A kind of activated carbon activation method of hydrogen combustion steam activation furnace

A technology of water vapor activation and activation method, applied in the field of activated carbon physical activation, can solve the problems of uneven activation effect, high feeding requirements and high technical requirements, and achieve the effect of improving activation effect, uniform activation reaction and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

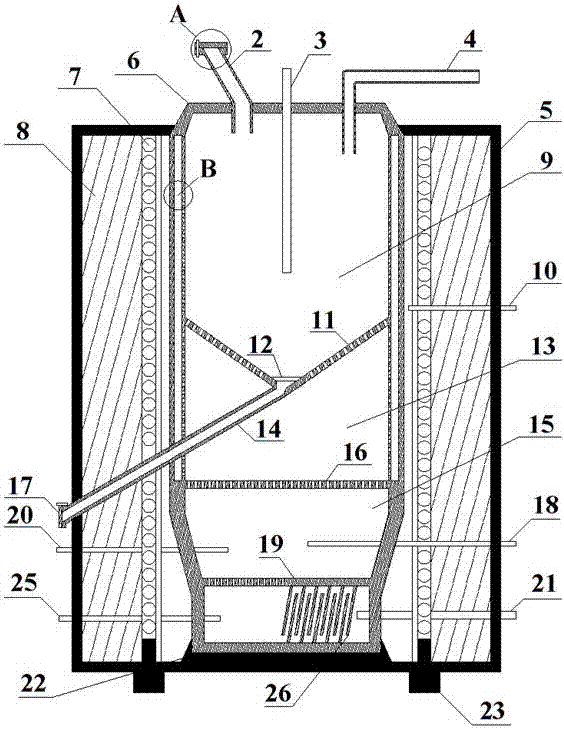

[0030] The specific implementation manners of the present invention will be further described below.

[0031] Implement a kind of gac activation method of hydrogen combustion steam activation furnace, the activation method of described gac is to carry out according to the following steps:

[0032] Firstly, the activated carbon carbonized material is pretreated;

[0033] Then the pretreated activated carbon is weighed, and 300g of activated carbon samples with a particle size of 8 × 10mm are weighed and replaced with

[0034] Then put the activated carbon into the activation reaction section 9 of the hydrogen combustion steam activation furnace and wait for the activation process.

[0035] Then set the reaction temperature, reaction time, ventilation time, heating rate and gas flow rate in the controller.

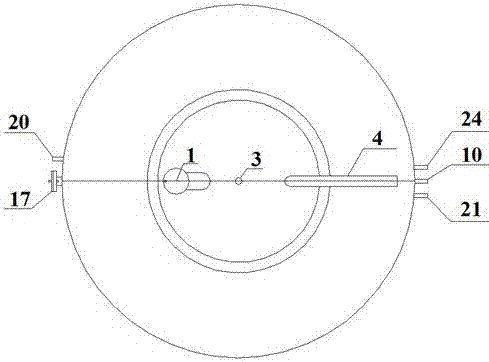

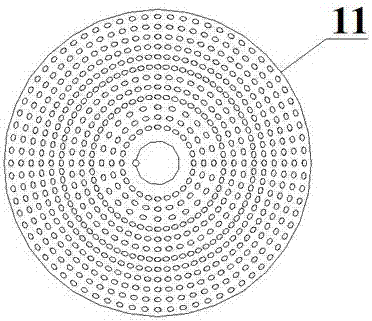

[0036] as attached figure 1 to attach Figure 7shown. The entire activation process begins. First, the activated carbon carbonized material is heated and activated in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com