Patents

Literature

59 results about "Steam activation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steam Activation Code. Launch Steam and log into your account. Go to Games then click on Activate a Product on Steam... Enter the code you purchased. Go to your games list in Steam, highlight the game, and click install.

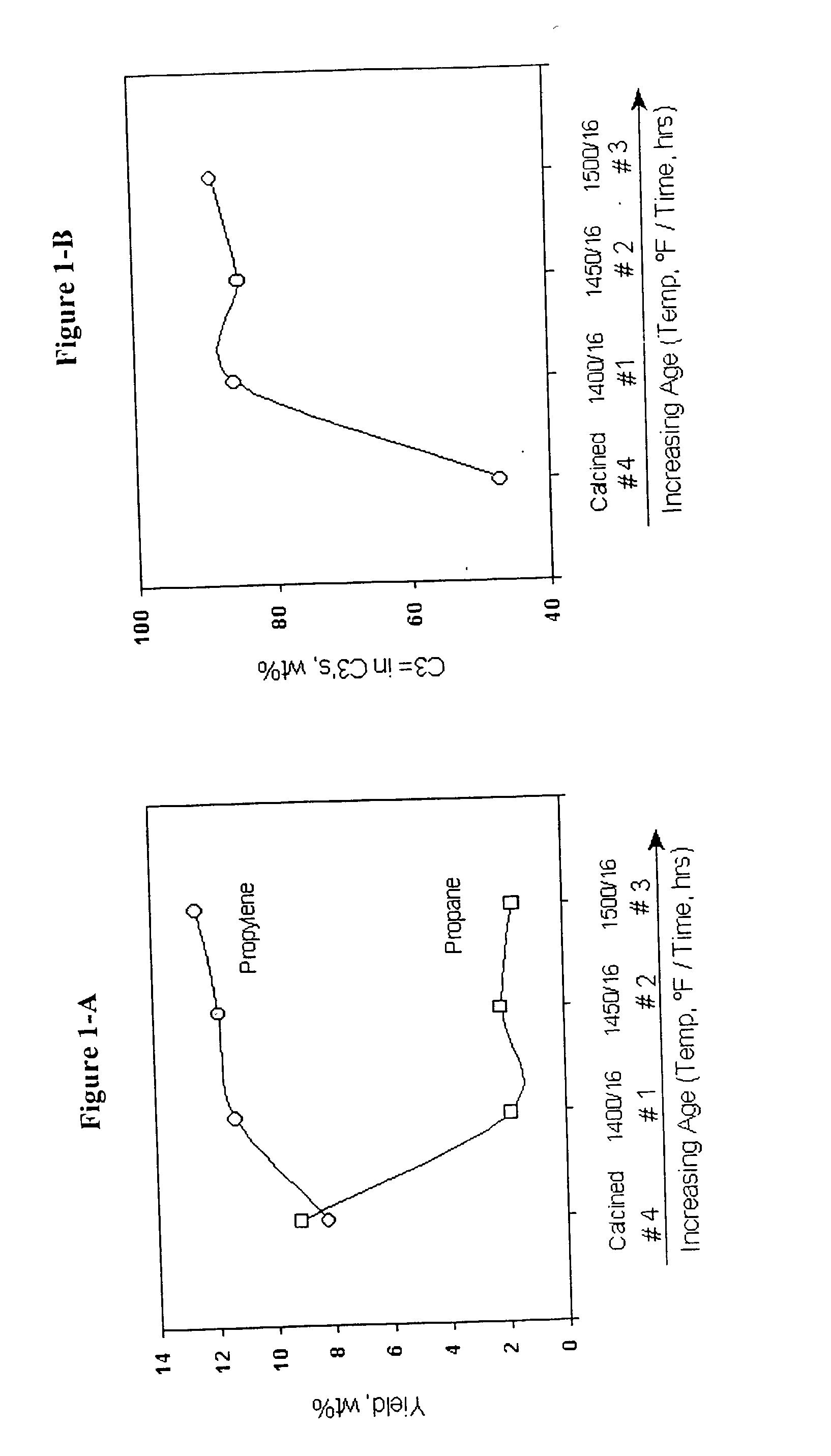

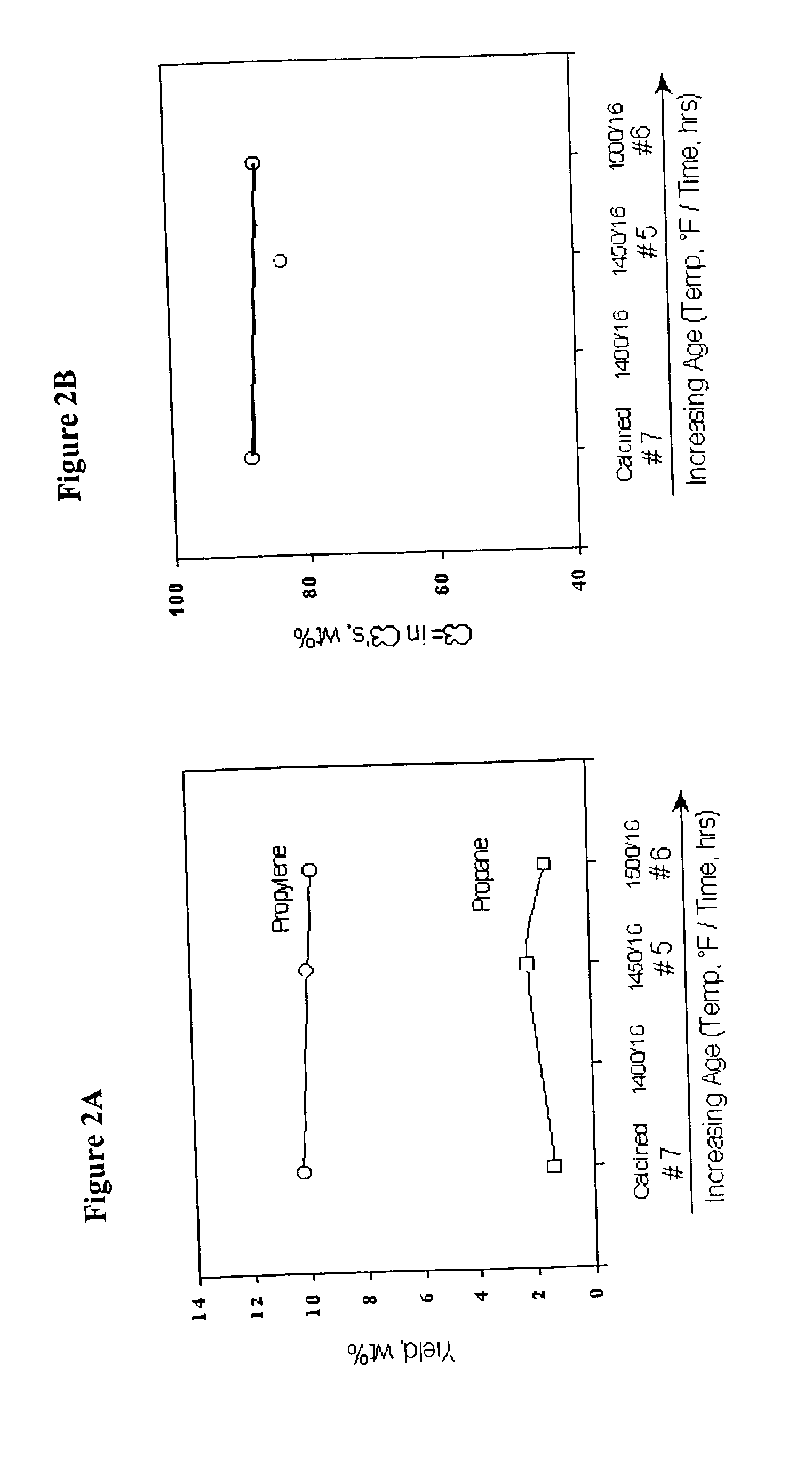

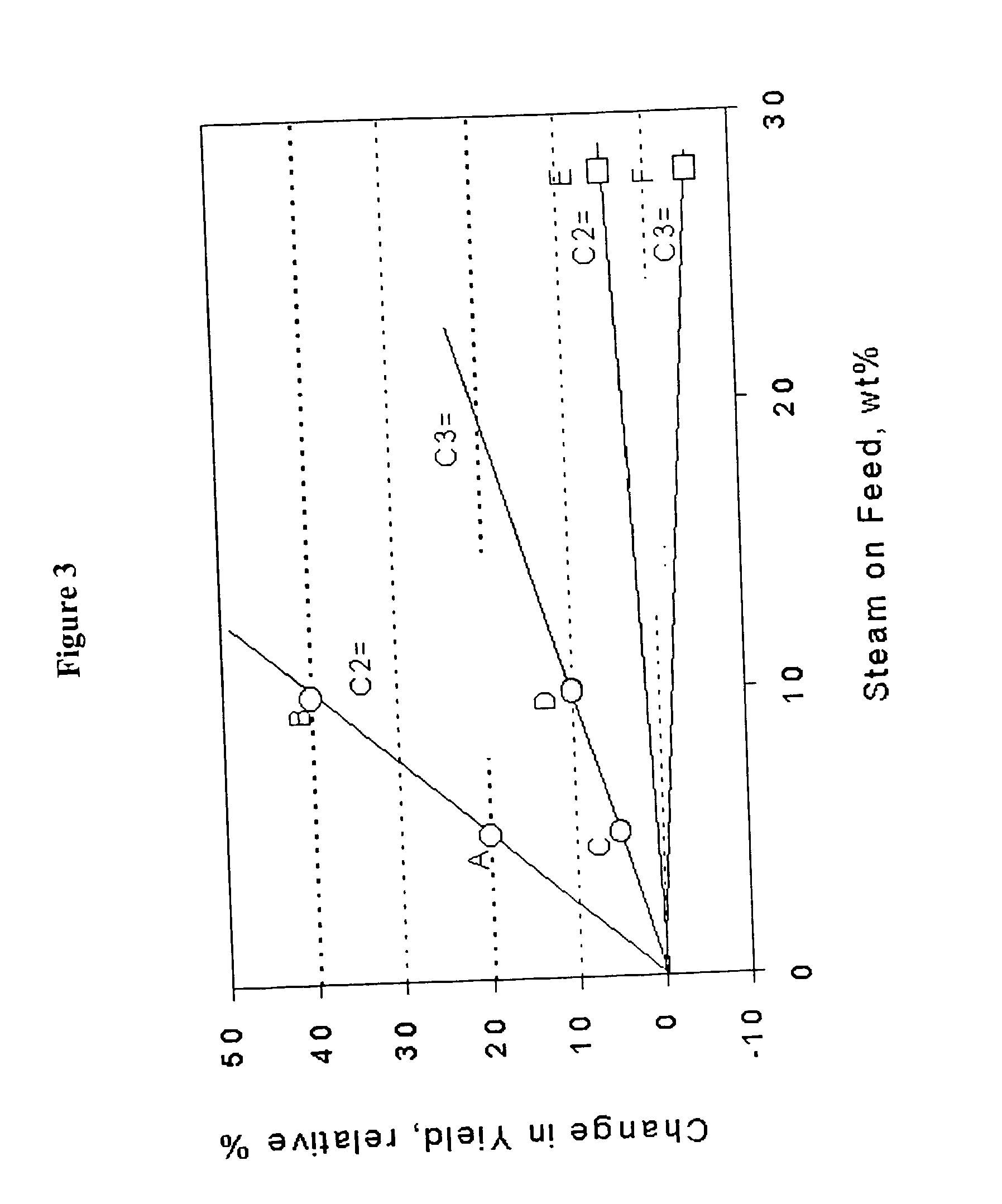

Process for selectively producing light olefins

InactiveUS6455750B1Treatment with plural serial cracking stages onlyCatalytic crackingNaphthaSteam activation

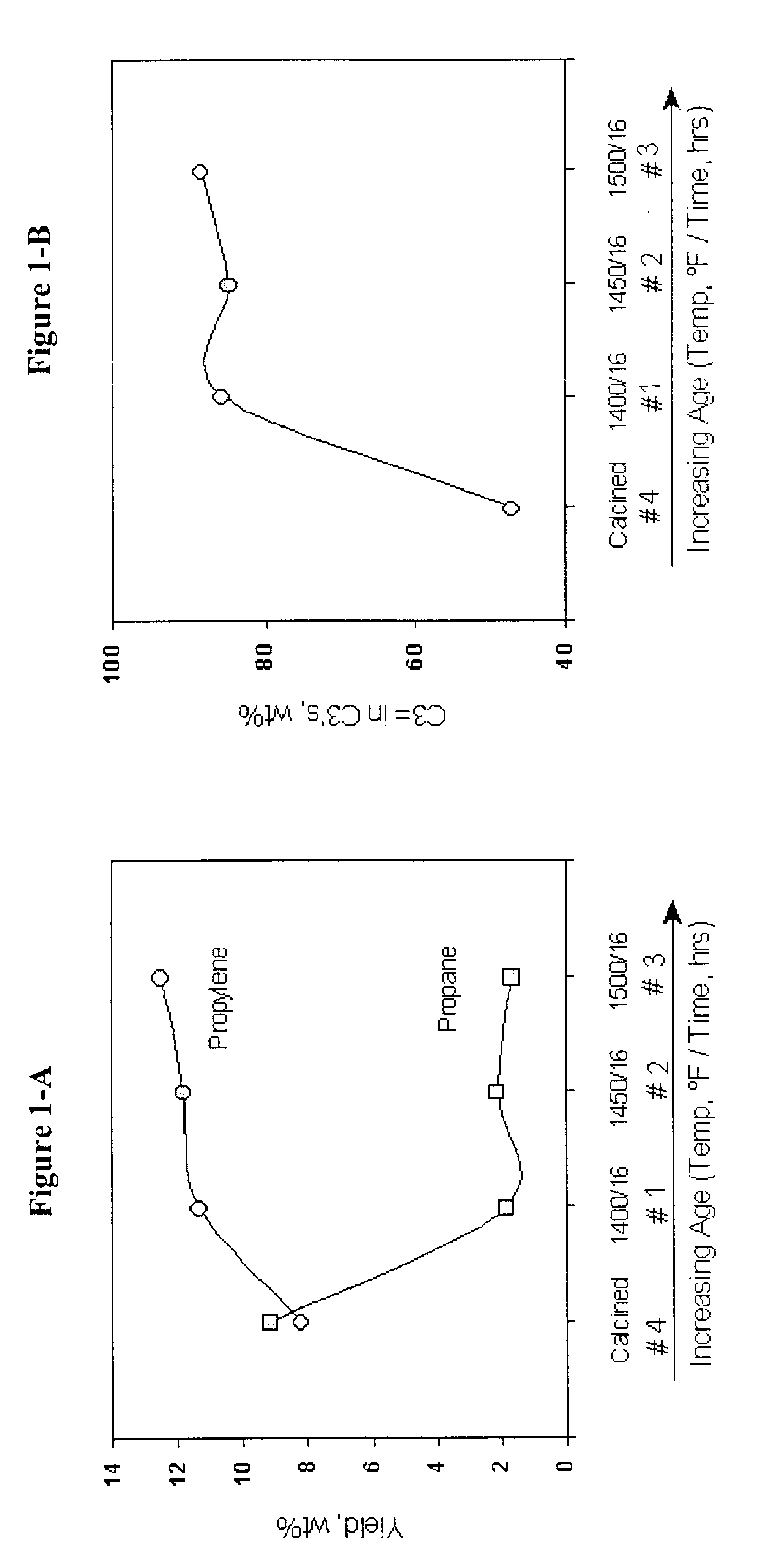

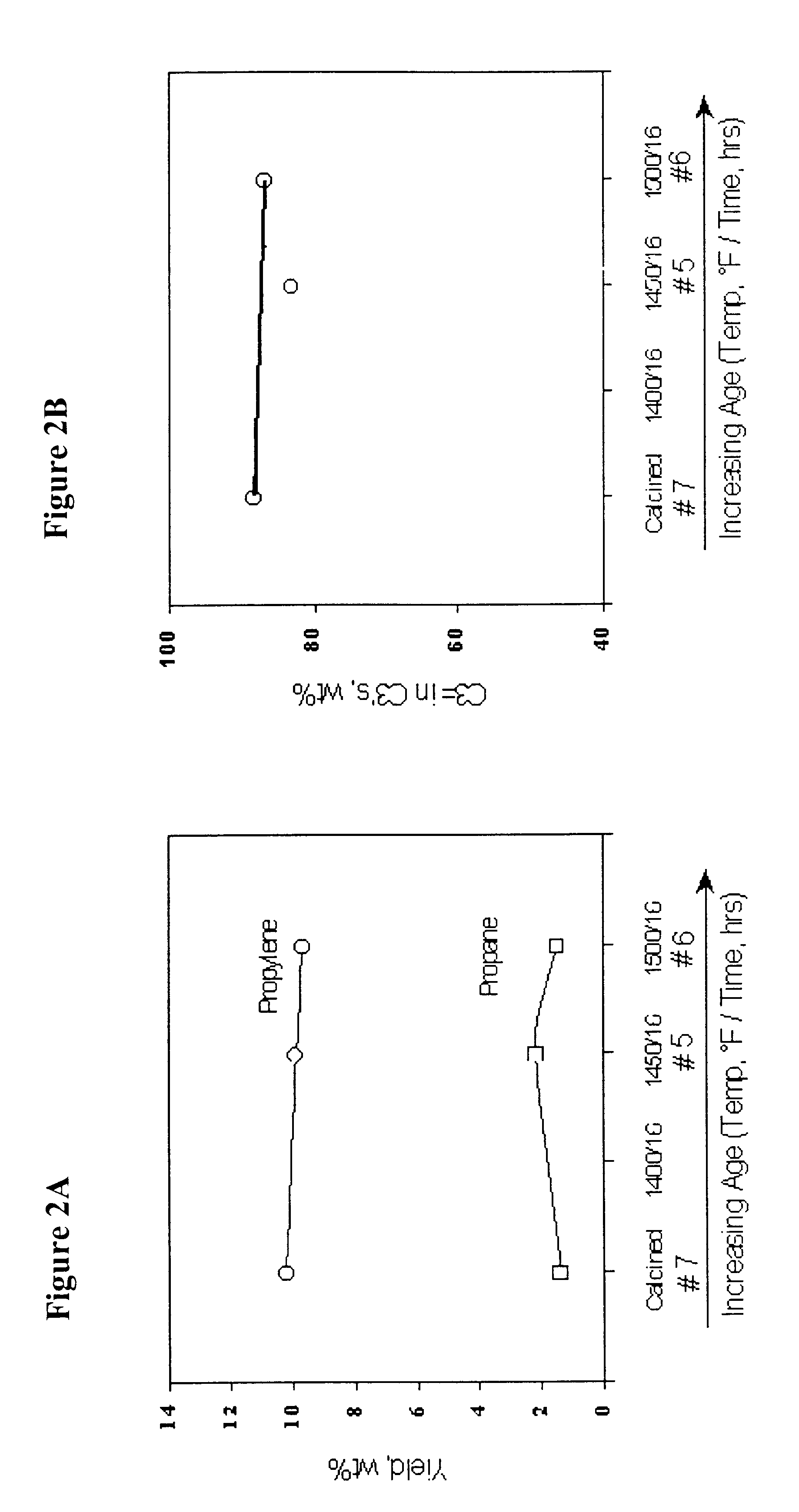

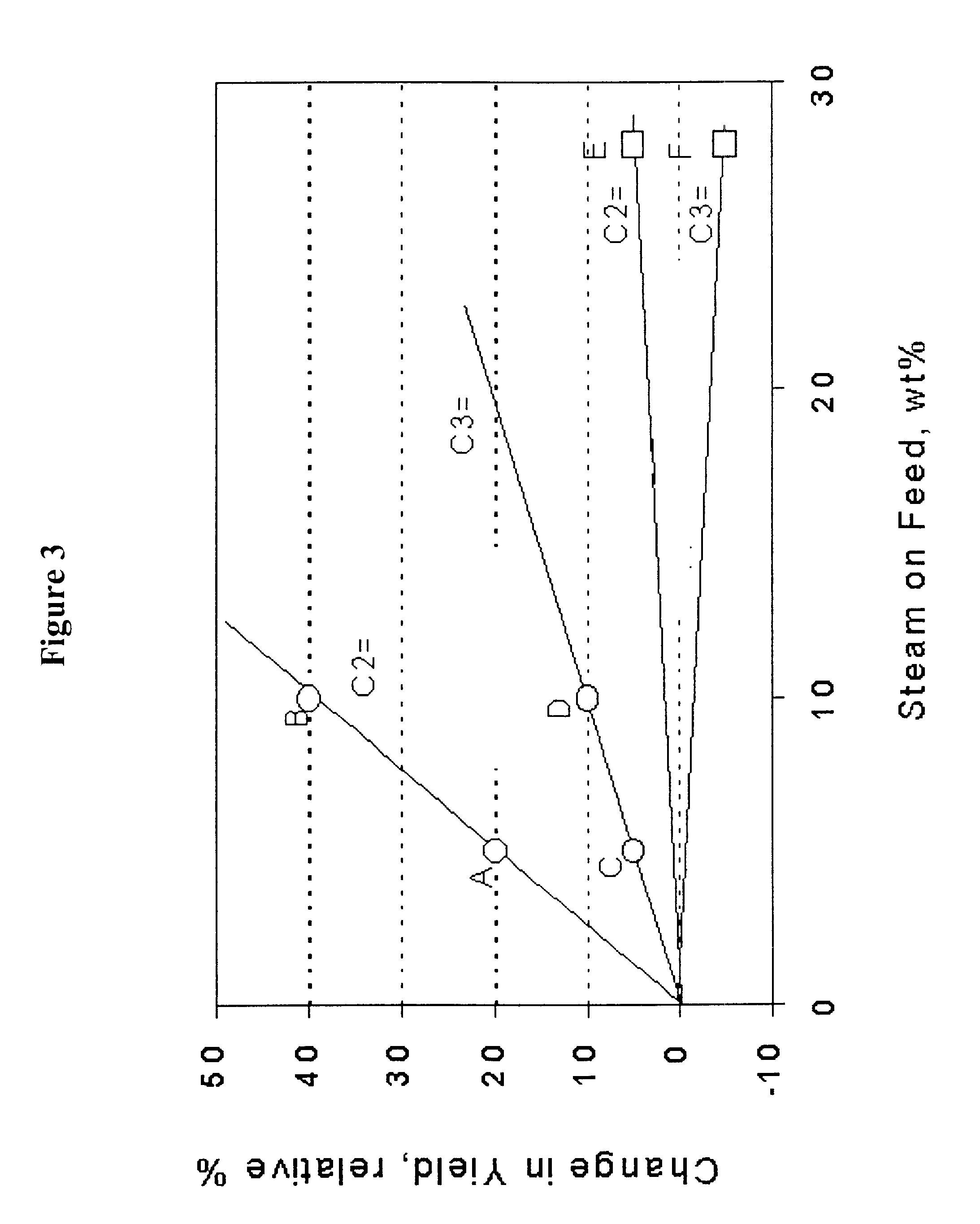

The invention is related to a catalyst and a process for selectively producing light (i.e., C2-C4) olefins from a catalytically cracked or thermally cracked naphtha stream. The naphtha stream is contacted with a catalyst containing from about 10 to 50 wt. % of a crystalline zeolite having an average pore diameter less than about 0.7 nanometers at reaction conditions. The catalysts do not require steam activation.

Owner:EXXONMOBIL CHEM PAT INC

Treatment for wastewater in para-nitraniline production and method for resource recovery and use

InactiveCN101244878AImprove adsorption capacityAchieve recyclingOrganic chemistryMultistage water/sewage treatmentAbsorption capacityPhosphate

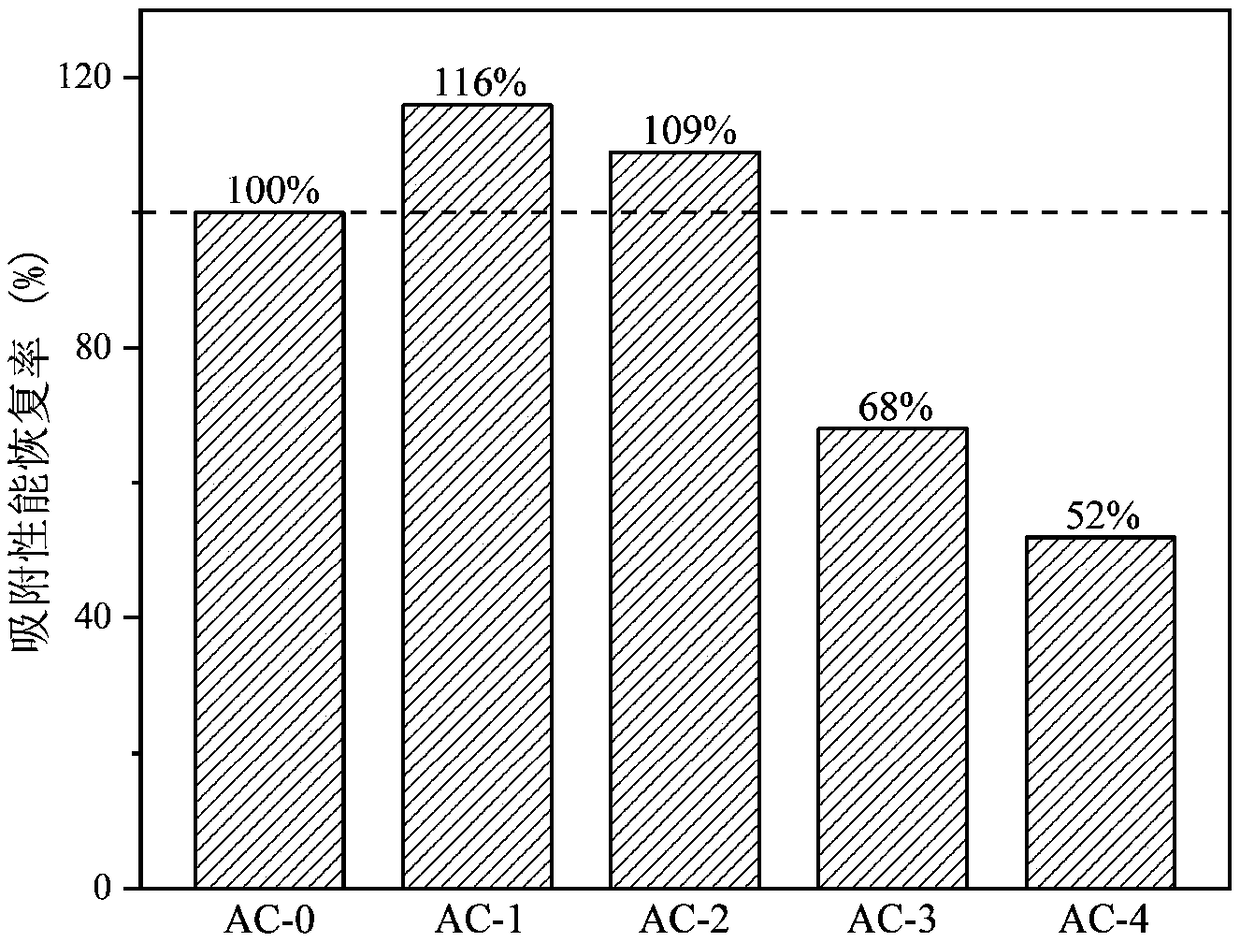

The invention discloses a method for nitroaniline wastewater treatment and recycling, comprising a plurality of steps: cool p-nitroaniline mother liquor wastewater and crystals are allowed to be separated out; filter the wastewater after crystal precipitation and remove the free ammonia in the filtrate; filter the effluent ever treated at the procedure B and change PH value to acidity or weak alkalinity; use the viscose-based active carbon fiber made by phosphate-impregnated high-temperature steam activation to absorb the p-nitroaniline wherein; evaporate and concentrate the absorbed water; precipitate crystal and filter out ammonium chloride crystal. The active carbon fiber has large absorption capacity and fast absorption speed for p-nitroaniline and can be utilize repeatedly, which makes the recovery rate of p-nitroaniline near 100%. The method has the advantages that the method can fully recover p-nitroaniline and free ammonia in the p-nitroaniline wastewater and the byproduct of ammonium chloride, realizing the unification of wastewater treatment and resources recovery; the method is of great economic and practical value in the treatment of p-nitroaniline wastewater.

Owner:NANJING UNIV

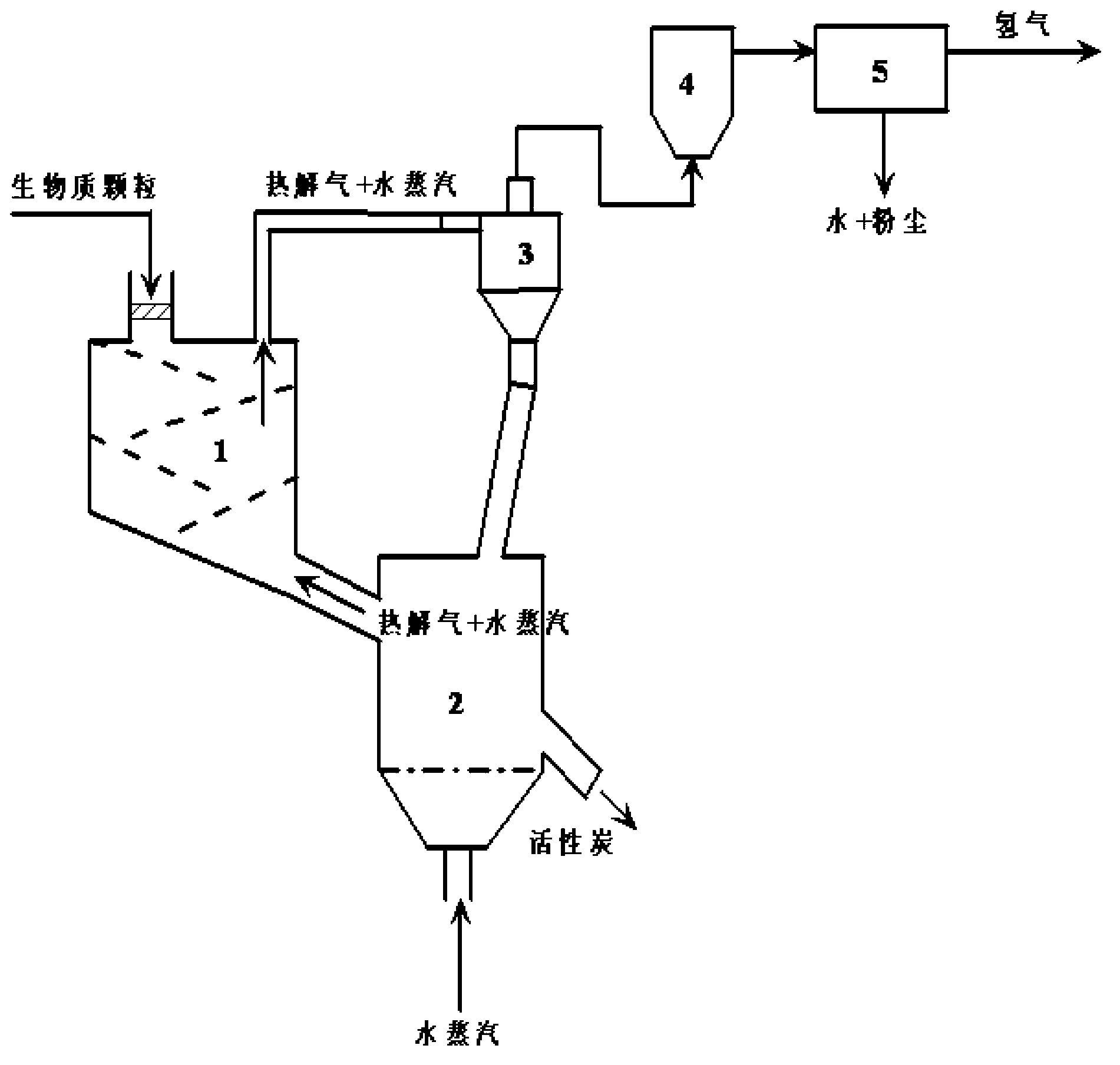

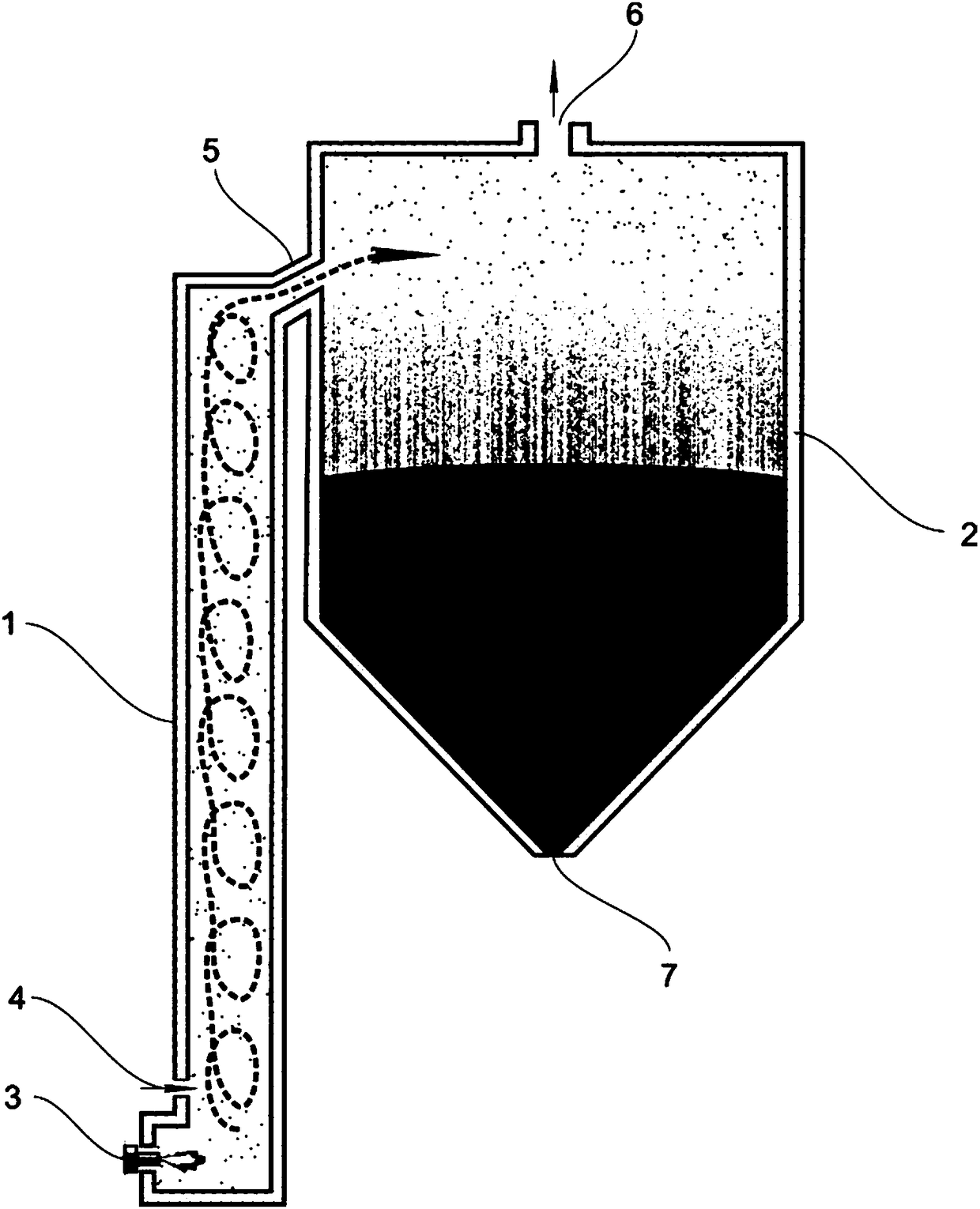

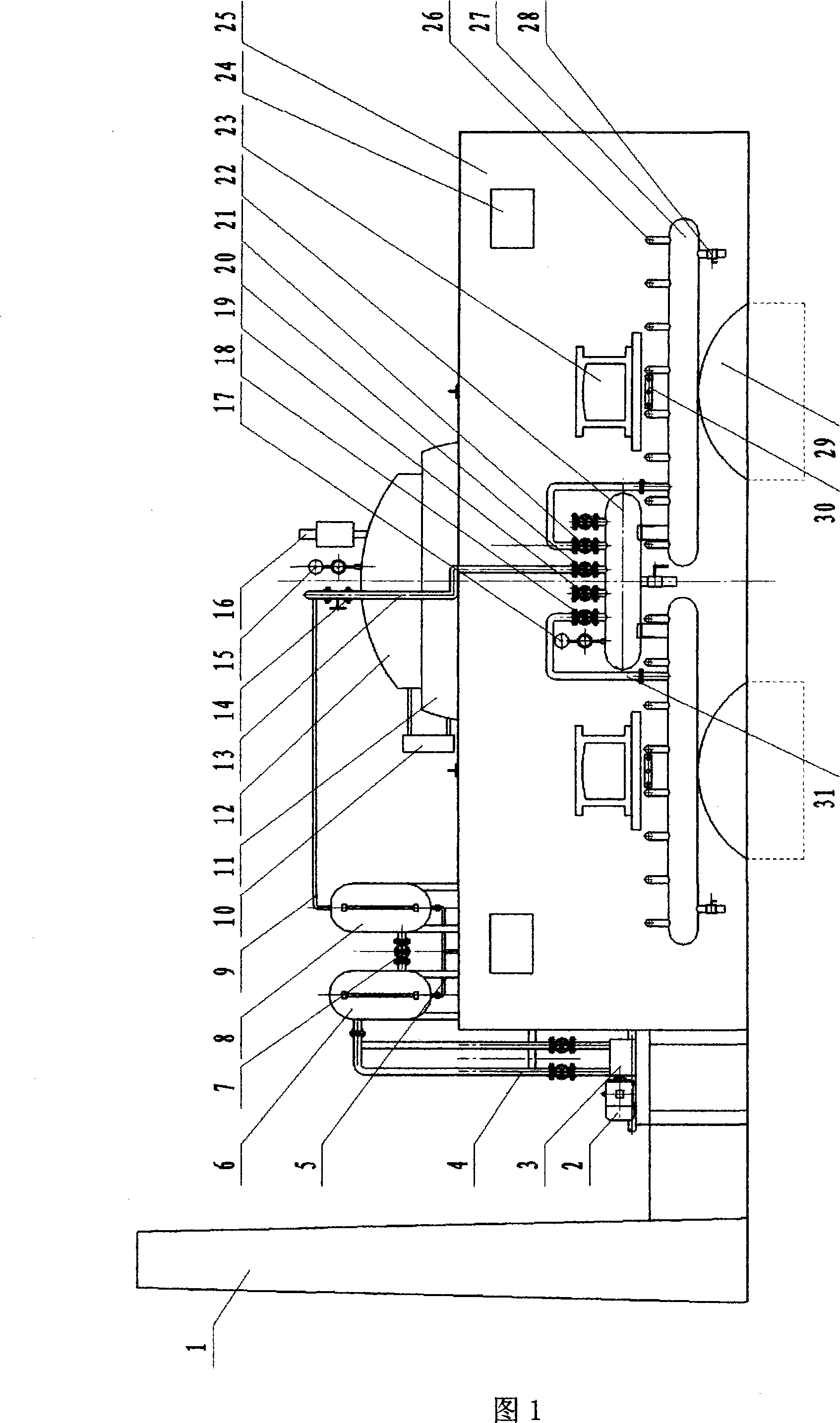

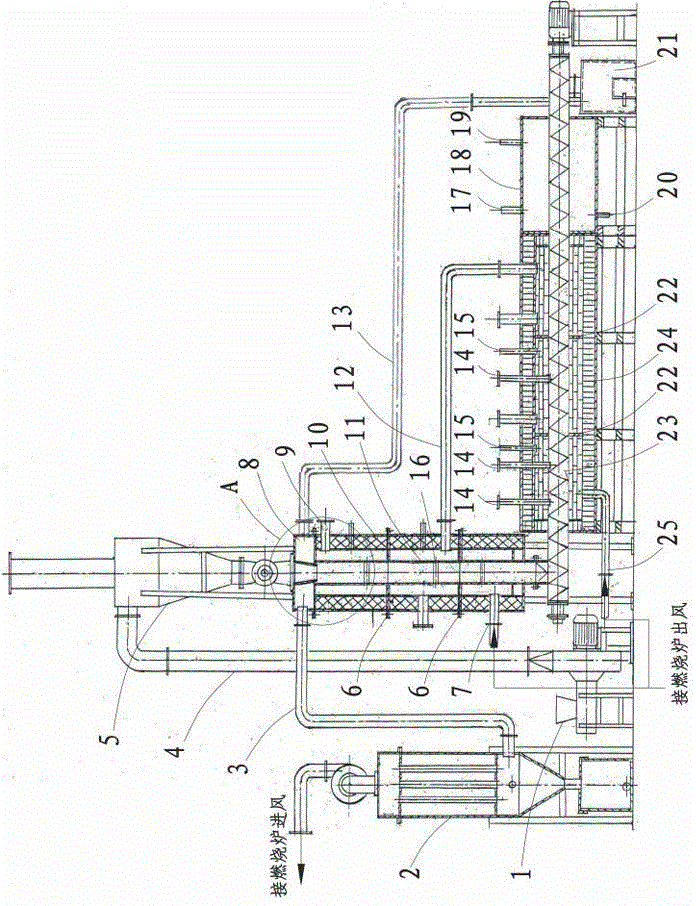

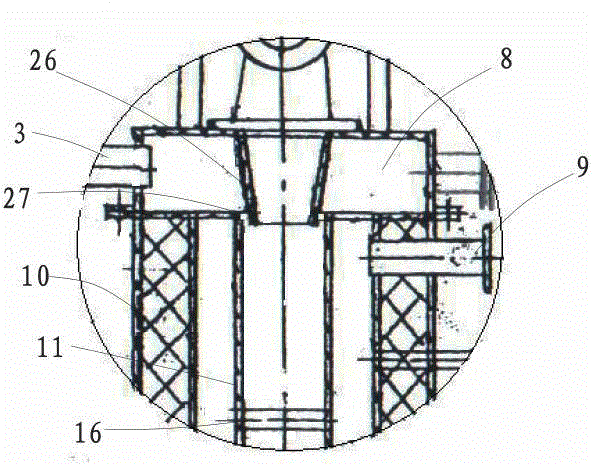

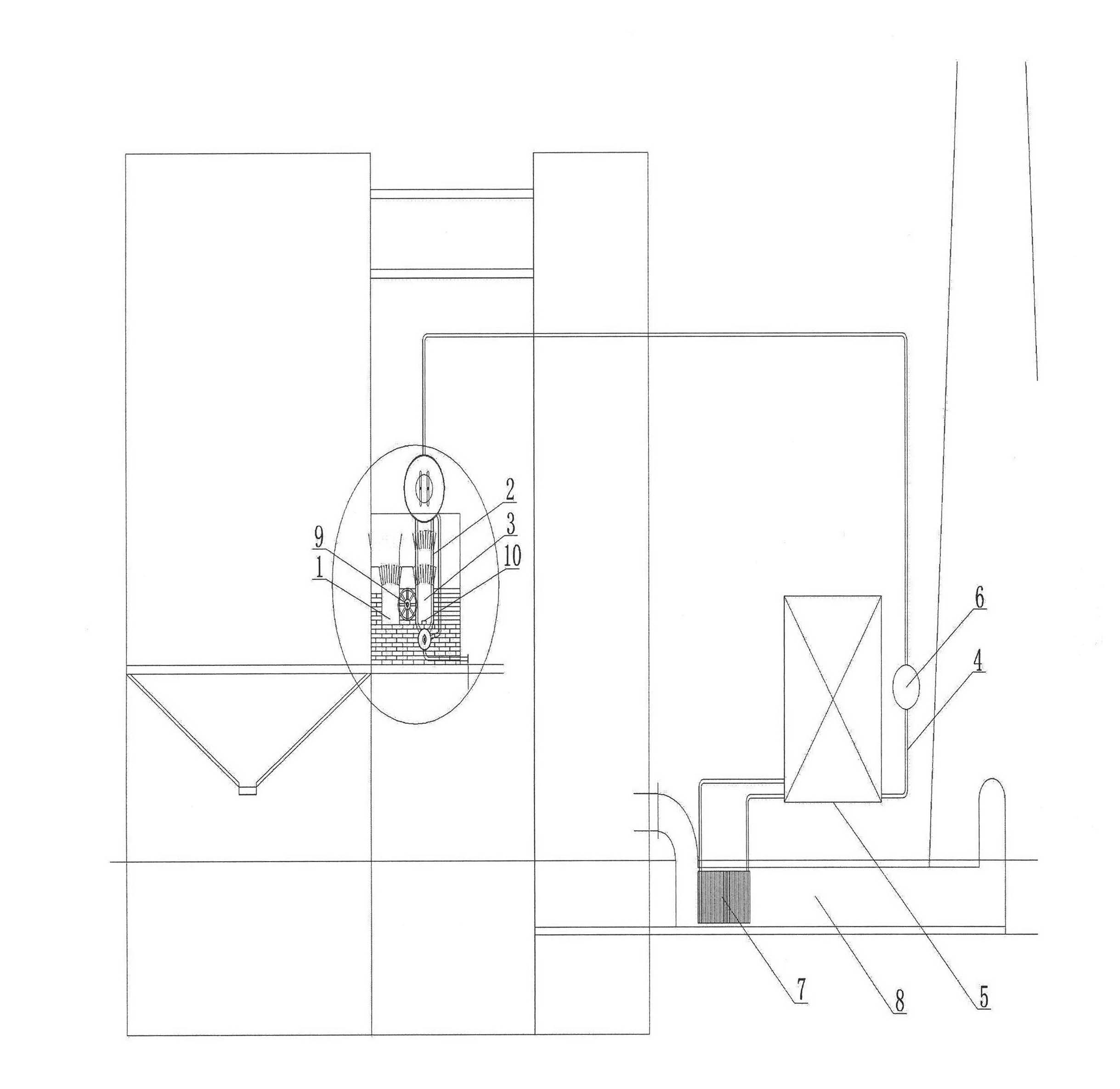

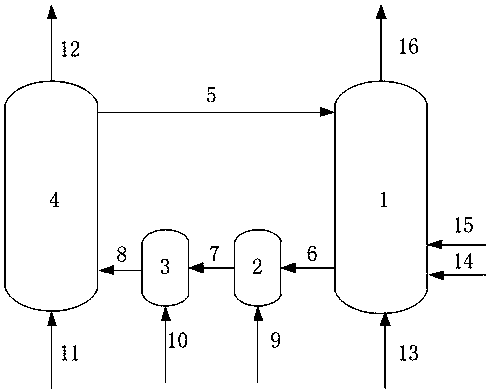

System and method for producing activated carbon and hydrogen through low-temperature pyrolysis of biomass steam

ActiveCN103011157ASimple production processReduce dustCarbon compoundsGranular/pulverulent flues gasificationCycloneCatalytic reforming

The invention provides a system for producing activated carbon and hydrogen through low-temperature pyrolysis of biomass steam. The system comprises a biomass pretreating and drying unit (1), a low-temperature steam pyrolyzing unit (2), a high-temperature cyclone separation unit (3), a steam catalytic reforming unit (4), hydrogen cooling and a purifying and separating unit (5), wherein the biomass pretreating and drying unit (1) is sequentially connected with the low-temperature steam pyrolyzing unit (2), the high-temperature cyclone separation unit (3), the steam catalytic reforming unit (4) and the hydrogen cooling, purifying and separating unit (5); and a gas outlet of the biomass pretreating and drying unit (1) is connected with the high-temperature cyclone separation unit (3). The system dries biomass, pyrolyzes the steam at a low temperature, performs steam activation on coke and performs catalytic reforming on pyrolysis gas and the steam, so that the system improves the heat utilizing rate in a pyrolyzing process, reduces the dust content and the coke content in pyrolysis air in a subsequent working section, simplifies the production process of the activated carbon and the hydrogen and is low in investment and energy consumption.

Owner:SHENWU TECH GRP CO LTD

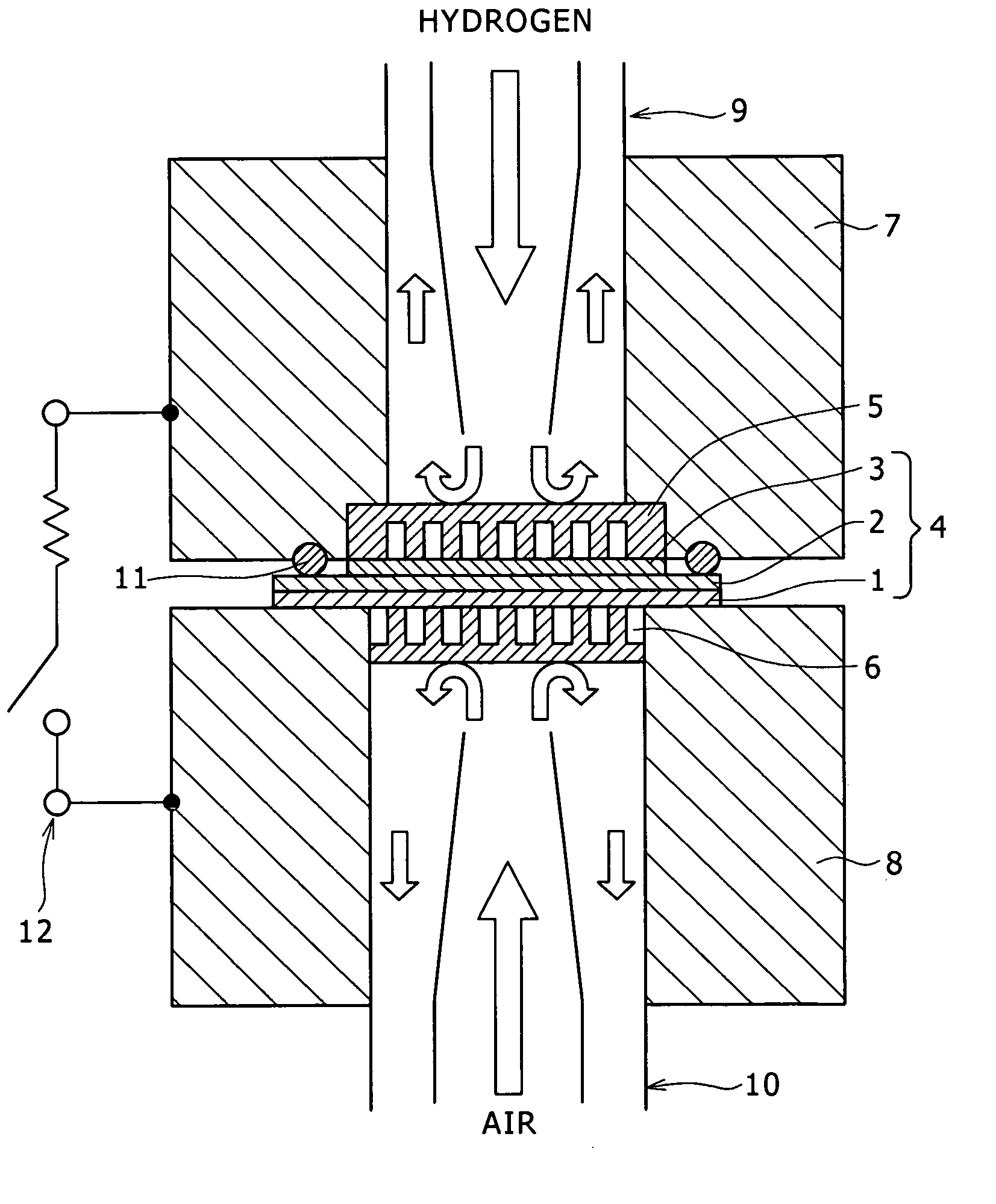

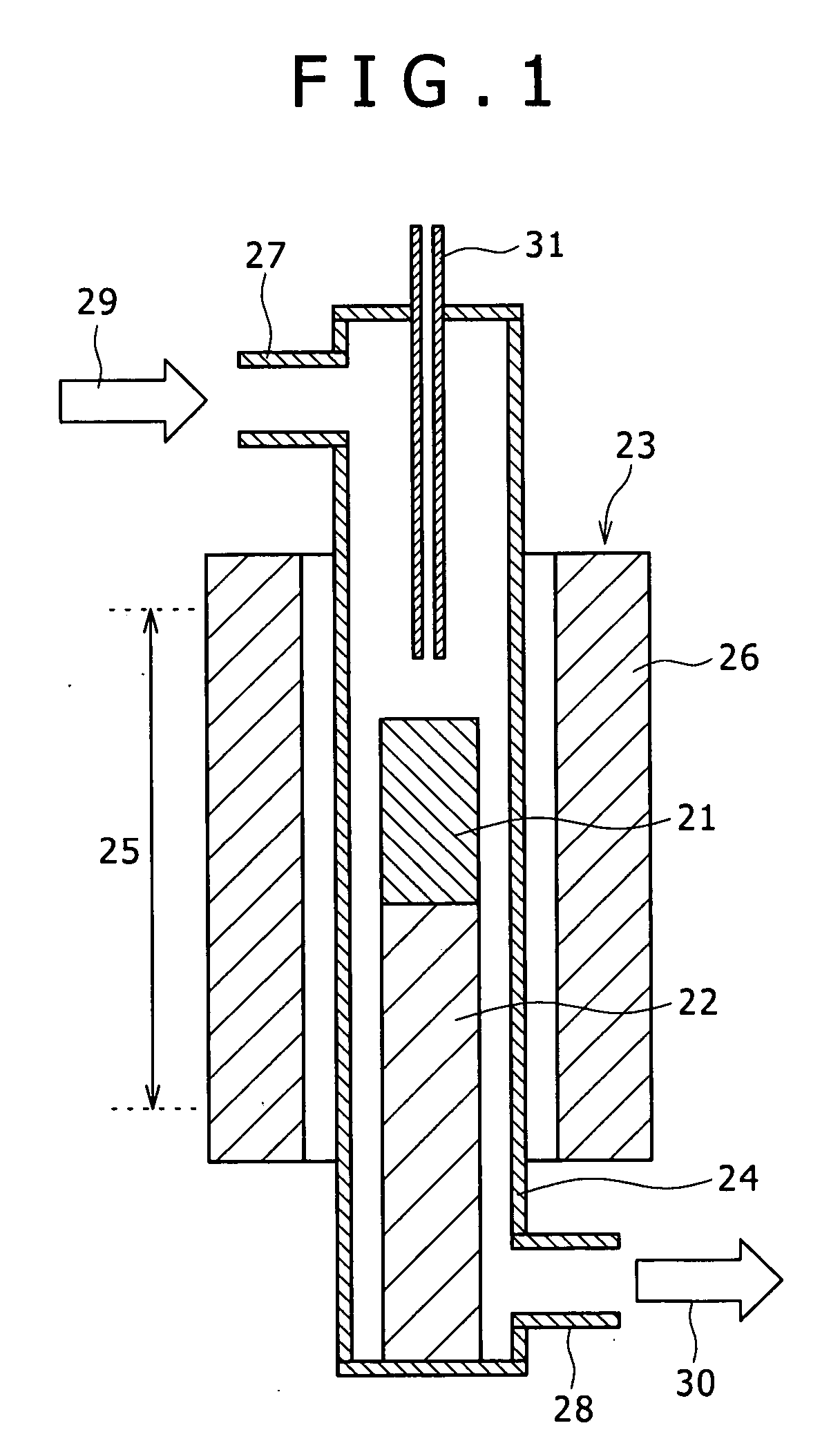

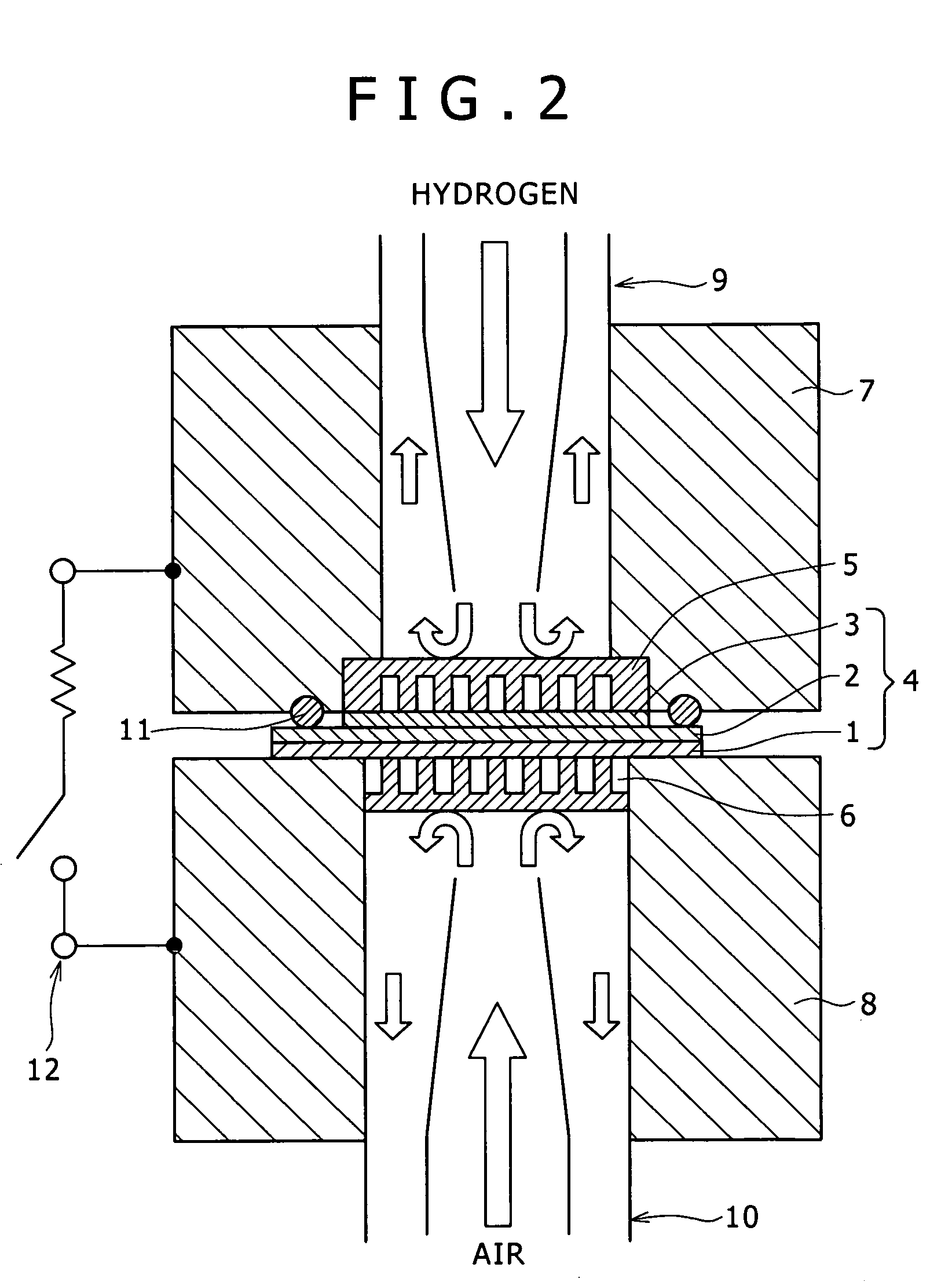

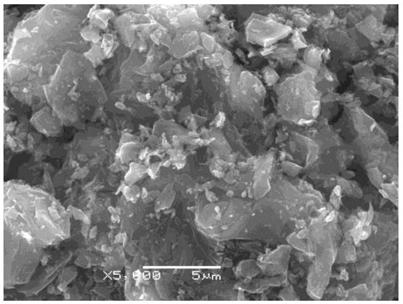

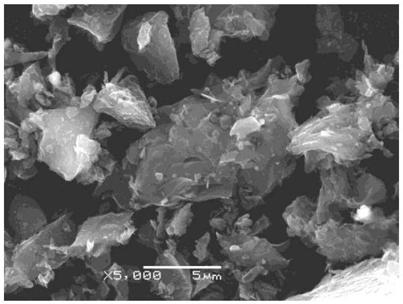

Catalyst and process for producing the same, catalytic electrode and process for producing the same, membrane/electrode union, and electrochemical device

InactiveUS20060263674A1Easy to moveEffective displayCarbon compoundsOrganic-compounds/hydrides/coordination-complexes catalystsConductive polymerCoal

In producing an oxygen reduction catalyst including a nitrogen-containing active carbide by converting either a mixture of a carbonaceous solid raw material (coal-derived binder pitch) and a nitrogen-containing organic compound (melamine or the like) or a nitrogen-containing organic polymer compound (polyacrylonitrile, melamine resin or the like) into a powdery material, baking the powdery material, and subjecting the baked product to steam activation, the presence ratio of nitrogen and the presence ratio of carbon relating to a shake-up process in the surface and the spin density of unpaired electrons showing Curie paramagnetism are controlled to be high, by selection of the baking temperature, the mixing ratio between the carbonaceous solid raw material and the nitrogen-containing organic compound, or the nitrogen-containing organic polymer compound material. In incorporating the catalyst into an electrochemical device, the catalyst and an ion conductive polymer are mixed and a catalyst layer is formed from the mixture so as to make smooth the movement of ions and electrons, and, in applying the catalyst to a polymer electrolyte type fuel cell, an MEA is produced. This makes it possible to provide a catalyst comprised of a nitrogen-containing active carbide and a production method thereof, and an electrochemical device using the catalyst.

Owner:SONY CORP

Prepn of photocatalytic titania fiber material

InactiveCN1772373AThe synthesis process is simpleMeet the requirements of "green chemistry"Physical/chemical process catalystsFiberSteam activation

The preparation process of photocatalytic titania fiber material includes the following steps: synthesizing polyacetyl ethyl acetate-titanium complex as the precursor; dissolving the synthesized polyacetyl ethyl acetate-titanium complex in tetrahydrofuran to compounding spinning liquid of viscosity 5-100 Pa.s, with the ratio between the synthesized polyacetyl ethyl acetate-titanium complex and tetrahydrofuran being 100 g to 400-800 ml; centrifugally spinning the spinning liquid of viscosity 5-100 Pa.s into short precursor fiber; dry spinning the spinning liquid of viscosity 50-100 Pa.s into continuous long precursor fiber; and final water steam activation of the precursor fiber and heat treatment and sintering. The preparation process has simple operation, easy control and low power consumption.

Owner:SHANDONG UNIV

Preparation method of millimeter activated carbon beads

The invention discloses a preparation method of millimeter activated carbon beads, comprising the following steps: dissolving 1 to 5 mass parts of polyacrylonitrile in 10 to 50 mass parts of dimethyl sulfoxide completely, and transferring the liquid into a liquid extruder gradually; keeping the distance between the liquid extruding plate at the bottom of the liquid extruder and the liquid level of the water bath liquid to 10 to 20 cm, and keeping the height of the liquid level in the liquid extruder constant with the height range of 2 to 10 cm; and dropwise adding the liquid into the water bath of 50 to 70 DEG C to obtain the spherical polyacrylonitrile resin; and carrying out the process of low temperature oxidation, carbonization and steam activation on the polyacrylonitrile resin to obtain the millimeter activated carbon beads. The invention has the advantages of simple operation, easy control, simple preparation process, low cost and low energy consumption. The preparation method is suitable for the mass production, and the activated carbon beads have the size of 1 to 3 mm.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

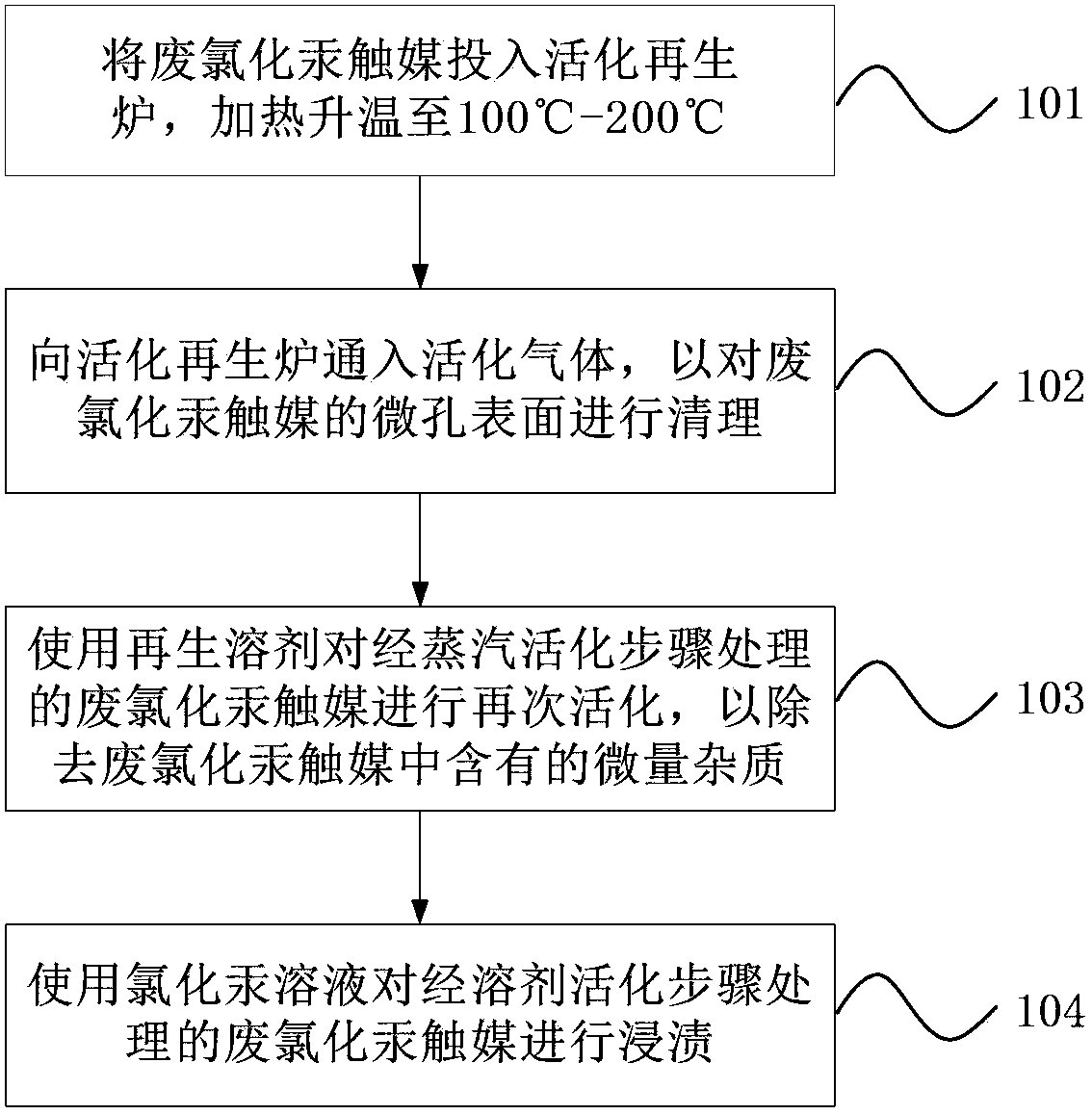

Activating and recovering method of waste mercuric chloride catalyst

ActiveCN104138767AEfficient recyclingImprove protectionPhysical/chemical process catalystsSteam activationBiological activation

An activating and recovering method of a waste mercuric chloride catalyst is provided. The method includes: a low-temperature carbonization step, namely a step of adding the waste mercuric chloride catalyst into an activation regeneration furnace and heating to 100-200 DEG C; a step of steam activation, namely a step of feeding an activating gas into the activation regeneration furnace so as to clean micropore surfaces of the waste mercuric chloride catalyst; a step of solvent activation, namely a step of activating the waste mercuric chloride catalyst again by using a regenerating solvent so as to remove a trace amount of impurities in the waste mercuric chloride catalyst; and a step of regenerating the mercuric chloride catalyst, namely a step of dipping the waste mercuric chloride catalyst with a mercuric chloride solution. The method can effectively recover and reutilize the waste mercuric chloride catalyst. Compared with the prior art, the method is advantageous in that: on the one hand, the waste mercuric chloride catalyst is free of innocent treatment, and on the other hand, the waste mercuric chloride catalyst can be reutilized, thus effectively reducing the production cost, increasing the production efficiency and facilitating environment protection.

Owner:贵州省万山银河化工有限责任公司

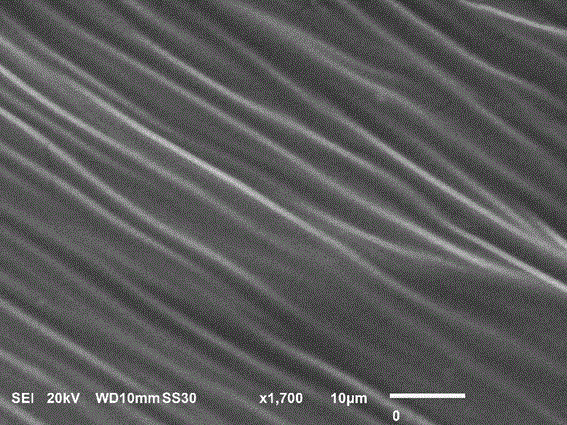

A preparation method of titanium dioxide fiber with photocatalytic function and nano-polycrystalline structure

InactiveCN102286804AImprove stabilityImprove spinnabilityPhysical/chemical process catalystsWater/sewage treatment by irradiationFiberSteam activation

The invention discloses a preparation method of titanium dioxide fibers with a photocatalysis function and a polycrystalline nanostructure. The preparation method comprises the following steps: respectively diluting titanium tetrachloride and potassium acetate, which are taken as raw materials, in ethanol, mixing at 0-10 DEG C under the condition of stirring to generate titanium acetate and potassium chloride, filtering to remove potassium chloride by taking advantage of the property that potassium chloride is insoluble to ethanol so as to acquire filtrate of ethanol in which titanium acetateis dissolved, concentrating the filtrate to obtain a titanium acetate sol spinning solution, centrifuging and spinning to obtain precursor fibers, and performing steam activation thermal treatment toobtain the titanium dioxide fibers. The preparation method disclosed by the invention has the advantages of lower raw material cost, simpler sol production process and pollution-free preparation process.

Owner:NANJING UNIV OF SCI & TECH

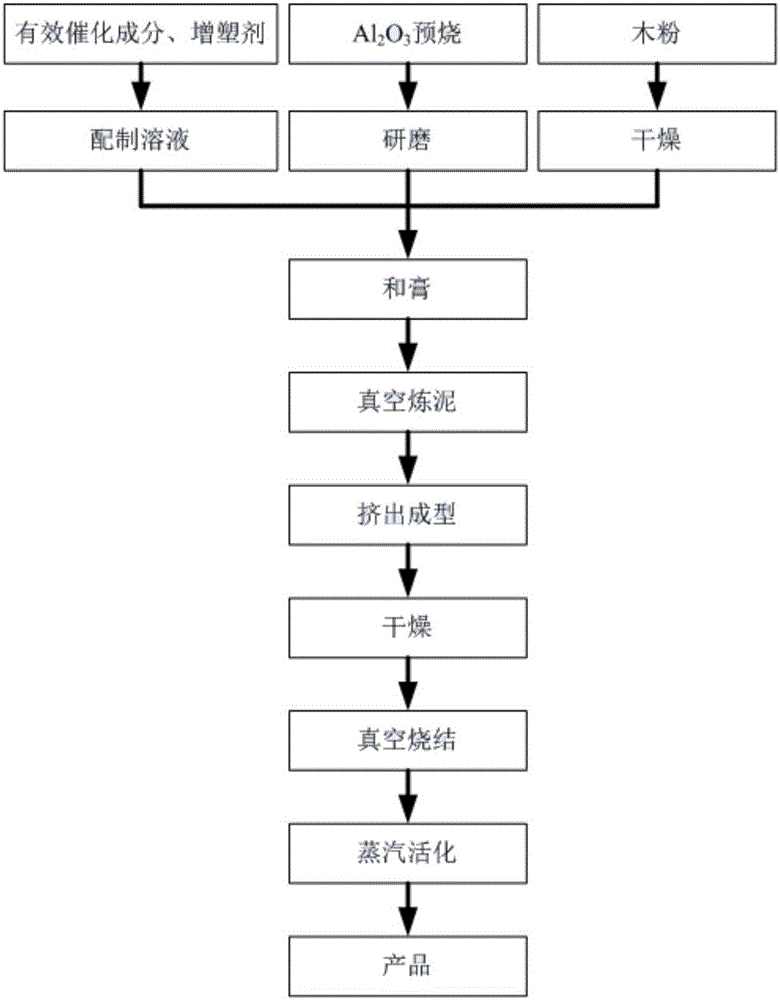

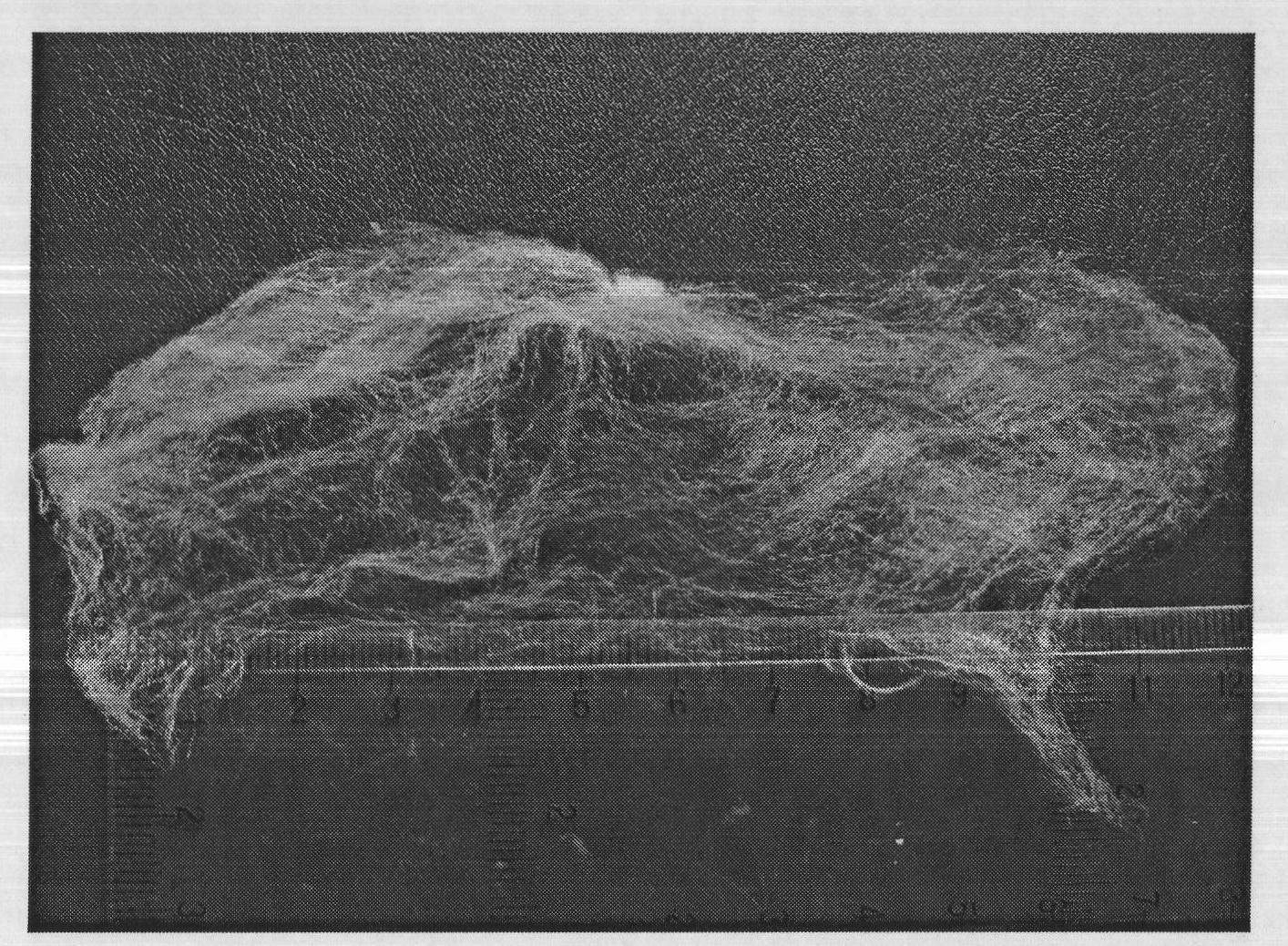

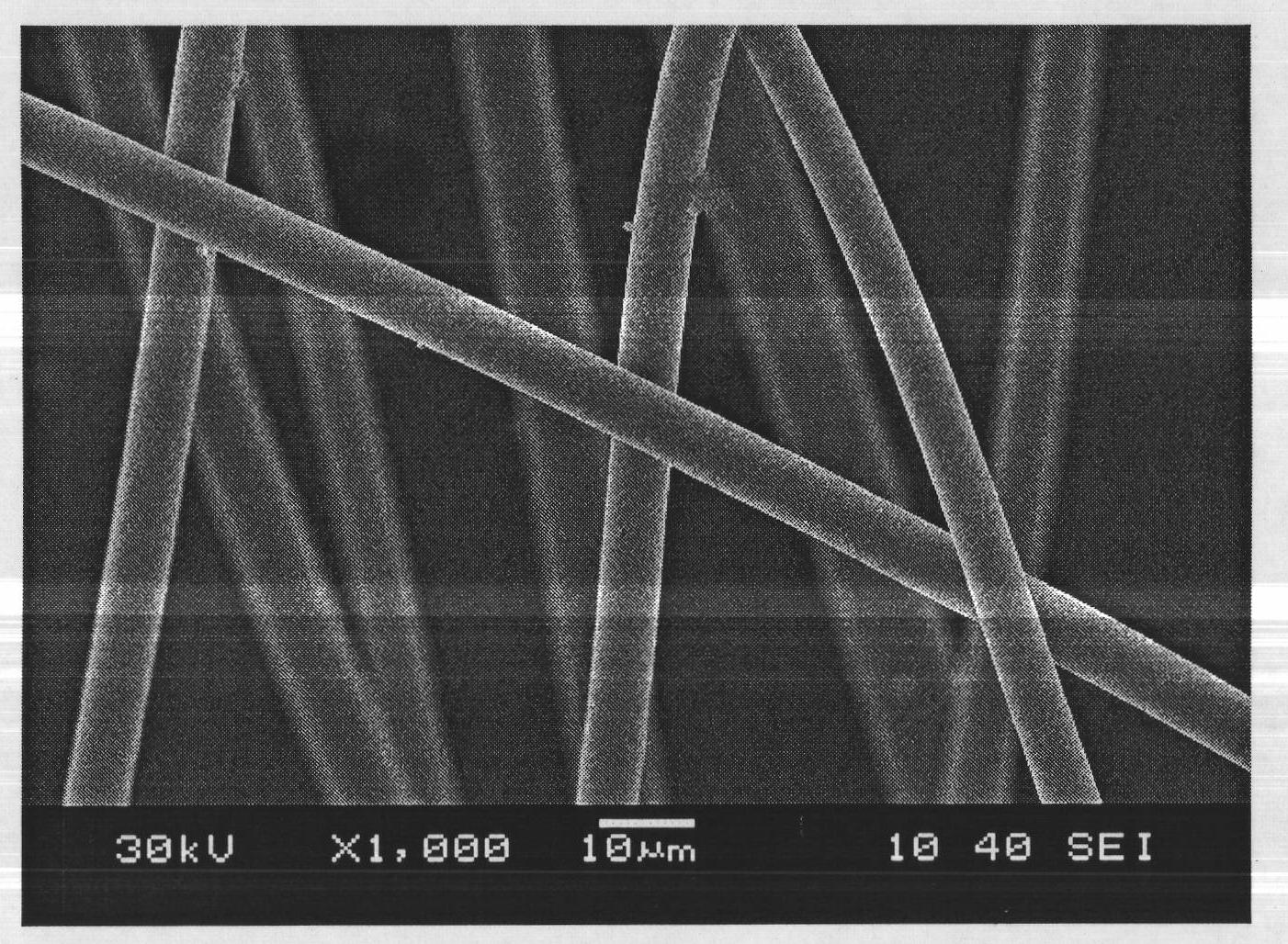

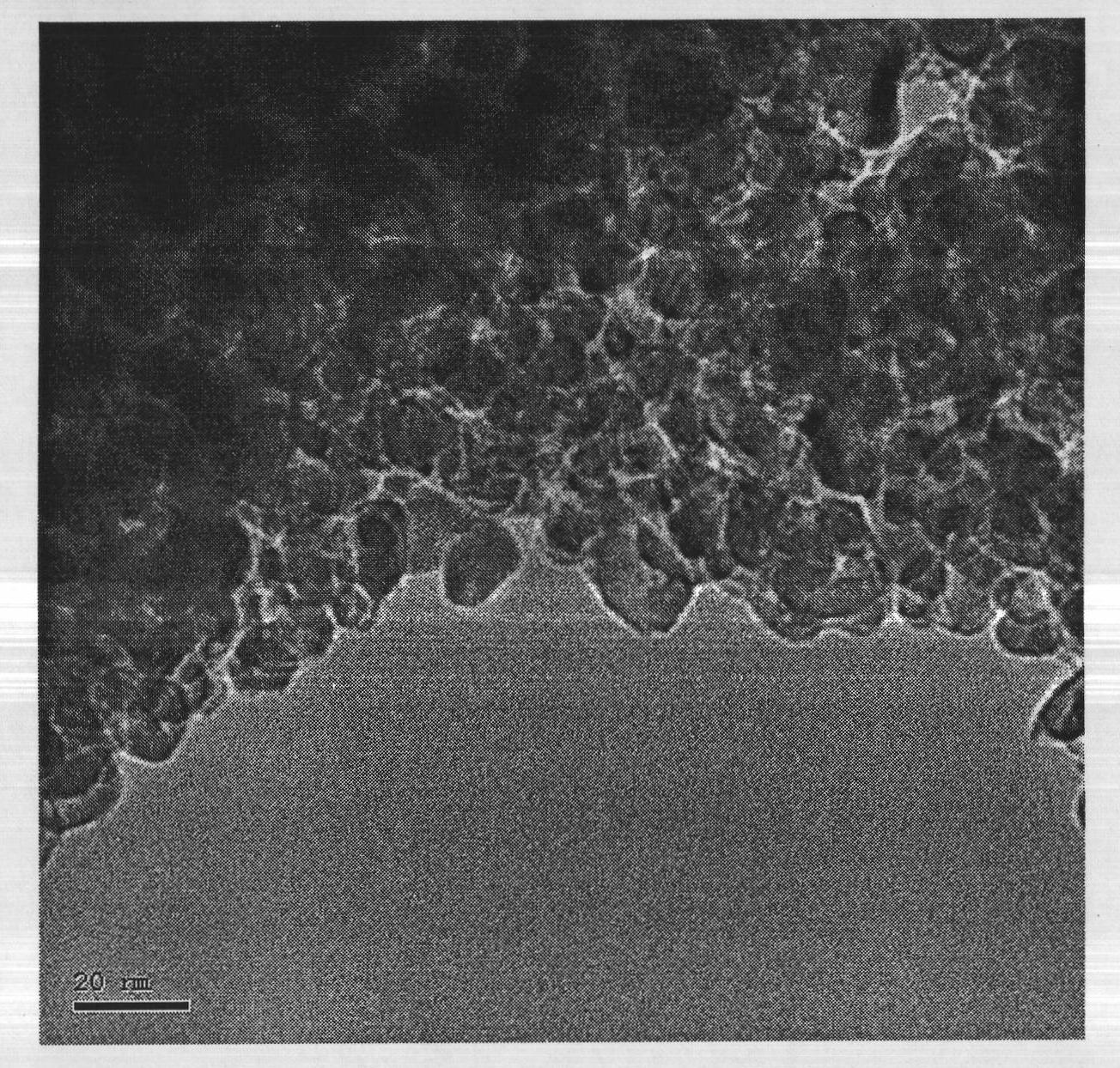

Regular honeycomb ceramic carbon carrier based doped ozone catalyst for advanced treatment of industrial wastewater and preparation method of regular honeycomb ceramic carbon carrier based doped ozone catalyst

ActiveCN106390988AHarmonized mechanical strengthCoordinating Contradictions in Enrichment and Mass TransferCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsSteam activationPolyethylene glycol

The invention discloses a regular honeycomb ceramic carbon carrier based doped ozone catalyst for advanced treatment of industrial wastewater and a preparation method of the regular honeycomb ceramic carbon carrier based doped ozone catalyst. The regular ozone catalyst is prepared by steps: mixing pre-calcined and ground 150-500-mesh Al2O3 powder with 150-500-mesh wood meal according to a specific proportion; taking hydroxypropyl methyl cellulose, polyethylene glycol and dysprosium nitrate and molybdenum nitrate aqueous solution as auxiliary forming agents, and performing paste mixing, refining, extrusion molding, drying, vacuum sintering, steam activation and the like to obtain the catalyst. The catalyst is capable of promoting enrichment and mass transfer of ozone and organic pollutants in water in an ozone catalytic oxidation process, and catalysis efficiency is improved; by adoption of aluminum oxide ceramics as skeletons, problems of damages and losses caused by reduction in material strength in the catalytic oxidation process of activated carbon are solved. The regular ozone catalyst is high in treatment efficiency, low in operating cost, convenient to fill and maintain and suitable for advanced treatment of wastewater, ozone oxidation effects are strengthened, and the decoloring rate and the COD removal rate are increased.

Owner:JIANGSU PROVINCIAL ACAD OF ENVIRONMENTAL SCI

Method for preparing nano-crystalline photocatalysis titanium dioxide fiber

InactiveCN101831728AImprove spinnabilitySpinnableInorganic material artificial filamentsFilament/thread formingFiberSteam activation

The invention discloses a method for preparing a nano-crystalline photocatalysis titanium dioxide fiber, which comprises the following steps of: synthesizing a poly-titanium sol spinning fluid by using titanium hydroxide, aqueous solution of hydrogen peroxide, organic acid and a sol as raw materials; performing centrifugal thread throwing to obtain a poly-titanium gelatinous fiber; and performing steam activation heat treatment on the poly-titanium gelatinous fiber to obtain the nano-crystalline photocatalysis titanium dioxide fiber. Compared with the prior art, the preparation of the spinning fluid is innovative and has obvious advantages, the titanium hydroxide, the hydrogen peroxide, the organic acid and the sol are used as the raw materials, and the poly-titanium sol spinning fluid can be prepared through direct reaction and concentration, so a synthetic process is greatly simplified without rigorous reaction conditions and complicated reaction equipment, and no pollution problems exist.

Owner:NANJING UNIV OF SCI & TECH

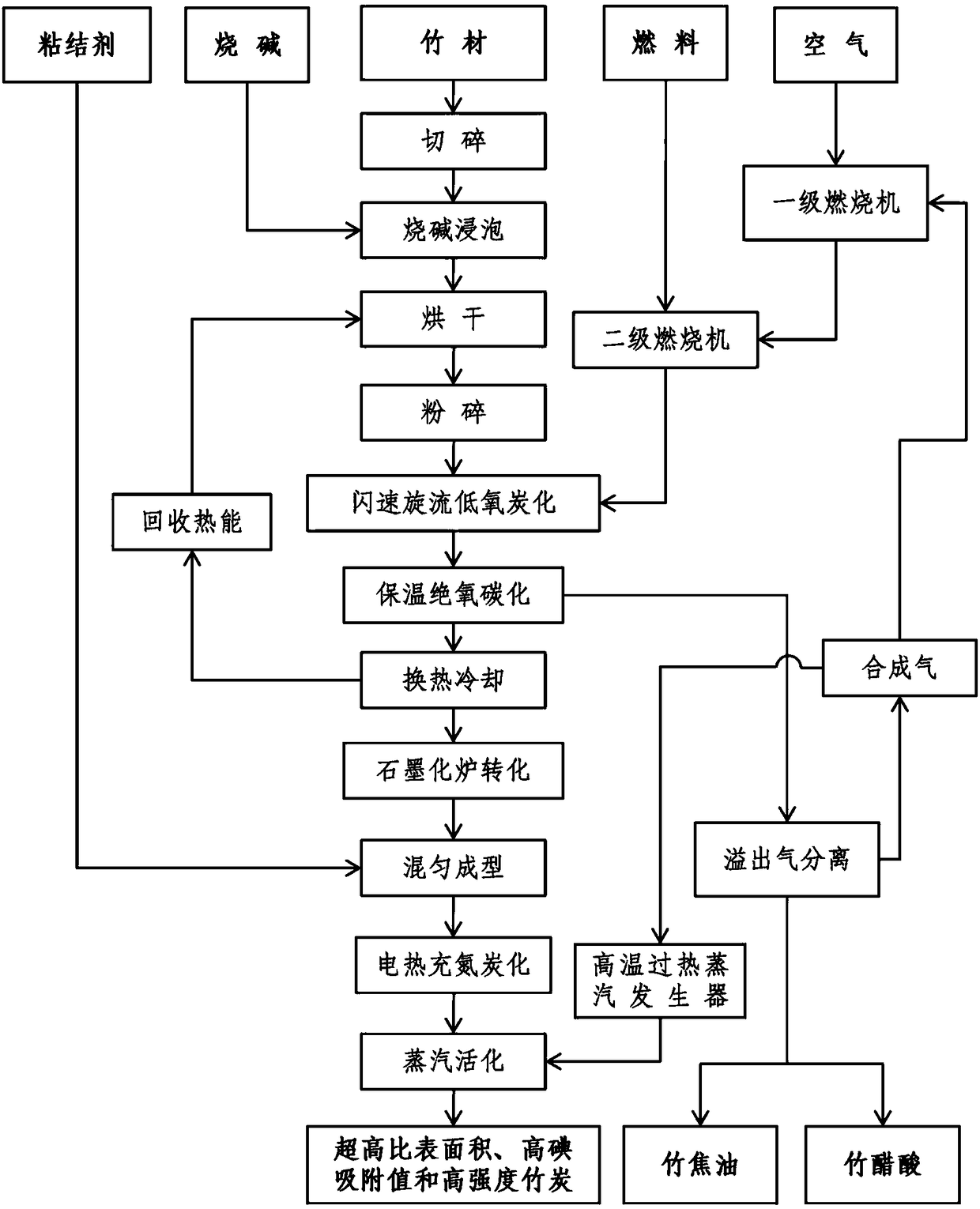

Bamboo charcoal production method and carbonization device used thereby

ActiveCN108059160AEnsure no oxidation lossAchieve recyclingCarbon compoundsBiofuelsSyngasSteam activation

The invention relates to a bamboo charcoal production method and a carbonization device used thereby. The production method comprises following steps: processing raw materials: cutting bamboos, soaking bamboos in caustic soda, and drying and grinding bamboos to obtain bamboo powder; carbonization: subjecting the bamboo powder to flash low-oxygen carbonization and oxygen free carbonization in sequence; heat transfer and cooling: subjecting the carbonization product to heat transfer and cooling in an oxygen free environment, and after cooling, obtaining first bamboo charcoal powder; conversion:converting the first bamboo charcoal powder in a graphitization furnace to obtain second bamboo charcoal powder; moulding: mixing the second bamboo charcoal powder with a binder to prepare a moulded material; electric heating carbonization: subjecting the moulded material to electric heating carbonization; and steam activation: subjecting the product of electric heating carbonization to steam activation to obtain bamboo charcoal. The method can prepare bamboo charcoal with an ultrahigh specific surface area, high iodine absorption value, and high strength, and moreover, byproducts (syngas, bamboo tar, and bamboo vinegar) are recovered. The carbonization device can also be used for the carbonization of other biomasses.

Owner:四川新磷环保技术有限公司

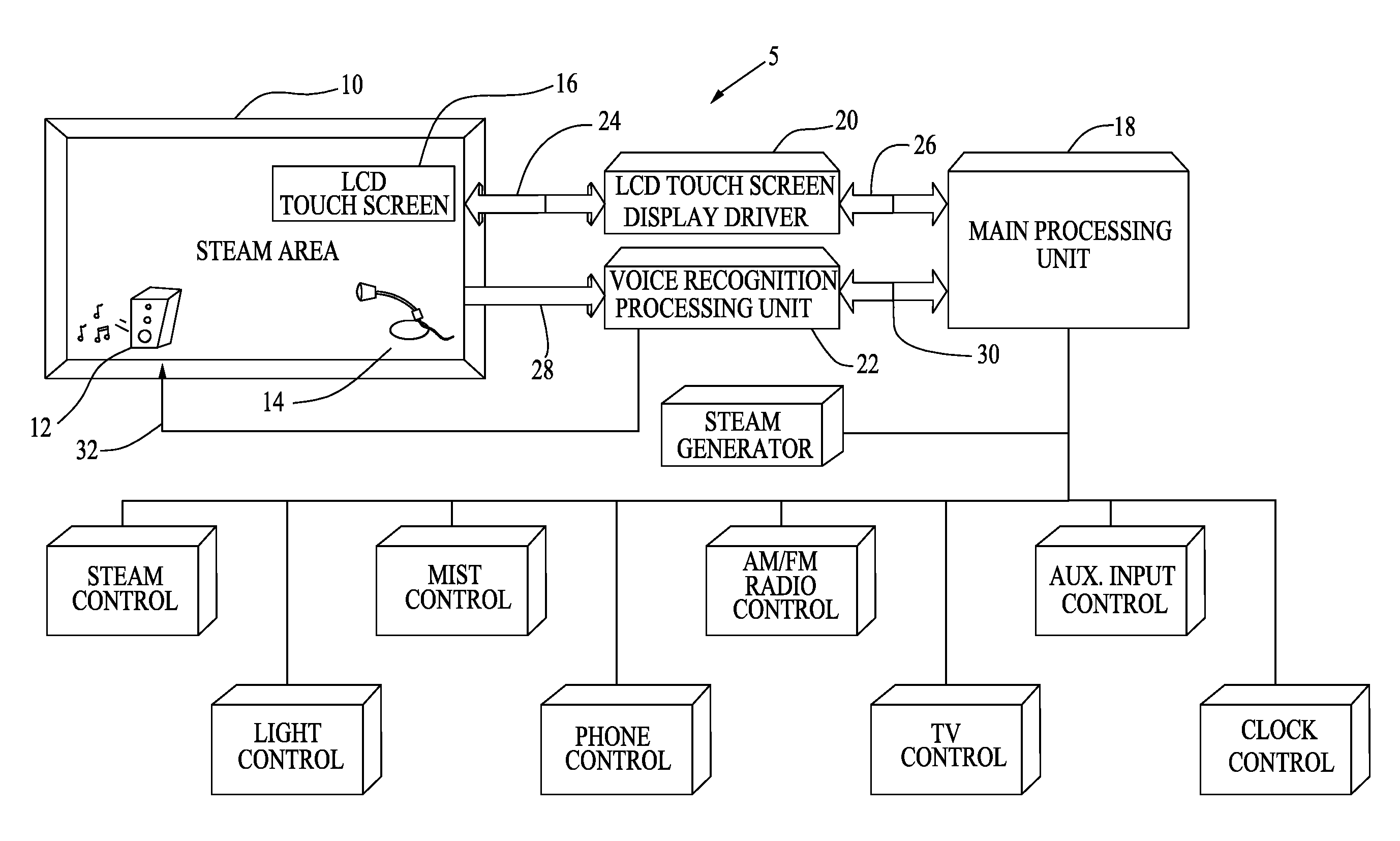

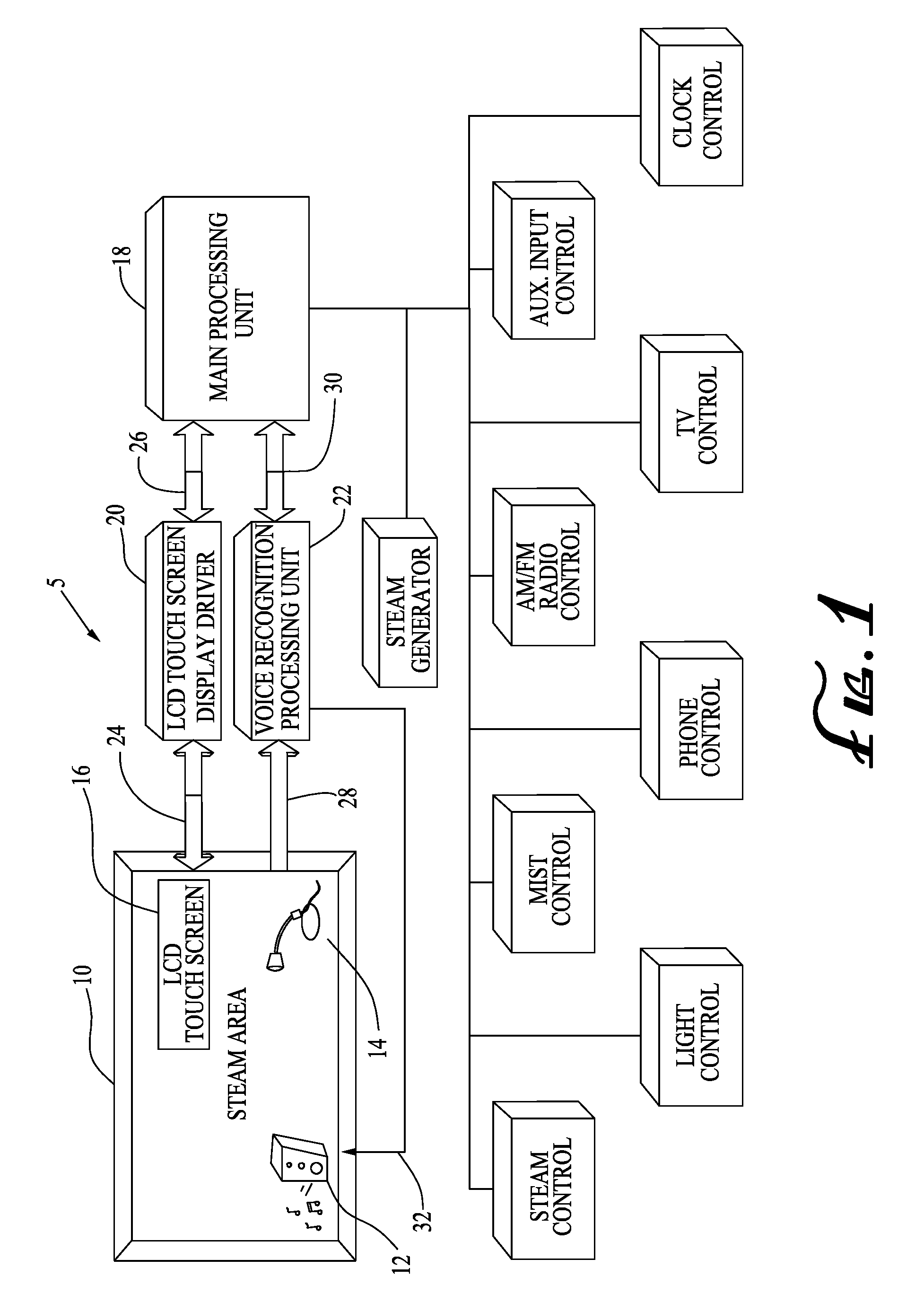

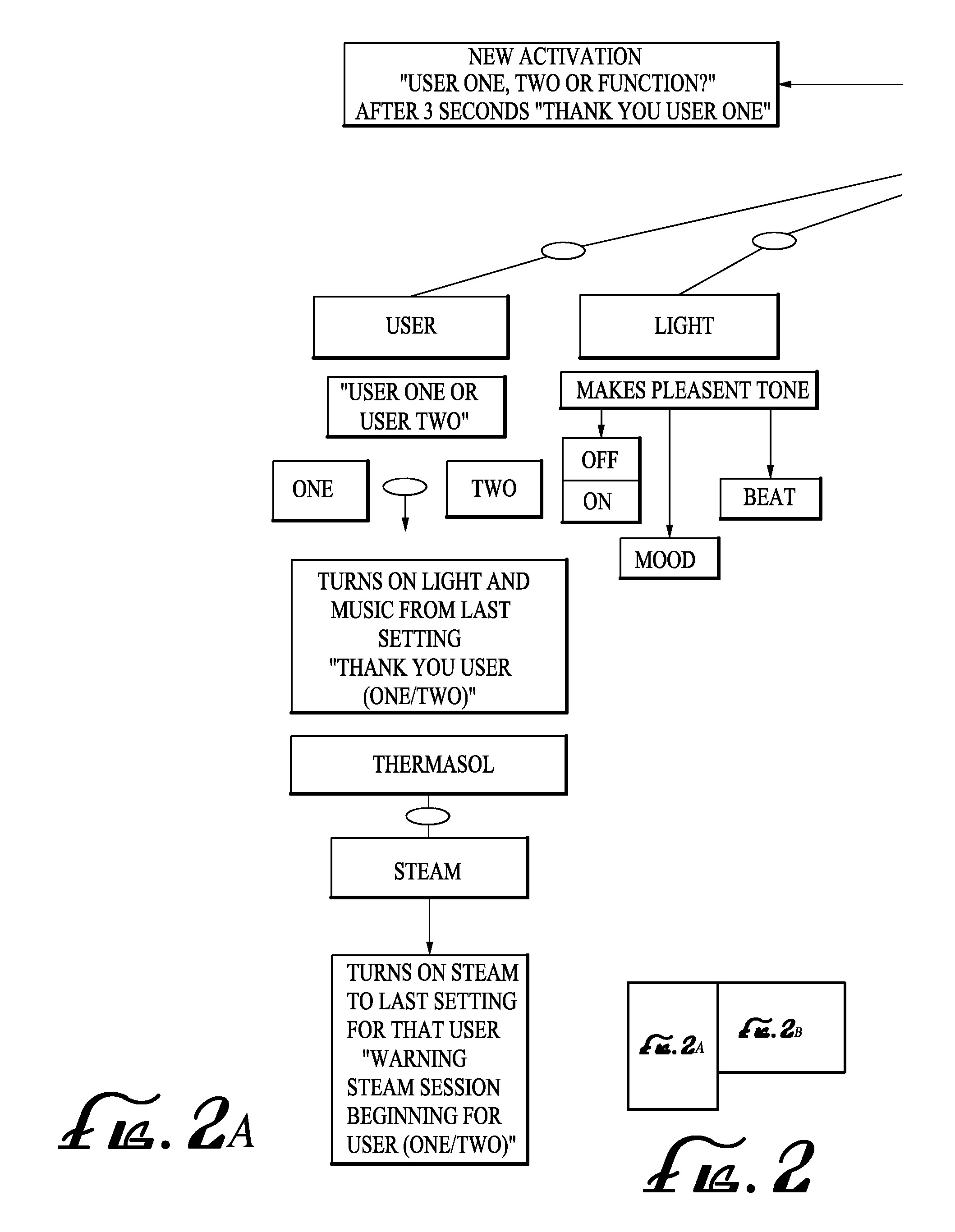

System And Method For Controlling The Environment Of A Steambath

InactiveUS20090031491A1Promote comfort and relaxation and restGain controlBathsControl signalSteam activation

A steambath system is responsive to verbal commands to control the various aspects of the shower and steam environment such as water flow rate, water temperature, steam activation / de-activation, lighting intensity and / or color, music volume, music content, quantity and type of fragrance released, showerhead selection, radio activation, volume and station selection, television activation, volume and channel selection, DVD player activation and DVD selection, CD player activation and CD selection, and humidity control.The system comprises (1) microphone means capable of converting audio signals into electrical signals and having output means for transmission of the electrical signals, (2) a voice recognition circuit having an input and an output, the input being operably connected to the microphone means output, the voice recognition circuit converting the transmitted electrical signals into digital output signals, (3) a computer processing unit operably connected to the output of the voice recognition circuit for responsive controlling of at least one control unit, the computer processing unit having an output port for transmission of control signals for said purpose; (4) a network having an input terminal and one or more output terminals, the input terminal operably connected to the output port of the computer processing unit; and (5) one or more control units, each control unit operably connected to an output terminal of the network, each control unit capable of adjusting ancillary units; wherein the microphone is located to be in audio communication with the steam room and is capable of converting audio waves in the steam room into electrical signals.

Owner:ALTMAN MITCHELL

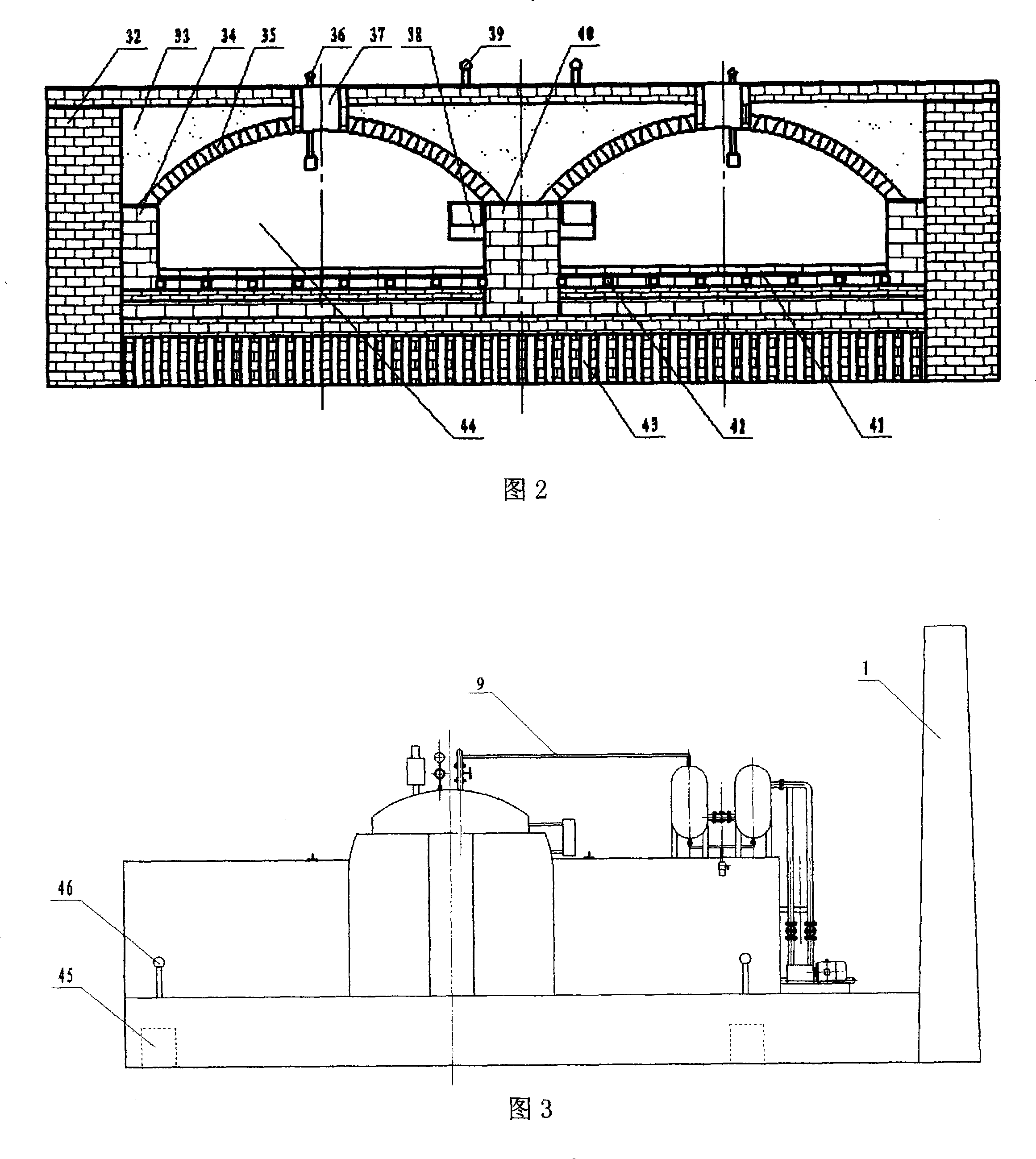

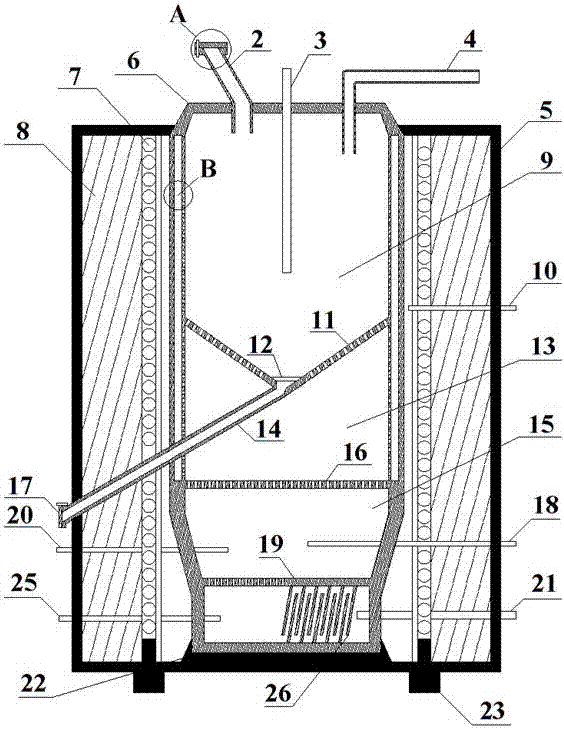

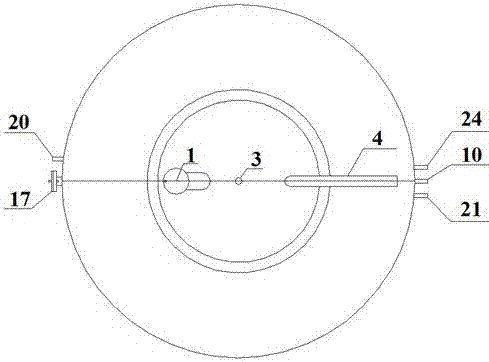

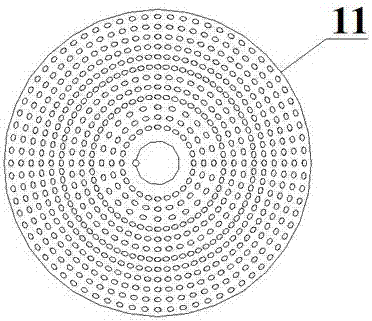

Energy-saving activating reaction furnace for preparing special activated carbon for sewage treatment

InactiveCN101224886AReduce pollution pressureReduce energy consumptionCarbon compoundsOther chemical processesCombustion chamberAdditive ingredient

The invention relates to an energy-saving activation reaction oven which is used for preparing active carbon that is specially used for wastewater treatment. The oven mainly consists of an oven body, a checker chamber, a secondary checker return combustion chamber, a steam generator, a water supply system, a steam supply system, a temperature control system and a fume extraction system. The invention adopts raw materials containing carboniferous material woodbase carbonized materials, the inherent fixed carbon content is 75-80 percent, the carbon material self-conbusts in high temperature during the activation process to produce heat quantity and the checker chamber and the secondary return combustion checker chamber are utilized for accumulating heat, the water supply system is adopted to supply water to the steam generator, a coal burning boiler is replaced by a heat-accumulating inductive steam generator of the checker chamber to generate steam, then a water steam activation agent is transferred to the hearth by a steam transfer system so as to lead the activation material in the oven to be activated under the condition of water steam and high temperature provided by the burning of the carbonized material, the activation temperature and speed can raise by the strong cycling extraction force of a chimney, the activation temperature can be controlled by an upper flue control valve and a return combustion control valve, the secondary return combustion checker chamber is utilized for raising the activation temperature in the oven and leading the activation material in the oven to be further activated sufficiently. The invention can be utilized for batch-producing active carbon with rich coarse micropores, the distribution of 10-16nm pores reaching 65 percent at least, the iodine sorption value greater than 950mg / g, and the methyl thionine chloride reaching 180-200mg / g, and the invention can be specially applied for urban multi-ingredient wastewater treatment.

Owner:盐城市炭化工业有限公司

Preparation method and application of desulfurization catalyst

InactiveCN108479744AIncreased Pore DistributionHigh activityDispersed particle separationCatalyst activation/preparationSteam activationActive ingredient

The invention provides a preparation method and application of a desulfurization catalyst, and belongs to the field of environmental protection. The catalyst takes coal gangue as a raw material, the coal gangue is subjected to calcining, steam activation, hole expanding and carbon skeleton structuring, and a porous C-Al2O3-SiO2 composite carrier is obtained; the active ingredients are loaded on the surface of the carrier. The catalyst is large in specific surface area and low in price, it is found through testing that the desulfurization efficiency is kept at 89.2% or above, and the time of duration exceeds 220 min; the catalyst can be widely applied to catalytic desulfurization of large flue gas emission enterprises such as steel enterprises, coal-fired power plants and the metallurgicalindustry; the catalyst preparation method provides a new way for comprehensive utilization of the coal gangue.

Owner:孙燕霞

Method for preparing honeycomb-shaped activated carbonwith high specific surface area

InactiveCN107235489AImprove adsorption capacityLarge specific surface areaCarbon compoundsOther chemical processesSteam activationHoneycomb

The invention discloses a method for preparing honeycomb-shaped activated carbonwith high specific surface area. The methodcomprises the following steps: 1) crushing and grinding waste powder activated carbon to be100 meshes or greater, mixing the waste powdered activated carbon andcoal tar in a mass ratio of 1:(0.5-3), and smelting at 60-150 DEG C for 1-3 hours in a kneading machine,so as to obtain a plasticized material; 2) extruding the plasticized material in a honeycomb ceramic tube extruder, and performing extrusion molding in a honeycomb mold, so as to obtain a honeycomb blank; 3) putting the molded honeycomb blank into a drying oven, drying for 12-72 hours at 80-110 DEG C, and cooling, so as to obtain a honeycomb blank; 4) carbonizing the dried honeycomb blank at 600-900 DEG C in a carbonization furnace, and cooling, so as to obtain a carbonized material; 5) performing steam activation on the honeycomb carbonized materialat 800-1000 DEG C for 1-2 hours in an activation furnace, thereby obtaining the honeycomb-shaped activated carbon. The honeycomb-shaped activated carbon prepared with the method has the characteristics of being high in strength, large in specific surface area, large in adsorption capacity, small in pressure loss, good in acid and alkali resistance and the like, and meanwhile the purpose of recycling waste powdered activated carbon is achieved.

Owner:NANJING FORESTRY UNIV

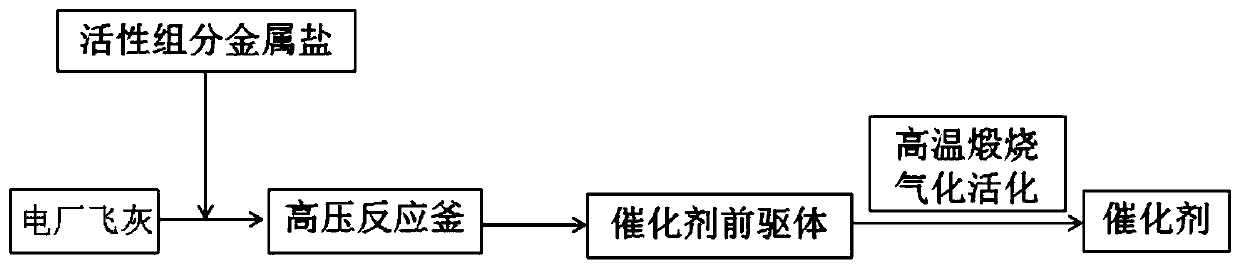

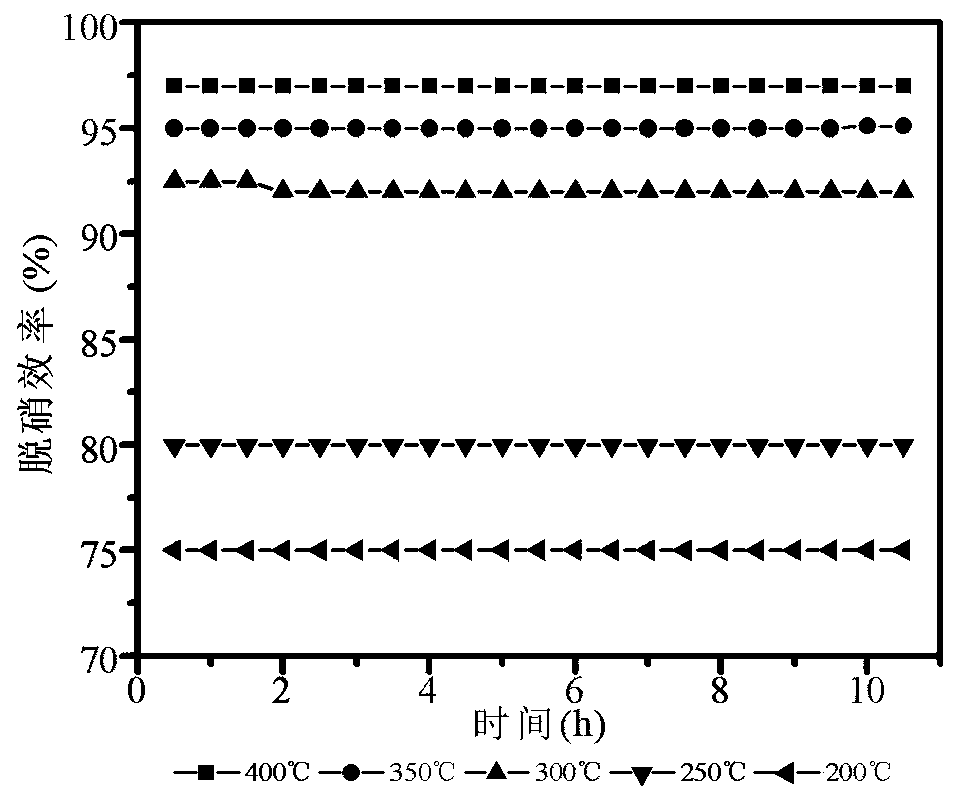

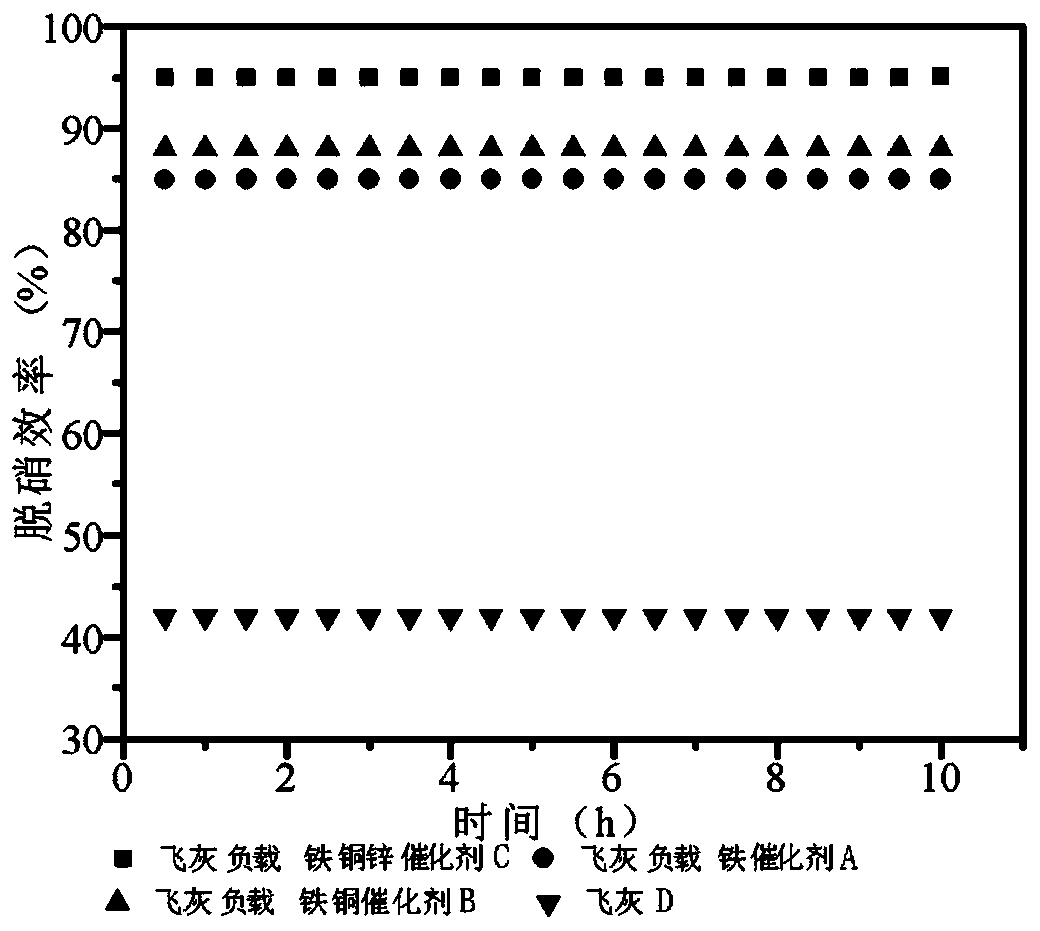

Low-cost flue gas denitration catalyst and preparation and use methods thereof

InactiveCN109794248ALow costNo secondary pollutionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsMass ratioSteam activation

The invention relates to a low-cost flue gas denitration catalyst, which is a fly ash supported metal ion catalyst prepared from metal salt and fly ash. The mass ratio of metal to fly ash in the catalyst is 1:20-1:10. The processes of the thermal decomposition of the fly ash of a power plant and the precursor of an active component and the uniform distribution of the active component is integrated. The surface of the fly ash of the power plant is smooth and compact, the pores of the fly ash are developed by using a high-pressure reaction kettle, the pore structure is richer, meanwhile, the steam activation is adopted, so that the active components are more fully and uniformly distributed on the surface of the fly ash of a carrier; the active component of the catalyst, iron-zinc-copper metal oxide, exists in the nanometer-scale particle size, so that the denitration efficiency of the catalyst is improved and the effective denitration time is prolonged; the catalyst has higher denitration efficiency, high denitration precision and strong capability of removing NOX in flue gas; the catalyst carrier fly ash raw material is cheap and easy to obtain, has no secondary pollution and reduces the cost; the equipment process is simple and the investment cost is low.

Owner:UNIV OF SCI & TECH LIAONING

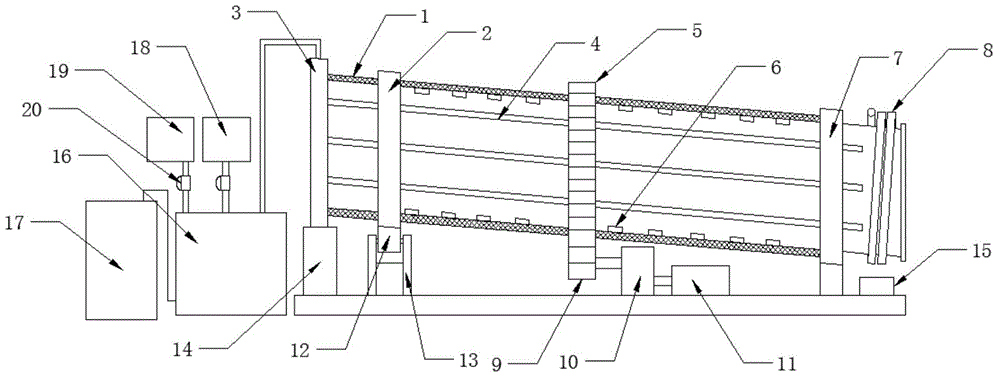

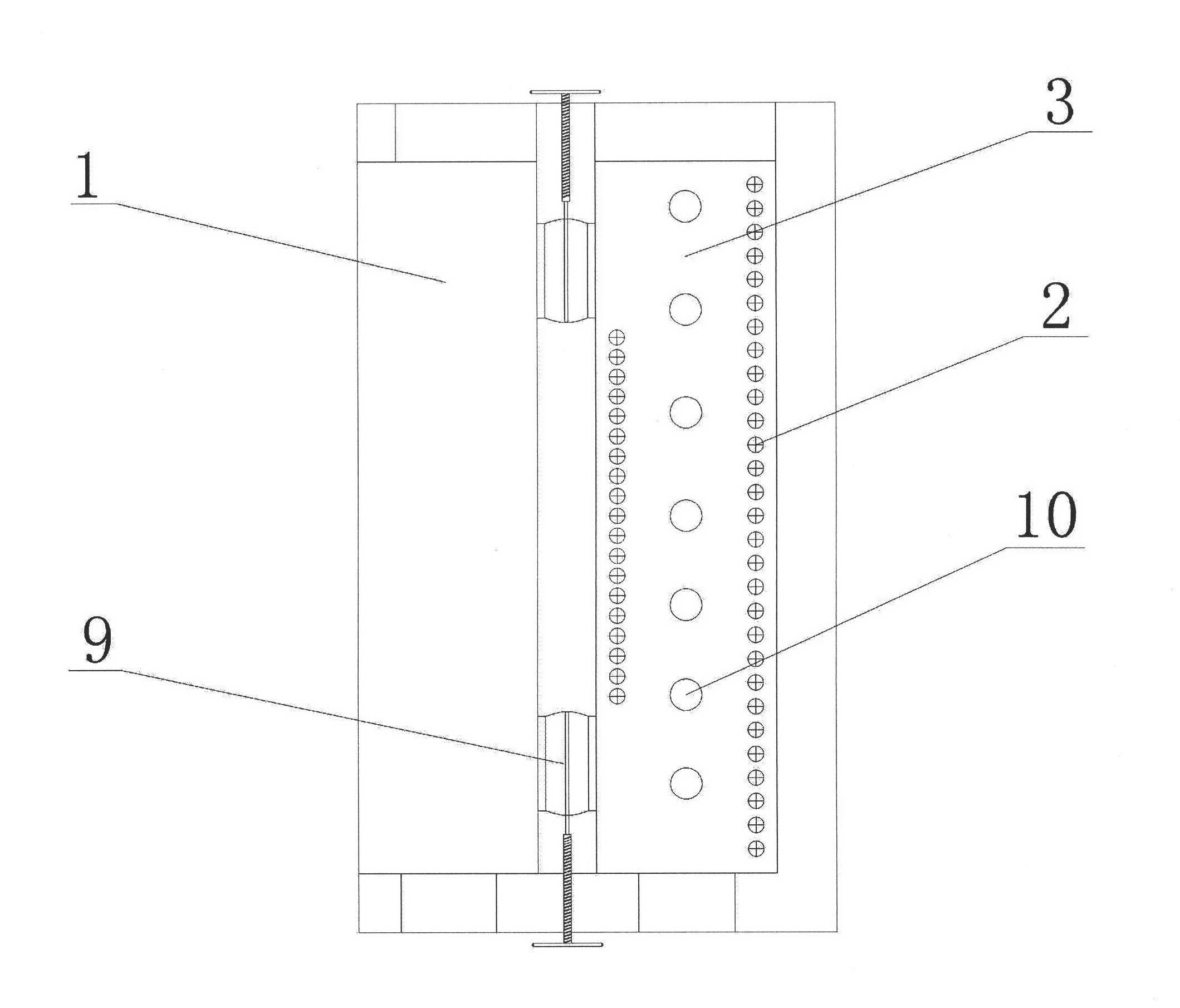

A biomass material carbonization-activation integrated device

The invention relates to a biomass material carbonization-activation integrated device, and overcomes the problems of carbonization-activation devices at present, namely a low efficiency, controlling difficulty of activation processes and high energy consumption. The device comprises a vertical carbonization furnace and a horizontal activation furnace. A vertical carbonization cylinder is disposed in the carbonization furnace. An activation spiral conveyer transversally penetrates the activation furnace. The lower end of the carbonization cylinder is connected to the initial end of the activation spiral conveyer. The carbonization furnace is also provided with steam spraying tubes communicating with the activation spiral conveyer and spraying steam to the inside of the activation spiral conveyer. The steam spraying tubes penetrate the furnace wall of the carbonization furnace. Both the activation furnace and the carbonization furnace are provided with a gas inlet and a gas discharging port. The gas inlets of the activation furnace and the carbonization furnace are connected to a combustion furnace. According to the device, steam activation has no influence on carbonization. An activation process adopts the steam spraying tubes to spray the steam, and the activation spiral conveyer is cooperated for control, thus effectively controlling the using amount of the steam, ensuring full contact between the steam and a carbon layer, ensuring activation effects, and reducing the using amount of the steam. The heat of the activation itself can be utilized to heat the steam in the steam spraying tubes, thus reducing extra energy consumption for heating steam.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

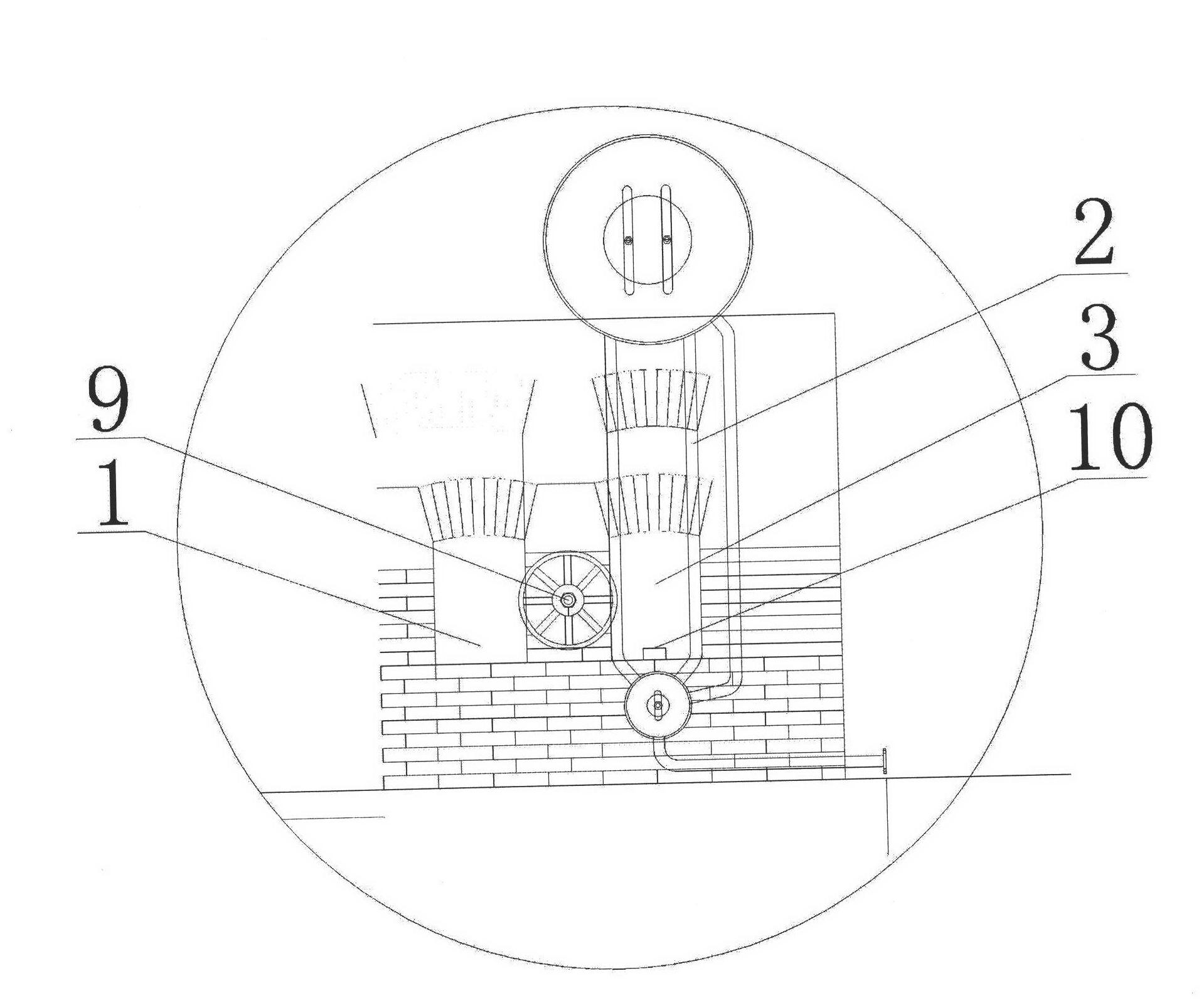

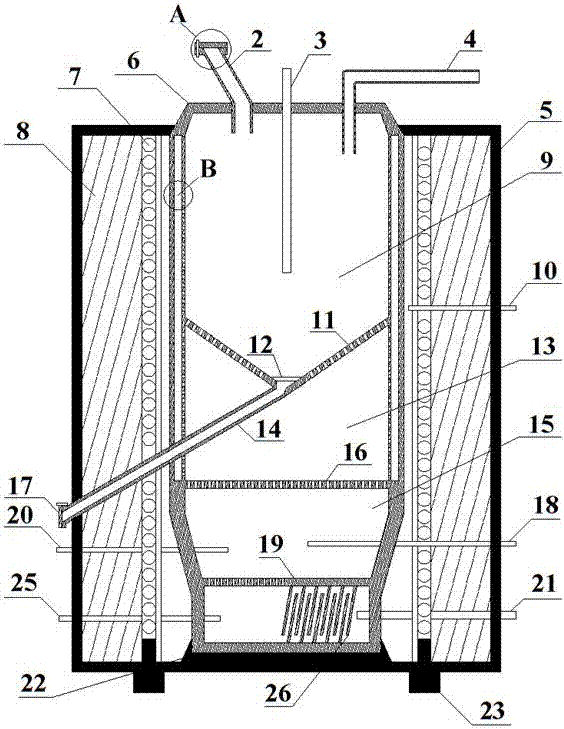

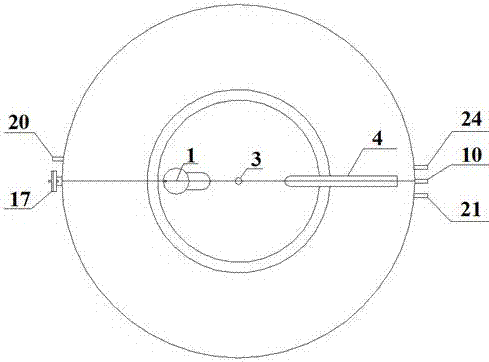

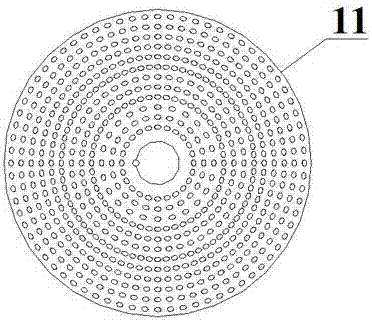

Rotational steam activation furnace

InactiveCN104973599AAvoid burnsReasonable structureCarbon compoundsEnergy inputCombustionSteam activation

The invention discloses a rotational steam activation furnace, which comprises a rotational furnace body, a fixed furnace body, an exhaust-heat boiler, and a water pot. One end of the rotational furnace body is movably installed on the fixed furnace body; both a front rolling wheel and a rear rolling wheel, arranged at two ends of the rotational furnace body, are supported via a bearing rolling wheel; a rotational gear in the middle of the rotational furnace body is engaged with an active gear; the active gear is connected to an electric motor via a speed reducer; a material collecting cylinder is arranged below a material discharging track arranged at the end of the rotational furnace body; a plurality of steam pipelines communicating with the fixed furnace body are arranged at the outer wall of the rotational furnace body; a plurality of steam jets connected to the steam pipelines are installed on the inner wall of the rotational furnace body; the top end of the fixed furnace body is connected to the exhaust-heat boiler and the water pot via pipelines in sequence; and the exhaust-heat boiler is connected with two gas separating bags. The rotational steam activation furnace is reasonable in structure, and can ensure burning charcoal to be in an oxygen-free state during material discharging and prevent the burning charcoal against combustion. The temperature is lowered; the loss ratio is reduced; the rotational steam activation furnace is energy-saving and environment-friendly; and the quality of a product is improved. At the same time, materials in the rotational furnace body are ensured to uniformly react.

Owner:HEBEI DEQIAN ENVIRONMENTAL PROTECTION TECH CO LTD

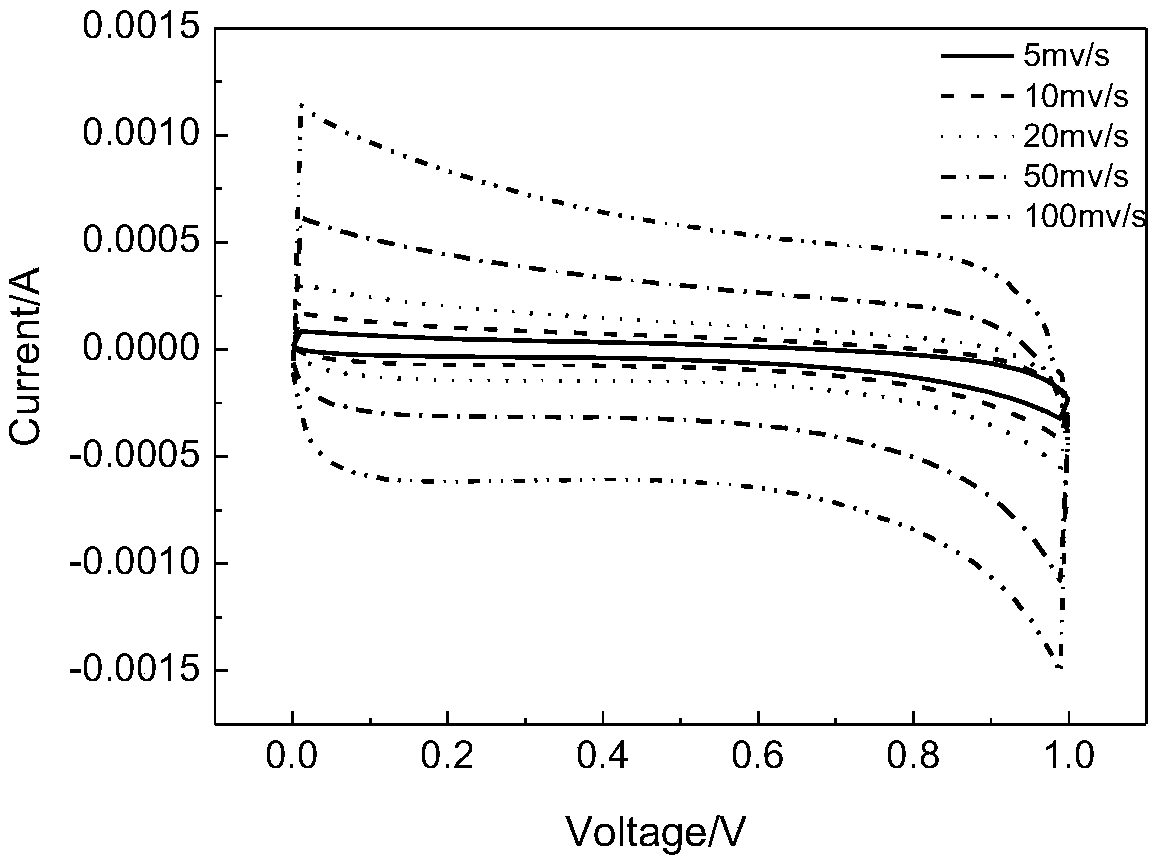

Preparation method of porous carbon electrode material for supercapacitor

ActiveCN109110758AEasy to getLow priceCarbon compoundsHybrid capacitor electrodesPorous carbonSteam activation

The invention provides a preparation method of a porous carbon electrode material for a supercapacitor. The method comprises the following steps of by taking asphalt as a main raw material, adding a pore-forming agent and a catalyst, and sequentially performing a mixing technology, an air oxidation stabilization technology, a carbonization technology and a water steam activation technology to obtain a high-specific surface area porous carbon material. Compared with the prior art, the preparation method has the beneficial effects that by taking coal asphalt as a raw material, the coal asphalt is liable to acquire and low in cost; and in addition, the disadvantages of high cost of an activator, corrosion on equipment, environmental pollution, residue of chemical medicines on products and thelike of the traditional technology of preparing the porous carbon material by using acid and alkali to perform activation. Therefore, the preparation method is economic, effective and environmentallyfriendly, is controllable in pore diameter distribution and high in specific surface area and is a preparation method relatively suitable for preparing an electrode material for the supercapacitor.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

A kind of activated carbon activation method of hydrogen combustion steam activation furnace

InactiveCN105800609BLarge specific surface areaPrecisely control the production volumeCarbon compoundsChemical industryActivation methodSteam activation

The invention discloses an active carbon activation method of a hydrogen burning water vapor activation furnace. The method comprises the following steps: adding the pretreated carbonization raw material into an activation reaction section of the activation furnace; in a nitrogen atmosphere with a normal pressure, heating to form primary active carbon; proportionally introducing hydrogen and oxygen into the bottom layer of the activation furnace at the same time and mixing; enabling the mixture to rise to a gas mixing firing section of the activation furnace through a first-level gas distribution plate, and mixing with the introduced nitrogen for reacting to generate water vapor; enabling the water vapor serving as an activator to rise into a gas buffering distribution section through a second-level gas distribution plate for buffering and then rise for an activation reaction with the primary active carbon through a material support gas distribution plate; and in the nitrogen atmosphere, cooling to obtain active carbon. In the method, a new activator introducing way is provided, and the generation amount of water vapor is accurately controlled through the introduced oxygen while the heat energy released by the burning of hydrogen and oxygen is utilized; and therefore, the energy is saved, and the activation efficiency is improved.

Owner:TAIYUAN UNIV OF TECH

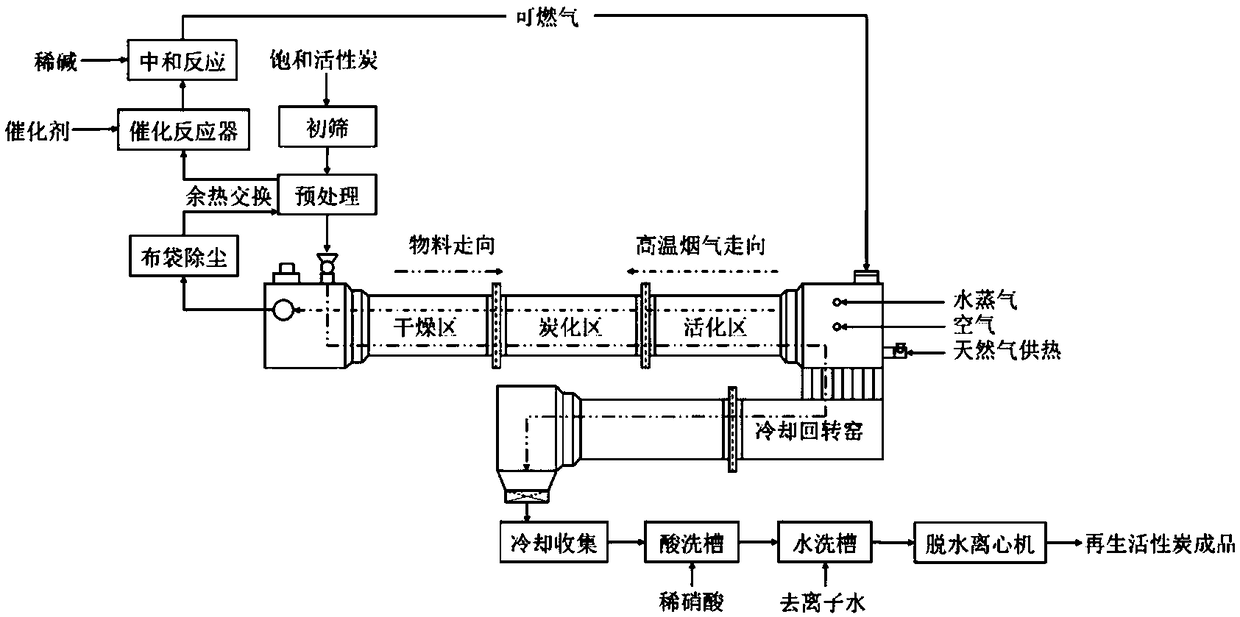

Technology for regeneration of waste activated carbon for adsorbing saturated chlorohydrocarbon organic compounds and treatment of waste gas thereof

ActiveCN109225179AImprove utilization efficiencyTo achieve the purpose of energy savingDispersed particle filtrationCombustible gas purificationCatalytic reformingSteam activation

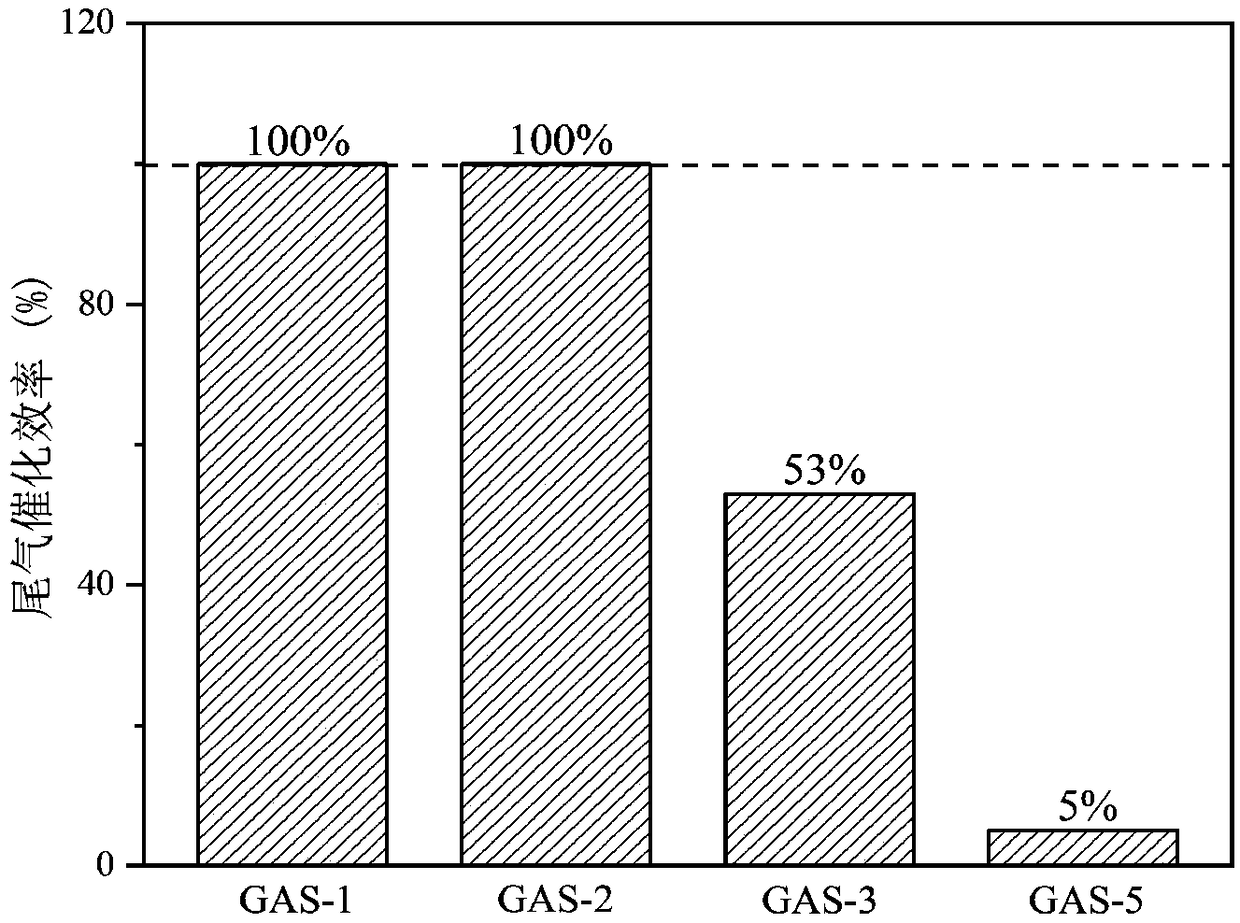

The invention discloses a technology for regeneration of waste activated carbon for adsorbing saturated chlorohydrocarbon organic compounds and treatment of waste gas thereof. A method is characterized in that the drying, heating and regeneration, carbon dioxide and water steam activation and the like are continuously performed on the waste activated carbon by a rotary kiln, and the acid oxidizingand other methods are used for activating. The technology has the advantages that the regeneration time is short, the restoration rate is high, and the adsorption property of the regenerated activated carbon is excellent; for a large amount of high-temperature tail gas of chloride-containing organic waste gas, the self high-temperature heat and water steam are used for catalytic reforming reaction, and the catalytic reforming efficiency can reach 100%; the organic waste gas is converted into hydrogen gas and other combustible gases, so that the waste resources can be recycled and reutilized,and the secondary pollution to environment is avoided.

Owner:CENT SOUTH UNIV +1

Saddle type activation furnace steam self-supply device

InactiveCN102275912AReduce manufacturing costImprove product qualityCarbon compoundsCombustion chamberWater storage tank

Saddle-type activation furnace steam self-sufficiency device, the purpose is to save resources, reduce pollution gas emissions, improve the quality of activated carbon products, the invention includes the main combustion chamber, auxiliary combustion chamber, evaporator network pipe, heat exchanger, heat storage tank bottom flue, soft water Water storage tank, soft water supply pipe, frequency conversion constant pressure pump, adjustable ram, adjustable air supply pipe. An adjustable ram is installed between the main combustion chamber and the auxiliary combustion chamber, the evaporator network pipe is installed inside the auxiliary combustion chamber, the heat exchanger is installed in the flue at the bottom of the heat storage tank of the activation furnace, and the frequency conversion constant pressure pump is installed In the soft water supply pipe between the tank and the evaporator network pipe of the auxiliary combustion chamber, the adjustable air supply pipe is installed at the bottom of the auxiliary combustion chamber. The amount of air required for gas combustion to fully burn the combustible gas, heat the evaporator, and generate steam.

Owner:泰州达能新能源有限公司

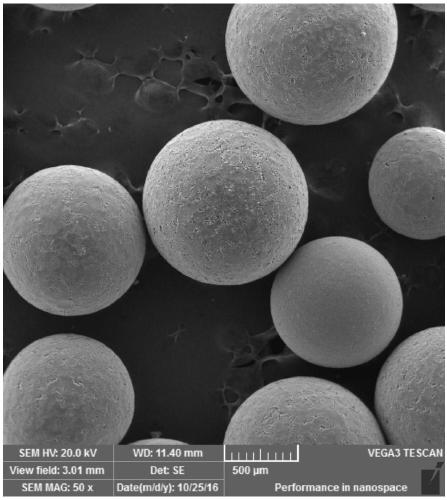

Method for preparing mesoporous asphalt base enriched spherical activated carbon

The invention discloses a method for preparing mesoporous asphalt base enriched spherical activated carbon. The method comprises the following steps: grinding an asphalt raw material and a Lewis acidcatalyst into micro powder, putting into a high-pressure reaction kettle, performing direct sealing heating to reaction temperature, stirring, performing a constant-temperature reaction so as to obtain asphalt with a part of a middle phase, grinding the asphalt, performing ultrasonic treatment in an organic solvent, pouring into the reaction kettle, adding a surfactant, namely polyvinyl alcohol, and water, performing stirring heating to obtain suspended spheres, oxidizing the spheres without melting, and performing water steam activation, thereby obtaining the mesoporous asphalt base enrichedspherical activated carbon. The mesoporous asphalt base enriched spherical activated carbon has the advantages of being simple in method, free of additives, large in specific surface area, good in heat conductivity and high in mesopore content.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

A hydrogen combustion steam activation furnace

InactiveCN105800608BIncrease engagementAvoid condensationCarbon compoundsChemical industrySteam activationWater vapor

The invention provides a hydrogen burning water vapor activation furnace. The activation furnace is formed by a material activation reaction section, a gas buffer distribution section and a gas mixed burning section, wherein a feeding hole and an exhaust emission pipe are formed in the material activation reaction section; a material supporting gas distribution plate and a discharge pipe upper baffle are arranged at the bottom of the material activation reaction section and the bottom is communicated with a discharge pipe; the gas buffer distribution section is arranged below the material supporting gas distribution plate and the discharge pipe; a secondary gas distribution plate is arranged at the bottom of the gas buffer distribution section; the gas mixed burning section is formed by the secondary gas distribution plate and a primary gas distribution plate; a nitrogen inlet pipe is communicated in the gas mixed burning section; a hydrogen and oxygen mixer is arranged below the primary gas distribution plate and is communicated with an oxygen inlet pipe and a hydrogen inlet pipe. The activation furnace has the beneficial effects that the water vapor is controlled by inlet oxygen to activate materials via the distribution plates, thus utilizing the heat energy and saving the energy; besides, the materials are activated uniformly, thus improving the activation efficiency.

Owner:TAIYUAN UNIV OF TECH

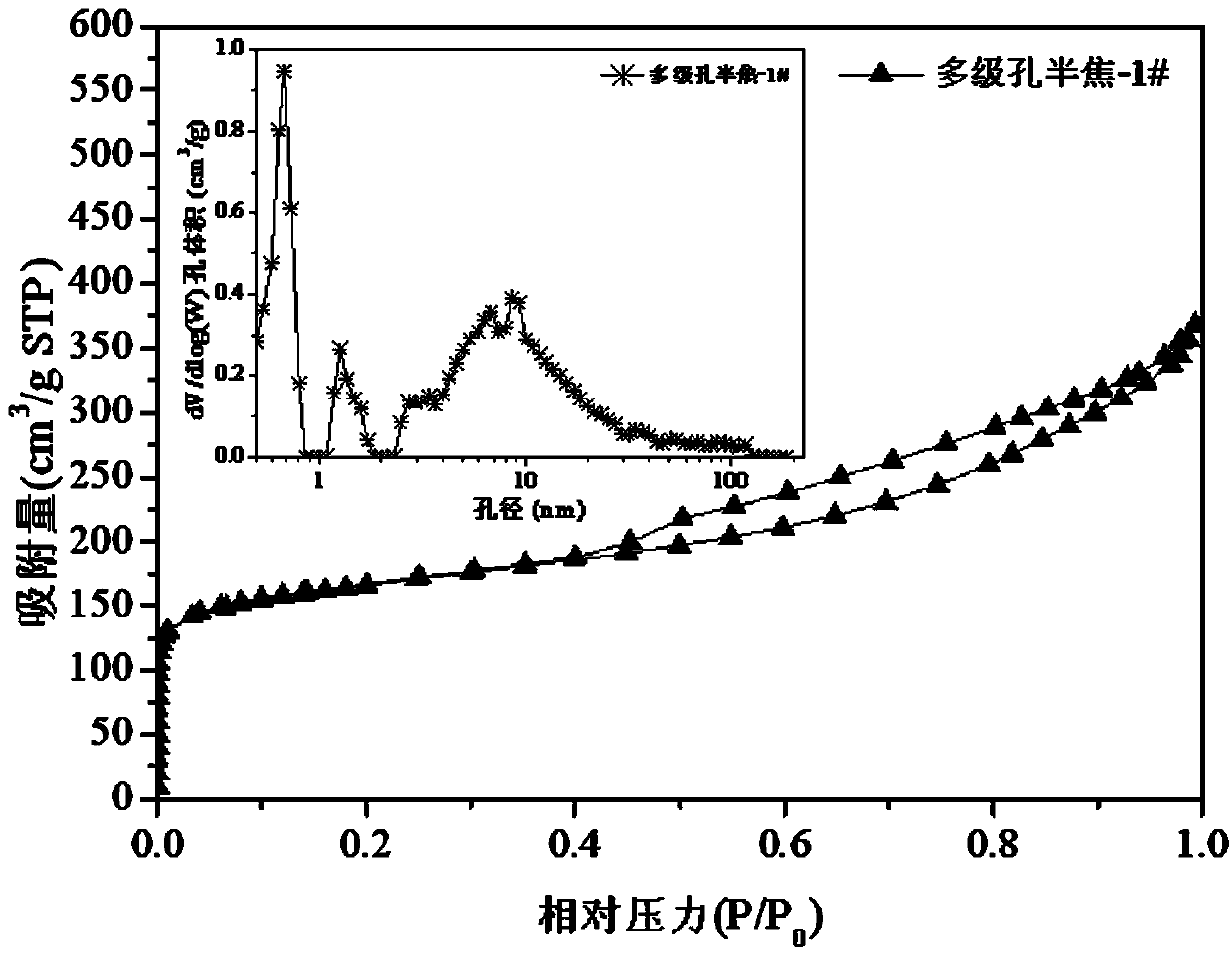

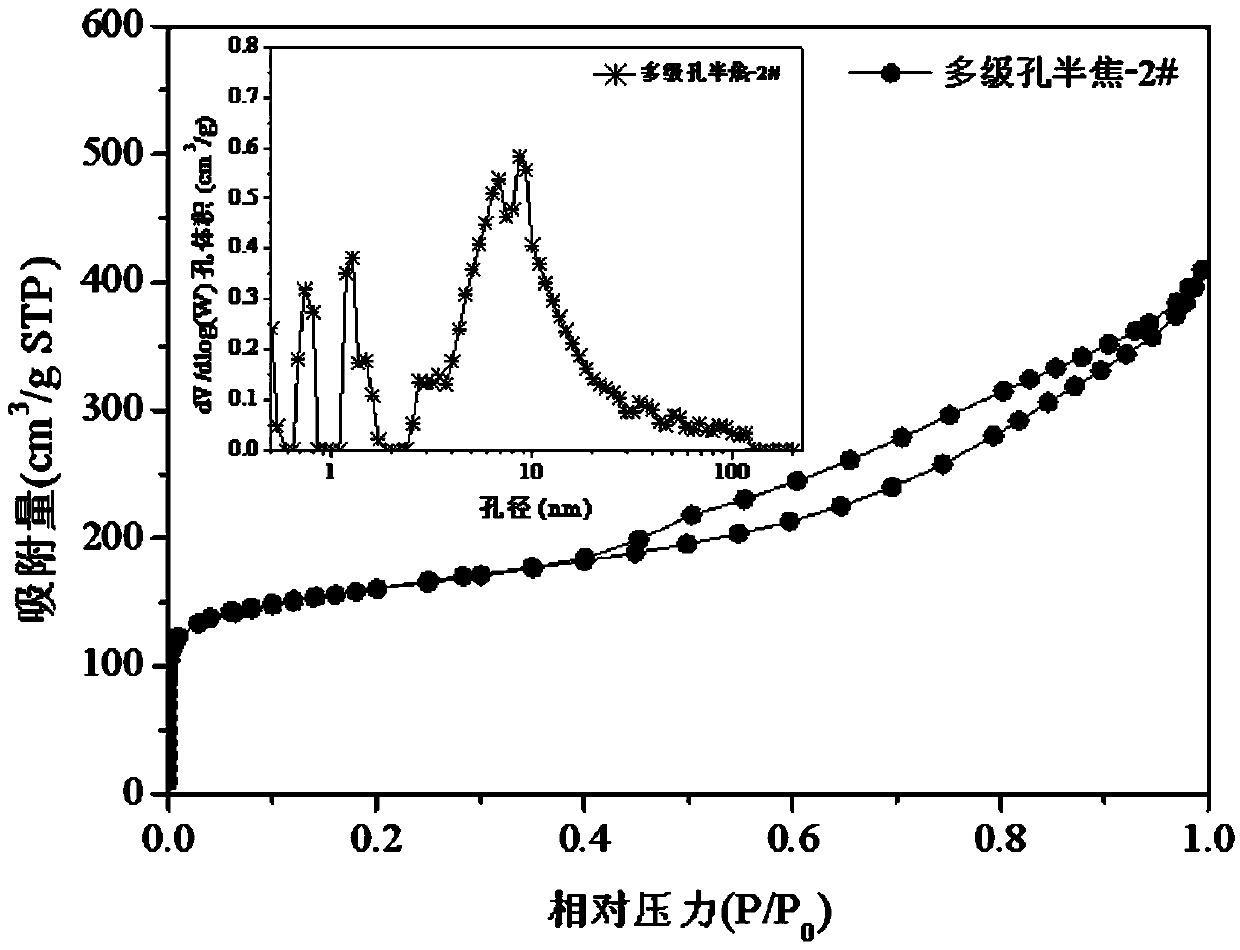

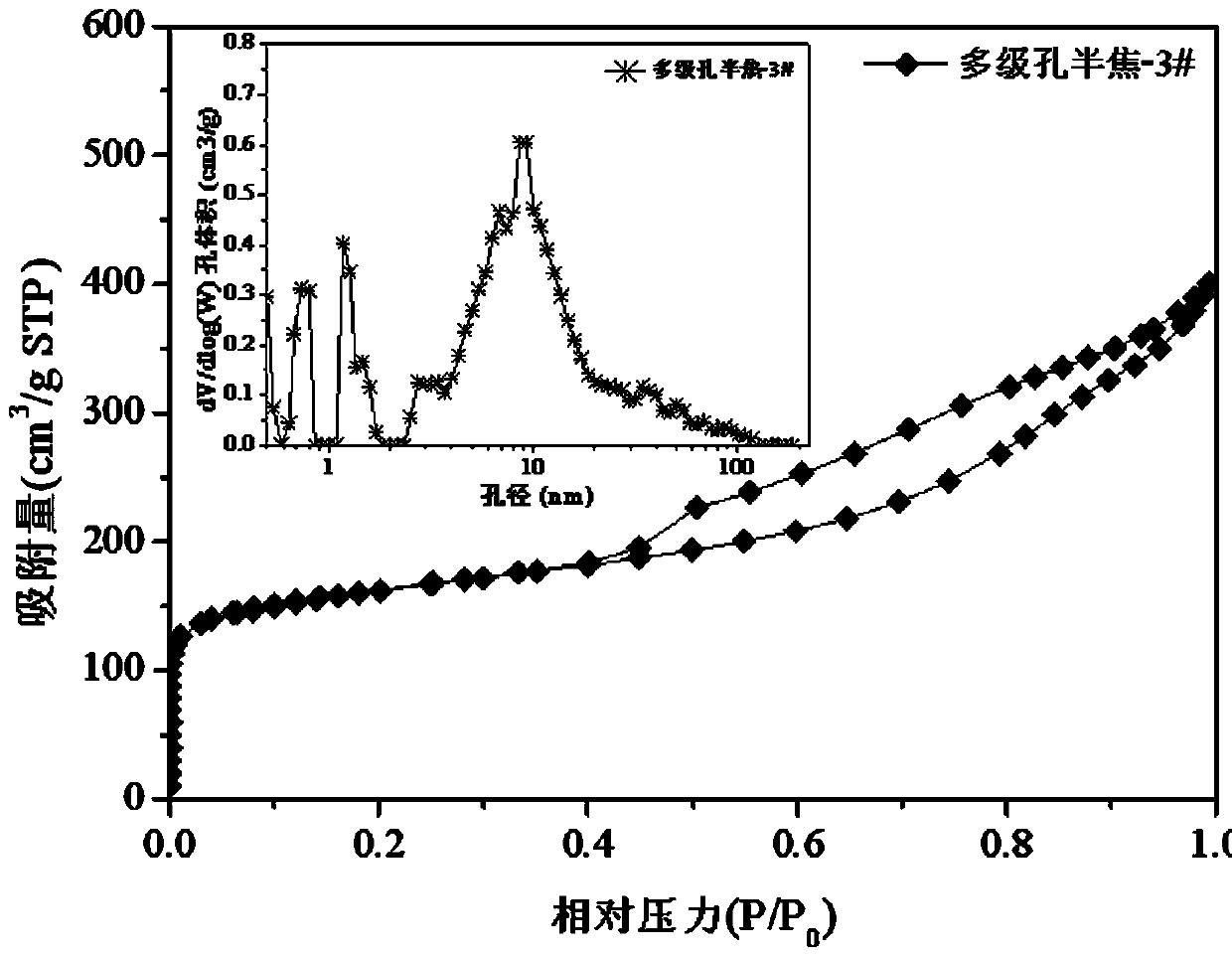

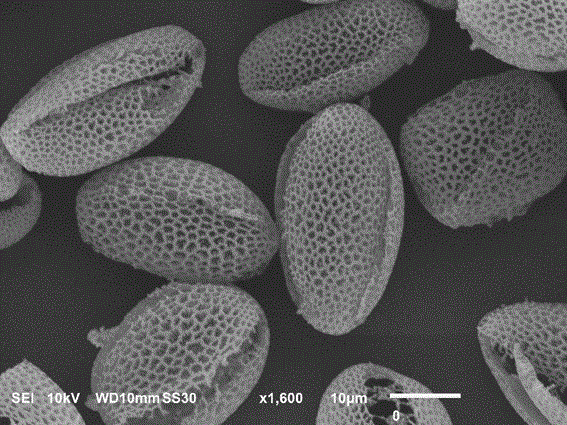

Preparation method of hierarchical pore carbon-based catalyst for catalytic reforming of coal tar

ActiveCN109529853AGood effect of catalytic modification of tarLow costCatalytic crackingMetal/metal-oxides/metal-hydroxide catalystsCatalytic reformingDiffusion resistance

A preparation method of a hierarchical pore carbon-based catalyst for catalytic reforming of coal tar belongs to the technical field of preparation of catalysts for catalytic reforming of coal tar, and can solve a problem that the large diffusion resistance of existing microporous carbon-based catalysts having a small pore size is not conducive to the proceeding of a catalytic reaction. The methodcomprises the following steps: carrying out steam activation on low metamorphic coal under the catalysis of a calcium-containing mineral matter to obtain semi-coke with a hierarchical pore structure,and using the semi-coke with the hierarchical pore structure as a carrier to support an active metal in order to prepare the carbon-based catalyst with a hierarchical pore structure. The catalyst hasdeveloped microporous and mesoporous structures, so the diffusion of heavy components in the tar in the pores of the catalyst and the contact of the heavy components with active sites are benefited,and the catalyst has a good catalytic effect in the catalytic reforming of coal tar, and has a broad application prospect.

Owner:TAIYUAN UNIV OF TECH

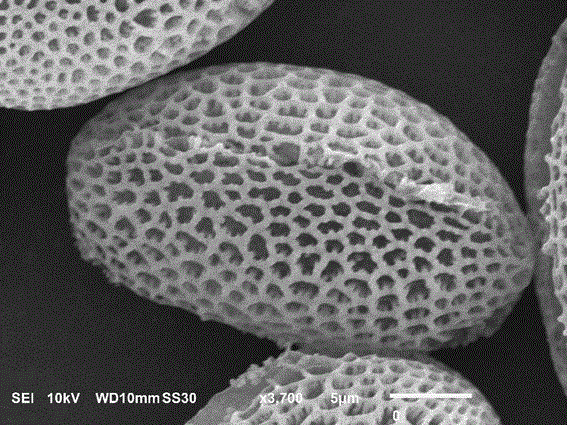

Preparation and application for modified pollen biomass carbon composite acrylate oil-absorbing material

InactiveCN106543349AAbundant resourcesSimple preparation processOther chemical processesCarbon preparation/purificationSteam activationPollen

The invention belongs to the technical field of preparation of modified functional polymer materials, and relates to preparation of an oil-absorbing material, specifically to preparation and application of a modified pollen biomass carbon composite acrylate oil-absorbing material. The preparation method disclosed by the invention comprises the following steps: subjecting pollen to pretreatment, carrying out steam activation with HNO3, then carrying out hydrophobic modification, with a deionized water solution containing a dispersant namely polyvinyl alcohol as a reaction system, carrying out heating to 60 to 90 DEG C, carrying out stirring for 30 min, carrying out cooling, and adding butyl acrylate, butyl methacrylate, hydrophobic pollen biomass carbon, an initiator, a crosslinking agent namely N-N-methylene bisacrylamide and a pore-forming agent namely an ethyl acetate mixed solution; and carrying out programmed heating synthesis by utilizing microwave radiation. The composite material prepared by utilizing the method provided by the invention has the advantages of good structure and thermal stability, an internal well-developed three-dimensional network structure, excellent hydrophobic lipophilicity, significantly-improved oil-absorbing effect, and capability of being applied to selective adsorption and recovery of various oil products and environment control problems like sewage treatment.

Owner:JIANGSU UNIV

Method for preparing low-cost asphalt-based spherical activated carbon with hierarchical porouse structure

The invention discloses a low-cost asphalt-based spherical activated carbon with hierarchical porouse structure. According to the invention, asphaltic coal with softening point of 130-230 DEG C is used as a raw material, a low-temperature decomposable organic matter is used as a pore forming agent, after mixing, crushing, spheroidizing, air oxidation, liquid phase oxidation, charring, steam activation, and pickling, the asphalt-based spherical activated carbon is prepared.Regarding the asphalt-based spherical activated carbon, sphere diameter is 0.4-1.5 mm, density is 0.5-0.85 g / cm<3>, ratiospecific surface area is 800-1,500 m<2> / g, vibration strength is greater than 95%, microporous content is 60-83%, mesoporous content is 30-5%, macroporous content is 10-12%, and sphericity is greater than 99%.The invention has significant important significance for promoting the engineering of asphaltpitch-based spherical activated carbon and promoting the application of spherical activated carbon in civil, industrial, aerospace and other fields.

Owner:湖南曦威新材料有限公司

Method for multi-level value-added utilization of camellia oleifera shells

The invention discloses a method for multi-level value-added utilization of camellia oleifera shells. The method comprises the following steps: firstly, crushing the camellia oleifera shells and screening by a 60-mesh sieve; obtaining tea saponins and tannins from the camellia oleifera shells by an ultrasonic-microwave synergistic stepwise extraction process; inoculating edible fungi after addinga small amount of brans into primary waste residues; raising the temperature and adding lysozyme to promote autolysis of edible fungal hyphae after the fungi grow all over a substrate; releasing cellulase and hemicellulase to obtain prebiotics rich in oligomeric cellulosic polysaccharide, oligomeric pentose and peptidoglycan; preparing secondary camellia oleifera shell waste residues with a high lignin content into an aromatic compound by a low-temperature microwave catalysis rapid-cracking technology; using the aromatic compound after separation and purification as a precursor for producing edible essence; and using residual biochar after steam activation for activated carbon for food industry. The method provided by the invention combines three major industries of edible camellia oleifera oil processing, food additive and biomass refining, proposes a new process of multi-level value-added utilization of the camellia oleifera shells, and can finally realize a new way of efficient value-added utilization of camellia oleifera shell resources without wastes in a whole process.

Owner:江西绿野轩生物科技有限公司

Process for selectively producing light olefins

InactiveUS20020169350A1Treatment with plural serial cracking stages onlyCatalytic crackingNaphthaSteam activation

The invention is related to a catalyst and a process for selectively producing light (i.e., C2-C4) olefins from a catalytically cracked or thermally cracked naphtha stream. The naphtha stream is contacted with a catalyst containing from about 10 to 50 wt. % of a crystalline zeolite having an average pore diameter less than about 0.7 nanometers at reaction conditions. The catalysts do not require steam activation.

Owner:STEFFENS TODD R +1

Method of regenerating activity of calcium based absorbent and cyclically removing CO2

InactiveCN107694340AInhibit activity declineEmission reductionGas treatmentDispersed particle separationHigh concentrationHydration reaction

The invention discloses a method of regenerating the activity of a calcium based absorbent and cyclically removing CO2. The method comprises the following steps: introducing CO2 containing flue gas generated by fossil fuel into a carbonation reactor, carrying out carbonation reactions between the flue gas and a CaO absorbent to generate CaCO3, obtaining flue gas without CO2 from the outlet of thereactor, delivering CaCO3 into a burning decomposition reactor, decomposing CaCO3 into CaO and CO2 by the heat generated by burning a carbon based fuel in a pure oxygen atmosphere, storing or using flue gas with a high concentration of CO2 from the burning decomposition reactor, delivering obtained CaO into a steam activation reactor, carrying out hydration reactions between CaO and steam to generate solid Ca(OH)2; then delivering solid Ca(OH)2 to a dehydration reactor to convert Ca(OH)2 into CaO and H2O; and transferring obtained regenerated CaO to the carbonation reactor to capture CO2. Cyclic utilization is realized.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com