Patents

Literature

394results about How to "Reduce mechanical load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

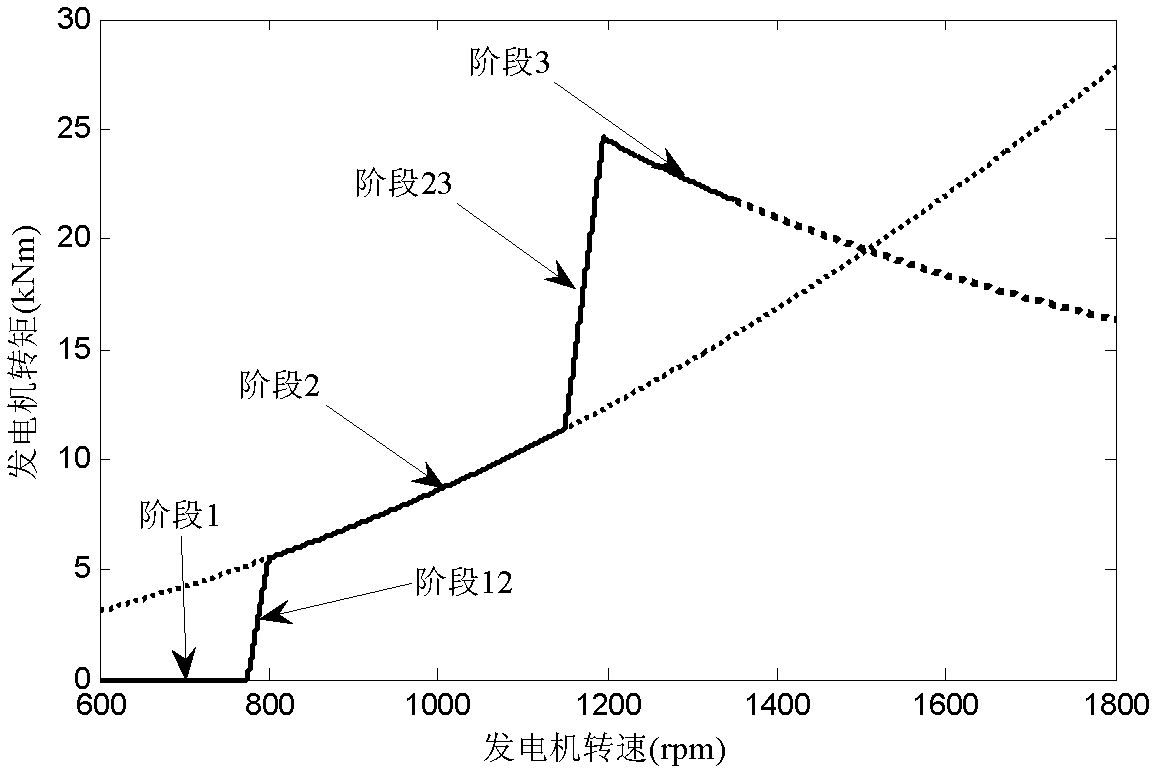

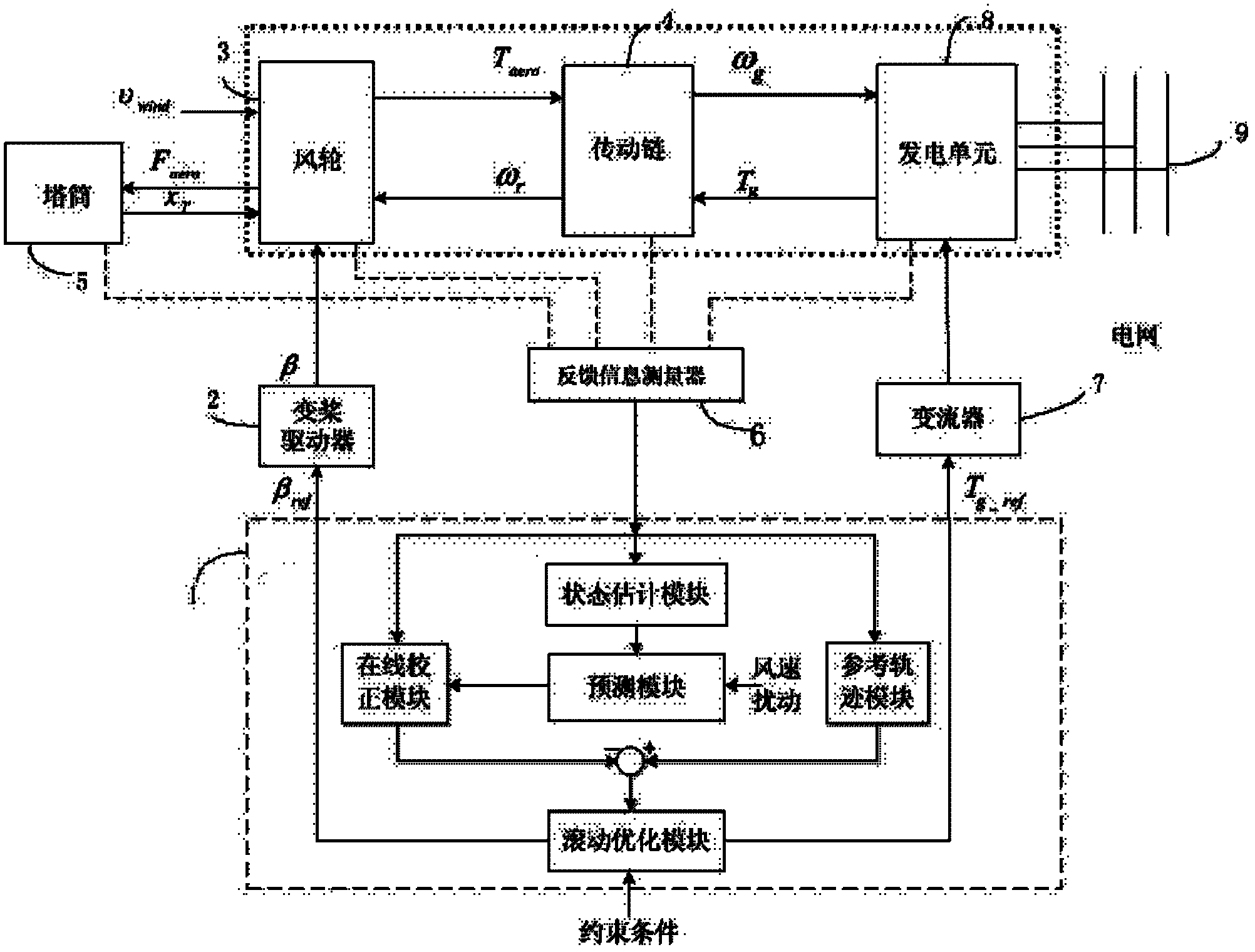

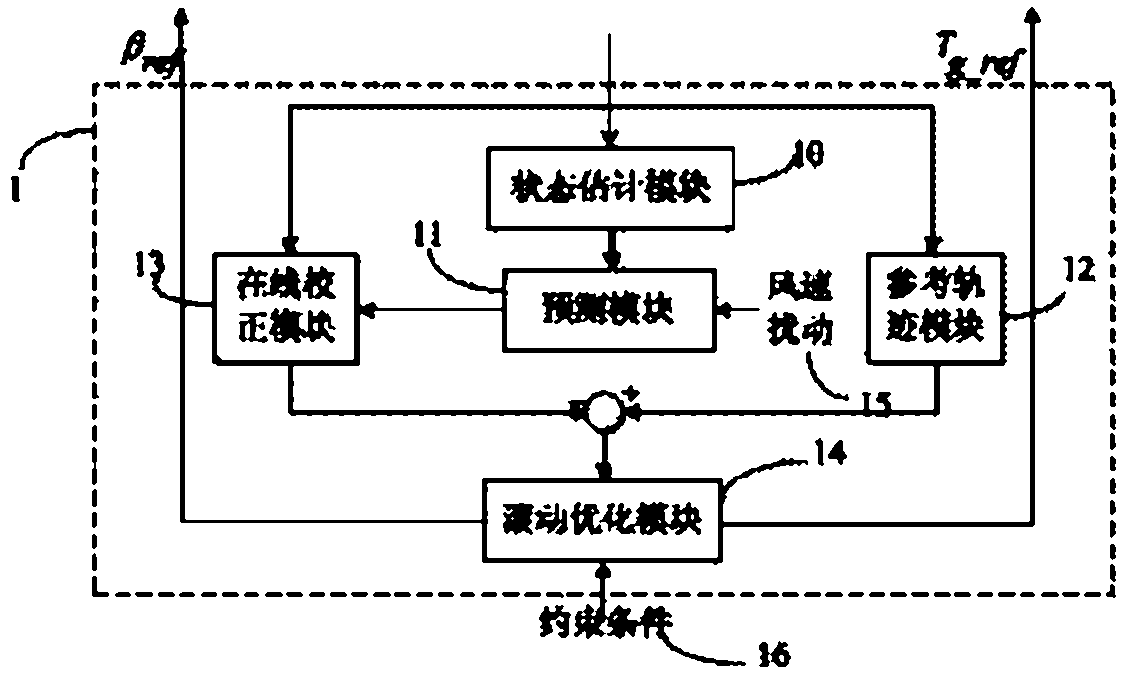

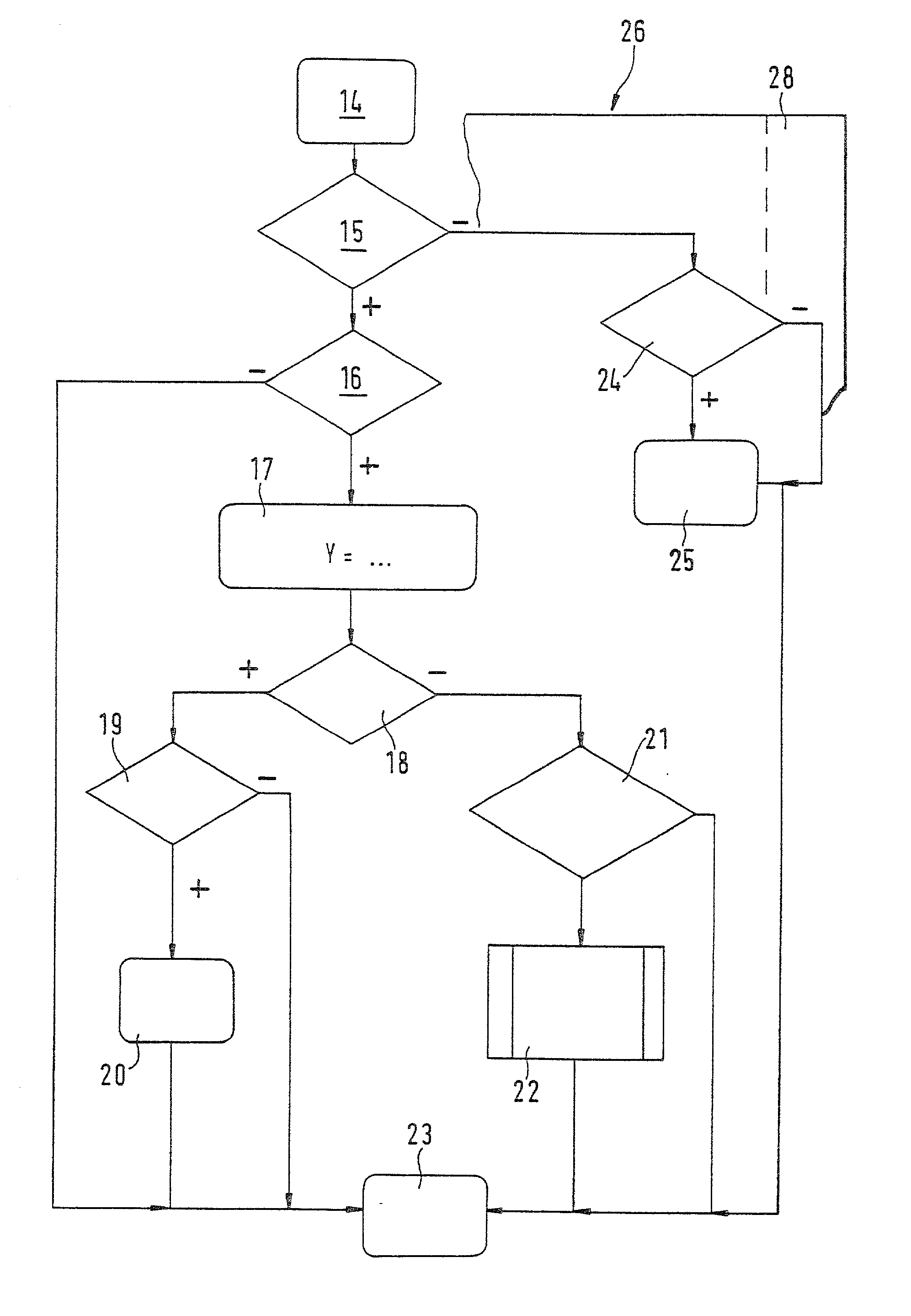

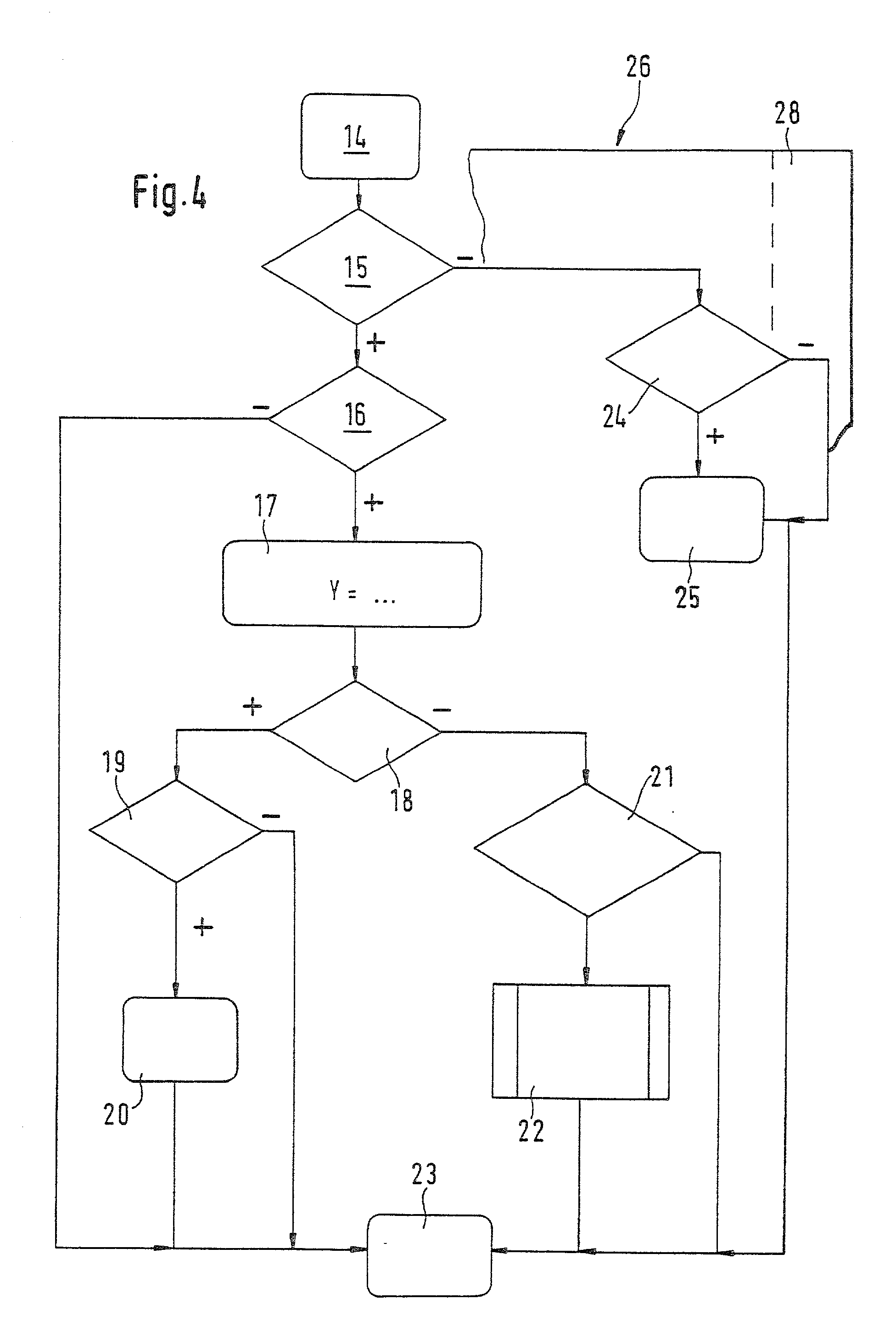

Model prediction control method and model prediction control system for all working conditions of wind generating set

ActiveCN102588211AAvoid the phenomenon of long-term oscillationReduce mechanical loadWind motor controlActive/predictive/anticipative controlControl systemModel predictive control

Disclosed are a model prediction control method and a model prediction control system for all working conditions of a wind generating set. The system comprises an MPC (model prediction control) device, a feedback information measurer, a wind wheel, a driving chain, a tower, a generating unit, a variable propeller driver and a converter. The feedback information measurer is used for detecting status variables of the wind wheel, the driving chain, the tower and the generating unit and transmitting detecting results to the MPC device, the MPC device is used for computing targets of the blade pitch angle and the generator torque, and the variable propeller driver and the converter are used for adjusting the blade pitch angle and the wind generator torque. The method is used for computing control increment by means of a variable propeller control prediction model and a torque control prediction model, takes the status variables including driving chain torsional displacement, driving chain torsional speed, blade plane external first-order flap displacement, blade plane external first-order flap speed, tower front-back first-order swing displacement, tower front-back first-order swing speed, mechanical loads of the unit and the like, and two prediction models can be automatically switched in different working conditions, so that the wind generating set can be operated in all working conditions.

Owner:SHENYANG HUAREN WIND POWER TECH

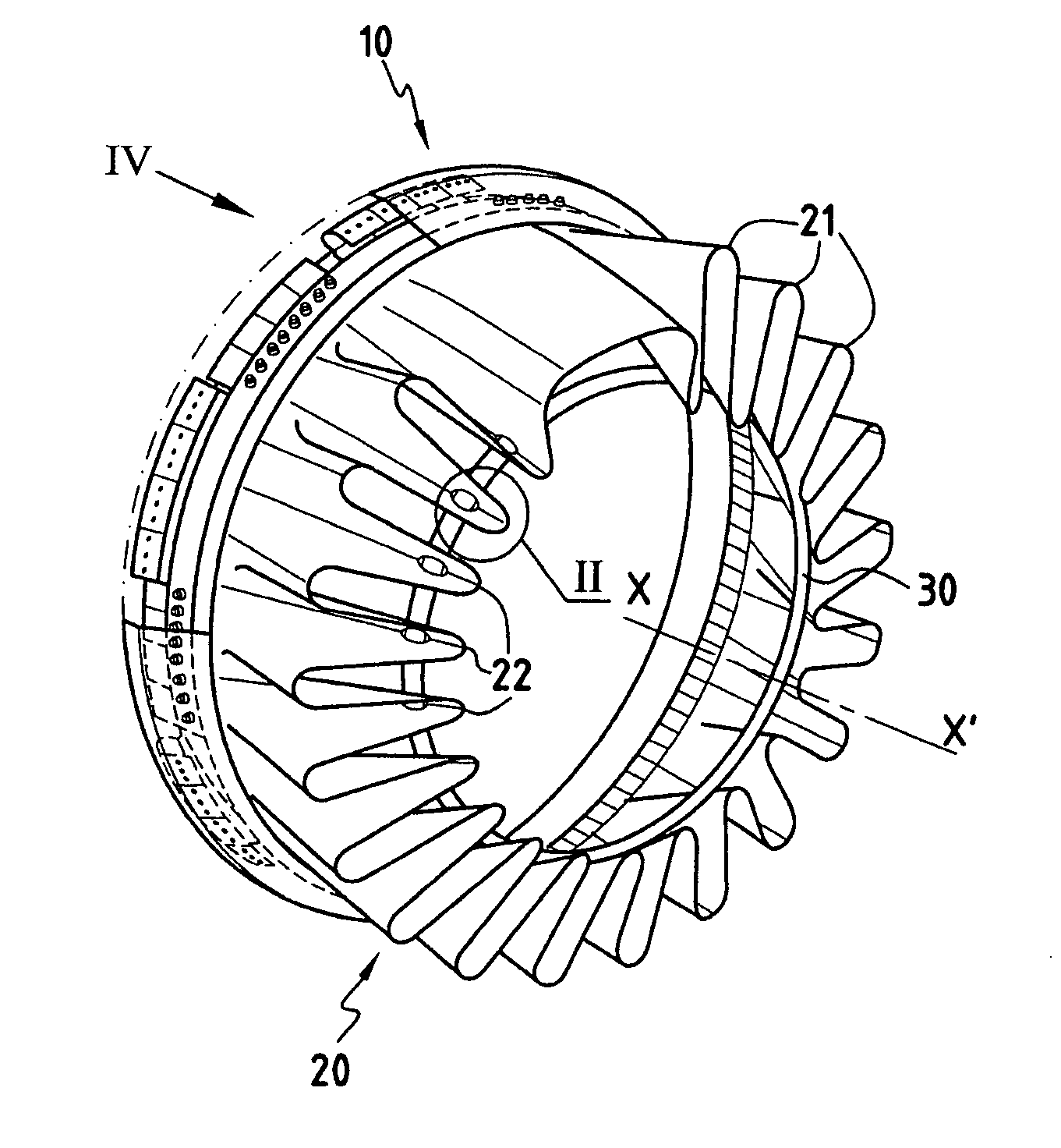

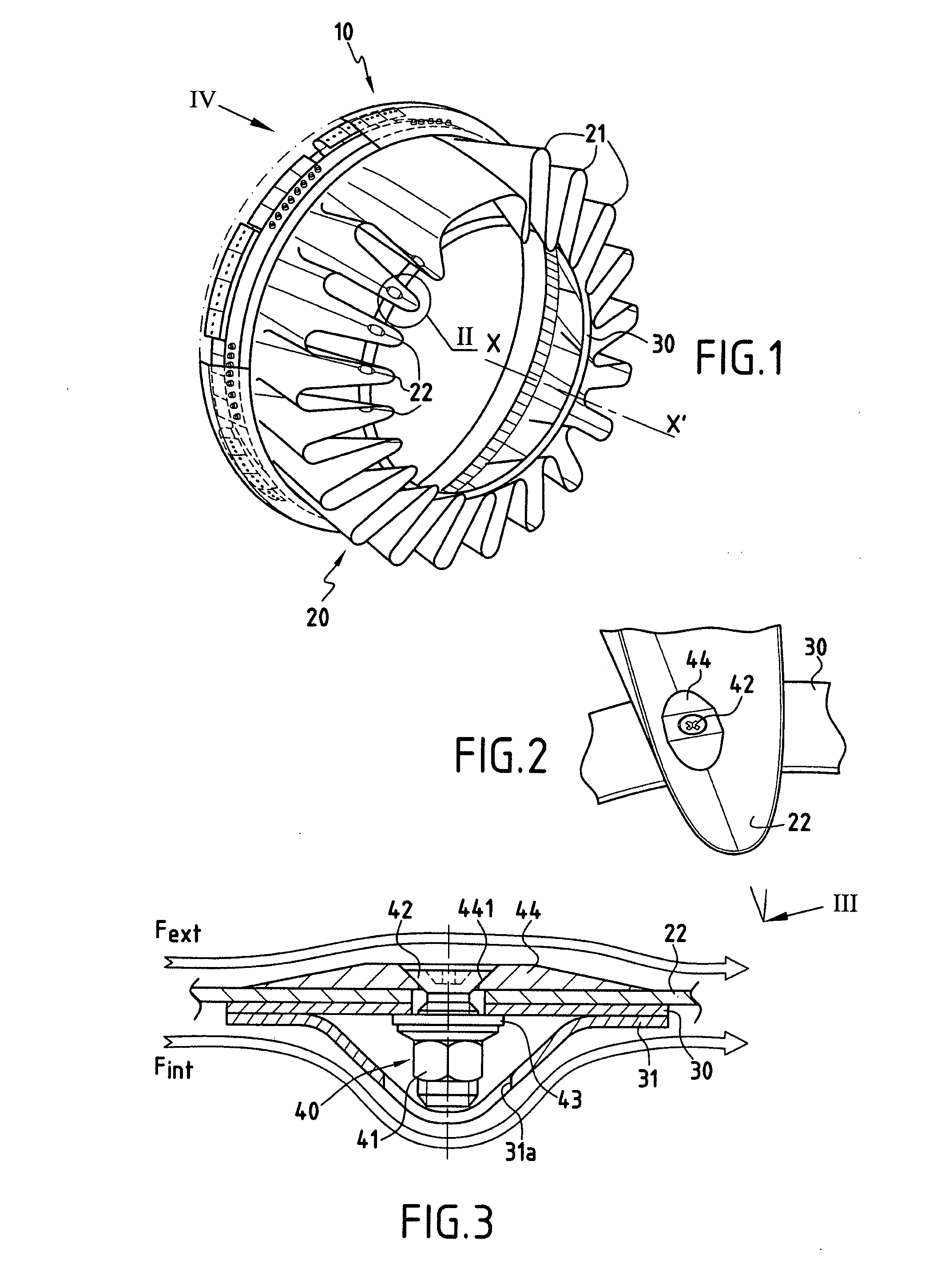

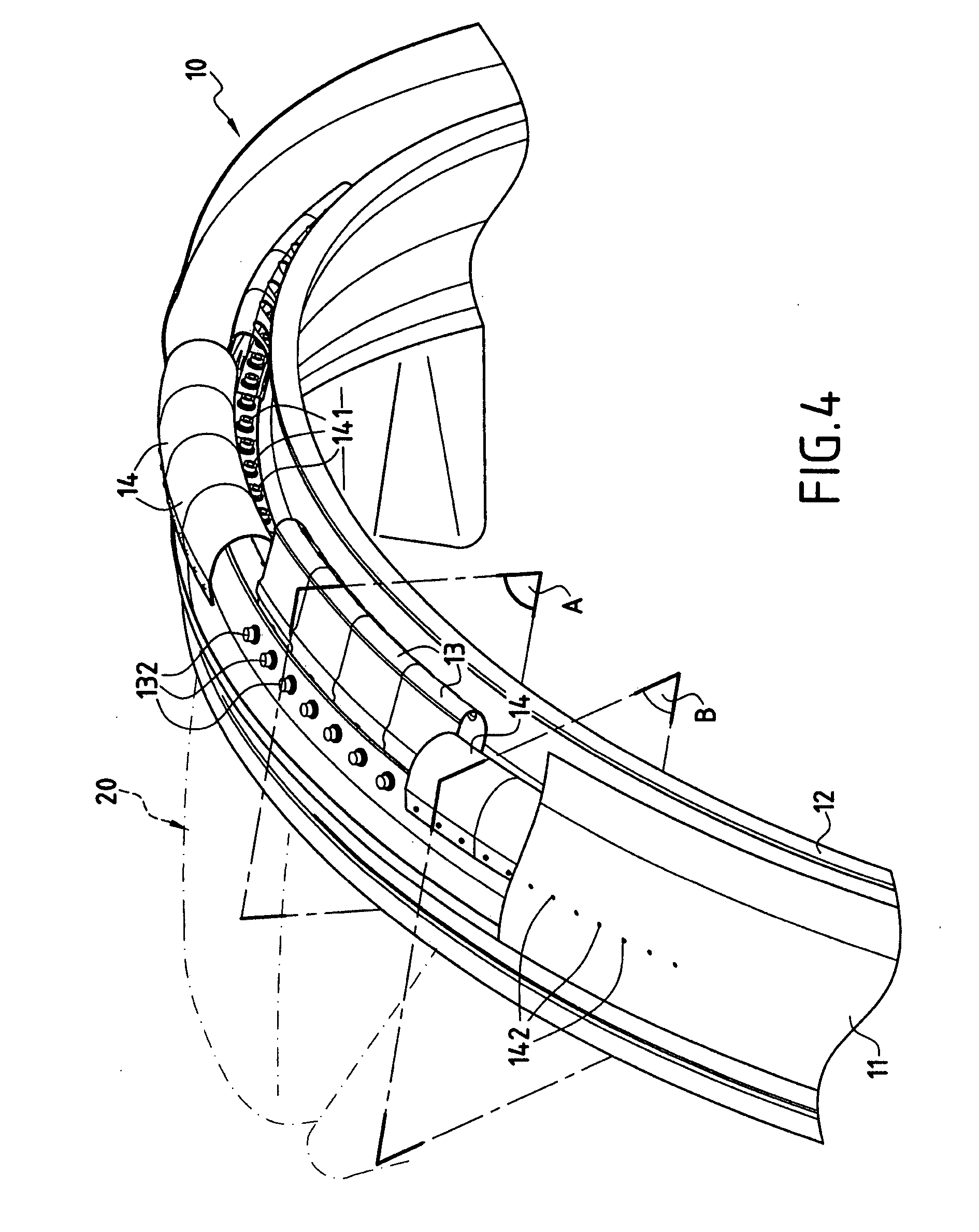

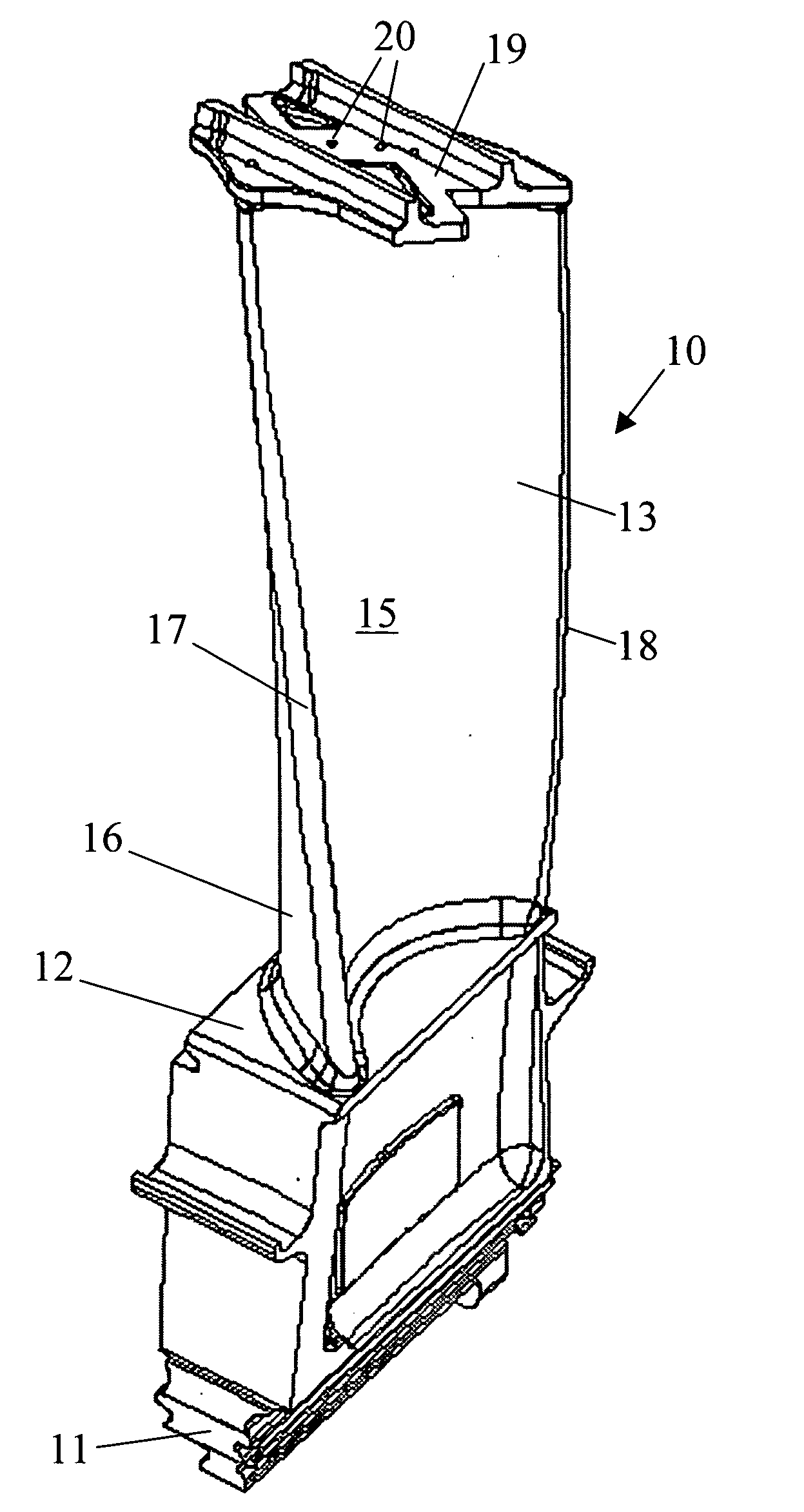

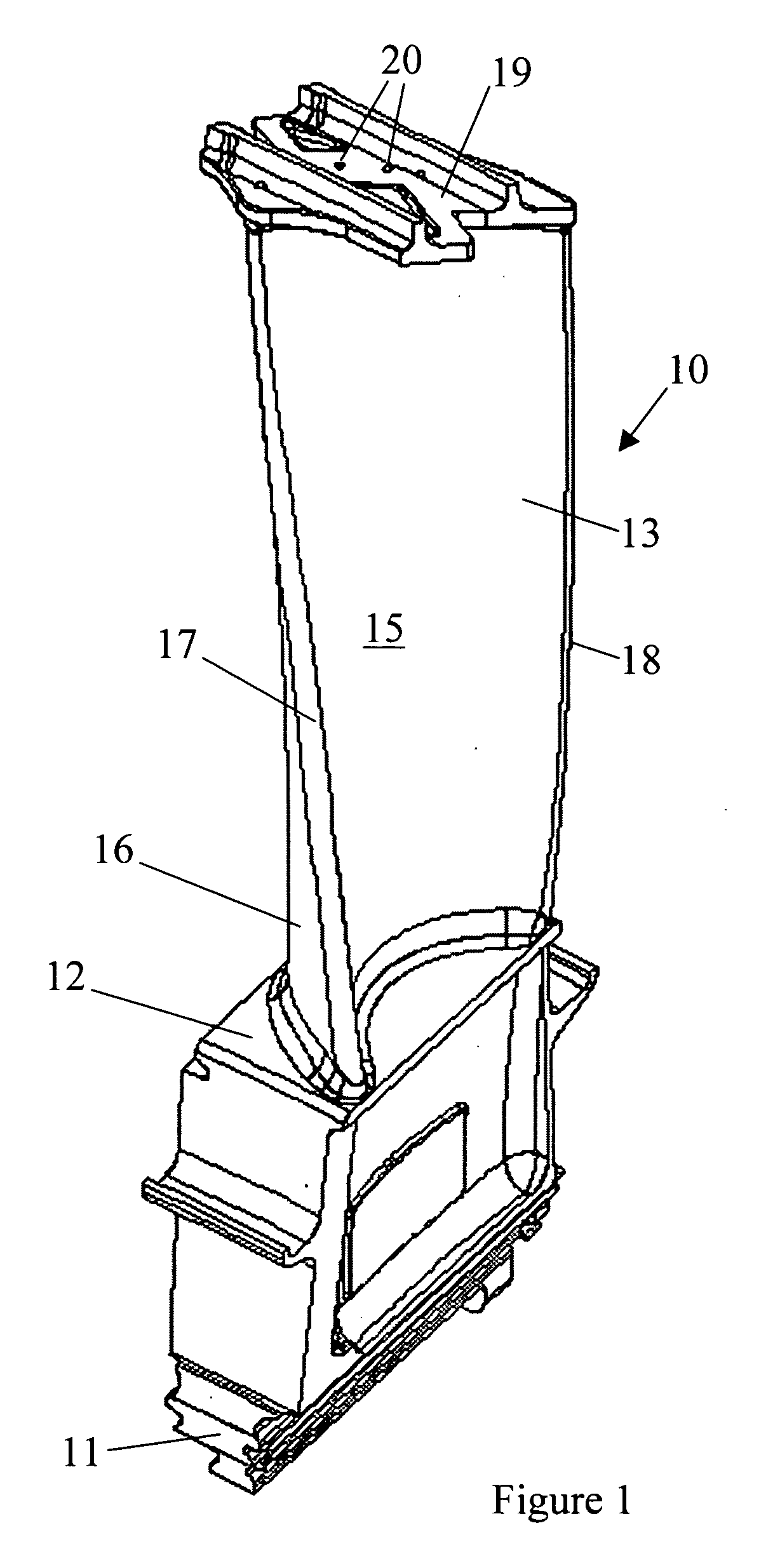

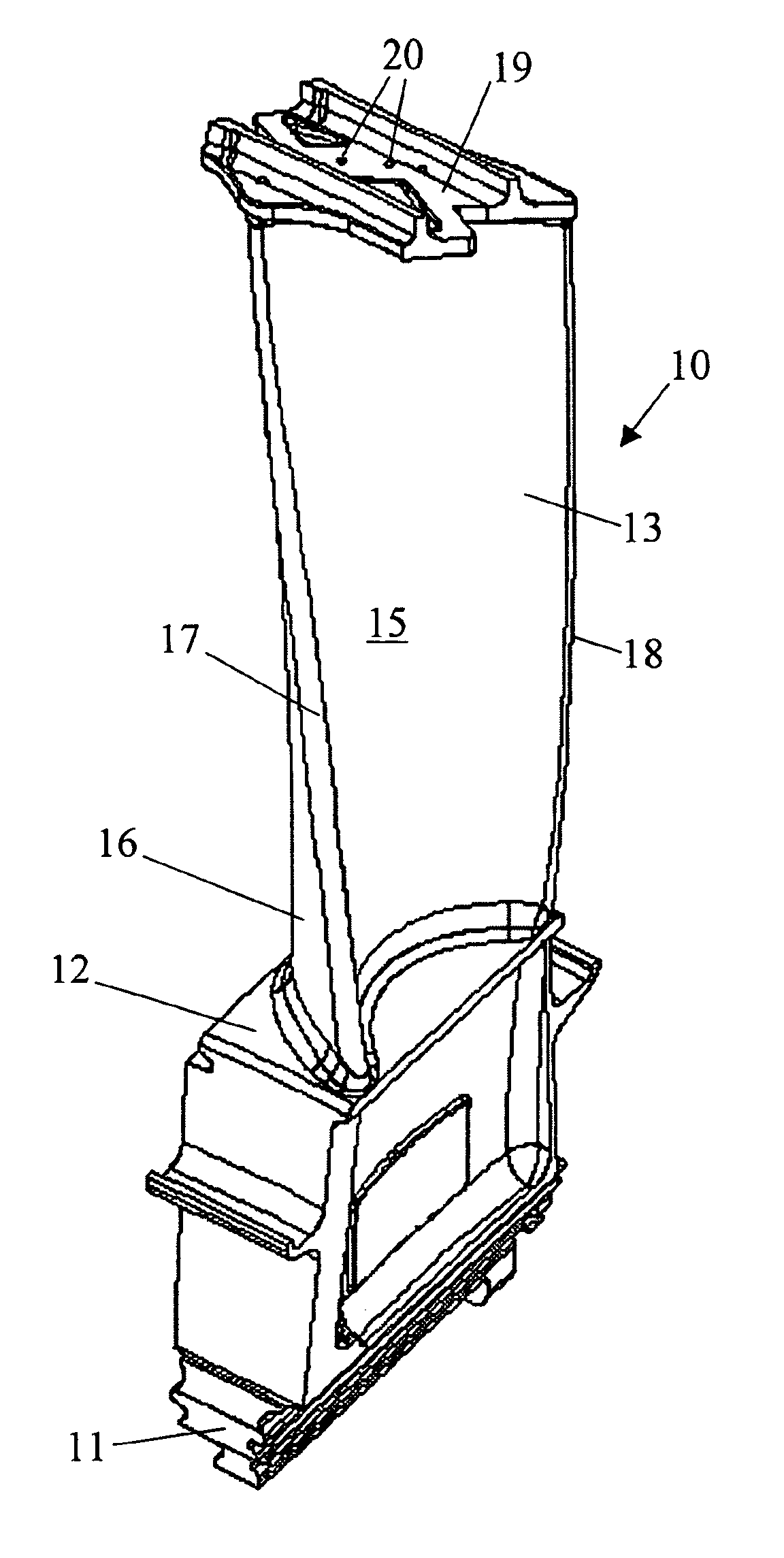

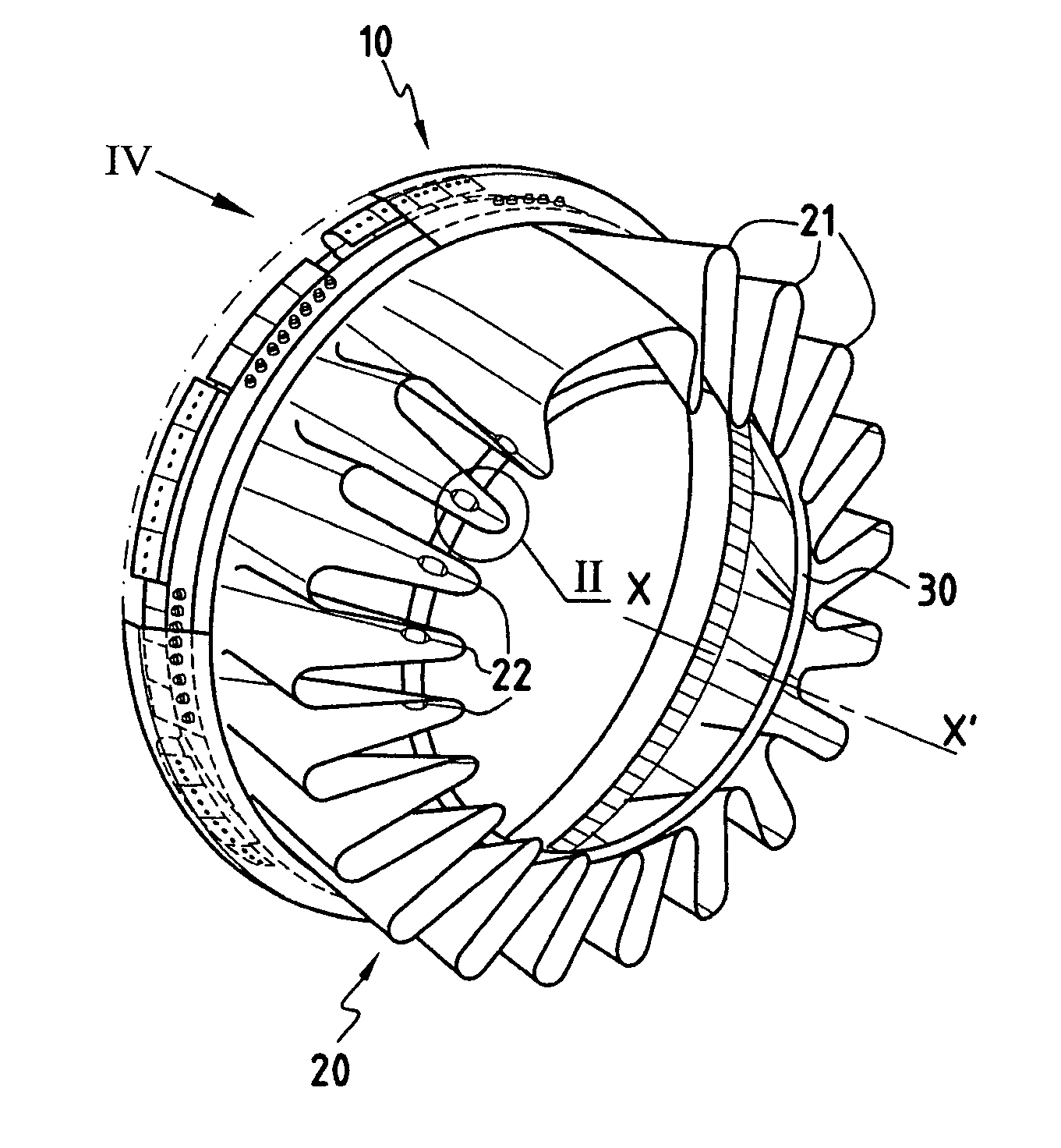

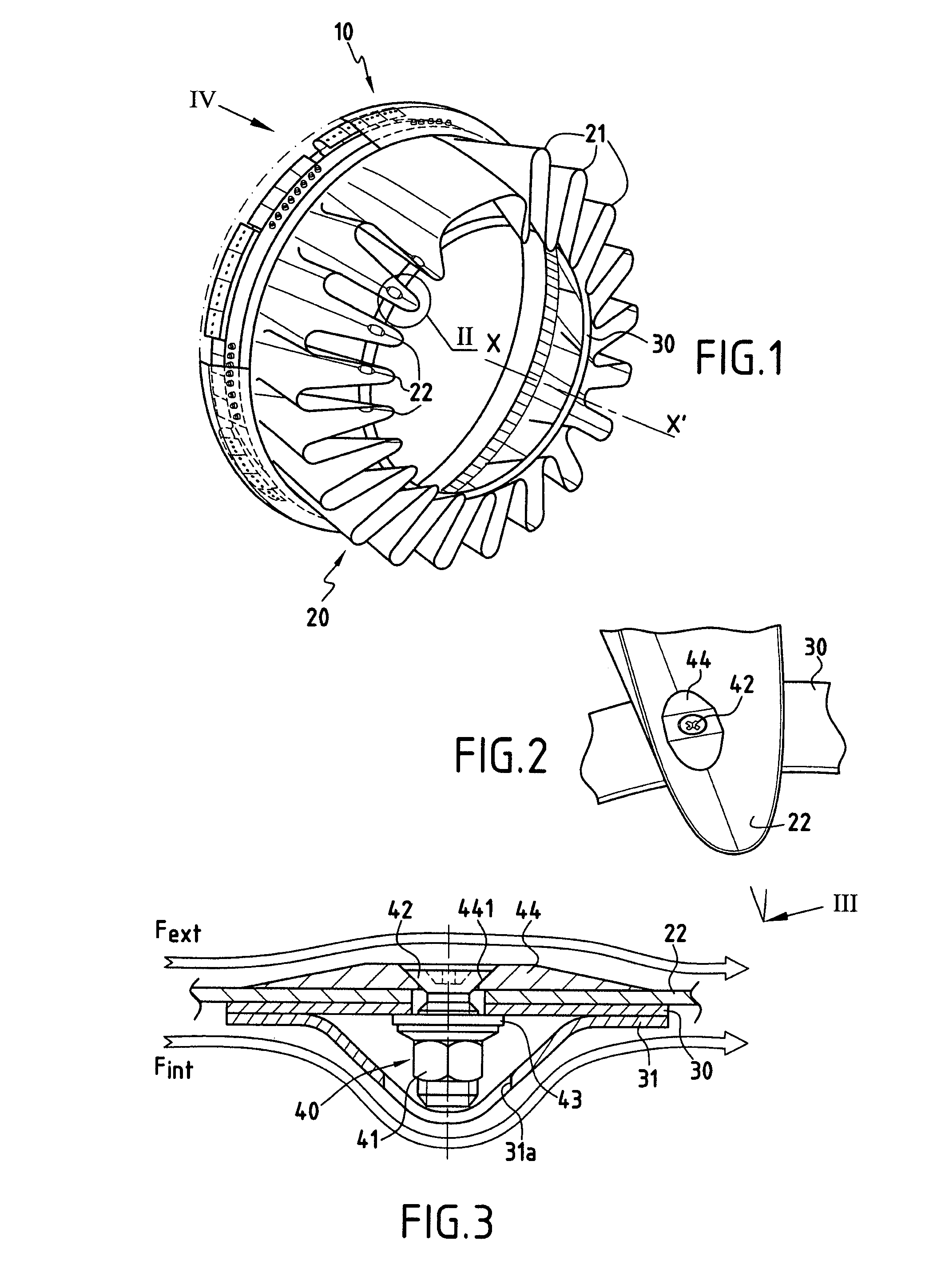

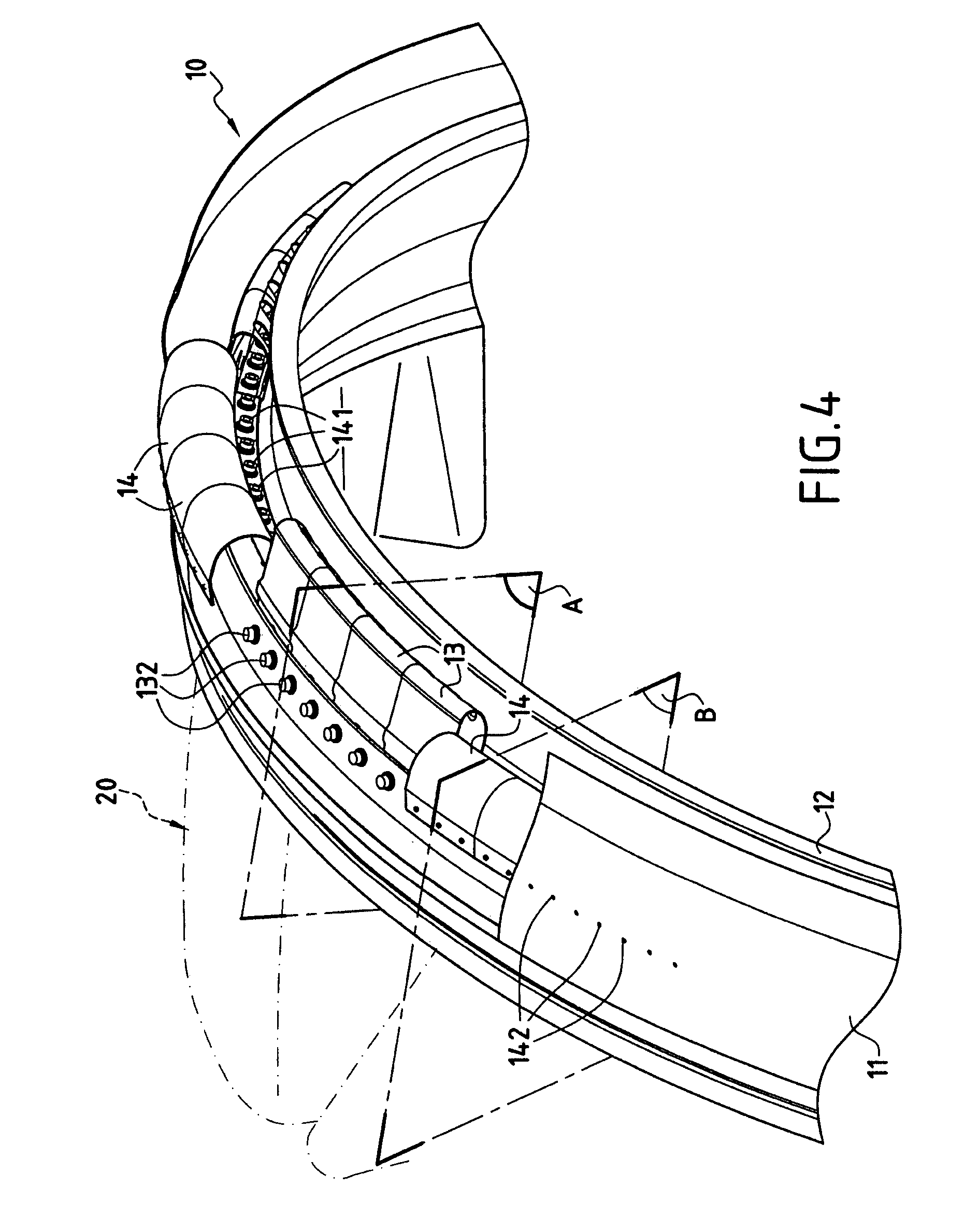

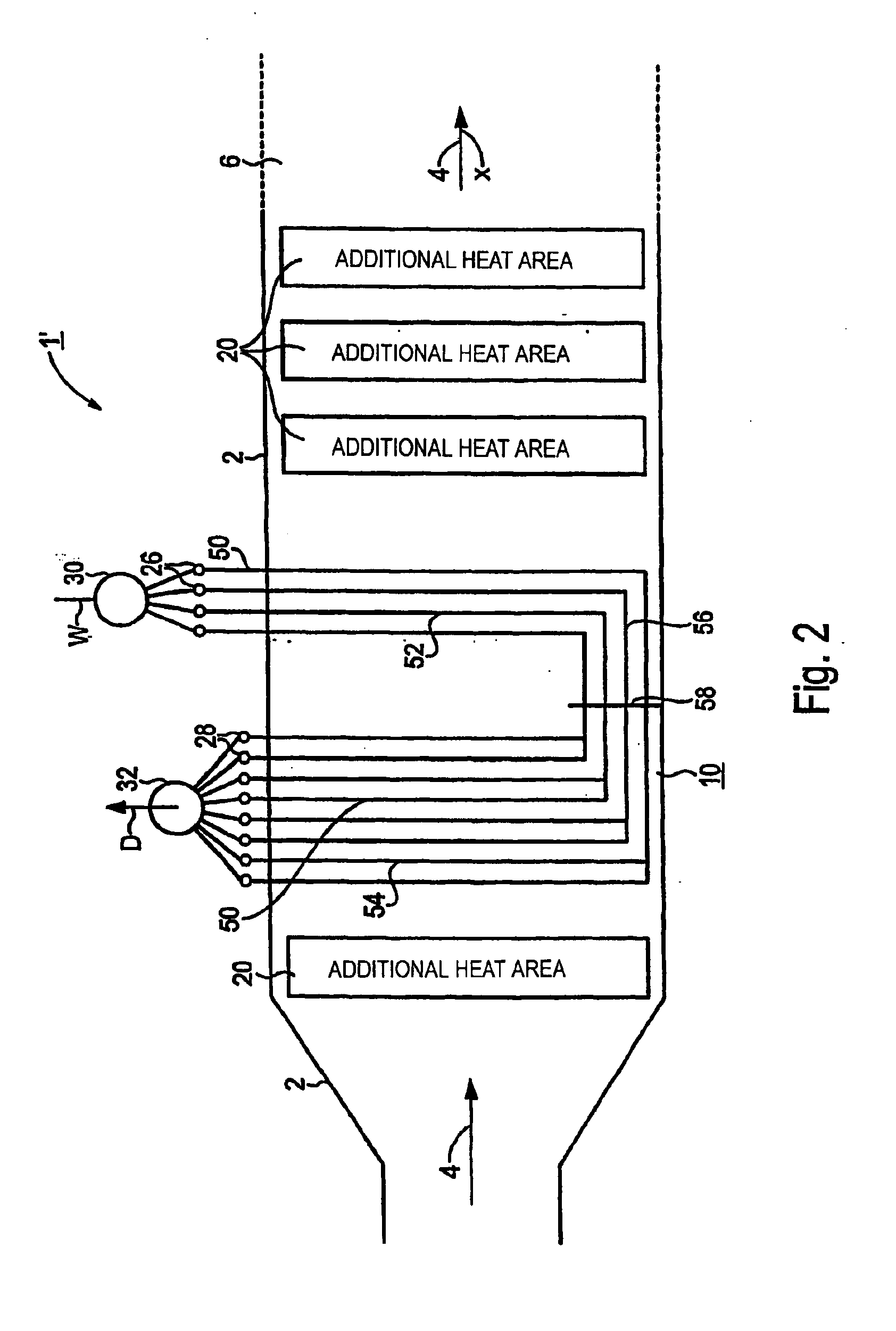

Mixer For Separate-Stream Nozzle

InactiveUS20080115484A1Reduce mechanical loadReduce weightPower plant exhaust arrangementsEngine fuctionsEngineeringTurbojet

A mixer for a separate-stream turbojet nozzle, the mixer comprising along a longitudinal axis (X-X′) both a fastener shroud (10) for connecting said mixer to the exhaust casing of the nozzle, and a lobe structure (20) presenting a succession of inner and outer lobes (22 and 21) distributed circumferentially around the longitudinal axis (X-X′) of the mixer. The lobe structure (20) is made of a ceramic matrix composite material and further comprises a stiffener ring (30) that forms a connection between at least some of the lobes of said structure. Thus, the major portion of the mixer, i.e. the lobe structure, is made of a ceramic matrix composite material, thereby significantly reducing the weight of the mixer, and consequently reducing the weight of the nozzle.

Owner:SAFRAN CERAMICS SA

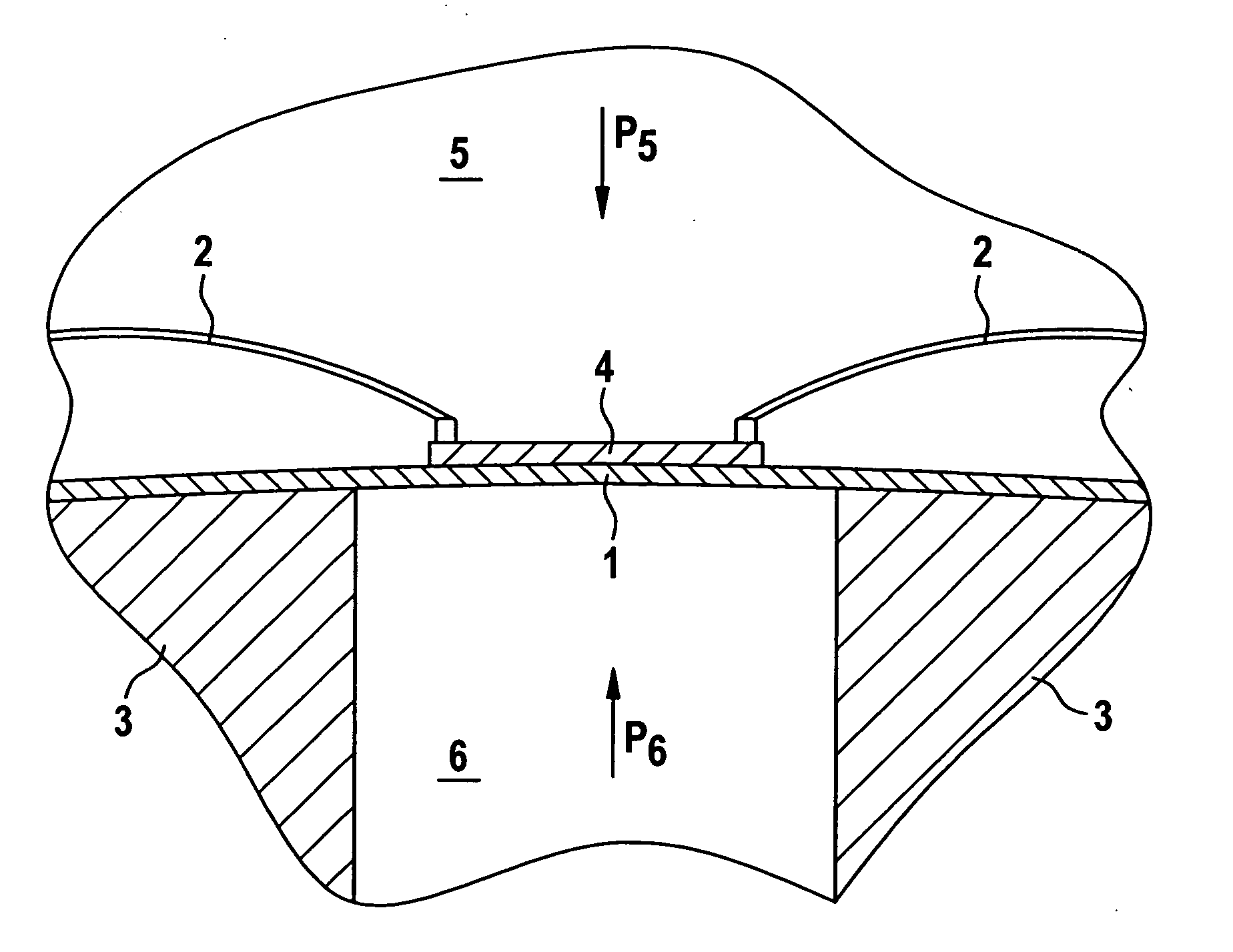

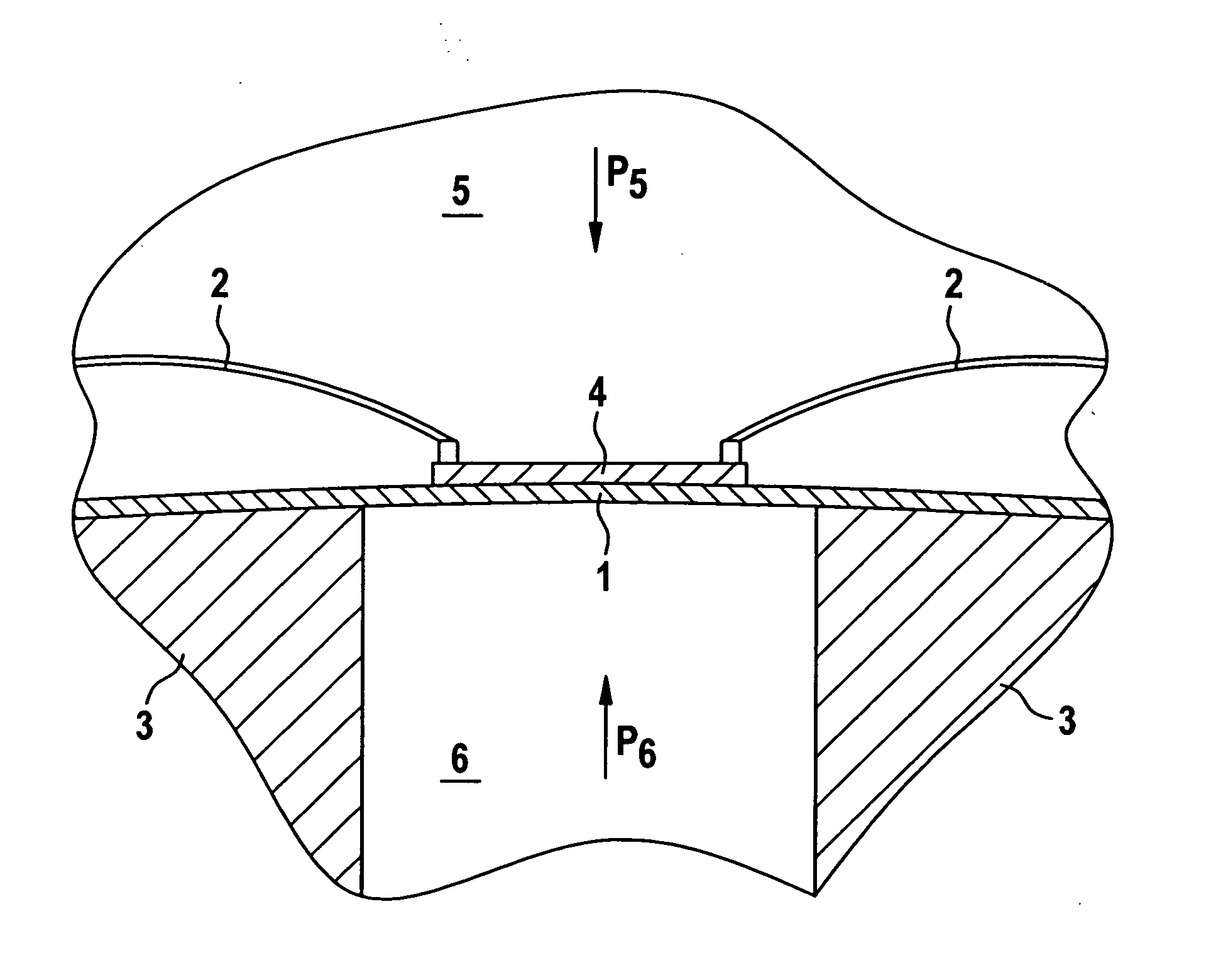

Micromechanical high-pressure sensor

InactiveUS20050188769A1Accelerated agingReduce resistanceFluid pressure measurement using piezo-electric devicesFluid pressure measurement using elastically-deformable gaugesEngineeringHigh pressure

A micromechanical pressure sensor and a method for producing a micromechanical pressure sensor. This pressure sensor has at least one membrane and a measuring element situated on the membrane. A pressure applied at the membrane or a pressure differential applied at the different sides of the membrane results in deformation of the membrane. Simultaneous with the deformation of the membrane, the measuring element is subjected to elastic elongation and / or compression. In a piezo-sensitive component, such elastic elongation and / or compression generates a measured variable in the measuring element, which represents the applied pressure or the applied pressure differential at the membrane. It is provided in this context that the measuring element have at least partially a NiCr(Si) layer. Due to an at least partial crystallization in the production of the micromechanical pressure sensor, this NiCr(Si) layer has more advantageous piezoelectrical characteristics than an amorphous NiCr(Si) layer.

Owner:ROBERT BOSCH GMBH

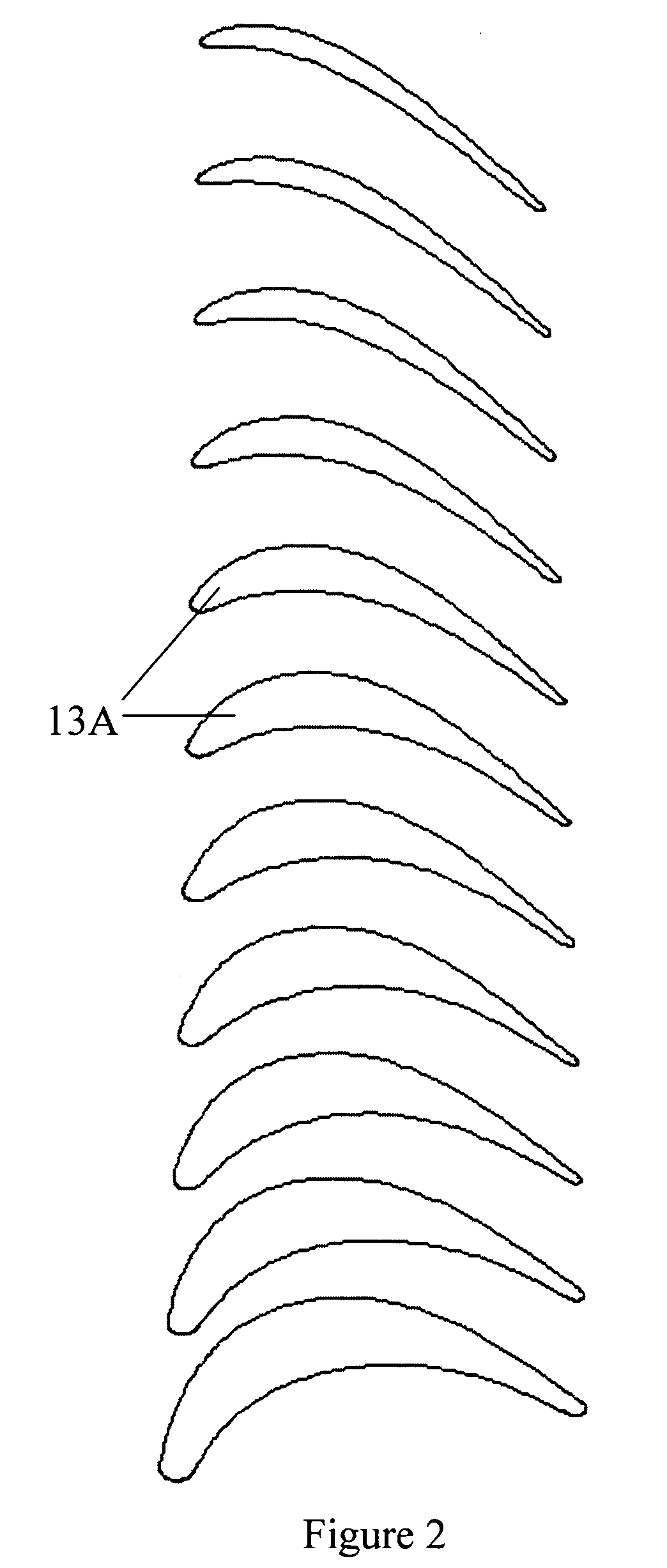

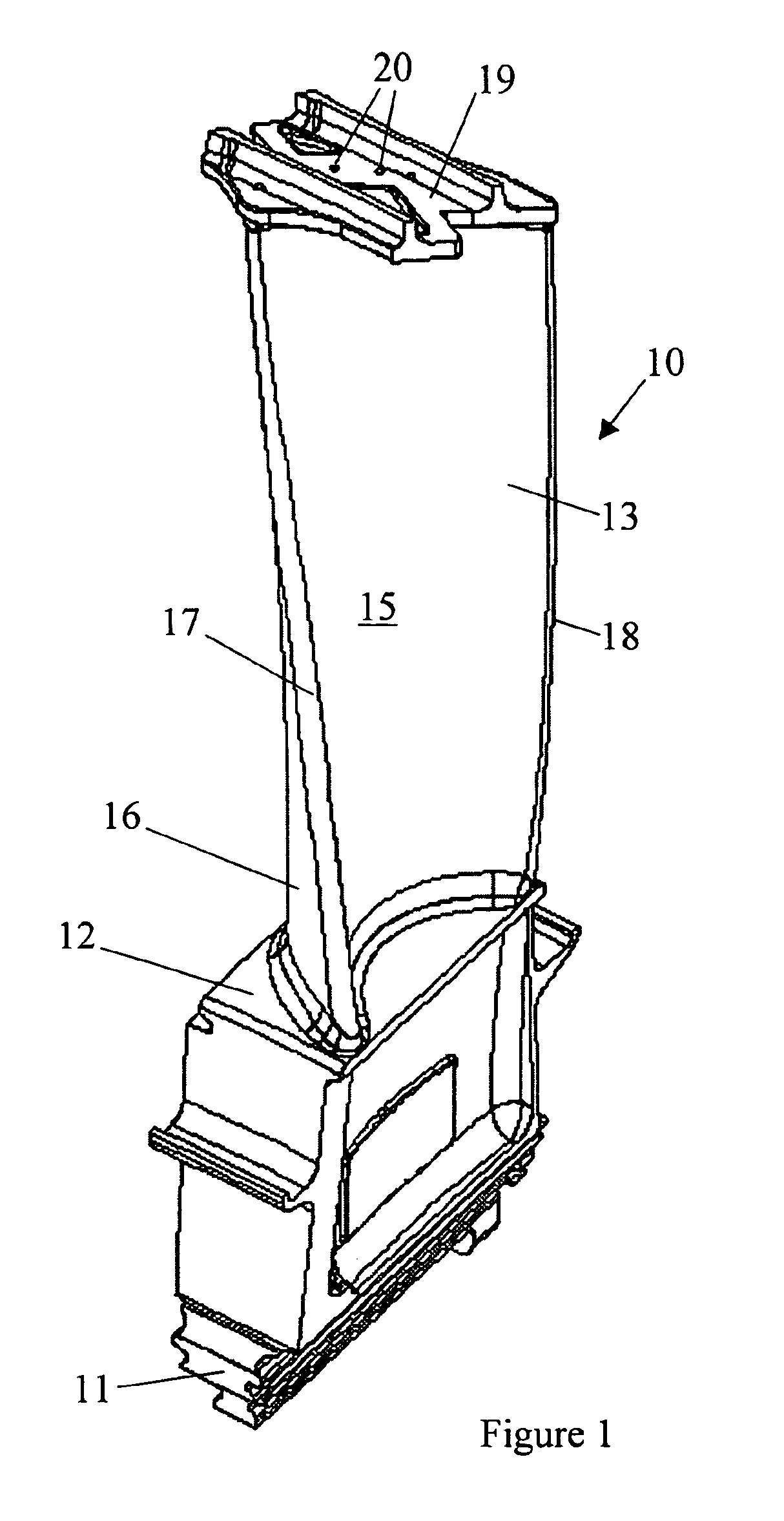

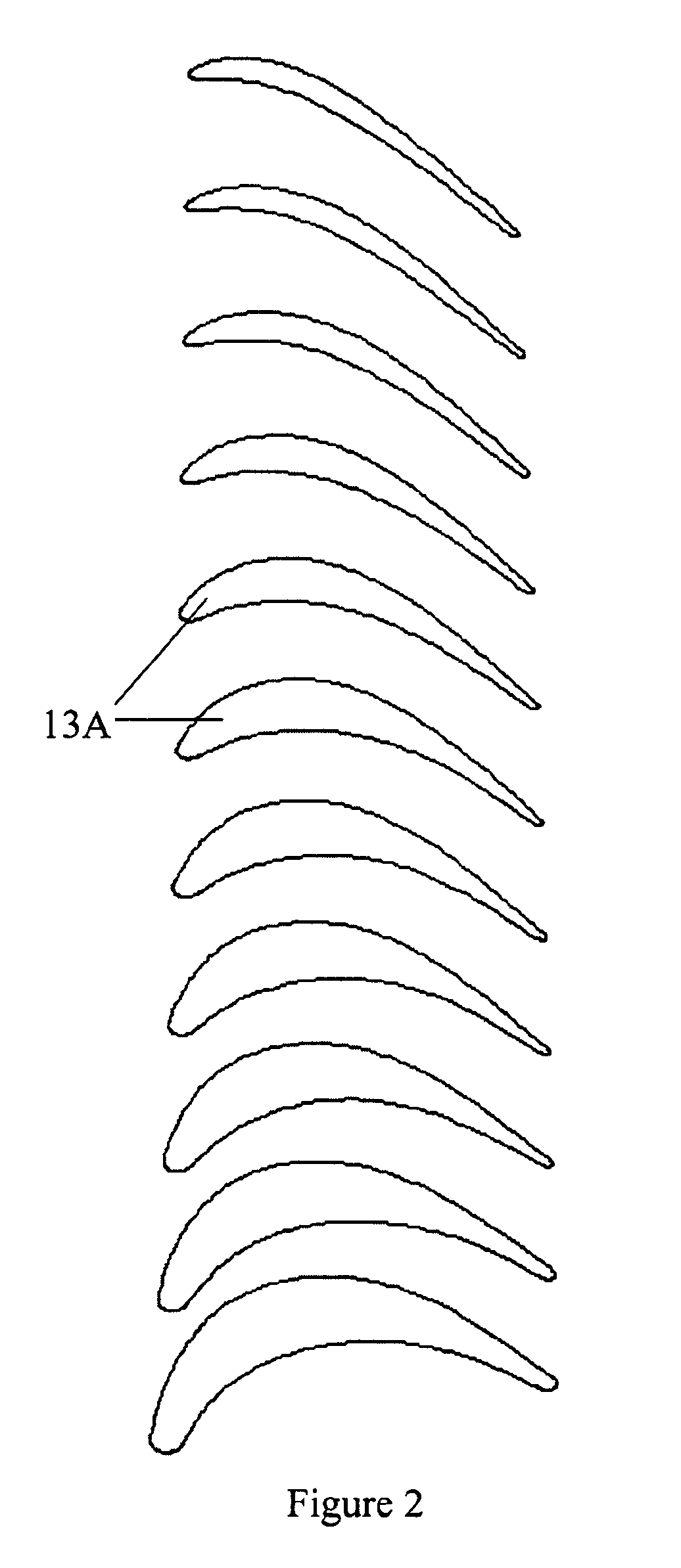

Turbine blade airfoil having improved creep capability

ActiveUS20050111978A1Increased creep lifeIncrease exposureRotary propellersBlade accessoriesTurbine bladeEngineering

A turbine blade including an airfoil having a profile in accordance with Table 1 is disclosed. The turbine blade has a plurality of cooling passages extending radially outward through the airfoil. The aerodynamic profile of the airfoil has been reconfigured to reduce airfoil stress for a given operating temperature, thereby resulting in increased creep rupture life of the airfoil.

Owner:ANSALDO ENERGIA SWITZERLAND AG

Turbine blade airfoil having improved creep capability

ActiveUS6932577B2Increased creep lifeReduce mechanical loadRotary propellersBlade accessoriesTurbine bladeOperating temperature

A turbine blade including an airfoil having a profile in accordance with Table 1 is disclosed. The turbine blade has a plurality of cooling passages extending radially outward through the airfoil. The aerodynamic profile of the airfoil has been reconfigured to reduce airfoil stress for a given operating temperature, thereby resulting in increased creep rupture life of the airfoil.

Owner:ANSALDO ENERGIA SWITZERLAND AG

Mixer for separate-flow nozzle

InactiveUS7677026B2Reduce mechanical loadReduce weightPower plant exhaust arrangementsEngine fuctionsEngineeringTurbojet

A mixer for a separate-stream turbojet nozzle, the mixer comprising along a longitudinal axis (X-X′) both a fastener shroud (10) for connecting said mixer to the exhaust casing of the nozzle, and a lobe structure (20) presenting a succession of inner and outer lobes (22 and 21) distributed circumferentially around the longitudinal axis (X-X′) of the mixer. The lobe structure (20) is made of a ceramic matrix composite material and further comprises a stiffener ring (30) that forms a connection between at least some of the lobes of said structure. Thus, the major portion of the mixer, i.e. the lobe structure, is made of a ceramic matrix composite material, thereby significantly reducing the weight of the mixer, and consequently reducing the weight of the nozzle.

Owner:SAFRAN CERAMICS SA

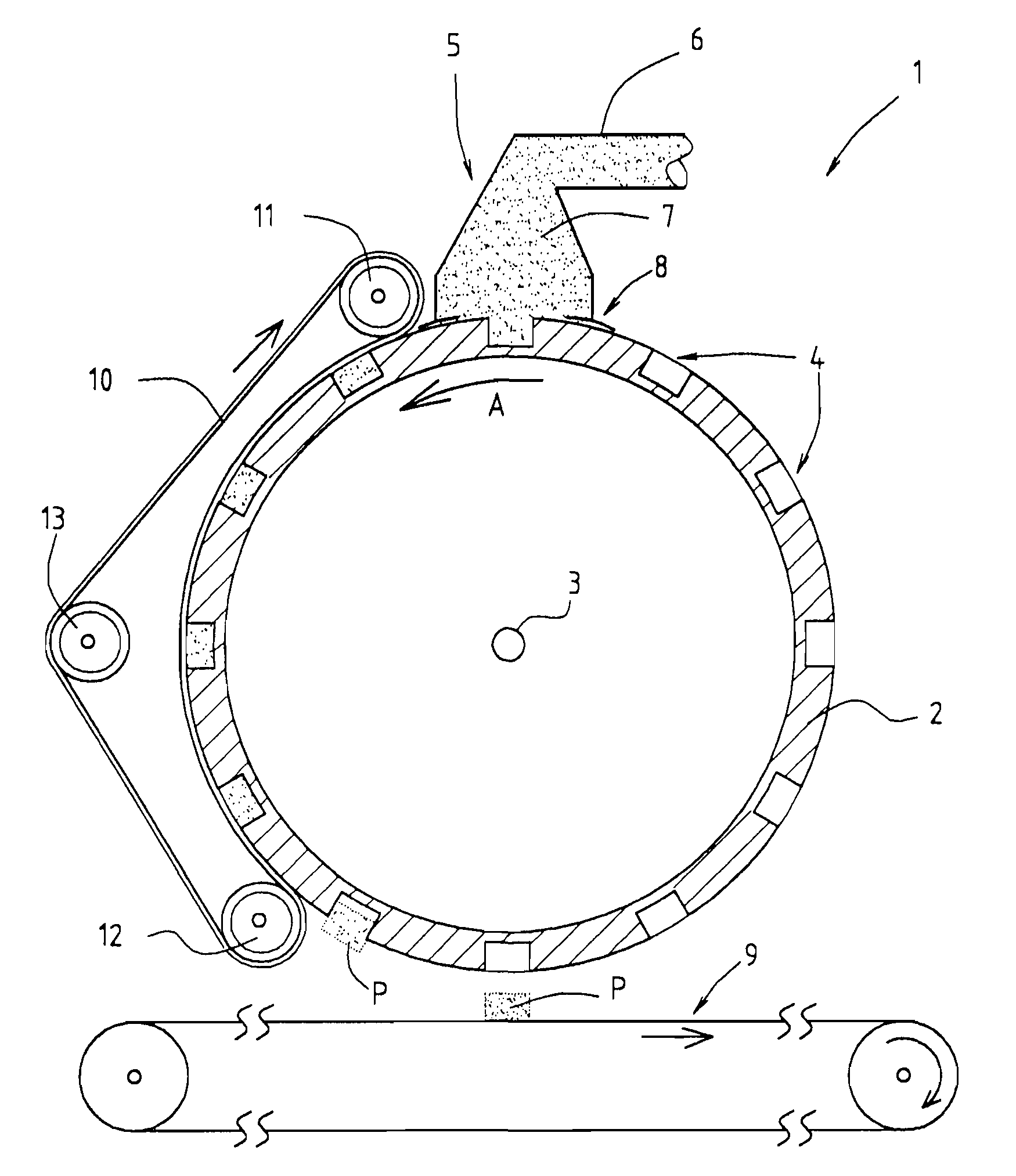

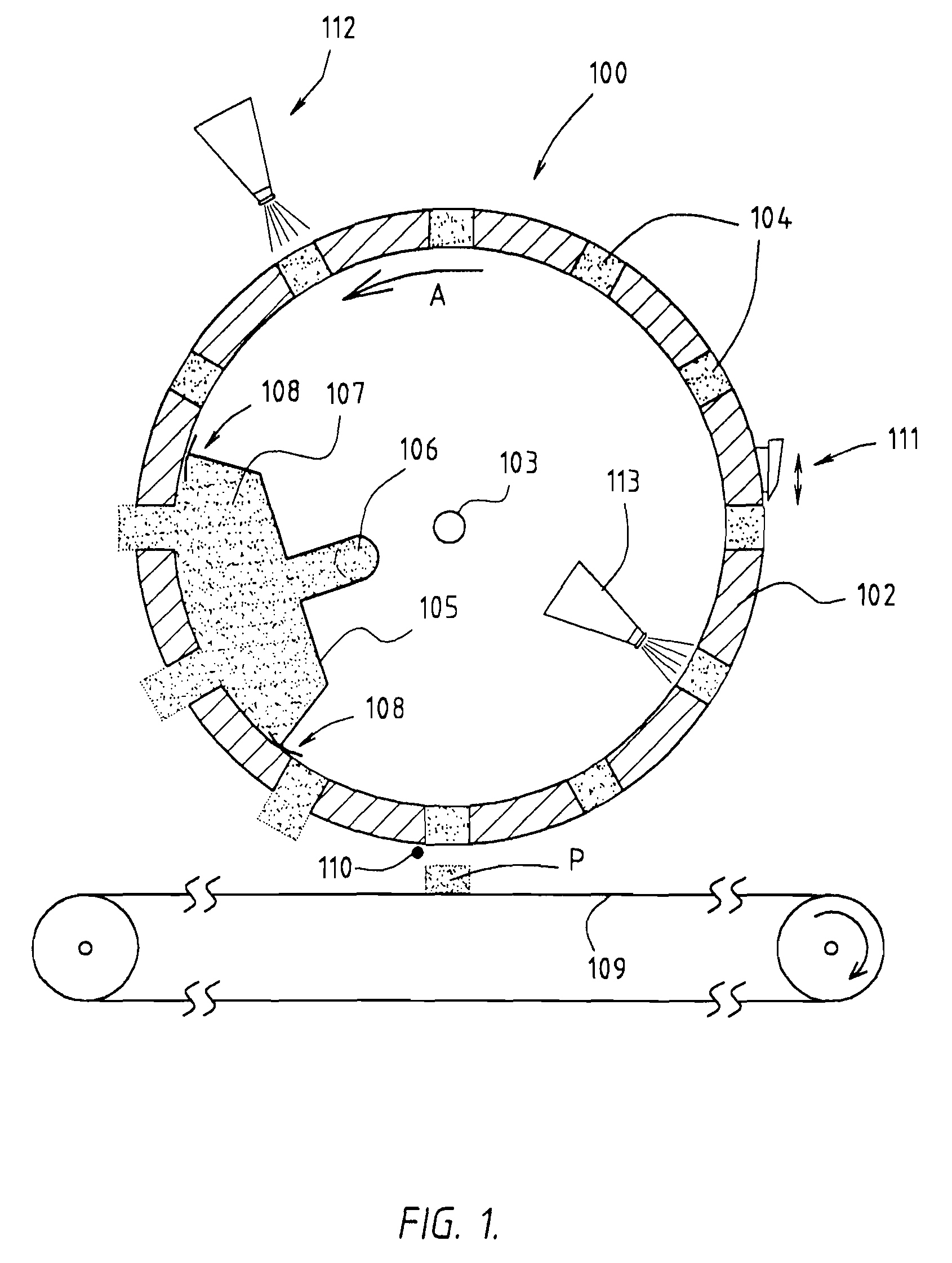

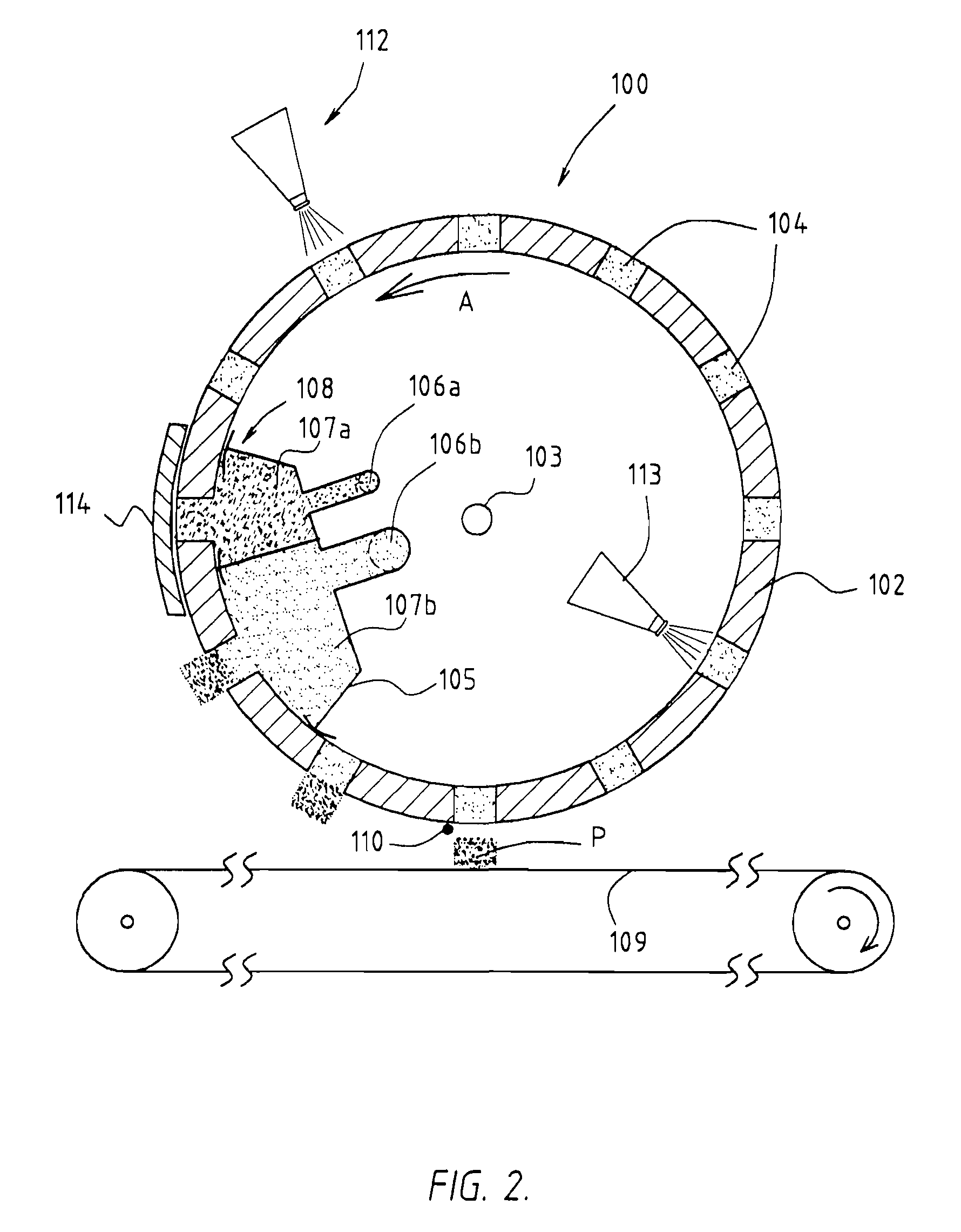

Moulding

InactiveUS20070224306A1High priceLarge capacityConfectioneryCeramic shaping apparatusPartial fillingMaterials science

Owner:STORK PMT

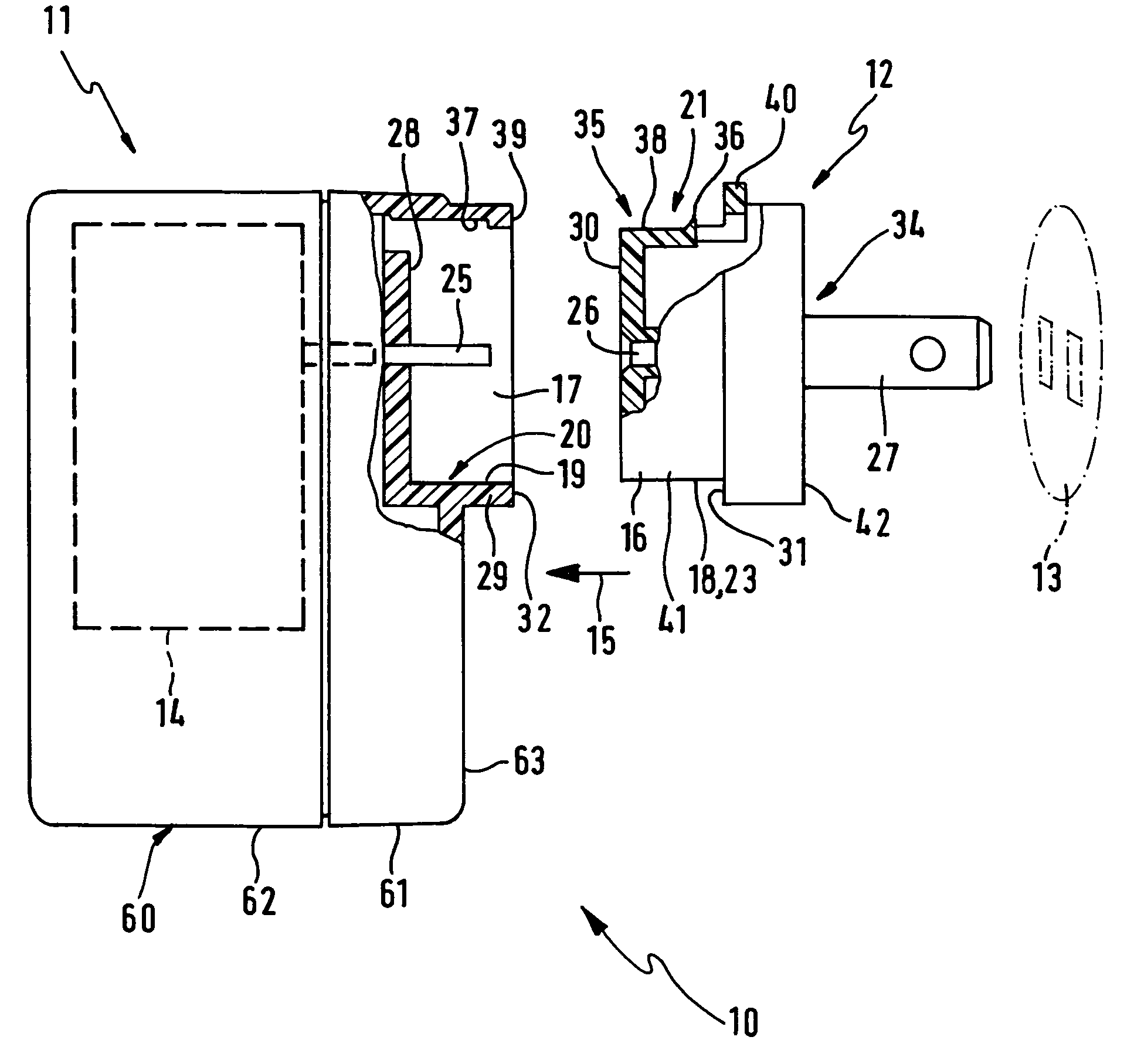

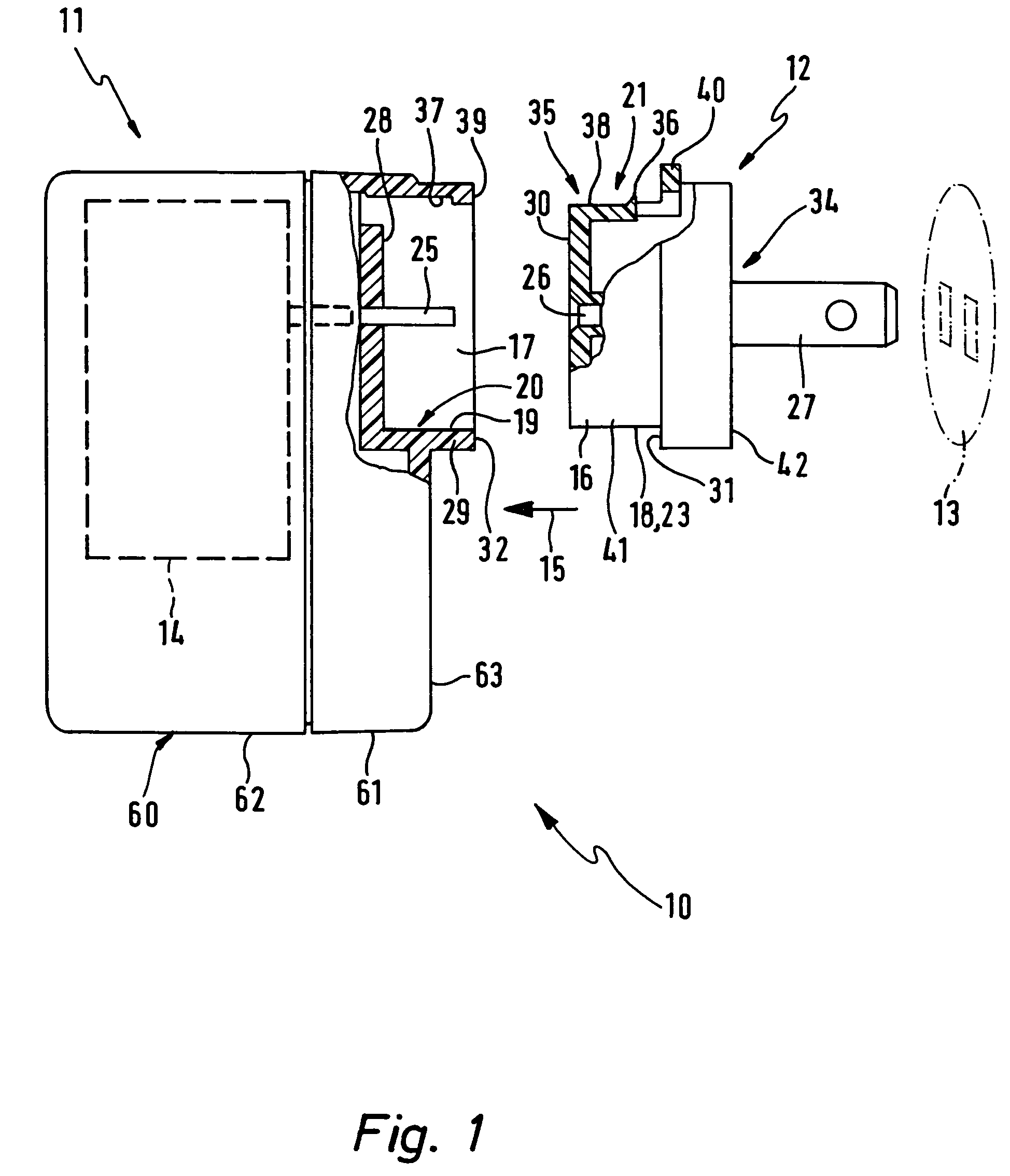

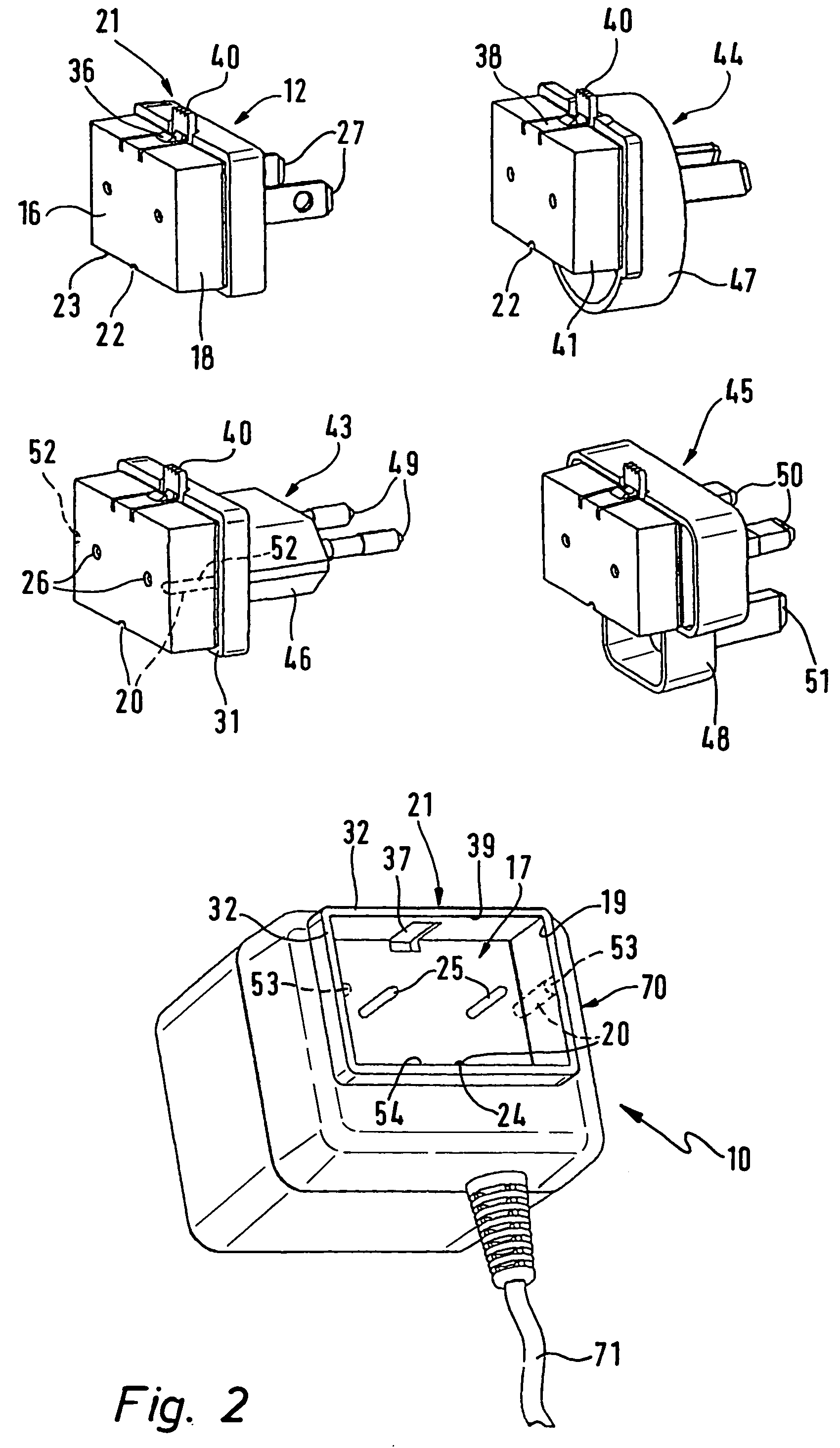

Plug device with a plug adapter

ActiveUS7223126B2Efficient use ofReliably connected with base partElectric discharge tubesCoupling device detailsEngineeringMechanical engineering

Owner:HELMS MAN IND

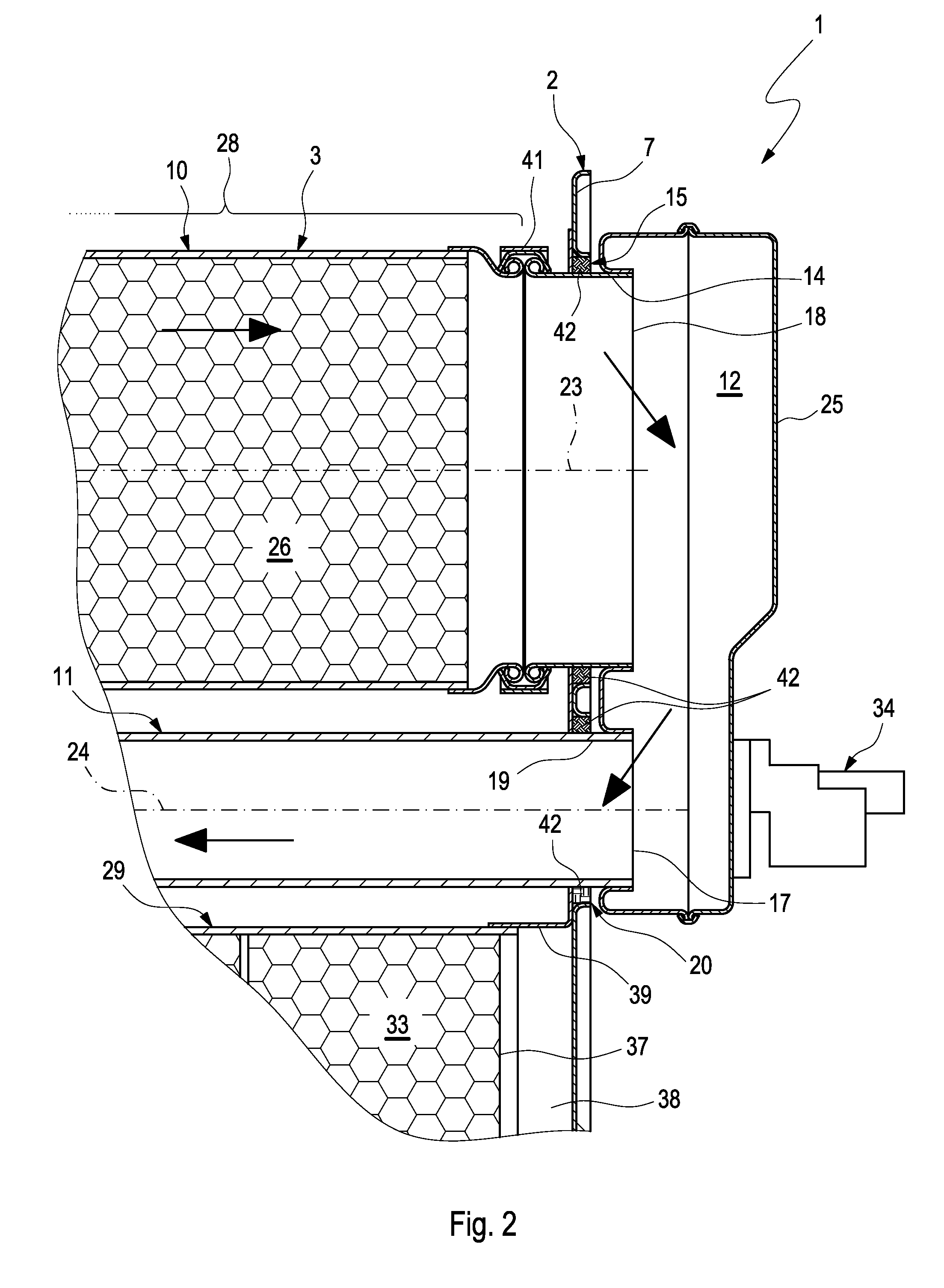

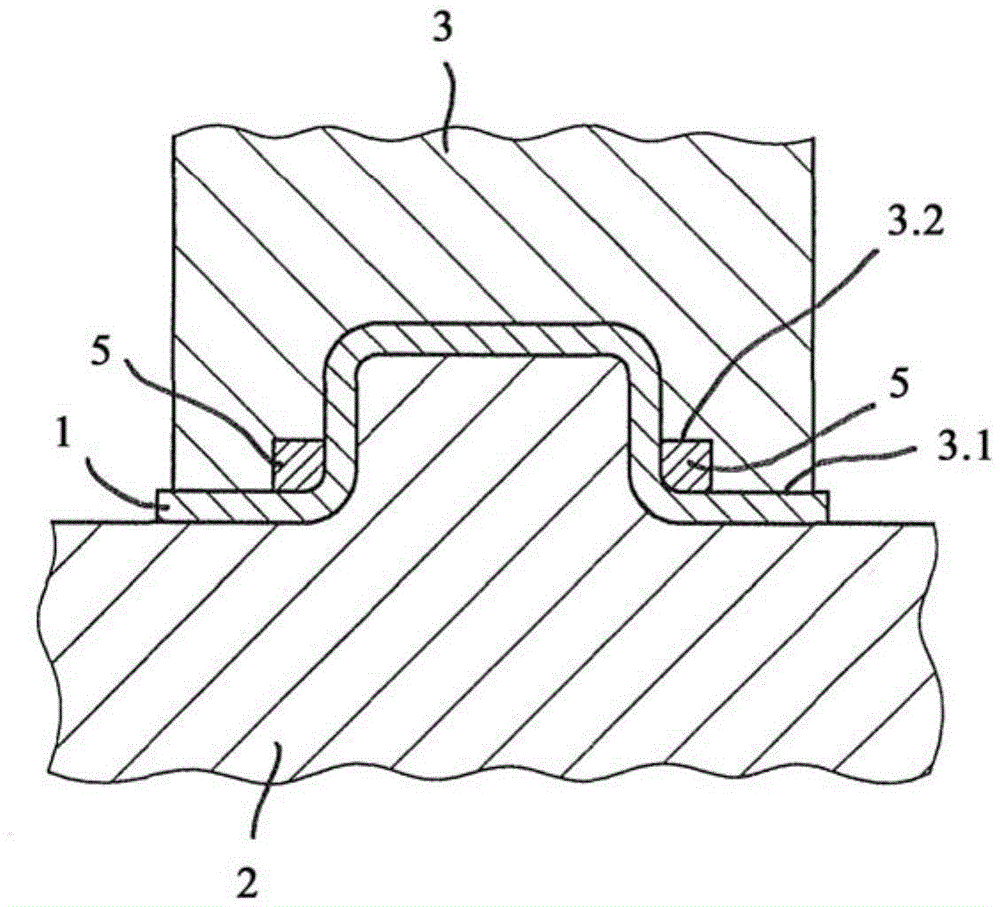

Sliding Seat And Exhaust Gas Treatment Facility

ActiveUS20090158720A1Improve mechanical stabilitySmall sizePipe supportsInternal combustion piston enginesCombustionExhaust fumes

The present invention relates to a sliding seat for mounting a thermally impacted pipe on a structural part so as to be axially movable, in particular in an exhaust gas system of a combustion engine, with a bearing material which is radially supported against pipe on the outside thereof and which is fixed on structural part via a retaining pipe fastened on structural part.

Owner:PUREM GMBH

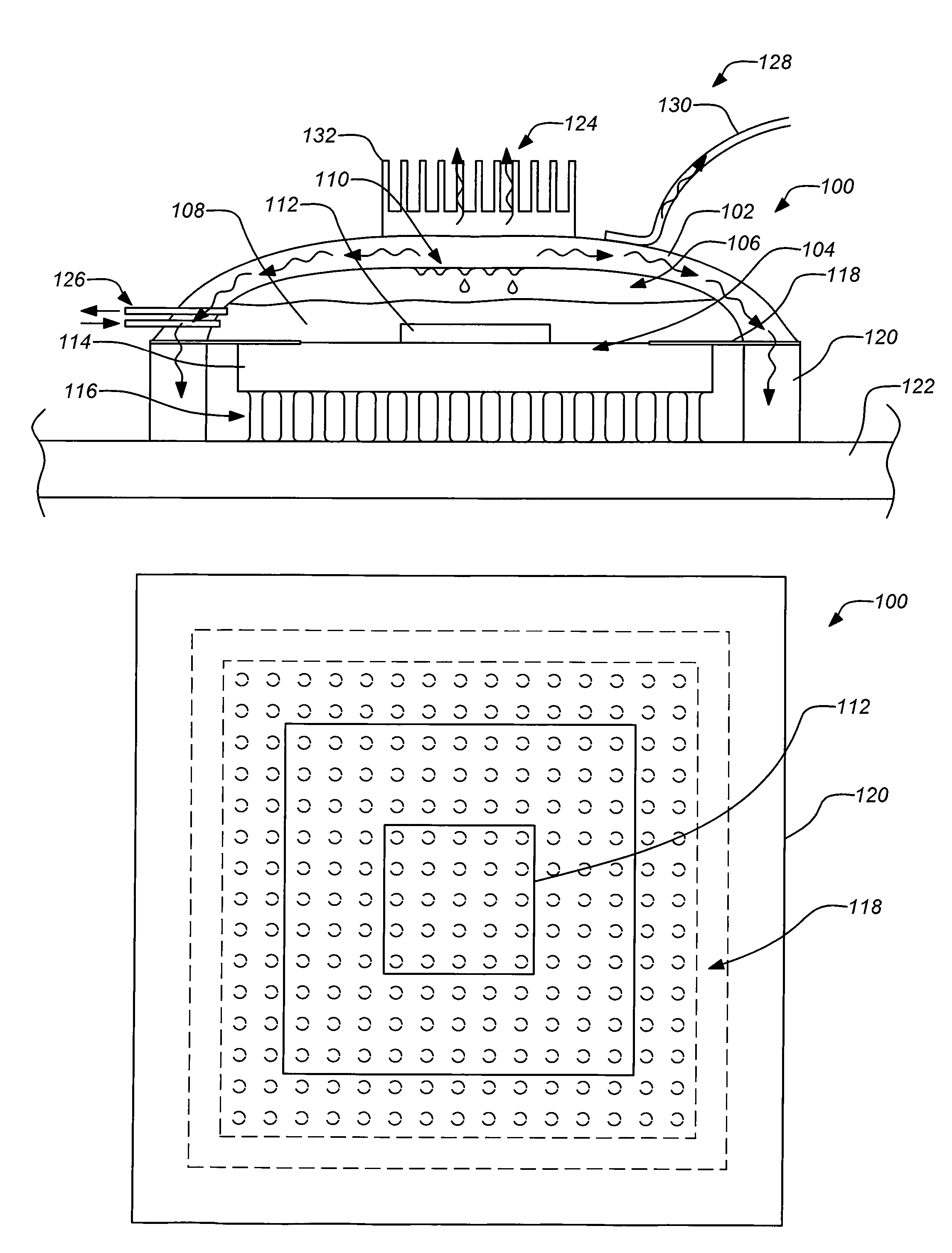

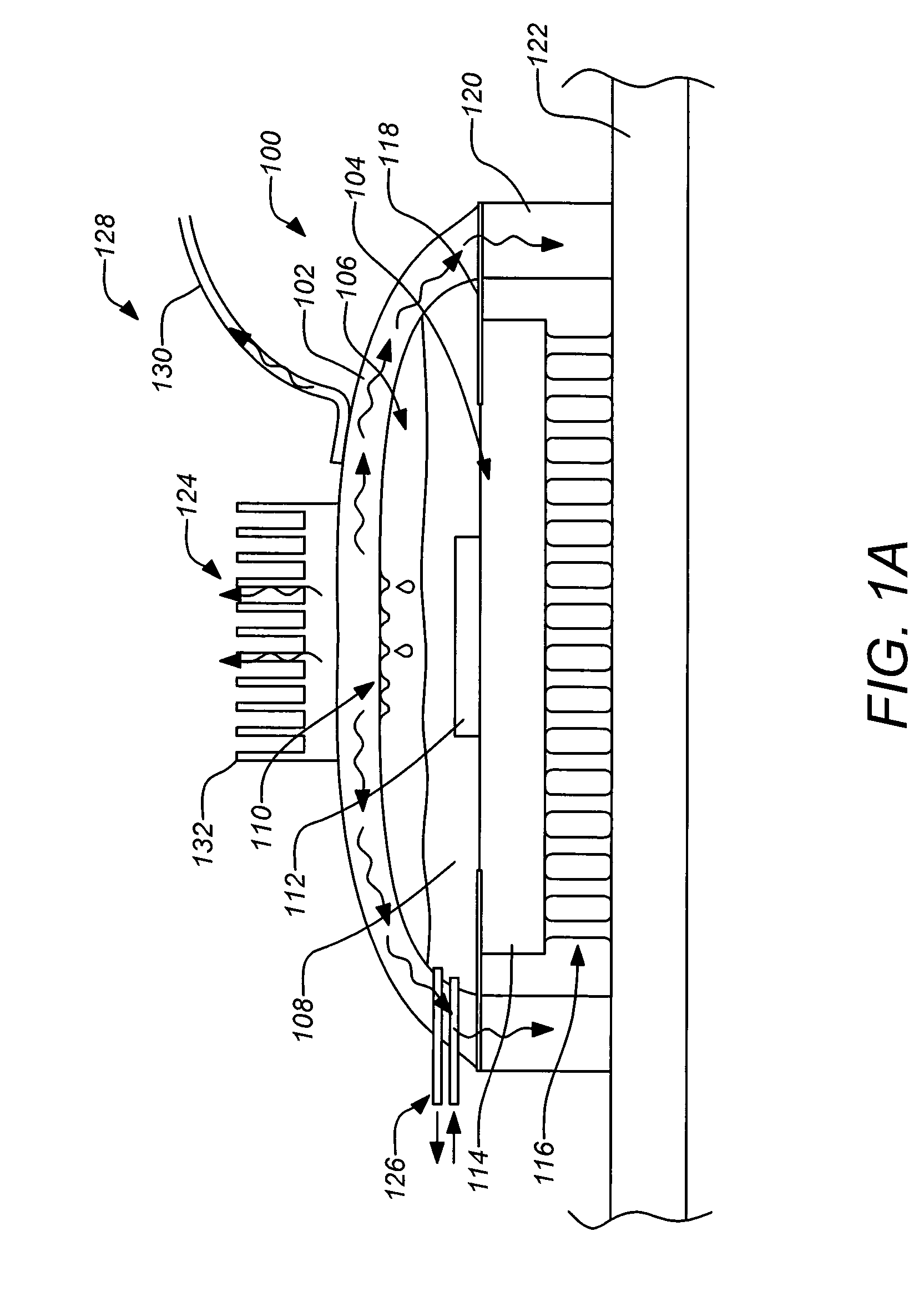

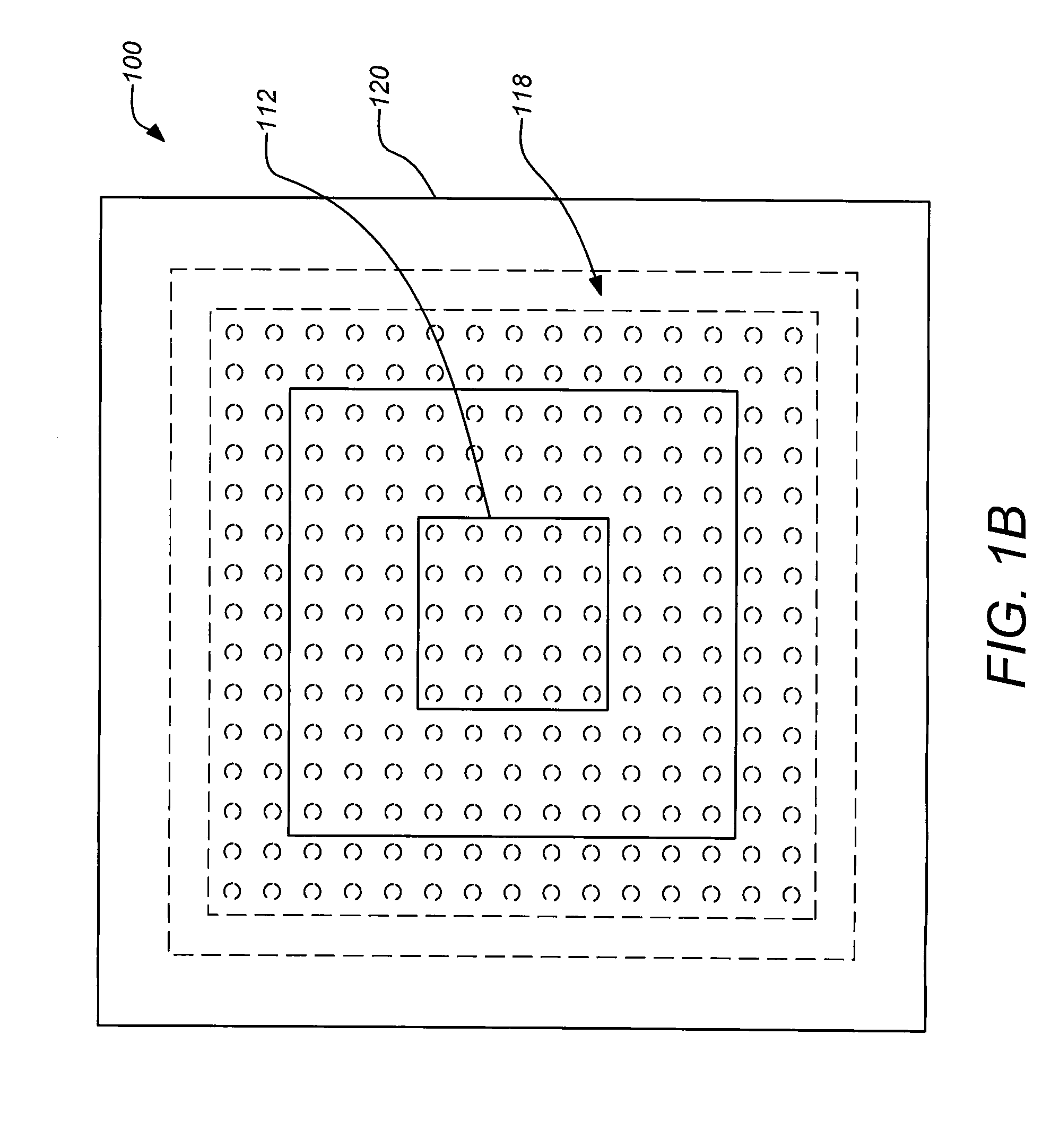

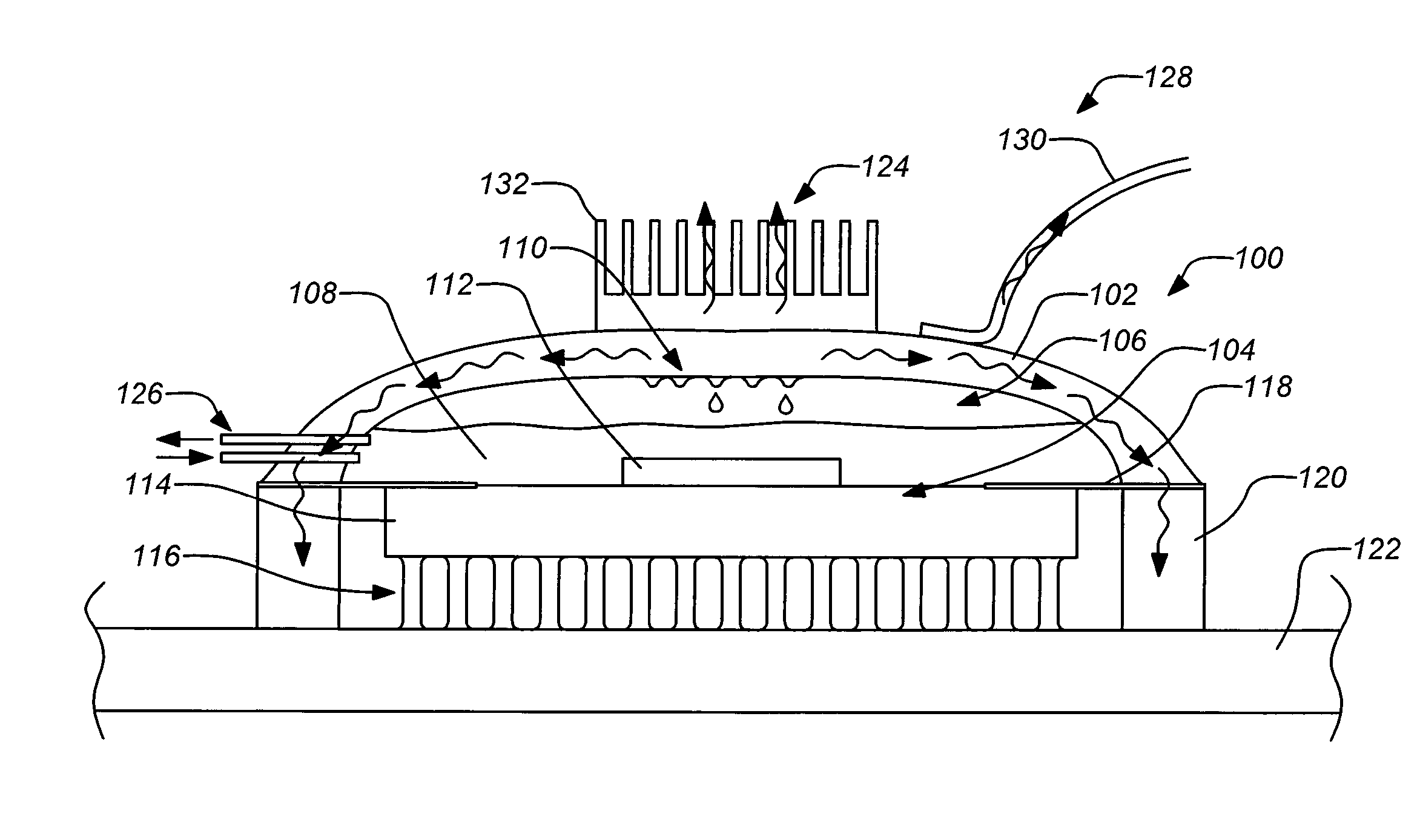

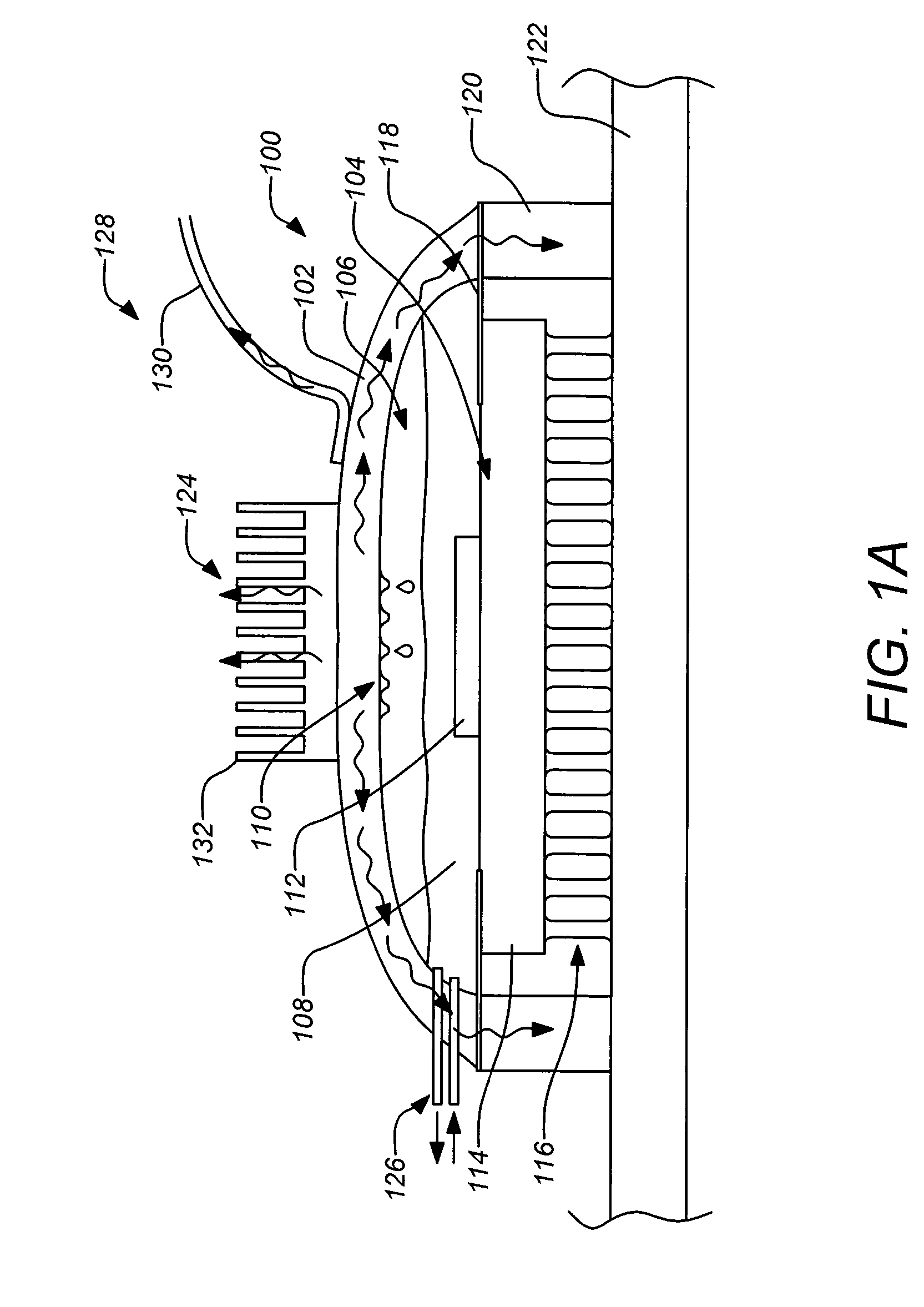

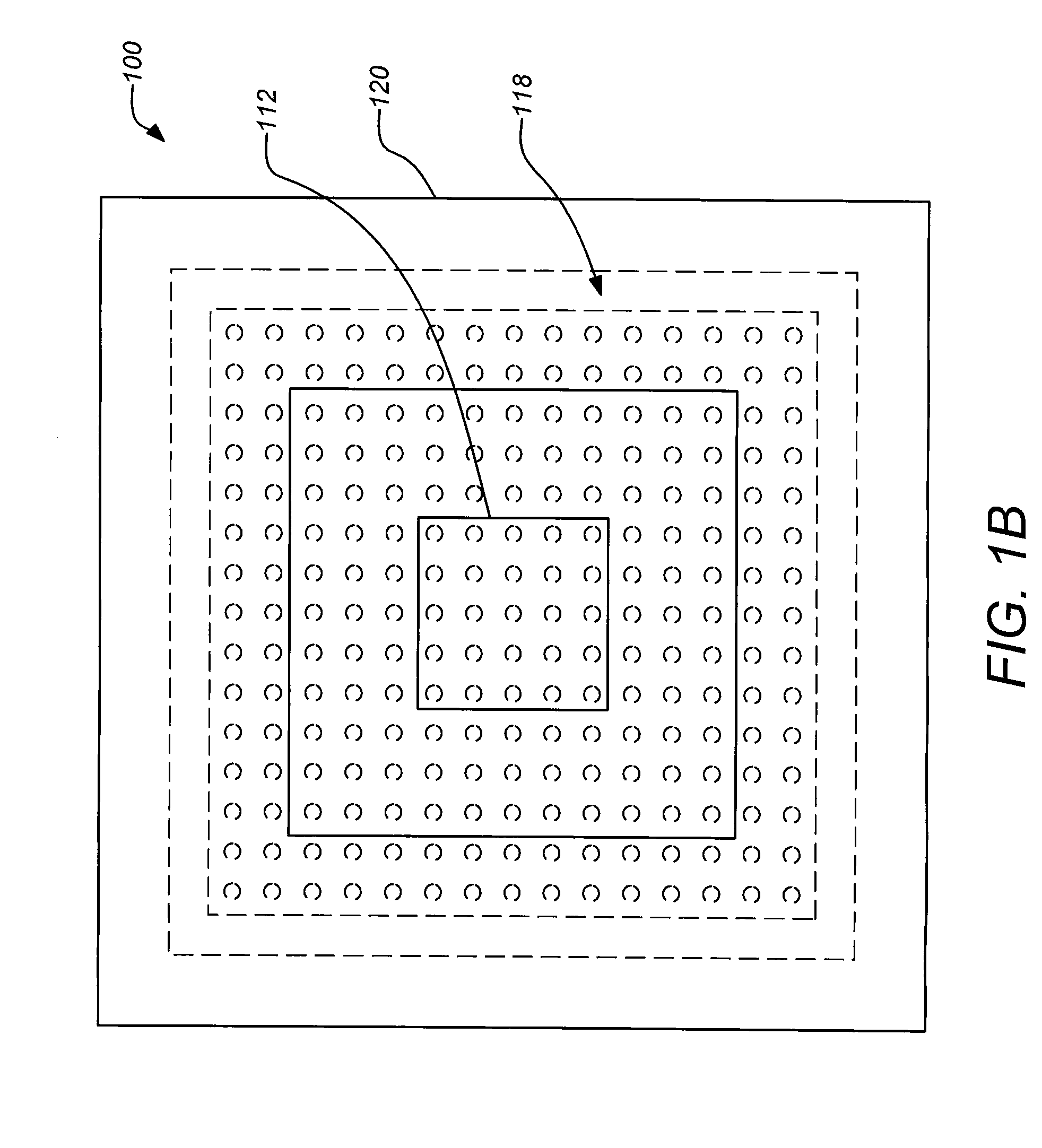

Encapsulated multi-phase electronics heat-sink

ActiveUS7561425B2Load minimizationPromote fluid circulationSemiconductor/solid-state device detailsPrinted circuit aspectsEngineeringMulti phase

An apparatus and method for cooling electronics is disclosed. An encapsulated inert non-conductive fluid is used to transfer heat directly from an electrical circuit including a die on a substrate to an external heatsink. The top of a flip chip die (e.g. a ceramic column grid array flip chip) may be enclosed with a metallic cover. The metallic cover is sealed to an outer frame, which in turn is sealed to metallization on the top of the flip chip through a flexure, minimizing mechanical load imparted to the flip chip. This forms a hermetic cavity enclosing the die. This hermetic cavity is partially filled with an inert non conductive fluid, which vaporizes when heated. Condensation occurs on the inner surface of the metal cover where the heat may be conducted into the outer frame for removal (e.g. rejection from the spacecraft).

Owner:THE BOEING CO

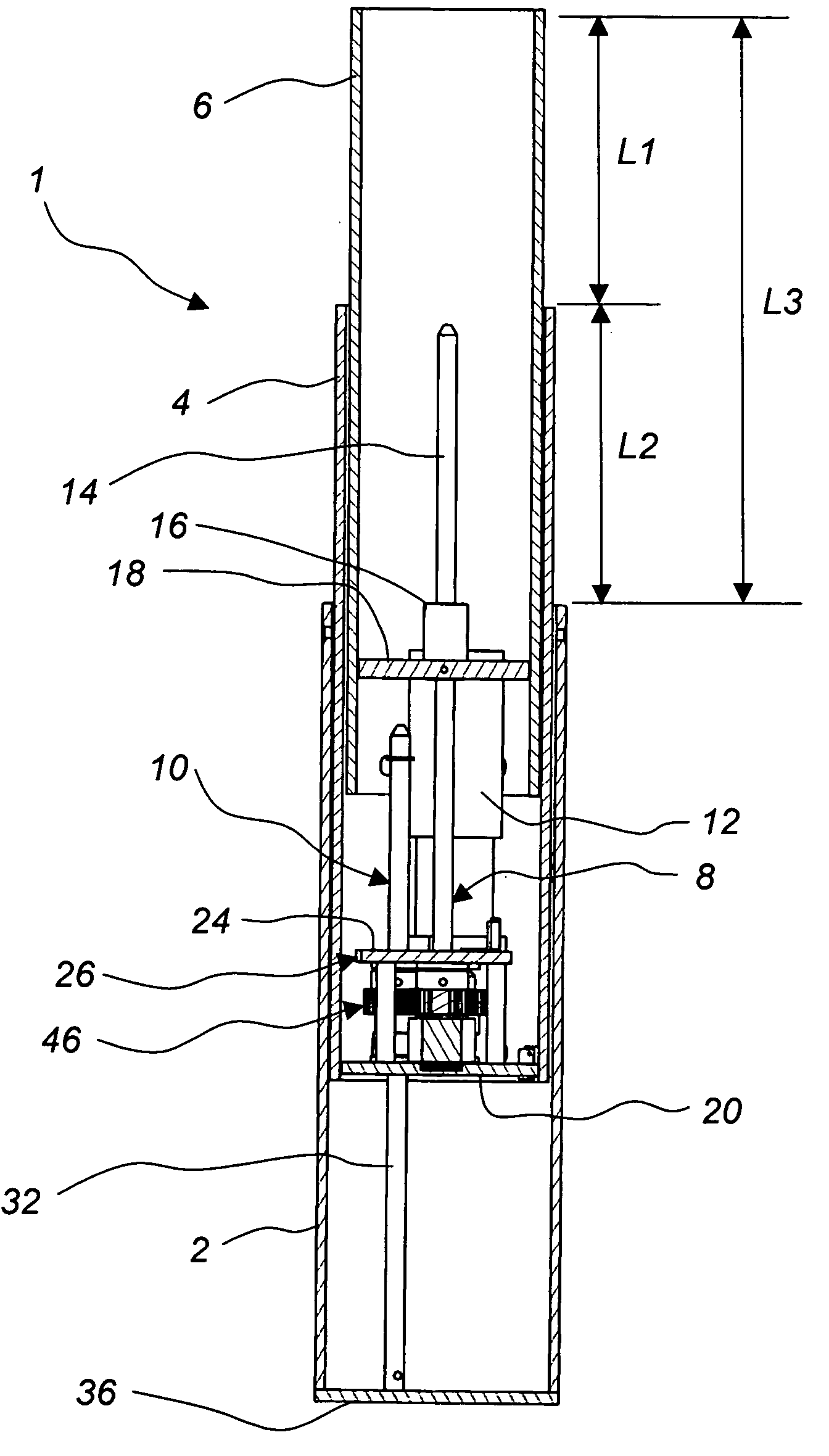

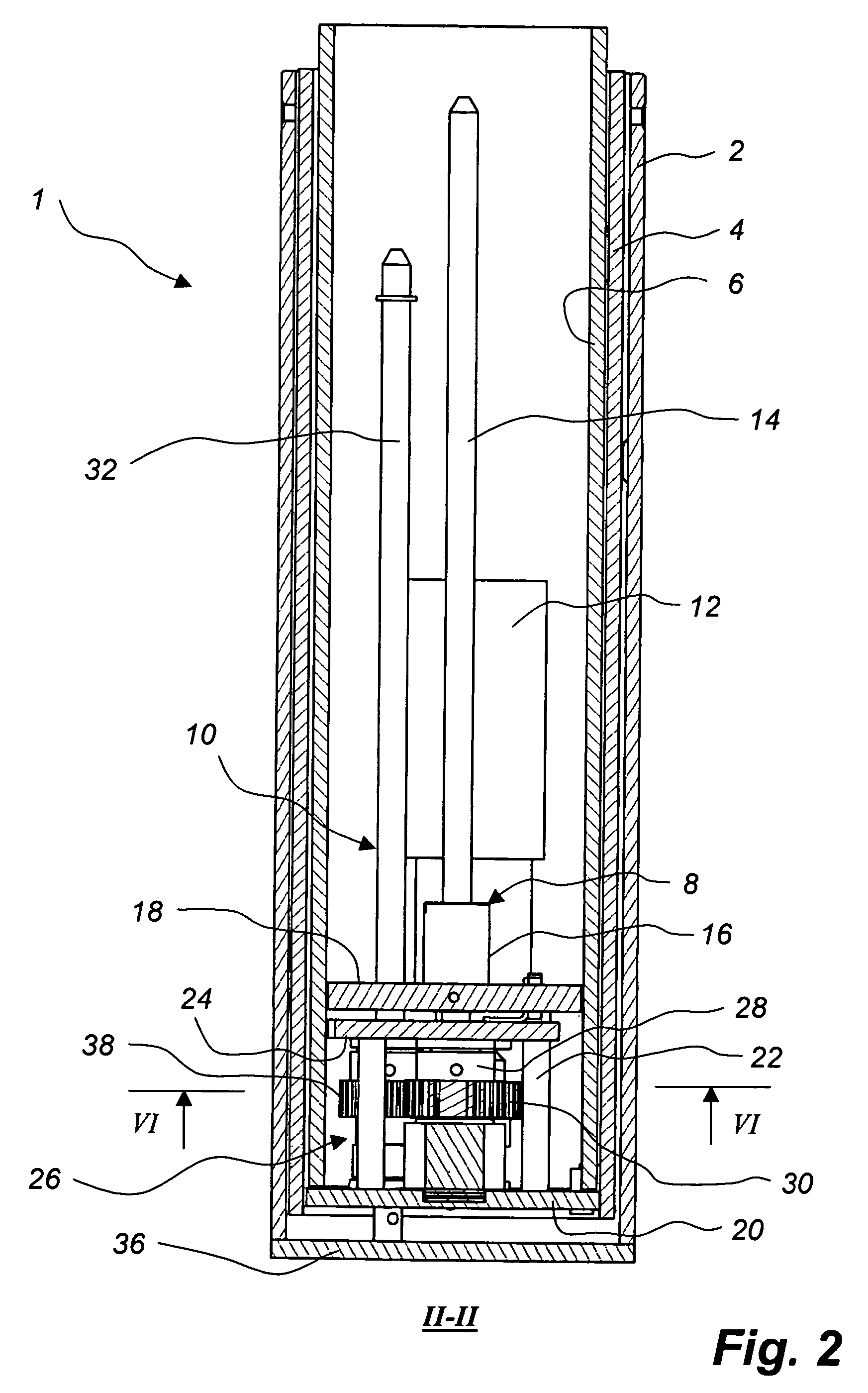

Telescopic device

InactiveUS20050236534A1Eliminate the problemReduce mechanical loadStands/trestlesKitchen equipmentEngineeringBiological activation

Owner:X2 TECH I VAXJO

Moulding

InactiveUS20050003062A1Efficient packagingHigh priceConfectionerySweetmeatsPartial fillingMaterials science

The invention provides methods and moulding devices for moulding three-dimensional products from a mass of foodstuff which is suitable for human consumption, in particular from a mass of meat, in particular chicken. The method comprises filling a mould cavity with a portion of the mass under the influence of a filling pressure exerted on the mass and for a filling period via a filling opening associated with the mould cavity, closing the filling opening of the mould cavity and holding the mass in the mould cavity for a fixing period. Then, the mould cavity is opened and the moulded product is removed from the mould cavity. The method uses fixing-pressure-exerting means which are designed to exert a fixing pressure which acts on the mass in the mould cavity after the filled mould cavity has been closed.

Owner:STORK PMT

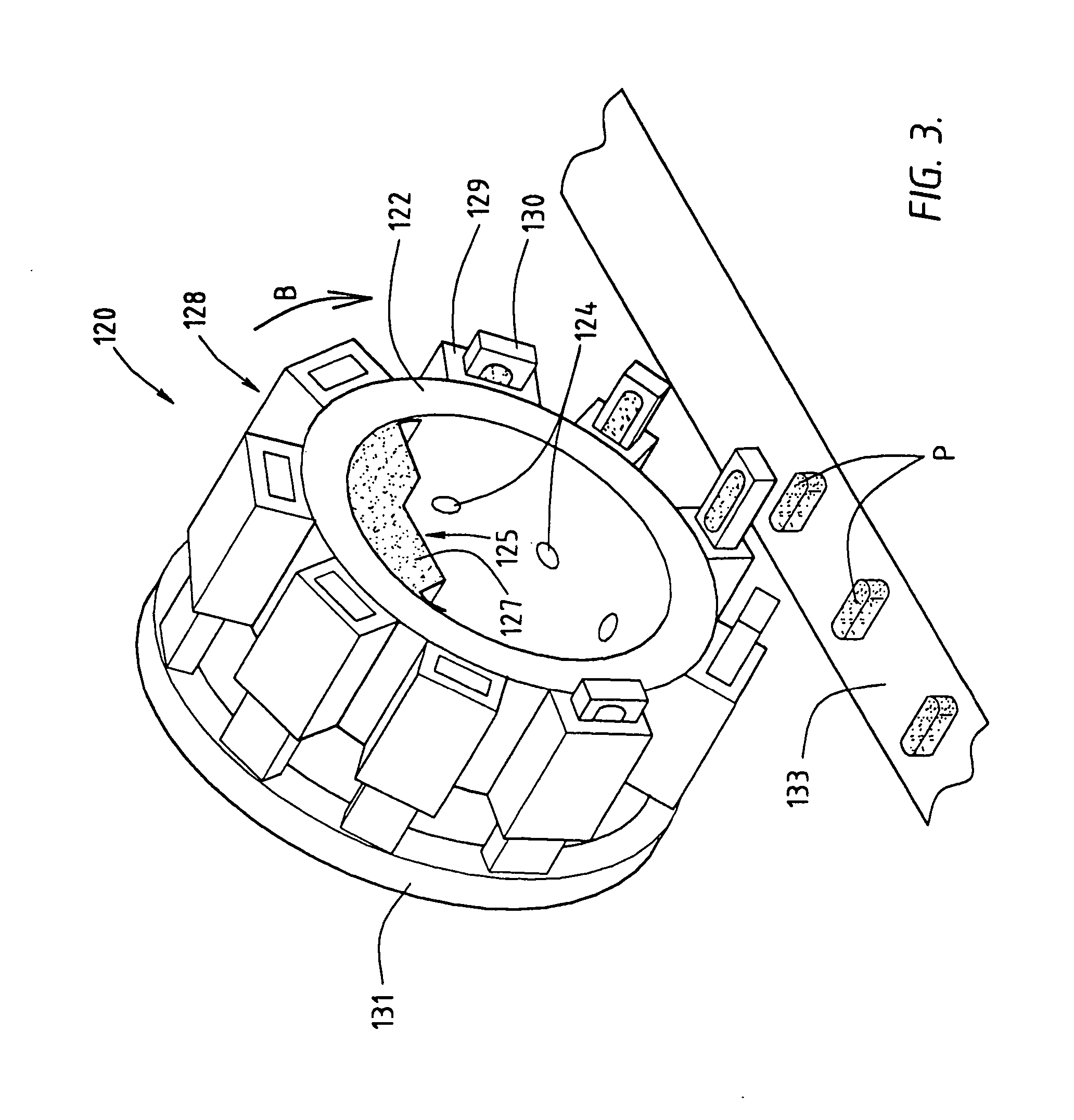

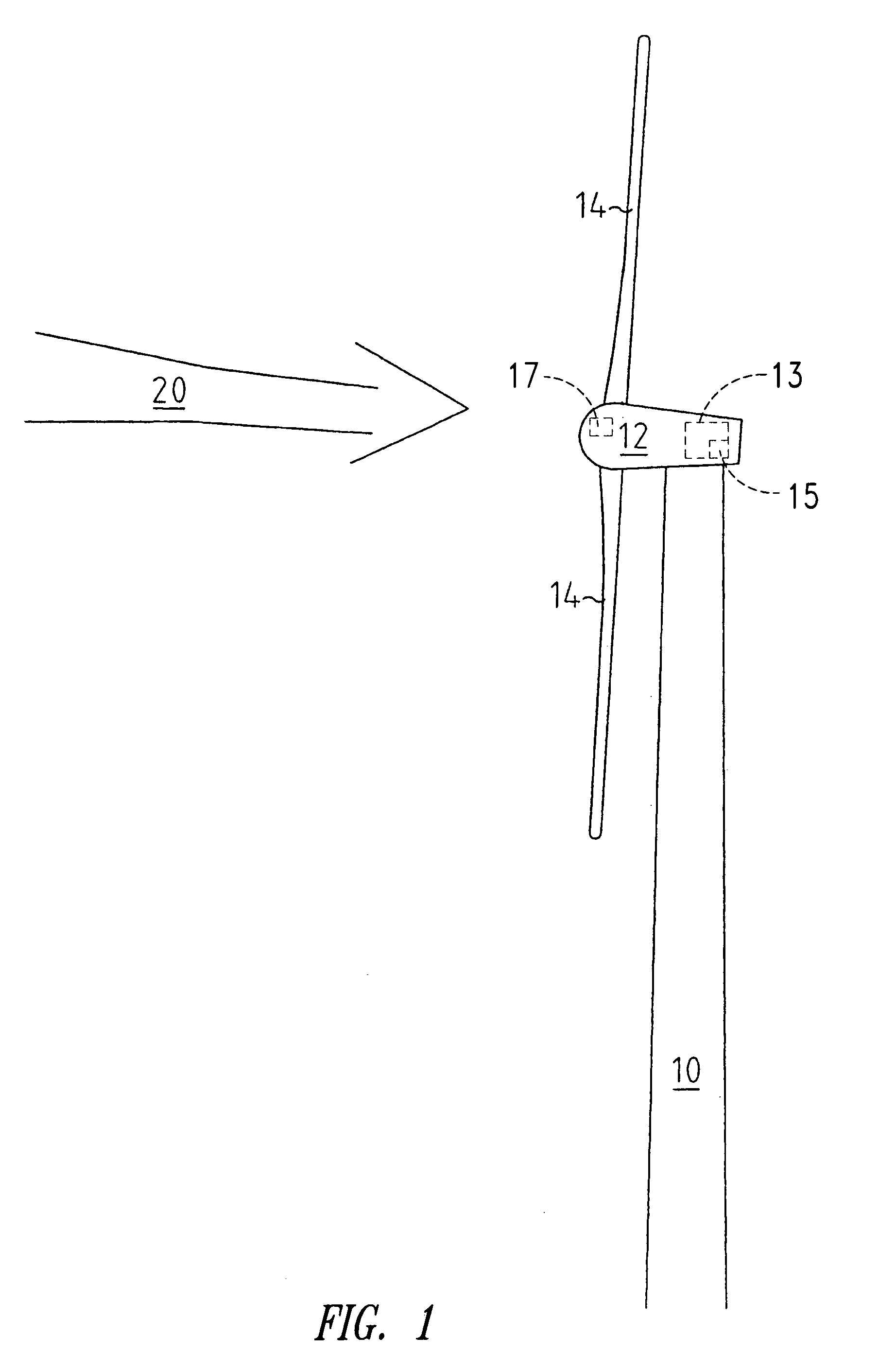

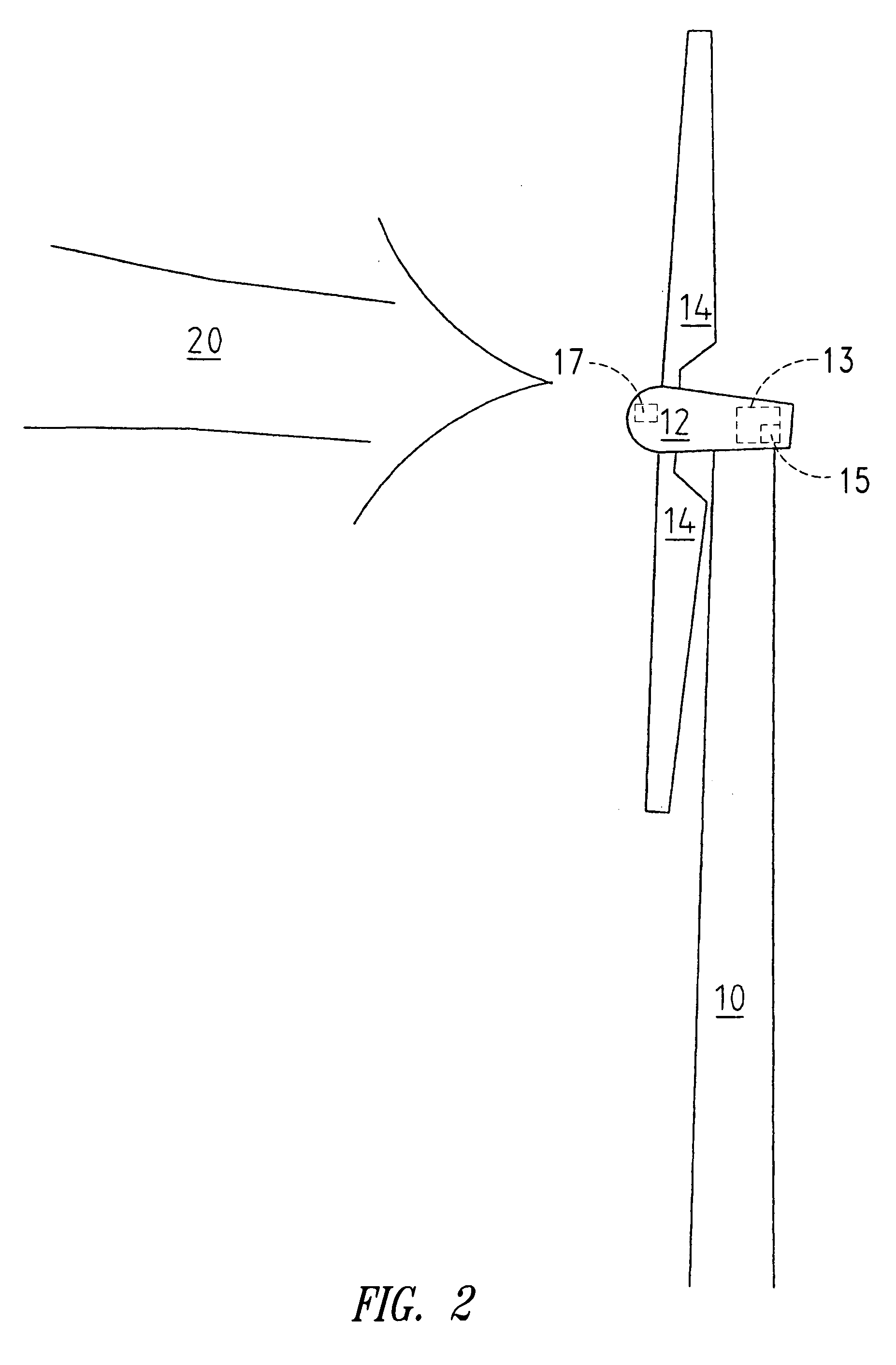

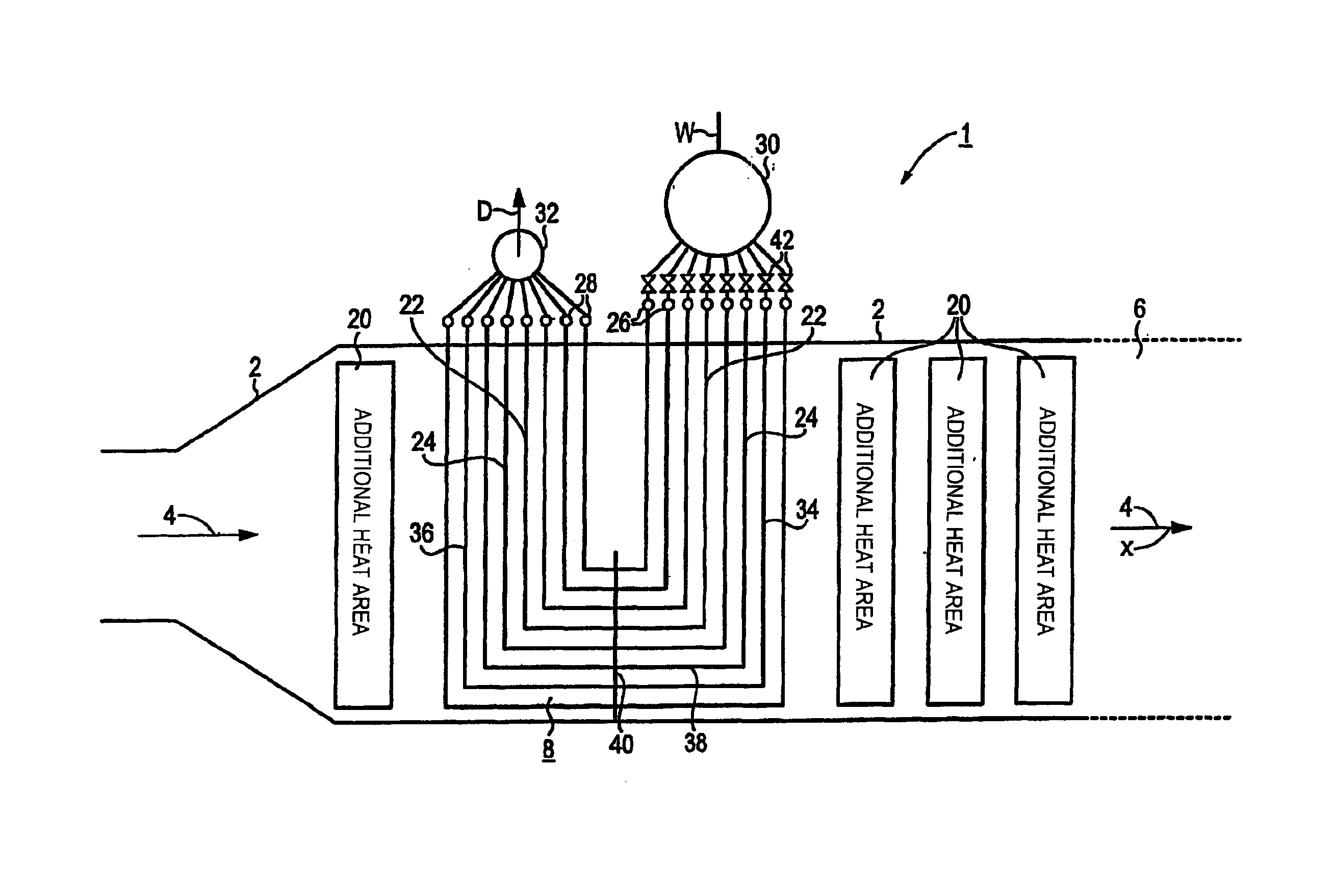

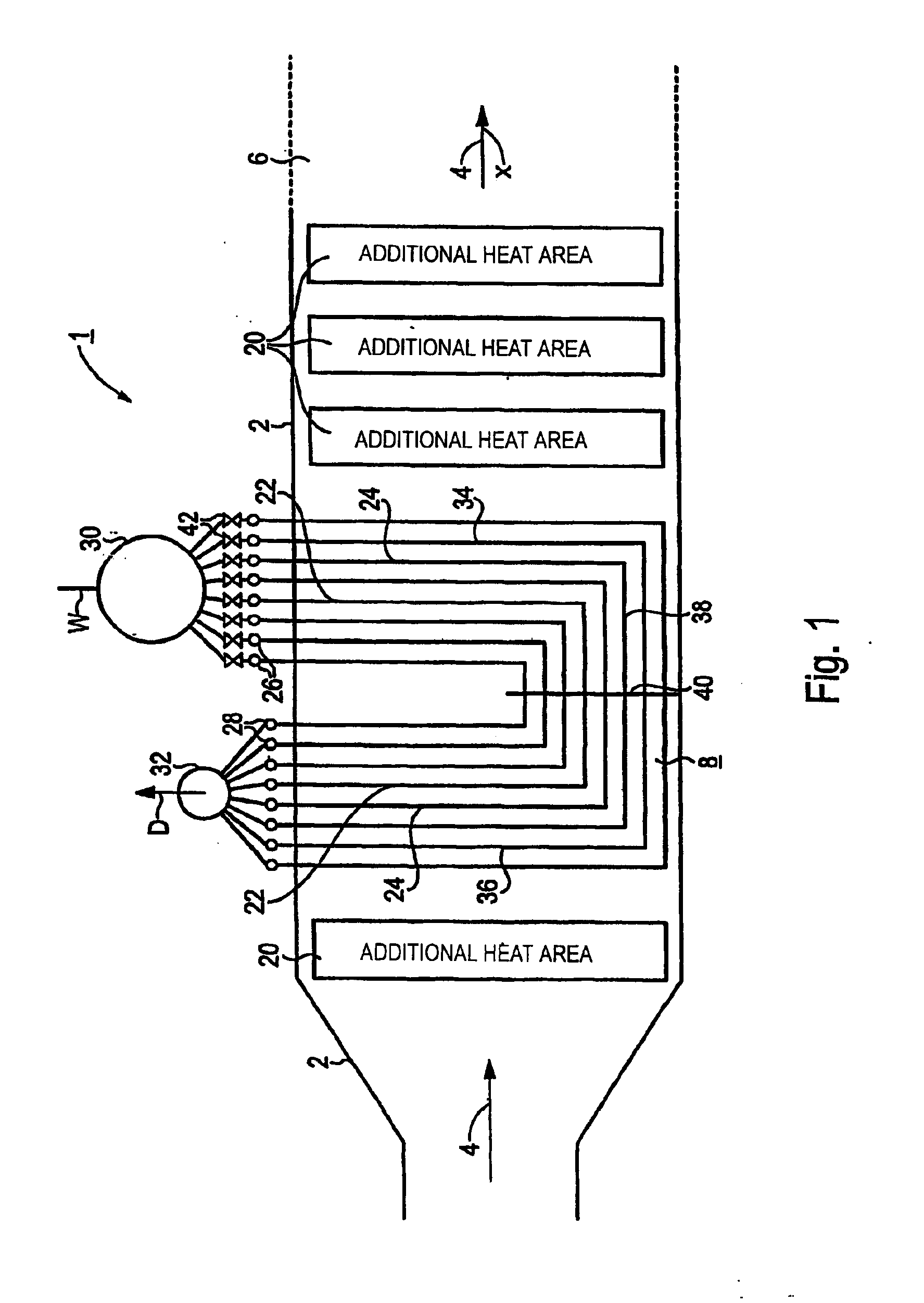

Method of controlling a wind power installation

InactiveUS7204673B2Avoid damageLow wind resistanceRotational speed controlPropellersWind forceEngineering

A method for controlling a wind power installation at very high wind speeds, in which there is predetermined a first wind speed at which the rotor blades of the wind power installation are put into a first predetermined setting. In addition, the method includes controlling the wind power installation during an extreme wind situation where the rotor blades moved to a position to reduce, as far as possible, mechanical loadings on the wind power installation caused by the extreme wind situation.

Owner:WOBBEN ALOYS

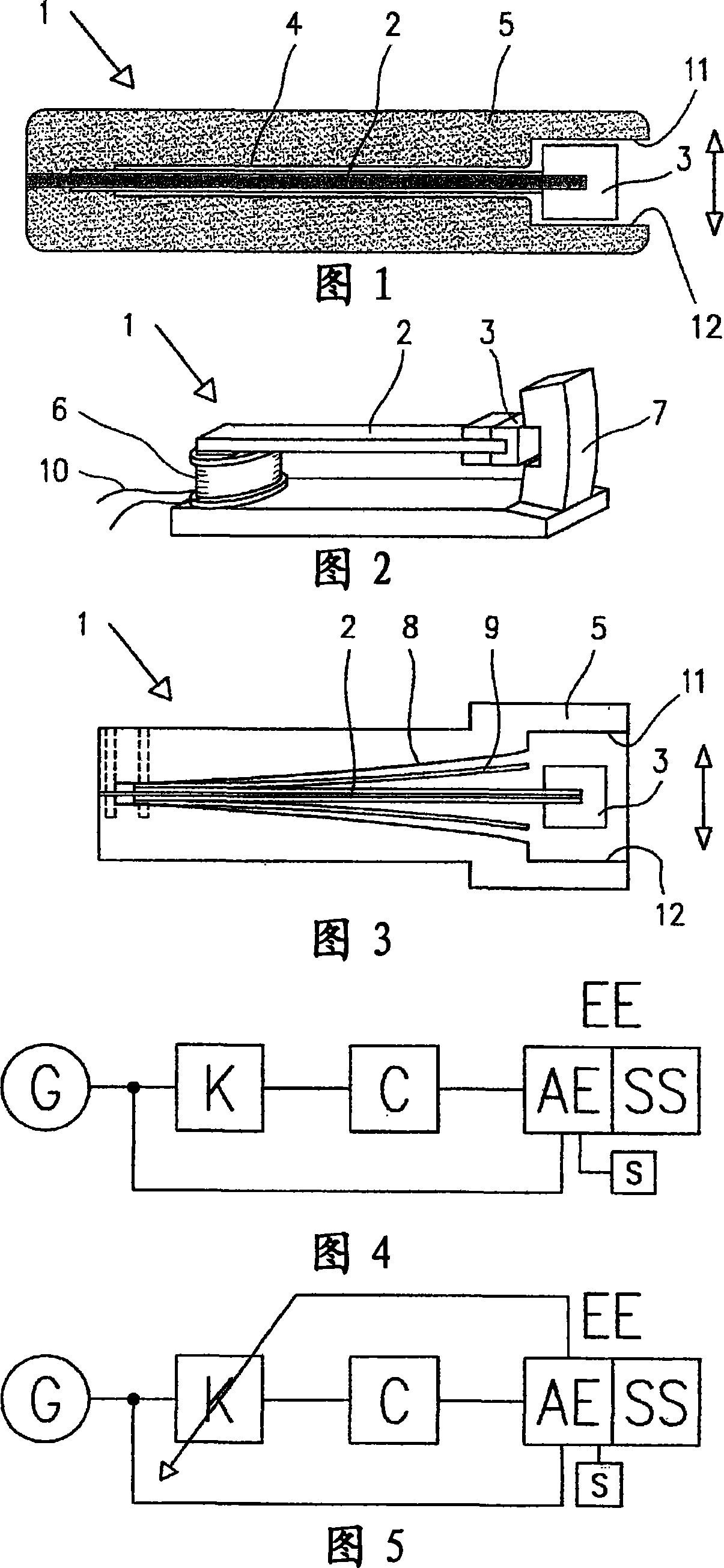

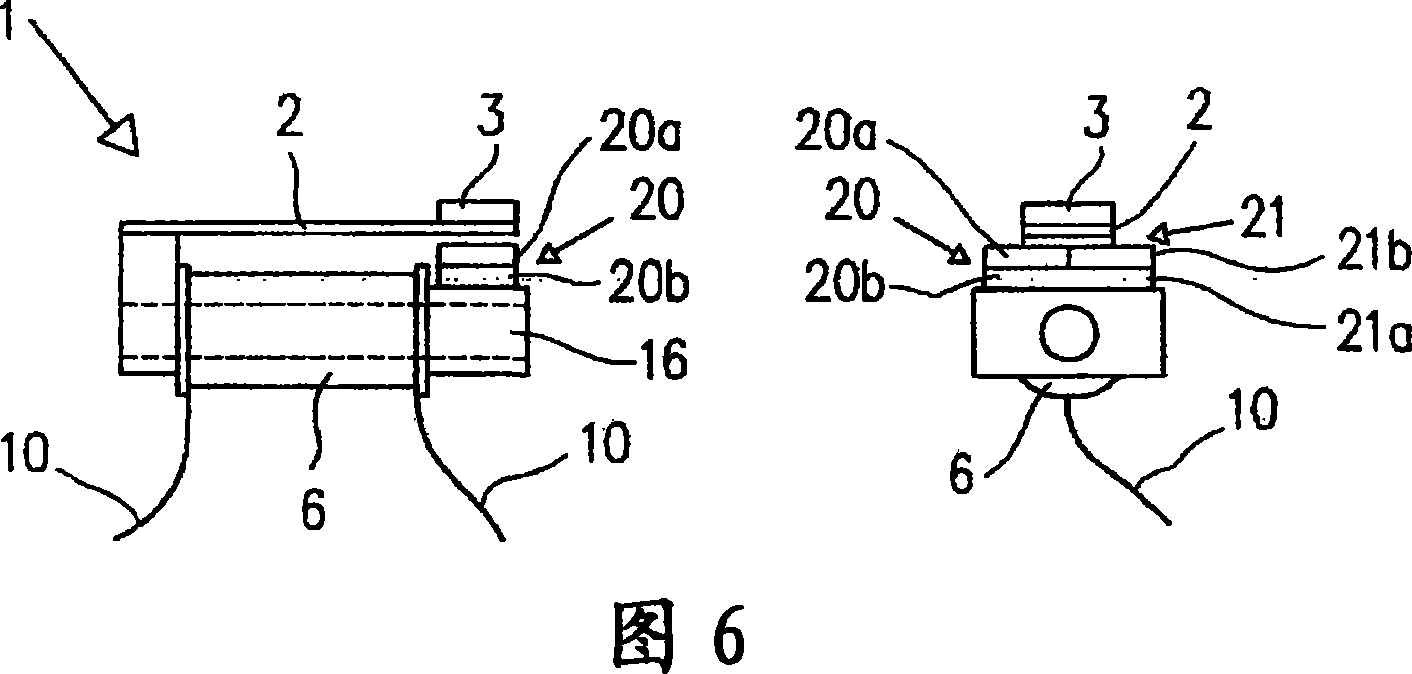

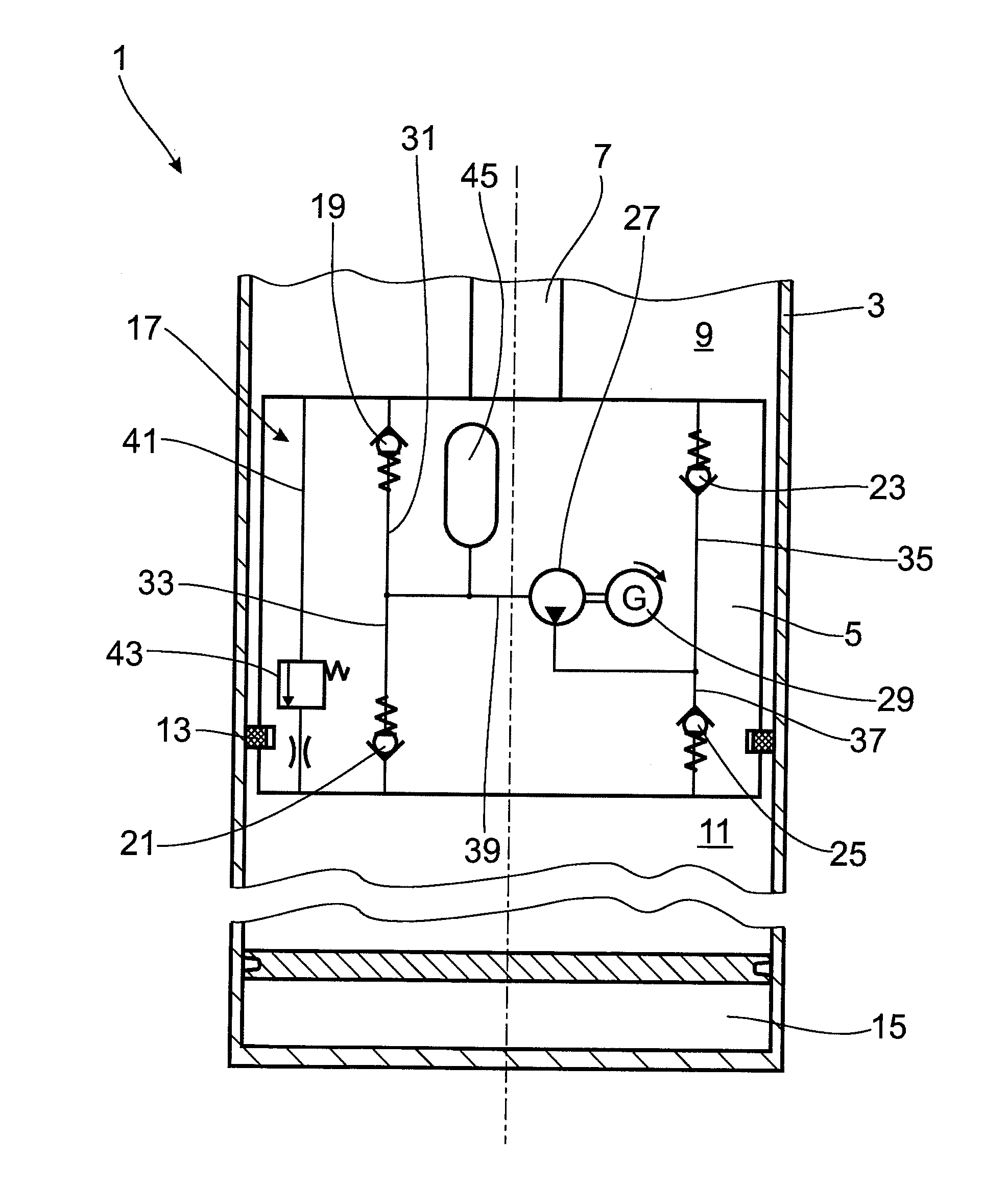

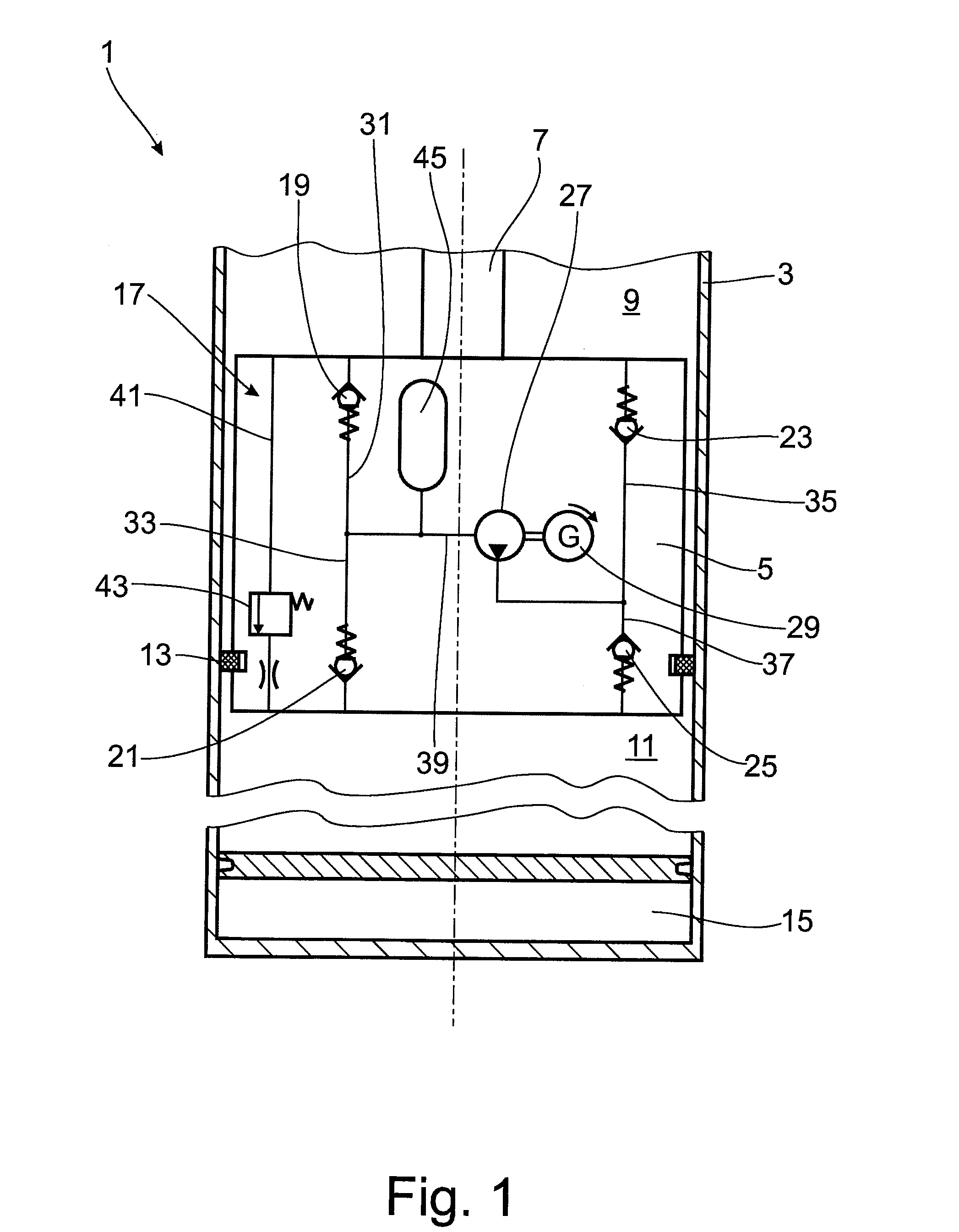

Tyre module and tyre comprising a module of this type

InactiveCN101098792AImprove efficiencyFavorable power conversionTyre measurementsDynamo-electric machinesElectric energyTorsion spring

The invention relates to a tyre module for recording tyre condition variables, comprising a spring element (2) that is fixed on one side and a conversion unit (2, 3, 4, 6, 7), in which the displacement energy is converted into electric energy. The spring element (2) is configured as a rod spring, torsion spring or leaf spring and carries a seismic mass (3) on its free end. The spring element transmits acceleration steps of the seismic mass (3) to the conversion unit (2, 3, 4, 6, 7).

Owner:CONTINENTAL TEVES AG & CO OHG

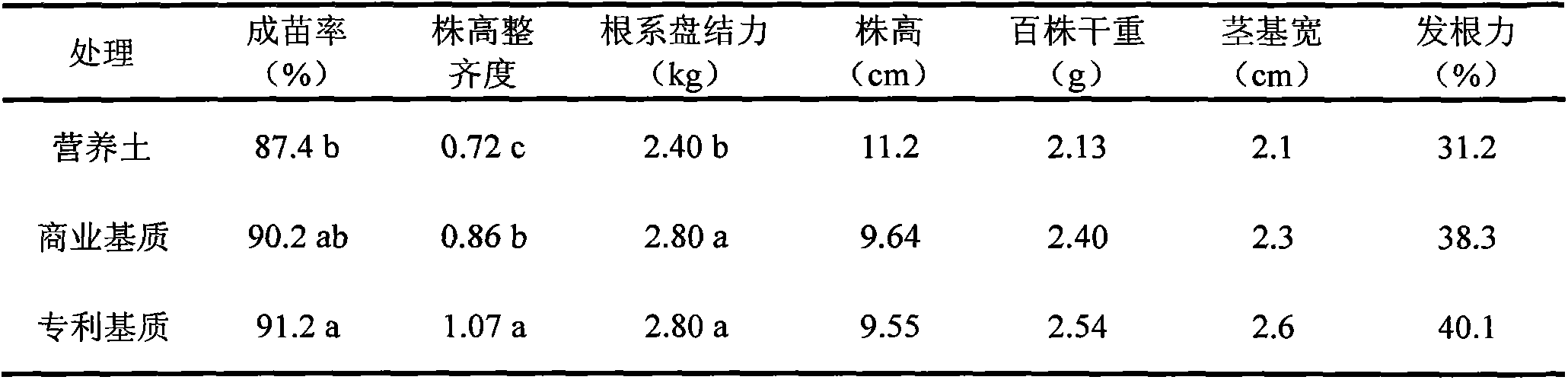

Special soilless organic composite matrix for raising seedlings of mechanically-transplanted japonica rice and preparation method of matrix

InactiveCN103848697AEasy to get materialsLow transportation and production costsFertilizer mixturesJaponica riceRice straw

The invention belongs to the field of rice culturing and in particulates to a special soilless organic composite matrix for raising seedlings of japonica rice. The matrix taking agricultural wastes as materials comprises the following components in percentage by weight: 55%-65% of rice straw, 25%-35% of cow dung, 5%-10% of rice husk, 2%-3% of carbamide, 1.5%-2.0% of straw-decomposing inoculants, 15% of peat, 1%-3% of nitrogen phosphorus and potassium fertilizers, 0.015%-0.006% of seedling growing agent and 0.002% of root growth promoting agent. The special soilless organic composite matrix for raising seedlings of japonica rice has the advantages that the local agricultural wastes serve as the main raw materials, so that the matrix is available in material, low in transportation and production cost, facilitates the cyclic utilization of the agricultural wastes, reduces the pollution to the environment, completely solves the problems that the vegetation is damaged when soil is extracted for raising the seedlings and the soil is extracted difficultly and reduces the labor strength and cost for processing the extracted soil; in addition, auxiliary additives are organic non-toxic products, easy to degrade in a farmland ecosystem and free of secondary pollution; the matrix is long in time period suitable for planting the seedlings; the time period of the matrix suitable for planting the seedlings can be extended to 28 days; and the matrix is great in range of seedling ages and strong in adaptively in date of seeding.

Owner:RICE RES ISTITUTE ANHUI ACAD OF AGRI SCI

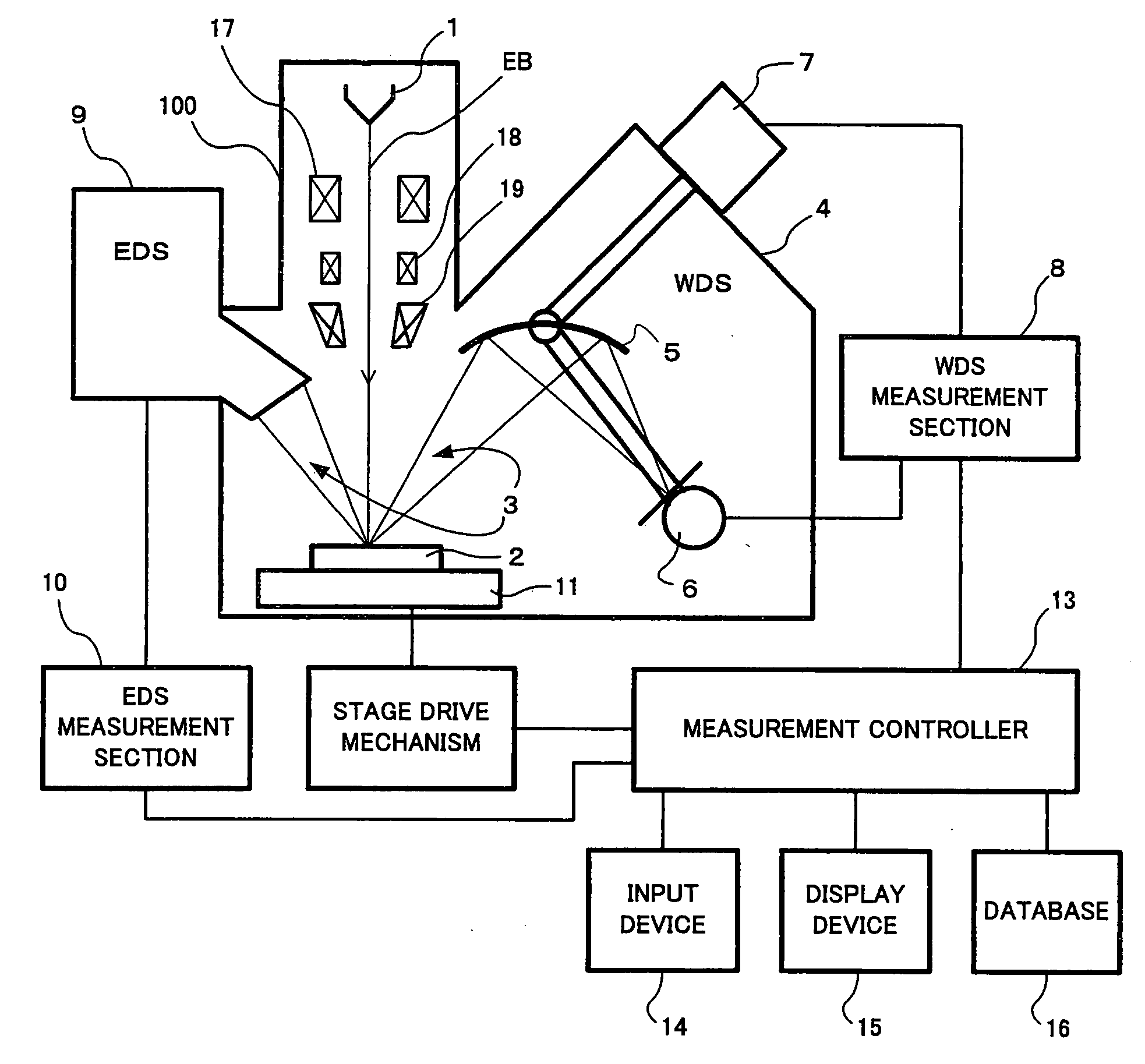

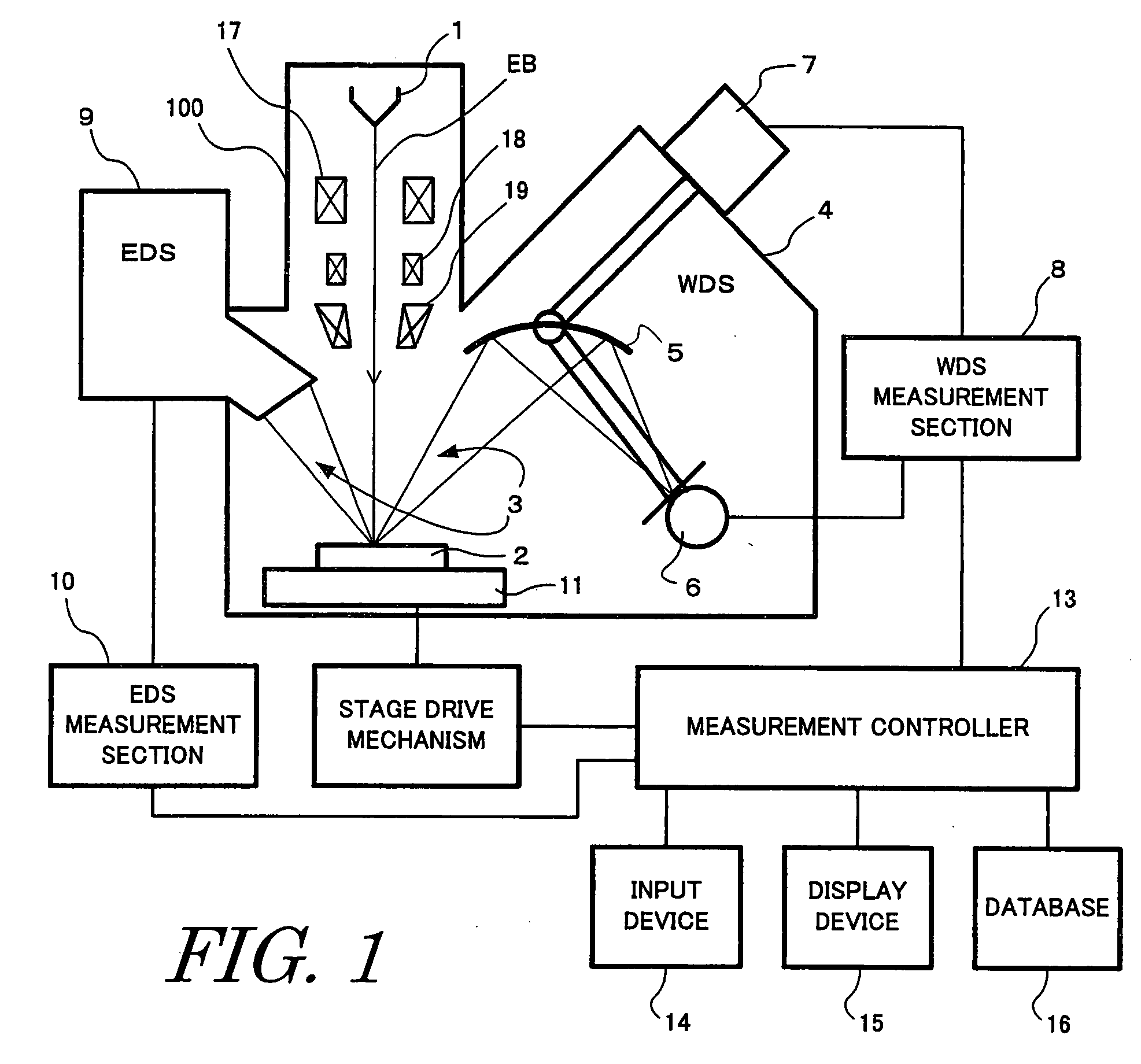

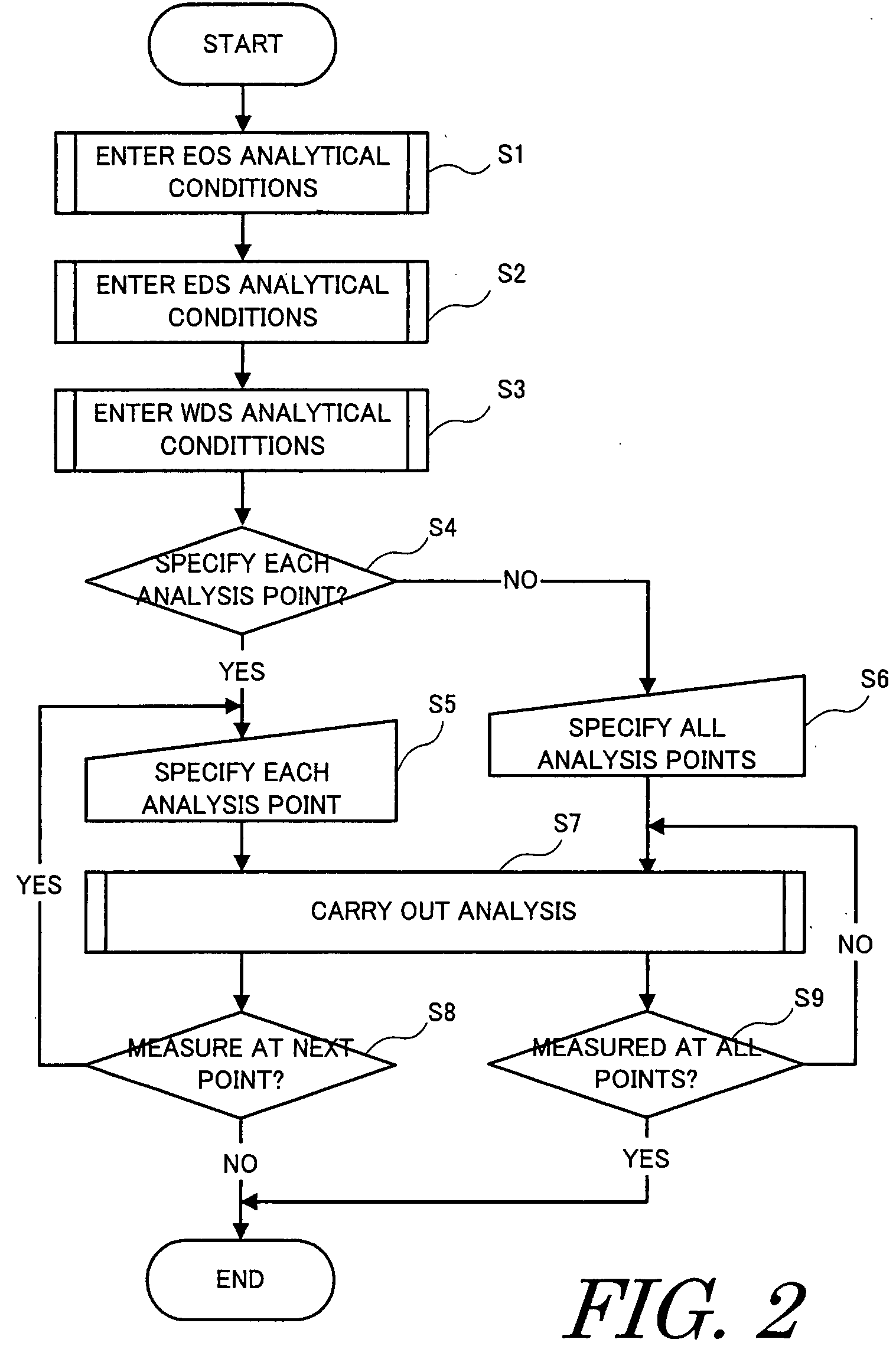

X-ray analyzer using electron beam

InactiveUS20080067379A1None be problem freeReliable analysisX-ray spectral distribution measurementElectric discharge tubesChemical compoundConfocal

An electron probe X-ray analyzer capable of automatically setting appropriate analytical conditions if there are unknown compounds by performing analysis under the analytical conditions adapted for analysis points having different compositions in a case where the numerous analysis points having the plural compositions are analyzed by WDS (wavelength-dispersive X-ray spectrometer). At each analysis point, the analyzer performs quantitative analysis using EDS (energy-dispersive X-ray spectrometer) permitting easy and quick analysis. Based on the results, chemical compounds are identified. If the results indicate that there is any new compound, analytical conditions adapted for the new compound are selected. If the new compound is already registered in a database, the analytical conditions are read from the database. Then, quantitative analysis is performed using WDS.

Owner:JEOL LTD

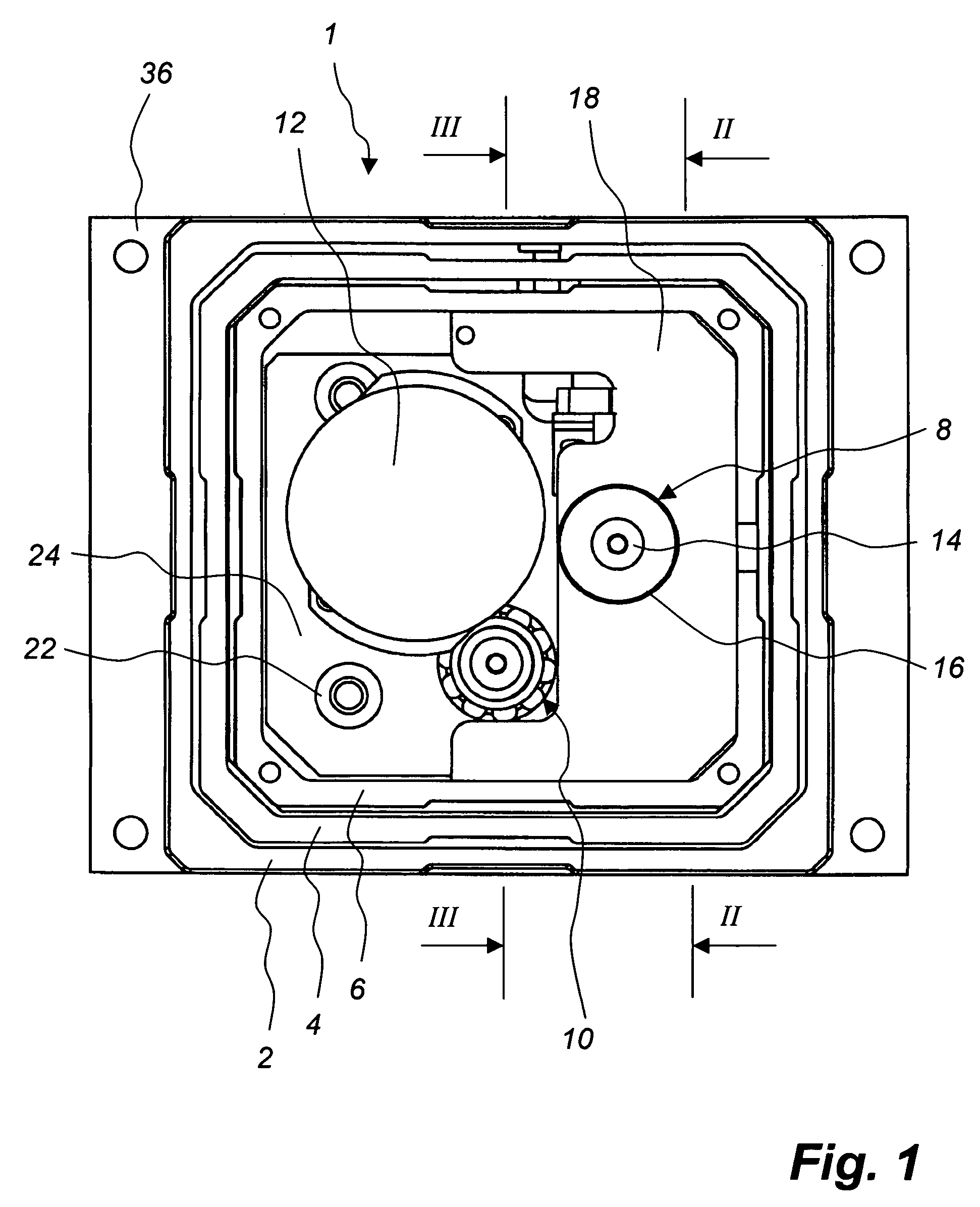

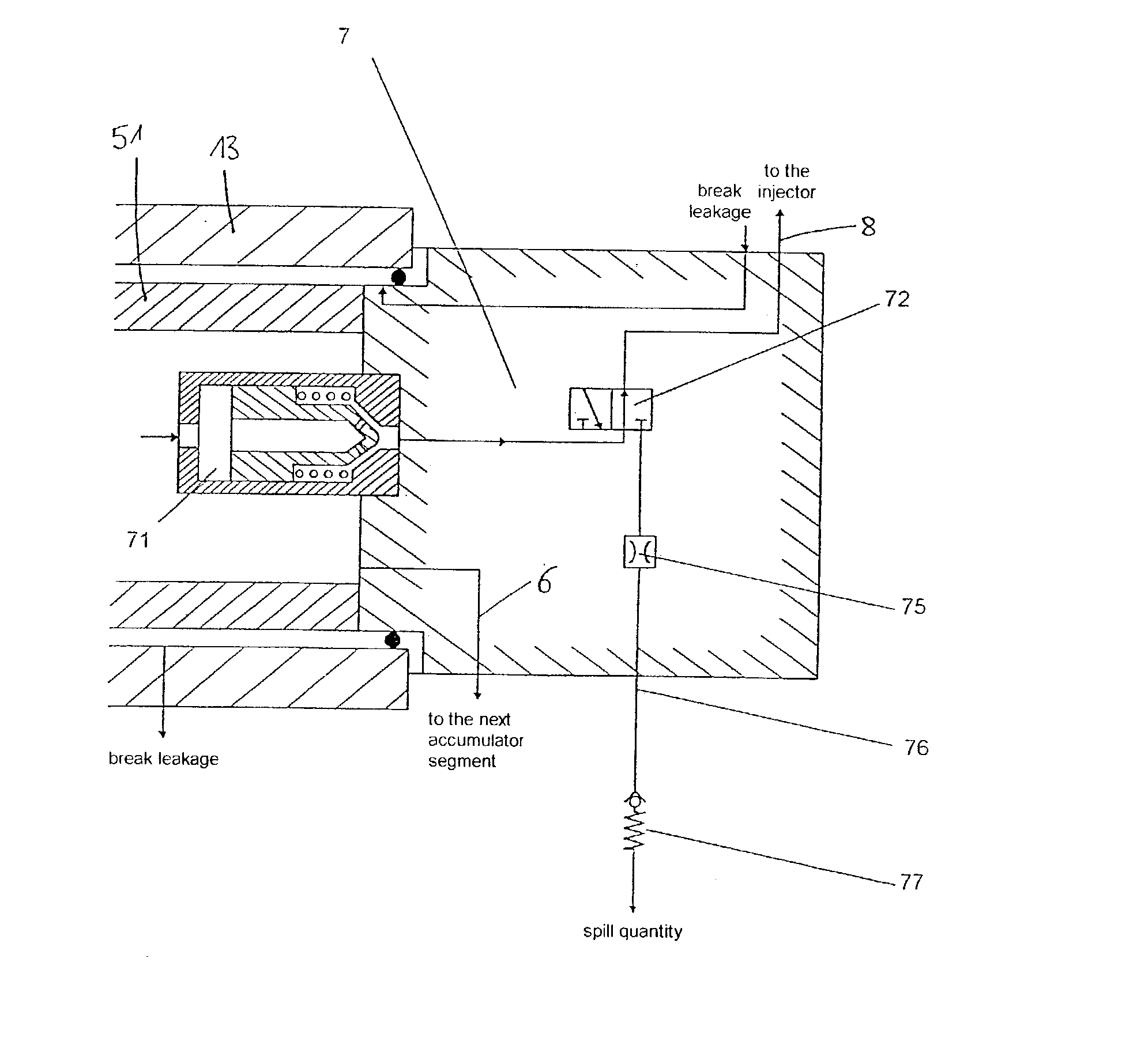

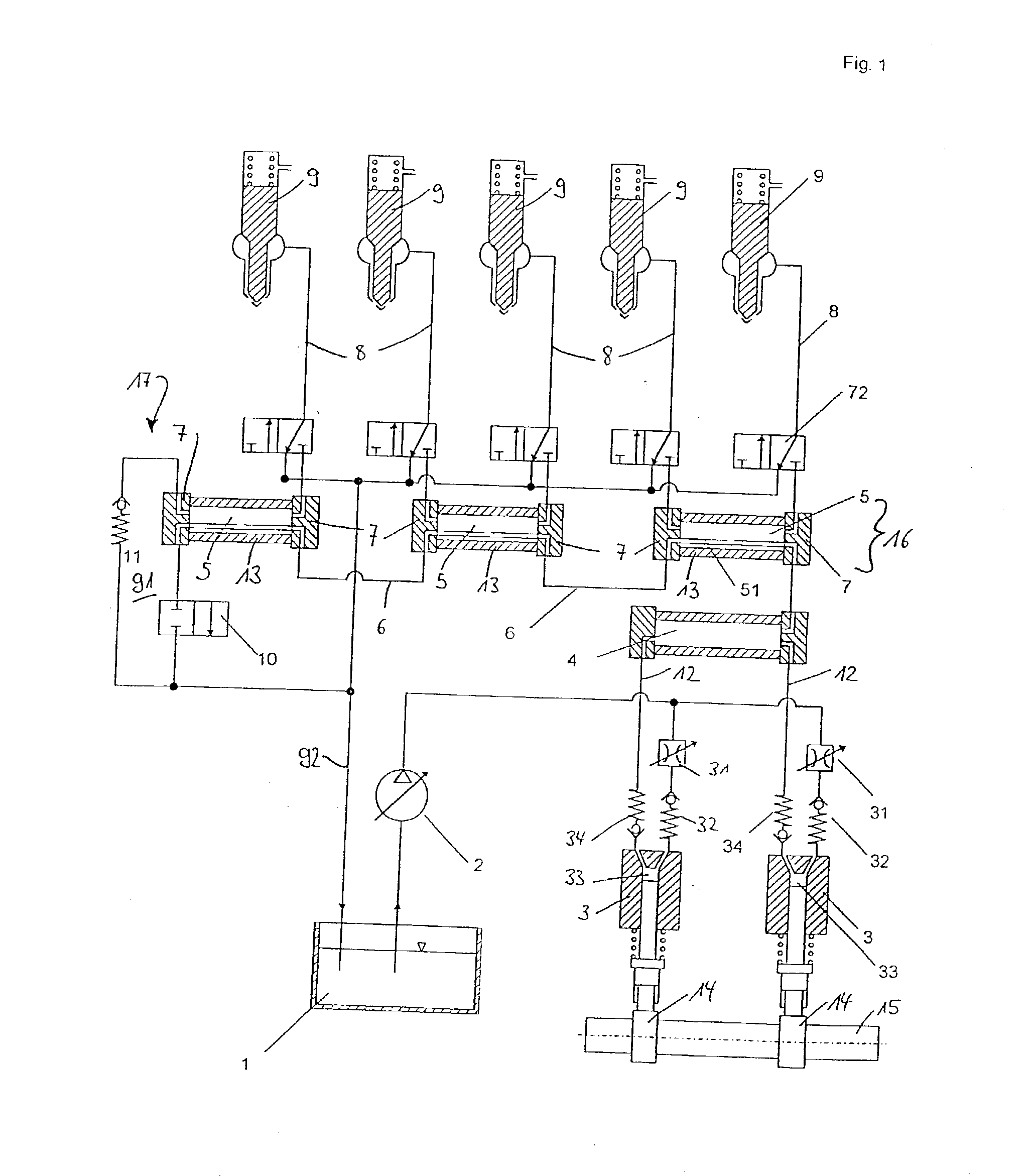

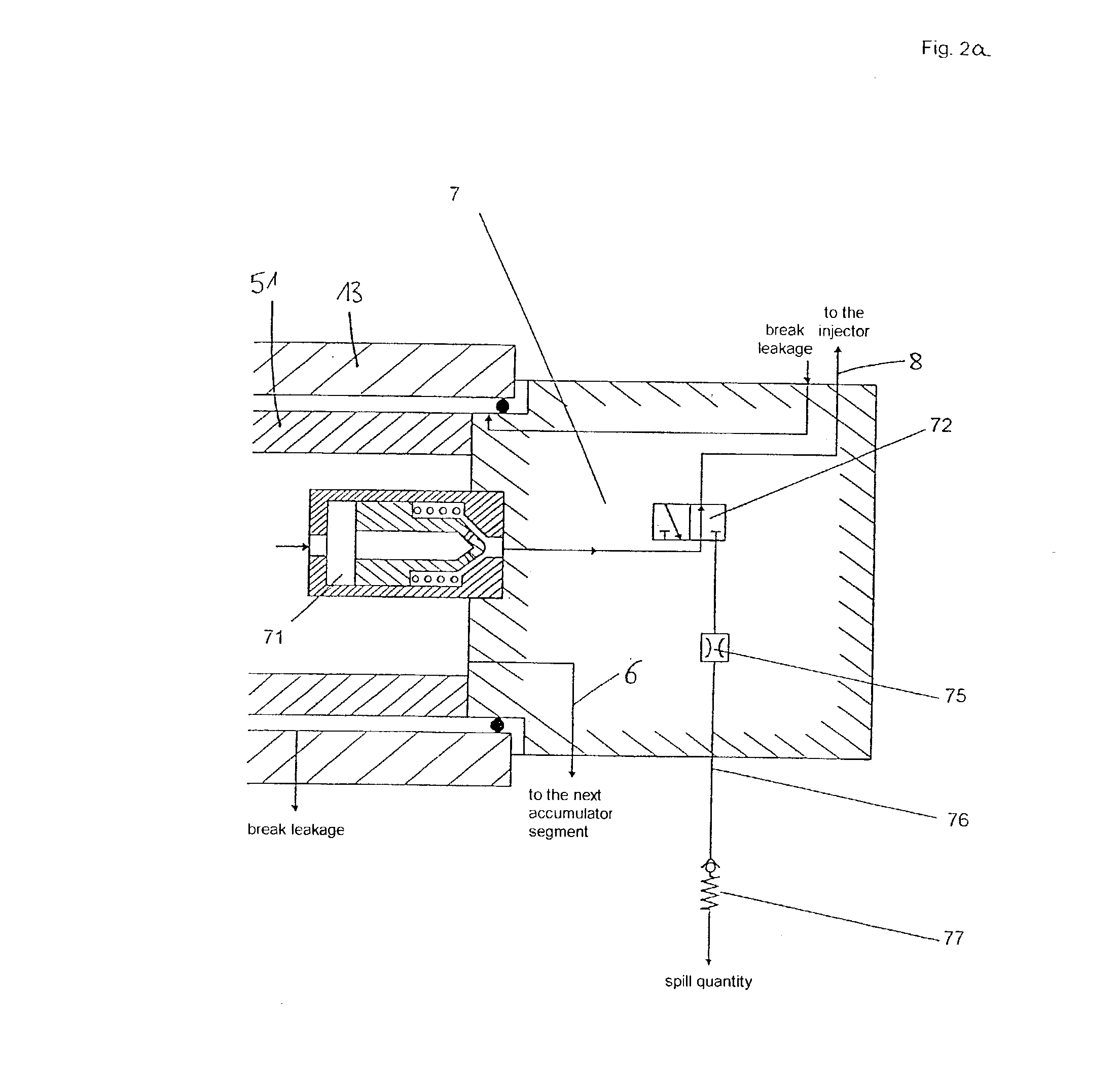

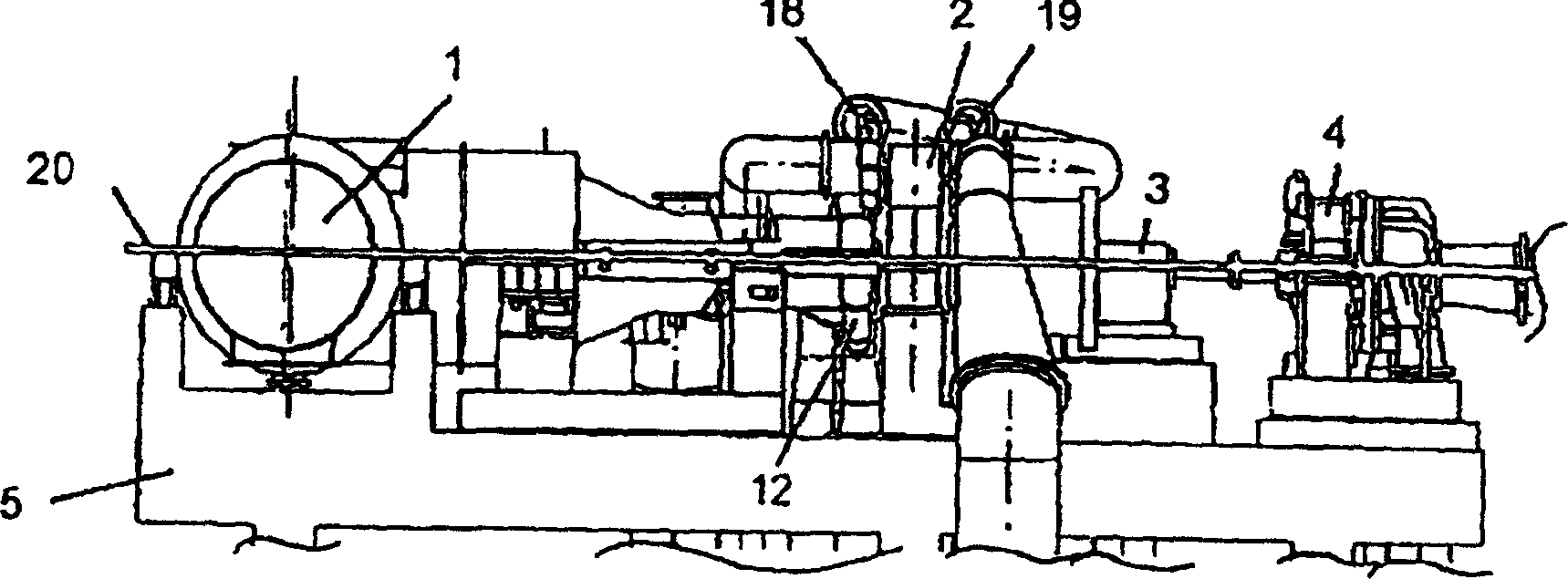

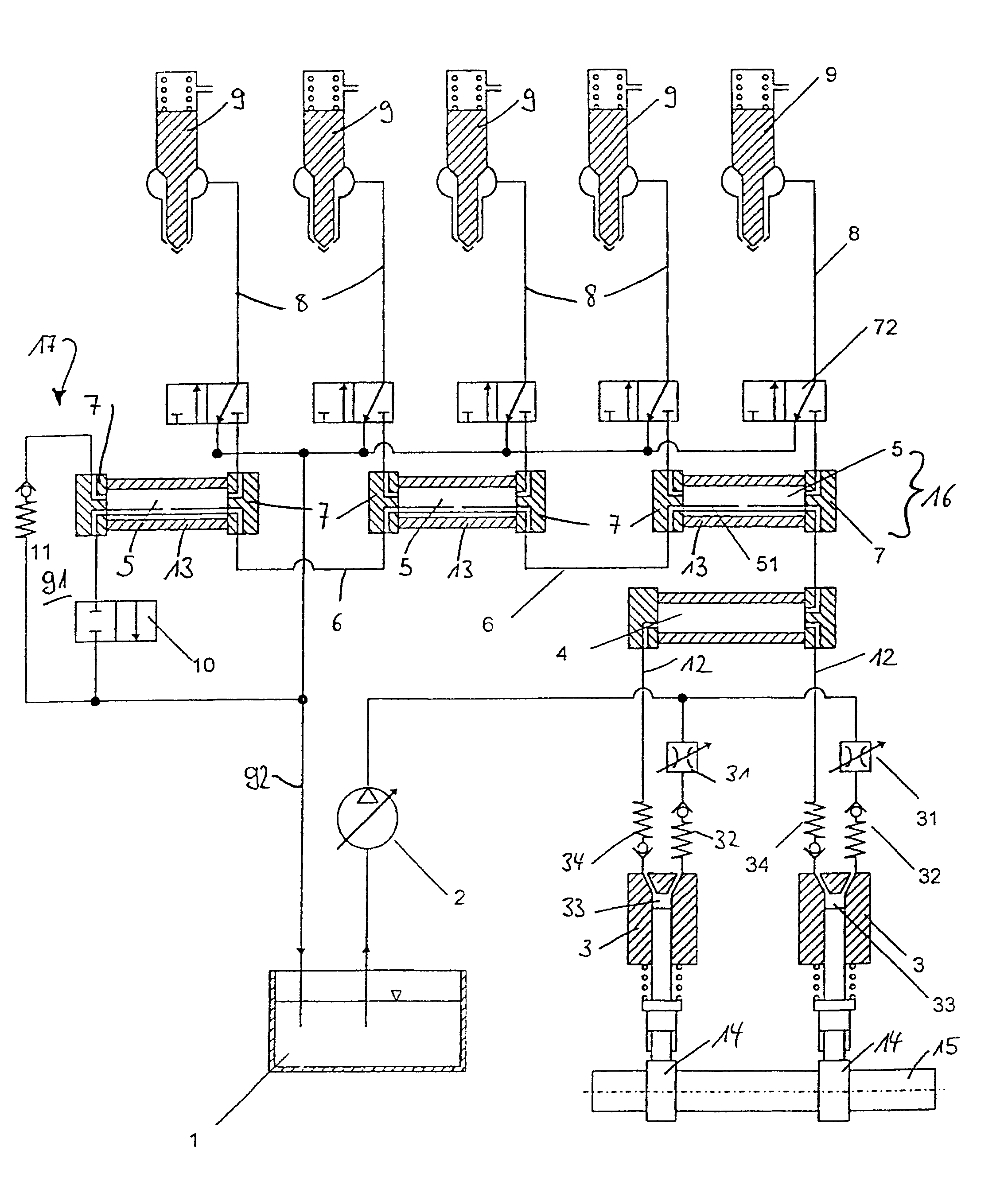

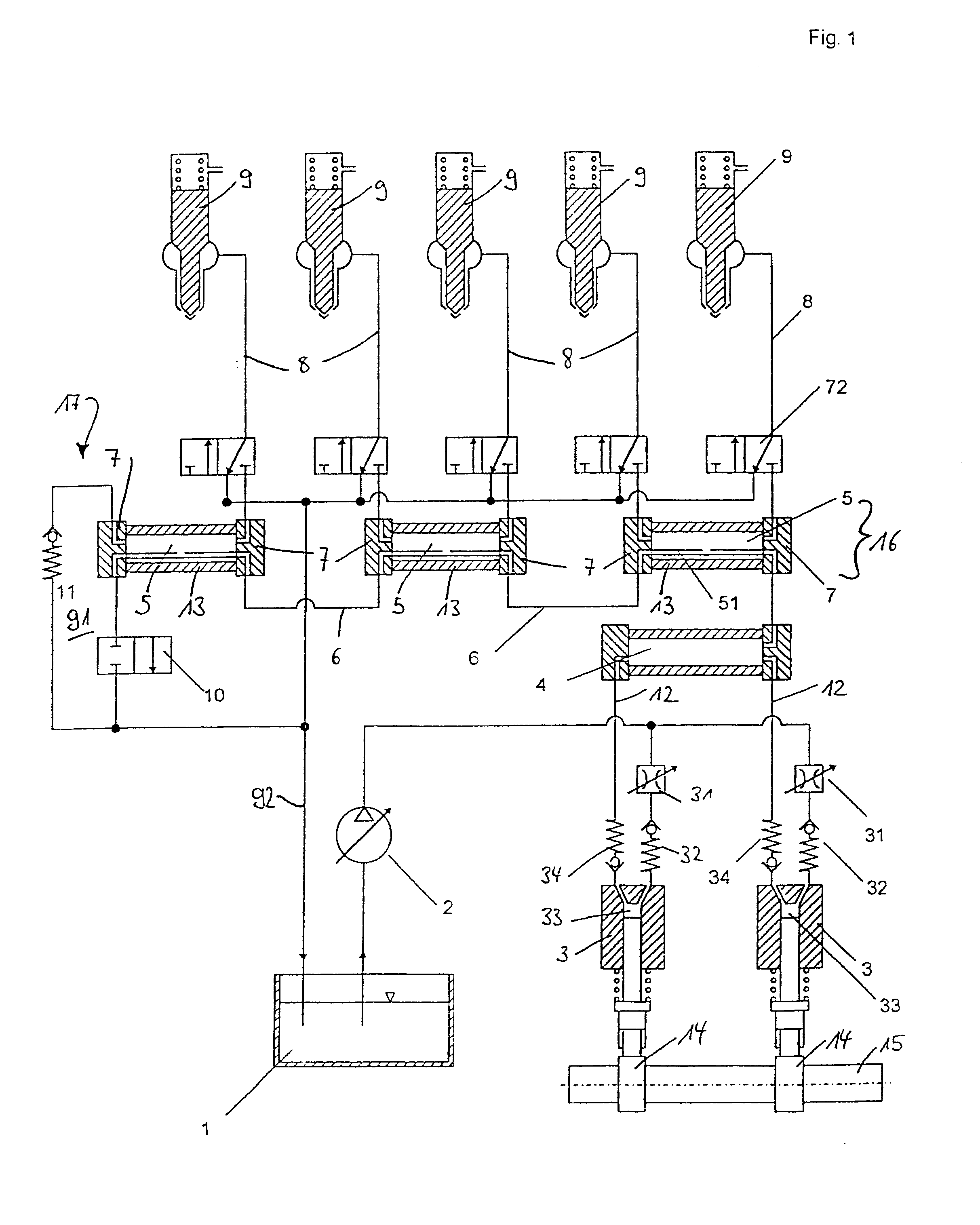

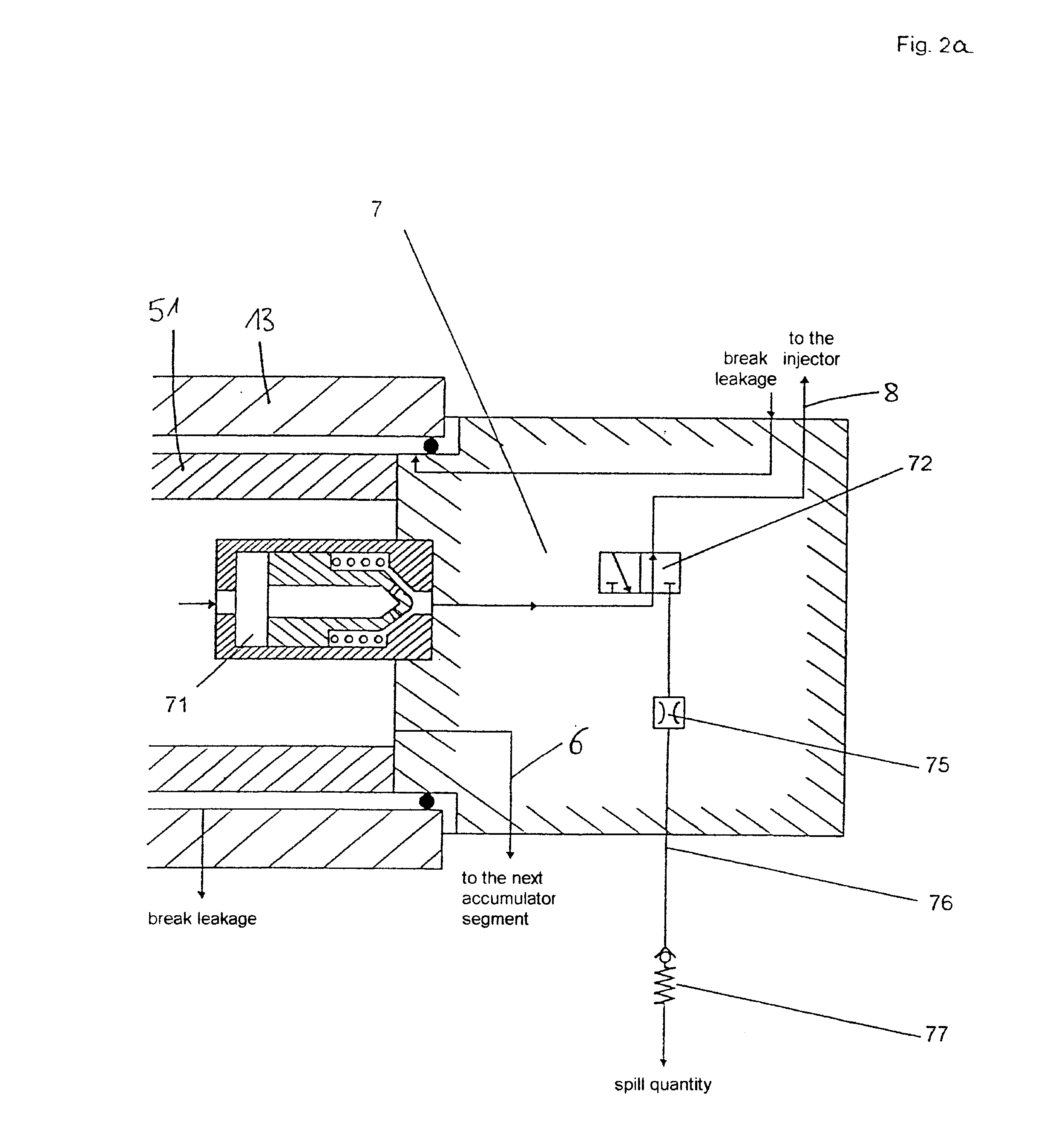

Fuel supply installation in the form of a common-rail system of an internal combustion engine having a plurality of cylinders

InactiveUS20030094158A1Guaranteed uptimeReduce dynamic pressureCasingsInternal combustion piston enginesCommon railEngineering

Fuel is conveyed by at least one high-pressure pump from a low-pressure region into a high-pressure region including a pressure-accumulator line consisting of at least two separate accumulator units connected to one another by means of feed lines, and to fuel injectors for the cylinders. The accumulator units each have an accumulator volume for serving at least two cylinders, and accumulator covers provided on both end faces. All the functional units are integrated into these accumulator covers in terms of fuel delivery and transfer, and at least one separate pump accumulator is arranged in the high-pressure region between the high-pressure pump and the assembled pressure-accumulator line. The pump accumulator is connected to at least one accumulator cover of an accumulator unit of the pressure-accumulator line for fuel conveyance and is capable of being acted upon by at least one high-pressure pump.

Owner:MAN ENERGY SOLUTIONS SA

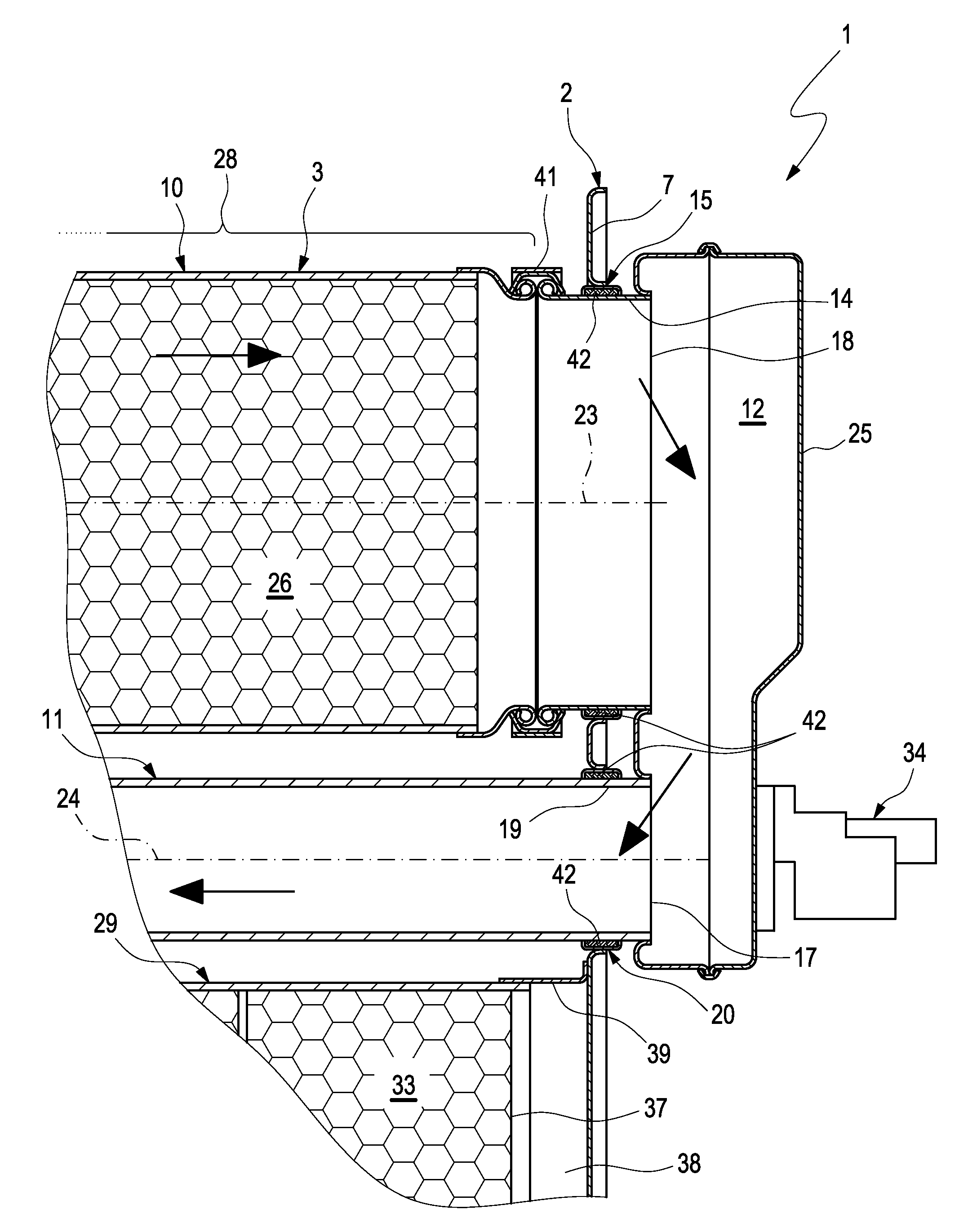

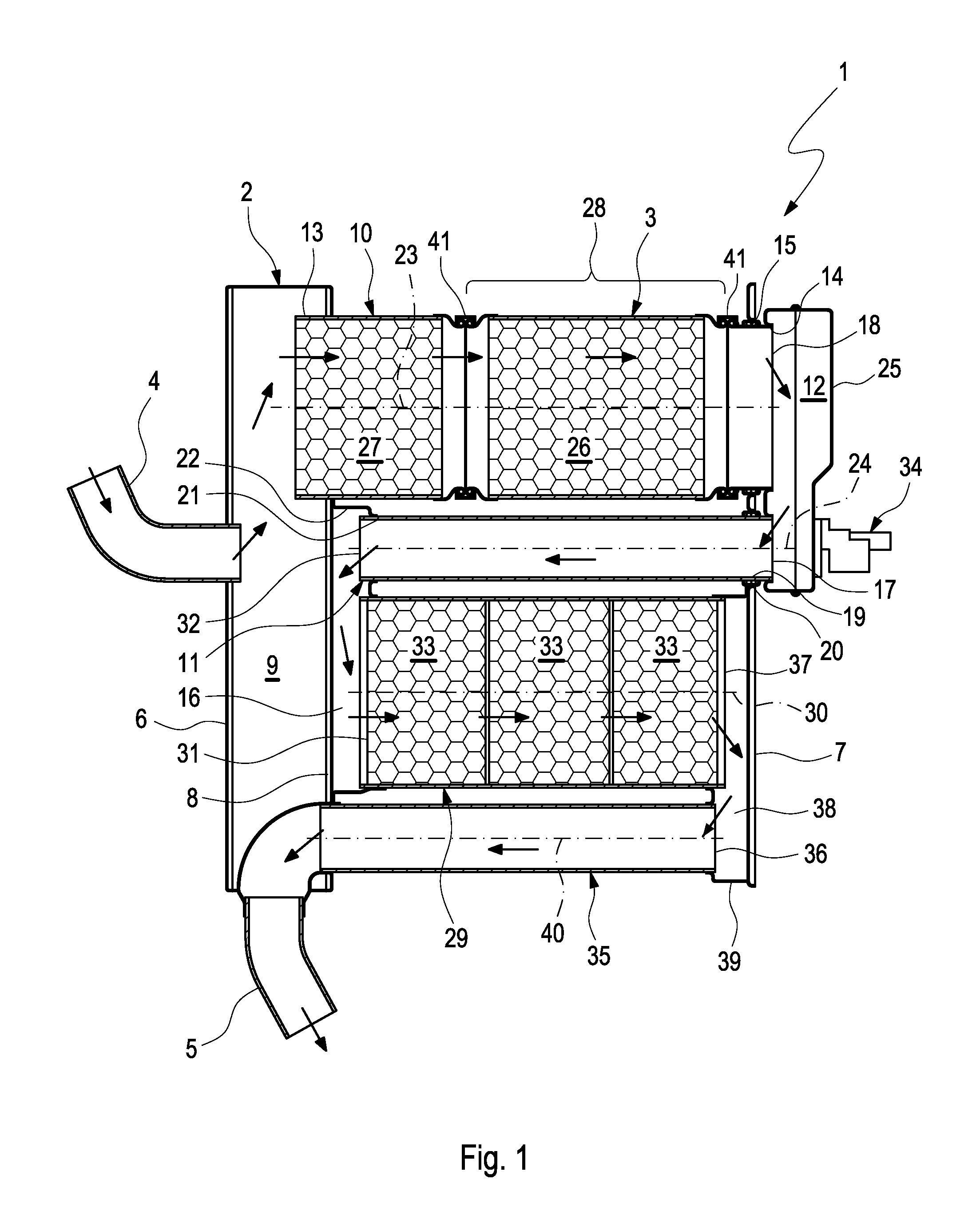

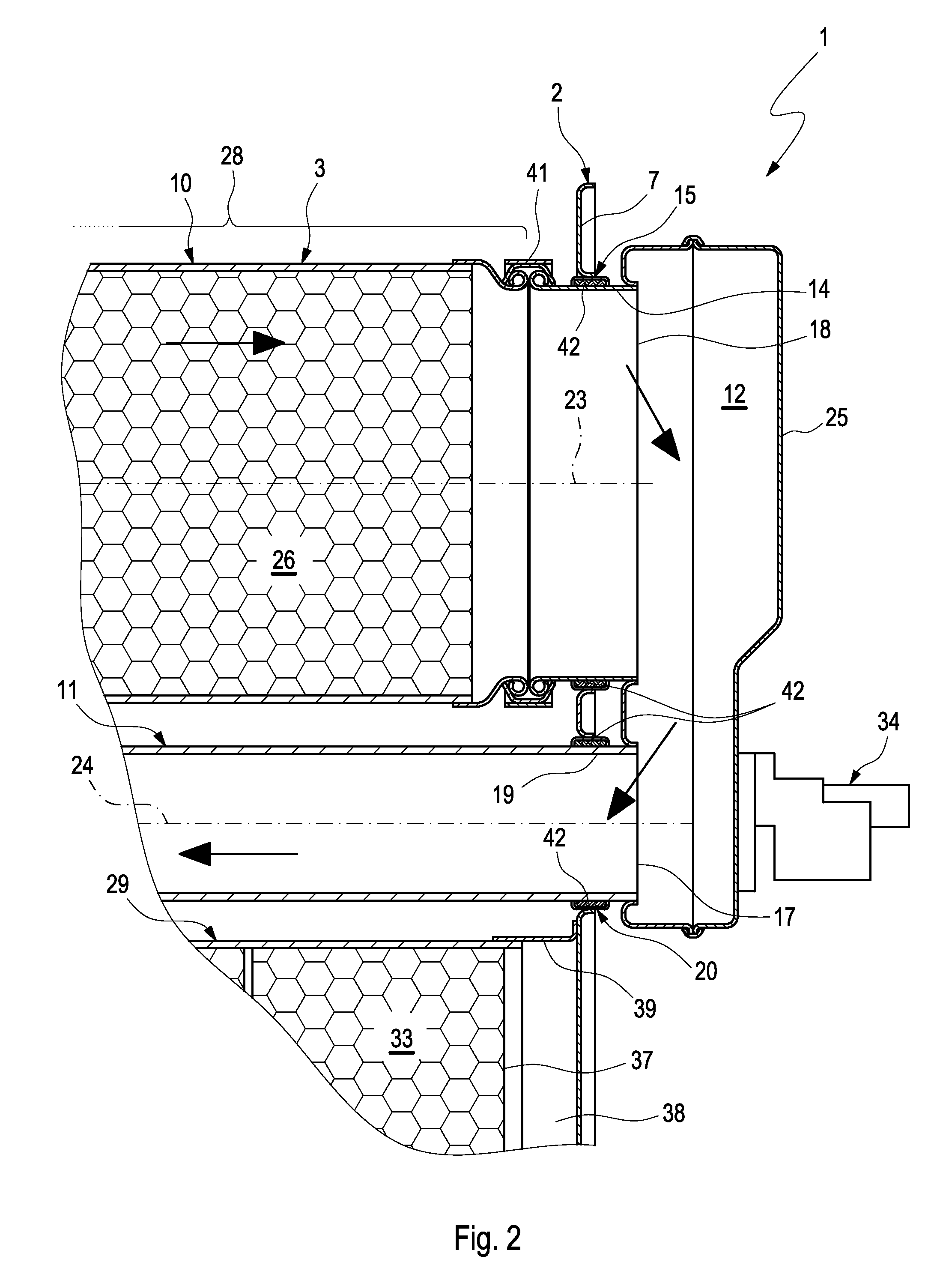

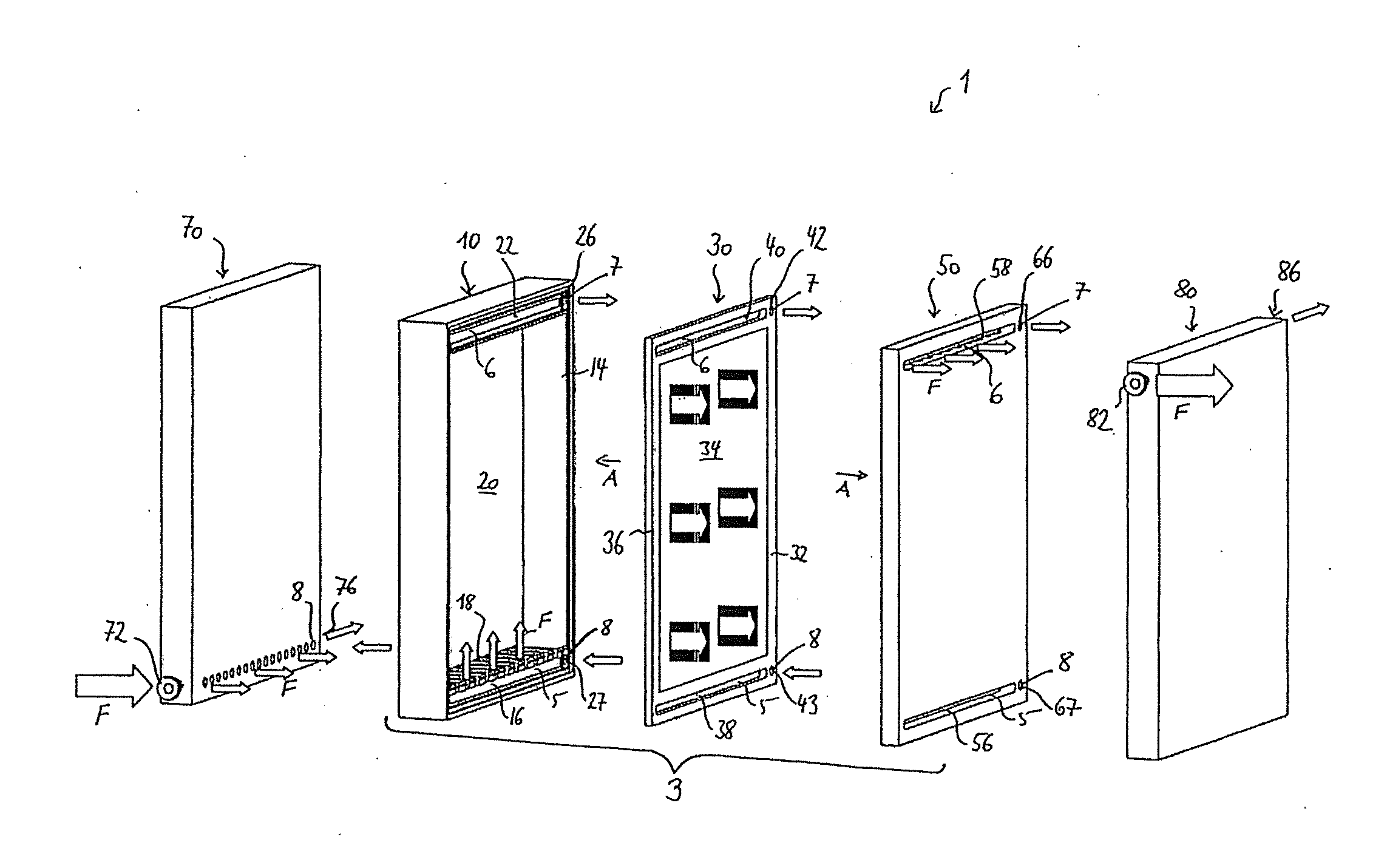

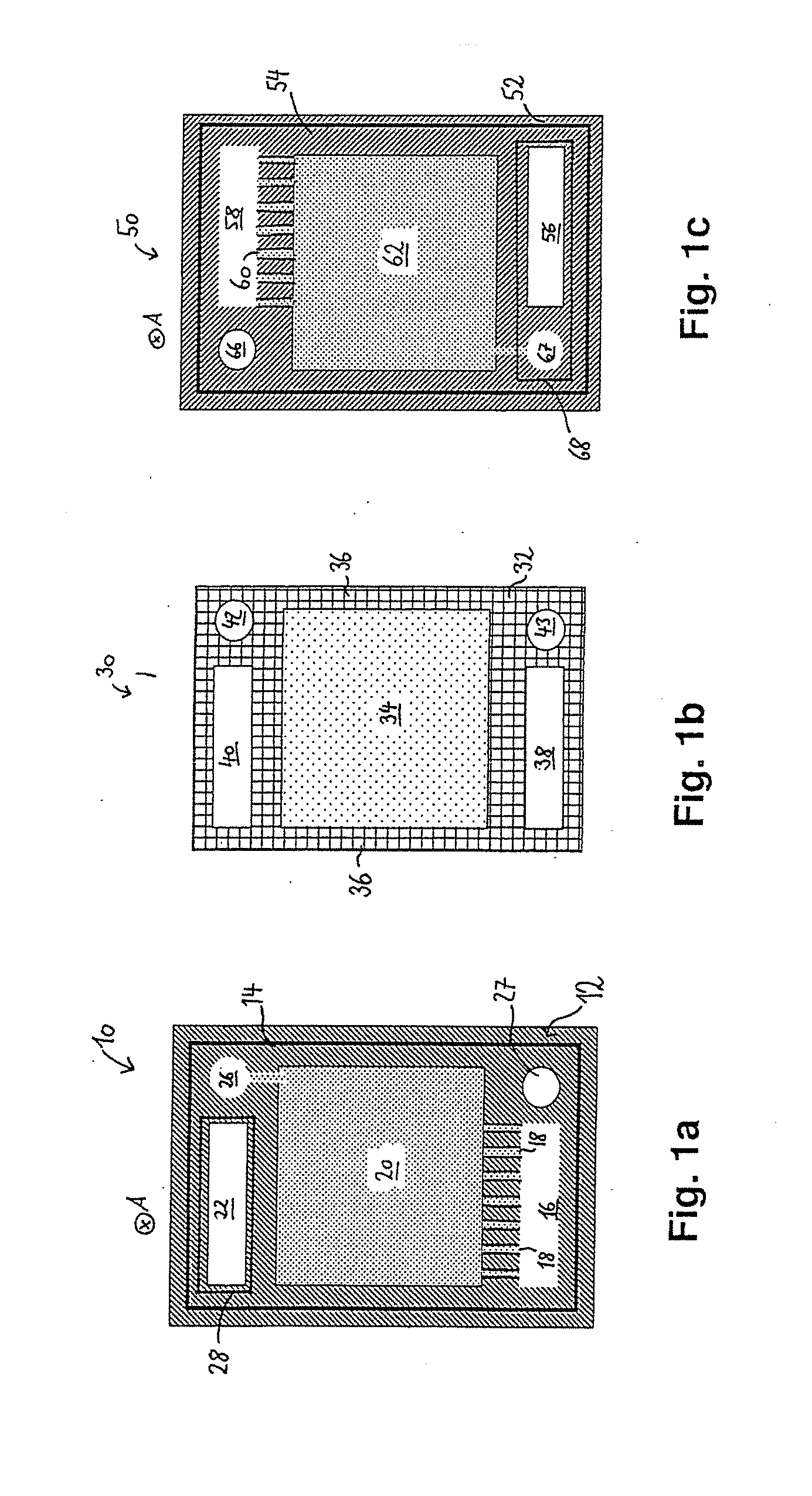

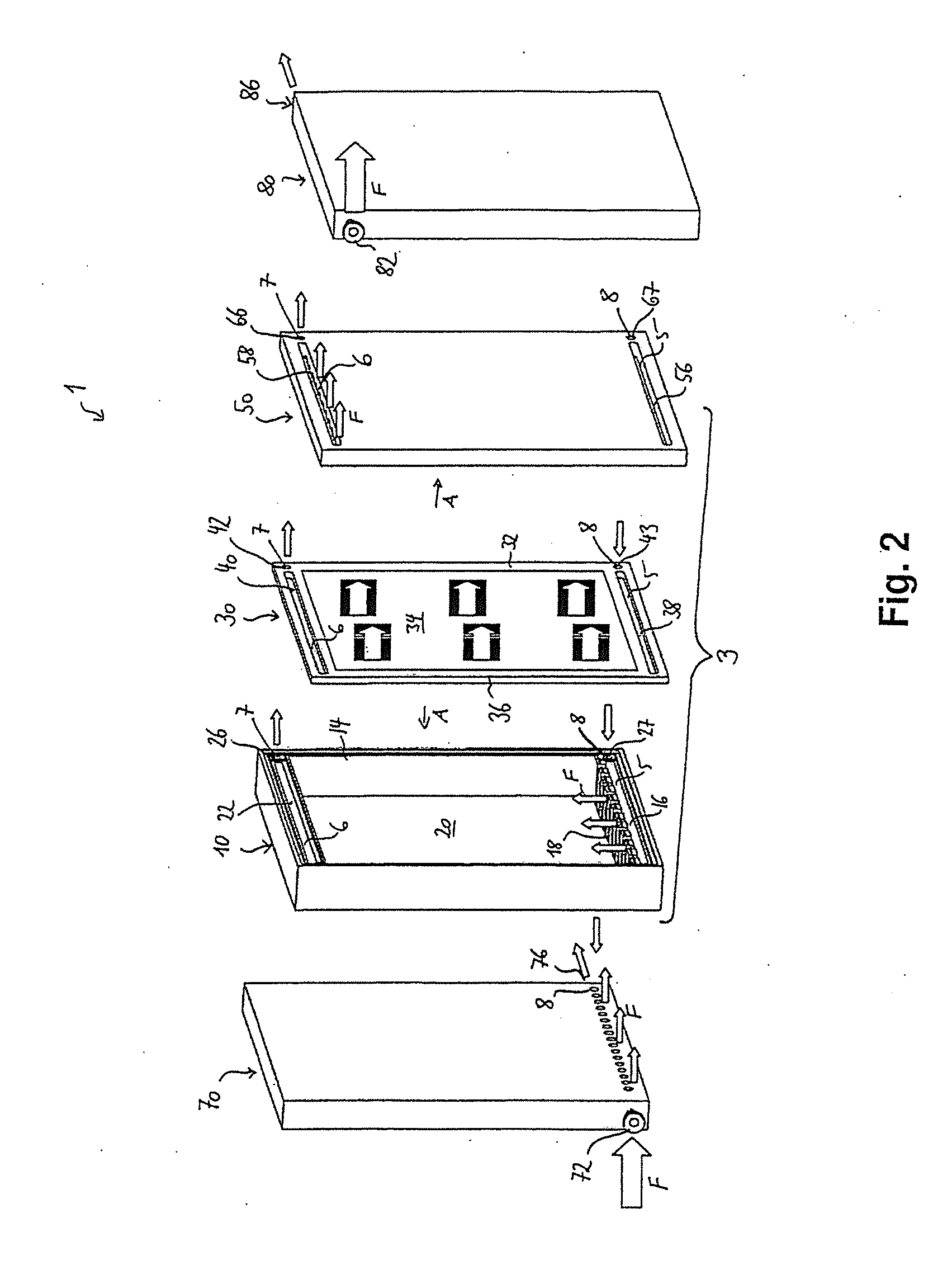

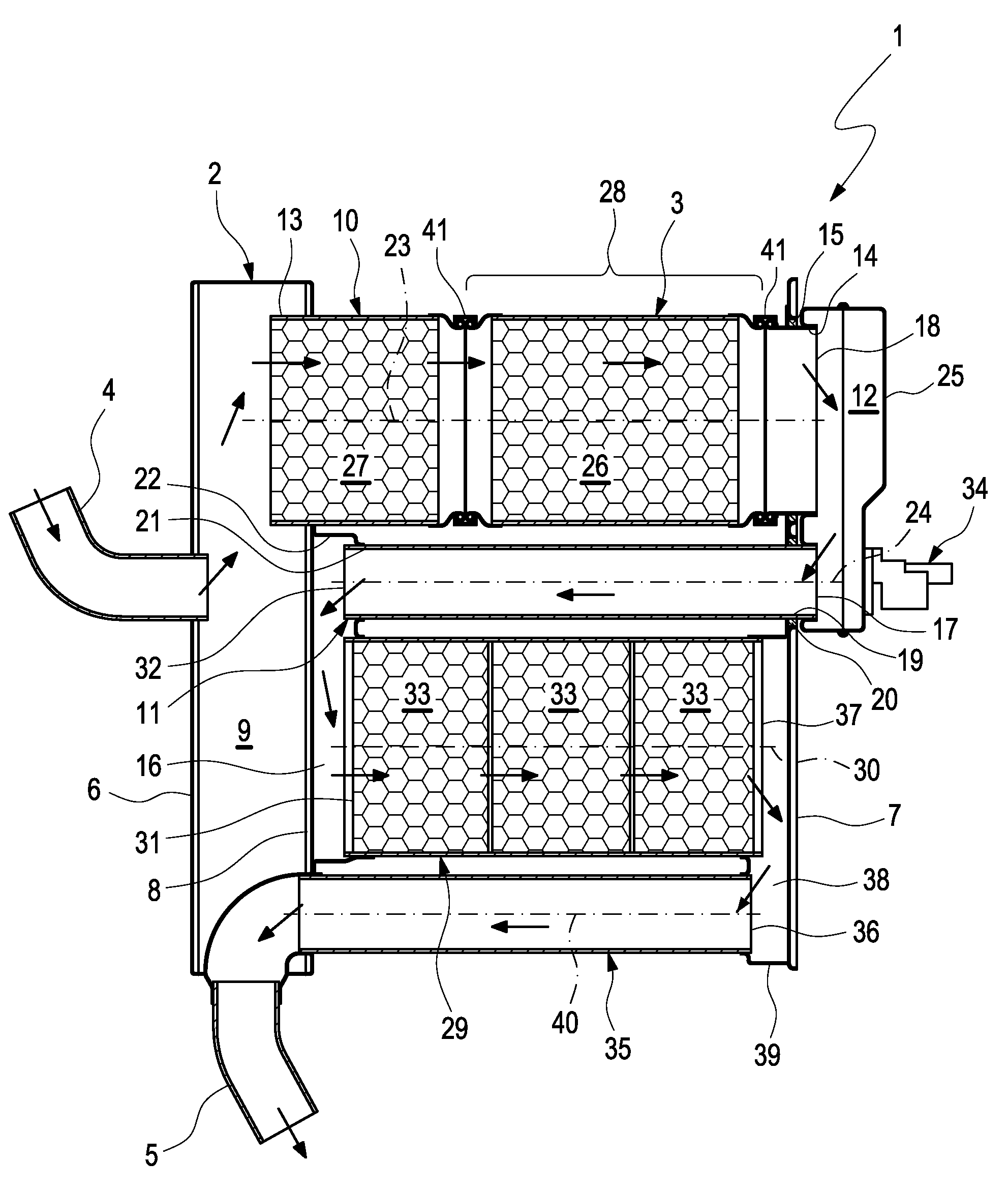

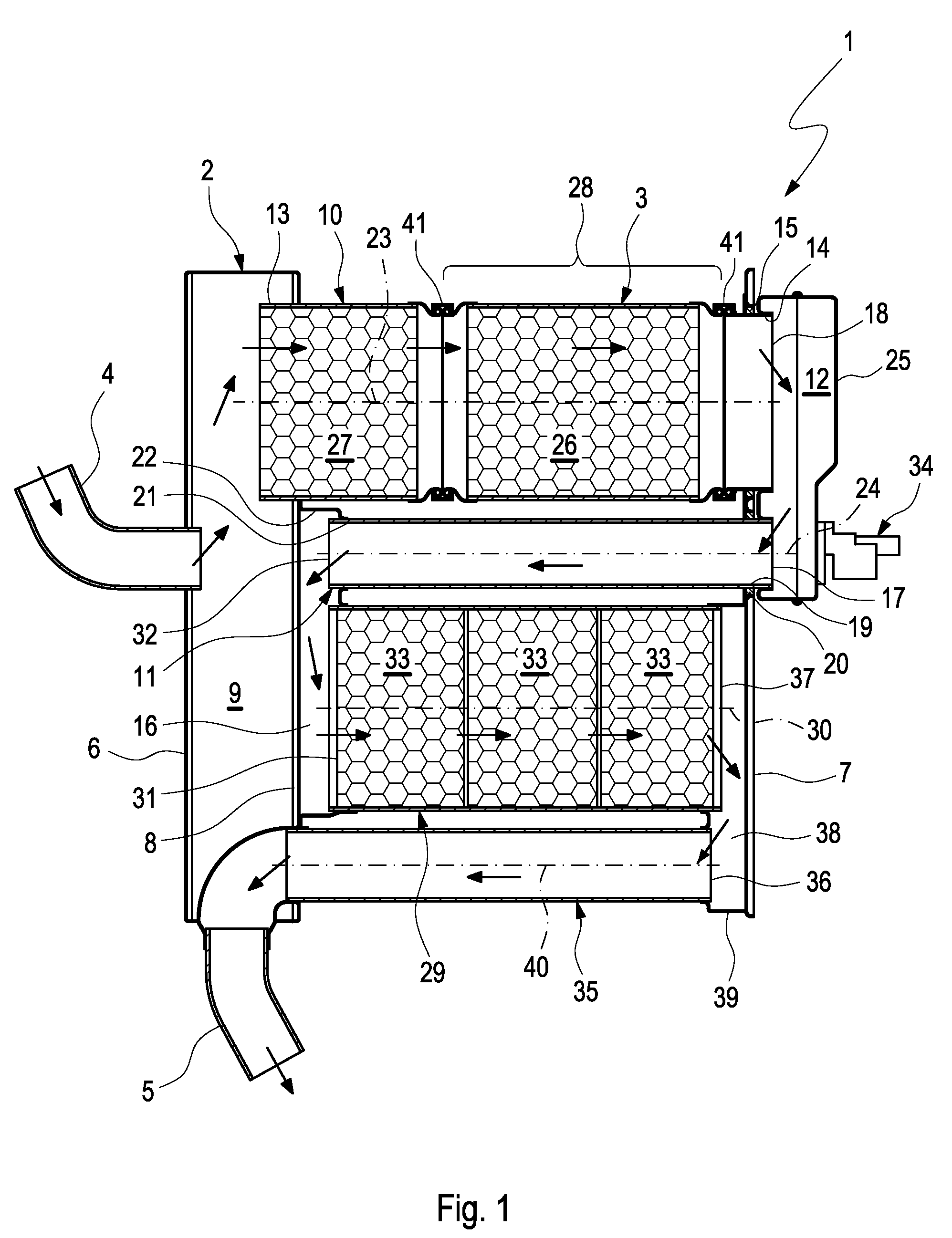

Filter module and modular filter system

ActiveUS20150001147A1Avoid contaminationAvoid damageSemi-permeable membranesMembranesFilter mediaFilter system

One aspect of the invention relates to a filter module comprising: —a filter element having at least one filter medium which separates a filtrate side and a retentate side of the filter element from one another, and having a filter medium holder to which the filter medium is attached and which has at least one holder intake channel and at least one holder discharge channel, —a first filter cartridge part having at least one first cartridge intake channel and at least one first cartridge discharge channel, —a second filter cartridge channel having at least one second cartridge intake channel and at least one second cartridge discharge channel, wherein the filter medium holder is arranged in an arrangement position between the first filter cartridge part and the second filter cartridge part in a fluid-tight manner, wherein the at least one holder intake channel has a fluid connection with the at least one first cartridge intake channel and the at least one second cartridge intake channel, in order to form a module intake channel, wherein the at least one holder discharge channel has a fluid connection with the at least one first cartridge discharge channel and the at least one second cartridge discharge channel, in order to form a module discharge channel, wherein the module intake channel has a fluid connection with the retentate side of the filter medium and wherein the module discharge channel has a fluid connection with the filtrate side of the filter medium, and a modular filter system.

Owner:SARTORIUS STEDIM BIOTECH GMBH

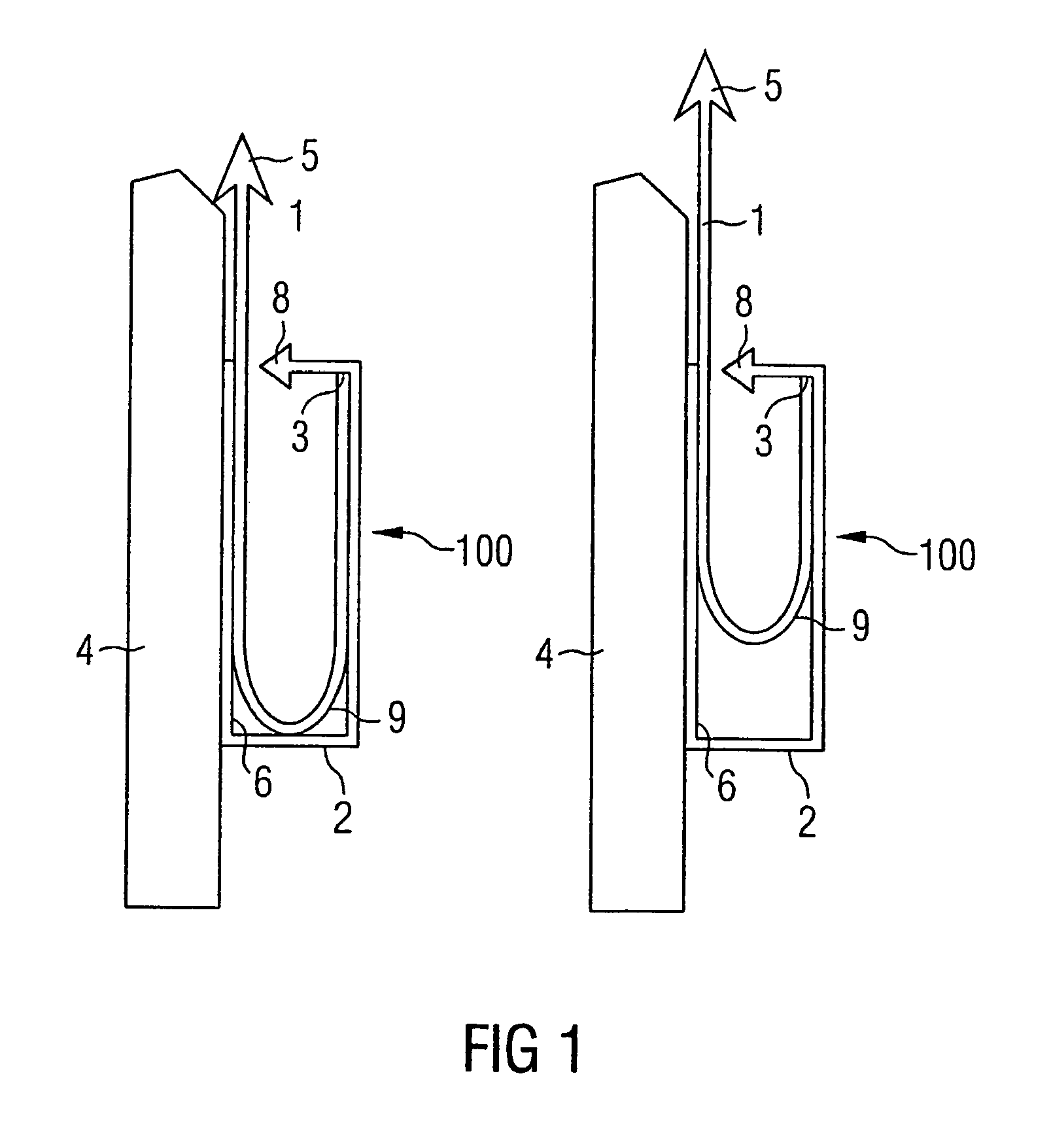

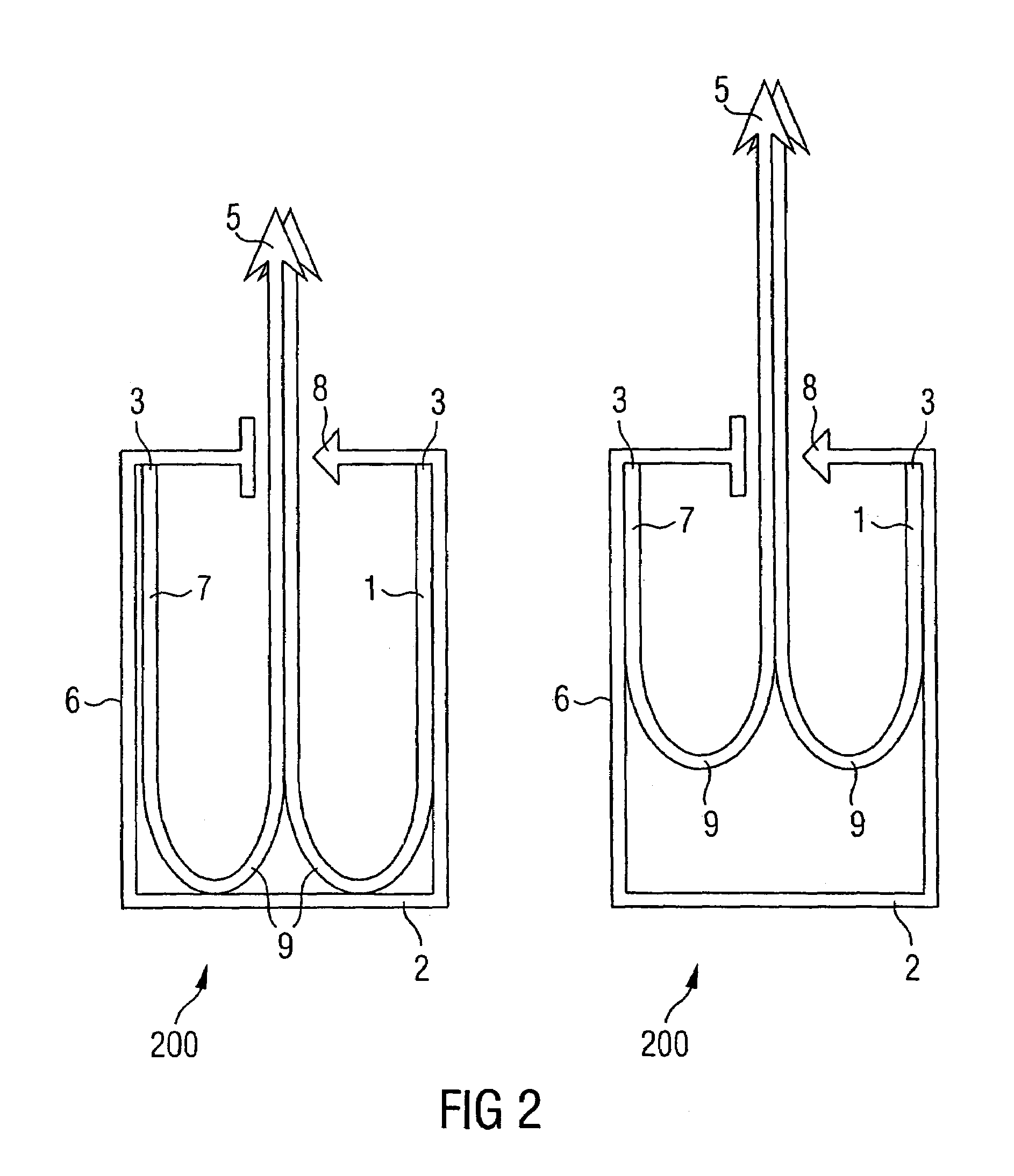

Steam generator

InactiveUS6868807B2Stable and reliable flowLow friction pressure lossWater circulationBoiler water tubesMechanical stabilityEngineering

A steam generator has a continuous heating surface located in a fuel gas channel that can be traversed in an approximately horizontal fuel gas directions. The continuous heating surface has a plurality of steam generator pipes that are connected in parallel for the passage of a flow medium and is designed in such a way that a steam generator pipe, which is heated to a greater extent than another steam generator pipe of the same continuous heating surface, has a higher throughput of the flow medium than the other steam generator pipe. The aim is to produce a low-cost steam generator with a particularly high level of mechanical stability, even when subjected to different thermal stresses. To achieve this, the or each steam generator pipe has a respective downpipe section, which is approximately vertical and through which the flow medium can flow downwards and a respective riser pipe section connected downstream of the downpipe on the flow medium side, which is approximately vertical and through which the flow medium can flow upwards.

Owner:SIEMENS AG

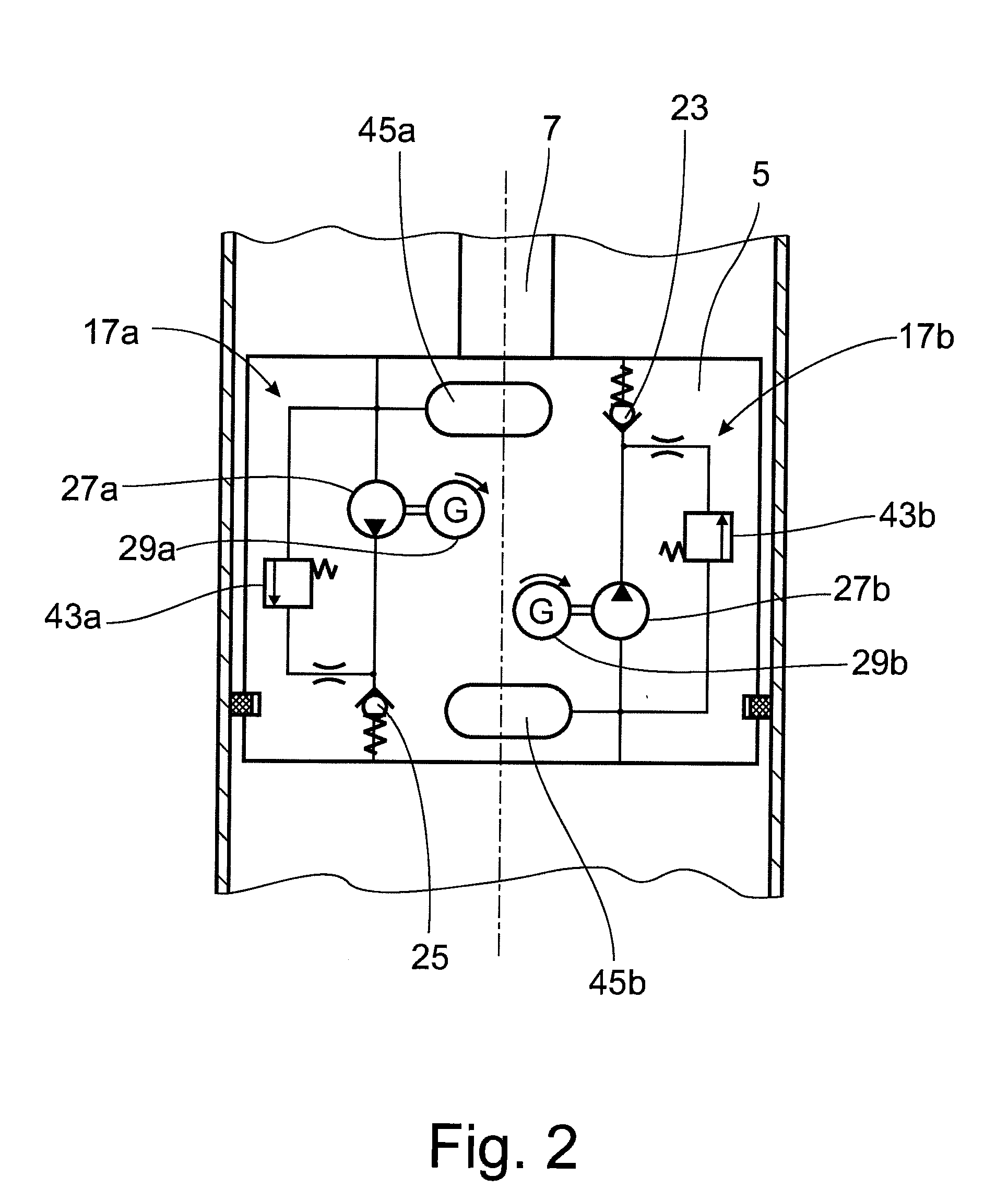

Energy-Recuperating Fluid Vibration Damper

InactiveUS20150192114A1Reduce mechanical loadUniform driving of the fluid motorSpringsMachines/enginesEnergy recoveryControl theory

Energy-recuperating vibration damper having a cylinder in which a displacer executes a limited operating movement in a working chamber so that a pressurized fluid is supplied to a fluid motor which drives a generator. A compensation chamber compensates for a change in volume of the pressurized fluid. A pressure accumulator is provided in addition to the compensation chamber, which pressure accumulator communicates with and is parallel-connected to the fluid motor.

Owner:ZF FRIEDRICHSHAFEN AG

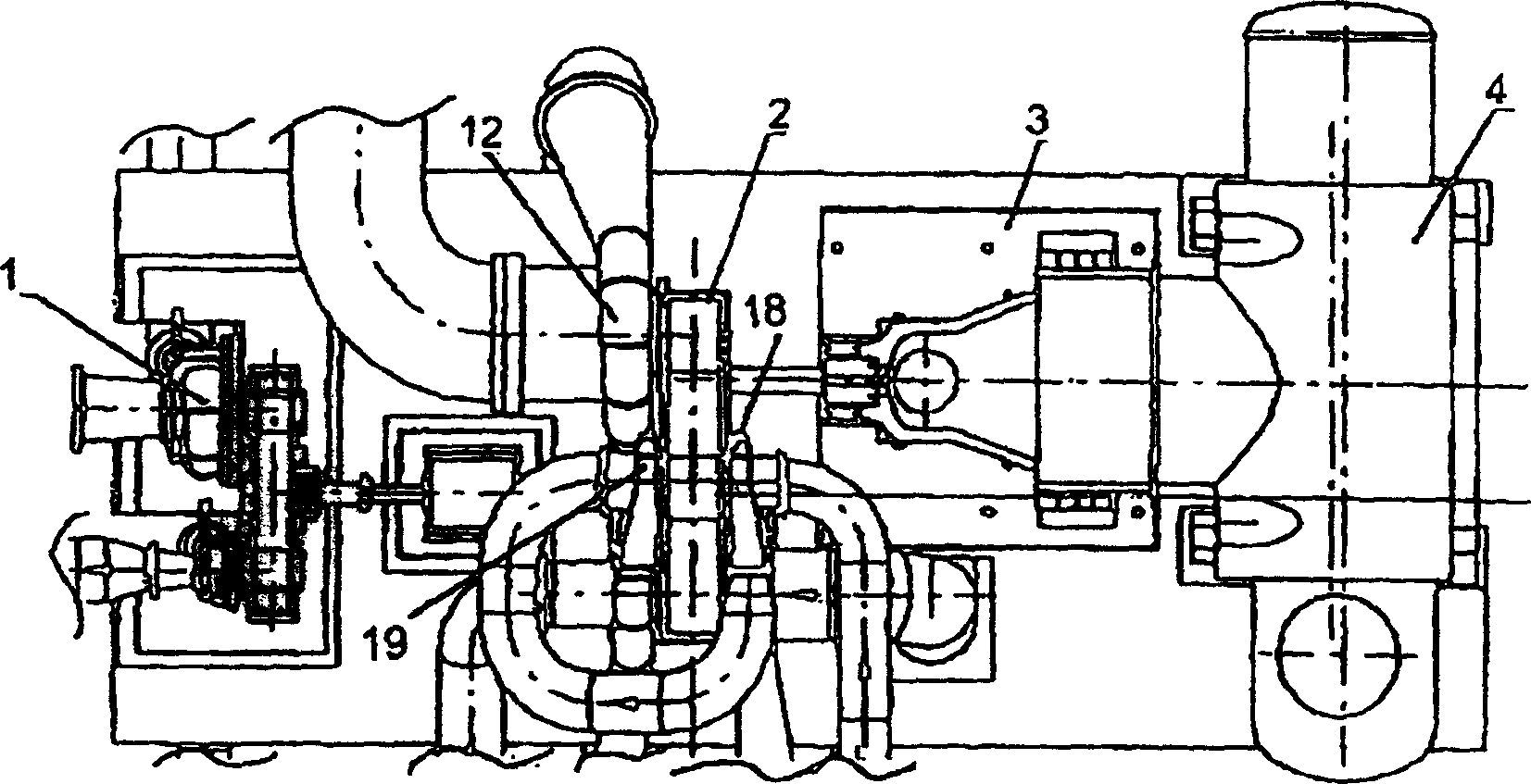

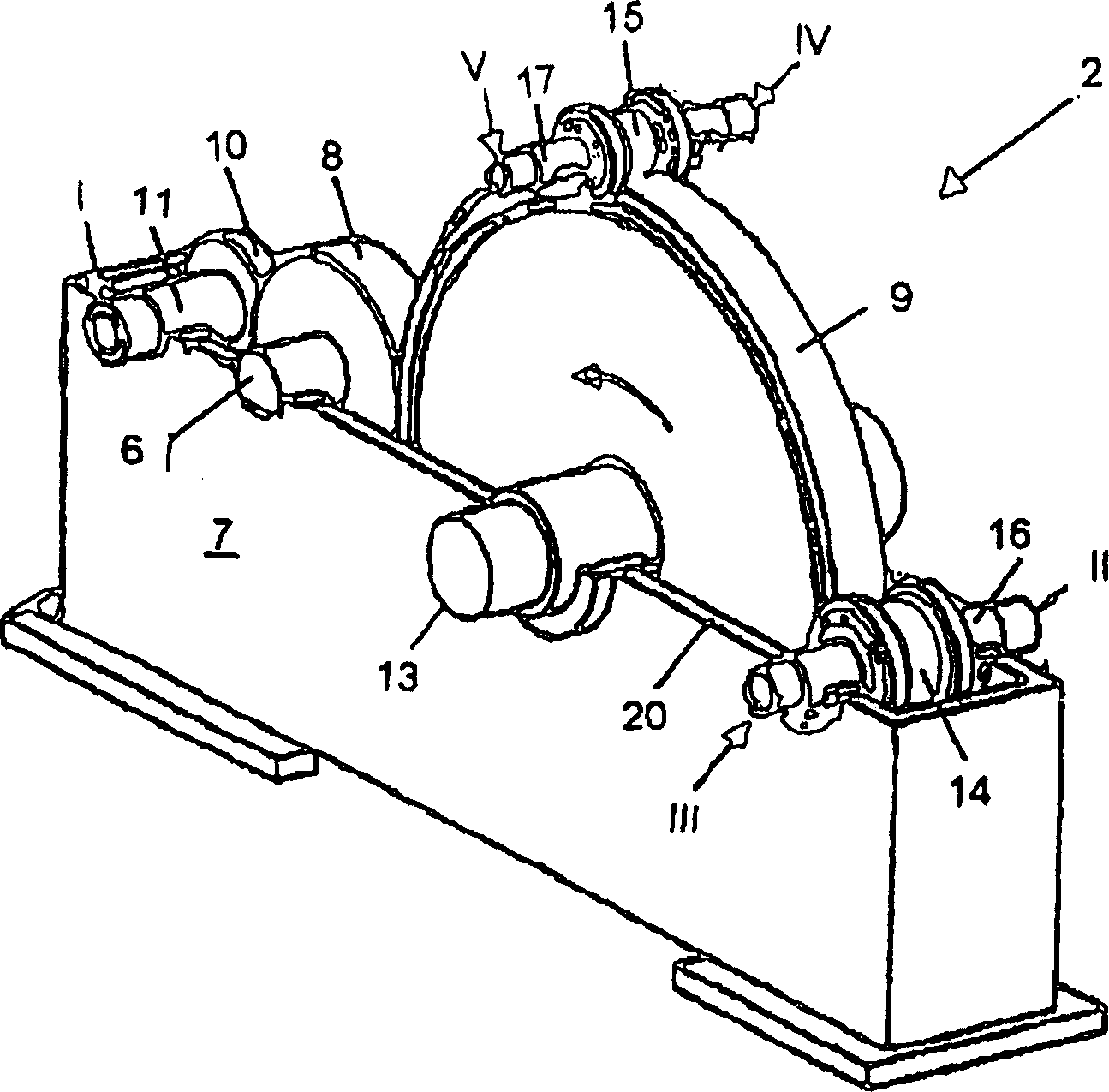

Multistage turbocompressor

ActiveCN1811194AReduce volumeEasy to manufactureToothed gearingsPump installationsPinionMechanical engineering

The turbocompressor has a geared compressor (2) with an integrated gear including a central greater wheel (9). The gear has a set of pinions that meshes with the greater wheel, where each pinion is mounted in a manner to rotate in unison with a respective pinion shaft. A set of bladed wheels respectively of one of a set of compressor stages, and a base frame on which individual units are assembled by a common central plane.

Owner:MAN ENERGY SOLUTIONS SA

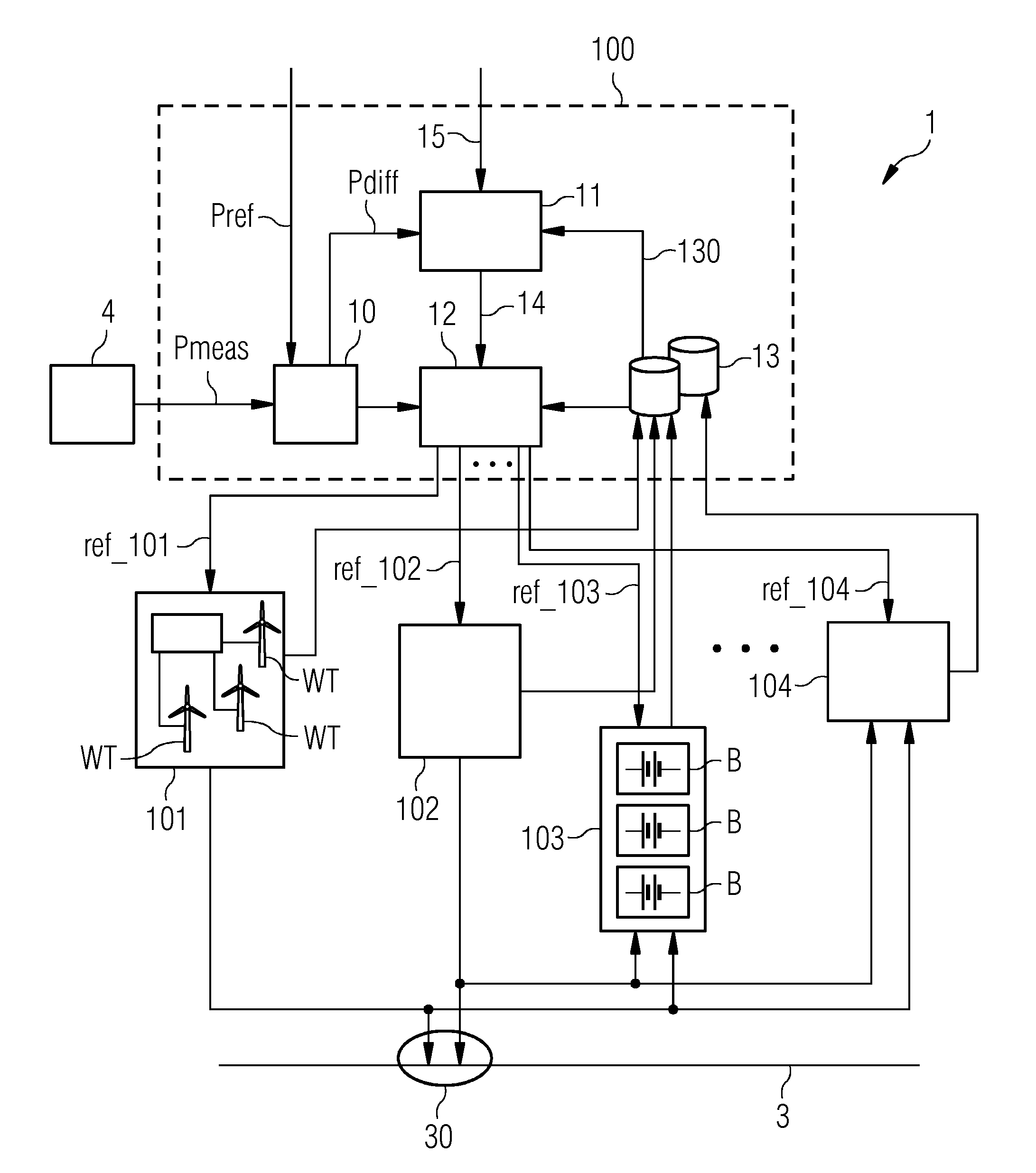

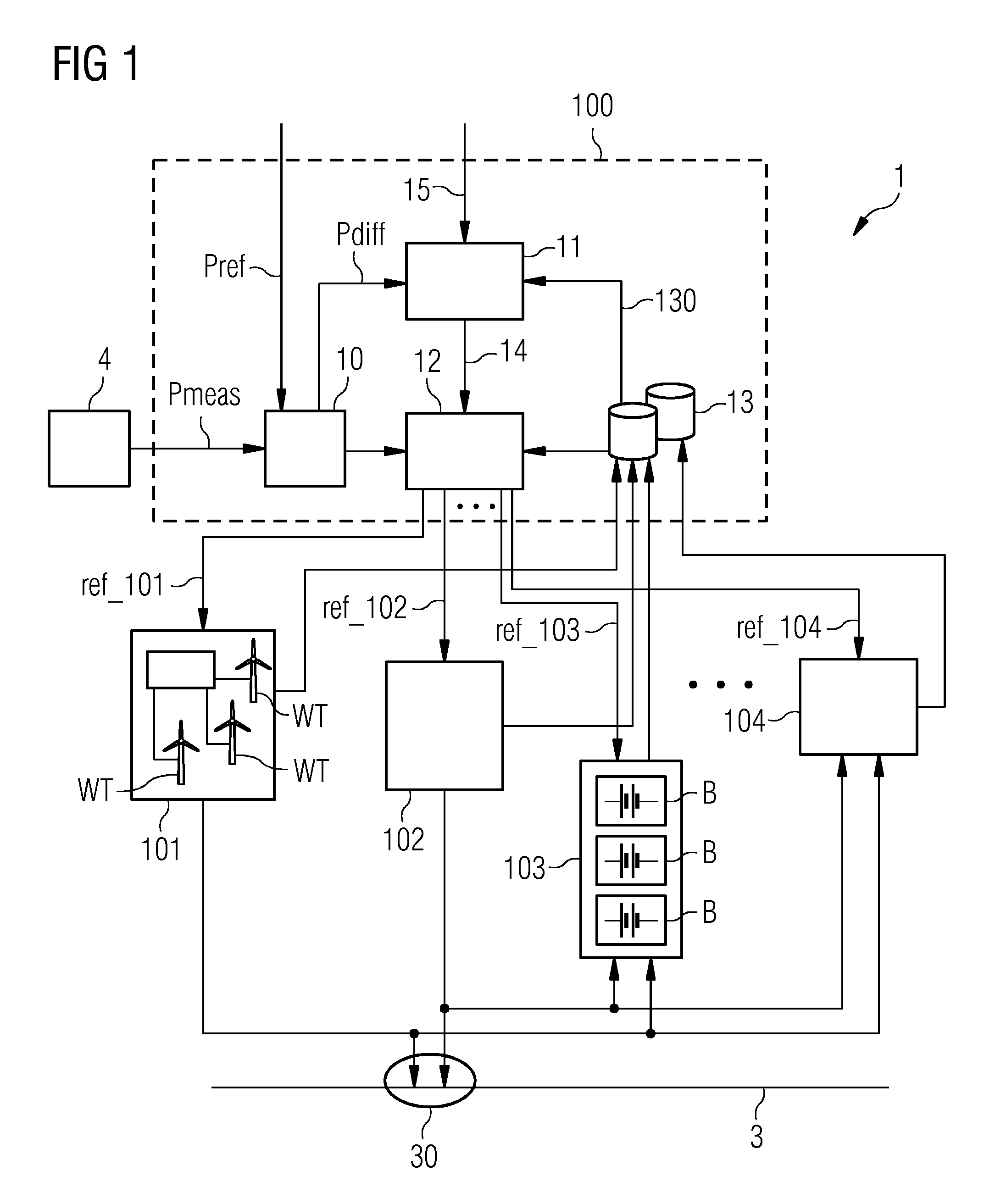

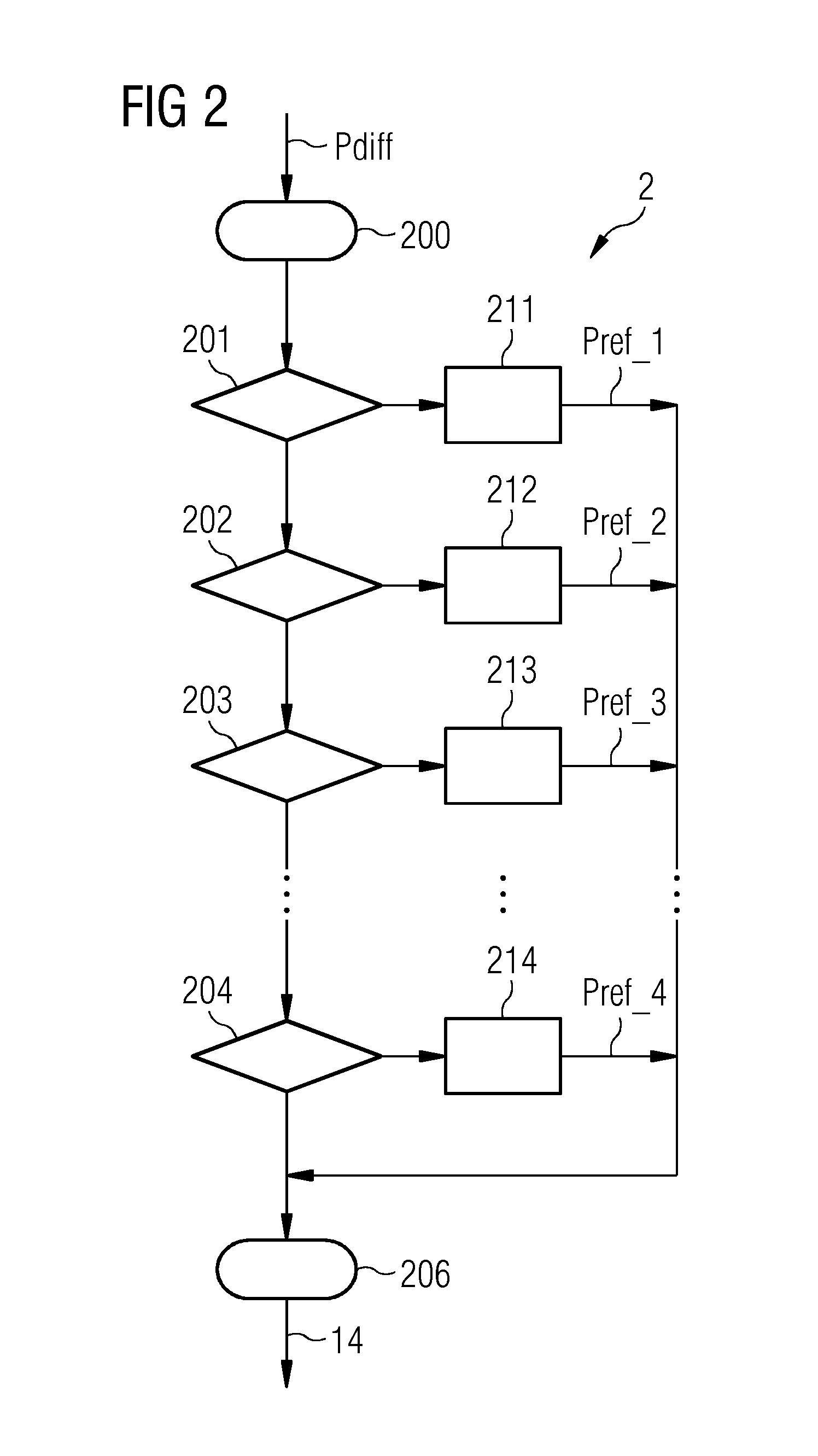

Method of controlling a power plant

InactiveUS20140142776A1Increase levelReduce mechanical loadMechanical power/torque controlBatteries circuit arrangementsPower storageNuclear engineering

A method of controlling a power plant connected at a point of connection to an electricity grid is provided. The power plant includes a renewable power production facility connected to a power storage facility. The method includes determining an active power grid demand of the electricity grid, obtaining operating data for the renewable power production facility and the power storage facility, determining, on the basis of the grid demand and the operating data, active power transfer quantities to be transferred between the renewable power production facility and the power storage facility and / or from the power plant facility to the grid, computing active power references for the facility of the power plant on the basis of the active power transfer quantities, and operating the power plant facility on the basis of the active power references. Further, a plant controller for controlling such a power plant and a power plant are provided.

Owner:SIEMENS AG

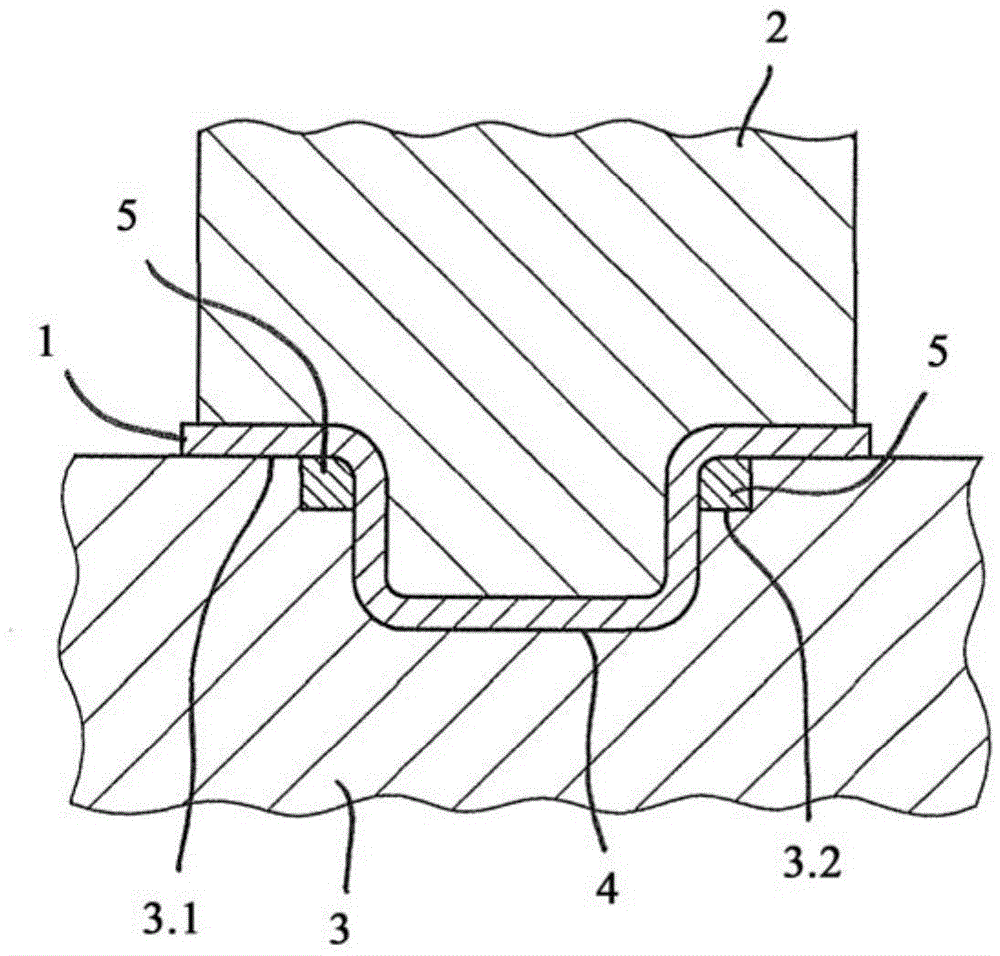

Sliding Fit, Pipe Arrangement And Exhaust Gas Treatment Device

ActiveUS20090158721A1Reduce mechanical loadReduce componentsSilencing apparatusAdjustable jointsExhaust gasExhaust fumes

The present invention relates to a sliding fit for the axially movable bearing of a thermally loaded pipe on a component, in particular on an exhaust system of an internal combustion engine, having a wire mesh which is radially supported on the outside of the pipe and is secured directly or indirectly to the component.

Owner:PUREM GMBH

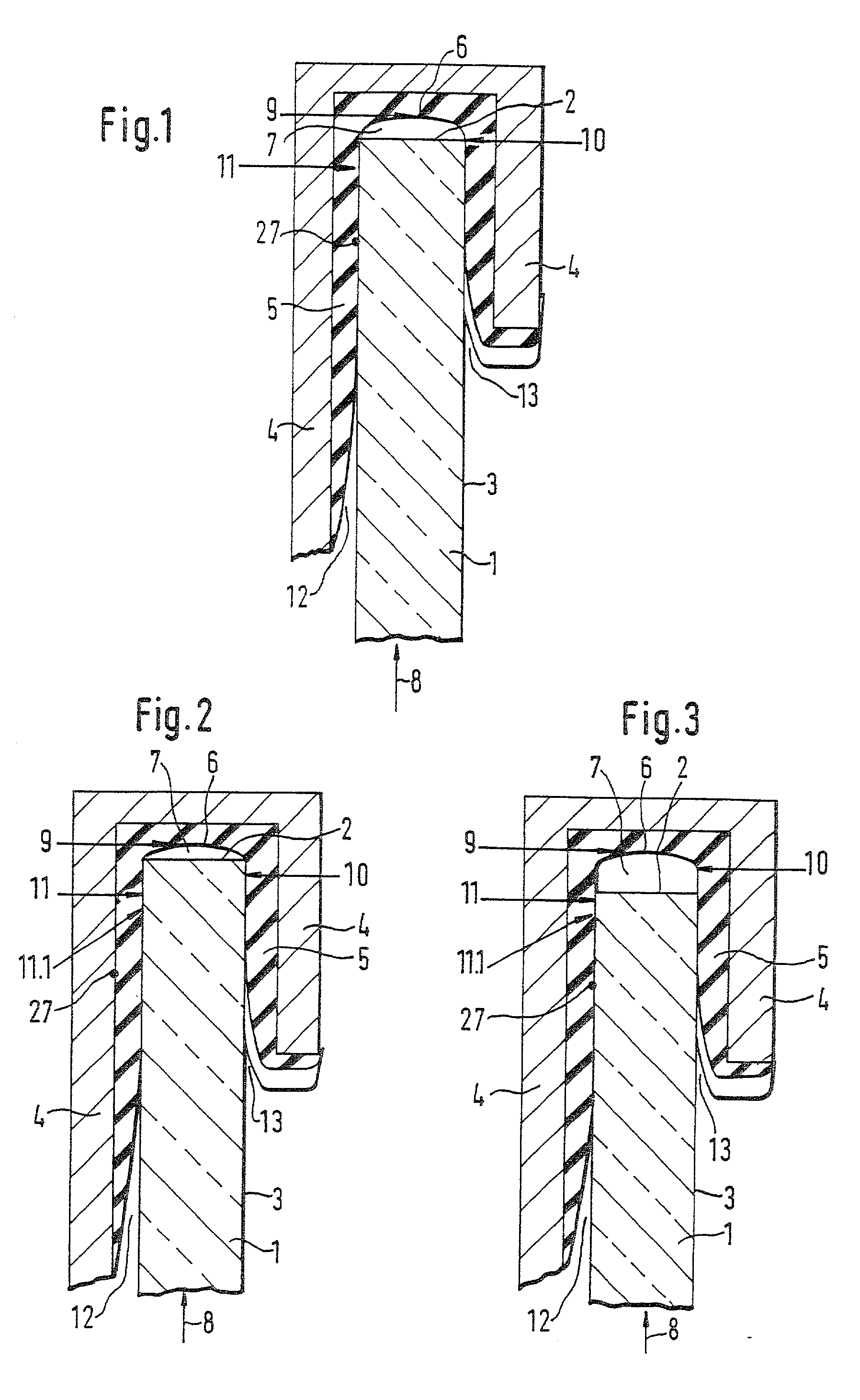

Method for positioning a closing surface which is actuated by an external force

InactiveUS20020152013A1Reduce mechanical loadReduced usabilityProgramme controlWindowsControl signalEngineering

The invention is based on a method for the contactless approaching of an upper stop position (A) outfitted with a seal (5) by a window pane (1) of a motor vehicle actuated by external force. When an upper window-pane edge (2) approaches the stop position (A), a control signal is generated by a control unit (26), by way of which the electric drive is switched off in a shutoff position (11) pa, and / or its driving direction is reversed, so that the upper window-pane edge (2) comes to a standstill at a zero position (10) p0. When the window pane (1) approaches the stop position (A), system parameters (S1 . . . Sn) are detected by sensors (27) and stored in a memory (28). A system state SZ (S1-Sn) dependent on the system parameters (S1 . . . Sn) is read out with the shutoff position (11) pa from a characteristic diagram. A difference DELTASZ is determined by comparing the respective current system states (SZcur (S1-Sn) and the reference system state SZref (S1 . . . Sn) stored in the memory (28). A new shutoff position (11.1) panew is calculated based on the deviation DELTASZ determined.

Owner:ROBERT BOSCH GMBH

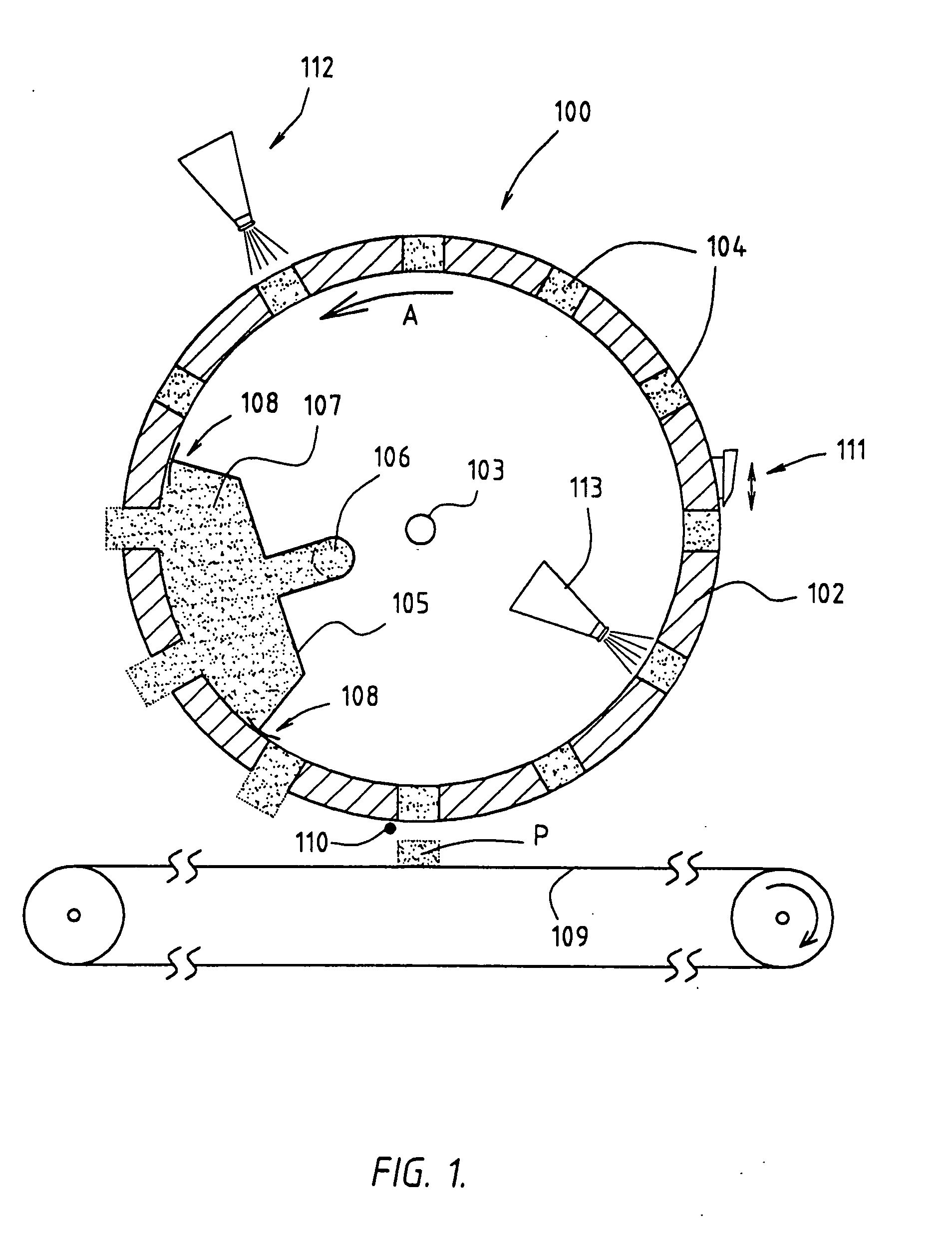

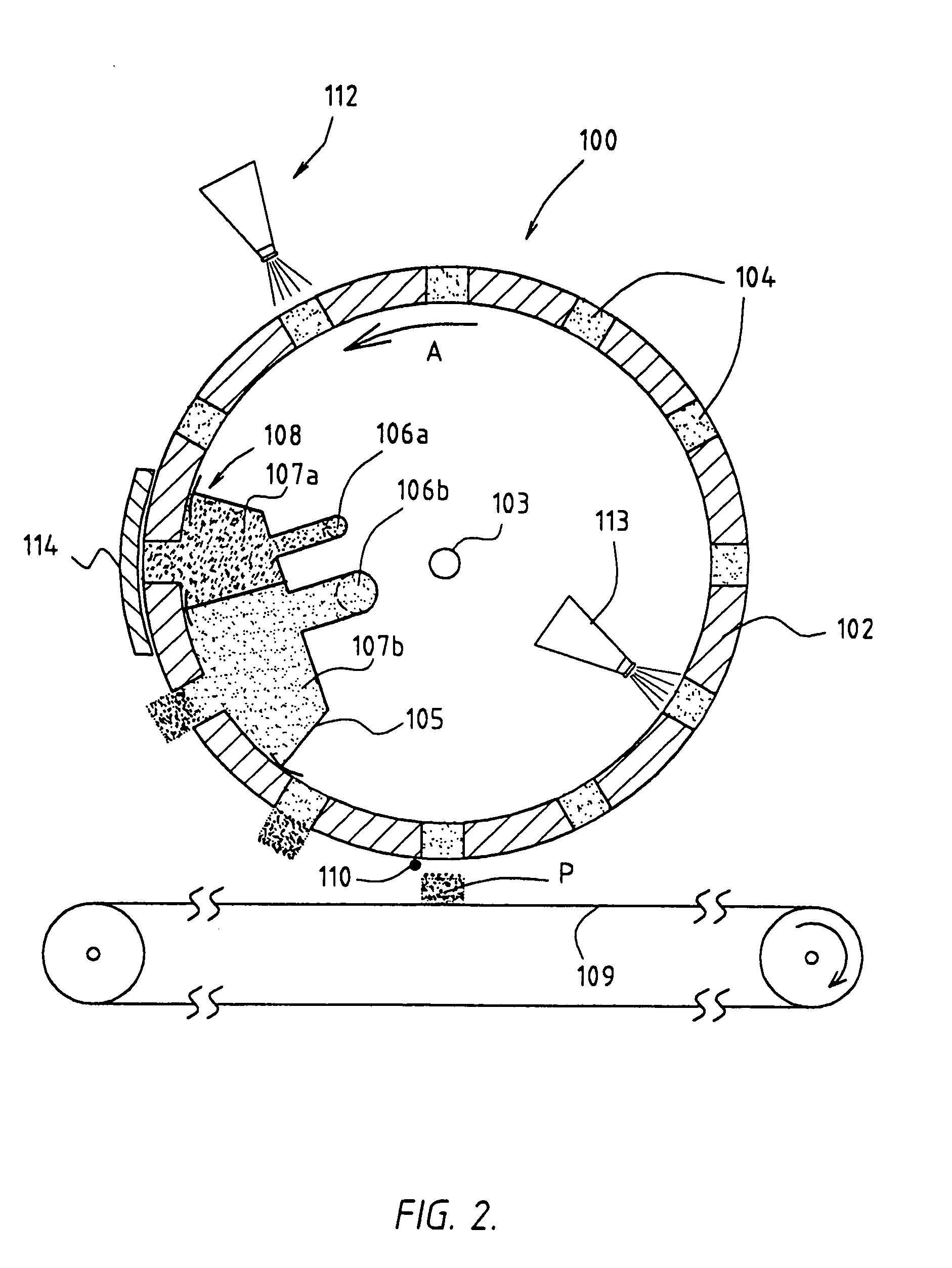

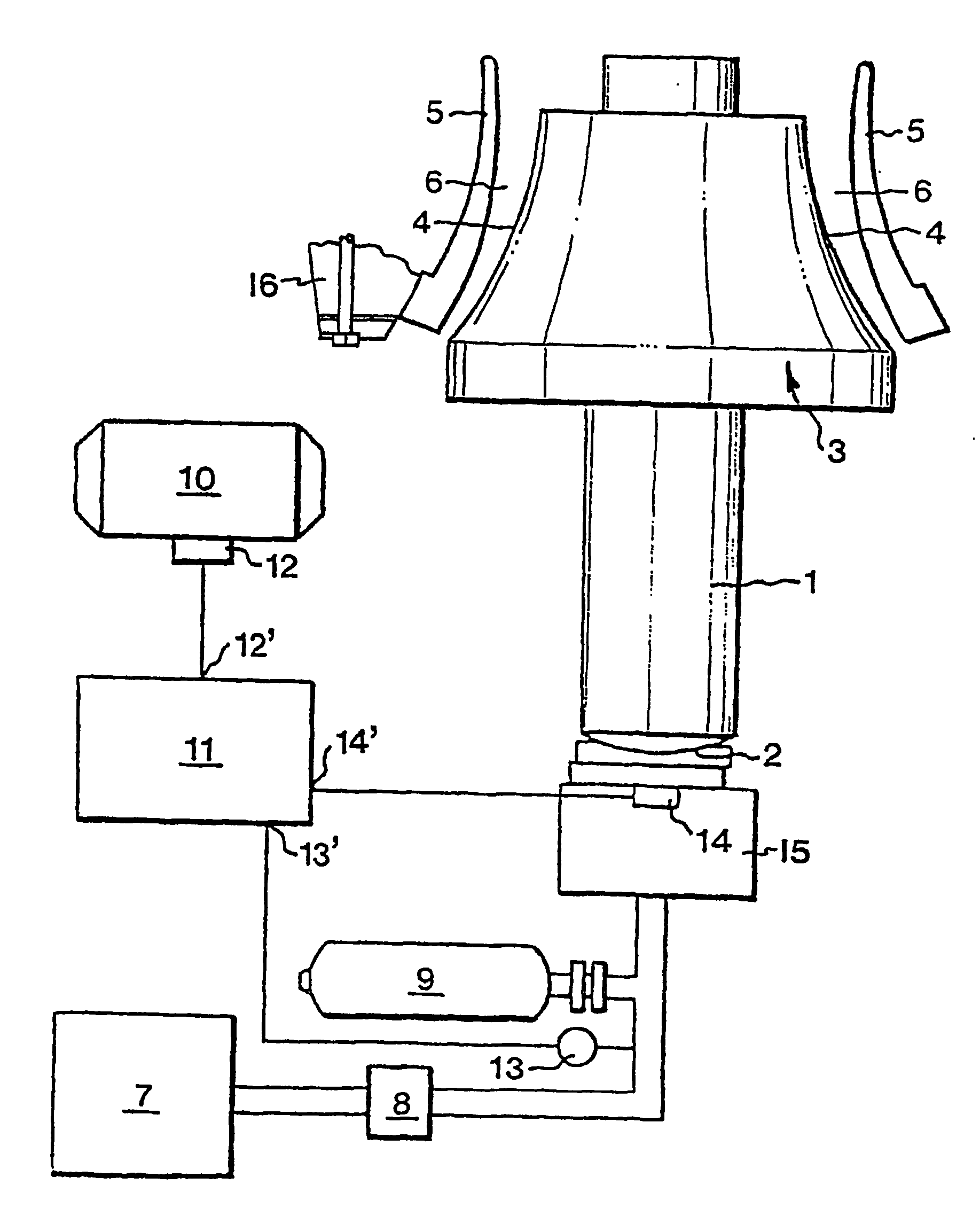

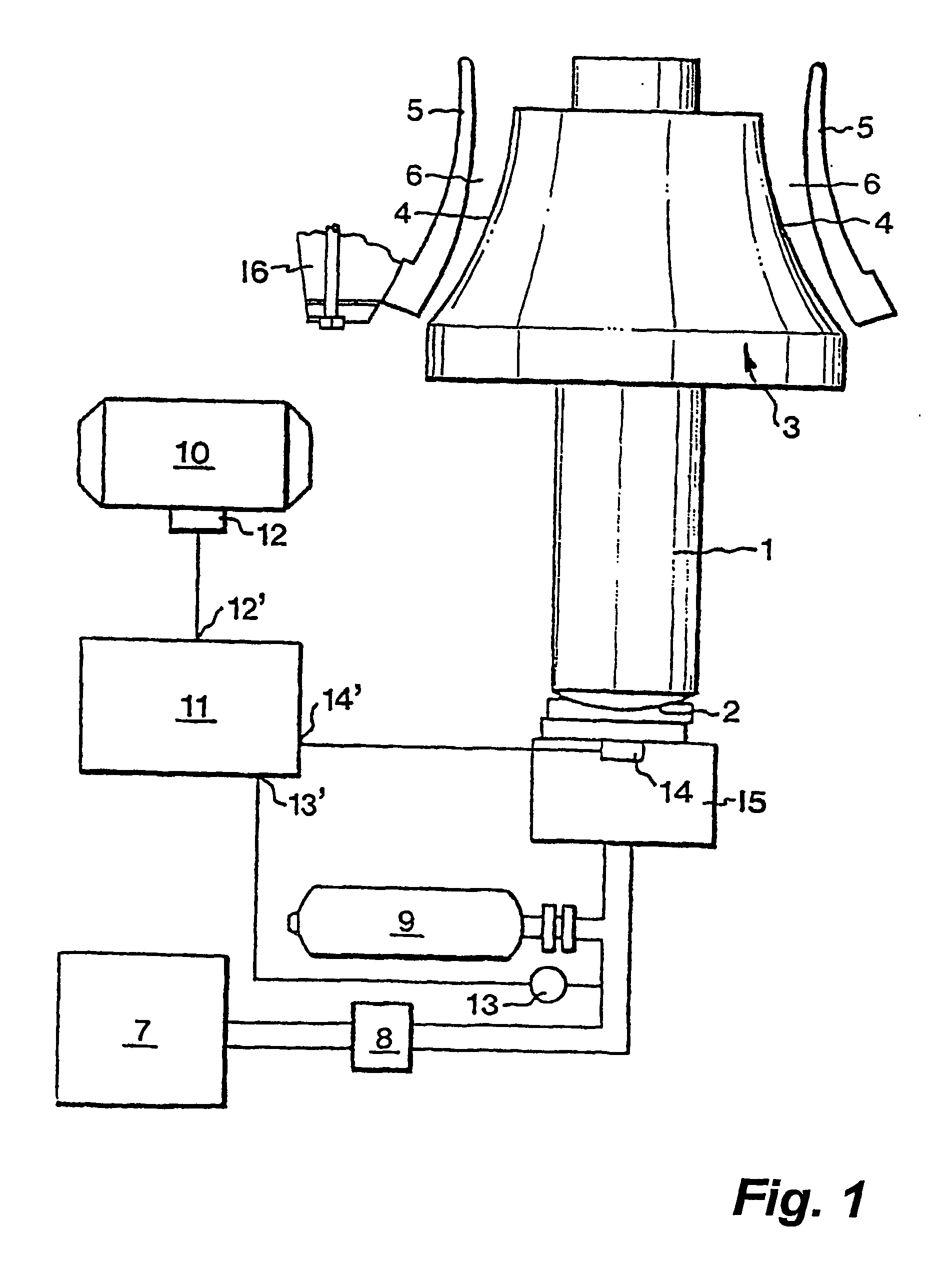

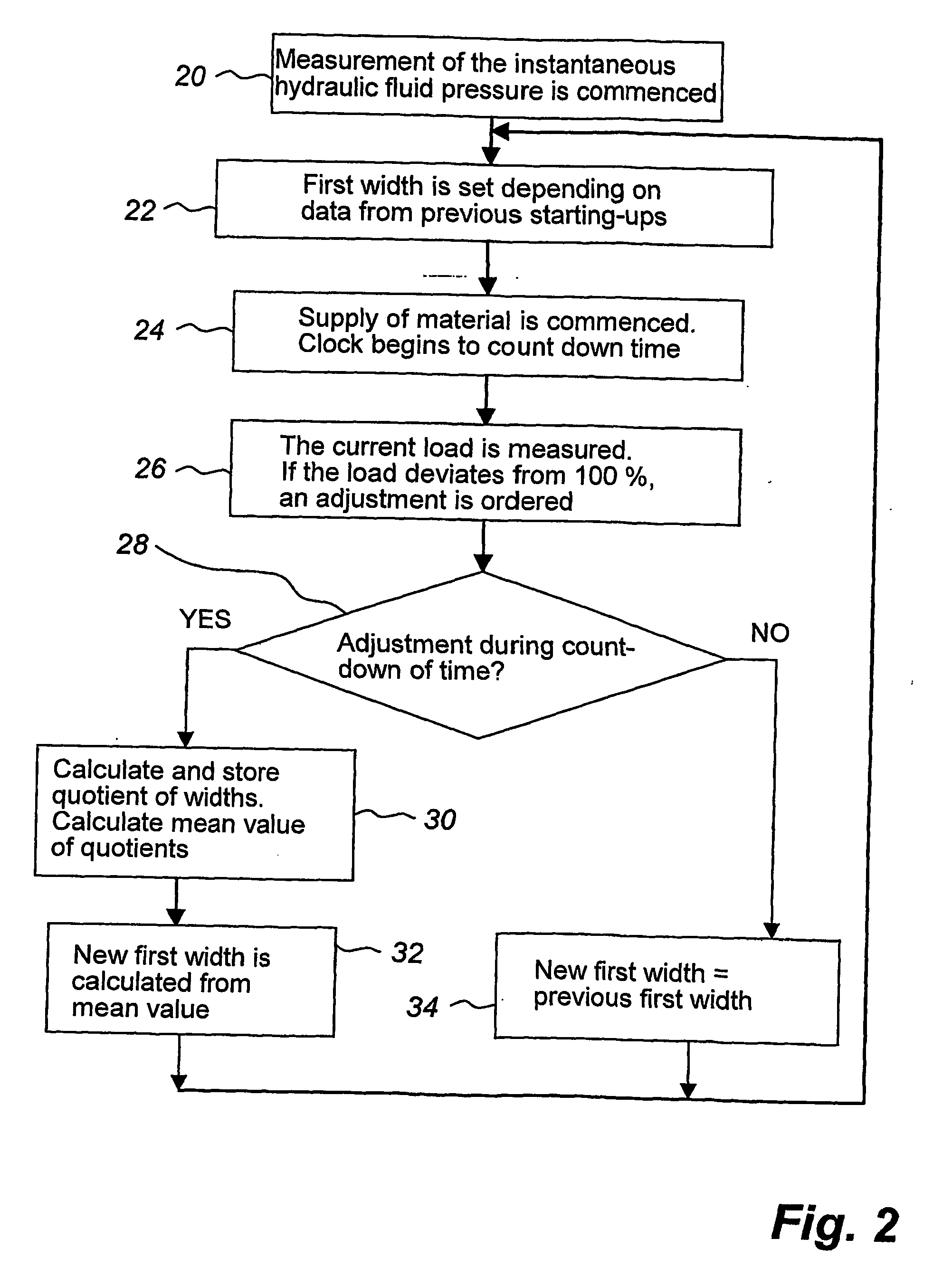

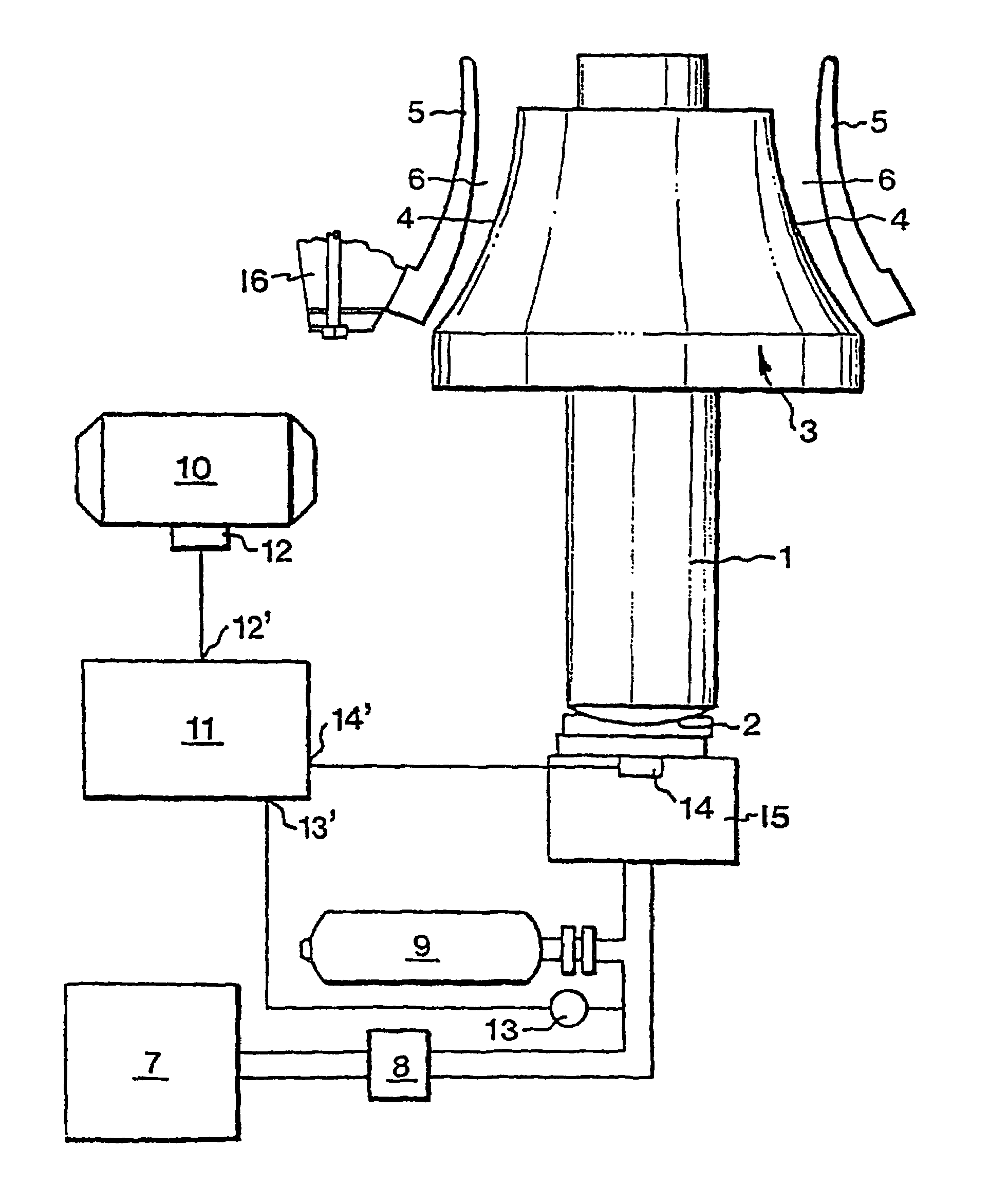

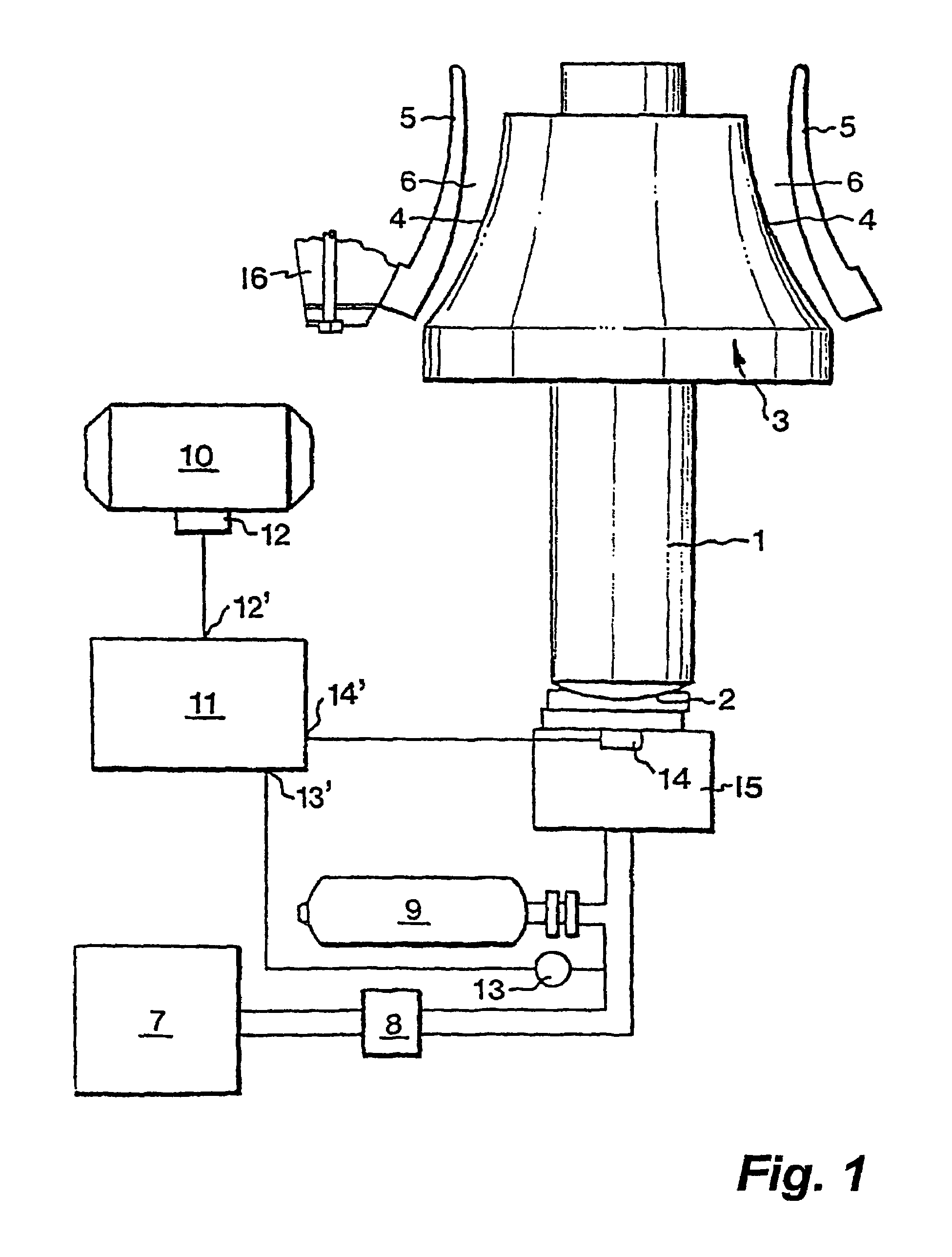

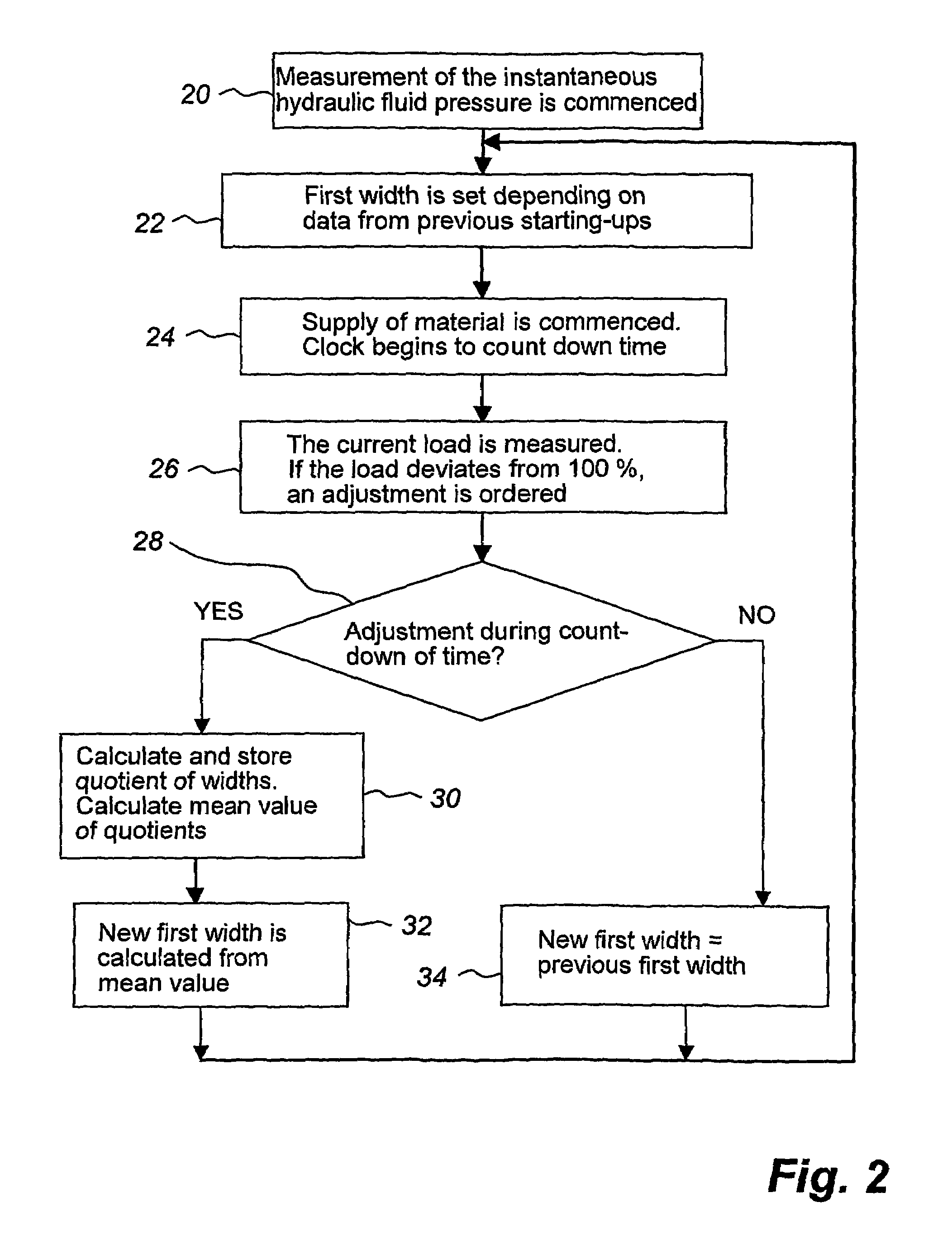

Method and control system for starting crushing in a gyratory crusher

InactiveUS20060231650A1Reduce mechanical loadImprove efficiencyCocoaGrain treatmentsControl systemEngineering

In a method for starting a crushing operation in a gyratory crusher in which rocks are passed through a crushing gap to be crushed, the following steps are carried out: (a) a driving device is started which causes a crushing head to execute a gyratory pendulum movement, and a first width of the crushing gap is set, (b) a supply of material to the gap is commenced, (c) the resulting load on the crusher is measured, (d) the width of the gap is adjusted so that the load approaches a desired value, (e) a measure which is representative of the width of the gap after adjustment, is read, and (f) such read measure is utilized for calculation of a gap width for use as a first width of the gap in carrying out step (a) of the next start-up of a crushing operation.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Method and control system for starting crushing in a gyratory crusher

InactiveUS7360726B2Reduce mechanical loadImprove efficiencyCocoaGrain treatmentsControl systemStructural engineering

In a method for starting a crushing operation in a gyratory crusher in which rocks are passed through a crushing gap to be crushed, the following steps are carried out: (a) a driving device is started which causes a crushing head to execute a gyratory pendulum movement, and a first width of the crushing gap is set, (b) a supply of material to the gap is commenced, (c) the resulting load on the crusher is measured, (d) the width of the gap is adjusted so that the load approaches a desired value, (e) a measure which is representative of the width of the gap after adjustment, is read, and (f) such read measure is utilized for calculation of a gap width for use as a first width of the gap in carrying out step (a) of the next start-up of a crushing operation.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

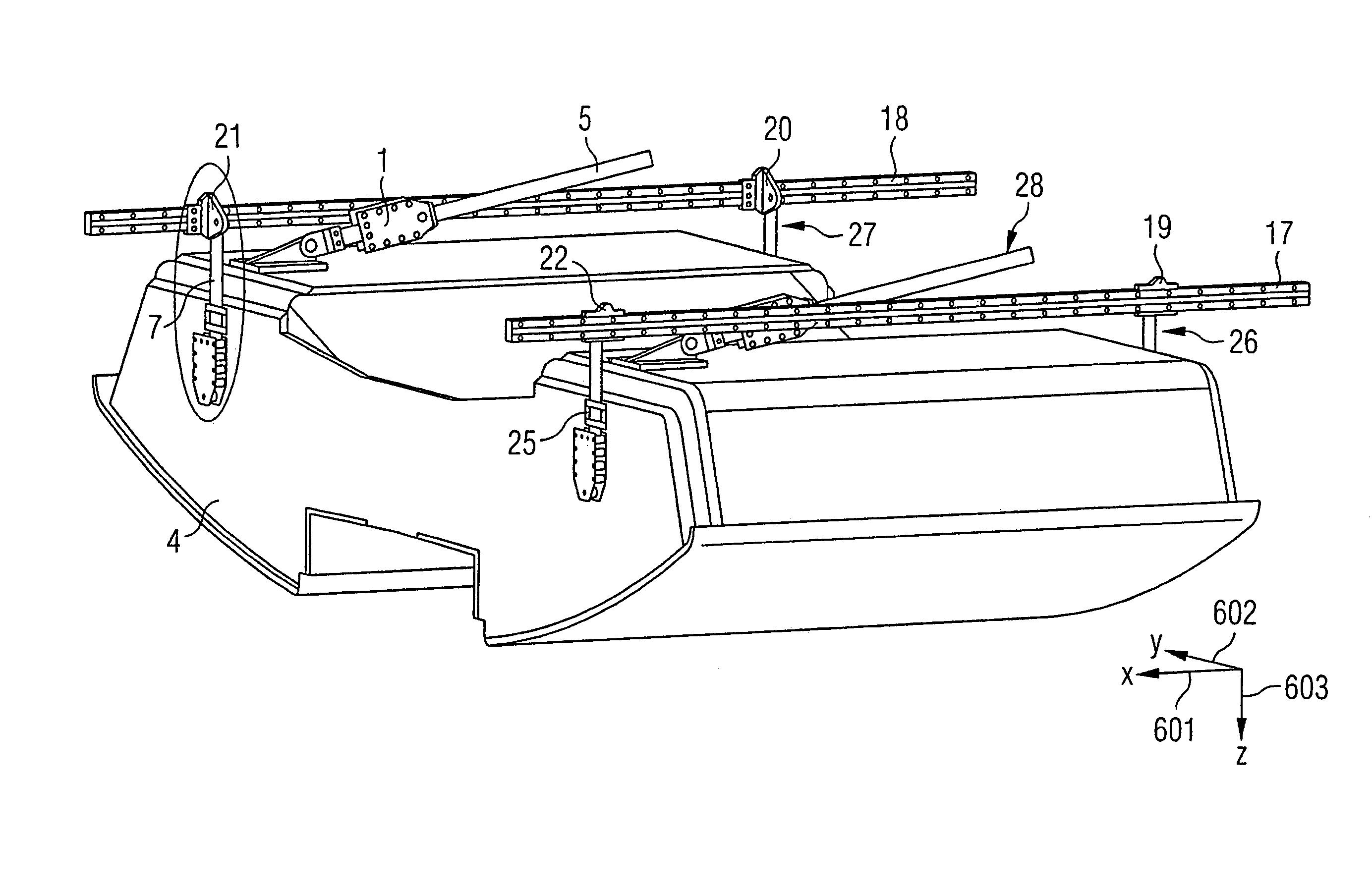

Mounting device for interior equipment in aircraft

InactiveUS7527221B2Control loadImprove passive safetyAir-treatment apparatus arrangementsWeight reductionFlight vehicleAirplane

A mounting device for aircraft comprises an energy absorber and wherein the mounting device is mounted between a primary structure of the aircraft and the interior equipment. In this way the load acting on an interior equipment connected to the primary structure of the aircraft by way of the mounting device can be limited if a crash impulse occurs. The load acting on the primary structure is also limited, which can result in enhanced passive safety for the passengers and in weight reduction.

Owner:AIRBUS OPERATIONS GMBH

Encapsulated multi-phase electronics heat sink

ActiveUS20070285892A1Load minimizationPromote fluid circulationSemiconductor/solid-state device detailsPrinted circuit aspectsMulti phaseMetal

An apparatus and method for cooling electronics is disclosed. An encapsulated inert non-conductive fluid is used to transfer heat directly from an electrical circuit including a die on a substrate to an external heatsink. The top of a flip chip die (e.g. a ceramic column grid array flip chip) may be enclosed with a metallic cover. The metallic cover is sealed to an outer frame, which in turn is sealed to metallization on the top of the flip chip through a flexure, minimizing mechanical load imparted to the flip chip. This forms a hermetic cavity enclosing the die. This hermetic cavity is partially filled with an inert non conductive fluid, which vaporizes when heated. Condensation occurs on the inner surface of the metal cover where the heat may be conducted into the outer frame for removal (e.g. rejection from the spacecraft).

Owner:THE BOEING CO

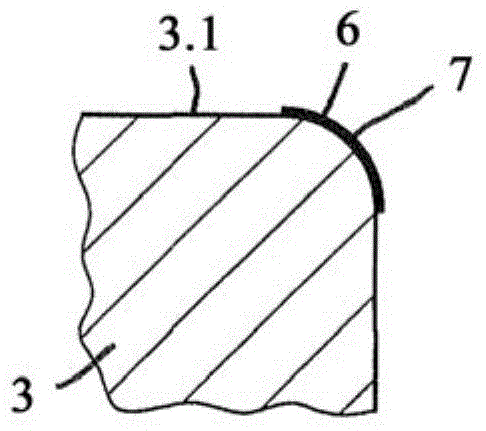

Method and forming tool for hot forming and press hardening work pieces made of sheet steel, in particular galvanized sheet steel

InactiveCN103958087AReduce or prevent damageReduce heat lossShaping toolsQuenching devicesSheet steelBond coating

The invention relates to a method for hot forming and press hardening plate-shaped or preformed workpieces made of sheet steel, in particular galvanized workpieces (1) made of sheet steel, in which the workpiece (1) is heated to a temperature exceeding the austenitizing temperature and subsequently formed and quenched in a cooled forming tool comprising a stamp (2) and a die (3), characterized in that the drawing edge region, which is defined by a positive die radius, of the die (3) used for hot forming and press hardening is provided with a materially bonded coating of a material (6, 6') and / or is provided with an insert (5) having a thermal conductivity that is lower than the thermal conductivity of section (3.1) of the die (3), which is adjacent to the drawing edge region, by at least 10 W / (m*K), which section comes into contact with the workpiece (1) during hot forming and press hardening of the same. The surface of the material (6, 6') applied to the drawing edge region and facing the workpiece (1) or the surface of the provided insert (5) has a lateral dimension extending across the drawing edge (7), which is in the range of 1.6 times to 10 times the positive die radius of the die (3). The invention also relates to a corresponding forming tool.

Owner:THYSSENKRUPP STEEL EURO AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com