Patents

Literature

96 results about "Liquation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

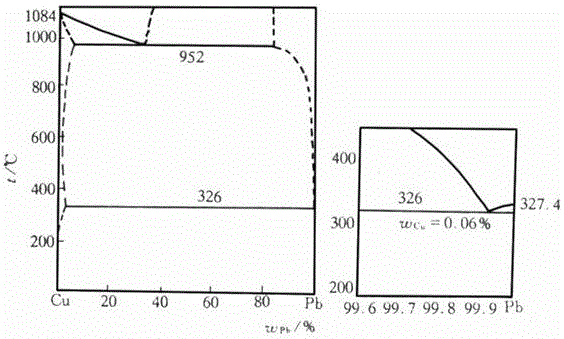

Liquation is a metallurgical method for separating metals from an ore or alloy. The material must be heated until one of the metals starts to melt and drain away from the other and can be collected. This method was largely used to remove lead containing silver from copper, but it can also be used to remove antimony minerals from ore, and refine tin.

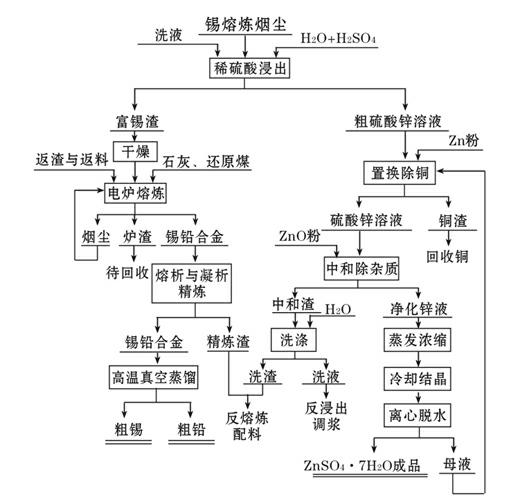

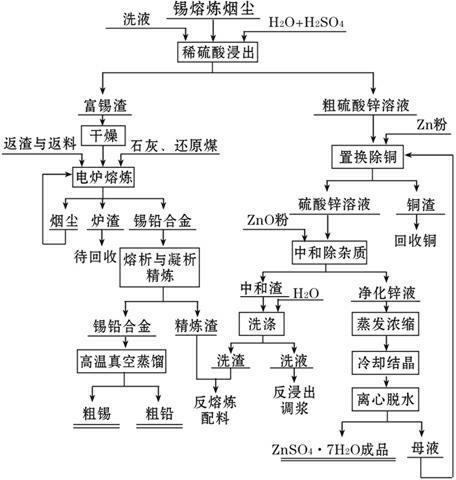

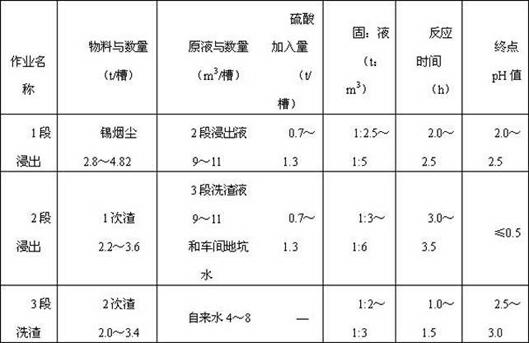

Method for producing zinc sulfate heptahydrate, crude tin and crude lead by using tin smelting dust

InactiveCN102352443AHigh recovery rateReasonable process structureZinc sulatesProcess efficiency improvementSulfateCopper

The invention discloses a method for producing zinc sulfate heptahydrate, crude tin and crude lead by using tin smelting dust. The method comprises the following steps of: (1) pretreating the raw material; (2) leaching with a dilute sulphuric acid to separate out zinc; (3) purifying the crude zinc sulfate solution, preparing zinc sulfate heptahydrate; (4) performing electric furnace smelting on the tin-rich residue to prepare a tin-lead alloy; (5) adopting the conventional liquation process (the temperature is 500-600 DEG C) and the agglutination method (the temperature is 230-240 DEG C) to refine the tin-lead alloy and increase the Sn-Pb grade of the alloy to 94%-96%, and sending the refining residue back to the electric furnace to perform smelting and dosing treatment; and (6) performing high temperature vacuum distillation to produce crude tin and crude lead. By adopting the method, the tin smelting dust can be effectively utilized, the resource can be saved and metals such as tin,lead, zinc and copper can be recovered together.

Owner:太仓市南仓金属材料有限公司

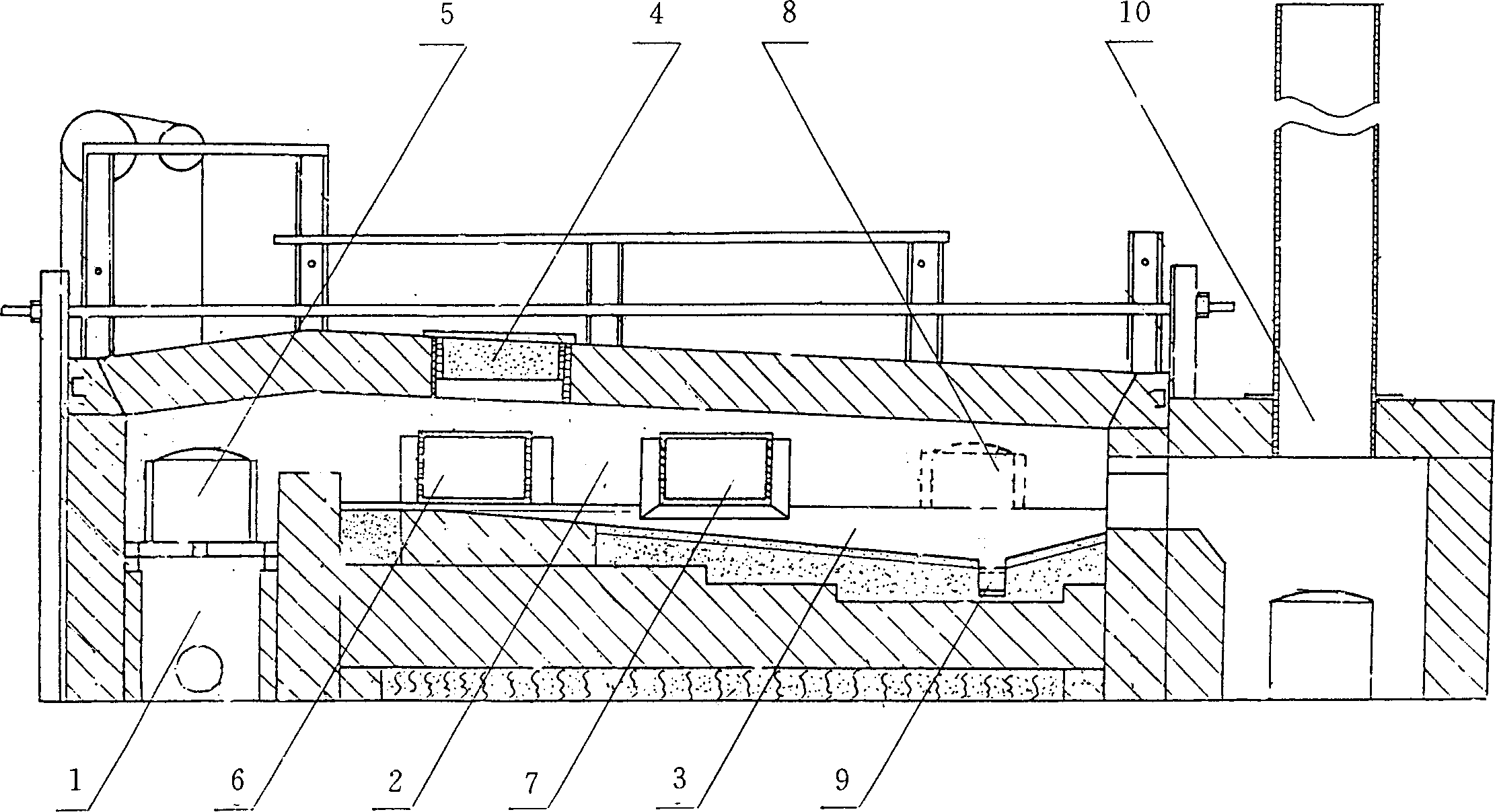

Aluminium-silicon-copper-magnesium series deforming alloy and its preparing method

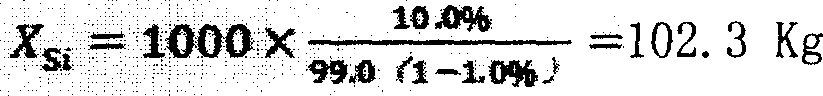

The invention discloses an Al-Si-Cu-Mg series distortion aluminum alloy and the manufacturing method. The alloy is made up from 9.0-12.0wt% Si, 3.0-4.0wt% Cu, 0.3-0.6wt% Mg, <0.30% Fe, <0.20% Zn, and other impurity <=0.15wt%, and the rest is Al. The method includes the following steps: smelting and refining the raw materials in reflecting smelter, after processing the allow liquation by Al-Sr intermediate alloy, gaining cast rod through hemicontinuous casting, extruding the cast rod and after forging and T6 thermal treatment to gain the product. The tensile strength of the alloy is over 397MPa, and broken tensile stretch is 6%, and rigidity is 136-141HB. It is mainly used to make wheel for vehicle and motorcycle, piston, bearing, bidirectional sloping cam plate, etc.

Owner:SHANDONG UNIV

Asphalt mixture anti-rutting additive agent, preparation method and use method thereof

The invention relates to an anti-rut asphalt additive, a method for preparing the same and a method for using the same. Polyethylene resin and polypropylene resin are adopted for using simultaneously; and through the use of liquation, cutting, mixing and extrusion pelletization technology at high temperature, compatibility between the materials is improved so as to further improve high-temperature stability of an asphalt surface layer. In order to reduce material cost, waste polyethylene resin and waste polypropylene resin can also be used so as to achieve the aims of reducing cost, realizing recycling of waste and reducing environmental pollution simultaneously.

Owner:BEIJING UNIV OF CHEM TECH

Method for making little odor polypropylene material using odor agglomerate

The invention relates to a method for making little odor polypropylene material using odor agglomerate, wherein the content of the flavor agglomerate is 20-70 wt% of the matrix resin, the content of flavor depressant is 30-80%, the matrix resin has good compatibility with polypropene material, which includes polypropylene or the copolymer of ethylene-octene, the liquation flow speed (230 deg C X 2.16kg) of the polypropene is 5-50g / 10min, the density of the copolymer of ethylene-octene (POE) is 0.88-0.90g / cm3, the melting index is 1-50g / 10min, the flavour depressant is physical adsorption material comprising one of molecular screen material or pore silica gel material or their combination, the molecular sieve material is a alkali metal aluminosilicate powder with sodium type crystal structure.

Owner:SHANGHAI PRET COMPOSITES

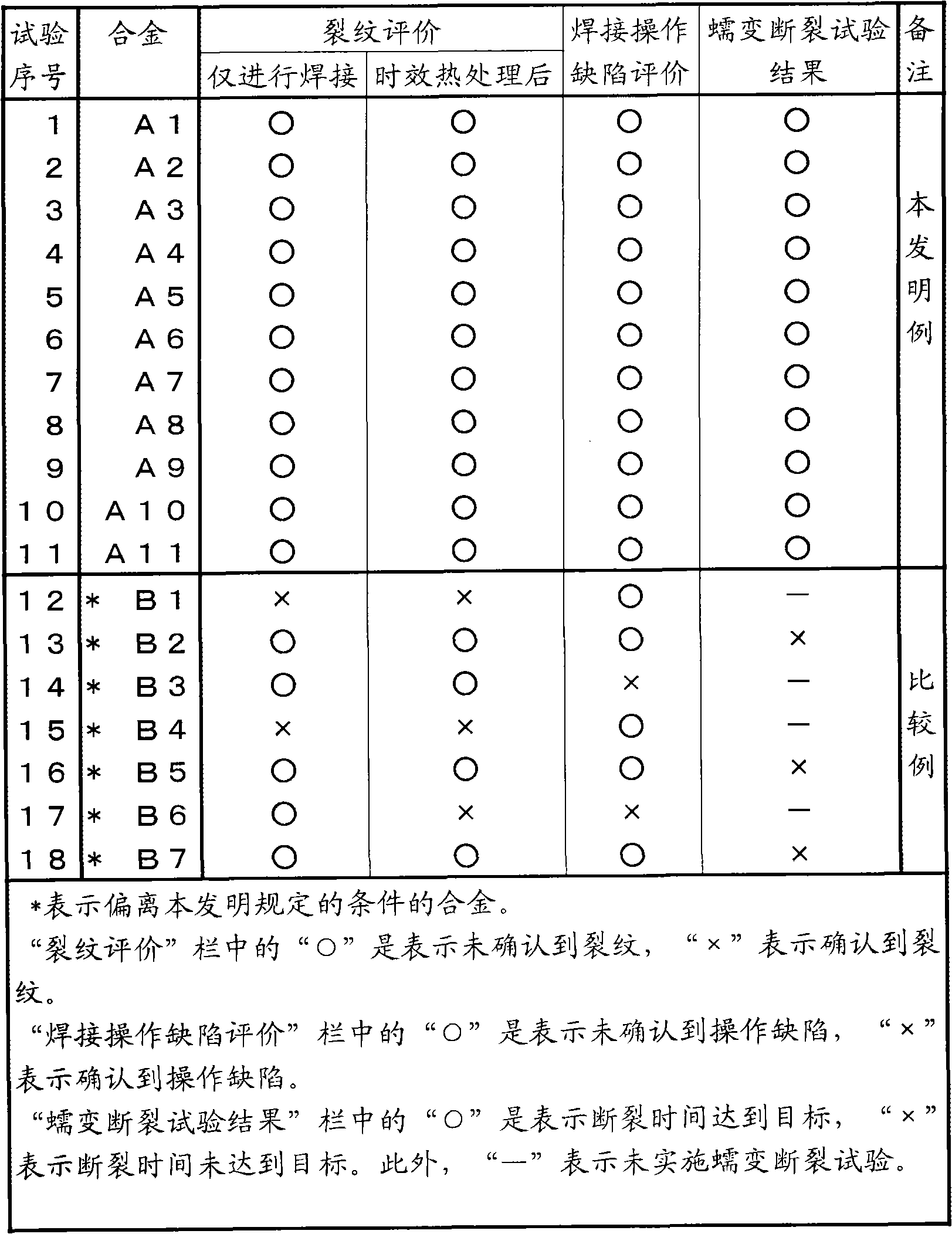

Austenitic heat resistant alloy

InactiveCN101864531APrevent liquefaction cracksPrevent embrittlement cracksSteam boilersSteam boilers componentsLiquationUltimate tensile strength

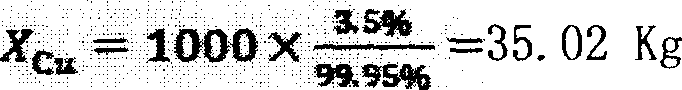

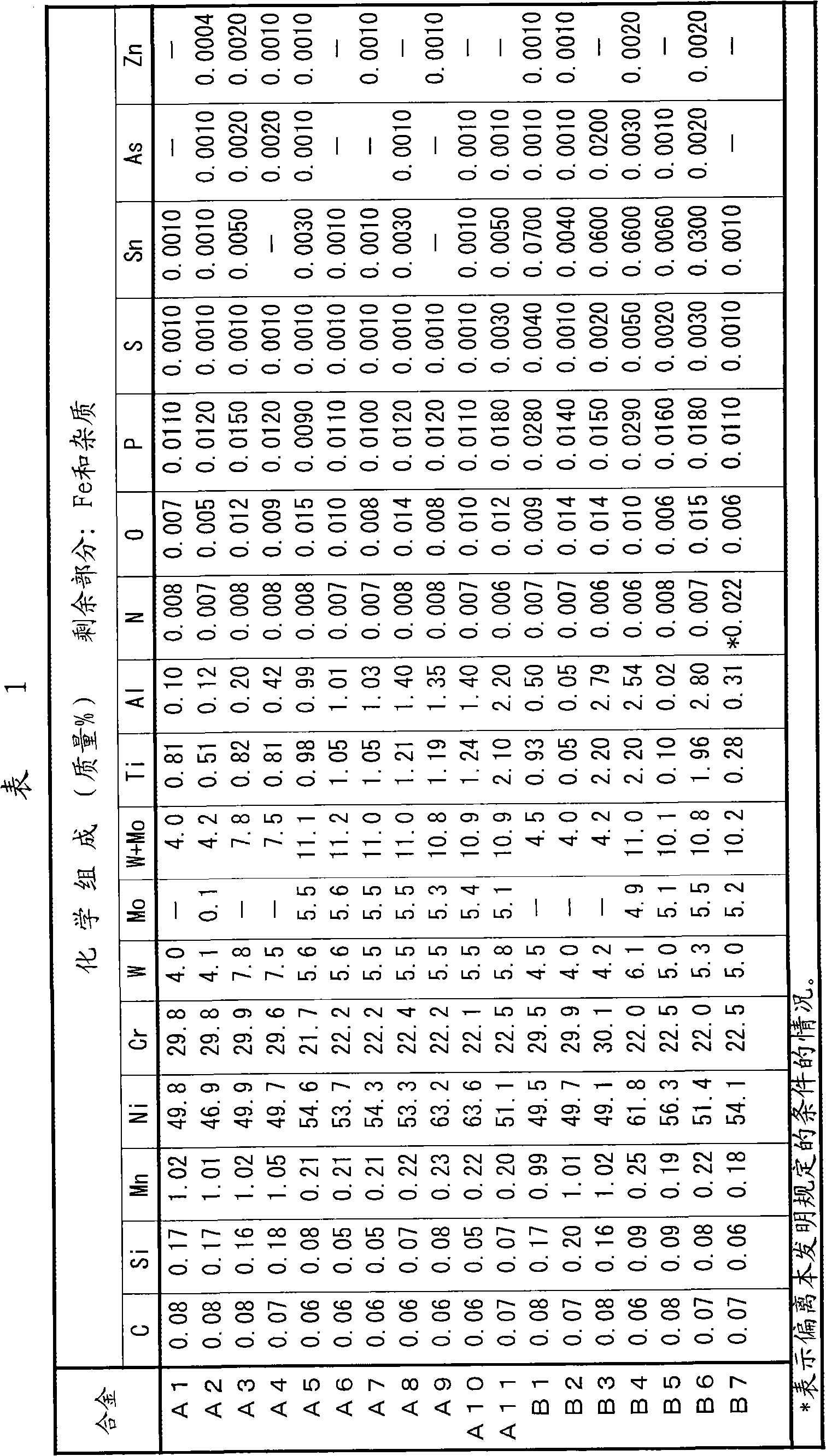

An austenitic heat resistant alloy, which comprises, by mass percent, C<=0.15%, Si<=2%, Mn<=3%, Ni: 40 to 80%, Cr: 15 to 40%, W and Mo: 1 to 15% in total content, Ti<=3%, Al<=3%, N<=0.03%, O<=0.03%, with the balance being Fe and impurities, and among the impurities P<=0.04%, S<=0.03%, Sn<=0.1%, As<=0.01%, Zn<=0.01%, Pb<=0.01% and Sb<=0.01%, and satisfies the conditions [P1=S+{(P+Sn) / 2}+{(As+Zn+Pb+Sb) / 5}<=0.050], [0.2<=P2=Ti+2Al<=7.5-10P1], [P2<=9.0-100O] and [N<=0.002P2+0.019] can prevent both the liquation crack in the HAZ and the brittle crack in the HAZ and also can prevent defects due to welding fabricability, which occur during welding fabrication, and moreover has excellent creep strength at high temperatures.

Owner:NIPPON STEEL CORP

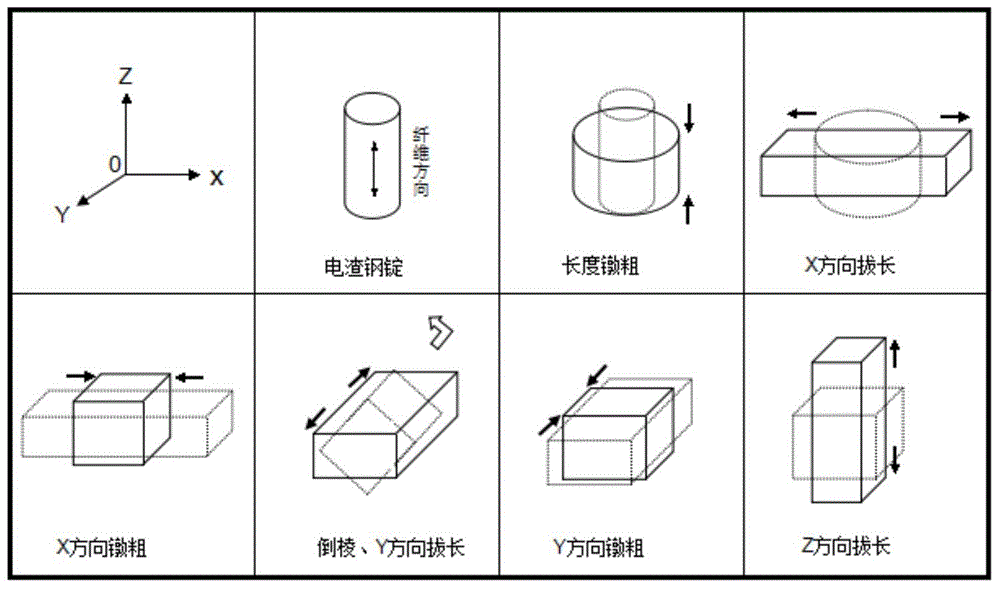

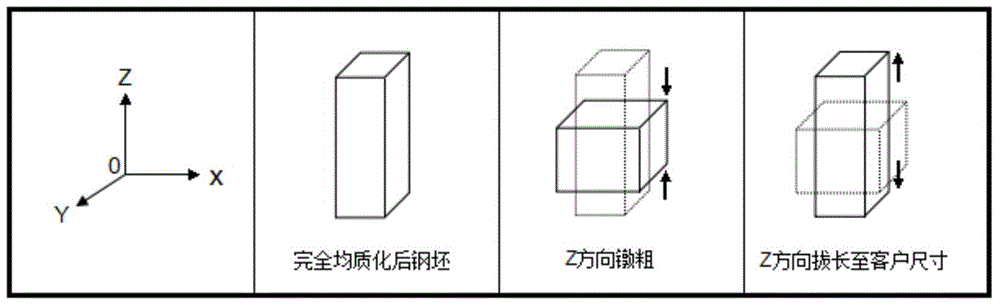

Production method of high-toughness high-isotropy large-section hot working die steel

The invention provides a production method of high-toughness high-isotropy large-section hot working die steel. The method comprises the following steps: carrying out primary homogenization on a steel ingot subjected to electroslag remelting at 1260-1300 DEG C for 5-8 hours; carrying out three-way forging on the steel ingot subjected to primary homogenization at the temperature of 900 DEG C or above, wherein the three-way forging temperature is lower than the first homogenization temperature; carrying out secondary homogenization on the steel billet subjected to three-way forging at 1260-1300 DEG C for 10-20 hours; carrying out upsetting and rolling finish forging on the steel billet subjected to secondary homogenization, wherein the initial forging temperature of the upsetting and rolling finish forging is 1150 DEG C or below, and the finish forging temperature is 850-950 DEG C; and carrying out grain refinement and annealing to obtain the product. By organically combining the double homogenization and double forging, the method creates dynamic conditions beneficial to carbon and alloy element diffusion, and thoroughly eliminates the liquation carbides in the steel billet and the zonal structures generated by dendritic segregation.

Owner:冯英育

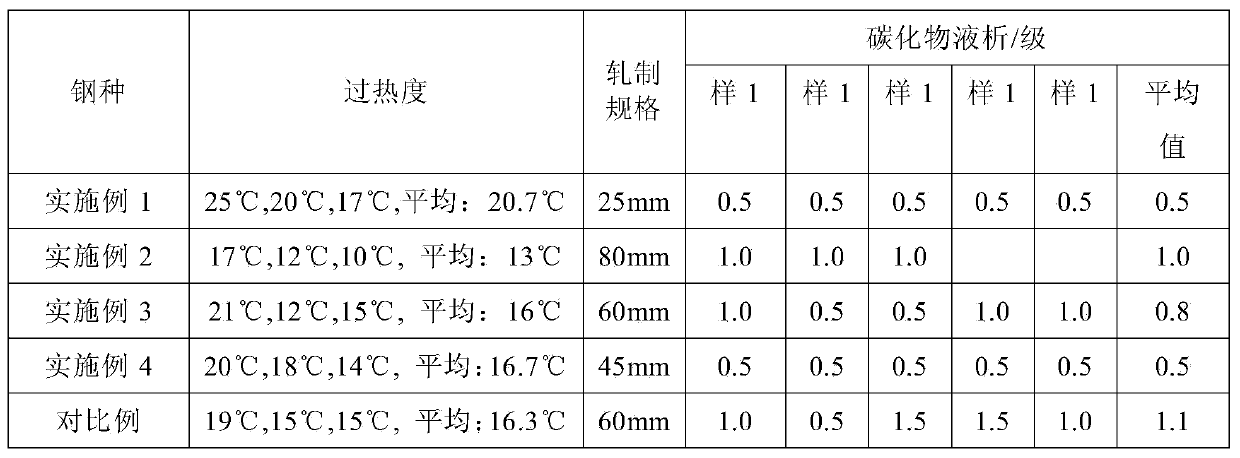

Phi 500-650mm Cr6 type forged-electroslag-steel cold-rolled work roll blank forging and deforming technology

ActiveCN106734805AReduce generationReduce crackingMetal-working apparatusWork rollNon-metallic inclusions

The invention discloses a Phi 500-650mm Cr6 type forged-electroslag-steel cold-rolled work roll blank forging and deforming technology. The technology includes the steps of converter producing plus LF refining plus VD vacuuming, continuous casting of round blank, hot annealing of electronic blank, clearing, electroslag remelting, annealing of electroslag ingot, forging and annealing after forging, wherein four-fire mode production is adopted in forging, upsetting and drawing out deformation methods are adopted in the first fire time, forging under great pressure is adopted in the second fire time, and forging to forming in the third and fourth fire time. Temperature and heat preservation time in high-temperature diffusion are key to control in forging, furnace return temperature and time in each fire time of forging and deformation and final forging temperature of each fire time are controlled. The spheroidized structure of the produced Cr6 type forged-electroslag-steel cold-rolled work roll blank is 2-3 in grade, carbide mesh is less than or equal to 2.0 in grade, carbide strap and liquation are below 1.0 in grade, total non-metallic inclusions is less than or equal to 2.0 in grade, flaw detection eligibility rate is increased from original 75% to 95%, carbide distribution is small and diffused, and long service life is achieved.

Owner:建龙北满特殊钢有限责任公司

Shot blasting check method for surface defects of blades

ActiveCN101520404AImprove fatigue resistanceUsing mechanical meansMaterial analysisSteam turbine bladeLiquation

The invention relates to a shot blasting check method for surface defects of blades. Turbine blades processed by the method can clearly show various surface defects easily generated in materials during processes, and specifically the method can check that the defects are the liquation of the materials, various processing burns, hardening and the like in the processes. The method is characterized in that the method for surface shot blasting achieves the show of the surface defects of the blades.

Owner:WUXI TURBINE BLADE

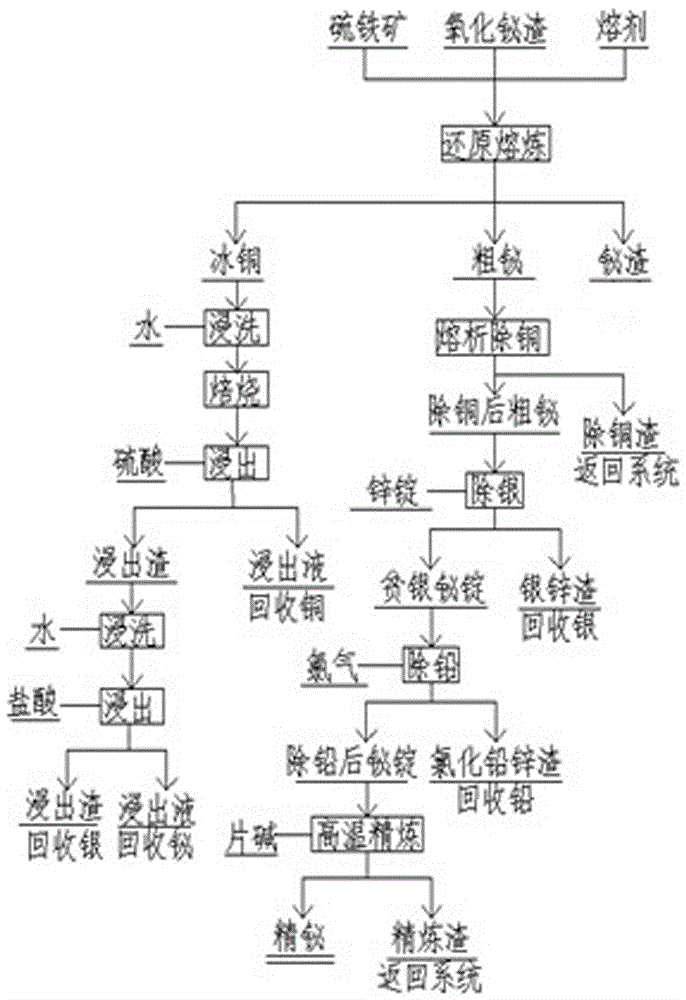

Regenerated lead fire method basic refining bottom-blowing process

The invention discloses a regenerated lead fire method basic refining bottom-blowing process. The process comprises the following steps: discharging lead of crude lead liquid from a melting furnace, casting the lead in a refining furnace, introducing argon from the bottom of the furnace, when the temperature of the lead liquid is reduced to about 330 DEG C, removing the slag, reducing the lead-containing copper to about 0.1% through liquation decoppering, injecting sulfur powder at the bottom of the refining furnace for removing copper after slag removal, heating the material to 450-480 DEG C, reacting the material for 30-60 min, taking the sulfuration slag out to complete a copper-removal process; when the lead liquid temperature is about 45 DEG C, blowing powdery sodium nitrate and sodium hydroxide into the bottom of the refining furnace, reacting the materials for 30 min, and blowing NaCl powder at the bottom of the refining furnace by following with argon to complete arsenic, antimony and tin removal. According to the bottom-blowing process, a refining agent and / or alloy loss are greatly reduced; the lead liquid contains inert gas with little solid solubility, the lead liquid and a lead ingot are difficulty oxidized, no lead slag is generated in the lead liquid and the lead ingot, lead slag is little when the regenerated lead is used, the slag yield is low; the lead liquid surface is protected by argon during a refining process, high temperature Ag removal can be carried out, the content of Ag in the regenerated lead is low; argon at the bottom and the minimal bismuth compound particles are floated, and the bismuth content in the lead ingot is low.

Owner:安徽省陶庄湖废弃物处置有限公司

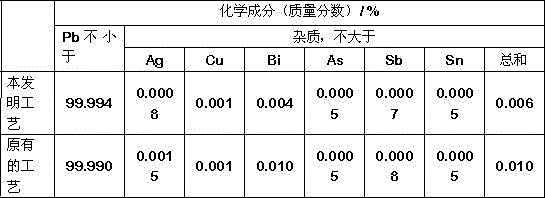

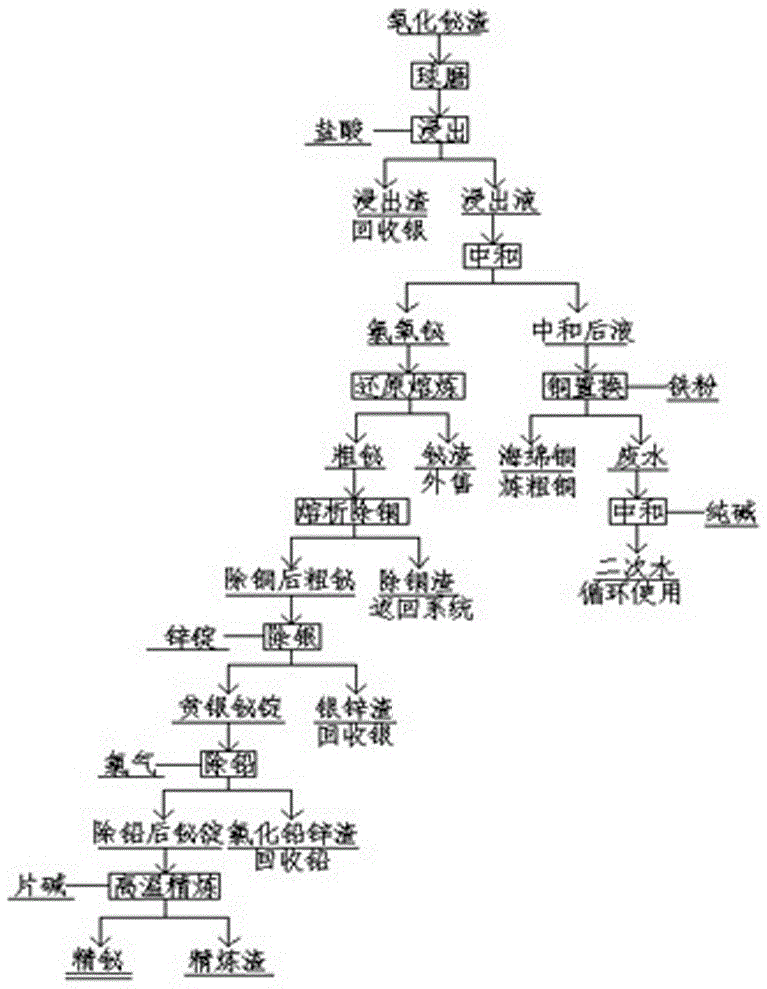

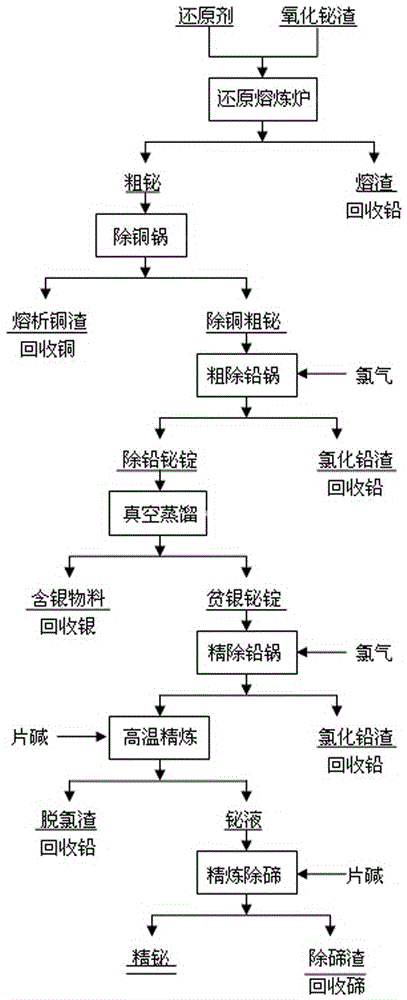

Method for refining bismuth from bismuth oxide slags

ActiveCN105803213AReduce usageAvoid it happening againProcess efficiency improvementSlagNitric oxide

The invention discloses a method for refining bismuth from bismuth oxide slags. The bismuth oxide slags and reduction agents are subjected to reduction smelting, liquation decoppering, primary lead removal through chlorine, vacuum distillation for silver removal, secondary lead removal through chlorine, high-temperature refining for dechloridation, and caustic soda flakes adding for tellurium removal, and finally refined bismuth is obtained. Alloy containing silver, copper, bismuth, lead and the like directly enters the decoppering procedure, wet pretreatment is omitted, the decoppering procedure is simplified, copper matte and silver-zinc crusts are prevented from being generated, the usage amount of nitric acid in a wet section is reduced, emission of nitric oxide in the nitric acid dissolving process is reduced, and pollution to the environment is reduced; after a zinc adding and silver removal technique is changed into the vacuum distillation for physical silver removal technique, the silver-zinc crusts which are difficult to treat are eradicated, physical separation of silver and bismuth is achieved to the maximum extent, and the recovery rate of silver is increased; and the usage amount of coal gas and auxiliary materials is reduced, the labor intensity of workers is relieved, the production period of the refined bismuth is shortened, the production cost of the refined bismuth is reduced, and the direct recovery rate and the recovery rate of the refined bismuth are increased.

Owner:河南金利金铅集团有限公司

3D printing plasma intelligent Mohole drilling and completion method

The invention discloses a 3D plasma intelligent Mohole drilling and completion method. The method comprises the following steps that a drilling platform is built, drilling equipment is mounted, and drilling is started. The drilling equipment comprises a 3D printer system assembly, a pumping system for muddy water, rock debris and the like as well as mixtures thereof, an intelligent well casing lifting and fixing system, a well casing printed by a 3D printer, a manifold system assembly, a downhole hole-drilling, hole-broadening and well-cementing intelligent executor (drilling robot), a drilling platform, an intelligent control treatment center and the like. The well casing is printed by the 3D printer, the pumping system discharges mud, the rock debris and the like, the plasma drilling executor implements drilling, and underground equipment is provided with thermal insulation and cooling protection. According to the 3D plasma intelligent Mohole drilling and completion method, a first 3D printing spray-head, a second 3D printing spray-head, a blockage system spray-head, plasma liquation well cementation, spray gun well cementation, a hole broadening spray-head, a hole-drilling spray-head and a high-pressure gas spray-head work cooperatively; the intelligent well casing lifting and fixing system fixes and lifts the well casing printed by the 3D printer intelligently; and drilling can be constructed in the land and at a deep sea.

Owner:张发旺 +1

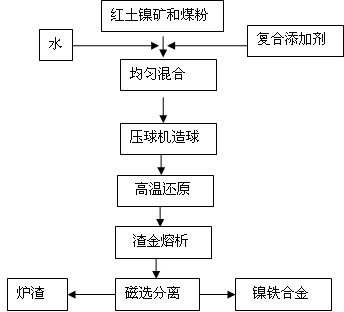

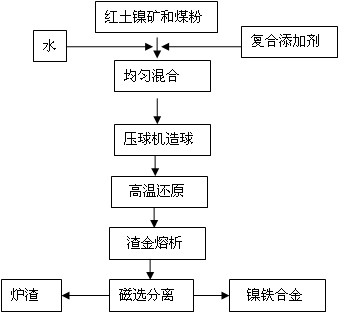

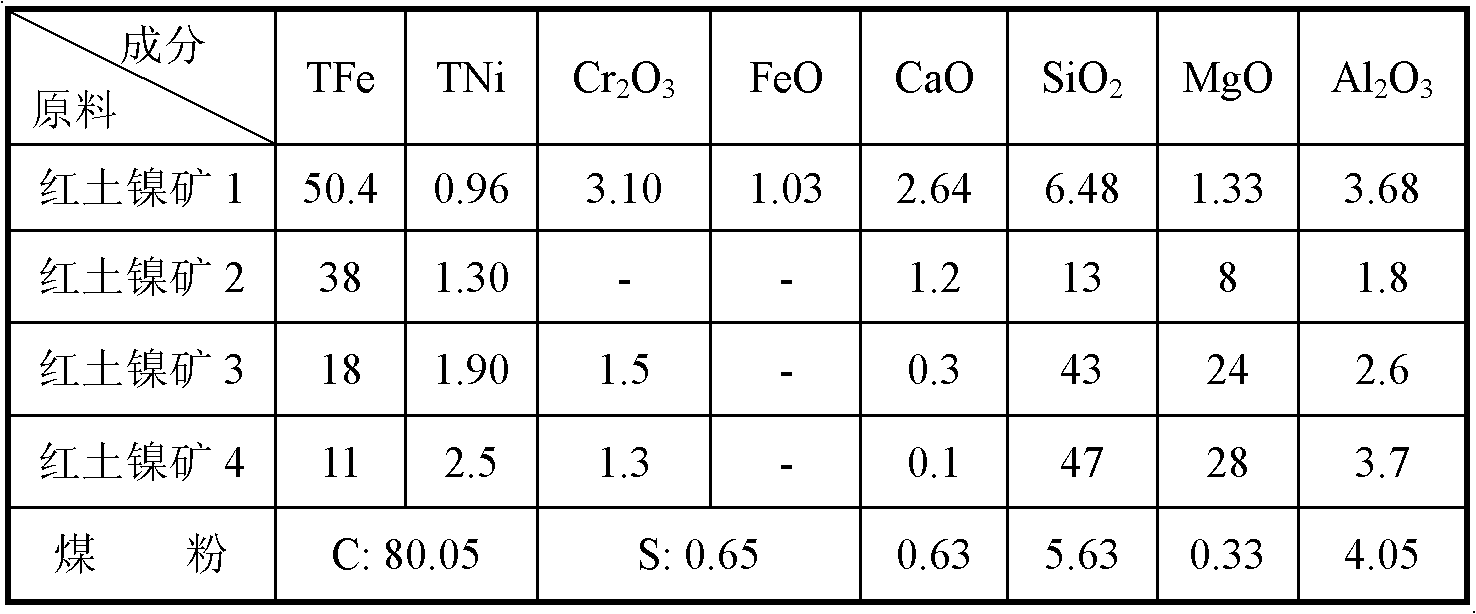

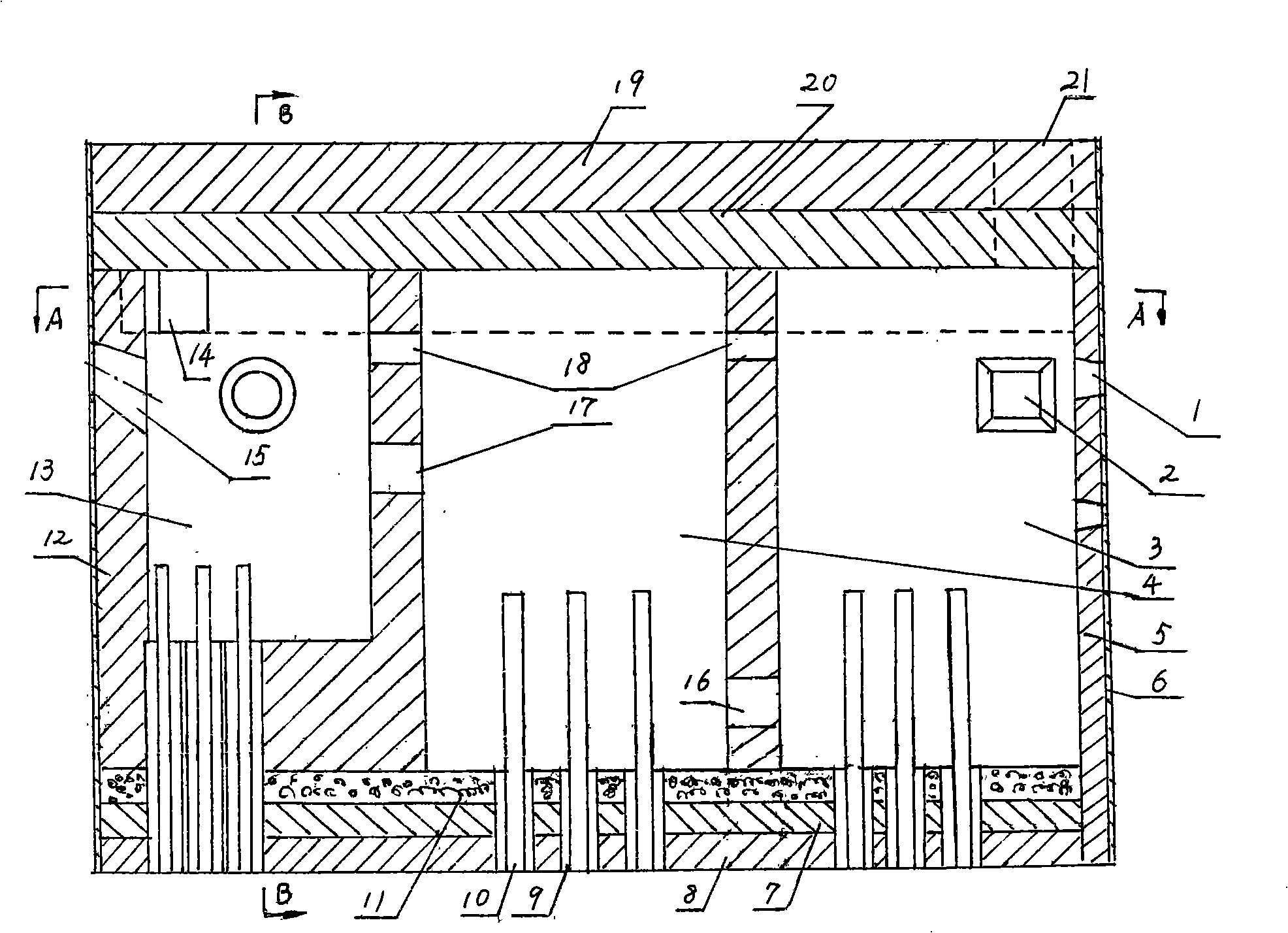

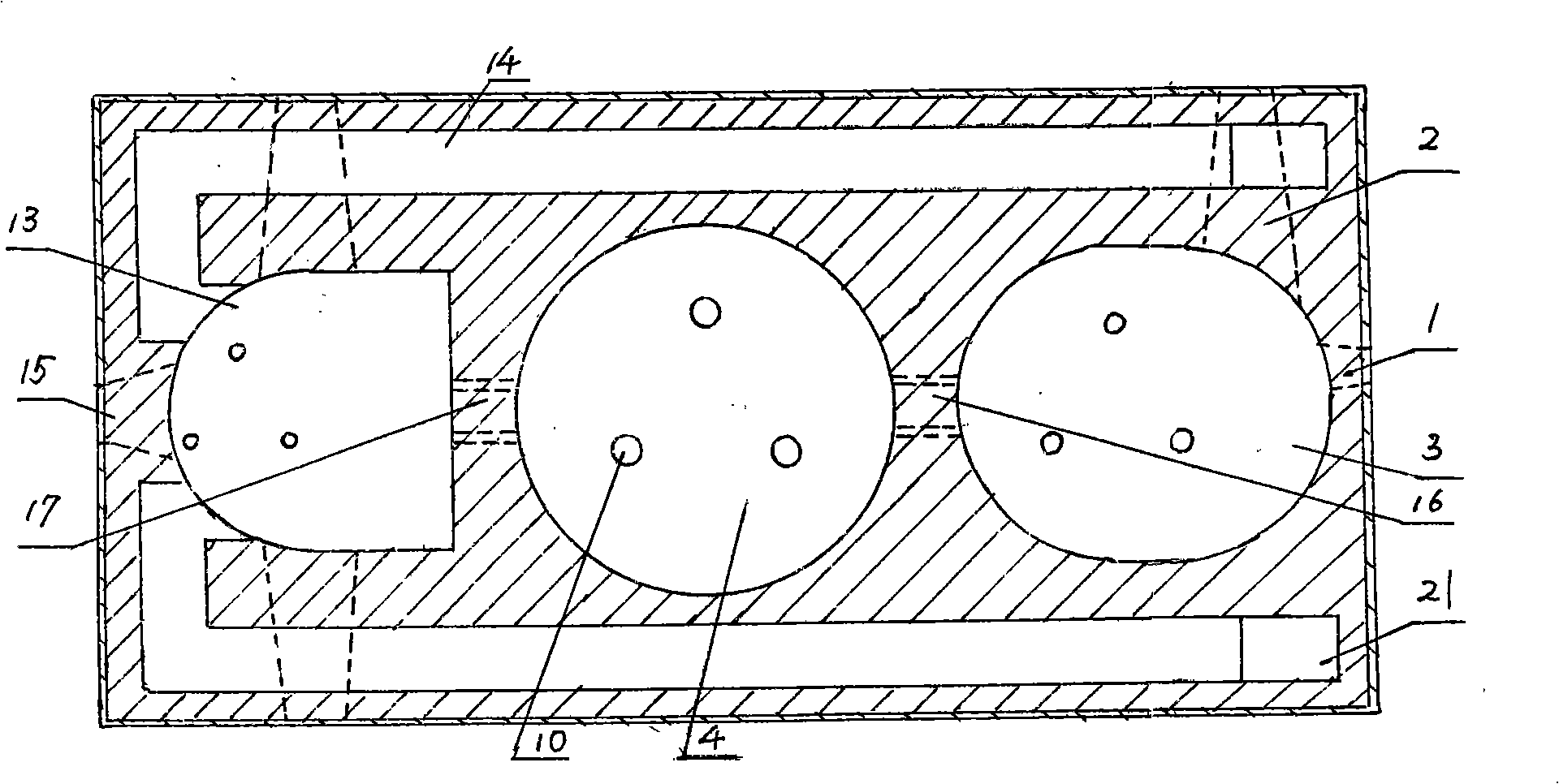

Composite additive for producing nickel-iron particles by using laterite, and application method thereof

The invention discloses a composite additive for producing nickel-iron particles by using laterite, which comprises the components by mass percent: 20-70% of fluorite, 10-50% of quick lime, 5-20% of sodium carbonate, 3-10% of boric acid and 0-10% of cryolite; and correspondingly, the invention also provides an application method of the composite additive, which comprises the steps of: mixing laterite powder, the composite additive and pulverized coal, adding water into the mixture to prepare carbon-containing laterite pellets; then, carrying out reduction on the carbon-containing laterite pellets at 1200-1400 DEG C for 2-8 hours, and then carrying out slag-metal liquation; and directly carrying out magnetic separation without carrying out the levigation step after cooling, and separating nickel-iron alloy from furnace slag.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Process and apparatus for processing municipal sewage sludge by using nepheline nucleated glass

InactiveCN101302044AAchieve combustion heat releaseSave diversion pipeline construction costsSludge treatment by oxidationByproduct vaporizationParaffin waxWater quality

The method relates to a sewage water and sludge treatment technology, in particular to a process and equipment for treating municipal sewage water and sludge by utilizing a nepheline nucleated glass technology. The invention solves the problems that the prior incinerator has secondary pollution and upflowing black smoke, etc. in the process of treating the municipal sludge. The process comprises the following steps that: nepheline nucleated glass raw material is used to absorb and filter the sewage water, then sludge water is rapidly separated; upper-layer water is disinfected by steam, volatilizes odor and is further filtered to drinking water; underlayer slurry is mixed with diesel oil and olefin to be used as fuel of a liquation furnace; and residue falls on a hearth and is mixed with the added nepheline nucleated glass raw material to fuse superior nepheline nucleated glass particles, which can be used to produce nepheline nucleated glass and metal mixed powder metallurgical products, mechanical members and building materials. The equipment has a high energy formula of combining a superhigh temperature and bottom inserting-type three-phase electrode liquation furnace and nepheline and realizes the separation of hydrogen and oxygen in the water and the heat release of hydrogen combustion. The process and the equipment have no requirement on the water quality of incoming water, achieve the recovery of purified water and the emission of air without odor and realize the added value utilization of the residua.

Owner:赵凤宇

Method for reducing carbide liquation level in high-carbon chromium bearing steel

ActiveCN104212955AUniform temperatureControl or reduce carbide liquidation levelFurnace typesHeat treatment process controlHeating timeHigh carbon

The invention discloses a method for reducing a carbide liquation level in high-carbon chromium bearing steel. The method comprises the following steps: (1) the superheat degree of continuous casting steel liquid is controlled in a range of 10-25 DEG C in smelting; (2) the temperature of a heating section and the temperature of a soaking section of a continuous casting steel blank obtained after heating and smelting are controlled; (3) the heating time is controlled according to the section size of the continuous casting steel blank; and (4) the flame spraying angle and the burning time of a heating furnace are controlled by a following manner in the burning reversing period of the heating furnace by using an adjusting plate in a nozzle; the flame spraying angle is uniformly adjusted from m degrees to n degrees; in reversing, the adjusting plate in the nozzle is transferred to the original position; m is 9-11; and n is 14-18. Compared with the prior art, the adjusting plate is only required to be added on the burning nozzle of the heating furnace, so that the burning airflow angle is slightly adjusted without transforming equipment and largely adjusting a process, and the temperature uniformity of the casting blank heated in the furnace can be guaranteed so as to achieve the control or reduction of the carbide liquation level in the bearing steel.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

Collagen membrane medical dressing and preparation method thereof

The invention discloses a collagen membrane medical dressing, which is prepared in the way that: 1swung dash10 parts of sodium carboxymethylcellulose and 15swung dash150 parts of deionized water are mixed in a reaction bulb into the transparent thick state; 0.05swung dash0.5 part of resina draconis and 0.2swung dash2 parts of polyvidon are mixed and prepared into solid dispersoid through a liquation method; 0.05swung dash0.5 part of collagen and 0.1swung dash1 part of starch are added into 1swung dash5 parts of glutaraldehyde solution, are stirred to dissolve at 20 swung dash30 DEG C, then are mixed with the prepared sodium carboxymethylcellulose solution, and are stirred at 30swung dash50 DEG C, so a pasty mixed liquor is prepared for standby application; and 0.05swung dash0.5 part of pseudo-ginseng and 0.25swung dash2.5 parts of solid dispersion are added into the pasty mixed liquor, and are uniformly mixed at 30swung dash50 DEG C, the pH of the pasty mixed liquor is controlled between 6swung dash8, the pasty mixed liquor is poured into a die to form, and is dried in a drying oven, and the collagen membrane medical dressing product is produced only after the dyestripping.

Owner:SICHUAN NORMAL UNIVERSITY

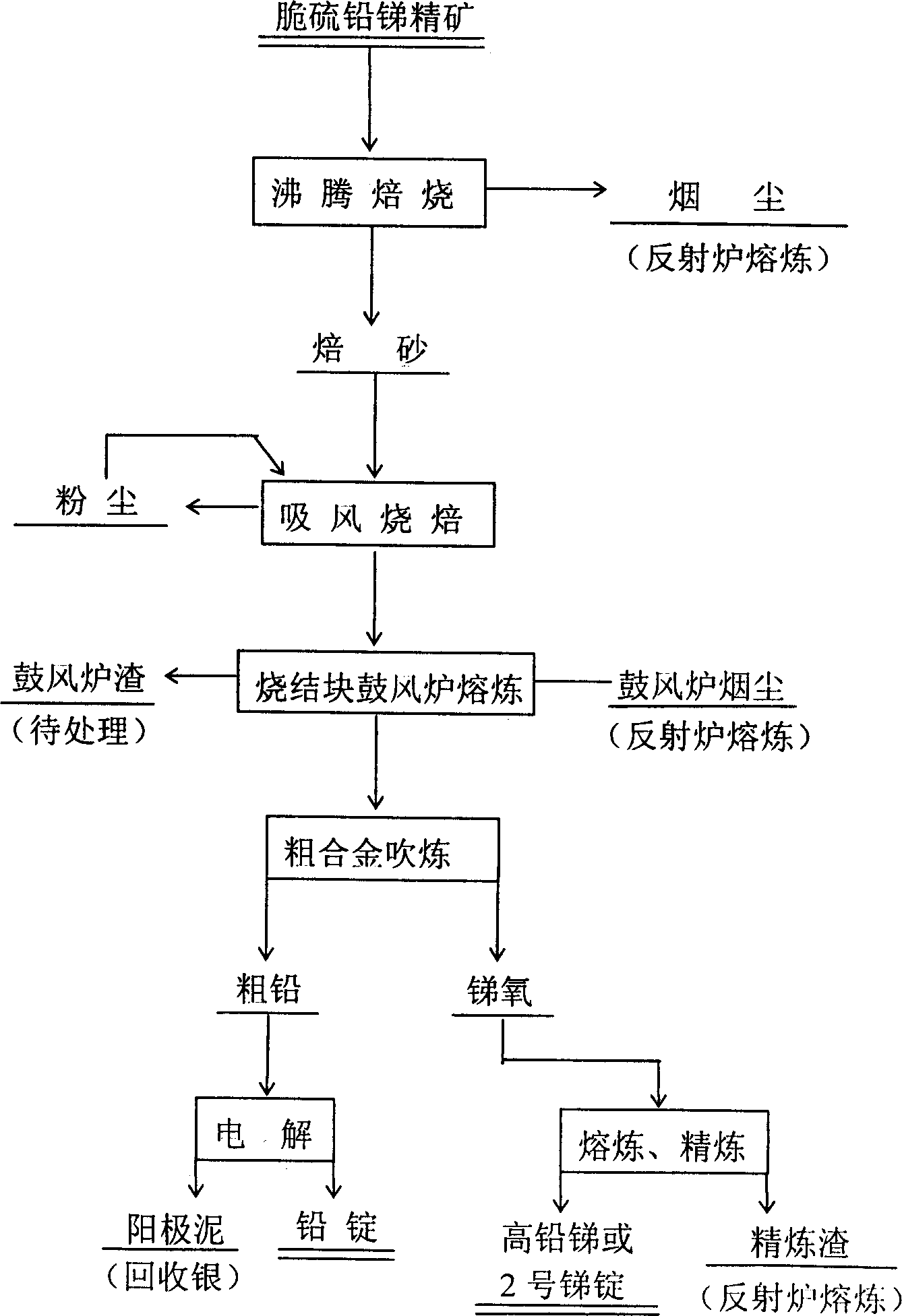

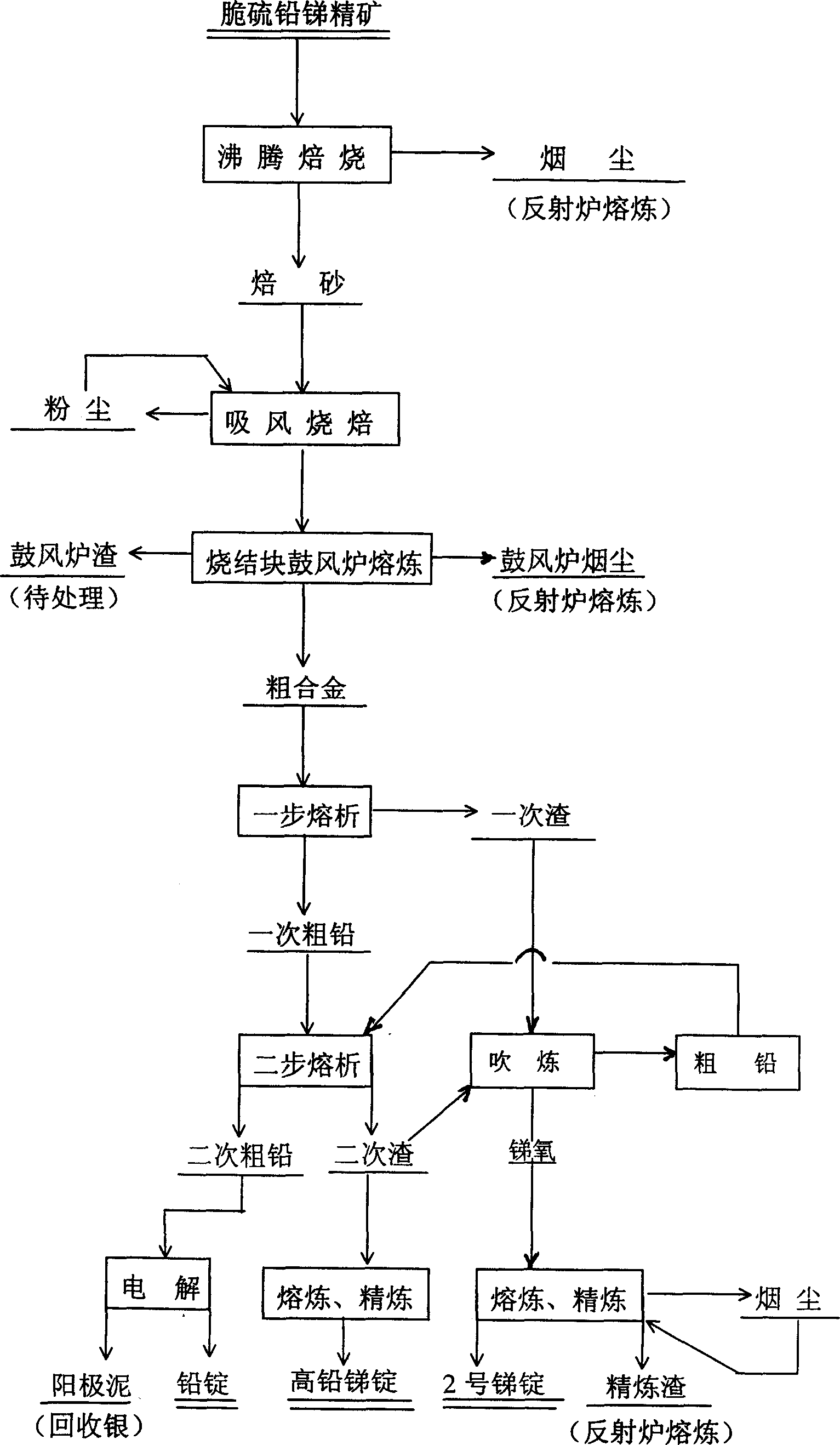

Method for separating lead and antimony from lead antimony crude alloy

The invention is a method of liquating plumbum and stibium from their rough alloy. Its character lies in that the rough alloy adopt the liquating furnace to make one or two-step liquation to produce rough plumbum. The one-step liquation is making the rough alloy of Pb>=62% further liquate to produce rough Pb of Pb<=78% adapted to electrolysis requirement. The two-step liquation is as follows: placing the alloy of 50%= C22B 13 / 00 C22B 30 / 02 4 5 1 2002 / 9 / 16 1405341 2003 / 3 / 26 1203198 2005 / 5 / 25 2005 / 5 / 25 2005 / 5 / 25 Huaxi Group LLC, Liuzhou Guangxi 545006 Wei Yuanji Lu Yongzhuang Wei Mingfang huang yongjiao 45104 The Patent Service Centre of Guangxi Zhuang Autonomous Region Shaoma Village, Xinghu Road, the City of Nanning, Guangxi Zhuang Autonomous Region 530002

Owner:广西华锡集团股份有限公司

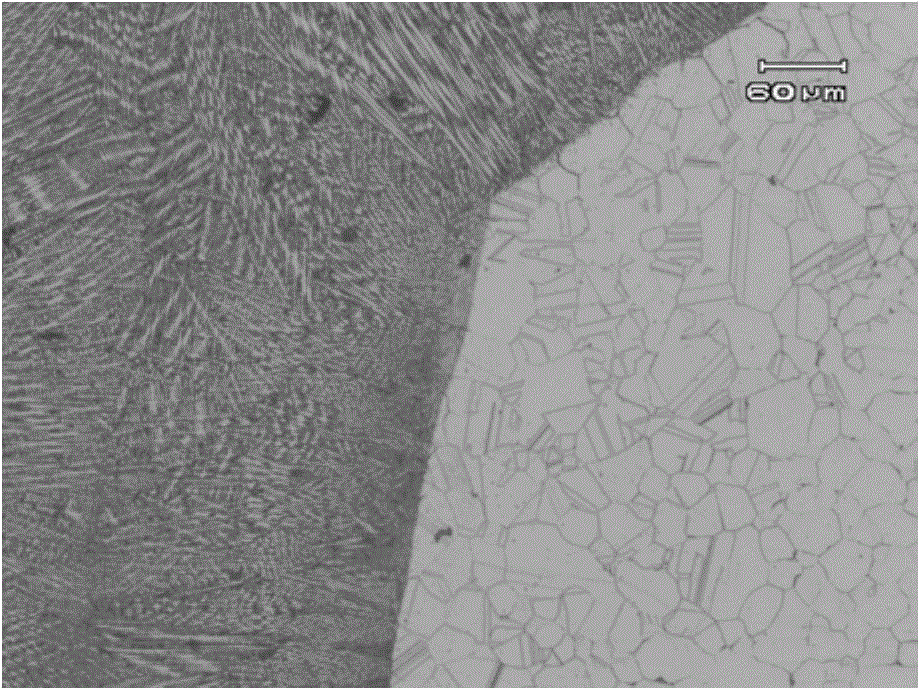

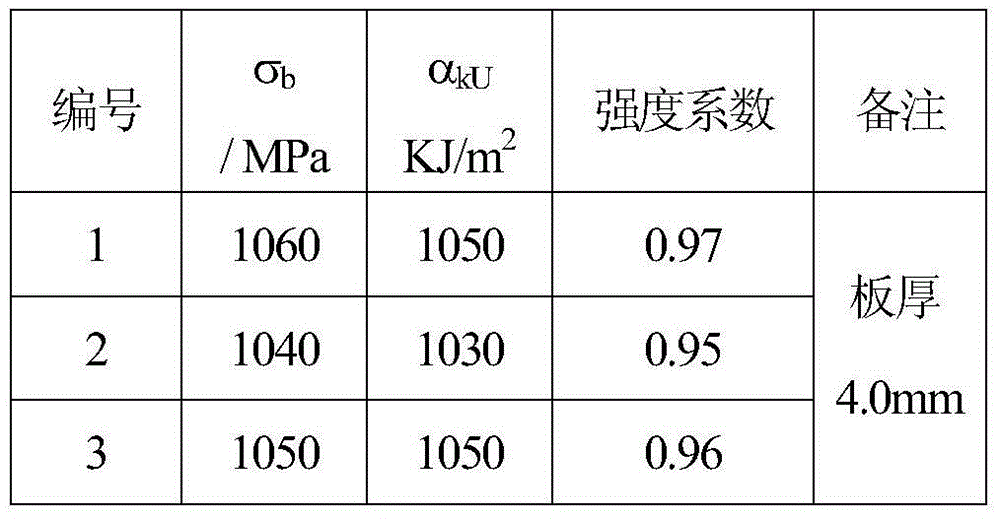

Ferronickel-based alloy welding joint heat-affected zone grain boundary liquation crack control method

ActiveCN104475960APrevent dent defectsControl welding deformationWelding/cutting auxillary devicesAuxillary welding devicesHeat-affected zoneLiquation

The invention relates to the field of ferronickel-based alloy welding, particularly to a ferronickel-based precipitation strengthening austenite alloy (J75) joint heat-affected zone grain boundary liquation crack control method. The method solves the problem ferronickel-based alloy joints are prone to forming relatively wide gamma'-depleted zones or grain boundary liquation cracks. The ferronickel-based alloy welding, particularly to a ferronickel-based precipitation strengthening austenite alloy joint heat-affected zone grain boundary liquation crack control method is implemented through vacuum electron beam welding and composed of the technological processes of pre-welding base metal treatment, vacuum welding chamber internal clamping and fixing, welding chamber vacuumizing, positioned welding, single-cycle welding with electron beam deflective scanning, post-welding modification welding and post-welding electron beam defocused welding joint scanning. Ferronickel-based alloy joints welded through the method have no gamma'-depleted zones and grain boundary liquation cracks on the heat-affected zones, are good in surface forming and achieve a joint strength higher than 980 MPa or even 1030 MPa, a strength coefficient of base metal higher than 0.9 and an impact toughness (akU) higher than 980 KJ / m2 or even higher than 1020KJ / m2.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

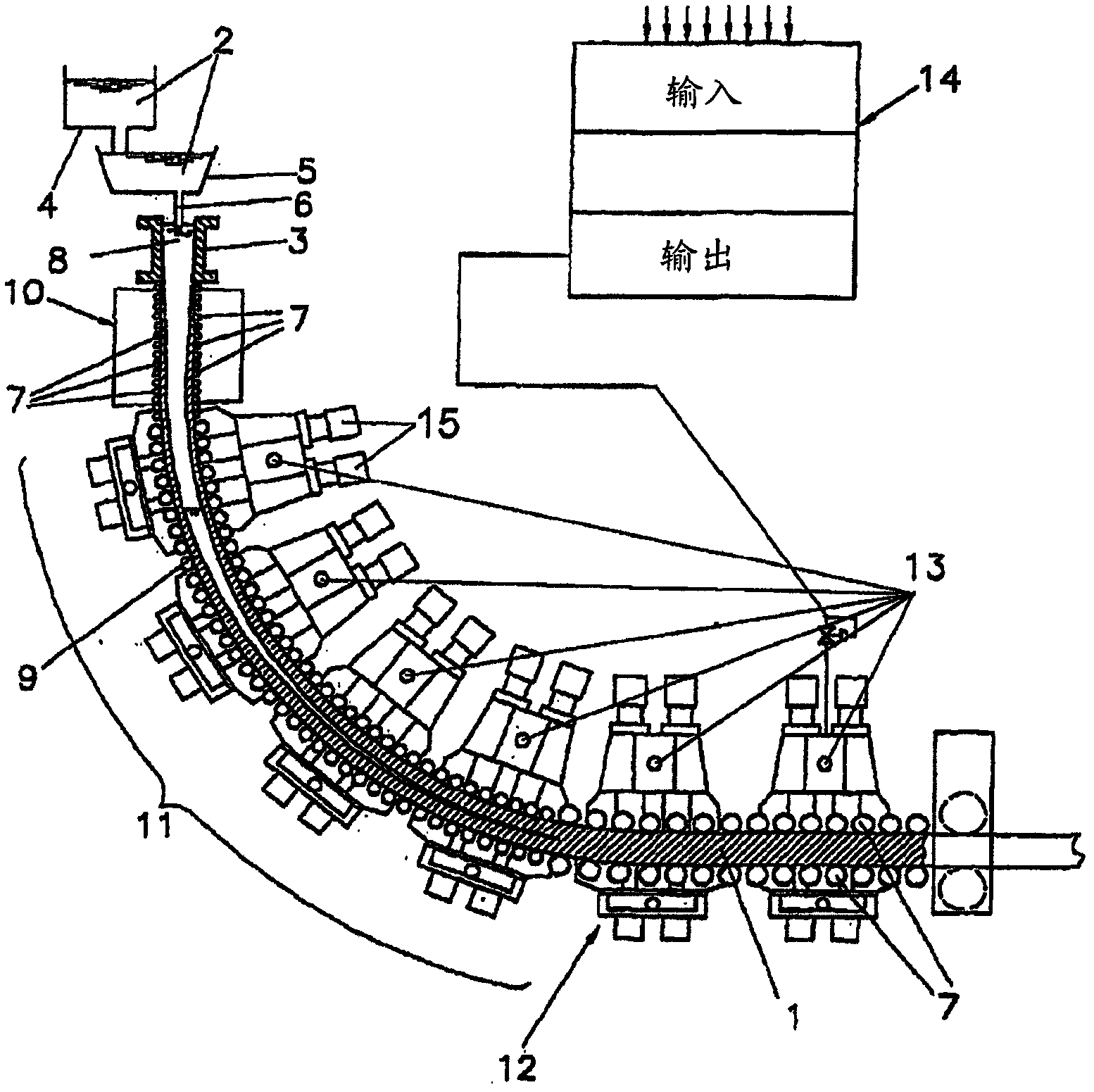

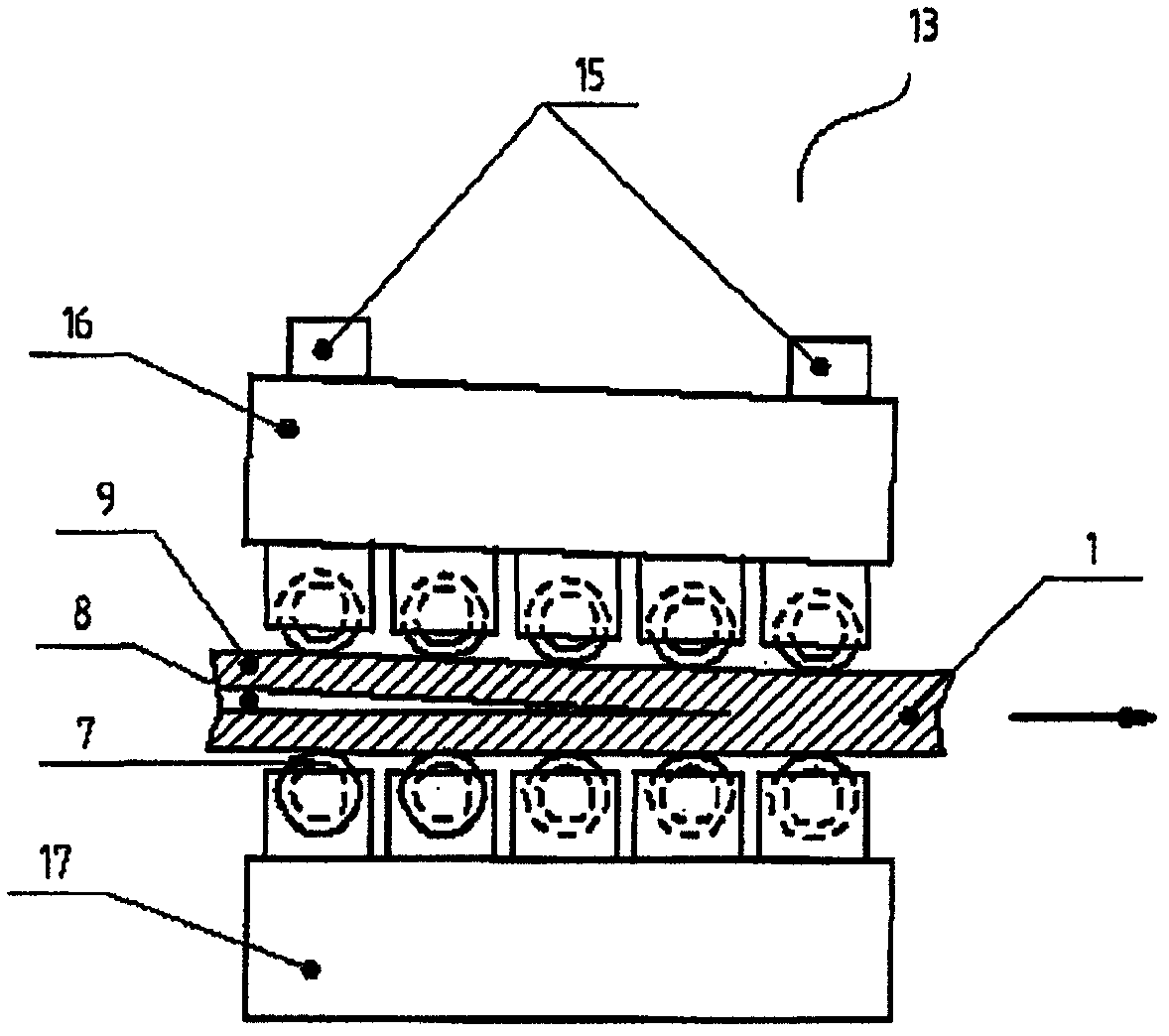

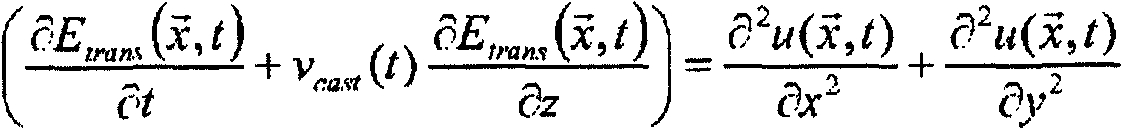

Method for the continuous casting of a metal strand

The invention relates to a method for the continuous casting of a metal strand in a continuous casting plant, a strand being withdrawn from an in-line die, supported in a strand support unit, cooled by a coolant and optionally metallurgically reduced, thermodynamic changes in the entire strand being calculated in a mathematical model containing a thermal conduction equation. The aim of the invention is to provide a method which can be used to improve the product quality of a metal strand, for example by reducing the porosity and / or liquation and by improving the surface quality and form stability. Said aim is achieved by a method, according to which the natural shrinkage of the strand is calculated in real time in the mathematical simulation model, taking into consideration the physical parameters of the metal, the temperature in the casting distributor, the frequently measured withdrawal speed, the cooling of the strand and the thickness of the strand and strand guide rollers of the strand support unit, said rollers being placed against the strand, are set by taking into consideration the natural shrinkage of the metal strand.

Owner:PRIMETALS TECH AUSTRIA GMBH

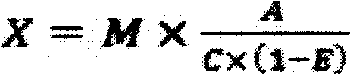

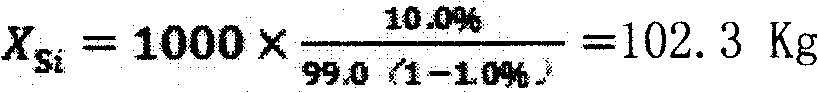

Method for Refining Solar Grade (SoG) Silicon by Using Physical Metallurgy

InactiveUS20100239484A1Simple processing methodShort construction periodSiliconEnergy inputChemical reactionShielding gas

The present invention discloses a method for physically refining solar grade silicon comprises: firstly, by using a vacuum induction furnace, selecting a high oxidizing crucible to avoid carbon pollution; secondly, conducting the vacuum-pumping during the heating process; thirdly, injecting a protective gas, after the smelting temperature reaches a predetermined temperature, the powerful oxidizing gas (chlorine) is injected into the bottom of the crucible; fourthly, producing chemical reaction with the powerful oxidizing gas and impurity such as Fe—Al—Ca—P—V, so that the reaction resultant is gasified, while the power oxidizing gas stirs with the metallic silicon liquation, and preserving the temperature; fifthly, injecting the refined metallic silicon into a pouring box to enter into a oriented crystallization procedure. The present invention has following advantages: being easy and convenient to be implemented, rapid heating, no pollution, and the purity of the silicon material refined by using the method in the present invention can be graded to 5N or more.

Owner:JIWEI SOLAR WUHAN

Aluminium-silicon-copper-magnesium series deforming alloy and its preparing method

The invention discloses an Al-Si-Cu-Mg series distortion aluminum alloy and the manufacturing method. The alloy is made up from 9.0-12.0wt% Si, 3.0-4.0wt% Cu, 0.3-0.6wt% Mg, <0.30% Fe, <0.20% Zn, and other impurity <=0.15wt%, and the rest is Al. The method includes the following steps: smelting and refining the raw materials in reflecting smelter, after processing the allow liquation by Al-Sr intermediate alloy, gaining cast rod through hemicontinuous casting, extruding the cast rod and after forging and T6 thermal treatment to gain the product. The tensile strength of the alloy is over 397MPa, and broken tensile stretch is 6%, and rigidity is 136-141HB. It is mainly used to make wheel for vehicle and motorcycle, piston, bearing, bidirectional sloping cam plate, etc.

Owner:SHANDONG UNIV

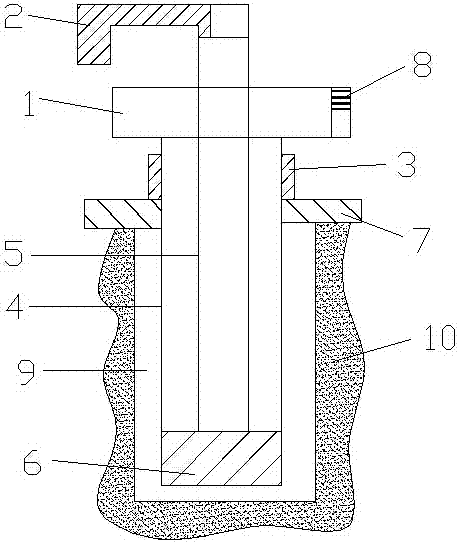

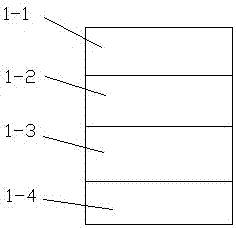

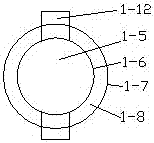

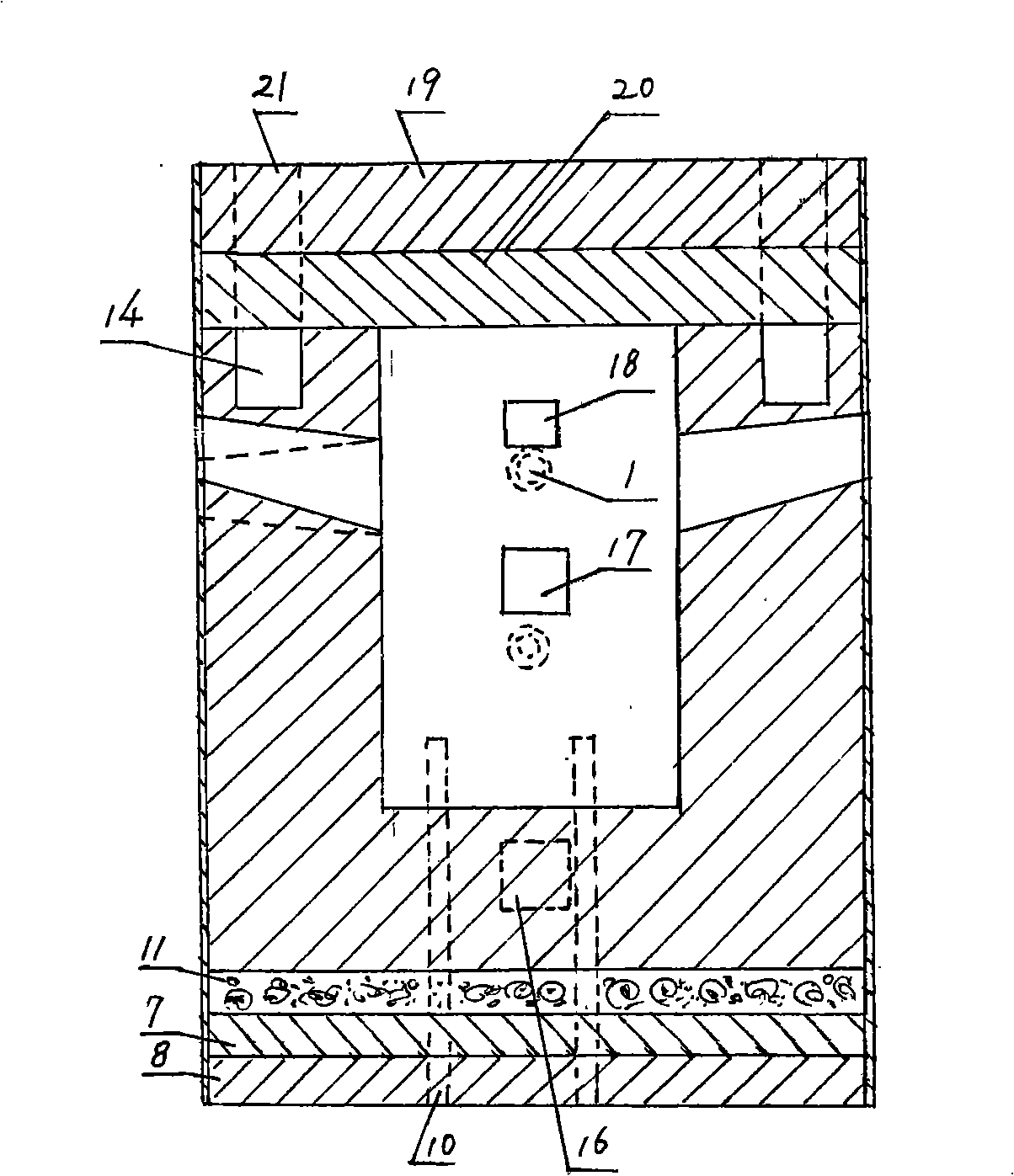

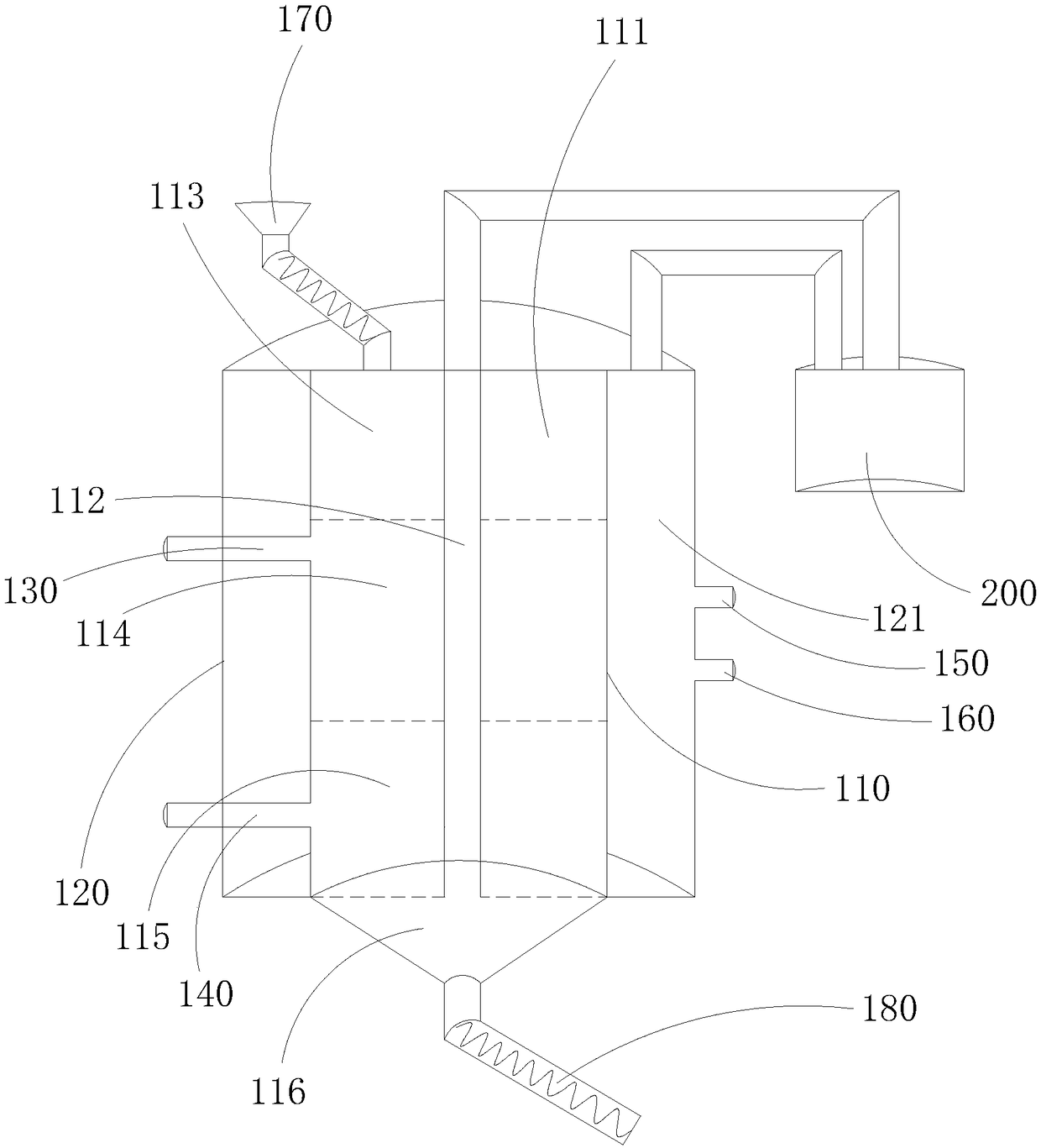

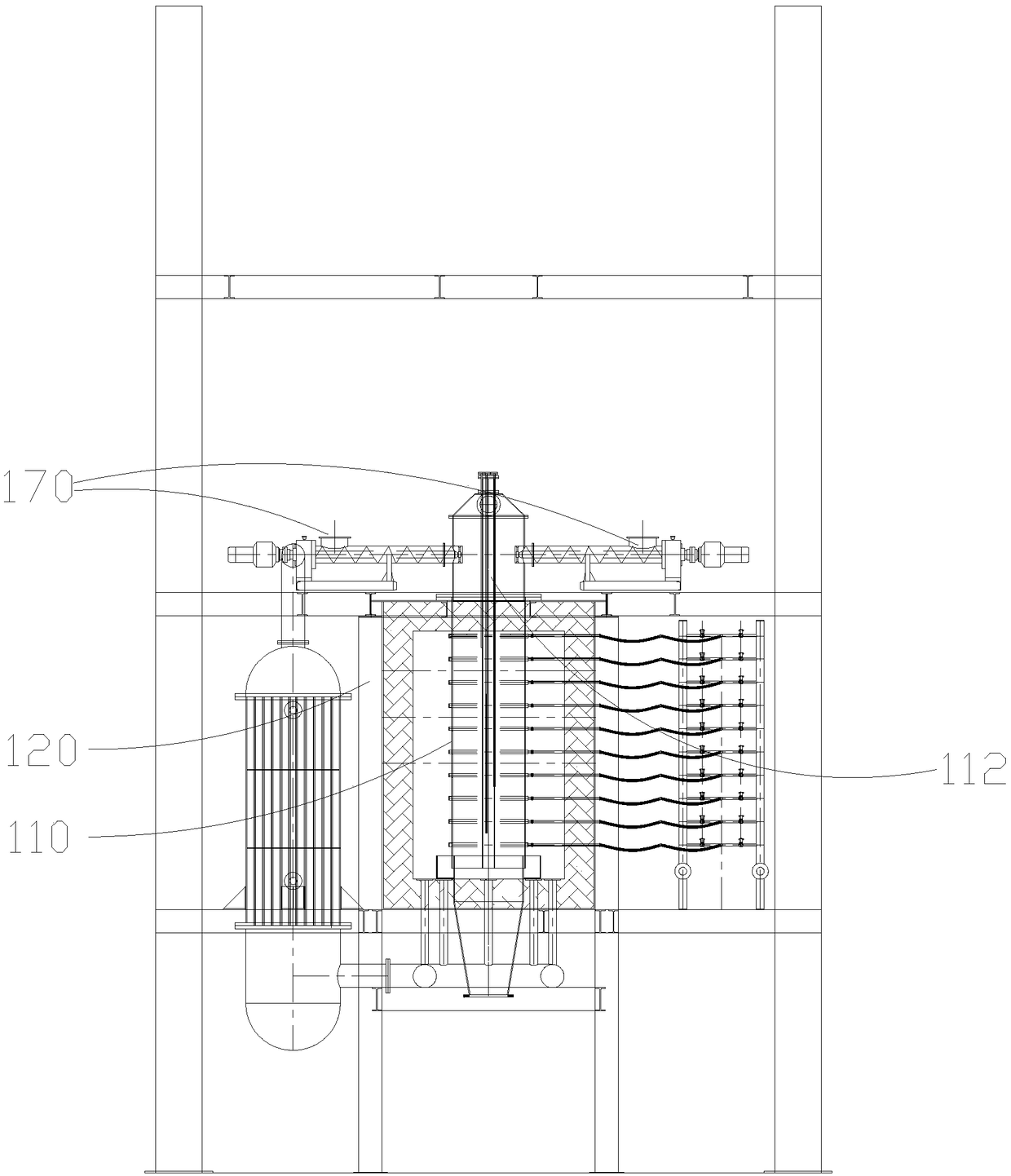

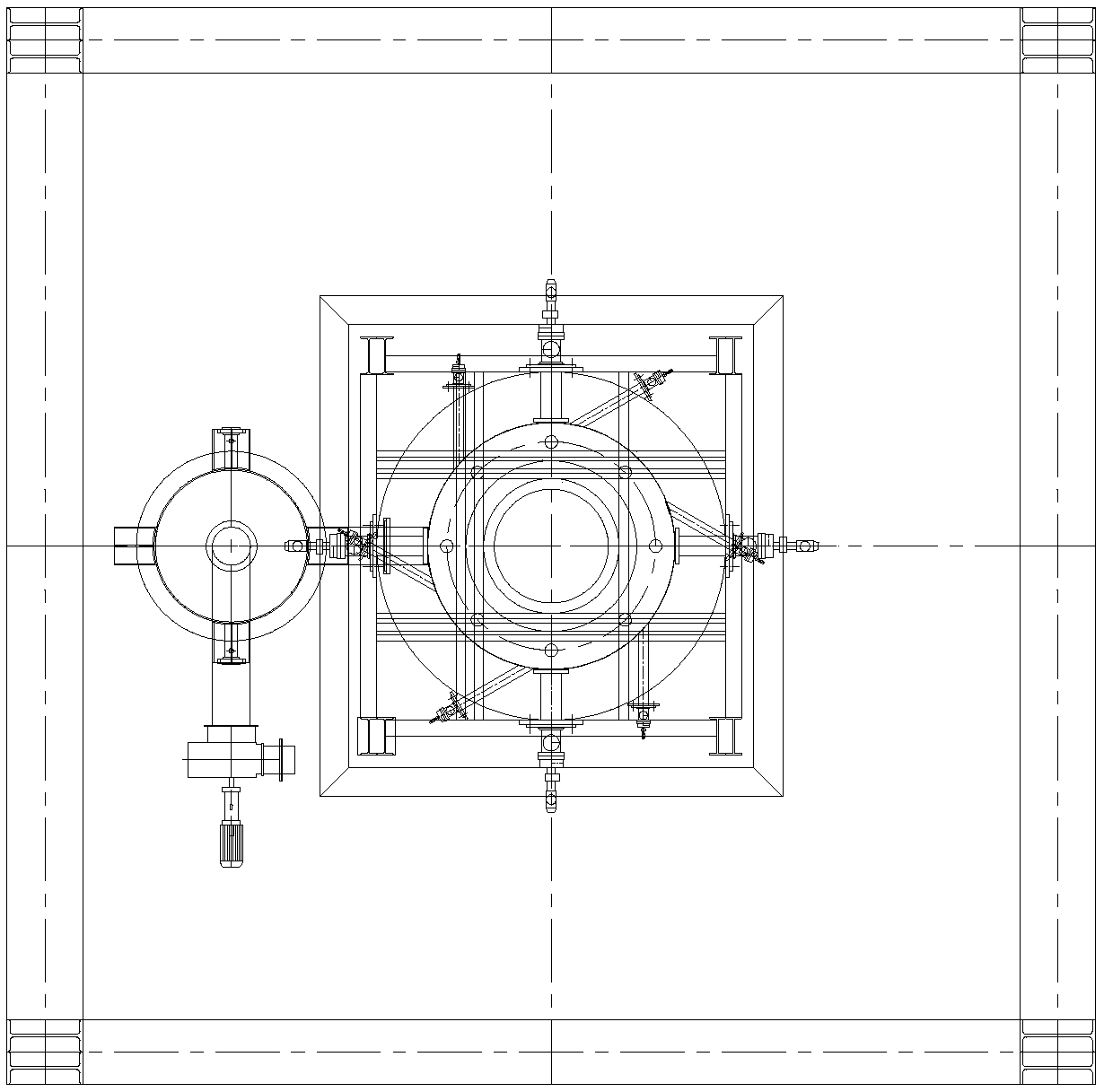

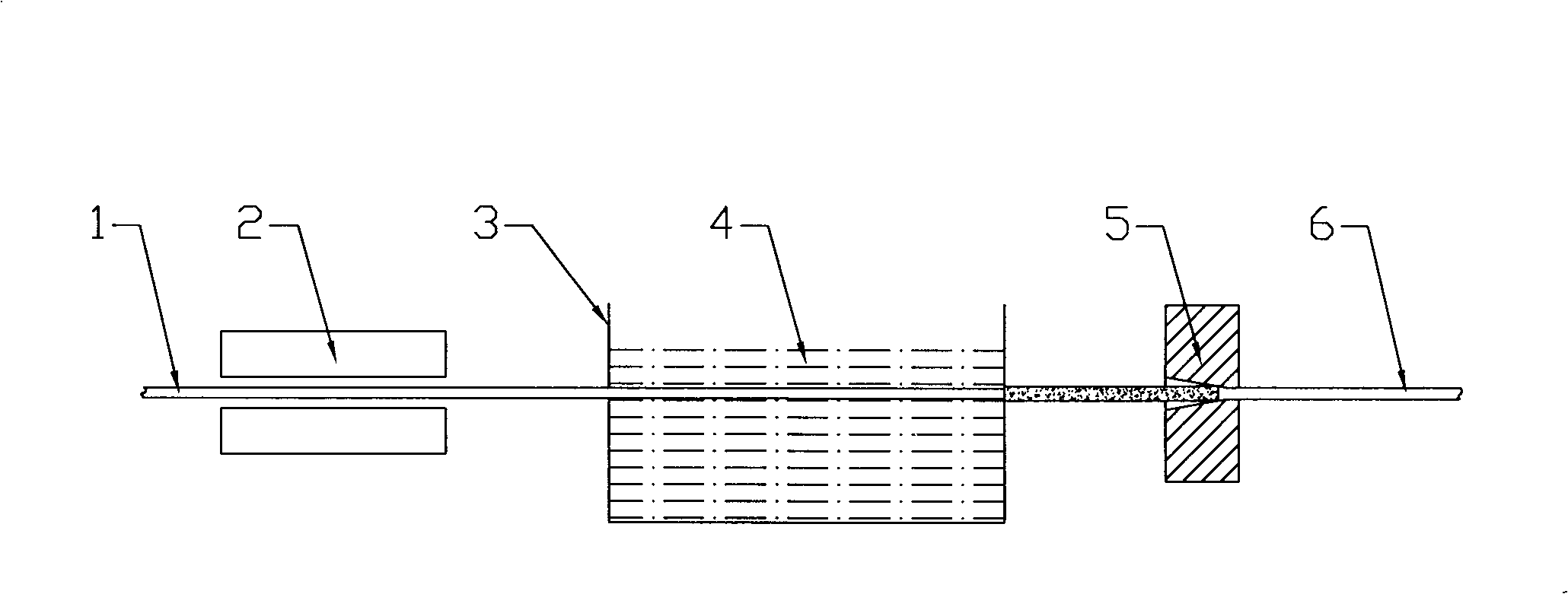

Continuous processing equipment for waste circuit boards/waste enameled wires on basis of pyrolysis liquation principle

ActiveCN108735399AAchieve recyclingImprove recycling efficiencyBasic electric elementsProcess efficiency improvementDecompositionOrganic matter

The invention relates to the technical field of processing equipment for waste circuit boards / waste enameled wires, and discloses continuous processing equipment for waste circuit boards / waste enameled wires on the basis of a pyrolysis liquation principle. The continuous processing equipment comprises a furnace with a heating chamber in the furnace and a furnace container; the furnace container isplaced in the heating chamber, and the heating chamber is provided with a heating ring chamber surrounding the periphery of the furnace container; the interior of the furnace container is provided with a processing chamber for conducting pyrolysis liquation on the waste circuit boards / waste enameled wires, and a preheating area, a pyrolysis area, an gasification area and an aggregation area are sequentially formed in the processing chamber in the direction from top to bottom; and dehydration preheating processing is conducted in the preheating area, organic matter in the waste circuit boards / waste enameled wires is decomposed in the pyrolysis area, coke formed by decomposition is gasified and alloys are separated in the gasification area, and metals separated from the alloys are aggregated in the aggregation area. Accordingly, recycling of the metals in the waste circuit boards / waste enameled wires is achieved, the resources are fully utilized, the processing mode is capable of achieving environmental protection and energy saving, and existing of dioxin is thoroughly eradicated.

Owner:阙南平 +1

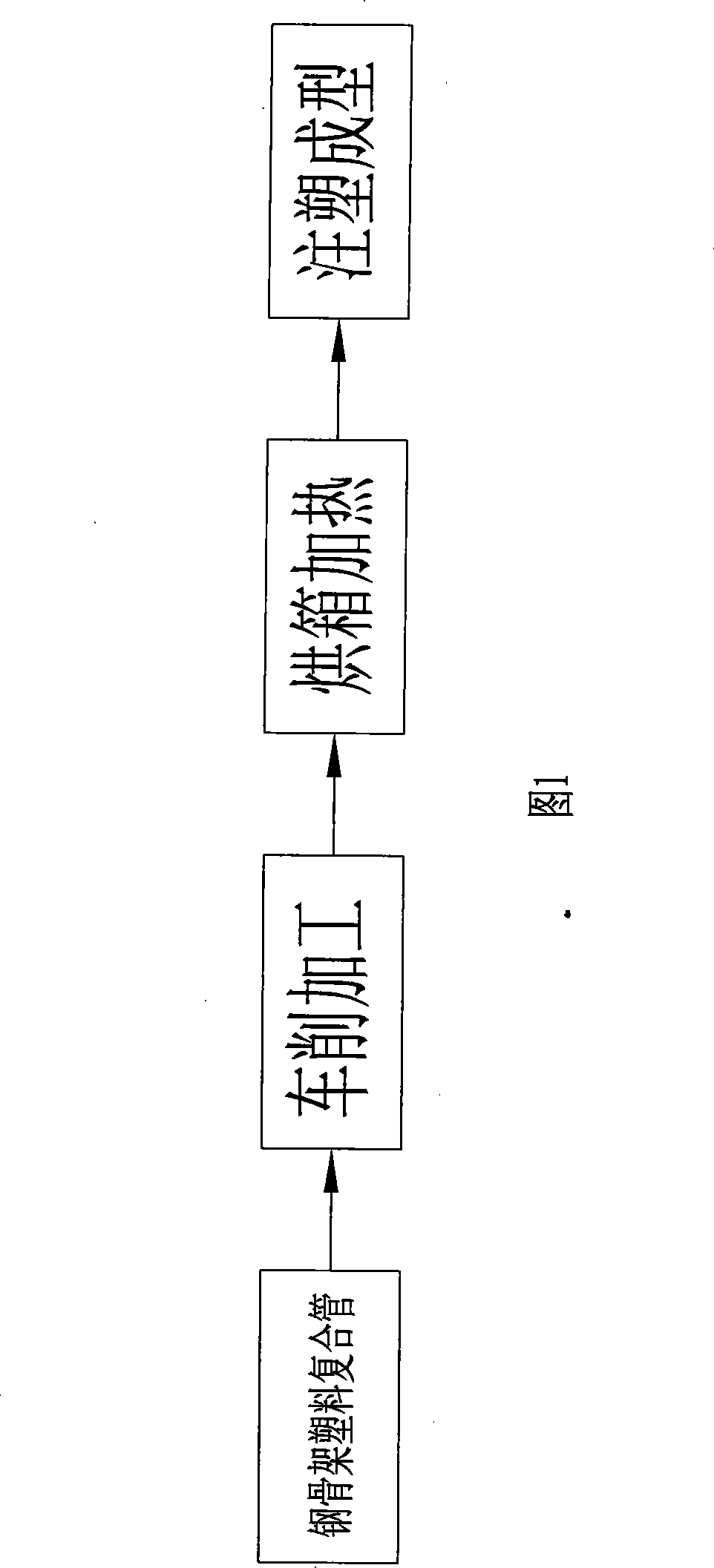

Production technique of steel skeleton plastic composite pipe having plastic end and products thereof

ActiveCN101249708ASolve the problem of difficult to use fusion butt jointsSolve the phenomenon of delaminationRigid pipesPipe connection arrangementsWhole bodyQuality assurance

The invention discloses a process for producing a steel-framed plastic clad pipe with a plastic end head and products thereof. The process has the following beneficial effects: since an injecting end head is arranged, the problem that the steal-framed plastic clad pipes are hard to be spliced is solved; as the steel-framed plastic clad pipe provided by the process, the steel frame and a plastic end face connector are connected into a whole body through liquation, the phenomenon that the steel-plastic interface of the end face of the clad pipe peels is eliminated; and the reliability is greatly improved. Meanwhile, the process has the advantages of saved materials, easy manufacture, low installation cost, controllability of the liquation pressure, less impact by human factors, easy quality assurance, etc.

Owner:李广忠

Method for producing large bimetal regulating nut

InactiveCN1900540AImprove reliabilityHigh bonding strengthNutsBoratesFlagellar basal bodyRoom temperature

The method includes following steps: casting and roughening inner cylindrical face from carbon steel to prepare basal body of nut in carbon steel; carrying out rust removing, degreasing, and drying processes for the basal body; putting the basal body into borax liquation, and heating to 850-900 deg.C; taking the basal body out from the borax liquation, removing redundant borax liquation from outer and inner surface of basal body of nut; then fixing nut in carbon steel on centrifuge rapidly, centrifugal casting brass alloy onto surface of inner cylindrical face of basal body of nut in carbon steel, materials and proportioning by weight of brass alloy are as following: Cu 60-65%, Zn 25-30%, Sn 1.5-5%, Mn 2.5-4%, Fe 1.5-3%, Ni 1-3%; taking bi metallic nut rough out from centrifuge, water cooling it to room temperature; process of removing stress, and shaping. Advantages are: low cost, reliable quality of product, and high production efficiency.

Owner:DALIAN SANHUAN COMPOSITE MATERIAL TECH DEV

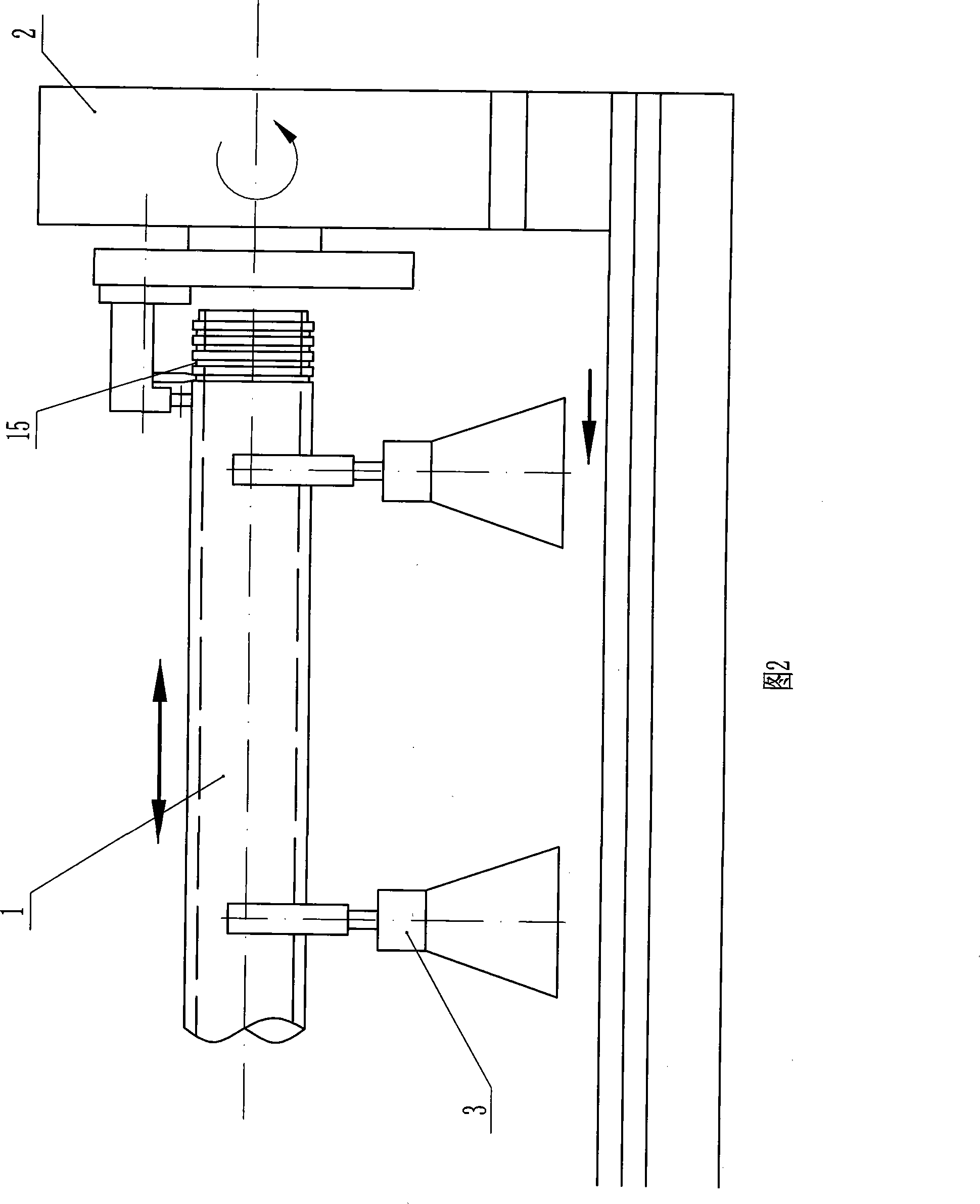

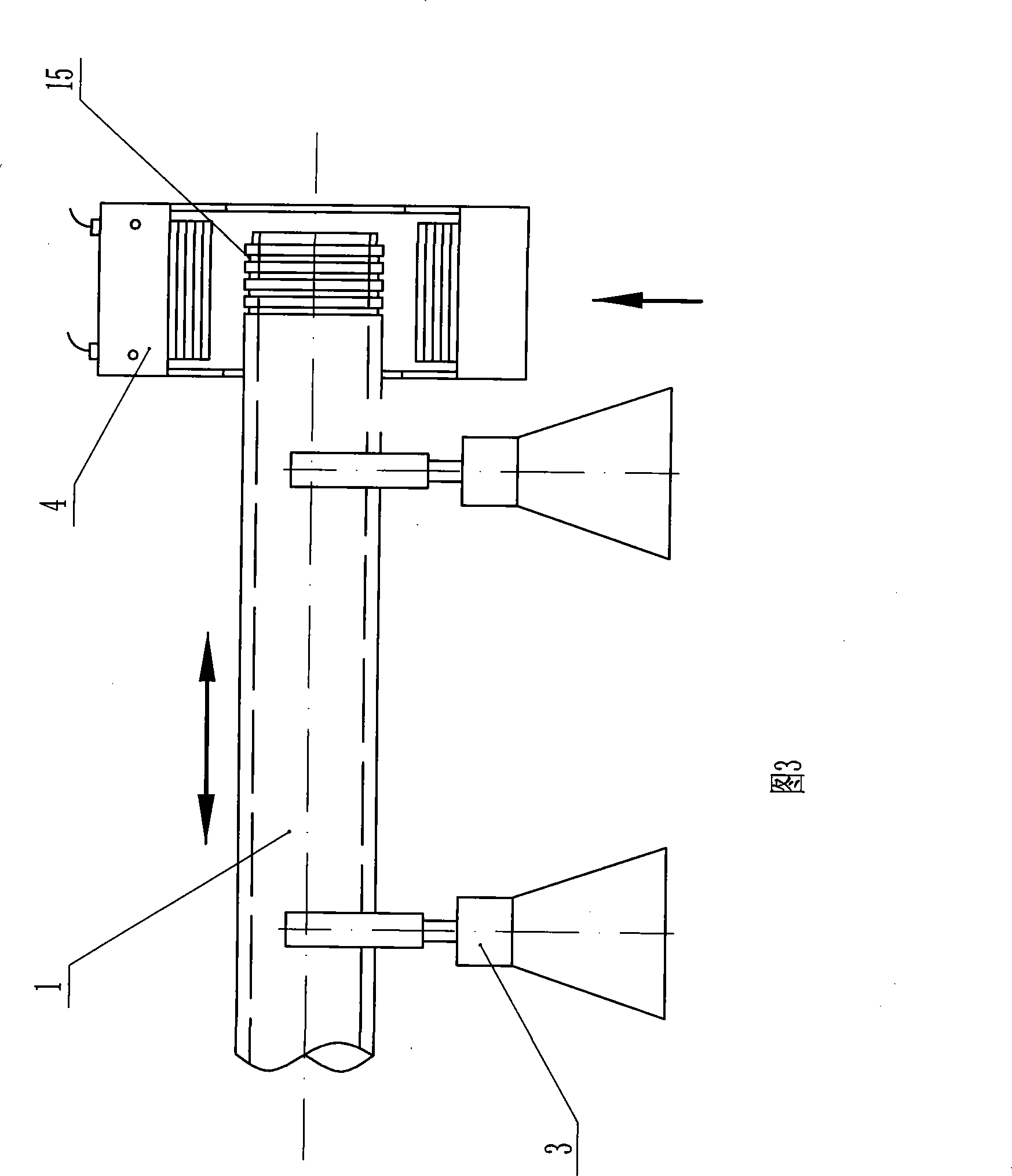

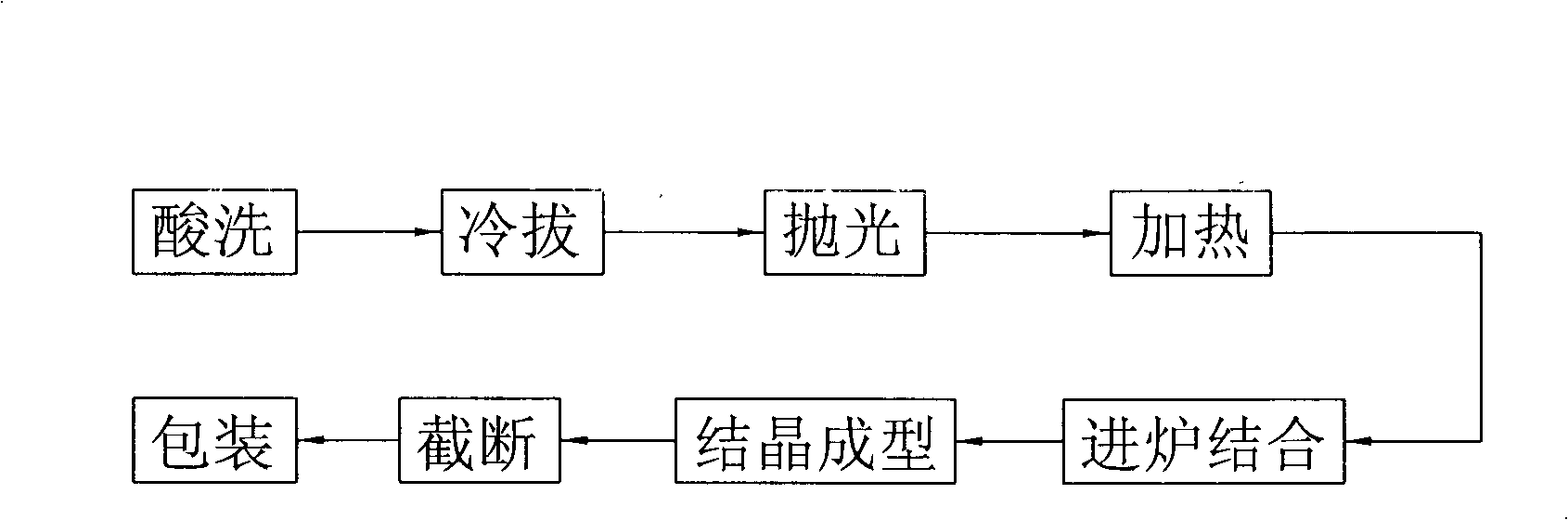

Method for manufacturing zinc-coating-steel grounding electrode continuously

ActiveCN101409390AThickness is easy to controlTightly boundHot-dipping/immersion processesConnection contact member materialElectrical resistance and conductanceComing out

The invention discloses a continuous manufacture method of a zinc-clad steel grounding electrode and belongs to the manufacture method of metal materials. The prior art has the defect of low production efficiency and the prepared zinc-clad steel grounding electrode has the defects of poor performance and short service life. In the invention, round steel after acid cleaning is carried out on round steel, the round steel is cold drawn to a required diameter and polished; then the round steel is heated to the temperature between 200 and 300 DEG C, enters the zinc liquid in a liquation furnace and is combined with the zinc liquid; finally, the round steel comes out from the zinc liquid in the liquation furnace and forms the zinc-clad steel grounding electrode the inner core of which is steel and the outer coating is zinc by a crystallizer. The zinc of the coating is tightly combined with the steel of the core layer and is hard to be separated; the contact resistance between the zinc of the coating and the steel of the core layer is low; the thickness of the core layer is easy to be controlled and can play the role of protection on the devices and pipelines on an anode; moreover, the production efficiency is high.

Owner:丁桂土

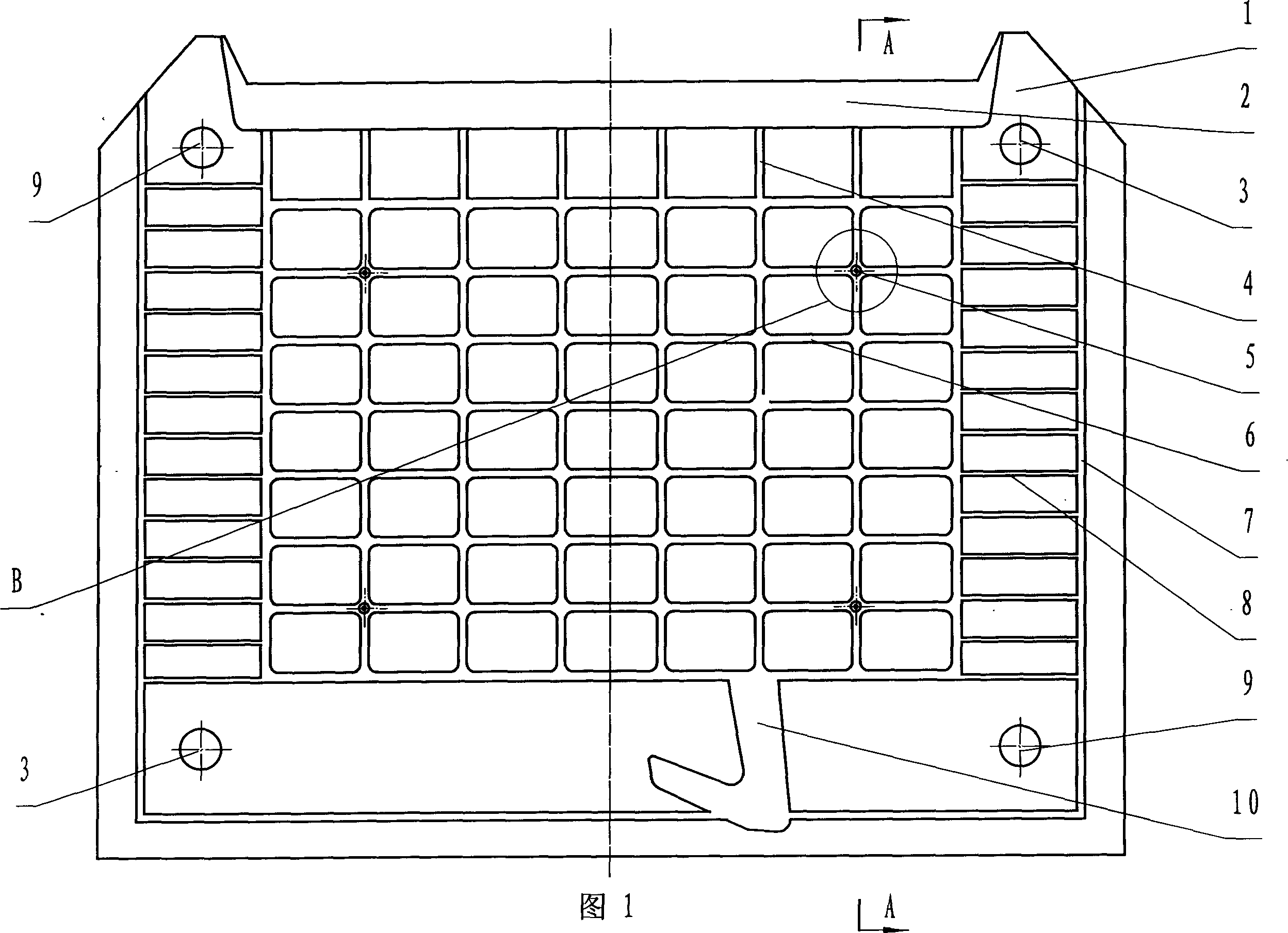

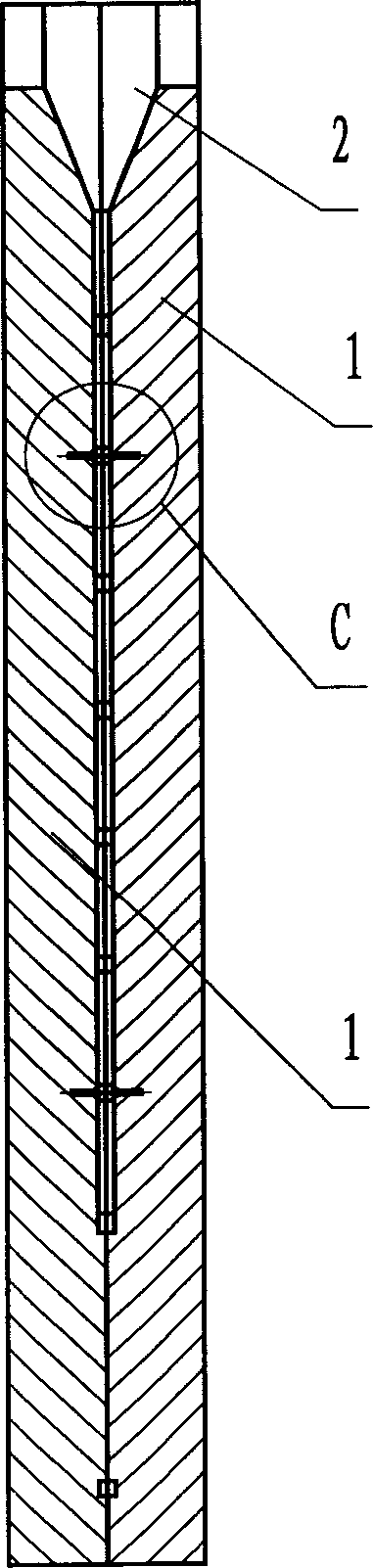

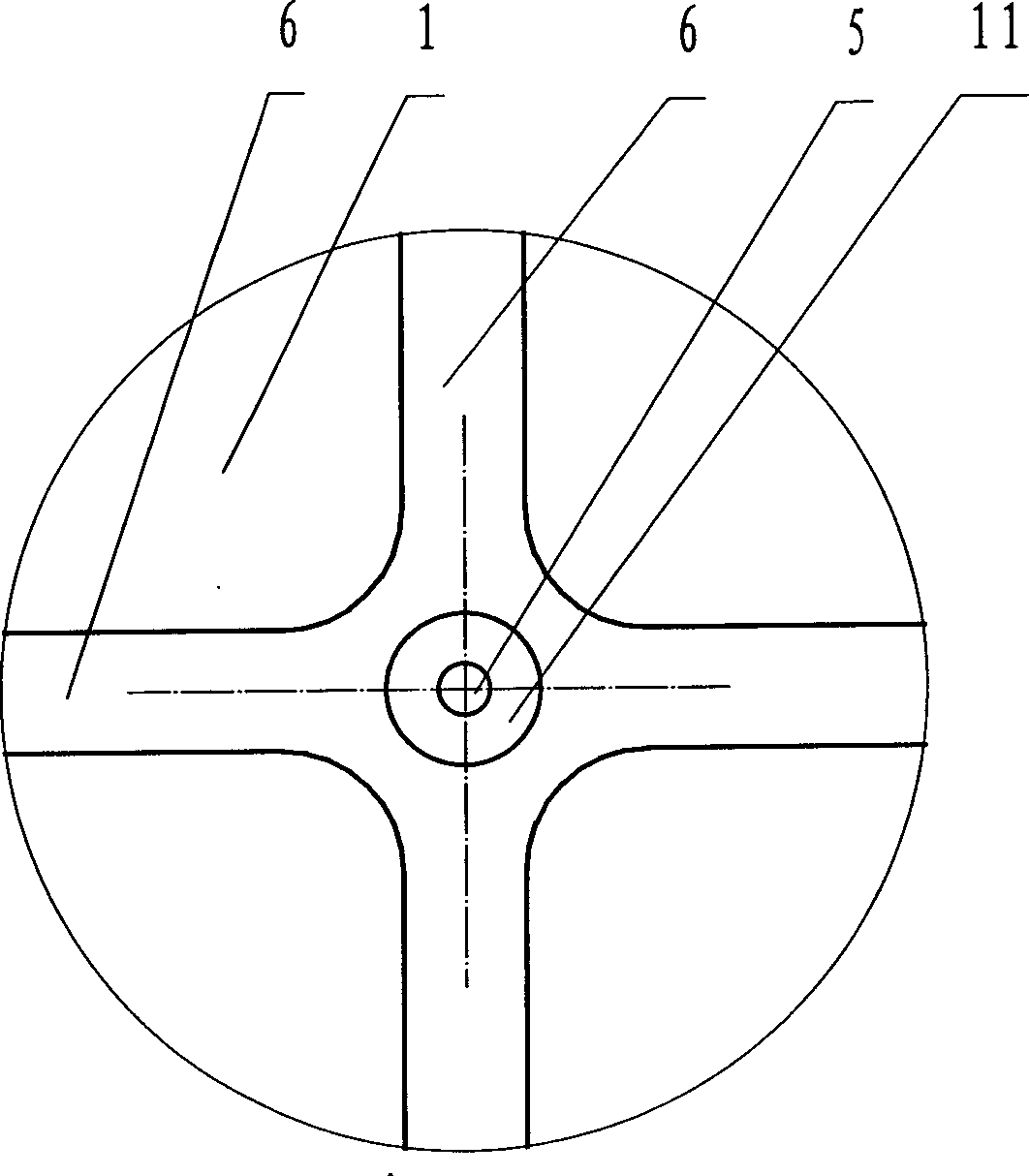

Method for producing copper sheet grating of lead acid battery, and dedicated die

InactiveCN1797818AReduce manufacturing costRealize large-scale industrial productionElectrode carriers/collectorsLead-acid accumulator electrodesGratingCopper

Copper sheet grating of lead acid battery is produced from casting method. The method includes steps: installing lead rings for positioning copper web as basal body; the thickness of the ring is same as the thickness of lead layer of cladding copper sheet grating; placing the copper web with rings installed to a die; heating the die to 328-600 deg.C, casting lead liquation into the die; after lead liquation and the die are cooled, the blank of copper sheet grating is taken out; cleaning out burrs of air flue on the blank; planishing redundant lead at positioning pinholes on the blank, and closing pinholes so as to produce product of copper sheet grating. The dedicated die includes two pieces of relevant dies. Being in shape same to copper web, the groove in size larger than section of copper web is located on junction plane. There are pins for positioning copper web on two pieces of die to fix copper web at cavity center of die.

Owner:苗维新

Method of titanium or titanium alloy melting liquid deoxidizing purification

InactiveCN1912155AHarm reductionImprove plasticityIncreasing energy efficiencyRare-earth elementMiddle frequency

The invention relates to a method to deoxidize and purify titanium or titanium alloy. It adopts rare earth as element purifying agent to take deoxidizing and purification process to titanium or titanium alloy. The agent includes La 35-55wt%, Ce 25-35wt%, Nd 5-25wt%, Pr 8-10wt%, and Y 4-5wt%. The added quantity agent is 0.01-0.1% of the weight of titanium metal liquation. The titanium or titanium alloy is melted in vacuum middle frequency induction furnace lime crucible. When the temperature reaches to 1650-1720 degree centigrade, the agent would be added and quieting for 15-25 minutes and casting to gain the titanium or titanium alloy with low oxygen content.

Owner:SHANGHAI UNIV

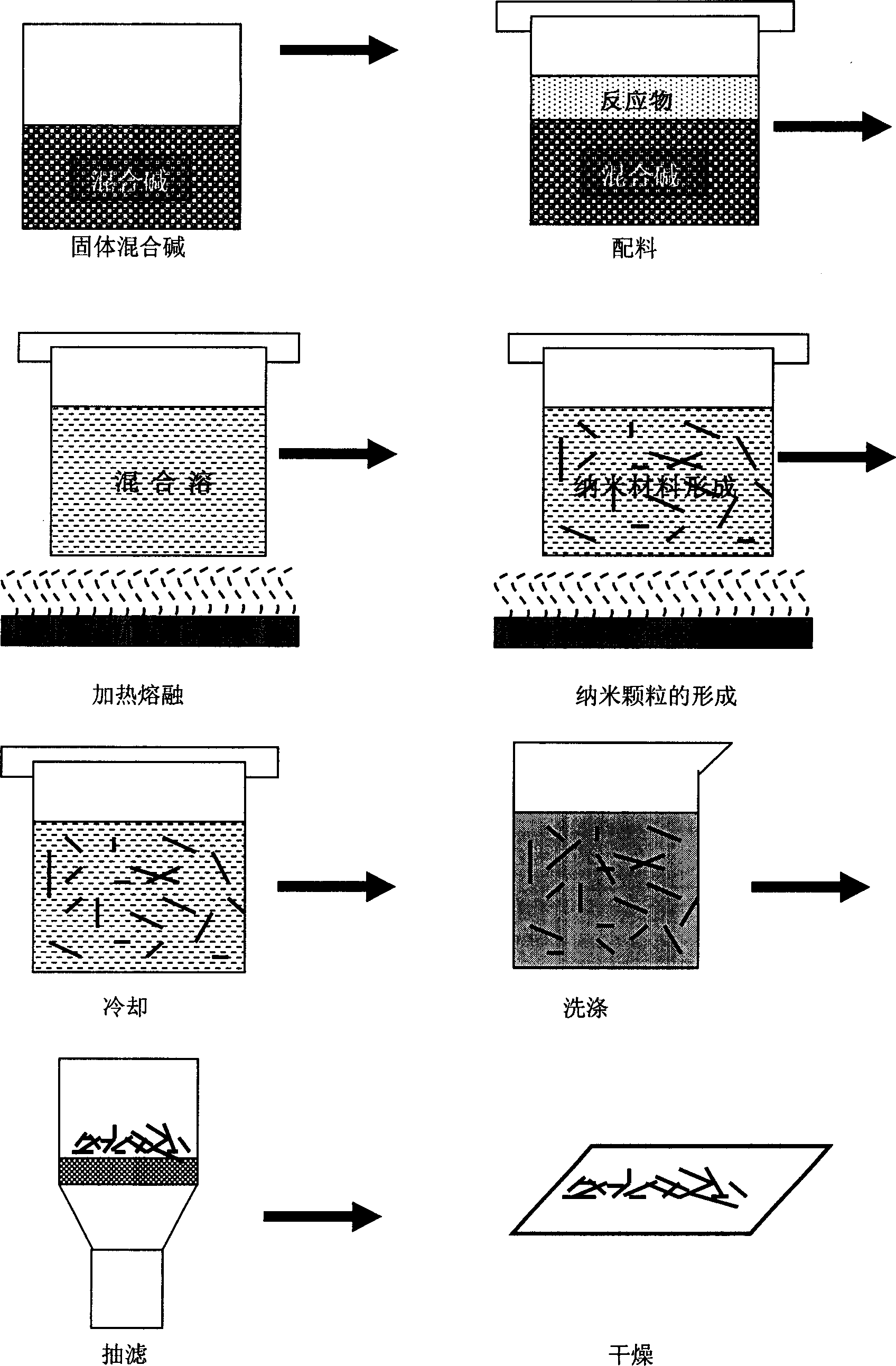

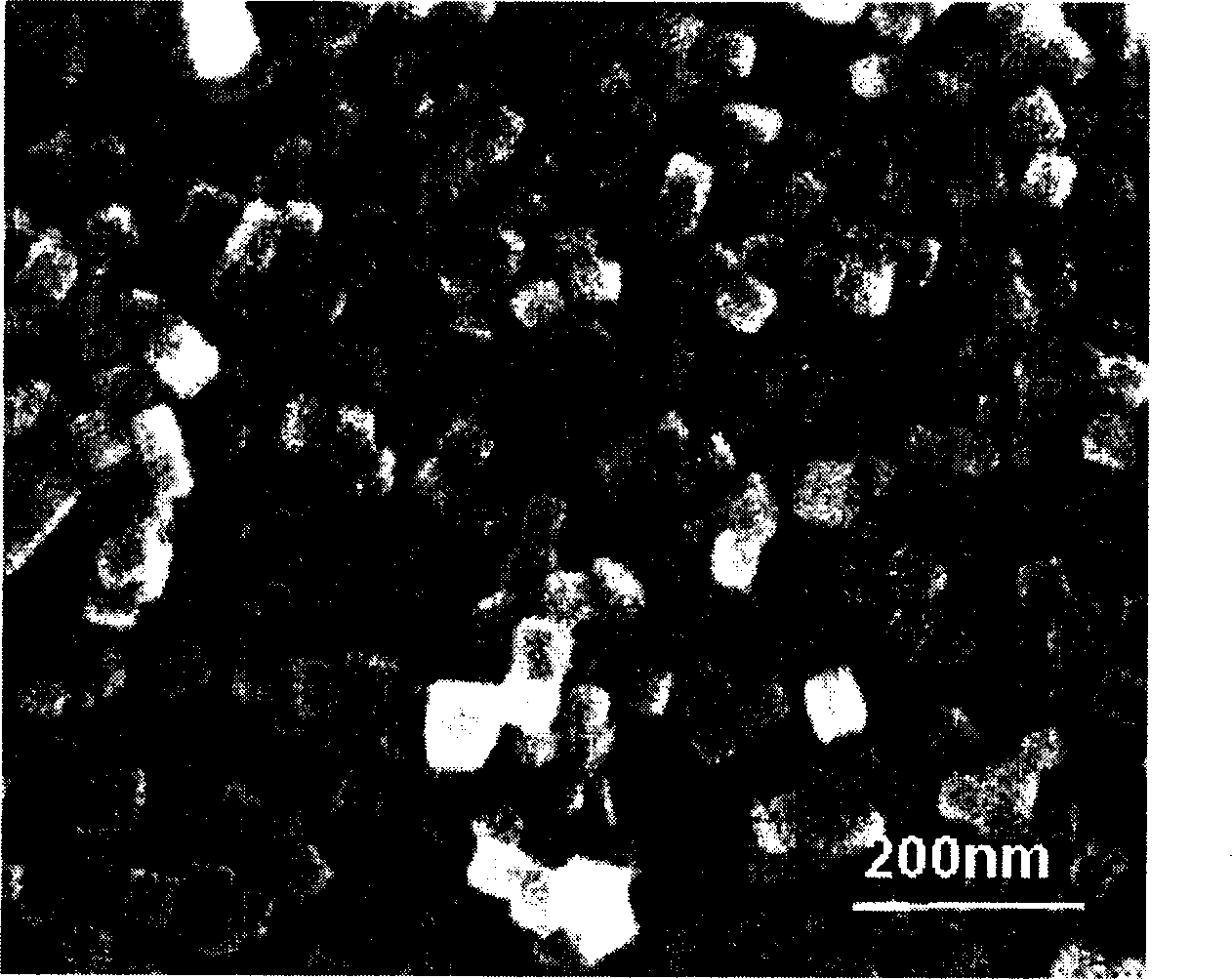

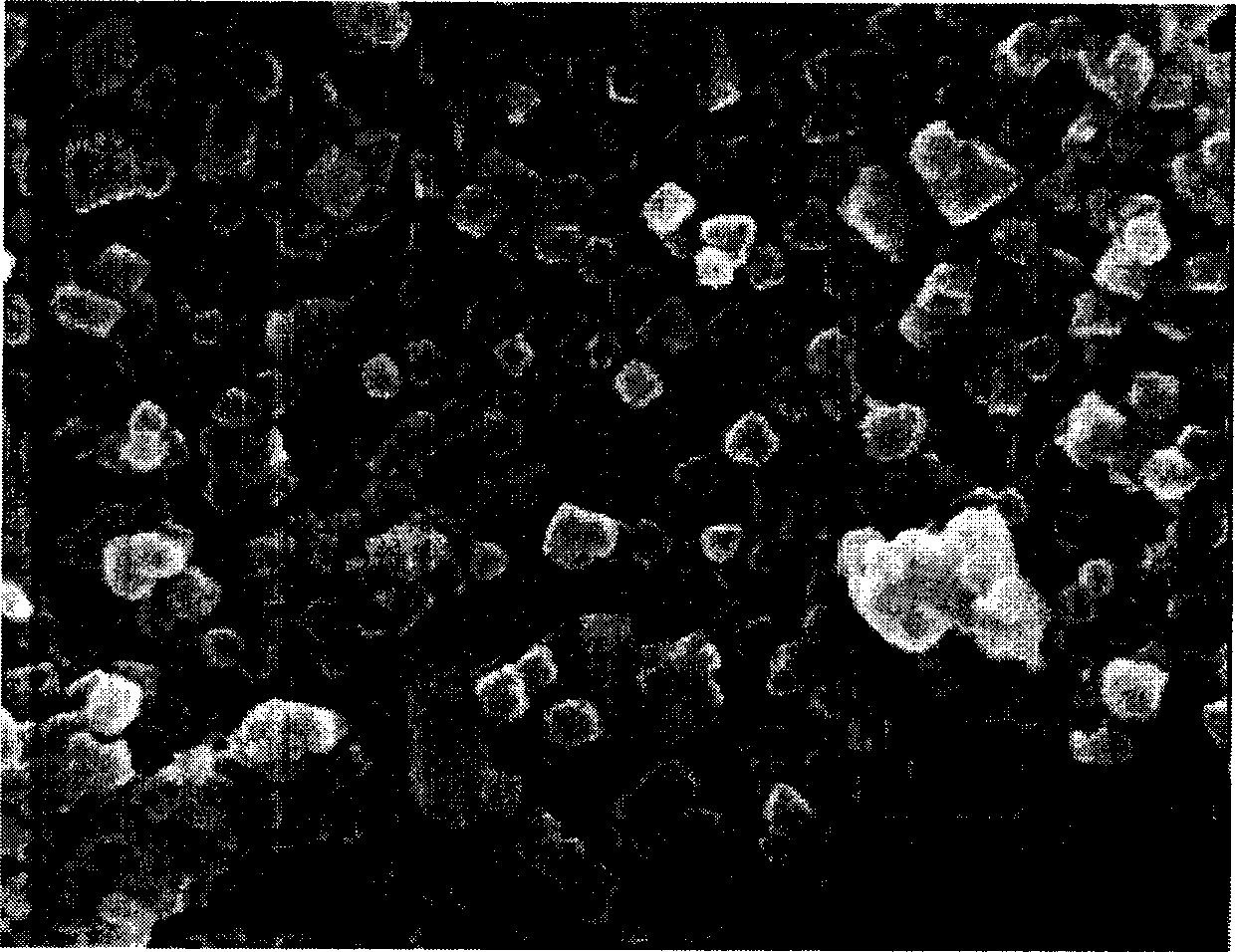

Low-temperature alkaline-solution synthesis of oxygen metal inorganic compound monocrystal nano-material

InactiveCN1896341AUniversal synthesis methodSuitable for synthesisPolycrystalline material growthSingle crystal growth detailsSemiconductor materialsInorganic compound

The present invention discloses a hypothermal alkali liquation synthesis process of monocrystalline nanometer materials of oxygenous metal inorganic compounds. The compound oxide monocrystalline nanometer materials are synthesized with the inorganic salt of a metal and the oxide of another metal as main materials, melted mixed alkali as solvent, at atmospheric pressure and relatively low temperature of about 200DEG C. The present invention uses melted alkali as solvent for the first time and can synthesize oxide nanometer materials of different structures, compositions and functions, or monocrystalline nanometer materials of simple oxide and hydroxide. This process utilizes conventional materials and only controls the time and temperature during synthesis in favor of the industrial application. The produced monocrystalline nanometer materials includes ferroelectric and piezoelectric materials, ferromagnetic materials, semiconductive materials, ionic conductive materials, colossal magnetoresistance materials, high dielectric materials superconductors and etc. that can be applied to microelectronics, photoelectronics and communication.

Owner:SHANDONG UNIV +2

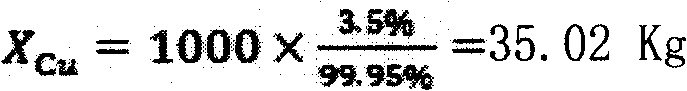

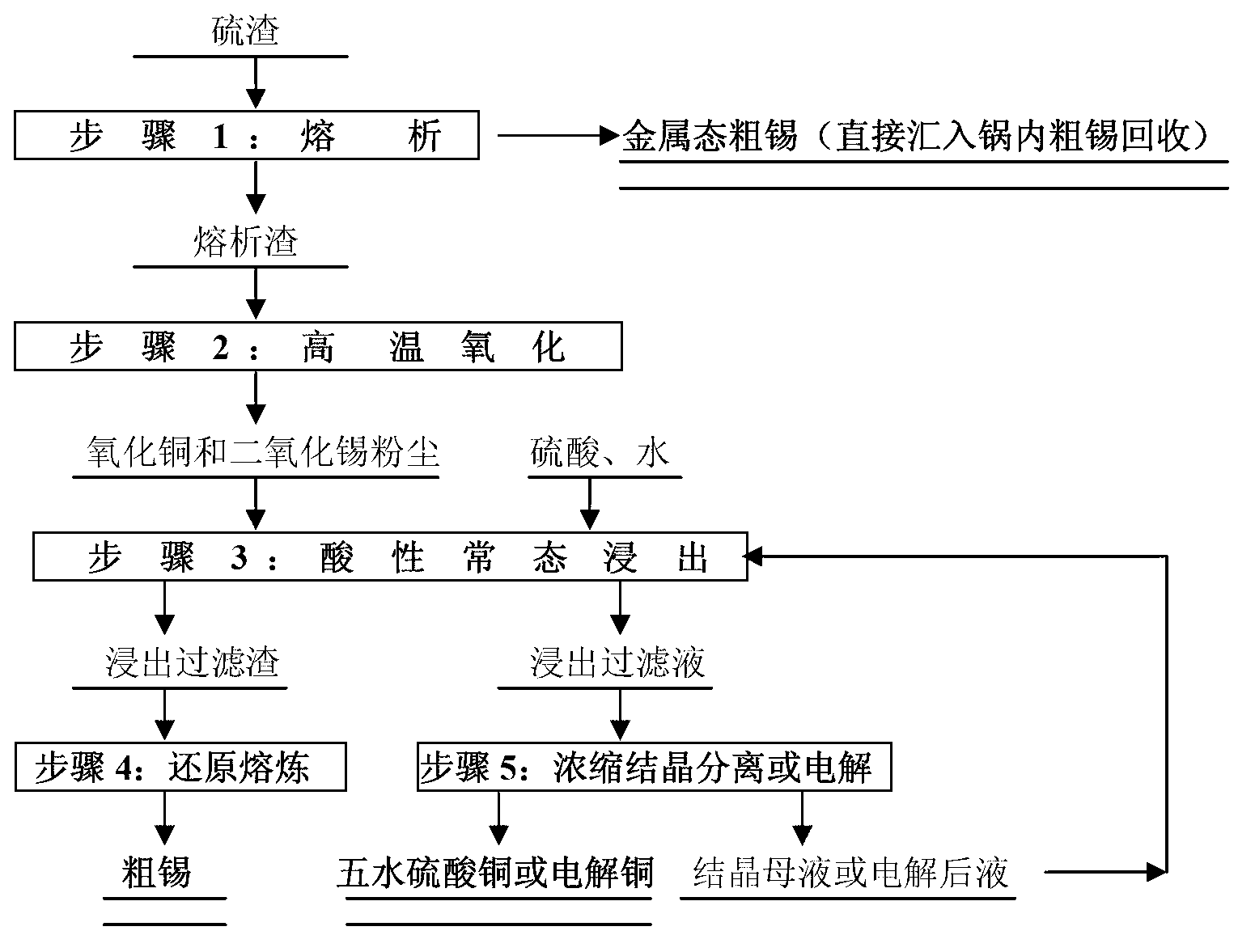

Method for treating sulfur slag

InactiveCN103194621AImprove direct yieldThe separation effect is thoroughPhotography auxillary processesProcess efficiency improvementTin dioxideElectrolysis

A method for treating sulfur slag comprises the following steps of: performing liquation treatment on sulfur slag containing 65-73% of tin and 6-15% of copper on the crude tin liquid in an iron pot in the range of 500-700 DEG C, thereby obtaining liquid crude tin and liquation slag containing 48-60% of tin and 8-23% of copper, recovering the liquid crude tin in the pot and completely oxidizing the liquation slag by industrial oxygen at a high temperature into mixed dust of copper oxide and tin dioxide, leaching the mixed dust for 2-3 hours under conditions of normal temperature and normal pressure, 70-120 g / L initial acid, and then filtering; reducing and smelting the filter residue to obtain crude tin, and concentrating, crystallizing and separating the filtrate to produce copper sulfate pentahydrate or performing electrolysis to produce electrolytic copper; and then returning the crystallization mother liquor or the liquid after electrolysis to the leaching process for liquid preparation. The method provided by the invention is capable of directly recovering most metal tin and realizing recovery of tin and copper in the sulfur slag without generating wastewater, waste gas and waste residues.

Owner:吴鋆

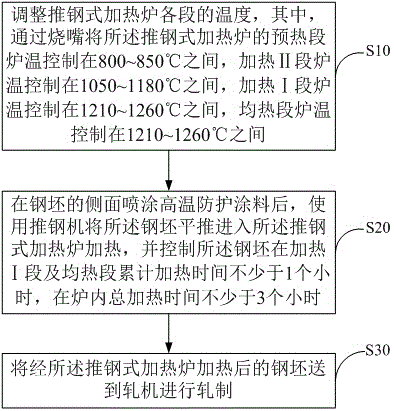

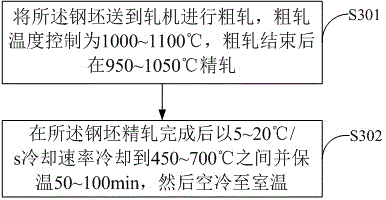

Steel rolling method for producing bearing steel based on pusher-type heating furnace

InactiveCN104087745AIncrease productivityGuaranteed qualifiedTemperature control deviceFurnace typesFurnace temperatureHeating time

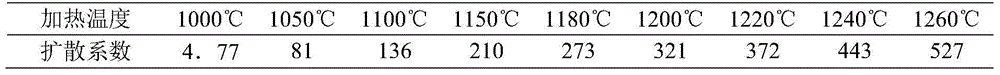

The invention discloses a steel rolling method for producing bearing steel based on a pusher-type heating furnace. The steel rolling method comprises the following steps: adjusting temperature of each section of the pusher-type heating furnace, wherein the furnace temperature of a preheating section of the pusher-type heating furnace is controlled to be between 800 and 850 DEG C through a nozzle, the furnace temperature of a heating section II is controlled to be between 1050 and 1180 DEG C, the furnace temperature of a heating section I is controlled to be between 1210 and 1260 DEG C, and the furnace temperature of a soaking zone is controlled to be between 1210 and 1260 DEG C; spraying high-temperature protective coatings on side faces of the billet, and flatly pushing the billet into the pusher-type heating furnace for heating, wherein the accumulated heating time of the billet in the heating section I and the soaking zone is controlled to be not less than an hour, and the total heating time in the furnace is controlled to be not less than 3 hours; rolling the billet heated by the pusher-type heating furnace in a rolling mill. According to the steel rolling method, the heating temperature is raised to the greatest degree under the conditions that carbide liquation is qualified and over-burning or adhesion on steel is avoided, and the temperature preservation time is shortened.

Owner:武钢集团有限公司

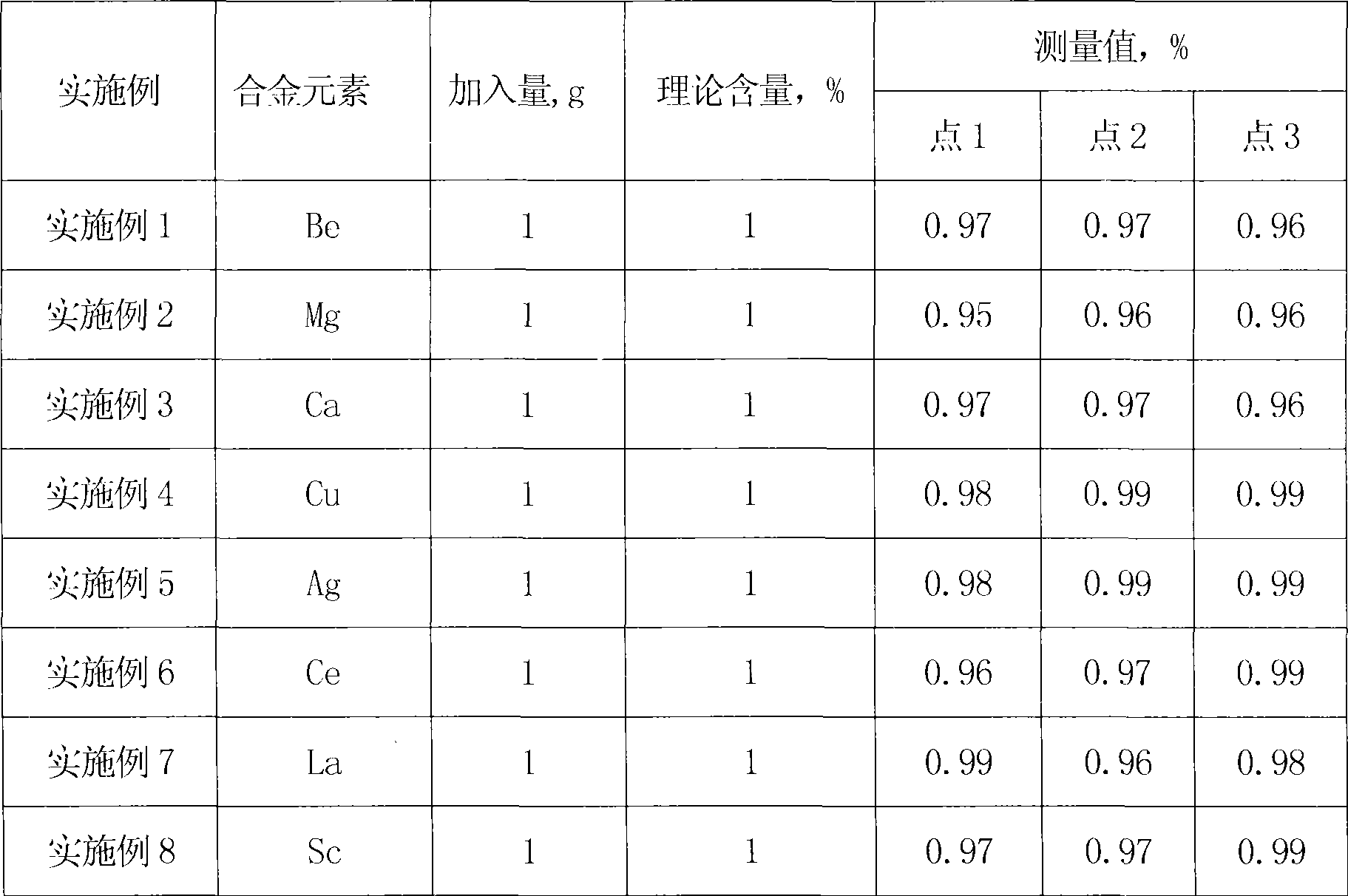

New preparation method of intermediate alloy for bonding gold wire

InactiveCN101508016ASolve burning loss is not easy to controlSolve for uniformitySolid-state devicesSemiconductor devicesIntermediate frequencyShielding gas

The invention discloses a method for preparing an intermediate alloy for producing a key alloy wire, which comprises the following steps: placing high-purity gold of which the purity is not lower than 5N and micro-alloy element with the adding amount of not more than 1 percent into a vacuum induction melting furnace, introducing a protective gas into the furnace under the high vacuum condition (10Pa), inductively heating the materials by using vacuum intermediate frequency, and quickly chilling the molten alloy at a high temperature by adopting a leakage pouring process to form small granular (similar to ball shape) intermediate alloy. The intermediate alloy prepared by the method has even granular components, does not cause liquation, has no pollution, does not need to process, and is convenient to use. The method for preparing the intermediate alloy for producing the key alloy wire solves the problems of difficult control for burning trace added components and even distribution of alloy elements, and provides a high-quality blank for subsequent processing of superfine wires.

Owner:SINO PLATINUM METALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com