Patents

Literature

272 results about "Bond coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bond coating is a technological breakthrough that solves the problem of bonding rubber to switches made of polyester. Before bond coating, keypads and switches were bonded mechanically, which is a far more expensive and time consuming method.

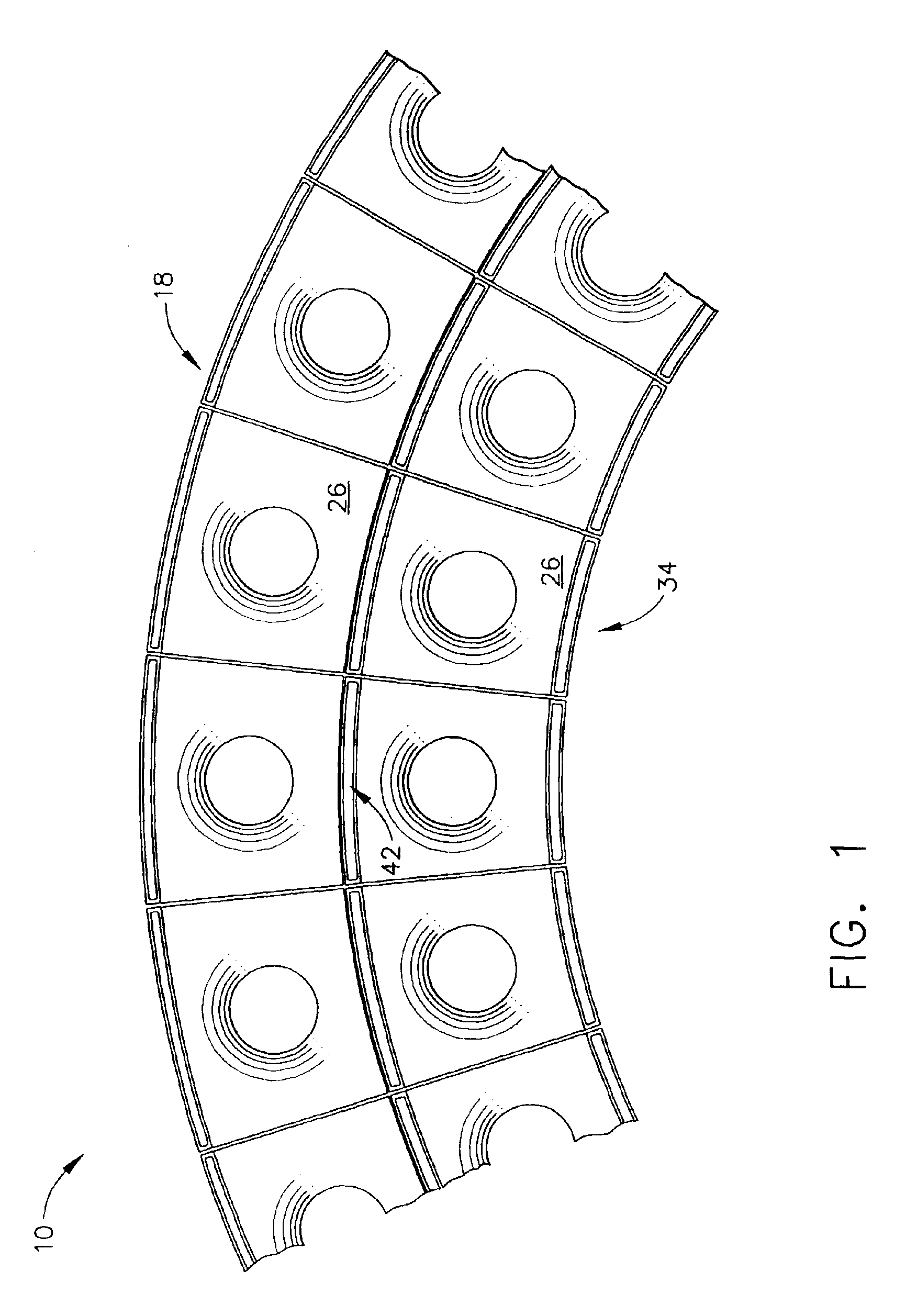

Apparatus and method for applying antifoulants to marine vessels

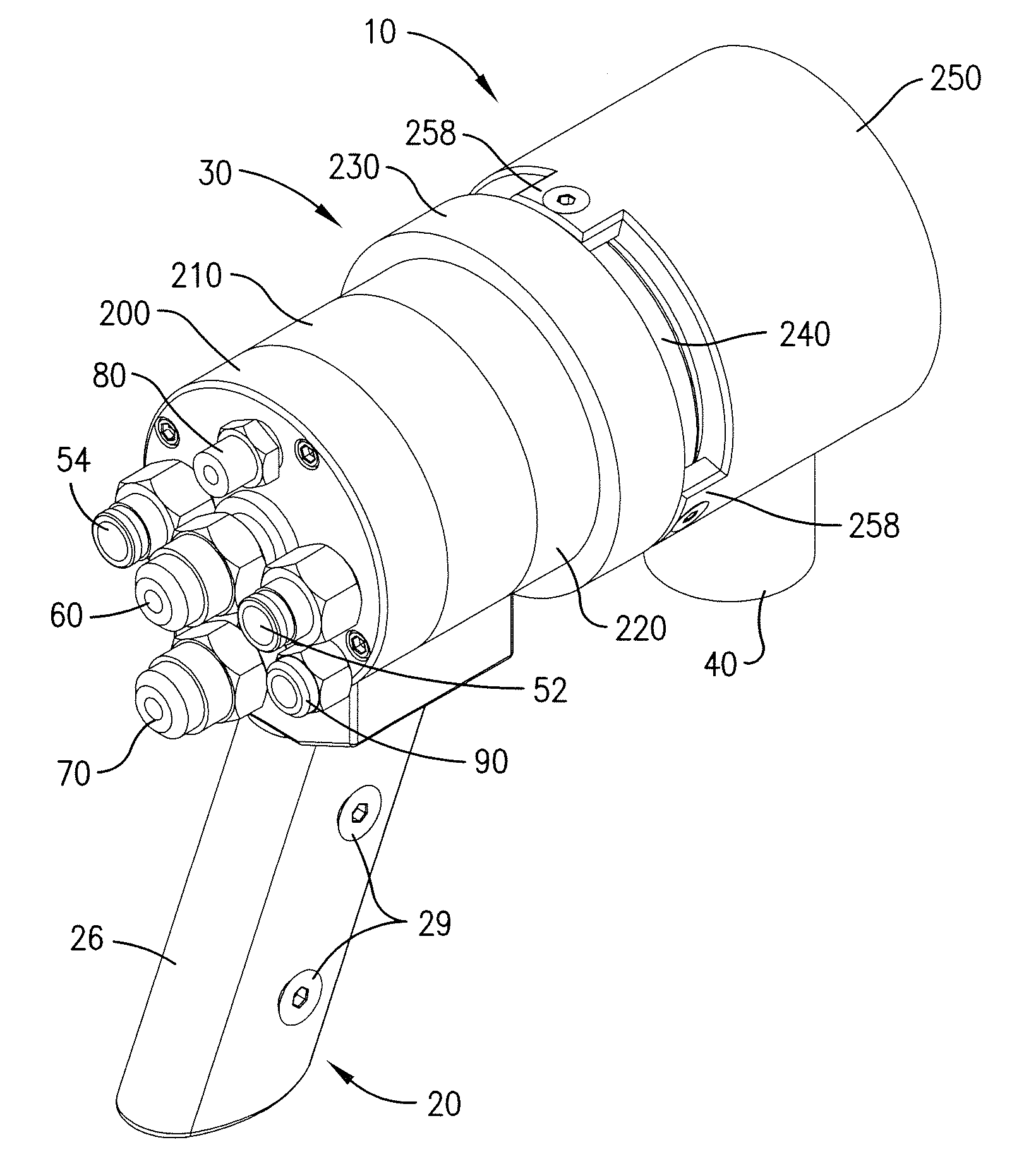

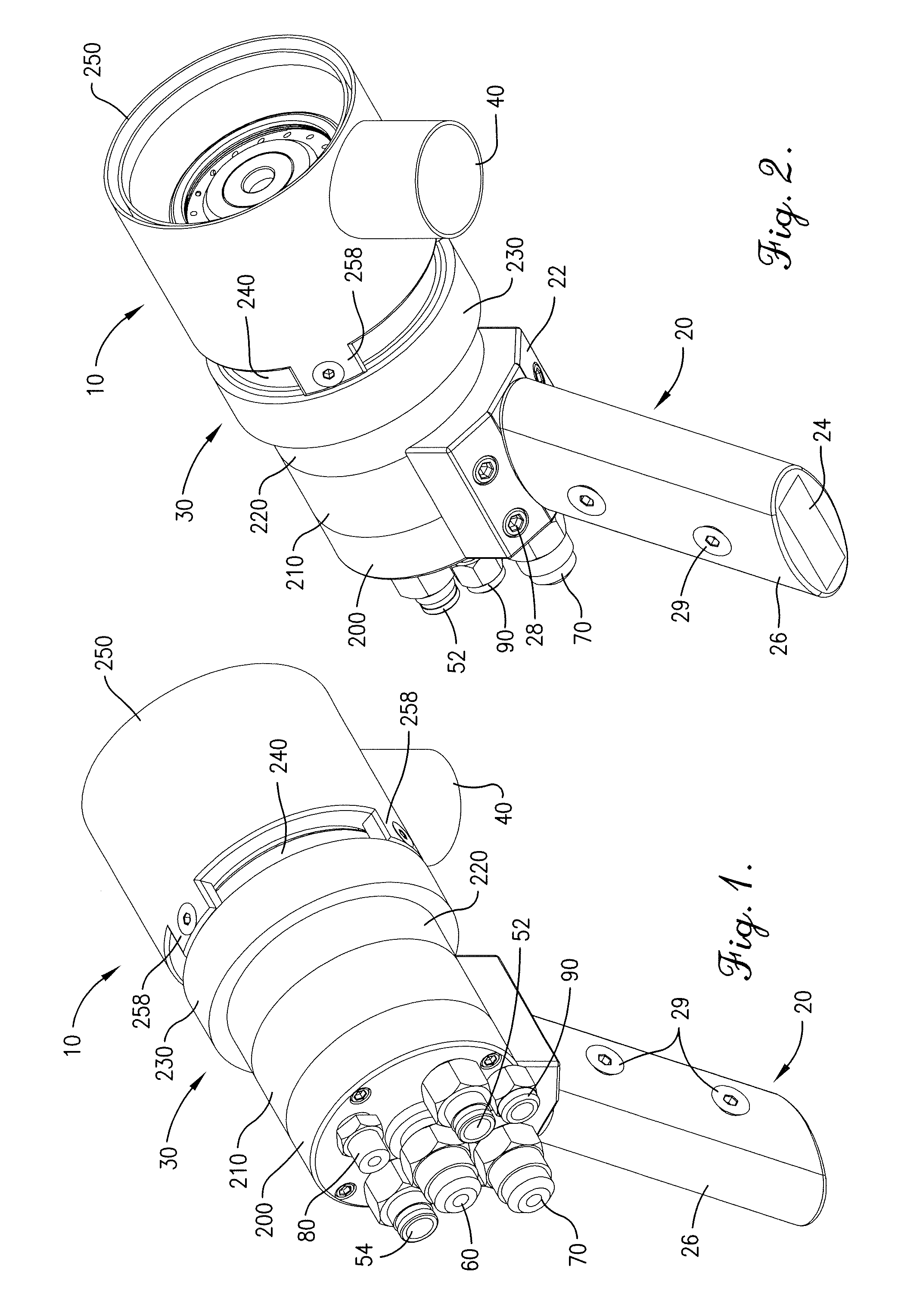

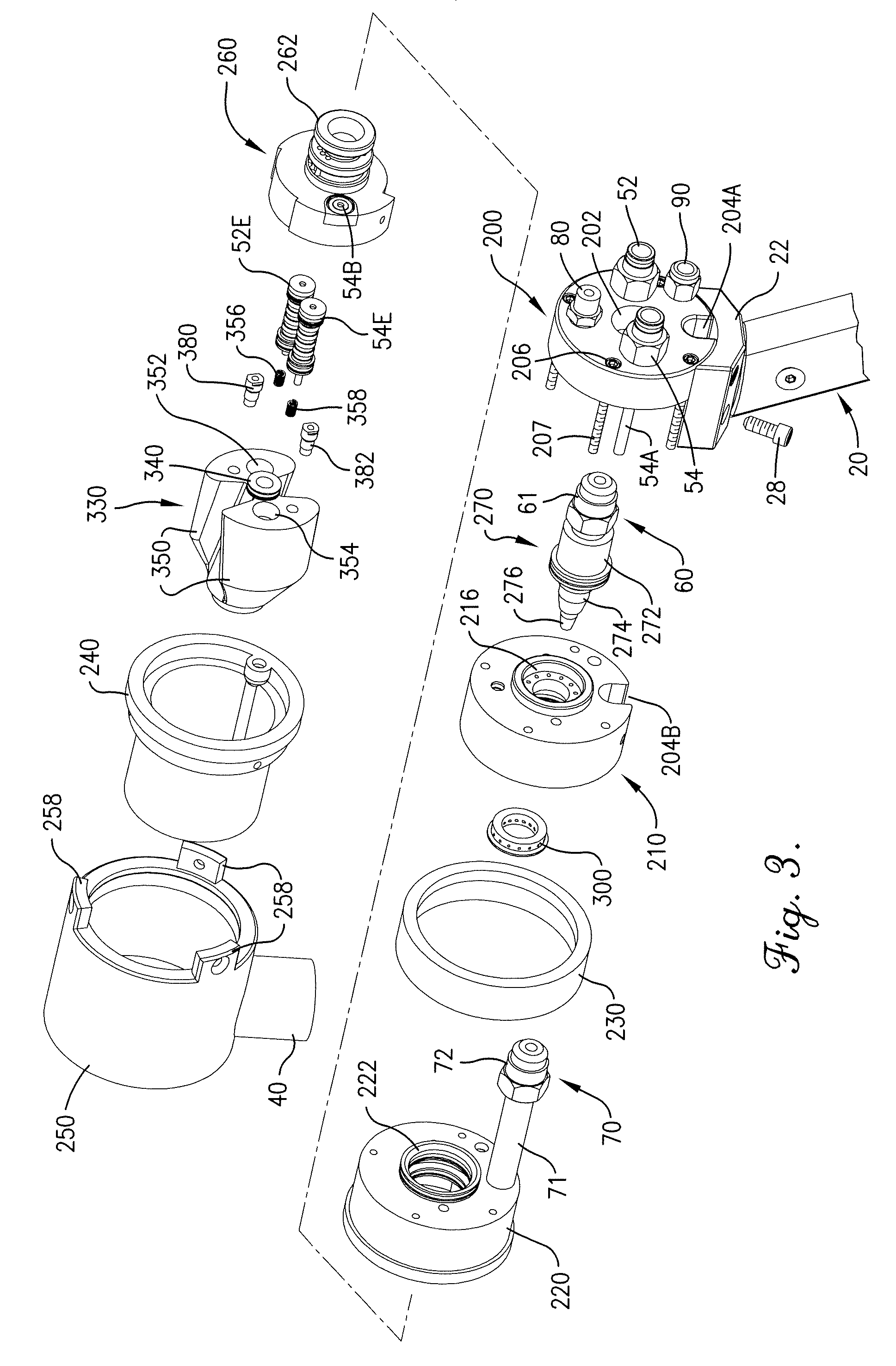

ActiveUS20080116178A1Avoid pollutionPrevent flame conditionLiquid surface applicatorsElectric heatingBond coatingPlasma generator

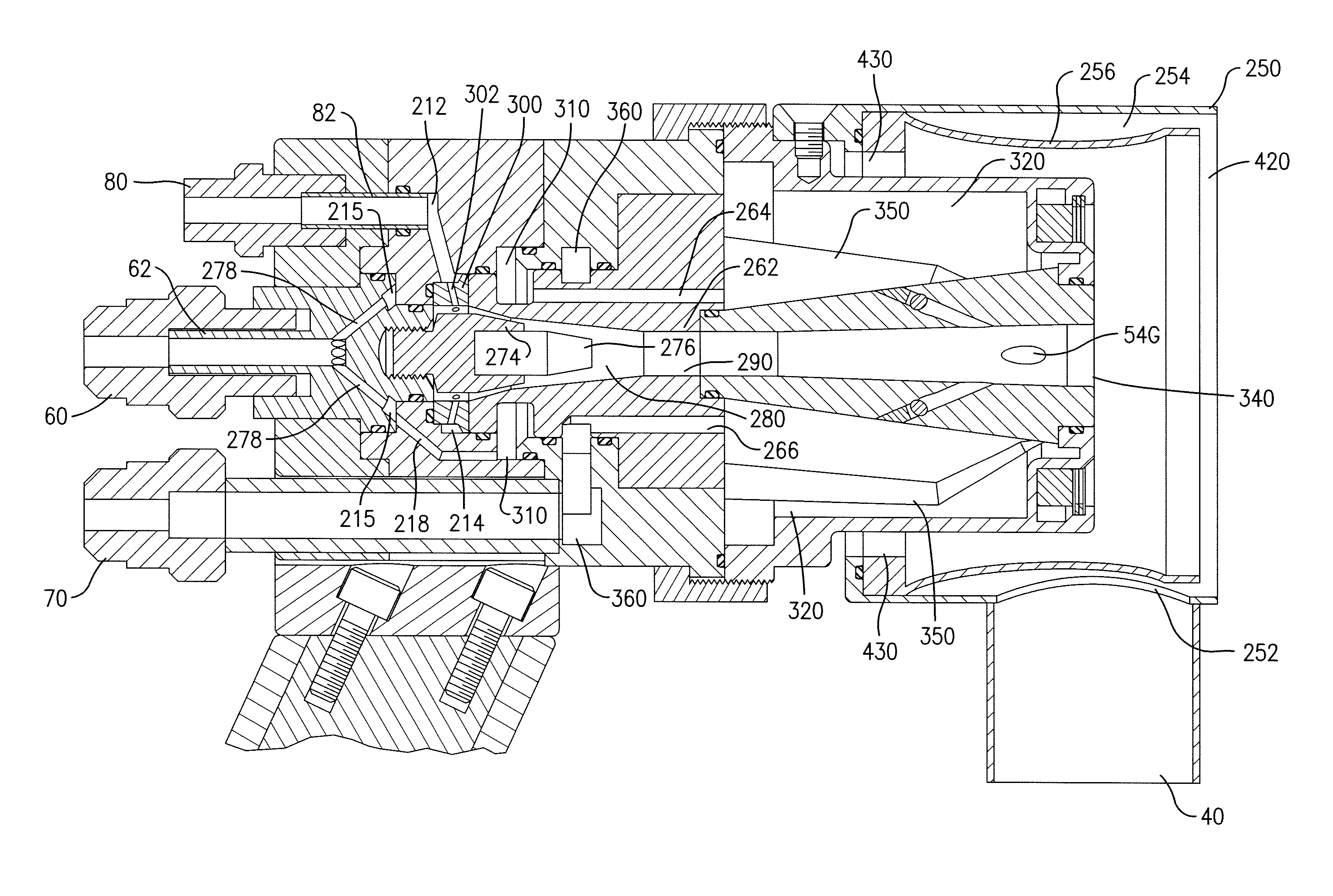

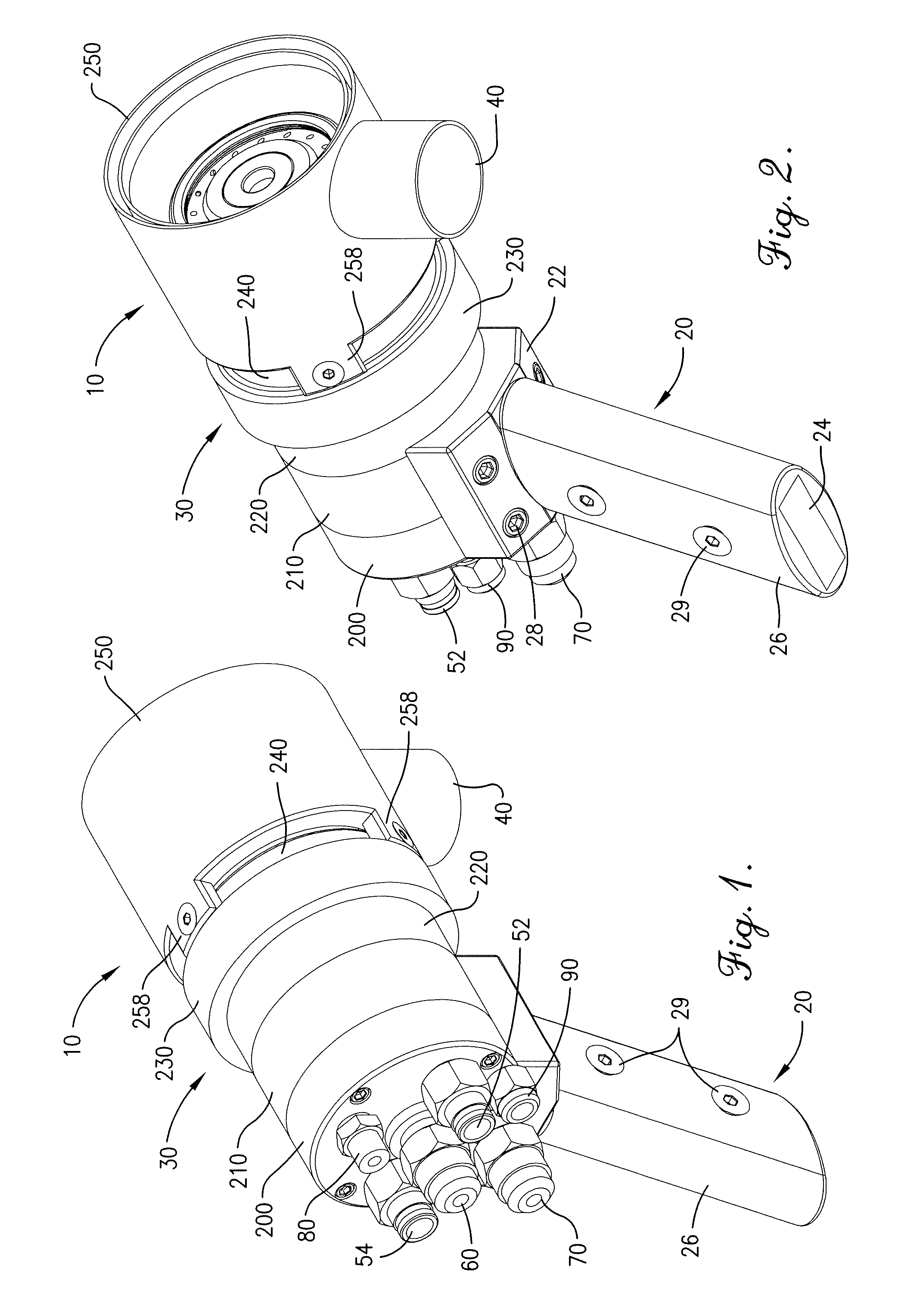

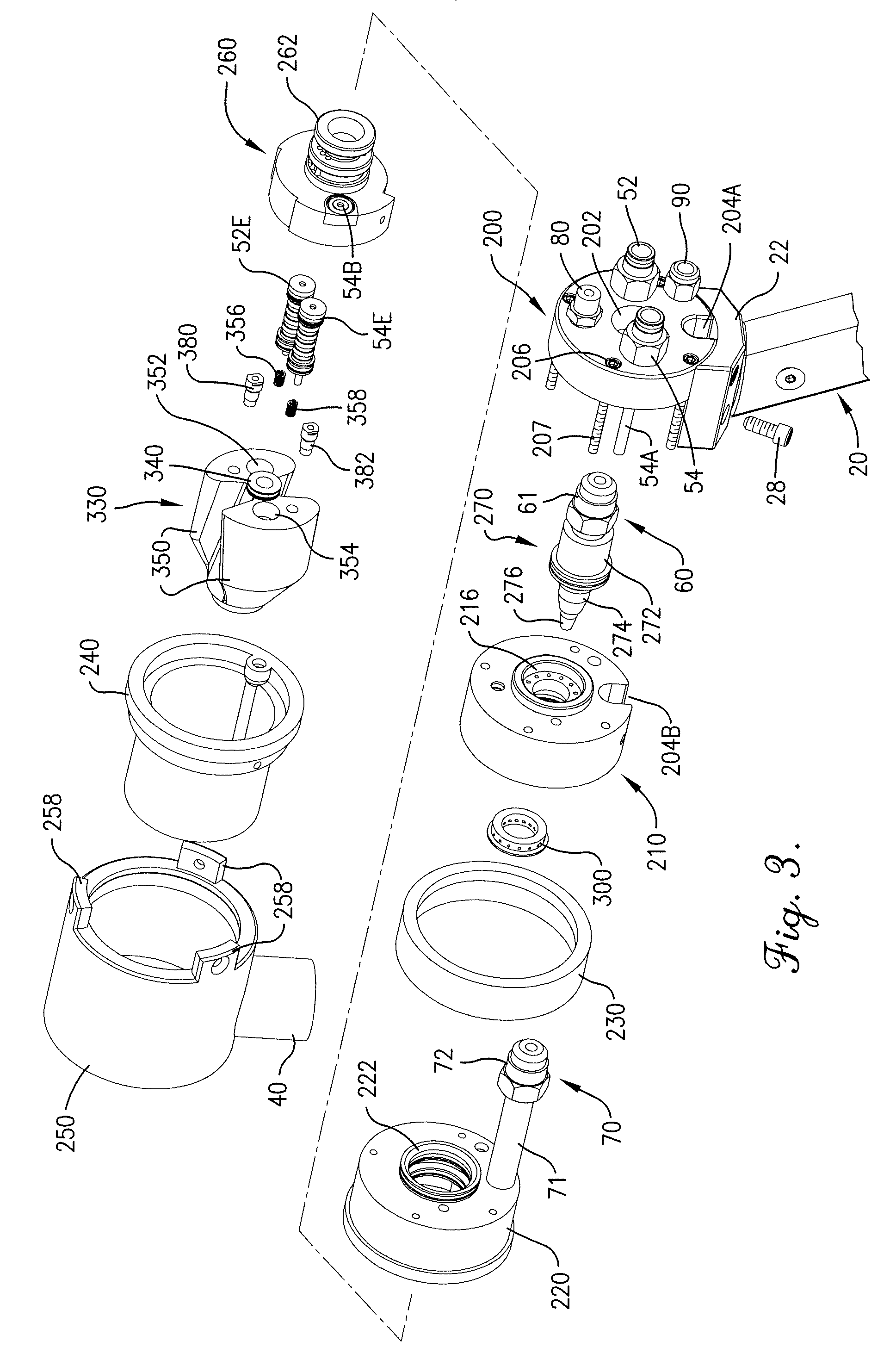

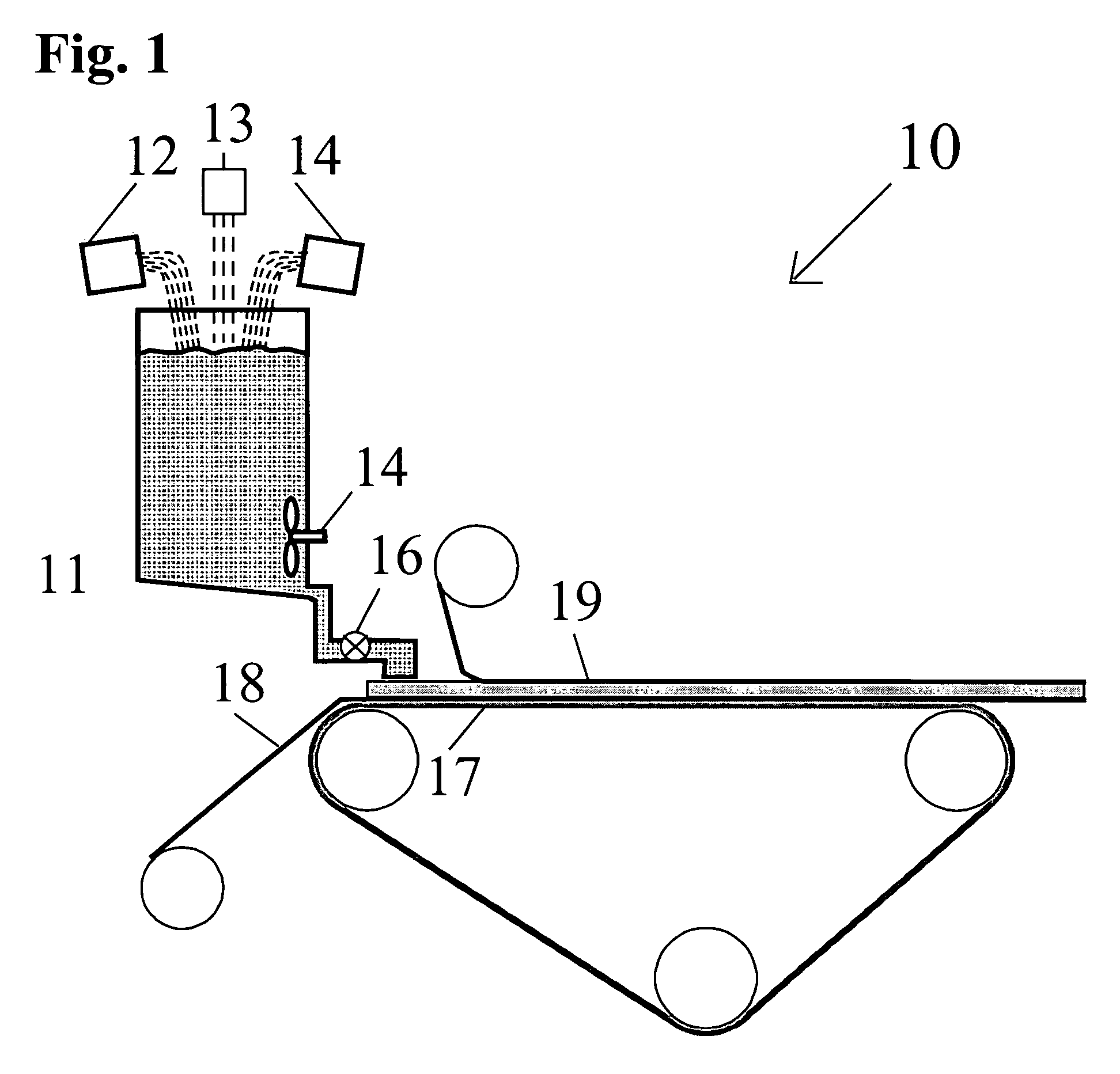

A plasma spray apparatus in the form of a gun is utilized to apply an antifoulant coating to marine vessels. The apparatus includes a plasma generator, an electrophoresis element, a heating element, a shield gas element, a liquid cooling system, a forced air system, and a vacuum system. The plasma generator ionizes gas to create a plasma stream, which is utilized in part to supply energy to the heating element that heats a powder material. The heated powder material is exposed to the electrophoresis element to create a covalently bonded coating material. The coating material is injected into the plasma stream and is applied to a target surface. The shield gas element injects a gas flow to surround and protect the plasma and coating material stream as the stream is in flight to the target surface. The liquid cooling system cools portions of the plasma generator and heating element. The forced air system cools a portion of the target surface as the coating material is being applied. The vacuum system removes fumes and stray particles during the application process.

Owner:REINTJES MARINE SURFACE TECH

Thermal barrier coating with stabilized compliant microstructure

ActiveUS20050013994A1Maintain integrityPrevent penetrationMolten spray coatingVacuum evaporation coatingParticulatesBond coating

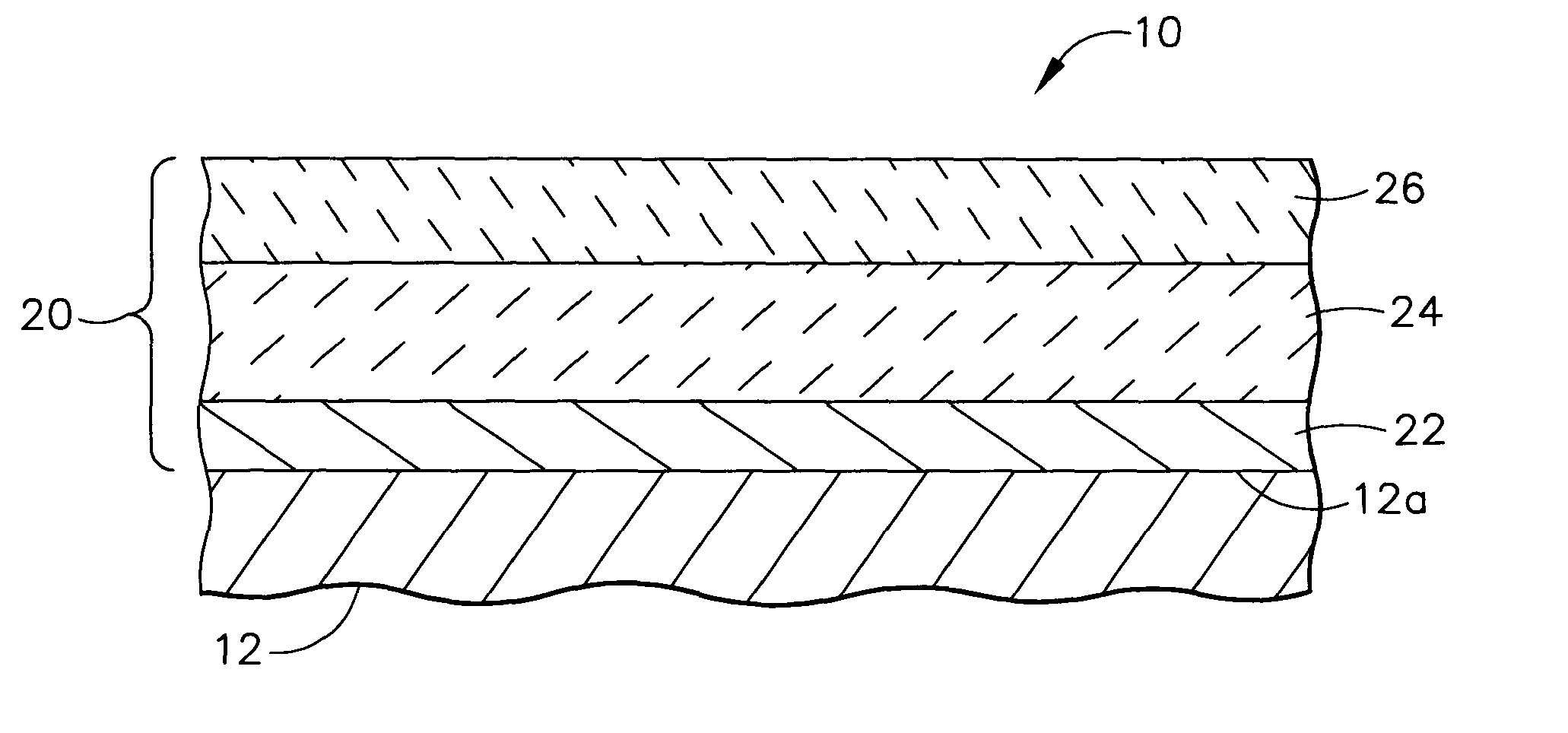

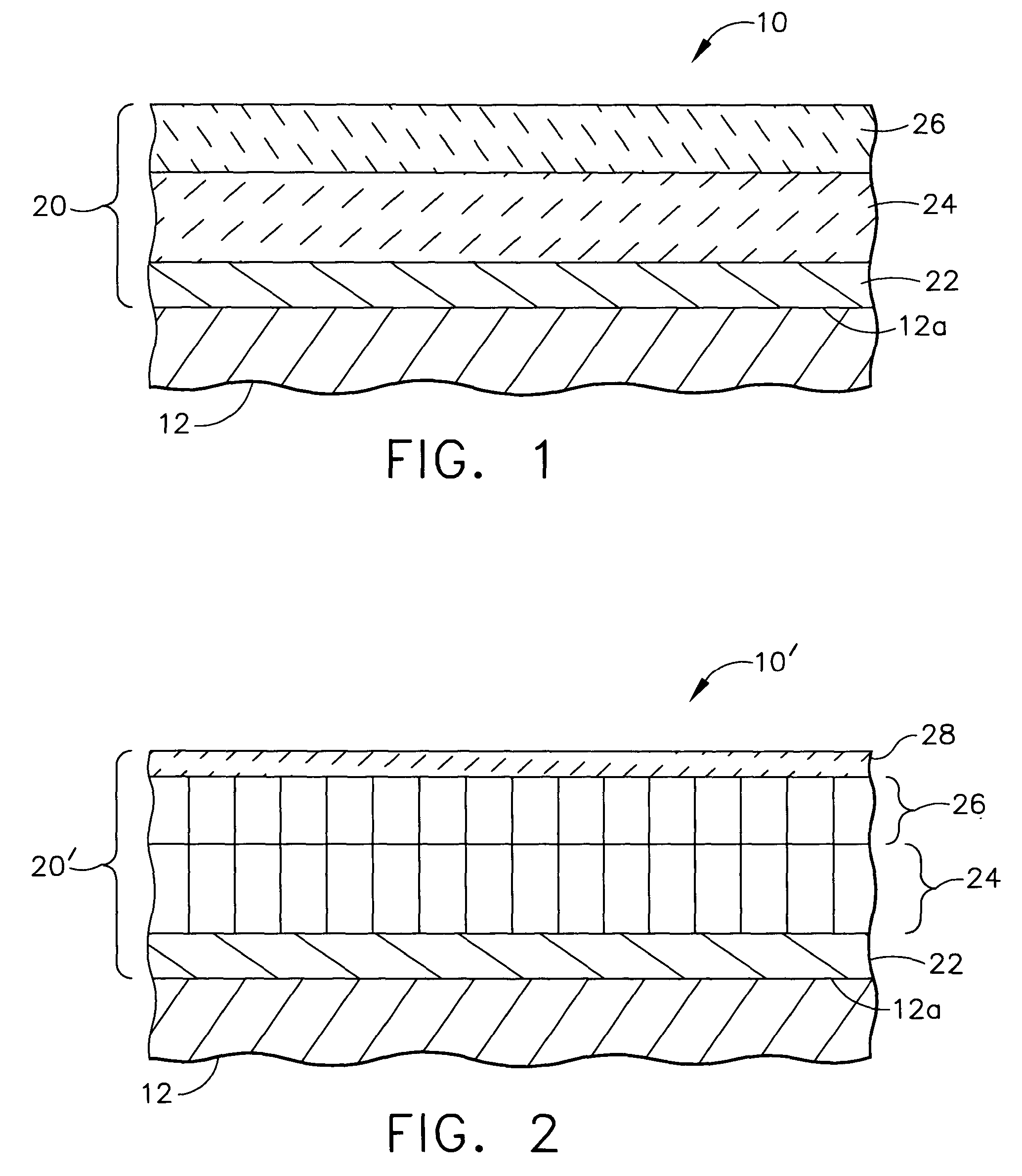

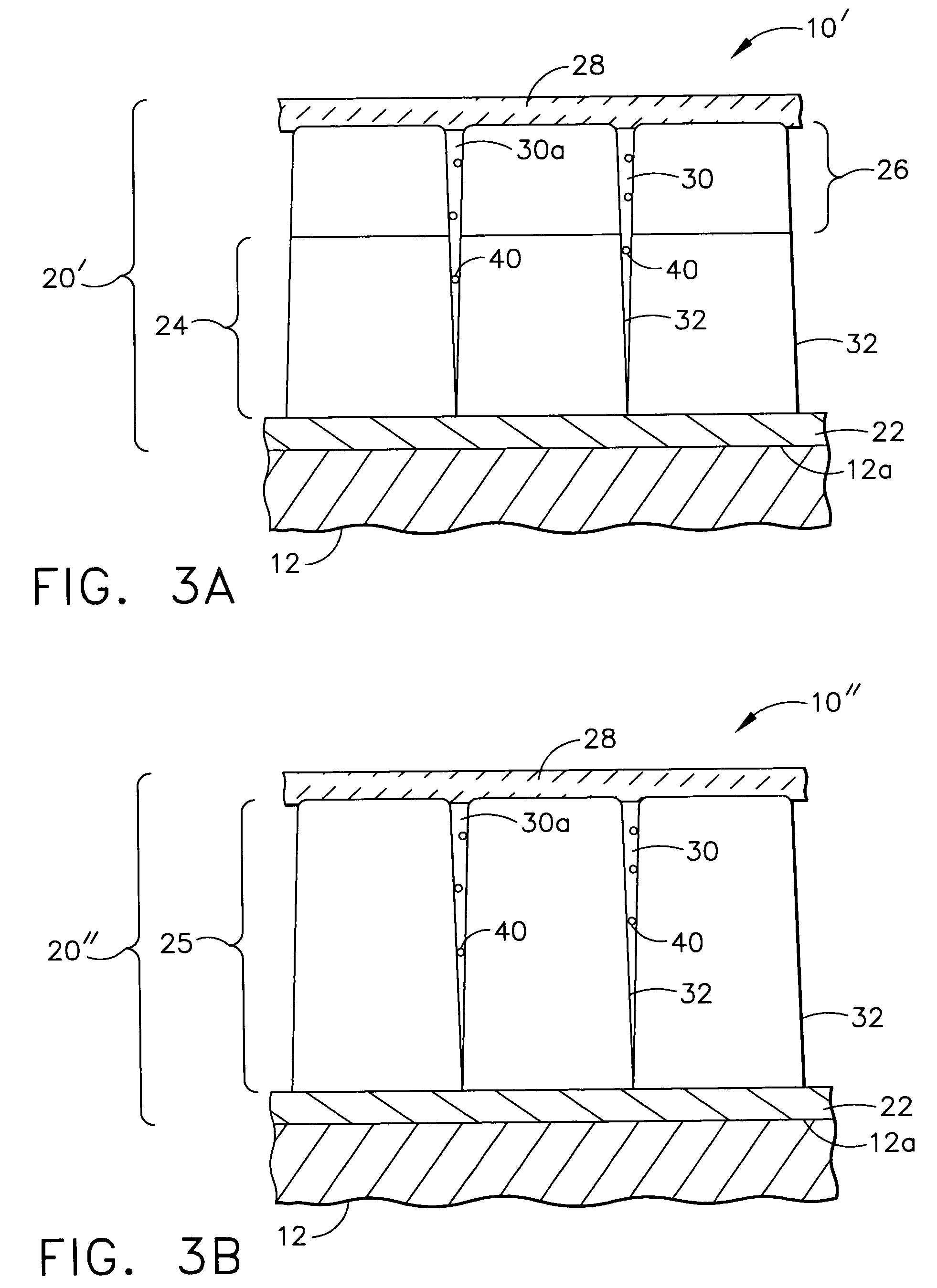

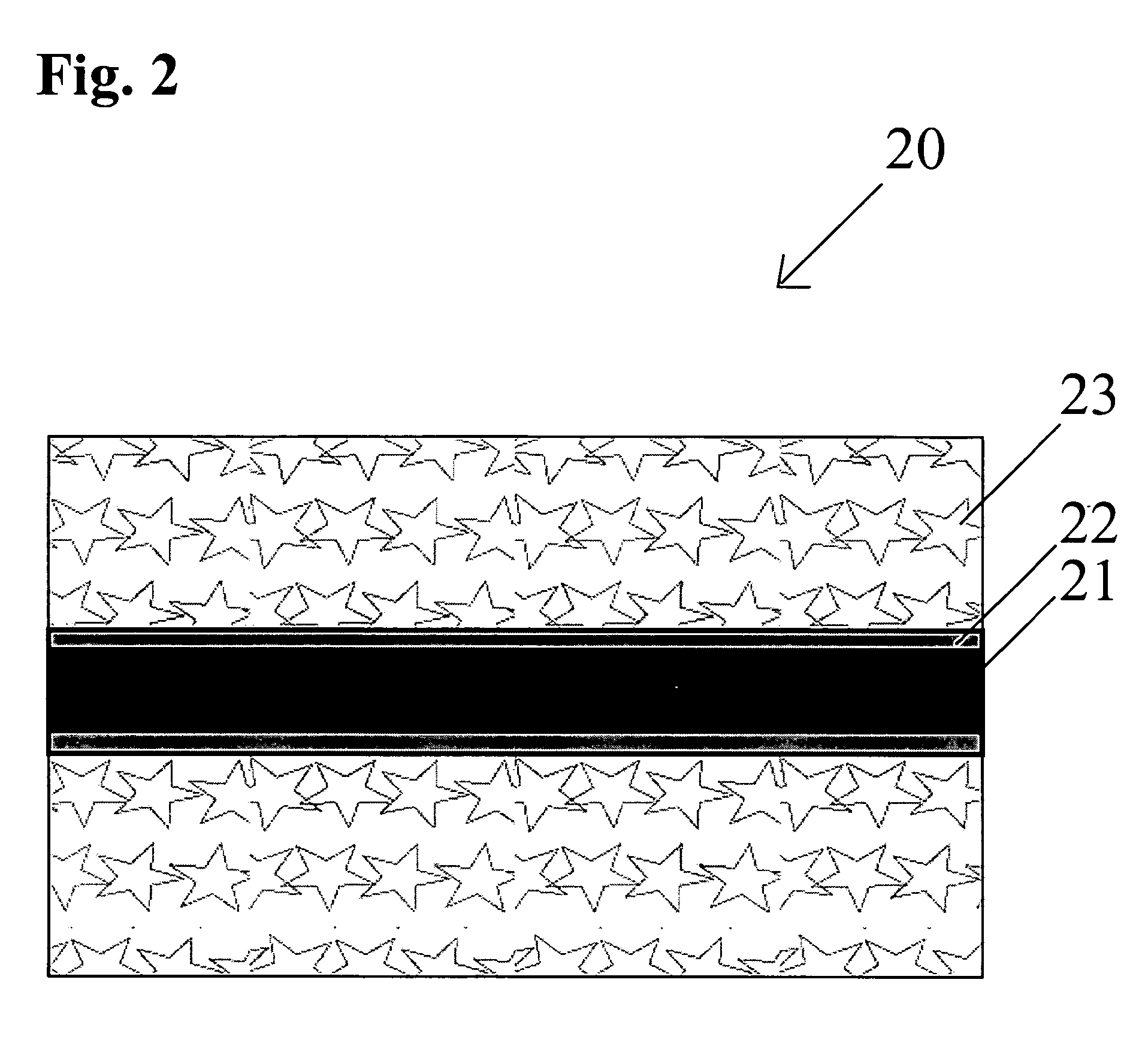

A thermal barrier coating for a gas turbine component includes a bond coating layer, at least a first segmented columnar ceramic layer on the bond coating layer, and a particulate structure-stabilizing material disposed within a plurality of segmentation gaps within the columnar ceramic layer(s). The thermal barrier coating may further comprise, a second segmented columnar ceramic layer of yttria stabilized hafnia on the first segmented columnar ceramic layer, and an outer, continuous, non-segmented sealant layer covering the yttria stabilized hafnia layer to prevent ingress of extraneous materials into the segmentation gaps. Methods for depositing a thermal barrier coating on a substrate are also disclosed.

Owner:HONEYWELL INT INC

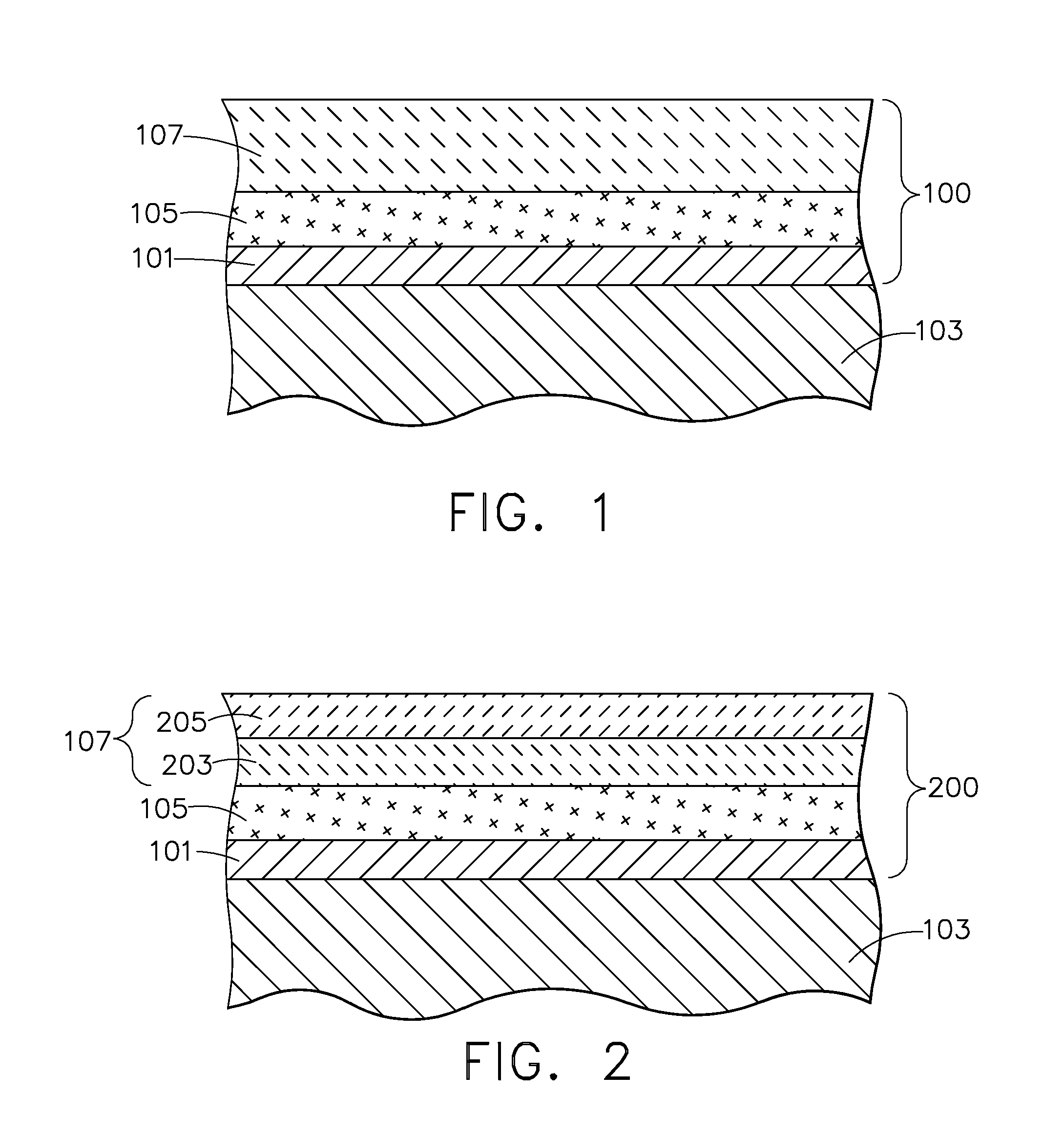

Yttria containing thermal barrier coating topcoat layer and method for applying the coating layer

ActiveUS20080145674A1Reduced and eliminated infiltrationIncrease gas turbine engine component lifePropellersReaction enginesCoating systemBond coating

A gas turbine engine component and coating system including a superalloy substrate having a coating system disposed thereon. A bond coating may be applied to the substrate. An adherent layer of ceramic material forming a thermal barrier coating is present on the bond coat layer. A topcoat layer overlies the thermal barrier coating. The topcoat layer includes greater than about 20 wt % yttria.

Owner:GENERAL ELECTRIC CO

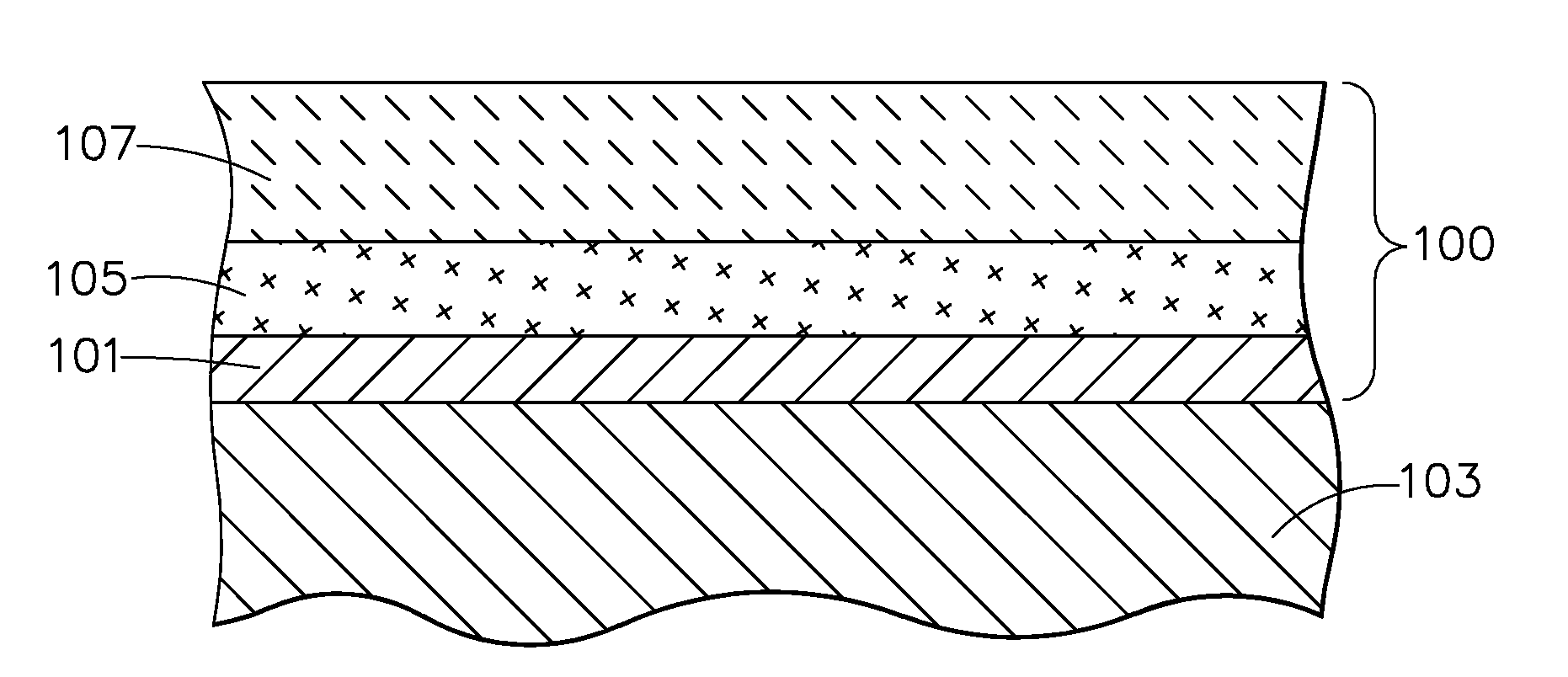

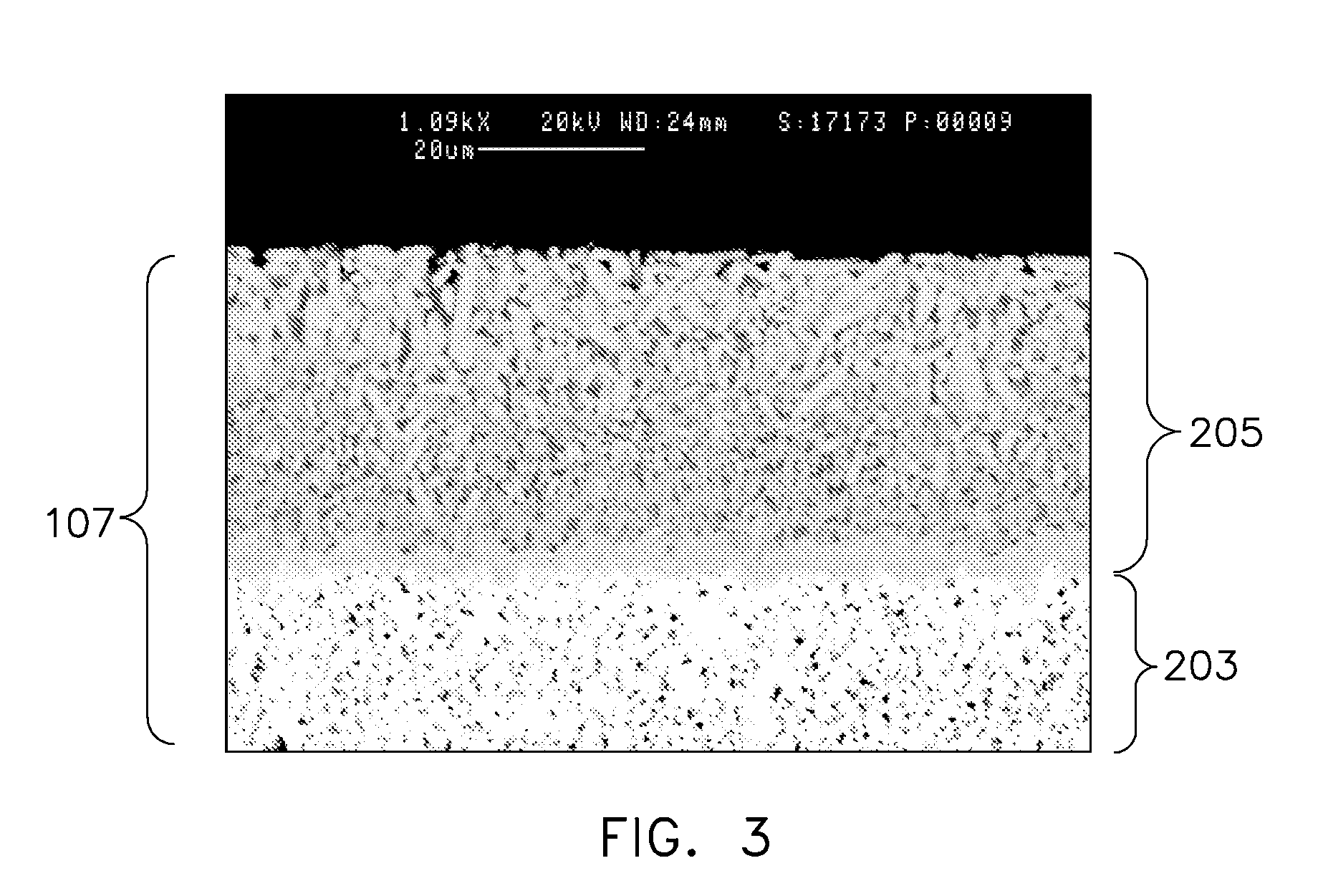

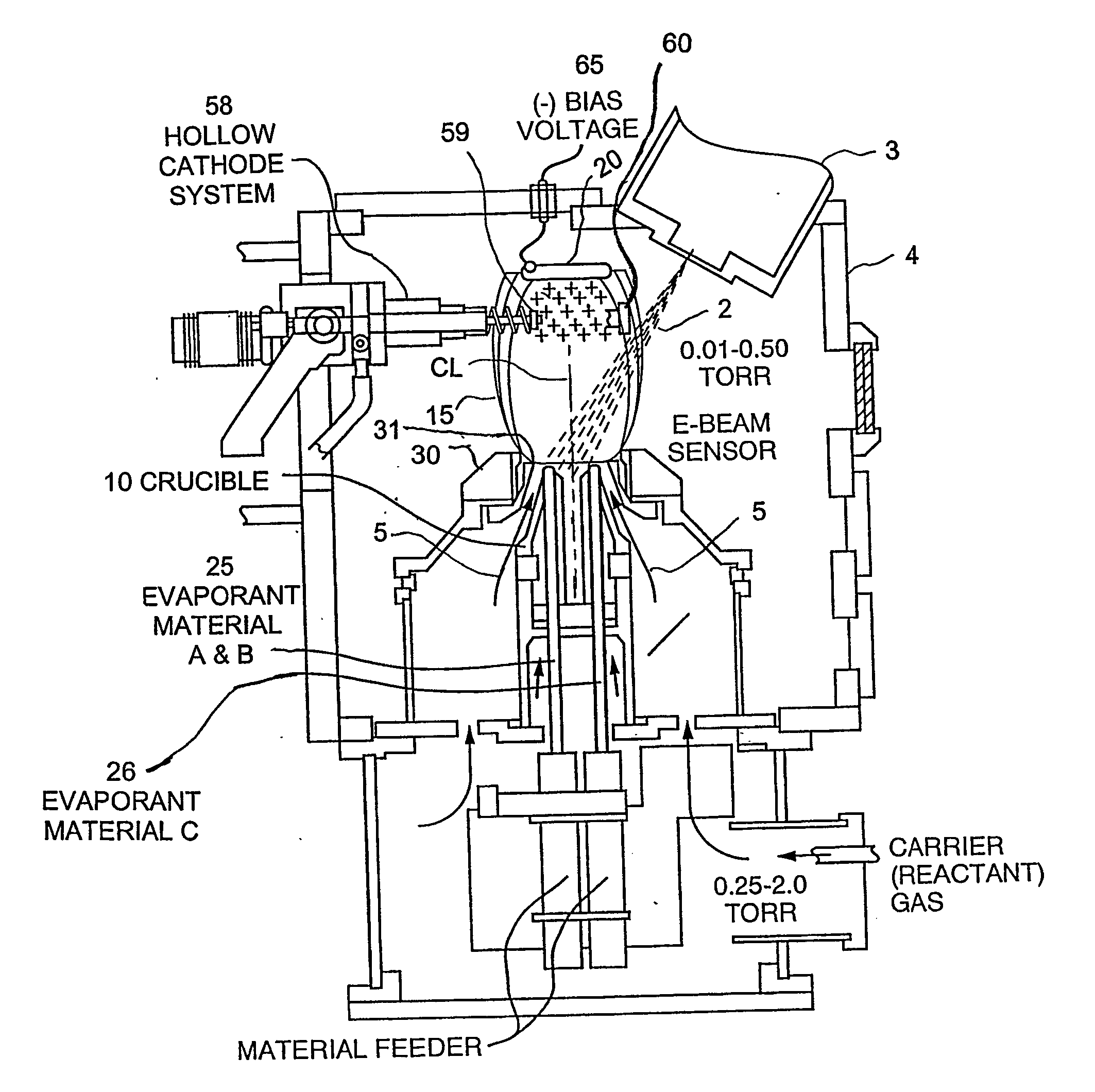

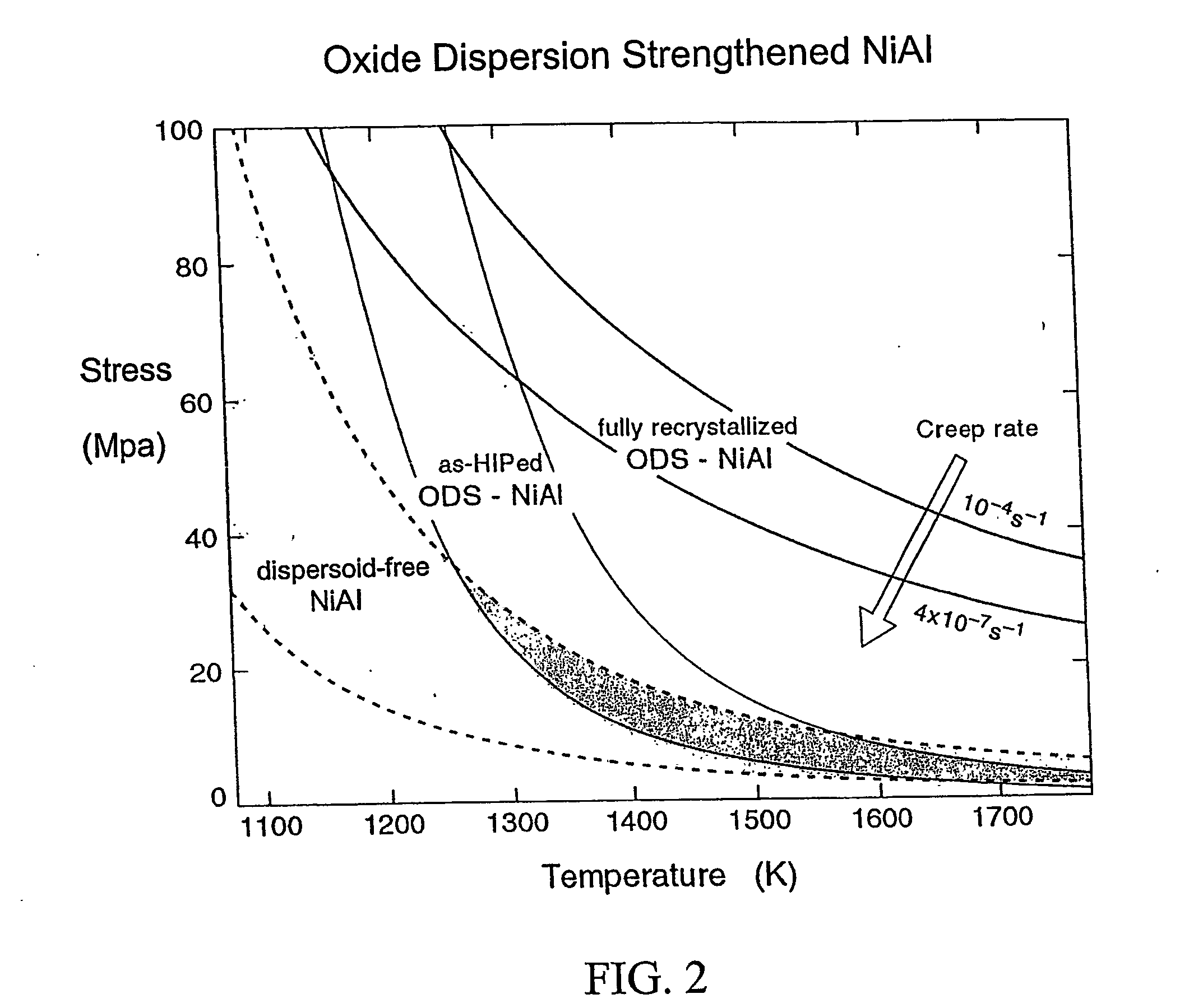

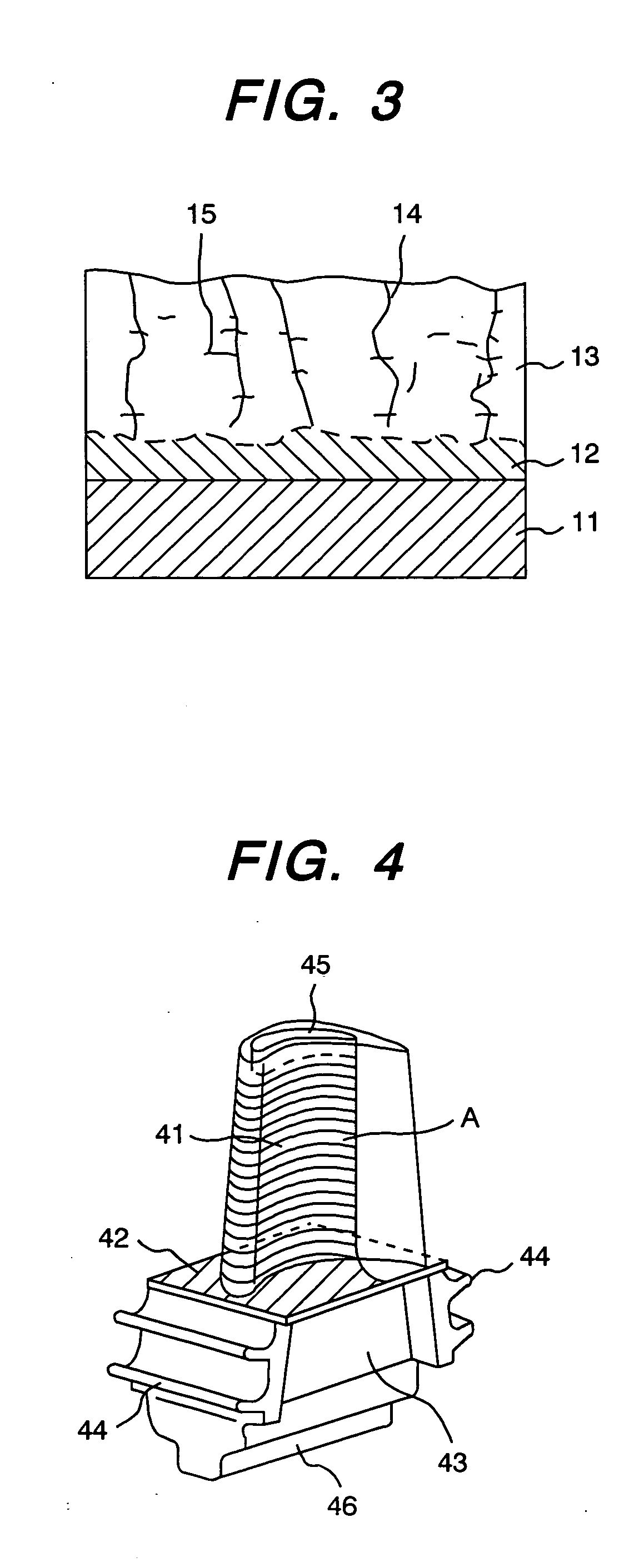

Method and apparatus for dispersion strengthened bond coats for thermal barrier coatings

InactiveUS20050287296A1Effective applicationIncrease chanceEngine manufactureElectric discharge tubesBorideGas phase

A directed vapor deposition (DVD) method and system for applying at least one bond coating on at least one substrate for thermal barrier coating systems. The method and system provides for alloy strengthening in high temperature metallic alloys that can be melt or solid state processed to materials that one applies by vapor deposition. The creep strengthened coating contains nanoscopic particles of oxides, nitrides, borides, carbides, and other materials which are formed by reactive codeposition. An approach for reactive codeposition is plasma assisted directed vapor deposition. Accordingly, the resultant structure may be utilized for, but not limited thereto, high temperature coatings, e.g. for protecting rocket or power turbines, or diesel engine components. The resultant structure is has a greatly extended lifetime attributed in part to the elimination of coating spallation by the “rumpling” mechanism.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

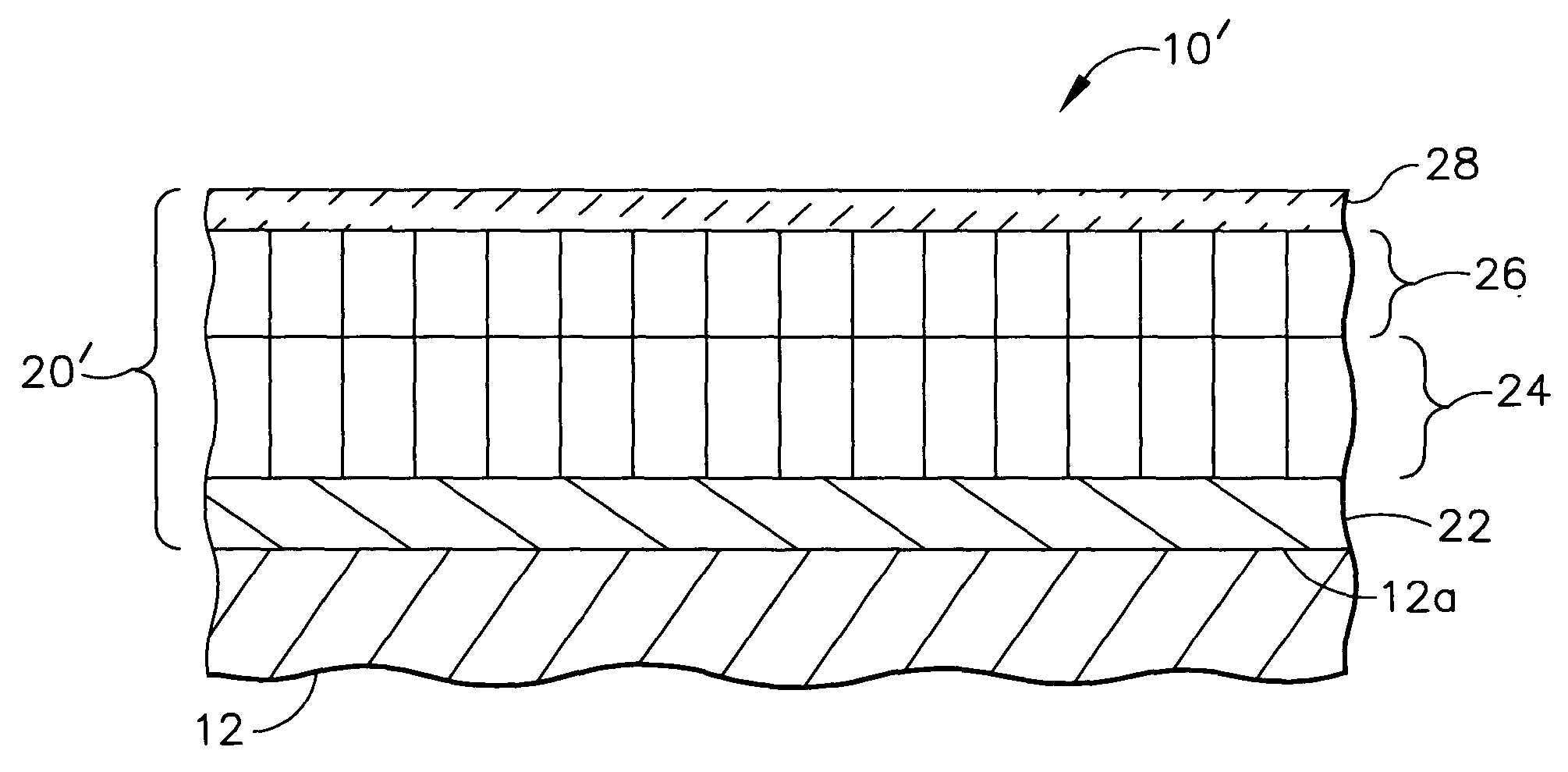

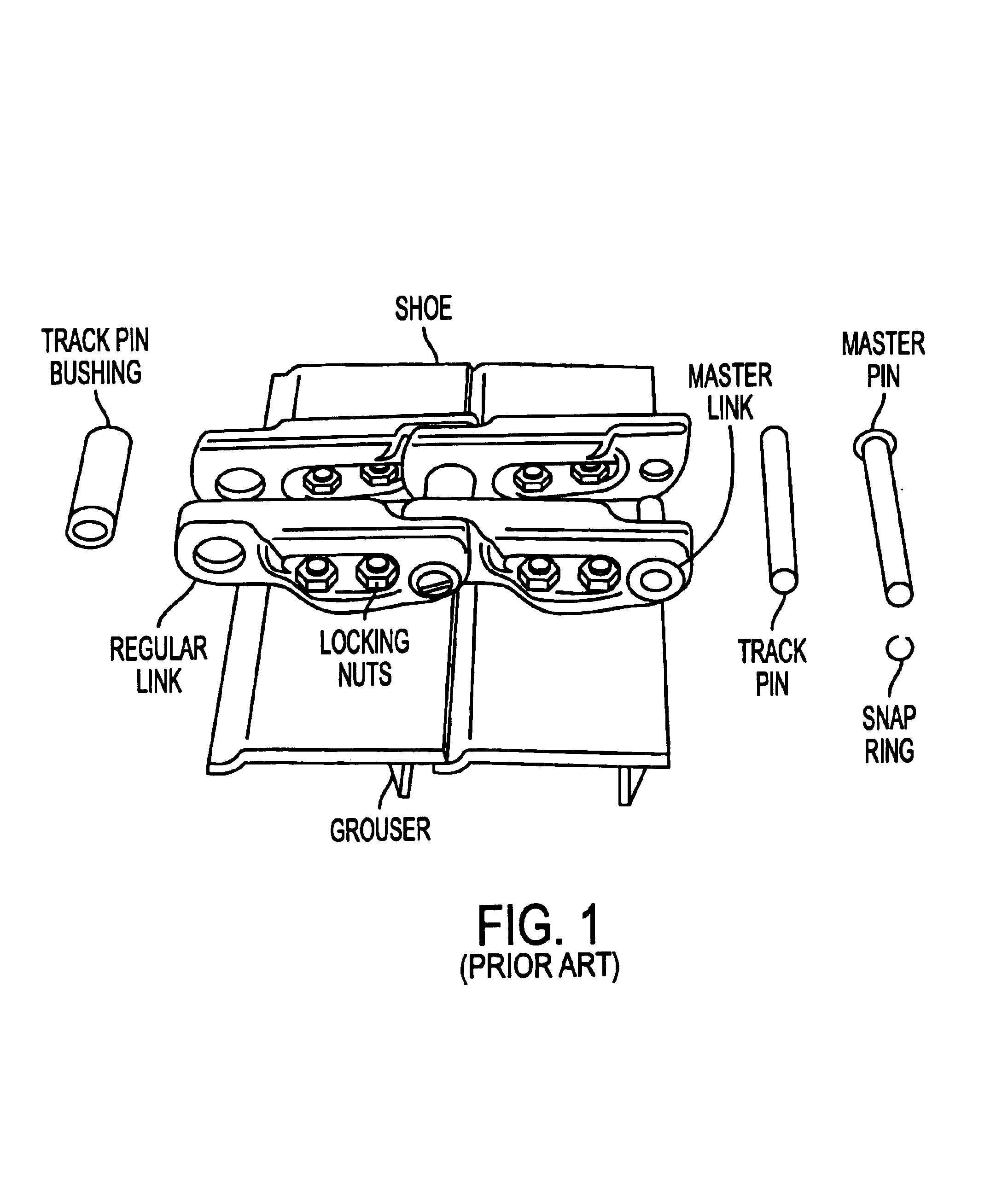

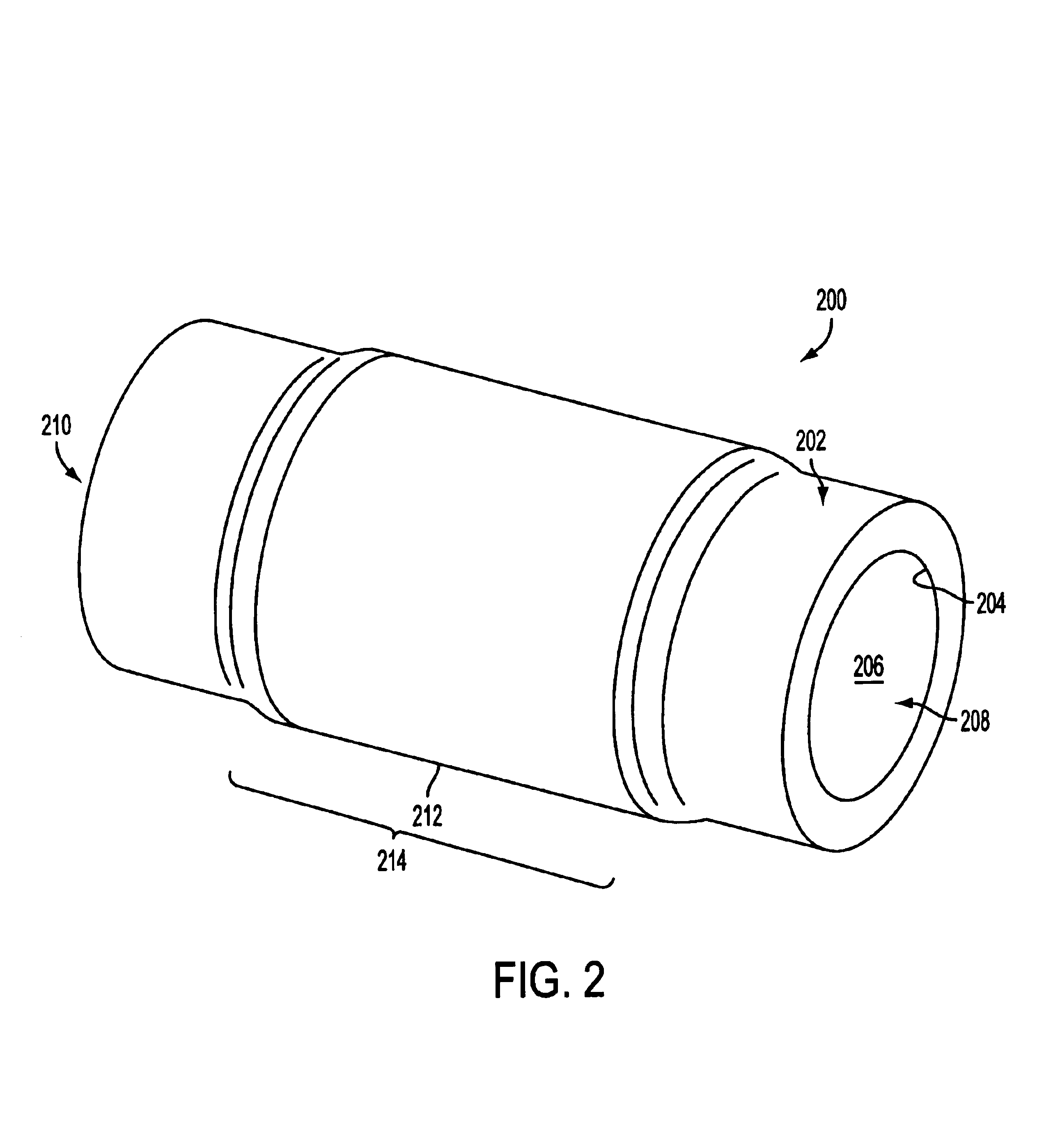

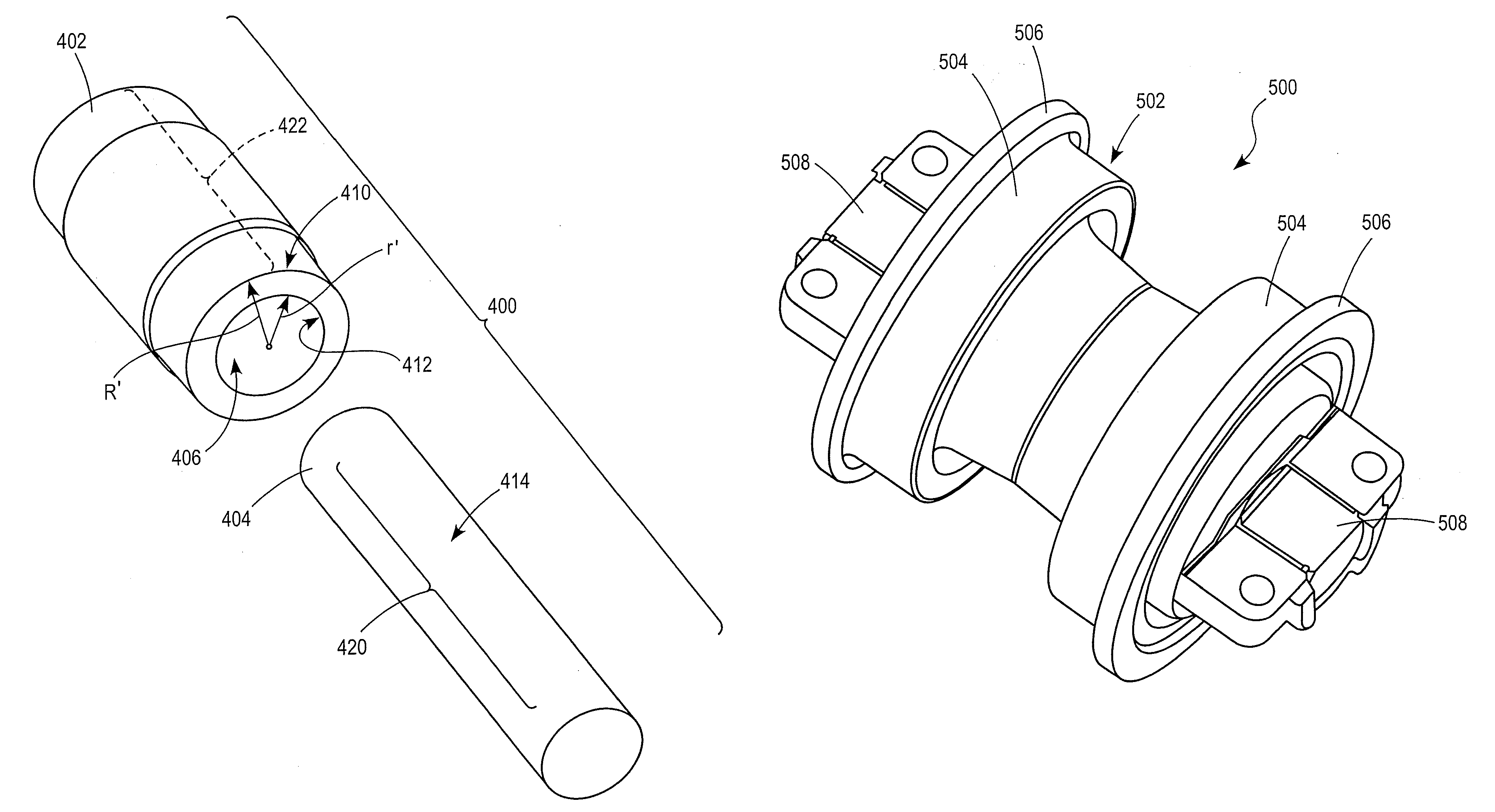

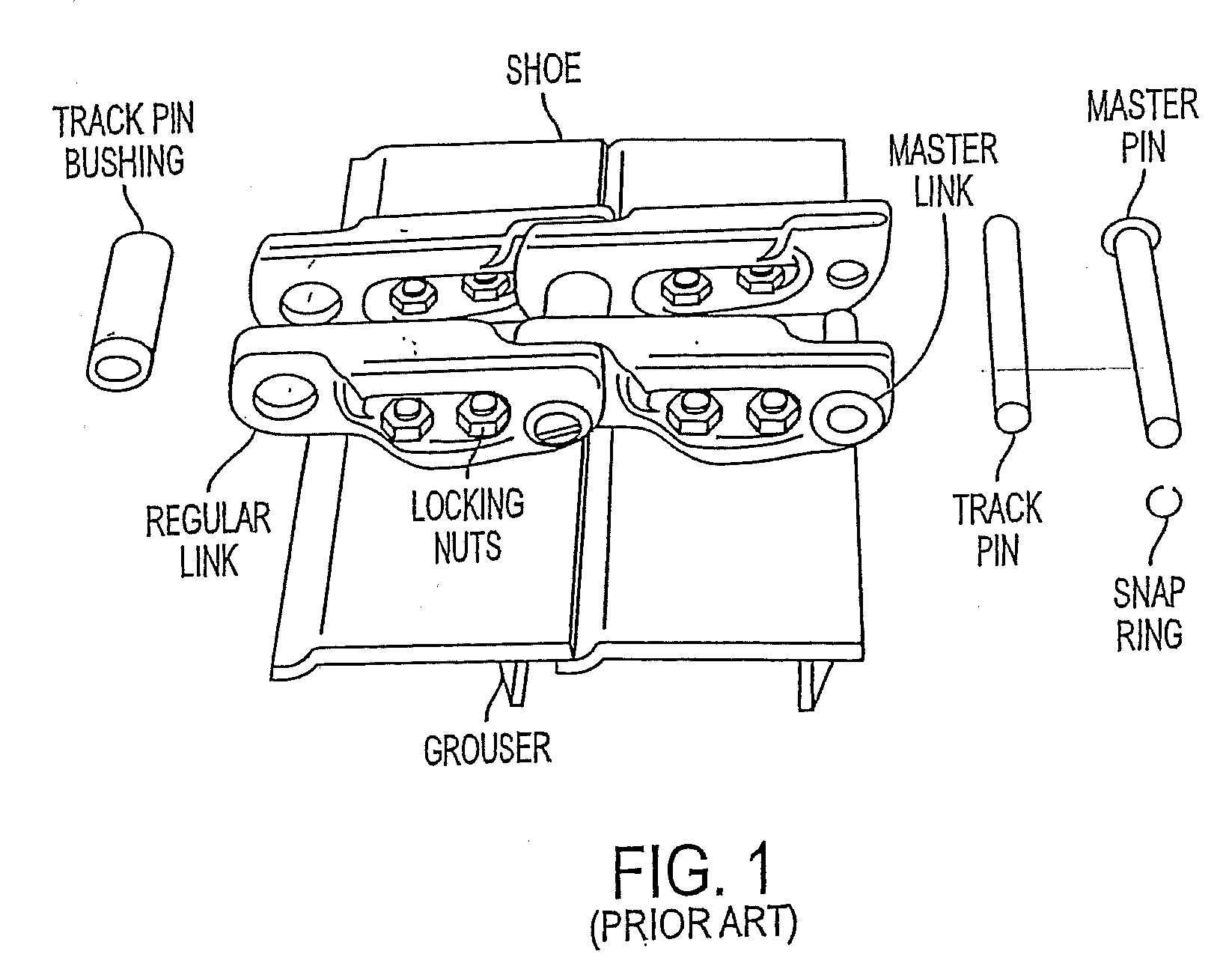

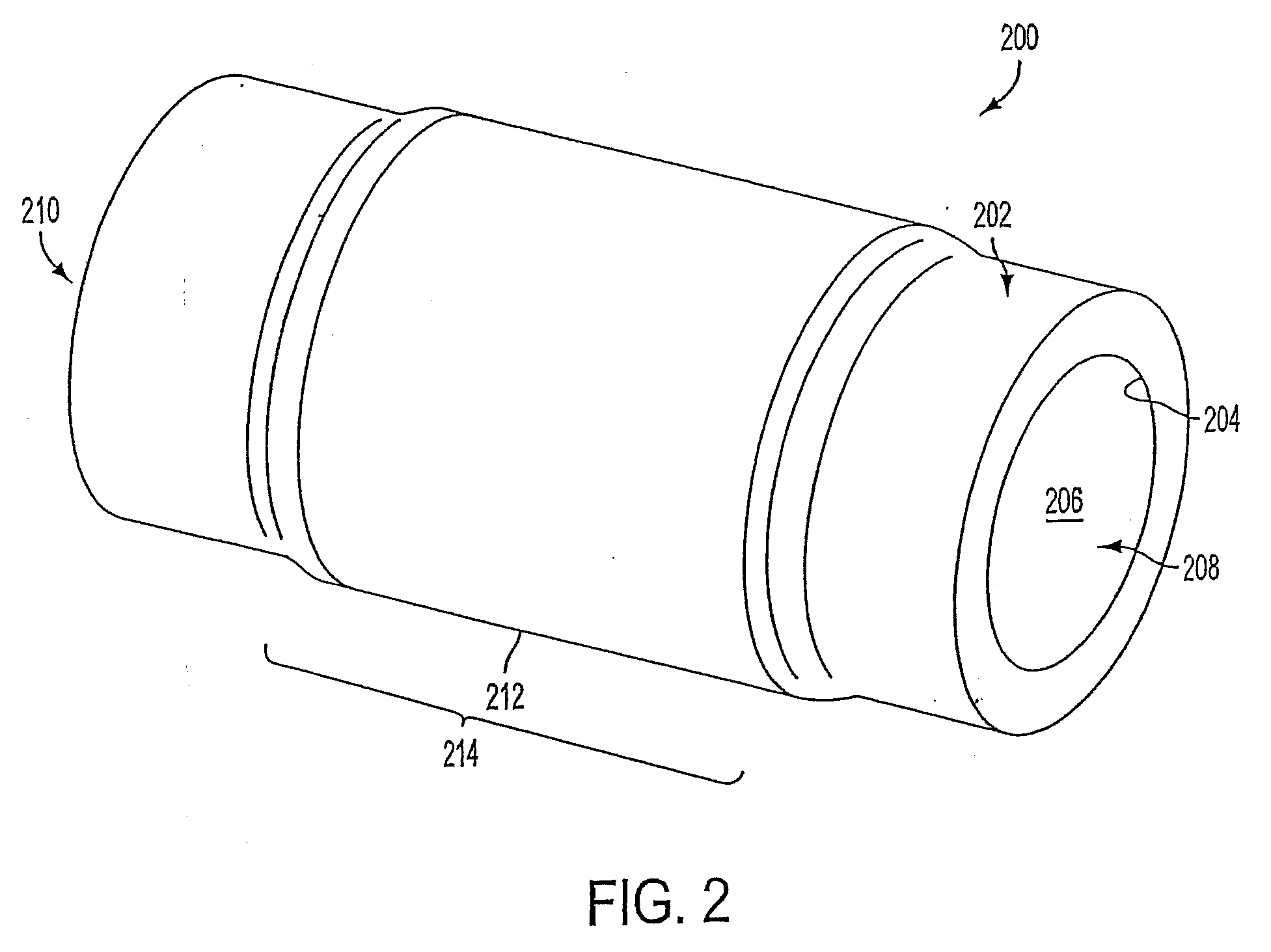

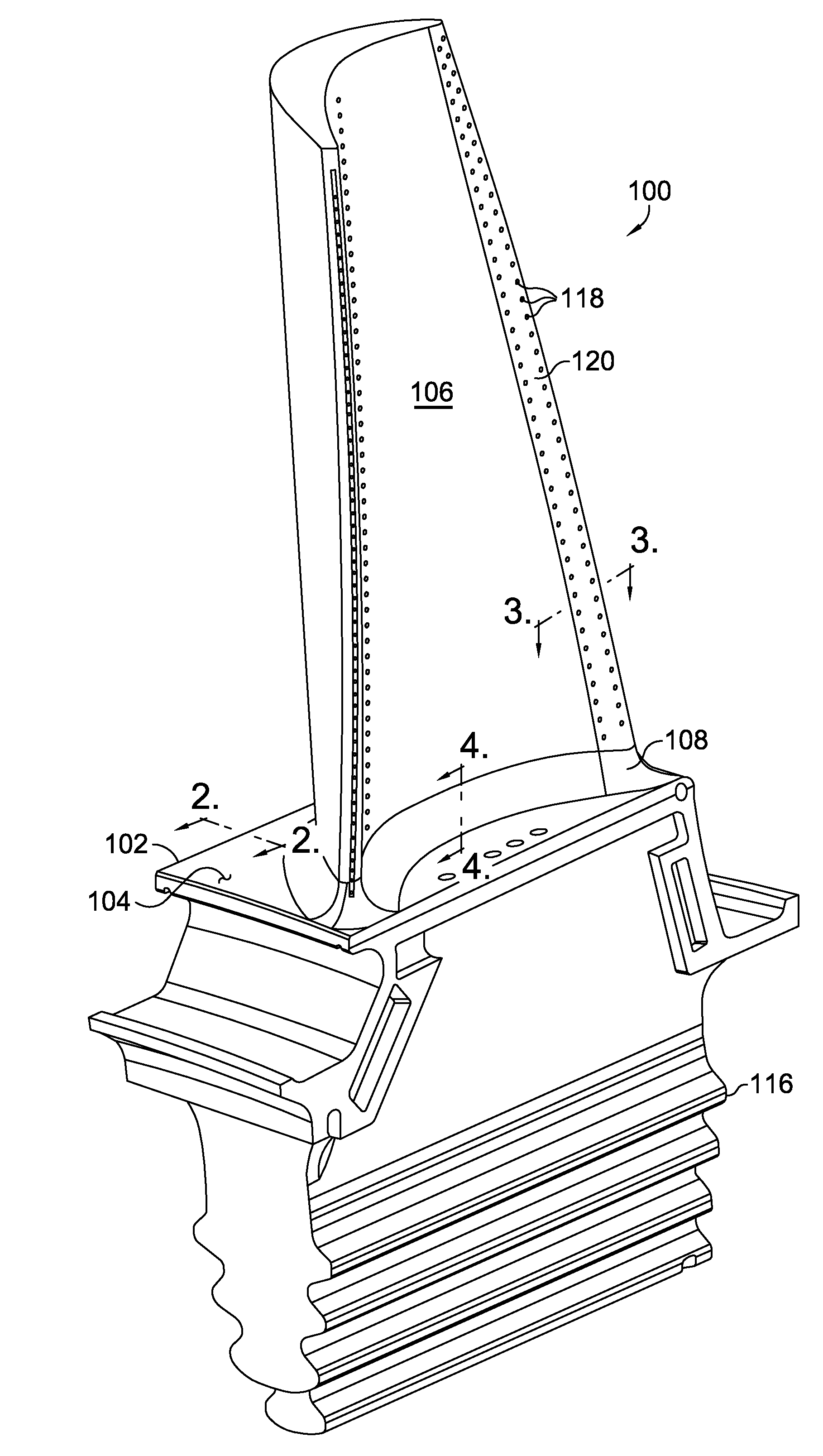

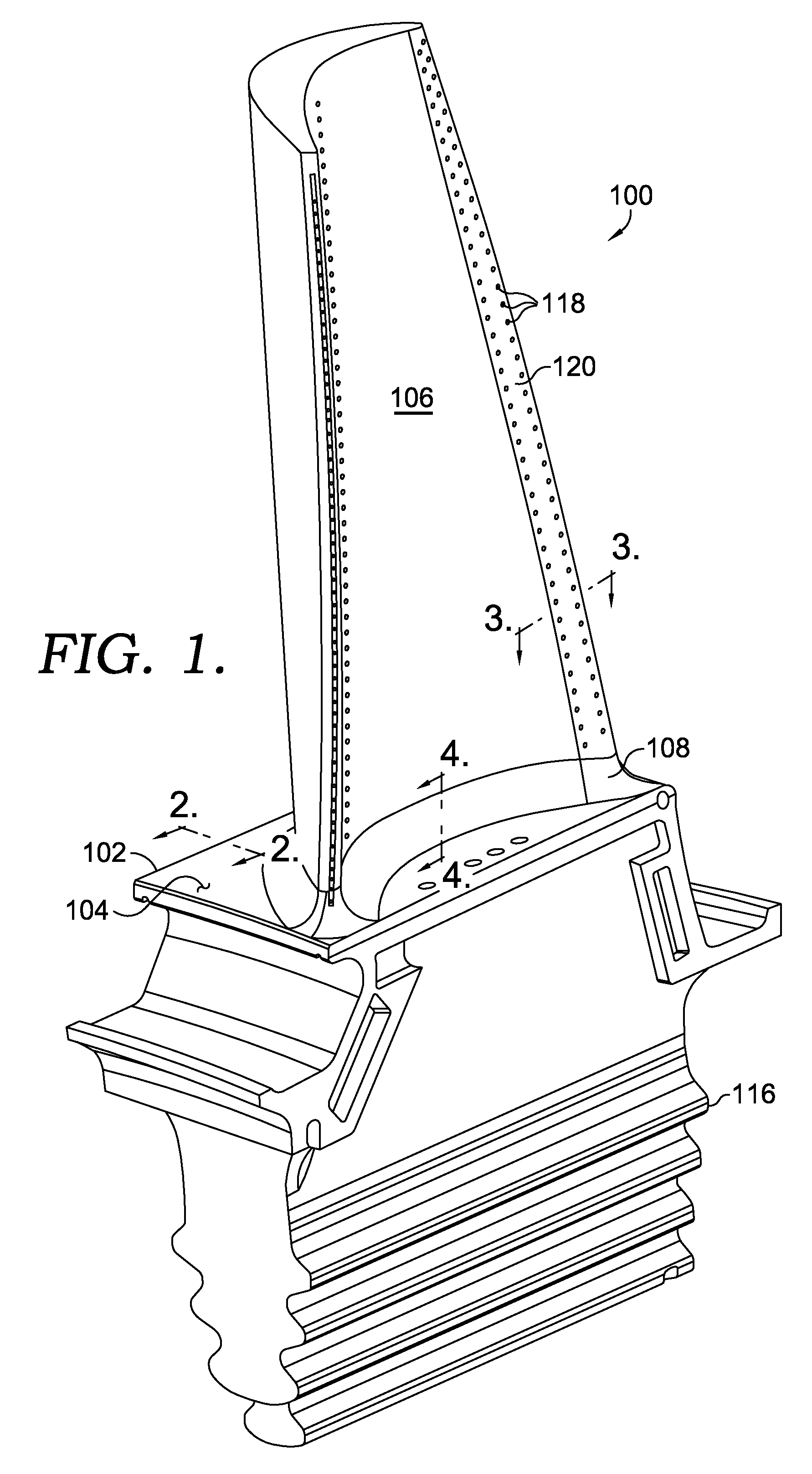

Track pin bushing having a metallurgically bonded coating

A track pin bushing for cooperating with a track pin in an endless track has a tubular body with a metallurgically bonded wear-resistant coating and a method for forming such a coated track pin bushing is taught herein. The tubular body, formed of an iron-based alloy, has an outer surface that is carburized and quenched, i.e., case-hardened, in at least a section thereof. At least a portion of the case hardened section has been removed to a depth sufficient to expose a non-carburized layer of the iron-based alloy. A hard metal alloy slurry is disposed on the non-carburized layer and forms a metallurgical bond between the non-carburized layer and the coated unfused slurry by fusing the hard metal alloy. The thickness of the unfused slurry is adjusted to be from 1.67 to 2.0 times a final thickness of the wear-resistant coating. The wear-resistant coating comprises a fused, metal alloy comprising at least 60% iron, cobalt, nickel, or alloys thereof. The portion of the outer surface with the wear-resistant coating corresponds to a contact surface adapted to engage with a drive sprocket in the endless track of the track-type vehicle.

Owner:DEERE & CO

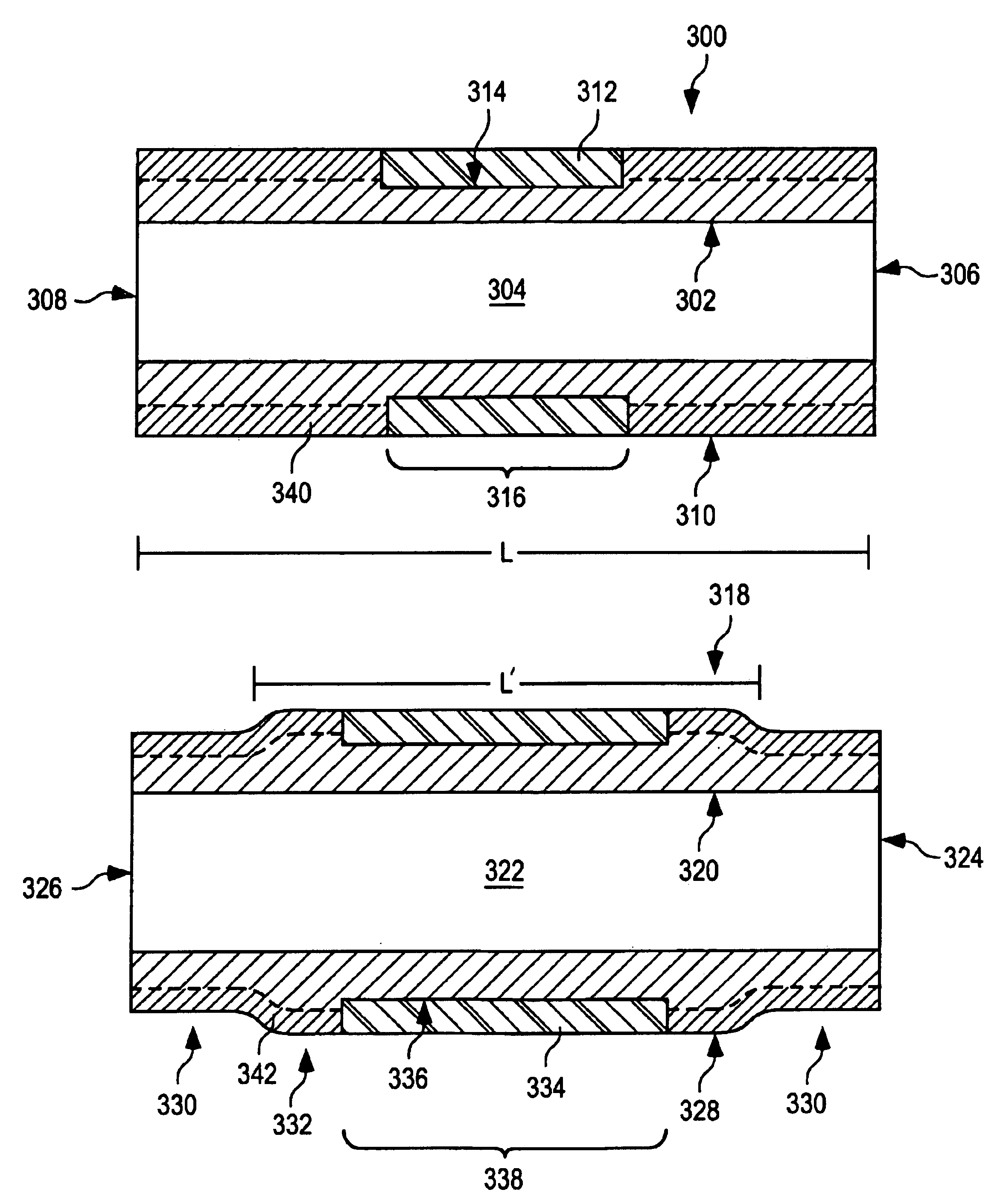

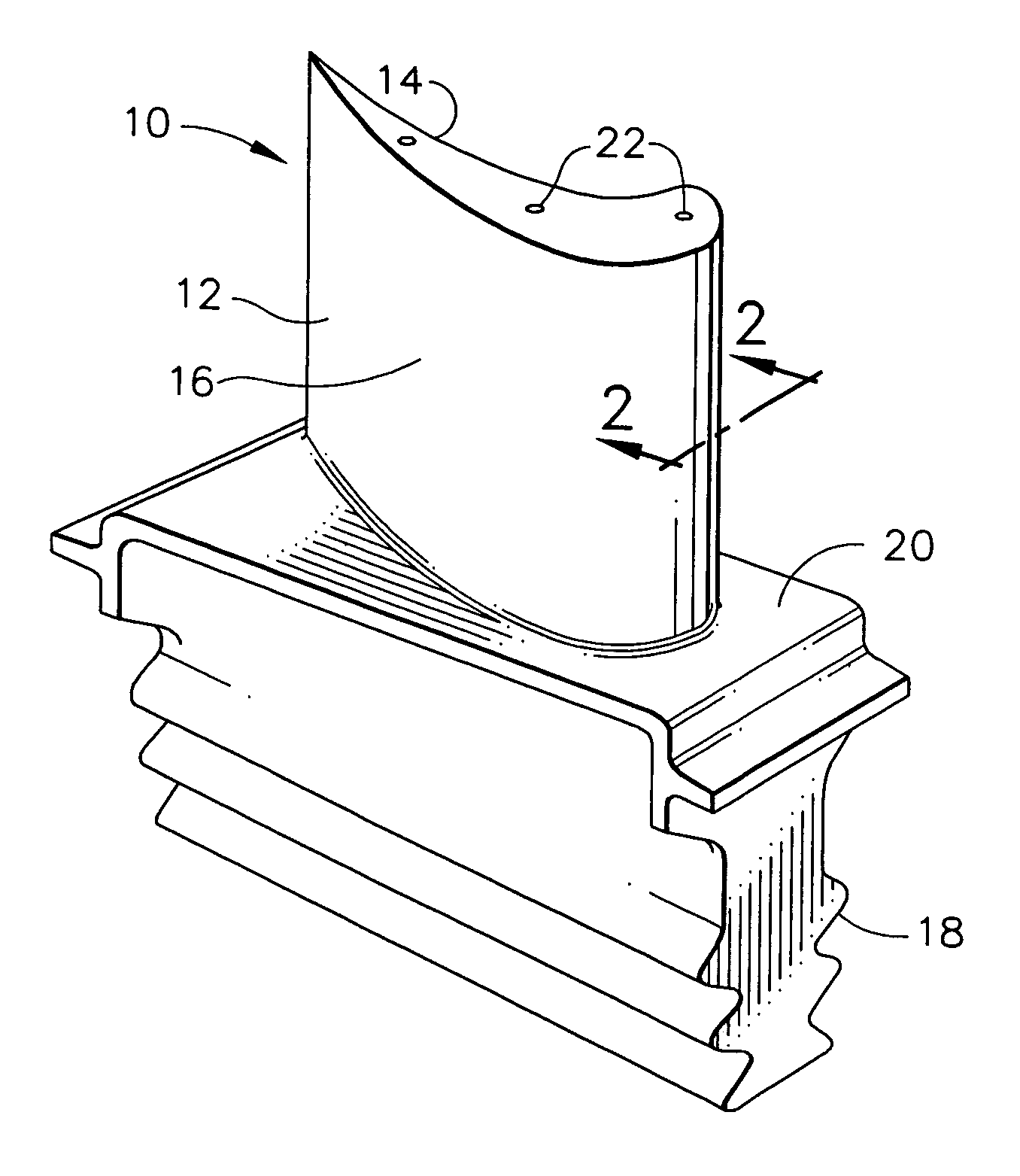

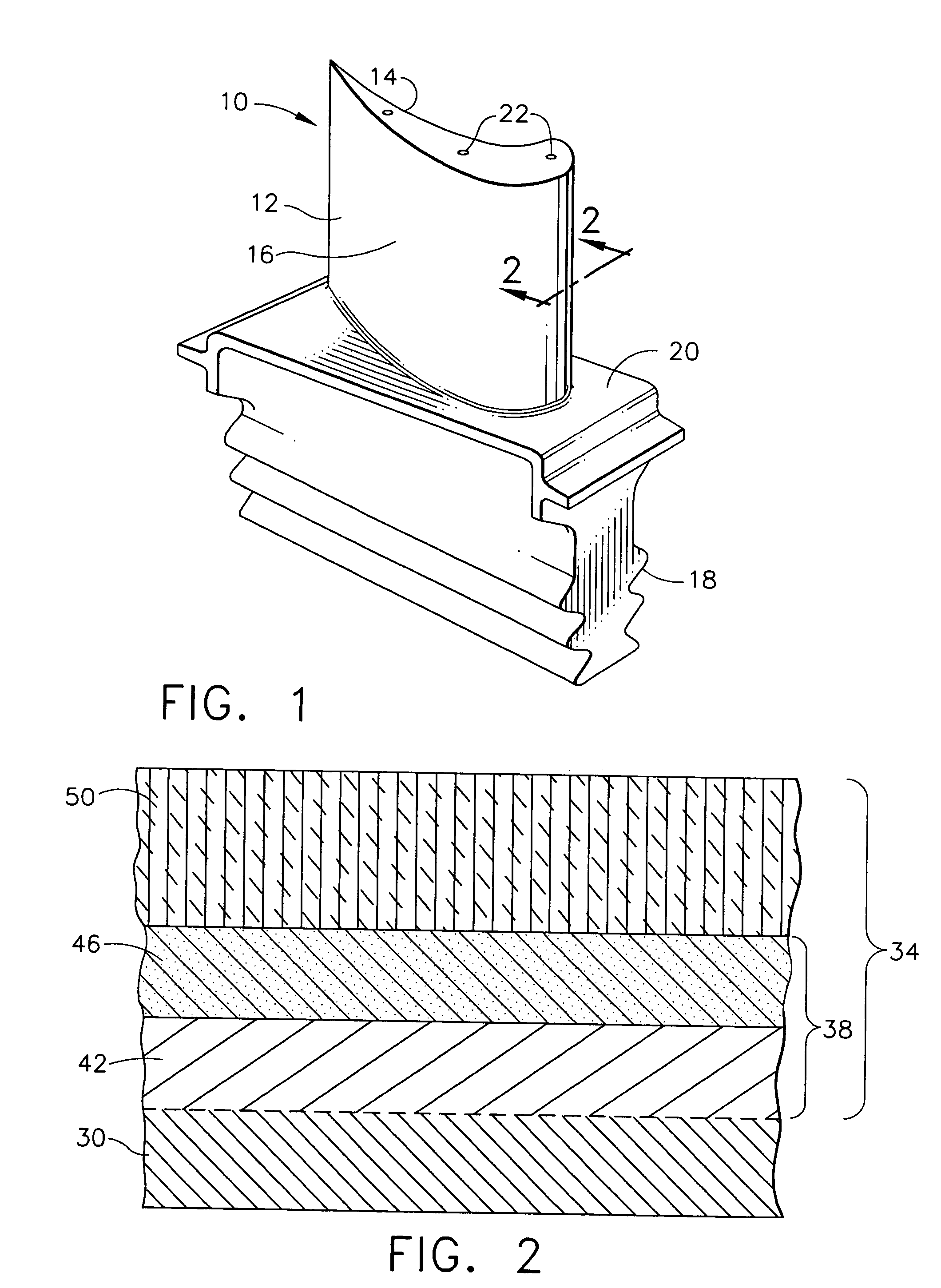

Non-Carburized Components of Track-Type Machines Having A Metallurgically Bonded Coating

Undercarriage assembly components of track-type machines having a metallurgically bonded wear-resistant coating and methods for forming such coated undercarriage assembly components is taught herein. The bodies of the undercarriage assembly components, formed of an iron-based alloy, have a hard metal alloy slurry disposed on a surface or into an undercut or channel and then fused to form a metallurgical bond with the iron-based alloy. The wear-resistant coating comprises a fused, metal alloy comprising at least 60% iron, cobalt, nickel, or alloys thereof. The portion of the outer surface of the undercarriage assembly components having the wear-resistant coating corresponds to a wear surface of the component during operation of the endless track of the track-type vehicle.

Owner:DEERE & CO

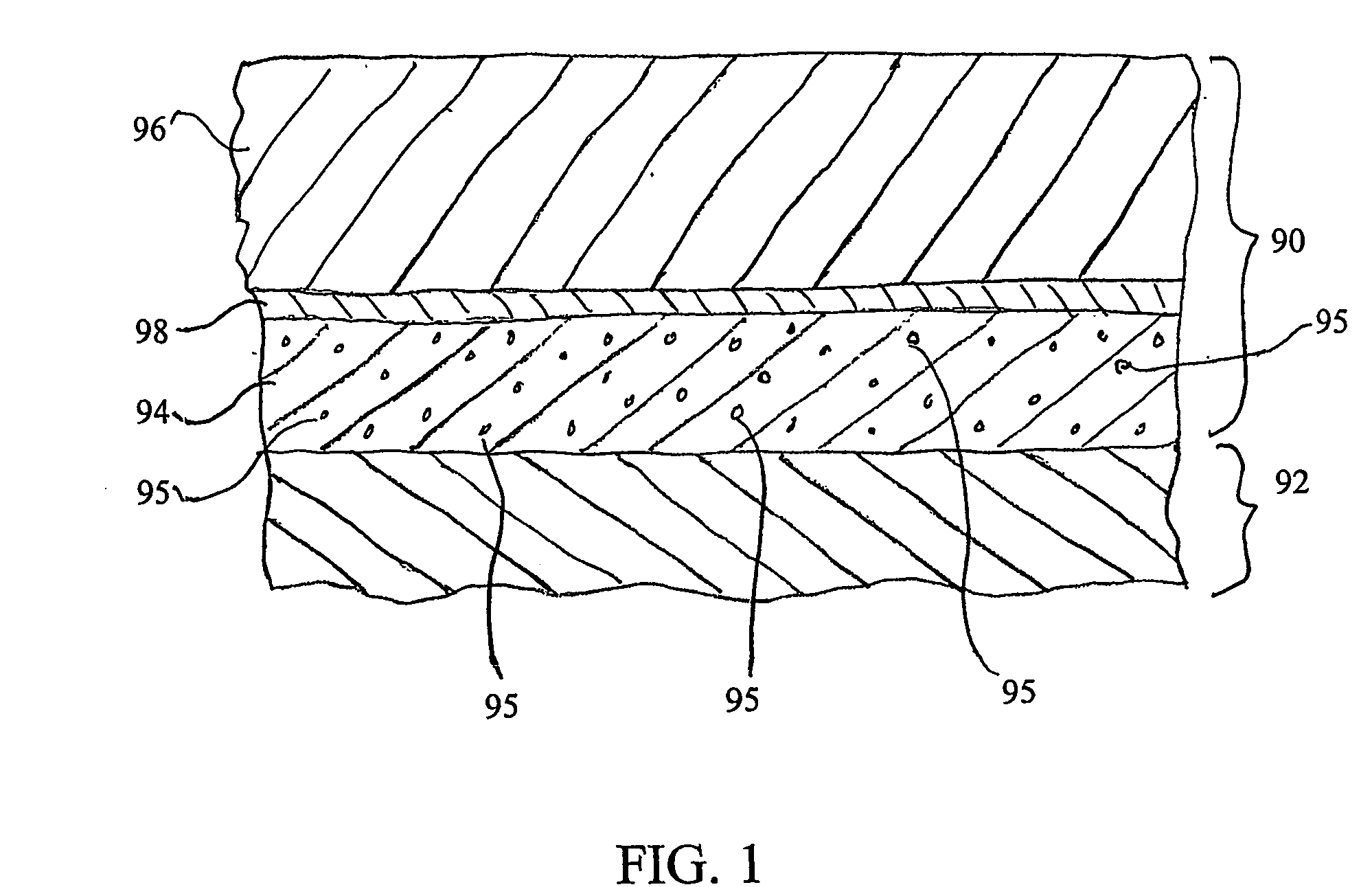

Strengthened bond coats for thermal barrier coatings

InactiveUS6979498B2Increase heightCoating is limitedPropellersRecord information storageBond coatingAlloy coating

A strengthened bond coat for improving the adherence of a thermal barrier coating to an underlying metal substrate to resist spallation without degrading oxidation resistance of the bond coat. The bond coat comprises a bond coating material selected from the group consisting of overlay alloy coating materials, aluminide diffusion coating materials and combinations thereof. Particles comprising a substantially insoluble bond coat strengthening compound and having a relatively fine particle size of about 2 microns or less are dispersed within at least the upper portion of the bond coat in an amount sufficient to impart strengthening to the bond coat, and thus limit ratcheting or rumpling thereof.

Owner:GENERAL ELECTRIC CO

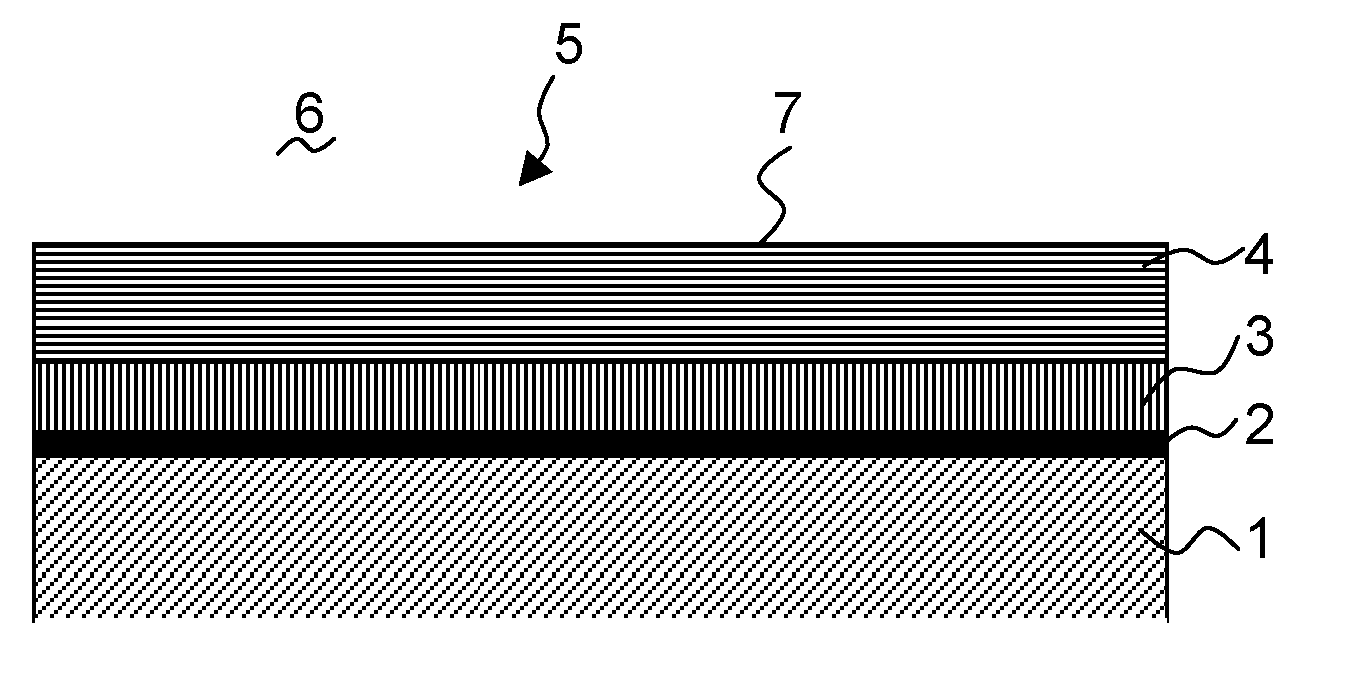

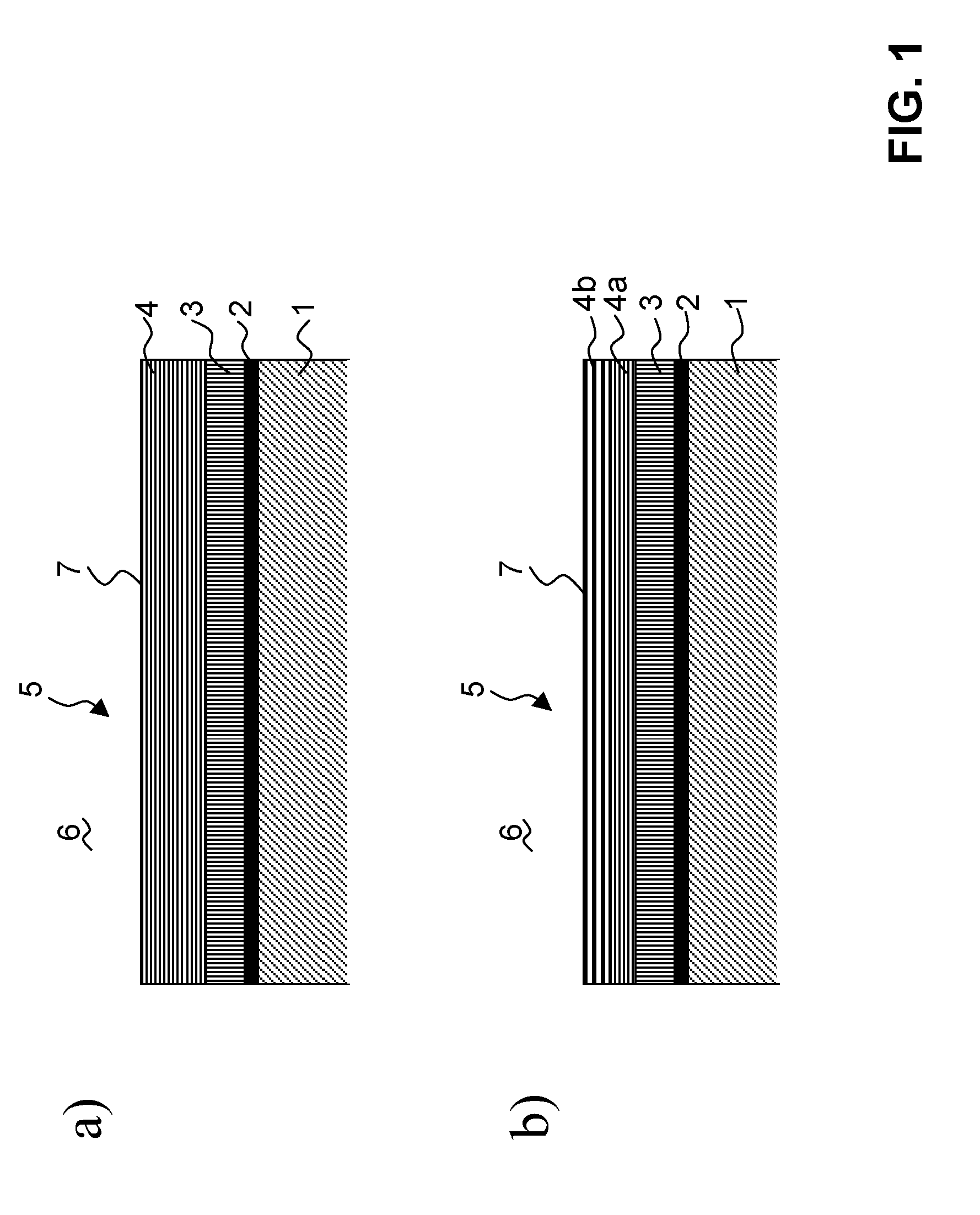

Thermal barrier coating system, components coated therewith and method for applying a thermal barrier coating system to components

A thermal barrier coating system on a base material includes a bond coat layer with a lower face in direct contact with the base material and an upper face, a first ceramic layer in direct contact with the upper face of the bond coating layer and a second ceramic layer disposed on an outermost surface of the coating system and configured to be exposed to hot gas. The first ceramic layer includes a layer, combination, mixture, alloy, blend or multilayer structure of at least one of yttria-stabilized zirconia with a yttria content in a range of 6-8 wt-%, YTaO4 doped zirconia, and titania doped zirconia. The second ceramic layer includes a layer, combination, mixture, alloy, blend or multilayer structure of at least one of YTaO4 doped zirconia, titania doped zirconia, scandia stabilized zirconia, ceria containing perovskite material, yttrium aluminium garnet material, Monazite material, and spinel material. A material of the second ceramic layer is different from a material of the first ceramic layer.

Owner:ANSALDO ENERGIA SWITZERLAND AG

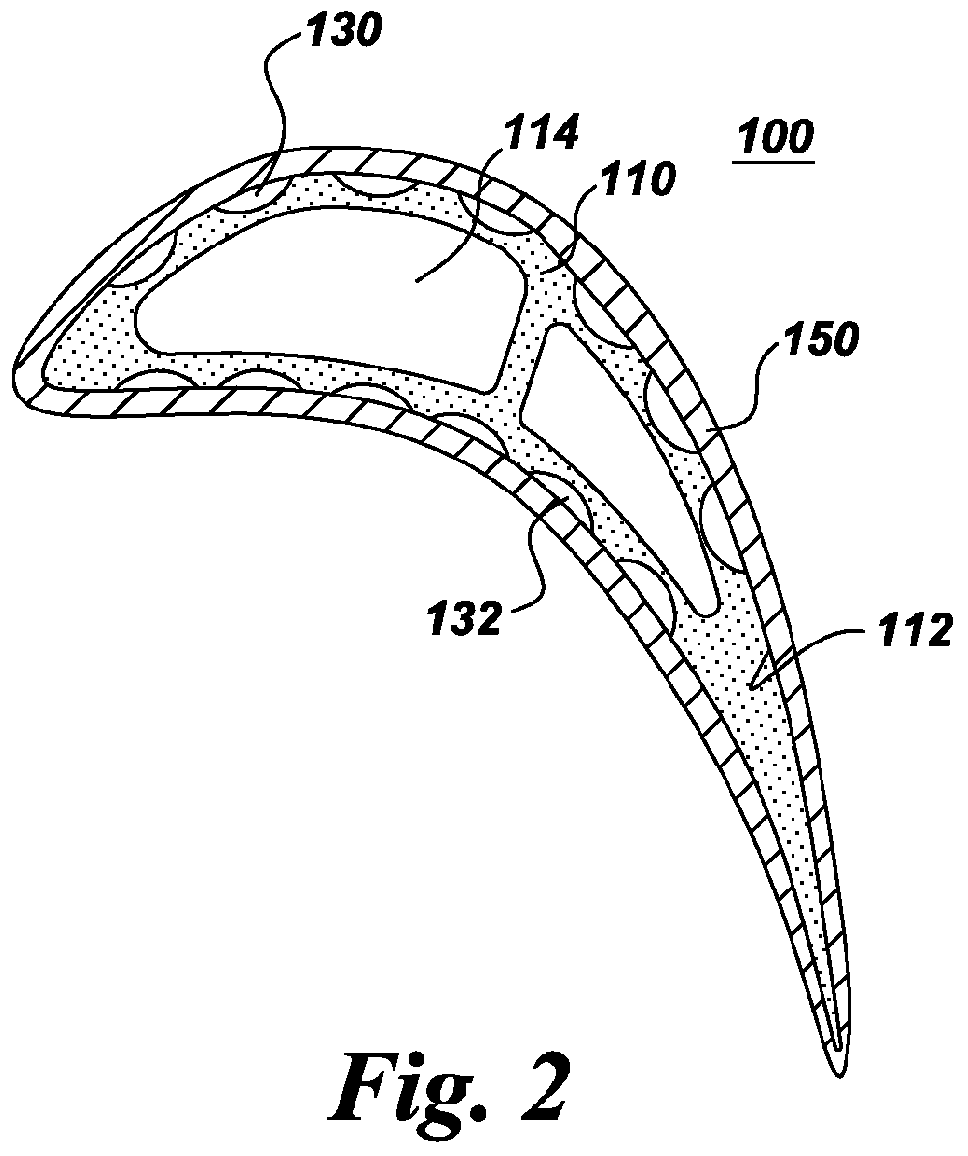

Application of Dense Vertically Cracked and Porous Thermal Barrier Coating to a Gas Turbine Component

InactiveUS20110038710A1Increase temperatureIncreased strain toleranceMolten spray coatingPropellersBond coatingEngineering

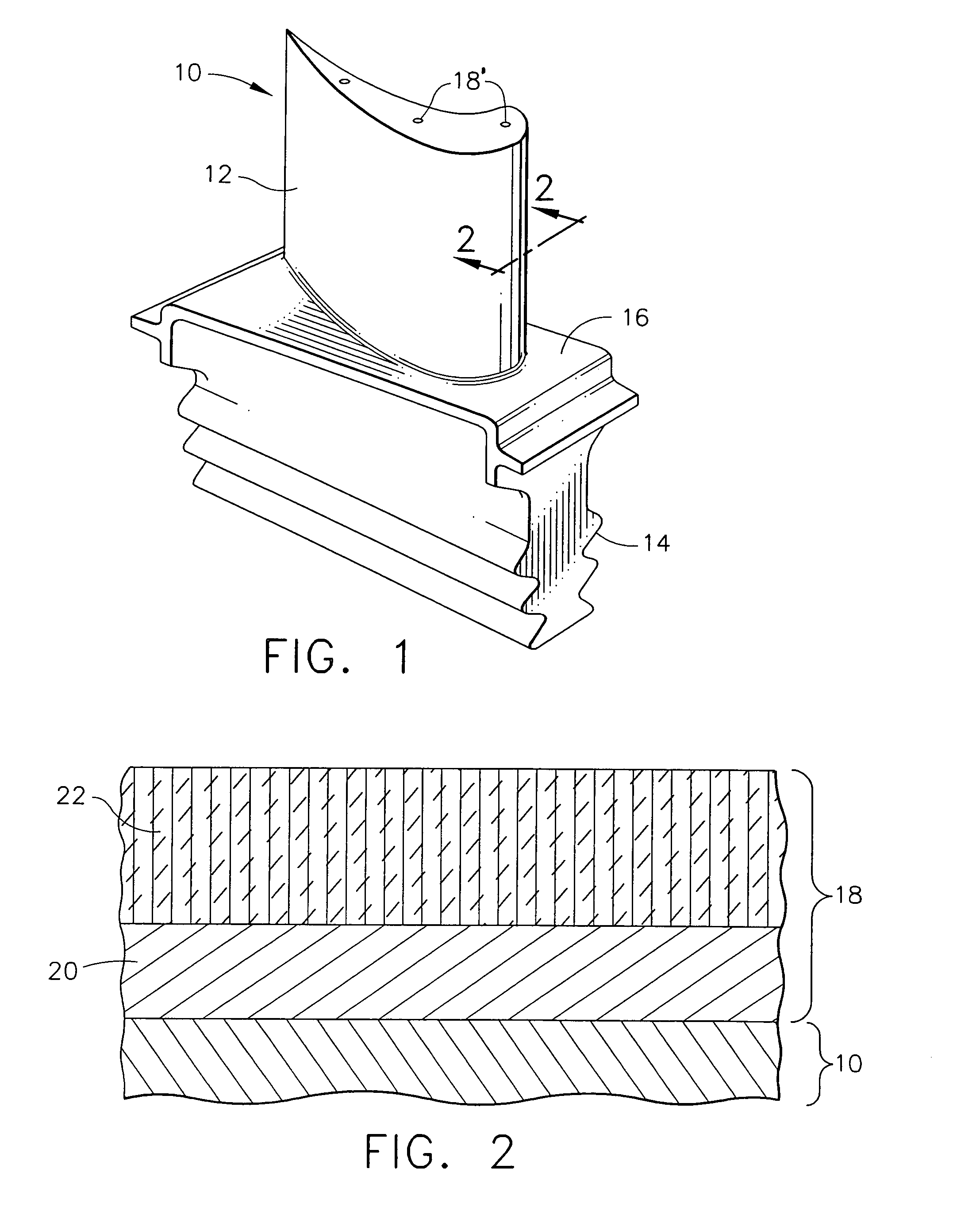

A configuration for coating a turbine component such as a blade or vane with various forms of thermal barrier coating to provide enhanced temperature capability and increased strain tolerance is disclosed. A gas path surface of the platform, airfoil and airfoil fillet region are first coated with a bond coating. A dense vertically cracked (DVC) thermal barrier coating is then applied to at least the gas path surface of the platform and can be applied to the fillet region. A porous thermal barrier coating is then applied to at least the airfoil. The porous thermal barrier coating can also be applied over the DVC thermal barrier coating if desired.

Owner:ANSALDO ENERGIA IP UK LTD

Annealing furnace roller surface peening coating and method for making same

InactiveCN101113487AImprove antioxidant capacityImprove wear resistanceMolten spray coatingFurnace typesThermal sprayingBond coating

The invention relates to a strengthening coating of the surface of an annealing furnace roller and a preparation method thereof. The preparation of the strengthening coating on the surface of a roller base is performed by a selected hot-spray method. The strengthening coating comprises a bonded coating, a working coating and a transition coating between the bonded coating and the working coating. The proportion of alloy and ceramic in every coating is changed according to gradient, which means that the proportion of alloy is decreased gradually from inner to outer in every coating; while the proportion of ceramic is increased gradually and at last a gradient coating is formed. The invention not only ensures the working coating to have good antioxidation, abrasion resisting and anti- nodulation performances, but also improves the binding performance of strengthening coating and the roller base and improves the cohesion binding performance of the coating inner. Under the function of the strengthening coating of the annealing furnace roller surface made by the method of the invention, the service life of the furnace roller can be prolonged and the using cost and repairing cost can be decreased.

Owner:常州杰耐机械有限公司

Method for applying or repairing thermal barrier coatings

ActiveUS7094450B2Sufficient adhesionLess time consuming and uncomplicated way to applyMolten spray coatingLayered productsGas phaseBond coating

Owner:GENERAL ELECTRIC CO

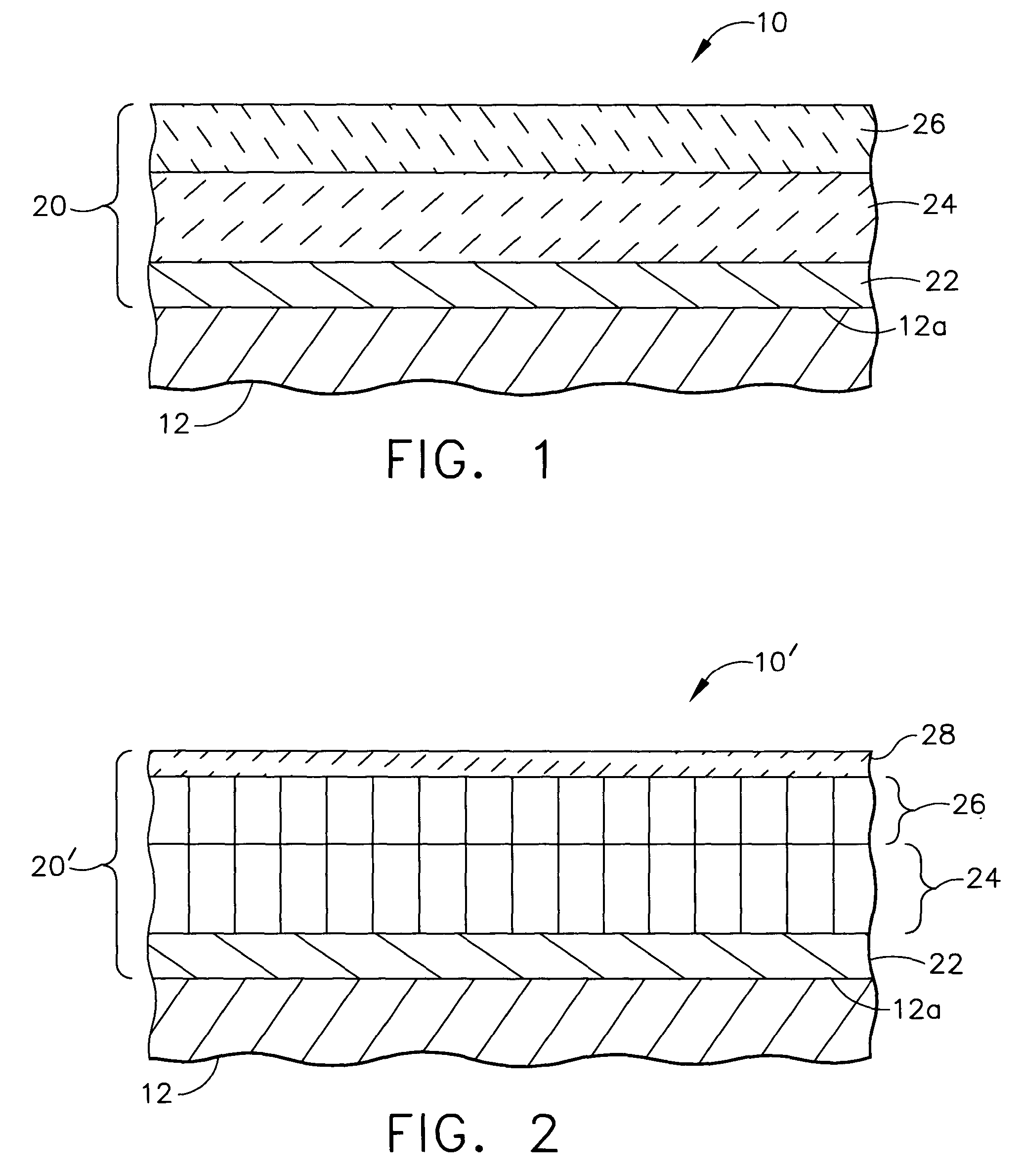

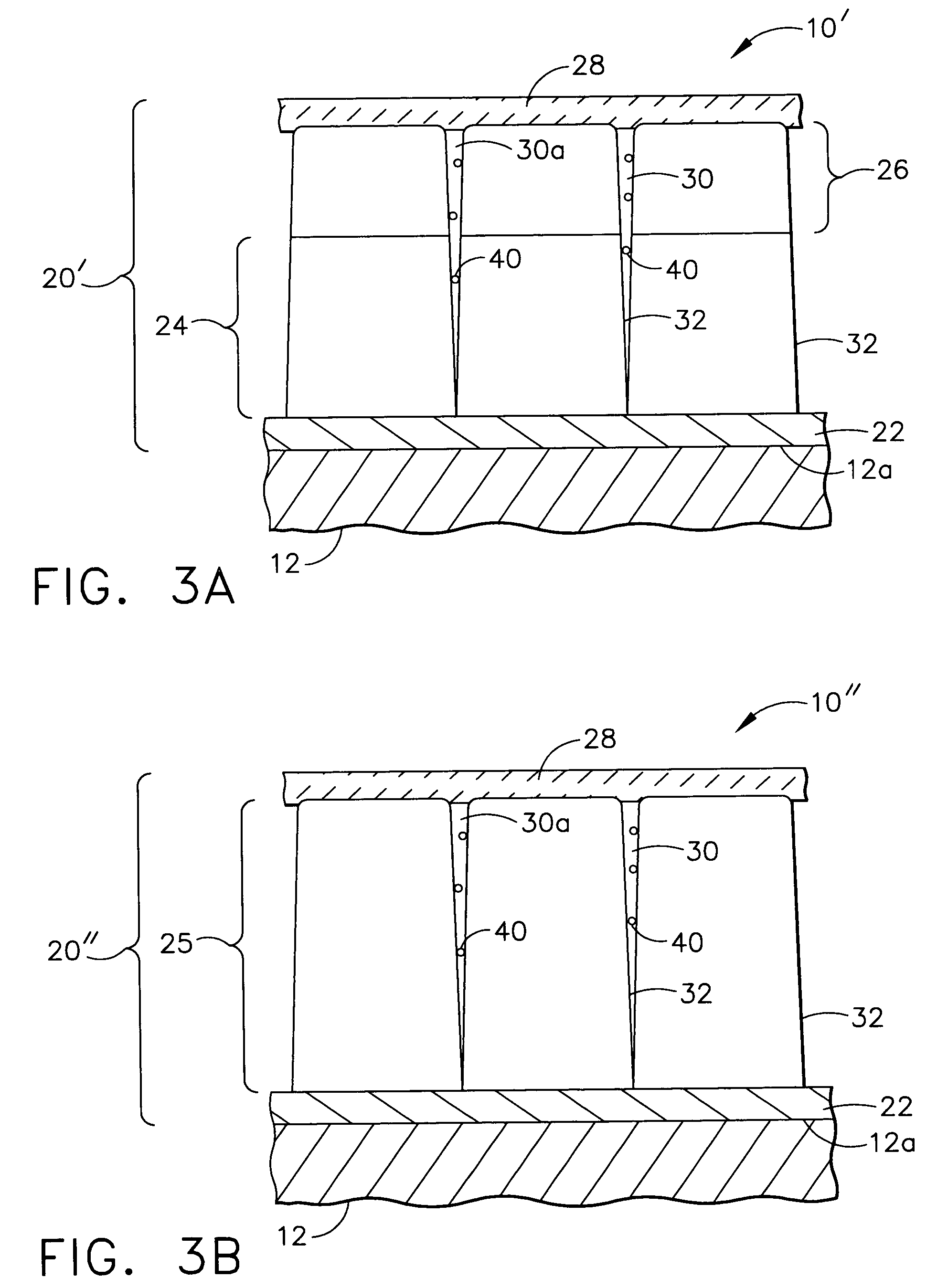

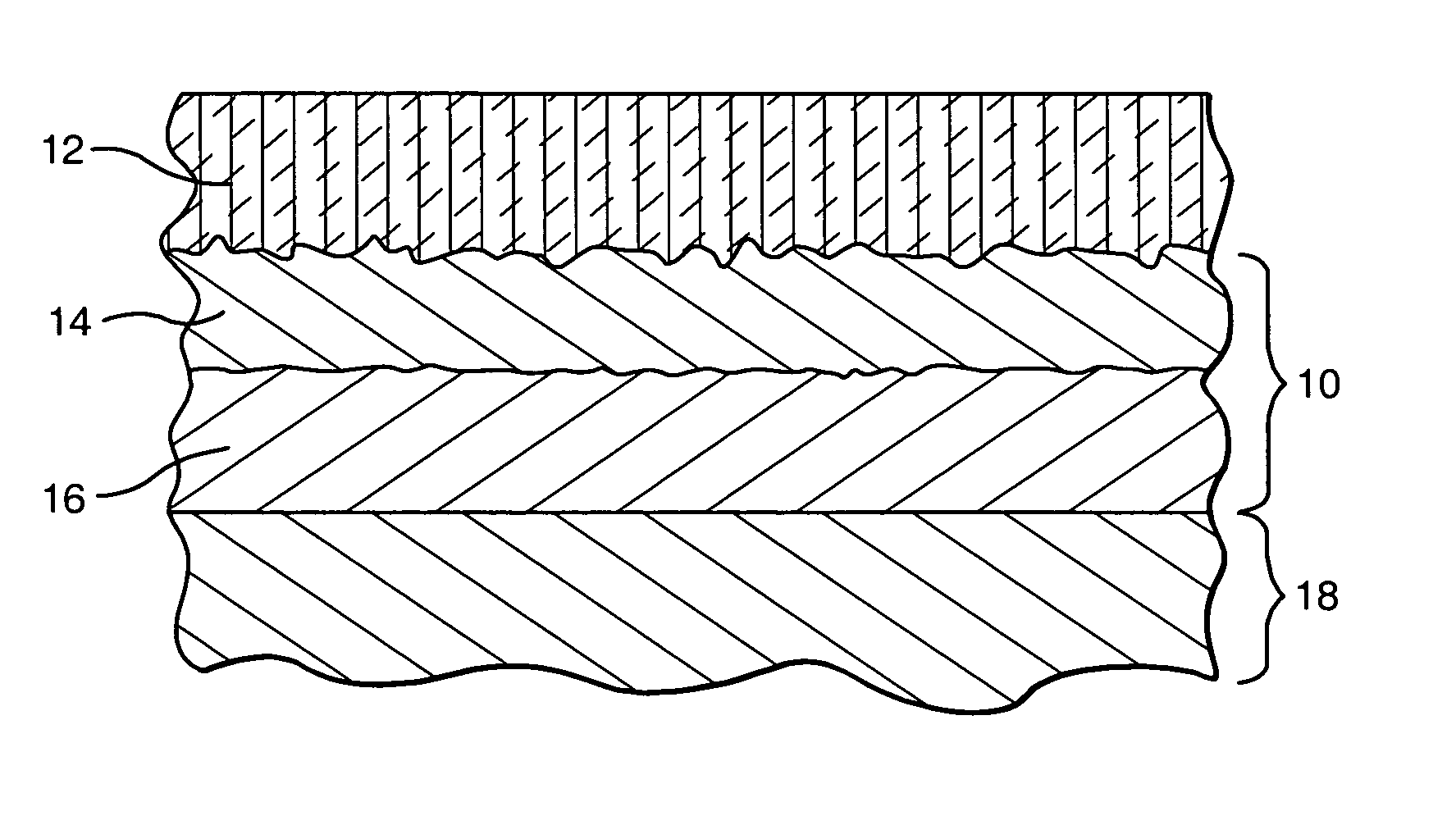

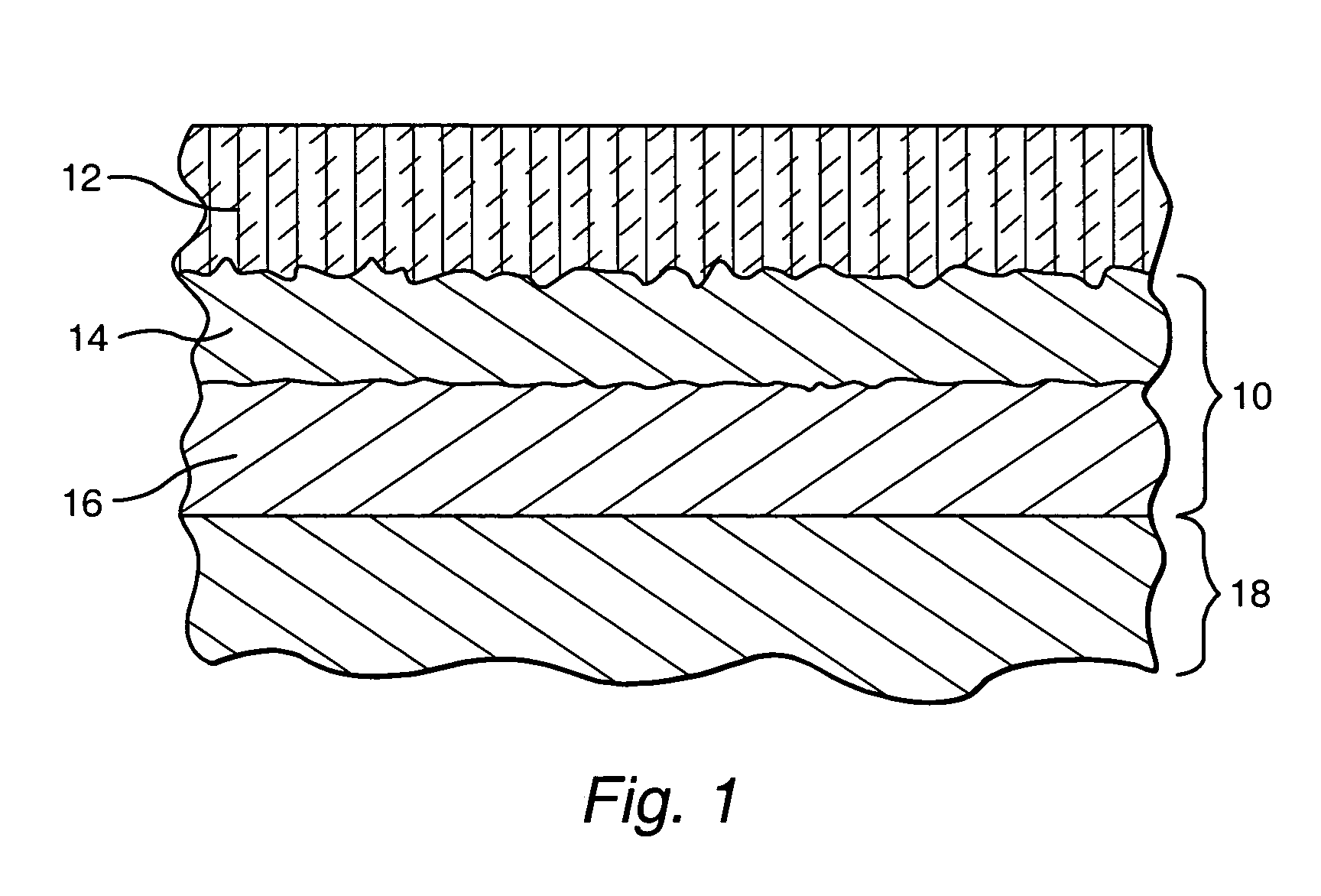

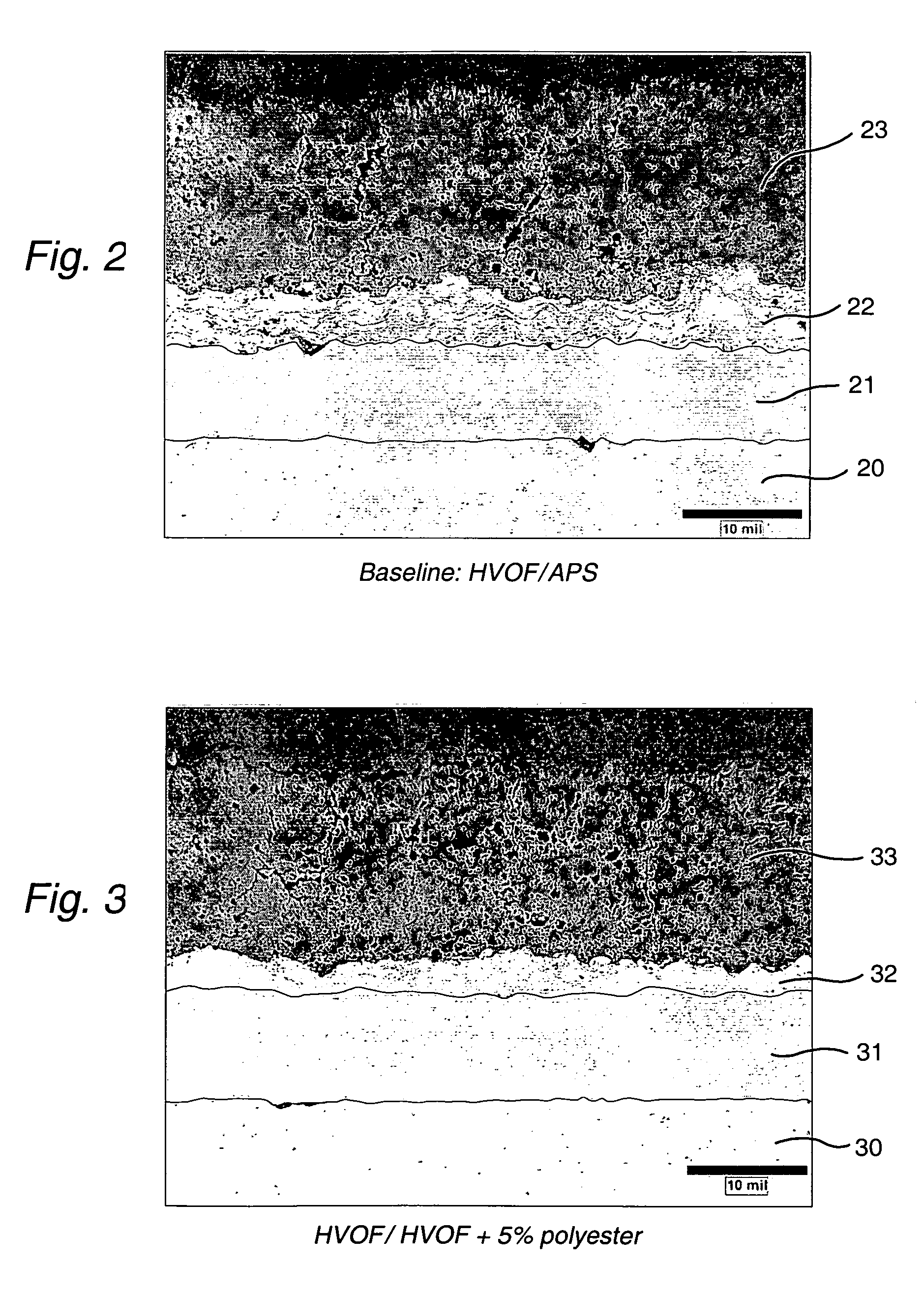

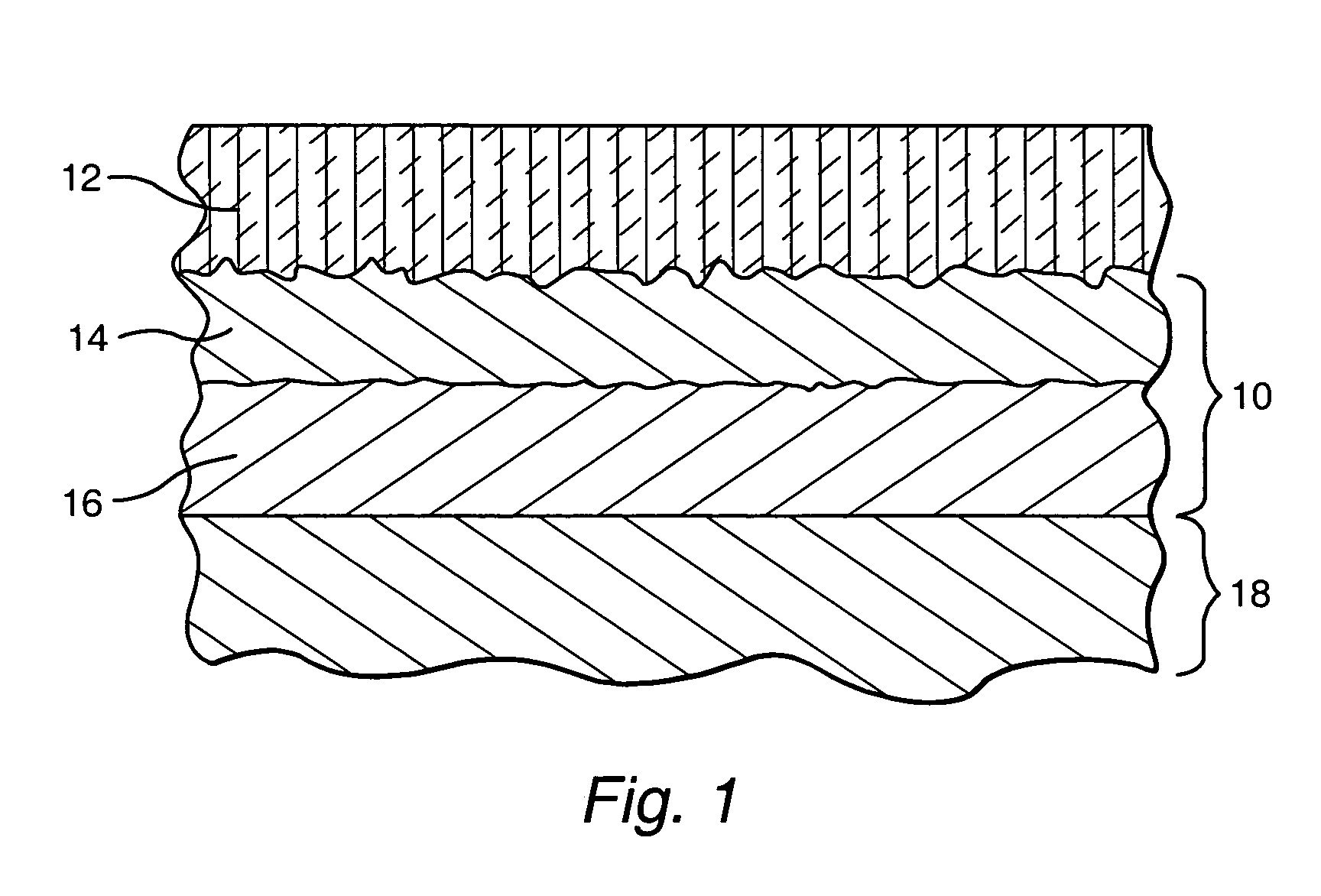

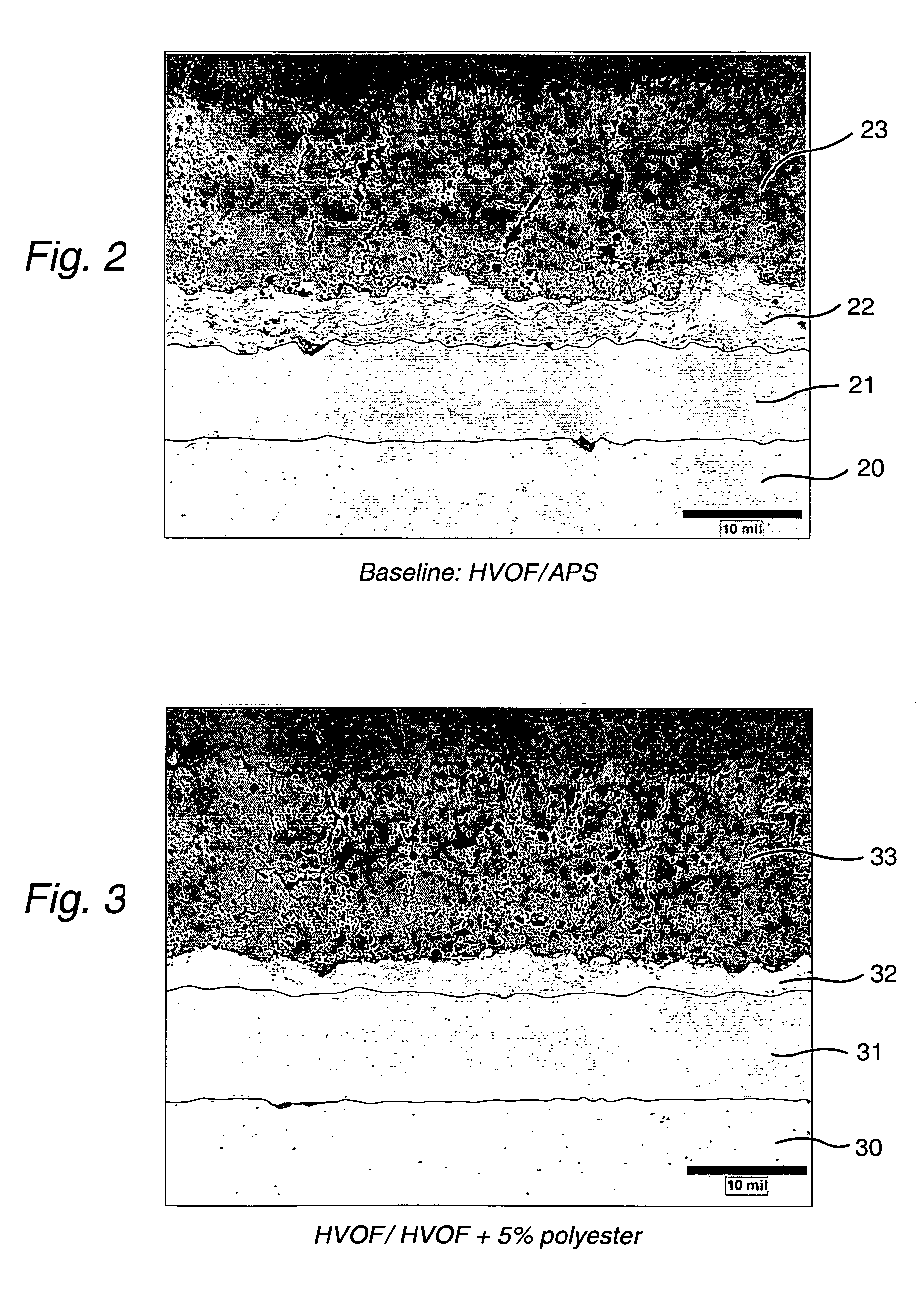

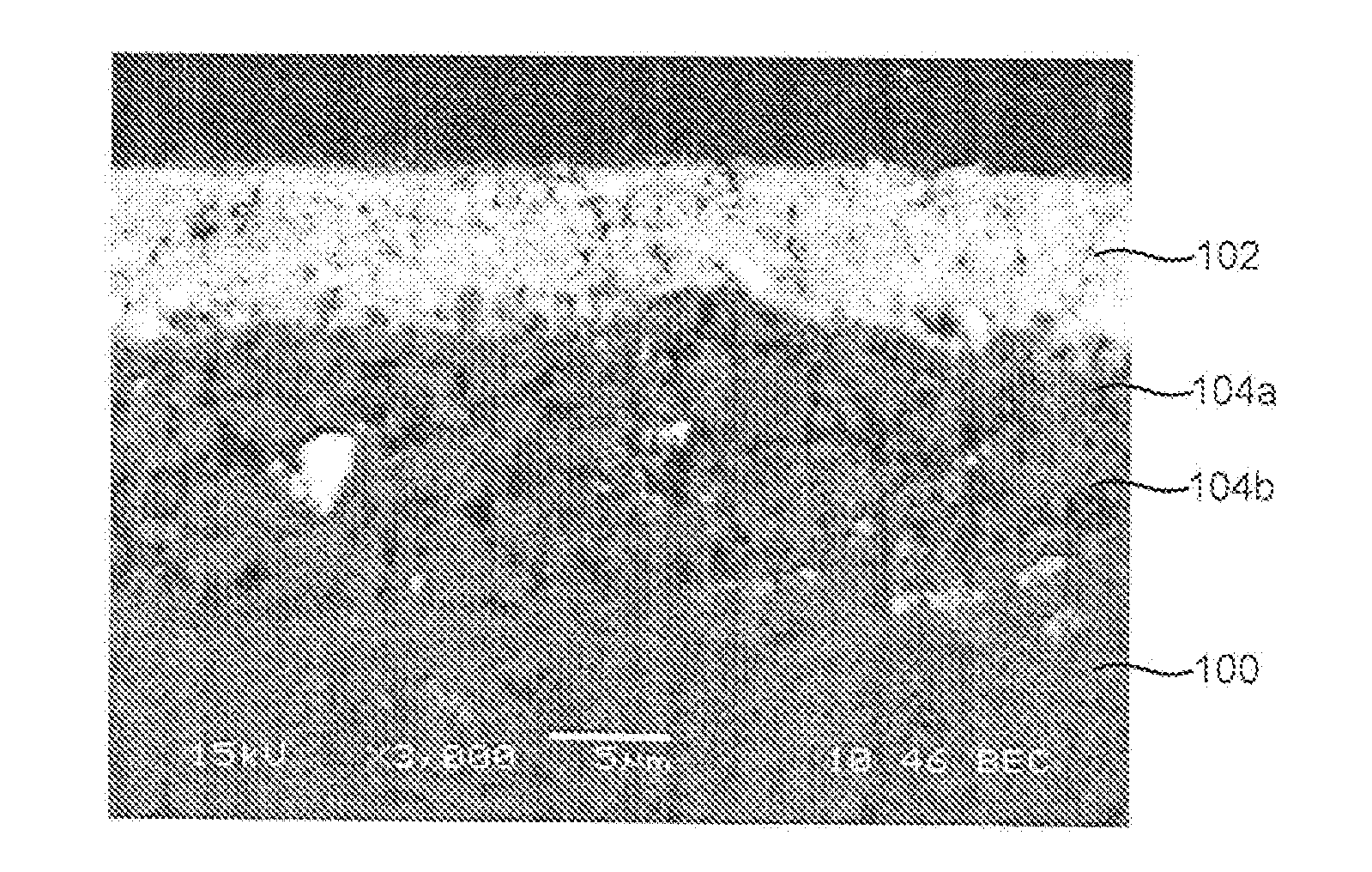

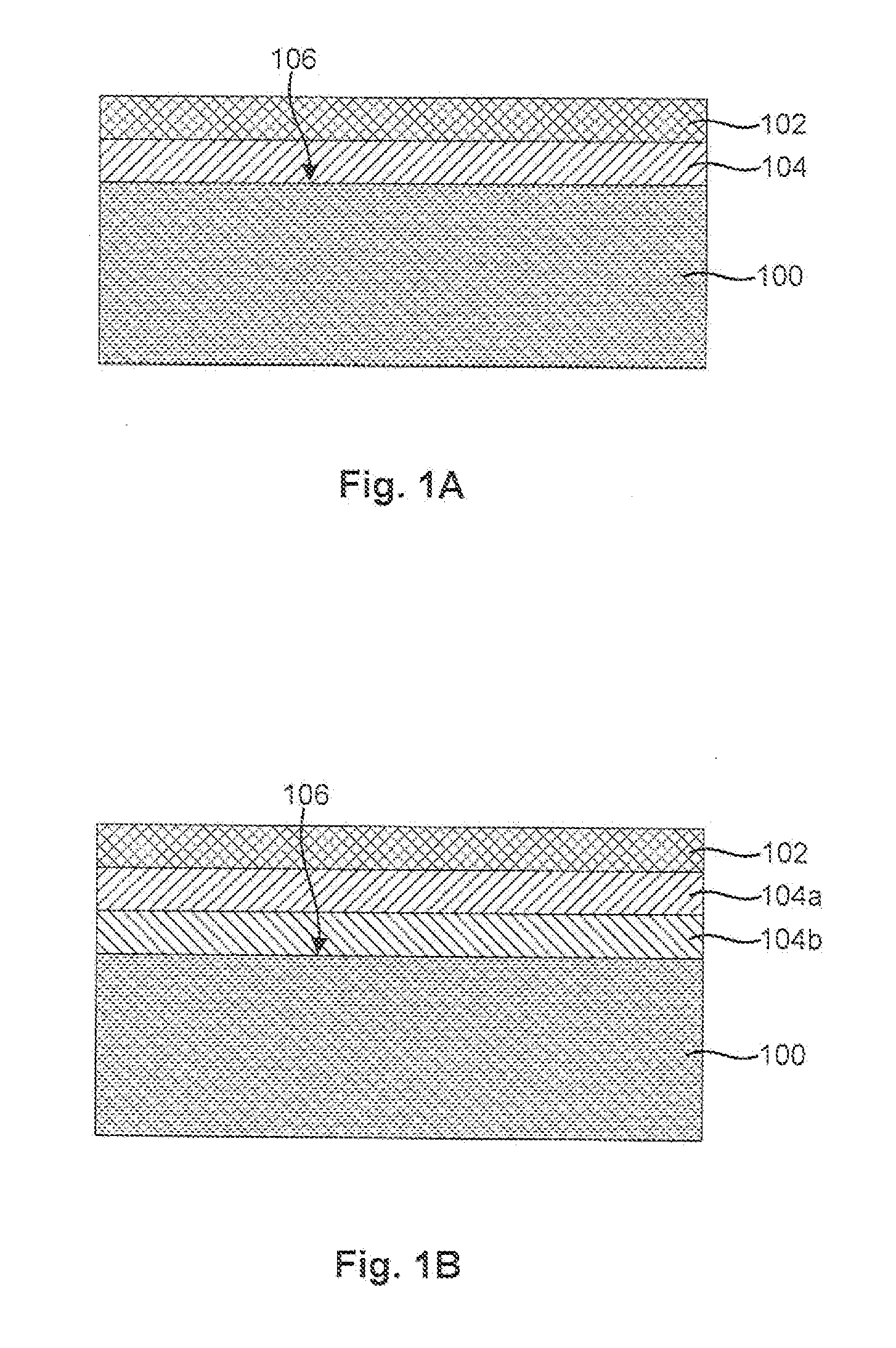

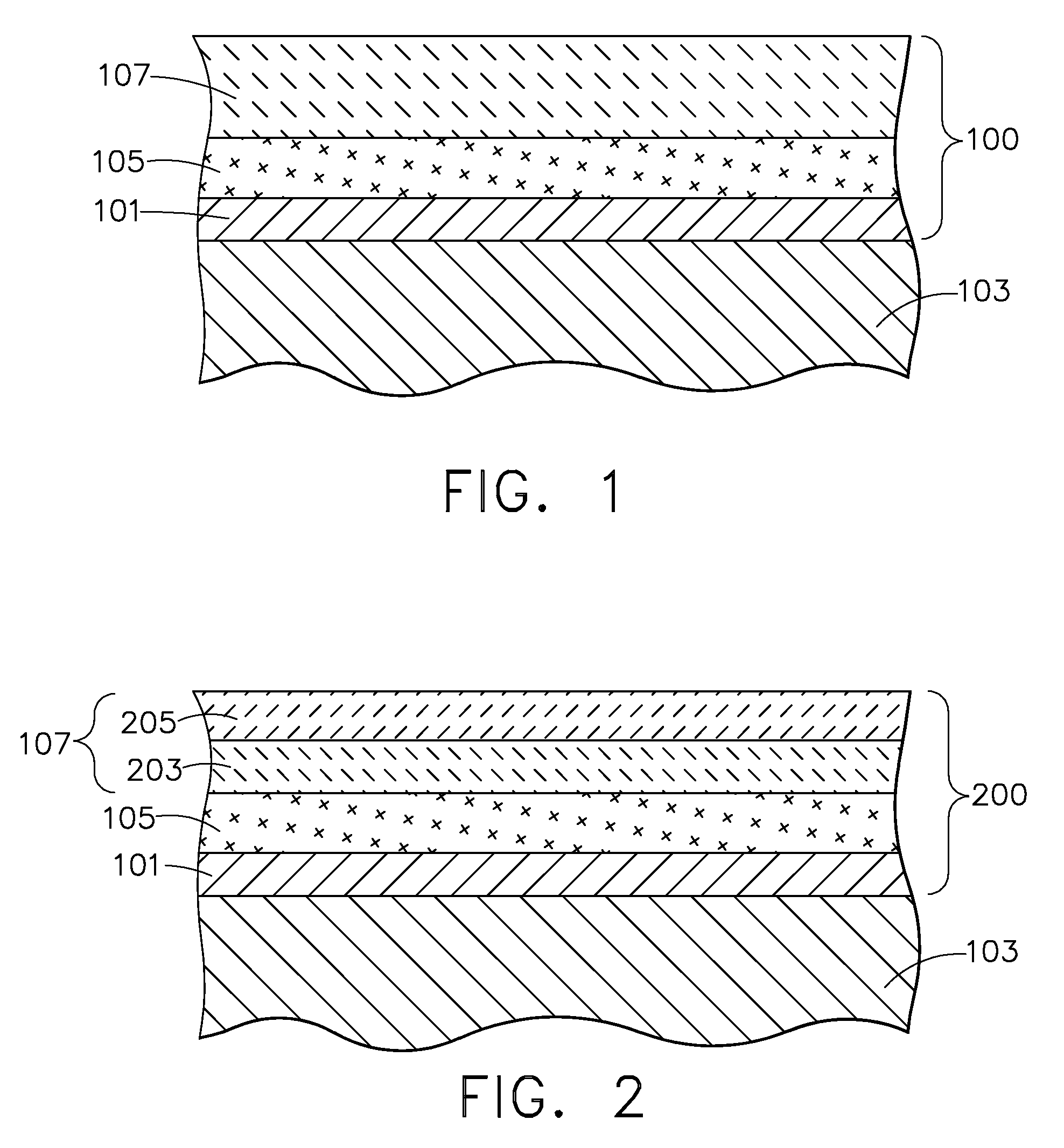

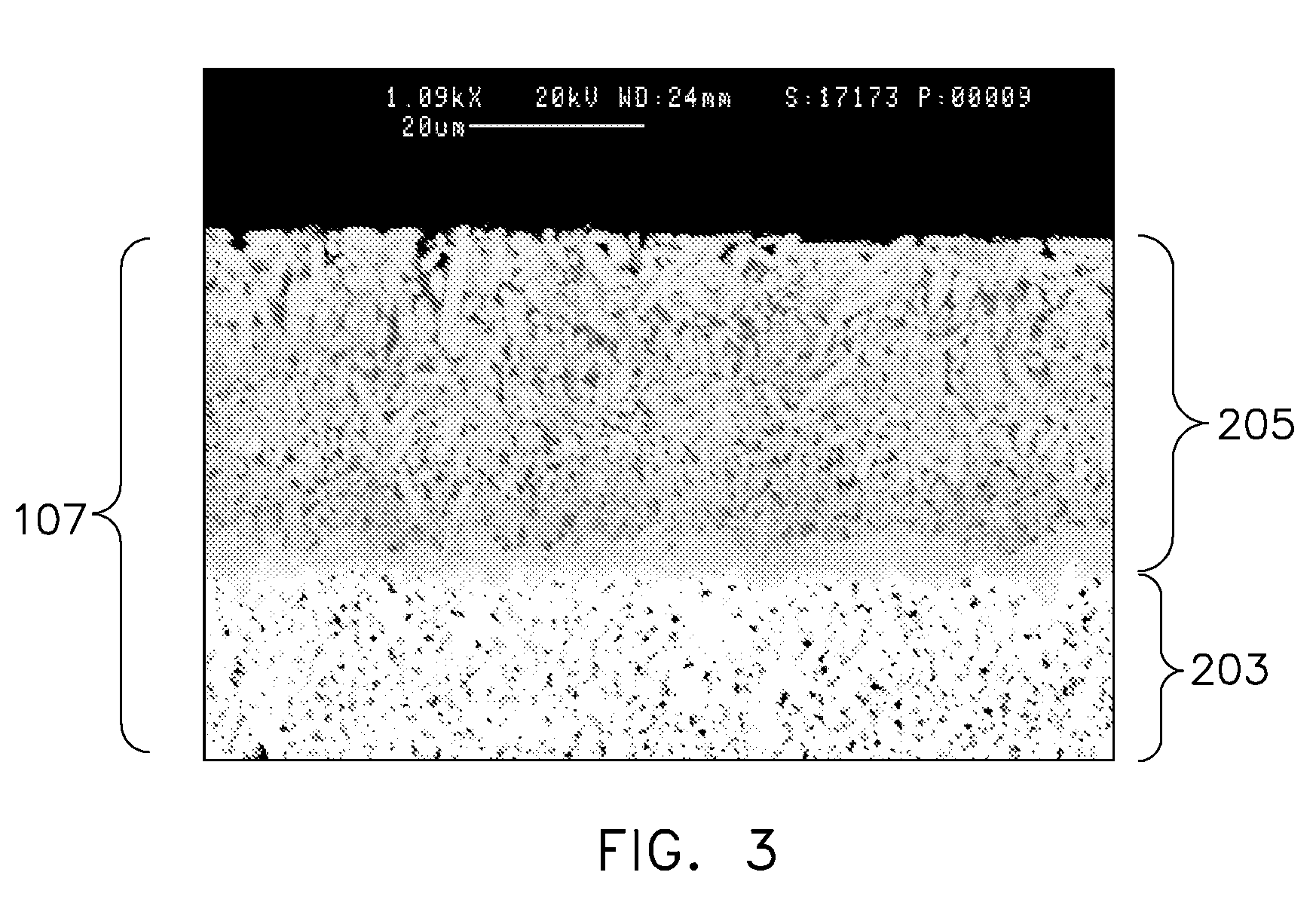

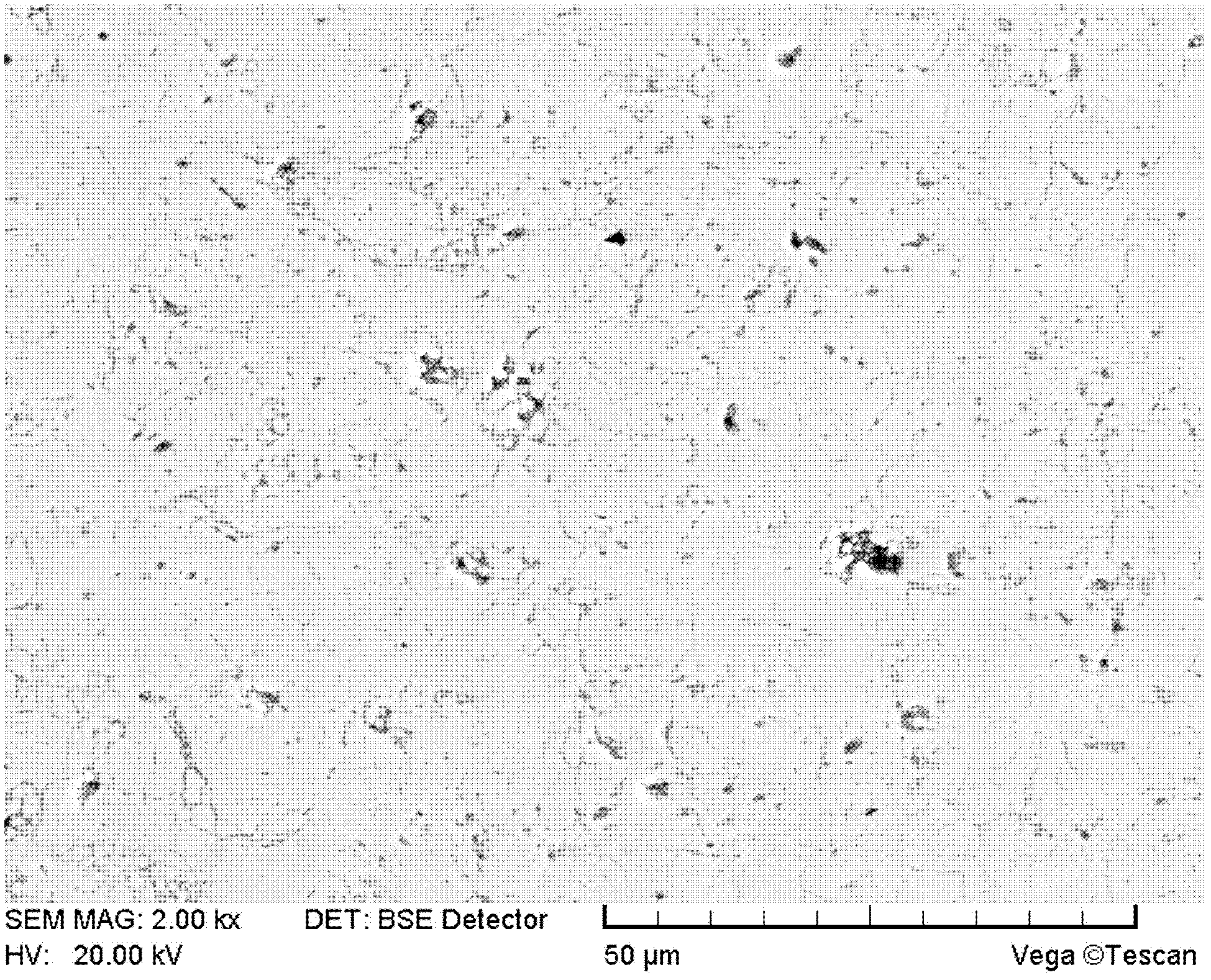

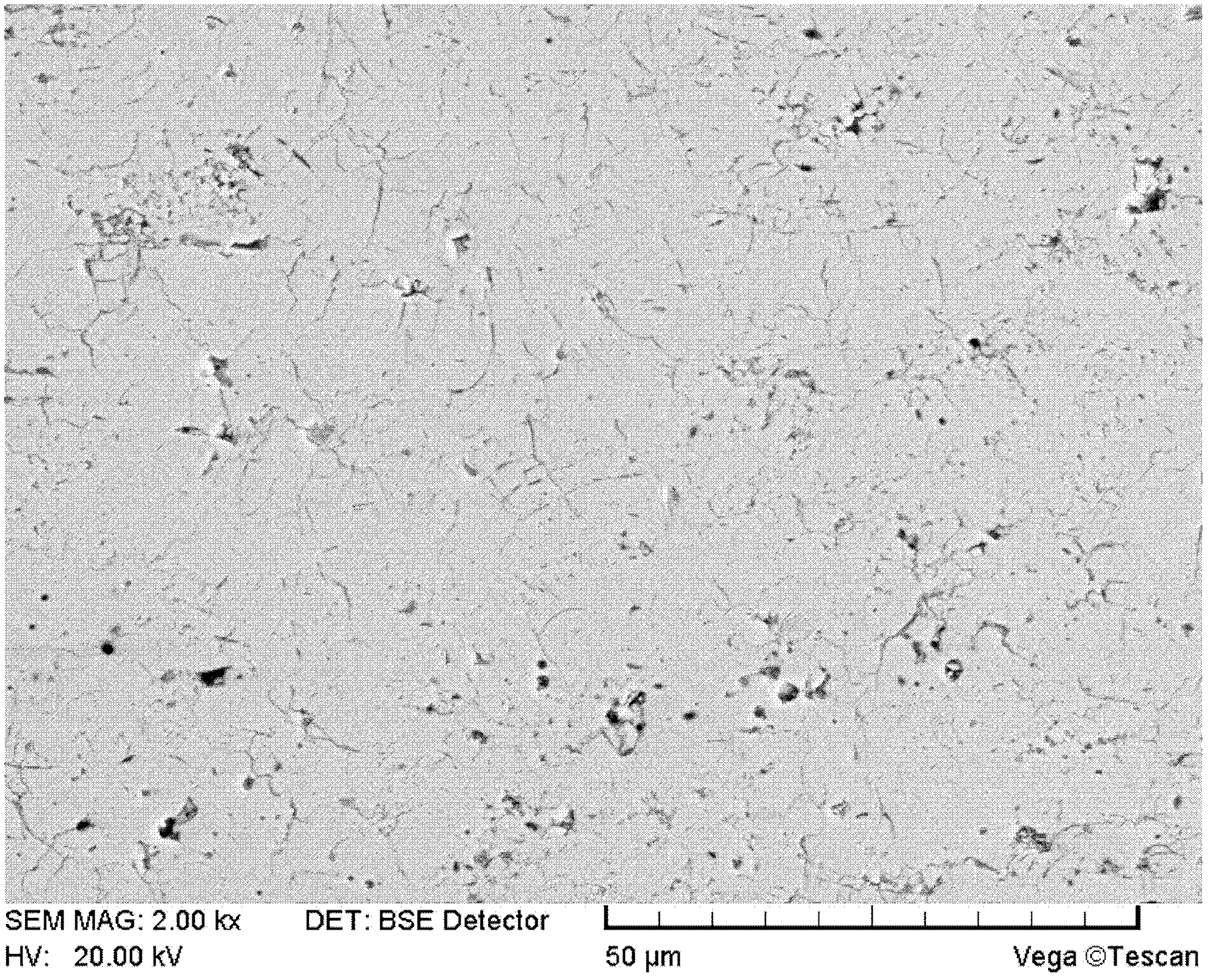

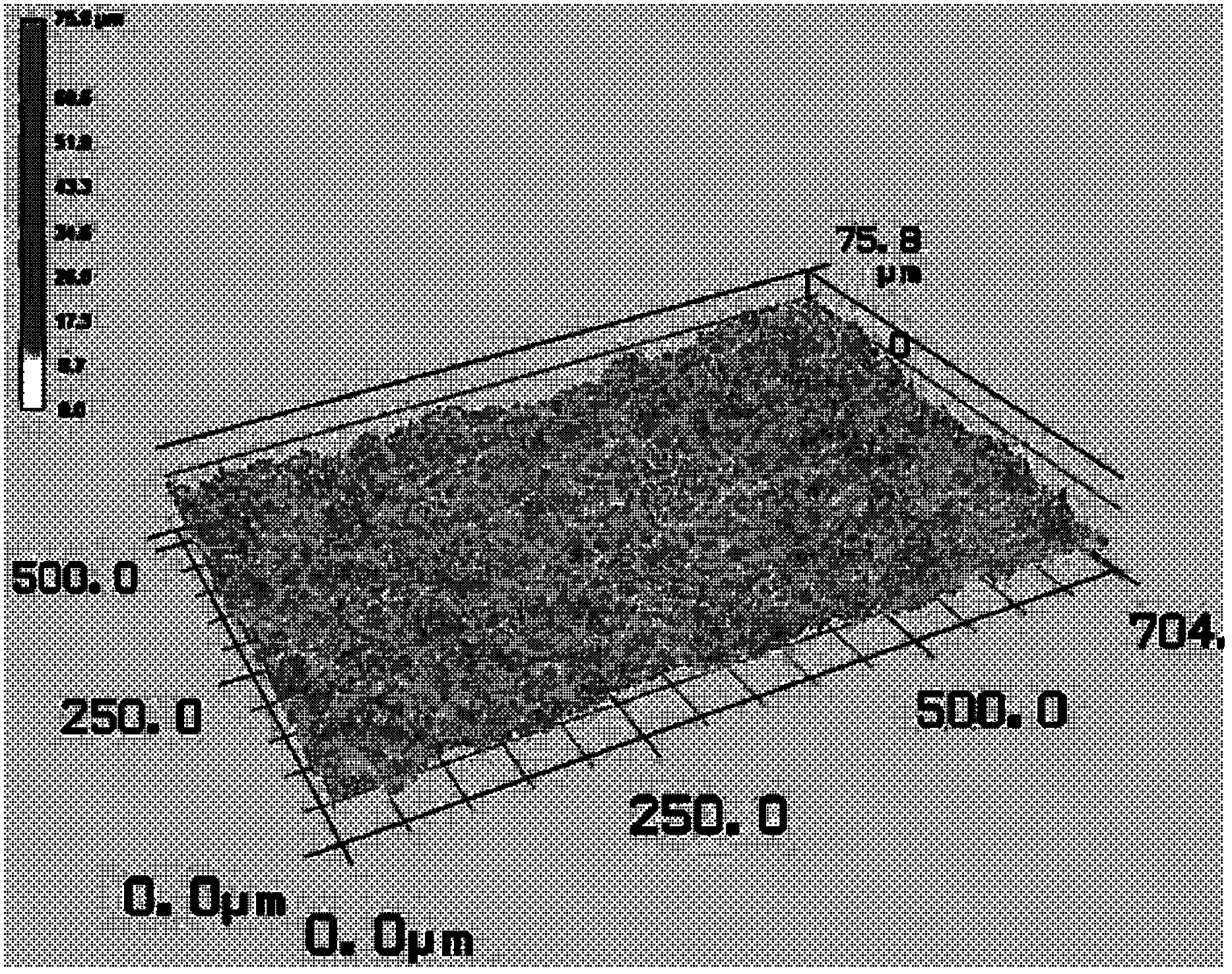

Bi-layer HVOF coating with controlled porosity for use in thermal barrier coatings

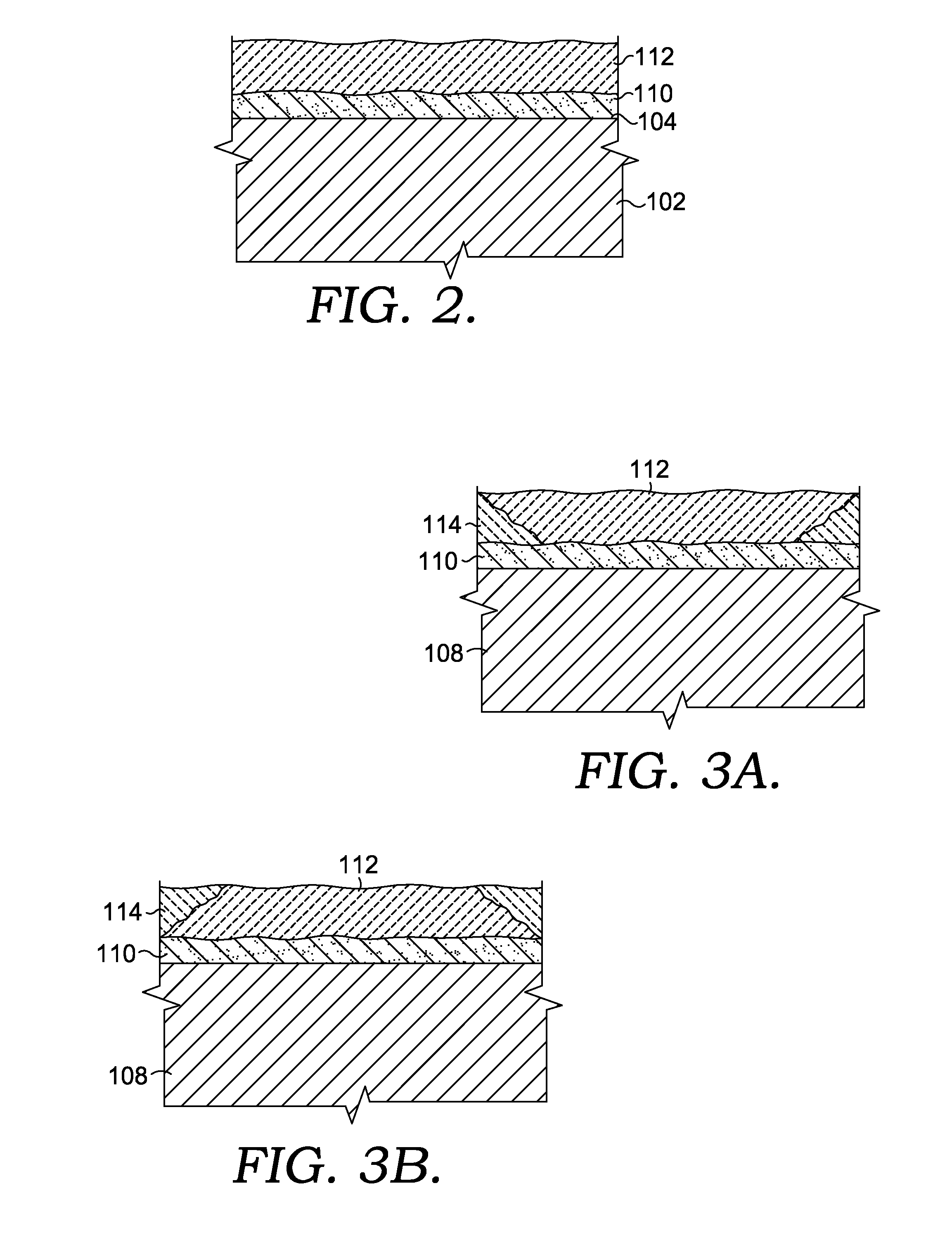

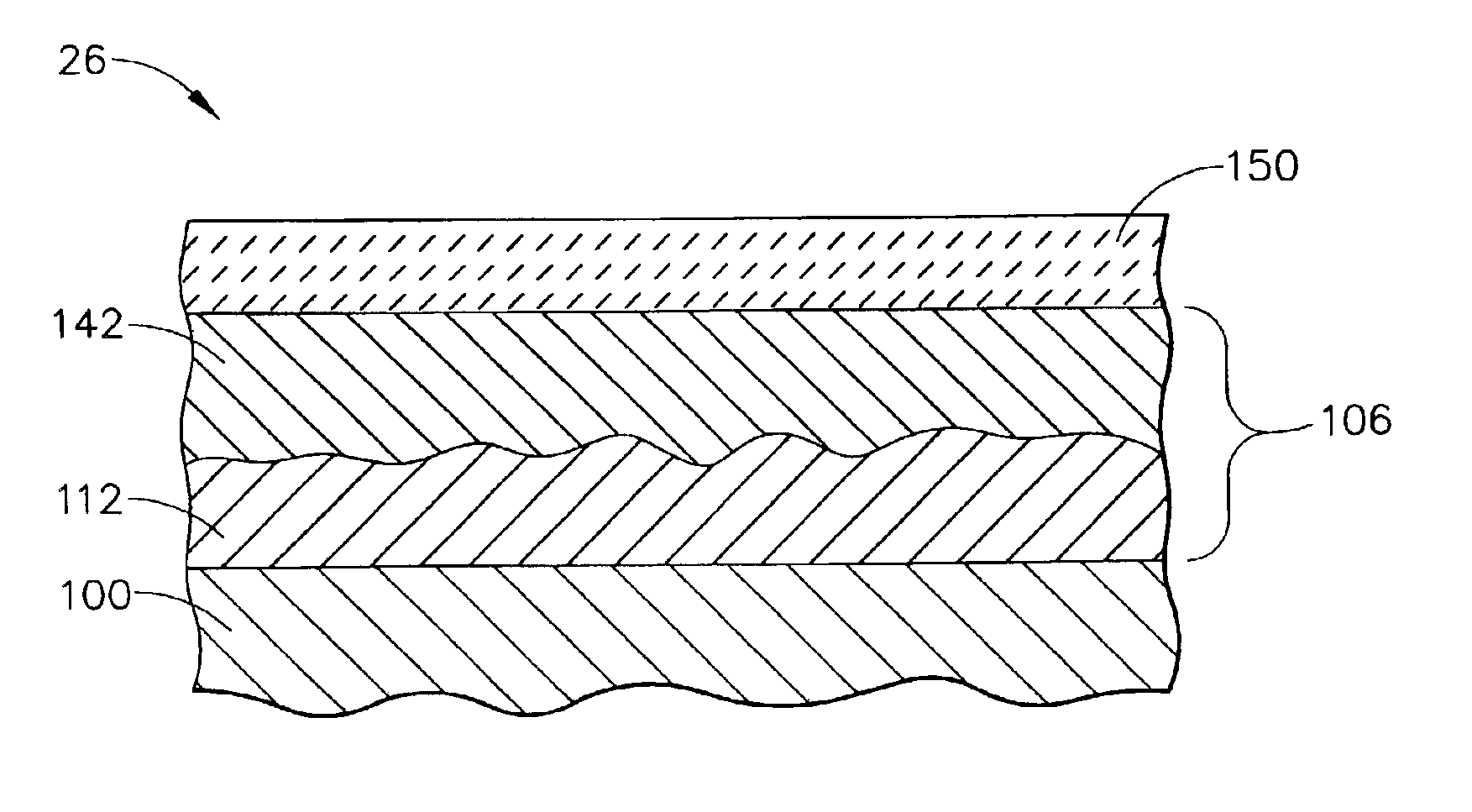

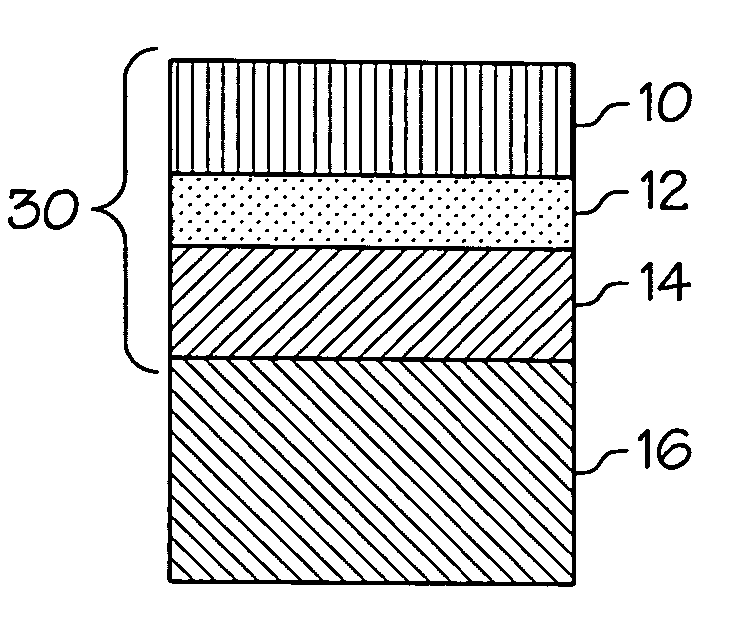

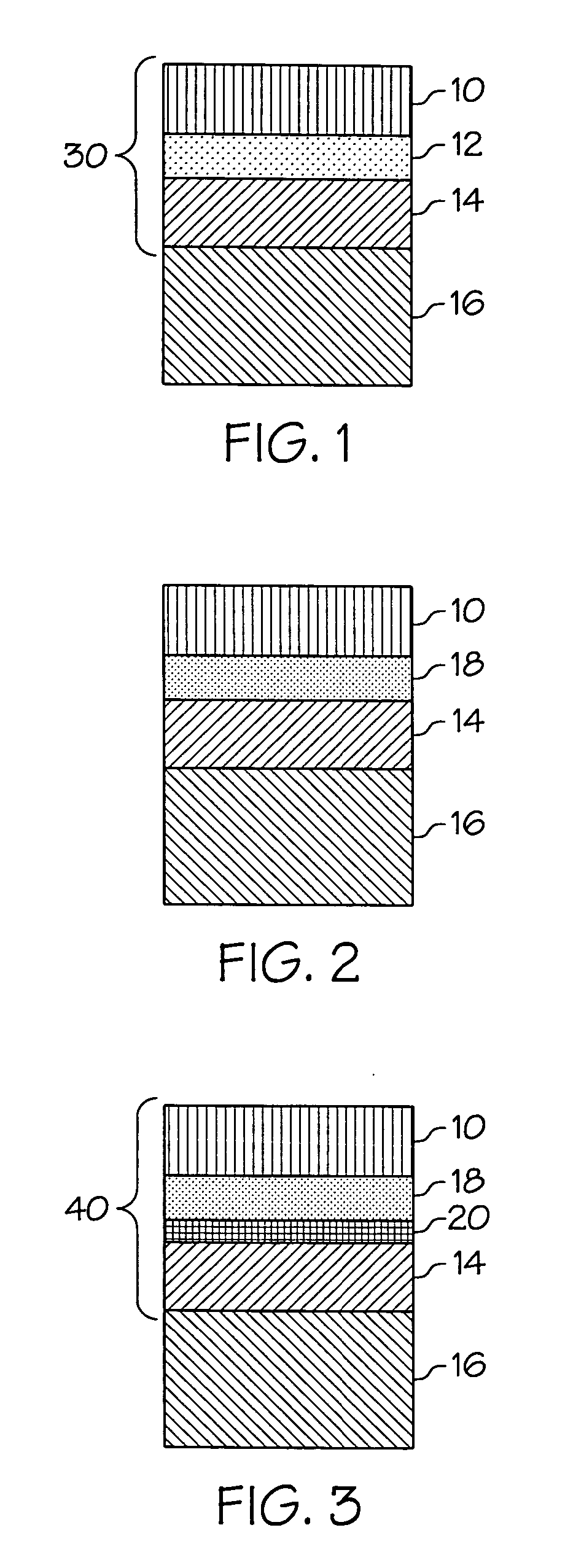

InactiveUS7150921B2Increase roughnessImprove ductilityMolten spray coatingPretreated surfacesPorosityPolyester

A bi-layer bond coating for use on metal alloy components exposed to hostile thermal and chemical environment, such as a gas turbine engine, and the method for applying such coatings. The preferred coatings include a bi-layer bond coat applied to the metal substrate using high velocity oxy-fuel (HVOF) thermal spraying. Bi-layer bond coatings in accordance with the invention consist of a dense first inner layer (such as iron, nickel or cobalt-based alloys) that provides oxidation protection to the metal substrate, and a second outer layer having controlled porosity that tends to promote roughness, mechanical compliance, and promotes adherence of the thermal barrier coating (TBC). Preferably, the outer, less dense layer of the bi-layer bond coat is formed from a mixture of metallic powder and polyester to adjust and control the porosity, but without sacrificing mechanical compliance.

Owner:GENERAL ELECTRIC CO

Bi-layer HVOF coating with controlled porosity for use in thermal barrier coatings

InactiveUS20050260434A1Increase roughnessImprove ductilityPropellersMolten spray coatingPolyesterPorosity

A bi-layer bond coating for use on metal alloy components exposed to hostile thermal and chemical environment, such as a gas turbine engine used to generate electricity and the method for applying such coatings. The preferred coatings include a bi-layer bond coat applied to the metal substrate, with both layers being applied using high velocity oxy-fuel (HVOF) thermal spraying. In one embodiment, bond coatings in accordance with the invention can be used in combination with a thermal barrier coating (“TBC”). However, the invention can also take other forms, such as a stand alone overlay coating. Bi-layer bond coatings in accordance with the invention consist of a dense first inner layer (such as iron, nickel or cobalt-based alloys) that provides oxidation protection to the metal substrate, and a second outer layer having controlled porosity that tends to promote roughness, mechanical compliance, and promotes adherence of the TBC. Preferably, the outer, less dense layer of the bi-layer bond coat is formed from a mixture of metallic powder and polyester to adjust and control the porosity, but without sacrificing mechanical compliance. Together, the layers enhance adherence to the substrate and improve the overall life of the coating system.

Owner:GENERAL ELECTRIC CO

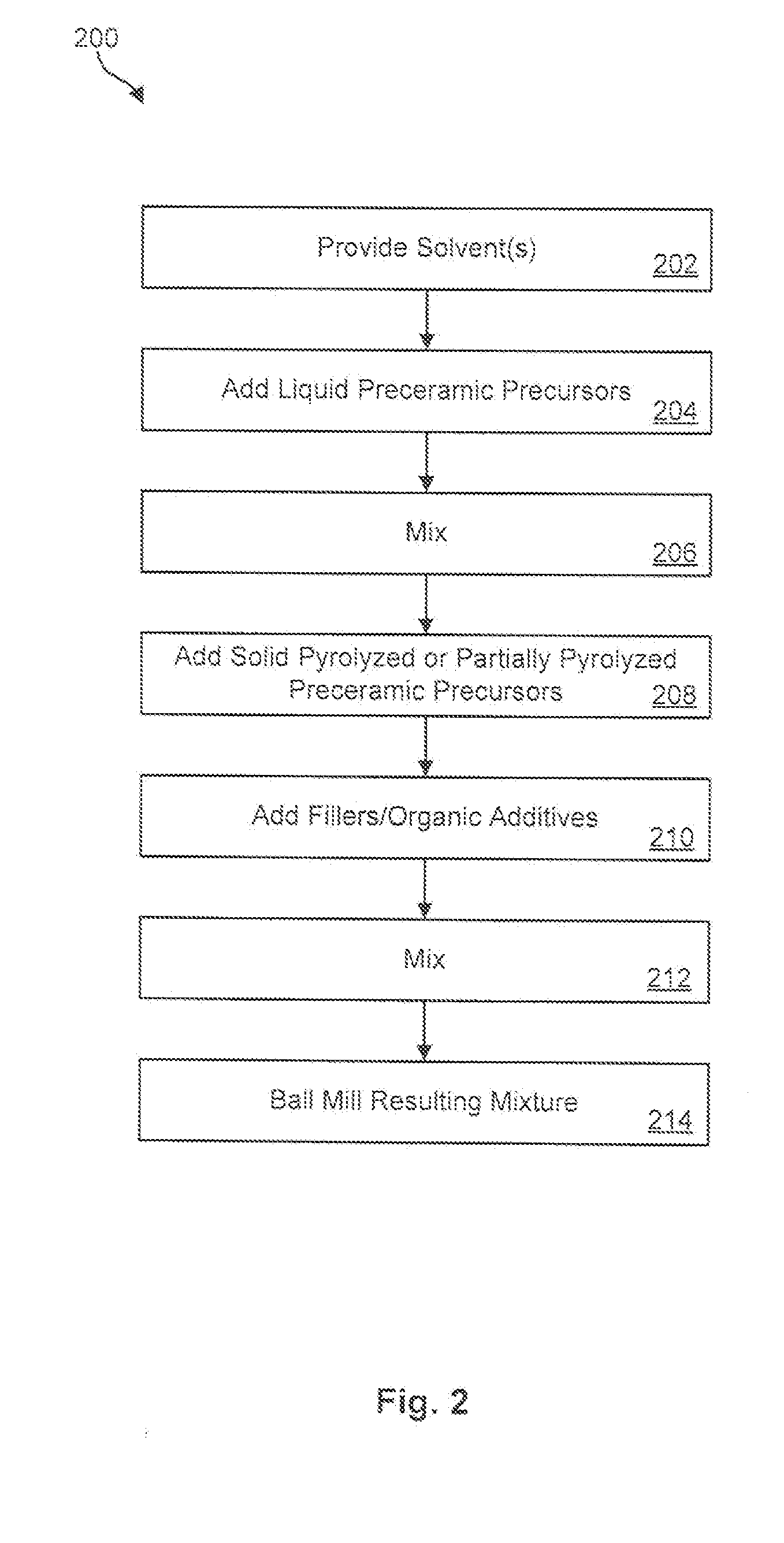

Aluminosilicate-Based Oxide Composite Coating and Bond Coat for Silicon-Based Ceramic Substrates

InactiveUS20100255289A1Improve adhesionReduce Shrinkage ProblemsPretreated surfacesCeramic layered productsBond coatingOxide composite

An article is disclosed in one embodiment of the invention as including a silicon-based ceramic substrate and a top coat. A bond coat is provided between the silicon-based ceramic substrate and the top coat. The bond coat is derived from a mixture containing preceramic polymer precursors, such as polycarbosilanes, polycarbosilazanes, or other silicocarbon polymers and pyrolyzed preceramic polymer precursors. A filler material may also be included in the mixture to modify the coefficient of thermal expansion (CTE) of the bond coat to more closely match the CTE of the silicon-based ceramic substrate, top coat, or both.

Owner:LEWINSOHN CHARLES +2

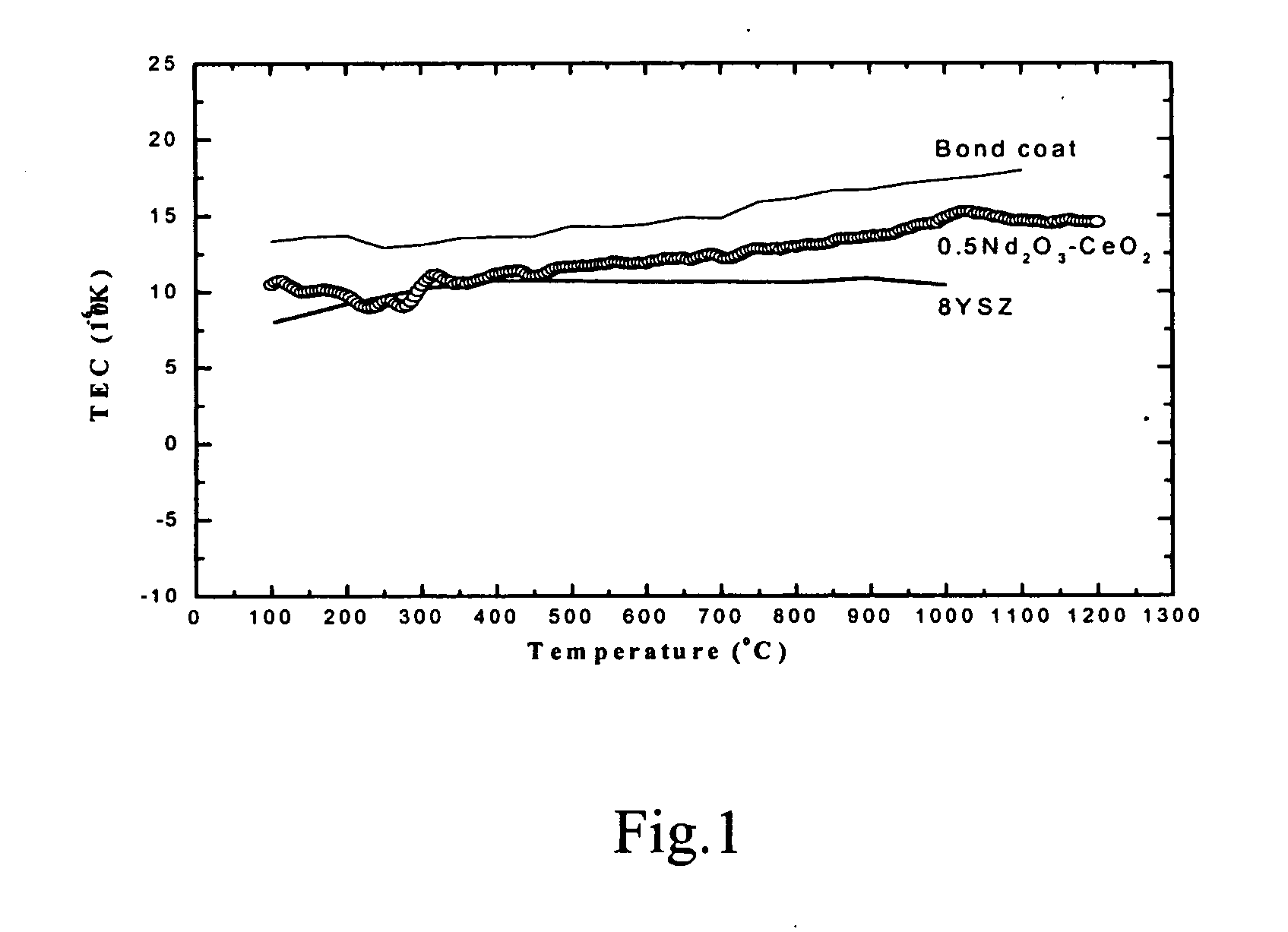

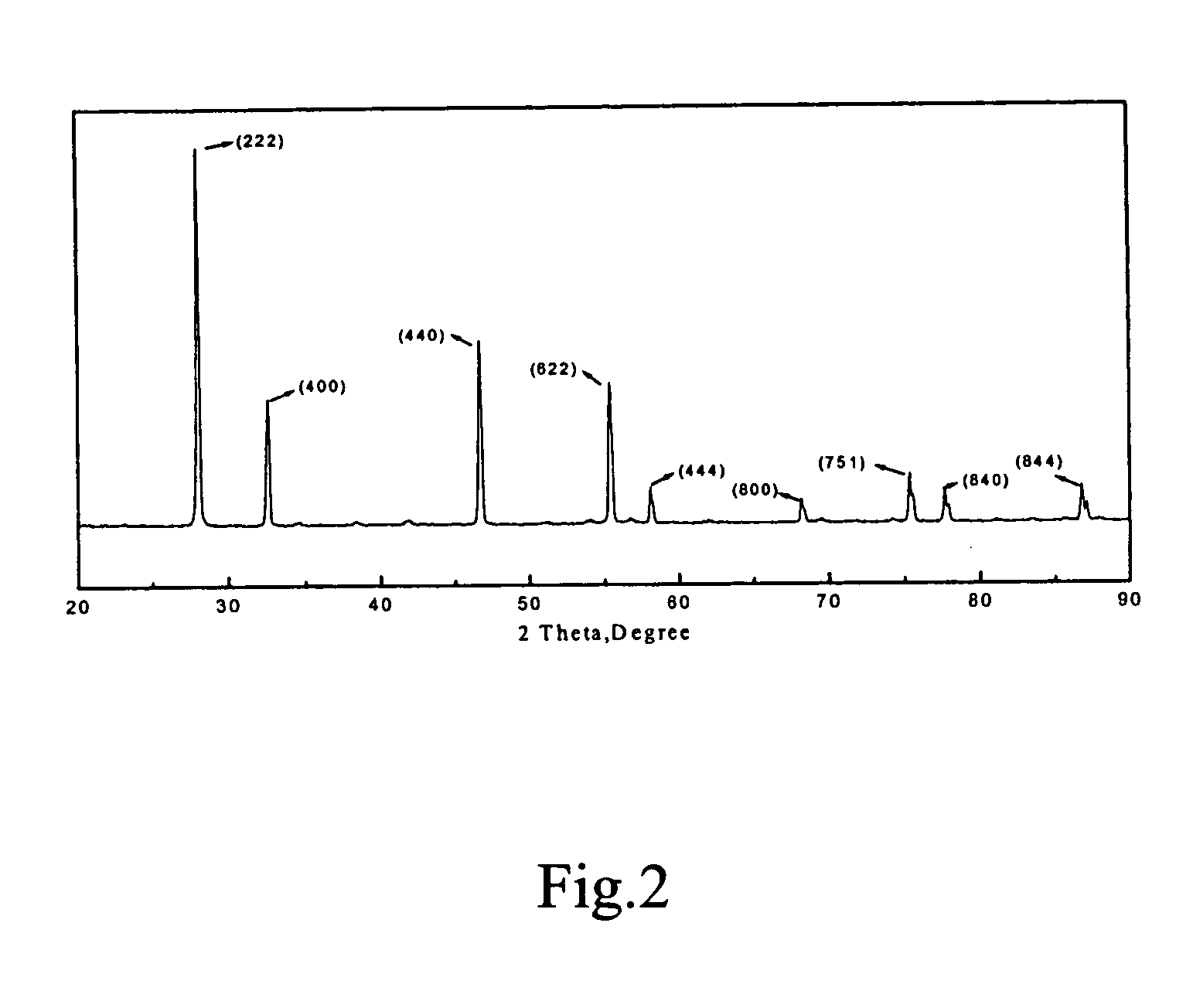

Thermal barrier coating material

InactiveUS20060246226A1Rare earth metal oxides/hydroxidesLiquid surface applicatorsChemical compositionBond coating

The present invention relates to a thermal barrier coating material having the chemical composition of (1−n)CeO2-nZrO2-0.5R2O3, where n is in the range of 0.9≧n≧0 and R is selected from a group consisting of Nd, Sm, Eu, Gd, Tb and combinations of at least two among them. It possesses a thermal expansion coefficient higher than 12×10−6 K−1 from ambient temperature up to 1200° C. and superior to those of the presently widely-used thermal barrier coating materials. Even if it is subjected to long time calcinations at 1400° C. or is quenched to room temperature, it can still maintain the stable crystal structure. In addition, its thermal expansion trend matches quite well with that of the bond coating alloy. This is beneficial to the elimination of thermal stress generated between the substrate and the ceramic top coating during the thermal cycle and can significantly improve the thermal shock resistance of the coating. The present invention further relates to a method for producing a thermal barrier coating material and a method for preparing a thermal barrier coating.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

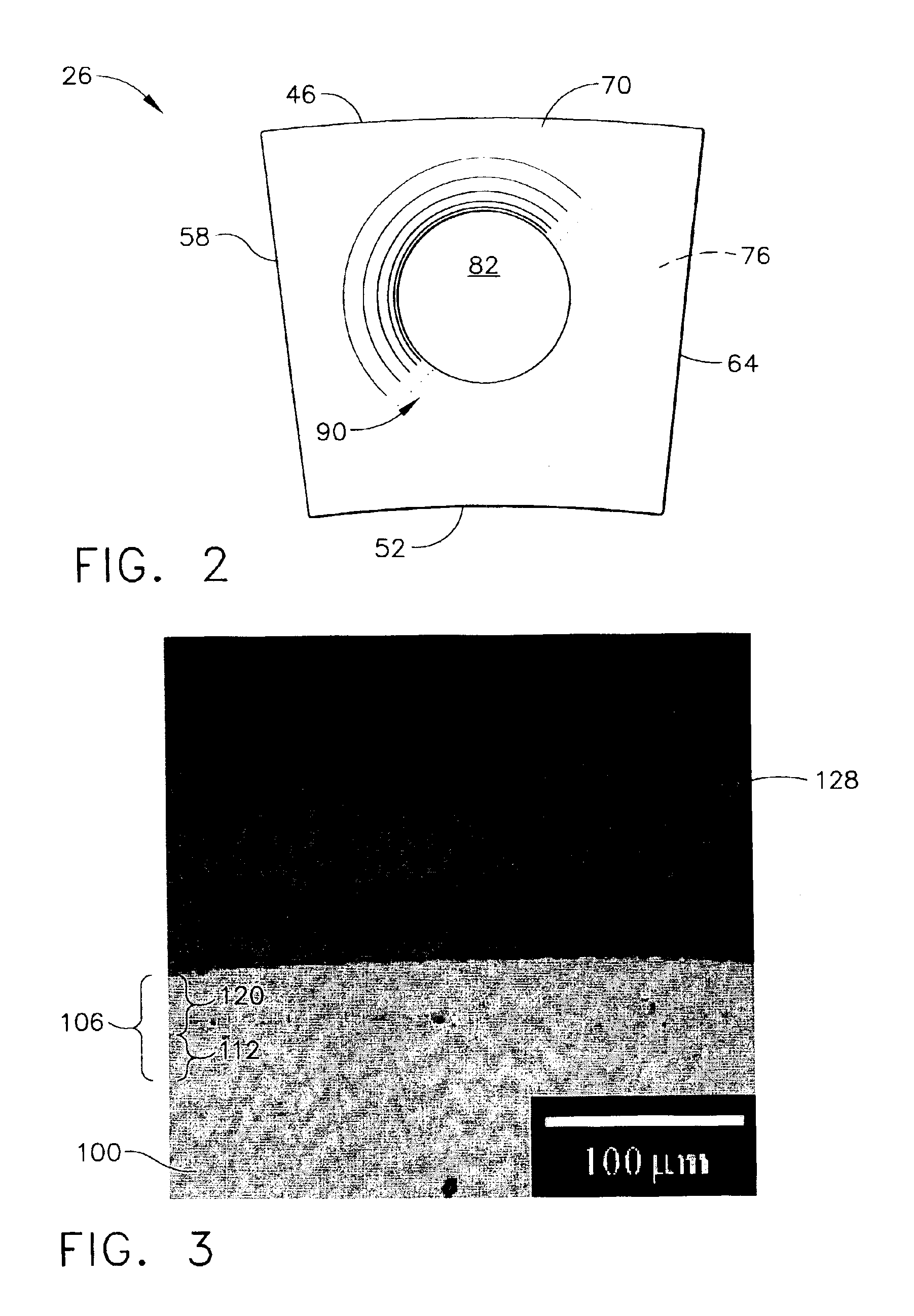

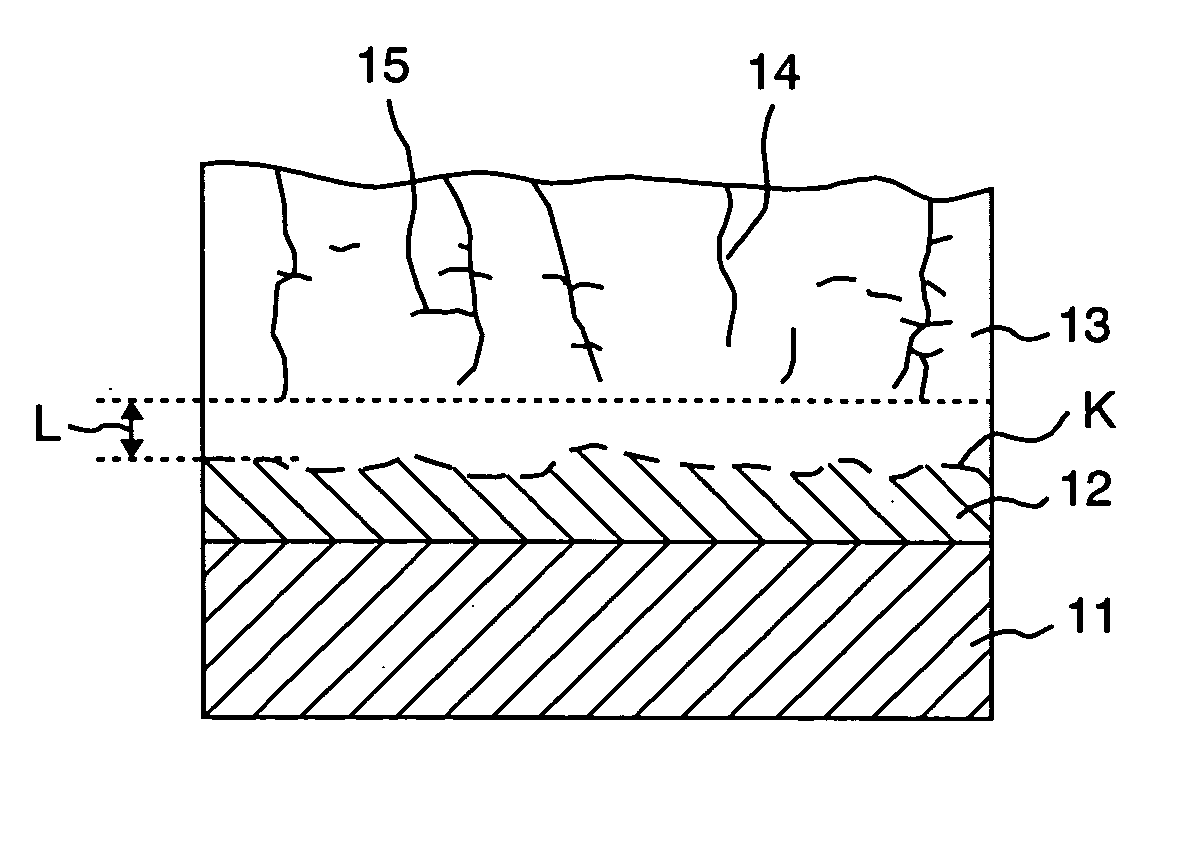

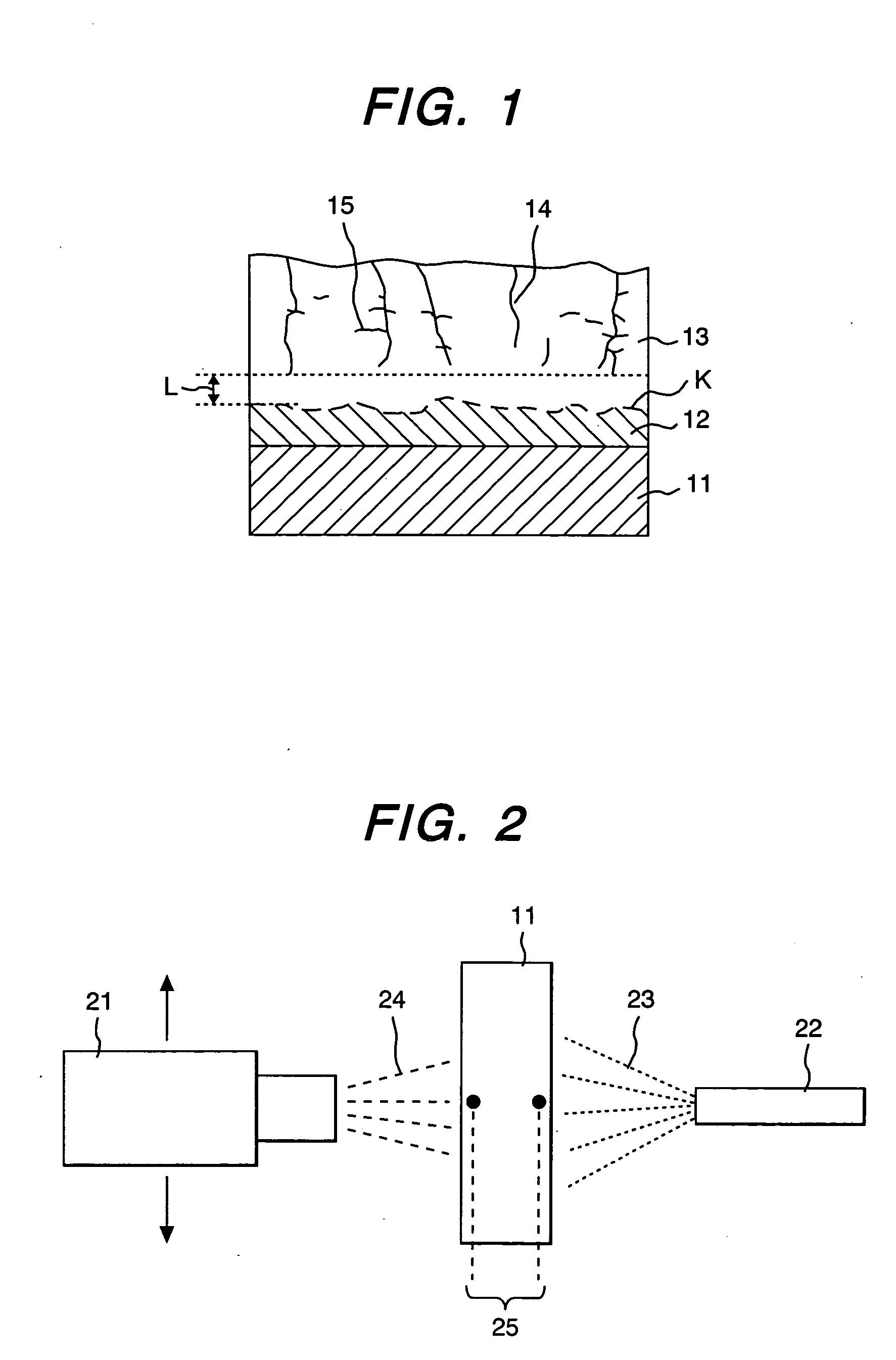

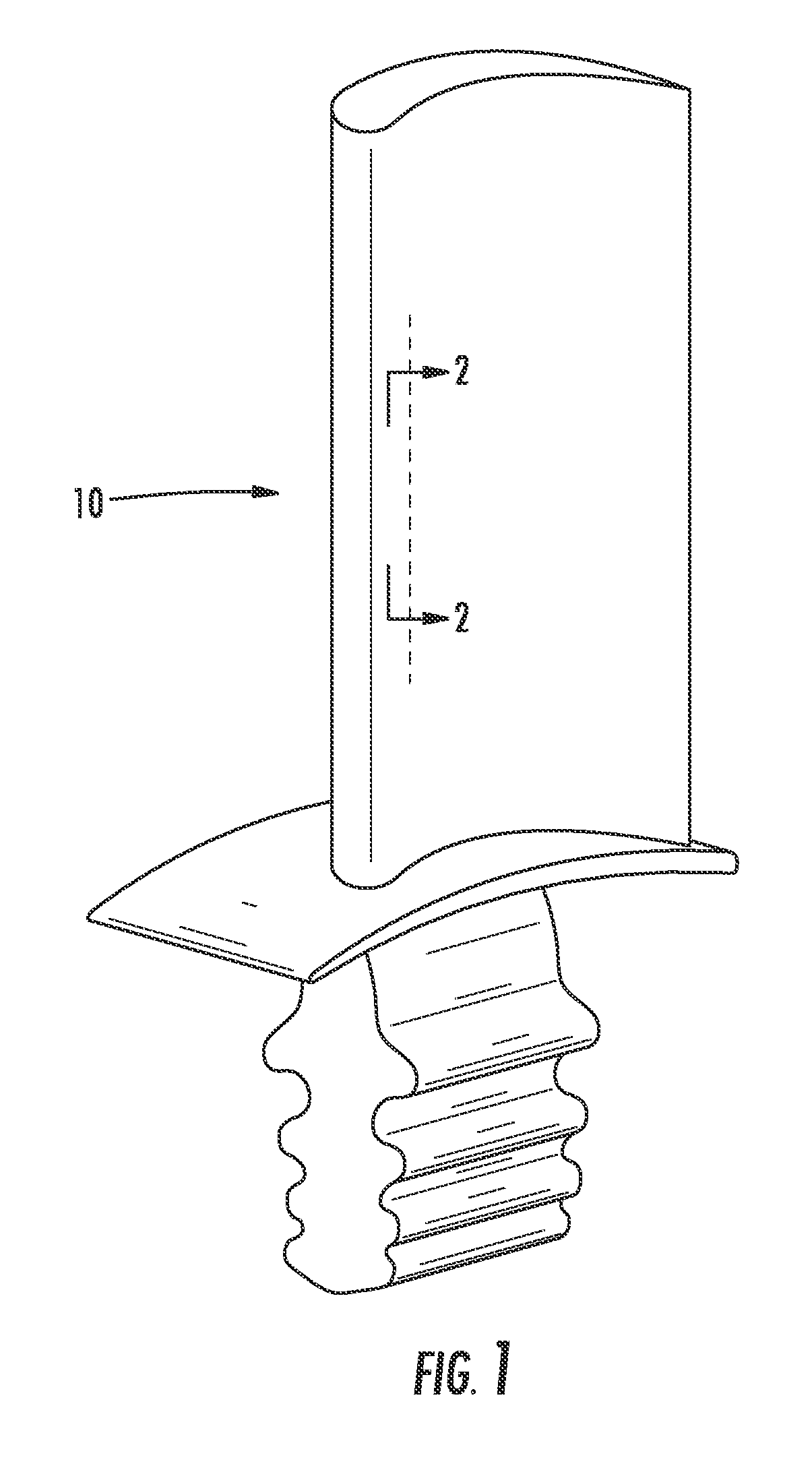

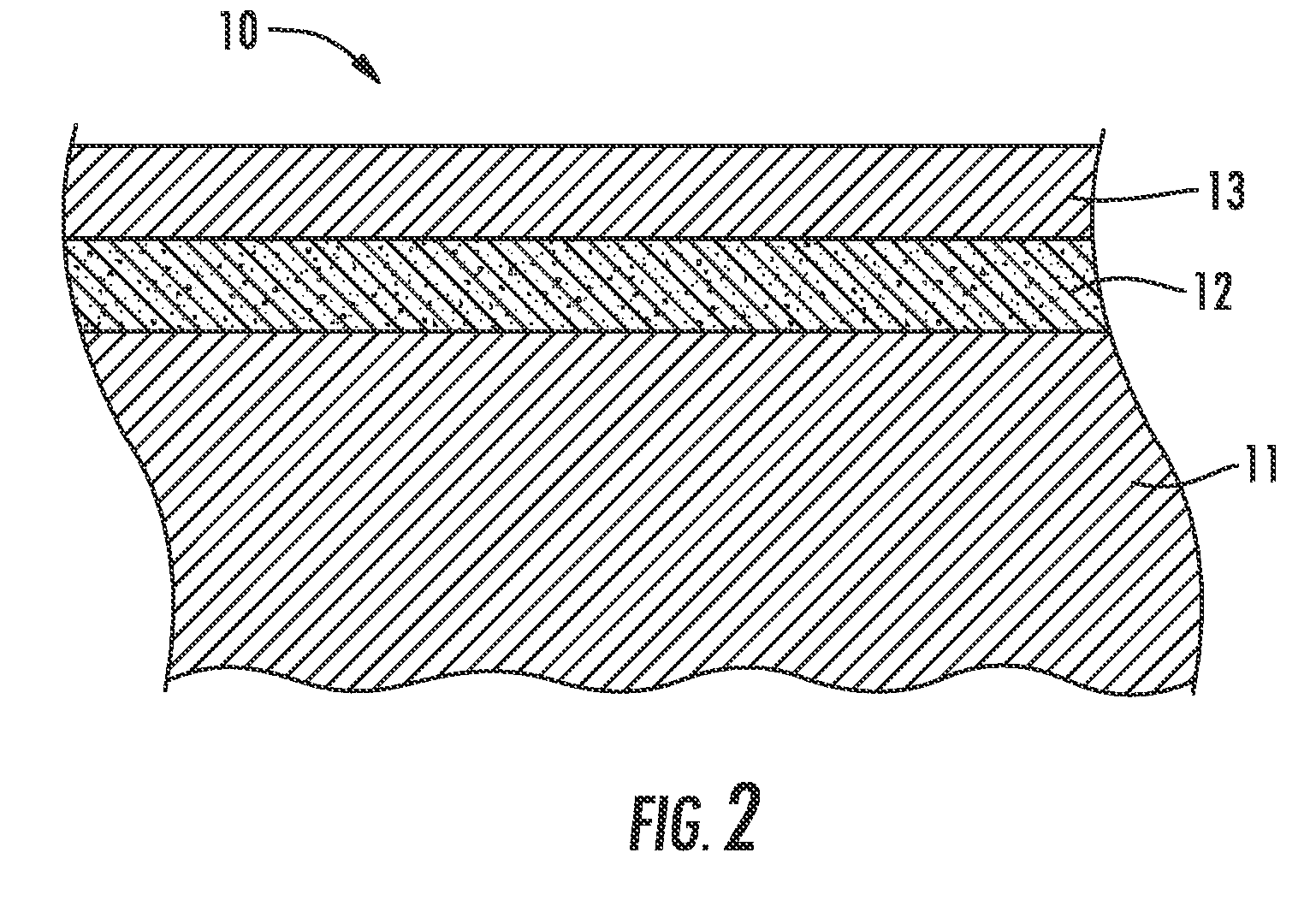

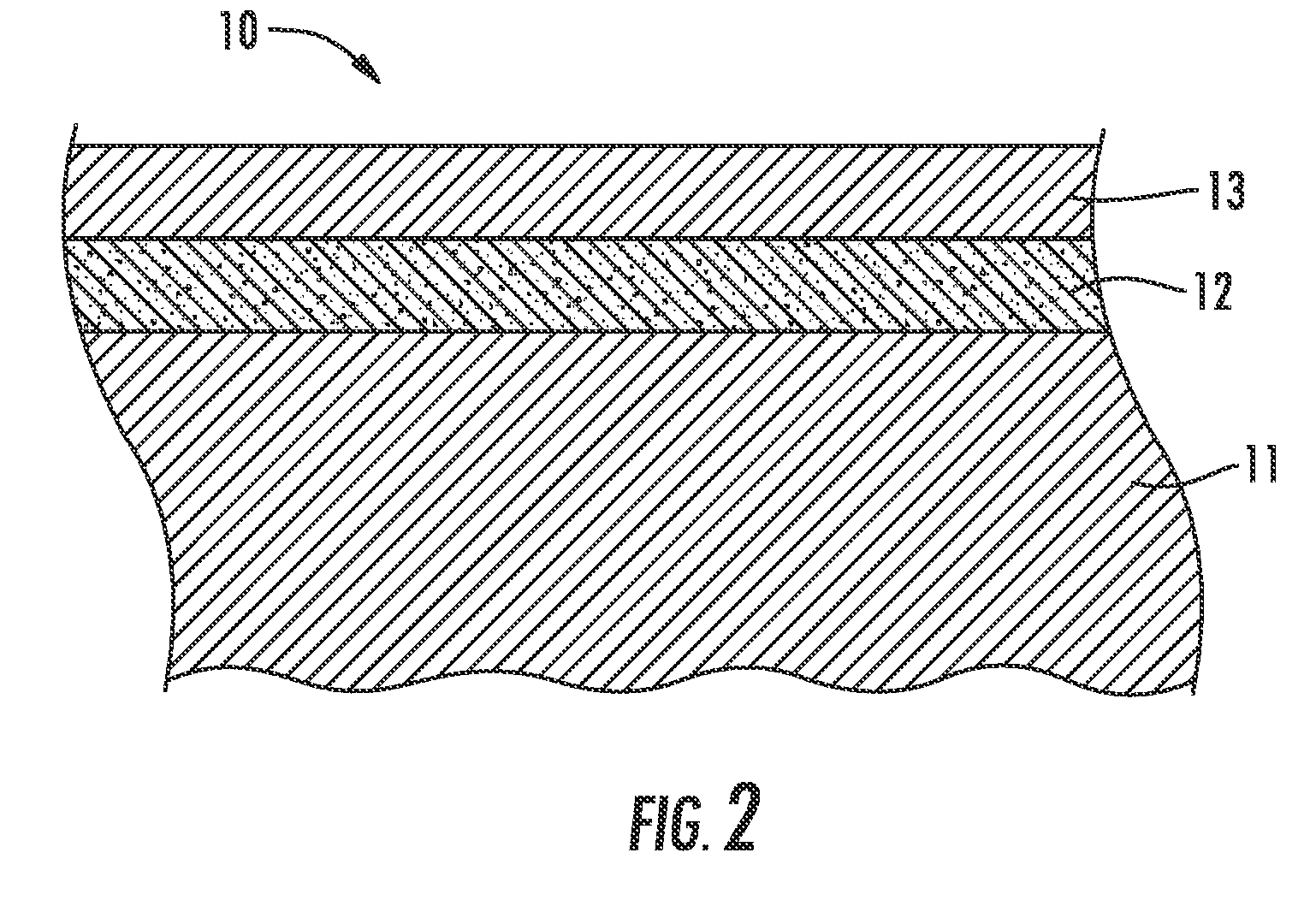

Heat resistant article having thermal barrier coatinging

ActiveUS20050136249A1Long operating timeLiquid surface applicatorsMolten spray coatingBond coatingHigh-temperature corrosion

A thermal barrier coating comprises a bond coating 12 made of high temperature corrosion resistance superior to a substrate 11 and a thermal barrier coating 13 made of ZrO2 series ceramics formed on the bond coating. The thermal barrier coating has cracks extending in the direction of the thickness of the barrier coat. Substantially all of the tips of the cracks have a distance between the tips and the boundary at the substrate side.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

Repair methods for cooled components

A method for repairing a component is provided, where the component has a substrate comprising an outer surface and an inner surface and defining one or more grooves. Each groove extends at least partially along the outer surface of the substrate. The component further includes a structural coating, a bond coating, and a thermal bather coating. The groove(s) and the structural coating define one or more channels for cooling the component. The repair method includes removing the thermal barrier and bond coatings, removing at least a portion of the structural coating in a vicinity of a damaged portion of the component, performing a repair operation on the damaged portion of the component, applying a structural coating at least in a vicinity of the repaired portion of the component, and applying a bond coating and a thermal barrier coating. Additional repair methods are also provided.

Owner:GENERAL ELECTRIC CO

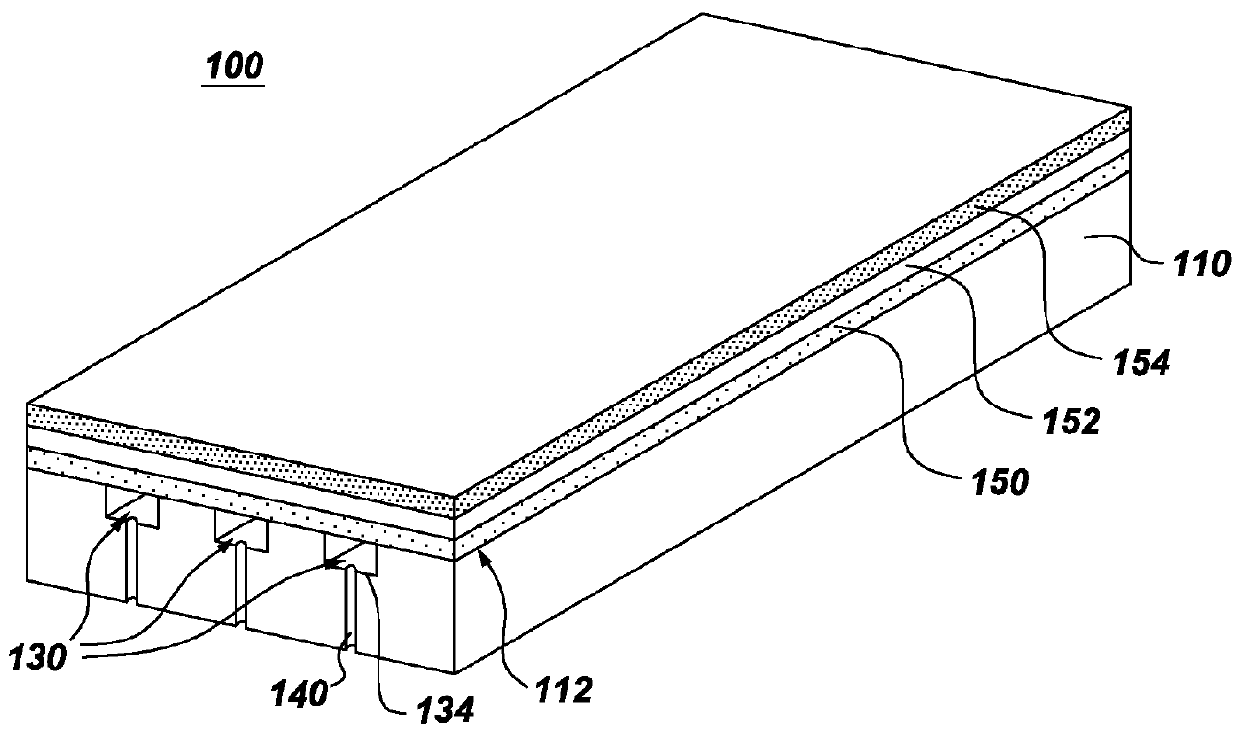

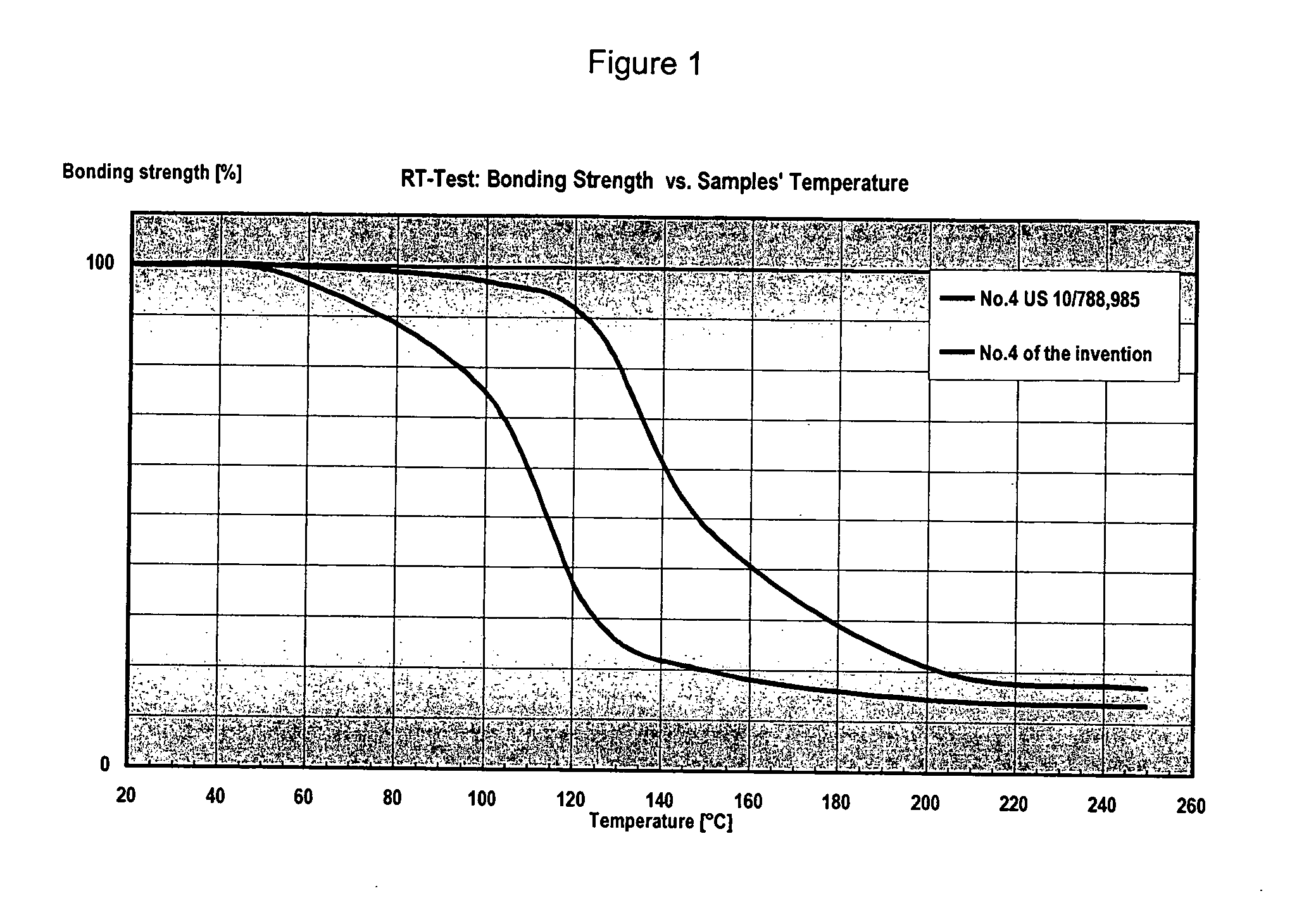

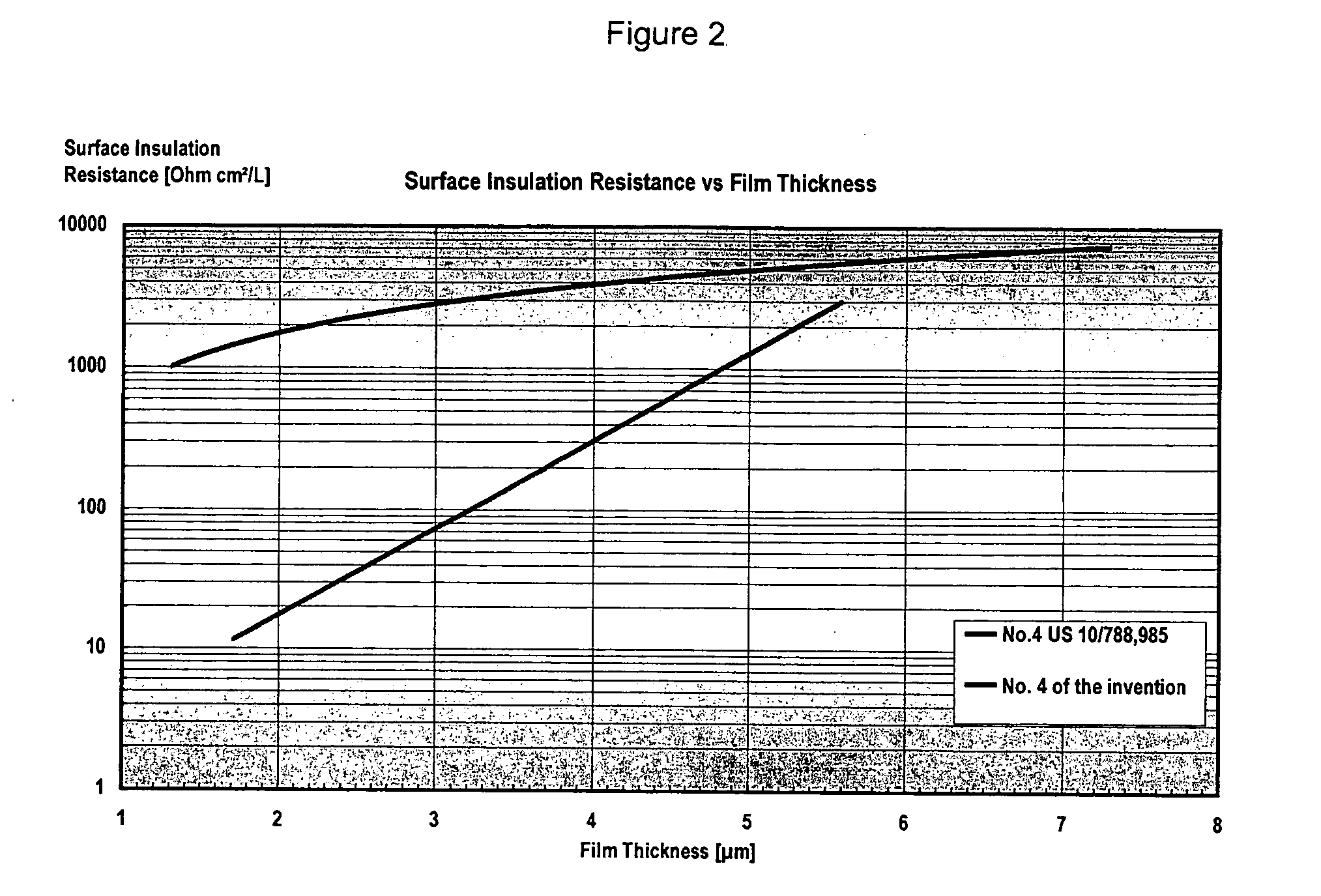

Self-bonding coating composition

InactiveUS20070087201A1Excellent bonding strength and corrosion resistanceIncrease temperatureMaterial nanotechnologySynthetic resin layered productsOrganic solventElectrical steel

A self-bonding coating composition for the production of electrical steel sheets cores comprising A) 100 parts per weight of at least one epoxy resin based on bisphenol-A-type and / or bisphenol-F-type, 100% of solids, B) 0.1 to 200 parts per weight of nano particles having an average radius ranging from 2 to 600 nm, C) 0 to 25 parts per weight of at least one curing agent selected from the group consisting of dicyandiamide, blocked isocyanate and Lewis acid or selected from the group consisting of phenolic resin, carboxylic acid, anhydride and Lewis acid, 100% of solids, D) 0.1 to 10 parts per weight of at least one additive, and E) 50 to 200 parts per weight of water or at least one organic solvent, ensuring increased re-softening temperatures as well as excellent bonding strength, corrosion resistance and electrical insulation of the coating.

Owner:EI DU PONT DE NEMOURS & CO

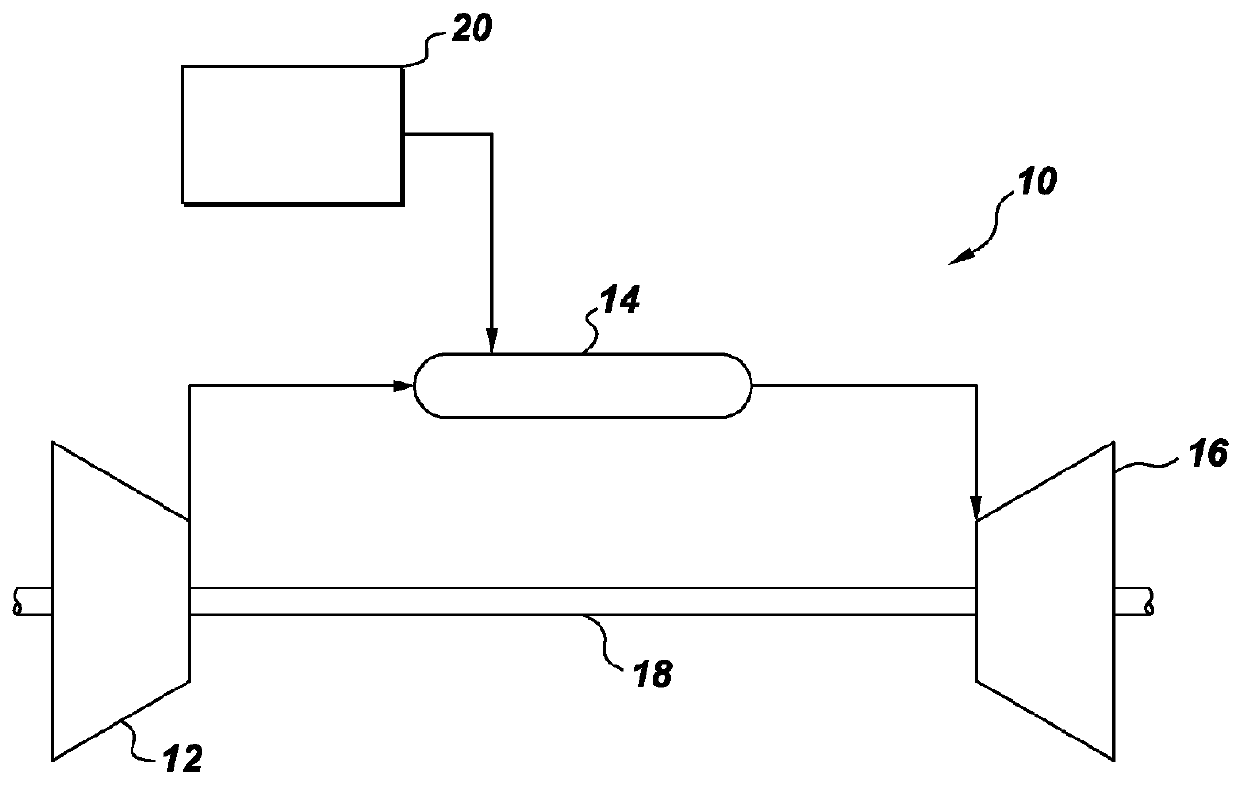

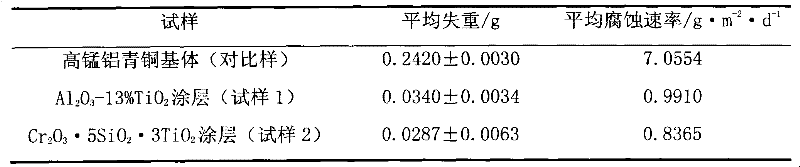

Method for preventing corrosion and marine creature fouling on ship propeller

InactiveCN102336256ASolve corrosiveSolve the defacementVessel cleaningMolten spray coatingOxide ceramicThermal spraying

The invention relates to a method for preventing corrosion and marine creature fouling on a ship propeller. Cathode protection, a ceramic insulating coating and a metallic antifouling coating are organically combined in the method. The method comprises the following steps of: removing scales on the surface of the copper alloy propeller, obtaining a uniform and rough surface, and spraying a metallic adhesive coating by adopting a thermal spraying method; preparing a metallic oxide ceramic insulating coating on the surface of the adhesive coating by adopting the thermal spraying method, wherein the ceramic insulating coating comprises single-component oxides such as Al2O3, Cr2O3 and the like and multi-component composite powder of TiO2 or SiO2 with low melting point; preparing the metallic antifouling coating on the ceramic insulating coating, wherein the metallic antifouling coating is made of pure copper or copper alloy with antifouling function; and meanwhile, performing cathode protection on the propeller. The ceramic and the metallic coating adopted in the method have higher bonding force and longer protection life, the current requirement of the ship cathode protection is reduced, the corrosion and marine creature fouling problems of the ship propeller can be simultaneously solved, and the ceramic and the metallic coating have obvious corrosion resistance and antifouling effect.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

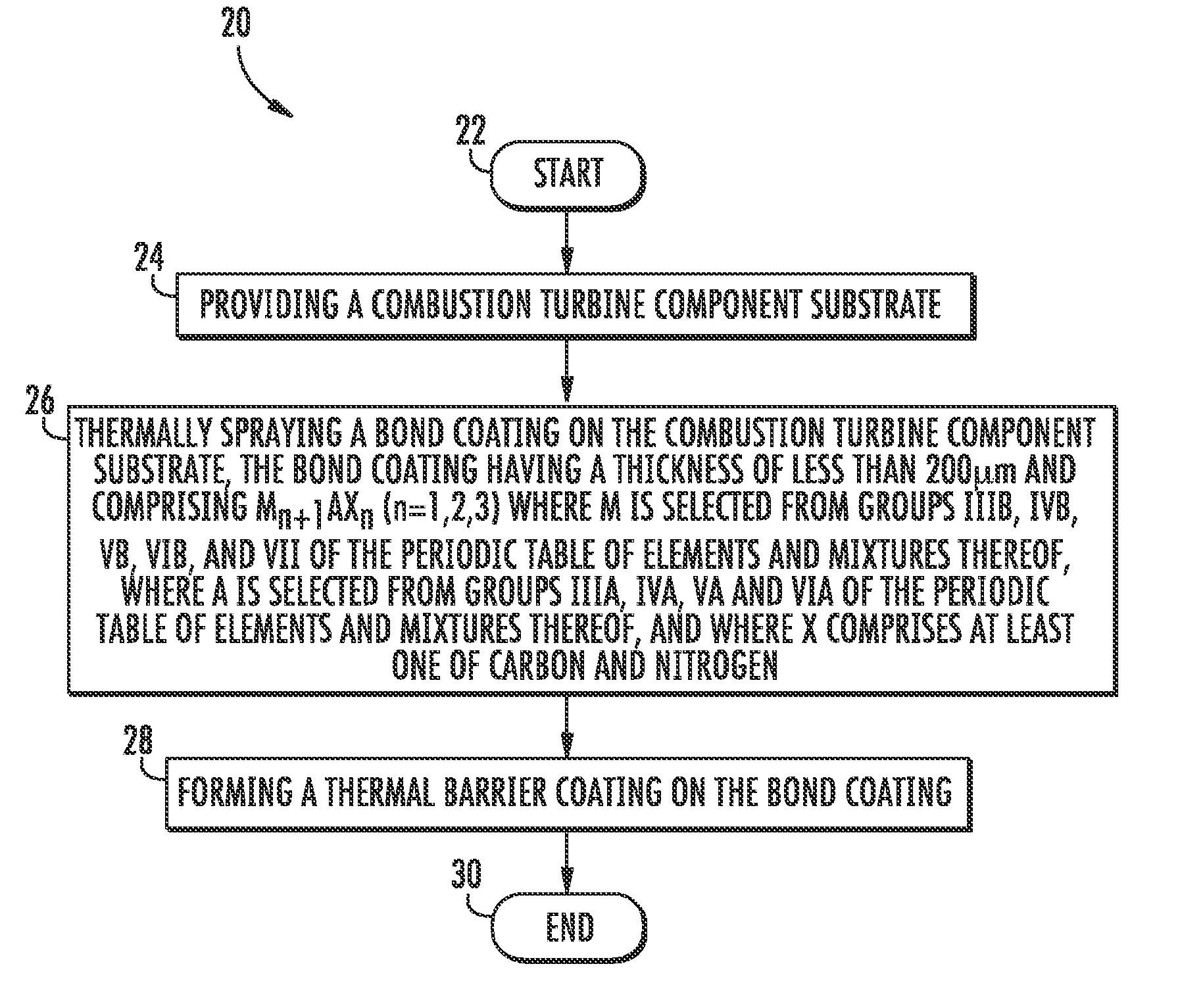

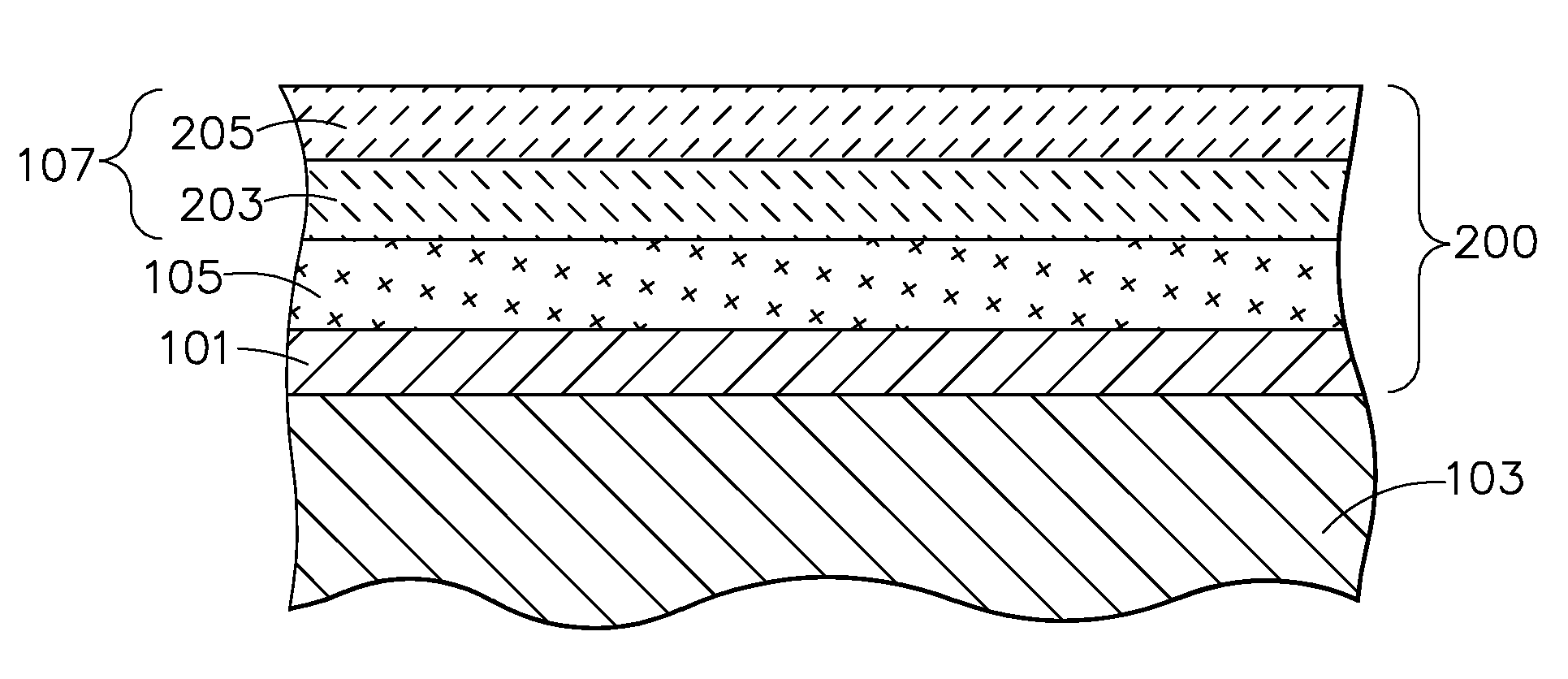

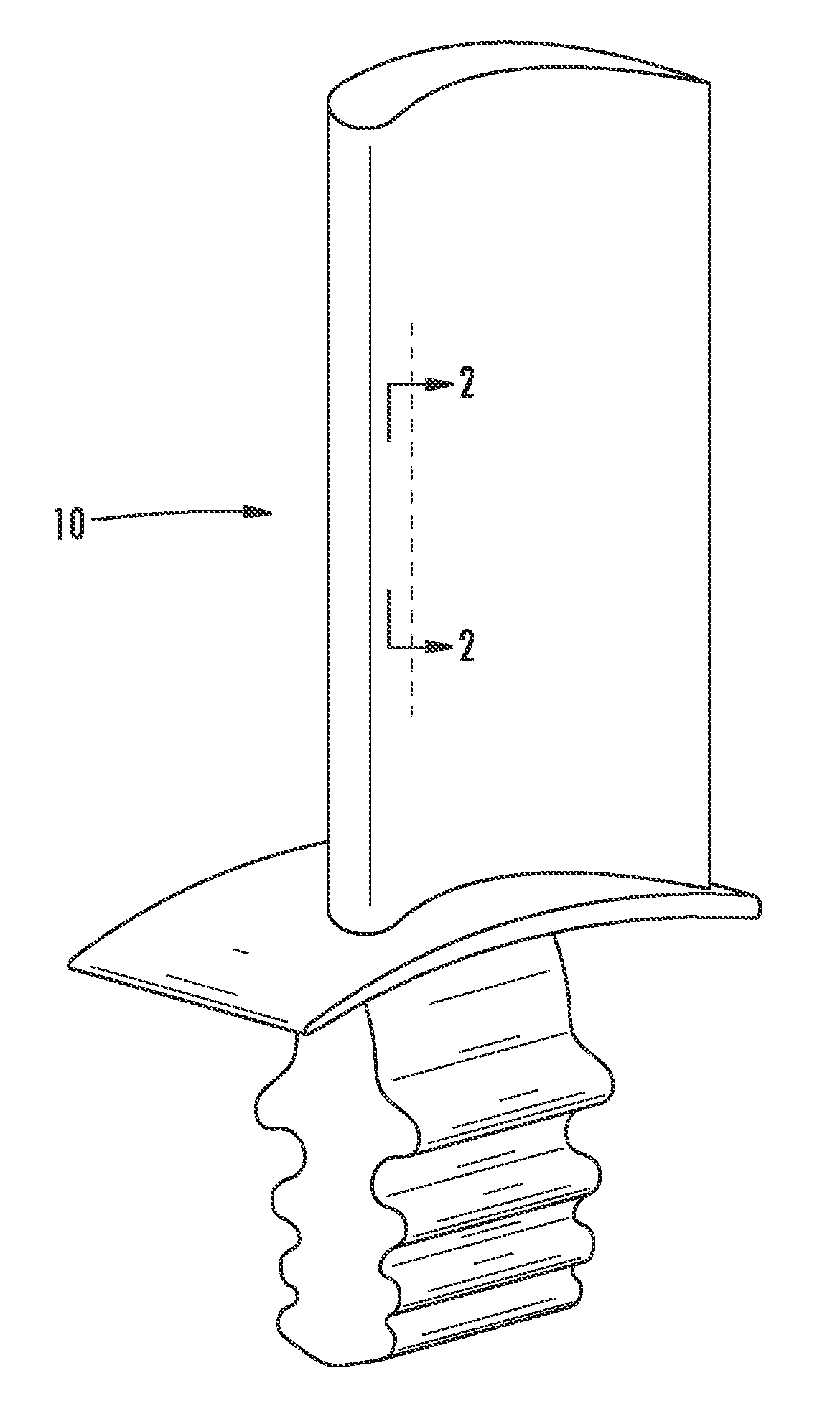

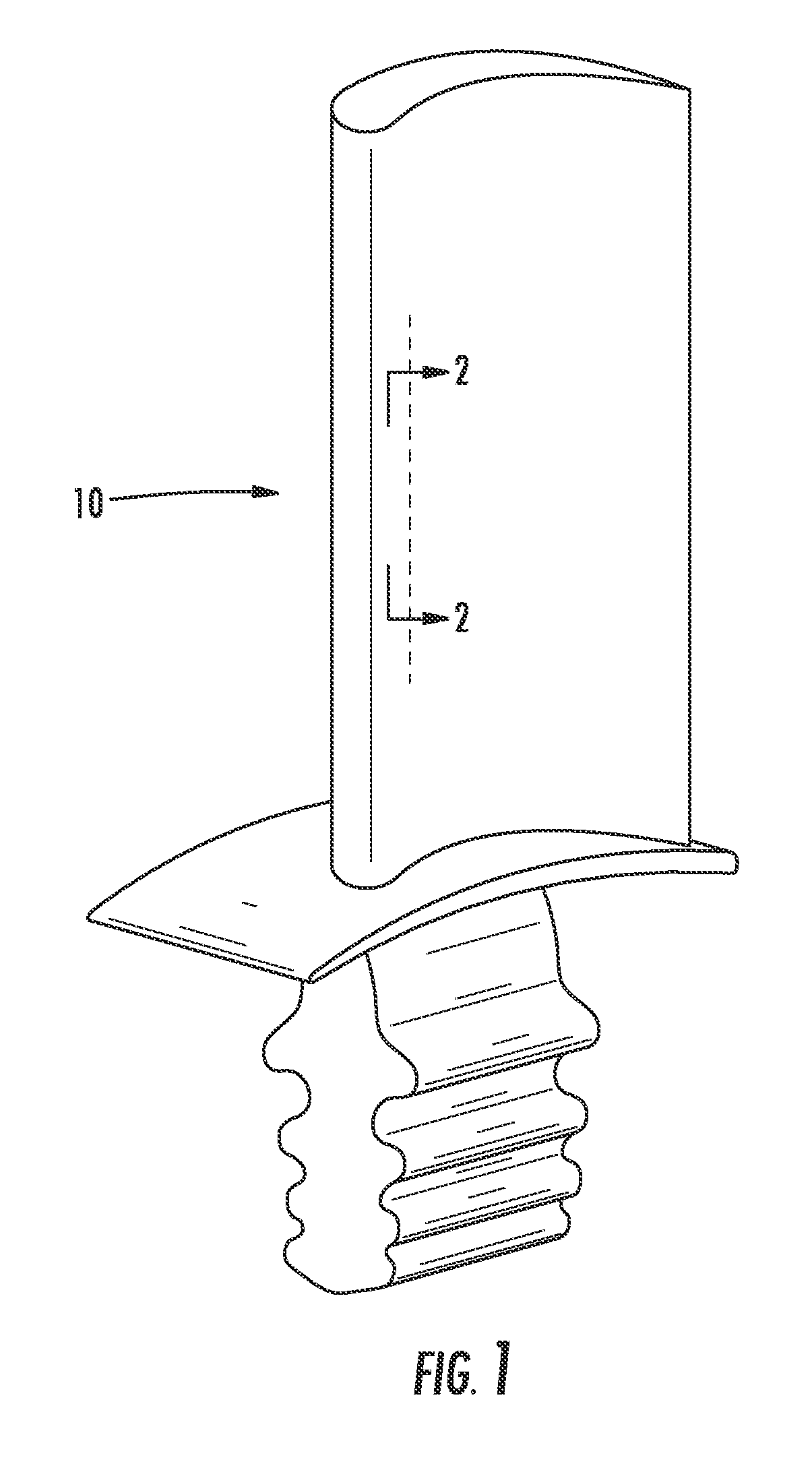

Combustion turbine component having bond coating and associated methods

InactiveUS8192850B2Avoid spallationImprove the immunityMolten spray coatingBlade accessoriesCombustionBond coating

A combustion turbine component includes a combustion turbine component substrate and a bond coating on the combustion turbine component substrate. The bond coating may include Mn+1AXn (n=1,2,3) where M is selected from groups IIIB, IVB, VB, VIB, and VII of the periodic table of elements and mixtures thereof, where A is selected from groups IIIA, IVA, VA, and VIA of the periodic table of elements and mixtures thereof, and where X includes at least one of carbon and nitrogen. A thermal barrier coating may be on the bond coating.

Owner:SIEMENS ENERGY INC

Yttria containing thermal barrier coating topcoat layer and method for applying the coating layer

ActiveUS7862901B2Reduced and eliminated infiltrationPropellersReaction enginesCoating systemBond coating

A gas turbine engine component and coating system including a superalloy substrate having a coating system disposed thereon. A bond coating may be applied to the substrate. An adherent layer of ceramic material forming a thermal barrier coating is present on the bond coat layer. A topcoat layer overlies the thermal barrier coating. The topcoat layer includes greater than about 20 wt % yttria.

Owner:GENERAL ELECTRIC CO

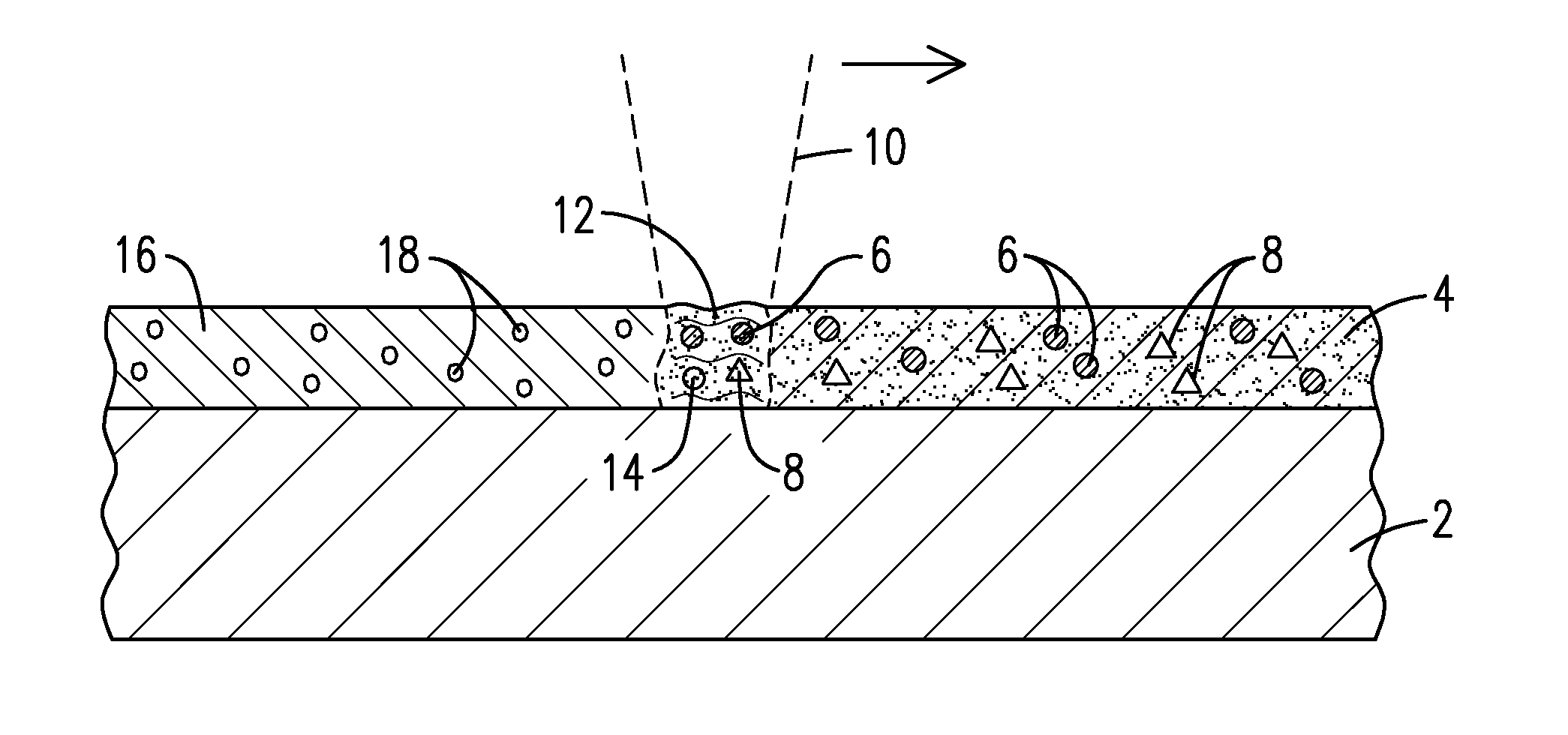

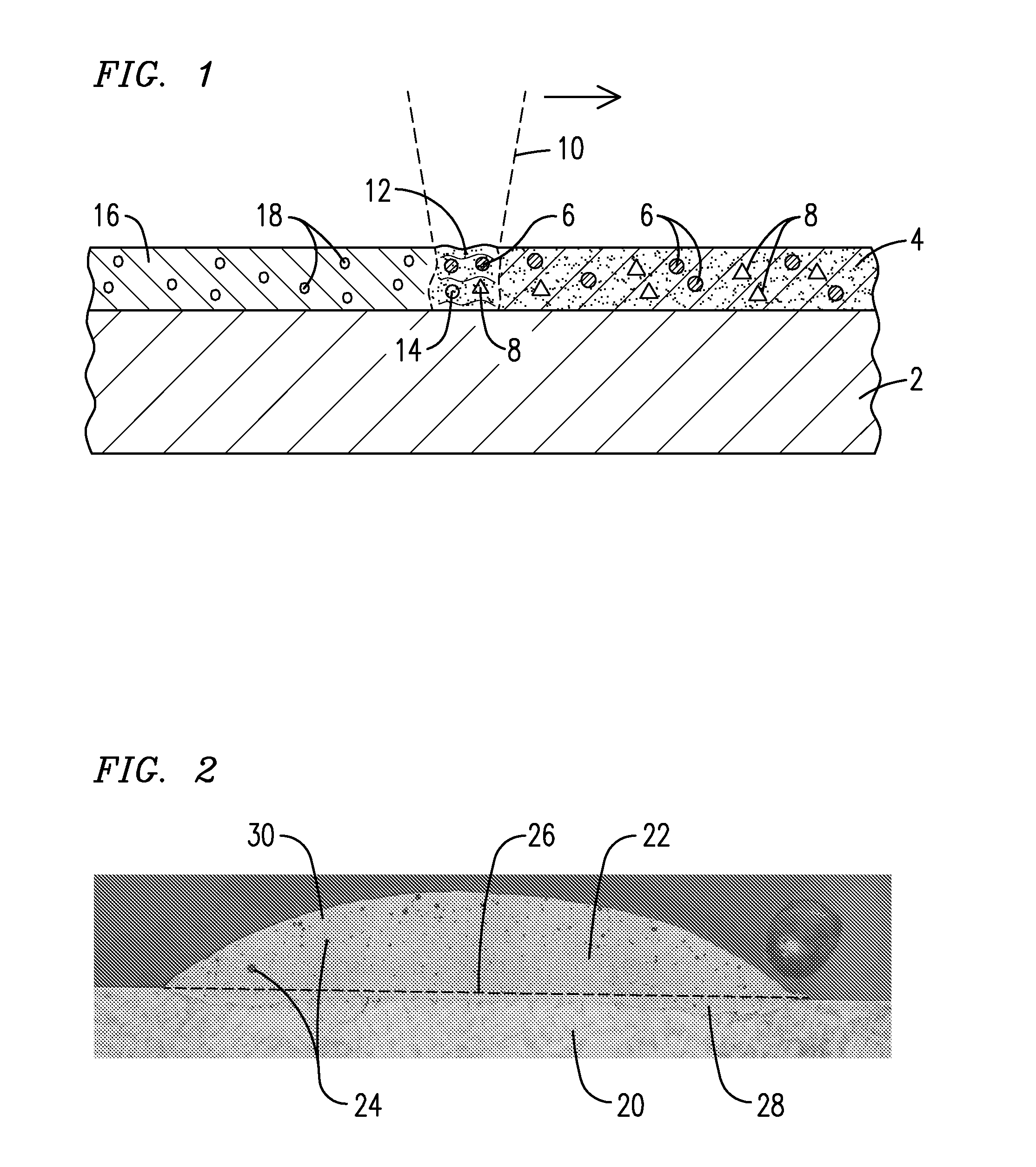

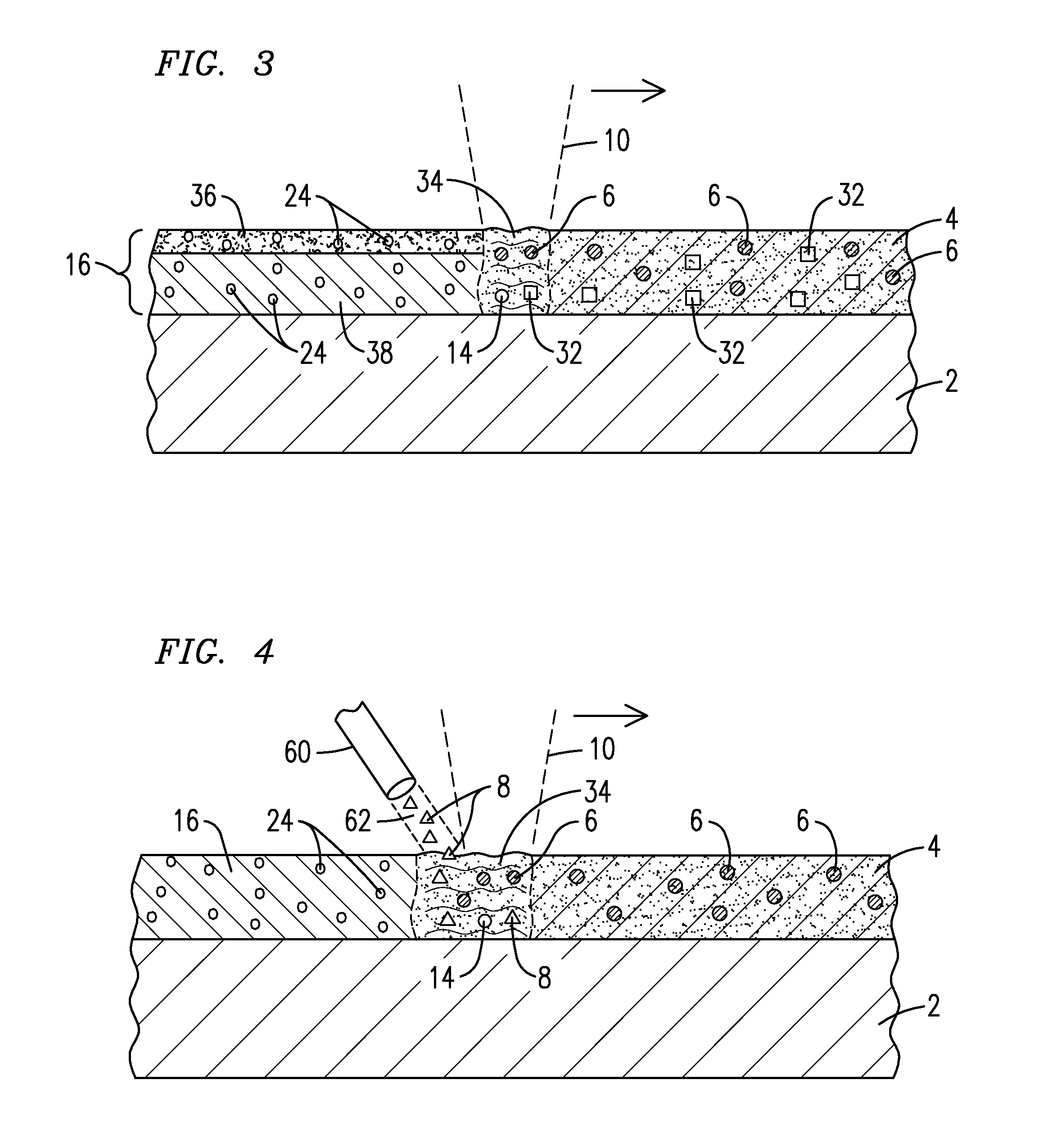

Method of inducing porous structures in laser-deposited coatings

A layer of a powdered material (4) is heated with an energy beam (10) such that at least one gas-generating agent (8) reacts to form at least one gaseous substance (14) to produce a void-containing coating (16) adhered to the surface of a substrate (2).The powdered material may contain a metallic material, a ceramic material, or both, and may also contain at least one of a flux material (32) containing the gas-generating agent and an exothermic agent (64). The heating may occur using a laser beam and may induce a melting or sintering of the powdered material to produce the void-containing coating. A gas turbine engine component exhibiting improved thermal and mechanical properties may be formed to include the void-containing coating, which may take the form of a bond coating, a thermal barrier coating, or both.

Owner:SIEMENS ENERGY INC

Epoxy coatings and surfaces coated therewith

InactiveUS6391464B1Effective combinationAntifouling/underwater paintsSynthetic resin layered productsEpoxyBond coating

Owner:GENERAL ELECTRIC CO

Apparatus and method for applying antifoulants to marine vessels

ActiveUS8030592B2Avoid pollutionPrevent flame conditionLiquid surface applicatorsElectric heatingBond coatingShielding gas

A plasma spray apparatus in the form of a gun is utilized to apply an antifoulant coating to marine vessels. The apparatus includes a plasma generator, an electrophoresis element, a heating element, a shield gas element, a liquid cooling system, a forced air system, and a vacuum system. The plasma generator ionizes gas to create a plasma stream, which is utilized in part to supply energy to the heating element that heats a powder material. The heated powder material is exposed to the electrophoresis element to create a covalently bonded coating material. The coating material is injected into the plasma stream and is applied to a target surface. The shield gas element injects a gas flow to surround and protect the plasma and coating material stream as the stream is in flight to the target surface. The liquid cooling system cools portions of the plasma generator and heating element. The forced air system cools a portion of the target surface as the coating material is being applied. The vacuum system removes fumes and stray particles during the application process.

Owner:REINTJES MARINE SURFACE TECH

Thermal barrier coating with stabilized compliant microstructure

ActiveUS7150926B2Maintain integrityPrevent penetrationMolten spray coatingVacuum evaporation coatingParticulatesBond coating

A thermal barrier coating for a gas turbine component includes a bond coating layer, at least a first segmented columnar ceramic layer on the bond coating layer, and a particulate structure-stabilizing material disposed within a plurality of segmentation gaps within the columnar ceramic layer(s). The thermal barrier coating may further comprise, a second segmented columnar ceramic layer of yttria stabilized hafnia on the first segmented columnar ceramic layer, and an outer, continuous, non-segmented sealant layer covering the yttria stabilized hafnia layer to prevent ingress of extraneous materials into the segmentation gaps. Methods for depositing a thermal barrier coating on a substrate are also disclosed.

Owner:HONEYWELL INT INC

Gypsum boards having glass fiber reinforcement with tacky compliant interface therebetween

ActiveUS20060029786A1Improve bending strengthRetain structurePaper/cardboard layered productsNon-woven fabricsPolymer dissolutionBond coating

A bond is created during gypsum board cure between a gypsum matrix and a tacky coating applied onto a glass fiber. The tacky coating is comprised of a polymer composed of methacrylic acid and dimethyldiallyammonium chloride. The polymer is dissolved in an acidic aqueous solution and is roller coated onto the glass fibers. The chopped glass fibers may also be placed in such an acidic solution, which is made alkaline by the addition of alkali, thereby precipitating the polymer out of solution as a tacky composition that produces a tacky coating on the glass fibers. The glass fibers with the tacky bond coating are incorporated in an alkaline gypsum slurry to form a gypsum board having a first and second facer sheet. The tacky coating on the glass fibers bonded to the gypsum matrix result in compliant load transfer between the gypsum matrix and the glass fibers, yielding improved flexure strength and nail pullout resistance.

Owner:JOHNS MANVILLE CORP

Durable thermal barrier coatings

A durable protective coating may be formed by applying a thin layer of metastable alumina to a bond coating on a substrate. A thermal barrier coating may then be applied to the metastable alumina and the resulting part may be heat treated to transform the metastable alumina to a mixed alpha alumina having particles of the thermal barrier coating, such as zirconia in the case of an yttria stabilized zirconia thermal barrier coating, dispersed therein. The resulting thermal barrier coating may inhibit microbuckling of the thermally grown oxide scale that grows over time at the thermal barrier coating-bond coating interface.

Owner:HONEYWELL INT INC

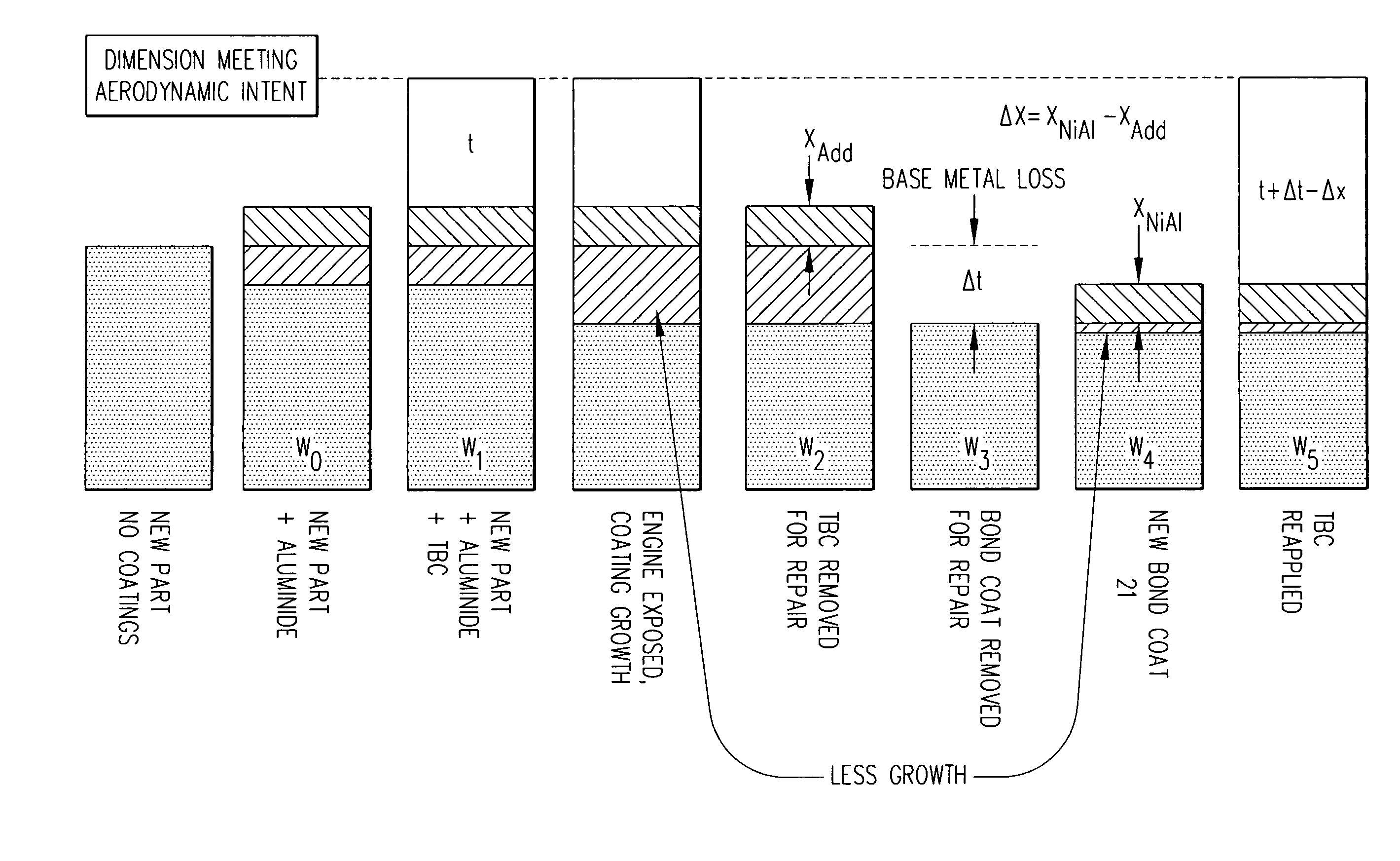

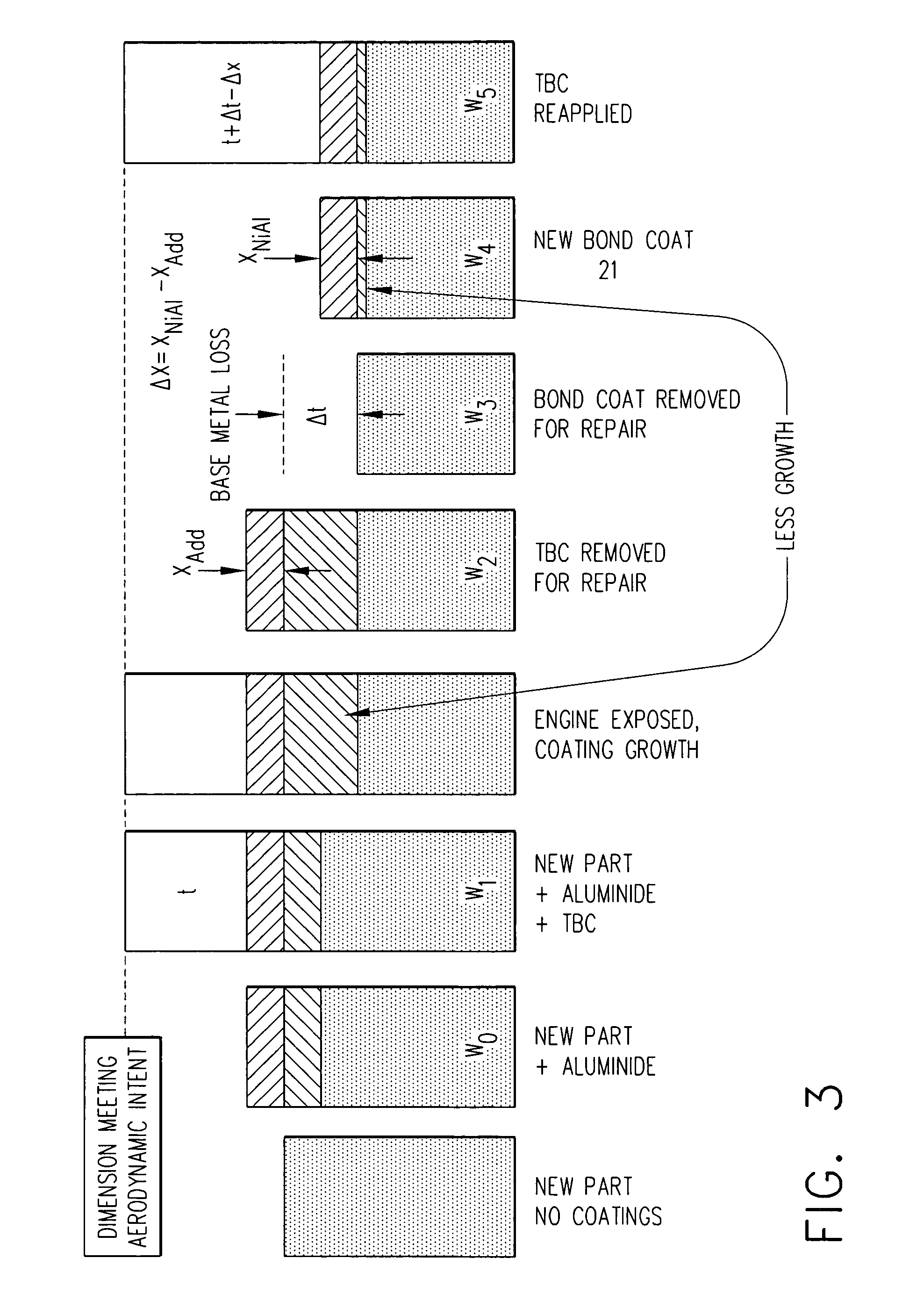

Method for repairing coated components using NiAl bond coats

InactiveUS7094444B2Guaranteed uptimeProlong lifeMolten spray coatingEngine manufactureBond coatingAlloy

Owner:GENERAL ELECTRIC CO

Combustion turbine component having bond coating and associated methods

InactiveUS20100047614A1Enhanced oxidation protectionHigh temperature operationMolten spray coatingBlade accessoriesCombustionBond coating

A combustion turbine component includes a combustion turbine component substrate and a bond coating on the combustion turbine component substrate. The bond coating may include Mn+1AXn (n=1,2,3) where M is selected from groups IIIB, IVB, VB, VIB, and VII of the periodic table of elements and mixtures thereof, where A is selected from groups IIIA, IVA, VA, and VIA of the periodic table of elements and mixtures thereof, and where X includes at least one of carbon and nitrogen. A thermal barrier coating may be on the bond coating.

Owner:SIEMENS ENERGY INC

Method for performing supersonic atmospheric plasma spraying of zirconium oxide on surface of crystallizer copper plate

InactiveCN102352477AHigh bonding strengthIncreased microhardnessMolten spray coatingPorosityBond coating

The invention relates to a method for performing supersonic atmospheric plasma spraying of zirconium oxide on the surface of a crystallizer copper plate. The method comprises the following steps: 1) performing surface pretreatment to a crystallizer copper plate matrix; 2) spraying a bonded coating on the surface of the pretreated matrix; 3) spraying a zirconium oxide base surface layer on the bonded coating; and 4) performing heat treatment to the product obtained in the step 3) and controlling the temperatures of the matrix and the coating below the matrix recrystallization temperature. By adopting the method, the bonding strength of the crystallizer copper plate matrix and the coating is high, the coating has high micro-hardness, low surface roughness and porosity and good high-temperature wear performance and thermal shock resistance. By applying the coating, the service life of the crystallizer can be effectively increased; and the coating can also be applied in the surface strengthening and repair of other copper or copper alloy elements.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com