Method and forming tool for hot forming and press hardening work pieces made of sheet steel, in particular galvanized sheet steel

A pressure quenching and forming mold technology, which is applied in the field of hot forming and pressure quenching of galvanized workpieces, and the field of forming molds for hot forming and pressure quenching of galvanized workpieces, and can solve problems such as component damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

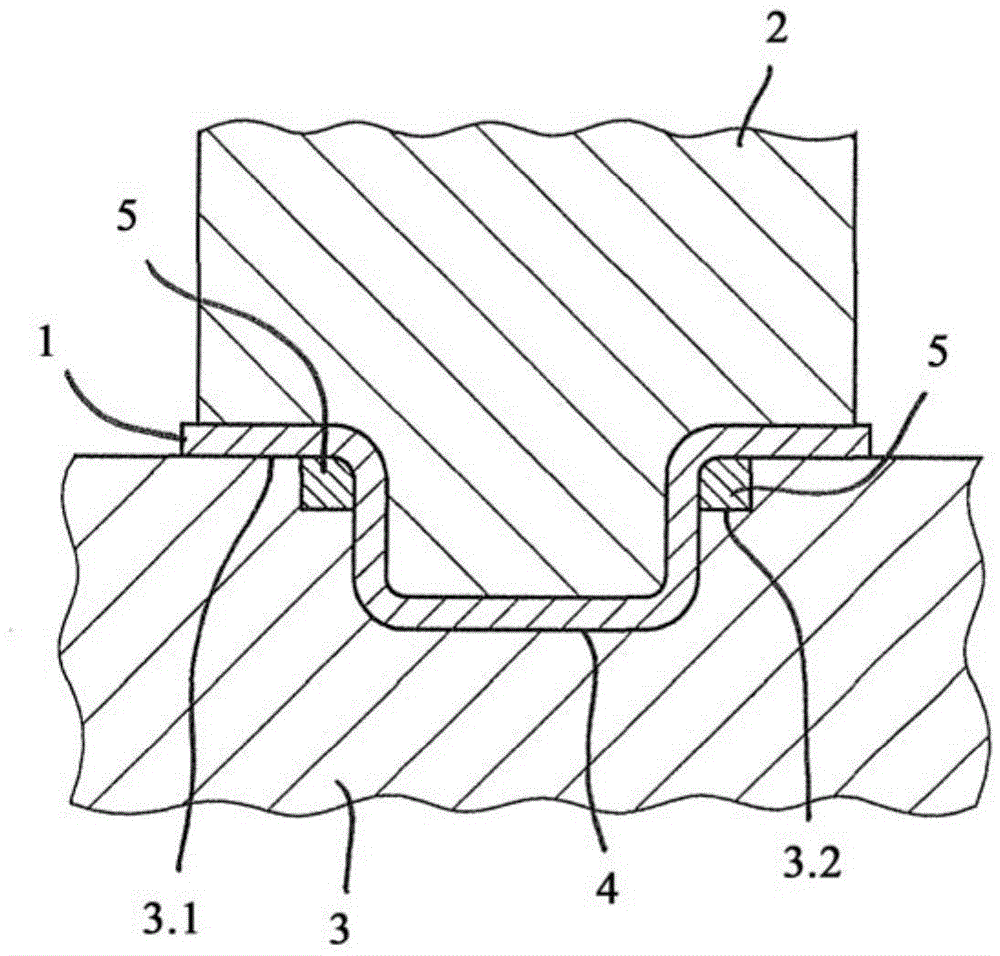

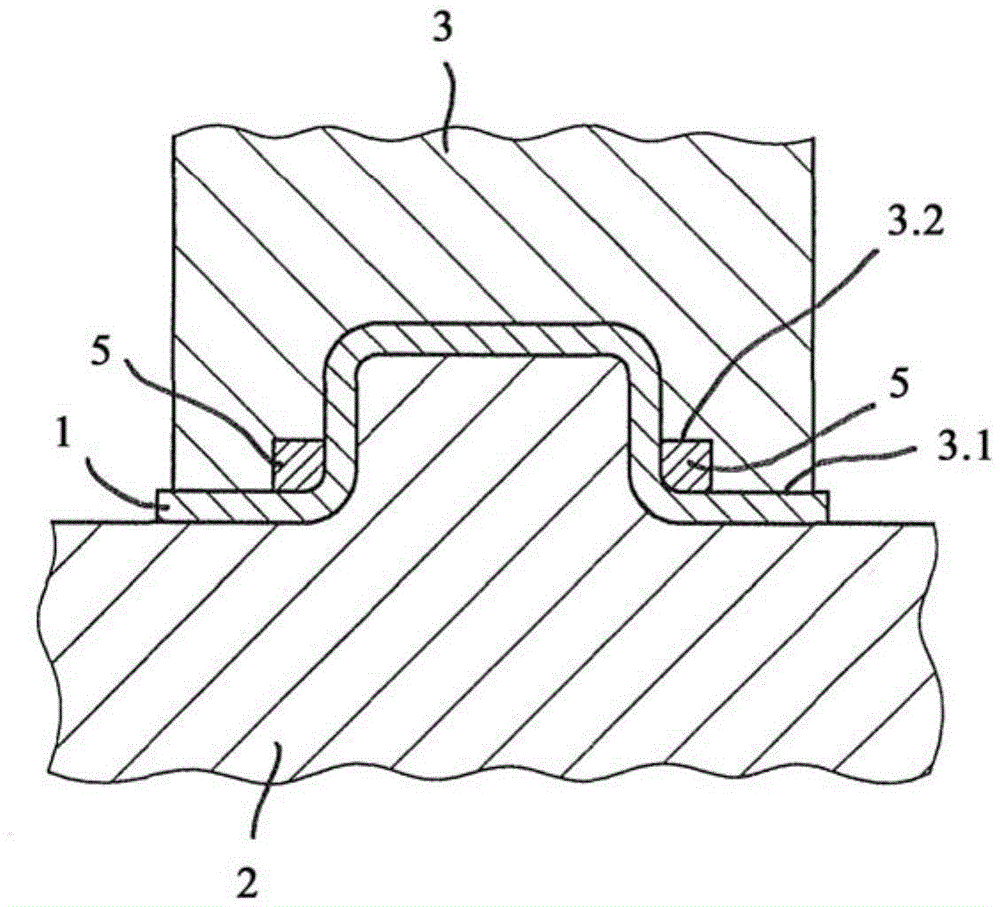

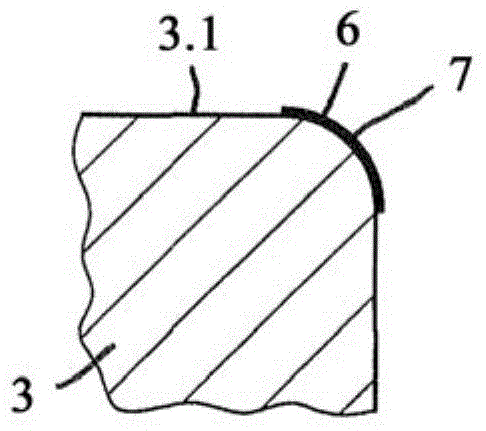

[0025] exist figure 1 with 2 shows a section of a cooled forming tool for hot forming and press hardening a sheet-shaped or prefabricated workpiece 1 made of steel sheet, in particular a galvanized workpiece made of sheet steel. The positive mold is indicated by reference numeral 2 , and the female mold (casting mold) of each forming die is indicated by reference numeral 3 . also, figure 1 and / or figure 2 The forming tool shown in can optionally have a hold-down device (binder tool) which presses against the die 3 during the forming of the workpiece 1 . However, the forming tool according to the invention is preferably formed as a forming tool without a blanking tool (without a hold-down device).

[0026] The female mold (casting mold) 3 contains a cavity 4 into which the male mold 2 enters during the shaping and deep drawing of the workpiece 1 . figure 1 with 2 The individual forming tools, which contain the formed workpiece 1 , are shown in each closed state.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com