Patents

Literature

338 results about "Particle coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanoparticle-based controlled release polymer coatings for medical implants

InactiveUS20050095267A1Improve solubilityFacilitated releaseStentsSurgeryControlled releaseSolubility

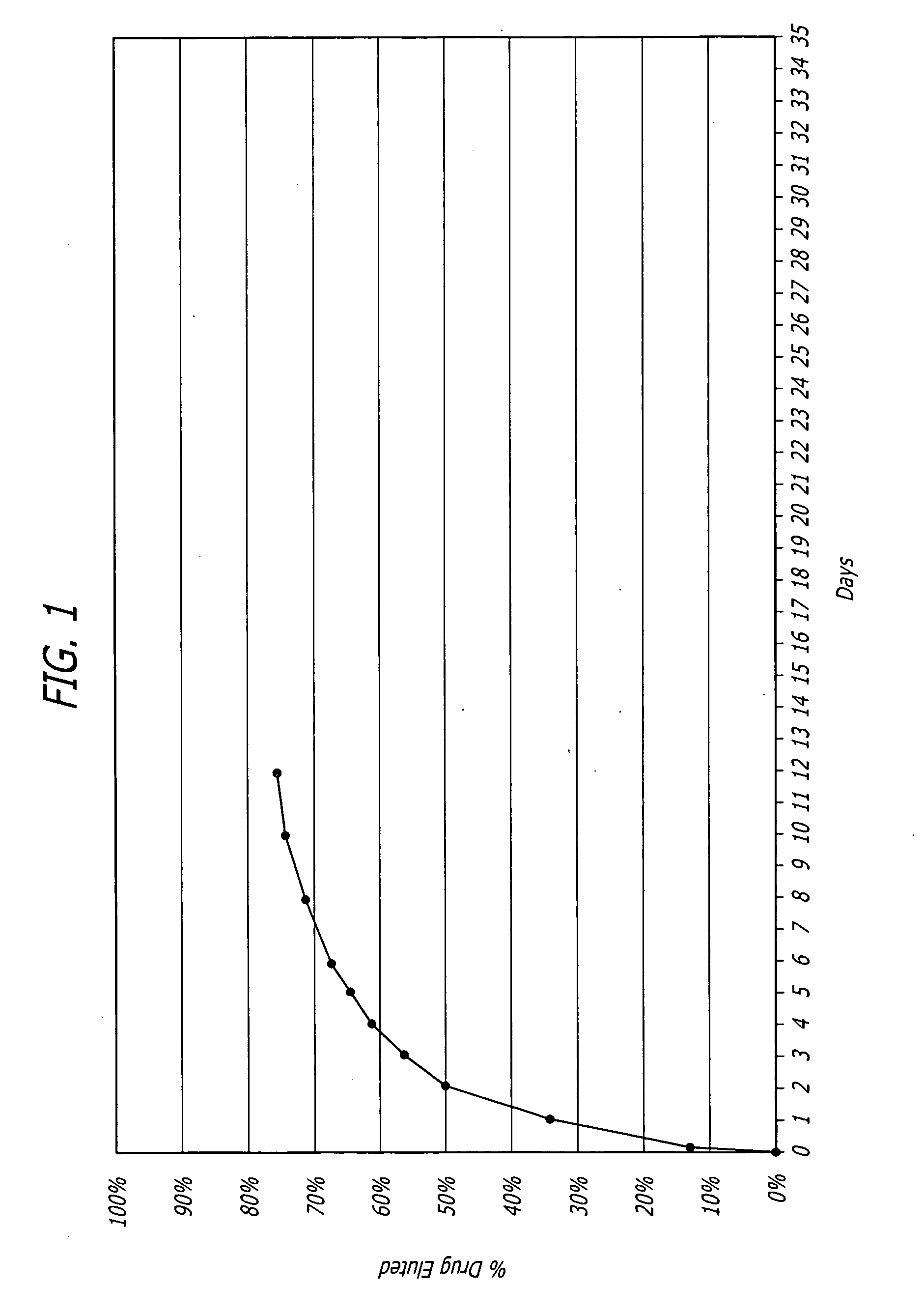

Implantable medical devices having a nanoparticle coating applied thereon. The nanoparticle coating comprises nanopulverized antiproliferative compounds. More specifically, the nanoparticulate antiproliferative compounds comprise particles less than 500 nm in size. The nanoparticle size of the compounds improves compounds' solubility. In addition to improving the solubility of otherwise insoluable antiproliferative compounds, the nanoparticle size minimizes the preparation and formulation required to prepare a dose of the antiproliferative compounds.

Owner:MEDTRONIC VASCULAR INC

Process for preparing detergent particles having coating or partial coating layers

InactiveUS7022660B1Improved surface and appearance and flow propertyImprove surface propertiesInorganic/elemental detergent compounding agentsDetergent mixture composition preparationDouble saltWater soluble

A process for preparing a detergent particle having a coating layer of a water-soluble material is provided. The process comprises providing a particle core of a detergent active material and the particle core is then at least partially covered by a particle coating layer of a water soluble coating material including double salt combinations of alkali metal carbonates and sulfates that reduces the surface area of the particle.

Owner:THE PROCTER & GAMBLE COMPANY

Nanoparticle and surface-modified particulate coatings, coated balloons, and methods therefore

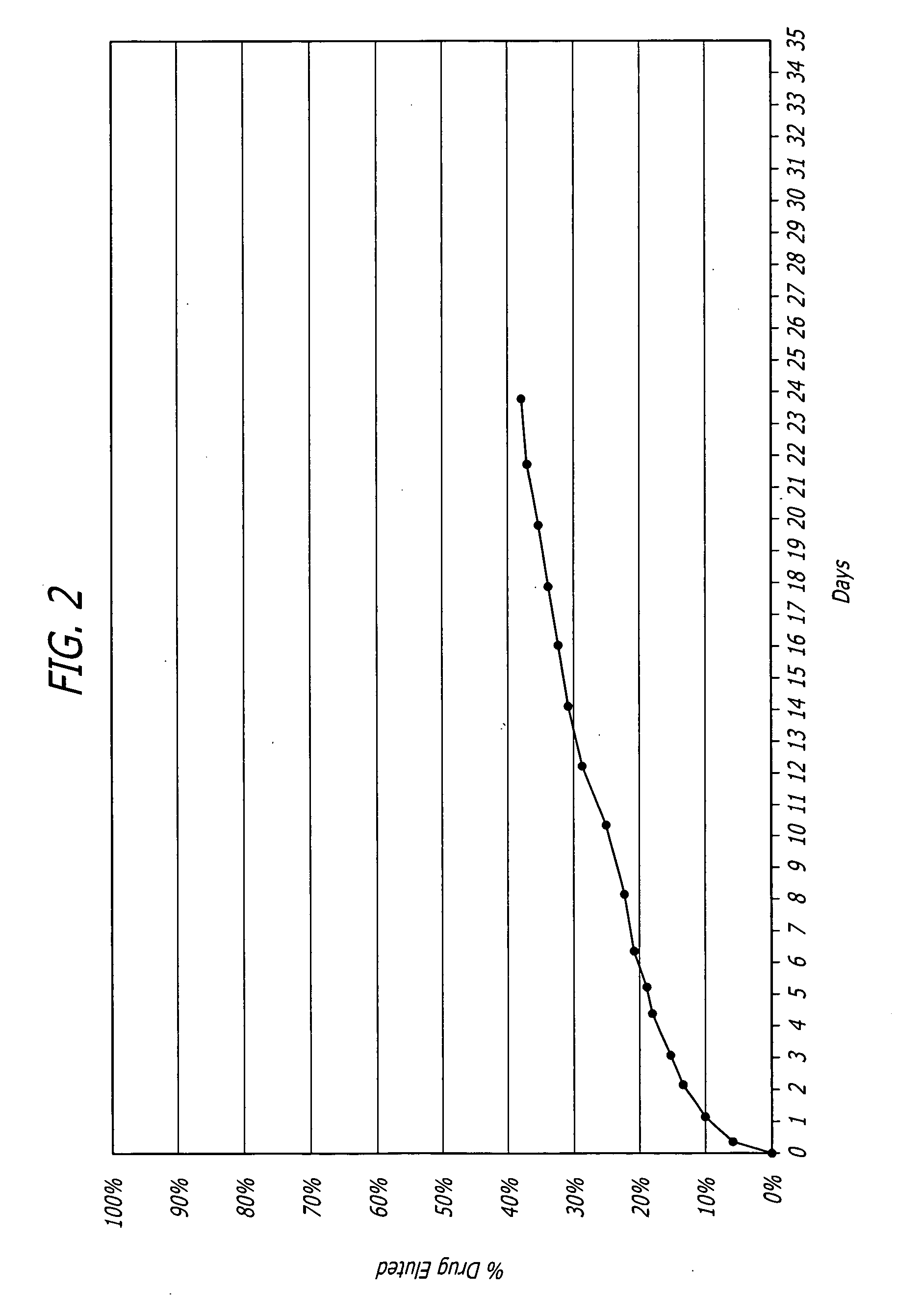

Devices, coatings, and methods therefore comprise a medical device for delivering nanoparticles of an active agent to a treatment site. A coating on the medical device comprises active agent nanoparticles, which delivers coating to the treatment site and releases active agent nanoparticles into the treatment site over at least one day. A coating may comprise a polymer, a surfactant, and the nanoparticles. The coating may be prepared by forming a nanoemulsion. A coating may comprise encapsulated active agent nanoparticles which comprise active agent nanoparticles encapsulated in a polymer. The coating may have a positive surface charge. The coating may deliver active agent nanoparticles into the treatment site over at least about one day. The coating may be formed of a surfactant and nanoparticles mixture. The active agent nanoparticles may be deposited on the medical device using electrostatic capture.

Owner:MICELL TECH INC

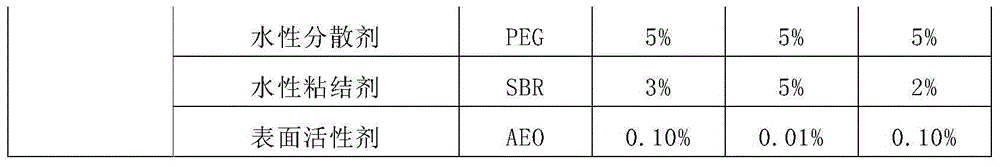

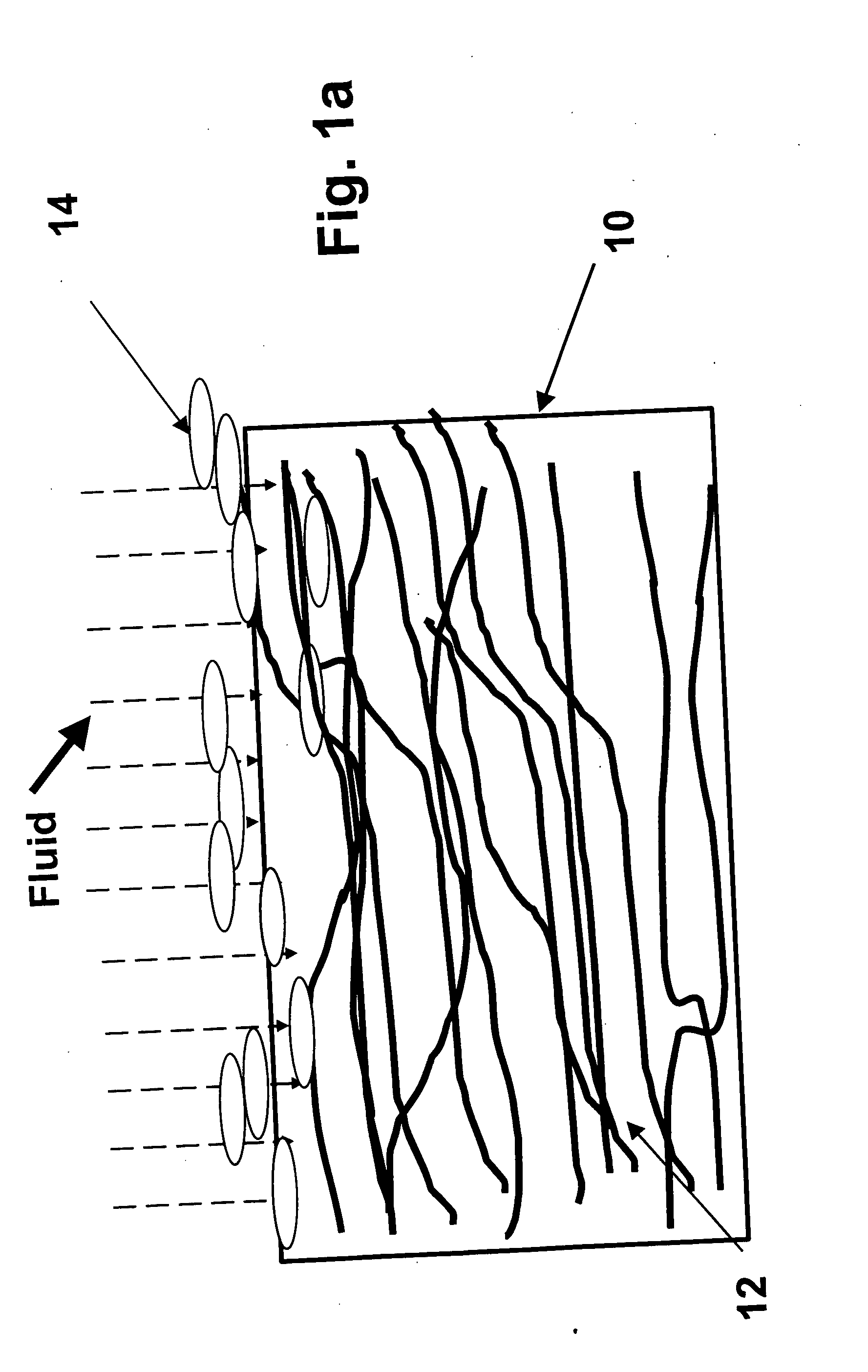

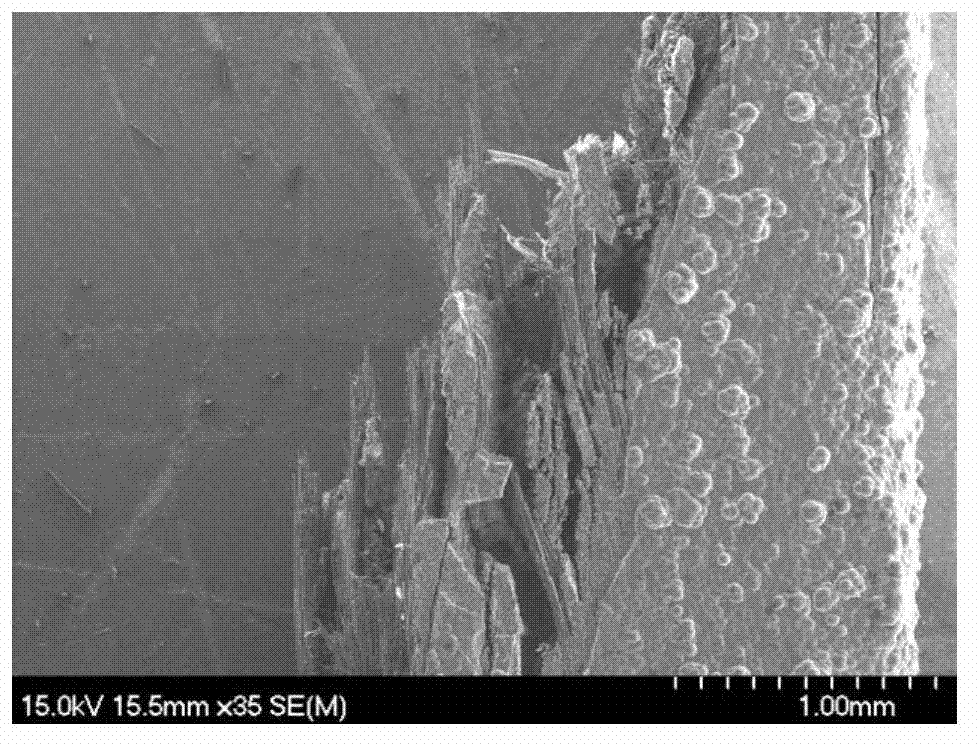

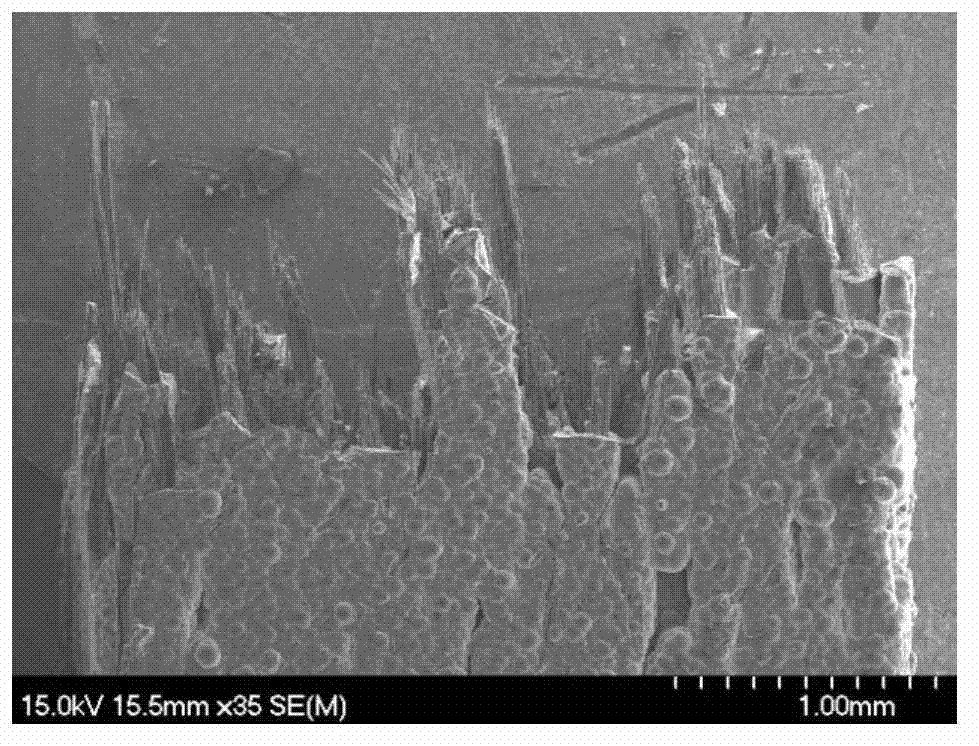

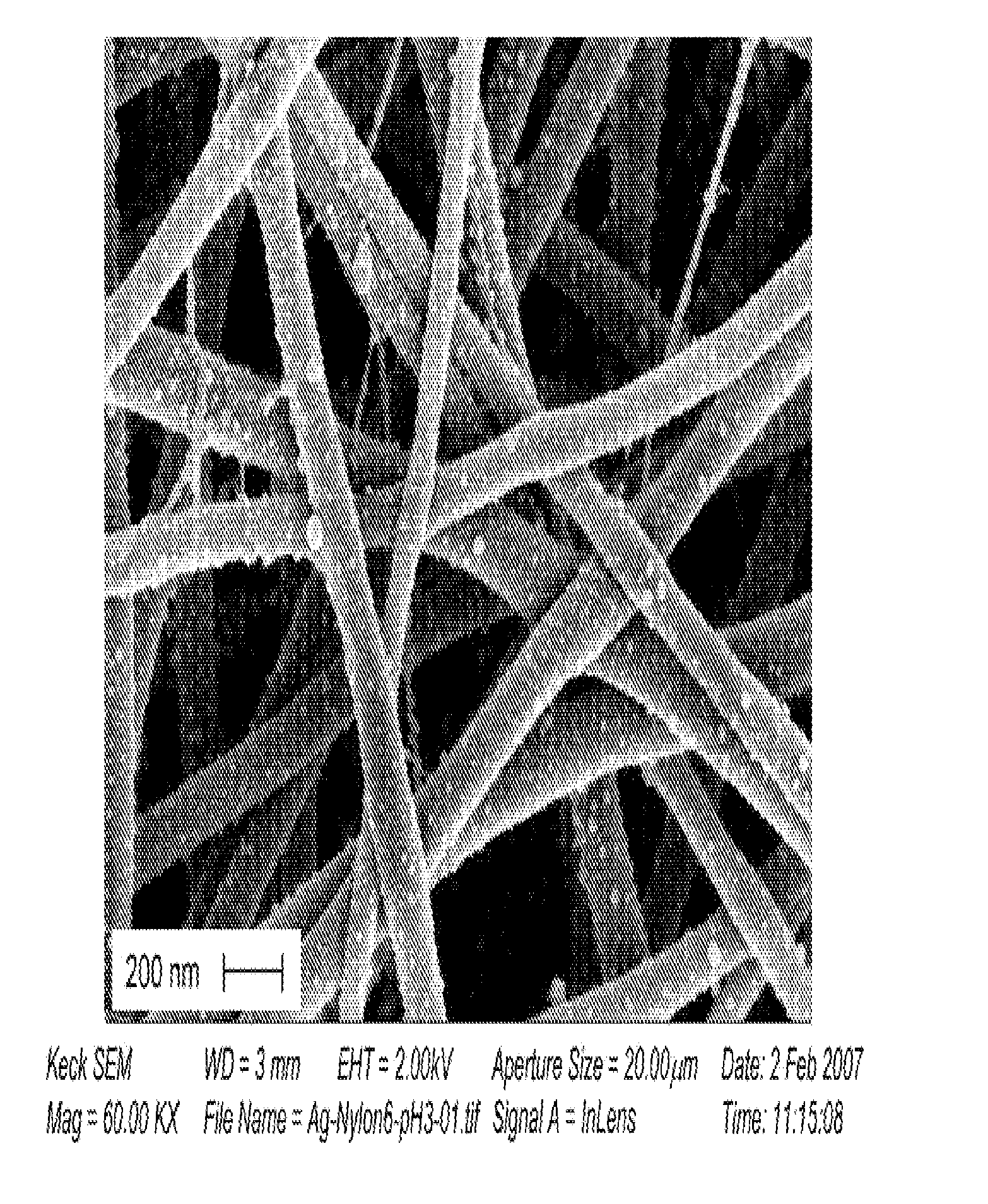

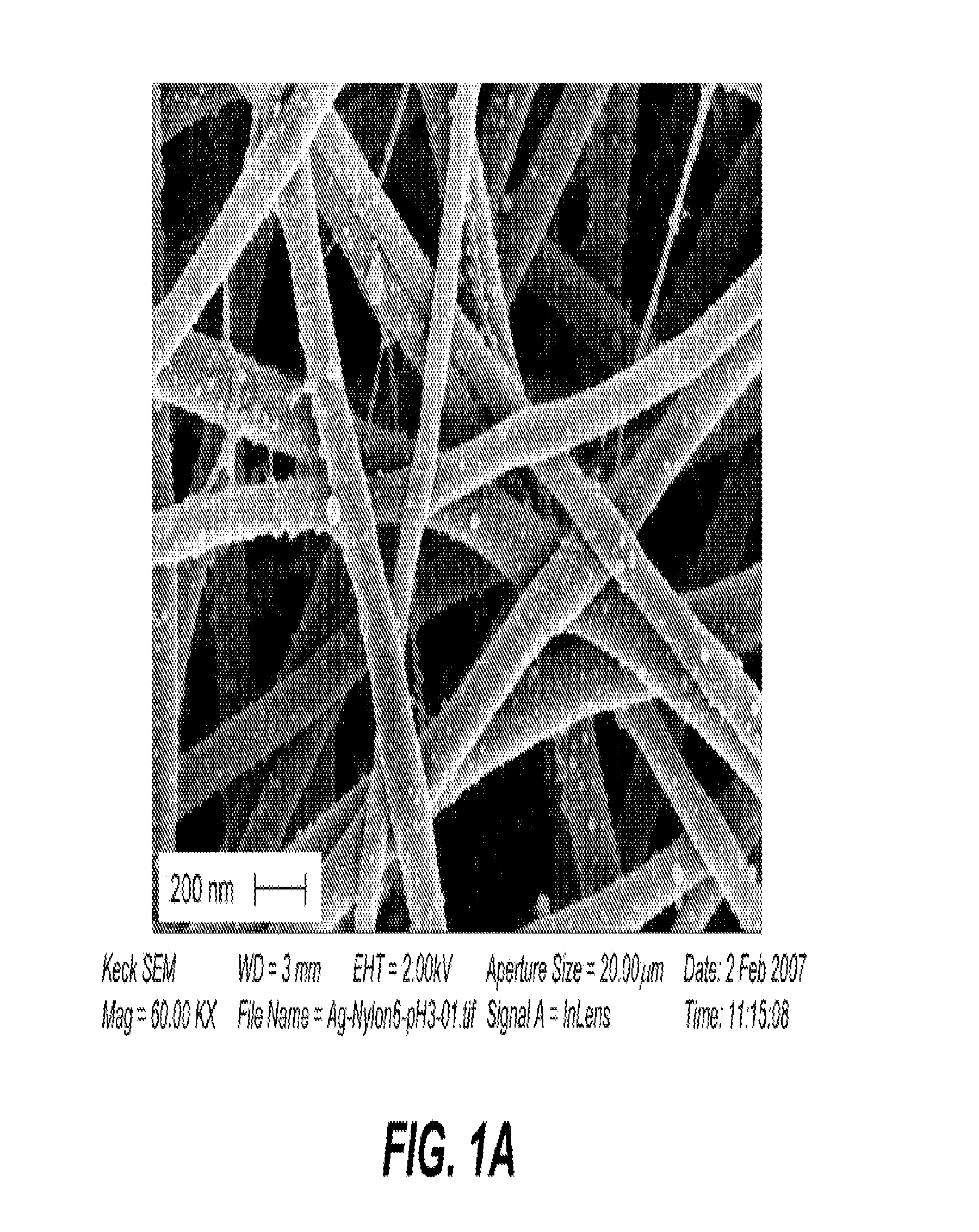

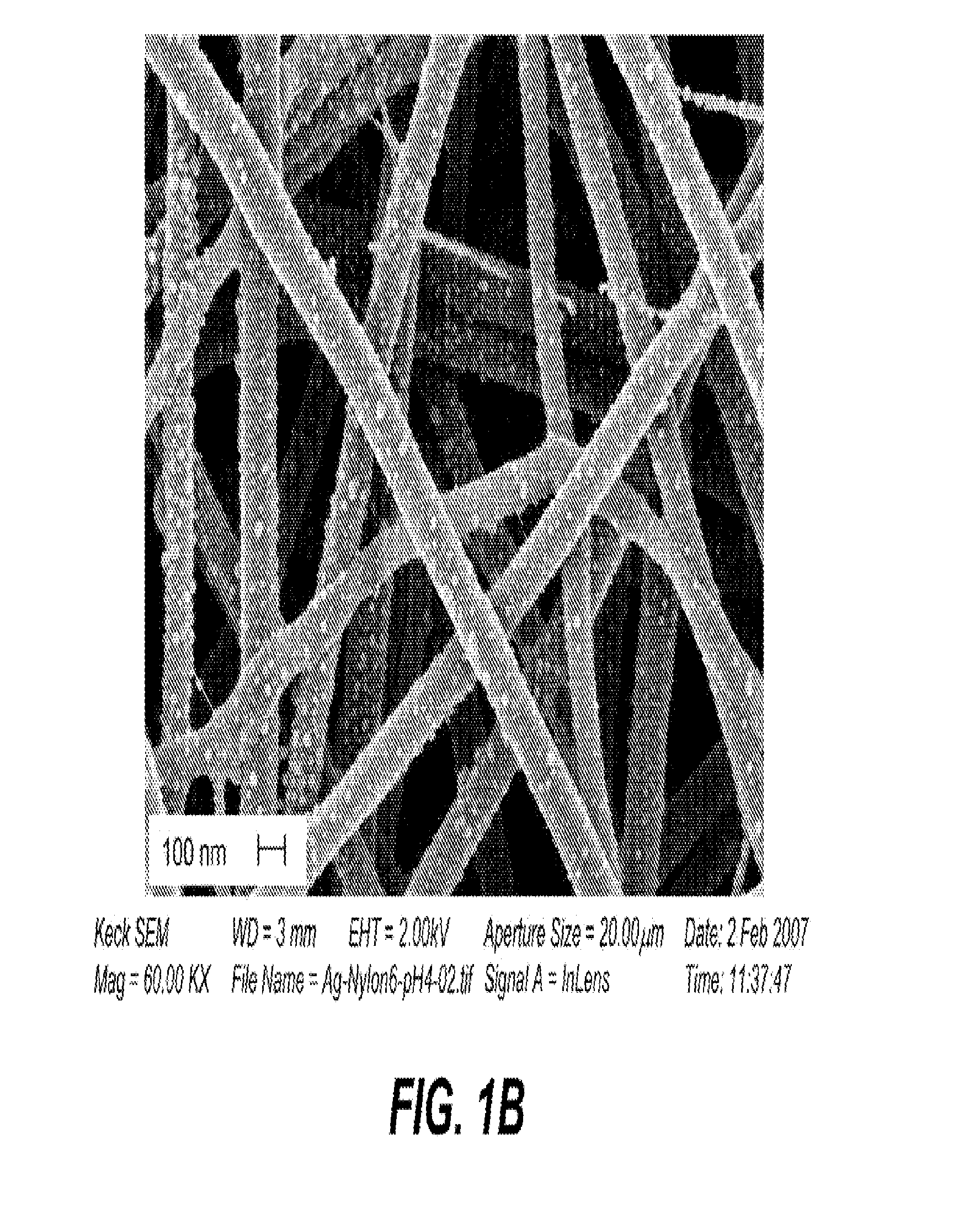

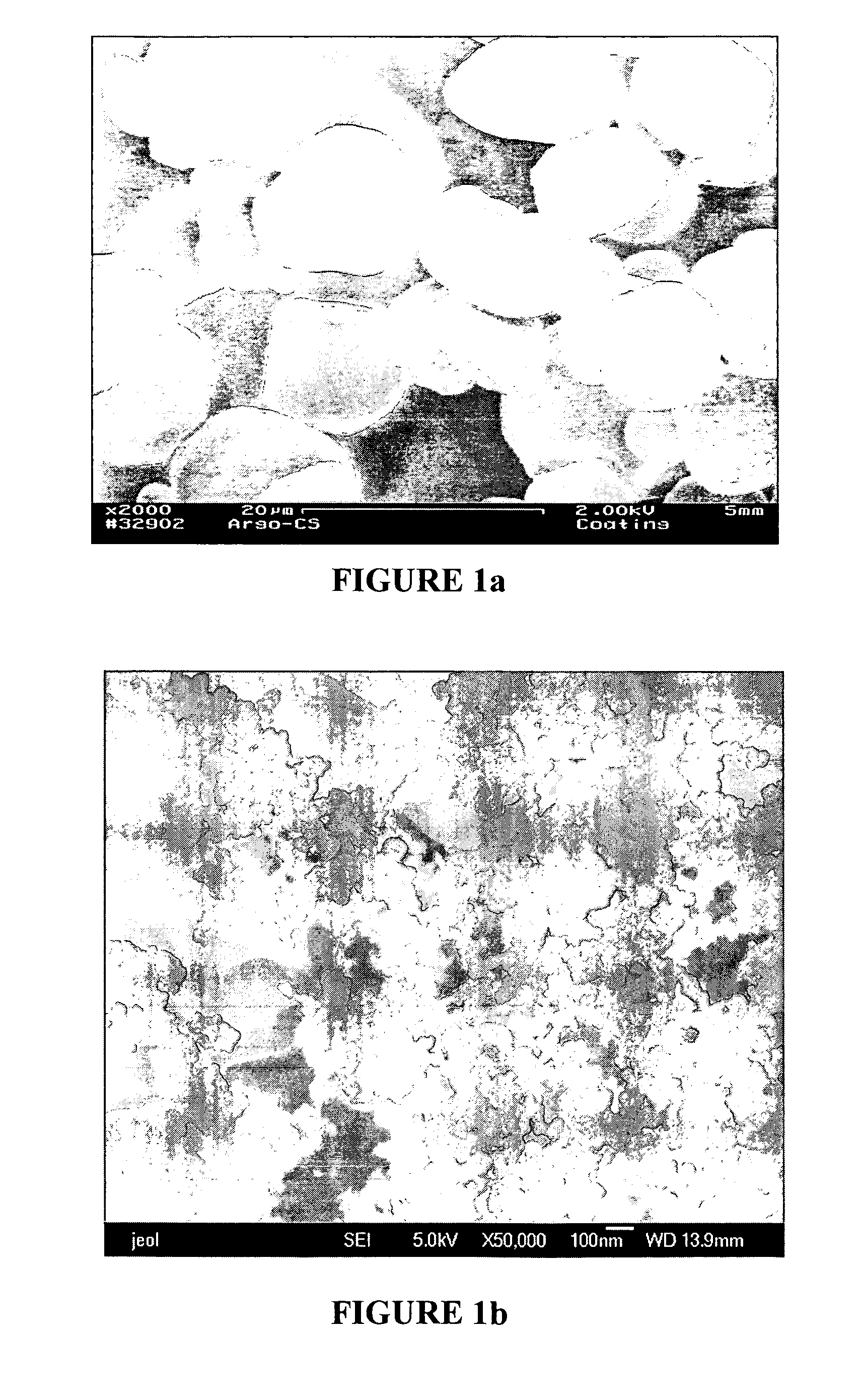

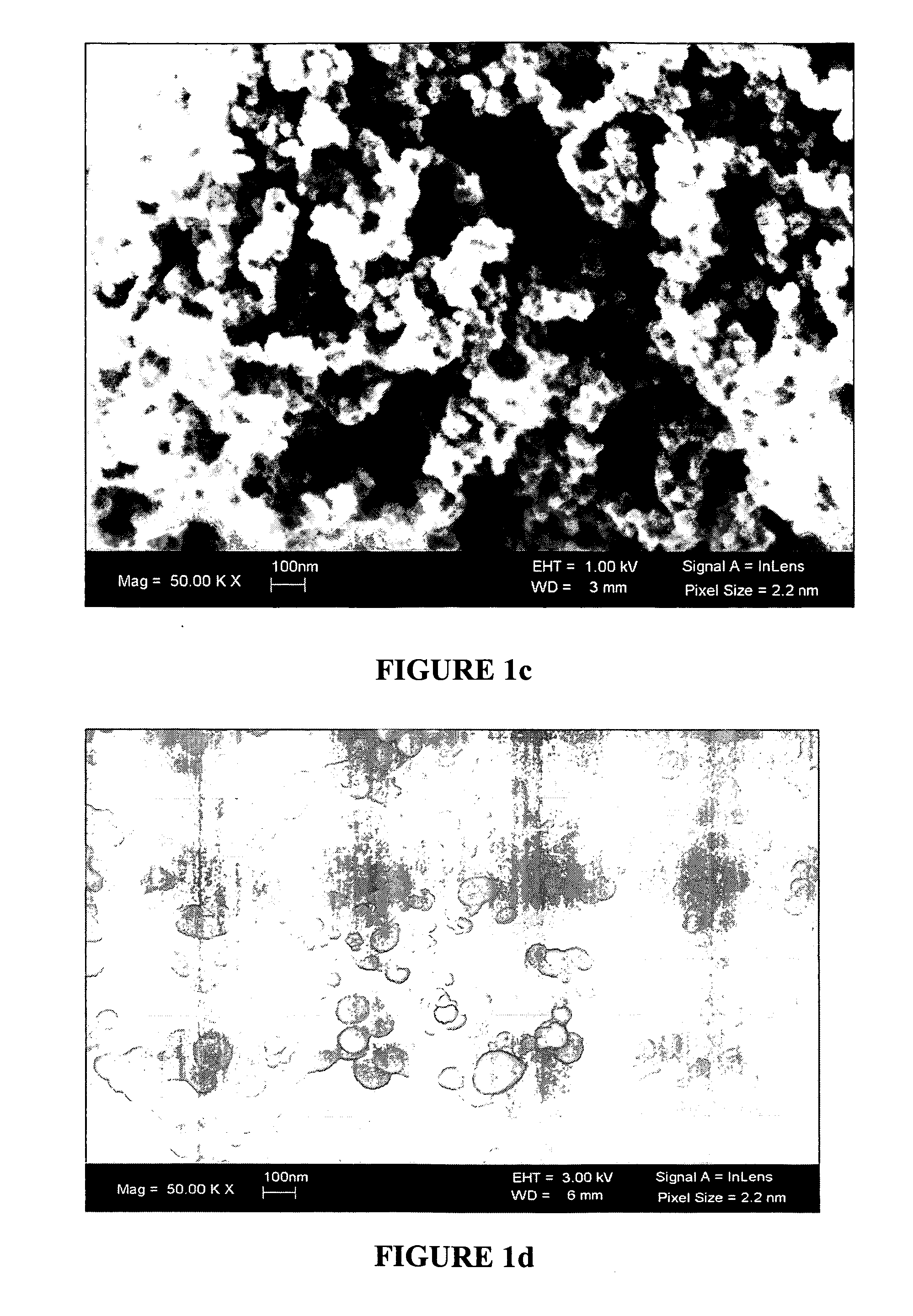

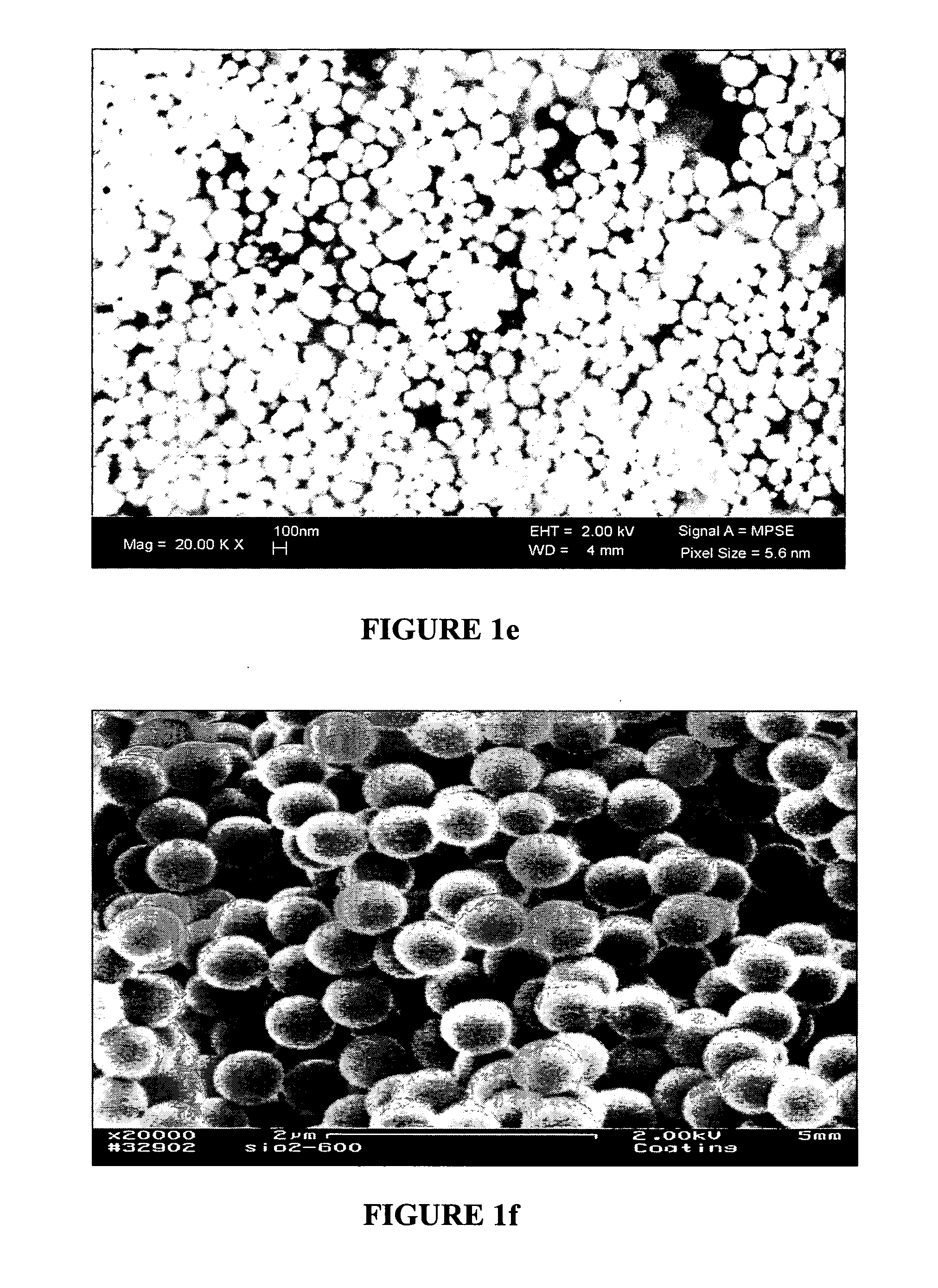

Conformal particle coatings on fiber materials for use in spectroscopic methods for detecting targets of interest and methods based thereon

InactiveUS20120058697A1Good spectral characteristicsMaterial nanotechnologyLayered productsTextile fiberFluorescence

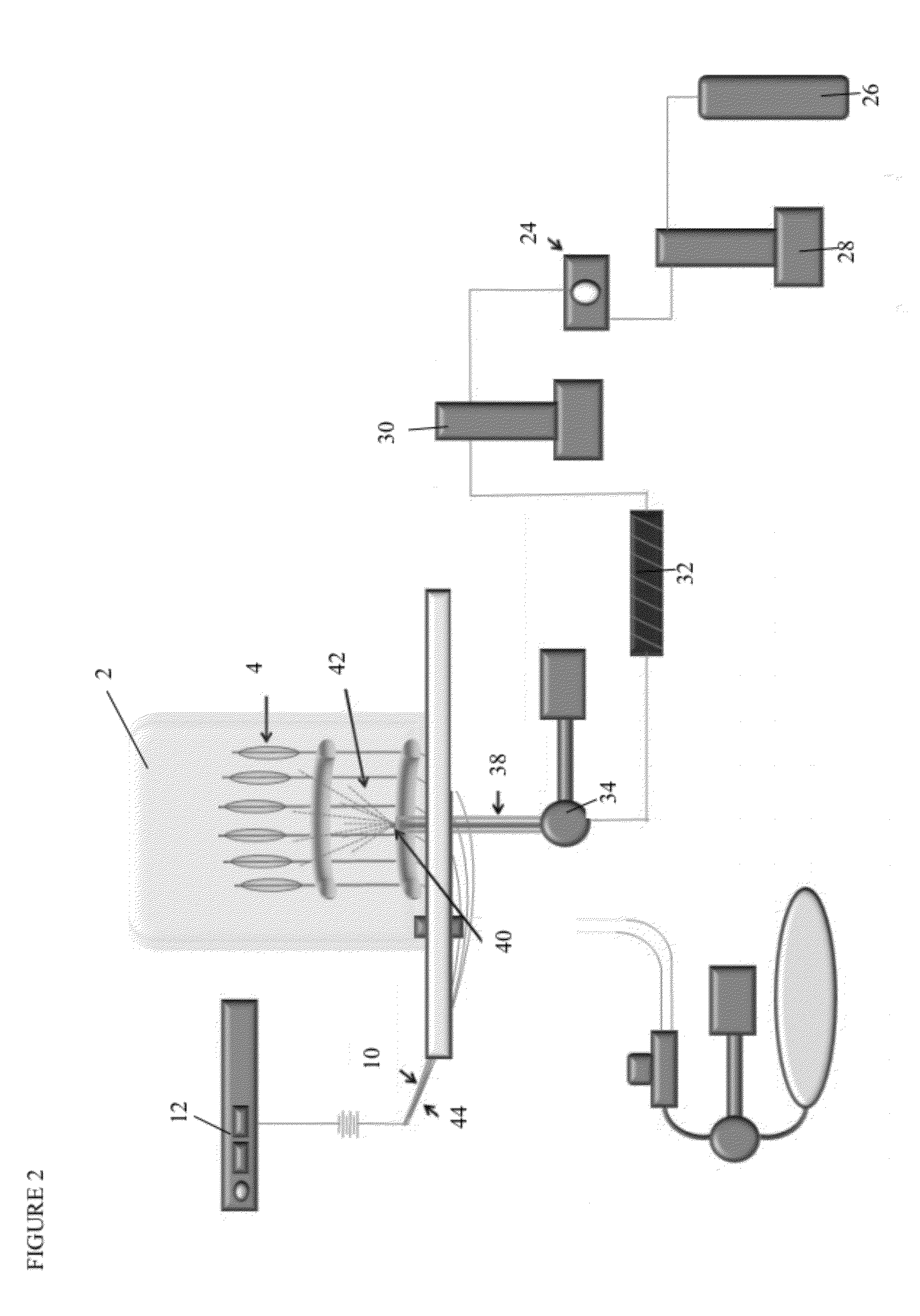

Textile fibers and other fibrous substrates functionalized with particles are provided for use in the detection of targets of interest by spectroscopic methods. In one embodiment, a substrate is provided that comprises a conformal coating on its surface, wherein the coating comprises a plurality of chemically functional particles that are spectroscopically enhancing. Methods for producing such functionalized textile fibers are also provided. These textiles can be used as platforms for spectroscopic detection, including surface-enhanced Raman scattering (SERS), surface-enhanced infrared absorption (SEIRA), and surface-enhanced fluorescence (SEF). Functionalized textile fibers for use in the signature detection methods are produced by performing layer-by-layer self-assembly of particles on natural and synthetic textile substrates.

Owner:CORNELL UNIVERSITY

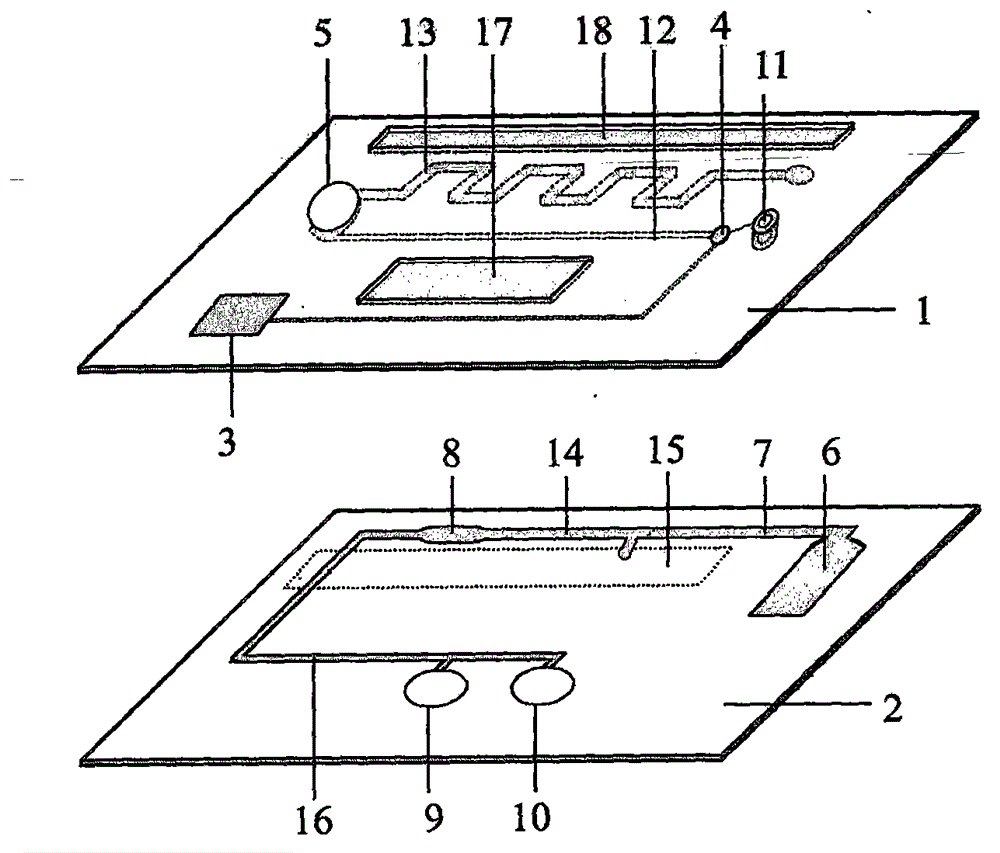

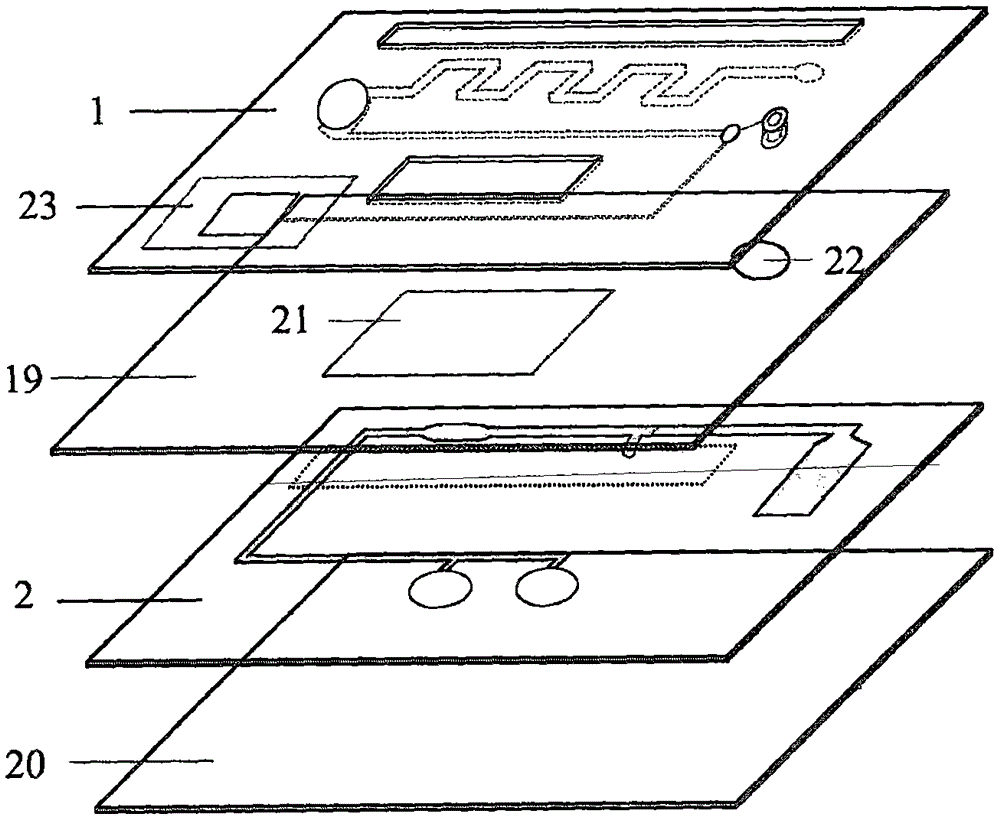

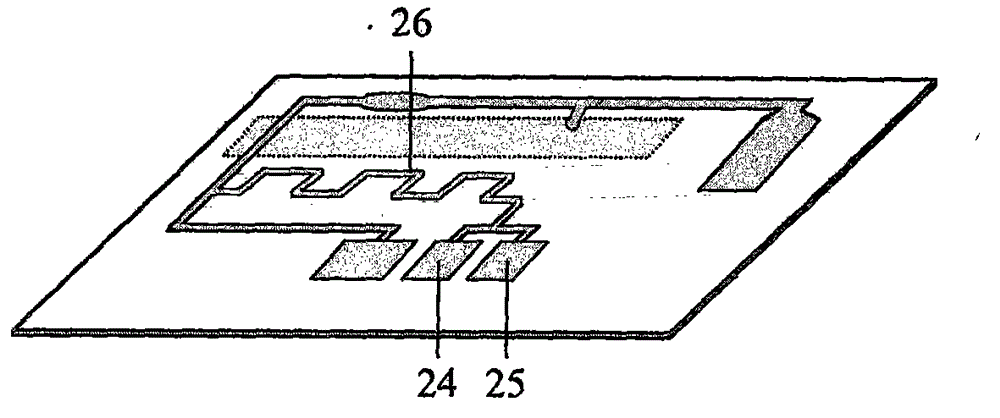

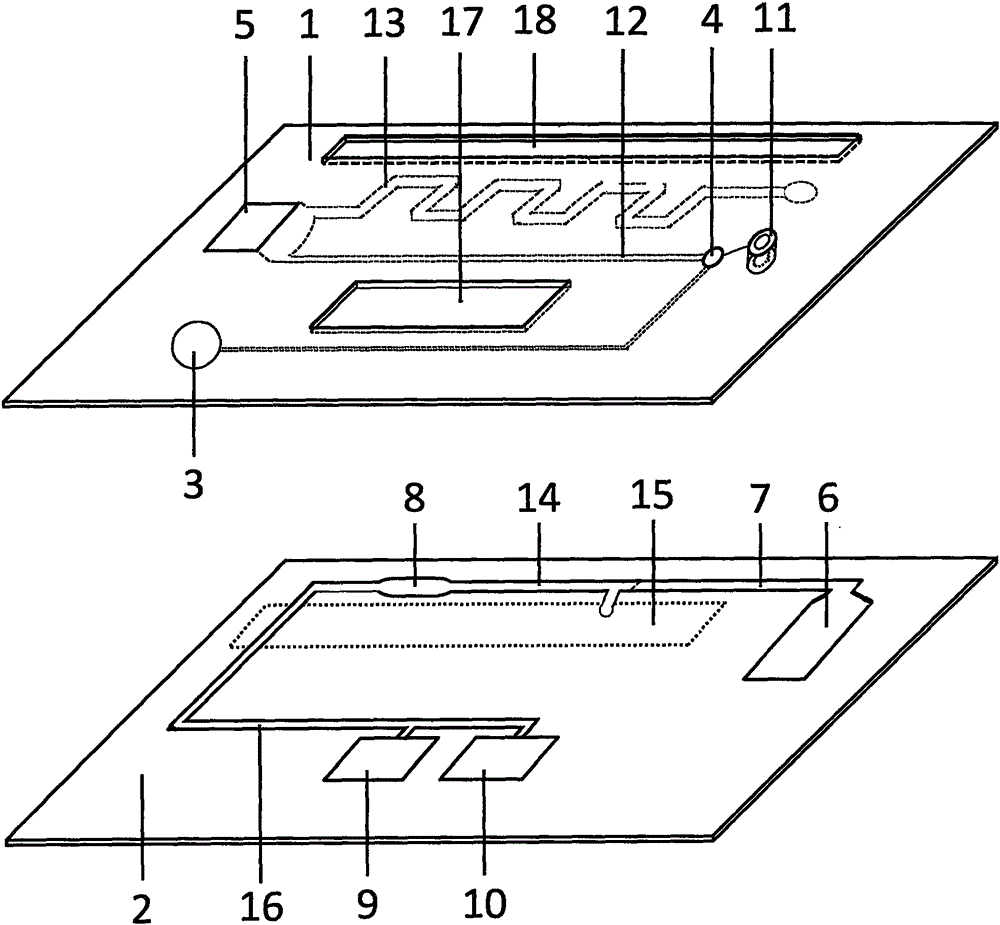

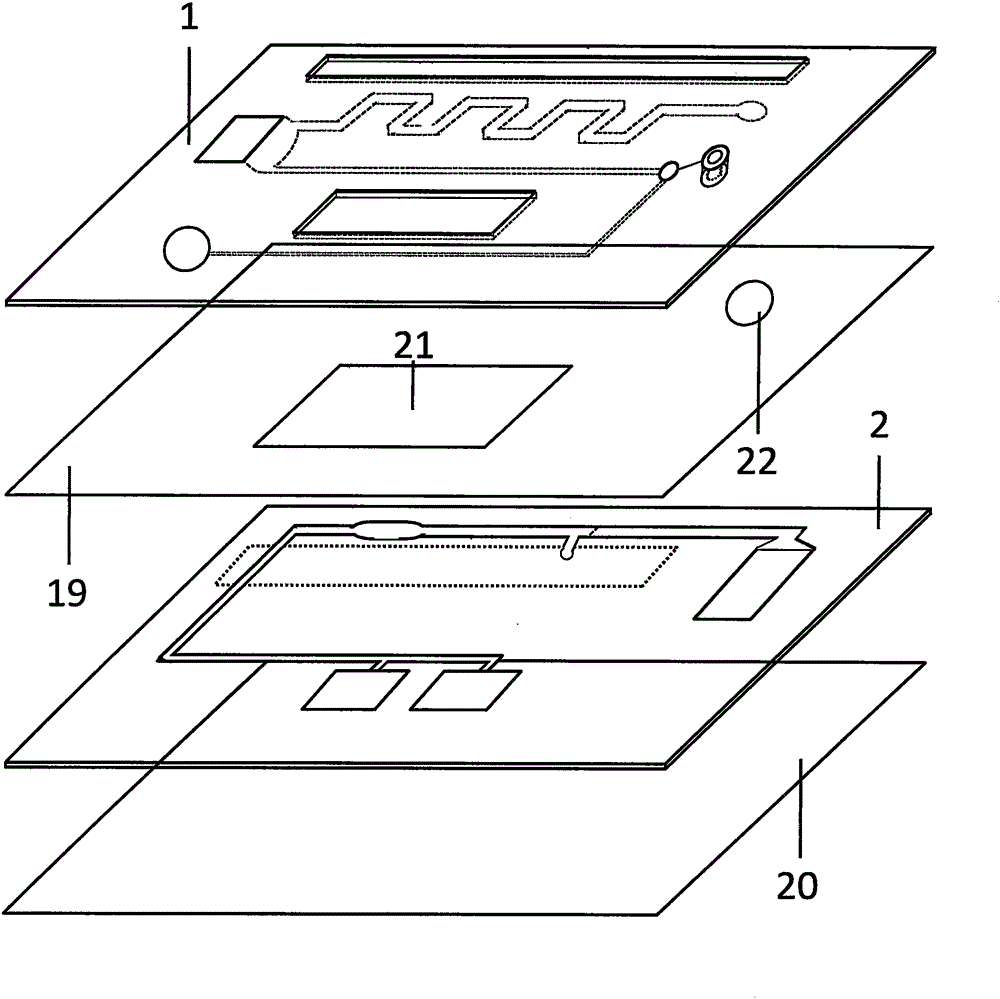

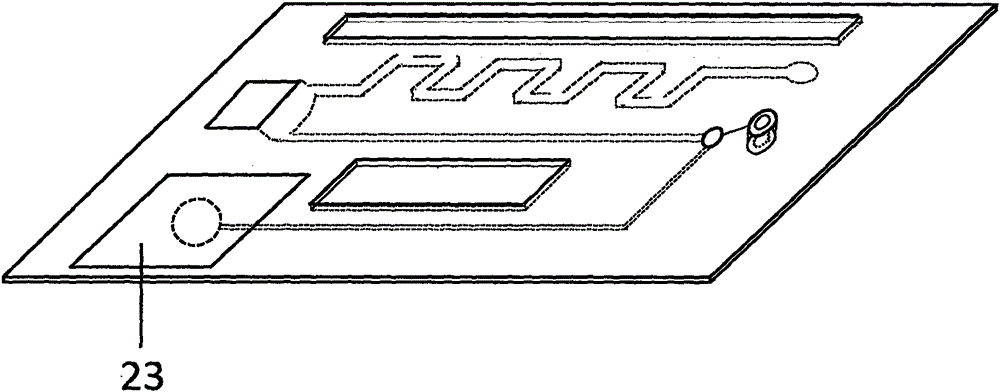

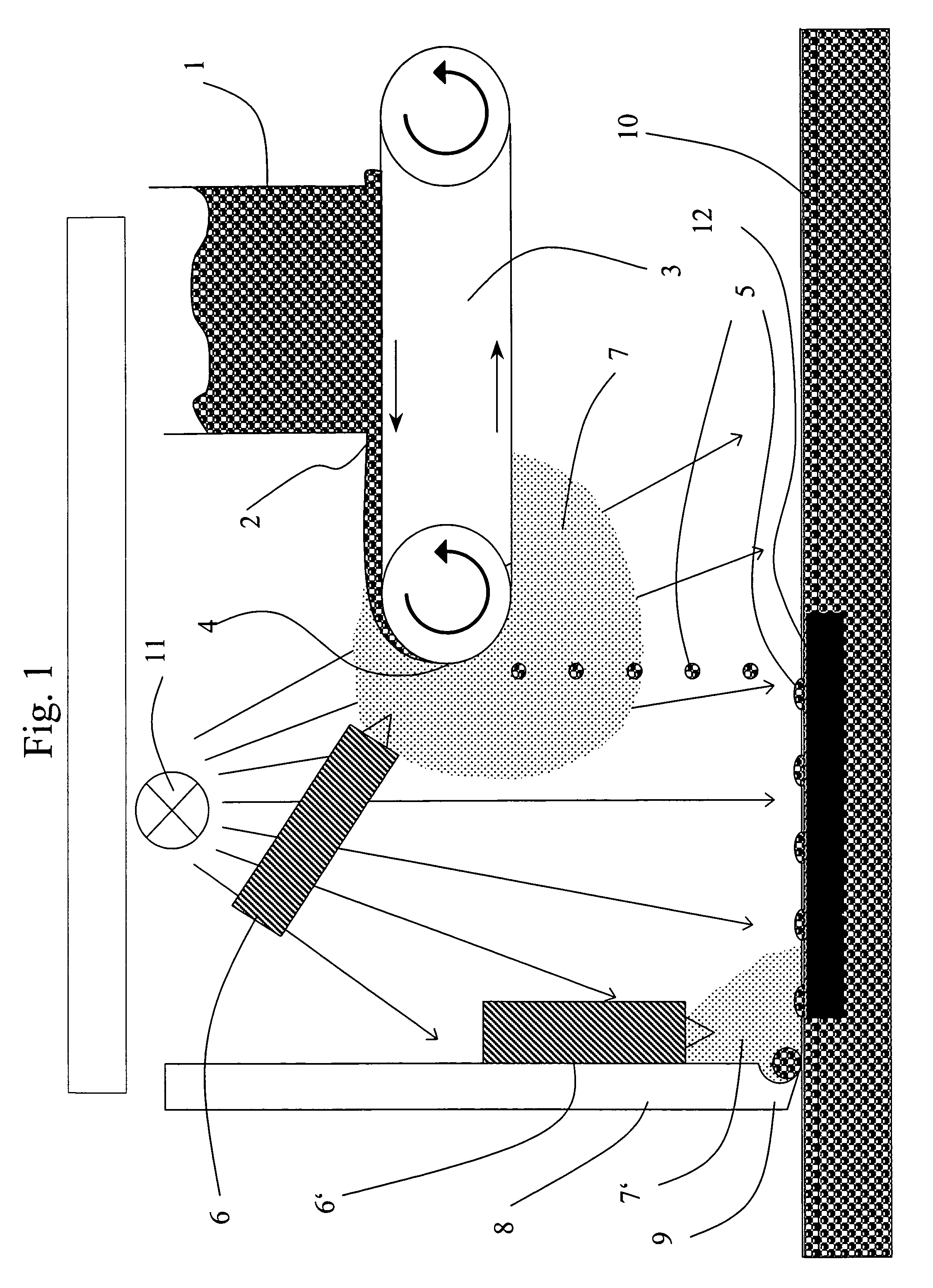

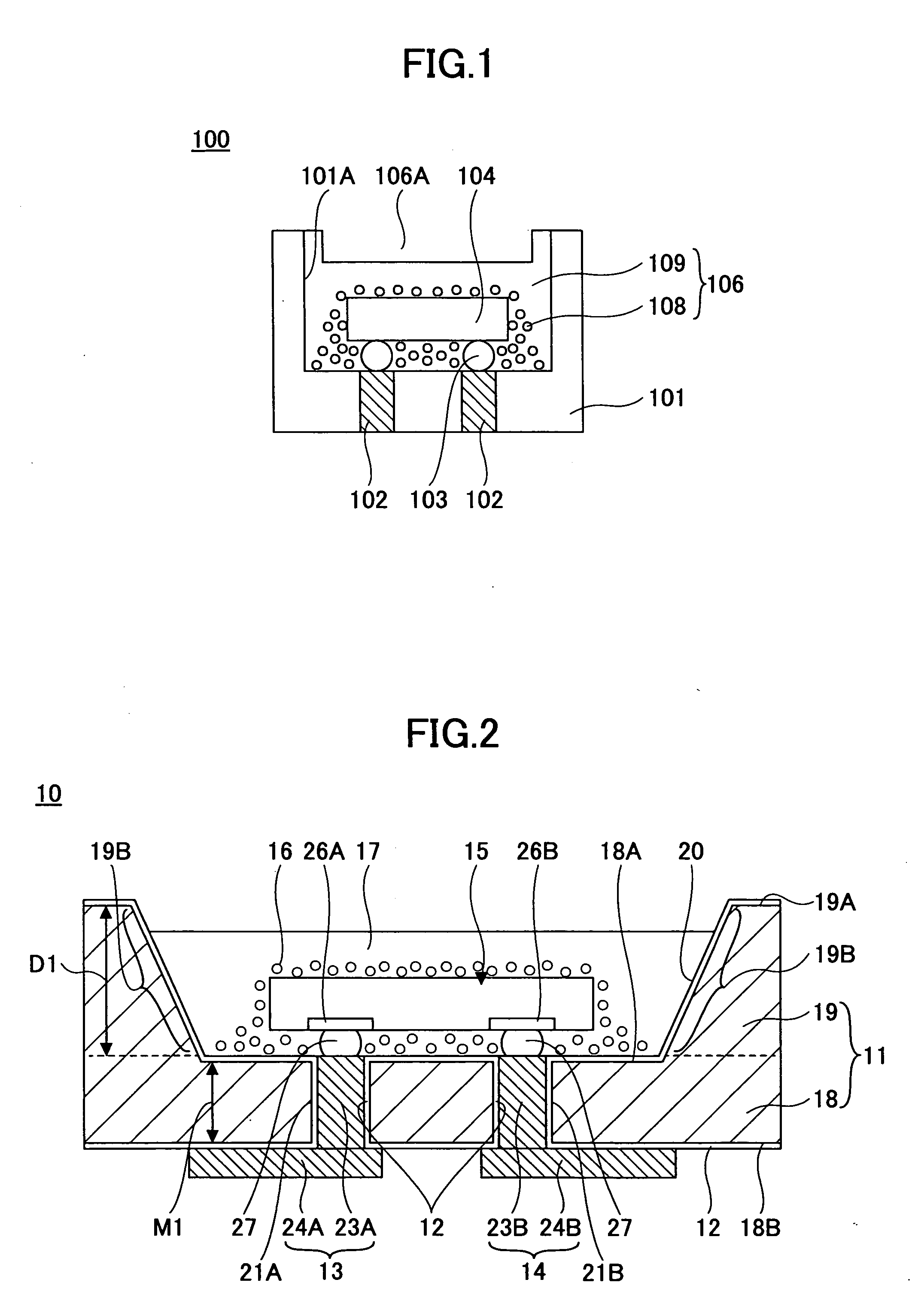

Magnetic particle chemiluminescence micro-fluidic chip

The invention discloses a magnetic particle chemiluminescence micro-fluidic chip. The micro-fluidic chip comprises a top plate (1) and a bottom plate (2), the top plate (1) comprises an air pump (3), a sample adding opening (4), a sample filling area (12), a marking ligand storage pool (5) and a sample mixing area (13). The bottom plate (2) comprises a filter area (6), a magnetic particle coating area (7), a washing area (14), a detecting area (8), a washing liquid storage pool (9), a light-emitting substrate storage pool (10) and a liquid release channel (16). The top plate and the bottom plate both comprise liquid sensing devices, and the liquid sensing devices are used for determining the flowing state of liquid in the micro-fluidic chip and whether bubbles are mixed into the micro-fluidic chip.

Owner:SHENZHEN HUAMAIXINGWEI MEDICAL TECH CO LTD

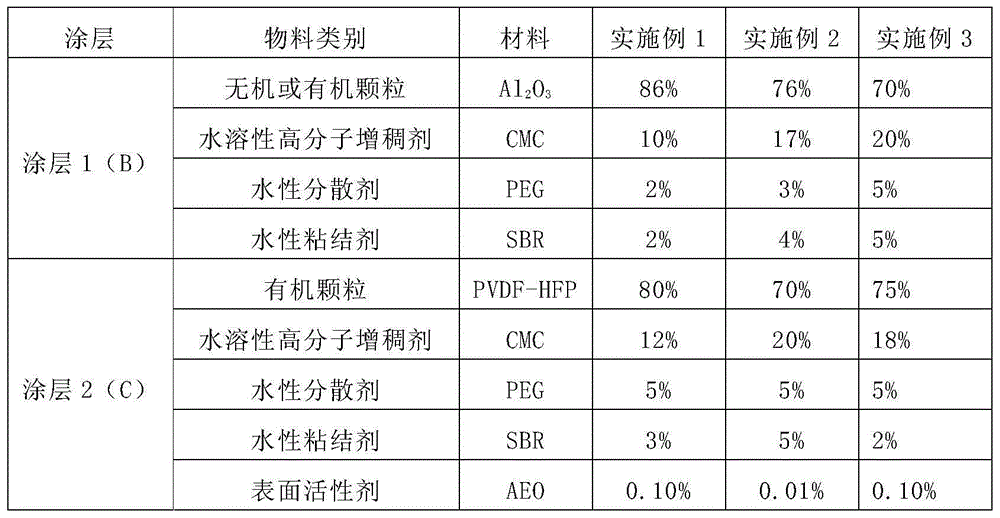

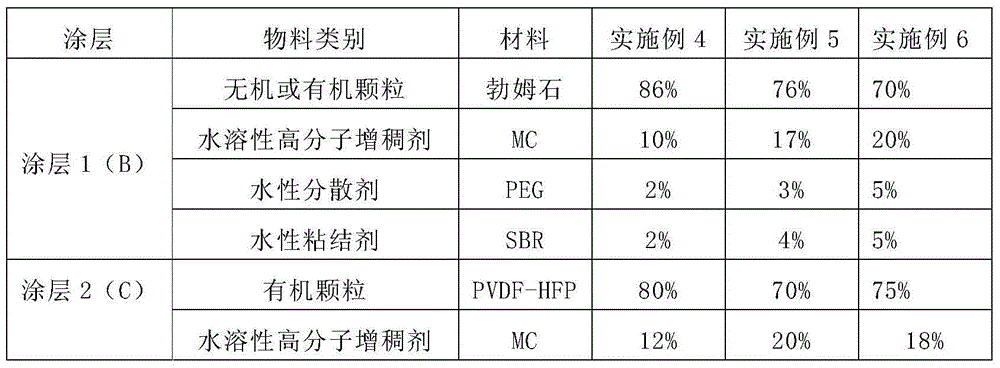

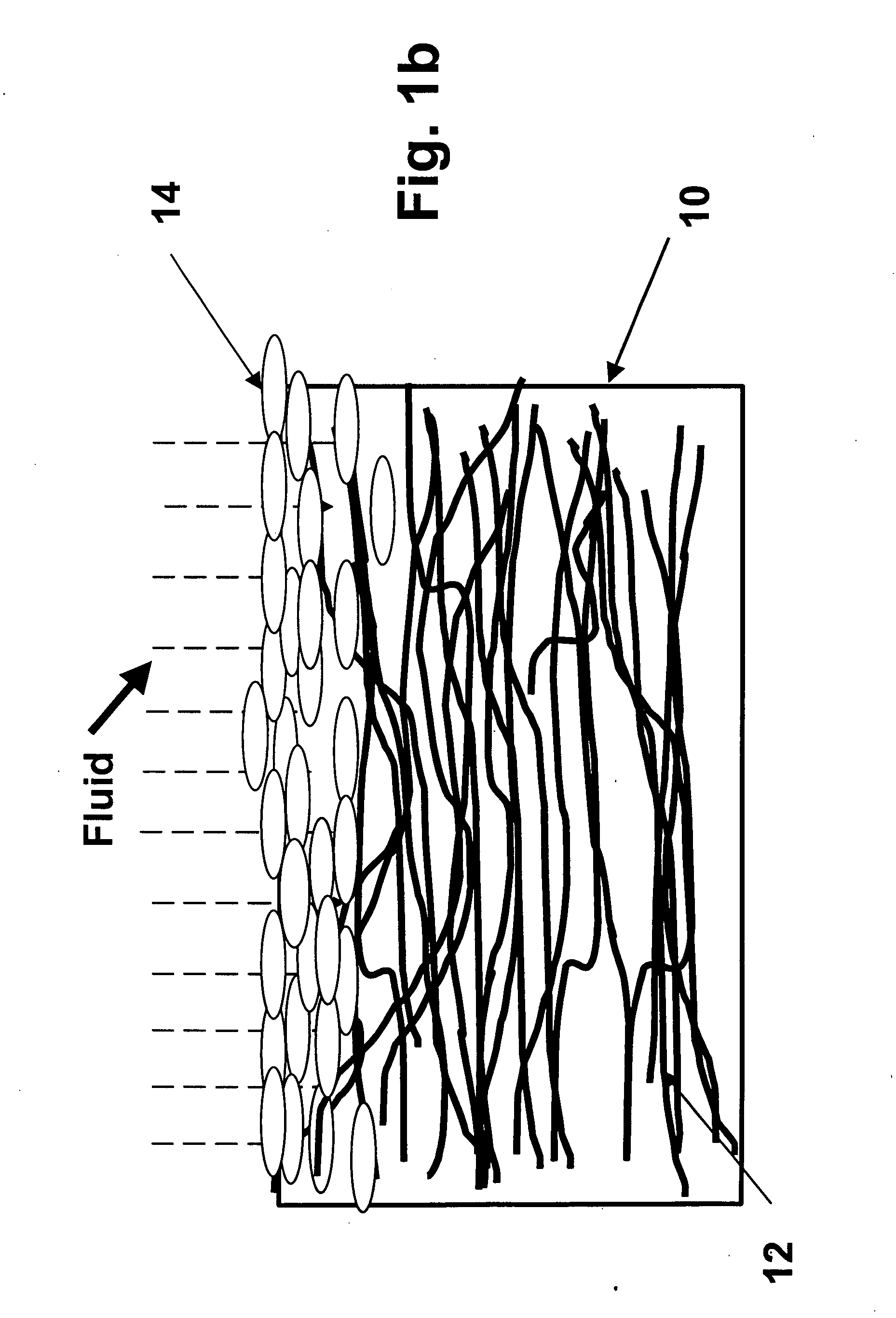

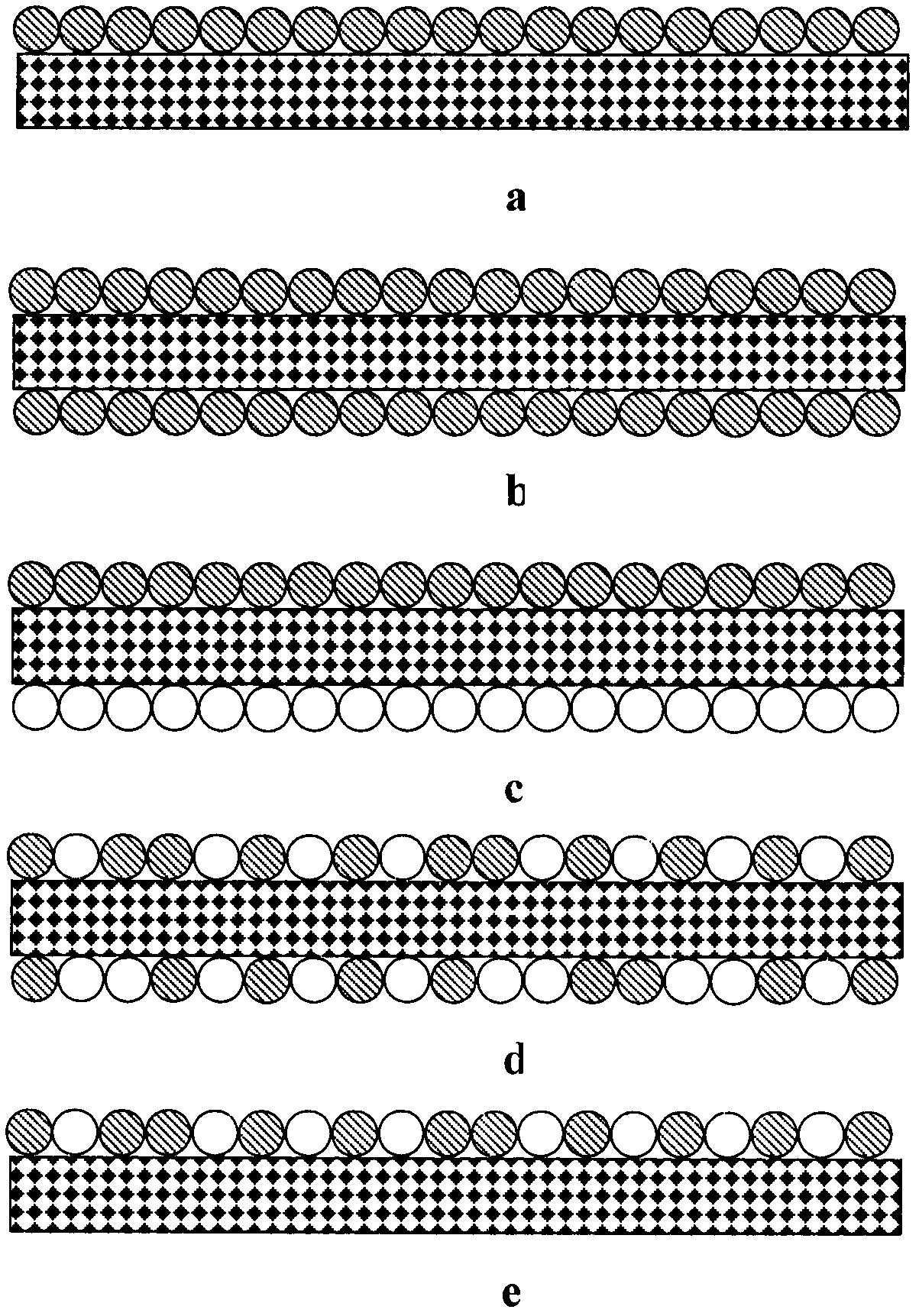

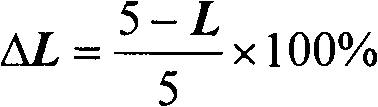

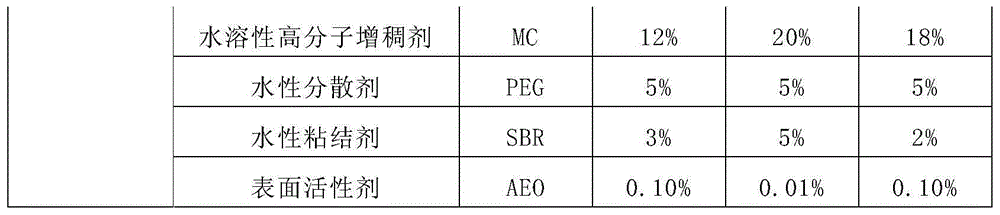

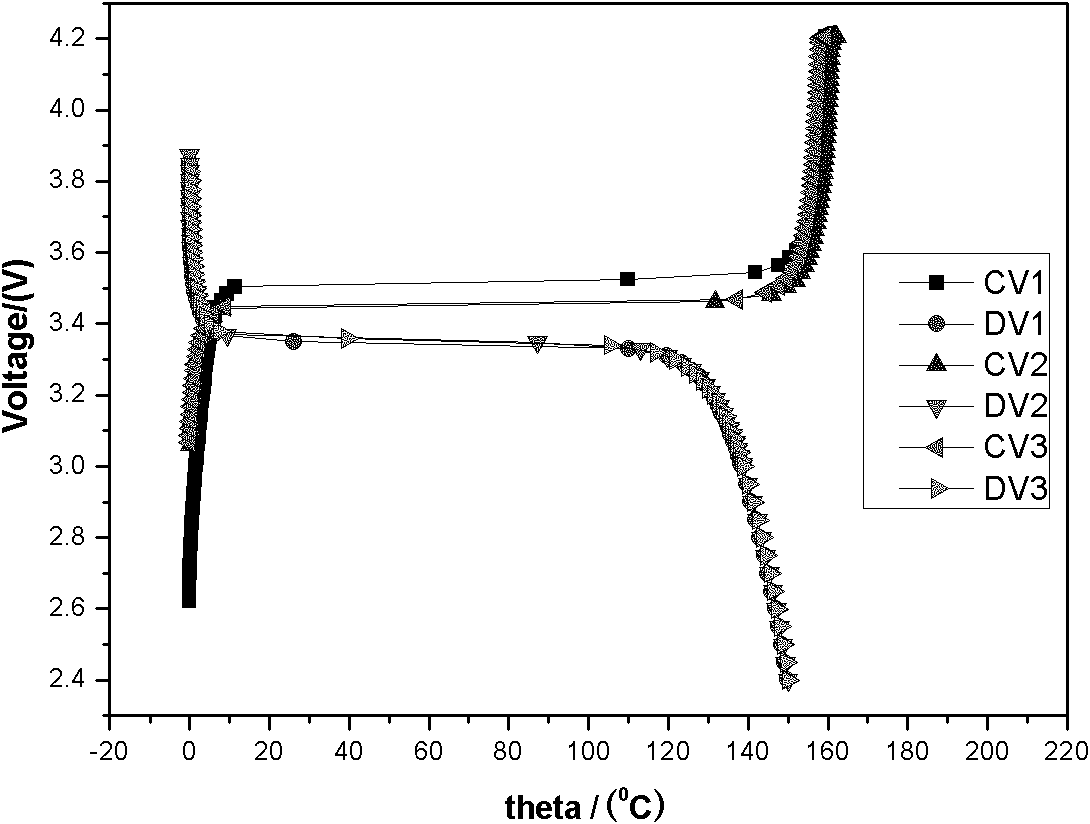

Water-based multi-layer membrane for lithium ion battery

InactiveCN104868081ACell seperators/membranes/diaphragms/spacersSecondary cellsWater basedElectrical battery

The invention provides a water-based multi-layer membrane for a lithium ion battery. The water-based multi-layer membrane comprises a polymer membrane substrate (A), an inorganic or organic particle coating (B) coating one or two sides of the polymer membrane substrate (A), and an organic particle coating (C) coating the inorganic or organic particle coating (B), wherein the inorganic or organic particle coating (B) is formed by a composition which comprises 15-70wt% of inorganic or organic particles and 30-85wt% of water; the inorganic or organic particles are selected from aluminum oxide, silica, barium sulfate, boehmite or polyimide; the organic particle coating (C) is formed by a composition which comprises 5-30wt% of organic particles and 70-95wt% of water; and the organic particles are selected from polyvinylidene fluoride-hexafluoropropylene, polyacrylonitrile, polyoxyethylene or polymethyl methacrylate.

Owner:SHANGHAI ENERGY NEW MATERIALS TECH CO LTD

High coefficient friction material with symmetrical friction modifying particles

InactiveUS20050064778A1Useful high performanceDurable friction materialOther chemical processesLayered productsParticle coating

The present invention relates to a friction material comprising a primary layer material layer and at least a partial coating of symmetrically shaped friction modifying particles on at least one surface of the primary layer for use as an anti-shudder friction material.

Owner:BORGWARNER INC

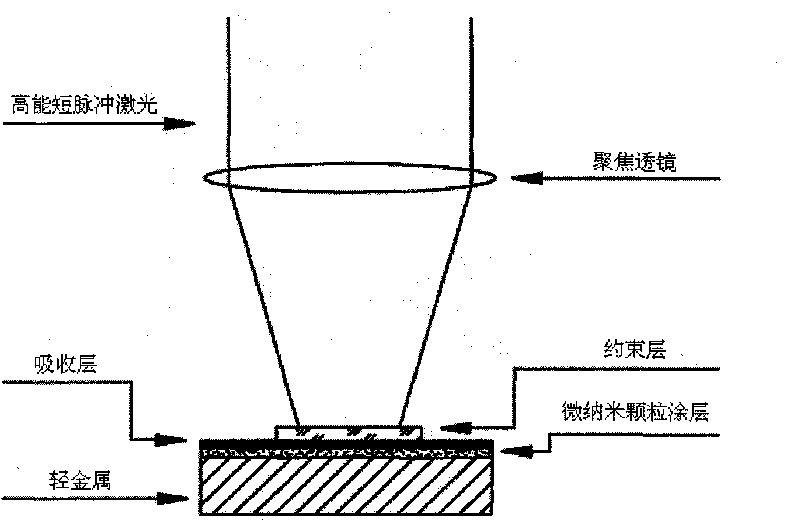

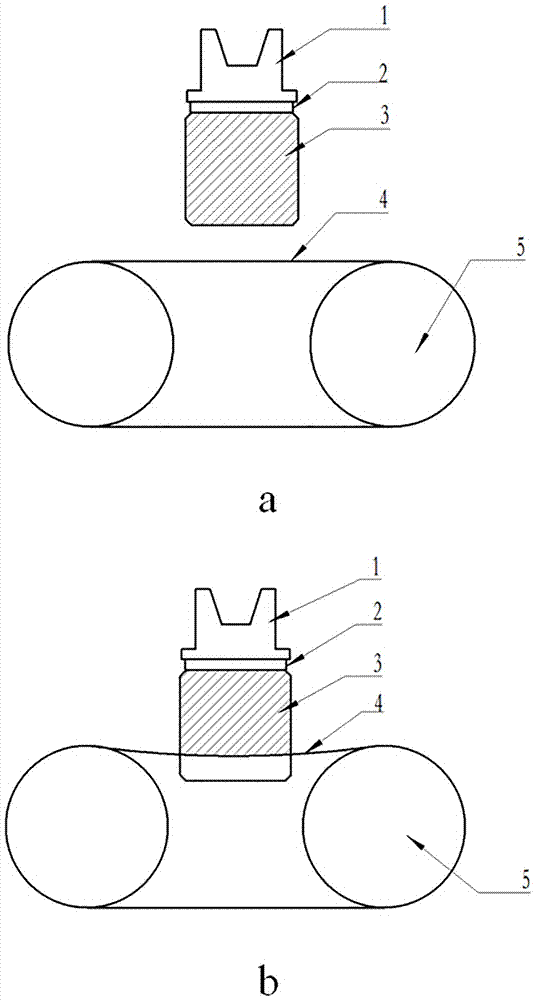

Light metal surface laser impact micronano particle injection reinforcing method

The invention relates to a light metal surface laser impact micronano particles injection reinforcing method, comprising the following steps: 1) removing the oxide layer probably existing on the surface of the light metal by a mechanical polishing or chemical corrosion method, then grinding and polishing with sand paper, and finally cleaning the surface of the light metal alloy with acetone or alcohol; 2) precoating the micronano particles on the surface of the light metal with inorganic bonding agent, recoating a layer of black paint on the surface of the micronano particle coating layer to serve as the absorption layer of laser impact after drying, and drying naturally; 3) impacting the absorption layer and the micronano particle layer with high-energy short pulse laser, and utilizing K9 glass or running water as a restriction layer during laser impact; and 4) soaking the micronano particle coating layer processed by acetone, and then removing the absorption layer through washing with running water or ultrasonic washing to obtain the micronano particle injection reinforcing layer. The invention integrates the actions of laser impact reinforcement, nano particle reinforcement and nano particle reinforcement, can dramatically improve hardness, abrasion resistance and fatigue resistance property of light metal surface layer, and has wide application prospect.

Owner:TSINGHUA UNIV

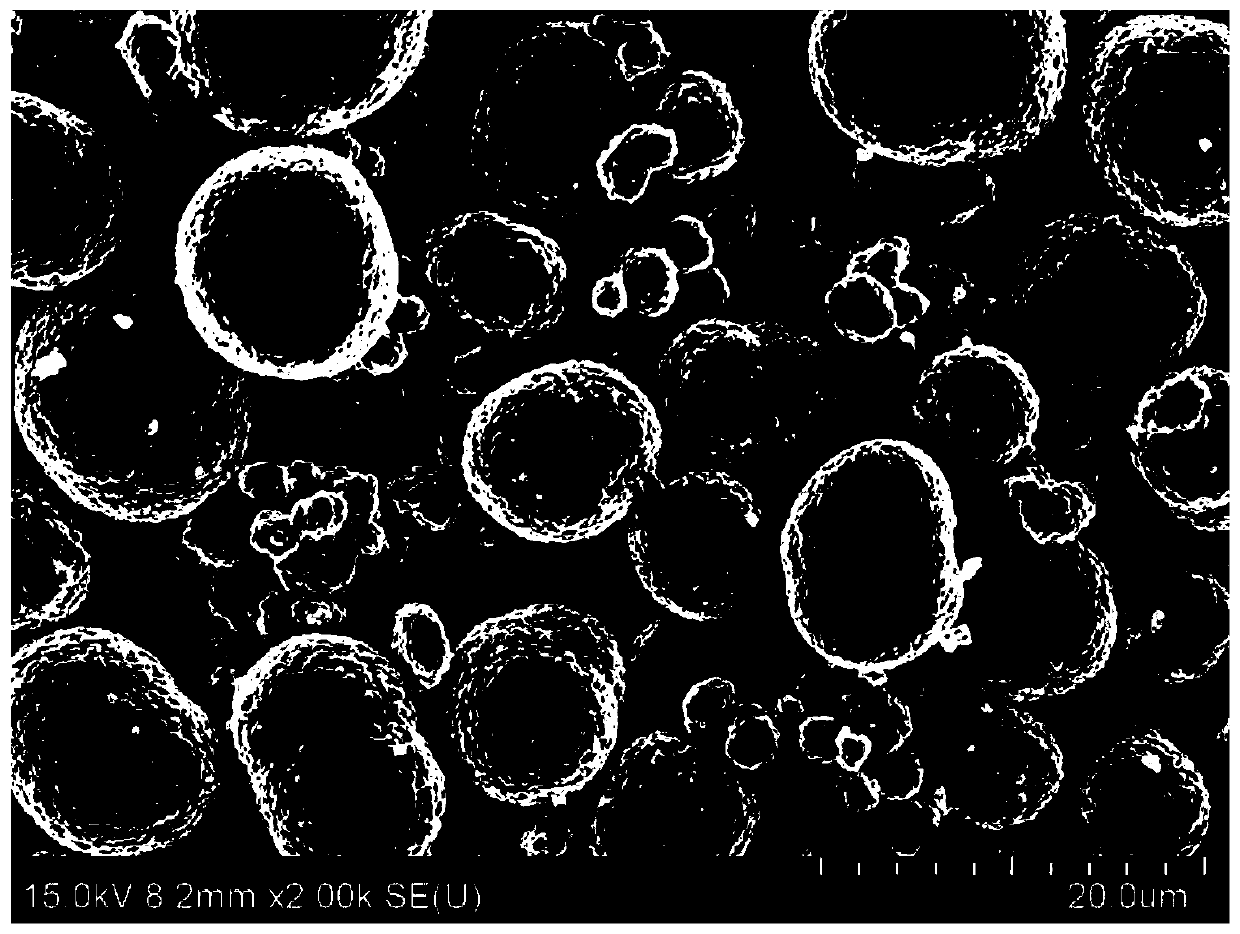

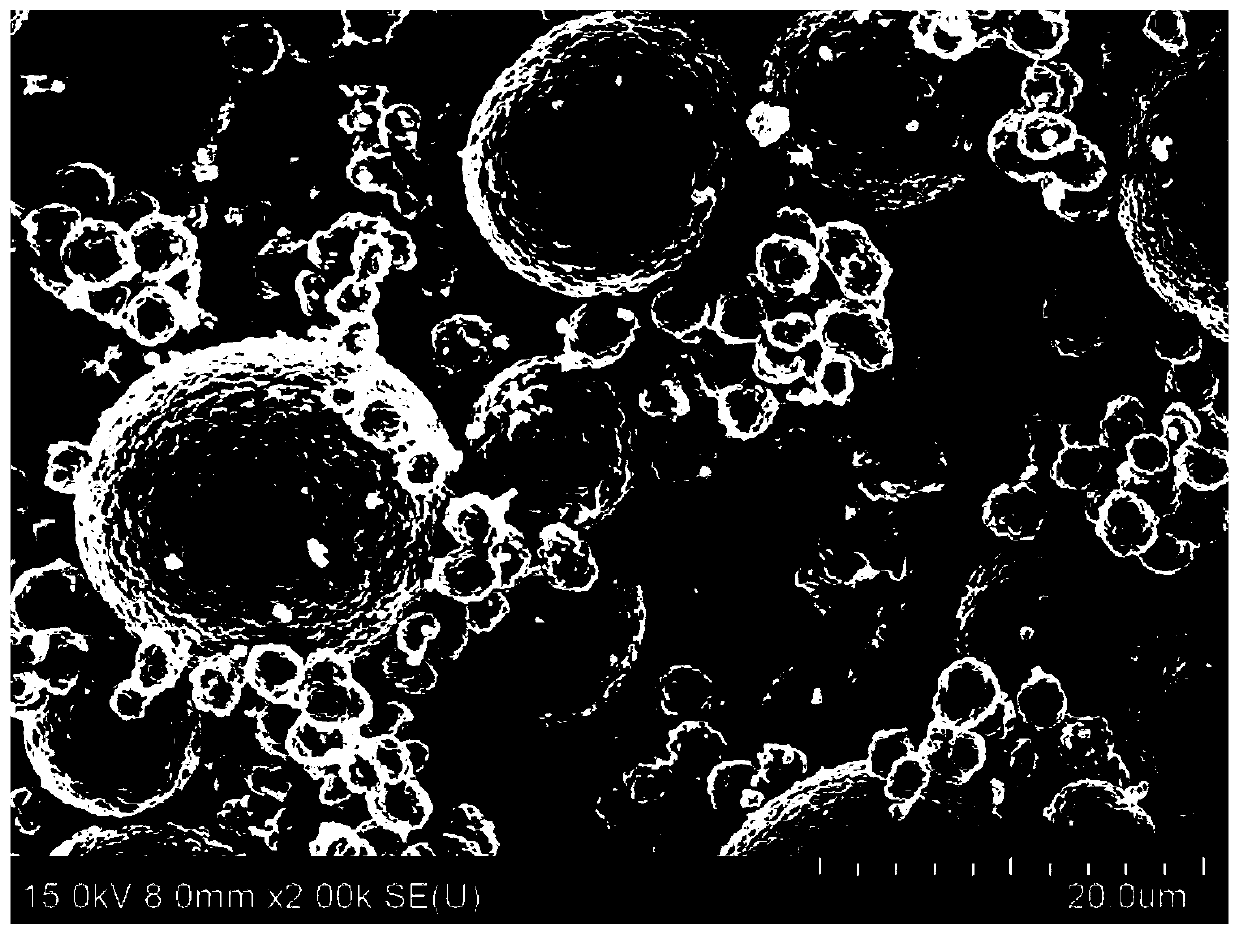

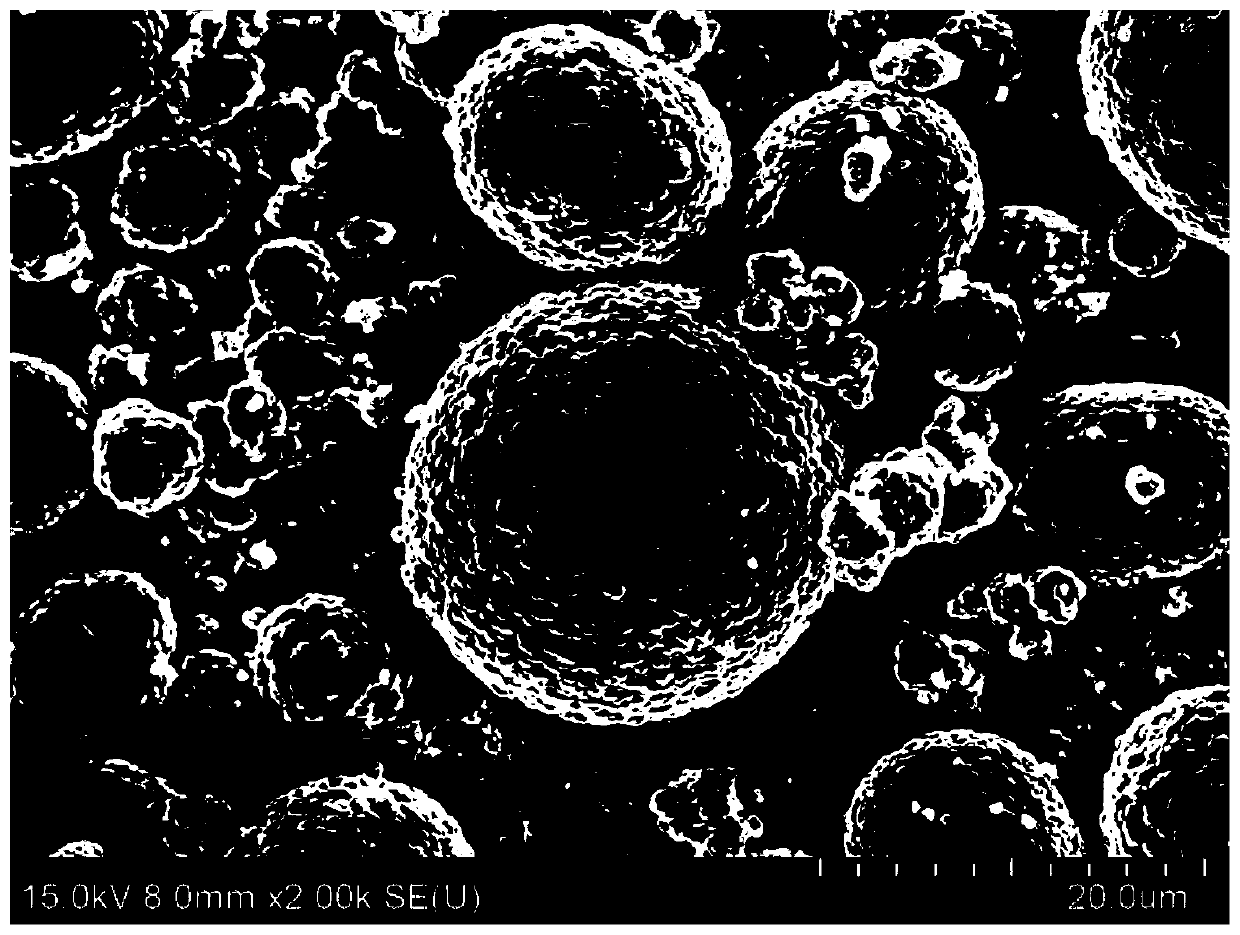

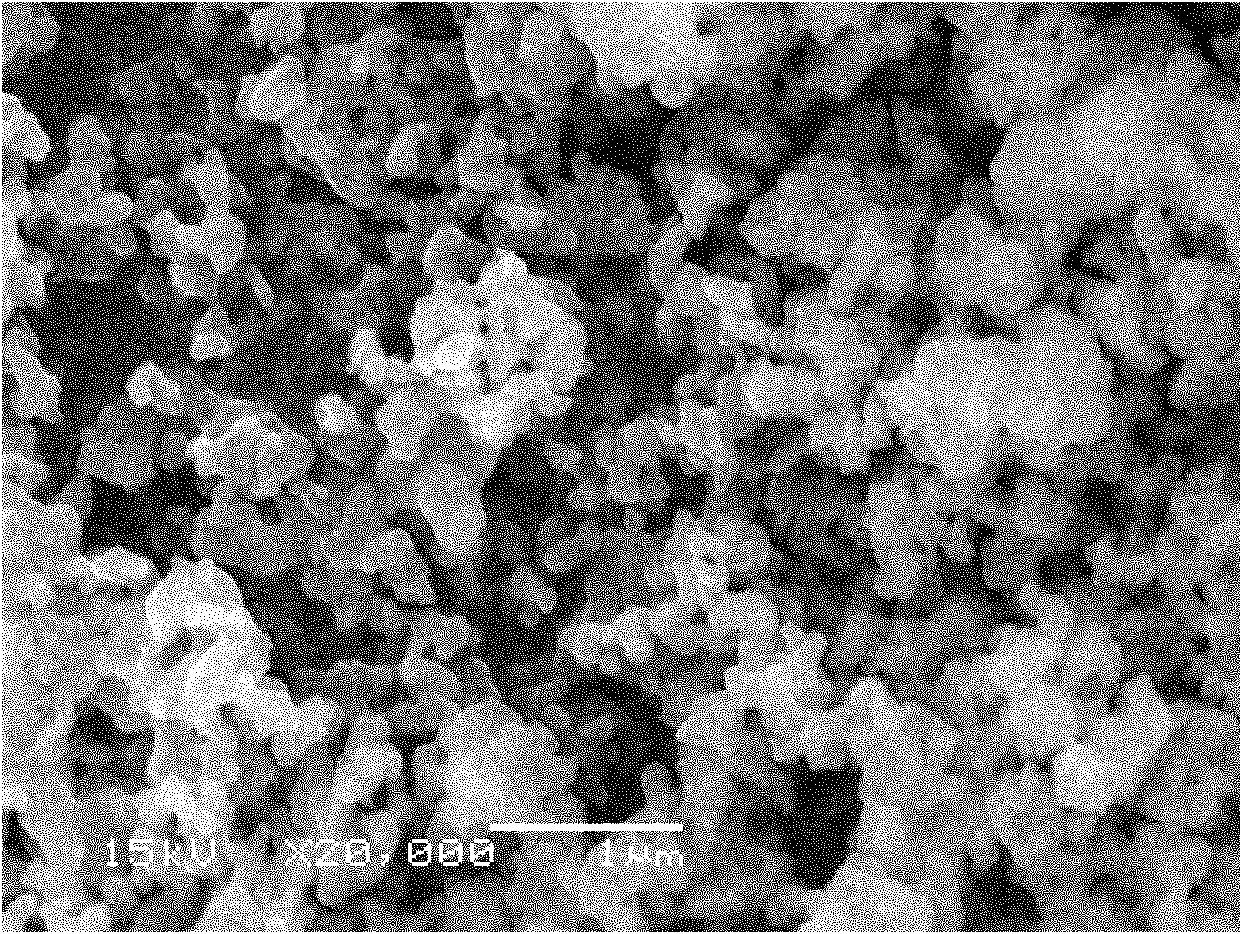

High-compaction and high-stability high-nickel cathode material and preparation method thereof, and lithium ion battery

ActiveCN110010889AImprove powder compactionIncrease the ultimate compaction densitySecondary cellsPositive electrodesHigh energyCerium

The invention discloses a high-compaction and high-stability high-nickel cathode material and a preparation method thereof, and a lithium ion battery. The high-nickel cathode material comprises a basematerial and a coating layer coating the surface of the base material, the base material is a compound as shown in the formula I: LinNixMyO2, wherein in the formula I, 0.98<n<=1.20, 0.50<x<1.00, 0.00<y<1.00, and 0.00<x+y<=1.00; the base material is consisted of a large-particle substrate and a small-particle substrate; and M is at least one selected from a group consisting of lithium, manganese,aluminum, molybdenum, chromium, vanadium, lanthanum, scandium, cerium, niobium, molybdenum, cobalt, magnesium, zirconium, strontium, yttrium, barium, titanium, fluorine, silicon, boron and phosphorus.The cathode material prepared by the invention has low residual alkali, uniform primary particle coating, primary particle pressure resistance and difficult breakage, so that the prepared lithium ionbattery has high energy density, lower internal resistance and excellent rate capability, safety performance and cycle performance.

Owner:GUIZHOU RONGBAI LITHIUM BATTERY MATERIAL CO LTD

Composite porous membrane and preparation method thereof

ActiveCN102437303AImprove securityExcellent cycle characteristicsCell component detailsInorganic particlePorous membrane

The invention provides a composite porous membrane, which comprises a porous membrane substrate, inorganic particles and / or thermo-sensitive particles, and a binding agent, wherein the inorganic particles and / or the thermo-sensitive particles are bound on one side or two sides of the porous membrane substrate through the binding agent, and thereby an independent inorganic particle coating and / or an independent thermo-sensitive particle coating and / or a mixed coating with the inorganic particles and the thermo-sensitive particles are formed; and pores at the inner part of the porous membrane substrate are not provided with the binding agent and / or the inorganic particles and / or the thermo-sensitive particles. The composite porous membrane provided by the invention has higher porosity while having good high-temperature-resistant performance, and is suitable for preparing power lithium-ion batteries with high discharge rates.

Owner:BEIJING NORMAL UNIVERSITY

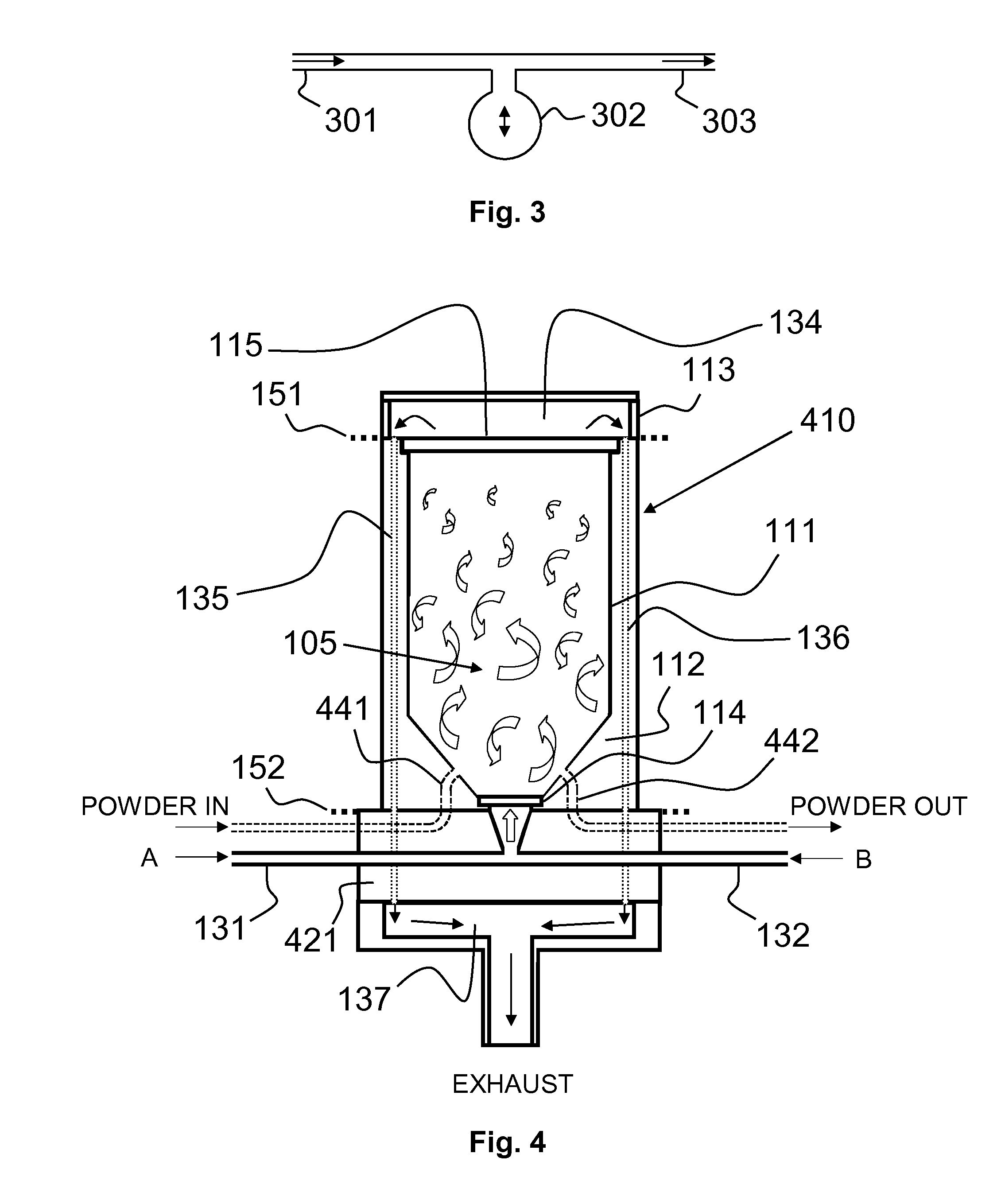

Powder particle coating using atomic layer deposition cartridge

InactiveUS20150125599A1Liquid surface applicatorsChemical vapor deposition coatingSurface reactionCoupling

A method includes receiving an atomic layer deposition (ALD) cartridge into a receiver of an ALD reactor by a quick coupling method. The ALD cartridge serves as an ALD reaction chamber, and the method includes processing surfaces of particulate material within the ALD cartridge by sequential self-saturating surface reactions.

Owner:PICOSUN OY

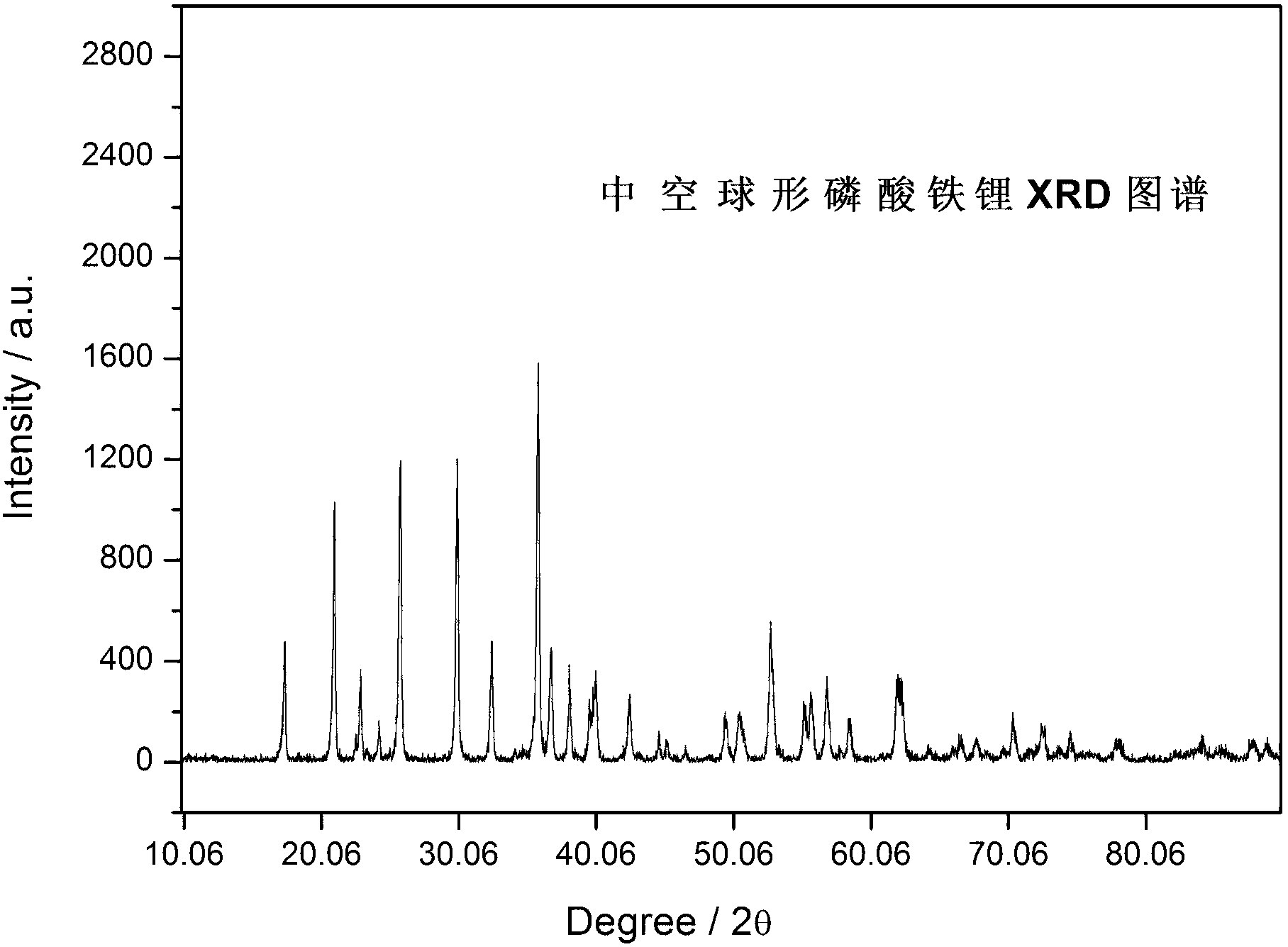

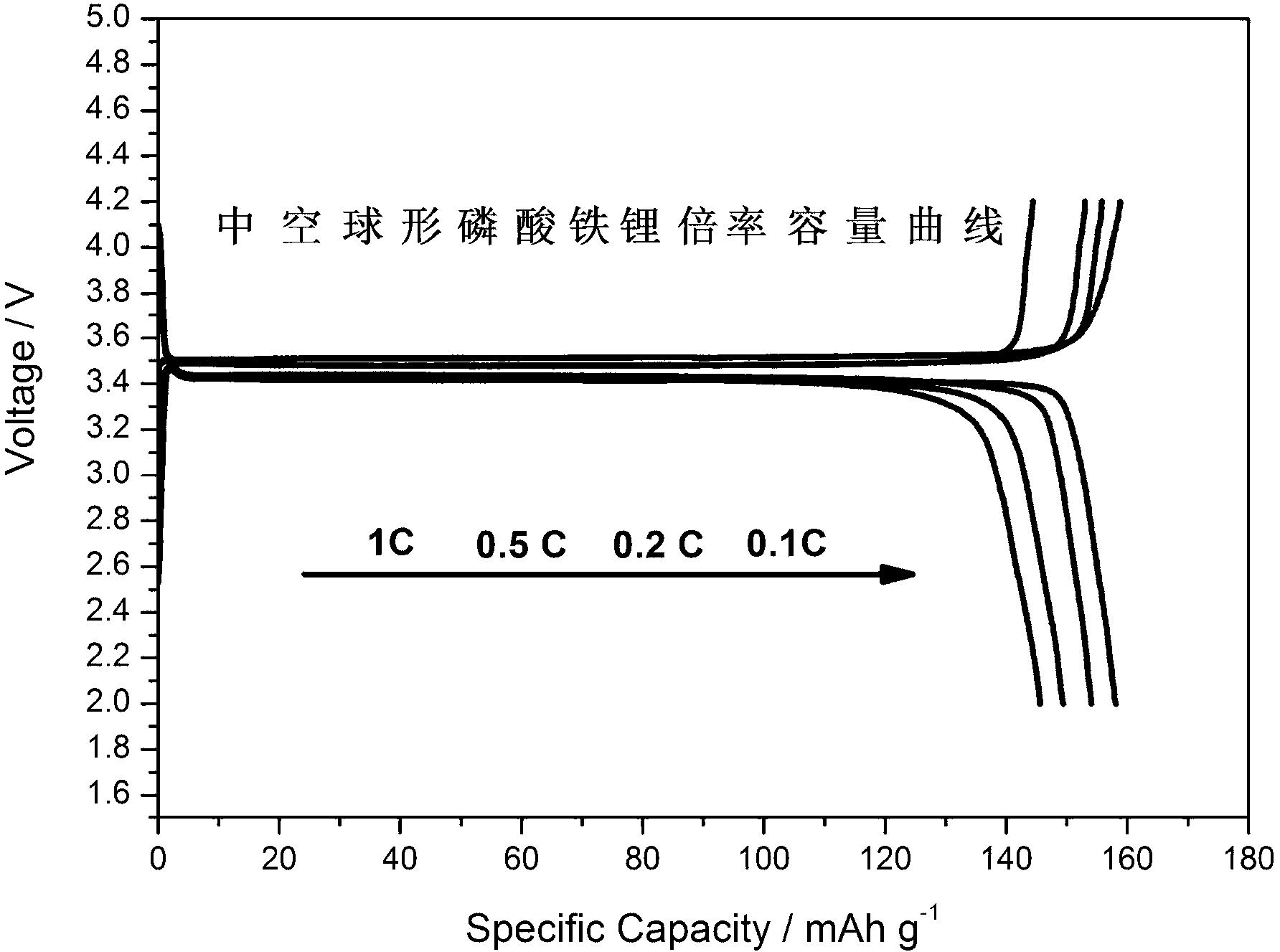

Spherical lithium iron phosphate anode material and preparation method thereof

InactiveCN103066280AImprove conductivityPlay a protective effectCell electrodesLithium compoundMaterials science

The invention discloses a spherical lithium iron phosphate anode material and a preparation method thereof and belongs to the field of lithium ion battery anode material preparation. The preparation method utilizes a soft template method to realize synthesis of the hollow spherical lithium iron phosphate anode material (Li(1-x)Ax Fe(1-y)ByPO4 / C) having high performances. The preparation method comprises the following steps of dissolving a soft-template agent in an aqueous solution, preparing a solution comprising a lithium-containing compound, an iron-containing compound, a phosphorous-containing compound and a carbon-containing compound which are fully mixed in an atomic level, adding a doping reagent into the solution, uniformly mixing to obtain a precursor mixed solution having good uniformity, wherein the adopted carbon-containing compound has a protective effect and a lithium iron phosphate particle coating effect in follow-up reactions and greatly improves anode material conductivity, carrying out spray drying treatment on the uniform precursor mixed solution with granulation and precursor drying to obtain a solid precursor having a uniform spherical structure, and carrying out heat treatment to remove the soft template and to obtain the spherical lithium iron phosphate anode material having a hollow structure.

Owner:珠海泰坦能源电子技术有限公司

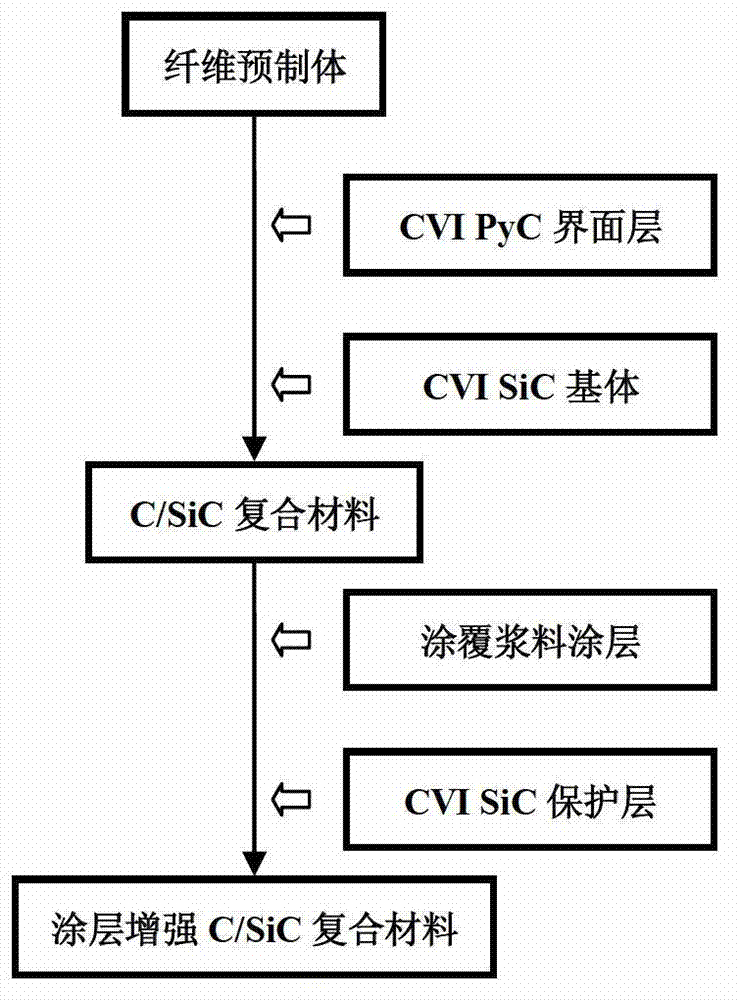

Method for preparing coating reinforced C/SiC composite material

The invention relates to a method for preparing a coating reinforced C / SiC composite material. According to a technical scheme, a slurry coating layer is coated on a test sample surface of a C / SiC composite material to facilitate the filling of aperture gaps remained by a prefabricated body structure and aperture gaps caused by a chemical vapor infiltration bottle neck process, so that the compactness of the composite material is improved, the modulus mismatching between the C / SiC composite material and a SiC protective layer can be effectively relieved and the obdurability of the composite material is improved. Compared with the C / SiC composite material in the prior art, the coating reinforced C / SiC composite material has the advantages that the bending strength of the two-dimensional SiC crystal whisker coating layer reinforced C / SiC composite material is 480-502MPa under the room temperature, the bending strength of the two-dimensional SiC particle coating layer reinforced C / SiC composite material is 440-470MPa, and the bending strength of the two-dimensional (SiC crystal whisker and SiC particle) coating layer reinforced C / SiC composite material is 485-515MPa. The thicknesses of PyC and SiC basal bodies and a protective layer are controlled by controlling deposition time, and the thickness of the slurry coating layer is controlled by controlling the viscosity of the slurry and the coating time the number of coatings so as to realize the control of the composite material structure.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

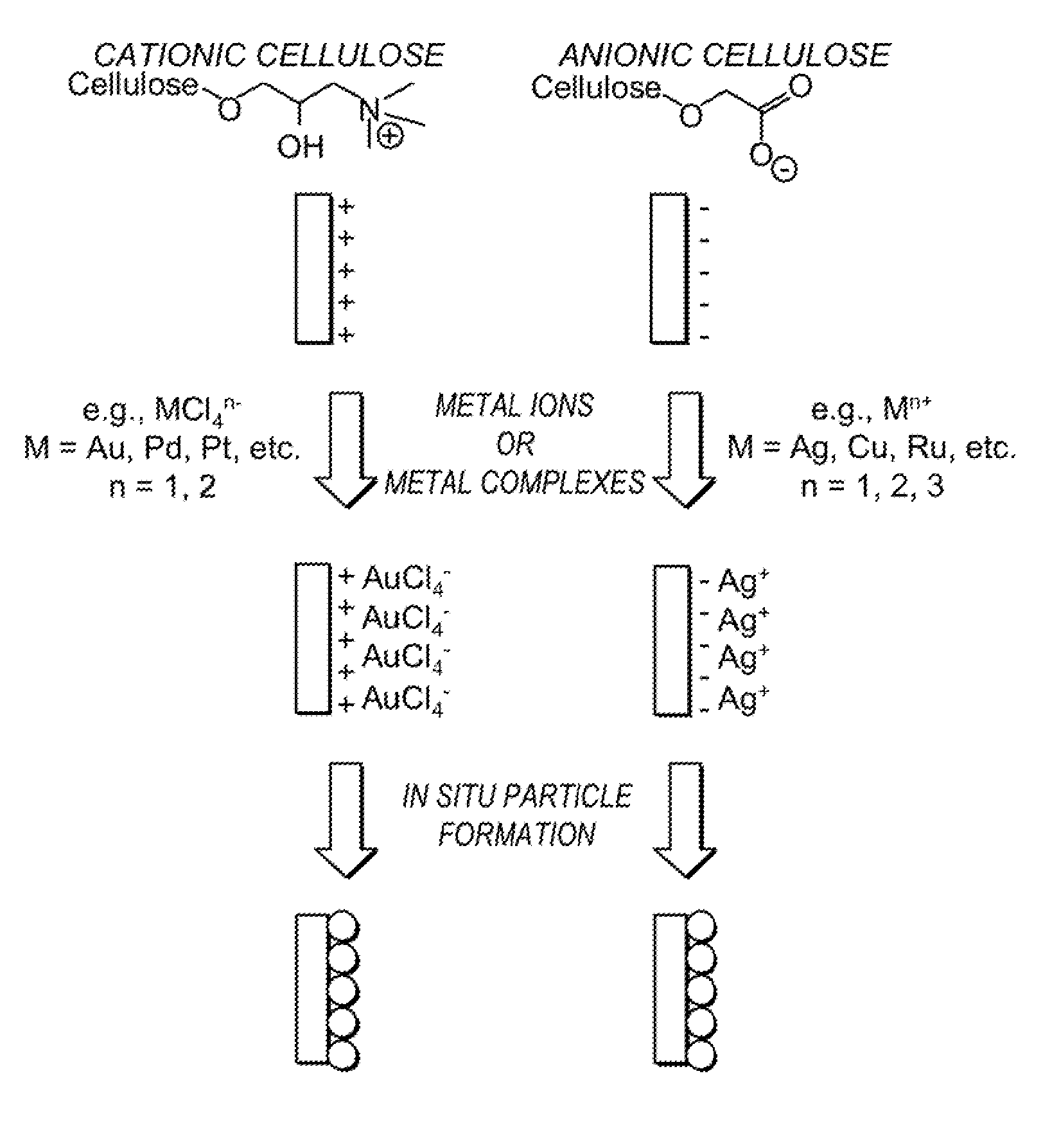

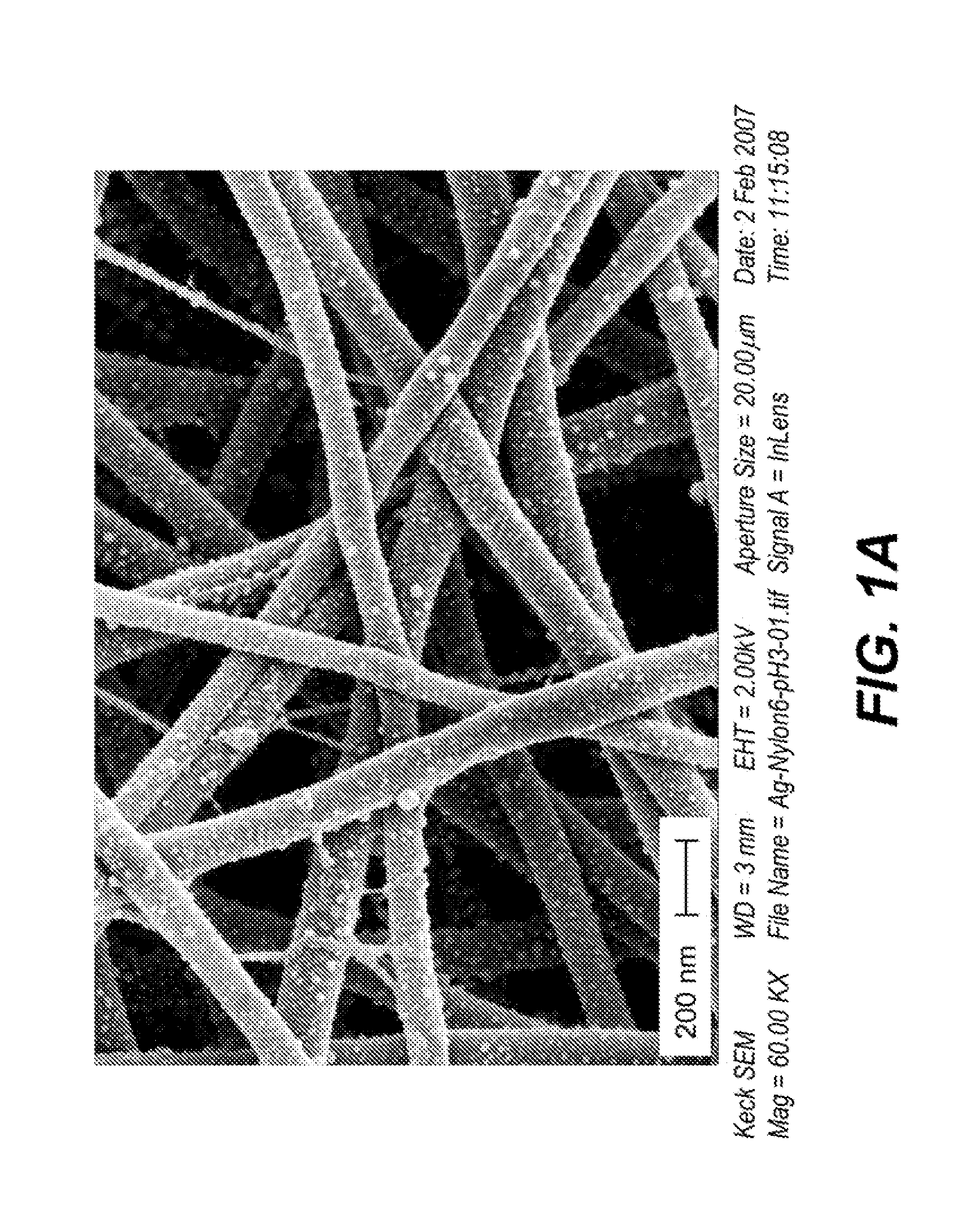

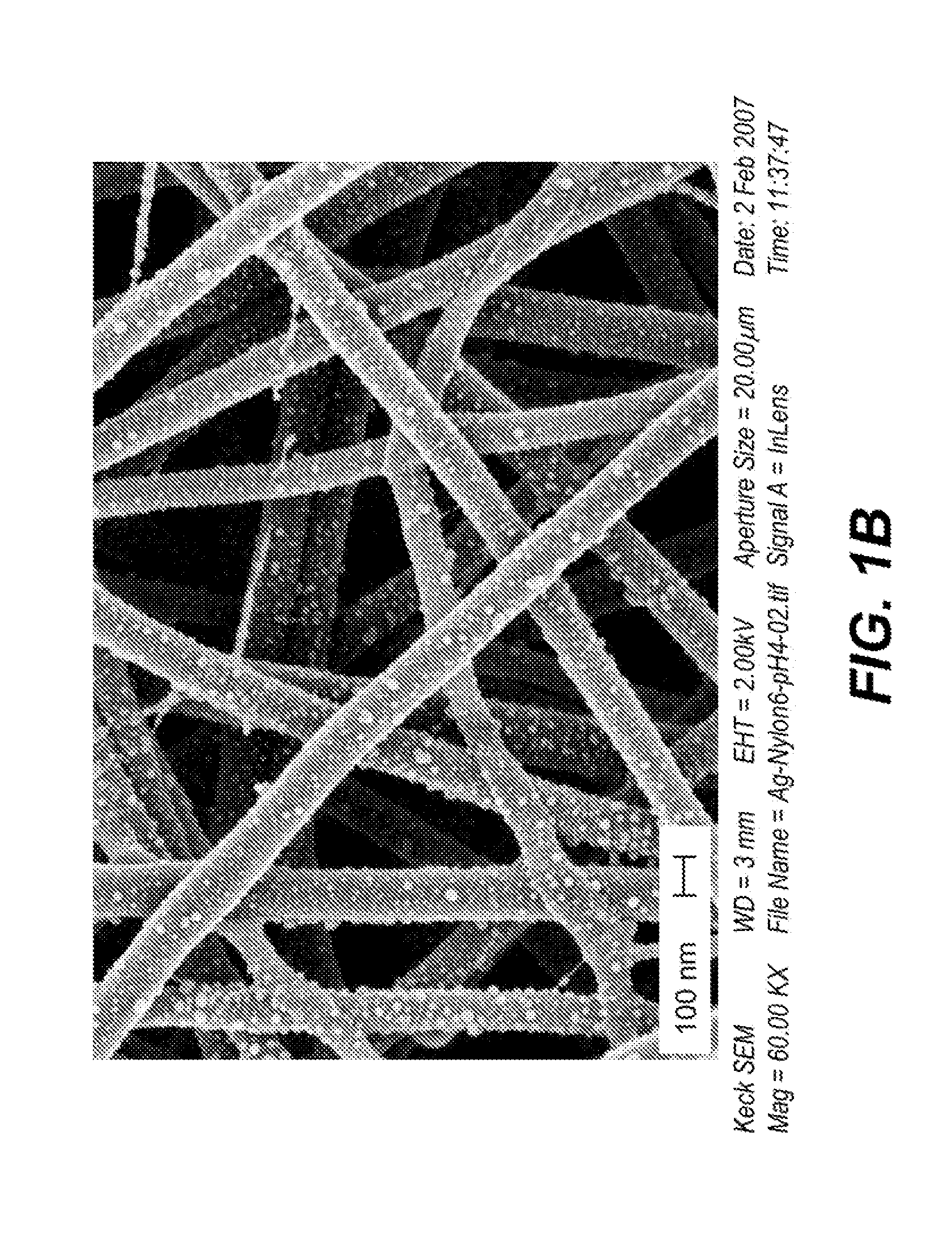

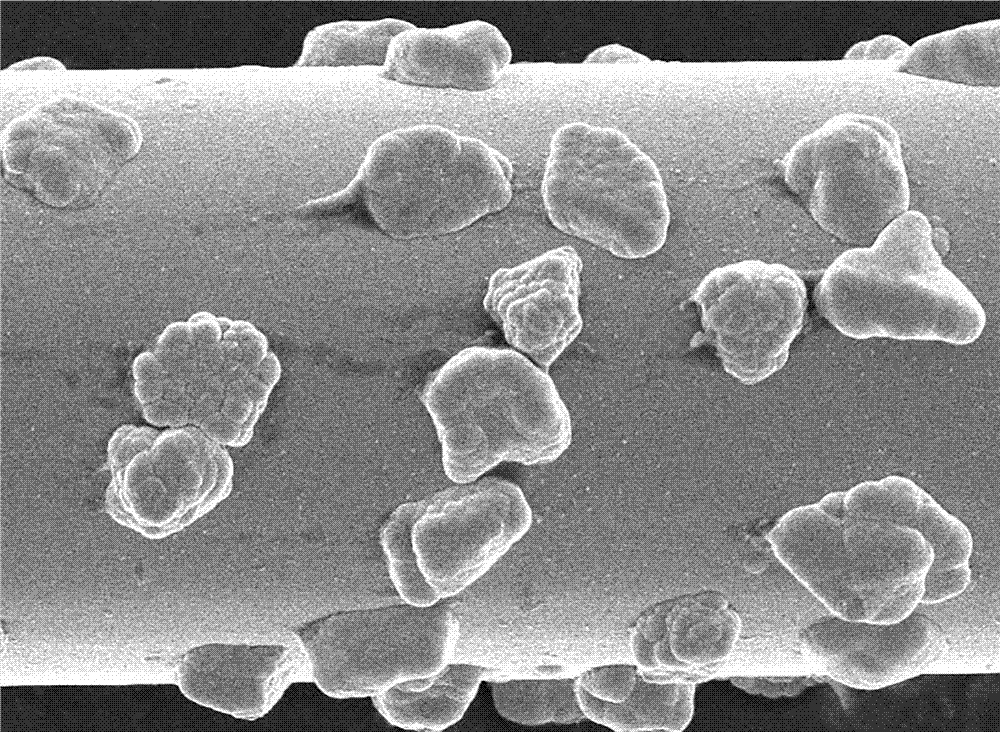

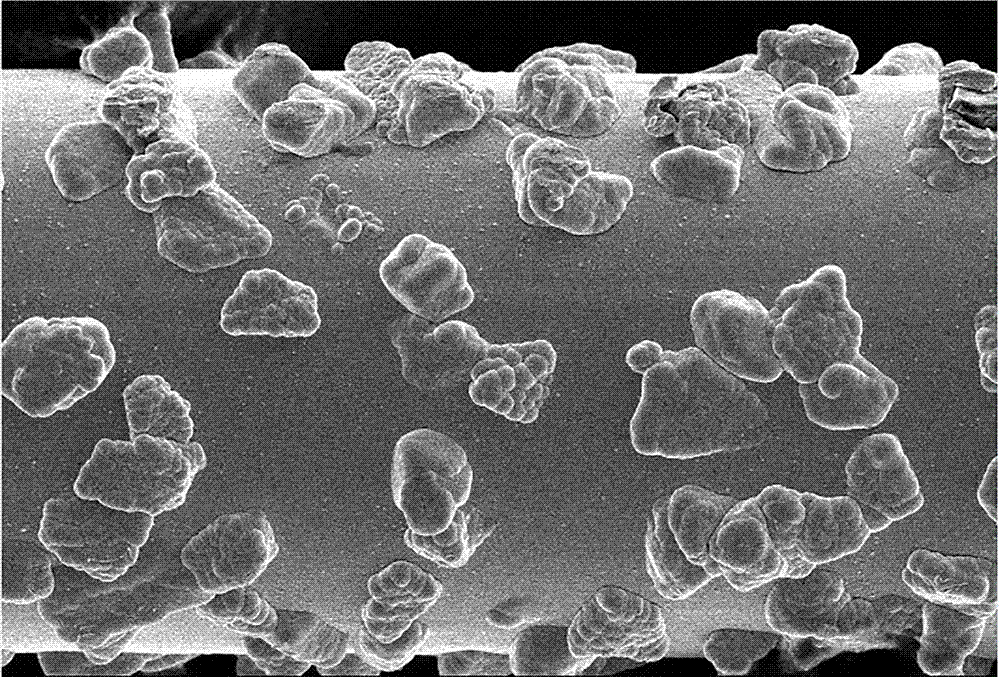

Conformal particle coatings on fibrous materials

InactiveUS20110197369A1High antibacterial activityAvoid Microbial ContaminationPhysical treatmentBiochemical fibre treatmentFiberHydrogen

Methods are provided for uniform deposition of particles on curved surfaces such as fibers and coatings formed by the particles. Particles in the size range of 10-2000 nm are deposited onto a fibrous material via electrostatic interaction between charge modified fiber material surfaces and oppositely charged particles or metal ions. Various nonmetallic, bimetallic or other charged particles are deposited onto a fibrous material via electrostatic interaction between charged modified fibrous material surfaces and oppositely charged particles. Particles can be directly assembled onto a surface of a fibrous material by controlling hydrogen bonding interactions between interfaces of fibers and functionalized particles. Metal particles can also be deposited by in situ synthesis. A method is also provided for layer-by-layer deposition of particles over a fibrous material.

Owner:CORNELL UNIVERSITY

Process for producing coated detergent particles

InactiveUS6858572B1Fine surfaceGood lookingInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsSulfateDouble salt

A process for preparing detergent particles having a coating layer of a water-soluble inorganic material is provided. The detergent particle comprises a particle core of a detergent active material. This particle core is then at least partially covered by a particle coating layer of a water soluble inorganic material. Particularly preferred are non-hydratable inorganic coating materials including double salt combinations of alkali metal carbonates and sulfates. The particle coating layer may also include detergent adjunct ingredients such as brighteners, chelants, nonionic surfactants, co-builders, etc. The process includes the steps of passing the particle core through a coating mixer such as a low speed mixer or fluid bed mixer and coating the particle core with a coating solution or slurry of the water soluble inorganic material. Upon drying, the resultant detergent particles have improved appearance and flow properties and may be packaged and sold as a detergent material or mixed with various other detergent ingredients to provide a fully formulated detergent composition.

Owner:THE PROCTER & GAMBLE COMPANY

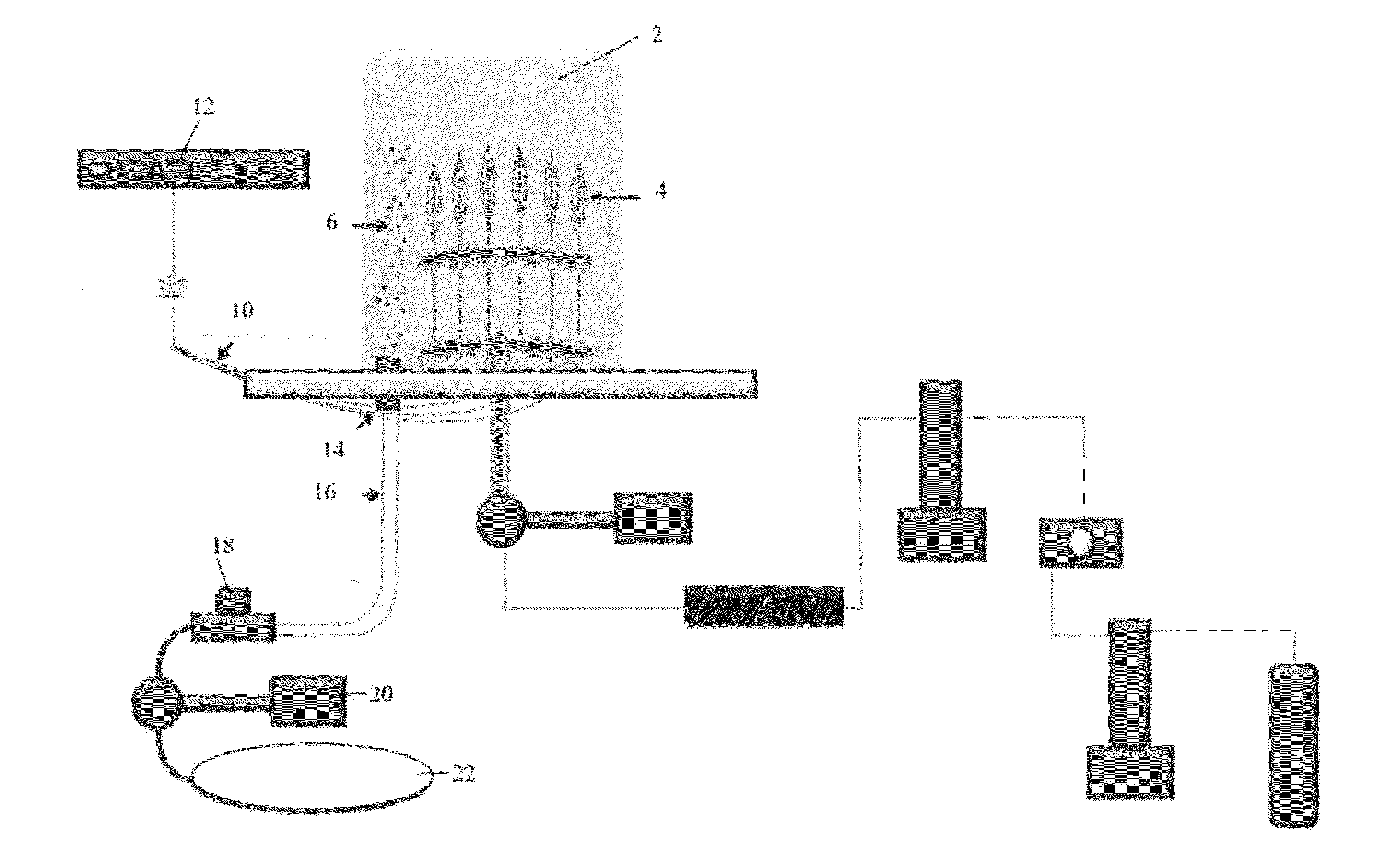

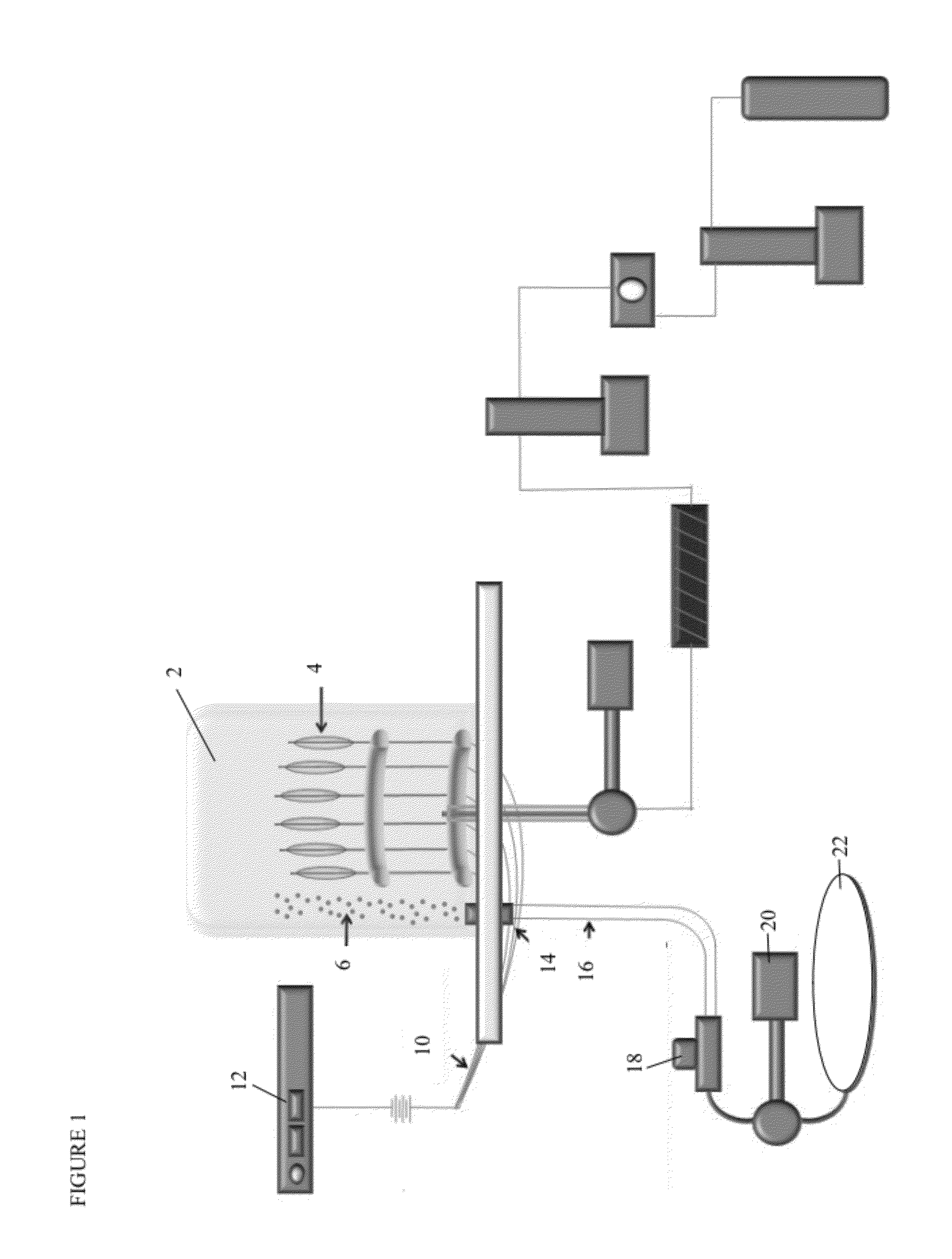

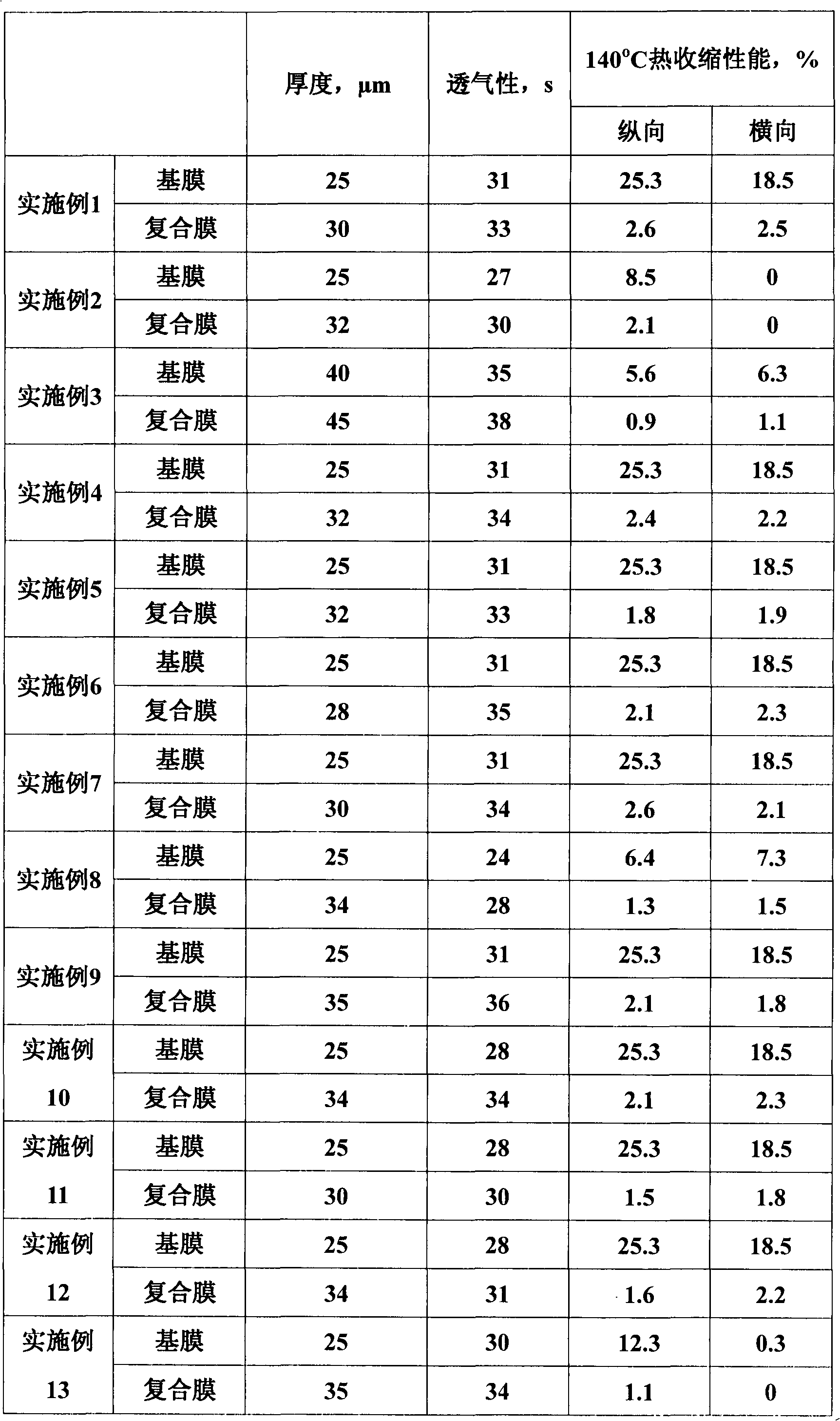

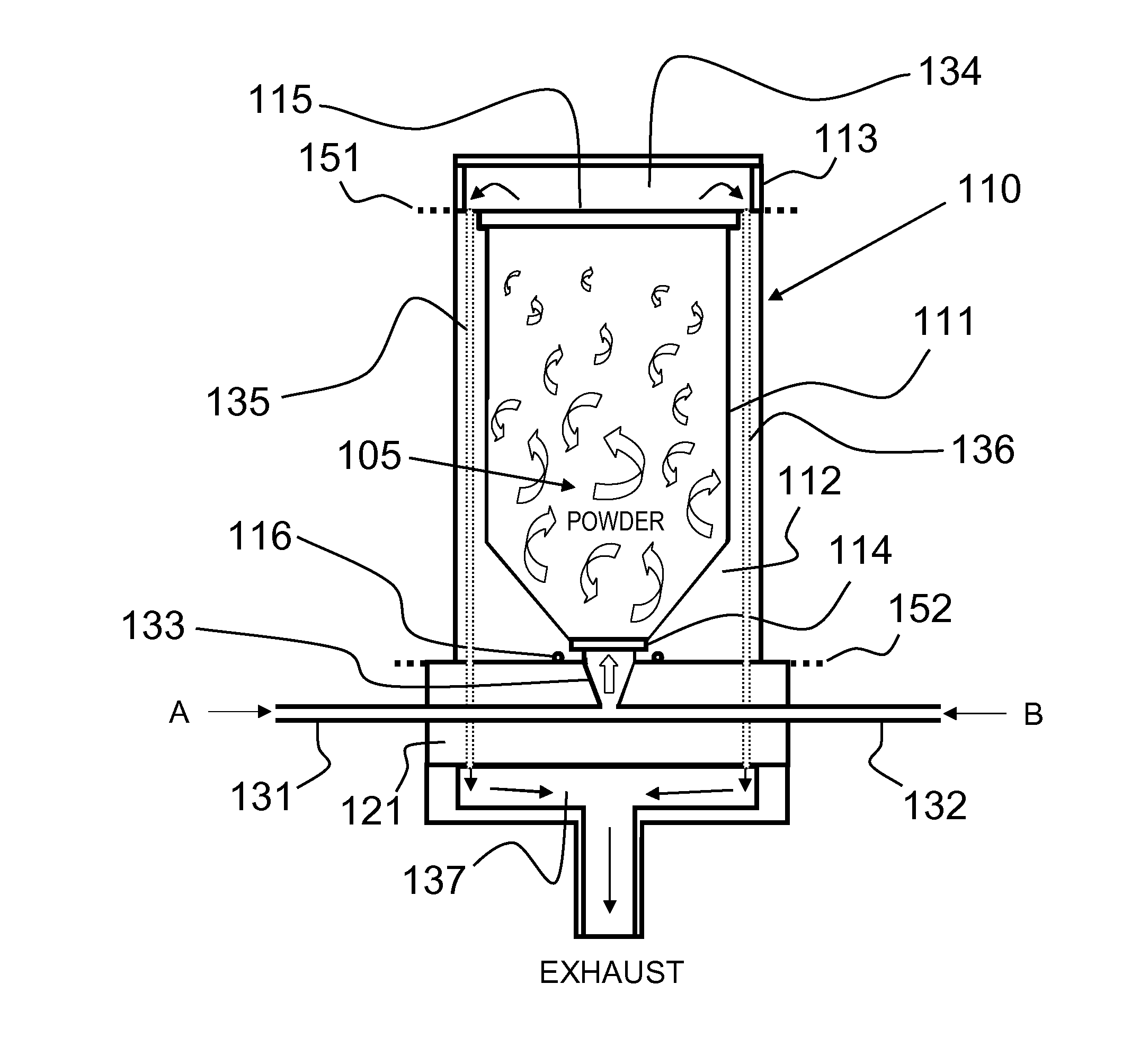

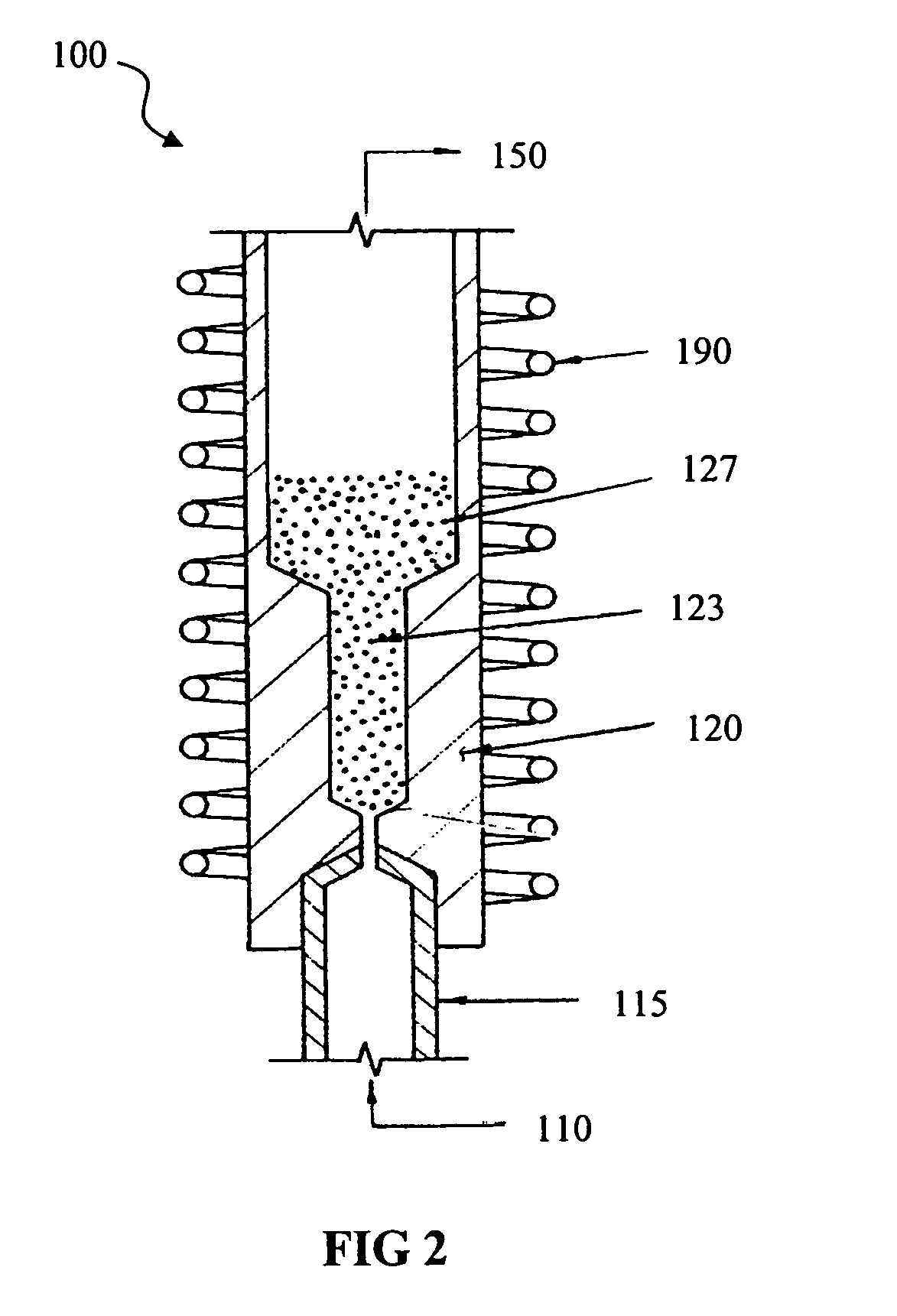

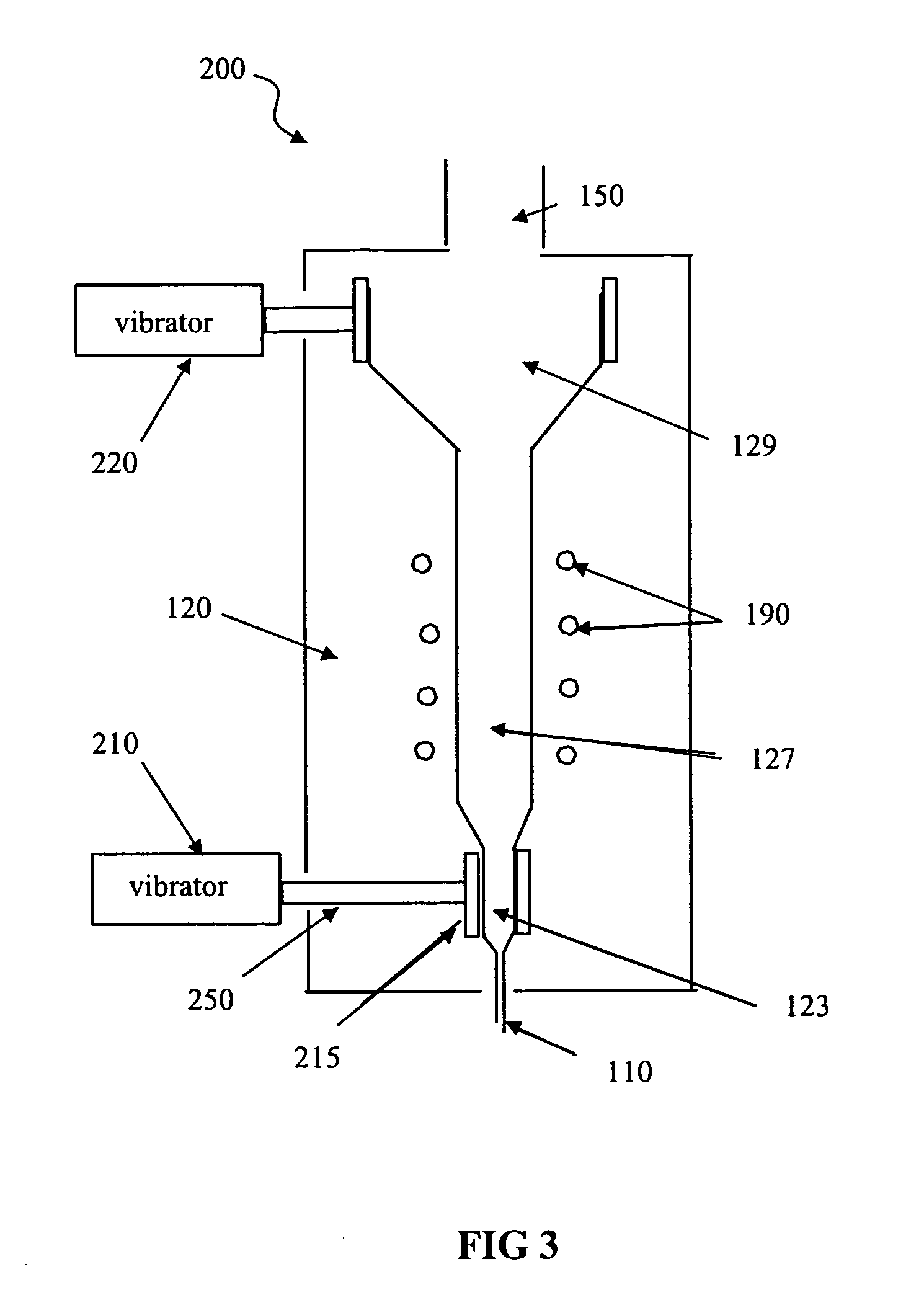

Methods and apparatuses for the development of microstructured nuclear fuels

ActiveUS7521007B1Ensure uniform motionLow costFuel elementsNuclear energy generationChemical vapor depositionMaterials science

Microstructured nuclear fuel adapted for nuclear power system use includes fissile material structures of micrometer-scale dimension dispersed in a matrix material. In one method of production, fissile material particles are processed in a chemical vapor deposition (CVD) fluidized-bed reactor including a gas inlet for providing controlled gas flow into a particle coating chamber, a lower bed hot zone region to contain powder, and an upper bed region to enable powder expansion. At least one pneumatic or electric vibrator is operationally coupled to the particle coating chamber for causing vibration of the particle coater to promote uniform powder coating within the particle coater during fuel processing. An exhaust associated with the particle coating chamber and can provide a port for placement and removal of particles and powder. During use of the fuel in a nuclear power reactor, fission products escape from the fissile material structures and come to rest in the matrix material. After a period of use in a nuclear power reactor and subsequent cooling, separation of the fissile material from the matrix containing the embedded fission products will provide an efficient partitioning of the bulk of the fissile material from the fission products. The fissile material can be reused by incorporating it into new microstructured fuel. The fission products and matrix material can be incorporated into a waste form for disposal or processed to separate valuable components from the fission products mixture.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

Magnetic particle chemiluminescence double-layer micro-fluidic chip used for whole-blood sample detection

The invention relates to a magnetic particle chemiluminescence double-layer micro-fluidic chip used for whole-blood sample detection. The micro-fluidic chip comprises a top plate (1) and a bottom plate (2). The top plate comprises a sample feeding port (4), a sample filling region (12), a marked ligand storage pool (5) and a sample mixing region (13). The bottom plate comprises a filtering region (6), a magnetic particle coating region (7), a cleaning region (14), a detecting region (8), a cleaning fluid storage pool (9), a luminous substrate liquid storage pool (10) and a liquid release channel (16).

Owner:SHENZHEN HUAMAIXINGWEI MEDICAL TECH CO LTD

Process and device for producing solid bodies by sequential layer buildup

ActiveUS7285234B2Mechanical working/deformationCork mechanical workingBiological activationRapid prototyping

Process for layer-wise production of a three dimensional body (generative rapid prototyping), in particular by 3D binder printer, including a multiple succession of the steps of depositing a powder particle layer, activating in defined areas an adhesive present on the powder particles and / or in the powder particle coating, as well as adhering the powder particles to each other and to the layer thereunder, wherein the powder particle layer is electrically discharged by ionized particles and brushed flat by means of an electrically insulated blade prior to activation of the adhesive material, and the invention further concerns a device adapted for application of thin powder particle layers, including at least one ionizing device.

Owner:DAIMLER AG

Medical product with a particle-free coating releasing an active substance

Embodiments described herein concern medical products, which come into contact with the organism, such as short-term implants and long-term implants, coated with at least one layer, containing a molecular-disperse distributed or dissolved active substance in at least one carrier and optionally one or more adjuvants, wherein the at least one layer forms a stably spreadable solution, methods for making this coating of stably spreadable solution and use of the medical products coated with the stably spreadable solution.

Owner:HEMOTEQ AG

Preparation method of ceramic-metal composite material

The invention discloses a preparing method of ceramic-metallic composite material, which comprises the following steps: 1) allocating basal body alloy material; choosing 2Cr33Ni48WC10MoFe8 nickel base metal as basal body alloy; 2) preparing composite ceramic phase particle; choosing Al2O3 particle coating with Ti powder as composite ceramic phase particle; 3) mixing the basal body alloy material and composite ceramic phase particle with volume ratio at 1:0. 15-0. 45; pelleting; 4) press-forming; 5) vacuum-drying; 6) vacuum-clinkering; getting the product. This invention possesses lower ceramic-metallic composite material heat transfer capacity and predominance high temperature property, which is fit for new type material of rolled steel heater block.

Owner:SHANDONG IRON & STEEL CO LTD +1

Method for rapidly cutting silicon wafers with electroplating diamond wire with ultrahigh efficiency

ActiveCN107160576AReduce the need for new linesReduce fatigueWorking accessoriesFine working devicesEngineeringCrystalline silicon

The invention provides a method for rapidly cutting silicon wafers with an electroplating diamond wire with ultrahigh efficiency. The method includes the following steps that firstly, bar sticking is conducted; secondly, feeding is conducted; thirdly, a cutting solution is prepared; fourthly, cutting is conducted; fifthly, discharging is conducted; sixthly, degumming and cleaning are conducted; and seventhly, checking and packaging are conducted. According to cutting, a cutting rack drives a silicon bar to move towards the electroplating diamond wire, and meanwhile a main roller drives an electroplating diamond wire net to conduct reciprocating movement to achieve cutting; in the cutting process, the linear speed of the electroplating diamond wire ranges from 1300 m / min to 1500 m / min, the workpiece cutting speed ranges from 1 mm / min to 4.5 mm / min, and the thickness of a diamond particle coating on the electroplating diamond wire ranges from 3 microns to 5 microns; and in the cutting process, the manner of conducting forward feeding firstly and backward feeding secondly is adopted in the electroplating diamond wire, and before each workpiece is machined, the 3 km-5 km electroplating diamond wire is fed to a wire collecting wheel. By means of the cutting method, 8.4 inch and 650 mm crystalline silicon bars can be smoothly cut within 1 h, and the problem that in the prior art the efficiency for cutting silicon wafers with electroplating diamond wire is low is solved.

Owner:杨凌美畅新材料股份有限公司

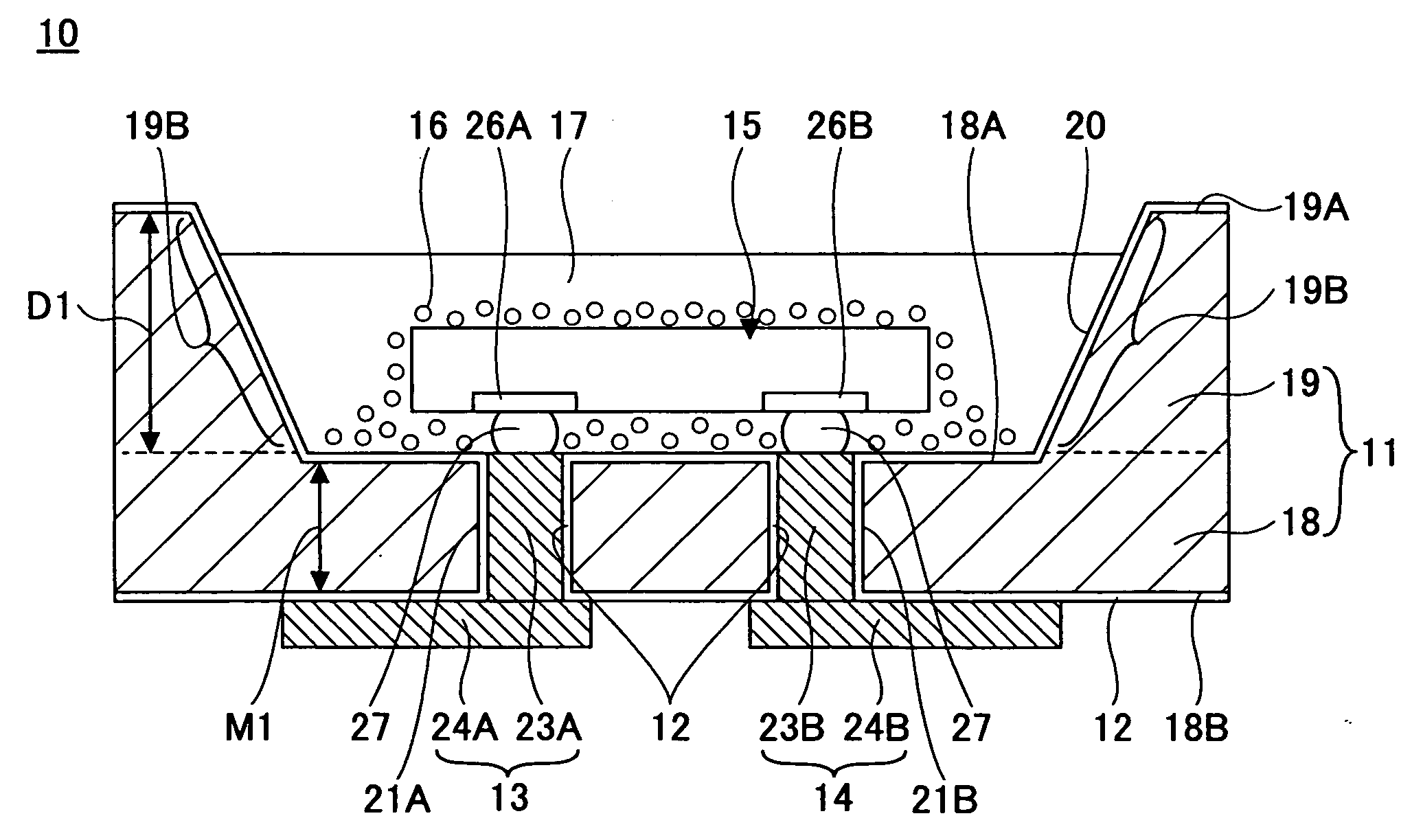

Method of manufacturing light emitting apparatus

A method of manufacturing a light emitting apparatus including a light emitting device and a light emitting device installing body having a concave part for installing the light emitting device therein is disclosed. The method includes the steps of a) forming a coating of plural fluorophor particles covering the light emitting device installed in the concave part, and b) forming a transparent resin covering the plural fluorophor particle coating. Step b) includes a step of performing illumination with the light emitting device so that the light emitted from the light emitting apparatus has a predetermined luminance and chromaticity.

Owner:SHINKO ELECTRIC IND CO LTD

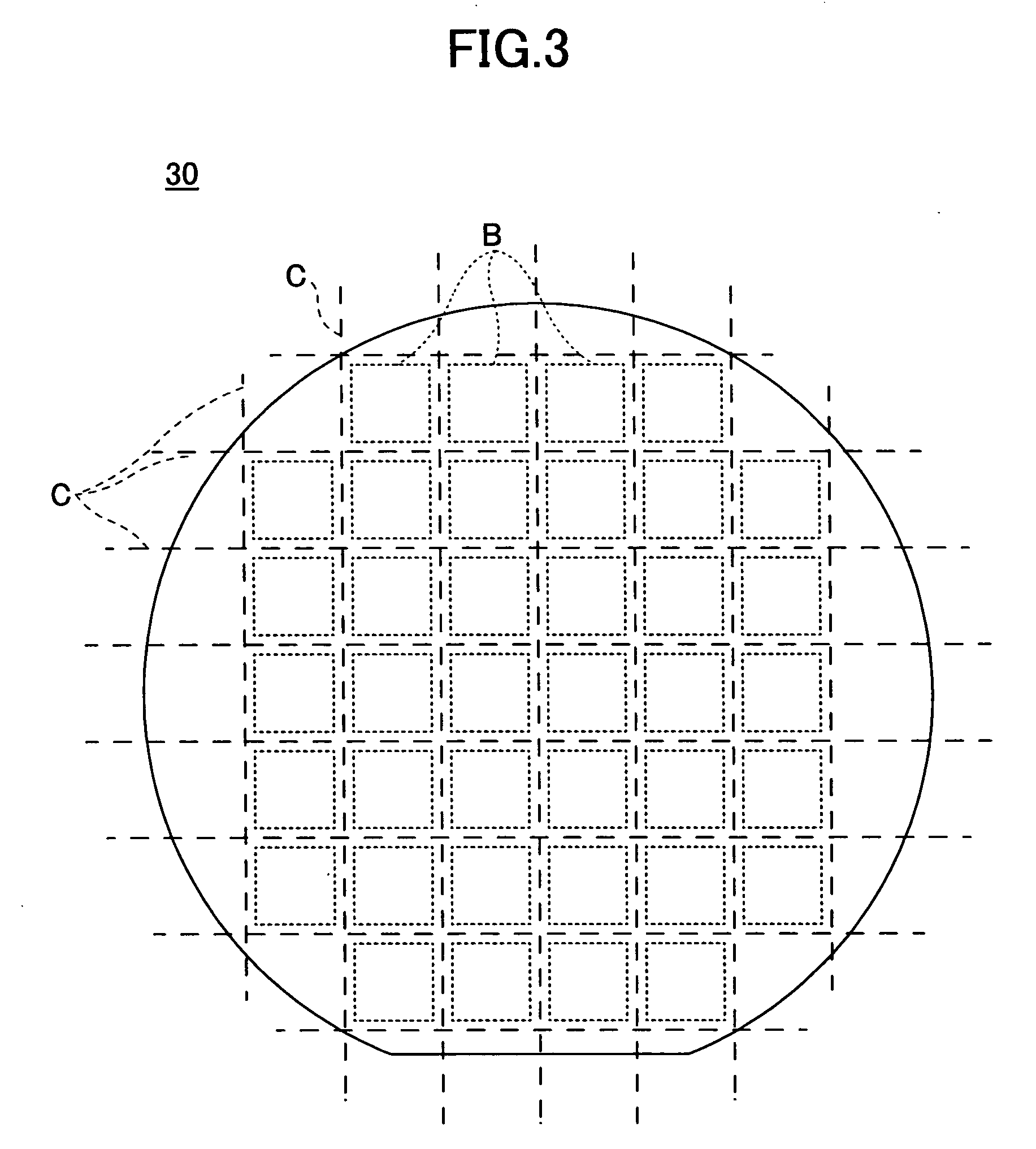

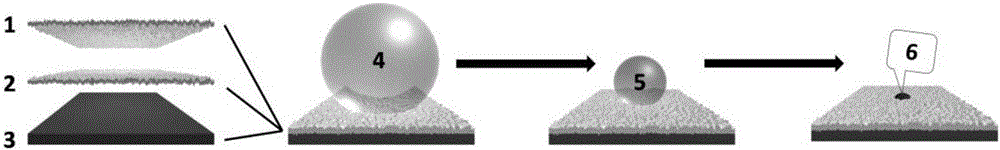

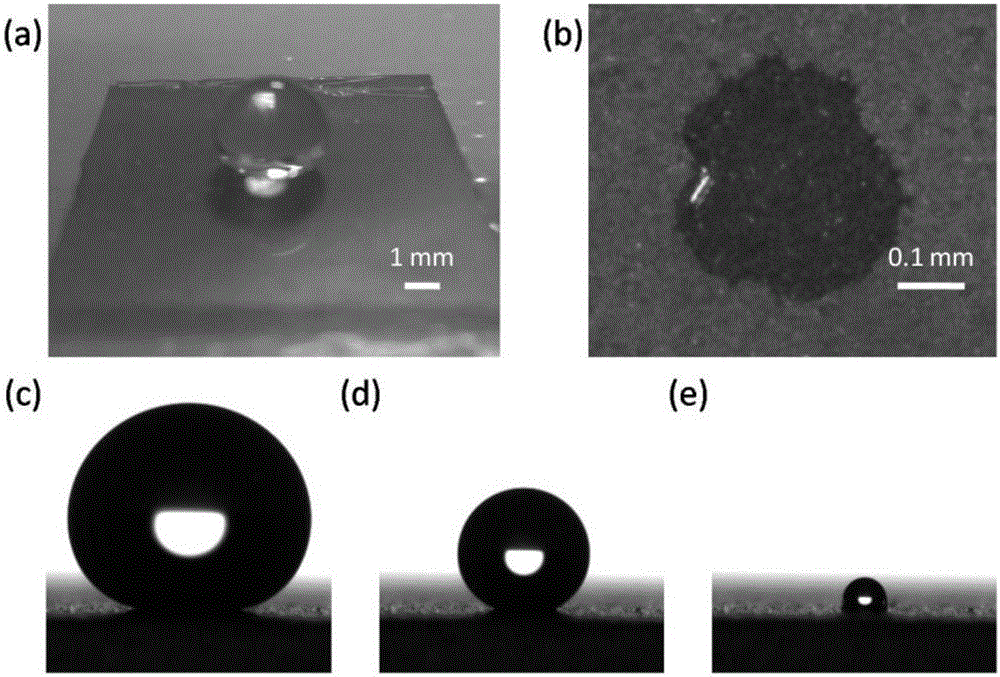

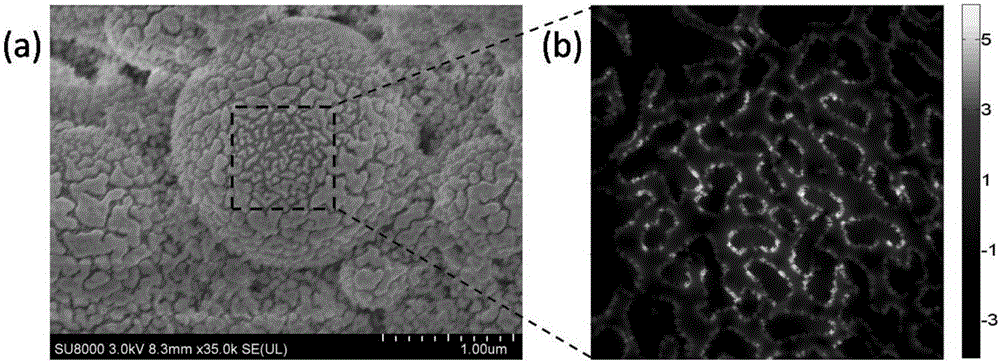

Method for producing low-friction super hydrophobic surface enhanced Raman substrate by using micro-nano particle coating layer

InactiveCN105973866AGood chemical hydrophobicityGood SHD performanceRaman scatteringCoated surfaceAnalyte

The invention relates to a method for producing a low-friction super hydrophobic surface enhanced Raman (SERS) substrate by using a micro-nano particle coating layer, and belongs to the field of analysis and detection. The method concretely comprises the following steps: dispersing micro-nano spheres in ethanol, and carrying out hydrophobization surface modification to prepare a hydrophobic coating; coating a substrate with the coating to form a super hydrophobic coating layer; and slowly and uniformly depositing silver on the surface of the coating layer to complete substrate production. A silver film has enough chemical hydrophobicity and roughness, and has low-friction Kaixi-state super hydrophobous properties; and the surface of the coarse silver film has abundant SERS hot spots. A solute can be enriched in a zone with a small area in a condensed manner in the surface evaporation process of an analyte solution in order to realize Raman detection of a trace quantity of a substance. The low-friction super hydrophobic surface enhanced Raman substrate has the advantages of extremely high SERS sensitivity, extremely low detection limit, and good repeated and quantitative detection ability.

Owner:JILIN UNIV

Lithium ion battery

InactiveCN104868156AImprove thermal stabilityIncrease contact interfaceSecondary cellsCell component detailsWater basedSilicon dioxide

The invention relates to a lithium ion battery and provides a lithium ion battery. The lithium ion battery comprises a cathode, an anode, and a water-based multi-layer diaphragm arranged between the anode and the cathode and an electrolyte. The water-based multi-layer diaphragm comprises: (A) a polymer diaphragm base material; (B) an inorganic or organic particle coating which coats one side or two sides of the polymer diaphragm base material (A); and (C) an organic particle coating which coats the inorganic or organic particle coating (B). The inorganic or organic particle coating (B) is formed by a following composition, wherein the following composition comprises 15-70 wt% of inorganic or organic particles and 30-85 wt% of water, and the inorganic or organic particles are selected from aluminum oxide, silicon dioxide, barium sulfate, boehmite or polyimide.

Owner:SHANGHAI ENERGY NEW MATERIALS TECH CO LTD

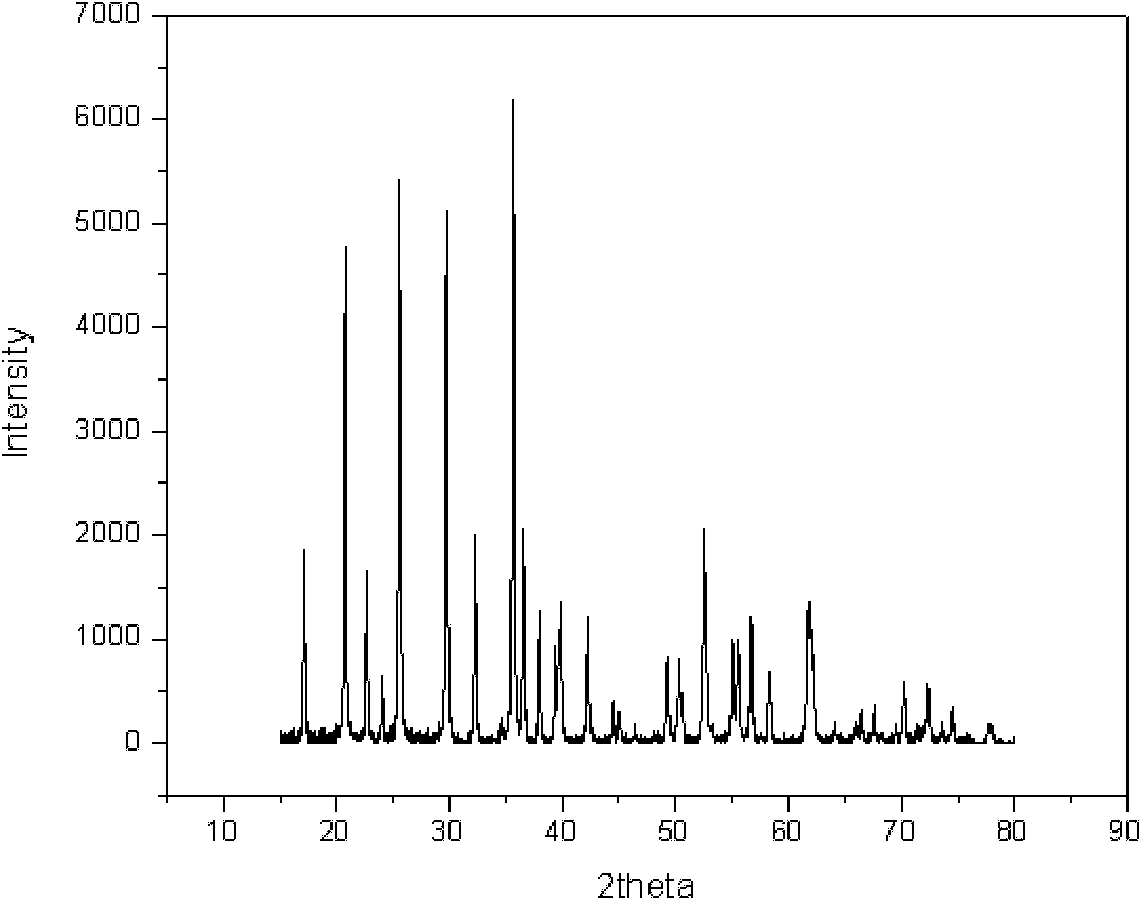

Lithium iron phosphate composite material, its preparation method and application

ActiveCN102437311AImprove conductivityFast charge and dischargeNon-aqueous electrolyte accumulator electrodesChemical compositionLithium iron phosphate

The invention is suitable for the technical field of batteries, and provides a lithium iron phosphate composite material, its preparation method and an application. The lithium iron phosphate composite material has a nanoparticle structure with lithium iron phosphate nanocrystals as the core. The external surface of the nanoparticle structure is covered with a nano-carbon particle coating, the external surface of which is covered with grapheme. The chemical composition of the lithium iron phosphate nanocrystals is LiFe1-xMxPO4, wherein M is metal ions and x is being less than 1 and greater than or equal to 0.001. By cladding the nano-carbon particles with the lithium iron phosphate crystals, adding grapheme and adding metal ions in the lithium iron phosphate crystals, conductivity of the lithium iron phosphate composite material in the embodiment of the invention is greatly improved. Simultaneously, the nano particle size of the lithium iron phosphate crystals guarantees rapid charge and discharge of the lithium iron phosphate crystals in the embodiment of the invention.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Method for preparing hard particle coating on hard substrate through laser-assisted cold spraying

ActiveCN103469197ALower the preheat temperatureReduce hardnessHeat inorganic powder coatingSand blastingLaser power density

The invention discloses a method for preparing a hard particle coating on a hard substrate through laser-assisted cold spraying. The method comprises the following steps: subjecting the hard substrate to sand blasting, wherein the hardness of the hard substrate is 300 HV; preheating a spherical hard particle with a diameter in a range of 30 to 50 mu m, wherein preheating temperature is 300 to 600 DEG C, and the hard particle is one or more selected from the group consisting of 2Cr13, 17-4PH, Ni45, Ni60 and Inconel718; carrying out spraying on the surface of the hard substrate by using compressed air having a pressure of 1.5 to 3.0 MPa and carrying the preheated hard particle; and starting laser to synchronously heat a spraying area so as to form the hard particle coating on the surface of the hard substrate, wherein laser power density is 3*10<5> to 5*10<5> W / cm<2>, and wavelength is 850 to 1060 nm. The method provided by the invention can substantially improve plastic deformation generated during collision between the hard particle and the substrate, so the binding force of the coating is improved; thus, the coating with higher stability is obtained.

Owner:ZHEJIANG UNIV OF TECH +1

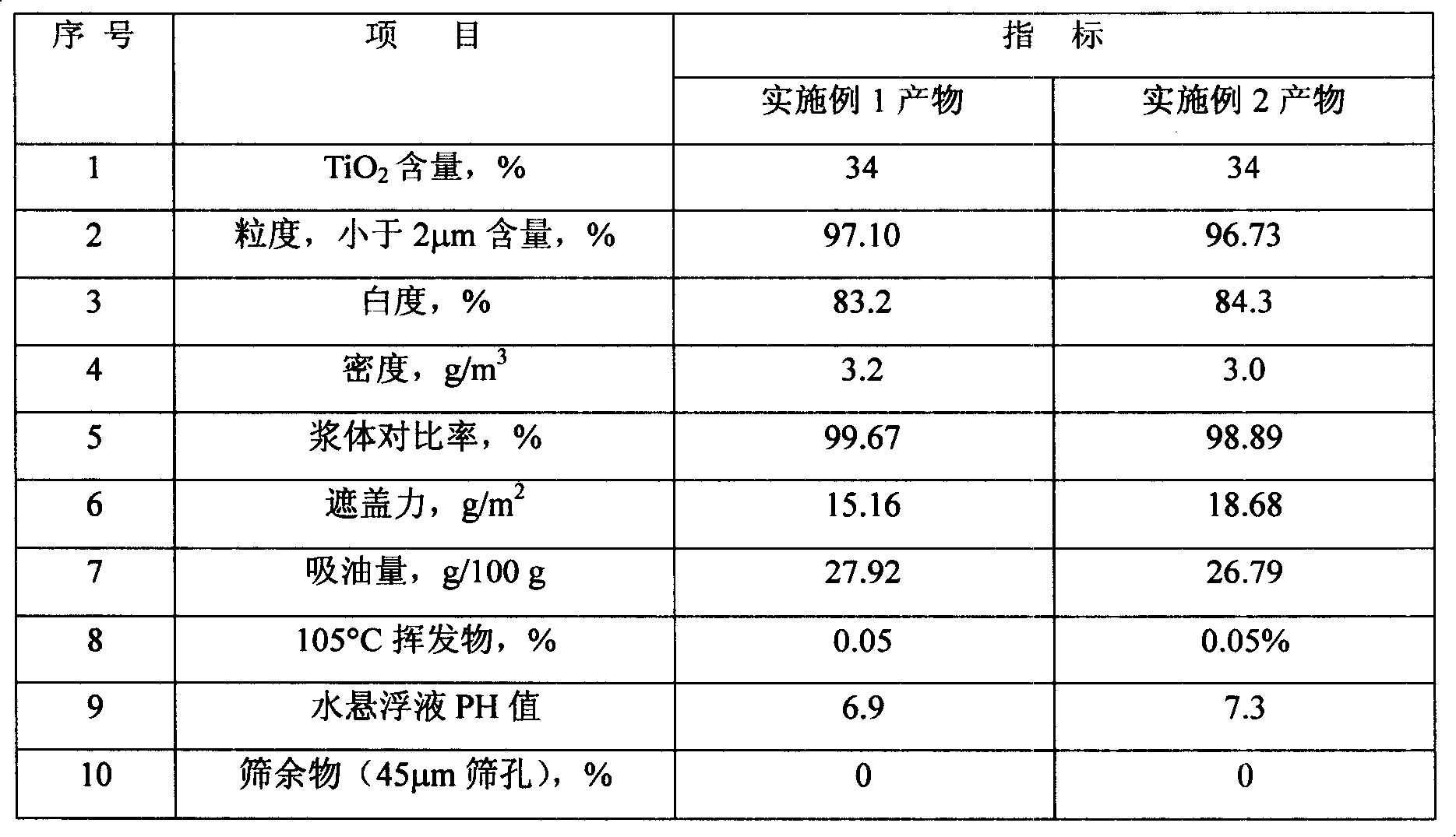

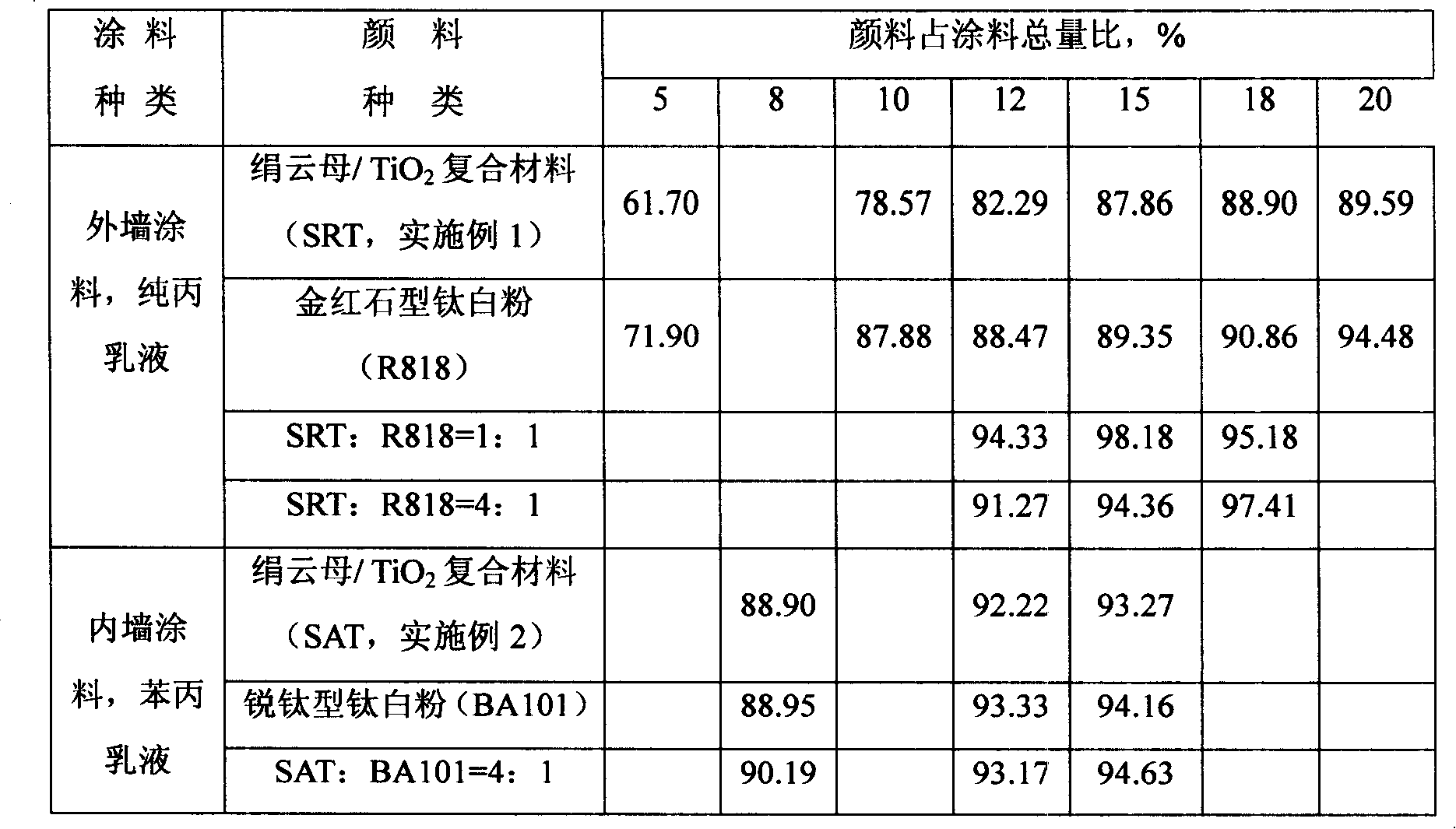

Sericite/TiO2 composite material with white pigment property

InactiveCN101210117AHas pigmentary titanium dioxide propertiesLow costInorganic pigment treatmentUltravioletRutile

The invention provides a sericite / TiO2 composite material with properties of pigment titanium dioxide and a preparation method thereof. The invention adopts high-grade sericite powder body as a core basic body and takes crystal TiO2 as an envelope object. In a wet method superfine grinding system, the reaction coating and the modification of TiO2 on the surface of the core basic body are realized in a way of particle-particle coating modification so as to prepare the sericite / TiO2 composite material with the properties of titanium dioxide. In materials of the invention, the TiO2 is evenly coated on the surface of sericite and the combination of the TiO2 and the sericite is stable. The integration of the properties of the surface of compound particles TiO2 and TiO2 and the performance of the sericite leads to the fact that the sericite / TiO2 composite material has paint properties such as great covering ability and good compatibility of an application system. When the envelope object is rutile type TiO2, the sericite / TiO2 composite material has the functions of absorbing ultraviolet radiation and anti-ultraviolet radiation which are equal to or superior to that of the rutile type TiO2. The sericite / TiO2 composite material also has the characteristics of simple technique and low cost, etc. The application of the sericite / TiO2 composite material in products such as paints can obtain the technical capability which is the same as that of the use of titanium pigment and can greatly lower the cost. The sericite / TiO2 composite material can be also used for the situations where the physical performance of white paint is adopted such as plastics and paper making, and have the functions of improving the performance of applications and reducing the cost.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Abrasive coated substrate and method for manufacturing thereof

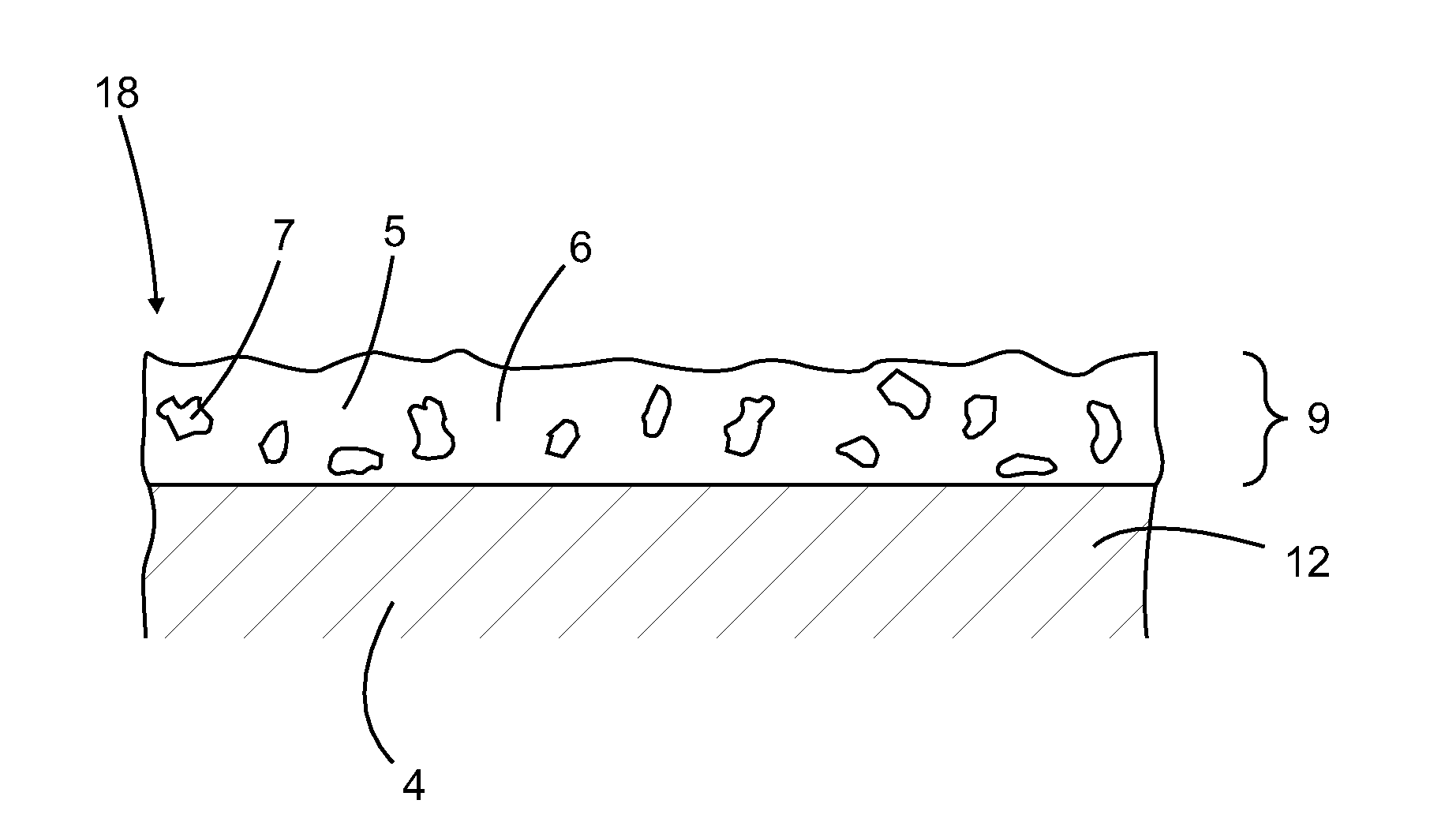

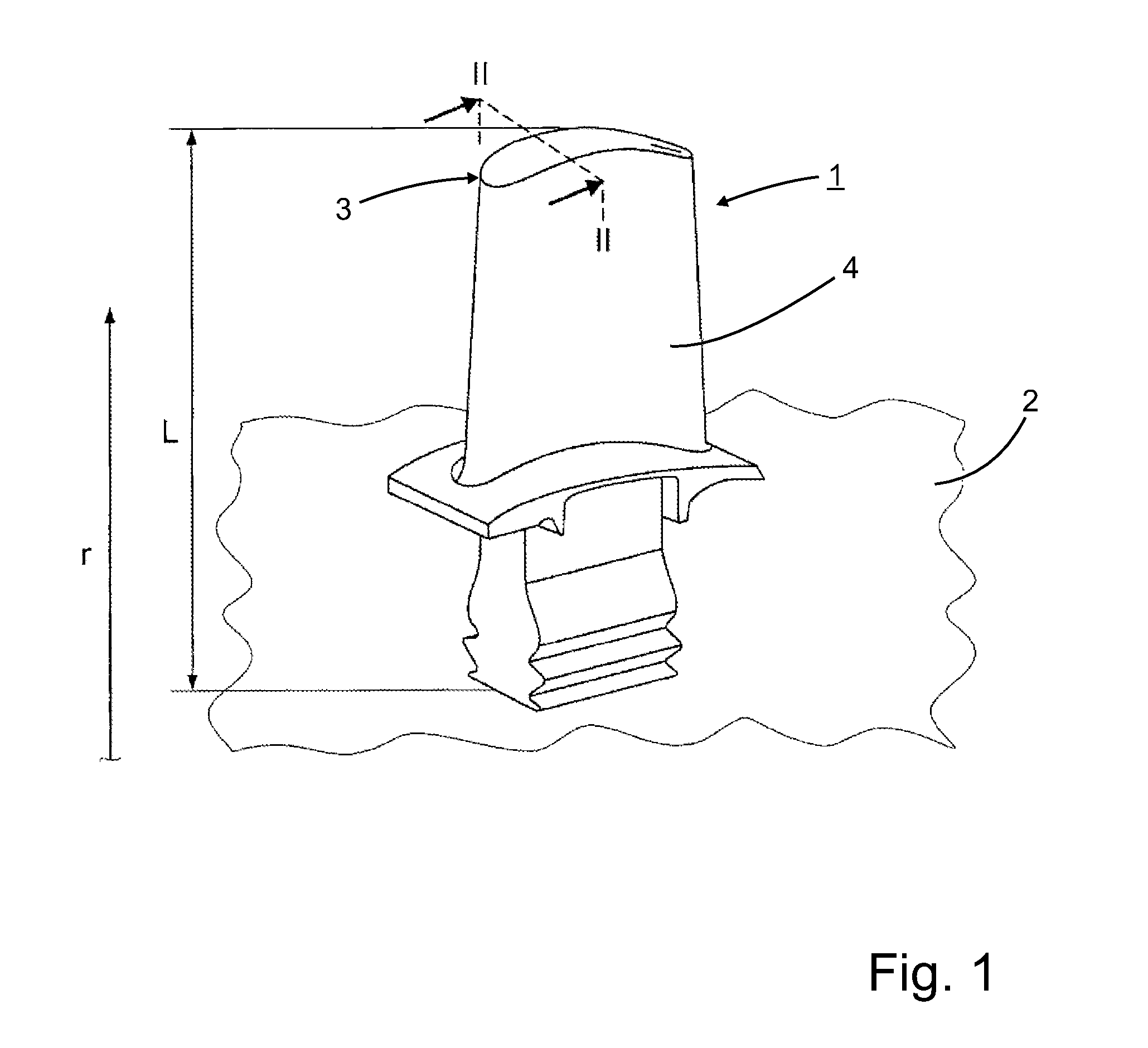

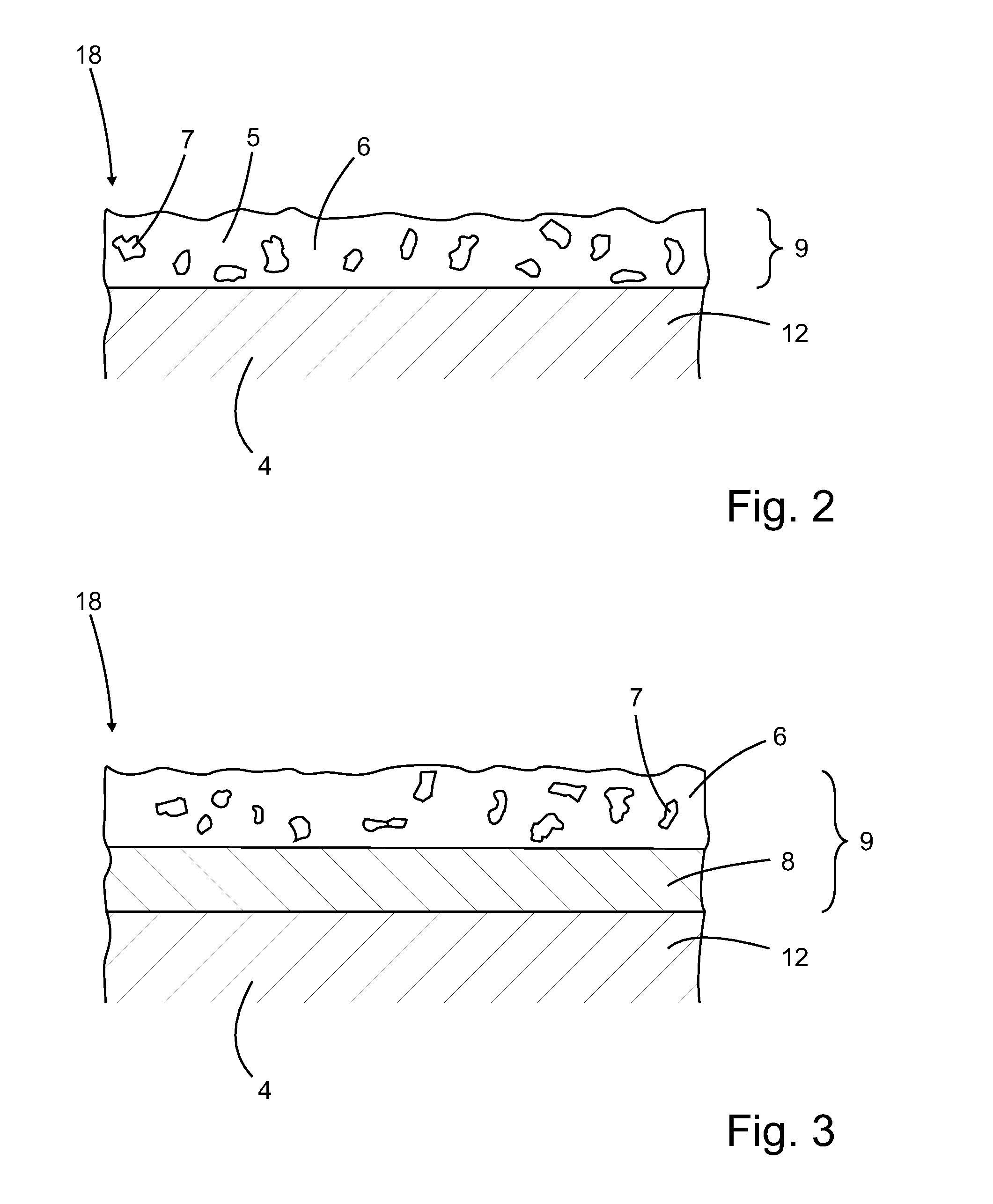

ActiveUS20160160661A1Produced quickly and inexpensivelyFaster and easy to producePropellersMolten spray coatingWear resistantOxidation resistant

A coated substrate is described including a substrate material, which is coated at least in part with an oxidation-resistant coating, wherein the coating consists of a wear-resistant abrasive coating layer, which contains or consists of coated abrasive particles embedded in an oxidation-resistant matrix material, wherein at least some of the abrasive particles consist of α-Al2O3 and the abrasive particles are coated with a first particle coating layer disposed on the abrasive particles and an optional second particle coating layer disposed on the first particle coating layer, wherein the matrix material contains or consists of the compound MCrAlY, wherein M is at least one element selected from the group consisting of Ni, Co and Fe. A method for manufacturing such a coated substrate is also disclosed.

Owner:ANSALDO ENERGIA SWITZERLAND AG

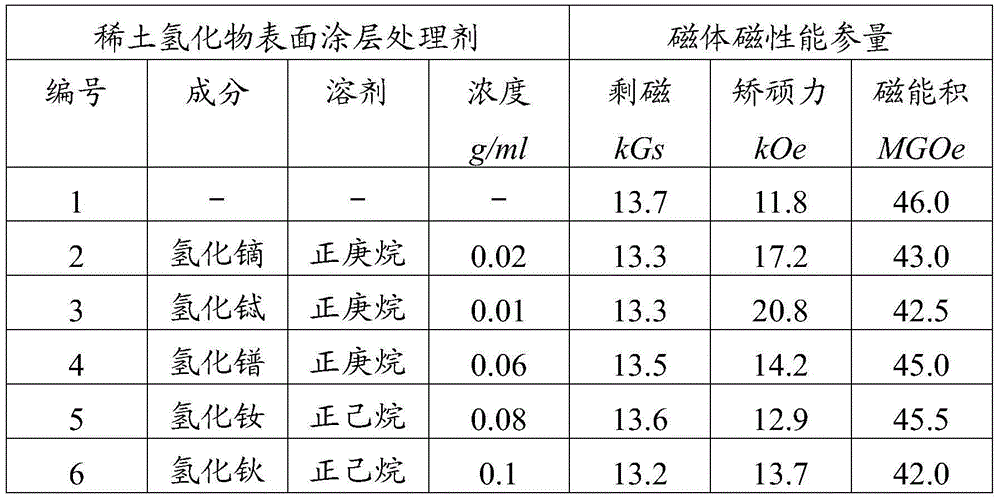

Treating agent and electro-deposition method for forming rare earth hydride particle coating

ActiveCN103556208AImprove magnetic propertiesStrong magnetismElectrolytic coatingsMagnetic materialsRare-earth magnetHeptane

The invention relates to a treating agent and an electro-deposition method for forming a rare earth hydride particle coating, and belongs to the technical field of magnetic materials. Rare earth hydride particles are dispersed in a dispersing agent, wherein n-hexane or n-heptane is taken as the dispersing agent; the rare earth is at least one element of Pr, Nd, Tb, Dy and Ho. The hydride particles are deposited on the surface of a sintered NdFeB rare earth magnet by using the electro-deposition method so as to form the uniform and dense coating with controllable thickness. The rare earth hydride particle coating can be used for obviously improving the magnetic property of the sintered NdFeB rare earth magnet and especially the coercivity of the magnet. As the method is adopted, the usage amounts of heavy rare earths in the sintered NdFeB rare earth is decreased on the premise of guaranteeing good magnetic property of the magnet, so that the manufacturing cost of the magnet with high coercivity is reduced.

Owner:BEIJING UNIV OF TECH +1

Dry coating and downstream processing of cohesive powders

InactiveUS20070053846A1Improve cohesionEasy to processPowder deliveryTransportation and packagingDownstream processingIngested food

The present disclosure is directed to systems and methods for dry particle coating of cohesive powders, and to the dry coated particles / powders produced thereby. The present disclosure is further directed to systems and methods for dry coating of cohesive particles, particularly nanosized particles, to provide enhanced flowability and other advantageous physical and / or functional properties. The disclosed systems and methods offer downstream processing advantages, e.g., for purposes of subsequent fluidization, coating, granulation and / or other particle processing operations, and have applicability in wide ranging industries, including specifically paint-related applications, pharmaceutical applications, food-related applications, cosmetic applications, defense-related applications, electronics-related applications, toner and ink-related applications, and the like.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com