Patents

Literature

1092results about How to "Increase drilling speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

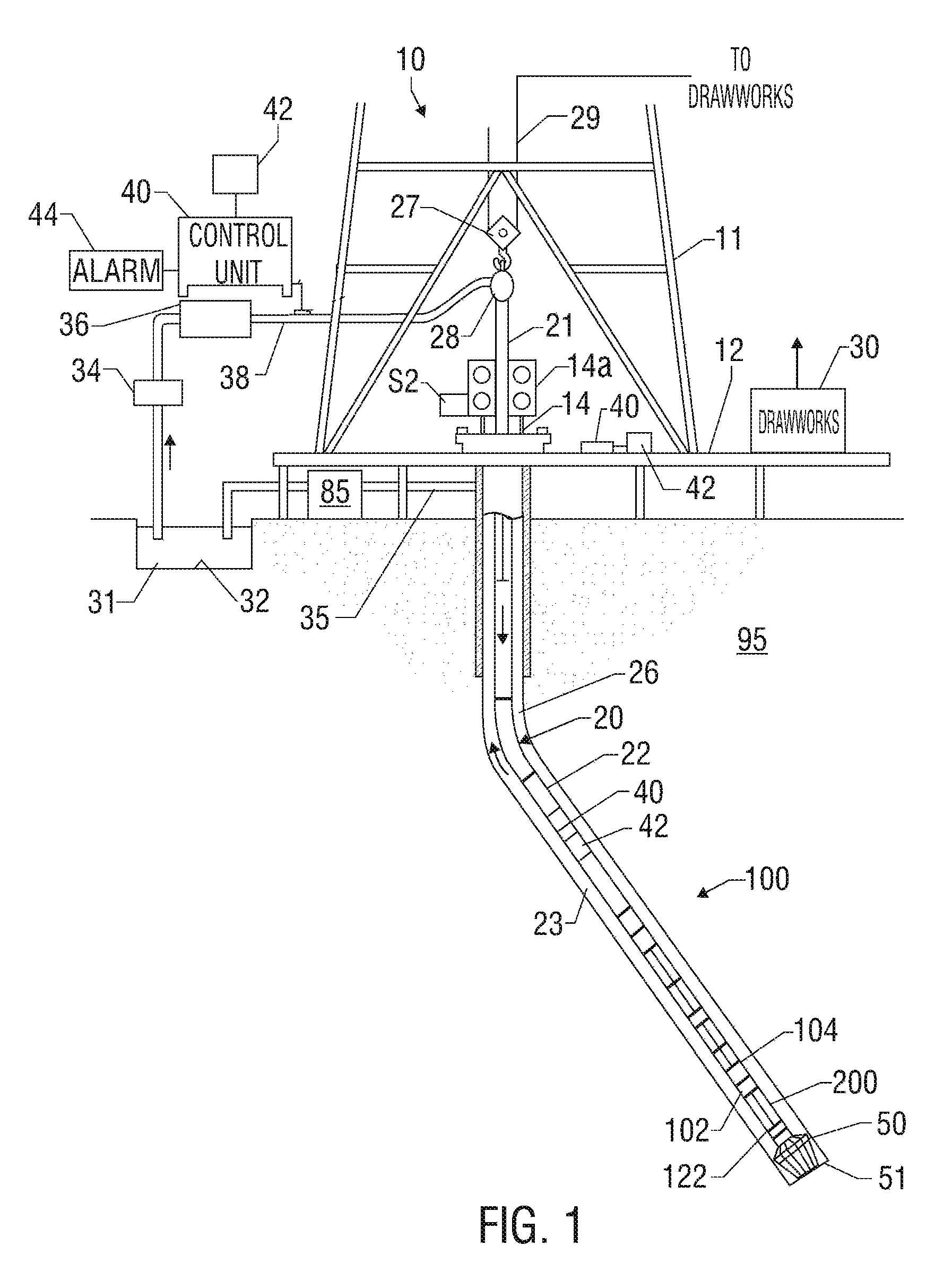

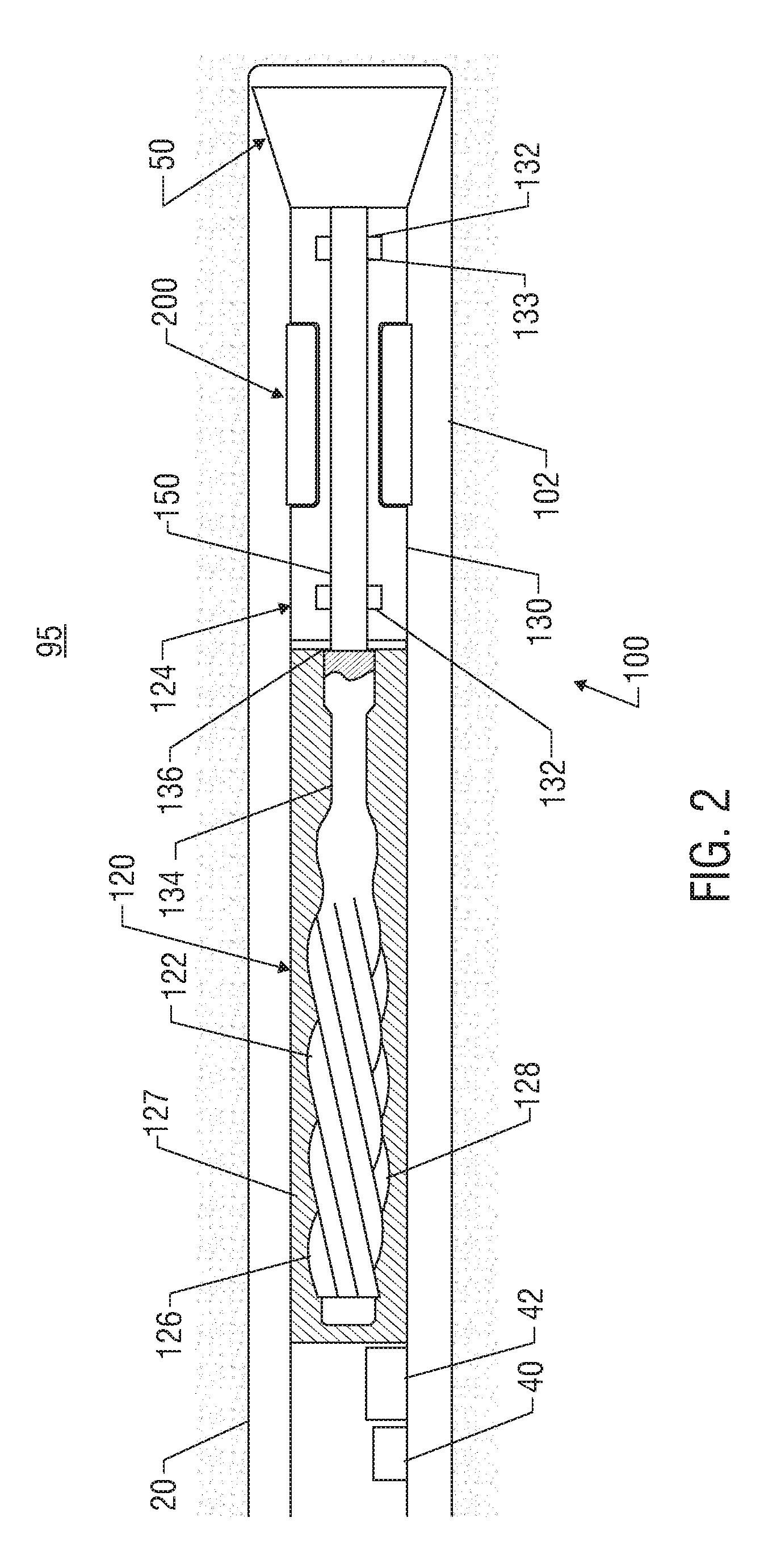

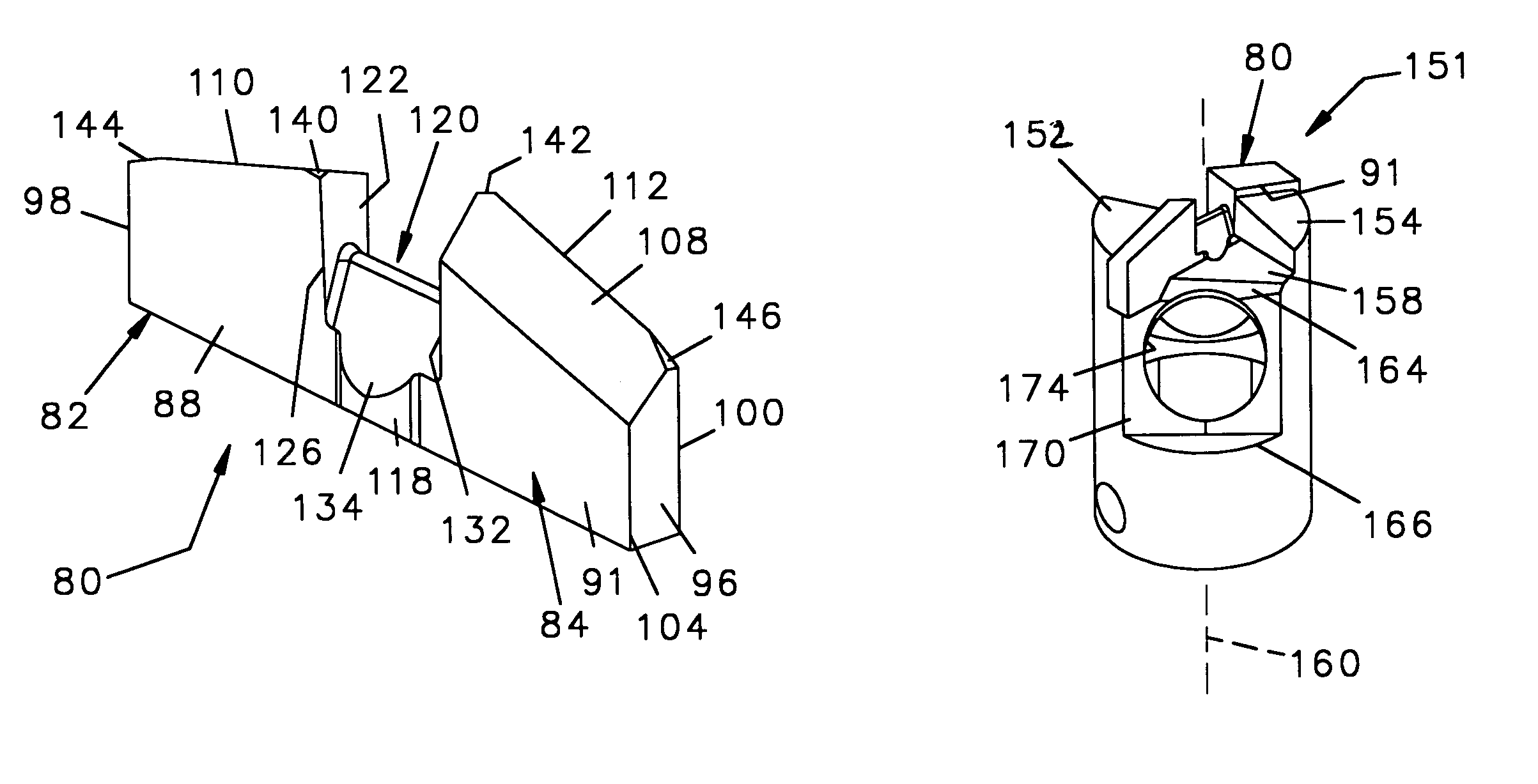

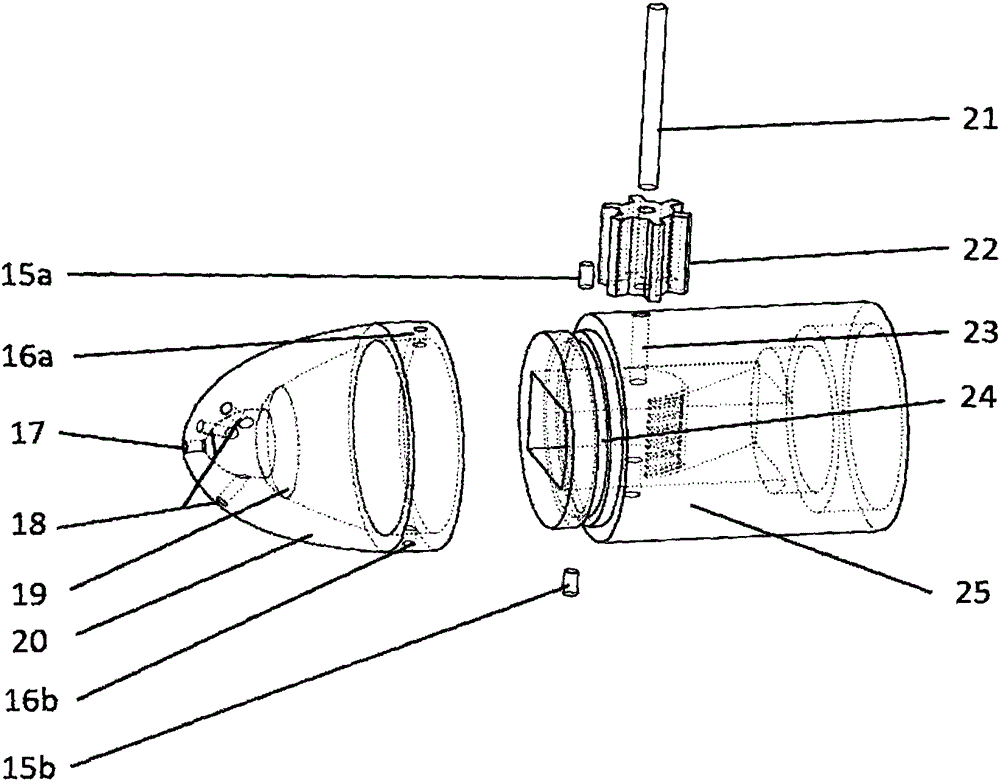

Closed loop drilling assembly with electronics outside a non-rotating sleeve

InactiveUS6913095B2Increase drilling speedExtended drilling assembly lifeDrilling rodsDerricks/mastsClosed loopEngineering

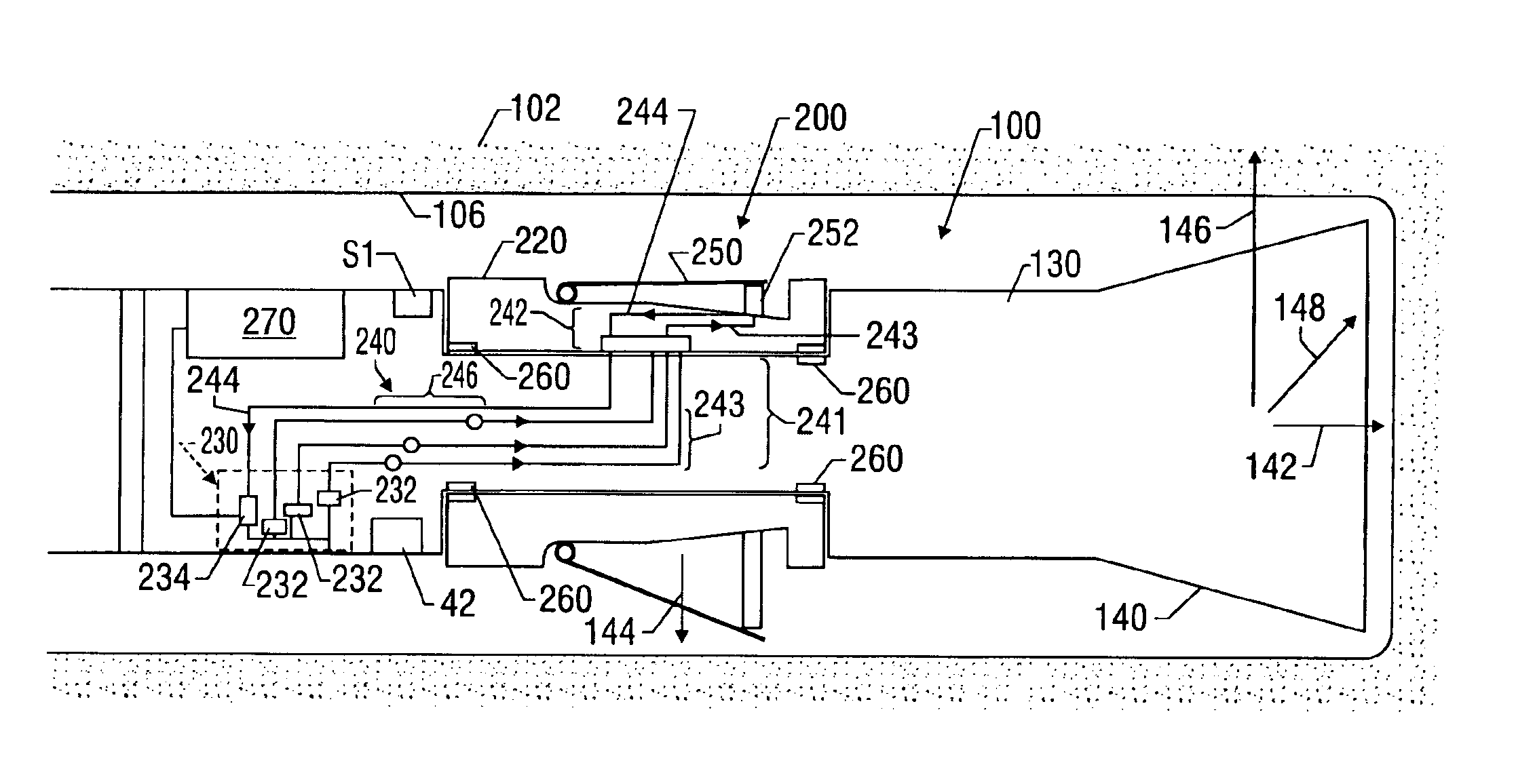

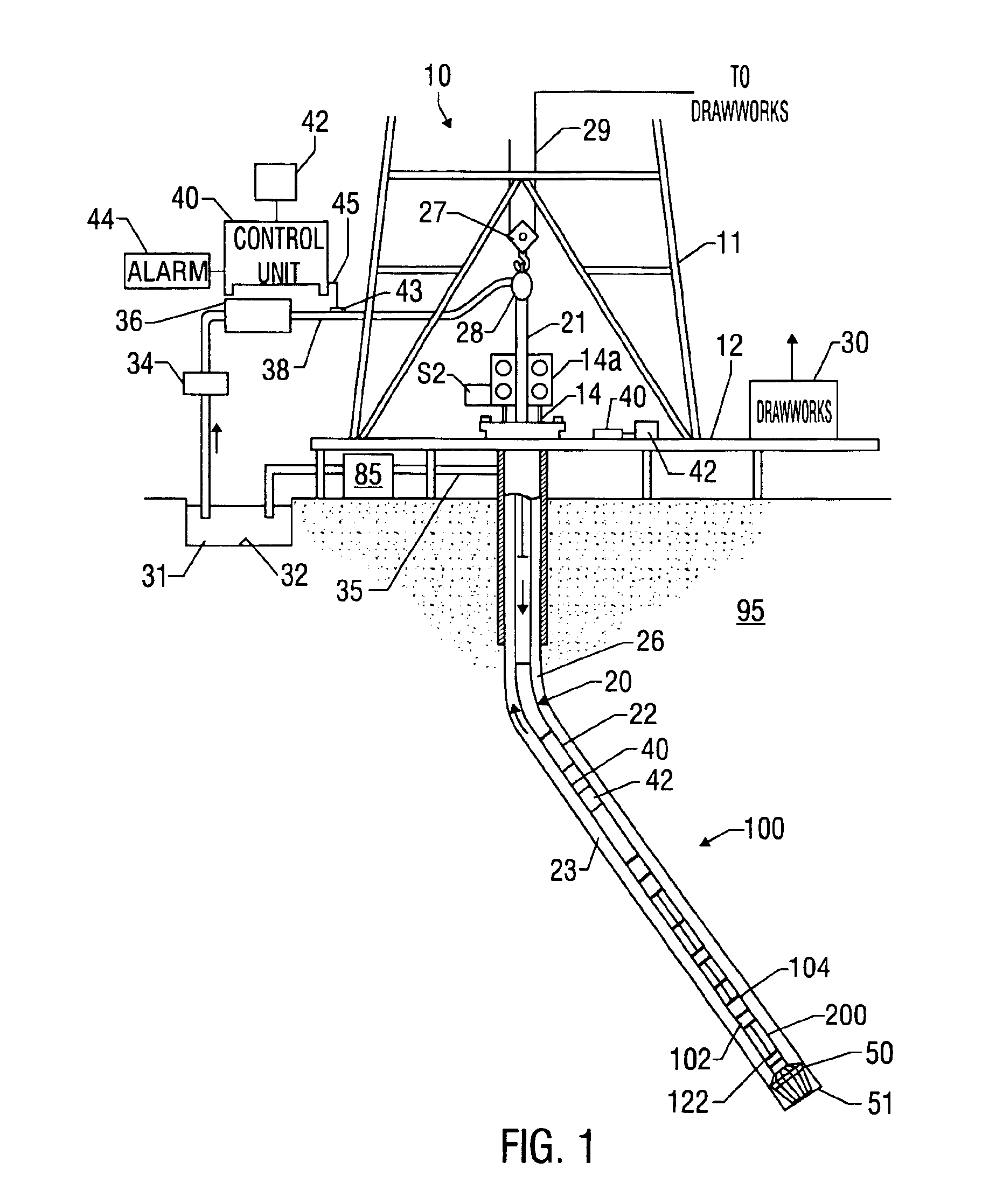

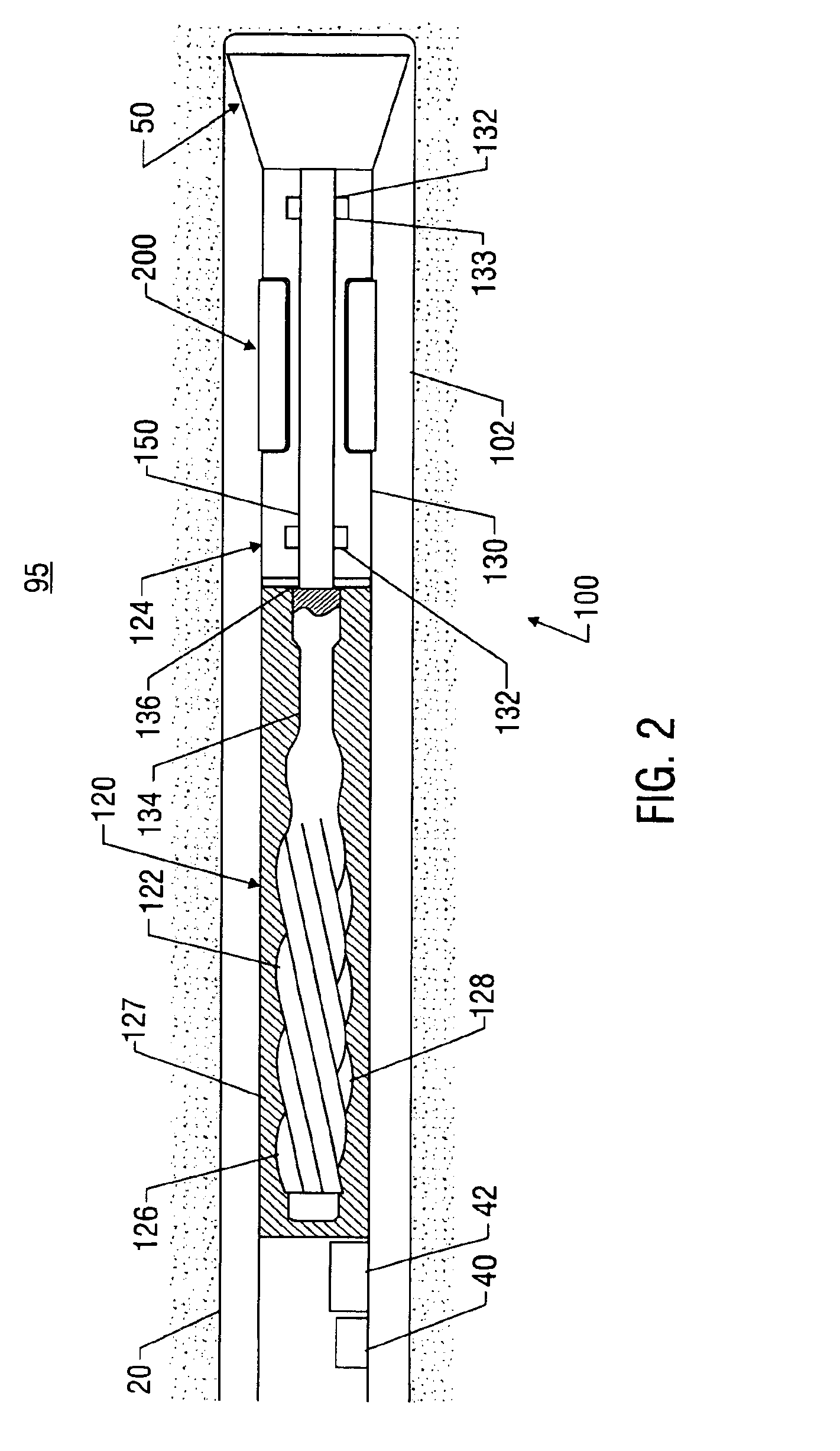

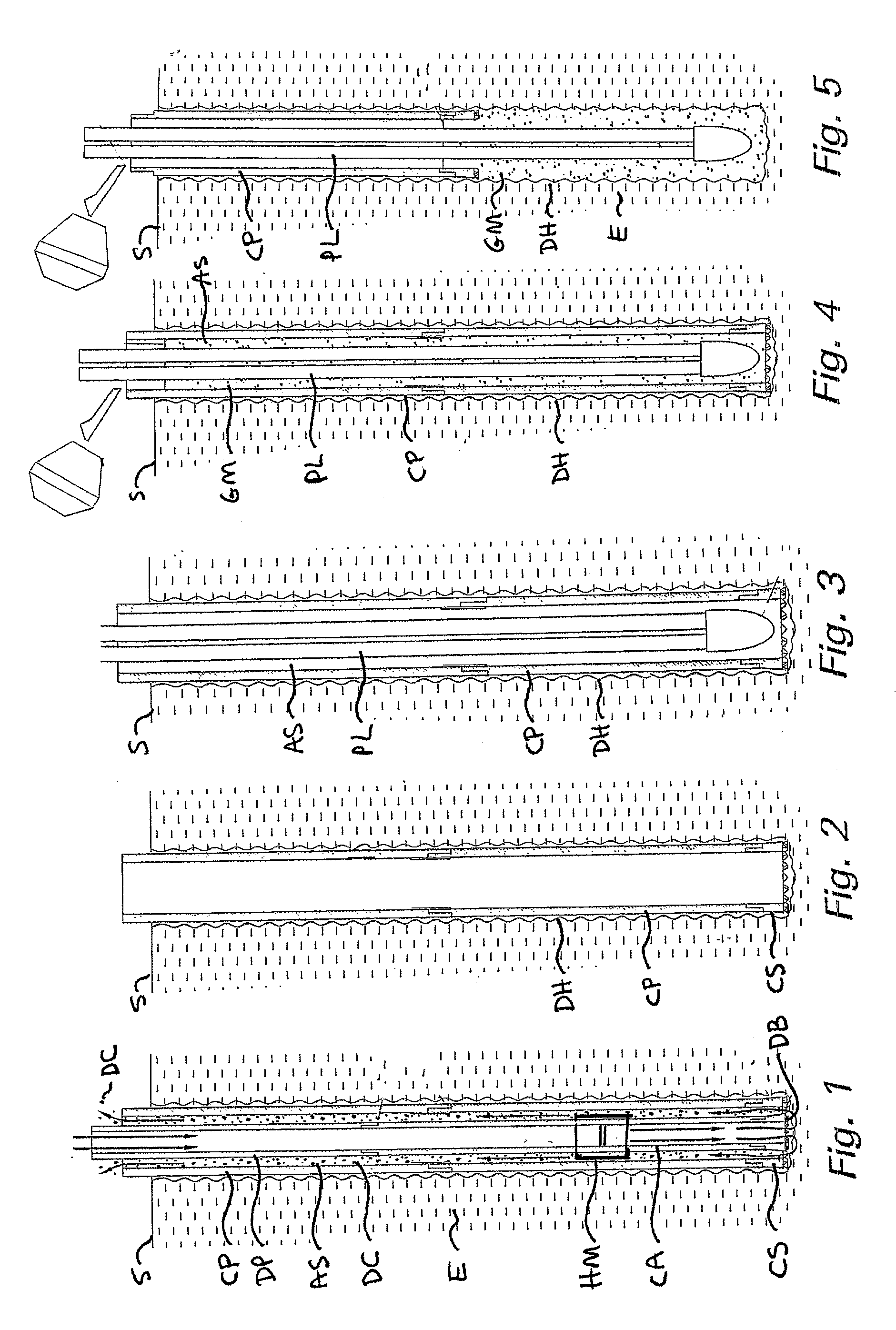

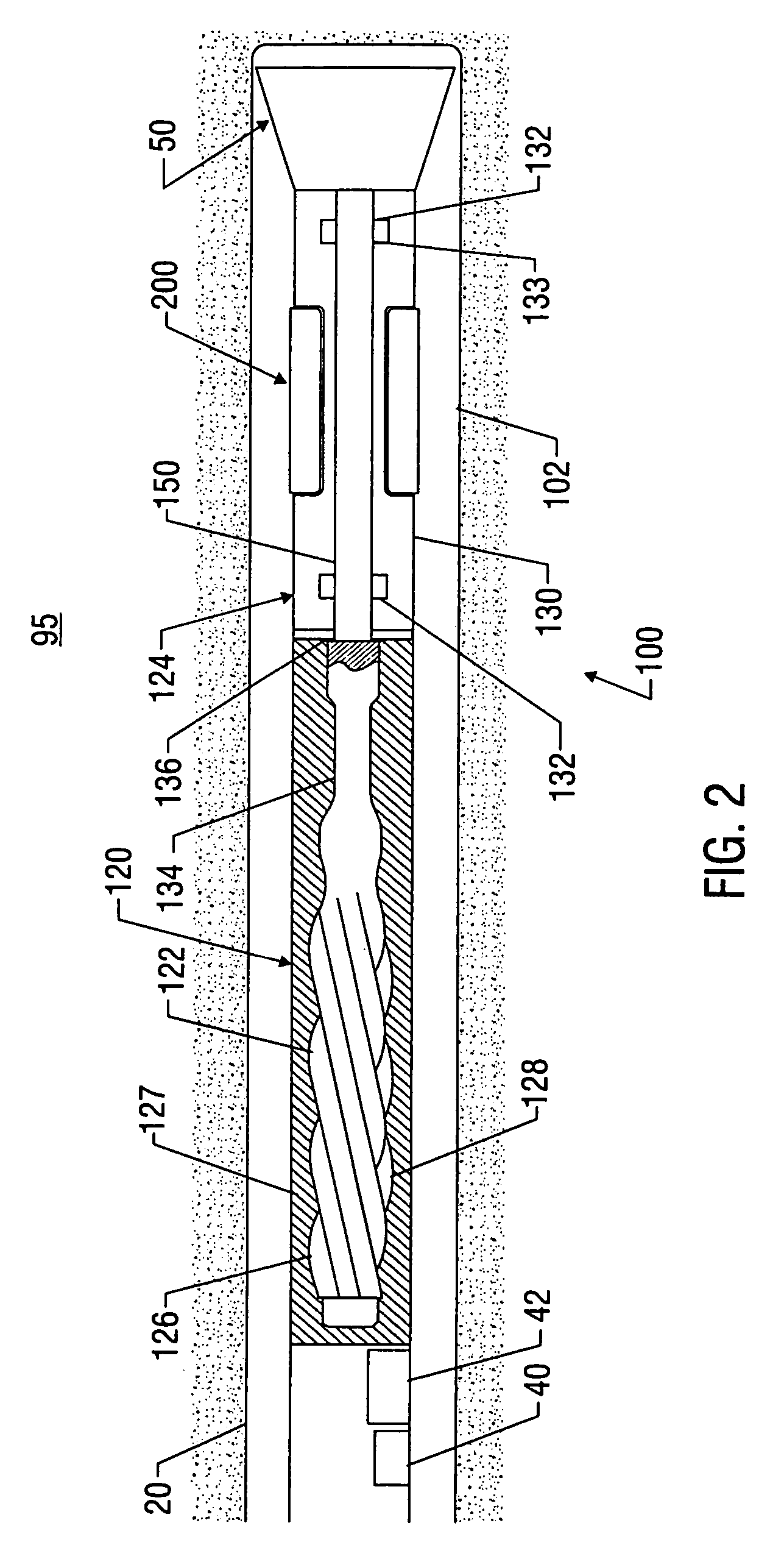

A closed-loop drilling system utilizes a bottom hole assembly (“BHA”) having a steering assembly having a rotating member and a non-rotating sleeve disposed thereon. The sleeve has a plurality of expandable force application members that engage a borehole wall. A power source and associated electronics for energizing the force application members are located outside of the non-rotating sleeve. A preferred drilling system includes a surface control unit and a BHA processor cooperate to guide the drill bit along a selected well trajectory in response to parameters detected by one or more sensors. In a preferred closed-loop mode of operation, the BHA processor automatically adjusts the force application members in response to data provided by one or more sensors. In a preferred embodiment, the non-rotating sleeve and rotating member include a sensor that determines the orientation of the sleeve relative to the rotating member.

Owner:BAKER HUGHES INC

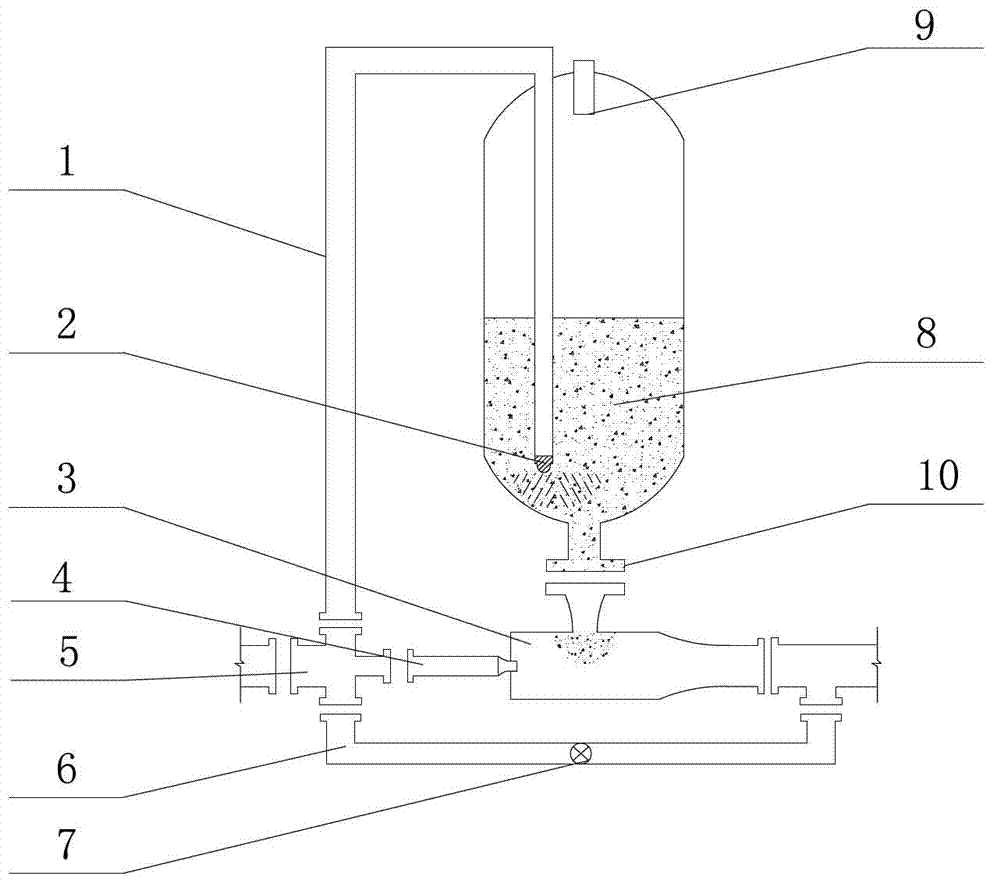

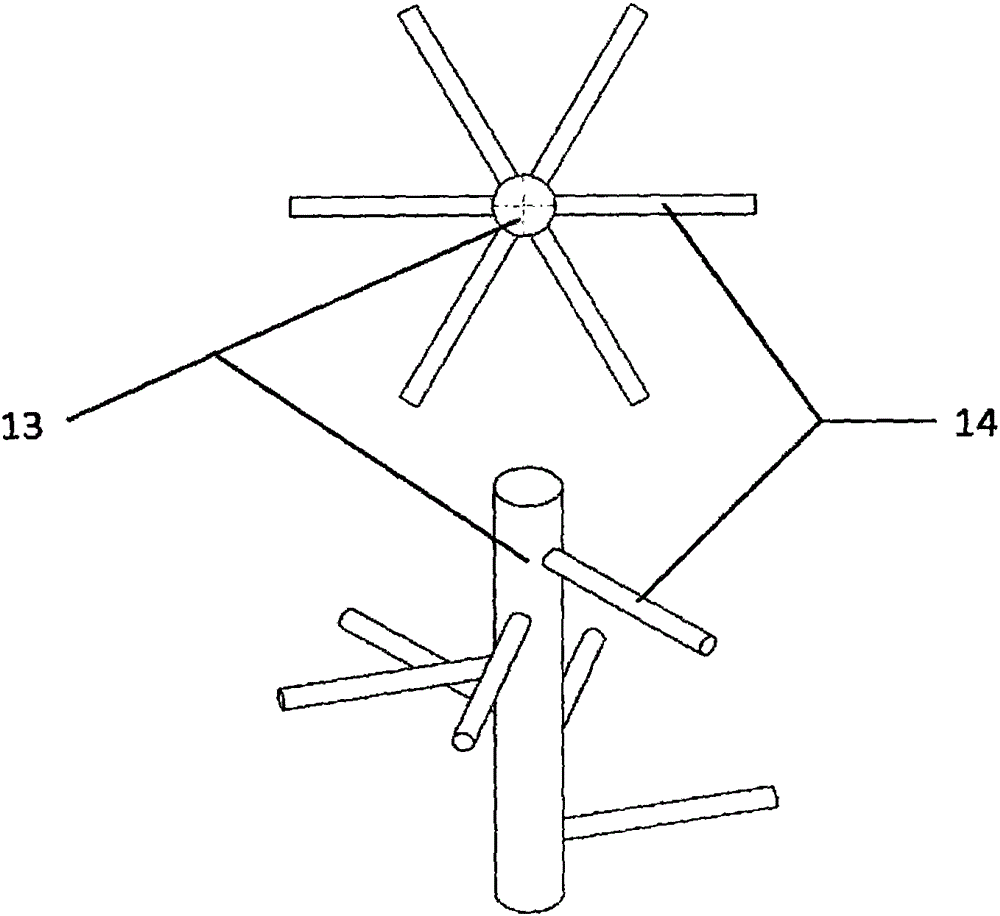

Hydro-oscillator for well drilling

InactiveCN102704842AIncrease frictional resistanceIncrease drilling speedVibration devicesVibration drillingWell drillingHarmonic vibration

The invention relates to a hydro-oscillator for well drilling. The hydro-oscillator consists of a hydraulic driving assembly, a fixed valve assembly, a bottom assembly and a vibrating pipe nipple, wherein the vibrating pipe nipple is connected with the hydraulic driving assembly; a rotor is connected with a vibrating valve; the fixed valve assembly is arranged on the bottom assembly; and a power shell is connected with the bottom assembly. A drilling fluid is used for driving the rotor to rotate, and the rotor is used for driving the vibrating valve to vibrate, so that flow holes of the vibrating valve and a fixed valve are staggered with each other, and simple harmonic pressure waves are modulated and are upwardly transmitted to a disc spring for driving the vibrating shell to perform continuous simple harmonic vibration in the axial direction, so that the friction resistance between a drilling column and a well wall is improved effectively, and the drilling speed is increased; and meanwhile, pressure waves are downwardly transmitted to drill bit jet flow, so that periodic change of rock breaking pressure is facilitated, and rocks are crushed effectively. The hydro-oscillator has the characteristics of simple structure, convenience for operating, safety, reliability, low pressure drop, high adaptability, no influence on the drilling tool structure and the like, and plays an important role in increasing the drilling speed and reducing cost.

Owner:CHINA PETROCHEMICAL CORP +1

Method and System for Forming a Non-Circular Borehole

InactiveUS20100032207A1Easy to installEasy to operateCollector components/accessoriesLighting and heating apparatusEngineeringDissolution

System and methods for creating shaped, non-circular boreholes in rocks especially for use with geothermal heat pump applications and for increasing wellbore support in applications such as horizontal oil and gas drilling are described. The systems and methods when applied to geothermal heat pumps create an elliptical shaped hole that is optimized for placing heat transfer tubes with a minimum of grout used. The significantly reduced cross-sectional area of the elliptical borehole also increases the overall drilling rate in rock and especially in hard rocks. In horizontal hard-rock drilling, creation of a horizontal non-circular borehole or modification of a circular borehole to a non-circular geometry is used to stabilize the borehole prior to casing insertion, and may also allow the use of lower mud pressures improving drilling rates. The system uses a non-contacting drilling system which in one embodiment uses a supersonic flame jet drilling system with a movable nozzle that swings between pivot points. In a second embodiment the elliptical shaped hole is created by an abrasive fluid or particle bearing-fluid or air jet drill that moves between pivot points. In another embodiment a non-contacting drill can use dual parallel nutating nozzles that create a pair of overlapping circular holes. The non-circular shaped hole is created by either the high temperature flame or water-particle jet or chemically active fluid jet as it removes rock material by erosion, dissolution and or thermal spalling. Modifications of circular boreholes to a generally elliptical shape can also be done using milling or jetting techniques.

Owner:POTTER JARED MICHAEL +3

Drilling fluid with synthesized substrate

A synthetic basic well-drilling liquid is proportionally prepared from the basic liquid composed of basic liquid and aqueous solution of CaCl2, primary emulsifier, secondary emulsifier, wetting agent, flowing regulator, filter loss reducer and organic earth through mixing. Its advantages are no pollution and high effect to protect oil-bearing stratum.

Owner:CNOOC TIANJIN BRANCH +3

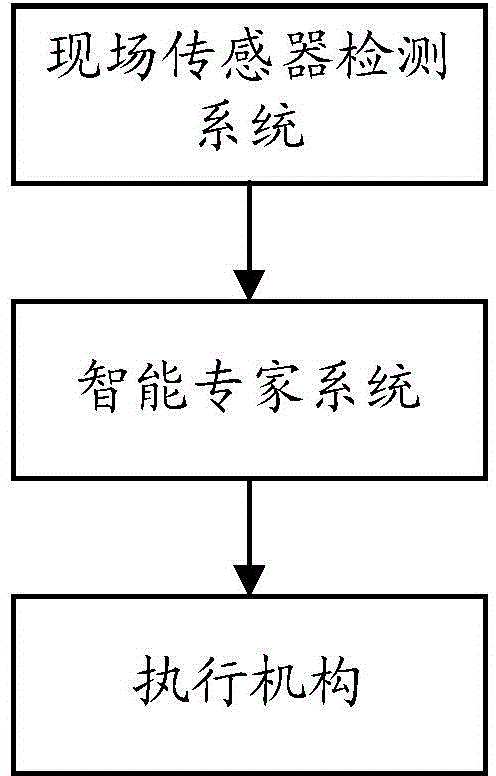

Intelligent drilling expert system

ActiveCN104806226AAccurate discoveryReal-timeAutomatic control for drillingEarly predictionAutomatic control

The invention provides an intelligent drilling expert system. The intelligent drilling expert system comprises a field sensor detection system, an intelligent expert system and an execution mechanism. An automatic closed-loop drilling regulation and control system is formed. Data in a whole drilling process are acquired through a field sensor; then, the acquired data are transmitted into a computer for processing, monitoring, prediction, analysis, explanation, control and the like. Most importantly, through the researched cross-specialty and cross-industry intelligent expert control models for drilling hydraulic control, well wall stability control, friction resistance and torque control, drilling speed and cost control, drilling complexity and accident control and the like, instantaneity, early discovery, early prediction, interpretation while drilling and an automatic control function can be realized, and accurate information is provided for drilling engineering; moreover, the intelligent drilling expert system has the advantages of reducing the drilling cost, increasing the drilling speed, avoiding sudden accidents and discovering oil and gas accurately.

Owner:北京四利通控制技术股份有限公司

Strong-inhibition anticaving drilling fluid and application thereof

InactiveCN105038737AReduce fluid lossAdjust the flow patternDrilling compositionOrganic chemistryPetroleum engineering

The invention discloses a strong-inhibition anticaving drilling fluid and application thereof. The strong-inhibition anticaving drilling fluid consists of 1000 parts of water, 20 to 60 parts of bentonite for drilling fluid, 5 to 20 parts of sodium carbonate, 5 to 20 parts of alkali, 10 to 20 parts of coating agent, 5 to 20 parts of flow pattern regulator, 5 to 20 parts of shale inhibitor, 10 to 30 parts of borehole stabilizer, 10 to 30 parts of plugging agent, 5 to 30 parts of lubricating agent, 5 to 40 parts of filtrate reducer, 1 to 10 parts of pH regulator, and a proper amount of salts and barite added according to the requirement. The strong-inhibition anticaving drilling fluid has the remarkable characteristics of properties of stabilizing a borehole, protecting an oil layer, improving the drilling speed, and preventing a balled bit and the like from approaching to oil-based drilling fluid.

Owner:北京中科天启油气技术有限公司

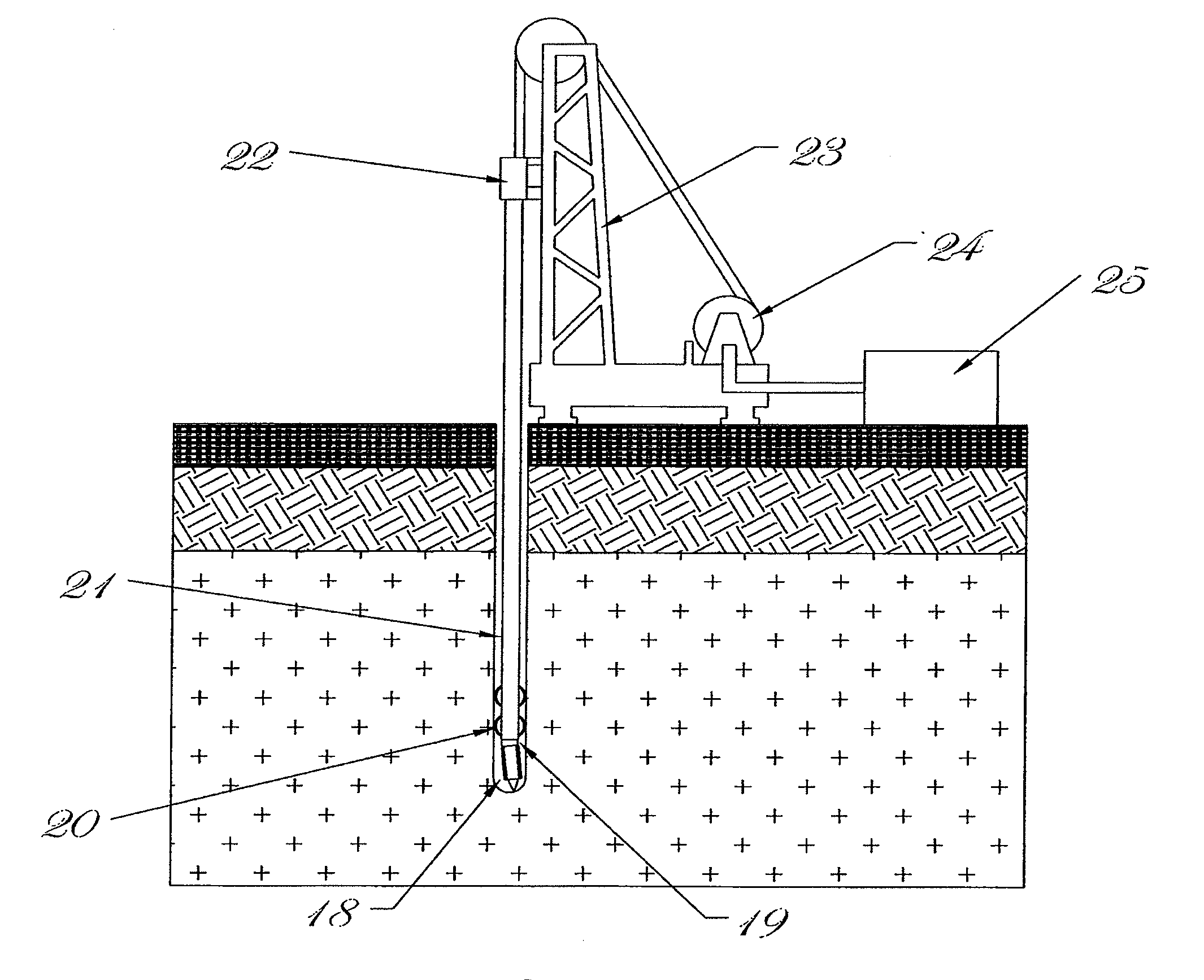

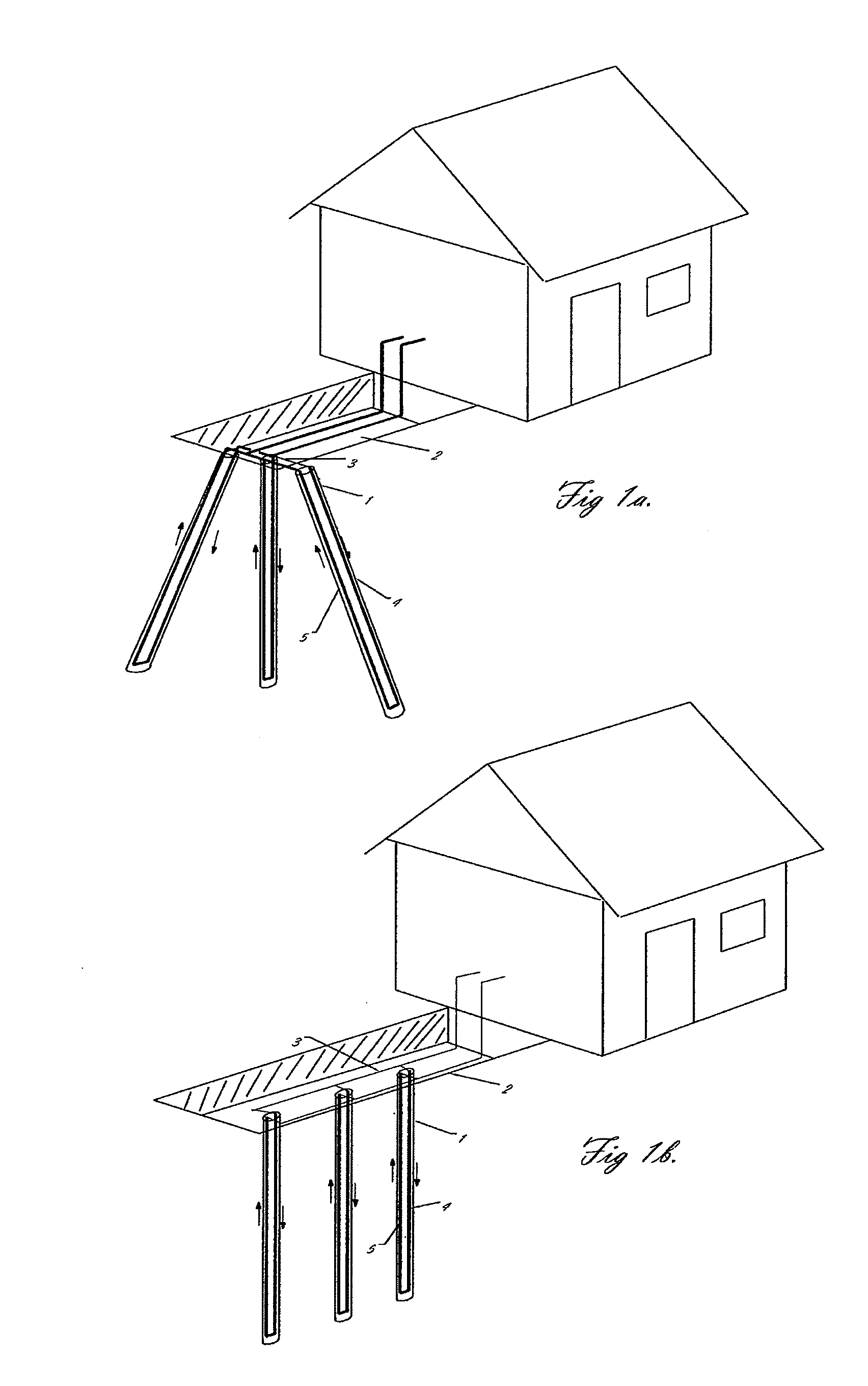

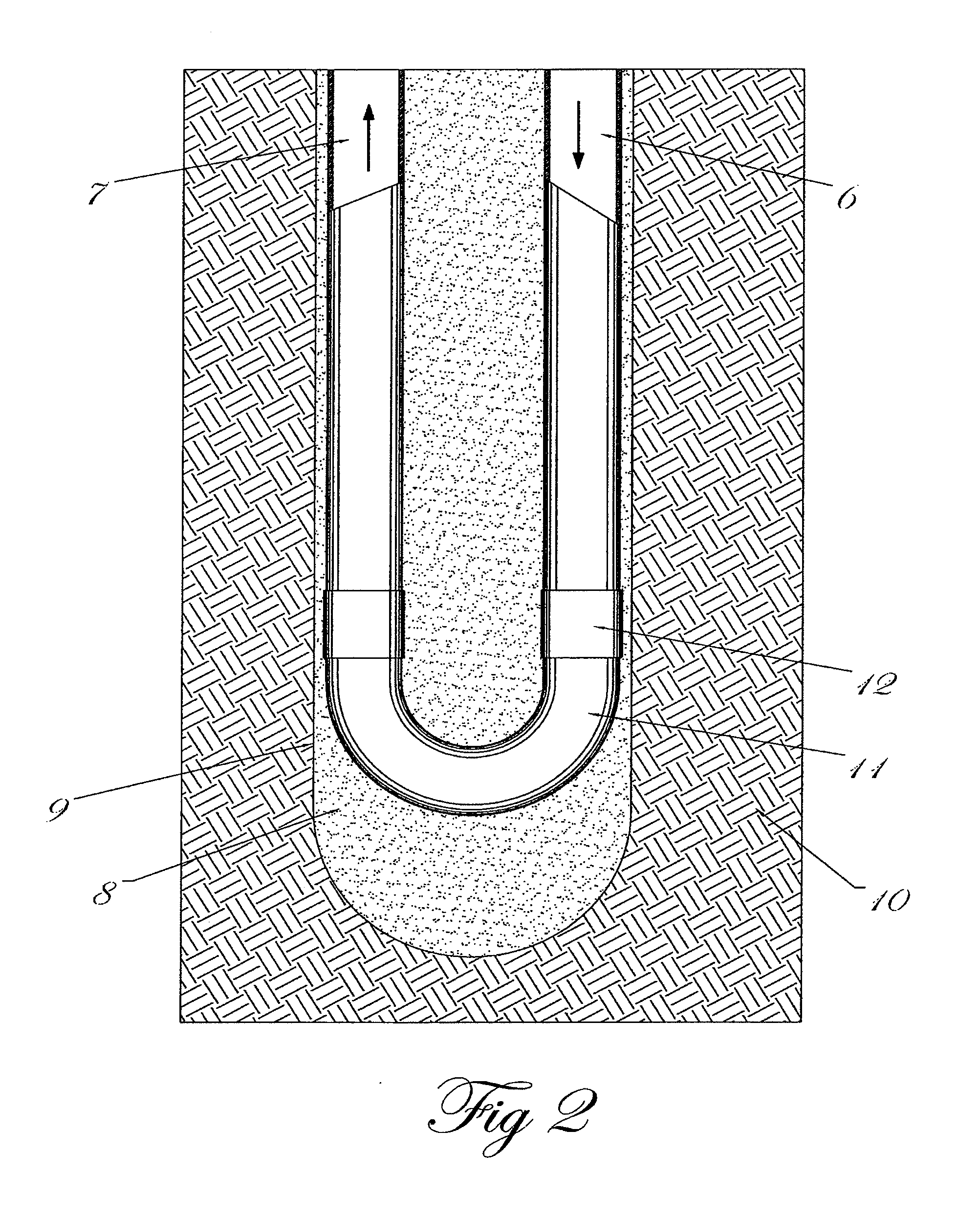

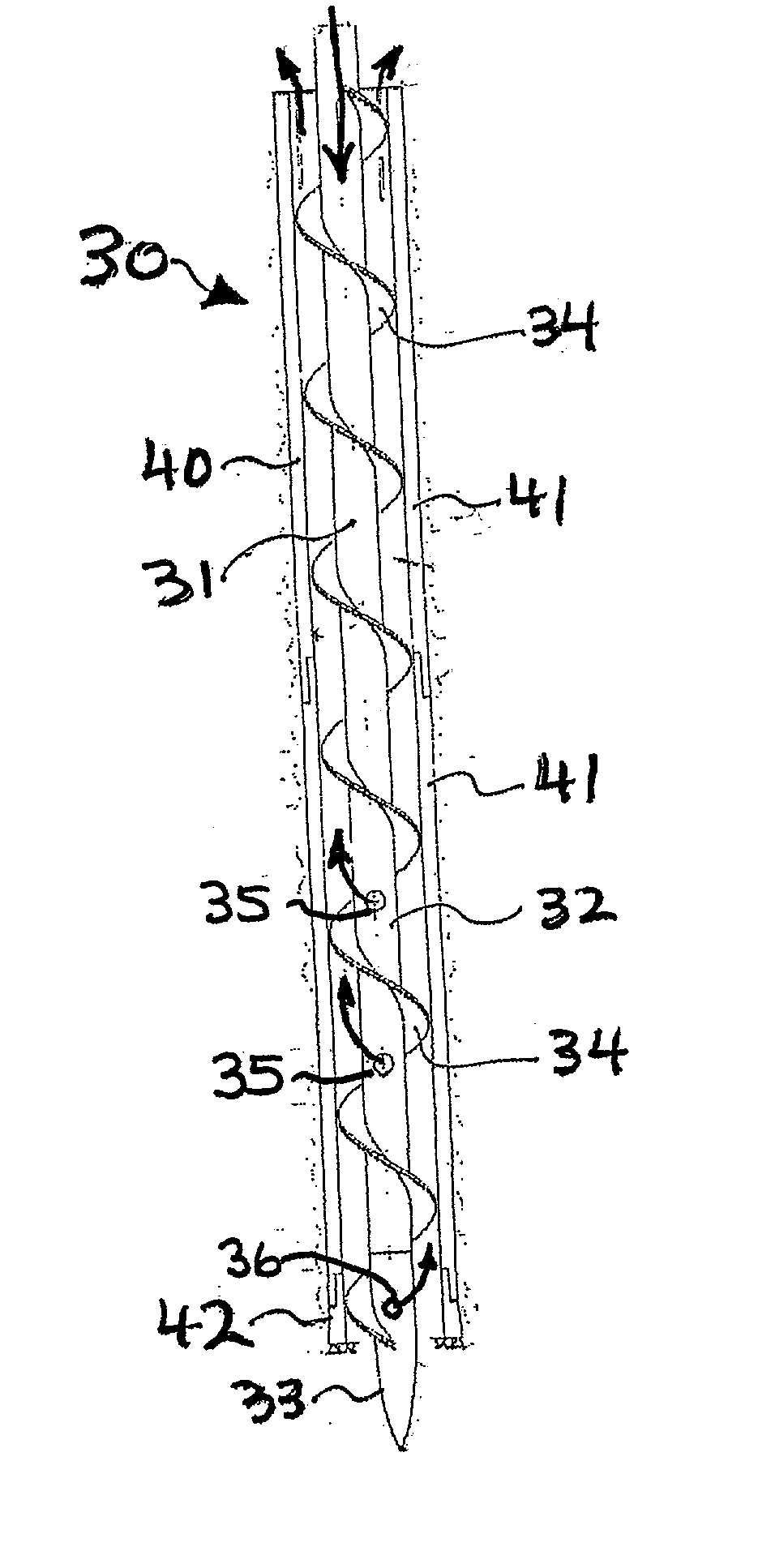

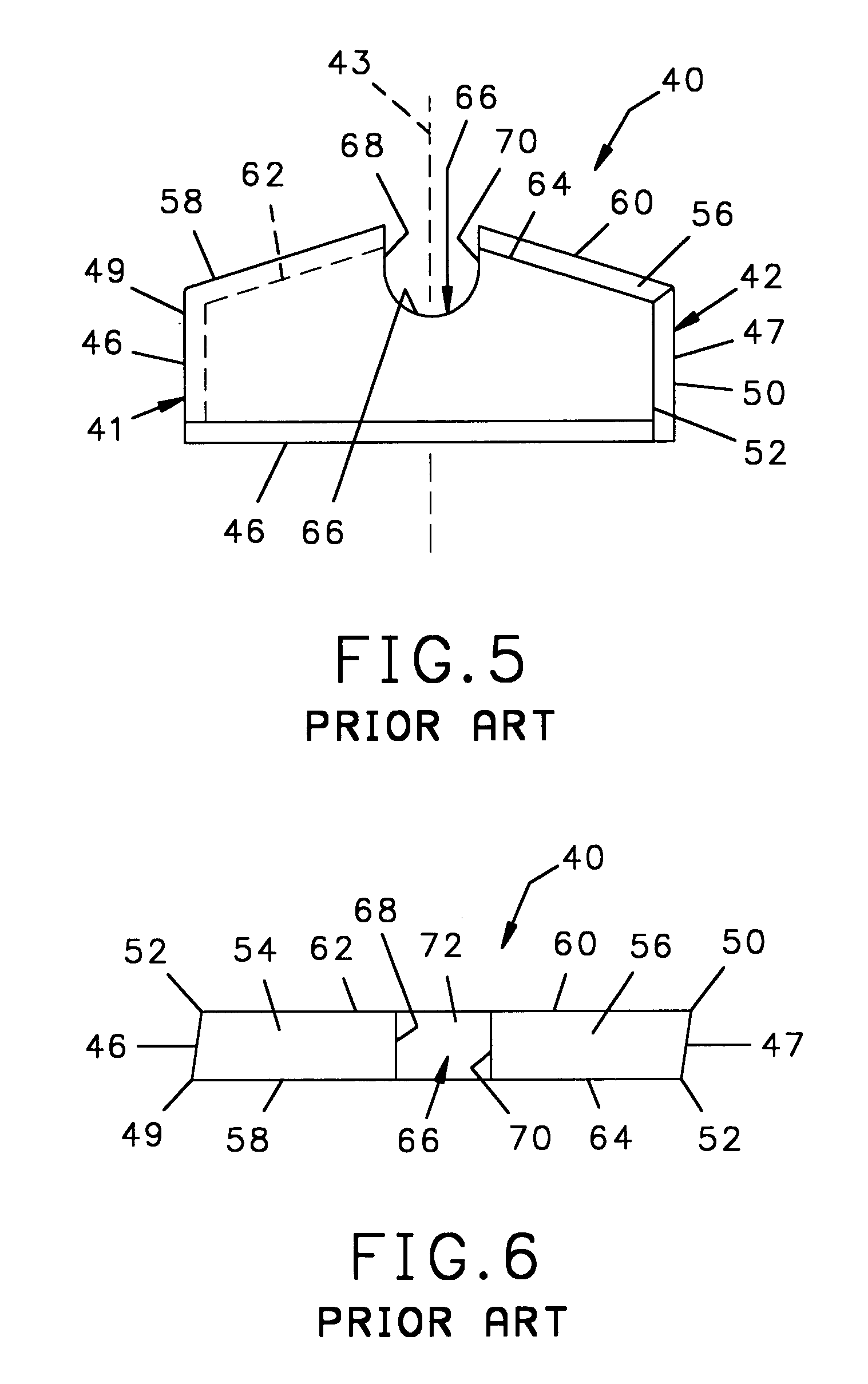

Earth loop heat exchange methods and systems

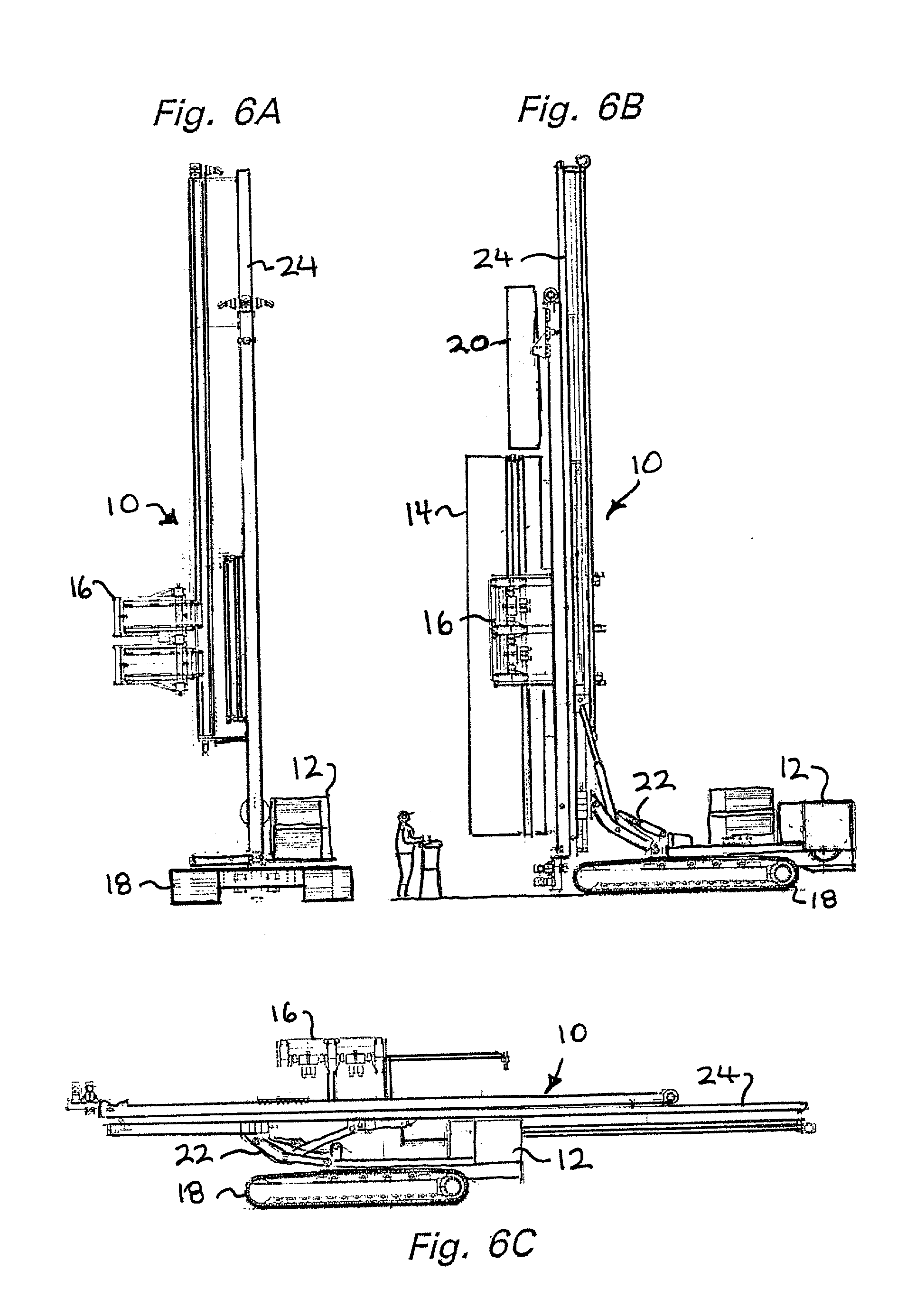

InactiveUS20030221870A1Prevent crashEasy to installCollector components/accessoriesDrill bitsWell drillingCasing string

A method and system for drilling creating a wellbore which, in at least certain aspects, includes positioning a drilling apparatus at a desired location at the earth surface, the drilling apparatus having rotating and hammering apparatus for simultaneously rotating and hammering a dual tubular string into the earth, the dual tubular string with an outer casing string spaced apart by an annular space from an inner drill pipe string, both the outer casing and inner drill pipe string being hollow, a drill bit secured to a lowermost end of the inner drill pipe string and, optionally, a casing drill apparatus secured at a lowermost end of the casing string, drilling through the earth to form the wellbore by simultaneously rotating and hammering the dual tubular string with the drilling apparatus; and, in certain aspects, installing a geothermal heat loop and grouting the space around it.

Owner:ENLINK GEOENERGY SERVICES

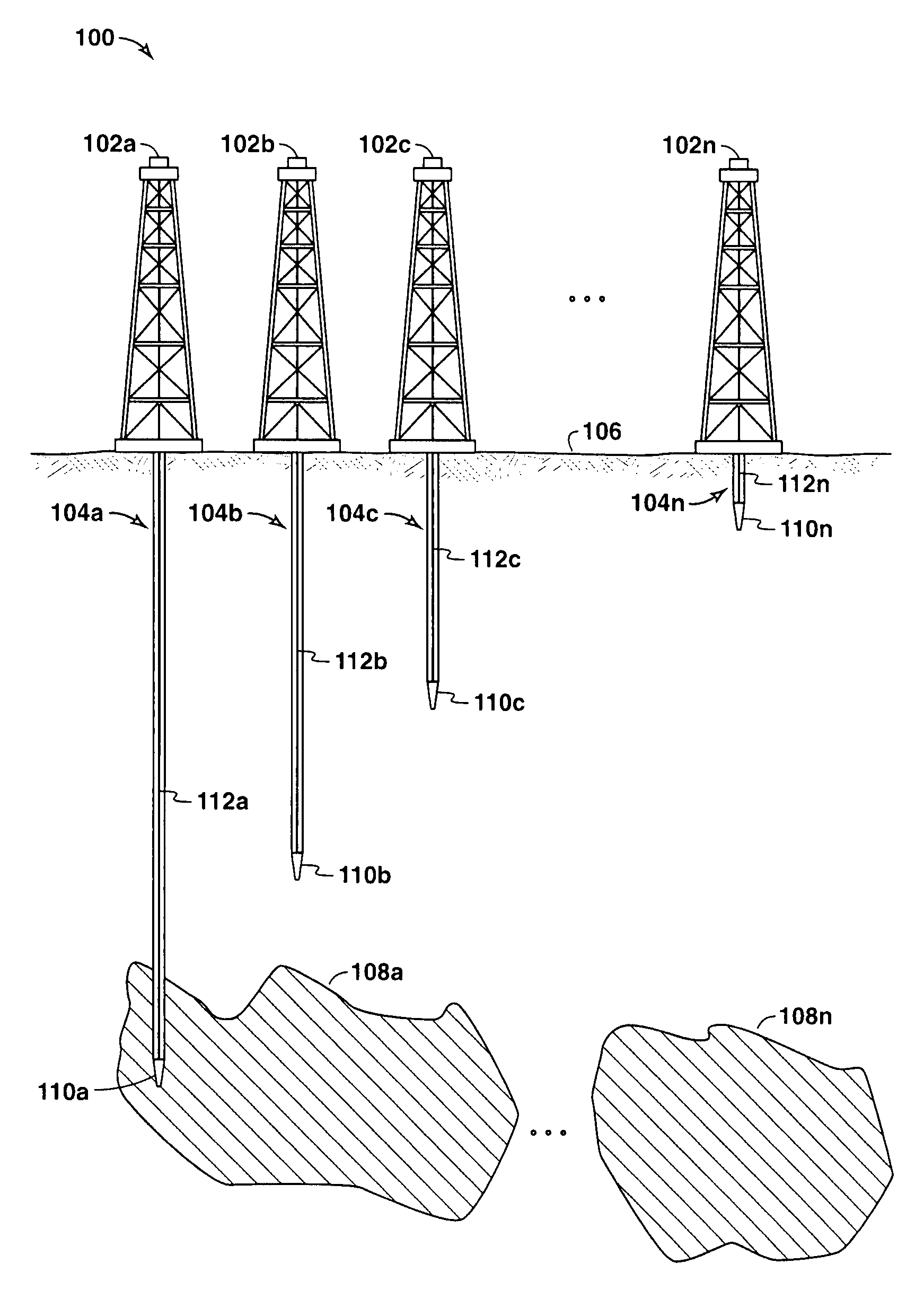

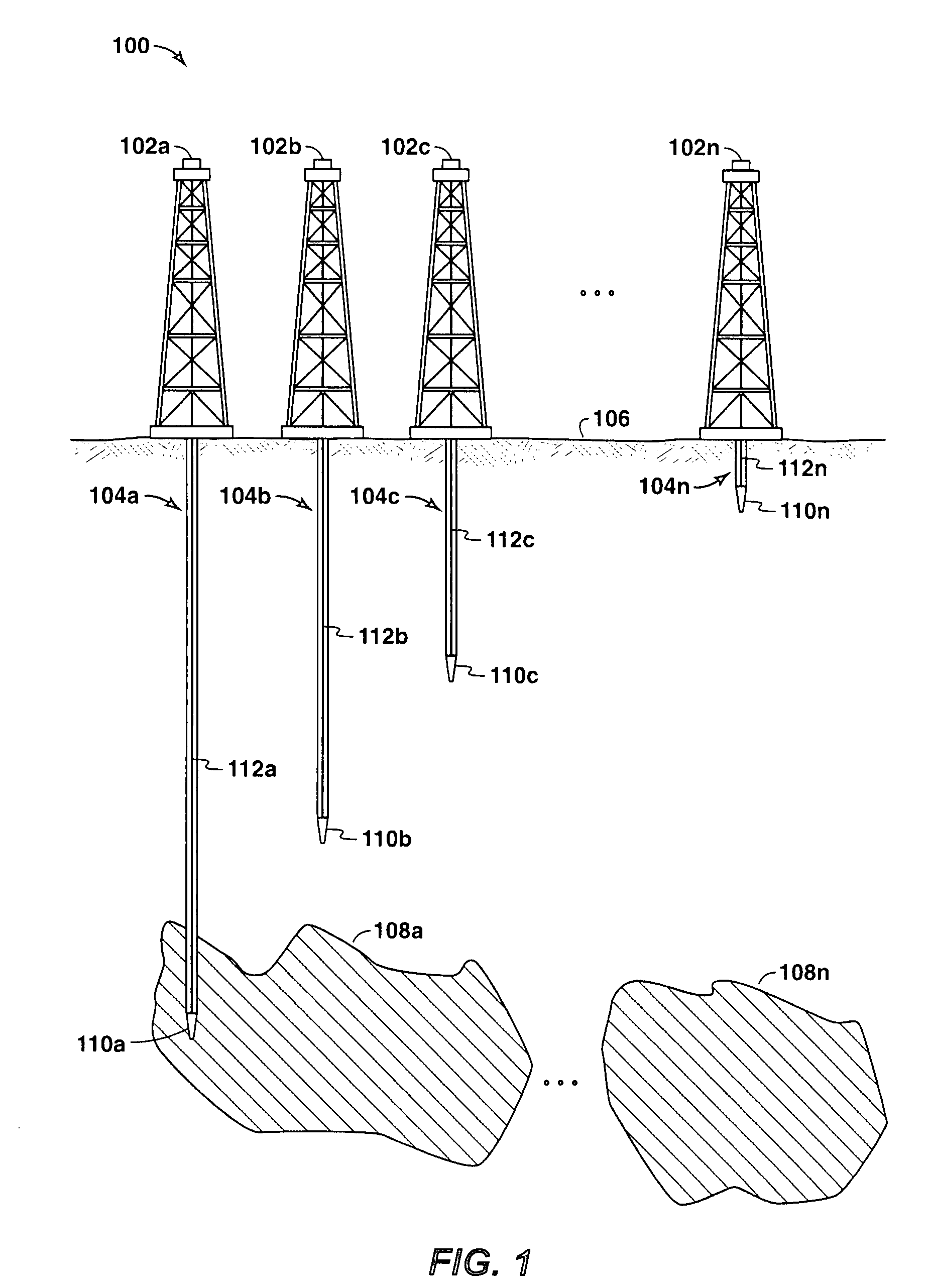

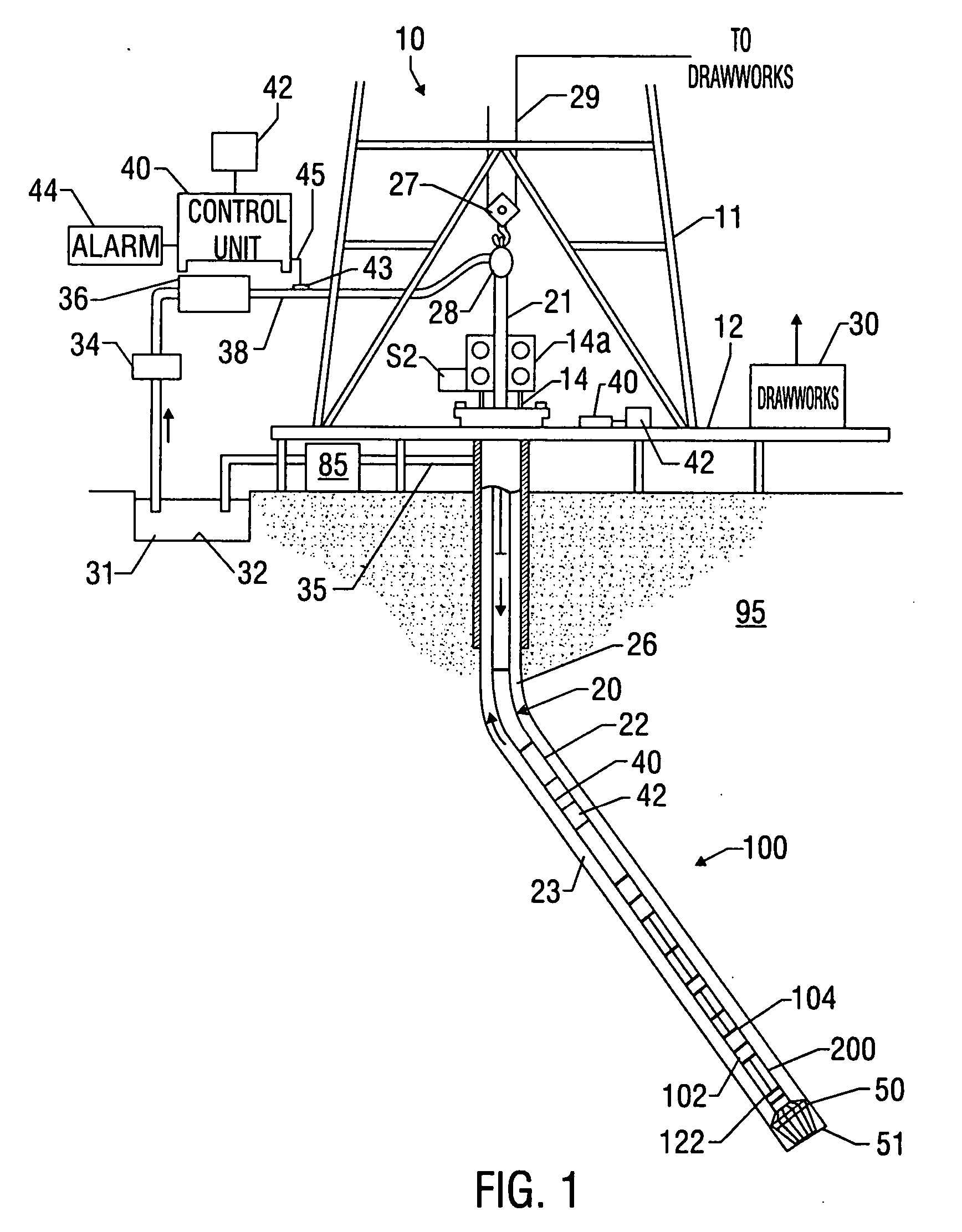

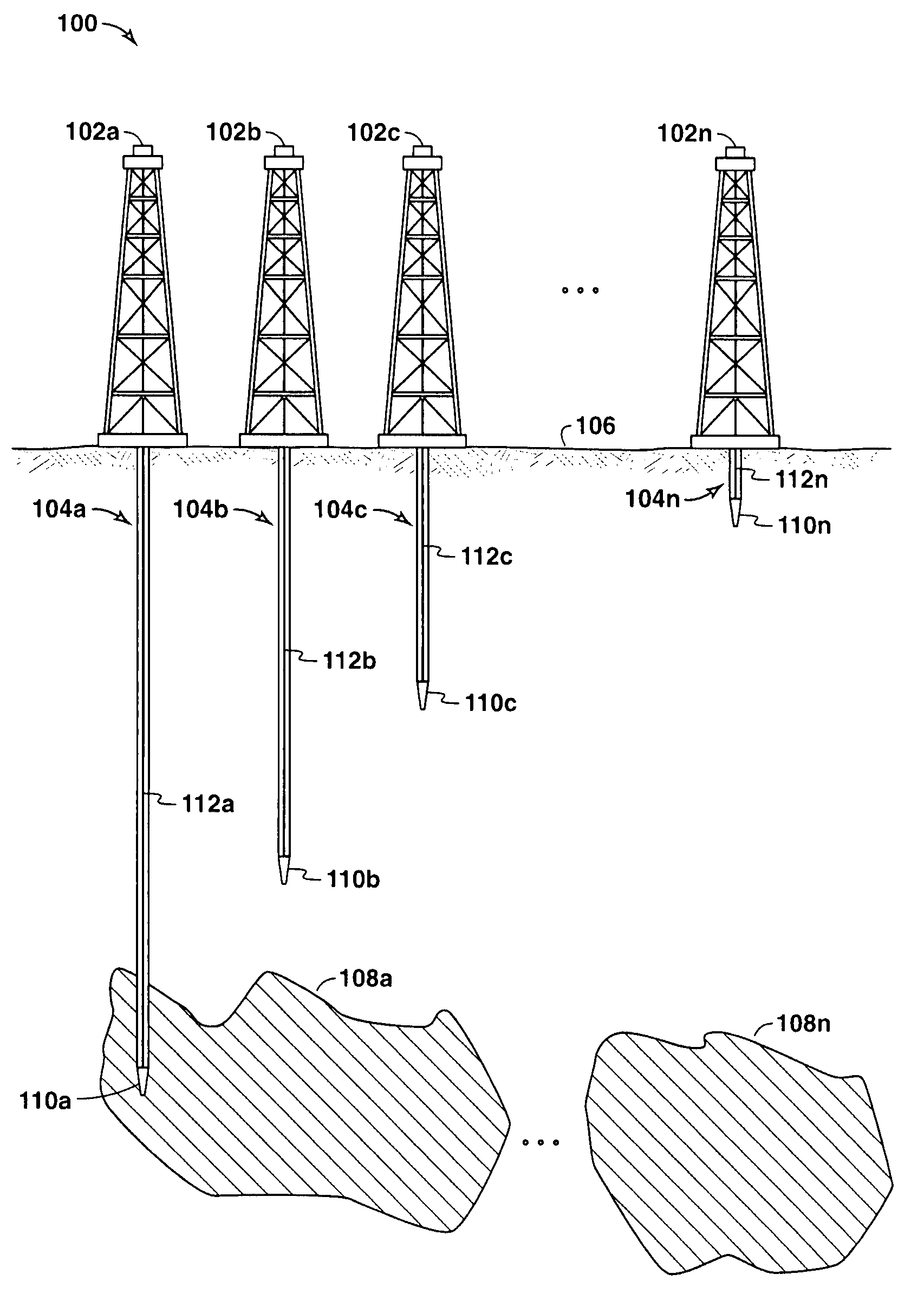

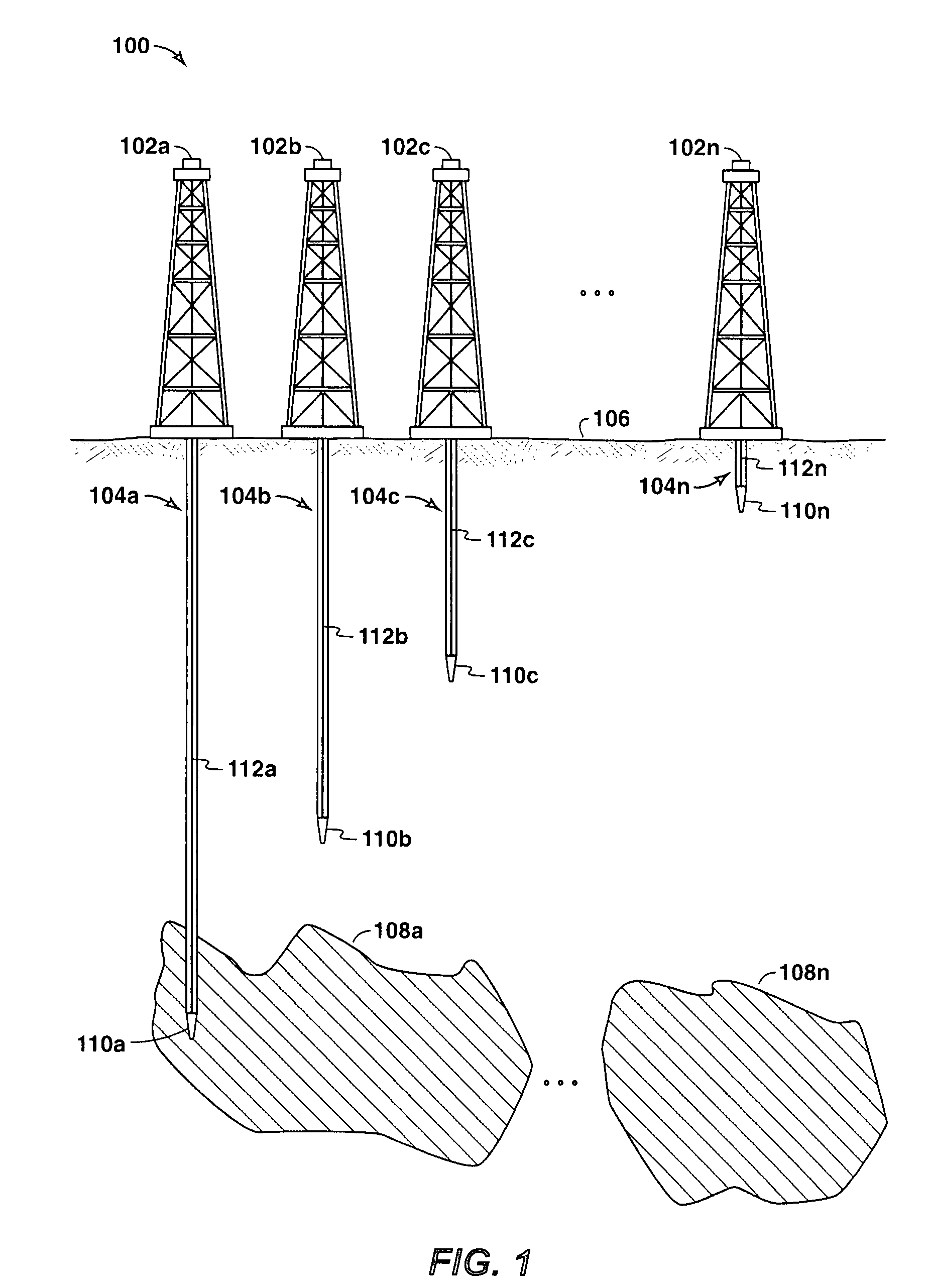

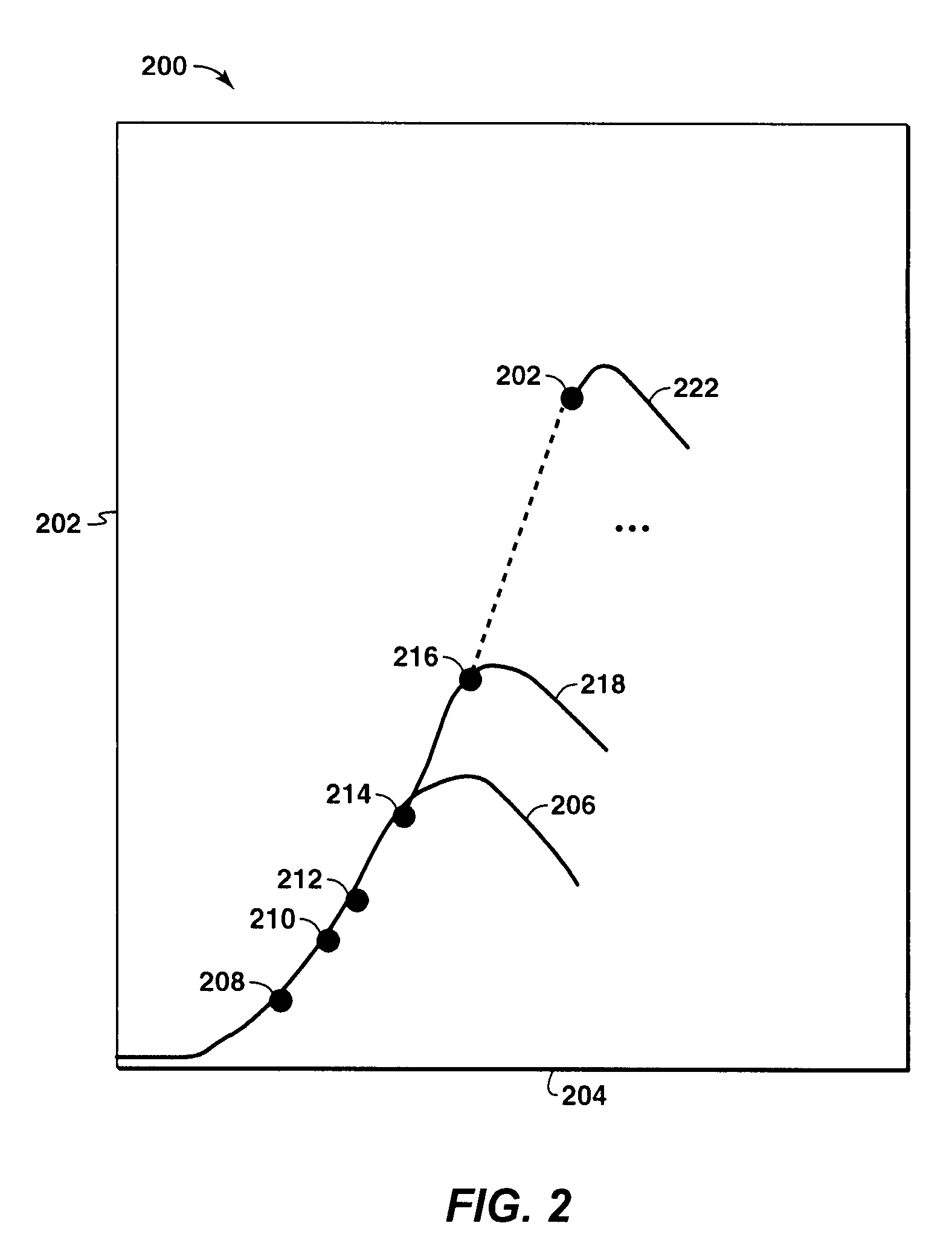

Method of drilling and producing hydrocarbons from subsurface formations

ActiveUS20080105424A1Increase drilling rateIncrease drilling speedEarth drilling toolsSurveySpecific energyGeophysics

A method associated with the production of hydrocarbons. In one embodiment, method for drilling a well is described. The method includes performing drilling operations at one or more wells to a subsurface location in a field to provide fluid flow paths for hydrocarbons to a production facility. The drilling is performed by (i) obtaining mechanical specific energy (MSE) data and other measured data during the drilling operations; (ii) using the obtained MSE data and other measured data to determine the existence of at least one limiter; (iii) obtaining and examining lithology data for the well; (iv) identifying a primary limiter of the at least one limiter based on the lithology data; and (v) adjusting drilling operations to mitigate at least one of the at least limiter.

Owner:EXXONMOBIL UPSTREAM RES CO

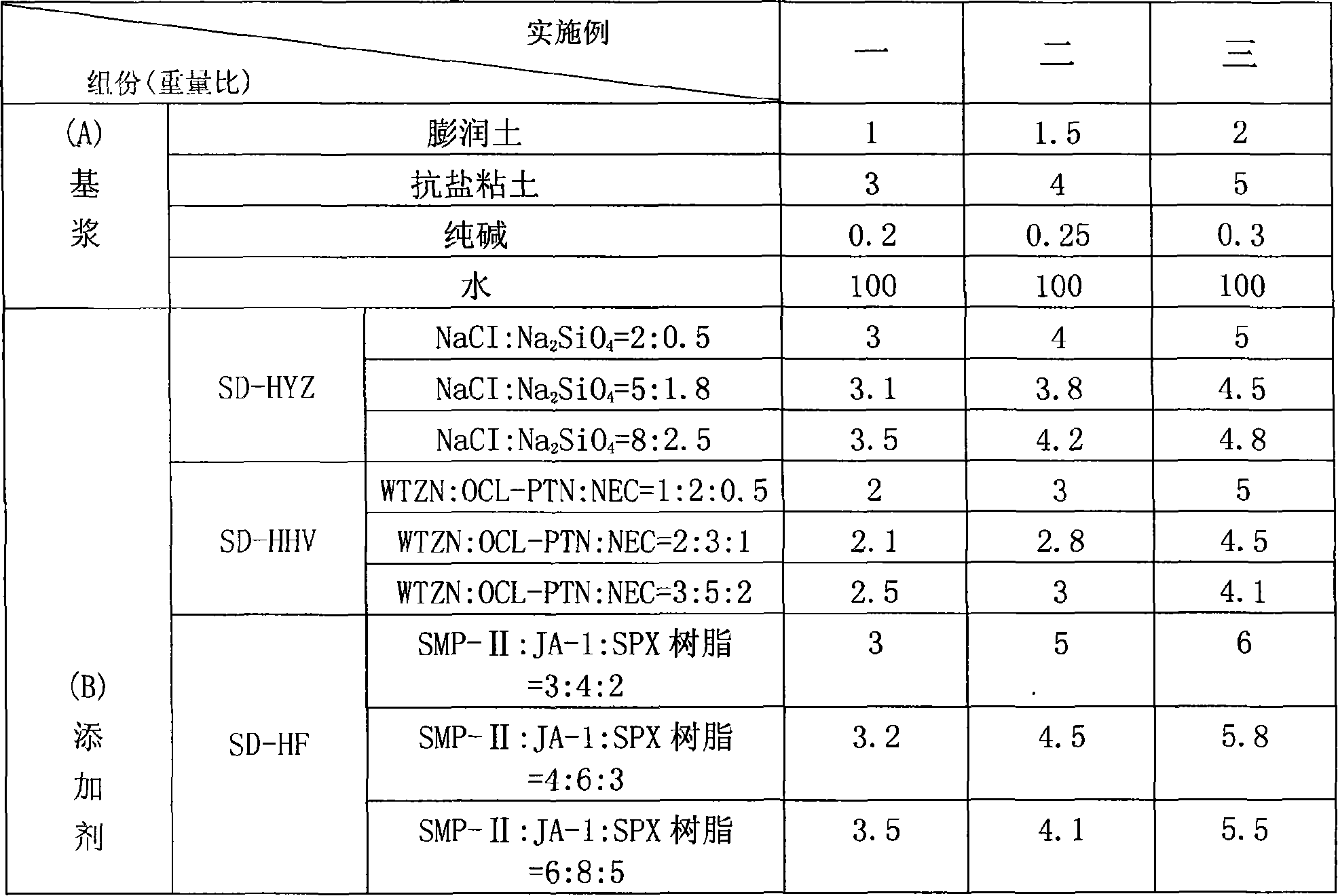

High temperature resistant circulating micro-foam drilling fluid or completion fluid

ActiveCN101148579AImprove stabilityHigh temperature resistanceDrilling compositionFoaming agentWell drilling

The present invention discloses one kind of high temperature recyclable microbubble drilling and completing fluid, which includes basic slurry comprising bentonite 1-2 (in weight portions, the same below), salt tolerant clay 3-5, sodium carbonate 0.2-0.3 and water 100; and additives comprising high temperature inhibitor 3-5, high temperature tackifier 2-5, high temperature filter loss reducing agent 3-6, high temperature salt resisting filter loss reducing tackifier 1-3, flow form regulator 1-3, high temperature foaming agent 2-5 and high temperature foam stabilizer 1-2.5. The high temperature recyclable microbubble drilling and completing fluid has excellent high temperature performance, high carrying, suspending capacity in low pressure deep well, and functions of inhibiting the hydrating expansion of mudstone and protecting oil and gas reservoir, is suitable for different types of high temperature stratum. It is applied in well drilling and well completing construction for low pressure and low permeation stratum.

Owner:DONGYING TAIER GASOLINE TECH

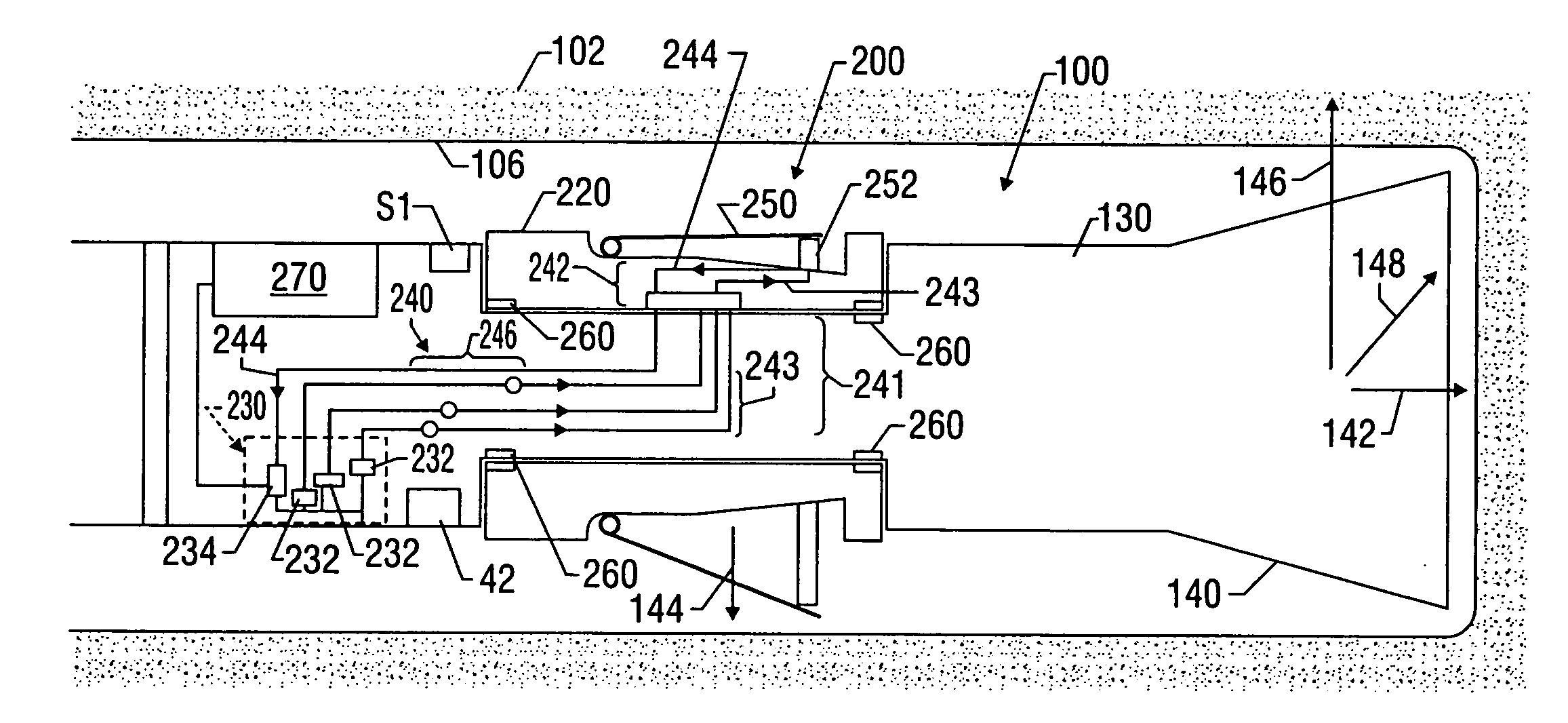

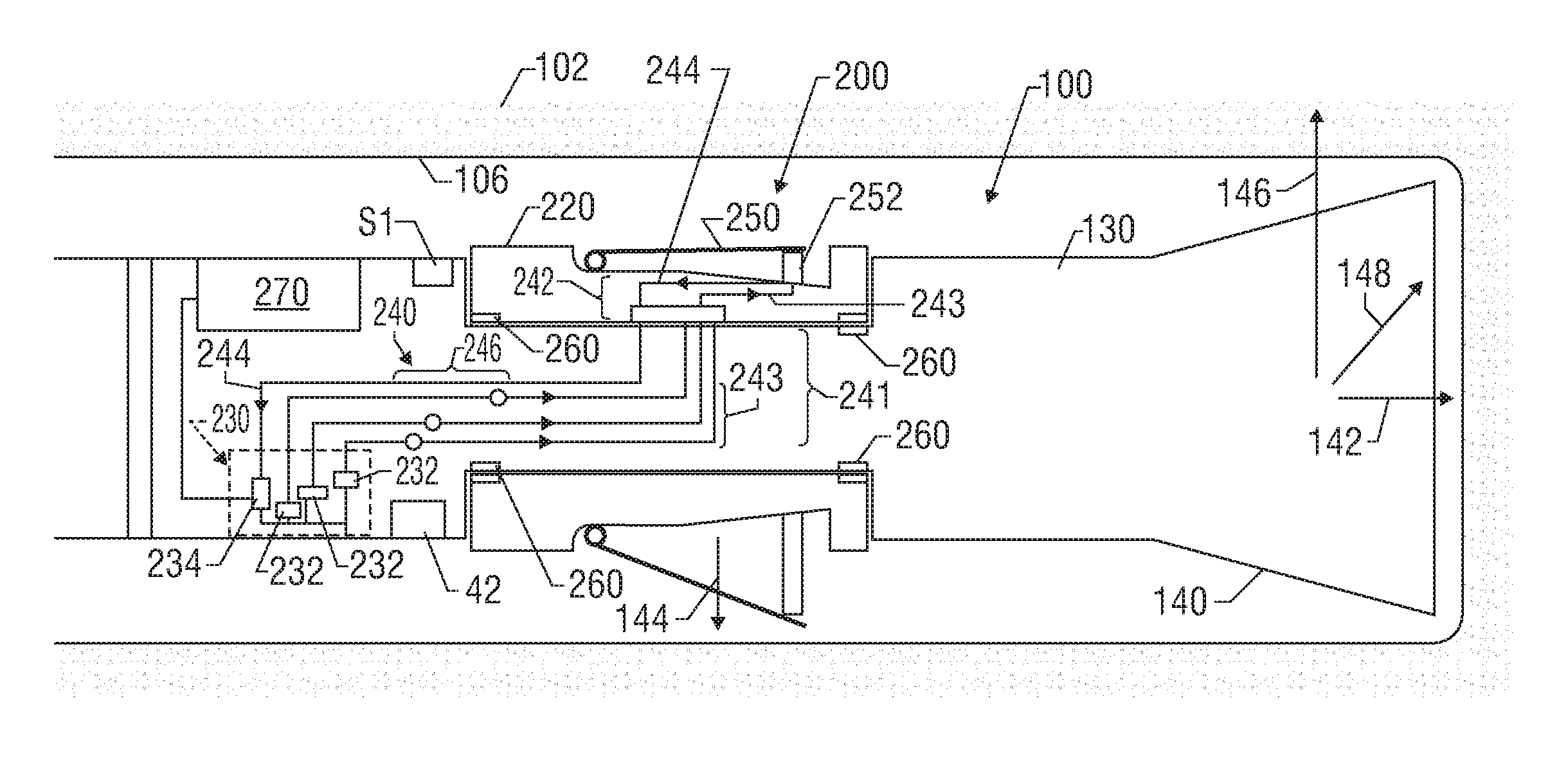

Closed loop drilling assenbly with electronics outside a non-rotating sleeve

ActiveUS20060021797A1Enhanced drilling rateExtend lifeArtificial islandsSurveyDrilling systemRadio wave

A closed-loop drilling system utilizes a bottom hole assembly (“BHA”) having a steering assembly having a rotating member and a non-rotating sleeve disposed thereon. The non-rotating sleeve has a plurality of expandable force application members that engage a borehole wall. An orientation sensing system associated with the rotating member and the non-rotating sleeve provides signals to determine an orientation of the non-rotating sleeve relative to the rotating member. In one embodiment, the orientation sensing system includes a first member positioned in the non-rotating sleeve and a second member positioned in the rotating member. Orientation of the non-rotating sleeve relative to the rotating member is determined from the coaction between the first and second members. The orientation sensing system can use magnetic waves, electrical signals, acoustic signals, radio waves, and / or physical contact.

Owner:BAKER HUGHES INC

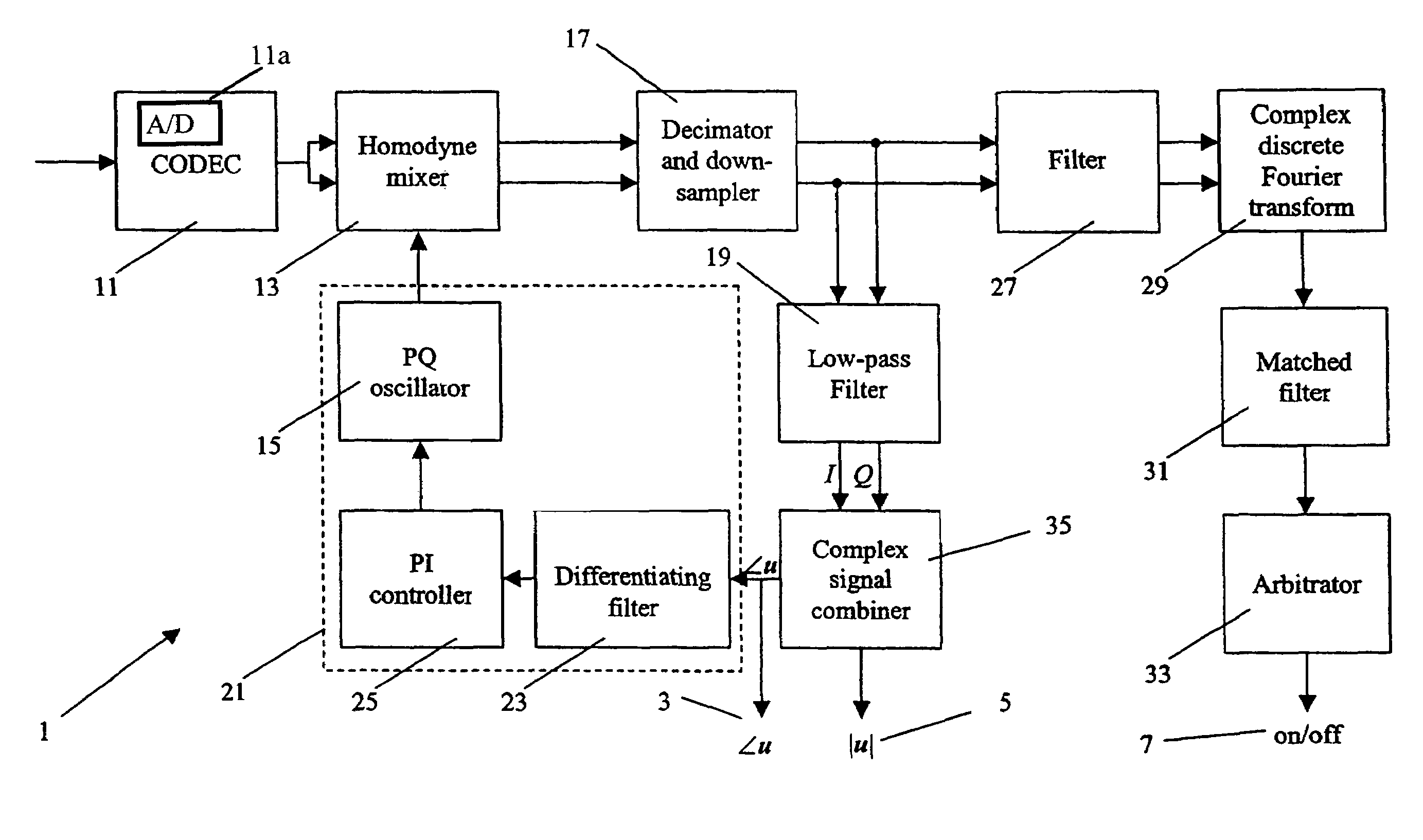

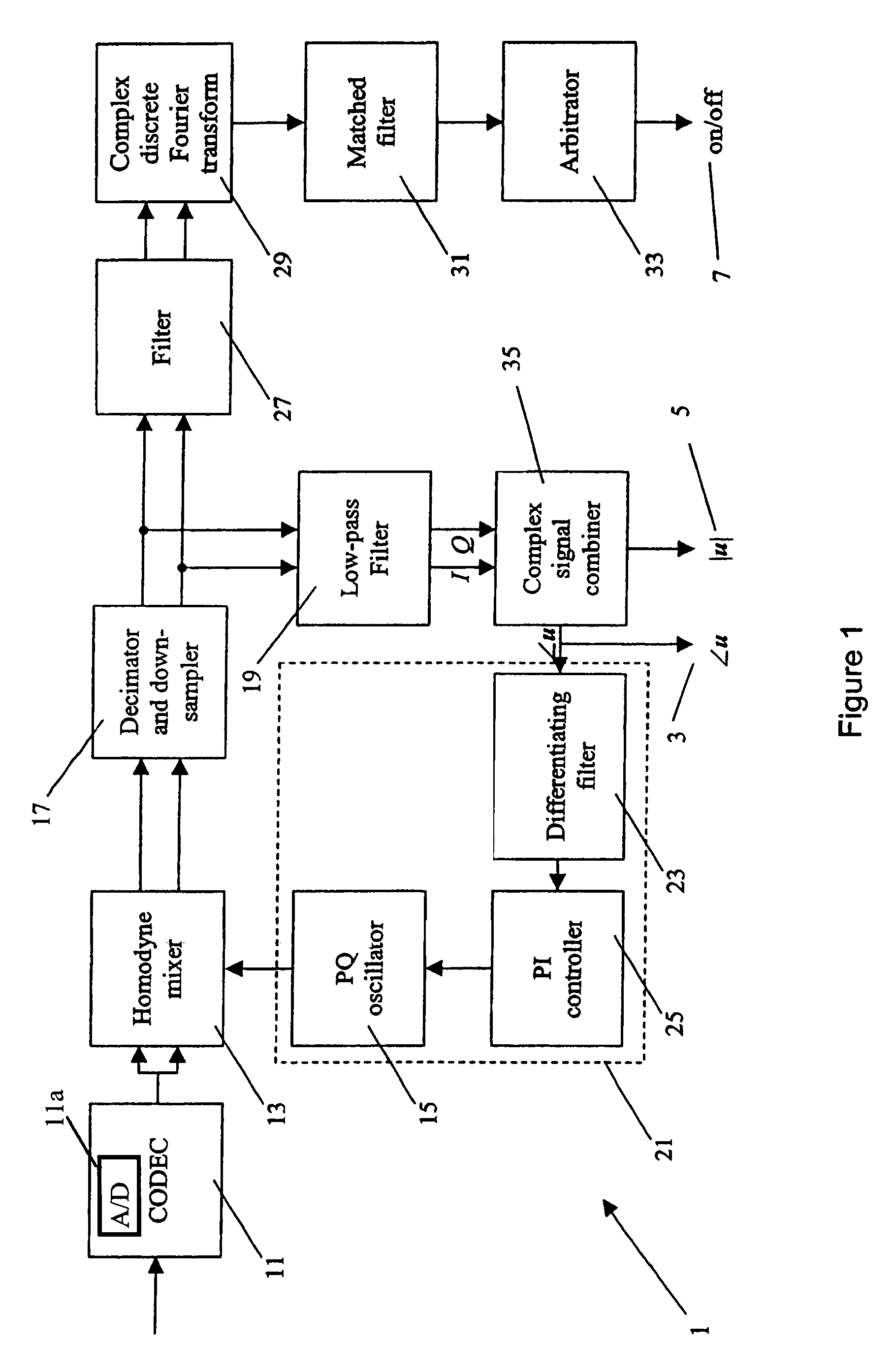

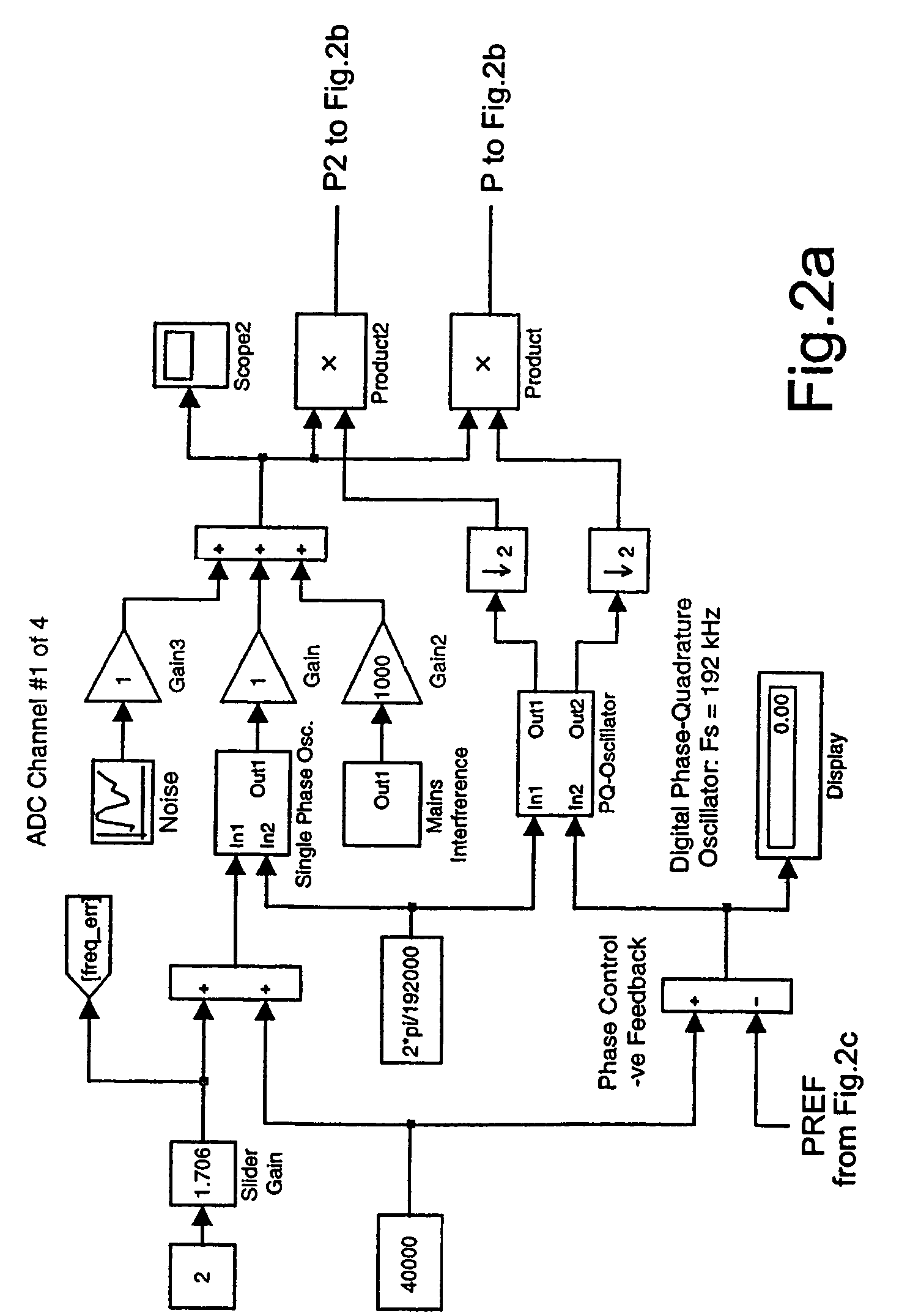

Enhanced sonde recognition

InactiveUS7310584B2Improve clarityLess-prone to jitterElectric/magnetic detection for well-loggingElectric signal transmission systemsDigital down converterA d converter

A detector for locating a sonde includes a plurality of antennas, an analogue to digital converter 11 and a digital signal processor to isolate the magnetic signal produced by the sonde. The digital signal processor includes a phase feedback loop 21 to allow the digital processing unit to follow variations in the frequency of oscillation of the magnetic signal produced by the sonde.

Owner:RADIODETECTION

Production process method of pipe whip restraint steel structure of main power house of nuclear power station conventional island

ActiveCN101862942AImprove perforation rateReduce distortionArc welding apparatusBoring/drilling machinesNumerical controlGusset plate

The invention belongs to the technical field of pipe whip restraint steel structures of main power houses of nuclear power station conventional islands, in particular to a production process method of the pipe whip restraint steel structure of the main power house of the nuclear power station conventional island, which comprises the lofting process, the marking-off and scribing process, the cutting processing process, the bevel processing process, the hole-making process, the correction process, the polishing surface, the material splicing process, the pre-splicing process of a steel member, the assembly process, the processing process of a friction surface, the welding process of the steel structure and the anti-slip test of the friction surface of the steel member before leaving a factory, sandblasting, derusting and coating of a base coat are carried out in the factory, and the production of the steel structure is divided into the production processing of a welded H-shaped steel column, the production of a steel beam, the assembly and the welding of a support part, the production of a combined steel beam, the assembly and the welding of a girder box body and an inclined support below the girder box body, and the assembly and the welding of a pipe whip restraint key. The production process method can improve the drilling precision, utilize a numerical control planar drilling machine to complete the drilling on a gusset plate, determine a variety of processing processes and welding process parameters, and ensure the dimension of the member after the assembly and the smooth proceeding of field installation.

Owner:EAST STEEL STRUCTURE BRIDGE

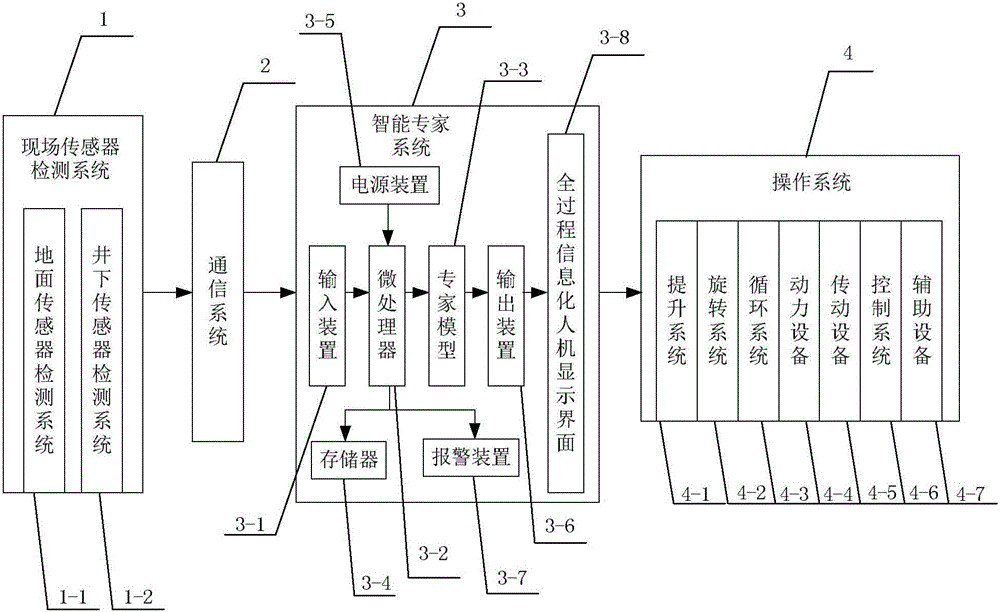

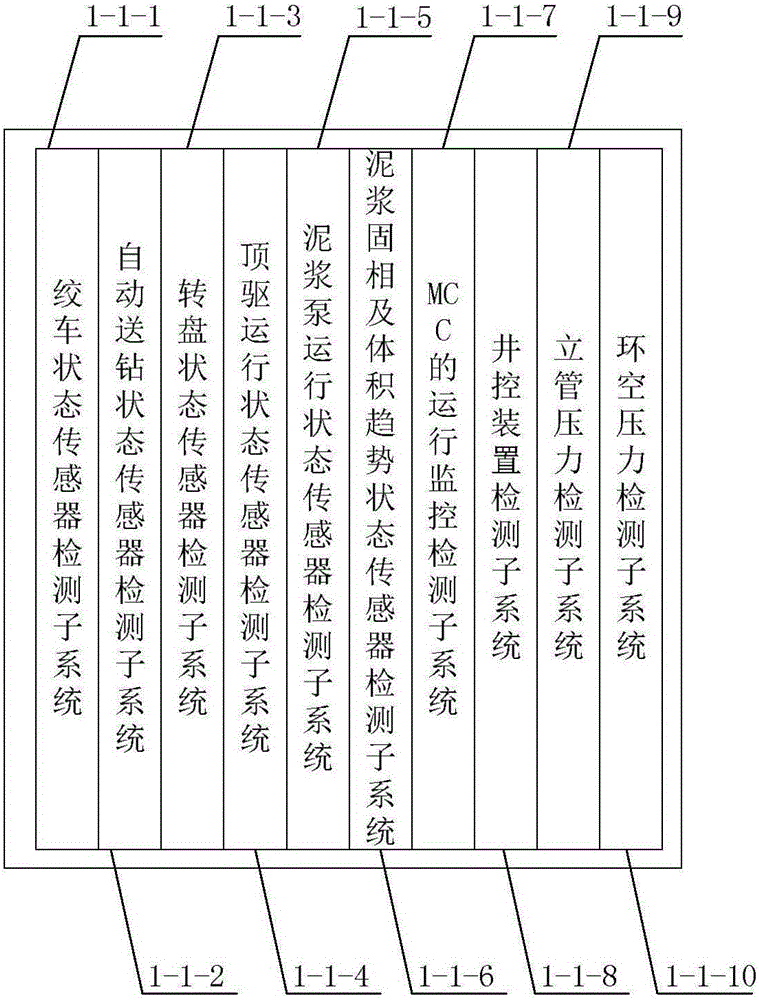

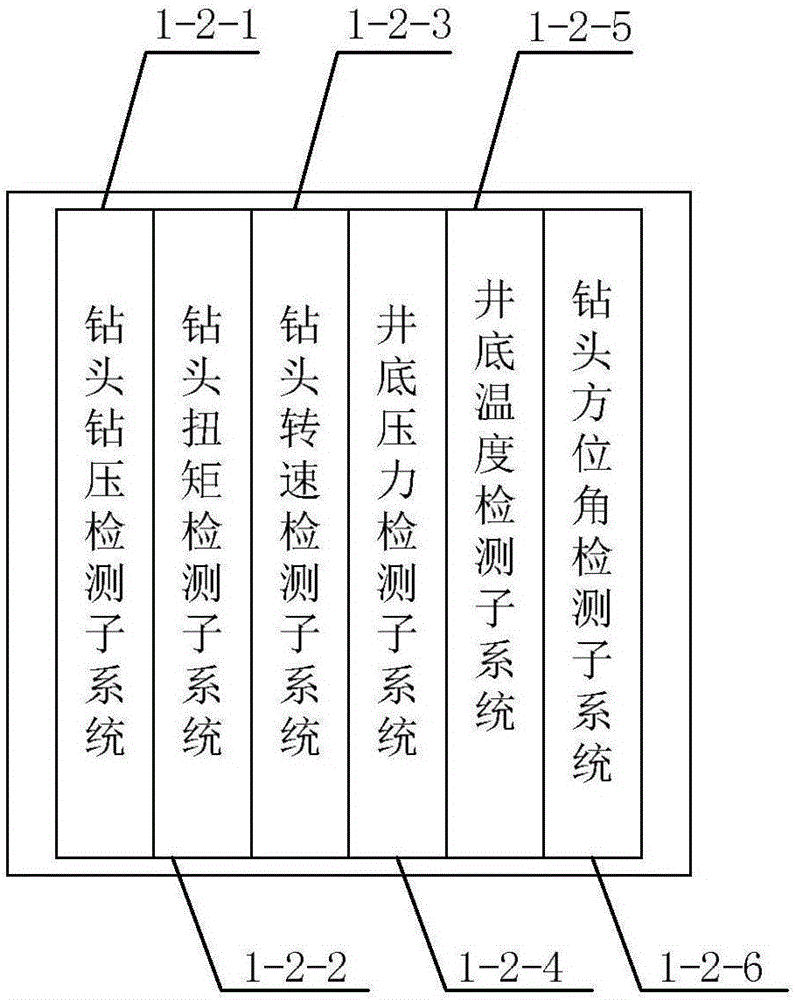

Intelligent well drilling expert system

InactiveCN106121621AAccurate discoveryReal-timeAutomatic control for drillingCommunications systemAutomatic control

The invention discloses an intelligent well drilling expert system. The intelligent well drilling expert system comprises an on-site sensor detection system, a communication system, an intelligent expert system and an operation system. The on-site sensor detection system is connected with the intelligent expert system through the communication system, the intelligent expert system is connected with the operation system, and thus the automatic closed loop well drilling adjusting and controlling system is formed. The on-site sensor detection system acquires data of the whole well drilling process. The acquired data are transmitted to the intelligent expert system through the communication system, so that processing monitoring, forecasting, analyzing, controlling and processing are conducted, and finally the operation system executes an operation instruction sent by the intelligent expert system after analyzing. The intelligent well drilling expert system can achieve real-time performance and the functions of early finding, early forecasting, explanation at any time and automatic control, and not only provides accurate information for well drilling engineering but also has the advantages of reducing well drilling cost, increasing well drilling speed, completely preventing accidents, and finding oil and gas accurately.

Owner:SOUTHWEST PETROLEUM UNIV

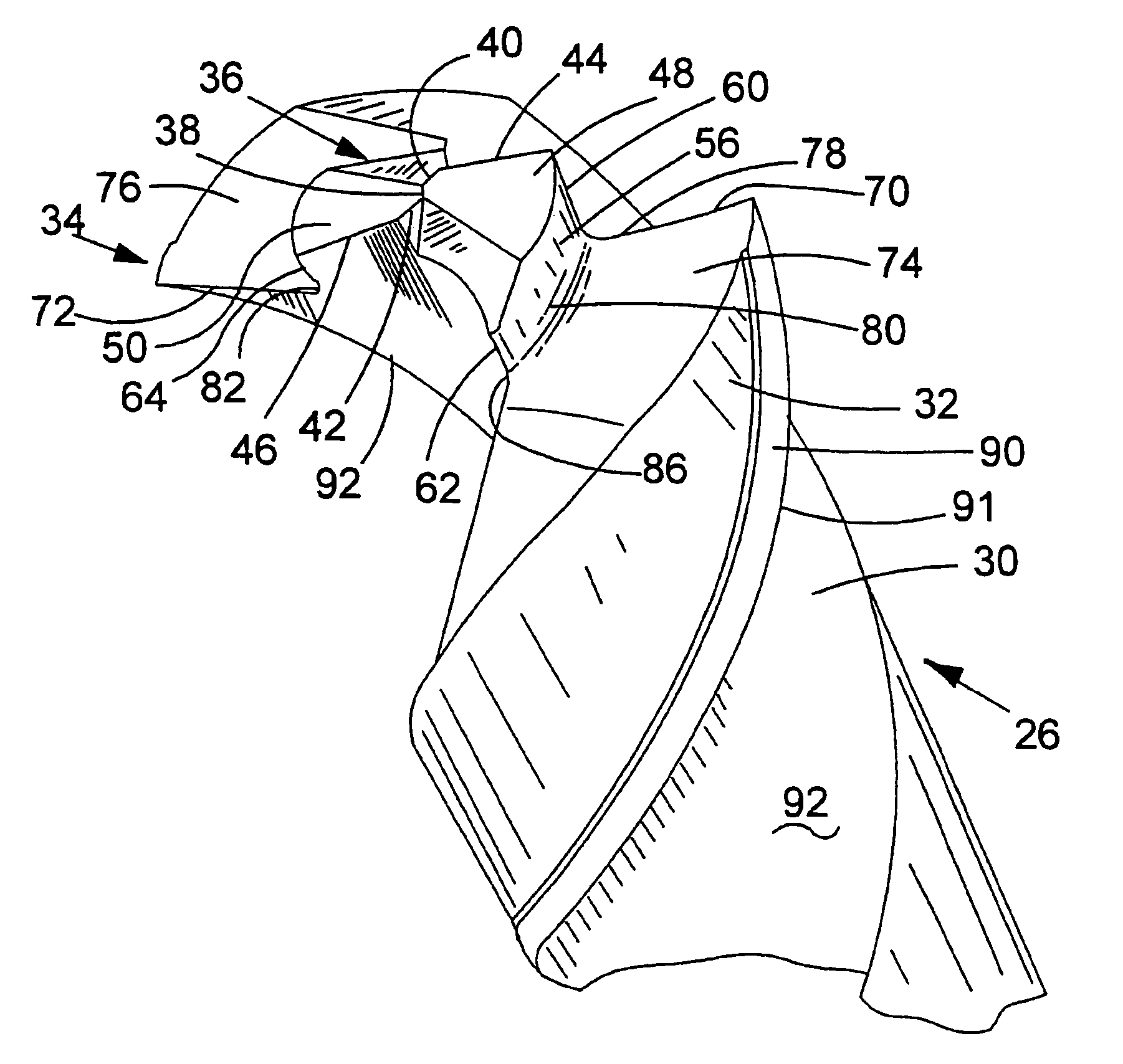

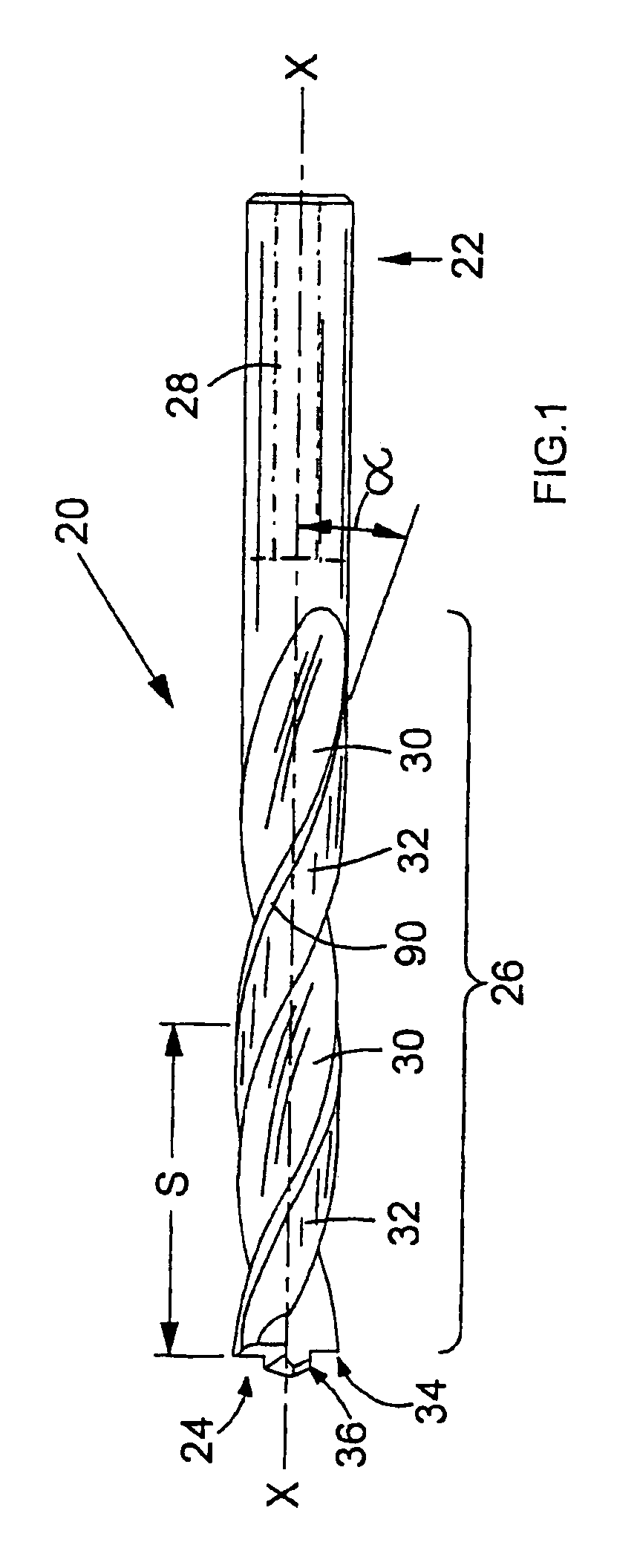

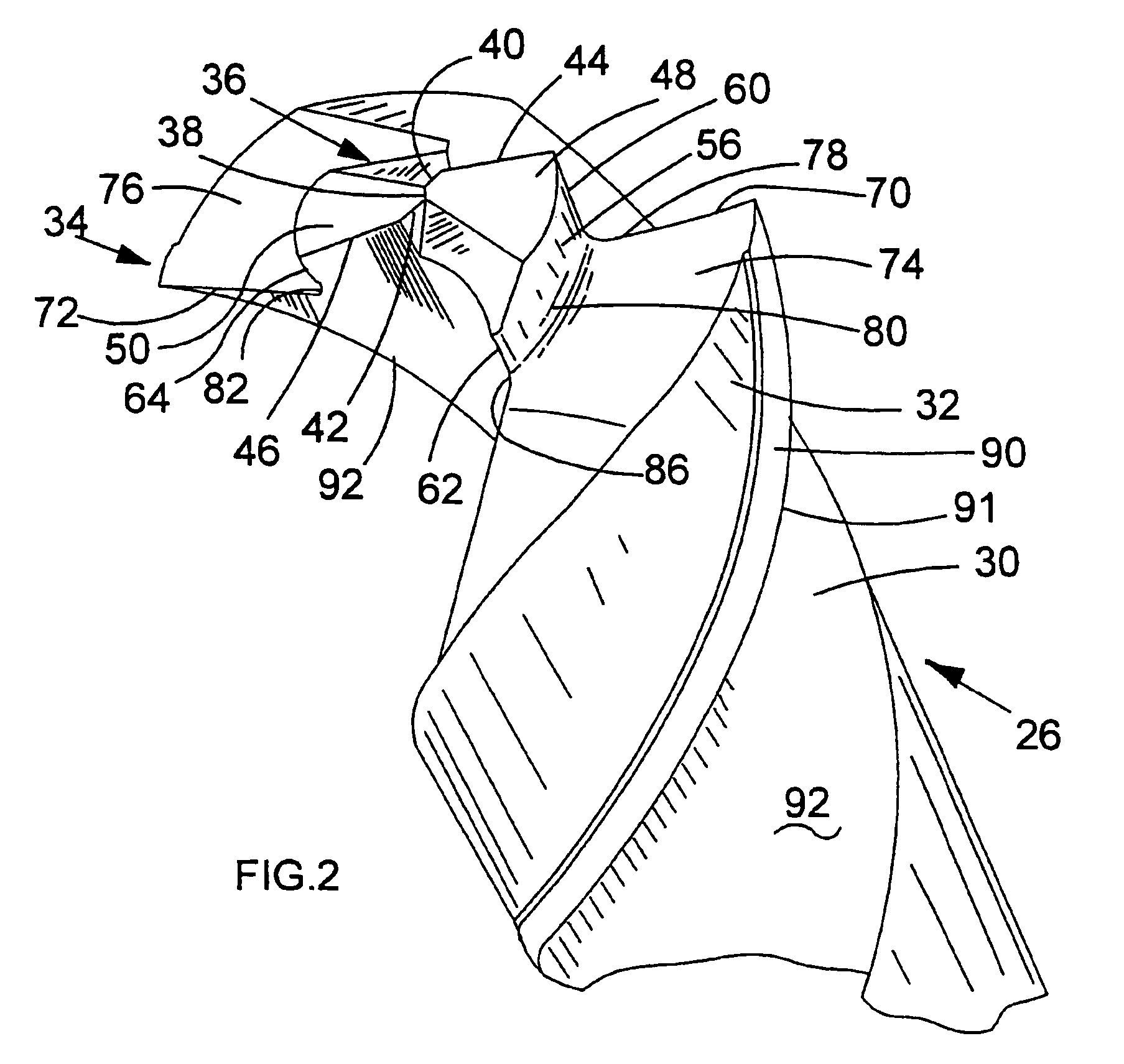

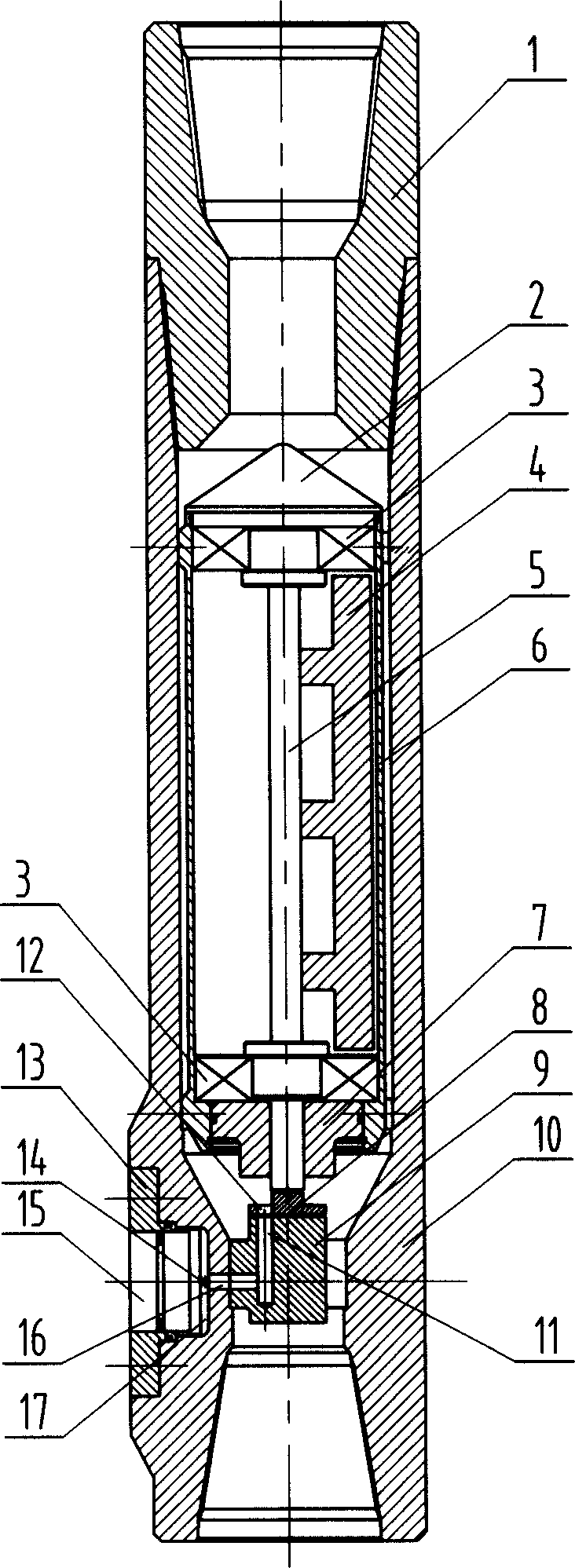

Self-centering drill bit with pilot tip

ActiveUS7267514B2Maintain strengthIncrease drilling speedWood turning toolsTransportation and packagingFluteMechanical engineering

An elongate drill bit (20) with a longitudinal axis (X-X) has a shank (28), a working end (24), and a fluted section (26) between the shank and the working end. The shank, the working end and the fluted section are all formed integrally in the drill bit. The working end has an outer cutting portion (34) and a central pilot tip (36) which extends axially ahead of the outer cutting portion. The pilot tip is formed with at least one pair of minor cutting edges (40, 42; 44, 46) arranged on opposite sides of the axis. The outer cutting portion is formed with a pair of major cutting edges (70, 72) arranged on opposite sides of the axis. The outer cutting portion has a major diameter (D) defined by the pair of major cutting edges. The pilot tip has a minor diameter (d) defined by the at least one pair of minor cutting edges. The fluted section has a pair of helical lands (32) each with a respective inner surface (92) extending axially rearward from one of the major cutting edges and from one of the minor cutting edges. The helical lands define a web (94). Each helical land defines a respective helical flute (30). The helical lands have a pitch (S) and the web has a web thickness (K) at the pilot tip such that the ratio of the pitch to the major diameter (S:D) falls within a range of about 380% to about 410%. Also, the ratio of the minor diameter to the web thickness at the pilot tip (d:K) falls within a range of about 220% to about 380%.

Owner:BLACK & DECKER INC

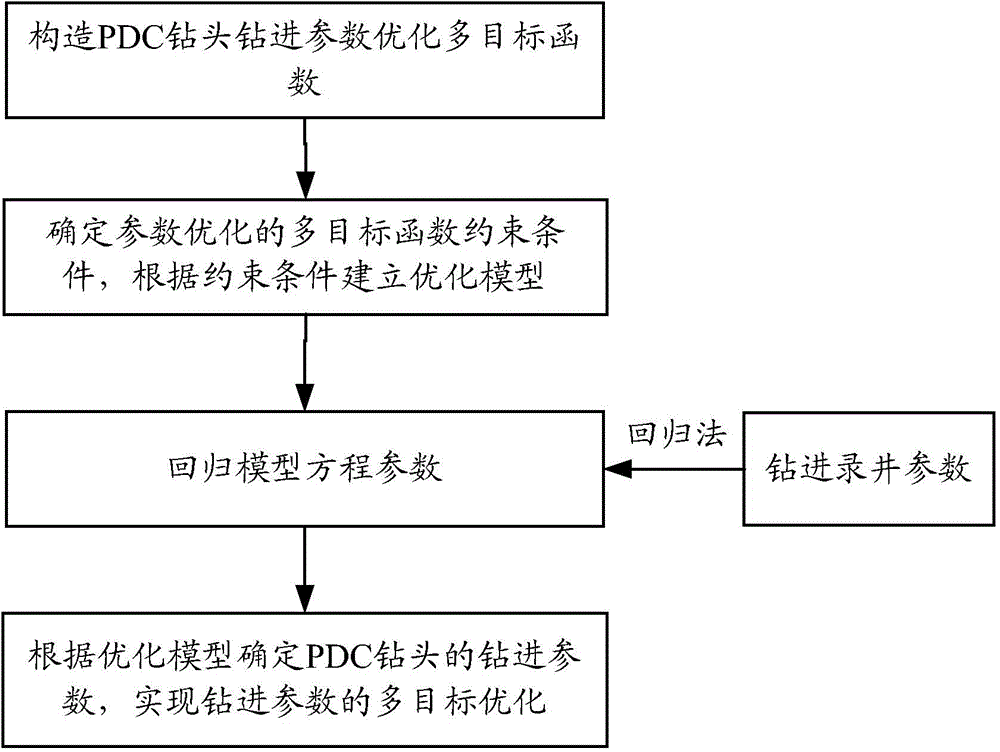

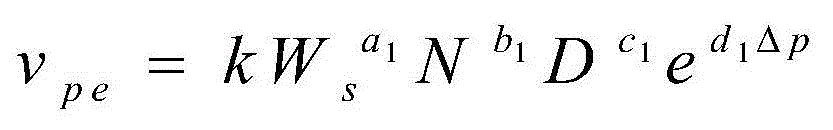

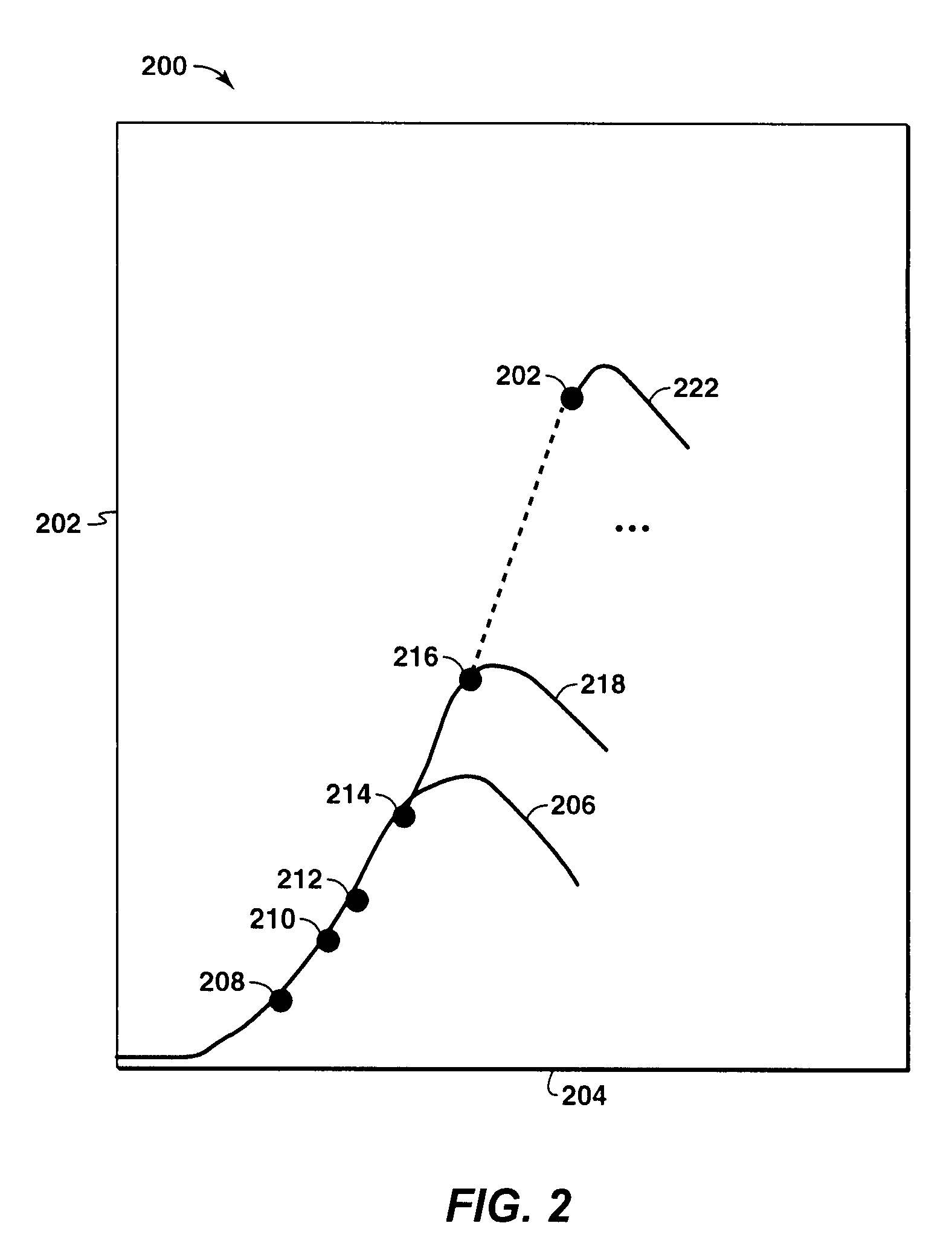

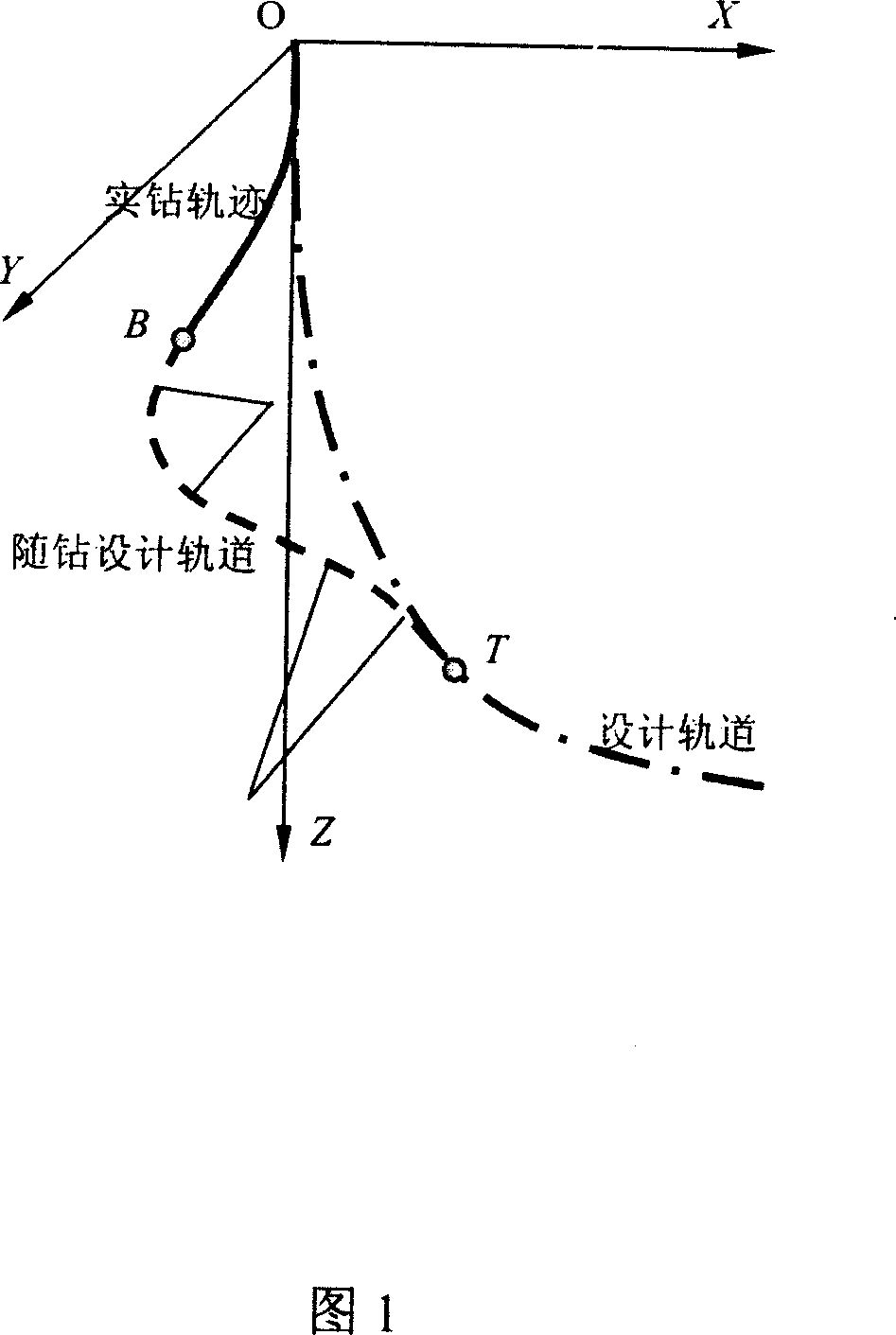

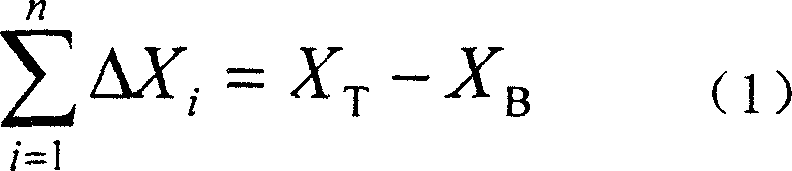

Design-while-drilling method for controlling borehole track while drilling well

InactiveCN1936263AIdeal control targetSafe completionSurveyDirectional drillingSection planePetroleum

The invention relates to well bore rail control and design that includes the process of determining well bore section shape, building equation set, expanding equation set, giving known parameters, and solving the equation set. It could meet the request of target intake direction and coordinate location, and could select 4 random feature parameters as the indeterminate parameters. The invention could improve drilling speed and wellbore quality, lower drilling cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of drilling and producing hydrocarbons from subsurface formations

Owner:EXXONMOBIL UPSTREAM RES CO

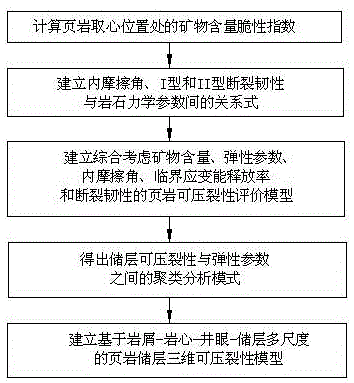

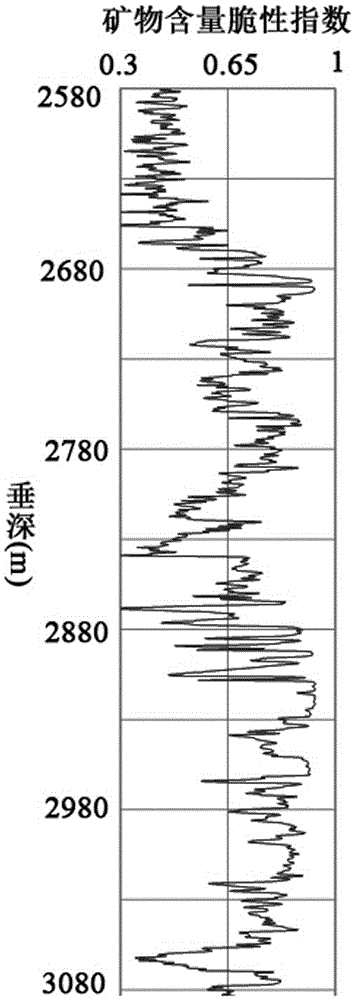

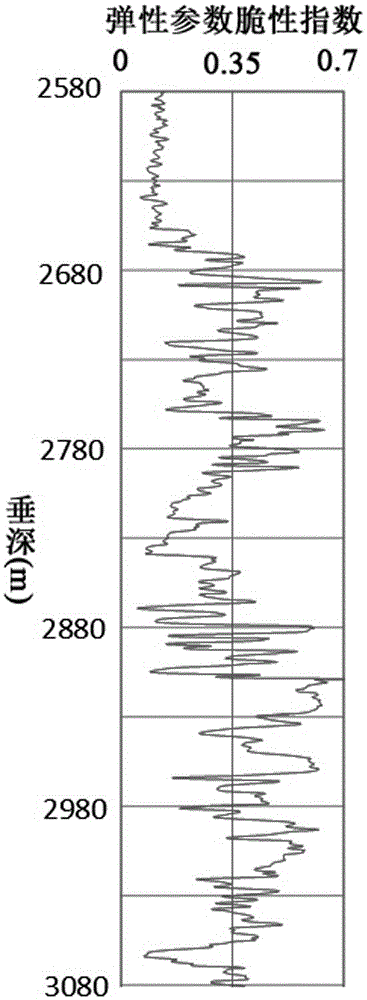

Debris-core-borehole-reservoir multiscale shale reservoir three-dimensional fracturing evaluation method

ActiveCN105156103ALarge capacityQuantification of fracabilityBorehole/well accessoriesType fractureWell placement

The invention relates to a debris-core-borehole-reservoir multiscale shale reservoir three-dimensional fracturing evaluation method. The method comprises the steps of: (S1) calculating mineral content brittleness indexes in a shale coring position; (S2) building relations among an internal friction angle, I type and II type fracture toughness and rock mechanical parameters; (S3) building shale fracturing evaluation models comprehensively considering a mineral content, elastic parameters, the internal friction angle, a critical strain energy release rate and the rapture toughness; (S4) applying a support vector machine algorithm to obtain a cluster analysis mode between a reservoir fracturing performance and the elastic parameters; and (S5) applying the cluster analysis mode and a reservoir three-dimensional elastic parameter data body to obtain a debris-core-borehole-reservoir multiscale shale reservoir three-dimensional fracturing model. The method can be applied to obtain the fracturing performance of any space position in a shale reservoir, so that the well position selection blindness is prevented, and the fracturing modification effect and the after-pressing yield are improved.

Owner:SOUTHWEST PETROLEUM UNIV +1

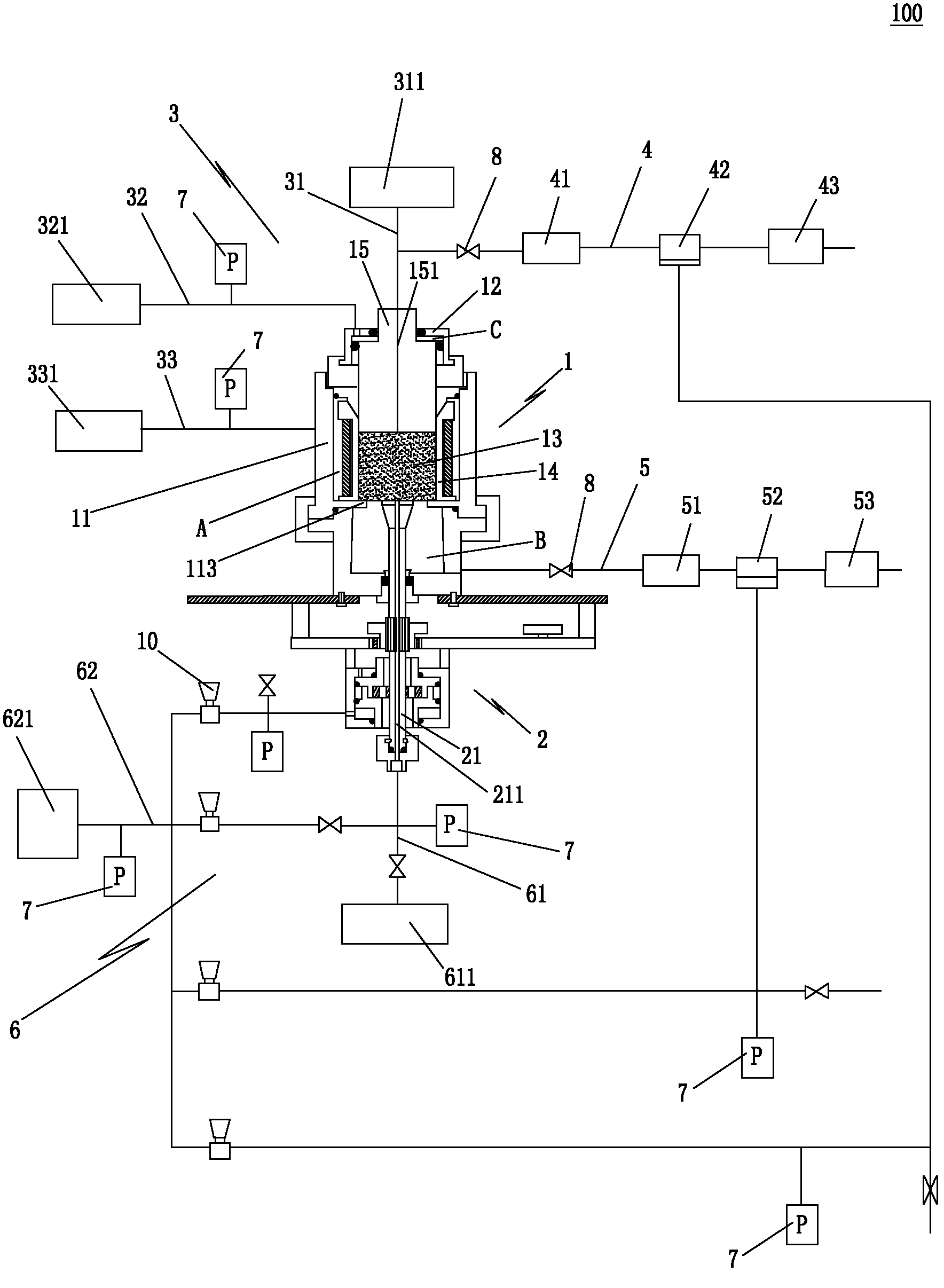

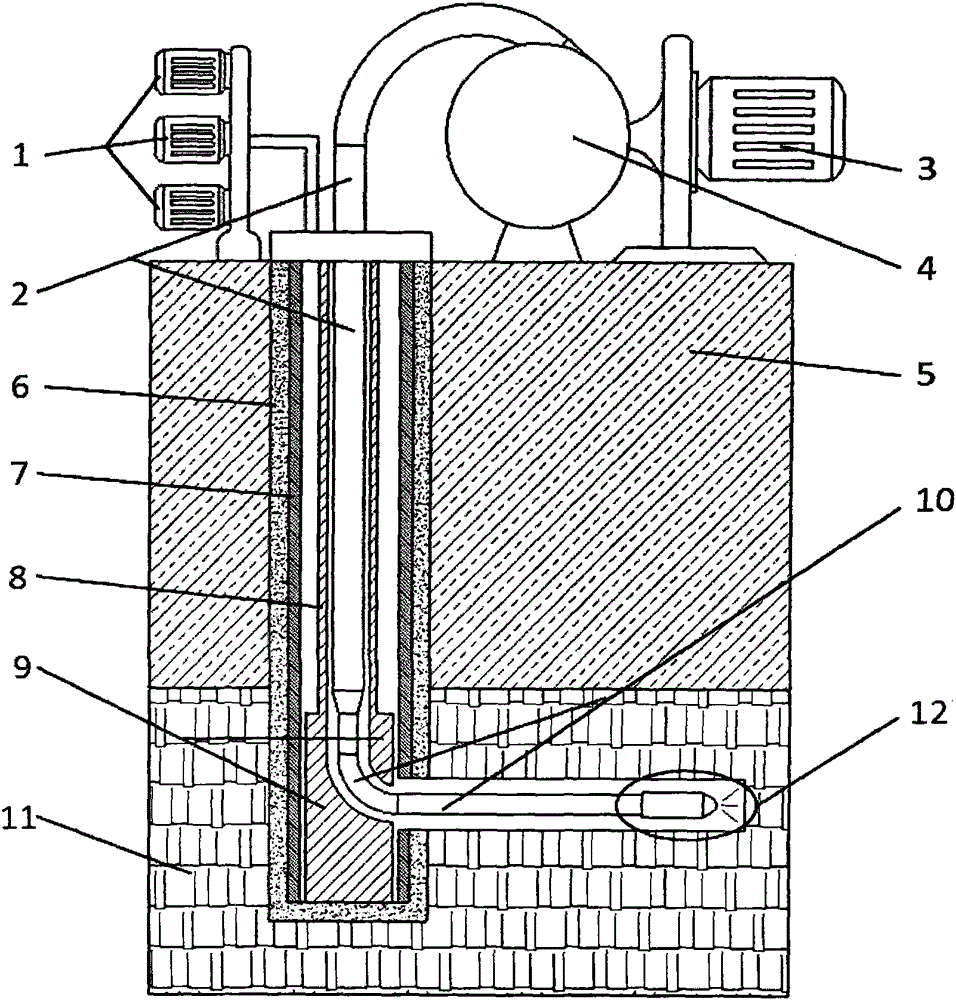

Drilling simulation experiment device

InactiveCN102288742AIncrease drilling speedImprove drilling qualityEarth material testingRock coreWell drilling

The invention relates to a well drilling simulation test device. The well drilling simulation test device comprises a rock core clamping mechanism, a drilling mechanism, a pressing mechanism and a pressing control pipeline, wherein the rock core clamping mechanism and the drilling mechanism are concentrically arranged above and below a test frame; constant pressure liquid which is applied to the upper end of the rock core by a constant pressure pump of the pressing mechanism and constant pressure liquid or high pressure gas which is pressed on the rock core by a constant pressure pump of the drilling mechanism or a high pressure gas source are converged in a simulated cavity at the bottom of the well, and are controlled to flow out by the pressing control pipeline consisting of a filter, a back pressure device and a flowmeter; the back pressure device is connected with the high pressure gas source of the drilling mechanism and controls the pressure of the simulated cavity at the bottom of the well by controlling the gas supply pressure of the high pressure gas source; the pressing mechanism, a pressure sensor of the back pressure device and the flowmeter transmit signals to a computer; and change of related parameters is controlled by the computer program, so that various drilling schemes are simulated and tested, and indoor test data is provided for increasing drilling speed,improving drilling quality and reducing drilling cost.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

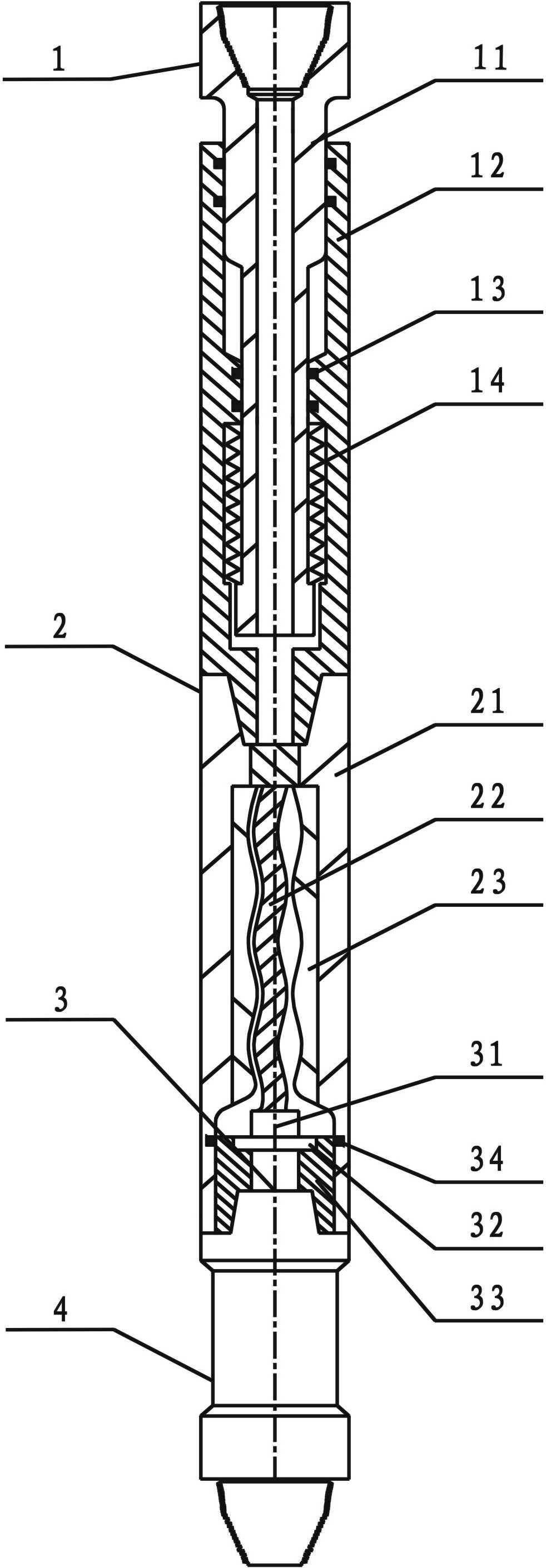

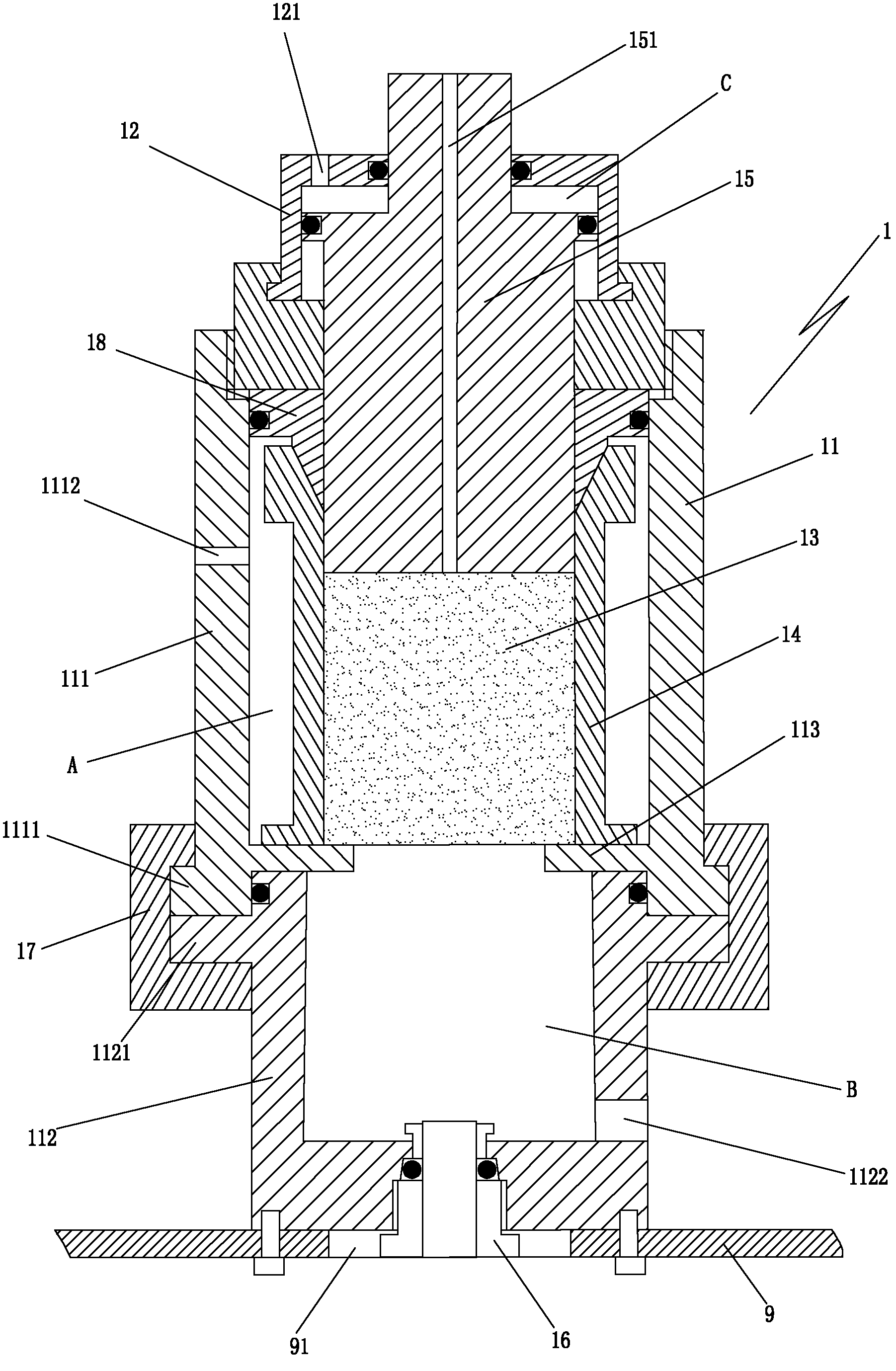

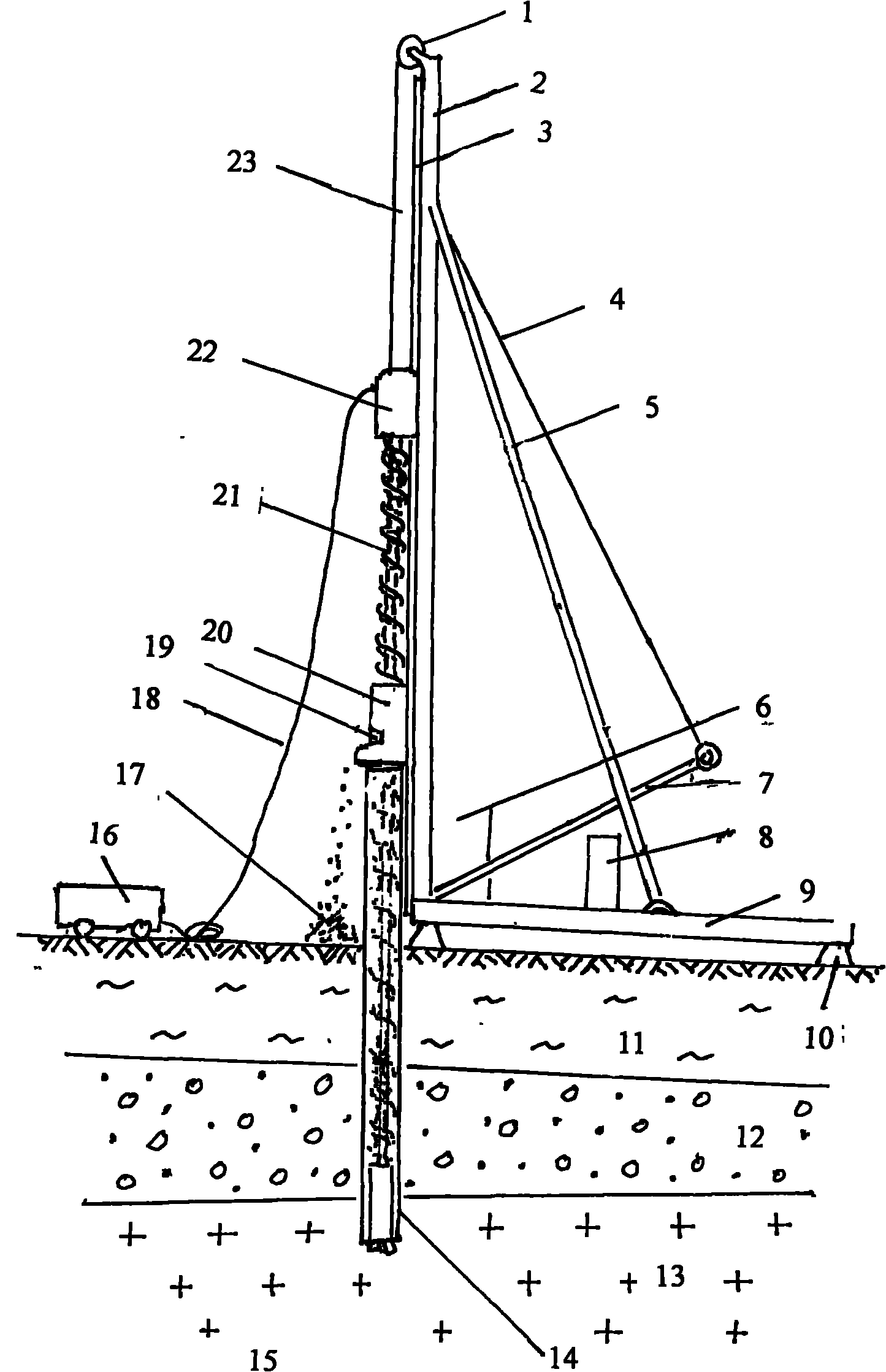

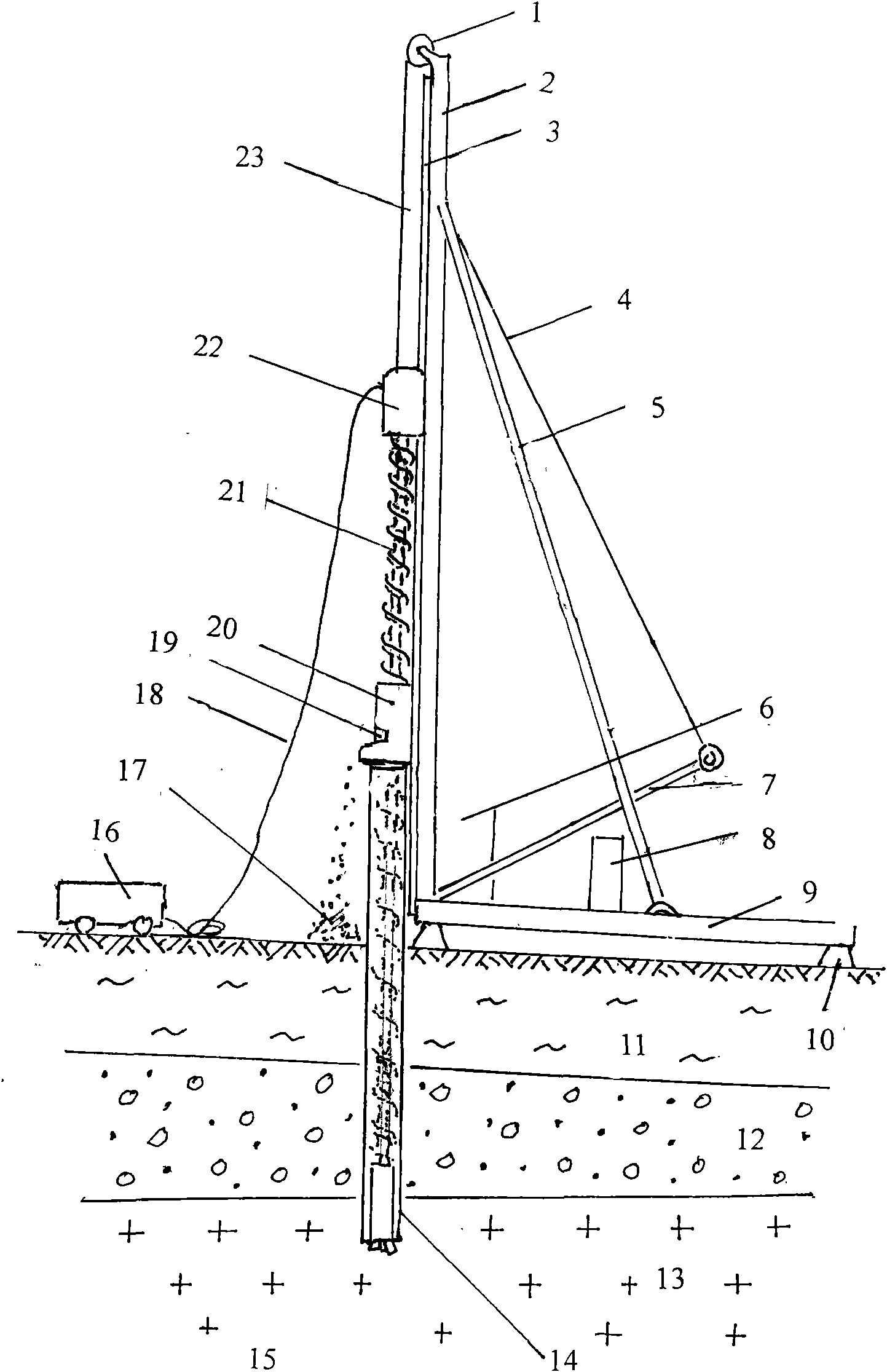

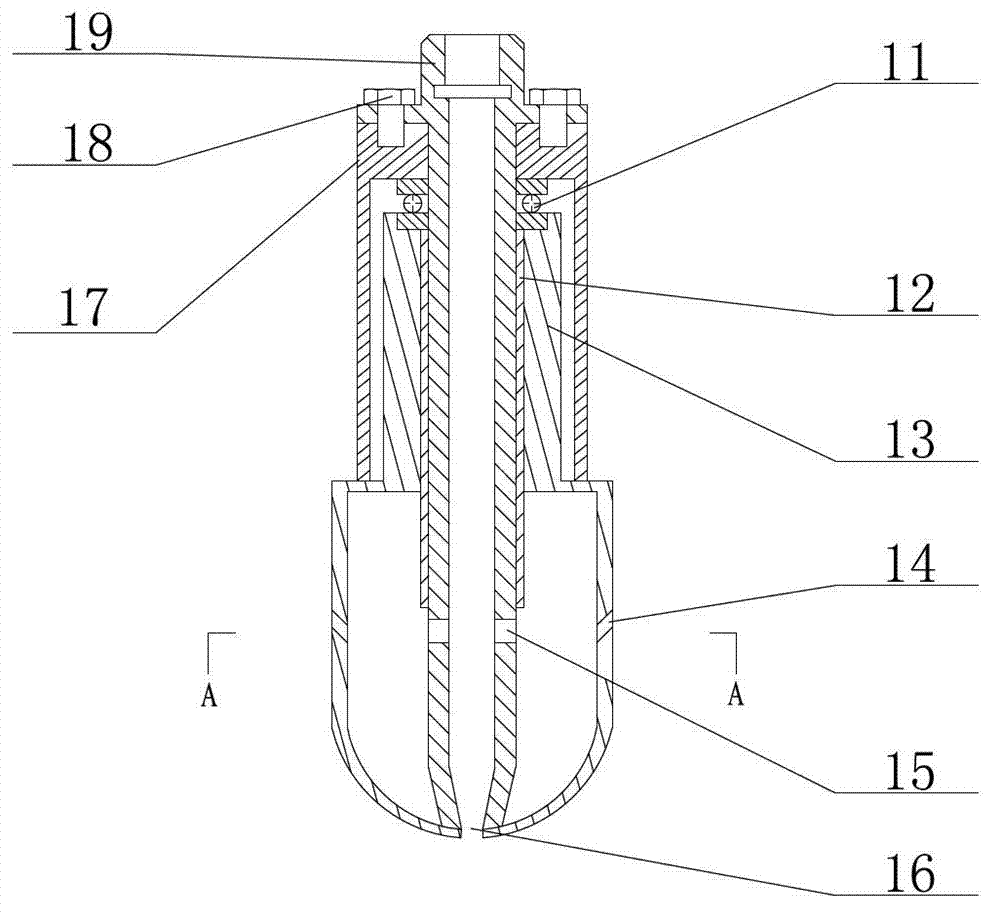

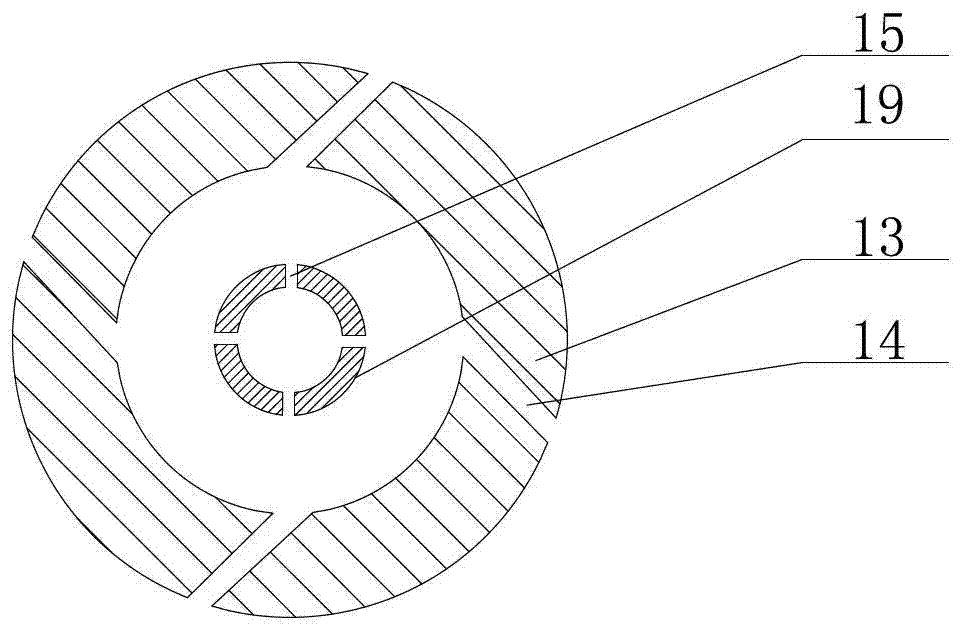

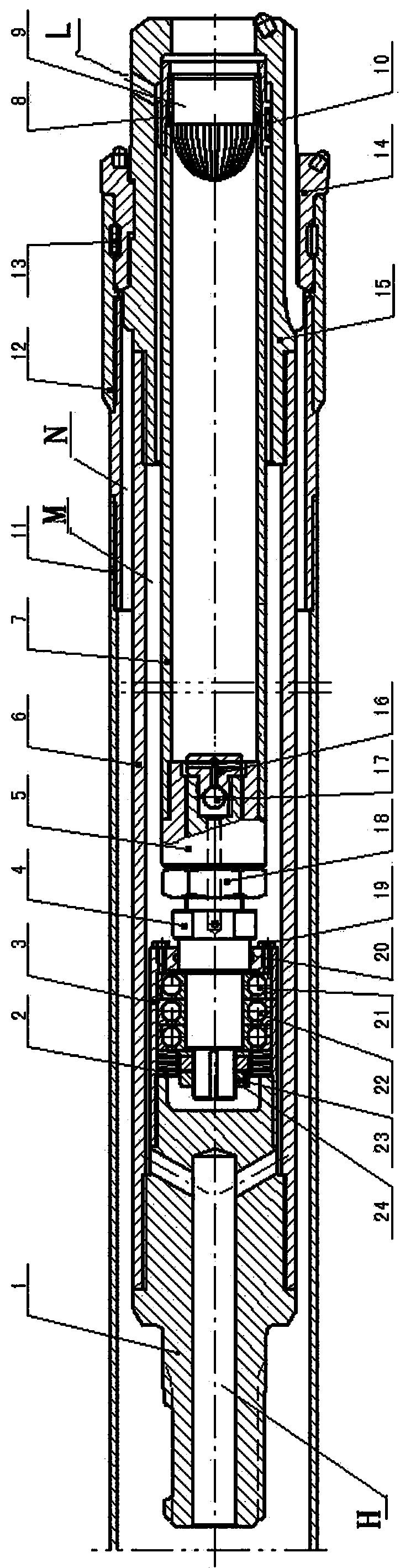

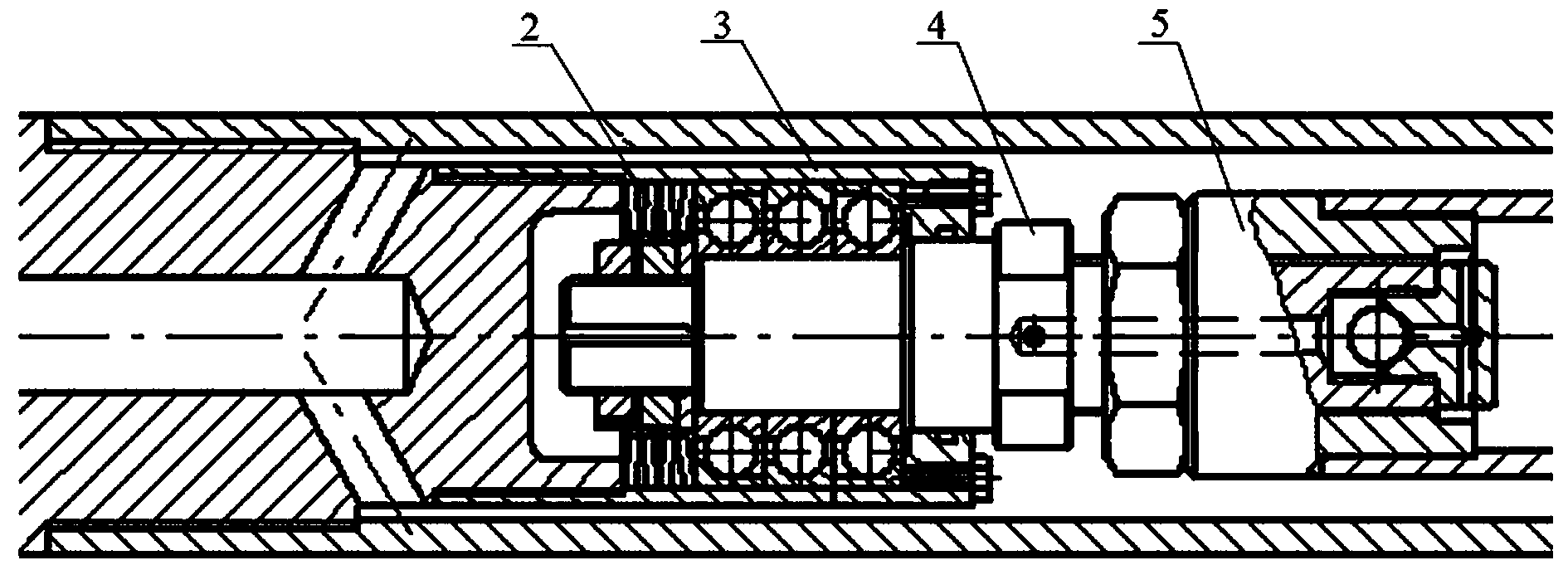

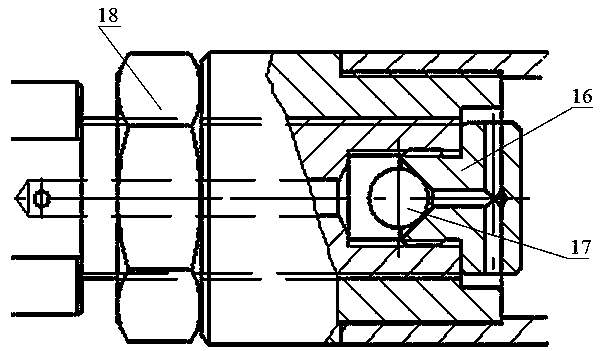

Mechanical automatic vertical drilling tool

InactiveCN1676862AIncrease drilling speedShorten the purification processDirectional drillingWell drillingDifferential pressure

One kind of mechanical type automatic vertically well-drilling tool, including turner, the conduction current head, the bearing, the counterweight, the spindle, in-tube, the back plate, above plate-valve, gets down plate-value, the shell, the piston cylinder back plate and the piston, its principle is at the right moment induces the well slanting gravity signal, by the gravity-actuates in the organization, the establishment drills inside and out the column high-low pressure channel between the fluid, uses two between the differential pressure, actuates the piston at the right moment to push depends on the wall of a well is high side, the wall of a well reacting force then pushes the drill bit to is low side, but in well-eye other positions, the piston does not push depends on the wall of a well, drills the column revolves, this process circulation reciprocation, the well is slanting namely is unceasingly induced and the revision, this invention realization is initiative, At the right moment guards against slanting at the same time, but also can effectively liberate distilling, largely enhances drills fast and well-eye the quality, reduces the construction risk, this invention has the structure is simple, reliable, is suitable to the many kinds of well drilling platform, the processing makes the maintenance cost is low and so on the characteristic.

Owner:SHENGLI PETROLEUM ADMINISTRATION BUREAU DRILLING TECH ACAD SINOPEC

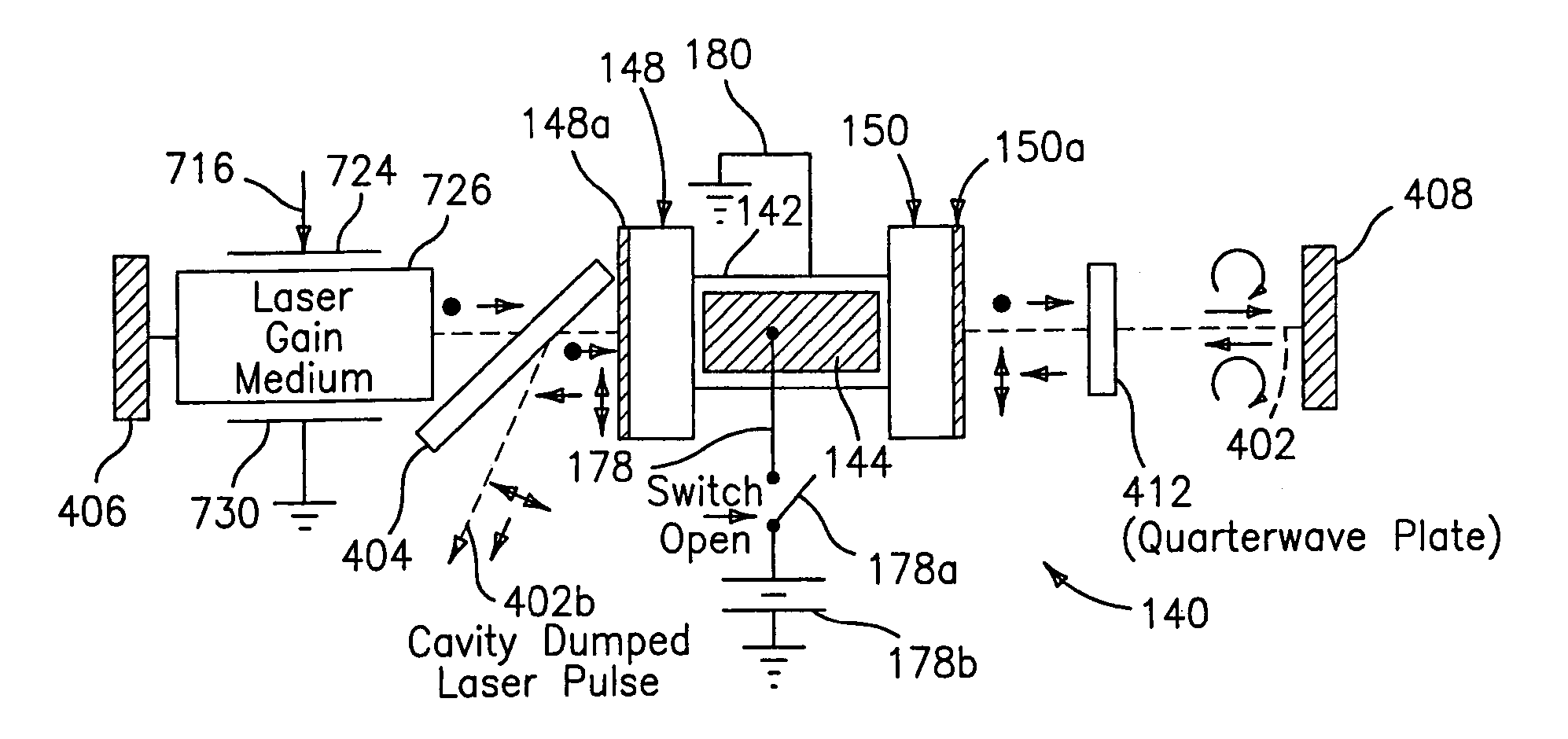

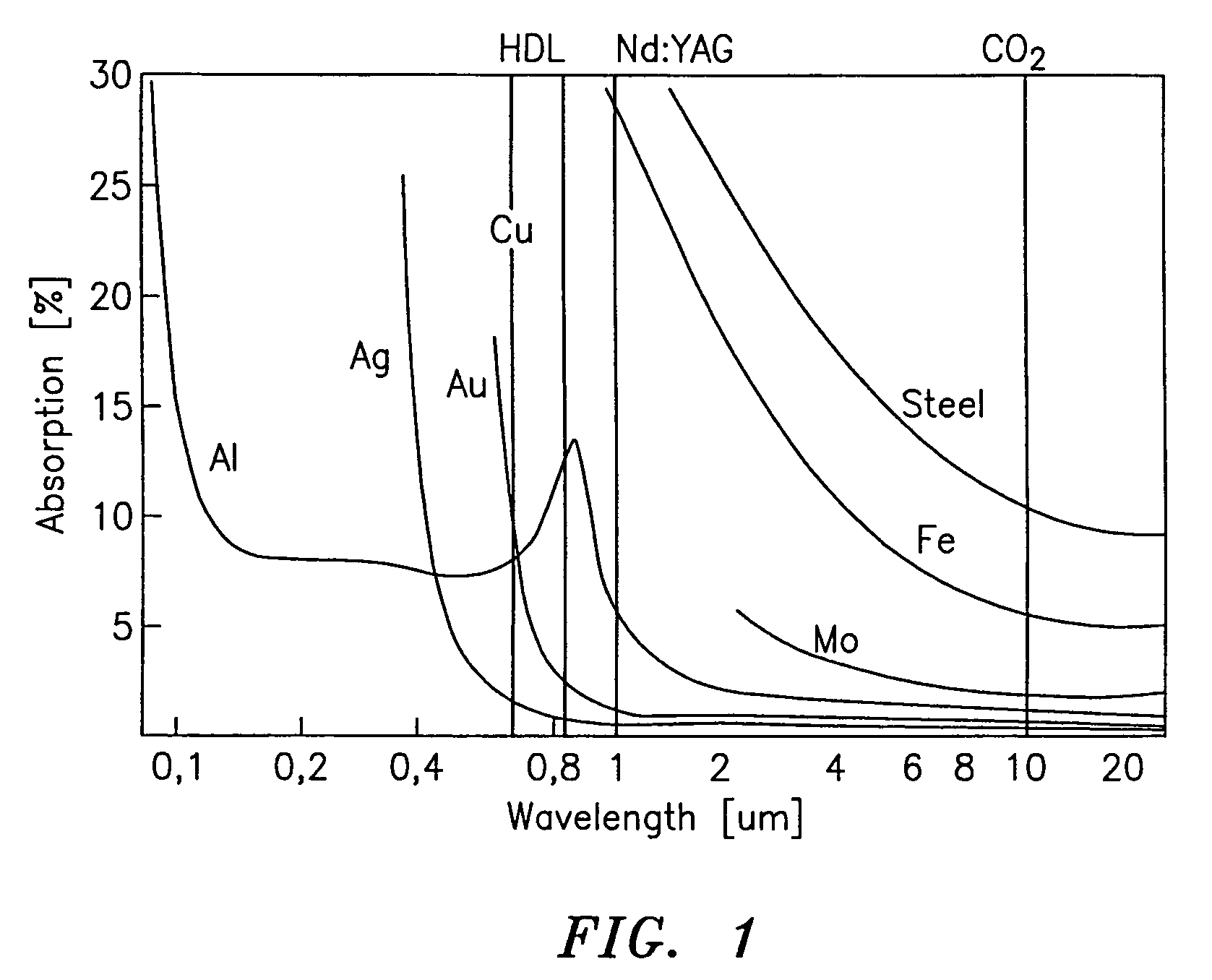

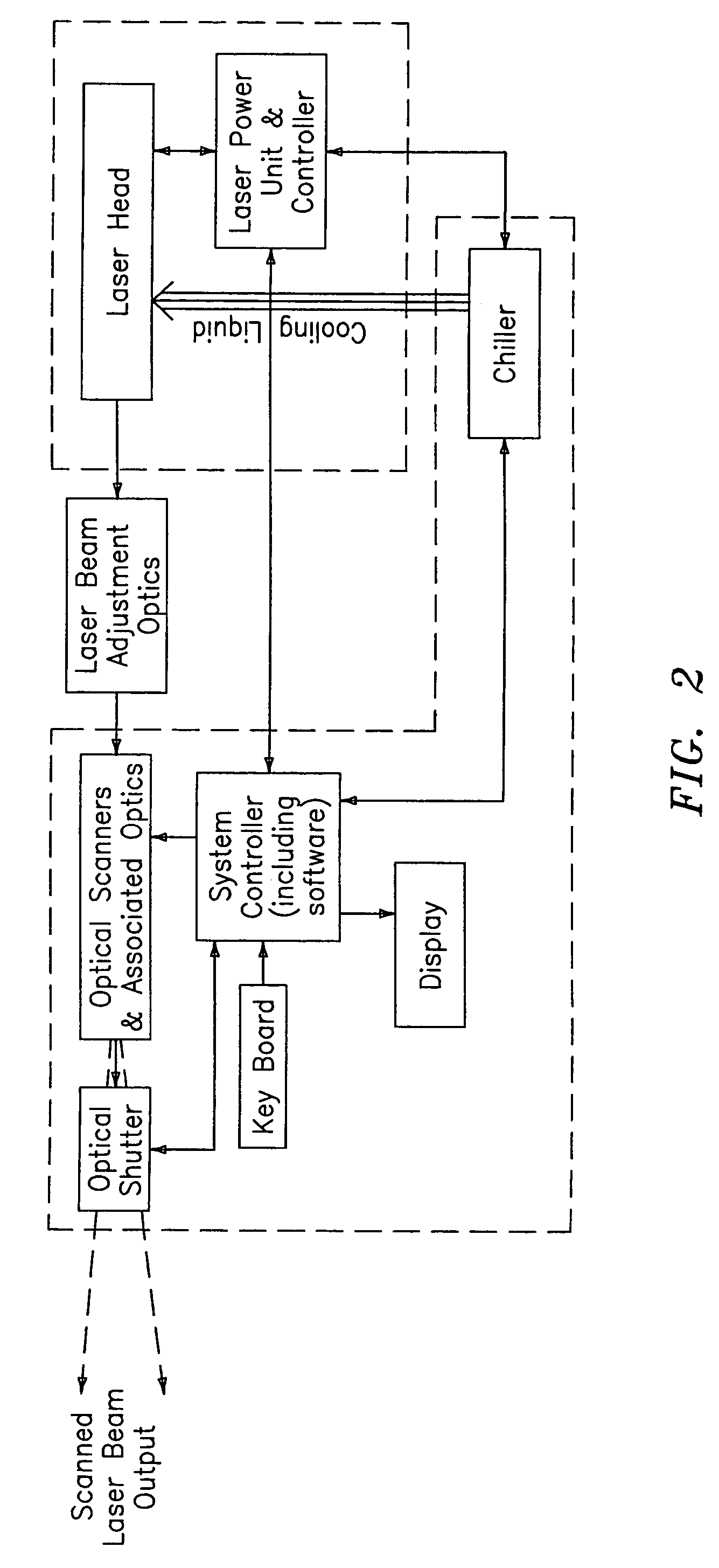

Q-switched, cavity dumped laser systems for material processing

InactiveUS7058093B2High strengthLow powerActive medium materialGas laser constructional detailsEngravingPeak value

This disclosure discusses techniques for obtaining wavelength selected simultaneously super pulsed Q-switched and cavity dumped laser pulses utilizing high optical damage threshold electro-optic modulators, maintaining a zero DC voltage bias on the CdTe electro-optic modulator (EOM) so as to minimize polarization variations depending on the location of the laser beam propagating through the CdSe EOM crystal, as well as the addition of one or more laser amplifiers in a compact package and the use of simultaneous gain switched, Q-switched and cavity dumped operation of CO2 lasers for generating shorter pulses and higher peak power for the hole drilling, engraving and perforation applications.

Owner:COHERENT INC

Closed loop drilling assembly with electronics outside a non-rotating sleeve

A closed-loop drilling system utilizes a bottom hole assembly (“BHA”) having a steering assembly having a rotating member and a non-rotating sleeve disposed thereon. The non-rotating sleeve has a plurality of expandable force application members that engage a borehole wall. An orientation sensing system associated with the rotating member and the non-rotating sleeve provides signals to determine an orientation of the non-rotating sleeve relative to the rotating member. In one embodiment, the orientation sensing system includes a first member positioned in the non-rotating sleeve and a second member positioned in the rotating member. Orientation of the non-rotating sleeve relative to the rotating member is determined from the coaction between the first and second members. The orientation sensing system can use magnetic waves, electrical signals, acoustic signals, radio waves, and / or physical contact.

Owner:BAKER HUGHES HLDG LLC

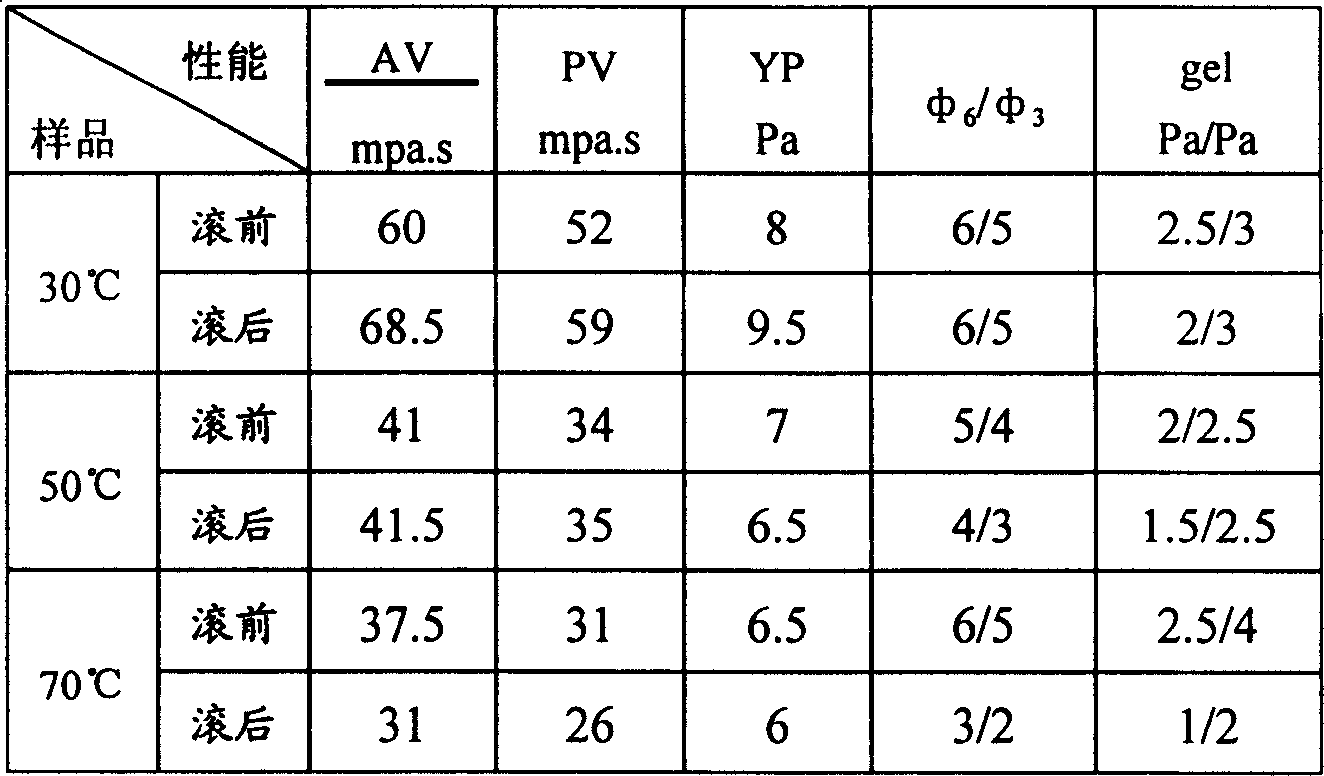

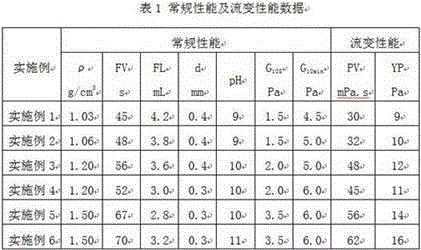

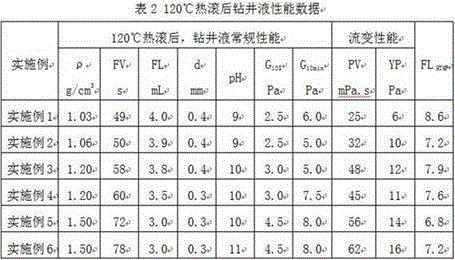

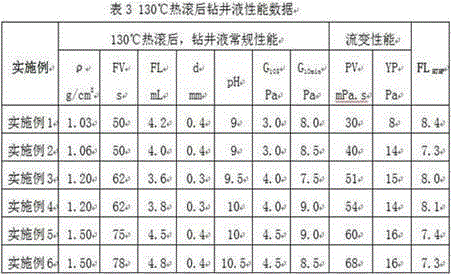

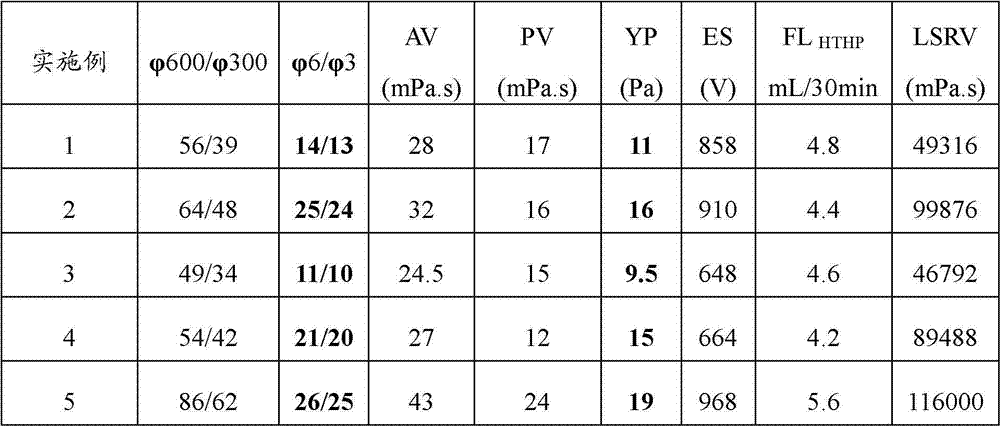

Weak-gel synthetic drilling fluid and preparation method thereof

ActiveCN102775970AGood thixotropyIncrease drilling speedDrilling compositionChemistryAqueous solution

The invention discloses a weak-gel synthetic drilling fluid, which comprises 60-95 parts by volume of gas oil synthetic base liquid, 5-40 parts by volume of calcium chloride watery solution of which the mass fraction is 25-35%, as well as 1.0-3.5% of organic soil, 0.5-4.0% of primary emulsifier, 0.5-3.5% of auxiliary emulsifier, 0.5-3.5% of calcium oxide, 0.5-2.5% of wetting agent, 1.0-4.0% of filtrate reducer, 20-100% of weighting agent and 0.3-1.5% of optional activating agent according to a mass-volume ratio based on total volume fractions of the gas oil synthetic base liquid and the calcium chloride watery solution. The drilling fluid disclosed by the invention has the advantages as follows: (1) the synthetic drilling fluid has good thixotropy, and high low-shear rate viscosity, and (2) the plastic viscosity of the drilling liquid is smaller than that of the traditional drilling liquid.

Owner:CHINA NAT OFFSHORE OIL CORP +2

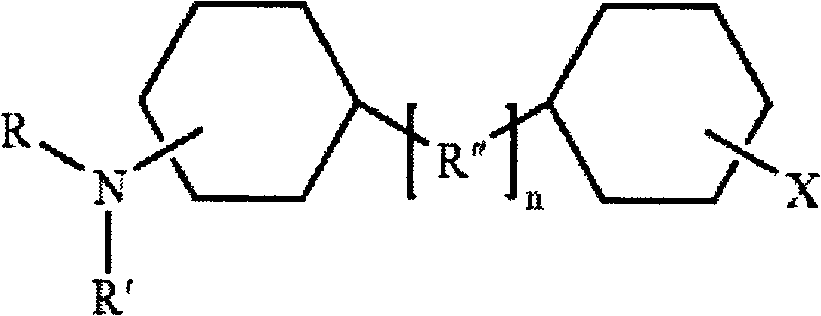

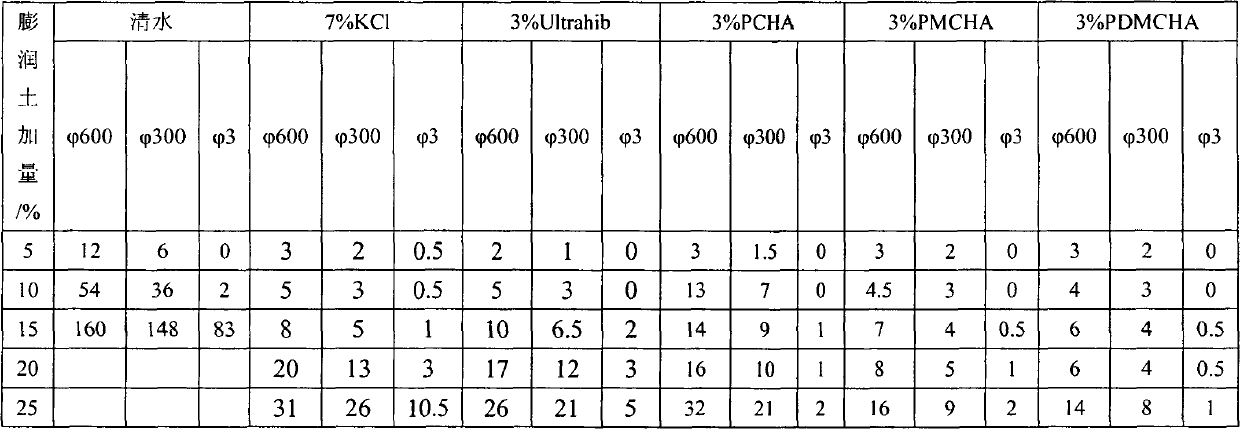

Water-based drilling fluid with high suppression and lubrication performance and preparation method thereof

The invention relates to a water-based drilling fluid with high suppression and lubrication performance and a preparation method thereof. The water-based drilling fluid mainly comprises 100 parts of fresh or sea water, 2 to 10 parts of inorganic salt, 0.2 to 5 parts of amine strong suppressant which is a product of reaction of a naphthenic amine compound and a bronsted acid, 0.1 to 1 part of coating inhibitor, 0.1 to 1 part of tackifier, 0.1 to 1.5 parts of filtrate reducer, 0.5 to 5 parts of anti-mud-coating lubricating agent, 1 to 10 parts of temporary plugging agent and a proper amount of weighting agent (added according to requirements). The drilling fluid provided by the invention has high suppression performance and lubrication performance, can effectively protect an oil gas layer and is a novel drilling fluid system which can replace oil-based drilling fluid.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

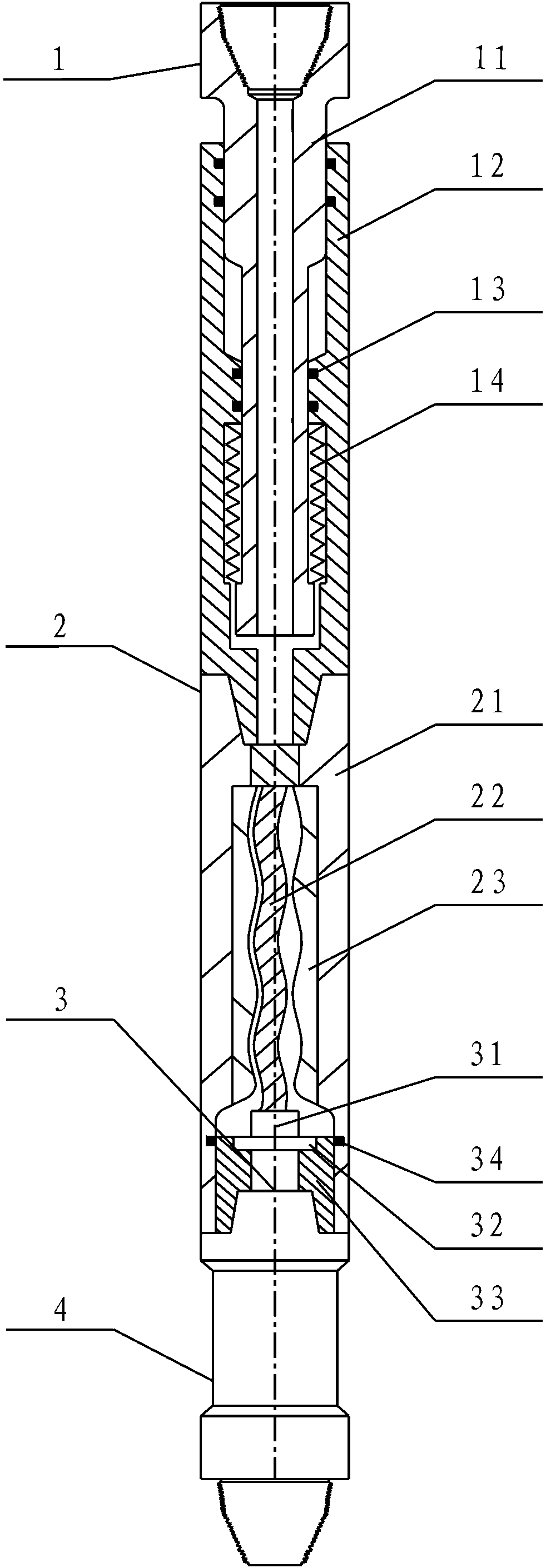

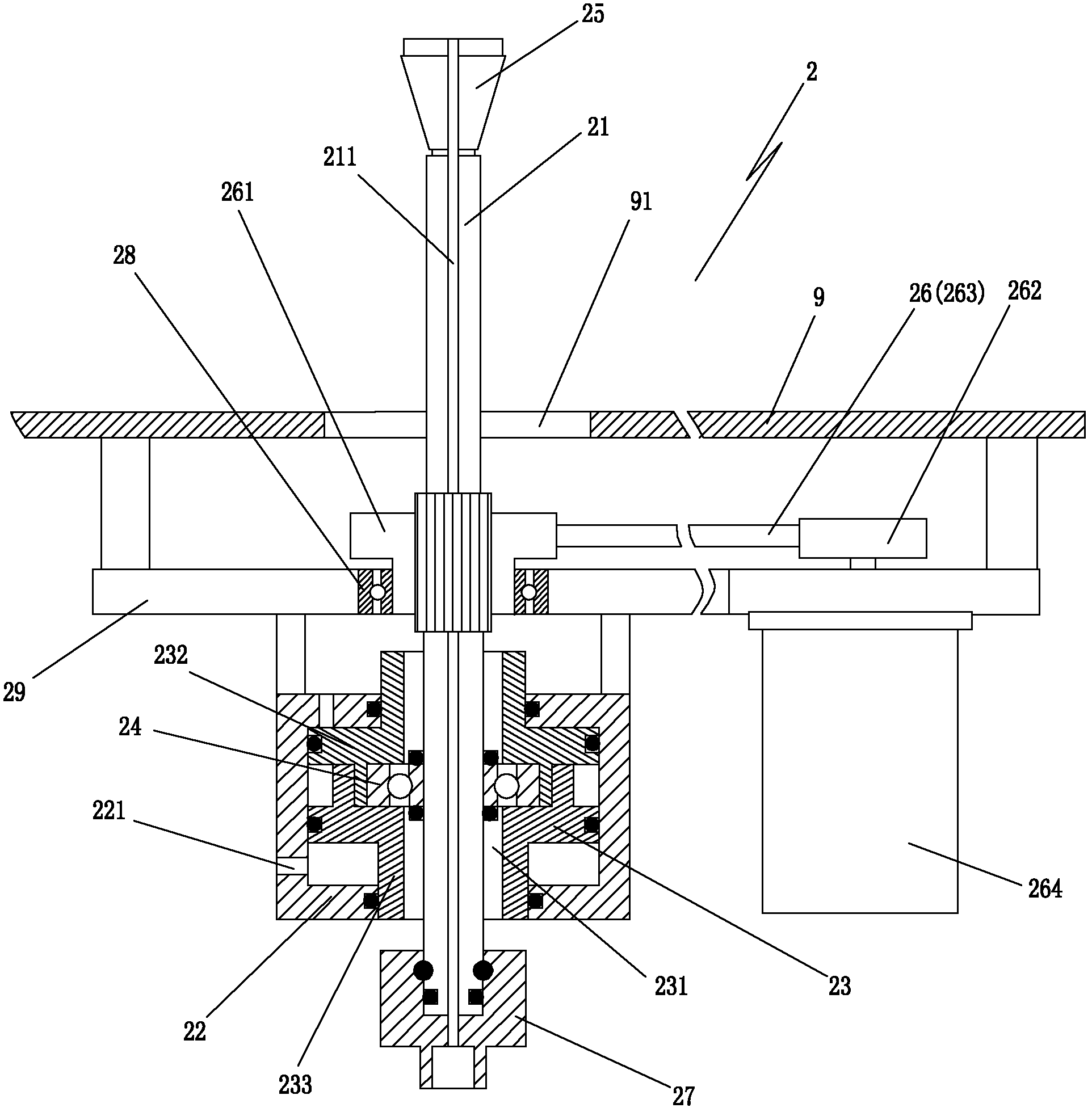

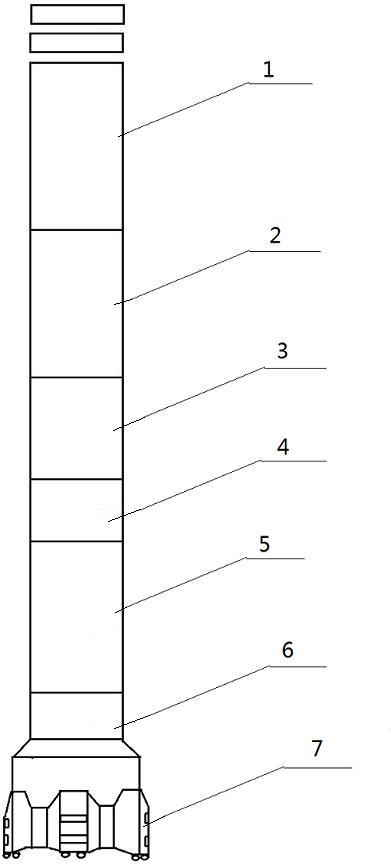

Self-excited resonance drilling device and drilling method thereof

InactiveCN102287137AReduce failureExtended service lifeVibration devicesVibration drillingSelf excitedWell drilling

The invention relates to a self-excitation sympathetic vibration well drilling device and method, wherein the self-excitation sympathetic vibration well drilling device comprises an upper drill rod, a drill collar, a shock absorber, an upper short connection part, a self-excitation resonator, a lower short connection part and a drill head from top to bottom. The drill collar is connected with theupper drill rod through threads. The shock absorber is connected with the drill collar through threads. The upper short connection part is connected with the shock absorber through threads. The self-excitation resonator is connected with the upper short connection part through threads. The other end of the self-excitation resonator is connected to the lower short connection part. The drill head is connected to the lower short connection part via threads. The invention is capable of making full use of lengthways vibration of the drill post, changing the harm into benefit, reducing the loss efficacy of the drill post effectively and enhancing the service life of the drill post. On the other hand, the invention is capable of converting the mechanical energy in lengthways impact and vibrationgenerated by the drill head and the drill collar to medium kinetic energy, achieving the rock crack sympathetic vibration condition and enhancing the well drilling speed.

Owner:NORTHEAST GASOLINEEUM UNIV

Dry type pneumatic rock drilling pile-driving machine and working method thereof

InactiveCN101831906ANo pollution in the processIncrease drilling speedBulkheads/pilesDrilling machines and methodsSlagHelical blade

The invention relates to a dry type pneumatic rock drilling pile-driving machine and a working method thereof. The pile-driving machine is characterized in that the pile-driving machine consists of a pile frame, an upper power head, a screw drill rod, a lower power head, a steel pile casing, a pneumatic down-the-hole hammer, a 30-60 m<3> air compressor and a high-pressure gas transmission pipe. The working method is characterized by comprising the steps of: firstly, installing equipment; secondly, crushing the rock by the pneumatic down-the-hole hammer, and discharging the crushed soil mass and rock ballast out of a pile hole from a slag outlet by using a helical blade; and thirdly, protecting the walls of a construction soil layer, a sand layer and a cobble and gravel layer by using the steel pile casing. Compared with the prior art, the invention has the advantages of high rock drilling speed, dry type and environment-protection construction, clean construction site, and no mud pollution in rock drilling and pile pouring construction.

Owner:温州长城基础工程有限公司

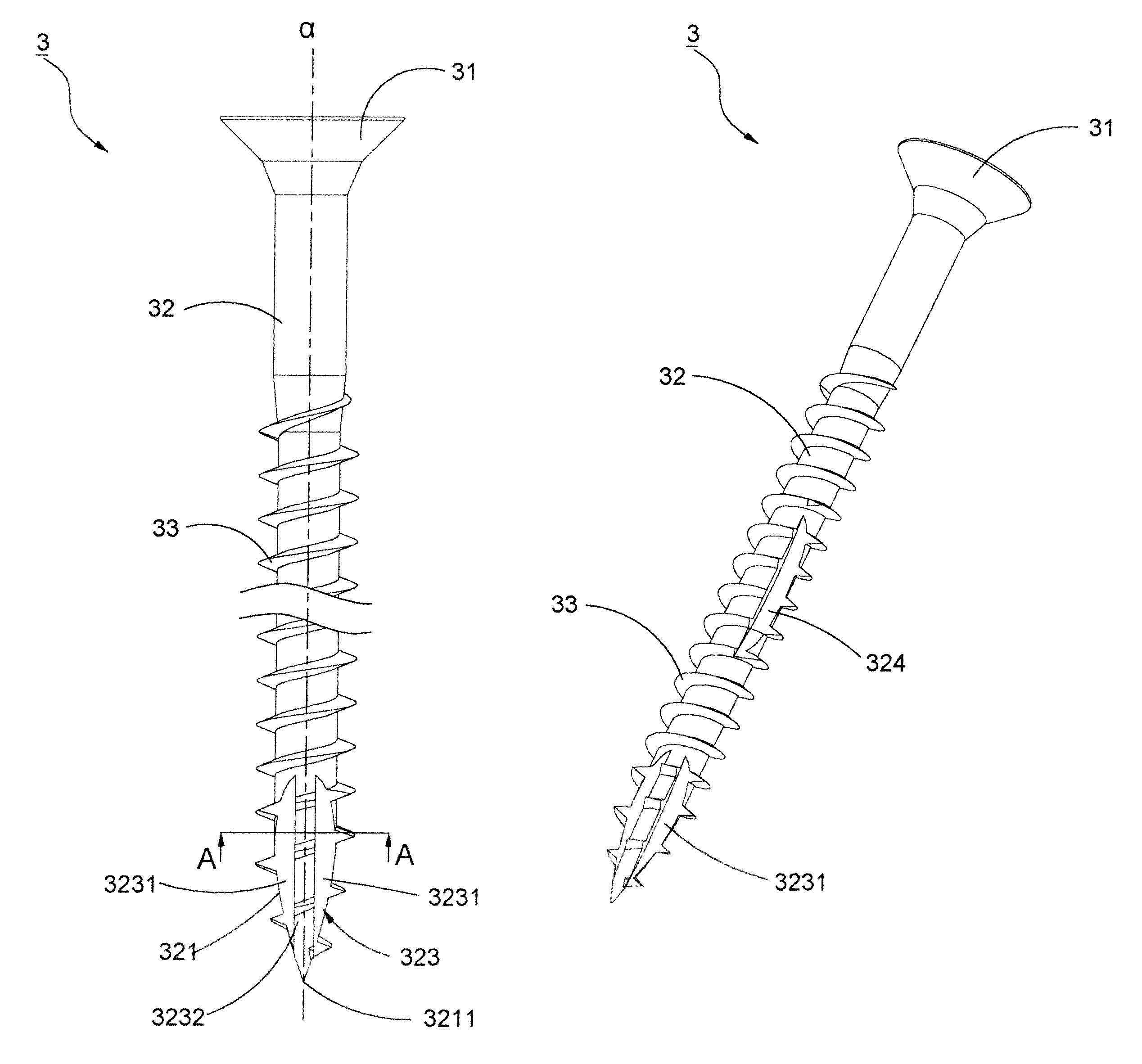

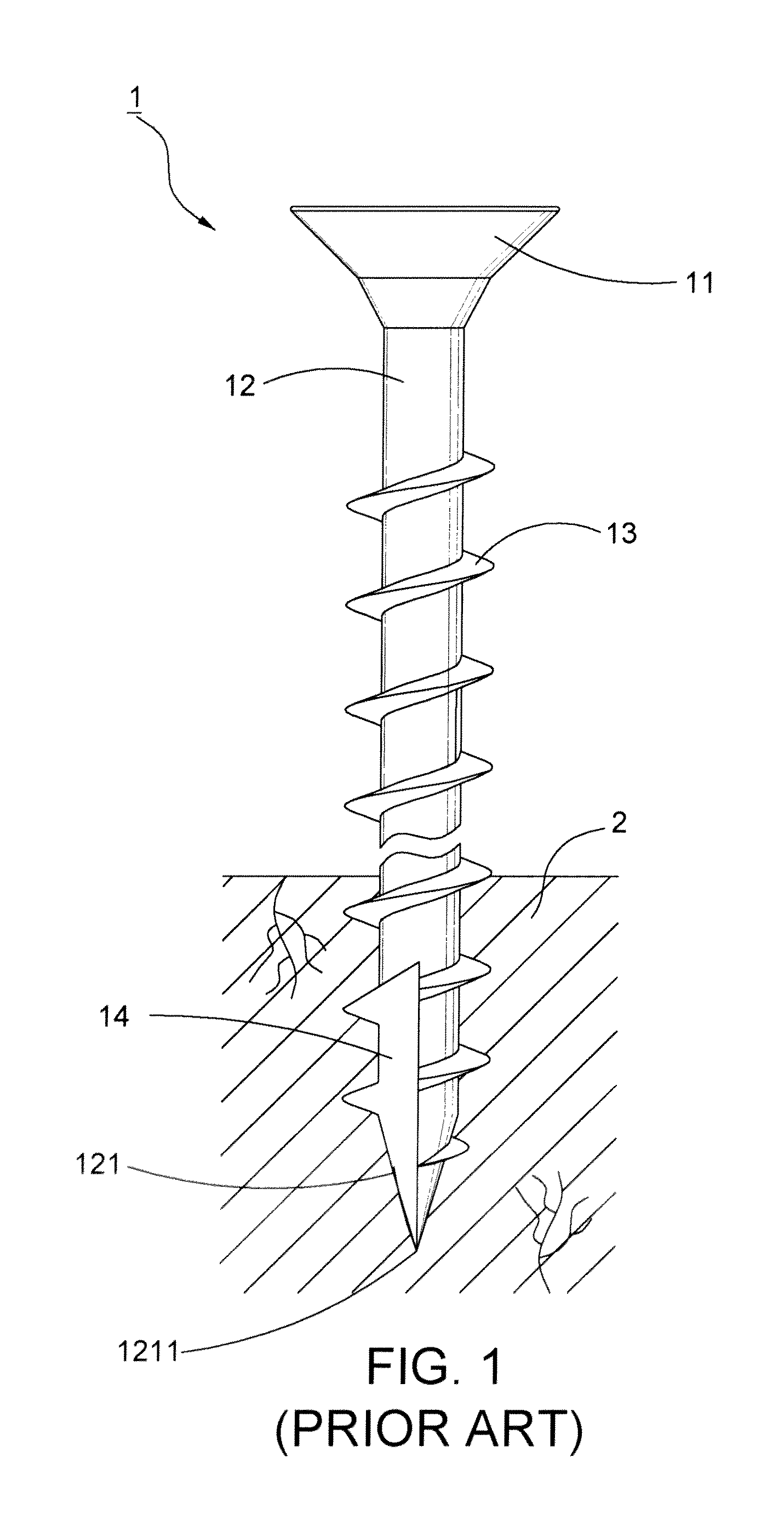

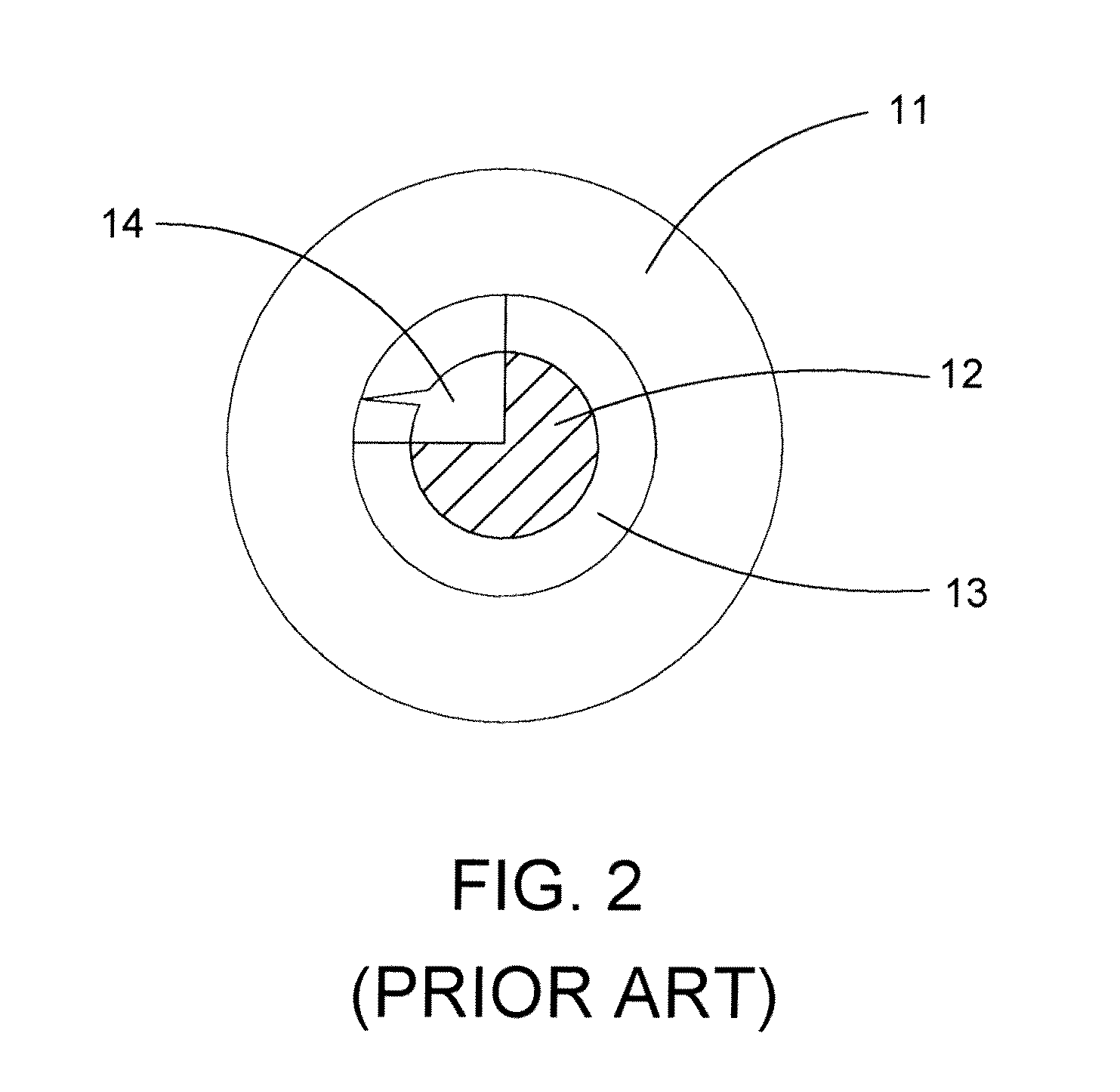

Screw with double notches

ActiveUS8511958B2Decreasing the drilling torqueIncrease drilling speedScrewsEngineeringUltimate tensile strength

A screw with double notches includes a head portion, a shank portion extended outward from the head portion, a threaded section spirally surrounded on the shank portion. Wherein, a raw section on the shank portion is provided with a cambered surface formed integral with the shank portion in cross-section, and a notched section relative to the raw section has two cutting notches separately depressed into the shank portion and disposed near an end of the shank portion, thereby forming a protrudent part between the two cutting notches. By means of the cooperation of the cutting notches and the raw section, the cutting capability and the removal of debris are increased so that a fastened object is prevented from split. Thereby, the drilling speed is promoted, and the effort to rotate the screw is lessened. While the supporting strength of the screw is improved, the screw does not break easily while screwing.

Owner:ESSENCE METHOD REFINE

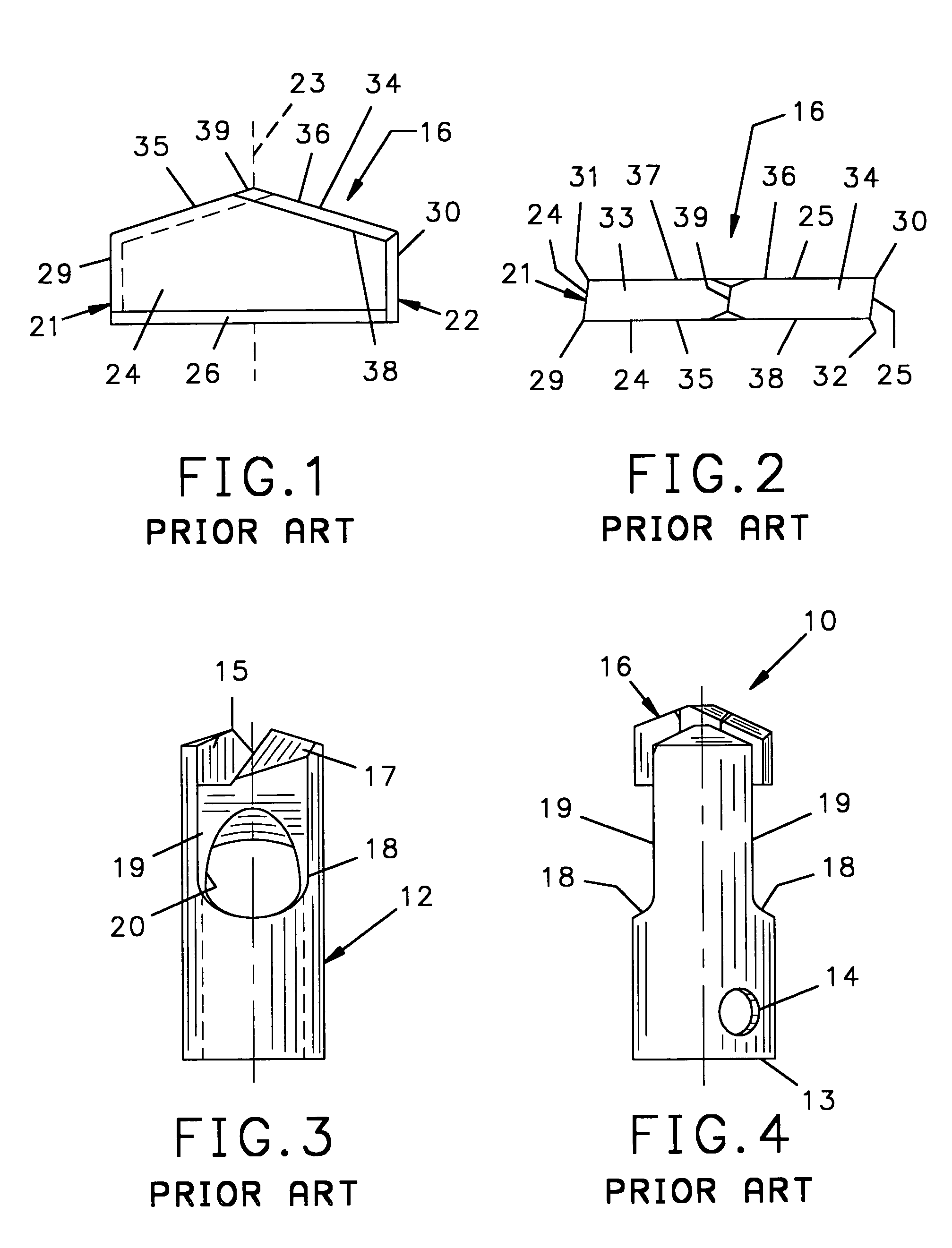

Mine ceiling drill bit and blade

InactiveUS7100714B1Prevent deterioration of cutting surfaceMinimal resistanceDrill bitsWood turning toolsDrill bitDrill hole

A drill bit consists of a bit body having a forward end and a slot in the forward end to hold a hardened cutting blade. The bit body has a table near the center of the blade to reduce the speed at which the drill bores into hard material. The blade has a central slot extending into the forward end thereof such that the slot defines inner side walls and a bridge extending between the inner side walls. The bridge has sloping sides the define a central cutting edge so as to cut particles of hard material accumulating in the slot. The inner side walls intersect the leading faces of the blade and form cutting edges which further cut particles loosened at the center of the cut. Also, relief flats relieve the concentration of forces at the ends of the primary cutting edges of the blade.

Owner:THE SOLLAMI COMPANY

Negative-pressure jet-type particle impact drilling injection device

InactiveCN103195363AGood effectSolve easy blockageSpray nozzlesDrilling machines and methodsPetroleumHigh pressure

The invention belongs to the technical field of petroleum drilling engineering and particularly relates to a negative-pressure jet-type particle impact drilling injection device. A balanced-pressure jet pipe is installed on one side of a material inlet at the top of a high-pressure particle injection tank, a jet anti-blocking sprayer is arranged at one end of the balanced-pressure jet pipe, the other end of the balanced-pressure jet pipe is arranged at the top of a main pipe manifold, the jet anti-blocking sprayer is arranged at the bottom of the high-pressure particle injection tank, a negative-pressure particle injection pipe is arranged at the bottom of a material outlet, a nozzle is arranged at one end of the negative-pressure particle injection pipe and communicated with the main pipe manifold, a regulating pipe is arranged at the bottom of the main pipe manifold, the tail end of the regulating pipe is communicated with an outlet of the negative-pressure particle injection pipe, and a regulating valve is arranged in the regulating pipe. The negative-pressure jet-type particle impact drilling injection device adopts the self-rotating type jet anti-blocking sprayer, achieves omnibearing and multi-angle stirring on the material outlet of the high-pressure particle injection tank, is easy, convenient and safe to operate, serves as one of three core systems of the particle impact drilling new technology, and is simple in processing and manufacturing, convenient to detach, stable in performance and capable of remarkably improving the drilling speed of extra-hard wear-resisting stratum of deep well.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

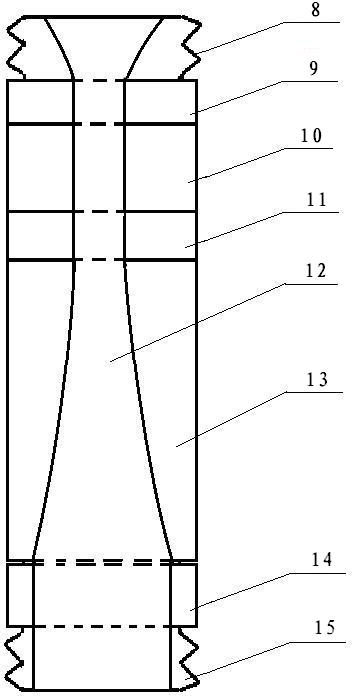

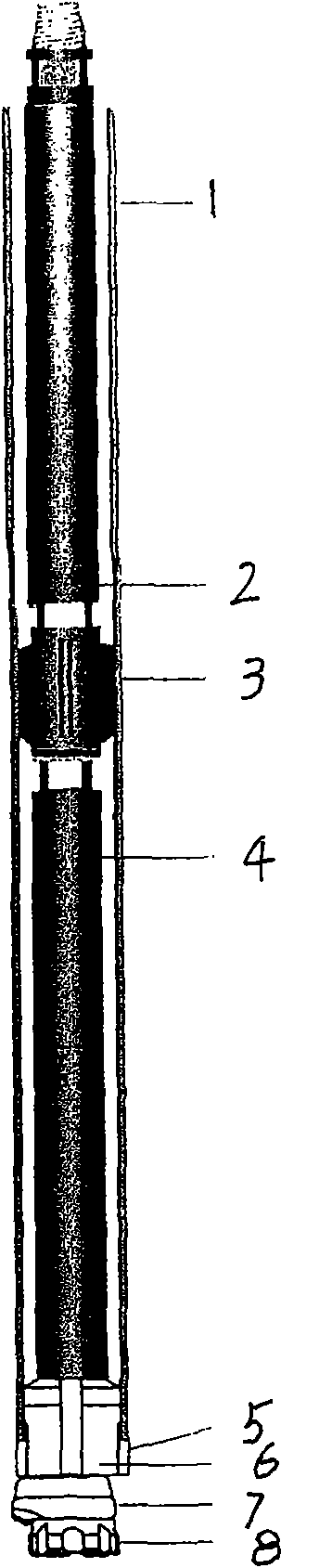

Single-action double-pipe coring overburden drill tool for air down-the-hole hammer

InactiveCN104295232AEliminate disadvantagesReduce frictional resistanceBorehole drivesCore removalBall bearingGeological survey

The invention relates to a single-action double-pipe coring overburden drill tool for an air down-the-hole hammer. The single-action double-pipe coring overburden drill tool comprises a central coring drill tool and an overburden drill tool. The central coring drill tool is a single-action double-pipe coring drill tool and comprises a single-action vibration reduction mechanism, an inner pipe adjusting mechanism and a coring mechanism with a bayonet device; the single-action vibration reduction mechanism comprises an impact connector, a disc spring, a bearing block, a connecting shaft, a thrust ball bearing and a radial ball bearing; the inner pipe adjusting mechanism comprises a connecting shaft, a core pipe connector, an inner pipe and a nut; the coring mechanism with the bayonet device comprises an outer pipe, an inner pipe, a connecting shaft, a core pipe connector, a coring drill bit, a rolling needle, a pawl spring seat and a pawl spring; the overburden drill tool comprises a casing, a casing connector, a casing shoe, a clamp ring and a casing drill bit. The single-action double-pipe coring overburden drill tool for the air down-the-hole hammer is applicable to relevant fields such as geological mineral exploration and engineering geological survey for complex formation with loose sand, cobbles, gravel, fracture, breakage and the like.

Owner:江苏省南京工程高等职业学校

Coal bed gas well pulse radial drilling and double-pulsating hydrofracturing method

InactiveCN105464638AIncrease drilling speedShorten working timeFluid removalFracturing fluidCoiled tubing

Disclosed is a coal bed gas well pulse radial drilling and double-pulsating hydrofracturing method and a whole construction scheme. Equipment matched with the method includes a continuous coiled tubing unit, a high pressure pump, a pulsating pump set, a guider, a pulse generator and a porous nozzle. In a coal bed gas well, the pulse generator and the porous nozzle are utilized to generate high-pressure pulse jets to drive a high-pressure hose to quickly drill into a coal bed to form a radial hole of certain length; a ball is cast into a coiled tubing for maintaining pressure, and a pin is cut off to separate the porous nozzle; the high pressure pump and the pulsating pump set are utilized to pump fracturing fluid in at the same time from the coiled tubing and an oil jacket annulus, the pulse generator generates high-frequency low-amplitude pressure fluctuation, the pulsating pump set generates low-frequency high-amplitude pressure fluctuation, double-pulsating fracturing construction with low-frequency hammering and high-frequency oscillating effects is formed to impact and damage the coal bed, size fracturing is realized finally, and the objectives of substantially improving permeability of the coal bed and increasing yield of a single coal bed gas well are achieved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com