Process and apparatus for processing municipal sewage sludge by using nepheline nucleated glass

A technology for glass-ceramic and urban sewage, which is applied in the fields of oxidation treatment of sludge, adsorption water/sewage treatment, added substance water/sewage treatment, etc., which can solve the problems of black smoke and secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

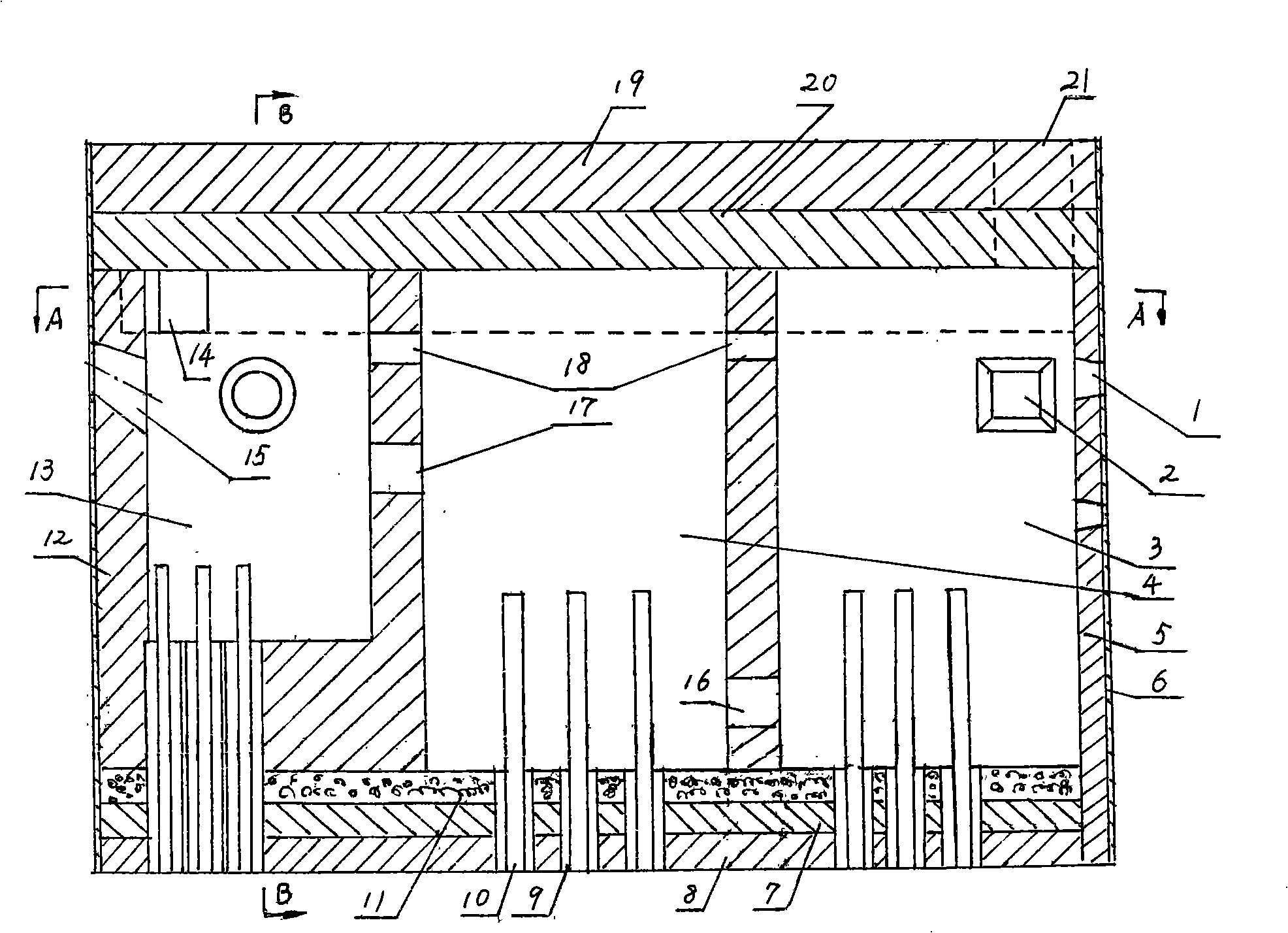

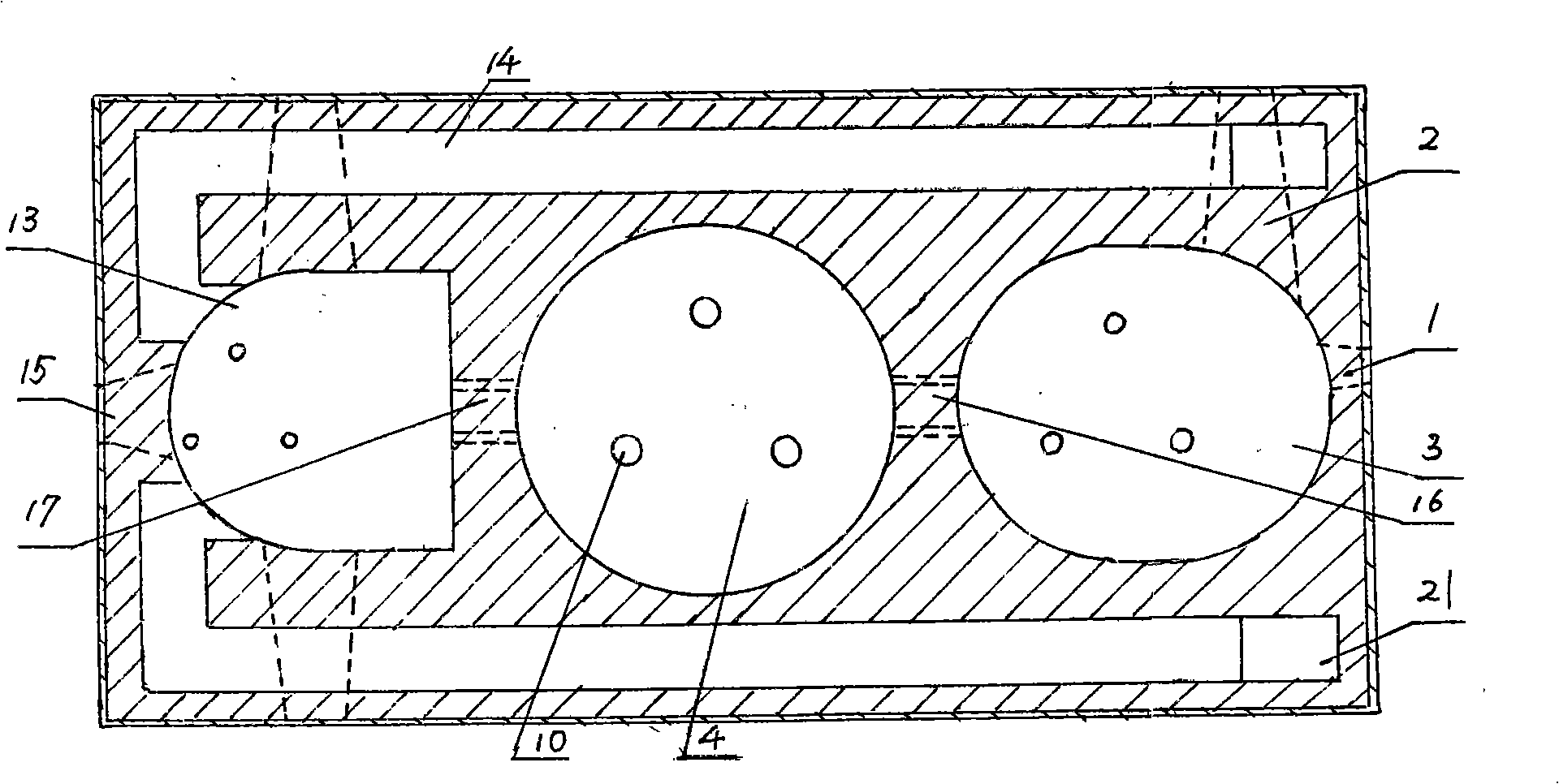

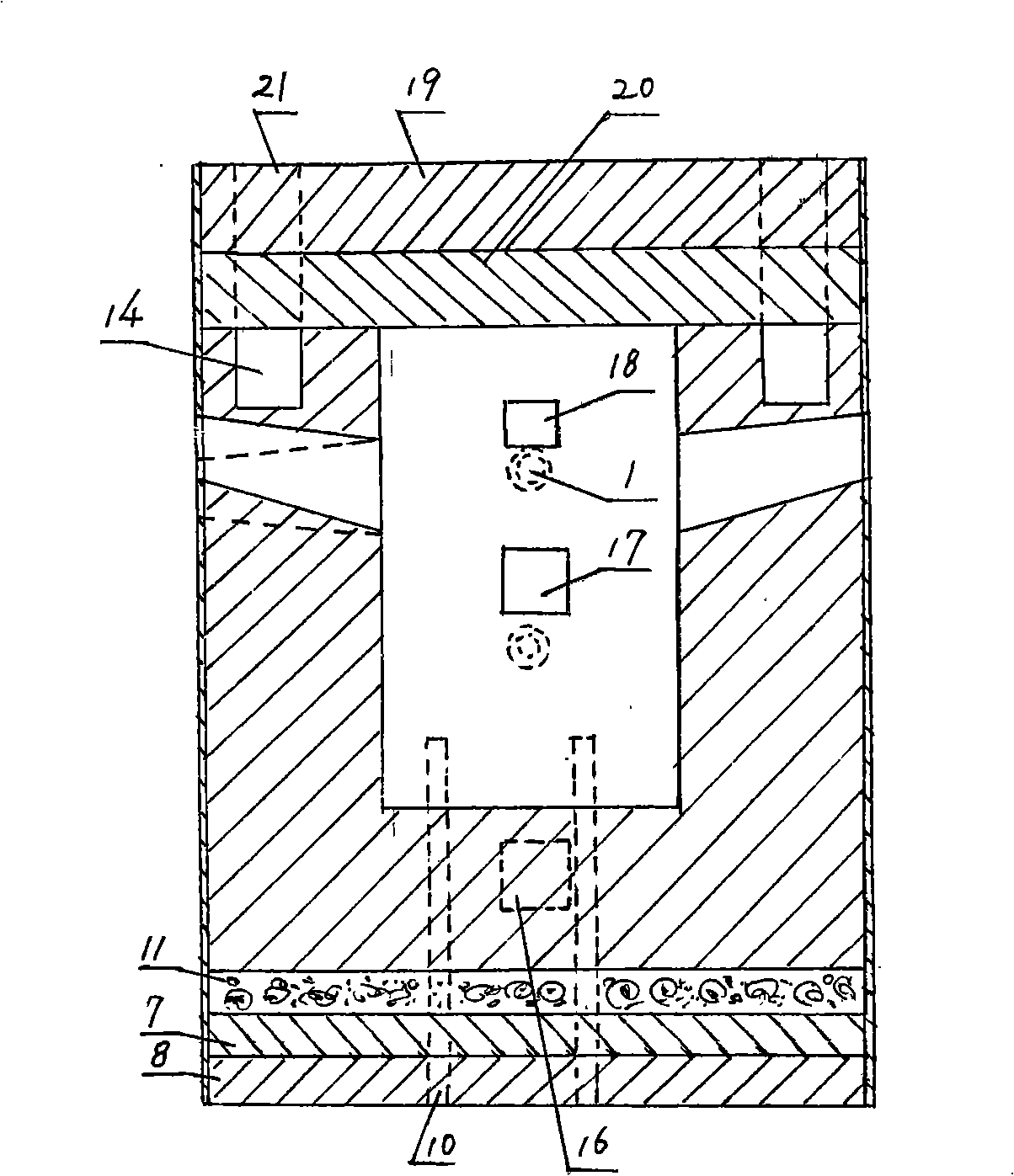

[0044] like Figure 1-3 Shown, the present invention handles the equipment structure of urban sewage sludge as follows:

[0045]The equipment includes a flame vent 1, a feed port 2, a feeding melting chamber 3, a high temperature melting chamber 4, a furnace wall 5, an outer iron sheet 6, an insulation layer 7, a bearing plate 8, a water seal sleeve 9, an electrode 10, and a cast heat-resistant layer 11. Furnace wall 12, clarification chamber 13, flue 14, discharge port 15, first liquid flow hole 16, second liquid flow hole 17, fire passage 18, insulation layer 19, furnace turning 20, flue exit 21. Bottom-inserted three-phase electrodes 10 are installed at the bottom of the feeding melting chamber 3, high-temperature melting chamber 4, and clarification chamber 13 arranged in sequence, and a first liquid flow hole 16 and a fire outlet 18 are arranged between the feeding melting chamber 3 and the high-temperature melting chamber 4. Between the high-temperature melting chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com