Patents

Literature

131 results about "Steam Bath" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Therapy of sitting in a hot steamy room followed by a cool bath or shower.

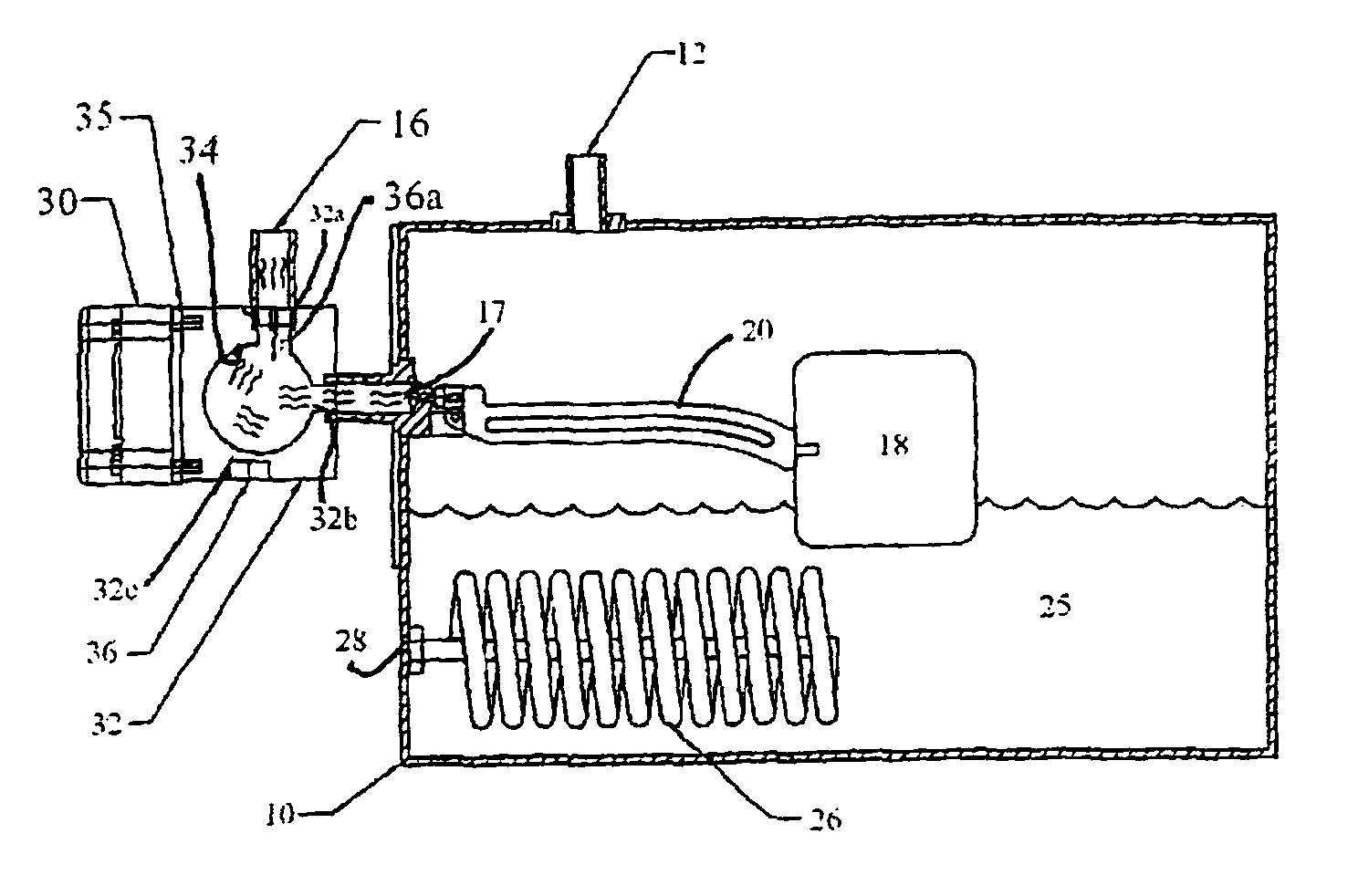

Convection steamer with forced recirculation through steam bath

InactiveUS6904903B1Efficient cookingSelf-cleaning stoves/rangesOven air-treatment devicesSteam cookingEngineering

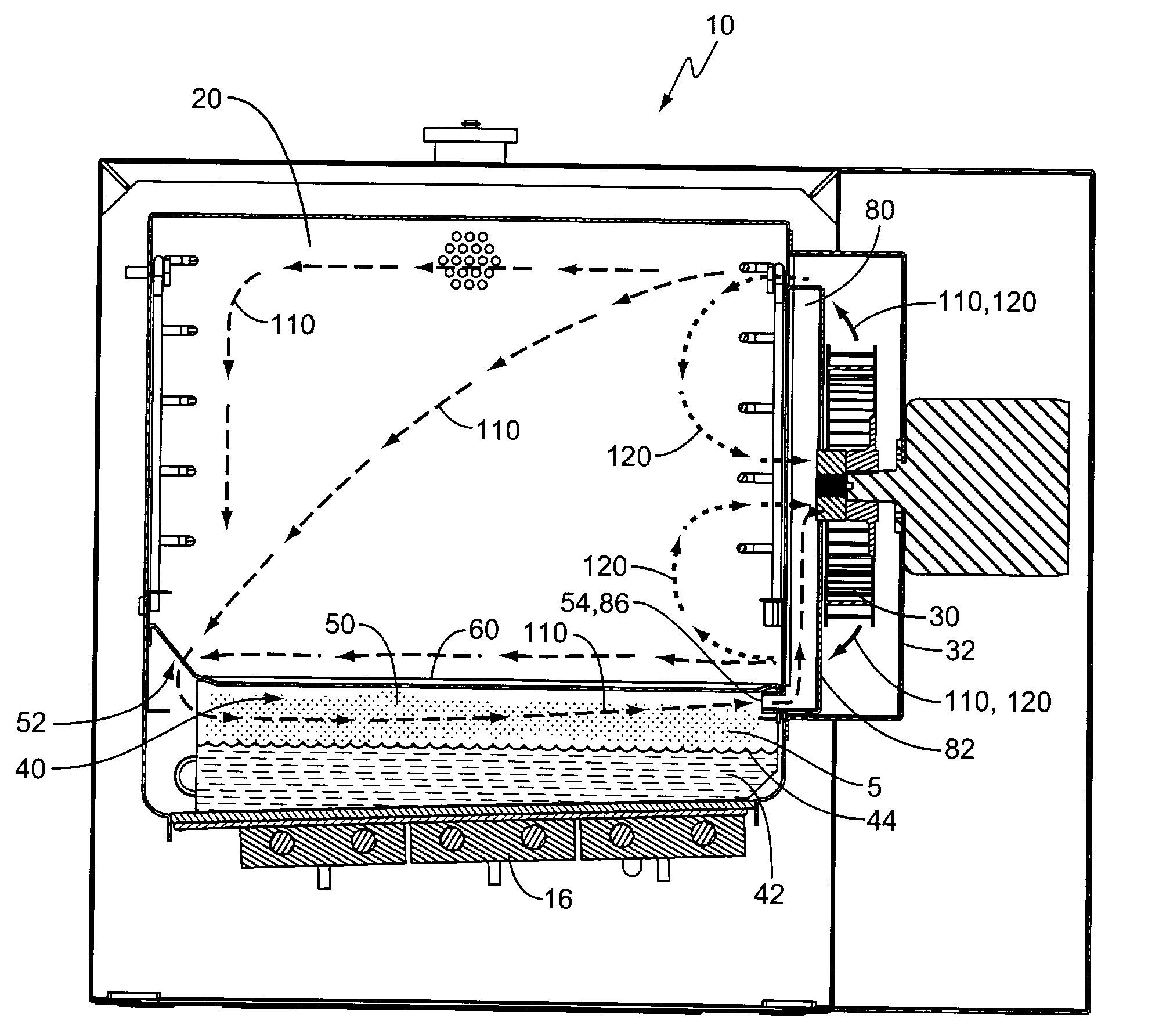

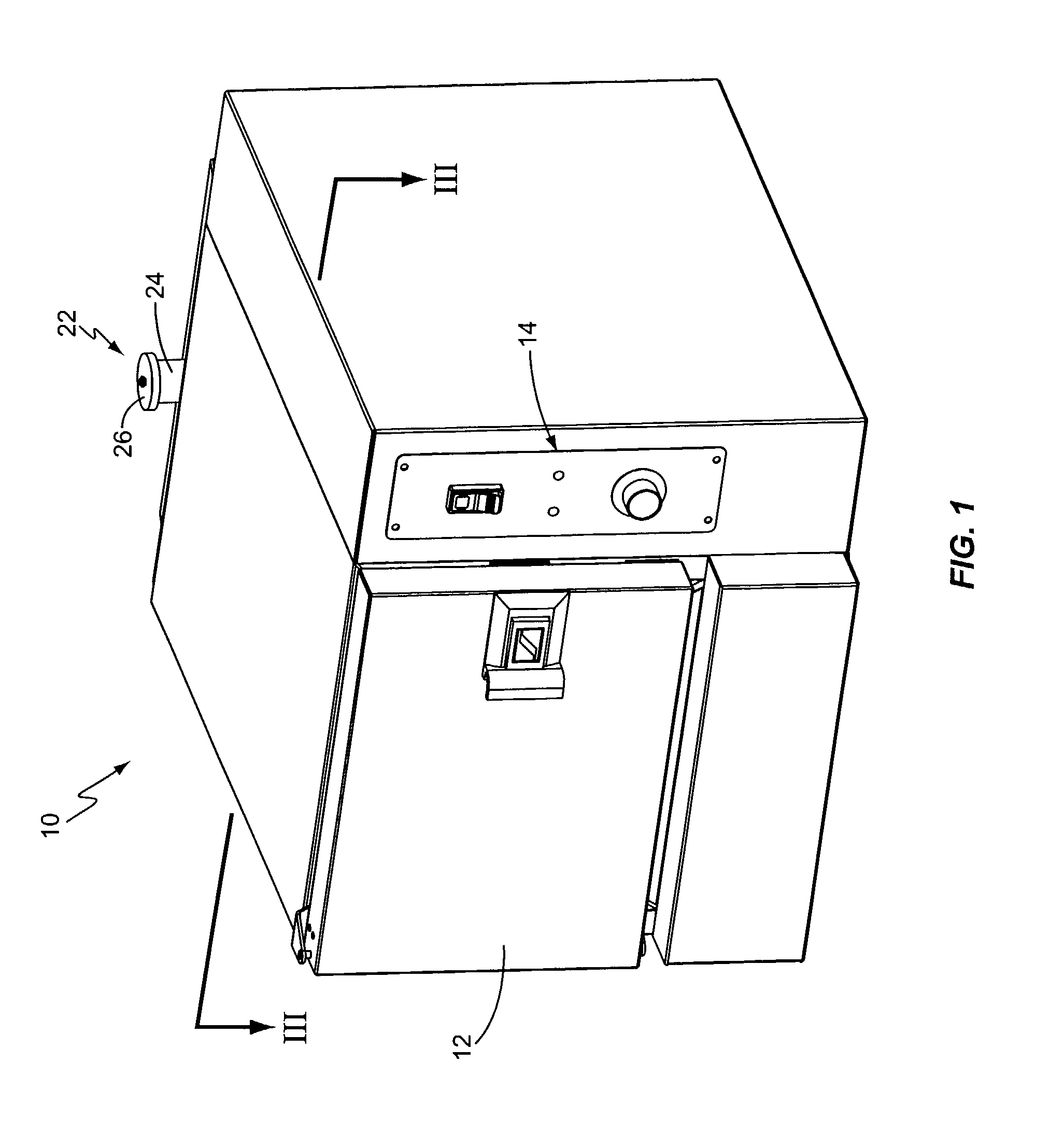

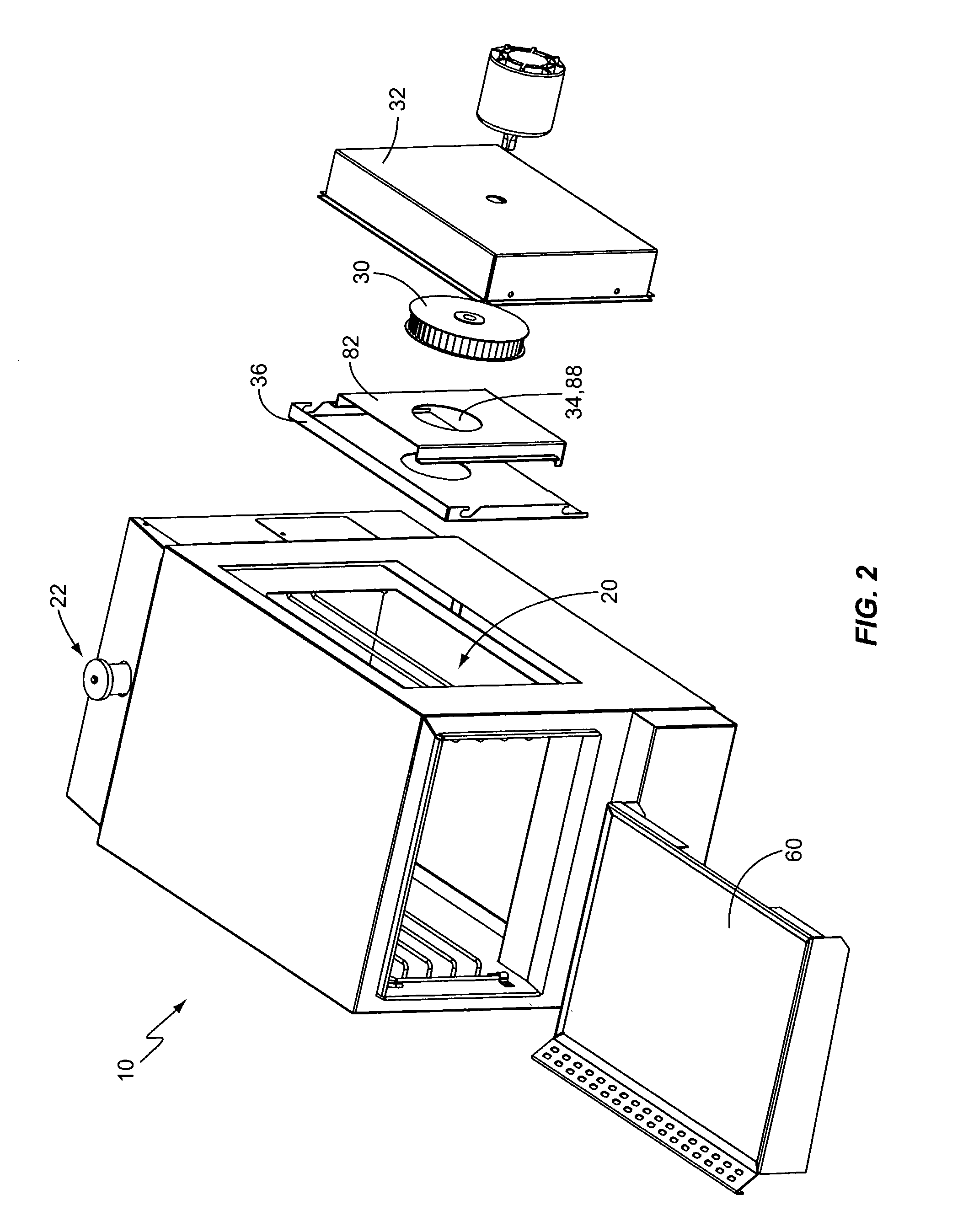

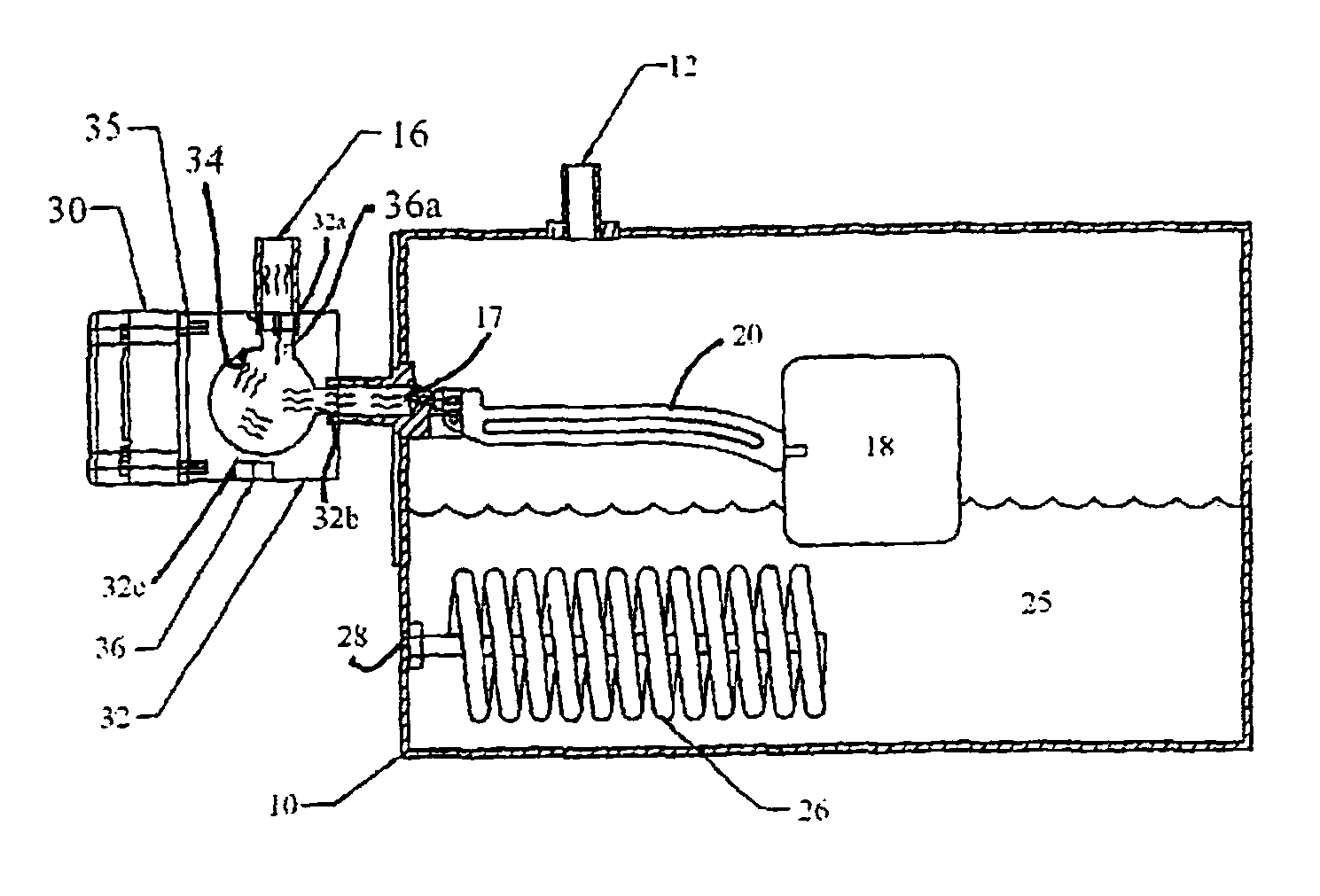

A convection steam cooking device utilizes forced recirculation of gases along a primary recirculation path that extends through a steam chamber so that gases from the cooking cavity flow through the steam chamber and are subjected to a “steam bath” that alters the gases by adding heat and / or moisture. The cooking device includes a cooking cavity, a fan, a steam chamber disposed beneath the cooking cavity with a lower pool area for holding water and an upper steam collecting area disposed directly above the pool area, and a removable baffle disposed between the cooking cavity and the steam chamber with a perforated section remote from the fan and disposed at an upward angle. The primary forced recirculation path extends from the main cooking cavity, through the baffle, substantially across the steam collecting area, through a duct to the fan, and back to the main cavity.

Owner:MIDDLEBY MARSHALL

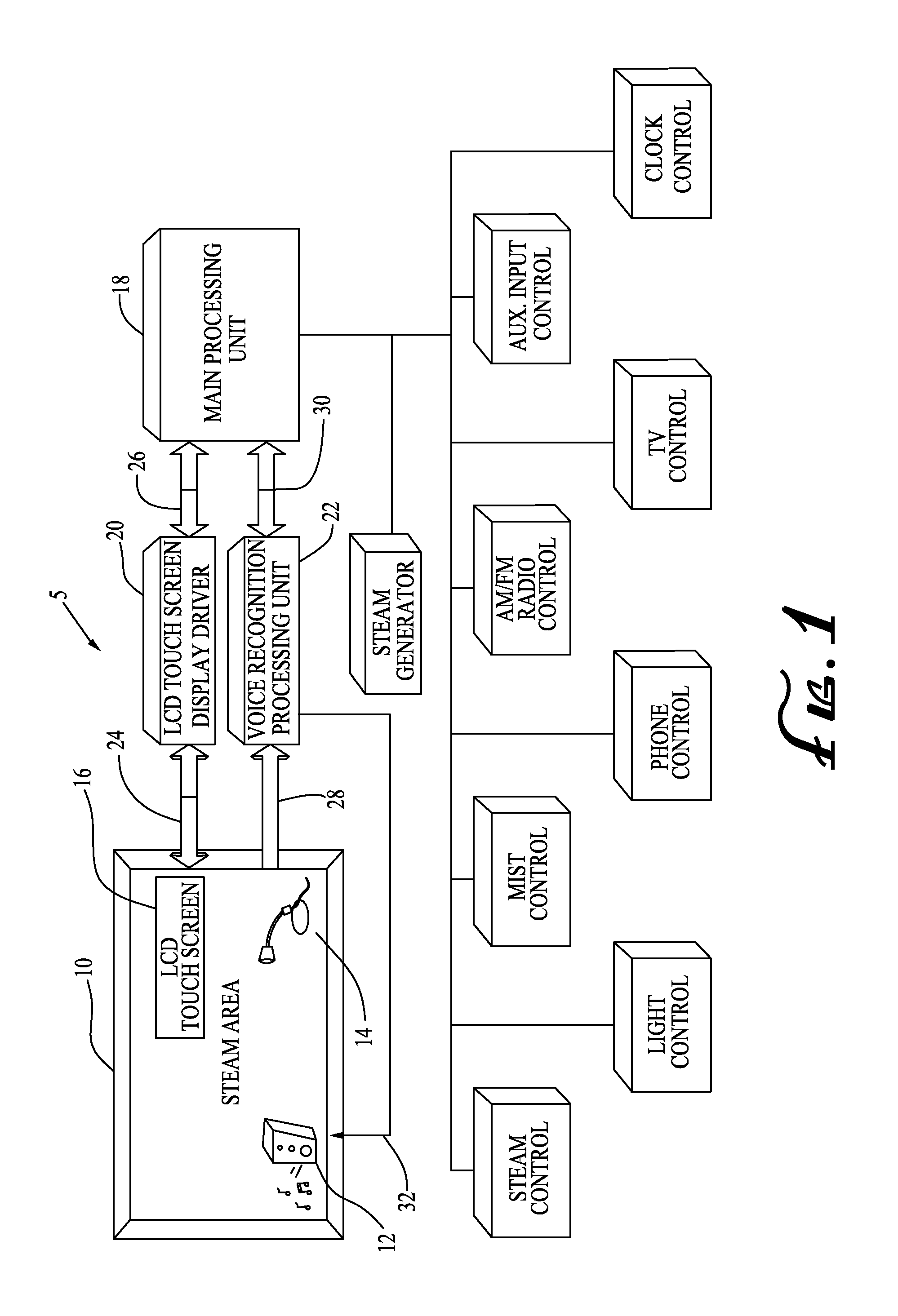

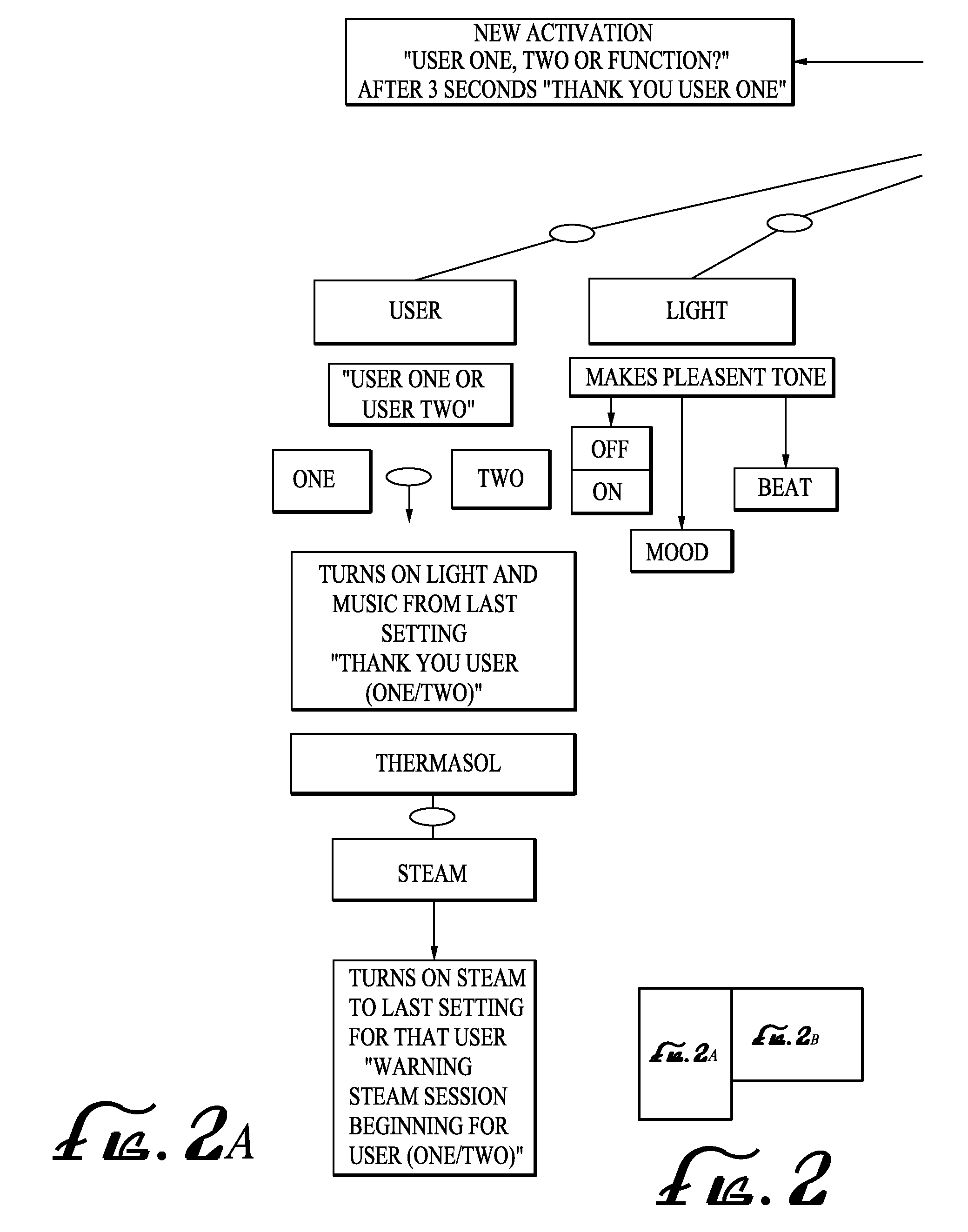

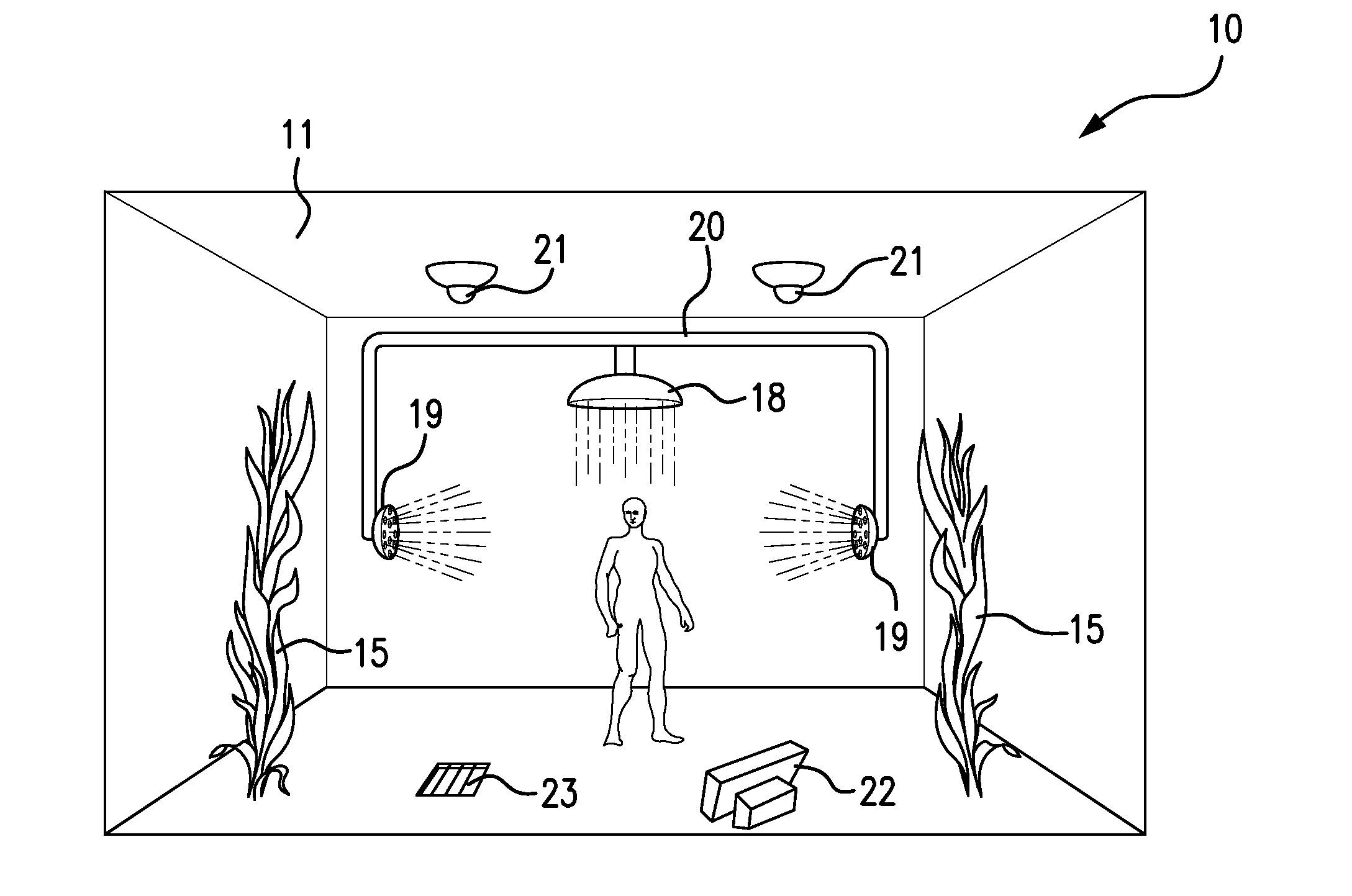

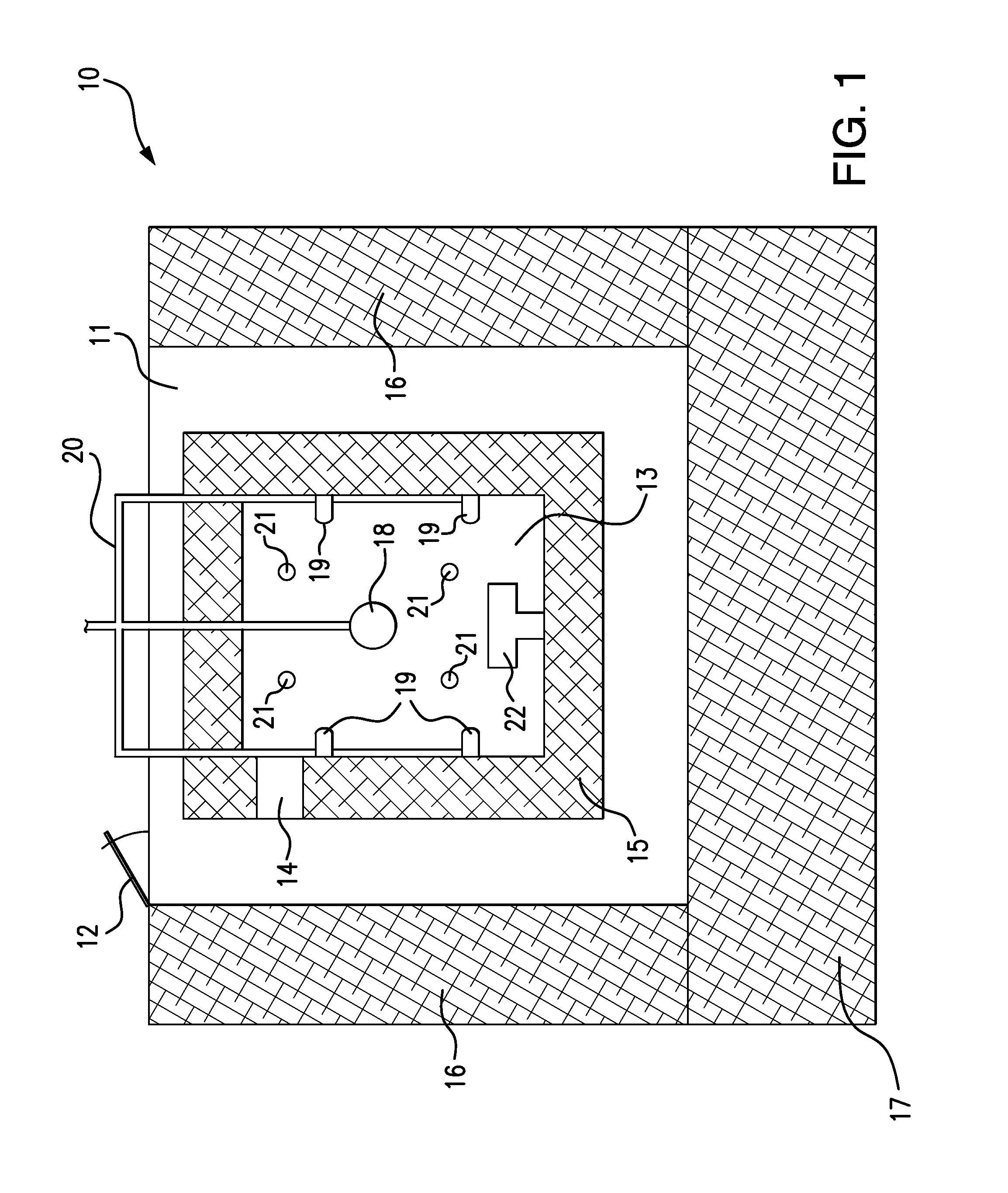

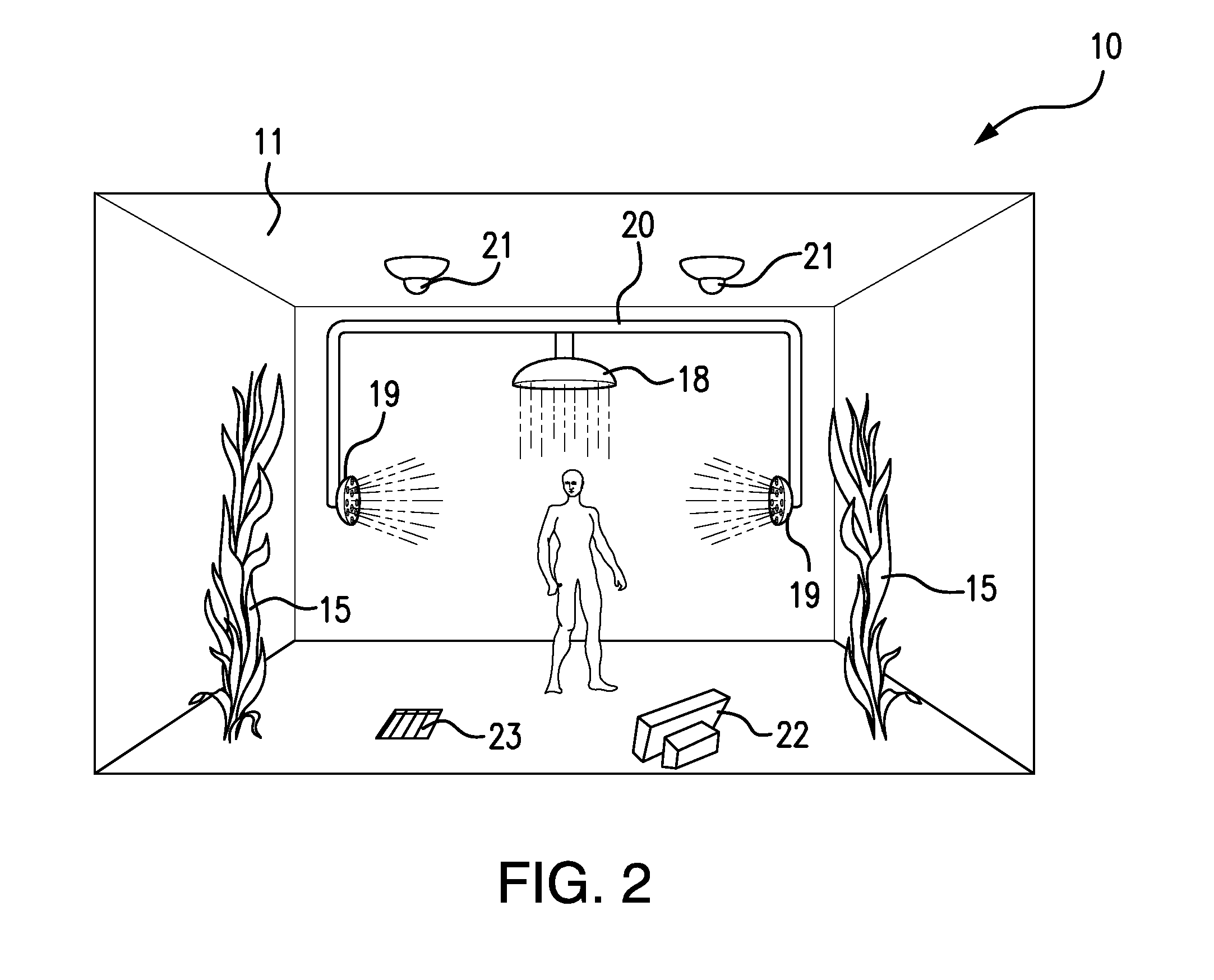

System and Method for Controlling the Environment of a Steambath

InactiveUS20120233765A1Promote comfortEasy to relaxBathing devicesSpeech recognitionRadio frequencyCD player

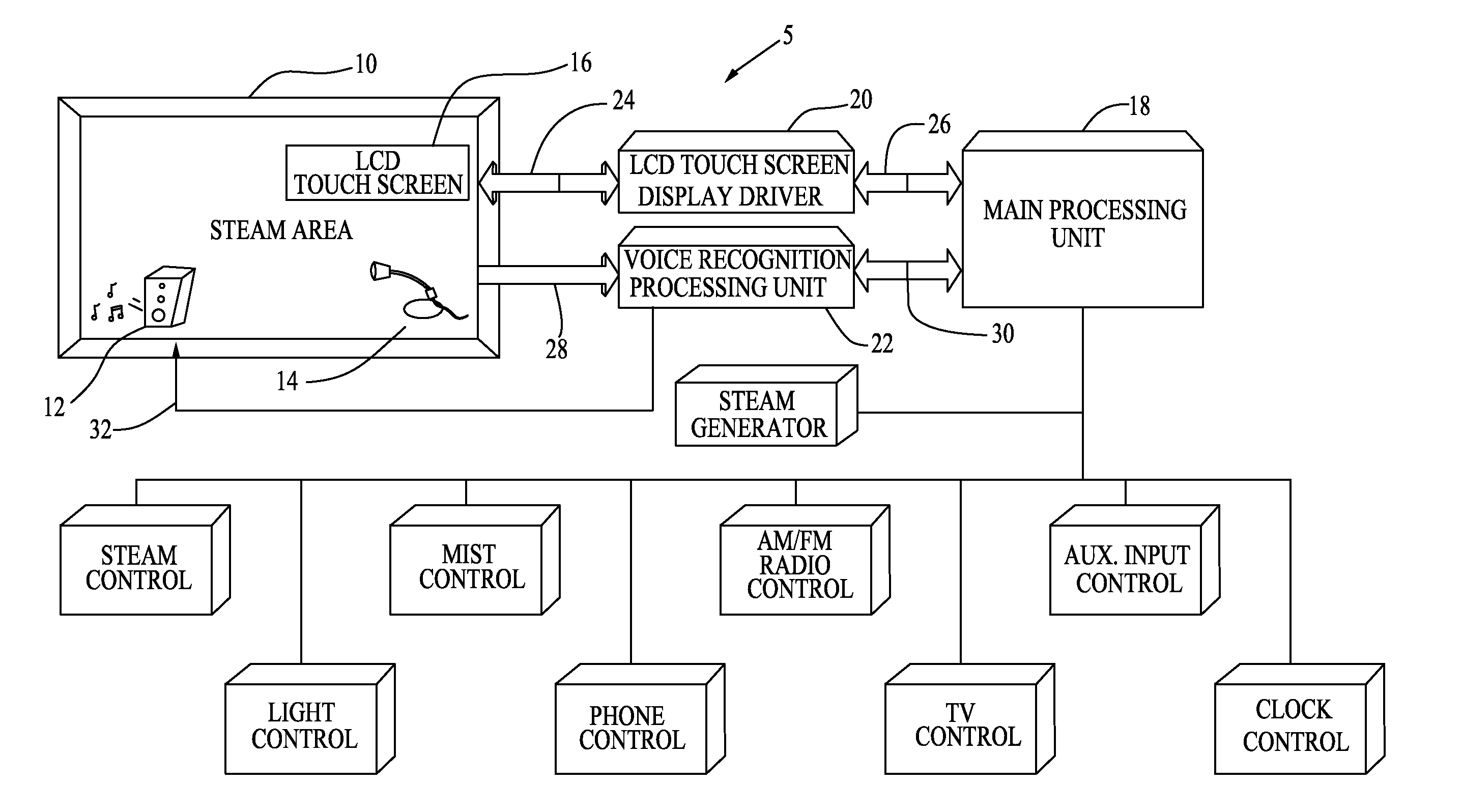

A steambath system is responsive to verbal commands to control the various aspects of the shower and steam environment such as water flow rate, water temperature, steam activation / de-activation, lighting intensity and / or color, music volume, music content, quantity and type of fragrance released, showerhead selection, radio activation, volume and station selection, television activation, volume and channel selection, DVD player activation and DVD selection, CD player activation and CD selection, and humidity control, and in a preferred embodiment utilizes radio frequency (RF) communication.

Owner:ALTMAN MITCHELL

High-heat-resistance skin-core structural polylactic acid fiber and preparation method thereof

InactiveCN106637500AImprove heat resistanceFilament/thread formingConjugated synthetic polymer artificial filamentsPreparing skinStructural unit

The invention discloses a high-heat-resistance skin-core structural polylactic acid (PLA) fiber and a preparation method thereof. The core layer of the skin-core structural PLA fiber is stereocomplex polylactic acid (scPLA), and the skin layer is PLA with the L-lactic acid structural unit (D-LA) content of 0 to 5 mol percent. The preparation method of the skin-core structural PLA fiber comprises the following steps: after raw materials are dried, adding the raw materials into corresponding hoppers of a composite spinning machine respectively, and carrying out melt conveying, spinning, blowing cooling, winding feeding, oil bath stretching, steam bath stretching, tension heat setting, oiling, stacking, curling, relaxation and cutting to prepare skin-core structural PLA short fiber; or after the raw materials are dried, adding the raw materials into the corresponding hoppers of the composite spinning machine respectively, and carrying out one step method of melt spinning, side blowing cooling, oiling, stretching and heat setting to prepare skin-core structural multifilaments. The prepared skin-core structural PLA fiber is relatively high in heat resistance, and can be used in the fields of textiles, composite materials and the like.

Owner:JIANGNAN UNIV

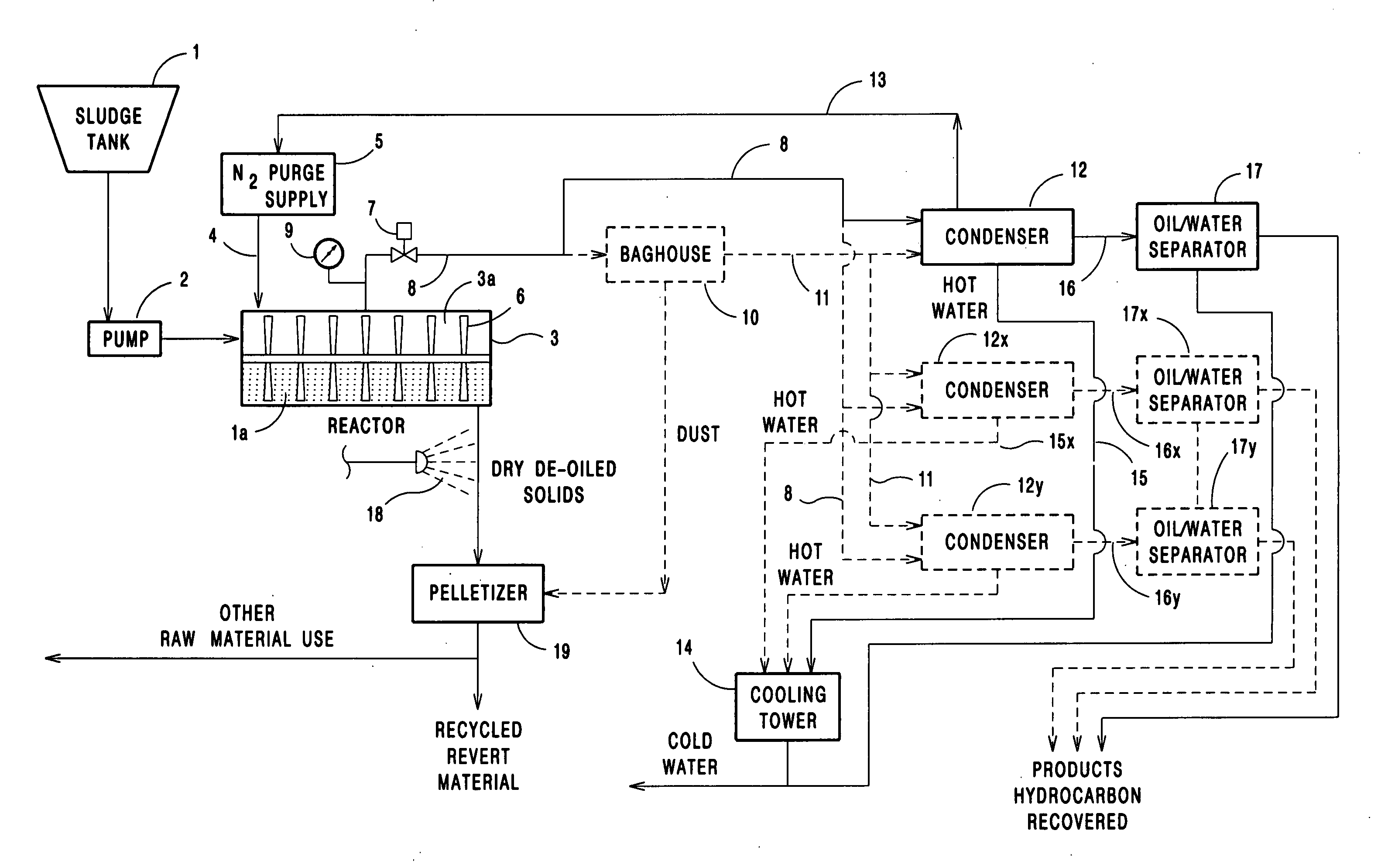

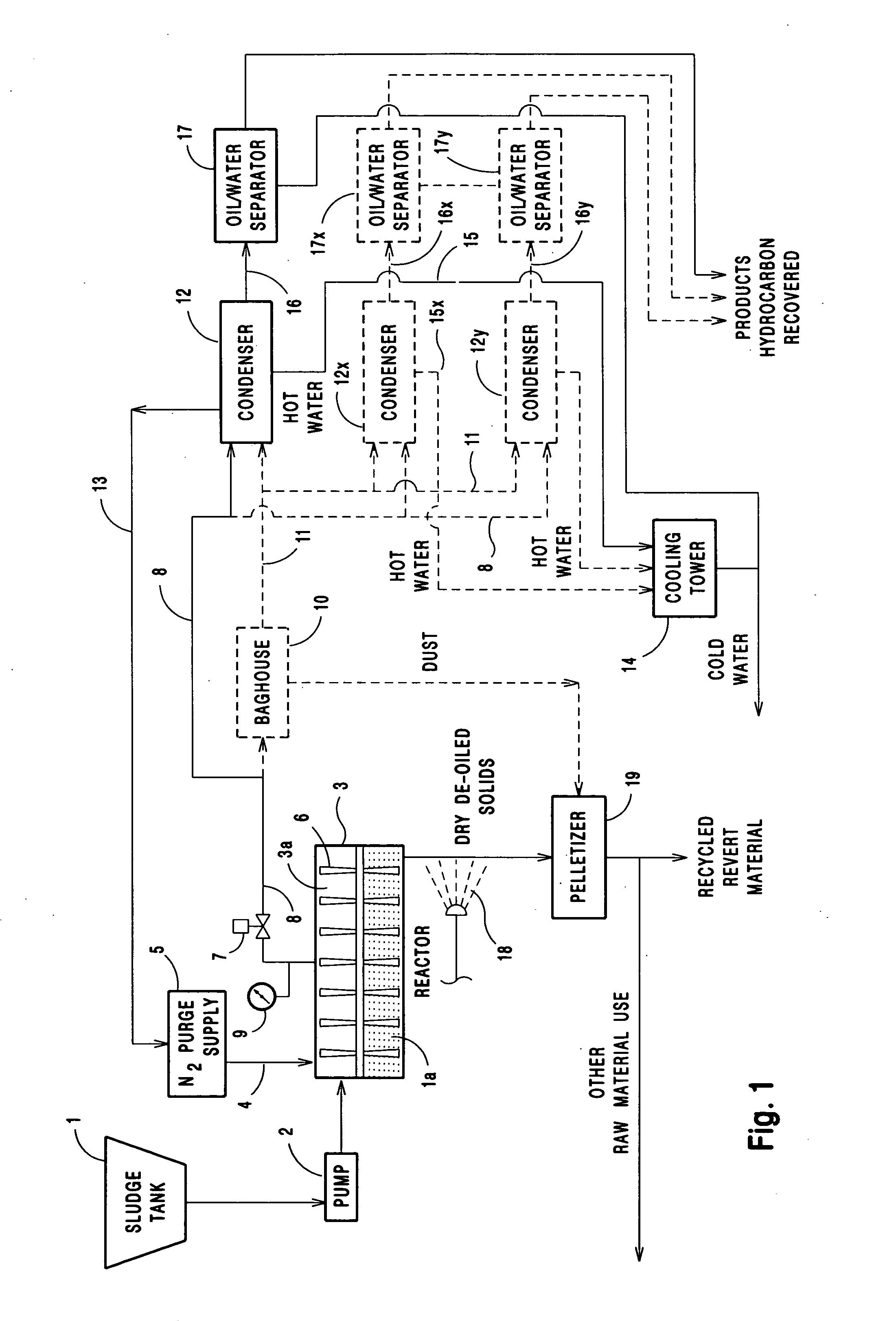

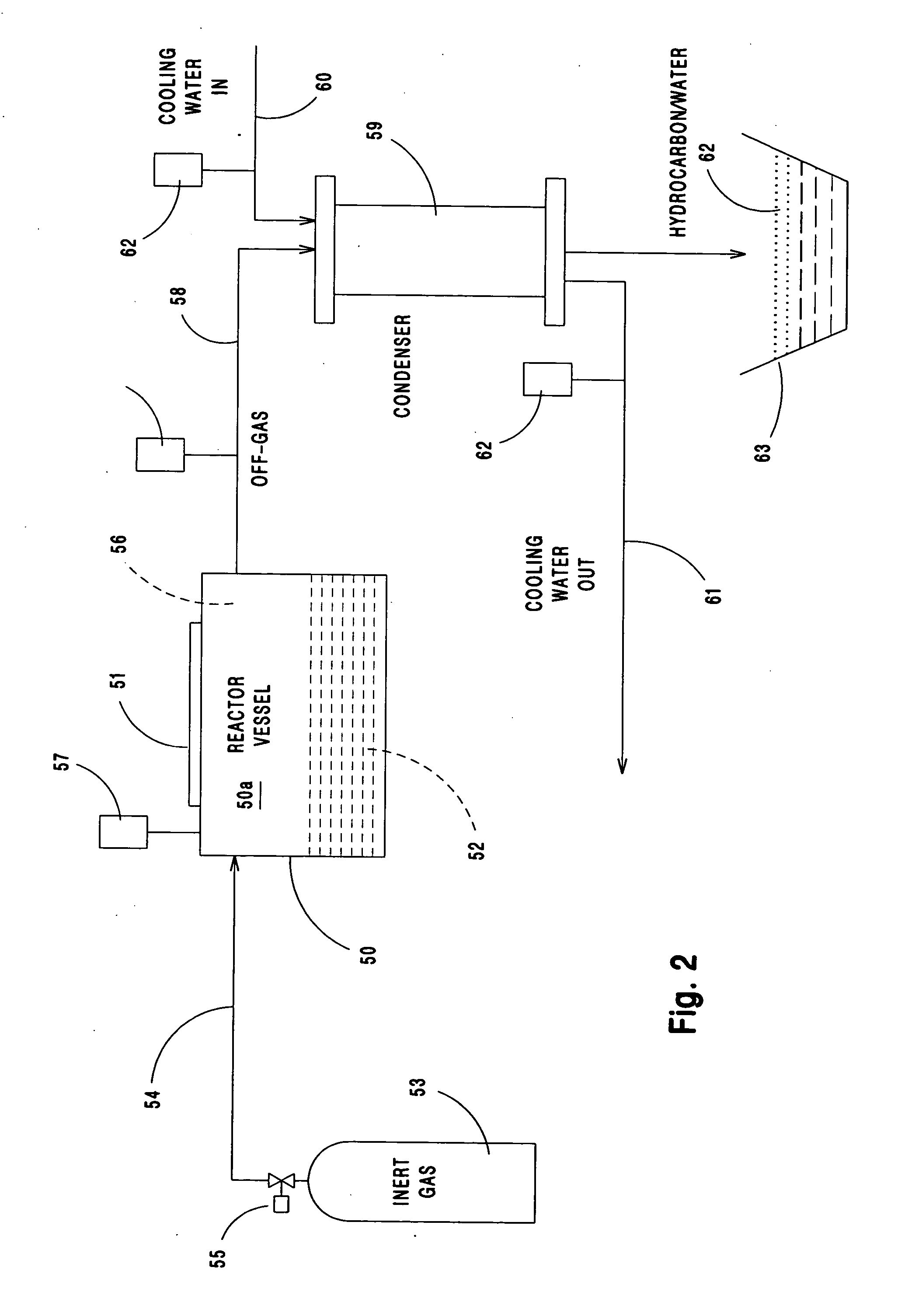

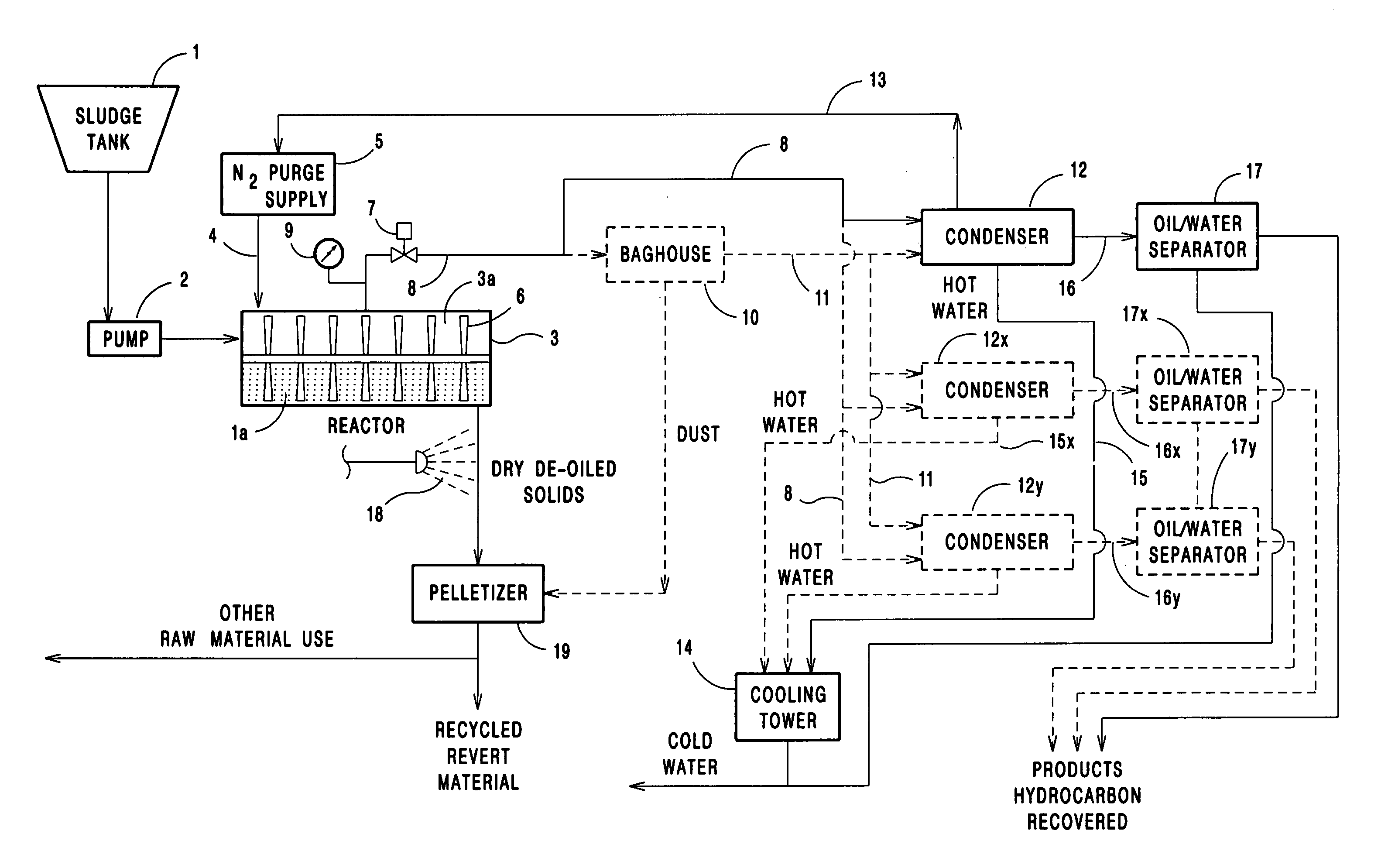

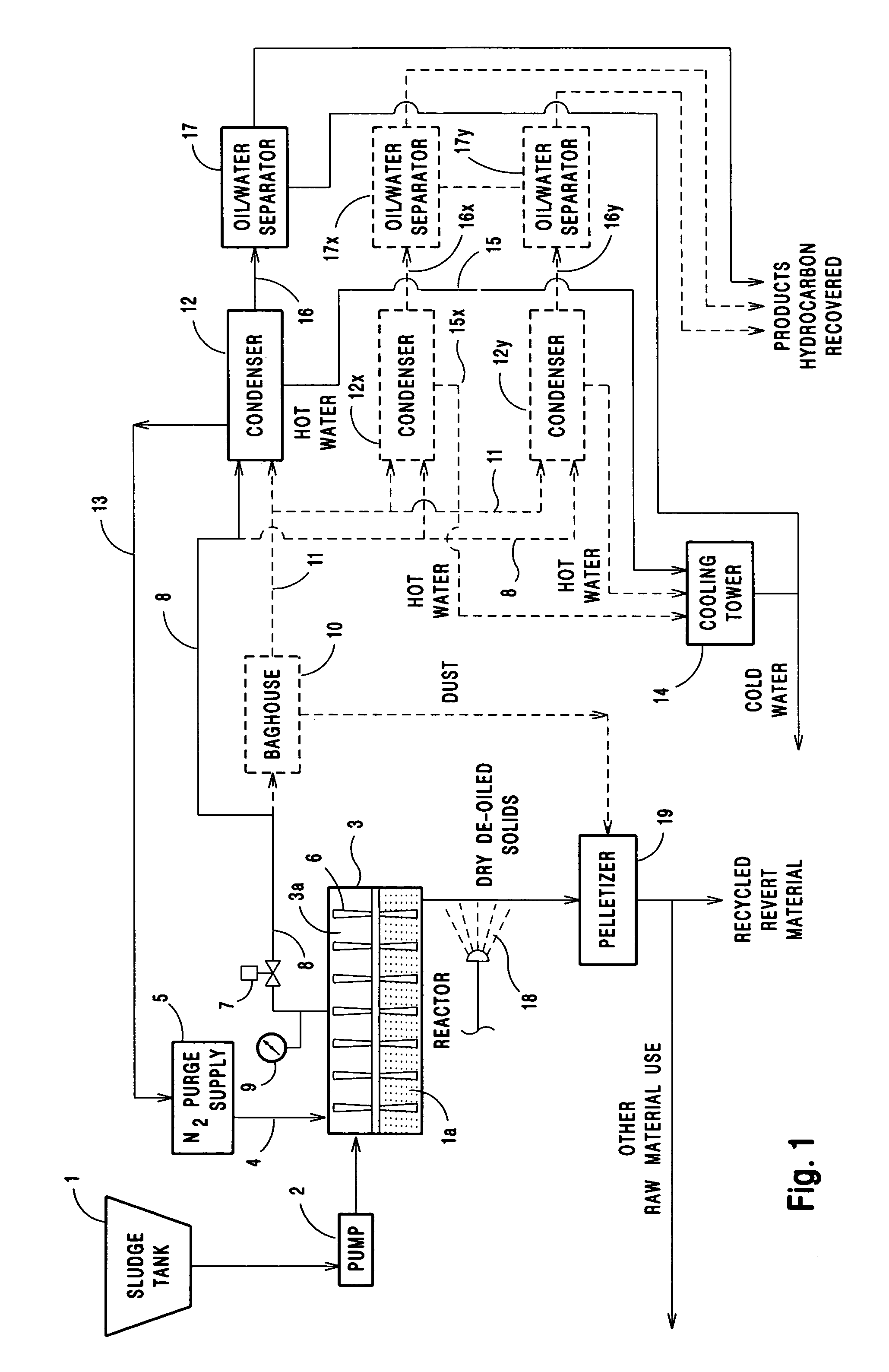

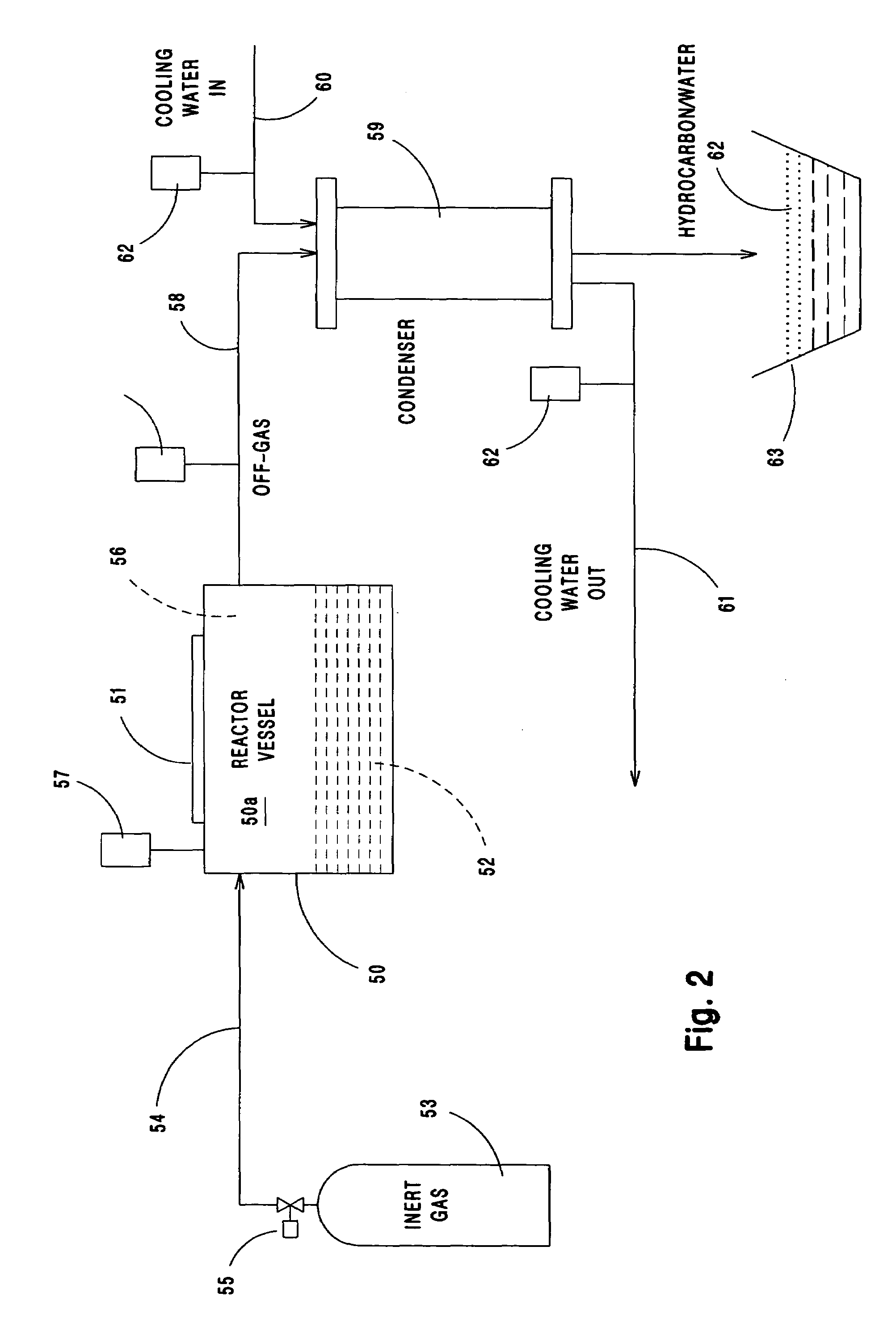

Process for de-oiling steelmaking sludges and wastewater streams

InactiveUS20060130611A1Impact processDrying using combination processesBlast furnace componentsSteelmakingSludge

The present invention is directed to a process for treating an oily mixture consisting of hydrocarbons, solid particles, and water. The steps of the process include placing the oily mixture into a reactor chamber, purging the reactor chamber with an inert gas, and creating a steam bath within the inert gas filled reactor chamber, the steam surge freeing hydrocarbon matter from the solid particles. The process further includes elevating reactor chamber temperature to a boiling point temperature corresponding to the hydrocarbons in the oily mixture, the elevated temperature vaporizing the hydrocarbons are vaporized within inert atmosphere. The reaction chamber is vented and the off-gas is processed into a hydrocarbon product while the de-oiled solid particles are discharged from the reaction chamber as a raw material or for disposal.

Owner:RECOVERY TECH LP

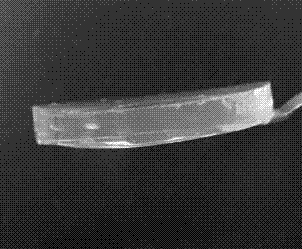

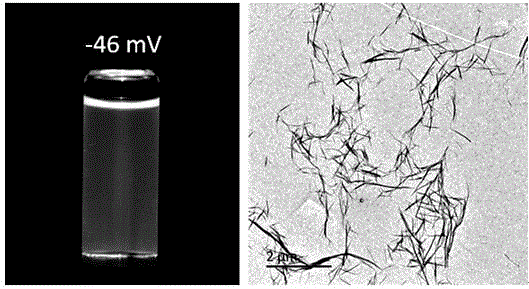

Preparation method of cellulose nanofiber biomass gel and aerogel

The invention relates to a preparation method of cellulose nanofiber biomass gel and airgel, comprising the following steps: (1) treating cellulose with a TEMPO / NaBr / NaClO oxidation system to prepare oxidized cellulose; (2) Mechanically treat oxidized cellulose in an aqueous solution or weakly alkaline aqueous solution to obtain a cellulose nanofiber dispersion; (3) process the cellulose nanofiber dispersion through an acidic coagulation bath or an acidic steam bath to obtain a raw cellulose nanofiber. (4) drying and dehydrating the cellulose nanofiber biomass gel to prepare the cellulose nanofiber biomass aerogel. The preparation method of a cellulose nanofiber biomass gel of the present invention is simple and easy to control, low in cost, and environmentally friendly, and can prepare biomass gels and aerogels with good shape, high strength, and low fiber content. Biocompatible, non-toxic and harmless; the prepared biomass gel and aerogel with negative electrical properties have better reactivity and biological activity.

Owner:HEYE HEALTH TECH CO LTD +1

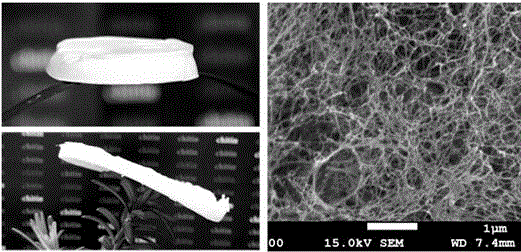

Preparation method of electronegative chitin nanofiber hydrogel and aerogel

The invention discloses a preparation method of electronegative chitin nanofiber hydrogel. The preparation method comprises the steps that 1, a chitin raw material is taken to be pretreated, and chitin slurry is obtained; 2, the chitin slurry obtained in the step 1 is treated through a 2,2,6,6-tetramethyl piperidine-nitrogen-oxide catalyst oxidization system to obtain TEMPO-oxidized electronegative chitin; 3, the electronegative chitin obtained in the step 2 is mechanically treated in a weakly-alkaline aqueous solution or water to prepare an electronegative chitin nanofiber dispersing solution; 4, the electronegative chitin nanofiber dispersing solution obtained in the step 3 is treated through an acidic coagulation bath or an acidic steam bath to prepare the physically-crosslinked electronegative chitin nanofiber hydrogel. According to the preparation method of the electronegative chitin nanofiber hydrogel and aerogel, the method is simple and high in operability, and hydrogel preparation can be achieved at low cost; chitin nanofiber hydrogel and aerogel materials prepared through the method have the advantages of being good in form, low in concentration and high in strength.

Owner:NANJING FORESTRY UNIV

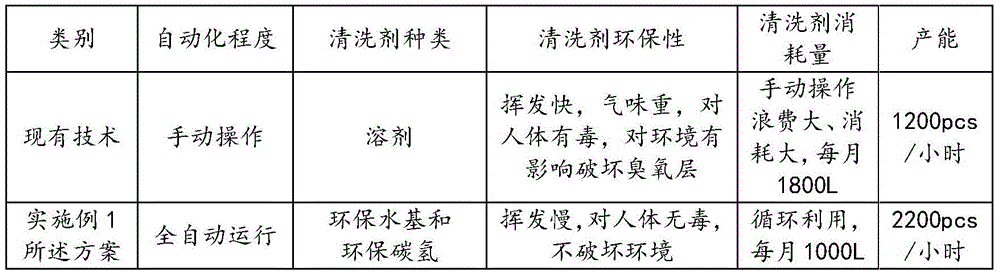

High-gloss fine-cleaning combined cleaning technology

ActiveCN105543860AReduce defective rateReduce the impactCleaning using liquidsWater basedEnvironmental effect

The invention belongs to the field of cleaning of chemical engineering and particularly relates to a high-gloss fine-cleaning combined cleaning technology. The technology comprises the following steps in sequence: water-based cleaning, vacuum water draining, vacuum ultrasonic hydrocarbon cleaning and steam-bath vacuum drying. Through the combined cleaning technology, the defective rate of white dot and white fog is reduced to about 3%, and the stable quality is guaranteed; vacuum cleaning and environment-friendly cleaning agents are employed in all procedures to cause little influence on a human body and the environment; and the combined cleaning technology has a great market prospect and economic value.

Owner:SHENZHEN XINCHENGNUO ENVIRONMENTAL PROTECTION IND CO LTD

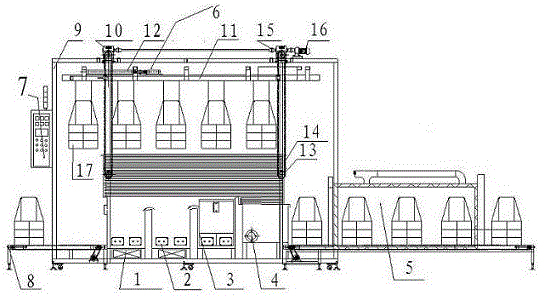

Full-automatic ultrasonic cleaning machine for nickel-based conductor materials

ActiveCN106111618ANot volatileNo wasteDrying gas arrangementsDrying machines with progressive movementsCleansing AgentsContamination

A full-automatic ultrasonic cleaning machine for nickel-based conductor materials is of a closed structure and comprises first ultrasonic rough cleaning tanks, second ultrasonic cleaning tanks, a heat soaking rinse tank, a steam bath wash tank, a hot air internal circulation tunnel type drying box, an automatic portal lifting and travelling mechanism and an electrical control system. According to the full-automatic ultrasonic cleaning machine for the nickel-based conductor materials, automatic all-round cleaning can be conducted, a net bag containing nickel pieces does not need to be rolled over manually, and cleaning can be conducted in place. Besides automatic cleaning, an automatic drying function can also be achieved, original manual airing is omitted, and the nickel pieces are prevented from secondary contamination. Further, an active carbon adsorption device is arranged at an air outlet of the cleaning machine, residual volatile cleaning agents brought out during drying can be effectively adsorbed, and the cleaning agent is prevented from contaminating the air.

Owner:JIANGSU K TECH PRECISION TECH +1

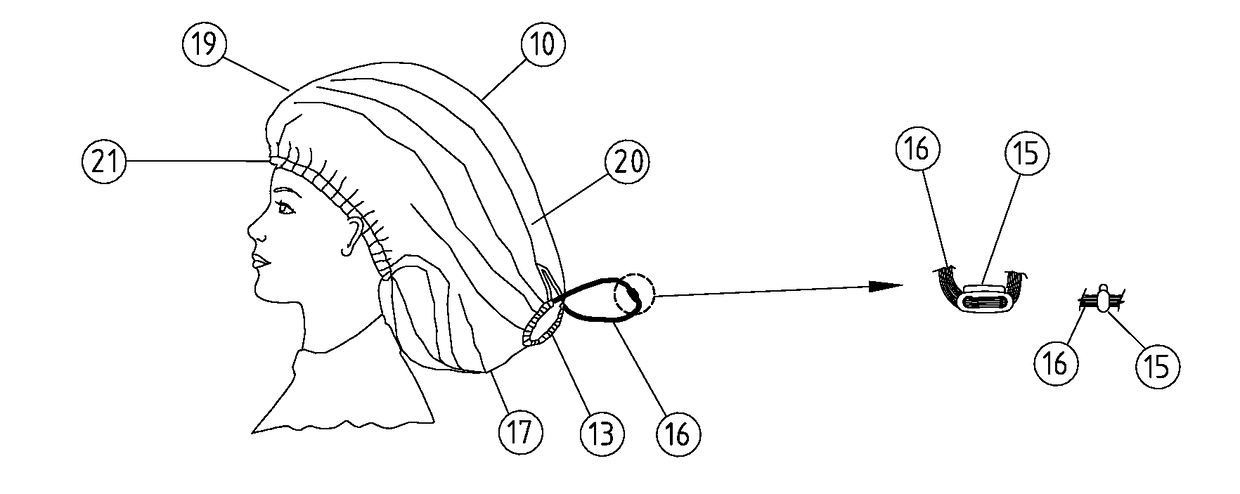

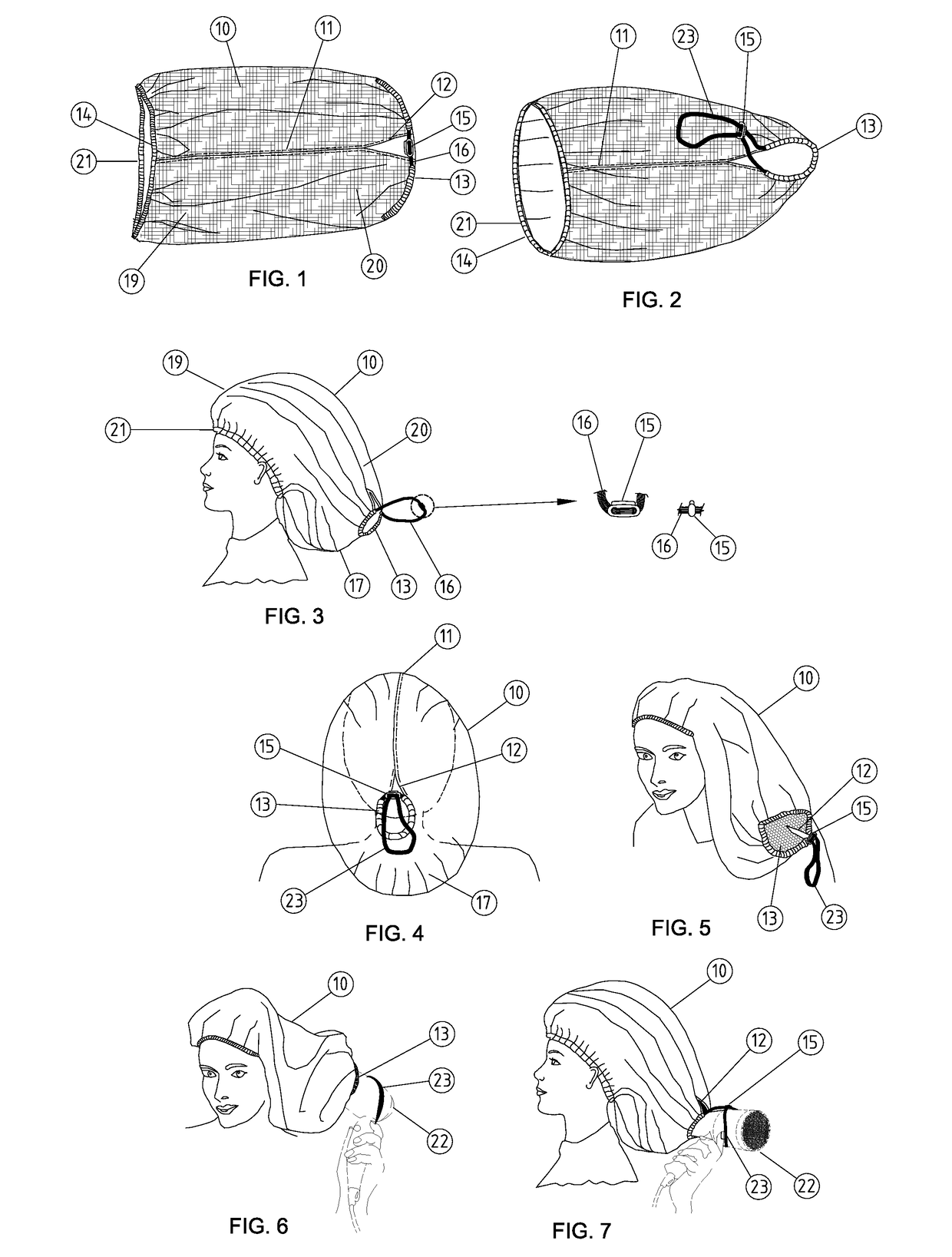

Hair drying net and turban towel

The multi-functional hair drying net and turban towel for upright application may be used on its own or so combination with a hand held hair dryer. Useful for managing dry and wet hair, to absorb water from wet hair after washing, swimming, or anytime the hair is wet, thereby avoiding dripping of water on the face, neck, or clothes. Used over dry hair to keep hair off the face, back and neck when applying make-up and treatments to the face. When required to dry hair by electrical means the device can be connected to a commercially available hair dryer and used as a conduit to direct warm air into the net cavity and dry hair using electrical means. It can be used to keep hair dry and off the face and back in the bath, shower, Jacuzzi spa or steam bath.

Owner:WALKER AURORA +1

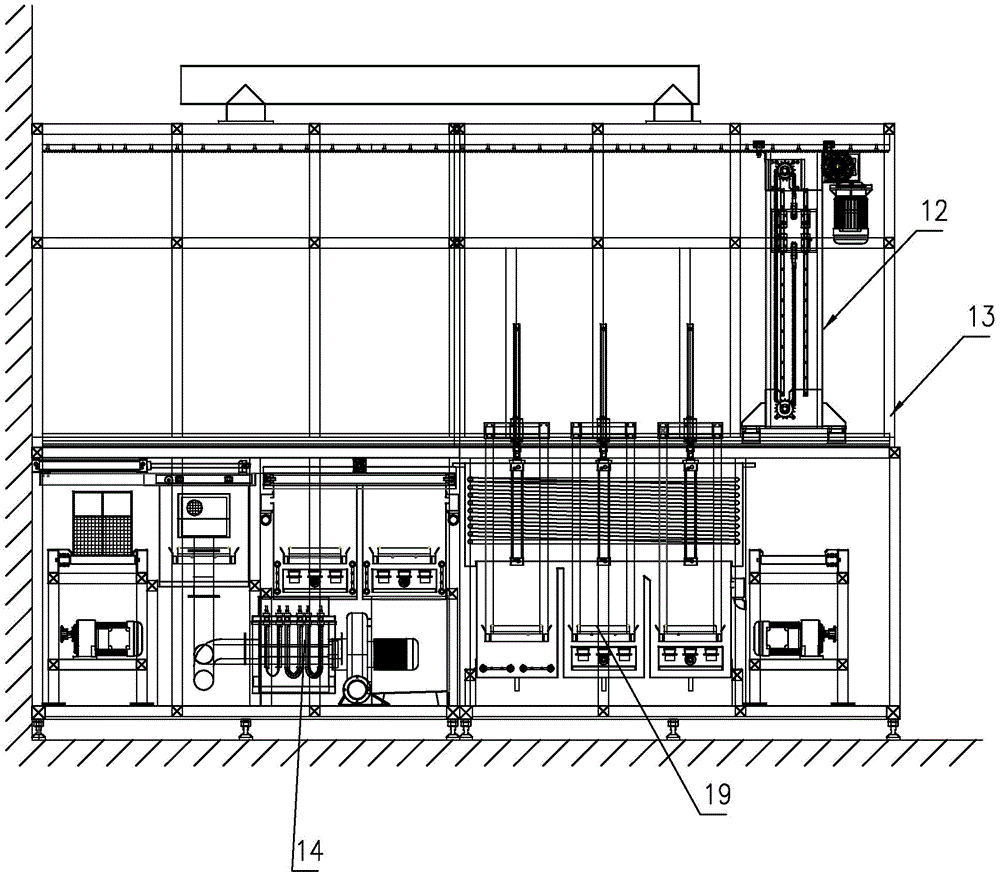

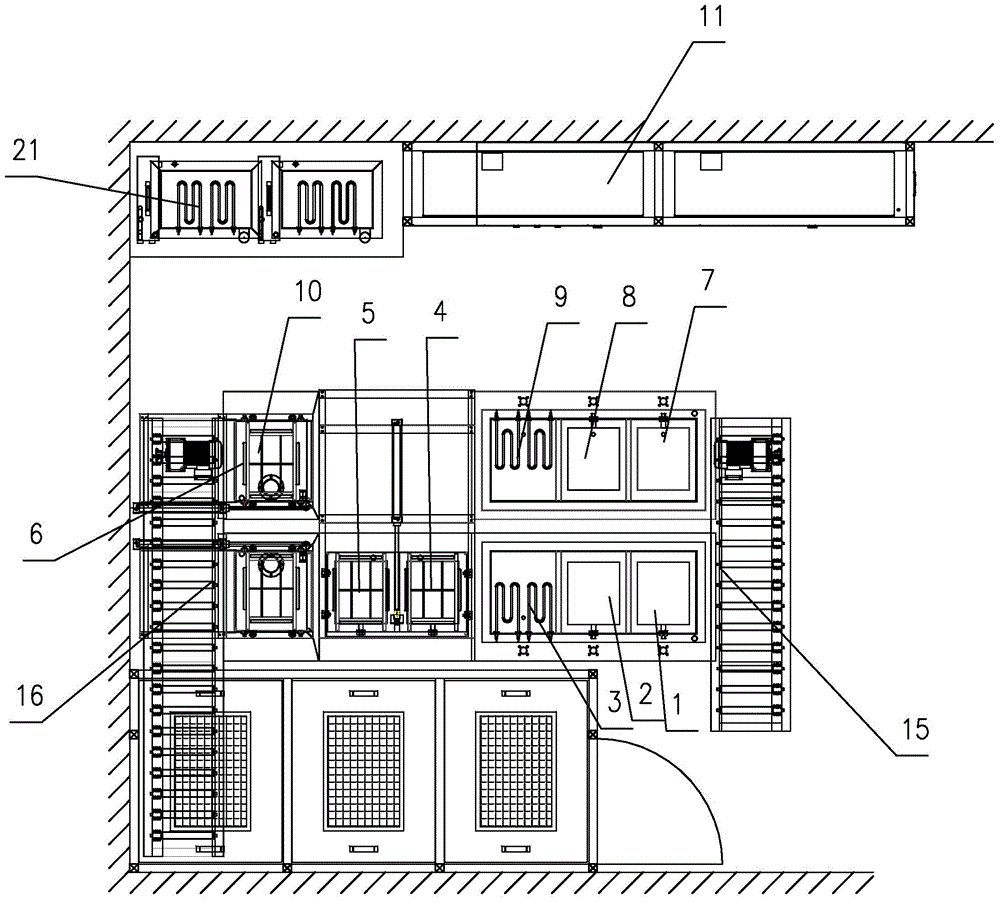

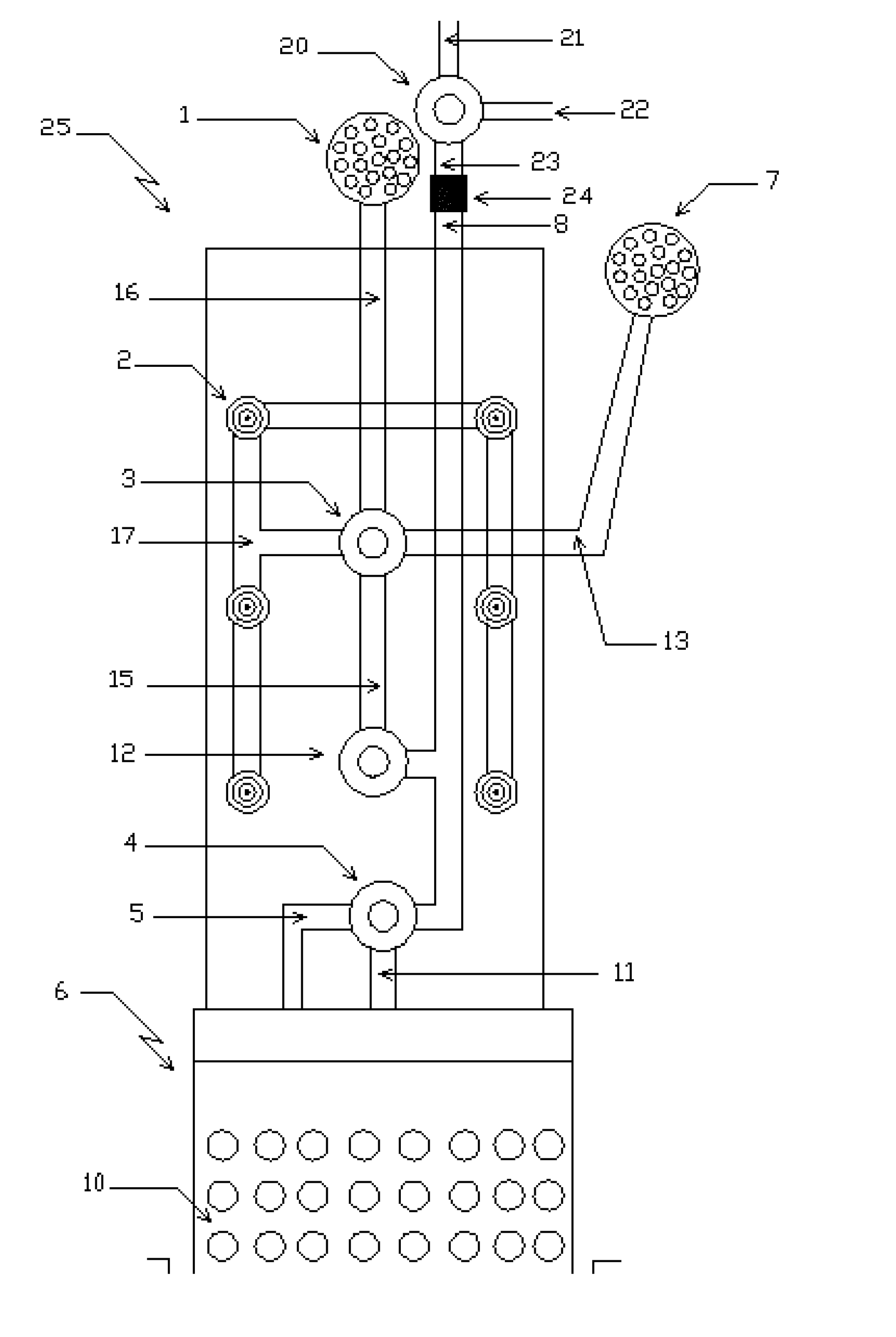

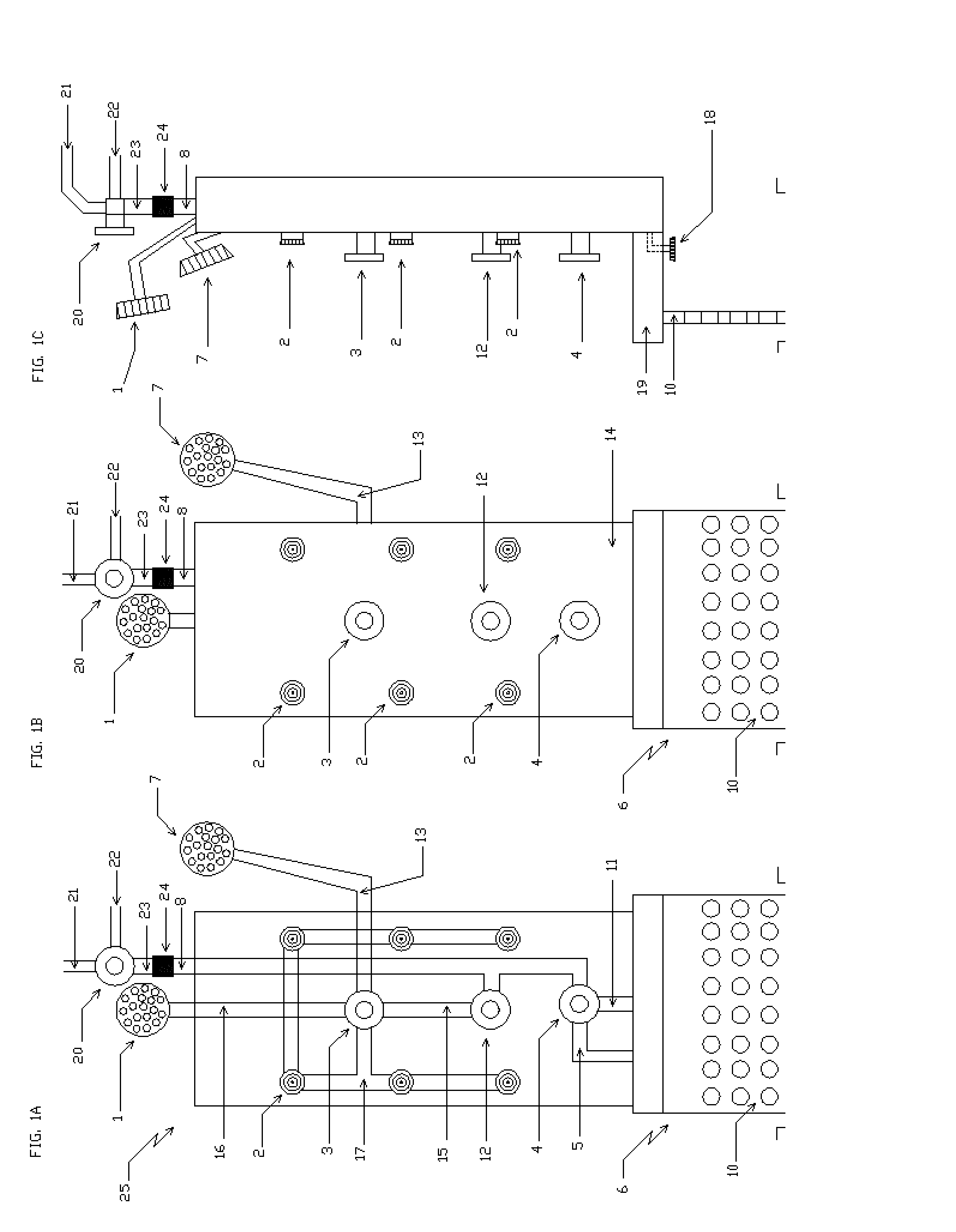

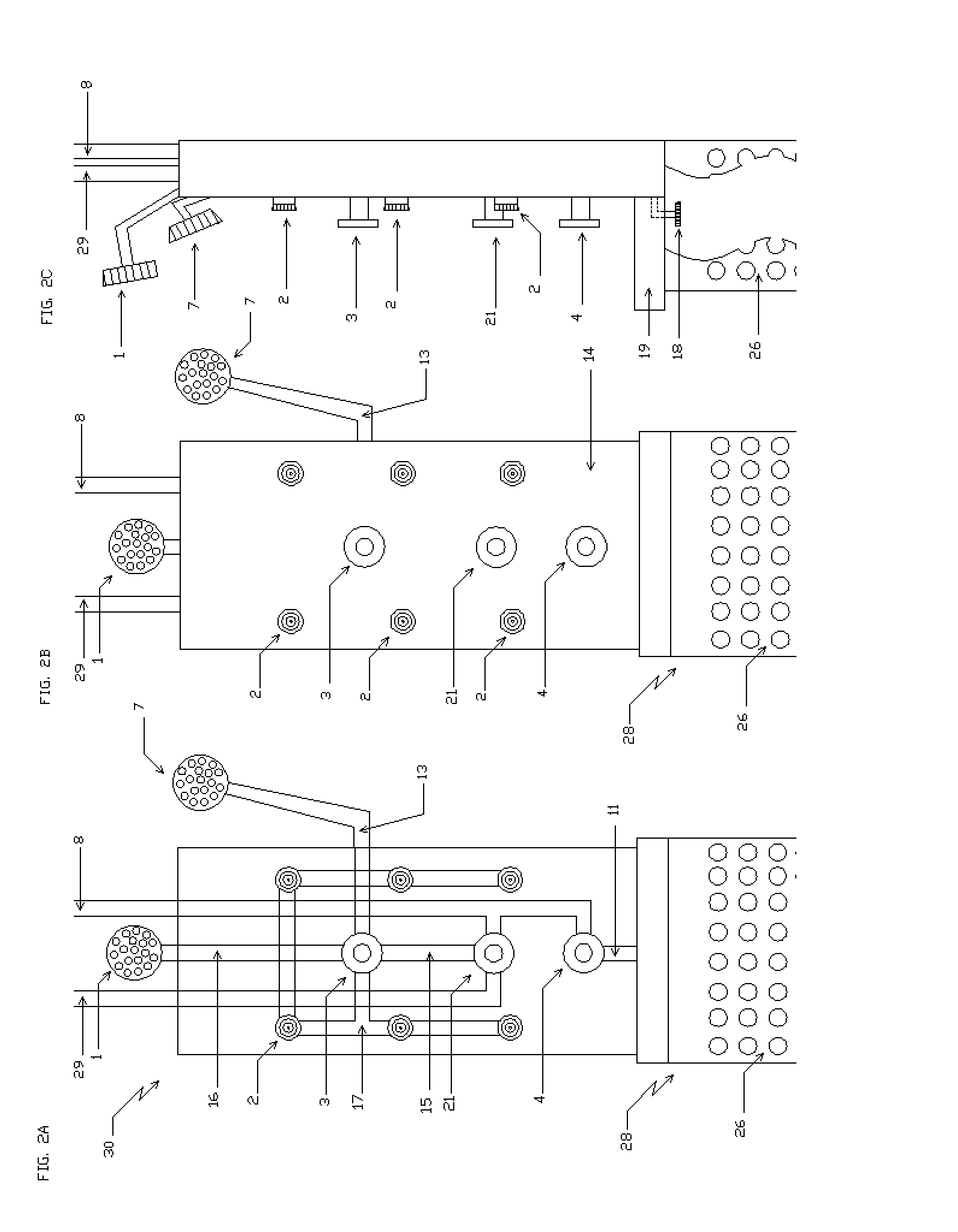

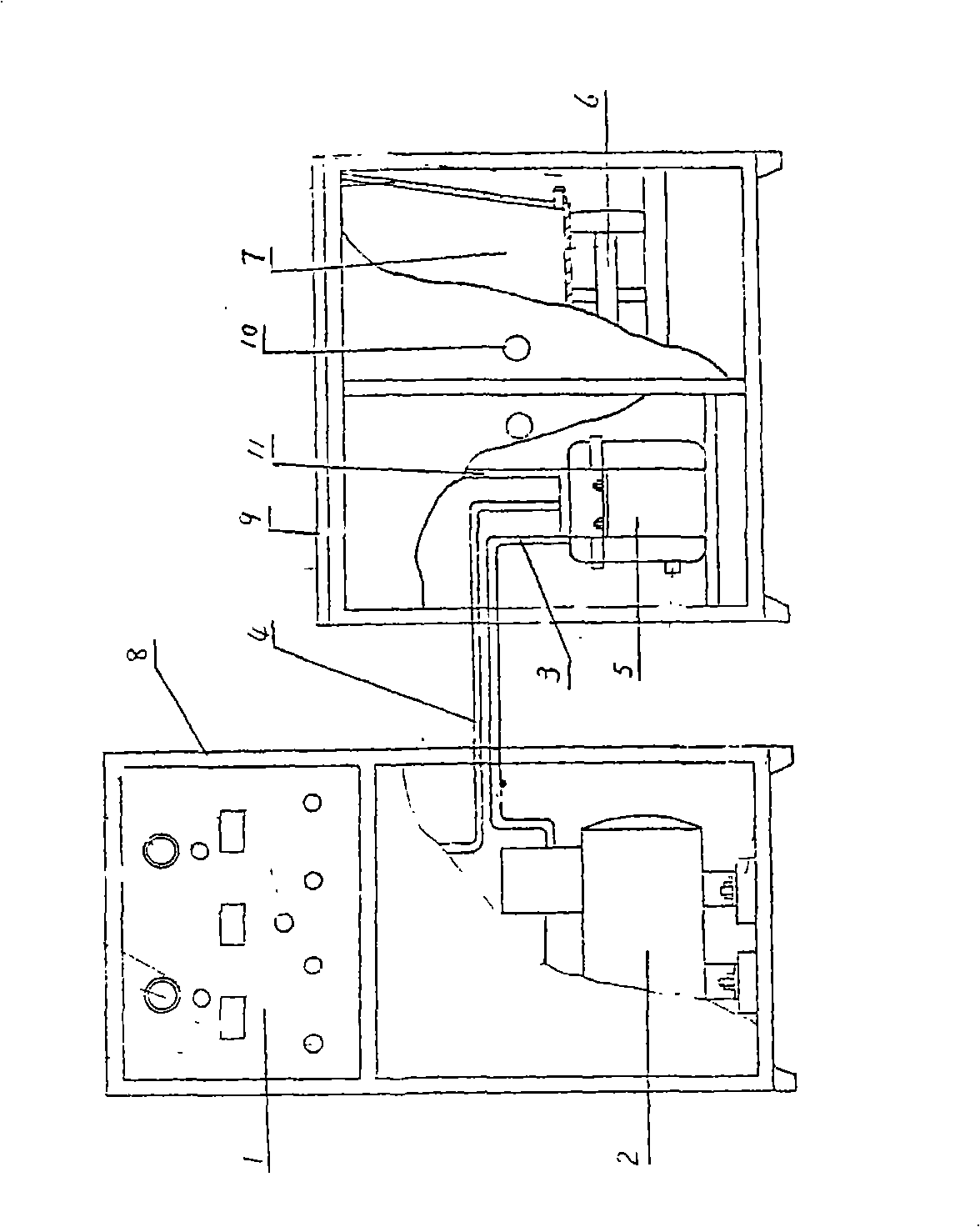

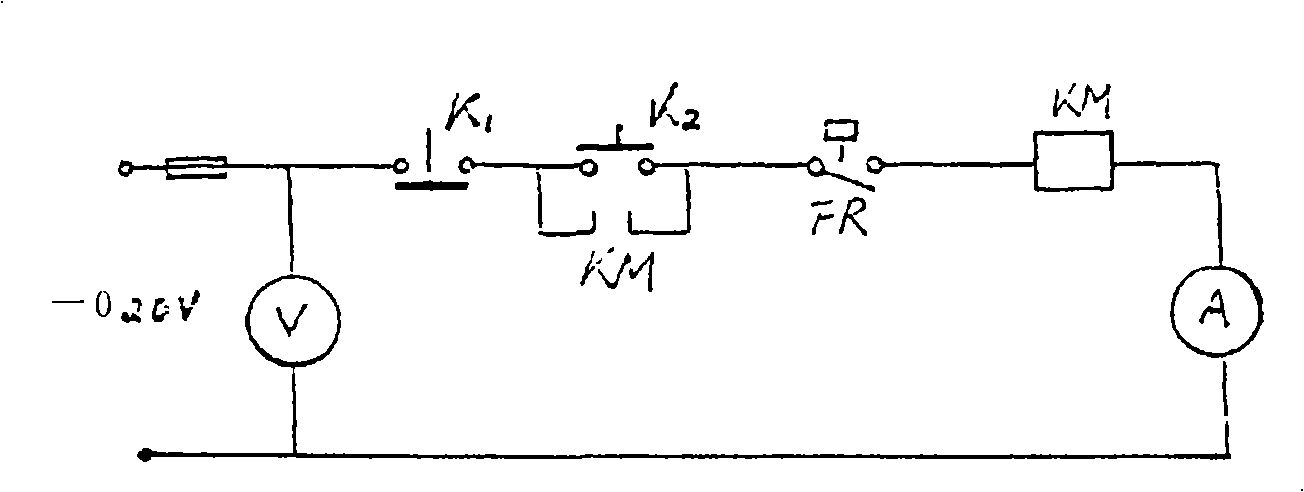

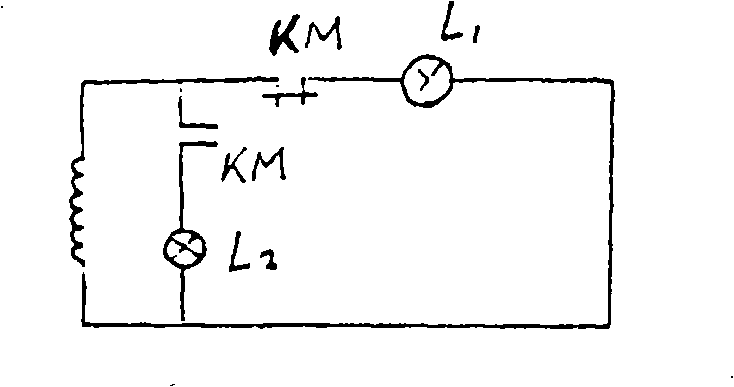

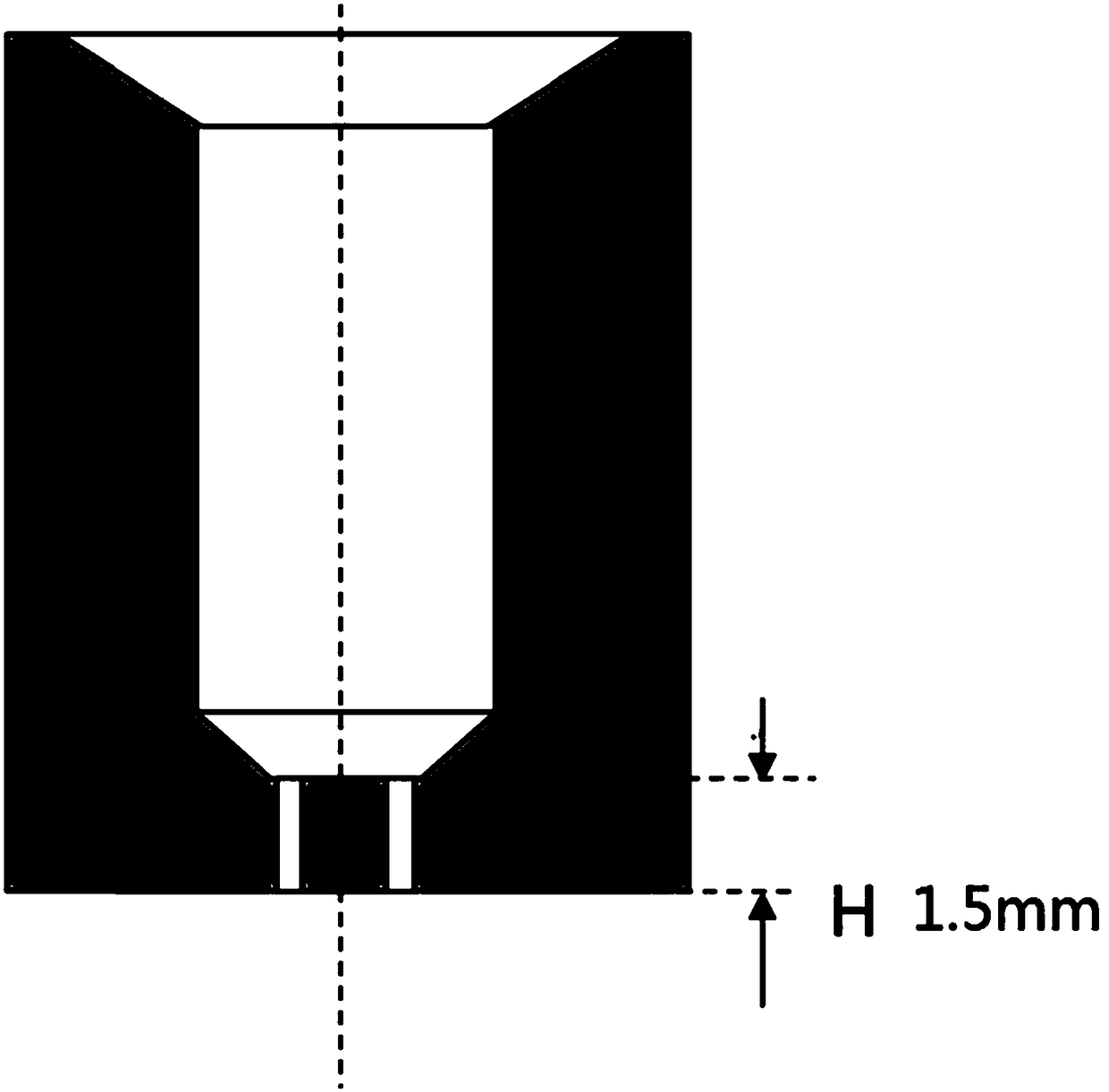

Ultrasonic steam bath cleaning machine for plane oxygen system accessories

ActiveCN105107788AImprove cleanlinessHigh degree of automationDrying solid materials with heatCleaning using liquidsOxygen systemElectrical control

The invention discloses an ultrasonic steam bath cleaning machine for plane oxygen system accessories. The ultrasonic steam bath cleaning machine comprises an electrical control device, a conveying mechanism , a cleaning system and a hot-air drying system, wherein the cleaning system and the hot-air drying system are arranged in the same sealed housing; an openable and closeable feed opening and an openable and closeable discharging opening are formed in the housing; the cleaning system comprises ultrasonic crude cleaning tanks, ultrasonic fine cleaning tanks and steam-bath cleaning tanks which are sequentially arranged from front to back; the feed opening is close to the ultrasonic crude cleaning tank; the hot-air drying system is positioned behind the cleaning system; the discharging opening is close to the hot-air drying system; the conveying mechanism comprises a track arranged above the cleaning system and the hot-air drying system, a mechanical hand arranged on the track and a driving mechanism used for driving the mechanical hand to move transversely and vertically; and the electrical control device is used for controlling a cleaning basket to enter from the feed opening, then controlling the cleaning basket to be grasped and fed into all cleaning tanks sequentially by the mechanical hand, cleaned in the cleaning tanks, and subjected to hot-air drying by the hot-air drying system and finally controlling the cleaning basket to be discharged from the discharging opening. The ultrasonic steam bath cleaning machine is good in cleaning effect and can ensure that the cleanliness of cleaned workpieces meets requirements.

Owner:GUANGZHOU AIRCRAFT MAINTENANCE ENG

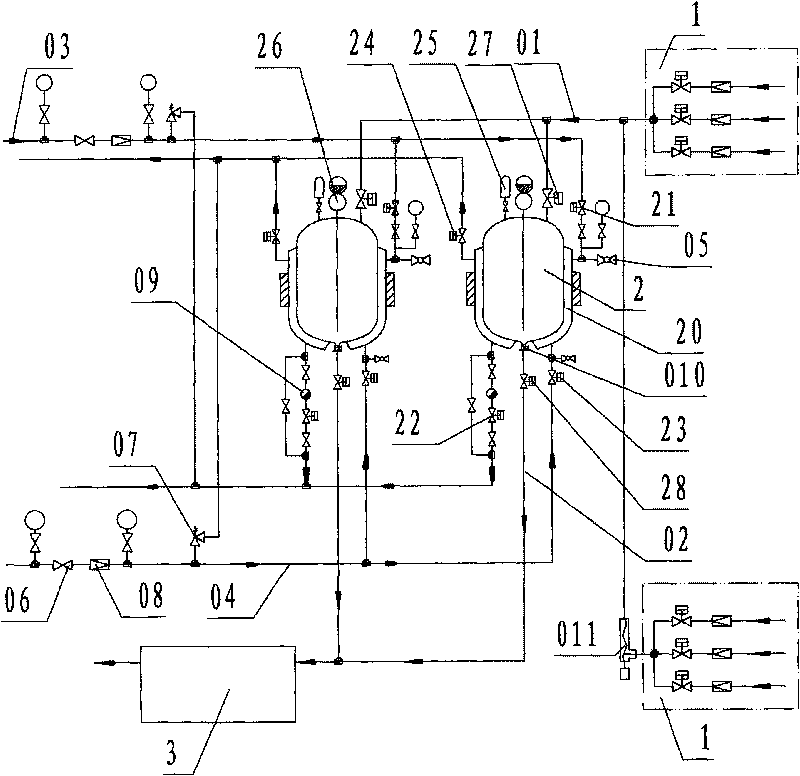

Pathogenic microorganism waste liquor treatment system

InactiveCN101691247ATimely processingThe overall collection and processing of the processing station is timelyWater/sewage treatment by heatingLiquid wastePathogenic microorganism

The invention discloses a pathogenic microorganism waste liquor treatment system, which comprises a waste liquor collecting pipeline system (1), a waste liquor sterilizing tank (2) and a sewage treatment station (3). The invention adopts a technical scheme that waste liquor is integrally collected and treated through the waste liquor collecting pipeline system, the high-temperature steam bath waste liquor sterilizing tank and the sewage treatment station special for the waste liquor so as to overcome the defects that the liquor collecting vehicle and liquor collecting bucket mode in the prior art has low waste liquor treatment capacity, occupation of on-site space of a clean area for transit storage, indefinite sterilization effect and easy chemical pollution to environment. The pathogenic microorganism waste liquor treatment system provided by the invention directly conveys the waste liquor generated by various viable bacteria and live virus areas of buildings to the waste liquor sterilizing tank for high-temperature steam sterilization, and then conveys the waste liquor to the common sewage treatment station for physicochemical treatment through a pipeline so as to achieve the aims of timely, massively, highly efficiently and reliably treating the pathogenic microorganism waste liquor with low cost, and reducing the chemical pollution.

Owner:NINGBO RONGAN BIOLOGICAL PHARMA

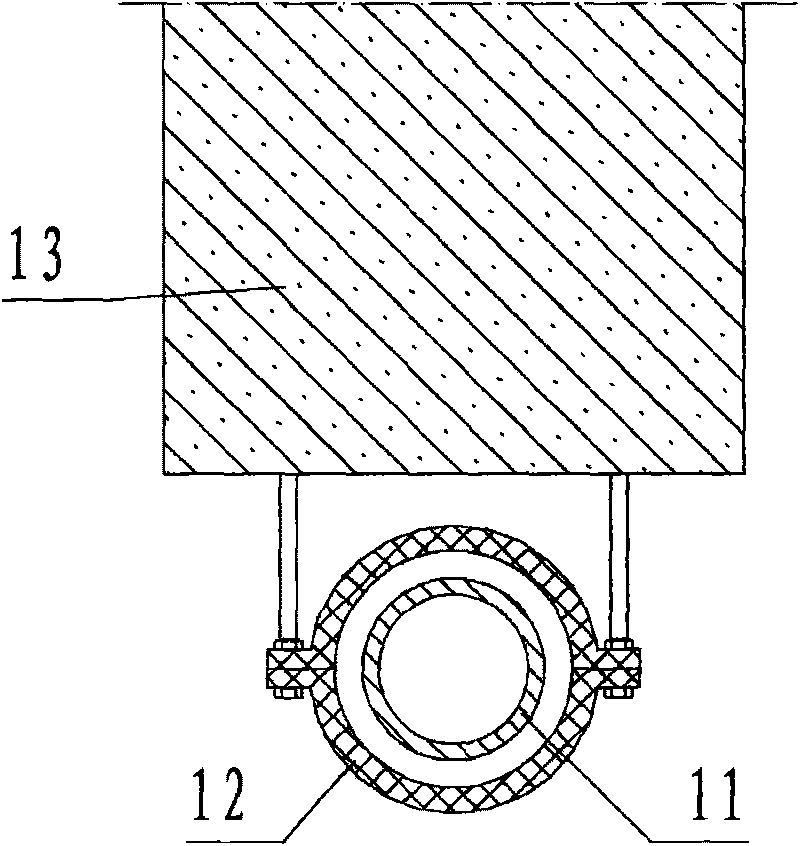

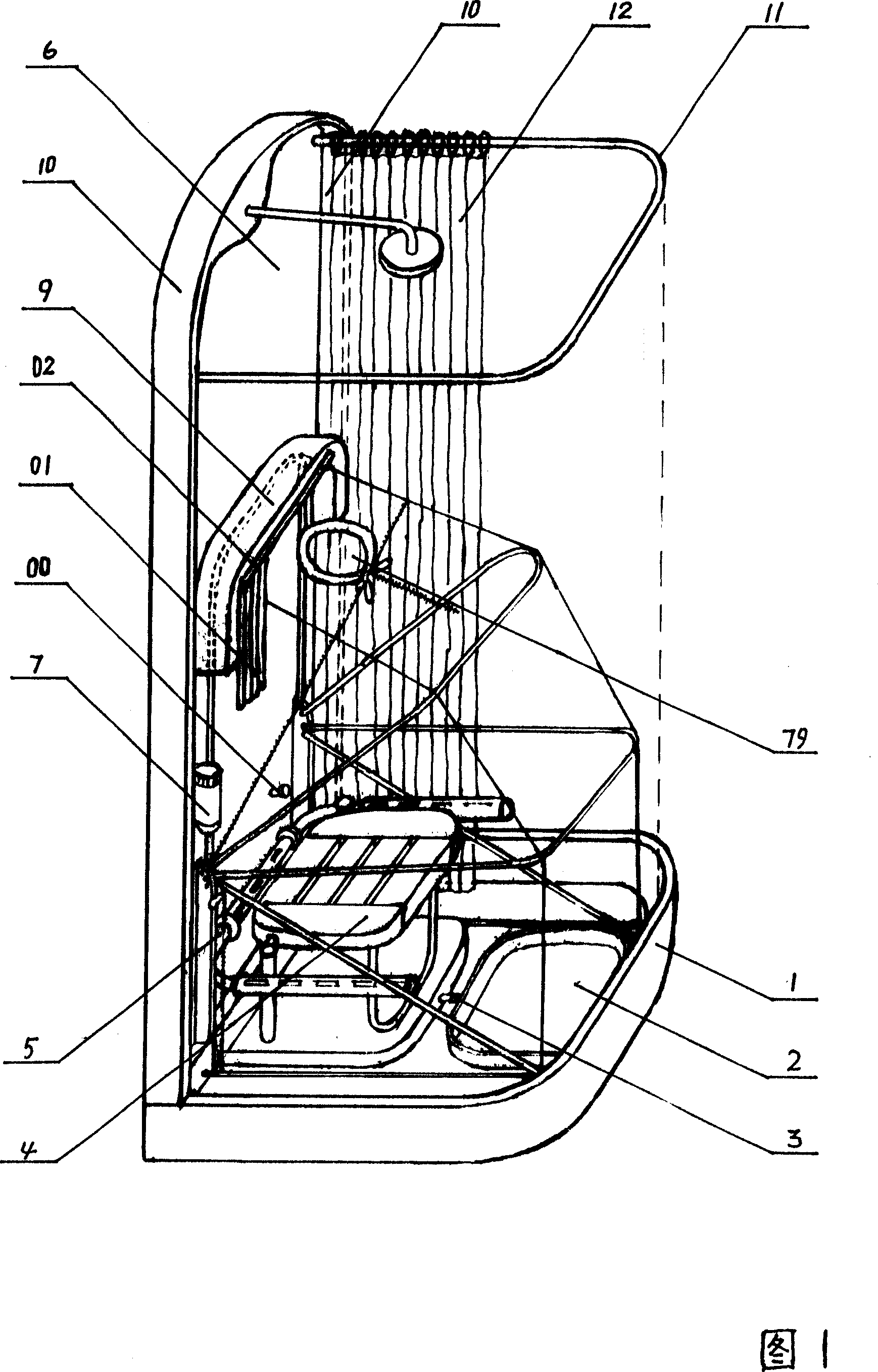

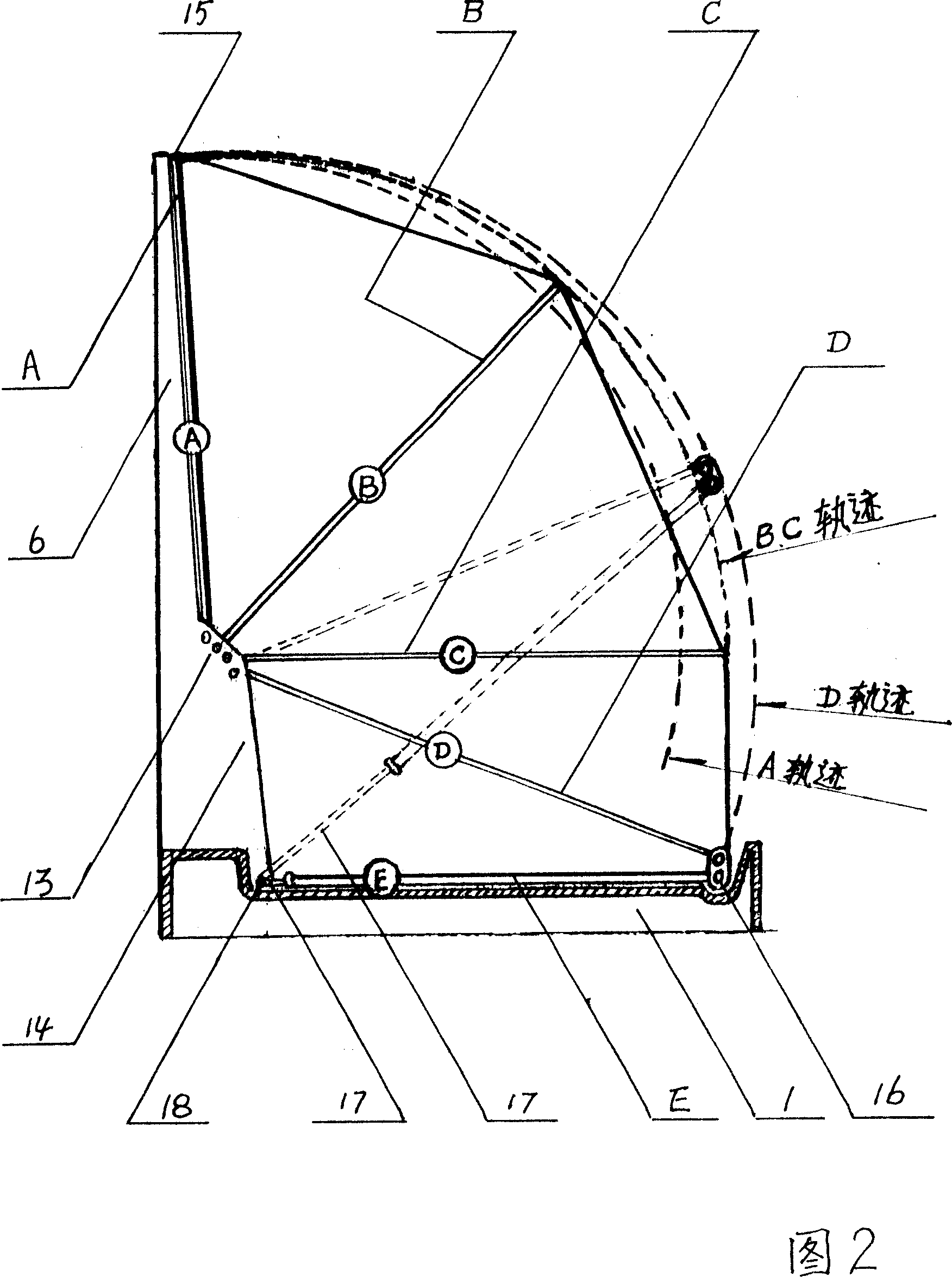

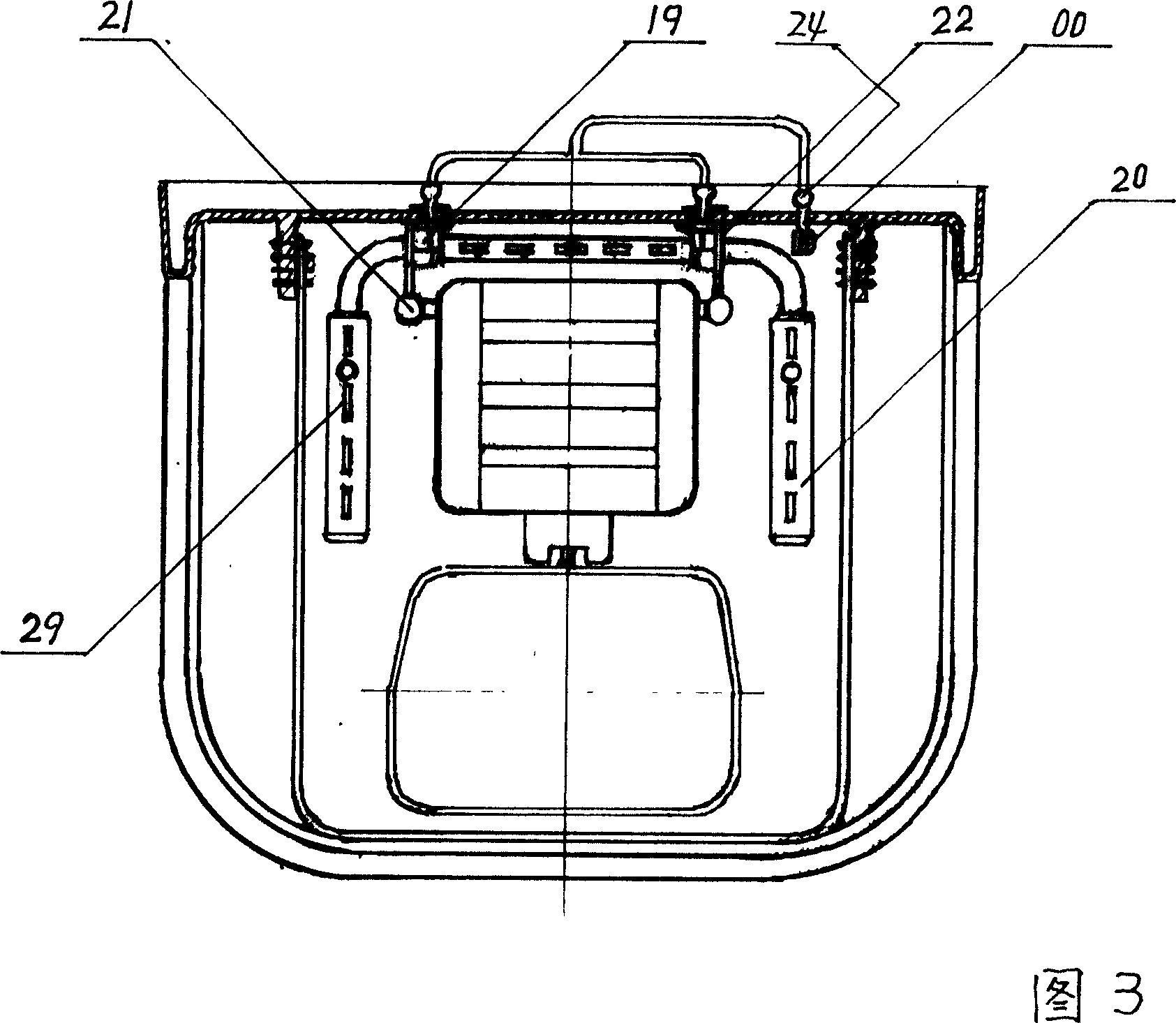

Wall hanging type steaming shower device

A back board of wall steaming shower fixed on the wall of architecture is presented and characterized by independent steaming and shower space according to different needs thereof. Membraneous shower space replacing the relative big space structure of whole steaming room, therefore meeting the needs of shower bigger space also not taking up space of toilet, further issue of moldy smell in the bath room being solved, within the bigger shower space setting up a smaller steam space thus becomes the best technical formula in applying steam bath.

Owner:宫本海

Precision tool cleaning process

InactiveCN107214130AAchieve the target effectReduce evaporationCleaning using liquidsEnvironmental resistanceWater based

The invention discloses a precision tool cleaning process, which comprises spray cleaning, ultrasonic water-based cleaning, vacuum water-draining cleaning, ultrasonic saponification cleaning, vacuum hydrocarbon cleaning, carrying out steam bath, and vacuum drying, wherein each cleaning step applies two or three of a water-based cleaning agent, a hydrocarbon water-draining agent and a hydrocarbon cleaning agent. The process comprises the concrete steps of precleaning through emulsification, penetration, cleaning and other functions of a surfactant; through displacement of the hydrocarbon water-draining agent, ultrasonic saponification and then water-draining, stripping the water-based cleaning agent and stains on the surface of a product; and then enhancing cleaning through the vacuum hydrocarbon cleaning agent so as to achieve the aim of thoroughly cleaning stains on the back face of the product. The new process provided by the invention takes the advantages of the three cleaning agents which act jointly to achieve a target effect, and each cleaning agent belongs to environment-friendly water-base and environment-friendly hydrocarbon, and is slow to volatilize, poisonless and harmless to a human body, and free of damaging the environment.

Owner:SHENZHEN XINCHENGNUO ENVIRONMENTAL PROTECTION IND CO LTD

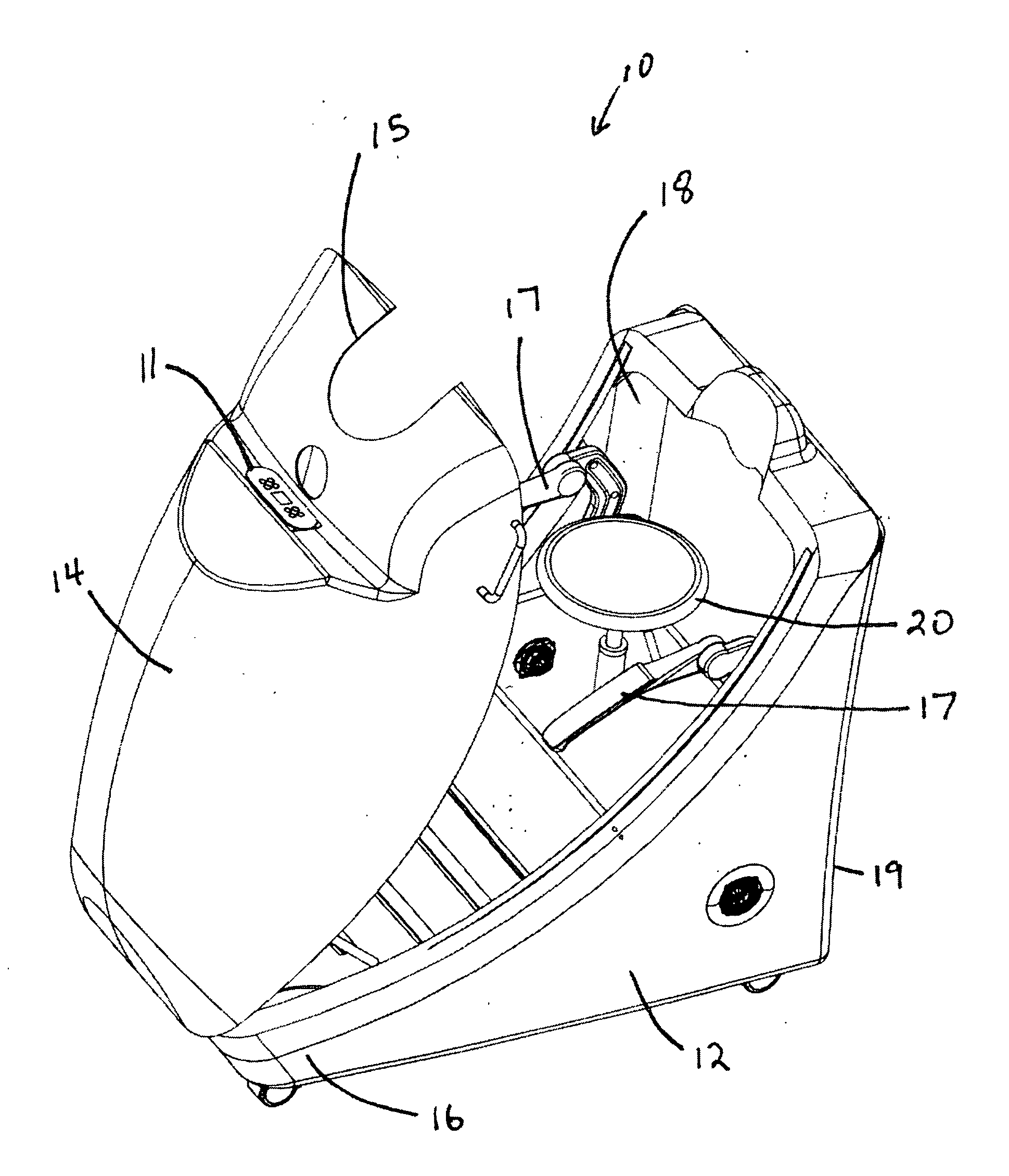

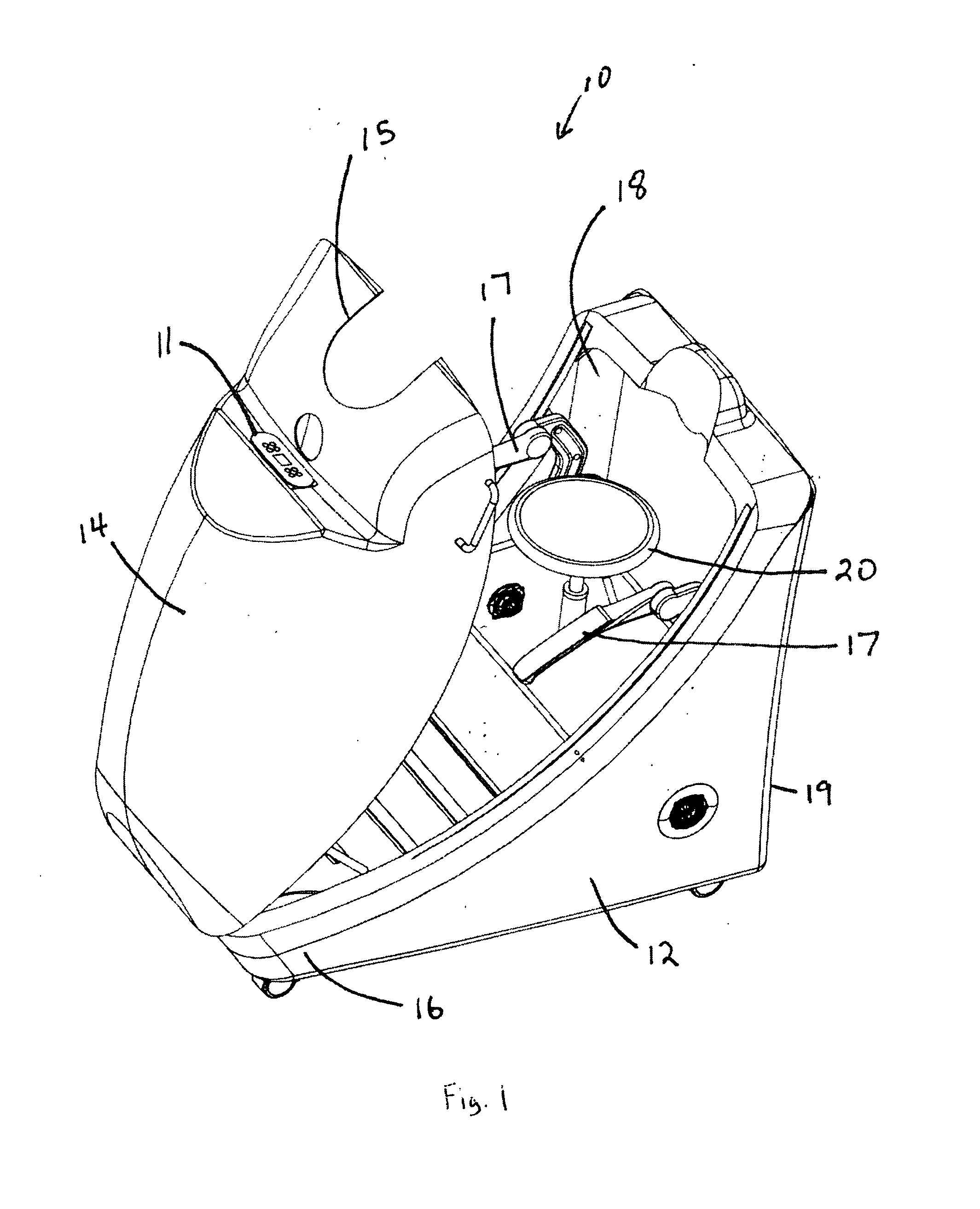

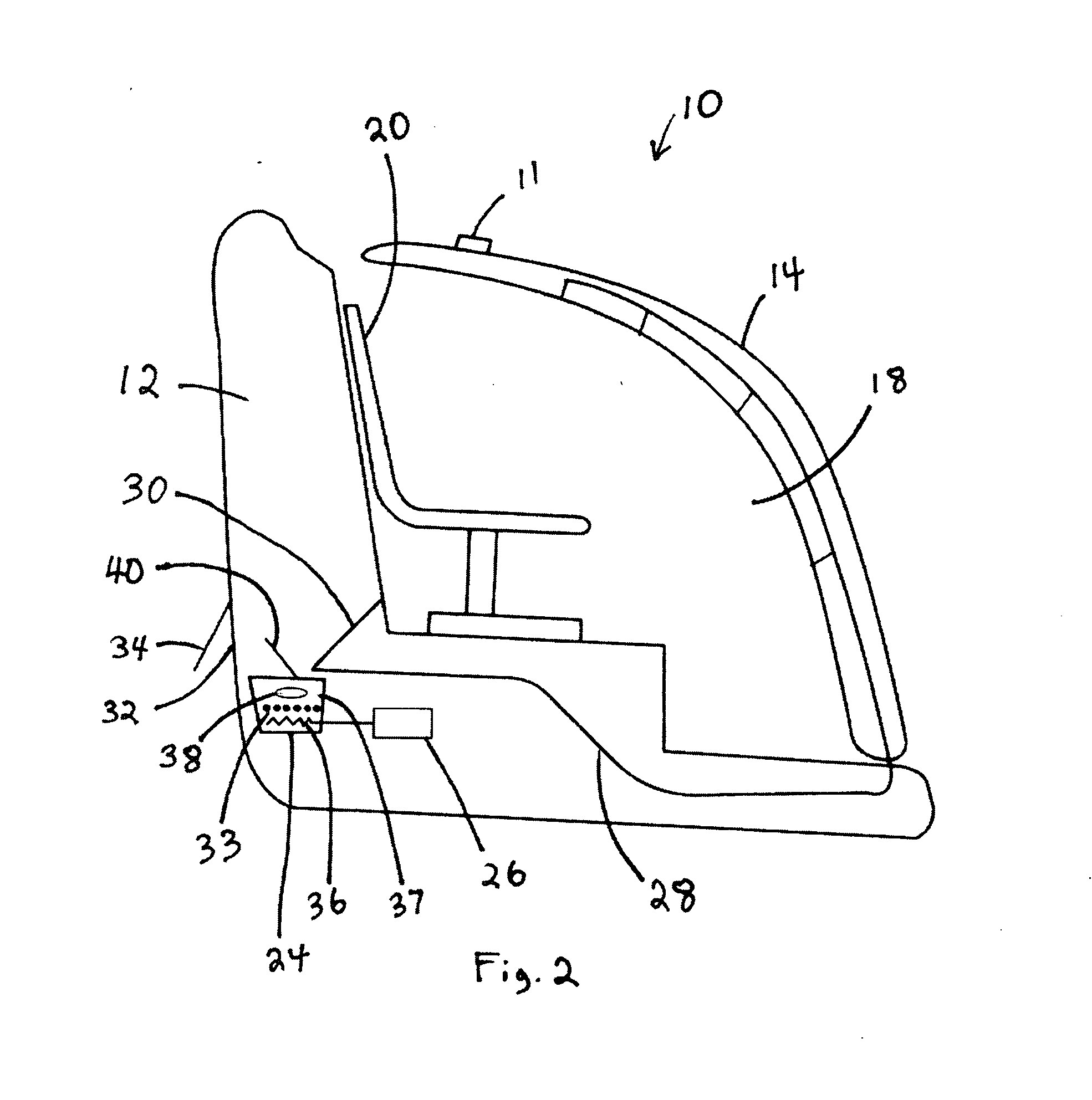

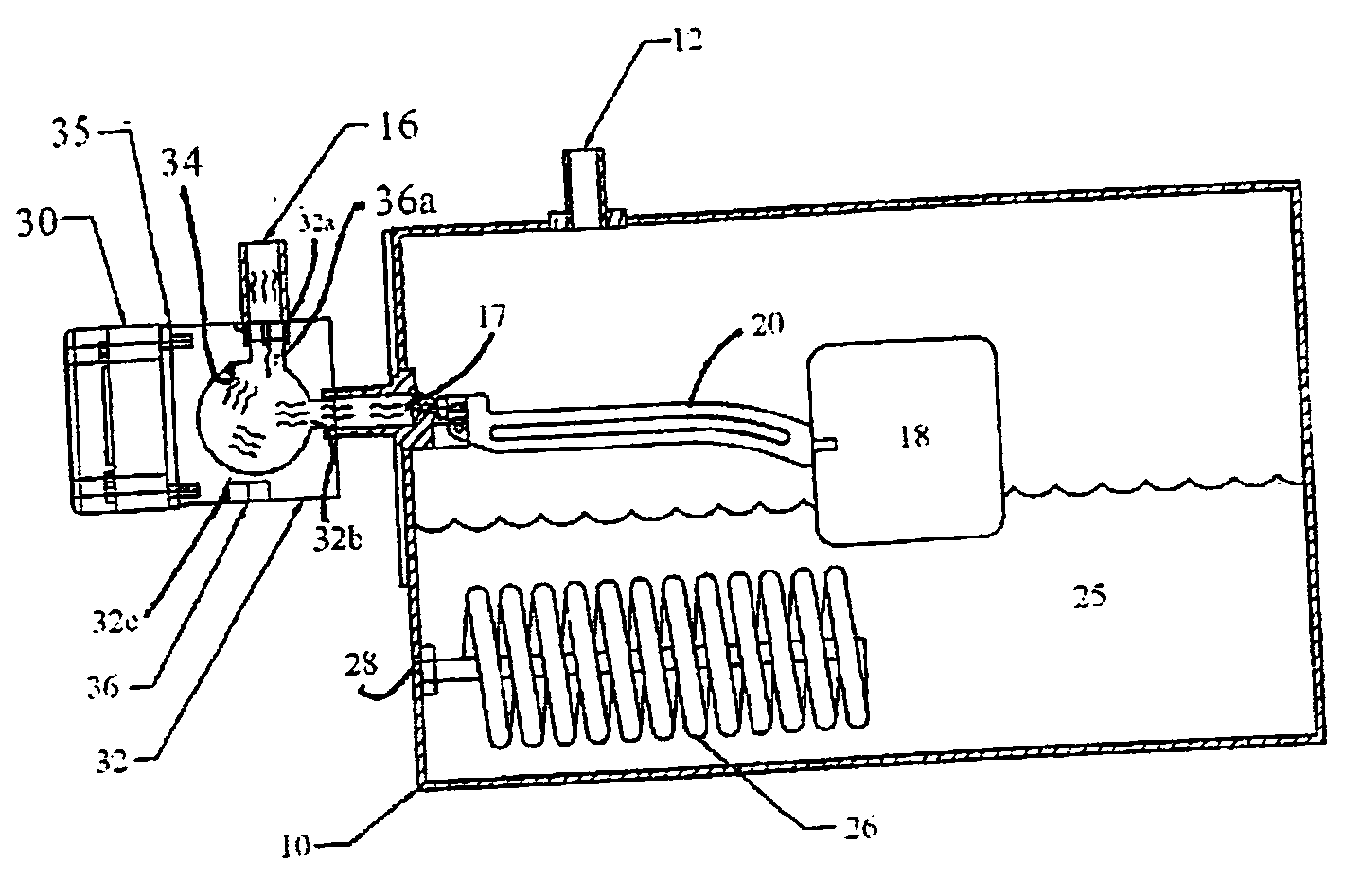

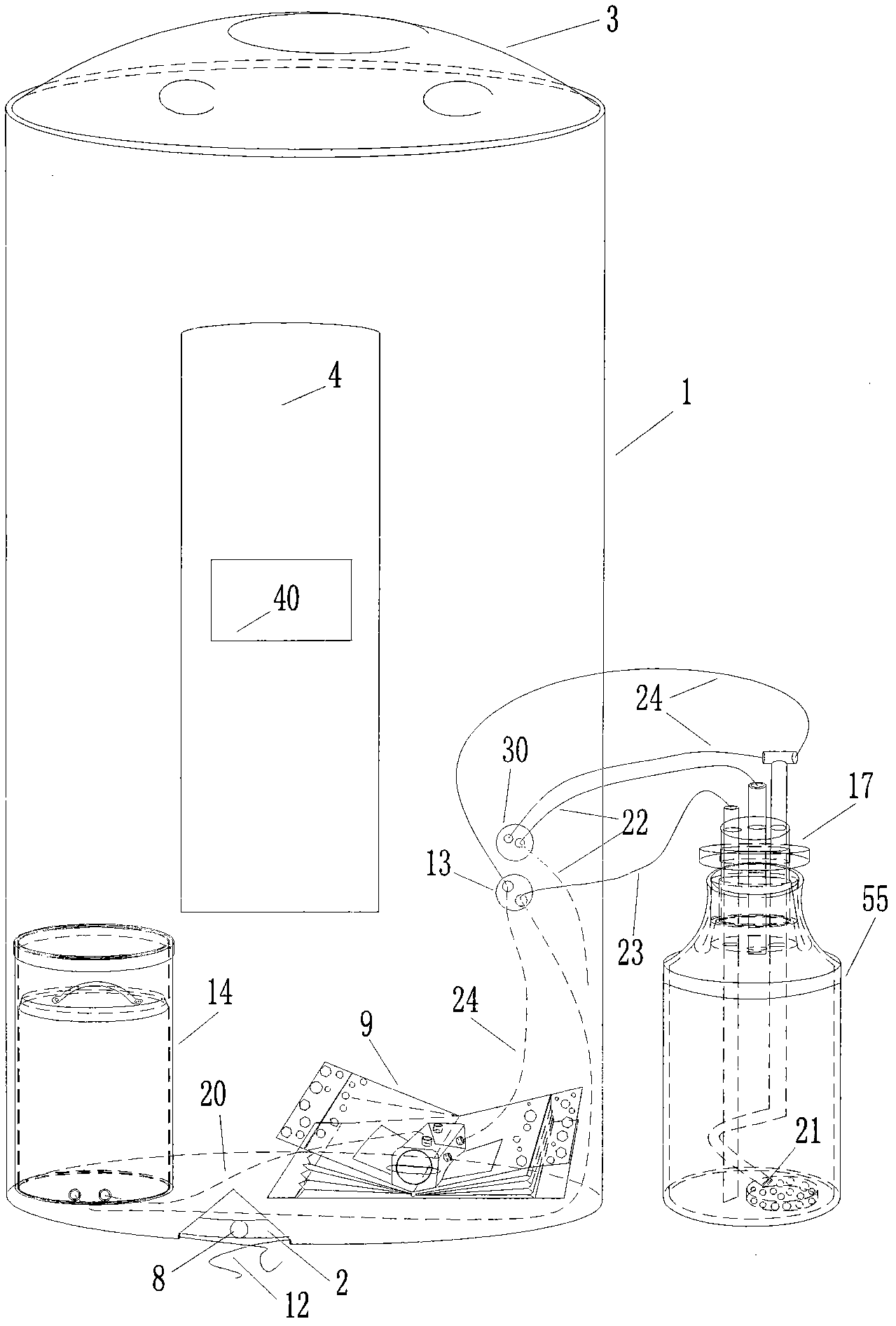

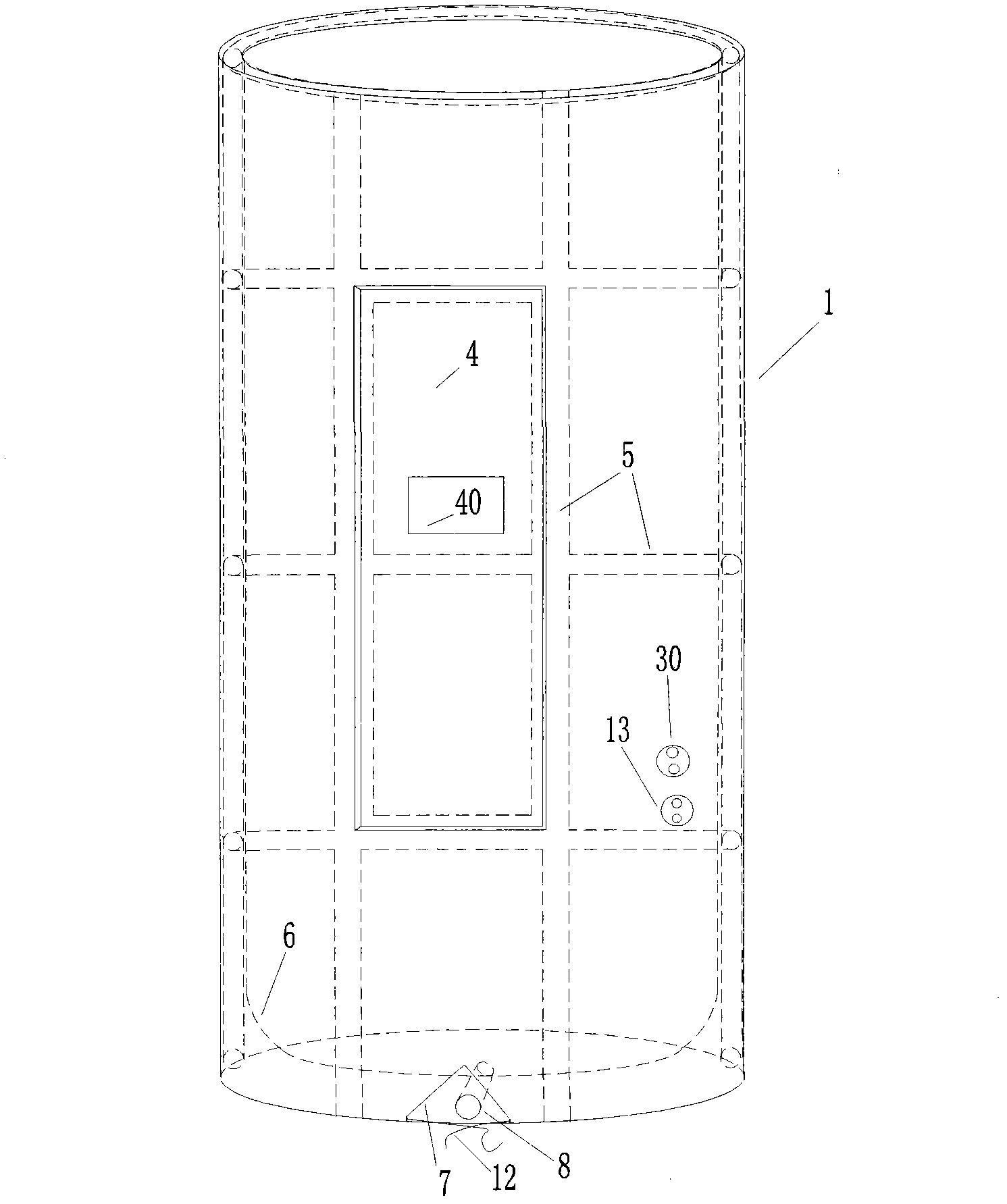

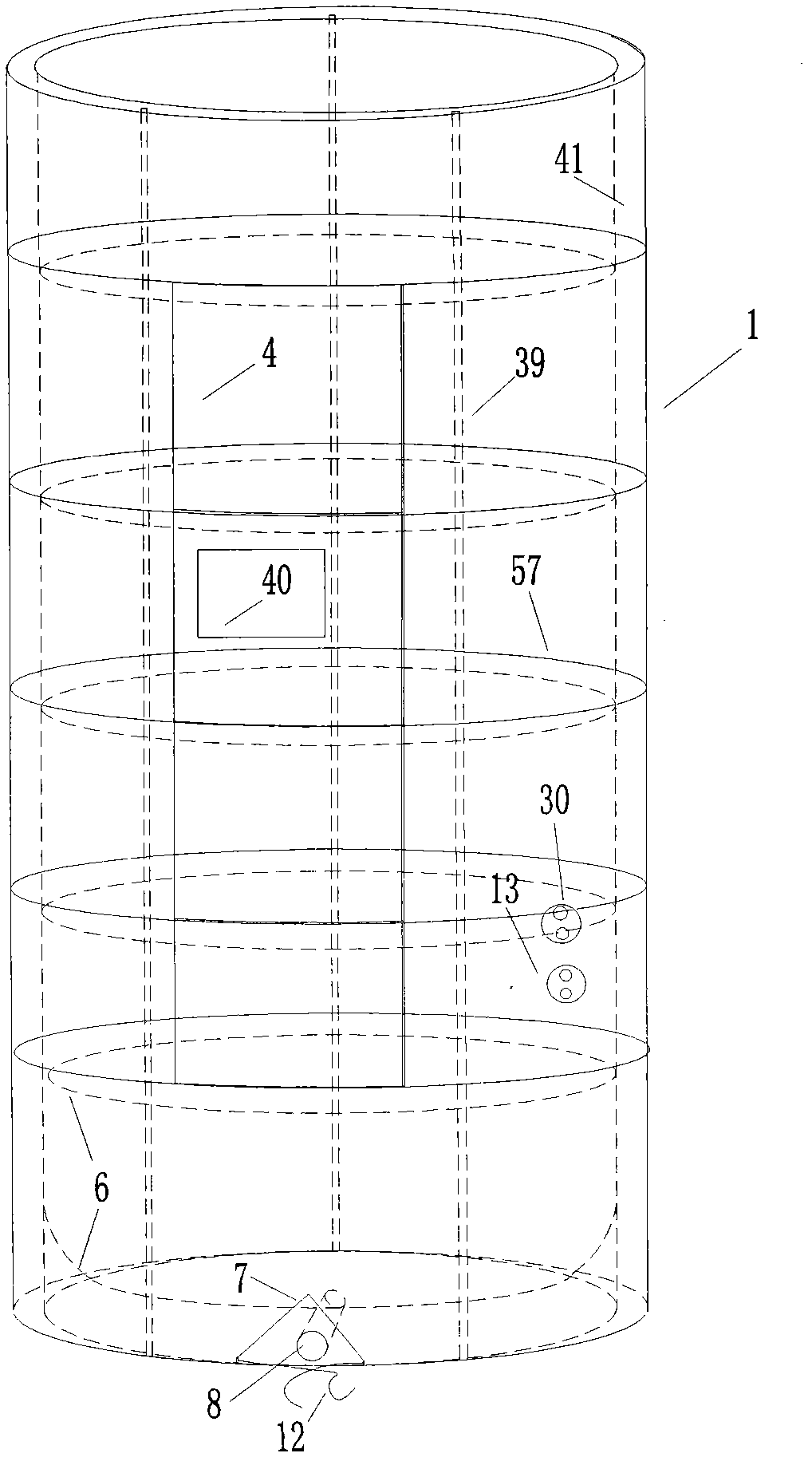

Medicated Steam Bath Cabin

An improved steam cabinet includes a housing having an interior configured to receive the person with a seat contained in the interior. The housing has a door through which the person can enter and exit the interior, the door having a head aperture dimensioned to permit the person's head to project outside of the interior while the user is seated inside the interior. A steam generator is contained in the housing and coupled to the interior. The steam generator includes a vessel having a vessel housing and a vessel interior, the vessel interior being divided into an infusion chamber and a heating chamber by a baffle. A heating element is contained in the heating chamber. The vessel has an opening communicating with the infusion chamber through which a packet containing the herbal therapeutic agent may be inserted into the infusion chamber. The steam generator includes a closure for closing off the opening and water supply conduits for supplying water to the steam generator. The cabinet also includes a control unit for controlling the operation of the heating element.

Owner:CHEN CHUN GUANG

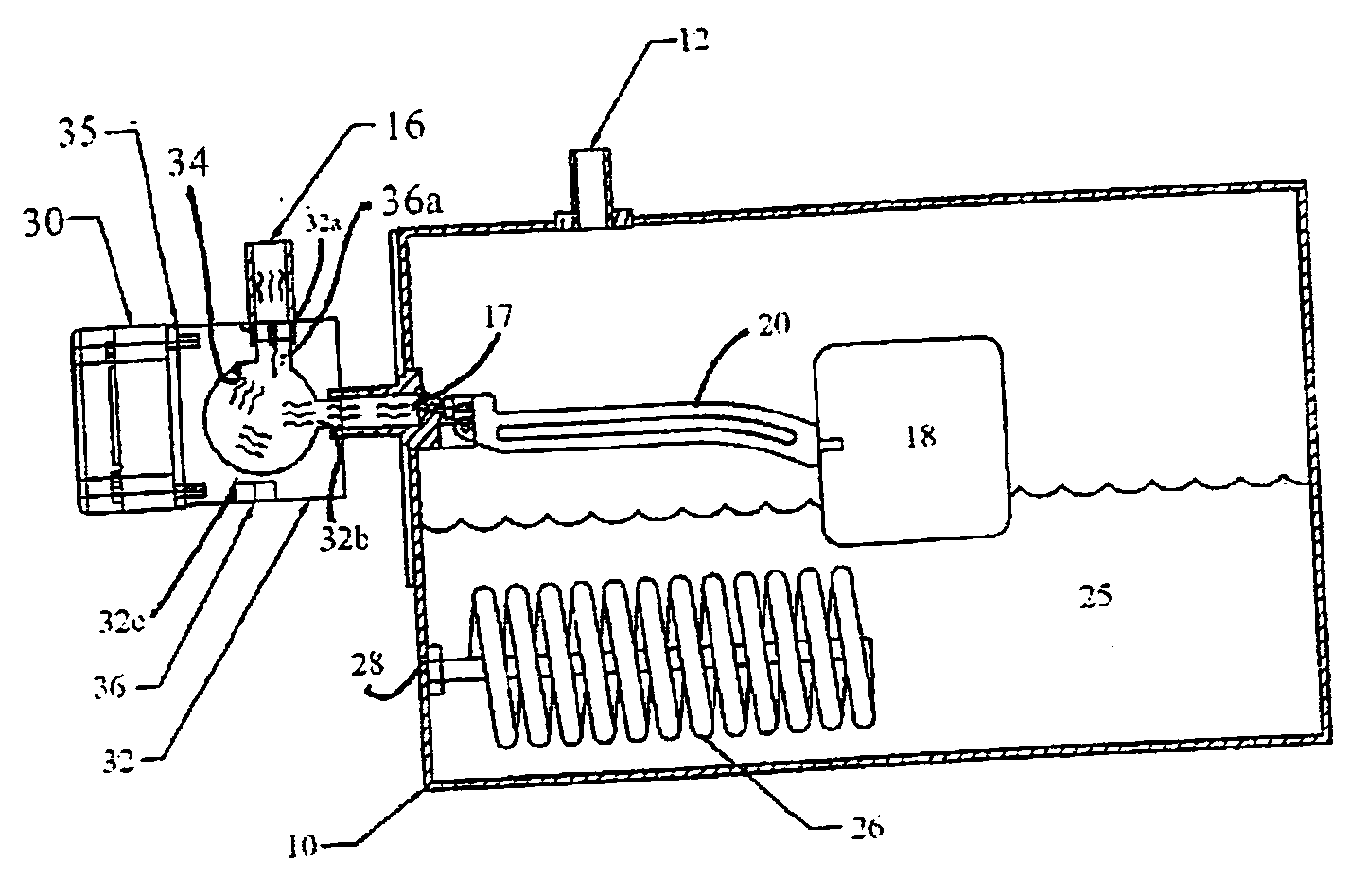

Steam Generating Apparatus With Water-Cooled Solid State Switch

ActiveUS20090290858A1Keep the environmentBathing devicesImmersion heating arrangementsElectricityWater flow

A steam generating system for use in a steam bath includes thermostatically controlled steam generating means for maintaining the steam bath environment at a desired temperature, means defining a water inlet path for conducting water from a water supply to the steam generating means, said inlet-defining means including an area of highly thermally-conductive material in thermal contact with the water. The thermostatically controlled steam generating means includes an electrically powered heating element, and a solid state switching device for controlling the amount of electricity flowing in the heating element. The solid state switching device is in thermal contact with said highly thermally-conductive material so that the switching device is cooled via heat transfer to the water flowing in the inlet path.

Owner:ALTMAN MITCHELL

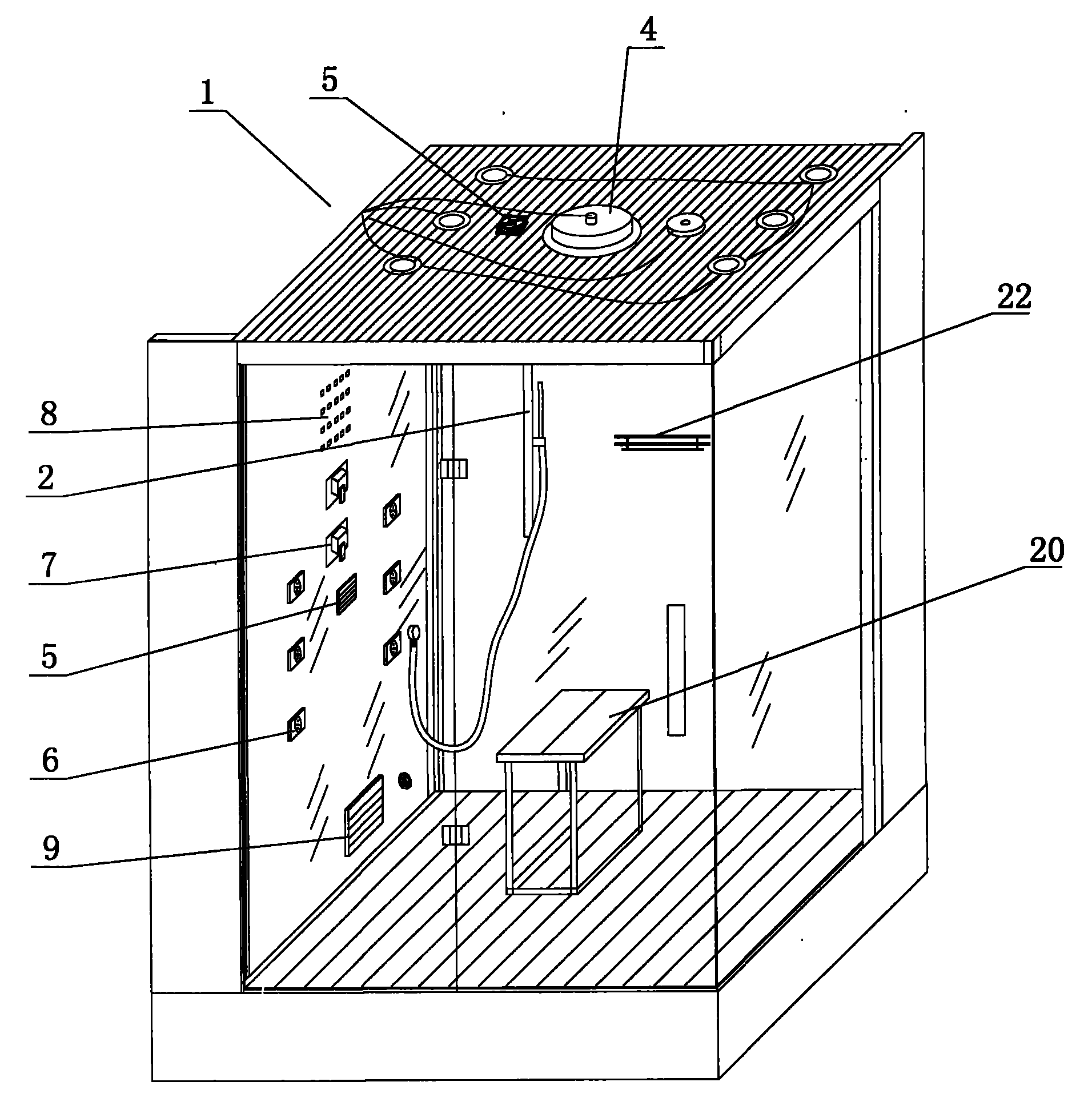

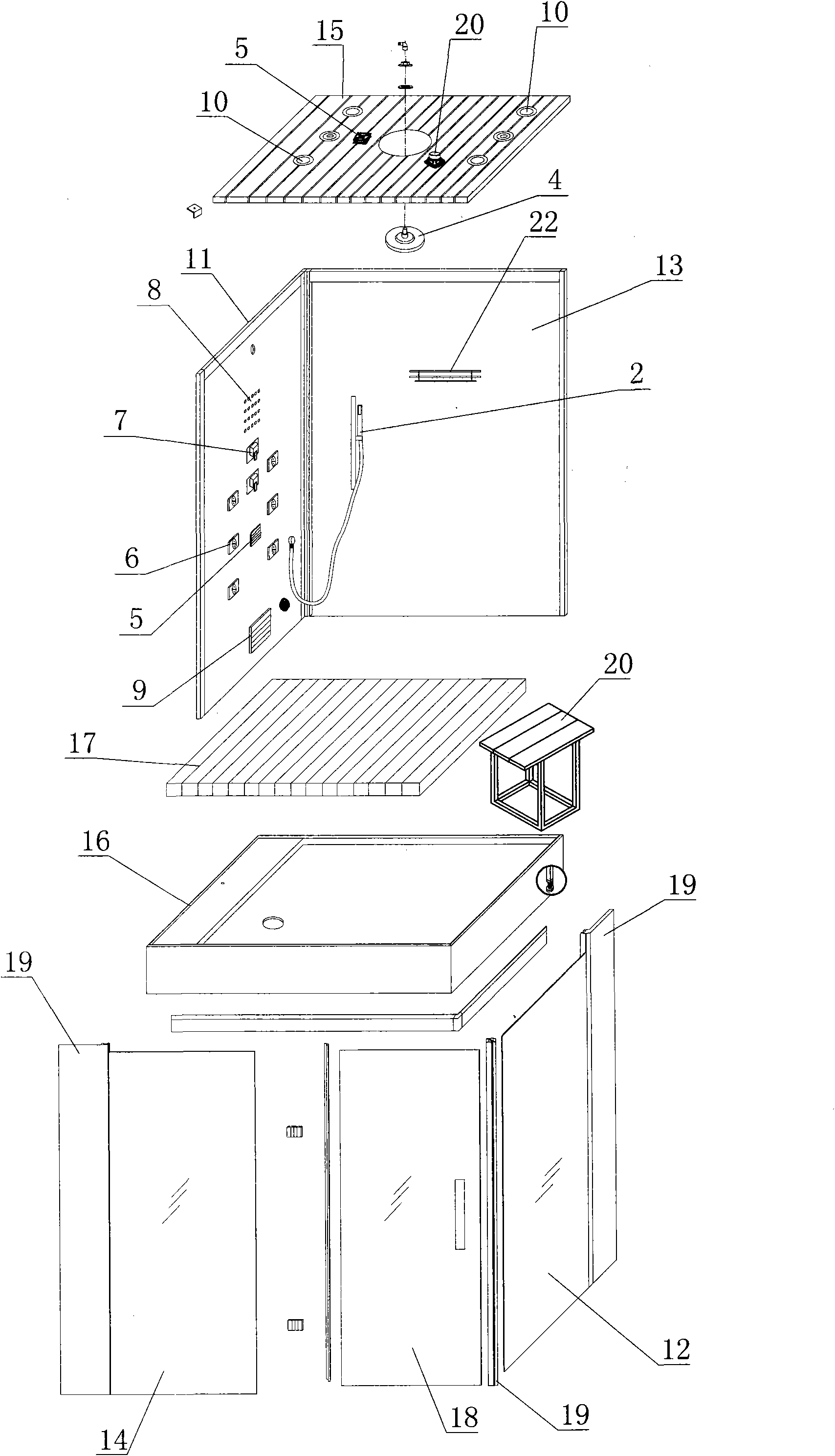

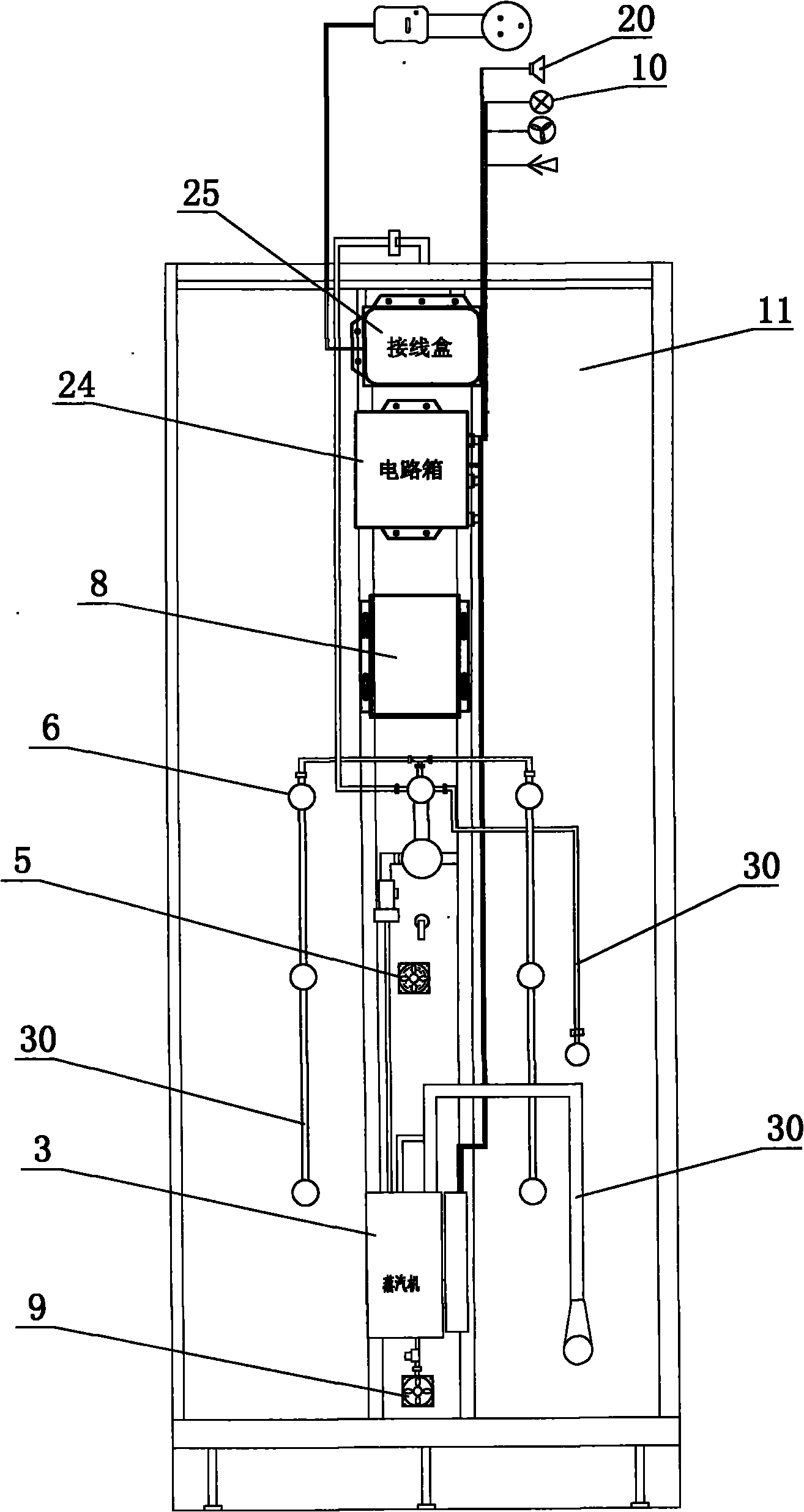

Multifunctional steam shower room

The invention relates to a multifunctional steam shower room, which comprises a shower room body, a shower sprinkler device and a steam generator. The shower room is characterized in that the shower room body is also provided with an ultrasonic atomizer; the spraying nozzle of the ultrasonic atomizer faces towards the inside of the shower room body, and a user can take an anionic atomizing bath in the shower room through the ultrasonic atomizer; and the shower room body is also provided with a stereo drying mechanism which comprises two blowers arranged on the top and the side wall of the shower room respectively. The invention can blow-dry the water droplets on the user body through the drying mechanism after the user takes a shower. Compared with the conventional steam shower room, the multifunctional steam shower room keeps the functions of realizing shower and steam bath and adds functions of realizing ultrasonic atomizing bath and blow-drying the body, thereby offering more choices to the bath items of users and better conforming to the pursuing of the people for high-quality life.

Owner:佛山市南海益高卫浴有限公司

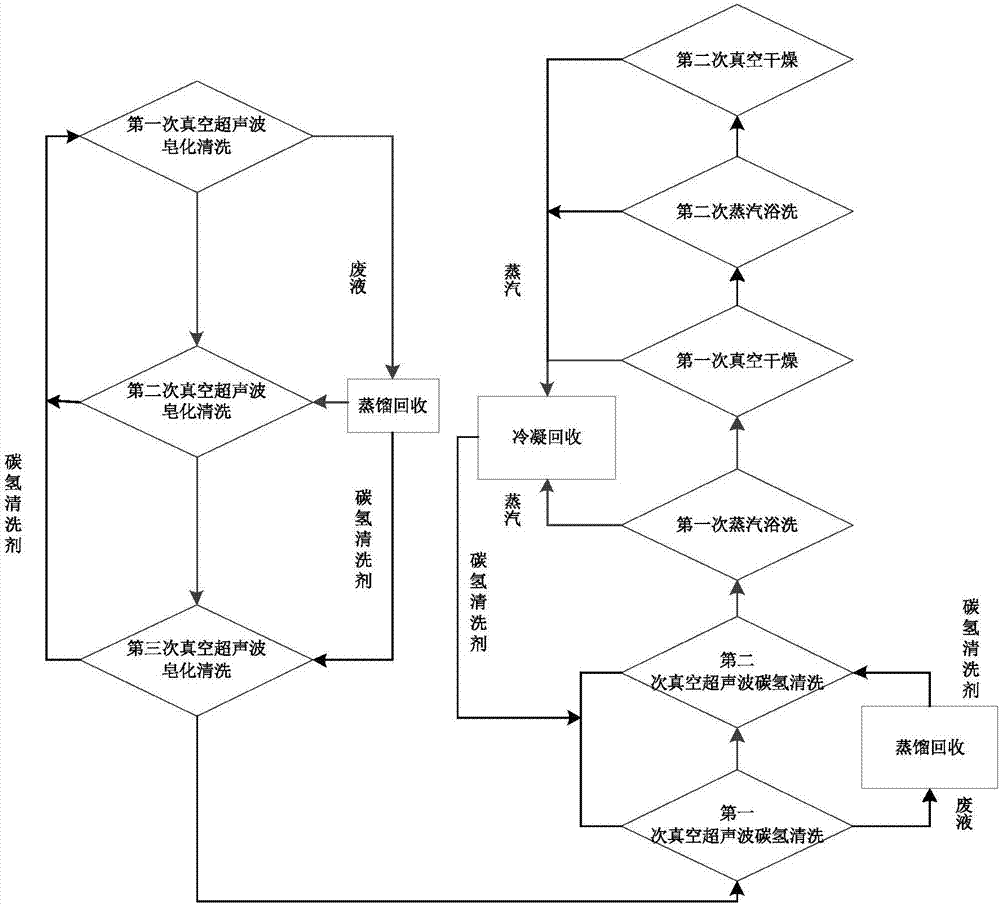

Hydrocarbon liquid saponifying washing technology

The invention discloses a hydrocarbon liquid saponifying washing technology. The hydrocarbon liquid saponifying washing technology comprises the steps of vacuum ultrasonic saponifying washing performed at three times, vacuum ultrasonic hydrocarbon washing performed twice, and steam bath washing and drying performed twice, wherein a washing agent in the step of vacuum ultrasonic saponifying washing is a G-100W hydrocarbon saponifying agent; the washing agents in the step of vacuum ultrasonic hydrocarbon washing and the step of steam bath washing and drying are G-100 hydrocarbon washing agents. According to the hydrocarbon liquid saponifying washing technology, the hydrocarbon saponifying agent and the hydrocarbon washing agents are used for washing, so that the effect of washing mineral grease and non-mineral grease on the surface of a workpiece can be improved; the repeating times of each step are controlled, so that the yield of the workpiece washing can be further increased and is up to 99%; meanwhile, the workpiece surface is free from grease, watermark, corrosion and the like; the washing quality is stable; the waste liquid treatment cost is low; the environment protection is realized; and the pollution is avoided.

Owner:SHENZHEN XINCHENGNUO ENVIRONMENTAL PROTECTION IND CO LTD

Multi-Purpose Shower Apparatus

An apparatus is able to convert a conventional stall shower into a multi-purpose shower facility, including a steam bath, a handheld shower, a water massage and a rain shower. It can be used with either single water input line or two separate hot and cold water input lines. The single water input line fit with the single output line of a common stall shower. To match different situations, two types of steam generator are also disclosed.

Owner:LEONG IEK HEI

Skin-core structure poly(3-hydroxybutyrate-co-3-hydroxyvalerate)fiber, nonwoven material and preparation methods of skin-core structure poly(3-hydroxybutyrate-co-3-hydroxyvalerate)fibers and nonwoven material

ActiveCN106521701AImprove bonding fastnessRenewable resourcesArtificial filament heat treatmentConjugated synthetic polymer artificial filamentsMaterials preparationCold air

The invention discloses a skin-core structure poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV) fiber, a nonwoven material and preparation methods of the skin-core structure poly(3-hydroxybutyrate-co-3-hydroxyvalerate)fiber and the nonwoven material, wherein the core layer of the fiber is PHBV having a 3-hydroxyvalerate (HV) content of 0-20 mol%, the skin layer is PHBV having a HV content of 20-100 mol%, and the melting point of the skin layer is lower than the melting point of the core layer. The skin-core structure PHBV fiber preparation method comprises: drying raw materials, respectively adding to the corresponding material hoppers of a compound spinning machine, carrying out melt transporting, spinning, cooling through cold air blowing, carrying out winding feeding, carrying out oil bath stretching, carrying out steam bath stretching, carrying out tension heat shaping, oiling, carrying out silk stacking, coiling, loosening, and cutting to prepare the skin-core structure PHBV short fiber. The corresponding nonwoven material preparation method comprises: (1) carrying out combing net forming by using the skin-core structure PHBV short fiber as a raw material to prepare a skin-core structure PHBV fiber net; and (2) carrying out thermal adhesion on the skin-core structure PHBV fiber net to obtain the PHBV nonwoven material, wherein the thermal adhesion temperature is between the melting points of the skin layer and the core layer, and the obtained PHBV nonwoven material is mainly used for medical health, and other fields.

Owner:JIANGNAN UNIV

Process and equipment for high-temp and high-pressure spray dyeing of colour fabrics

InactiveCN101333741AImprove utilizationSave energyTextile treatment machine arrangementsDyeing processEngineeringHigh pressure

Owner:骆有福

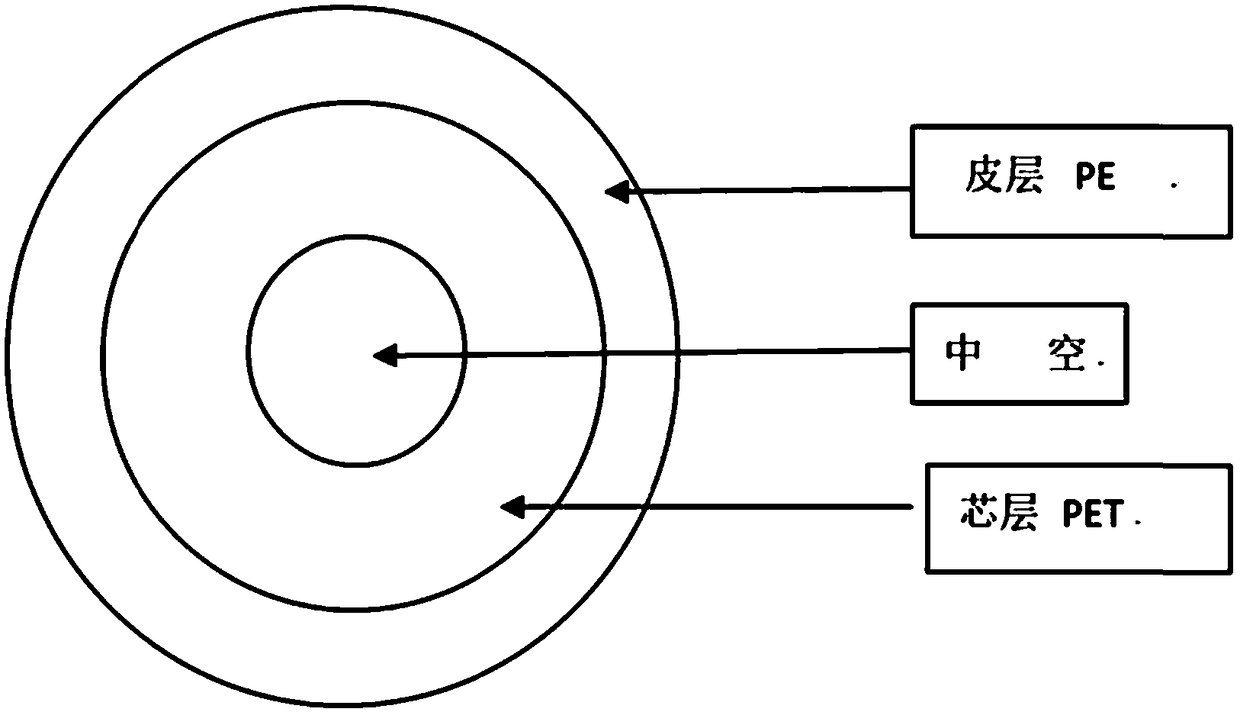

Preparation method of Kangshu (healthy and confortable) composite staple fiber

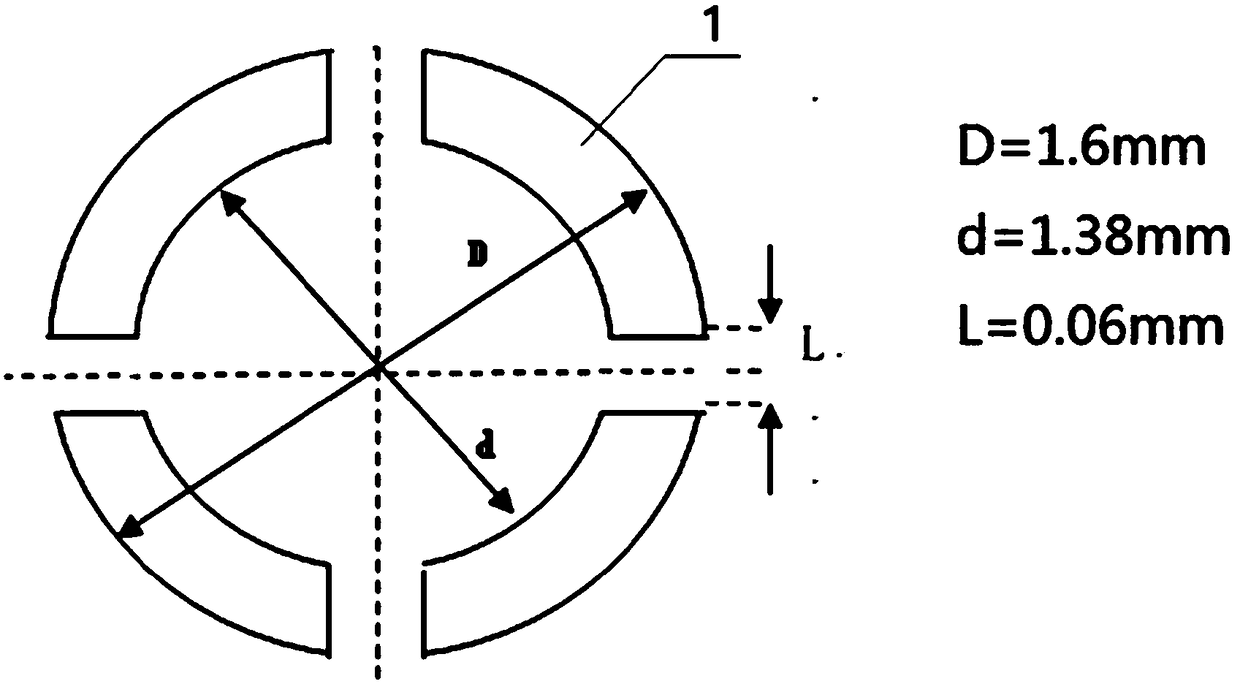

PendingCN109234846AImprove antibacterial propertiesRaise the stretching temperatureFilament forming substance formingHollow filament manufactureYarnFiber

The invention discloses a preparation method of Kangshu (healthy and confortable) composite staple fiber, comprising the steps: esterification reaction of PTA and EG is carried out; polycondensation reaction of the esterification product is carried out to obtain PET; polyethylene is melted into a PE melt by entering a screw extruder; the PET melt and the PE melt respectively enter a composite spinning manifold and are ejected from a composite hollow spinneret to obtain a hollow skin-core structure yarn; part of PE melt is taken out from the main pipe of the spinning manifold into which the PETmelt enters and a zinc-based ultrafine powder antibacterial agent and a dispersing agent potassium tripolyphosphate supported by zeolite are added to the part of the melt, and after uniformly mixing,the mixture returns to the main pipe; in the stretching process, secondary stretching is performed, and primary stretching is controlled in 1.88-2.14 times; the primary stretching adopts steam bath,and the temperature is controlled at 115 DEC C to 125 DECC. The first stage stretching of the invention is steam stretching. Stretching temperature can be improved to soften the PE, and the surface ofthe produced fiber is smooth with good bonding effect.

Owner:JIANGSU JIANGNAN HIGH POLYMER FIBER

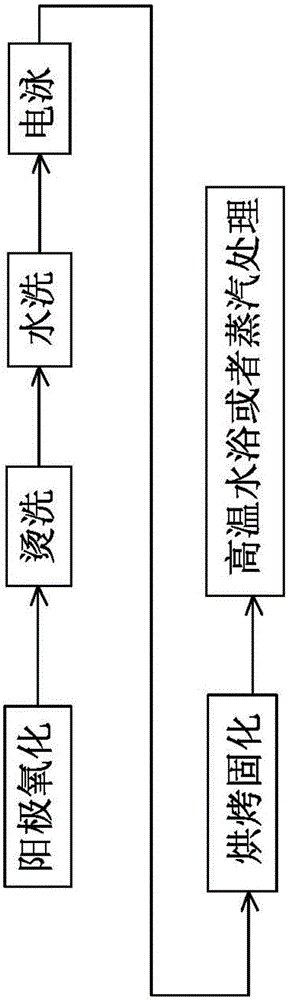

Aluminum alloy anodic oxidation surface treatment process

InactiveCN106149027ASolve defects in workmanshipImprove corrosion resistanceAnodisationElectrophoretic coatingsWater bathsThermal water

The invention belongs to the technical field of anodic oxidation technology, and provides an aluminum alloy anodic oxidation surface treatment process, which comprises the following steps: anodic oxidation, scalding, water washing, electrophoresis, baking and curing, and high-temperature water (steam) post-treatment. The advantage of the present invention is that by adding a high-temperature water (steam) post-treatment process, the cured product is reheated in a hot water bath or steam, and the incomplete oxidation of the electrophoretic hole sealing is performed by using the hot water or steam molecules penetrating through the ED layer. The hole is further sealed, which can solve the defects of the existing anodic oxidation ED sealing process, such as whitening of dripping water, etc., and can further improve the corrosion resistance of the material.

Owner:NINGBO XINTAI MACHINERY

Greenhouse Outdoor Shower

InactiveUS20150052675A1Promote plant growthImprove welfareClimate change adaptationBathsGreenhouseEngineering

In a combination outdoor shower and greenhouse, privacy for the shower component is provided by the strategic arrangement of plantings within the greenhouse. Optionally, the shower can be enhanced with heaters, steam generators, mist generators and / or lighting to create a spa, sauna and / or steam-bath effect. The shower and spa enhancements will operate synergistically with the greenhouse plantings, which will be selected and positioned so as to benefit optimally from the temperature, humidity and lighting associated with the shower / spa features.

Owner:DESMELYK STEVEN

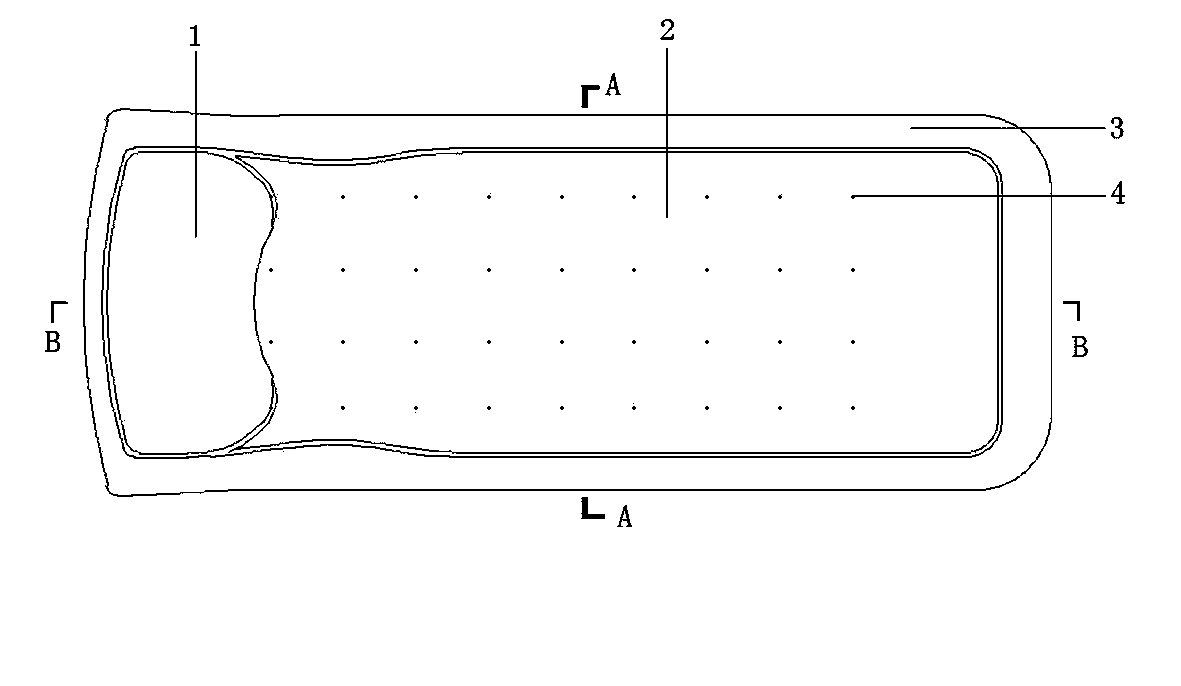

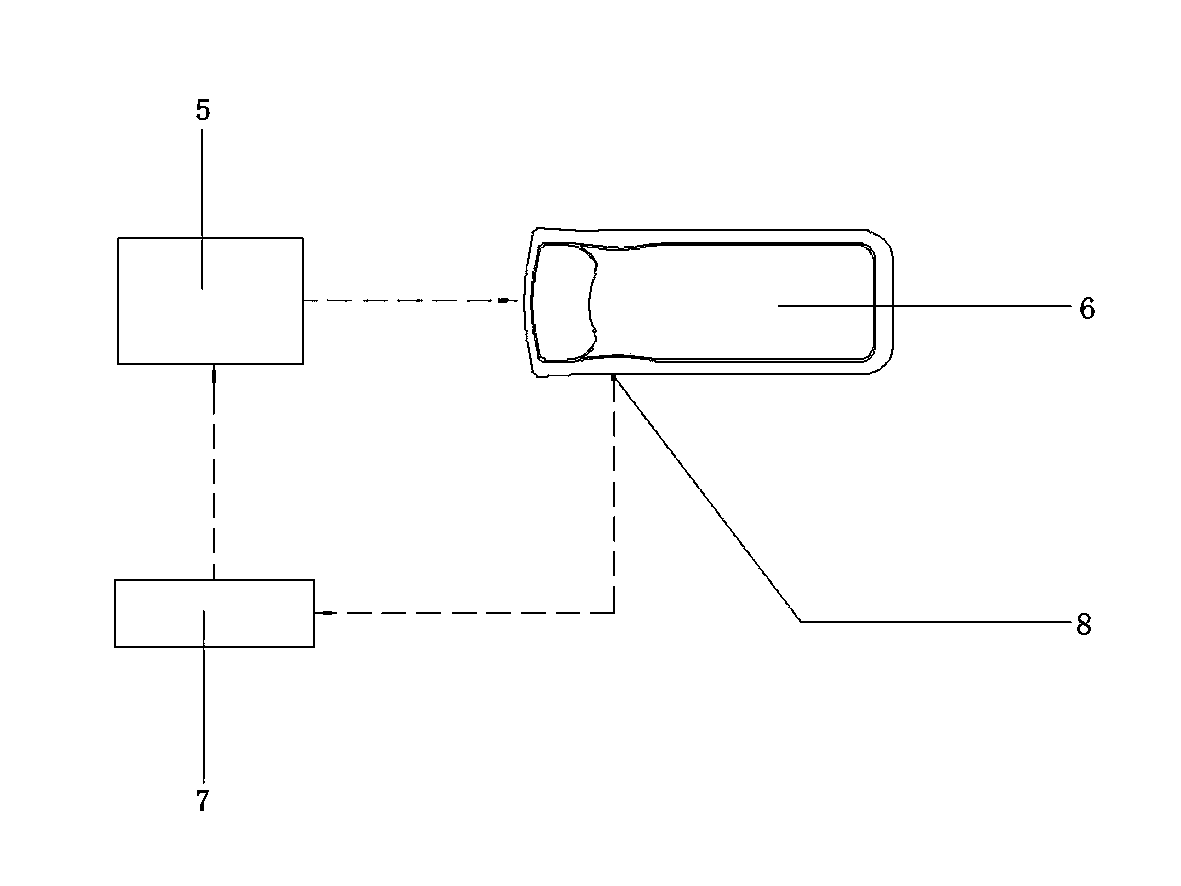

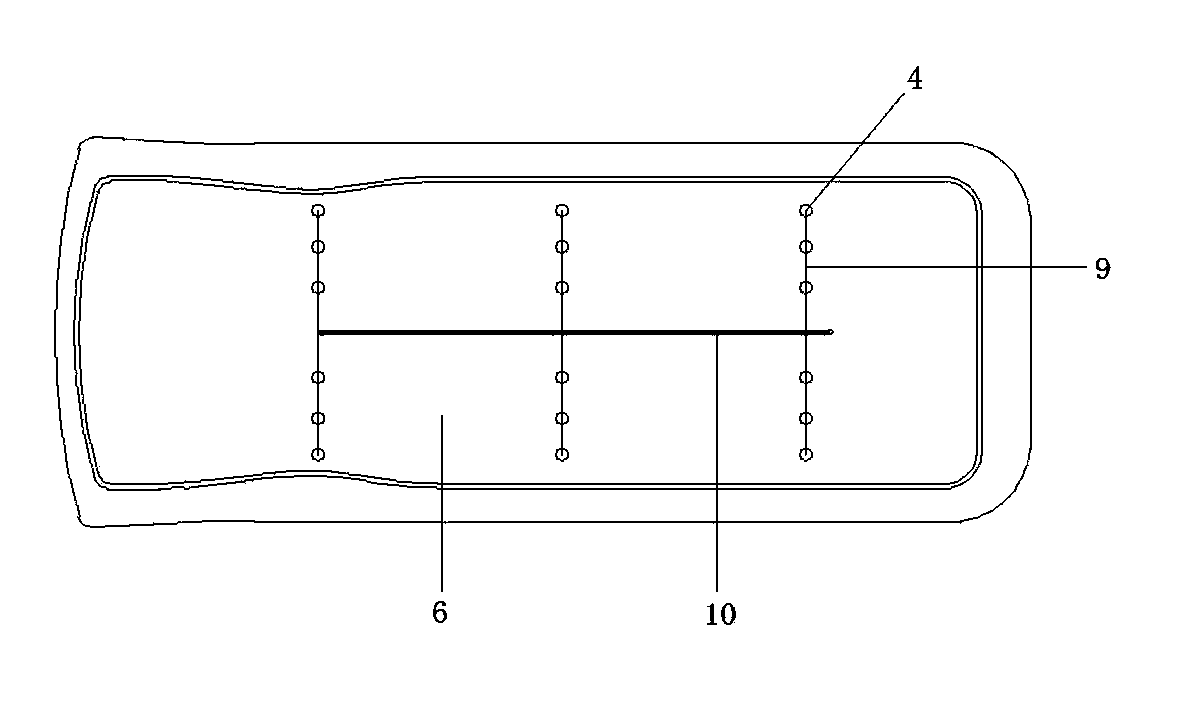

Chinese herb healthcare fumigation bed

The invention discloses a Chinese herb healthcare fumigation bed. The Chinese herb healthcare fumigation bed structurally comprises a pillow, a steam bath board, steam holes, a bath bed guard, a steam generator, a controller, a temperature sensing probe, steam delivery branch pipes, a steam delivery manifold, a supporting shell, a base, a pillow guard, a medical herb steaming device, a Chinese herb board, a steam inlet pipe and a herb steam inlet. The Chinese herb healthcare fumigation bed is high in safety, convenient to operate and capable of realizing real-time control; since the steam generator is independent from equipment and excluded in the equipment structure, many potential safety hazards caused by the steam generator are avoided; since the unified high-power steam generator is adopted, the steam generator can have high capacity utilization, energy resources are saved, and the purpose of providing steam to multiple Chinese herb healthcare fumigation bed at the same time on a large scale is achieved.

Owner:云南沃润特环境工程有限公司

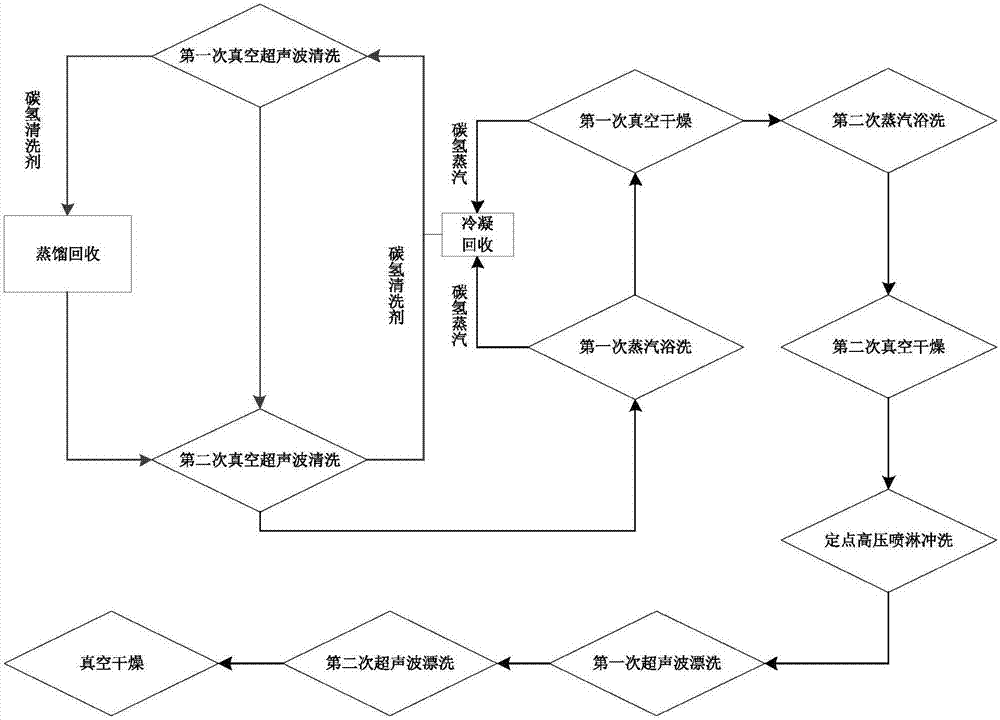

High-precision cleaning process with particulate matter requirement

InactiveCN107051967AReduce manufacturing costEasy to operateDrying solid materials without heatDrying gas arrangementsParticulatesMegasonic cleaning

The invention discloses a high-precision cleaning process with a particulate matter requirement. The high-precision cleaning process comprises the steps of primary vacuum ultrasonic cleaning, secondary vacuum ultrasonic cleaning, primary steam bath washing and vacuum drying, secondary steam bath washing and vacuum drying, fixed-point high-pressure spray washing, preliminary ultrasonic rinsing, secondary ultrasonic rinsing and vacuum drying, and hydrocarbon cleaning agents in the steps of vacuum ultrasonic cleaning, steam bath washing and vacuum drying are all naphthene type cleaning agents with the molecular formula being CnH2n. Machining oil of a workpiece is cleaned through the similarity and intermiscibility principle of the hydrocarbon cleaning agents, fine burrs and particulate matters in product machining holes and on surfaces are washed away through fixed-point high-pressure washing, surface extension of the particulate matters and a product is lowered through pure water so that the particulate matters can be completely separated from the surface of the product, the particle size of the particulate matters on the surface of the workpiece obtained after compound cleaning is smaller than 200 microns, the cleaning process is environmentally friendly, the cost is low, and operation is simple.

Owner:SHENZHEN XINCHENGNUO ENVIRONMENTAL PROTECTION IND CO LTD

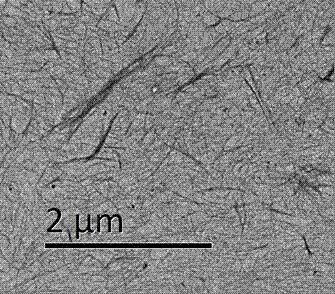

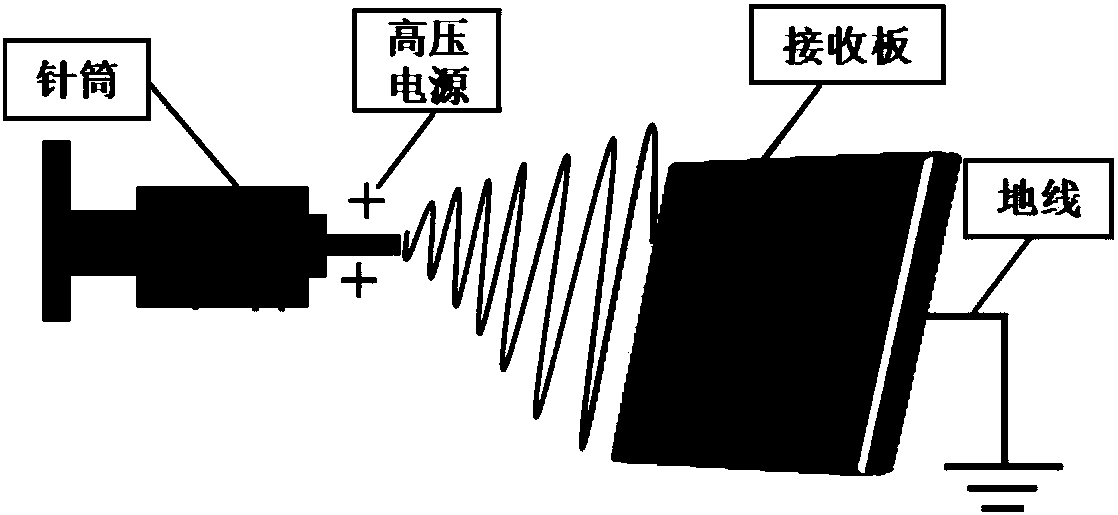

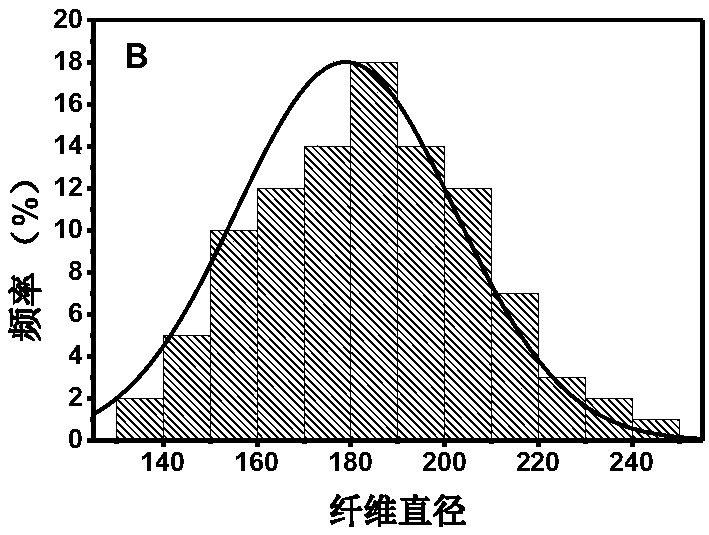

Method for preparing ion conductivity membrane for flow battery through electrostatic spinning

ActiveCN108598520AHigh mechanical strengthIncreased swelling resistanceShrinkingNanotechnologySwelling capacityCarbon nanotube

The invention belongs to the technical field of electrochemical engineering and relates to a method for preparing an ion conductivity membrane for a flow battery through electrostatic spinning. In a high-voltage electric field, a carbon nanotube-doped non-fluorinated cation exchange polymer is dispersed into a spinning solution of an N,N-dimethyl formamide or N,N-dimethyl acetamide solvent; the spinning solution forms electrospun nanofiber on a receiving plate through the electrostatic force traction of a spinning nozzle to obtain the electrospun nanofiber with a three-dimensional network structure; and then solvent steam bath, hot pressing and protonation are carried out to prepare a compact membrane with ionic conductivity for the flow battery. Ions are conducted along the axial direction of the fiber to form a long-range ordered conducting channel; penetration of vanadium ions through a hydrophilic channel is significantly reduced through excellent ion barrier property of a carbon nanotube; and the electrospun membrane has relatively high mechanical strength and swelling resistance through fibration, therefore, the membrane disclosed by the invention obtains relatively high charge-discharge property of an all-vanadium flow battery.

Owner:DALIAN UNIV OF TECH

Steam generating apparatus with water-cooled solid state switch

Owner:ALTMAN MITCHELL

Portable multifunctional sauna/shower equipment

InactiveCN102525316AEasy function switchingEasy to adjust water temperatureBathsDouchesEngineeringControl valves

The invention relates to sauna / shower equipment and discloses portable multifunctional sauna / shower equipment which comprises a sac, a composite expansion seal pipe bundle device, a folding adjustable passage massage multi-chamber pump, a multifunctional heat-insulating water bucket, a gas control valve, a water delivery pipe, a hot water pipe, an air delivery pipe and a hot steam pipe, wherein the sac is connected with the composite expansion seal pipe bundle device and the folding adjustable passage massage multi-chamber pump through the air delivery pipe, the water delivery pipe and the hot steam pipe; and the multifunctional heat-insulating water bucket is connected with the composite expansion seal pipe bundle device and the folding adjustable passage massage multi-chamber pump through the hot water pipe and the water delivery pipe. The multifunctional bath equipment integrates the functions of sauna bath, shower bath, tub bath, massage, beautification and steam bath. The portable multifunctional sauna / shower equipment is complete and perfect as well as safe and comfortable, is convenient to use, has a wide application range, provides convenience for water temperature control, minimizes energy consumption and water consumption, is compatible, and has a simple structure and a low cost.

Owner:陈卫

Process for de-oiling steelmaking sludges and wastewater streams

InactiveUS7531046B2Impact processDrying using combination processesBlast furnace componentsSteelmakingSludge

Owner:RECOVERY TECH LP

Ultrafine cleaning process before PVD coating of compound component

InactiveCN107470253AGuaranteed qualityImprove permeabilityDrying solid materials without heatCleaning using liquidsEngineeringWater cut

The invention discloses an ultrafine cleaning process before PVD coating of a compound component. The ultrafine cleaning process comprises the steps of vacuum ultrasonic cleaning, vacuum ultrasonic rinsing, vacuum water cutting cleaning, vacuum fluid cutting, vacuum hydrocarbon ultrasonic cleaning, slow-pulling dehydration, steam bath-washing, vacuum drying and plasma cleaning. The ultrafine cleaning process can radically clean a water cutting agent and dirt on the product surface and smudge in cracks, and contributes to guaranteeing the follow-up PVD coating quality.

Owner:SHENZHEN XINCHENGNUO ENVIRONMENTAL PROTECTION IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com