3D printing plasma intelligent Mohole drilling and completion method

A 3D printing and 3D printer technology, applied in drilling equipment, wellbore/well parts, drilling automatic control system, etc., can solve the problems of impossible drilling depth of 10,000-50,000 meters, limited drilling depth, long drilling cycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

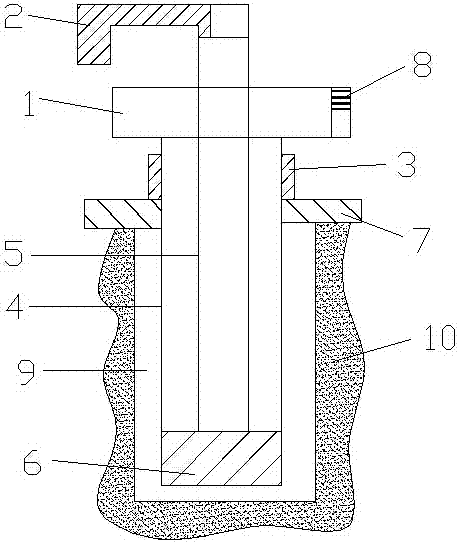

[0126]When drilling for single-pipe or casing on land, after the drilling location is selected according to geophysical prospecting, the drilling platform 7 is built, and various drilling equipment, materials, and control systems arrive at the preset positions and are installed and prepared. The hole cementing intelligent actuator 6 is placed at the drilling position, and it is docked with the lower end joint of the manifold system integration. The upper end of the well pipe sample pipe of the downhole drilling, reaming and cementing intelligent actuator 6 is inserted into the top of the remelting section of the mold system. It is clamped and fixed by the intelligent well pipe lifting and fixing system 3; the 3D printer nozzle II is turned on, and the metal section on the top of the well pipe sample pipe is remelted. When the metal section is melted, the 3D printer nozzle II is automatically closed, and the 3D printer nozzle is automatically turned on Ⅰ Jet the metal liquid, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com