Patents

Literature

920results about How to "Increased diffusion rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

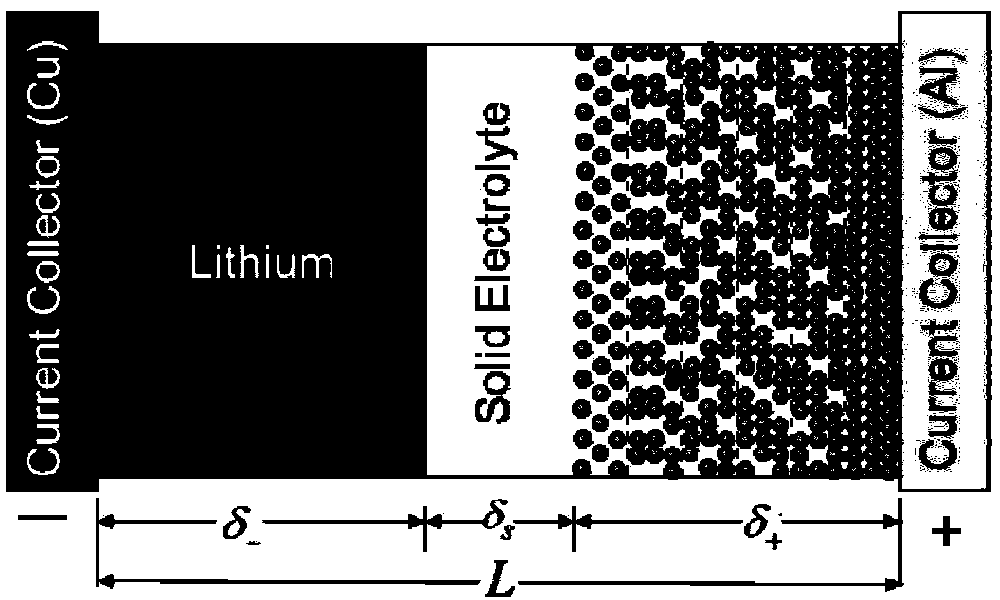

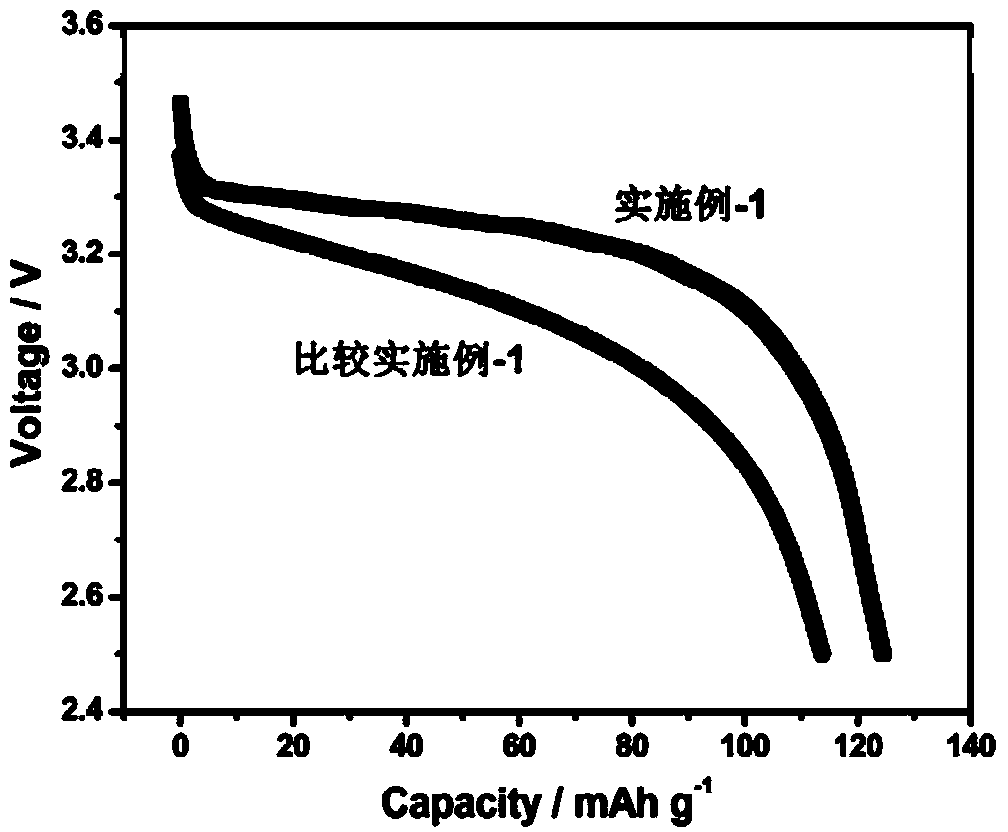

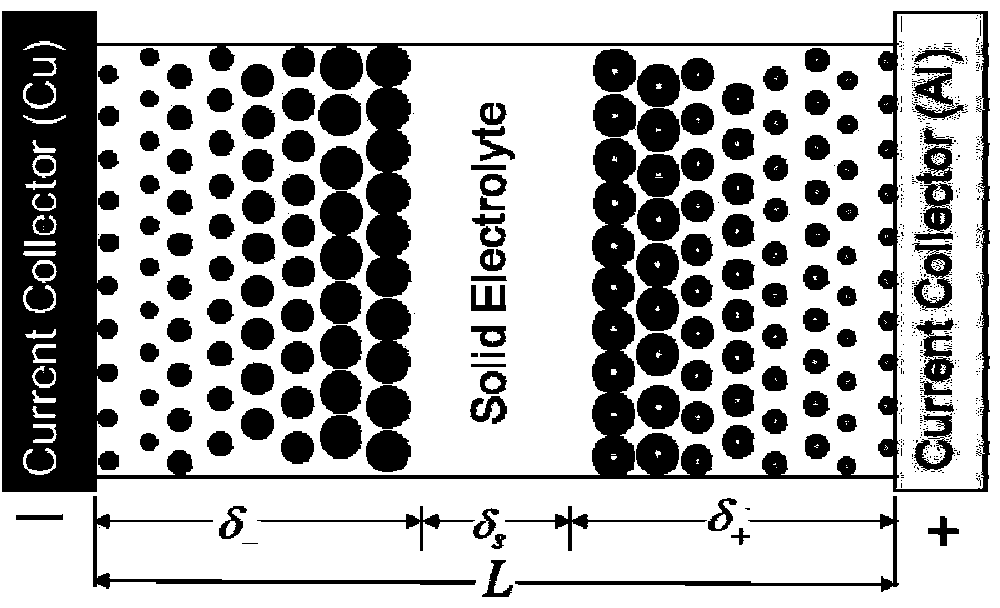

All-solid-state lithium battery with gradient structure and preparation method thereof

ActiveCN103746089AObvious solid electrolyteObvious electrode interfaceFinal product manufactureNon-aqueous electrolyte accumulator electrodesAll solid statePower flow

The invention discloses an all-solid-state lithium battery with a gradient structure and a preparation method thereof. The all-solid-state lithium battery comprises a cathode with a gradient structure layer, a solid electrolyte layer, and a metal anode or an anode with a gradient structure layer; the preparation method comprises the following steps: preparing cathode slurries with different component concentrations or particle sizes or molecular weights, coating a collector electrode with the cathode slurries according to the component concentration gradient or particle size gradient or molecular weight gradient to prepare an electrode layer, coating the electrode layer with the solid electrolyte layer, finally attaching the metal anode, or preparing anode slurries with different component concentrations or particle sizes or molecular weights, coating the electrolyte layer with the anode slurries according to an opposite concentration gradient or particle size gradient or molecular weight gradient based on the preparation method of the cathode electrode layer, and finally attaching a collector electrode to obtain the all-solid-state lithium battery with a gradient structure; the preparation method is simple, and the prepared all-solid-state lithium battery is stable in large-rate charge and discharge, and can work normally at large current.

Owner:王海斌

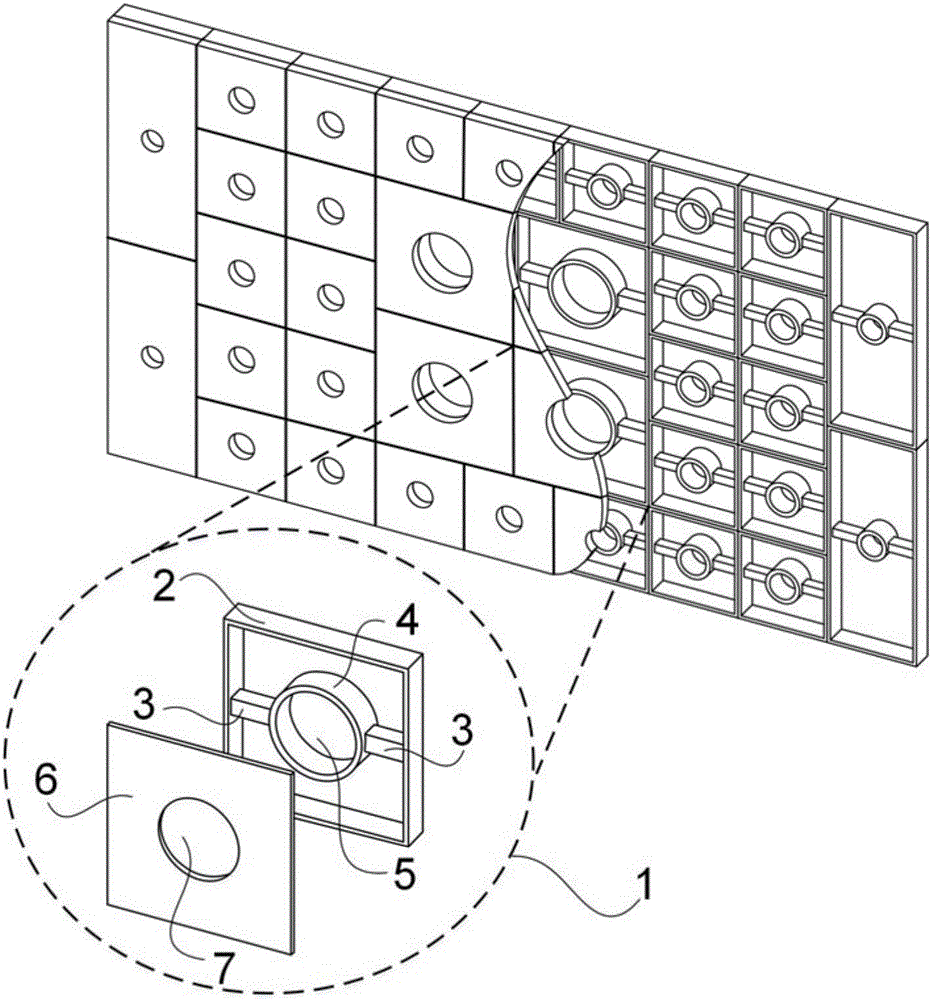

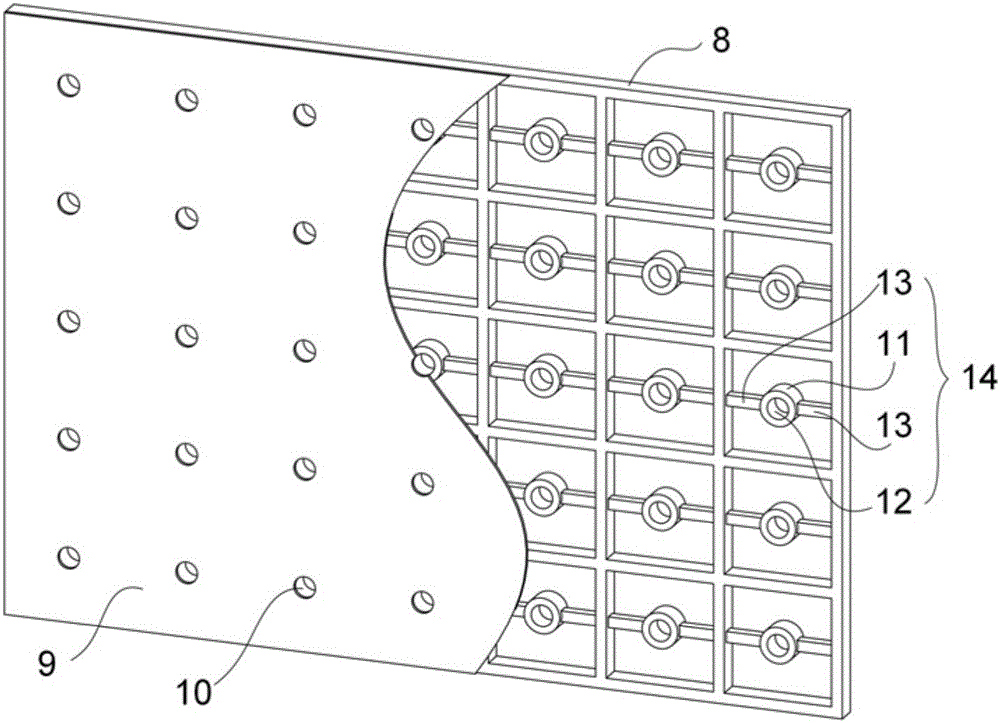

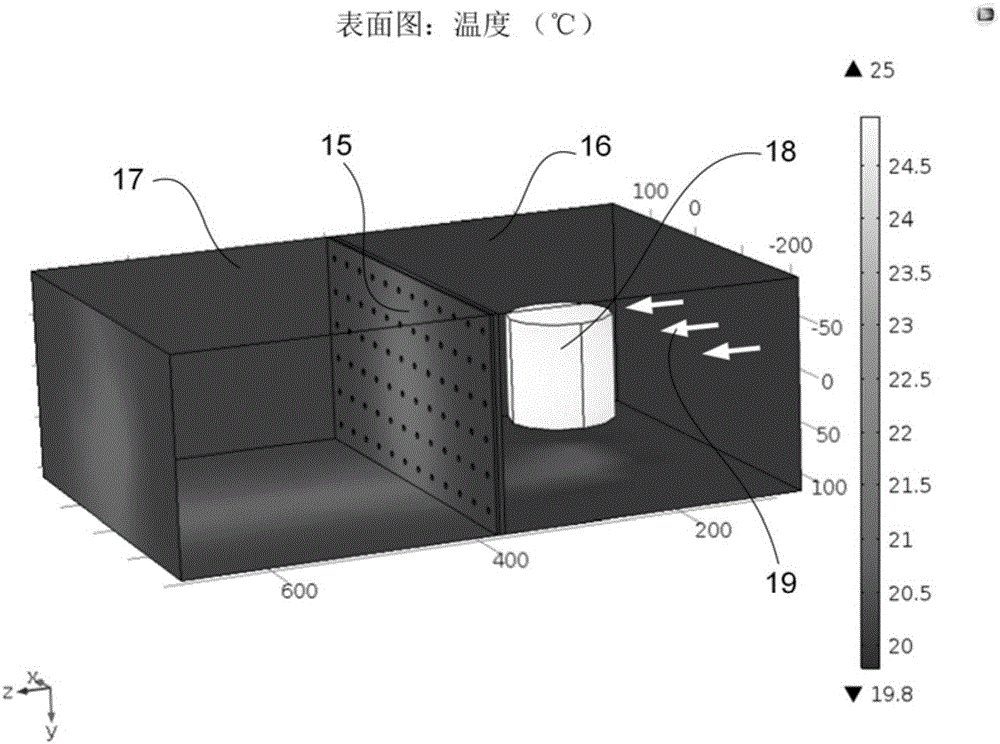

Sound-insulating, ventilating and heat transfer enhancing acoustic metamaterial unit, composite structure and preparation method

ActiveCN105845121AWorking frequency bandwidthImprove sound insulationStringed musical instrumentsSound producing devicesEngineeringComposite plate

The invention relates to a sound-insulating, ventilating and heat transfer enhancing acoustic metamaterial structural unit, which comprises a frame, wherein a restraining body is arranged inside the frame, and at least one of the upper and lower surfaces of the frame is coated with a thin film; and at least one hole is formed in the restraining body and the thin film. In addition, the invention provides an acoustic metamaterial composite plate and an acoustic metamaterial composite structure comprising the acoustic metamaterial structural unit, as well as a frequency modulation method and an assembly method. The acoustic metamaterial structural unit has sound insulation capability superior to that of an ordinary perforated plate or micro-perforated plate within a broadband, can ensure that sufficient heat flow, air flow or liquid flow can pass through smoothly, and increases heat diffusion rate of fluid media on both sides of holes and accelerates heat convection efficiency through unit localized vibration generated by the structure under excitation of acoustic waves. The acoustic metamaterial structural unit and the array composite structure have the advantages of simple assembly technology and stable working performance.

Owner:黄礼范

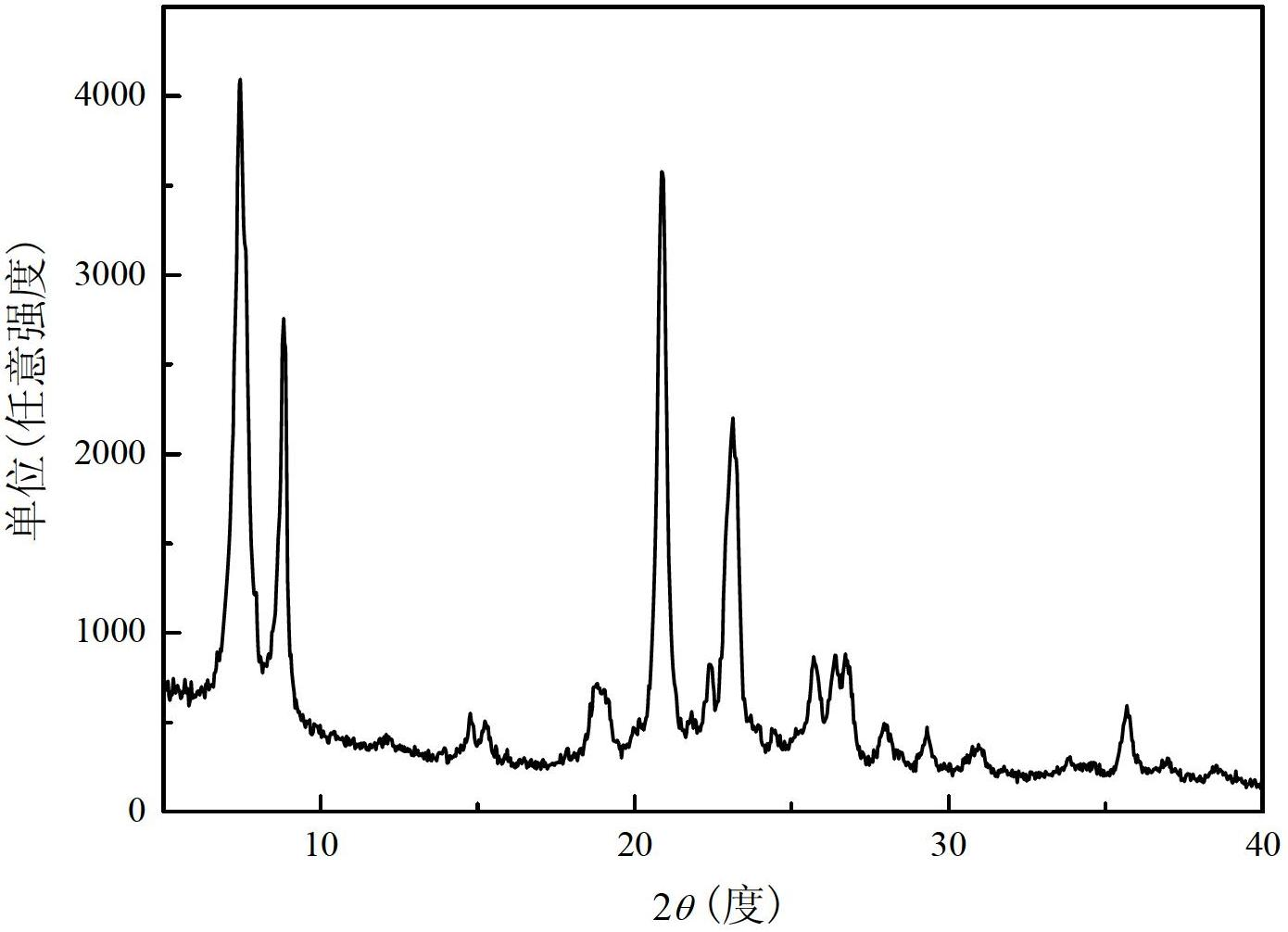

Catalyst for normal paraffin hydroisomerization reaction and preparation method as well as application thereof

InactiveCN102658197AExtend your lifeIncreased diffusion rateHydrocarbon by isomerisationMolecular sieve catalystsMolecular sieveHydrogen

The invention relates to a catalyst for a normal paraffin hydroisomerization reaction and a preparation method as well as an application thereof. The catalyst has the characteristics that the activity is high in an n-hexane hydroisomerization reaction, and the selectivity and stability are good for a double-branched-chain product. The catalyst comprises modified zeolite molecular sieve ZSM-12 treated by alkaline solution and noble metal of family VIII, wherein the zeolite molecular sieve ZSM-12 adopts zeolite molecular sieve ZSM-12 containing organic amine template. The preparation method of the catalyst comprises the following steps of: desilication of zeolite molecular sieve ZSM-12 containing template after being treated with alkaline solution to obtain zeolite molecular sieve ZSM-12 with high content of mesoporous, and preparing isomerized catalyst by loading Pt. The catalyst is applied in the normal paraffin hydroisomerization reaction, when the catalyst is applied, the n-hexane hydroisomerization reaction is carried out on a fixed bed miniature reactor, the reacting raw material n-hexane is fed into the reactor by a force pump, and is contacted with the catalyst to react in the reactor after being mixed with hydrogen in a mixer.

Owner:ZHEJIANG NORMAL UNIVERSITY

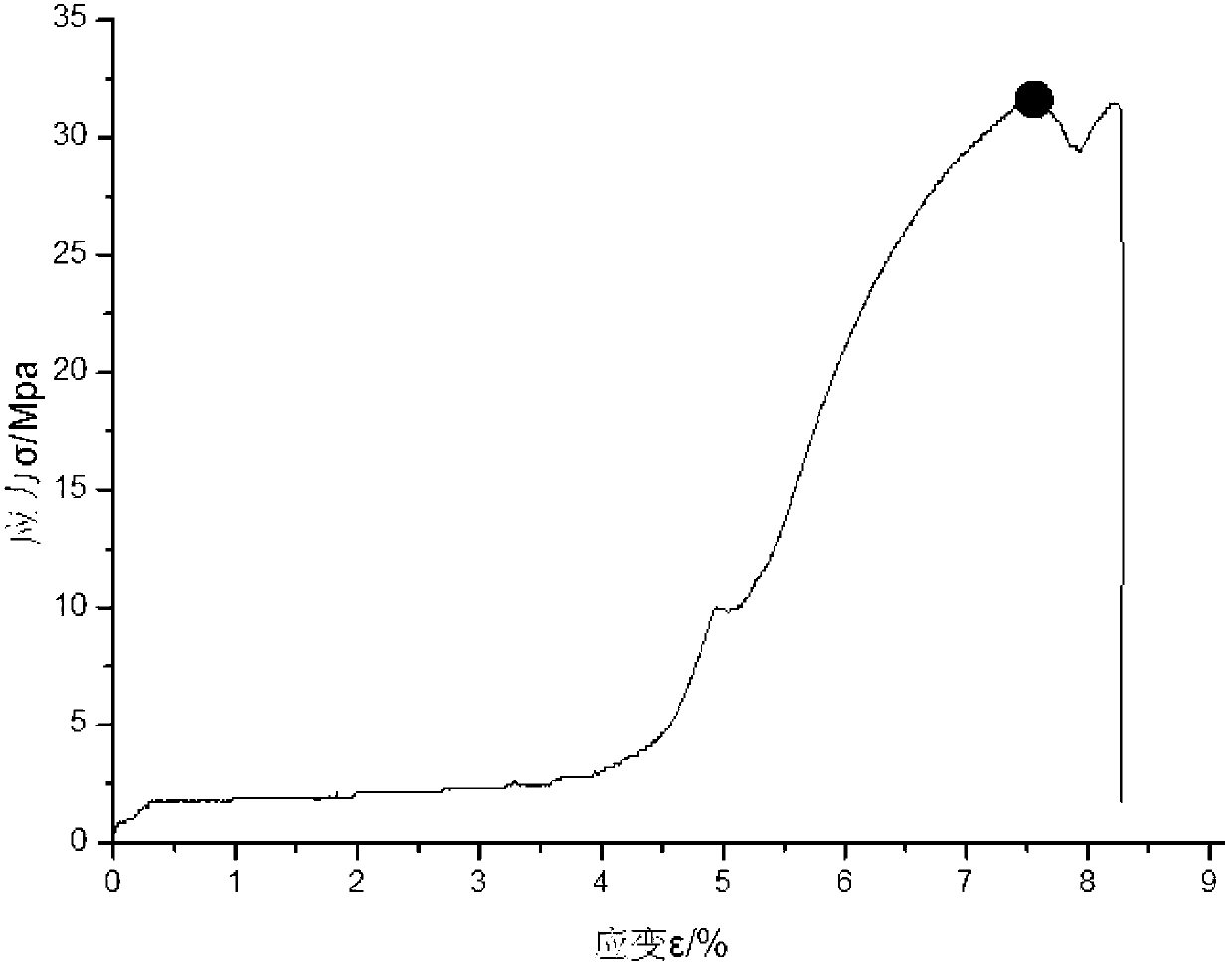

Conductive composite waterborne adhesive as well as one-pot preparation method and application thereof

ActiveCN107663428AGood dispersionGood film formingCell electrodesMacromolecular adhesive additivesPolymer scienceConductive polymer

The invention discloses a conductive composite waterborne adhesive as well as a one-pot preparation method and application thereof. A conductive composite waterborne adhesive material is prepared by adopting a one-pot method by simultaneously initiating grafting polymerization between double bond-containing grafting monomers and hydroxyl-containing waterborne polymers and chemical oxidative polymerization of conductive polymer monomers by adopting the same polymerization initiator, wherein the double bond-containing grafting monomers and the hydroxyl-containing waterborne polymers perform grafting polymerization reaction, and simultaneously, the conductive polymer monomers perform chemical oxidative polymerization; the conductive composite waterborne adhesive prepared by the invention hasgood dispersity, film forming property and chemical stability, can be dispersed in an aqueous solution for a long time in the form of colloid, does not settle, exists stably, has excellent electronicconductivity, solves the problem about dispersity of an adhesive and conductive particles in an electrode slurry preparation process, realizes uniform distribution of various components in an electrode, and ensures high-efficiency electron and ion transportation in the electrode.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

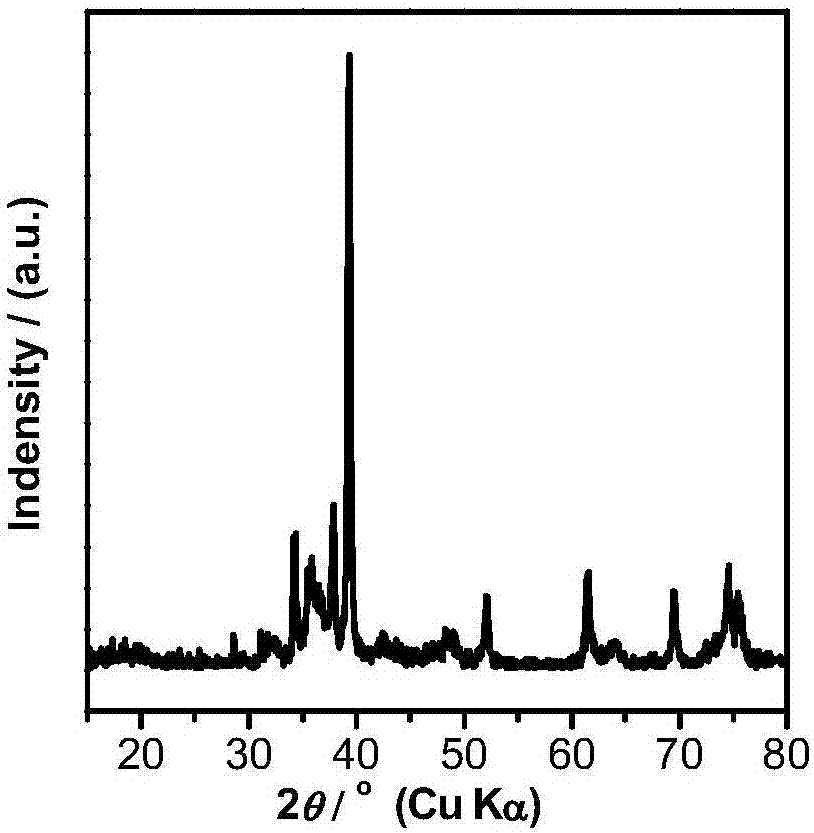

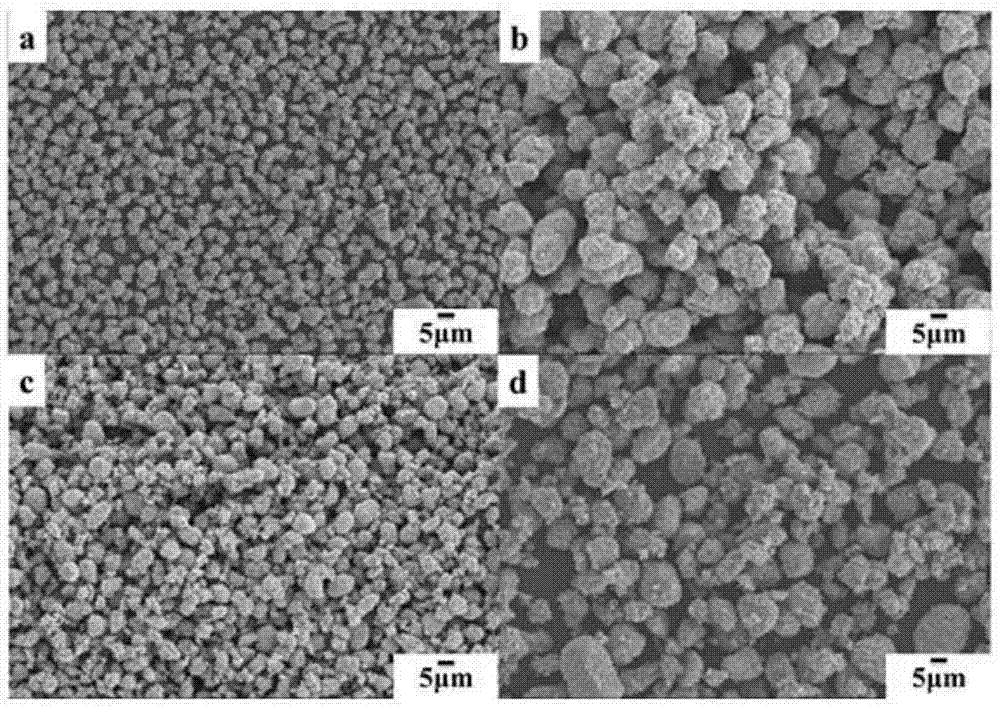

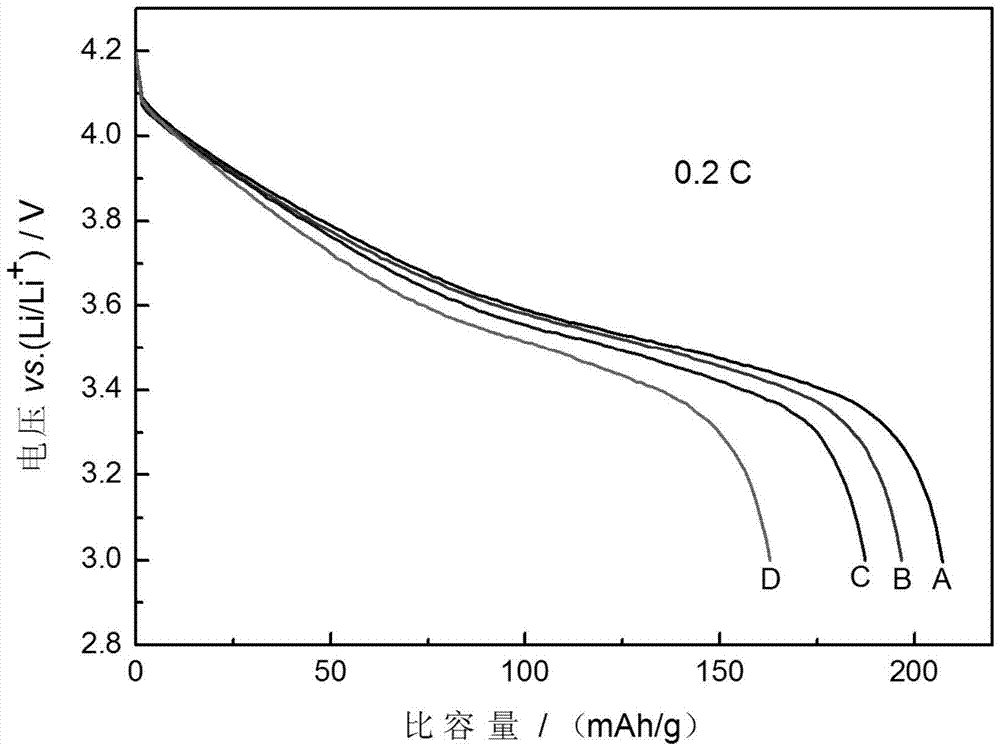

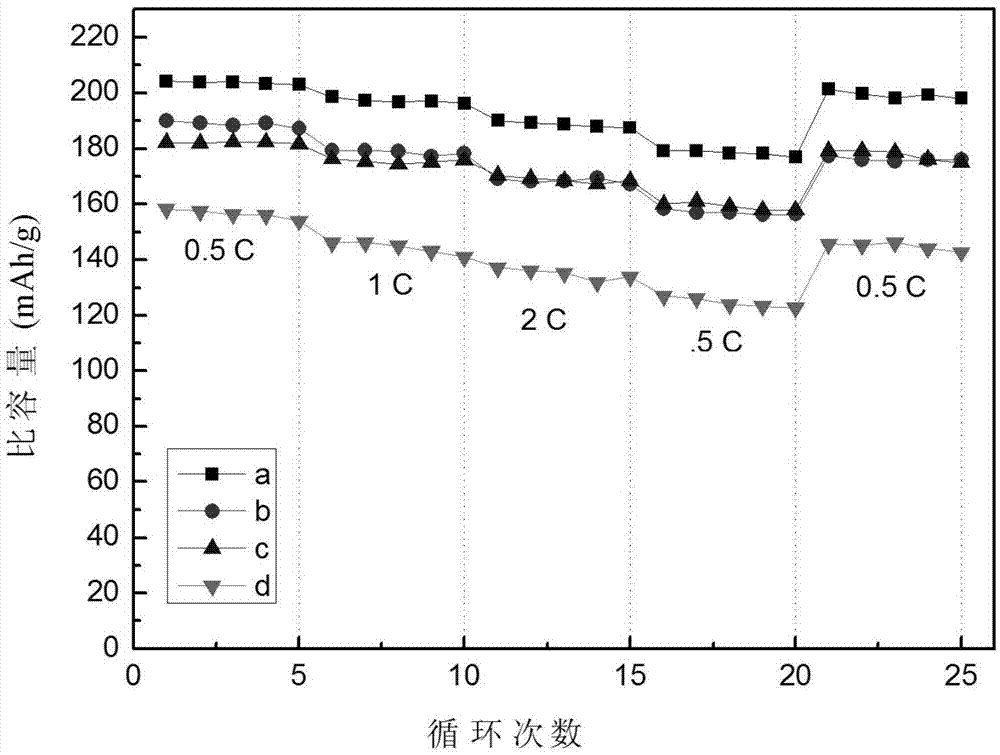

Method for preparing ternary anode material of long-service-life and high-capacity lithium ion battery

ActiveCN103682316AIncrease capacityImprove cycle performanceCell electrodesCapacity lossMaterial synthesis

A method for preparing a ternary anode material of a long-service-life and high-capacity lithium ion battery and belongs to the technical field of material synthesis. The method comprises the following steps: weighing a lithium source and NixCoyMnz(OH)2, uniformly mixing, pre-burning at a temperature of 400-600 DEG C for 2-6 h, and forging at a temperature of 700-1000 DEG C for 6-16 h; uniformly mixing the ternary anode material, the lithium source and nanometer TiO2; forging at a temperature of 700-950 DEG C for 3-8 h to obtain the ternary anode material which is prepared by twice lithium adding and twice forging. The ternary anode material is prepared through twice lithium adding and twice forging, and the extra lithium source which is introduced through twice lithium adding and twice forging is electrochemically pre-embedded in an anode. Meanwhile, the Li+ diffusion rate can be effectively increased through the doping of Ti4+, and the irreversible capacity loss is reduced. In an interval of 2.3-4.6 V, a discharging platform is prolonged, and the first discharging capacity, the cyclic performance and the rate performance of the material are obviously improved. The method is simple, effective, economical and practical and has a remarkable industrial application effect.

Owner:HARBIN INST OF TECH

High-performance variable-pressure adsorption 5A molecular sieve and preparing method thereof

InactiveCN1530167AReduce dosageHigh adsorption capacityOther chemical processesMolecular sieveKaolinite

A high-performance 5A molecular sieve with pressure-variable adsorption function is prepared through proportionally mixing the raw powder of 4A molecular sieve with kaolinite-type clay, adding plant fibres, granulating, sieving, baking, calcining at 200-1000 deg.C, immersing in the solution of sodium hydroxide, washing, Ca ion exchanging in CaCl2 solution, washing, baking, and calcining at 100-800 deg.C. Its advantages are high adsorption capacity, diffusing speed, and mechanical strength.

Owner:江苏洁欧康科技有限公司

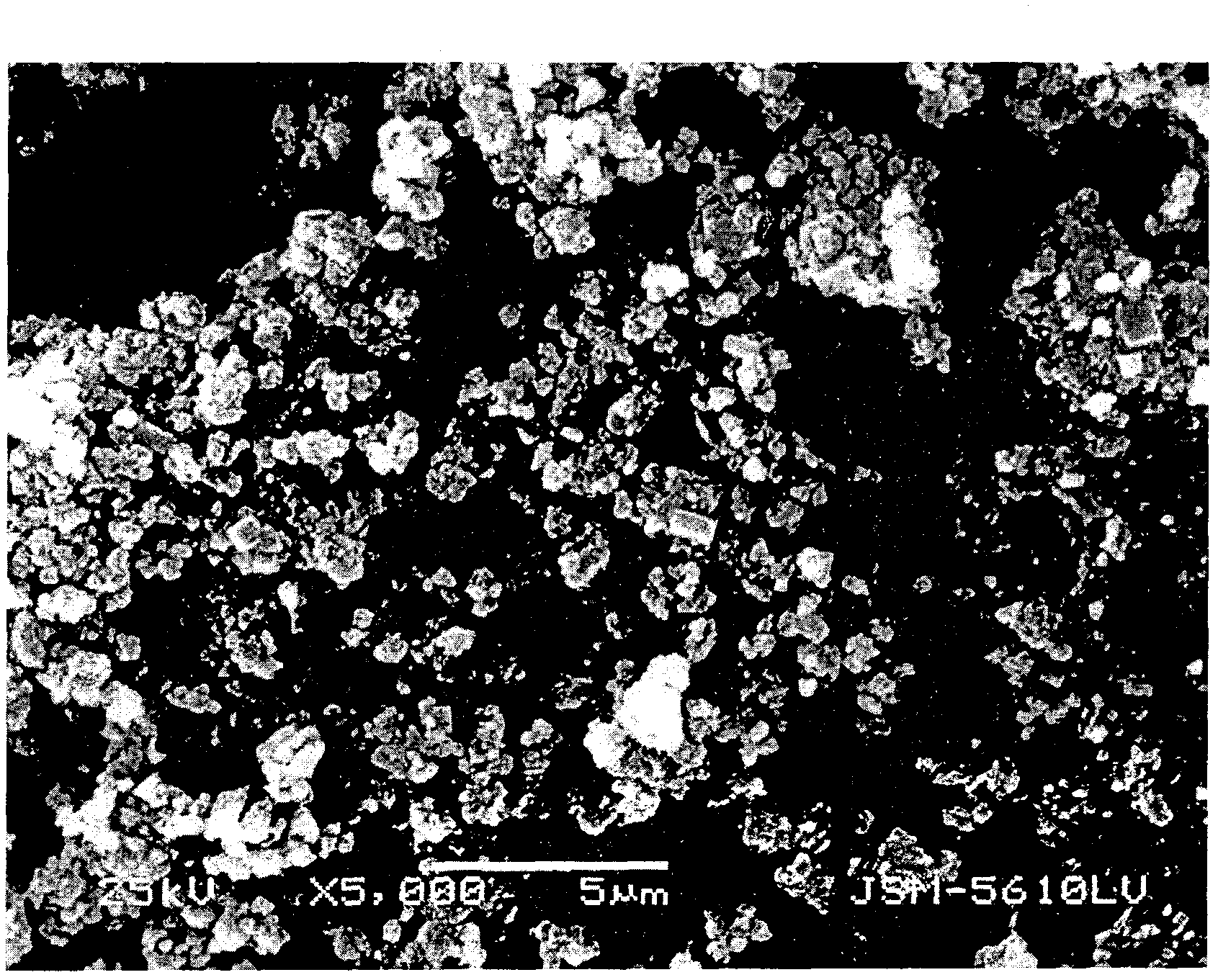

Preparation method of micro-nano molybdenum carbide powder

InactiveCN107352543AGuaranteed to dissolveAvoid contactTungsten/molybdenum carbideMicro nanoMolybdate

The invention discloses a preparation method of micro-nano molybdenum carbide powder. The preparation method comprises the specific steps that an organic precursor serves as a carbon source, molybdate serves as a molybdenum source, fused salt serves as a reaction medium, high-temperature processing, washing and drying are conducted in sequence in an air environment, and the micro-nano molybdenum carbide powder is prepared. The preparation method is quick in reaction speed, and the reaction time is effectively shortened. Besides, the fused salt exists between the generated solid-phase molybdenum carbide particles in the reaction process, so that the mutual bonding between the particles can be stopped, and the agglomeration phenomenon can be reduced. In the method, no special atmospheric conditions are needed, the micro-nano molybdenum carbide material can be prepared at a relatively low temperature; the process is simple, the preparation conditions are mild, and a large scale of production is easy to achieve.

Owner:DONGGUAN UNIV OF TECH

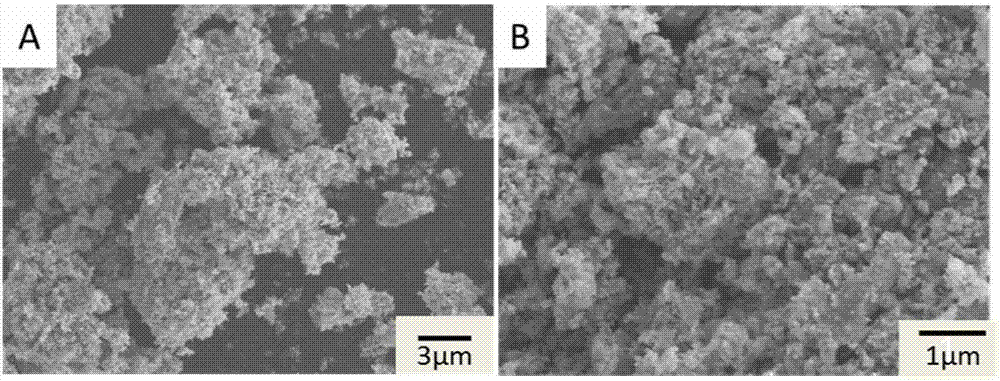

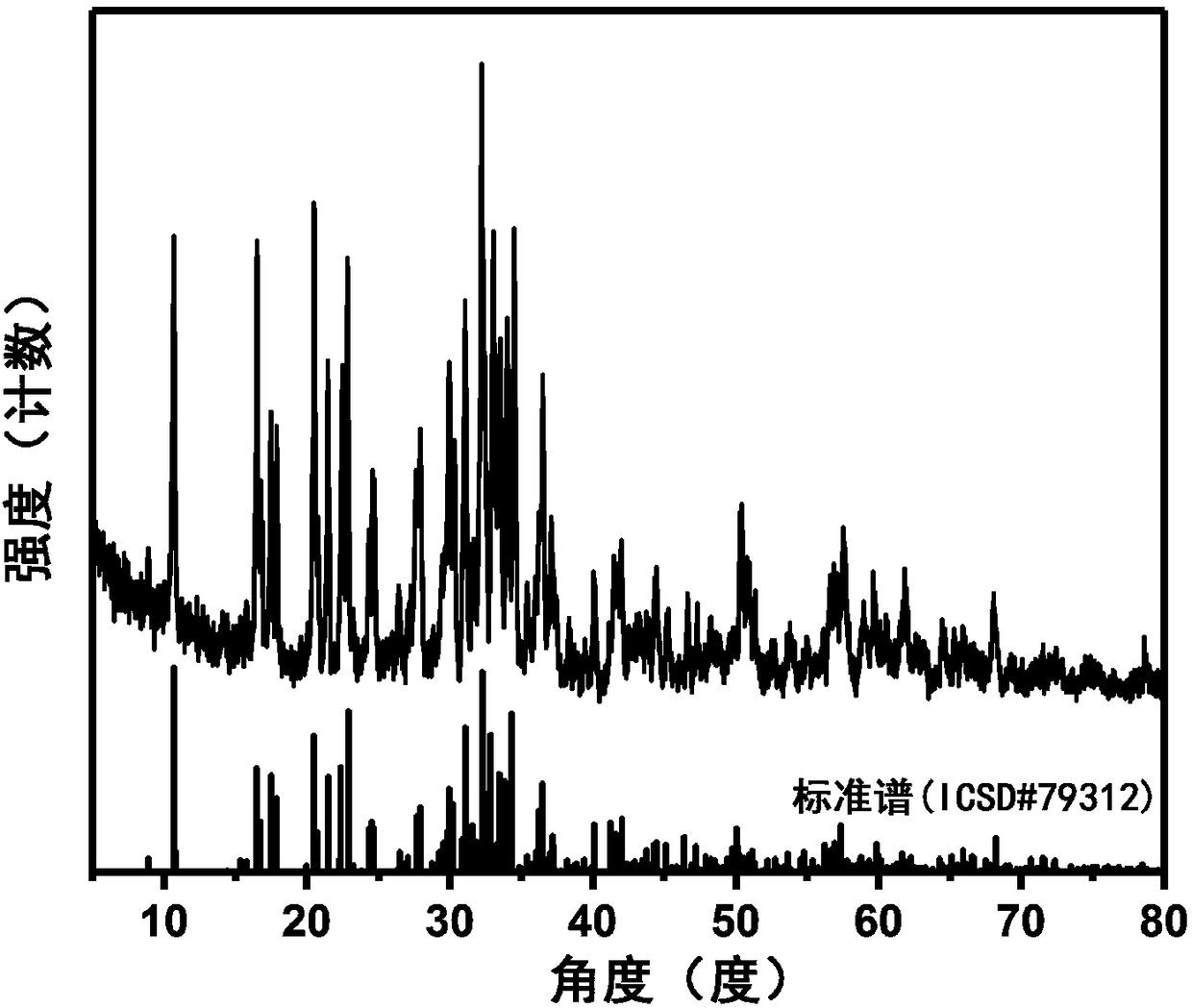

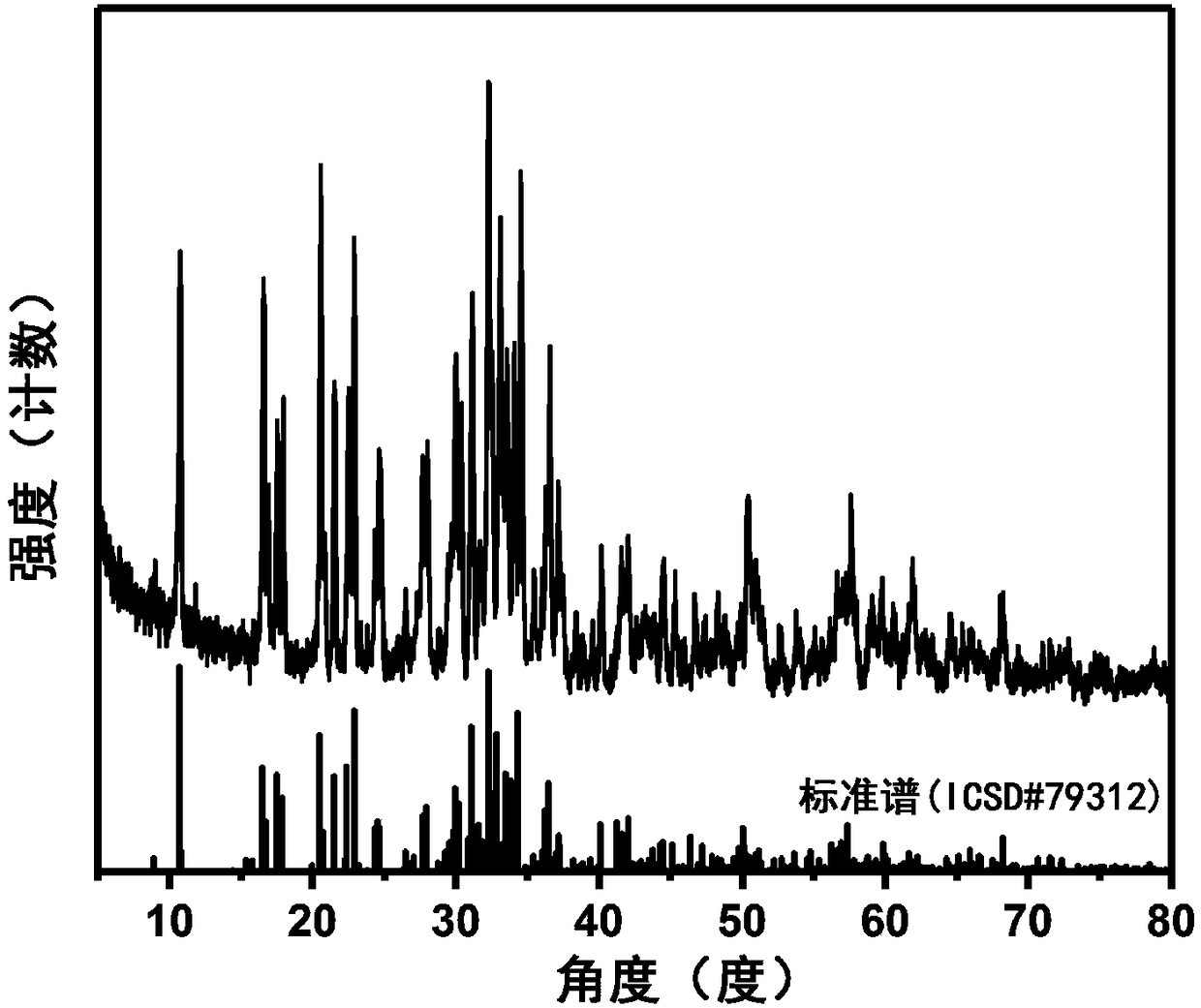

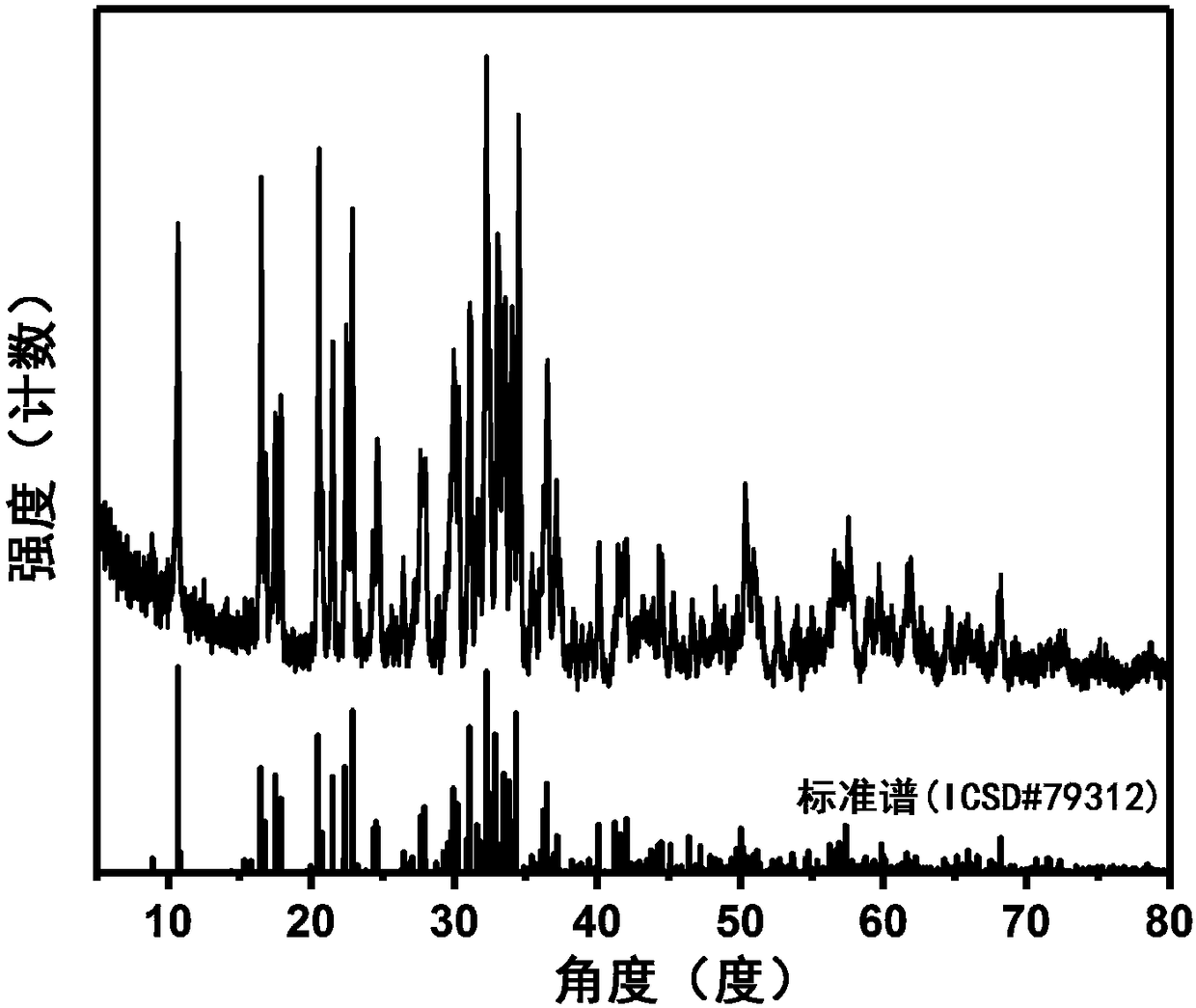

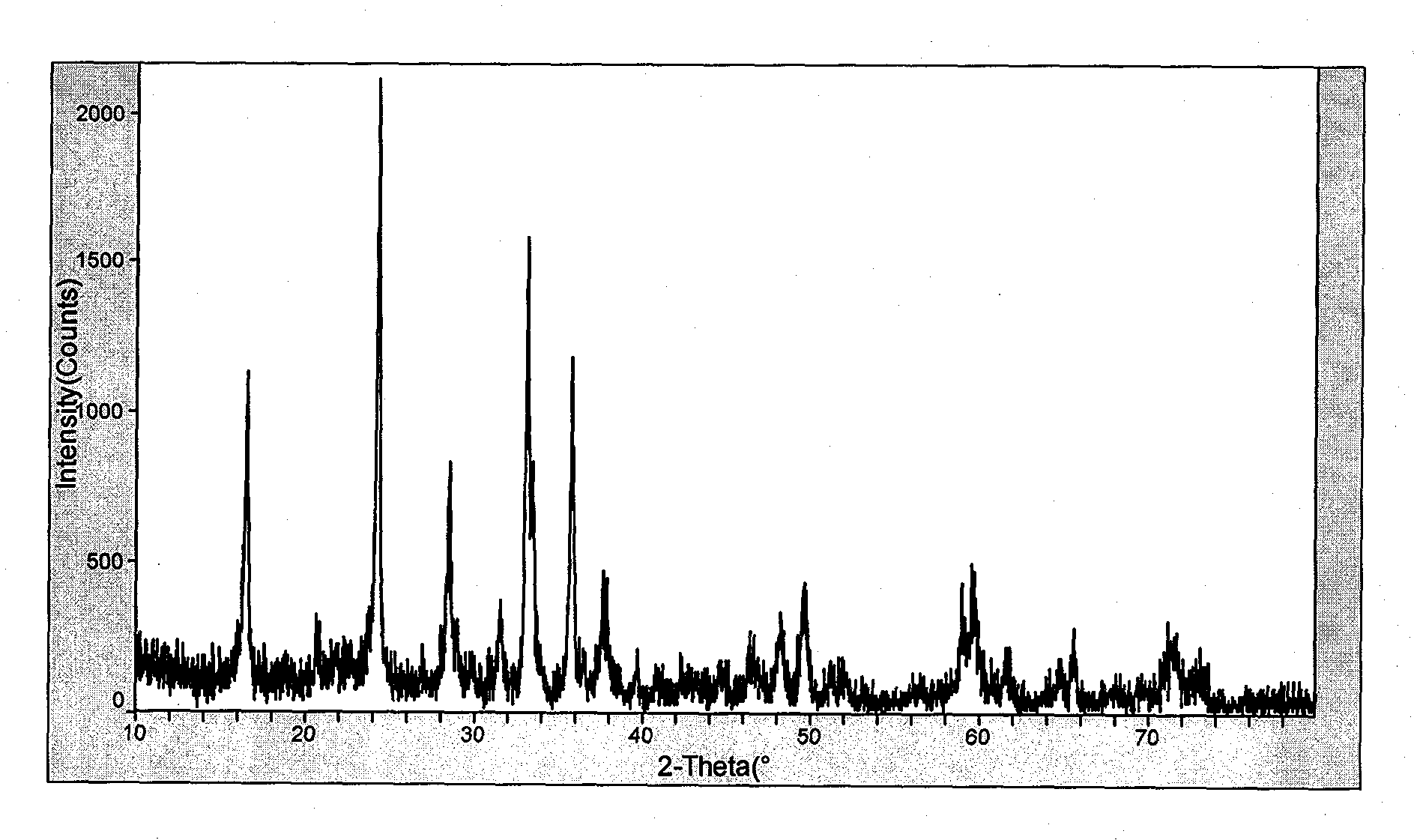

Carbon-cladded sodium ferric pyrophosphate material and preparation method thereof as well application of carbon-cladded sodium ferric pyrophosphate material serving as sodium-ion battery positive electrode material

InactiveCN108123129AIncrease contact areaShort diffusion pathMaterial nanotechnologySecondary cellsCarbon layerHydrocarbon mixtures

The invention discloses a carbon-cladded sodium ferric pyrophosphate material and a preparation method thereof as well application of the carbon-cladded sodium ferric pyrophosphate material serving asa sodium-ion battery positive electrode material. The carbon-cladded sodium ferric pyrophosphate material has an ordered nano-structure and the surface of the material is uniformly cladded with a carbon layer; the preparation method of the carbon-cladded sodium ferric pyrophosphate material comprises the following steps: sequentially carrying out ball milling and mixing on an organic macromolecular surfactant, a phosphorous source, a hydrocarbon type mixture, an iron source and a sodium source to obtain a precursor; putting the precursor into a protective atmosphere and calcining to obtain the carbon-cladded sodium ferric pyrophosphate material. The carbon-cladded sodium ferric pyrophosphate material has the ordered nano-structure and a large contact area with electrolyte; an ion dispersion path is short and an ion dispersion speed in a battery system is effectively improved; an electron transmission speed and the stability of the electrode material are effectively improved through aconductive carbon layer; the carbon-cladded sodium ferric pyrophosphate material is used as the sodium-ion battery positive electrode material and has excellent electrochemical performance, and is anideal sodium-ion battery positive electrode material; a preparation process is simple in technology and low in cost; large-scale production is easy to enlarge and the carbon-cladded sodium ferric pyrophosphate material has a very great application prospect.

Owner:CENT SOUTH UNIV

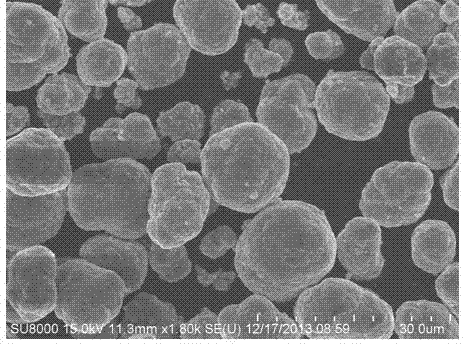

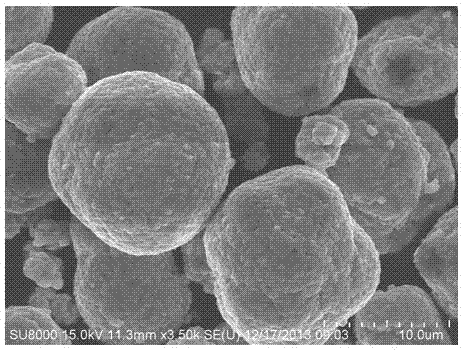

Method for preparing lithium nickel cobalt manganese oxide ternary cathode material in liquid-phase sugar coating and spray drying manners

InactiveCN104733721AImproved magnification performanceLower impedanceCell electrodesSecondary cellsRare-earth elementDispersity

The invention discloses a method for preparing a lithium nickel cobalt manganese oxide ternary cathode material in liquid-phase sugar coating and spray drying manners. The method comprises the steps of firstly mixing sulphate liquids of Ni, Co and Mn, performing a coprecipitation reaction under an alkaline condition to prepare a ternary composite precursor (NixCoyMnz)(OH)2, filtering, washing, drying, adding the ternary composite precursor, a soluble metal lithium compound, a rare earth compound to a sugar-dissolved solvent, uniformly mixing, and spray drying to obtain a sugar-coated rare-earth-element-doped ternary precursor, finally performing high-temperature calcination to obtain a rare-earth-element-doped ternary material LiNixCoyMnzRnO2, wherein R is a doped rare earth element, the sum of x, y and z is equal to 1, and n is not less than 0.002 and is not greater than 0.1. According to the method for preparing the lithium nickel cobalt manganese oxide ternary cathode material in the liquid-phase sugar coating and spray drying manners, sugar coating is utilized, so that the dissipation of pungent smell is reduced in a spray drying process; the prepared stoichiometric-ratio ternary material has the advantages that the secondary particle dispersity is good, the size is uniform, the infiltration of electrolyte is facilitated, the diffusion rate of lithium ions is increased basically, and the impedance of the lithium ions during diffusion is reduced, so that the electrical property of a material is improved, and the stable production is convenient.

Owner:CHONGQING TERUI BATTERY MATERIAL

Diffusion connection method for TiAl alloy and Ti2AlNb alloy

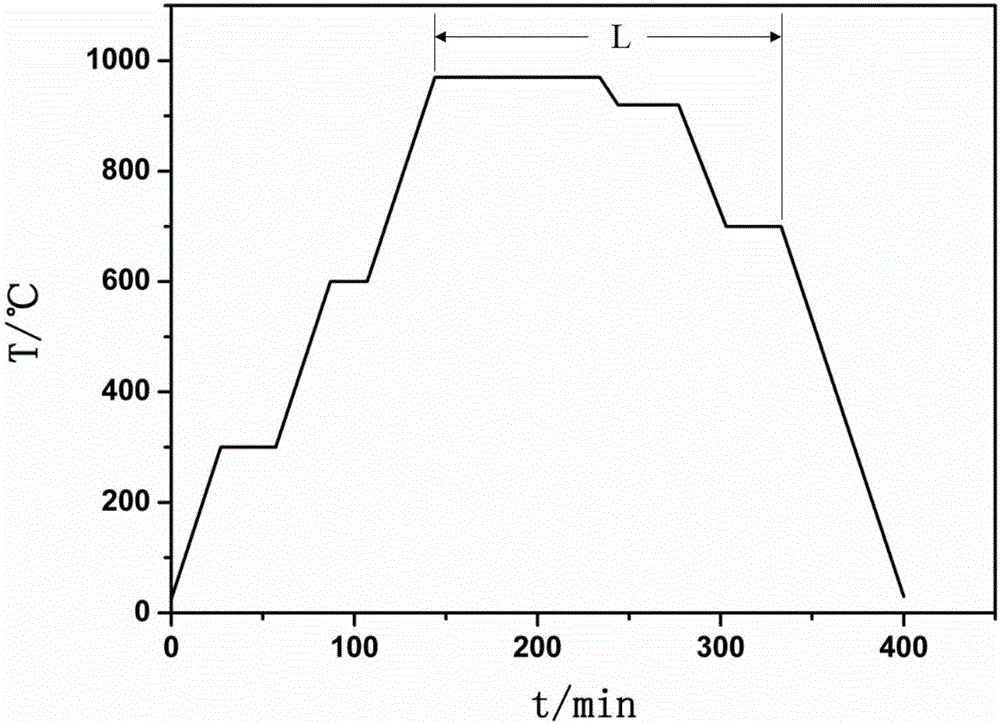

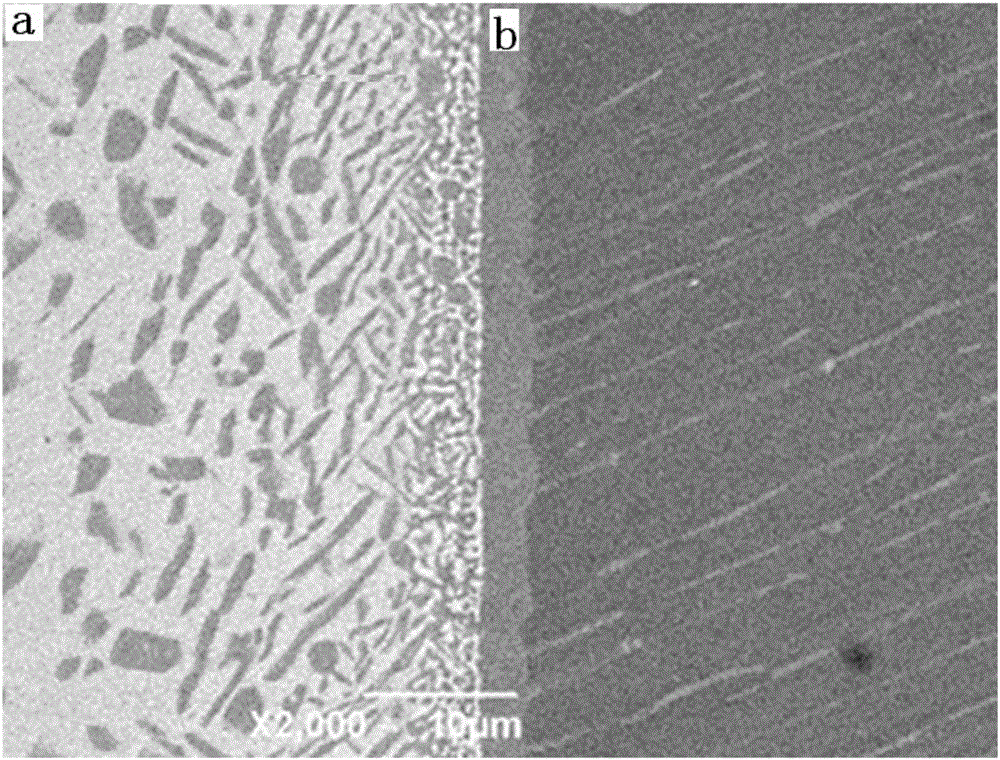

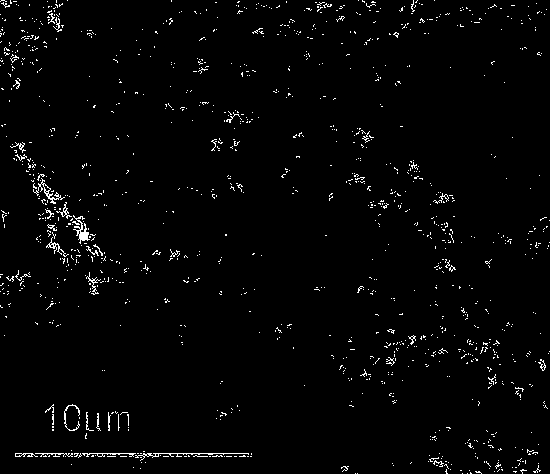

ActiveCN106808079AFirmly connectedControl organizationWelding/soldering/cutting articlesNon-electric welding apparatusFurnace temperatureIntermetallic

The invention discloses a diffusion connection method for a TiAl alloy and a Ti2AlNb alloy. By controlling diffusion connection process parameters and carrying out furnace pressure and temperature keeping treatment, reliable connection between dissimilar intermetallic compounds is achieved, and a certain basis and support is provided for the study and manufacturing of complex structural components. According to the diffusion connection method, by controlling three variable parameters of the diffusion connection temperature, the deformation amount and the time and carrying out furnace temperature keeping treatment, an interlayer is not added, reliable connection of the alloys is achieved through mutual reactions and diffusion of main elements of Ti, Al and Nb and other microelements, and application and popularization of the TiAl series intermetallic compounds are facilitated; and a TiAl alloy and Ti2AlNb alloy diffusion connection piece is used for aerospace light high-temperature structural components, the properties of the two kinds of materials can be effectively achieved, and great application prospects are achieved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

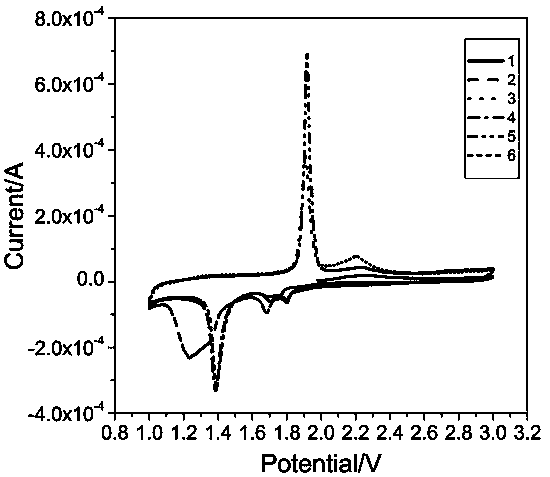

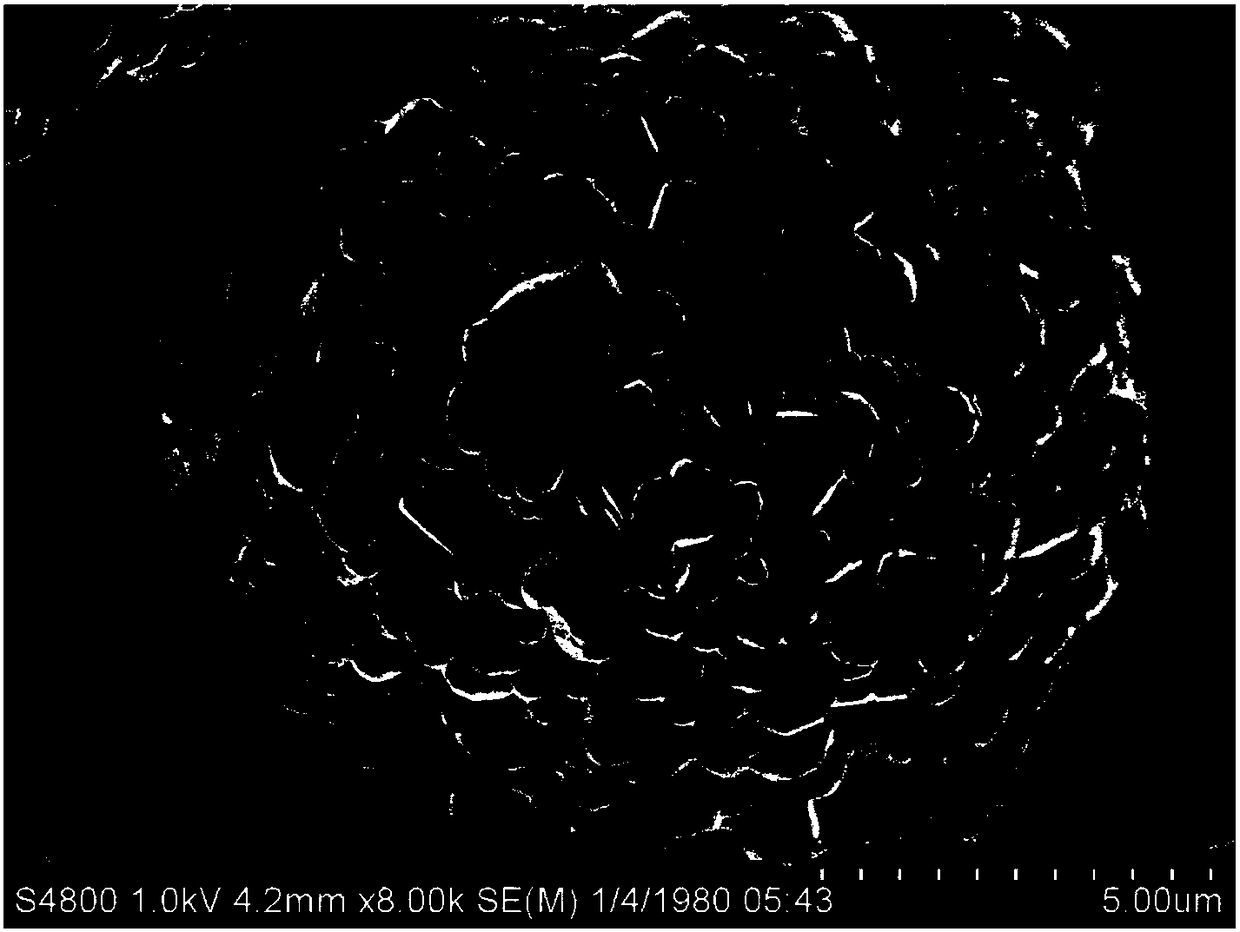

Graphene/nickel sulphide nano composite electrode material and preparation method thereof

InactiveCN104183848AEasy to synthesizeEasy to operateMaterial nanotechnologyCell electrodesSolventNickel sulfide

The invention discloses a graphene / nickel sulphide nano composite electrode material and a preparation method thereof. The graphene / nickel sulphide nano composite electrode material is prepared under the crosslinked action of graphene with graphene oxide as a carrier, nickel acetate as a nickel source and carbon disulphide as a sulphur source. The graphene / nickel sulphide nano composite electrode material comprises graphene nanosheets and nickel sulphide flower-type submicrostructure ingredients in a mass ratio of (5-35%): (95-65%). The preparation method of the graphene / nickel sulphide nano composite electrode material has the advantages that graphene oxide, nickel acetate and carbon disulphide are taken as raw materials and the graphene / nickel sulphide nano composite electrode material is obtained by adopting a one-pot solvothermal method in an organic solvent, and the graphene / nickel sulphide nano composite electrode material has good electrochemical lithium storage property and can serve as a cathode material for a lithium ion battery.

Owner:NANCHANG HANGKONG UNIVERSITY

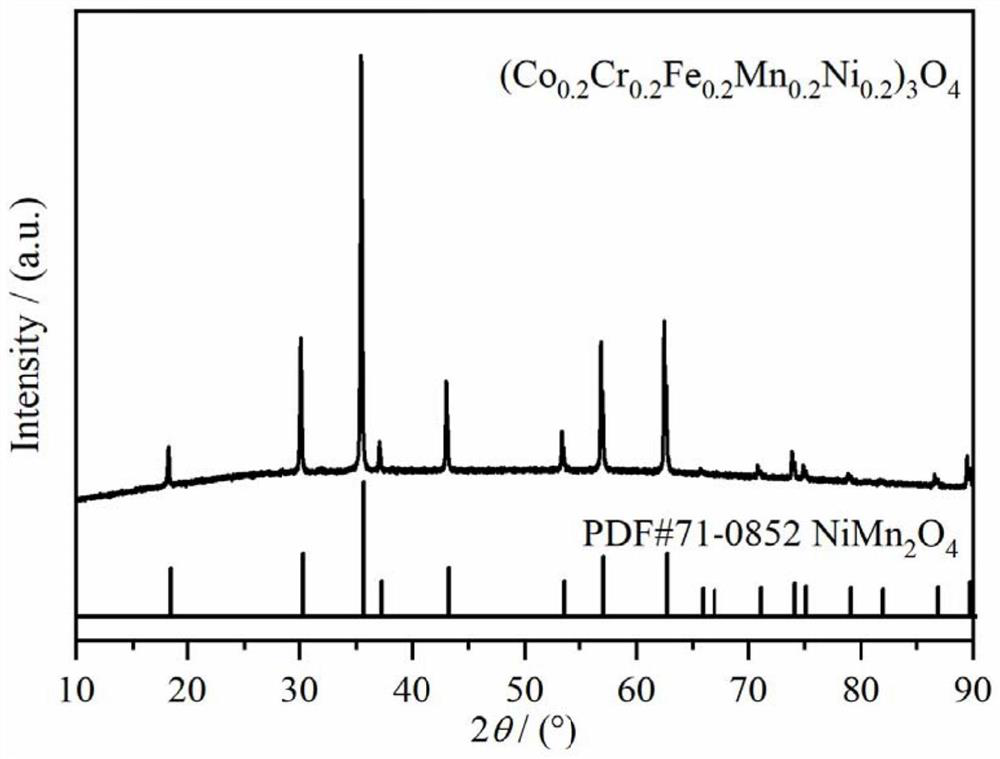

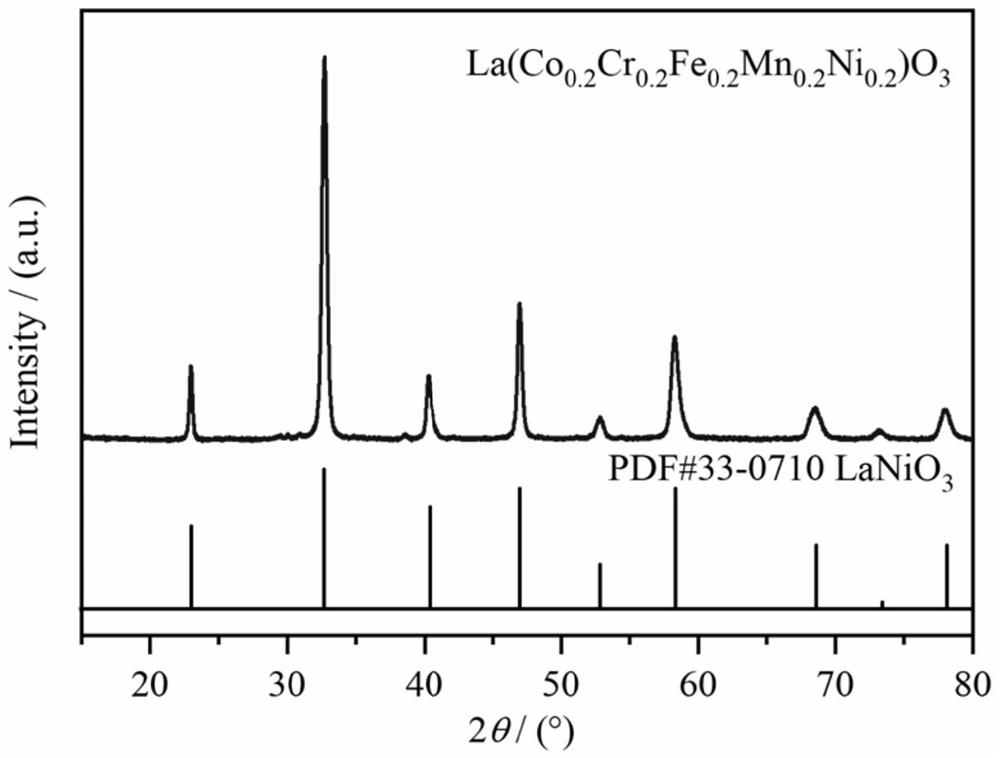

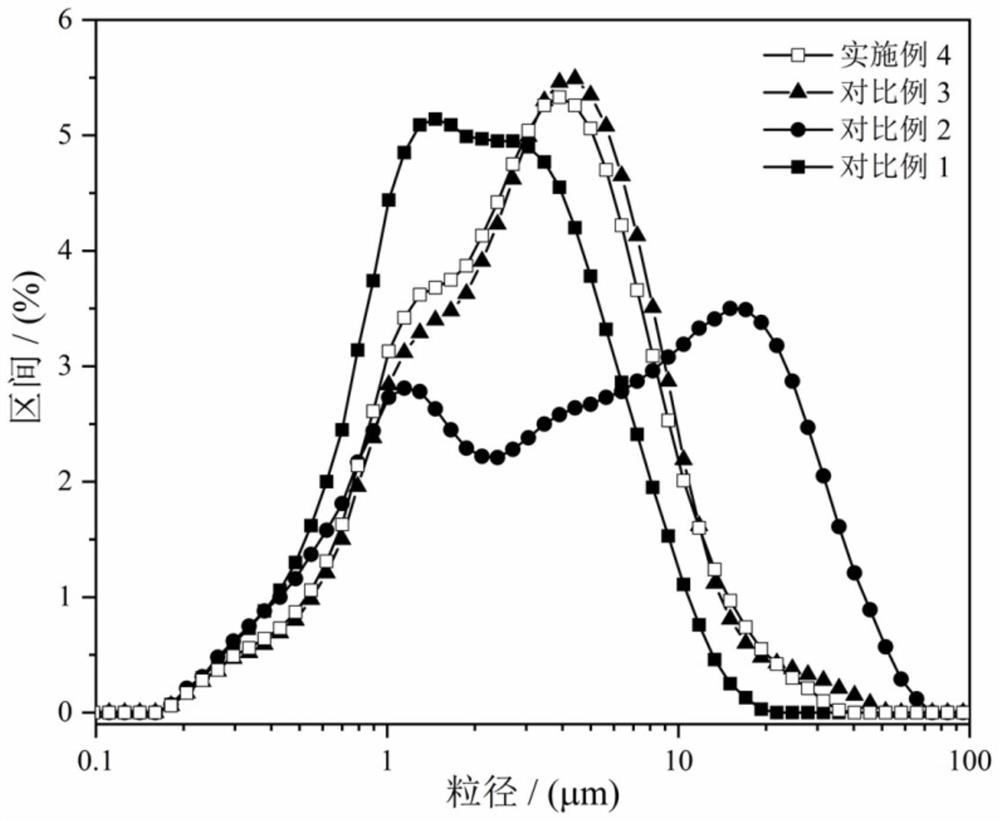

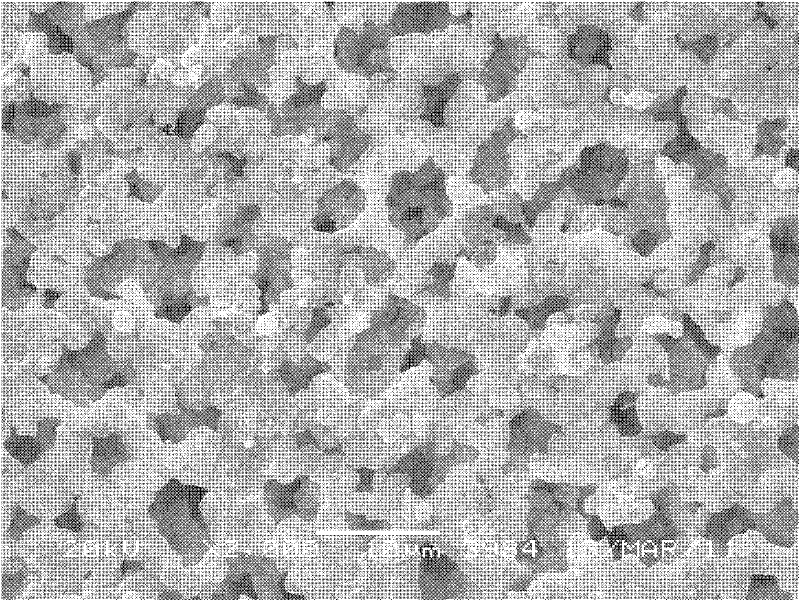

The method for preparing high-entropy oxide ceramic material is simple and low in consumption

ActiveCN112723862AThe primary particle size is fine and uniformHigh activityOxide ceramicPlasma activation

The invention relates to the technical field of high-entropy ceramic preparation, and discloses a simple and low-consumption method for preparing a high-entropy oxide ceramic material, which comprises the following steps: S1, weighing raw materials: weighing the raw materials required for preparation according to a set ratio; s2, performing particle refinement: adding the raw materials weighed in the step S1 and a dispersing agent into a ball milling tank of a planetary ball mill together for particle refinement grinding to prepare uniformly mixed slurry, then drying the slurry, and grinding again to obtain refined powder; s3, performing spark plasma treatment: performing spark plasma activation on the refined powder obtained in the step S2 to obtain a ceramic raw material; and S4, performing microwave sintering: carrying out microwave sintering on the ceramic raw material obtained in the step S3 to obtain the high-entropy oxide ceramic material.

Owner:TAIYUAN UNIV OF TECH

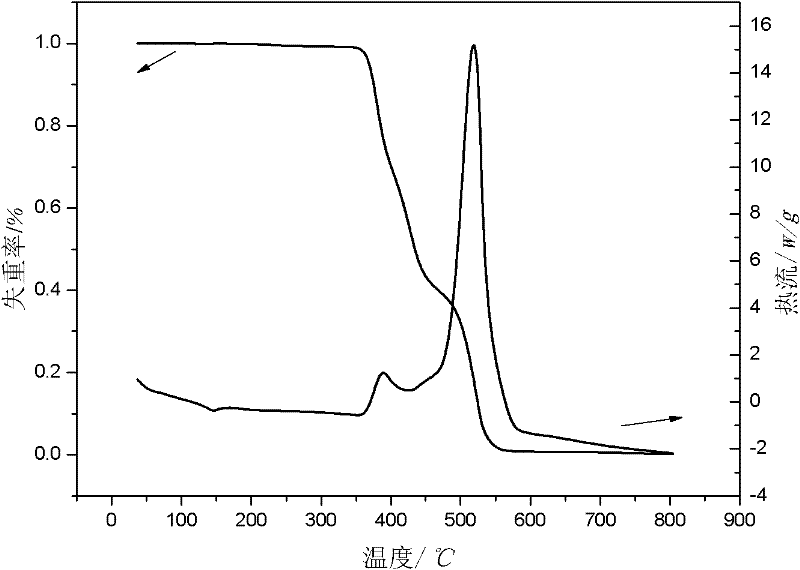

Method for extracting purple potato pigment by using ultrasonic wave and compound enzyme

InactiveCN101530191AIncreased diffusion rateImprove extraction efficiencyFood preparationSolventMacroporous resin

The invention relates to a method for extracting purple potato pigment by using ultrasonic wave and compound enzyme, which includes steps of (1) preprocessing raw material; (2) extracting the purple potato pigment by using ultrasonic wave and compound enzyme; and (3) refining extract by using macroporous resin. By using ultrasonic wave extraction technology, the present invention accelerates diffusion speed of educt from the raw material to solution, and has characteristics high extraction efficiency, no need of high temperature low energy consumption, and greatly shortened extraction time, the enzyme has characteristics of high catalytic efficiency, strong effect specificity and mild catalytic condition, and can increase productivity, lower energy consumption, reduce pollution, simplify process when being used in industry. By combining the ultrasonic wave extraction technology and the biological enzyme technology, the invention has advantages of short extraction time, high production yield, simple process, easy control of operation, convenience for large scale industrialization production and obvious economic benefit.

Owner:HEFEI UNIV OF TECH

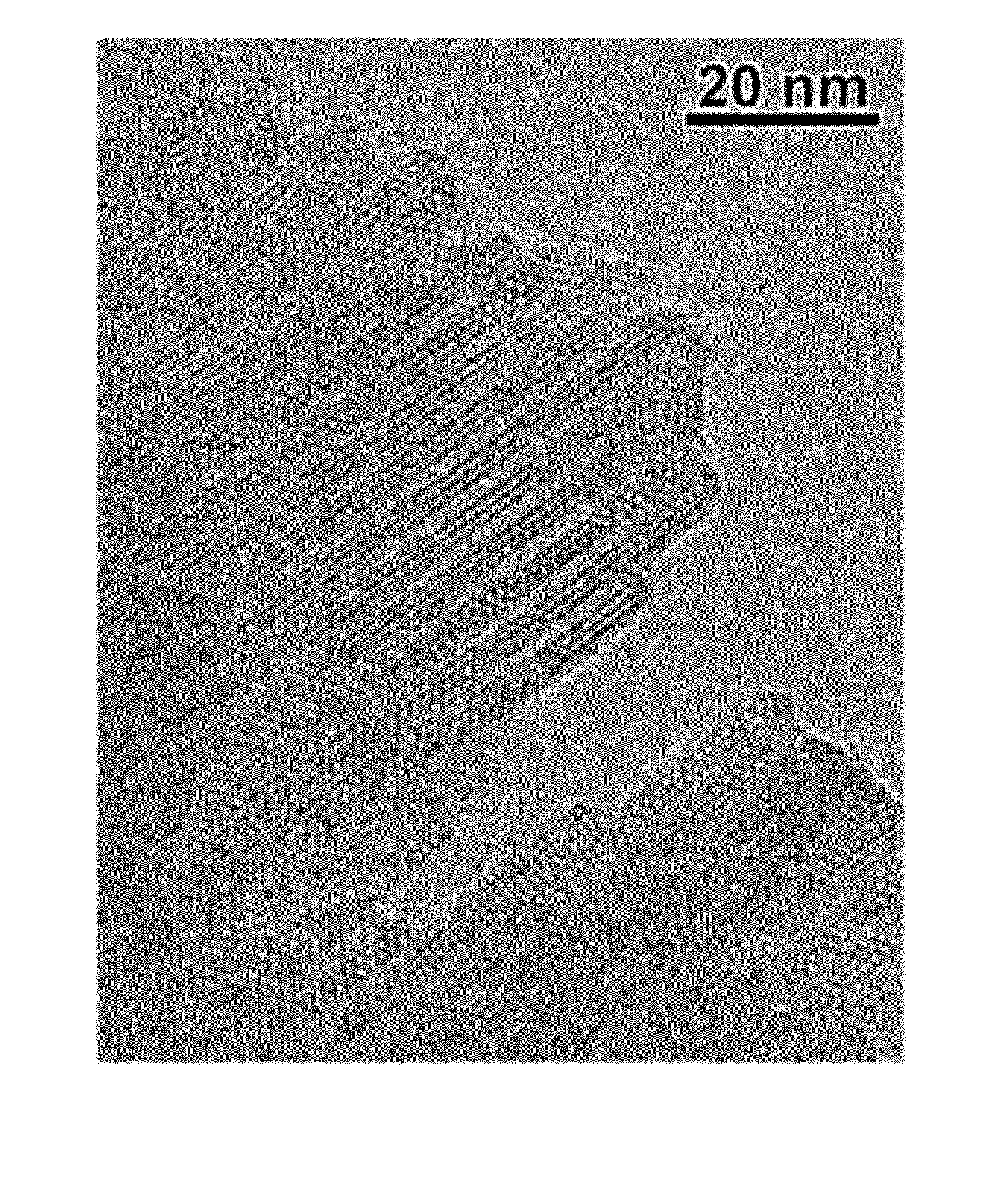

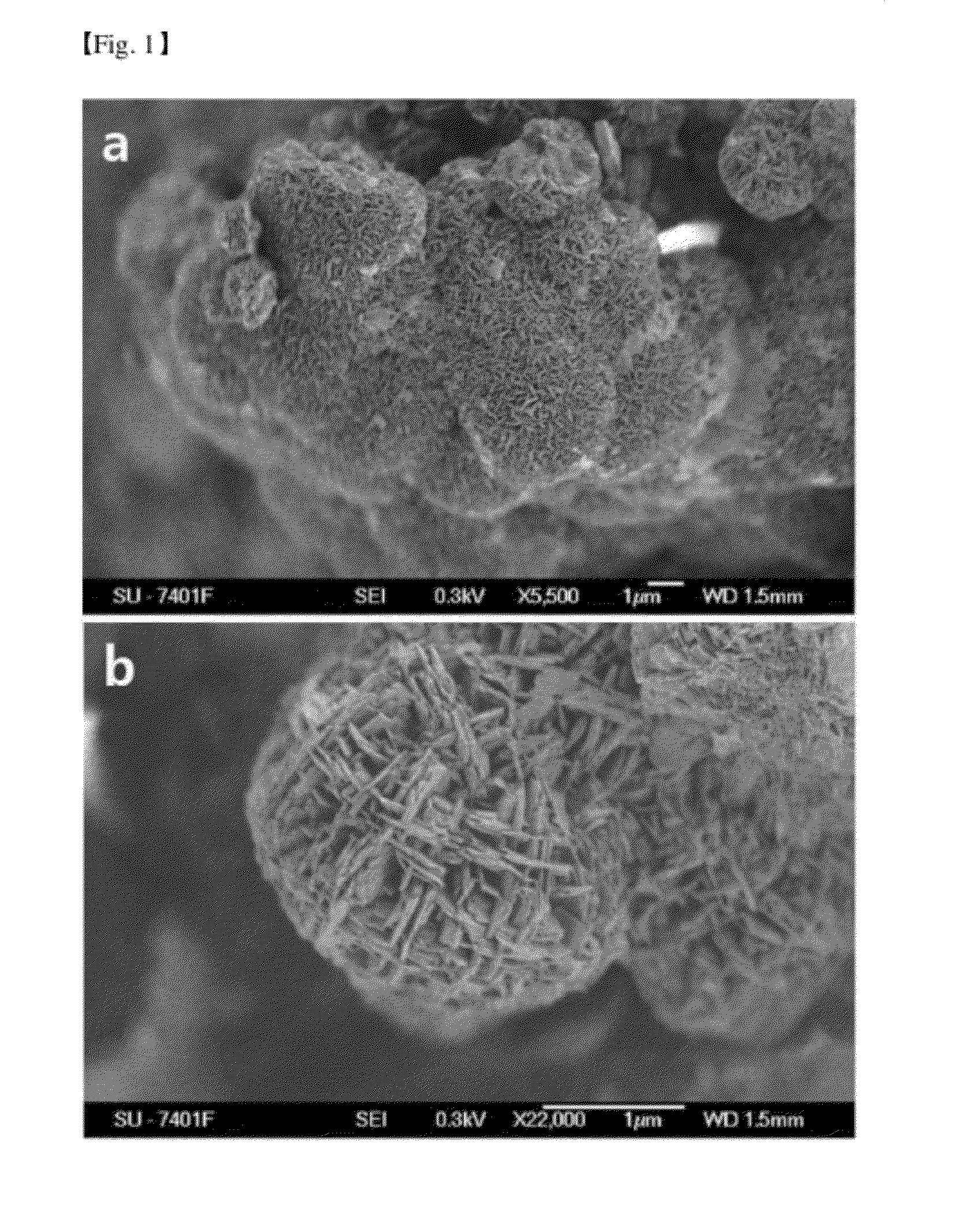

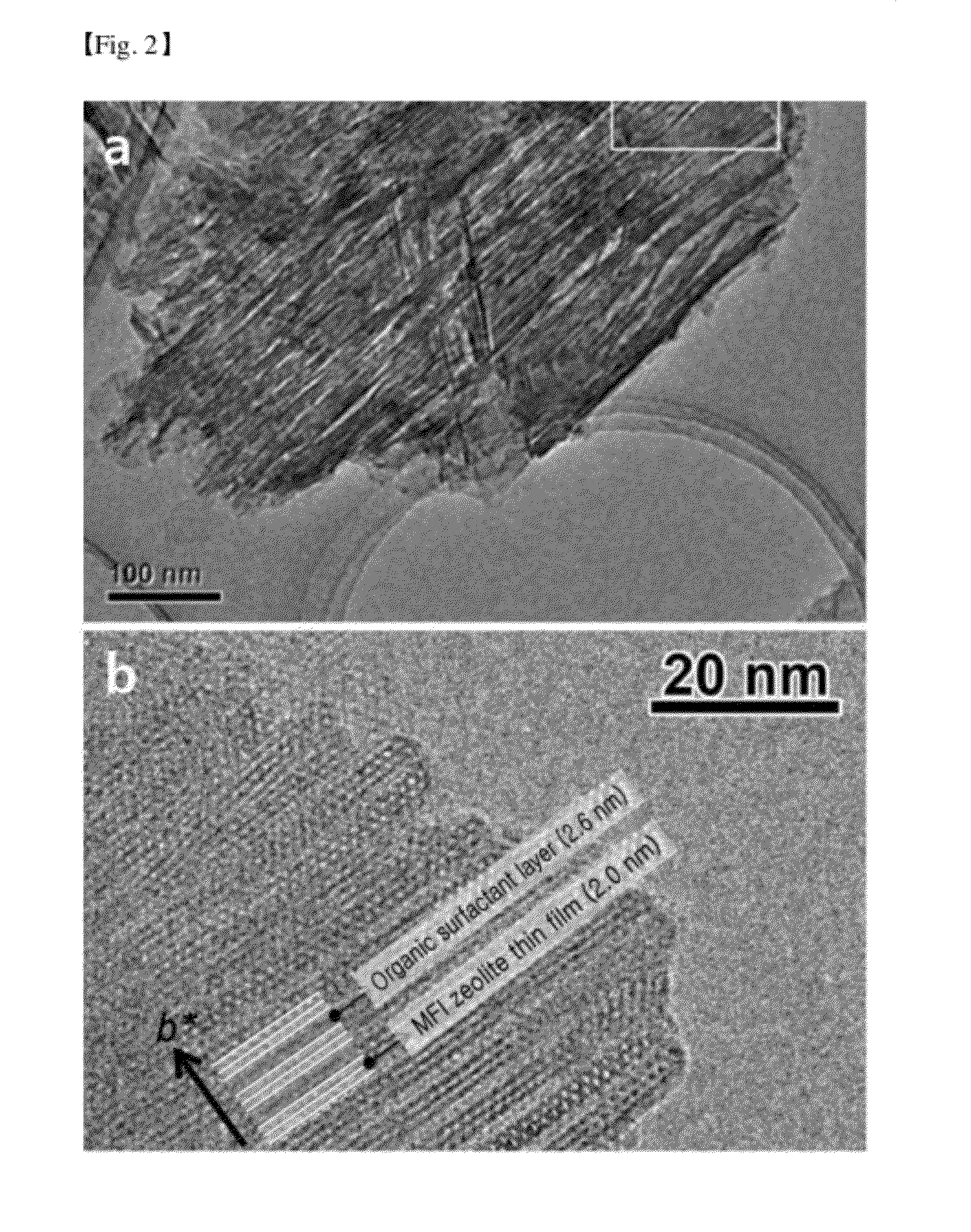

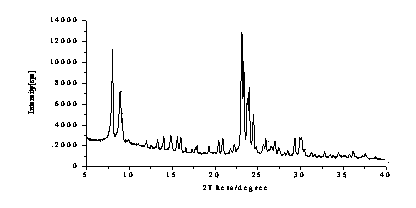

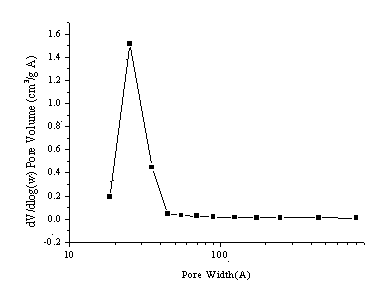

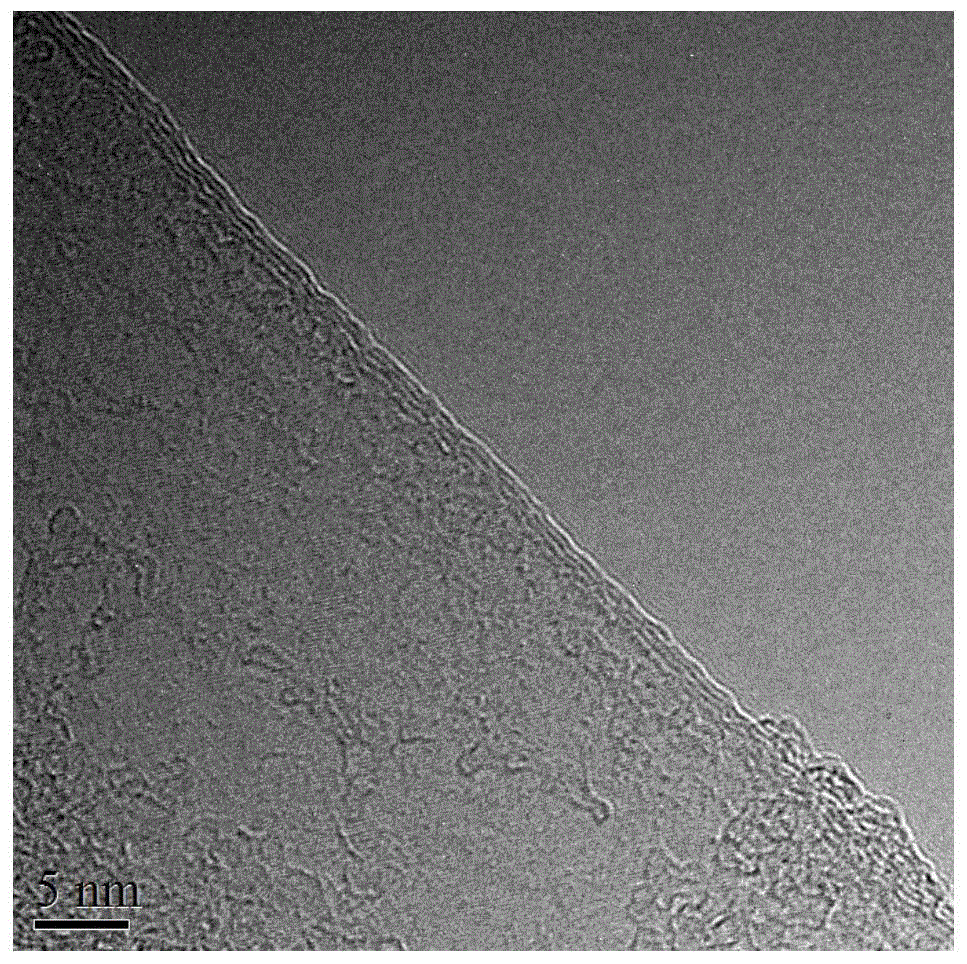

Regularly stacked multilamellar and randomly aligned unilamellar zeolite nanosheets, and their analogue materials whose framework thickness were corresponding to one unit cell size or less than 10 unit cell size

InactiveUS20120165558A1Increase surface areaHigh catalytic activityHydrogenAluminium compoundsIon exchangeOrganic reaction

The present invention relates to microporous molecular sieve materials and their analogue molecular sieve materials having a crystalline unilamellar or multilamellar framework with a single unit cell thickness in which layers are aligned regularly or randomly, the molecular sieve materials being synthesized by adding an organic surfactant to the synthesis composition of zeolite. In addition, the present invention relates to micro-mesoporous molecular sieve materials activated or functionalized by dealumination, ion exchange or other post treatments, and the use thereof as catalyst. These novel materials have dramatically increased external surface area by virtue of their framework with nano-scale thickness, and thus exhibit improved molecular diffusion, and thus have much higher activities as catalyst and ion exchange resin than conventional zeolites. In particular, the materials of the present invention exhibit high reactivity and dramatically increased catalyst life in various organic reactions such as carbon-carbon coupling, alkylation, acylation, etc. of organic molecules.

Owner:KOREA ADVANCED INST OF SCI & TECH

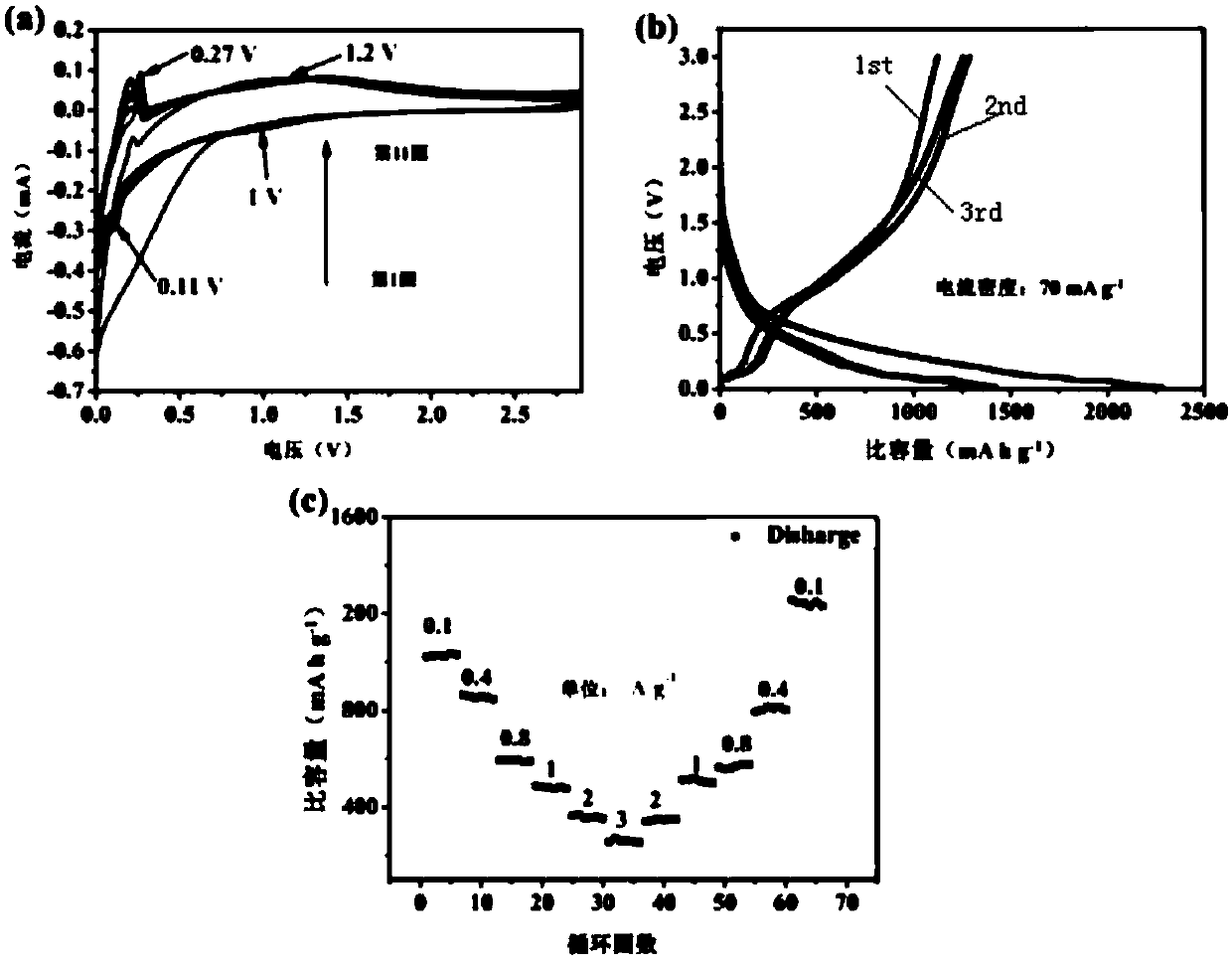

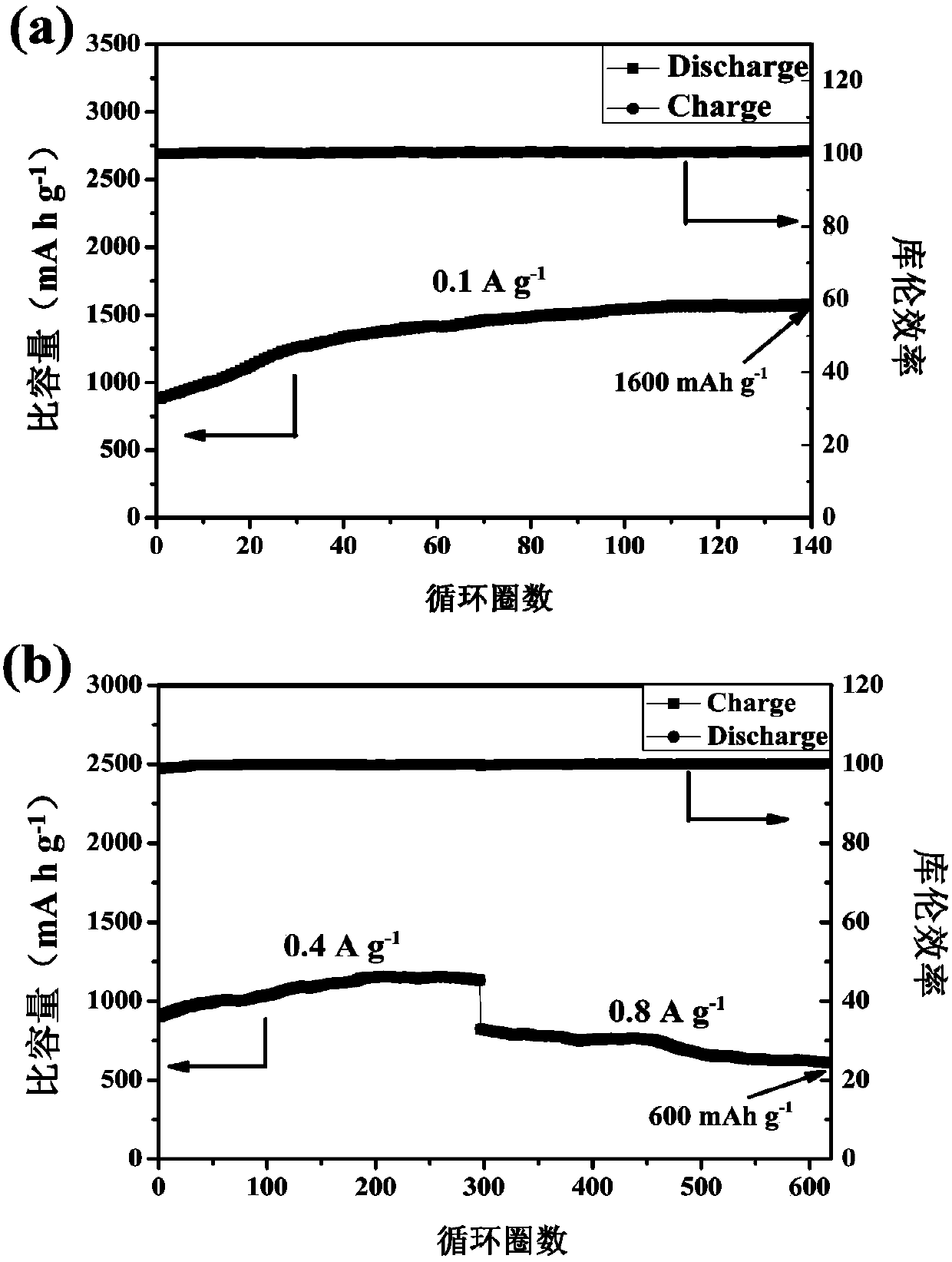

Lithium ion battery negative electrode MOF material and application thereof

ActiveCN107732248AHigh lithium storage capacityWith lithium storage performanceNon-aqueous electrolyte accumulator electrodesLithiumHigh energy

The invention discloses a lithium ion battery negative electrode MOF material. The MOF material disclosed by the invention is prepared by reacting porphyrin or porphyrin derivative of the porphyrin with transition metal or a transition metal cluster through a solvent thermal or wet chemistry method. When the MOF material is utilized as a lithium ion battery negative electrode material, the MOF material has a series of advantages of high specific capacity, long cycle life, outstanding rate capability and the like. Theoretical calculation proves that an active site of the action between the MOFmaterial disclosed by the invention and metal lithium has excellent performance, and the MOF material can be applied to developing high energy density lithium ion batteries.

Owner:南京铁鸣能源科技有限公司

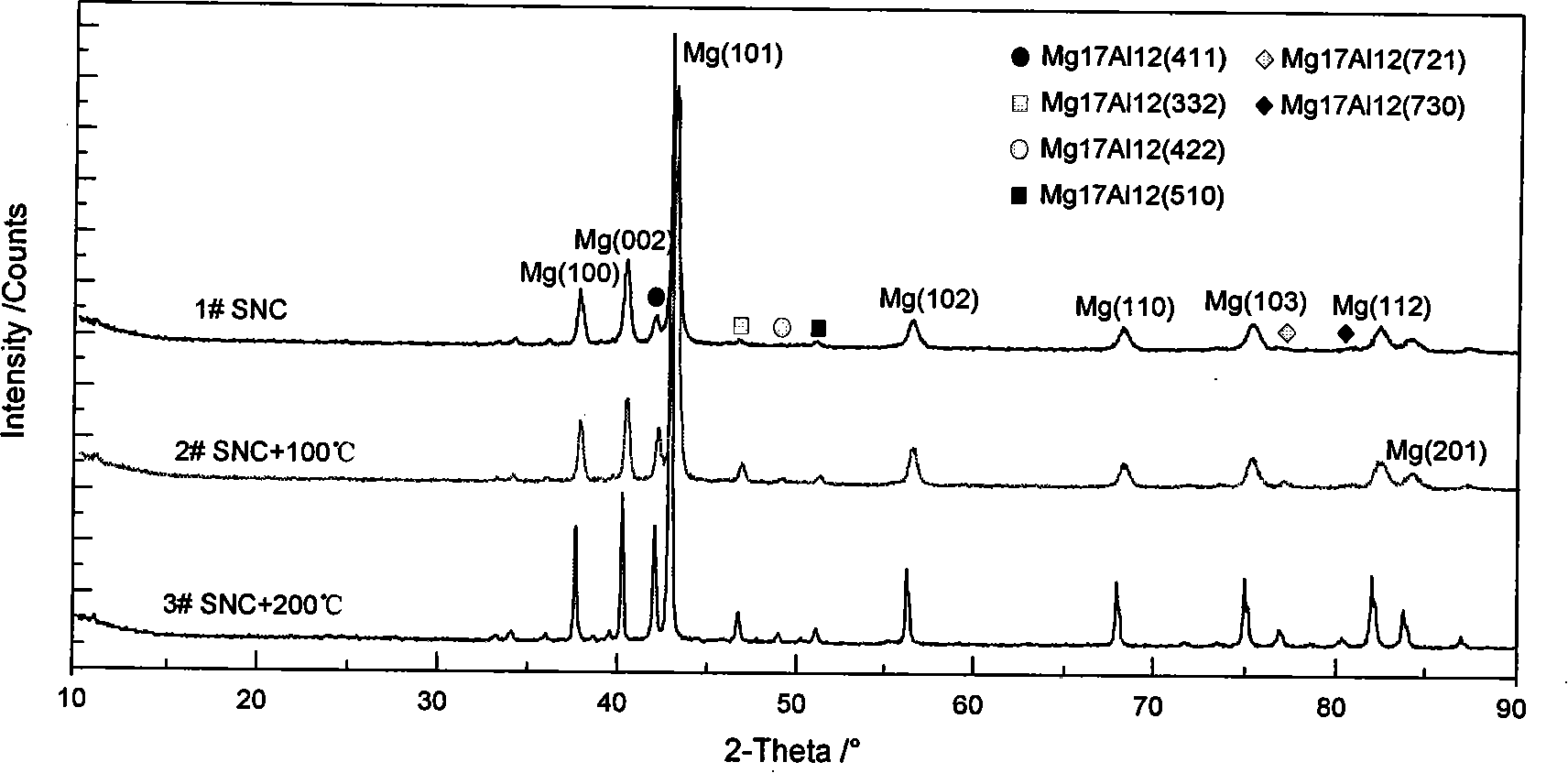

Method for reducing diffusion temperature of magnesium alloy surface spraying coating

InactiveCN101161853AIncreased diffusion rateImprove diffusion abilityMolten spray coatingNano sizeThermal spraying

The invention provides a method for reducing the diffusion temperature of spraying coating of magnesium alloy surface. First, nanocrystallization treatment is done on the magnesium alloy surface before the hot spray coating is done on the magnesium alloy matrix surface, which ensures the thinning of the crystal grain on the magnesium surface to the size of nanometer and eliminates the roll scale of the magnesium surface and coarsening to increase the mechanical riveted bonding force of matrix and coating; and then the magnesium alloy surface is hot sprayed by aluminum or zinc or a zinc / aluminium complex coating; finally, the magnesium alloy is treated to preserve heat in an ordinary heat treatment furnace at a temperature of 200 to 400 degrees, which facilitates the coating and the matrix to form metallurgical bonding. The invention adopts the surface nanocrystallization technique, which can not only reduce the diffusion temperature of spraying coating of magnesium alloy surface, but also avoid the necessary sand blasting pretreatment technology before spray finishing. In addition, special processing step is not needed, which eliminates the roll scale of the matrix surface and coarsening surface and ensures that a layer of nanocrystal is formed on the magnesium alloy matrix surface, thereby saving the processing time before spray finishing and raising the productivity effect.

Owner:重庆工学院

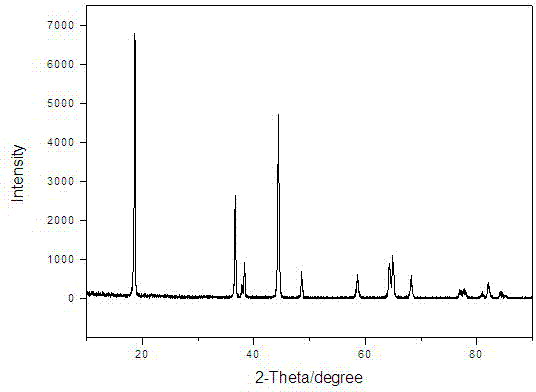

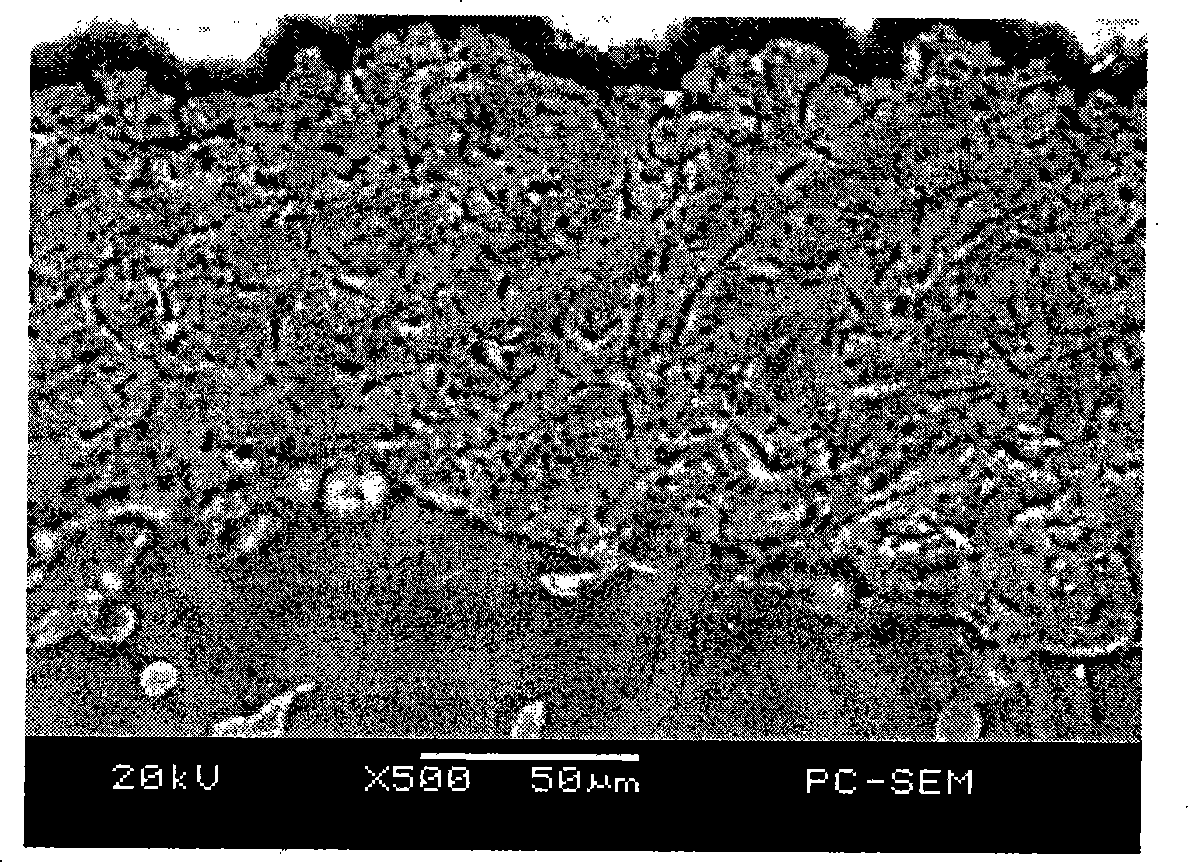

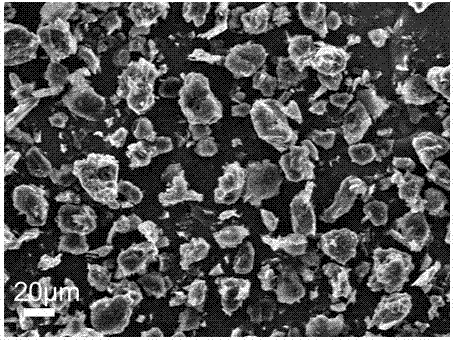

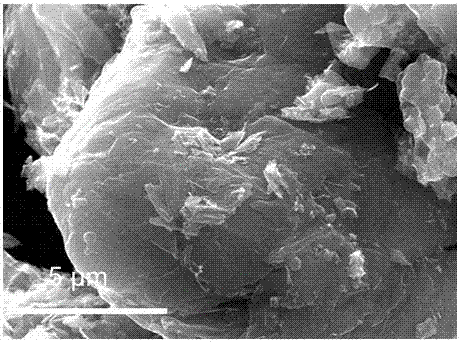

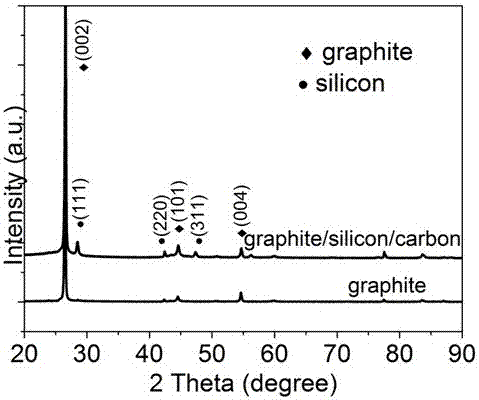

Graphite/silicon@carbon core-shell structure composite spherical cathode material and preparation method thereof

InactiveCN107093721ASimple preparation processReduce the first irreversible capacityCell electrodesSecondary cellsCarbon compositesComposite cathode

The invention discloses a graphite / silicon@carbon core-shell structure composite spherical cathode material and a preparation method thereof. By means of the material, the volume expansion effect of silicon in the lithium de-intercalation process can be inhibited, and a high-capacity lithium iron battery silicon / carbon composite cathode material is obtained. By means of the technical scheme, a spherical graphite / silicon framework precursor serves as the core of the composite cathode material, and an amorphous pyrolytic carbon or graphite-like carbon material wrapping layer serves as the shell; nanometer or micrometer silicon is embedded in flake graphite cracks to form a graphite framework, the volume expansion effect of silicon in the lithium de-intercalation process is inhibited through the mechanical characteristics of the graphite framework, then a spherical framework is formed by mixing and granulating 3-20 wt% of nanometer or micrometer silicon, 50-80 wt% of flake graphite and 10-40 wt% of amorphous pyrolytic carbon or graphite-like carbon, and an amorphous pyrolytic carbon or graphite-like carbon spherical composite conductive carbon net structure wrapping a graphite / silicon surface is formed.

Owner:四川聚能仁和新材料有限公司

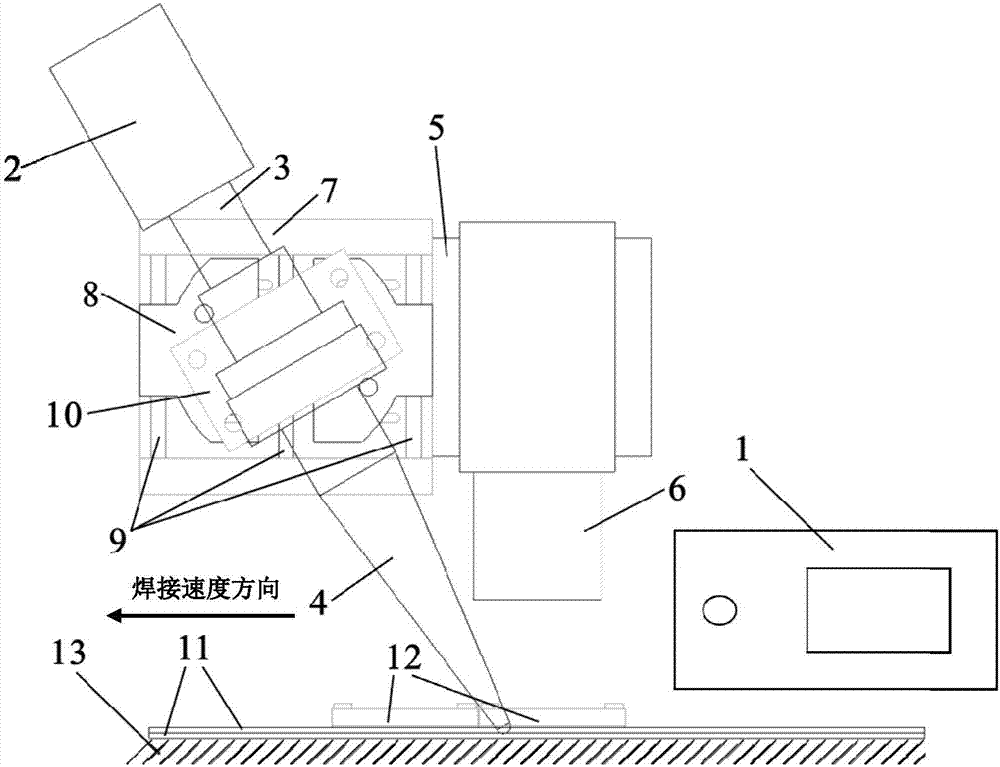

Ultrasonic vibration assisted laser welding method for heterogeneous material

ActiveCN107570872ASpeed up the flowFully dilutedLaser beam welding apparatusWeld seamAlternating current

The invention belongs to the technical field of laser welding and relates to an ultrasonic vibration assisted laser welding method for a heterogeneous material. Ultrasonic vibration is introduced intolaser welding of the heterogeneous material, specially, ultrasonic-frequency alternating current is produced by an ultrasonic generator, vibration production and amplitude magnification are implemented by an ultrasonic vibrator, and finally, the ultrasonic vibration is guided into a welding pool by the welding material. Follow-up regulation is performed on the laser welding process of the heterogeneous material by means of special effect produced through ultrasonic vibration in the welding pool. Compared with a traditional laser welding method for the heterogeneous material, designed ultrasonic vibration assisted laser welding equipment for the heterogeneous material can effectively inhibit formation of an incomplete fusion area and a brittle phase in a welding seam and homogenizes element distribution in the welding seam, so that mechanical performance and corrosion resistance of a welding joint are improved, meanwhile, a laser machining system is not required to be changed, and theapplication of the method is not limited by size of the welding material.

Owner:DALIAN UNIV OF TECH

Process for preparing fine-grain X zeolite

InactiveCN1448338ALower aging temperatureLower gelling temperatureFaujasite aluminosilicate zeoliteThermal stabilitySodium hydroxide

The preparation of small crystal grain X zeolite includes the steps of: mixing siliceous compound, aluminum compound, sodium hydroxide and water and ageing at 0-10 deg.c to prepare guide agent in thecomposition of (11-18)Na2O:Al2O3:(10-17)SiO2:(100-350)H2O; mixing siliceous compound, aluminum compound, water and the guide agent to prepare the mixture of molar composition of (2.5-5)Na2O:Al2O3:(3-5)SiO2:(100-200)H2O; crystallization at 80-120 deg.c for 2-40 hr; water washing, filtering and drying. The X zeolite thus prepared has crystal grain of 0.5-1.0 micron and excellent thermal stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

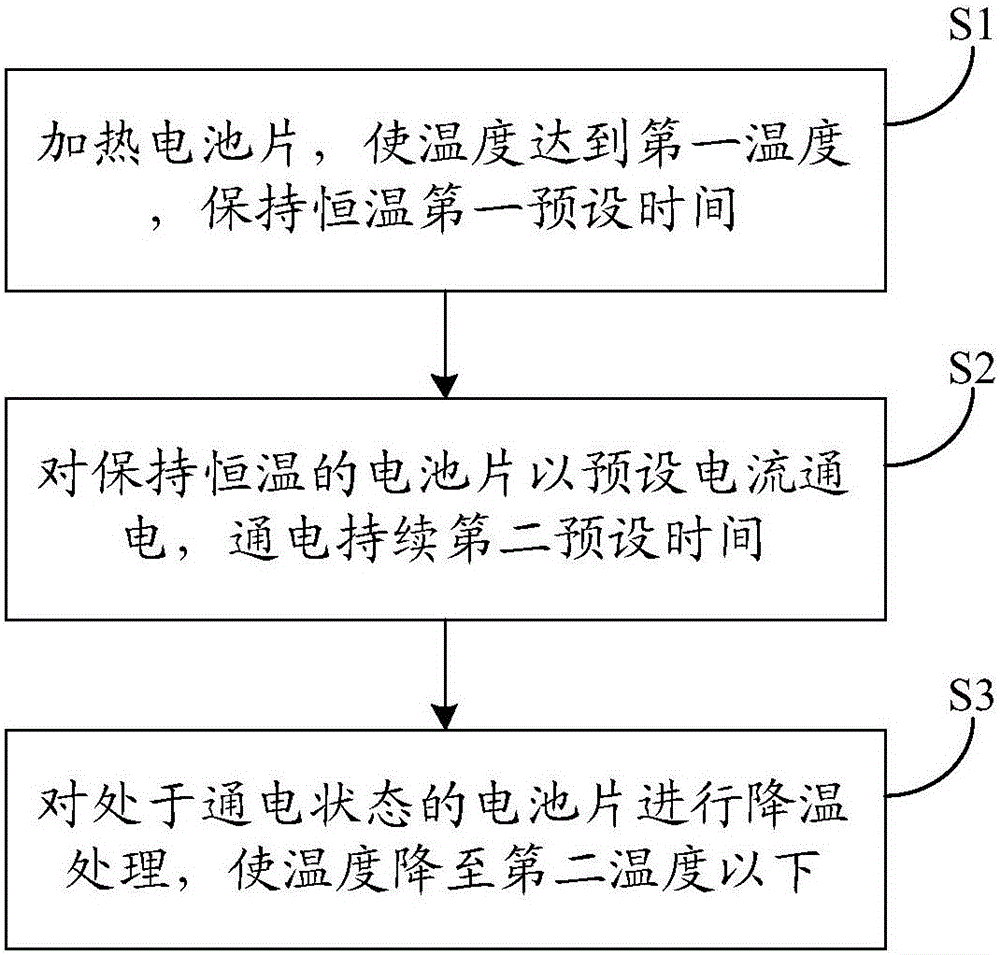

Method for improving light degradation of boron-doped crystalline silicon solar cell

InactiveCN105789382AImprove light-induced attenuationMethods of Improving Light-Induced AttenuationFinal product manufacturePhotovoltaic energy generationHydrogen atomOxygen

The invention discloses a method for improving light degradation of a boron-doped crystalline silicon solar cell. The method comprises the following steps: heating a solar cell to enable the temperature to reach a first temperature and keeping constant temperature for a first preset time; electrifying the solar cell at constant temperature with preset current; electrifying for a second preset time; cooling the solar cell under electrifying state and reducing the temperature to be below the second temperature; after heating and performing constant temperature treatment on the solar cell, electrifying, combining boron atom and oxygen atom in the solar cell into a B-O pair, and combining with hydrogen atom in the surface film and forming into an H-B-O pair; generating the H-B-O pair to enable the B-O pair to deactivate. After the treatment according to the method provided by the invention, the B-O pair complex in the solar cell is reduced, so that the light degradation amplitude is reduced and the light degradation phenomenon of the boron-doped crystalline silicon solar cell can be effectively improved.

Owner:ZHEJIANG JINKO SOLAR CO LTD +1

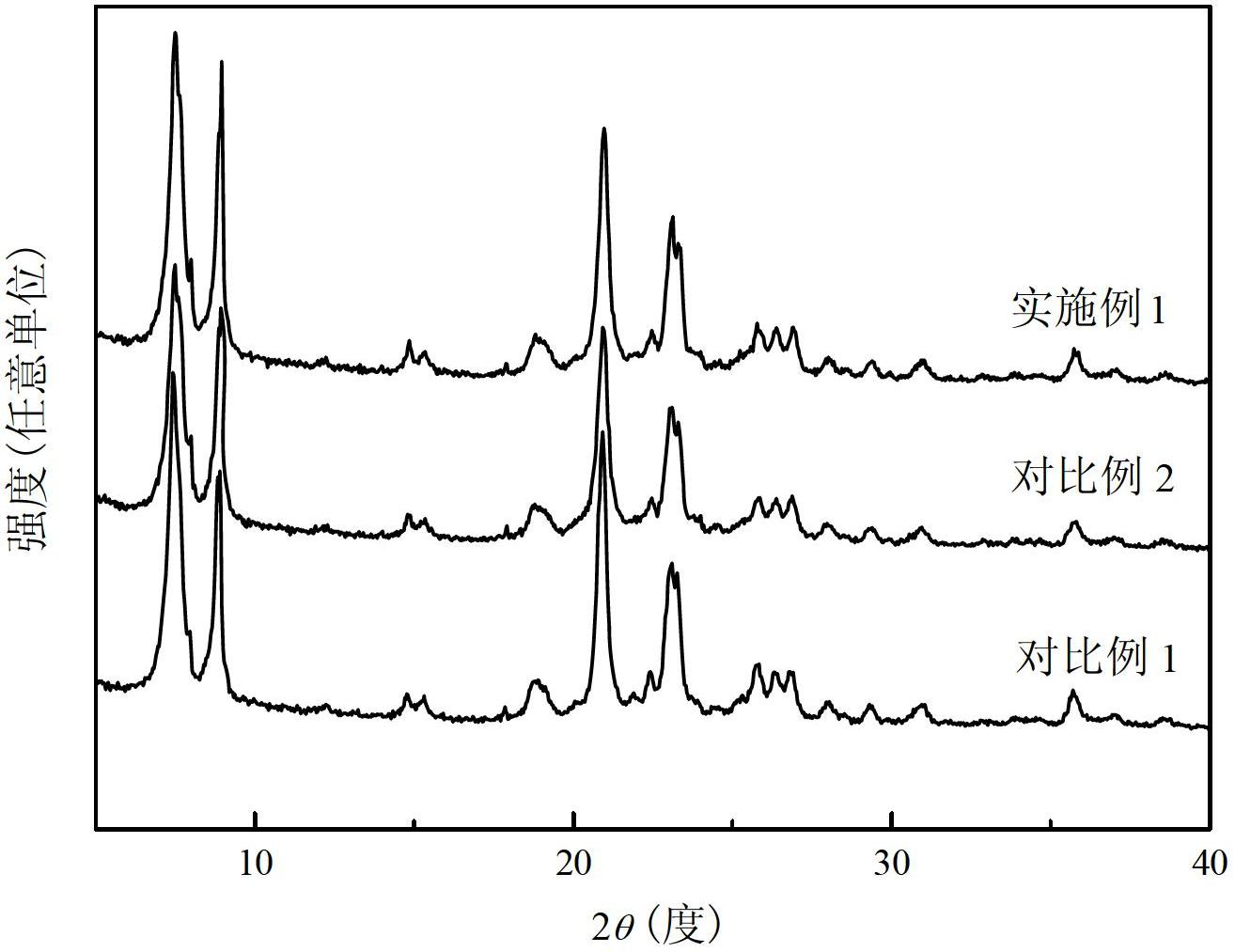

ZSM-5 composite molecular sieve with a core-shell structure and preparation method and application thereof

ActiveCN103803581AIncreased diffusion rateImprove conversion rateCatalyst carriersMolecular sieve catalystsCore shellAromatic hydrocarbon

The invention discloses a ZSM-5 composite molecular sieve with a core-shell structure, a preparation method and an application thereof. The molecular sieve is characterized in that: the core phase is a ZSM-5 molecular sieve, the shell phase is a ZSM-5 molecular sieve with a mesoporous structure, the total molar ratio of silica to alumina is 30-80, the total specific surface area is 460-550 m2 / g, the total pore volume is 0.25-0.38 ml / g, the size of the mesopore in the shell phase is 2-2.5 nm, the specific surface area of the mesopore in the shell phase is 480-650 m2 / g, and the pore volume of the mesopore in the shell phase is 0.2-0.31 ml / g. The preparation method comprises the following steps: firstly performing crystallization of a mixture containing sodium hydroxide, a template, water, a silicon source, an aluminium source, a surfactant and the ZSM-5 molecular sieve, then performing washing, drying, roasting of the crystallized product to obtain the ZSM-5 composite molecular sieve. The composite molecular sieve is applicable to aromatic hydrocarbon conversion reaction, and has the advantages of high conversion rate and selectivity, and long catalyst life.

Owner:CHINA PETROLEUM & CHEM CORP +1

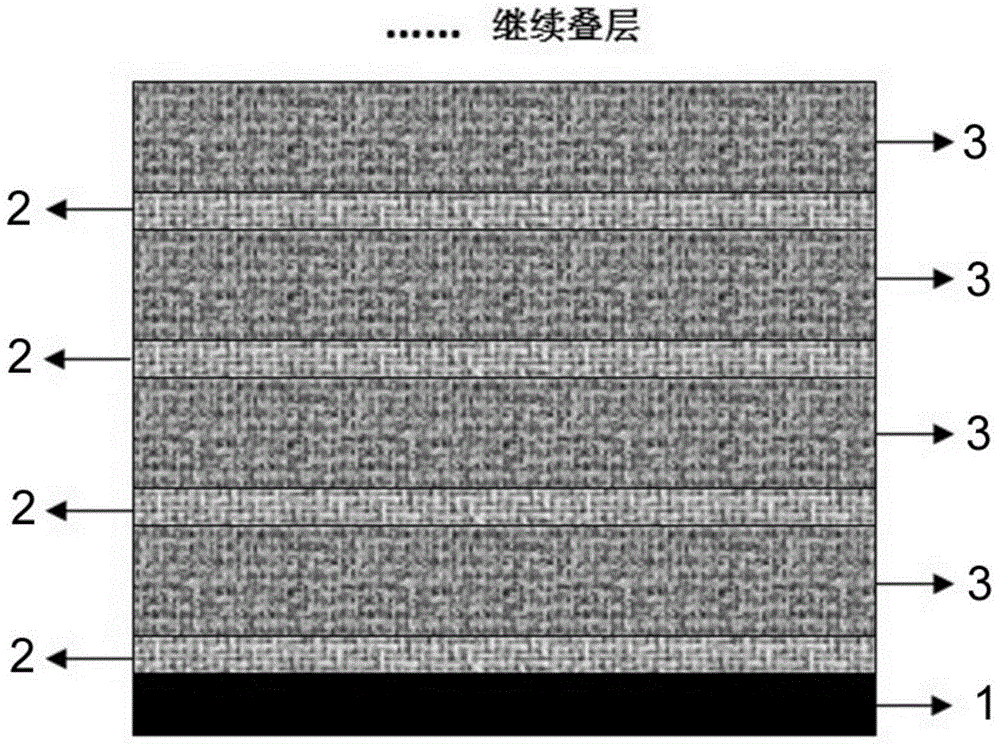

Lithium ion battery electrode structure and preparation method thereof

ActiveCN104425825AReduce dosageHigh densityMaterial nanotechnologySecondary cellsElectrical batteryNano carbon

The invention relates to a lithium ion battery electrode structure and a preparation method thereof, belonging to the technical field of a lithium ion battery. According to the method, a nano carbon material and an active substance are laminated, so that the content of non-active substances, such as positive and negative current collectors, positive and negative tabs and a diaphragm in positive and negative electrodes of the lithium ion battery can be reduced on the basis that the capacity of the lithium ion battery is not reduced, and the mass energy density and the volume energy density of the lithium ion battery can be greatly improved. The preparation method of the lithium ion battery electrode structure is compatible with the traditional process, so that the process is simple, the operation is convenient, the effect is obvious, and the application significant is great.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for extracting propolis by simulative biological fluid bed supercritical CO2 fluid

ActiveCN101530178AImprove extraction yieldImprove permeabilityFood preparationCyclic processLow speed

The invention provides a method for extracting propolis by simulative biological fluid bed supercritical CO2 fluid, which comprises that: bran (or rice bran and the like) taken as biomembrane carrier and original gum particles after physical treatment simulate a fluid bed in an extraction kettle to perform gridded filling, the supercritical CO2 fluid is used for extraction, and the lowest speed of a granular bed converting from a stationary state to fluidization is regulated by regulating temperature, pressure and flow rate of the fluid in the extraction process so as to reach the critical fluidization state; therefore, high-quality and high-yield propolis extract is obtained through a cyclic process of fluidization diffusion, dissolution and separation between granules and the fluid. The method improves the yield of the propolis extract, reduces the cost, and extracts nearly all terpene compounds and 40 to 50 percent of flavonoid compounds in the propolis at the same time; and products do not have organic solvent.

Owner:JIANGSU JIANGDAYUAN ECOLOGICAL BIOLOGICAL TECH

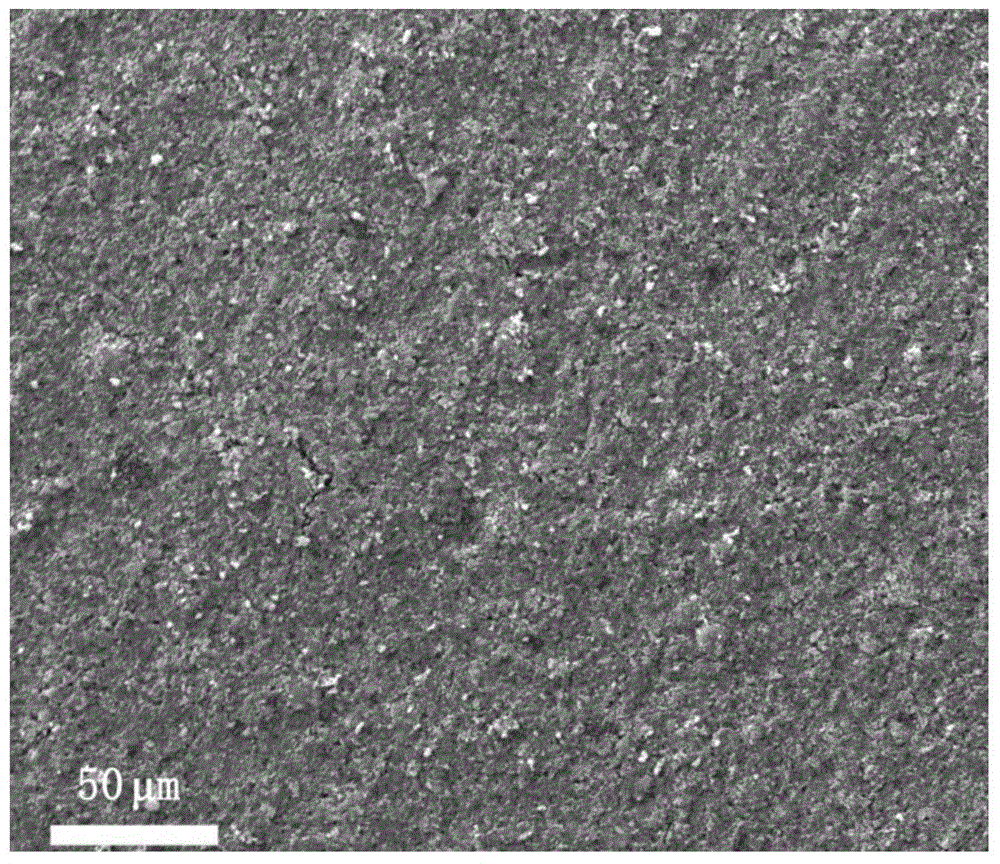

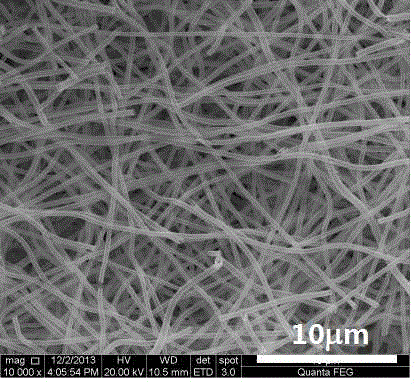

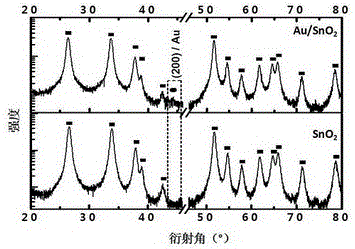

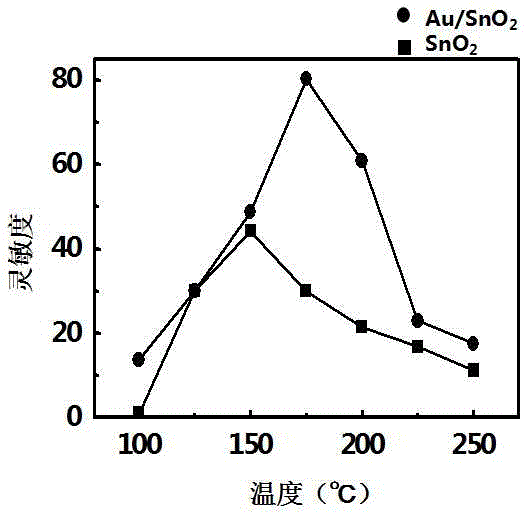

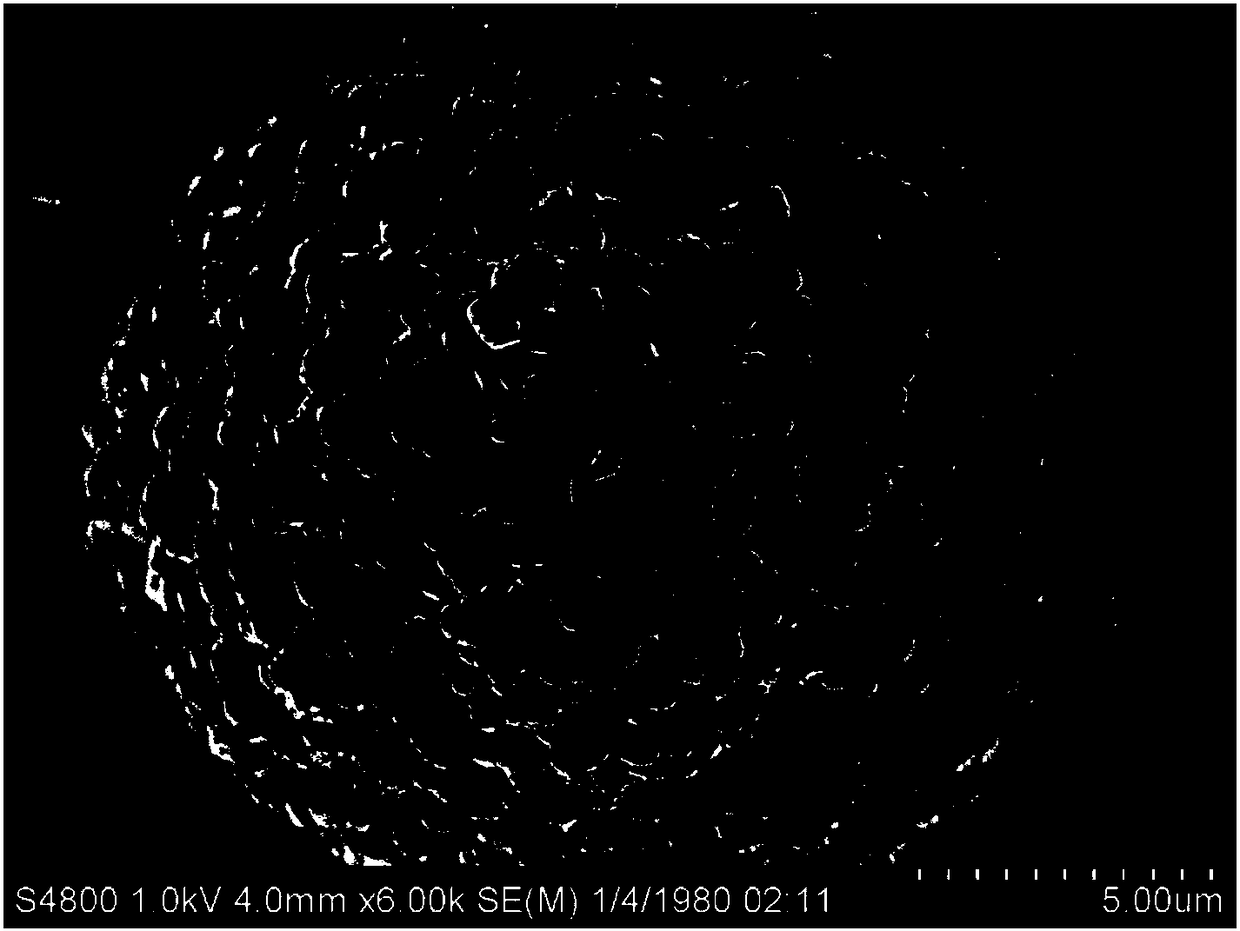

Gas-sensitive material for detecting NO2 and method for manufacturing gas-sensitive element made of gas-sensitive material

InactiveCN105606660AEasy transferSmall sizeMaterial nanotechnologyMaterial resistanceNanostructureRutile

The invention discloses a gas-sensitive material for detecting NO2 and a method for manufacturing a gas-sensitive element made of the gas-sensitive material. The gas-sensitive material is prepared into a SnO2 nano-fiber with a rough surface and a hollow tubular structure by adopting an electrospinning method and high-temperature processing, the hollow SnO2 nano-fiber is of a rutile structure, the SnO2 nano-fiber diameter is about 250-300nm, and the thickness of a particle layer is about 40nm. Au particle modification is performed on the surface of SnO2 in an in-situ reduction manner without changing the crystal structure of SnO2. The specific surface area of the material is increased by the one-dimensional hollow nano-structure characteristic of the gas-sensitive material, the gas-sensitive performance of SnO2 is obviously improved by precious metal modification, and higher sensitivity to NO2 and a larger measurement range are presented. The obtained material is applied to the surface of a ceramic tube, annealing is performed, and a calcined ceramic tube core and a nickel-chromium heating wire are welded to a base, accordingly, the gas-sensitive element is manufactured.

Owner:NORTHEAST NORMAL UNIVERSITY

C/Li2MSiO4-xNy/C (M=Fe, Mn, Co) composite positive electrode material for lithium ion battery and preparation method thereof

InactiveCN102315432AHigh charge and discharge capacityImproved magnification performanceCell electrodesCarbon compositesIon content

The invention relates to a C / Li2MSiO4-xNy / C (M=Fe, Mn, Co) composite positive electrode material with outstanding electrochemical performances for a secondary lithium ion battery and a preparation method thereof. According to the technical scheme of the invention, the nitrogen element is doped to partially replace oxygen in a crystal structure; the charge balance in a material is controlled by the lithium ion content; a solid phase reactor is formed by organic carbon and inorganic porous carbon; and an N-doped silicate carbon composite positive electrode material with outstanding electrochemical performances for the secondary lithium ion battery is synthesized by utilizing a high-temperature carbon thermal reduction method. The material prepared by the method provided by the invention has the advantages of higher charge-discharge specific capacity, preferable multiplying power efficiency and very good use value, and is especially suitable for power batteries.

Owner:JIANGSU ZHENGTONG ELECTRONICS TECH

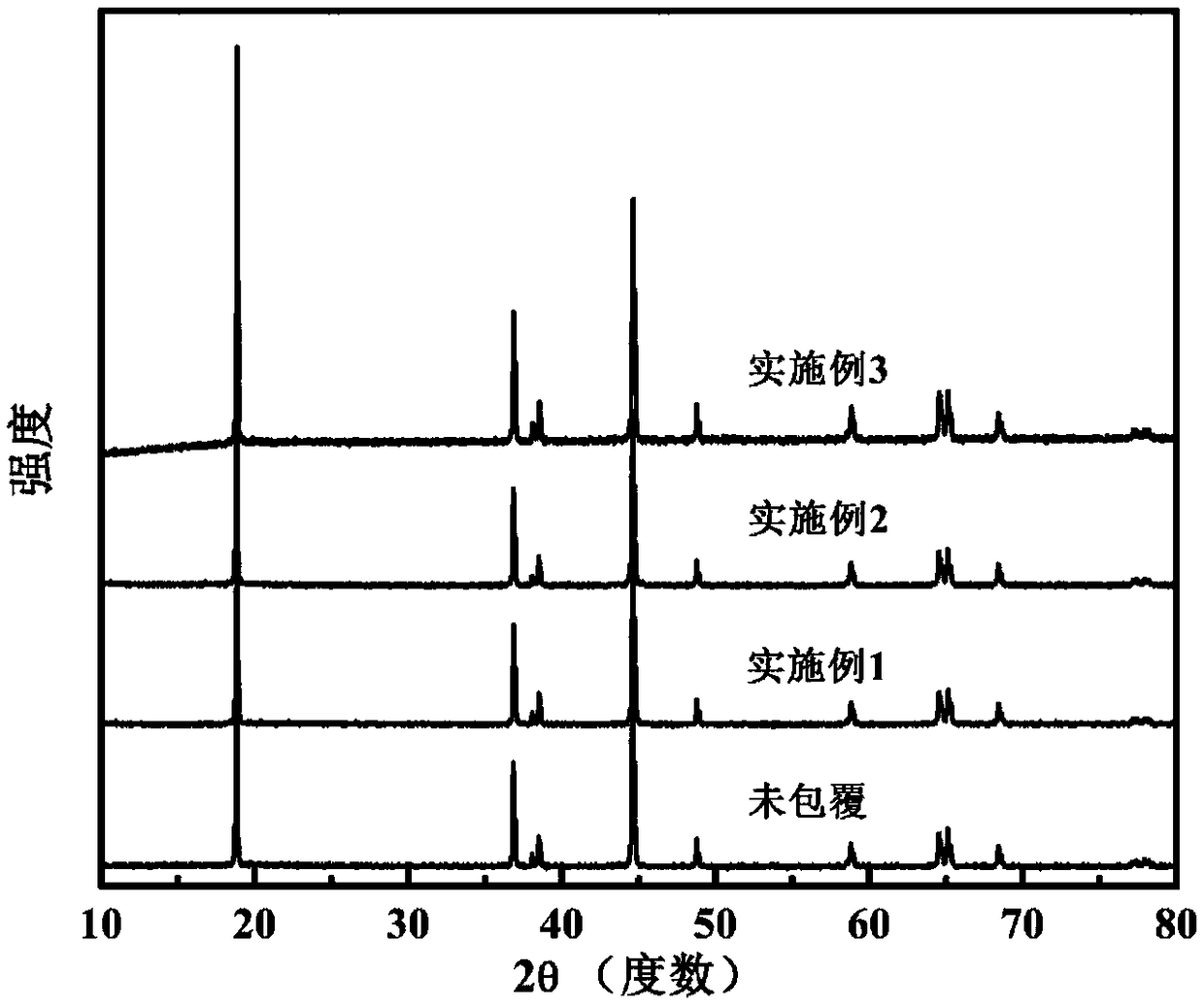

Method for eliminating residual lithium and preparing lithium ion conductor-coated high-nickel ternary positive electrode material

InactiveCN108172821AIncreased diffusion rateReduce adverse effectsCell electrodesElectrical conductorLithium-ion battery

The invention belongs to the technical field of a lithium ion battery material, specifically a method for eliminating residual lithium and preparing a lithium ion conductor-coated high-nickel ternarypositive electrode material. According to the method, a high-nickel ternary positive electrode material and a lithium ion conductor precursor are subjected to ball milling in a ball mill based on a certain proportion; and the mixture obtained by above-mentioned processing is calcined in the air to obtain a lithium ion battery high-nickel ternary positive electrode modified material. The method issimple in process, convenient to operate, and capable of avoiding adverse influence from water content introduction to the high-nickel ternary material by adopting the dry ball milling mode; and meanwhile, a lithium ion conductor coating layer is formed by adopting surface residual lithium in-situ processing, so that the diffusion rate of lithium ions is accelerated, interface stability is improved, and excellent electrochemical performance is achieved.

Owner:FUDAN UNIV

Paste solder for hard soldering of SiCp/Al composite material and preparation method and use method thereof

InactiveCN103100800AReduce in quantityImprove automationWelding/cutting media/materialsSoldering mediaAdhesiveTubing types

The invention relates to a paste solder for the hard soldering of a SiCp / Al composite material and a preparation method and use method thereof, and relates to a solder for the hard soldering of the SiCp / Al composite material and a preparation method and use method thereof. The paste solder for the hard soldering of the SiCp / Al composite material aims at the problem that the traditional strip-shaped solder or foil-shaped solder is adverse to the automation in a hard soldering process and is not suitable to weld an irregular, small-sized or geometrical complicated part. The paste solder for the hard soldering of the SiCp / Al composite material is prepared by mixing solder alloy powder, a soldering flux and an adhesive. The preparation method comprises the following steps of: 1, preparing the solder alloy powder; 2, preparing the soldering flux; 3, preparing the adhesive; and 4, mixing to prepare the hard soldering of the paste solder for the SiCp / Al composite material. The use method comprises the following steps of: adopting coating type cloth or needle tube type cloth; and then carrying out vacuum heating treatment so as to complete welding. The preparation method disclosed by the invention is mainly used for preparing the paste solder for the hard soldering of the SiCp / Al composite material.

Owner:HENAN POLYTECHNIC UNIV +2

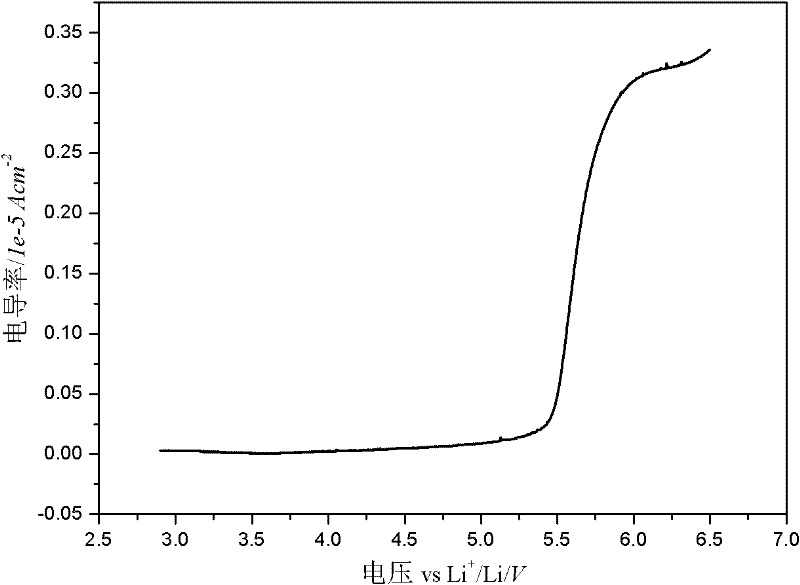

Method for preparing ionic liquid plasticized composite polymer electrolyte for lithium ion battery

ActiveCN102244293AIncreased diffusion ratePromote absorptionSecondary cellsElectrochemistryLithium electrode

The invention relates to a method for preparing ionic liquid plasticized composite polymer electrolyte for a lithium ion battery. In the invention, the conductivity of a polymer electrolyte membrane is increased, meanwhile, the electrochemical stability window and the mechanical properties of the membrane are also further enhanced. The method comprises two parts. The first part is to prepare an inorganic particle doped polymer-matrix microporous membrane with a steam bath exchange method and mainly comprises the following steps of: firstly, uniformly dispersing inorganic particles in an organic solvent; then, dissolving a polymer matrix and a pore forming agent in the uniform organic solvent to form transparent gel under the condition of agitation; and finally, preparing the inorganic particle doped polymer-matrix microporous membrane through casting membrane formation and with the steam bath exchange method. The second part is to prepare the ionic liquid plasticized gel-like composite polymer electrolyte and mainly comprises the following steps of: directly soaking the prepared doped polymer-matrix microporous membrane in a mixed solution of imidazole ionic liquid and lithium salt so as to swell and plasticize the polymer-matrix microporous membrane. Because steam bath is adopted to form the membrane and the imidazole ionic liquid is introduced to perform plasticization, the prepared electrolyte membrane has good mechanical strength and flexibility, high ionic conductivity, wide electrochemical stability window and simple preparation process and is easy for realization of industrial production.

Owner:CENT SOUTH UNIV

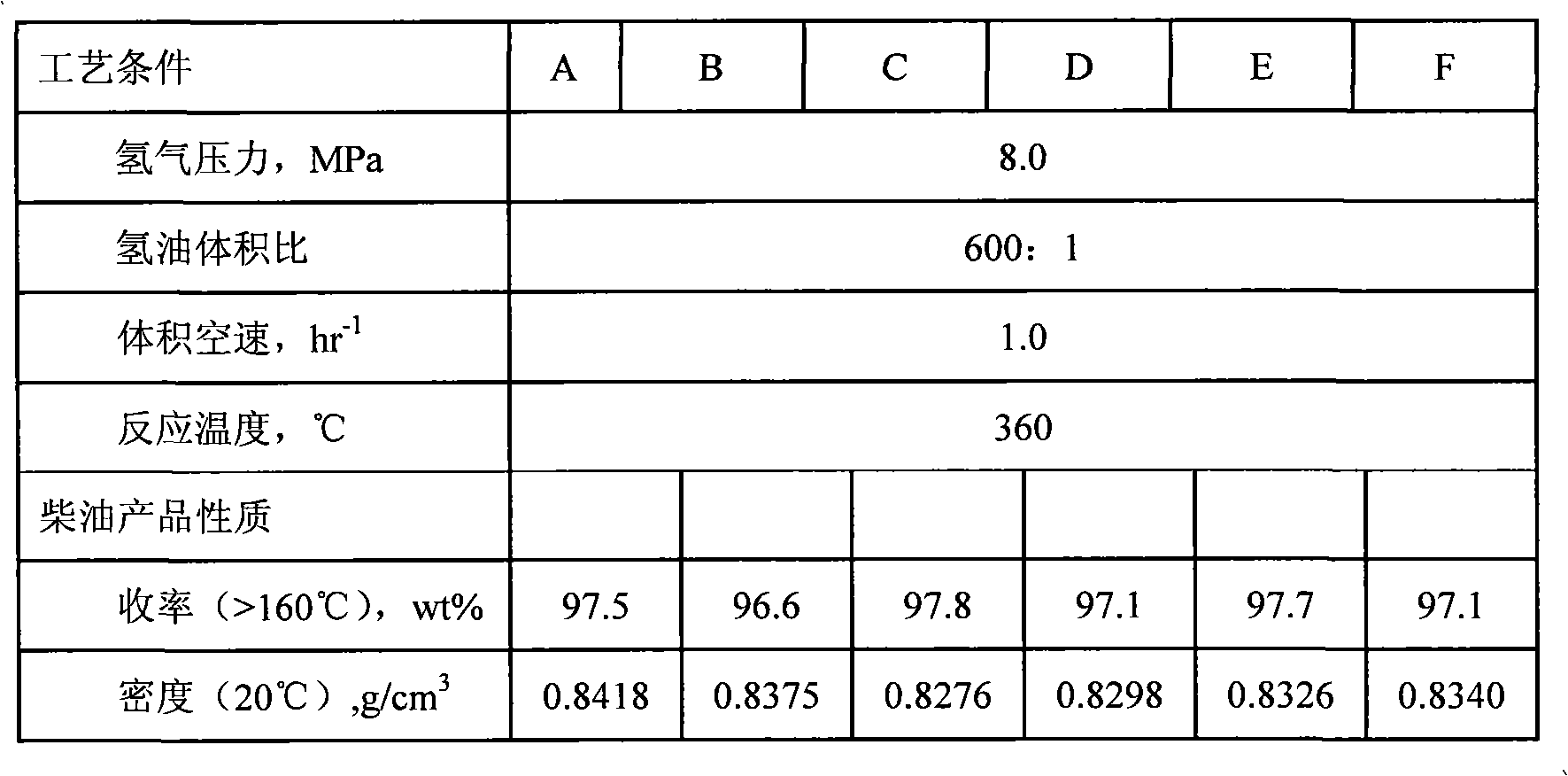

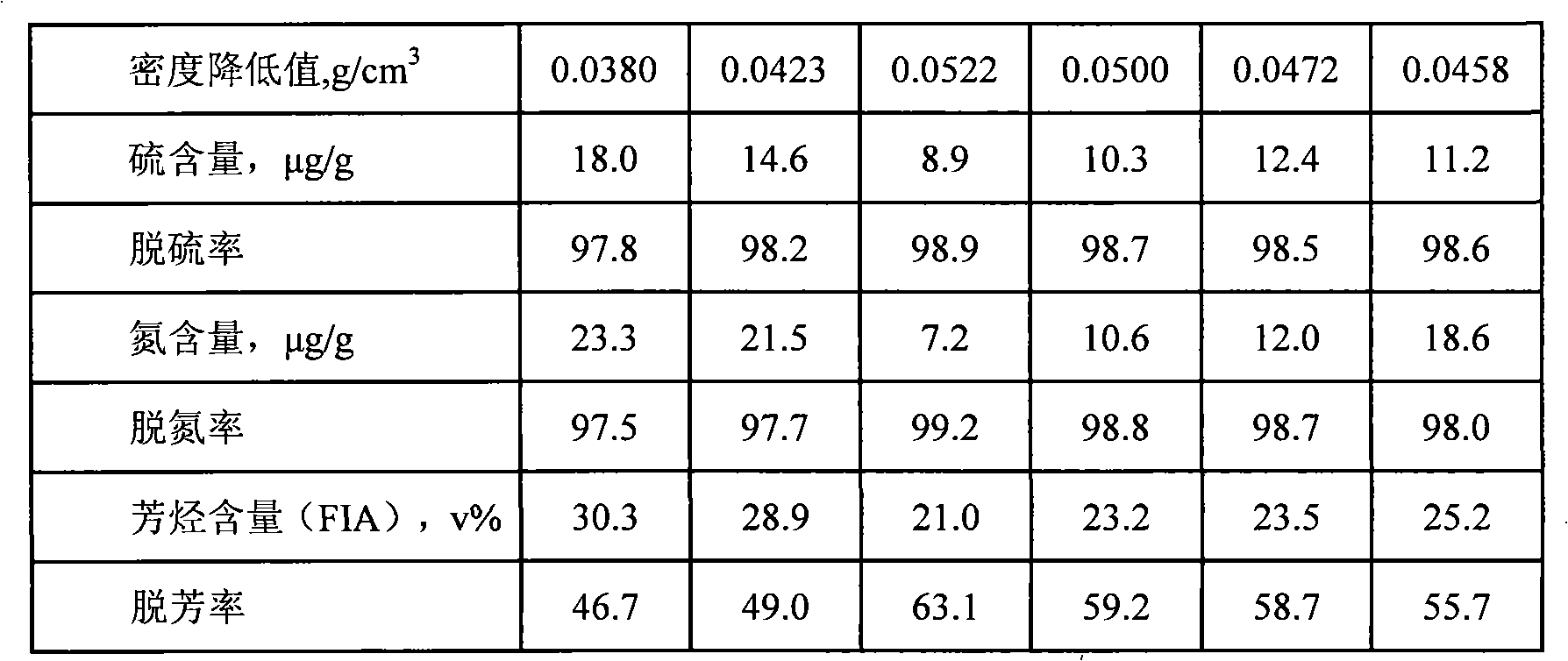

Method for hydro-dearomatization for catalyzing diesel

ActiveCN101328430AIncreased diffusion rateImprove activity stabilityRefining by aromatic hydrocarbon hydrogenationMolecular sieveDistillation

The invention relates to a method for catalyzing diesel oil to realize hydrogenation dearomatization. The method comprises the following steps that: distillation range of catalyzing diesel oil feeding is at a temperature of between 150 and 380 DEG C; in the presence of hydrogen, a reaction is carried out, the reaction temperature is between 330 and 370 DEG C, the hydrogen partial pressure is between 6 and 9 MPa, the hydrogen-oil volume ratio is between 500:1 and 1,000:1 and the liquid hourly volume space velocity is between 1.0 and 2.0 hr-1; the compositions in percentage by weight of a catalyst are: 15 to 40 percent of amorphous silica alumina, 5 to 30 percent of aluminum oxide, 10 to 40 percent of VIB group metal oxide, 1 to 15 percent of VIII group metal oxide and 5 to 30 percent of Beta / Y molecular sieve; moreover, the total weight of the compositions is counted as 100 percent. The method has the advantages that: diesel oil yield is more than 97 weight percent, and the dearomatization rate of diesel oil reaches to above 60 percent; meanwhile, total desulfurization rate and total denitrification rate reach above 98.5 percent, and product density is reduced by above 0.0400g / cm3.

Owner:PETROCHINA CO LTD

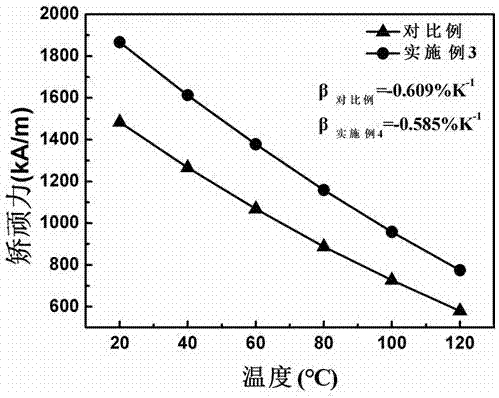

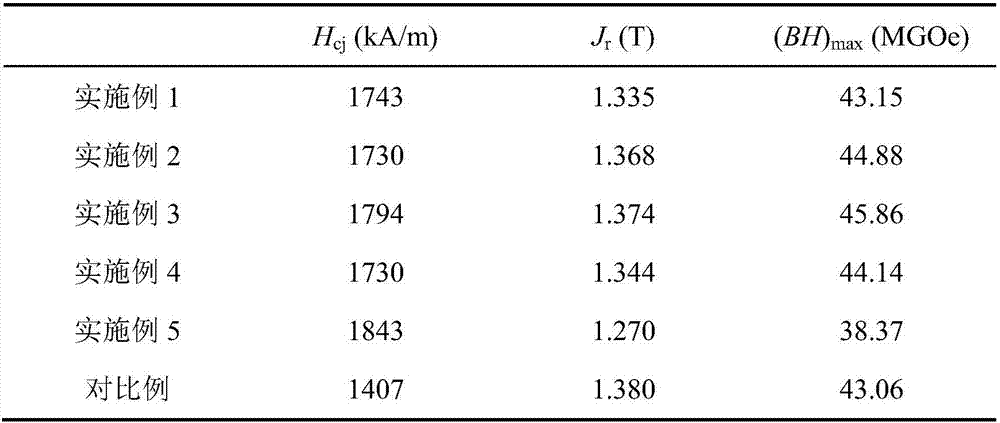

Crystal boundary diffusion method for improving coercive force and thermal stability of neodymium-iron-boron magnet

InactiveCN107093516ADiffusion rate is fastInhibit growthInductances/transformers/magnets manufactureRare earthHeat treated

The invention discloses a crystal boundary diffusion method for improving the coercive force and the thermal stability of a neodymium-iron-boron magnet, and belongs to the field of rare earth permanent magnet materials. According to the method, a quaternary alloy Dy-Ni-Al-Cu with a low melting point is used as a diffusion source and melted and prepared into a rapid-hardening strip, after coarse breaking, the strip casting is laid around the neodymium-iron-boron magnet, and by the adoption of a heat treatment method, the rapid-hardening strip diffuses and enters the magnet along the crystal boundary. After the processing, the coercive force of the magnet is significantly improved, and the magnetic energy product is improved to a certain extent; meanwhile, since the temperature of the diffusion treatment is low, energy consumption can be reduced, the cost can be lowered, and Nd2Fe14B crystal grains can be prevented from growing up; compared with a coating and magnetron sputtering method, the crystal boundary diffusion method omits a powder preparing and coating process in a coating technology and a thin film preparing process in a magnetron sputtering technology. After the technology processing of the crystal boundary diffusion method, the neodymium-iron-boron magnet with the high coercive force and the high thermal stability is finally obtained.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com