Spherical lithium iron phosphate anode material and preparation method thereof

A technology of lithium iron phosphate and positive electrode materials, which is applied in the direction of battery electrodes, electrical components, circuits, etc., can solve the problems that limit the large-scale application of lithium iron phosphate materials, are not suitable for large-scale industrial production, and the performance has not been expressed in the patent, etc. problems, to achieve the effect of convenient material capacity and rate performance, easy embedding and moving out, and excellent fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

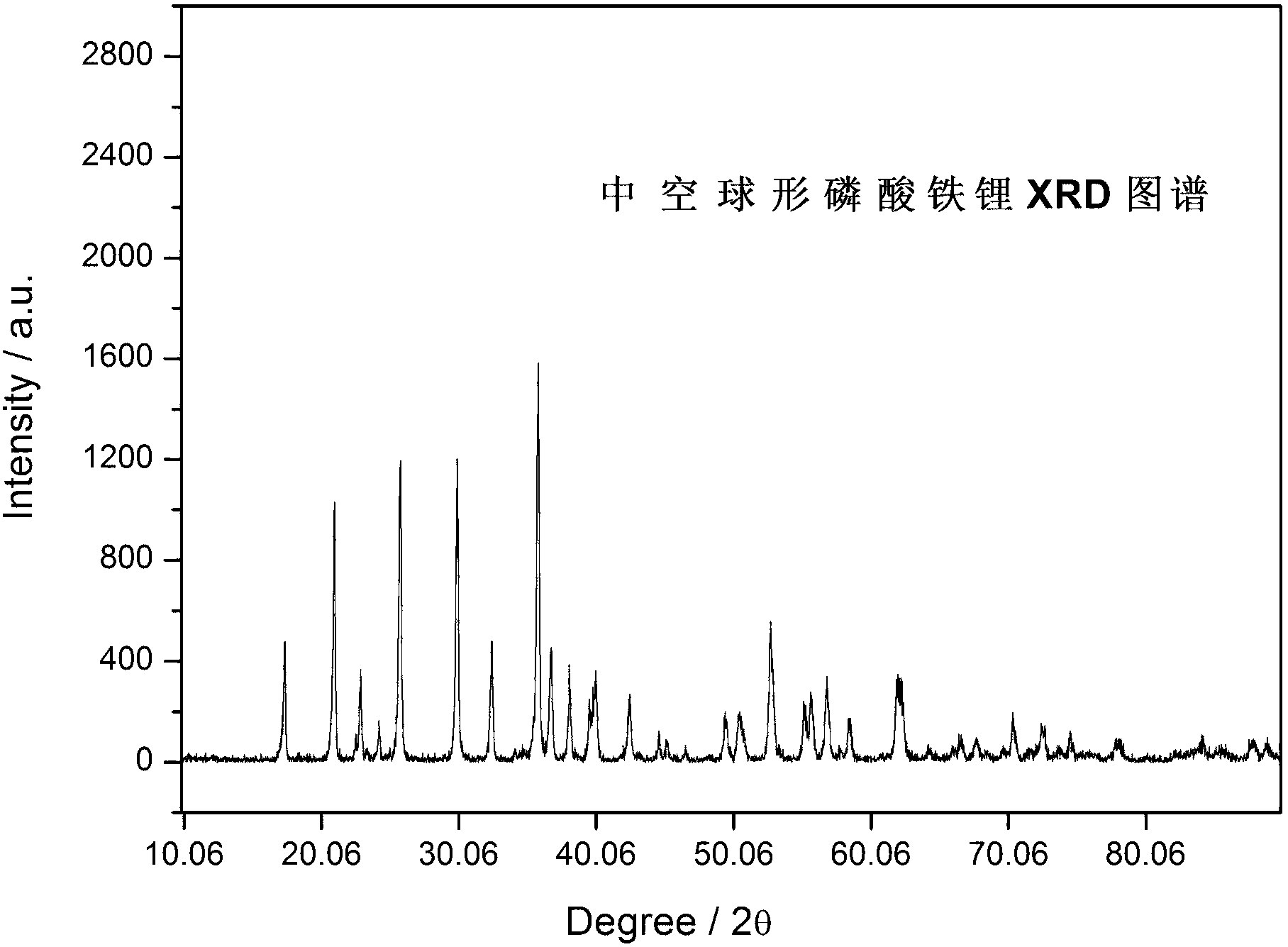

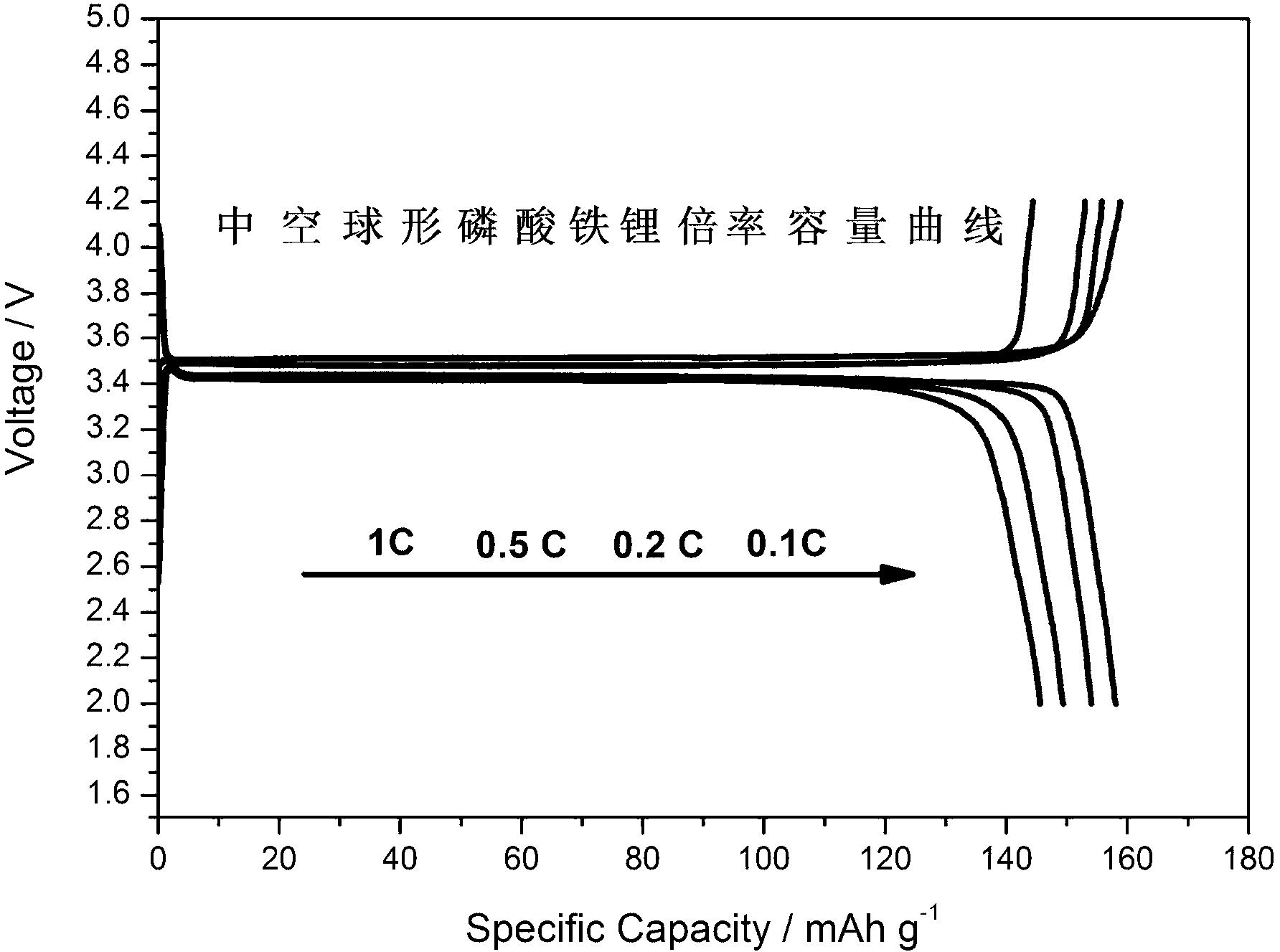

[0030] First, according to the method used to prepare Li (1-x) A x Fe (1-y) B y PO 4 / C stoichiometric ratio of lithium iron phosphate material particles, weigh 12wt% soft template polyacrylamide and dissolve it in 35kg water, stir for about 10 minutes to prepare solution A; then, add 6.91kg dihydrogen phosphate to solution A ammonium, 9.73kg ferric chloride, 6.13kg lithium acetate, and 19wt% glucose to obtain a mixed solution B; then use high-speed grinding to make the solution B uniform and nano-sized, and finally obtain the liquid precursor C'; then, use spray The drying equipment is used for drying to obtain the solid precursor D; the obtained dried solid precursor D is heat-treated in a high-temperature calcination furnace for 20 hours at a treatment temperature of 650° C. to finally obtain spherical lithium iron phosphate with a hollow structure. figure 1 Be the X-ray diffraction pattern of this embodiment, the material that analyzes gained is the lithium iron phosp...

Embodiment example 2

[0032] First, take 15wt% soft template agent cetyltrimethylammonium bromide (CTAB) and dissolve in the ethanol mixed solution of 30kg water and 5kg, stir about 12 minutes, make solution A; Then, add to Add 9.06kg of iron phosphate, 6.13kg of lithium acetate, and 16wt% glucose to solution A, the resulting mixed solution is B, and then use high-speed grinding to make it uniform and nano-sized, and finally obtain liquid precursor C'; then, use spray drying equipment Drying is carried out to obtain a solid precursor D; the obtained dried solid precursor D is heat-treated in a high-temperature calcination furnace for 12 hours at a treatment temperature of 700°C, and finally a spherical lithium iron phosphate with a hollow structure is obtained. The average particle size of the hollow spherical lithium iron phosphate cathode material obtained in this example is 16 μm, and its specific surface area is about 28 μm. 2 / g; the hollow spherical lithium iron phosphate positive electrode m...

Embodiment example 3

[0034] First, take 18wt% of the soft template agent polyvinyl alcohol and dissolve it in 30kg of water, stir for about 8 minutes to prepare solution A; then, add 6.91kg of phosphoric acid, 24.25kg of iron nitrate, and 4.14kg of lithium nitrate to solution A , and 12wt% glucose and 6wt% graphite, the resulting mixed solution is B, and then use high-speed grinding to make it uniform and nano-sized to obtain a liquid precursor C'; then, use a spray drying device to dry to obtain a solid precursor D; the obtained The dry solid precursor D is heat-treated in a high-temperature calcination furnace for 24 hours at a treatment temperature of 600° C. to finally obtain spherical lithium iron phosphate with a hollow structure. The average particle size of the hollow spherical lithium iron phosphate cathode material obtained in this example is about 13 μm, and its specific surface area is about 20 μm. 2 / g; the hollow spherical lithium iron phosphate cathode material also shows excellent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain diameter | aaaaa | aaaaa |

| Average specific surface area | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com