Patents

Literature

199 results about "Hydrogen combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogen combustion is the process by which hydrogen reacts with an oxidizing agent and burns. Hydrogen combustion is an exothermic combustion, meaning that it releases heat energy.

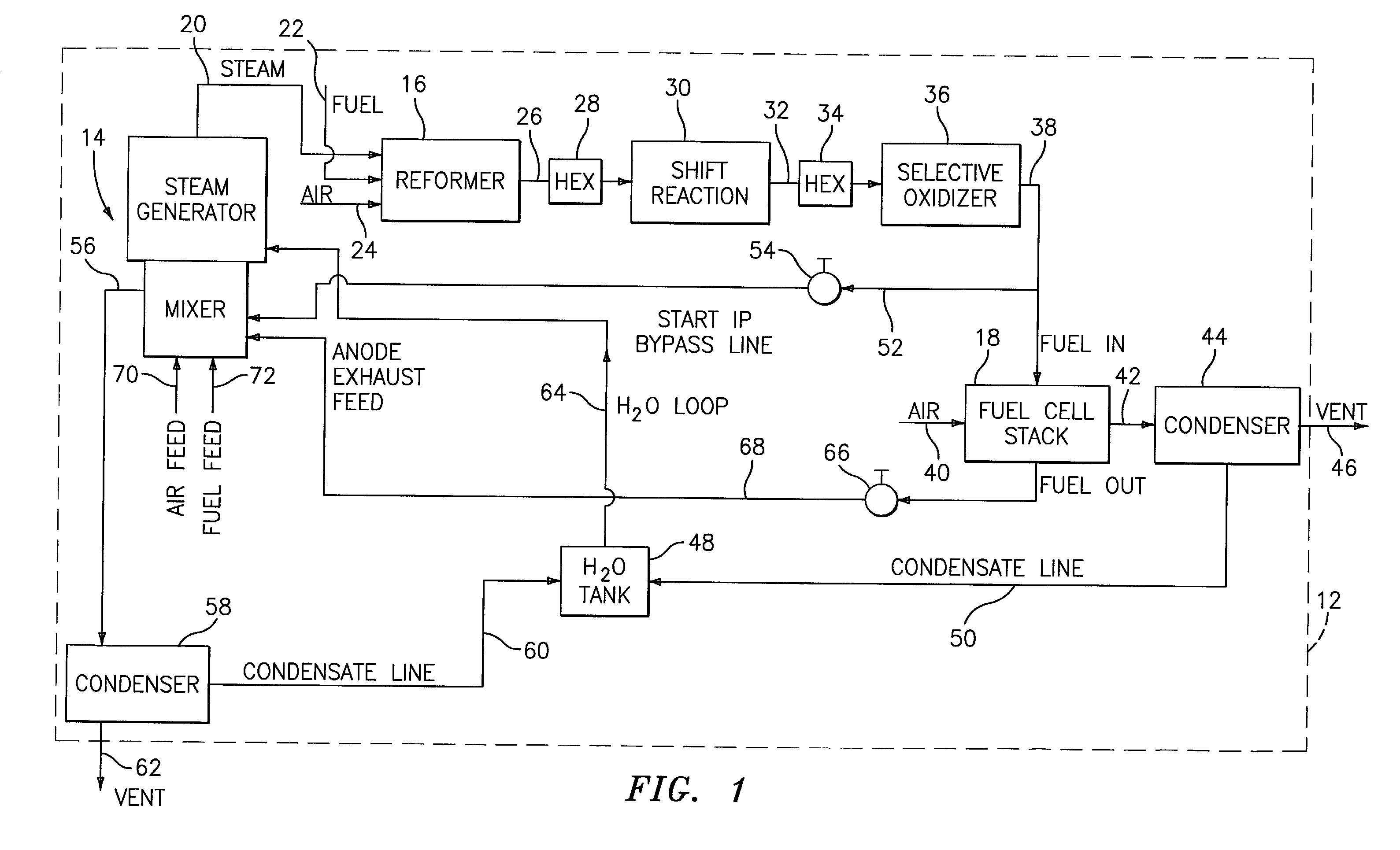

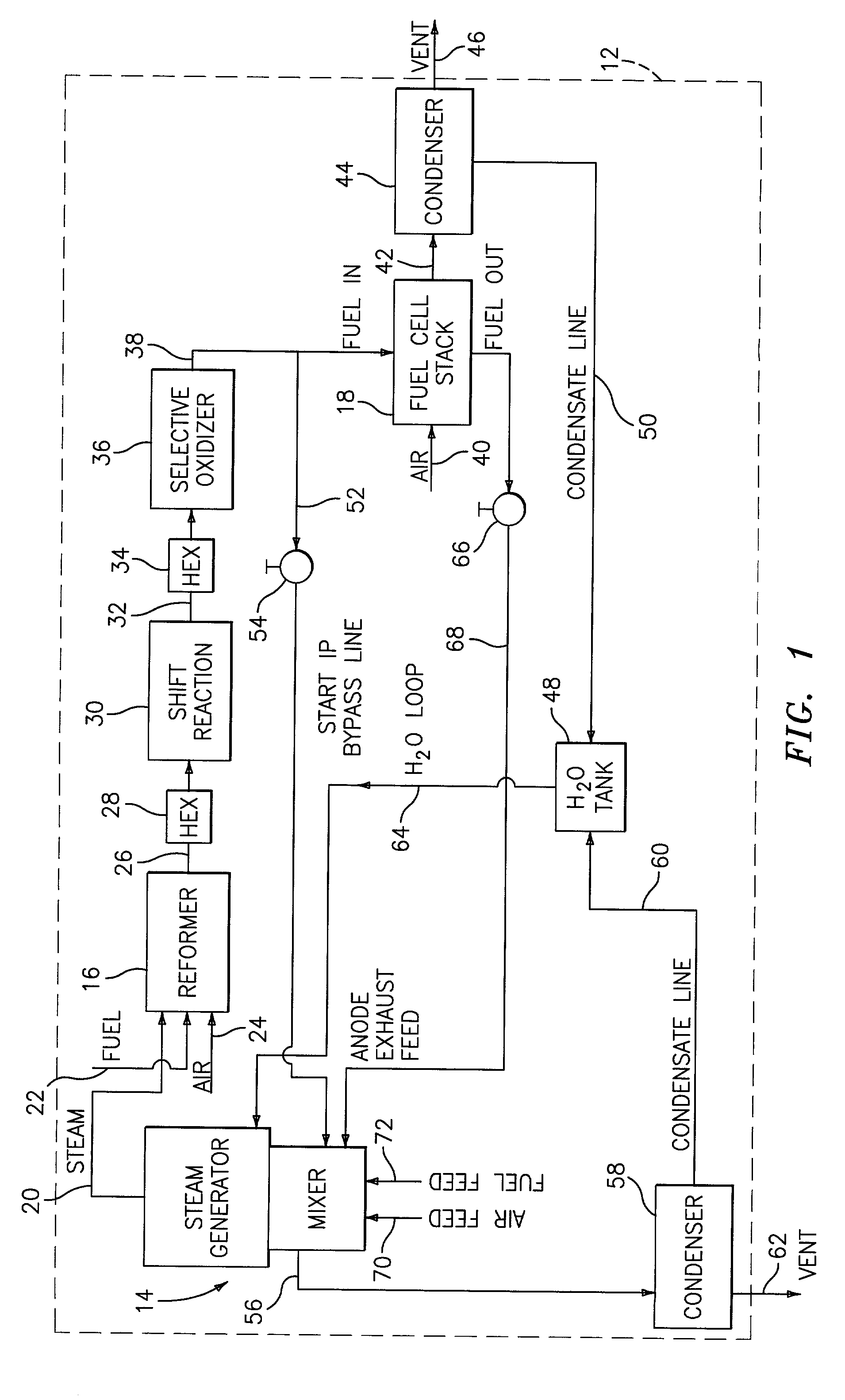

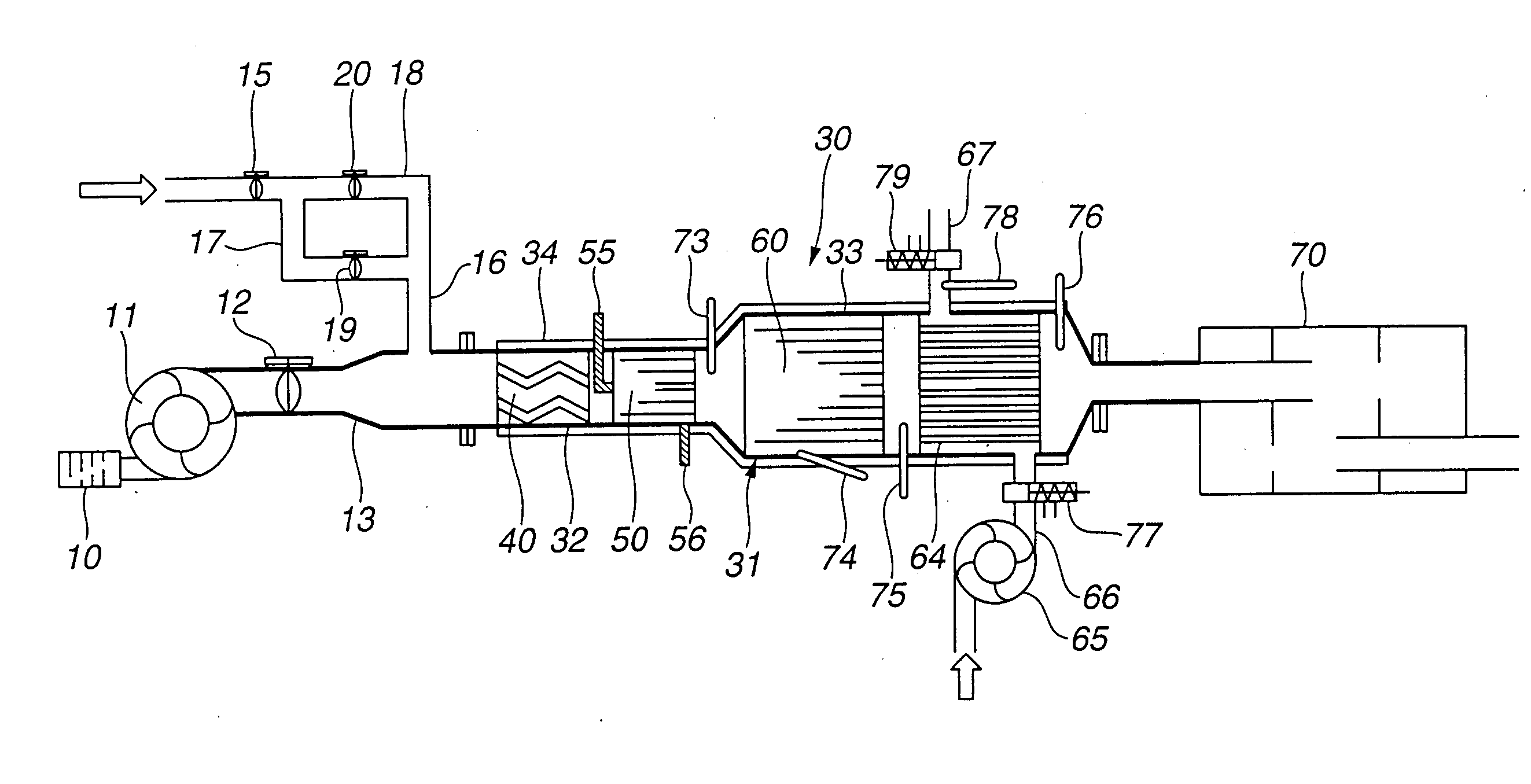

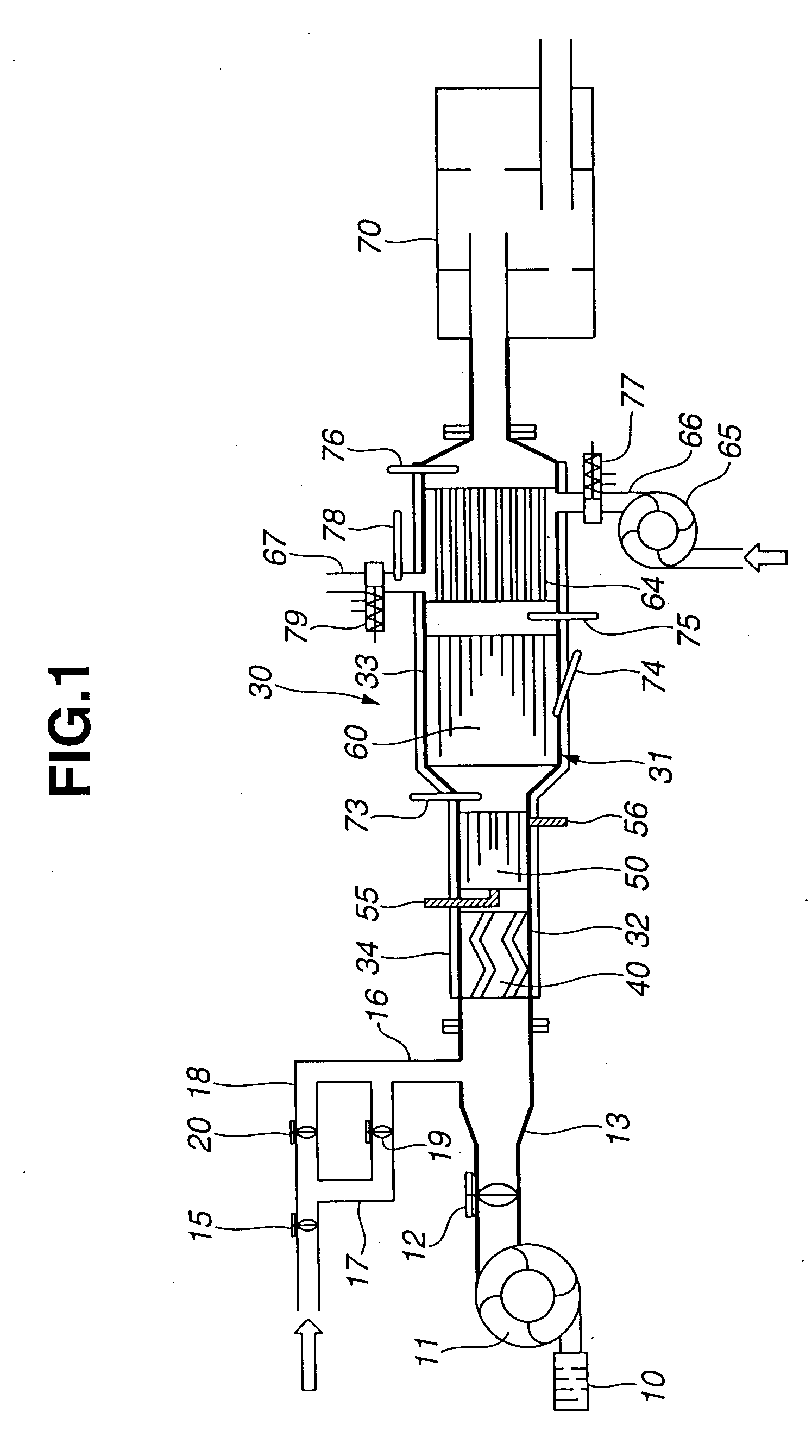

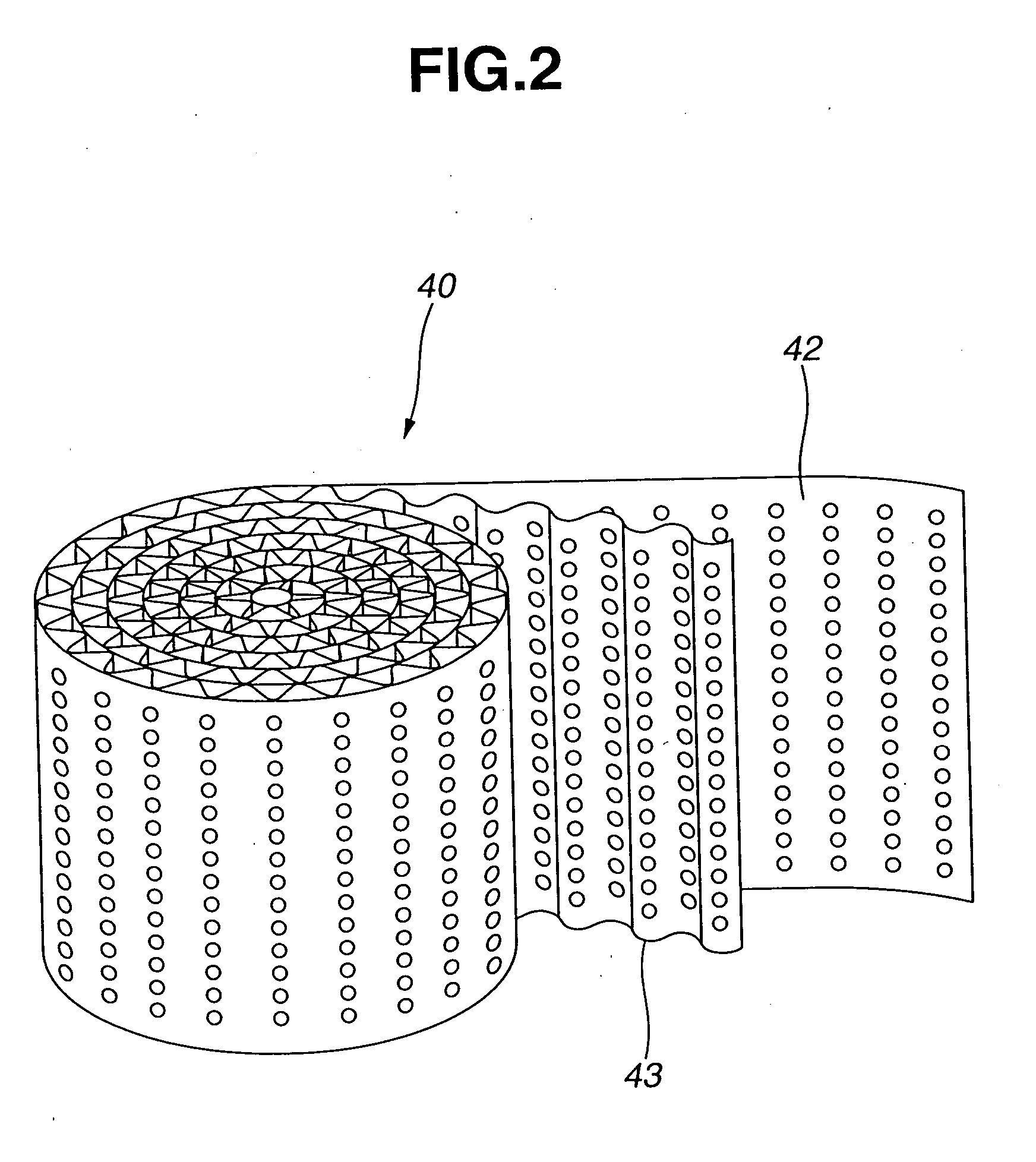

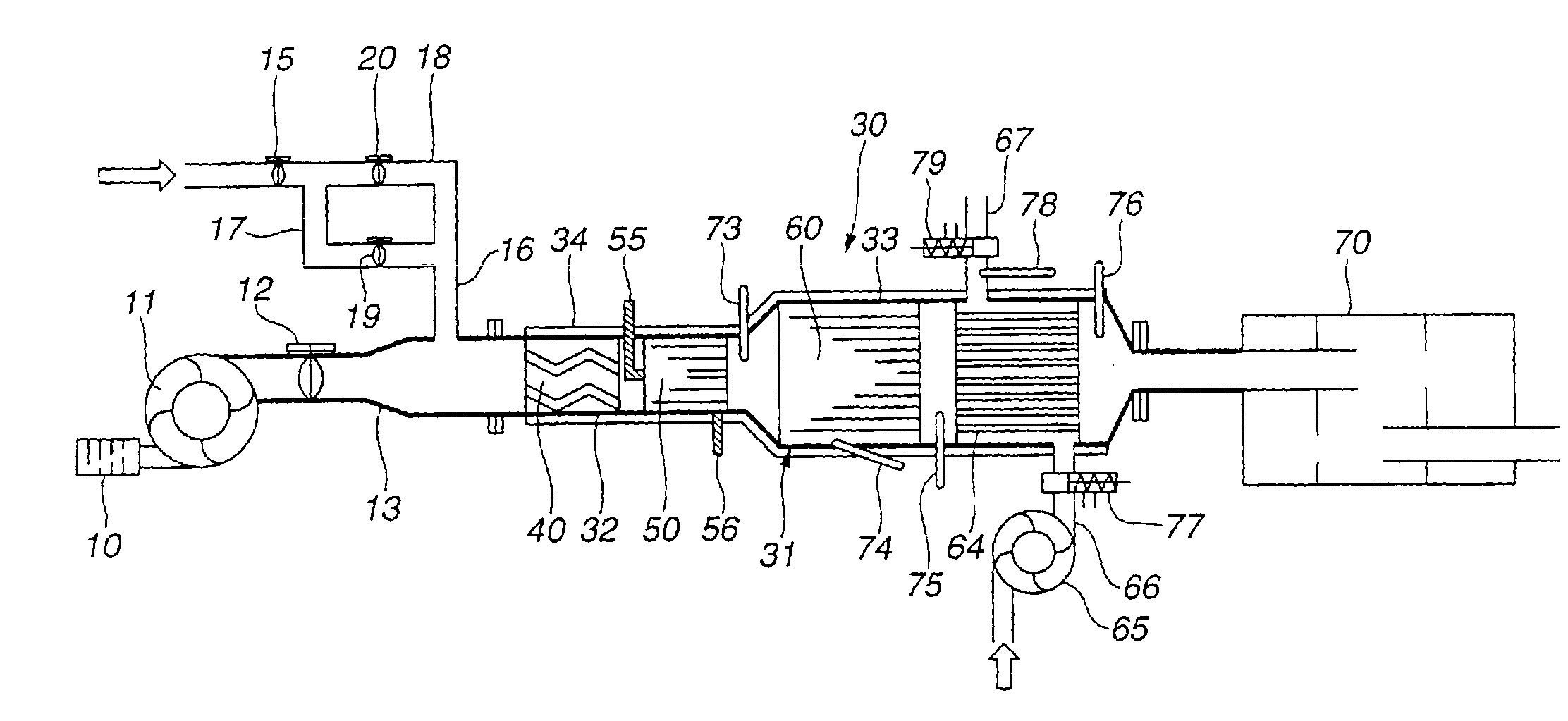

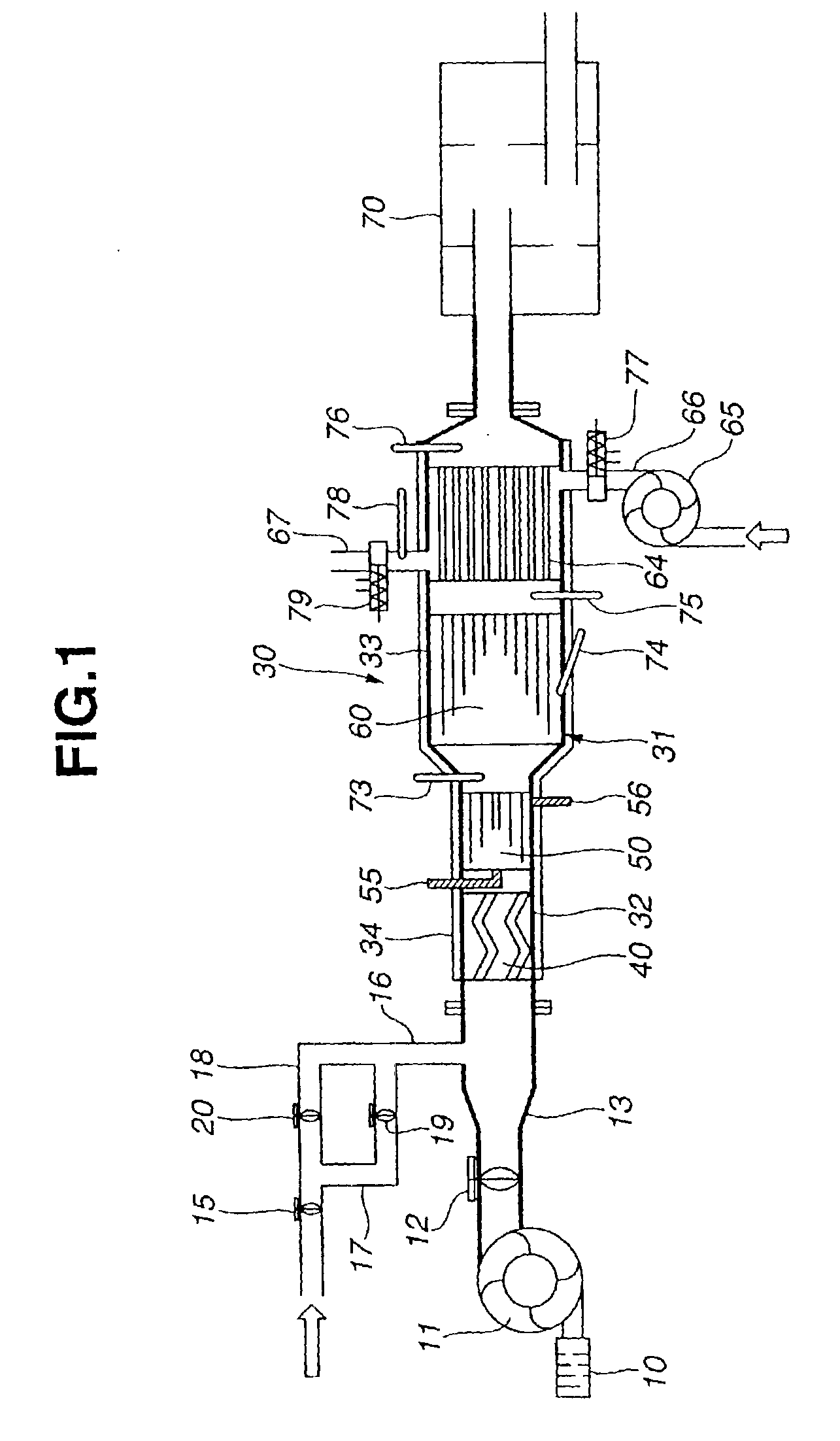

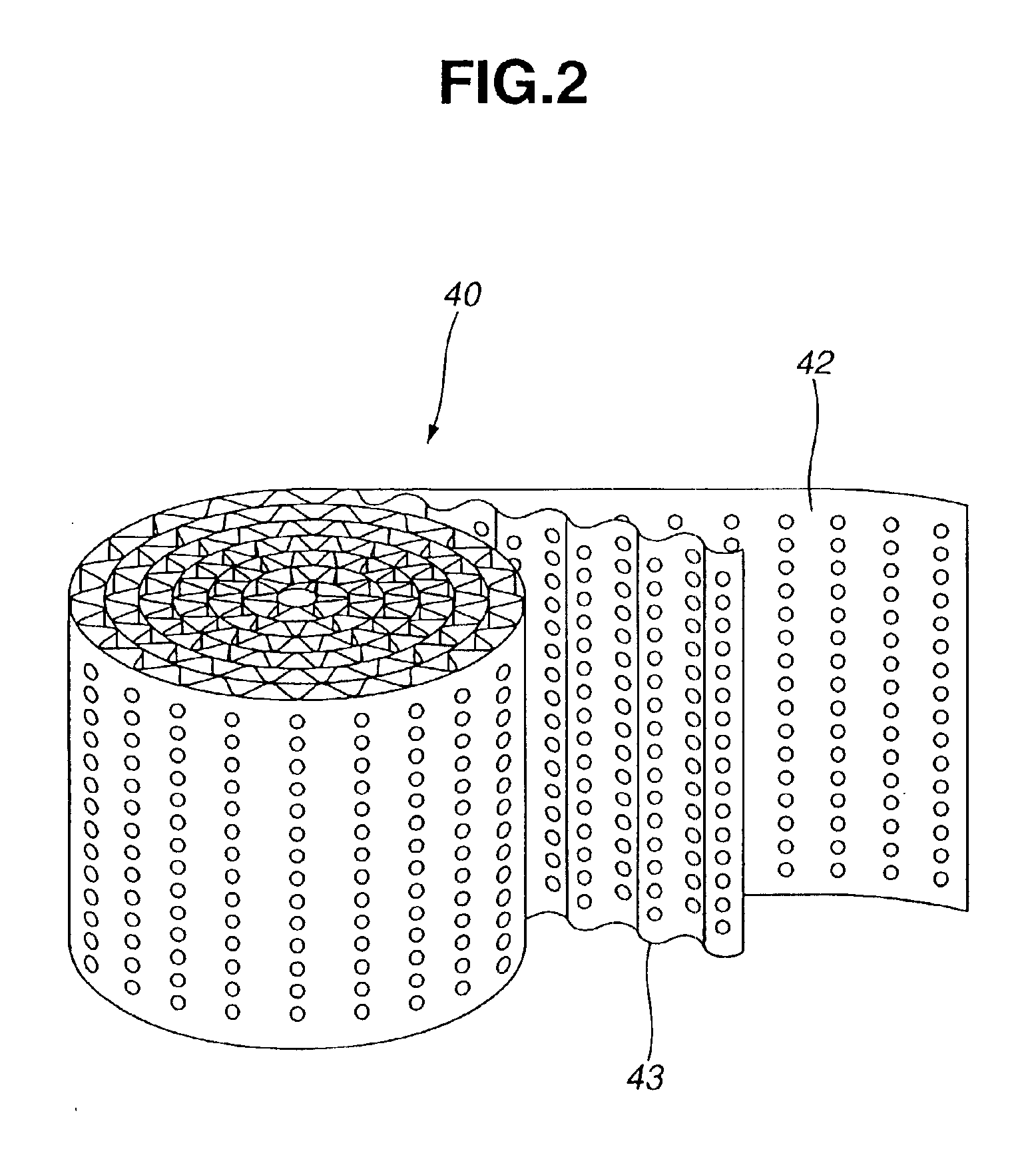

Steam generator for a PEM fuel cell power plant

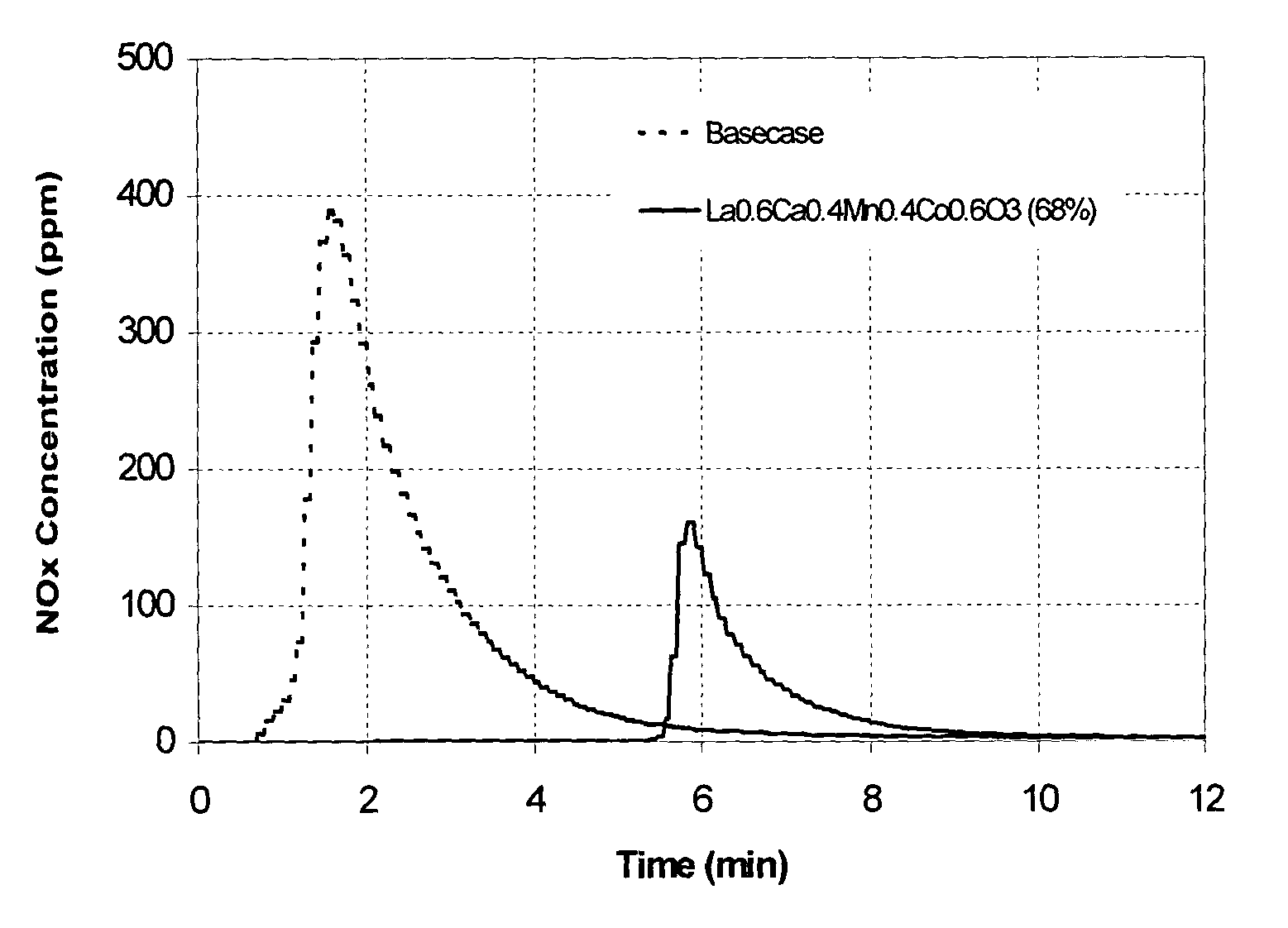

A burner assembly includes a catalyzed burner for combusting an anode exhaust stream from a polymer electrolyte membrane (PEM) fuel cell power plant. The catalysts coated onto the burner can be platinum, rhodium, or mixtures thereof. The burner includes open cells which are formed by a lattice, which cells communicate with each other throughout the entire catalyzed burner. Heat produced by combustion of hydrogen in the anode exhaust stream is used to produce steam for use in a steam reformer in the PEM fuel cell assembly. The catalyzed burner has a high surface area wherein about 70-90% of the volume of the burner is preferably open cells, and the burner has a low pressure drop of about two to three inches water from the anode exhaust stream inlet to the anode exhaust stream outlet . The burner assembly operates at essentially ambient pressure and at a temperature of up to about 1,700° F. (646° C.). The burner assembly can combust anode exhaust during normal operation of the fuel cell assembly. The burner assembly also includes an adjunct burner which can combust gasoline or anode bypass gas (the latter of which is a reformed fuel gas which is tapped off of the fuel cell stack fuel inlet line) during startup of the fuel cell power plant. Once start up of the fuel cell power plant is achieved, the burner assembly will need only combustion of the anode exhaust by the catalytic burner to produce steam for the reformer.

Owner:BALLARD POWER SYSTEMS

Combined cracking and selective hydrogen combustion for catalytic cracking

A catalyst system and process for combined cracking and selective hydrogen combustion of hydrocarbons are disclosed. The catalyst system contains at least one solid acid component and at least one metal-based component which consists of (a) oxygen and / or sulfur and (b) a metal combination selected from the group consisting of: i) at least one metal from Group 3 and at least one metal from Groups 4-15 of the Periodic Table of the Elements; ii) at least one metal from Groups 5-15 of the Periodic Table of the Elements, and at least one metal from at least one of Groups 1, 2, and 4 of the Periodic Table of the Elements; iii) at least one metal from Groups 1 and 2, at least one metal from Group 3, and at least one metal from Groups 4-15 of the Periodic Table of the Elements; and iv) two or more metals from Groups 4-15 of the Periodic Table of the Elements, wherein the at least one of oxygen and sulfur is chemically bound both within and between the metals and, optionally, (3) at least one of at least one support, at least one filler and at least one binder. The process is such that the yield of hydrogen is less than the yield of hydrogen when contacting the hydrocarbons with the solid acid component alone. Further the emissions of NOx from the regeneration cycle of the catalyst system are reduced.

Owner:EXXONMOBIL CHEM PAT INC

Gas reformulation system comprising means to optimize the effectiveness of gas conversion

InactiveUS20080277265A1Facilitate speedImprove efficiencyCombustible gas chemical modificationHydrogenHydrogenControl system

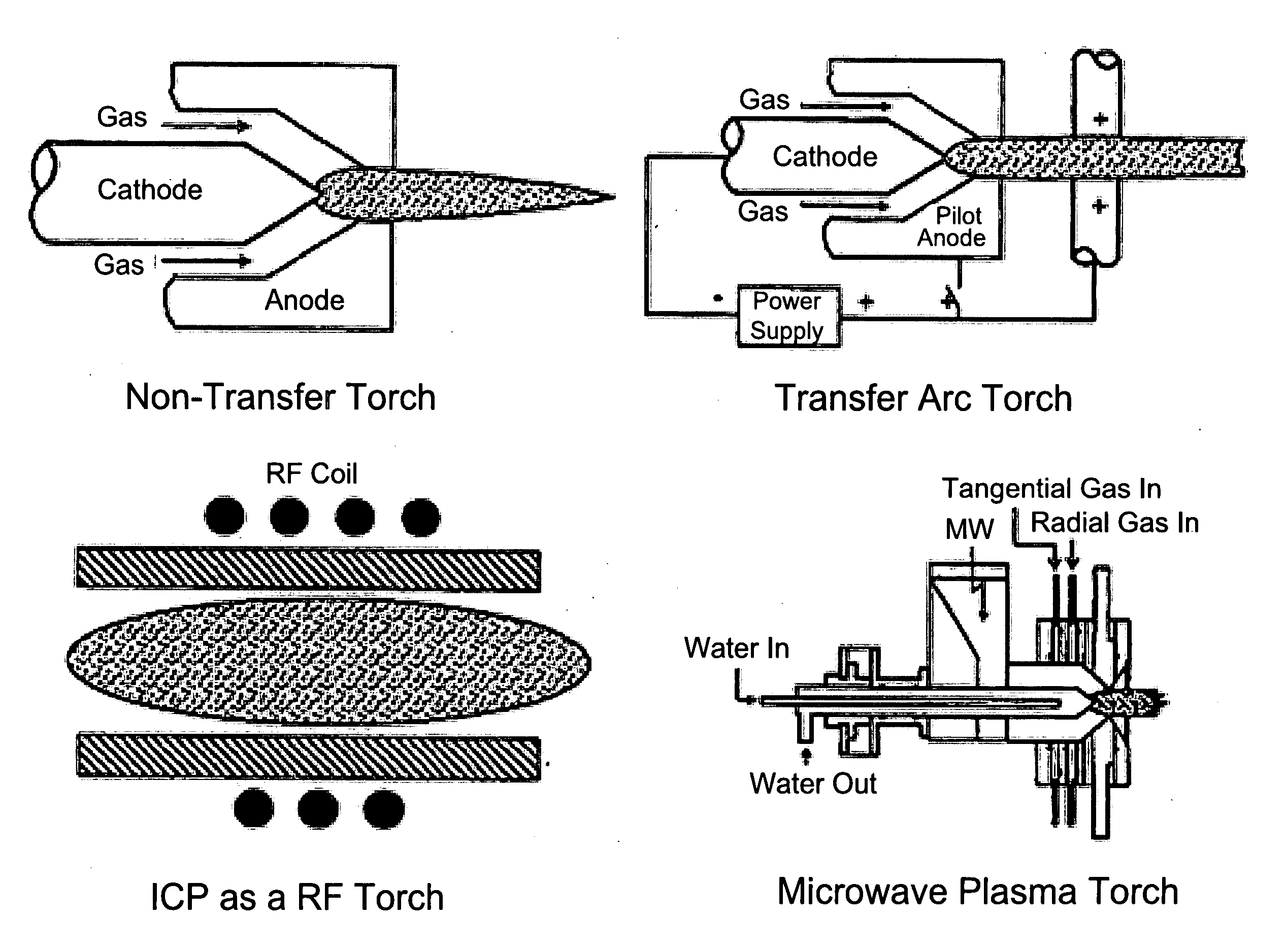

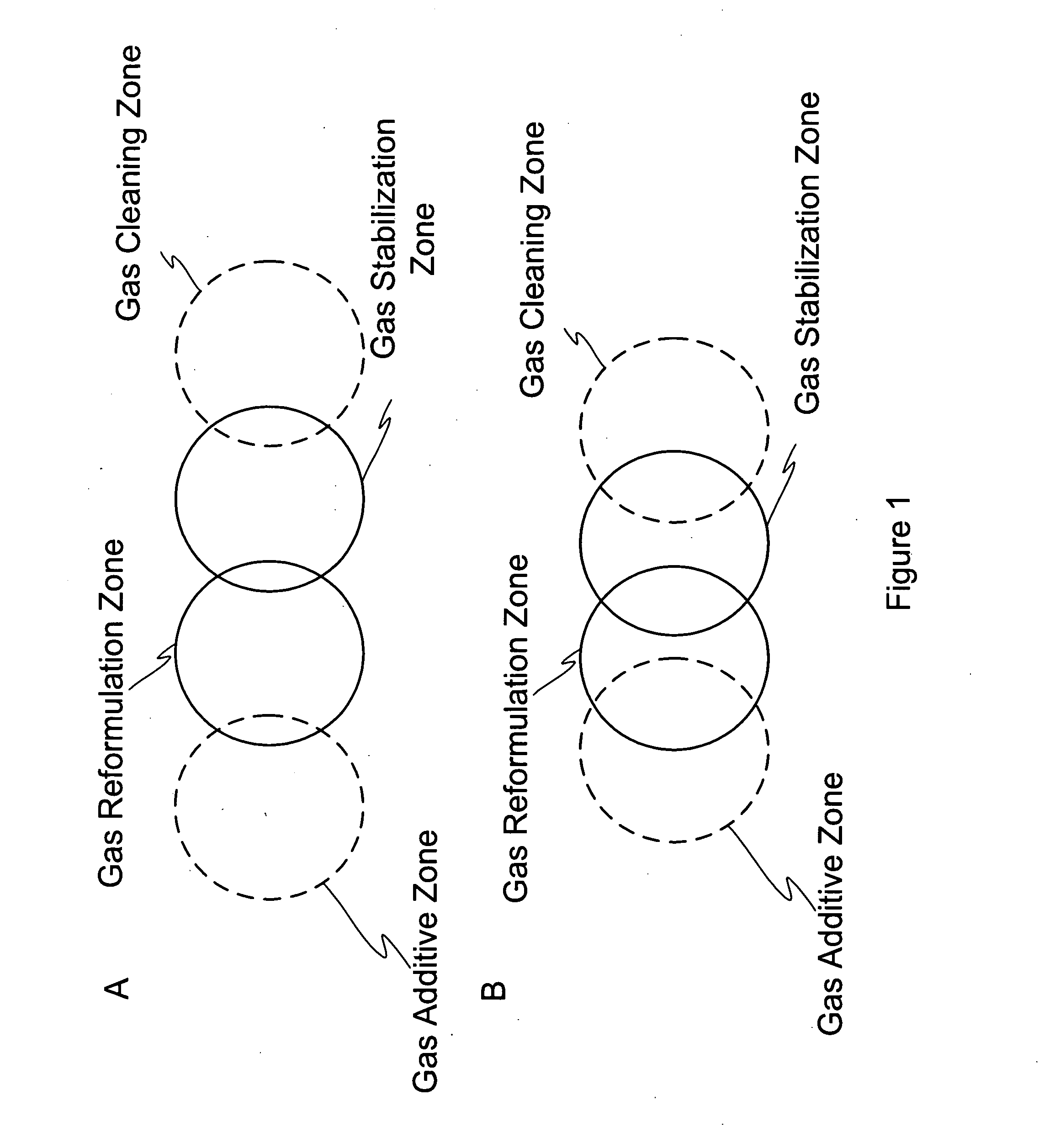

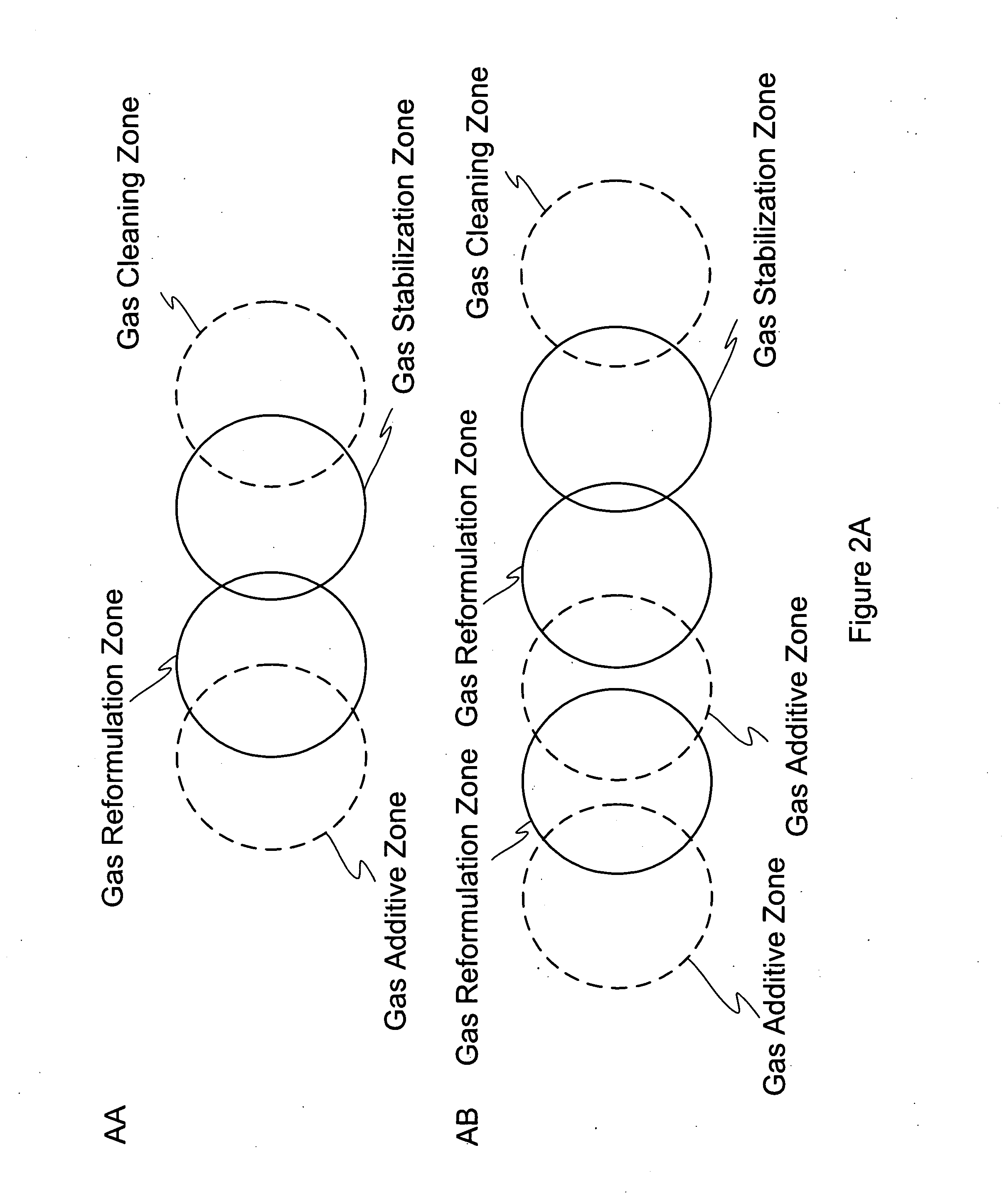

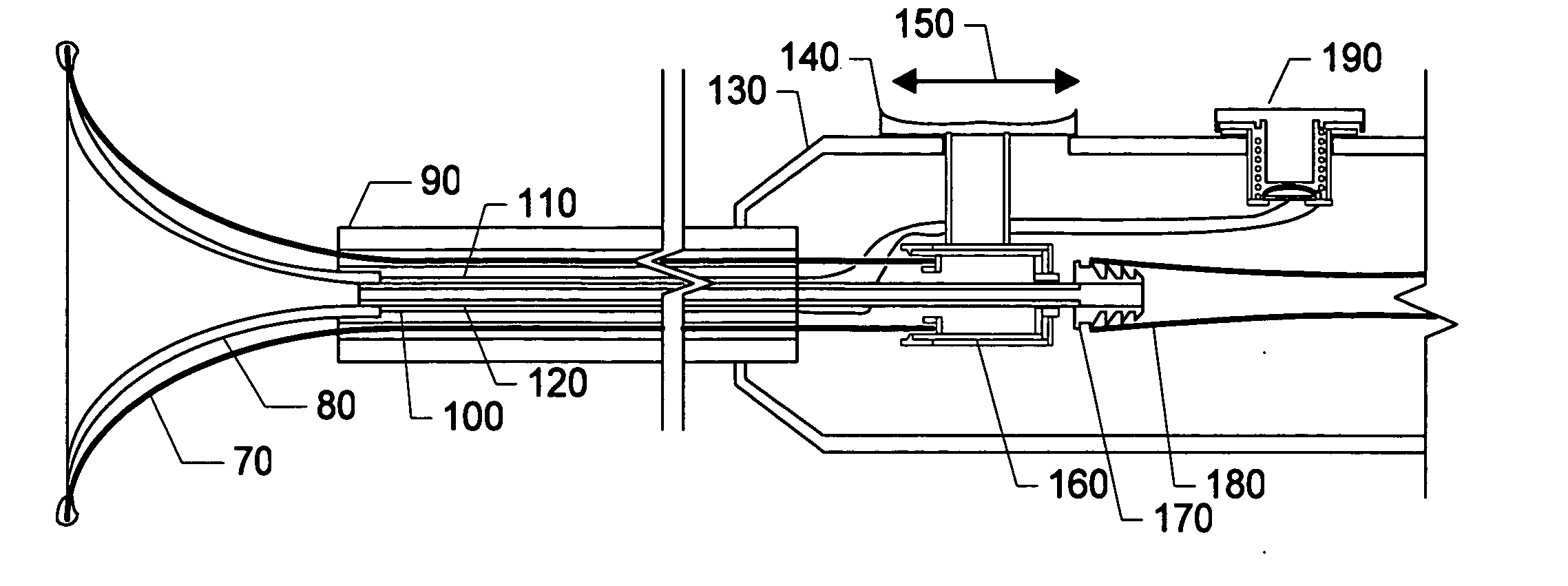

This invention provides a system and method for efficient reformulation of an initial gas with associated characteristics into an output gas with desired characteristic parameters, within a substantially sealed, contained, and controlled environment. The gas reformulating system uses a gas energizing field to disassociate the initial gas molecules and molecules of injected process additives of appropriate types and amounts, into their constituents that then recombine to form the output gas with the desired parameters. The gas reformulating system further comprises a control system that regulates the process and thereby enables the process to be optimized. The gas energizing field may be provided at least partly by hydrogen burners or plasma torches.

Owner:PLASCO ENERGY GROUP INC

Methods for electrosurgical electrolysis

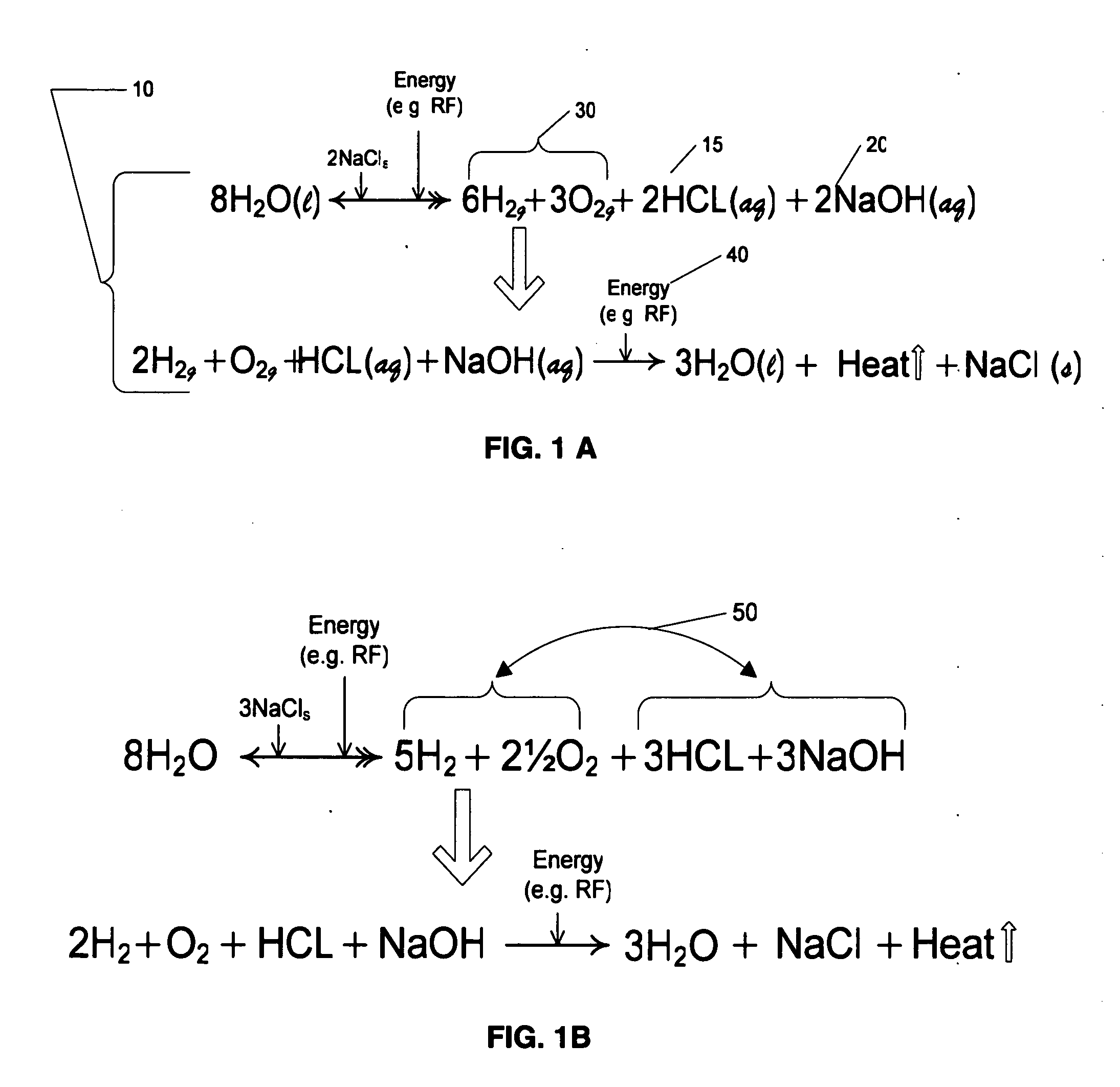

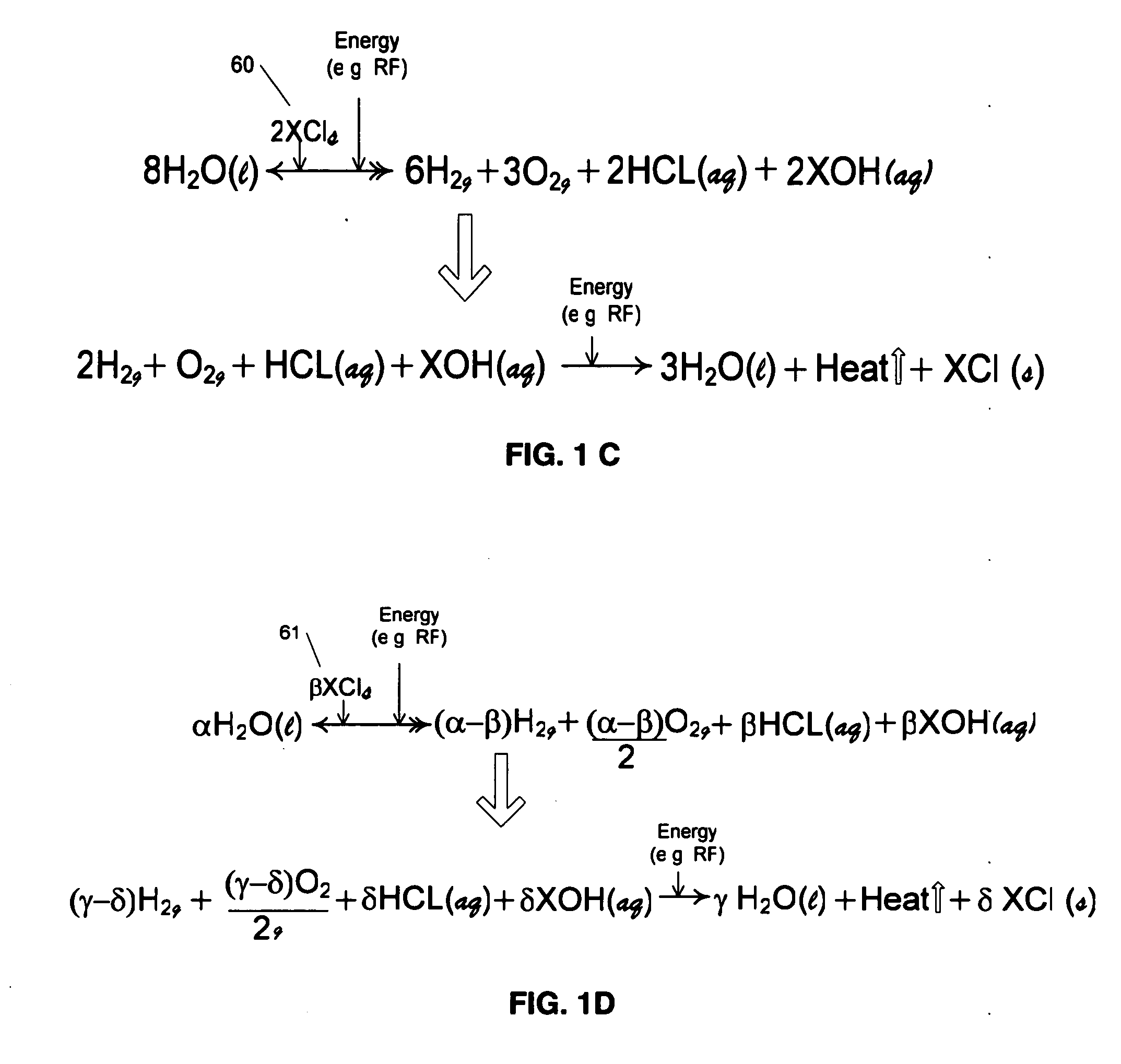

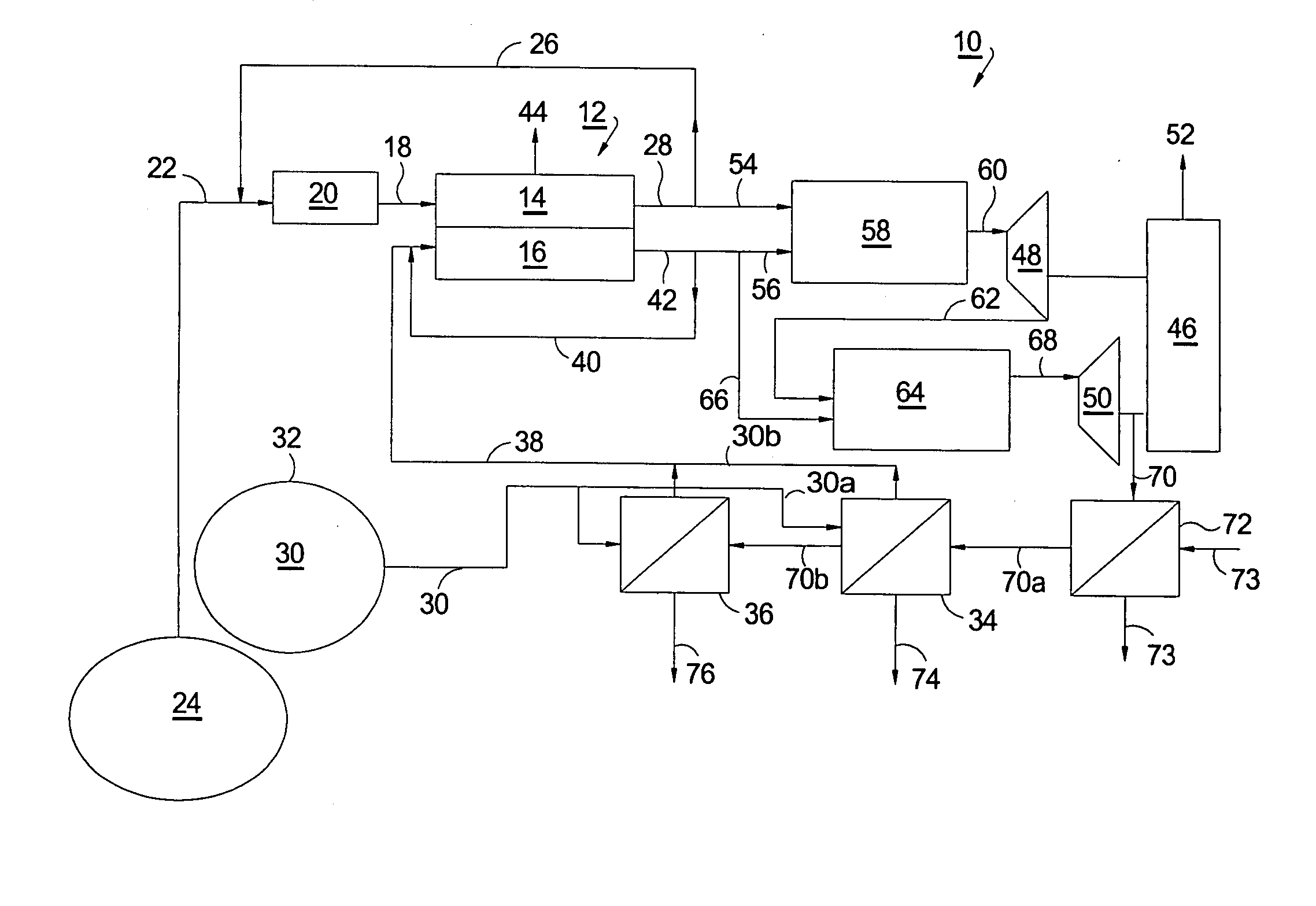

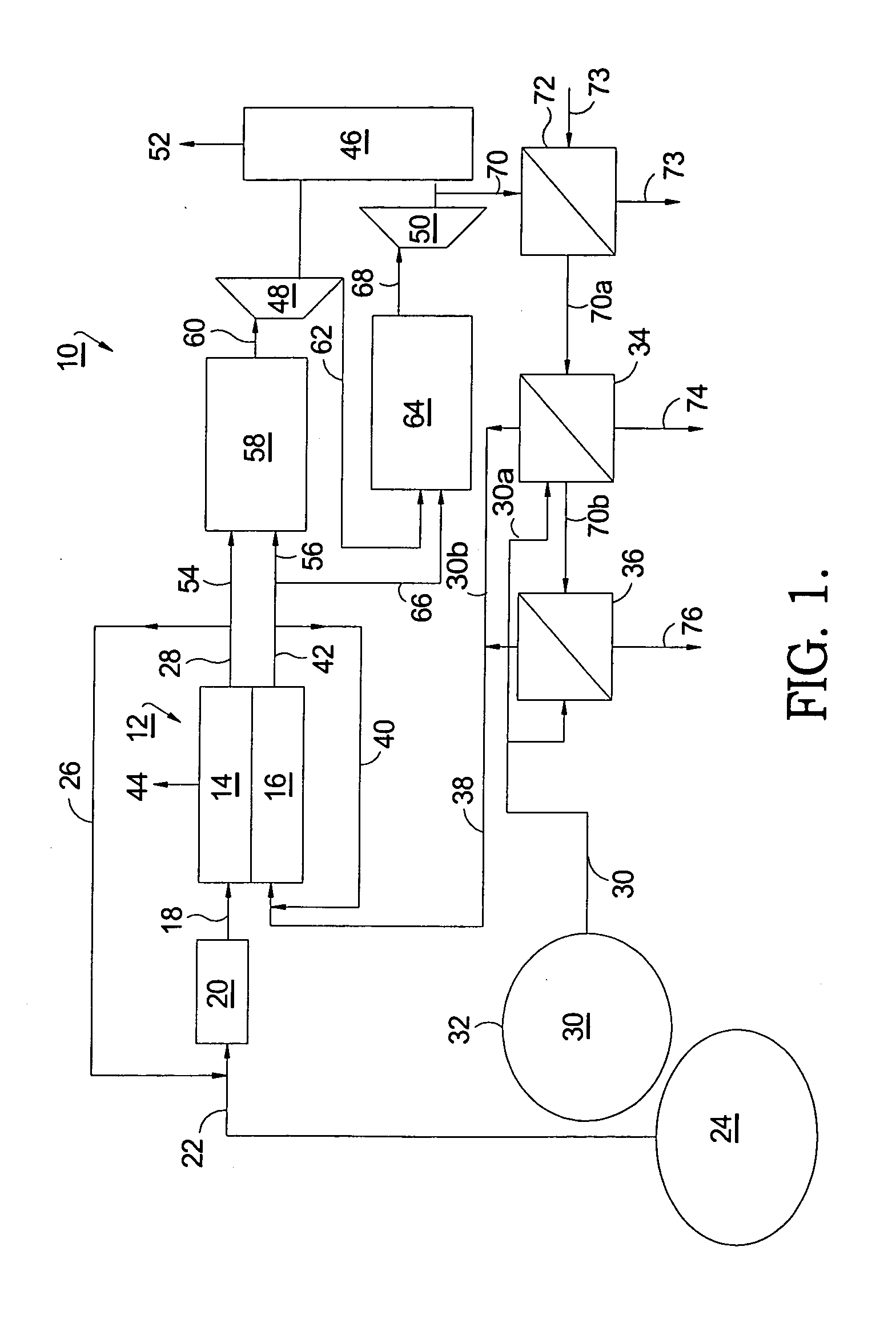

InactiveUS20050182449A1Improve responseSufficient energyElectrotherapySurgical instruments for heatingElectrolysisHydrogen combustion

Methods for electrosurgical electrolysis for treating tissue within a body, including methods that operate in an electrolyzable medium, including an aqueous electrolyzable medium, by means of electrolysis, and optionally by means of oxy-hydrogen combustion for use in treatment, including therapeutic methods of electrolysis to effect advantageous tissue changes.

Owner:NUORTHO SURGICAL

Combined cracking and selective hydrogen combustion for catalytic cracking

A catalyst system and process for combined cracking and selective hydrogen combustion of hydrocarbons are disclosed. The catalyst comprises (1) at least one solid acid component, (2) at least one metal-based component comprised of one or more elements from Group 3 and one or more elements from Groups 4-15 of the Periodic Table of the Elements; and at least one of oxygen and sulfur, wherein the elements from Groups 3, Groups 4-15 and the at least one of oxygen and sulfur are chemically bound both within and between the groups and (3) at least one of at least one support, at least one filler and at least one binder. The process is such that the yield of hydrogen is less than the yield of hydrogen when contacting the hydrocarbons with the solid acid component alone.

Owner:EXXONMOBIL CHEM PAT INC

Hybrid solid oxide fuel cell and gas turbine electric generating system using liquid oxygen

InactiveUS20070163822A1Increasing oxygen pressureImprove efficiencyHybrid vehiclesAuxillary drivesHydrocotyle bowlesioidesElectric generator

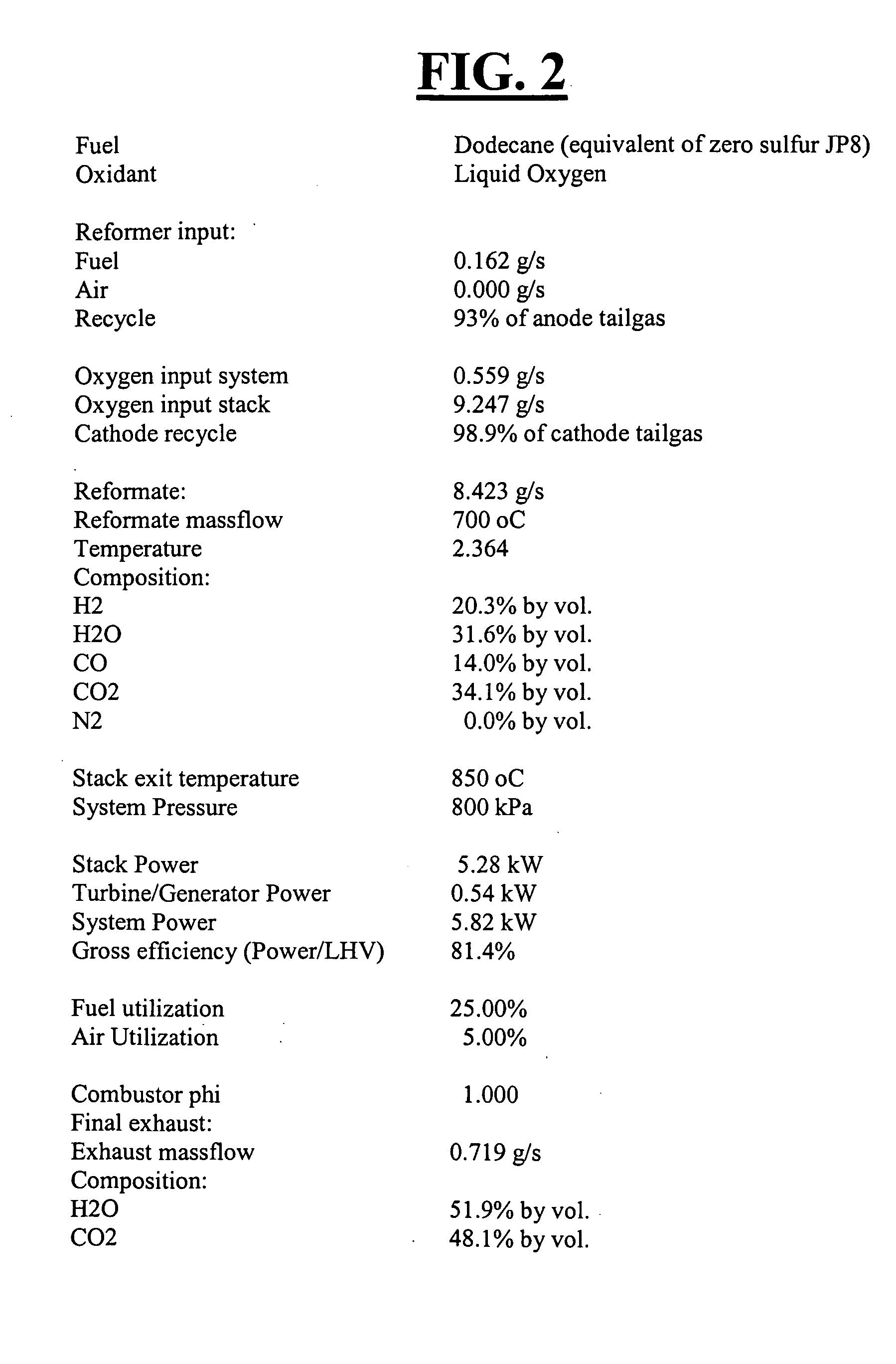

A hybrid SOFC / gas turbine electric generating system comprising an SOFC stack, a hydrocarbon reformer, a first anode tailgas hydrogen-rich combustor to drive a first gas turbine stage, and a second stoichiometric combustor to drive a second gas turbine stage to drive a generator. Anode tailgas is also recycled into the reformer for substantially endothermic reforming of hydrocarbon fuel. Oxidant is provided as pure oxygen—which may be stored as liquid oxygen. All nitrogen may be excluded. Cathode exhaust is passed to the first combustor, to the second combustor, and is recycled into the cathodes. The turbine exhaust is passed through successive heat exchangers cooled by liquid oxygen being vaporized, precipitating water and solid CO2. The system is operated at about 800 kPa (about 8 atmospheres), thereby increasing the power output of the stack. The system may be operated with no gaseous exhaust or with by-products of water and CO2.

Owner:DELPHI TECH INC

Combined cracking and selective hydrogen combustion for catalytic cracking

A catalyst system and process for combined cracking and selective hydrogen combustion of hydrocarbons are disclosed. The catalyst comprises:(1) at least one solid acid component,(2) at least one metal-based component comprised of(i) at least one of oxygen and sulfur(ii) one or more elements from Groups 5–15 of the Periodic Table of the Elements; and(iii) one or more elements from at least one of(a) Groups 1–2 and(b) Group 4; of the Periodic Table of the Elements; and(3) at least one of at least one support, at least one filler and at least one binder. The process is such that the yield of hydrogen is less than the yield of hydrogen when contacting the hydrocarbons with the solid acid component alone.

Owner:EXXONMOBIL CHEM PAT INC

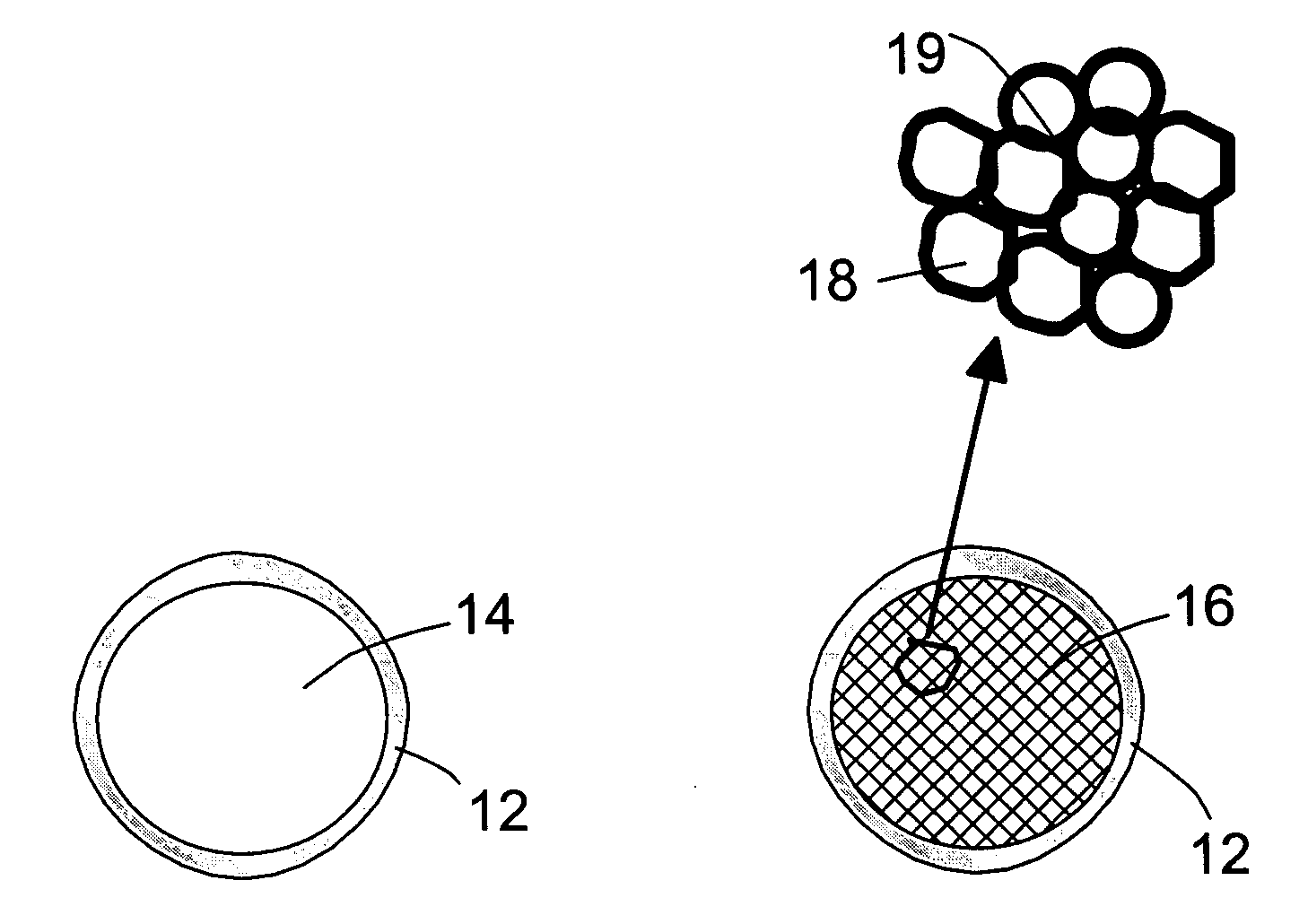

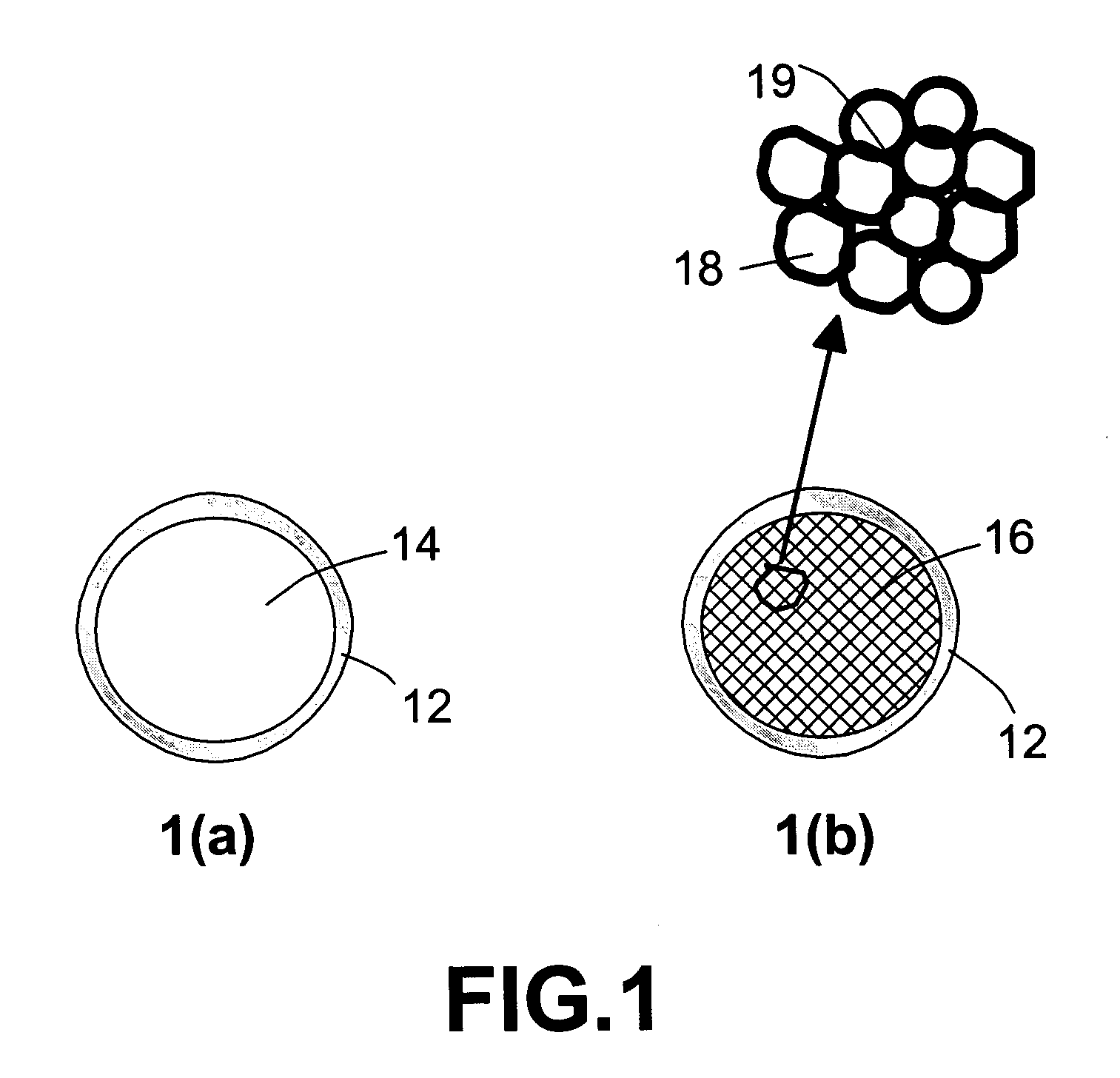

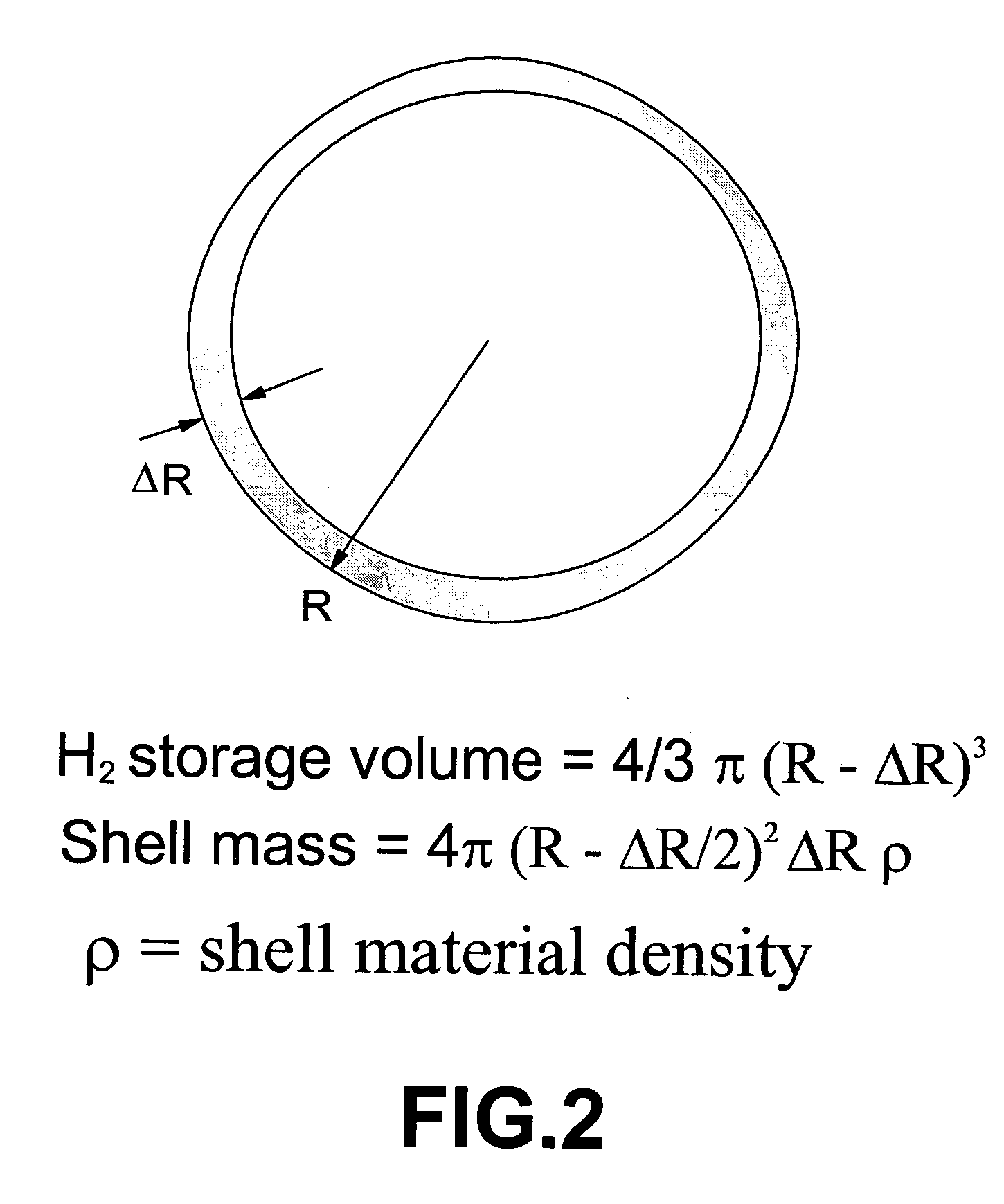

Infrared-absorbing glass micro-spheres for storing and delivering hydrogen to fuel cells

InactiveUS20060063003A1Reduce shell tensile strengthAchieve temperatureReactant parameters controlReversible hydrogen uptakeHydrogen fuelHydrogen combustion

Core-shell glass micro-spheres with a glass shell and a hollow or porous core for storing and releasing hydrogen fuel. The shell comprises a glass composition with a glass transition temperature (Tg) below 450° C. (preferably below 300° C. and most preferably below 200° C.) and a heat-absorbing materials, preferably comprising an infrared-absorbing ingredient. A combination of low Tg and the presence of an IR-absorbing material makes it possible to readily achieve a desired temperature T to reduce the shell tensile strength σt to an extent that a tensile stress a experienced by a shell of the micro-spheres meets the condition of a σ≧ασt for causing hydrogen to diffuse out of the micro-spheres. The released hydrogen can be fed into a fuel cell or hydrogen combustion engine. Here, α is a material-specific constant, typically in the range of 0.3 to 0.7.

Owner:YANG LAIXIA +1

Combined cracking and selective hydrogen combustion for catalytic cracking

A catalyst system and process for combined cracking and selective hydrogen combustion of hydrocarbons are disclosed. The catalyst comprises (1) at least one solid acid component, (2) at least one metal-based component comprised of one or more elements from Groups 1 and 2; one or more elements from Group 3; one or more elements from Groups 4–15 of the Periodic Table of the Elements; and at least one of oxygen and sulfur and (3) at least one of at least one support, at least one filler and at least one binder. The process is such that the yield of hydrogen is less than the yield of hydrogen when contacting the hydrocarbons with the solid acid component alone.

Owner:EXXONMOBIL CHEM PAT INC

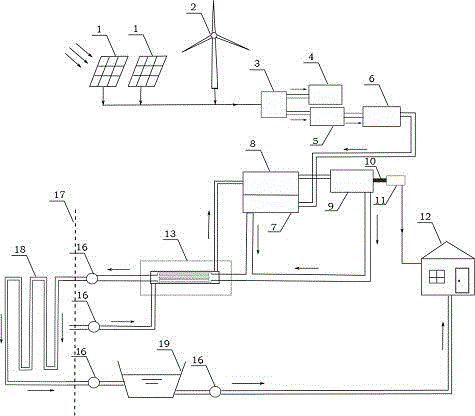

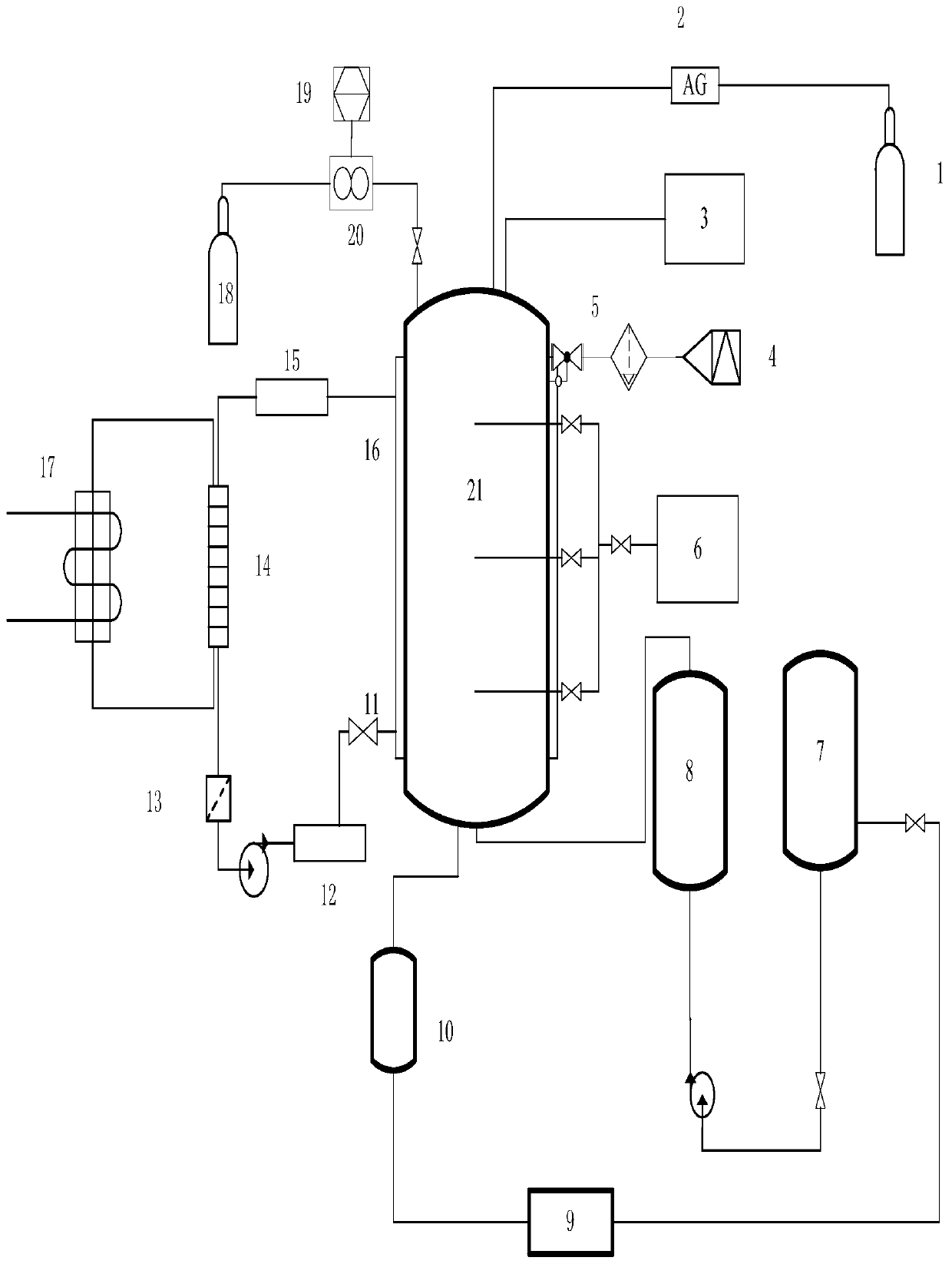

Renewable energy generation and fresh water production integrated system for isolated island

InactiveCN106058921AAchieve fadeDiversified and efficient useGeneral water supply conservationSeawater treatmentWind drivenHydrogen combustion

The invention discloses a renewable energy generation and fresh water production integrated system for an isolated island. The renewable energy generation and fresh water production integrated system comprises solar cell panels, a wind driven generator, a seawater electrolytic tank, an oxygen storage tank, a hydrogen storage tank, an alkali filtering tank, a hydrogen combustion chamber, a seawater heating furnace, a turbine, a main shaft, a generator, a user, a heat exchanger, a pipeline, a small heat exchange pipe, pumps, a coastline, a condenser pipe and a water storage tank; electricity generation is carried out by utilizing randomly fluctuated solar energy and wind energy; hydrogen is generated by electrolyzing seawater, so that energy storage is realized; combustion is carried out by utilizing hydrogen; seawater is heated to generate superheated steam, so that the turbine is driven to rotate; then, the generator is driven to output the steady power; tail gas after hydrogen combustion and water vapour discharged by the turbine are introduced into seawater for condensation through the condenser pipe, so that fresh water is generated; seawater desalination is realized; energy is effectively utilized in a diversified manner; the problem that power and fresh water are stably supplied when the isolated island is offline can be solved; the heat exchanger heats seawater by utilizing waste water vapour; therefore, utilization of waste heat is realized; and the energy utilization efficiency is increased.

Owner:HOHAI UNIV

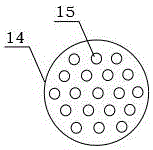

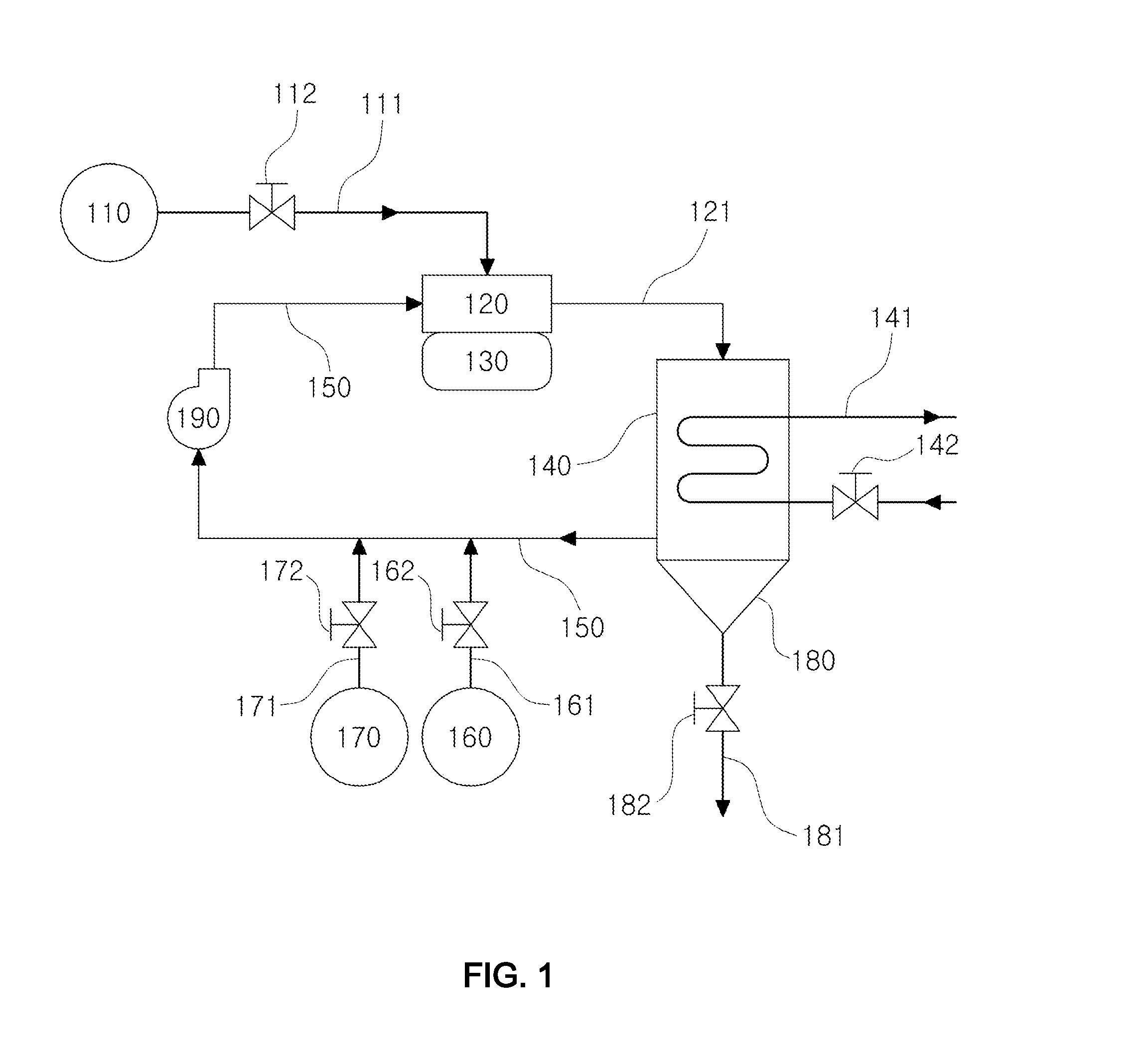

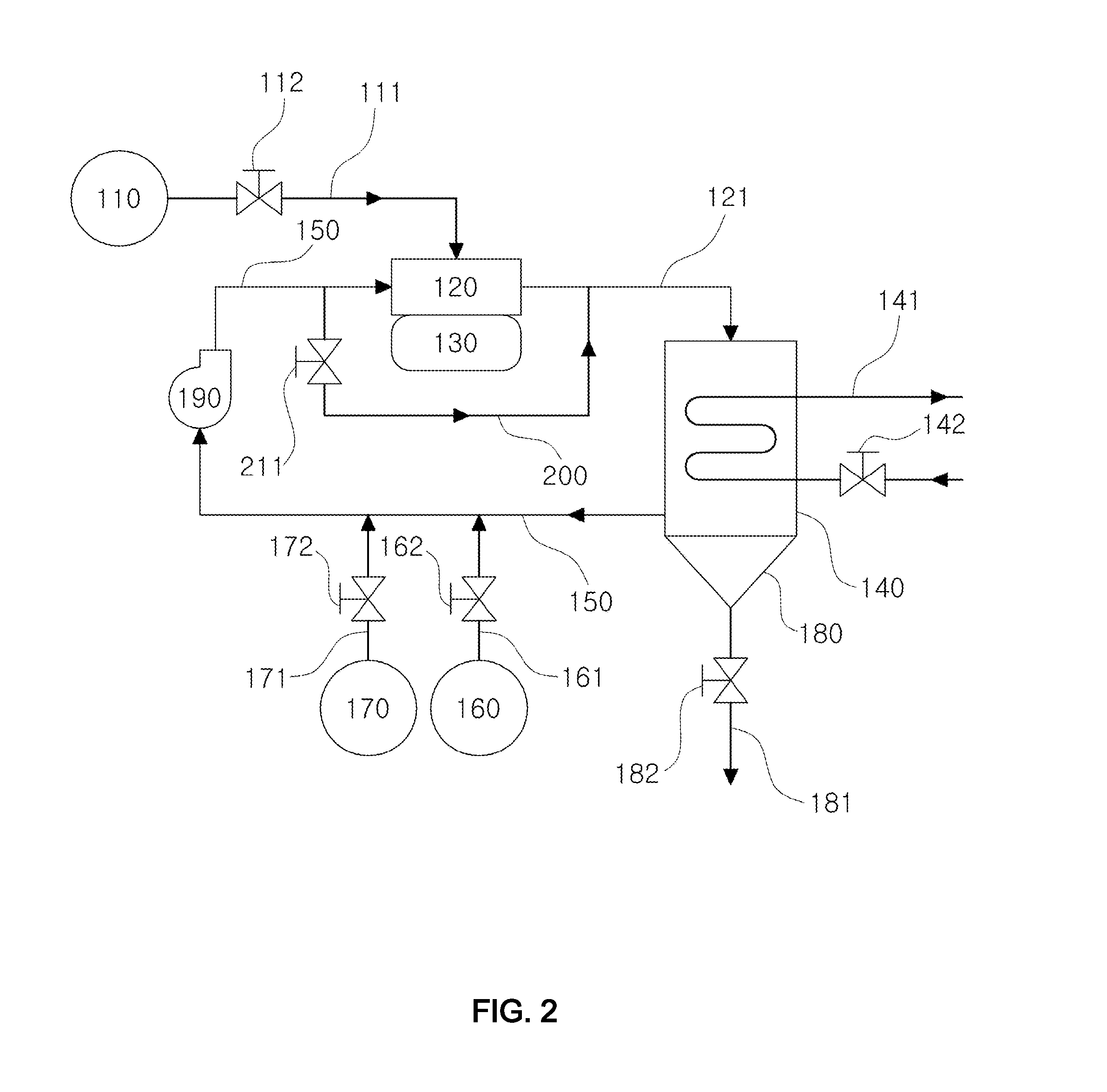

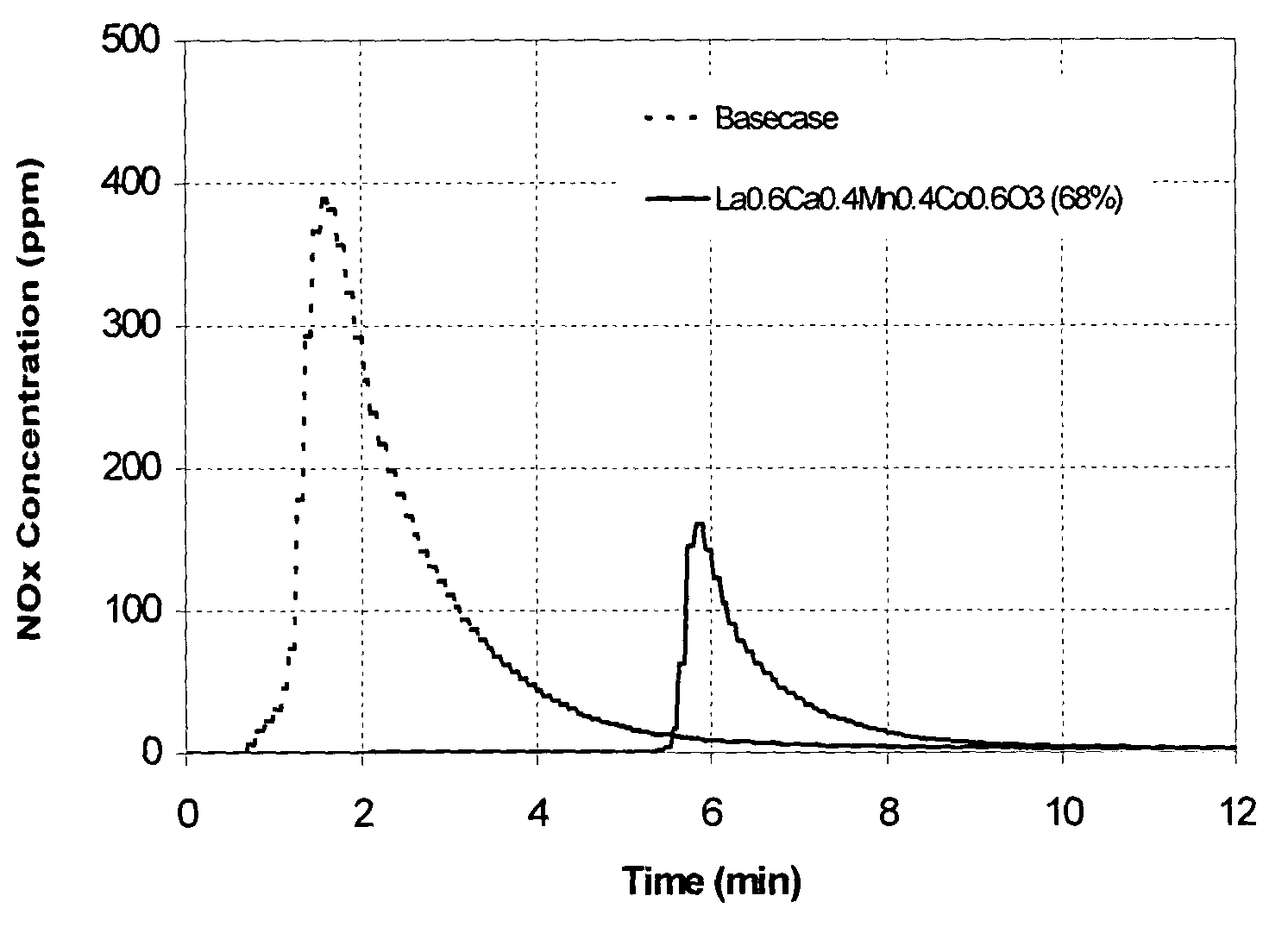

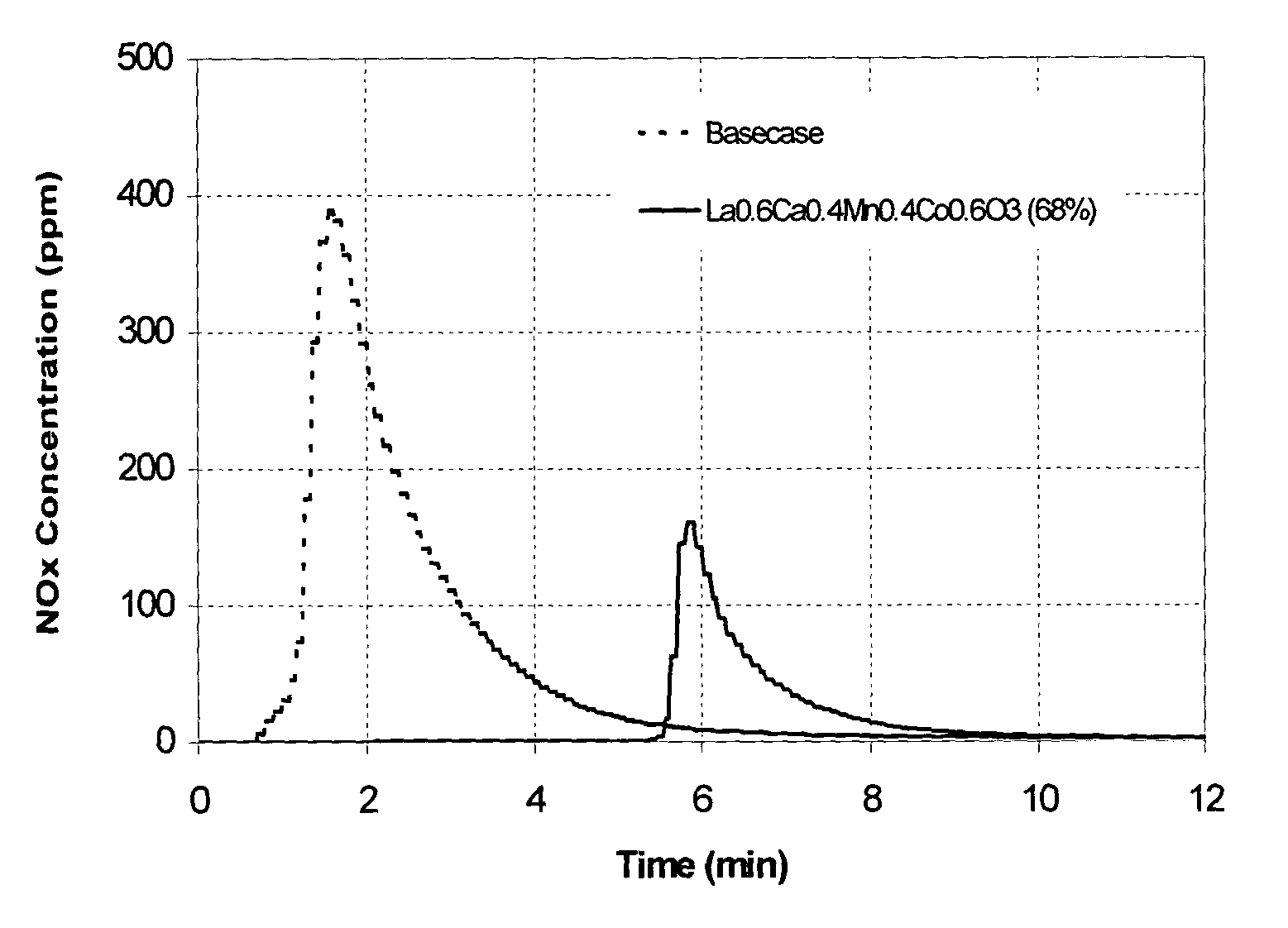

Hydrogen combustion system with closed-cycle recycling of exhaust gas and method thereof

InactiveUS20110192139A1Improve efficiency and operabilityPromote combustionInternal combustion piston enginesExhaust apparatusCombustion chamberExhaust fumes

Disclosed is a hydrogen combustion system with closed-cycle recycling comprising a hydrogen combustion system with closed-cycle recycling of exhaust gas, comprising: a hydrogen supplier 110 which supply hydrogen used as a fuel, a combustion chamber 120 which is located in the engine 130 and connected to the hydrogen supplying pipe 111 in which the hydrogen is combusted, a condenser 140 which converts the hot exhaust gas emitted through the discharge pipe 121 installed on the outlet of the combustion chamber 120 into the cold exhaust gas and condensed water, and a recycling pipe 150 which performs recycling of a part of the cold exhaust gas from the condenser 140 to the inlet of the combustion chamber 120.

Owner:AGENCY FOR DEFENSE DEV

Combined cracking and selective hydrogen combustion for catalytic cracking

A catalyst system and process for combined cracking and selective hydrogen combustion of hydrocarbons are disclosed. The catalyst comprises (1) at least one solid acid component, (2) at least one metal-based component comprised of one or more elements from Groups 1 and 2; one or more elements from Group 3; one or more elements from Groups 4-15 of the Periodic Table of the Elements; and at least one of oxygen and sulfur and (3) at least one of at least one support, at least one filler and at least one binder. The process is such that the yield of hydrogen is less than the yield of hydrogen when contacting the hydrocarbons with the solid acid component alone.

Owner:EXXONMOBIL CHEM PAT INC

Combined cracking and selective hydrogen combustion for catalytic cracking

Owner:EXXONMOBIL CHEM PAT INC

Hydrogen combustion heater

InactiveUS20050142507A1Easy constructionImprove the heating effectCapillary burnersIndirect carbon-dioxide mitigationPtru catalystEngineering

The invention relates to a hydrogen combustion heater. This heater includes (a) a passage for allowing hydrogen gas and air to flow therethrough; (b) a first catalyst provided in the passage, the first catalyst being heated, when electricity is applied thereto, thereby starting a first combustion of a first mixture of the hydrogen gas and the air in the first catalyst; and (c) a heat exchanger provided downstream of the first catalyst in the passage, the heat exchanger being adapted to transfer heat generated by the first combustion to a heating medium of the heat exchanger.

Owner:CALSONIC KANSEI CORP

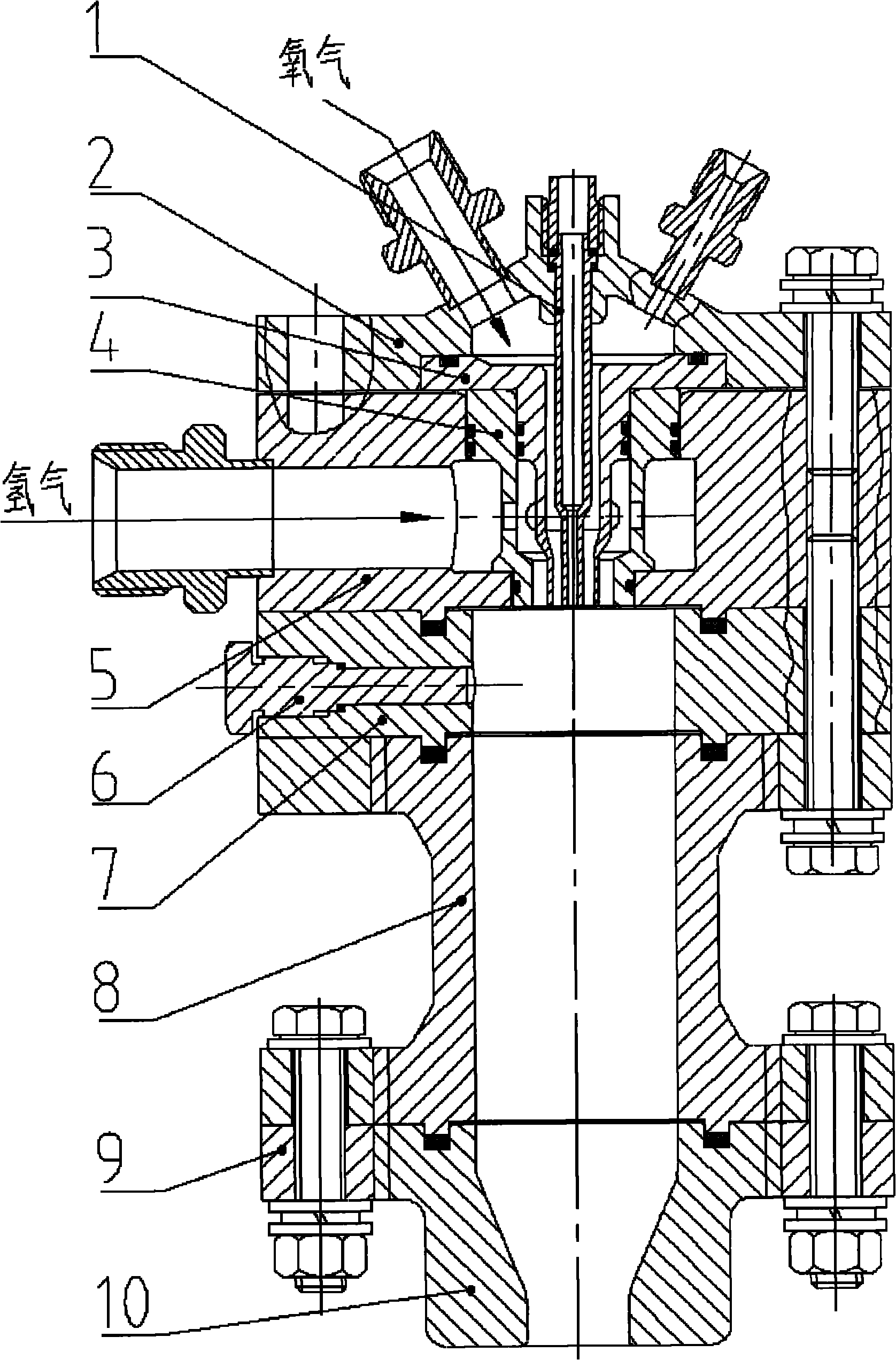

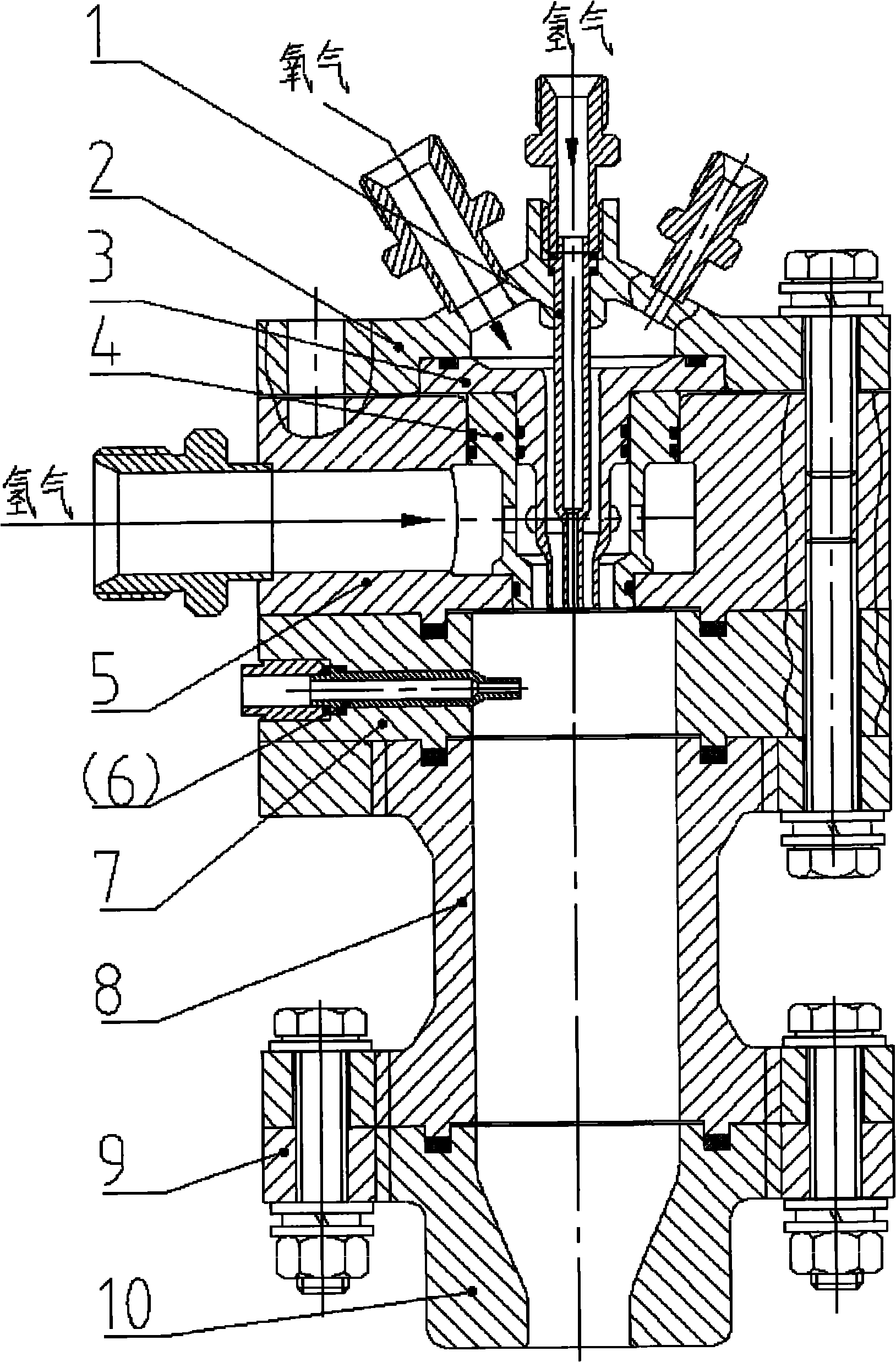

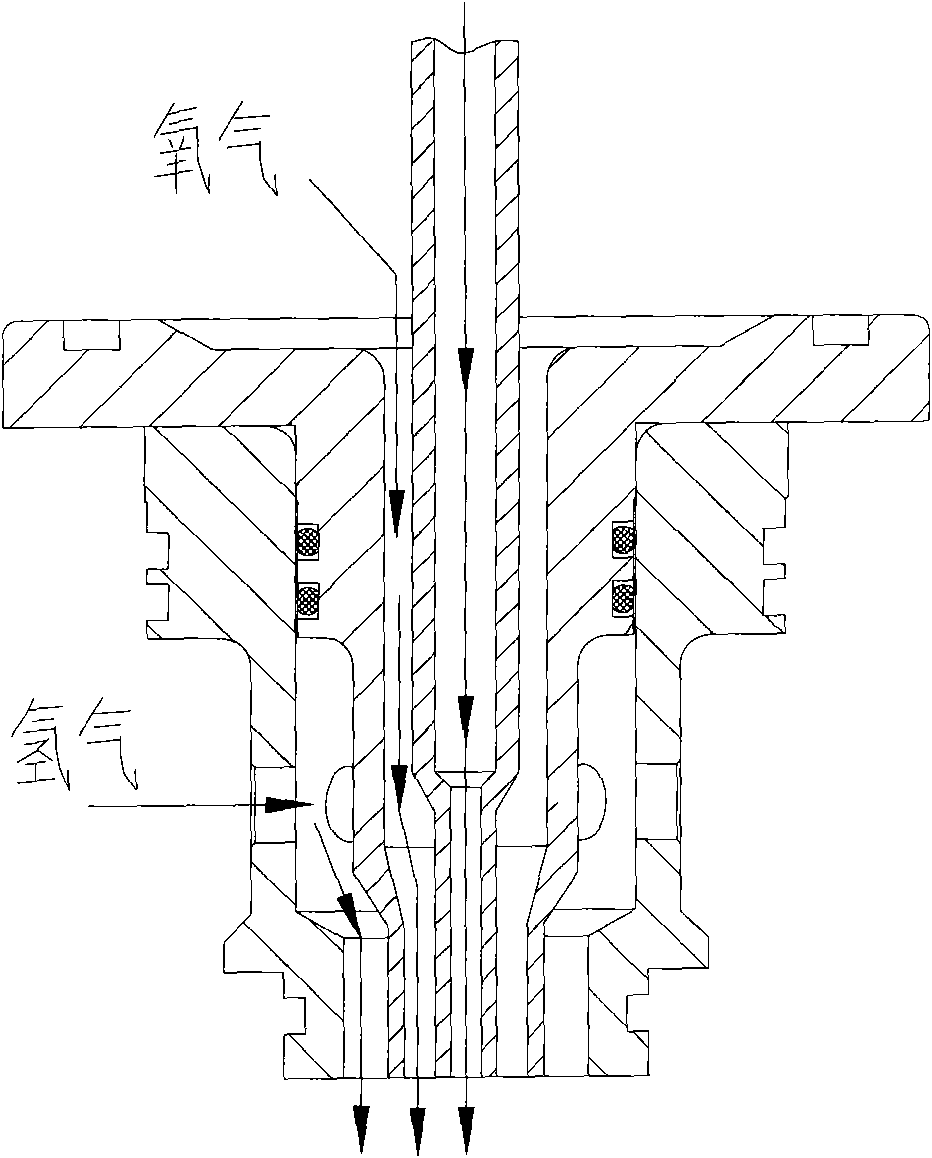

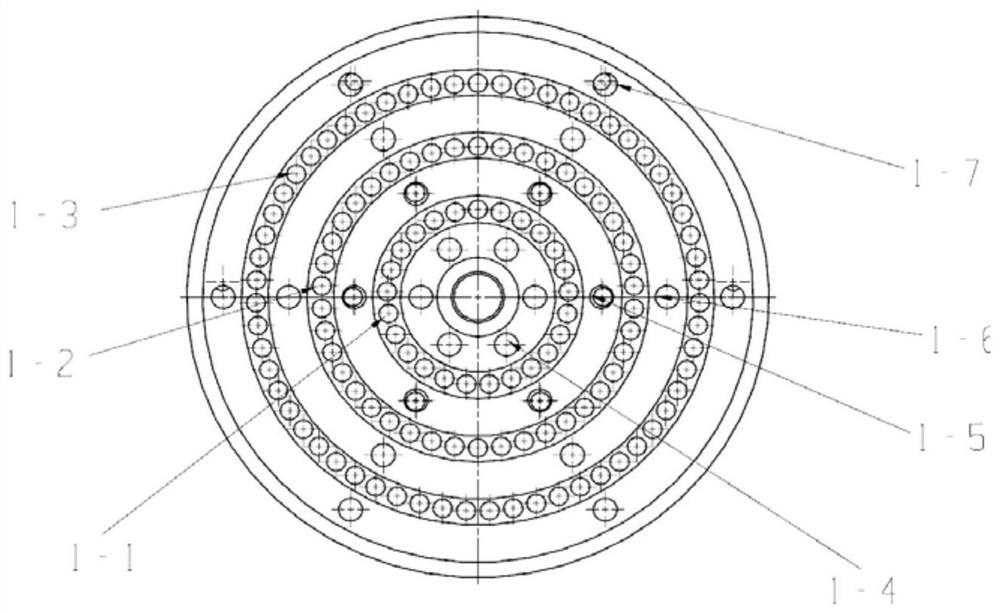

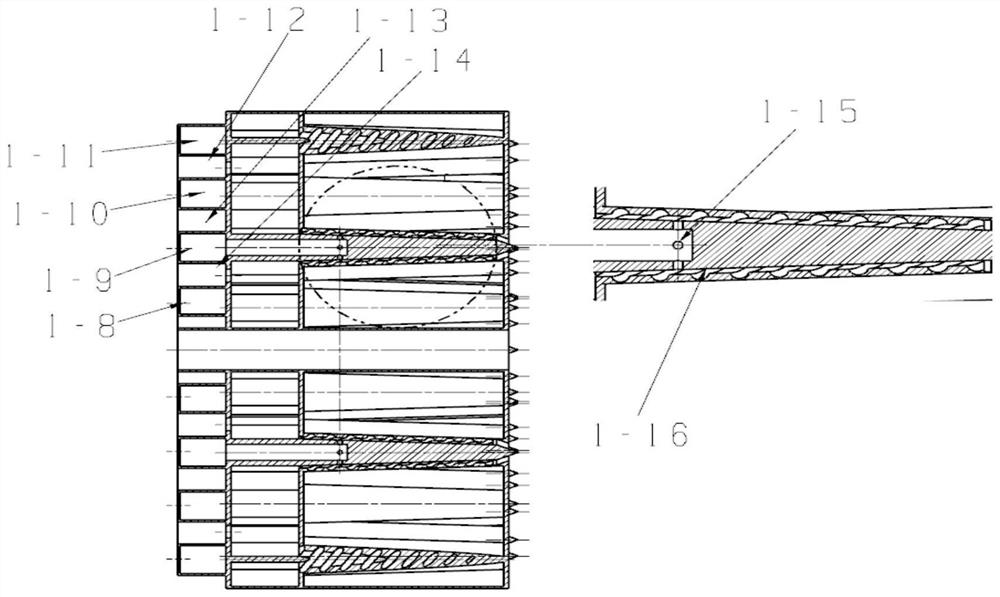

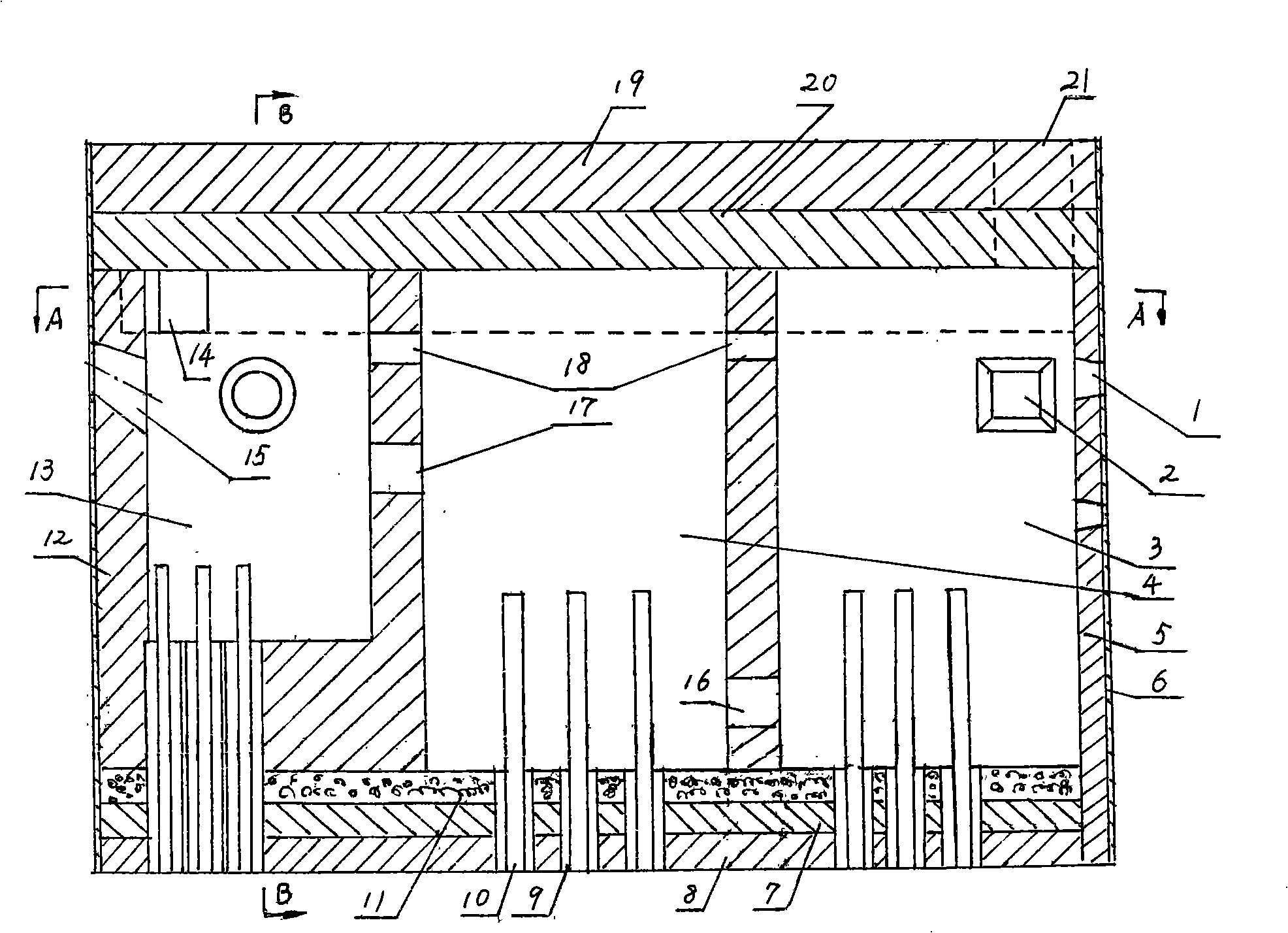

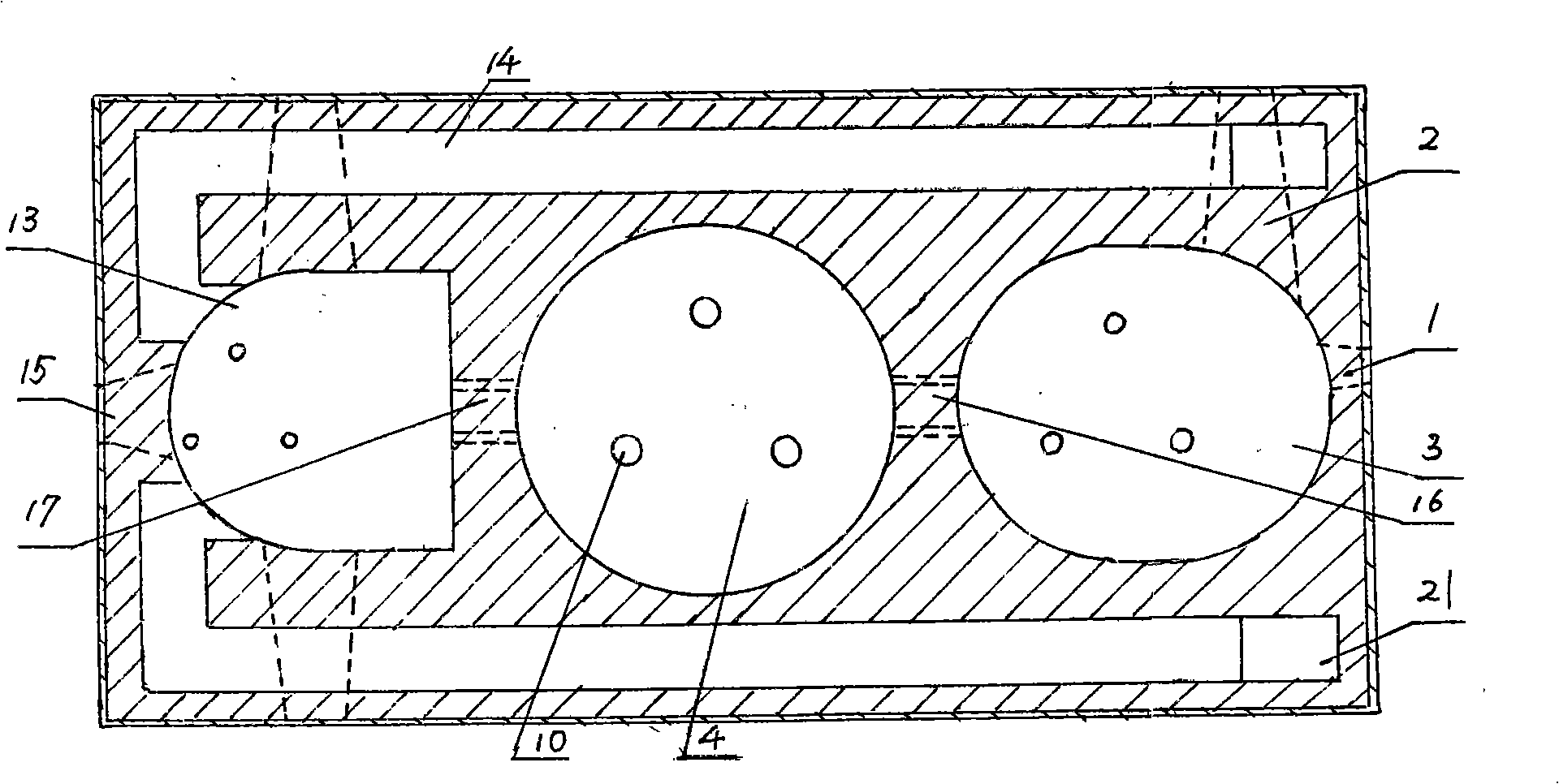

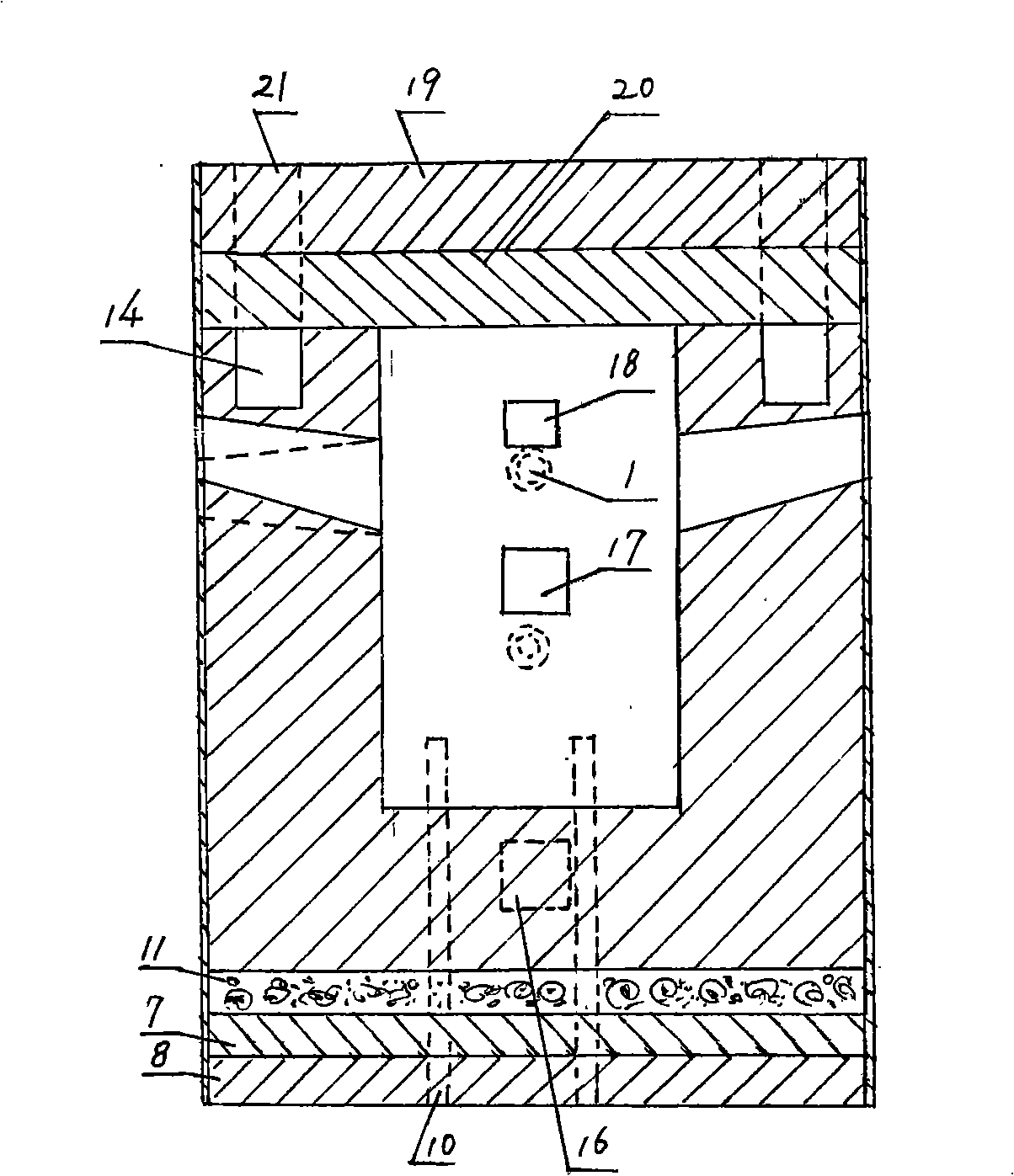

Hydrogen-oxygen fuel-rich precombustion chamber for full flow staged combustion cycle engine

InactiveCN101782028AGood for blending and burningMeet different flow requirementsRocket engine plantsResonanceEngineering

The invention discloses a hydrogen-oxygen fuel-rich precombustion chamber used for a full flow staged combustion cycle engine system, and belongs to the field of structural design of a rocket engine. The hydrogen-oxygen fuel-rich precombustion chamber comprises an ignition tube 1, an oxygen cavity 2, an oxygen nozzle component 3, a hydrogen nozzle component 4, a hydrogen cavity 5, a choke plug 6 or an ignition tube (6), a connecting section 7, a body part 8, a threaded flange 9 and a contraction section 10. In the precombustion chamber, a hydrogen-oxygen pneumatic resonance igniter for combusting the hydrogen and oxygen is adopted, and the hydrogen and oxygen are supplied by a hydrogen ignition line and an oxygen ignition line respectively. The igniter has three mounting positions so as to form the following three ignition schemes: 1, ignition of the head; 2, ignition of the front part of the body part; and 3, ignition of the rear part of the body part. The three ignition schemes can form the hydrogen-oxygen-hydrogen combustion mode and are favorable for mixing combustion of propellants. The oxygen nozzle component 3 and the hydrogen nozzle component 4 can be detached and replaced and can meet different flow requirements. The length of the whole precombustion chamber is variable and is adjusted by increasing the number of the body part 8 or increasing the dimension of the body part 8. Due to the adoption of the threaded flange, the material is saved and the weight is lightened. The whole structural scheme of the precombustion chamber is favorable for deeply researching the ignition schemes, the hydrogen-oxygen-hydrogen combustion mode, the influence of a spoiler ring on fuel gas uniformity, and other problems.

Owner:BEIHANG UNIV

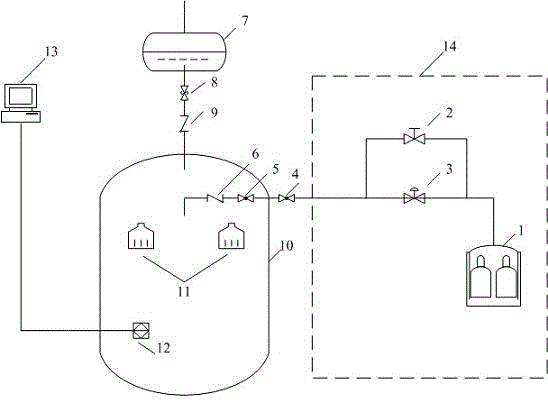

Test system for measuring aerosol concentration and behavior under test conditions

PendingCN110797128AConvenience behavior testNuclear energy generationNuclear monitoringCombustion systemNuclear plant

The invention relates to the technical field of aerosol tests in a containment, and specifically discloses a test system for measuring aerosol concentration and behavior under test conditions. The test system includes a test container, an aerosol generation system, a water temperature control system, a steam generation system, an aerosol measurement system and a hydrogen combustion system, whereinthe aerosol generation system, the water temperature control system, the steam generation system, the aerosol measurement system and the hydrogen combustion system are simultaneously connected with the test container. The test container is of a tube structure of which an interlayer is arranged on the side wall, and thetemperature in the test container is controlled through the water temperature control system. The aerosol generation system can generate aerosols and transport the aerosols to the test container. The steam generation system can provide saturated steam at a fixed temperature forthe test container. The hydrogen combustion system generates required expanded air flow for the test container by controlling hydrogen combustion. The test system for measuring the aerosol concentration and behavior under the test conditions can provide test simulation of a real aerosol environment as much as possible, and systematic and comprehensive test simulation study of the aerosol migrationbehavior in apassive containment of a third-generation nuclear power plant is convenient.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

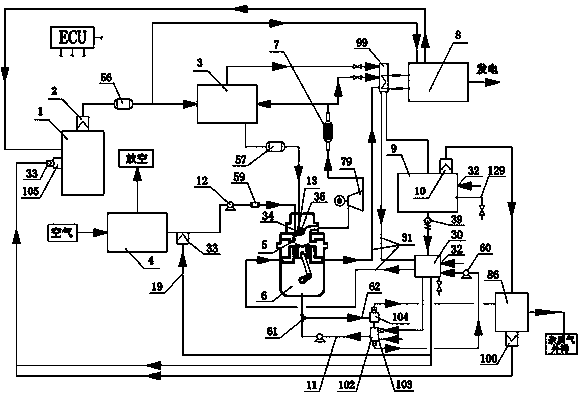

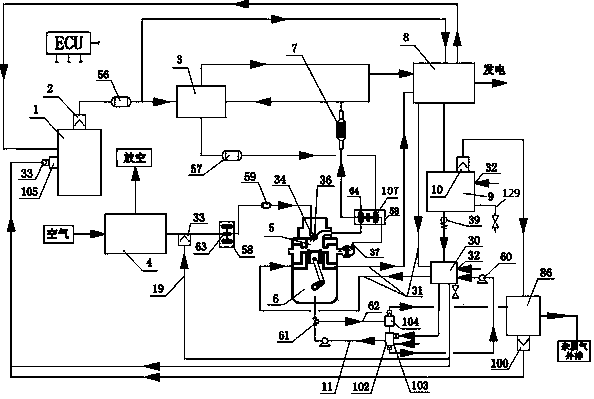

Oxygen direct-injection pure-hydrogen combustion engine and power system thereof

ActiveCN108443010AIncrease diversityIncrease flexibilityCellsHydrogenVapor–liquid separatorHigh pressure oxygen

The invention relates to an oxygen direct-injection pure-hydrogen combustion engine and a power system thereof. The oxygen direct-injection pure-hydrogen combustion engine comprises a hydrogen fuel engine body, a magnesium hydride storage tank, a pressure swing adsorption oxygenerator, a three-way catalyst, a tail gas waste heat utilization unit and a hydrogen purification unit. The magnesium hydride storage tank is connected to a hydrogen opening of the hydrogen fuel engine body through a low-pressure hydrogen buffering tank, and the pressure swing adsorption oxygenerator is connected to an oxygen nozzle of the hydrogen fuel engine body through a high-pressure oxygen buffering tank. Exhausting holes of the hydrogen fuel engine body are connected to the three-way catalyst through a tail gas expander or a turbocharging unit, and an outlet of the three-way catalyst is connected to a gas-liquid separator through a kelaipu unit / combined type kelaipu unit. A gas outlet of the gas-liquid separator is connected to a steam inlet of the magnesium hydride storage tank through the hydrogen purification unit, and a water outlet of the gas-liquid separator is connected to a cooling water tank.The oxygen direct-injection pure-hydrogen combustion engine is combined with the kelaipu unit / combined type kelaipu unit through the hydrogen fuel engine body, tail gas waste heat of the engine body is fully utilized, and the heat efficiency of the engine body is improved.

Owner:SHANGHAI KELAIPU ENERGY TECH CO LTD

High-efficiency low-emission combustion chamber head capable of premixing hydrogen

InactiveCN114183772AImprove uniformityGuaranteed uniformityContinuous combustion chamberCombustion chamberEngineering

According to the hydrogen premixing efficient low-emission combustion chamber head, the characteristic that hydrogen premixing flames are high in propagation speed and the advantage that the hydrogen flames are thin are combined, the low-emission combustion chamber stable-combustion head structure is designed, the structural design that the multiple stages of fuel annular cavities are connected with the annular cavities is adopted, and the combustion efficiency is improved; the multi-stage premixing flow channel is arranged in the combustor head, the uniformity of fuel entering the combustor head can be greatly improved, the multi-stage premixing flow channel is gradually shrunk, the spiral grooves are formed in the premixing flow channel, mixing of the fuel and air is enhanced, the combustion temperature field is improved, reliable and stable combustion of hydrogen under the premixing condition is achieved, and therefore emission of nitric oxide in the hydrogen combustion process is reduced, and the combustion efficiency is improved. And clean and efficient hydrogen combustion is realized. The scheme has the advantages of light and handy structure, high space utilization rate, high volume heat intensity, low pollutant emission, uniform outlet temperature, good universality, simplicity in processing and maintenance and the like.

Owner:HARBIN ENG UNIV

Hydrogen combustion heater

InactiveUS6851947B2Easy constructionStable in heating capabilityCapillary burnersCatalytic ignitersElectricityPlate heat exchanger

The invention relates to a hydrogen combustion heater. This heater includes (a) a passage for allowing hydrogen gas and air to flow therethrough; (b) a first catalyst provided in the passage, the first catalyst being heated, when electricity is applied thereto, thereby starting a first combustion of a first mixture of the hydrogen gas and the air in the first catalyst; and (c) a heat exchanger provided downstream of the first catalyst in the passage, the heat exchanger being adapted to transfer heat generated by the first combustion to a heating medium of the heat exchanger.

Owner:CALSONIC KANSEI CORP

Combined cracking and selective hydrogen combustion for catalytic cracking

A catalyst system and process for combined cracking and selective hydrogen combustion of hydrocarbons are disclosed. The catalyst comprises (1) at least one solid acid component, (2) at least one metal-based component comprised of one or more elements from Group 3 and one or more elements from Groups 4–15 of the Periodic Table of the Elements; and at least one of oxygen and sulfur, wherein the elements from Groups 3, Groups 4–15 and the at least one of oxygen and sulfur are chemically bound both within and between the groups and (3) at least one of at least one support, at least one filler and at least one binder. The process is such that the yield of hydrogen is less than the yield of hydrogen when contacting the hydrocarbons with the solid acid component alone.

Owner:EXXONMOBIL CHEM PAT INC

Method of manufacturing new type heating elements

InactiveCN1447625ASuitable for a wide temperature rangeIncrease the applicable temperature rangeOhmic-resistance heatingCeramic sinteringTemperature control

The molten metals is printed on the surface of ceramic, which is then carried out ceramic metallization in hydrogen combustion furnace by using wet hydrogen. Then, one layer of ceramics sintering auxiliary agent is coated on the metal ceramic plates sintered. Another ceramic plate with notch is covered on the said ceramic plate and agglutinated each other. Then, the sintering procedure is processed for agglutinated two ceramic plates in furnaces again. Nickel is plated on the electrode on the said notch of the ceramic plate. Fusion welding is carried out in the place, where nickel is plated, for leading out the wire for use in high temperature by using silver solder. Finally, the thermostat is connected to the wire for temperature control.

Owner:邓泰均

Combined cracking and selective hydrogen combustion for catalytic cracking

A catalyst system and process for combined cracking and selective hydrogen combustion of hydrocarbons are disclosed. The catalyst comprises: (1) at least one solid acid component, (2) at least one metal-based component comprised of (i) at least one of oxygen and sulfur (ii) one or more elements from Groups 5-15 of the Periodic Table of the Elements; and (iii) one or more elements from at least one of (a) Groups 1-2 and (b) Group 4; of the Periodic Table of the Elements; and (3) at least one of at least one support, at least one filler and at least one binder. The process is such that the yield of hydrogen is less than the yield of hydrogen when contacting the hydrocarbons with the solid acid component alone.

Owner:EXXONMOBIL CHEM PAT INC

Process and apparatus for processing municipal sewage sludge by using nepheline nucleated glass

InactiveCN101302044AAchieve combustion heat releaseSave diversion pipeline construction costsSludge treatment by oxidationByproduct vaporizationParaffin waxWater quality

The method relates to a sewage water and sludge treatment technology, in particular to a process and equipment for treating municipal sewage water and sludge by utilizing a nepheline nucleated glass technology. The invention solves the problems that the prior incinerator has secondary pollution and upflowing black smoke, etc. in the process of treating the municipal sludge. The process comprises the following steps that: nepheline nucleated glass raw material is used to absorb and filter the sewage water, then sludge water is rapidly separated; upper-layer water is disinfected by steam, volatilizes odor and is further filtered to drinking water; underlayer slurry is mixed with diesel oil and olefin to be used as fuel of a liquation furnace; and residue falls on a hearth and is mixed with the added nepheline nucleated glass raw material to fuse superior nepheline nucleated glass particles, which can be used to produce nepheline nucleated glass and metal mixed powder metallurgical products, mechanical members and building materials. The equipment has a high energy formula of combining a superhigh temperature and bottom inserting-type three-phase electrode liquation furnace and nepheline and realizes the separation of hydrogen and oxygen in the water and the heat release of hydrogen combustion. The process and the equipment have no requirement on the water quality of incoming water, achieve the recovery of purified water and the emission of air without odor and realize the added value utilization of the residua.

Owner:赵凤宇

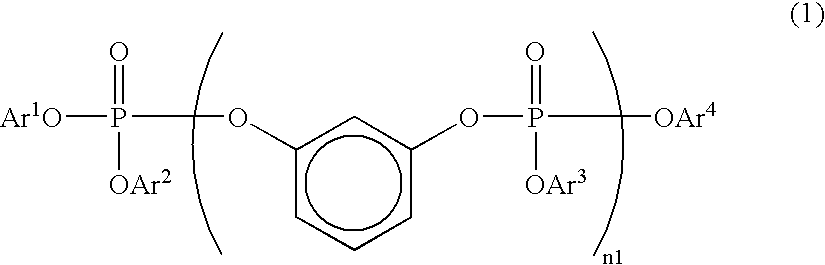

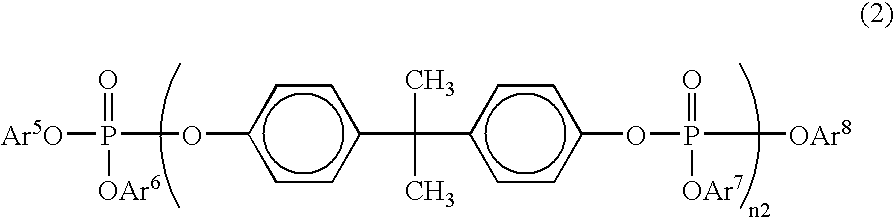

Flame-retardant polytrimethylene terephthalate resin composition

InactiveUS7094819B2Improve mechanical propertiesExcellent characteristicsPlastic/resin/waxes insulatorsDyeing processHydrogen halideCombustion

A flame retardant polytrimethylene terephthalate resin composition, comprising:30 to 99 parts by weight of (A) a polytrimethylene terephthalate resin, and1 to 70 parts by weight of at least one flame retardant selected from the group consisting of (B-1) phosphorus-containing flame retardant and (B-2) nitrogen-containing flame retardant, is disclosed. The composition has superior mechanical characteristics, chemical resistance, electrical characteristics, weatherability, heat aging resistance and hydrolysis resistance, and has superior moldability, good appearance with less warpage deformation when molded, and furthermore has superior flame retardance and does not generate highly corrosive hydrogen halide gas upon combustion.

Owner:ASAHI KASEI CHEM CORP

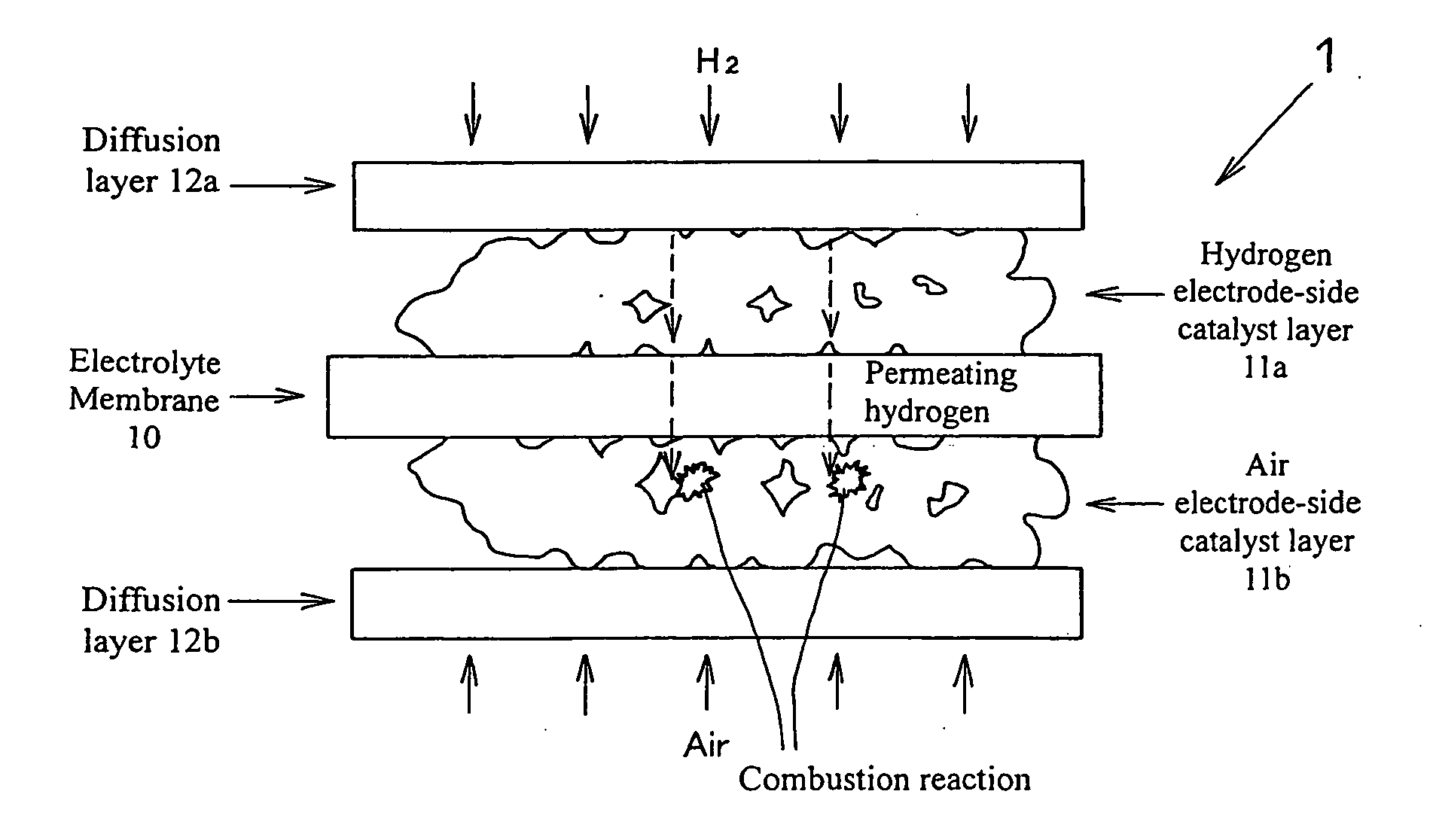

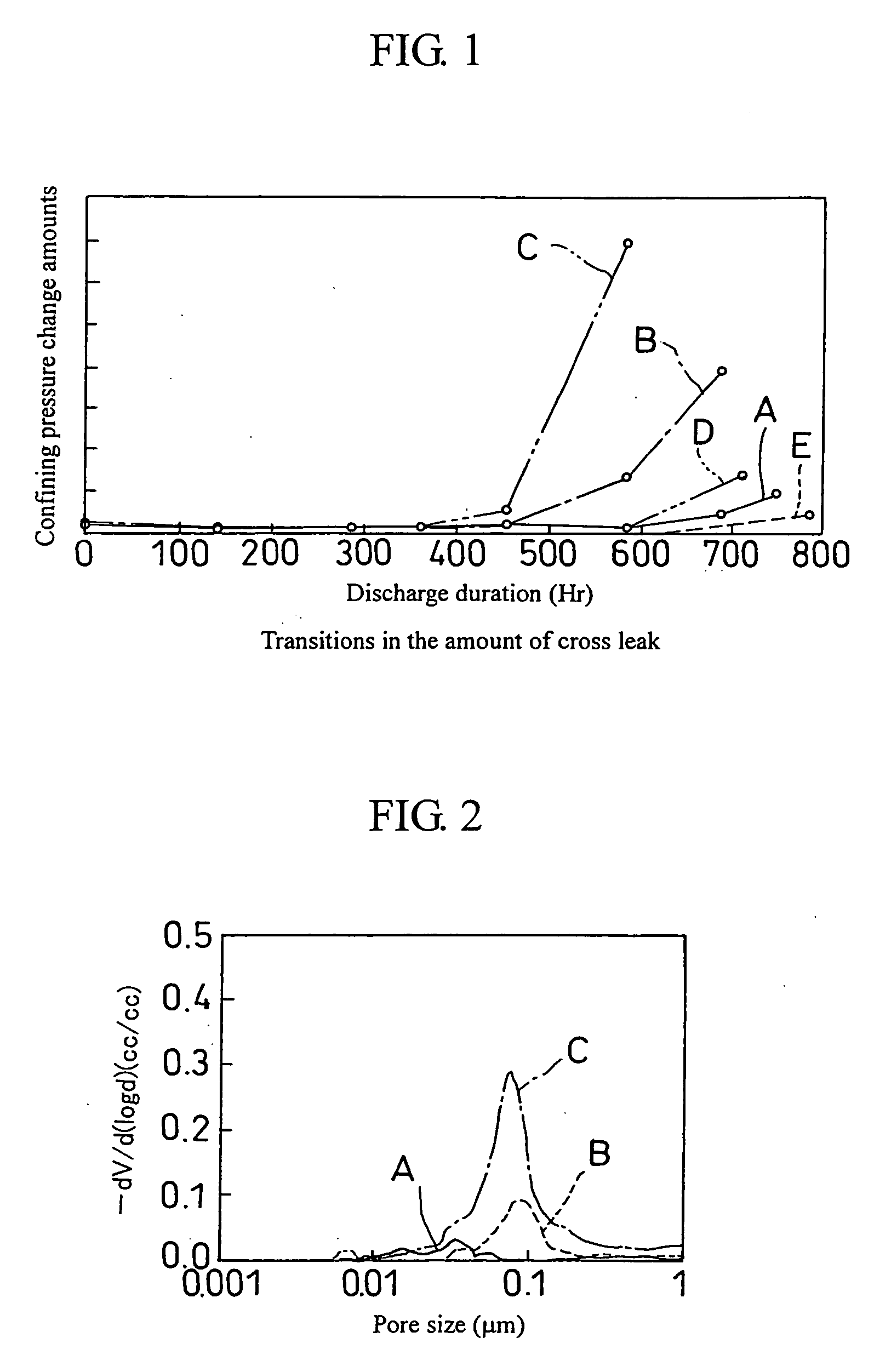

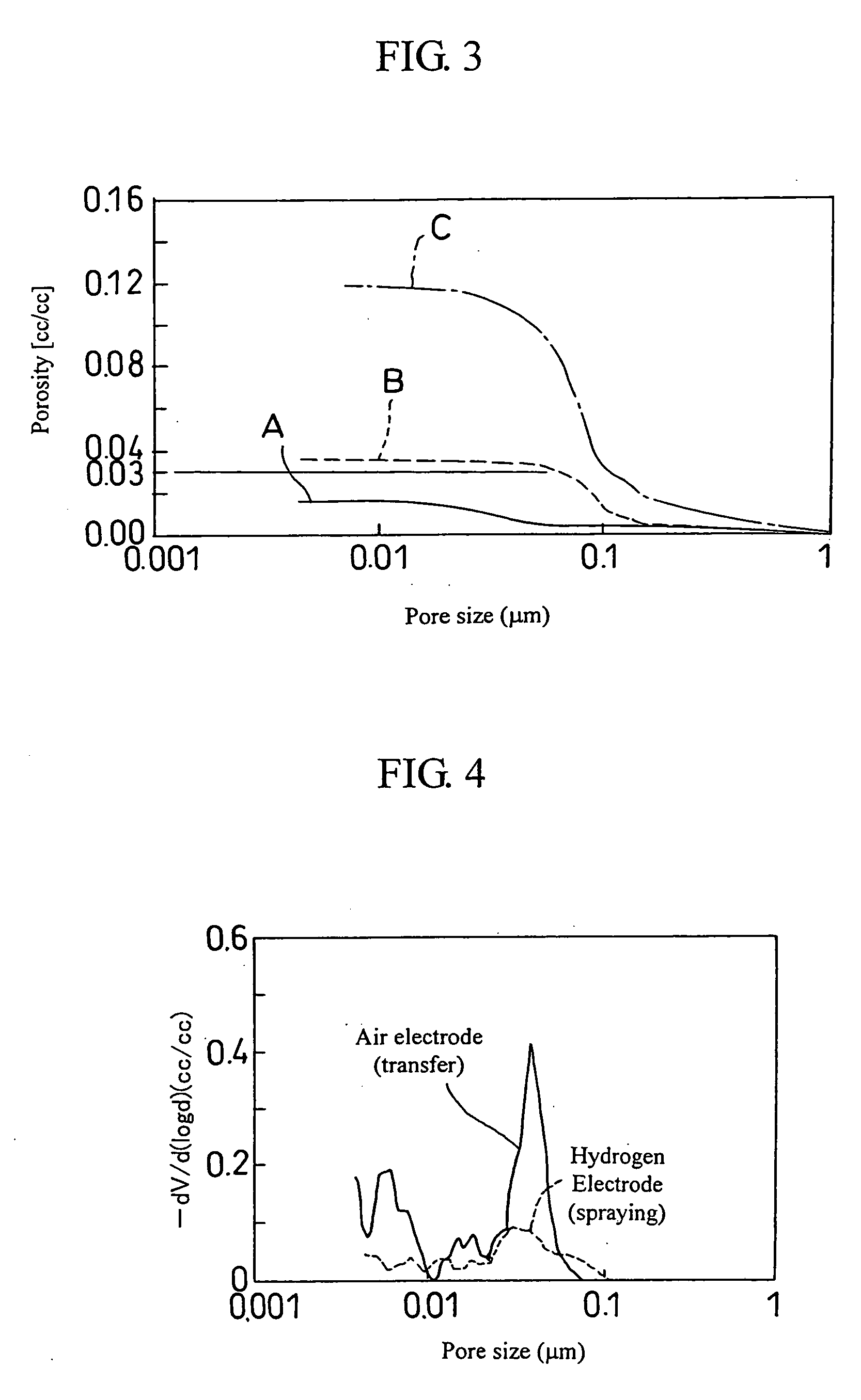

Fuel cell

ActiveUS20060166073A1Reduced pore volumeReduce porosityFuel cell auxillariesActive material electrodesPorosityFuel cells

In a membrane electrode assembly 1 of a fuel cell, the porosity of a hydrogen electrode-side catalyst layer 11a is made to be lower than that of an air electrode-side catalyst layer 11b. Specifically, the weight ratio of ion-exchange resin to carbon carriers of the hydrogen electrode-side catalyst layer is made to be larger than such ratio of the air electrode-side catalyst layer, the hydrogen electrode-side catalyst layer is allowed to contain an additive having a certain particle diameter or less, or the hydrogen electrode-side catalyst layer is formed by spraying a catalyst ink and the air electrode-side catalyst layer is formed by a transfer method. According to the present invention, the amount of hydrogen that permeates from the hydrogen electrode-side catalyst layer to the air electrode-side catalyst layer via an electrolyte membrane is reduced to suppress a direct hydrogen combustion reaction in the air electrode-side catalyst layer, thereby improving the fuel cell durability.

Owner:TOYOTA JIDOSHA KK

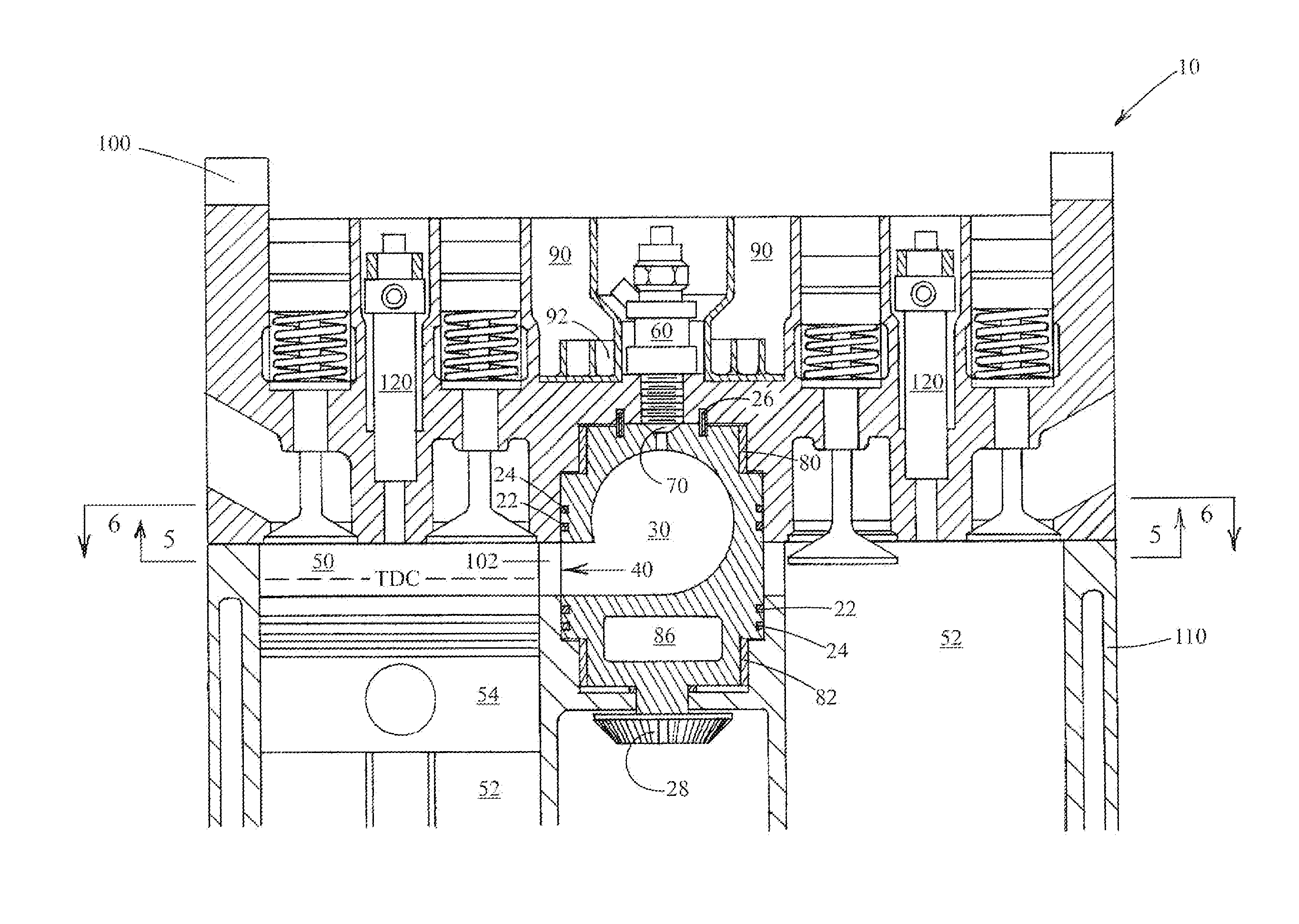

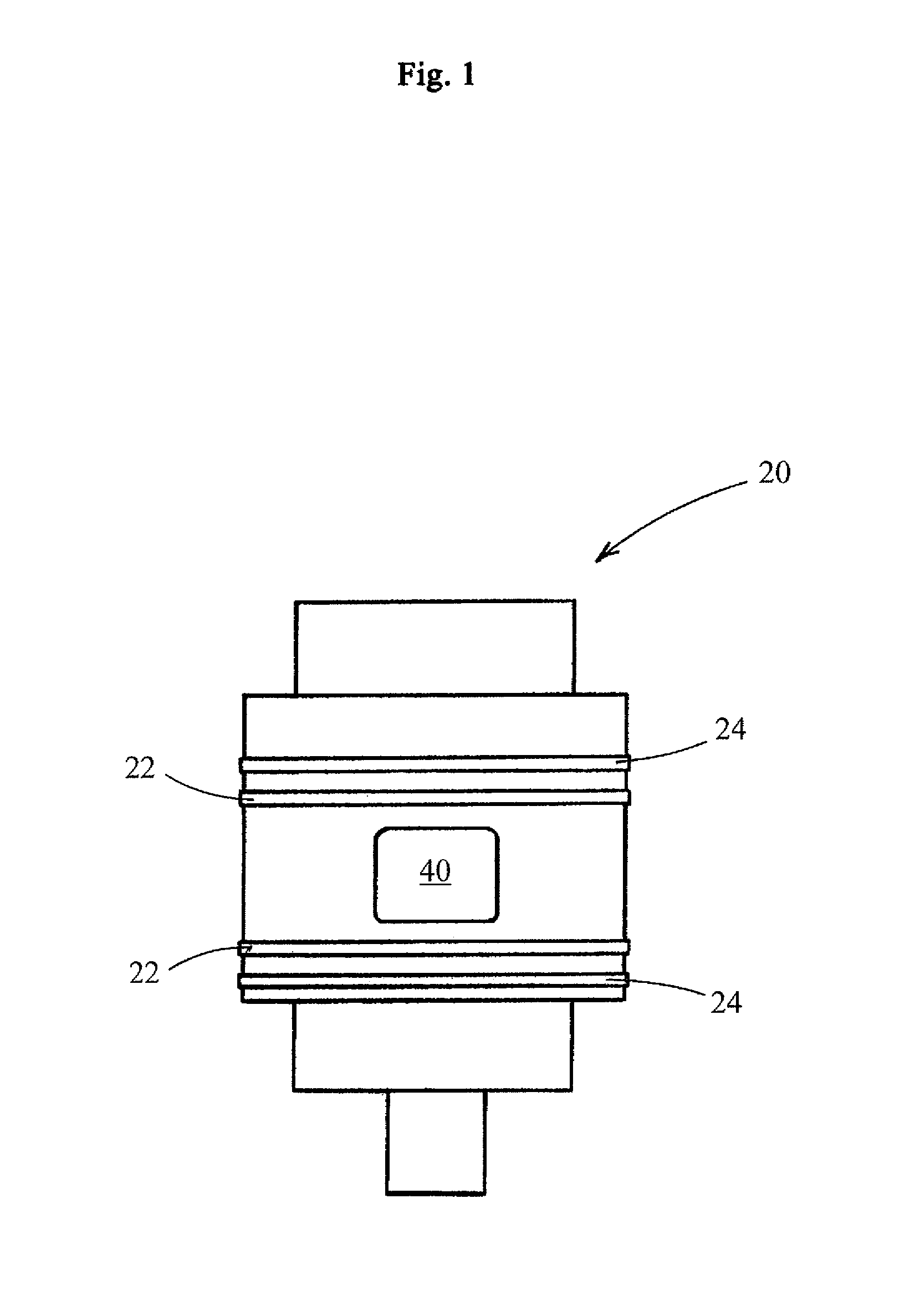

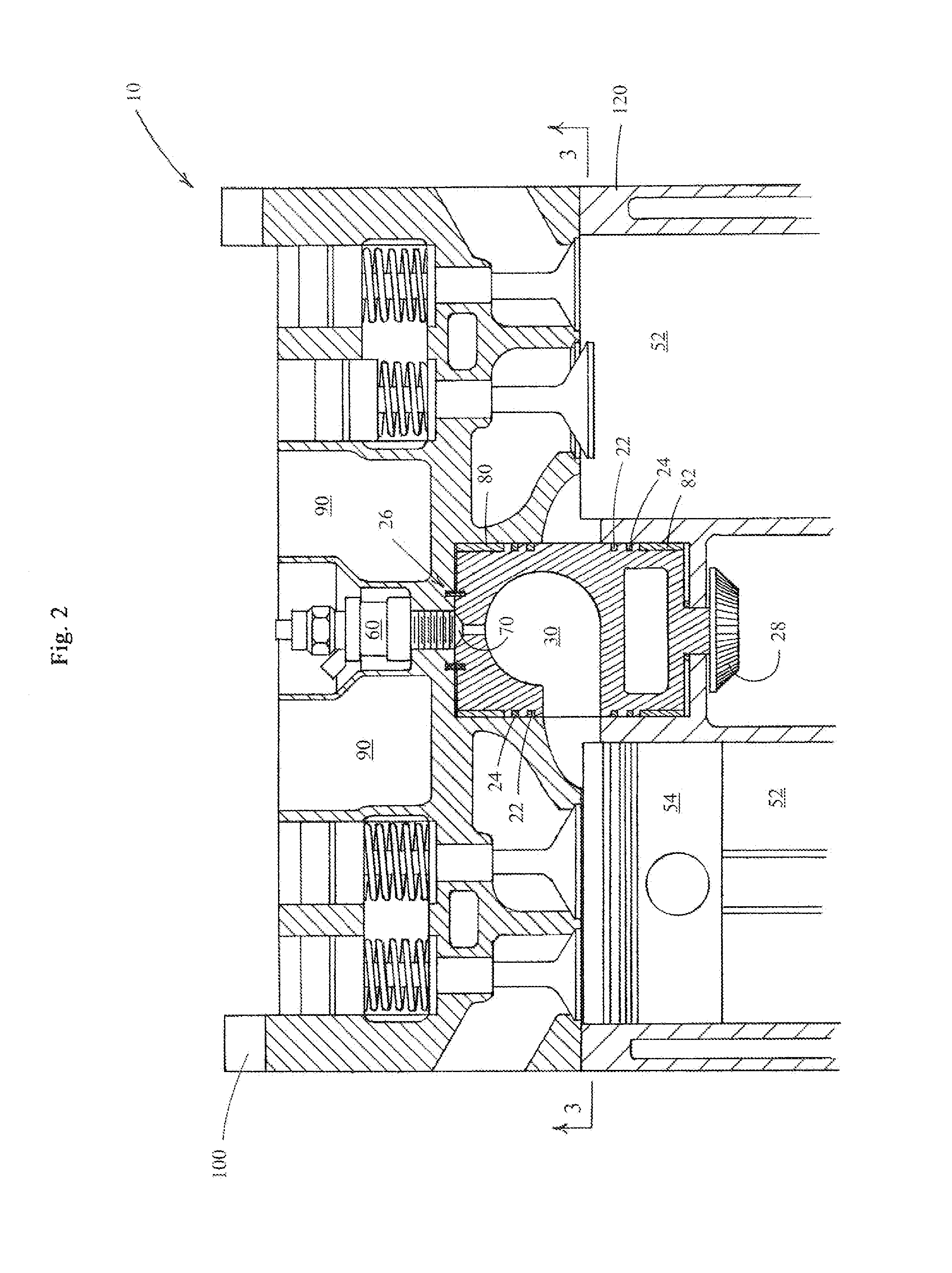

Engine having a rotary combustion chamber

InactiveUS9003765B1Reduced operating temperature rangePromote combustionInternal combustion piston enginesGas turbine plantsOn boardCeramic coating

A poppet valve engine incorporates a single rotary combustion chamber serving multiple cylinders to decrease emissions and increase thermodynamic efficiency. Virtually zero emissions are achievable by on-board fuel reforming to hydrogen. Limited heat range exposure of the rotary combustion chamber, low temperature combustion, and ceramic coatings reduce heat loss while three stage combustion, intake and fuel preheating, and fuel reforming reduce combustion process irreversibility. A supercharger increases the power density to allow engine displacement reduction. A z-crankshaft assembly coupled with a pre-combustion chamber allow knock-less and stable hydrogen combustion at virtually all load and speed conditions. Variable compression, possible in certain configurations of the z-crankshaft assembly, further increases thermal efficiency.

Owner:MUTH BARRY A

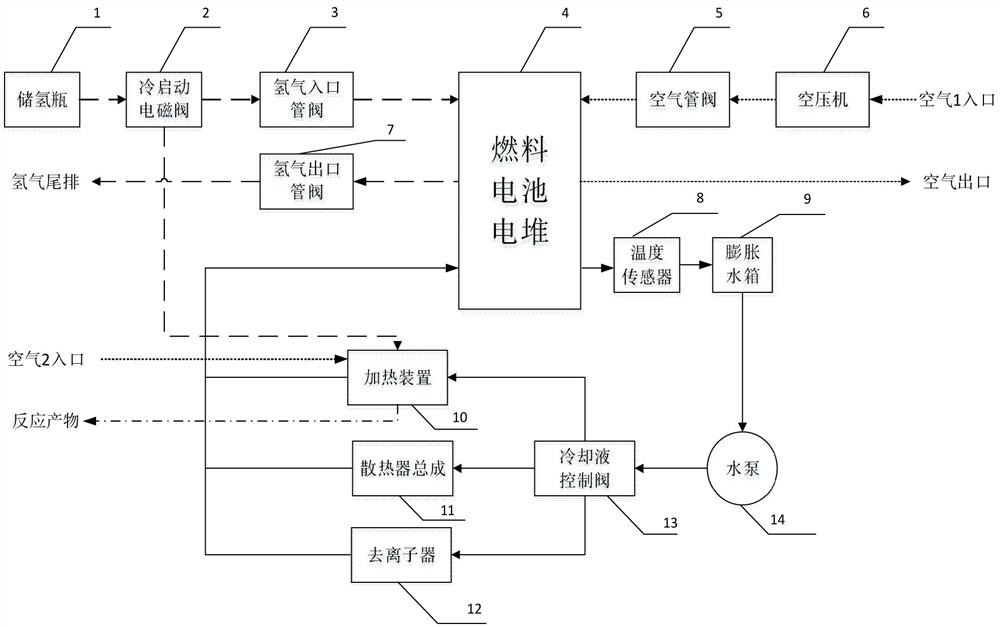

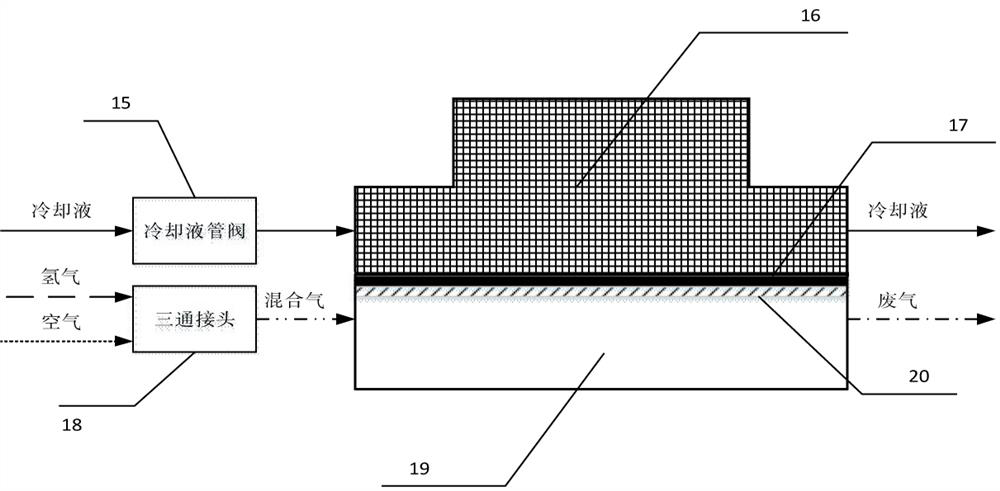

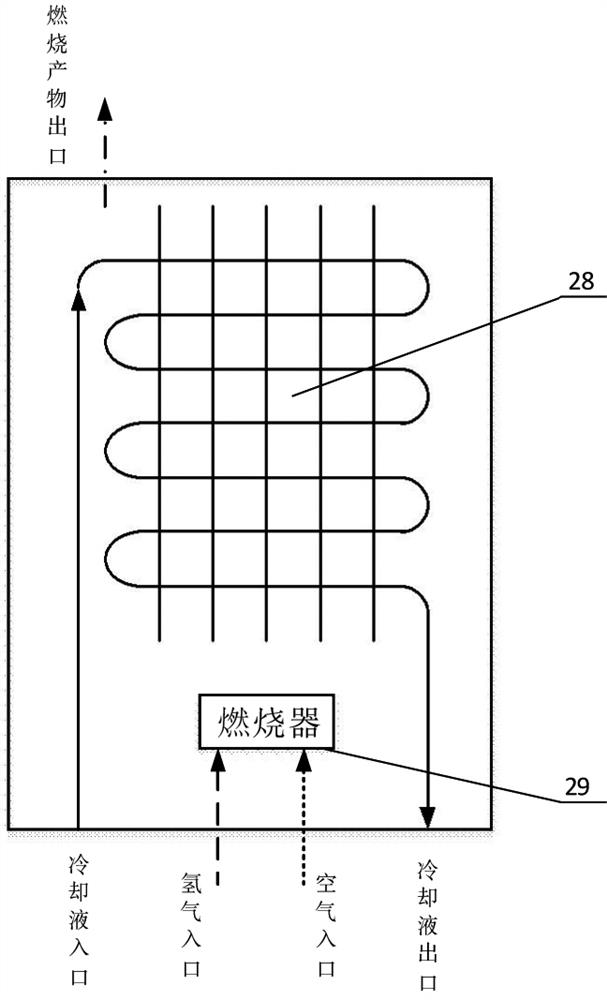

Hydrogen combustion heater of fuel cell engine and extremely-low-temperature self-starting method

The invention discloses a hydrogen combustion heater of a fuel cell engine. The hydrogen combustion heater comprises a partition plate, an enhanced heat exchange device and a catalytic reactor, the enhanced heat exchange device and the catalytic reactor are arranged on the two sides of the partition plate respectively, the enhanced heat exchange device comprises a cooling water way, a catalyst covering layer is arranged between the partition plate and the catalytic reactor, and cooling liquid pipe valves and three-way connectors are arranged on the heat exchange device and the catalytic reactor respectively. The method for realizing low-temperature self-starting of the fuel cell engine comprises the following steps that: after receiving a starting signal, the engine self-checks the ambienttemperature; when the environment temperature ranges from -8 DEG C to -3 DEG C, a signal is sent to the cold start electromagnetic valve, and the hydrogen pipeline cold start electromagnetic valve isopened; hydrogen flows into the heater to be mixed with air to generate chemical reaction to generate heat, cooling water is heated, meanwhile, the cooling liquid control valve acts to disconnect theradiator assembly and an inlet of the deionizer branch, and the cooling liquid only flows through the heating device and is heated; and the heated cooling water heats an electric pile of the engine,so that rapid low-temperature cold start of the fuel cell engine is realized.

Owner:WUHAN MARINE ELECTRIC PROPULSION RES INST CHINA SHIPBUILDING IND CORP NO 712 INST

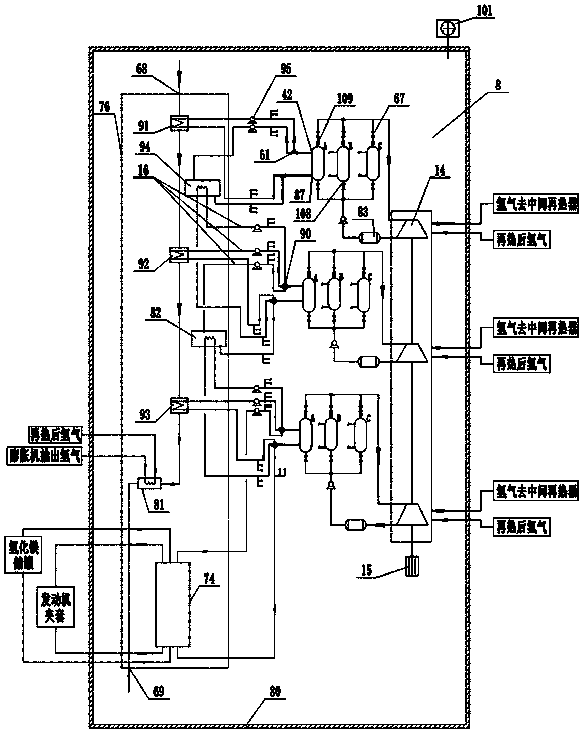

Hydrogen risk control system and control method for small-power nuclear reactor containment

ActiveCN104979020AEliminate the risk of combustion and explosionPower plant safety arrangementNuclear energy generationNuclear reactorControl system design

The invention discloses a hydrogen risk control system and a control method thereof for a small-power nuclear reactor containment. The hydrogen risk control system comprises a passive inert gas supply system and a steel containment system, wherein the steel containment system comprises a steel pressure-bearing containment; a passive hydrogen removing device is arranged inside the steel pressure-bearing containment; the passive inert gas supply system comprises an inert gas storage tank which communicates with the interior of the steel pressure-bearing containment; the steel pressure-bearing containment also communicates with an air-discharging system; moreover, the hydrogen risk control system also comprises a monitoring system for monitoring oxyhydrogen concentration in the containment. The system and method have the following advantages: a novel hydrogen control system design method applicable to a small-power nuclear reactor is provided by the invention; through injection of inert gas into a small steell containment of the small-power nuclear reactor and combination of the passive hydrogen removing device, gas mixture in the containment is ensured to remain a non-combustible state; thus, the risk of hydrogen combustion explosion is eliminated.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

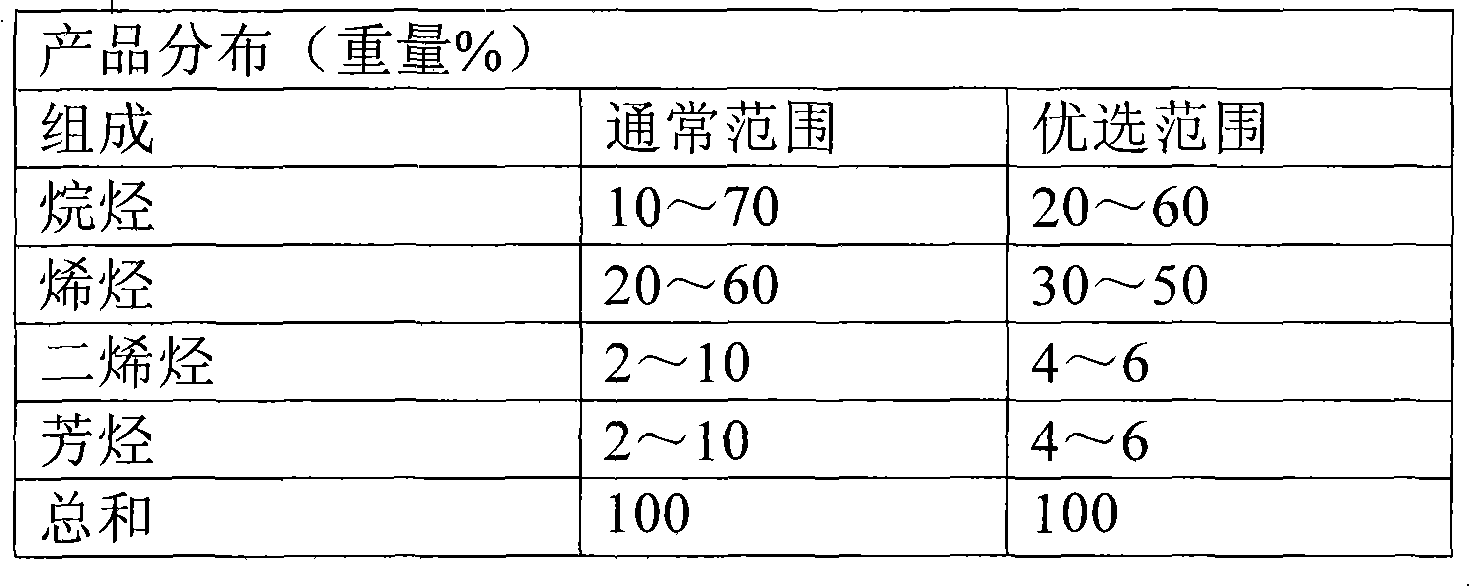

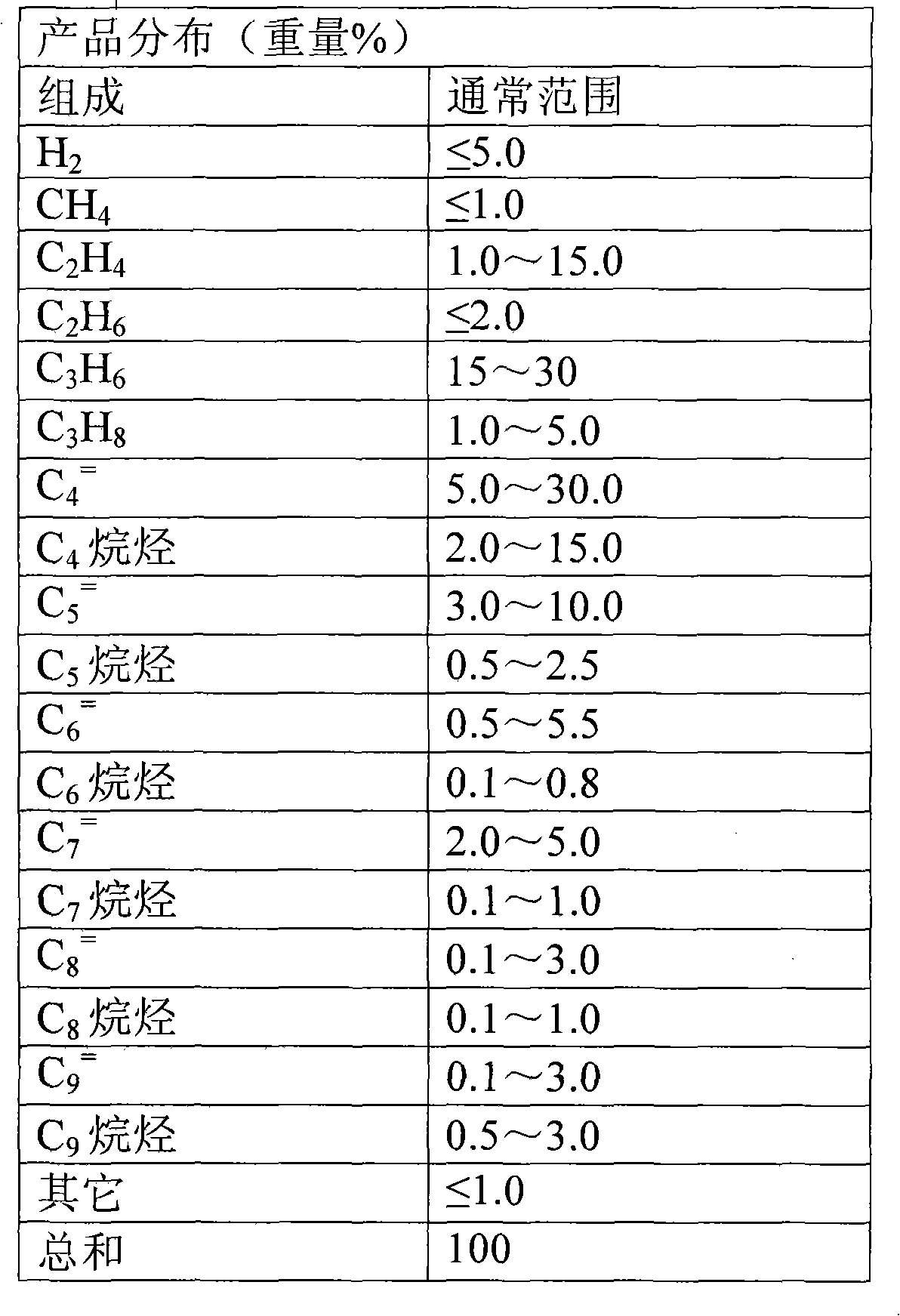

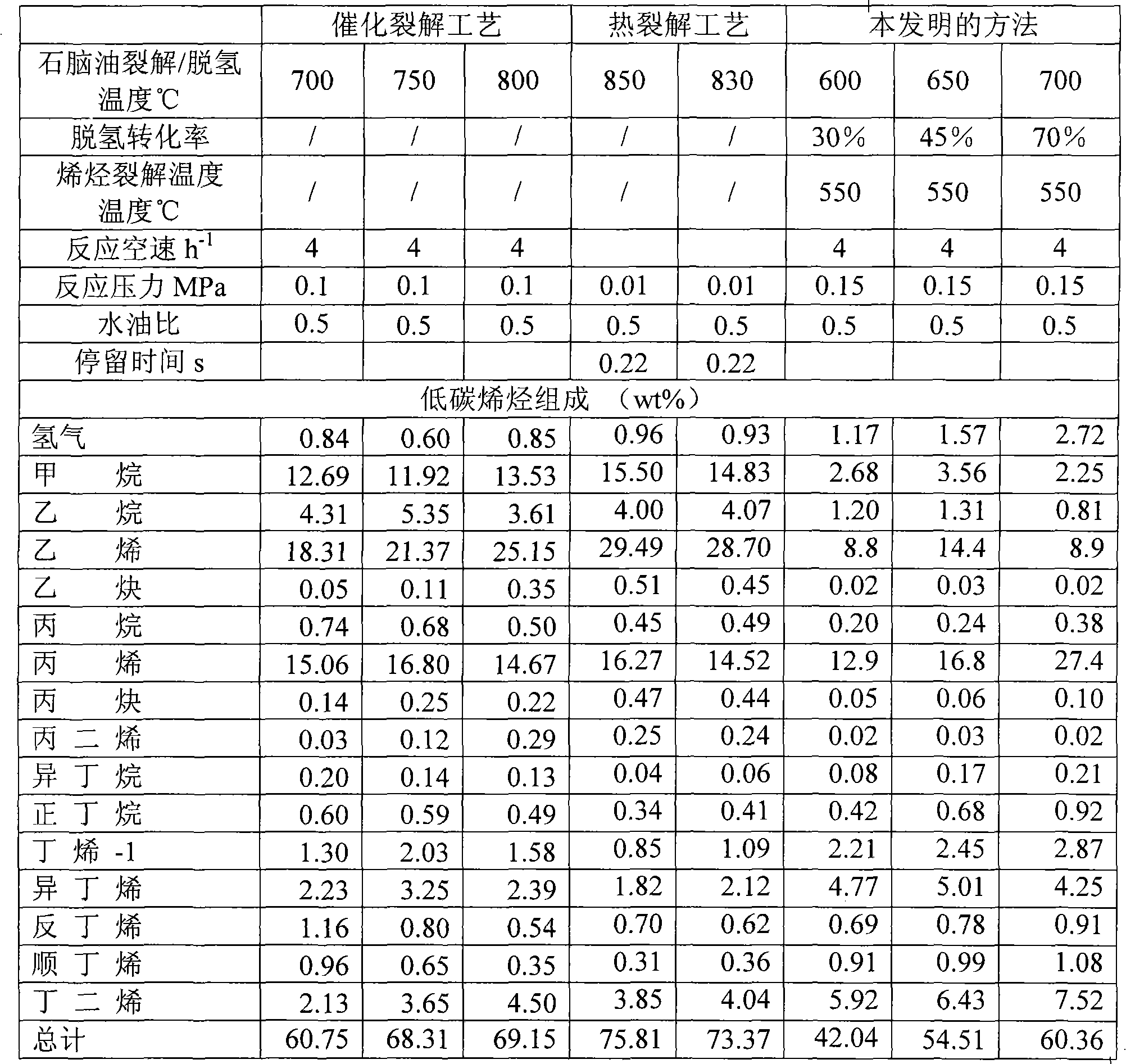

Method for producing low-carbon olefins by using petroleum hydrocarbon

InactiveCN101870633AImprove heat transfer performanceImprove heat transfer efficiencyCatalytic crackingHydrocarbon by hydrocarbon crackingUnsaturated hydrocarbonCarbon product

The invention discloses a method for producing low-carbon olefins by using petroleum hydrocarbon. The method comprises the following steps of: making a preheated petroleum hydrocarbon raw material contact a hydrogen combustion catalyst in a hydrogen combustion heating area to directly obtain heat, which is required by the dehydrogenization of the petroleum hydrocarbon, of a hydrogen combustion reaction; allowing the petroleum hydrocarbon to contact a dehydrogenization catalyst in a dehydrogenization area to obtain petroleum hydrocarbon material flow which contains unsaturated olefin compounds, wherein the conversion rate of a dehydrogenization reaction is at least 20 percent; and allowing the obtained petroleum hydrocarbon material flow which contains the unsaturated olefin compounds to contact an olefin cracking catalyst in an olefin cracking reaction area to obtain a petroleum hydrocarbon material flow which contains C2 to C9 olefins and separating the petroleum hydrocarbon material flow which contains C2 to C9 olefins to obtain low-carbon products. When the technical process of the invention is used for producing the low-carbon olefins, the heat transfer effect and the heat transfer efficiency are improved, the energy is saved, the environment is protected, the energy consumption in a separation process is reduced and the low-carbon olefin selectivity of the petroleum olefin raw materials is obviously improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

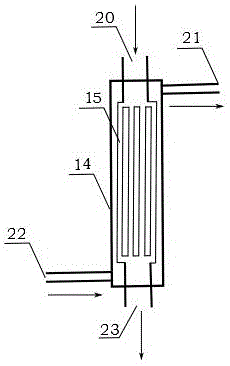

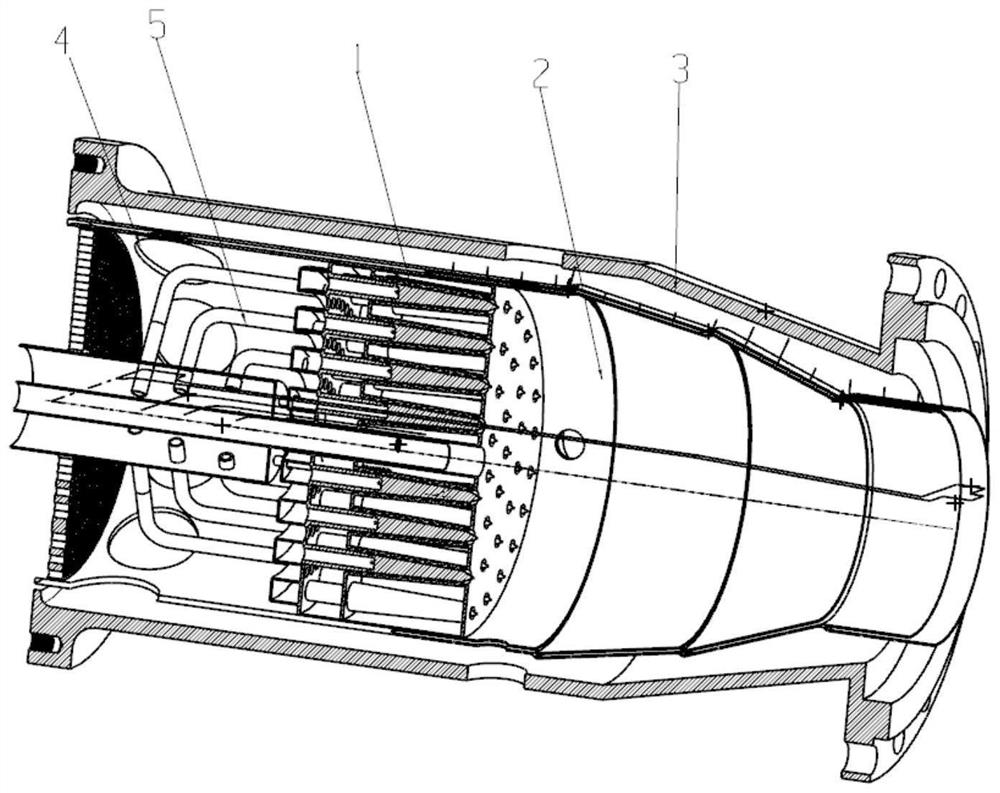

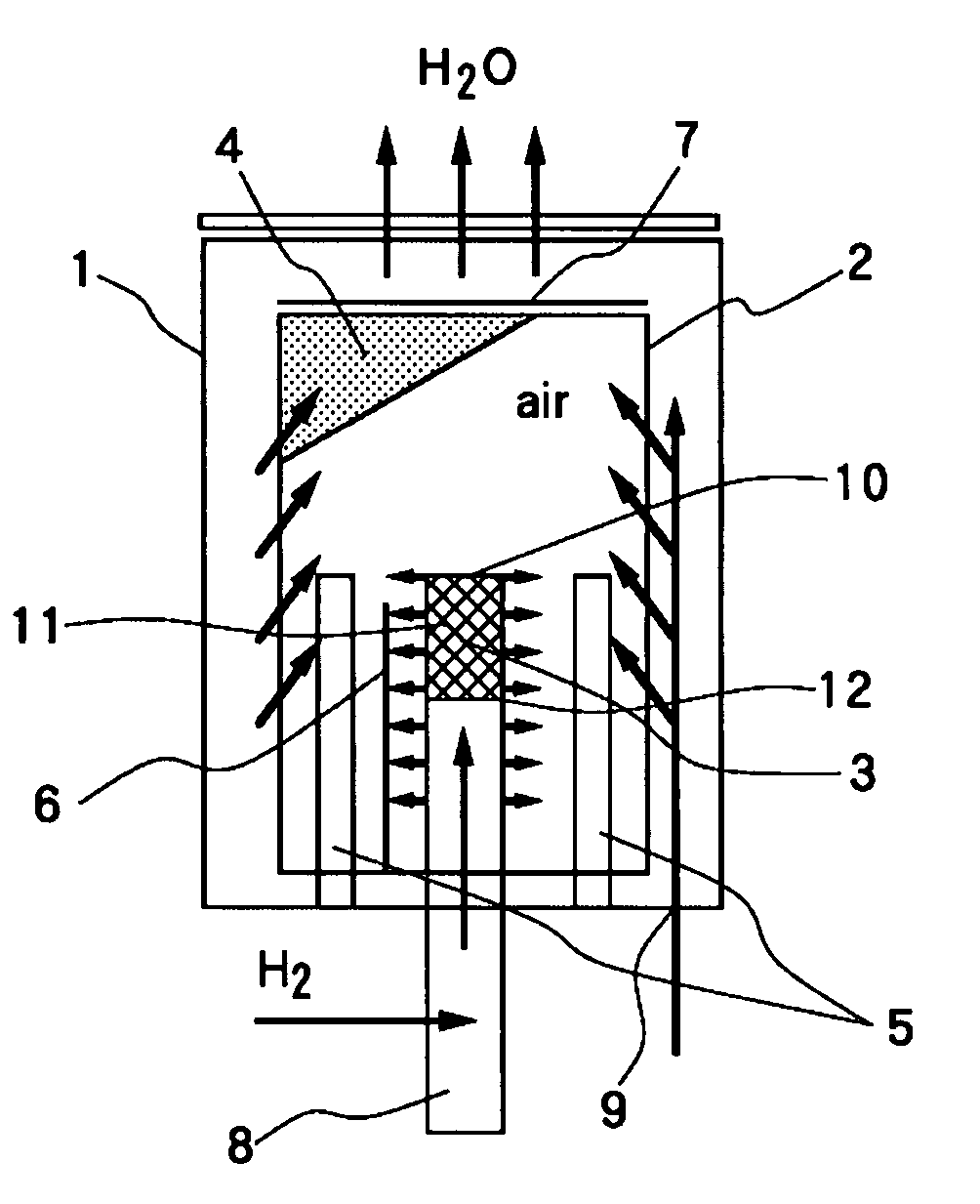

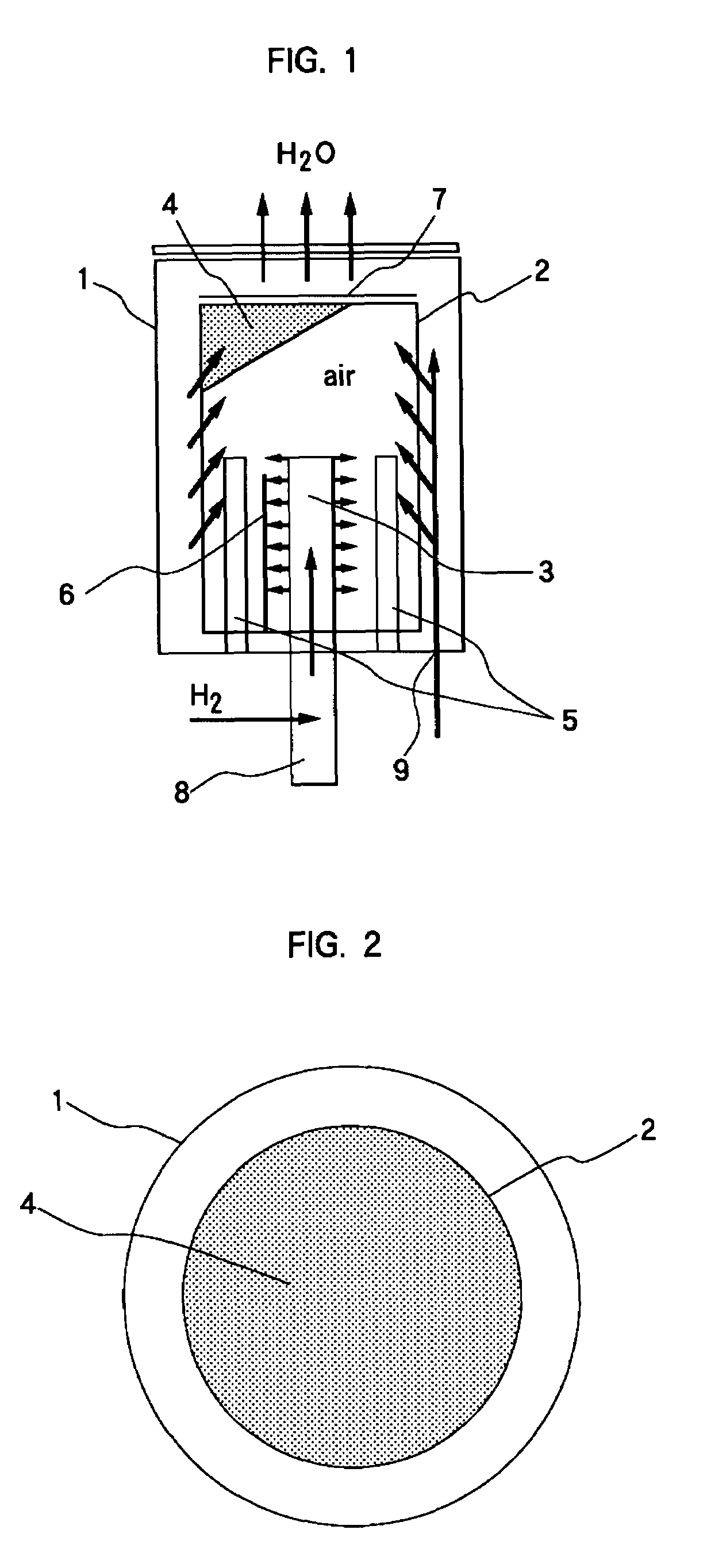

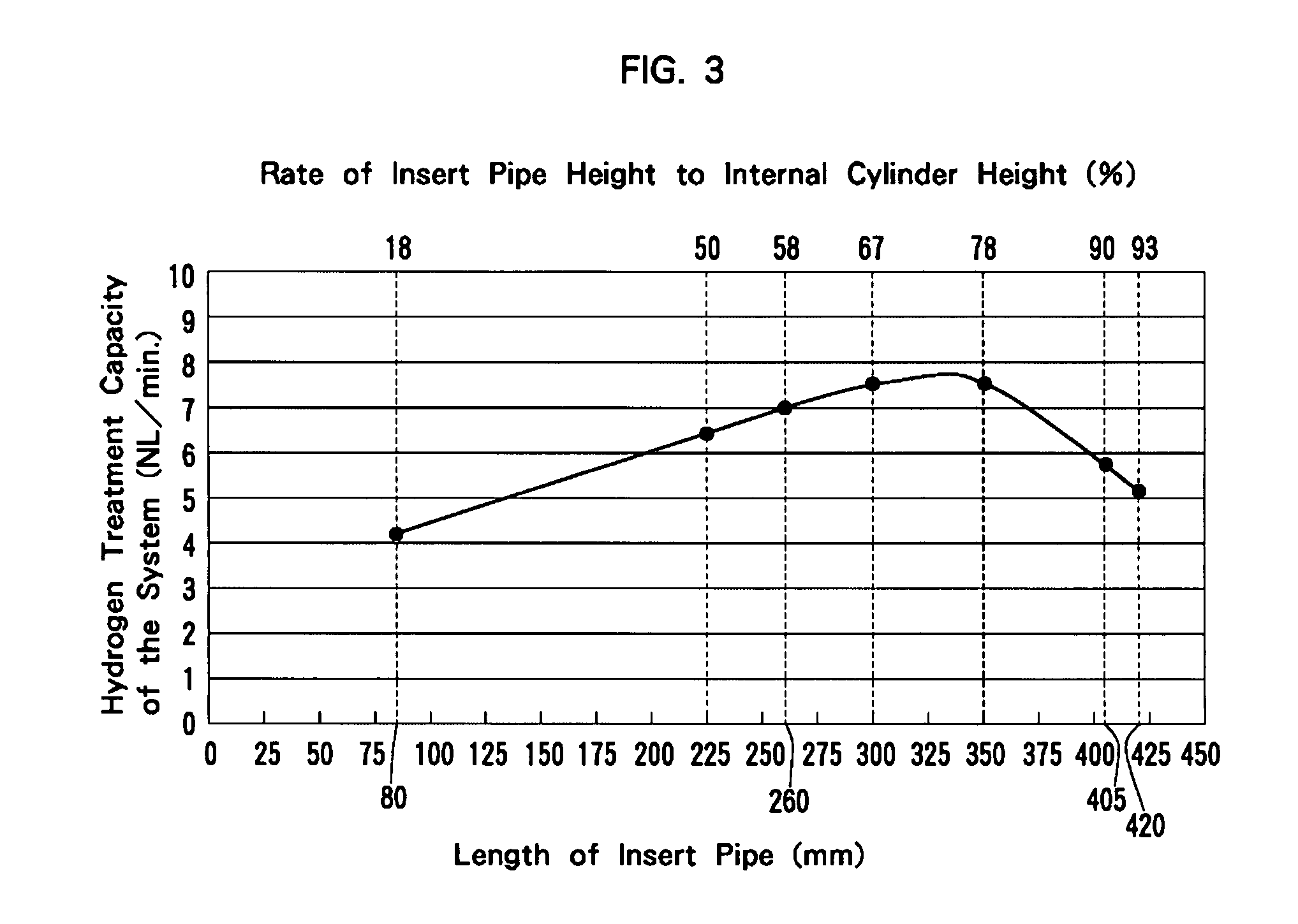

Hydrogen combustion system

InactiveUS7700055B2Small sizeMaximum efficiencyPhysical/chemical process catalystsWaterDouble tubeDifferential pressure

A hydrogen combustion system comprising: an external cylinder 1 constituting the exterior of a double tube construction; an internal cylinder 2 formed by a porous metal plate constituting the interior of said double tube construction; hydrogen combustion catalyst 4 supported with precious metals on spherical ceramic support surface, formed in pellet state, being packed in said internal cylinder 2; an insert pipe 3 formed by porous metal plate inserted in the center of said internal cylinder 2; pre-heating heaters 5 installed between said insert pipe 3 and said internal cylinder 2 to preheat said hydrogen combustion catalyst 4 to ambient atmosphere of over catalytic reaction temperatures; a hydrogen introducing port 8 connecting to said insert pipe 3; an air introducing port 9 provided at the bottom of said external cylinder 1 in the area between said external cylinder 1 and said internal cylinder 2, wherein air for hydrogen combustion is introduced by the drift effect resulting from the differential pressure generated between the packed layer of hydrogen combustion catalyst and the outside, by thermal convection, achieving safe combustion treatment of hydrogen in simple construction, small size and high treatment efficiency.

Owner:DE NORA PERMELEC LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com