Patents

Literature

750results about "Fuel elements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

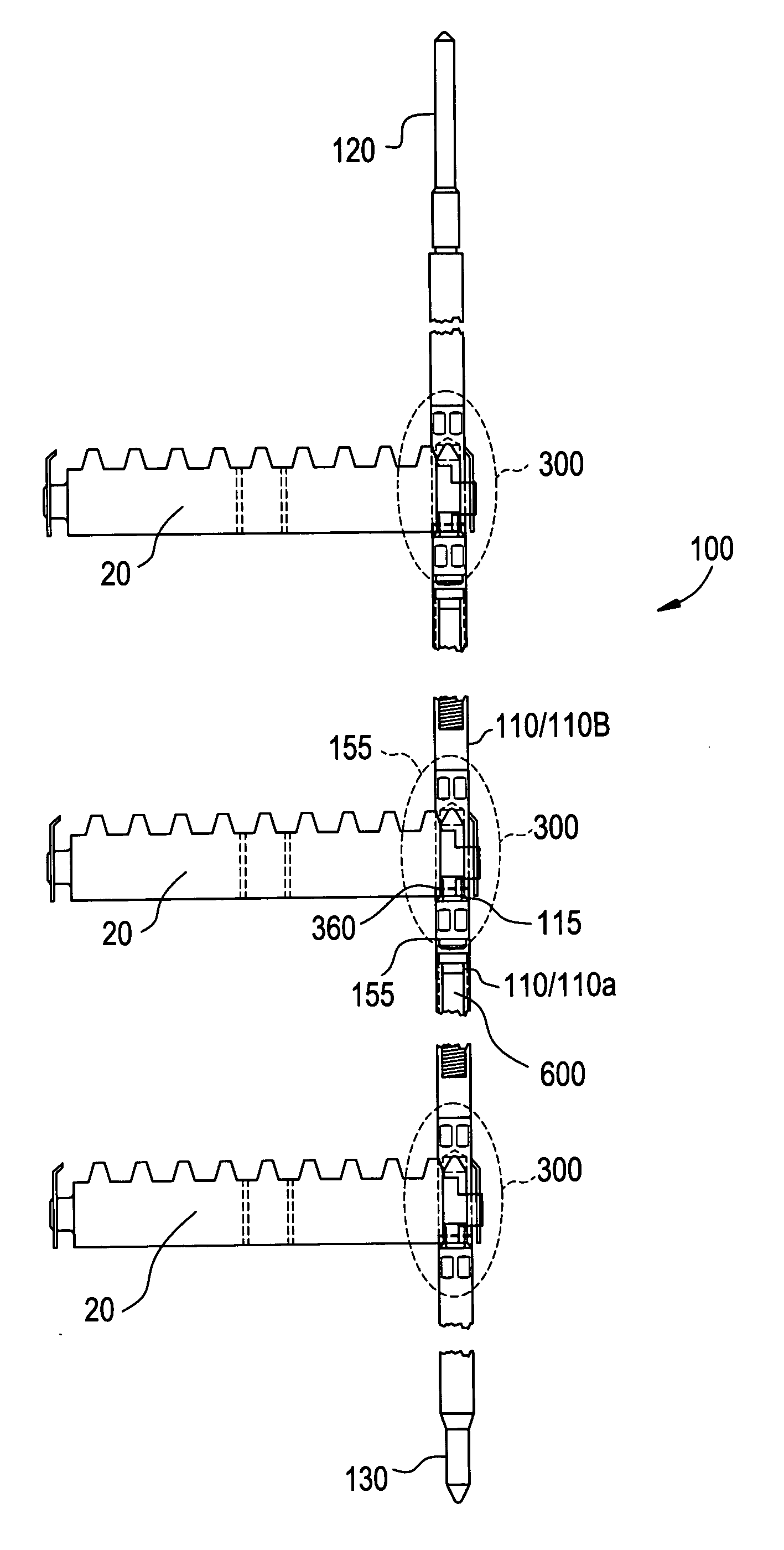

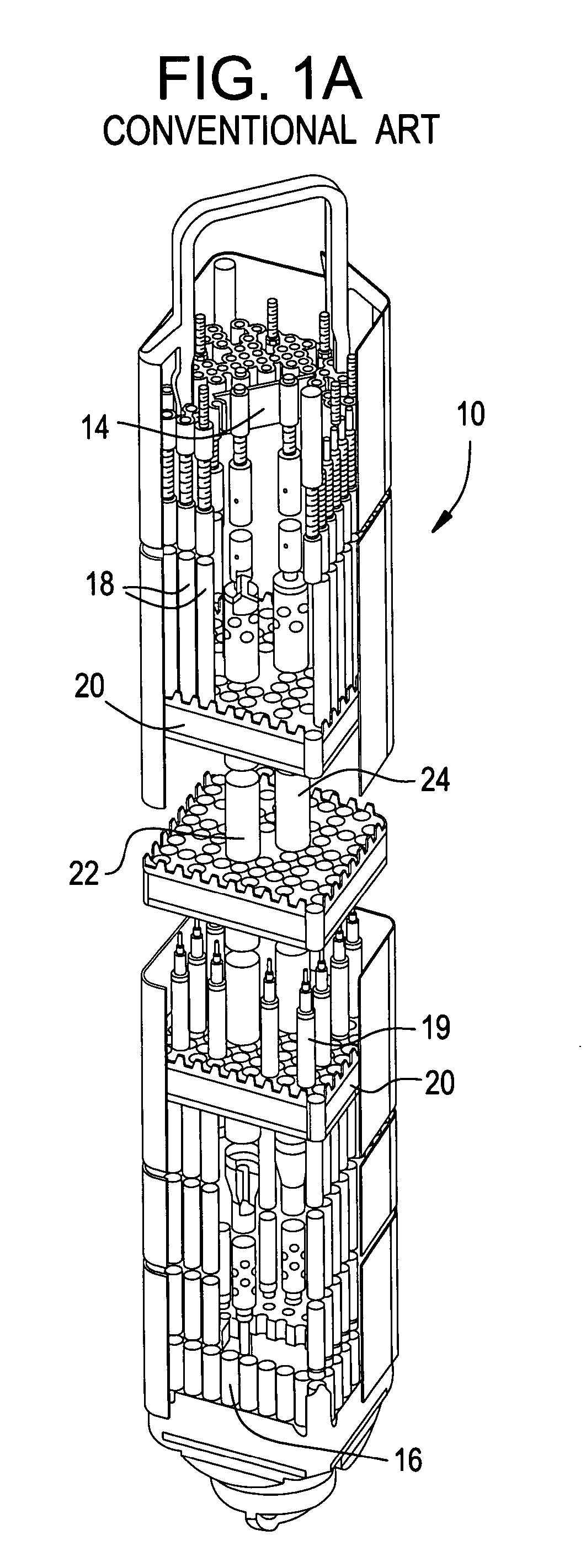

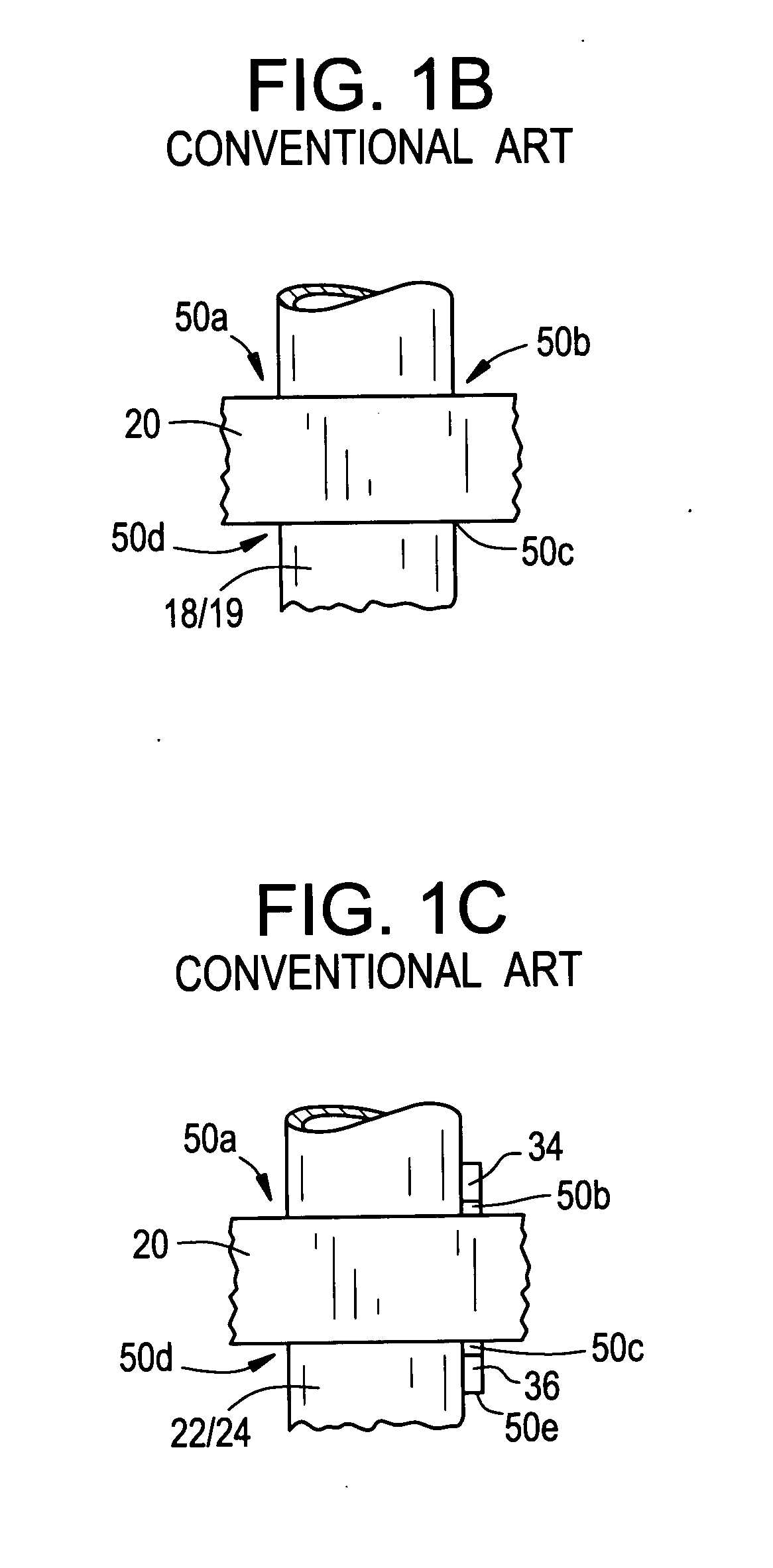

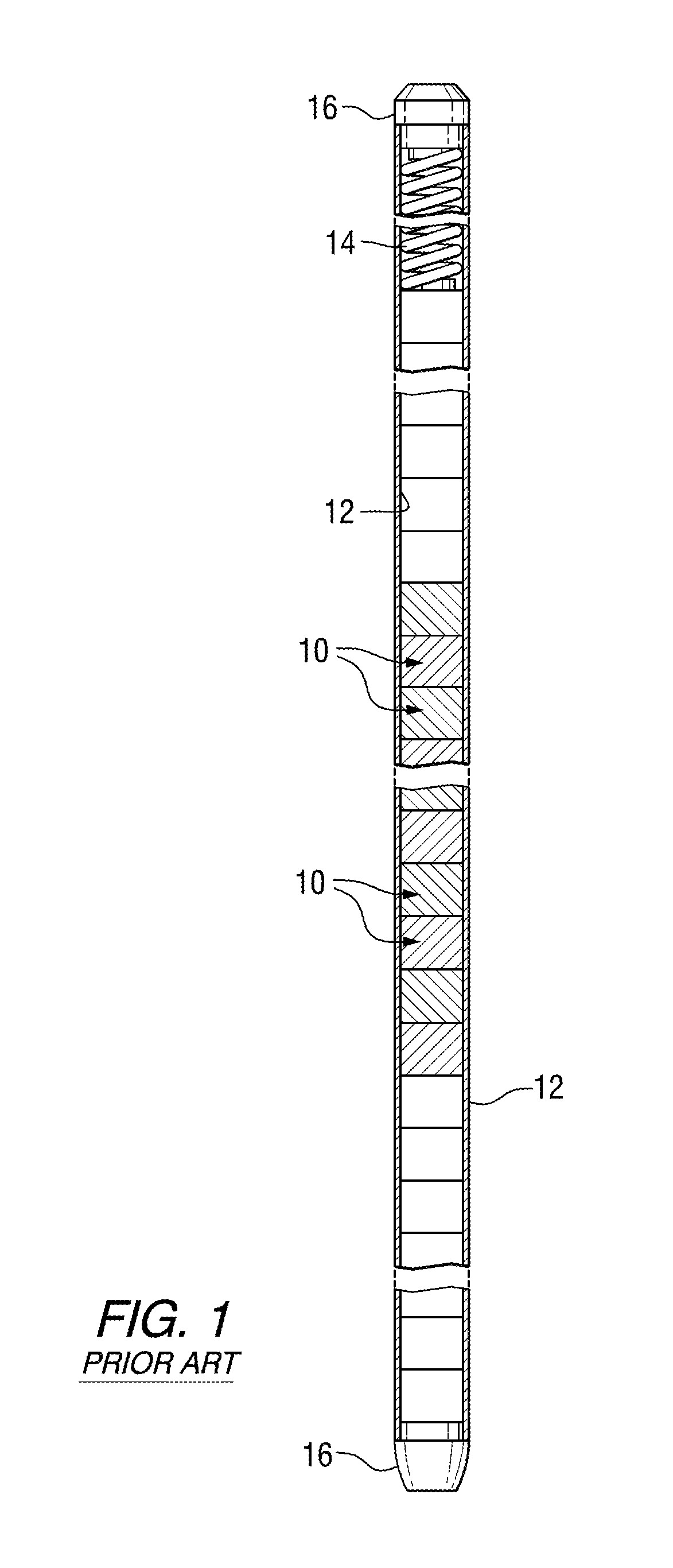

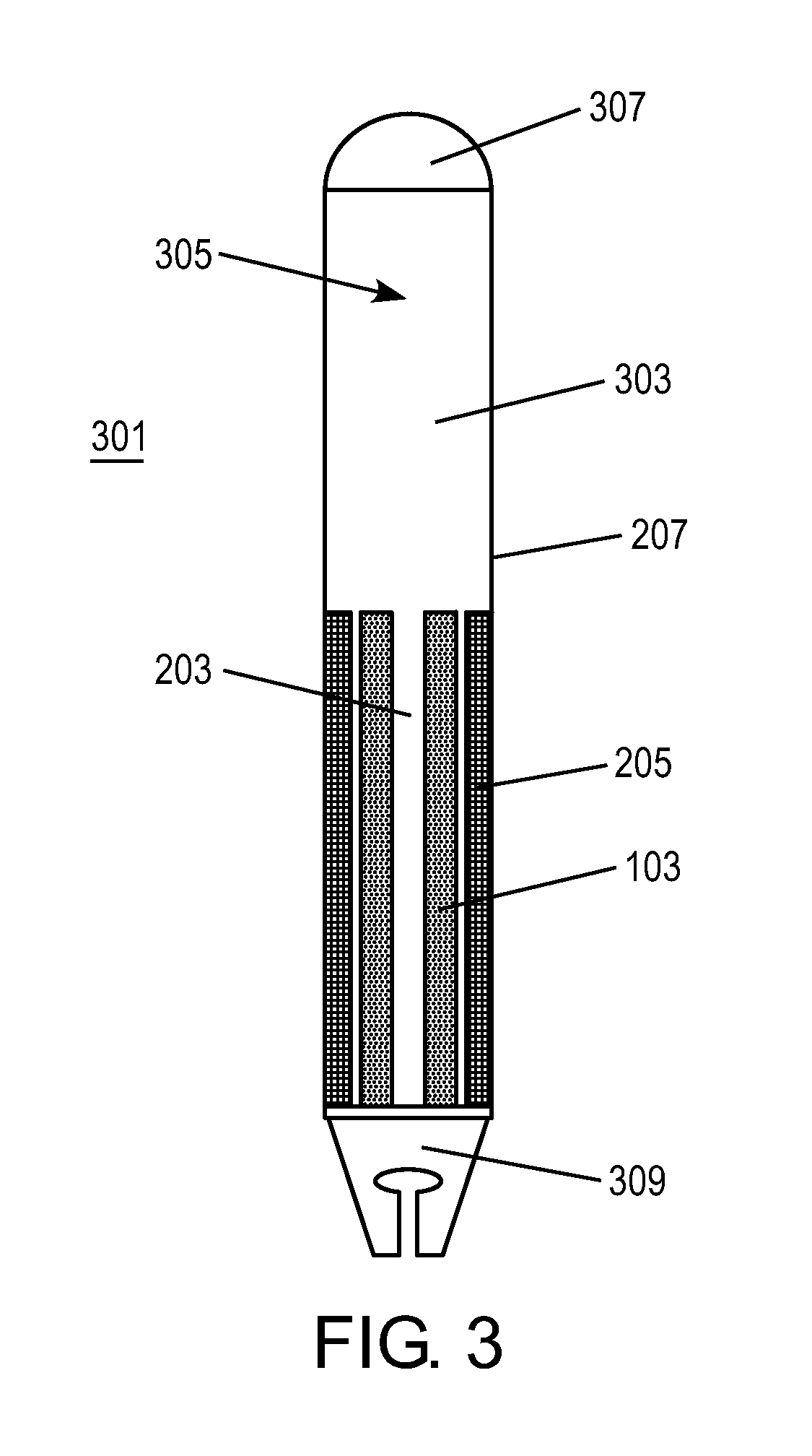

Rod assembly for nuclear reactors

A rod assembly for a fuel bundle of a nuclear reactor may include an upper end piece, lower end piece and a plurality of rod segments attached between the upper and lower end pieces and to each other so as to form an axial length of the rod assembly. The rod assembly may include an adaptor subassembly provided at given connection points for connecting adjacent rod segments or a given rod segment with one of the upper and lower end pieces. The connection points along the axial length of the rod assembly may be located where the rod assembly contacts a spacer in the fuel bundle. One (or more) of the rod segments may include an irradiation target therein for producing a desired isotope when a fuel bundle containing one (or more) rod assemblies is irradiated in a core of the reactor.

Owner:NORDION (CANADA) INC

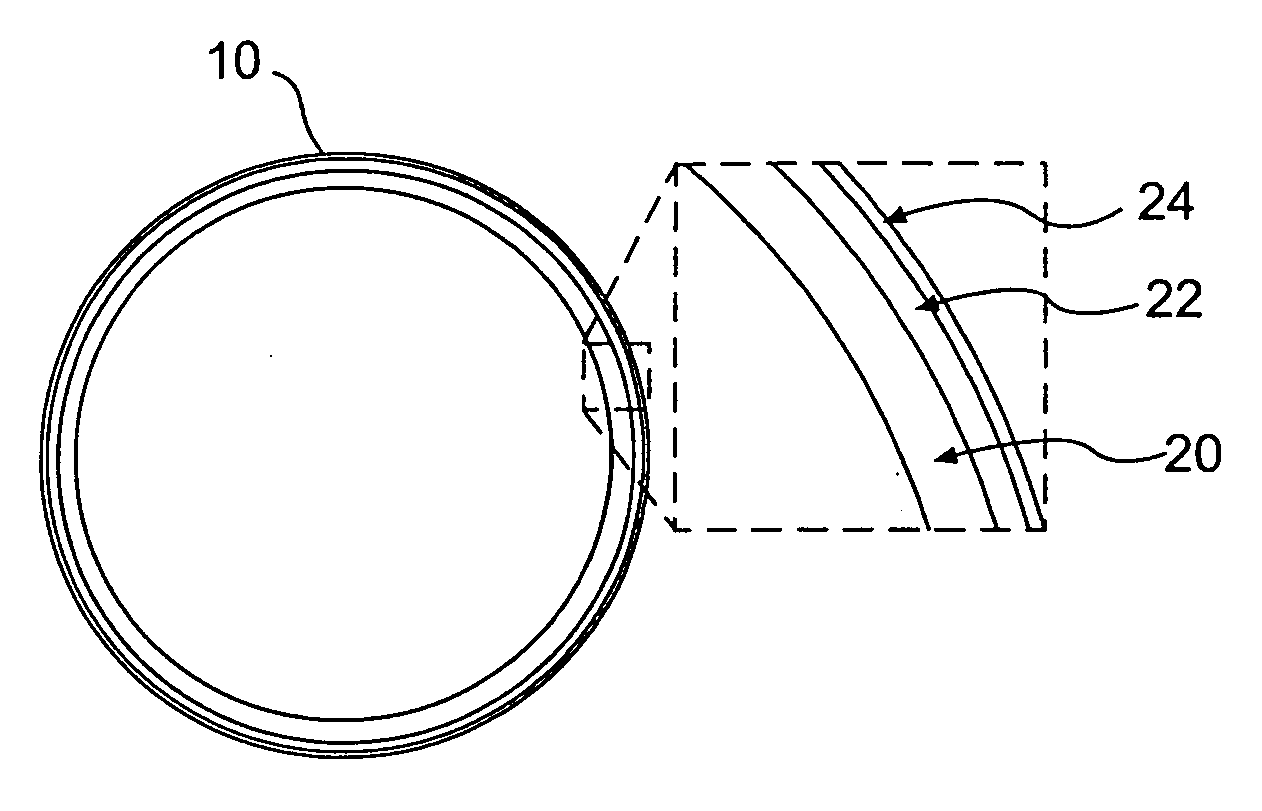

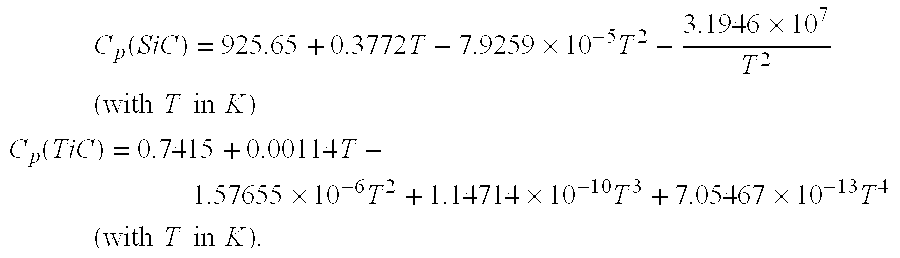

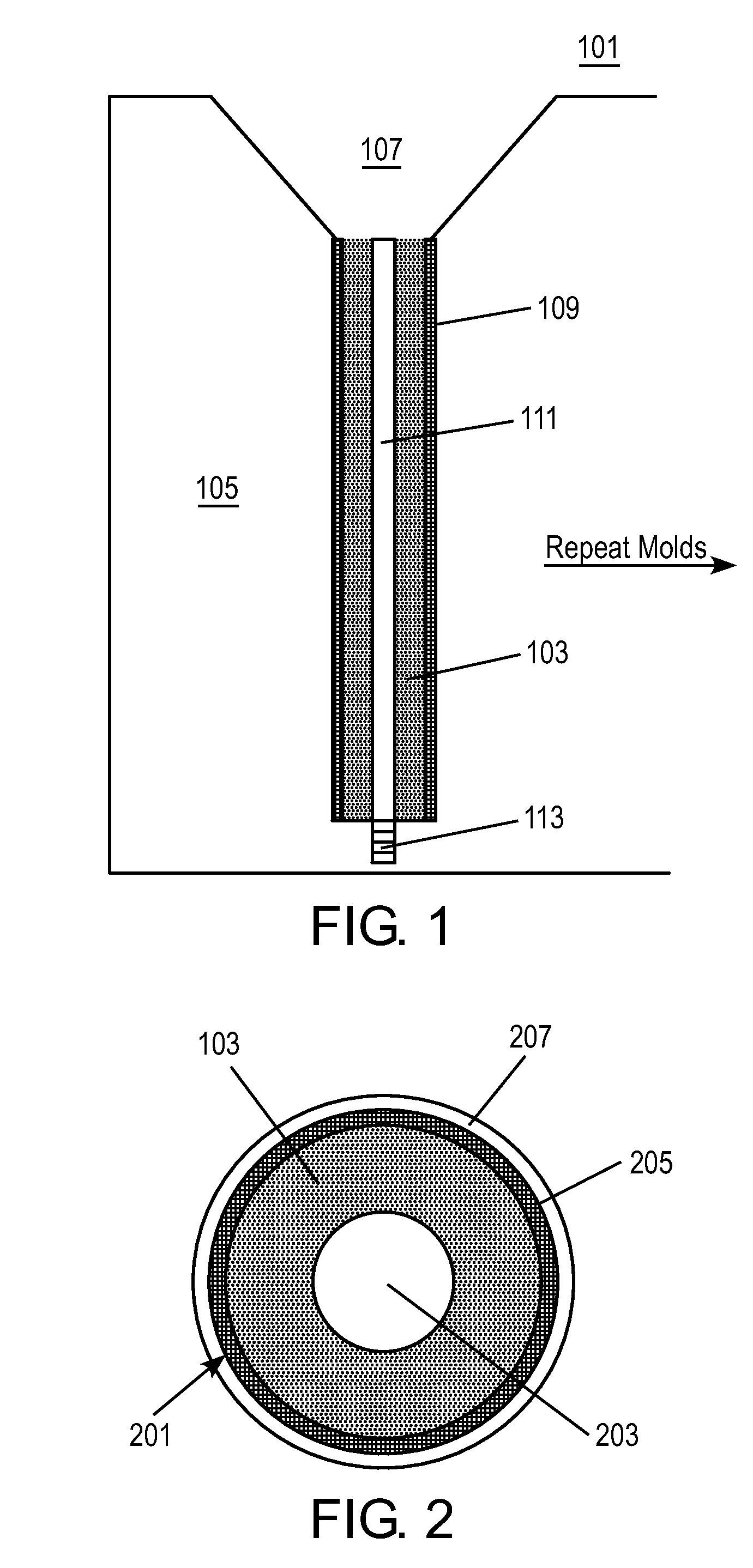

Multi-layered ceramic tube for fuel containment barrier and other applications in nuclear and fossil power plants

A multi-layered ceramic tube having an inner layer of high purity beta phase stoichiometric silicon carbide, a central composite layer of continuous beta phase stoichiometric silicon carbide fibers, and an outer layer of fine-grained silicon carbide. The ceramic tube is particularly suited for use as cladding for a fuel rod used in a power plant or reactor. The ceramic tube has a desirable combination of high initial crack resistance, stiffness, ultimate strength, and impact and thermal shock resistance.

Owner:GAMMA ENG CORP

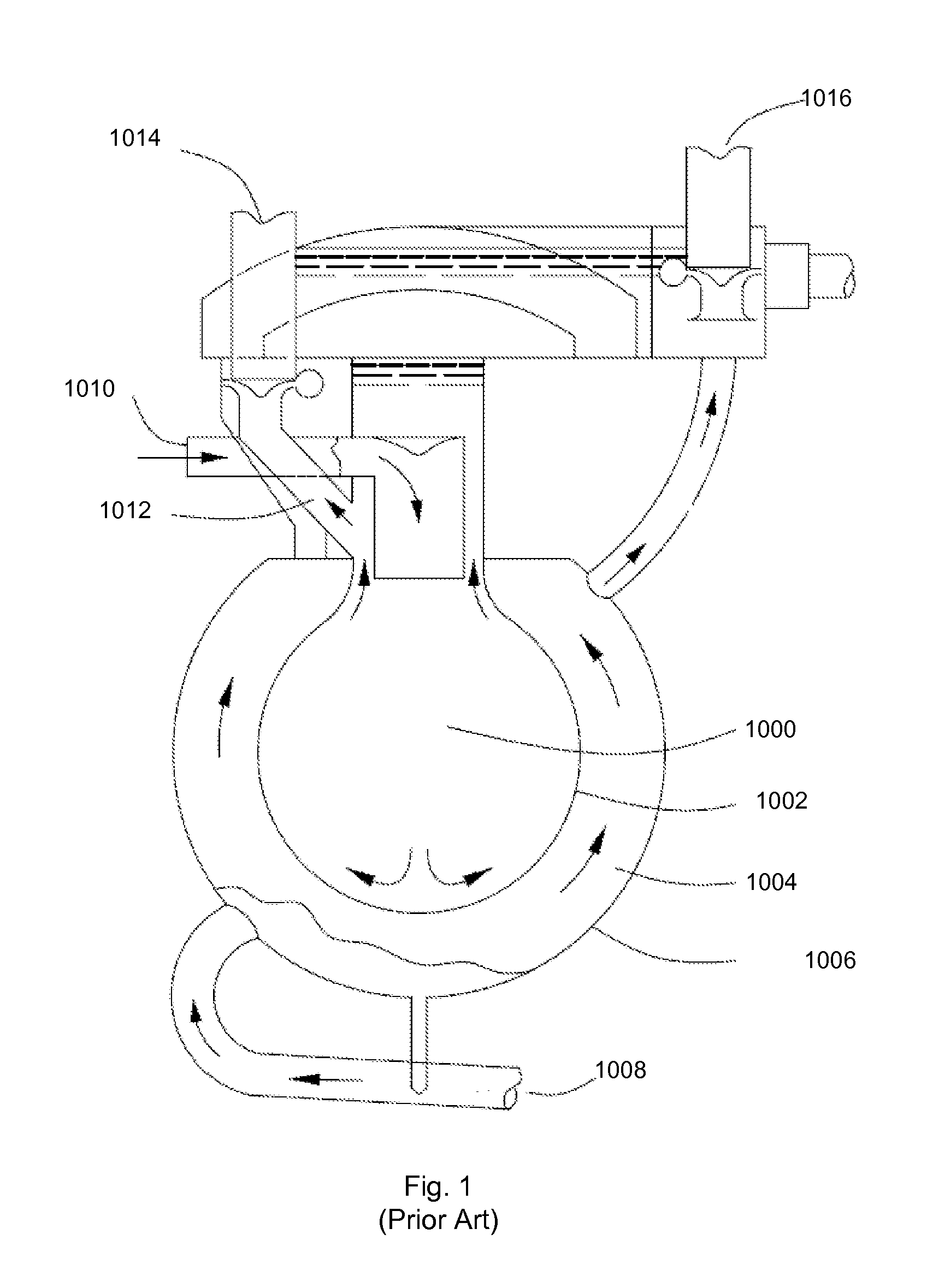

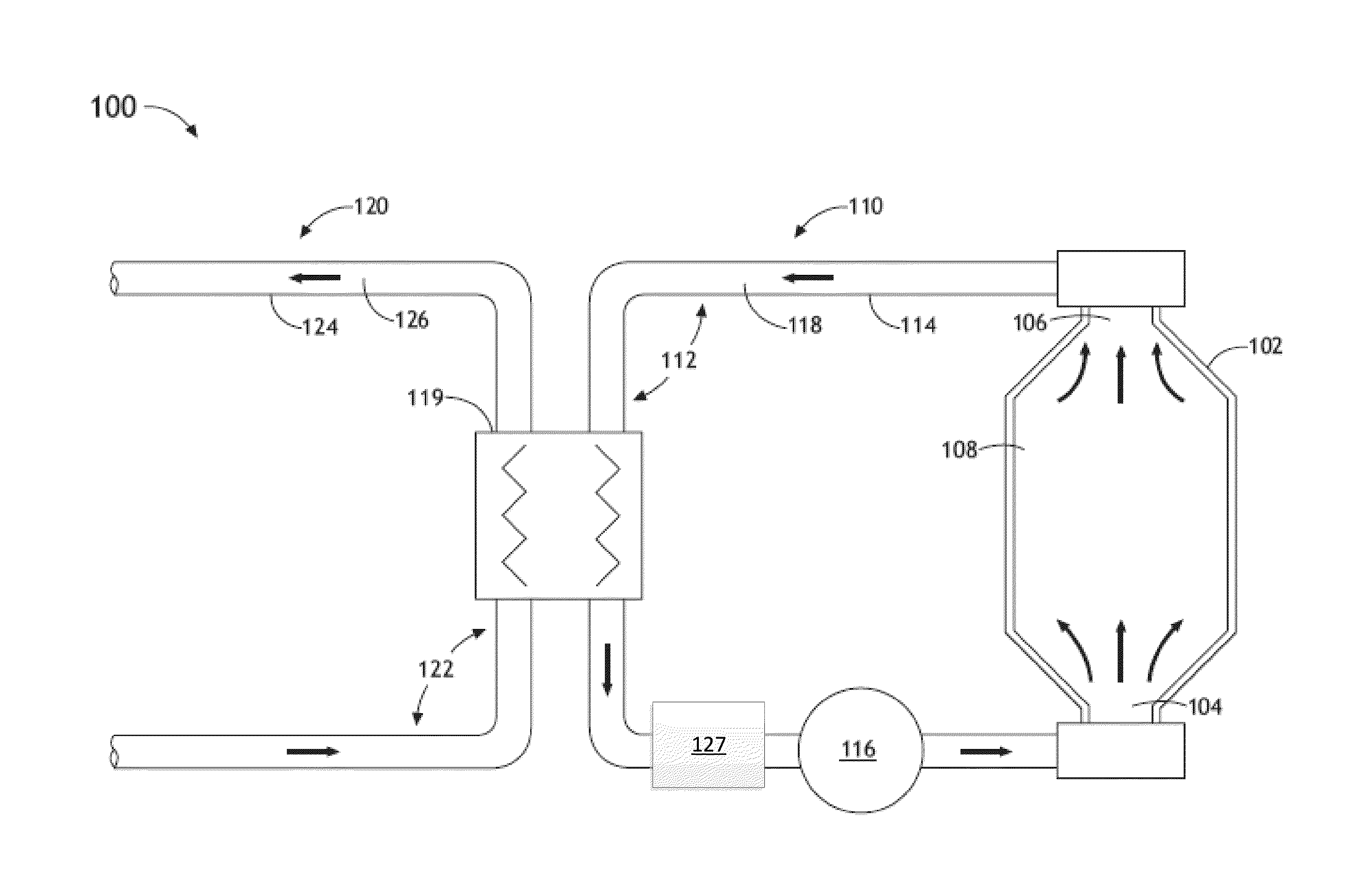

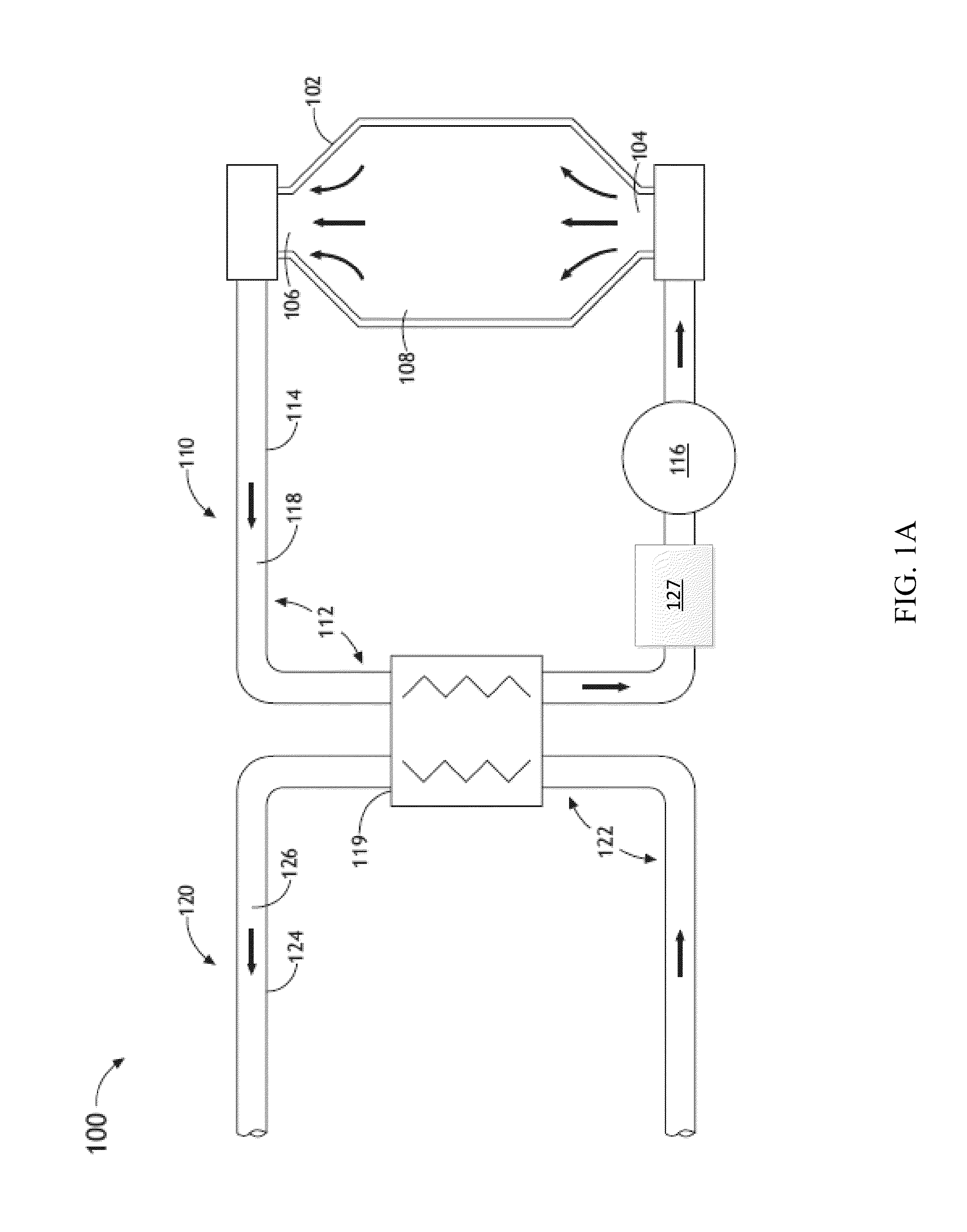

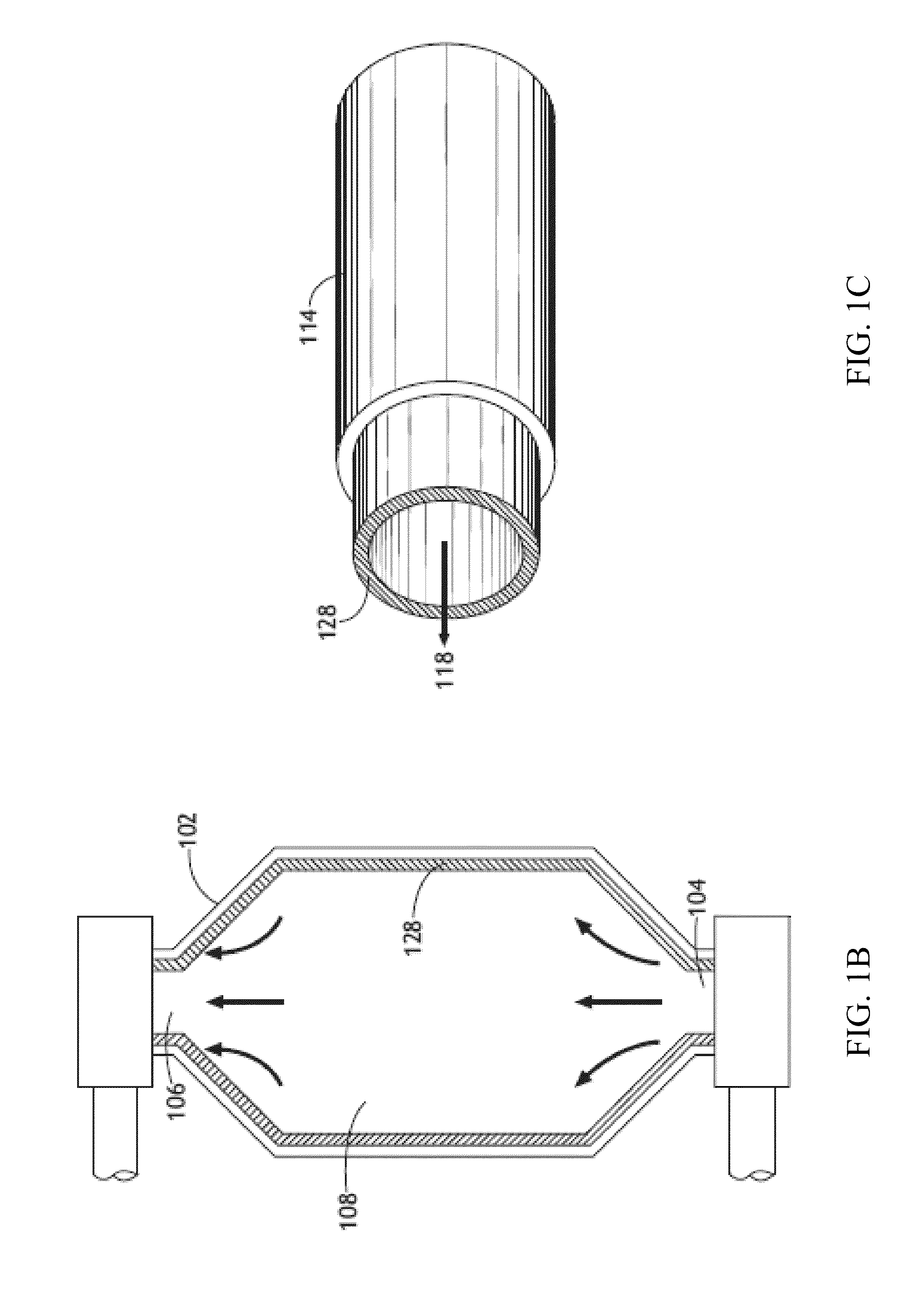

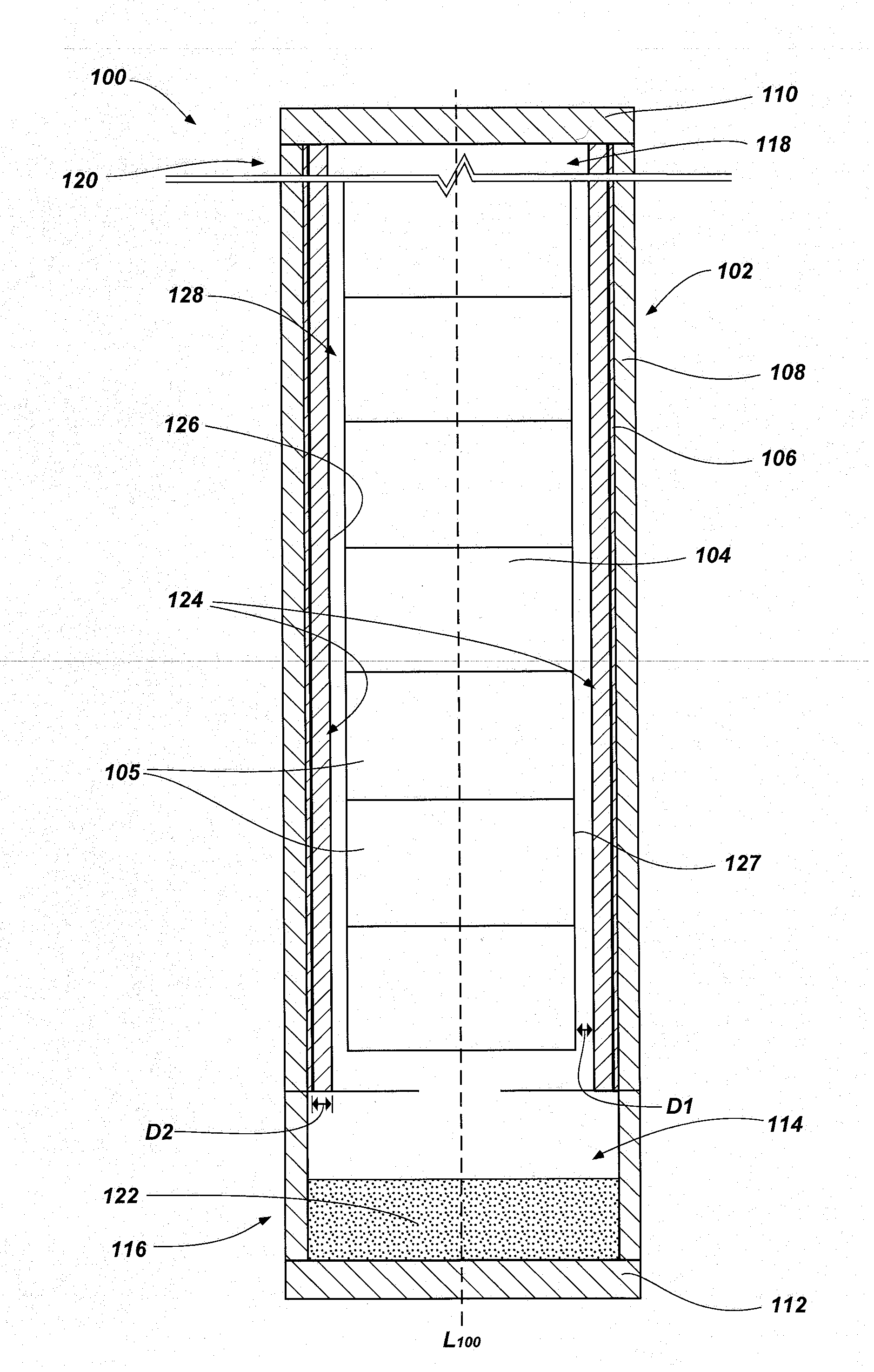

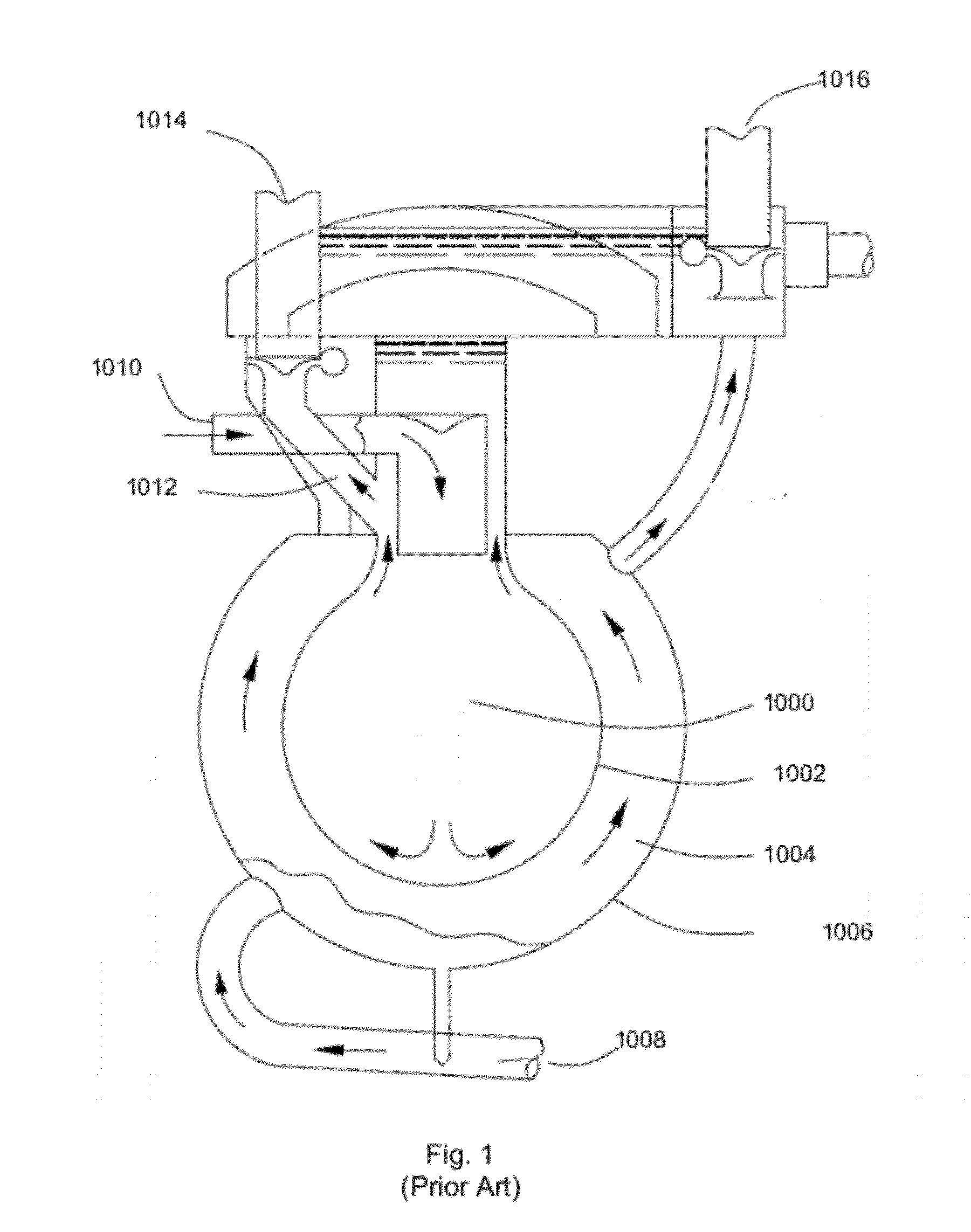

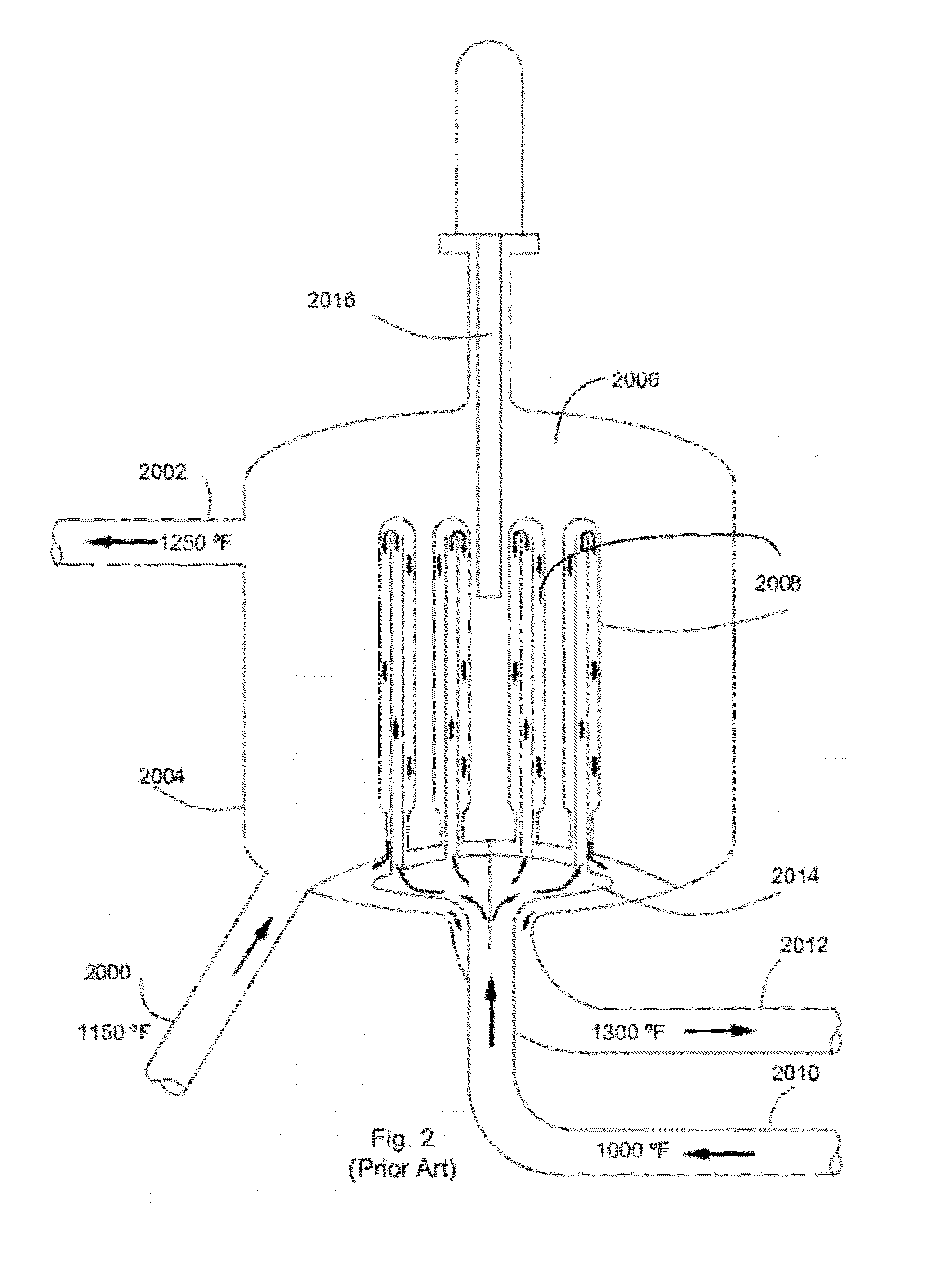

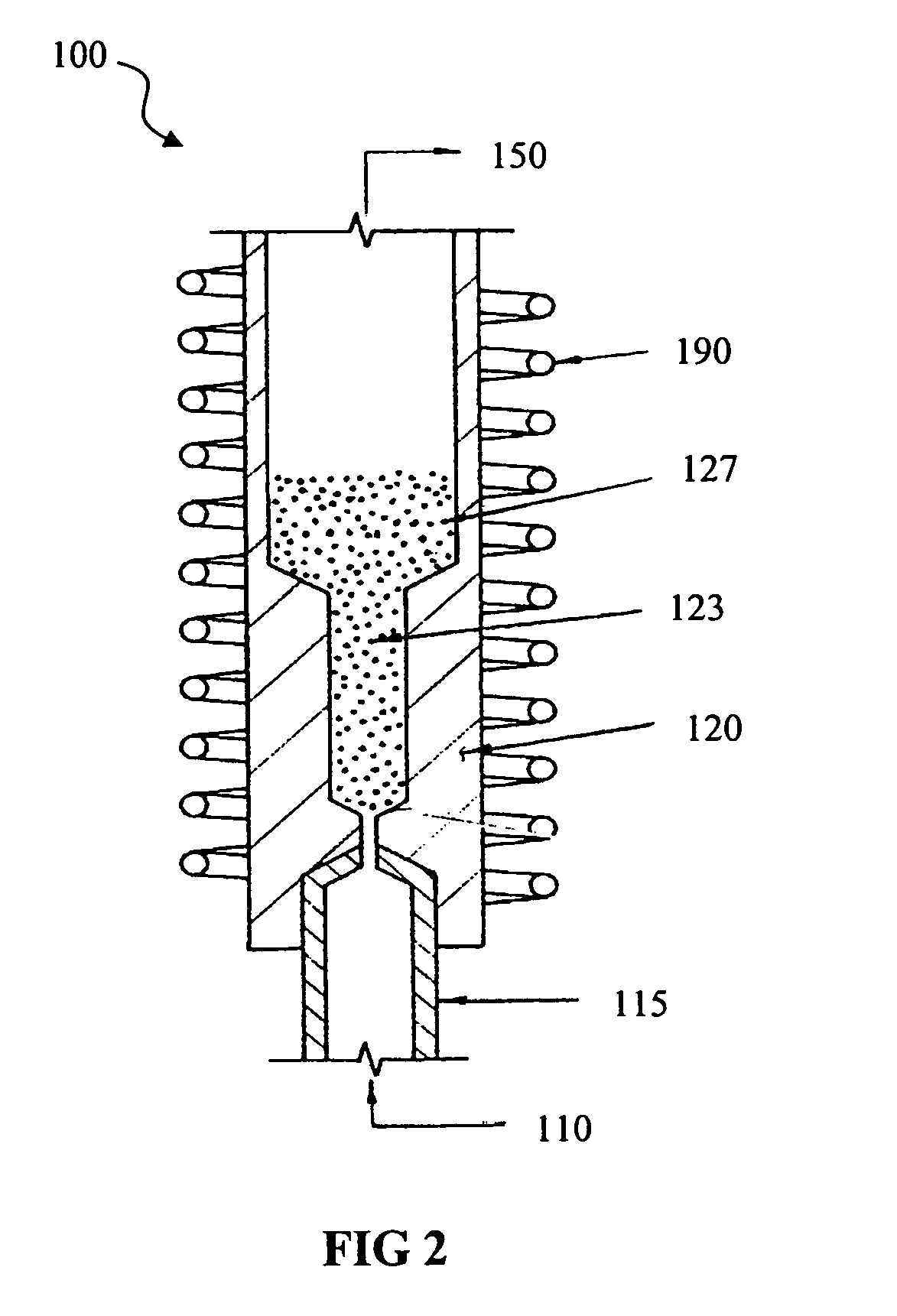

Molten salt nuclear reactor

InactiveUS20090279658A1Maximize probabilityFuel elementsNuclear energy generationBreeder reactorNuclear reactor

A molten salt breeder reactor that has fuel conduit surrounded by a fertile blanket. The fuel salt conduit has an elongated core section that allows for the generation of electrical power on a scale comparable to commercially available nuclear reactors. The geometry of the fuel conduit is such that sub-critical conditions exist near the input and output of the fuel salt conduit and the fertile blanket surrounds the input and output of the fuel salt conduit, thereby minimizing neutron losses.

Owner:OTTAWA VALLEY RES ASSOCS

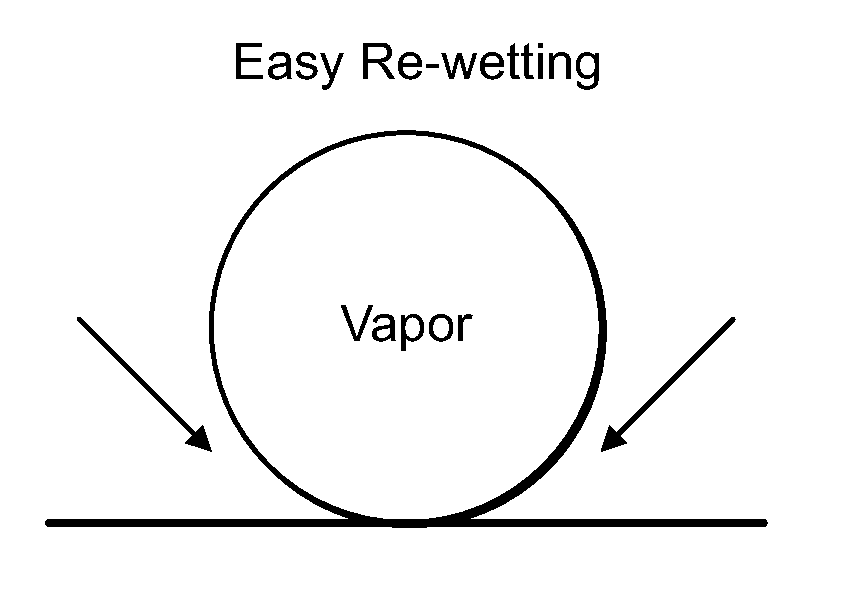

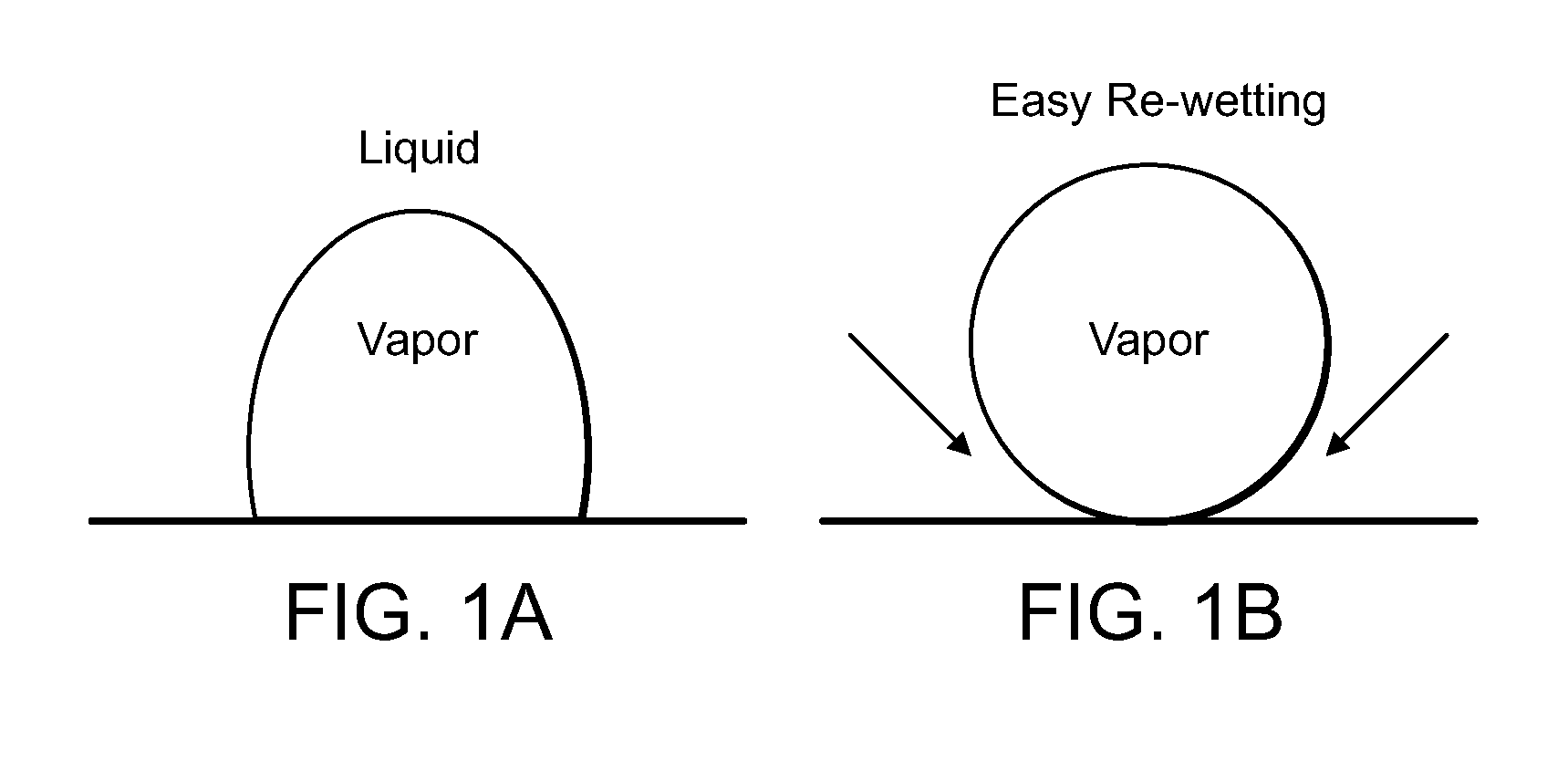

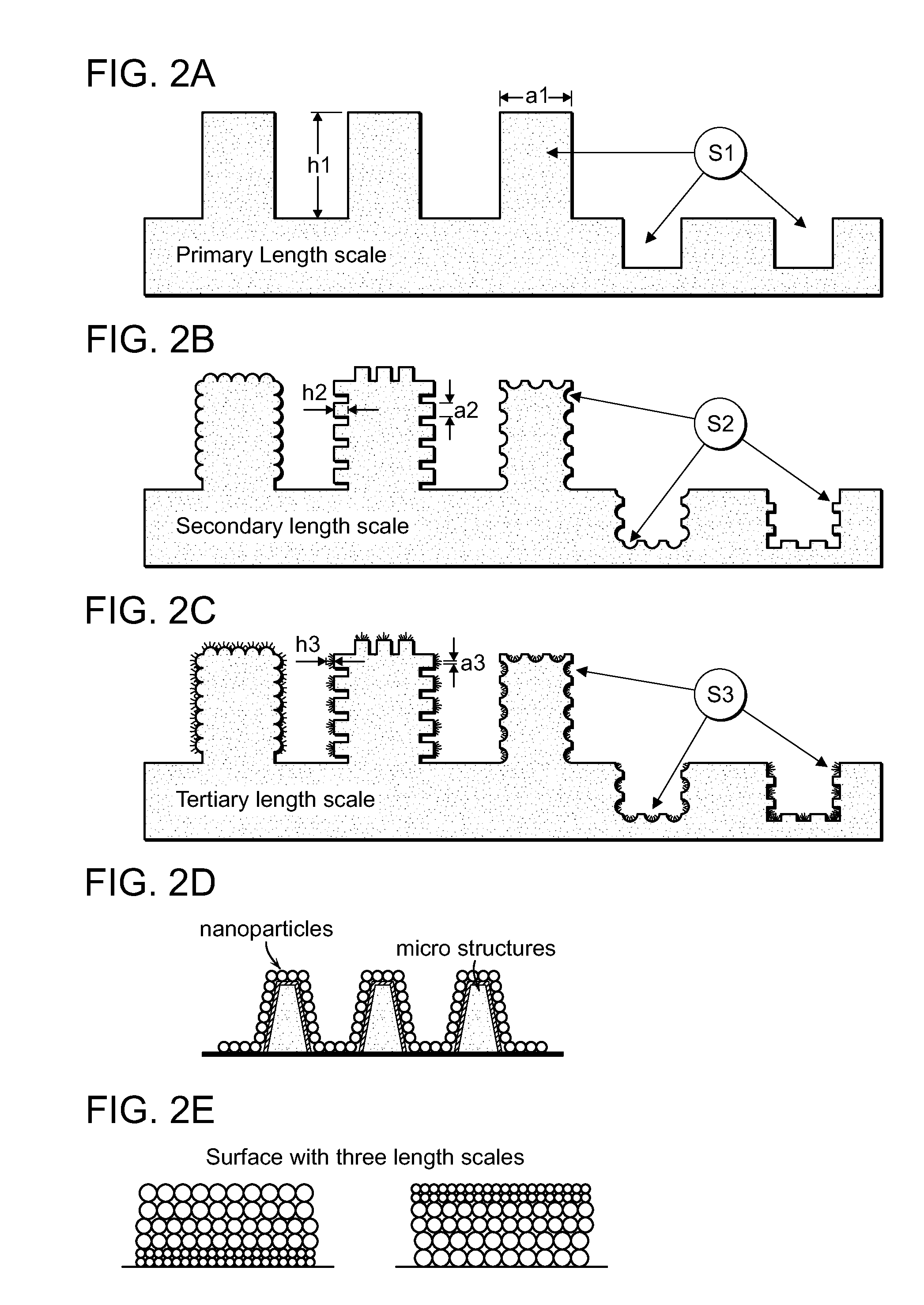

Superwetting surfaces for diminishing leidenfrost effect, methods of making and devices incorporating the same

ActiveUS20120051489A1Increasing Leidenfrost temperatureMaximize Leidenfrost temperatureFuel elementsNuclear energy generationEngineeringNanoscopic scale

Textured surface for increasing Leidenfrost temperature. The texture comprises of surface features over multiple length scales—from micro to nanoscale—wherein the features at each length scale have a size, aspect ratio, and spacing selected to increase the Leidenfrost temperature. The structure includes an array of microscale structures disposed on the surface, the structure having size, aspect ratio and spacing selected to increase Leidenfrost temperature. The microscale structures may also include nanoscale structures on their surface to create a hierarchical structure. The structures result in an increased Leidenfrost temperature.

Owner:MASSACHUSETTS INST OF TECH

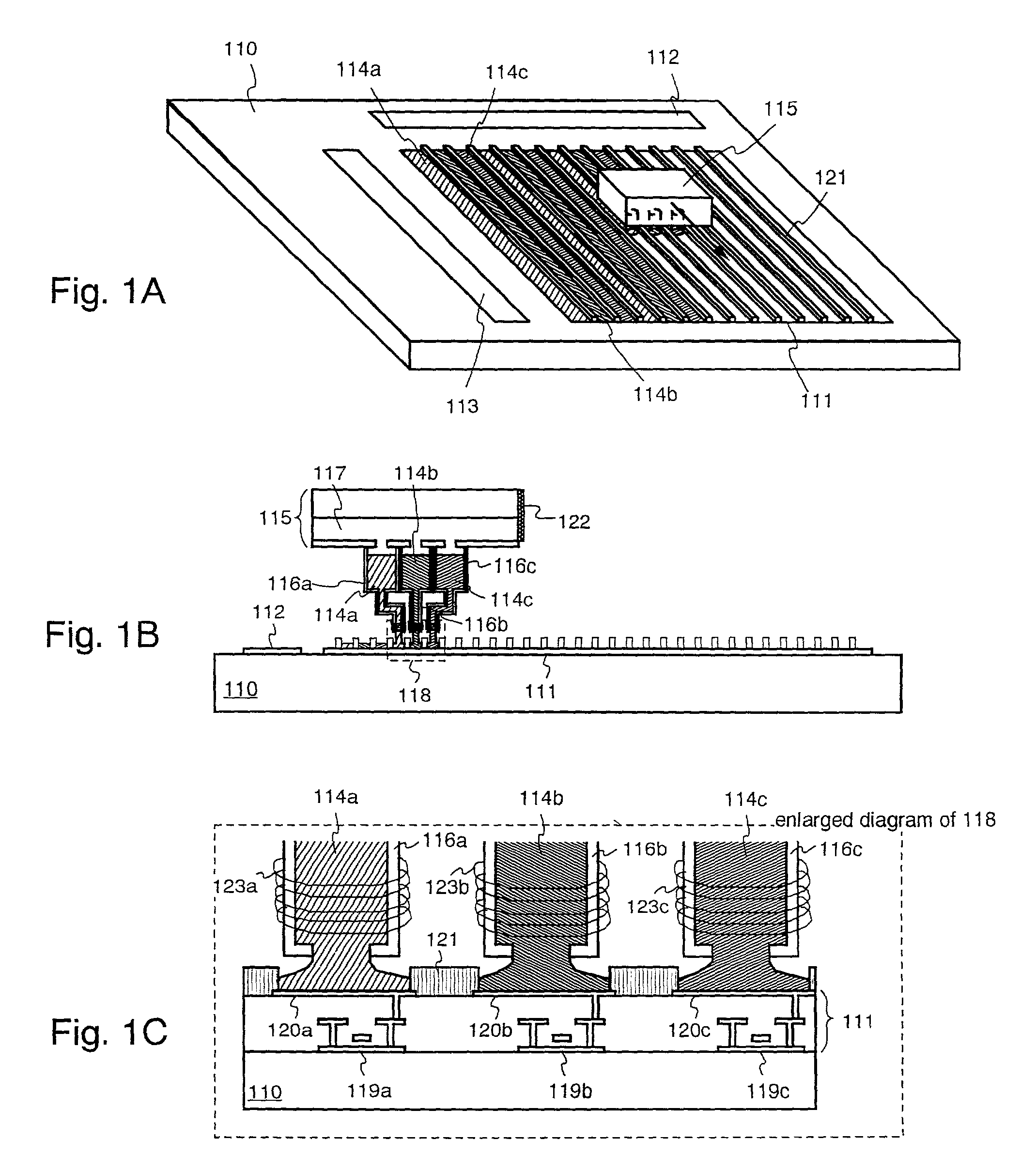

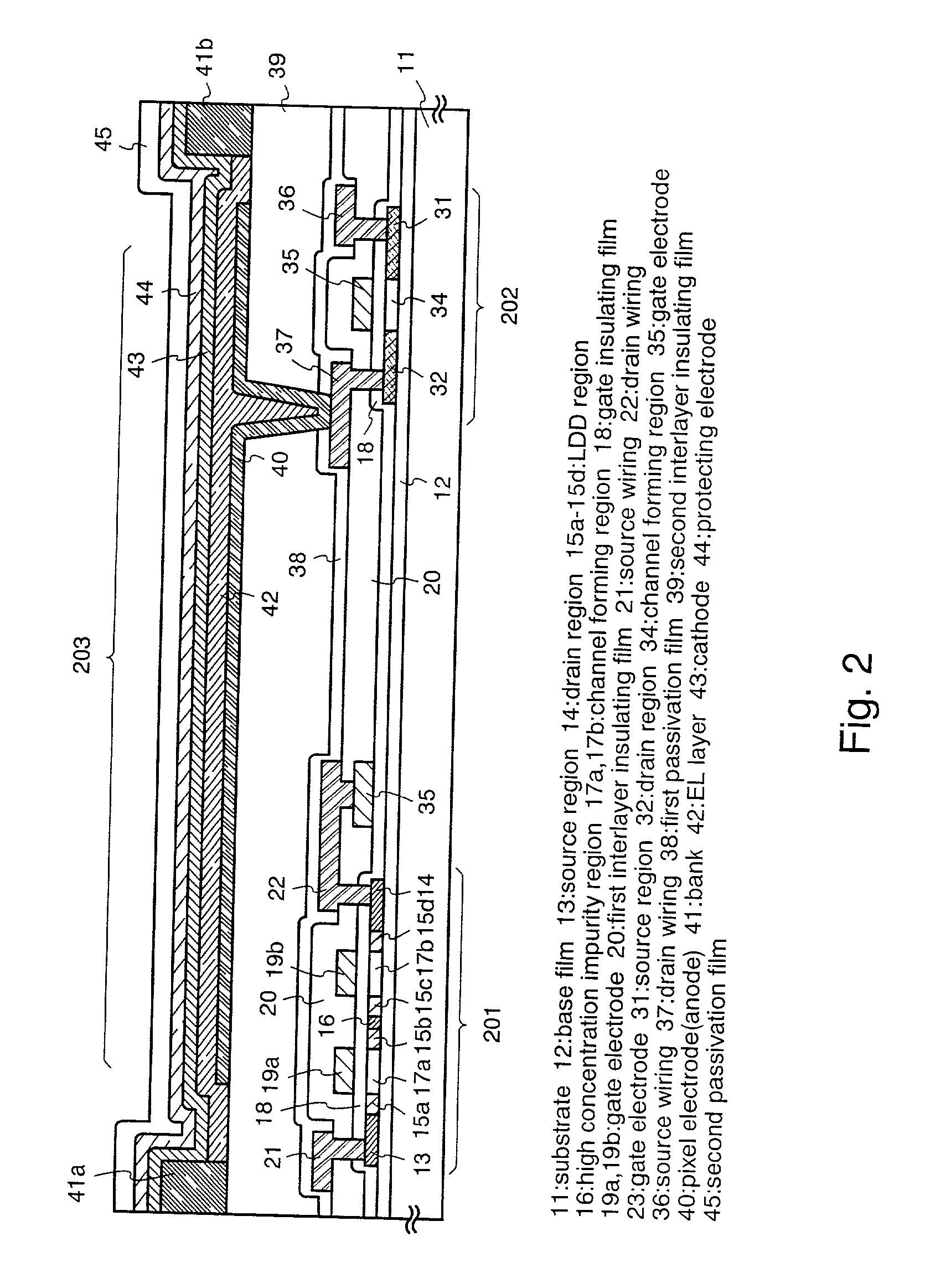

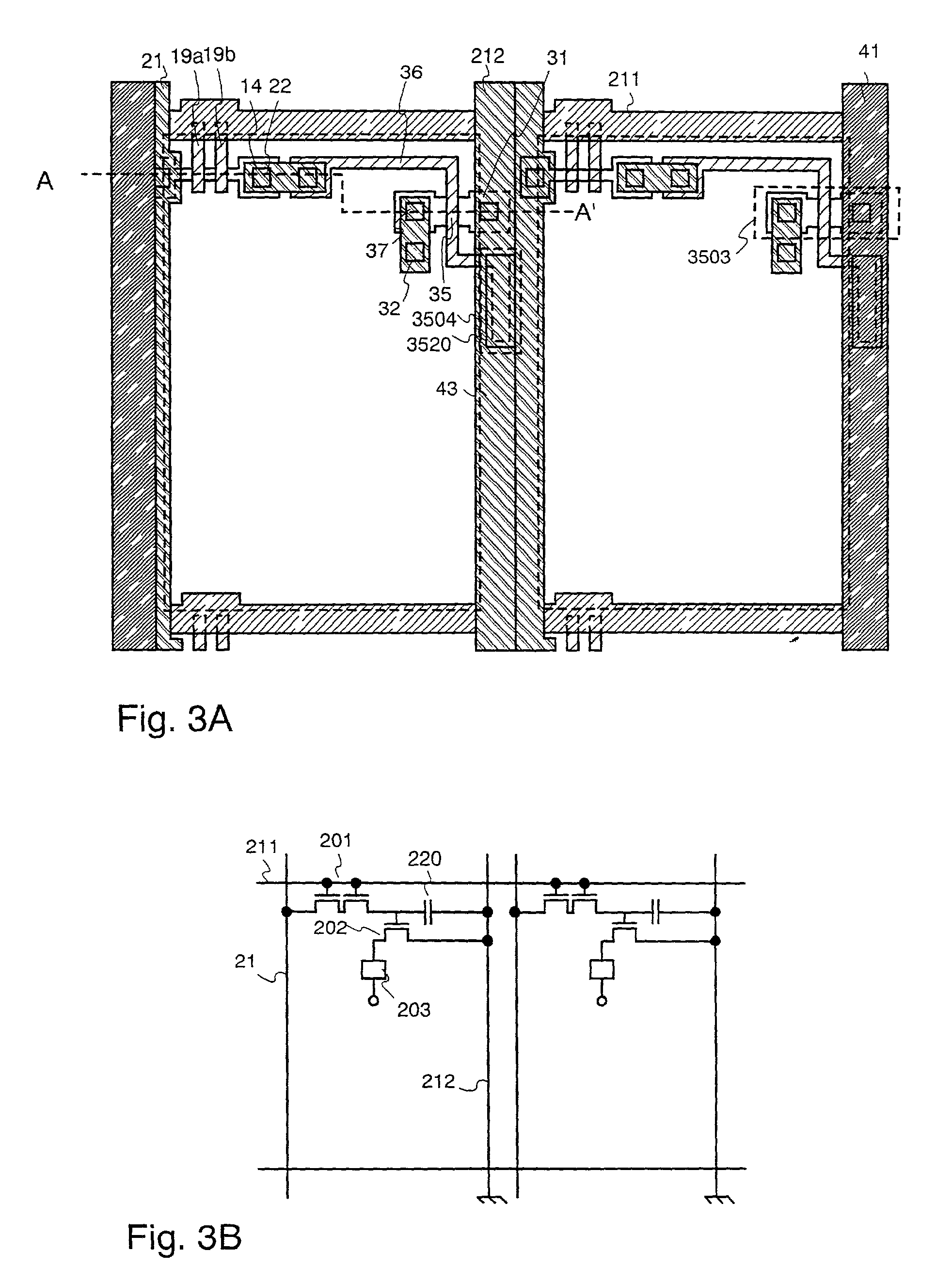

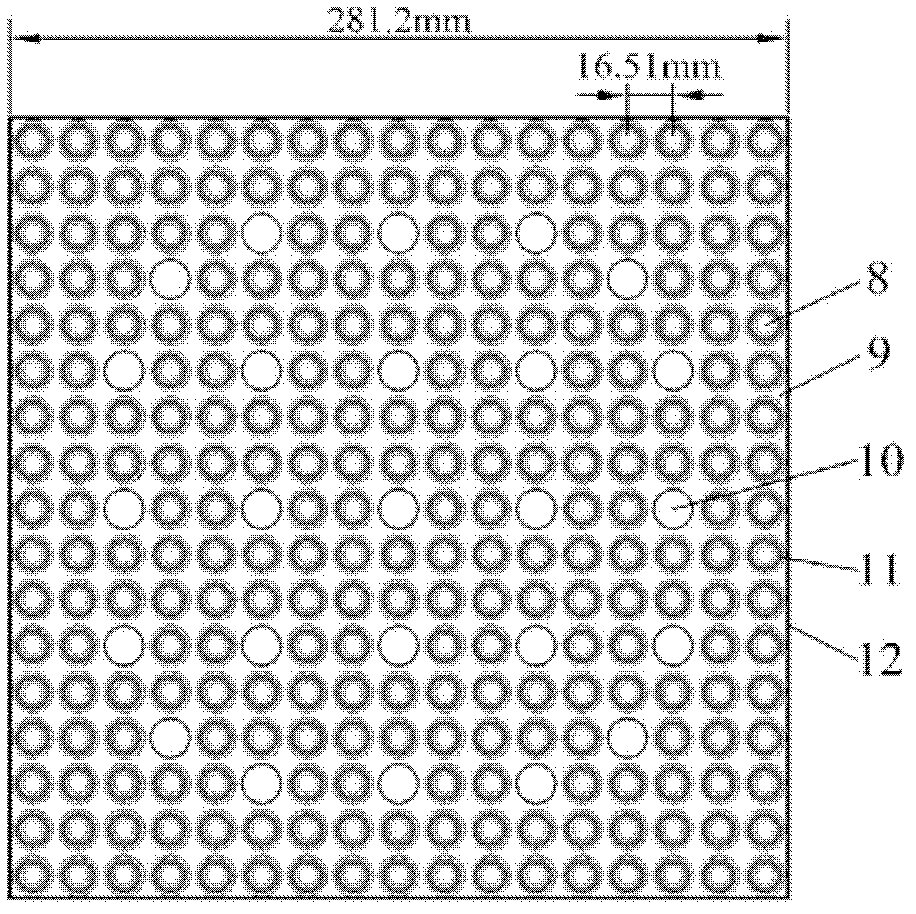

Thin film formation apparatus and method of manufacturing self-light-emitting device using thin film formation apparatus

InactiveUS20010023661A1Solve the real problemLarge diameterFuel elementsSolid-state devicesEngineeringLight emitting device

A means of effectively applying an organic EL material application liquid with good application liquid cut-off is provided. A heater and an ultrasonic oscillator are formed in a thin film formation apparatus when applying the application liquid, and heat and ultrasonic oscillations are imparted to the application liquid. Defective application liquid cut-off and liquid clogging can thus be resolved.

Owner:SEMICON ENERGY LAB CO LTD

Niobium-containing zirconium alloy for nuclear fuel claddings

InactiveUS6261516B1Improve corrosion resistanceIncrease resistanceOptical rangefindersFuel elementsNiobiumManganese

The invention presented herein relates to a niobium-containing zirconium alloy for use in nuclear fuel cladding. The Zr alloy of this invention with superior corrosion resistance is characterized as comprising an alloy composition as follows:1) niobium (Nb), in a range of 0.8 to 1.2 wt. %; one or more elements selected from the group consisting of iron (Fe), molybdenum (Mo), copper (Cu) and manganese (Mn), in a range of 0.1 to 0.3 wt. %, respectively; oxygen (O), in a range of 600 to 1400 ppm; silicon (Si), in a range of 80 to 120 ppm; and the balance being of Zr,2) Nb, in a range of 1.3 to 1.8 wt. %; tin (Sn), in a range of 0.2 to 0.5 wt. %; one element selected from the group consisting of Fe, Mo, Cu and Mn, in a range of 0.1 to 0.3 wt. %; O, in a range of 600 to 1400 ppm; Si, in a range of 80 to 120 ppm; and the balance being of Zr,3) Nb, in a range of 1.3 to 1.8 wt. %; Sn, in a range of 0.2 to 0.5 wt. %; Fe, in a range of 0.1 to 0.3 wt. %; one element selected from the group consisting of chromium (Cr), Mo, Cu and Mn, in a range of 0.1 to 0.3 wt. %; O, in a range of 600 to 1400 ppm; Si, in a range of 80 to 120 ppm; and the balance being of Zr, and4) Nb, in a range of 0.3 to 1.2 wt. %; Sn, in a range of 0.4 to 1.2 wt. %; Fe, in a range of 0.1 to 0.5 wt. %; one element selected from the group consisting of Mo, Cu and Mn, in a range of 0.1 to 0.3 wt. %; O, in a range of 600 to 1400 ppm; Si, in a range of 80 to 120 ppm; and the balance being of Zr.

Owner:KOREA HYDRO & NUCLEAR POWER CO LTD +1

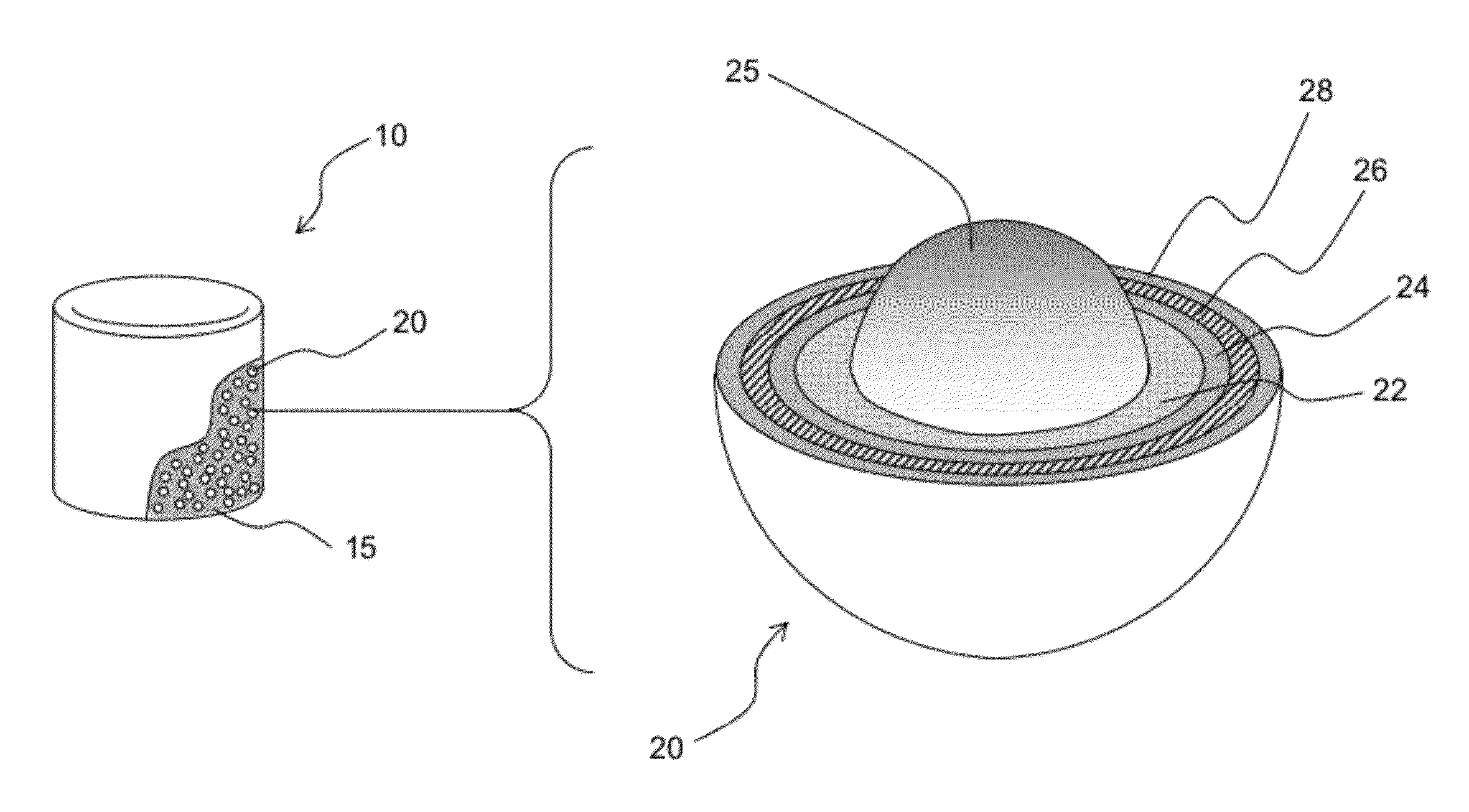

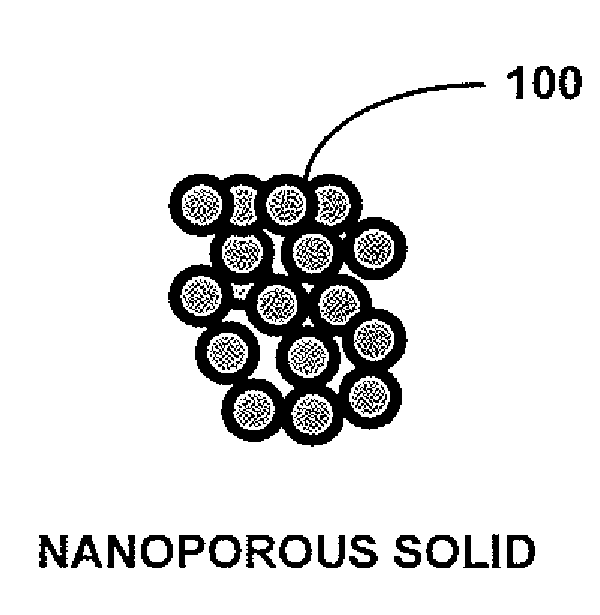

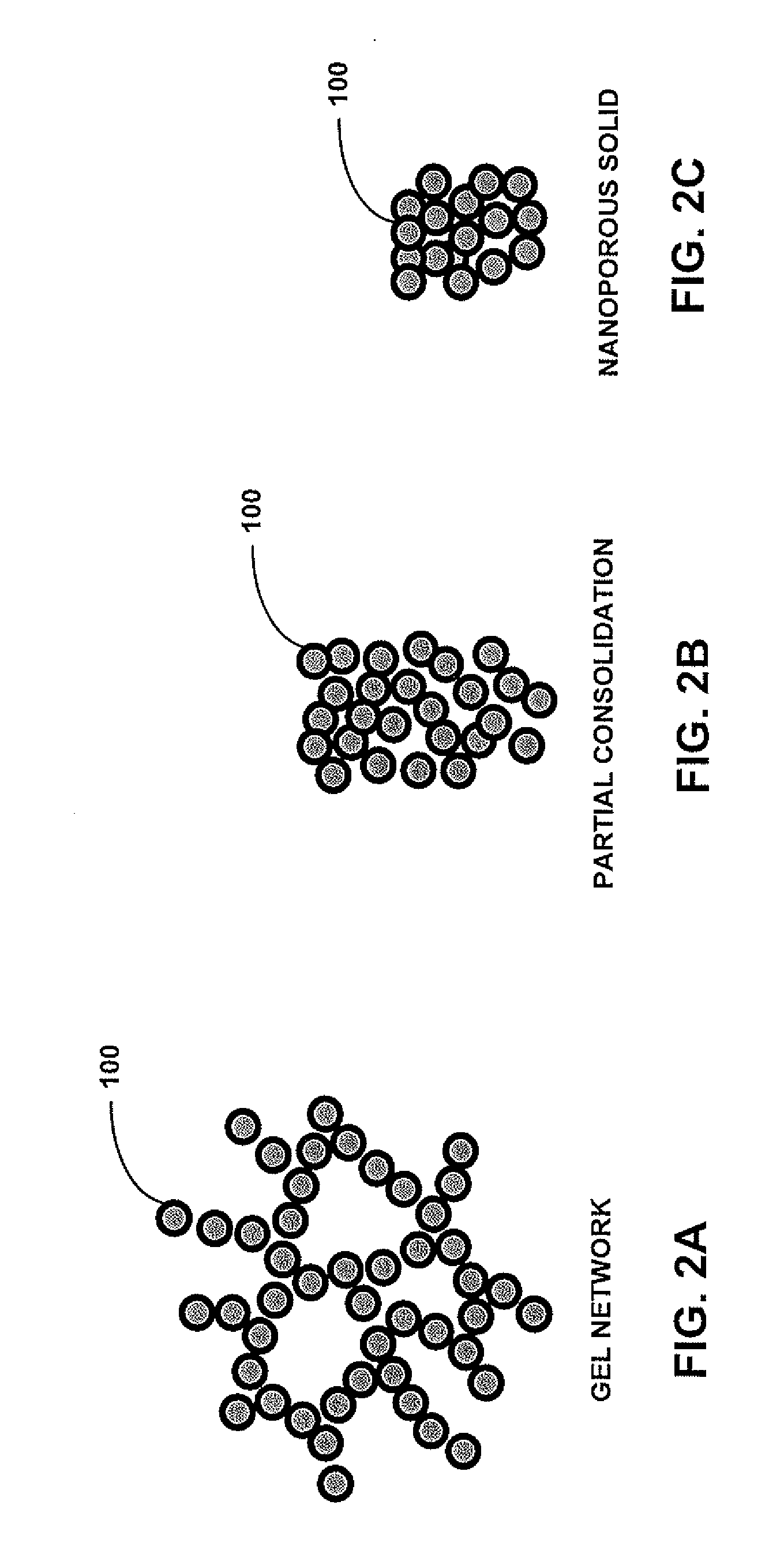

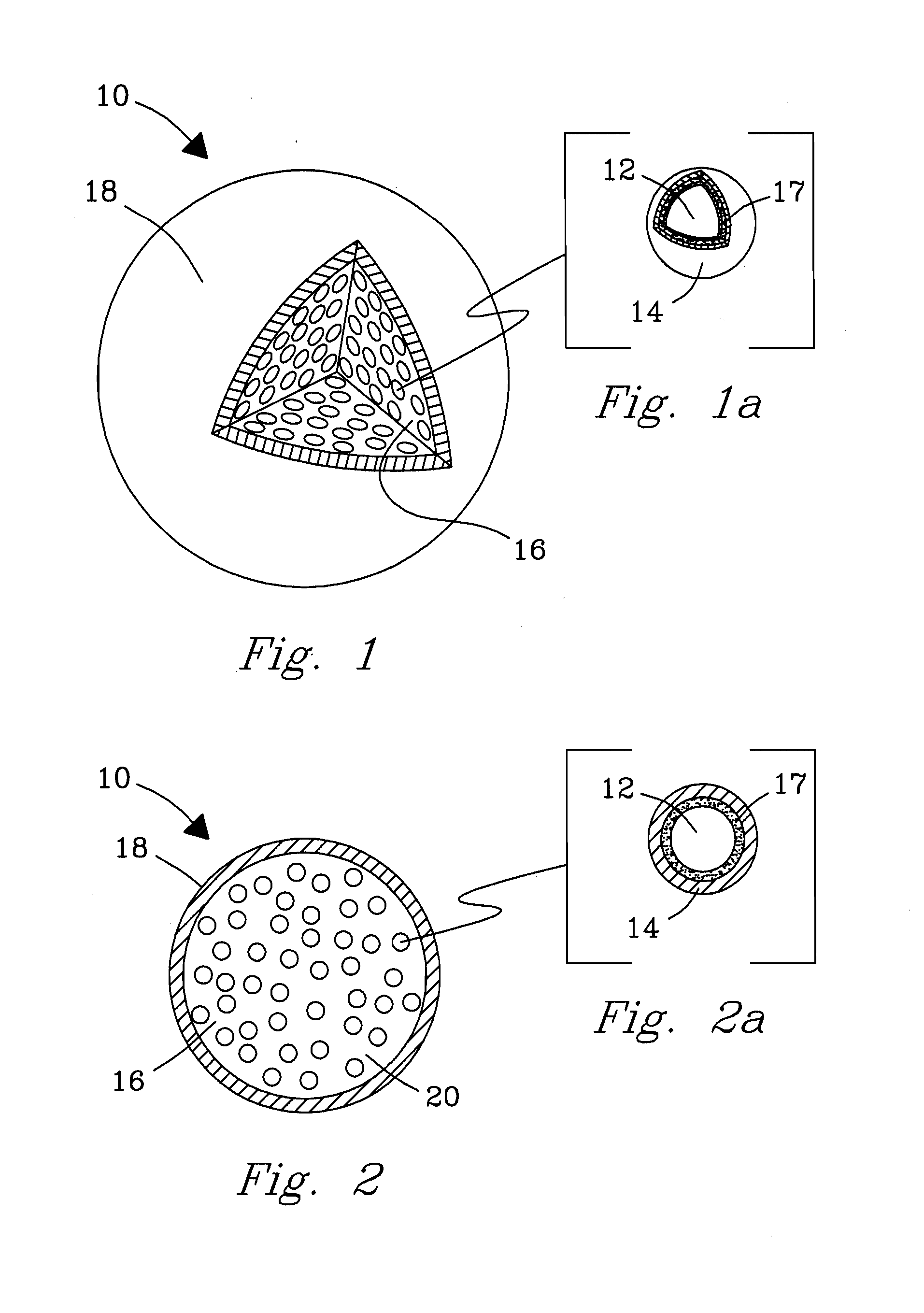

Fully ceramic nuclear fuel and related methods

Various embodiments of a nuclear fuel for use in various types of nuclear reactors and / or waste disposal systems are disclosed. One exemplary embodiment of a nuclear fuel may include a fuel element having a plurality of tristructural-isotropic fuel particles embedded in a silicon carbide matrix. An exemplary method of manufacturing a nuclear fuel is also disclosed. The method may include providing a plurality of tristructural-isotropic fuel particles, mixing the plurality of tristructural-isotropic fuel particles with silicon carbide powder to form a precursor mixture, and compacting the precursor mixture at a predetermined pressure and temperature.

Owner:UT BATTELLE LLC +1

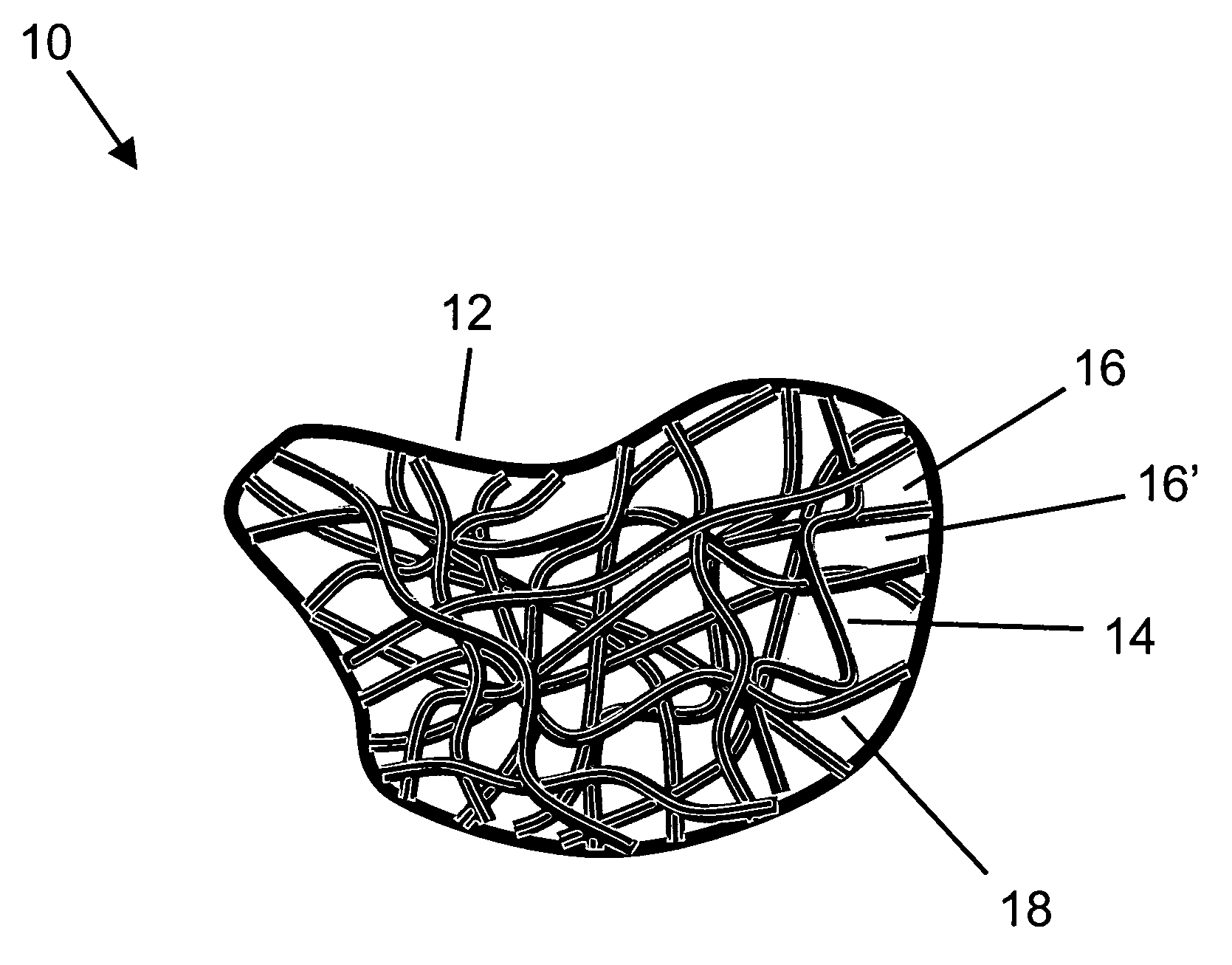

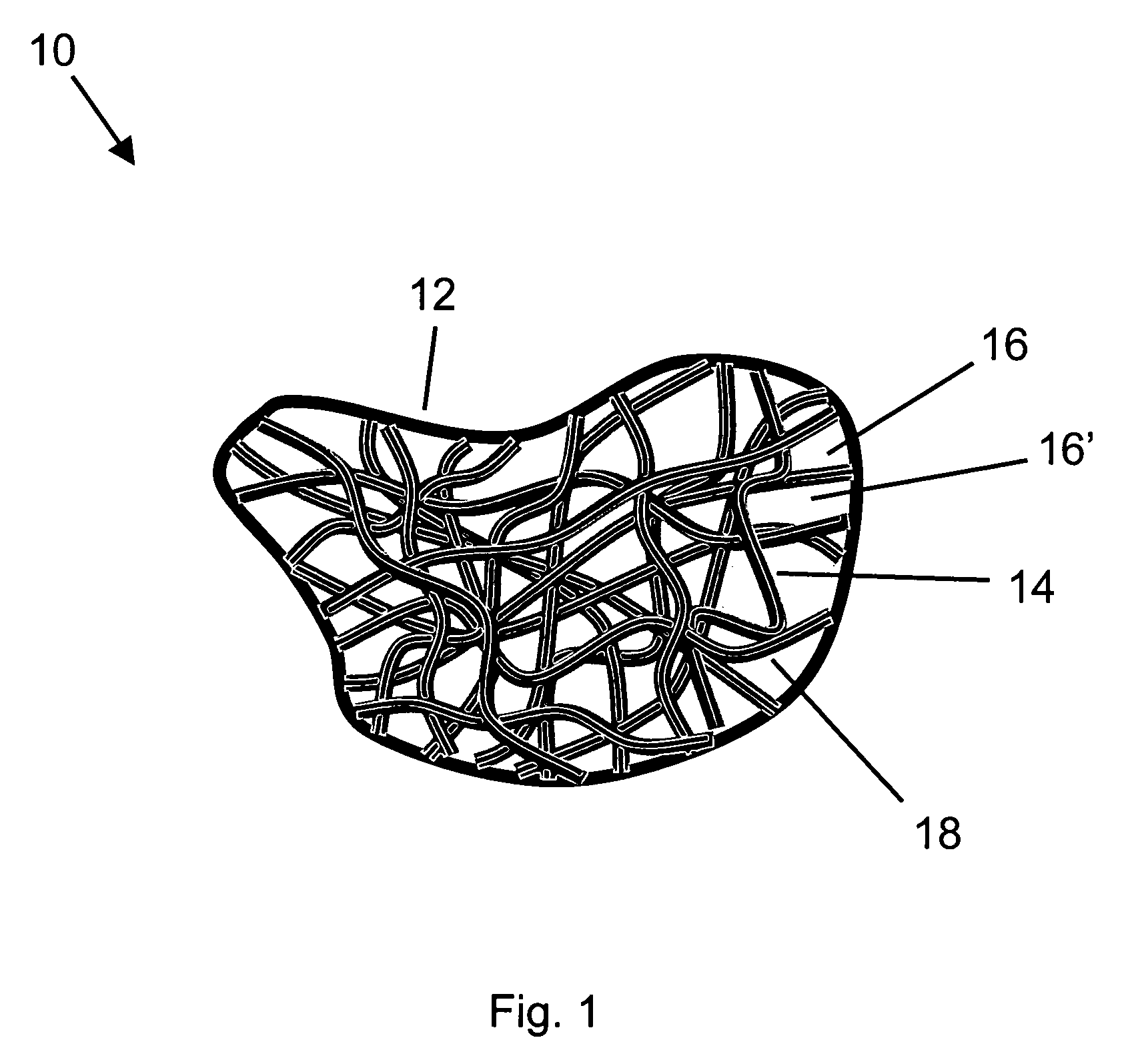

Swelling-resistant nuclear fuel

A nuclear fuel according to one embodiment includes an assembly of nuclear fuel particles; and continuous open channels defined between at least some of the nuclear fuel particles, wherein the channels are characterized as allowing fission gasses produced in an interior of the assembly to escape from the interior of the assembly to an exterior thereof without causing significant swelling of the assembly. Additional embodiments, including methods, are also presented.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

High-density, solid solution nuclear fuel and fuel block utilizing same

A nuclear fuel element includes a core formed from a high density solid solution fissile material that is substantially free of carbon and void space. A cladding substantially surrounds the core.

Owner:MICRON TECH INC +1

Molten nuclear fuel salts and related systems and methods

InactiveUS20160189813A1Improve power densityImprove the level ofFuel elementsNuclear energy generationPresent methodChloride

This disclosure describes nuclear fuel salts usable in certain molten salt reactor designs and related systems and methods. Binary, ternary and quaternary chloride fuel salts of uranium, as well as other fissionable elements, are described. In addition, fuel salts of UClxFy are disclosed as well as bromide fuel salts. This disclosure also presents methods and systems for manufacturing such fuel salts, for creating salts that reduce corrosion of the reactor components and for creating fuel salts that are not suitable for weapons applications.

Owner:TERRAPOWER

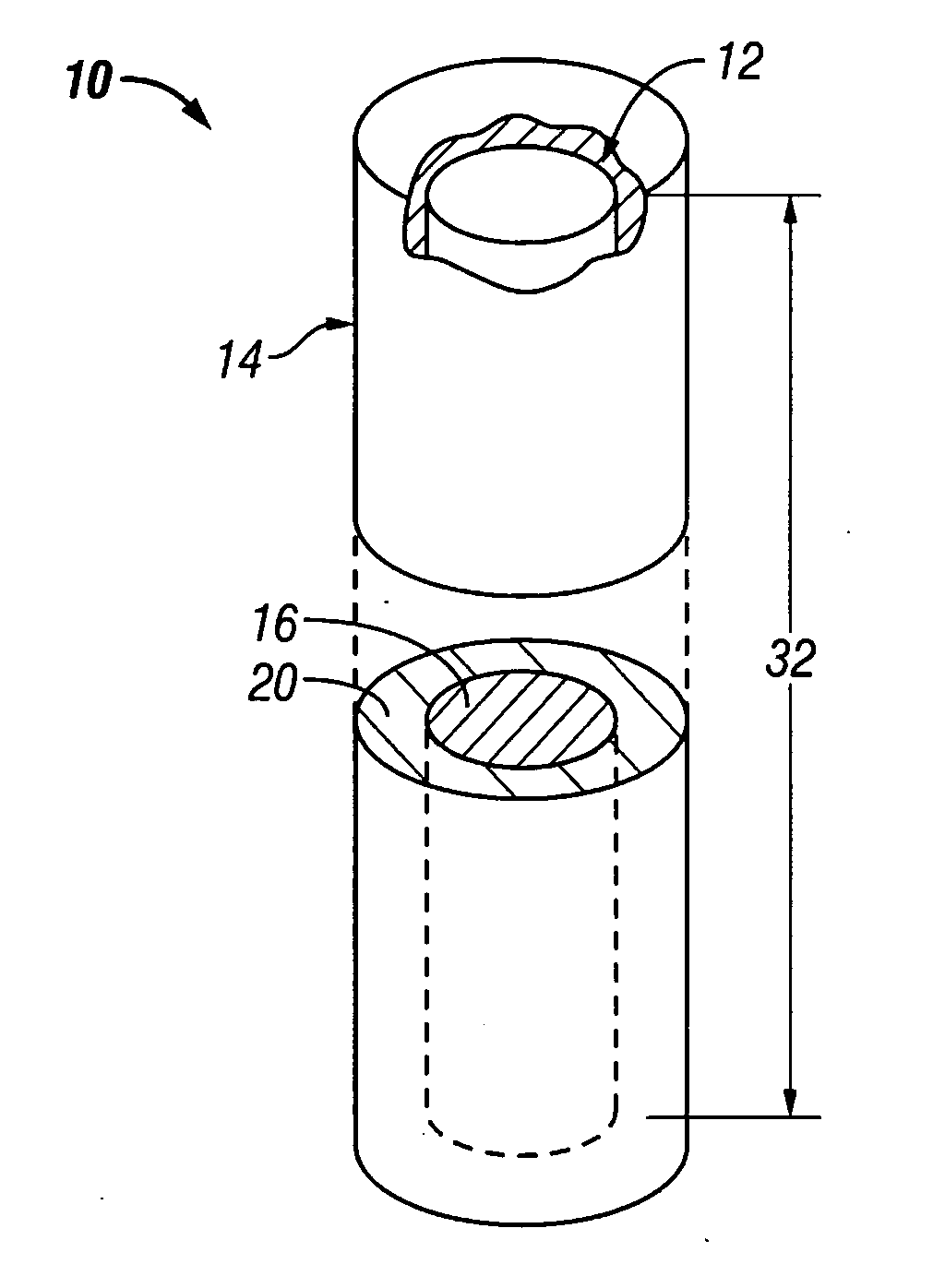

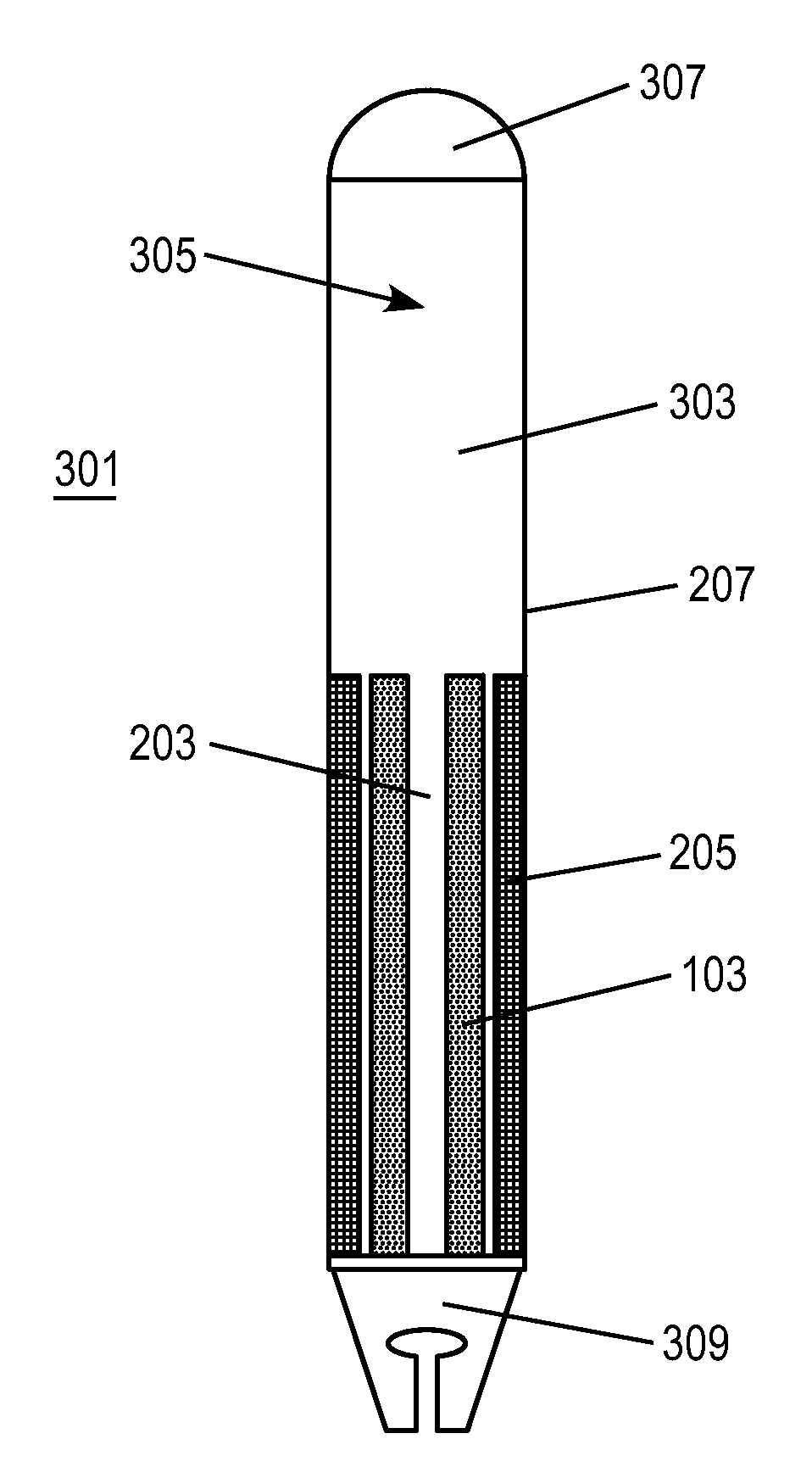

Reactor fuel elements and related methods

Fuel elements for use in reactors include a cladding tube having a longitudinal axis and fuel disposed therein. At least one channel is formed in at least one of the fuel and the cladding tube and extends in a direction along the longitudinal axis of the cladding tube. The fuel element further includes a plenum having at least one getter material disposed therein. Methods of segregating gases in fuel elements may include forming a temperature differential in the fuel element, enabling at least one gas to travel into at least one channel formed in the fuel element, and retaining a portion of the at least one gas with at least one getter material. Methods of segregating gases in fuel elements also may include enabling at least one gas to travel through at least one channel of a plurality of channels formed in the fuel element.

Owner:BATTELLE ENERGY ALLIANCE LLC

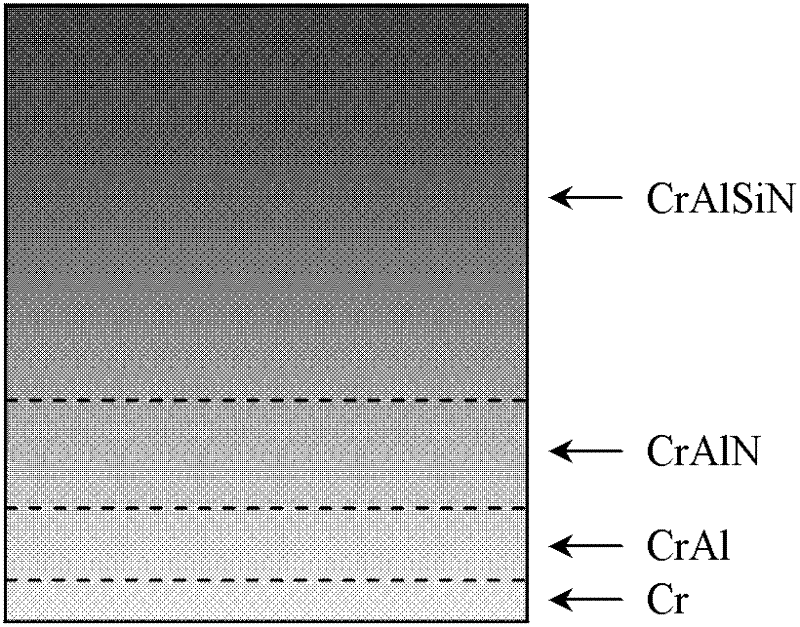

Technology for preparing nuclear fission reactor fuel clad surface CrAlSiN gradient coating

InactiveCN102400099ABeneficial technical effectExcellent resistance to high temperature oxidation and corrosionFuel elementsNuclear energy generationNuclear fissionOxidation resistant

The invention relates to a new technology for depositing a CrAlSiN gradient coating with high-temperature oxidation corrosion resistance and excellent mechanical properties on a supercritical water-cooled reactor fuel clad surface in a nuclear fission reactor. The CrAlSiN gradient coating is deposited on the surface of a base material by adopting a multi-target reaction magnetron sputtering method, and the technology comprises the following four continuous stages of: 1, preparing a Cr gradient coating; 2, preparing a CrAl gradient coating; 3, preparing a CrAlN gradient coating; and preparing the CrAlSiN gradient coating, and annealing. By reasonably designing the gradient variable microstructure of each element, the anti-oxidation temperature of the coating reaches 950 DEG C, the hardnessof the coating reaches over 37GPa, and the adhesive force of the coating adhered to the base material reaches 34N; the coating also has excellent thermal shock resistance, abrasion resistance and thelike; and the service property of the supercritical water-cooled reactor fuel clad part can be greatly improved, and the service life of the clad part can be greatly prolonged.

Owner:SICHUAN UNIV

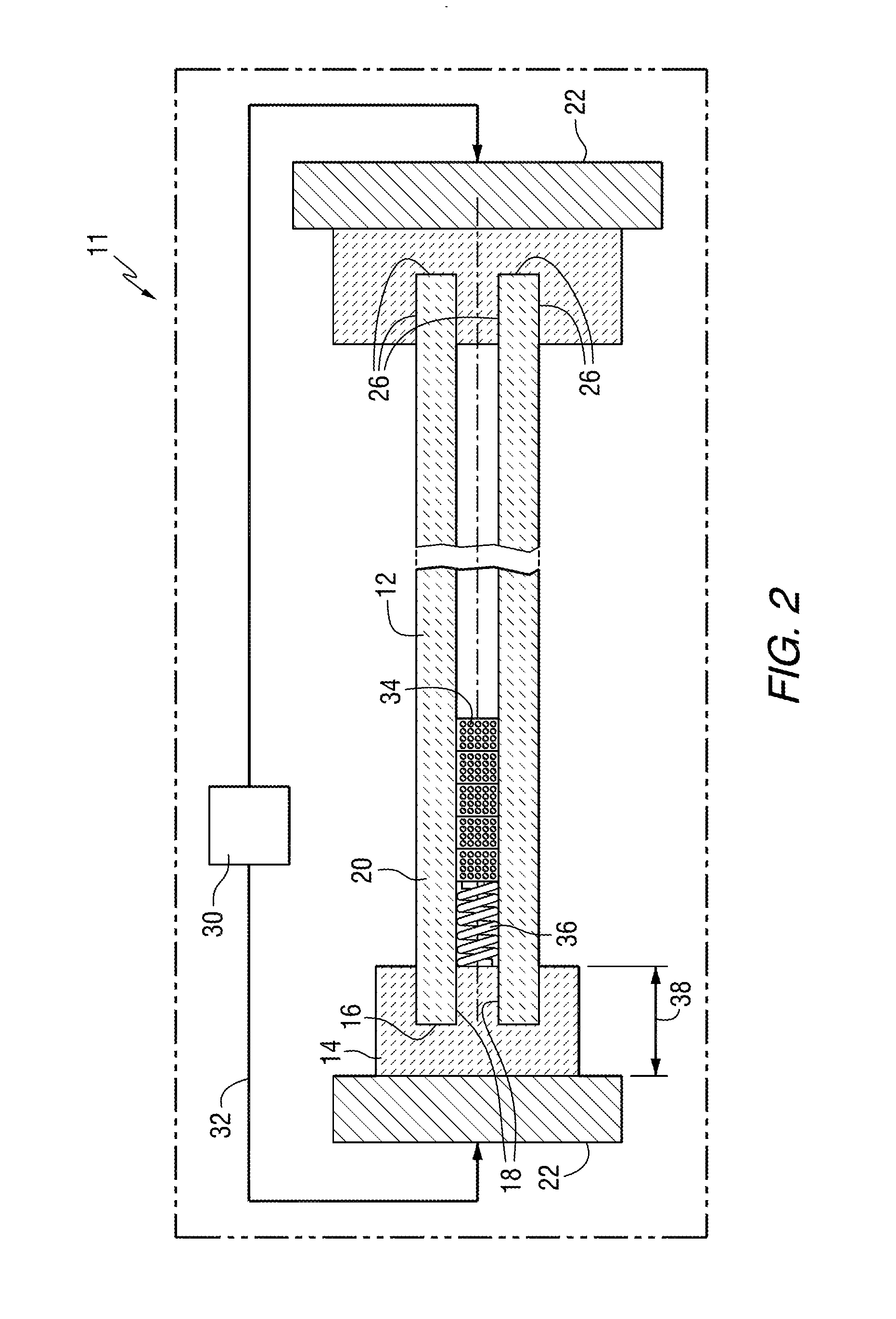

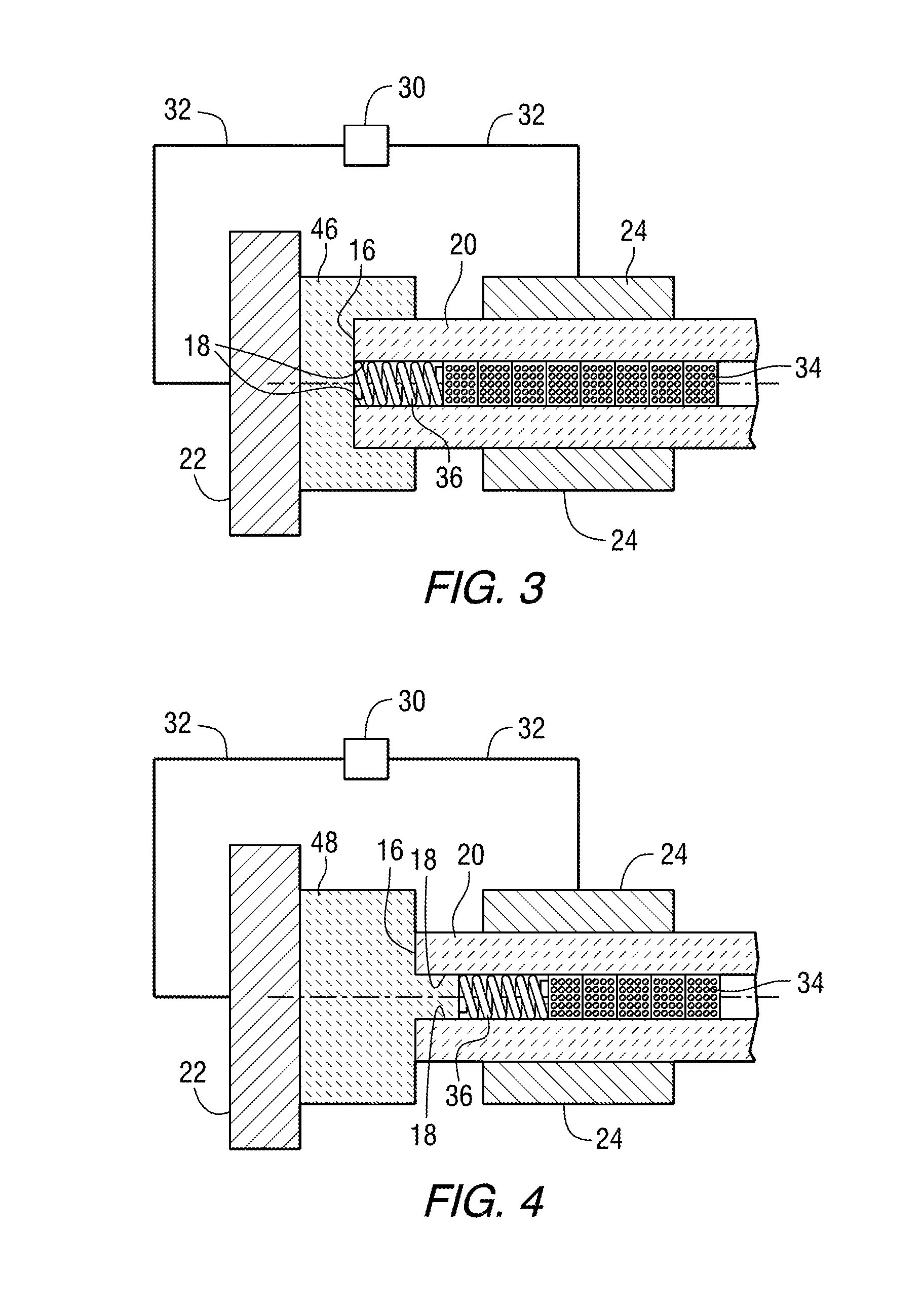

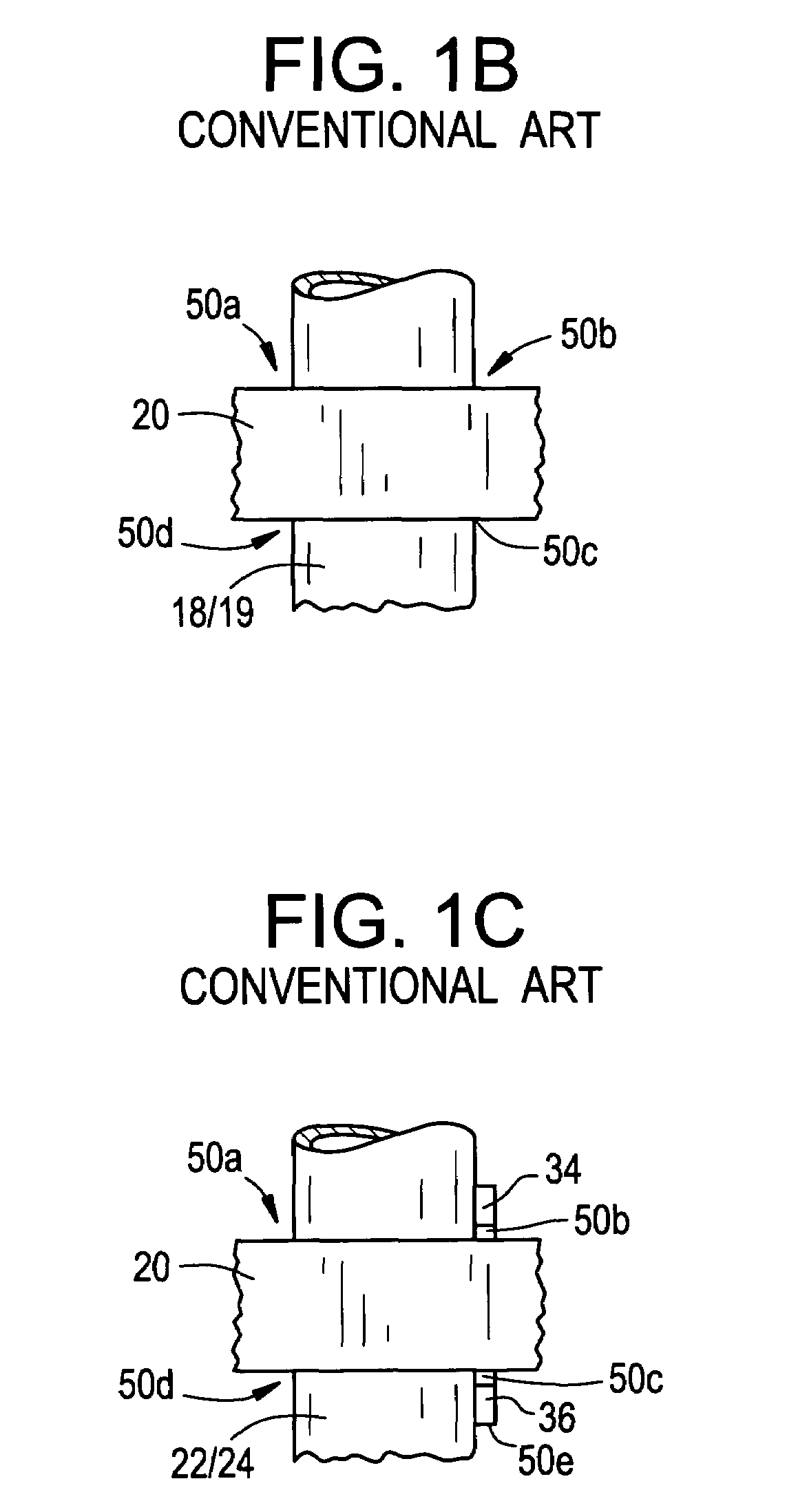

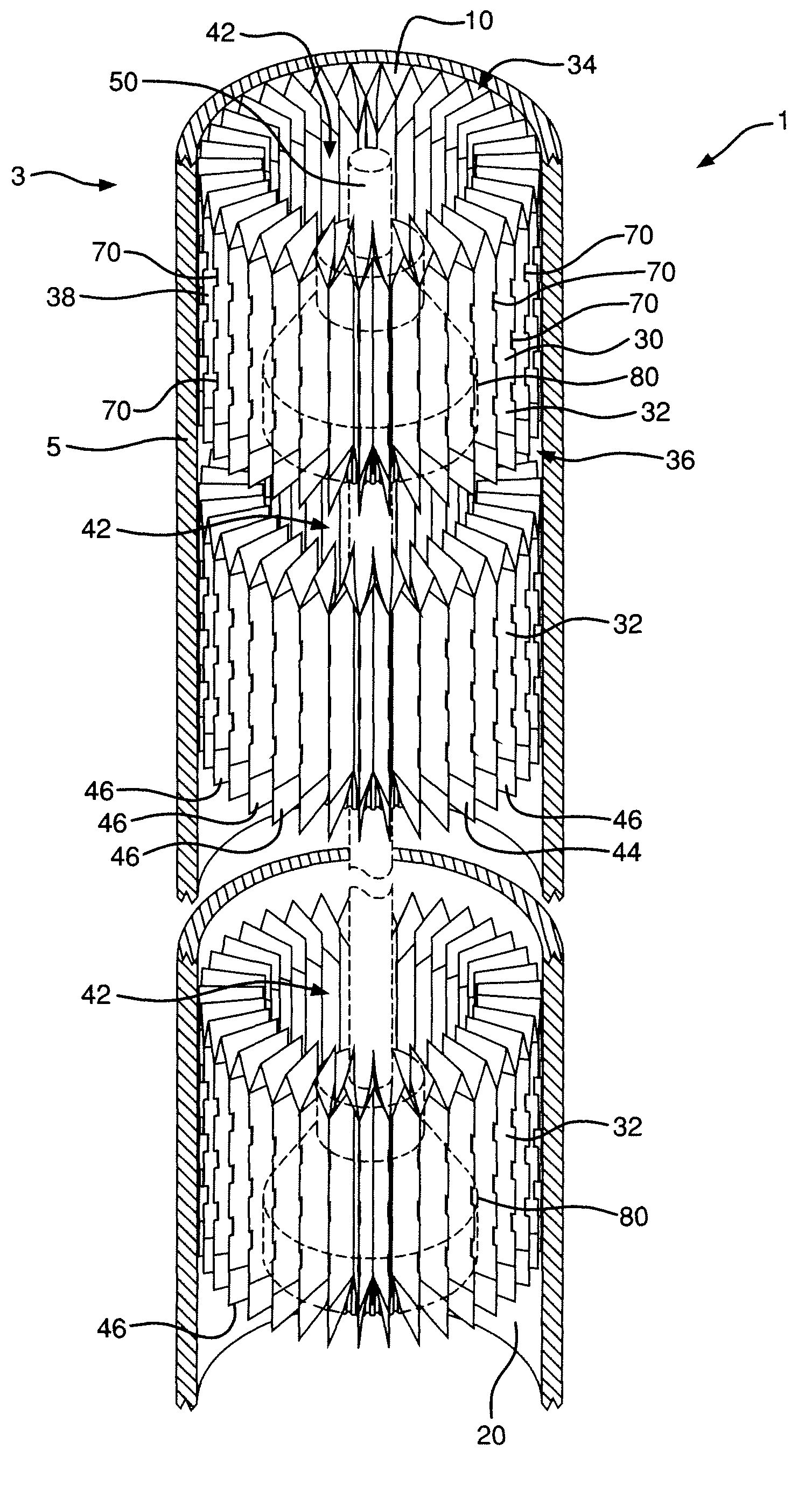

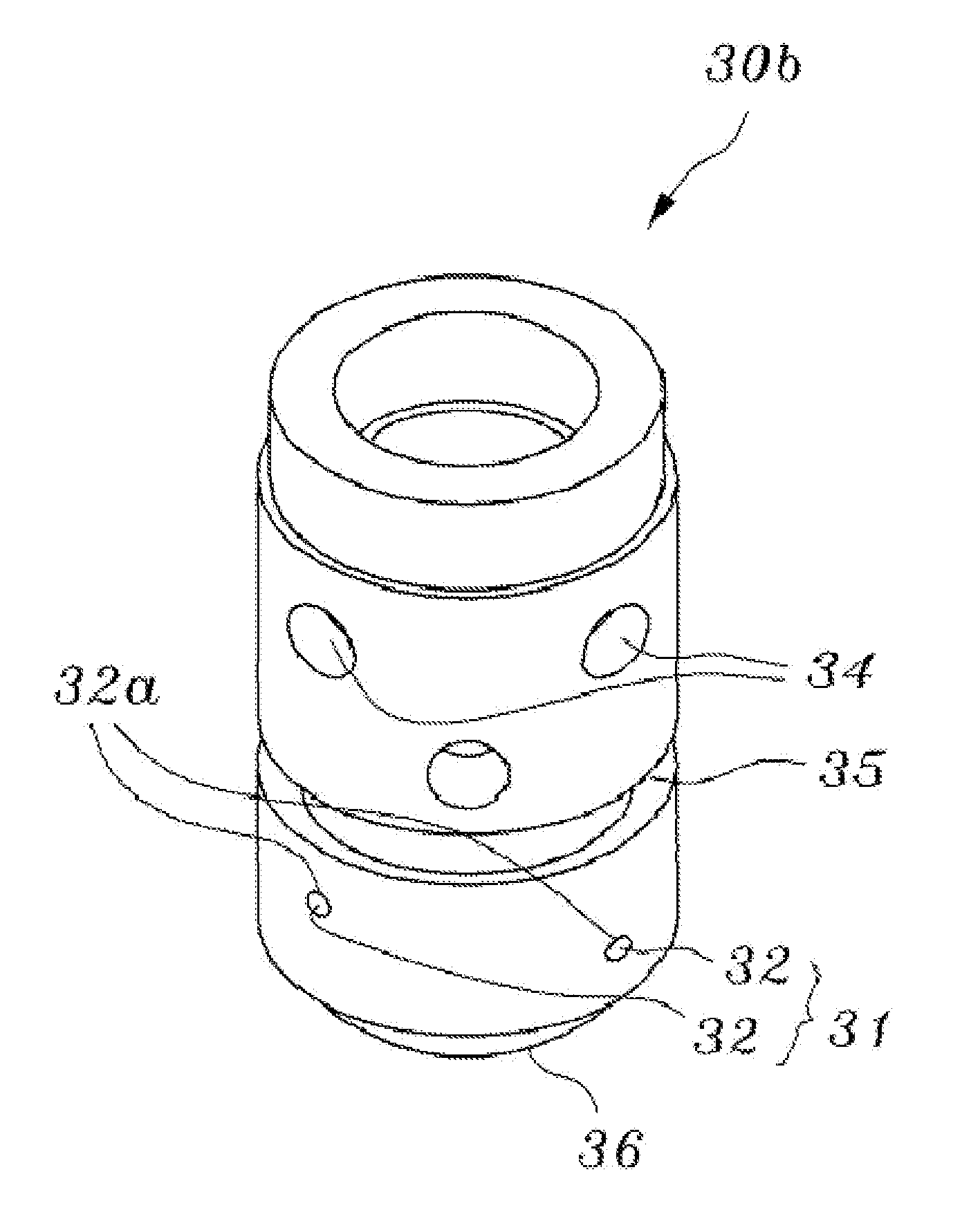

Sic matrix fuel cladding tube with spark plasma sintered end plugs

ActiveUS20150078505A1Increase temperatureResilient to flex and fractureFuel elementsNuclear energy generationCeramic compositeNuclear reactor

A method of providing an end-capped tubular ceramic composite for containing nuclear fuel (34) in a nuclear reactor involves the steps of providing a tubular ceramic composite (40), providing at least one end plug (14, 46, 48), applying (42) the at least one end plug material to the ends of the tubular ceramic composite, applying electrodes to the end plug and tubular ceramic composite and applying current in a plasma sintering means (10, 50) to provide a hermetically sealed tube (52). The invention also provides a sealed tube made by this method.

Owner:WESTINGHOUSE ELECTRIC CORP +1

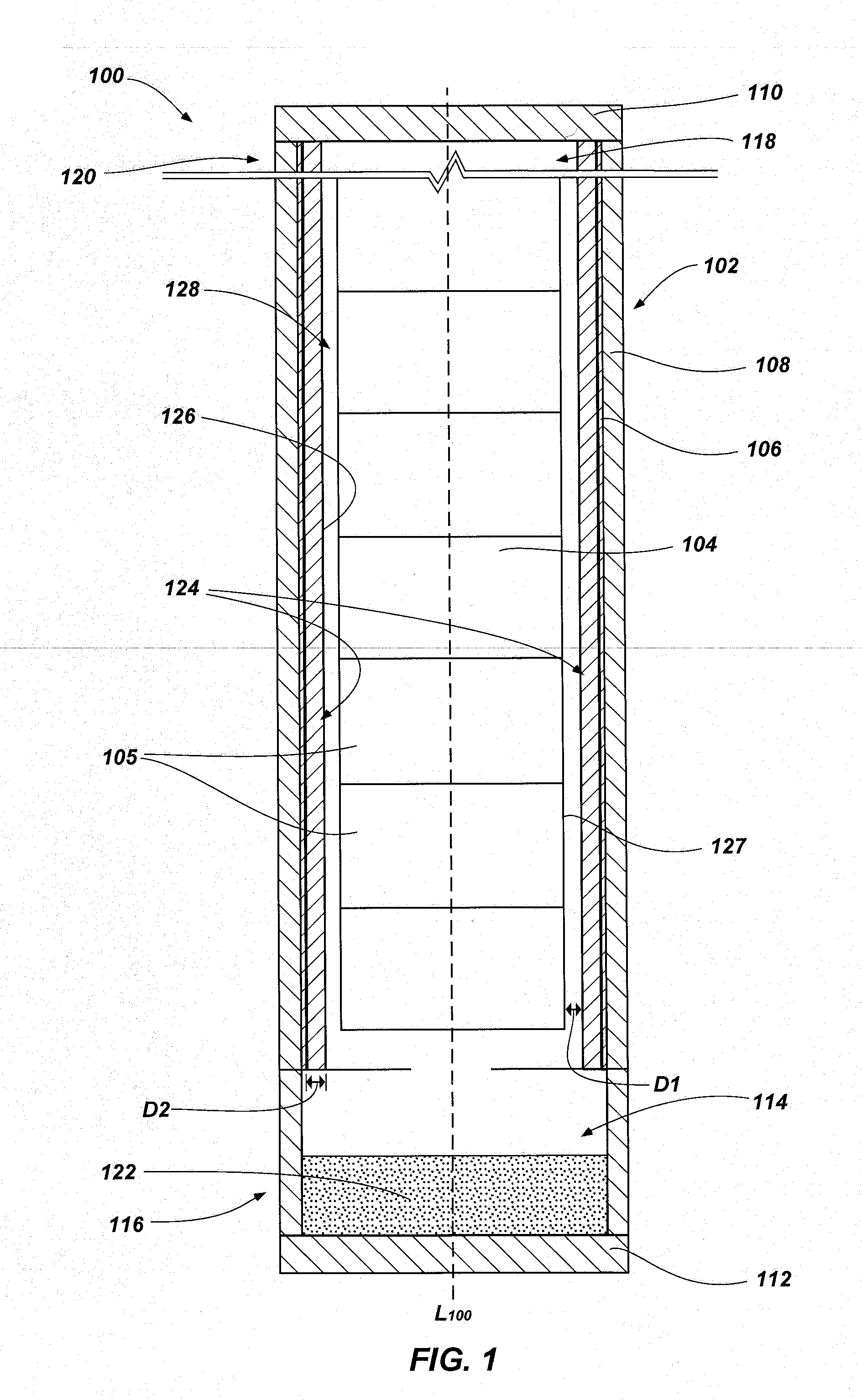

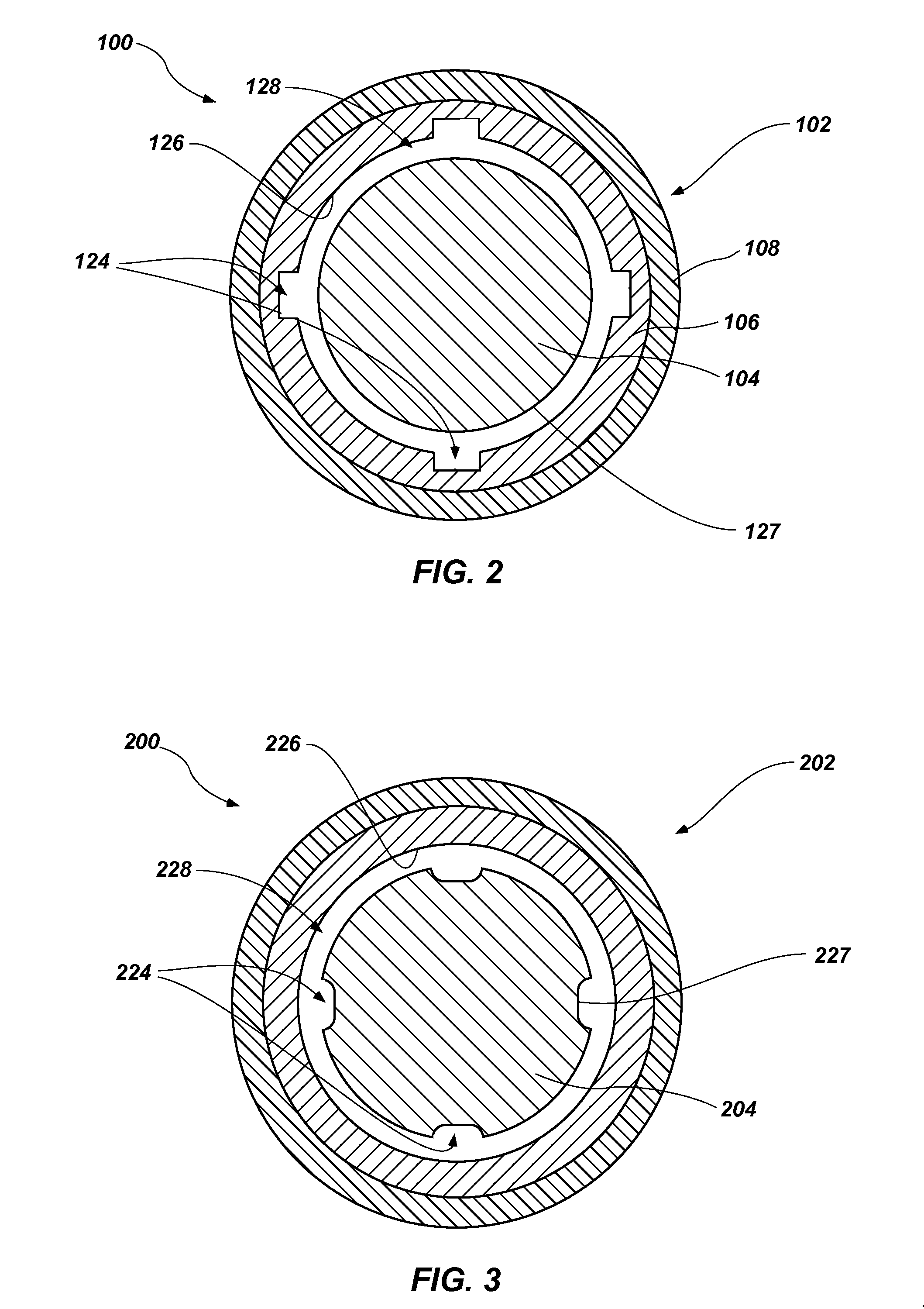

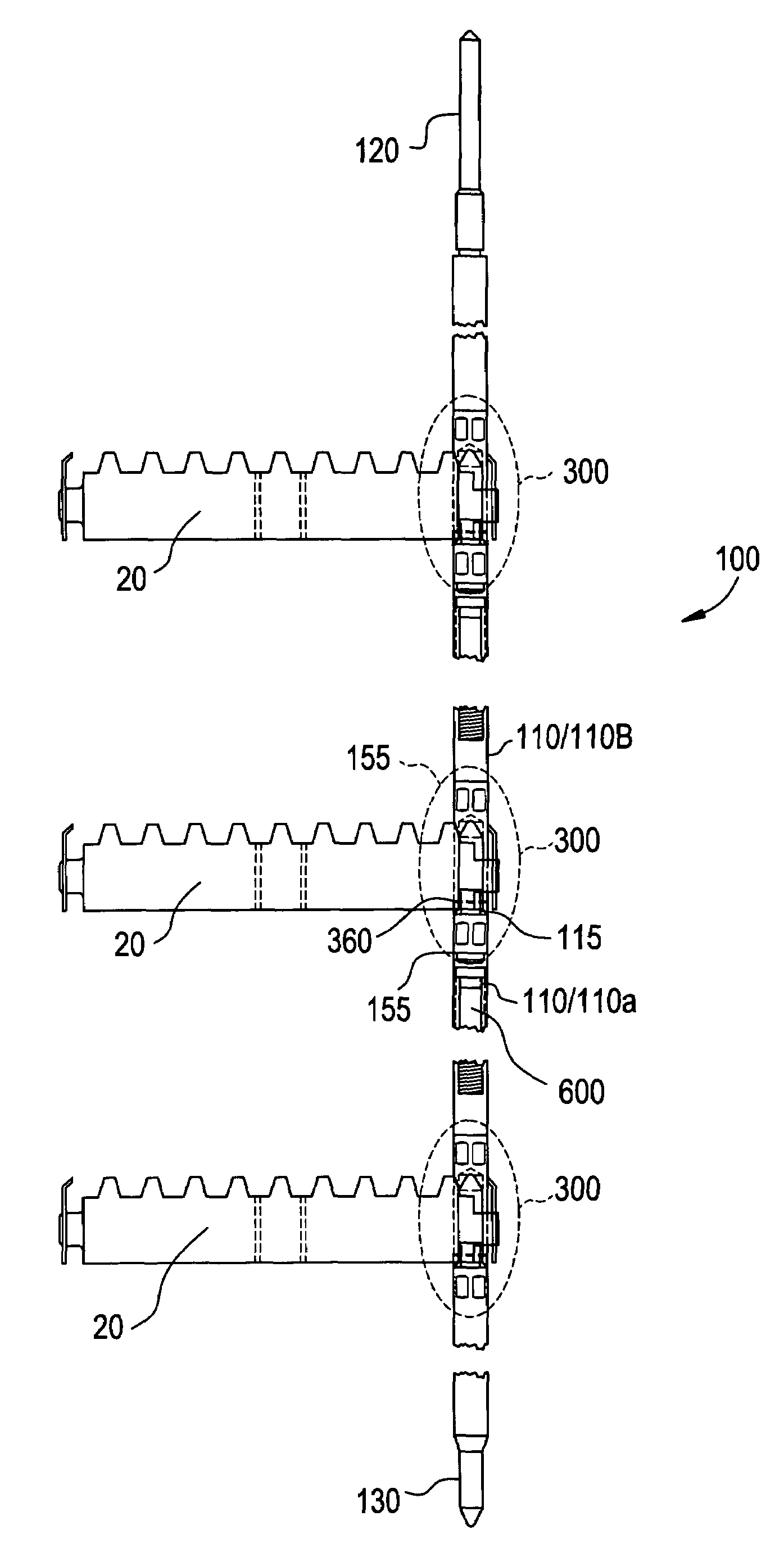

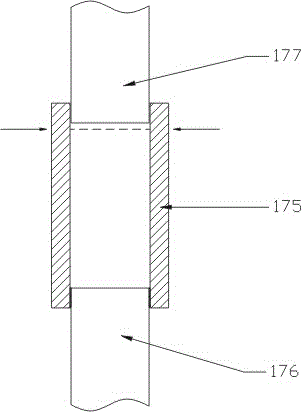

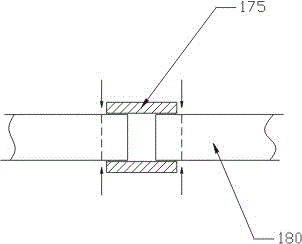

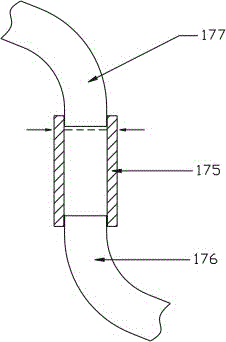

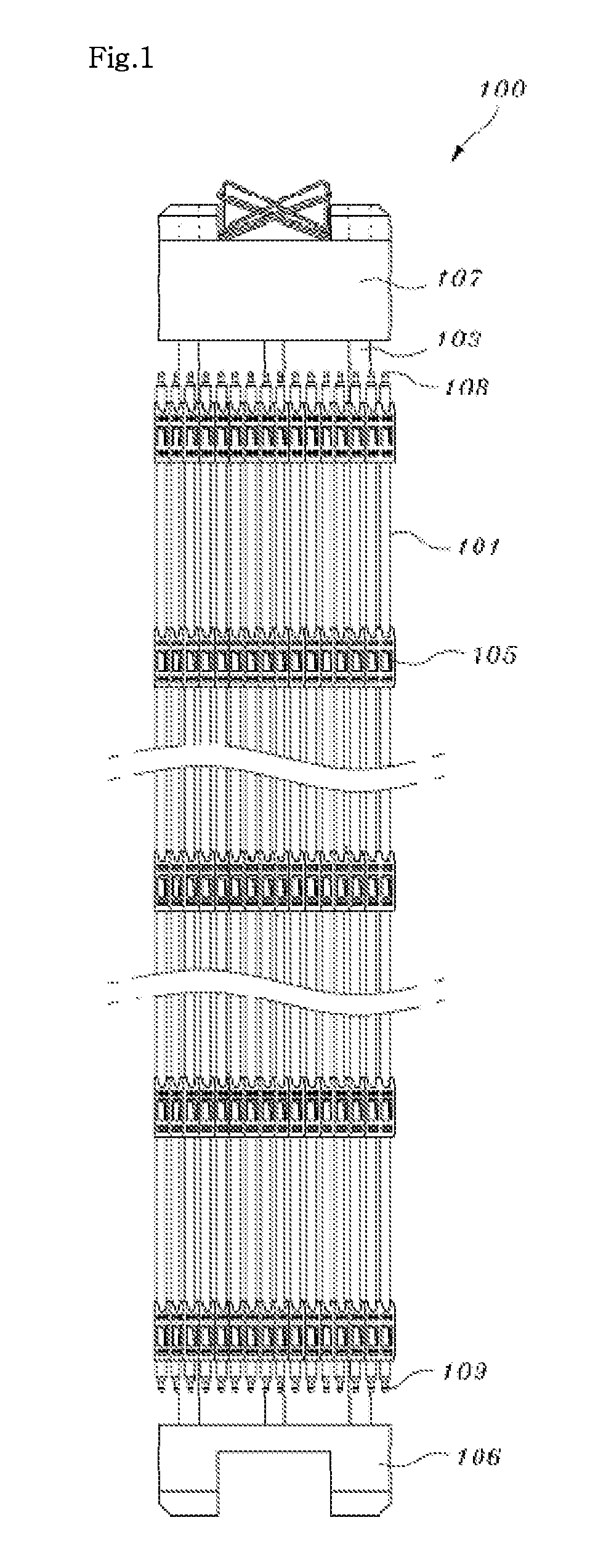

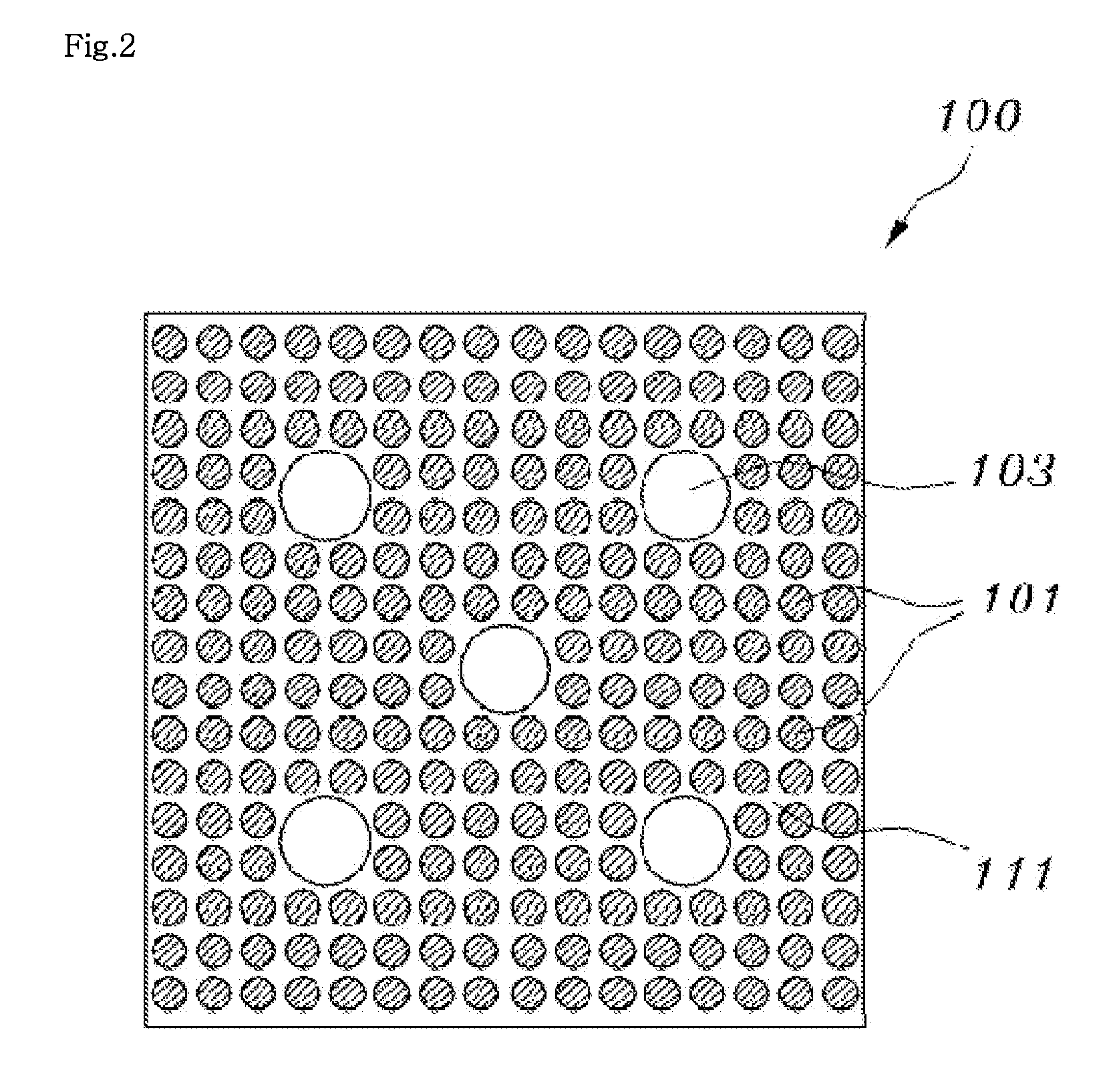

Rod assembly for nuclear reactors

A rod assembly for a fuel bundle of a nuclear reactor may include an upper end piece, lower end piece and a plurality of rod segments attached between the upper and lower end pieces and to each other so as to form an axial length of the rod assembly. The rod assembly may include an adaptor subassembly provided at given connection points for connecting adjacent rod segments or a given rod segment with one of the upper and lower end pieces. The connection points along the axial length of the rod assembly may be located where the rod assembly contacts a spacer in the fuel bundle. One (or more) of the rod segments may include an irradiation target therein for producing a desired isotope when a fuel bundle containing one (or more) rod assemblies is irradiated in a core of the reactor.

Owner:NORDION (CANADA) INC

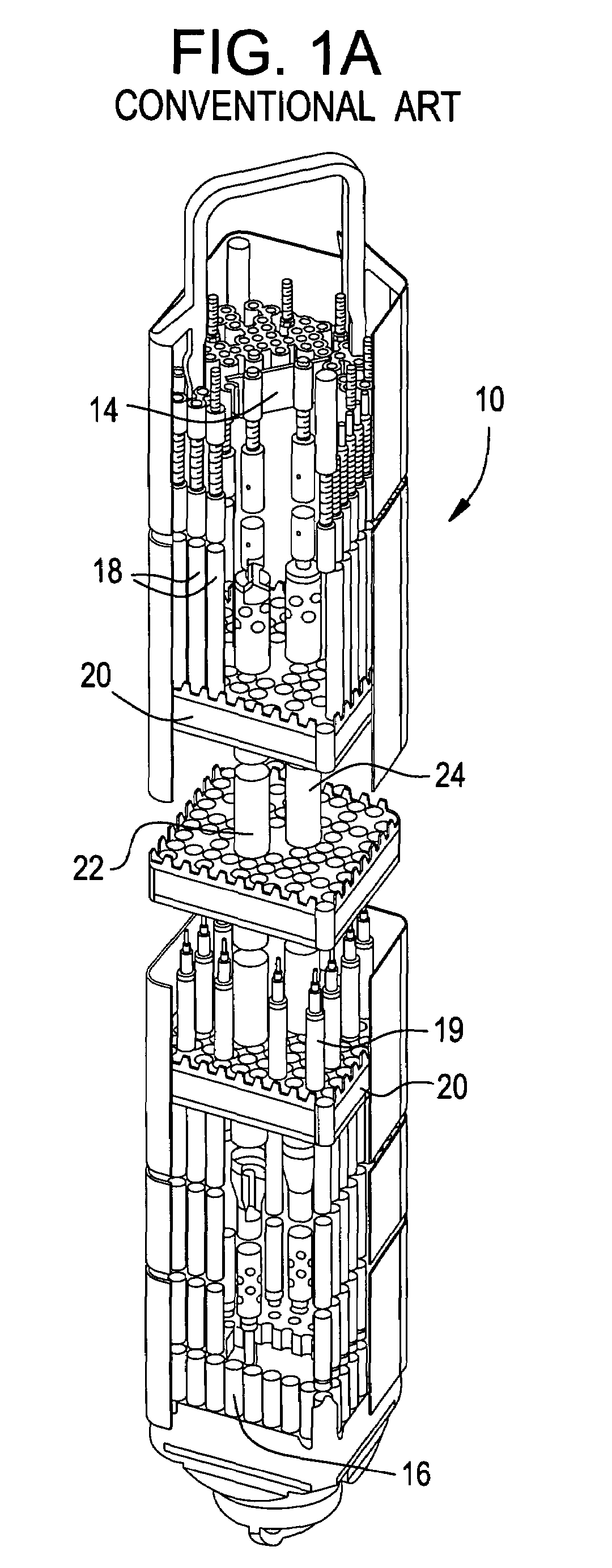

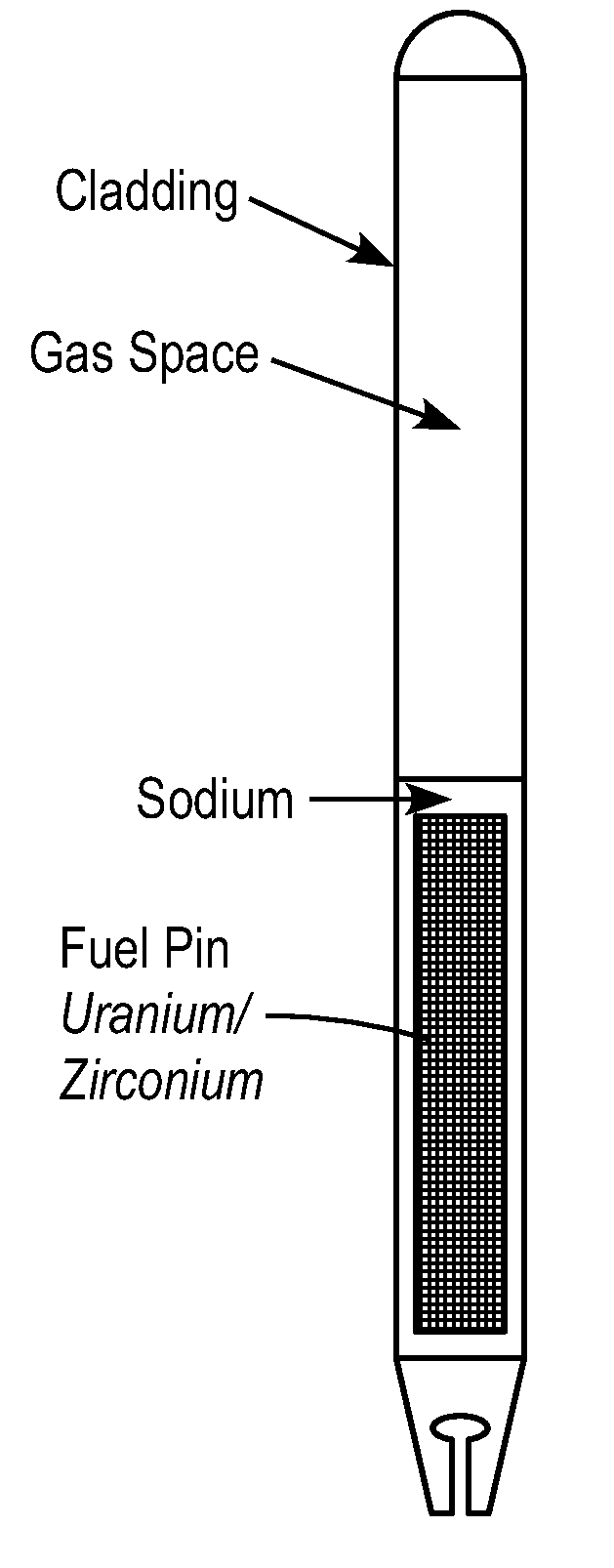

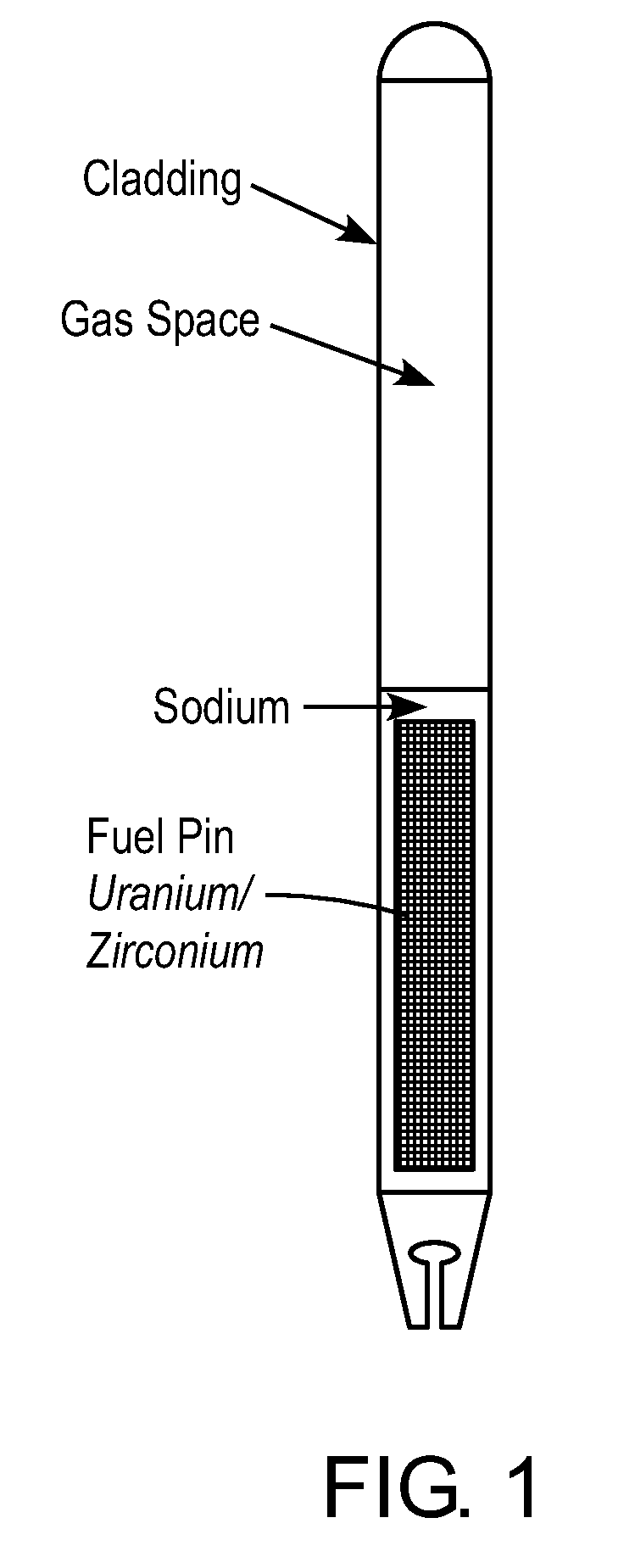

Particulate metal fuels used in power generation, recycling systems, and small modular reactors

ActiveUS20100303193A1Fix fuel costEliminate needNuclear fuel reprocessingFuel elementsNuclear reactor coreNuclear reactor

A metal particulate fuel system is described. The metal fuel system may include particulate metal fuel for use in nuclear reactors. The particulate metal fuel may include a plurality of particles of at least one enriched alloy where the particles are compacted into a fuel column. The metal particulate fuel system may also include a cladding and / or a gas-filled plenum.

Owner:ADVANCED REACTOR CONCEPTS

Fast reactor type coupling nuclear reaction implementation method and nuclear reactor for same

InactiveCN105023621AInherently safeReduce engineering difficultyFuel elementsNuclear energy generationNuclear reactor coreInherent safety

The present invention relates to a fast reactor type coupling nuclear reaction implementation method and a nuclear reactor for same. The main contents comprise: a fast reactor type coupling nuclear reaction implementation method, a reactor modular design approach, a fast reactor type coupling nuclear reactor, a reactor core, a fuel element, a nuclear control system, and a proliferation fuel system. The fast reactor type coupling nuclear reactor mainly combusts thorium and nuclear waste, and has inherent security. The reactor main container is composed of a fission pool and a moderating pool that are completely isolated from each other but coupling to each other. A primary coolant is separated from a moderator. A thermal insulation layer is disposed between the fission pool and the moderating pool so that both can perform neutron exchange but heat exchange is blocked. Fast neutrons produced by the fission pool and moderated neutrons reflected by the moderating pool may enable the reactor core to simultaneously perform coupling nuclear reaction of the two types of neutrons. The moderating pool may be provided with the nuclear control system, and ex-core coupling core control may be implemented. The moderating pool is provided with a thorium purification fuel system, and on-line extraction of the purification fuel can be performed, and separation of nuclide is safe and simple, thereby providing a solution to the technical bottleneck of "thorium reactor".

Owner:陈安海

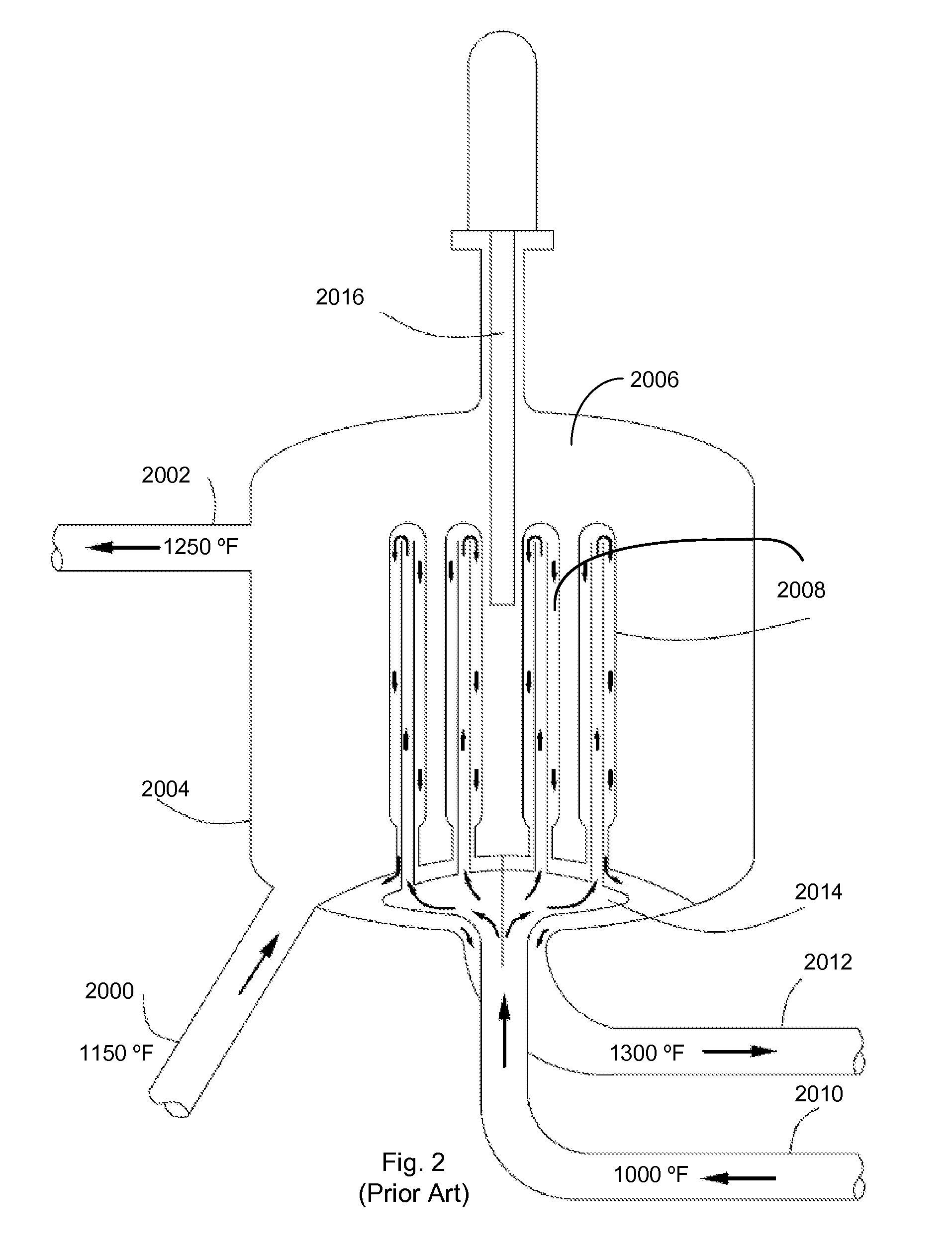

Tubular reactor with expandable insert

A tubular reactor having an insert for improving heat transfer characteristics of the tubular reactor. The insert comprises a catalyst and metal structures consecutively arranged in a lengthwise direction of the tube. The metal structures have radially expandable side walls and orifices for squeezing fluid between the metal structures and the tube wall. The radially expandable side walls form hollows between the radially expandable side walls and the tube wall of the tubular reactor. The radially expandable side walls deform responsive to the fluid pressure difference between the inside of the metal structure and the outer space between the metal structure and the tube wall thereby maintaining the gap between the orifice opening and the tube wall to adjust for tube creep.

Owner:AIR PROD & CHEM INC

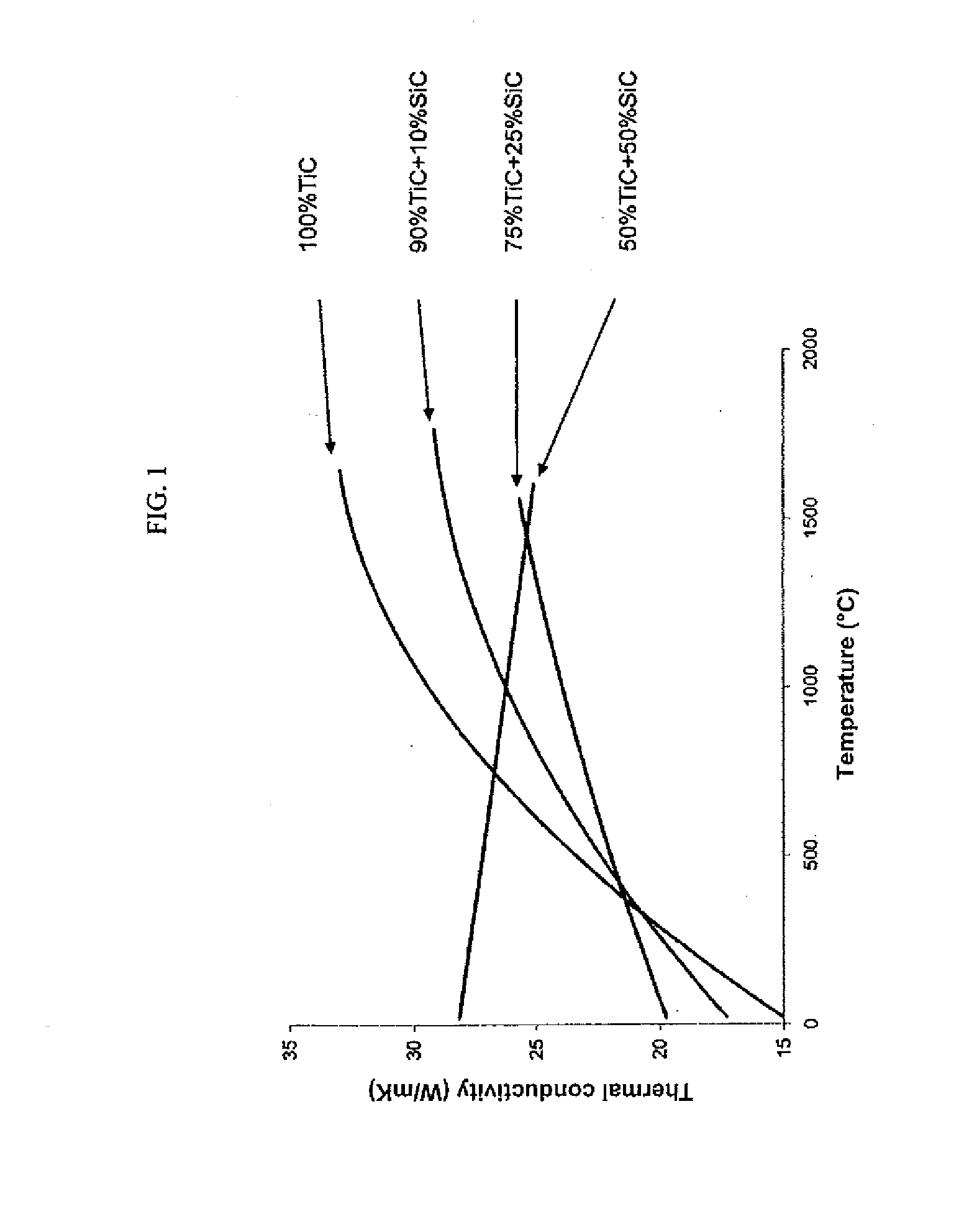

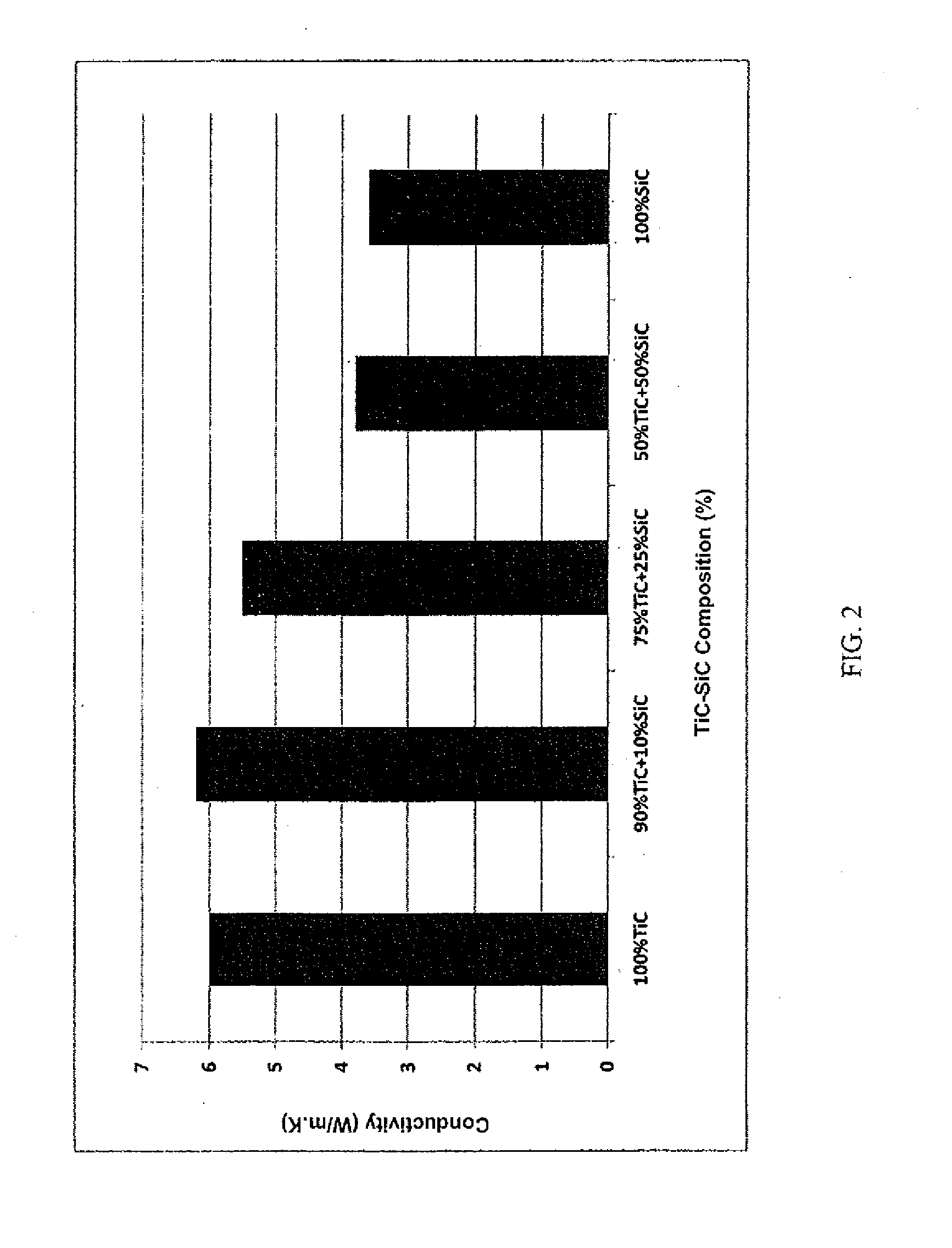

Nuclear fuel cladding with high heat conductivity and method for making same

ActiveUS20110170653A1Optimal transfer of thermal energyEasy transferFuel elementsNuclear energy generationThermal energyFiber

The invention relates to a nuclear fuel cladding totally or partially made of a composite material with a ceramic matrix containing silicon carbide (SiC) fibers as a matrix reinforcement and an interphase layer provided between said matrix and said fibers, the matrix including at least one carbide selected from titanium carbide (TiC), zirconium carbide (ZrC), or ternary titanium silicon carbide (Ti3SiC2).When irradiated and at temperatures of between 800° C. and 1200° C., said cladding can mechanically maintain the nuclear fuel within the cladding while enabling optimal thermal-energy transfer towards the coolant.The invention also relates to a method for making the nuclear fuel cladding.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

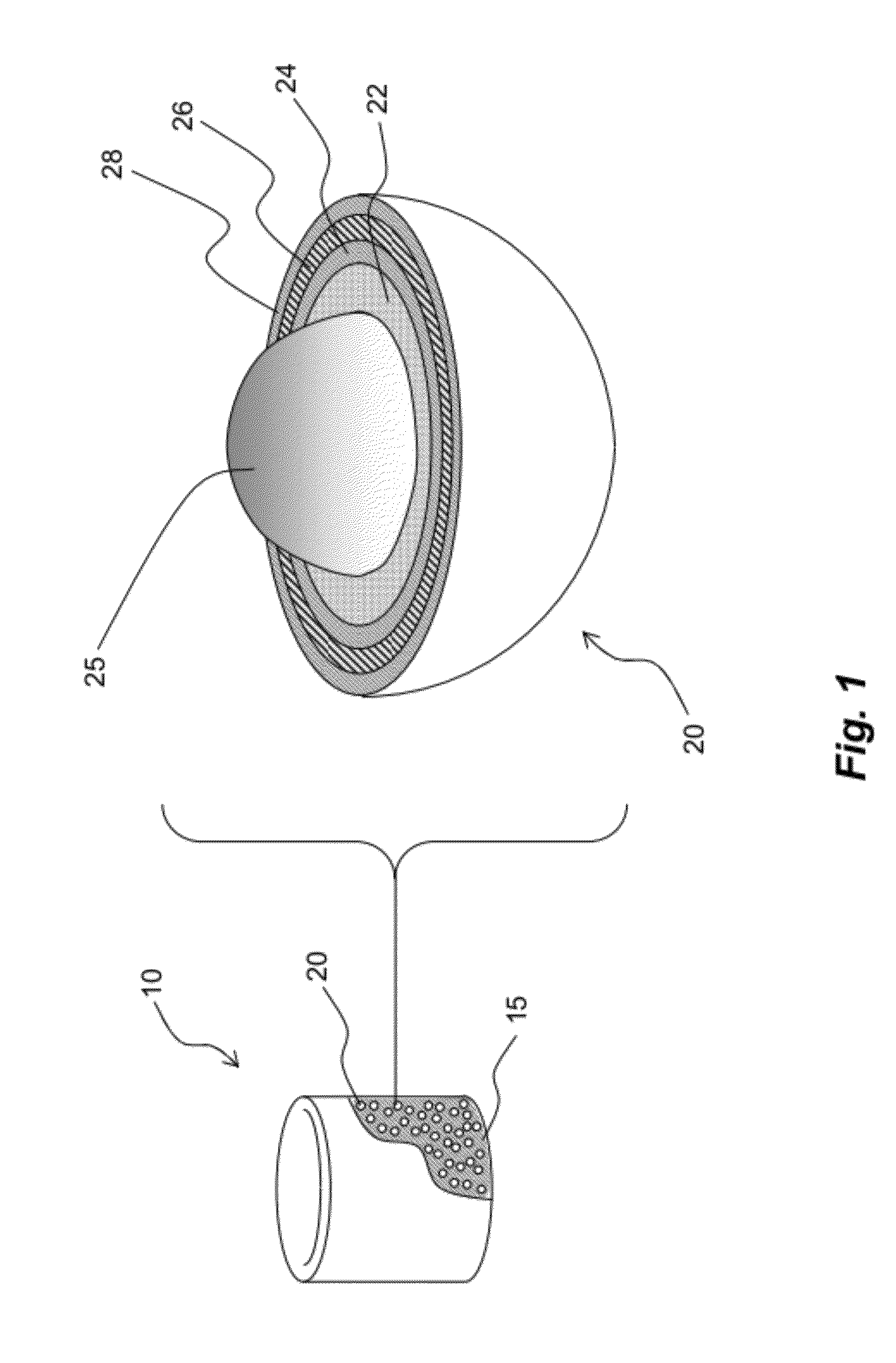

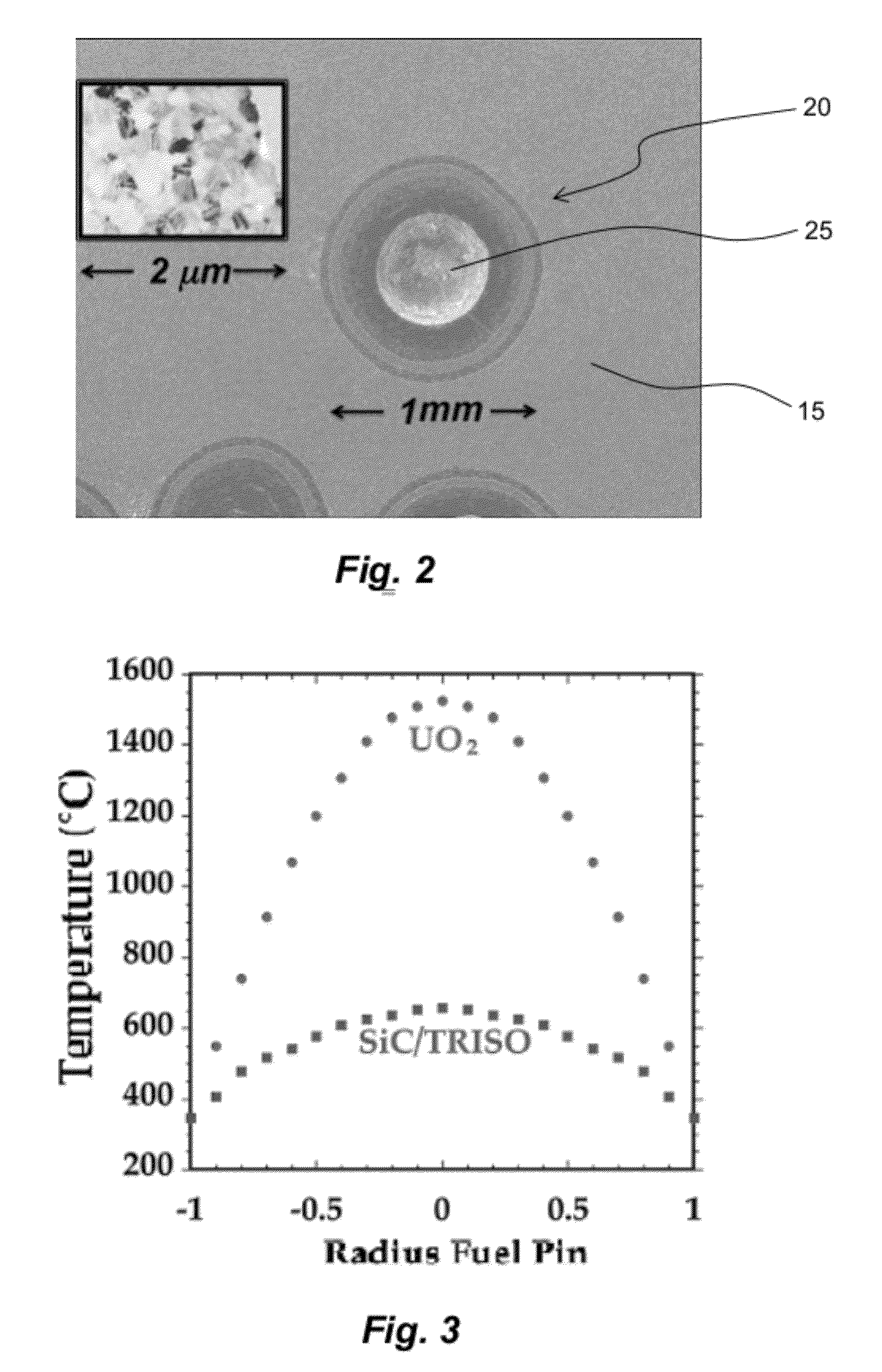

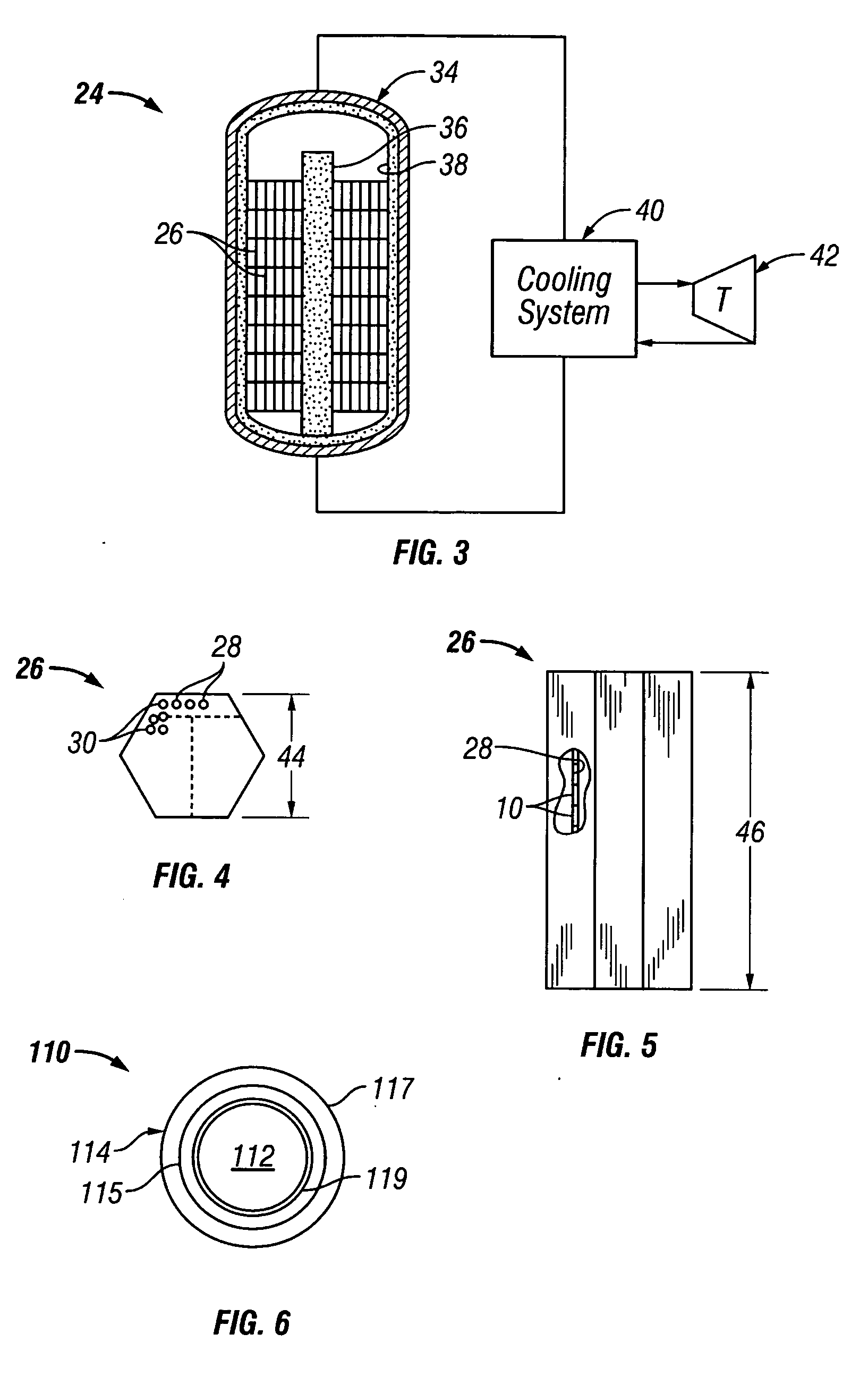

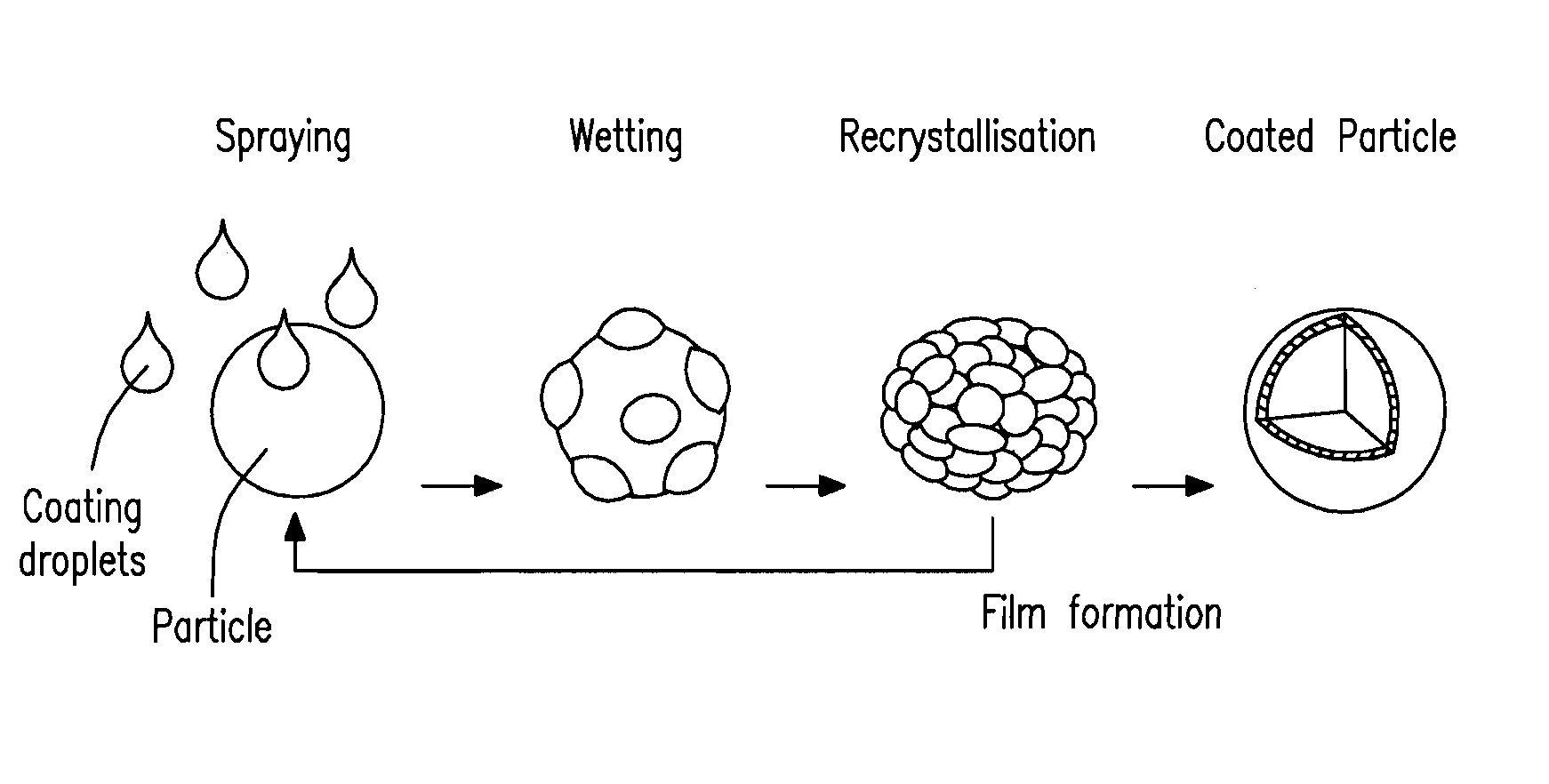

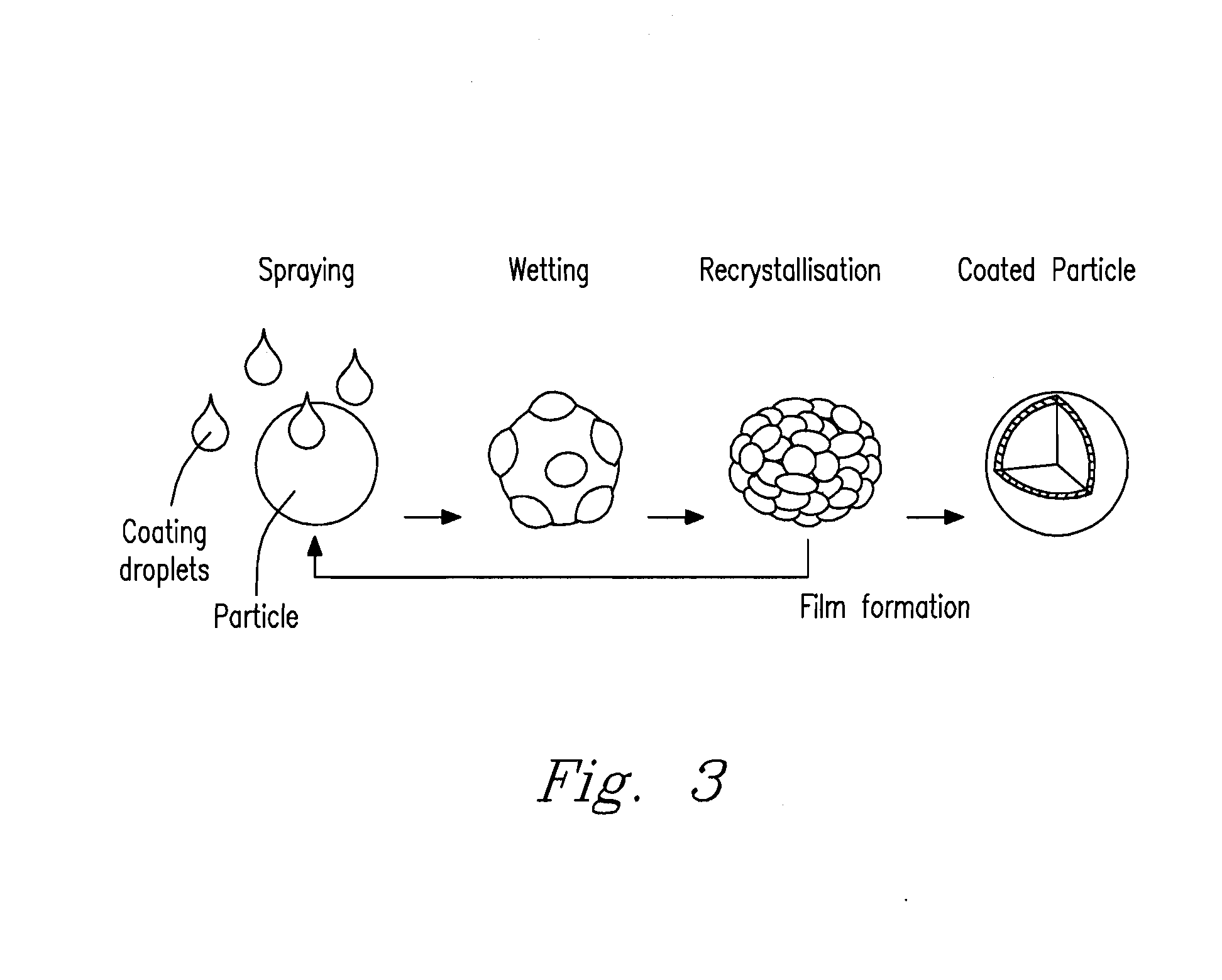

Fuel elements for nuclear reactor system

A fuel element for nuclear power generation made up of at least one coated UO2 fuel kernel embedded in a matrix containing Zr. The kernel and the element each having a coating that provides desired spacing and fission product barrier protection. The fuel enables the functioning and deployment of small scale nuclear reactors with a various features desired for deployment of such devices in developing nations, with limited electrical distribution infrastructure.

Owner:BATTELLE MEMORIAL INST

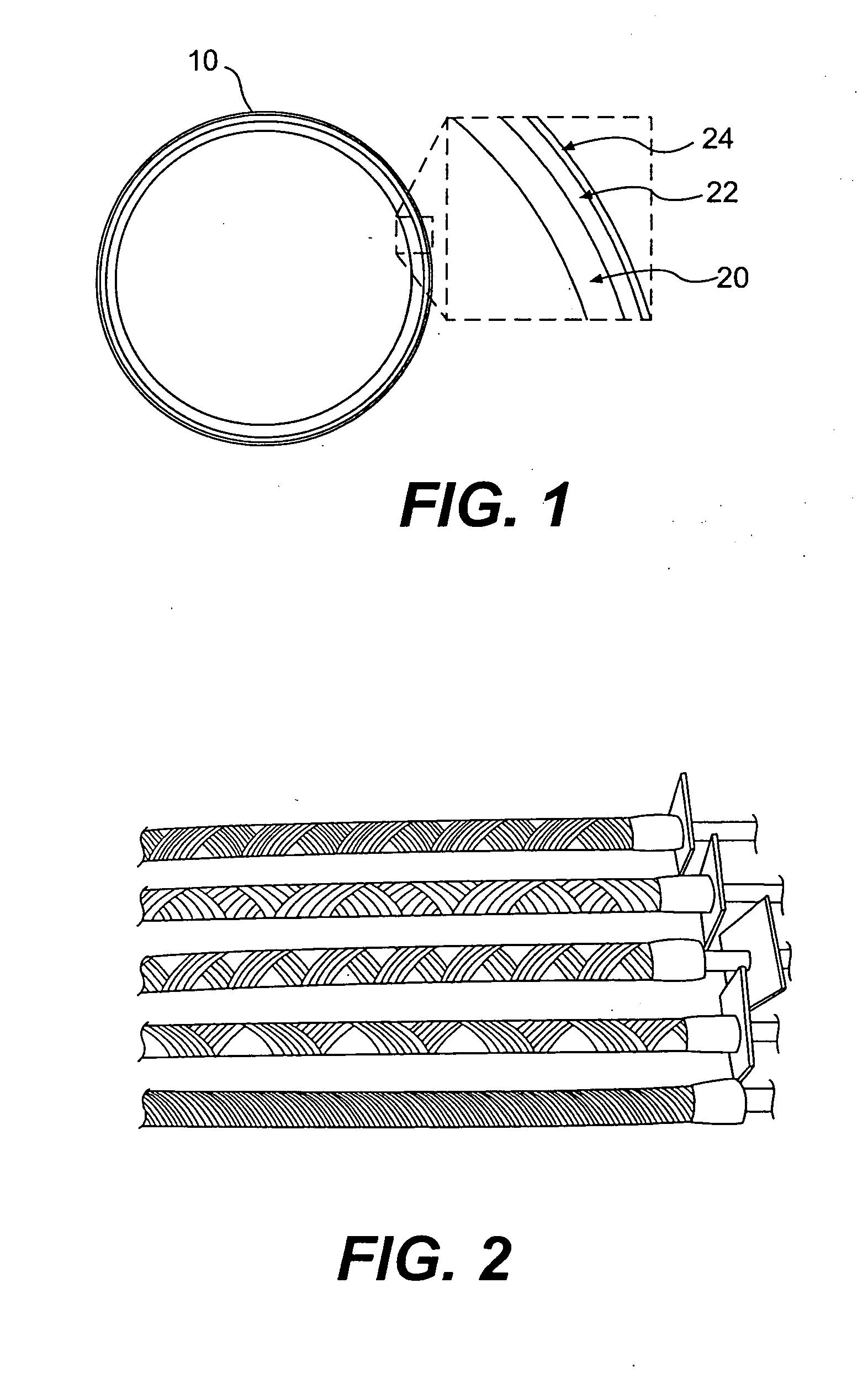

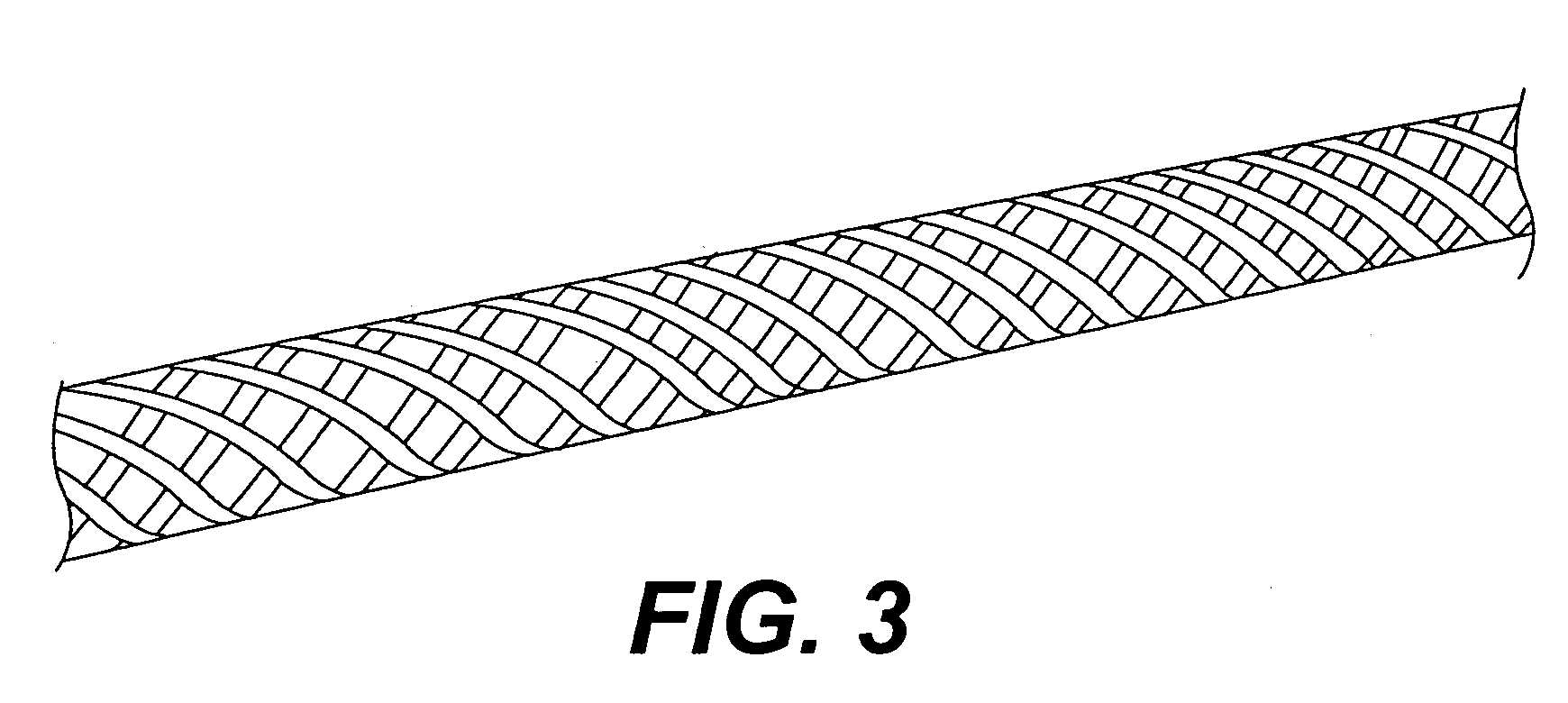

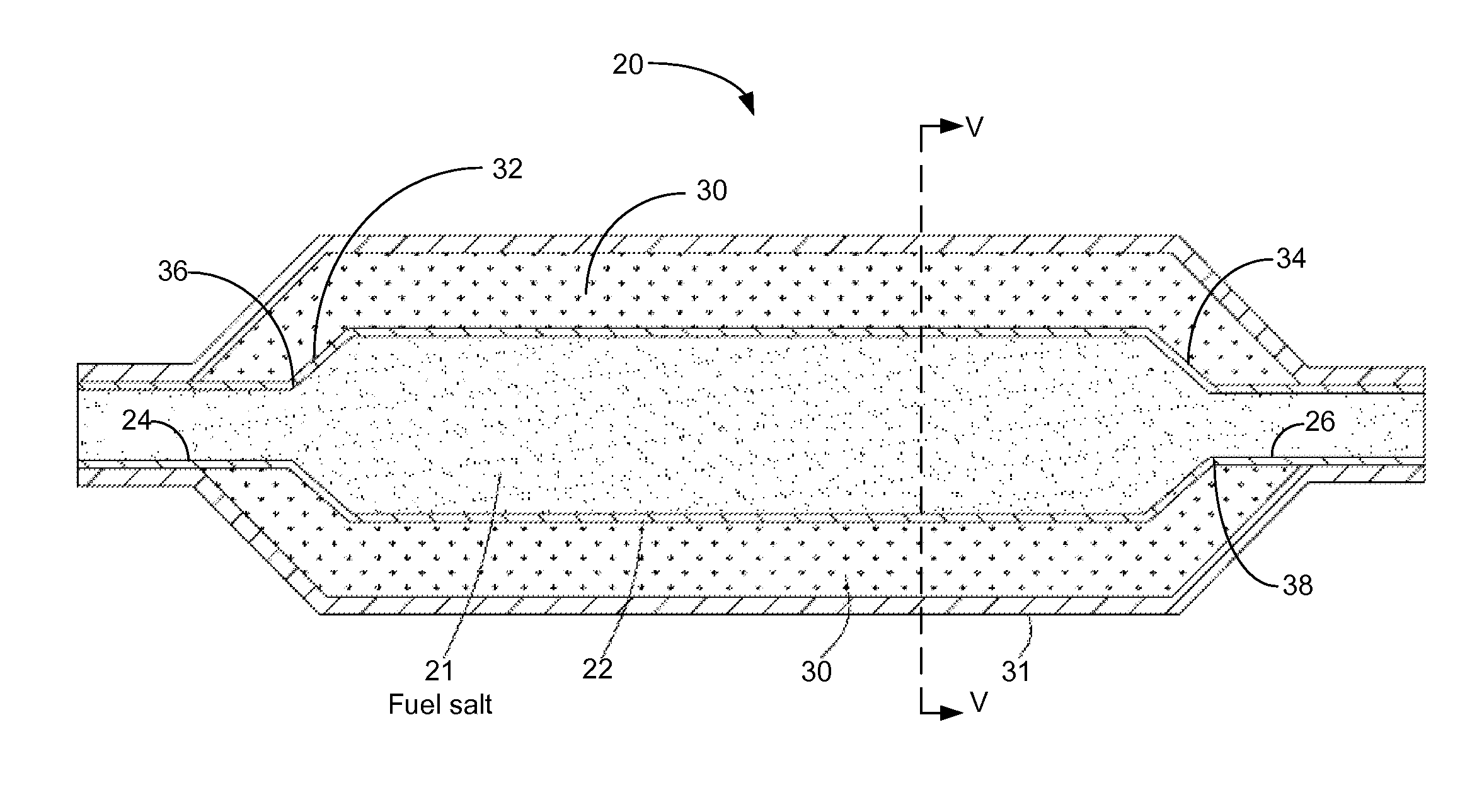

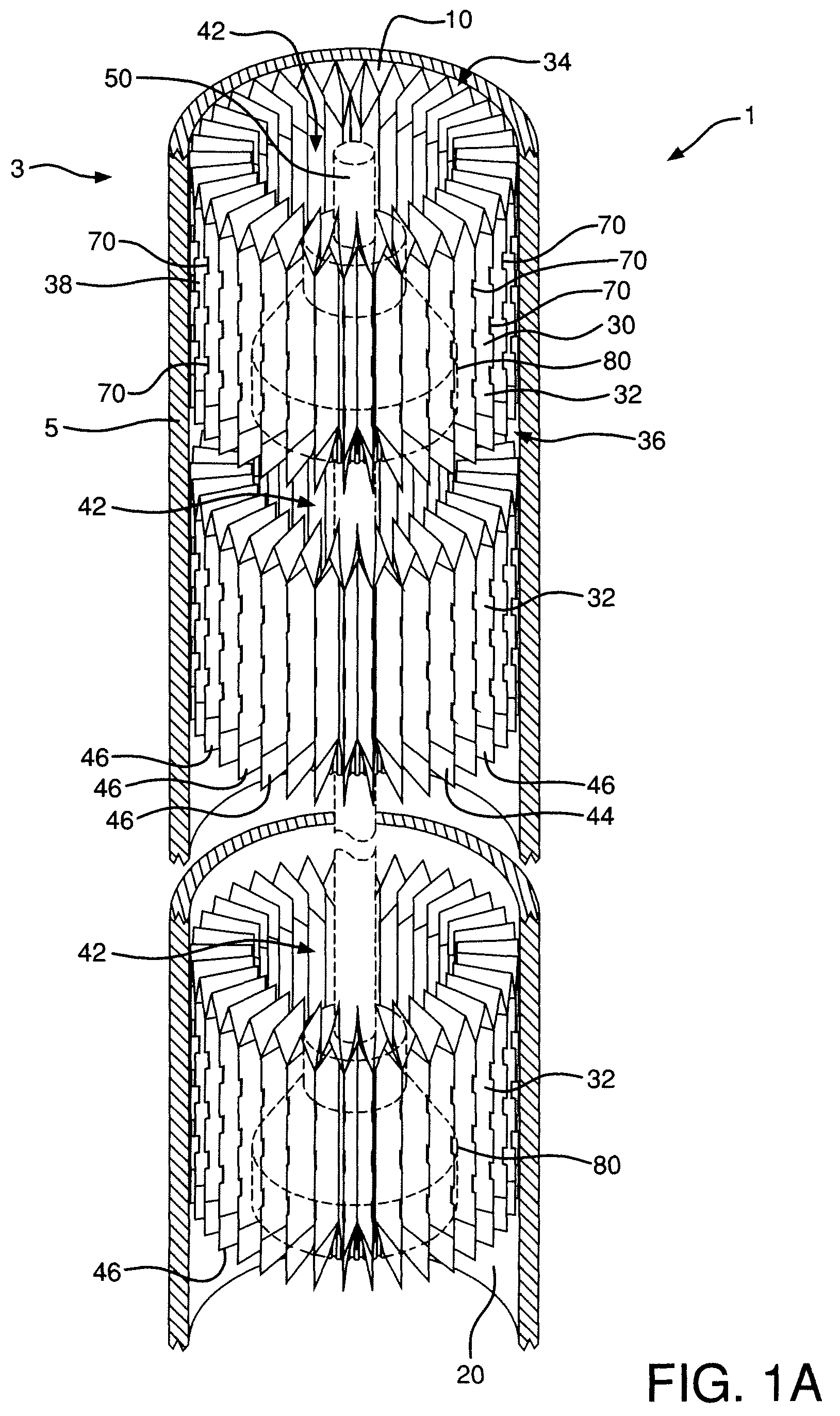

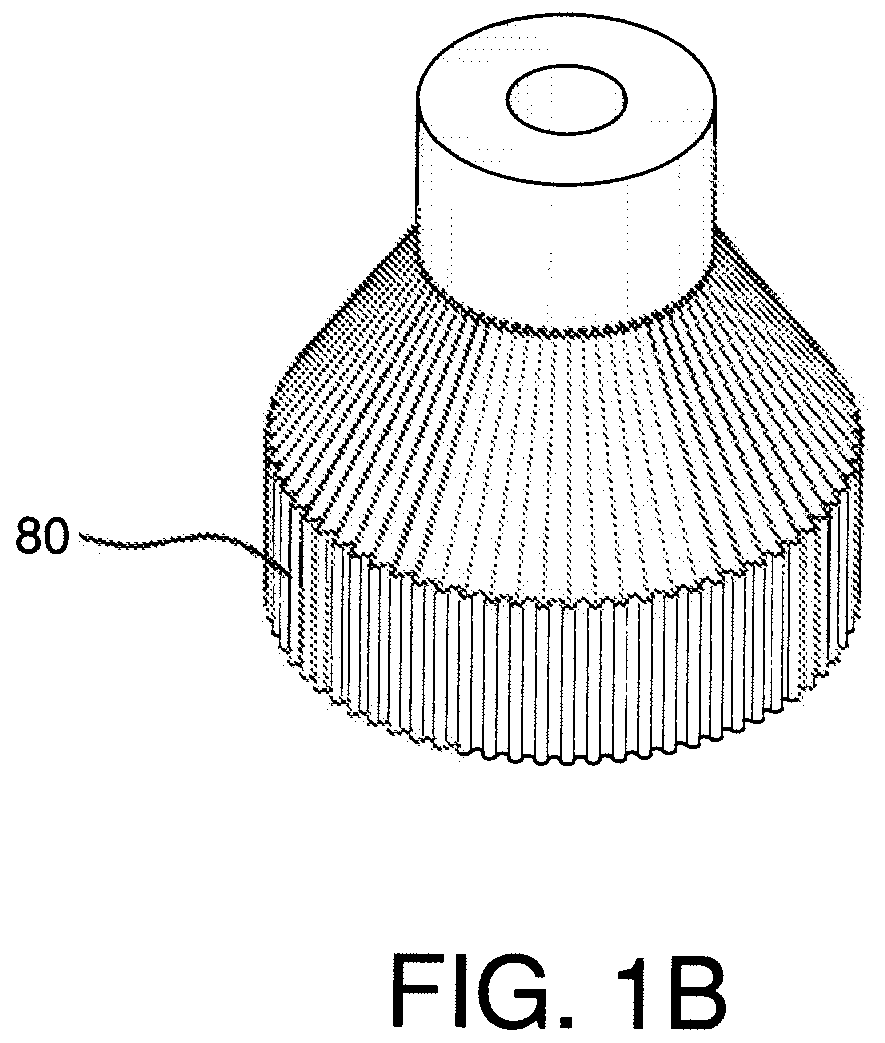

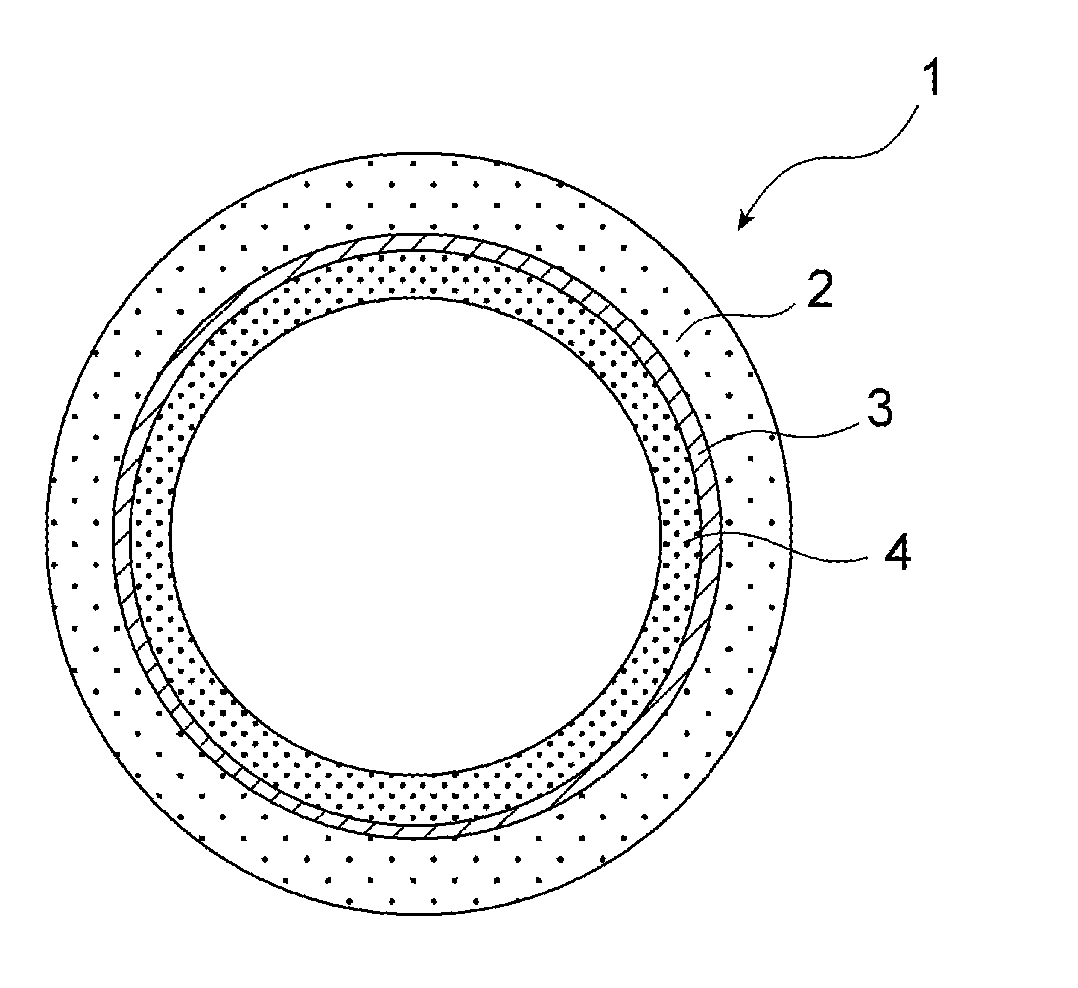

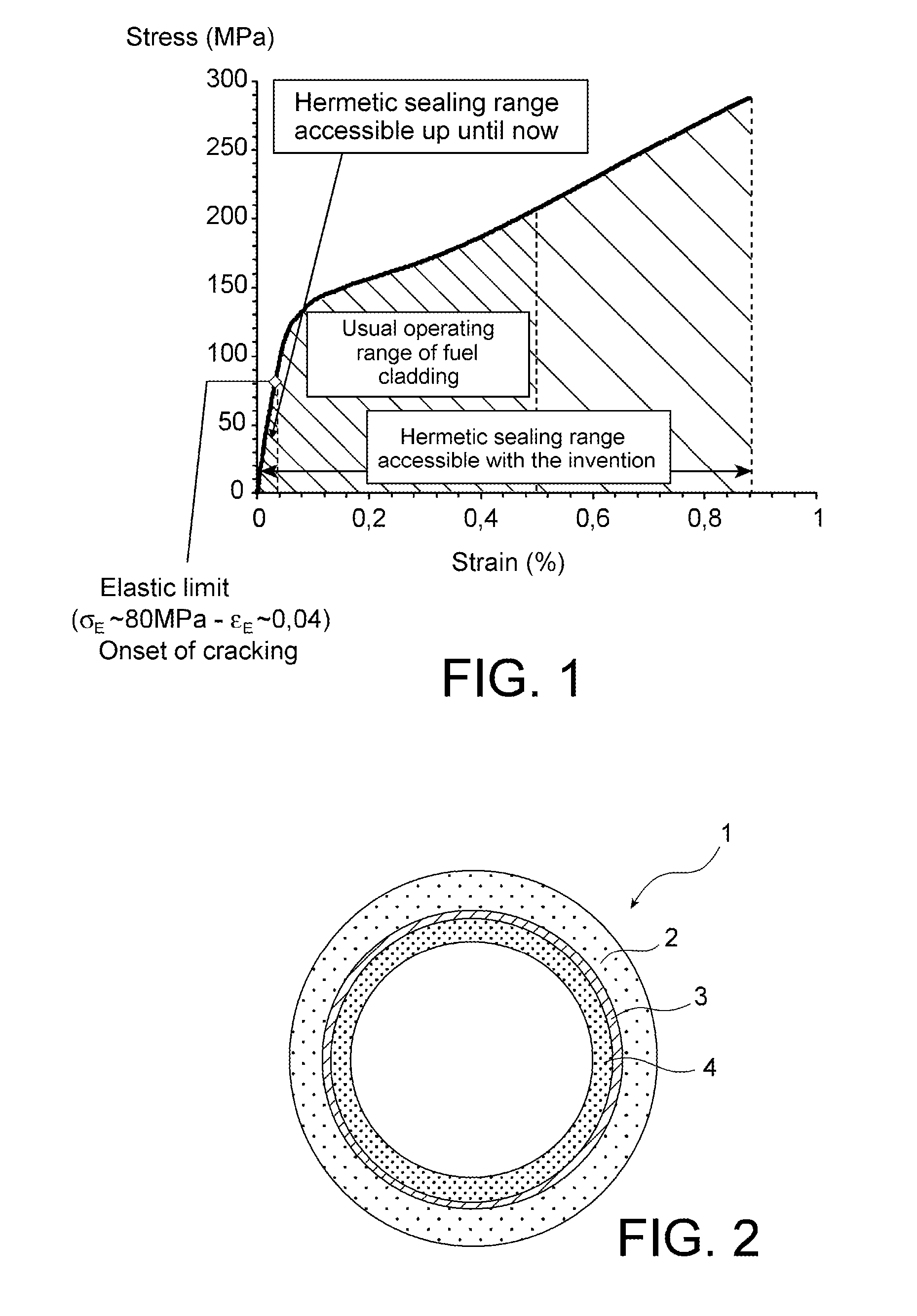

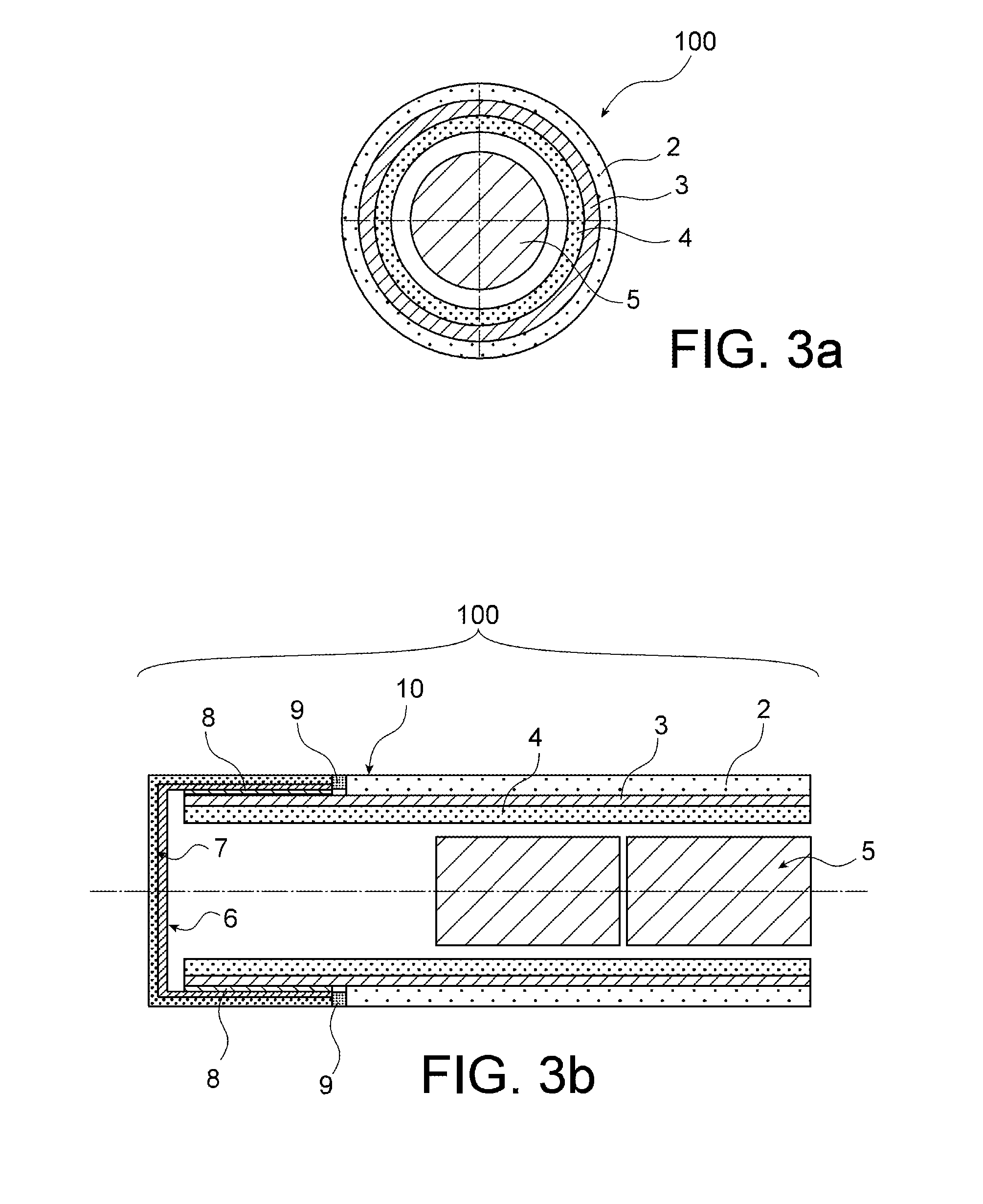

Multilayer tube in ceramic matrix composite material, resulting nuclear fuel cladding and associated manufacturing processes

ActiveUS20140153688A1Improve sealingOptical rangefindersFuel elementsMetal alloyCeramic matrix composite

The invention relates to a multilayer tubular part (1) comprising a metal layer forming a metal tubular body (3) and two layers in ceramic matrix composite material covering the metal tubular body, wherein one of the two layers in ceramic matrix composite material covers the inner surface of the metal tubular body to form an inner tubular body (4), whilst the other of the two layers in ceramic matrix composite material covers the outer surface of the metal tubular body to form an outer tubular body (2), the metal tubular body therefore being sandwiched between the inner and outer tubular bodies. The metal tubular body is in metal or metal alloy. Finally, the metal tubular body has a mean thickness smaller than the mean thicknesses of the inner and outer tubular bodies. A said part is useful in particular for producing nuclear fuel claddings.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

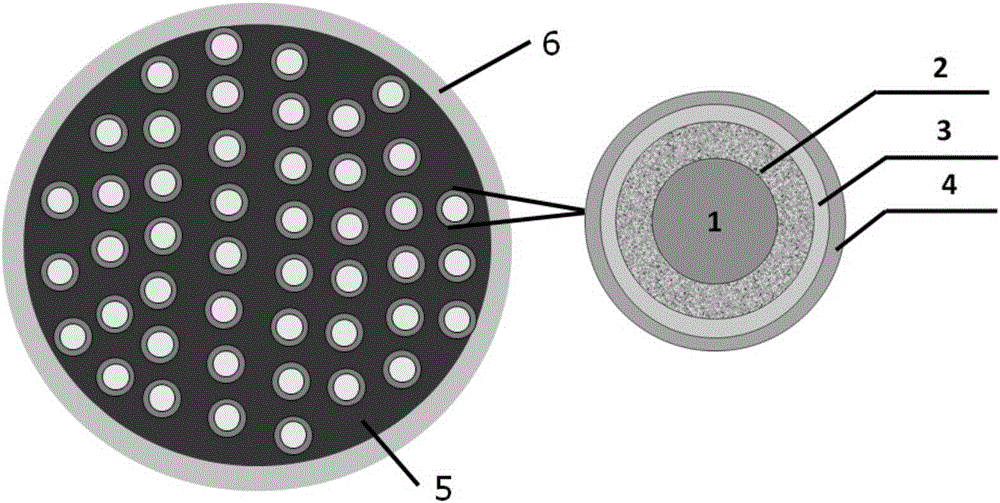

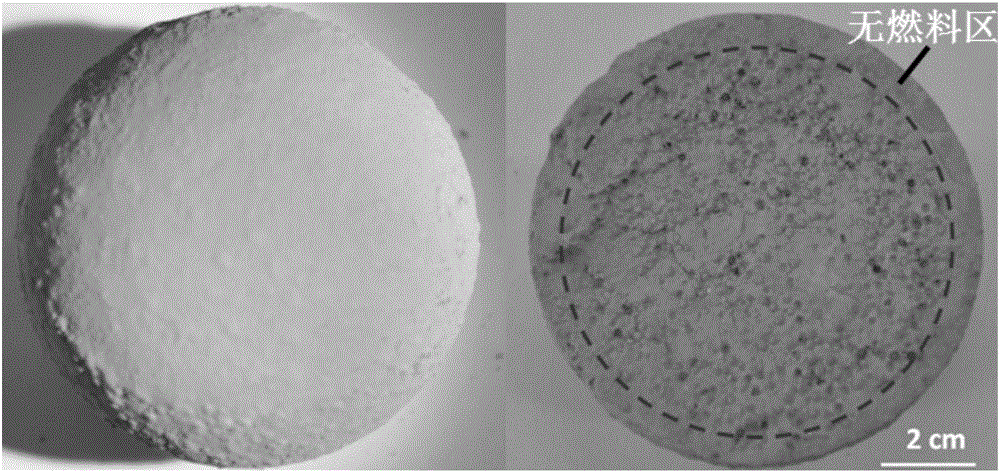

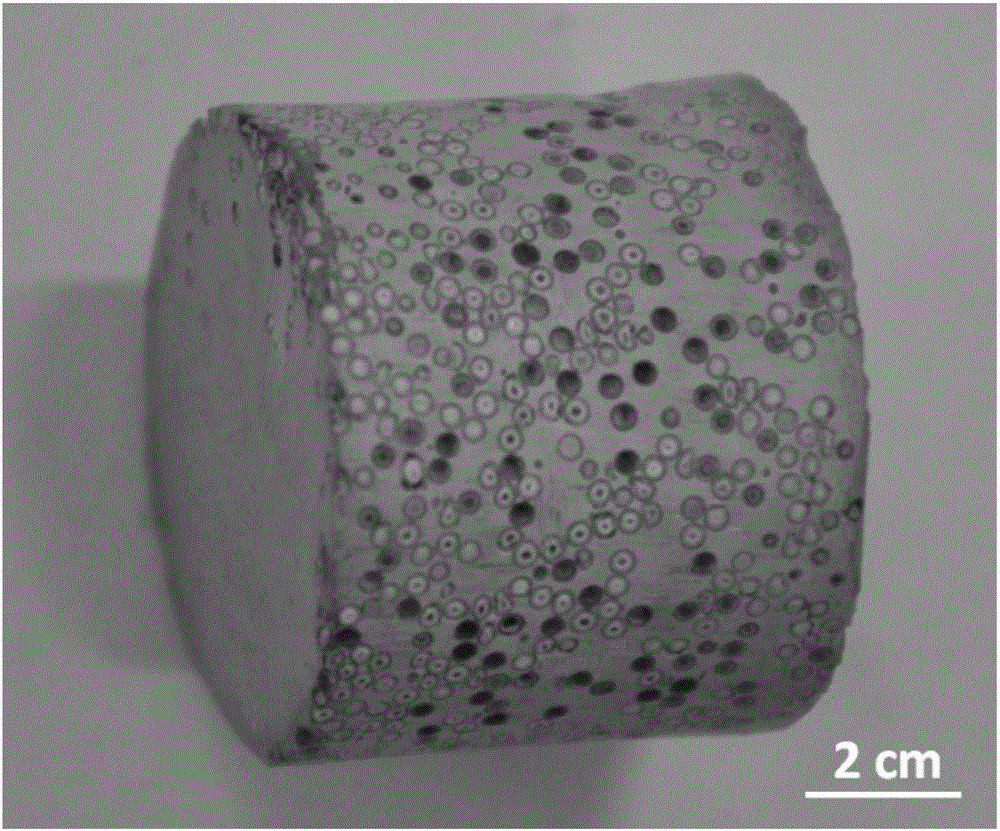

Full ceramic type covering fuel particle, preparation method of full ceramic type covering fuel particle and fuel element

ActiveCN105185418ASimple processEasy to operateFuel elementsNuclear energy generationGas-cooled fast reactorMolten salt reactor

The invention relates to a full ceramic type covering fuel particle, a preparation method of the full ceramic type covering fuel particle and a fuel element prepared from the full ceramic type covering fuel particle. The full ceramic type covering fuel particle comprises a nuclear fuel core, a loose silicon carbide layer, a silicon carbide transition layer and a compact silicon carbide layer, wherein the loose silicon carbide layer, the silicon carbide transition layer and the compact silicon carbide layer sequentially cover the outside of the nuclear core. The full ceramic type fuel element is prepared by dispersing and distributing covering fuel particles in a silicon carbide substrate. When the fuel element provided by the invention is used, the problems of oxidation and corrosion of the existing covering fuel particles and the fuel element during air and water injection under the condition of reactor accidents can be solved. The fuel element can be used for the reactor types such as high-temperature air-cooled reactors, gas-cooled fast reactors, molten salt reactors, space reactors and pressurized water reactors.

Owner:TSINGHUA UNIV

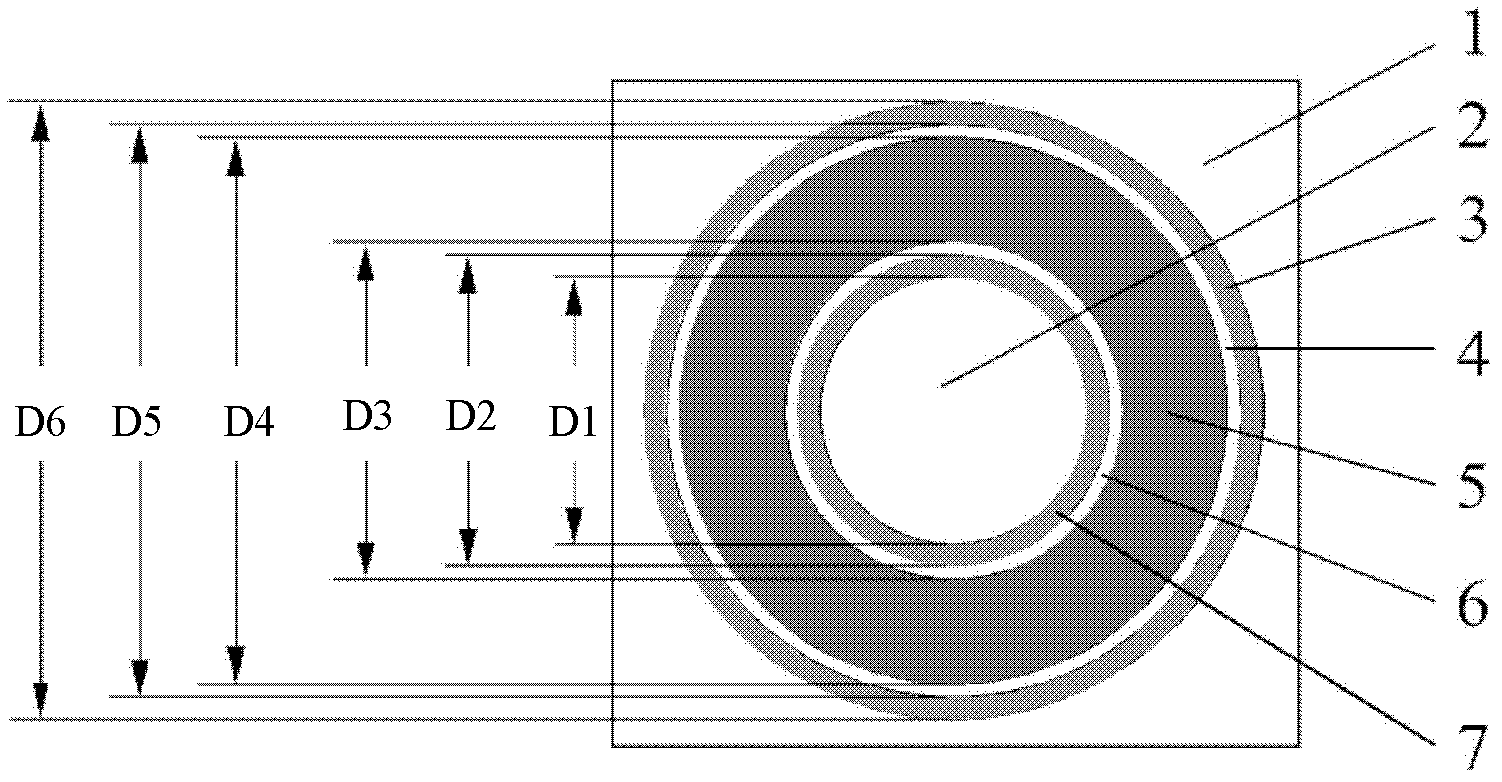

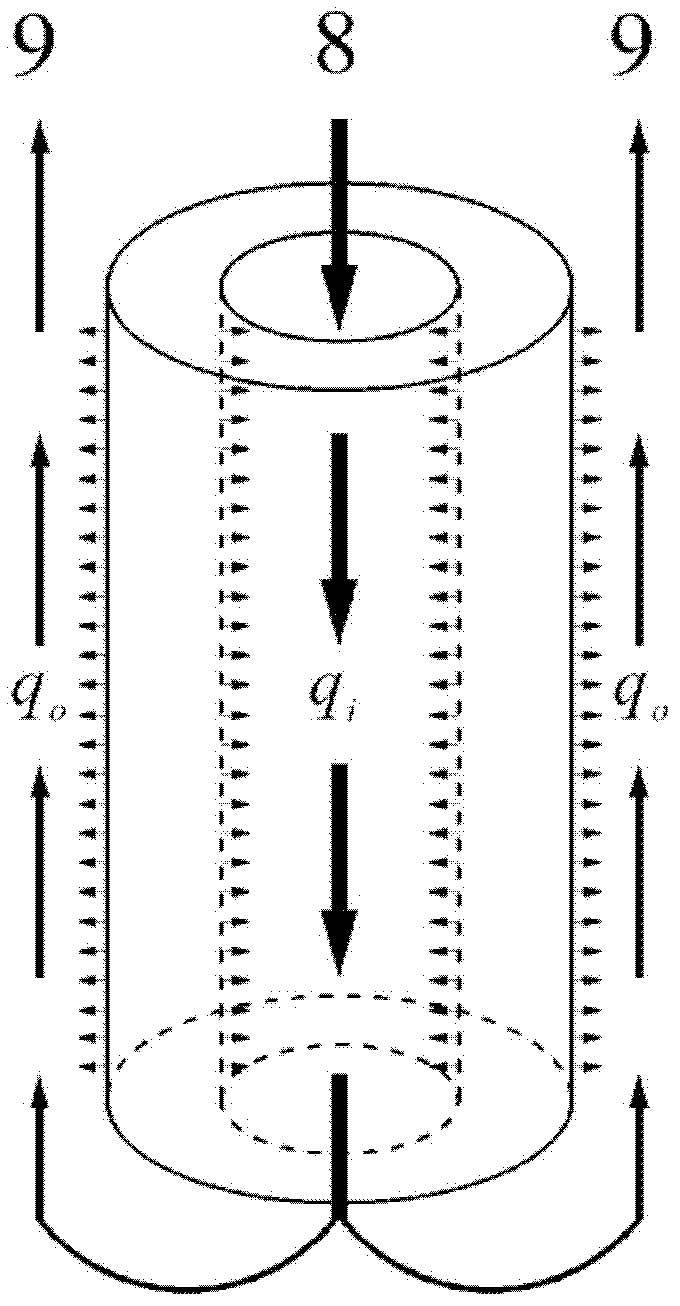

Annular fuel element and annular fuel supercritical water reactor

InactiveCN102354539AReduce radial power factorTake away quicklyFuel elementsNuclear energy generationNuclear engineeringPower factor

The invention discloses an annular fuel element and an annular fuel supercritical water reactor. The annular fuel element is a cylindrical structure of which the cross section is annular, and consists of an outer wrapping shell, an outer gas gap, a fuel core block, an inner gas gap and an inner wrapping shell from an outer layer to an inner layer. The water reactor consists of a pressure container, a descending section, a reactor core basket and an annular fuel assembly from outside to inside, wherein the annular fuel assembly is formed by arranging a plurality of square annular fuel assemblies or a plurality of hexagonal annular fuel assemblies axially in parallel. In the annular fuel element and the annular fuel supercritical water reactor, the temperature of the fuel core block and the wrapping shells are reduced by increasing a heat transfer area effectively; and low-temperature water serving as a moderator is positioned in an inner channel of the fuel element, so the physical feedback is more uniform, and radial power factors can be reduced effectively.

Owner:XI AN JIAOTONG UNIV +1

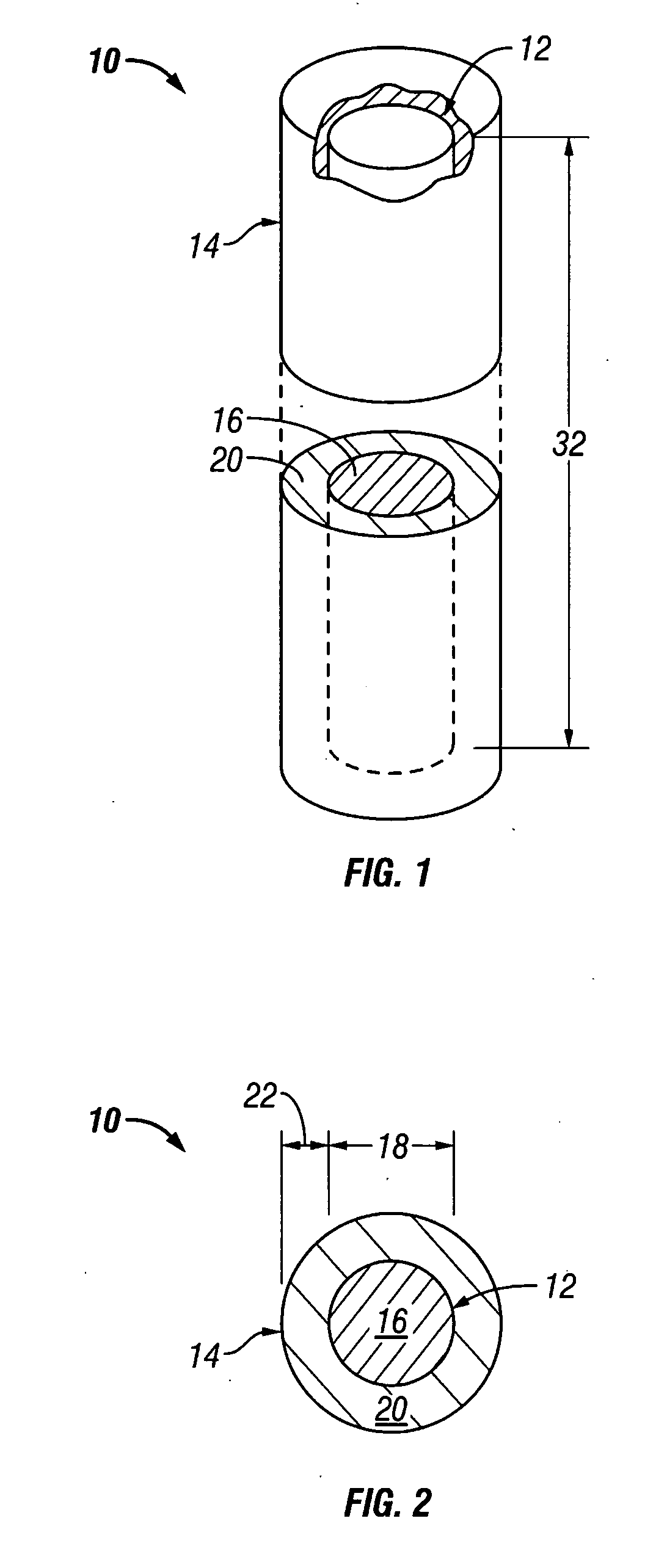

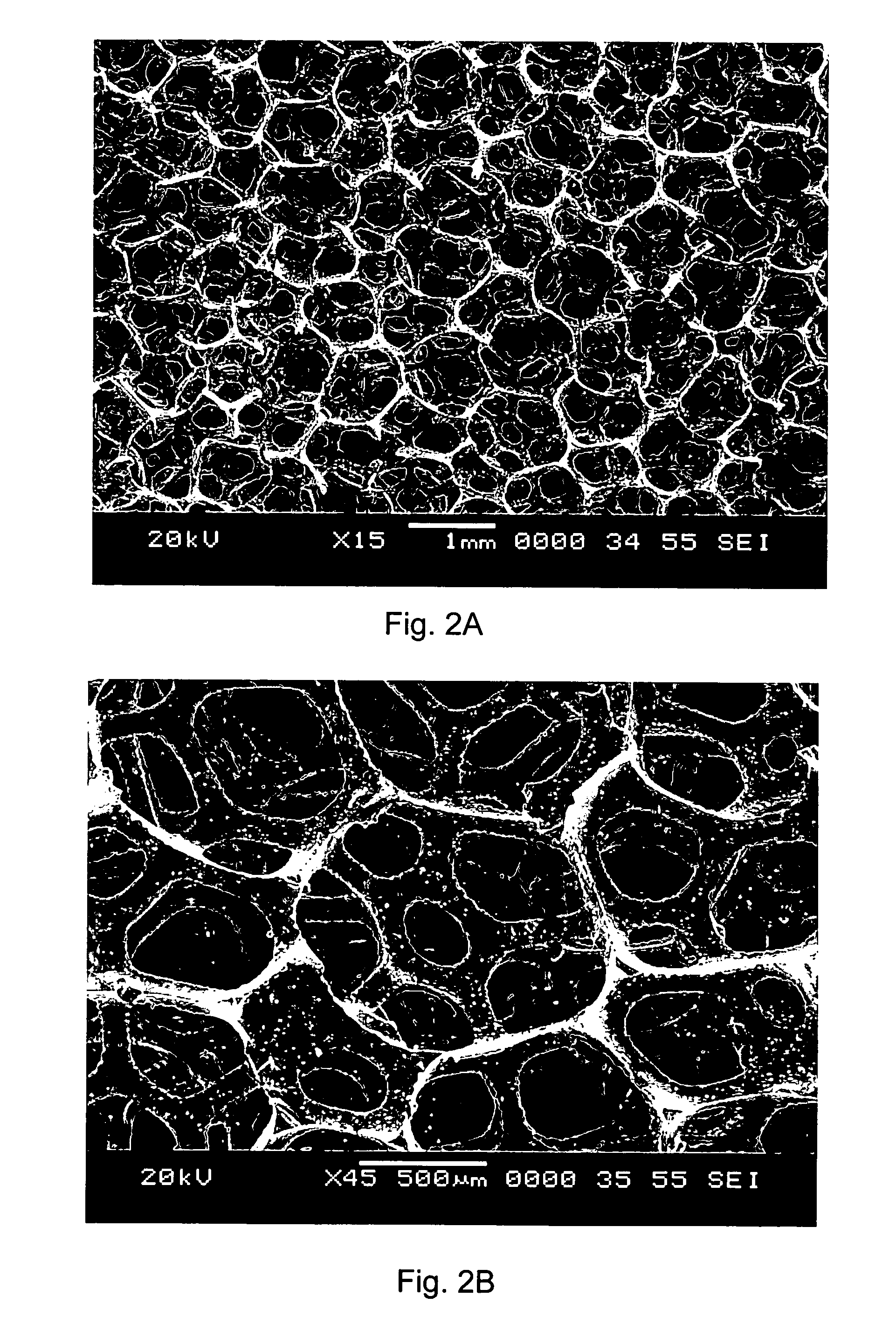

Methods for manufacturing porous nuclear fuel elements for high-temperature gas-cooled nuclear reactors

Methods for manufacturing porous nuclear fuel elements for use in advanced high temperature gas-cooled nuclear reactors (HTGR's). Advanced uranium bi-carbide, uranium tri-carbide and uranium carbonitride nuclear fuels can be used. These fuels have high melting temperatures, high thermal conductivity, and high resistance to erosion by hot hydrogen gas. Tri-carbide fuels, such as (U,Zr,Nb)C, can be fabricated using chemical vapor infiltration (CVI) to simultaneously deposit each of the three separate carbides, e.g., UC, ZrC, and NbC in a single CVI step. By using CVI, a thin coating of nuclear fuel may be deposited inside of a highly porous skeletal structure made, for example, of reticulated vitreous carbon foam.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Lower and upper end plugs of an annular fuel rod

Owner:KOREA ATOMIC ENERGY RES INST +1

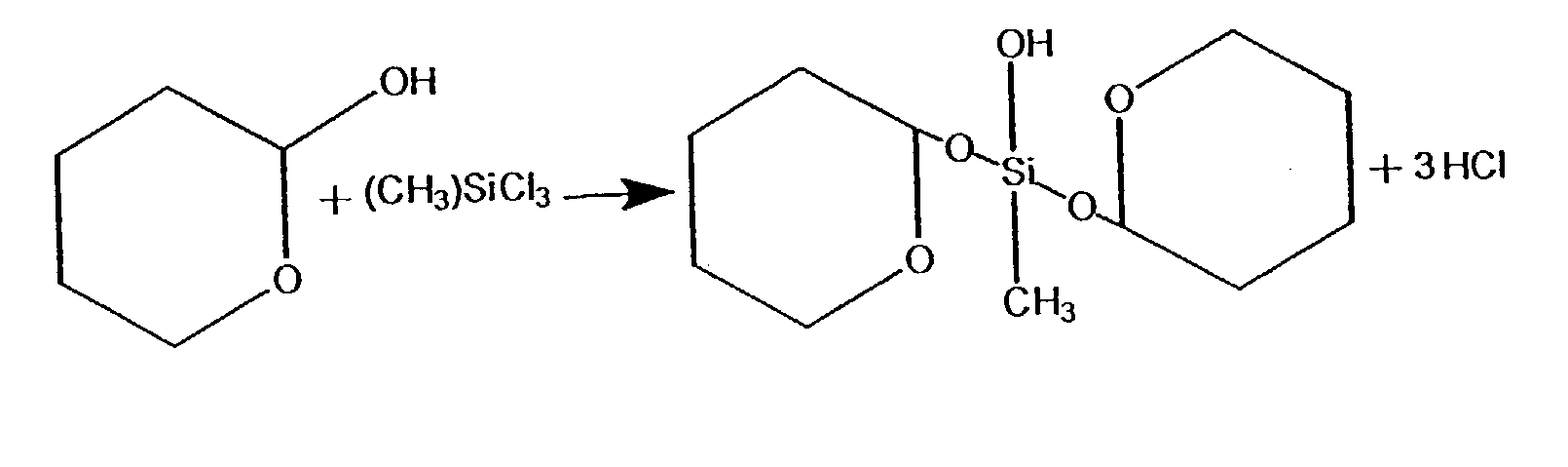

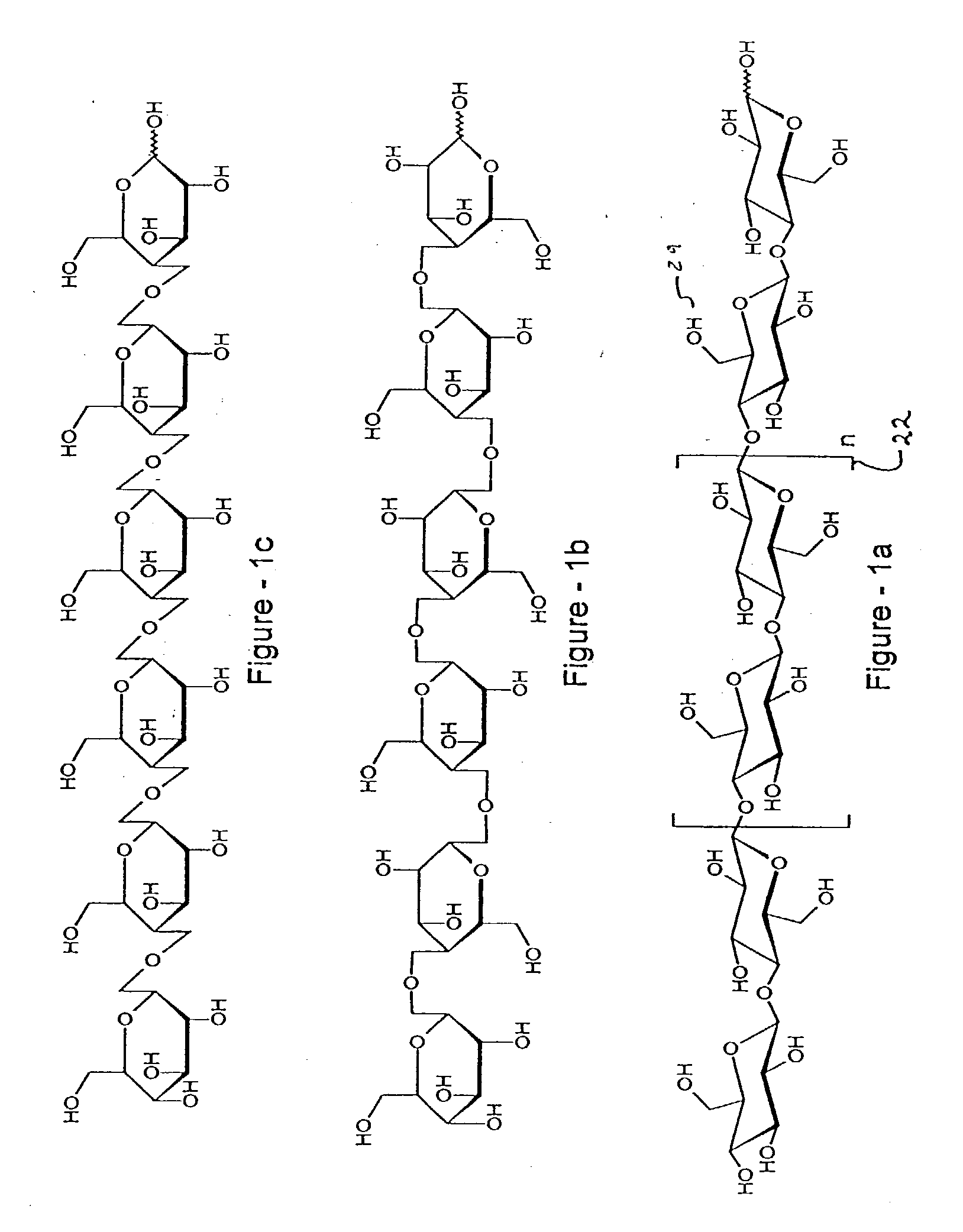

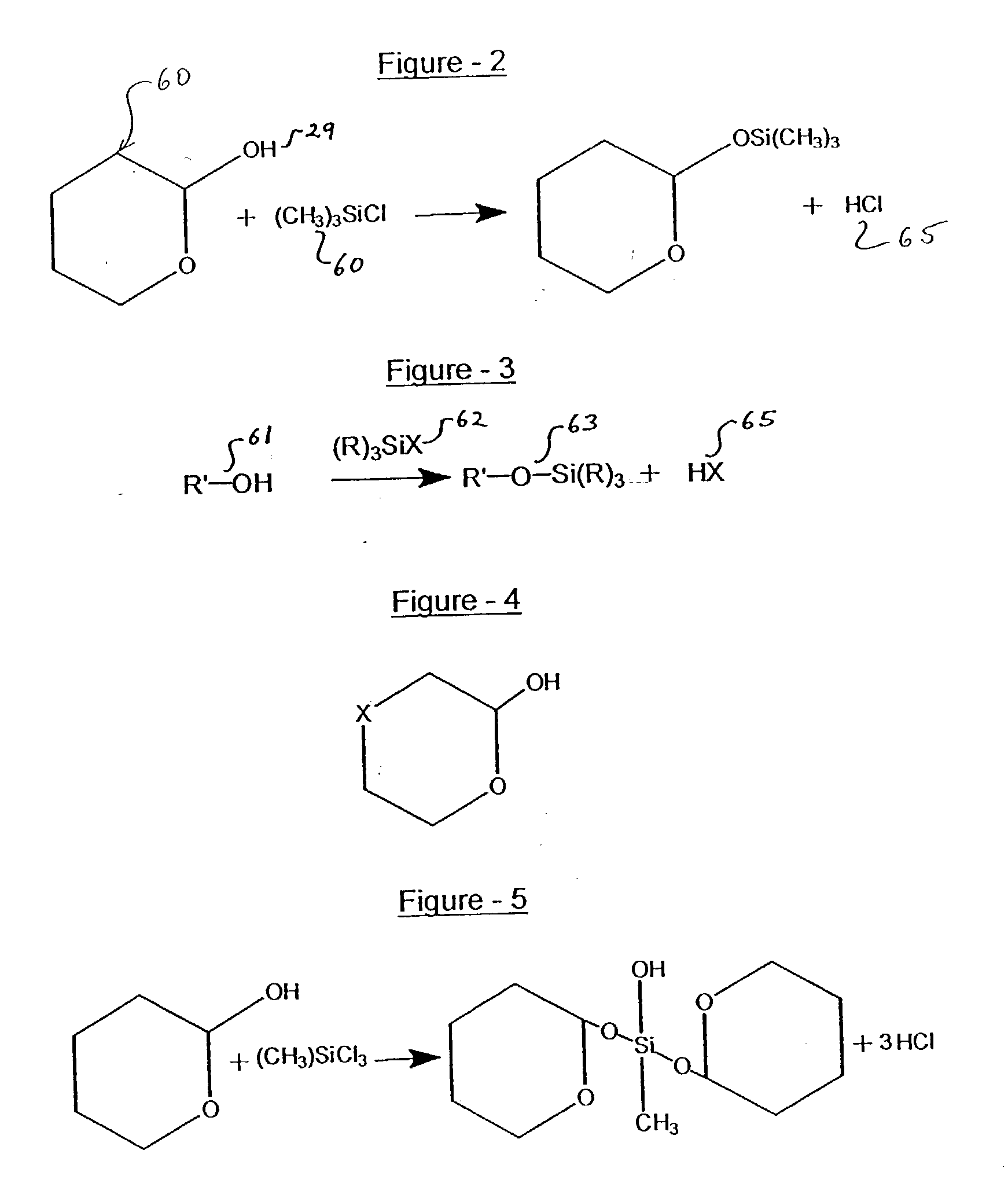

Process for treating wood and products from treated wood

Wood cellulose is treated with a reactive silicate. The reaction is done to cellulose within the wood and may be catalyzed with acid or base catalysts or a carbon silicon halogen combination which produces in situ acid catalysts or a different combination to produce an in situ base catalyst which replaces some of the molecules or atoms within the cellulose structure with silicon, boron or other hydrophobic or anti-degrading agents. Preferably an organic solvent, such as alcohol is used to accelerate the reaction with the water in the wood. Here, the hydroxyl (OH) group on some or all of the cellulose molecules is partially replaced with silicon or an alternative atom or molecule to changes the character of the wood. The process may be modified to insert a preliminary step of adding a reactive agent to be locked into the wood. Manufacturing techniques to enhance the process using ultrasound or other wave generating techniques are also taught.

Owner:D & L +1

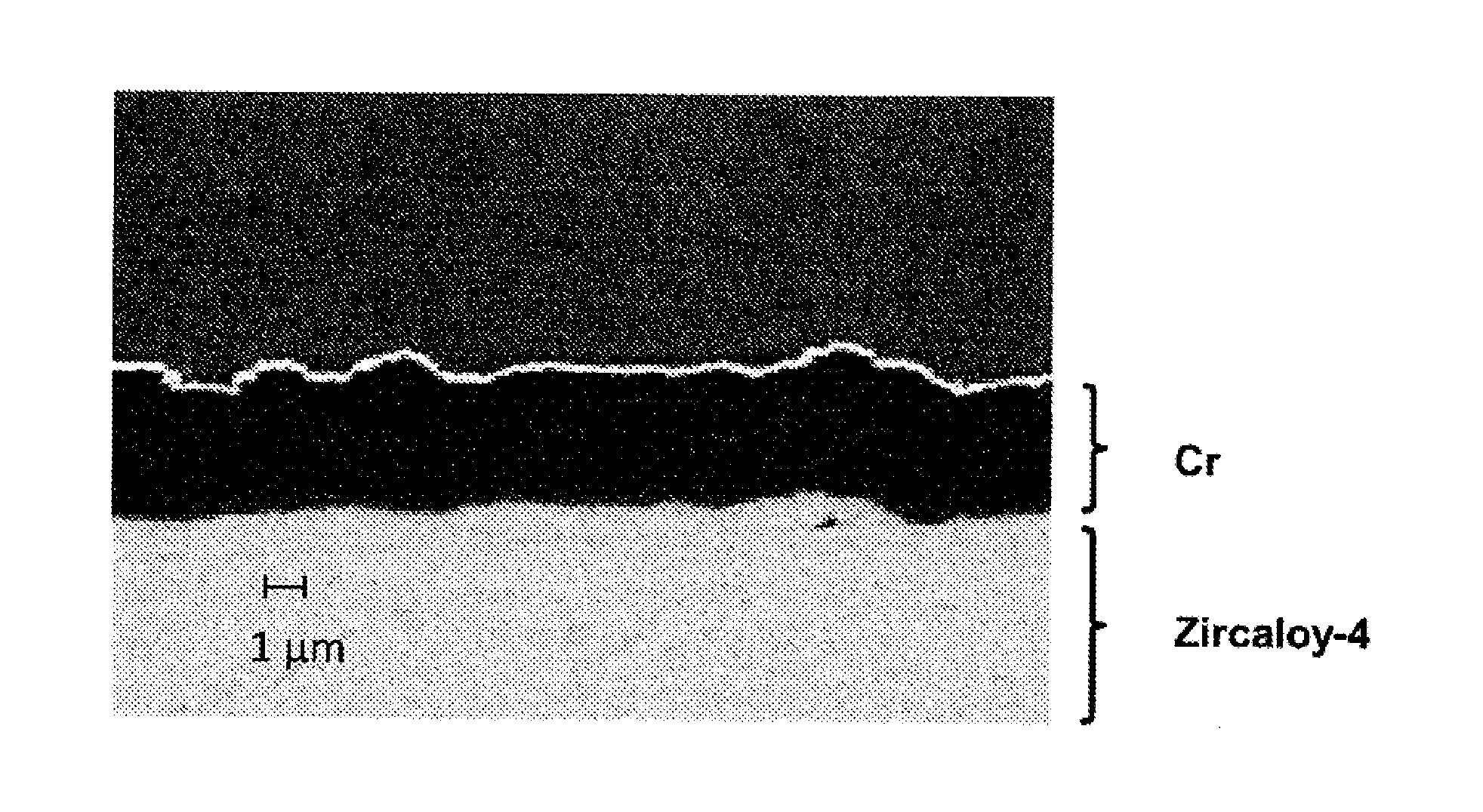

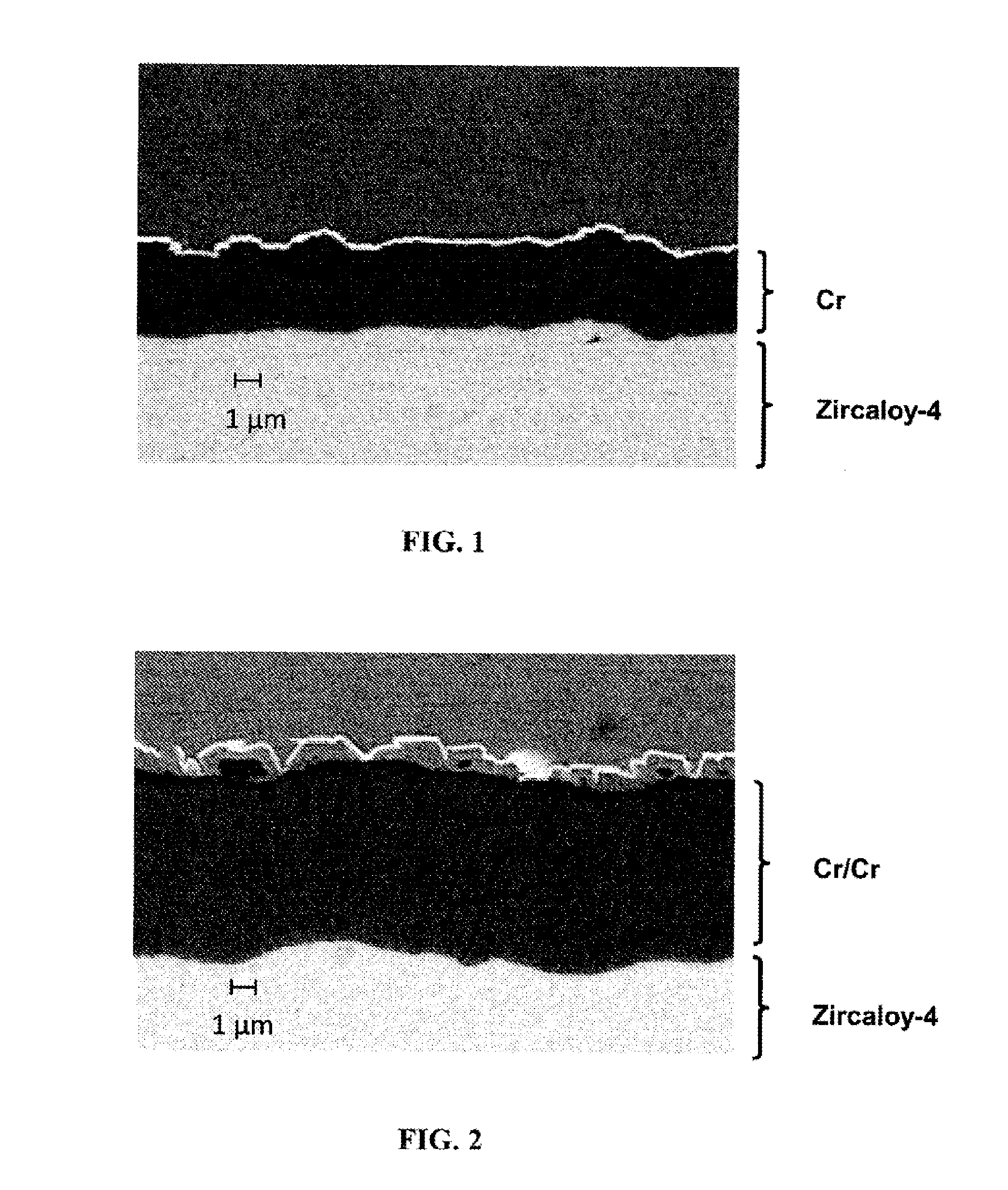

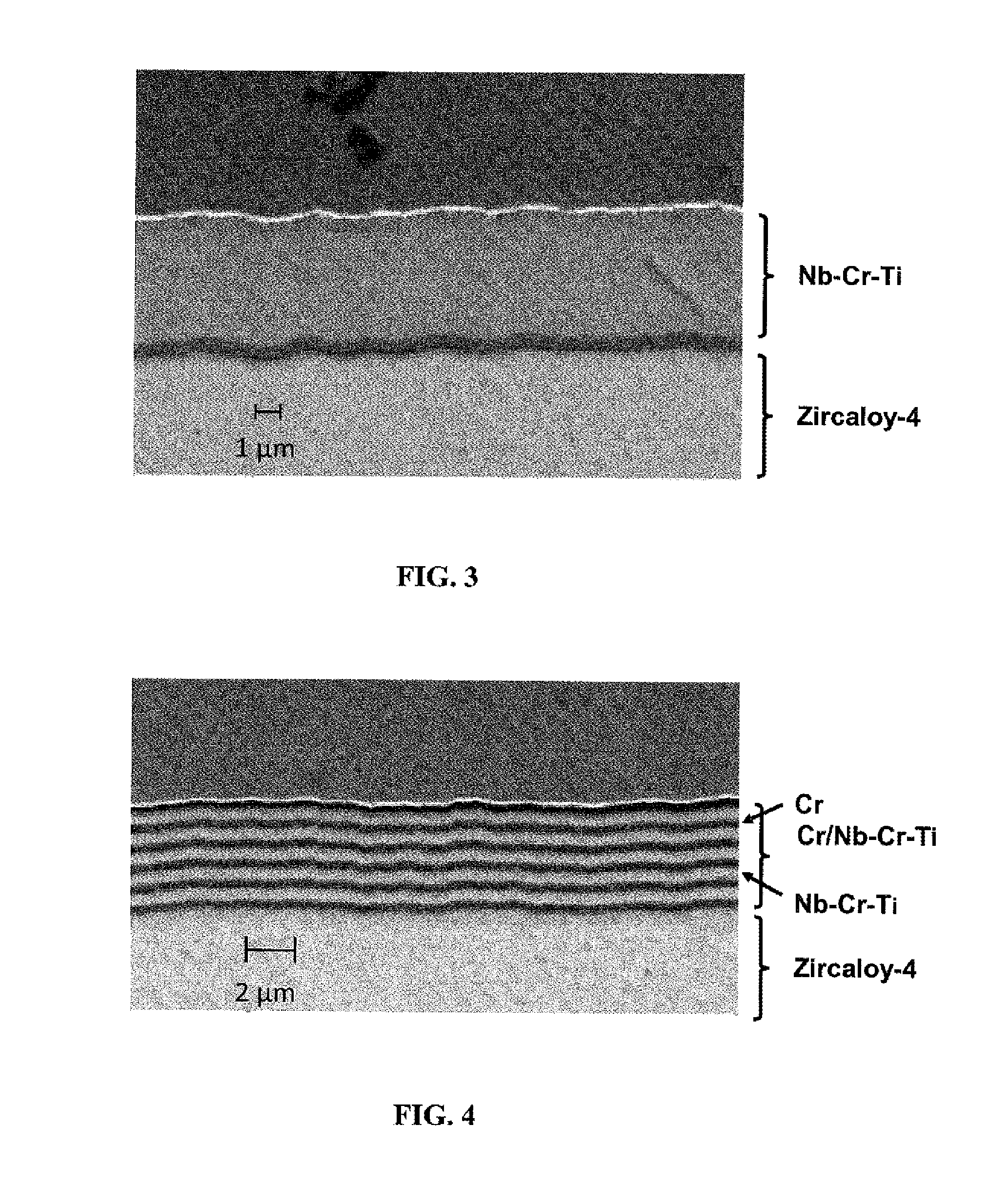

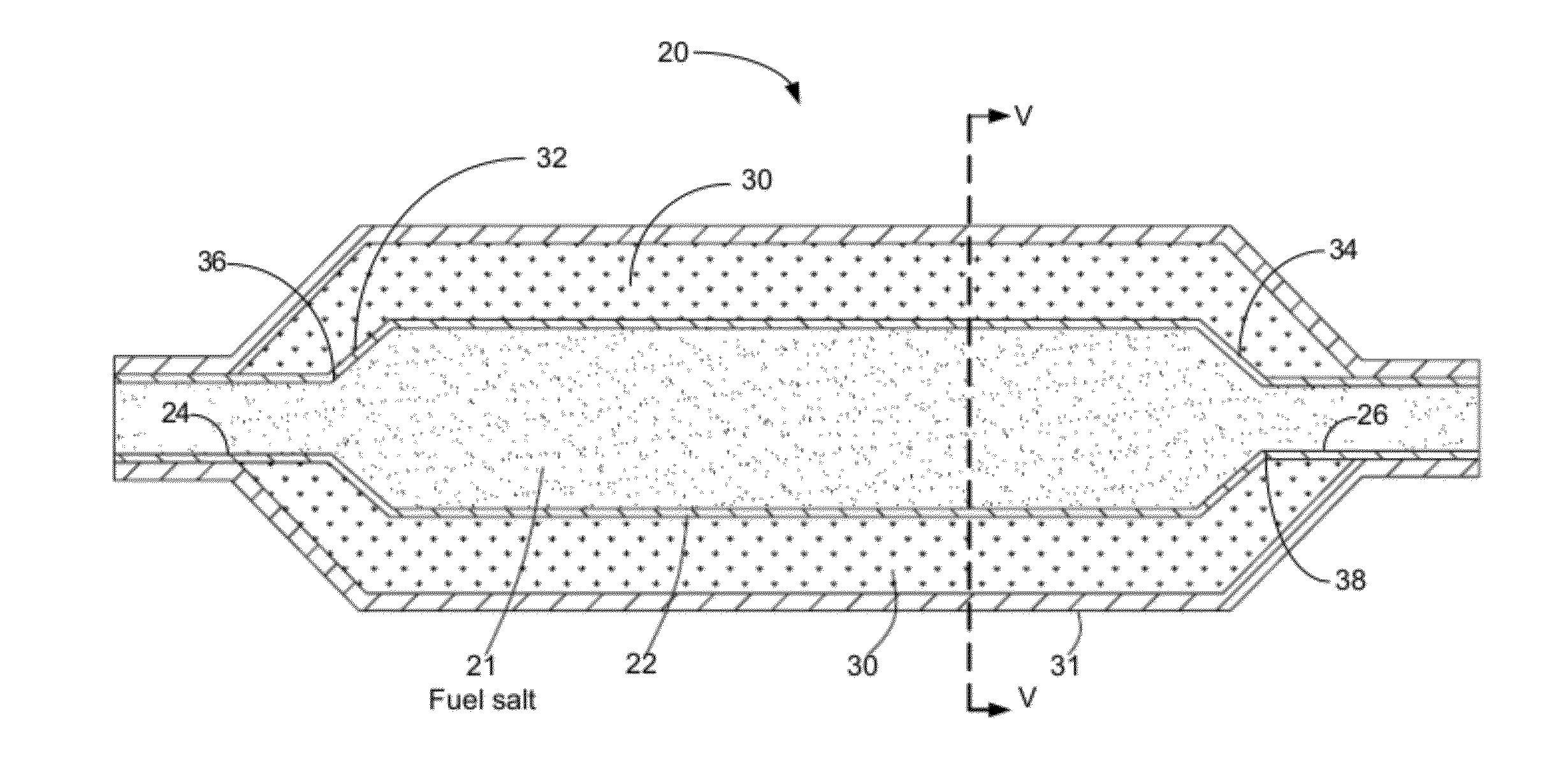

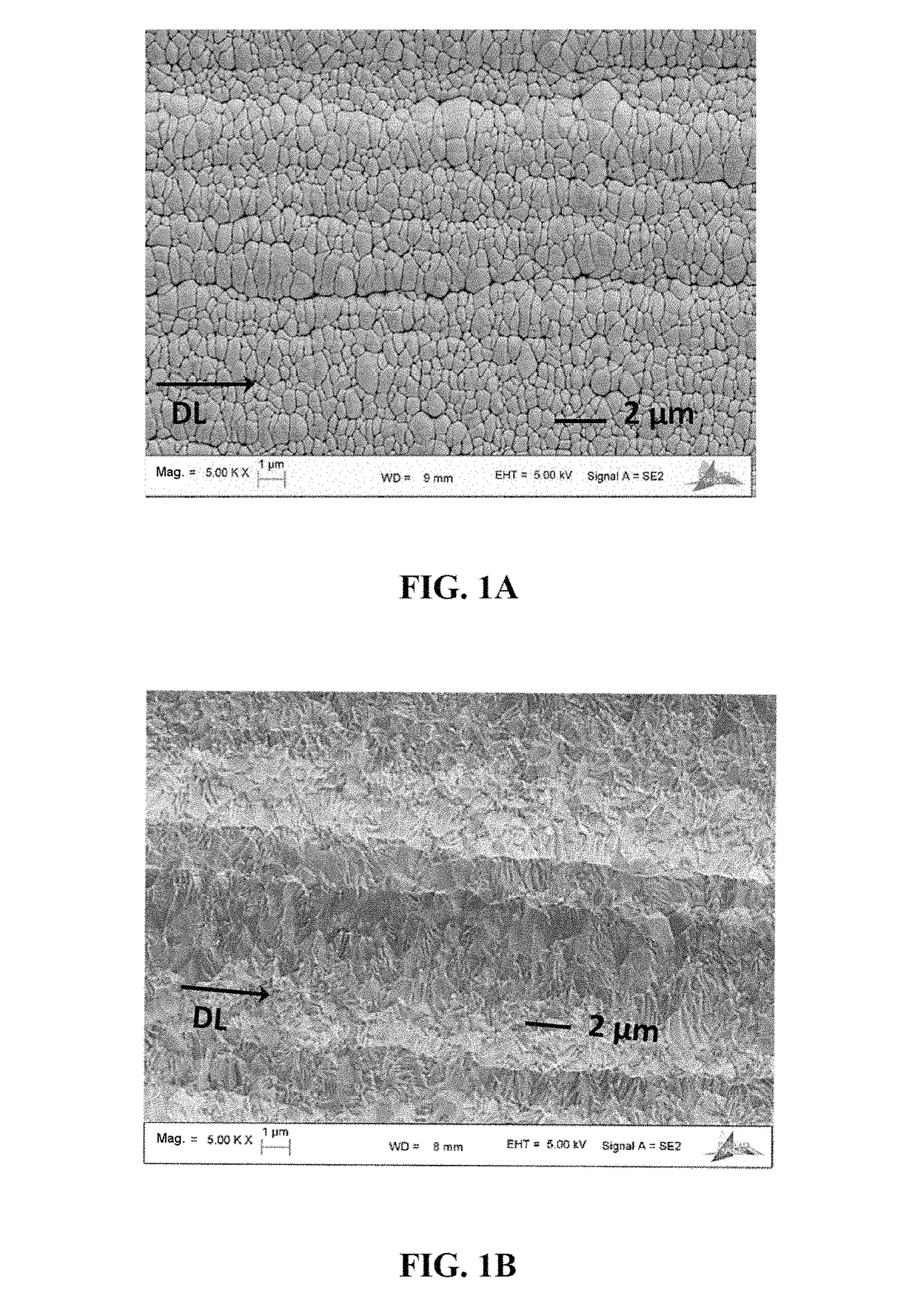

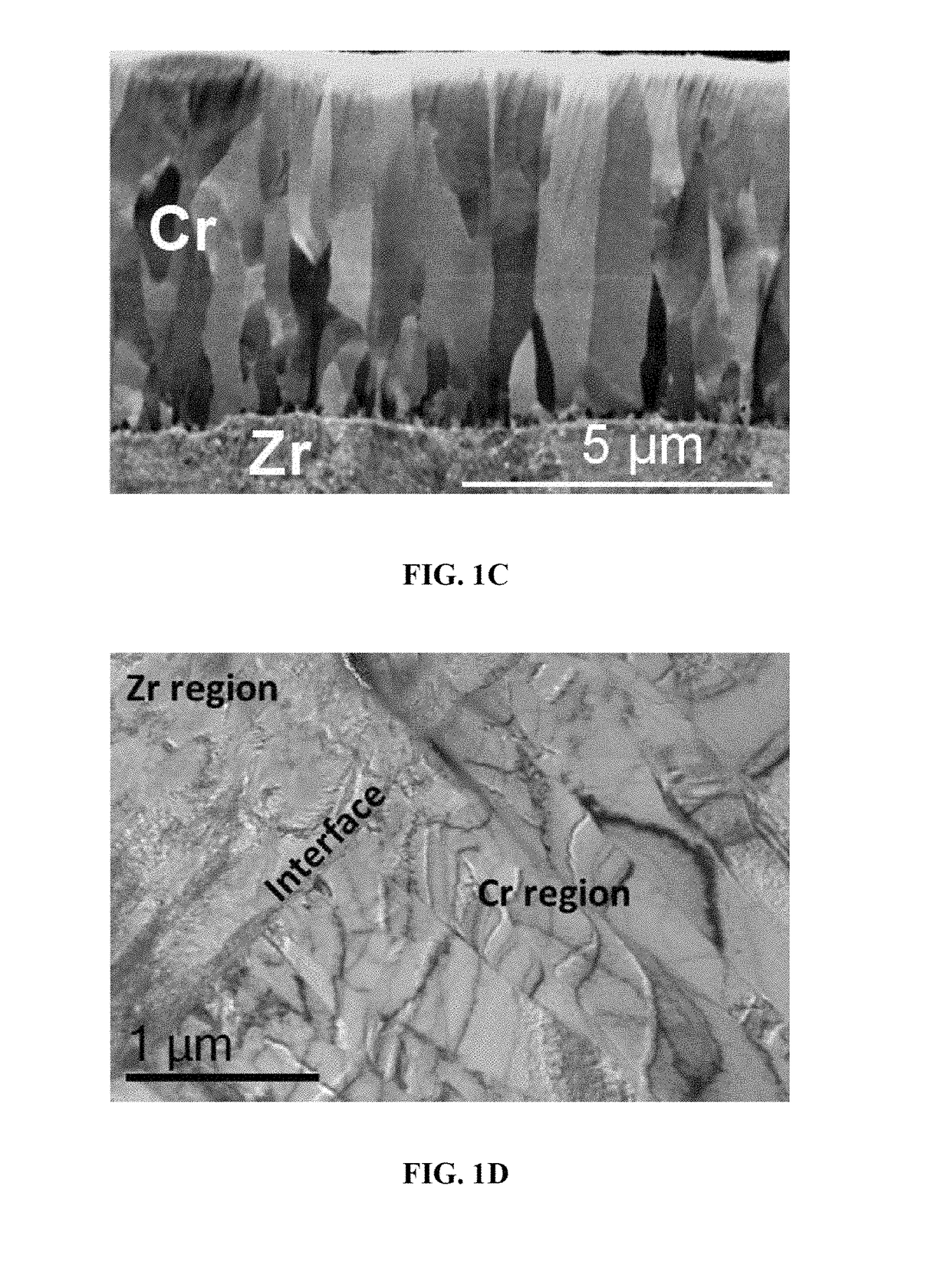

Multilayer material resistant to oxidation in a nuclear environment

ActiveUS20150050521A1Improve the immunityPromote oxidationFuel elementsNuclear energy generationNuclear reactorMetal

Multilayer material comprising a zirconium-based substrate covered with a multilayer coating, the multilayer coating comprising metallic layers composed of identical or different substances chosen from chromium, a chromium alloy or a ternary alloy of the Nb—Cr—Ti system. Such a material has improved resistance to oxidation in accident conditions of a nuclear reactor. The invention also relates to a multilayer coating, a part composed wholly or partly of the multilayer material or of the multilayer coating, as well as the method for manufacturing the multilayer material such as for example a magnetron cathodic sputtering process.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Molten salt nuclear reactor

InactiveUS20120183112A1Maximize probabilityFuel elementsConversion outside reactor/acceleratorsNuclear reactor coreBreeder reactor

A molten salt breeder reactor that has fuel conduit surrounded by a fertile blanket. The fuel salt conduit has an elongated core section that allows for the generation of electrical power on a scale comparable to commercially available nuclear reactors. The geometry of the fuel conduit is such that sub-critical conditions exist near the input and output of the fuel salt conduit and the fertile blanket surrounds the input and output of the fuel salt conduit, thereby minimizing neutron losses.

Owner:OTTAWA VALLEY RES ASSOCS

Nuclear fuel claddings, production method thereof and uses of same against oxidation/hydriding

ActiveUS20170287578A1Improve the immunityHigh strengthFuel elementsNuclear energy generationEtchingNiobium

The invention relates to a nuclear fuel cladding comprising: i) a substrate containing a zirconium-based inner layer, optionally coated with at least one intermediate layer formed by at least one intermediate material selected from among tantalum, molybdenum, tungsten, niobium, vanadium, hafnium or the alloys thereof; and ii) at least one protective outer layer placed on the substrate and formed by a protective material selected from either chromium or an alloy of chromium. The nuclear fuel cladding produced using the method of the invention has improved resistance to oxidation / hydriding. The invention also relates to the method for the production of the nuclear fuel cladding by ion etching of the surface of the substrate and deposition of the outer layer on the substrate with a high power impulse magnetron sputtering method (HiPIMS), as well as to the use thereof to protect against oxidation and / or hydriding.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Sheathed, annular metal nuclear fuel

A sheathed, annular metal fuel system is described. A metal fuel pin system is described that includes an annular metal nuclear fuel alloy. A sheath may surround the metal nuclear fuel alloy, and a cladding may surround the sheath. A gas plenum may also be present. Mold arrangements and methods of fabrication of the sheathed, annular metal fuel are also described.

Owner:ADVANCED REACTOR CONCEPTS

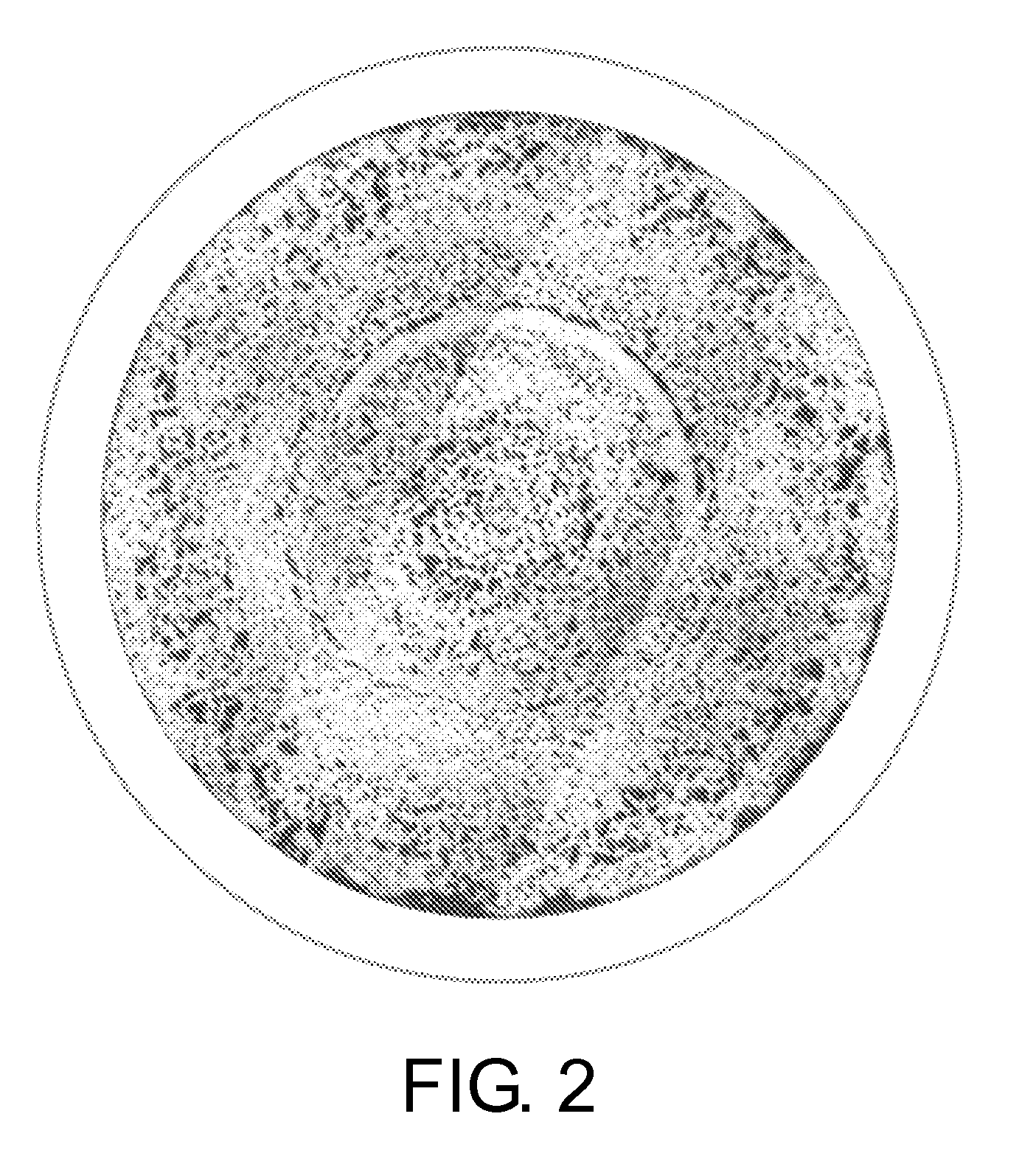

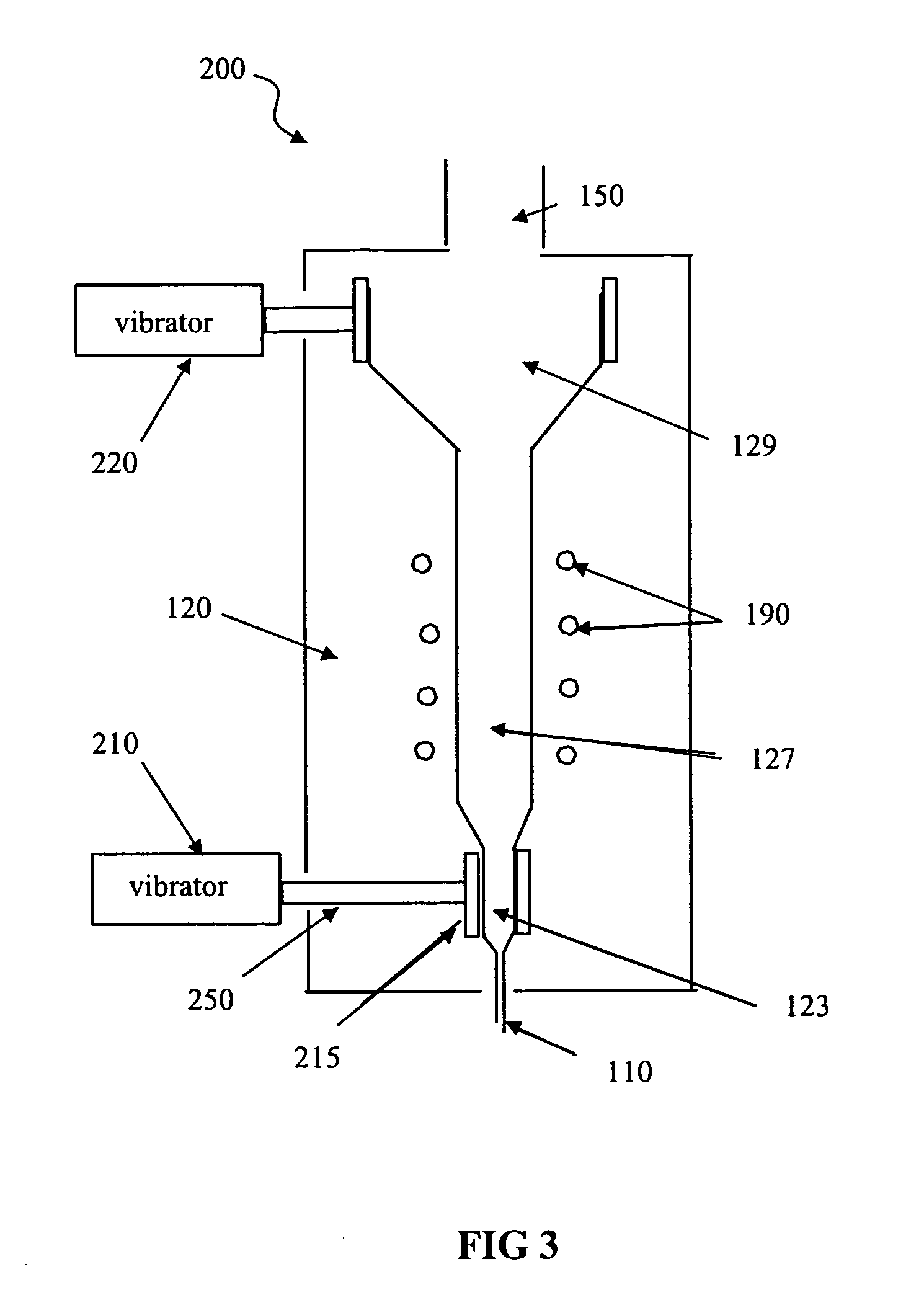

Methods and apparatuses for the development of microstructured nuclear fuels

ActiveUS7521007B1Ensure uniform motionLow costFuel elementsNuclear energy generationChemical vapor depositionMaterials science

Microstructured nuclear fuel adapted for nuclear power system use includes fissile material structures of micrometer-scale dimension dispersed in a matrix material. In one method of production, fissile material particles are processed in a chemical vapor deposition (CVD) fluidized-bed reactor including a gas inlet for providing controlled gas flow into a particle coating chamber, a lower bed hot zone region to contain powder, and an upper bed region to enable powder expansion. At least one pneumatic or electric vibrator is operationally coupled to the particle coating chamber for causing vibration of the particle coater to promote uniform powder coating within the particle coater during fuel processing. An exhaust associated with the particle coating chamber and can provide a port for placement and removal of particles and powder. During use of the fuel in a nuclear power reactor, fission products escape from the fissile material structures and come to rest in the matrix material. After a period of use in a nuclear power reactor and subsequent cooling, separation of the fissile material from the matrix containing the embedded fission products will provide an efficient partitioning of the bulk of the fissile material from the fission products. The fissile material can be reused by incorporating it into new microstructured fuel. The fission products and matrix material can be incorporated into a waste form for disposal or processed to separate valuable components from the fission products mixture.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com