Patents

Literature

7157 results about "Thermal shock" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal shock occurs when a thermal gradient causes different parts of an object to expand by different amounts. This differential expansion can be understood in terms of stress or of strain, equivalently. At some point, this stress can exceed the strength of the material, causing a crack to form. If nothing stops this crack from propagating through the material, it will cause the object's structure to fail.

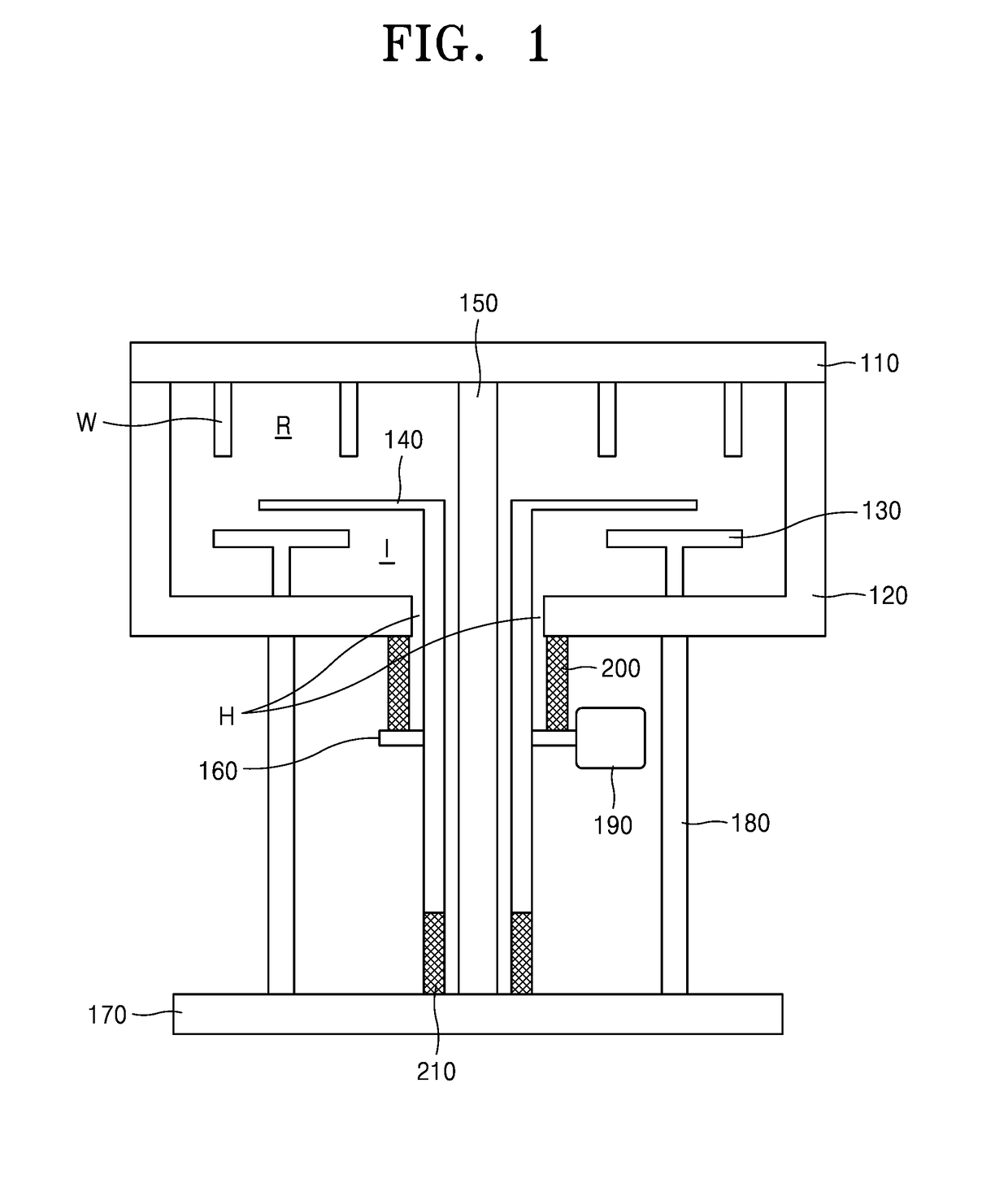

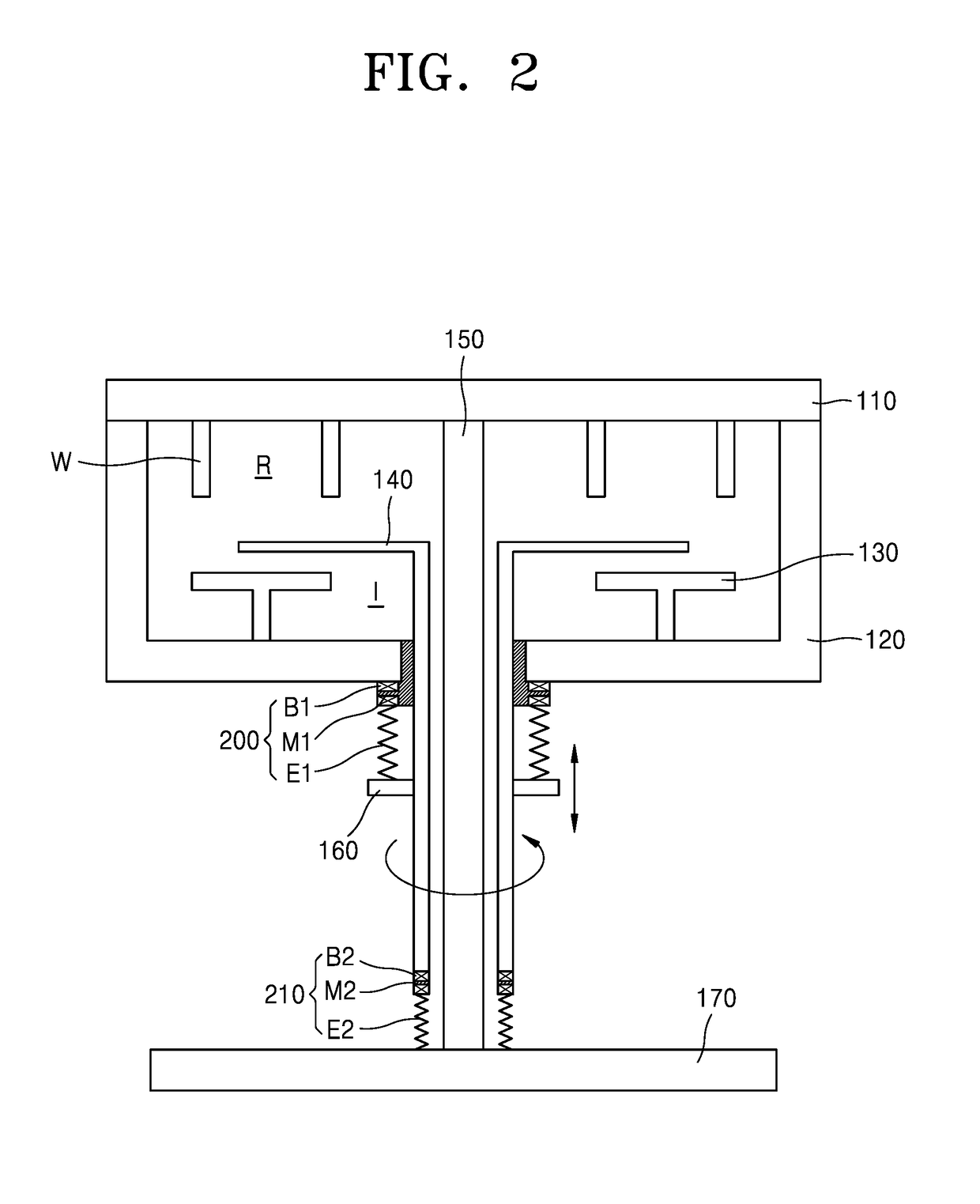

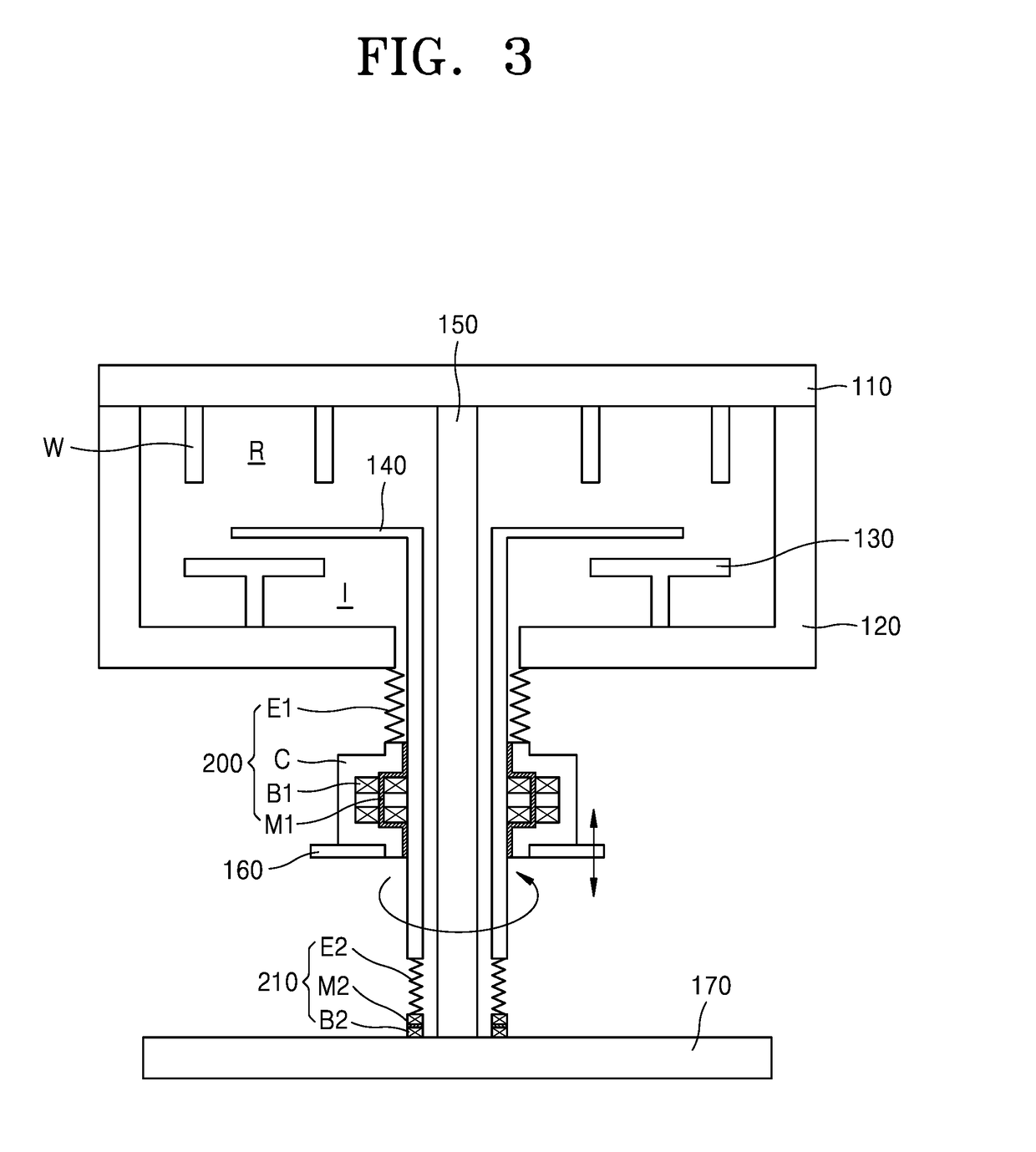

Substrate processing device

Provided is a substrate-processing device capable of preventing a top lid from sagging downward by the own weight of the substrate-processing device and / or a vacuum suction force generated by a vacuum pump and / or thermal shock at high temperature process, in a chamber including a plurality of reactors. Also, provided is a rotating shaft for transferring a substrate between the plurality of reactors.

Owner:ASM IP HLDG BV

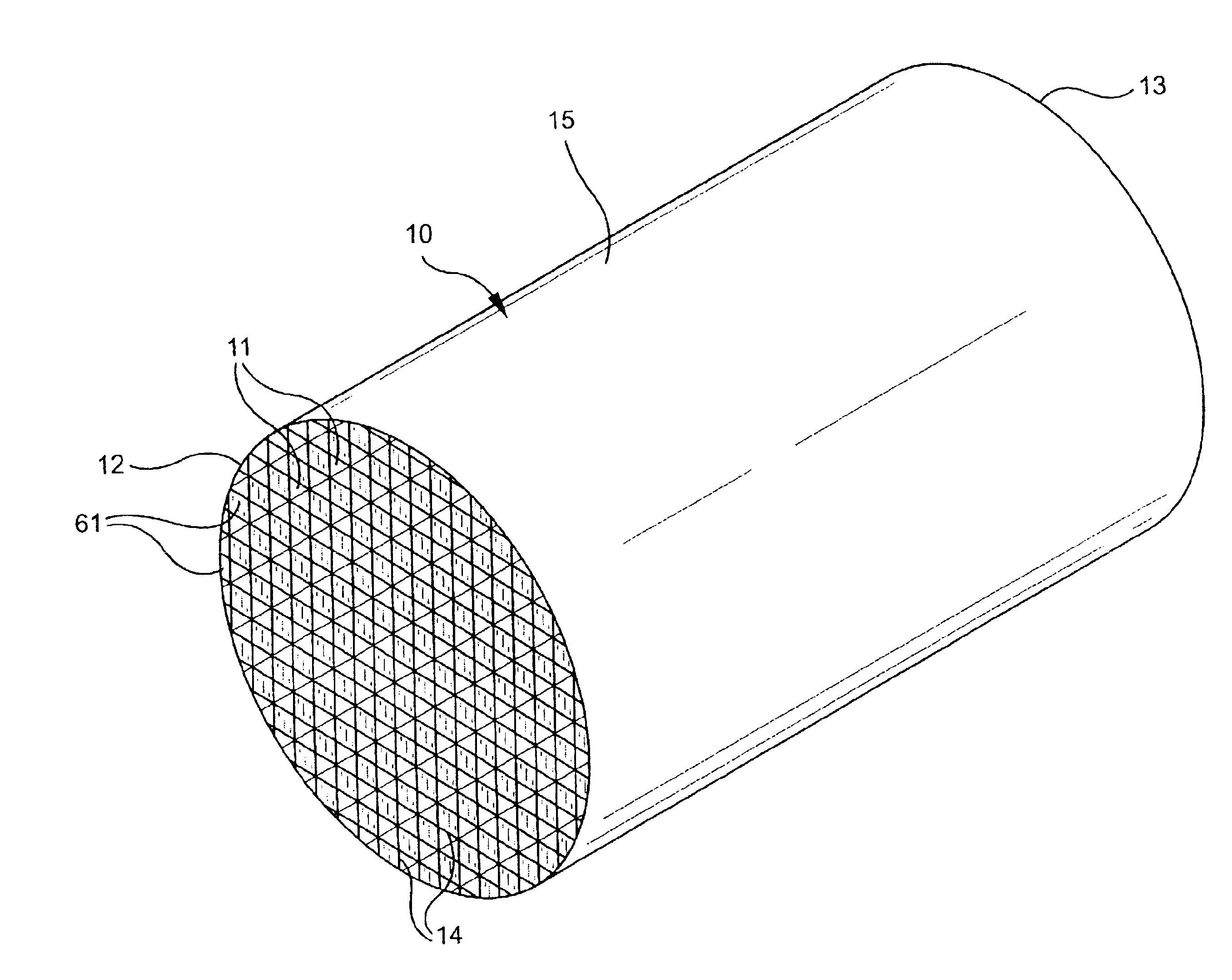

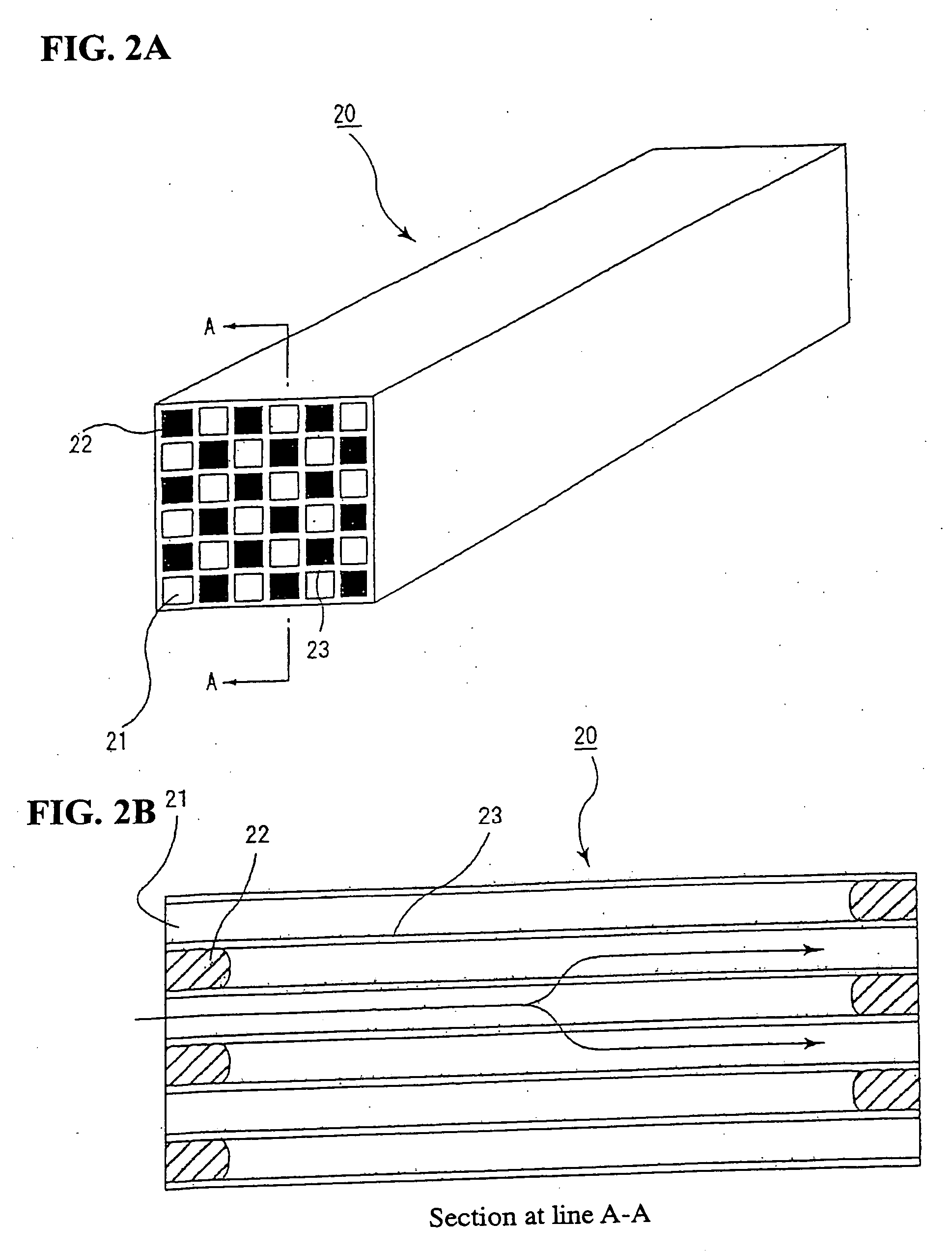

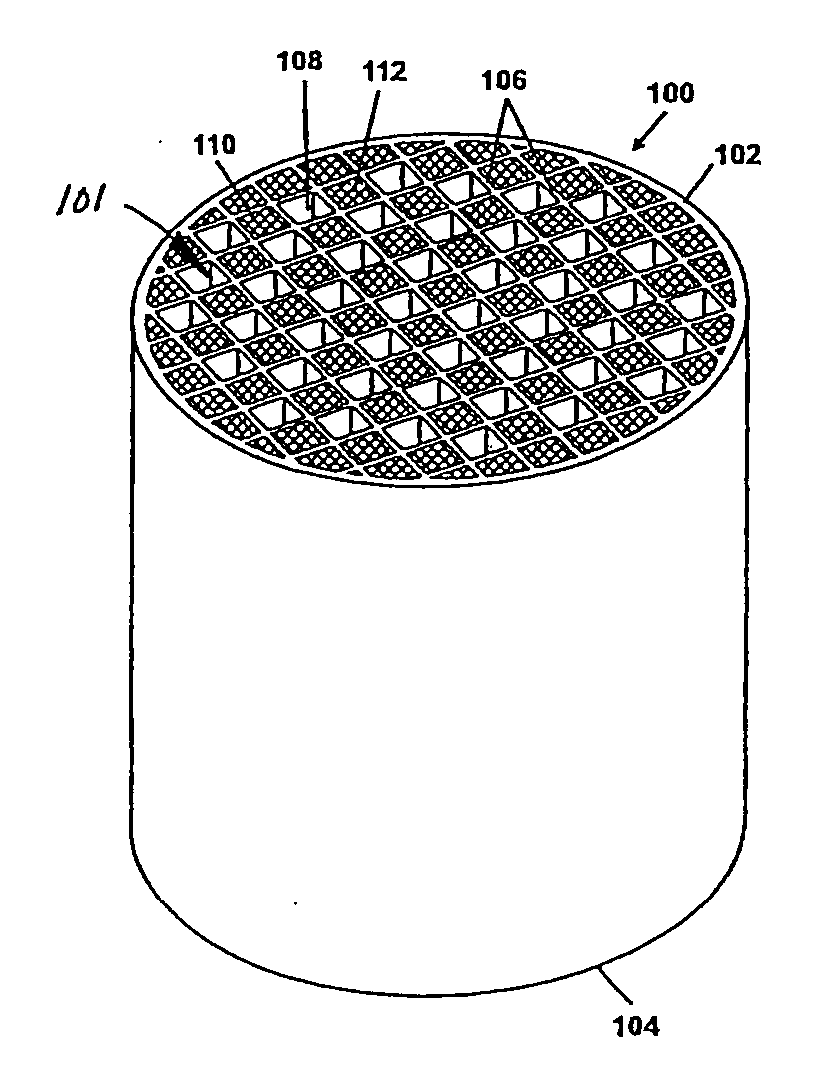

Mullite-aluminum titanate diesel exhaust filter

InactiveUS6849181B2High porosityLarge apertureIron oxides/hydroxidesExhaust apparatusFiltrationMullite

The invention is directed at a mullite-aluminum titanate porous diesel particulate filter constituting a porous ceramic body containing, expressed in terms of weight percent of the total body, of 60-90%, preferably 70-80%, most preferably 70% iron-aluminum titanate solid solution having a stoichiometry of Al2(1−x)Fe2xTiO5, where x is 0-0.1, and 10-40%, preferably 20-30%, most preferably 30% mullite (3Al2O3.2SiO2), and consists essentially, expressed in terms of weigh percent on the oxide basis, of 3 to 15% SiO2, 55 to 65% Al2O3, 22 to 40% TiO2, and 0 to 10% Fe2O3, and being useful for filtration of diesel exhaust. The inventive diesel particulate filter exhibits high interconnected open porosity and large median pore size, in combination with high permeability when fired to a temperature of between 1650° to 1700° C., along with high thermal shock resistance and good filtration capability.

Owner:CORNING INC

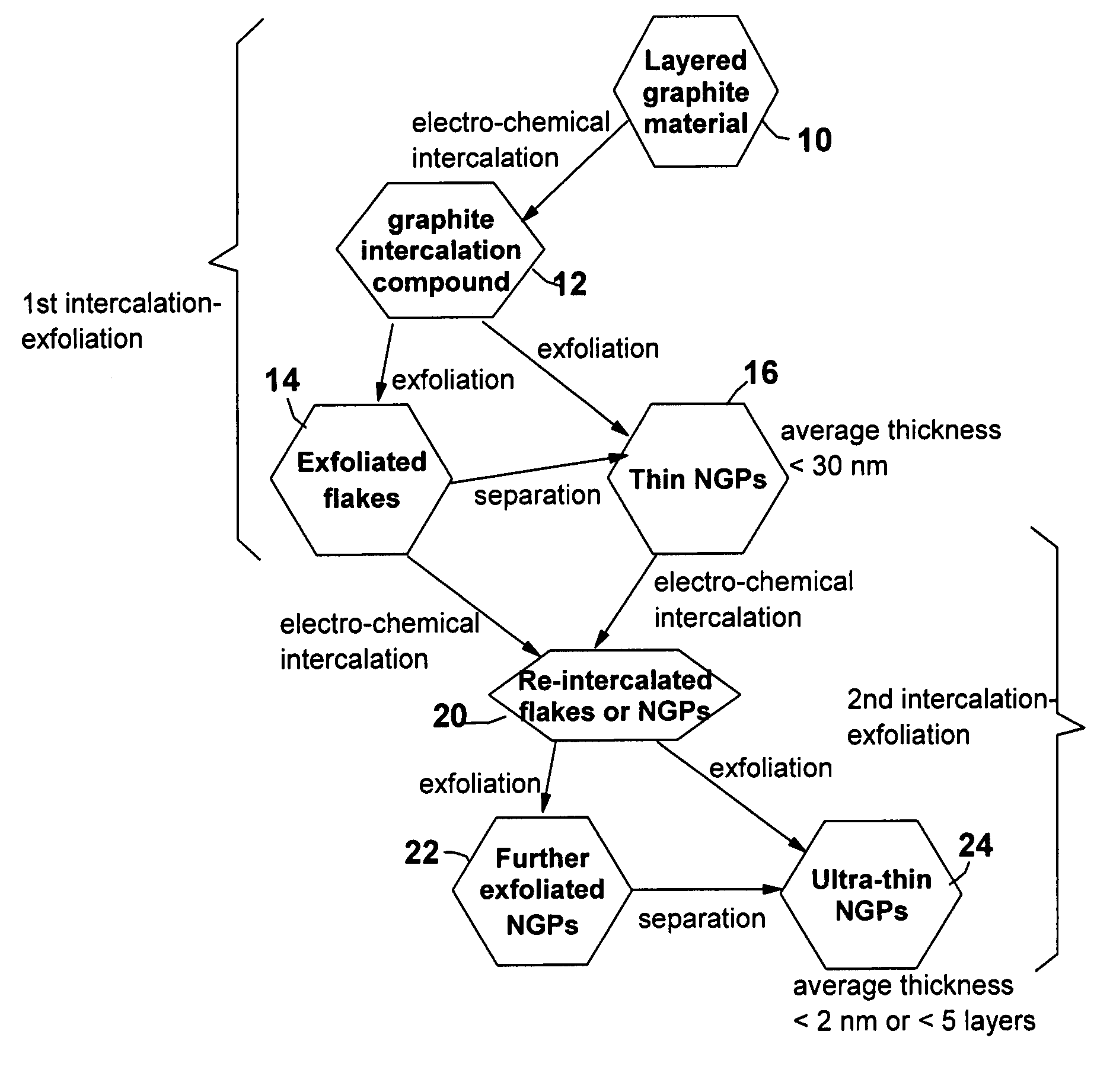

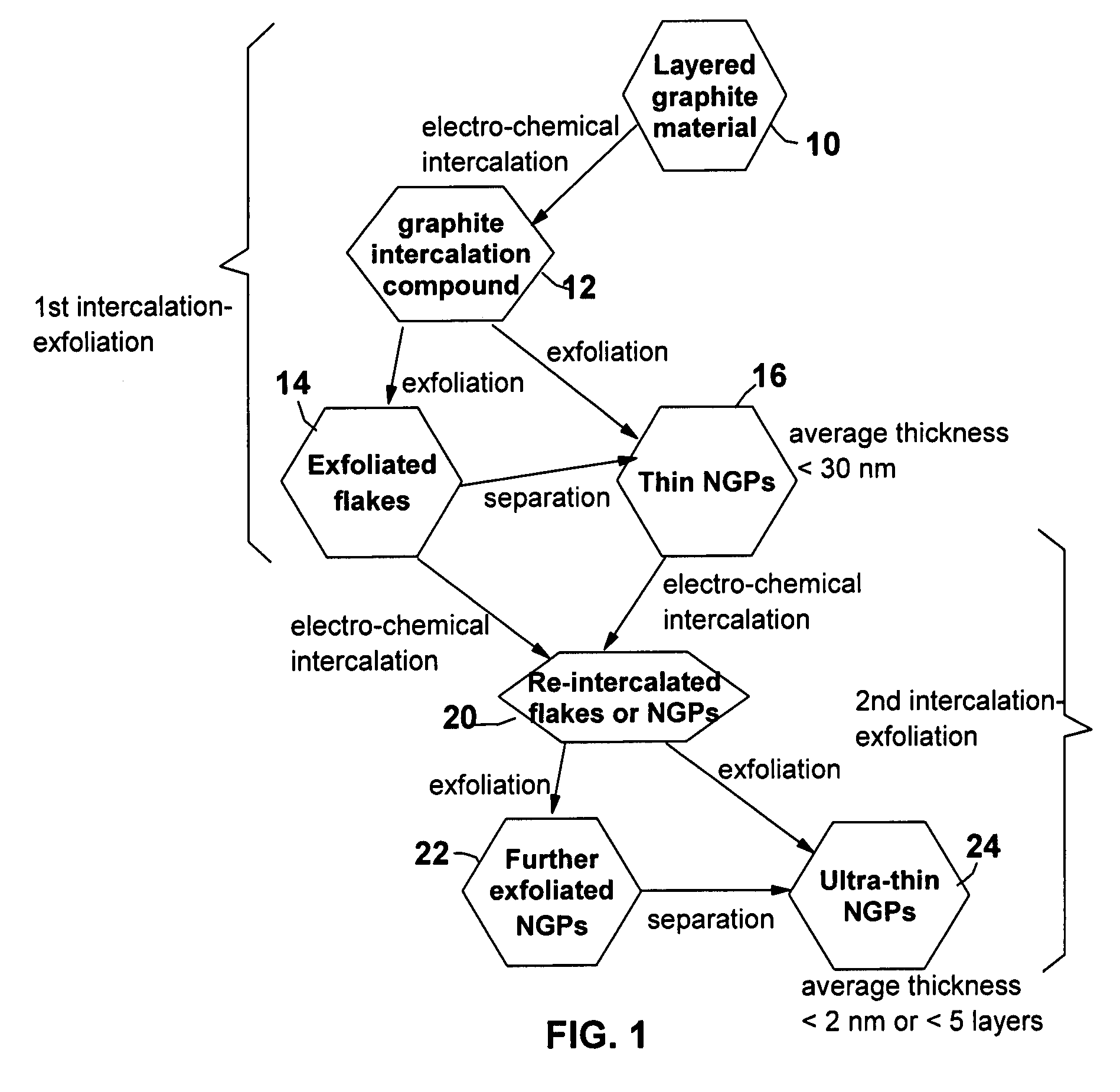

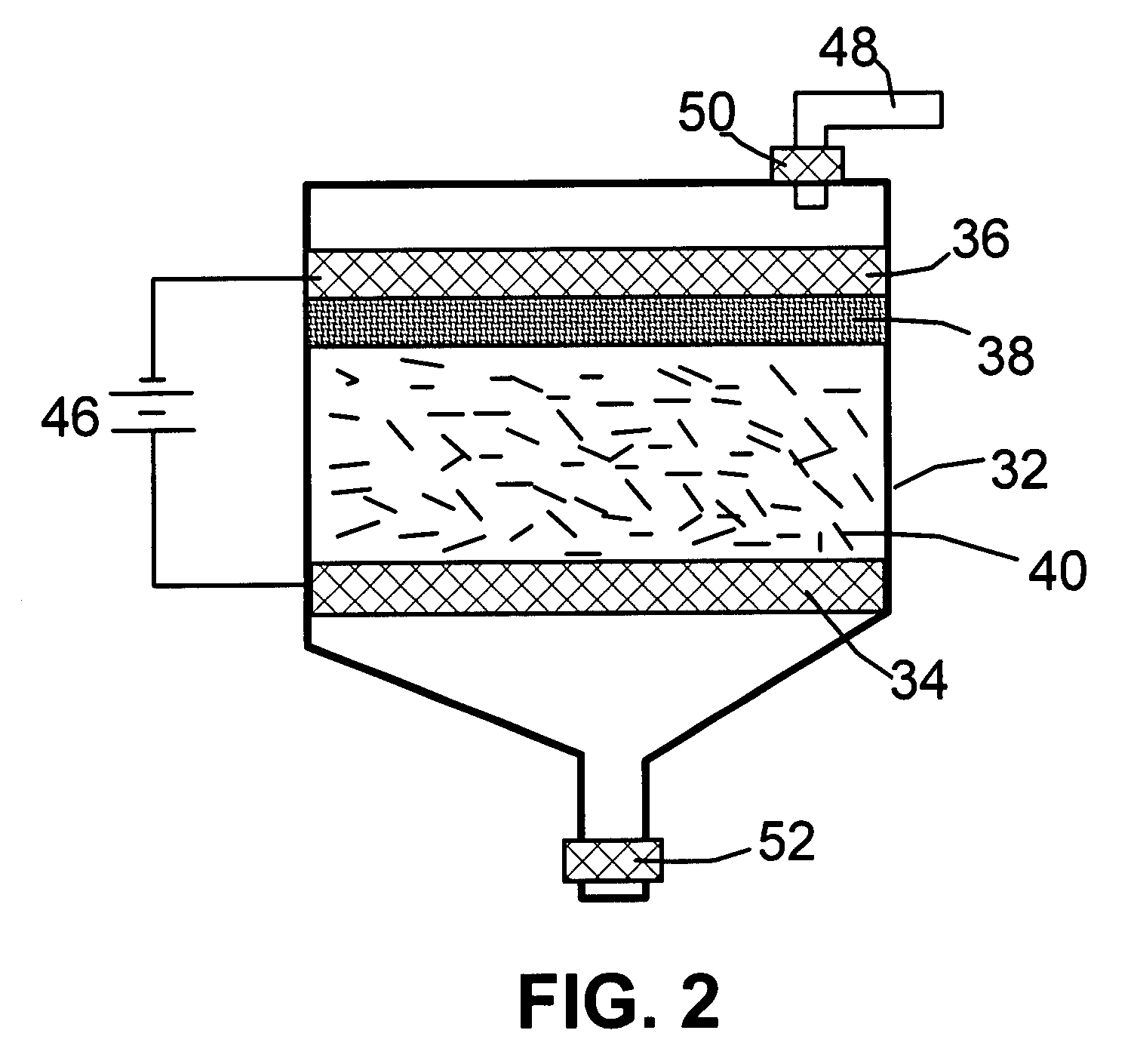

Electrochemical method of producing nano-scaled graphene platelets

A method of producing nano-scaled graphene platelets with an average thickness smaller than 30 nm from a layered graphite material. The method comprises (a) forming a carboxylic acid-intercalated graphite compound by an electrochemical reaction which uses a carboxylic acid as both an electrolyte and an intercalate source, the layered graphite material as an anode material, and a metal or graphite as a cathode material, and wherein a current is imposed upon the cathode and the anode at a current density for a duration of time sufficient for effecting the electrochemical reaction; (b) exposing the intercalated graphite compound to a thermal shock to produce exfoliated graphite; and (c) subjecting the exfoliated graphite to a mechanical shearing treatment to produce the nano-scaled graphene platelets. Preferred carboxylic acids are formic acid and acetic acid. The exfoliation step in the instant invention does not involve the evolution of undesirable species, such as NOx and SOx, which are common by-products of exfoliating conventional sulfuric or nitric acid-intercalated graphite compounds. The nano-scaled platelets are candidate reinforcement fillers for polymer nanocomposites. Nano-scaled graphene platelets are much lower-cost alternatives to carbon nano-tubes or carbon nano-fibers.

Owner:GLOBAL GRAPHENE GRP INC

Resin composition, method of its composition, and cured formulation

InactiveUS20060029811A1Improve flame retardant performanceMaintain good propertiesSemiconductor/solid-state device detailsSynthetic resin layered productsCarboxylic acidMicroparticle

It is an object of the present invention to provide a resin composition which can form cured formulations having various excellent properties such as an insulating property, thermal shock resistance, moldability / formability and strength, and exhibit an excellent appearance in which transparency is enhanced, a resin composition whose cured thin film has excellent flame retardancy, good mechanical property and heat resistance, a dispersing element containing an inorganic microfine particle which can give a flame retardancy to a resin, to which the inorganic microfine particle is added, and can reduce a hygroscopic property to the extent possible, a method for producing the same and a cured formulation obtained by using the resin composition. The present invention relates to a resin composition comprising a compound having at least one of a glycidyl group and / or an epoxy group and an inorganic microfine particle, a resin composition comprising three components of a phenolic compound, a compound having at least one of a glycidyl group and / or an epoxy group and an inorganic microfine particle, a flame retardant resin composition comprising a polyhydric phenol and an inorganic microfine particle, and a dispersing element containing an inorganic microfine particle obtained by a hydrolysis condensation reaction of alkoxide and / or metal carboxylate in a dispersion medium.

Owner:NIPPON SHOKUBAI CO LTD

Mullite-aluminum titanate diesel exhaust filter

InactiveUS20040020846A1High interconnected porosityReduce back pressureIron oxides/hydroxidesExhaust apparatusFiltrationWhole body

The invention is directed at a mullite-aluminum titanate porous diesel particulate filter constituting a porous ceramic body containing, expressed in terms of weight percent of the total body, of 60-90%, preferably 70-80%, most preferably 70% iron-aluminum titanate solid solution having a stoichiometry of Al2(1-x)Fe2xTiO5, where x is 0-0.1, and 10-40%, preferably 20-30%, most preferably 30% mullite (3Al2O3.2SiO2), and consists essentially, expressed in terms of weigh percent on the oxide basis, of 3 to 15% SiO2, 55 to 65% Al2O3, 22 to 40% TiO2, and 0 to 10% Fe2O3, and being useful for filtration of diesel exhaust. The inventive diesel particulate filter exhibits high interconnected open porosity and large median pore size, in combination with high permeability when fired to a temperature of between 1650° to 1700° C., along with high thermal shock resistance and good filtration capability.

Owner:CORNING INC

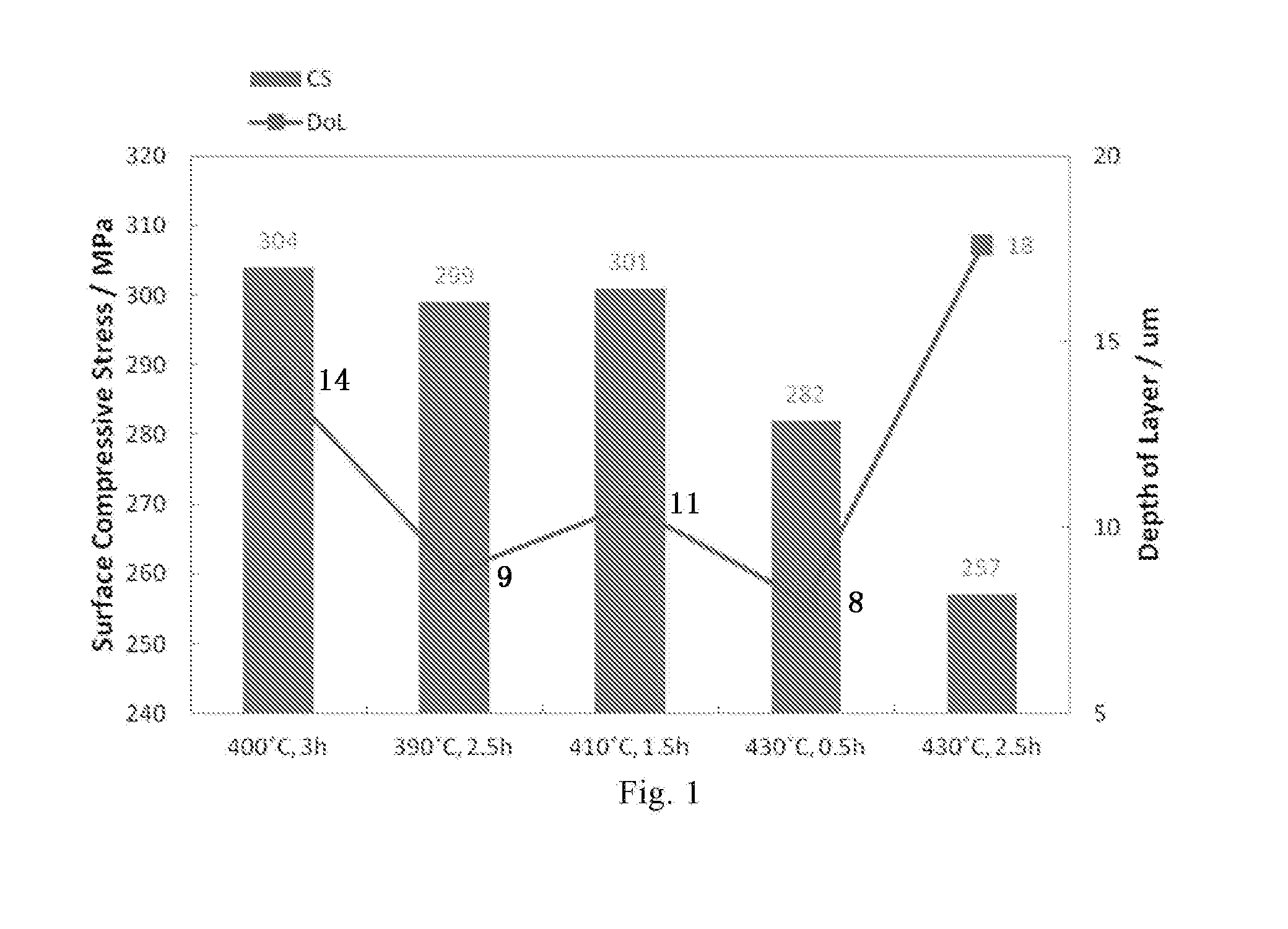

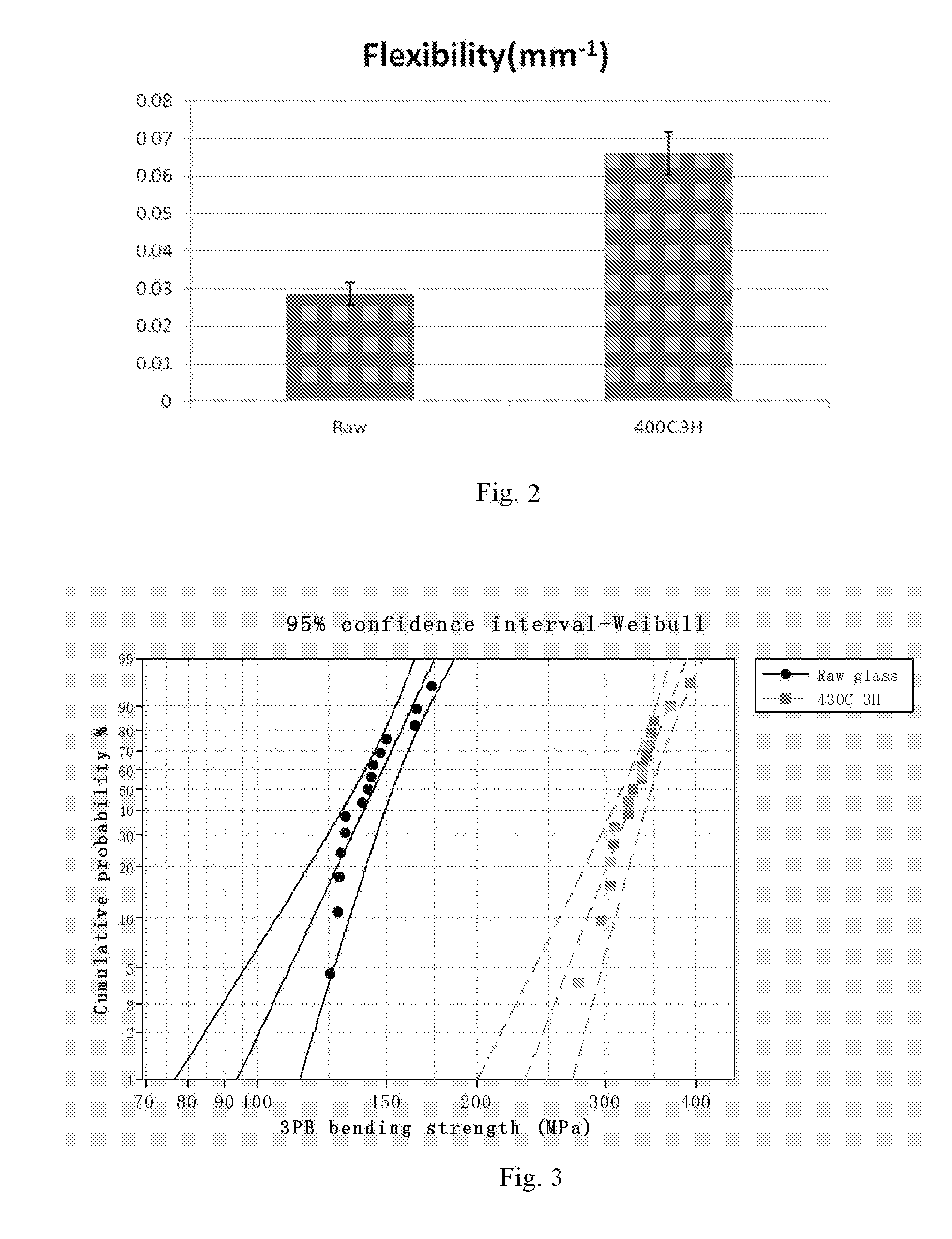

Chemically Toughened Flexible Ultrathin Glass

ActiveUS20160002103A1Reduce compressive stressIncrease flexibilityFilm/foil adhesivesSynthetic resin layered productsGlass sheetThermal shock

A chemically toughened ultrathin glass is provided. The glass has a thickness less than 500 μm and a surface compressive layer having a depth of at most 30 μm. The toughened ultrathin glass sheet is more flexible and has extraordinary thermal shock resistance with the glass being easier to handle for processing.

Owner:SCHOTT GLASS TECH (SUZHOU) CO LTD

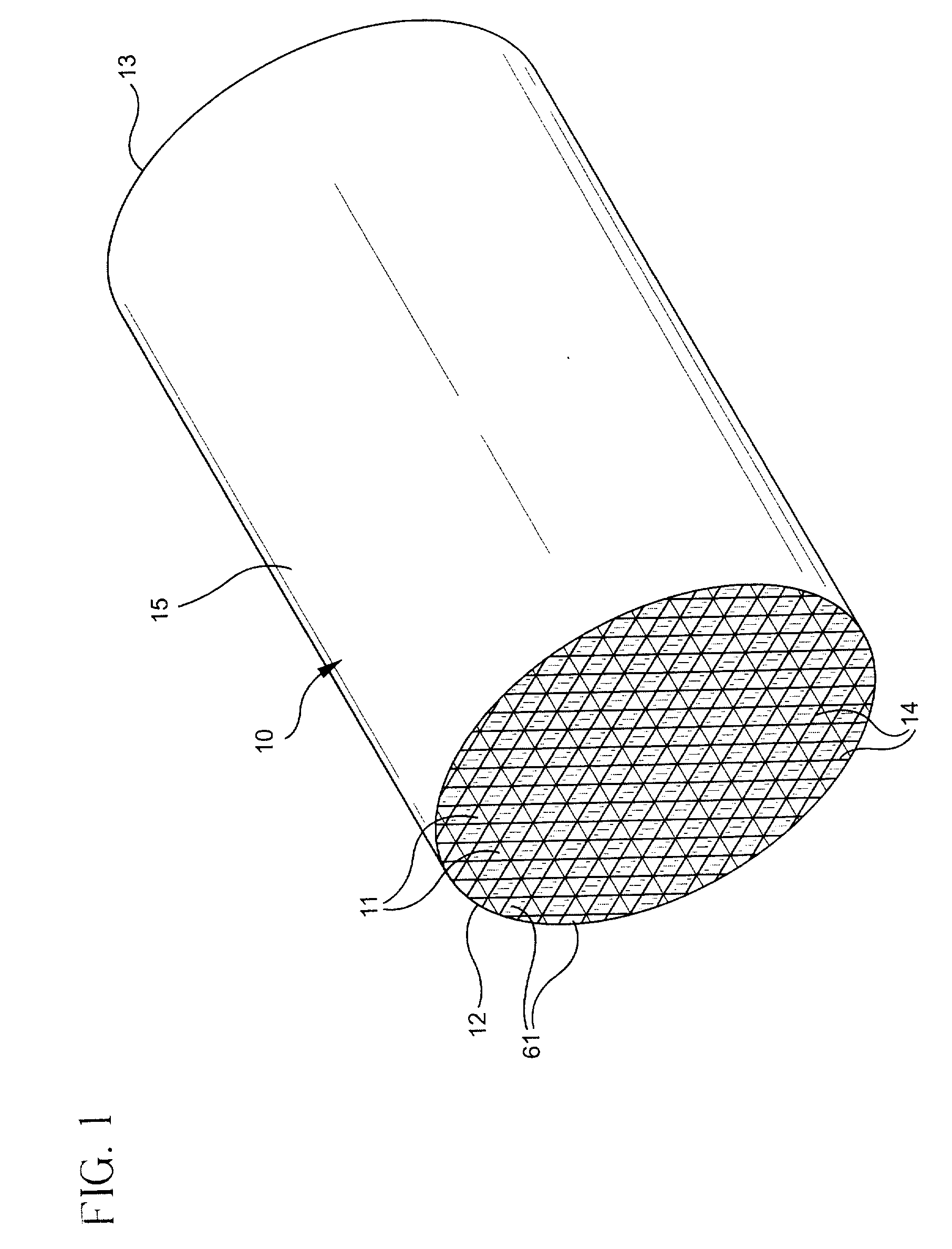

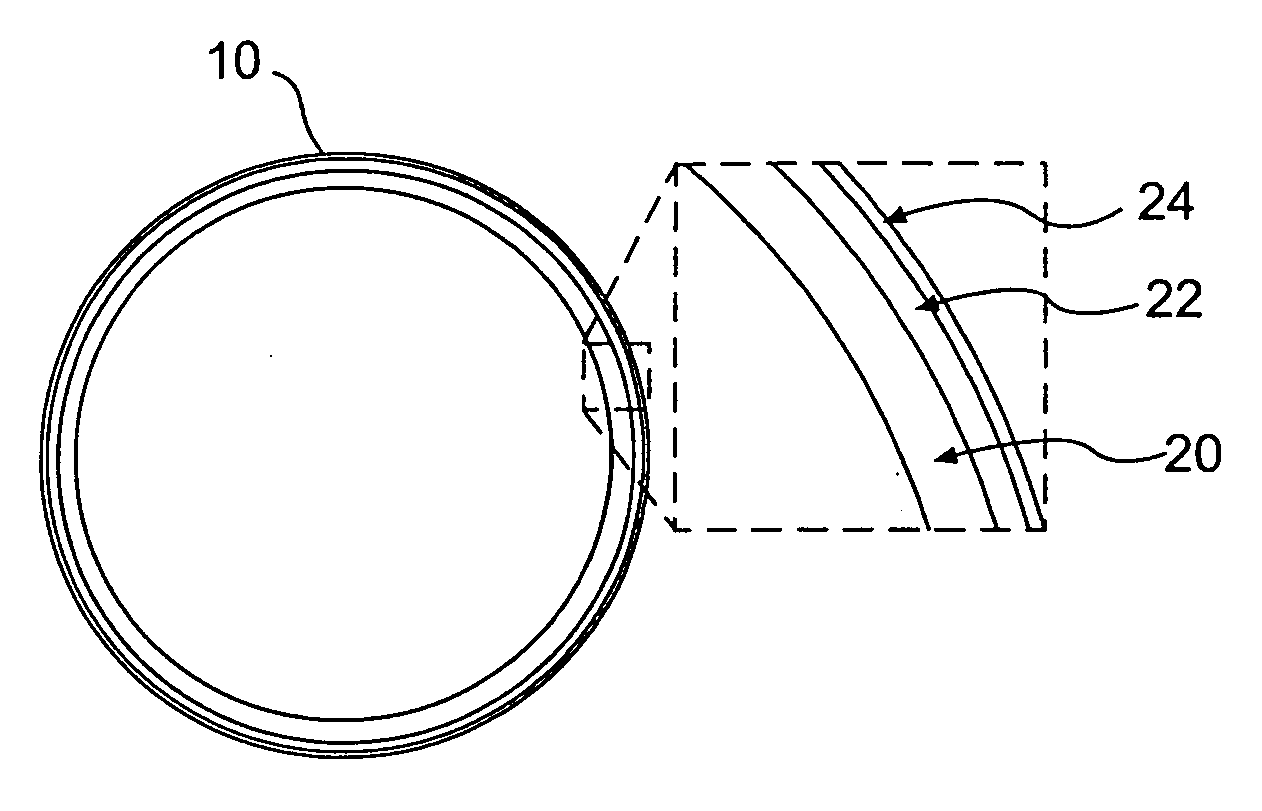

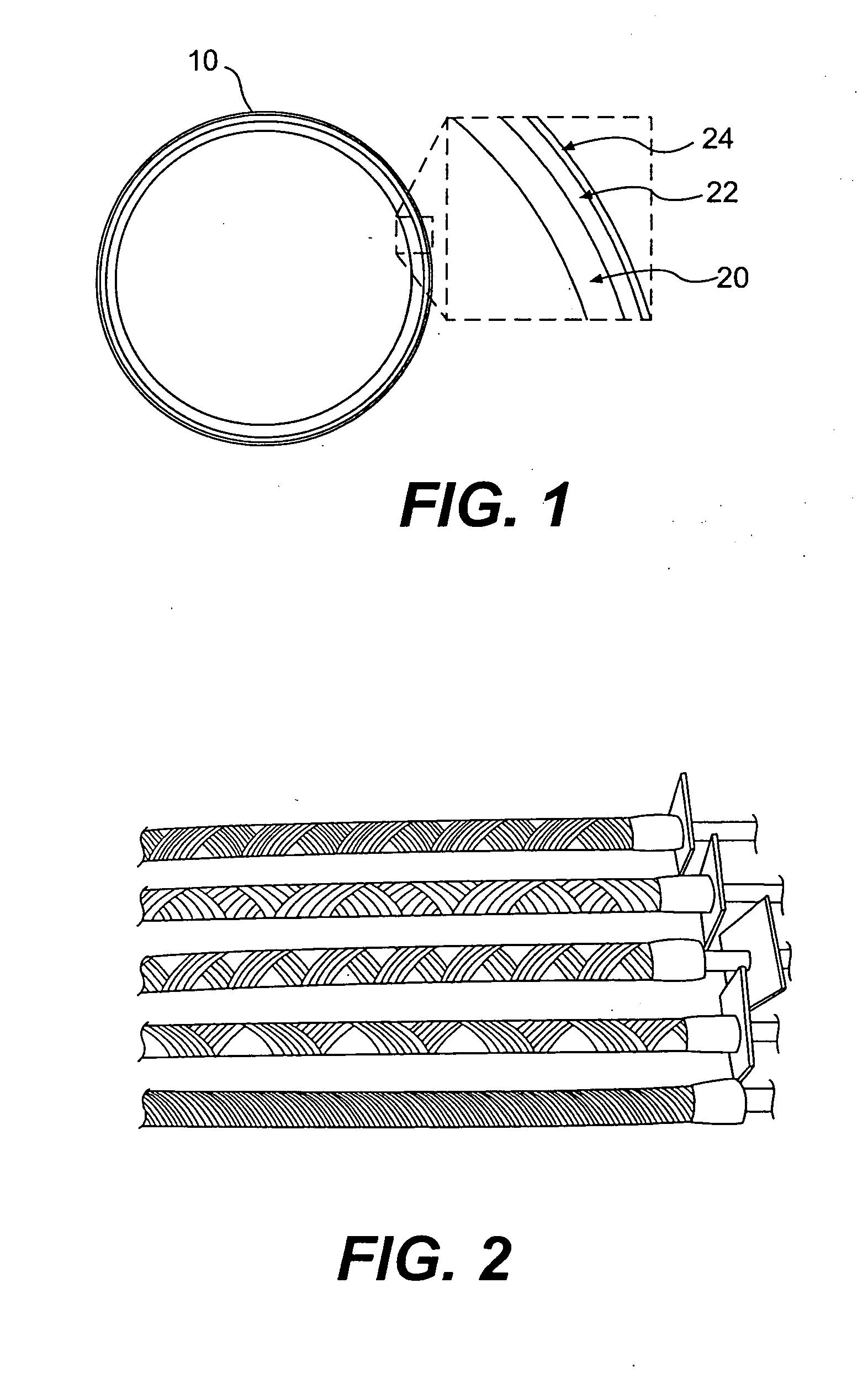

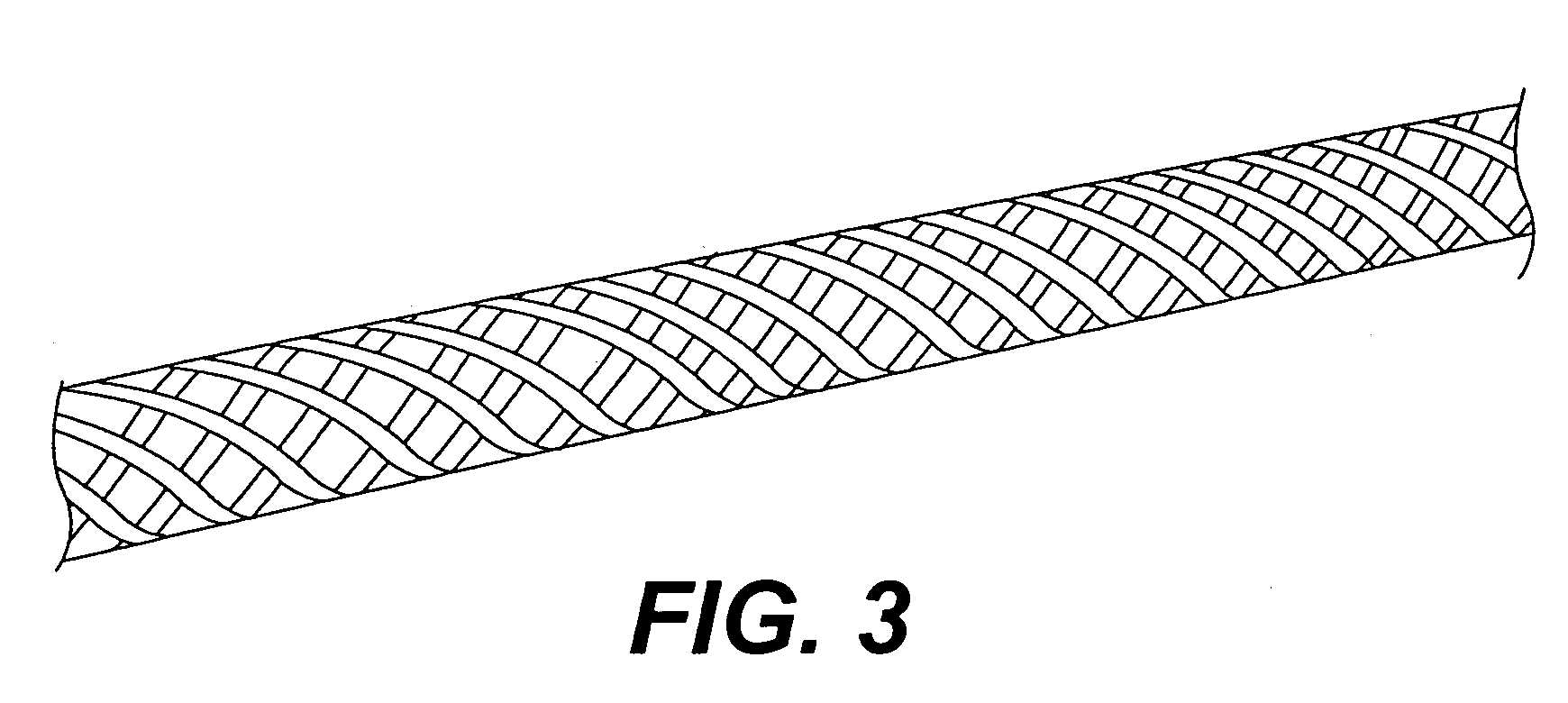

Multi-layered ceramic tube for fuel containment barrier and other applications in nuclear and fossil power plants

A multi-layered ceramic tube having an inner layer of high purity beta phase stoichiometric silicon carbide, a central composite layer of continuous beta phase stoichiometric silicon carbide fibers, and an outer layer of fine-grained silicon carbide. The ceramic tube is particularly suited for use as cladding for a fuel rod used in a power plant or reactor. The ceramic tube has a desirable combination of high initial crack resistance, stiffness, ultimate strength, and impact and thermal shock resistance.

Owner:GAMMA ENG CORP

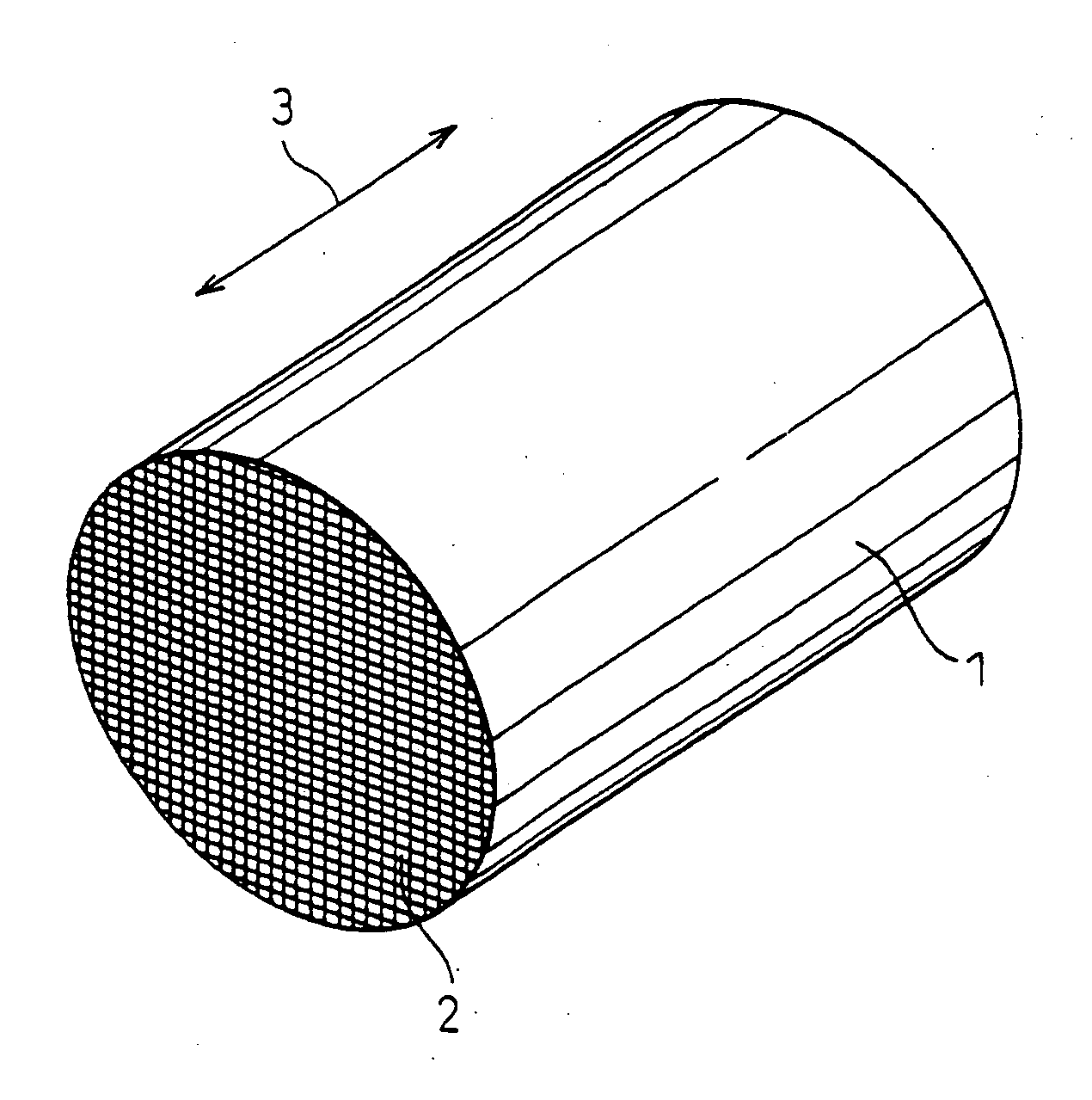

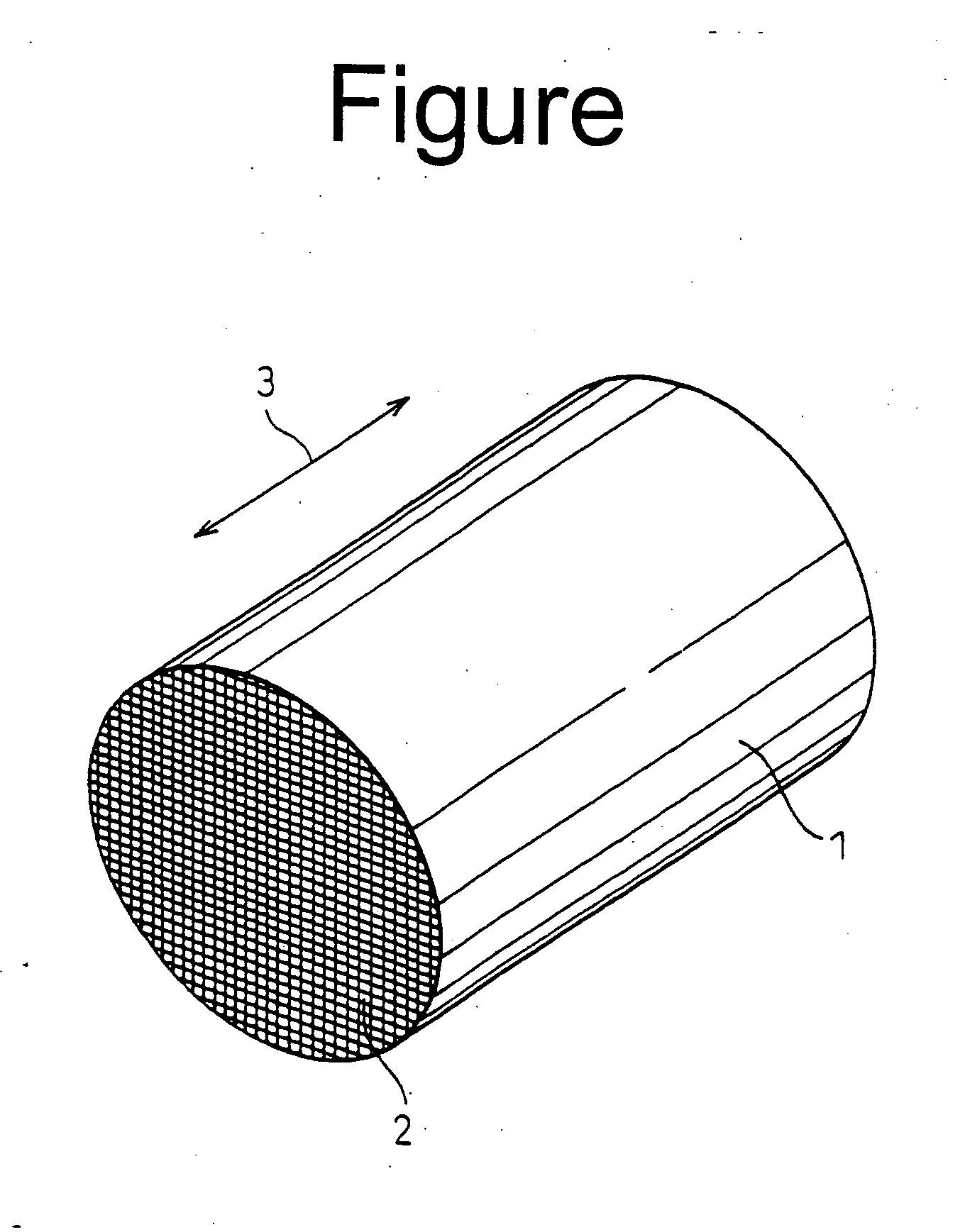

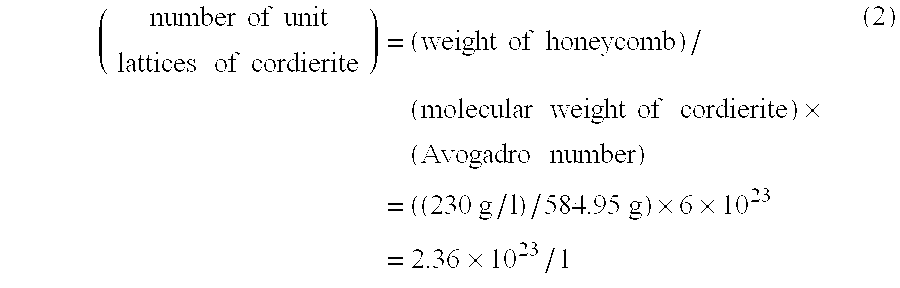

Ceramic support capable of supporting a catalyst, a catalyst-ceramic body and processes for producing same

InactiveUS20070173403A1Easy to cleanExhibits its performance more effectivelyMembranesSemi-permeable membranesLattice defectsOxygen vacancy

A ceramic support capable of supporting a catalyst comprising a ceramic body having fine pores with a diameter or width up to 1000 times the ion diameter of a catalyst component to be supported on the surface of the ceramic body, the number of the fine pores being not less than 1×1011 pores per liter, is produced by introducing oxygen vacancies or lattice defects in the cordierite crystal lattice or by applying a thermal shock to form fine cracks.

Owner:NIPPON SOKEN +1

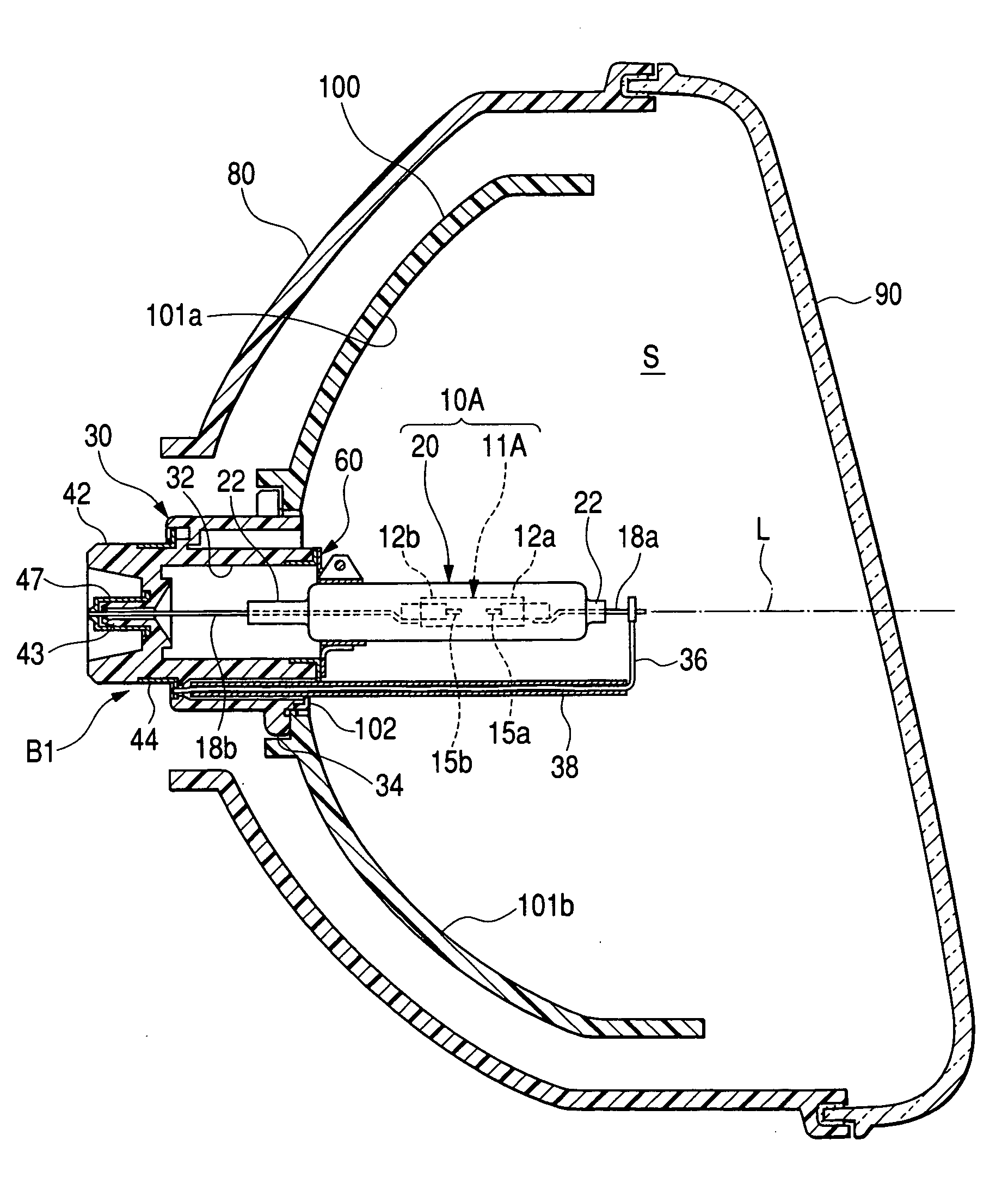

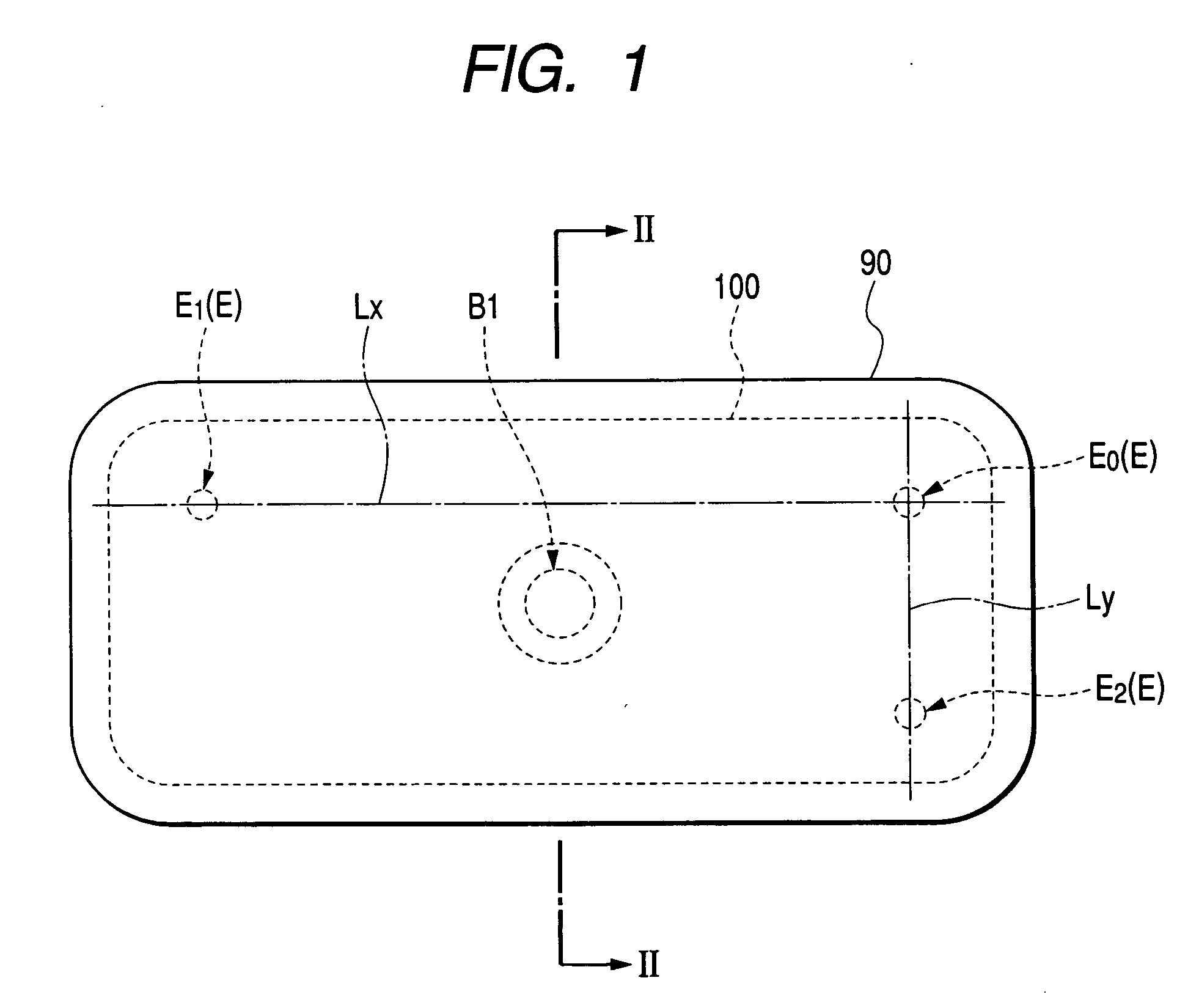

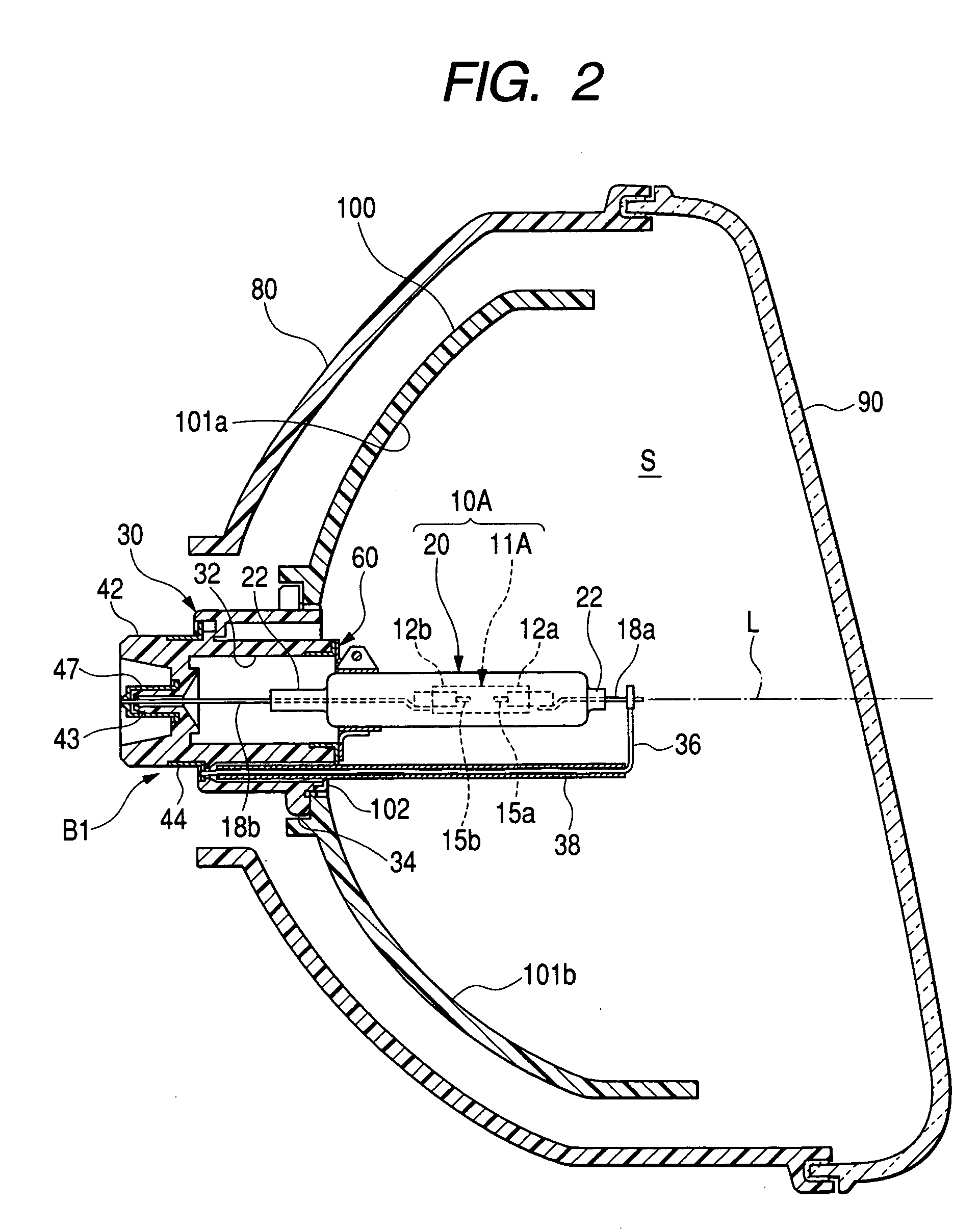

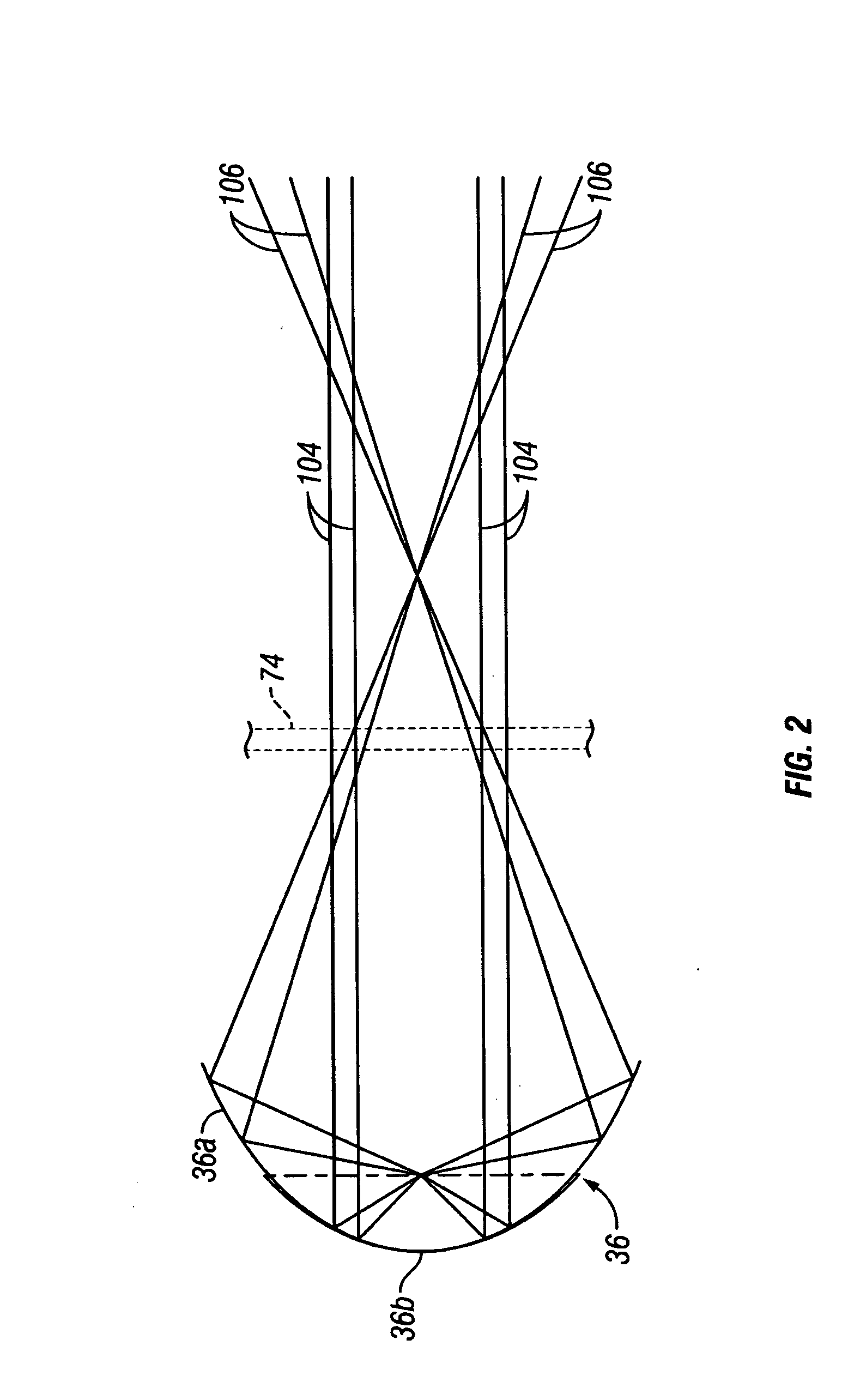

Automotive discharge bulb and automotive headlamp

InactiveUS20050007020A1Wasteful consumption can be reducedReduce the ratioDischarge tube luminescnet screensPoint-like light sourceNoble gasLuminous flux

An automotive discharge bulb having a light emitting tube includes a ceramic tube with paired electrodes oppositely placed, and contains a light emitting material and starting rare gas. A transversal section of the ceramic tube is longitudinally elongated. Because the capacity of an enclosed space of the ceramic tube is small, after discharging begins, the enclosed space temperature increases. Consequently, the ceramic tube has a good luminous flux rising characteristic. Because of the small surface area of the ceramic tube, the load imposed on the wall surface increases. Consequently, the ceramic tube has good luminous efficiency. In the ceramic tube having a longitudinally elongated transversal section, an arc generated into an upwardly convex shape and the tube wall do not make contact. Thermal shock resistance required of the ceramic tube is alleviated, durability is enhanced, and the ceramic tube is made of a ceramic material hitherto unusable.

Owner:KOITO MFG CO LTD

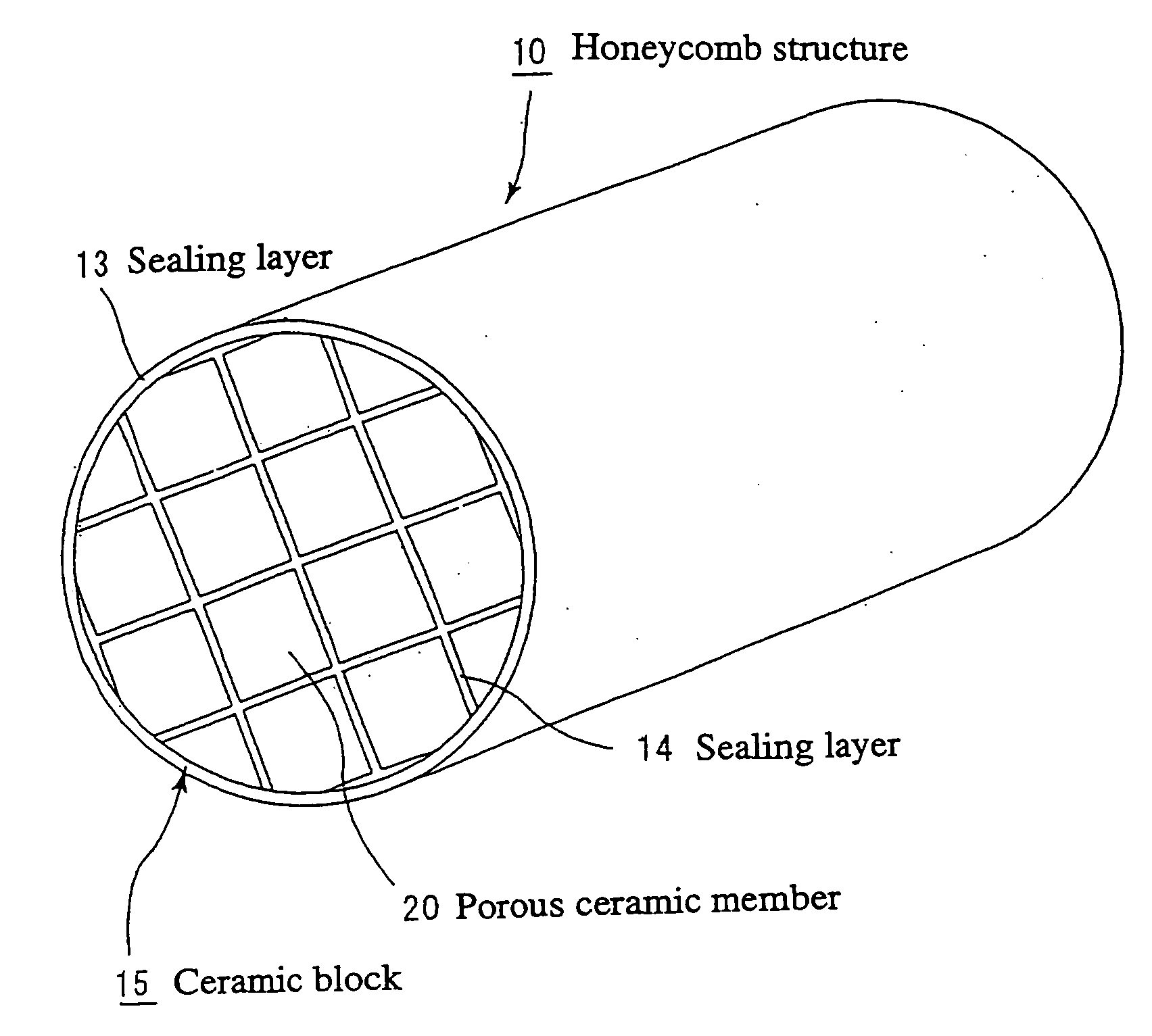

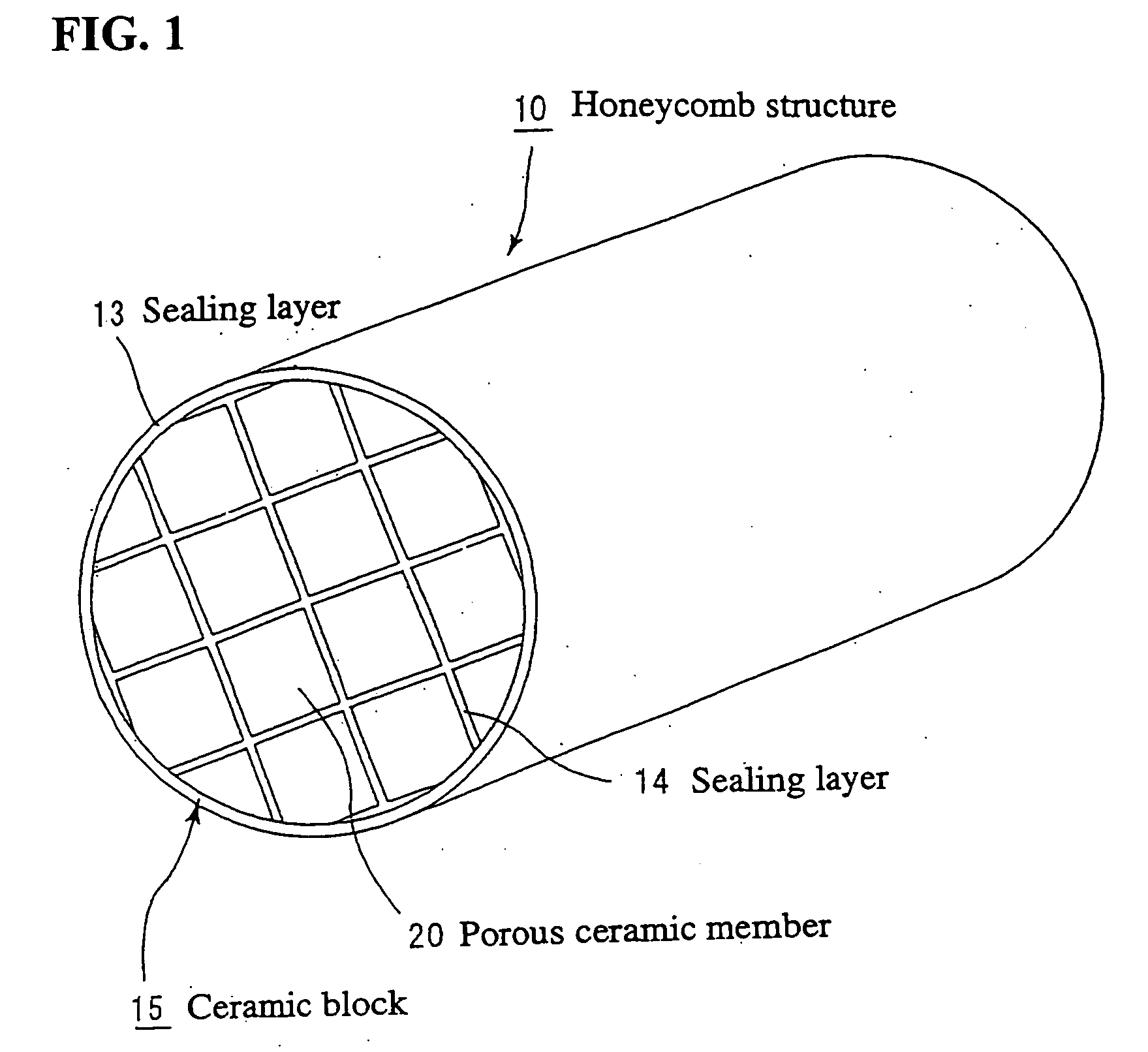

Exhaust gas purifying apparatus and method of regenerating the same

InactiveUS20060059877A1Absorb evenlySmooth releasePhysical/chemical process catalystsNon-fuel substance addition to fuelParticulatesPtru catalyst

An exhaust gas purifying apparatus is provided which includes a honeycomb structure used as a filter to capture particulates in exhaust gas from an internal combustion engine such as diesel engine and as a carrier of a catalyst to convert the exhaust gas. The honeycomb structure is formed from a composite material comprising ceramic particles and crystalline silicon. The particulates captured by the honeycomb structure are removed by combustion at a temperature of 250 to 800° C., thereby, even if a relatively low temperature is distributed or a heat cycle has been repeated from a long term, thermal stress is prevented from being stored, cracking is prevented and thermal shock resistance is thus improved.

Owner:IBIDEN CO LTD

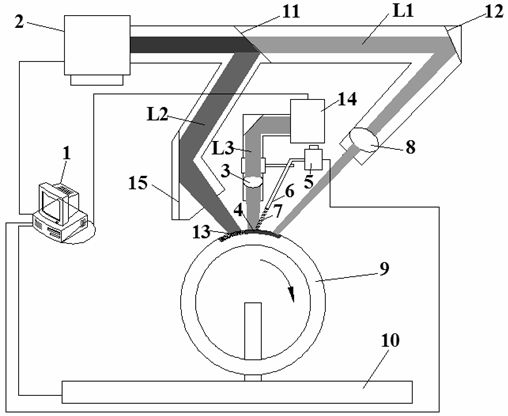

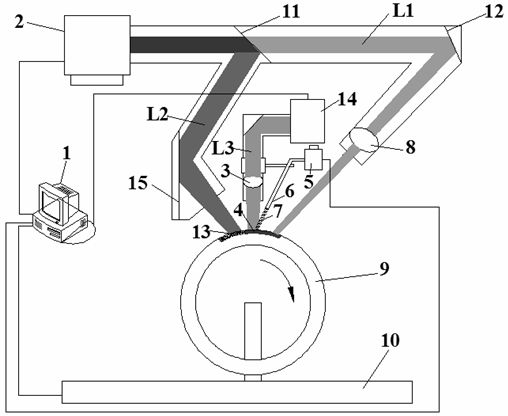

Method with functions of preheating and postheating for forming crack-free coating with high efficiency by three-light-beam laser-cladding technique

InactiveCN102383126ALow and adjustable dilution rateSmall heat affected zoneMetallic material coating processesLaser beam welding apparatusMelting tankHeat-affected zone

The invention discloses a method with functions of preheating and postheating for forming crack-free coating with high efficiency by a three-light-beam laser-cladding technique. The method comprises the following steps of: splitting a laser beam emitted by an Nd: YAG laser into two laser beams by using a laser beam splitter, namely a preheating laser beam for preheating the surface of a base material and a postheating laser beam for postheating the formed coating; then blowing alloy powder into a molten pool which is formed by focusing a laser beam emitted by a CO2 laser and acting the focused laser beam on the surface of the base material by using a powder nozzle, wherein after the CO2 laser beam moves away, a molten layer is cured and crystallized quickly to form the coating; and postheating the formed coating by adopting the postheating laser beam. The method has the advantages that: (1) the dilution rate of the coating is low and adjustable, and the coating is metallurgically combined with the base material, so the base material has a small thermal influence area and is deformation-free and crack-free; (2) residual inner stress in the coating can be eliminated effectively, a tissue can be improved, and the coating has high abrasion resistance, high corrosion resistance, high anti-cracking performance and high thermal shock resistance; and (3) relative to the processing efficiency in the conventional laser cladding technology, the processing efficiency in the method can be improved by 50 times to the maximum extent, so the processing cost is reduced greatly, and a large-scale industrialized application potential is realized.

Owner:NANCHANG HANGKONG UNIVERSITY

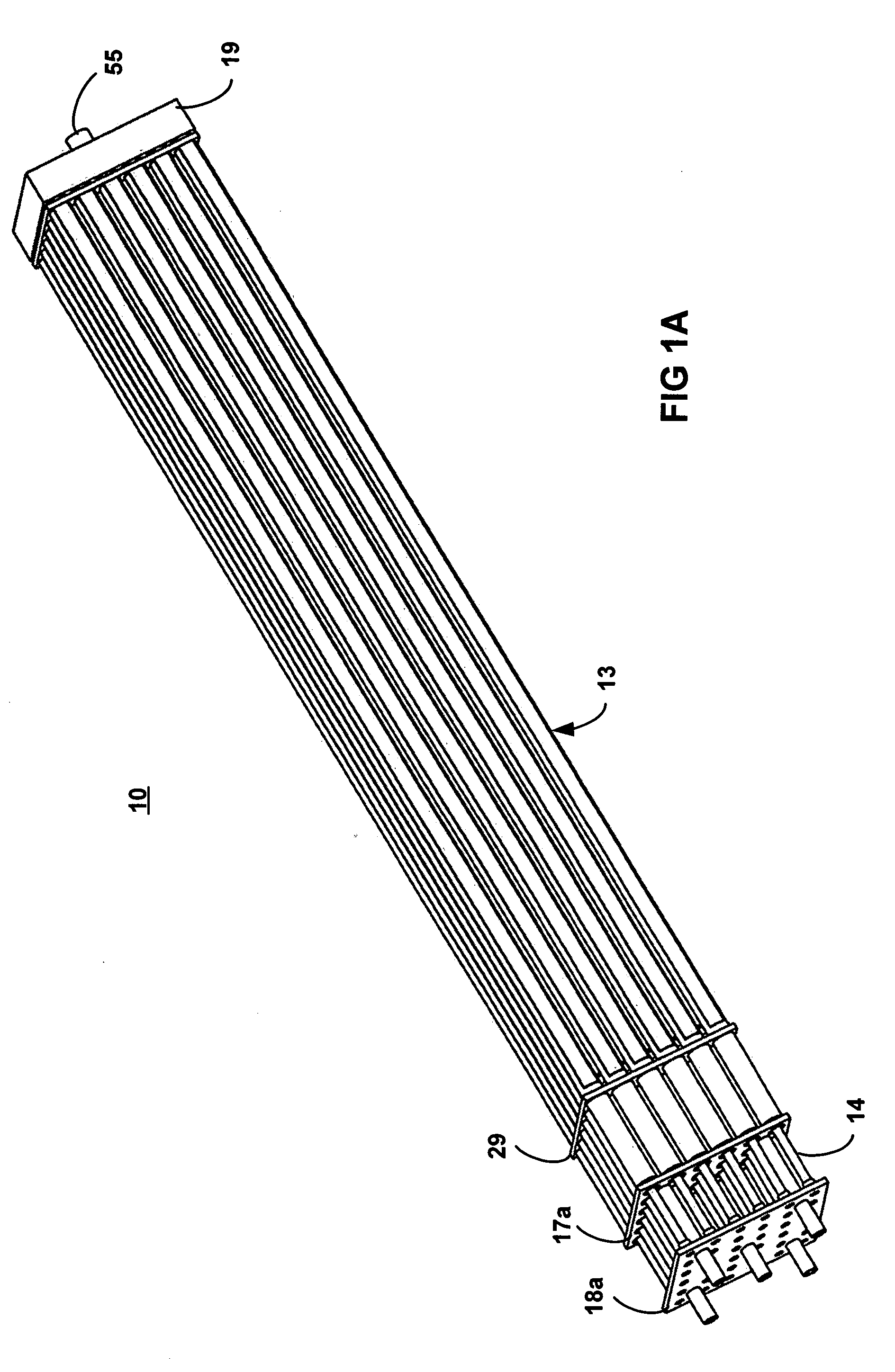

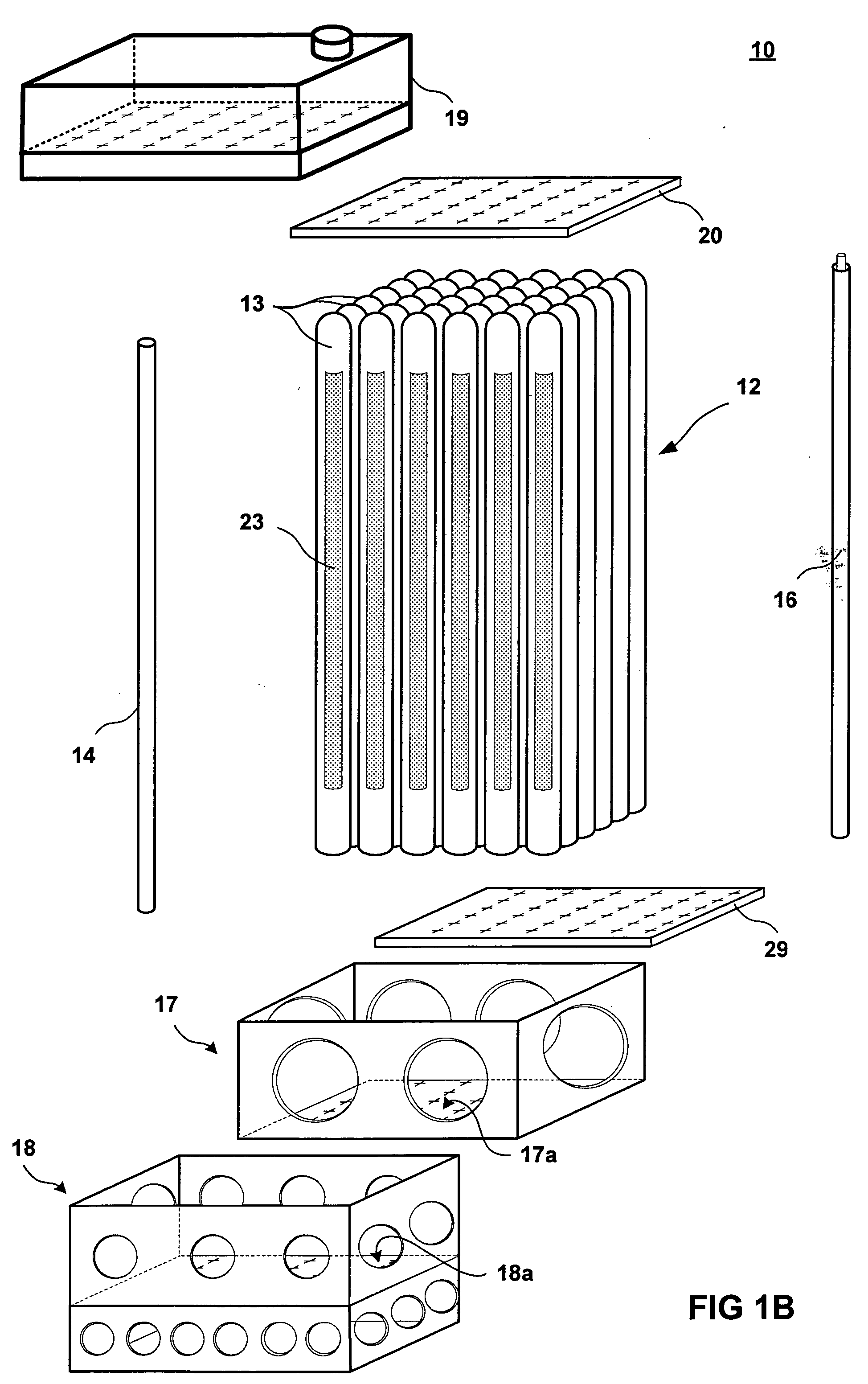

Multi-function solid oxide fuel cell bundle and method of making the same

ActiveUS20050208363A1Easy to practiceFuel cells groupingFinal product manufactureFuel cellsFeeding tube

A multi-function bundle having all of the basic support functions integrated therein can be used as a basic building block component, for example, in a fuel cell engine. The multi-function bundle is modular, easy to assemble, and able to withstand the physical and thermal shocks encountered in mobile applications. The multi-function bundle utilizes fully distributed fuel and oxidant supply systems which help to reduce temperature gradients throughout the array of fuel cells. The multi-function bundle may be comprised of a plurality of fuel cells, an oxidant supply system, a fuel supply system and a support structure which integrates the fuel cells, oxidant supply system, and fuel supply system into a single unit. The oxidant and fuel supply systems may be fully distributed. The fuel supply system may include one or more fuel feed tube assemblies which allow distributed internal fuel reformation and reduce temperature gradients throughout the array of fuel cells.

Owner:WATT FUEL CELL CORP

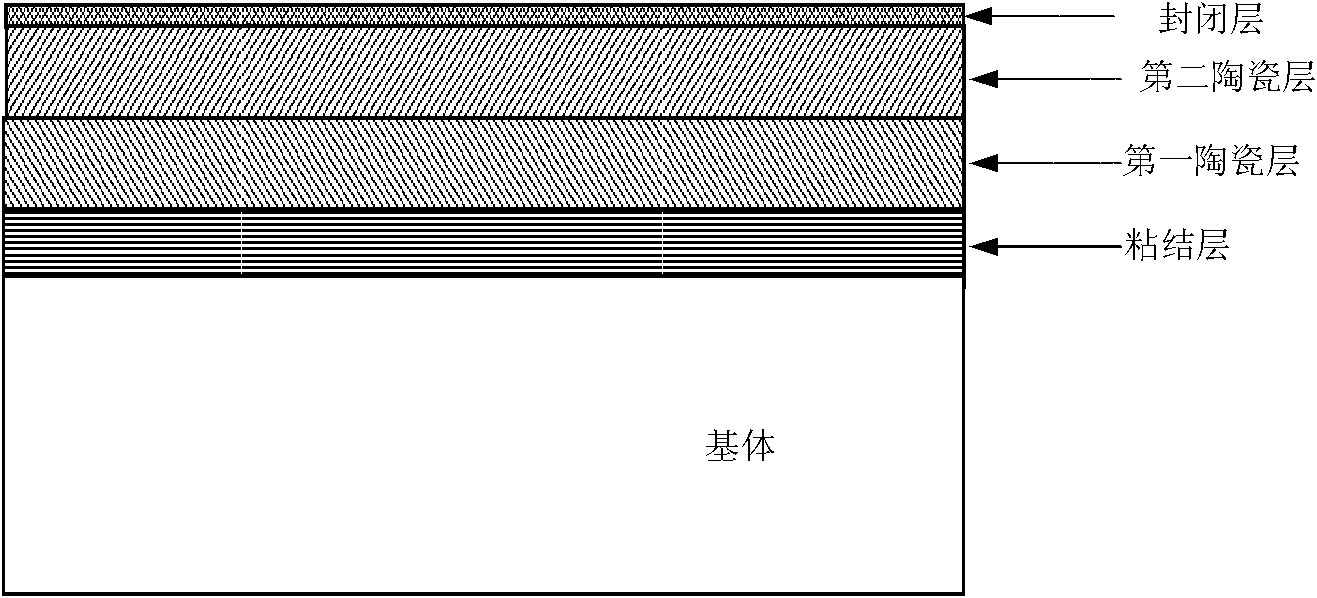

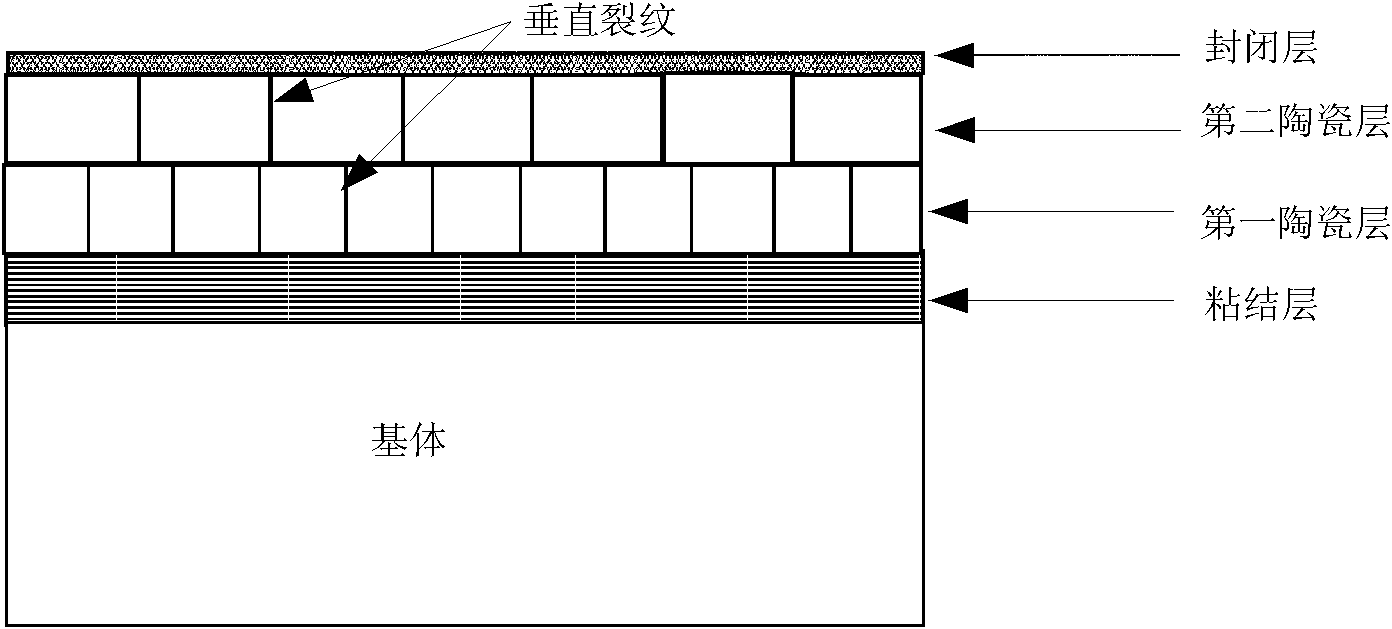

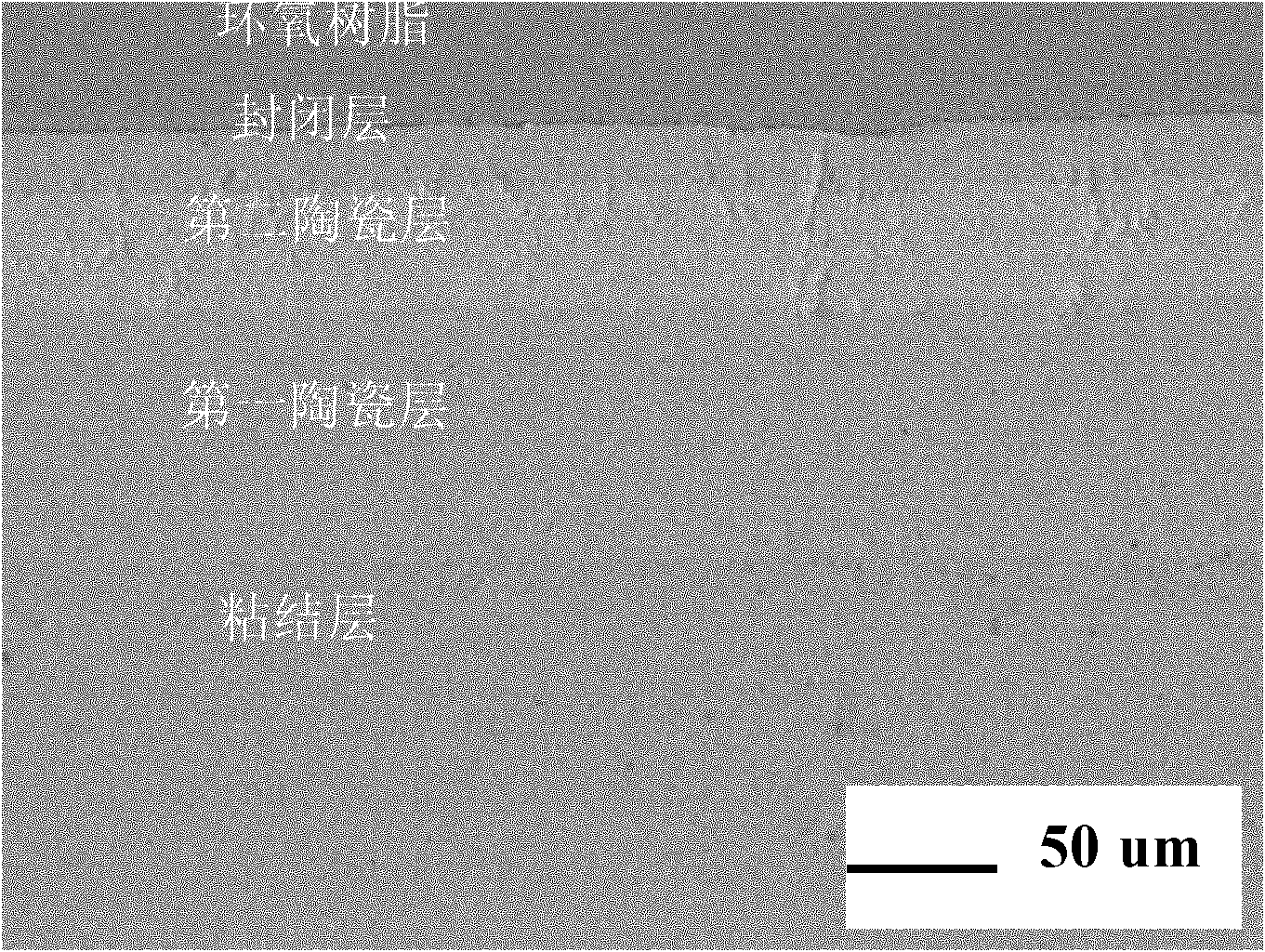

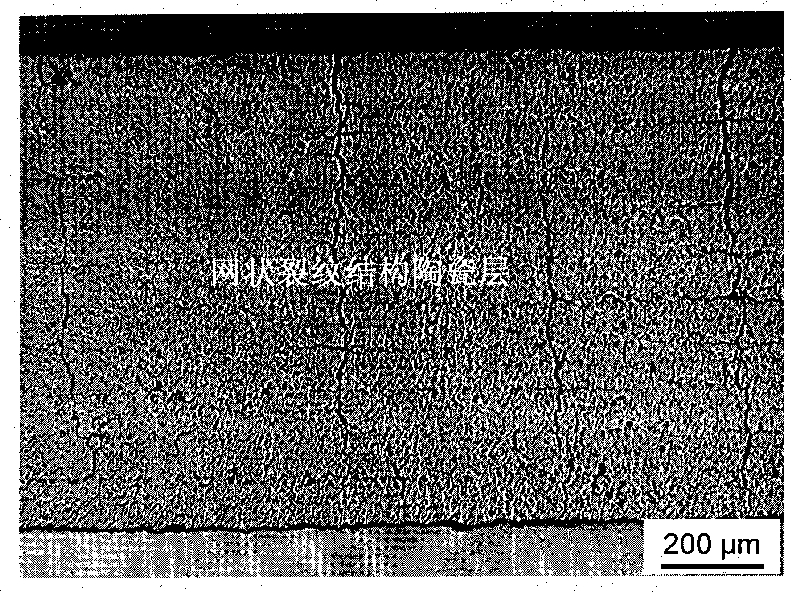

Multilayer thermal barrier coating and preparation method thereof

InactiveCN102127738ANo layer peeling phenomenon occursImprove hot corrosion resistanceMolten spray coatingVacuum evaporation coatingPorosityElectron beam physical vapor deposition

The invention provides a multilayer thermal barrier coating and a preparation method thereof. The multilayer thermal barrier coating sequentially comprises an adhesion layer, a first ceramic layer, a second ceramic layer and a closing layer from bottom to top, wherein the closing layer has the thickness of 10-30 micros and the porosity of 2-8 percent and is made from the Al2O3. The thermal barrier coating can be prepared by adopting an electron beam physical gas-phase deposition technology or a plasma spraying method. The multilayer thermal barrier coating provided by the invention can avoid the stripping of the ceramic layers in a thermal circulating process, the thermal erosion resistance of the thermal barrier coating is greatly improved than the dual ceramic layers; and vertical crackles are introduced in the ceramic layer through improving a conventional plasma spraying process so that the thermal shock life of the thermal barrier coating is greatly prolonged.

Owner:BEIHANG UNIV

Densification method for carbon fiber reinforced silicon carbonitride ceramic composite material

ActiveCN103724035ASmall coefficient of thermal expansionImprove thermal shock resistanceCeramic compositeCarbon fibers

The invention provides a densification method for a carbon fiber reinforced silicon carbonitride ceramic composite material. The method comprises the following steps: firstly, preparing a C / SiC ceramic composite material by using CVI or PIP; performing CVI on the C / SiC ceramic composite material to carbonize silicon, and as the cross gap between fiber bundles is large, prolonging the CVI time to 20-30 hours ; when the silicon being subjected to carbonization is densified to 80-90% by CVI, brushing silicon powder on the C / SiC surface, and filling large holes particularly; performing nitridation processing after drying; after completion of the nitridation, preparing an SiC coating on the CMC surface through CVD for 20-30 hours to complete the densification of the carbon fiber reinforced silicon carbonitride ceramic composite material. Through the adoption of the densification method, the CMC preparation efficiency is improved, the coefficients of thermal expansion of matrixes are reduced, and the thermal shock resistance of CMC is improved.

Owner:TAICANG PAIOU TECH CONSULTING SERVICE

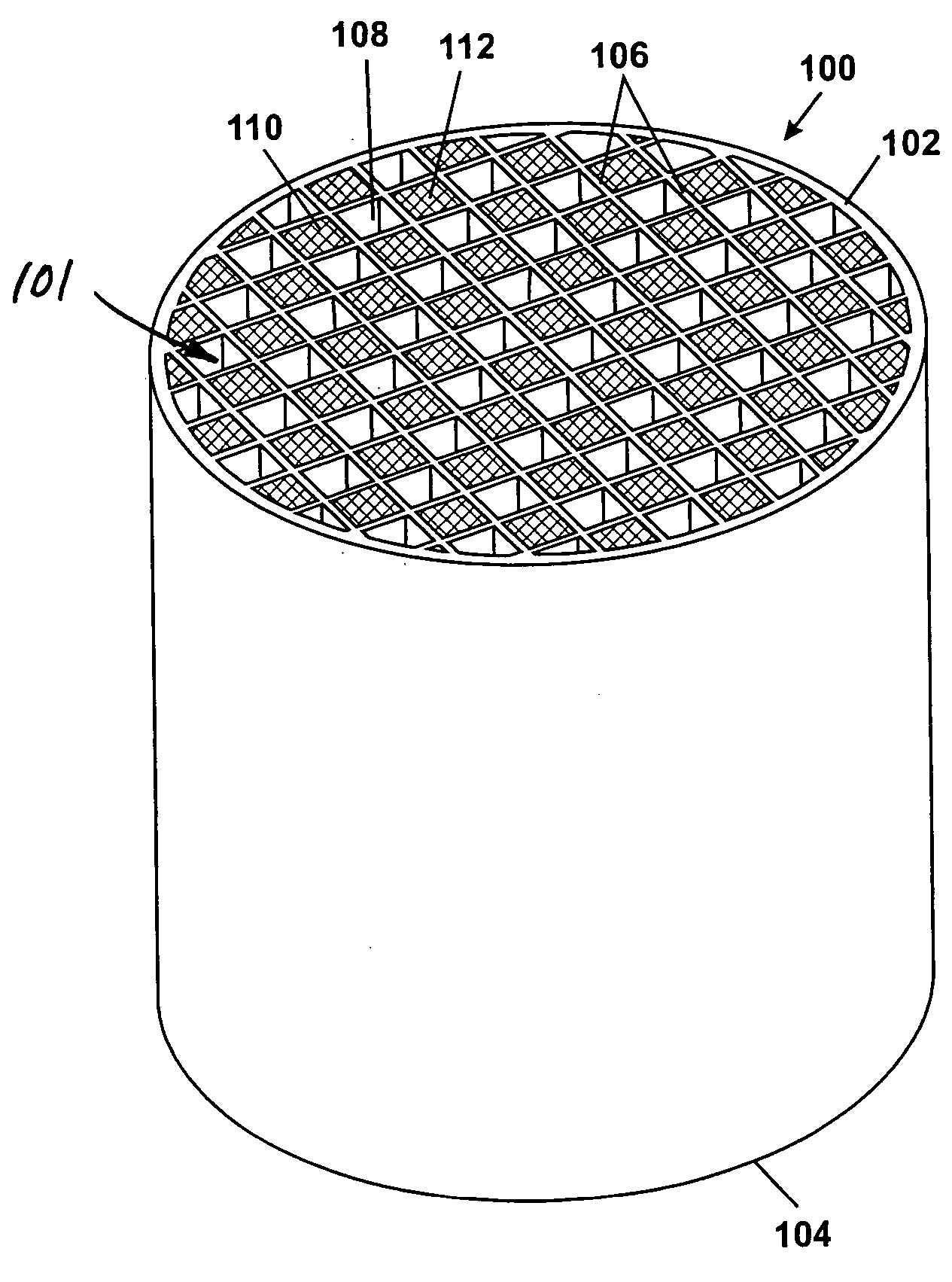

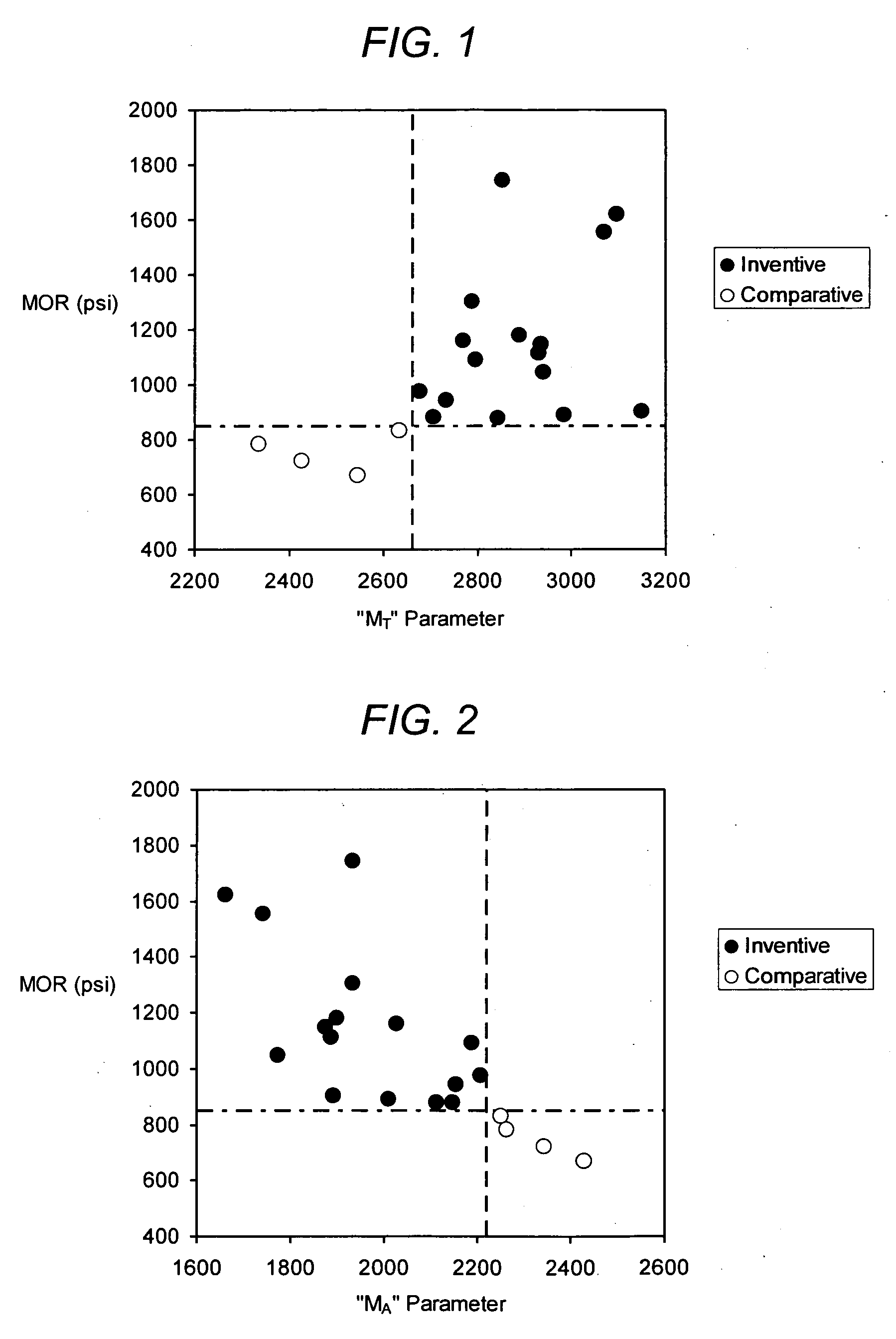

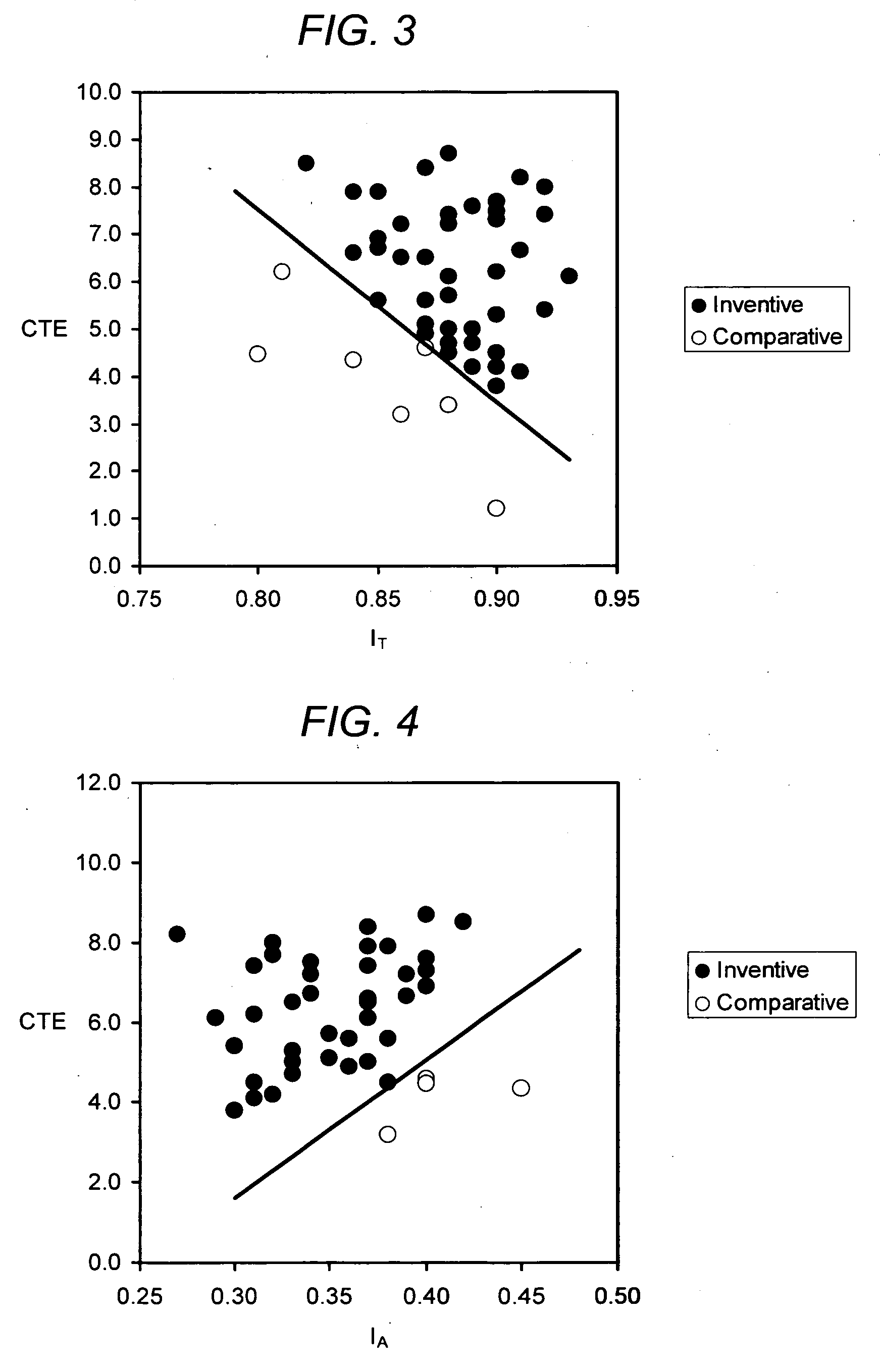

Porous cordierite ceramic honeycomb article with improved strength and method of manufacturing same

ActiveUS20070119133A1Reduce the amount requiredIncrease volume fractionCombination devicesAuxillary pretreatmentCordieritesSilicon dioxide

A porous cordierite ceramic honeycomb article with increased mechanical strength and thermal shock resistance. The porous cordierite ceramic honeycomb article has MA<2220, or MT>2660 wherein MA=3645 (IA)−106 (CTE)+19 (d90)+17 (% porosity), MT=4711 (IT)+116 (CTE)−26 (d90)−28 (% porosity), and a CTE≦9×10−7 / ° C. in at least one direction. A method of manufacturing is also disclosed wherein the inorganic raw material mixture contains talc, an alumina-forming source, a silica-forming source, and 0-18 wt. % of a kaolin or calcined kaolin containing not more than 8 wt. % of a fine kaolin source having a median particle diameter of less than 7 μm, wherein the fired porous ceramic cordierite honeycomb article has a porosity<54% . Alternatively, if greater than 8 wt. % of the fine kaolin source is used, then a slow ramp rate is utilized from 1200° C. to 1300° C. of not more than 20° C. / hr.

Owner:CORNING INC

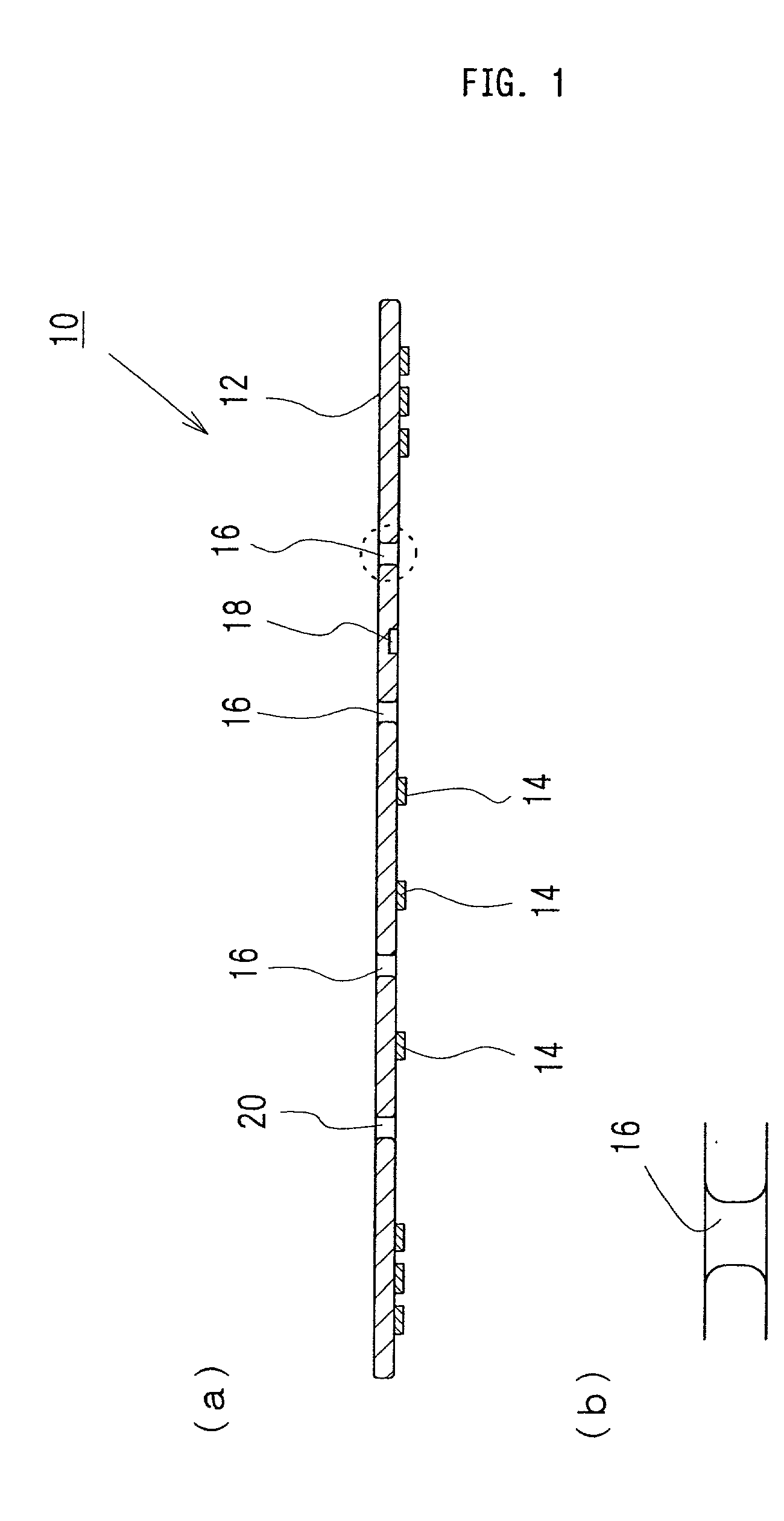

Ceramic heater

InactiveUS20030015521A1Maintain good propertiesLow costHot plates heating arrangementsHeating element shapesSlurryThermal shock

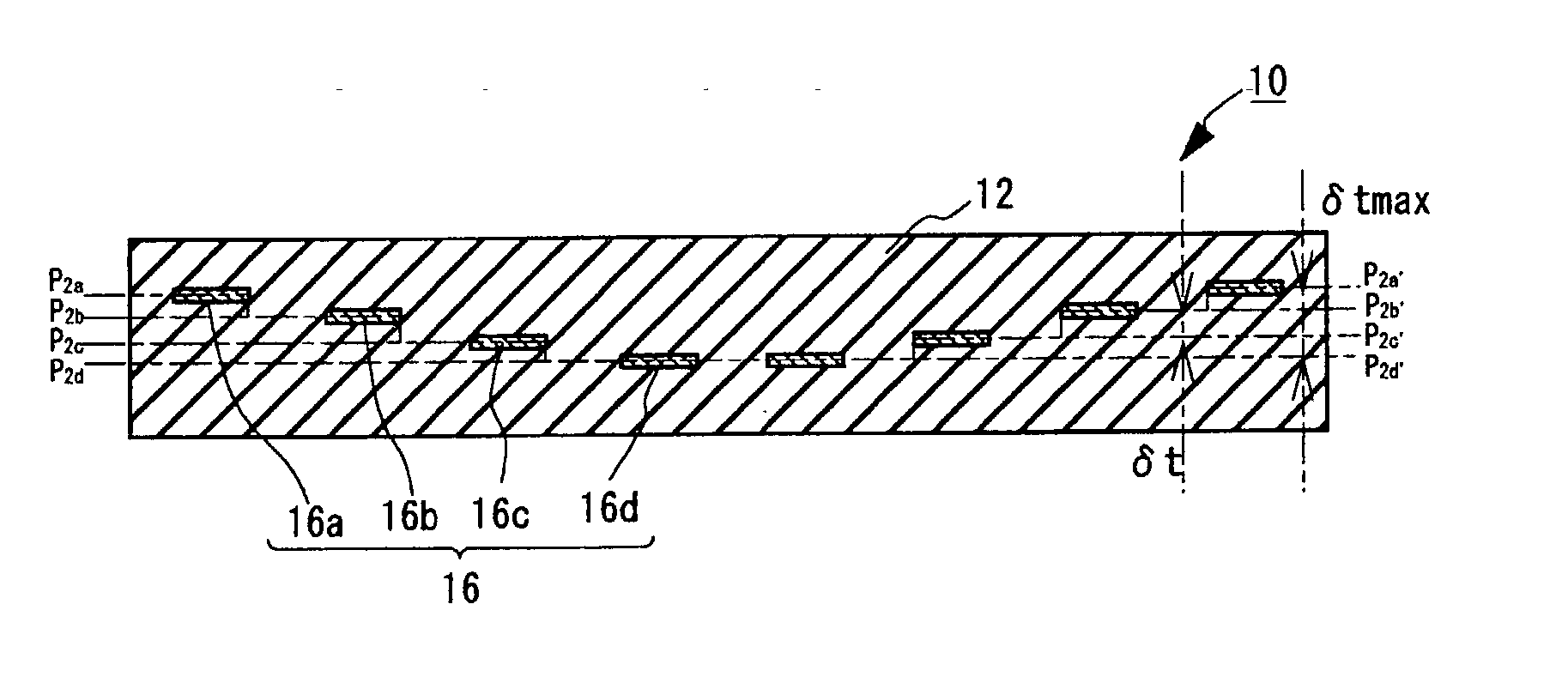

The present invention provides a ceramic heater having better anti thermal shock property. A ceramic substrate 12 is formed by providing heat generation bodies 14a and 14b on the surface of a green sheet made from a slurry containing powdered ceramics, sandwiching the green sheet with other green sheets from both upper and lower sides and then laminating and pressing the compiled green sheets. At least some of the heat generation bodies 14a and 14b are disposed on a level P1b offset from a level P1a of other heat generation bodies in the direction of thickness of the ceramic substrate 12.

Owner:IBIDEN CO LTD

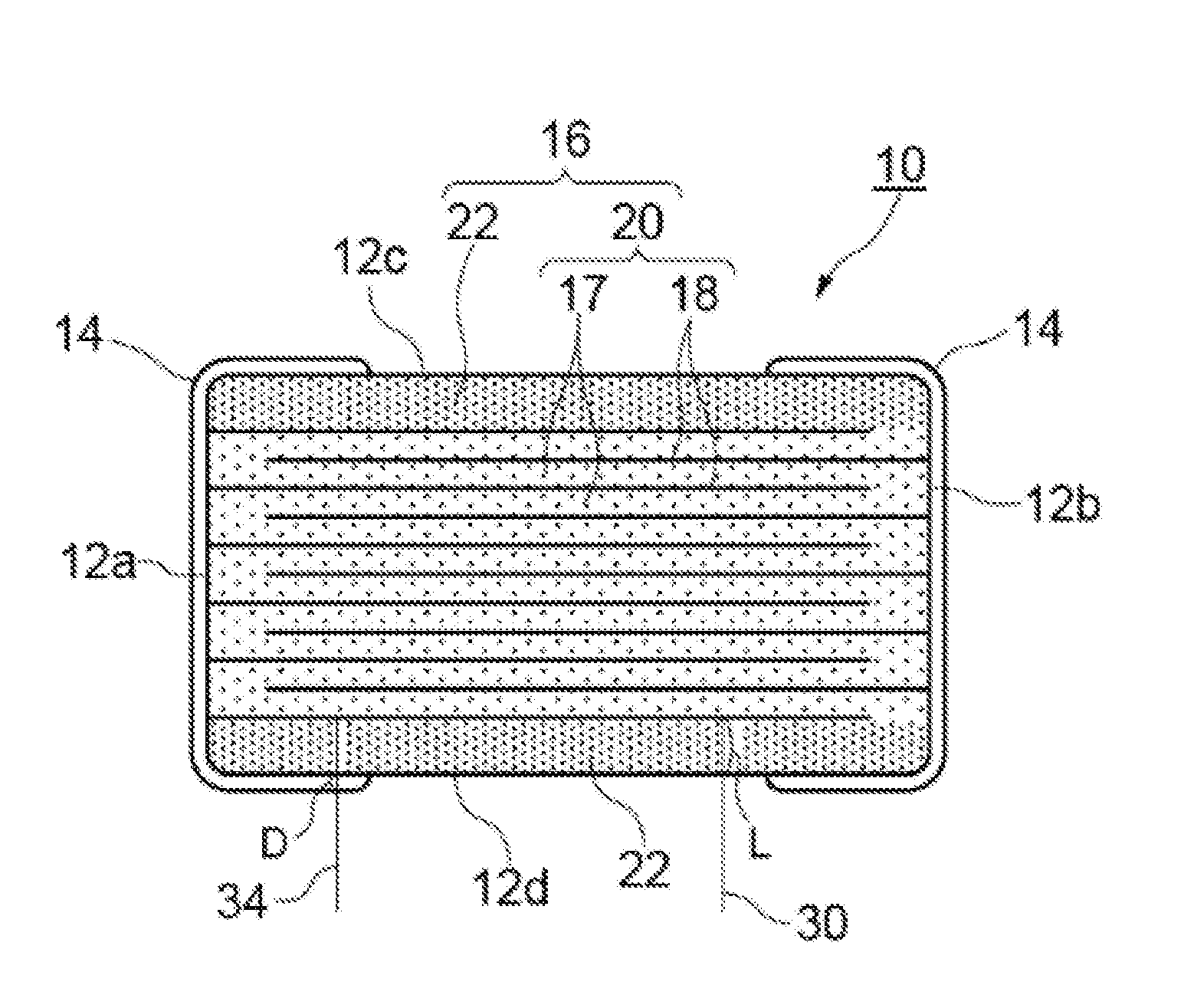

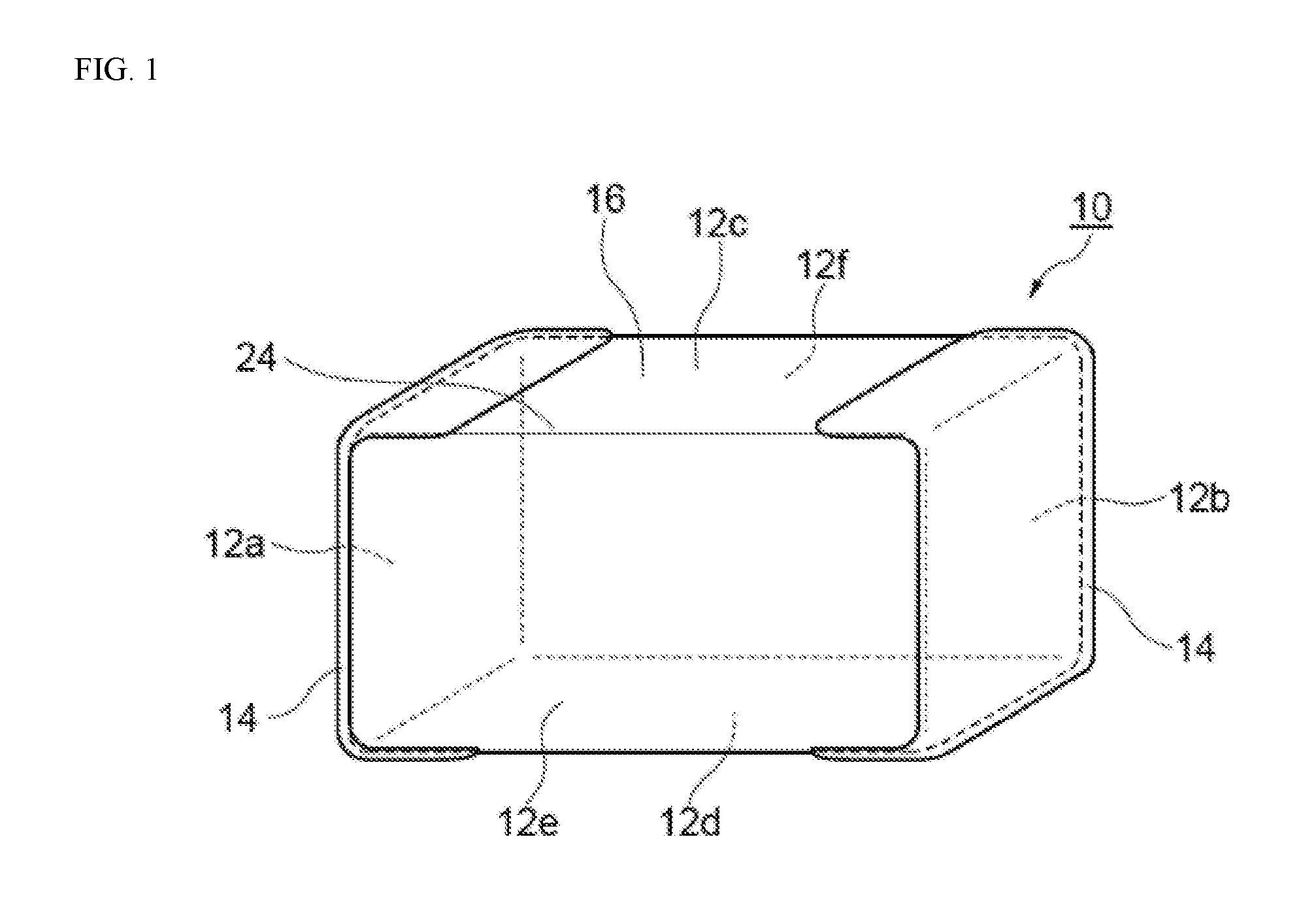

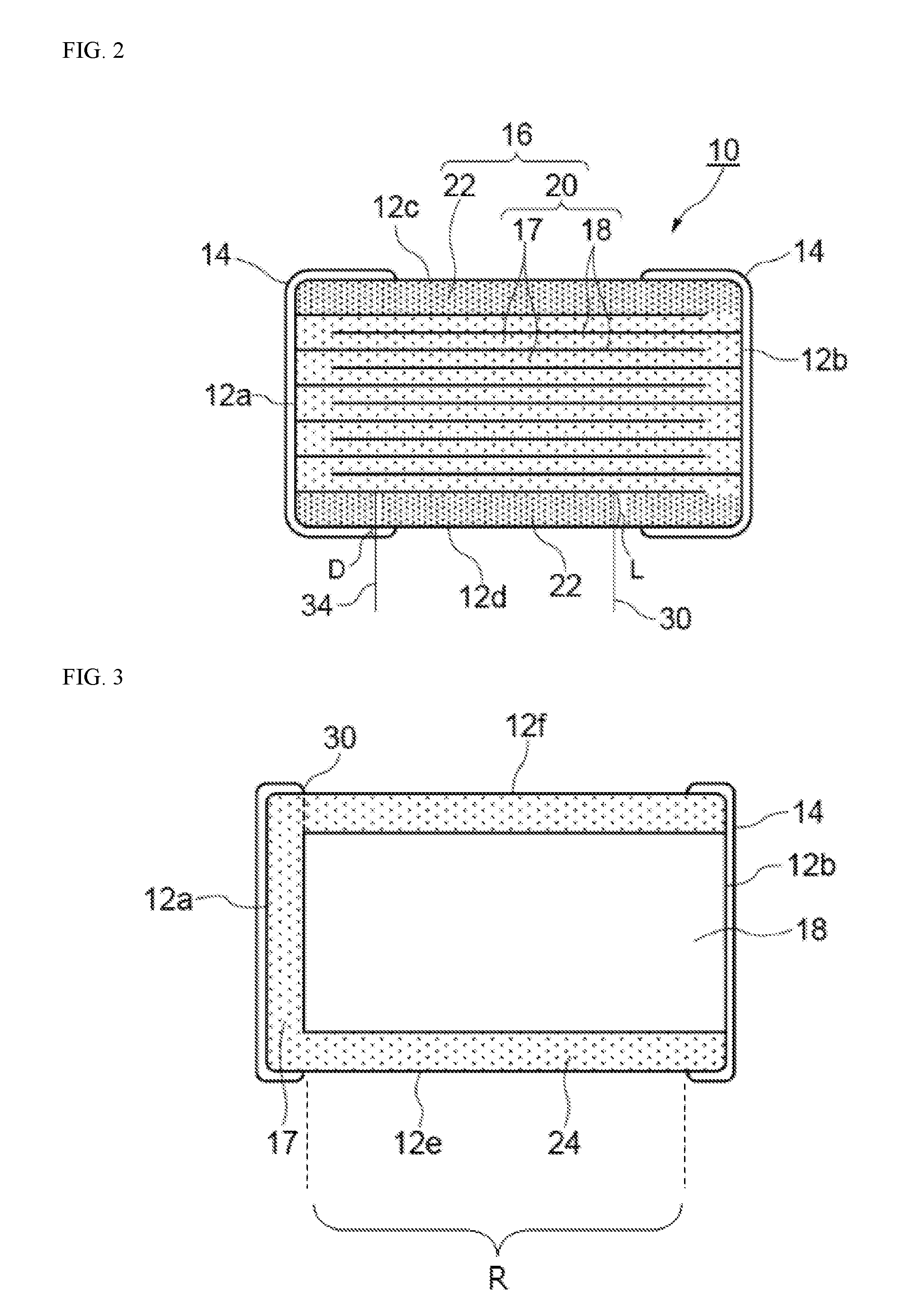

Multilayer ceramic capacitor

InactiveUS20160293331A1Reduce the effective areaReduce capacitanceFixed capacitor dielectricStacked capacitorsCapacitanceCeramic capacitor

A multilayer ceramic capacitor includes an element body of roughly rectangular solid shape which is constituted by dielectric layers alternately stacked with internal electrode layers having different polarities, with a pair of cover layers formed on it to cover the top and bottom faces in the direction of lamination of the foregoing, and which has a pair of principal faces, a pair of end faces, and a pair of side faces, wherein external electrodes are formed on the pair of end faces and at least one of the pair of principal faces of the element body, and Tt representing the thickness of the external electrode and Tc representing the thickness of the cover layer satisfy the relationship of Tt≦Tc. The multilayer ceramic capacitor has large capacitance and also exhibits excellent thermal shock resistance while sufficiently suppressing generation of cracks.

Owner:TAIYO YUDEN KK

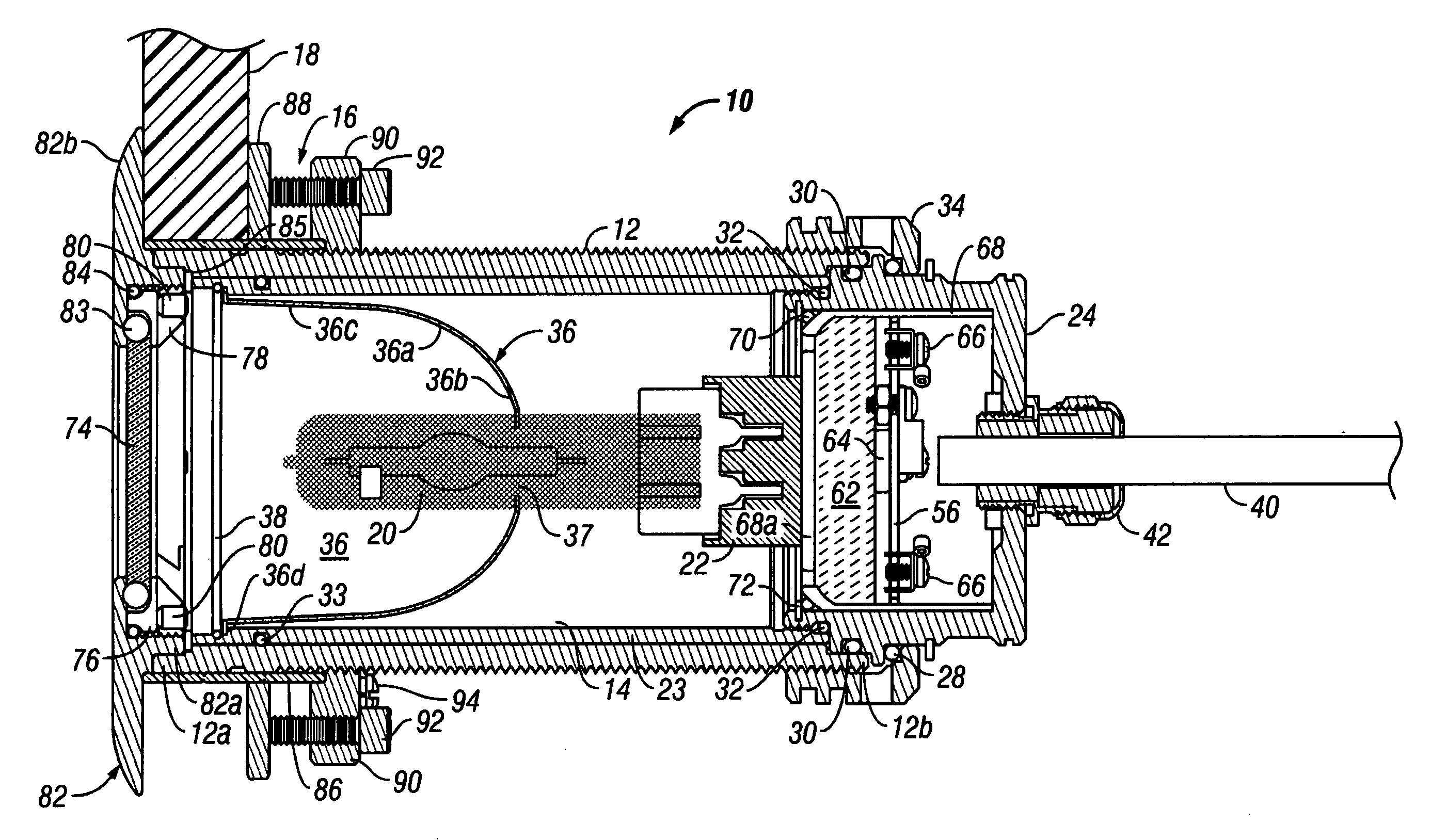

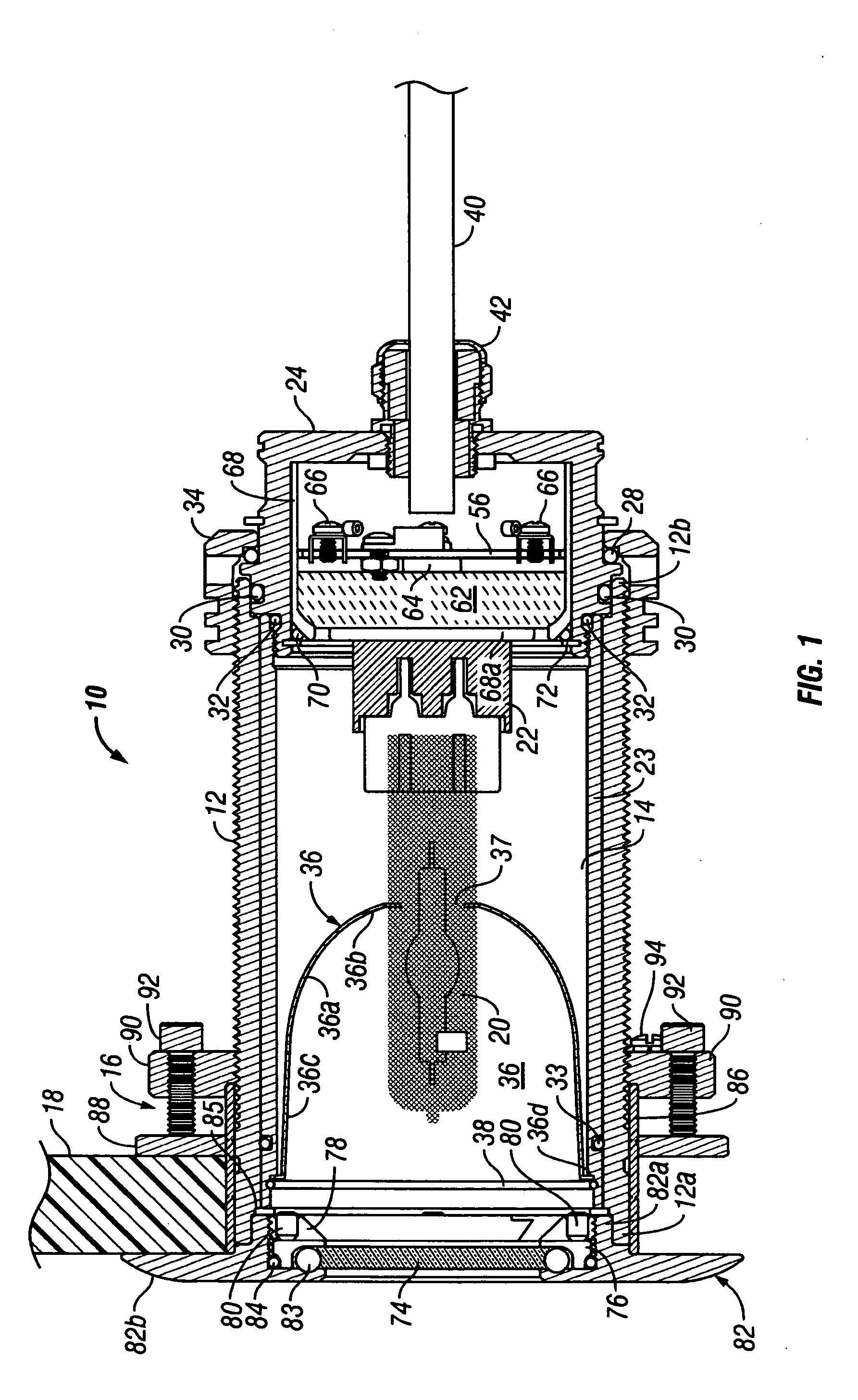

Thru-hull light

ActiveUS20050111222A1Less scratchesPoint-like light sourceLighting support devicesEngineeringLeak detection

A thru-hull fitting assembly is connected to the forward end of a hollow lamp housing for mounting to a hole in the hull of a vessel in a water-tight fashion. An HID or other lamp is mounted in the lamp housing and is surrounded by a reflector which may have an outer elliptical section and an inner parabolic section. A protective transparent window extends across the forward end of the lamp housing and is sealed thereto. The window may be made of sapphire to provide improved heat dissipation and to resist scratching during hull cleaning and breakage due to thermal shock and wave slap. A circuit may be connected to the lamp to provide over-heat protection, leak detection, as well as fault and power status indicators. Alternate embodiments utilize a solid light pipe or a hollow reflective tube to convey light from the lamp to the protective window.

Owner:SEESCAN

Nanoclay modified waterborne compositions for coating plastic and methods for making the same

InactiveUS20050059765A1Improve thermal shock resistanceMaterial nanotechnologySpecial tyresWater dispersibleWater insoluble

The present invention provides aqueous dispersion compositions comprising one or more than one of each of aqueous dispersions of water-dispersible polymers and aqueous nanocomposite dispersions of at least partially exfoliated layered silicates and water-insoluble polymers to enhance the thermal shock resistance of a waterborne coating, film, or article comprising the composition. Only 2 to 10 phr of the layered silicate, e.g. sodium montmorillonite surprisingly enhances thermal shock resistance. Optional fillers, such as nepheline syenite, may be added. Such compositions may be coated on automotive plastic, TPO or resinous substrates, and provide coatings having a 19 or greater thermal shock resistance according to Ford laboratory test method BI 107-05 when coated on TPO and baked for 15 minutes at from 74 to 90° C. Further, the present invention provides methods of making aqueous nanocomposite dispersions comprising mixing unmodified layered silicate and water insoluble neat resin in water to at least partially exfoliate the clay and subjecting the resulting mixture to high shear.

Owner:NIPPON PAINT USA

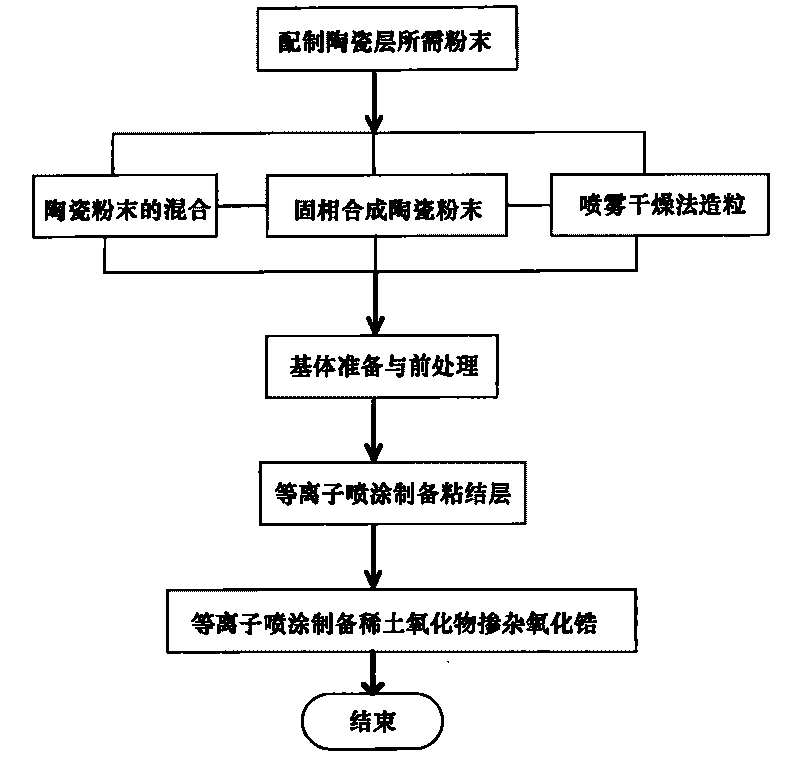

Multielement rare earth oxide doped zirconia thermal barrier coating with craze crack structure and preparing method thereof

InactiveCN101723667AGood phase stability at high temperatureLow temperature for long-term useMolten spray coatingEfficient propulsion technologiesThermal insulationRare earth

The invention discloses a method for preparing a rare earth oxide doped zirconia thermal barrier coating with a craze crack structure, which solves the problems of low thermal shock resistance property, difficult further thermal conductivity reduction and the like of the thermal coating prepared by conventional plasma spraying. Under the condition of the plasma spraying technology, the preheating temperature of a base body, the moving speed of a plasma spraying gun and a powder delivery rate are adjusted, then a rare earth oxide doped zirconia thermal barrier coating (BH-TBCO1) with a craze crack structure and stable thermodynamics is prepared. The rare earth oxide doped zirconia thermal barrier coating with a craze crack structure has good high-temperature phase stability at the temperature below 1300 DEG C; the thermal insulation property of the thermal barrier coating is further enhanced, and the thermal insulation temperature achieves more than 150 DEG C and is enhanced by more than 50% when compared with the coating prepared by the conventional plasma spraying; the thermal shock life of the coating exceeds 4000 cycles and is enhanced by more than 1 time when compared with the coating prepared by the conventional plasma spraying.

Owner:BEIHANG UNIV

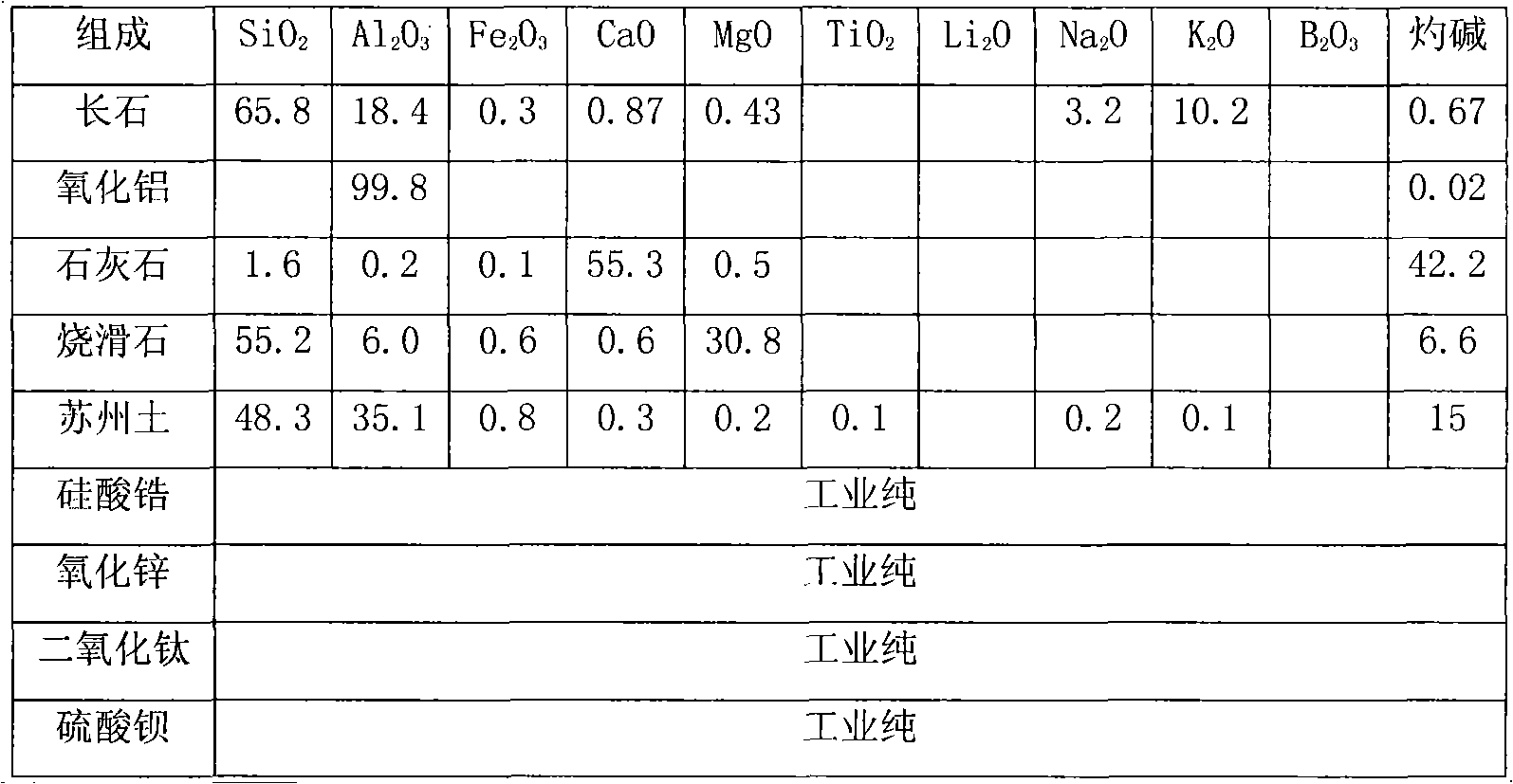

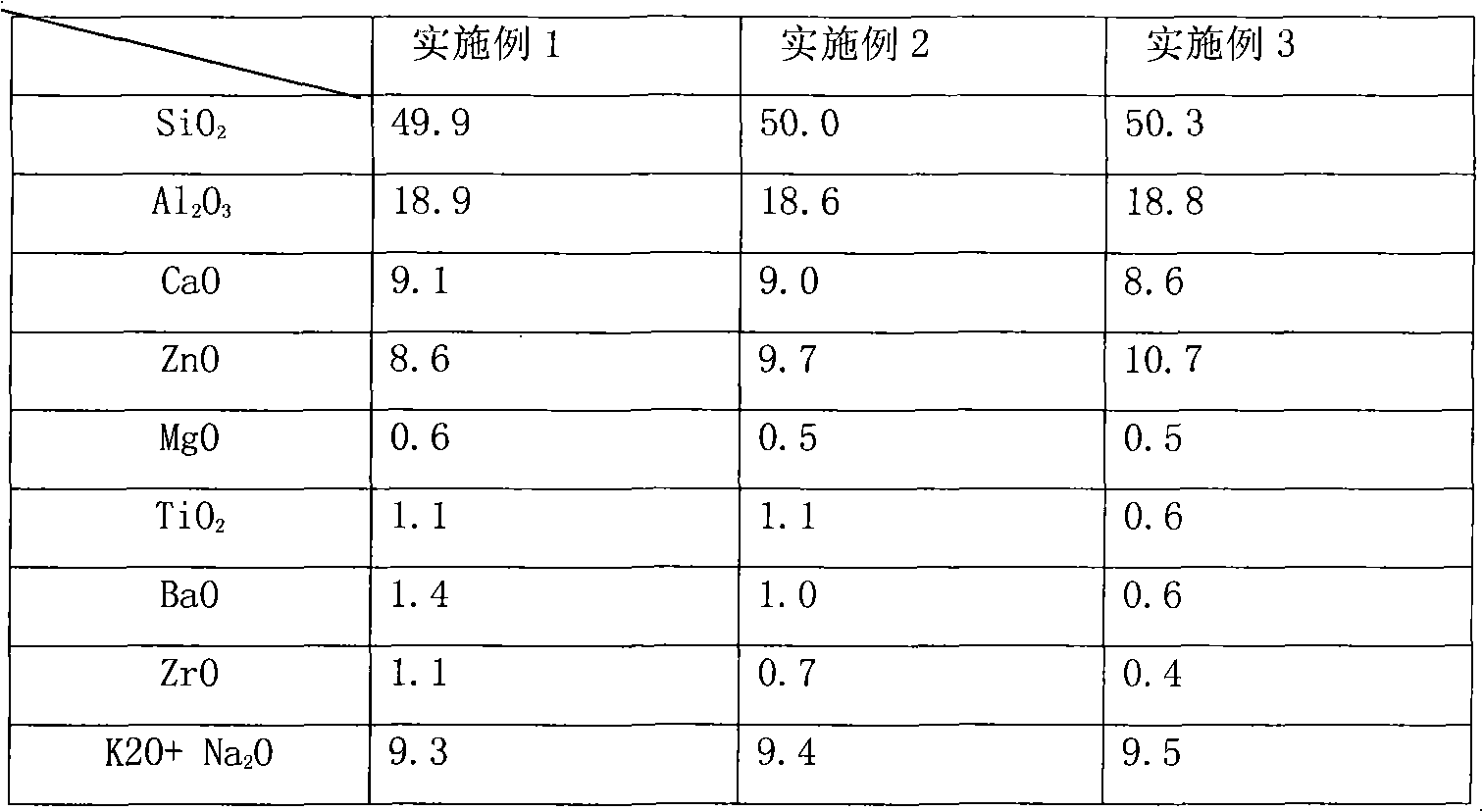

Raw material matting glaze

The invention relates to ceramic glaze, in particular to raw material matting glaze used for producing high-quality matting bone china products. The raw material matting glaze comprises the following chemical components in percent by weight: 48-60 percent of SiO2, 12.0-22.0 percent of Al2O3, 5.0-12.0 percent of ZnO, 5-12 percent of CaO, 0.5-2.0 percent of MgO, 0.0-3 percent of BaO, 0.0-3.0 percent of ZrO2, 0.0-2.0 percent of TiO2 and 5.0-15.0 percent of K2O and Na2O. The feldspar of the mineral raw material is mainly introduced. The invention has simple, scientific and reasonable constituent and is the raw material glaze; and the glaze does not need to be made into frits, therefore, energy sources are largely saved; the blank glaze has good adaptability, low firing temperature and wide firing range; the fired finished-product ceramic glaze surface is fine, moist, smooth and soft and does not have strong reflect light; and the glaze surface has strong corrosion resistance, high mechanical strength and good thermal shock stability and is easy to clean, therefore, the glaze is especially suitable for tableware dish-washing machines. The invention thoroughly solves the problems of the gloss and the texture of high-grade bone china.

Owner:张垠

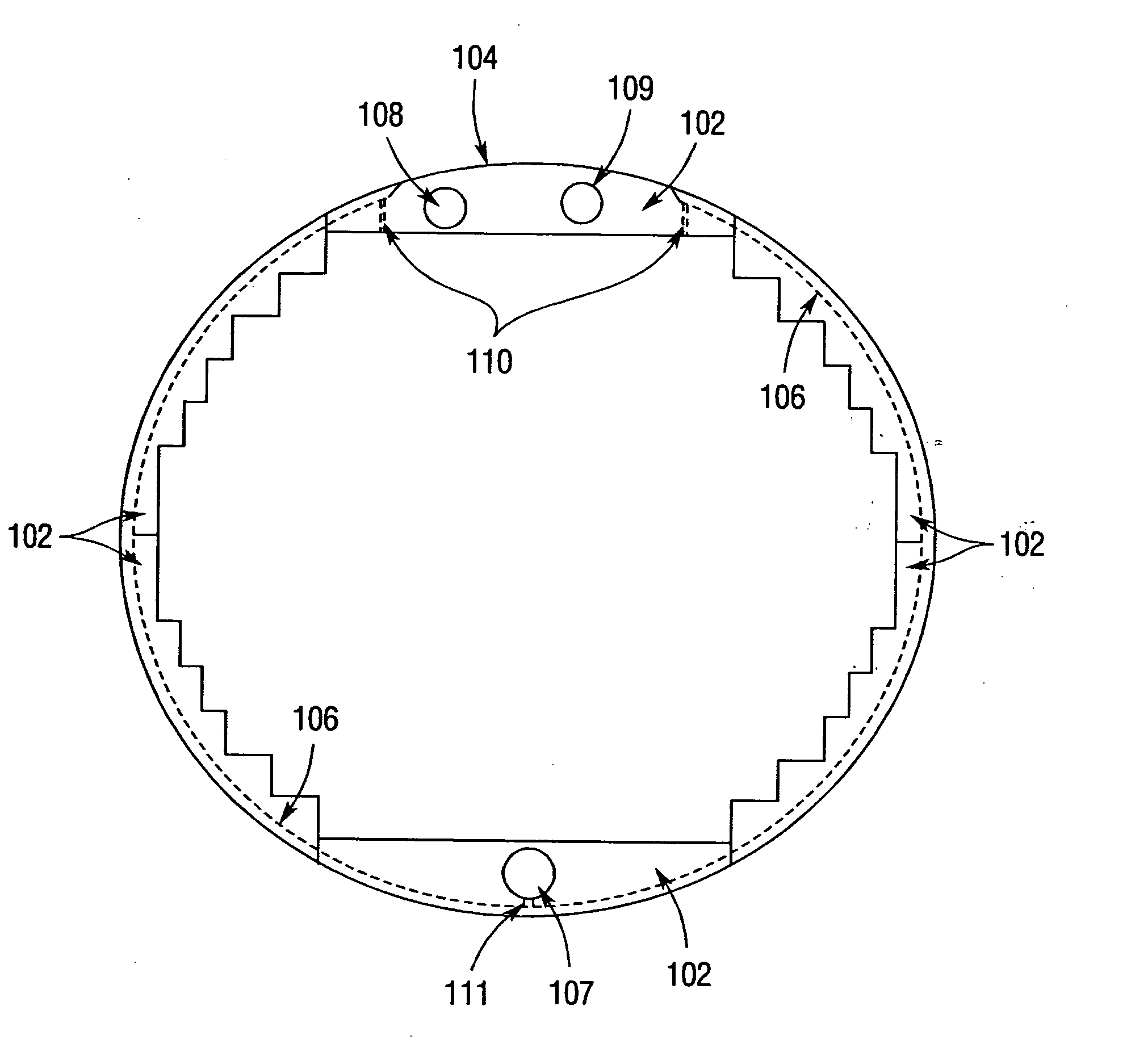

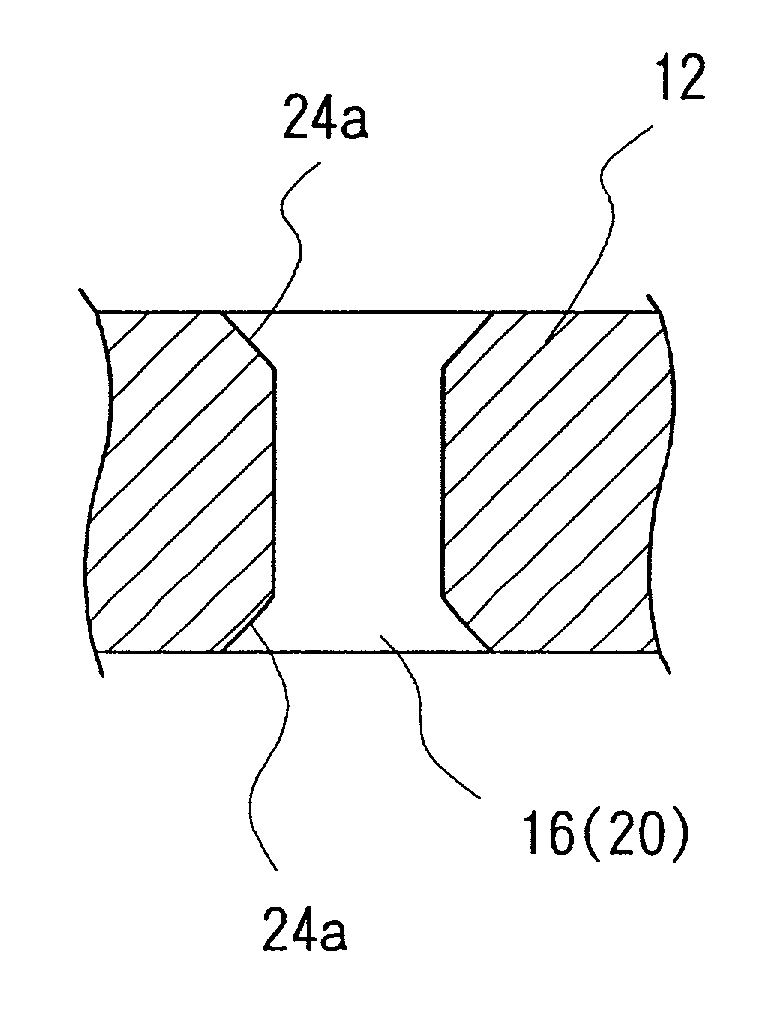

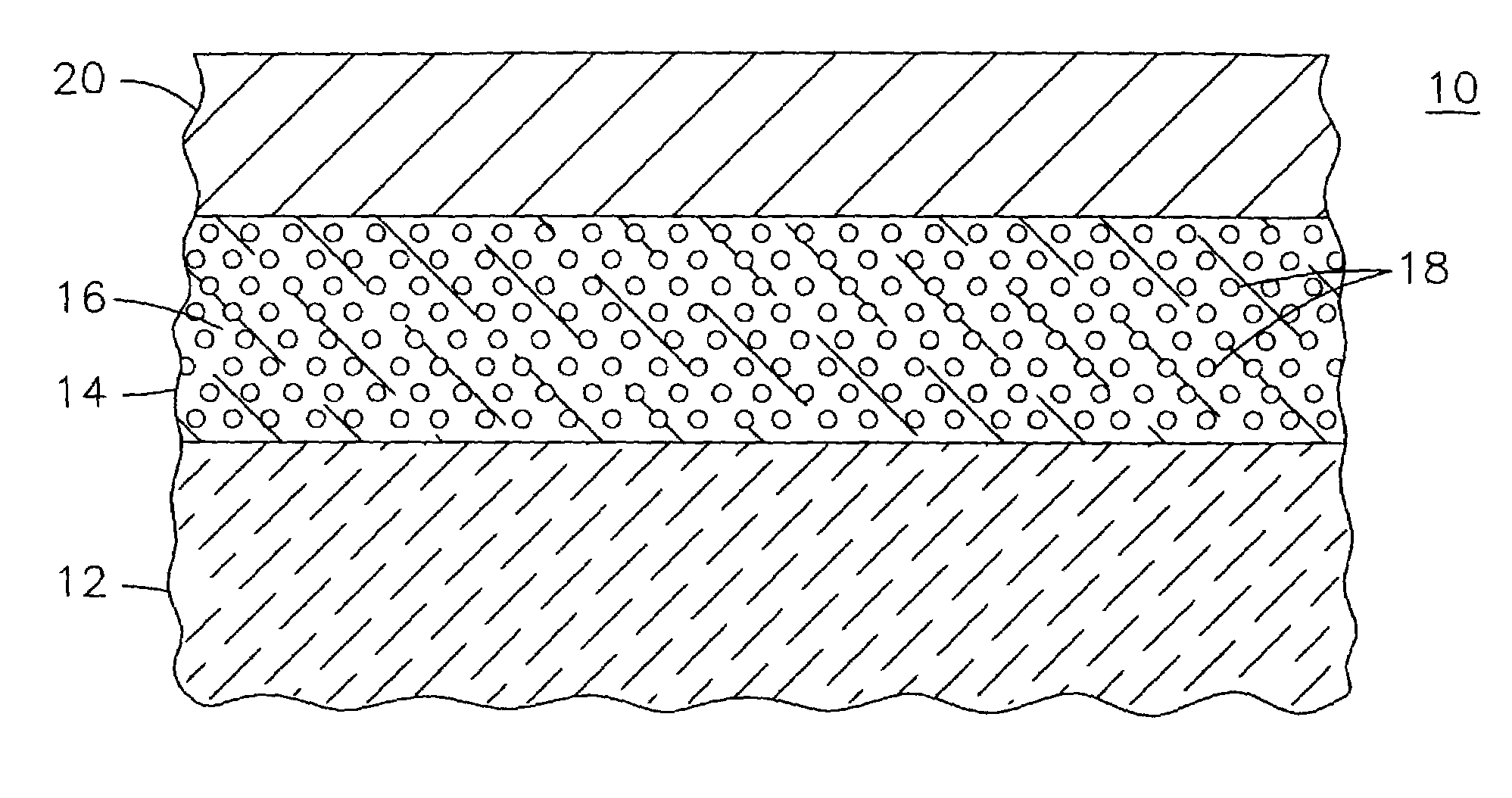

Ceramic heater

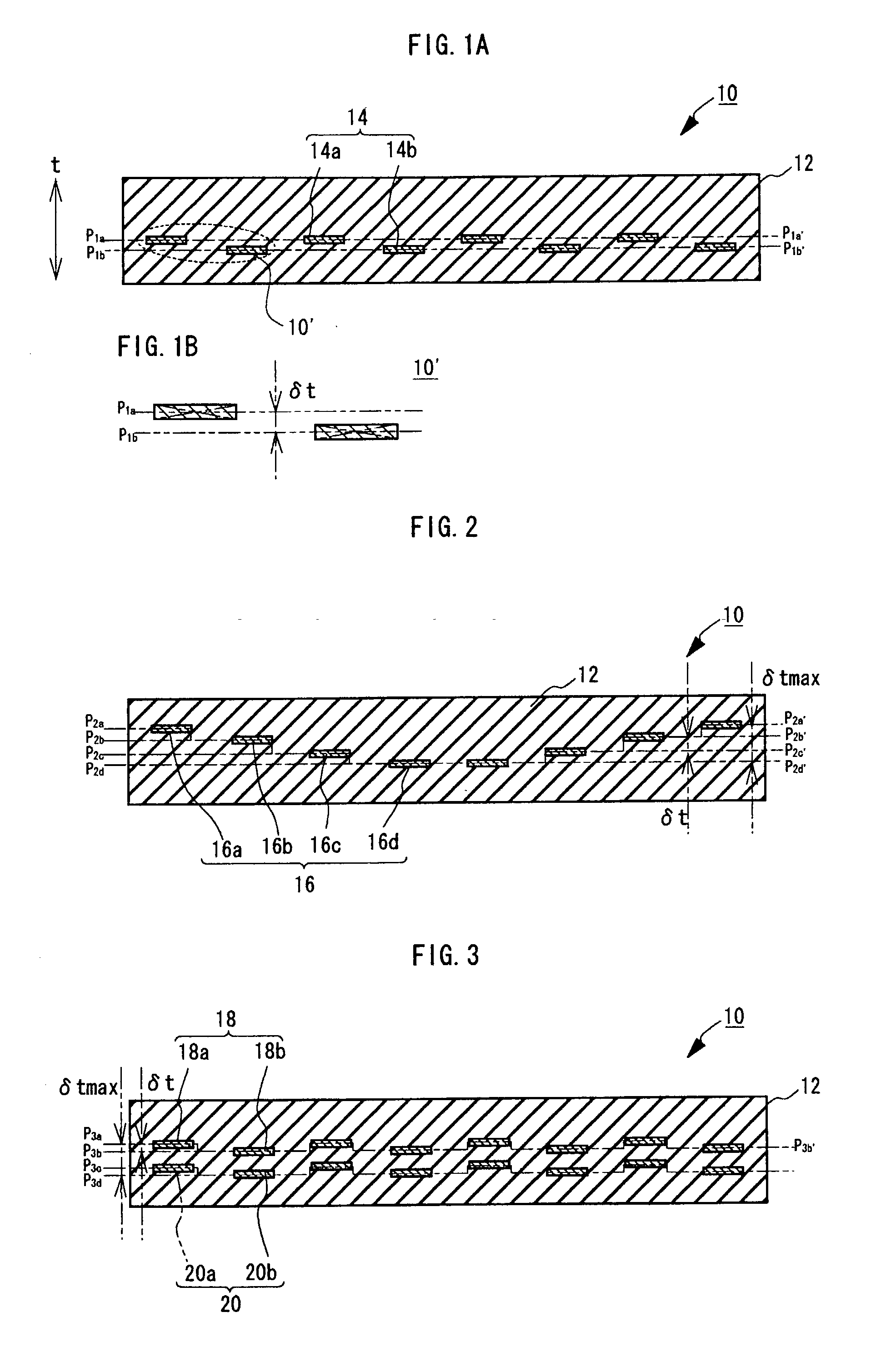

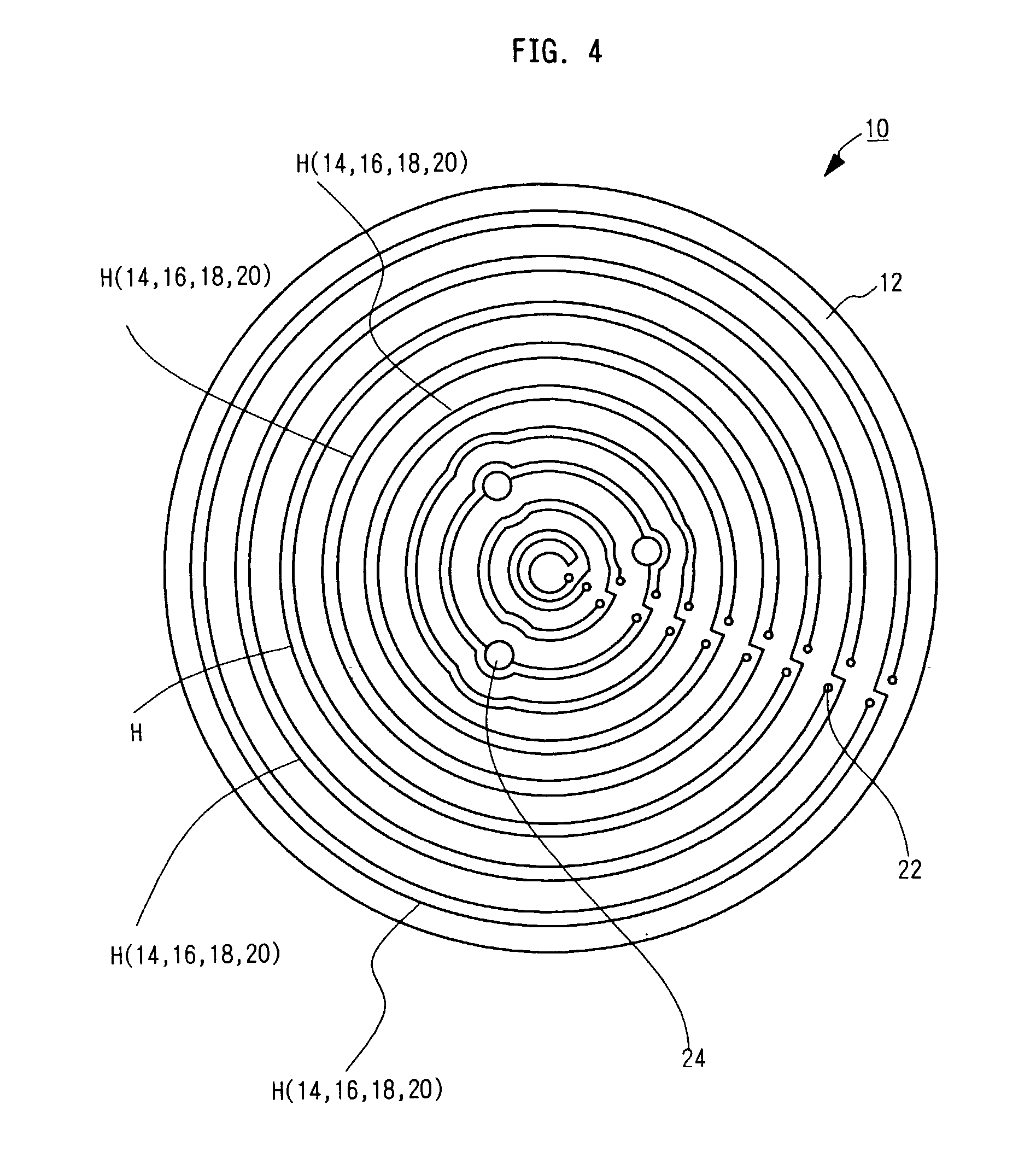

InactiveUS20020043527A1Improve unevennessSemiconductor/solid-state device manufacturingHot plates heating arrangementsTemperature controlThermocouple

To provide a ceramic heater capable of reducing temperature uniformity at the periphery of through holes such as insertion holes and vacuum suction holes, thereby protecting the wafer against thermal shocks and having improved controllability for temperature control parts such as thermocouples and temperature fuse. Further, a ceramic heater capable of uniform resin curing is provided. A heat generation body 14 is disposed on the surface or inside of the ceramic substrate 12. Further, corners for the insertion holes 16, the recesses 18 and the vacuum suction holes 20 of the ceramic substrate 12 are chamfered.

Owner:IBIDEN CO LTD

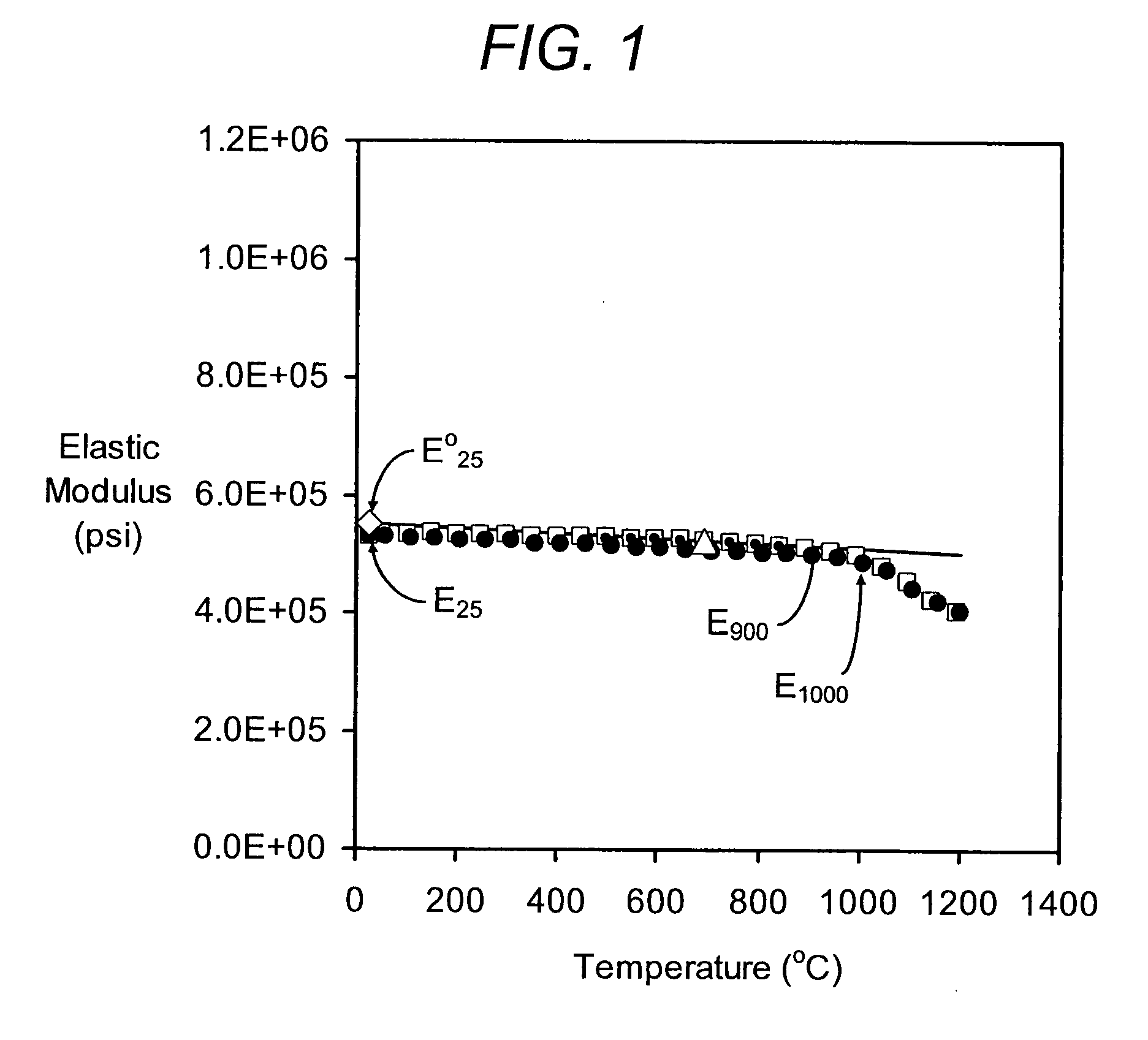

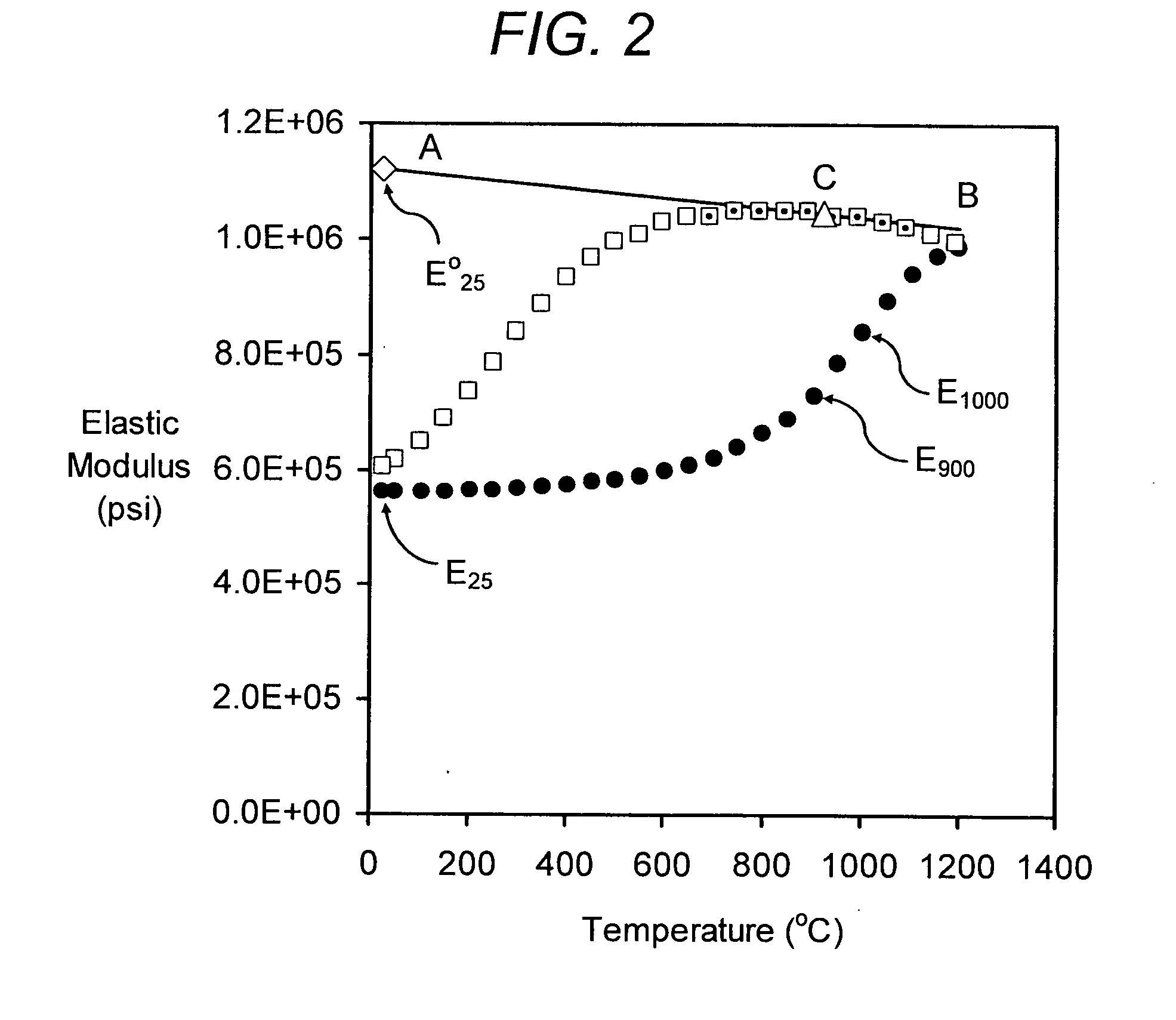

Low-microcracked, porous ceramic honeycombs and methods of manufacturing same

ActiveUS20080032090A1Improve efficiencyHigh strengthLayered productsCeramic shaping apparatusThermal expansionInterconnected porosity

Substantially non-microcracked, porous, cordierite ceramic honeycomb bodies are provided. Although exhibiting moderately high thermal expansion (CTE) between 7×10−7 to 16×10−7 / ° C. (25-800° C.), the honeycomb bodies exhibit relatively high thermal shock parameter (TSP), such as TSR≧525° C. by virtue of a high MOR / E ratio, and / or low Eratio=ERT / E1000° C. and well interconnected porosity, as witnessed by a relatively high pore connectivity factor (PCF). A method of manufacturing the honeycomb ceramic structure is also provided.

Owner:CORNING INC

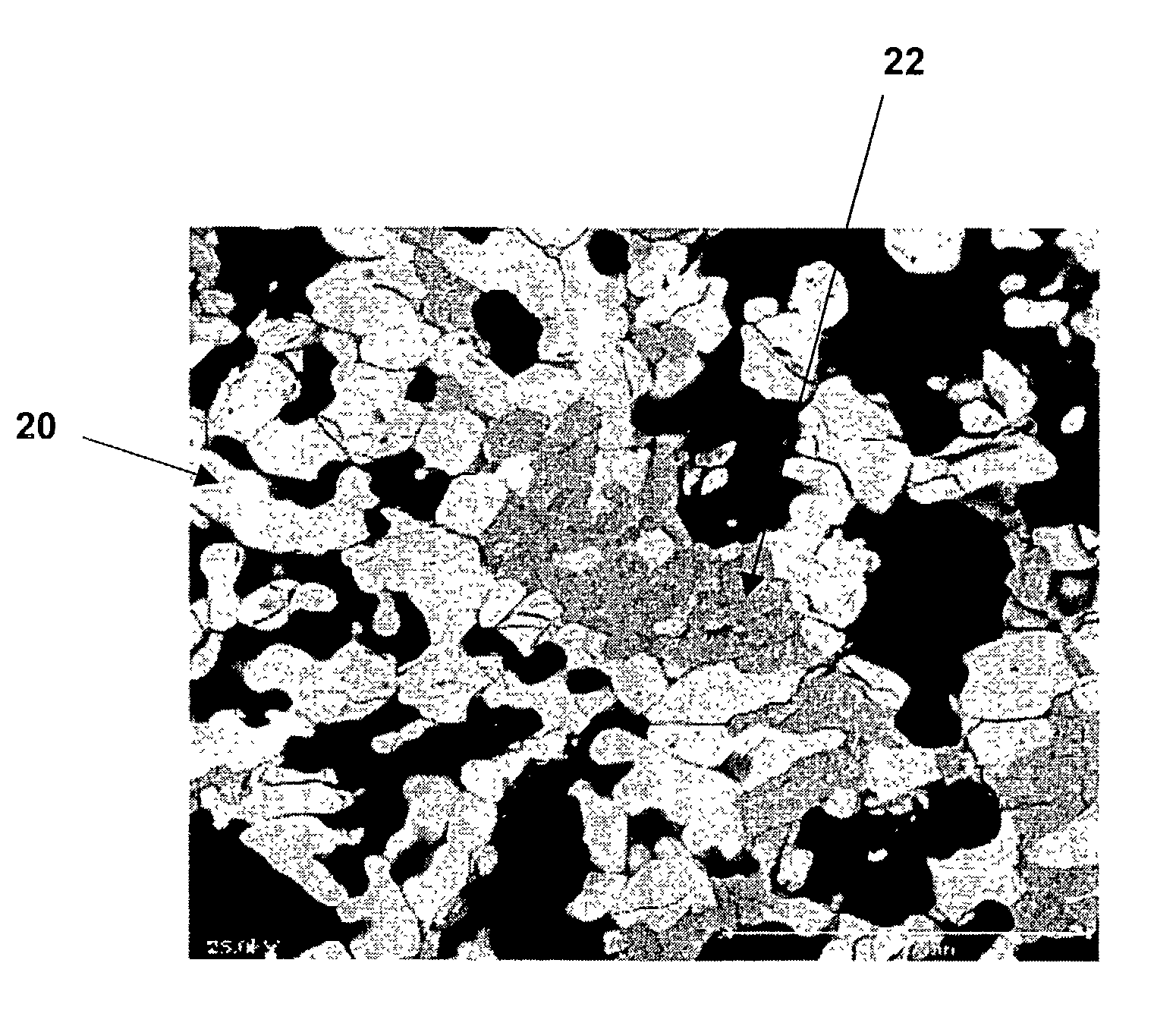

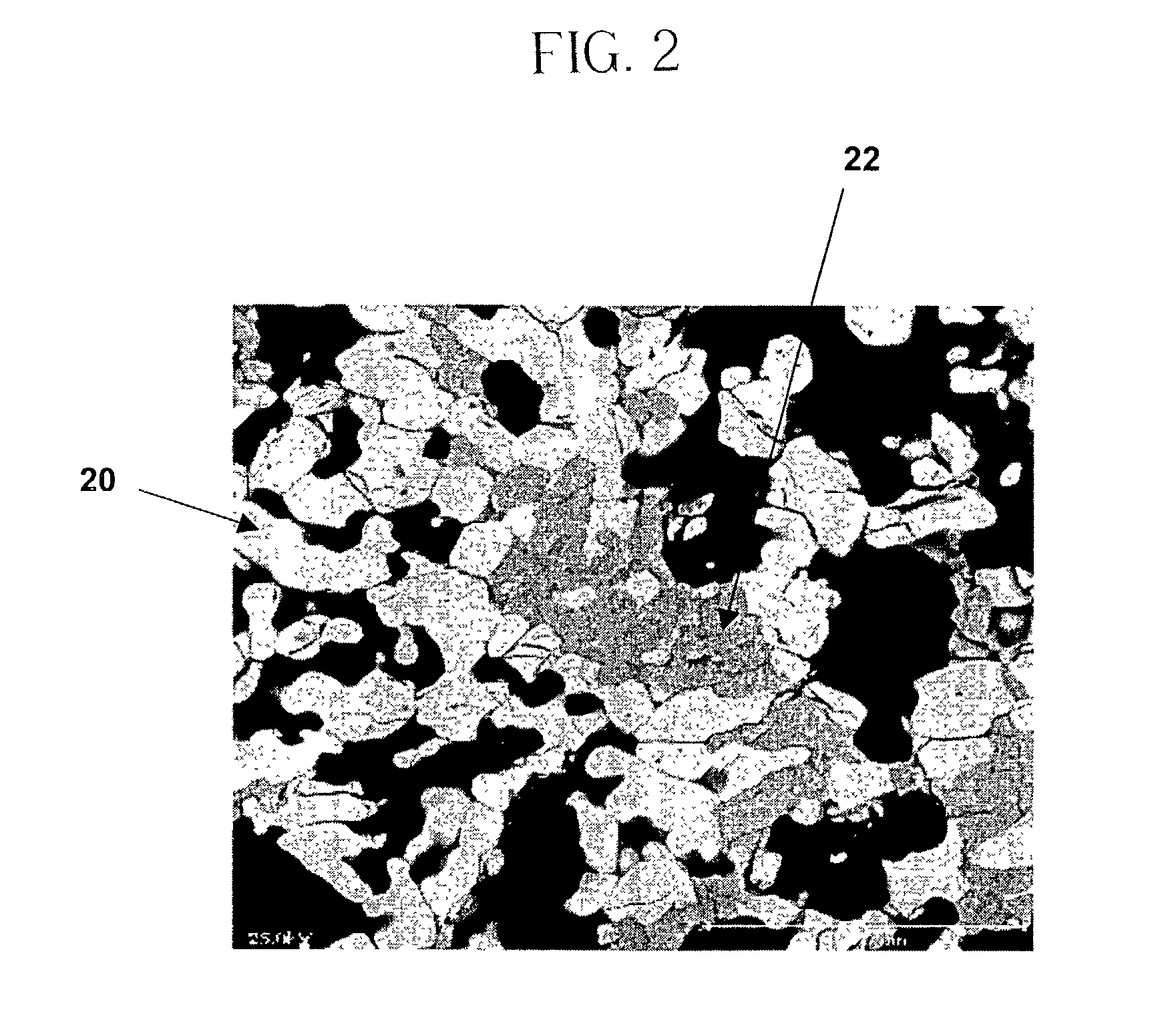

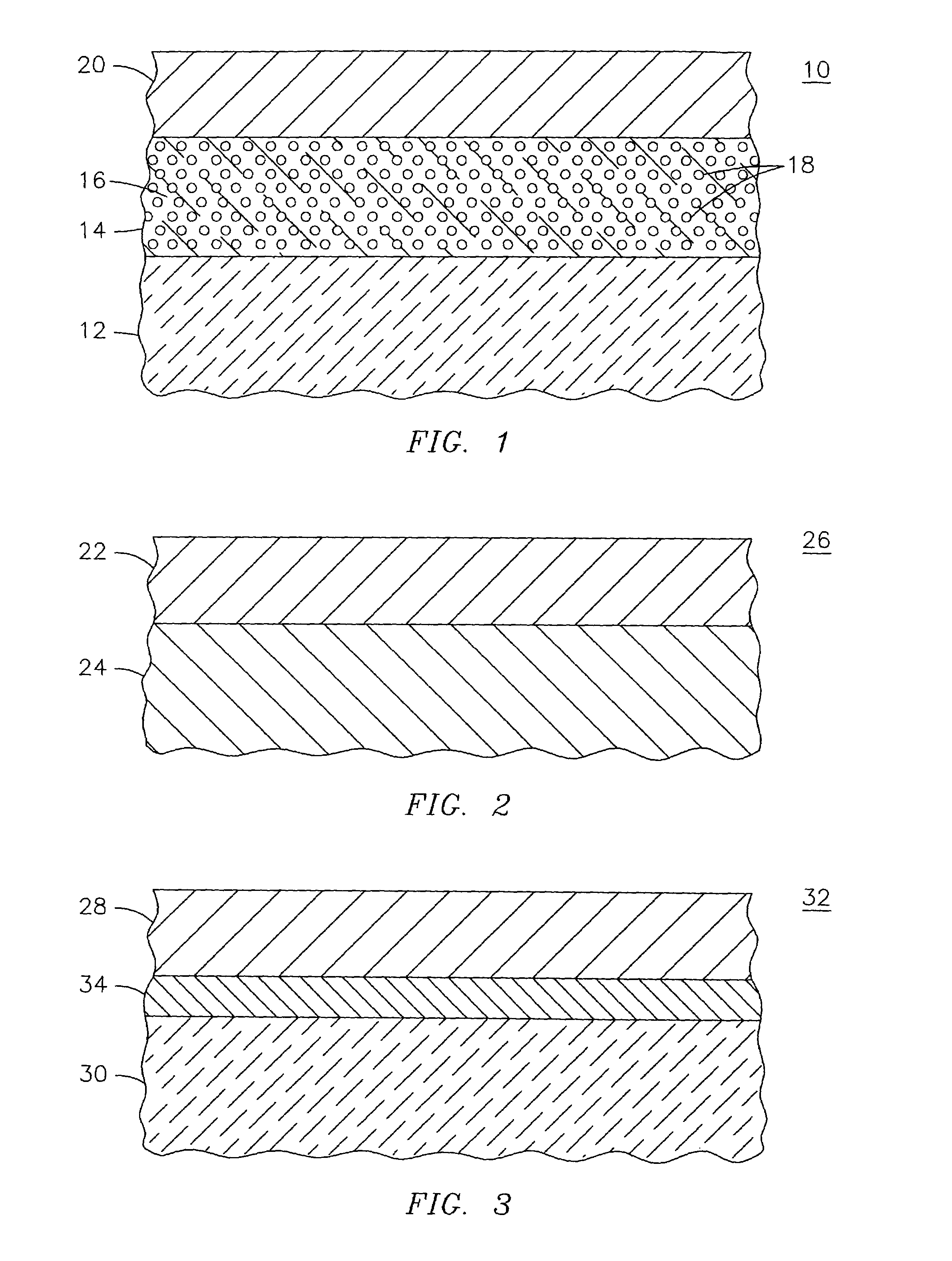

Protective overlayer for ceramics

A xenotime phosphate protective overlayer (22) for protecting a ceramic material (24) from a high temperature, moisture-containing environment. Yttrium phosphate may be used as a protective overlayer to protect an underlying mullite layer to temperatures in excess of 1,500° C. The coating may have porosity of greater than 15% for improved thermal shock protection. To prevent the ingress of oxygen to an underlying ceramic non-oxide material, such as silicon carbide or silicon nitride, an oxygen barrier layer (34) is disposed between the xenotime phosphate coating and the non-oxide material. Such a protective overlayer may be used for an article having a ceramic matrix composite substrate.

Owner:SIEMENS ENERGY INC

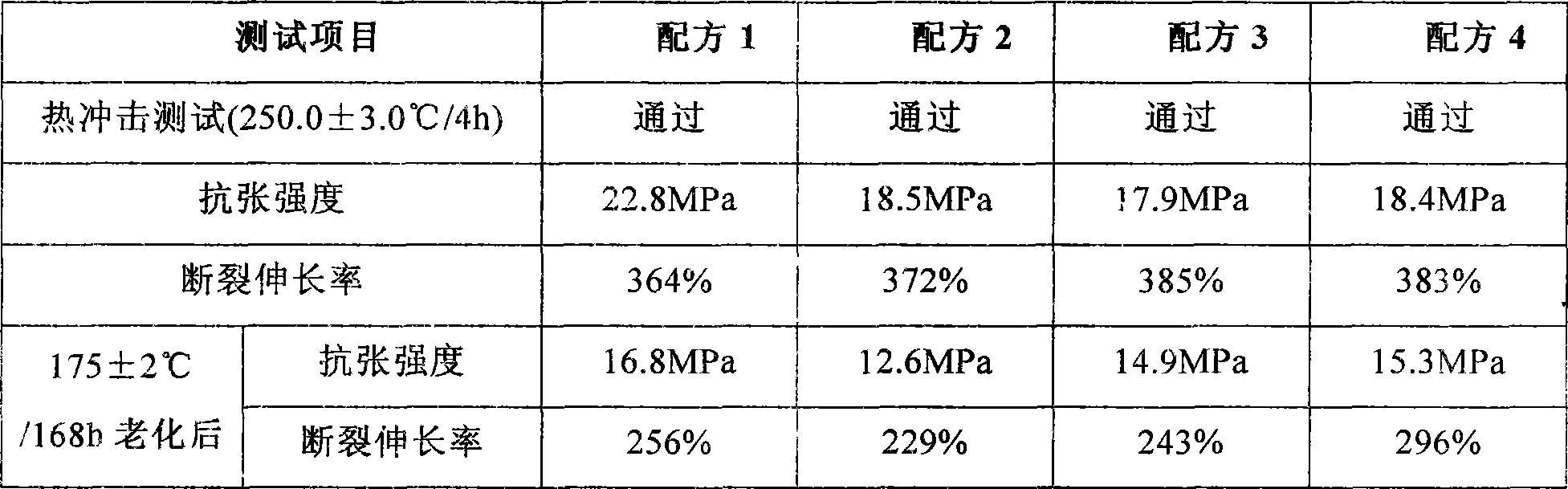

Radiation crosslinking flame-retardant polyolefin heat-shrinkable material and preparation method thereof

InactiveCN101386693AImprove insulation performanceEasy to preparePlastic/resin/waxes insulatorsPolymer sciencePolyolefin

The invention relates to a radiation crosslinking flame-retardant polyolefin thermal shrinking material, which comprises the following substances in weight portion: 100 portions of polyolefin base material, 0 to 100 portions of composite flame retardant, 1 to 3 portions of lubricating agent, 0 to 5 portions of color master batch, 1 to 5 portions of composite antioxidant and 0 to 2 portions of titanium pigment. The radiation crosslinking flame-retardant polyolefin thermal shrinking material can pass a thermal shock test, can be used for manufacturing various thermal shrinking devices, has the advantages of environmental protection, excellent insulating property, simple preparation method, easily bought raw materials and low cost, and is suitable for industrialized production.

Owner:CHANGYUAN GRP +1

Magnesium aluminate spinel foamed ceramic filter as well as preparation method thereof

ActiveCN103553686APrevent plastic crackingImprove high temperature stabilityCeramicwareMg alloysSlurry

The invention relates to a magnesium aluminate spinel foamed ceramic filter which is excellent in high-temperature chemical stability and thermal shock resistance. A preparation method of the magnesium aluminate spinel foamed ceramic filter comprises the following steps: firstly, using water-base resin, a dispersing agent and water as a solvent, forming ceramic powder by using magnesium aluminate spinel powder, aluminum oxide powder and magnesium hydroxide powder, and mechanically stirring to prepare slurry; soaking polyurethane porous sponge serving as a carrier in slurry, pressing to remove excessive slurry to prepare a preform body, drying and sintering to obtain the magnesium aluminate spinel foamed ceramic filter. The foamed ceramic filter disclosed by the invention can satisfy rigorous requirements of filtering of molten magnesium alloy, has good high-temperature stability, does not pollute the alloy, has good filtering and adsorbing effect on inorganic impurities in the molten magnesium alloy, and is good in filtering and purifying effect, small in fluid resistance, and large in filtration yield; and good using effect is obtained through trial in casting production of metal magnesium and magnesium alloy.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

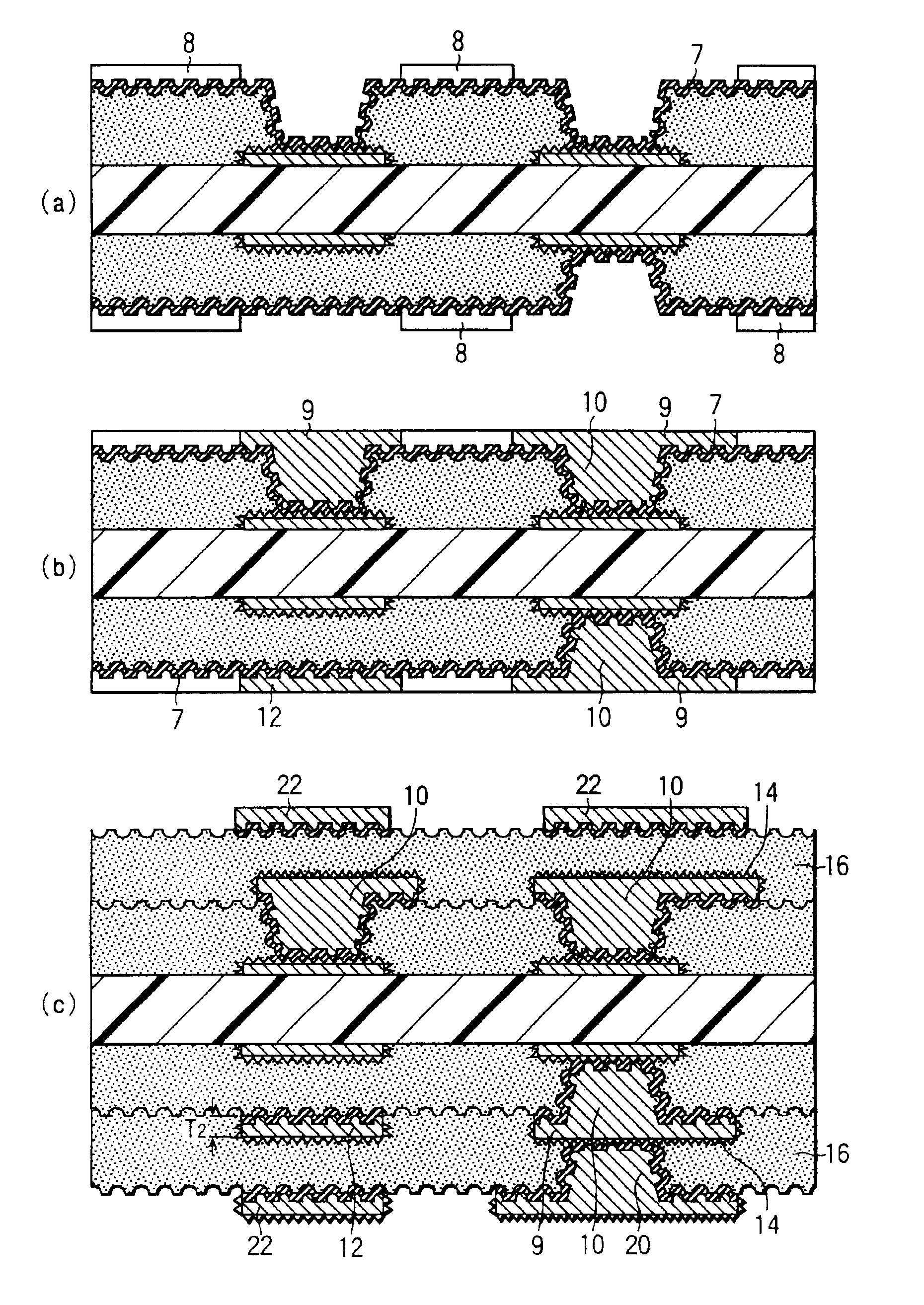

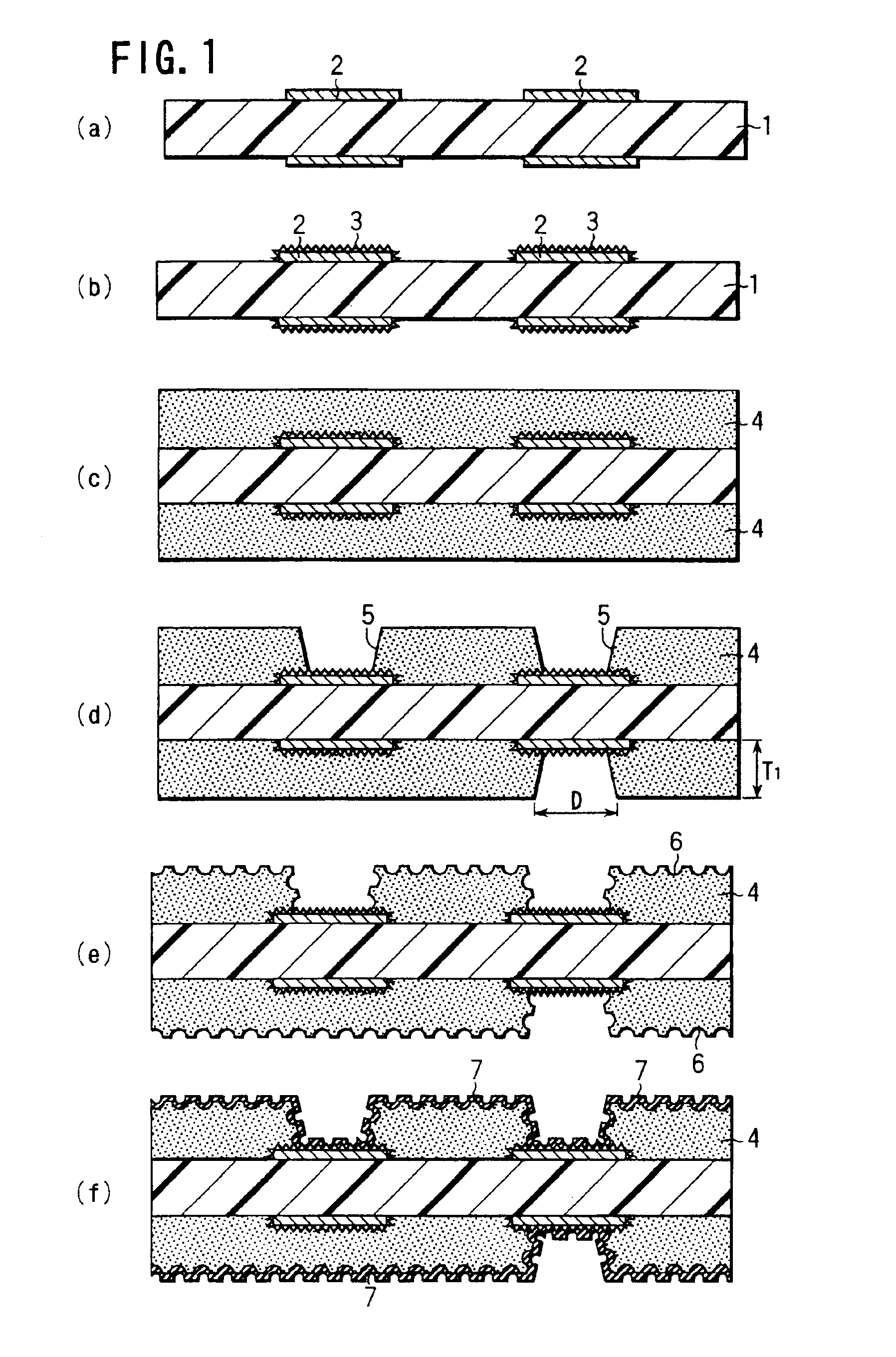

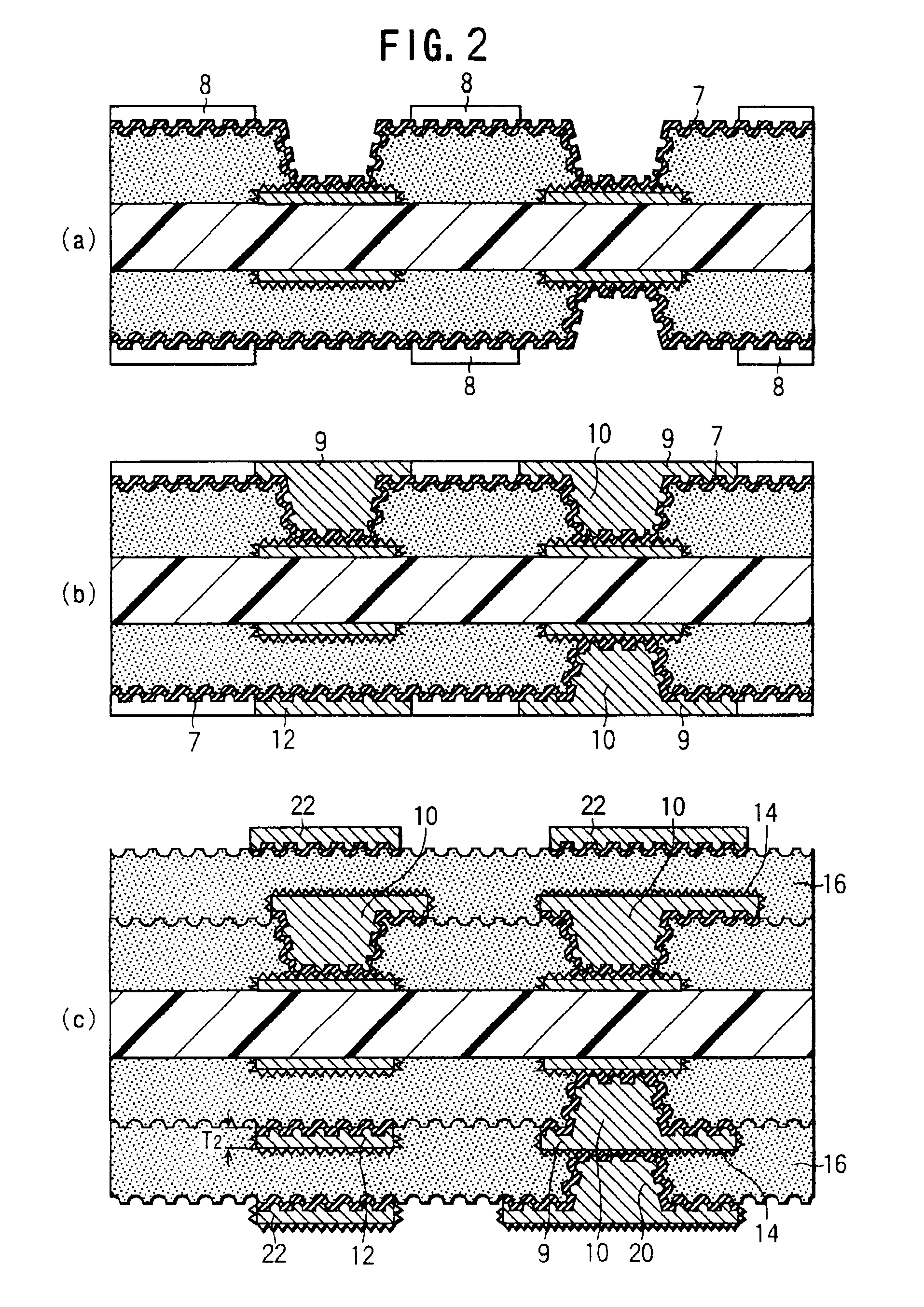

Multilayer printed wiring board having filled-via structure

InactiveUS7071424B1More highly reliableUniform thicknessInsulating substrate metal adhesion improvementDielectric materialsHigh fractureElectrical conductor

The present invention provides a multilayer printed wiring board having a filled viahole structure advantageously usable for forming a fine circuit pattern thereon, and having an excellent resistance against cracking under a thermal shock or due to heat cycle. The multilayer printed wiring board is comprised of conductor circuitry layers and interlaminar insulative resin layers deposited alternately one on another, the interlaminar insulative resin layers each having formed through them holes each filled with a plating layer to form a viahole. The surface of the plating layer exposed out of the hole for the viahole is formed substantially flat and lies at a substantially same level as the surface of the conductor circuit disposed in the interlaminar insulative resin layer. The thickness of the conductor circuitry layer is less than a half of the viahole diameter and less than 25 μm. The inner wall of the hole formed in the interlaminar insulative resin layer is roughened and an electroless plating layer is deposited on the roughened surface. An electroplating layer is filled in the hole including the electroless plating layer to form the viahole. The interlaminar insulative resin layer is formed from a composite of a fluororesin showing a high fracture toughness and a heat-resistant thermoplastic resin, a composite of fluororesin and thermosetting resin or a composite of thermosetting and thermoplastic resins.

Owner:IBIDEN CO LTD

Cast high-boron high-speed steel for composite ring roller and heat treatment method thereof

ActiveCN101240402AHigh hardnessIncrease rolling capacityFurnace typesHeat treatment furnacesWear resistantAlloy

The invention discloses a casting high-boron high-speed steel for manufacturing a composite roll ring roller and hot processing method thereof. The steel is a wear-resistant material having superior thermal-shock resistance, and can be applied to other suitable working conditions. The chemical compositions of the steel are (weight%): 0.20 to 1.10 of C, 1.0 to 2.5 of B, 3.0 to 5.0 of Cr, 0.5 to 0.9 of Si, 0.6 to 1.3 of Mn, 2.0 to 10.0 of V, 0.5 to 1.5 of Ni, 1.0 to 4.0 of Mo, 0.2 to 4.0 of W, 0.1 to 2.0 of Nb, less than 0.04 of S, less than 0.04 of P and residue of Fe. The hot processing method includes annealing, quenching and 2 to 3 times of temper. The annealing heating temperature is 800 to 860 DEG C, furnace cooling or air cooling is carried out after furnace cooling to less than 500 DEG C; the quenching heating temperature is 1020 to 1150 DEG C, wind cooling or air cooling is carried out thereafter; 2 to 3 times of temper are carried out, the heating temperature is 500 to 550 DEG C, furnace cooling or air cooling is carried out thereafter. Compared with traditional high-nickle-chrome-molybdenum roller, the roller of the invention greatly improves alloy wearing resistance, heat resistance and thermal-shock resistance, and reduces thermal endurance crack phenomena appearing during use, as well as pits and crack arising therefrom, embodying good organic combination of safety and wearing resistance.

Owner:HUNAN 3T NEW MATERIAL

Flat panel liquid-crystal display such as for a laptop computer

InactiveUS6867158B2Improve heat resistanceFavorable processing rangeSemiconductor devicesHigh resistanceAlkali free

Flat panel liquid-crystal displays, such as for laptop computers. The displays include twisted nematic displays, supertwisted nematic displays, active matrix liquid-crystal displays, thin film transistor displays, and plasma addressed liquid-crystal displays. The displays are furnished with glass substrates. The glass substrates exhibit high resistance to thermal shock, a high transparency over a broad spectral range in the visible and ultra violet ranges and the glass being configured to be free of bubbles, knots, inclusions, streaks, and surface undulations, which glass substrates are made from alkali-free aluminoborosilicate glasses. There are also provided analogous thin-film photovoltaics.

Owner:SCHOTT AG

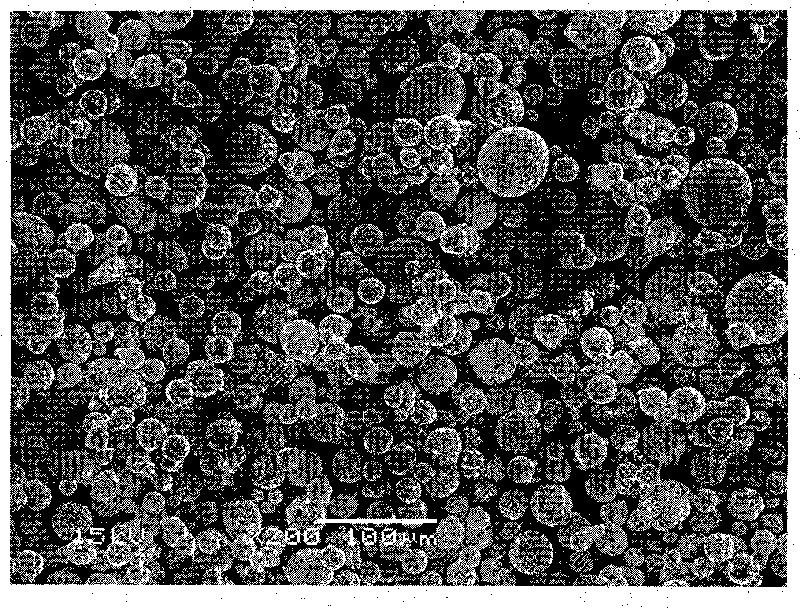

Nanometer zirconium oxide thermal barrier coating and preparation method thereof

ActiveCN102094164AWon't spreadHigh strengthMolten spray coatingEfficient propulsion technologiesThermal insulationThermal barrier coating

The invention relates to a nanometer zirconium oxide thermal barrier coating and a preparation method thereof. The nanometer zirconium oxide thermal barrier coating is characterized by comprising an adhesive layer and a ceramic layer, wherein NiCrAlY is prepared on the adhesive layer by adopting supersonic flame spraying and comprises the following components in percentage by weight: 20-30% of Cr, 4.0-10% of Al, 0.3-0.7% of Y, and the balance of Ni; a ZrO2 / Y2O3 layer is prepared as the ceramic layer by adopting plasma spraying, the ceramic layer is a nanometer zirconium oxide layer comprising5%-8% of partially stable yttrium oxide, and zirconium oxide powder is at a nanometer grade. The oxidation-resisting thermal barrier coating is prepared on a metal surface by combining the supersonic flame spraying with the plasma spraying, has better combining capacity with a base body and both thermal shock resistance and thermal insulation superior to those of a common ZrO2 / Y2O3 thermal barrier coating.

Owner:沈阳天贺新材料开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com