Method for performing supersonic atmospheric plasma spraying of zirconium oxide on surface of crystallizer copper plate

A crystallizer copper plate, zirconia technology, applied in the direction of coating, fusion spraying, metal material coating technology, etc., can solve the problem of reducing the oxidation resistance and wear resistance of the coating, the roughness of the coating surface, and the increase of the coating Failure and other problems, to achieve excellent high temperature wear performance and thermal shock resistance, low surface roughness and porosity, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

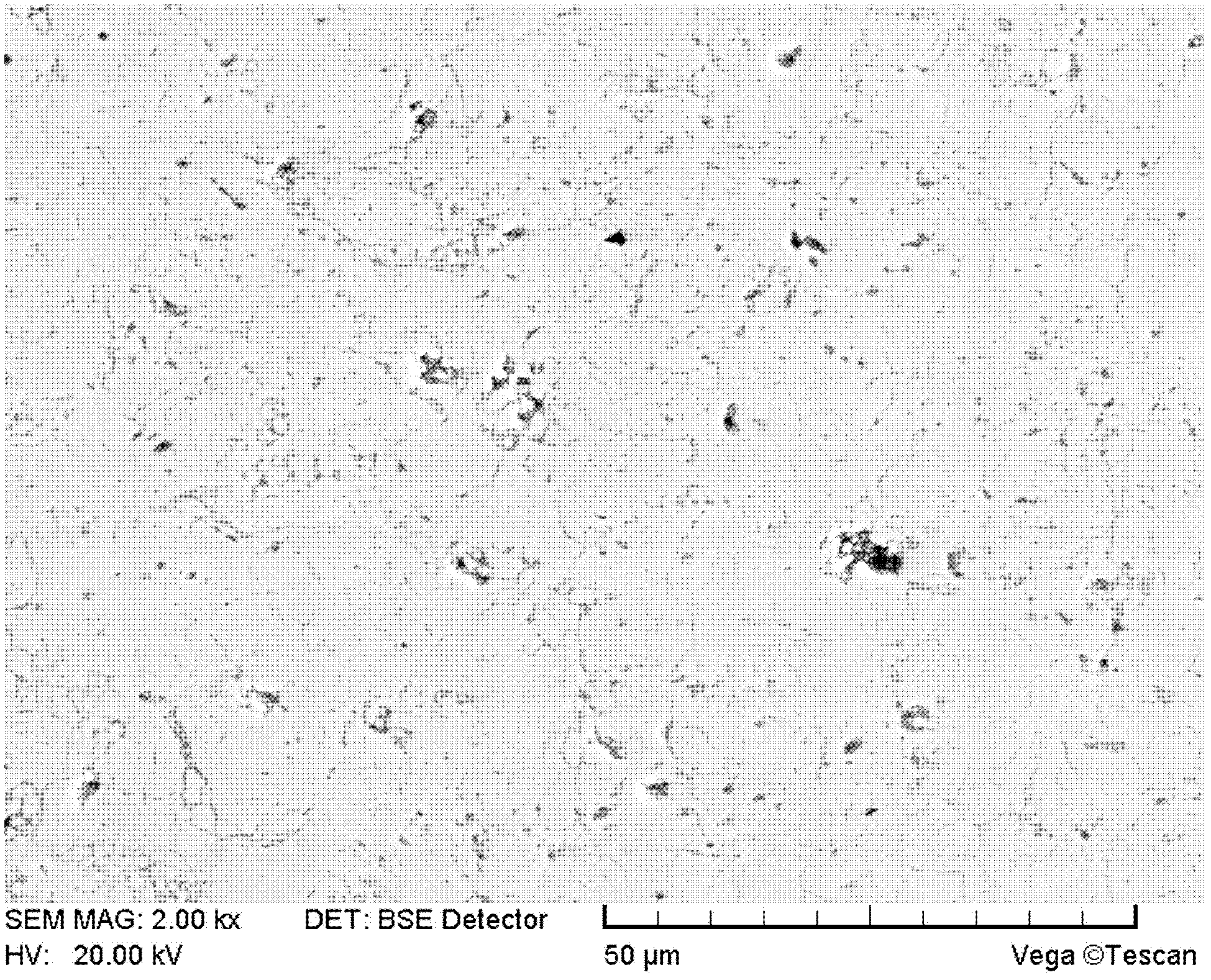

[0024] A method for spraying zirconia by atmospheric ions such as supersonic velocity on the surface of a crystallizer copper plate, comprising the following steps:

[0025] Step 1, the surface of the pure copper substrate is pretreated by alkali bath-acid bath-sand blasting to complete degreasing, rust removal and surface roughening. The alkali bath is Na with a concentration of 10wt.%. 2 CO 3 solution, 80°C, 15 minutes; the acid bath is a HCl solution with a concentration of 40wt.%, 80°C, 15 minutes, and then sandblasting for roughening;

[0026] Step 2: Spray a layer of Ni-5wt.% Al bonding layer with a thickness of 80-100 μm on the surface of the pretreated copper substrate using HEPJet high-performance supersonic atmospheric plasma. The spraying parameters are spraying voltage 100V, spraying current 350A, main gas Ar flow rate 50sl / m, auxiliary gas H 2 The flow rate is 5sl / m, the moving speed of the spray gun is 700mm / s, the powder feeding rate is 30g / min, and the sprayi...

Embodiment 2

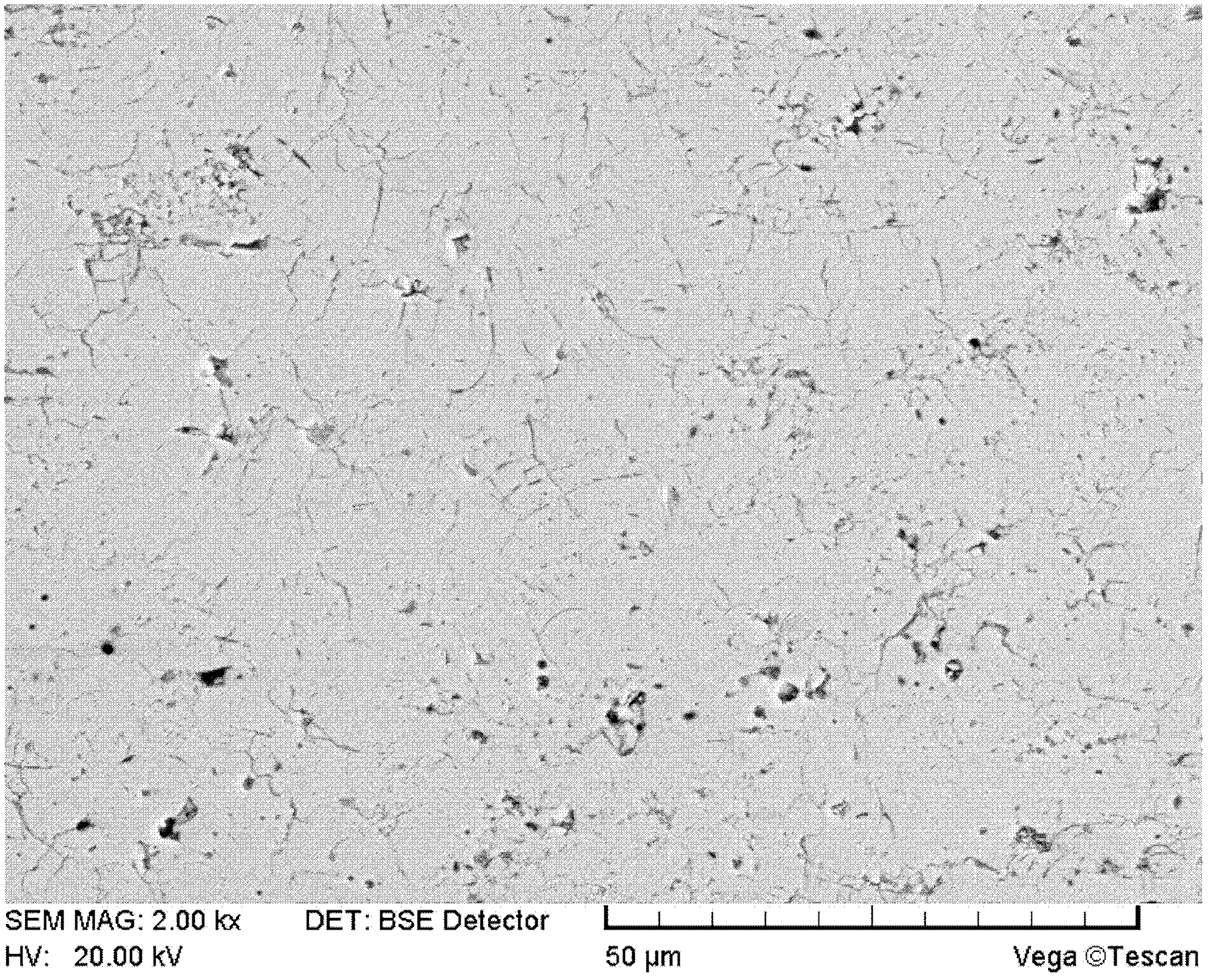

[0034] A method for supersonic atmospheric plasma spraying zirconia on the surface of a crystallizer copper plate, comprising the following steps:

[0035] Step 1, the chromium-zirconium-copper substrate is subjected to surface pretreatment by ultrasonic cleaning-sandblasting to complete degreasing, rust removal and surface roughening. The ultrasonic cleaning uses acetone for 15 minutes, and then sandblasting for roughening;

[0036] Step 2: Spray a layer of NiCoCrAlY bonding layer with a thickness of 40-50 μm on the surface of the pretreated chromium-zirconium-copper substrate using HEPJet high-performance supersonic atmospheric plasma. The spraying parameters are spraying voltage 100-150V, spraying current 350A, main gas ( Ar) flow rate 50sl / m, auxiliary gas (H 2 ) The flow rate is 15sl / m, the moving speed of the spray gun is 800mm / s, the powder feeding rate is 45g / min, and the spraying distance is 80mm; NiCoCrAlY powder has wettability with the substrate and ceramic powder,...

Embodiment 3

[0041] A method for supersonic atmospheric plasma spraying zirconia on the surface of a crystallizer copper plate, comprising the following steps:

[0042] Step 1, the CuAg substrate is subjected to surface pretreatment by ultrasonic cleaning-sandblasting to complete degreasing, rust removal and surface roughening. The ultrasonic cleaning uses acetone for 15 minutes, and then sandblasting for roughening;

[0043] Step 2: Use HEPJet high-efficiency supersonic atmospheric plasma to spray a layer of NiCrBSi bonding layer with a thickness of 60-80 μm on the surface of the pretreated CuAg substrate. The spraying parameters are spraying voltage 120V, spraying current 380A, and main gas (Ar) flow rate 60sl / m, auxiliary gas (H 2 ) The flow rate is 10sl / m, the moving speed of the spray gun is 750mm / s, the powder feeding rate is 40g / min, and the spraying distance is 100mm; NiCrBSi powder has wettability with the substrate and ceramic powder, and its thermal expansion coefficient is clo...

PUM

| Property | Measurement | Unit |

|---|---|---|

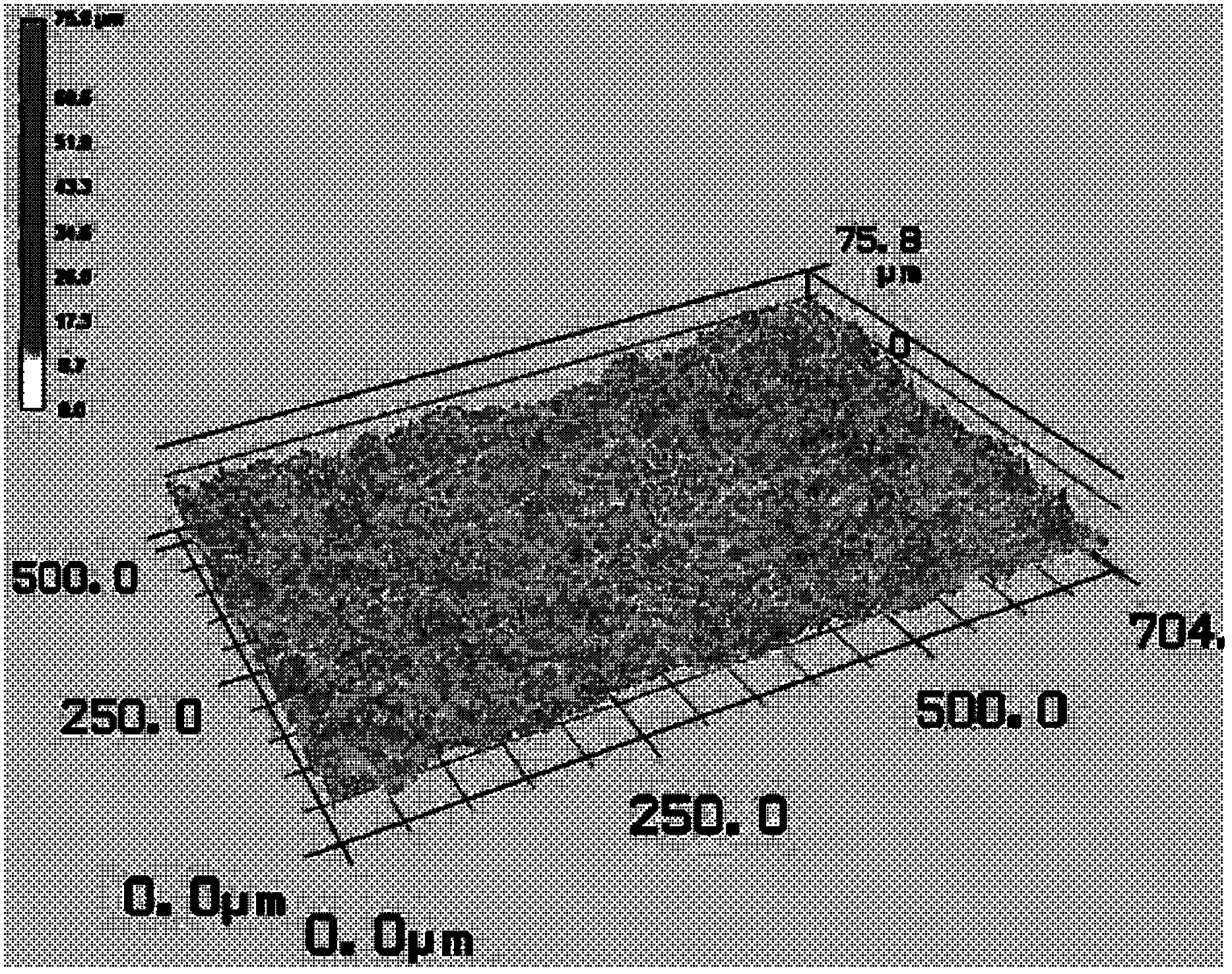

| Roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com