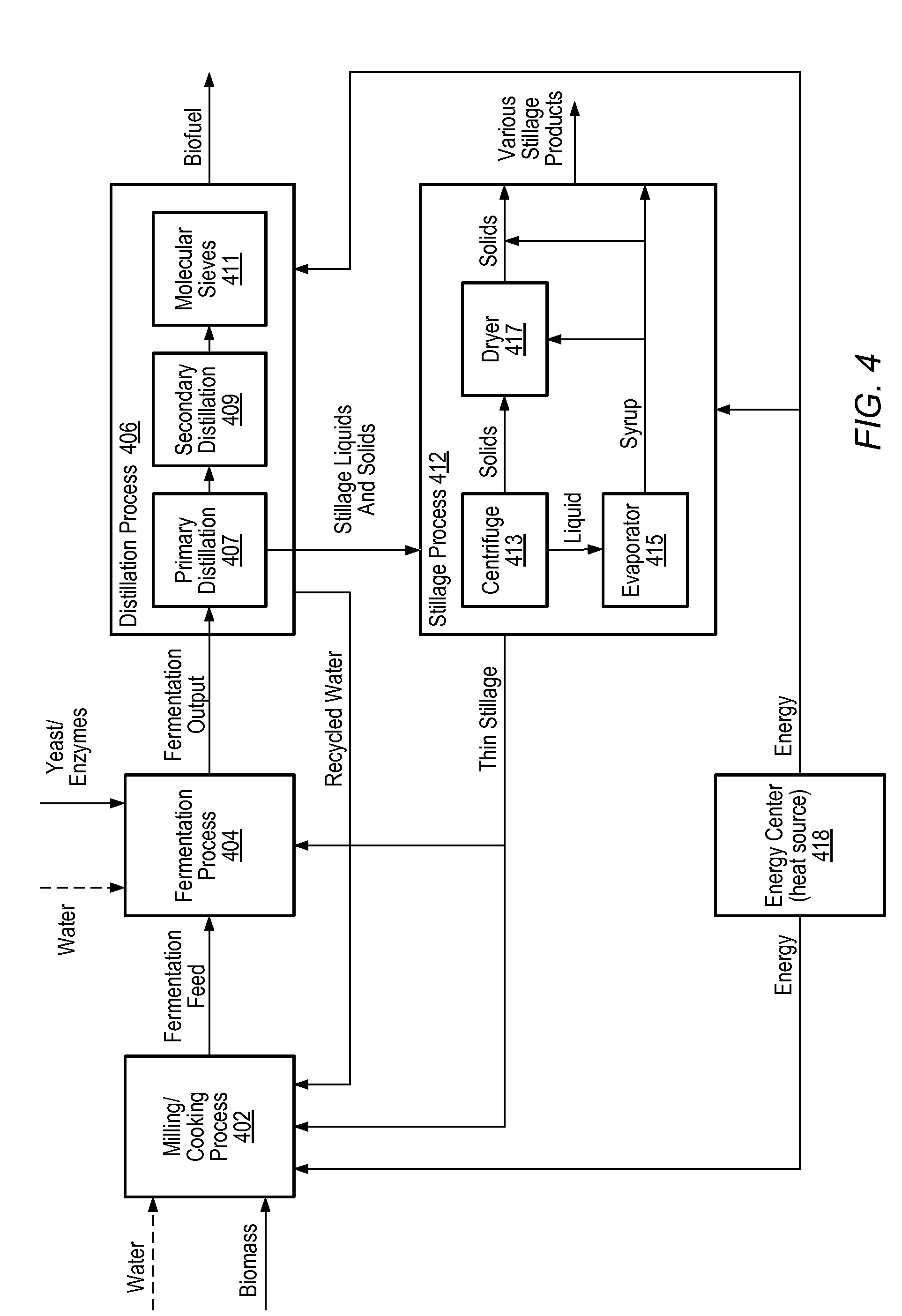

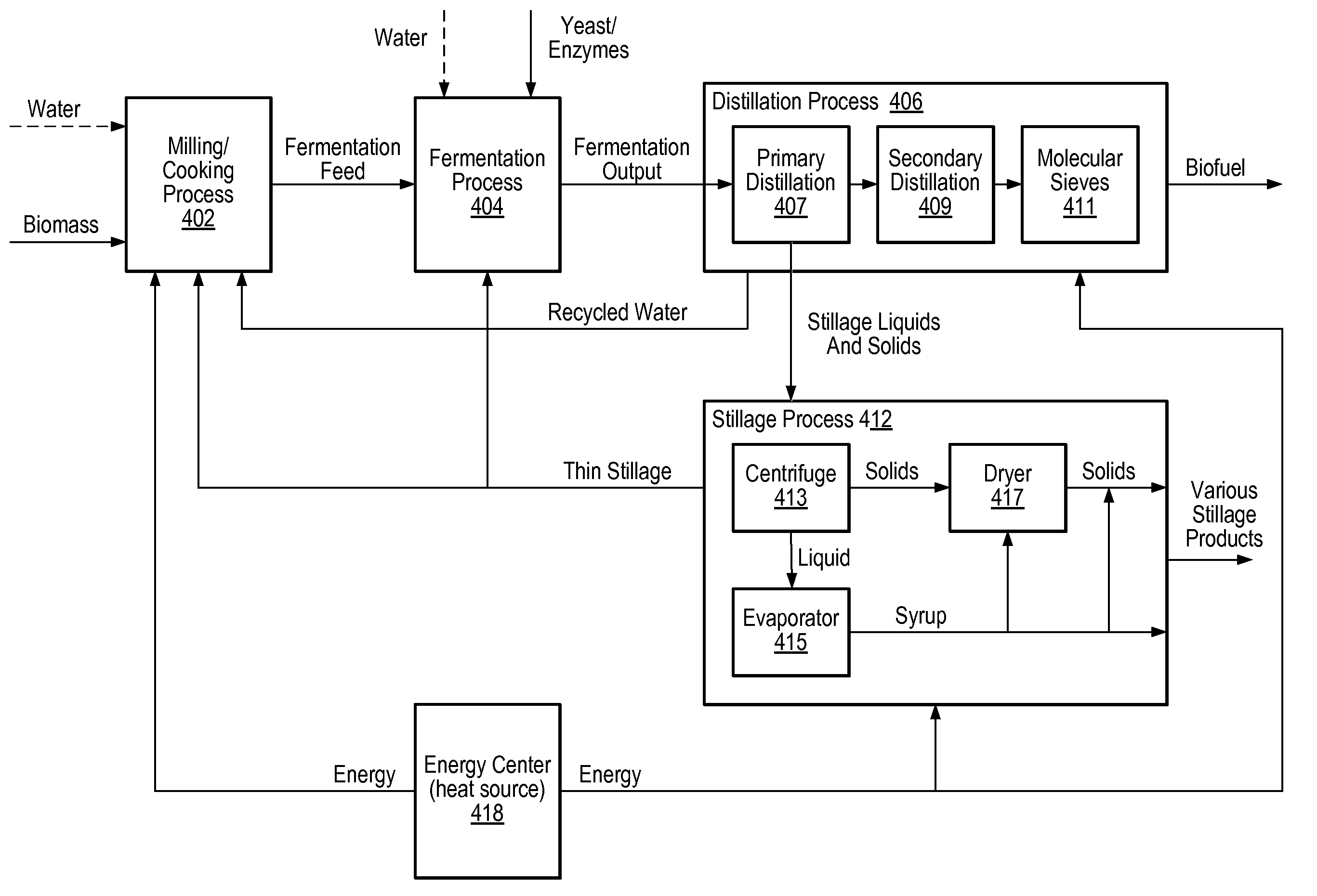

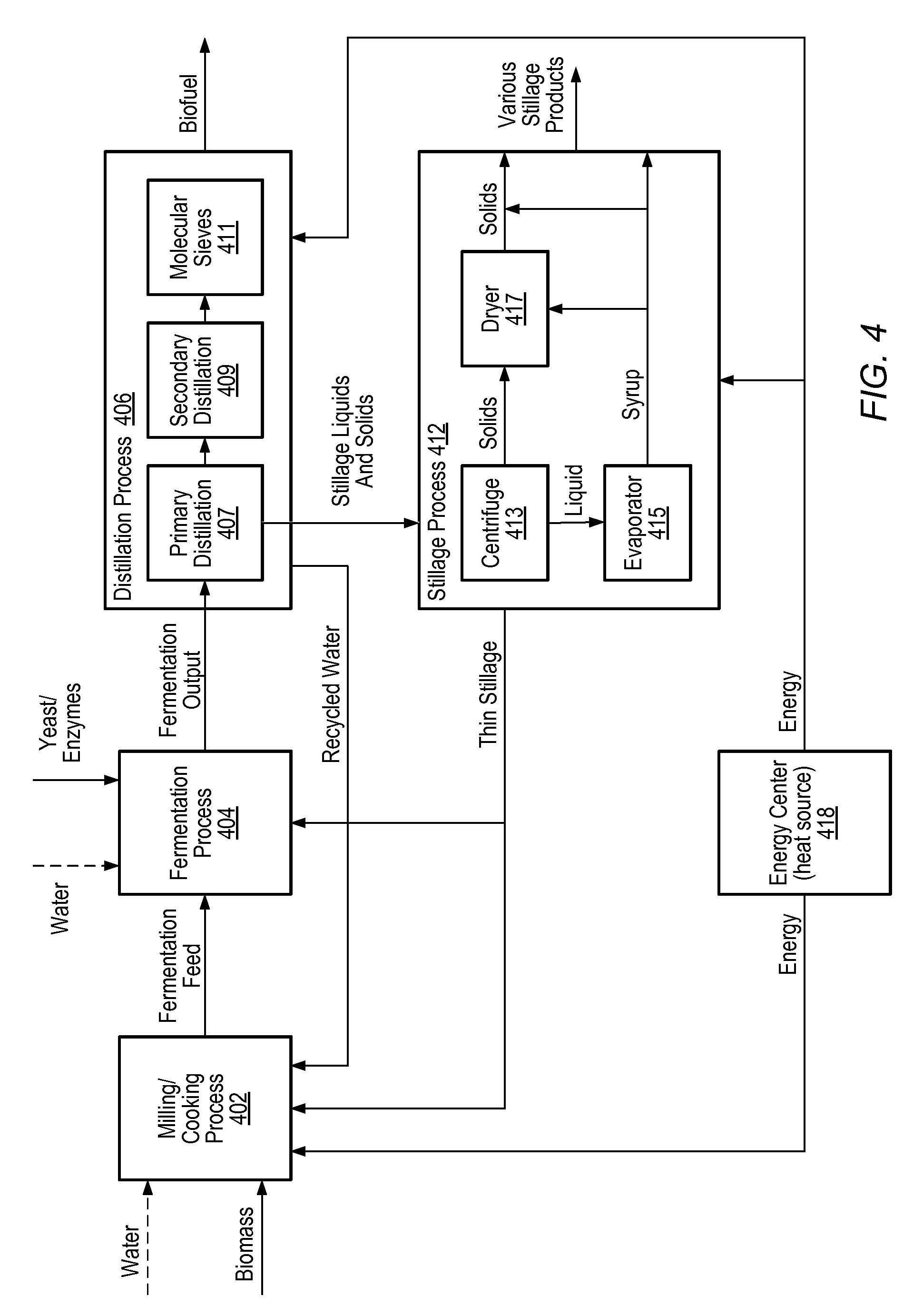

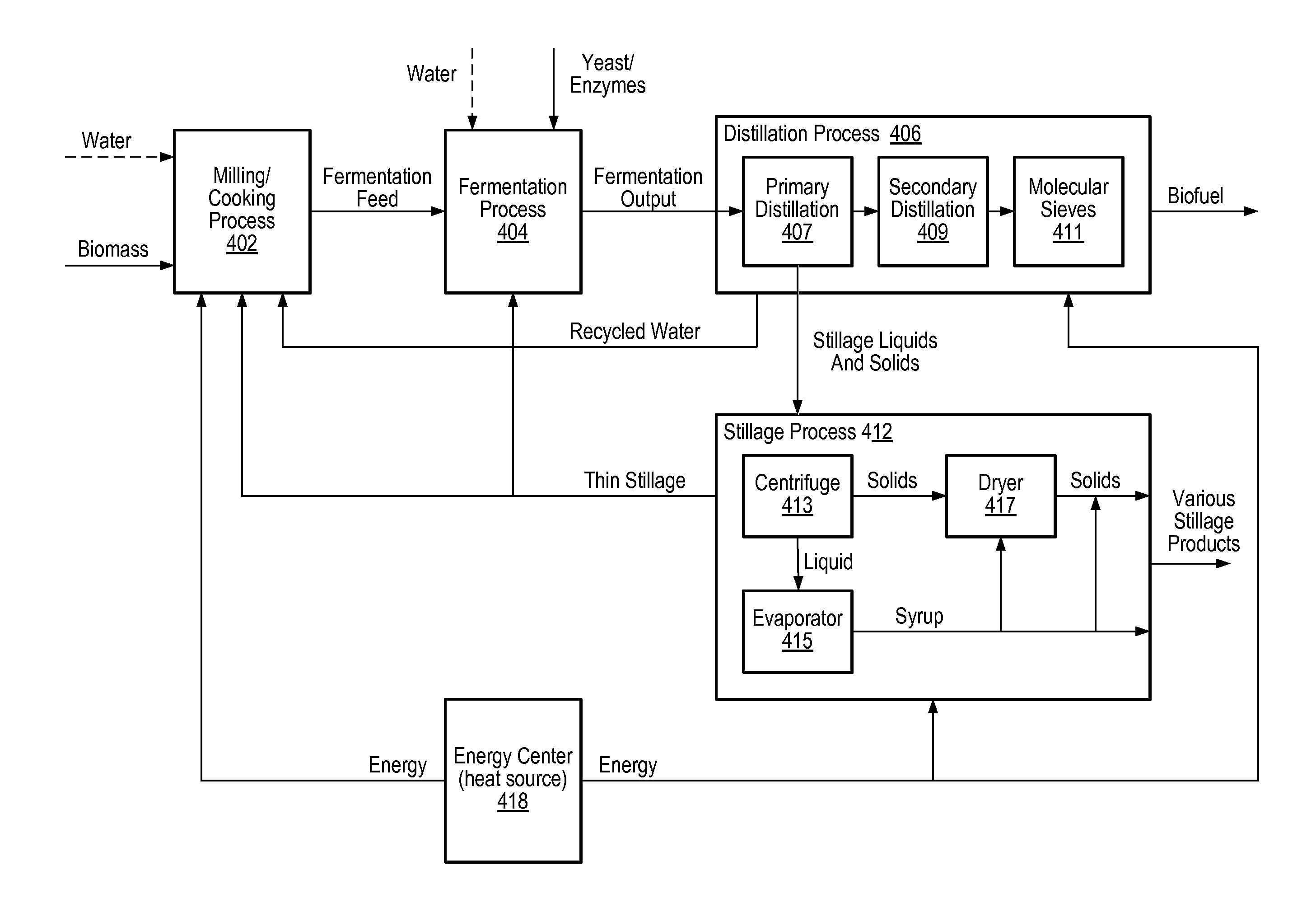

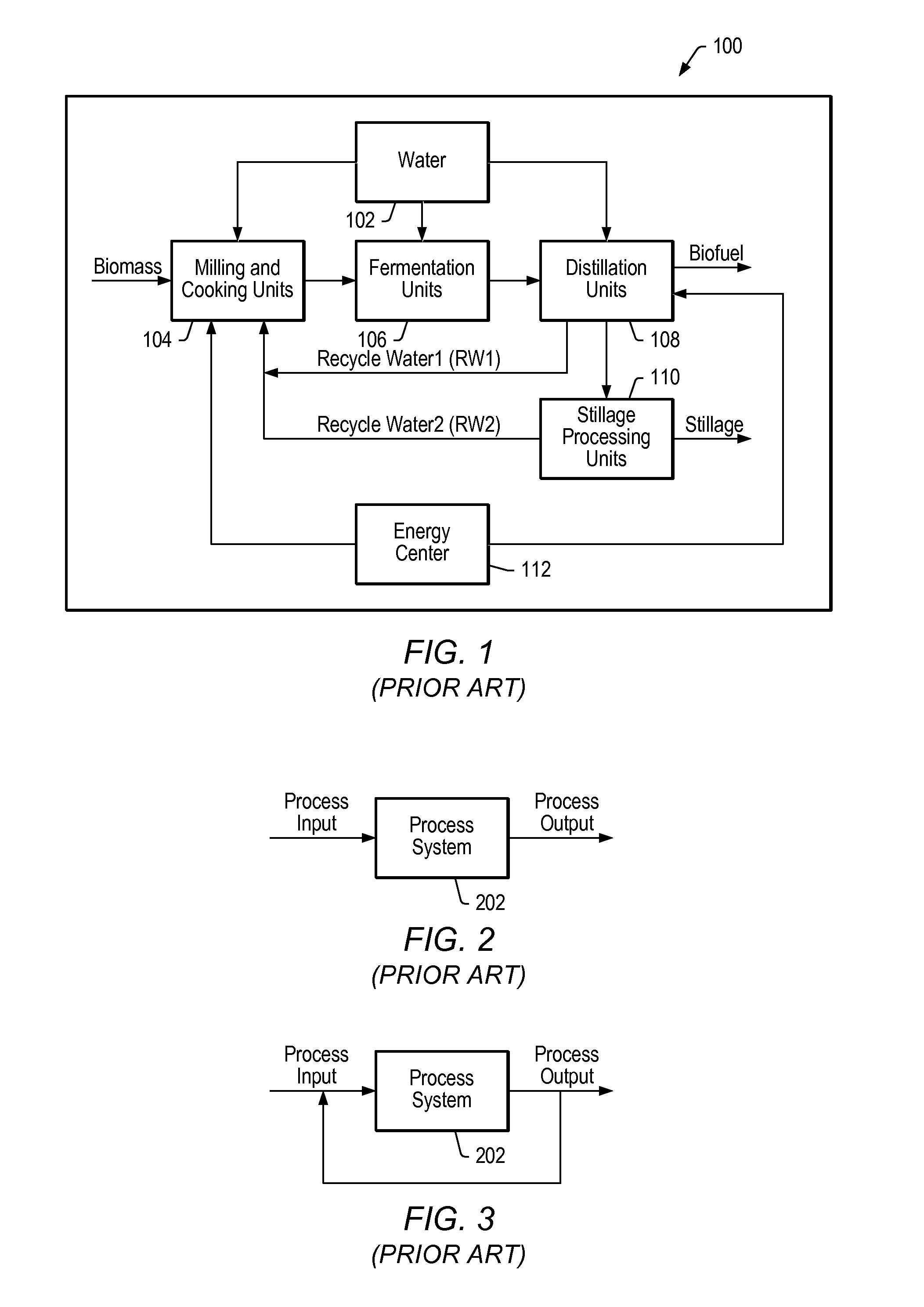

Model predictive control of a fermentation feed in biofuel production

ActiveUS20080104003A1Guaranteed balance and stabilityBioreactor/fermenter combinationsSimulator controlBiofuelModel based controller

System and method for managing fermentation feed in a biofuel production process, comprising a dynamic multivariate predictive model-based controller coupled to a dynamic multivariate predictive model. The model is executable to: receive process information, including water inventory and biomass information, from the biofuel production process; receive a specified objective for the fermentation feed specifying a target biomass concentration; and generate model output comprising target values for a plurality of manipulated variables of the biofuel production process, including target flow rates of water and / or biomass contributing to the fermentation feed in accordance with the specified objective. The controller is operable to dynamically control the biofuel production process by adjusting the plurality of manipulated variables to model-determined target values to stabilize water / biomass balance in the fermentation feed in accordance with the specified objective, including the specified target biomass concentration.

Owner:ROCKWELL AUTOMATION TECH

Model predictive control of a stillage sub-process in a biofuel production process

InactiveUS20080103747A1Analogue computers for chemical processesAdaptive controlProcess systemsTarget control

System and method for managing a biofuel stillage sub-process of a biofuel production process using a dynamic multivariate predictive model of the stillage sub-process. An objective for the stillage sub-process is received specifying target production of output of the stillage sub-process, including a target value for moisture content of one or more of: dry distillers grain, wet distillers grain, or evaporator syrup. Process information comprising stillage sub-process information is received from the biofuel production process. The dynamic multivariate predictive model is executed in accordance with the objective using the process information as input, to generate model output comprising target values for a plurality of manipulated variables related to the stillage sub-process, in accordance with the objective. The biofuel production process is controlled in accordance with the target values of the plurality of manipulated variables to control production of outputs or inputs of the stillage sub-process in accordance with the objective.

Owner:ROCKWELL AUTOMATION TECH

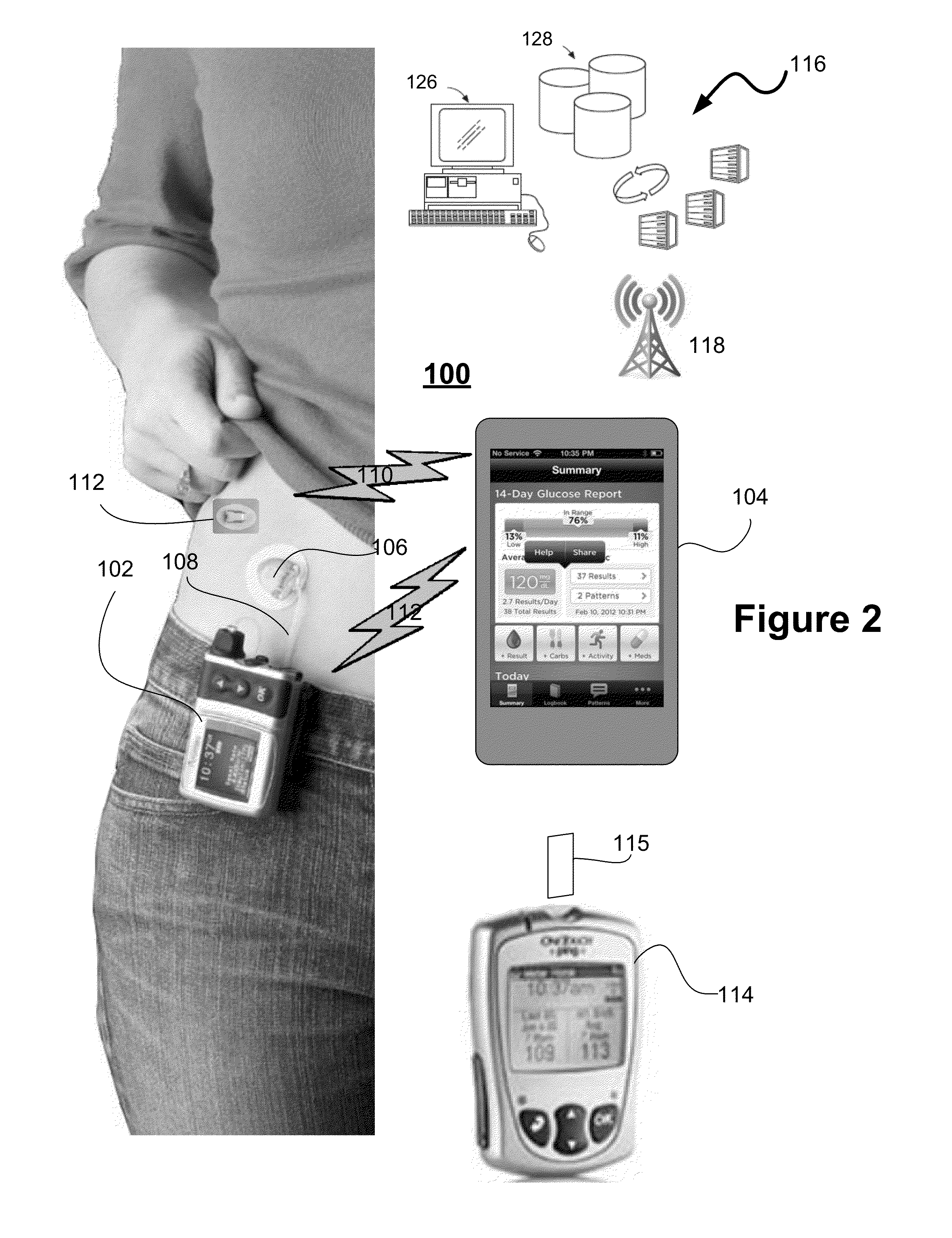

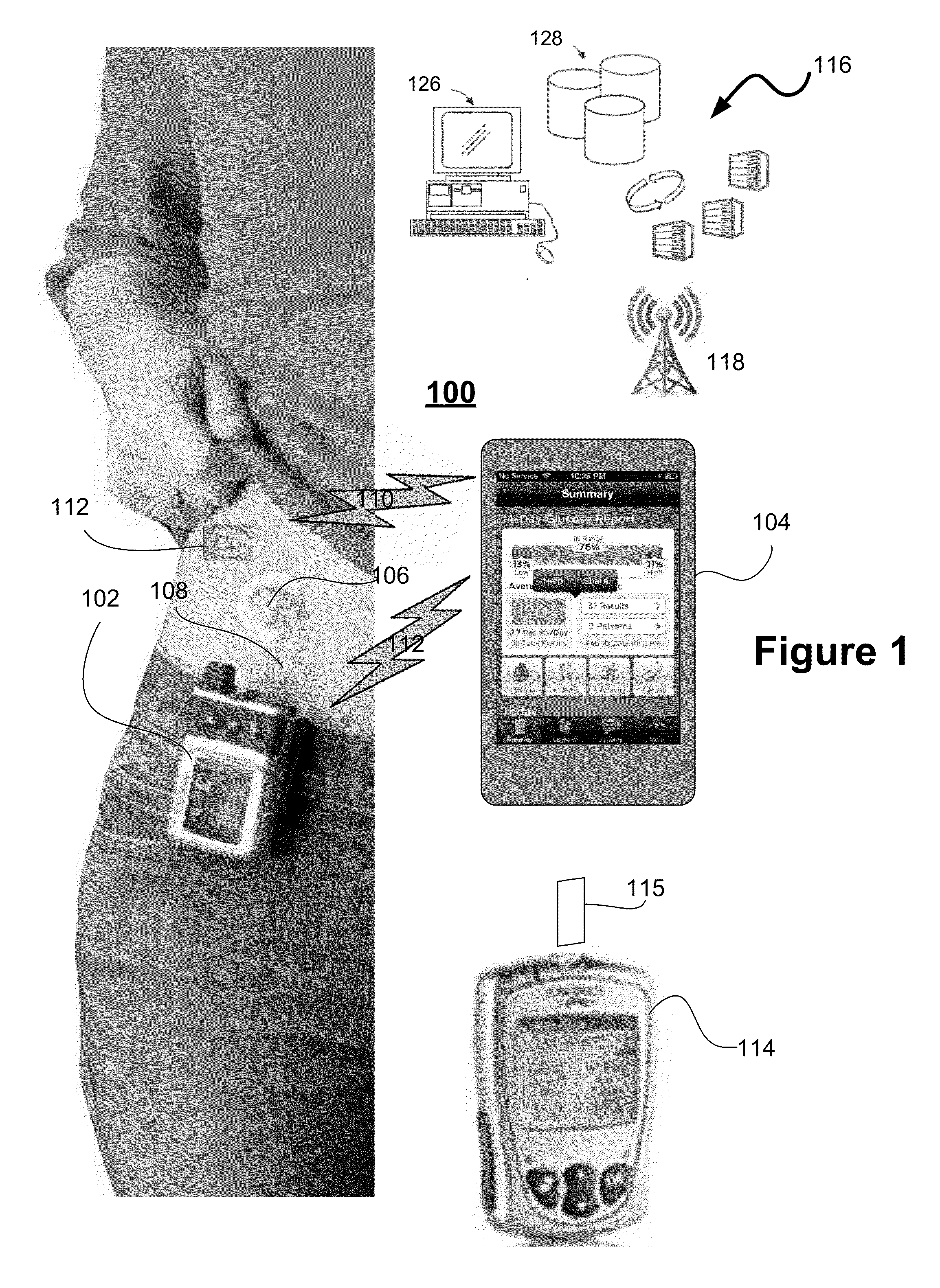

Method and system to handle manual boluses or meal events for closed-loop controllers

ActiveUS20140005633A1Negates portionReduce the impactDrug and medicationsMedical devicesGlucose sensorsDiabetes management

Described and illustrated is a diabetes management system that includes an infusion pump, glucose sensor and controller with a method programmed into the controller. The infusion pump is configured to deliver insulin to a subject. The glucose sensor is configured to sense glucose levels in the subject and provide output signals representative of the glucose levels in the subject. The controller is programmed to receive signals from at least one of the glucose sensor and the pump and configured to issue signals to the pump to deliver an amount of insulin determined by a feedback controller that utilizes a model predictive control and also configured to deliver at least the basal amount of insulin whenever the subject has initiated a manual bolus of insulin and a sensed or measured glucose level is at least a first threshold within a first duration of time.

Owner:JDRF INT +1

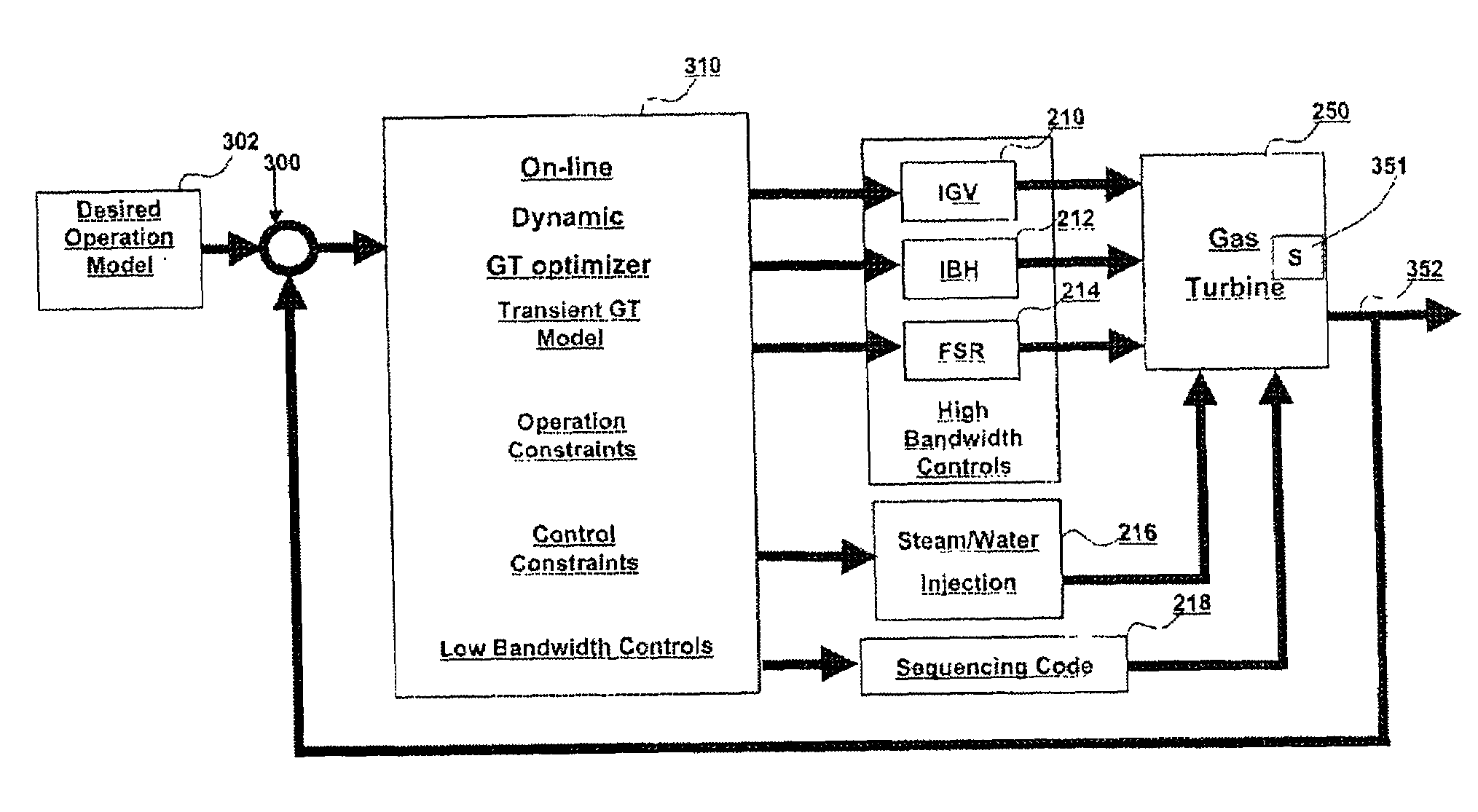

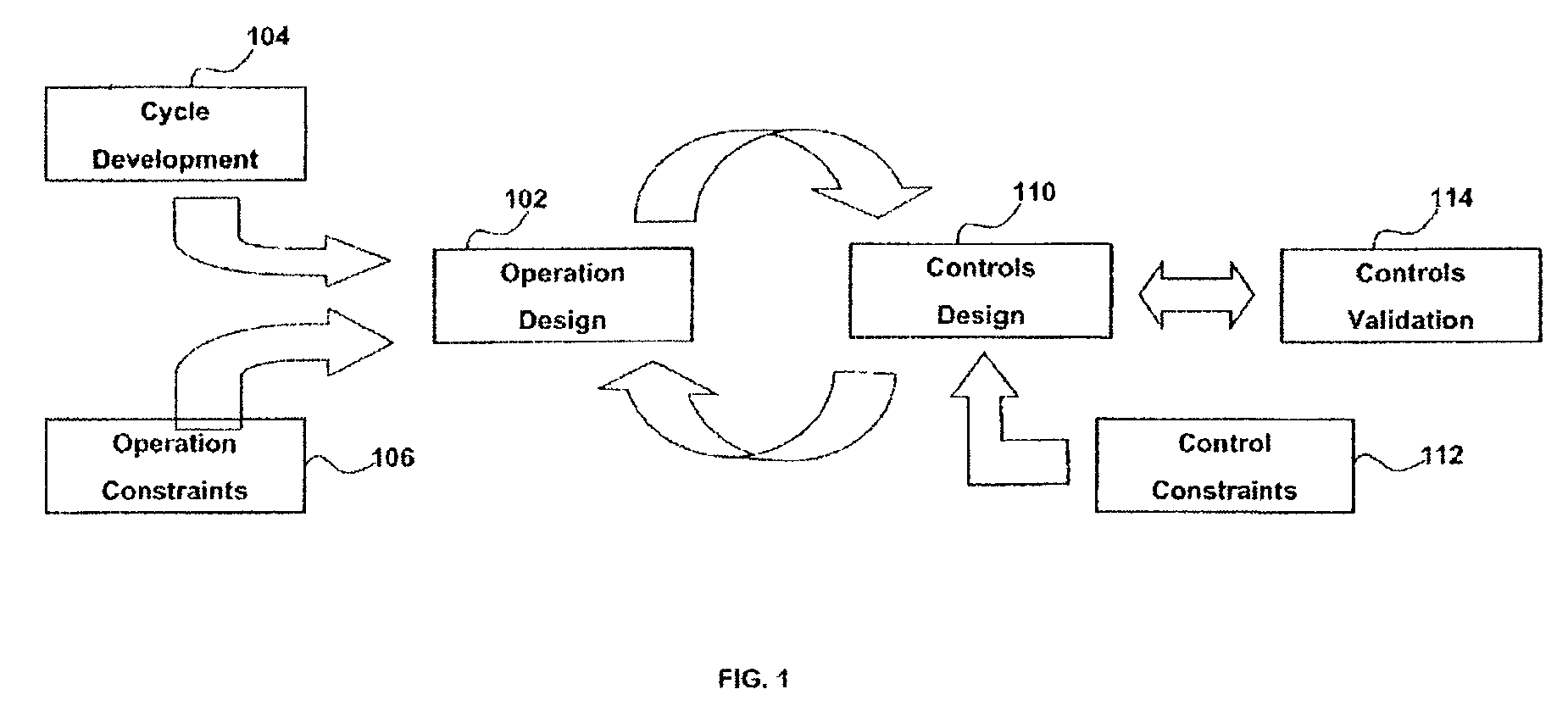

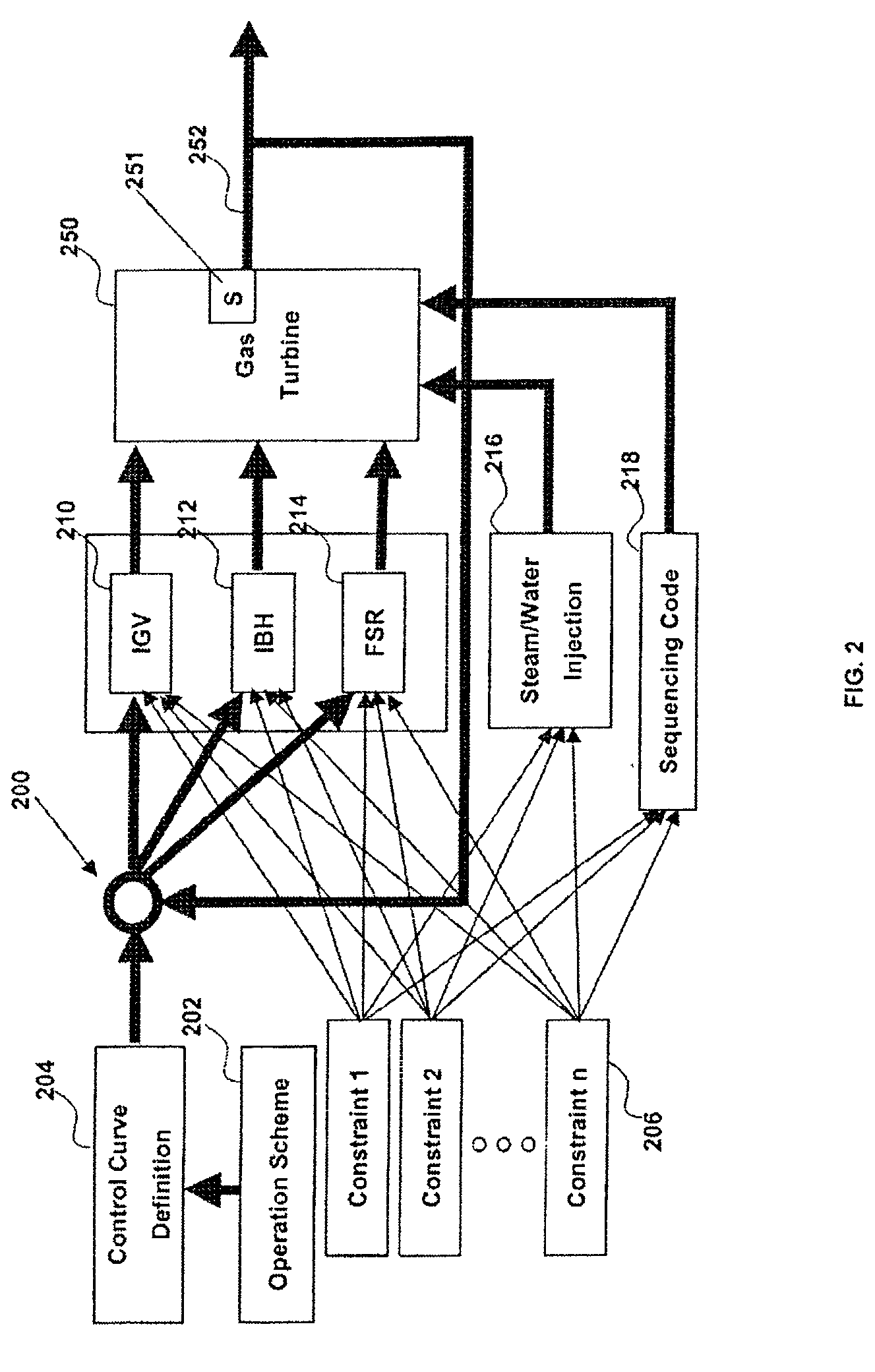

Method and system for model based control of heavy duty gas turbine

ActiveUS7219040B2Reduce riskAnalogue computers for vehiclesLevel controlDynamical optimizationProcess engineering

A method and system of designing the operations and controls of a gas turbine, includes generating an operations model for the gas turbine including at least one objective function and defining operations and control constraints for the operations model of the gas turbine. An online dynamic optimizer / controller dynamically optimizes and controls operation of the gas turbine using model based control based on the operations model and the operations and control constraints. The model based control may include model predictive control.

Owner:GENERAL ELECTRIC CO

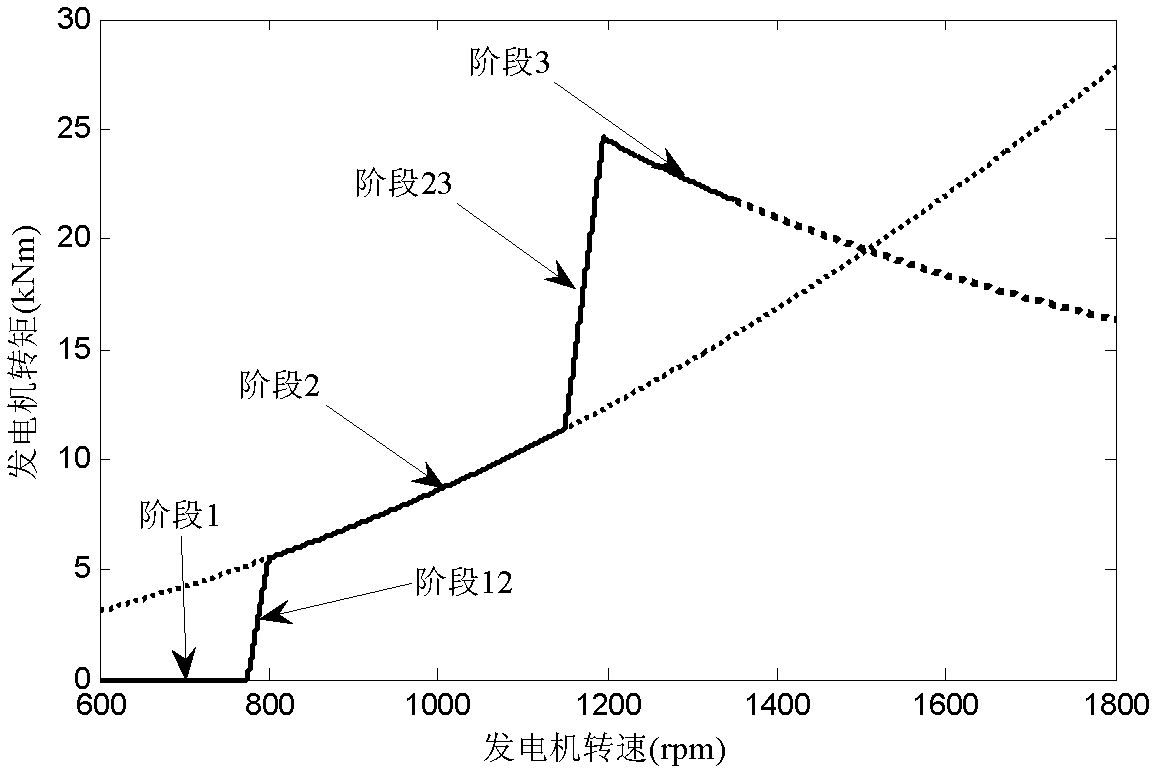

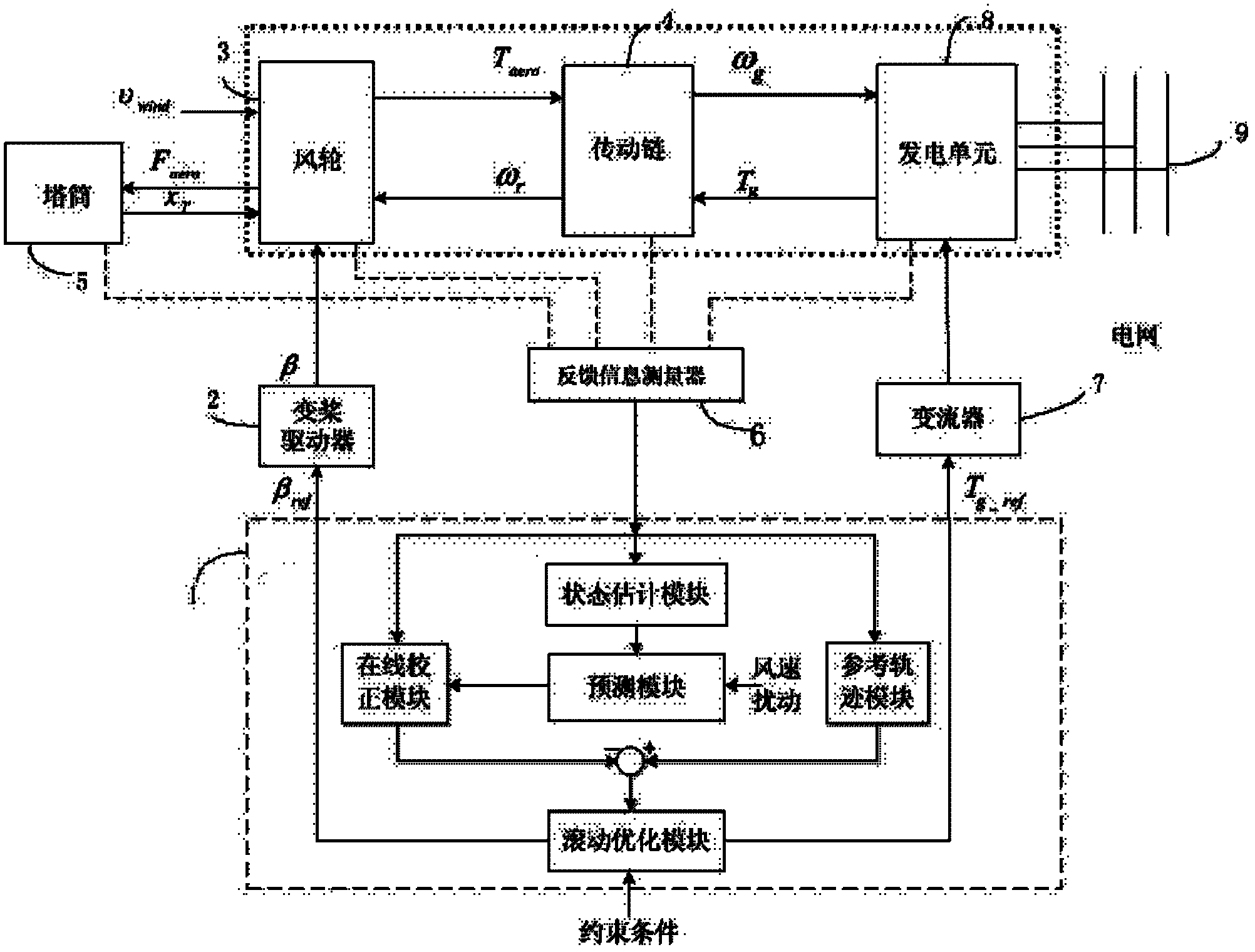

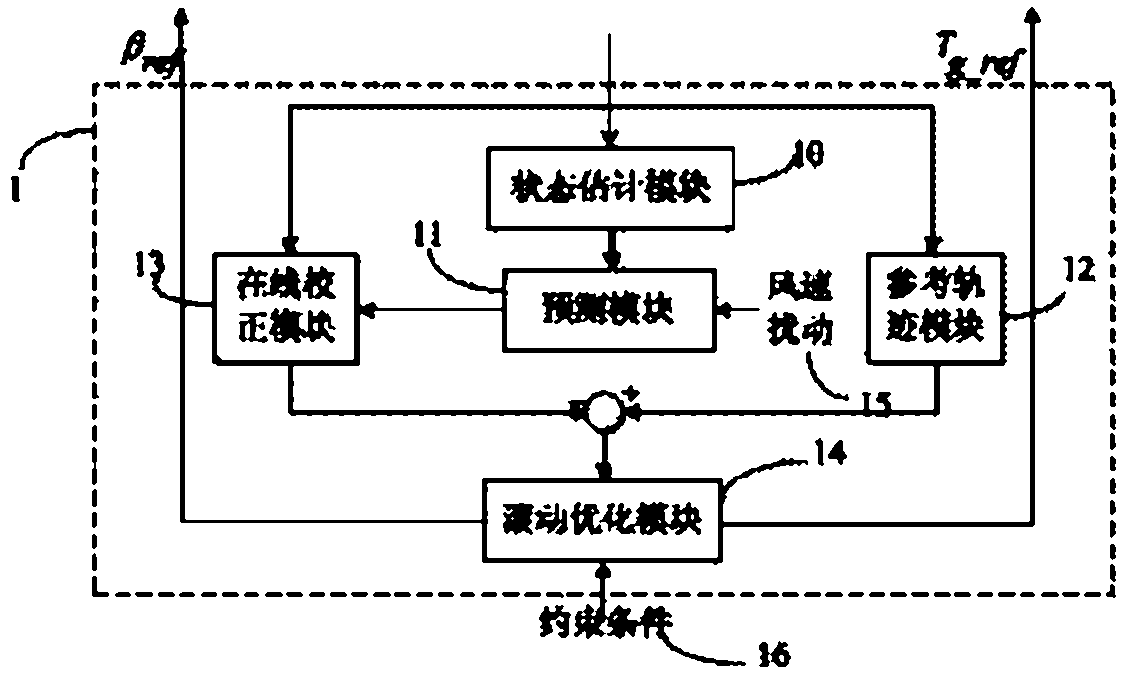

Model prediction control method and model prediction control system for all working conditions of wind generating set

ActiveCN102588211AAvoid the phenomenon of long-term oscillationReduce mechanical loadWind motor controlActive/predictive/anticipative controlControl systemModel predictive control

Disclosed are a model prediction control method and a model prediction control system for all working conditions of a wind generating set. The system comprises an MPC (model prediction control) device, a feedback information measurer, a wind wheel, a driving chain, a tower, a generating unit, a variable propeller driver and a converter. The feedback information measurer is used for detecting status variables of the wind wheel, the driving chain, the tower and the generating unit and transmitting detecting results to the MPC device, the MPC device is used for computing targets of the blade pitch angle and the generator torque, and the variable propeller driver and the converter are used for adjusting the blade pitch angle and the wind generator torque. The method is used for computing control increment by means of a variable propeller control prediction model and a torque control prediction model, takes the status variables including driving chain torsional displacement, driving chain torsional speed, blade plane external first-order flap displacement, blade plane external first-order flap speed, tower front-back first-order swing displacement, tower front-back first-order swing speed, mechanical loads of the unit and the like, and two prediction models can be automatically switched in different working conditions, so that the wind generating set can be operated in all working conditions.

Owner:SHENYANG HUAREN WIND POWER TECH

Integrated model predictive control of distillation and dehydration sub-processes in a biofuel production process

ActiveUS20080103748A1Efficiently manipulatedBioreactor/fermenter combinationsAnalogue computers for chemical processesProcess systemsProduction rate

System and method for integrated management of a biofuel distillation process and a biofuel dehydration process of a biofuel production process, comprising a dynamic multivariate model-based controller coupled to a dynamic multivariate predictive model. The model is executable to: receive distillation and dehydration process information including biofuel compositions, receive an objective for biofuel production output from the distillation and dehydration processes, e.g., target product composition, production rate, and / or feed rate, and generate model output comprising target values for a plurality of manipulated variables related to the distillation and dehydration processes in accordance with the objective. The controller is operable to dynamically control the biofuel production process by adjusting the plurality of manipulated variables to the model-determined target values in accordance with the objective for biofuel production.

Owner:ROCKWELL AUTOMATION TECH

Overnight closed-loop insulin delivery with model predictive control and glucose measurement error model

A closed-loop system for insulin infusion overnight uses a model predictive control algorithm (“MPC”). Used with the MPC is a glucose measurement error model which was derived from actual glucose sensor error data. That sensor error data included both a sensor artifacts component, including dropouts, and a persistent error component, including calibration error, all of which was obtained experimentally from living subjects. The MPC algorithm advised on insulin infusion every fifteen minutes. Sensor glucose input to the MPC was obtained by combining model-calculated, noise-free interstitial glucose with experimentally-derived transient and persistent sensor artifacts associated with the FreeStyle Navigator® Continuous Glucose Monitor System (“FSN”). The incidence of severe and significant hypoglycemia reduced 2300- and 200-fold, respectively, during simulated overnight closed-loop control with the MPC algorithm using the glucose measurement error model suggesting that the continuous glucose monitoring technologies facilitate safe closed-loop insulin delivery.

Owner:CAMBRIDGE ENTERPRISE LTD +1

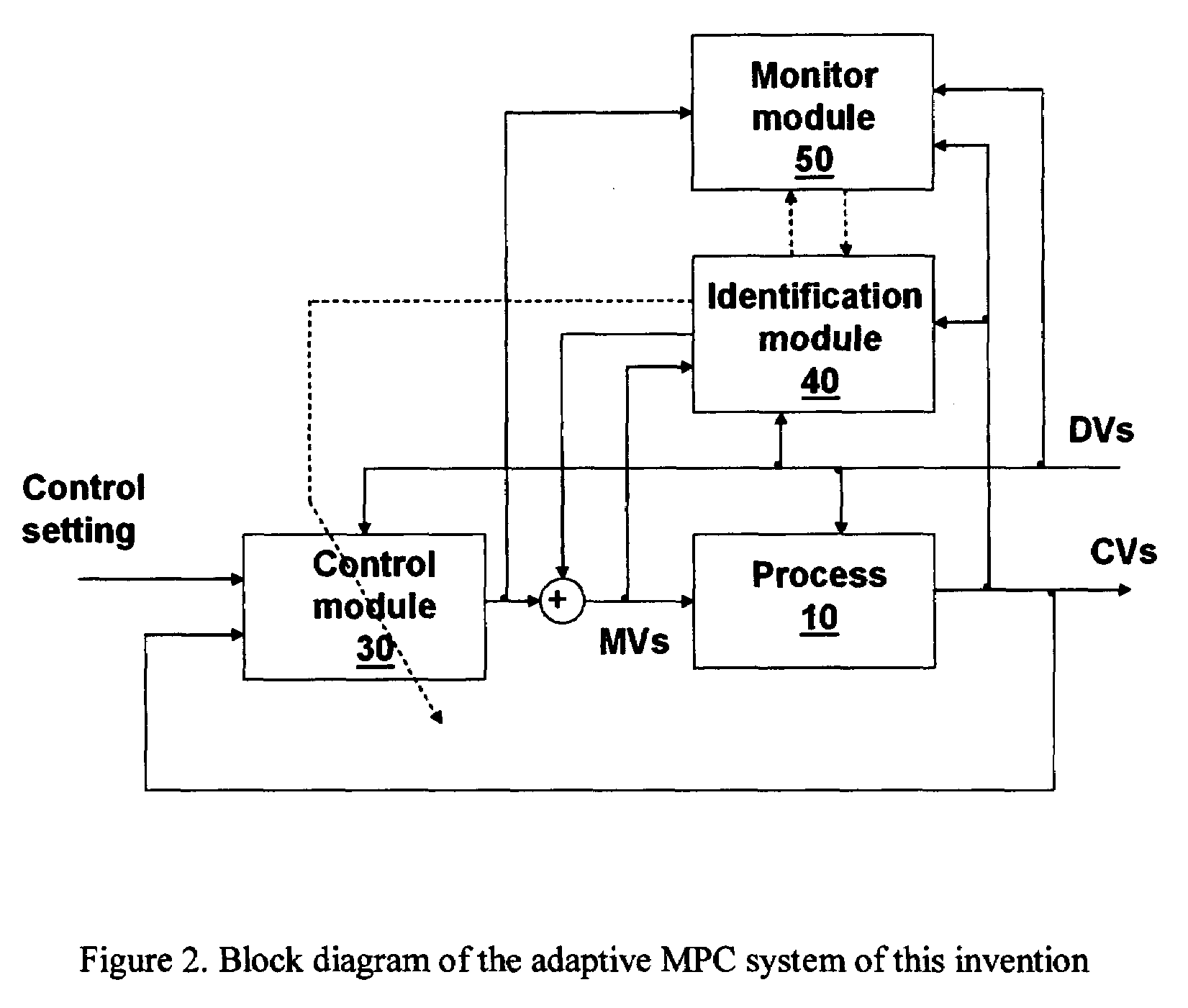

Computer method and apparatus for adaptive model predictive control

InactiveUS20070225835A1Automatically efficiently performLow costAdaptive controlControl engineeringModel quality

A computer method and apparatus for adaptive model predictive control (MPC) of multivariable processes is disclosed. The adaptive MPC system can perform automatic implementation for a new MPC controller, and, for an existing MPC controller, it can perform automatic maintenance when necessary. The adaptive MPC system consists of three modules: an MPC control module, an online identification module and a control monitor module. In MPC implementation, the online identification module and the MPC control module work together and perform various steps in MPC implementation automatically and efficiently. When the MPC controller is online, the control monitor module continuously monitors the MPC performance and model quality. When control performance becomes poor and considerable model degradation is detected, monitor module will start the maintenance by activating the online identification module. The identification module will re-identify the model and replace the old model. For strongly nonlinear process units, multiple models are identified and used in control.

Owner:ZHU YUCAI

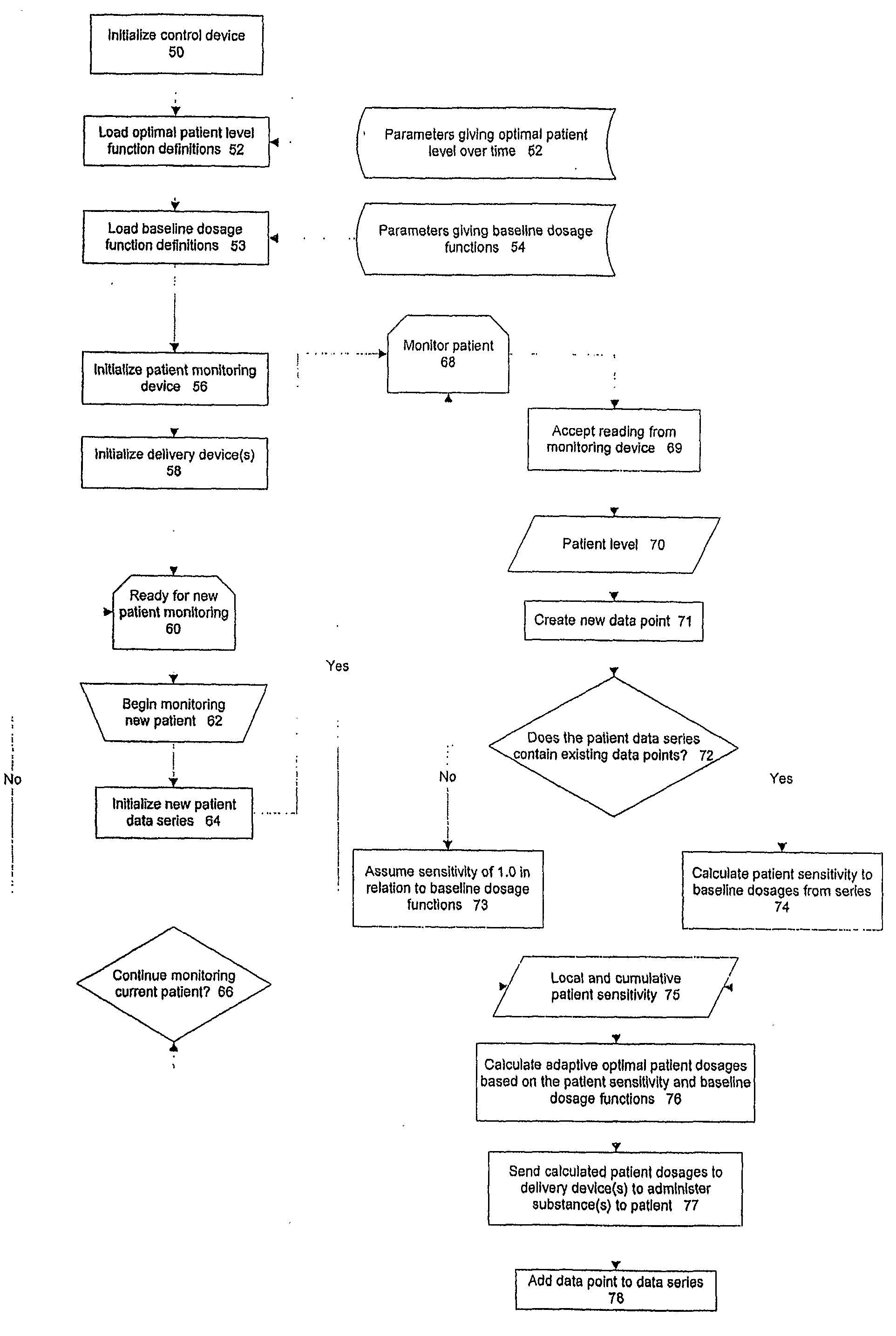

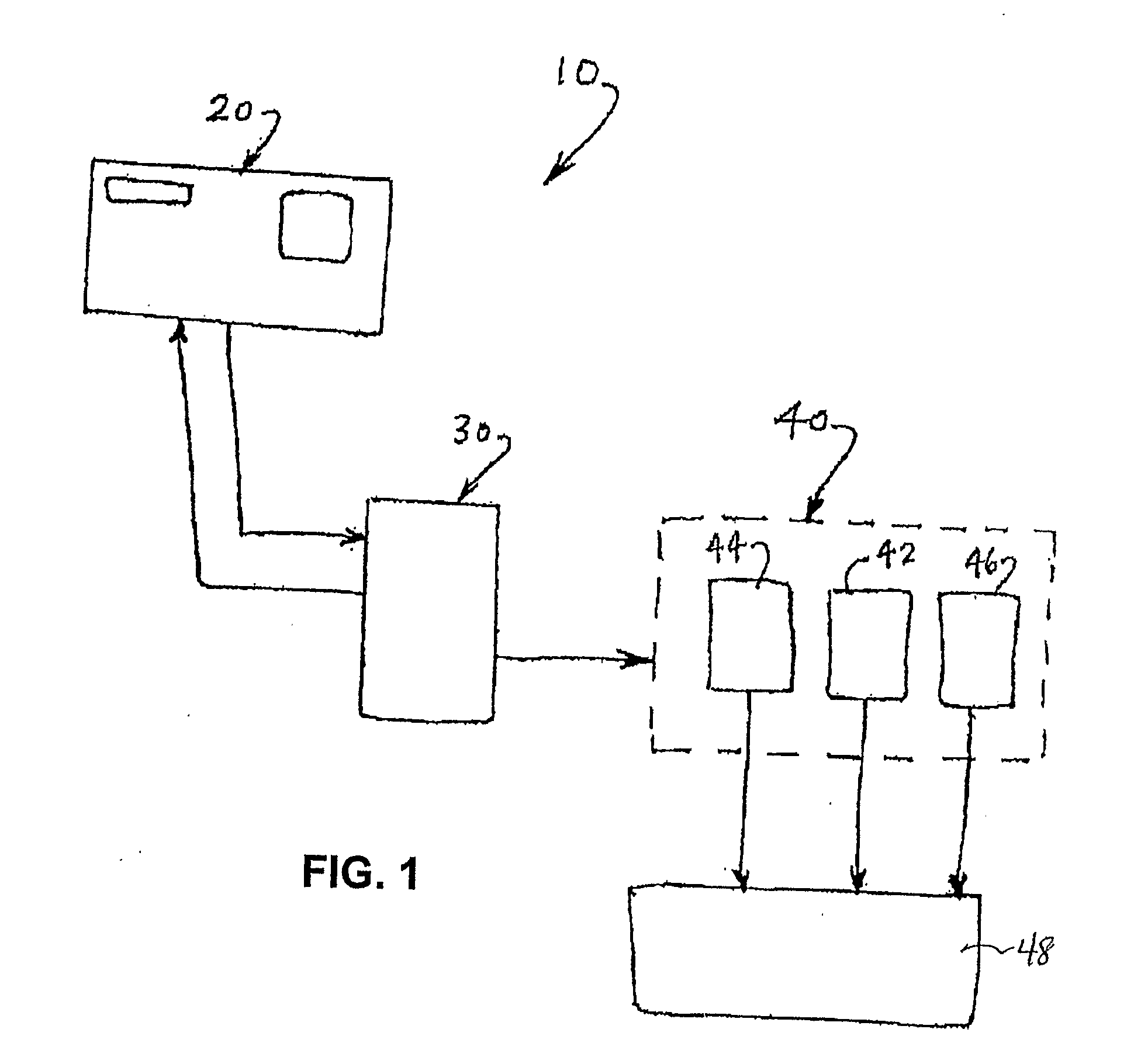

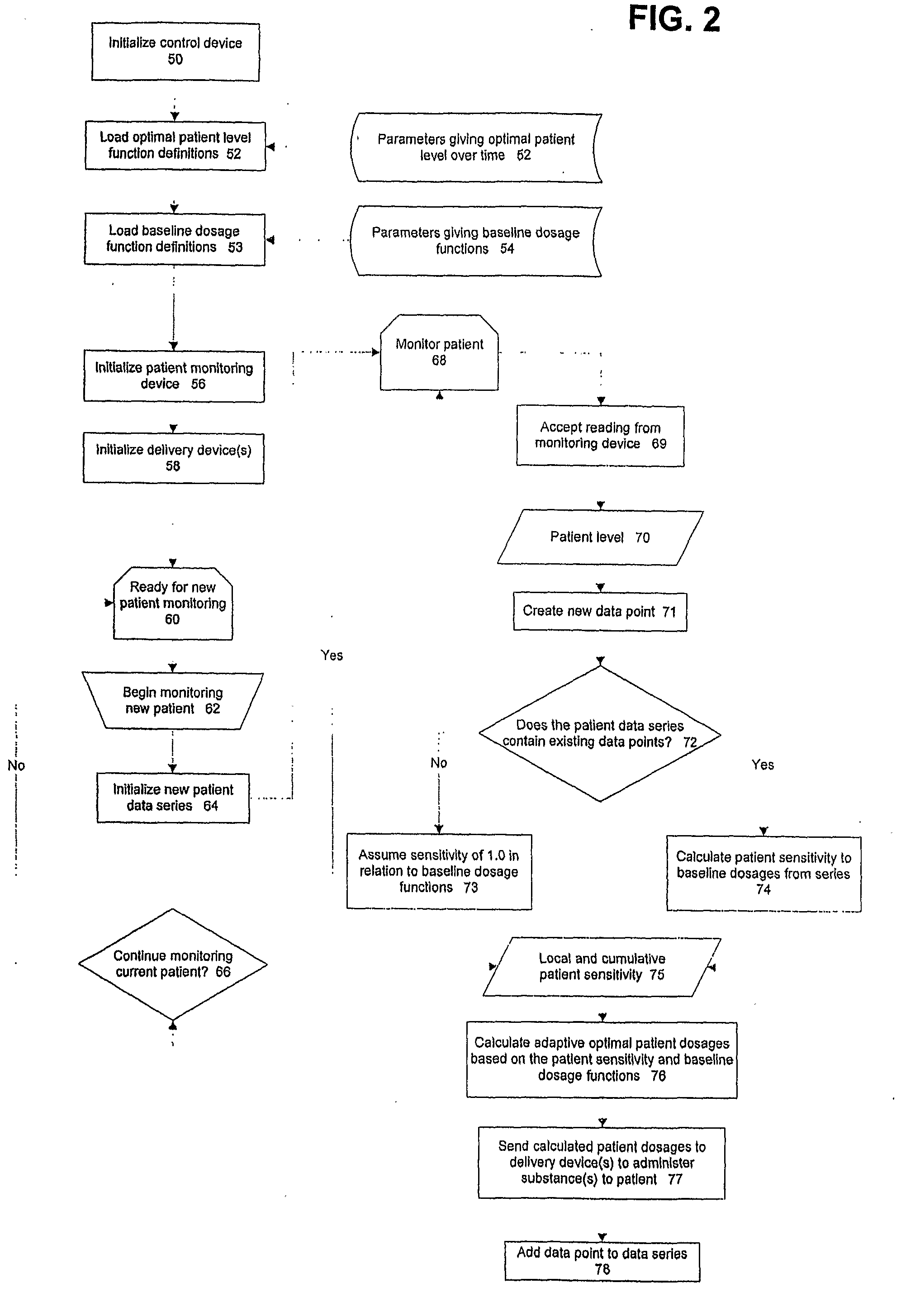

Balanced Physiological Monitoring and Treatment System

A system and method for providing balanced, automated regulation of a patient's physiological condition by monitoring at least one physiological parameter and, optionally, monitoring and controlling additional physiological parameters, is disclosed. The system includes a physiological parameter monitor, an intelligent control device and a multi-channel delivery device for providing controlled intravenous delivery of at least two medications that affect the physiological condition being controlled. Control logic in the intelligent control device is derived by an algorithm based on model predictive control. The control logic includes mathematically modeled systems, empirical data systems or a combination thereof. The system of the present invention is optionally included in a networked system to provide centralized data storage and archival of system information as well as data export and query capabilities that can be used for patient file management, health care facility management and medical research.

Owner:ADMETABYS CORP

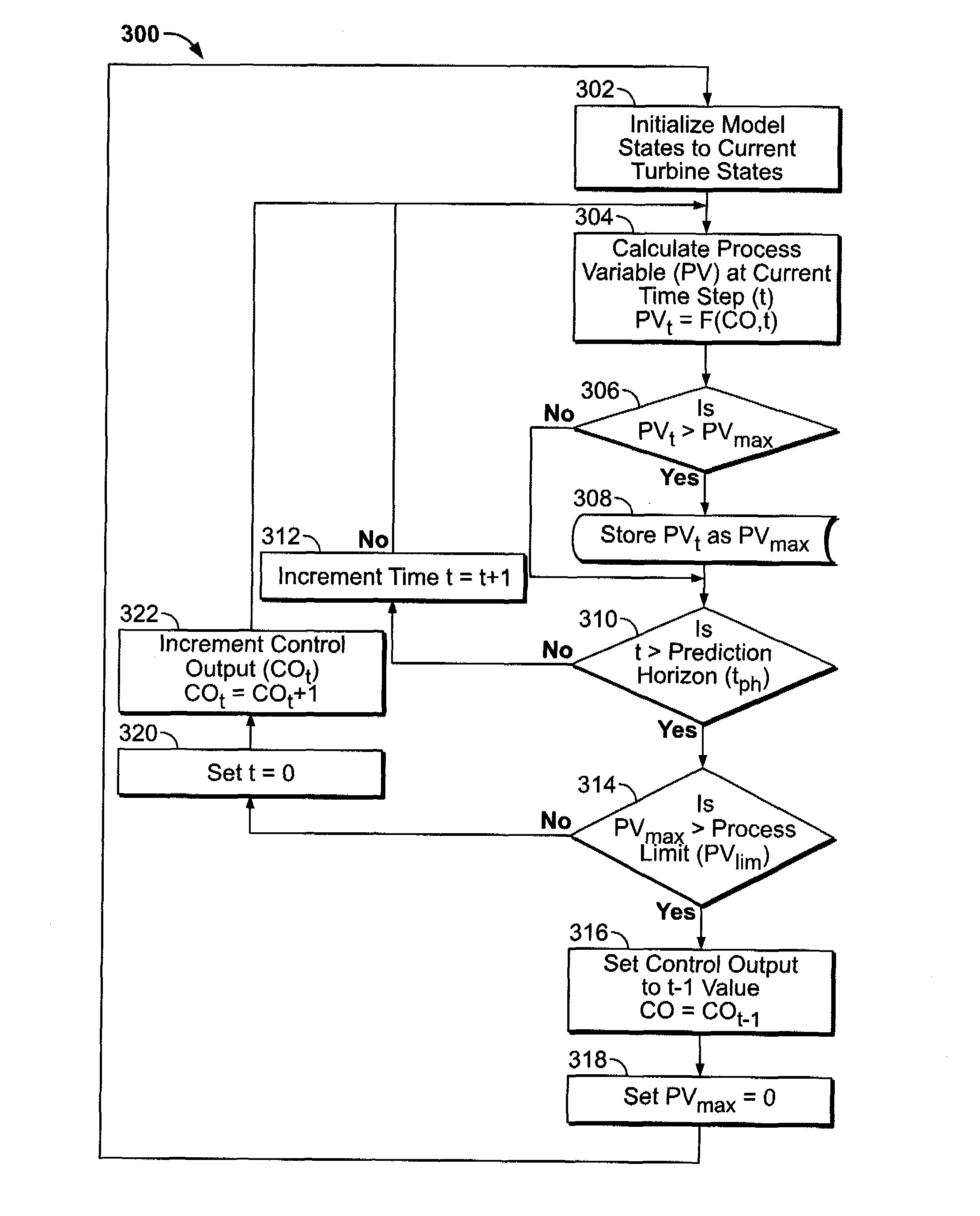

Methods and apparatus for model predictive control in a real time controller

InactiveUS8005575B2Mechanical power/torque controlLevel controlModel predictive controlProcess variable

Owner:GENERAL ELECTRIC CO

Method and system for a hybrid control-to-target and control-to-range model predictive control of an artificial pancreas

InactiveUS20140180240A1Medical simulationDrug and medicationsGlucose sensorsModel predictive control

Described and illustrated is a system for management of diabetes that includes an infusion pump, glucose sensor and controller with a method programmed into the controller. The infusion pump is configured to deliver insulin to a subject. The glucose sensor is configured to sense glucose levels in the subject and provide output signals representative of the glucose levels in the subject. The controller is programmed to switchover from one mode of MPC control based on a predetermined range of blood glucose values to another MPC mode based on a predetermined target.

Owner:JDRF INT +1

Model predictive control apparatus

InactiveUS20050267608A1Quick responseAnalogue computers for vehiclesVehicle fittingsEngineeringModel predictive control

A model predictive control apparatus includes an initial solution generation section, an abnormality handling section, and an objective function adjustment section. The abnormality handling section performs initial solution generation when it is determined that performed optimization is abnormal. The initial solution generation section generates an initial optimal value of a future time series control input in accordance with an initial objective function, without reference to a candidate value of the time series control input. The objective function adjustment section adjusts the current objective function so that the current objective function varies stepwise with time toward the normal objective function when it is determined that the current objective function is different from the normal objective function.

Owner:NISSAN MOTOR CO LTD

Model Predictive Control System and Method for Reduction of Steady State Error

A technique is disclosed for reducing an error in a controlled variable via model predictive control. A predicted error in the controlled variable is determined for a forward-looking control horizon based upon measured or computed variables. The integral of the predicted error is computed. If the error or the integral exceed a tolerance for a determined time period, the model predictive control algorithm is modified to drive the error or the integral to within a tolerance. The modifications to the control algorithm may include changes to coefficients for terms based upon the error and / or the integral of the error.

Owner:ROCKWELL AUTOMATION TECH

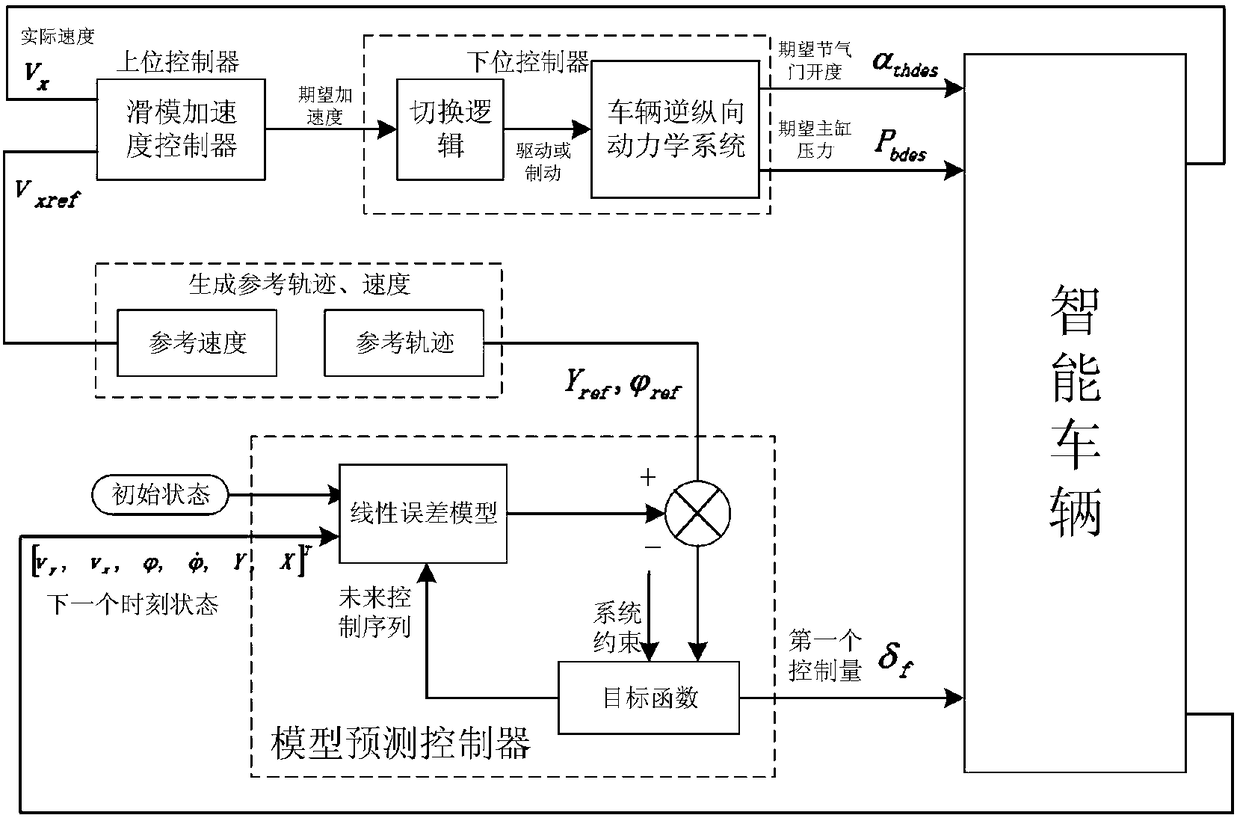

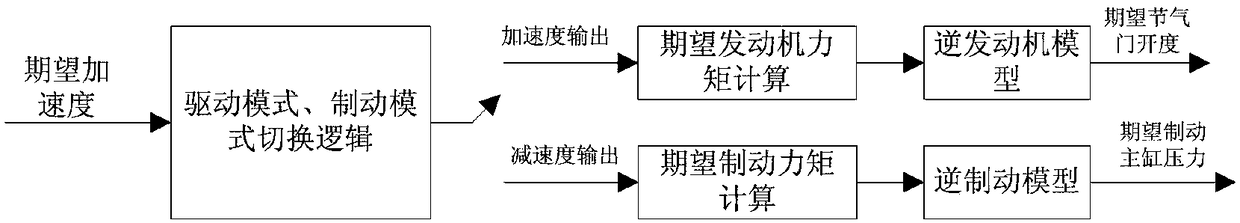

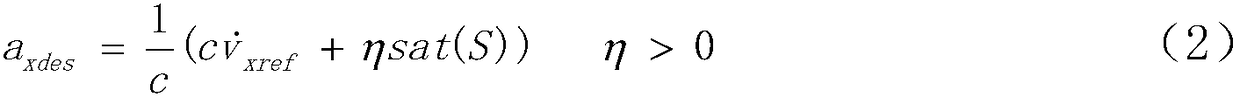

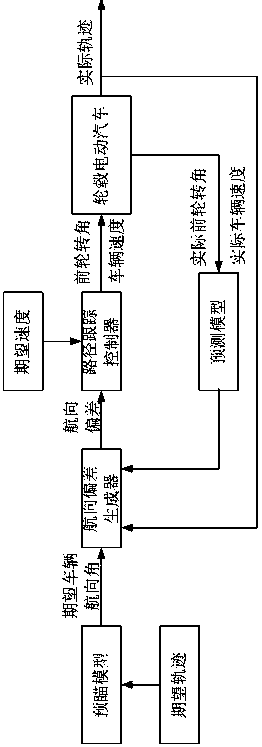

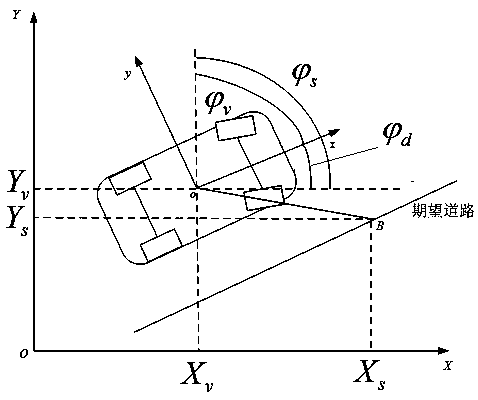

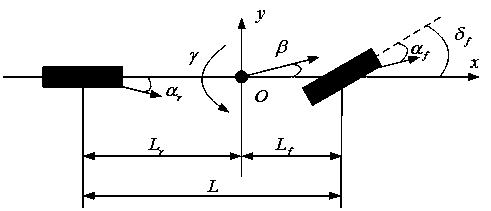

Horizontal and vertical coordination control method for trajectory tracking of intelligent vehicle

InactiveCN108248605AImprove lateral stabilityRealize longitudinal speed tracking controlControl devicesControl systemModel predictive control

The invention relates to a horizontal and vertical coordination control method for trajectory tracking of an intelligent vehicle. For association and coupling characteristics of horizontal and vertical dynamics of the intelligent vehicle, a horizontal and vertical coordination controller for trajectory tracking of the intelligent vehicle is designed. By applying a model prediction control and sliding mode control algorithm, the opening degree of a throttle valve of an engine, the pressure of a main braking cylinder and the deflection angle of a front wheel are cooperatively controlled. In thedesign of a horizontal MPC, the state amount of the vehicle is selected at the formula which is shown in the description, and the state amount (vertical speed vx) is real-time changable vehicle speedoutput by the vehicle after vertical control; vy is a horizontal speed at the mass center of the vehicle; the formulas which are shown in the description are the heading angle and heading angle speedat the mass center of the vehicle; Y and X are a horizontal position and a vertical position under world coordinates. According to a horizontal and vertical coordination control system, the intelligent vehicle efficiently and stably tracks an expectation trajectory at the expected speed. Large-steering operation can be remarkably improved, and the horizontal stability of the intelligent vehicle inthe trajectory tracking process is improved.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

Intelligent electric vehicle path tracking model prediction control method

ActiveCN109795502AImprove path tracing performanceImprove mechanical propertiesModel predictive controlElectric vehicle

The invention relates to an intelligent electric vehicle path tracking model prediction control method, belonging to the technical field of control. The aim of the invention is to adopt the intelligent electric vehicle path tracking model prediction control method, wherein the model prediction control method can take account of the safety constraints of a whole vehicle simultaneously and realizeseclectic optimization among vehicle path tracking performance, safety and whole vehicle performance effectively. The method gives thought to intelligent electric vehicle path tracking model building in limited conditions and yaw stabilization controller design based on model prediction control as well as the tracking performance of the vehicle, the safety of the vehicle, the whole vehicle performance, driving comfort and saving and control of energy in the process of carrying out control strategy deduction, and improves the dynamic performance of the whole vehicle. The method gives thought tothe tracking performance of the vehicle (path following and speed following), the safety of the vehicle (preventing slipping, locking, sideward inclining or drifting), the whole vehicle performance (accelerating and braking performance), driving comfort (the change of torque cannot be too great) and saving and control of energy (saving energy on the premise of meeting the performance). The dynamicperformance of the whole vehicle is improved.

Owner:JILIN UNIV

Model predictive control of fermentation temperature in biofuel production

InactiveUS20080108048A1Easy to controlBioreactor/fermenter combinationsBiological substance pretreatmentsBiofuelBatch fermentation

Owner:ROCKWELL AUTOMATION TECH

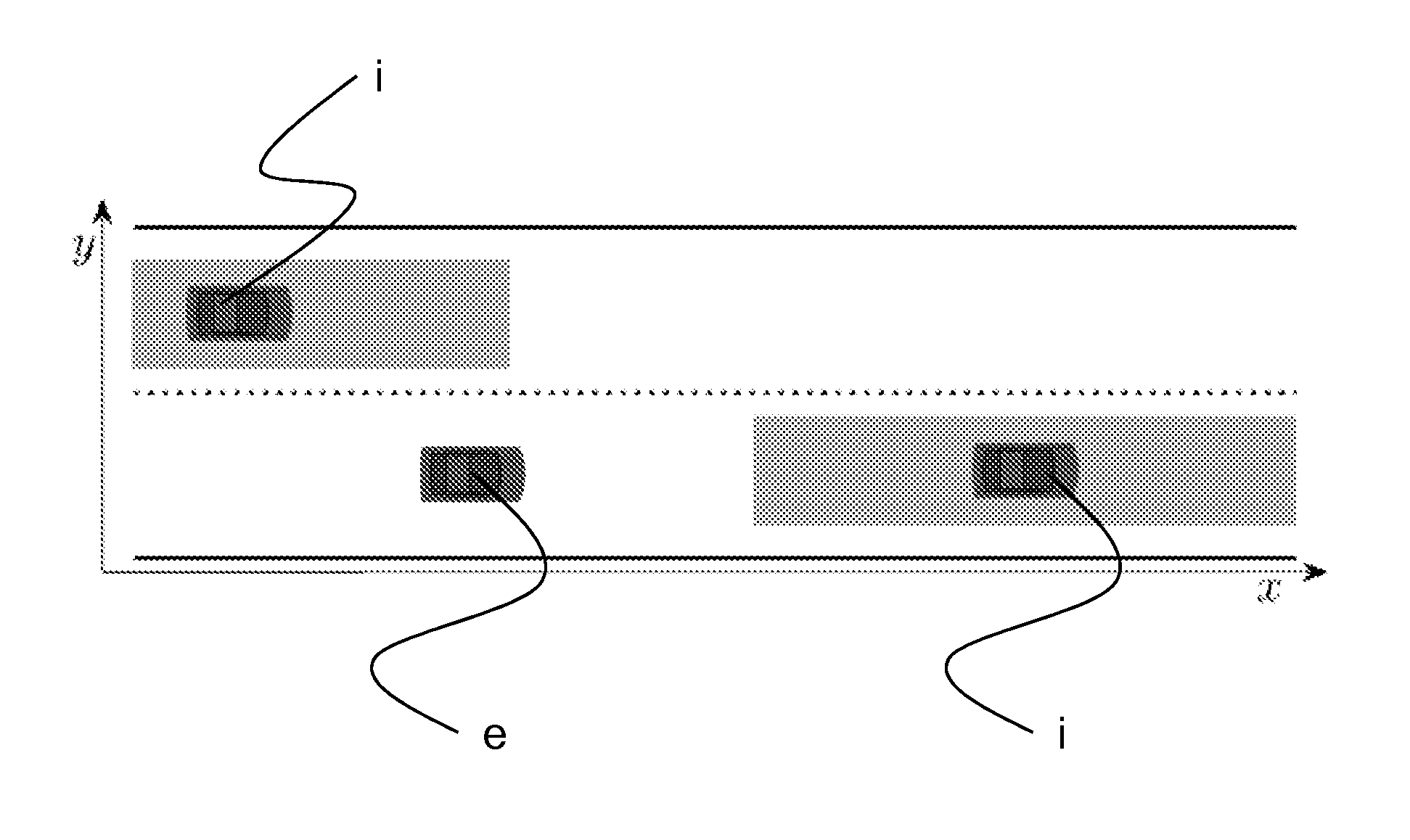

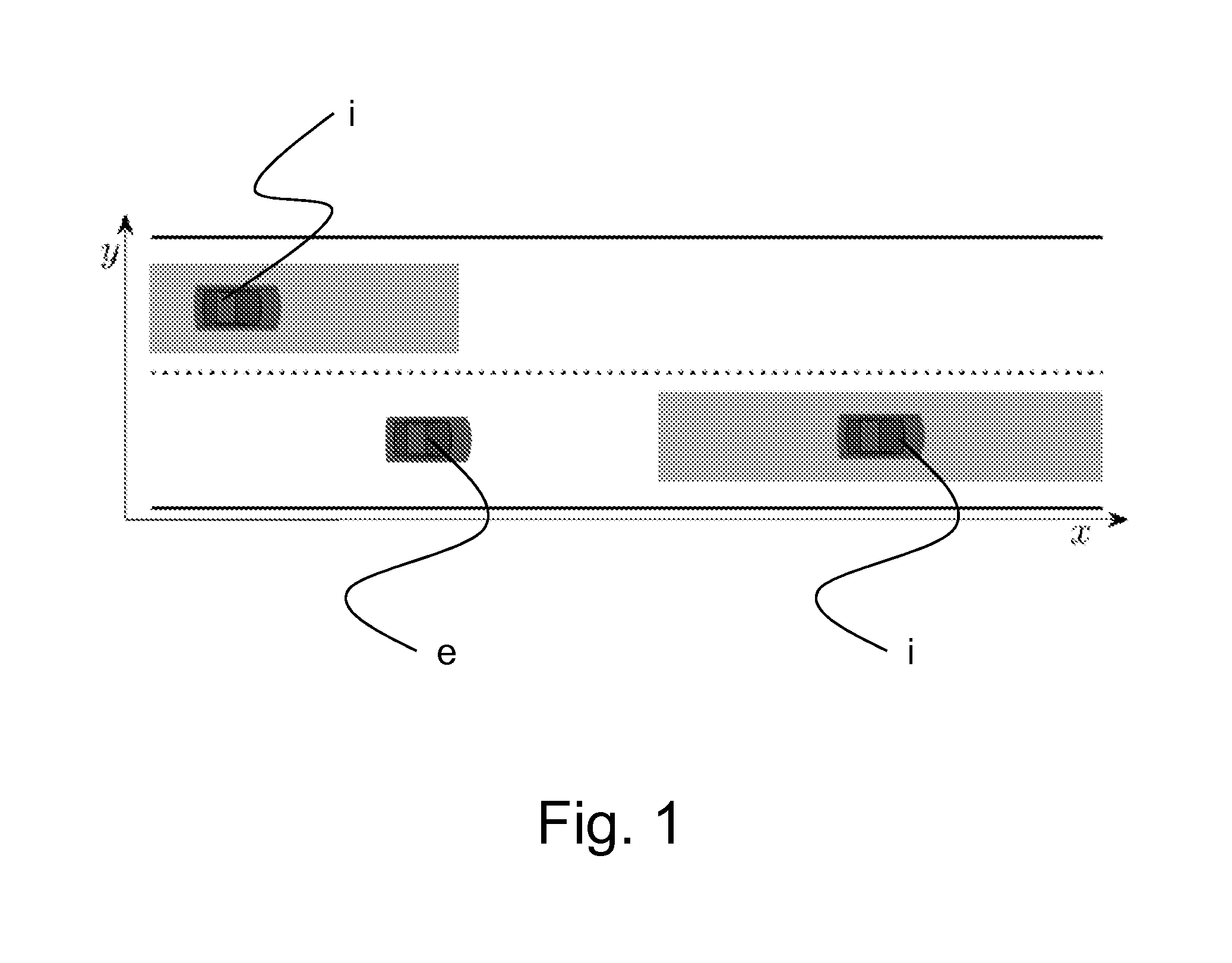

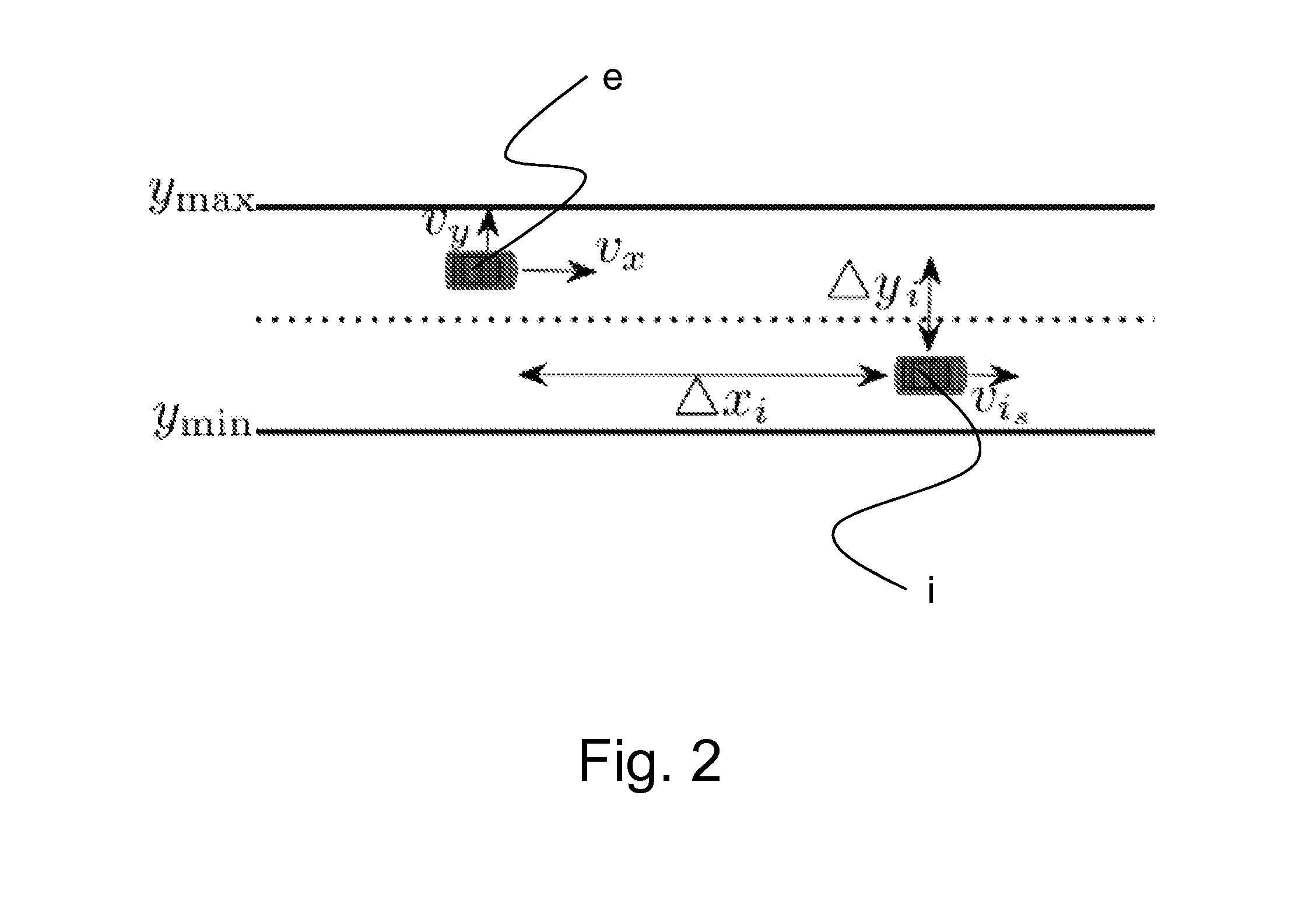

Manoeuver generation for automated driving

ActiveUS20150073663A1Convenient ArrangementEasy to planDigital data processing detailsSteering initiationsDriver/operatorModel predictive control

A method and arrangement are described for manoeuvre generation for automated driving on a one-way road of a vehicle (e) hosting the arrangement, the host vehicle (e) further including one or more advanced driver assistance systems. A collision free reference trajectory for longitudinal and lateral movement of the host vehicle (e) is determined repeatedly, with a fix time interval, for allowing the host vehicle (e) to retain a desired velocity and maintain the host vehicle (e) in a preferred lane utilizing model predictive control and quadratic program formulation. A control scheme where the structured environment of the one-way road is exploited in order to linearly formulate collision avoidance constraints is utilized. Manoeuvre generation is performed through solving the quadratic program. The one or more advanced driver assistance systems are controlled to perform the generated manoeuvre.

Owner:VOLVO CAR CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com